Page 1

MF-7900D-H24

INSTRUCTION MANUAL

I

Page 2

CONTENTS

1. SPECIFICATIONS ............................................................................................................................ 1

2. DRAWING OF TABLE (TABLE-FIXED TYPE / V-BELT TYPE) ....................................................... 2

3. DRAWING OF TABLE (TABLE-FIXED TYPE / DIRECT-DRIVE TYPE) .......................................... 3

4. DRAWING OF TABLE (SEMI-SUBMERGED TYPE / V-BELT TYPE) ............................................. 4

5. DRAWING OF TABLE (SEMI-SUBMERGED TYPE / DIRECT-DRIVE TYPE) ................................ 5

6. THREADING THE MACHINE HEAD ................................................................................................ 6

7. ADJUSTING THE SILICON CONTAINER THREAD GUIDE ........................................................... 7

8. ADJUSTING THE ROCKING THREAD TAKE-UP ........................................................................... 7

9. ADJUSTING THE ROCKING THREAD TAKE-UP HOLDER .......................................................... 8

10. INSTALLING THE WASTE CLOTH PIPE ........................................................................................ 8

11. ADJUSTING THE UPPER KNIFE PRESSURE ............................................................................... 9

12. ADJUSTING THE LATERAL POSITION OF THE LOWER KNIFE ................................................. 9

13. ADJUSTMENT PROCEDURE OF ENGAGEMENT AMOUNT OF KNIVES .................................. 10

14. REPLACEMENT PROCEDURE OF UPPER KNIFE AND LOWER KNIFE ................................... 10

15. ADJUSTING THE UPPER KNIFE STROKE ...................................................................................11

i

Page 3

1. SPECIFICATIONS

Model MF-7900D-H24

Class name Covering stitch machine with left hand fabric undertrimmer

(for extra light-weight materials)

Application Hemming of knit and jersey products

Sewing speed Max. 5,000 sti/min (at the time of intermittent operation)

Speed of stitch at the delivery. 4,500 sti/min (at the time of intermittent operation)

Needle gauge 3-needle 5.6 mm, 6.4 mm

2-needle 3.2 mm, 4.0 mm

Differential feed ratio 1 : 0.9 to 1 : 1.6 (stitch length : less than 2.5 mm)

(1 : 0.6 to 1 : 0.9, when the differential link hinge screw is changed)

Micro-differential feed adjustment mechanism is provided. (Micro-adjustment)

Stitch length 0.9 to 3.6 mm

Noise

- Equivalent continuous emission sound pressure level (LpA) at the workstation :

A-weighted value of 79.5 dB; (Includes KpA = 2.5 dB); according to ISO 10821- C.6.2

-ISO 11204 GR2 at 4,000 sti/min.

