Page 1

Semi-dry head, Flat-bed Top and Bottom Coverstitch Machine

MF-7700D Series

ENGINEER’S MANUAL

®

40084333

No.E386-00

Page 2

PREFACE

This Engineer’s Manual is written for the technical personnel who are responsible for the service and maintenance

of the machine.

The Instruction Manual for these machines intended for the maintenance personnel and operators at an apparel

factory contains operating instructions in detail. And this manual describes "Standard Adjustment", "Adjustment

Procedures", "Results of Improper Adjustment", and other important information which are not covered by the

Instruction Manual.

It is advisable to use the relevant Instruction Manual and Parts List together with this Engineer’s Manual as well as

the MF-7700, SC-500, and SC-510 Series Manuals when carrying out the maintenance of these machines.

In addition, for the motor for the sewing machine with thread trimmer, refer to the separate Instruction Manual or

Engineer’s Manual for the motor. And for the control panel, refer to the Instruction Manual for the control panel.

This manual gives the "Standard Adjustment" on the former page under which the most basic adjustment value is

described, and on the latter page "Results of Improper Adjustment" under which stitching errors and troubles arising

from mechanical failures are described together with the "Adjustment Procedures".

Page 3

CONTENTS

1. SPECIFICATIONS................................................................................................... 1

2. CONFIGURATION OF THE MACHINE COMPONENTS........................................ 2

3. MODEL NUMBERING SYSTEM ............................................................................ 3

(1) MF-7700D Series . ................................................................................................................... 3

(2) MF-7700D Series Thread trimmer.......................................................................................... 4

4. MOTOR PULLEY AND BELT ................................................................................. 5

5. ST ANDARD ADJUSTMENT ................................................................................... 6

(1) Threading the machine head . ............................................................................................... 6

(2) Adjusting the rocking thread take-up ................................................................................... 8

(3) Adjusting the position of the needle thread guide rod ..................................................... 10

(4) Adjusting the position of the thread receiver .................................................................... 12

(5) Adjusting the position of the spreader thread guide and spreader thread take-up....... 14

(6) Adjusting the spreader......................................................................................................... 16

(7) Adjusting the timing relation between the looper and needle bar................................... 20

(8) Returning amount of the looper .......................................................................................... 22

(9) Height of the needle ............................................................................................................. 24

(10)Locus and longitudinal motion of the looper..................................................................... 26

(11)Adjusting the needle guard ................................................................................................. 28

(12)Installing cover of the looper and needle guard after adjusting ...................................... 32

(13)Adjusting the feed dog ......................................................................................................... 34

(14)Adjusting the feed relation .................................................................................................. 40

(15)Adjusting the presser foot ................................................................................................... 42

(16)Adjusting the micro-lifter ..................................................................................................... 44

(17)Adjusting the looper thread cam......................................................................................... 46

(18)With regard to lubrication .................................................................................................... 48

(19)Setting for functions of SC-500 ........................................................................................... 52

(20)Adjusting and setting SC-510 .............................................................................................. 54

(21) MF-7700D/MF-7800D How to use the timing gauge .......................................................... 58

6. E10/MD10.............................................................................................................. 59

(1) Specifications (E10).............................................................................................................. 59

(2) Specifications (MD10) .......................................................................................................... 59

(3) Adjusting the needle guard ................................................................................................. 60

(4) Adjustment of knife .............................................................................................................. 62

(5) Presser adjustments ............................................................................................................ 66

(6) Method of lubrication ........................................................................................................... 68

(7) Adjustment of the amount of feeding ................................................................................. 70

(8) Adjustments for heavy material sewing ............................................................................. 72

(9) Mounting position of the eccentric cam............................................................................. 74

Page 4

7. MF-7724DU10D60 (4 needles)............................................................................. 77

(1) Specifications . ..................................................................................................................... 77

(2) Needle .................................................................................................................................... 77

(3) Standard adjustments .......................................................................................................... 78

1) Needle mounting.............................................................................................................................78

2) Threading the machine head .........................................................................................................80

3) Adjusting the rocking thread take-up ...........................................................................................82

4) Adjusting the position of the needle thread guide rod ............................................................... 84

5) Adjusting the rocking thread take-up thread receiver ................................................................86

6) Adjusting the looper.......................................................................................................................88

7) Adjusting the height of the needle................................................................................................ 88

8) Adjusting the rear needle guard....................................................................................................90

9) Adjusting the looper thread cam...................................................................................................90

10)Installing position of the spreader ................................................................................................92

8. UT31...................................................................................................................... 94

(1) Installation of SC-500 ........................................................................................................... 94

(2) Change of the setting ........................................................................................................... 96

(3) Adjusting the synchronizer ................................................................................................. 98

(4) Installation of SC-510 ......................................................................................................... 100

(5) Adjusting the looper thread trimmer mechanism............................................................ 106

9. UT33.................................................................................................................... 120

(1) Installation of SC-500 ......................................................................................................... 120

(2) Installation of SC-510 ......................................................................................................... 122

(3) Piping of the thread trimmer device ................................................................................. 124

(4) Adjusting the looper thread trimmer mechanism............................................................ 126

(5) Adjusting the top covering thread trimmer mechanism ................................................. 130

(6) Adjusting the air-blow wiper.............................................................................................. 132

10.TC13 (Tape cutter) ............................................................................................. 134

(1) Specifications ..................................................................................................................... 134

(2) Adjustment of knife ............................................................................................................ 136

(3) TC13C .................................................................................................................................. 140

11. OTHER CAUTIONS ............................................................................................ 146

(1) MF-7700D dry section......................................................................................................... 146

(2) Application of appropriate grease .................................................................................... 146

(3) Adhesives application spots ............................................................................................. 148

12.TROUBLES AND CORRECTIVE MEASURES .................................................. 149

13.DRAWING OF TABLE......................................................................................... 163

(1) Semi-Submerged Type ....................................................................................................... 163

(2) For MF-7700D/E10 (Semi-Submerged Type) .................................................................... 164

Page 5

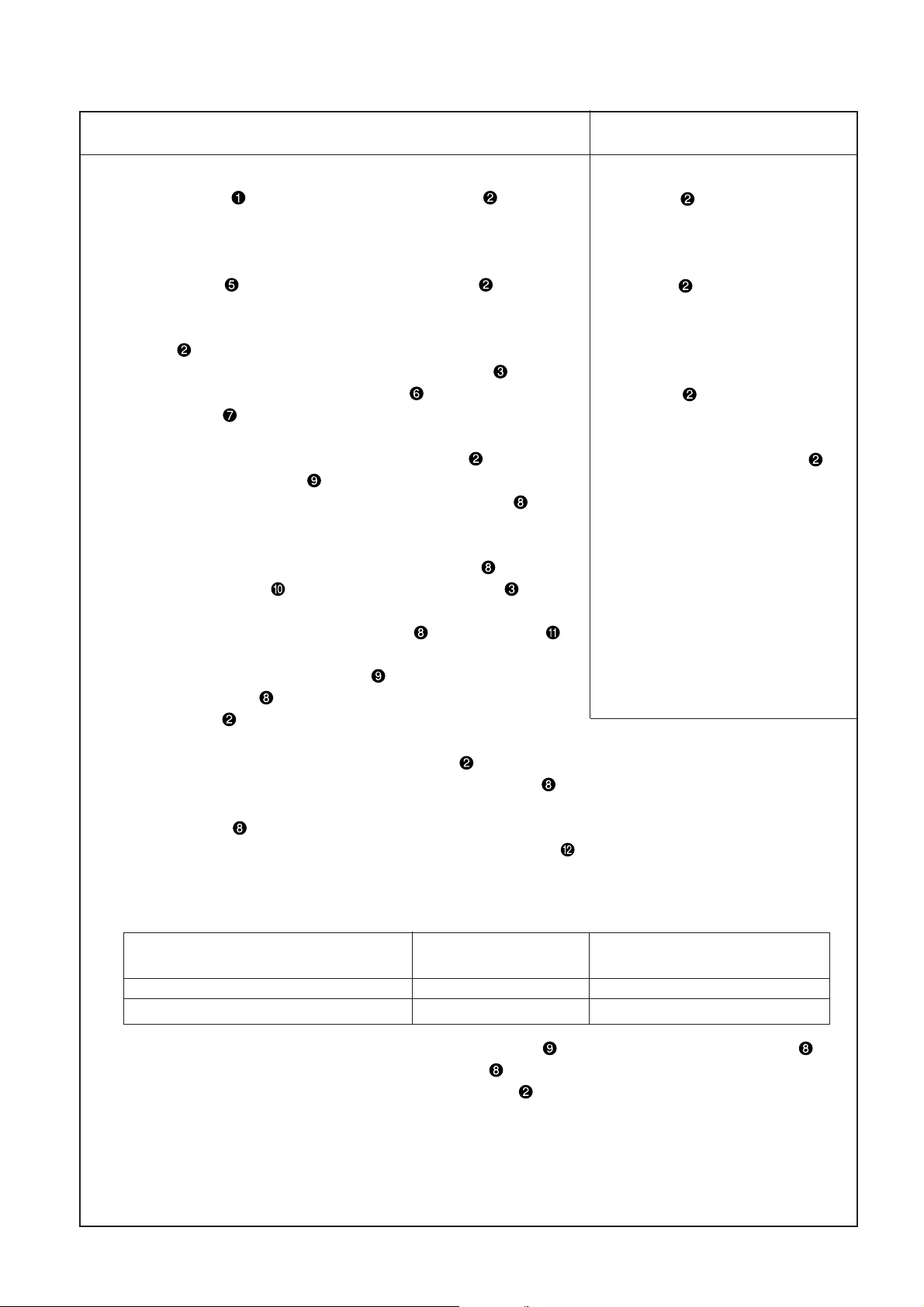

1. SPECIFICATIONS

No. Item Specifications

1Model name Semi-dry head, flat-bed top and bottom coverstitch machine

2 Model MF-7700D series

3Stitch type ISO standard 406, 407, 602, 605 and 607

4 Example of application

5Max. sewing speed 4,000 sti/min (at the time of intermittent operation)

6Needle gauge

7 Differential feed ratio Micro-differential feed adjustment mechanism is provided.

8 Stitch length 1.2 mm to 3.6 mm (can be adjusted up to 4.4 mm)

9 Needle

10 Needle bar stroke 31mm

11 Dimensions Height: 451 mm, Width: 515 mm, Length: 265 mm

12 Weight 46kg, 49kg (with UT33), 52kg (with UT31)

13 Lift of presser foot

14 Feed adjustment method Differential feed....... lever adjustment method (micro-adjustment

15 Looper mechanism Spherical rod drive method

16 Lubricating system Forced lubrication method by gear pump

17 Lubricating oil JUKI MACHINE OIL 18 (Equivalent to ISO VG18)

18 Oil reservoir capacity Oil gauge lower line : 600 cm3 to upper line : 900 cm

19 Installation Semi-submerged type

20 Micro-lifter Provided as standard

21 Provided as standard

22 Cartridge oil filter Provided as standard

Needle tip, needle thread silicone tank

Hemming, covering, and elastic tape attachment for knits and general knitted fabrics

3-needle...........5.6 mm and 6.4 mm 4-needle .................... 6.0 mm

2-needle...........4.0 mm

1 : 0.7 to 1 : 2 (stitch length : less than 2.5 mm)

(Micro-adjustment)

UY128GAS #9S to #12S (standard #10S)

(Nm65 to Nm80, standard Nm70)

5 mm (with top covering)

8 mm (without top covering)

Main feed ................ dial type stitch pitch adjustment method

mechanism is provided.)

