Page 1

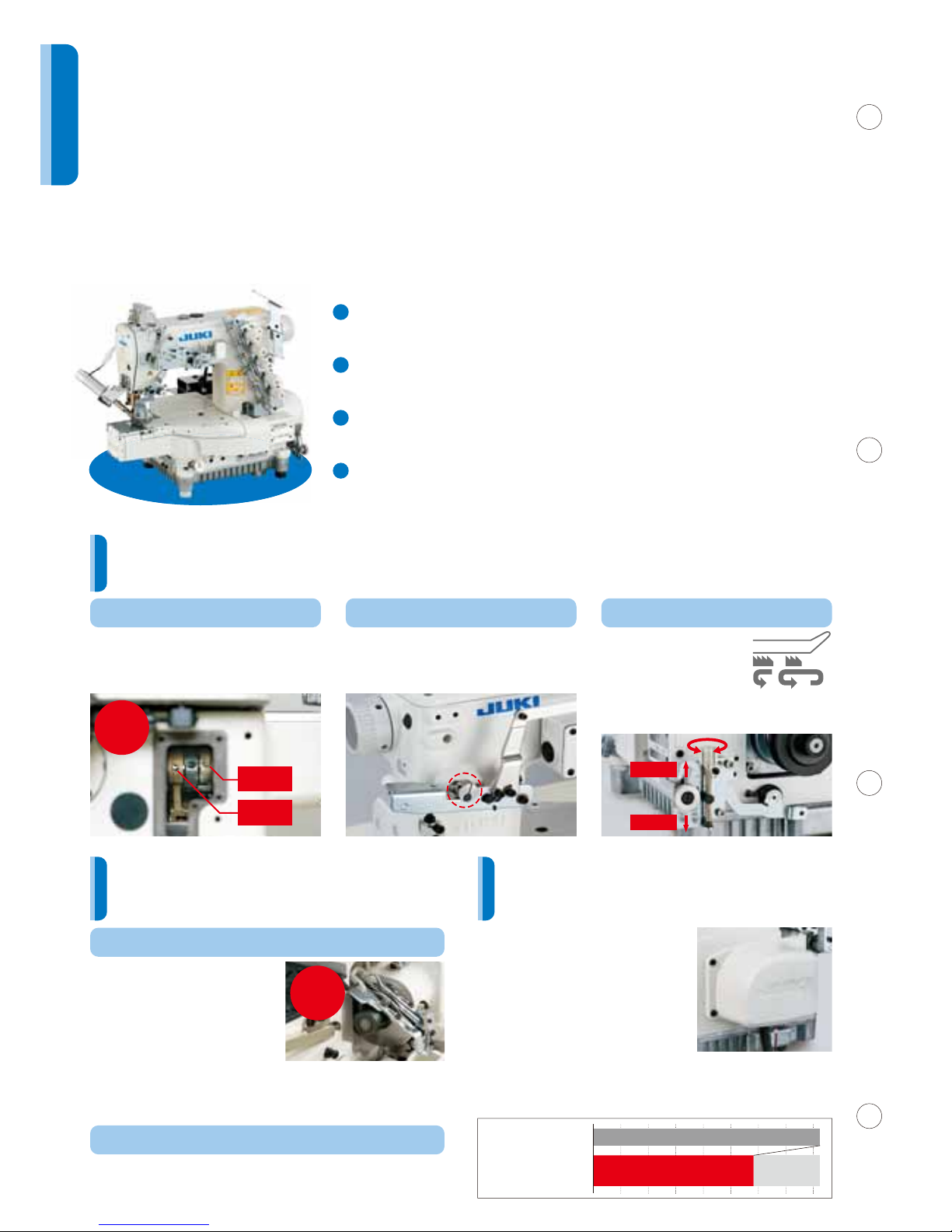

MF-7900 Series

High-speed, Cylinder-bed, Top & Bottom Coverstitch Machine

MF-7900D Series

Semi-dry-head, Cylinder-bed, Top & Bottom Coverstitch Machine

MF-7923D-U11-B56

Page 2

In the case of looper thread breakage,

the looper thread twining prevention

mechanism is activated to trim the

looper thread before the thread twines

on the looper thread cam. In this way,

the looper thread twining prevention

mechanism prevents the looper

thread from twining on the looper thread cam. In addition, the looper

thread cam, which has been incorporated in the sewing machine, has

been changed so that it is mounted outside of the sewing machine. The

externally-mounted looper thread cam promises improved maintainability.

