Page 1

MS-1261A-DWS

INSTRUCTION MANUAL

Page 2

CONTENTS

1. SPECIFICATIONS ............................................................................................................ 1

1-1. Specications of the sewing machine head ..................................................................... 1

1-2. Specications of the control box ....................................................................................... 1

2. SETUP ..............................................................................................................................2

2-1. Setting up the sewing machine .......................................................................................... 2

2-1-1. Adjusting the sewing machine head ........................................................................................ 2

2-1-2. Changing the position of the operation panel ........................................................................3

2-2. Installing the thread stand .................................................................................................. 3

2-3. Oiling and draining of oil .................................................................................................... 4

3. PREPARATION BEFORE SEWING ................................................................................ 5

3-1. Attaching the needle ........................................................................................................... 5

3-2. Threading the machine head .............................................................................................. 6

3-3. Adjusting the thread tension .............................................................................................. 7

3-4. Adjusting the stitch length ................................................................................................. 8

3-5. Adjusting the needle guard ................................................................................................ 9

3-6. Adjusting the looper thread cam ...................................................................................... 10

3-7. Adjusting the feed dog height .......................................................................................... 10

3-8. Adjusting the take-up thread tension control lever ........................................................ 11

3-9. Adjusting the position of the intermediate tension release lever and needle thread

tension controller .............................................................................................................. 11

3-10. How to adjust the cloth puller .......................................................................................... 12

3-10-1. Adjusting the cloth puller belt and its longitudinal position .............................................12

3-10-2. Adjusting the inclination of the cloth puller belt.................................................................13

3-11. LED hand light ...................................................................................................................13

3-12. To use the sewing machine with a cloth puller for sewing heavy-to medium-weight

materials ............................................................................................................................. 14

3-12-1. Replacing the feed dog .........................................................................................................14

3-12-2. Changing the throat plate .....................................................................................................14

3-12-3. Adjusting the difference in height of the presser foot ......................................................15

3-12-4. Replacing the needle thread guide ......................................................................................15

3-13. Table of replaceable gauges ............................................................................................. 16

3-14. Adjusting the material edge detector .............................................................................. 17

3-15. Needle cooler ..................................................................................................................... 18

3-15-1. Adjusting the position of the blow pipe ............................................................................... 18

3-15-2. Adjusting the air ow.............................................................................................................18

3-16. Chain-off thread cutter (suction of thread waste) .......................................................... 18

4. HOW TO USE THE OPERATION PANEL .....................................................................19

4-1. Explanation of the operation panel switch ..................................................................... 19

4-2. Operation to be done at rst ............................................................................................ 20

4-2-1. Selection of the language .......................................................................................................20

4-3. How to select a sewing pattern ........................................................................................ 23

4-4. How to change the sewing data ....................................................................................... 24

4-4-1. Method of changing the sewing data ..................................................................................... 24

4-4-2. Method of selecting a specic sewing data item .................................................................. 24

4-4-3. How to change the part number, process or comment for the sewing pattern data .........26

i

Page 3

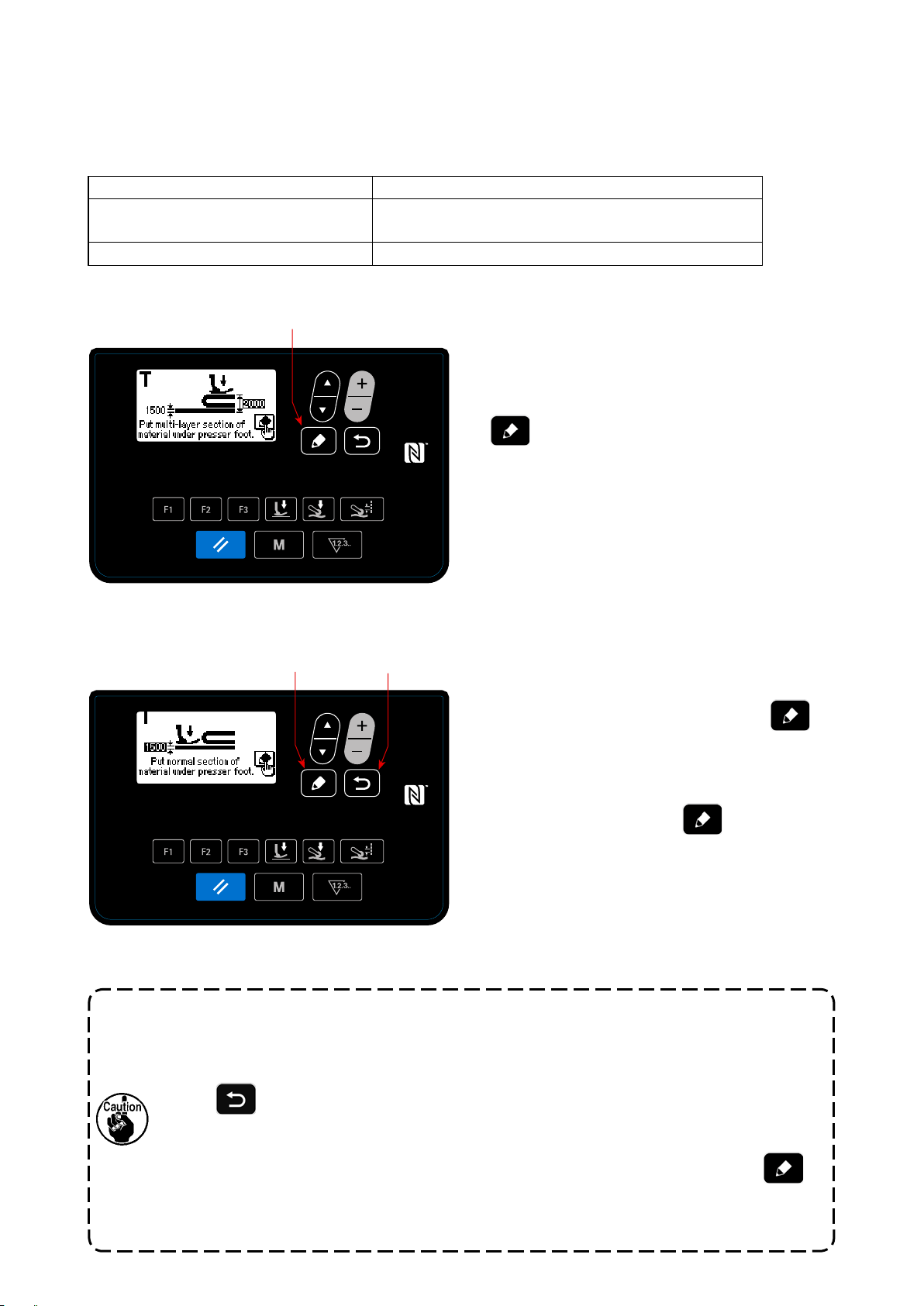

4-4-4. How to carry out teaching of the multi-layered section of material .................................... 27

4-4-5. Sewing data on a free sewing pattern ...................................................................................28

4-4-6. How to edit a step sewing pattern .......................................................................................... 34

4-4-7. How to carry out the teaching of the number of stitches ....................................................38

4-4-8. List of sewing data ...................................................................................................................39

4-5. How to edit/check the data other than sewing data ....................................................... 44

4-5-1. Memory switch data .................................................................................................................45

4-5-2. Counter function ...................................................................................................................... 50

4-5-3. How to copy / newly create a pattern ..................................................................................... 54

4-5-4. How to use the warning function ...........................................................................................56

4-5-5. How to use the F key ...............................................................................................................59

4-5-6. Checking the version information .......................................................................................... 62

4-5-7. Adjusting the contrast of the LCD of the operation panel ...................................................62

4-5-8. Communication function .........................................................................................................63

4-6. Information ......................................................................................................................... 64

4-6-1. Simple lock ............................................................................................................................... 64

4-7. List of errors ...................................................................................................................... 65

4-8. External interface .............................................................................................................. 69

4-8-1. USB ...........................................................................................................................................69

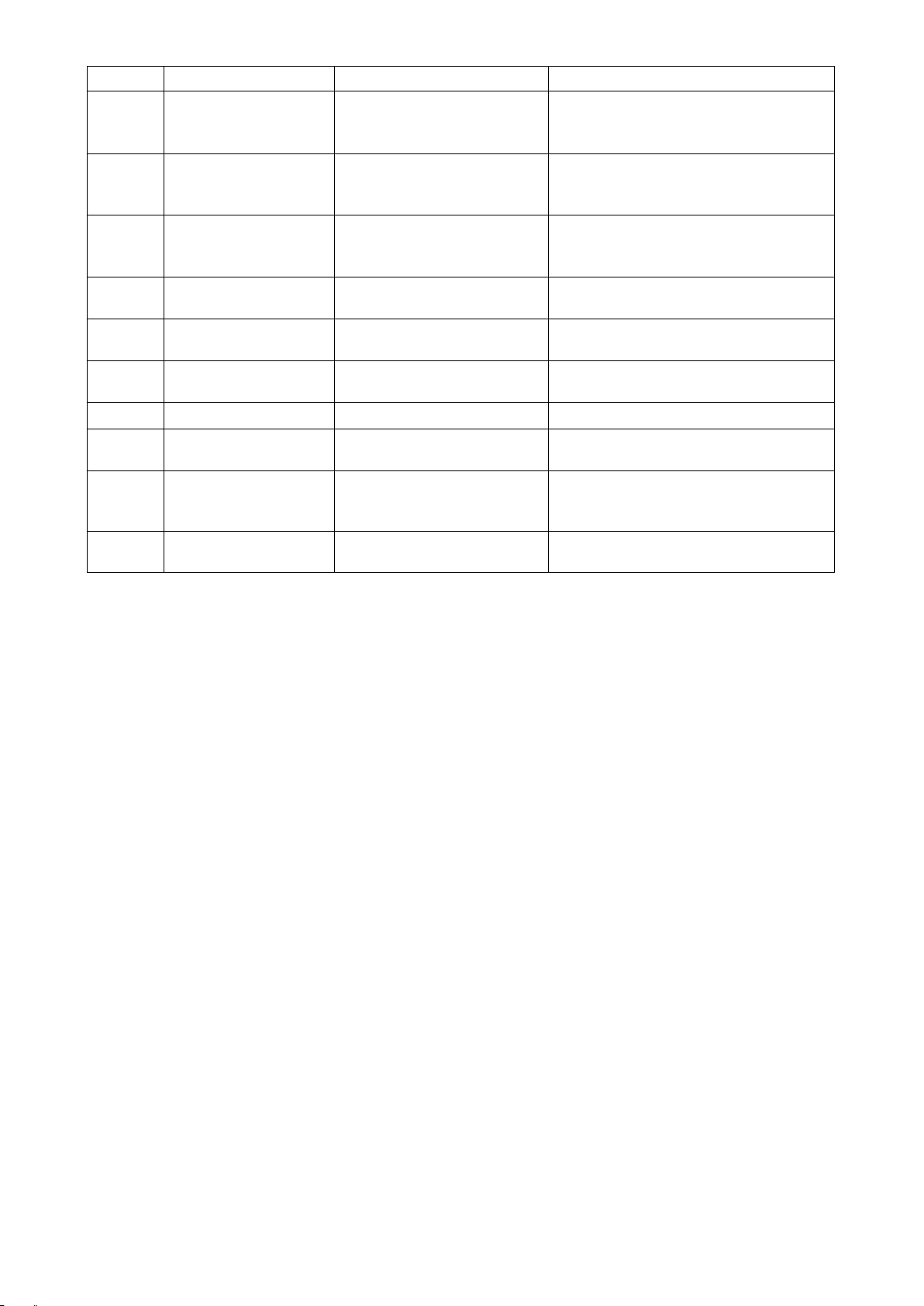

4-8-2. NFC ............................................................................................................................................70

5. CARE ............................................................................................................................. 71

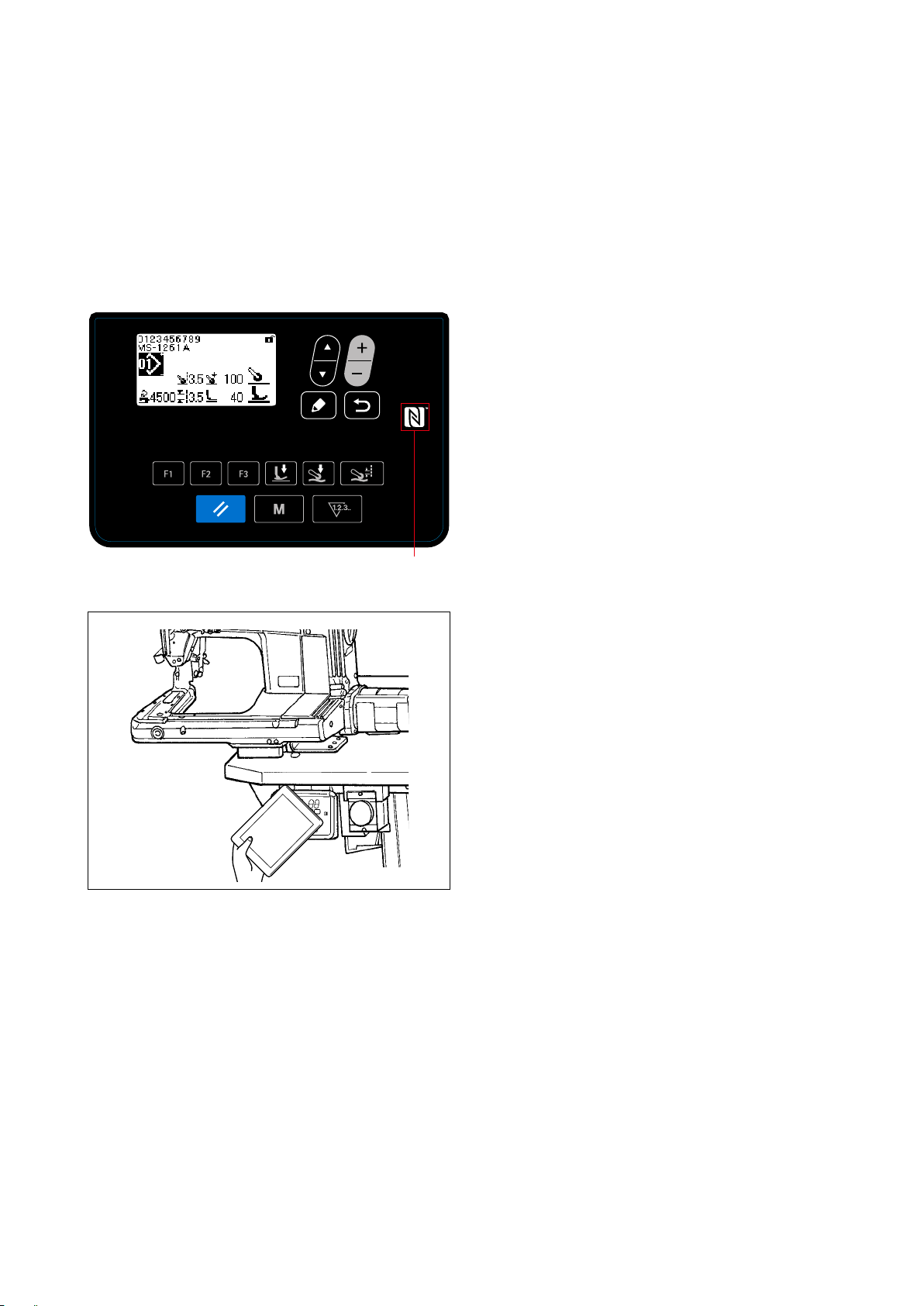

5-1. Oil quantity in the oil tank ................................................................................................. 71

5-2. Lubricating the chain off thread cutter ............................................................................ 71

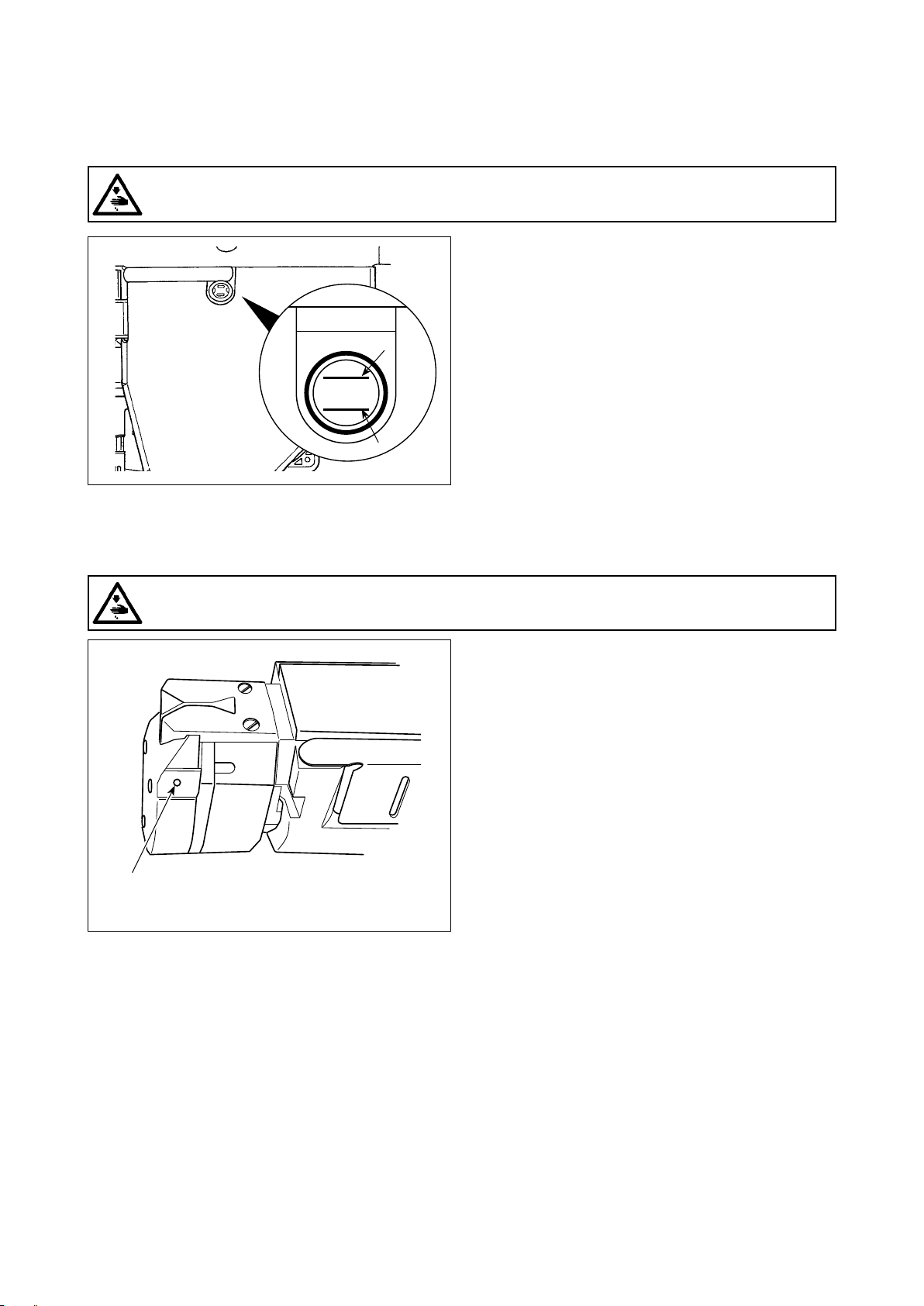

5-3. Changing the cloth puller belt .......................................................................................... 72

5-4. Cleaning ............................................................................................................................. 73

5-5. Replacing the fuse ............................................................................................................. 74

ii

Page 4

1. SPECIFICATIONS

1-1. Specications of the sewing machine head

MS-1261A DWS

Sewing material type

Space

M Heavy-weight materials

Needle gauge

F 6.4mm(1/4)

Model MS-1261A△DWS MS-1261AM△DWS

Application For heavy- to extra-heavy-weight materials For medium- to heavy-weight materials

Max. sewing speed 5500 sti/min

Number of needle 3

Needle UY×128GAS #16 to 22

Cloth puller system Electronic control

Height of presser foot 10 mm

Stitch length 1.4 to 4.2 mm

Needle gauge 6.4 mm(1/4)

Circumference of cylinder 194 mm

Lubricating oil JUKI NEW DEFRIX OIL No. 1 or JUKI CORPORATION GENUINE OIL 7

Noise

Extra heavy-weight materials

(standard)

UY×128GAS #16 to 21

(Standard #21

- Equivalent continuous emission sound pressure level (LpA) at the workstation:

A-weighted value of 84.5 dB ; (Includes KpA = 2.5 dB) ; according to ISO 10821- C.6.2

-ISO 11204 GR2 at 4,500 sti/min.

- Sound power level (LWA);

A-weighted value of 91.0 dB; (Includes KWA = 2.5 dB); according to ISO 10821- C.6.2

-ISO 3744 GR2 at 4,500 sti/min.

)

(Standard #19

)

1-2. Specications of the control box

Supply

voltage

Frequency 50Hz/60Hz 50Hz/60Hz 50Hz/60Hz

Operating

environment

Input 820VA 820VA 680VA

Temperature : 0 to 35˚C

3-phase

220 to 240V

Humidity : 90% or less

Single phase

220 to 240V

Temperature : 0 to 35˚C

Humidity : 90% or less

– 1 –

Single phase

220 to 240V CE

Temperature : 0 to 35˚C

Humidity : 90% or less

Page 5

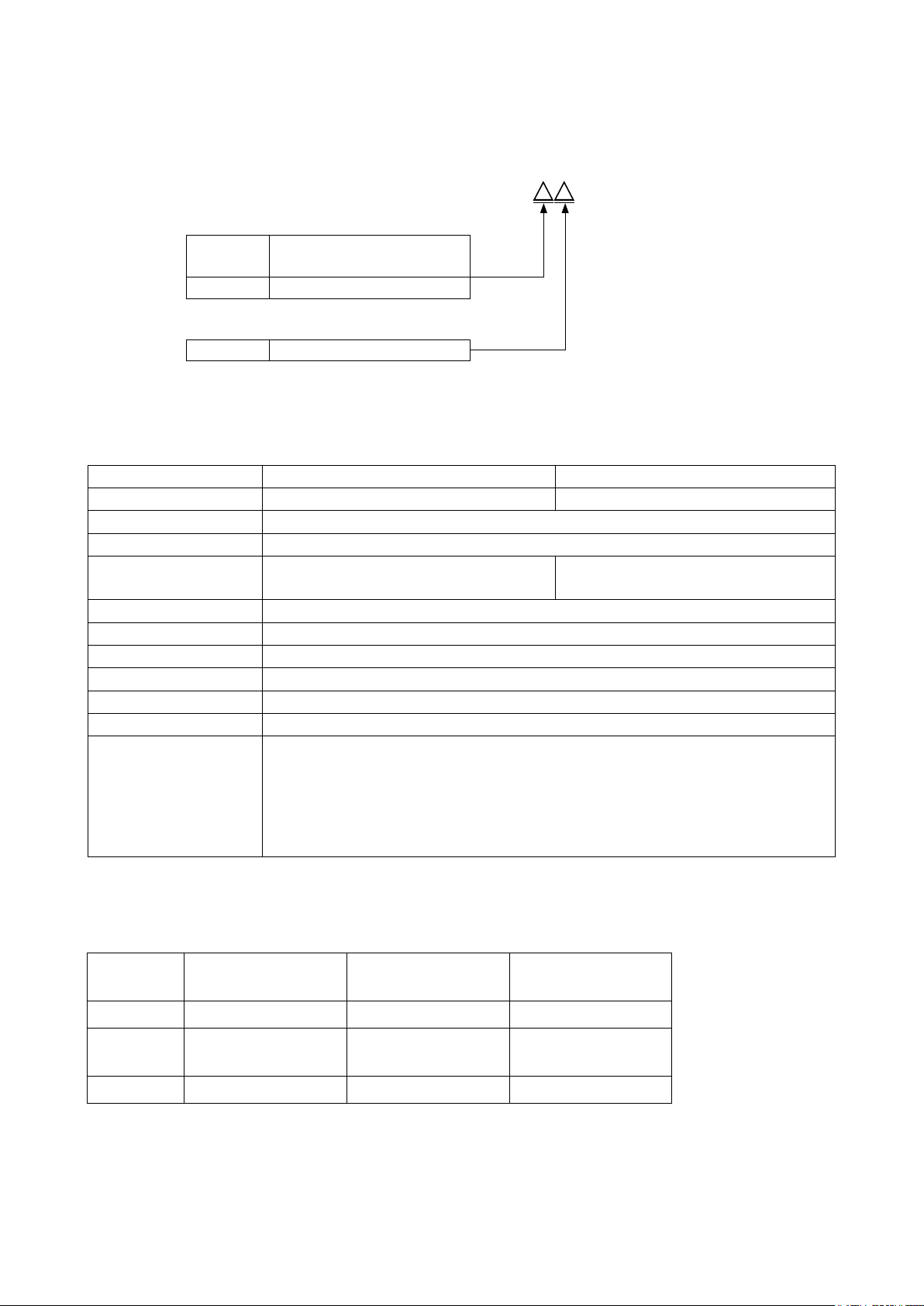

2. SETUP

2-1. Setting up the sewing machine

Fix the sewing machine on the oor with adjuster

bolts ❶ (four pieces).

