JUKI MF-7800D Series Engineer's Manual

40084355

No.E387-00

ENGINEER’S MANUAL

Semi-dry head, Cylinder-bed Top and Bottom Coverstitch Machine

MF-7800D Series

®

PREFACE

This Engineer’s Manual is written for the technical personnel who are responsible for the service and maintenance

of the machine.

The Instruction Manual for these machines intended for the maintenance personnel and operators at an apparel

factory contains operating instructions in detail. And this manual describes "Standard Adjustment", "Adjustment

Procedures", "Results of Improper Adjustment", and other important information which are not covered by the

Instruction Manual.

It is advisable to use the relevant Instruction Manual and Parts List together with this Engineer’s Manual as well as

the MF-7800, SC-500, and SC-510 Series Manuals when carrying out the maintenance of these machines.

In addition, for the motor for the sewing machine with thread trimmer, refer to the separate Instruction Manual or

Engineer’s Manual for the motor. And for the control panel, refer to the Instruction Manual for the control panel.

This manual gives the "Standard Adjustment" on the former page under which the most basic adjustment value is

described, and on the latter page "Results of Improper Adjustment" under which stitching errors and troubles arising

from mechanical failures are described together with the "Adjustment Procedures".

CONTENTS

1. SPECIFICATIONS................................................................................................... 1

2. CONFIGURATION OF THE MACHINE COMPONENTS........................................ 2

3. MODEL NUMBERING SYSTEM ............................................................................ 3

(1) MF-7800D Series . ................................................................................................................... 3

(2) MF-7800D Series Thread trimmer.......................................................................................... 4

4. MOTOR PULLEY AND BELT ................................................................................. 5

5. ST ANDARD ADJUSTMENT ................................................................................... 6

(1) Threading the machine head . ............................................................................................... 6

(2) Adjusting the rocking thread take-up ................................................................................... 8

(3) Adjusting the position of the needle thread guide rod ..................................................... 10

(4) Adjusting the position of the thread receiver .................................................................... 12

(5) Adjusting the position of the spreader thread guide and spreader thread take-up....... 14

(6) Adjusting the spreader......................................................................................................... 16

(7) Adjusting the timing relation between the looper and needle bar................................... 20

(8) Returning amount of the looper .......................................................................................... 22

(9) Height of the needle ............................................................................................................. 24

(10)Locus and longitudinal motion of the looper..................................................................... 26

(11)Adjusting the needle guard ................................................................................................. 28

(12)Adjusting the feed dog ......................................................................................................... 32

(13)Adjusting the feed relation .................................................................................................. 38

(14)Adjusting the presser foot ................................................................................................... 40

(15)Adjusting the micro-lifter ..................................................................................................... 42

(16)Adjusting the looper thread cam......................................................................................... 44

(17)With regard to lubrication .................................................................................................... 46

(18)Adjusting and setting SC-510 .............................................................................................. 50

(19)MF-7700D/MF-7800D How to use the timing gauge ........................................................... 54

(20)MF-7800D-H21 ....................................................................................................................... 55

(21)MF-7800D-E10 ....................................................................................................................... 63

(22)MF-7800D-UT25/UT24 ........................................................................................................... 81

(23)MF-7800D-UT22 ....................................................................................................................111

(24)MC-35/MC-36 ....................................................................................................................... 121

(25)PL11 ..................................................................................................................................... 131

6. OTHER CAUTIONS ............................................................................................ 140

(1) MF-7800D dry section......................................................................................................... 140

(2) Application of appropriate grease .................................................................................... 140

(3) Adhesives application spots ............................................................................................. 142

7. TROUBLES AND CORRECTIVE MEASURES .................................................. 143

8. DRAWING OF TABLE......................................................................................... 157

(1) Top mount type ................................................................................................................... 157

(2) Half-sunk table .................................................................................................................... 158

(3) Table for H21 ....................................................................................................................... 159

(4) Table for 7800D-E10............................................................................................................ 160

– 1 –

1. SPECIFICATIONS

No. Item Specifications

1Model name Semi-dry head, cylinder-bed top and bottom coverstitch machine

2 Model MF-7800D series

3Stitch type ISO standard 406, 407, 602, and 605

4 Example of application Hemming and covering for knits and general knitted fabrics

5Max. sewing speed 4,000 sti/min (at the time of intermittent operation)

3-needle...........5.6 mm, 6.4 mm

2-needle...........4.0 mm, 4.8 mm

1 : 0.9 to 1 : 1.8 (stitch length : less than 2.5 mm)

7 Differential feed ratio Micro-differential feed adjustment mechanism is provided.

(Micro-adjustment)

8 Stitch length 0.9 mm to 3.6 mm (can be adjusted up to 4.5 mm)

UY128GAS #9S to #12S (standard #10S)

(Nm65 to Nm80, standard Nm70)

10 Needle bar stroke 31 mm

11 Dimensions Height: 450 mm, Width: 456 mm, Length: 267 mm

12 Weight 42 kg, 44 kg (with UT25), 48 kg (with UT22)

5 mm (with top covering)

8 mm (without top covering)

Main feed ................ dial type stitch pitch adjustment method

14 Feed adjustment method Differential feed....... lever adjustment method (micro-adjustment

mechanism is provided.)

15 Looper mechanism Spherical rod drive method

16 Lubricating system Forced lubrication method by gear pump

17 Lubricating oil JUKI MACHINE OIL 18 (Equivalent to ISO VG18)

18 Oil reservoir capacity Oil gauge lower line : 600 cm3 to upper line : 900 cm

3

19 Installation Top mount type, Semi-submerged type

20 Micro-lifter Provided as standard

21 Provided as standard

22 Cartridge oil filter Provided as standard

6Needle gauge

9 Needle

13 Lift of presser foot

Needle tip, needle thread silicone tank

– 2 –

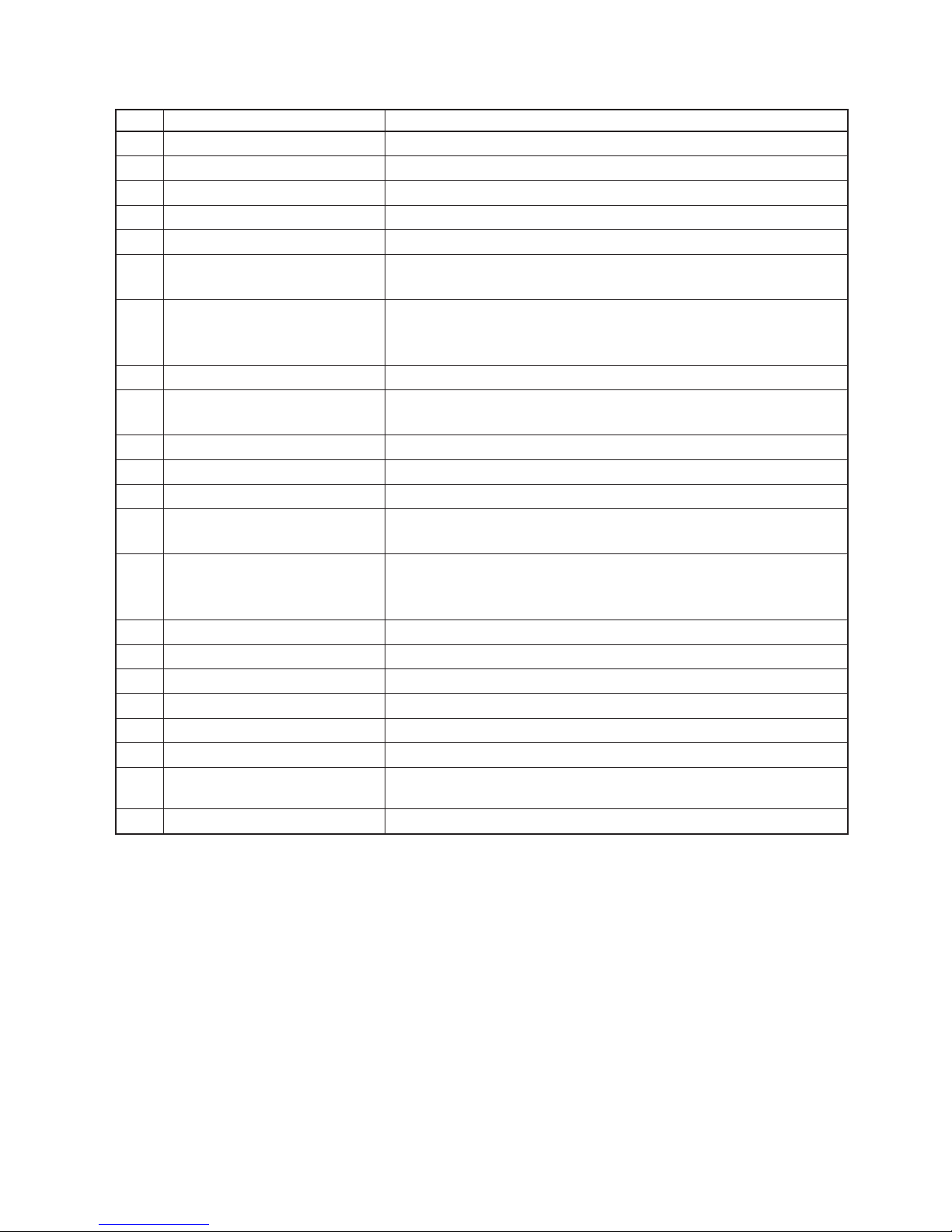

2. CONFIGURATION OF THE MACHINE COMPONENTS

Presser spring regulator Oil gauge Rocking thread take-up

Needle bar thread take-up cover Feed regulating knob Front cover

Oil circulation identification window Eye guard cover Slide cover

Oil hole cap Throat plate Needle bar thread take-up thread

Micro-lifter Needle tip silicon oil lubricating unit receiver

Needle thread silicon oil Differential lock nut

Rocking thread take-up thread guide

lubricating unit Micro-adjustment knob Silicon container thread guide

Thread guide No. 1 Finger guard Belt cover

Upper pulley Thread trimming knife Differential feed regulating lever

Thread tension nut Rocking thread take-up receiver

– 3 –

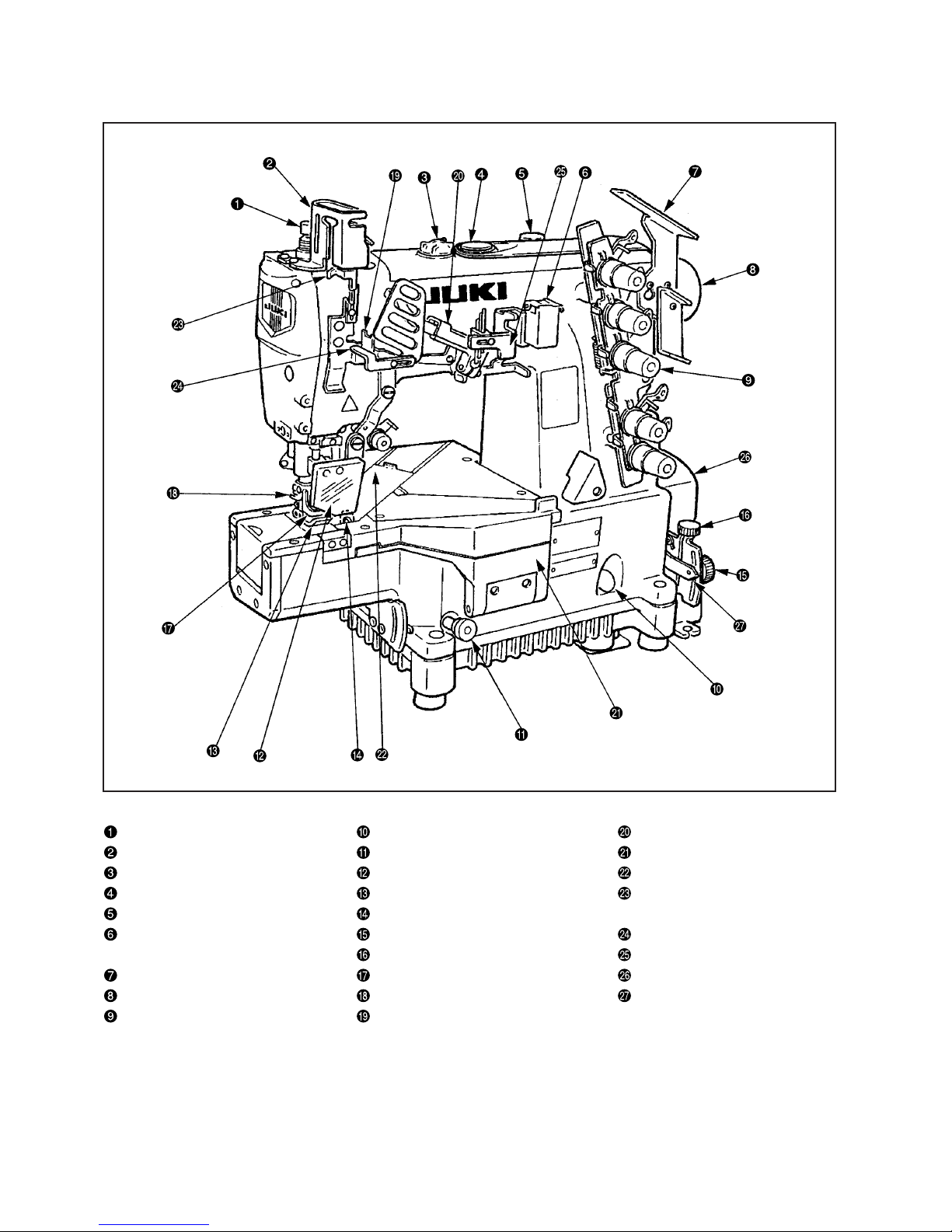

1234567891011121314 15 16 17 18 19 20 21

MF78 D –

3 to 6 Model code

7822 2-needle top & bottom covering stitch

7823 3-needle top & bottom covering stitch

8 to 10 Application code

Application Description

U10 For universal Lapseam, Covering, Hemming

K10 For covering Flatting-out

H21 For Hemming With left hand fabric trimmer

E10 For elastic band attaching With left hand fabric trimmer/tension roller

C10 For collarette For regular binder

12 to 13 Needle gauge

40 4.0 mm

56 5.6mm

64 6.4 mm

*In case of 3-needle, it is not possible to select 40.