As a result of the commonality of components, commercially-available

components (presser foot, throat plate and needle clamp) are now

applicable and easily obtainable.

Seam quality is improved!!

Simplified maintenance mechanism

All of the sewing machines with

a thread trimmer are provided

with a direct-drive motor.

The direct-drive motor system has been

adopted by all of the sewing machines with

a thread trimmer. As a result, the sewing

machine starts up swiftly and promises

increased stop accuracy, thereby

demonstrating improved responsiveness.

In addition, the machine is no longer

provided with a V-belt. This means that the

adoption of the direct-drive motor is also

effective in the elimination of belt shavings. Power is directly transmitted

from the motor to the sewing machine, thereby contributing to reduced

power consumption. (This sewing machine reduces power consumption

by 27% as compared with the conventional models.)

MF7823/UT22/SC510

MF-7923/UT57/SC921/CP18

Servomotor

Direct-drive motor

Commercially-available gauge components

are applicable with no additional work.

The looper thread twining prevention mechanism has been

improved and is provided as standard for the sewing machine.

The

world's

first

27%

Power

consumption

Reduced by

Main

feed dog

Differential

feed dog

The feed locus can be adjusted externally. The

feed locus is now adjustable in terms of the

vertical direction and horizontal direction, thereby

improving responsiveness to sewing materials.

Thanks to the new feed mechanism,

many different types of sewing are achieved.

Elastic material or delicate material can be

sewn with the presser foot kept slightly raised.

This effectively helps reduce the degree of

slippage, warpage and damage of the material.

Micro-lifter mechanism

It is possible to finely adjust

the differential feed amount

to a best-suited value for the

material to be used.

The differential feed ratio is

constant even if the stitch

length is changed.

Differential-feed micro-adjustment

mechanism

It is provided with many different sewing-related mechanisms which contribute to

improved seam quality, such as the new feed mechanism, and differential-feed

micro-adjustment mechanism. In addition, the machine is provided as standard with

a looper thread twining prevention mechanism for improved maintenance.

The MF-7900 Series is a newly developed

coverstitch machine provided with lots of

mechanisms for improving the seam quality.