❶

Be sure to move the sewing machine with two or more persons.

❶

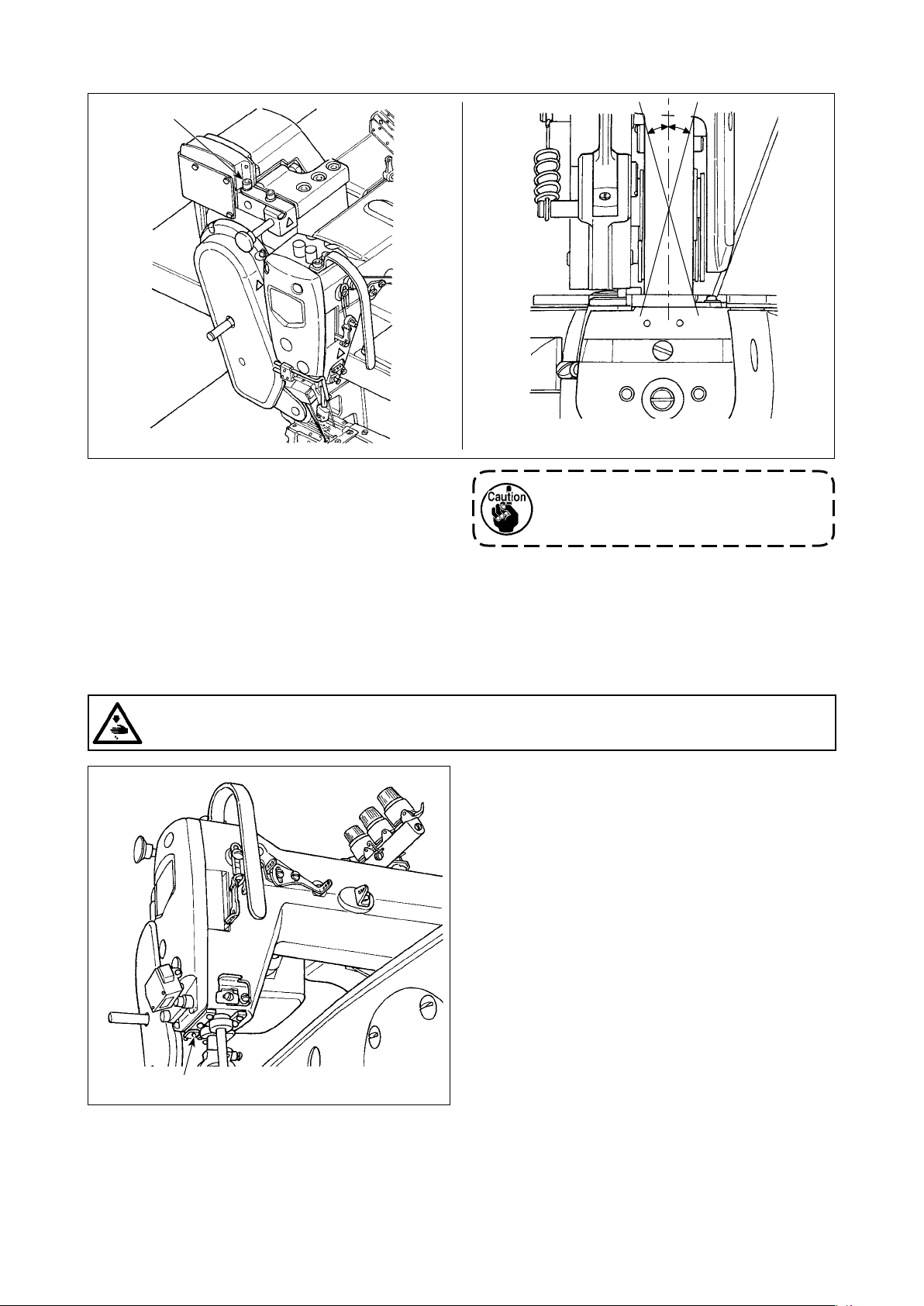

2-1-1. Adjusting the sewing machine head

Loosen bolts ❶ (four pieces) and adjust the height of sewing machine.

1. Total weight of the sewing machine, machine table and control box is 110 kg or more. It is

necessary to adjust the sewing machine height with four or more persons.

2. Adjust the sewing machine height so that it is levelled.

❶

❶

– 2 –

Page 6

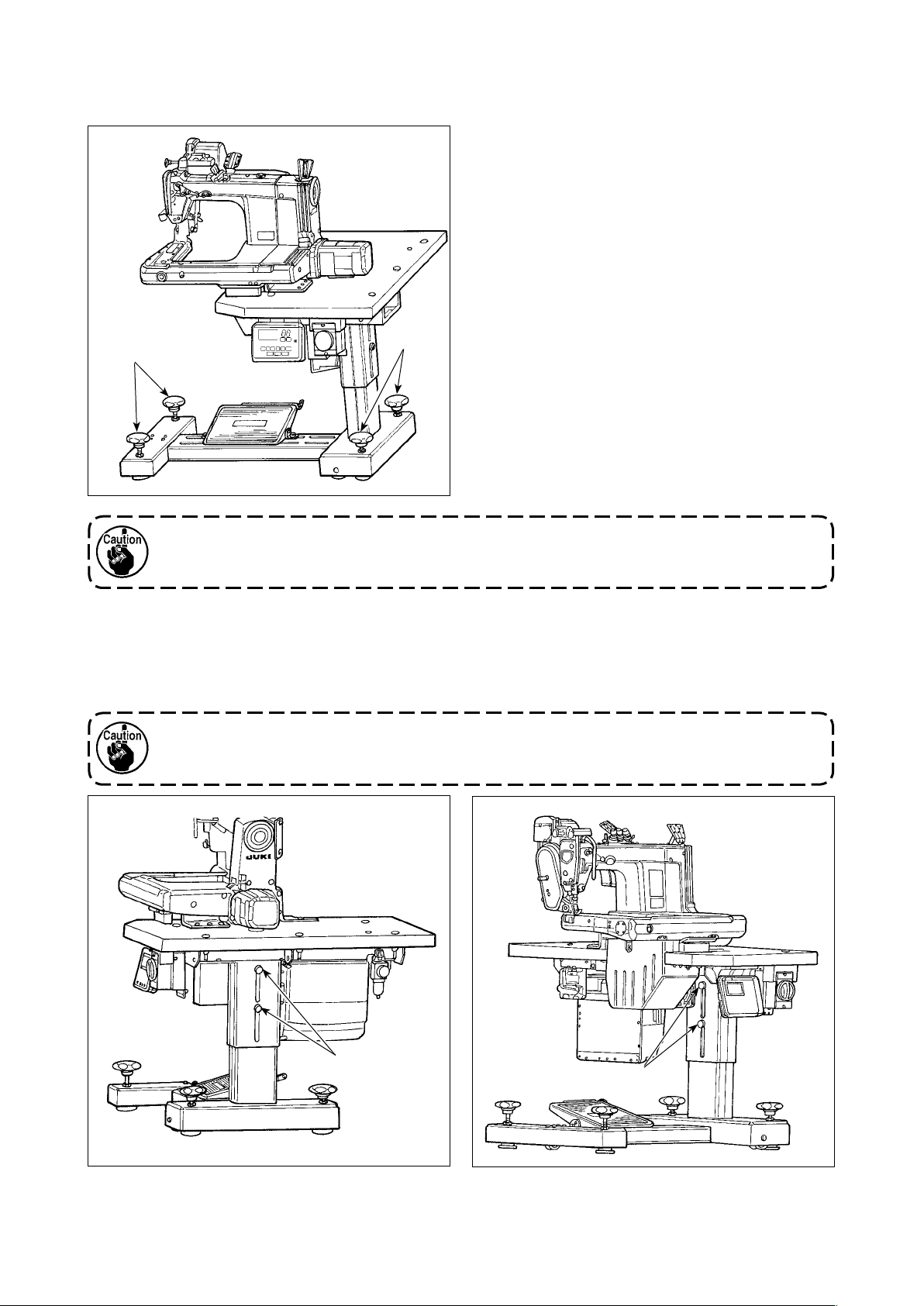

2-1-2. Changing the position of the operation panel

The operation panel has been installed on the undersurface of the sewing machine table at the time of deliv-

ery. When you install it on the top surface of the sewing machine table, it is necessary to pass panel cord ❶

through hole ❸ in the lower section of motor cover ❷.

At the time of shipment

(undersurface of the sewing machine table)

In the case of changing the position of the operation

panel to the top surface of the sewing machine table

❶

❷

❸

❶

2-2. Installing the thread stand

1) Assemble the thread stand device. Fit it

in the hole in the table. Tighten locknut

so that the thread stand does not uc-

❶

tuate.

2) Fix thread stand bracket ❷ on the table

with wood screw ❸.

❸

❷

❶

❸

❷

– 3 –

Page 7

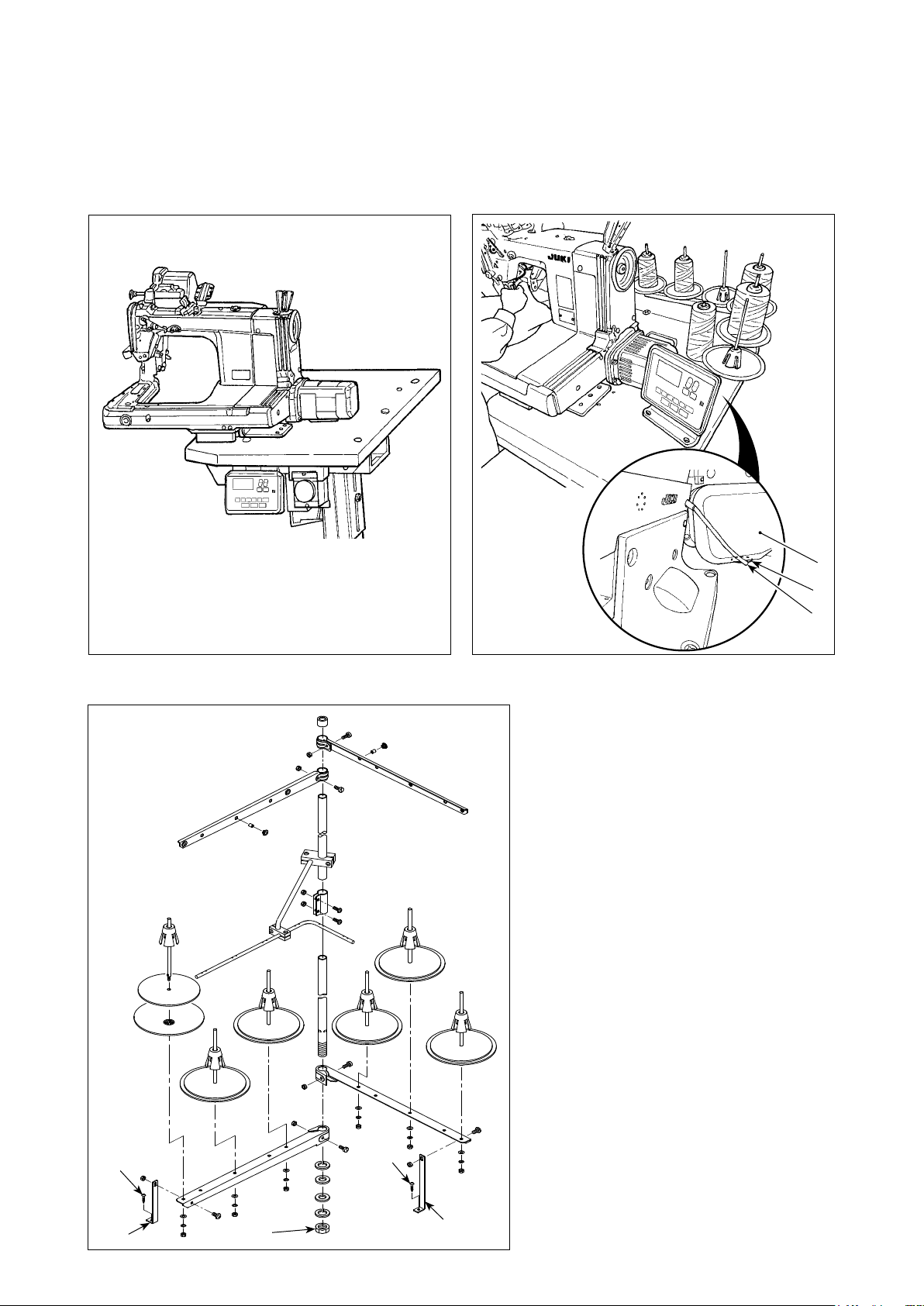

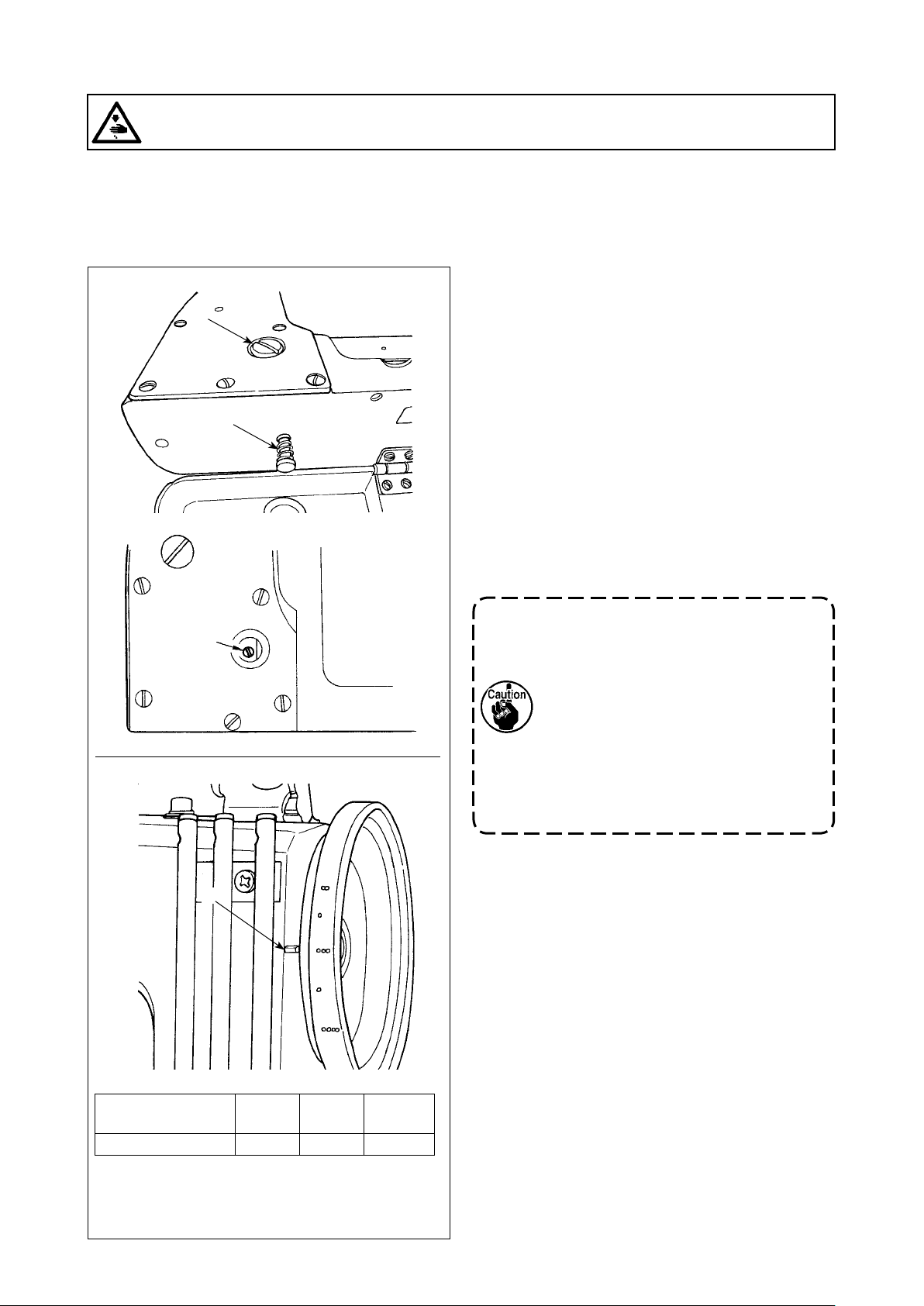

H

L

2-3. Oiling and draining of oil

Before putting your sewing machine into use, ll the oil tank with the oil supplied with the sewing machine.

1) Feeding oil

❶

A

Fill the oil tank with the aforementioned oil until

the oil surface reaches between two indicator

lines (upper marker line A and lower marker line

). After lling the oil tank, be sure to t oil sight

B

window ❶ back to its home position.

Detach oil sight window ❶.

Put JUKI New Defrix Oil

No. 1 or JUKI CORPORA-

TION GENUINE OIL 7 into

the oil tank through the oil

hole.

B

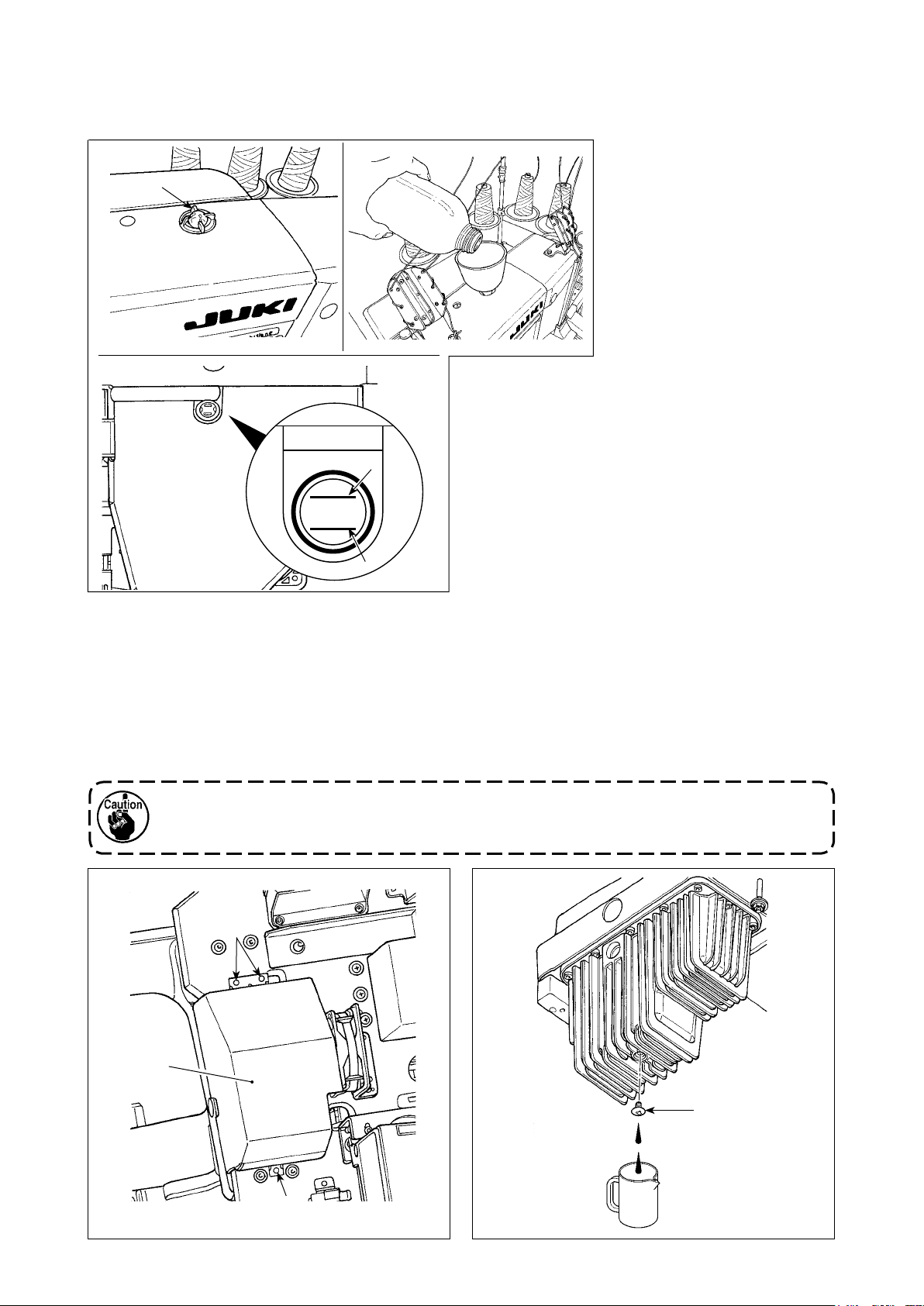

2) Draining the oil and changing the oil

Firstly, loosen wood screws ❶ (three pieces). Detach oil tank cover ❷. Then, loosen screw ❸. Discharge

the oil remaining in the oil tank completely. After discharging the oil, be sure to tighten screw ❸.

In order to increase durability of the sewing machine, it is recommended to change the oil with new oil af-

ter the rst four weeks have passed since the rst use of the sewing machine, then carry out an oil change

at an appropriate interval.

The waste oil must be disposed of properly according to the relevant laws and regulations in

your area.