11 Tongue shape of throat plate

BStandard

D D-type

14 to 17 Device and attachment

MC36 Pneumatic dust collection unit (mechanical valve type)

21 Classification of table specifications

1 Desktop

2 Semi-submerged

3. MODEL NUMBERING SYSTEM

(1) MF-7800D Series

Semi-dry head, cylinder-bed top and bottom coverstitch machine

Applicable model : MF-7800D Series

19 Specification Code for Destination

A Standard

G For China (domestic China)

H For Turkey

*1 (desk top) only for E10

20 Accessory Specification Code

A

G

Standard (Foreign language manuals in Japanese, English,

Chinese, German, French, Italy, Turkey, and Spanish)

Chinese (available only in China) (2-language manual in

English and Chinese)

– 4 –

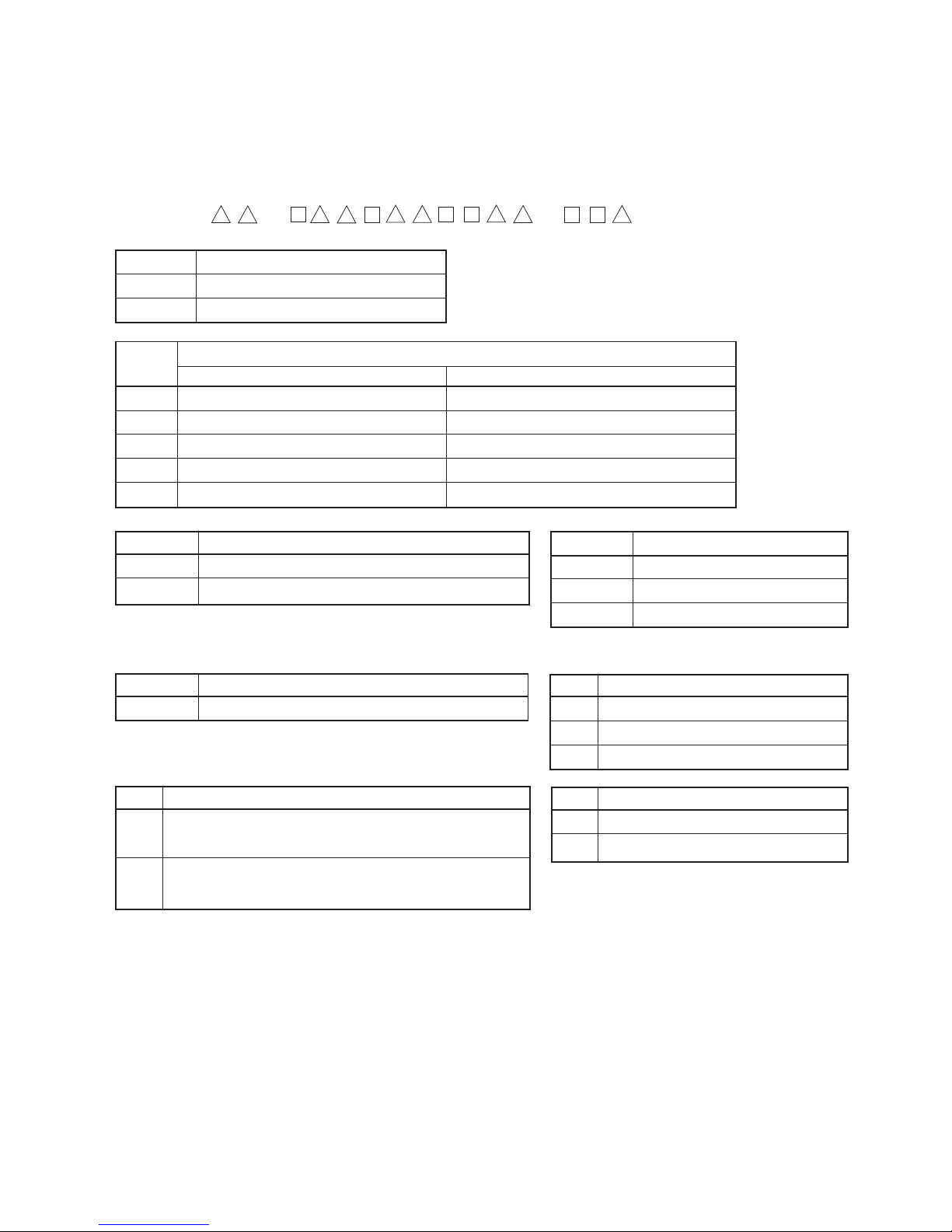

Semi-dry head, cylinder-bed top and bottom coverstitch machine

Applicable model : MF-7800D Series Thread trimmer

(2) MF-7800D Series Thread trimmer

8 to 10 Application code

Application Description

U10 For universal Lapseam, Covering, Hemming

K10 For covering Flatting-out

H21 For Hemming With left hand fabric trimmer

E10 For elastic band attaching

With right hand fabric trimmer/tension roller

123456789101112131415161718192021222324252627282930

MF78 D –

14 to 25 Device and attachment

UT22 Solenoid type vertical thread trimmer unit

UT24 Pneumatic blow bobbin thread trimmer unit

UT25 Pneumatic vertical thread trimmer unit

MC35 Pneumatic dust collection unit (solenoid type)

PL11 Cloth flat rollers

3 to 6 Model code

7822 2-needle top & bottom covering stitch

7823 3-needle top & bottom covering stitch

7813 3-needle one-side covering stitch

12 to 13 Needle gauge

40 4.0mm

56 5.6mm

64 6.4mm

* In case of 3-needle, it is not possible to select 48.

11 Tongue shape of throat plate

B Standard

D D-type

27 Specification Code for Destination

A Standard

G For China (domestic China)

H For Turkey

30 Classification of table specifications

1 Desktop

2 Semi-submerged

28 Accessory Specification Code

A

G

Standard (Foreign language manuals in Japanese, English,

Chinese, German, French, Italy, Turkey, and Spanish)

Chinese (available only in China) (2-language manual in

English and Chinese)

29 Control box and motor classification

B SC-500/M50

C SC-510/M51

– 5 –

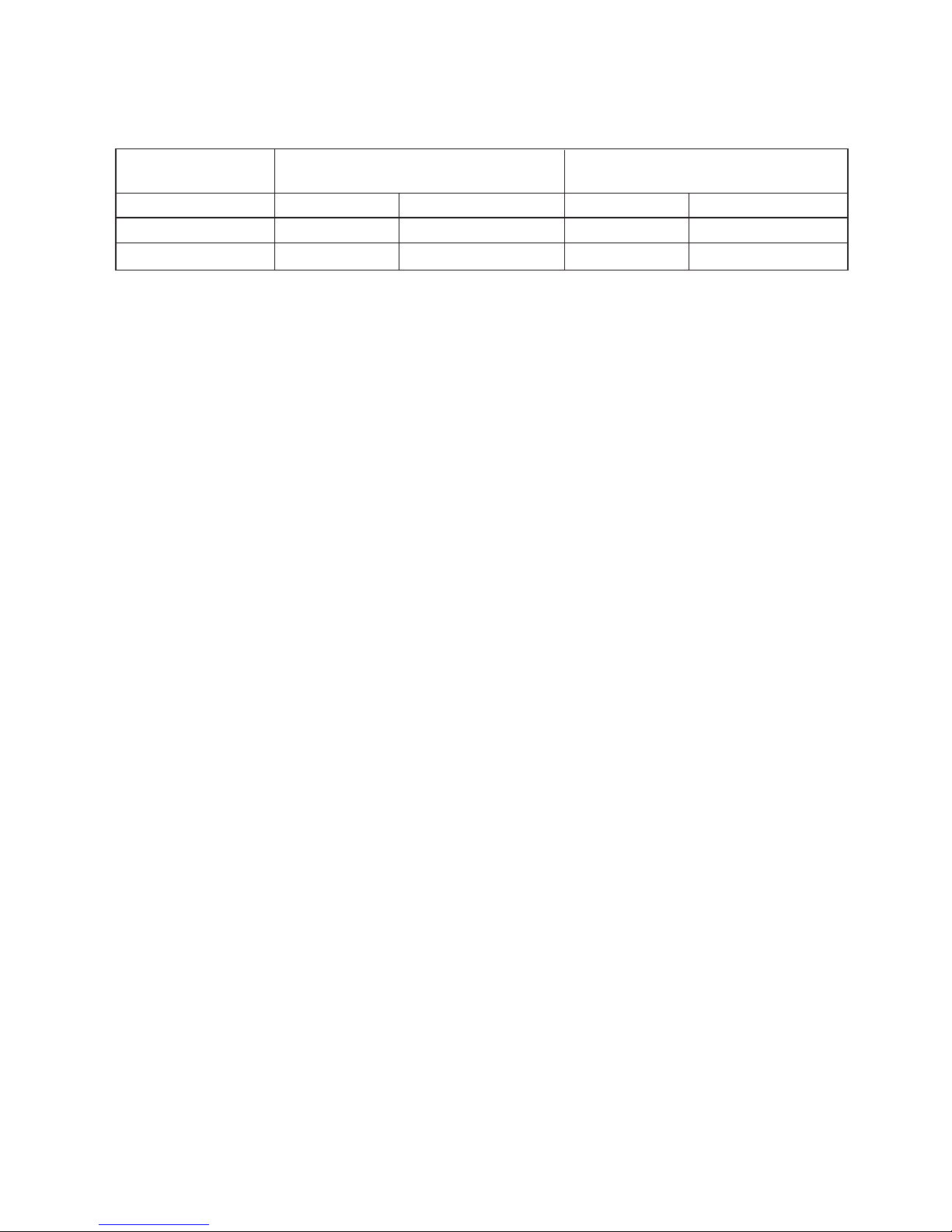

4. MOTOR PULLEY AND BELT

MF-7800D Series

50Hz 60Hz

(sti/min) Pulley size (mm) Belt size (inch) Pulley size (mm) Belt size (inch)

3,500 ø80 M-38 ø65 M-37

4,000 ø90 M-38 ø75 M-37

1 . The table shows the numbers when a 3-phase 2-pole 400 W clutch motor (1/2 HP) is used.

2 . The commercially-available motor pulley near to the counted value is designated since the outside diameter of

the commercially-available motor pulley counts by 5 mm.

3 . When you use a new sewing machine, use the machine at a speed of 4,000 sti/min or less for the first 200 hours

(approximately one month). A good result can be obtained in terms of the durability.

(Caution) 1. Use a motor pulley which is adaptable to this sewing machine.

2. This sewing machine will exceed its max. revolutions and max. sewing speed, finally leading

to the occurrence of malfunction, unless the adaptable motor pulley is used.

Sewing speed of the

machine

– 6 –

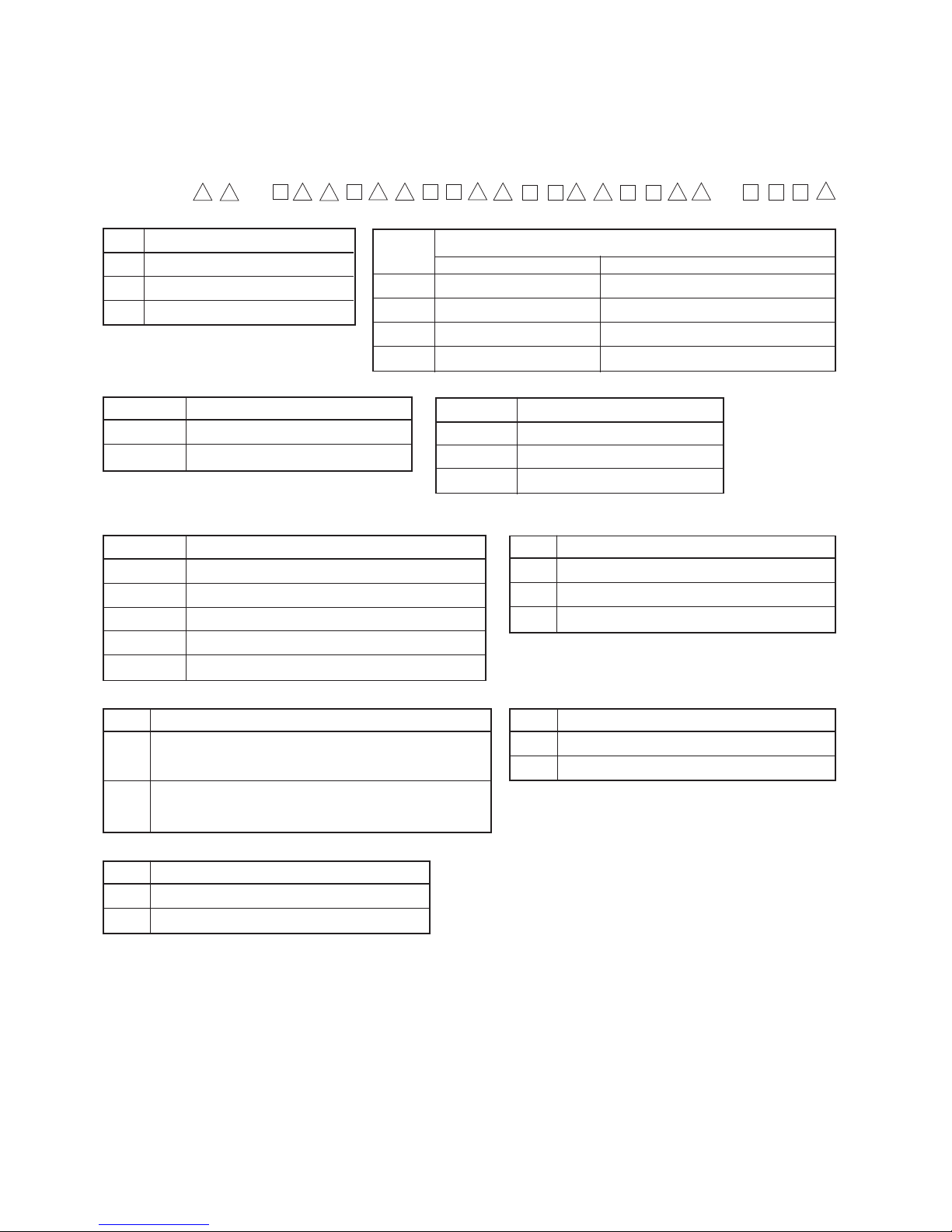

(Caution) In case of threading for standard seams, rocking thread take-up thread guide is not used.