– 1 –

Page 4

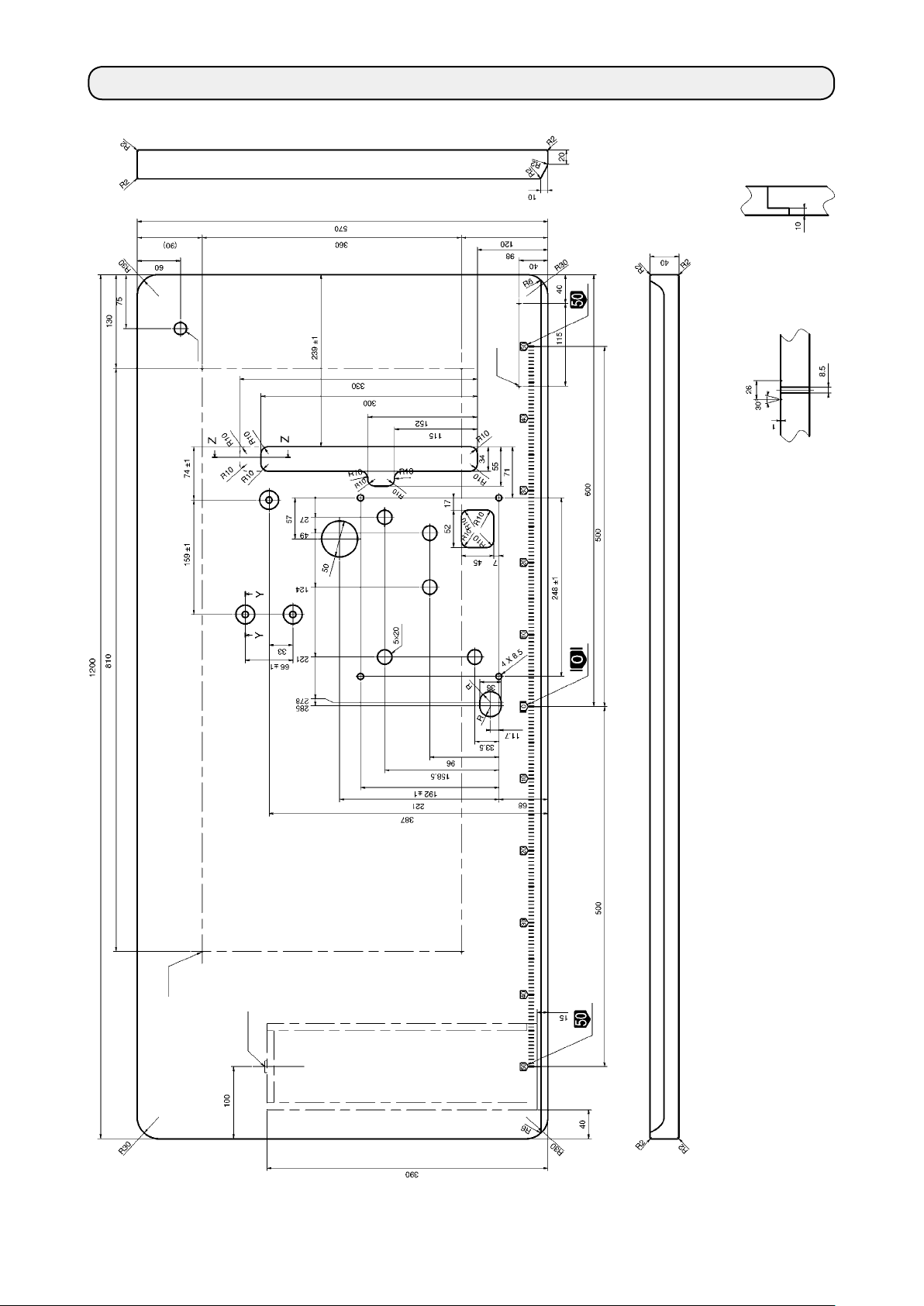

2. DRAWING OF TABLE (TABLE-FIXED TYPE / V-BELT TYPE)

Z-Z

C

D

(3 locations)

Y-Y

2 - ø 3.4 on the bottom surface, depth 10

D

(Drill a hole at the time of set-up.)

A

B

– 2 –

4 - ø 3.4 on the bottom surface, depth 20

Installing position of drawer stopper

A

(Drill a hole at the time of set-up.)

B

Drilled hole 17

(on the reverse side)

C

Page 5

3. DRAWING OF TABLE (TABLE-FIXED TYPE / DIRECT-DRIVE TYPE)

C

D

(3 locations)

Y-Y

A

B

2 - ø 3.4 on the bottom surface, depth 10

D

(Drill a hole at the time of set-up.)

4 - ø 3.4 on the bottom surface, depth 20

Installing position of drawer stopper

A

(Drill a hole at the time of set-up.)

B

Drilled hole 17

(on the reverse side)

C

– 3 –

Page 6

4. DRAWING OF TABLE (SEMI-SUBMERGED TYPE / V-BELT TYPE)

(4 locations)

Z-Z

C

(3 locations)

Y-Y

D

X-X

E

A

B

– 4 –

2 - ø 3.4 on the bottom surface, depth 10

4 - 10.5 hole, 26 hole facing depth 3.5

D

(Drill a hole at the time of set-up.)

E

4 - ø 3.4 on the bottom surface, depth 20

Installing position of drawer stopper

A

(Drill a hole at the time of set-up.)

B

Drilled hole 17

(on the reverse side)

C

Page 7

5. DRAWING OF TABLE (SEMI-SUBMERGED TYPE / DIRECT-DRIVE TYPE)

C

D

(4 locations)

Z-Z

A

E

B

2 - ø 3.4 on the bottom surface, depth 10

4 - 10.5 hole, 26 hole facing depth 3.5

D

(Drill a hole at the time of set-up.)

E

4 - ø 3.4 on the bottom surface, depth 20

Installing position of drawer stopper

A

(Drill a hole at the time of set-up.)