❶

❷

❸

❶

– 4 –

Page 8

3. PREPARATION BEFORE SEWING

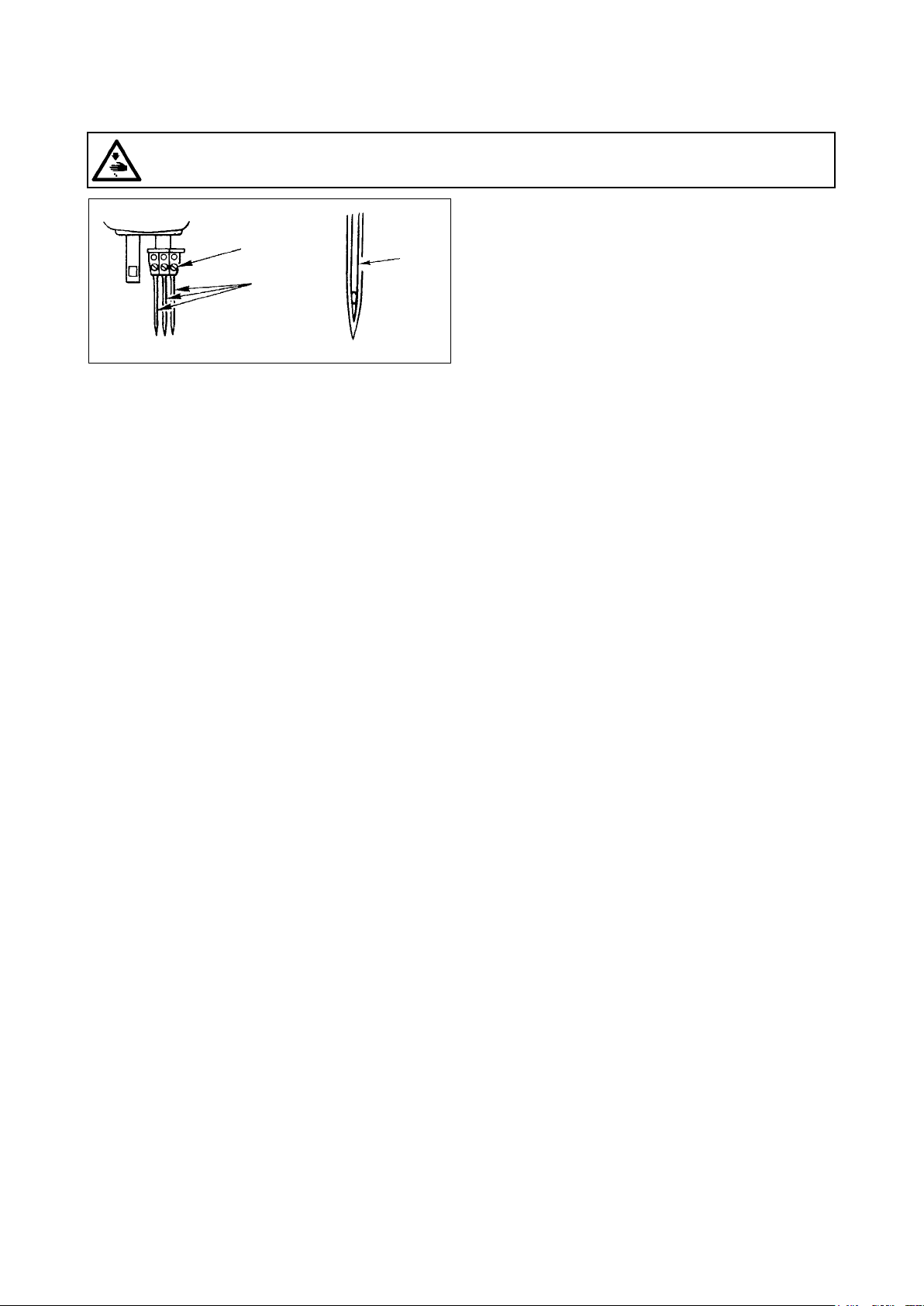

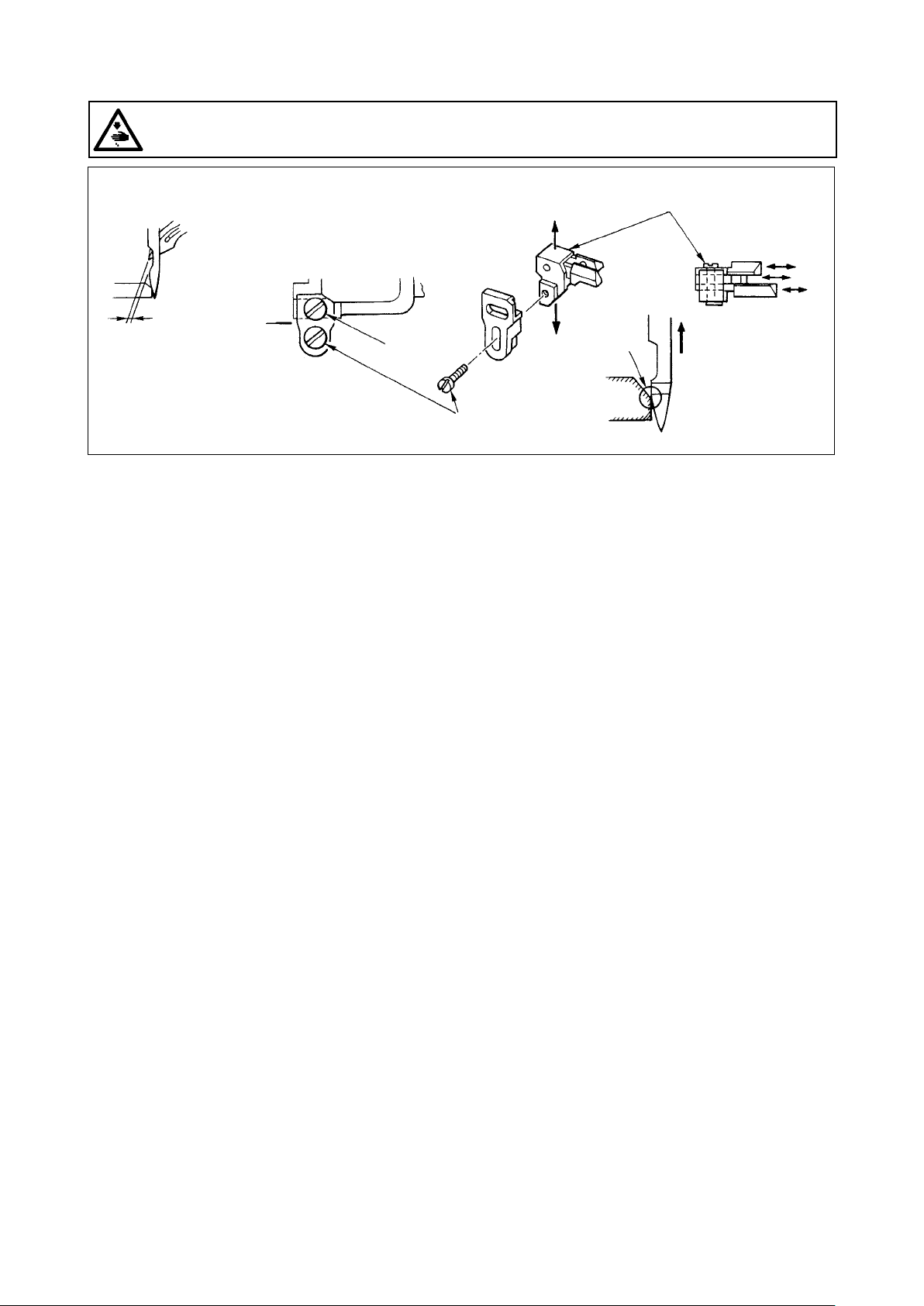

3-1. Attaching the needle

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

❷

❶

Long

groove

Make a choice of the needle count in accordance

with thickness of the thread and type of the material

to be used.

1) Turn the hand wheel until the needle bar reaches

to the highest position of its stroke.

2) Loosen screw ❷ in the needle clamp, and turn

needles ❶ so that the long groove on the respec-

tive needles is brought in front of you.

3) Insert the needles into the needle clamp hole until

they will go no further.

4) Securely tighten needle clamp screw ❷.

– 5 –

Page 9

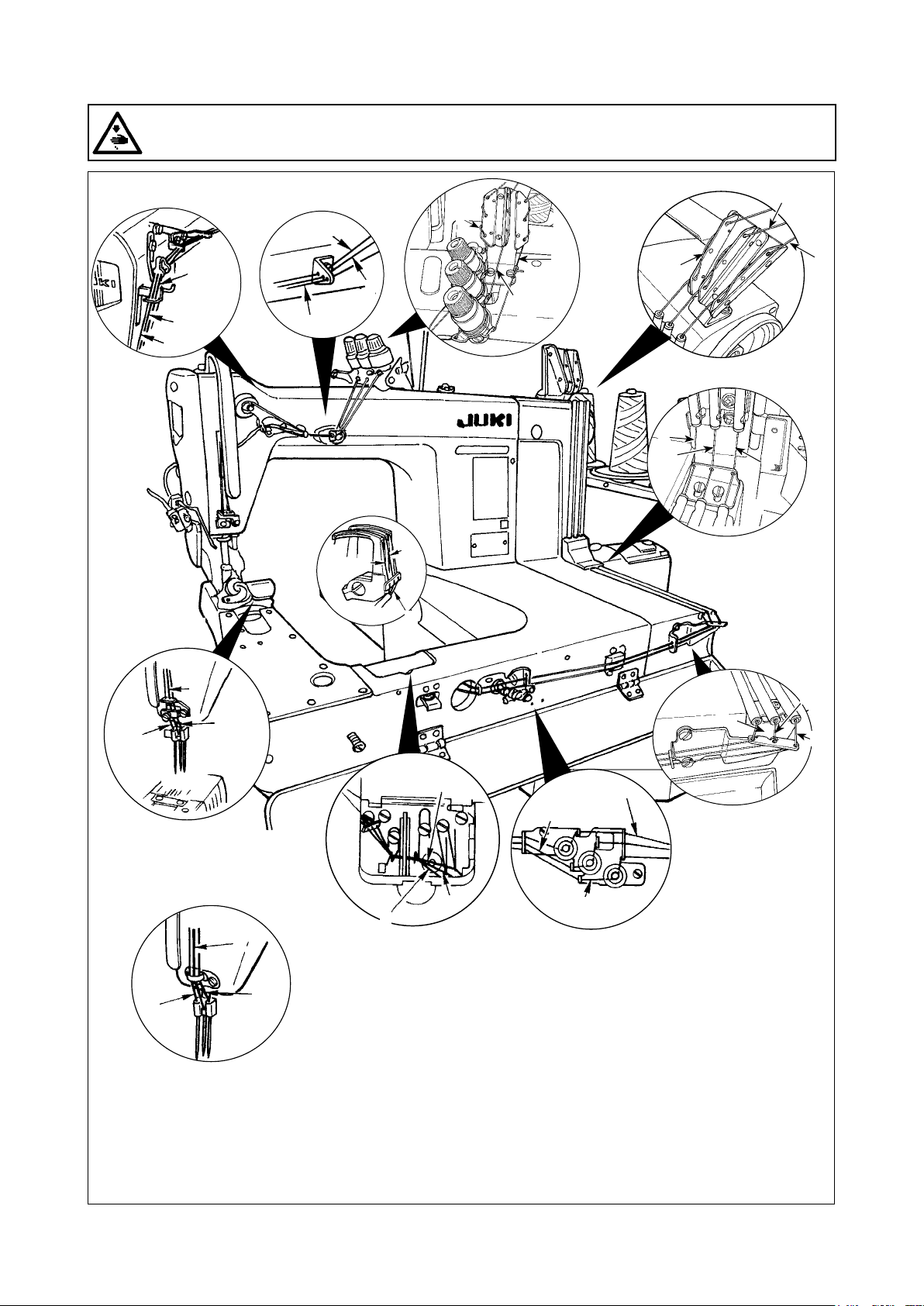

3-2. Threading the machine head

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

c

③

a

b

c

②

a

a'

c

❶

c'

❶

a

b

b

b'

①

b'

a'

❷

❷

c'

MA-1261A

c

MA-1261AM

c

a'

c'

❻

b'

b

a

b'

a'

c'

④

❺

c'

b

a

b'

a'

a'

b'

c'

❹

❸

④

Pass the needle thread on the sewing machine head in numerical order form ①.

Pass the looper thread on the sewing machine head in numerical order from ❶.

a = Right-hand needle thread b = Intermediate needle thread c = Left-hand needle thread

a' = Right-hand looper thread b' = Intermediate looper thread c' = Left-hand looper thread

– 6 –

Page 10

3-3. Adjusting the thread tension

1) Adjusting the needle thread tension

❶

Turn thread tension nut ❶ clockwise to increase or

counterclockwise to reduce the needle thread ten-

sion.

2) Adjusting the looper thread tension

❷

Turn tension adjusting screw ❷ clockwise to in-

crease or counterclockwise to reduce the looper

thread tension.

– 7 –

Page 11

3-4. Adjusting the stitch length

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

For the stitch length, adjust it on the sewing machine alone. Then, adjust the feed amount of the cloth puller

belt. Then, nely adjust the stitch length while visually checking the nished state of sewing material.

Adjusting the stitch length of the sewing machine alone

■

1) Remove screw ❸, and loosen the lock screw in

the feed rock cam.

❸

❶

2) Lightly pressing push-button ❶, turn the hand-

wheel by hand.

3) When push-button ❶ bites, the sewing machine

will stop running.

4) In the aforementioned state, further pressing the

push-button ❶, turn the handwheel by hand.

5) Aligning the marker dot (to be used for reference)

on the handwheel with marker line ❷ on the tim-

ing belt cover, release your hand from push-button

.

❶

6) Tighten the lock screw in the feed rock cam.

7) Attach screw ❸ in place.

Lock screw

1. Never press the push-button ❶ while

the sewing machine is in operation.

2. Be sure to operate the sewing machine

after tightening the lock screw.

3. Never operate the machine with screw

❸ removed.

4. The lock screw has a locking setscrew

to prevent the screw from loosening.

The lock screw head can be damaged

if you forcefully remove it.

❷

Marker dot on the

handwheel

Stitch length 2 3 4

* The aforementioned marker dot is only a

reference. Be aware that the adjustment result

may differ with the material used.

。。 。。。 。。。。

– 8 –

Page 12

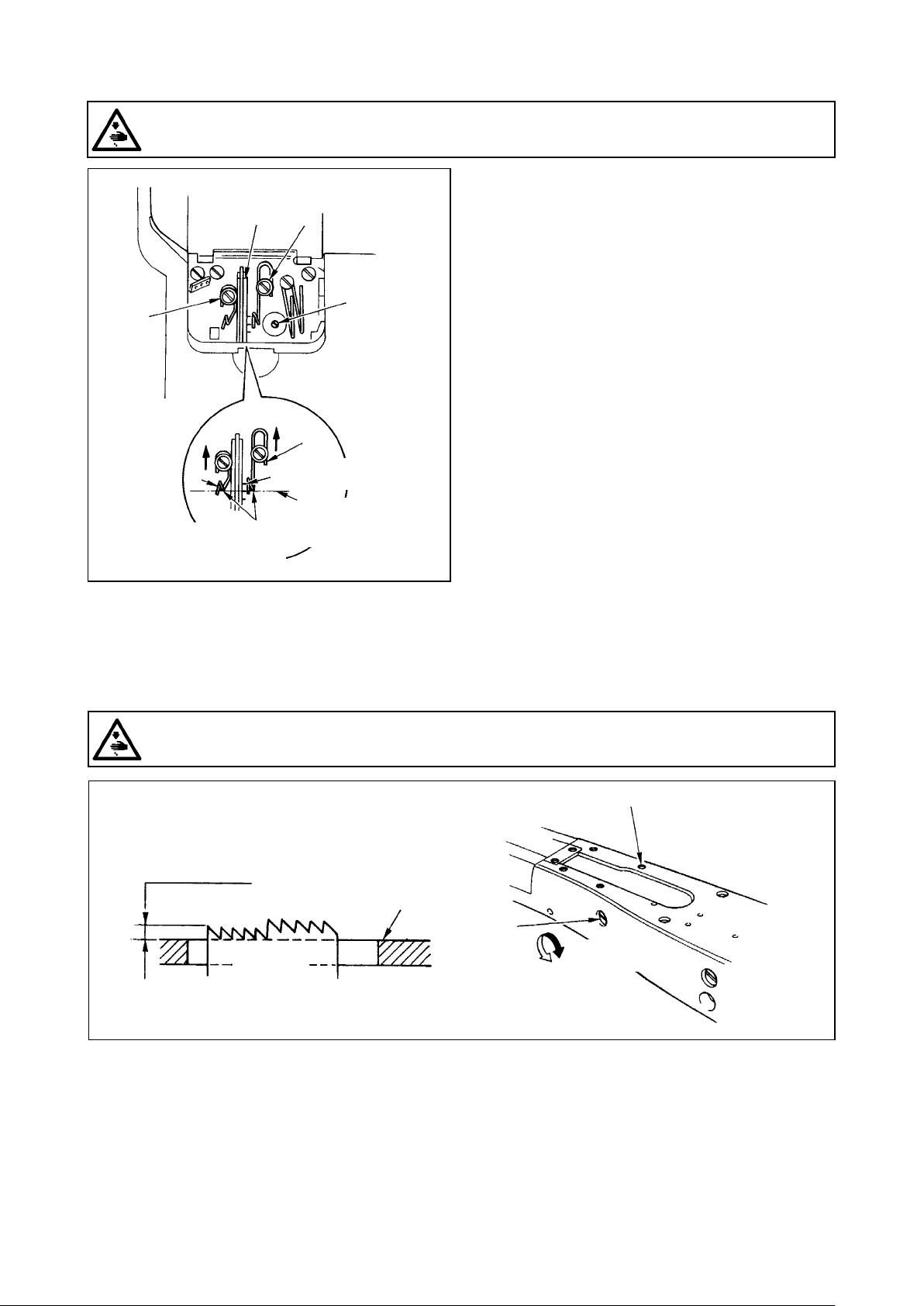

3-5. Adjusting the needle guard

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

❸

Press the

section below

MS-1261A :

0.1~0.15mm

MS-1261AM :

0.05~0.1mm

❶

❷

The needle guard has been mounted on the feed dog. It therefore necessary to adjust the needle guard

whenever the feed amount is changed.

the needle

eyelet.

(Adjusting the clearance provided between the needle and the looper)

1) Turn the hand wheel to make the top end of the looper align with the center of the needle.

2) Loosen screw ❶, move the entire unit of the needle guard to the right or left to make the needle guard

press the needle so that the clearance of 0.1 to 0.15 mm is provided between the looper and the needle.(0.05

to 0.1 mm for MS-1261AM)

(Adjusting the vertical position of the needle guard)

1) Turn the handwheel to bring the needle guard at a position where the needle guard starts pressing the

needle.

2) Loosen screw ❷, and move the entire unit of the needle guard up or down so that the needle guard is lo-

cated at a position where it does not press and deform needle thread loops (just below the needle eyelet).

(Adjusting the clearances between the respective needles and loopers)

If the clearances between the respective loopers and needles are not equal after the clearance between

each needle and looper has been adjusted by moving the entire unit of the needle guard, adjust so that the

equal clearance is provided between the respective loopers and needles following the steps described below.

1) Turn the handwheel to make the top end of the looper align with the center of the needle.

2) Loosen screw ❸, move the respective needle guards to adjust so that the equal clearance is provided

between the respective needles and loouers.

– 9 –

Page 13

3-6. Adjusting the looper thread cam

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

❶ ❹

❷

❸

❻

❺

Align the marker line with

the bottom end of the

thread guide.

Position of the looper thread

can for cotton thread

Standard position

of the looper thread

cam

Loosen screw ❷, and adjust looper thread cam ❶

so that the looper starts drawing the thread when it

starts returning to its home position after it has pro-

jected the most.

Adjusting the looper thread cam thread guide

■

1) Align the end face of thread guide ❻ to the marker

line on thread guide ❻. Then adjust thread guide

so that its end face is ush with the end face of

❺

thread guide ❻.

The standard position of the thread guide is ob-

tained when the end face of the thread guide is

aligned with the center marker line.

2) When using a cotton thread, loosen screws ❸

and ❹, and align the end faces of thread guides

and ❻ to the marker line located far side. At

❺

this time, it is not necessary to re adjust the looper

thread cam timing.

3-7. Adjusting the feed dog height

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

❶

1.4mm

Throat plate

❷

Feed dog

Higher

The top end of the feed dog should rise 1.4 mm above the surface of the throat plate when the feed dog is in

the highest position of its stroke.

Adjusting the feed dog height

■

1) Loosen screw ❶ in the side plate of the bed and remove it.

2) Remove the screw ❶, and loosen a hexagon socket head screw under the screw ❶ with an L-shaped

hexagon wrench key.

3) Adjust the feed dog height by turning feed driving amount adjusting shaft ❷.

4) Fix the shaft with the hexagon socket head screw and tighten screw ❶.

Lower

– 10 –

Page 14

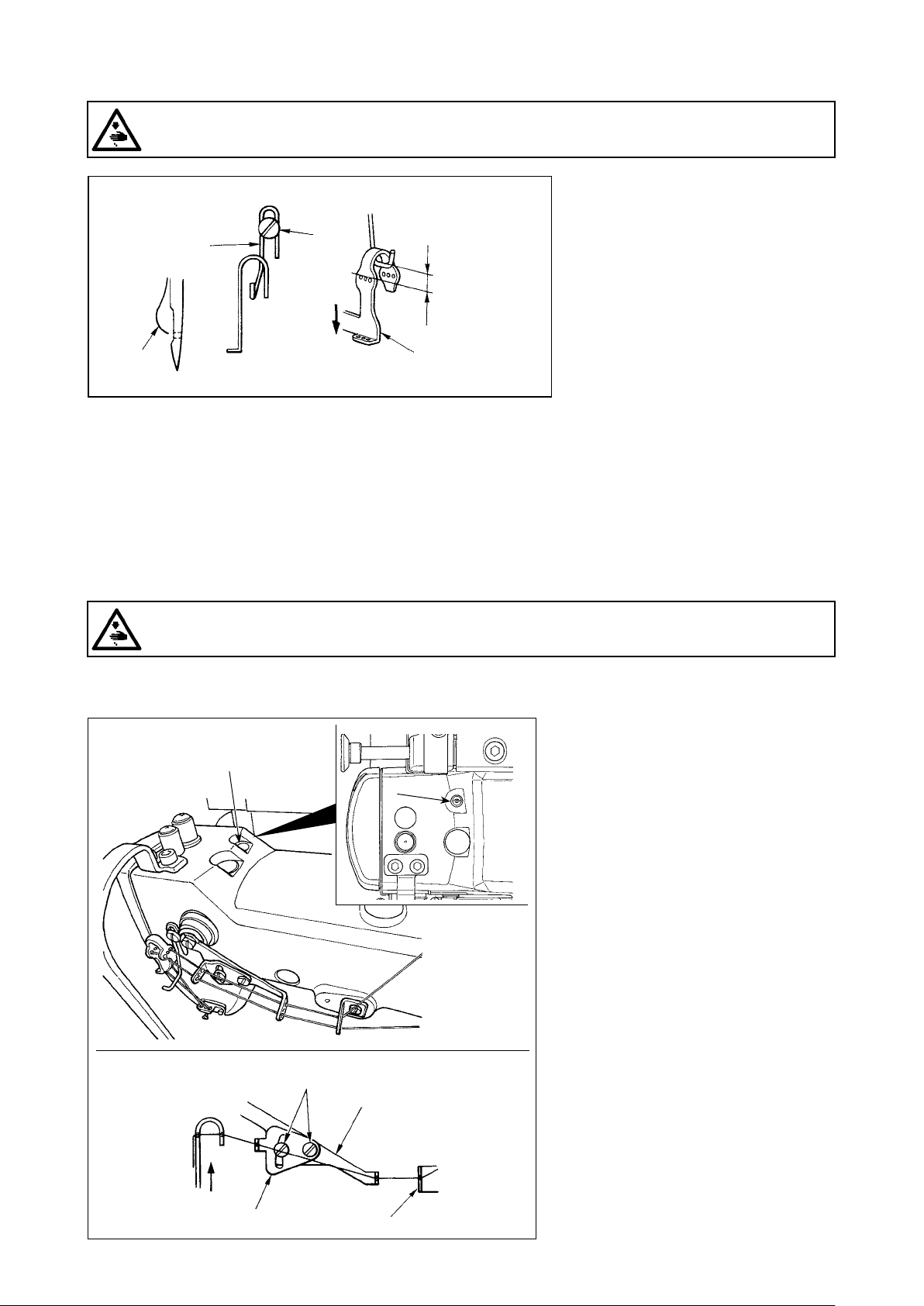

3-8. Adjusting the take-up thread tension control lever

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

Needle thread loop size is determined

by adjusting the position of take-up

❶

point dead

Needle

thread loop

❷

Lowest

MS-1261A

: 3 mm

MS-1261AM

: 0 mm

❸

2) Adjust so that, when the needle bar is in the lowest dead point, the top end of the thread tension control

lever is positioned 3 mm above the top end of thread hole in needle bar thread take-up lever ❸. (0 mm for

MS-1261AM)

3) Lowering thread tension control lever ❶ decrease the loop size. Lifting the lever increases it.

thread tension control lever ❶.

The needle thread loop size changes

in accordance with the thread and

material used. So, adjust the thread

loop size upon occasion.

1) Loosen two screws ❷, and adjust

the position of the thread take-

up lever guide by moving it up or

down.

3-9. Adjusting the position of the intermediate tension release lever and needle thread ten-

sion controller

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

Adjust the position of intermediate thread tension releasing lever ❶ and thread guide ❹ of the needle thread

tension controller as described below.

1) Turn the handwheel to bring the nee-

❷

❻

dle bar to the highest dead point.