2. Threading for soft seams

(1) When soft seams are required, change the threading of needle thread and slide the position of looper thread

cam eyelet.

(2) Do not pass needle thread through needle bar thread take-up . Pass the thread from rocking thread

take-up to rocking thread take-up thread guide .

(3) Other points are same as those of "1. Threading for standard seam".

1. Threading for standard seam

A

Broken lines A when stretcher thread is used

C

B

D

When covering thread is

excessively loosened =

B

When covering thread is

excessively loosened even

after passing

B

=

C

When covering thread is

excessively tense =

D

When using more

stretchable thread

When using less

stretchable thread

1. Adjust the bottom end of left-hand thread guide

to the engraved marker line on the front side.

2. Adjust the position of the hole of right-hand

thread guide to the left.

Standard Adjustment

5. ST ANDARD ADJUSTMENT

(1) Threading the machine head

(Caution) In case of the soft seams, rocking thread

take-up thread guide is used.

E

In case of soft seams

Engraved marker line

Right

Left

– 7 –

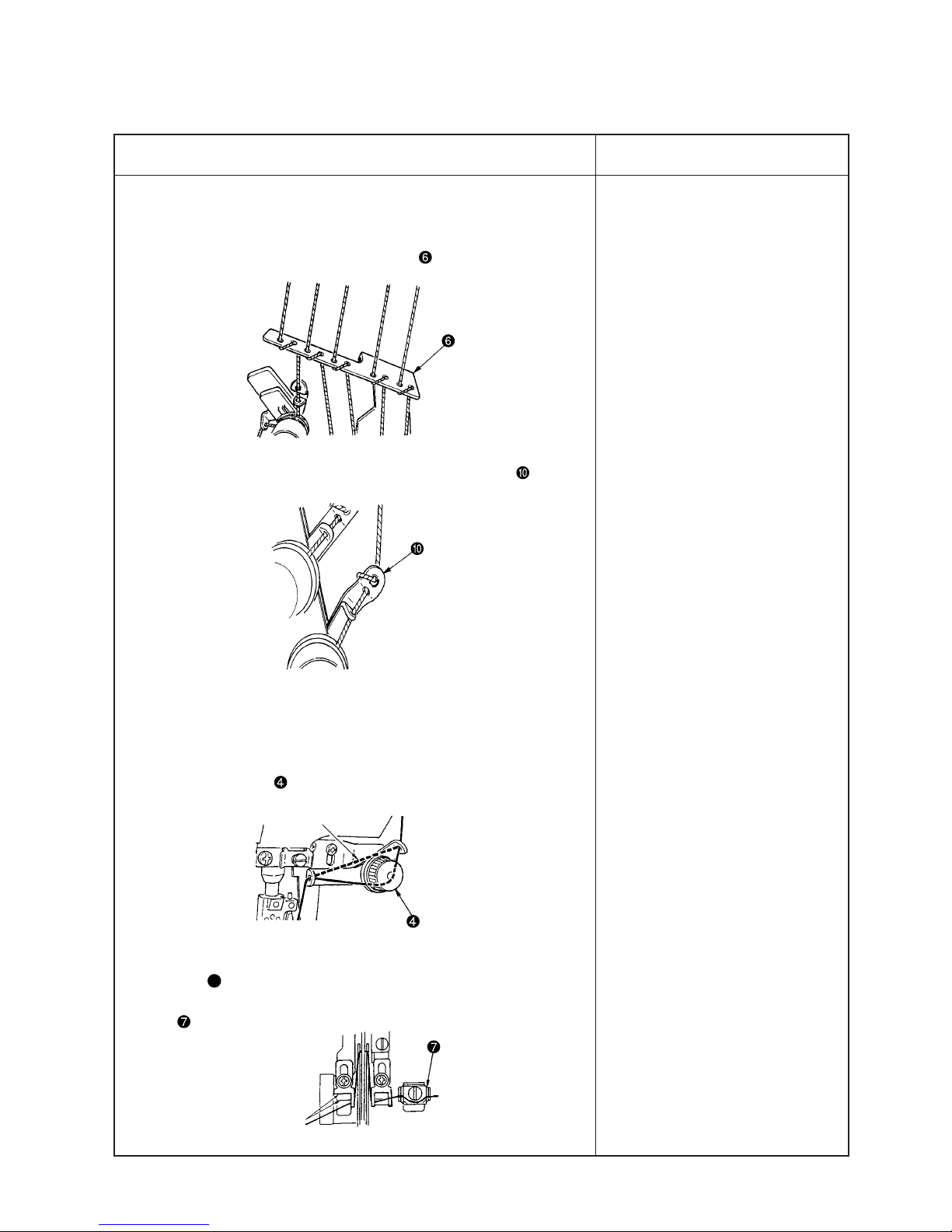

1. When motion of thread is very rough, and stable seams can not be

obtained, there are cases where the condition can be improved by

the following threading.

(1) Wind thread around 1st thread guide .

(2) Wind thread around the thread tension thread guide .

2. When using more stretchable thread (wooly thread or the like), the

threading as given below does not make thread stretch and neat

seams can be obtained.

(1) Do not pass thread (for spreader) through spreader auxiliary

thread tension .

(2) Do not pass thread (for spreader) through the thread tension

disk E.

(3) Do not pass thread through the looper thread small tension disk

.

o When threading is not properly

performed, not only sewing

trouble occurs, but also needle

breakage is caused. So, be

careful.

Adjustment Procedure

Results of Improper Adjustment

Do not pass thread.

