Page 1

R

ENGINEER’S MANUAL

13371604

No.E361-01

High-speed, Flat-bed Coverstitch Machine

MF-7700 Series

Page 2

PREFACE

This Engineer’s Manual is written for the technical personnel who are responsible for the service and maintenance of

the machine.

The Instruction Manual for these machines intended for the maintenance personnel and operators at an apparel

factory contains operating instructions in detail. And this manual describes “Standard Adjustment”, “Adjustment

Procedures”, “Results of Improper Adjustment”, and other important information which are not covered by the Instruction

Manual.

It is advisable to use the relevant Instruction Manual and Parts List together with this Engineer’s Manual when carrying

out the maintenance of these machines.

In addition, for the motor for the sewing machine with thread trimmer, refer to the separate Instruction Manual or

Engineer’s Manual for the motor. And for the control panel, refer to the Instruction Manual for the control panel.

This manual gives the “Standard Adjustment” on the former page under which the most basic adjustment value is

described, and on the latter page “Results of Improper Adjustment” under which stitching errors and troubles arising

from mechanical failures are described together with the “Adjustment Procedures”.

Page 3

CONTENTS

1. SPECIFICATIONS ............................................................................................. 1

2. CONFIGURATION OF THE MACHINE COMPONENTS .................................. 2

3. MODEL NUMBERING SYSTEM ....................................................................... 3

4. MOTOR PULLEY AND BELT MF-7700 Series ................................................ 4

5. STANDARD ADJUSTMENT ............................................................................. 5

(1) Threading the machine head ........................................................................................... 5

(2) Adjusting the rocking thread take-up............................................................................. 7

(3) Adjusting the position of the needle thread guide rod ................................................. 9

(4) Adjusting the position of the thread receiver .............................................................. 11

(5) Adjusting the position of the spreader thread guide and spreader thread take-up ...... 13

(6) Adjusting the spreader .................................................................................................. 15

(7) Adjusting the timing relation between the looper and needle bar............................. 19

(8) Retuming amount of the looper .................................................................................... 21

(9) Height of the needle ....................................................................................................... 23

(10) Locus and longitudinal motion of the looper ............................................................ 25

(11) Adjusting the needle guard ......................................................................................... 27

(12) Instlling cover of the looper and needle guard after adjusting................................ 31

(13) Adjusting the feed dog................................................................................................. 33

(14) Adjusting the feed relation .......................................................................................... 39

(15) Adjusting the presser foot........................................................................................... 41

(16) Adjusting the micro-lifter............................................................................................. 43

(17) Adjusting the looper thread cam ................................................................................ 45

(18) How to change needle bar stroke ............................................................................... 47

(19) How to change the spreader ....................................................................................... 51

(20) With reagard to lubrication .......................................................................................... 53

(21) Adjusting and setting SC-380...................................................................................... 55

6. TROUBLES AND CORRECTIVE MEASURES............................................... 57

7. DRAWING OF TABLE (SEMI-SUBMERGED TYPE) ..................................... 71

Page 4

–1 –

No. Item Specifications

1 Model name High-speed, flat-bed coverstitch machine

2 Model MF-7700 series

3 Stitch type ISO standard 406, 407, 602, and 605

4 Example of application Hemming and covering for knits and general knitted fabrics

5 Max. sewing speed Max. 6,500 rpm (at the time of intermittent operation)

6 Needle gauge 3-needle ... 4.8 mm, 5.6 mm, and 6.4 mm

2-needle ... 4.0 mm (3.2 mm can be accepted as special order)

7 Differential feed ratio 1 : 0.7 to 1 : 2 (stitch length : less than 2.5 mm)

Micro-differential feed adjustment mechanism is provided. (Micro-adjustment)

8 Stitch length 1.2 mm to 3.6 mm (can be adjusted up to 4.4 mm)

9 Needle UY128GAS ORGAN #9S to #14S (standard #10S)

(SCHMETZ Nm65 to Nm90, standard Nm70)

10 Needle bar stroke 31mm (standard), possible up to 33 mm by adjustment)

11 Dimensions (Height) 451 x (Width) 515 x (Length) 265

12 Weight 46kg

13 Lift of presser foot 8 mm (needle gauge : 5.6 mm without top covering), and 5 mm (with top covering)

Micro-lifter mechanism is provided.

14 Feed adjustment method Main feed ... dial type stitch pitch adjustment method

Differential feed ... lever adjustment method (micro-adjustment mechanism is provided.)

15 Looper mechanism Spherical rod drive method

16 Lubricating system Forced lubrication method by gear pump

17 Lubricating oil JUKI MACHINE OIL 18 (Equivalent to ISO VG18)

18 Oil reservoir capacity Oil gauge lower line : 600 cc to upper line : 900 cc

19 Installation Semi-submerged type

20 Needle tip, needle thread and Provided as standard

silicon oil lubricating unit

21 Noise Workplace-related noise at sewing speed

n= 5000 min-1 : LPA ≦78 dB (A)

Noise measurement according to DIN 45635-48-A-1.

1. SPECIFICATIONS

Page 5

–2 –

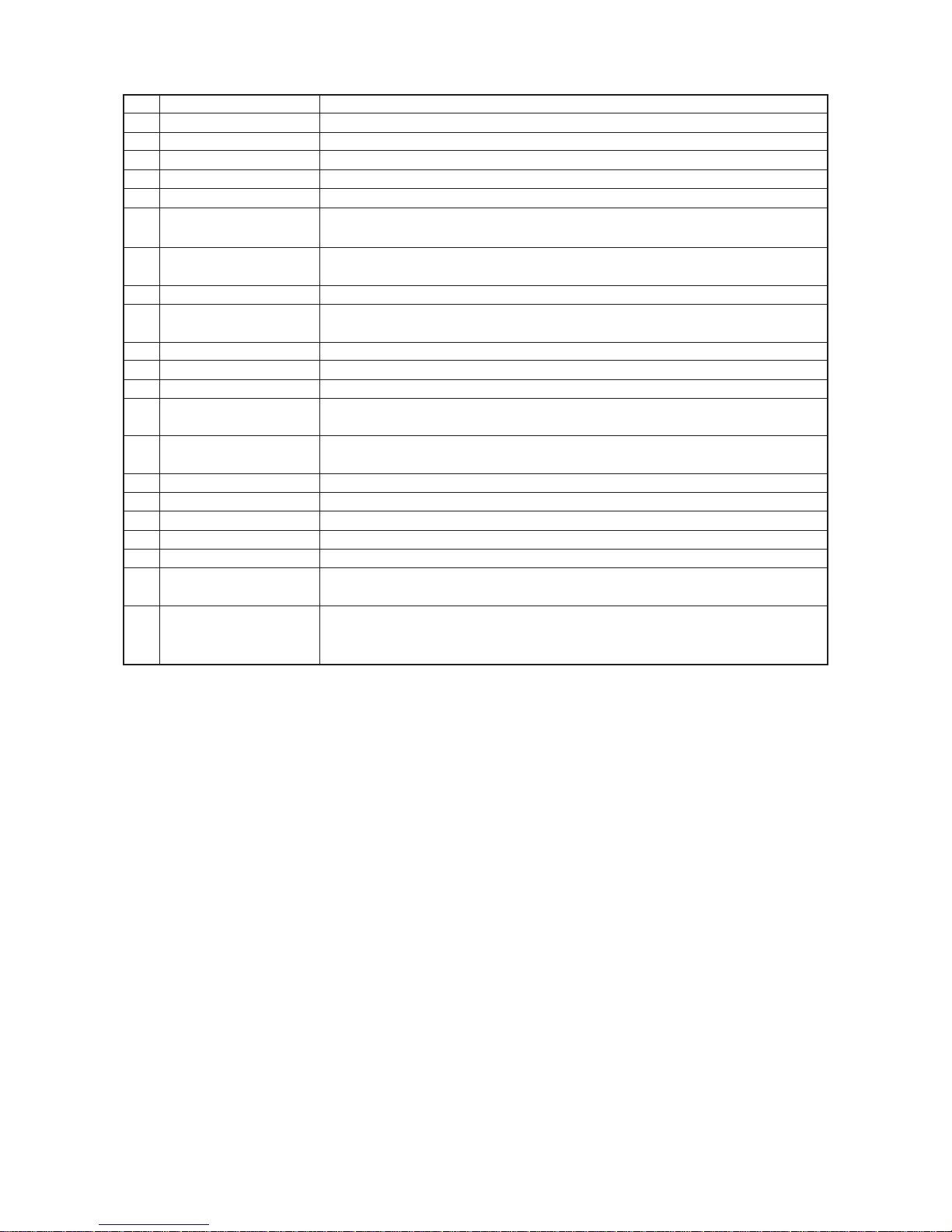

2.CONFIGURATION OF THE MACHINE COMPONENTS

1 Presser spring regulator !0 Thread tension nut !9 Thread trimming knife

2 Needle bar thread take-up cover !1 Oil gauge @0 Rocking thread take-up receiver

3 Oil circulation identification window !2 Feed regulating knob @1 Rocking thread take-up

4 Oil hole cap !3 Eye guard cover @2 Front cover

5 Micro-lifter !4 Throat plate @3 Slide cover

6 "Oil" indication !5 Needle tip silicon oil lubricating unit @4 Needle bar thread take-up thread

7 Needle thread silicon !6 Differential lock nut receiver

oil lubricating unit !7 Micro-adjustment knob @5

Rocking thread take-up thread guide

8 Thread guide No. 1 !8 Finger guard @6 Silicon container thread guide

9 Upper pulley @7 Belt cover

1

2

3

4

5

6

7

8

9

!0

!1

!2

!3

!4

!5

!6

!7

!8

!9

@0

@1

@7

@3

@2

@5

@4

@6

Page 6

–3 –

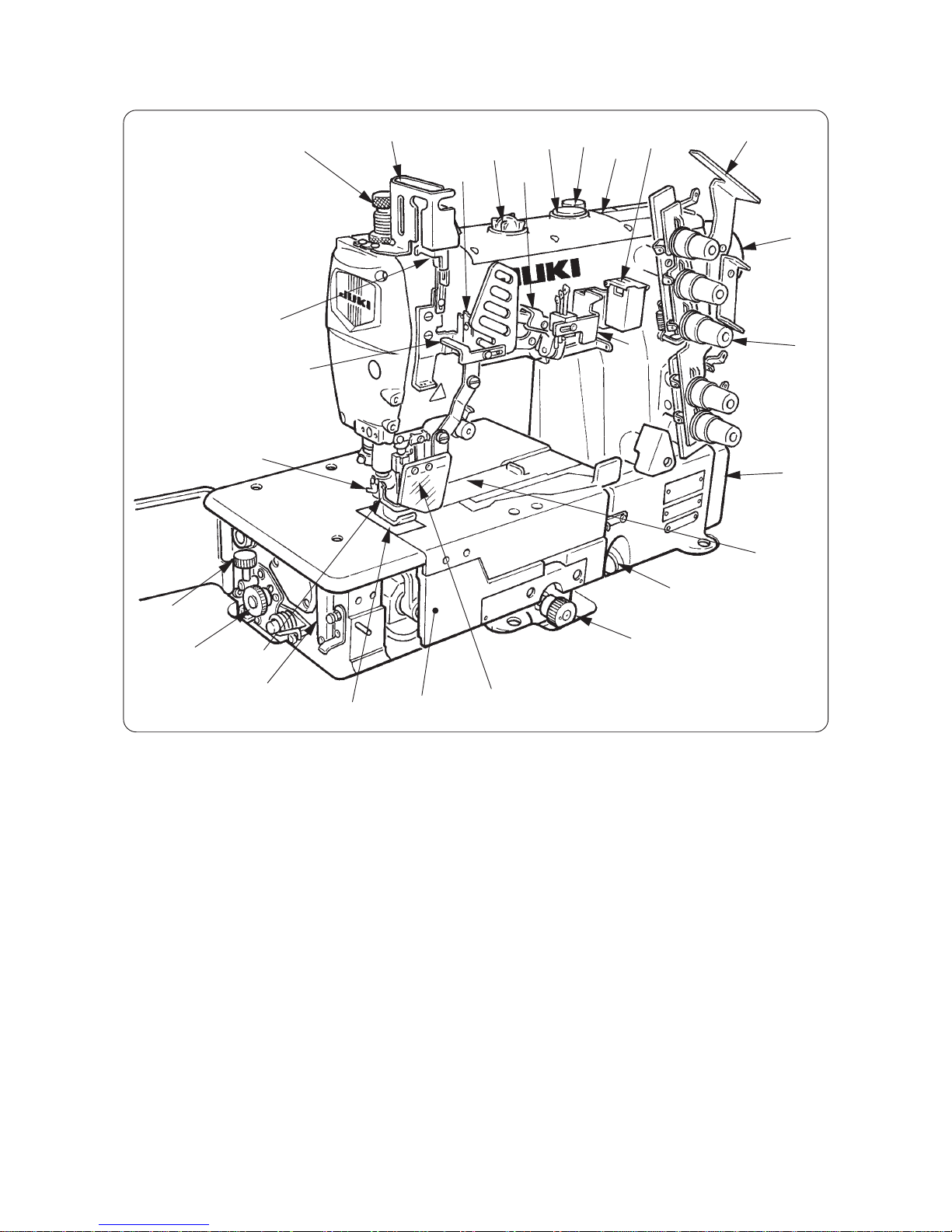

3.MODEL NUMBERING SYSTEM

High-Speed, Flat-bed Coverstitch Machine

Applicable model : MF-7700 Series

3~6 Model code

7722 2-needle top & bottom covering stitch

7723 3-needle top & bottom covering stitch

Application code

7~9 Application Description

U10 For universal Lapseam, Covering, Hemming

C10 For collarette Collarette

10 Tongue shape of throat plate

B B-type (Standard)

Availabilty

11~12 Needle gauge For 2-needle For 3-needle U10 C10

40 4.0mm Avail – – Avail

48 4.8mm Avail Avail Avail –

56 5.6mm Avail Avail Avail Avail

64 6.4mm Avail Avail Avail Avail

14~22 Device and attachment

(blank) Not provided

24 Destination

A Standard

25 Accessory

A Standard

* When device or attachment is one, delete slash (/) of 13th digit.