2) Remove rubber cap ❷. Loosen

setscrew ❻ locating under the rub-

ber cap. Adjust intermediate thread

tension release lever ❶ so that the

thread coming out of intermediate

needle thread guide ❸ is horizontal.

3) Then, loosen two screws ❺, and

adjust the position of thread guide ❹

of the needle thread tension control-

ler so that the thread coming from

intermediate thread tension releasing

lever ❶ makes a beeline.

Highest dead

point

❹

❺

❶

❸

– 11 –

Page 15

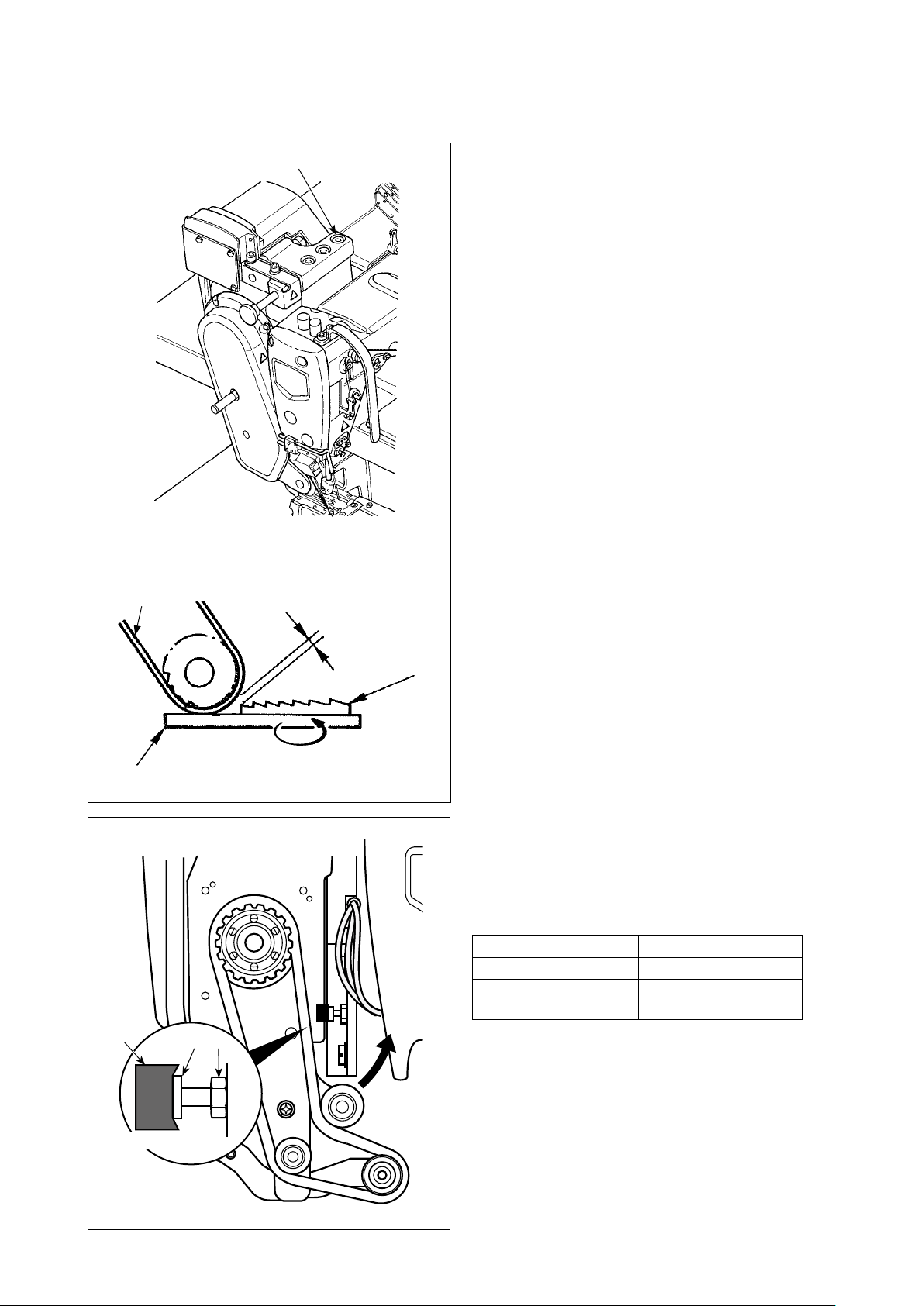

3-10. How to adjust the cloth puller

3-10-1. Adjusting the cloth puller belt and its longitudinal position

Cloth puller belt

❶

3 to 4mm

Feed dog of

the sewing

machine

(largest feed

pitch)

1) Loosen hexagon head setscrews ❶ (three piec-

es).

Maximize the feed amount of the main body of

sewing machine. Adjust the feed amount to 3 to

4 mm by moving the cloth puller back and forth

when the feed dog approaches closest to the belt.

Throat plate

❹

Slightly sinks

❷

❸

2) Loosen screw ❷ and adjust the longitudinal posi-

tion of the cloth puller so that the head of screw ❷

comes in contact with rubber ❹ to such an extent

that rubber ❹ slightly sinks.

3) Tighten nut ❸ to secure the cloth puller.

SM9051603SC

❷

NM6050003SC

❸

Cloth puller base

❹

binding part

Screw

Nut

Anti-vibration rubber

– 12 –

Page 16

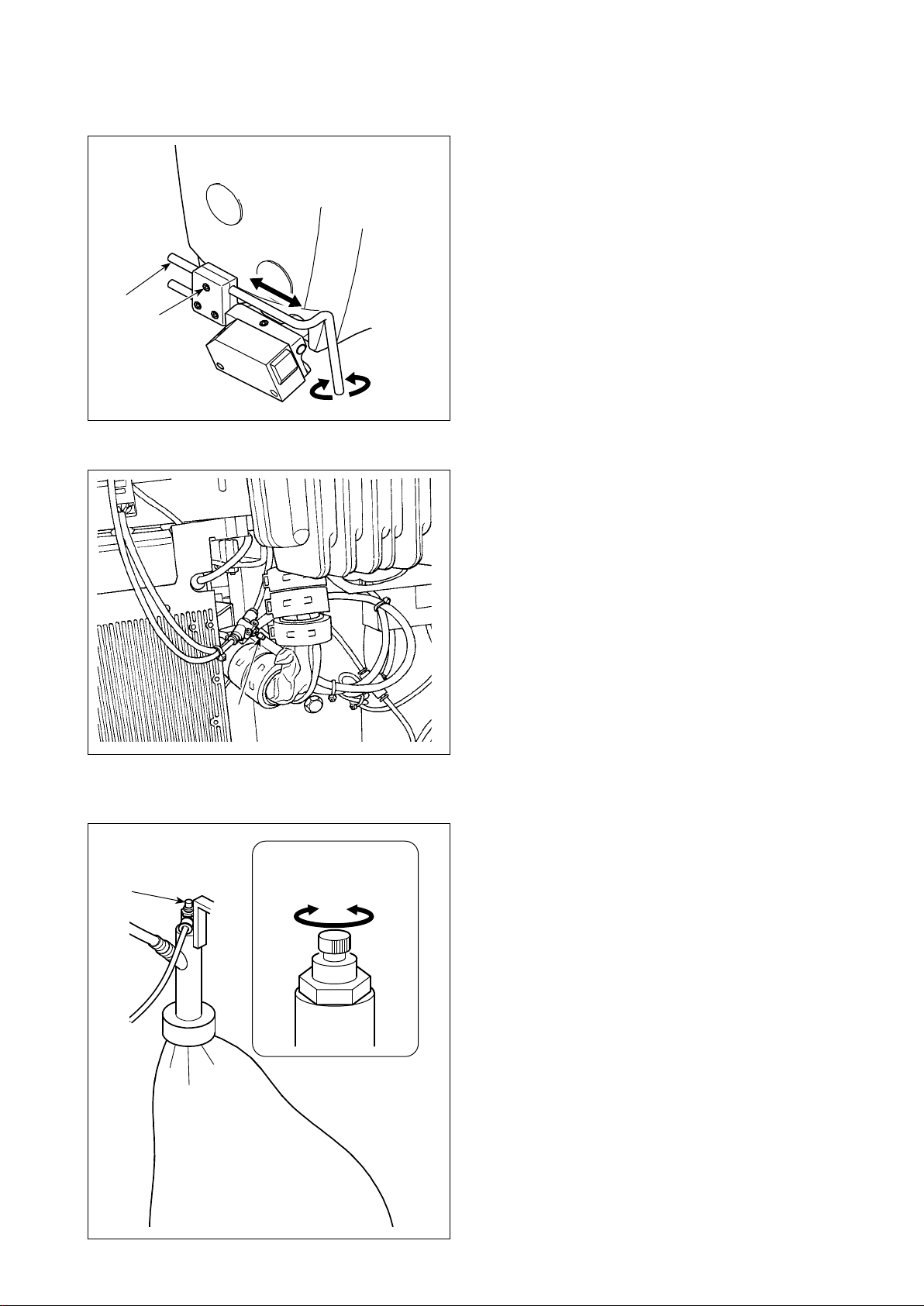

3-10-2. Adjusting the inclination of the cloth puller belt

❷

1) Loosen hexagon head setscrews ❷ (two pieces).

Rotate the cloth puller so that it is in parallel with

the feed dog.

θ

θ

If the cloth puller inclines (as shown

with θ), the chain-off thread skipping

may occur.

3-11. LED hand light

WARNING :

When adjusting the sensor, neither put your hand close to the needle entry area nor put your foot on

the pedal in order to protect against injuries.

❶

* This LED is intended to improve operability

of the sewing machine and is not intended for

maintenance.

The sewing machine is provided as standard with an

LED light which illuminates the needle entry area.

Intensity adjustment and turn-off of the light is carried

out by pressing switch ❶. Every time the switch is

pressed, the light is adjusted in intensity in ve steps

and is turned off in turn.

[Change of intensity]

1

⇒

...... 4

⇒

5

⇒

1

Bright⇒...... Dim⇒Off⇒Bright

In this way, every time the switch ❶ is pressed, the

hand lamp status is changed in repetition.

– 13 –

Page 17

3-12. To use the sewing machine with a cloth puller for sewing heavy-to medium-weight ma-

terials

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

The MS-1261A has been developed to sew extra heavy-weight materials as standard. Various kinds of gauges have been prepared to enable the machine to be used for sewing heavy- to medium-weight materials. Replace the gauge, when sewing heavy- to mediumweight materials, following the procedure described below.

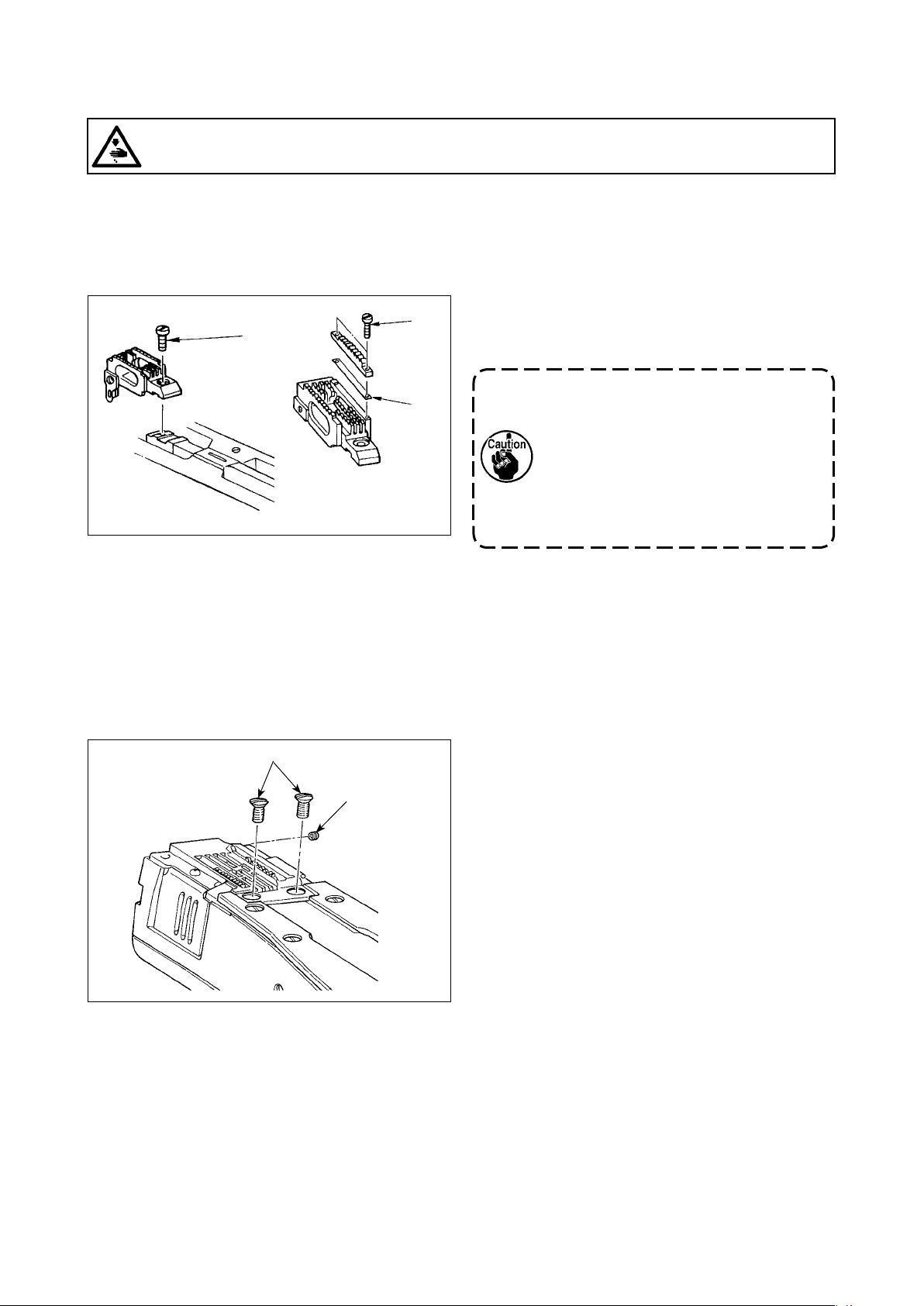

3-12-1. Replacing the feed dog

Remove the throat plate. Loosen screw ❶ in the

❶

❶

feed dog and remove the feed dog. Then, replace

the feed dog with an appropriate one.

Each of the feed dogs for heavy- to

❷

medium-weight materials has been

designed so that it can be used only

by replacing it without adjusting the

feed dog height. However, it is really

necessary to adjust the feed dog height,

refer to "3-7. Adjusting the feed dog

height" p. 10

3-12-2. Changing the throat plate

❶

❷

To change the height in difference on the

★

righthand side of the feed dog

Loosen two serews ❶ in the adjusting feed dog and

remove spacer ❷ (plate thickness: 0.5 mm).

Many different types of spacers are available.

Detach throat plate setscrews ❶ (two pieces) and

(one piece). Then, change the throat plate with an

❷

appropriate one.

– 14 –

Page 18

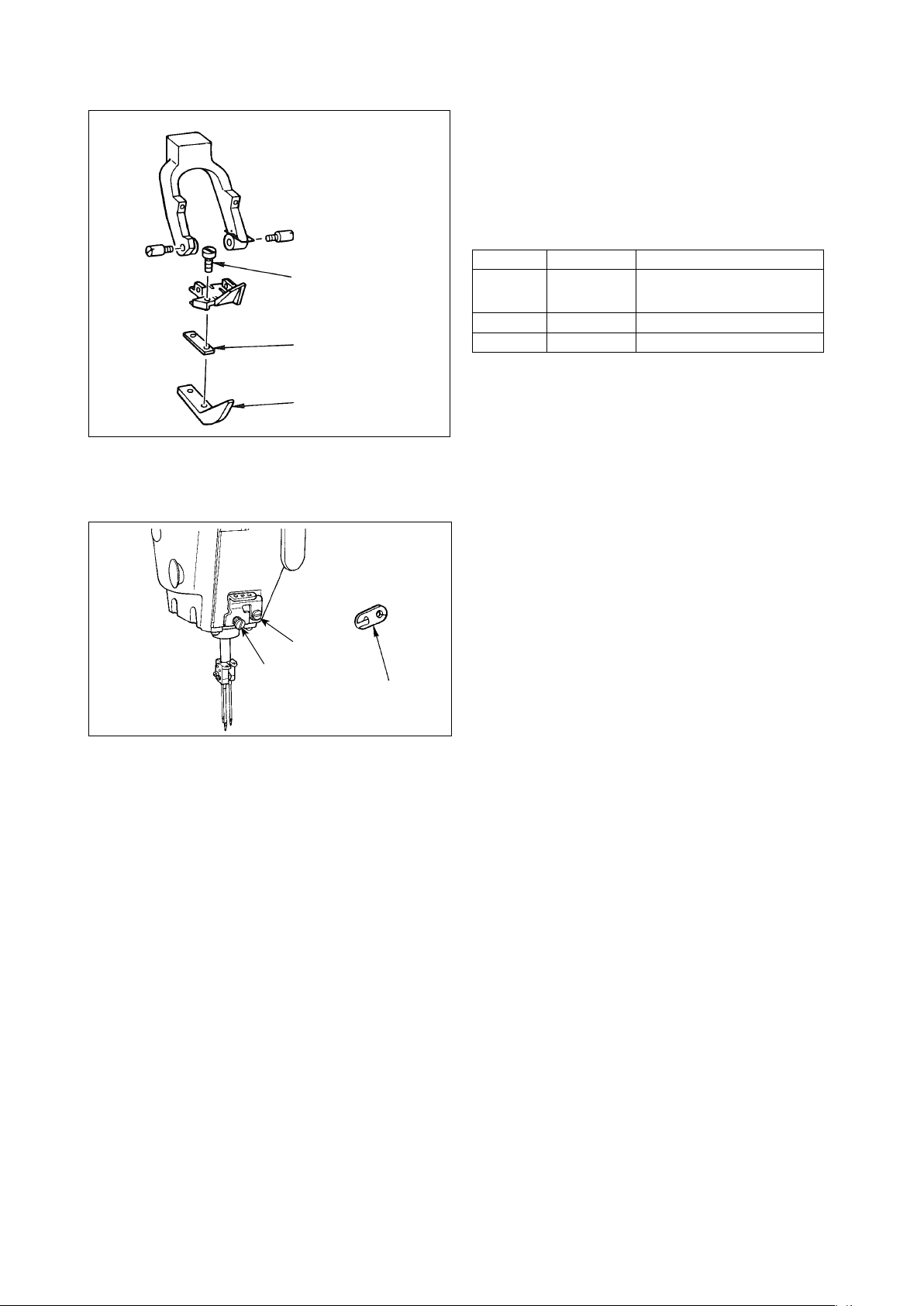

3-12-3. Adjusting the difference in height of the presser foot

Remove two screws ❷ that are used to retain ad-

justing presser foot ❶, and adjust the difference in

height of the presser foot by replacing spacer ❸.

Thicknesses of spacers that match the respective

throat plates and feed dogs are as shown in the

table.

No. Plate Thickness Specication

(Standard L: 3.5 mm)

❷

❸

❶

1 1.0mm Extra heavy-weight mate-

2 0.5mm Heavy-weight materials

3 None Medium-weight materials

To replace spacer ❸ with a spacer (0.5 mm or

none), replace screw ❷ with a shorter one (L=3.0

mm SS5060310SP).

3-12-4. Replacing the needle thread guide

rials (standard)

❶

❷

❸

When sewing a medium-weight material using a thin

thread, larger needle thread loops will be produced

and they will be likely to tilt causing stitch skipping.

To prevent the aforementioned trouble, replace

thread guide ❶ located above the needle clamp with

an appropriate one.

Loosen screw ❷ that is used to x thread guide ❶,

and replace the thread guide with thread guide ❸ for

medium-weight materials.

– 15 –

Page 19

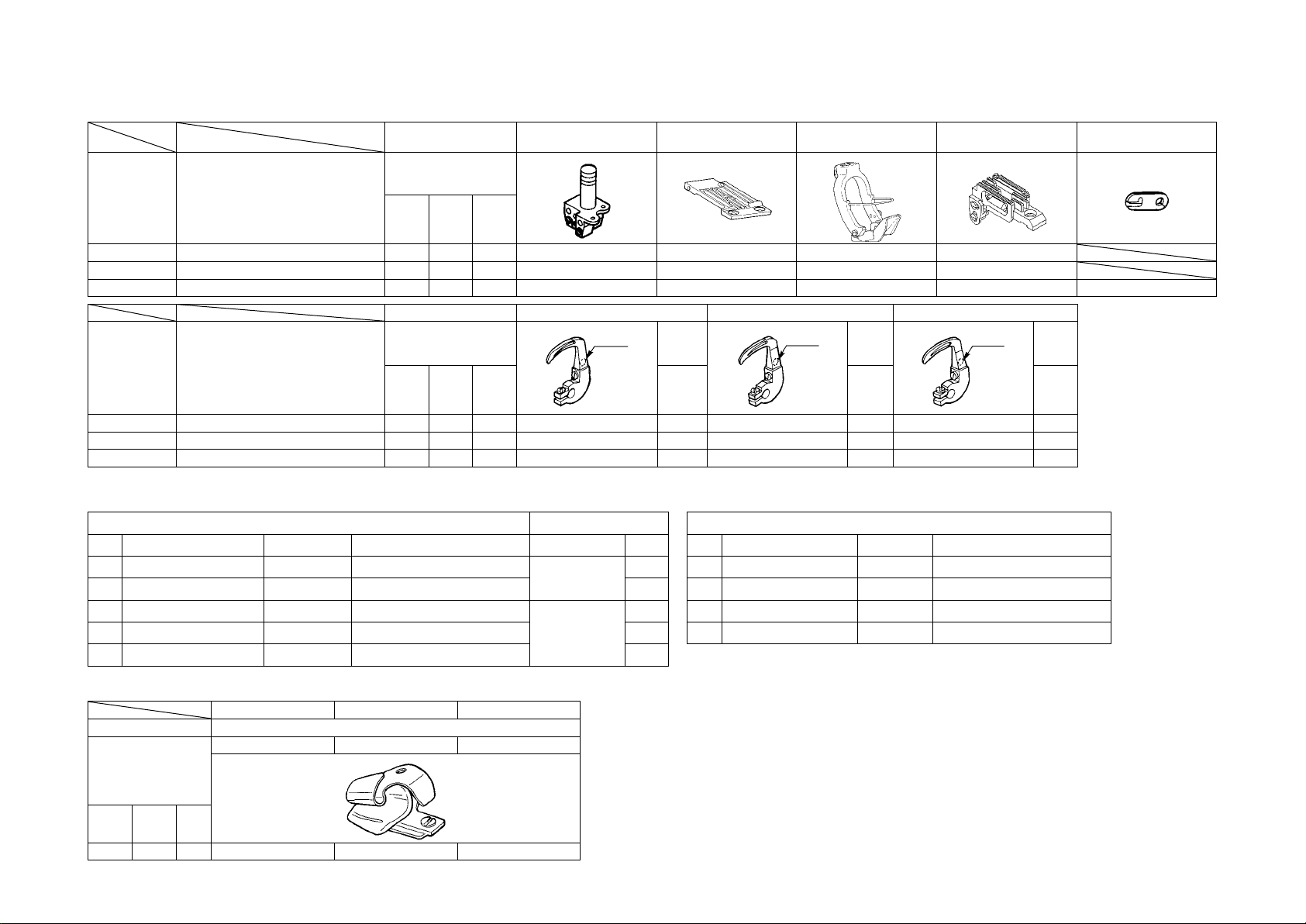

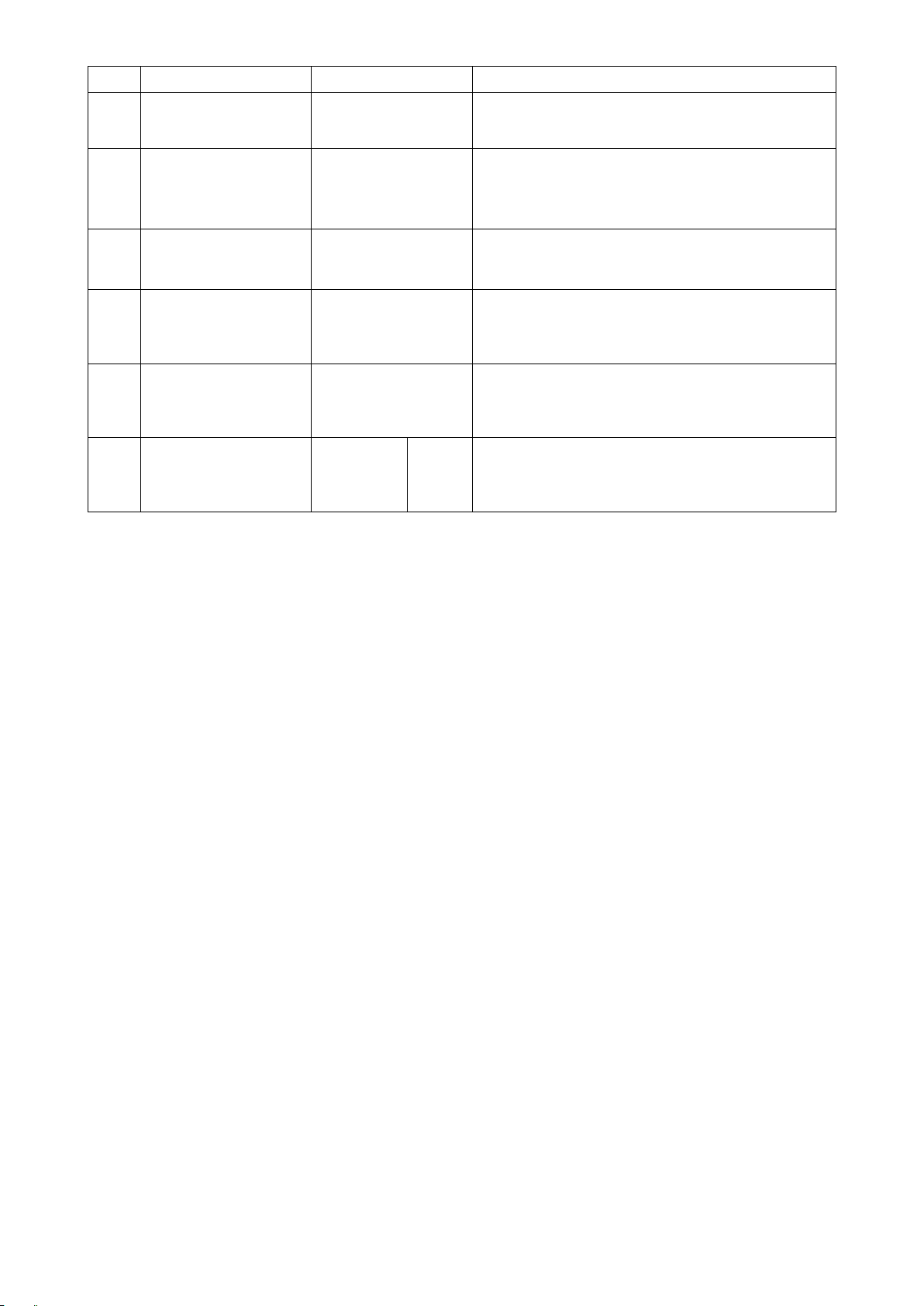

3-13. Table of replaceable gauges

Part name Needle clamp (asm.) Throat plate

Needle gauge

Model Application

Code inch mm

MS-1261A Extra-heavy-weight materials F 1/4 6.4 12956256 40202942 40202943 12963351