MF-7900

Series

High-speed, Cylinder-bed,

Top & Bottom Coverstitch Machine

MF-7900/UT

Series

Direct-drive, High-speed, Cylinder-bed,

Top & Bottom Coverstitch Machine with Needle- and Looper- Thread Trimmer

MF-7900D

Series

Semi-dry-head, Cylinder-bed,

Top & Bottom Coverstitch Machine

MF-7900D/UT

Series

Semi-dry-head, Direct-drive, Cylinder-bed,

Top & Bottom Coverstitch Machine with Needle- and Looper- Thread Trimmer

Horizontal

direction

Vertical

direction

Expand

Contract

The

world's

first

Page 3

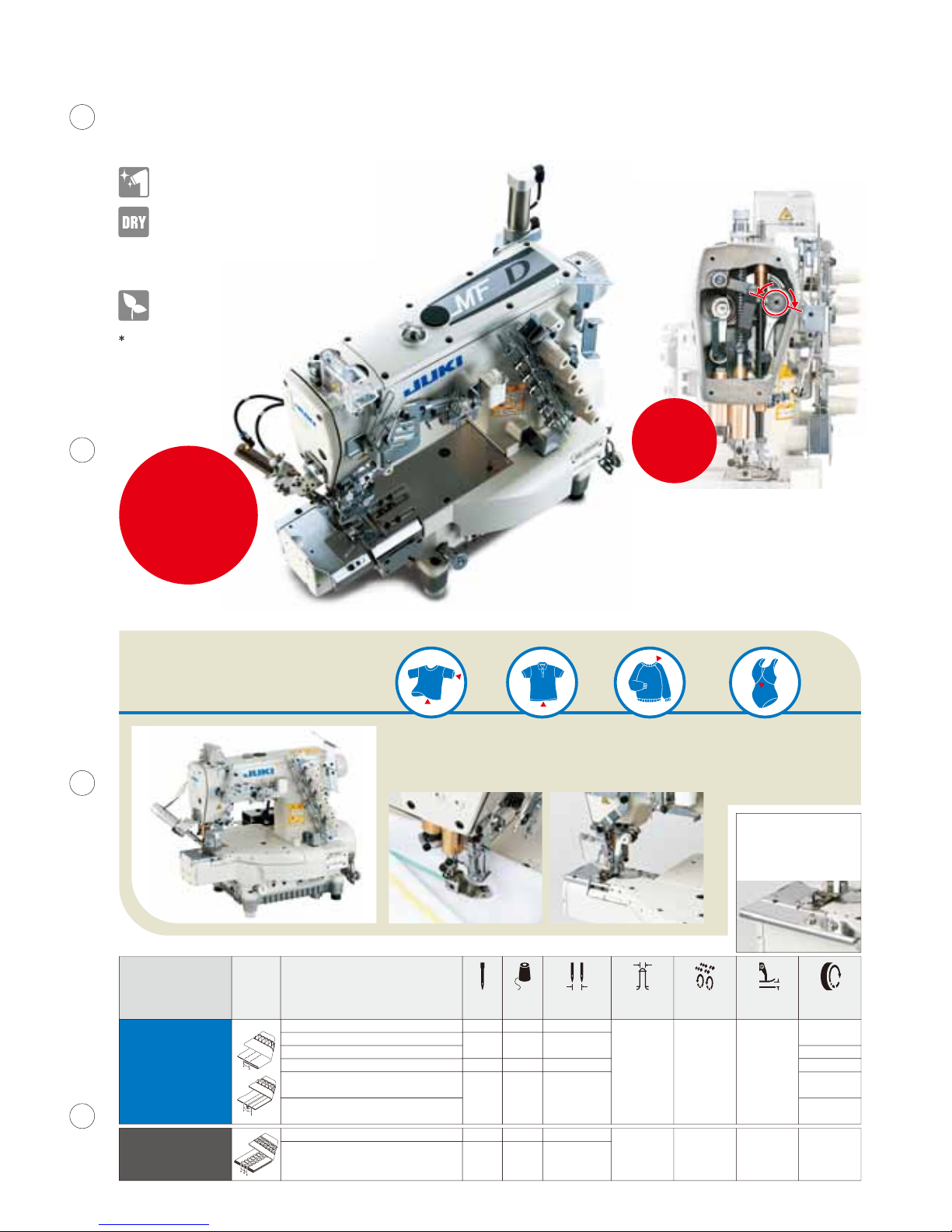

JUKI's dry-head technology

protects sewing products from being stained with oil.

With the excellent functions inherited from the MF-7900 Series, the MF-7900D is provided with a dry frame

mechanism to eliminate the cause of oil stains. Stain removing work or re-sewing work is substantially reduced

by protecting sewing products from being stained with oil, thereby improving the quality of finished products.

The frame no longer requires oiling.

Dry-head technology has materialized

a frame which does not need oiling.

Environmental consciousness

Dichlorofluoroethane (HCFC-141), which is

generally used in oil stain cleaning fluid, is included

in those chemicals which need to be reduced, as it

is a substances that can harm the ozone layer.

Since oil stains on sewing products are reduced, the quantity

of the use of stain remover generally used in sewing plants

can be reduced.

The needle bar mechanism and spreader mechanism have been applied with a

special surface treatment.

JUKI's unique special grease is used for lubrication. Grease-filled bearings have

been adopted for the crank rod. These allow the machine's frame mechanism to

demonstrate outstanding durability without being oiled.

Unlike the conventional models, the oiling mechanism inside the frame has been eliminated.

As a result, oil does not leak from the needle bar, presser bar or spreader shaft.

The semi-dry

head sewing machine

increases its sewing

speed to

5,000

sti/min

Application Seam

Model No.

Number

of

needles

Number

of

threads

Needle

gauge

(mm)

Stitch

length *

1

(mm)

Differentialfeed

ratio *

2

Presser foot

lifting amount *

3

(mm)

Max. sewing

speed

(sti/min)*

4

Binder mounting base

Various binders can be

installed by loading the

binder mounting base

supplied with the unit.

List of subclass machines

MF-7900/U11

Universal type

(basic type)

By changing over the needle bar stroke, penetrating force of

the needle as well as thread tension to fit heavy-weight

materials (fleece, blankets) can be obtained. The needle bar

stroke can be changed by adjusting the eccentric pin.