1 2 3 4 5 6 7 8 9 10111213141516171819202122232425

MF 7 7 B / / –

Page 7

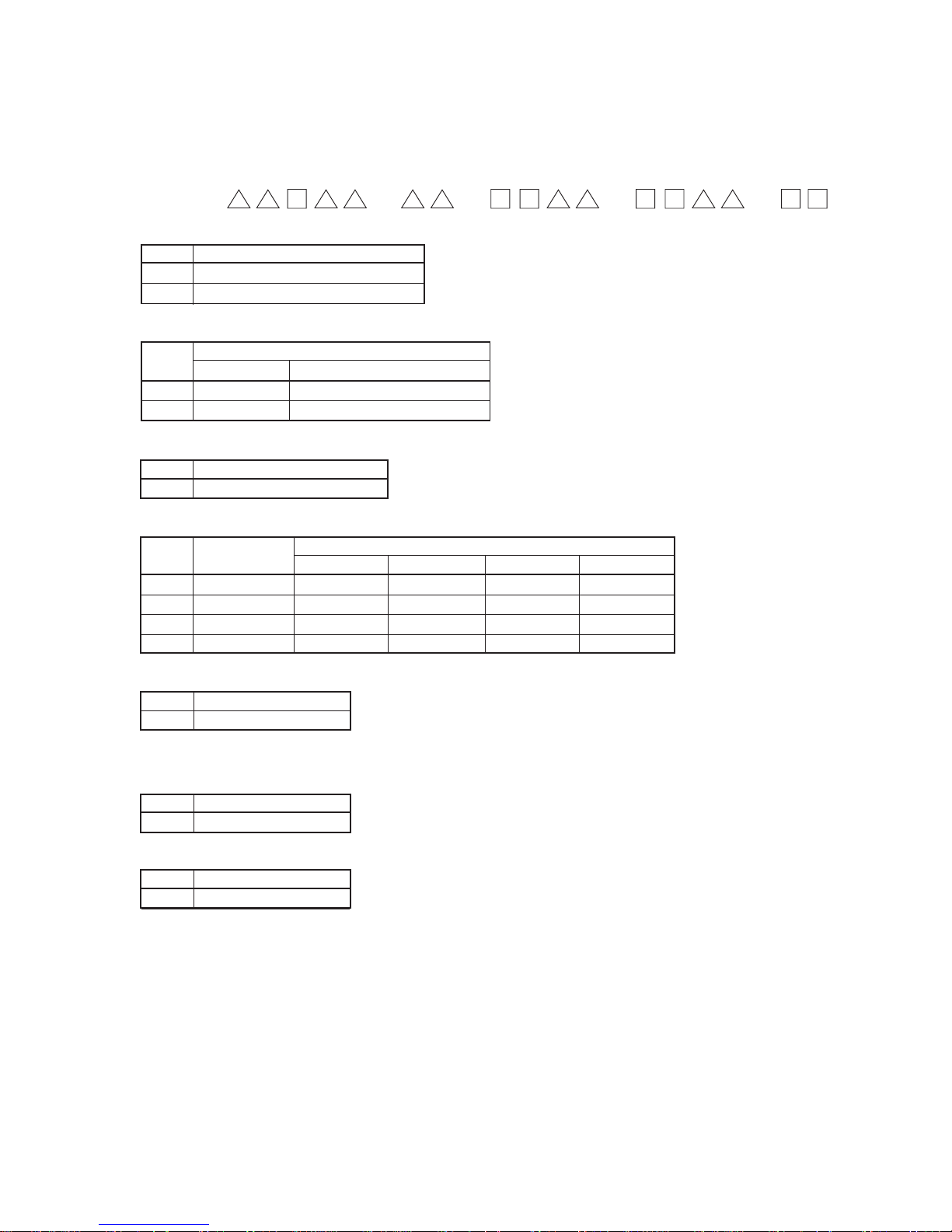

–4 –

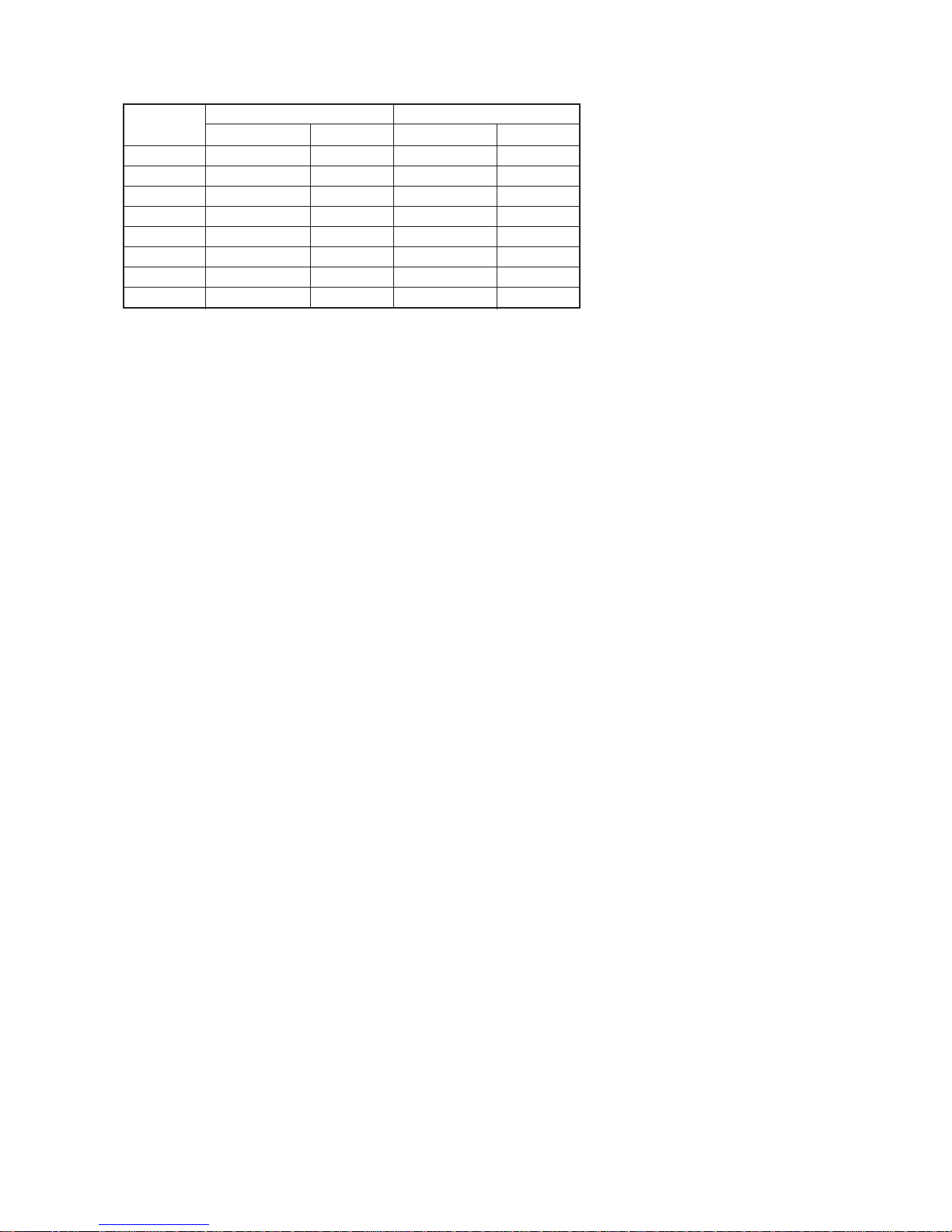

50Hz 60Hz

Pulley size (mm) Belt size (inch) Pulley size (mm) Belt size (inch)

4,500 ø 100 M-35 ø 85 M-35

4,800 ø 105 M-36 ø 90 M-35

5,000 ø 115 M-36 ø 95 M-35

5,500 ø 125 M-37 ø 105 M-36

5,800 ø 130 M-37 ø 110 M-36

6,000 ø 135 M-37 ø 115 M-37

6,200 ø 140 M-38 ø 120 M-38

6,500 ø 150 M-39 ø 125 M-38

4. MOTOR PULLEY AND BELT MF-7700 Series

1 . The table shows the numbers when a 3-phase 2-pole 400 W clutch motor (1 / 2 HP) is used.

2 . The commercially-available motor pulley near to the counted value is designated since the outside diameter of the

commercially-available motor pulley counts by 5 mm.

3 . When you use a new sewing machine, use the machine at a speed of 5,000 rpm or less for the first 200 hours

(approximately one month). A good result can be obtained in terms of the durability.

(Caution) 1. Use a motor pulley which is adaptable to this sewing machine.

2. The sewing speed exceeds the max. sewing speed of this sewing machine and machine trouble will be

caused unless a motor pulley which is adaptable to this sewing machine is used.

Sewing

speed(rpm)

Page 8

–5 –

5. STANDARD ADJUSTMENT

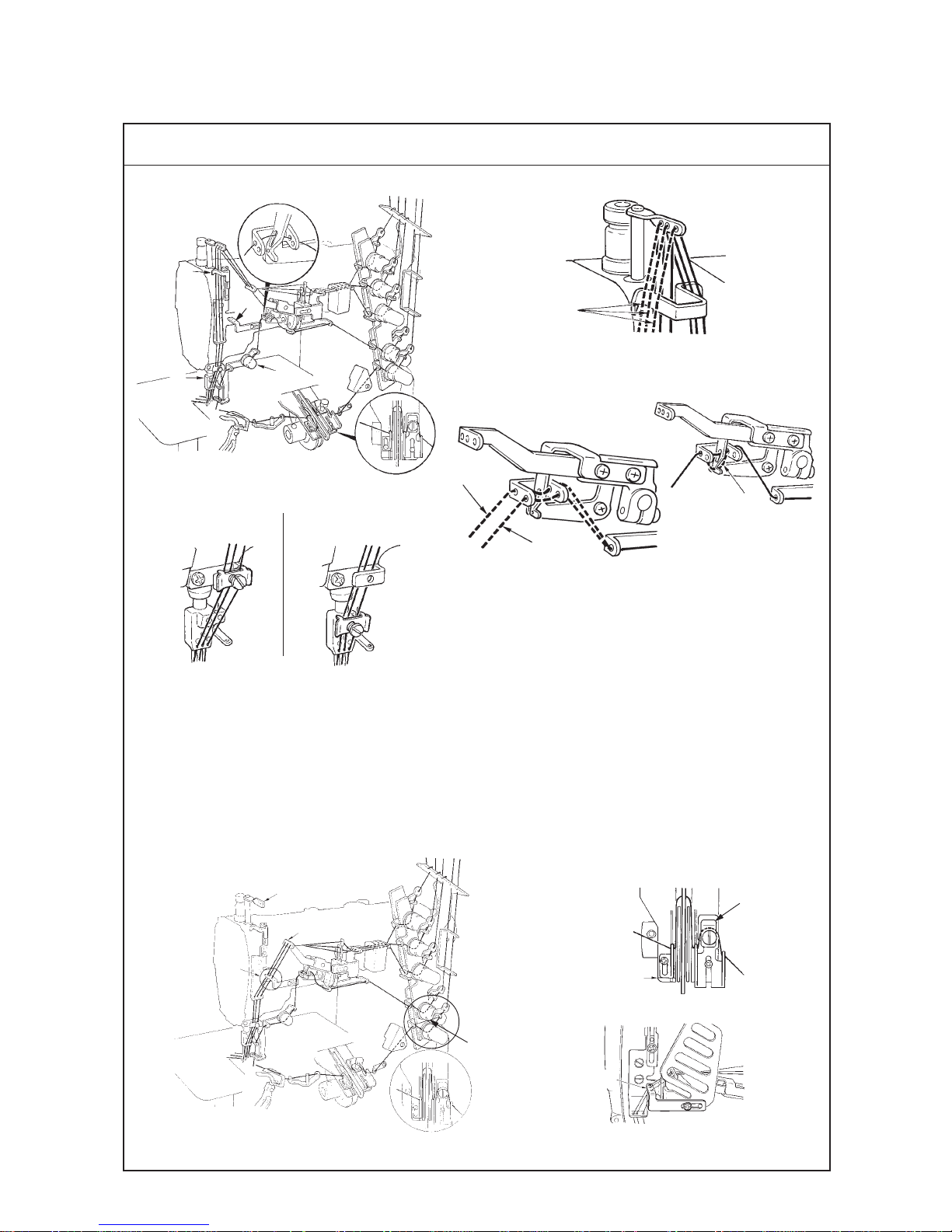

1. Threading for standard seame

(Caution) In case of threading for standard seams, rocking thread take-up thread guide 5 is not used.

(Caution) In case of the soft seams, rocking thread take-up thread guide 5 is used.

2

When covering thread is

excessively tense = D

When covering thread is

excessively loosened = B

When covering thread is

excessively loosened even

after passing B = C

B

C

D

1

Broken lines A when stretcher

thread is used

A

Standard Adjustment

(1) Threading the machine head

2. Threading for soft seams

(1) Do not pass needle thread through needle bar thread take-up 8.

(2) When soft seams are required, change the threading of needle thread and slide the position of looper thread cam

eyelet.

(3) Do not pass needle thread through needle bar thread take-up 8. Pass the thread from rocking thread take-up 9 to

rocking thread take-up thread guide

5.

(4) Other points are same as those of “1. Threading for standard seame”.

In case of soft seams

Engraved marker line

Left

Right

7

5

When using more

stretchable thread

When using less

stretchable thread

3

8

9

5

E

1

2

4

5

3

Page 9

–6 –

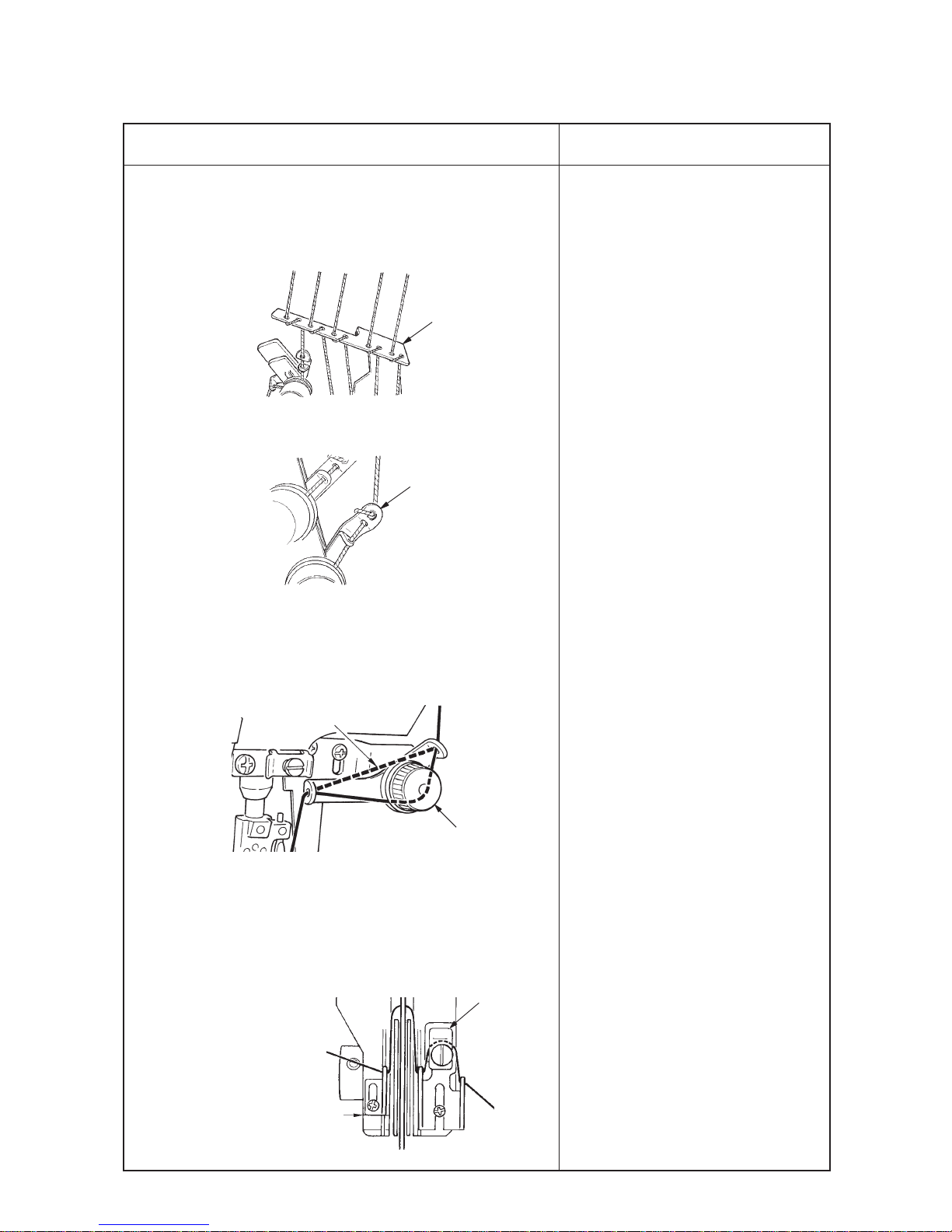

1. When motion of thread is very rough, and stable seams can not be

obtained, there are cases where the condition can be improved by

the following threading.

