JUKI MF-7700D, MF-7723D-U10-B56, MF-7700D/UT31, MF-7723D-U10-B56/UT33, MF-7700D/UT33 Brochure & Specs

MF-7700D

Series

The advanced dry-head technology

prevents oil stains.

Semi-dry-head, Top and Bottom Coverstitch Machine

DRY-HEAD

TECHNOLOGY

A world-

first

feature

A world-

first

feature

MF-7723D-U10-B56

MF-7700D Series

Semi-dry-head, Flat-bed, Top and Bottom Coverstitch Machine

Semi-dry-head, Flat-bed, Top and Bottom Coverstitch Machine

JUKI's dry-head technology protects

sewing products from being stained with oil.

MF-7700D Series

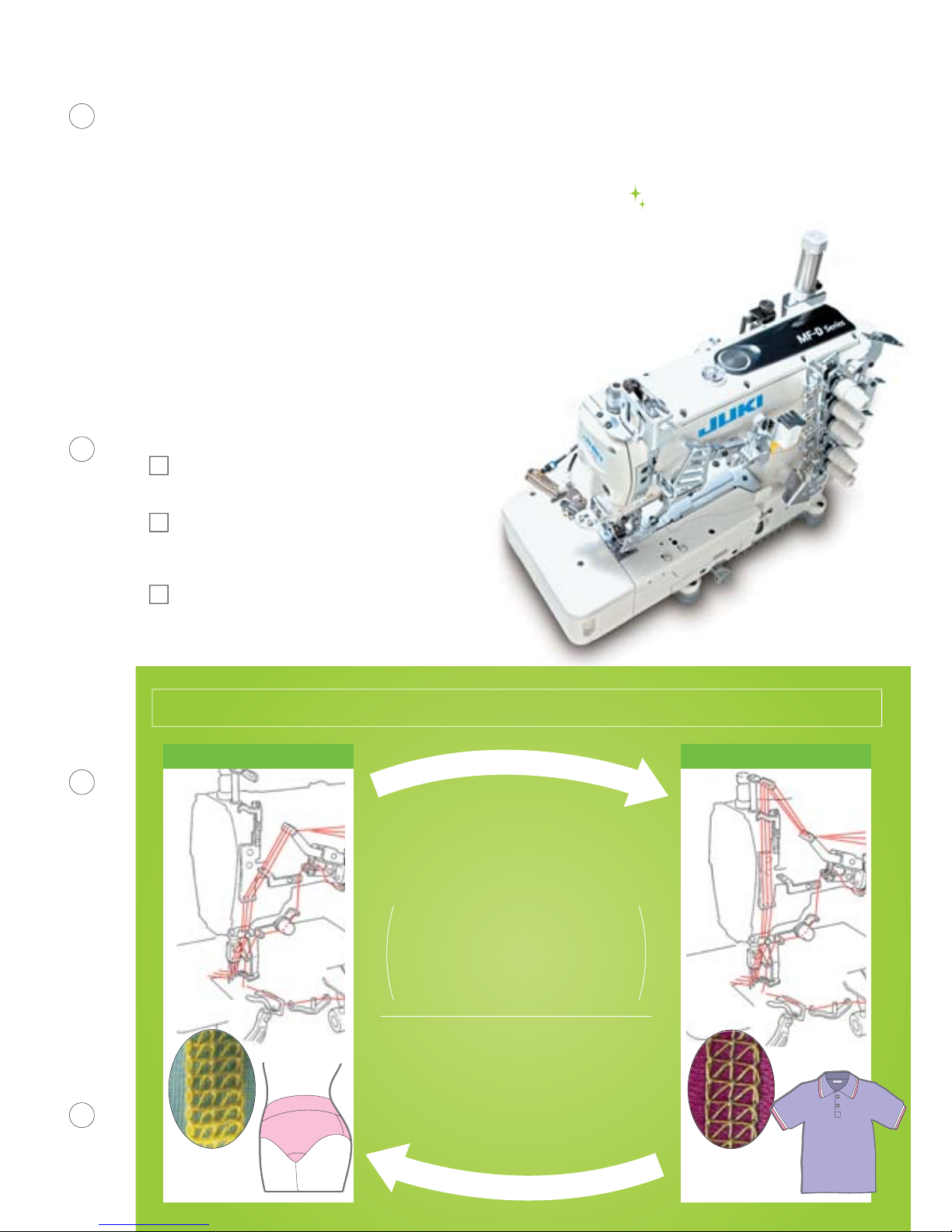

The seam conditions can be changed over

according to the application or material, i.e., soft

and low-tensed seams for inner wear and

high-grade well-tensed seams for outer wear.