(Changing of parts is not required. Factory-set at the time of

delivery: 31mm; for sewing heavy-weight materials: 33mm)

Needle bar stroke conversion mechanism

head type sewing

machine has been

added.

A semi-dry

Universal type

(

basic type

)

U11

The machine can be used for the hemming process of the sleeves and bottoms of T-shirts and for

the covering process for sportswear and knitwear.

The front cover is trimmed to allow operators to bring their hands closer near the needle entry area,

thereby increasing work efficiency in the covering process, etc.

MF-7923-U11-B56/UT51

Polo

shirts

T-shirts knitwear sportswear

6,500

6,000

5,000

5,000

6,000

2 4

0.9~3.6

1:0.9~1:1.8

(1:0.6~1:1.1)

5 (8)

3.2,4.0,4.8

MF-7922-U11-B**

3 5 5.6,6.4

MF-7923-U11-B**

2 4

4.8

MF-7922-U11-B48/UT51

3 5

5.6,6.4

MF-7923-U11-B** /PL12,PL13

MF-7923-U11-B** /UT52/PL12

MF-7923-U11-B** /UT57/PL13

MF-7923-U11-B** /UT51,UT57

MF-7923-U11-B** /UT59

*1 Stitch length can be adjusted to 4.5mm at the maximum. *2 Differential ratio can be switched by adjustment.

*3 The lift of the presser foot is 5mm for the top and bottom coverstitch machine, and 8mm for the bottom coverstitch machine. *4 "sti/min" stands for "Stitches per Minute."

5,000

2 4

0.9~3.6

1:0.9~1:1.8

(1:0.6~1:1.1)

5 (8)

4.0

3 5 5.6,6.4

MF-7922D-U11-B40

MF-7923D-U11-B**

MF-7923D-U11-B** /UT51,UT57

MF-7923D-U11-B** /UT59

MF-7900D/U11

Universal type

(basic type)

Page 4

Application Seam

Model No.

Number

of

needles

Number

of

threads

Needle

gauge

(mm)

Stitch

length *

1

(mm)

Differentialfeed

ratio *

2

Presser foot

lifting amount *

3

(mm)

Max. sewing

speed

(sti/min)*

4

List of subclass machines

For elastic band welting

H11 with PL

This model is best suited to elastic-band welting for swimwear, briefs, etc. It welts the elastic

band which has been overlocked on the garment body.

H22,H23

This model is best suited to hemming processes for sleeves and the bottoms of T-shirts, Polo

shirts, etc. It comes with a left hand fabric trimmer for trimming fabric in parallel, at all times,

to the seam with consistency. The upper knife stroke can be adjusted with ease.

*1 Stitch length can be adjusted to 4.5mm at the maximum. *2 Differential ratio can be switched by adjustment.

*3 The numeric value indicates the lifting amount of the presser foot for top and bottom coverstitch. The numeric value given in parentheses indicates the lifting amount of the presser foot for bottom coverstitch.

*4 "sti/min" stands for "Stitches per Minute."

MF-7900/H11

Elastic band welting

5,0000.9~3.6

1:0.9~1:1.8

(1:0.6~1:1.1)

5 (8)35

5.6,6.4

MF-7923-H11-B** /PL12

MF-7923-H11-B** /PL13

MF-7923-H11-B** /UT52,UT57/PL12

MF-7923-H11-B** /UT57/PL13

For hemming

(with left hand fabric trimmer)

MF-7923D-H23-B56/UT57

Polo

shirts

T-shirts

★:The world's

fastest

sewing machine

with left hand

fabric trimmer

Application Seam

Model No.

Number

of

needles

Number

of

threads

Needle

gauge

(mm)

Stitch

length *

1

(mm)

Differentialfeed

ratio *

2

Presser foot

lifting amount *

3

(mm)

Max. sewing

speed

(sti/min)*

4

List of subclass machines

*1 Stitch length can be adjusted to 4.5mm at the maximum. *2 Differential ratio can be switched by adjustment.

*3 The lift of the presser foot is 5mm for the top and bottom coverstitch machine, and 8mm for the bottom coverstitch machine. *4 "sti/min" stands for "Stitches per Minute."