3

– 1 –

Page 6

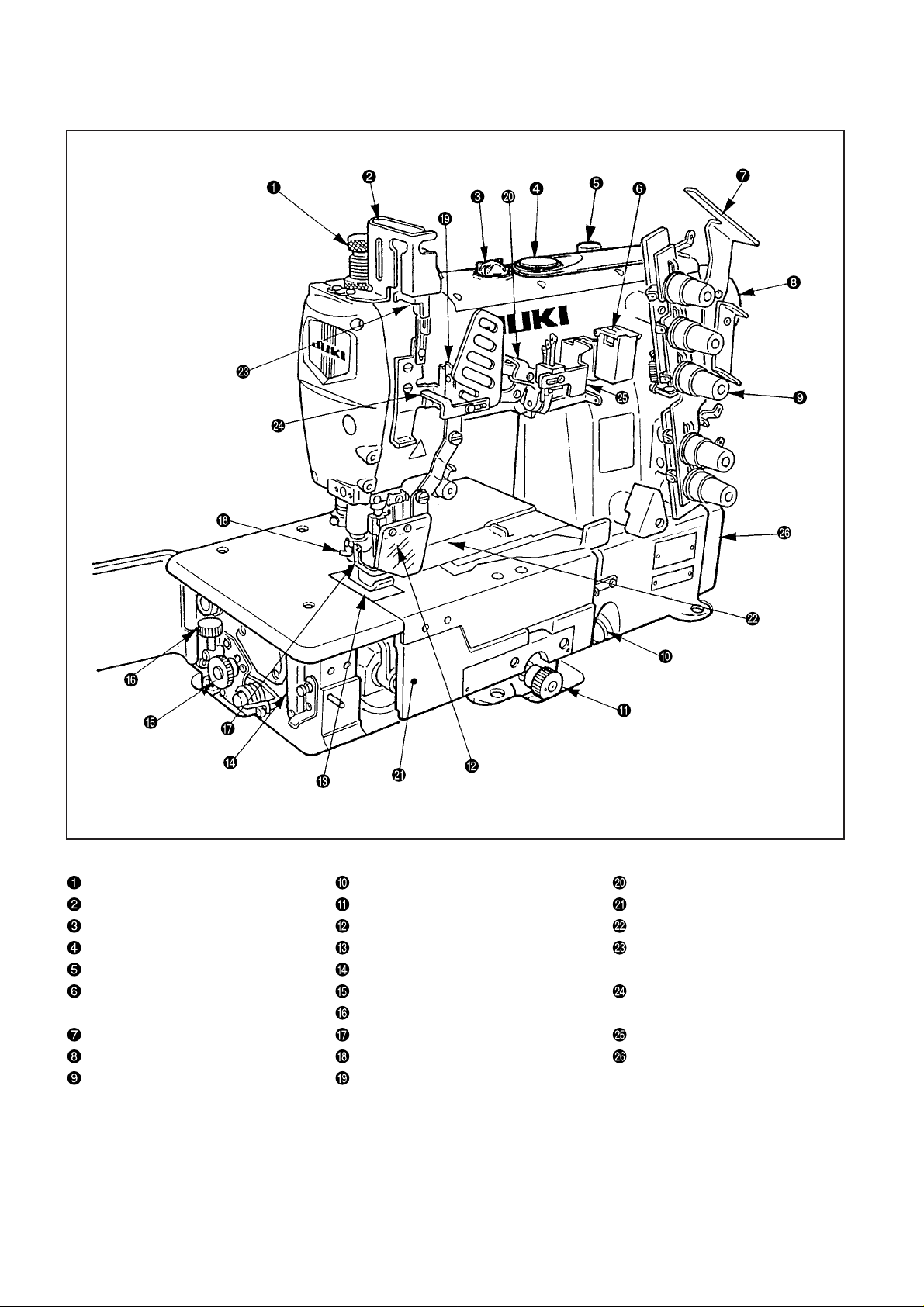

2. CONFIGURATION OF THE MACHINE COMPONENTS

Presser spring regulator Oil gauge Rocking thread take-up

Needle bar thread take-up cover Feed regulating knob Front cover

Oil circulation identification window Eye guard cover Slide cover

Oil hole cap Throat plate Needle bar thread take-up

Micro-lifter Needle tip silicon oil lubricating unit thread receiver

Needle thread silicon Differential lock nut Rocking thread take-up

oil lubricating unit Micro-adjustment knob thread guide

Thread guide No. 1 Finger guard Silicon container thread guide

Upper pulley Thread trimming knife Belt cover

Thread tension nut Rocking thread take-up receiver

– 2 –

Page 7

3. MODEL NUMBERING SYSTEM

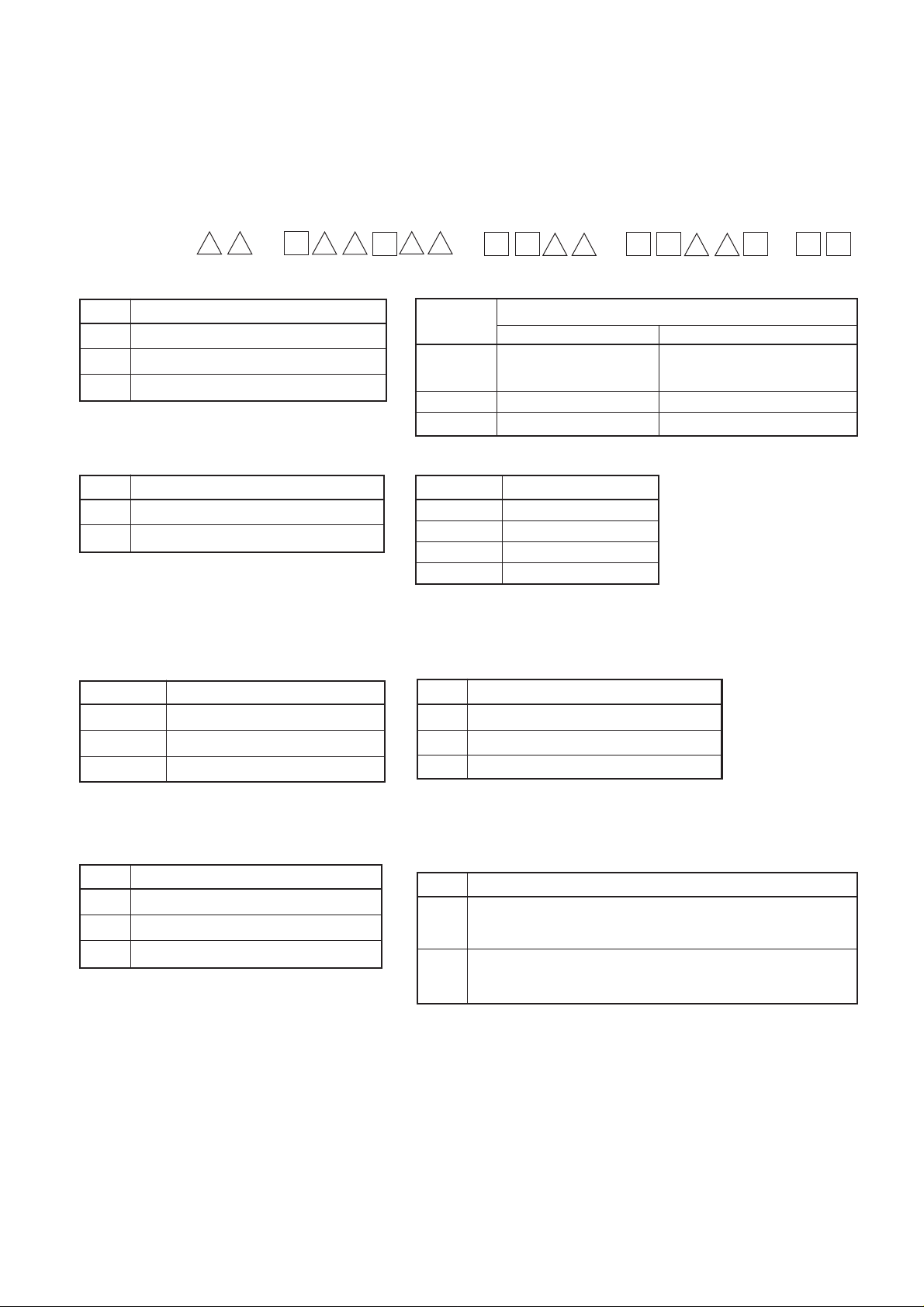

(1) MF-7700D Series

Semi-dry head, flat-bed top and bottom coverstitch machine

Applicable model : MF-7700D Series

123456789101112 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27

MF77 D / / –

3 to 6 Model code

7722 2-needle top & bottom covering stitch

7723 3-needle top & bottom covering stitch

7724 4-needle top & bottom covering stitch

11 Tongue shape of throat plate

B Standard

D D-type

15 to 23 Device and attachment

Blank Not provided

TC13 Solenoid type tape cutter

MD10 Mechanical metering device

8 to 10

U10

C10 For collarette For regular binder

E10 Elastic tape attachment With right hook knife

12 to 13 Needle gauge

40 4.0mm

56 5.6mm

60 6.0mm

64 6.4mm

* Selection of 56 and 64 is prohibited for 2-needle type.

* For the triple needle type, the selection of 40 only is possible for the U10.

* Applicable only to 60 for 4-needle type

24 TC control voltage division

A 220 to 440V

B 100 to 240V

C SC-510

Application Description

For universal Lapseam, Covering,

Application code

Hemming

*When device or attachment is one, delete slash

(/) of 14th digit.

26 Specification Code for Destination

A Standard

G For China (domestic China)

H For Turkey

* Selected only for TC unit attachment type

27 Accessory Specification Code

Standard (Foreign language manuals in Japanese, English,

A

Chinese, German, French, Italy, Turkey, and Spanish)

Chinese (available only in China) (2-language manual in

G

English and Chinese)

– 3 –

Page 8

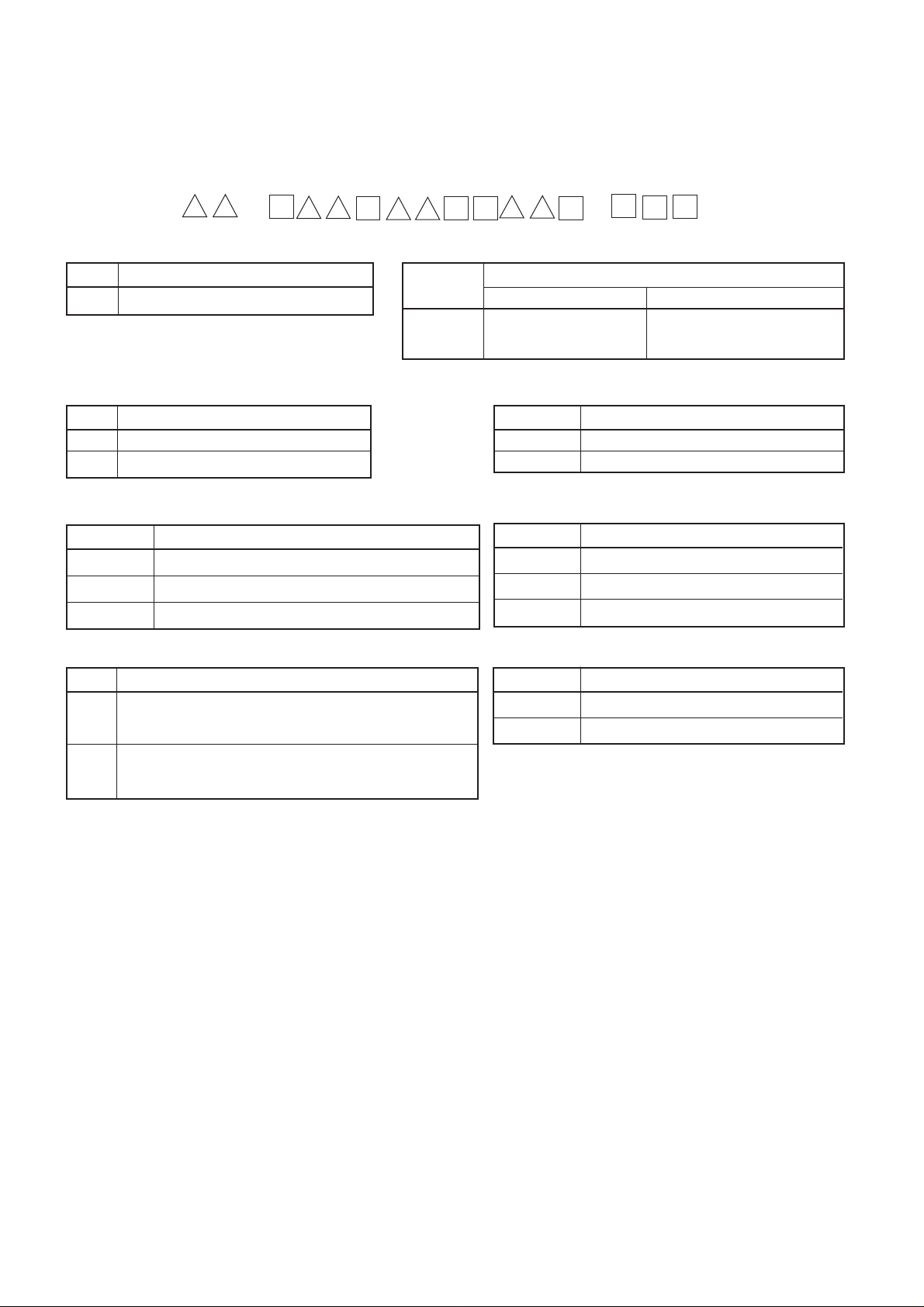

(2) MF-7700D Series Thread trimmer

Semi-dry head, flat-bed top and bottom coverstitch machine

Applicable model : MF-7700D Series Thread trimmer

1 2345678910111213141516171819202122

MF77 D –

3 to 6 Model code

7723 3-needle top & bottom covering stitch

11 Tongue shape of throat plate

B Standard

D D-type

14 to 18 Device and attachment

UT31 Solenoid type vertical thread trimmer unit

UT33 Pneumatic type vertical thread trimmer unit

UT33A Pneumatic type vertical thread trimmer unit (ASTAS)

21 Accessory Specification Code

Standard (Foreign language manuals in Japanese, English,

A

Chinese, German, French, Italy, Turkey, and Spanish)

8 to 10

U10

Application code

Application Description

For universal Lapseam, Covering,

Hemming

12 to 13 Needle gauge

56 5.6mm

64 6.4mm

19 Specification Code for Destination

A Standard

G For China (domestic China)

H For Turkey

22 Control box and motor classification

B SC-500/M50

C SC-510/M51

Chinese (available only in China) (2-language manual in

G

English and Chinese)

– 4 –

Page 9

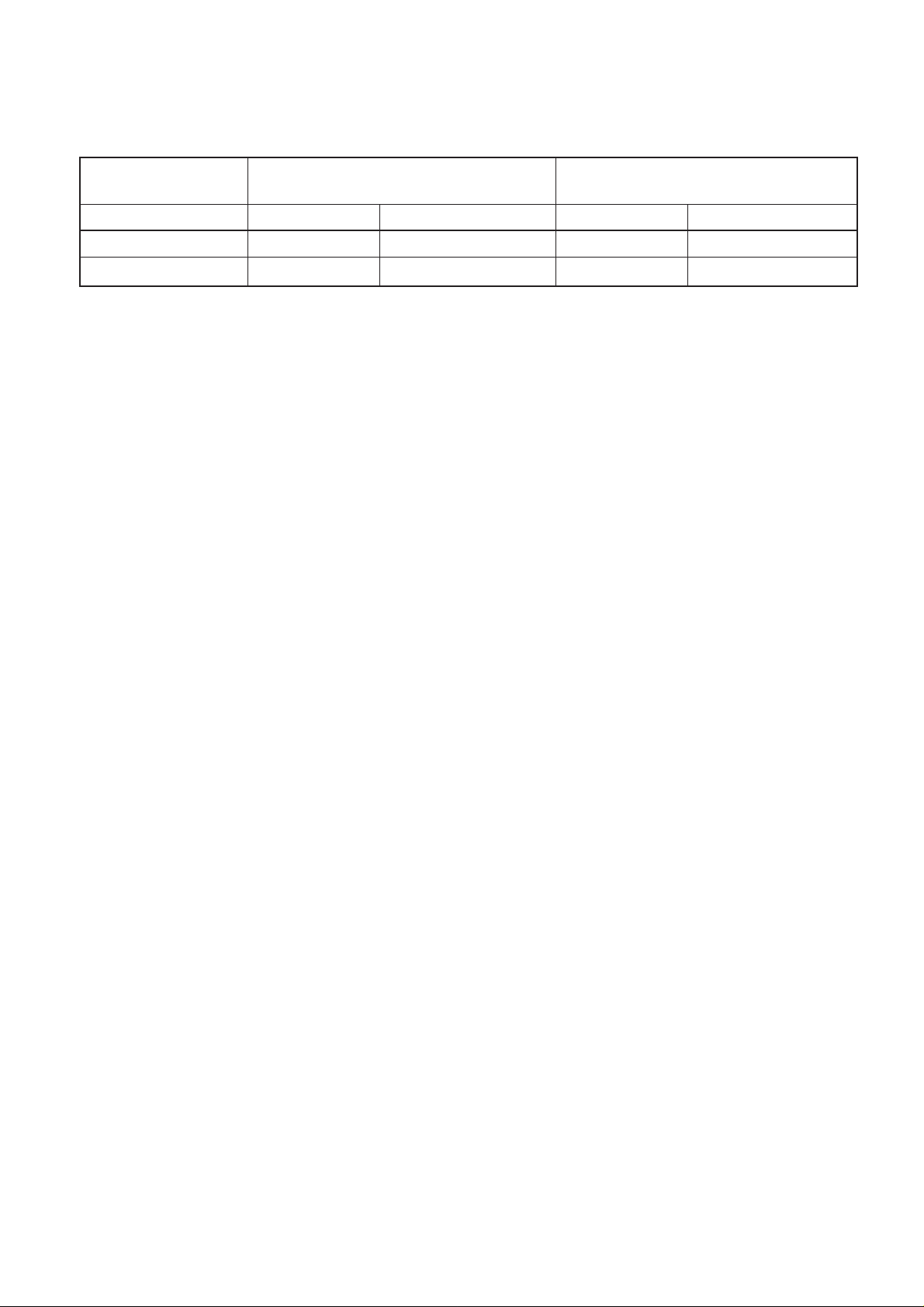

4. MOTOR PULLEY AND BELT

MF-7700D Series

Sewing speed of the

machine

(sti/min) Pulley size (mm) Belt size (inch) Pulley size (mm) Belt size (inch)

3,500 ø80 M-34 ø65 M-33

4,000 ø90 M-35 ø75 M-34

1 . The table shows the numbers when a 3-phase 2-pole 400 W clutch motor (1/2 HP) is used.

2 . The commercially-available motor pulley near to the counted value is designated since the outside diameter of

the commercially-available motor pulley counts by 5 mm.

3 . When you use a new sewing machine, use the machine at a speed of 4,000 sti/min or less for the first 200 hours

(approximately one month). A good result can be obtained in terms of the durability.

(Caution) 1. Use a motor pulley which is adaptable to this sewing machine.

2. This sewing machine will exceed its max. revolutions and max. sewing speed, finally leading

to the occurrence of malfunction, unless the adaptable motor pulley is used.

