Page 1

POSITIONER

Technical

Manual

INSTALLATION

INSTRUCTION

TROUBLE

SERVICE

SHOOTING

PARTS

LIST

TOKYO JUKI INDUSTRIAL CO., LTD.

Page 2

TABLE

OF

CONTENTS

Subject

1 INTRODUCTION 1

2 FEATURES 1

3 MODEL AND TYPES 2

4 INSTALLATION 3

5 ELECTRICAL CONNECTIONS 4

6 OPERATION 5

7 MAINTENANCE 8

8 HOW TO CHECK THE DRIVE

9 DIMENSION

10 PARTS

LIST

UNIT

Page

13

15

16

Page 3

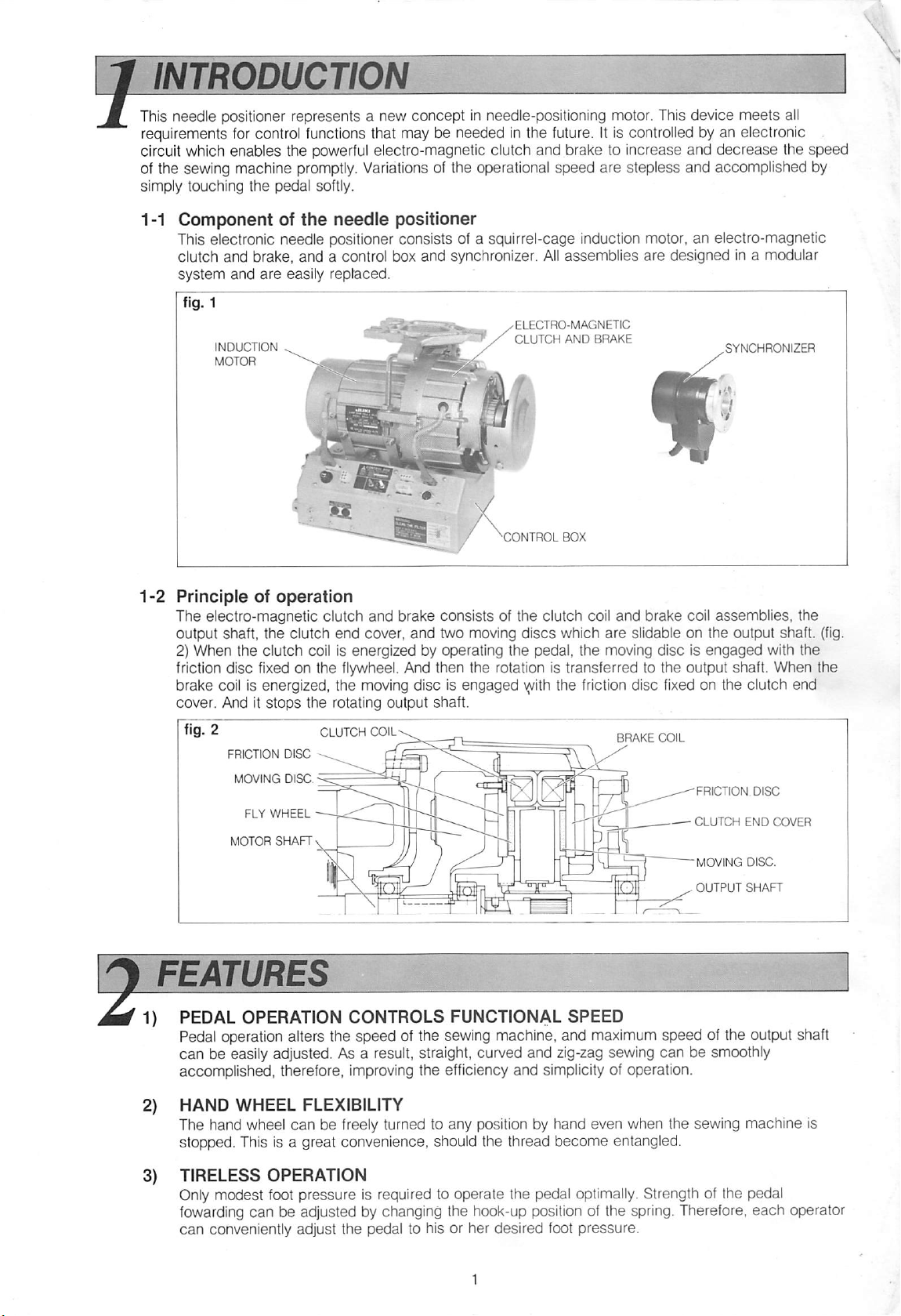

INTRQWCTION

This needle positioner represents a new

concept

in needle-positioning motor. This device

meets

all

requirements for control functions that may be needed in the future. It is controlled by an electronic

circuit which enables the

of the sewing machine

simply touching

1-1

Componentofthe

the

powerful

promptly.

pedal softly.

needle

electro-magnetic clutch and brake to increase and decrease the speed

Variations of the operational speed are stepless and accomplished by

positioner

This electronic needle positioner consists of a squirrel-cage induction motor, an electro-magnetic

clutch and brake, and a control box

system

and

are

INDUCTION

MOTOR

easily

• ^

replaced.

and

synchronizer.

All

assemblies

ELECTRO-MAGNETIC

CLUTCH

^CONTROL

AND

BOX

BRAKE

are

designed in a modular

1-2

Principleofoperation

The electro-magnetic clutch

output shaft, the clutch end cover,

2) When the clutch coil is energized by operating the pedal, the moving disc is

and

brake consists of the clutch coil

and

two moving

discs

which

and

brake coil assemblies, the

are

slidable on the output shaft, (fig.

engaged

friction disc fixed on the flywheel. And then the rotation is transferred to the output shaft. When the

brake

coil

is energized, the

cover, And it

FRICTION

MOVING

FLY

MOTOR

stops

the rotating output shaft.

DISC

DISC.

WHEEL

SHAFT

CLUTCH

moving

COIL

disc is engaged

\(t/ith

the

friction

disc

BRAKE

fixed

on the clutch end

COIL

FRICTION

CLUTCH

MOVING

OUTPUT

END

DISC,

SHAFT

FEATURES

PEDAL

Pedal operation alters the speed of the sewing machine, and maximum speed of the output shaft

can be easily adjusted. As a result, straight, curved and zig-zag sewing can be smoothly

accomplish^,

OPERATION

therefore,

CONTROLS

improving

the

FUNCTIONAL

efficiency

and

SPEED

simplicityofoperation.

with the

DISC

COVER

HAND

The hand wheel

WHEEL

FLEXIBILITY

can

be freely turned to any position by hand even when the sewing machine is

stopped. This is a great convenience, should the thread become entangled,

TIRELESS

OPERATION

Only modest foot pressure is required to operate the pedal optimally. Strength of the pedal

fowarding can be adjusted by changing the hook-up position of the spring. Therefore,

can

conveniently adjust the pedal to hisorher

desired

foot

pressure.

each

operator

Page 4

AUTOMATED

Long operational

QUALITY

life

and extraordinarily high

CONTROL

CIRCUITRY

reliability

are characteristic of the most advanced

analog and digital semi-conductor elements. Because all control circuitry is controlled by electric

signals, programmed operation and control can be systematized. This enables automatically-

controlled operation of a number of sewing machines,

NEEDLE

POSITIONING

AND

STOPPING

ACCURACY

Specially designed electro-magnetic clutch and brake ensure veryprecise needle

stopping accuracy, which helps prevent needle breakage.