H11

MF-7923-H11-B56/PL13

Swimwear Briefs

MF-7922-H22, H23-B**

MF-7922-H22, H23-B48/MC40

MF-7923-H22, H23-B**

MF-7923-H22, H23-B** /MC40

MF-7923-H22, H23-B** /UT51, UT57

MF-7923-H22, H23-B** /UT57/MC37

MF-7923-H22, H23-B** /UT59/MC37

MF-7922-H22, H23-B48/UT51, UT57

MF-7922-H22, H23-B48/UT57/MC37

MF-7922-H23-D40/UT59/MC37

2 4

3 5

2 4

3 5

5.6,6.4

4.8

5.6,6.4

MF-7923D-H22, H23-B56

MF-7923D-H22, H23-B56/MC40

MF-7922D-H22, H23-B48/UT57/MC37

MF-7922D-H23-D40/UT59/MC37

MF-7923D-H22, H23-B** -UT51, UT57

MF-7923D-H22, H23-B** -UT57/MC37

3 5

2 4

5.6,6.4

3 5

5.6,6.4

4.0,4.8

4.8

4.8

4.0

4.0

0.9~3.6

0.9~3.6

5 (8)

5 (8)

6,000

★

6,000

★

0.9~3.6

1:0.9~1:1.8

(1:0.6~1:1.1)

1:0.9~1:1.8

(1:0.6~1:1.1)

5,0005 (8)

1:0.9~1:1.8

(1:0.6~1:1.1)

For hemming

(with left hand fabric

trimmer)

MF-7900D/

H22,23

For hemming

(with left hand fabric

trimmer)

MF-7900/

H22,23

Page 5

E11

This model is best suited to endless flat elastic band sewing processes for briefs, boxer briefs,

etc. The right hand fabric trimmer trims the fabric, even at a multi-layered joined part, to

produce a beautiful finish with the seam and fabric edge aligned with consistency. Cloth cutting

knife can be detached with one touch operation in case of sewing without using the knife.

For elastic band attaching

(with right hand fabric trimmer and tension roller)

MF-7913-E11-B56/PL12/MC37

E22

For endless spandex elastic

band attaching

(with manual binder and tension roller)

E23

For endless spandex elastic

band attaching

(with air binder and tension roller)

5,0000.9~3.6

1:0.9~1:1.8

(1:0.6~1:1.1)

6 (7)3 5 5.6,6.4

MF-7923-E22-B** /PL13

MF-7923-E23-B** /PL13

MF-7923-E22-B** /UT52/PL13

MF-7923-E23-B** /UT57/PL13

*1 Stitch length can be adjusted to 4.5mm at the maximum. *2 Differential ratio can be switched by adjustment.

*3 The numeric value indicates the lifting amount of the presser foot for top and bottom coverstitch. The numeric value given in parentheses indicates the lifting amount of the presser foot for bottom coverstitch.

*4 "sti/min" stands for "Stitches per Minute."

MF-7923-E22-B56/PL13 MF-7923-E23-B56/PL13

Boxer

briefs

Briefs

Briefs

5,000

2 4

0.9~3.6

1:0.9~1:1.8

(1:0.6~1:1.1)

5 (7)

5,0000.9~3.6

1:0.9~1:1.8

(1:0.6~1:1.1)

5 (7)

MF-7900/E11

Elastic band attaching

(with right hand fabric

trimmer)

MF-7900D/E11

Elastic band attaching

(with right hand fabric

trimmer)

4.0

5.6,6.4

3

5

5.6,6.4

4

5.6

3 4

5.6

*1 Stitch length can be adjusted to 4.5mm at the maximum. *2 Differential ratio can be switched by adjustment.

*3 The numeric value indicates the lifting amount of the presser foot for top and bottom coverstitch. The numeric value given in parentheses indicates the lifting amount of the presser foot for bottom coverstitch.

*4 "sti/min" stands for "Stitches per Minute."

Application Seam

Model No.

Number

of

needles

Number

of

threads

Needle

gauge

(mm)

Stitch

length *

1

(mm)

Differentialfeed

ratio *

2

Presser foot

lifting amount *

3

(mm)

Max. sewing

speed

(sti/min)*

4

List of subclass machines

Application Seam

Model No.

Number

of

needles

Number

of

threads

Needle

gauge

(mm)

Stitch

length *

1

(mm)

Differentialfeed

ratio *

2

Presser foot

lifting amount *

3

(mm)

Max. sewing

speed

(sti/min)*

4

List of subclass machines

This model is best suited for sewing elastic bands on briefs.