50Hz 60Hz

– 5 –

Page 10

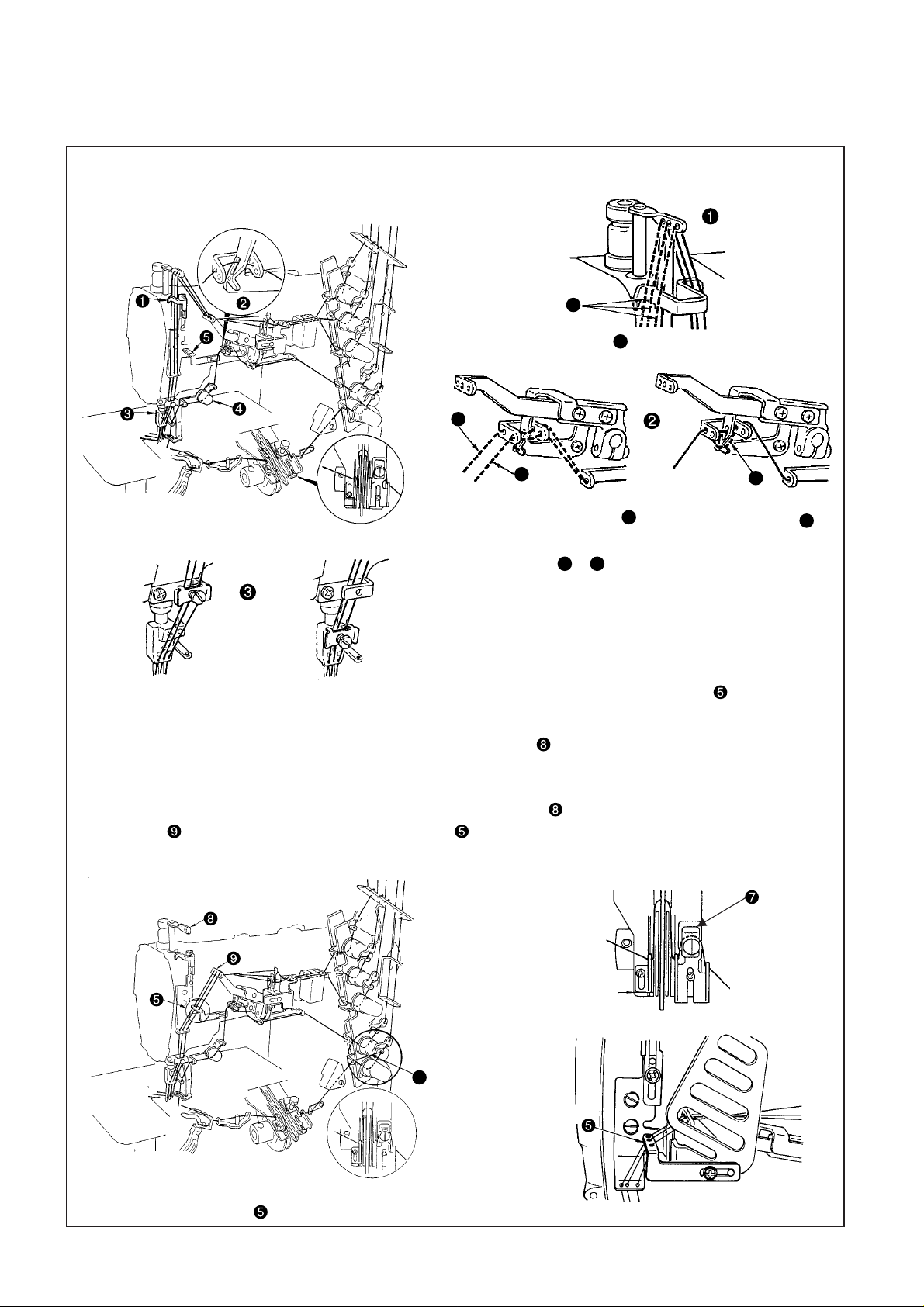

5. ST ANDARD ADJUSTMENT

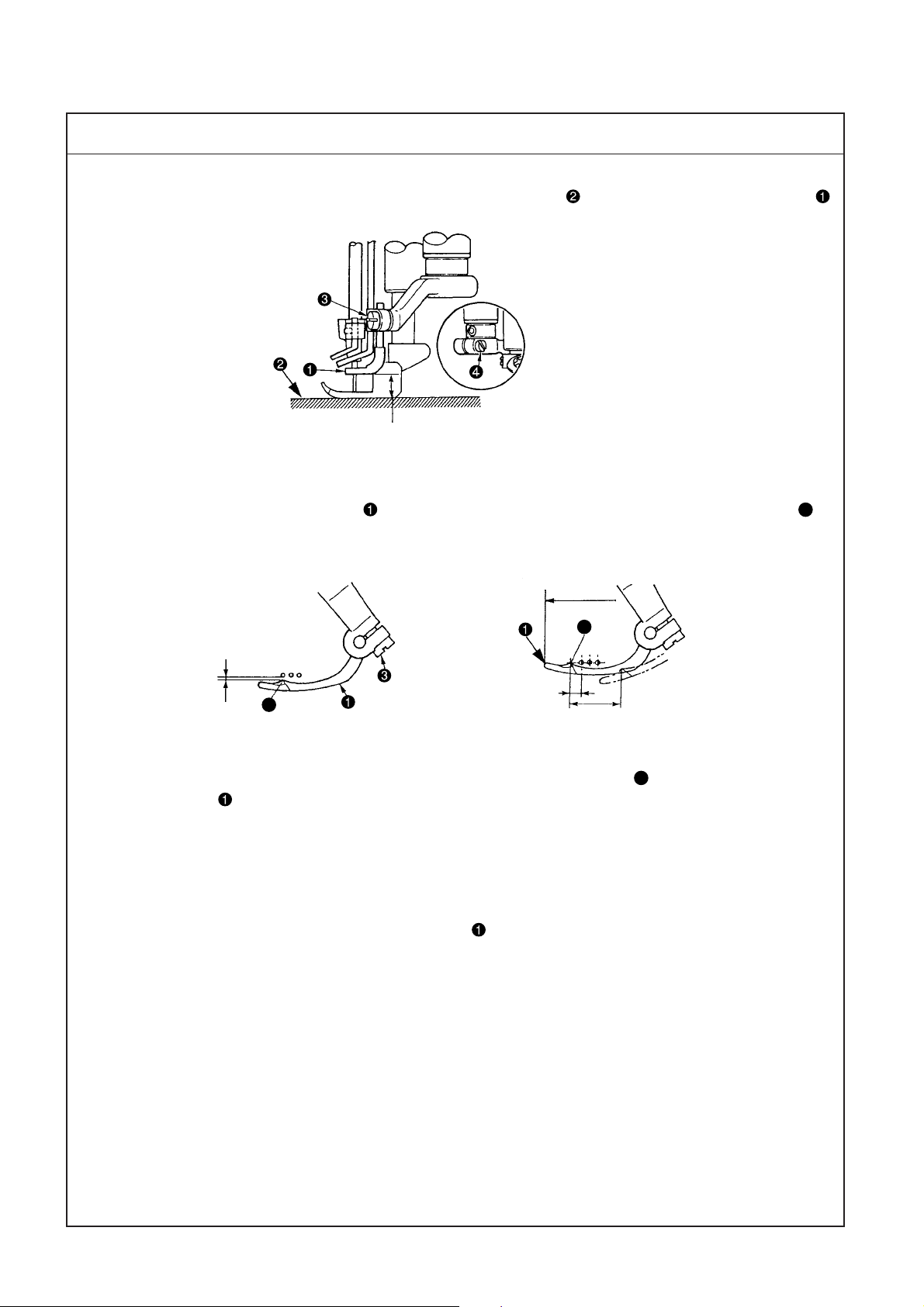

(1) Threading the machine head

Standard Adjustment

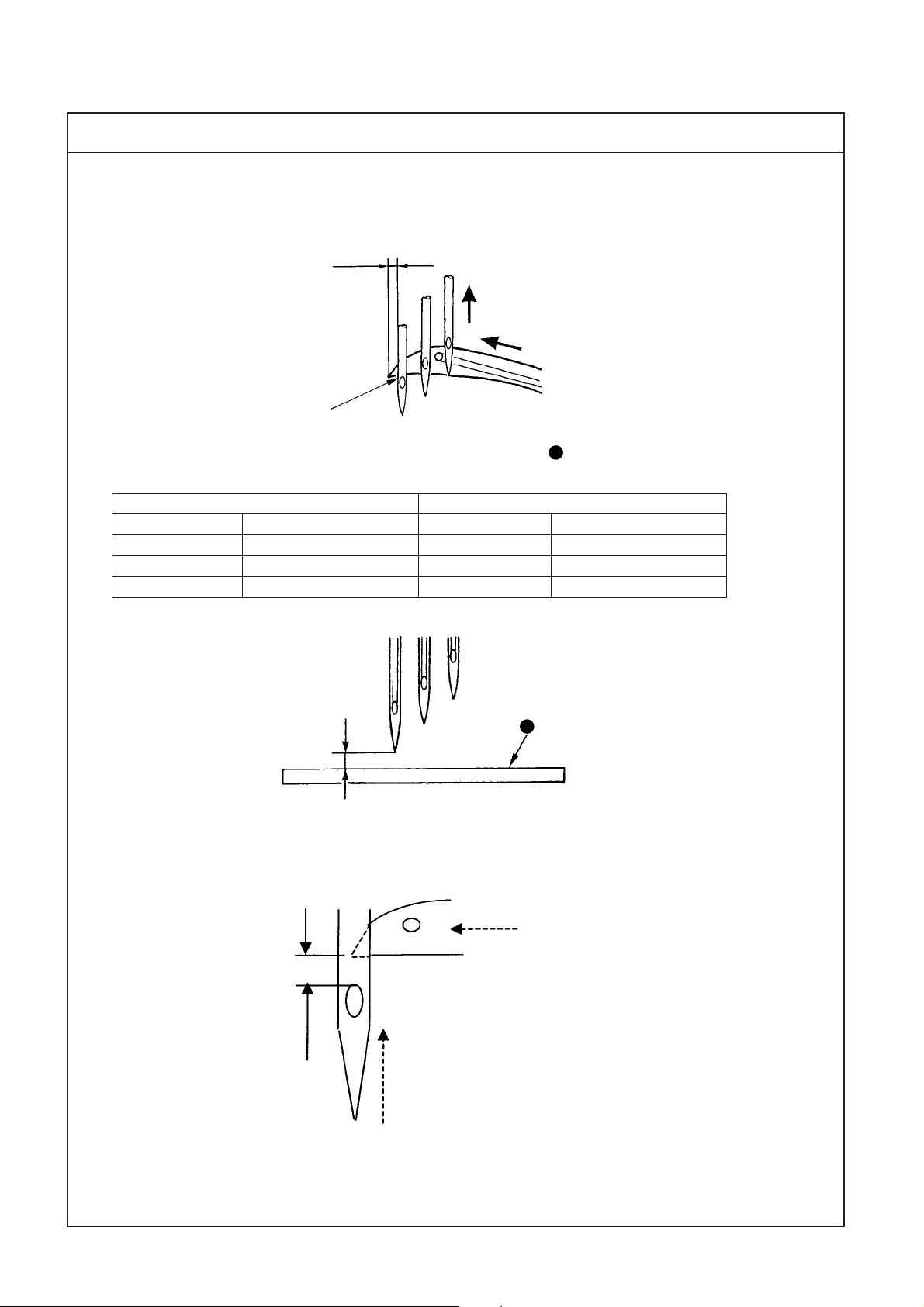

1. Threading for standard seam

A

Broken lines A when stretcher thread is used

B

When using more

stretchable thread

When using less

stretchable thread

C

When covering thread is

excessively loosened =

When covering thread is

excessively loosened even

after passing

B

=

B

C

When covering thread is

excessively tense =

D

D

(Caution) In case of threading for standard seams, rocking thread take-up thread guide is not used.

2. Threading for soft seams

(1) Do not pass needle thread through needle bar thread take-up .

(2) When soft seams are required, change the threading of needle thread and slide the position of looper thread

cam eyelet.

(3) Do not pass needle thread through needle bar thread take-up . Pass the thread from rocking thread

take-up to rocking thread take-up thread guide .

(4) Other points are same as those of "1. Threading for standard seam".

In case of soft seams

Engraved marker line

E

(Caution) In case of the soft seams, rocking thread take-up

thread guide is used.

– 6 –

Left

Right

Page 11

Adjustment Procedure

Results of Improper Adjustment

1. When motion of thread is very rough, and stable seams can not be

obtained, there are cases where the condition can be improved by

the following threading.

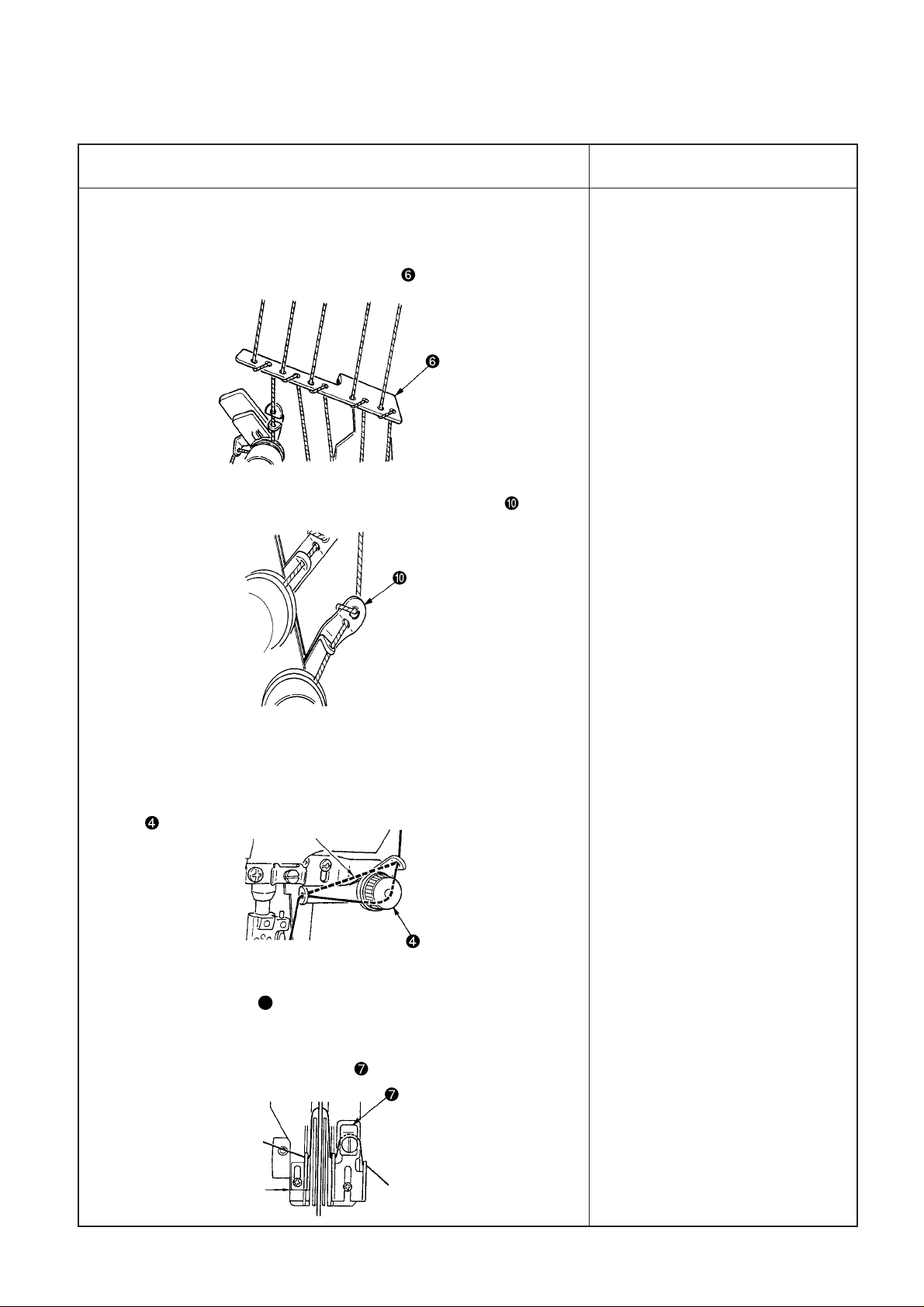

(1) Wind thread around 1st thread guide .

(2) Wind thread around the thread tension thread guide .

o When threading is not properly

performed, not only sewing

trouble occurs, but also needle

breakage is caused. So, be

careful.

2. When using more stretchable thread (wooly thread or the like), the

threading as given below does not make thread stretch and neat

seams can be obtained.

(1) Do not pass thread through spreader auxiliary thread tension

.

Do not pass thread.

(2) Do not pass thread through the looper thread tension disk.

Refer to section E.

(Caution) Even when using wooly thread or the like, seams are

more stabilized by passing thread through looper thread

auxiliary thread tension .

Engraved marker line

– 7 –

Page 12

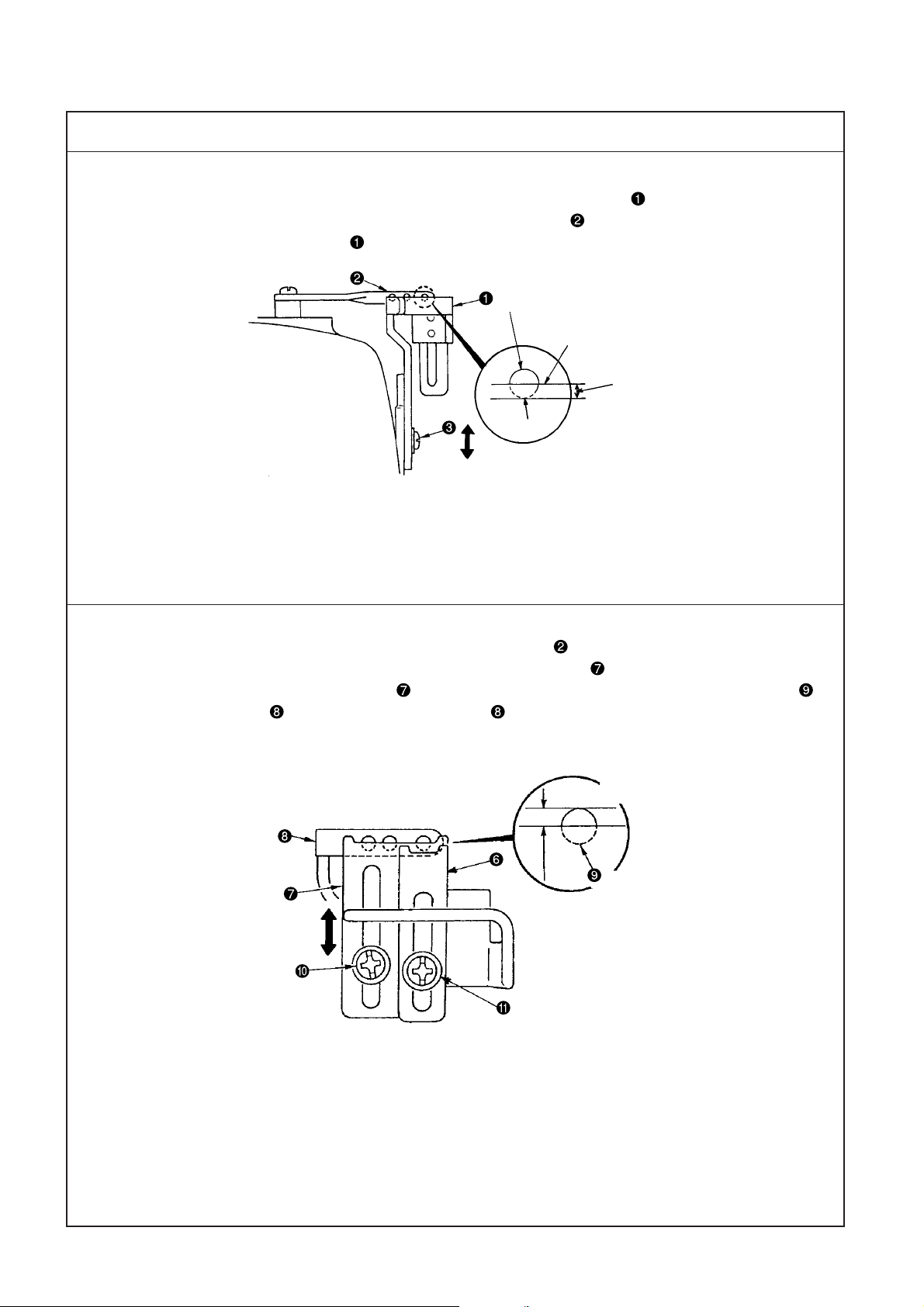

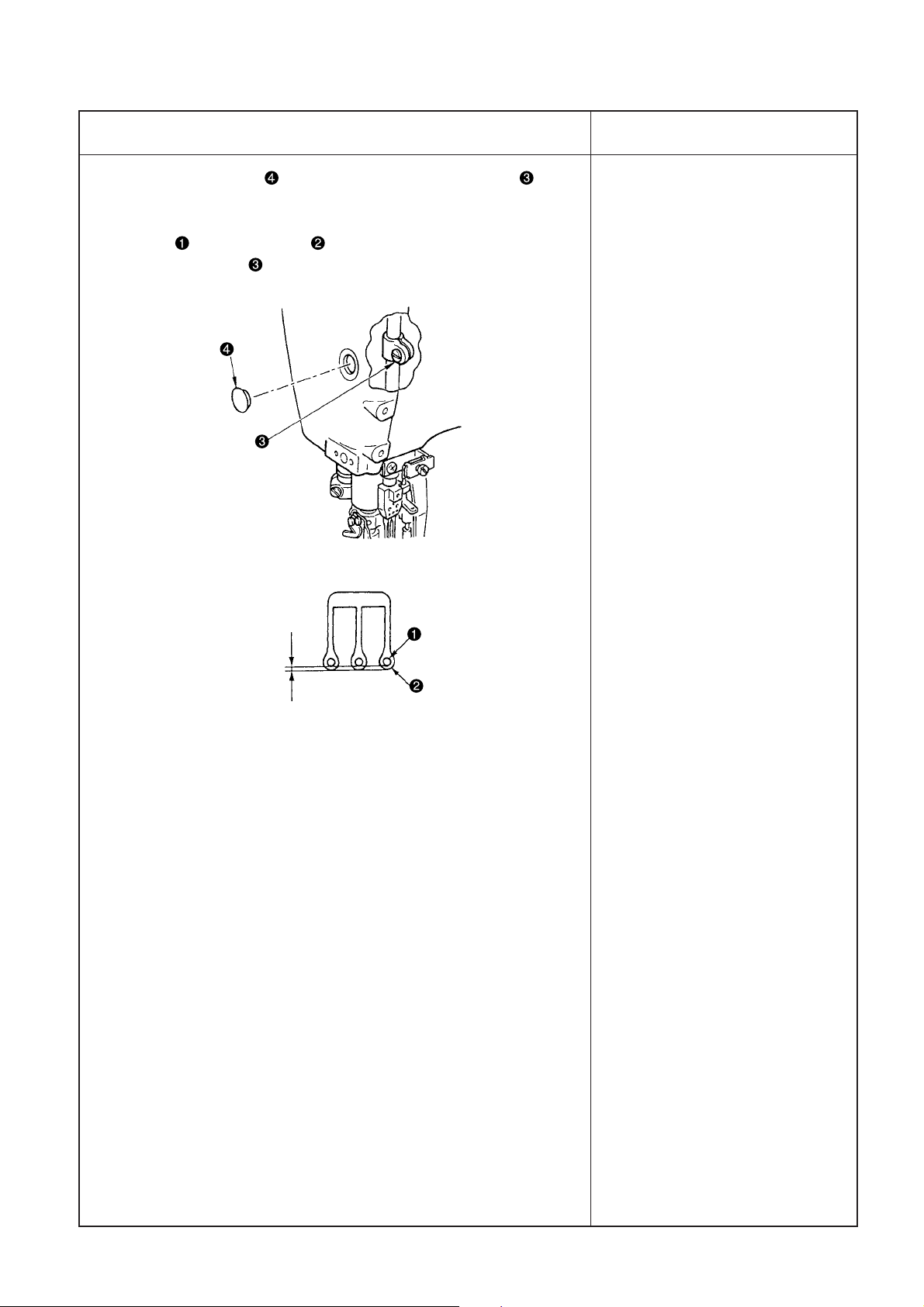

(2) Adjusting the rocking thread take-up

Standard Adjustment

1. Length of the rocking thread take-up

(1) It is the standard that the length of rocking thread take-up from the center of the shaft of rocking thread

take-up support arm to the thread hole face of rocking thread take-up is 95 mm.

