Page 1

MEB-3810N

INSTRUCTION MANUAL

COVERI

Page 2

CONTENTS

1. SPECIFICATIONS .............................................1

2. NAME OF EACH COMPONENT

3. INSTALLATION

3-1. Table ............................................................................. 3

(1) Drawing of the stand ....................................................... 3

(2) Drawing of the table(Table-xed type)

(3) Drawing of the table (Semi-sunken type)

3-2. Installing the control box ........................................... 6

3-3. Installing and connecting the power switch

3-4. Taking out the sewing machine

3-5. Installing the sewing machine

(1) In the case of the table-xed type machine head......... 9

(2) In the case of the semi-sunken type machine head....11

3-6. Raising and returning the sewing machine ............ 16

3-7. Installing the poly oiler

3-8. Installing the operation panel

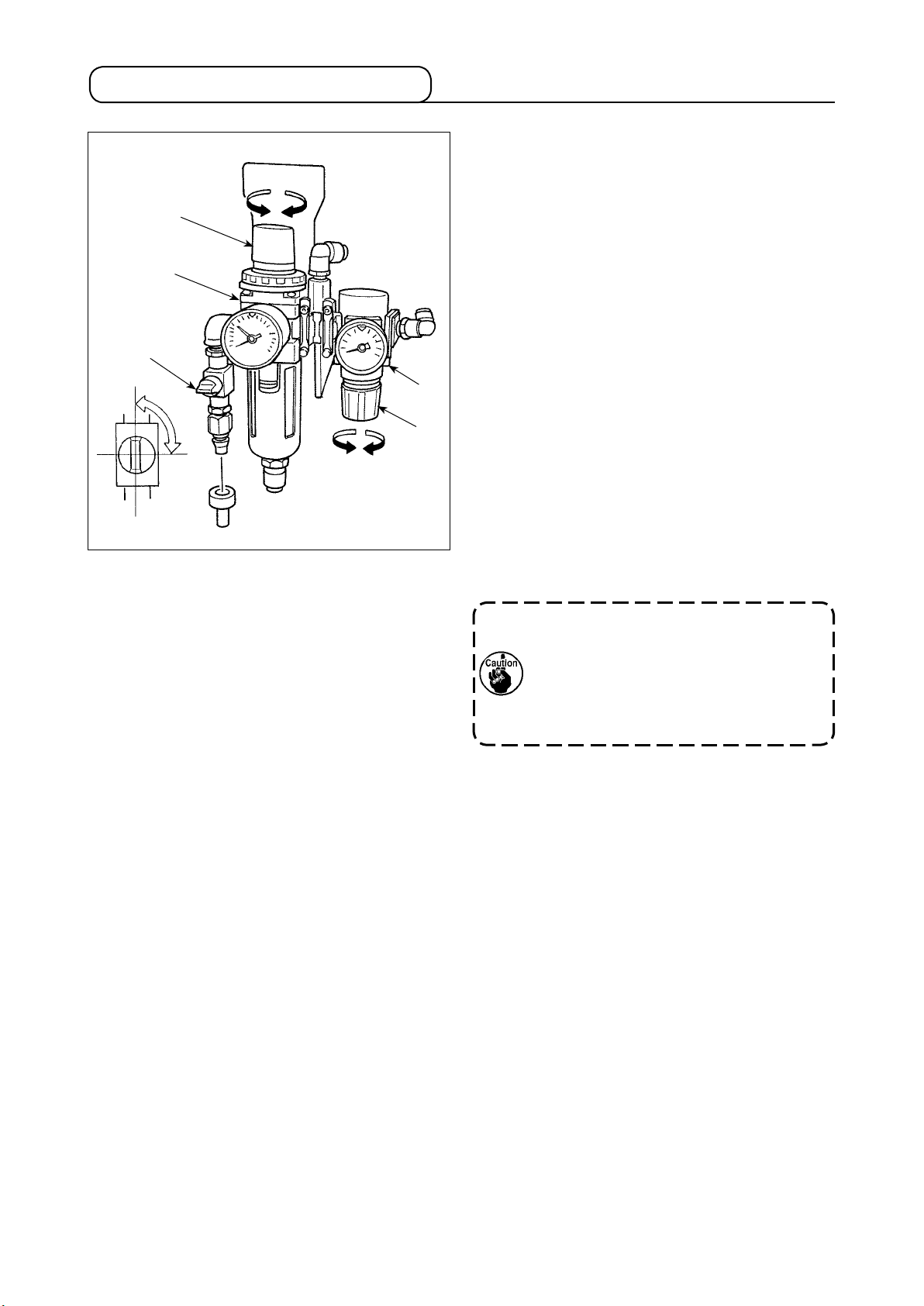

3-9. Installing the regulator and the manifold

3-10. Connecting the cords

3-11. Handling the cords

3-12. Installing the foot pedal switch (optional)

3-13. Connecting the air supply

(1) Connecting the regulator and the manifold ................ 25

(2) Connecting the air tubes

3-14. Installing the air hose ............................................. 27

3-15.

Cautions for the compressed air supply (source

of supply air) facility

3-16. Installing the thread stand ..................................... 29

3-17. Installing the thread guides

3-18. Installing the eye protection cover and the

nger guard

3-19. Installing the cloth chip bag

3-20. Installing/removing the presser unit

................................................. 3

............................................. 19

............................................. 22

..................................................23

.............................................. 26

................................................. 28

.............................................................31

......................2

.......................... 4

...................... 5

............ 6

................................. 8

................................... 9

.................................. 19

............... 20

............ 24

...................................... 25

................................... 30

..................................32

..................... 33

4. PREPARATION BEFORE OPERATION ......... 34

4-1. Lubrication of the machine and how to lubricate .. 34

(1) Lubricating the arm oil tank ......................................... 34

(2) Lubricating the bed oil tank

(3) Lubricating the looper and spreader components

(4) Lubricating the looper bracket oil tank

(5) Lubricating the needle bar and the gear section

4-2. Attaching the needle ................................................. 37

4-3. Threading the machine head

(1) Threading the upper thread (needle thread) ............... 38

(2) Threading the lower thread (looper thread)

(3) Threading the machine with gimp

4-4. How to set the cloth on the sewing machine ......... 40

......................................... 34

.... 35

....................... 35

....... 36

................................... 38

................ 39

............................... 40

5. STRUCTURE OF THE OPERATION

SWITCH

5-1. Structure of the operation panel .............................41

5-2. Temporary stop switch

5-3. Hand switch

5-4. Foot switch (optional)

..........................................................41

............................................. 43

............................................................... 43

...............................................43

6. HOW TO USE THE OPERATION PANEL ......44

6-1. Basic operation of the sewing machine ................. 44

6-2. Setting the thread tension

6-3. Temporarily stopping the sewing machine

........................................44

............ 45

6-4. Performing re-sewing

6-5. Performing threading

6-6. How to use the counter

6-7. When dropping of the knife is temporarily not

desired

6-8. Changing the operation mode

6-9. Changing procedure of the sewing pattern

6-10. Conrming the pattern shape

.....................................................................48

............................................... 46

...............................................47

............................................ 47

................................. 48

............ 50

................................ 50

7. SETTING PROCEDURE OF THE SEWING

DATA

...............................................................51

7-1. Setting the knife No. ................................................. 52

7-2. Setting the cut length

7-3. Setting the cut-before/cut-after knives

7-4. Setting the number of stitches of the parallel

section

7-5. Setting the number of stitches of the eyelet

7-6. Setting the cut space

7-7. Setting the eyelet space

7-8. Knife position compensation

7-9. Number of stitches of sewing end compensation

7-10. Turning angle compensation

7-11. Turning angle compensation at the parallel sec-

tion

7-12. Compensation of eyelet in lateral direction

7-13. Compensation of eyelet in longitudinal direction

7-14. Compensation of eyelet, left in longitudinal

direction

7-15. Compensation of left parallel section of a but-

tonhole

7-16. Compensation of cutting space, left

7-17.