(1) Wind thread around 1st thread guide 6.

(2) Wind thread around the thread tension thread guide !0.

2. When using more stretchable thread (wooly thread or the like), the

threading as given below does not make thread stretch and neat

seams can be obtained.

(1) Do not pass thread through spreader auxiliary thread tension 4.

(2) Do not pass thread through the looper thread tension disk.

Refer to section E.

(Caution) Even when using wooly thread or the like, seams are more

stabilized by passing thread through looper thread

auxiliary thread tension 7.

™ When threading is not properly

performed, not only sewing trouble

occurs, but also needle breakage is

caused. So, be careful.

Engraved marker line

7

Do not pass thread.

4

Standard Adjustment Results of lmproper Adjustment

6

!0

Page 10

–7 –

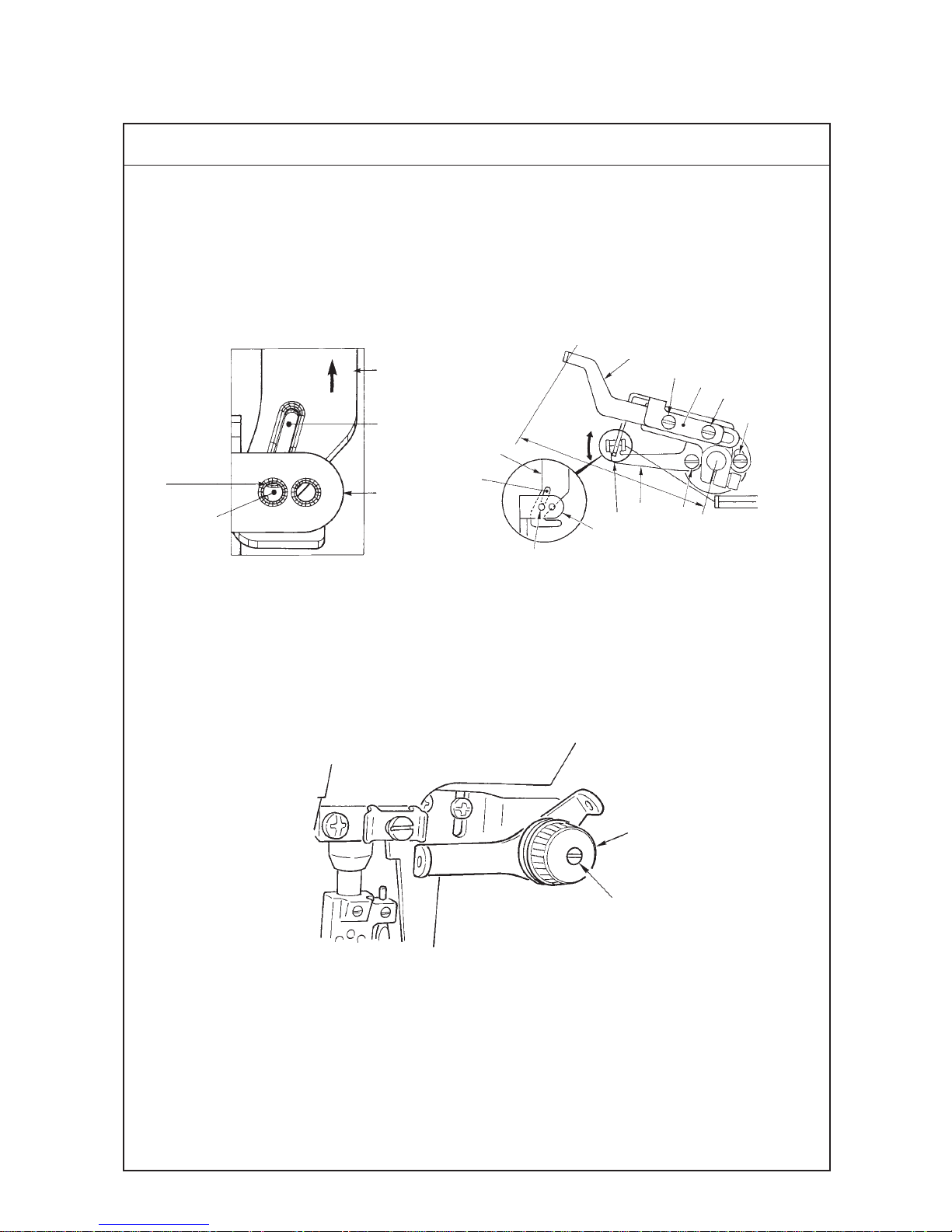

(2) Adjusting the rocking thread take-up

Standard Adjustment

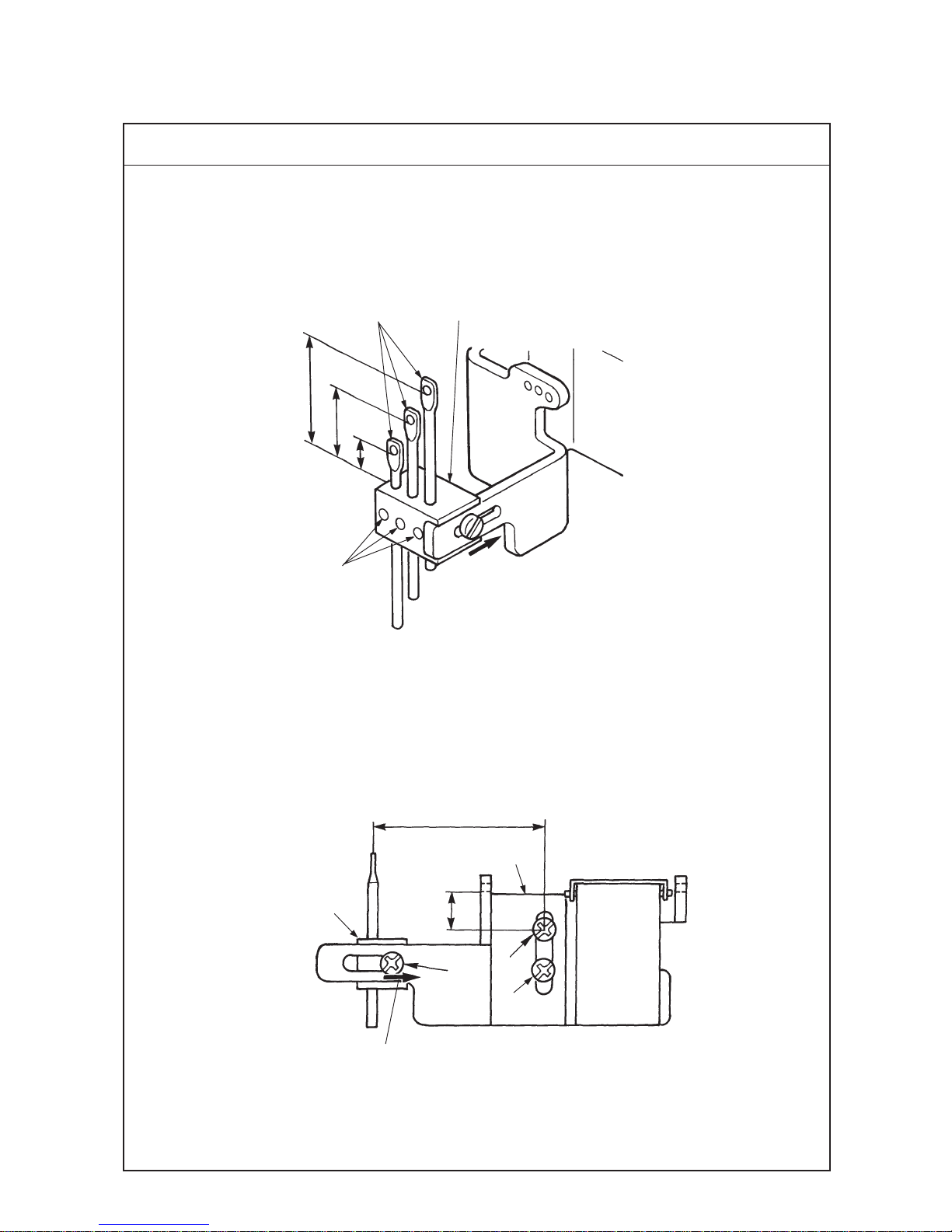

1. Length of the rocking thread take-up

(1) It is the standard that the length of rocking thread take-up 2 from the center of the shaft of rocking thread take-up

support arm 4 to the thread hole face of rocking thread take-up 2 is 95 mm.

2. Position of the rocking thread take-up

(1) Install so that rocking thread take-up 2 is flush with rocking thread take-up 2 when the needle bar is in its lowest

position.

3. Timing of the rocking thread take-up

(1) It is the standard timing that rocking thread take-up 2 is in

its lowest position as well when the needle bar is in its lowest

position.

Timing of rocking thread take-up 2 is performed by adjusting

the position of rocking thread take-up ball arm 8.

4. Relation between the timing of rocking thread take-up and

the needle thread loop

(1) When using the excessively stretchable thread or the hard-

to-stretch thread, the size of needle thread loop can be

changed by by changing the timing of rocking thread takeup 2.

(2) Relation between the timing of the rocking thread take-up

and the size of needle thread loop is as shown in the table

on the next page.

(The relation becomes reverse when using the needle bar

thread take-up = standard seams and when it is not used =

soft seams. So, be careful.)

1

2

4

95 mm

2

7

3

6

2

5

Flush

!1

3

8

4mm

Anti-operator’s side

Operator’s side

9

!2

/

/

!0

Page 11

–8 –

Standard Adjustment Results of lmproper Adjustment

™ When length of rocking thread take-

up 2 is lengthened, needle thread is

tightened.

(Caution) When lengthening rocking

thread take-up 2, check

whether it comes in contact

with the thread take-up cover.

™ When length of rocking thread take-

up 2 is shortened, needle thread is

loosened.

™ When installing position of rocking

thread take-up 2 is raised, needle

thread is loosened when the needle

bar thread take-up is used, and needle

thread is tightened when the needle

bar thread take-up is not used.

1. Length of the rocking thread take-up

(1) Loosen screws 1 and move rocking thread take-up 2 to the right

or left to adjust the length.

2. Position of the rocking thread take-up

(1) Loosen screw 5 and move rocking thread take-up 2 up or down

to adjust the position.

(Caution) When adjusting the position of rocking thread take-up 2,

adjust the rocking thread take-up to the same plane of the

edge of rocking thread take-up shaft 3 and fix it so that

spreader thread take-up 6 and spreader thread guide 7

do not come in contact with each other.

3. To adjust the timing of the rocking thread take-up 2 , remove the top

cover, loosen setscrew 9 in the rocking thread take-up ball arm and

move the position of rocking thread take-up ball arm 8 to and fro.

(1) Standard adjustment figure is the position where the rear end (anti-

operator’s side) of rocking thread take-up ball arm 8 aligns with engraved

marker line !0 on rocking thread take-up shaft 3. (As the standard at this

time, note that the clearance provided between the rear end of rocking

thread take-up ball arm 8 and thrust collar !1 is 4 mm.)

(Caution) 1. When loosening screw 9 in rocking thread take-up

ball arm 8, there is a case where rocking thread take-up

2 rotates by its weight. After the adjustment, be sure to

check the rocking position (flush at the lowest position)

of rocking thread take-up 2.

2. When moving rocking thread take-up ball arm 8 to the

operator’s side, adjust rocking thread take-up ball arm

8 within the range where it does not come in contact

with rocking thread take-up bushing !2 (operator’s side).

4. Relation between timing of rocking thread take-up and needle

thread loop

When needle bar thread take-up is used Loop becomes small. Loop becomes large.

When needle bar thread take-up is not used Loop becomes large. Loop becomes small.

Advance timing

(Move to anti-operator’s side.)

Delay timing

(Move to operator’s side.)

Adjusting procedure is the same as step 3. Loosen setscrew 9 in rocking thread take-up ball arm 8 and adjust

the position of rocking thread take-up ball arm 8.

(Caution) Adjust the timing of rocking thread take-up 2 each time in accordance with thread used or conditions.

Page 12

–9 –

Standard Adjustment

1. Position of the needle thread guide rod

(1) It is the standard that the height of needle thread guide rods 1 is the position where the dimensions from the top

surface of needle thread guide base 2 to the bottom end of the hole are as follows.

Left needle A : 7 mm

Middle needle B : 15 mm

Right needle C : 23 mm

2. Adjusting the position of needle thread guide base and silicon container thread guide

(1) It is the standard that the height of silicon containder thread guide 4 (refer to 2. CONFIGURATION OF THE

MACHINE COMPONENTS) is the position where the height from the center of setscrew 5 to the bottom end of

thread hole is 9 mm.

(2) Move the lateral position of needle thread guide base 2 fully to the right of slot (43 mm).

Extreme right position

C

B

A

A : 7mm B : 15mm C : 23mm

1

2

3

Extreme right position

7

43mm

9mm

5

4

6

2

(3) Adjusting the position of the needle thread guide rod

Page 13

–10 –

Standard Adjustment Results of lmproper Adjustment

1. Loosen setscrews 3, adjust the height of respective needle thread

guide rods 1, and fix the rods with setscrews 3.

(Caution) 1. Move the lateral position of needle thread guide base 2

fully to the right of slot.

2. When adjusting the height of needle thread guide rods

1, install the rods so that the thread holes are parallel to

the thread holes of silicon container thread guide 4 so

that excessive resistance is not applied to threads.