95mm

2. Position of the rocking thread take-up

(1) Install so that rocking thread take-up is flush with rocking thread take-up when the needle bar is in its

lowest position.

Flush

3. Timing of the rocking thread take-up

(1) It is the standard timing that rocking thread take-up is in

its lowest position as well when the needle bar is in its lowest

position.

Timing of rocking thread take-up is performed by

adjusting the position of rocking thread take-up ball arm

.

4. Relation between the timing of rocking thread take-up and

the needle thread loop

(1) When using the excessively stretchable thread or the hard-

to-stretch thread, the size of needle thread loop can be

changed by changing the timing of rocking thread take-up

.

(2) Relation between the timing of the rocking thread take-up

and the size of needle thread loop is as shown in the

table on the next page.

(The relation becomes reverse when using the needle bar

thread take-up = standard seams and when it is not used =

soft seams. So, be careful.)

↑

Anti-operatorís side

4mm

Operatorís side

↓

– 8 –

Page 13

Adjustment Procedure

Results of Improper Adjustment

1. Length of the rocking thread take-up

(1) Loosen screws and move rocking thread take-up to the right

or left to adjust the length.

2. Position of the rocking thread take-up

(1) Loosen screw and move rocking thread take-up up or down

to adjust the position.

(Caution) When adjusting the position of rocking thread take-up

, adjust the rocking thread take-up to the same plane

of the edge of rocking thread take-up shaft and fix it

so that spreader thread take-up and spreader thread

guide do not come in contact with each other.

3. To adjust the timing of the rocking thread take-up , remove the

top cover, loosen setscrew in the rocking thread take-up ball arm

and move the position of rocking thread take-up ball arm to and

fro.

(1) Standard adjustment figure is the position where the rear end (anti

operator’s side) of rocking thread take-up ball arm aligns with

engraved marker line on rocking thread take-up shaft . (As the

standard at this time, note that the clearance provided between the

rear end of rocking thread take-up ball arm and thrust collar is

4 mm.)

(Caution) 1. When loosening screw in rocking thread take-up

ball arm , there is a case where rocking thread takeup rotates by its weight. After the adjustment, be

sure to check the rocking position (flush at the lowest

position) of rocking thread take-up .

2. When moving rocking thread take-up ball arm to

the operator’s side, adjust rocking thread take-up ball

arm within the range where it does not come in

contact with rocking thread take-up bushing

(operator’s side).

o When length of rocking thread

take-up is lengthened, needle

thread is tightened.

(Caution) When lengthening

rocking thread take-up

, check whether it

comes in contact with

the thread take-up

cover.

o When length of rocking thread

take-up is shortened, needle

thread is loosened.

o When installing position of

rocking thread take-up is

raised, needle thread is loosened

when the needle bar thread takeup is used, and needle thread is

tightened when the needle bar

thread take-up is not used.

4. Relation between timing of rocking thread take-up and needle thread loop

Delay timing Advance timing

(Move to operator’s side.) (Move to anti-operator’s side.)

When needle bar thread take-up is used Loop becomes small. Loop becomes large.

When needle bar thread take-up is not used Loop becomes large. Loop becomes small.

Adjusting procedure is the same as step 3. Loosen setscrew in rocking thread take-up ball arm and

adjust the position of rocking thread take-up ball arm .

(Caution) Adjust the timing of rocking thread take-up each time in accordance with thread used

or conditions.

– 9 –

Page 14

(3) Adjusting the position of the needle thread guide rod

Standard Adjustment

1. Position of the needle thread guide rod

(1) It is the standard that the height of needle thread guide rods is the position where the dimensions from

the top surface of needle thread guide base to the bottom end of the hole are as follows.

Left needle A : 7 mm

Middle needle B : 15 mm

Right needle C : 23 mm

C

B

A

Extreme right position

A : 7mm B : 15mm C : 23mm

2. Adjusting the position of needle thread guide base and silicon container thread guide

(1) It is the standard that the height of silicon container thread guide (refer to 2. CONFIGURATION OF THE

MACHINE COMPONENTS) is the position where the height from the center of setscrew to the bottom

end of thread hole is 9 mm.

(2) Move the lateral position of needle thread guide base fully to the right of slot (43 mm).

43mm

9mm

Extreme right position

– 10 –

Page 15

Adjustment Procedure

Results of Improper Adjustment

1. Loosen setscrews , adjust the height of respective needle thread

guide rods , and fix the rods with setscrews .

(Caution) 1. Move the lateral position of needle thread guide base

fully to the right of slot.

2. When adjusting the height of needle thread guide rods

, install the rods so that the thread holes are parallel

to the thread holes of silicon container thread guide

so that excessive resistance is not applied to

threads.

2. Adjusting the position of needle thread guide base and silicon

container thread guide

(1) Loosen setscrews and and move silicon container thread guide

up or down to adjust the height.

(2) Loosen setscrew and adjust the lateral position of needle thread

guide base .

o When needle thread guide rod

is raised, needle thread is

loosened.

o When needle thread guide rod

is lowered, needle thread is

tightened.

oWhen silicon container thread

guide is raised, needle thread

is loosened.

o When silicon container thread

guide is lowered, needle

thread is tightened.

o When needle thread guide base

is moved to the left, needle

thread is loosened.

– 11 –

Page 16

(4) Adjusting the position of the thread receiver

Standard Adjustment

1. Position of the needle bar thread take-up thread receiver (in case of standard seams)

(1) It is the standard that the height of needle bar thread take-up thread receiver is in the position where the

bottom end of thread hole to the center of needle bar thread take-up aligns with the top surface of needle

bar thread take-up thread receiver when the needle bar is in its lowest position.

Thread hole

Center of hole

This range

To align

2. Position of the rocking thread take-up thread receiver (in case of soft seams)

(In case thread is not passed through needle bar thread take-up )

(1) It is the standard that the height of rocking thread take-up receiver is in the position where the top

surface of rocking thread take-up receiver is in the range of the center to the top end of thread hole of

rocking thread take-up when rocking thread take-up is in its lowest position.

This range

– 12 –

Page 17

Adjustment Procedure

Results of Improper Adjustment

1. Loosen setscrew and move needle bar thread take-up thread

receiver up or down to adjust the height.

2. When desired to make needle bar thread take-up thread receiver

work especially on the right needle where loop is hard to be made,

adjust the height of right needle thread receiver with setscrew .

o When the needle bar thread

take-up thread receiver is

raised, loop becomes large.

o When the needle bar thread

take-up thread receiver is

excessively raised.

1. Loosen setscrew and move rocking thread take-up receiver

up or down to adjust the height.

2. When desired to make rocking thread take-up receiver work

especially on the right needle where loop is hard to be made, adjust

the height of the right needle thread receiver with screw .

– 13 –

Page 18

(5) Adjusting the position of the spreader thread guide and spreader thread take-up

Standard Adjustment

1. Relation of the position between spreader thread take-up and spreader thread guide is the standard

when the top end of thread hole of spreader thread guide aligns with the bottom end of slot of

spreader thread take-up when spreader thread take-up is in its highest position.

Adjust the relation of the position so that thread is moderately stretched when spreader thread take-up

is in its highest position in accordance with thread used or conditions.

Highest position

To align

A

2. Standard position of the spreader auxiliary thread tension

Standard adjustment figure of the spreader auxiliary thread tension is the standard when the top end of

thread tension rod is flush with knob .

– 14 –

Page 19

Adjustment Procedure

Results of Improper Adjustment

1. Loosen setscrews in spreader thread guide and adjust the

position of spreader thread guide . (Spreader thread take-up

is fixed to rocking thread take-up and can not be adjusted in the

height direction.)

2. After the adjustment, turn the sewing machine by hand and check

whether spreader thread take-up comes in contact with spreader

thread guide , or section A of clearance is too small.

3. Adjusting procedure of the clearance

(1) Loosen setscrews in spreader thread guide and adjust in the

lateral direction, or loosen setscrews in the rocking thread takeup and move spreader thread take-up to the right or left to adjust

the clearance.

(Caution) When loosening setscrews in the rocking thread take-

up and adjusting the position of spreader thread takeup , adjust so that 95, length of rocking thread takeup (95mm) does not change.

o When the relation of position

between spreader thread takeup and the spreader thread

guide is not proper, sewing

troubles such as stitch skipping

and the like will be caused.

o If thread is less stretched and

slackness of thread occurs at the

thread take-up section when

spreader thread take-up is in

its highest position, the spreader

fails to pick up thread and stitch

skipping occurs.

o If stretch or feeding of thread is

excessive when spreader thread

take-up is in its highest

position, not only thread on the

seam side is drawn and needle

thread can not be tightened, but

also needle bend or needle

breakage will be caused.

o If stretch or feeding of thread is

excessive when spreader thread

take-up is in its lowest

position, thread slacks when the

spreader moves from left to right

and stitch skipping occurs.

– 15 –

Page 20

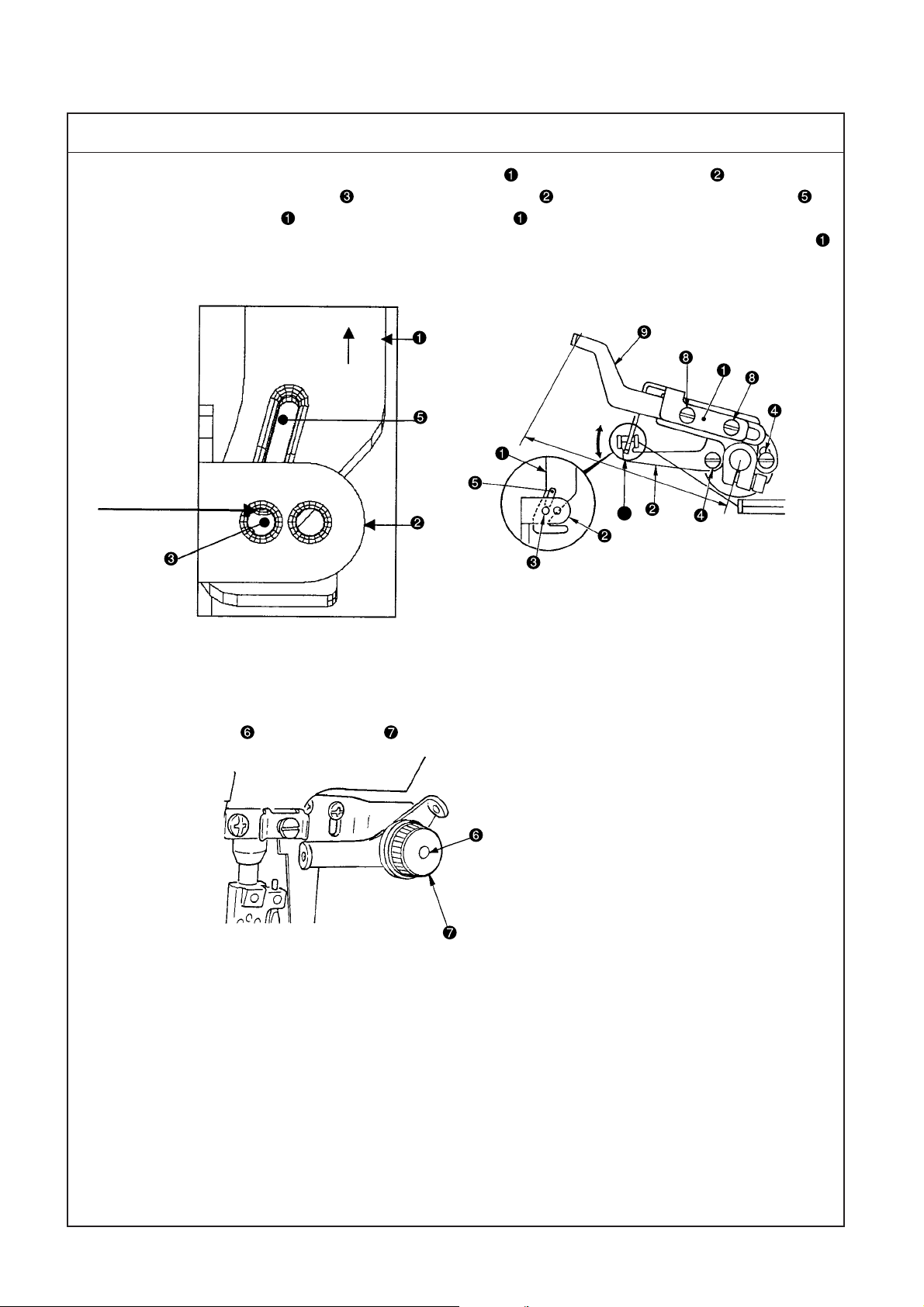

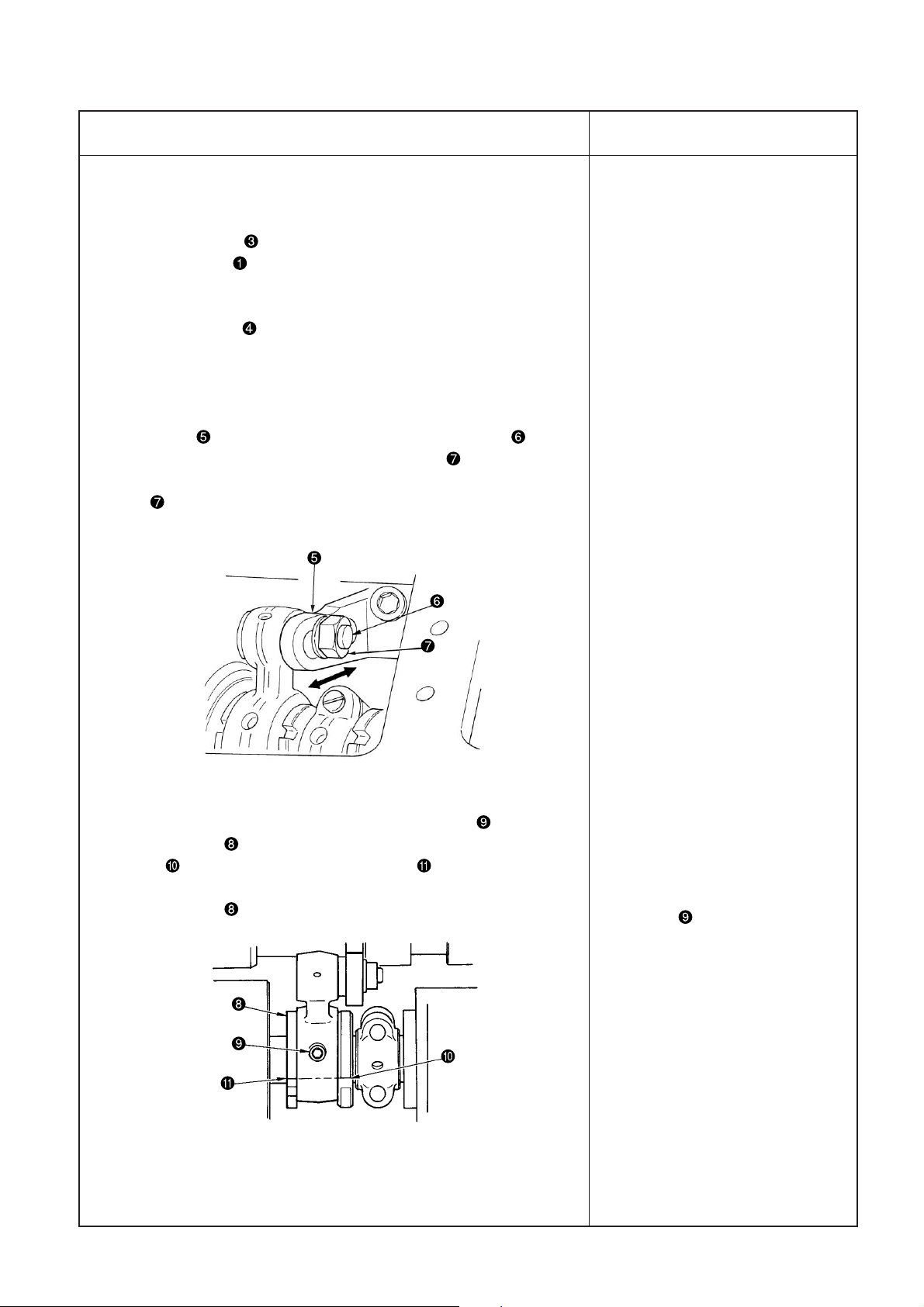

(6) Adjusting the spreader

Standard Adjustment

1. Height of the spreader

It is the standard that the height from the top surface of throat plate to the bottom surface of spreader

is 8.3 to 8.7 mm.