ABNORMAL

(a)

Abnormal

function

operation.

(b)incase

clutch automatically.

{c)When

the protection circuit disconnects the back tack solenoid in 12

from burning.

These

JAMMING

Aspecial

clutch, and therefore, protecting the motor

CLUTCH

Should

with a turn of the adjustment screw.

the

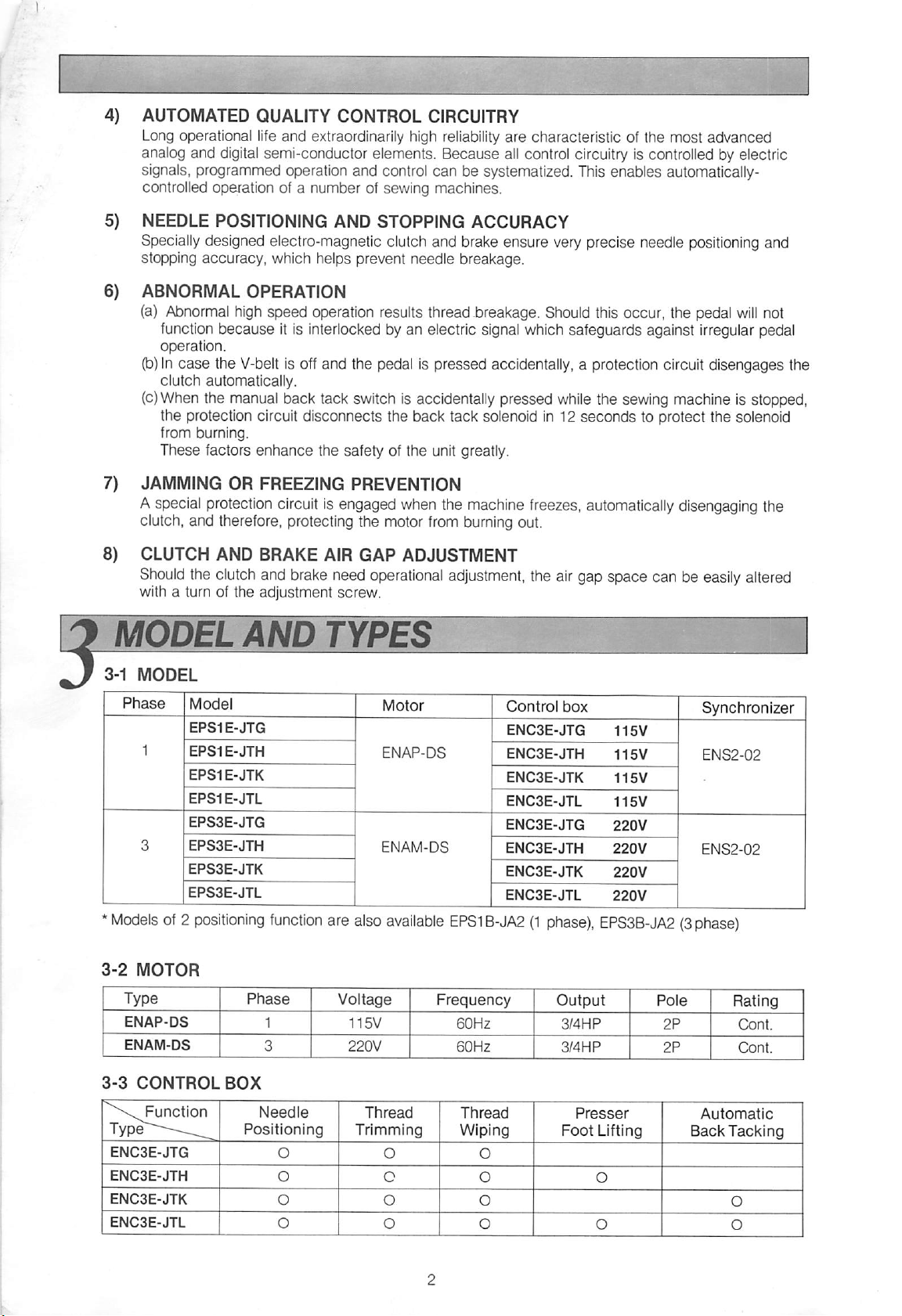

MODEL

3-1

MODEL

OPERATION

high

because

the

V-belt

the

manual

factors

OR

protection

AND

clutch

AND

speed operation results thread-breakage.

Should

this occur, the pedal

it is interlocked by an electric signal which safeguards against irregular pedal

is off and the pedal is pressed accidentally, a protection circuitdisengages the

back tack

switchIsaccidentally pressed

while

the

seconds

enhance

FREEZING

BRAKE

and

the safety of the unit greatly.

PREVENTION

circuit

brake

is engaged

AIR

need

when

GAP

ADJUSTMENT

operational

the

machine

from

burning out.

adjustment,

freezes,

automatically

the airgap space can be

'or': ,V

TYPES

positioning

sewing

machine is stopped,

to protect the solenoid

disengaging

easily

^'2

will

altered

and

not

the

Phase

*

Modelsof2

3-2

MOTOR

ENAP-DS

ENAM-DS

3-3

CONTROL

Function

ENC3E-JTG

ENC3E-JTH

ENC3E-JTK

ENC3E-JTL

Model

EPS1E-JTG

EPS1E-JTH

EPS1E-JTK

EPS1E-JTL

EPS3E-JTG

EPS3E-JTH

EPS3E-JTK

EPS3E.JTL

positioning

Phase

BOX

Positioning

function

Needle

are

also

Voltage

115V

Trimming

Motor

ENAP-DS

ENAM-DS

available

Thread

O

Control

ENC3E-JTG

ENC3E-JTH

ENC3E-JTK

ENC3E-JTL

ENC3E-JTG

ENC3E-JTH

ENC3E-JTK

ENC3E-JTL

EPS1B-JA2(1phase),

Frequency

60Hz

60Hz

Thread

Wiping

O

Output

box

EPS3B-JA2(3phase)

3/4HP

3/4HP

Presser

Foot

Lifting

Pole

2P

2P

Synchronizer

ENS2-02

ENS2-02

Rating

Cont.

Cont.