2. Adjusting the position of needle thread guide base and silicon

container thread guide

(1) Loosen setscrews 5 and 6 and move silicon container thread

guide 4 up or down to adjust the height.

(2) Loosen setscrew 7 and adjust the lateral position of needle thread

guide base 2.

™ When needle thread guide rod 1 is

raised, needle thread is loosened.

™ When needle thread guide rod 1 is

lowered, needle thread is tightened.

™ When silicon container thread guide

4 is raised, needle thread is loosened.

™ When silicon container thread guide

4 is lowered, needle thread is

tightened.

™ When needle thread guide base 2 is

moved to the left, needle thread is

loosened.

Page 14

–11 –

(4) Adjusting the position of the thread receiver

Standard Adjustment

1. Position of the needle bar thread take-up thread receiver (in case of standard seams)

(1) It is the standard that the height of needle bar thread take-up thread receiver 1 is in the position where the bottom

end of thread hole to the center of needle bar thread take-up 2 aligns with the top surface of needle bar thread

take-up thread receiver 1 when the needle bar is in its lowest position.

1. Position of the rocking thread take-up thread receiver (in case of soft seams)

(In case thread is not passed through needle bar thread take-up 2)

(1) It is the standard that the height of rocking thread take-up receiver 7 is in the position where the top surface of

rocking thread take-up receiver 7 is in the range of the center to the top end of thread hole 9 of rocking thread

take-up 8 when rocking thread take-up 8 is in its lowest position.

This range

6

!0

!1

7

8

9

This range

1

2

3

Thread hole

Center of hole

To align

Page 15

–12 –

Standard Adjustment Results of lmproper Adjustment

1. Loosen setscrew 3 and move needle bar thread take-up thread

receiver 1 up or down to adjust the height.

2. When desired to make needle bar thread take-up thread receiver

1 work especially on the right needle where loop is hard to be

made, adjust the height of right needle thread receiver 4 with

setscrew 5.

1. Loosen setscrew !0 and move rocking thread take-up receiver 7 up

or down to adjust the height.

2. When desired to make rocking thread take-up receiver 7 work

especially on the right needle where loop is hard to be made, adjust

the height of the right needle thread receiver 6 with screw !1.

™ When the needle bar thread take-up

thread receiver 1 is raised, loop

becomes large.

™ When the needle bar thread take-up

thread receiver 1 is excessively

raised,

4

5

Page 16

–13 –

Standard Adjustment

(5) Adjusting the position of the spreader thread guide and spreader thread take-up

1. Relation of the position between spreader thread take-up 1 and spreader thread guide 2 is the standard when

the top end of thread hole 3 of spreader thread guide 2 aligns with the bottom end of slot 5 of spreader thread

take-up 1 when spreader thread take-up 1 is in its highest position.

Adjust the relation of the position so that thread is moderately stretched when spreader thread take-up 1 is in its

highest position in accordance with thread used or conditions.

2. Standard position of the spreader auxiliary thread tension

Standard adjustment figure of the spreader auxiliary thread tension is the standard when the top end of thread

tension rod 6 is flush with knob 7.

To align

Highest position

1

5

2

3

4

1

8

A

2

2

4

9

3

5

1

8

7

6

Page 17

–14 –

1. Loosen setscrews 4 in spreader thread guide 2 and adjust the

position of spreader thread guide 2. (Spreader thread take-up 1

is fixed to rocking thread take-up 9 and can not be adjusted in the

height direction.)

2. After the adjustment, turn the sewing machine by hand and check

whether spreader thread take-up 1 comes in contact with spreader

thread guide 2, or section A of clearance is too small.

3. Adjusting procedure of the clearance

(1) Loosen setscrews 4 in spreader thread guide 2 and adjust in the

lateral direction, or loosen setscrews 8 in the rocking thread takeup and move spreader thread take-up 1 to the right or left to adjust

the clearance.

(Caution) When loosening setscrews 8 in the rocking thread take-

up and adjusting the position of spreader thread take-up

1, adjust so that 95, length of rocking thread take-up 9

(95mm) does not change.

Standard Adjustment Results of lmproper Adjustment

™ When the relation of position between

spreader thread take-up 1 and the

spreader thread guide is not proper,

sewing troubles such as stitch skipping

and the like will be caused.

™ If thread is less stretched and

slackness of thread occurs at the

thread take-up section when spreader

thread take-up 1 is in its highest

position, the spreader fails to pick up

thread and stitch skipping occurs.

™ If stretch or feeding of thread is

excessive when spreader thread takeup 1 is in its highest position, not only

thread on the seam side is drawn and

needle thread can not be tightened, but

also needle bend or needle breakage

will be caused.

™ If stretch or feeding of thread is

excessive when spreader thread takeup 1 is in its lowest position, thread

slacks when the spreader moves from

left to right and stitch skipping occurs.

Page 18

–15 –

Standard Adjustment

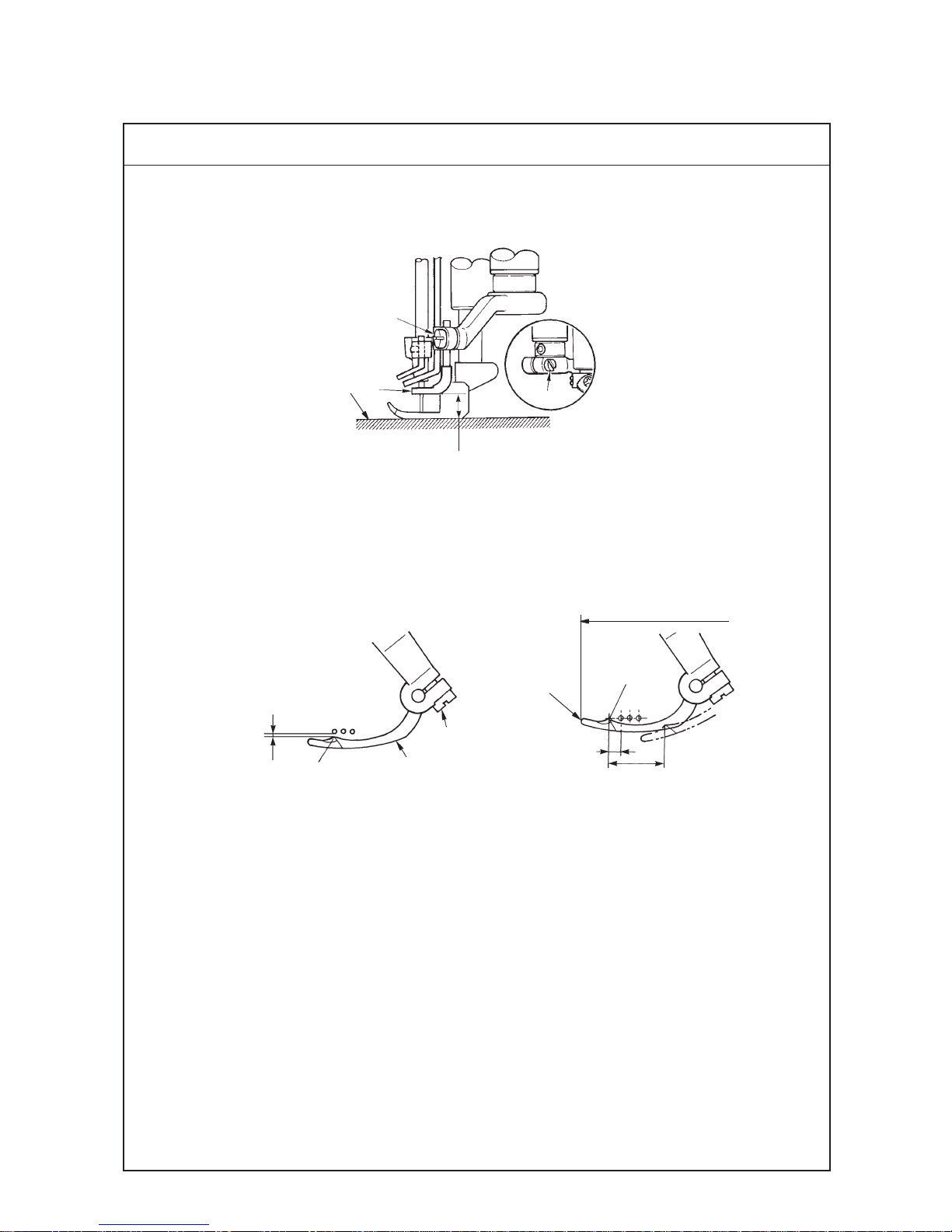

1. Height of the spreader

It is the standard that the height from the top surface of throat plate 2 to the bottom surface of spreader 1 is 8.3

to 8.7 mm.

2. Longitudinal position of the spreader

It is the standard that when spreader 1 returns from the extreme left position to the right and top end A of thread

hooking section reaches to the front of left needle, the clearance between the spreader and the left needle is 0.1

to 0.3 mm.

3. Protruding amount

It is the standard that the dimension from the center of left needle to top end A of thread hooking section, when

spreader 1 is in the extreme left position, is 4.5 to 5.5 mm.

4. Spreader stroke

It is the standard that the spreader stroke is 16 to 18 mm at the stroke of thread hooking section.

5. Timing of the spreader

Standard position is the position where the spreader 1 is in the extreme left position when the needle bar comes

down from the upper dead point by 1.1±0.1 mm.

(6) Adjusting the spreader

8.3 to 8.7 mm

4

1

2

3

0.1 to 0.3 mm

4.5 to 5.5 mm

16.0 to 18.0 mm

Extreme left position

1

A

A

1

3

Page 19

–16 –

Standard Adjustment Results of lmproper Adjustment

1. Adjusting the height of the spreader

2. Adjusting the longitudinal position of the spreader

Loosen setscrew 3 and adjust the height and longitudinal position

of the spreader 1.

3. Protruding amount of the spreader

Loosen setscrew 4 in the spreader folder and adjust the protruding

amount. Adjust aiming the adjustment figure of 5 mm.

4. Adjusting the spreader stroke

Standard position is the position where the engraved marker line of

spreader drive lever 5 aligns with the center of the shaft of

connecting pin 6. When desired to increase the stroke, loosen

lock nut 7 and move in the right direction. When desired to decrease

the stroke, loosen lock nut 7 and move in the left direction. Adjust

aiming the adjustment figure of 17 mm.

5. Adjusting the timing between the needle bar and the spreader

When changing the timing, loosen two setscrews 9 in spreader

eccentric cam 8 to adjust. Standard position is the position where

notch !0 in the main shaft aligns with notch !1 in spreader eccentric

cam. When changing, turn the upper pulley and change with

spreader eccentric cam 8 fixed.

™ Height of the spreader is improper,

stitch skipping of spreader occurs.

™ Adjust the height in accordance with

the needle gauge.

™ Even when the protruding amount is

excessive or insufficient, stitch

skipping of spreader will be caused.

™ When the protruding amount is

insufficient, it will be the cause for left

needle not to scoop covering thread

at overlapped section.

™ When the stroke is increased, disorder

of covering thread stitching will be

caused.

™ When the stroke is decreased, stitch

skipping of spreader will be caused.

™ When the timing is excessively

advanced, needle does not take

covering thread when it comes down

and stitch skipping will be caused.

™ When the timing is excessively

retarded, resistance increases when

covering thread slips out from the

spreader and a load is applied to the

right needle. As a result, needle

breakage or stitch skipping will be

caused.

(Caution) When changing, temporarily

tighten No. 2 screw in the

rotation direction of setscrews

9 and turn the upper pulley

to change.

8

9

!0

!1

7

6

5

Page 20

–17 –

Standard Adjustment

6. Adjustment figures of the spreader thread guide

(1) It is the standard that the clearance provided between spreader 1 and spreader thread guide !2 is 0.4 to 1.0 mm.

(2) It is the standard that the clearance provided between spreader thread guide !2 and needle clamp thread guide !3

is 0.8 to 1.2 mm.

(3) Lateral position of the spreader thread guide

Top end of thread hooking section D of the spreader aligns with center E of slot C in spreader thread guide !2

when spreader 1 is in the extreme right position.

(6) Adjusting the spreader

0.8 to 1.2 mm

0.4 to 1.0 mm

1

!4

!3

!2

1

C

E

D

!3

!4

!5

!2

!2

Page 21

–18 –

Standard Adjustment Results of lmproper Adjustment

6. Spreader thread guide

(1) Adjust the height of spreader 1 to 8.3 to 8.7 mm. Loosen setscrews

!5 in the spreader thread guide and adjust the clearance provided

between the top surface of spreader 1 and spreader thread guide

!2 to 0.4 to 1.0 mm.

(2) Needle clamp thread guide

Loosen setscrew !4 in the needle clamp thread guide and adjust

the clearance provided between the needle clamp thread guide

and spreader thread guide !2 to 0.8 to 1.2 mm.

(3) For the lateral direction, align the hole of needle clamp thread guide

!3 to the prolonged line of the slot of spreader thread guide.

(Caution) When adjusting spreader thread guide !2 in the lateral

direction, check whether there is any contact at section B

(left side of spreader thread guide !2 and needle clamp !6)

™ When height or position of the

spreader thread guide is improper,

stitch skipping of spreader thread will

be caused.

™ When height or position of the needle

clamp thread guide is improper, stitch

skipping of spreader thread will be

caused.