8.3 to 8.7mm

2. Longitudinal position of the spreader

It is the standard that when spreader returns from the extreme left position to the right and top end A of

thread hooking section reaches to the front of left needle, the clearance between the spreader and the left

needle is 0.1 to 0.3 mm.

Extreme

left position

A

0.1 to 0.3mm

A

4.5 to 5.5mm

16.0 to 18.0mm

3. Protruding amount

It is the standard that the dimension from the center of left needle to top end A of thread hooking section,

when spreader is in the extreme left position, is 4.5 to 5.5 mm.

4. Spreader stroke

It is the standard that the spreader stroke is 16 to 18 mm at the stroke of thread hooking section.

5. Timing of the spreader

Standard position is the position where the spreader is in the extreme left position when the needle bar

comes down from the upper dead point by 1.1 ± 0.1 mm.

– 16 –

Page 21

Adjustment Procedure

Results of Improper Adjustment

1. Adjusting the height of the spreader

2. Adjusting the longitudinal position of the spreader

Loosen setscrew and adjust the height and longitudinal position

of the spreader .

3. Protruding amount of the spreader

Loosen setscrew in the spreader folder and adjust the protruding

amount. Adjust aiming the adjustment figure of 5 mm.

4. Adjusting the spreader stroke

The standard position is located where the notch section of spreader

drive lever aligns with the shaft center of connecting pin . When

desired to increase the stroke, loosen lock nut and move in the

right direction. When desired to decrease the stroke, loosen lock

nut and move in the left direction. Adjust aiming the adjustment

figure of 17 mm.

5. Adjusting the timing between the needle bar and the spreader.

When changing the timing, loosen two setscrews in spreader

eccentric cam to adjust. Standard position is the position where

notch in the main shaft aligns with notch in spreader eccentric

cam. When changing, turn the upper pulley and change with spreader

eccentric cam fixed.

o Height of the spreader is improper,

stitch skipping of spreader occurs.

o Adjust the height in accordance

with the needle gauge.

o Even when the protruding amount

is excessive or insufficient, stitch

skipping of spreader will be

caused.

o When the protruding amount is

insufficient, it will be the cause for

left needle not to scoop covering

thread at overlapped section.

o When the stroke is increased,

disorder of covering thread

stitching will be caused.

o When the stroke is decreased,

stitch skipping of spreader will be

caused.

o When the timing is excessively

advanced, needle does not take

covering thread when it comes

down and stitch skipping will be

caused.

o When the timing is excessively

retarded, resistance increases

when covering thread slips out

from the spreader and a load is

applied to the right needle. As a

result, needle breakage or stitch

skipping will be caused.

(Caution) When changing,

temporarily tighten No.

2 screw in the rotation

direction of setscrews

and turn the upper

pulley to change.

– 17 –

Page 22

(6) Adjusting the spreader

Standard Adjustment

6. Adjustment figures of the spreader thread guide

(1) It is the standard that the clearance provided between spreader and spreader thread guide is 0.4 to

1.0 mm.

(2) It is the standard that the clearance provided between spreader thread guide and needle clamp thread

guide is 0.8 to 1.2 mm.

(3) Lateral position of the spreader thread guide

Top end of thread hooking section D of the spreader aligns with center E of slot C in spreader thread

guide when spreader is in the extreme right position.

0.8 to 1.2mm

0.4 to 1.0mm

D

C

E

– 18 –

Page 23

Adjustment Procedure

Results of Improper Adjustment

6. Spreader thread guide

(1) Adjust the height of spreader

to 8.3 to 8.7 mm. Loosen setscrews

in the spreader thread guide and adjust the clearance provided

between the top surface of spreader and spreader thread guide

to 0.4 to 1.0 mm.

8.3 to 8.7mm

(2) Needle clamp thread guide

Loosen setscrew in the needle clamp thread guide and adjust

the clearance provided between the needle clamp thread guide and

spreader thread guide to 0.8 to 1.2 mm.

(3) For the lateral direction, align the hole of needle clamp thread guide

to the prolonged line of the slot of spreader thread guide .

(Caution) When adjusting spreader thread guide in the lateral

direction, check whether there is any contact at section

B

(left side of spreader thread guide and needle

clamp )

o When height or position of the

spreader thread guide is improper, stitch skipping of

spreader thread will be caused.

oWhen height or position of the

needle clamp thread guide is

improper, stitch skipping of

spreader thread will be caused.

B

– 19 –

Page 24

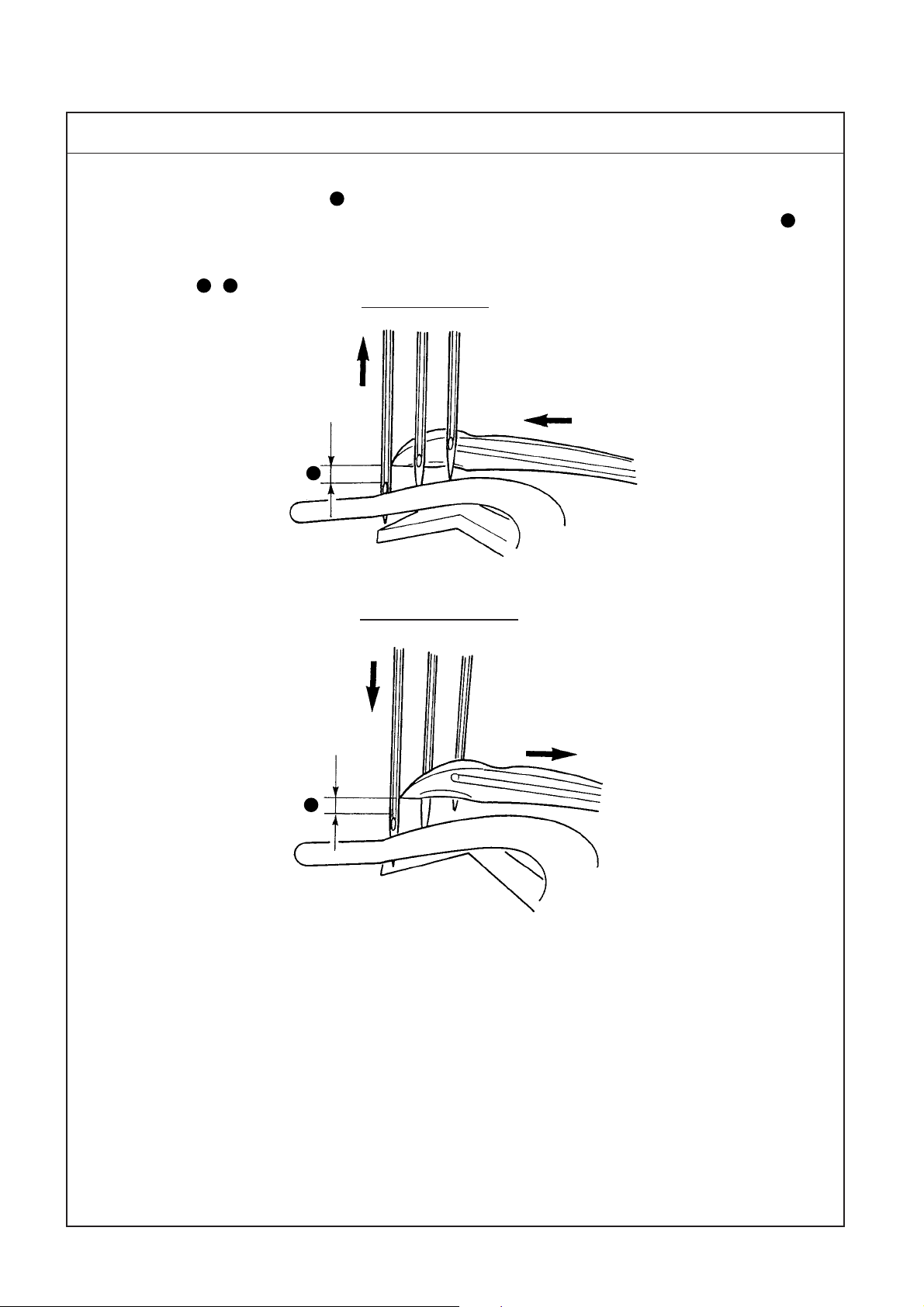

(7) Adjusting the timing relation between the looper and needle bar

Standard Adjustment

1. Timing relation between the looper and the needle bar (synchronization)

It is the standard that dimension A from the top end of needle eyelet to the blade point of looper passes the

rear of the needle and comes to the position of the right end of left needle is the same as dimension B from

the top end of needle eyelet to the blade point of looper when needle bar comes down from the upper dead

point, the blade point of looper passes the front of needle bar and comes to the position of the right end of

left needle. (A=B)

A

Going of looper

Returning of looper

B

– 20 –

Page 25

Adjustment Procedure

Results of Improper Adjustment

1. To adjust the timing relation between the needle and the looper,

remove the top cover, loosen four setscrews in the sprocket and

turn upper pulley in the state that the sprocket is held.

2. Adjusting procedure

(1) When adjusting the timing to "0" (zero)

1) In case dimension A when the looper advances is smaller than

dimension B when the looper retreats, the looper timing is

retarded (needle timing is advanced). In this case, loosen

setscrews in the sprocket and finely turn upper pulley in

the reverse direction.

2) In case dimension A when the looper advances is larger than

dimension B when the looper retreats, the looper timing is

advanced (needle timing is retarded). In this case, loosen

setscrews in the sprocket and finely turn upper pulley in

the normal direction.

(Caution) Be careful not to excessively turn upper pulley .

oWhen the difference in timing

(going and returning) of looper is

excessively large, stitch skipping

or entangling of needle thread

will be caused.

3. After the adjustment, fix four setscrews in the sprocket.

– 21 –

Page 26

(8) Returning amount of the looper

Standard Adjustment

1. It is the standard that returning amount of looper from top end of looper to the center of needle bar is

6.5 mm regardless of the needle gauge when looper is in the extreme right position.

6.5mm

2. Returning amount of looper for each gauge (dimension A)

2-needle 3-needle

Needle gauge Returning amount

4 4.5 — —

——5.6 3.7

——6.4 3.3

(Dimension

A

is the dimension fromthe center of right needle to the top end of looper .)

A

A

Needle gauge Returning amount

0 to 0.05mm

Unit : mm

A

– 22 –

Page 27

Adjustment Procedure

Results of Improper Adjustment

1. Loosen setscrew in the looper holder and move looper indicator

arm to the right and left for adjust.

2. After the adjustment, tighten setscrew in the looper holder.

Without fine adjustments

With fine adjustments

(Caution) When adjusting looper indicator arm , adjust the lateral

position while being careful that the looper indicator arm

does not move to and fro.

3. Longitudinal position

(1) Without fine adjustments

Adjust so that the clearance provided between blade point of

looper and middle needle is 0 to 0.05 mm when the top end of

looper comes to the center of middle needle from the extreme right

position.

(2) With fine adjustments

Turn adjusting screw to adjust the longitudinal position.

Turn clockwise to move the looper supporting arm to the rear

side and counterclockwise to move it to the front side.

o When the returning amount is

large, loop of needle thread becomes large and it is apt to fall.

As a result, stitch skipping or

thread breakage will be caused,

and stitch skipping on the back

is apt to occur.

In addition, thread tangling will be

caused.

o When the returning amount is

small, loop of needle thread is

small and stitch skipping or

thread breakage will be caused.

In addition, thread tangling will be

caused.

After the adjustment, fix the looper holder with setscrew in the

looper holder.

* Blade point of the looper comes in contact with the right needle

when rear needle guard fails to work. So, be careful.

– 23 –

Page 28

(9) Height of the needle

Standard Adjustment

1. It is the standard that the top end of needle eyelet of left needle aligns with the bottom end of looper when

the top end of looper passes the rear of the needle from the extreme right position and protrudes from the

left end of left needle by approximately 1 mm (1.1 mm), dimension B.

B

To align

Reference : Dimension C, height of left needle from top surface A of throat plate

Unit : mm

2-needle 3-needle

Needle gauge Height of left needle C Needle gauge Height of left needle C

4.0 9.3 — —

——5.6 8.5

——6.4 8.0

A

C

2. Scooping height of looper , dimension from the top end of needle eyelet to the top end of looper is 1.2 to 1.4 mm.

1.2 to 1.4mm

– 24 –

Page 29

Adjustment Procedure

Results of Improper Adjustment

1. Remove rubber cap in the face plate, loosen setscrew in the

needle bar bracket and adjust the height of the needle bar.

2. After adjusting the height, equally adjust the clearance A between

needle and needle hole in the throat plate and fix the needle

bar with setscrew in the needle bar bracket.

o When the height of the needle

is excessively different, stitch

skipping, needle breakage,

thread breakage, etc. will be

caused.

A

Equal

– 25 –

Page 30

(10)Locus and longitudinal motion of the looper

Standard Adjustment

1. Standard longitudinal motion of the looper

(1) It is the standard that the top end of left needle touches

the position of 1/4 to 1/3 from the bottom face of the

back of the looper when the looper returns from the

extreme left position.

(2) The position where the engraved marker line on looper

drive arm aligns with the center of the shaft of pin

is the standard.

1/4 to 1/3

—

2. Locus of the looper

0.1 to 0.2mm

2.5 to 2.7mm

It is the standard locus of the looper that the

clearance between the top end of looper and middle

needle is within 0.05mm (when the rear needle guard

fails to work) and the looper passes the left needle

with a clearance of 0.1 to 0.2 mm.

+

Lower pulley side

The standard position of the cam is the position

where the notch of looper longitudinal motion

eccentric cam aligns with notches of looper

driving shaft.

– 26 –

Page 31

Adjustment Procedure

Results of Improper Adjustment

1. Changing the longitudinal motion of the looper

(1) Remove 11 setscrews in bed top cover and remove the cover.

(2) When increasing the longitudinal motion of the looper, loosen nut

and lower the arm downward . from the engraved marker line.

(3) When decreasing the longitudinal motion of the looper, loosen nut

raise the arm upward from the engraved marker line.

Perform the adjustment in accordance with the needle used.

(Caution) After adjusting the longitudinal motion of the looper,

move the looper holder and re-adjust the longitudinal

position of the needle and the looper. (Refer to "(8)

Returning amount of the looper.)

2. Changing the locus of the looper

(1) Loosen two setscrews in the cam and change the locus of the

looper by turning the upper pulley with the cam fixed.

When it is turned in the direction of rotation, the timing is retarded,

and when turning in the reverse direction of rotation, the timing is

advanced.

(Caution) 1. It is possible to change the locus of the looper.

However, do not excessively change it from the

standard position.

2. When changing the locus of the looper, be sure to

check whether the top end of left needle touches the

position of 1/4 to 1/3 from the bottom face of the back

of the looper.

—

+

o When the longitudinal motion of

the looper is small, the rate that

needle touches the back of the

looper is increased and blunt

needle tip will be caused.

o When the longitudinal motion of

the looper is large, the clearance

provided between the needle and

the back of the looper is increased

and stitch skipping at the time of

returning of the looper will be

caused.

o When the timing is retarded, stitch

skipping is apt to occur at the time

of going of the looper, and

especially the clearance provided

between the looper and the left

needle is widened.

Needle strongly touches the back

of the looper and blunt needle tip

will be caused.

o When the timing is advanced,

stitch skipping is apt to occur at

the time of returning of the looper.

Chain-off thread does not come

out smoothly.

– 27 –

o When removing the top cover for

adjustment or the like, sealant is

peeled off. As a result, oil leakage

will be caused.