Engraved marker line

– 8 –

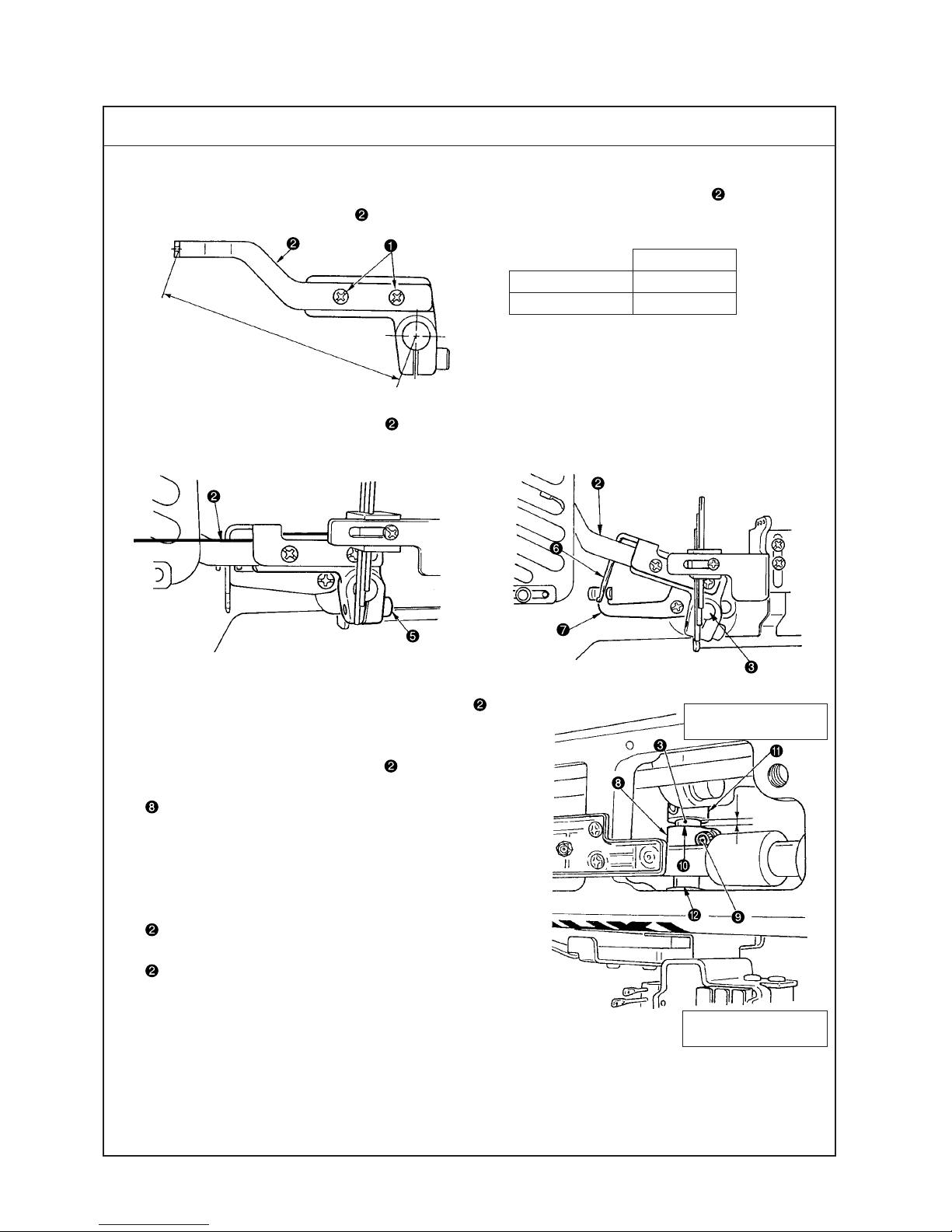

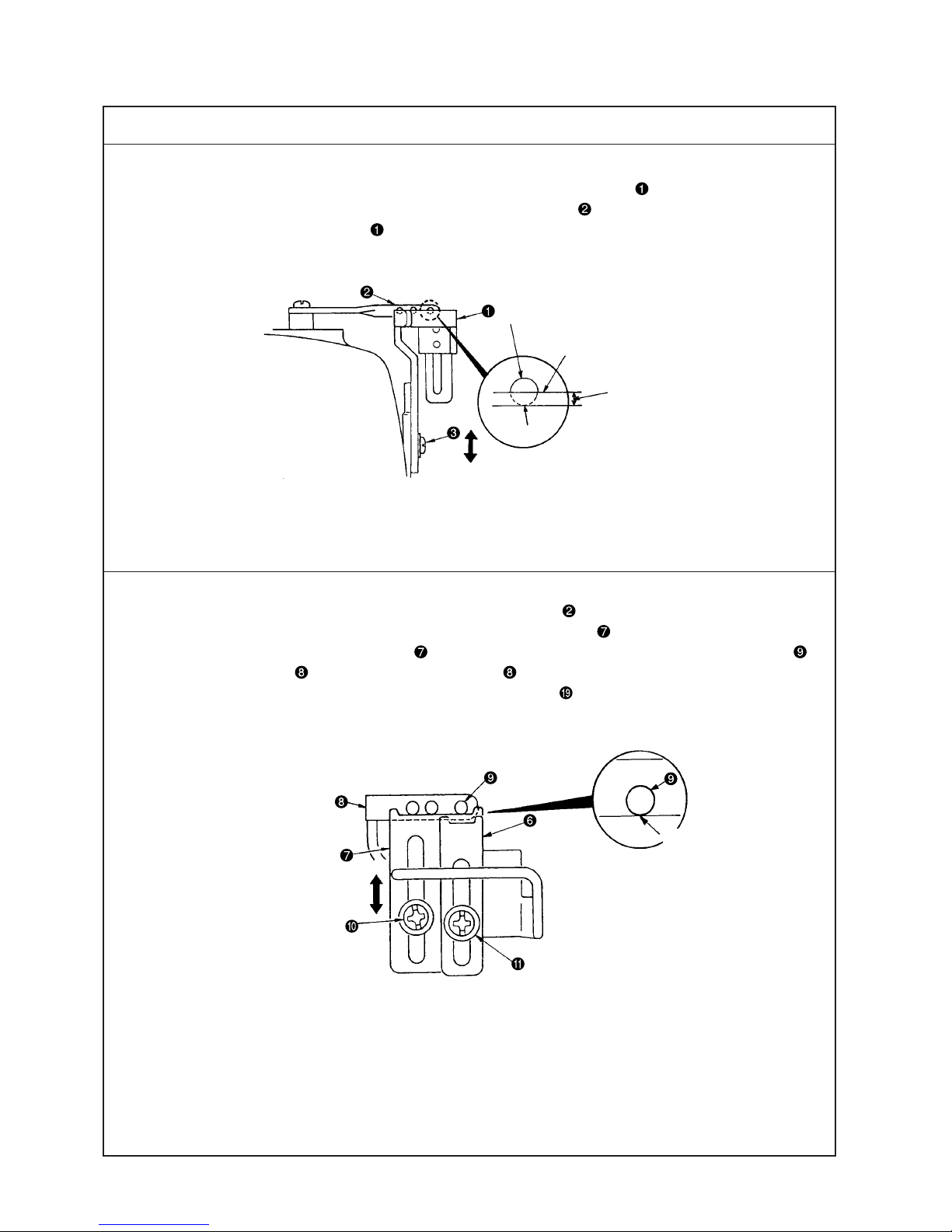

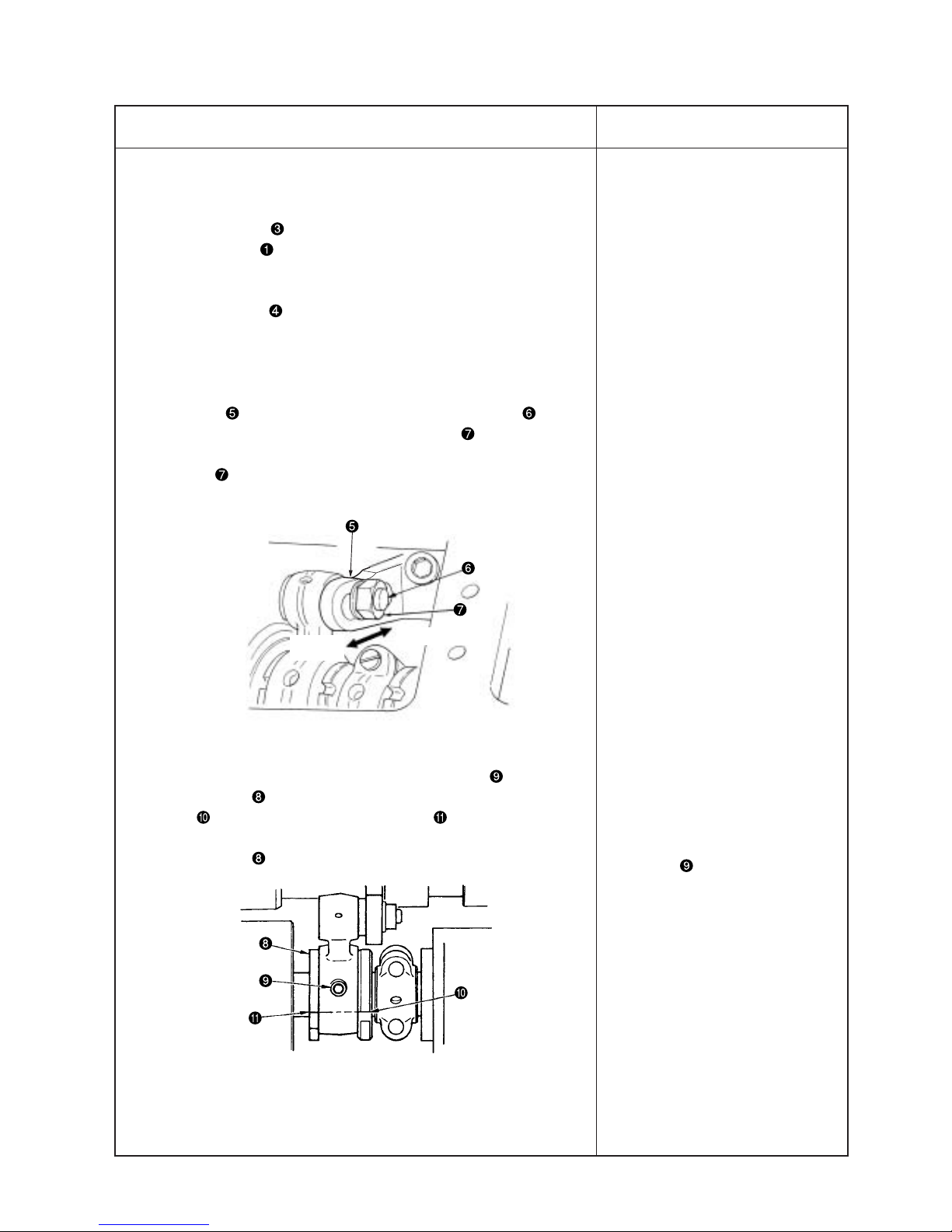

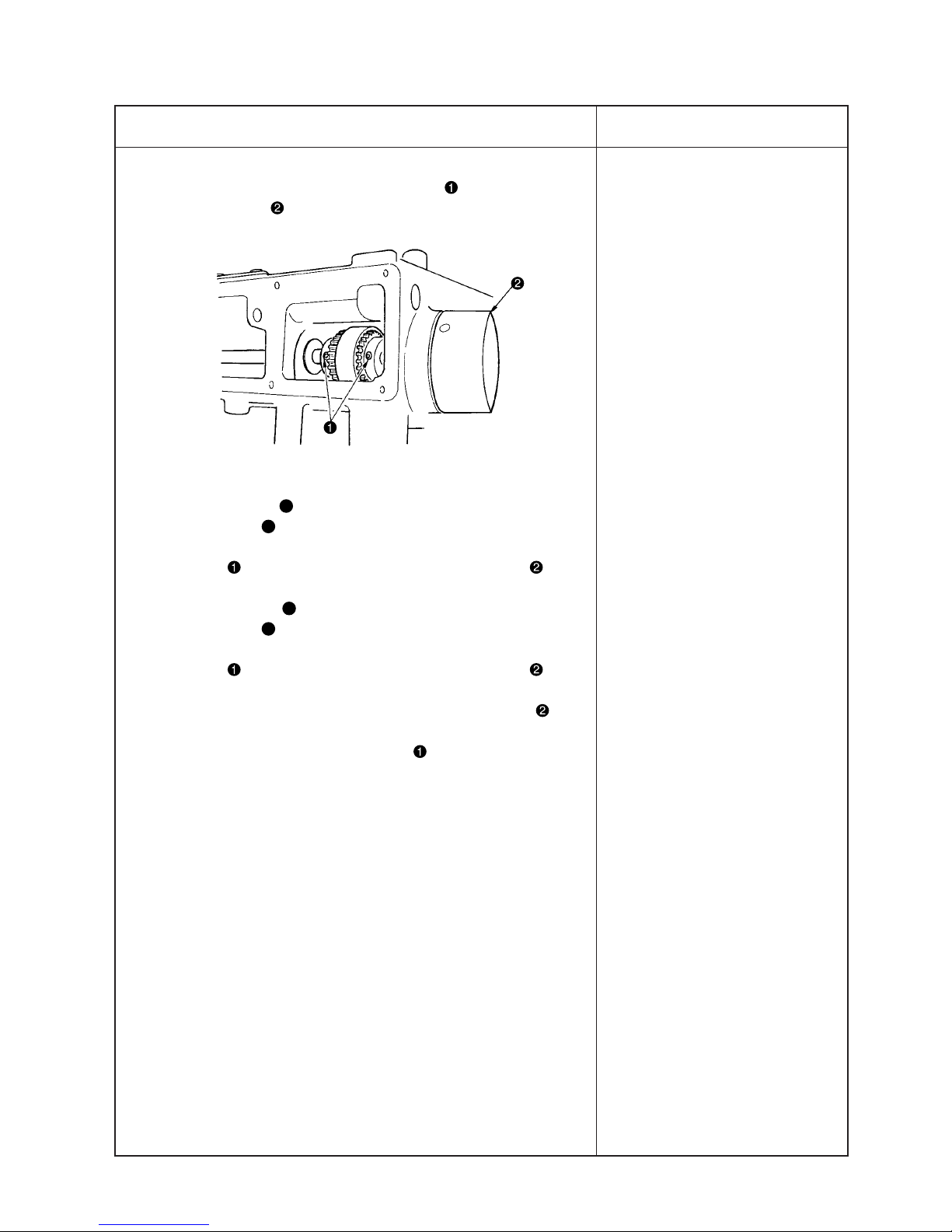

(2) Adjusting the rocking thread take-up

1. Length of the rocking thread take-up

(1) Dimension A from the center of the shaft to the thread hole face of rocking thread take-up is the standard

length of rocking thread take-up .

2. Position of the rocking thread take-up

(1) Install so that rocking thread take-up is flush when the needle bar is in its lowest position.

3. Timing of the rocking thread take-up

(1) It is the standard timing that rocking thread take-up is in

its lowest position as well when the needle bar is in its lowest

position.

Timing of rocking thread take-up is performed by

adjusting the position of rocking thread take-up ball arm

.

4. Relation between the timing of rocking thread take-up and

the needle thread loop

(1) When using the excessively stretchable thread or the hard-

to-stretch thread, the size of needle thread loop can be

changed by changing the timing of rocking thread take-up

.

(2) Relation between the timing of the rocking thread take-up

and the size of needle thread loop is as shown in the

table on the next page.

(The relation becomes reverse when using the needle bar

thread take-up = standard seams and when it is not used =

soft seams. So, be careful.)

A

4mm

A

Standard Adjustment

↑

Anti-operator’s side

Operator’s side

↓

Dimension A

Standard seams 90

Soft seams 98

Unit : mm

Flush

– 9 –

1. Length of the rocking thread take-up

(1) Loosen screws and move rocking thread take-up to the right

or left to adjust the length.

2. Position of the rocking thread take-up

(1) Loosen screw and move rocking thread take-up up or down

to adjust the position.

(Caution) When adjusting the position of rocking thread take-up

, fix the rocking thread take-up with setscrew in

the rocking thread take-up so that spreader thread takeup and spreader thread guide do not come in

contact with each other.

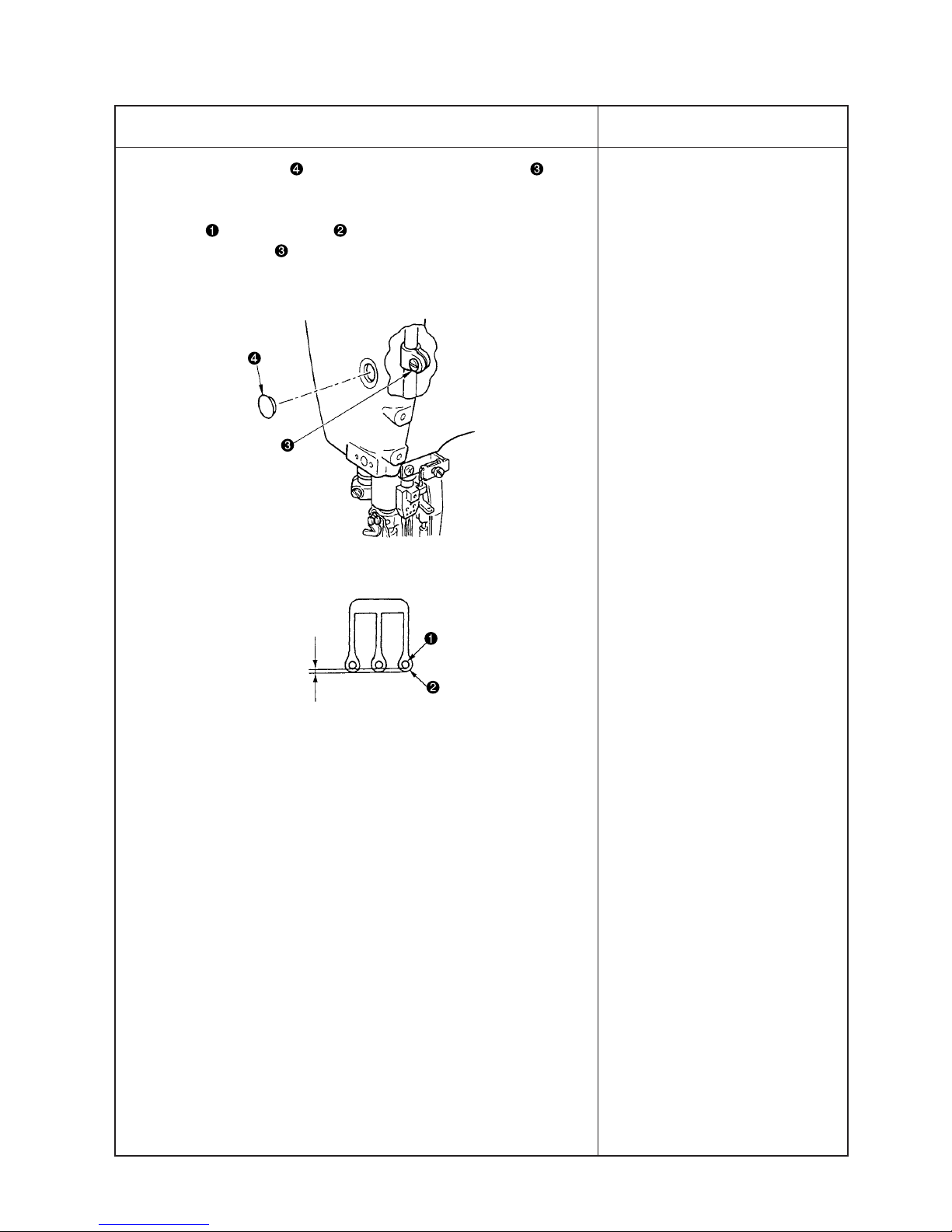

3. To adjust the timing of the rocking thread take-up , remove the

top cover, loosen setscrew in the rocking thread take-up ball arm

and move the position of rocking thread take-up ball arm to and

fro.

(1) Standard adjustment figure is the position where the rear end (anti-

operator’s side) of rocking thread take-up ball arm aligns with

engraved marker line on rocking thread take-up shaft . (As the

standard at this time, note that the clearance provided between the

rear end of rocking thread take-up ball arm and thrust collar is

4 mm.)

(Caution) 1. When loosening screw in rocking thread take-up

ball arm , there is a case where rocking thread takeup rotates by its weight. After the adjustment, be

sure to check the rocking position (flush at the lowest

position) of rocking thread take-up .

2. When moving rocking thread take-up ball arm to

the operator’s side, adjust rocking thread take-up ball

arm within the range where it does not come in

contact with rocking thread take-up bushing

(operator’s side).

o When length of rocking thread

take-up is lengthened, needle

thread is tightened.

(Caution) When lengthening

rocking thread take-up

, check whether it

comes in contact with

the thread take-up

cover.

o When length of rocking thread

take-up is shortened, needle

thread is loosened.

o When installing position of

rocking thread take-up is

raised, needle thread is loosened

when the needle bar thread takeup is used, and needle thread is

tightened when the needle bar

thread take-up is not used.

Adjustment Procedure

Results of Improper Adjustment

Delay timing Advance timing

(Move to operator’s side.) (Move to anti-operator’s side.)

When needle bar thread take-up is used Loop becomes small. Loop becomes large.

When needle bar thread take-up is not used Loop becomes large. Loop becomes small.

4. Relation between timing of rocking thread take-up and needle thread loop

Adjusting procedure is the same as step 3. Loosen setscrew in rocking thread take-up ball arm and

adjust the position of rocking thread take-up ball arm .