Automatic

Back

Tacking

Page 5

3-4

SYNCHRONIZER

Type Coupling to

ENS2-02 Flange type

3-5

AVAILABLE

MODEL

EPS1E-JTG

EPS1E-JTH

EPS3E-JTG

EPS3E-JTH

EPS1E-JTK

EPS1E-JTL

EPS3E-JTK

EPS3E-JTL

All

motors

If

your machine speed is not 5000

supplier.

EPS1B-JA2,

MODELS

are

supplied with the pulley for

EPS3B-JA2

canbeapplicabletoany

the

sewing machine

SEWING

DDL-555-4-3

DDL-555H-4-1

DDL-555H-4-3

DLD-432-4-1

DLN-415-4-1

DLU-45D-4-1

DDL-555-4-3B

DDL-555H-4-3B

DLN-415-4-1B

DLD-432-4-3B

DLU-450-4-1B

5000

RPM

{refer

Performance

Needle down

and

up position signal,

tachogenerator

MACHINE

MACHINE

5000

4000

4000

4500

5000

4000

5000

4000

5000

4500

4000

SPEED

RPM

RPM

RPM

RPM

RPM

RPM

RPM

RPM

RPM

RPM

RPM

RPM.

above table), please ask the proper pulleyto your

machine.

and

(MAX)

INSTALLATIQ

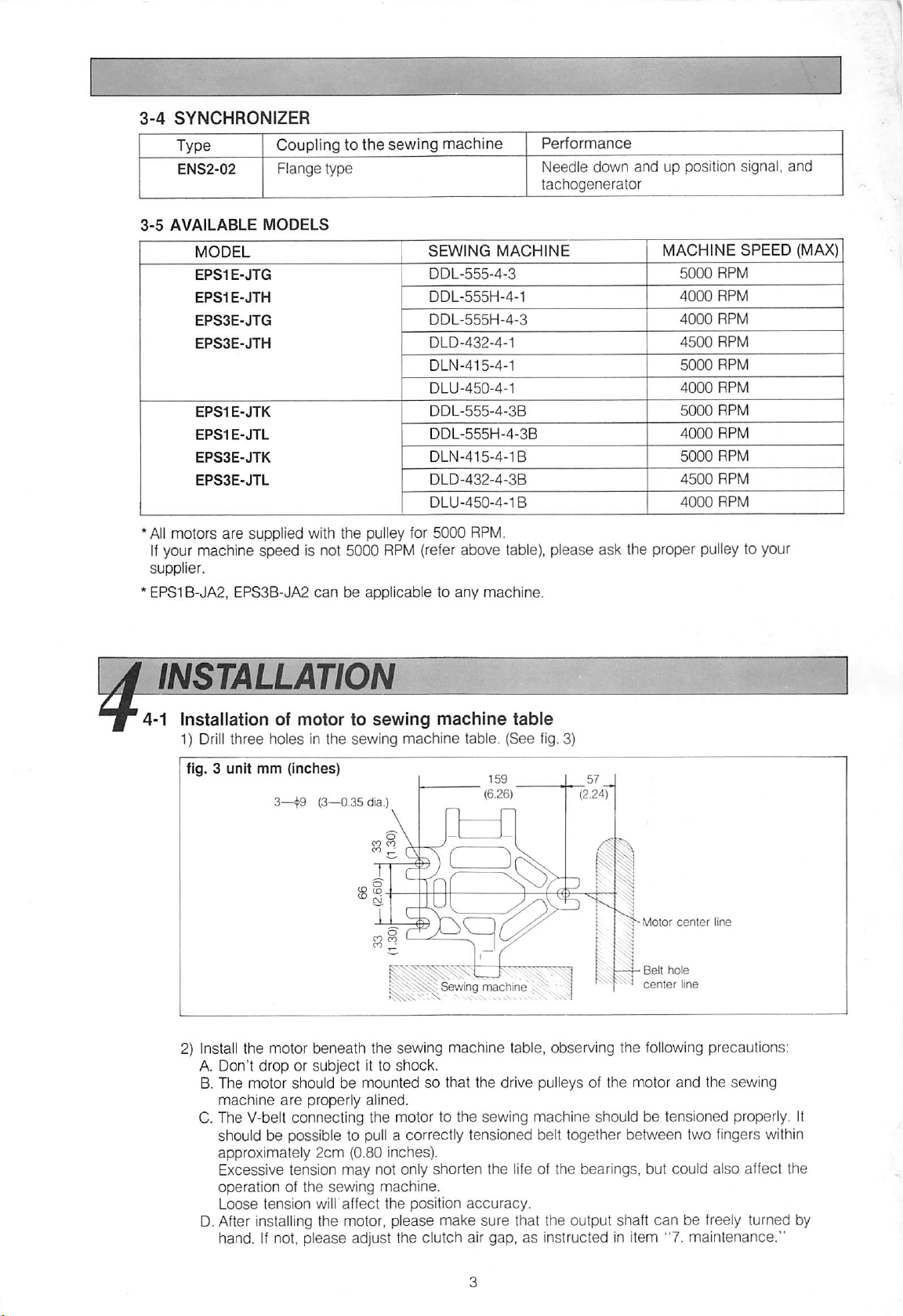

4-1 Installation of

1)

Drill

three holes in the sewing machine table. (See fig. 3)

ftg. 3

unit

2) Install the motor beneath the sewing machine table, observing the

A. Don't

B. The motor should be

machine

C. The V-belt connecting the motor to the sewing machine should be tensioned properly. It

should

approximately

Excessive tension may not only shorten the life of the bearings, but could also affect the

operation of the

Loose tension will'affect the position

D.After installing the motor,

hand. If not,

motortosewing

mm

(Inches)

3—^9 (3—0.35dia.)

droporsubject

are

properly alined.

be

possible to pull a correctly tensioned belt together between two fingers within

2cm

It to

mountedsothat

(0.80 Inches).

sewing

machine.

shock.

machine

machine

the

table

drive pulleys of the motor

accuracy.

please

please

adjust the clutch air gap,asinstructed in item "7, maintenance,"

make

sure

that the output shaft

Moior

center

line

Beit

hole

center

line

following

can

precautions:

