Page 1

ENGLISH

MF-7500D,7900D

INSTRUCTION MANUAL

vi

Page 2

CONTENTS

!

.SPECIFICATIONS

@

.SELECTING THE MOTOR PULLEY AND THE BELT

#

.OILING

$

.REPLACING THE LUBRICATING OIL

........................................................................................................2

......................................................................................1

...................................................... 2

..............................1

i

Page 3

HOW TO USE THE INSTRUCTION MANUAL FOR MF-7500D/7900D

(Caution) Only the exclusive portions of MF-7500D/7900D are described in this Instruction Manual. For the items

other than those, refer to the Instruction Manual for MF-7500 or MF-7900.

.

!

SPECIFICATIONS

日本語

Model name

Model

Stitch type ISO standard 406, 407, 602, and 605

Example of application Hemming and covering for knits and general knitted fabrics

Sewing speed

Needle gauge

Differential feed ratio

Stitch length

Needle UY128GAS #9S to #12S (standard #10S)

Needle bar stroke 31mm (or 33 mm when changing over the eccentric pin)

Dimensions (Height) 451 x (Width) 515 x (Length) 263 (Height) 450 x (Width) 468 x (Length) 264

Weight 46 kg 42 kg

Lift of presser foot

Feed adjustment

method

Looper mechanism Spherical rod drive method

Lubricating system Forced lubrication method by gear pump

Lubricating oil JUKI GENUINE OIL 18

Oil reservoir capacity Oil gauge lower line : 600 cc to upper line : 900 cc

Installation Semi-submerged type Top mount type, Semi-submerged type

Noise

Semi-dry head, high-speed, at-bed coverstitch

machine

MF-7500D series MF-7900D series

Max. 5,000 sti/min (during intermittent operation)

Factory-set sewing speed at the time of shipment. 4,000 sti/min (during intermittent operation)

3-needle ... 4.8mm, 5.6 mm and 6.4 mm

2-needle ... 3.2 mm and 4.0 mm

1 : 0.7 to 1 : 2 (stitch length : less than 2.5 mm)

Micro-differential feed adjustment mechanism is

provided. (Micro-adjustment)

1.2 mm to 3.6 mm (can be adjusted up to 4.4 mm) 0.9 mm to 3.6 mm (can be adjusted up to 4.5 mm)

8 mm (needle gauge : 5.6 mm without top covering), and 5 mm (with top covering)

Micro-lifter mechanism is provided.

Main feed ... dial type stitch pitch adjustment method

Differential feed ... lever adjustment method (micro-adjustment mechanism is provided.)

- Equivalent continuous emission sound

pressure level (LpA) at the workstation :

A-weighted value of 74.0 dB; (Includes KpA =

2.5 dB); according to ISO 10821- C.6.2 -ISO

11204 GR2 at 4,000 sti/min.

Semi-dry head, high-speed, cylinder-bed

coverstitch machine

3-needle ... 5.6 mm and 6.4 mm

2-needle ... 3.2 mm, 4.0 mm and 4.8 mm

1 : 0.9 to 1 : 1.8 (stitch length : less than 2.5 mm)

(1:0.6 to 1:1.1, when the differential link hinge

screw is changed)

Micro-differential feed adjustment mechanism is

provided. (Micro-adjustment)

- Equivalent continuous emission sound pressure

level (LpA) at the workstation :

A-weighted value of 76.5 dB; (Includes KpA = 2.5

dB); according to ISO 10821- C.6.2 -ISO 11204

GR2 at 4,000 sti/min.

FRANÇAISDEUTSCH

ESPAÑOL ITALIANO

.

@

SELECTING THE MOTOR PULLEY AND THE BELT

Motor pulley and belt

MF-7500D MF-7900D

Sewing speed

(sti/min)

3,500 ø 80 M-34 ø 65 M-33 ø 80 M-38 ø 65 M-37

4,000 ø 90 M-35 ø 75 M-34 ø 90 M-38 ø 75 M-37

4,500

5,000

Pulley size Belt size Pulley size Belt size Pulley size Belt size Pulley size Belt size

50Hz 60Hz 50Hz 60Hz

ø 100 M-35 ø 85 M-35 ø 100 M-39 ø 85 M-38

ø 115 M-36 ø 95 M-35 ø 115 M-40 ø 95 M-39

* The table shows the numbers when a 3-phase 2-pole 400 W clutch motor (1 / 2 HP) is used.

* The commercially-available motor pulley near to the counted value is designated since the outside diameter of the

commercially-available motor pulley counts by 5 mm.

Use a motor pulley which is adaptable to this sewing machine. The sewing speed exceeds the max. sew-

ing speed of this sewing machine and machine trouble will be caused unless a motor pulley which is

adaptable to this sewing machine is used.