E22 is opened / closed with the knee lever and E23 is opened

/ closed with the knee switch. The machine comes provided

as standard with a tension roller to smoothly sew elastic bands

on different-sized garment bodies. The machine flexibly

adapts to varying elasticities due to its soft seams.

MF-7922-E11-B40/PL12/MC40

MF-7923-E11-B** /PL12/MC40

MF-7923-E11-B** /PL13/MC40

MF-7913D-E11-B56/UT56/PL13/MC37

MF-7913-E11-B56/UT55,UT56/PL12/MC37

MF-7913-E11-B56/UT55/PL13/MC37

MF-7913-E11-B** /UT56/PL13/MC37

For endless spandex

elastic band attaching

MF-7900/

E22,23

Page 6

Device

UT51

Electromagnetic needle thread /

looper thread trimming device / Auto-lifter

It is an electromagnetic needle

thread / looper thread trimming

device / Auto-lifter. The machine

does not need an air compressor to

achieve easy layout changing.

It is an electromagnetic needle

thread / looper thread trimming

device / Auto-lifter with cloth puller.

UT52

Electromagnetic needle thread /

looper thread trimming device / Auto-lifter

Pneumatic type bottom

thread trimming device

Air blow type wiper

UT55

Pneumatic type bottom

thread trimming device

+ Electromagnetic type wiper

/ Auto-lifter

This is a pneumatic type bottom

thread trimming device / auto-lifter. It

is used for processes which do not

need top covering.

UT56

Pneumatic type bottom

thread trimming device

+ Air blow type wiper

/ Auto-lifter

This is a pneumatic type bottom

thread trimming device / auto-lifter. It

pneumatically handles the needle

thread (i.e, places the needle thread

above the presser foot) instead of

the mechanical wiper.

PL12

Cloth puller : Gear type

This is a gear type cloth puller. It helps

feed difficult-to-feed materials to assist

smooth sewing.

(Example: Attaching flat elastic bands)

PL13

Cloth puller : Flat type

This is a flat type cloth puller. It helps

feed soft material which requires a

higher feeding force to assist sewing.

(Example: Hemming)

UT59

Pneumatic type top and bottom thread trimming

device with thread-fray-prevention function

MC37

•

MC40

Pneumatic cloth chip suction device

MC37 (solenoid valve type) : Part No.40023706,

MC40 (mechanical valve type) : Part No.40023707

SS11

Short stitch device : Part No.70004376

The needle thread tightening

mechanism helps produce

well-tensed seams even when the

machine performs short stitching.

The short stitch pitch can be

adjusted with ease.

This is a device for preventing the thread from coming undone at the end of

sewing. The device is able to sew condensation stitches by the number

specified as desired. It prevents the needle thread from being poorly tensed,

which is likely to occur in cases where the amount of condensation is

reduced.

Electromagnetic needle thread /

looper thread trimming device

Electromagnetic needle thread /

looper thread trimming device

It is the state-of-the-art function to make the thread-fray-prevention at the end

of sewing more reliable.

1

1

2

2

2

1

Presser lifter drive mechanism magnet

Thread trimmer drive mechanism magnet

1

2

Presser lifter drive mechanism magnet

Thread trimmer drive mechanism magnet

1

2

It is a pneumatic type needle thread /

looper thread trimming device /

Auto-lifter. Since the automatic lift of

the presser foot and automatic thread

trimming can be activated by lightly

depressing the pedal, work efficiency

is dramatically increased. The air

blow type wiper is supplied with the

sewing machine as an accessory.

UT57

Pneumat ic typ e needle t hread /

looper thread trimming device

Presser lifter drive mechanism air cylinder

Thread trimmer drive mechanism air cylinder

1

2

Pneumatic type needle thread /

looper thread trimming device / Auto-lifter

UT59 cannot be attached to the machine as a device.

Please order with the machine head.

Page 7

MF79 B /

MF79 BD/

MF79 D / /

/ /

MF79 B

*Refer to the subclass

models list for the

needle gauge of the

respective models.