and

the sewing

be freely turned by

Page 6

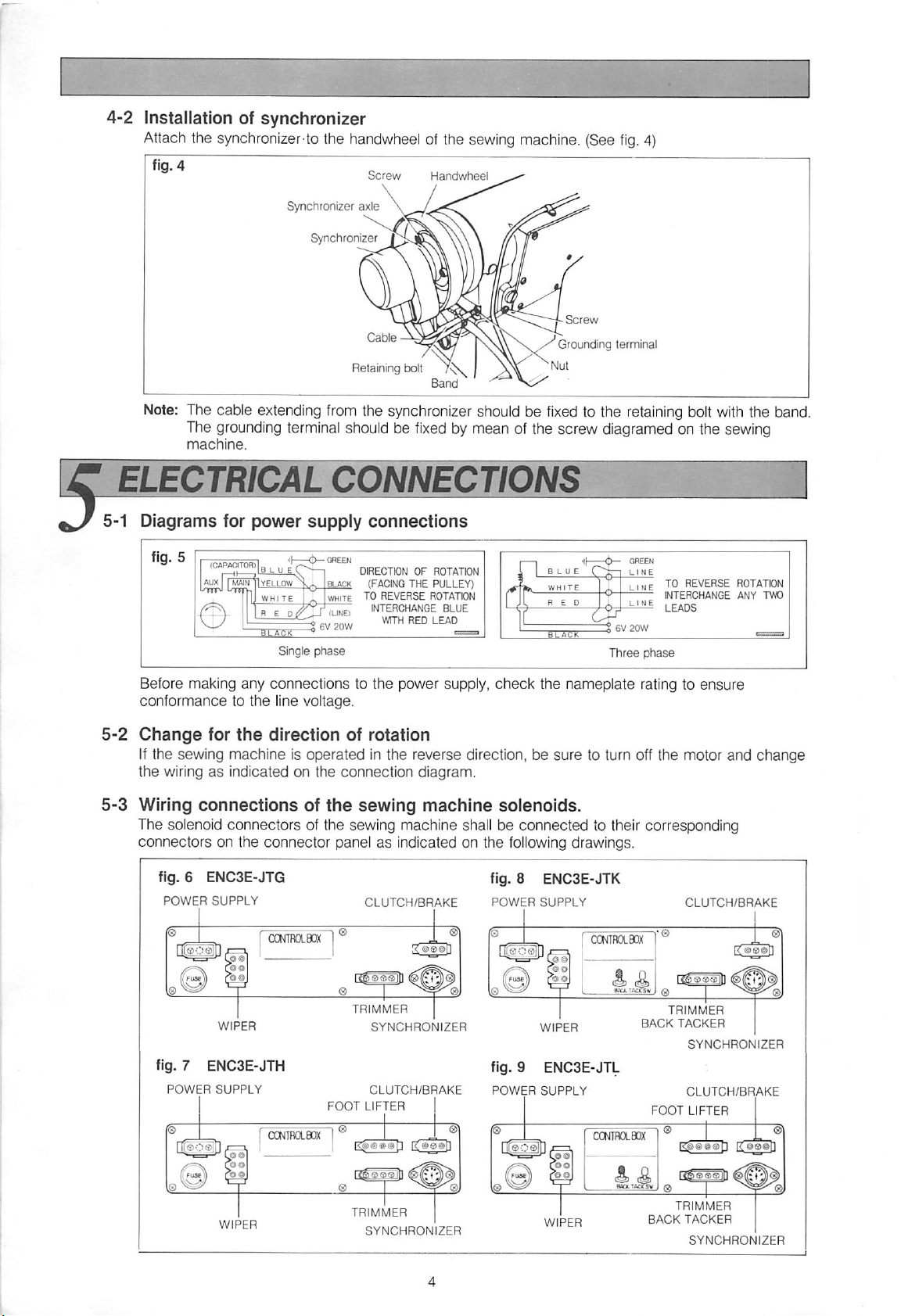

4-2

Installation of

Attach

synchronizer

the synchronizer-to the

handwheel

of the

sewing

machine.

(See

fig.

4)

ftg. 4

Synchronizer axle

Screw

Handwheel

Synchroniz^^r^^^^^N

Retaining bolt

Band

Note: The cable extending from the synchronizer should be

5-1

The grounding terminal should be

machine.

TTMCAICONNECTIO

Diagrams

fig. 511.^.oAriT^

y

for

I

torn.

,,

MAIN

power

'IB

LUE(

"IyELLOW

1^

WHITE

I n E

iLACK

'ii—<t>—

Di

Single

supply

QR^

GREEN

Bu>CK

WHITE

^

20W

^

phase

connections

DIRECTION OF ROTATION

(FACING

TO REVERSE

fixed

THE

INTERCHANGE

RED

PULLEY)

ROTATION

BLUE

LEAD

Grounding terminal

•Nut

fixed

to the retaining bolt

with

the band.

by mean of the screw diagramed on the sewing

I I

GREEN

LINE

LIMETOREVERSE

INTERCHANGE

^

LEADS

LE

t 6V

20W

Three

phase

ROTATION

ANY TWO

Before making any connections to

conformancetothe

5-2

Change

for

the

line voltage.

direction

If the sewing machine is

operated

the

of rotation

in the reverse direction,besure

the wiringasindicated on the connection diagram.

5-3

Wiring

The solenoid

connectors

connections

connectors

of

the

sewing

of the sewing machine shall be

on the connector panelasindicated on the following drawings.

fig. 6 ENC3E-JTG

POWER

fig. 7 ENC3E-JTH

POWER

1

SUPPLY

1

WIPER

SUPPLY

TRIMMER

FOOT

CLUTCH/BRAKE

SYNCHRONIZER

CLUTCH/BRAKE

LIFTER

power supply,

machine

1 1

1

check

the nameplate rating to

to turn off the motor

solenoids.

connected

fig. 8 ENC3E-JTK

POWER

SUPPLY

WIPER

fig. 9 ENC3E-JTL

POWER

SUPPLY

to their corresponding

1

TRIMMER

BACK

FOOT

ensure

and

CLUTCH/BRAKE

TACKER

SYNCHRONIZER

CLUTCH/BRAKE

LIFTER

change

1

Page 7

5-4

Synchronizer

Before starting operation, Insert the synchronizer connector into the corresponding

connector

5-5

Connection

Two black wires

Please

5-6

Changing

The transformer which is located in the control box

At ex-factory, it is

Before starting operation,

proper

connect

terminal.

panel.

the

connection

of

the

lighting

are

provided for 6 Volt 20 Watt lighting fixture in the

properly

when

primary

used

the 220v tap.

check

fixture

it willbeneeded.

taps

of

the

transformer

your power supply and if

has

connector

end

coverofthe

used

in 220V

the four taps (190v-208v-220v-240v).

necessary,

control

change

the connection to

motor.

box

on the

the

OPERATION

When the foot pedal of the sewing machine is pressed forward, the pitman rod moves the speed governor

in the control box. The clutch coil is energized by a control system so that the sewing machine can be

operated

When the sewing operation is completed and the foot pedal is released to Its neutral position, the brake

coil is energized through the control circuit. By means of the synchronizer, the sewing machine

in the needle down position immediately. By heeling the foot pedal backward, the clutch coil is

reenergized. Therefore, the sewing machine

speed and the thread

needle up position, the thread wiping operation is performed once.

at the desired

speed;

trimming

depending on the position of the foot pedal.

will

move into the needle up position at the thread

operation

will

be performed.

After

the sewing machine is stopped in the

will

stop

trimming

fig.

10

Fool pedal

Pressed

forward

Pressed

backward

Note:

(a) The handwheel of the sewing machine can be turned

not operating.

(b.)