Setting the needle throwing width of the

right bottom of eyelet

7-18.

Setting the needle throwing width of the left

bottom of eyelet

7-19. Setting the needle throwing width ........................58

7-20. Setting the type of bartack

7-21. Setting the length of taper bar

7-22. Setting the number of stitches of taper bar

7-23. Setting the offset of taper bar

7-24. Setting the number of stitches of slant section

of taper bar

7-25. Compensation of the number of stitches of the

right side taper bar

7-26. Setting the straight bar length

7-27. Setting the number of stitches of straight bar

7-28. Setting the overlapping amount of straight bar

7-29. Setting the needle throwing width of straight bar

7-30. Setting the number of stitches of round bar

7-31. Setting the number of overlapping stitches of

round bar 2

7-32. Setting the needle throwing width of the round

bar

7-33. Setting the needle throwing width at the upper

section of eyelet bar

7-34. Setting the reduced sewing speed for straight/

round bar

7-35. Setting the sewing speed

7-36. Setting the reduction speed of eyelet

......................................................................53

............................................................................55

................................................................... 56

.....................................................................57

..............................................................60

..............................................................62

.............................................................................62

.................................................................63

............................................... 52

................... 53

.......... 53

................................................ 54

........................................... 54

...................................54

. 55

................................. 55

......... 56

56

..................... 57

.........................................57

.................................................58

..................................... 58

............................... 59

......... 59

................................ 59

..................................................60

............................... 60

..... 61

... 61

61

........ 62

...............................................63

....................................... 63

................... 63

i

Page 3

7-37. Setting the soft start ............................................... 64

7-38.

Setting the number of stitches at the beginning of

sewing of thread tension

7-39.

Setting the number of stitches at the end of sewing of thread tension

.................................................. 64

................................................. 64

8. ADJUSTMENT OF EACH PART ....................65

8-1. Adjusting the pressure of the cloth trimming

knife

.......................................................................... 65

8-2. Adjusting the stitch bite width

8-3. Adjusting the presser

8-4. Adjusting the presser opening amount

8-5. Adjusting the needle thread drawing amount

8-6. Adjusting the thread take-up thread guide

8-7. Adjusting the remaining amount of the gimp.........70

8-8. Adjusting the gimp thread tension

8-9. Needle thread clamp unit (optional)

8-10. Adjusting the brightness of the hand lamp

............................................... 67

.................................66

.................. 68

........ 69

............. 69

.......................... 70

........................ 71

.......... 72

9. HOW TO USE THE VARIOUS FUNCTIONS ..73

9-1.

Operating procedure of thread tension compensa-

tion of each section

9-2. Changing the setting position of cloth ................... 76

9-3. Changing over the mode of the start switch

9-4. Changing over the presser movement

9-5. Changing over the counter (DOWN counting)

9-6. Changing over to the mode of the stop before

cloth cut

9-7. Copying the pattern data

9-8. Deleting the pattern data

...................................................................76

................................................... 73

.......... 76

................... 76

....... 76

..........................................77

.......................................... 78

(6) Standard of replacing time of the gas spring

(7) Replacing the gas spring

............................................. 95

............. 94

11. EXCHANGING GAUGE PARTS AND OPTIONAL

11-1. Throat plate ..............................................................96

11-2. Presser set

11-3. Presser holding plate

11-4. Cloth cutting knife

11-5. Hammer

11-6. Others

........................................................... 96

............................................................... 96

..............................................97

...................................................97

.................................................................... 98

.......................................................................98

12. TROUBLES AND CORRECTIVE MEASURES IN SEWING

13. MEMORY SWITCH

13-1. Operating procedure ............................................101

13-2. Memory switch list

........................................ 99

.....................................101

................................................ 102

14. ERROR LIST ............................................... 104

15. STANDARD PATTERN LIST

16. SEWING DATA ENTRY SHEET

......................107

..................108

10. MAINTENANCE ............................................ 79

10-1. Looper thread trimming (overall thread trimmer

type)

..........................................................................79

10-2. Timing between the needle and the looper

10-3. Height of the needle bar

(1) Adjusting the needle bar height ................................... 82

(2) Reference height of the needle bar

10-4. Adjustment to prevent triangular stitch skip-

ping in the case of a narrow needle throwing

width

......................................................................... 83

10-5. Clearance between the needle and the looper

10-6. Adjusting the needle guard

10-7. Clearance between the spreader and looper

and the opening timing of the spreader

10-8. Height of the throat plate

(1) Height of the throat plate .............................................. 87

(2) Adjusting the height of the throat plate

10-9. Position of the presser foot ................................... 88

10-10. Adjusting the knife dropping position

10-11. Installing position of the needle thread trim-

ming knife

10-12. Cleaning

10-13. Draining

10-14. Replacing consuamables

(1) Worn-out of the hammer face ...................................... 91

(2) Replacing the cloth cutting knife and the hammer

(3) Replacing the looper thread trimming knife (overall

thread trimmer type)

(4) Replacing the needle thread trimming knife

(5) Changing the thread trimmer retaining plate (needle

thread trimmer type)

................................................................89

................................................................. 90

.................................................................90

......................................... 82

............................. 82

....................................84

.......................................87

..................................... 91

..................................................... 93

..................................................... 94

.......... 79

..... 84

................ 85

...................... 87

................ 88

.... 92

.............. 94

ii

Page 4

1. SPECIFICATIONS

Specications J type C type

1 Application Jeans Cotton pants, working pants

Operating temperature

2

3 Operating humidity range 35 % to 85 % (with no condensation)

Number of patterns that

4

can be stored in memory

5 Input power

6

7 Thread trimmer type

8 Sewing length 10 to 38 mm 10 to 34 mm 10 to 38 mm 10 to 34 mm

9 Buttonhole length 10 to 38 mm

10 Needle throwing width

Length of buttonhole with

11

12 Lift of presser foot Standard 13 mm

13 Change of stitch shape Selection by program

14 Buttonhole cutting Cut-before knife + Cut-after knife, without knife

Cloth cutting knife drive

15

16 Feed method Intermittent feed by stepping motor

17 Needle used DO x 558 Nm90 to 120 (Needle count attached at the time of delivery: Nm110)

18 Safety device Pause switch & automatic stop function at the time of detection of a trouble

19 Lubricating oil JUKI MACHINE Oil No. 18

20 Air pressure

21 Air consumption

22 Machine dimensions

23 Power consumption 200 VA

24 Mass

25

*1 : For the machine provided with the optional needle thread clamp unit, the buttonhole length is 10 to 28 mm.

