Page 1

MF-7500-E11

INSTRUCTION MANUAL

1

Page 2

CONTENTS

1. SPECIFICATIONS ........................................................................................................................ 1

2. DRAWING OF TABLE (SEMI-SUBMERGED TYPE) .................................................................. 2

3. INSTALLATION OF THE DUST CHUTE ..................................................................................... 3

4. OPENING AND CLOSING THE COVER ..................................................................................... 4

5. ADJUSTMENT PROCEDURE OF THE KNIFE PRESSURE ...................................................... 4

6.

ADJUSTMENT PROCEDURE OF KNIFE CUTTING POSITION .............................................................. 5

7. ADJUSTMENT PROCEDURE OF ENGAGEMENT AMOUNT OF KNIVES ............................... 5

8. REPLACEMENT PROCEDURE OF MOVING KNIFE AND FIXED KNIFE ................................. 6

9. OILING ......................................................................................................................................... 6

10. ADJUSTMENT PROCEDURE OF FRONT-UP AMOUNT OF THE PRESSER FOOT ............... 7

11. ADJUSTMENT PROCEDURE OF THE POSITION OF THE TAPE GUIDE ............................... 7

12. ADJUSTMENT PROCEDURE OF THE WIDTH OF THE TAPE GUIDE ..................................... 7

13. ADJUSTMENT PROCEDURE OF THE FABRIC PRESSER ...................................................... 7

14. ADJUSTING THE ANGLE OF MESH OF THE KNIFE ................................................................ 8

i

Page 3

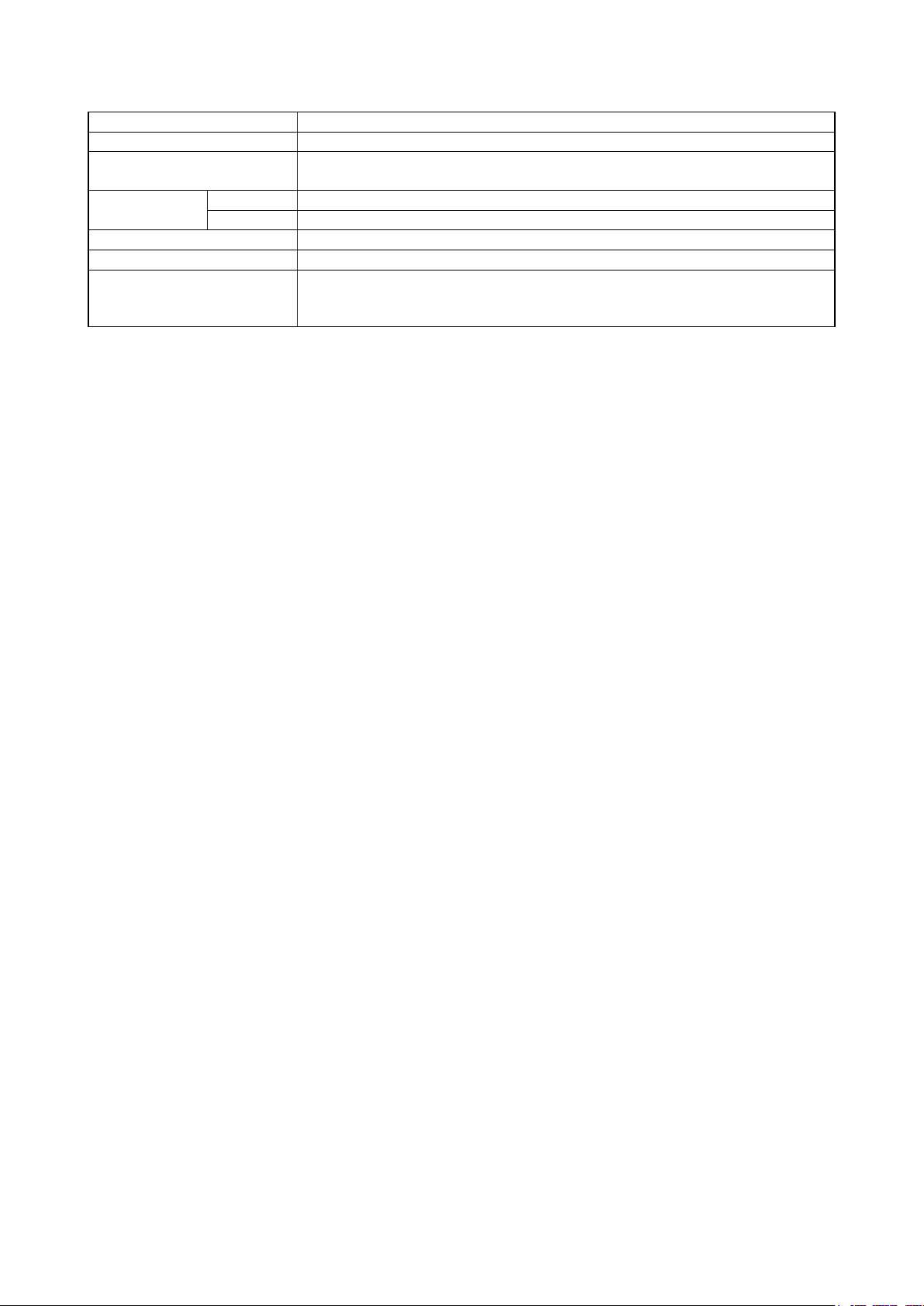

1. SPECIFICATIONS

Model MF-7500-E11

Class name With fabric undertrimmer for elastic tape attaching

Sewing speed

Needle gauge 3-needle 5.6 mm, 6.4 mm

2-needle 4.0 mm

Differential feed ratio 1 : 0.7 to 1 : 1

Stitch length 0.9 to 3.6 mm (Adjustable up to 4.0 mm)

Noise

Max. 6,000 sti/min (5,000 sti/min with MD) (at the time of intermittent operation)

Speed of stitch at the delivery. 4,000 sti/min (at the time of intermittent operation)

-

Equivalent continuous emission sound pressure level (LpA) at the workstation :