!2

B

!6

8.3 to 8.7 mm

2

1

3

Page 22

–19 –

Standard Adjustment

(7) Adjusting the timing relation between the looper and needle bar

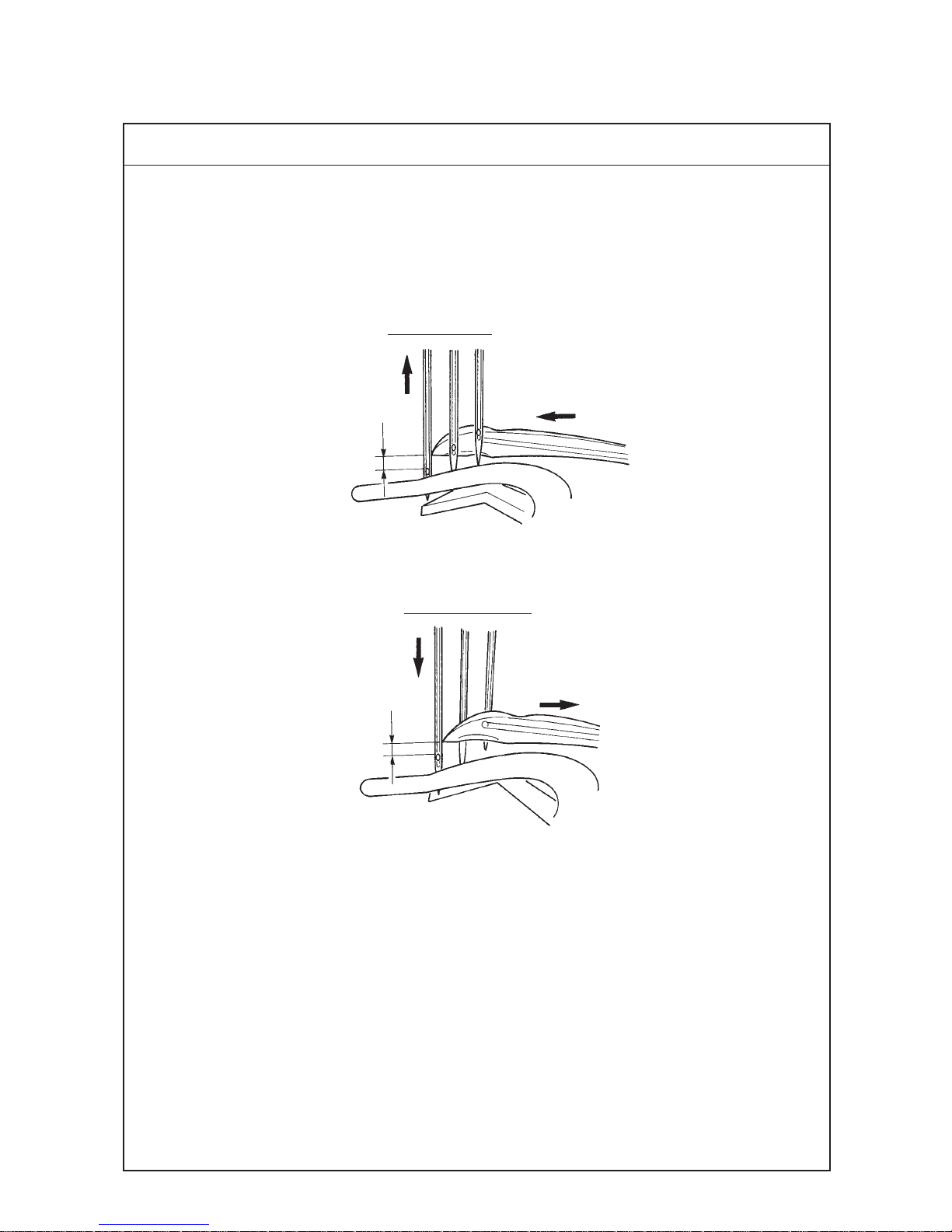

1. Timing relation between the looper and the needle bar (synchronization)

It is the standard that dimension A from the top end of needle eyelet to the blade point of looper passes the rear

of the needle and comes to the position of the right end of left needle is the same as dimension B from the top end

of needle eyelet to the blade point of looper when needle bar comes down from the upper dead point, the blade

point of looper passes the front of needle bar and comes to the position of the right end of left needle. (A=B)

Going of looper

A

Returning of looper

B

Page 23

–20 –

Standard Adjustment

Results of lmproper Adjustment

1. To adjust the timing relation between the needle and the looper,

remove the top cover, loosen four setscrews 1 in the sprocket and

turn upper pulley 2 in the state that the sprocket is held.

2. Adjusting procedure

(1) When adjusting the timing to "0" (zero)

1) In case dimension A when the looper advances is smaller than

dimension B when the looper retreats, the looper timing is retarded

(needle timing is advanced). In this case, loosen setscrews 1 in

the sprocket and finely turn upper pulley 2 in the reverse direction.

2) In case dimension A when the looper advances is larger than

dimension B when the looper retreats, the looper timing is advanced

(needle timing is retarded). In this case, loosen setscrews 1 in the

sprocket and finely turn upper pulley 2 in the normal direction.

(Caution) Be careful not to excessively turn upper pulley 2.

3. After the adjustment, fix four setscrews 1 in the sprocket.

™ When the difference in timing (going

and returning) of looper is excessively

large, stitch skipping or entangling of

needle thread will be caused.

2

1

Page 24

–21 –

Standard Adjustment

(8) Retuming amount of the looper

1. It is the standard that returning amount of looper 1 from top end of looper 1 to the center of needle bar is 6.5 mm

regardless of the needle gauge when looper 1 is in the extreme right position.

2. Returning amount of looper for each gauge (dimension A)

2-needle 3-needle

Needle gauge Returning amount A Needle gauge Returning amount A

3.2 4.9 – –

4 4.5 – –

4.8 4.1 4.8 4.1

5.6 3.7 5.6 3.7

6.4 3.3 6.4 3.3

(Dimension A is the dimension fromthe center of right needle to the top end of looper 1.)

Unit : mm

A

1

5

4

0 to 0.05 mm

1

6.5mm

Page 25

–22 –

Standard Adjustment Results of lmproper Adjustment

1. Loosen setscrew 2 in the looper holder and move looper holder 3

to the right and left to adjust.

2. After the adjustment, tighten setscrew 2 in the looper holder.

(Caution) When adjusting looper holder 3, adjust the lateral

position while being careful that the holder does not move

to and fro.

3. Longitudinal position

Adjust so that the clearance provided between blade point 5 of

looper and middle needle 4 is 0 to 0.05 mm when the top end of

looper comes to the center of middle needle from the extreme right

position.

After the adjustment, fix the looper holder with setscrew 2 in the

looper holder.

* Blade point 5 of the looper comes in contact with the right needle

when rear needle guard 6 fails to work. So, be careful.

™ When the returning amount is large,

loop of needle thread becomes large

and it is apt to fall. As a result, stitch

skipping or thread breakage will be

caused, and stitch skipping on the

back is apt to occur.

In addition, thread tangling will be

caused.

™ When the returning amount is small,

loop of needle thread is small and

stitch skipping or thread breakage will

be caused.

In addition, thread tangling will be

caused.

2

1

3

6

Page 26

–23 –

Standard Adjustment

(9) Height of the needle

1. It is the standard that the top end of needle eyelet of left needle aligns with the bottom end of looper when the top

end of looper passes the rear of the needle from the extreme right position and protrudes from the left end of left

needle by approximately 1 mm (1.1 mm), dimension B.

To align

B

Reference : Dimension C, height of left needle from top surface A of throat plate

Unit : mm

2-needle 3-needle

Needle gauge Height of left needle C Needle gauge Height of left needle C

3.2 9.7 – –

4.0 9.3 – –

4.8 8.8 4.8 8.8

5.6 8.5 5.6 8.5

6.4 8.0 6.4 8.0

A

C

1.2 to 1.4 mm

2. Scooping height of looper, dimension from the top end of needle eyelet to the top end of looper is 1.2 to 1.4 mm.

Page 27

–24 –

Standard Adjustment Results of lmproper Adjustment

1. Remove rubber cap 4 in the face plate, loosen setscrew 3 in the

needle bar bracket and adjust the height of the needle bar.

2. After adjusting the height, equally adjust the clearance A between

needle 1 and needle hole 2 in the throat plate and fix the needle

bar with setscrew 3 in the needle bar bracket.

™ When the height of the needle is

excessively different, stitch skipping,

needle breakage, thread breakage,

etc. will be caused.

Equal

1

2

A

4

3

Page 28

–25 –

Standard Adjustment

(10) Locus and longitudinal motion of the looper

1. Standard longitudinal motion of the looper

(1) It is the standard that the top end of left needle touches the position of 1/4 to 1/3 from the bottom face of the back

of the looper when the looper returns from the extreme left position.

(2) The position where the engraved marker line on looper drive arm 2 aligns with the center of the shaft of pin is the

standard.

2. Locus of the looper

It is the standard locus of the looper that the

clearance between the top end of looper and

middle needle is within 0.05mm (when the rear

needle guard fails to work) and the looper

passes the left needle with a clearance of 0.1

to 0.2 mm.

The standard position of the cam is the position

where the notch of looper longitudinal motion

eccentric cam 4 aligns with notches 5 of

looper driving shaft.

0.1 to 0.2 mm

2.5 to 2.7mm

Lower pulley side

4

5

6

2

3

+

–

1

1/4 to 1/3

Page 29

–26 –

Standard Adjustment Results of lmproper Adjustment

1. Changing the longitudinal motion of the looper

(1) Remove 11 setscrews in bed top cover 1 and remove the cover.

(2) When increasing the longitudinal motion of the looper, loosen nut

3 and lower the arm downward (+). from the engraved marker

line.

(3) When decreasing the longitudinal motion of the looper, loosen nut

3 raise the arm upward (-) from the engraved marker line.

Perform the adjustment in accordance with the needle used.

(Caution) After adjusting the longitudinal motion of the looper, move

the looper holder and re-adjust the longitudinal position

of the needle and the looper. (Refer to "(8) Returning

amount of the looper.)

2. Changing the locus of the looper

(1) Loosen two setscrews 6 in the cam and change the locus of the

looper by turning the upper pulley with the cam fixed.

When it is turned in the direction of rotation, the timing is retarded,

and when turning in the reverse direction of rotation, the timing is

advanced.

(Caution) 1. It i s possible to change the locus of the looper.

However, do not excessively change it from the standard

position.

2. When changing the locus of the looper, be sure to check

whether the top end of left needle touches the position

of 1/4 to 1/3 from the bottom face of the back of the looper.

™ When the longitudinal motion of the

looper is small, the rate that needle

touches the back of the looper is

increased and blunt needle tip will be

caused.

™ When the longitudinal motion of the

looper is large, the clearance provided

between the needle and the back of

the looper is increased and stitch

skipping at the time of returning of the

looper will be caused.

™When the timing is retarded, stitch

skipping is apt to occur at the time of

going of the looper, and especially the

clearance provided between the

looper and the left needle is widened.

Needle strongly touches the back of

the looper and blunt needle tip will be

caused.

™When the timing is advanced, stitch

skipping is apt to occur at the time of

returning of the looper.

Chain-off thread does not come out

smoothly.

™ When removing the top cover for

adjustment or the like, sealant is

peeled off. As a reult, oil leakage will

be caused.

Page 30

–27 –

Standard Adjustment

(11) Adjusting the needle guard

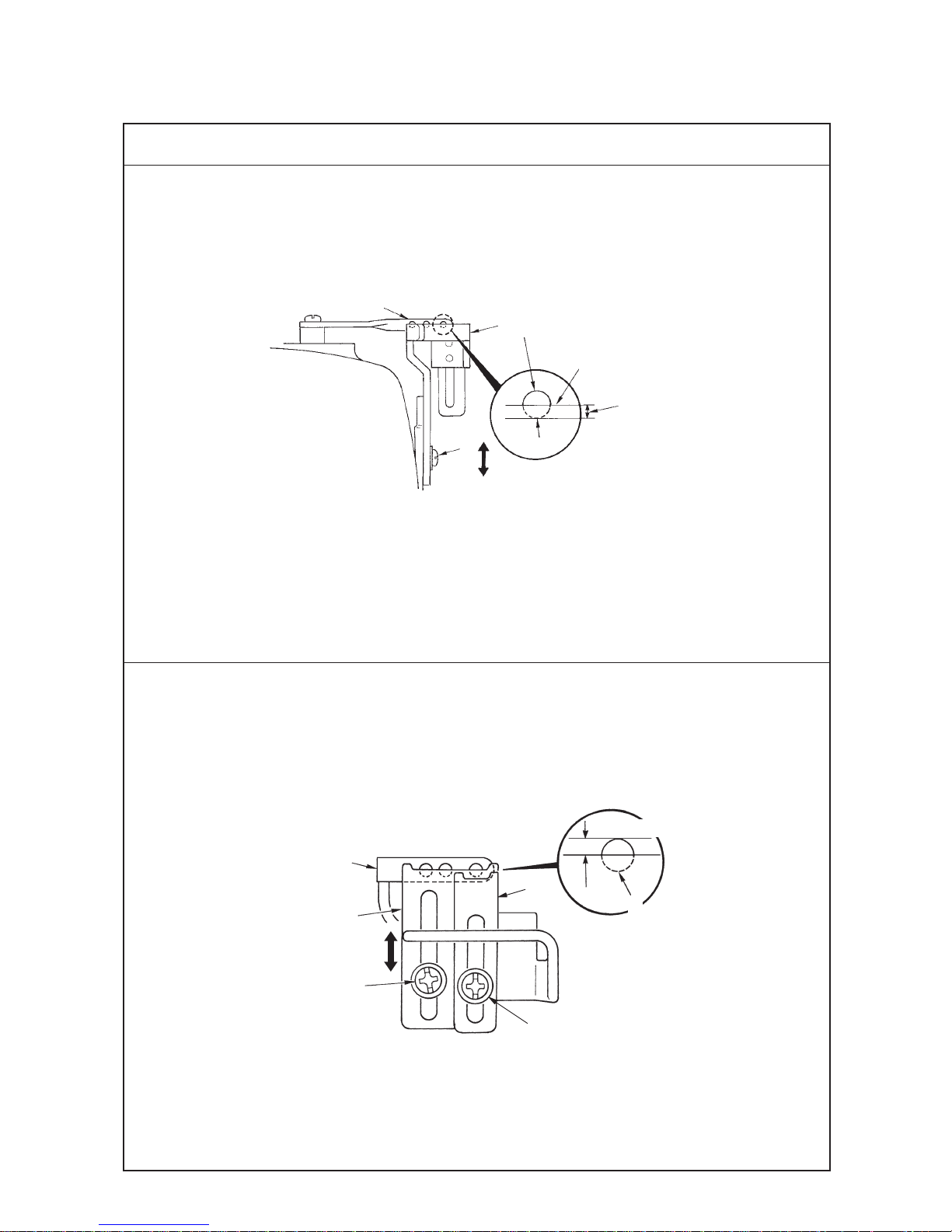

1. Standard position of the rear needle guard

(1) Lateral position of rear needle guard 1

It is the standard that the lateral position of rear needle guard 1 is the position where the rear needle guard

receives the needle in the range of B.

(2) Position of the height of the rear needle guard

It is the standard that ridge line A of rear needle guard 1 enters in the needle eyelet of right needle when the

needle bar is in its lower dead position.

(3) Pressing amount of the rear needle guard

When the top end of looper 3 comes from the extreme right position to the center of right needle, the clearance

provided between the needle and the top end of looper 3 becomes 0 to 0.05 mm. Make rear needle guard 1

lightly touch the right needle and the pressing amount of the top end of needle becomes 0.1 to 0.2 mm.

It is the standard for the middle needle that when the top end of looper 3 comes to the center of middle needle, the

clearance provided between the middle needle and the top end of looper becomes 0 to 0.05 mm and the pressing

amount of the top end of the needle is such an amount that rear needle guard 1 lightly touches the middle needle.

3

1

1

0 to 0.05 mm

0 to

0.05 mm

0.1 to 0.2 mm

1

2

A

B

Details of section A

Ridge line

Needle eyelet

Page 31

–28 –

Standard Adjustment Results of lmproper Adjustment

1. Loosen setscrew 4 in the rear needle guard holder and perform

the adjustment in the lateral direction.

2. Loosen setscrew 2 in the rear needle guard and perform adjustment

in the height direction and the direction of rotation.

3. After the adjustment, tighten setscrews 2 and 4.

(Caution) After the adjustment, check by manual turning whether

the top end of looper 3 does not come in contact with

the needle.

™ When the pressing amount of rear

needle guard 1 is small, needle

deflection increases and stitch

skipping, thread breakage, needle

breakage and worn-out of the top end

of looper 3 will be caused.