Stitch type Code

2-needle, top and bottom coverstitch 22

3-needle, top and bottom coverstitch 23

Tongue shape of throat plate Code

B type B

Needle gauge

Code

3.2mm 32

4.0mm 40

4.8mm 48

5.6mm 56

6.4mm 64

Stitch type Code

2-needle, top and bottom coverstitch 22

3-needle, top and bottom coverstitch 23

Tongue shape of throat plate Code

B type B

Needle gauge

Code

4.0mm 40

5.6mm 56

6.4mm 64

Stitch type Code

2-needle, top and bottom coverstitch 22

3-needle, bottom coverstitch 13

3-needle, top and bottom coverstitch 23

Tongue shape of throat plate Code

B type B

Needle gauge

Code

4.8mm 48

5.6mm 56

6.4mm 64

*Refer to the subclass

models list for the

needle gauge of the

respective models.

*Refer to the subclass

models list for the

needle gauge of the

respective models.

Stitch type Code

2-needle, top and bottom coverstitch 22

3-needle, bottom coverstitch 13

3-needle, top and bottom coverstitch 23

Tongue shape of throat plate Code

B type B

D type D

Needle gauge

Code

4.8mm 48

4.0mm 40

5.6mm 56

6.4mm 64

*Refer to the subclass

models list for the

needle gauge of the

respective models.

Application Code

Universal type U11

For elastic band attaching E11

For wider hemming H11

For endless spandex elastic band attaching

(with manual binder and tension roller)

E22

Hemming (with left hand fabric trimmer,

for medium-weight materials)

H23

Hemming (with left hand fabric trimmer,

for light-weight materials)

H22

For endless spandex elastic band attaching

(with air binder and tension roller)

E23

Application Code

Universal type U11

For elastic band attaching E11

For wider hemming H11

For endless spandex elastic band attaching

(with manual binder and tension roller)

E22

Hemming (with left hand fabric trimmer, for medium-weight materials) H23

Hemming (with left hand fabric trimmer, for light-weight materials) H22

For endless spandex elastic band attaching

(with air binder and tension roller)

E23

Device and attachment

Not provided

Pneumatic cloth chip suction device

(mechanical valve type)

Code

MC40

Cloth puller: Gear type PL12

Cloth puller: Flat type PL13

Application Code

Universal type U11

Hemming (with left hand fabric trimmer, for medium-weight materials) H23

Hemming (with left hand fabric trimmer, for light-weight materials) H22

Device and attachment

Not provided

Pneumatic cloth chip suction device

(mechanical valve type)

Code

MC40

Thread trimming device

Electromagnetic type top and bottom thread trimming device

Code

UT51

Electromagnetic type top and bottom thread trimming device UT52

Pneumatic type bottom thread trimming device

+ Electromagnetic type wiper

UT55

Pneumatic type bottom thread trimming device

+ Air blow type wiper

UT56

Pneumatic type top and bottom thread trimming device UT57

Pneumatic type top and bottom thread trimming device

with thread-fray-prevention function

UT59

Pneumatic cloth chip suction device (electromagnetic valve type)

MC37

Cloth puller: Gear type PL12

Cloth puller: Flat type PL13

Thread trimming device

Electromagnetic type top and bottom thread trimming device

Code

UT51

Pneumatic type bottom thread trimming device

+ Air blow type wiper

UT56

Pneumatic type top and bottom thread trimming device UT57

Pneumatic type top and bottom thread trimming device

with thread-fray-prevention function

UT59

Pneumatic cloth chip suction device (electromagnetic valve type)

MC37

Cloth puller: Flat type PL13

Application Code

Universal type U11

For elastic band attaching E11

Hemming (with left hand fabric trimmer,

for medium-weight materials)

H23

Hemming (with left hand fabric trimmer,

for light-weight materials)

H22

MF-7900D (Semi-dry-head)

WHEN YOU PLACE ORDERS

Please note when placing orders, that the model name should be written as follows:

MF-7900

Without automatic thread trimmer

With automatic thread trimmer (Direct-drive motor)

Without automatic thread trimmer

With automatic thread trimmer (Direct-drive motor)

SC-921B

CP-18B

Control box

Operation panel

SC-921B

CP-18B

Control box

Operation panel

Page 8

SEPTEMBER, 2013 Printed in Japan(C)

SEWING MACHINERY BUSINESS UNIT

2-11-1, TSURUMAKI, TAMA-SHI,

TOKYO

206-8551, JAPAN

PHONE : (81) 42-357-2254

FAX :

(

81

)

42-357-2274

http://www.juki.com

✽

Specifications and appearance are subject to change without prior notice for improvement.