B

Drilled hole 17

(on the reverse side)

C

– 5 –

Page 8

6. THREADING THE MACHINE HEAD

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the follow-

ing work after turning the power off and ascertaining that the motor is at rest. If threading is wrong, stitch

skipping, thread breakage, needle breakage or irregular stitches will be caused. So, be careful.

[ Standard threading ]

Thread the machine head according to the following threading illustrations.

❶

❷

B

C

When covering thread is excessively loosened =

When covering thread is excessively loosened even

after passing B =

C

❸

❷

When using more stretchable

thread

When using less stretchable

thread

❶

D

B

When covering thread is excessively tense =

D

❸

Broken line E when using more stretchable thread

E

– 6 –

Page 9

7. ADJUSTING THE SILICON CONTAINER THREAD GUIDE

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following

work after turning the power off and ascertaining that the motor is at rest.

29 mm

❹

10 mm

❶

❷

1) Loosen setscrews ❶. Adjust so that a distance of

10 mm is provided between the center of the upper

setscrew and top end ❹ of the base. Then, tighten

setscrews ❶.

2) Loosen setscrew ❷. Adjust so that a distance of 29

mm is provided between the center of setscrews ❶

and the center of medium needle thread guide bar.

After the adjustment, x the needle guide bars with

A B C

9 mm 15 mm 21 mm

3) Loosen setscrews ❸. Adjust the height of the

bottom end of hole in the respective needle thread

guide bars from the top end of base ❺ to the

distances as shown in the table above. After the

adjustment, x the needle thread guide bars with

setscrews ❸.

setscrew ❷.

8. ADJUSTING THE ROCKING THREAD TAKE-UP

❺

C

B

A

❸

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following

work after turning the power off and ascertaining that the motor is at rest.

Adjust so that rocking thread take-up base ❶ is level

Horizontal

when the rocking thread take-up is in its lowest position.

Retighten screw ❷ to x the rocking thread take-up

❶

❷

base.

– 7 –

Page 10

9. ADJUSTING THE ROCKING THREAD TAKE-UP HOLDER

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following

work after turning the power off and ascertaining that the motor is at rest.

1) Loosen setscrew ❶. Adjust so that the top end

of thread-hole ❺ in the rocking thread take-up is

aligned with the top end of rocking thread take-up

❹

❶

❺

1 mm

❻

❸

holder ❹ when rocking thread take-up ❸ is brought

to its lower end. After the adjustment, x the rocking

thread take-up holder with setscrew ❶.

2) Loosen setscrew ❷. Adjust so that a distance of

1 mm is provided between the top end of rocking

thread take-up ❸ and the top end of right needle

guard ❻ when rocking thread take-up ❸ is brought

to its lower end. After the adjustment, x the rocking

thread take-up holder with setscrew ❷.

❷

10. INSTALLING THE WASTE CLOTH PIPE

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following

work after turning the power off and ascertaining that the motor is at rest.

❷

❸

❹

❶

1) Fix waste cloth pipe asm. ❶ with waste cloth pipe

setscrews ❷.

2) Insert waste cloth pipe ❸ into waste cloth pipe

asm. ❶, and x it with joint asm. ❹.

3) Connect the dust collection hose from the dust collection device to dust collection pipe asm. ❶. When

connecting it, use speed controller (accessories) ❺.

When installing waste cloth pipe ❸, install

it so as not to interfere with section A of

the upper knife holder.

A

❺

❸

– 8 –

Page 11

11. ADJUSTING THE UPPER KNIFE PRESSURE

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following

work after turning the power off and ascertaining that the motor is at rest.

Standard adjustment position of thrust collars ❶ and ❷

is such that a clearance of 10 mm is provided between

them.

Place thrust collar ❶ between spring ❺ and lower knife

holder ❸. Press thrust collar ❶ against the end face of

lower knife holder ❸ and Fix thrust collar ❶, using setscrew ❹, with pressed against the end face of bushing ❸.

1) To increase the knife pressure

Move thrust collar ❷ to the left (in direction B).

Then, tighten setscrew ❻. Loosen setscrew ❹

of thrust collar ❶ once. Tighten setscrew ❹ to x

thrust collar ❶ with pressed against the end face of

bushing ❸ by the spring pressure.

2) To decrease the knife pressure

Move thrust collar ❷ to the right (in direction C).