(Caution) Adjust the timing of rocking thread take-up each time in accordance with thread used

or conditions.

– 10 –

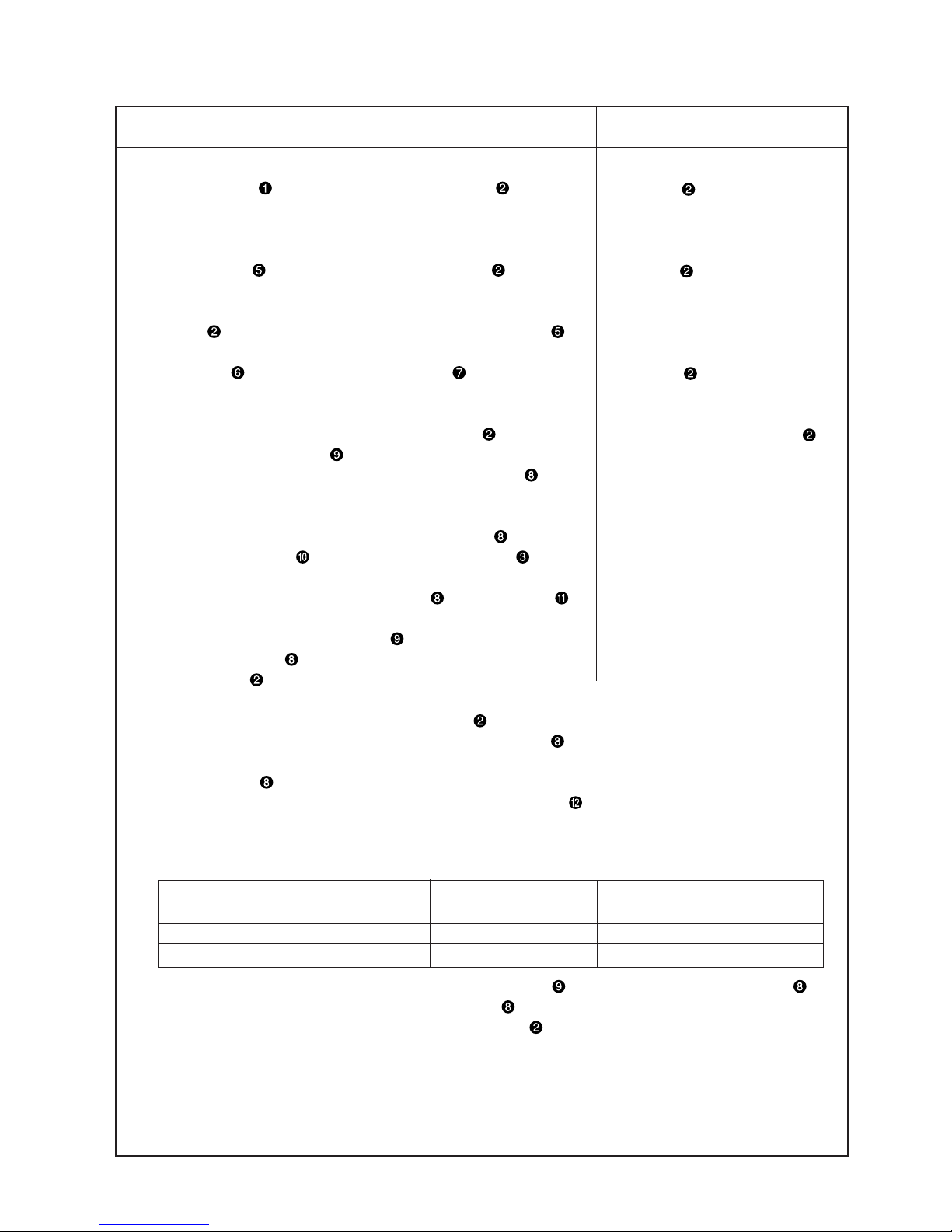

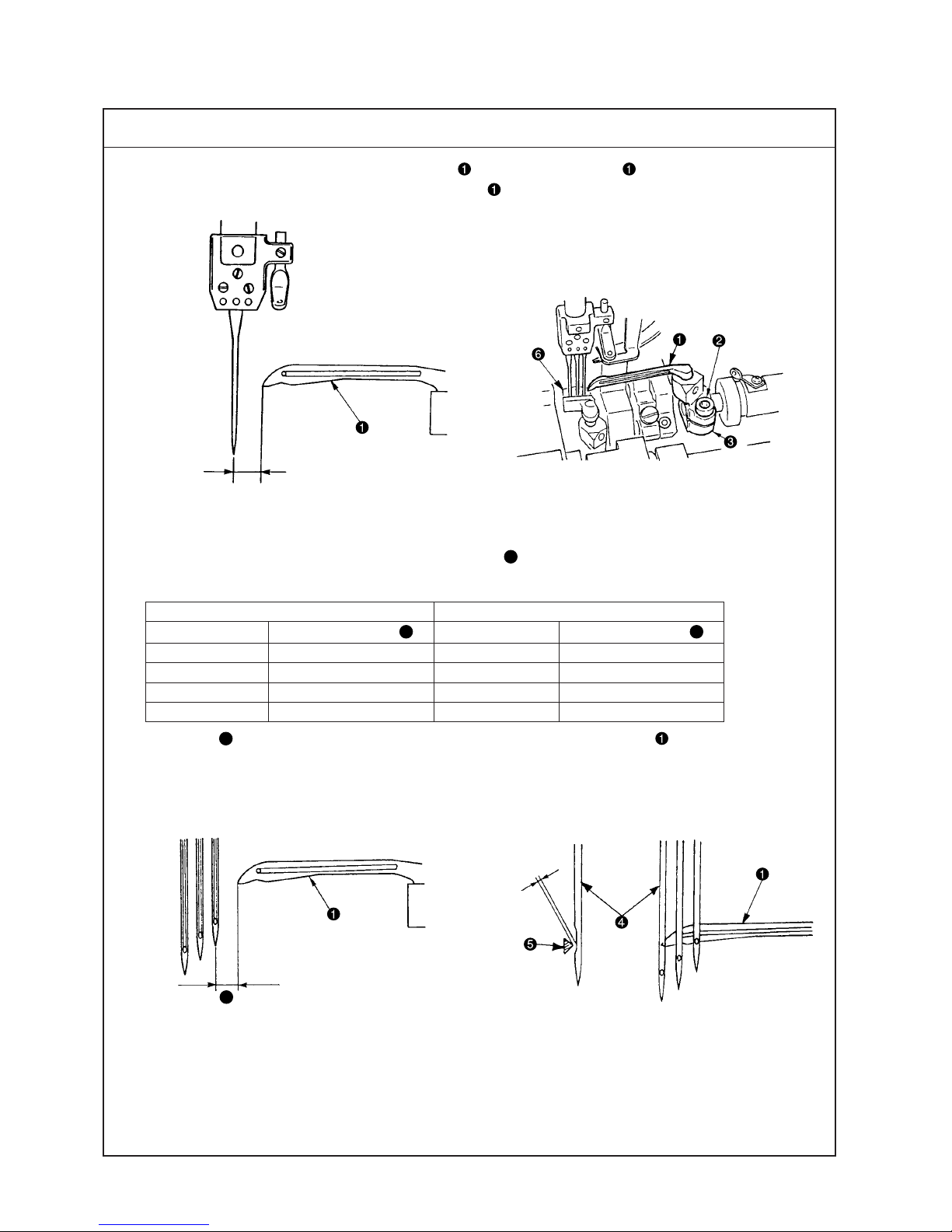

(3) Adjusting the position of the needle thread guide rod

1. Position of the needle thread guide rod

(1) Dimensions of left needle A, middle needle B and right needle C from the top surface of needle thread

guide base to the bottom ends of holes are the standard height of needle thread guide rods .

2. Adjusting the position of needle thread guide base and silicon container thread guide

(1) It is the standard that the height of silicon container thread guide (refer to 2. CONFIGURATION OF THE

MACHINE COMPONENTS) is the position where the height from the center of setscrew to the bottom

end of thread hole is 9 mm.

(2) Move the lateral position of needle thread guide base fully to the right of slot (43 mm).

Extreme right position

43mm

9mm

Left Middle Right

needle A needle B needle C

Standard seams 13 16 19

Soft seams 15 13 11

Unit : mm

Standard Adjustment

C

B

A

Extreme right position

– 11 –

1. Loosen setscrews , adjust the height of respective needle thread

guide rods , and fix the rods with setscrews .

(Caution) 1. Move the lateral position of needle thread guide base

fully to the right of slot.

2. When adjusting the height of needle thread guide rods

, install the rods so that the thread holes are parallel

to the thread holes of silicon container thread guide

so that excessive resistance is not applied to

threads.

2. Adjusting the position of needle thread guide base and silicon

container thread guide

(1) Loosen setscrews and and move silicon container thread guide

up or down to adjust the height.

(2) Loosen setscrew and adjust the lateral position of needle thread

guide base .

o When needle thread guide rod

is raised, needle thread is

loosened.

o When needle thread guide rod

is lowered, needle thread is

tightened.

oWhen silicon container thread

guide is raised, needle thread

is loosened.

o When silicon container thread

guide is lowered, needle

thread is tightened.

o When needle thread guide base

is moved to the left, needle

thread is loosened.

Adjustment Procedure

Results of Improper Adjustment

– 12 –

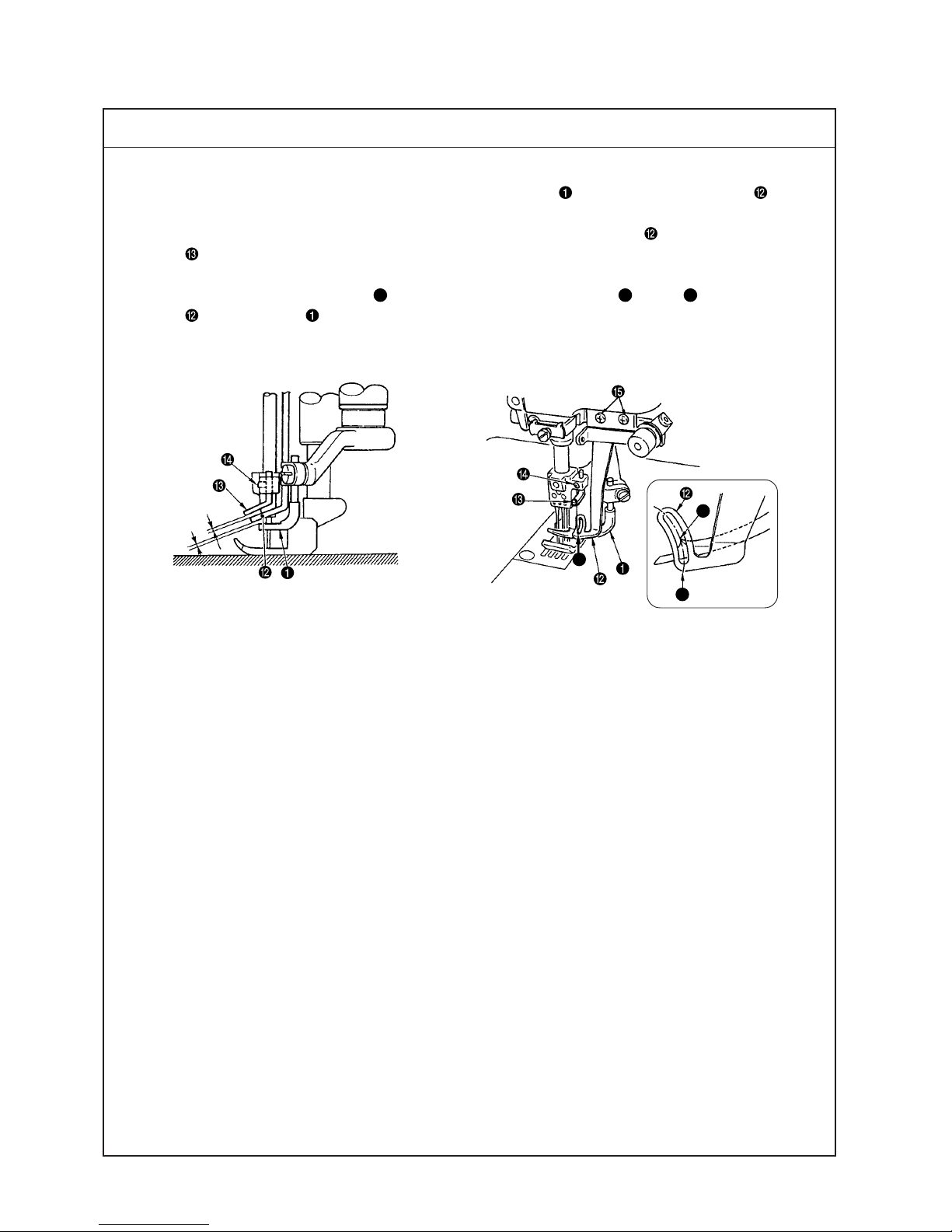

(4) Adjusting the position of the thread receiver

1. Position of the needle bar thread take-up thread receiver (in case of standard seams)

(1) It is the standard that the height of needle bar thread take-up thread receiver is in the position where the

bottom end of thread hole to the center of needle bar thread take-up aligns with the top surface of needle

bar thread take-up thread receiver when the needle bar is in its lowest position.

Standard Adjustment

Thread hole

Center of hole

This range

To align

1. Position of the rocking thread take-up thread receiver (in case of soft seams)

(In case thread is not passed through needle bar thread take-up )

(1) It is the standard that the height of rocking thread take-up receiver is in the position where the top

surface of rocking thread take-up receiver is in the range of the center to the top end of thread hole of

rocking thread take-up when rocking thread take-up is in its lowest position.

(For the details of the position of the illustration below, refer to Rocking thread take-up receiver of 2.

CONFIGURATION OF THE MACHINE COMPONENTS.)