*2 : Parallel section: Taper length can be set to such a value that does not exceed the total of the eyelet section and the

bartacking section.

*3 : The height of the completed unit differs with the height of the table stand.

range

Sewing speed

taper bar

method

Noise

99 (1 to 99) (standard patterns have been factory-numbered 90 to 99)

Single-/3-phase 200 to 240 V 50/60 Hz

Supply voltage uctuation: Rating ± 10 %

400 to 2,500 sti/min (in 100 sti/min steps)

Needle thread

trimmer type (00)

*1

2.0 to 4.0 mm (factory-setting at the time of delivery: 2.5 mm)

Hammer pressure regulator: Standard 0.35 MPa (max. 0.4 MPa)

Machine head: 382 mm (width) x 656 mm (length) x 584 mm (height)

: 1050 mm (width) x 700 mm (length) x 1248 mm (height) *3 (excluding the thread stand)

: 1060 mm (width) x 790 mm (length) x 1096 mm (height) *3 (excluding the thread stand)

Machine head: Approx. 110 kg; Operation panel: Approx. 0.3 kg

-

Equivalent continuous emission sound pressure level (LpA) at the workstation :

A-weighted value of 82.0 dB; (Includes KpA = 2.5 dB); according to ISO 10821-

C.6.3 -ISO 11204 GR2 at 2,500 sti/min for the sewing cycle, 3.8 sec. (Pattern :

No.90).

-

Sound power level (LWA) ;

A-weighted value of 92.5 dB; (Includes KWA = 2.5 dB); according to ISO 10821-

C.6.3 -ISO 3744 GR2 at 2,500 sti/min for the sewing cycle, 3.8 sec. (Pattern :

No.90).

Overall thread

trimmer type (01)

10 to 28 mm 10 to 38 mm

[1.5 to 5.0 mm by compensation on the feed panel]

49.5 ℓ /min (11.6 cycles/min)

Complete unit (Table-xed type)

Complete unit (Semi-sunken type)

Control box: Approx. 4.5 kg

5°C to 35°C

Needle thread

trimmer type (00)

3 to 15 mm *2

Driven by air cylinder

Main regulator: 0.5 MPa

trimmer type (01)

*1

Overall thread

10 to 28 mm

– 1 –

Page 5

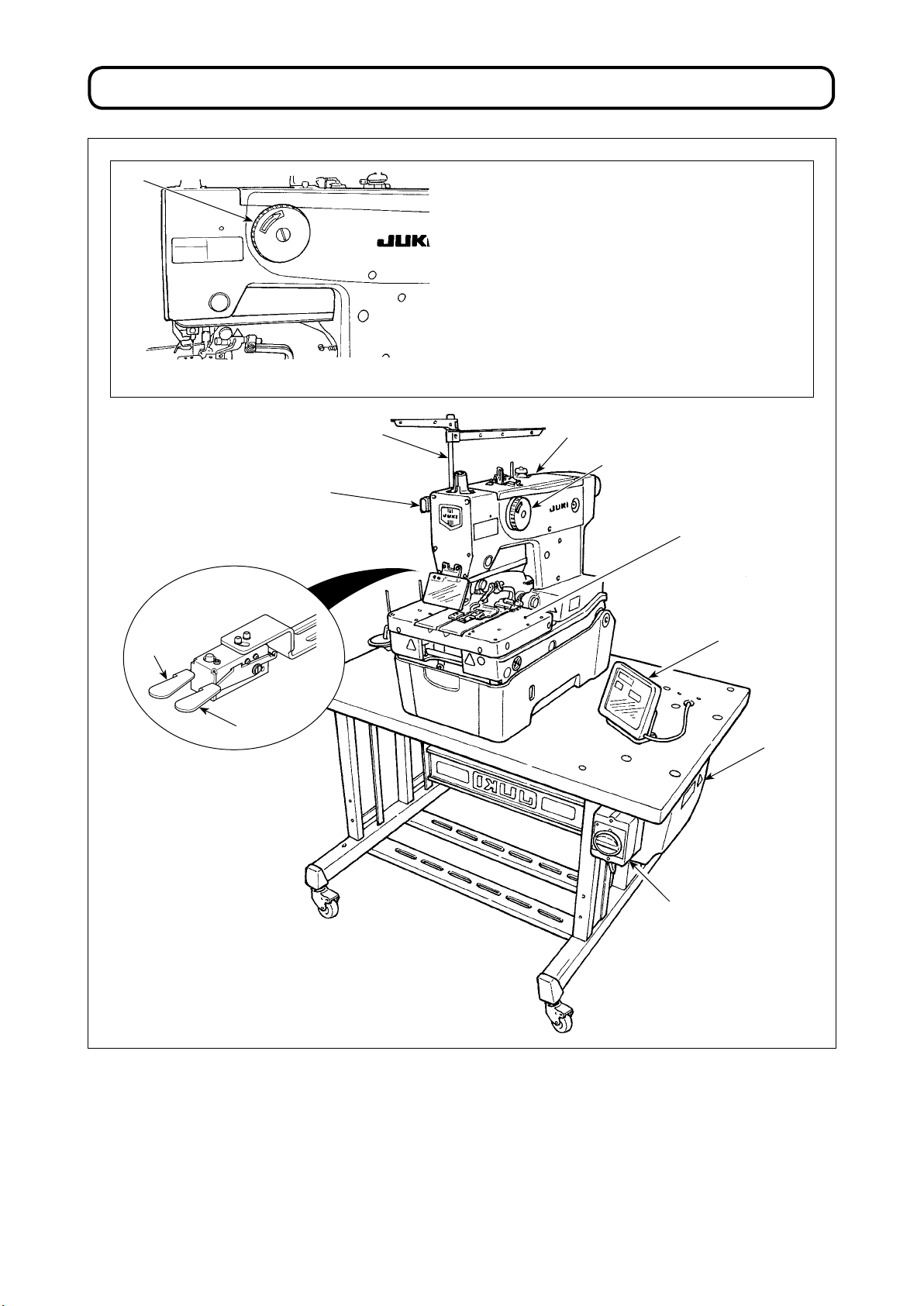

2. NAME OF EACH COMPONENT

❼

❶

❾

• Hand pulley ❼

The needle bar can be lifted or lowered by hand

with the hand pulley.