When the operator stops the sewing machine in the needle down position, once

freely

when the sewingmachine is

she

the handwheel of the sewing machine manually, the thread trimming and thread wiping

operations

BACK

JTK and JTL type motors have an automatic back tack operation. The automatic start

is performed at the beginning of the sewing operation by pressirig the pedal forward. The end back

tacking is performed at the completion of the sewing operation by heeling the pedal backward.

Even when the pedal is released to Its neutral position at the end back tack, the sewing machine is

moved

tacking. The sewing

When the pedal is released to its neutral position at the start back tack, the sewing machine

immediately stop in the needle down position. By heeling the pedal backward during the start back

tack,

tacking.

TACKING

into

the

the

sewing

cannot

needle

machine

be performed even when the foot pedal is heeled backward.

up position: performing

machine

then

performs

performs

the

thread

the

the

thread

trimming

thread

trimming operation after the

wiping operation.

and

wiping operation without the

back

end

turns

tacking

back

end

will

back

Page 8

1) Back

The

Start

back

End

back

fig. 11

tack

patterns

tacking

tacking

patterns

are

selectedbychanging

START

upper

OFF

down

A—,B

B-r---A

A

OFF

.bVbs

START

BACK

TACK

BACK

position

position

position

END

SW.

TACK

the

BACKTACK SW.

SW.

upper

position

OFF

position

down

position

locatedonthe

Pattern

connector

panel.

Programming

2)

The switch to program the stitches of

control

the

box. {fig. 12)

stitchesofback

tacking

back

Back tacking is consisted of two portions, Part A

PART A; forward portion of

PART B:

backward

portion of

The stitches of part A and B

switch.

Note:

Part

A Is

double

The

programming should be

back

back

can

only.

donebychanging

tacking

tacking

be programmed independently from 0 to 15 by changing

tacking is located on the "L P. C. Board" in the

Conirol

box

L P.C.Board

Switchestoprogram

the

stitchesofback

Screwstofix

and

'

the

cover

Part B.

the switchasper

tacking

(fig.

o

i=^t=]i=iao

O 0

13)

the

following combination table.

the

table

6.2

Switches

AI B 0

1 1 OFF

2 2 OFF

4 4 OFF

8 ^

Combination

table

1

ON

OFF

OFF

OFF

OFF OFF

Ml

Number

2

5

m

6

Bl

OFF

ON ON

ON

OFF

SWITCH

of

ON

ON

OFF

stitches

B

OFF

OFF

ON

9

ON

OFF

OFF

ON

10

10

OFF

ON

OFF

ON

11

12 13 14

OFF

ON

OFF

Page 9

Example:

When

the

start

back

tacking is programmed to 3 stitches forward and 4 backward, the

tacking is

4

stitches

forward

and3backward.

fig. 15

6-2

FOOT

JTH

backwardtothe

and

LIFTING

JTL type

Switches

B

4

8_

1

A 2

motors

intermediate position while the

haveapresser

foot lifter.

T

The

needle

presser

is down position.

Position

OFF

OFF

ON

OFF

ON

ON

OFF

OFF

foot is lifted by heeling pedal

When

the

pedal is fully

heeled backward, the needle is positioned at the upper position while thread trimming and wiping

are

operations

pedalisheeled

performed before

backward.

lifting

the

presser

foot. The

presser

foot is kept liftedaslongasthe

end

back

6-3

fig.

16

SLOW

1)

START

AND

Numberofneedle

NUMBER

positions

OF

NEEDLE

POSITIONS

When the single positioning is. required, open the control box

located on the "L P. C. Board" from

2)

Slow

start

When the slow start is required at

the

select

switch

combination

table

"3"

and

"4"

table,

(table 6.3)

-

imczzicncn

o o

6.3

Switch

Number

3

^

"OFF"to"ON"

the

beginning of the sewing, open the control box and

located on the "L P.0.Board" in

— L

P.O.Board

^

Select

switch

Number

oil

OFF

OFF

OFF

Intermediate

Full

and

position,

m-

•]"

zo

of

stiches

change

(fig.

accordance

—»

—

"1

—^

-T

at

I 2 I

ON

the select switch

19)

Numberofneedle

Slow

start

slow

start

with the following

~3~

ON

ON I OFF ON

"1"

change

position

Page 10

REPAIRS

1)

Adjustment

A) Turn the

AND

counterclockwise

untilItbecomes not to turn the output

ADJUSTMENT

of

clutch

adjustment

at

air

screw

least

two

gap

turns,

ft—

Clutch

Clutch

end

end

cover

cover

B) Turn

the

adjustment

carefully until

tighter.

zero

(At

and

this

the

screw

the

rotation

point,

output

shaftisturned

clockwise

becomes

clutch

air

gap

is

J

li—

iLJi

1l^Tll\

\|

Complete

the

(8

stepsofnotches).

C)

When

brake

2)

Replacement

A)Switch off the motor, remove the pitman rod from the

B) Pull out all

C) Remove the control box from the motor and replace it with the new control box.

3)

Replacement

A)

Pull

board.

B) Remove the strain relief.

C) Unscrew

from

D)

Replace

the

adjustmentbyturning

adjustment

the

air

out the connector connected from the

the

screw

clutch air

gapisdone

of

the

connectors

of

speed

five

screws

control

it with

box,

the

120®

clockwise

gapisadjusted,

accordingly.

control

which

new

and

speed

box

unscrew

control

(JTK,

JTL type)

fix

the speed control lever assembly to the control box, and remove it

control lever

the four bolts which hold the control box to the motor.

lever

W

1

assembly

speed

control lever assembly to another printed circuit

assembly.

speed

control lever.

Ihuuu^^

HI

llvQ^

Adjustment

screw

JTG,

JTK, JTL

Important:

Removal

to avoid

4)

Replacement

A) Pull

B)

C)

D) Reinsert

JTH

type

type

and

replacement of circuit

static

electricity

of

out

all

connectors

connectedtothe

Remove

printed circuit

Replace

board

the

it with a

"M."

securely

four

board

damageto"MOS"

printed

printed circuit

screws

new

all

circuit

which

which fix

"M."

printed circuit

connectors.

are

! I

board

boards

board

the

must be done by qualified service personnel with

component.

"M"

FT

(JTK, JTL

77

screws

type)

u

care

Page 11

Replacement

A) Puli out all

B) Push the nail to free the lock of the nylon

of printed circuit

connectors

which

are

connected

board

"L"

(JTK, JTL

to the printed circuit board "L."

spacer,

and

C) Relace itwith a new printed circuit board "L" and push

D)Reinsert

securely

all

connectors.

type)

remove the P, C. Board

until

the board is snapped completely.

"L"

fig. 21

6)

Replacementofprinted

Nylon

Cover

Push

spacer

heretofree

—

circuit

the

lock

board

"C"

(JTG, JTH type)

Refer to the Instruction of replacement for the printed circuit board "M."

7)

Replacement

A)

Remove

B)

Unscrew

machine.