Page 32

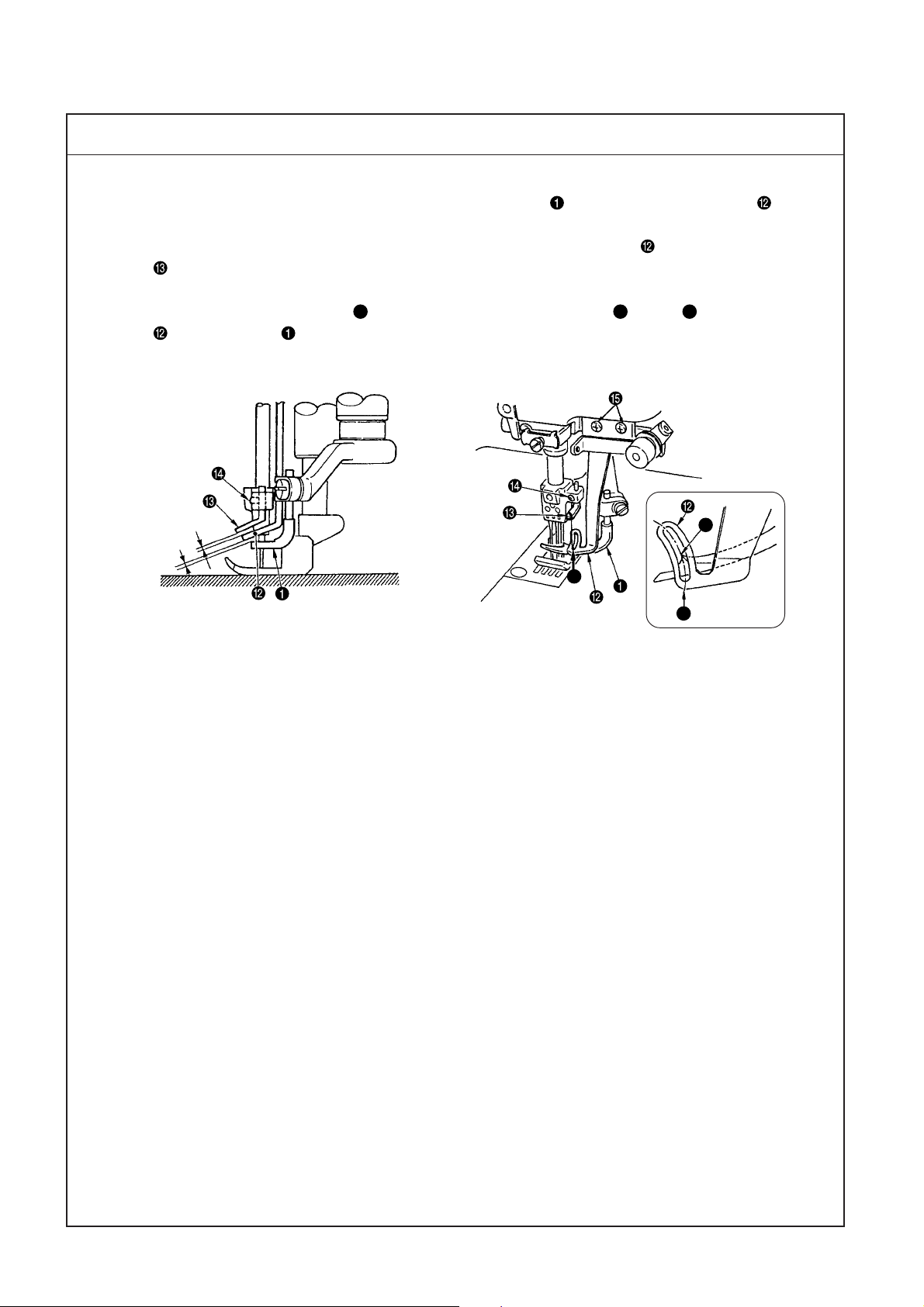

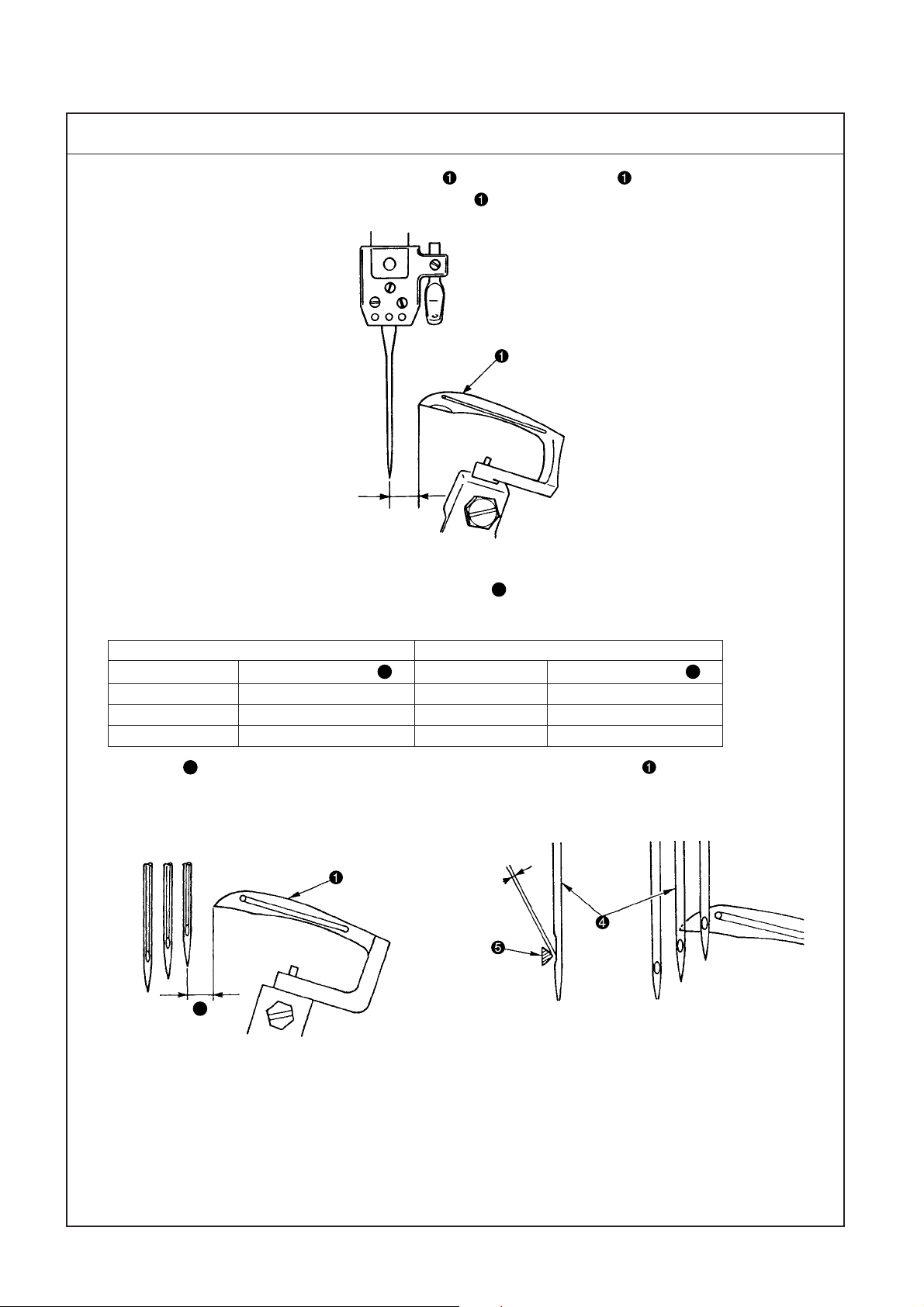

(11) Adjusting the needle guard

Standard Adjustment

1. Standard position of the rear needle guard

(1) Lateral position of rear needle guard

It is the standard that the lateral position of rear needle guard is the position where the rear needle guard

receives the needle in the range of B.

(2) Position of the height of the rear needle guard

It is the standard that ridge line A of rear needle guard enters in the needle eyelet of right needle when

the needle bar is in its lower dead position.

Details of section A

A

Ridge line

B

Needle eyelet

(3) Pressing amount of the rear needle guard

When the top end of looper comes from the extreme right position to the center of right needle, the

clearance provided between the needle and the top end of looper becomes 0 to 0.05 mm. Make rear

needle guard lightly touch the right needle and the pressing amount of the top end of needle becomes

0.1 to 0.2 mm.

It is the standard for the middle needle that when the top end of looper comes to the center of middle

needle, the clearance provided between the middle needle and the top end of looper becomes 0 to 0.05

mm and the pressing amount of the top end of the needle is such an amount that rear needle guard

lightly touches the middle needle.

0 to

0.05m

m

0 to

0.05m

m

– 28 –

0.1 to 0.2mm

Page 33

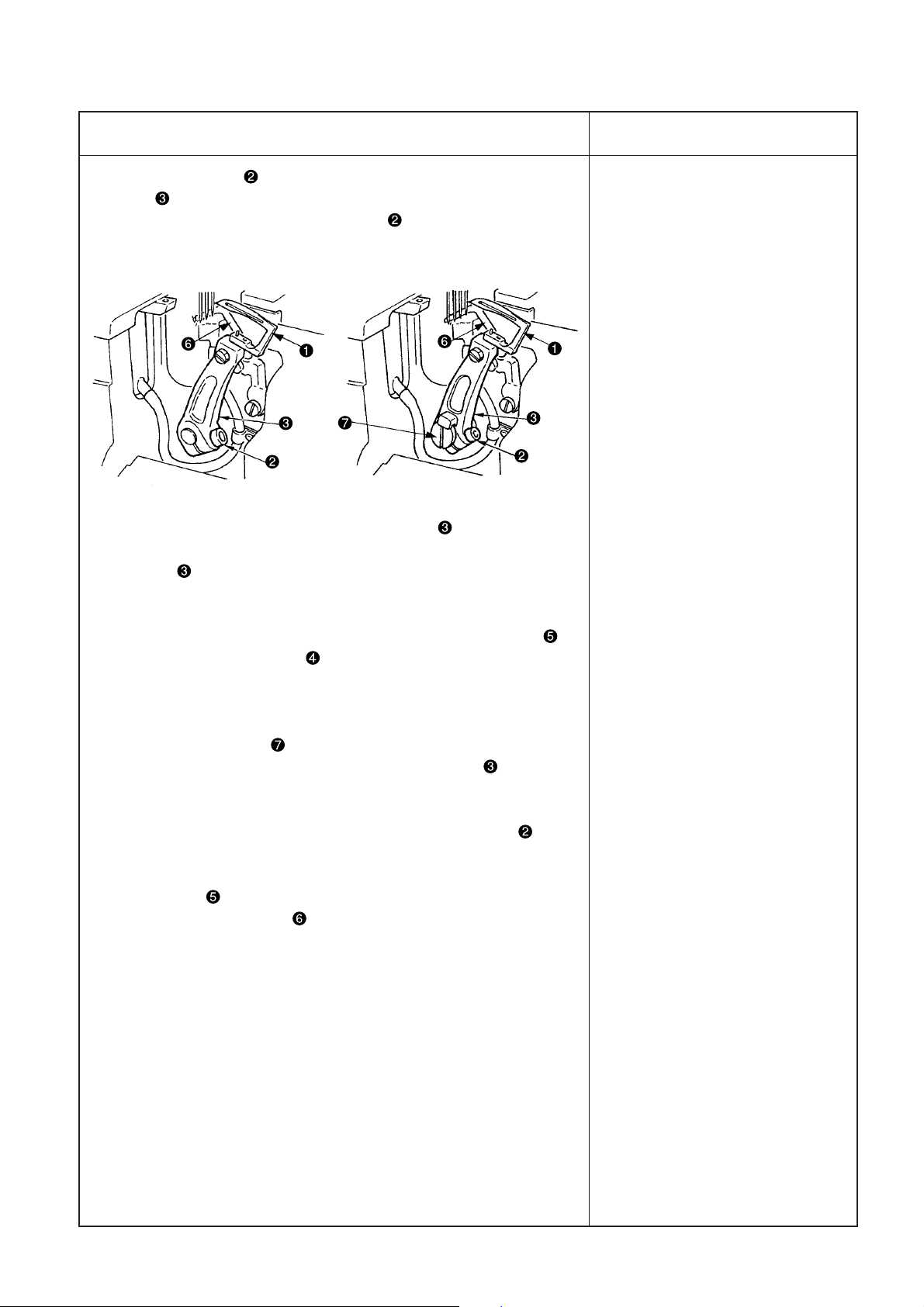

Adjustment Procedure

Results of Improper Adjustment

1. Loosen setscrew in the rear needle guard holder and perform

the adjustment in the lateral direction.

2. Loosen setscrew in the rear needle guard and perform adjustment

in the height direction and the direction of rotation.

3. After the adjustment, tighten setscrews and .

(Caution) After the adjustment, check by manual turning whether

the top end of looper does not come in contact with

the needle.

o When the pressing amount of

rear needle guard is small,

needle deflection increases and

stitch skipping, thread breakage,

needle breakage and worn-out of

the top end of looper will be

caused.

– 29 –

Page 34

(11) Adjusting the needle guard

Standard Adjustment

For MF-7700D-U10

(4) Timing of the rear needle guard

The standard position of rear needle guard cam is the position where timing mark in rear needle

guard cam aligns with the center of the notch of looper longitudinal cam .

To align

2. Front needle guard

(1) It is the standard that the clearance provided between front needle guard and the needle is 0.1 to 0.3 mm.

0.1 to 0.3mm

– 30 –

Page 35

Adjustment Procedure

Results of Improper Adjustment

For MF-7700D-U10

4. Remove the bed top cover.

Loosen two setscrews in rear needle guard cam and adjust

the timing.

When moving the cam in direction, timing is advanced, and when

moving in direction, it is retarded.

Pulley side

—

+

—

+

1. Loosen setscrew in the front needle guard and adjust the

clearance.

Adjust so that the clearance provided between the needle and front

needle guard is 0.1 to 0.3 mm when looper moves from the

extreme right position to the left and passes the rear side of the

respective needles and fix the front needle guard with setscrew .

* Place front needle guard as near as the needle to such an extent

that needle thread passes smoothly in accordance with kind and

thickness of thread.

o The cam is excessively changed

from the standard position,

needle breakage or stitch skipping will be caused.

o When the front needle guard and

the needle come excessively

near, stitch skipping or needle

breakage will be caused.

(Caution) Check by manual turning whether the needle is pinched

with front needle guard and the rear needle guard.