MS-1261A Heavy-weight materials F 1/4 6.4 12956256 40204587 40204601 12974150

MS-1261AM Medium-heavy-weight materials F 1/4 6.4 12956256 40204592 40205581 12974952 B1130051000

Part name Looper (L) (asm.) Looper (R) (asm.) Looper (C) (asm.)

Needle gauge

Model Application

Code inch mm

MS-1261A Extra-heavy-weight materials F 1/4 6.4 12968558 1 12968855 1 12969150 1

– 16 –

MS-1261A Heavy-weight materials F 1/4 6.4 12968558 1 12968855 1 12969150 1

MS-1261AM Medium-heavy-weight materials F 1/4 6.4 12968558 1 12968855 1 12969150 1

Mark

Mark

No.

Presser foot (asm.)

(with nger guard)

Mark

Mark

No.

Feed dog Needle thread guide

Mark

Mark

No.

Options

1. Spacer for presser foot 2. Setscrews

No. Plate thickness (mm) Part No. Part name Part No. Plate

①

②

③

④

⑤

0.3 12973509 Presser foot adjusting plate B

0.5 12973608 Presser foot adjusting plate C 2

0.8 12973707 Presser foot adjusting plate D

1.0 12962106 Presser foot adjusting plate A 2

1.2 12973806 Presser foot adjusting plate E 2

SS5060310SP

SS5060410SP

2

2

No. Plate thickness (mm) Part No. Part name

①

②

③

④

0.3 12975702 Feed dog adjusting plate B

0.5 12964102 Feed dog adjusting plate A

0.8 12975801 Feed dog adjusting plate C

1.0 12975900 Feed dog adjusting plate D

3. Spacer for feed dog

Folder

1 2 3

Part name Folder (asm.)

M297 M298 M299

Needle gauge

Code inch mm

F 1/4 6.4 MAM2970EEBA MAM2980BBBA MAM2990BBBA

Code of folder

M297 — For medium-weight materials

(Equipped on MS-1261AM as standard)

M298 — For heavy-weight materials (Optional)

M299 — For extra-heavy-weight materials

(Equipped on MS-1261A as standard)

Page 20

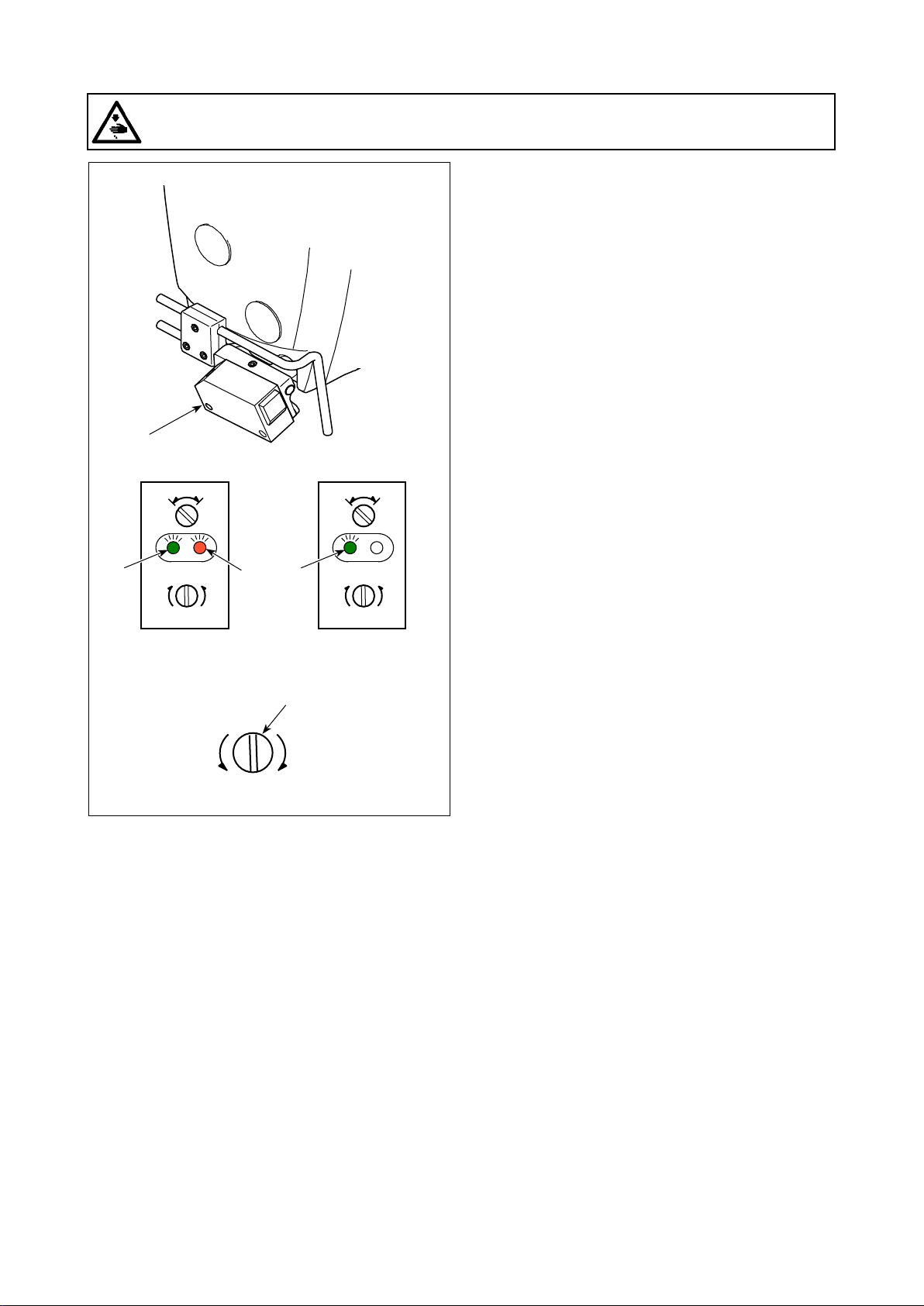

3-14. Adjusting the material edge detector

WARNING :

When adjusting the sensor, neither put your hand close to the needle entry area nor put your foot on

the pedal in order to protect against injuries.

❶

Material edge detector ❶ detects the presence /

absence of the material at the beginning and end of

sewing.

A

L

max

Material is

present

min

D

min

L

D

When the material is present, the green LED (A) and

the orange LED (B) light up at all times.

When the material is absent, only the green LED (A)

A

B

Material is

absent

max

min

lights up.

The detecting device of the sewing machine has

been factory-adjusted at the time of shipment so

❷

that it detects the presence / absence of the material

without additional adjustment. However, the detect-

ing device may fail to detect the material properly

max

depending on the type of material used.

In such a case, adjust the detecting device of the

sewing machine by turning control knob ❷.

[Adjustment procedure]

* The orange LED (B) lights up even when the ma-

terial is not present on the sewing machine.

→ Turn control knob ❷ toward the "min".

* The orange LED (B) goes out even when the ma-

terial is present on the sewing machine.

→ Turn control knob ❷ toward the "max".

– 17 –

Page 21

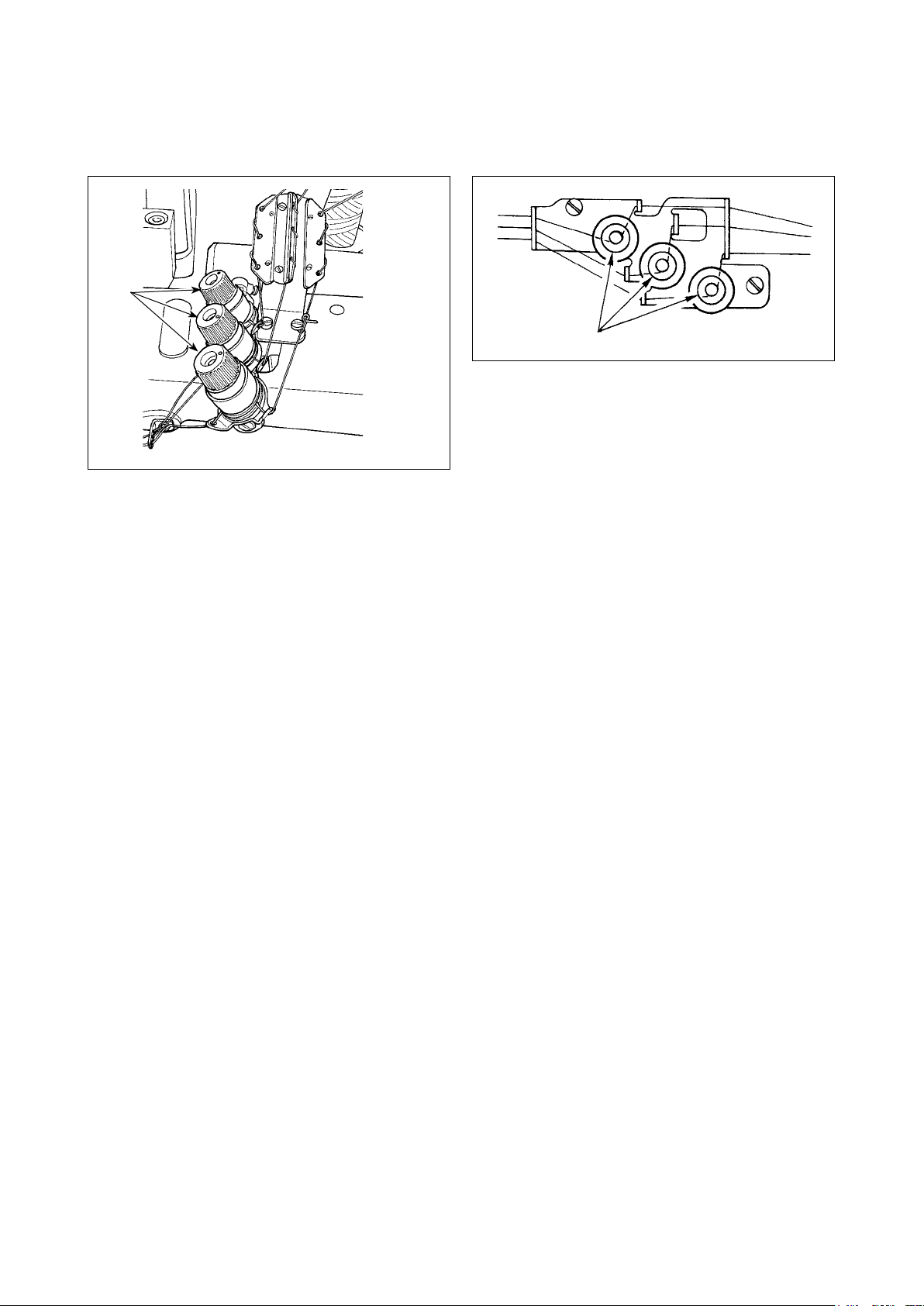

3-15. Needle cooler

3-15-1. Adjusting the position of the blow pipe

❷

❶

3-15-2. Adjusting the air ow

1) Loosen screw ❶.

2) Adjust the position of blow pipe ❷in terms of the

longitudinal direction and rotational direction.

3) Tighten screw ❶ to secure blow pipe ❷.

Adjust the air ow of the needle cooler by turning

speed controller knob ❶. Turn the speed controller

knob clockwise to decrease the air ow or counter-

clockwise to increase it.

❶

3-16. Chain-off thread cutter (suction of thread waste)

Adjust the air ow of the needle cooler by turning

speed controller knob ❶. Turn the speed controller

knob clockwise to decrease the air ow or counter-

clockwise to increase it.

❶

To

decrease

To

increase

– 18 –

Page 22

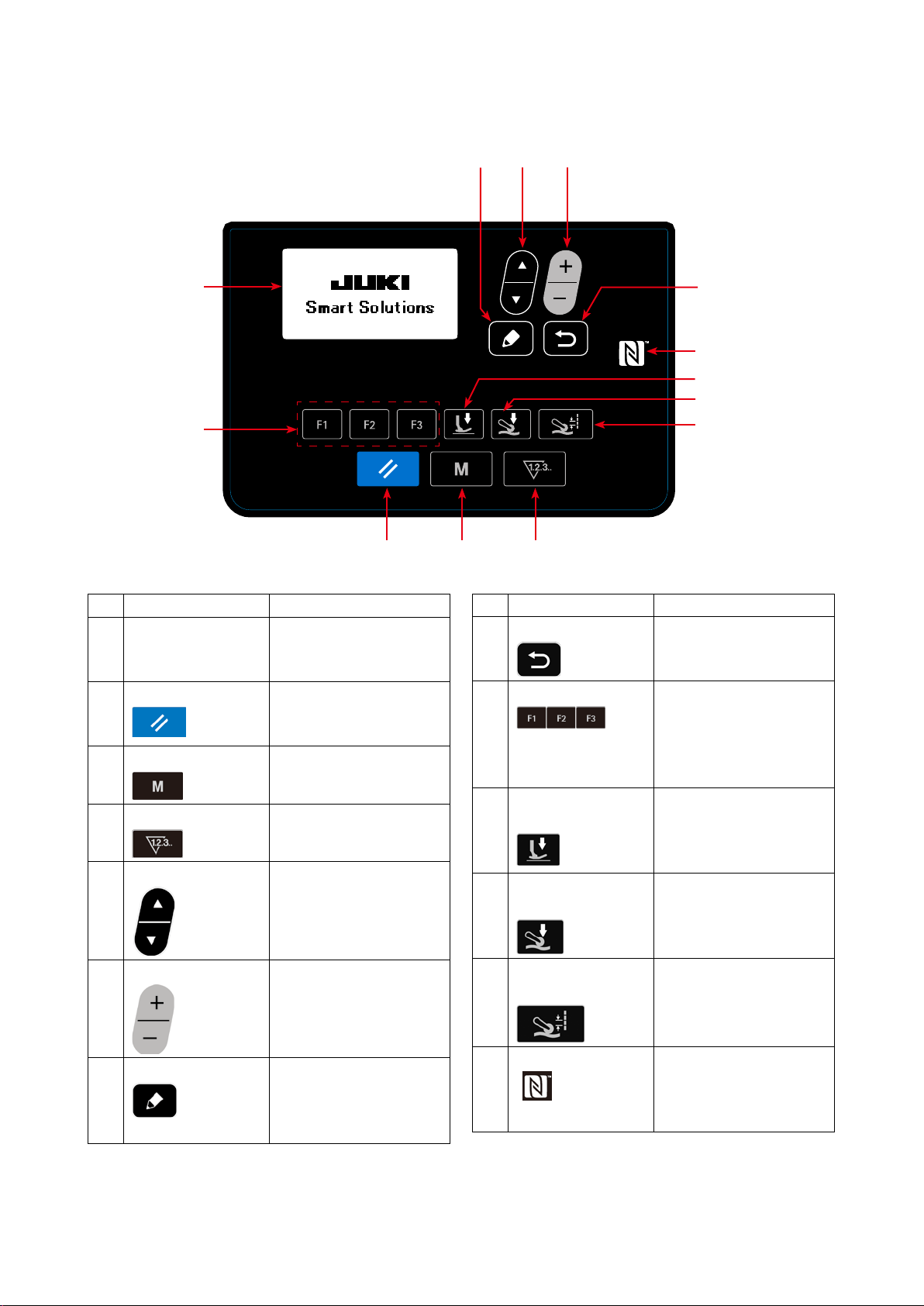

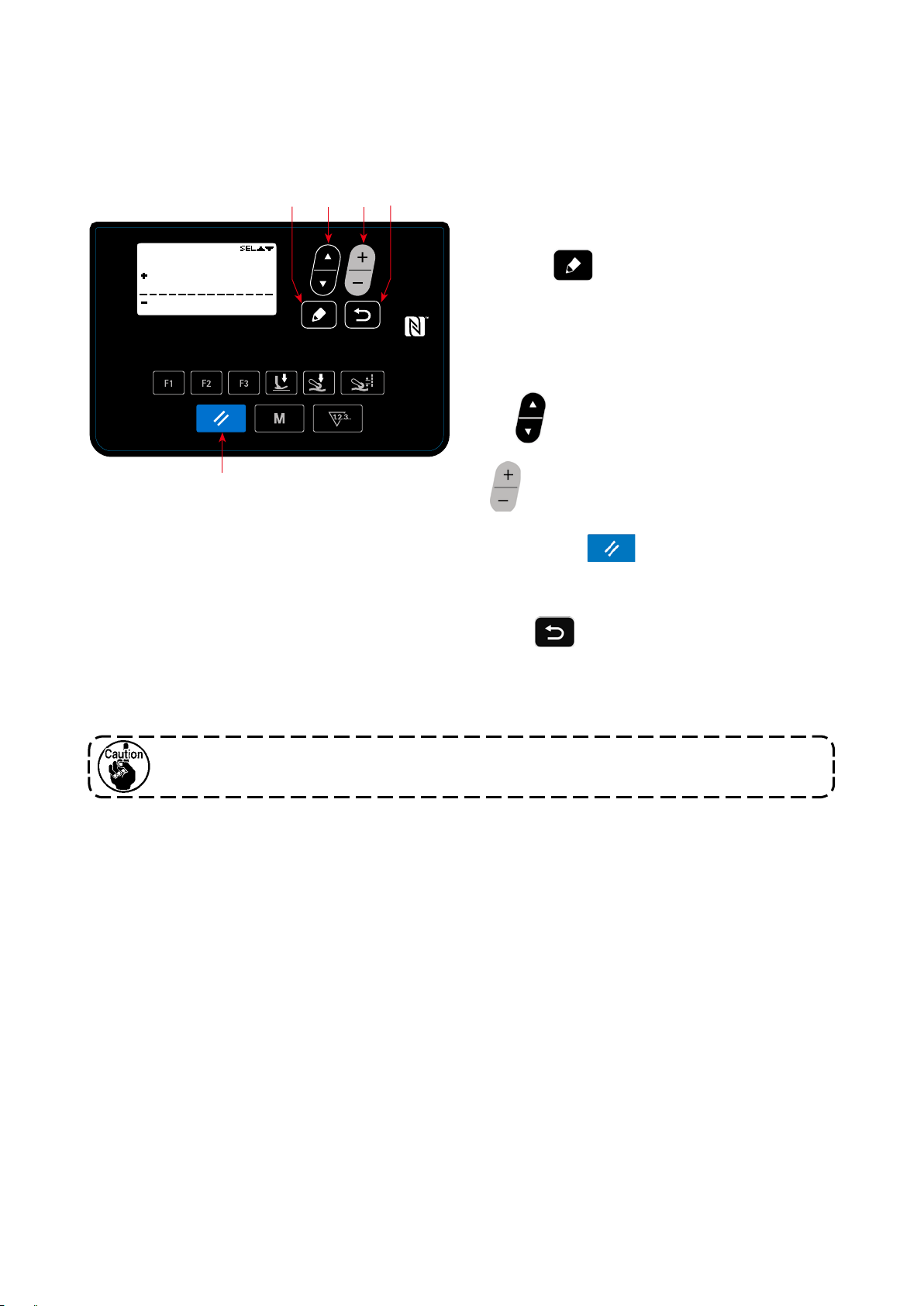

4. HOW TO USE THE OPERATION PANEL

4-1. Explanation of the operation panel switch

❼

❺

❻

❶

❾

❷

No. NAME FUNCTION

LCD display Various data such as pat-

❶

tern No., shape, etc. are

displayed.

RESET key Press this key to reset

❷

the error or reset the

counter(s), etc.

MODE key This key is used for dis-

❸

playing the mode screen.

COUNTER key This key selects counter

❹

display.

ITEM SELECT key This key is used to select

❺

the data No. and other

kinds of data.

DATA CHANGE key This key is used to change

❻

the pattern No. and other

kinds of data.

EDIT key This key is used to display

❼

the edit screen, to select

the item or to display the

detail screen.

❽

❹❸

No. NAME FUNCTION

RETURN key This key is used to return

❽

the screen to the previous

one.

F key When data or function is

❾

registered to the F key,

the registered data or the

function can be used by

pressing the F key.

Presser foot pres-

sure key

Cloth puller pressure

key

Cloth pulling amount

key

NFC mark Bring the tablet or smart-

Sewing data about the

presser foot pressure is

displayed by pressing this

key.

Sewing data about the

cloth puller pressure is

displayed by pressing this

key.

Sewing data about the

cloth pulling amount is

displayed by pressing this

key.

phone close to the NFC

mark when carrying out

communication.