✽

Read the instruction manual before putting the machine into service to ensure safety.

✽

This catalogue prints with environment-friendly soyink on recycle paper.

JUKI ECO PRODUCTS

The MF-7923U11B56/UT57 is an eco-friendly product which complies with

JUKI ECO PRODUCTS standards for protecting the environment.

This sewing machine reduces power consumption by 27% as compared with the conventional models.

The sewing machine complies with the "Juki Group Green Procurement Guidelines" on the use of hazardous substances,

which is stricter than other restrictions, such as those of the RoHS Directive.

For details of JUKI ECO PRODUCTS, refer to : http://www.juki.co.jp/eco_e/index.html

The RoHS Directive is an EU Directive limiting the use of 6 hazardous substances (lead, hexavalent chromium, mercury, cadmium, PBB and PBDE) in electrical and electronic equipment.

The Juki Green Procurement Guideline is the voluntarily established criteria to eliminate not only the aforementioned six substances, but also other ones which also adversely affect the environment.

Juki Corporation operates an environmental management system

to promote and conduct the following as the company engages in

the research, development, design, sales, distribution,and

maintenance of industrial sewing machines, household sewing

machines, industrial robots, etc., and in the provision of sales and

maintenance services for data entry systems:

(1) The development of products and engineering processes

that are safe to the environment

(2) Green procurement and green purchasing

(3)

Energy conservation (reduction in carbon-dioxide emissions)

(4) Resource saving (reduction of papers purchased, etc.)

(5) Reduction and recycling of waste

(6) Improvement of logistics efficiency (modal shift and

improvement of packaging, packing, etc.)

Model name

MF-7900 series MF-7900D series

SPECIFICATIONS (U11, H11, H22, H23, E11, E22, E23

)

Compressedair / Air consumption (with automatic thread trimmer)

※ "H11" excepts MF-7900D Series.

Device

UT57, UT59

UT56

UT55

Bottom

thread trimmer

Auto-lifter

―

―

―

―

●

●

●

Top and bottom

thread trimmer

Auto-lifter

●

●

●

●

―

―

―

Air blow type

wiper

―

●

―

●

●

●

―

MC37

MC40

―

―

●

●

―

●

●

Air consumption

dm3/min (ANR)

0.7

182

456

637

182

637

456

Compressed air

MPa

0.5

0.5

0.5

41kg (without device), 49kg (with UT51), 51kg (with PL/UT52), 44kg (with UT57)

43kg (without device), 51kg (with UT52), 46kg (with UT57)

43kg (without device), 51kg (with UT52), 46kg (with UT57)

44kg (without device), 48kg (with UT55), 47kg (with UT56)

42kg (without device), 50kg (with UT51), 45kg (with UT57)

U11

H11 (with PL)

※

E22, E23 (with PL)

E11 (with PL)

H22, H23

Weight of the

machine head

Needle

Lift of the presser foot

Lubrication

Lubricating oil

Feed dog inclination adjustment

Micro-lifter

Needle gauge (mm)

Stitch pitch adjustment

Differential feed adjustment

Silicon oil tank for needle tip

and needle thread

Cartridge oil filter

Needle bar stroke

converting function

Power requirement /

Power consumption

UY128GAS (#10S) #9~#12S

JUKI Machine Oil 18 (equivalent to ISO VG18)

Provided as standard

Provided as standard

3.2, 4.0, 4.8, 5.6, 6.4

By dial

By micro-adjustment mechanism

U11, H11, H22, H23, E11 : Provided as standard: 31mm: at the time of delivery /

When sewing a heavy-weight material: 33mm

※

Provided as standard

Provided as standard

Single-phase 100~120V / 200~240V,

3-phase 200~240V / 500VA (with automatic thread trimmer)

5mm (with top and bottom covering stitch),

8mm (with bottom covering stitch)

Stitch type

Automatiac

2-needle/3-needle top

and bottom covering stitch

E22, E23 : Provided as standard: 33mm:

at the time of delivery /

When sewing a heavy-weight material: 35mm

Automatic (frame: no lubrication)

2-needle/3-needle top

and bottom covering stitch

—

Loading...

Loading...