A-weighted value of 76.5 dB; (Includes KpA = 2.5 dB); according to ISO

10821- C.6.2 -ISO 11204 GR2 at 4,000 sti/min.

– 1 –

Page 4

2.DRAWING OF TABLE (SEMI-SUBMERGED TYPE)

)

4 locations

(

Z-Z

)

B

C

D

F

Y-Y(3 locations

E

A

– 2 –

4 x ø3.4 on the bottom surface, depth 20 (Drill a hole at the time of set-up.)

2 x ø3.4 on the bottom surface, depth 10 (Drill a hole at the time of set-up.)

4 x 10.5 hole, depth 26, spot facing depth 3.5

C

D

C5 (urban white, at and gloss 50 coatings are applied after nishing)

E

Drilled hole 17

A

B

3 x ø3 on the bottom surface, depth 10 (Drill a hole at the time of set-up.)

F

Page 5

3.INSTALLATION OF THE DUST CHUTE

❹

❶

❷

1) Install dust chute

2) Install dust chute bracket

screws ❹.

with two wood screws ❷.

❶

with three wood

❸

❺

❺

❸

❻

3) Install dust chute A

Dust chute A can be installed in two different

orientations.

with three screws ❻.

❺

❻

– 3 –

Page 6

❺

❼

4.OPENING AND CLOSING THE COVER

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following work after turning the power off and ascertaining that the motor is at rest.

B

4) Put dust chute B

on the claws of dust

❼

chute A ❺ to x it.

When opening and closing main cover ❶, open it

on this side with slip cover ❷ pressed to the right.

A

❶

❷

A : Press to the right.

B :

Open on this side.

5.ADJUSTMENT PROCEDURE OF THE KNIFE PRESSURE

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following work after turning the power off and ascertaining that the motor is at rest.

Make the engagement pressure of moving knife

and xed knife as low as possible within the range

of smooth cutting of fabric.Loosen setscrew ❶ of

thrust collar A and setscrew ❷ of thrust collar B in

the written order. Shift thrust collar B to the right and

tighten setscrew ❷ to increase the knife pressure.

Once the desired knife pressure is achieved, tighten

setscrew ❶.

❷

❶

– 4 –

Page 7

6.

ADJUSTMENT PROCEDURE OF KNIFE CUTTING POSITION

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following work after turning the power off and ascertaining that the motor is at rest.

❸

❹

Adjust the distance between the right-hand needle

and cutting position as described below.