– 19 –

Page 23

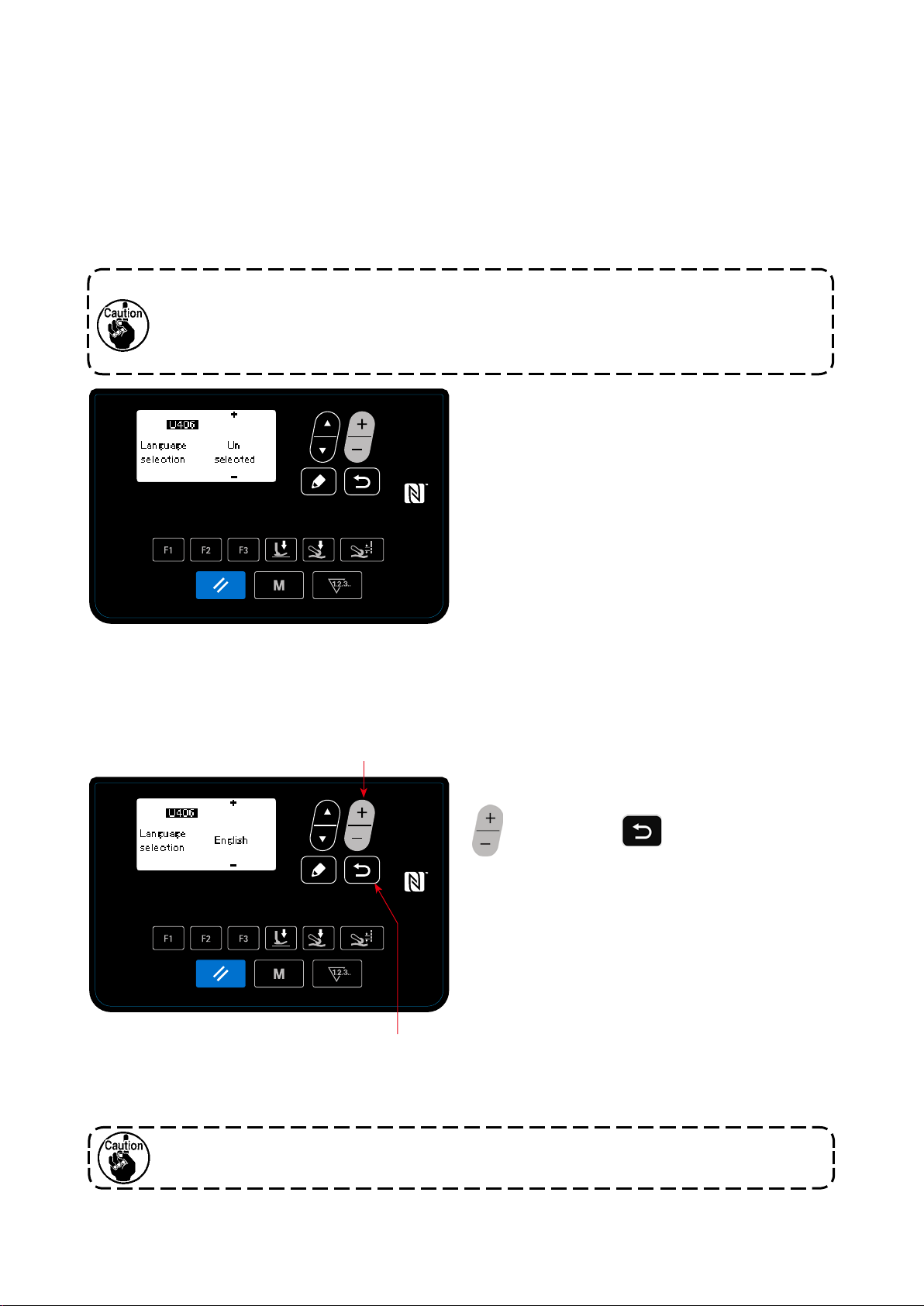

4-2. Operation to be done at rst

4-2-1. Selection of the language

Select the language to be displayed on the operation panel when you turn ON the power to your sewing

machine for the rst time after the purchase. Note that, if you turn the power OFF without selecting the

language, the language selection screen will be displayed every time you turn ON the power to the sewing

machine.

Turning ON the power switch

①

Be aware that the needle bar moves automatically when you turn ON the power to the sewing

machine for the rst time after the purchase. It is also possible to prevent the needle bar from

moving automatically using the memory switch U090. Refer to "4-5-1. Memory switch data" p.

45 for details.

When you turn ON the power switch, the language

selection screen is displayed.

<Language selection screen>

Selecting the language

②

❻

Select the language you want to use for display with

. Then, press

❻

to nalize your selec-

❽

tion of the language.

❽

The language to be displayed on the operation panel can be changed using the memory switch U406.

Refer to

"4-5-1. Memory switch data" p. 45

for details.

If you do not select your language for display, English will be used for display as default.

– 20 –

Page 24

When you turn ON the power to the sewing machine, the sewing screen for the pattern that is currently se-

lected is displayed.

This sewing machine is able to sew free sewing patterns and step sewing patterns. As many as 99 different

sewing patterns can be created by combining free sewing patterns and step sewing patterns.

In the case of a free sewing pattern, different sewing conditions can be adopted respectively for sewing at

sections and multi-layered sections of material.

In the case of a step sewing pattern, separate sewing conditions can be adopted for sewing a material on a

step-by-step basis.

The below-stated section of this Instruction Manual describes the free sewing patterns. Refer to

to edit a step sewing pattern" p. 34

for the description about step sewing patterns.

C

"4-4-6. How

J

A

B

D

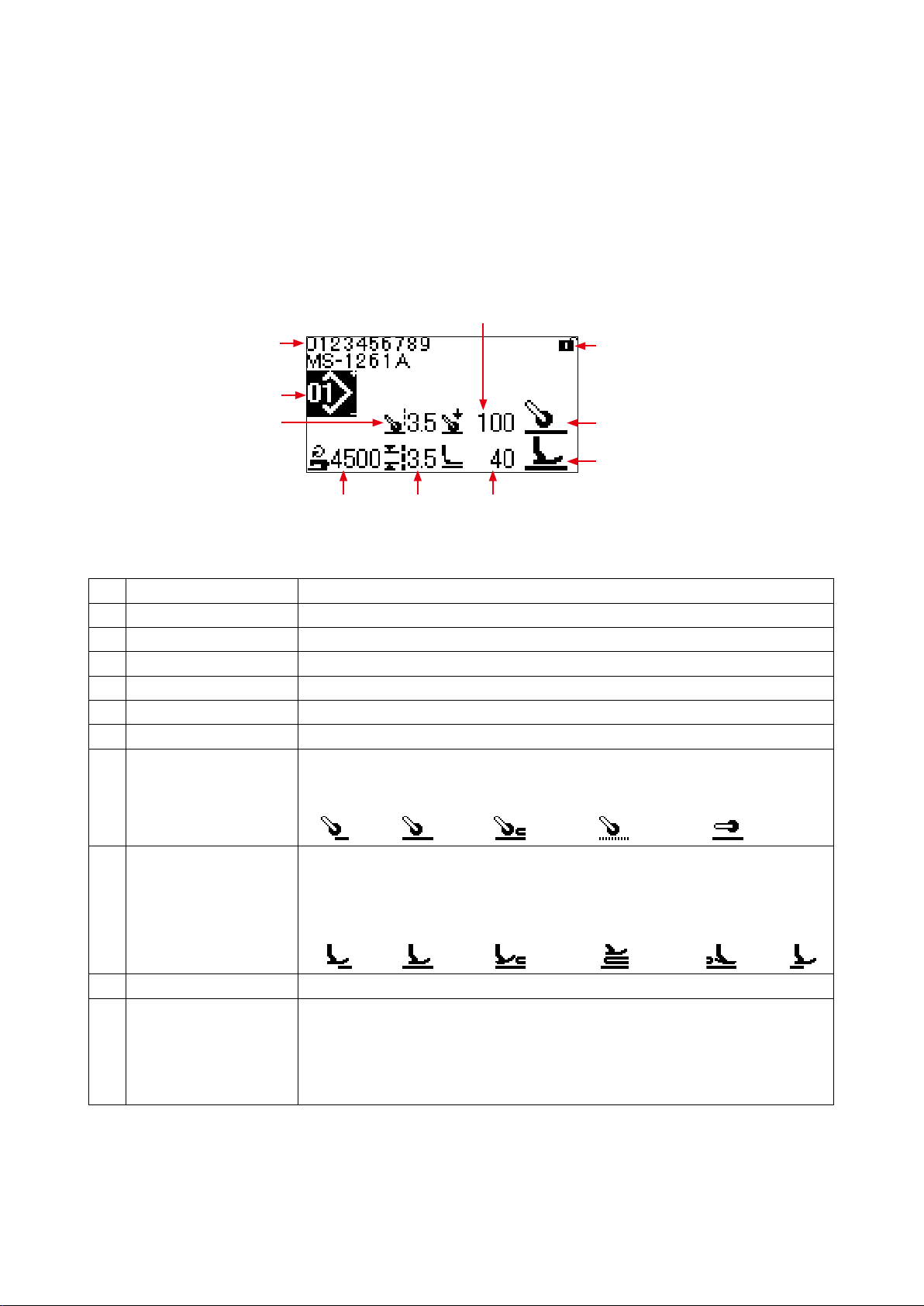

Sewing screen <Free sewing pattern>

Display Content

Pattern No. Pattern No. that is being selected is displayed. (No. 1 to No. 99)

A

*1

*1

Cloth pulling amount is displayed.

*1

Cloth puller pressure is displayed.

Sewing speed is displayed.

Stitch length set with the memory switch S003 is displayed.

*1

Presser foot pressure is displayed.

State of the material placed under the cloth puller is displayed.

Top end of

material

Cloth pulling amount

B

Cloth puller pressure

C

Sewing speed

D

Stitch length

E

Presser foot pressure

F

State of the material

G

under the cloth puller

*3

E

Flat section

F

Multi-layered

section begins

I

G

H

No material

Cloth puller is

not used

State of the material

H

under the presser foot

Simple-locked state ON / OFF of the simple lock is displayed.

I

Part number / process or

J

comment

State of the material placed under the presser foot is displayed.

Top end of

material

Part number is displayed on the upper line and the process is displayed on the low-

er line. Or, comment is displayed on two lines (upper and lower lines). (Content of

display, i.e., the "part number and process" or the "comment", can be changed over

with the memory switch U404. Refer to

details).

Flat section

Multi-layered

section be-

– 21 –

gins

During the

multi-layered

section of mate-

rial

"4-5-1. Memory switch data" p. 45

End of the

multi-layered

section of mate-

rial

No ma-

terial

for

Page 25

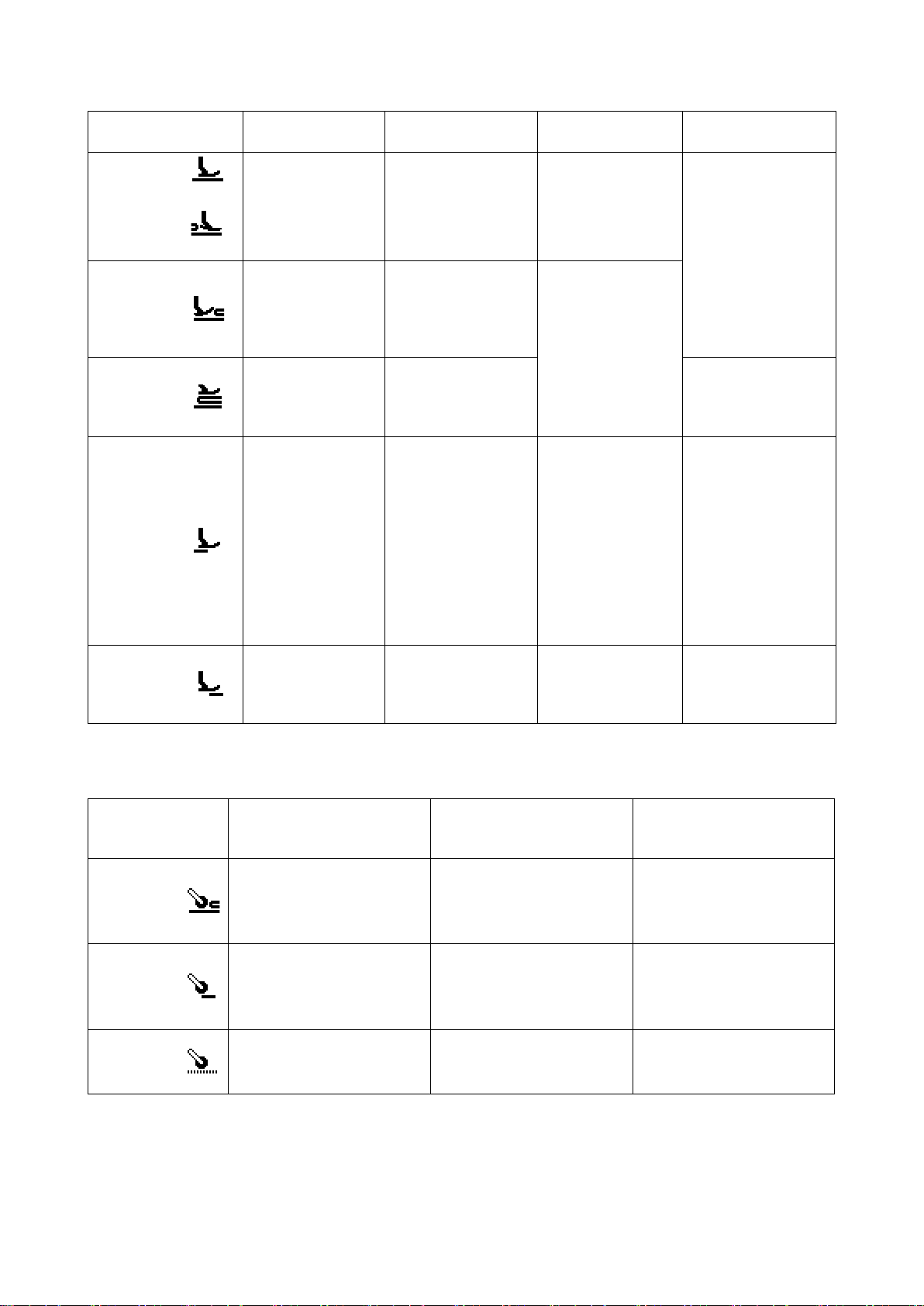

*1 Cloth pulling amount, the cloth puller pressure, sewing speed and the presser foot presser can be set using

the sewing data items given below according to the state of the material placed under the presser foot.

State of the material

under the presser foot

Flat section

End of the

multi-layered

section of

material

Multi-layered

section begins

During the

multi-layered

section of

material

No material

Top end of

material

/

Cloth pulling amount Cloth puller pressure Sewing speed Presser foot pressure

S006

Cloth pulling amount

S015

Cloth pulling amount

when the presser

foot runs on the

multi-layered section

S019

Cloth pulling amount

for sewing the

multi-layered section

S072

Cloth pulling amount

when detecting no

material

(In the case the

material under the

cloth puller is at

section, the cloth

pulling amount set

with S006 will be

employed.)

S072

Cloth pulling amount

when detecting no

material

S007

Cloth puller pressure

S016

Cloth puller pressure

when the presser foot

runs on the multi-layered section

S020

Cloth puller pressure for sewing the

multi-layered section

S073

Cloth puller pressure

when detecting no

material

(In the case the material under the cloth

puller is at section,

the cloth pulling puller

pressure set with S007

will be employed.)

S073

Cloth puller pressure

when detecting no

material

S004

Limit of sewing

speed

S012

Multi-layered section

sewing speed

S052

Limit to the sewing

speed to be applied

after the detection of

absence of material

(While the sewing

machine is at rest,

the highest one of

four sewing speeds

shown in the table is

displayed.)

S031

Sewing speed for

starting sewing of the

top end of material

S005

Presser foot pressure

S018

Presser foot pressure for sewing the

multi-layered section

S005

Presser foot pressure

S032

Presser foot pressure

for starting sewing of

the top end of material

It should be noted, however, that the presser foot pressure, cloth pulling amount and the cloth puller pressure can

be set as sewing data as described below according to the condition of material placed under the cloth puller.

State of the material

placed under the

cloth puller

Multi-layered section

begins

Top end of

material

No material

Refer to "4-4-8. List of sewing data" p. 39 for details of sewing data items to be used in the respective

states of the material.

Presser foot pressure Cloth pulling amount Cloth puller pressure

S078

Presser foot pressure when

the cloth puller runs on the

multi-layered section

(The presser foot pressure will

be as given in the table shown

above.)

(The presser foot pressure will

be as given in the table shown

above.)

S070

Cloth pulling amount when

the cloth puller runs on the

multi-layered section

S076

Cloth pulling amount when

the cloth puller runs on the

multi-layered section

S072

Cloth pulling amount when

detecting no material

S071

Cloth puller pressure when

the cloth puller runs on the

multi-layered section

S077

Cloth puller pressure when

the cloth puller runs on the top

end of material

S073

Cloth puller pressure when

detecting no material

– 22 –

Page 26

*2. For the sewing speed, the maximum sewing speed is limited by the set values of the stitch length and cloth

pulling amount. The set value of sewing speed before the limit is applied is displayed on the operation panel.

In the case the set value of stitch length is 3.1 mm or more: Maximum sewing speed 5000 sti/min

In the case the set value of cloth pulling amount is 4.6 mm or more: Maximum sewing speed 4000 sti/min

*3. Input the stitch length using the memory switch S003 according to the feed amount of the sewing machine. (If

this value is changed, the feed amount of the sewing machine itself will not change.)

→ Referto"4-4. How to change the sewing data" p. 24.

4-3. How to select a sewing pattern

❻

The sewing pattern can be selected by pressing

on the sewing screen.

❻

The sewing pattern can also be changed by press-

❾

Sewing screen

<

ing

❾

to which a sewing pattern has

been registered.

→

Refer to "4-5-5. How to use the F key" p. 59.

>

– 23 –

Page 27

4-4. How to change the sewing data

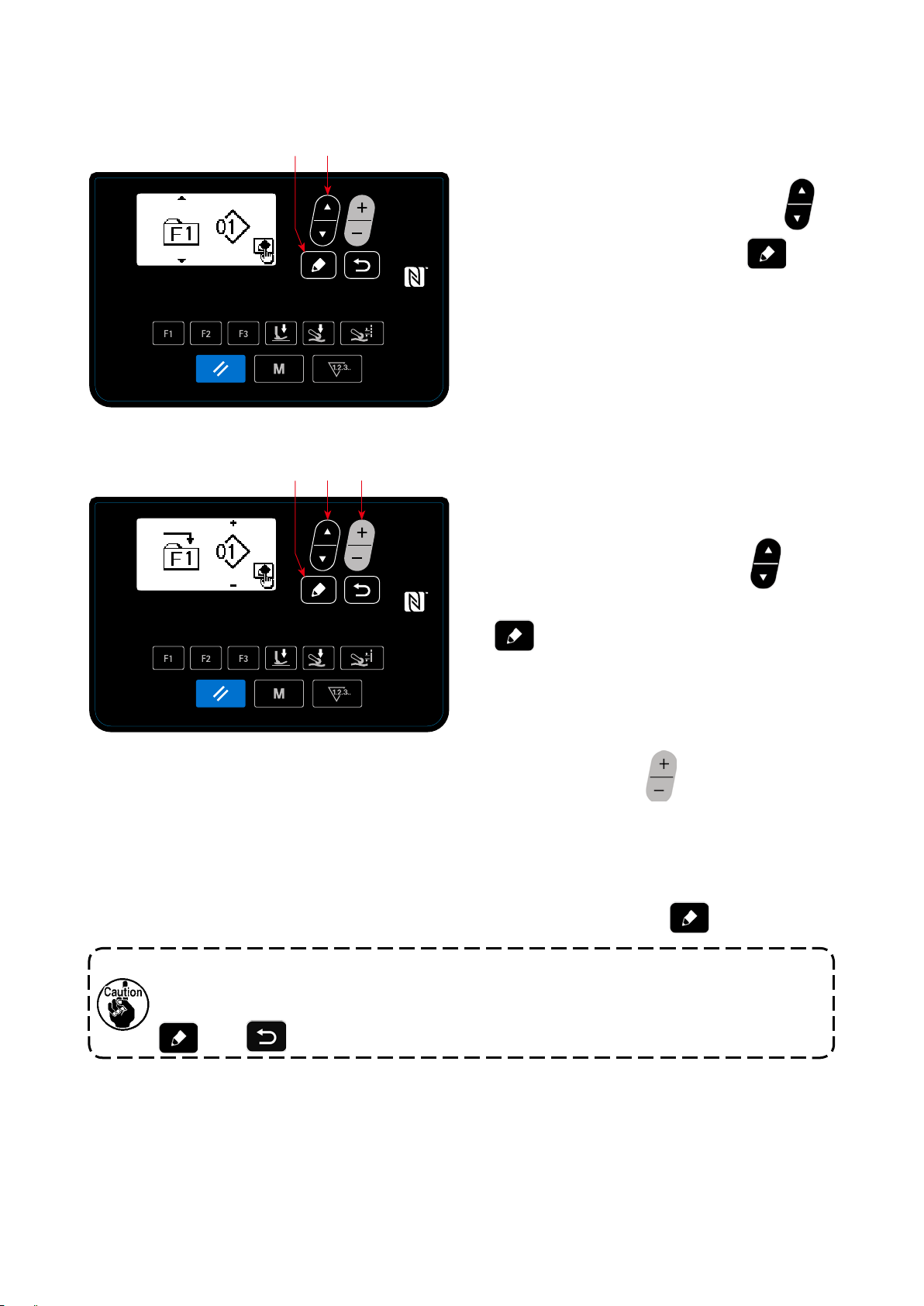

4-4-1. Method of changing the sewing data

❽

❼

❻❺

Calling the sewing data edit screen

①

When the

screen, the sewing data edit screen for the cur-

rently-selected sewing pattern is displayed.

Selecting the sewing data to change

②

Data you want to change can be selected by

is pressed on the sewing

❼

< Sewing data edit screen >

pressing

Changing the sewing data

③

Data can be changed by pressing

The sewing data edit screen is returned to the

sewing screen by pressing

❺

.

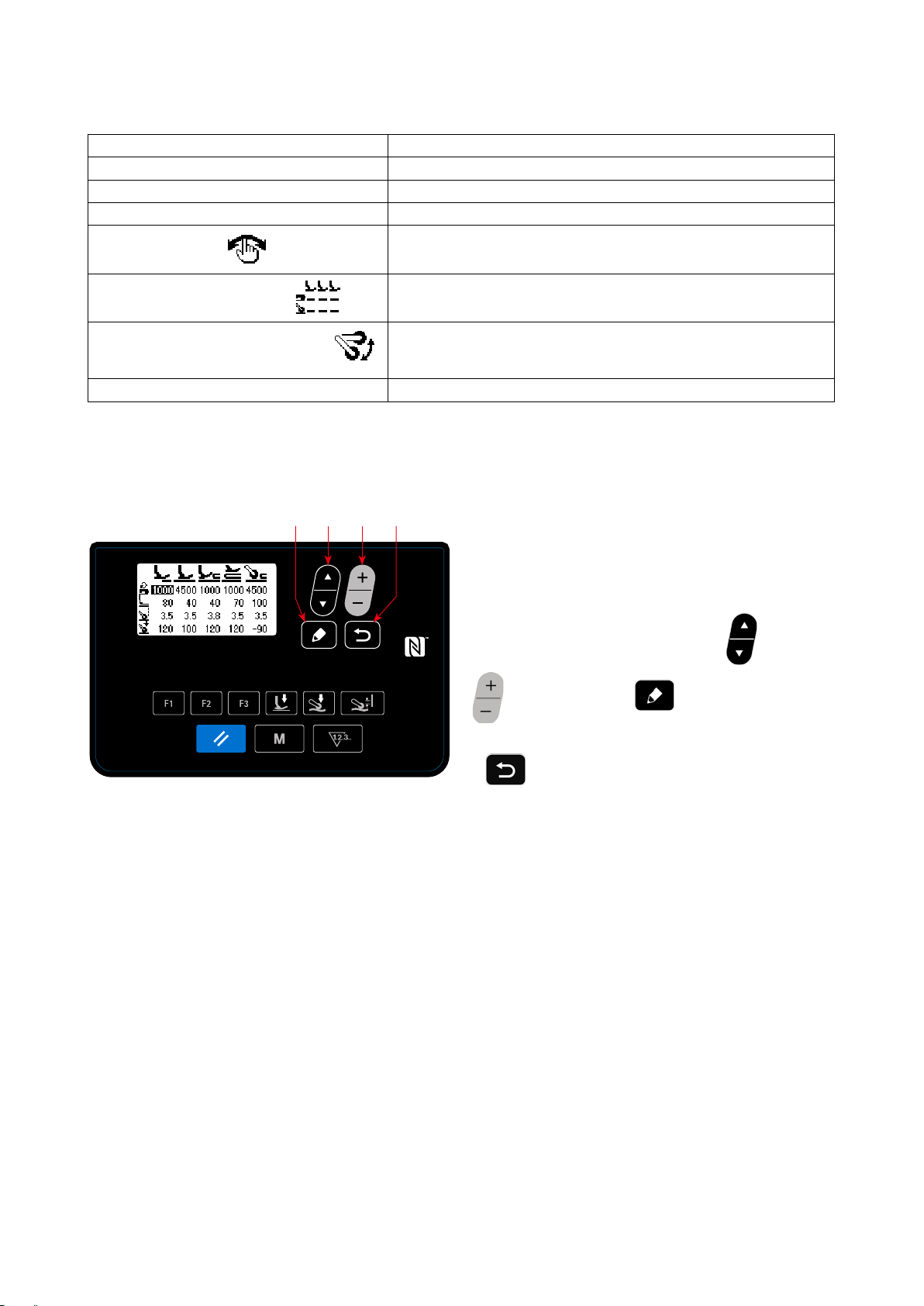

4-4-2. Method of selecting a specic sewing data item

When

is pressed, the sewing data edit screen is displayed according to the key pressed.