4

2

Page 32

–29 –

Standard Adjustment

(4) Timing of the rear needle guard

The standard position of rear needle guard cam 5 is the position where timing mark 7 in rear needle guard cam

5 aligns with the center of the notch of looper longitudinal cam 6.

2. Front needle guard

(1) It is the standard that the clearance provided between front needle guard 9 and the needle is 0.1 to 0.3 mm.

5

7

6

To align

(11) Adjusting the needle guard

0.1 to 0.3 mm

3

9

!0

Page 33

–30 –

Standard Adjustment Results of lmproper Adjustment

4. Remove the bed top cover.

Loosen two setscrews 8 in rear needle guard cam 5 and adjust

the timing.

When moving the cam in + direction, timing is advanced, and when

moving in – direction, it is retarded.

2. Loosen setscrew !0 in the front needle guard and adjust the

clearance.

Adjust so that the clearance provided between the needle and front

needle guard 9 is 0.1 to 0.3 mm when looper 3 moves from the

extreme right position to the left and passes the rear side of the

respective needles and fix the front needle guard with setscrew !0.

* Place front needle guard 9 as near as the needle to such an extent

that needle thread passes smoothly in accordance with kind and

thickness of thread.

Pulley side

™ The cam is excessively changed from

the standard position, needle

breakage or stitch skipping will be

caused.

™ When the front needle guard and the

needle come excessively near, stitch

skipping or needle breakage will be

caused.

8

(Caution) Check by manual turning whether the needle is pinched

with front needle guard 9 and the rear needle guard.

–

+

3

9

!0

Page 34

–31 –

Standard Adjustment

(12) Instlling cover of the looper and needle guard after adjusting

1. Installing bed top cover 1

1

A

Page 35

–32 –

Standard Adjustment Results of lmproper Adjustment

1. When the adjustment of (10) Locus and longitudinal motion of the

looper or (11) Adjusting the needle guard has been performed, apply

sealant to section A and install bed top cover 1

™ When removing bed top cover 1 for

adjustment or the like, sealant is

peeled off and oil leakage will be

caused.

Page 36

–33 –

Standard Adjustment

(13) Adjusting the feed dog

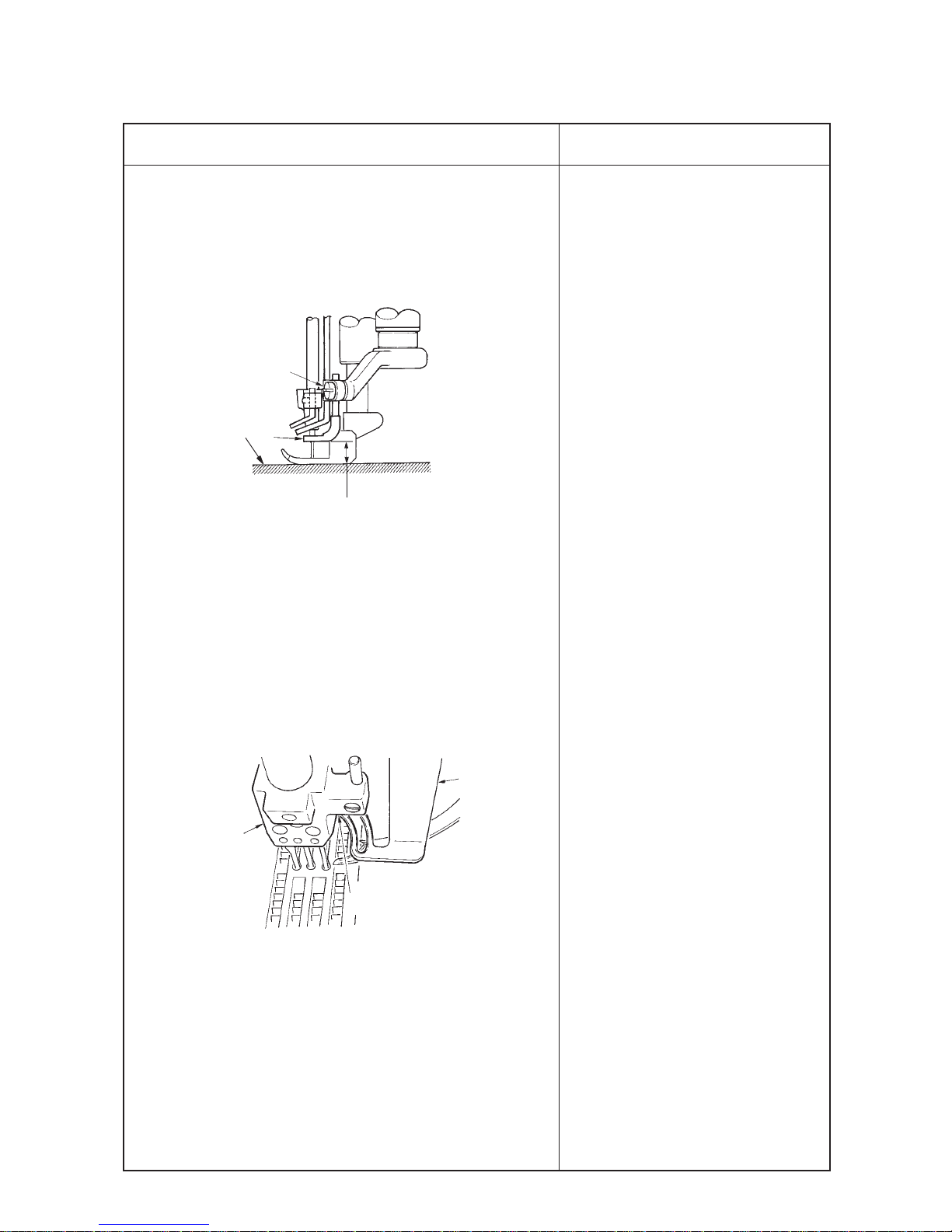

1. Height of the feed dog

It is the standard that the height of feed dogs (main feed dog 2 and differential feed dog 4) is 1 mm from the top

surface of the throat plate 1 when feed dogs 2 and 4 are in the highest position.

2. Tilt of the feed dog

It is the standard that the tilt of feed dogs 2 and 4 is flush with throat plate 1 when feed dogs 2 and 4 are in the

highest position.

7

3

8

9

Flush

1mm

2

56

1

4

Page 37

–34 –

Standard Adjustment Results of lmproper Adjustment

1. Loosen setscrew 7 in the differential feed dog and setscrew 3 in

the main feed dog, and adjust the height.

(1) Adjust the top surface of throat plate 1 and the height of the rear

end of main feed dog 2 to 1 mm when feed dogs 2 and 4 come

to the highest position, and fix the main feed dog with setscrew 3

in the main feed dog.

(2) Fot the height of differential feed dog 4, adjust the height of front

end 5 of main feed dog 2 and rear end 6 of differential feed dog

4, and fix the differential feed dog with setscrew 7 in the differential

feed dog.

2. Adjusting the tilt of the feed dog

(1) Remove rubber plug 8 in the cover located in the rear of the bed

and loosen the setscrew in the feed tilt adjustment shaft located in

the rear with a hexagonal wrench key of 2.5 mm.

(2) When turning feed dog tilt adjustment shaft 9 to the right or left,

the top ends of feed dogs 2 and 4 move up or down and the tilt of

feed dogs 2 and 4 can be adjusted.

(Caution) After the adjustment check the height of feed dogs 2

and 4.

™ When the position of the feed dog is

high, stitch skipping, defective chainoff, return of feed, etc. will be caused.

Throat plate comes in contact with

feed dod and damage of components

or abnormal noise will be caused.

™ When the position of the feed dog is

low, the stitch length becomes short

when the sewing is finished and

performance of getting over the

overlapped section is deteriorated.

™ When the position of the feed dog is

excessively low, looper and feed dog

may come in contact with each other.

™ When the tilt of the feed dog is raised

toward you, performance of catching

material is improved.

™ When the tilt of the feed dog is lowered

toward you, it is effective in irregular

stitches and puckering.

Page 38

–35 –

Standard Adjustment

(13) Adjusting the feed dog

3. Lateral position of the feed dog

It is the standard of the lateral position of the feed dog that the left and right clearances A of the feed dog in terms

of the slots of the throat plate are parallel and equal.

!1

!0

A

A

@1

@0@2@3

!7

!4

!6 !3

!2

!8

!5

!9

@4

@5

@6

Page 39

–36 –

Standard Adjustment Results of lmproper Adjustment

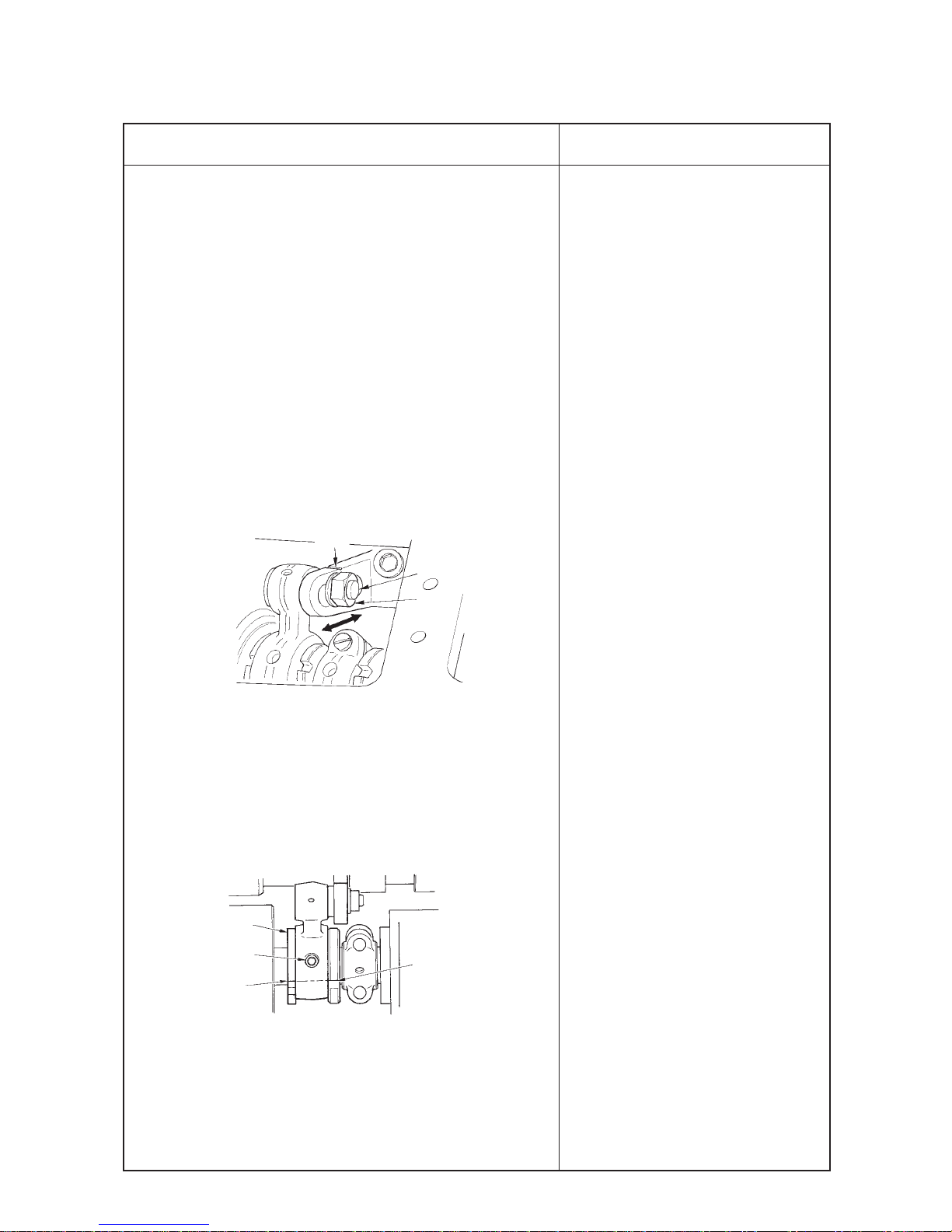

3. Adjusting the lateral position of the feed dog

(1) Remove the bed top cover and remove setscrews !1 in rocking bar

guide 2 !0.

(Caution) When setting the feed motion amount to 3.6 mm (max.)

and the differential feed ratio to 1 : 1 before the

adjustment, the adjustment at the time of assembling can

be performed with ease.

(2) Loosen setscrew !2 in the feed tilt adjustment shaft and setscrew

!3 in the feed tilt eccentric shaft !4. Move feed tilt eccentric shaft by

approximatelt 2mm in the left direction shaft, move feed tilt

adjustment shaft !5 by approximately 2mm in the right direction,

and open a clearance to the right and left of square block !6.

(Caution) When moving feed tilt eccentric shaft !4, lower downward

differential lever pin !7 with differential feed ratio change

lever @6. Edge of feed tilt eccentric shaft !4 comes in contact

with the pin and a clearance can not be made.

(3) When loosening setscrew !8 in the differential feed lever and

setscrew !9 in the main feed lever, adjustment of the rocking bar in

the lateral direction can be performed.

(4) Loosen setscrew @1 in rocking bar guide 1 @0 and adjust main feed

rocking bar @2 and differential feed rocking bar @3 to the right and

left so that the clearances of the feed dog in terms of the slots of

the throat plate are parallel and equal with feed dog and throat

plate attached. When the equal clearances are set, tighten setscrew

@1 to fix rocking bar guide 1 @0, attach rocking bar guide 2 !0 and

guide setscrews !1, and fix the rocking bar so that it is put between

the setscrews.

(5) Bring feed tilt adjustment shaft !5 and feed tilt eccentric shaft !4 to

their home positions to get rid of the right and left clearances of

square block !6.

(6) After adjusting the lateral position of the feed dog, loosen setscrew

@5 in the thrust collar, remove the thrust of the shaft with thrust

collar @4 and fix the thrust collar with the setscrew.

(Caution) 1. After fixing, check the lateral play of the rocking bar

by moving the feed dog to the right or left. At the same

time, move the rocking bar to and fro and check

whether it moves smoothly.

2. For the fixing of setscrew !8 in the differential feed

lever and setscrew !9 in the main feed lever, refer to

the longitudinal adjustment value of the feed dog.

3. When fixing setscrew !2 in the feed tilt adjustment

shaft, check the tilt of the feed dog and when fixing

setscrew !3 in the feed tilt eccentric shaft, there

should be no lateral play of square block !6.

™ When the lateral position of the feed

dog is incorrect, worn-out of throat

plate and feed dog will be caused.

™ Heating or abnormal noise will occur.

™ The feed components will wear out

early, or the looseness will be caused.

Page 40

–37 –

Standard Adjustment

4. Longitudinal position of the feed dog

(1) Position of the main feed dog : it is the standard that the position where the clearance from the edge of the slot of

the throat plate to the front face of the main feed dog is 0.6±0.2 mm at the position where the main feed dog travels

to the extreme front position (operator’s side) when feed momentum is set to 3.6 mm (maximum).