1) Loosen setscrew

, turn adjustment screw ❷,

❶

and laterally adjust moving knife ❸ and fixed

knife ❹.

and ❹ move to the left when adjustment screw

❸

is turned clockwise, and to the right when it is

❷

turned counterclockwise.

2) After the adjustment, tighten setscrew

3) After the adjustment of the knife width, readjust

the spring pressure.

❷

❶

7.ADJUSTMENT PROCEDURE OF ENGAGEMENT AMOUNT OF KNIVES

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following work after turning the power off and ascertaining that the motor is at rest.

at the position where moving

❷

❸

❶

1) Loosen setscrew

knife ❶ is fully lowered and make a state that

moving knife ❶ can be moved up and down.

2) Adjust the engagement amount of moving knife

and xed knife❸ to approximately 0.5 mm from

the top end of moving knife, and tighten setscrew

.

❷

❶

.

❶

0.5mm

❷

– 5 –

Page 8

8.REPLACEMENT PROCEDURE OF MOVING KNIFE AND FIXED KNIFE

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following work after turning the power off and ascertaining that the motor is at rest.

❺

❷

❶

❸

❻

When replacing moving knife ❶, remove screws ❷

and guard ❸. Then remove screw ❹ and replace the

moving knife. When replacing xed knife ❺, loosen

screw ❻ and remove xed knife ❺ for replacement.

❹

9.OILING

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following work after turning the power off and ascertaining that the motor is at rest.

Be sure to apply a few drops of oil to oil wick ❷ of

moving knife driving link ❶ before using the sewing

machine for the rst time after the delivery or using it

after an extended period of disuse.

❶

For the lubricating oil, use JUKI GENUINE OIL 18.

❷

– 6 –

Page 9

❷

❸

❺

❹

❽

❻

❾

❼

❶

10.ADJUSTMENT PROCEDURE OF FRONT-UP AMOUNT OF THE PRESSER FOOT

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following work after turning the power off and ascertaining that the motor is at rest.

When sewing a thick rubber sheet or the like together, fabric can be smoothly fed by raising the front of

presser foot ❶. Loosen nut ❷, turn setscrew ❸ to the right (clockwise), and raise the front ❶of presser

foot for adjustment.

11. ADJUSTMENT PROCEDURE OF THE POSITION OF THE TAPE GUIDE

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following work after turning the power off and ascertaining that the motor is at rest.

Loosen setscrew

, and move tape guide base ❺ to the right and left to adjust the position of the tape.

❹

12.ADJUSTMENT PROCEDURE OF THE WIDTH OF THE TAPE GUIDE

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following work after turning the power off and ascertaining that the motor is at rest.

Loosen setscrew ❼ move tape guide ❻ to the right and left to adjust the width of the tape.

13.ADJUSTMENT PROCEDURE OF THE FABRIC PRESSER

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following work after turning the power off and ascertaining that the motor is at rest.

Loosen setscrew

and adjust the knife cutting position so that moving knife enters between knife guide ❾.

❽

– 7 –

Page 10

14.ADJUSTING THE ANGLE OF MESH OF THE KNIFE

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following work after turning the power off and ascertaining that the motor is at rest.

❶

❷ ❸

1) Remove cloth plate, left

2) Loosen screws

and ❸.

❷

❶

.

❹

Horizontal

position

Counterclockwise turn

B

C

D

: Standard adjustment angle

B

:

Angle adjusted for hard-to-sew materials

C

:

Angle adjusted when the knife has worn

D

* If the knife engagement angle is adjusted to

from the start, the knife can wear earlier

D

than the case where the angle is adjusted

the standard one.

3) Adjust the sharpness of the knife by turning

eccentric pin ❹ counterclockwise according

to the sharpness of the knife.

1. The extent of the adjustment of the angle

of mesh is until the marker line on the

eccentric pin is perpendicularly positioned

by turning the pin counterclockwise. If the

eccentric pin is turned beyond the above,

the angle between the upper knife and the

lower knife will increase.

If the depth of engagement is excessively

2.

increased, the knife can wear.

3. Adjust the knife so that it cuts well and the

depth of engagement is not excessive.

4)

After the adjustment, tighten screws ❷ and ❸.

– 8 –

Loading...

Loading...