❽

❼

❸

❷

❶ Temporary stop switch

❷ Presser switch

❸ Start switch

❹ Operation panel

❺ Control box

❻ Power switch

❼ Hand pulley

❽ Machine head

❹

❺

❻

❾ Thread stand

Feed base

– 2 –

Page 6

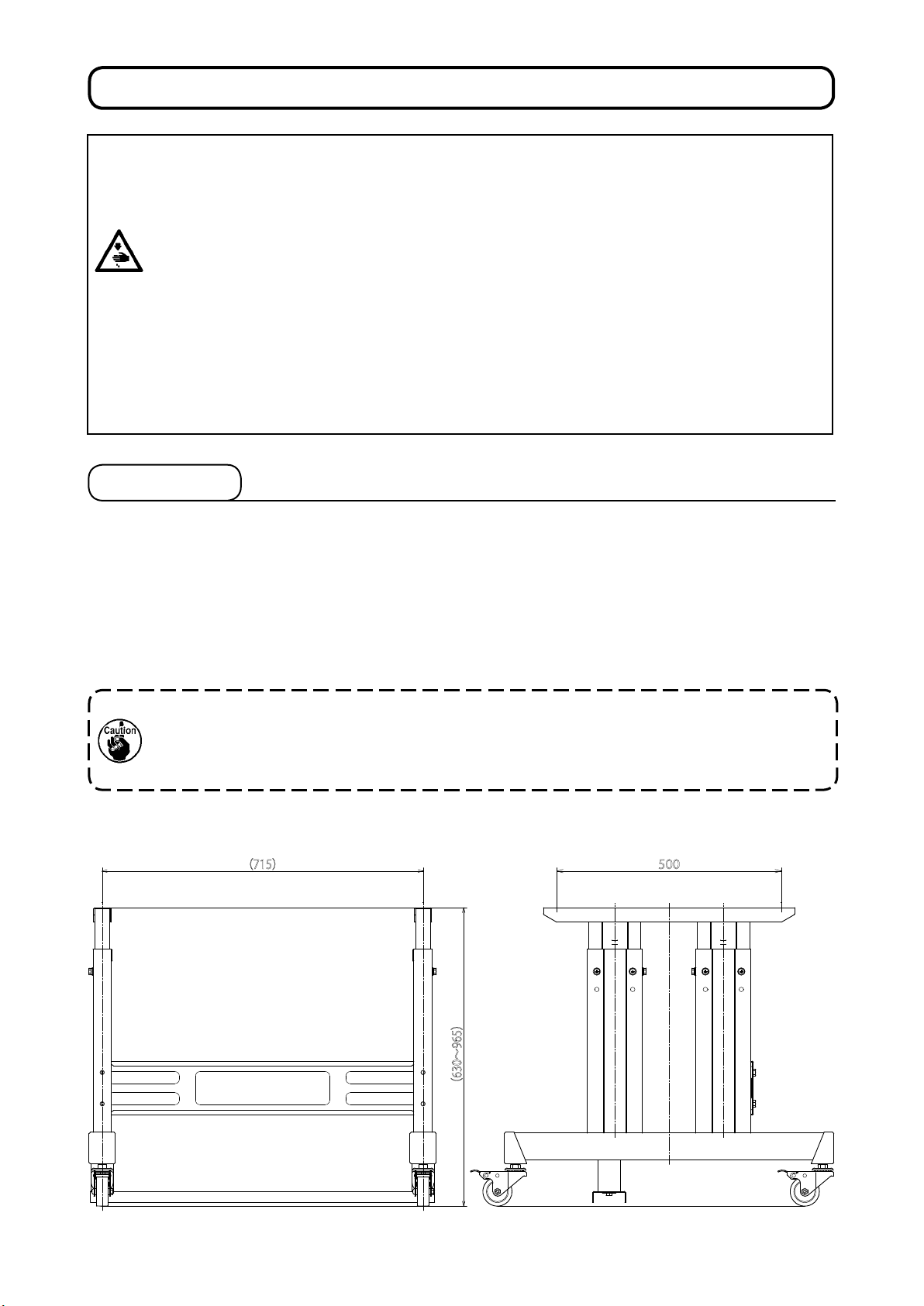

3. INSTALLATION

DANGER :

1. The sewing machine should be installed by a trained technician.

2. Contact the distributor or a professional electrician to ask him/her to carry out electric wiring.

3. The sewing machine has a mass of approximately 110 kg. Four or more workers are required

to carry out the installation of the sewing machine and adjustment of the table height.

4. Never connect the power plug until the installation of the sewing machine is completed in order

to protect against an accident due to an abrupt startup of the sewing machine.

6. Be sure to raise/return the sewing machine from/to its home position by holding it with both

7. Do not apply an unreasonable force to the sewing machine when it is in the raised position. If

• Use the table and stand which are able to withstand the sewing machine mass (110 kg) and vibration. The

• Use the table stand which has an appropriate height for the sake of the operator's ease of use.

• The xing bolt for xing the table and the stand should be of the length which matches the thickness of the

• The table differs between the table-xed type and the semi-sunken type machine heads. Appropriately

5.

Be sure to ground the earthing wire in order to protect against an accident due to electrical

leakage.

hands.

such a force is applied, the sewing machine can lose its balance to fall alone or fall together

with the table, resulting in personal injury or sewing-machine breakage.

3-1. Table

table thickness of which is 40 - 60 mm should be used.

table.

machine the table referring to the table drawing corresponding to the type of the machine head.

1. In the case the table thickness exceeds 60 mm, the length of the bolts supplied with the unit as

accessories is adequate.

2. In the case the xing bolt for xing the table and the stand is too long for the table thickness,

unexpected injury to hands or head can occur.

(1) Drawing of the stand

(715)

(630~965)