By reducing the thread tension, beautifully-finished

seams and satisfactorily-finished body-fitting

products are produced. In addition, the machine

has achieved low-vibration and low-noise

operation, laying importance on comfort of sewing

and ease of handling.

It is possible to select (change over) the stitch type according to sewing items.

MF-7700D

MF-7700D/UT31

MF-7700D/UT33

Semi-dry-head, Flat-bed, Top and Bottom Coverstitch Machine

Semi-dry-head, Flat-bed, Top and Bottom Coverstitch Machine

with Electromagnetic Type Top and Bottom Thread Trimming Device

Semi-dry-head, Flat-bed, Top and Bottom Coverstitch Machine

with Pneumatic Type Top and Bottom Thread Trimming Device

The world's first semi-dry-head top and bottom coverstitch machine has been developed.

With the excellent functions inherited from the MF-7700 Series, the MF-7700D is

provided with a dry frame mechanism to eliminate the cause of oil stains.

Stain removing work or re-sewing work is substantially reduced by

protecting sewing products from being stained with oil,

thereby improving the quality of finished products.

Neither the replacement of parts nor the

changing of thread tension is required.

The stitch type can be changed over

(soft-seams/well-tensed seams) simply by

changing the thread path.

MF-7723D-U10-B56/UT33

Soft-seam Well-tensed seam

Expand

Expand

Expand

Contract

Contr act

Contract

Simplified maintenance mechanism

The machine comes with diverse and trouble-free functions in consideration of the shop-floor.

As a result of the commonality of components,

commercially-available components (presser foot, throat plate

and needle clamp) are now applicable and easily obtainable.

It is possible to finely adjust the differential feed amount to a

best-suited value for the material to be used. In addition, the dif ferential

feed ratio remains the same even when the stitch length is changed.

components are applicable with no additional work

.

Elastic material or delicate

material can be sewn with the

presser foot kept slightly

raised.

This effectively helps reduce

the degree of slippage,

warpage and damage of the

material.

The feed dog inclination can be externally adjusted with ease.

This adjustment mechanism effectively helps improve the

material holding ability of the feed dog and prevent uneven

material feed and puckering.

Micro-lifter mechanis

m

Feed dog inclination adjustment mechanism

Unlike the conventional models, the oiling mechanism inside

the frame has been eliminated. As a result, oil does not leak

from the needle bar, presser bar or spreader shaft.

The needle bar mechanism and spreader mechanism have

been applied with a special surface treatment.

JUKI's unique special grease is used for lubrication.

Grease-filled bearings have been adopted for the crank rod.

These allow the machine's frame mechanism to

demonstrate outstanding durability without being oiled.

Since oil stains on sewing products are reduced, the

quantity of the use of stain remover generally used in sewing

plants can be reduced.

Dichlorofluoroethane (HCFC-141), which is generally used in oil stain cleaning

fluid, is included in those chemicals which need to be reduced, as it is a

substa nces that c an harm th e ozone layer.

Main feed Differential feed

The frame no longer requires oiling.

Dry-head technology has materialized

a frame which does not need oiling.

Environmental consciousness

Differential-feed micro-adjustment mechanism

Smooth feeding

Material

Throat plate

Clamping the material

Direction of feed

The material holding ability is improved

MF-7700D Series

*1Stitch length can be adjusted to 4.4mm at the maximum.

*2The numeric value indicates the lifting amount of the presser foot for top and bottom coverstitch. The numeric value given in parentheses indicates the lifting amount of the presser foot

for bottom coverstitch.

*For the shape of the throat plate, B type is standard.

The D type throat plate allows the needle thread to stretch moderately.

List of subclass machines

List of gauges and knives

Application

Type

Needle gauge

Needle clamp

B

D

Throat plate

*

tongue shape of

throat plate

Presser foot asm

Main feed dog

Differential-feed dog

U10 C10 E10

U10

(4needle)

Seam

U10

Universal type

(basic type)

U10

4-needle

C10

Collarette

attaching

E10

Elastic lace

attaching

Model No.