(2) Position of the differential feed dog : it is the standard that the position where the clearance provided between

main feed dog and differential feed dog is 1.6±0.2 mm when the differential feed ratio is set to 1 : 1 after adjusting

the position of the main feed dog.

(13) Adjusting the feed dog

1.6±0.2mm

0.6±0.2mm

!9

!8

Page 41

–38 –

Standard Adjustment Results of lmproper Adjustment

4. Longitudinal position of the feed dog (condition : feed momentum

3.6 mm (maximum))

(1) When fixing setscrew !9 in the main feed lever, adjust the clearance

from the edge of the slot of the throat plate to the front face of the

main feed dog to 0.6±0.2 mm when the feed dog travels to the

extreme front position (operator’s side), press the main feed lever

to the rocking bar side, and fix it with setscrew.

(2) When fixing setscrew !8 in the differential feed lever, set the

differential feed ratio to 1 : 1, adjust the clearance provided between

the main feed dog and the differential feed dog to 1.6±0.2 mm,

press the differential feed lever to the rocing bar side, and fix it with

setscrew.

(Caution) When the adjustment value changes greatly, feed dog or

throat plate will be broken.

™ When the fixing position of the

main feed lever slips greayly out

of position, abnormal noise or

abrasion will be caused.

™ When the fixing position of the

differential feed lever slips greatly

out of position, abnormal noise or

abrasion will be caused.

Page 42

–39 –

Standard Adjustment

(14) Adjusting the feed relation

1. Changing the stitch length

It is possible for the standard stitch length to adjust up to 1.2 to 3.6 mm.

Turning feed adjust knob 1 clockwise increases the stitch length and turning it counterclockwise decreases the

stitch length.

2. Changing the differential feed ratio

Differential feed ratio is 1 : 0.7 to 1 : 2 (stitch length : less than 2.5 mm).

1

2

32

3

1

Gathering

Stretching

6

4

7

5

Page 43

–40 –

Standard Adjustment Results of lmproper Adjustment

1. When making the stitch length more than 3.6 mm, loosen setscrew

2 of the feed adjustment stopper pin, turn feed adjust knob 1

clockwise, and adjust the stitch length. By turning feed adjust knob

1, pin 3 is pushed out. Fix pin 3 with setscrew 2 in the feed

adjustment stopper pin after adjudting the stitch length.

Maximum stitch length is 4.4 mm.

2. Loosen lock nut 4 and raise release lever 5 to increase the

differential feed ratio, and lower it to decrease the differential feed

ration.

Fine adjustment of the differential feed ratio can be performed with

micro-adjust knob 6.

When engraved marker 7 of the differential feed lever is aligned

with the long engraved marker line on the dial plate, the momentum

of the main feed dog and the differential feed dog becomes almost

1 : 1.

™ When the stitch length is set to more

than 3.6 mm, the contact of main feed

dog, differential feed dog and throat

plate occurs due to the adjustment in

case of the standard position of the

feed dog. Additionally machine the

feed dog to satisfy the need.

™ When using the machine with the

stitch length of more than 2.5 mm and

the maximum differential feed ratio,

turn the machine by hand and check

whether there is any contact with feed

dog and throat plate.

In addition, when more gathering is

necessary, grind the differential feed

dog.

Page 44

–41 –

Standard Adjustment

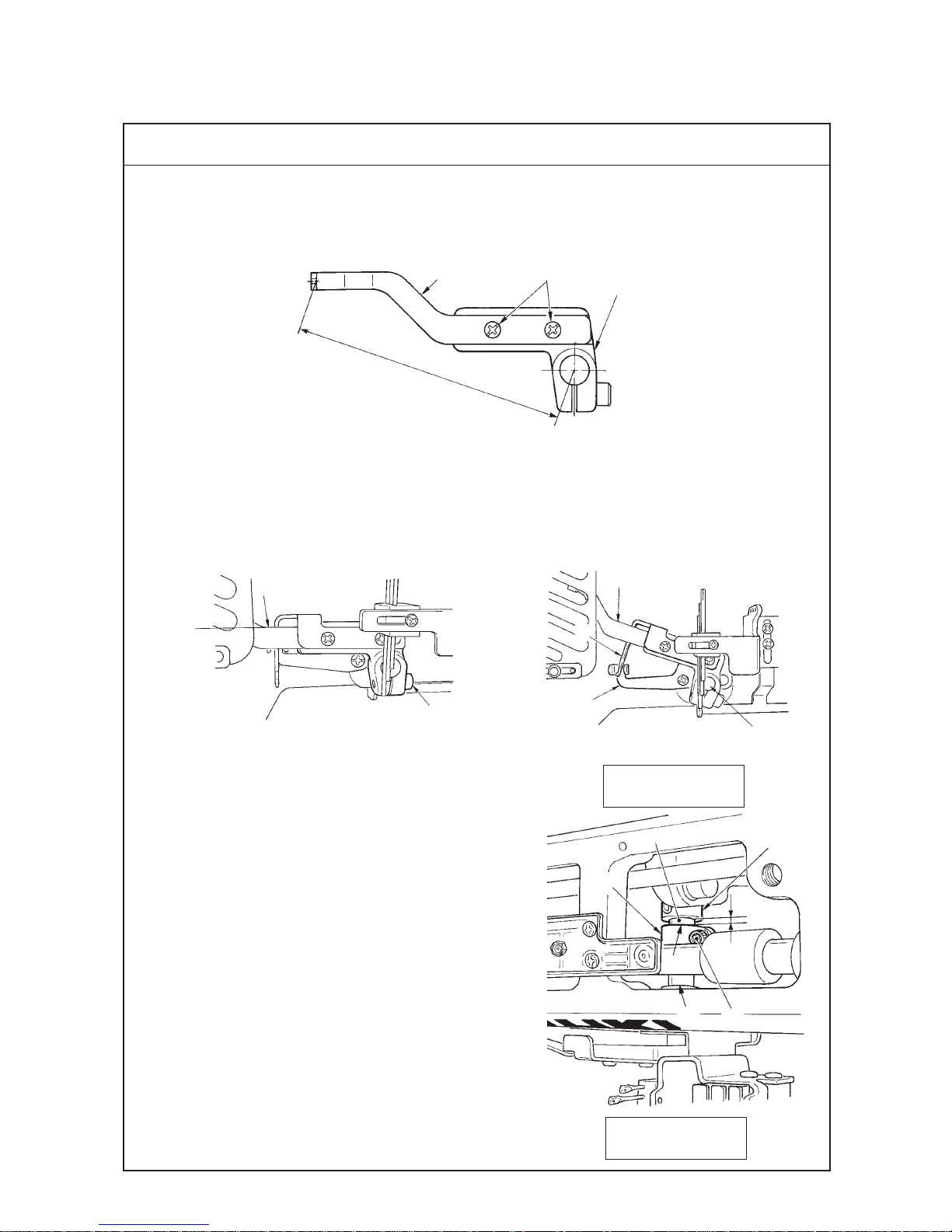

(15) Adjusting the presser foot

1. Height of the presser foot

Height of the presser foot has to be the position the presser foot does not come in contact with other components

at the position where lifter lever 1 is lowered and comes in contact with height adjustment screw 3.

1

2

3

Dimension A

8 mm in case of needle gauge 5.6 mm without top covering

5 mm in case of needle gauge 5.6 mm with top covering

2. Position of the thrust collar

(1) Clearance provided between thrust collar 5 and presser shaft bushing 4 is 0.1 mm at the position where lifter

lever 1 is lowered and comes in contact with height adjustment screw 3.

3. Position of the lifter connecting plate

(1) Adjust the clearance provided between lifter connecting plate 6 and hinge screw 7 to 0.5 mm when the presser

foot is lowered in the state that the feed dog comes down below the throat plate.

(2) Adjust so that the needle enters in the center of needle entry of the presser foot and fix the presser foot with

setscrew 8 in the presser bracket.

7

6

0.5mm

0.1mm

A

4

5

8

9

Throat plate

Center of needle entry

Page 45

–42 –

Standard Adjustment Results of lmproper Adjustment

1. Adjusting the height of the presser foot

Loosen adjustment nut 2. Lower lifter lever 1, adjust height

adjustment screw 3, and fix nut 2 at the position where the presser

foot does not come in contact with other components.

2. Adjusting the thrust collar

Loosen setscrew 9 in the thrust collar and adjust the clearance.

When the height of the presser foot is changed, Be sure to perform

the adjustment of the clearance of thrust collar 5 and check the

clearance.

3. Adjusting the lifter connecting plate

For the adjustment of the clearance provided between lifter

connecting plate 6 and hinge screw 7, loosen setscrew !0 in the

liftrer lever shaft when the feed dog lowers from the top surface of

the throat plate and the bottom face of the presser foot comes in

close contact with the throat plate.

™ When the position of the presser foot

is too high, it comes in contact with

the spreader, and breakage, stitch

skipping, etc. will be caused.

In addition, the needle tip comes out

from the sole of the presser foot. As a

result, sewing material is damaged or

needle breakage will be caused.

™ In case the clearance of thrust collar

5 is large, when the presser foot gets

over the overlapped section, the

presser foot comes in contact with

other components and will cause the

damage.

™ When replacing the presser foot due

to the replacement of the gauge or the

like, check the clearance provided

between thrust collar 5 and lifter

connecting plate 6.

™ When the clearance of lifter

connecting plate 6 does not exist, not

only feed force is reduced but also

components are led to breakage since

the presser foot does not come down

to the top surface of the throat plate

when the feed dog comes down from

the top surface of the throat plate.

™ When adjusting the lever shaft, adjust

the height of lifter lever 1.

!0

Page 46

–43 –

Standard Adjustment

(16) Adjusting the micro-lifter

1. Micro-lifter

Adjust the micro-lifter in accordance with sewing conditions for use.

Major applicable process

1. When twist occurs in the hemming bottom process.

2. When tape is twisted in collarette.

3

2

1

Down

Up

Page 47

–44 –

Standard Adjustment Results of lmproper Adjustment

1. Adjusting the micro-lifter

(1) When micro-lifter knob 1 is turned counterclockwise, micro-lifter

stopper 2 lowere and comes in contact with presser lifting lever 3.

Then the pressr foot goes up.

Adjust the height accordance with the sewing conditions.

(2) When micro-lifter knob 1 is turned clockwise, micro-lifter stopper

2 is raisedand comes in contact with presser lifting lever 3. Then

the presser foot comes down.

(Caution) When the micro-lifter is not used, turn clockwise mocro-

lifter knob 1 and fix micro-lifter stopper 2 at the highest

position.

Page 48

–45 –

Standard Adjustment

(17) Adjusting the looper thread cam

1. Adjust so that thread comes off from the highest place of looper thread cam 2 when needles come down and the

top end of left needle 3 aligns with the bottom surface of looper 4. Then tighten setscrews 1 to fix the looper

thread cam.

2. Preventing thread winding around the looper thread cam

Adjust the clearance provided between the top end of section A of looper thread winding prevention plate 5 and

the edge of looper thread cam 2 to approximately 0 to 0.3 mm (the plate should not come in contact with looper

thread cam 2).

Theread

3

4

2

1

To align

7

6

5

5

2

A

Page 49

–46 –

Standard Adjustment Results of lmproper Adjustment

1. Loosen setscrews 1 in the looper thread cam 2 and adjust while

checking that looper thread comes off from the periphery of the

looper thread cam.

(Caution) When setscrews 1 in the looper thread cam are loosened,

looper thread cam 2 moves in the shaft direction as well.

Assemble so that the clearances provided between the

cam and the thread guide are equal.

2. Adjusting the looper thread winding prevention plate

Adjust the clearance provided between the top end of section A of

looper thread winding prevention plate 5 and the edge of looper

thread cam 2 to approximately 0 to 0.3 mm (looper thread winding

prevention plate 5 has a slot at the section of setscrew 6 and

moves as if it rotates making setscrew 7 as the center), and tighten

setscrews 6 and 7 to fix the looper thread winding prevention

plate.

™ When the position of looper thread

cam 2 slips greatly out of position,

stitch skipping or defect of thread

tightness on the back of the looper 4

is apt to occur.

™ It is effective to adjust as narrow as

possible the clearance provided

between the top end of click section

(section A) of looper thread winding

prevention plate 5 and the edge of

looper thread cam 2. However, when

making them come too near and come

in contact with each other, looper

thread cam 2 is scratched and

winding is caused by this adjustmrent,

instead.

Equal clearances

Page 50

–47 –

Standard Adjustment

1. Changing the needle bar stroke (31 mm 33 mm)

Needle bar stroke is 31 mm in the state that notch mark 4 on the edge of the eccentric pin 5 is located on the side

of the center of main shaft (standard delivery adjustment).

At the time of 31 mm

(18) How to change needle bar stroke

Draw out by more than 1 mm.

7

6

At the time of 31 mm

4

6

5

At the time of 33 mm

5

/

Page 51

–48 –

Standard Adjustment Results of lmproper Adjustment

1. Changing the needle bar stroke

(1) Loosen setscrew 6 (remove the rubber plug) in eccentric pin 5.

(2) Draw out eccentric pin 5 by more than 1 mm, turn eccentric pin 5

by 180fl, position notch mark 4 of the eccentric pin away from the

center of main shaft, push the pin, and fix the pin with setscrew 6.

* Position of the notch mark of eccentric pin

At the time of needle bar stroke 31 mm : notch mark is on the side

of the center of main shaft.

At the time of needle bar stroke 33 mm : notch mark is on the side

away from the center of main shaft.

(Caution) There is a groove to fit, when eccentric pin 5 is turned

by 180˚, at the fitting section of eccentric pin 5 and

counter weight 7. After the change, check that the pin

has completely entered the groove. At the same time,

check whether eccentric pin 5 has completely entered

up to the end.

When the pin is excessively pressed, abnormal noise or

worn-up will be caused.

™ In case of the thick materials, the

stroke is changed. However, basically,

use the machine with the standard

stroke.

™ When the needle bar stroke is

increased, needle heat or sewing

trouble mat occur.

™ When the needle bar stroke is

increased, reduse the sewing speed

for use.

Good result is obtained from the

viewpoint of durability.

6

Page 52

–49 –

Standard Adjustment

(18) How to change Needle bar stroke

2. Adjusting the height of the needle bar

When the needle bar stroke is changed, be sure to adjust the height of the needle bar.

1) Adjust clearances C provided between needles 8 and needle holes 9 in the throat plate to equal.

2) Adjust the height of the needle bar so that the top end of the needle eyelet of left needle aligns with the bottom end

pf the looper when the looper moves from the extreme right position to the left and top end D of looper 3 protrudes

by approximately 1 mm from the left end of left needle, remove rubber cap !1 in the face plate, and tighten the

needle bar with setscrew !0 in the needle bar bracket.

Reference : When the needle is in the highest position, height E from top surface A of the throat plate to the top end

of left needle is as shown in the table below.