500

– 3 –

Page 7

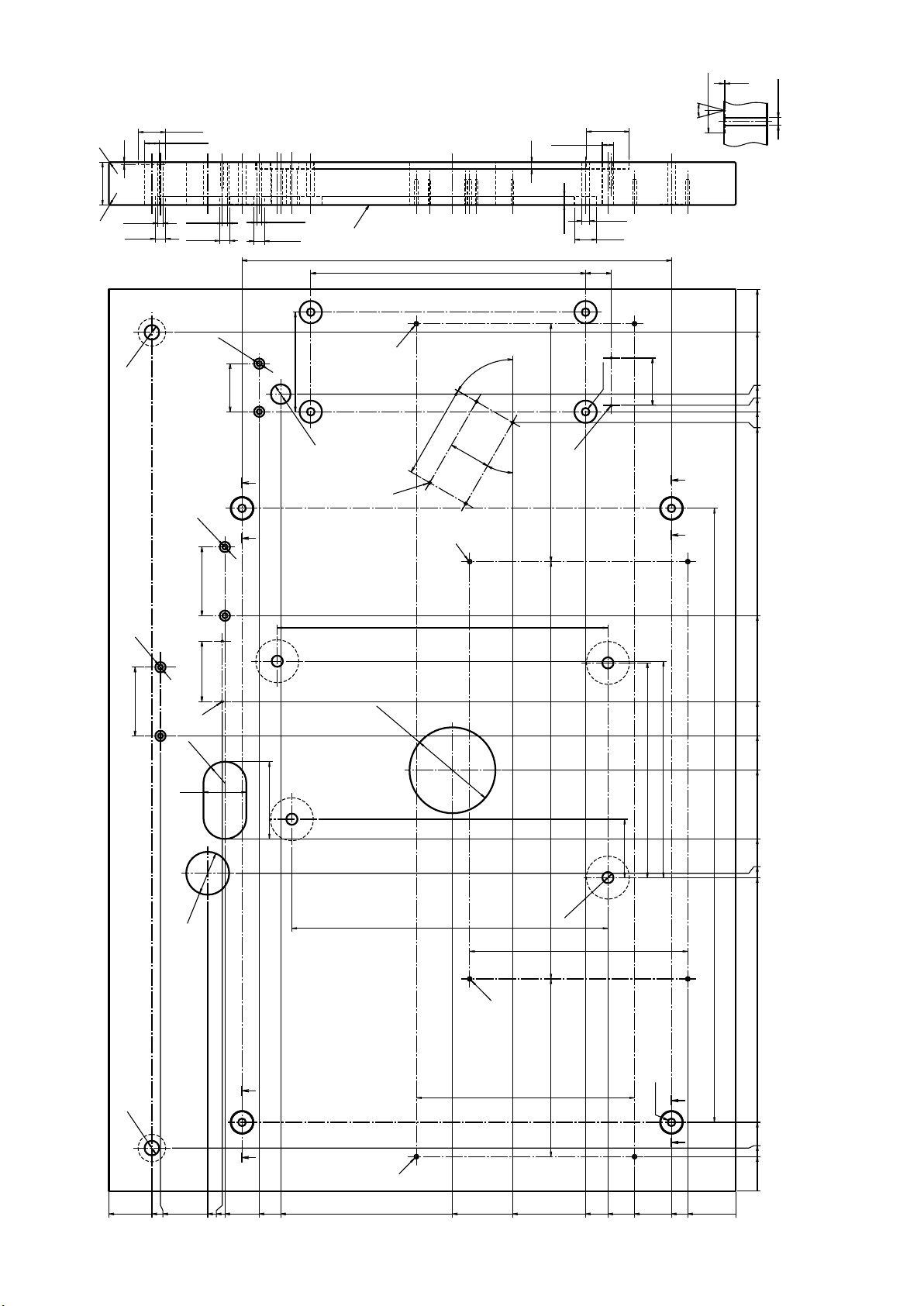

(2) Drawing of the table(Table-xed type)

2X

Ø32

2X(

Ø12

Ø17)

2X(

2X(

2X

Ø6)

Ø12

2X

Ø6

2X

56±1

Ø6)

Ø12

2X(

2X

116±4

-1

+2

23

I

F

Ø

109±1

ZZ

D

H

±1

50

H

3±1

Ø

Ø6)

+2

-1

17

500±1.5

320±1

60°±5°

48.5±1

0

+0.1

0

1

4X

26

+0.1

Ø

4X

30°

Z-Z

4X

55±1

(4箇所)

Z-Z

(4 locations)

ZZ

4X

Ø50

4X(

Ø13)

8±1

4X(

G

Ø9

4X

Ø9)

Ø26

30±2

4X

10±1

277±3.5

(30°)

Ø9)

(4X

1050

1000

928

915

907.5

895

Ø6

80±1

2X

50±4

Ø

80±1

70±1

C

X(R)

2

50±4

Ø6

2X

90±4

±5

100

Ø

±1

±1

368

385

E

486±3.5207±3.5

X

4

Ø13

254±3.5

68±1

250±1

252±1

715±3

670

G 2×ø3.5±0.5 depth 30 (on the bottom surface)

H R2 (all corners)

I Right side

570

530

490

410

370

365

D 4×ø2.5±0.5 depth 30

E 2×ø4.5±0.5 depth 30

F 2×ø4.5±0.5 depth 30

730

B

254±3.5

-1

+2

17

Ø

Z Z

ZZ

Ø9

X

4

80

50

40

A

680

670

615

598

595

555

530

330

260

175

149

118

75

A 2×ø4.5±0.5 depth 30

B 2×ø4.5±0.5 depth 30

C 2×ø3.5±0.5 depth 30 (on the bottom surface)

56

– 4 –

Page 8

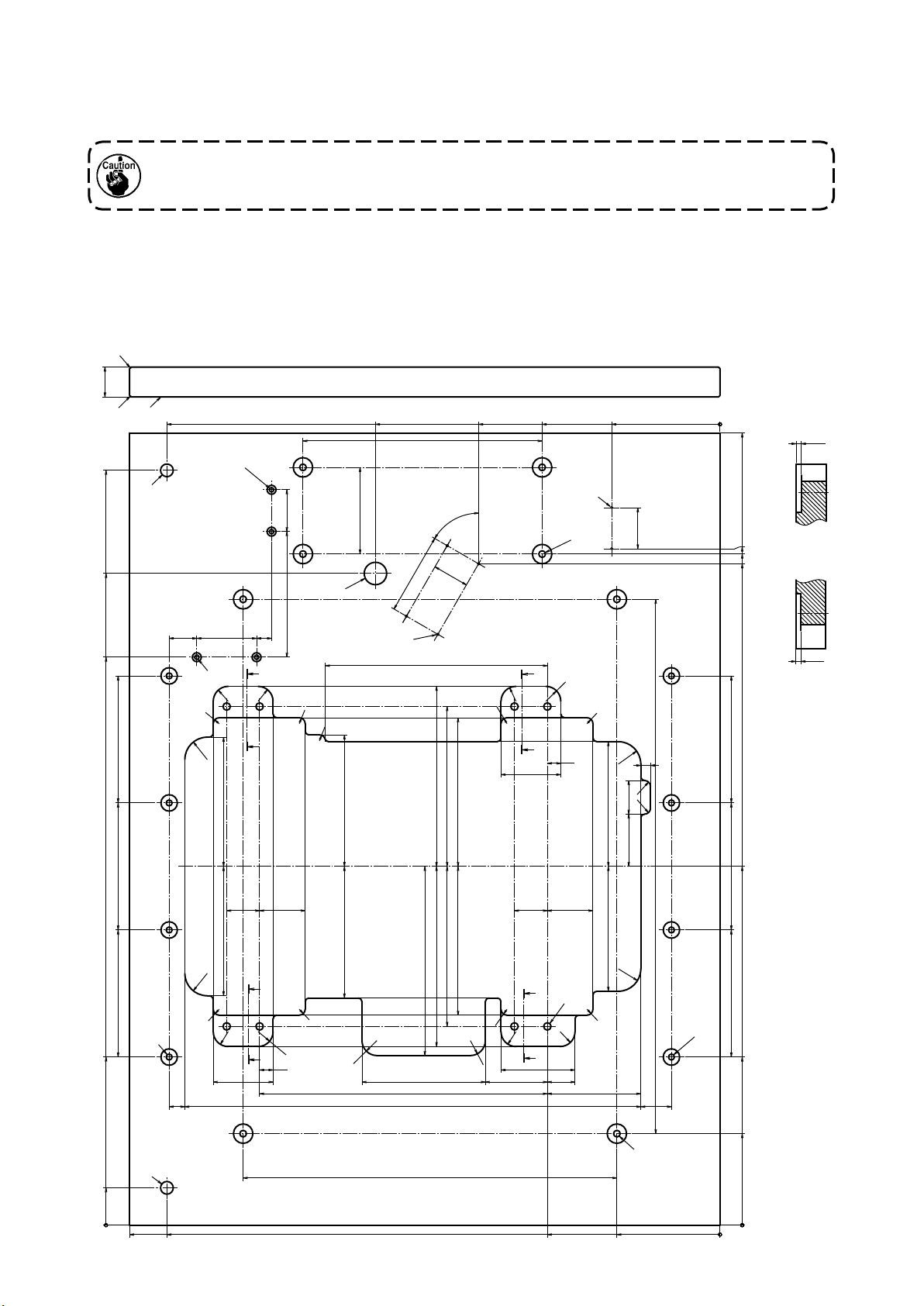

(3) Drawing of the table (Semi-sunken type)

In the case the semi-sunken type machine head is used, the kit for semi-sunken type (part number : 40157881)

is required. Prepare the kit simultaneously with the table.