MF-7722D-U10-B□□

MF-7723D-U10-B□□

MF-7723D-U10-D□□

MF-7723D-U10-B□□ /UT31

MF-7723D-U10-D□□ /UT31

MF-7723D-U10-B□□ /UT33

MF-7723D-U10-D□□ /UT33

MF-7724D-U10-D60

MF-7722D-C10-B□□

MF-7722D-C10-B□□ /TC13

MF-7723D-C10-B□□

MF-7723D-C10-B□□ /TC13

MF-7722D-E10-B□□

MF-7722D-E10-B40/MD10

MF-7722D-E10-B40/MD10/TC13

MF-7723D-E10-B□□

MF-7723D-E10-B□□ /MD10

MF-7723D-E10-B□□ /MD10/TC13

3.2mm

13350004

40058587

40058589

4.0mm

13350103

40058706

40058956

40058708

4.8mm

13350202

40040514

40060923

13376058

5.6mm

13350301

40040515

40040516

40082974

6.4mm

13350400

40040513

40061463

40082974

13353701

13357603

6.0mm

40049609

40049382

40049394

3.2mm

13350004

40058549

40073947

40058579

40058555

40058556

4.0mm

13350103

13351408

40073948

40056504

4.8mm

13350202

40057971

40073949

40057973

5.6mm

13350301

13351606

40073950

40056410

6.4mm

13350400

13351705

40056411

3.2mm

13350004

40058580

40058591

40079714

40058582

4.0mm

13350103

13356001

40018288

40079715

13358106

5.6mm

13350301

13356209

6.4mm

13350400

13356308

40018289

40079716

13358205

40038754

40038091

13353909

13357801

13353800

13357702

13354204

13358304

Number

of

needles

Number

of

threads

Needle

gauge

(mm)

Stitch

length*

1

(mm)

Differential-

feed ratio

Presser lifting

amount*

2

(mm)

Max. sewing

speed

(sti/min)

2

3

4

2

3

2

3

4

5

6

4

5

4

5

3.2,4.0

4.8,5.6,6.4

6.0

3.2,4.0

4.8,5.6,6.4

3.2,4.0

4.0

5.6,6.4

1.2〜3.6

1.2〜2.5

(Max.3.6)

1.2〜3.6

1.2〜3.6

1:0.7〜1:2

1:0.7〜1:2

1:0.7〜1:1.1

1:0.7〜1:1

5(8)

4

5(8)

3(6)

4,000

4,000

4,000

4,000

()

Upper knife

Lower knife

U10

Universal type

(basic type)

Polo shirtsT-shirts

The machine can be used for the hemming process of the sleeves and bottoms of

T-shirts and for the covering process for sportswear and knitwear.

It is not a specific-purpose model, but a basic one which can be used for a broader

range of processes independently.

★C10: Modification to the collarette attaching type model is easily achieved simply

by changing the throat plate and feed dog.

C10

For collarette attaching

BriefsUnderwear

This model is best suited for attaching collarettes on underwear, briefs and knitwear.

Ease of use is further improved by using the electromagnetic type tape cutter (TC13).

E10

Shorts

Ladies'

inner wear

This model is best suited for the sewing of elastic lace in shorts and underwear.

The right hand fabric trimmer cuts the multi-layered part of a joined section with

outstanding consistency.

Beautifully finished products are achieved with the seams and material edges

aligned.

The right hand fabric trimmer mechanism’s easy installation / removal of the entire

unit facilitates the adjustment of related parts, such as the alignment of a looper.

For elastic lace attaching

(with right hand fabric trimmer)

Device

UT31

Compressed air / Air consumption (sewing machine with UT33)

It is an electromagnetic type

automatic thread trimming

device/auto-lifter.

The machine does not need an

air compressor to achieve easy

layout changing.

MF-7723D-U10-B56 / UT31 Electromagnetic type top and bottom

thread trimming mechanism

Presser lifter drive mechanism

Thread trimmer drive mechanism

Presser lifter drive mechanism

Thread trimmer drive mechanism

UT33

It is a pneumatic automatic

thread trimming device /

auto-lifter.

Since the automatic lift of the

presser foot and automatic

thread trimming can be

activated by lightly depressing

the pedal, work efficiency is

dramatically increased.

By using an air blow type wiper nozzle (supplied as an accessor y), the needle

thread can be blown upon thread trimming at the end of bottom coverstitching.