To align

– 13 –

1. Loosen setscrew and move needle bar thread take-up thread

receiver up or down to adjust the height.

2. When desired to make needle bar thread take-up thread receiver

work especially on the right needle where loop is hard to be made,

adjust the height of right needle thread receiver with setscrew .

1. Loosen setscrew and move rocking thread take-up receiver

up or down to adjust the height.

2. When desired to make rocking thread take-up receiver work

especially on the right needle where loop is hard to be made, adjust

the height of the right needle thread receiver with screw .

o When the needle bar thread

take-up thread receiver is

raised, loop becomes large.

o When the needle bar thread

take-up thread receiver is

excessively raised.

Adjustment Procedure

Results of Improper Adjustment

– 14 –

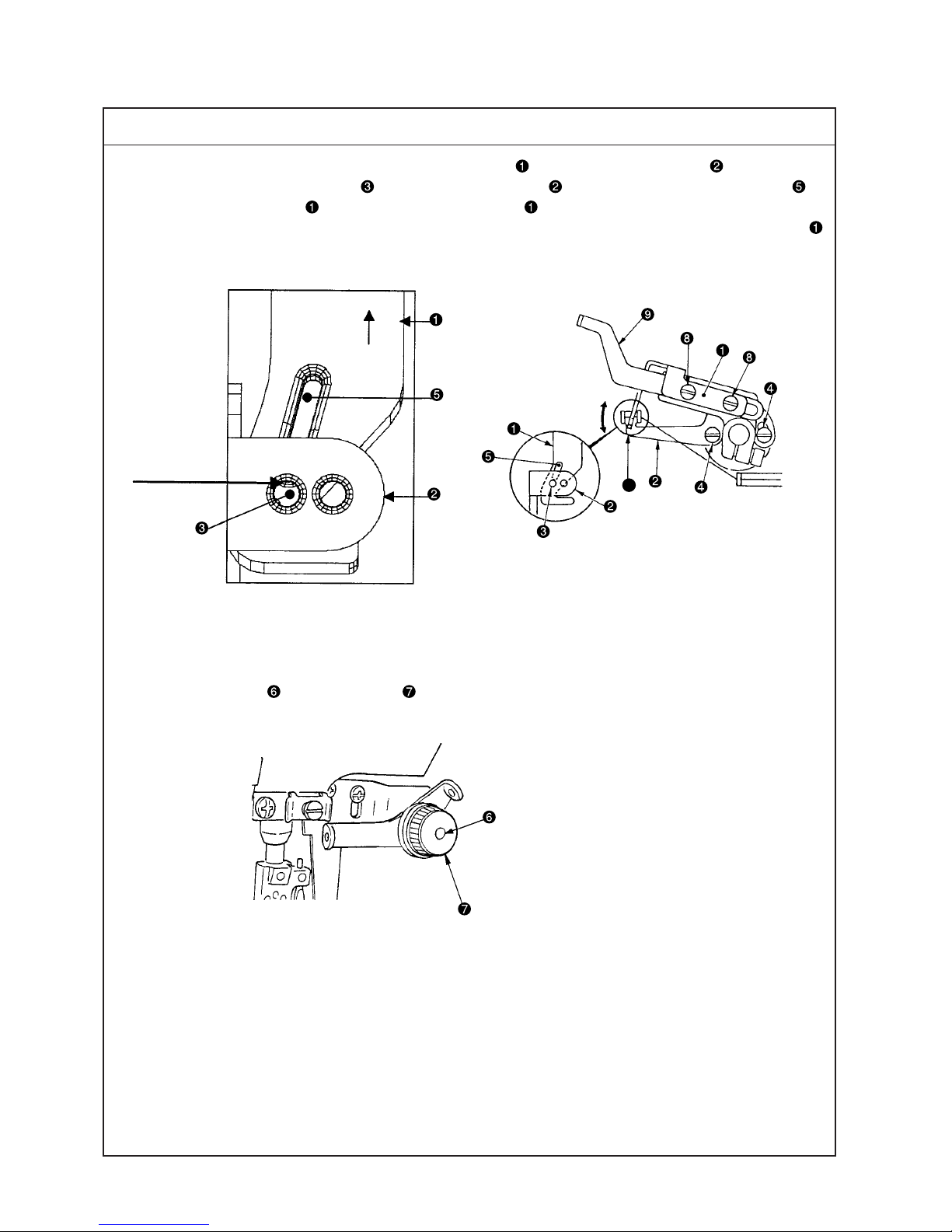

(5) Adjusting the position of the spreader thread guide and spreader thread take-up

1. Relation of the position between spreader thread take-up and spreader thread guide is the standard

when the top end of thread hole of spreader thread guide aligns with the bottom end of slot of

spreader thread take-up when spreader thread take-up is in its highest position.

Adjust the relation of the position so that thread is moderately stretched when spreader thread take-up

is in its highest position in accordance with thread used or conditions.

2. Standard position of the spreader auxiliary thread tension

Standard adjustment figure of the spreader auxiliary thread tension is the standard when the top end of

thread tension rod is flush with knob .

A

Standard Adjustment

Highest position

To align

– 15 –

1. Loosen setscrews in spreader thread guide and adjust the

position of spreader thread guide . (Spreader thread take-up

is fixed to rocking thread take-up and can not be adjusted in the

height direction.)

2. After the adjustment, turn the sewing machine by hand and check

whether spreader thread take-up comes in contact with spreader

thread guide , or section A of clearance is too small.

3. Adjusting procedure of the clearance

(1) Loosen setscrews in spreader thread guide and adjust in the

lateral direction, or loosen setscrews in the rocking thread takeup and move spreader thread take-up to the right or left to adjust

the clearance.

(Caution) When loosening setscrews in the rocking thread take-

up and adjusting the position of spreader thread takeup , adjust so that 95, length of rocking thread takeup does not change.

o When the relation of position

between spreader thread takeup and the spreader thread

guide is not proper, sewing

troubles such as stitch skipping

and the like will be caused.

o If thread is less stretched and

slackness of thread occurs at the

thread take-up section when

spreader thread take-up is in

its highest position, the spreader

fails to pick up thread and stitch

skipping occurs.

o If stretch or feeding of thread is

excessive when spreader thread

take-up is in its highest

position, not only thread on the

seam side is drawn and needle

thread can not be tightened, but

also needle bend or needle

breakage will be caused.

o If stretch or feeding of thread is

excessive when spreader thread

take-up is in its lowest

position, thread slacks when the

spreader moves from left to right

and stitch skipping occurs.