In the case the semi-sunken type machine head is used, the table reinforcing plate (part number:

32080707)(supplied with the kit (part number: 40157881)) has to be installed without exceptions.

(Refer to "3-5.(2) ① Installing the table reinforcing plate" p. 11.)

40±1

1010

872

760

Note) When no

H

H

instruction is given,

740

I

K

±1

170

0

+ 1

1

26 Depth of coun-

terbore

the corner radius

A 4×9 drilled hole

shall be R5.

B 4×8 drilled hole 22

N

±1

56

±1

168

80

±1

37±2

20

±1

F

20

20

R

R

8

R

30

R

±2

173

Y Y

Depth of counter-

8

R

0

+ 1

1

bore

0

+ 1

1

26 Depth of coun-

terbore

hole,depth 20±3

C 4×9 drilled hole

D 4×2.5±0.5 drilled

461

±4

116

M

8

R

±2

176

4×8 drilled hole

E

109±1

D

320

±1

0

+ 1

1

22 Depth of coun-

terbore

60°±5°

297±3

±2

241

±1

214

48.5±1

±2

199

F 2×6 drilled hole

+ 1

12 Depth of coun-

323

8

R

0

1

terbore

G 2×3.5±0.5 drilled

20

R

±1

0

+ 1

1

12 Depth of coun-

N 2×6 drilled hole

terbore

1060

Z-Z

(2カ所)

Z-Z

7

±0.5

hole,depth 20±3

(on the bottom

surface)

R2 (all corners)I Right side

17 drilled hole

H

238

J

145±3

K 17 drilled hole

L 8×10 drilled hole

M 30 drilled hole

G

(2 locations)

C

55±1

YY

20

R

8

R

30

18

±1

80

R

13

8

R

45

8

±2

R

167

905

898

885

Y-Y

(2カ所)

Y-Y

(2 locations)

7

±0.5

±1

170

70

±1

170

61

61

±2

44±144±1

±2

173

30

E

R

8

R

R

21

±1

±1

170

225

ZZ

20

20

R

18

80

±1

±1

±2

176

8

R

20

R

385

±1.5

±2

±1

199

214

±2

±2

241

253

8

R

20

R

20

R

165

±2

610

±2

83

±2

±2

±2

167

ZZ

L

8

R

20

R

99

±1

37

±1

125

±2

±3

715

30

R

B

41

±1

480

±1

170

±1

170

225

122.5

A

500

50

J

740

790

±1.5

231

138

– 5 –

Page 9

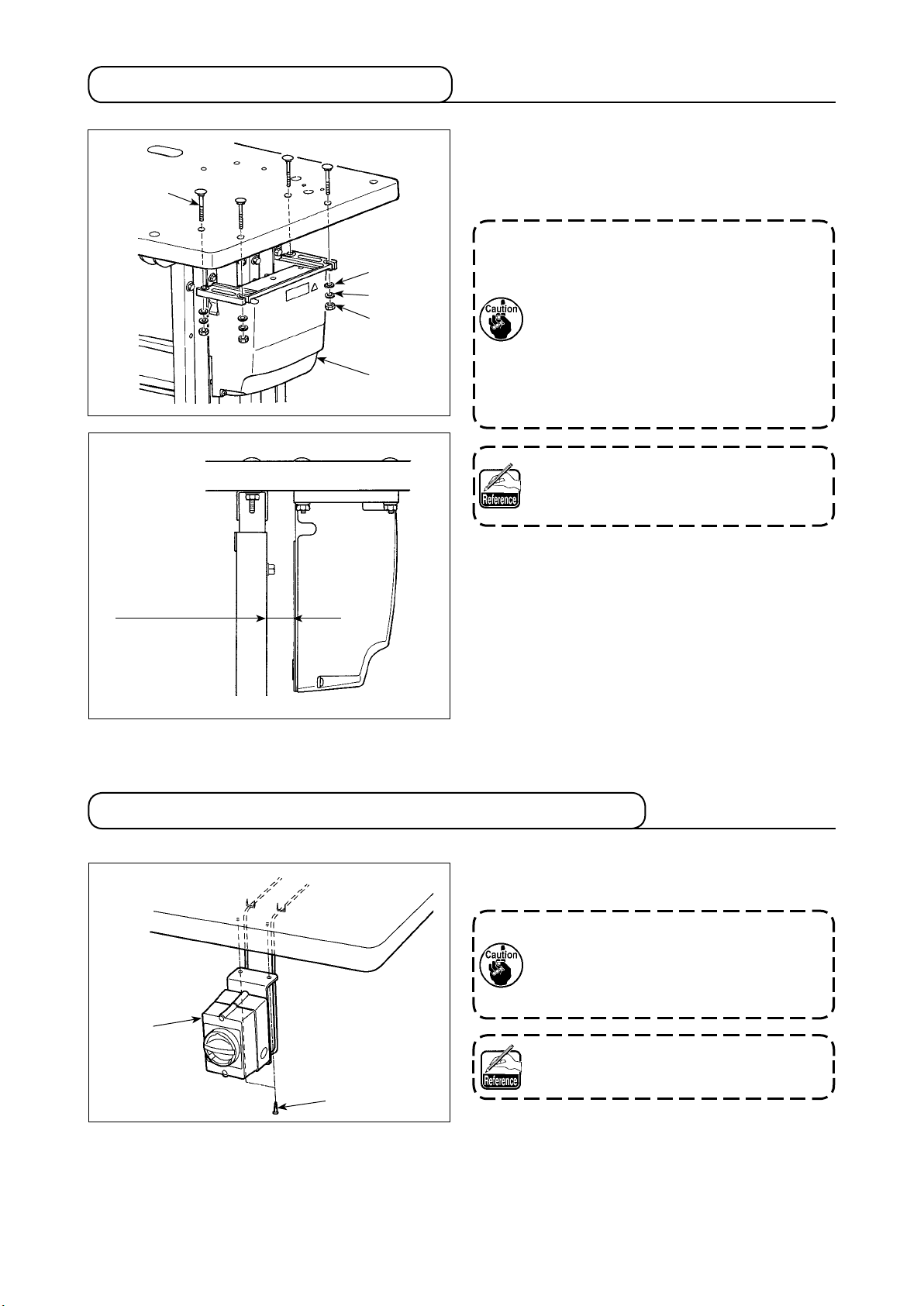

3-2. Installing the control box

❷

❸

❹

❺

❶

Install control box ❶ to the location illustrated in the

gure using four bolts ❷, four plain washers ❸ and

four spring washers ❹ and four hexagonal nuts ❺

supplied with the unit.