(Refer to

Screens to be displayed are as shown below:

"4-5-5. How to use the F key" p. 59

to which the sewing data has been registered,

❾

for the method of registering sewing data to the F key.)

.

❻

.

❽

,

or

❾

<Sewing screen>

– 24 –

Page 28

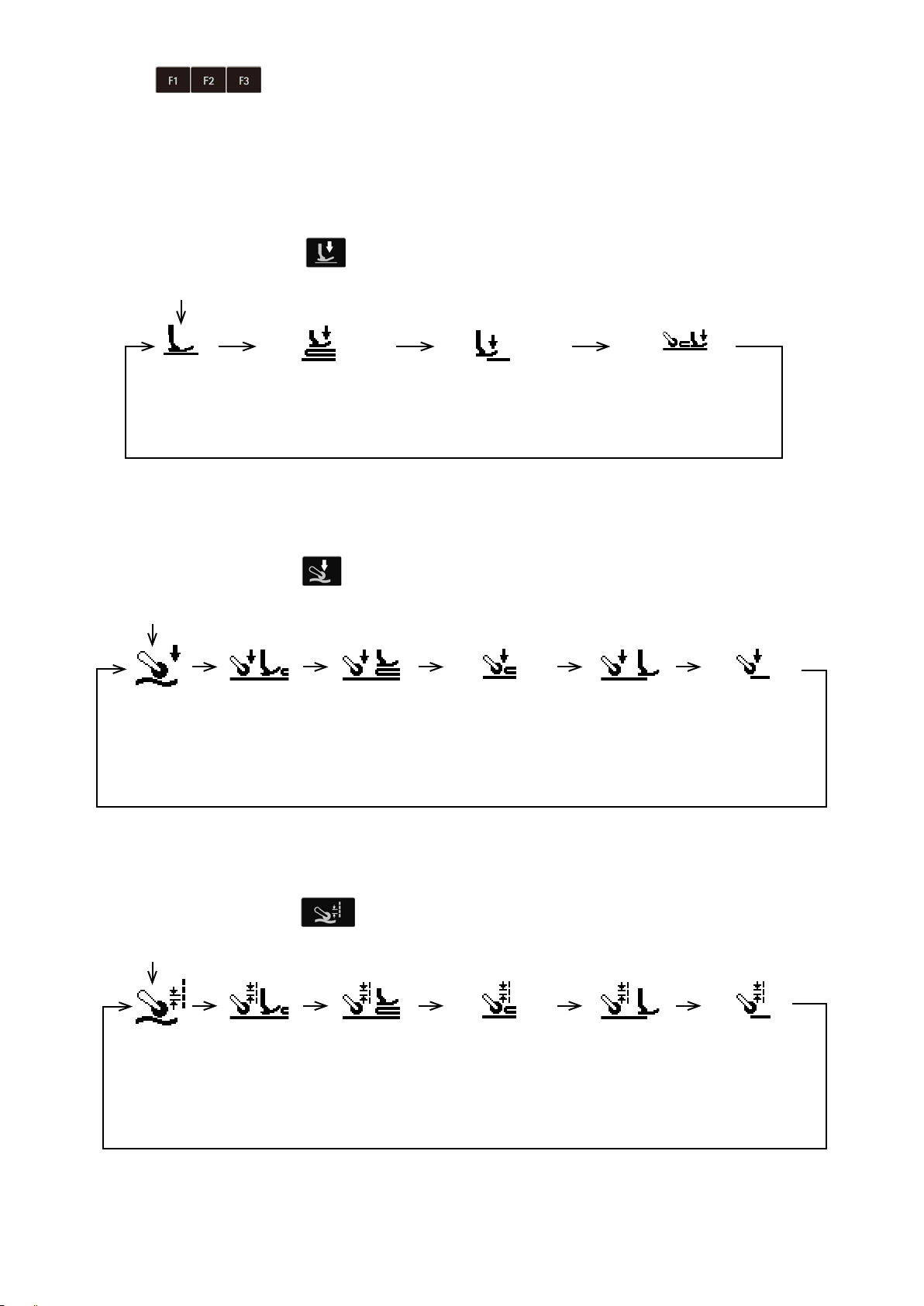

(1) F key

❾

<Sewing screen>

(The state the sewing data which has been registered to the F key is selected)

→

(2) Presser foot pressure key

<Sewing screen>

S005

Presser foot

pressure

<Sewing data edit screen>

S018

Presser foot pressure

for sewing the multi-lay-

ered section

< Sewing data edit screen >

S032

Presser foot pressure

for starting sewing of

the top end of material

S078

Presser foot pressure when

the cloth puller runs on the

multi-layered section

(3) Cloth puller pressure key

<Sewing screen>

S007

Cloth puller

pressure

S016

Cloth puller pres-

sure when the

presser foot runs

on the multi-lay-

ered section

Cloth puller pres-

sure for sewing

the multi-layered

(4) Cloth pulling amount key

<Sewing screen>

S020

section

< Sewing data edit screen >

S071

Cloth puller pressure

when the cloth puller

runs on the multi-lay-

ered section

S073

Cloth puller pres-

sure when detect-

ing no material

S077

Cloth puller pres-

sure when the cloth

puller runs on the

top end of materia

l

S006

Cloth pulling

amount

S015

Cloth pulling

amount when the

presser foot runs

on the multi-lay-

ered section

S019

Cloth pulling

amount for sewing

the multi-layered

section

< Sewing data edit screen >

S070

Cloth pulling amount

when the cloth puller

runs on the multi-lay-

ered section

– 25 –

S072

Cloth pulling

amount when de-

tecting no material

S076

Cloth pulling amount

when the cloth puller

runs on the top end

of material

Page 29

4-4-3. How to change the part number, process or comment for the sewing pattern data

Part number, process or comment can be entered to allow the operator to easily understand the application

of sewing pattern.

The method to enter a part number is described below. Same method applies when entering a process or

comment.

❽

❼

❻❺

Calling the part number setting screen

①

The part number setting screen is displayed by

❷

< Part number setting screen >

pressing

ber" on the sewing data edit screen.

Entering the part number

②

The place (what character number) at which a

part number is entered can be selected by press-

ing

number) can be entered at that place by pressing

One of the entered characters that is selected can

be deleted by

can be deleted by keeping reset key held pressed

for one second.

When

returns to the sewing data edit screen.

Characters that can be entered

A - Z, 0 - 9, ., +, -, /, #, (line feed), (blank)

❻

❺

.

after selecting "S061 Part num-

❼

. Characters (representing the part

. All entered characters

❷

is pressed, the current screen

❽

Whether the part number / process or the comment is displayed can be changed with the

memory switch U404. Refer to "4-5-1. Memory switch data" p. 45 for details.

– 26 –

Page 30

4-4-4. How to carry out teaching of the multi-layered section of material

It is possible to perform teaching of the thresholds of the lower part (thinner part) and of the upper part (thicker

part) of multi-layered section of material while using the actual sewing product.

Sewing data items that can be used for teaching are as follows:

Sewing pattern that is currently selected Sewing data that can be used for teaching

Free sewing patter S011 Multi-layered section changeover sensor ON value

S021 Multi-layered section changeover sensor OFF value

Step sewing pattern "S103 Step changeover" sensor *

* "S103 Step changeover sensor value" can only be selected in the case "S101 Step changeover" is set to the

material thickness sensor value.

❼

Teaching of the multi-layered section starts and

①

the teaching screen for the lower part of multi-lay-

ered section is displayed by pressing edit key

after selecting the aforementioned data

❼

on the sewing data edit screen.

< Teaching screen

for the lower part of multi-layered section >

❼

❽

Teaching screen for the upper part of multi-layered

②

section is displayed by pressing edit key

after placing the lower part of multi-layered section

under the presser foot.

Teaching screen returns to the sewing data edit

③

screen by pressing edit key

after placing

❼

the upper part of multi-layered section under the

presser foot.

Value of the data selected in the aforementioned 1)

< Teaching screen

for the upper part of multi-layered section >

will be automatically changed to the intermediate

value between the thickness of lower part and that

of upper part of multi-layered section.

1. When the pedal is depressed during teaching of the multi-layered section of material, the

sewing machine operates. It is convenient to depress the pedal to feed the material until the

upper part of multi-layered section is brought to the presser foot after having carried out

teaching of the lower part of multi-layered section.

❼

2. If the

the teaching of the multi-layered section of material and the screen will return to the sewing

data edit screen.

3. If the feed dog appears above the throat plate in the aforementioned ② or ③, the

cannot be operated.

4. Be aware that the sensor may detect the multi-layered section of material by mistake by

excessively decreasing the aforementioned data value.

is pressed in the aforementioned ② or ③, the sewing machine will quit from

❽

❼

– 27 –

Page 31

4-4-5. Sewing data on a free sewing pattern

The following sewing data are used in each sewing state of a free sewing pattern.

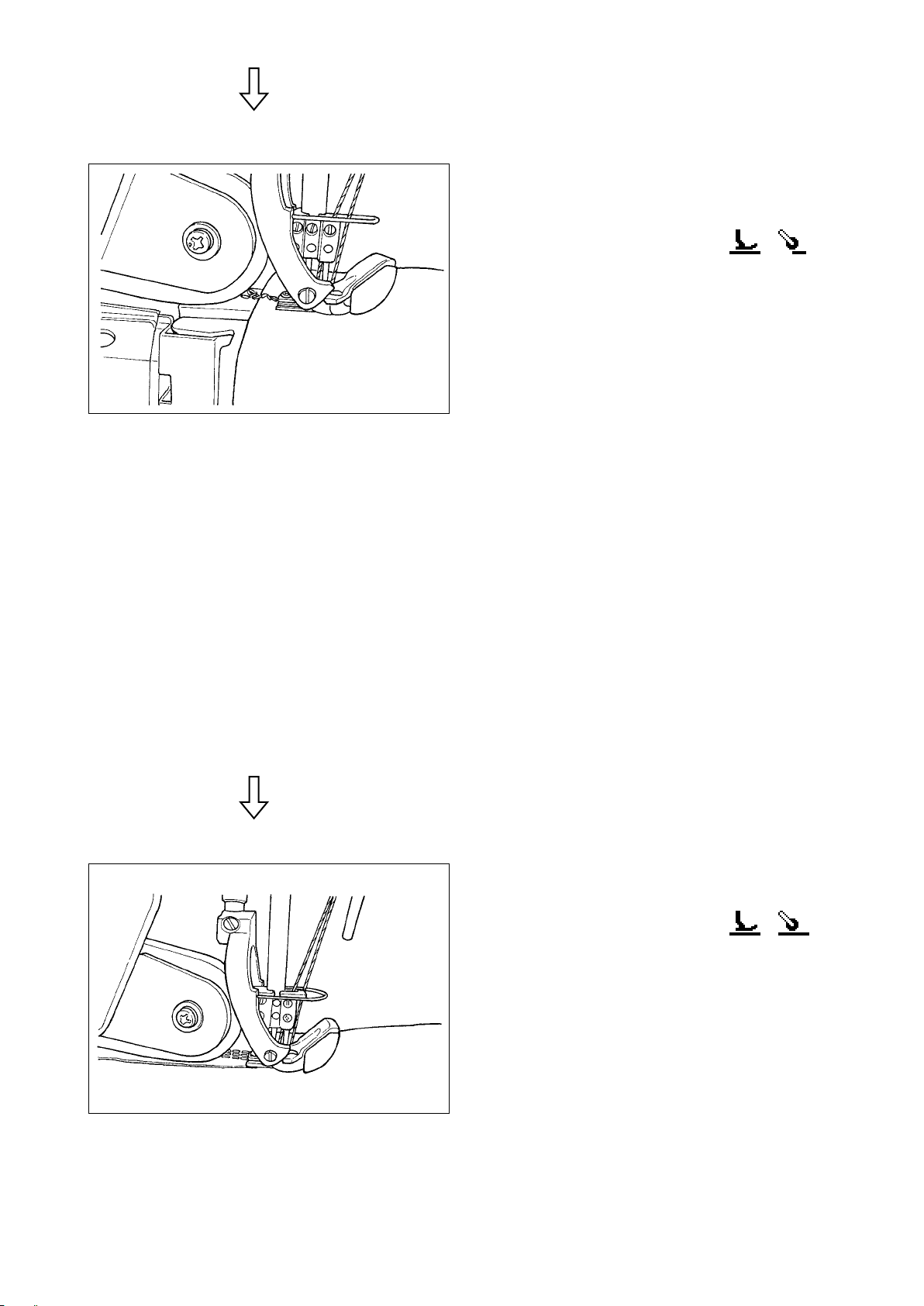

Top-of-material sewing

①

Setting of the sewing data to be used from the time

at which the material is detected to the time at which

the top of material reaches the cloth puller is carried

out.

State display on the operation panel:

The following data items are used.

S031 Sewing speed for starting sewing of the top end of material

← (When the sewing machine completes sewing of "S033 The number of stitches at which the sew-

ing speed is changed at the beginning of sewing the top of material", the sewing state shifts to "S004

Sewing speed.")

S032 Presser foot pressure for starting sewing of the top end of material

S073 Cloth puller pressure when detecting no material

S072 Cloth pulling amount when detecting no material

S033 Number of stitches for changing the sewing speed for starting sewing of the top end of material

S034

* If the material cannot be fed consistently from the time at which the material is detected to the time

When the sewing machine completes sewing of "S034 The number of stitches at which the presser foot

pressure is changed at the beginning of sewing the top of material" in the "top of material sewing state", the

sewing state shifts to "Flat section state."

Number of stitches for changing the presser foot pressure for starting sewing of the top end of material

at the top of material reaches the cloth puller, change the setting appropriately.

Flat section

②

State display on the operation panel:

The following data items are used.

S004 Limit of sewing speed

S005 Presser foot pressure

S007 Cloth puller pressure

S006 Cloth pulling amount

When the sewing machine completes sewing of "S074 The number of stitches from which the cloth puller

runs on the top of material" from the beginning of sewing of the top of material (①), the sewing state shifts

to the "cloth puller runs on the top of material".

– 28 –

Page 32

Cloth puller runs on the top of material

③

Setting of the sewing data to be used when the top

of material is fed to reach the cloth puller is carried

out.

State display on the operation panel:

* Depending on the "S034 The number of stitches

at which the presser foot pressure is changed at

the beginning of sewing the top of material" and

the "S074 The number of stitches from which the

cloth puller runs on the top of material", the state

of the presser foot side may remain in the "state

of sewing the top end of material".

Parameter

S004 Limit of sewing speed

S005 Presser foot pressure

S077 Cloth puller pressure when the cloth puller runs on the top end of material

S076 Cloth pulling amount when the cloth puller runs on the top end of material

S074 Number of stitches at which the cloth puller starts running on the top end of material

S075 Number of stitches while the cloth puller runs on the top end of material

S005 Presser foot pressure

S007 Cloth puller pressure

S006 Cloth pulling amount

* If the top of material is caught in the cloth puller, change the setting appropriately.

When the sewing machine completes sewing of "S075 The number of stitches at which the cloth puller runs

on the top of material" in the "state the cloth puller runs on the top of material", the sewing state shifts to the

"at section state".

While the sewing machine sews a at section of material

④

Setting of the sewing data for normal sewing is car-

ried out.

State display on the operation panel:

The following data items are used.

S004 Limit of sewing speed

S005 Presser foot pressure

S007 Cloth puller pressure

S006 Cloth pulling amount

When the measured value by the multi-layered section sensor reaches the "S011 Multi-layered section

changeover sensor ON" value or more, the sewing state shifts to the "state of running on the multi-layered

section".

* The multi-layered section detection timing can be advanced by decreasing the "S011 Multi-layered

section changeover sensor ON" set value. Be aware, however, that false detection of the multi-layered section can occur if the timing is advanced excessively.

– 29 –

Page 33

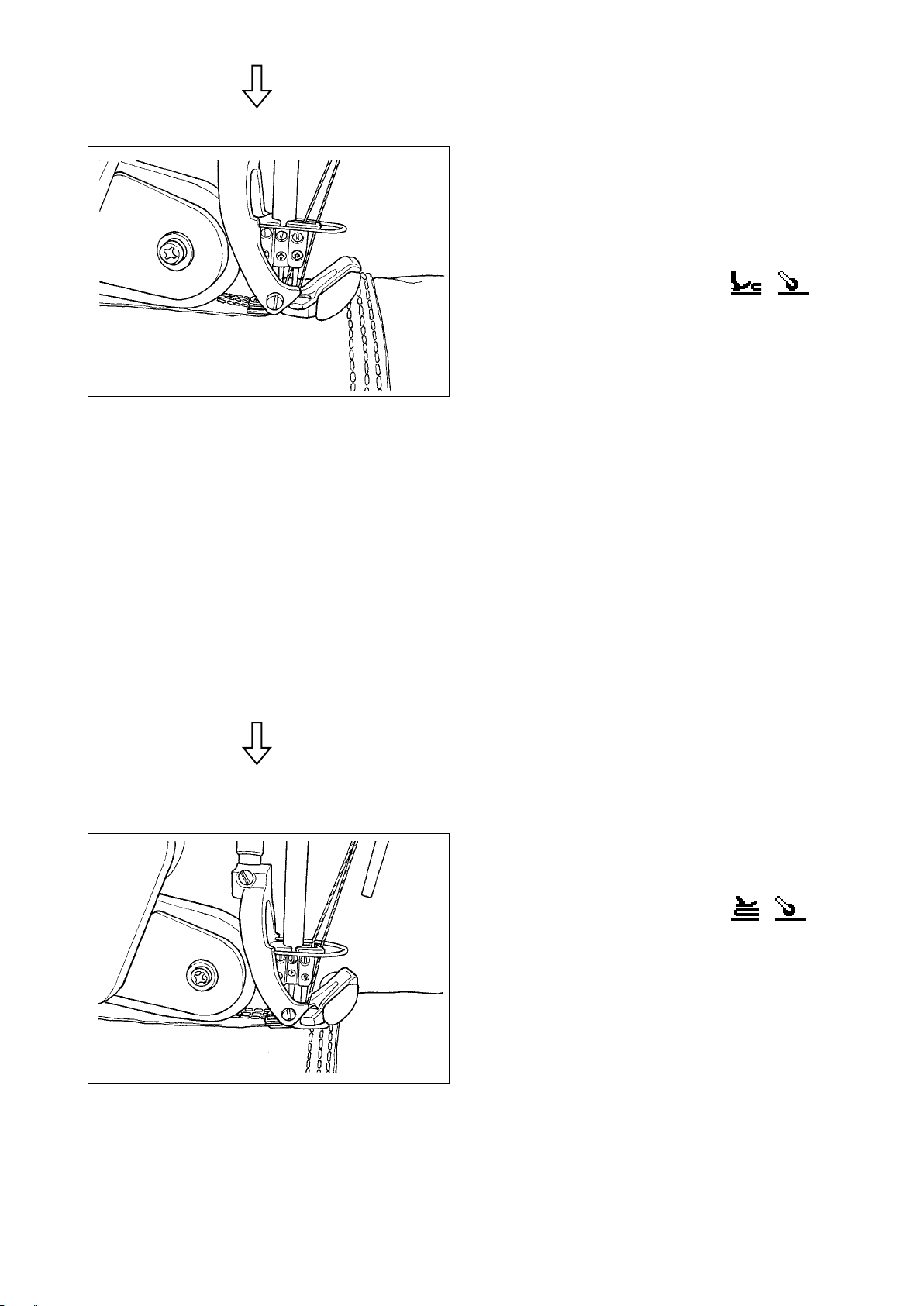

State the sewing machine runs on the multi-layered section of material

⑤

Setting of the sewing data to be used from the time

at which a multi-layered section of material is detect-

ed to the time at which the the presser foot of the

sewing machine completely runs on the multi-lay-

ered section is carried out.

State display on the operation panel:

The following data items are used.

S012 Multi-layered section sewing speed

S005 Presser foot pressure

S016 Cloth puller pressure when the presser foot runs on the multi-layered section

S015 Cloth pulling amount when the presser foot runs on the multi-layered section

S011 Multi-layered section changeover ON sensor value

S013 Number of stitches when the presser foot runs on the multi-layered section

After the sewing machine completes sewing of "S013 The number of stitches to be sewn when running on

the multi-layered section" in the "state of the sewing machine runs of the multi-layered section of material",

the sewing state shifts to the "state of sewing the multi-layered section of material".

Set "S013 Number of stitches to be sewn when running on the multi-layered section" according to the length

and shape of the multi-layered section of material.

State of sewing the multi-layered section of material

⑥

Setting of the sewing data to be used after the press-

er foot of the sewing machine completely runs on the

the multi-layered section of material is carried out.

State display on the operation panel:

The following data items are used.

S012 Multi-layered section sewing speed

S018 Presser foot pressure for sewing the

multi-layered section

S020 Cloth puller pressure for sewing the multi-lay-

ered section

S019 Cloth pulling amount for sewing the multi-lay-

ered section

S017 The number of stitches to be sewn on the

multi-layered section

S021 Multi-layered section changeover OFF sen-

sor value

– 30 –

Page 34

After the sewing machine completes sewing of "S017 The number of stitches to be sewn on the multi-layered

section" in the "state of sewing the multi-layered section of material", the sewing state shifts to the state of

the "end of the multi-layered section of material". (In the case the number of stitches set for "S017 The num-

ber of stitches to be sewn on the multi-layered section" is "0 (zero)", the sewing states will shift to the state

of the "end of the multi-layered section of material" when the measured value by the multi-layered section

sensor reaches the "S021 Multi-layered section changeover sensor OFF value" or less.)

Set "S017 Number of stitches to be sewn on the multi-layered section" according to the length and shape of

the multi-layered section of material

* Sewing conditions may differ according to the type of material and the condition of the multi-lay-

ered section. If the stitch gathers at the multi-layered section of material, change the settings of

sewing data to be used in ⑤ and ⑥.

The end of the multi-layered section of material

⑦

State display on the operation panel:

The following data items are used.

S004 Limit of sewing speed

S005 Presser foot pressure

S007 Cloth puller pressure

S006 Cloth pulling amount

When the measured value by the multi-layered section sensor reaches the "S011 Multi-layered section

changeover sensor ON" value or less, the sewing state shifts to the "state of the at section of material".

Flat section

⑧

State display on the operation panel:

The following data items are used.

S004 Limit of sewing speed

S005 Presser foot pressure

S007 Cloth puller pressure

S006 Cloth pulling amount

After the sewing machine completes sewing of "S068 The number of stitches at which the cloth puller runs

on the multi-layered section" from the start of running on the multi-layered section (⑤), the sewing state

shifts to the state of the "cloth puller runs on the multi-layered section of material".