Adjustment Procedure

Results of Improper Adjustment

– 16 –

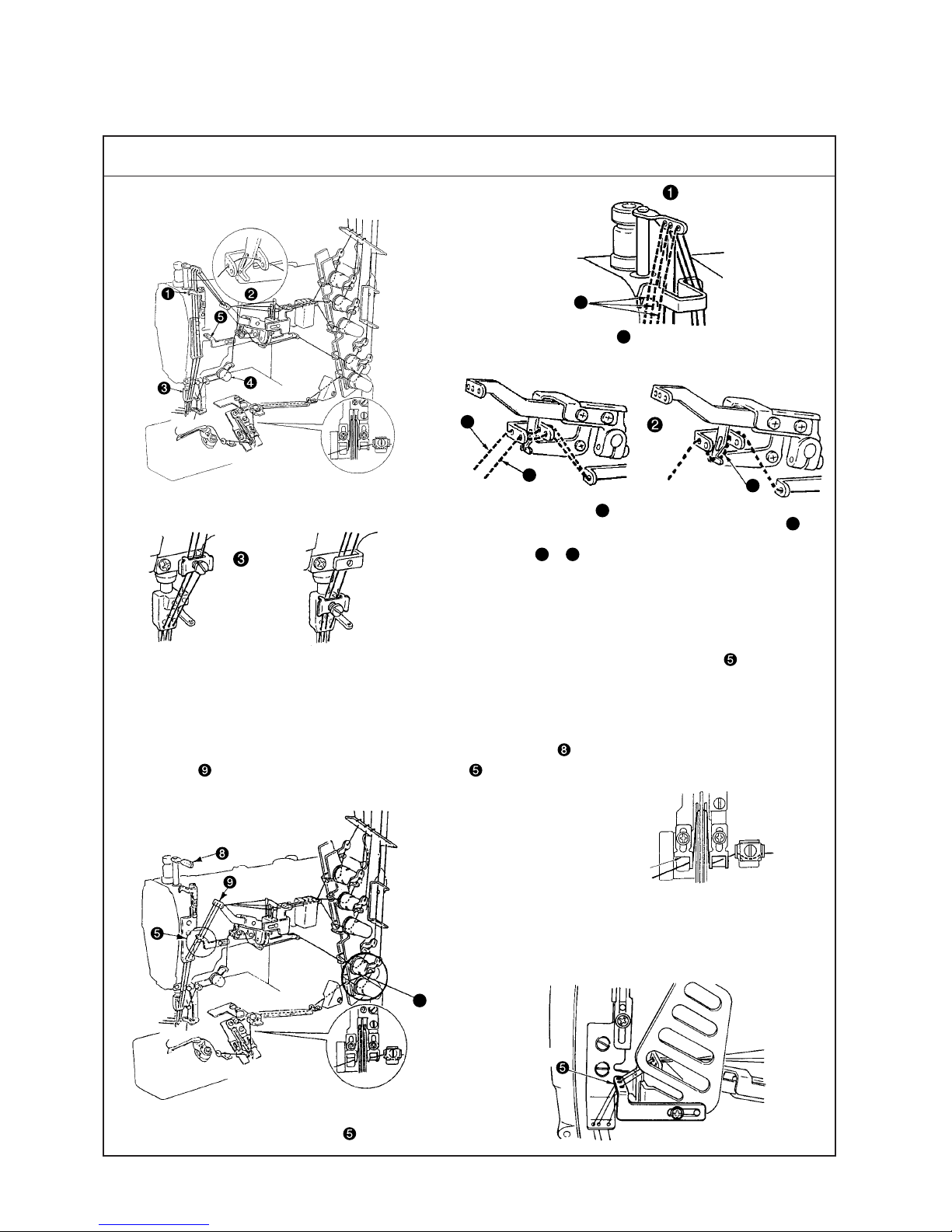

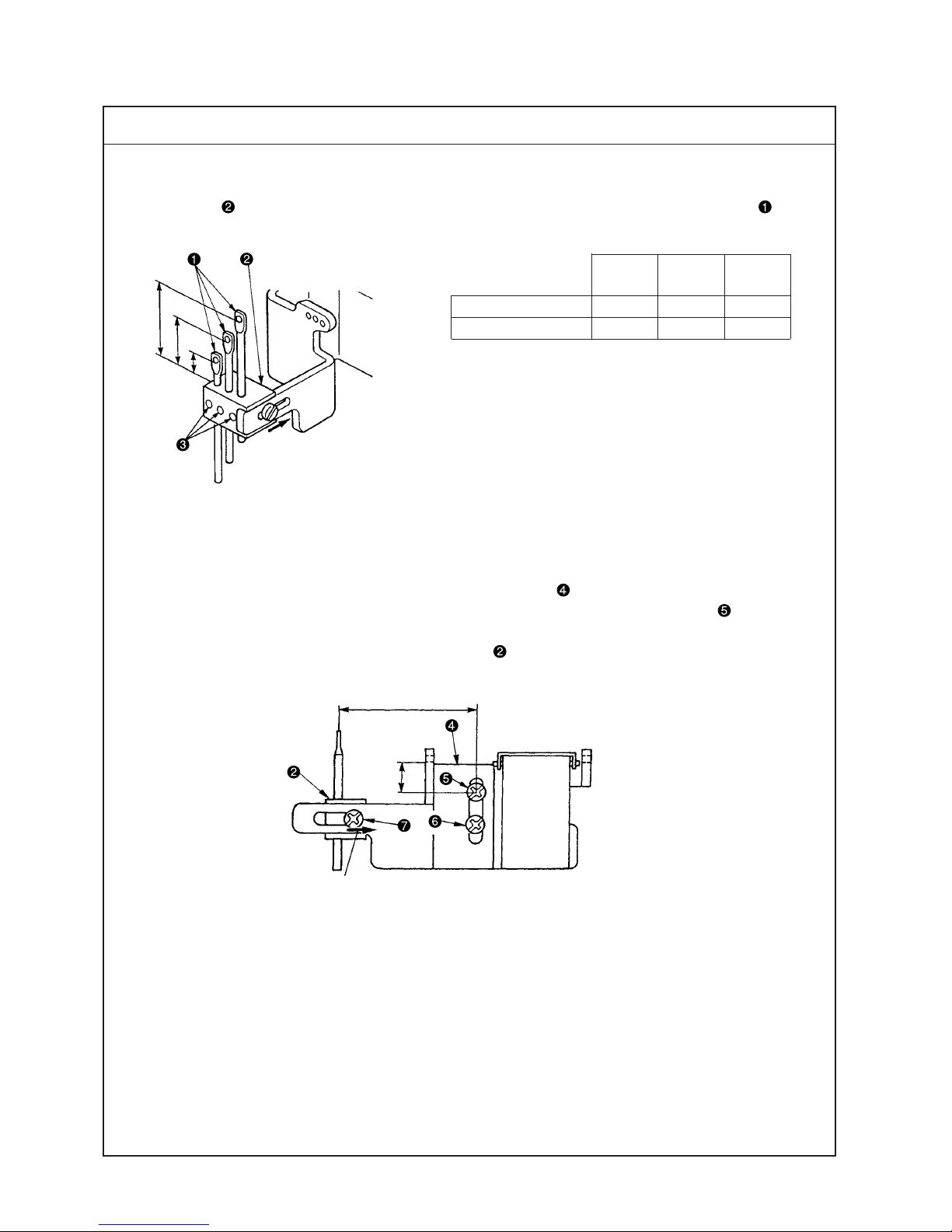

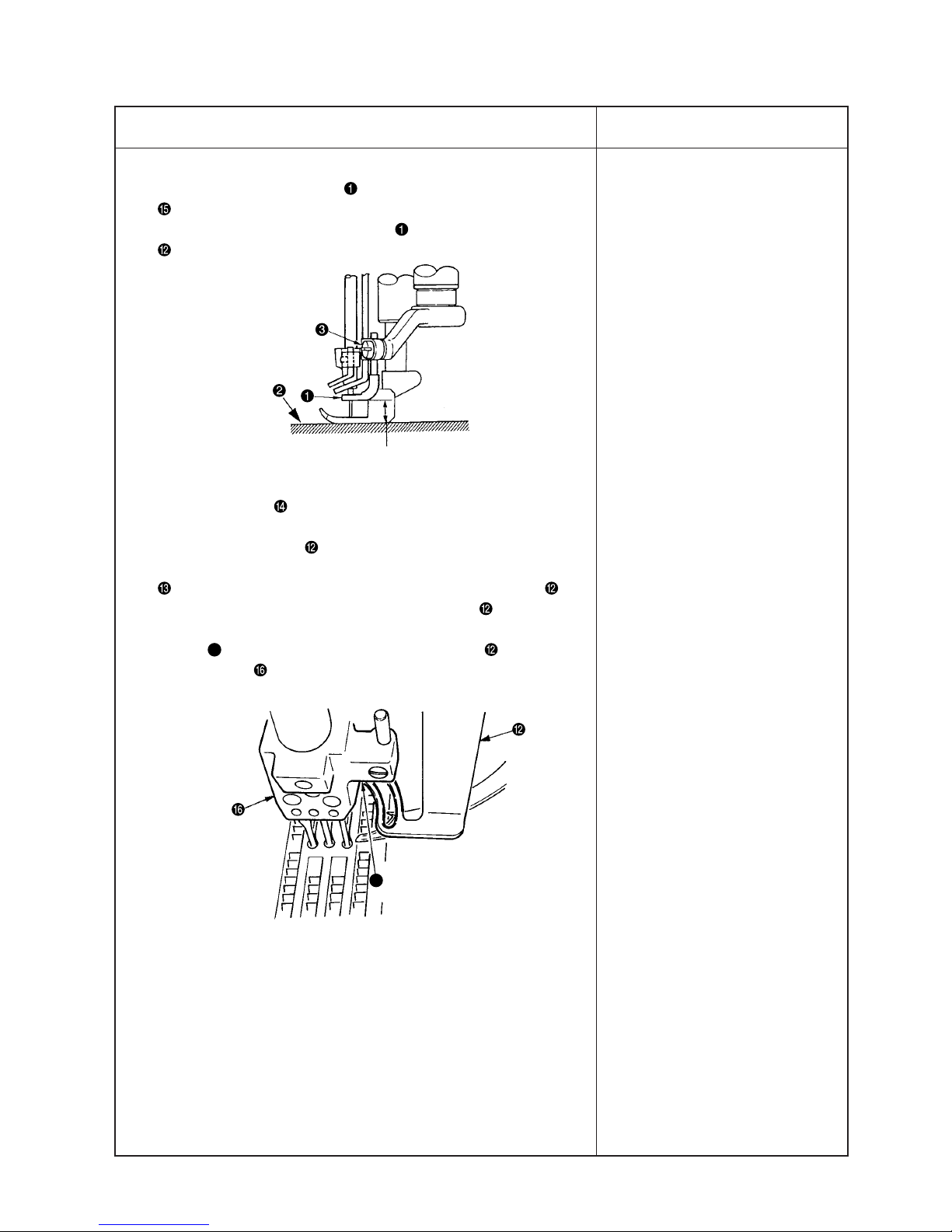

(6) Adjusting the spreader

1. Height of the spreader

It is the standard that the height from the top surface of throat plate to the bottom surface of spreader

is 7.8 to 8.2 mm.

7.8 to 8.2mm

0.1 to 0.3mm

A

Standard Adjustment

2. Longitudinal position of the spreader

It is the standard that when spreader returns from the extreme left position to the right and top end A of

thread hooking section reaches to the front of left needle, the clearance between the spreader and the left

needle is 0.1 to 0.3 mm.

3. Protruding amount

It is the standard that the dimension from the center of left needle to top end A of thread hooking section,

when spreader is in the extreme left position, is 4.5 to 5.5 mm.

4. Spreader stroke

It is the standard that the spreader stroke is 17.0 to 18.0 mm at the stroke of thread hooking section.

5. Timing of the spreader

Standard position is the position where the spreader is in the extreme left position when the needle bar

comes down from the upper dead point by 1.1 ± 0.1 mm.

A

4.5 to 5.5mm

17.0 to 18.0mm

Extreme

left position

– 17 –

1. Adjusting the height of the spreader

2. Adjusting the longitudinal position of the spreader

Loosen setscrew and adjust the height and longitudinal position

of the spreader .

3. Protruding amount of the spreader

Loosen setscrew in the spreader folder and adjust the protruding

amount. Adjust aiming the adjustment figure of 5 mm.

4. Adjusting the spreader stroke

The standard position is located where the notch section of spreader

drive lever aligns with the shaft center of connecting pin . When

desired to increase the stroke, loosen lock nut and move in the

downward direction. When desired to decrease the stroke, loosen

lock nut and move in the upward direction. Adjust aiming the

adjustment figure of 17.5 mm.

5. Adjusting the timing between the needle bar and the spreader.

When changing the timing, loosen two setscrews in spreader

eccentric cam to adjust. Standard position is the position where

notch in the main shaft aligns with notch in spreader eccentric

cam. When changing, turn the upper pulley and change with spreader

eccentric cam fixed.

o Height of the spreader is improper,

stitch skipping of spreader occurs.

o Adjust the height in accordance

with the needle gauge.

o Even when the protruding amount

is excessive or insufficient, stitch

skipping of spreader will be

caused.

o When the protruding amount is

insufficient, it will be the cause for

left needle not to scoop covering

thread at overlapped section.

o When the stroke is increased,

disorder of covering thread

stitching will be caused.

o When the stroke is decreased,

stitch skipping of spreader will be

caused.

o When the timing is excessively

advanced, needle does not take

covering thread when it comes

down and stitch skipping will be

caused.

o When the timing is excessively

retarded, resistance increases

when covering thread slips out

from the spreader and a load is

applied to the right needle. As a

result, needle breakage or stitch

skipping will be caused.

(Caution) When changing,

temporarily tighten No.

2 screw in the rotation

direction of setscrews

and turn the upper

pulley to change.

Adjustment Procedure

Results of Improper Adjustment

Downward

Upward

– 18 –

(6) Adjusting the spreader

6. Adjustment figures of the spreader thread guide

(1) It is the standard that the clearance provided between spreader and spreader thread guide is 0.4 to

1.0 mm.

(2) It is the standard that the clearance provided between spreader thread guide and needle clamp thread

guide is 0.8 to 1.2 mm.

(3) Lateral position of the spreader thread guide

Top end of thread hooking section D of the spreader aligns with center E of slot C in spreader thread

guide when spreader is in the extreme right position.

0.8 to 1.2mm

0.4 to 1.0mm

Standard Adjustment

D

C

E

– 19 –

6. Spreader thread guide

(1) Adjust the height of spreader to 7.8 to 8.2 mm. Loosen setscrews

in the spreader thread guide and adjust the clearance provided

between the top surface of spreader and spreader thread guide

to 0.4 to 1.0 mm.

(2) Needle clamp thread guide

Loosen setscrew in the needle clamp thread guide and adjust

the clearance provided between the needle clamp thread guide and

spreader thread guide to 0.8 to 1.2 mm.

(3) For the lateral direction, align the hole of needle clamp thread guide

to the prolonged line of the slot of spreader thread guide .

(Caution) When adjusting spreader thread guide in the lateral

direction, check whether there is any contact at section

B

(left side of spreader thread guide and needle

clamp )

7.8 to 8.2mm

o When height or position of the

spreader thread guide is improper, stitch skipping of

spreader thread will be caused.

oWhen height or position of the

needle clamp thread guide is

improper, stitch skipping of

spreader thread will be caused.

B

Adjustment Procedure

Results of Improper Adjustment

– 20 –

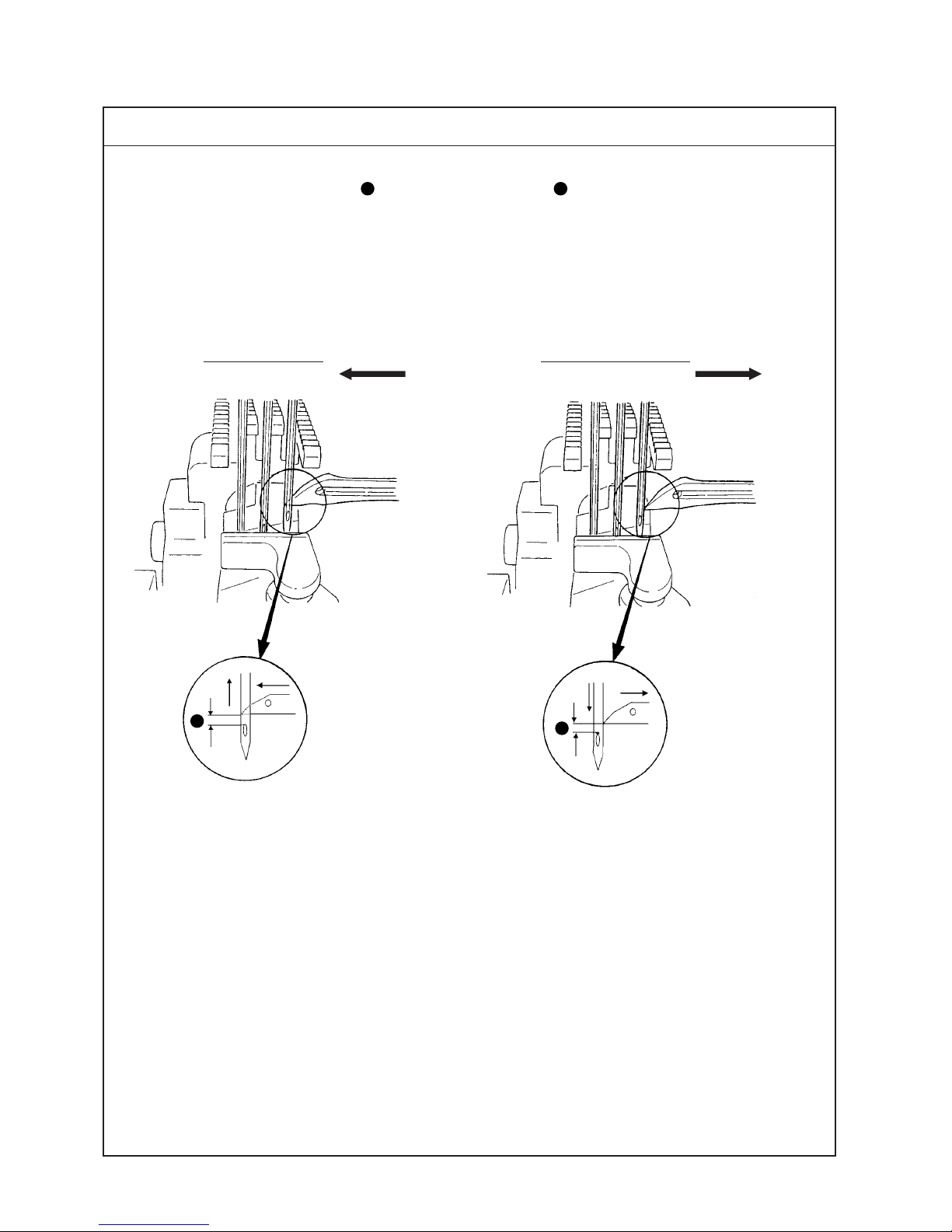

(7) Adjusting the timing relation between the looper and needle bar

1. Timing relation between the looper and the needle bar (synchronization)

It is the standard that dimension A is the same as dimension B when the needle bar goes up from the

lower dead point, the blade point of looper passes the rear of needle, and the left end of right needle aligns

with the blade point of looper, and when the needle bar comes down from the upper dead point, the blade

point of looper passes the front of needle, and the right end of right needle aligns with the blade point of

looper.

(Looper timing is more advanced by a piece of needle than the needle bar timing.)

Standard Adjustment

Going of looper Returning of looper

B

A

– 21 –

1. To adjust the timing relation between the needle and the looper,

remove the top cover, loosen four setscrews in the sprocket and

turn upper pulley in the state that the sprocket is held.

2. Adjusting procedure

(1) In case dimension A when the looper advances (going) is smaller

than dimension B when the looper retreats (returning), the looper

timing is retarded (needle timing is advanced). In this case, loosen

setscrews in the sprocket and finely turn upper pulley in the

reverse direction.

(2) In case dimension A when the looper advances (going) is larger

than dimension B when the looper retreats (returning), the looper

timing is advanced (needle timing is retarded). In this case, loosen

setscrews in the sprocket and finely turn upper pulley in the

normal direction.

(Caution) Be careful not to excessively turn upper pulley .

3. After the adjustment, fix four setscrews in the sprocket.

oWhen the difference in timing

(going and returning) of looper is

excessively large, stitch skipping

or entangling of needle thread

will be caused.