– 1 –

中文

TÜRKÇE

Page 4

.

#

OILING

If inside of the frame is oiled, the grease

NO OILING

.

$

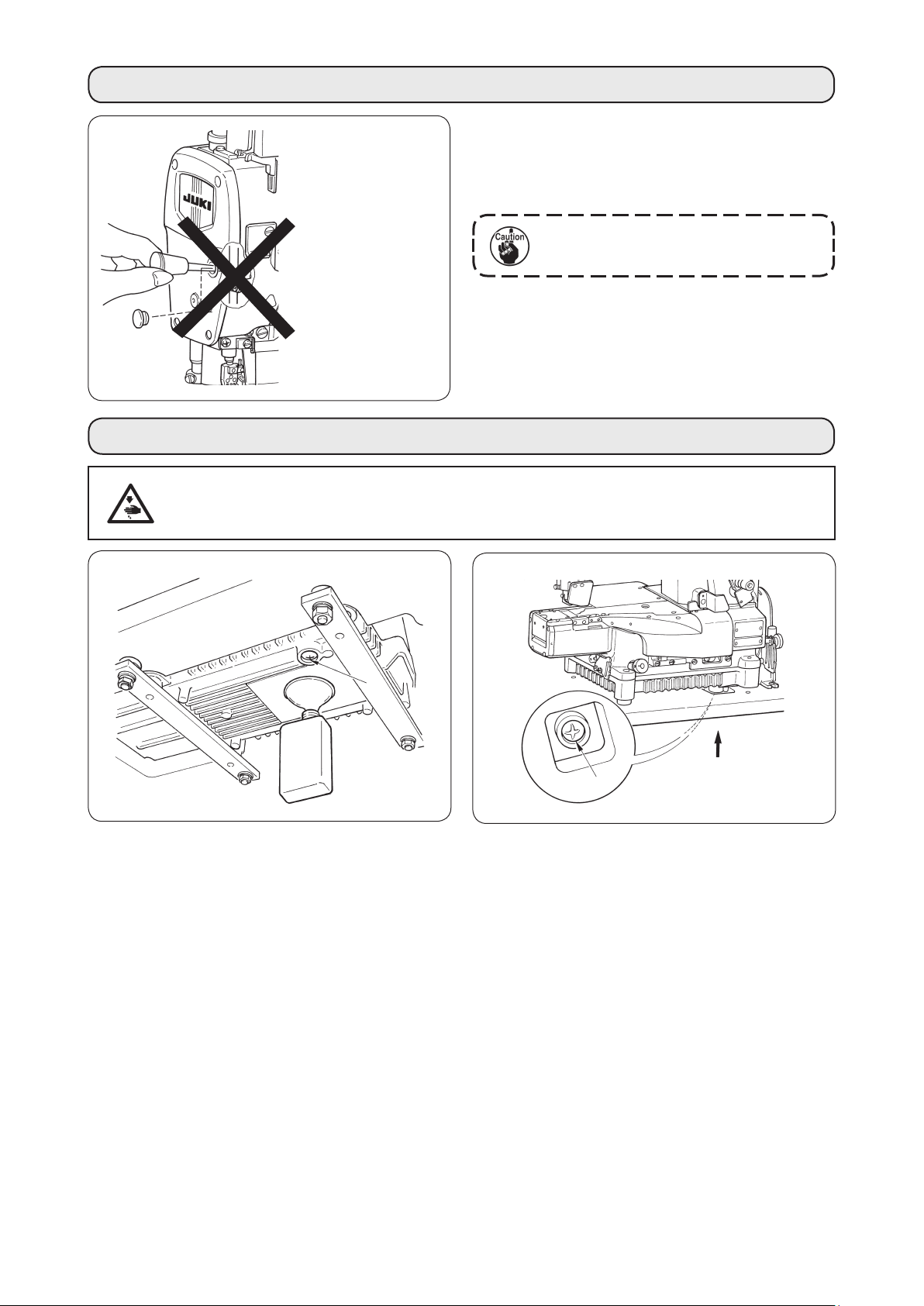

REPLACING THE LUBRICATING OIL

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following

work after turning the power off and ascertaining that the motor is at rest.

The mechanisms inside the frame such as the

needle bar, presser lift and spreader components

are lubricated with grease. Never add oil inside

the frame.

will be expelled, resulting in mechanical

failure.

MF-7500D

1

In case of the new sewing machine, replace the lubricating oil (JUKI GENUINE OIL 18) with new one after using it for

approximately one month. Then replace the lubricating oil every six months.

1) Set a container to receive the lubricating oil under drain screw

2) Remove drain screw

3) After the drain, wipe out the oil and attach the drain screw

. The lubrication oil is drained.

1

MF-7900D

.

1

.

1

1

– 2 –

Loading...

Loading...