C)

Then

replace

Coution:

With cover removed

cause

severe

plates

with

Note: If

necessary,

sewing

rotation is

magnet carrier plate; which

of

the

the

connector

the

three

it with a

and

synchronizer

from the control box.

screws,

and

new

adjusted

power on, the rotation of

remove

synchronizer.

(See

fig. 22)

the

synchronizer from the

the

synchronizer

physical injury to hands, arms, etc. Never remove cover or adjust magnet carrier

power

on.

readjust the needle stop position by turning the

machine

manually into

correct!)

Remove

the

has

the

needle

cover

the red

down position. (Make

from

the

synchronizer, loosen

magnet

so that it

on the synchronizer socket. Then turn the sewing machine to the needle up position and

"2"

make

magnet

position on

a fine

adjust the

in

the

To

A) Pullout the solenoid

B)

Operate

C)

Press

the

D) Make

sure

carrier plate; which has the yellow

the

synchronizer

adjustment;

connectors

the

sewing

foot pedal forward

the

sewing

machine.

machine

of the sewing machine from the control box.

and

release.

is in

socket.

the

needle

down position.

E) Correct to the required needle position by adjusting the red

F) Heel the foot pedal backward. (Needle stops in the up position.)

G)Correct to the required position by adjusting the yellow

H)Tighten

I) Finally reinsert the solenoid connectors of the sewing machine to the control box.

the

screw

and

install

the

synchronizer

cover.

P. C.

will

magnet

magnet

Board

"L"

handwheel

magnet

magnet

carrier plate

carrier plates. Turn the

sure

that

the

be located in the

so that the plate

magnet

carrier plate.

carrier plate.

of the

the

direction of

screw,

sewing

can

and

"1"

will

be located

turn

position

the

fig. 22

Magnet carrier plate (red)

Magnet carrier plate

Synctironlzer

(yellow)

socket

Page 12

Use of

special

lining application material

For longer lining life, it is important that the lining shouldbecoated

use

the

materialifnoiseisheardinthe

Note: Don't

use

any

application material

clutch

other

and

brake.

than this for

the

PANA-STOP E. This

enough for 4 applications, and the material should be used accordingly.

at least

once

a half year. Also

tube

contains

How to

A)

use;

Motor

disassembly

a) Switch off the motor,

b) Pull

c)

out

Remove

the

the clutch

(fig. 23)

three-pole

end

and

connector

d) Remove the spline cover

remove the pulley cover and V-belt.

from

the

control box.

coverbyunscrewing

and

the spring.

the

three

bolts.

e) Remove the clutch disc from the output shaft, and remove the nylon ring together with the

brake

disc.

Note: Be careful not to drop otherwise

lining

surfaces.

fig. 23

Motor

Don't permit

disassembled.

bracket

dusttoadheretothe

Flywheel

Bearing

damage

lining

housing

the movable plates, nor to

surfacesofthe

Nylon ring

(Clutch)

Moving

moving

disc

-&J

scratchorscar

discs

while they

Clutch

end

\-

Bolt

cover

Three-pole

connector

the

are

8)

Cleaningofmoving

Clean

away

any

flywheel

any

C)

Applicationtolining

a)

and

each

cotton

waste

Squeezeanamount

surfacesofeither

Note: Be careful not to apply

precision, or

b) Firmly

press

c) Rotate the moving

discs

cotton

wasteorother

ventilation

adheredtothe

surfaces

equal to

the

clutchorbrake

the

the

uncoated

discs

and

motor

channelofthe

lining

about2match

too

motor might not

lining

surface

against

each

d) Clean away any excessive material which

fig.

24

KooJ

fig. 26

interior

dirt

adheredtothe

motor

surfaces.

heads

in 8

places.

much,

because

operate

against

other. (See fig. 26)

comes

moving

bracket.

from

(See

fig. 24)

this

may

evenifpower

the

coated

Use

the

tube

cause

surface.

discs,

clutch

end

a soft, dry

and

apply to

clothtoclean

the

a malfunction of stopping

Is turned on.

(See

fig. 25)

cover,

away

lining

out between the lining surfaces. (See fig. 27)

fig. 25

fig. 27

Page 13

9)

D)

Applicationtoclutch

Clean

away

any

of the clutch shaft, and apply the material evenly.

E)

Motor

assembly

Assemble

F)

Break-in

Perform a break-in operation soon after application of material to the lining surfaces.

a) Switch on

b)

After

more

Note: Iftoo much material Is applied to the lining surfaces, the motor might not

the

motor In the

operation

the

the motor is operating

than

100

cotton

motor.

times.

shaft

waste

adhered

opposite

normally,

to the

cogs

orderofdisassembly.

perform the break-In operation by operating the pedal

power is turned on.Ifthis happens, remove excessive material from the

Cleaning

When

shorten

Cleaning

A)

Remove

up

the

filter

the

filter is filled up with the

the

service

up:

the

life of

filterbypulling

the

cotton

motor

and

the

partAshown

waste,

reduce

the motor will be

efficiency.

in

29

heated

up. This

(a)

operate

friction

may

even if

disc surfaces.

0)

Replace

10)

Adjustment

The pull strength of the

the spring. When the

the

filter.

of

the

Clutch

end

ccwer;

speed

speed

pull

control

control lever

strength is adjusted too lighter, positioning accuracy

lever

strength

willbechanged

by relocating the hooked position of

m\7(

will

/

be Impaired.

Page 14

Adjustment of

The potentiometers to adjust the

a) f^aximum

The maximum

the

maximum

speed

(JIG, JTH, JTK and JTL)

speed

is adjustable by the potentiometer

speed

speeds

and back tacking

are

located on the front of the control box.

"MAX."

lower than 2000RPM. At ex-factory, it is adjusted the highest position.

speed

The lower

speed

will

b) Back tacking

The start back tacking speed is

upper

limit

back tacking is

The upper

back

tacking should be adjusted by the potentiometer "B.T." from 1000RPM to 2500RPM.

fig. 31

is convenient for the training the beginner. However, the longer

shorten

which is adjusted

limit

the

life of

the

clutch

and

brake

linings.

speed

(JTK

and JTL)

2000RPM

linearly

2000RPM

and the speed of forward portion of the end back tacking is

variable by pressing the pedal

at ex-factory.The speed of backward portion of the end

of the start back tacking speed and the speed of backward portion of the end

speed

from the synchronous

use

forward

from

speed

of the lower

180RPM

1500RPM.

to

to

HOW

In

case

the trouble,

1) Switch off

2) Pull out all

TROUBLESHOOTING

PROBLEM

Motor

does

start

when

main

switch

Motor

runs,

when

activating

sewing

pedal,

the

machine

start.

TO

the

connectors,

not

turning

on.

but

machine

does

motor.

not

CAUTION

JTG,

JTH.

CHECK

proceedasfollows:

then

reinsert

PROBABLE

Power supply

switch)

Power supply

protection

Motor winding

Plug for

clutch

in plug for

interrupted-

Plug for

brake not inserted.