3. Adjusting the needle guard

A

E

!0

!1

D

3

9

8

C

Unit : mm

2-needle 3-needle

Needle gauge Height of left needle E Needle gauge Height of left needle E

3.2 11.1 – –

4.0 10.7 – –

4.8 10.2 4.8 10.2

5.6 9.9 5.6 9.9

6.4 8.8 6.4 8.8

3

1

1

0 to

0.05 mm

0.1 to 0.2 mm

0 to

0.05 mm

2

B

A

1

Ridge line

Details of section A

Needle eyelet

Page 53

–50 –

Standard Adjustment Results of lmproper Adjustment

(1) Loosen setscrew !0 in the needle bar bracket and adjust the height

of the needle bar.

(2) After adjusting the height of the needle bar, adjust clearances C

provided between needles 8 and needle holes 9 in the throat

plate to equal and fix the needle bar with setscrew !0.

* Refer to 5.- (9) Height of the needle.

1. Standard position of the rear needle guard

It is the standard that the lateral position of rear needle guard 1 is

the position where the rear needle guard receives the needle in the

range of B in the illustration.

2. It is the standard that the ridge line of rear needle guard 1 enters

in the eyelet of right needle (section A) when the needle bar is in

the lowest position.

3. When the top end of looper 3 comes from the extreme right position

to the center of right needle, the clearance provided between the

right needle and the top end of looper 3 becomes 0 to 0.05 mm

and the pressing amount of the top end of the needle becomes 0.1

to 0.2 mm.

It is the standard for the middle needle that when the top end of

looper 3 comes to the center of middle needle, the clearance

provided between middle needle and the top end of looper 3

becomes 0 to 0.05 mm and the pressing amount of the top end of

needle is such an amount that the rear needle guard touches the

middle needle.

* For the details, refer to the standard adjustment procedure in 5.-

(11) Adjusting the needle guard.

™ When the position of the height of the

needle bar is excessively different,

stitch skipping, needle breakage,

thread breakage, etc. will be caused.

™ When the adjustment value is

excessively different from the specified

value, needle breakage or stitch

skipping will be caused.

Page 54

–51 –

Standard Adjustment

(19) How to change the spreader

1. Changing the spreader

When the needle bar stroke is changed, be sure to perform the adjustment of (6) -1. the height of the spreader.

(1). Height from the top surface of throat plate 2 to spreader 1 is 10.0 to 10.5 mm.

(2). Clearance provided between spreader 1 and spreader thread guide 2 is 0.4 to 1.0 mm.

(3). Clearance provided between spreader thread guide 3 and needle clamp thread guide 4 is 0.8 to 1.2 mm.

0.8 to 1.2 mm

0.4 to 1.0 mm

10.0 to 10.5 mm

4

3

1

2

Page 55

–52 –

Standard Adjustment Results of lmproper Adjustment

1. Refer to (6) Adjusting the spreader.

Page 56

–53 –

Standard Adjustment

(20) With reagard to lubrication

1. Replacing the oil filter

Normal lubrication cannot be performed if dust collects in

oil filter 1.

Inspect it evry 6 months.

2. Oil circulation identification window

Make sure that lubricating oil rises to oil circulation

identification window 3 during operation.

<When using the sewing machine for the first time>

Lubricating oil has been taken out at the time of delivery.Be

sure to supply lubricating oil before using the sewing machine

for the first time.

• Oil used : JUKI MACHINE OIL 18

(Caution) Do not use oil addition agent sinse deterioration

of lubricating oil or machine trouble will be caused.

Remove oil hole cap !1 on which “OIL” is indicated and fill

the oil reservoir with lubricating oil up to the level between

the upper and lower engraved marker lines of oil gauge !0.

<Checking before using the sewing machine>

1) Check oil gauge !0 and make sure that lubricating oil level

is between the upper and lower two lines. When lubricating

oil level lowers below the lower line, supply lubricating oil.

2) Make sure that lubricating oil comes out from the nozzle of

oil circulation identification window 4 when rotating the

sewing machine. When lubricating oil does not come

out,perform “Inspecting and replacing the oil filter 1”.

6

5

6

2

1

3

!0

!1

4

Lubrication

Page 57

–54 –

Standard Adjustment Results of lmproper Adjustment

1. Inspection and replacement

Loosen setscrews 3 in the oil filter cap and remove oil filter cap 2.

Draw out oil filter 1 to inspect it. When it is clogged with dust,

replace it with a new one.

After the replacement, fix oil filter cap 2 with setscrews 1 in the oil

filter cap.

(Caution) When removing the oil filter cap 2, lubricating oil

collected in oil filter 1 will leak out. So, be careful.

2. Oil circulation identification

(1) In case the oil does not come out from oil circulation identification

window 4 even when oil filter 1 is replaced with a new one, remove

six setscrews 6 in the oil pan, remove oil pan 5, and tilt the machine

head to the rear up to the position where pipe connecting joint screw

9 can be removed.

(2) Oil sucked up from gear pump 7 passes oil pipe 8 and enters oil filter 1

from pipe connecting joint screw 9. When the lubricatin oil does not rise

to oil circulation identifacation window 4, The hole in pipe connecting

joint screw 9 may be clogged with dust. So, check it.

(Caution) When there is any foreign material in oil pan 5, remove it.

™ In case oil cannot be observed from

oil circulation identification window 4

even when the sewing speed is 2,500

rpm or over, the machine will be in

danger of seizure if the operation is

continued.

7

9

8

Page 58

–55 –

1. When SC-380 is used, install the motor referring to the Instruction Manual for SC-380.

2. To use SC-380 with MF-7700, it is necessary to set the followings after set-up of SC-380.

(Caution) When MF is selected in case of machine model selection, change the direction of rotation since the

direction of rotation of MF-7700 becomes reverse. In addition, there is the possibility that the pulley

rotates up to the home position at the time of turning ON the power.

™ Change over the setting of SC-380 to MF-7700

(When changing, refer to the Instruction Manual for SC-380 as well)

1

2

3

4

5

* Program mode (2) Model selection

Select MF with

+ [C] + [D], and keep pressing [D] for more than two

seconds to return to the normal mode. (When the thread trimmer is not

installed, proceed to 2 C mode Thread trimmer safety switch release to

release the safety switch since LED.M does not rotate.)

* C mode Thread trimmer safety switch release

(Setting when thread trimmer is not used)

IA S6 is displayed with

+ [C]. Set IA S6 to IA NO.

Screen returns to the normal mode with

+ .

* Prohibition function of J mode direction of rotation changeover

+ .+ A + B CWC ON / OFF

Screen returns to the normal mode with

+ .

* Change of the direction of rotation

Set the direction of rotation to the clockwise rotation with + [M].

* Operating function of P mode when power is turned ON

When 1-position is set :

+ P1P ON / OFF

When 2-position is set :

+ P2P ON / OFF

Screen returns to the normal mode with

+ .

(21) Adjusting and setting SC-380

Page 59

–56 –

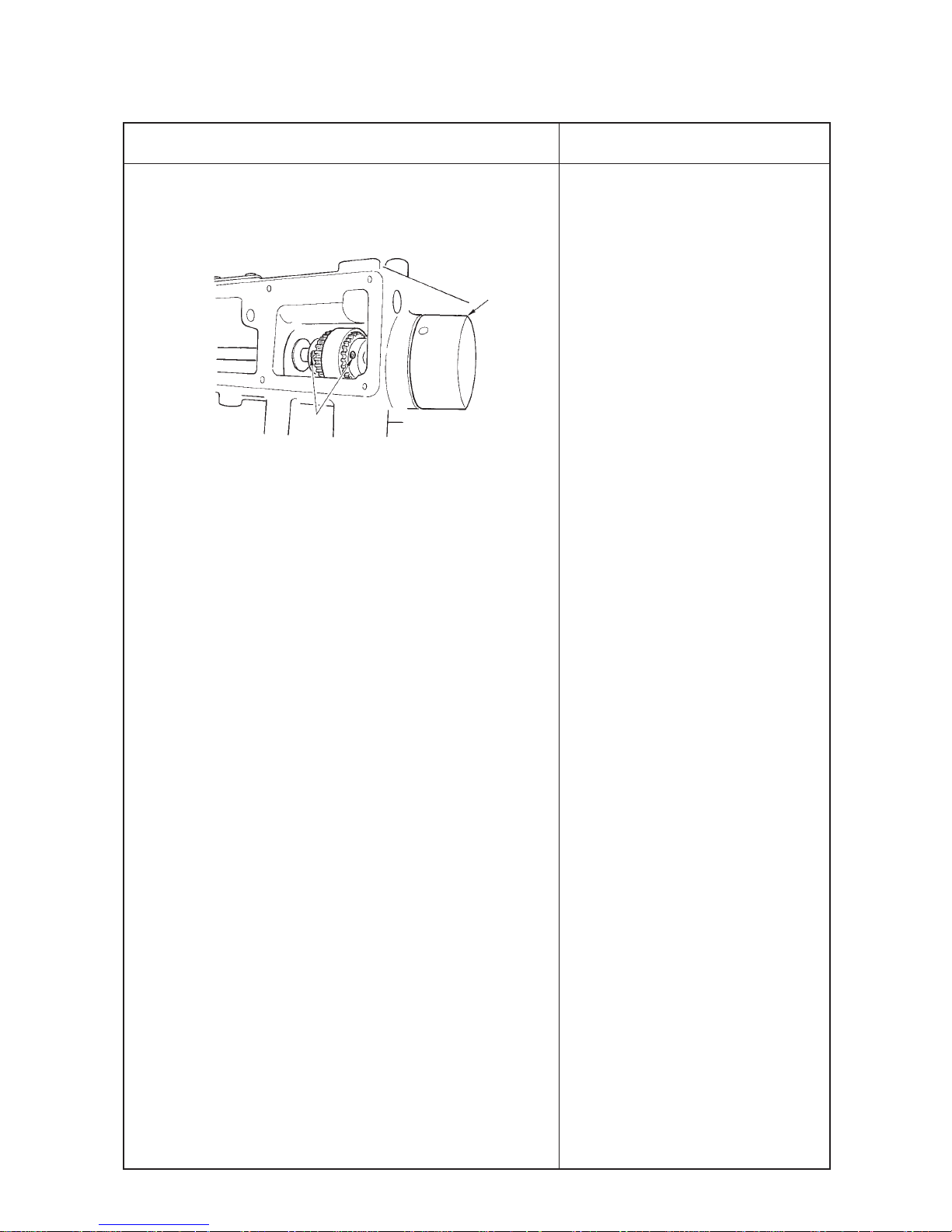

3. Adjusting the position detector of SC-380

1) When using the position detector for MF-7700,

change DOWN position of the needle and adjust

DOWN position of the position detector so that the

needle stops after the top end of looper B has

scooped left needle thread A as shown in the figure.

4. Adjusting procedure

In the state that the position detector is actually

installed on the sewing machine, adjust the stopping

position.

1) Temporarily install detector 1 onto the lower pulley

with setscrews 2.

2) Wind the ground wire (green/yellow) around the cord

of detector 1, connect the ground wire to the ground

mark in the rear of the sewing machine head, and fix

the cord of the detector at the position in the figure

with cord clamp 6 and setscrew 7 supplied with the

machine.

3) Connect the connector of detector 1 to the connector

of detector of SC-380 control box. Turn ON the power,

set the sewing machine controller to 1 position setting

(needle UP position stop) and lightly depress the pedal

to operate the sewing machine by 2 to 3 stitches. Then

turn OFF the power at the position where the sewing

machine has stopped. Loosen setscrews 2 in detector

1, turn the upper pulley with joint 4 fixed, and adjust

the stopping position.

Fix detector 1 with setscrews 2.

4) Remove the cover of detector 1 and adjust the red

mark ▼ 5 on the outside of DOWN position detector

plate 3 to 11 to 12 of the scale (inside DOWN position

detector plate).

5) After adjustment of stopping position, replace the cover

of detector 1.

6) Turn ON the power again, and set the sewing machine

controller to 2 position setting.

B

A

1

2

4

6

7

5

13

Page 60

– 57 –

6. TROUBLES AND CORRECTIVE MEASURES

Troubles Cause (1) Cause (2) Corrective measures

1. Thread breakage

2. Looper thread breakage

Refer to threading diagram.

Remove the flaw, burr etc. and process the thread guide

finish. However, replace such important parts as looper or

throat plate etc. with the new part because their shape is

changed by being processed.

In case needle exchanger, or looper needle guard is worn

out, replace it with the new part.

Replace it with an appropriate needle.

Use thinner needle. Reduce the sewing speed. Use silicon

oil lubricant device.

Replace it with the thread of good quality.

Reduce thread tension. needle thread guide rod is positioned

too high making the thread tension too strong.

Mount it in the correct position.

Remove the flaw, burr etc.

Remove the flaw, burr etc. and process the thread guide

finish. However, replace such parts as looper with the new

part because its shape is changed by being processed.

Refer to the standard adjustment figures.

Reduce the thread tension while checking to see the tension

balance against the needle thread, top covering thread.

1-1) Threading

1-2) Thread path

1-3) Needle guard

1-4) Needle

1-5) Needle heat

1-6) Thread

1-7) Thread tension

1-8) Interference

1-9) Chain-off thread defect

2-1) Thread guide

2-2) Looper thread cam adjustment

2-3) Thread tension

To the next page

1-A) Thread caught in thread guide, Incorrect

threading

2-A) Resistance produced by flaw, burr, rust etc.

around needle entry of throat plate, stitch

tongue, looper, spreader, needle thread takeup auxiliary thread tention adjustment, needle

guide, thread tension disc etc.

3-A) Strong contact of needle against needle

guard produces a sharp edge in needle

guard resulting in thread breakage.

4-A) Too thin needle for the thread used

5-A) Needle is heated depending on fabric

type, number of fabrics, sewing speed

resulting in thread breakage.

6-A) Poor quality and weakness of thread

7-A) Too strong thread tension

8-A) Interference with feed dog, throat plate due

to the incorrect mounting height of looper

9-A) Flaw produced in stitch tongue in throat

plate, feed dog, tongue in presser foot,

underside in presser foot

1-A) Resistance produced by flaw, burr, rust

etc. in stitch tongue in throat plate, looper,

looper thread cam, thread guide, thread

tension disc

2-A) Excessive tension applied due to the

incorrect position of looper thread cam

timing, thread guide

3-A) Too strong tension of looper thread

Page 61

– 58 –

Troubles Cause (1) Cause (2) Corrective measures

From the previous page

3. Needle breakage

4. Worn out needle point

2-4) Thread

2-5) Looper avoid

2-6) Needle heat

3-1) Needle entry

3-2) Spreader

3-3) Interference of looper with

scooping movement of needle

3-4) Needle guard

3-5) Needle thickness No.

3-6) Thread tension

3-7) Feed height, Needle height

4-1) Needle guard

4-2) Interference with looper

4-A) Poor quality and weakness of thread

5-A) Too strong contact of looper back with

needle resulting in thread breakage

6-A) In case needle heat is generated looper