Then, tighten setscrew ❻. Loosen setscrew ❹

of thrust collar ❶ once. Tighten setscrew ❹ to x

thrust collar ❶ with pressed against the end face of

bushing ❸ by the spring pressure.

* Standard assembly procedure of the thrust collar

for the MF-7900D-H24 :

Assemble the thrust collar, spring and thrust collar

in the written order.

❹

❸

❶

❺

10 mm

❷

❻

B

C

Set the knife pressure as low as possible

within the range where cloth is smoothly

cut for use.

12. ADJUSTING THE LATERAL POSITION OF THE LOWER KNIFE

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following

work after turning the power off and ascertaining that the motor is at rest.

❸

❷

A

B

❹

❶

1) Loosen waste cloth pipe setscrews ❶.

2) Loosen lower knife holder setscrew ❷. Adjust the

lateral position of the lower knife by turning adjustment screw ❹ to move lower knife holder ❸ to the

right or left.

The lower knife moves to the left by turning the

adjustment screw in direction A.

The lower knife moves to the right by turning the

adjustment screw in direction B.

After the adjustment, tighten lower knife holder

setscrew ❷.

The tightening torque is 1.5 to 2 N・m (15 to 20

kgf・cm).

3) After the adjustment, x the lower knife holder with

the lower knife holder setscrew ❷.

4) Perform the adjustment of the position of waste

cloth pipe with waste cloth pipe setscrews ❶.

– 9 –

Page 12

13. ADJUSTMENT PROCEDURE OF ENGAGEMENT AMOUNT OF KNIVES

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following

work after turning the power off and ascertaining that the motor is at rest.

1) Loosen upper knife holder setscrew ❸. Adjust so

❶

0.5 mm

that the top end of upper knife is located 0.5 mm

above lower knife ❷ when upper knife ❶ is brought

to its lower end.

2) After the adjustment, perform "11. ADJUSTING

THE UPPER KNIFE PRESSURE" p.9.

❷

❸

14. REPLACEMENT PROCEDURE OF UPPER KNIFE AND LOWER KNIFE

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following

work after turning the power off and ascertaining that the motor is at rest.

1) Loosen setscrew ❶ in the joint asm., and remove

waste cloth pipe ❷.

❷

❶

2) Loosen setscrews . In this state, loosen lower

knife retaining plate setscrew ❸. Pull out lower

❸

❽

knife ❺ in direction B while pulling upper knife holder ❽ in direction A .

3) Insert a new lower knife in the groove of lower knife

holder ❻, and tighten setscrew ❸ in the lower knife

A

presser plate in the state that the blade point is

aligned with the top surface of the throat plate.

❽

❹

❺

❻

B

4) When replacing the upper knife, loosen setscrew ❼

in the upper knife holder, remove upper knife holder

❽, loosen setscrew ❾ in the upper knife, and remove upper knife .

5)

Fix new upper knife with setscrew ❾ in the upper knife.

6)

❾

After replacing the upper knife, align the left end face of

upper knife holder ❽ and the left end face of knife shaft

❹, and tighten setscrew ❼ in the upper knife holder.

7) After replacing the upper knife, perform "11. AD-

❼

JUSTING THE UPPER KNIFE PRESSURE" p.9

and

"13. ADJUSTMENT PROCEDURE OF EN-

GAGEMENT AMOUNT OF KNIVES" p.10.

– 10 –

Page 13

15. ADJUSTING THE UPPER KNIFE STROKE

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following

work after turning the power off and ascertaining that the motor is at rest.

1) Loosen setscrews ❶ in the waste cloth pipe and

❶

❷

2) Remove setscrews ❸ in the installing base cover,

remove waste cloth pipe ❷.

and remove installing base cover ❹.

❻

❸

❹

❼

❺

B A

3) Loosen lock nut ❺ of the adjustment pin and move

adjustment pin ❻ up or down to adjust the stroke of

the upper knife.

4) The standard adjustment position is the position

where the engraved marker dot A of adjustment

lever ❼ aligns with the engraved marker line B of

adjustment pin ❻. Loosen nut ❺ and raise adjustment pin ❻ to increase the stroke of the upper

knife, and lower it to decrease the stroke. After the

adjustment, perform "13. ADJUSTMENT PROCE-

DURE OF ENGAGEMENT AMOUNT OF KNIVES"

p.10.

– 11 –

Loading...

Loading...