Power

for

plug not inserted.

Fuse

Clutch air

narrow, or

use,

defective.

Control

not properly

synchronizer,

cord

synchronizerorclutch

supply

control

in control box

gap

clutch

box

THE

them.

CAUSE

cord

cord

switch)

defective.

defective:

clutch

cord

box

defective,

too

after

a long

lining

defective.

DRIVE

(plug, protection

connected.

(plug, cord,

defective.

clutch,

connection

and

brake

(plug,

cord)

or

open.

time

of

worn

down

or

CAUTION

JTK.

JTL.

UNITt

CORRECTIVE

Correct

with

Instructions.

Replace

Replace

repaired by

or

and

Replace

repair

connections

Plug in.

Replace

or plug in.

Replace

Adjust

clutch

ordance

If

necessary

brake

discs.

Replace

ACTION

connection

defective parts.

motor or

manufacturer.

defective

defective parts,

fuse.

with

control box.

in

have

parts

respectively.

air

gapinacc

Instructions.

replace

accordance

motor

or

clutch

and

Page 15

Motor

decreases

speed

considerably

stops

entirely.

Motor

Motor

Once

turned

machine

without

being

overheats.

overheats.

main

on

operates

pedal

actuated.

Stopisonly

possible

by

switching

switch

off.

or

PROBABLE

CAUSE

Voltage too low.

Machine or

trimmer) binding or

devices

seized.

Power rating of motor

for particular operation.

Control

Air

clutch

Machine or

trimmer) binding or

Clutch air

Clutch

box

channels

filled

and/or

defective.

within

with

devices

gap

brake

motor

lint.

(e.g.

seized.

too narrow.

coil

defective.

Motor

winding

Control

Two

phase

phase

motor.

Machine

actuates

Clutch air

Control

box

box

defective.

defective.

operation for three

pedalisjammed

by own weight.

gap

too narrow.

defective.

(e.g.

too

thread

low

and

thread

or

CORRECTIVE

ACTION

Have power supply checked,

Repair

Exchange

higher

Replace

Clean

machineordevices.

motor

for

another

power

rating.

control

air

channels

box.

in

motor

clutch.

Repair

Adjust clutch air

accordance

Replace

Replace

Replace

Check the power supply.

Replace

Adjust clutch air

accordance

Replace

machine

or devices.

gap

with

Instructions.

defective parts.

motor.

control

or repair pedal.

control box.

with

box.

gap

Instructions.

in

in

with

and

Machine

first

actuation

full

speed.

only

possible

switching

Irregular

or

stopping

continuation

operation

stop

signal

Stop

only

by

switching

Intermediate

speed

ranges

missing.

runs

only

positioning

maximum

runs

at

at

Stop

by

off.

of

after

given.

possible

off.

are

(Machine

at

or

speed.)

Cord of

connection

plug

Synchronizer

Control

synchronizer

in synchronizer or

broken.

defective.

box

defective.

torn off,

Hub of synchronizer in-

securely

TensionofV-belt

enough.

Machine pedal is

actuatesbyown

Positioning

machine

synchronizerismounted)

too

Synchronizer

Control

Synchronizer

Control

high.

fixed on

V-belt

speed

shaft

box

defective.

box

defective.

machine

not

taut

slips.

jammed

weight.

(speed

on

which

defective.

defective.

or

of

shaft.

Repair

Replace

Replace

Fix

Instructions.

Correct

with

Repair or

Adjust

speedinaccordance

Instructions.

Replace

Replace

Replace

Replace

cordorconnections.

synchronizer.

control box.

hubinaccordance

tensioninaccordance

Instructions.

replace

correct

positioning

synchronizer.

control box.

synchronizer.

control box.

with

pedal.

with

Page 16

PROBLEM

Motor

noise

and

vibration.

has

unusual

PROBABLE

Clutch

Clutch

Clutch

friction

defective.

Hub of

fixed

Control

TensionofV-beit

nottaut

CAUSE

air gap too

bearing defective.

and/or

brake

disc

worn

synchronizer

on machine shaft.

box defective.

enough.

Pulleys of motor

are not alined.

Additional

connected,

No

additional

functions

trimming,

foot

lifting,

{e.g.

wiping,

etc.)

defective.

Additional

(e.g.

valve is

knife

Control

\A/hen

ordering extra control box, printed circuit board, or

repair,

please

refer to

the

following tables.

device

device

magnet

jammed

jams,

box

cord

or magnetic

etc.)

defective.

wide.

lining, or

down

or

insecurely

too

taut

or

and

machine

improperly

wrong

or

defective

or burn out,

speed

CORRECTIVE

ACTION

Adjust clutch air gap.

Replace

Replace

Fix

instructions.

Replace

Correct

with

Alined.

Correct

replace

bearing.

defective parts.

hubinaccordance

control box.

tensioninaccordance

instructions.

connections,ifnecessary,

cord.

Repair devices.

Replace control box.

adjuster

assembly

with

for service or

1)

Control

I

box

TYPE

2) Printed circuit

PHASE

1

3

1

3

1

3

1

3

boards&Speed

"M"

P.O.

Board

MTS-N5801101 MTS-N5801501

MTS-N5801201

adjuster

MTS-N5801501

( I

P.O.

assembly

Board

"C"

P.O.

Board

fvlTS-N5801401

PARTS

NUMBER

MTS-N5905501

IV1TS-N5905101

MTS-N5905601

MTS-N5905201

MTS-N5905701

MTS-N5905301

MTS-N5905801

MTS-N5905401

Speed

MTS-N5905901

adjuster

ass'y

Page 17

Page 18

Note

Part

No.

MTS-N2007601~

MTS-N7001213

MTS-N7000112

SL-4Q5tQ41-SE

MTS-N2007701

NM-6100002-SE

MTS-N2500501

SL-4040841-SE

M'^-N2007a01

MTS-N1300301

MTS-N7001006

MTS-N7000606

MTS-N20Q7901

MTS-N70006Q7

MTS-N7t0011t

MTS-N2501401

MTS-N1300401

MTS-N7100316

MTS-N2501501

MTS-N2700501

SL-4041091-SE

MTS-N2006001

WT-0400QQ1-KE

MTS-N7000109

MTS-N5101601

MTS-N5101501

MTS-N7000113

M7S-N5906501

MT5-N2500601

MTS-N7100112

MTS-N10Q2301

MTS-N2QQ80Q1

VVT-04Q(X>04-KE

SM-1040e01-SE

MTS-N7000114

MTS-N20081QT~

MTS-N1002401

MTS-N

2003201

MTS-N1002501

MTS-N7001001

MTS-N7001003

MTS-N7001222

MTS-N2009501

MTS-N7000608

•20

MTS-N5200601

•10

MTS-N52007Q1

MTS-N2Q0B301

MTS-N7000115

•20

MTS-N5101701

•10

MTS-N5101B01

•20

MTS-N5102201

•10

MTS-N5102301

NU-6100002-SE

WS-1020002-KR

WP-1052001-SE

MTS-N7000207

MTS-N20096Q1

MTS-N2008401

MTS-N2009701

MTS-N20085Q1

MTS-N1002601

MTS-N70002Q5

MTS-N7001216

WS-Oe20002-KR

NM-6060002-SE

•20

MTS-N7109941

•10

MTS-N7109942

MTS-N7000116

MTS-N2008601

MTS-N7000117

•20

MTS-N2008701

•10

MTS-N

2008801

MTS-N20C8901

MTS-N

7000122

SM-8051030-SE

MTS-N7001223

♦10

MTS-N7109943

•10

MTS-N2009001

•10

MTS-N7000116

"74

MTS-N1300501

For single

10

...