– 31 –

Page 36

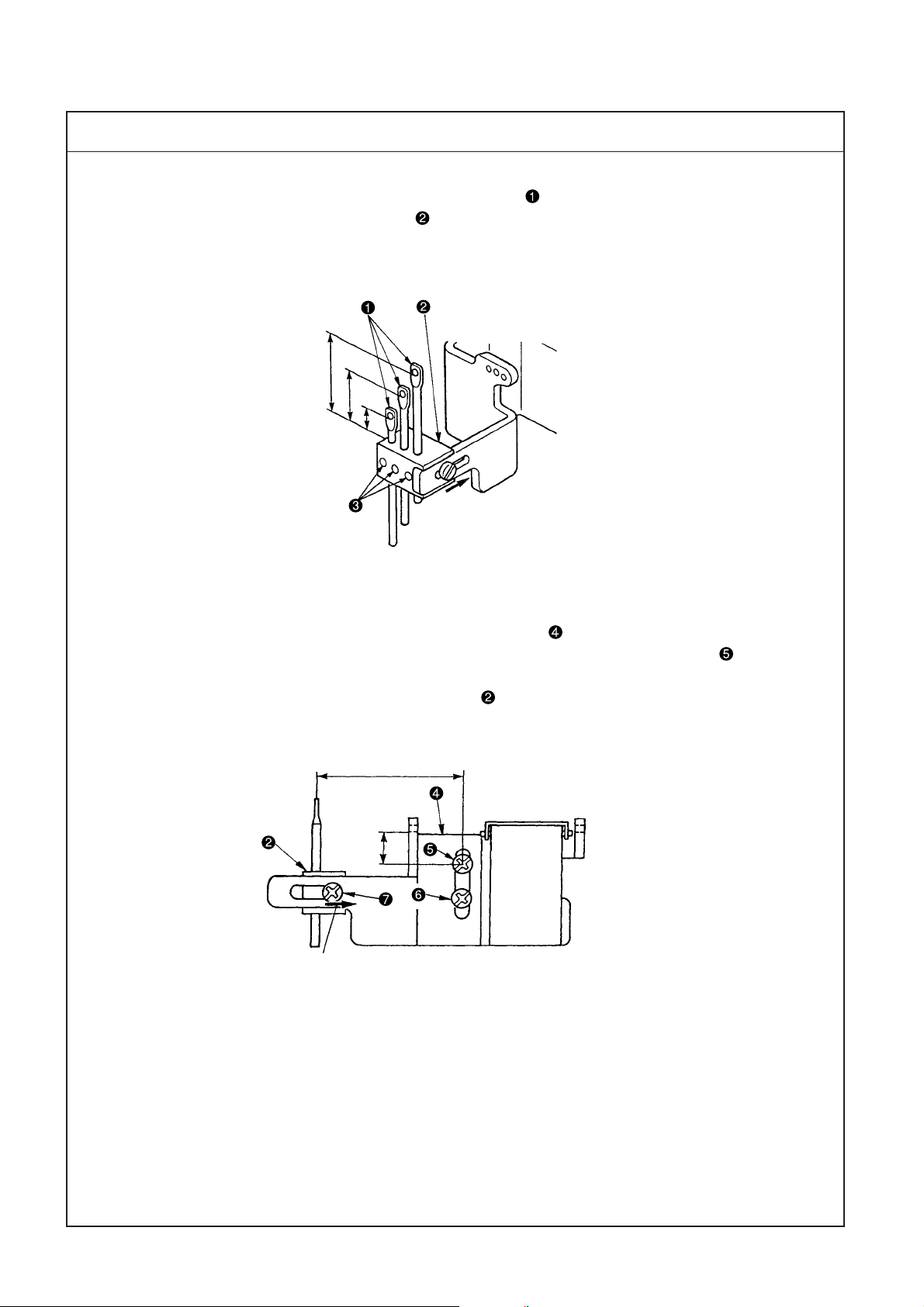

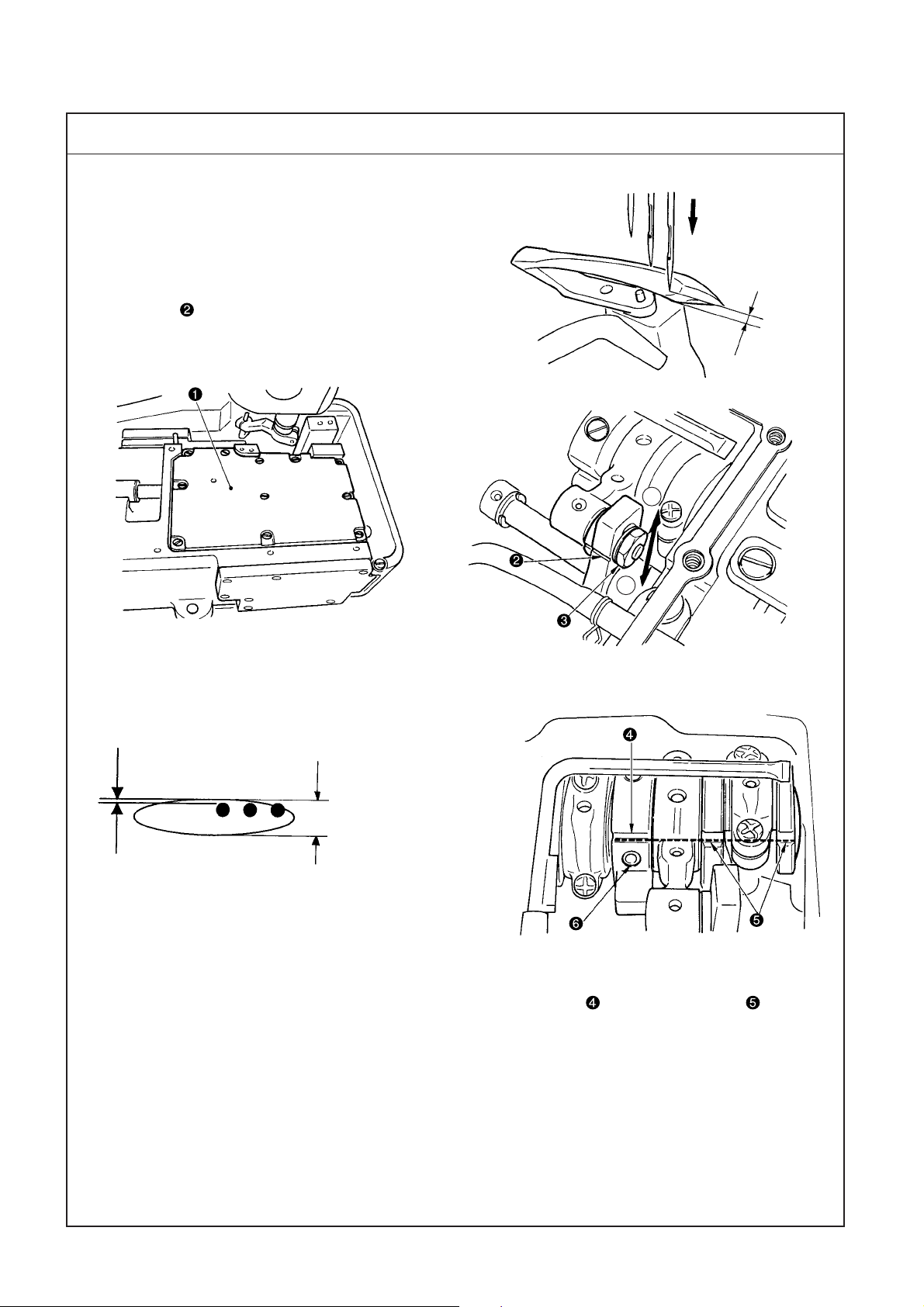

(12)Installing cover of the looper and needle guard after adjusting

Standard Adjustment

1. Installing bed top cover

A

– 32 –

Page 37

Adjustment Procedure

Results of Improper Adjustment

1. When the adjustment of (10) Locus and longitudinal motion of the

looper or (11) Adjusting the needle guard has been performed, apply

sealant to section A and install bed top cover .

oWhen removing bed top cover

for adjustment or the like, sealant is peeled off and oil leakage

will be caused.

– 33 –

Page 38

(13)Adjusting the feed dog

Standard Adjustment

1. Height of the feed dog

It is the standard that the height of feed dogs (main feed dog and differential feed dog ) is 1 mm from

the top surface of the throat plate when feed dogs and are in the highest position.

2. Tilt of the feed dog

It is the standard that the tilt of feed dogs and is flush with throat plate when feed dogs and

are in the highest position.

Flush

1mm

– 34 –

Page 39

Adjustment Procedure

Results of Improper Adjustment

1. Loosen setscrew in the differential feed dog and setscrew in

the main feed dog, and adjust the height.

(1) Adjust the top surface of throat plate and the height of the rear

end of main feed dog to 1 mm when feed dogs and come

to the highest position, and fix the main feed dog with setscrew

in the main feed dog.

(2) For the height of differential feed dog , adjust the height of front

end of main feed dog and rear end of differential feed dog

, and fix the differential feed dog with setscrew in the differential

feed dog.

2. Adjusting the tilt of the feed dog

(1) Remove rubber plug in the cover located in the rear of the bed

and loosen the setscrew in the feed tilt adjustment shaft located in

the rear with a hexagonal wrench key of 2.5 mm.

(2) When turning feed dog tilt adjustment shaft to the right or left, the

top ends of feed dogs and move up or down and the tilt of

feed dogs and can be adjusted.

(Caution) After the adjustment check the height of feed dogs

and .

o When the position of the feed

dog is high, stitch skipping, defective chain-off, return of feed,

etc. will be caused.

Throat plate comes in contact

with feed dog and damage of

components or abnormal noise

will be caused.

o When the position of the feed

dog is low, the stitch length

becomes short when the sewing

is finished and performance of

getting over the overlapped

section is deteriorated.

o When the position of the feed

dog is excessively low, looper

and feed dog may come in

contact with each other.

oWhen the tilt of the feed dog is

raised toward you, performance

of catching material is improved.

oWhen the tilt of the feed dog is

lowered toward you, it is effective

in irregular stitches and

puckering.

– 35 –

Page 40

(13)Adjusting the feed dog

Standard Adjustment

3. Lateral position of the feed dog

It is the standard of the lateral position of the feed dog that the left and right clearances A of the feed dog in

terms of the slots of the throat plate are parallel and equal.

A

A

– 36 –

Page 41

Adjustment Procedure

Results of Improper Adjustment

3. Adjusting the lateral position of the feed dog

(1) Remove the bed top cover and remove setscrews in rocking bar

guide 2 .

(Caution) When setting the feed motion amount to 3.6 mm (max.)

and the differential feed ratio to 1 : 1 before the

adjustment, the adjustment at the time of assembling

can be performed with ease.

(2) Loosen setscrew in the feed tilt adjustment shaft and setscrew

in the feed tilt eccentric shaft . Move feed tilt eccentric shaft by

approximately 2mm in the left direction shaft, move feed tilt

Adjustment shaft by approximately 2mm in the right direction,

and open a clearance to the right and left of square block .

(Caution) When moving feed tilt eccentric shaft , lower

downward differential lever pin with differential feed

ratio change lever . Edge of feed tilt eccentric shaft

comes in contact with the pin and a clearance can not

be made.

(3) When loosening setscrew in the differential feed lever and

setscrew in the main feed lever, adjustment of the rocking bar in

the lateral direction can be performed.

(4) Loosen setscrew in rocking bar guide 1 and adjust main feed

rocking bar and differential feed rocking bar to the right and

left so that the clearances of the feed dog in terms of the slots of the

throat plate are parallel and equal with feed dog and throat plate

attached. When the equal clearances are set, tighten setscrew to

fix rocking bar guide 1 , attach rocking bar guide 2 and guide

setscrews , and fix the rocking bar so that it is put between the

setscrews.

(5) Bring feed tilt adjustment shaft and feed tilt eccentric shaft to

their home positions to get rid of the right and left clearances of

square block .

(6) After adjusting the lateral position of the feed dog, loosen setscrew

in the thrust collar , remove the thrust of the shaft with thrust collar

and fix the thrust collar with the setscrew.

(Caution) 1. After fixing, check the lateral play of the rocking bar

by moving the feed dog to the right or left. At the

same time, move the rocking bar to and fro and check

whether it moves smoothly.

2. For the fixing of setscrew in the differential feed

lever and setscrew in the main feed lever, refer to

the longitudinal adjustment value of the feed dog.

3. When fixing setscrew in the feed tilt adjustment

shaft, check the tilt of the feed dog and when fixing

setscrew in the feed tilt eccentric shaft, there

should be no lateral play of square block .

o When the lateral position of the

feed dog is incorrect, worn-out of

throat plate and feed dog will be

caused.

o Heating or abnormal noise will

occur.

o The feed components will wear

out early , or the looseness will be

caused.

– 37 –

Page 42

(13)Adjusting the feed dog

Standard Adjustment

4. Longitudinal position of the feed dog

(1) Position of the main feed dog : it is the standard that the position where the clearance from the edge of the

slot of the throat plate to the front face of the main feed dog is 0.6±0.2 mm at the position where the main

feed dog travels to the extreme front position (operator’s side) when feed momentum is set to 3.6 mm

(maximum).

(2) Position of the differential feed dog : it is the standard that the position where the clearance provided

between main feed dog and differential feed dog is 1.6±0.2 mm when the differential feed ratio is set to 1 :

1 after adjusting the position of the main feed dog.

0.6±0.2mm 1.6±0.2mm

5. For C10

– 38 –

0.6±0.2mm

±0.2mm

1

Page 43

Adjustment Procedure

Results of Improper Adjustment

4. Longitudinal position of the feed dog (condition : feed momentum

3.6 mm (maximum))

(1) When fixing setscrew in the main feed lever , adjust the clearance

from the edge of the slot of the throat plate to the front face of the

main feed dog to 0.6±0.2 mm when the feed dog travels to the

extreme front position (operator’s side), press the main feed lever to

the rocking bar side, and fix it with setscrew.

(2) When fixing setscrew in the differential feed lever, set the

differential feed ratio to 1 : 1, adjust the clearance provided between

the main feed dog and the differential feed dog to 1.6±0.2 mm, press

the differential feed lever to the rocking bar side, and fix it with

setscrew.

(Caution) When the adjustment value changes greatly, feed dog

or throat plate will be broken.

o When the fixing position of the

main feed lever slips greatly out

of position, abnormal noise or

abrasion will be caused.

o When the fixing position of the

differential feed lever slips greatly

out of position, abnormal noise

or abrasion will be caused.

5. For C10

Front and rear positions of the feed dog

(1) When the main feed dog has a pitch of 3.6mm, the clearance

between the most advanced position of feed (worker side) and the

throat plate shall be 0.6 ± 0.2mm.

(2) When the differential feed dog has a pitch of 2.5mm and the

differential feed ratio is 1:1 at that time, the clearance between the

main feed dog and the differential feed dog shall be 1 ± 0.2mm.

– 39 –

Page 44

(14)Adjusting the feed relation

Standard Adjustment

1. Changing the stitch length

It is possible for the standard stitch length to adjust up to 1.2 to 3.6 mm.

Turning feed adjust knob clockwise increases the stitch length and turning it counterclockwise decreases

the stitch length.

2. Changing the differential feed ratio

Differential feed ratio is 1 : 0.7 to 1 : 2 (stitch length : less than 2.5 mm).

Gathering

Stretching

– 40 –

Page 45

Adjustment Procedure

Results of Improper Adjustment

1. When making the stitch length more than 3.6 mm, loosen setscrew

of the feed adjustment stopper pin, turn feed adjust knob

clockwise, and adjust the stitch length. By turning feed adjust knob

, pin is pushed out. Fix pin with setscrew in the feed

adjustment stopper pin after adjusting the stitch length.

Maximum stitch length is 4.4 mm.

o When the stitch length is set to

more than 3.6 mm, the contact

of main feed dog, differential feed

dog and throat plate occurs due

to the adjustment in case of the

standard position of the feed dog.

Additionally machine the feed

dog to satisfy the need.

o When using the machine with the

stitch length of more than 2.5 mm

and the maximum differential

feed ratio, turn the machine by

hand and check whether there is

any contact with feed dog and

throat plate.

In addition, when more gathering

is necessary , grind the differential

feed dog.

2. Loosen differential lock nut and raise lever to increase the

differential feed ratio (shrinkage in stitched material cloth). When

the lever is lowered, the differential feed ratio becomes small

(elongation in stitched material cloth).

Fine adjustment of the differential feed ratio can be performed with

micro-adjust knob .

When engraved marker of the differential feed lever is aligned with

the long engraved marker line on the dial plate, the momentum of the

main feed dog and the differential feed dog becomes almost 1 : 1.

(Caution) For some stitch lengths and differential feed ratios,

improper adjustments may give rise to breakage as a

result of contact between feed dogs or between feed

dog and throat plate.

– 41 –

Page 46

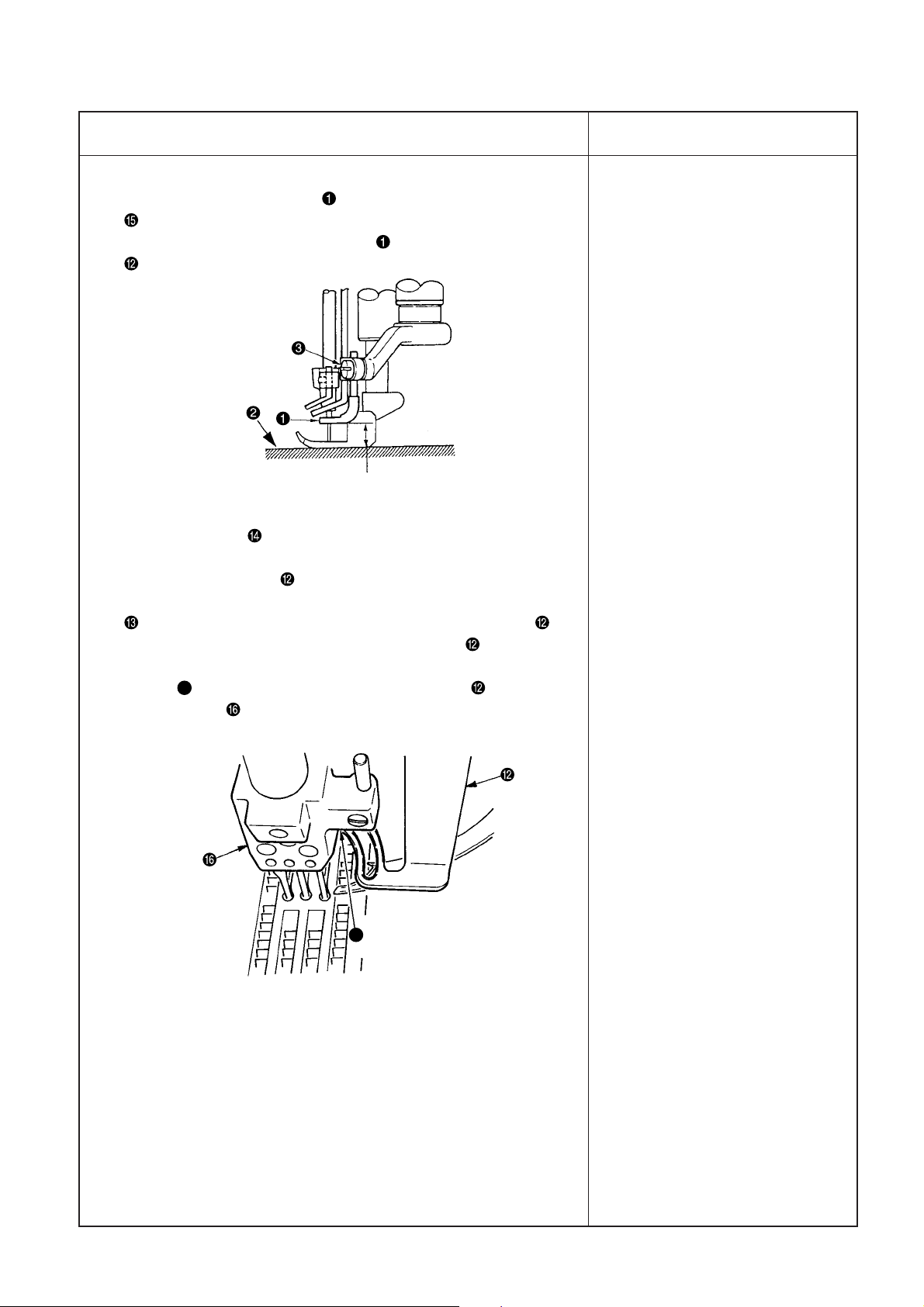

(15)Adjusting the presser foot

Standard Adjustment

1. Height of the presser foot

Height of the presser foot has to be the position the presser foot does not come in contact with other

components at the position where lifter lever is lowered and comes in contact with height adjustment

screw .

Dimension A

8 mm in case of needle gauge 5.6 mm without top covering

5 mm in case of needle gauge 5.6 mm with top covering

2. Position of the thrust collar

(1) Clearance provided between thrust collar and presser shaft bushing is 0.1 mm at the position where

lifter lever is lowered and comes in contact with height adjustment screw .

0.1mm

A

Throat plate

3. Position of the lifter connecting plate

(1) Adjust the clearance provided between lifter connecting plate and hinge screw to 0.5 mm when the

presser foot is lowered in the state that the feed dog comes down below the throat plate.

(2) Adjust so that the needle enters in the center of needle entry of the presser foot and fix the presser foot with

setscrew in the presser bracket.

0.5mm

– 42 –

Center of needle entry

Page 47

Adjustment Procedure

Results of Improper Adjustment

1. Adjusting the height of the presser foot

Loosen adjustment nut . Lower lifter lever , adjust height

adjustment screw , and fix nut at the position where the presser

foot does not come in contact with other components.

2. Adjusting the thrust collar

Loosen setscrew in the thrust collar and adjust the clearance.

When the height of the presser foot is changed, Be sure to perform

the adjustment of the clearance of thrust collar and check the

clearance.

3. Adjusting the lifter connecting plate

For the adjustment of the clearance provided between lifter

connecting plate and hinge screw , loosen setscrew in the

lifter lever shaft when the feed dog lowers from the top surface of

the throat plate and the bottom face of the presser foot comes in

close contact with the throat plate.

o When the position of the presser

foot is too high, it comes in contact with the spreader, and breakage, stitch skipping, etc. will be

caused.