– 31 –

Page 35

Cloth puller runs on the multi-layered section of material

⑨

Setting of the sewing data to be used while the cloth

puller runs on the multi-layered section of material is

carried out.

State display on the operation panel:

* Depending on the " S017 The number of stitch-

es to be sewn on the multi-layered section" and

"S068 The number of stitches at which the cloth

puller runs on the multi-layered section", the state

of the presser foot side may remain in the "state

of sewing the multi-layered section of material".

The following data items are used.

S004 Limit of sewing speed

S078 Presser foot pressure when the cloth puller runs on the multi-layered section

S071 Cloth puller pressure when the cloth puller runs on the multi-layered section

S070 Cloth pulling amount when the cloth puller runs on the multi-layered section

S068 Number of stitches at which the cloth puller starts running on the multi-layered section

S069 Number of stitches during which the cloth puller runs on the multi-layered section

* If the stitch gathering occurs at the multi-layered section of material in the cloth puller, change the

setting appropriately.

After the sewing machine completes sewing of "S069 The number of stitches during which the cloth puller

runs on the multi-layered section" in the "cloth puller runs on the multi-layered section" state, the sewing

state shifts to the state of the "at section of material".

Flat section

⑩

State display on the operation panel:

The following data items are used.

S004 Limit of sewing speed

S005 Presser foot pressure

S007 Cloth puller pressure

S006 Cloth pulling amount

When the cloth detection sensor detects "absence of material". the sewing state shifts to the "no material

state".

– 32 –

Page 36

No material

⑪

Setting of the state no material is detected is carried

out.

State display on the operation panel:

The following data items are used.

S052 Limit to the sewing speed to be applied after

the detection of absence of material

S005 Presser foot pressure

S073 Cloth puller pressure when detecting no ma-

terial

S072 Cloth pulling amount when detecting no ma-

terial

When the cloth detection sensor detects a material from the "no material state", the sewing state shifts to the

"top of material" sewing state.

(①Return to the sewing of the top end of material)

1. Regardless of the current status of sewing such as the sewing of the at section or that of

the multi-layered section of material, the sewing machine state will shift to the "no-material"

state whenever the cloth detection sensor detects the absence of material.

2. False detection of material can occur if the operator places his / her hand under the cloth

detection sensor. Take care not to place the hand under the sensor.

– 33 –

Page 37

4-4-6. How to edit a step sewing pattern

A step sewing pattern consists of 10 steps at the maximum. Different sewing conditions can be set for each

step on a step-by-step basis.

The condition to be satised to proceed to the next step can be set with "S101 Step changeover condition".

As many as 10 different step sewing patterns can be created.

Step changeover condition Details

Number of stitches When the sewing machine completes sewing of the number of stitches set with "S102

The number of stitches for step changeover", the sewing machine proceeds to the next

step.

Material thickness When the material thickness that exceeds the value set with "S103 The sensor value for

step changeover" changes to a value that is smaller than the aforementioned set value (or

the material thickness that falls below the aforementioned set value changes to a value

that is larger than the set value), the sewing machine proceeds to the next step.

Optional input When the sewing machine accepts an optional input, the sewing machine proceeds to

the next step.

Final step No further step is possible. When there is no material on the sewing machine, the sewing

machine returns to the rst step.

In the state there is no material on the sewing machine, the sewing machine will not proceed to

the next step.

BA

< Sewing screen (Step sewing pattern) >

Display Content

A

Current step The number of the current step is displayed.

B

Total number of steps The total number of steps is displayed.

C

Step changeover condition

set value

The set value for the step changeover condition is displayed. This set value is not

displayed at the nal step.

The number of stitches Material thickness sensor value Optional input

C

– 34 –

Page 38

No step sewing pattern is registered in the sewing machine at the time of purchase. It is, therefore, neces-

sary to create a step sewing pattern using one of the below-stated procedures.

(1) Changing the shape of a free sewing pattern to a step sewing pattern

❺

< Sewing pattern edit screen >

❼

❽

❽

Starting the change in shape

①

When

❺

(or

) is pressed after

❽

changing "S001 Shape" to the step sewing on

the sewing data edit screen for the free sewing

pattern, "Are you sure you want to continue? Yes /

No" message is displayed.

When

is pressed after the aforemen-

❼

tioned message is displayed, "Are you sure you

want to overwrite the pattern in use? Yes / No"

message is displayed.

If

is pressed, the change in shape is

❽

< M613 Message screen >

❼

< M614 Message screen >

❽

cancelled and the screen returns to the sewing

data edit screen.

Changing the shape

②

When

is pressed, the shape is changed

❼

to a step sewing. Then, the screen returns to the

sewing screen.

If

is pressed, the screen for selecting a

❽

pattern number with which a step sewing pattern

is newly created.

In the case there is no pattern number

with which a new pattern is created, the

message "Overwrite" message is dis-

played by pressing

When

aforementioned screen is displayed, the

screen for selecting the pattern number

of the pattern to be overwritten with a

step sewing pattern.

is pressed after the

❼

❽

.

(2) Creating a new step sewing pattern

Refer to

"4-5-3. How to copy / newly create a pattern" p. 54

for details.

– 35 –

Page 39

Displaying the step sewing pattern edit screen

①

❼

< Sewing screen (Step sewing pattern) >

Selecting the step you want to edit

②

Display the step sewing edit screen by keeping

held pressed for one second on the sew-

❼

ing screen for selecting the step sewing.

Step that is being selected

❷

< Step sewing pattern edit screen >

A step is added after the currently-selected step by pressing "+", or before the currently-selected step by

・

pressing "−" of

A step is added at the end of steps by pressing "▼" of

・

❻

❼

.

❻ ❽❺

1. Select the step by pressing

that is being selected is displayed in reverse vid-

eo.)

2.

In the case there is an unused step(s), a step(s)

can be added by following the procedure de-

scribed below.

If

will be cancelled and the sewing screen will be

displayed. (Added step is conrmed by pressing

lected.)

is pressed, the addition of a step

❽

while a step that is being added is se-

❼

while the leading step is being selected.

❺

❺

.

(The step

When "▲" of

・

added at the end of the existing steps.

3. The step that is being selected can be deleted by pressing

second, all existing steps in the sewing pattern can be deleted.

is pressed while the last step of the existing steps is being selected, a new step is

❺

– 36 –

If reset key is held pressed for one

❷ .

Page 40

Editing the selected step

③

❻❺❼

< Step sewing pattern step edit screen >

Sewing the sewing pattern you have edited

④

❽

1. When

selected, the step sewing pattern step edit screen

is displayed.

2. Select the sewing data item you want to edit by

pressing

.

❻

Refer to

details.

* When the edit key is pressed while the number of

stitches of "S102 Step changeover condition" is

being selected, the number of stitches teaching

screen is displayed. Refer to

out the teaching of the number of stitches" p.

38

"4-4-8. List of sewing data" p. 39

for the number of stitches teaching function.

is pressed while the step is being

❼

. Edit the item by pressing

❺

"4-4-7. How to carry

for

< Sewing screen (Step sewing pattern) >

When

rmed, and the screen returns to the step sewing

pattern edit screen.

The data you have set is reected on the screen.

When

returns to the sewing screen for the step sewing

pattern that has been edited.

is pressed, the edited data is con-

❽

is pressed again, the screen

❽

– 37 –

Page 41

4-4-7. How to carry out the teaching of the number of stitches

Teaching of the number of stitches is possible for a step sewing pattern in the case the number of stitches is

used as the step changeover condition.

Displaying the number of stitches teaching screen

①

❼

< Step sewing pattern step edit screen >

Starting the teaching of the number of stitches

②

A

Display the teaching screen by pressing

❼

after selecting "S102 The number of stitches for

step changeover" on the step sewing pattern step

edit screen.

Pictograph A is displayed and the operation mode

enters the teaching mode.

<The number of stitches teaching screen >

Depress the back part of pedal after completing

the sewing of a pattern (until the last stitch is

sewn). Then, the sewing machine exits from the

teaching mode and returns to the previous screen.

– 38 –

Page 42

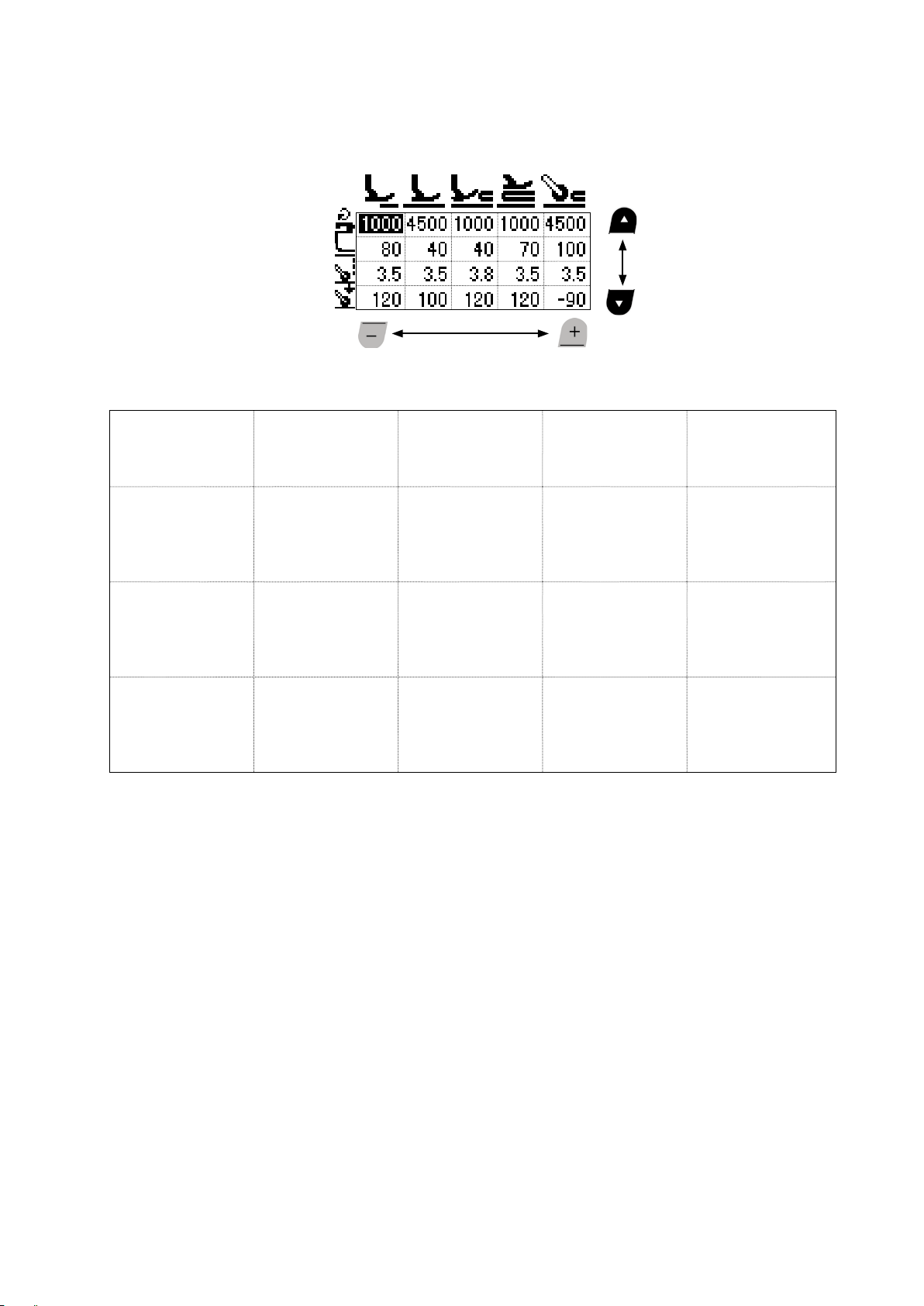

4-4-8. List of sewing data

(1) Sewing data to be used for free sewing patterns and step sewing patterns

No. Item name Input range

S001 Shape Free sewing Step

sewing

S003 Stitch length

S004 *1Limit of sewing speed

S005 *2Presser foot pressure

S006 Cloth pulling amount

S007 *3Cloth puller pressure

S011 Multi-layered section

changeover ON sensor

value

S012 *1Multi-layered section

sewing speed

S013 Number of stitches when

the presser foot runs on

the multi-layered section

S015 Cloth pulling amount

when the presser foot

runs on the multi-layered

section

S016 *3Cloth puller pressure

when the presser foot

runs on the multi-layered

section

1.4 to 4.2mm

150 to

5500sti/min

350 to 200

–

1.2 to

5.5mm

90 to 120

–

500 to 3000

/

Multi-layered

section is not

detected

150 to

5500sti/min

0 to 200

stitches

1.2 to

5.5mm

90 to 160 -

–

Enter the stitch length according to the feed amount of

sewing machine. (The feed amount of the sewing machine will not change if this value is changed.)

‐

‐

‐

‐

- If the multi-layered section sensor value exceeds this

value, the multi-layered section is detected.

This data item is used for setting the sewing speed to be

applied from the time at which the multi-layered section

is detected to the time at which the multi-layered section

sewing ends.

This data item is used for setting the number of stitches

to be sewn from the time at which the multi-layered sec-

tion of material is detected to the time at which the entire

presser foot runs on the multi-layered section.

While the sewing machine is engaged in the sewing of

this number of stitches, the sewing machine operates

using the cloth pulling amount set with "S015" and the

cloth puller pressure set with "S016".

-

*1: The actual sewing speed is limited by "S003 Stitch length" and the set value of cloth pulling amount.

In the case the set value of stitch length is 3.1 mm or more: Maximum sewing speed 5000 sti/min

In the case the set value of cloth pulling amount is 4.6 mm or more: Maximum sewing speed 4000 sti/min

*2: If this value is set to a negative value (minus value), the presser foot will go up. If the presser foot height is set so

that it oats, the multi-layered section changeover function will be disabled.

*3: If this value is set to a negative value (minus value), the cloth puller will go up.

– 39 –

Page 43

No. Item name Input range

S017 The number of stitches to

be sewn on the multi-layered section

S018 *2Presser foot pressure for

sewing the multi-layered

section

S019 Cloth pulling amount for

sewing the multi-layered

section

S020 *3Cloth puller pressure for

sewing the multi-layered

section

S021

Multi-layered section

changeover OFF sensor

value

0 to 200

stitches

350 to 200 -

–

1.2 to

5.5mm

90 to 160 -

–

500 to 3000

Multi-layered

section is

not detected

This data item is used for setting the number of stitches

to be sewn from the time at which the presser foot runs

on the multi-layered section to the time at which the

presser foot leaves the multi-layered section. While the

sewing machine is engaged in sewing of this number of

stitches, the sewing machine operates using the presser

foot pressure set with "S018", the cloth pulling amount

set with "S019" and the cloth puller pressure set with

“S020”.

-

- When the multi-layered section sensor value falls below

this value while the sewing machine is engaged in the

sewing of the multi-layered section of material, the

sewing machine nishes the sewing of the multi-layered

section. This set value is rendered effective in the case

the number of stitches for multi-layered section (S017)

is not set (0 stitch).

S031

1

*

S032

2

*

S033

S034

S041

Sewing speed for starting

sewing of the top end of

material

Presser foot pressure for

starting sewing of the top

end of material

Number of stitches for

changing the sewing

speed for starting sewing

of the top end of material

Number of stitches for

changing the presser

foot pressure for starting

sewing of the top end of

material

Number of stitches to be

sewn from the beginning

of sewing until the chainoff thread cutter is actuated

150 to 5500sti/min

350 to 200

–

0 to 200 stitches

0 to 200 stitches

0 to 2000 stitches

This data item is used for setting the sewing speed to

be employed when the material is detected after the

state no material has been detected. In the case a cloth

sensor is not used, the speed limit by this parameter will

not be applied. In the case both this function and "U037

Soft start function" are enabled, the sewing machine will

operate using the lower sewing speed.

This data item is used for setting the presser foot pres-

sure to be applied when the material is detected after

the state no material has been detected.

This data item is used for setting the number of stitches

to be sewn with the sewing speed set with "S031 Sewing

speed for starting sewing of the top end of material".

This data item is used for setting the number of stitches

to be sewn with the sewing speed set with "S032 Sewing

speed for starting sewing of the top end of material".

This data item is used for setting the number of stitches

to be sewn from the time at which the material is detect-

ed to the time at which chain-off thread cutter is actuat-

ed.

*1: The actual sewing speed is limited by "S003 Stitch length" and the set value of cloth pulling amount.

In the case the set value of stitch length is 3.1 mm or more: Maximum sewing speed 5000 sti/min

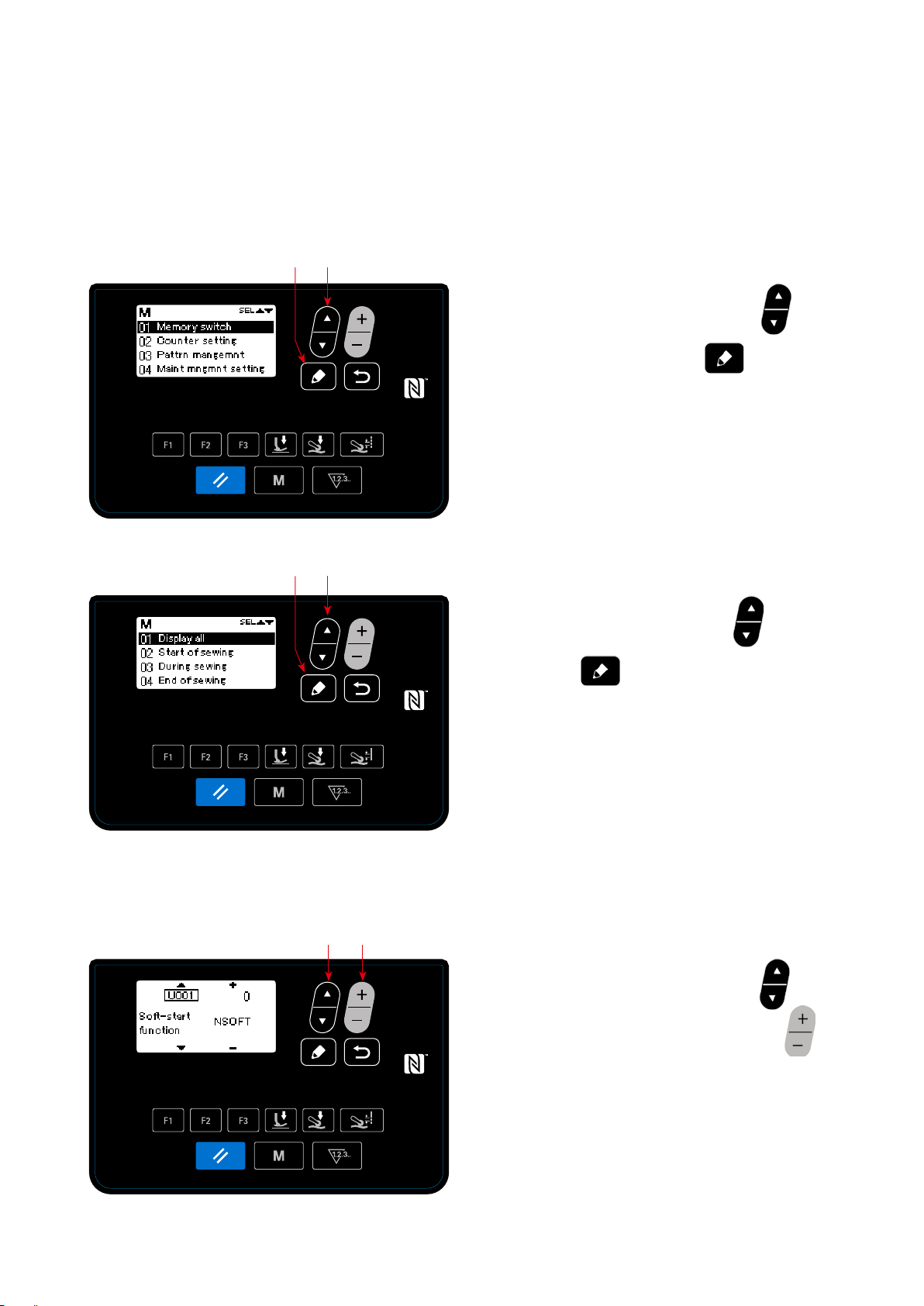

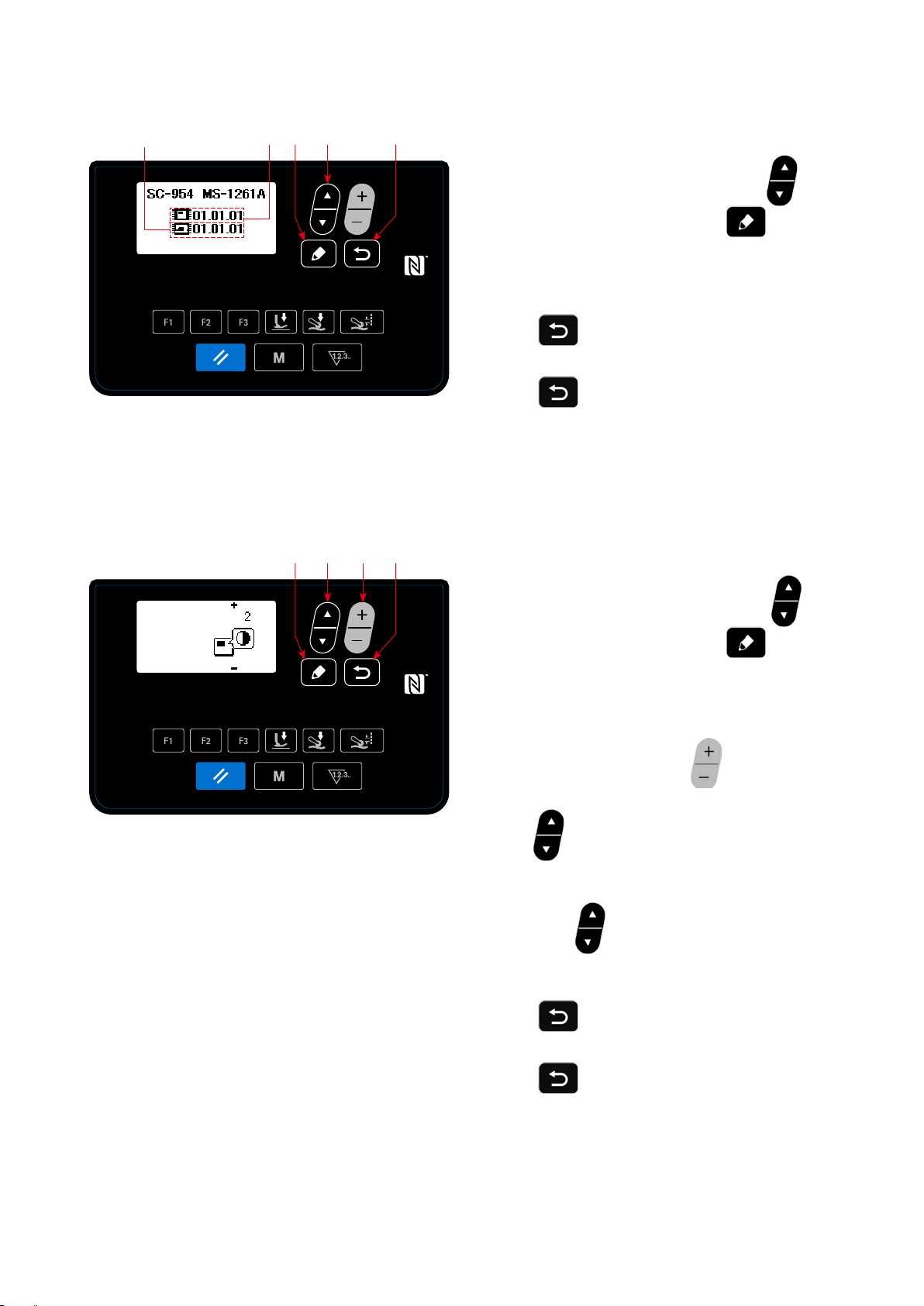

In the case the set value of cloth pulling amount is 4.6 mm or more: Maximum sewing speed 4000 sti/min