MF-7723D-U10-B56 / UT33

Pneumatic type top and bottom

thread trimming mechanism

Air blow type wiper

TC13 MD10

-

Air blow

type wiper

0.7

182

0.5

Air consumption

dm

3

/min (ANR)

Compressed air

MPa

Electromagnetic type top and bottom thread trimming

device/Auto-lifter

Pneumatic type top and bottom thread trimming device/

Auto-lifter

Electromagnetic type

tape cutter

Mechanical type metering

device

Micro adjustment screw

Micro adjustment screw

Micro adjustment screw

Main adjustment nut

Main adjustment nut

Main adjustment nut

It is a device for cutting the tape or lace at the

beginning or end of sewing. It is easily actuated to

cut tape with the knee switch.

●

The knife is able to cut lace and tape up to

40mm wide.

●

The sharpness of the knife can be easily

adjusted. In addition, replacement of the

moving knife and counter knife, as well as the

adjustment of their mesh, can be carried out

with ease.

TC13 Adjustment of the tape feeding amount

●

The metering device supplies a consistent

length of tape in synchronization with the feed.

(tape lengths: 0.9 to 3.5mm per stitch.)

●

Elastic tapes of up to 80mm in width can be used.

The tape width can be easily adjusted. For lace of

which the width is 15 to 80mm, change the

currently-mounted guide with the wider-tape guide

that is supplied with the unit as an accessory.

●

The drive roller/driven roller can be held open to

facilitate tape placement.

Universal type

Application Code

U10

3.2mm

4.0mm

4.8mm

Needle gauge Code

32

40

48

5.6mm

6.4mm

Needle gauge Code

56

64

Electromagnetic type top and

bottom thread trimming device

Pneumatic type top and bottom

thread trimming device

Thread trimming device Code

UT31

UT33

2-needle, top and bottom coverstitch

Stitch type

Code

22

3-needle, top and bottom coverstitch

23

B type (Standard)

D type

Tongue shape of throat plate

Code

B

D

△△

△△ △△ △△

△△ △△ △△/

/

2-needle, top and bottom coverstitch

Stitch type

Code

22

3-needle, top and bottom coverstitch

23

4-needle, top and bottom coverstitch

24

B type (Standard)

*For model category "24"(4-needle),

tongue shapis type D.

*1 Specify the MD10 when placing your order.

*2 The TC13 can be retrofitted to the machine.

*For stitch type category "24" (4-needle),needle gauge category only 60 can be selected.

*For stitch type category "22" (2-needle),needle gauge category "56" and "64" cannot be selected.

*For stitch type category "23" (3-needle),needle gauge category "32","40" and "48" cannot be selected.

*For stitch type category "22" (2-needle),

needle gauge category "56" and "64" cannot be selected.

*For stitch type category "23" (3-needle),

needle gauge category "32","40" and "48" cannot be selected.

Tongue shape of throat plate

Code

B

D type

D

Universal type

Application Code

U10

Collarette attaching

C10

Elastic band attaching (with right hand fabric trimmer)

E10

3.2mm

4.0mm

4.8mm

Needle gauge

Code

32

40

48

5.6mm

6.0mm

6.4mm

Needle gauge

Code

56

60

64

Not provided

Mechanical type metering device

*1

Electromagnetic type tape cutter

*2

Thread trimming device Code

MD10

TC13

Model name

Stitch type

Needle

Lift of the presser foot

Stitch pitch adjustment

Differential feed adjustment

Lubrication

Lubricating oil

Feed dog inclination adjustment

Micro-lifter

Needle bar stroke converting function

Silicon oil tank for needle tip and needle thread

Cartridge oil filter

Weight of the machine head

MF-7700D Series

3-needle top and bottom covering stitch

UY128GAS (#10S) #9S

~ #12S

5mm (with top and bottom covering stitch), 8mm (with bottom covering stitch)

By dial

By micro-adjustment mechanism

Automatic (frame: no lubrication)

JUKI MACHINE OIL 18 (equivalent to ISO VG18)

Provided as standard

Provided as standard

31mm

Provided as standard

Provided as standard

46kg (without device), 49kg (with UT33), 52kg (with UT31)

Specifications

When you place orders

Please note when placing orders, that the model name should be written as follows:

•

To order, please contact your nearest JUKI distributor.

SEWING MACHINERY BUSINESS UNIT

✽

Specifications and appearance are subject to change without prior notice for improvement.

✽

Read the instruction manual before putting the machine into service to ensure safety.

JUNE, 2011 Printed in Japan(C)

2-11-1, TSURUMAKI, TAMA-SHI,

TOKYO

206-8551, JAPAN

PHONE : (81) 42-357-2254

FAX :

(

81

)

42-357-2274

http://www.juki.com

Loading...

Loading...