In addition, the needle tip comes

out from the sole of the presser

foot. As a result, sewing material

is damaged or needle breakage

will be caused.

o In case the clearance of thrust

collar is large, when the

presser foot gets over the

overlapped section, the presser

foot comes in contact with other

components and will cause the

damage.

o When replacing the presser foot

due to the replacement of the

gauge or the like, check the

clearance provided between

thrust collar and lifter

connecting plate .

o When the clearance of lifter

connecting plate does not

exist, not only feed force is

reduced but also components

are led to breakage since the

presser foot does not come down

to the top surface of the throat

plate when the feed dog comes

down from the top surface of the

throat plate.

o When adjusting the lever shaft,

adjust the height of lifter lever .

– 43 –

Page 48

(16)Adjusting the micro-lifter

Standard Adjustment

1. Micro-lifter

Adjust the micro-lifter in accordance with sewing conditions for use.

Major applicable process

1. When twist occurs in the hemming bottom process.

2. When tape is twisted in collecting.

Down

Up

– 44 –

Page 49

Adjustment Procedure

1. Adjusting the micro-lifter

(1) When micro-lifter knob is turned counterclockwise, micro-lifter

stopper lower and comes in contact with presser lifting lever .

Then the presser foot goes up.

Adjust the height accordance with the sewing conditions.

(2) When micro-lifter knob is turned clockwise, micro-lifter stopper

is raised and comes in contact with presser lifting lever . Then

the presser foot comes down.

(Caution) When the micro-lifter is not used, turn clockwise micro-

lifter knob and fix micro-lifter stopper at the highest

position.

Results of Improper Adjustment

– 45 –

Page 50

(17)Adjusting the looper thread cam

Standard Adjustment

1. Adjust so that thread comes off from the highest place of looper thread cam when needles come down

and the top end of left needle aligns with the bottom surface of looper . Then tighten setscrews to

fix the looper thread cam.

Theread

To align

2. Preventing thread winding around the looper thread cam

Adjust the clearance provided between the top end of section A of looper thread winding prevention plate

and the edge of looper thread cam to approximately 0 to 0.3 mm (the plate should not come in contact

with looper thread cam ).

A

– 46 –

Page 51

Adjustment Procedure

Results of Improper Adjustment

1. Loosen setscrews in the looper thread cam and adjust while

checking that looper thread comes off from the periphery of the looper

thread cam.

(Caution) When setscrews in the looper thread cam are

loosened, looper thread cam moves in the shaft

direction as well.

Assemble so that the clearances provided between the

cam and the thread guide are equal.

Equal clearances

oWhen the position of looper

thread cam slips greatly out

of position, stitch skipping or defect of thread tightness on the

back of the looper is apt to

occur.

2. Adjusting the looper thread winding prevention plate

Adjust the clearance to approximately 0 to 0.3mm, provided between

the top end of Section A of looper thread winding prevention plate

and the edge of looper thread cam . (Loosen setscrews (2

pcs.) of looper thread cam and move them to the right and left to

adjust the clearance to 0 to 0.3mm. After that, tighten setscrews

(2 pcs.).) Since then, tighten setscrews (2 pcs.) to fix the looper

thread winding prevention plate.

o It is effective to adjust as narrow

as possible the clearance

provided between the top end of

click section (section A) of looper

thread winding prevention plate

and the edge of looper thread cam

. However, when making them

come too near and come in

contact with each other, looper

thread cam is scratched and

winding is caused by this

adjustment, instead.

– 47 –

Page 52

(18)With regard to lubrication

1. Replacing the oil filter

Normal lubrication cannot be performed if dust

collects in oil filter .

Inspect it every 6 months.

Standard Adjustment

2. Oil circulation identification window

Make sure that lubricating oil rises to oil circulation

identification window during operation.

<When using the sewing machine for the first time>

Lubricating oil has been taken out at the time of

delivery. Be sure to supply lubricating oil before

using the sewing machine for the first time.

*Oil used : JUKI MACHINE OIL 18

(Caution) Do not use oil addition agent since

deterioration of lubricating oil or

machine trouble will be caused.

Remove oil hole cap and fill the oil reservoir

with lubricating oil up to the level between the upper

and lower engraved marker lines of oil gauge .

<Checking before using the sewing machine>

1) Check oil gauge and make sure that lubricating

oil level is between the upper and lower two lines.

When lubricating oil level lowers below the lower

line, supply lubricating oil.

2) Make sure that lubricating oil comes out from the

nozzle of oil circulation identification window

when rotating the sewing machine. When

lubricating oil does not come out, perform

"Inspecting and replacing the oil filter ".

Lubrication

– 48 –

Page 53

Adjustment Procedure

Results of Improper Adjustment

1. Inspection and replacement

Loosen setscrews in the oil filter cap and remove oil filter cap .

Draw out oil filter to inspect it. When it is clogged with dust, replace

it with a new one.

After the replacement, fix oil filter cap with setscrews in the oil

filter cap.

(Caution) When removing the oil filter cap , lubricating oil

collected in oil filter will leak out. So, be careful.

2. Oil circulation identification

(1) In case the oil does not come out from oil circulation identification

window even when oil filter is replaced with a new one, remove

six setscrews in the oil pan, remove oil pan , and tilt the machine

head to the rear up to the position where pipe connecting joint screw

can be removed.

(2) Oil sucked up from gear pump passes oil pipe and enters oil

filter from pipe connecting joint screw . When the lubrication oil

does not rise to oil circulation identification window , The hole in

pipe connecting joint screw may be clogged with dust. So, check

it.

(Caution) When there is any foreign material in oil pan , remove

it.

o In case oil cannot be observed

from oil circulation identification

window even when the sewing speed is 2,500 rpm or over,

the machine will be in danger of

seizure if the operation is continued.

– 49 –

Page 54

(18)With regard to lubrication

3. Oiling

Standard Adjustment

No oiling

4. Replacing the lubricating oil

– 50 –

Page 55

Adjustment Procedure

3. Oiling

The mechanisms inside the frame such as the needle bar, presser

lift and spreader components are lubricated with grease. Never add

oil inside the frame.

(Caution) If inside of the frame is oiled, the grease will be expelled,

resulting in mechanical failure.

Results of Improper Adjustment

4. Replacing the lubricating oil

In case of the new sewing machine, replace the lubricating oil (JUKI

MACHINE OIL 18) with new one after using it for approximately one

month. Then replace the lubricating oil every six months.

(1) Set a container to receive the lubricating oil under drain screw

.

(2) Remove drain screw . The lubrication oil is drained.

(3) After the drain, wipe out the oil and attach the drain screw .

– 51 –

Page 56

(19)Setting for functions of SC-500

Functions can be selected and specified by means of the four setting switches and light emitting diode located

inside the front cover of the SC-500.

Specified No. Specified value

Switch for entering specified value changed Down switch (DOWN)

and updating setting No. in DOWN direction Up switch (UP)

Switch for entering specified value changed

and updating setting No. in UP direction

(Caution) 1. Do not perform switch operations other than those described in the following explanations.

2. Be sure to re-turn the power switch ON after one second or more has passed. If the power is

turned ON immediately after turning it OFF, the sewing machine may not work normally.

In this case, turn ON the power again.

How to change over to the function setting mode

(1) Turn OFF the power to the unit.

(2) Pressing switch , turn ON the power to the unit.

(3) Indication , will be shown on the display. (If the

indication fails to change, re-perform the procedure

1) and 2).

– 52 –

Page 57

Specified

No.

(4) When you want to advance the setting No., press

switch to advance the setting No.

When you want to return the setting No., press switch

to return the setting No.

(Caution) 1. When switch (switch ) is held

pressing, the setting No. will return

(will advance) continuously.

2. When the setting No. is advanced (returned), the contents which are before

by one (after by one) will be changing

the contents (up/down switch is

touched).

EXAMPLE) CHANGING THE FLICKER REDUCING

FUNCTION (SETTING No. 5)

Press switch five times to set the setting No. to “5”.

Press switch five times to change the set No. to “5”

since the current set value is displayed on LED .

(Standard : “0”)

(Caution) Keep pressing switch or switch , and

the setting value can be changes continuously.

(5) When the change has been completed, press switch

or to specify the changed value.

(Caution) 1. When turning OFF the power before

performing this work, the contents

which have been changed are not updated.

2. Press switch , and screen display

will change to the contents of thew

setting No. which is before by one.

3. Press switch , and screen display

will change to the contents of next setting No. After completing the operation, turn OFF the power and turn ON

the power again to return to the normal operation.

After completing the operation, turn OFF the power and

turn ON the power again return to the normal operation.

– 53 –

Page 58

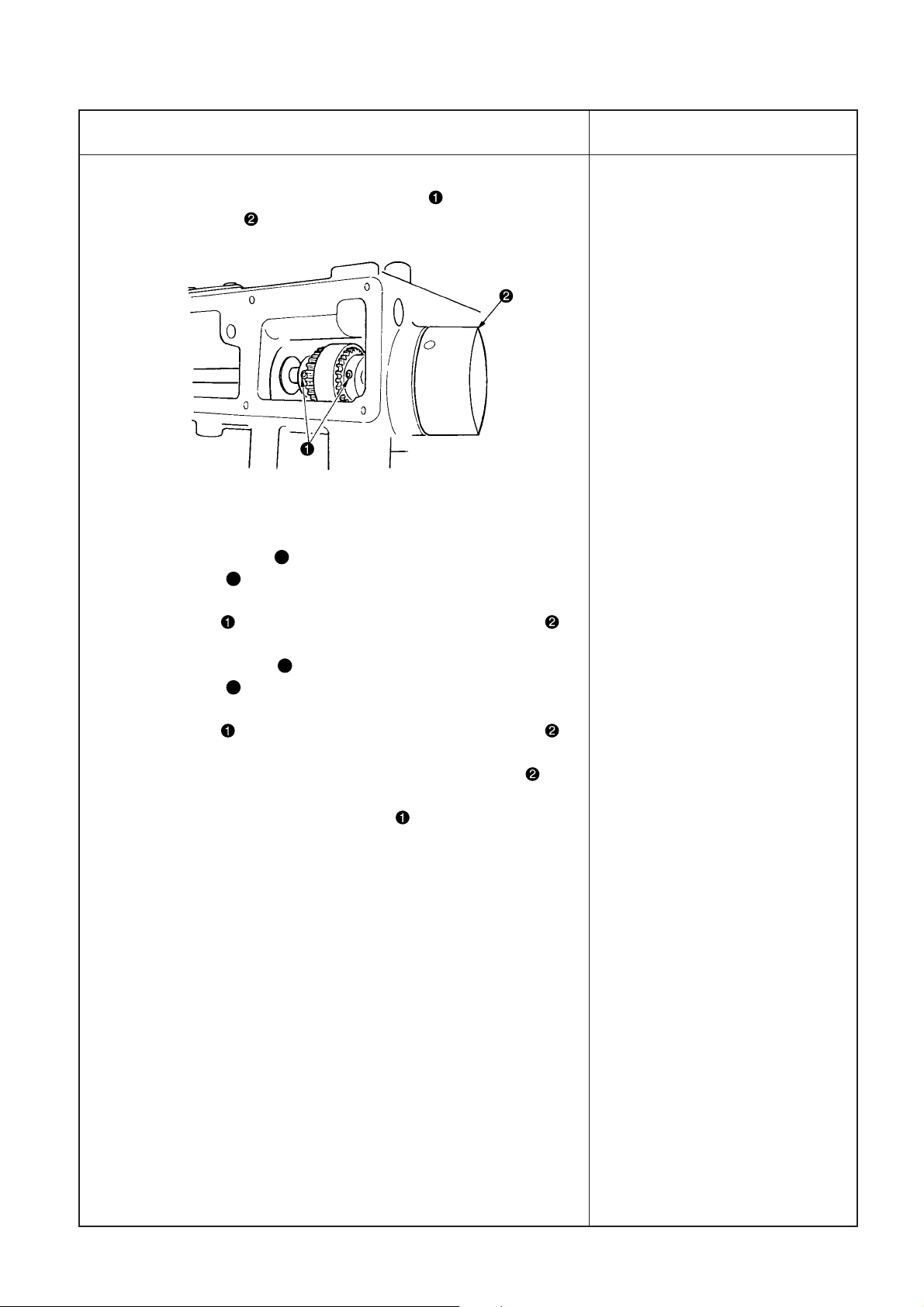

(20) Adjusting and setting SC-510

1. When SC-510 is used, install the motor referring to the Instruction Manual for SC-510.

2. Installation of the synchronizer

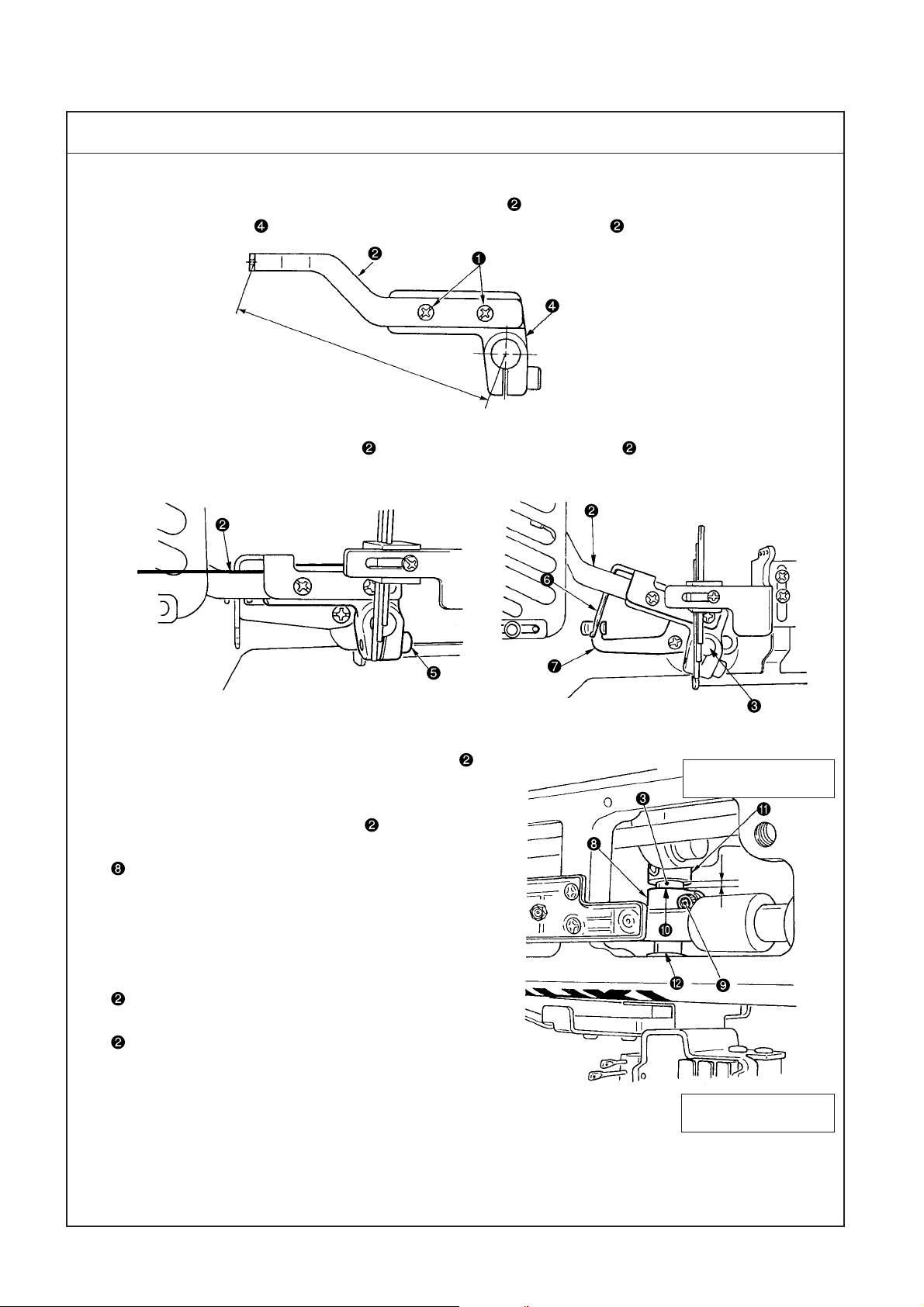

1) Synchronizer can be installed by the method below.

2) Using two setscrews , mount synchronizer fixing

plate on the sewing machine. Then, install

synchronizer on it.

3) Fix a cord of synchronizer to synchronizer fixing

plate by means of cable clip band . Fasten the

cord in the illustrated position, using cord clamp

and setscrew .

– 54 –

Page 59

3. Synchronizer adjustments

The synchronizer can be adjusted in the procedures specified below.

WARNING :

To protect against possible injury to hands or fingers due to abrupt start of the machine during performing

adjustment, perform the adjustment of the stop position under the function setting mode.

A

1) Loosen screw and remove cover .

2) Turn disk on this side by hand, and adjust the

adjusting mark “B” of disk in the rear to edge

of disk .

3) Temporarily tighten the synchronizer to the lower

main shaft handwheel with screw .

4) When the power is turned ON, the sewing machine

turns approximately by one half and stops.

5) Turn OFF the power, and loosen screw .

6) Holding section B of the synchronizer so as not to

move, turn the upper main shaft handwheel, and

temporarily tighten screw in the position where

mark of the handwheel is adjusted to mark on

the machine head side.

7) Turn ON the power again and make sure that the

sewing machine stops where mark of the

handwheel is apart from mark on the machine

head side. Then tighten screw .

B

8) After the adjustment, be sure to attach cover and

tighten screw .

9) After the adjustment above has been performed,

when the sewing machine stops at the DOWN position, top end C of the looper is located at the position where it has scooped loop D of left needle

D

thread as shown in the figure.