1. Install control box ❶ 30 mm or more

away from the stand. If control box ❶ is

located too close to the stand, the for-

mer can get hot or the sewing machine

can malfunction.

2. In the case the semi-sunken type machine head used, install the control box

after carrying out the procedure written

in "3-9. Installing the regulator and the

manifold" p. 20.

Bolt ❷ is a cup head square neck bolt (M8;

Length: 70 mm) and nut ❺ is a hexagonal

nut (M8).

30 mm or more

3-3. Installing and connecting the power switch

1) Installing the power switch

Fix power switch ❶ on the underside of the table with

two wood screws ❷.

In the case the semi-sunken type machine

head used, install the control box after

carrying out the procedure written in "3-9.

Installing the regulator and the manifold"

p. 20.

❶

❷

Wood screw ❷ has the nominal diameter of

5.1 mm and a length of 20 mm.

– 6 –

Page 10

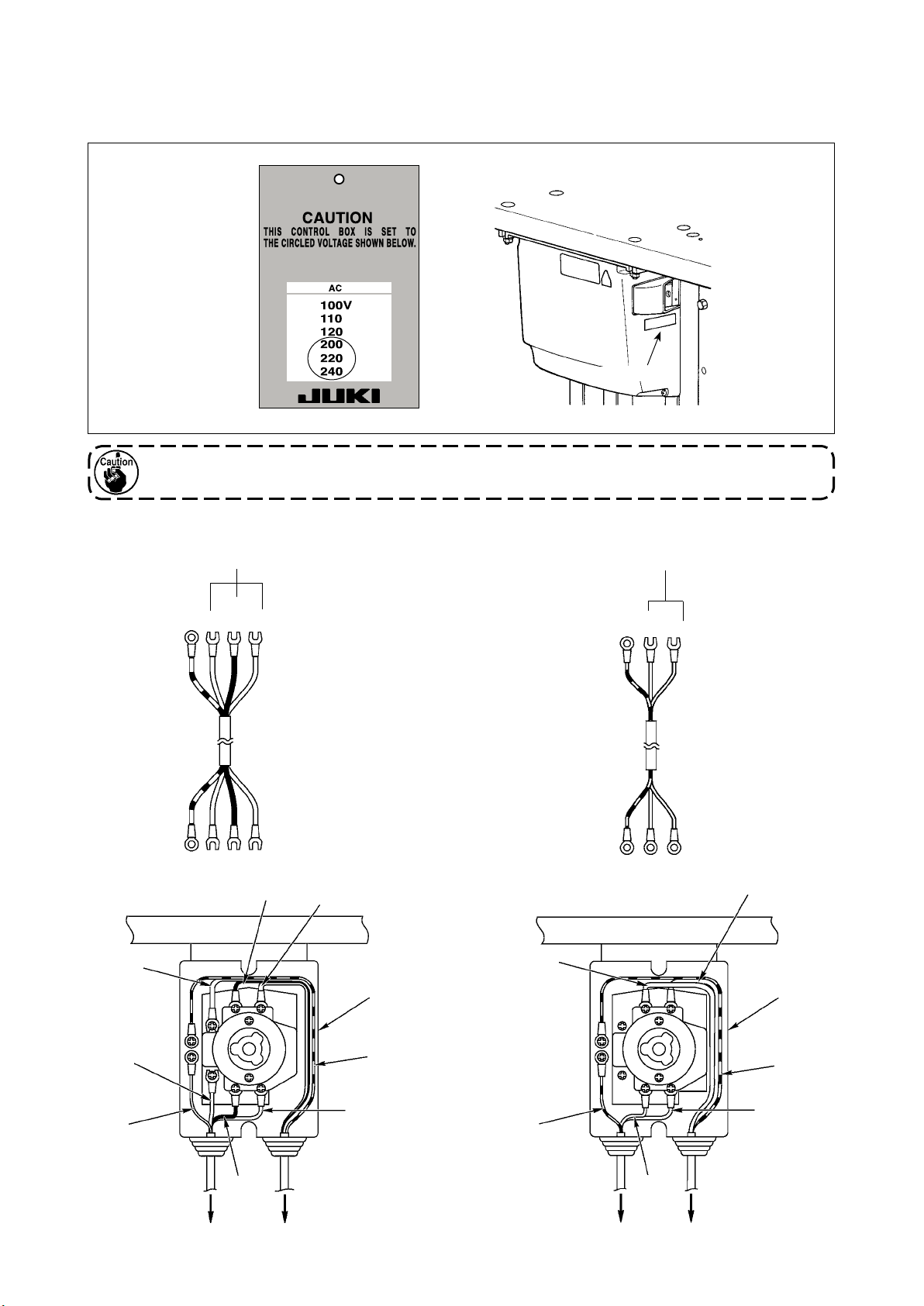

2) Connecting the power cable

Voltage specications are shown on the power indication tag attached on the power cable and on the rating

plate adhered on the power box. Connect the cable which matches the specications.

Power indication tag

Rating plate

(For example: In the case of 200V)

Never use the machine unless the voltage specications described on the power indicator label

are satised.