Adjustment Procedure

Results of Improper Adjustment

– 22 –

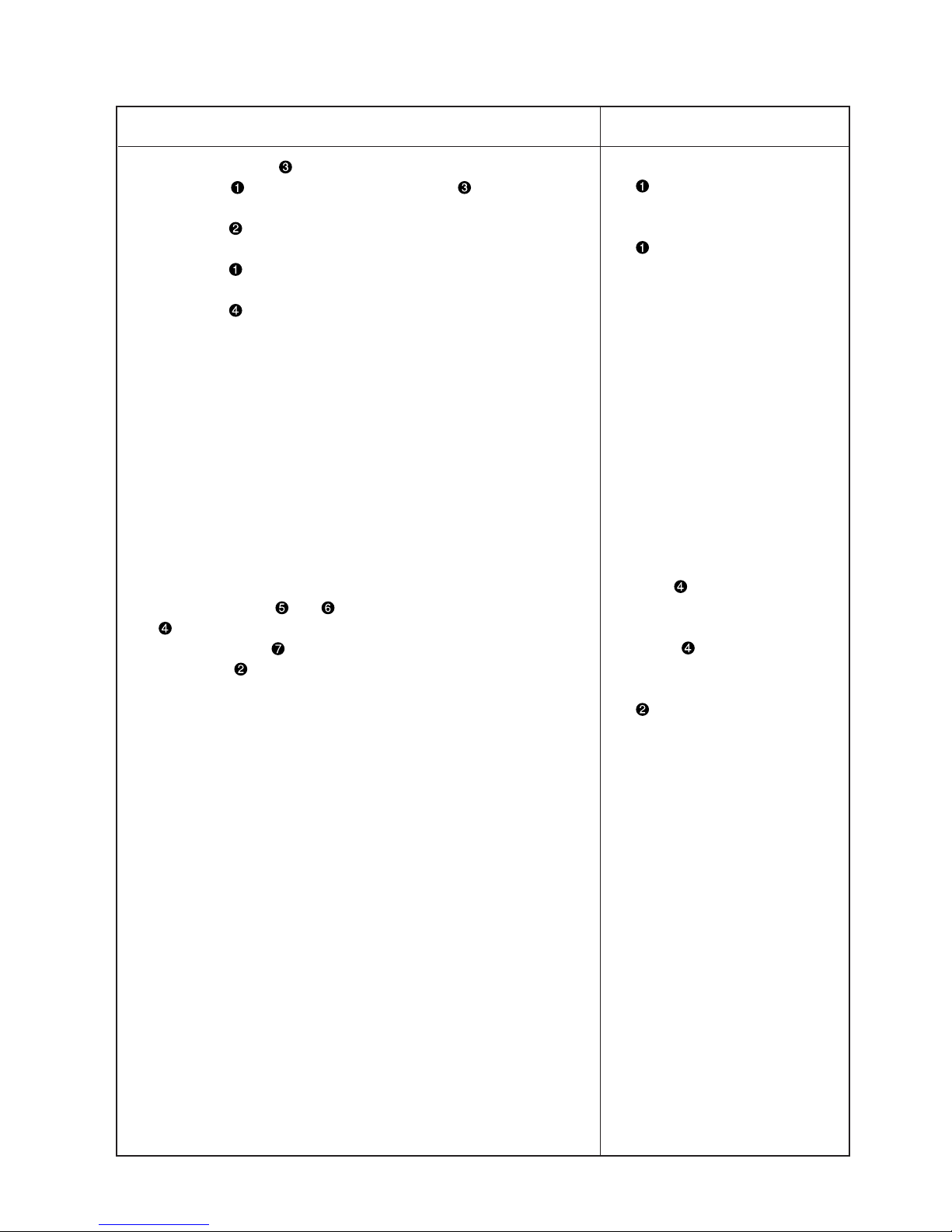

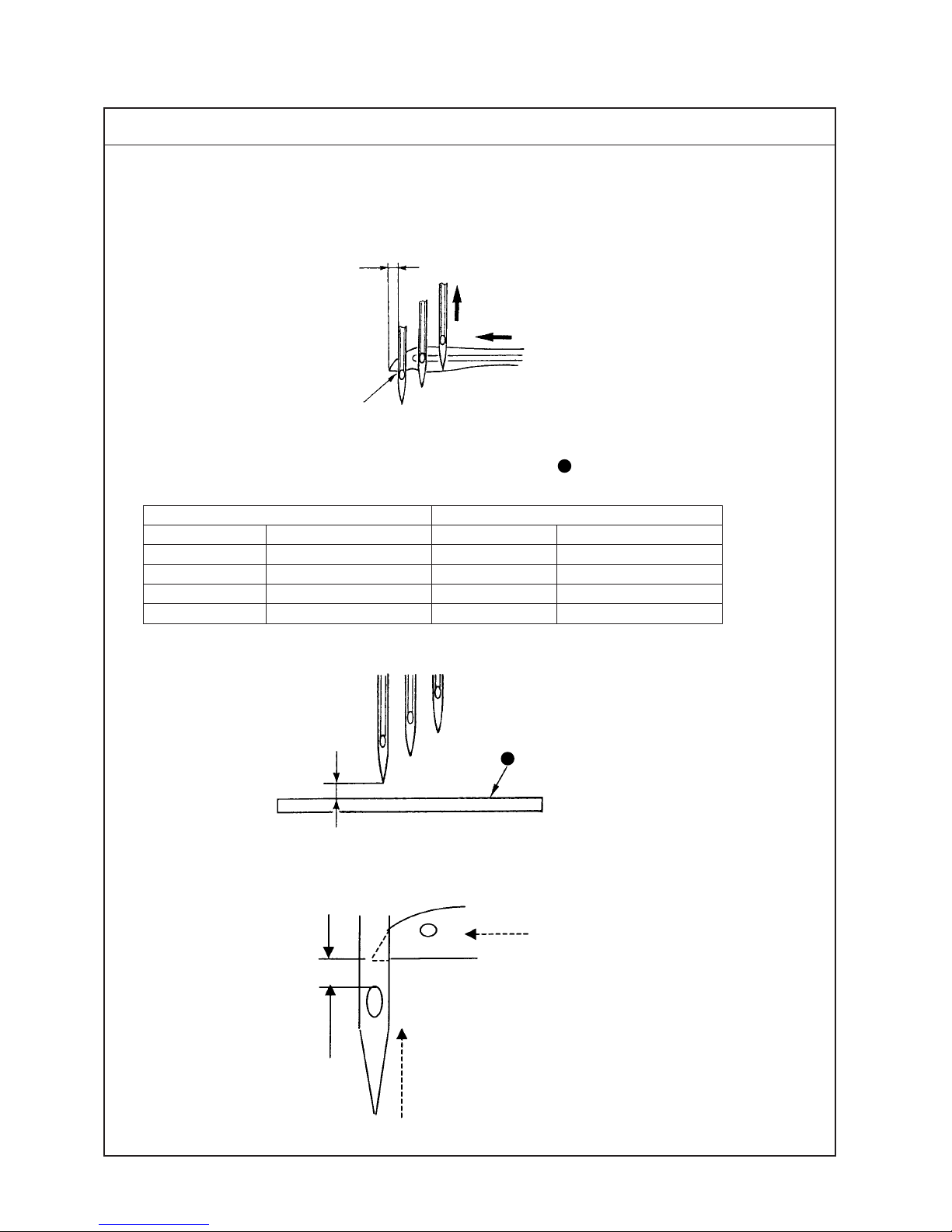

(8) Returning amount of the looper

1. It is the standard that returning amount of looper from top end of looper to the center of needle bar is

5.9 mm regardless of the needle gauge when looper is in the extreme right position.

2. Returning amount of looper for each gauge (dimension A)

5.9mm

A

0.05 to 0.1mm

Standard Adjustment

2-needle 3-needle

Needle gauge Returning amount

A

Needle gauge Returning amount

A

4.0 3.9 – –

4.8 3.5 – –

––5.6 3.1

––6.4 2.7

Unit : mm

(Dimension

A

is the dimension from the center of right needle to the top end of looper .)

– 23 –

1. Loosen setscrew in the looper holder and move looper holder

to the right and left to adjust.

2. After the adjustment, tighten setscrew in the looper holder.

(Caution) When adjusting looper holder , check the longitudinal

position of looper after adjusting the lateral position

since looper holder rotates to and fro and moves.

3. Longitudinal position

Adjust so that the clearance provided between blade point of

looper and left needle is 0.05 to 0.1 mm when the top end of

looper comes to the center of left needle from the extreme right

position.

After the adjustment, fix the looper holder with setscrew in the

looper holder.

*Blade point of the looper comes in contact with right needle and

middle needle when rear needle guard fails to work. So, be careful.

o When the returning amount is

large, loop of needle thread becomes large and it is apt to fall.

As a result, stitch skipping or

thread breakage will be caused,

and stitch skipping on the back

is apt to occur.

In addition, thread tangling will be

caused.

o When the returning amount is

small, loop of needle thread is

small and stitch skipping or

thread breakage will be caused.

In addition, thread tangling will be

caused.

Adjustment Procedure

Results of Improper Adjustment

– 24 –

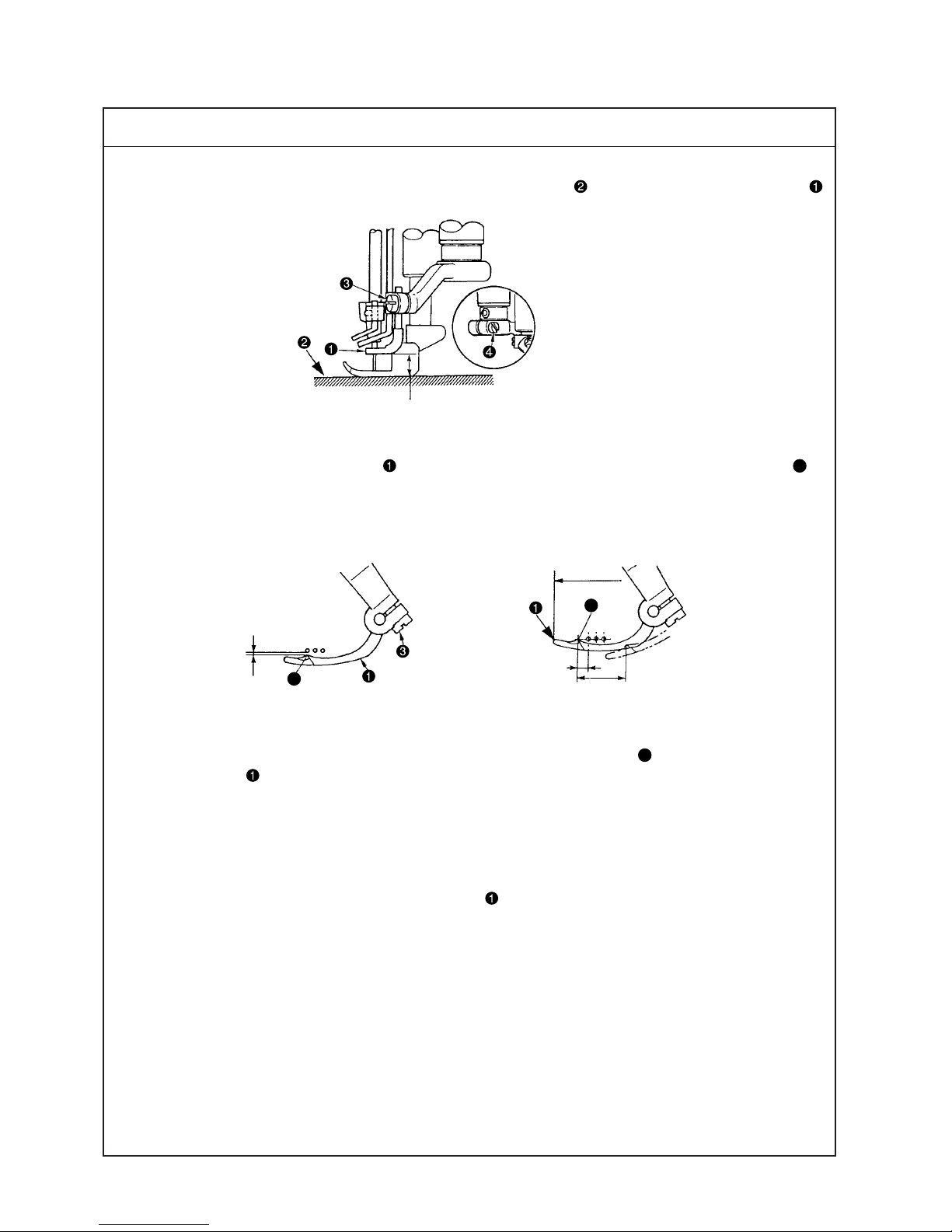

(9) Height of the needle

1. It is the standard that the top end of needle eyelet of left needle aligns with the bottom end of looper when

the top end of looper passes the rear of the needle from the extreme right position and protrudes from the

left end of left needle by approximately 1 mm (Calculated value : 1.1 mm), dimension B. (Dimension B :

standard needle size #10S)

A

C

Reference : Dimension C, height of left needle from top surface A of throat plate

1.2 to 1.4mm

Standard Adjustment

Reference : The scooping height of the looper, the dimension from the top end of the left needle eyelet to

the tip of the looper, is 1.2 to 1.4mm.

Unit : mm

B

To align

2-needle 3-needle

Needle gauge Height of left needle C Needle gauge Height of left needle C

4.0 8.8 – –

4.8 8.3 – –

––5.6 7.8

––6.4 7.5

– 25 –

1. Remove rubber cap in the face plate, loosen setscrew in the

needle bar bracket and adjust the height of the needle bar.

2. After adjusting the height, equally adjust the clearance A between

needle and needle hole in the throat plate and fix the needle

bar with setscrew in the needle bar bracket.

o When the height of the needle

is excessively different, stitch

skipping, needle breakage,

thread breakage, etc. will be

caused.

A

Equal

Adjustment Procedure

Results of Improper Adjustment

– 26 –

(10)Locus and longitudinal motion of the looper

1. It is the standard that the top end of left needle touches

the position of 1/4 to 1/3 from the bottom face of the back

of the looper when the looper returns from the extreme

left position in the standard looper motion locus.

2. Longitudinal motion timing of the looper

(1) The standard position of the cam is the position where

the engraved marker line on looper longitudinal motion

eccentric cam is adjusted to the center of notches

on looper driving shaft.

(2) It is the standard motion locus of the looper that the top

end of looper lightly comes in contact with right needle

and middle needle, and passes left needle with a

clearance of 0.05 to 0.1 mm when the rear needle guard

does not work.

0.05 to 0.1mm

1/4/ to 1/3

A

B

C

D

Standard Adjustment

Loading...

Loading...