... For 3

... For JTG

... For JTK

phase

type

type

20

...

70

...

71 ...... For JTH type

72

...

phase

motor

Description

Pulley

coverB

Washer

Screw

Screw

Pulley

cover

NutMIO

Tutje

Screw

Cover

Adjusimeni

Ball

bearing

Key

Output

shall

Key

Spring

Filter

ass'y

Ciulch-end

Connectorass'y

Strain

relief

Bushing

Screw

Friction

disc

Toothed

ioci<

Screw

Brake

coil

ass'y

Clutch

coilass'y

Screw

Moving

disc

Nylon

ring

Spring

Bearinghousing

Washer

Toothed

lock

Screw

Screw

Collar

Flywheel

Fan

Motor-end

cover

Ball

bearing

Ball

bearing

Thrust

wave

Retainingring

Key

Rotor

ass'y

Rotorass'y

Collar

Screw

Frame

ass'y

Frameass'y

Frame

ass'y

Frame

ass'y

NuiMiO

Spring

washer

Washer

Belt

adjusting

Retaining

ring

Belt tightener hinge pin

Belt

tightener

Washer

Belt

tightener

Mounting

bolt

Washer

Spring

washer

Nut

MS

Terminal

block

Terminal

block

Screw

Terminalwasher

Terminal

screw

End-cover

End-cover

Strain

relief

Grounding

screw

Set screw

Washer

Capacitor

Mounting

plate

Screw

Control

box

motor

•73

•74

•75

•76

A

screw

6302

cover

washer

ass'y

washer

6202

6203

washer

M10

bolt

hinge

pin

M8

... .. For JTL type

... .. For JTG, JTH type

.. For JTK. JTL type

..

... For JTH. JTL type

...

Big

Big

Big

Big

BiH

Biia

BiEl

gpi

Bn

MTS-N

1300602

MTS-N59Q5901

MTS-N5906001

MTS-N59Q6101

MTS-N59C6201

MTS-N7000119

MTS-N20091D1

MTS-N2009201

MTS-N2009301

MTS-N2009401

MTS-N7109944

MTS-N7109945

MTS-N7000120

MTS-N2700601

MTS-N71C9946

NM-6040002-SE

WS-04t0002-KR

WP-0430801-SE

SM-4041001-SE

MTS-N7109947

MTS-N7000121

MTS-N5705601

MTS-N5705701

WP-0531001-SE

MTS-N7109926

MTS-N570580t

MTS-N5705901

MTS-N5706001

MTS-N5706101

MTS-N5706201

MTS-N5706301

MTS-N5706401

MTS-N5706501

MTS-N5801101

MTS-N5801201

MTS-N7001221

MTS-N7001220

MTS-N58C1501

MTS-N7109948

MTS-N7109927

MTS-N2501601

MTS-N2501701

SM-4041Q01-SE

ST-4040321-SH

MTS-N5801301

MTS-N5801401

MTS-N7109949

MTS-N2501801

MTS-N7109950

MTS-N5906601

MTS-N7000111

MTS-N2500601

MTS-N2500901

MTS-N5901101

MTS-N5901201

MTS-N2501001

SM-1C51601-SE

MTS-N2S01101

MTS-N7000304

MTS-N7000407

MTS-N2501901

MTS-N5101901

MTS-N5102001

MTS-N6102101

MTS-N5901301

MTS-N7109935

MTS-N7109951

MTS-NS905501

MTS-N5905601

MTS-N5905701

MTS-N5905801

MTS-N5905101

MTS-N5905201

MTS-N5905301

MTS-N59054Q1

MTS-N57022Q1

MTS-N570660t

MTS-N5706701

Control

Speed conirollever ass'y

Speed controlleverass'y

Speed conirol lever

Speed controlleverass'y

Screw

Washer

Mounting plate A

Mounting

Mounting

Potentiometer

Potentiometer

Screw

Cap

Reslster

Nut

^rlng

Washer

Screw

Rectllier

Screw

Transformer

Transformer(Ph.

Washer

Capacitor

Connector

Connector

Connector

Connector

Connector

Connector

Connector

Connector panel

Printed

Printed

Nylon

Nylon

Printed

(Dover

Mounting

Strain

Strainrelief

Screw

Tapping

Printed

Printed

(Dover

Nylon

Fuseholder

Tachogenerator ass'y

Mounting

Spacer

Spacer

Magnetcarrier plate

Magnet carrier plate

Magnet

Screw

Cover

Retainingboll

NutSM

Nylon

Clutch-endcover ass'y

Rotorand

Rotorand

Synchronizer

Fuse

Special

CDontiol

(Dontrol box

(Dontrol box

(Doniioi

(Dontrol

(Dontrol

Conirolboxass'y

(Dontrol

Springass'y

Springass'y

Spring

. with trimmer an(J wiper

. with trimmer, wiper

. with

trimmer,

with

trimmer,

presser

foot

wiper

wiper,

lifter

and

and

back

Pox

plate B

plate

with

washer

(Ph.

220V)

115V)

panel

ass'y

panel

ass'y

panel

ass'y

panel

ass'y

panel

ass'y

panel

ass

panel

ass'y

ass'y

circuit

boardMass'y

circuit

tioardMass'y

washer

washer

circuit

boardLass'y

ass'y

spacer

relief

screw

circuit

board

circuit

board

ass'y

bushing

screw

for

magnet

carrier

plate

15(64

band

flywheel

flywheei

lining

application

box

ass'y

ass'y

ass'y

boxass'y (ti5V)

boxass y

boxass'y

box

ass'y

ass'y

presser

back

tacker

tacker

ass'y

switches

(HSV)

(115V)

(115V)

(115V)

(220V)

'y (220V)

(220V)

(220V)

cass'y

cass'y

carrier

holder

ass'y

ass'y

material

(ttSV)

(itSV)

(itSV)

(22QV)

(220V)

(220V)

|22QV)

foot lifter

and

plate

Page 19

EXPLODED

116

/

372 350

VIEW

119

1

Life

120

116 ®

n (S» •

-"»

Loading...

Loading...