• Connecting three phase 200V to 240V

AC200 to AC240 V

Green/Yellow

– GND

Table

Red

Black

Red White

Power source cord

Black

Power switch side

Plug side

White

Power switch

• Connecting single phase 200V to 240V

AC200 to AC240 V

Green/Yellow

– GND

Table

Brown

Brown

Light blue

Power source cord

Power switch side

Plug side

Light blue

Power switch

Red

Green

Black

Green/

Yellow

White

PlugControl box

Green/

Yellow

Brown

Control box

Plug

Green/

Yellow

Light blue

– 7 –

Page 11

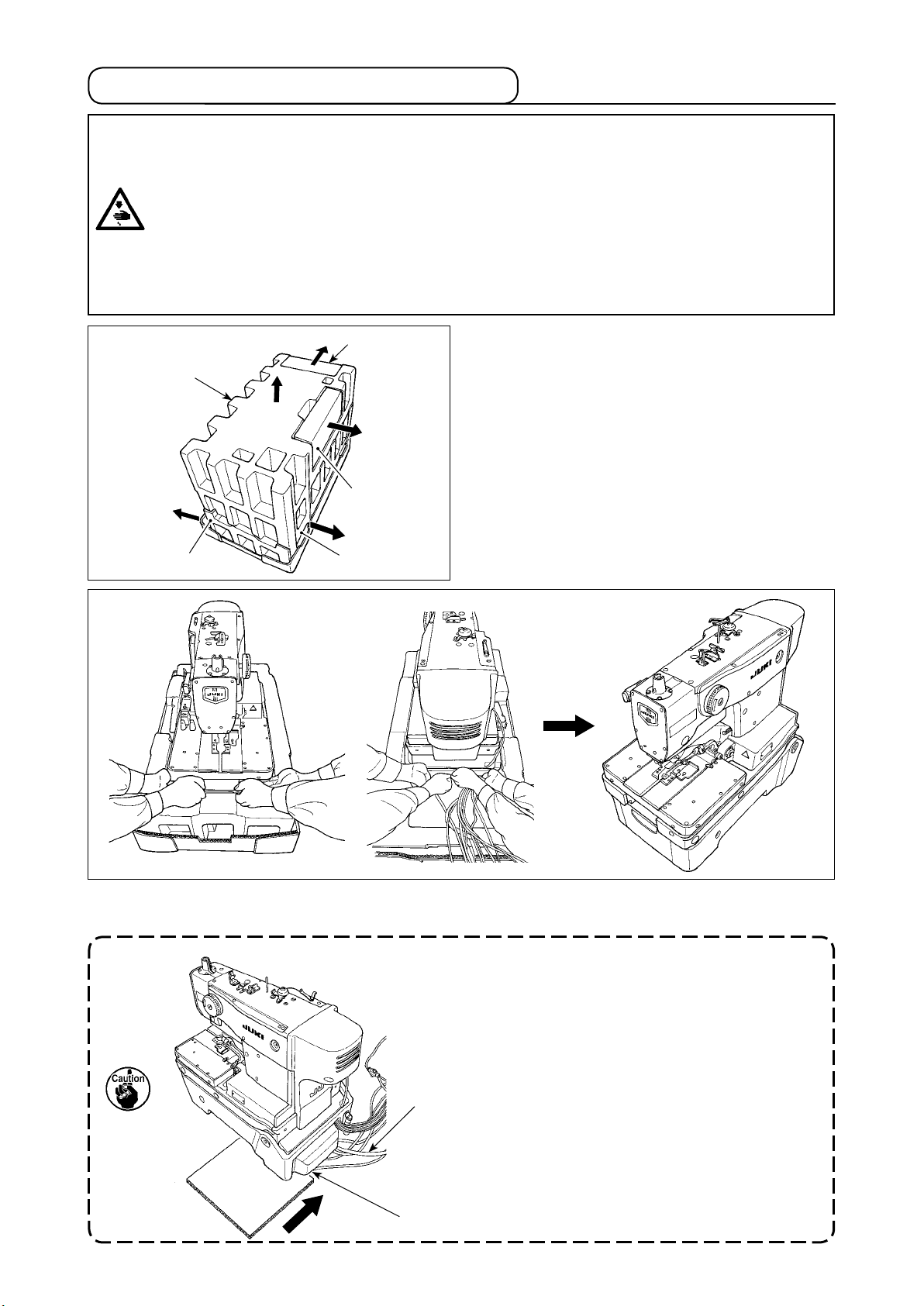

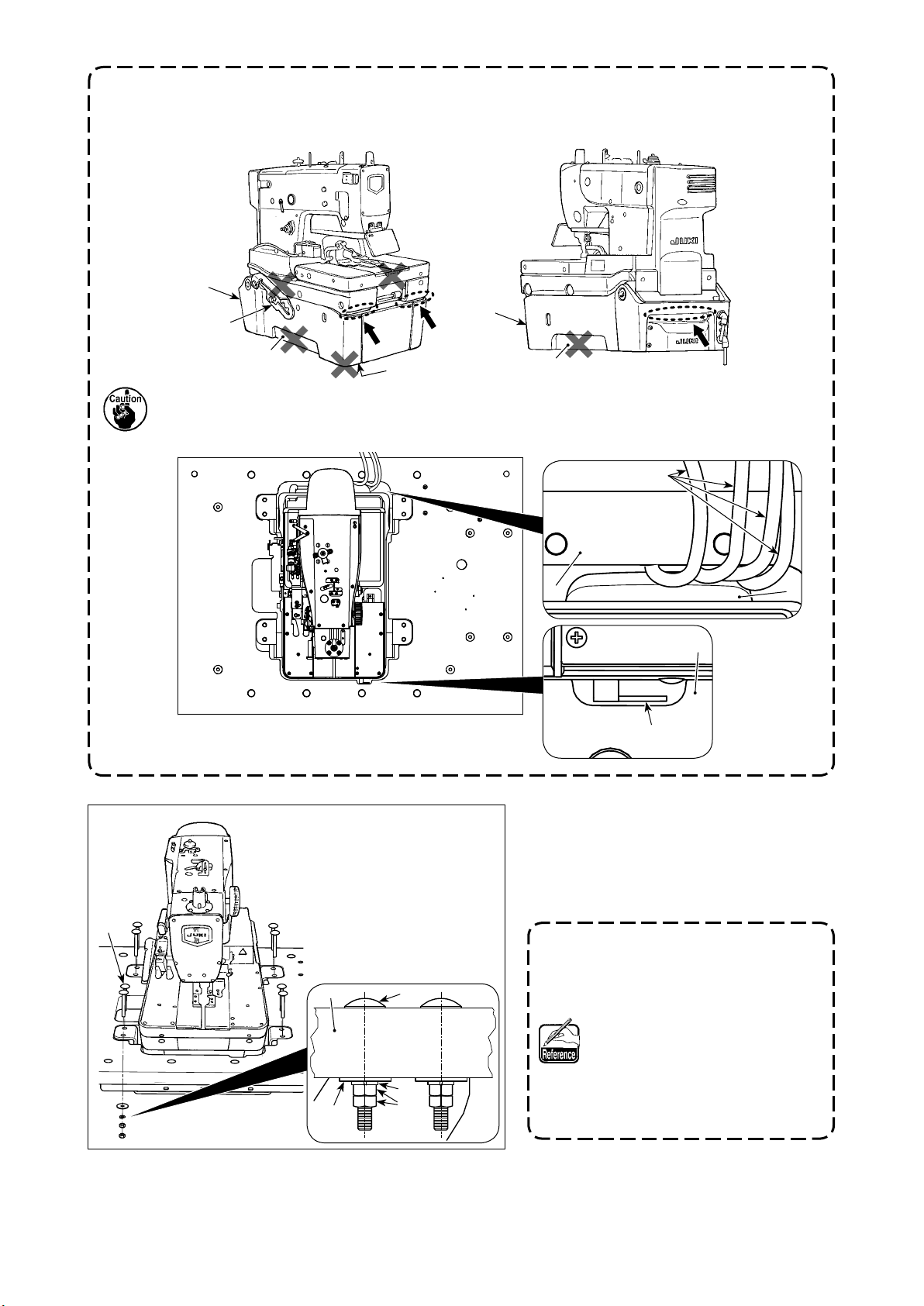

3-4. Taking out the sewing machine

DANGER :

1. The sewing machine should be taken out by a trained technician(s).

2. The sewing machine has a mass of approximately 110 kg. Four or more workers are required

to take out the sewing machine.

4. Never connect the power plug until the installation of the sewing machine is completed in order

3. Do not apply an unreasonable force to the sewing machine until the installation of the sewing machine is completed. If such a force is applied, the sewing machine can lose its balance and can fall

alone or together with the table, resulting in personal injury or sewing-machine breakage.

to protect against an accident due to an abrupt startup of the sewing machine.

❹

❸

❺

❷

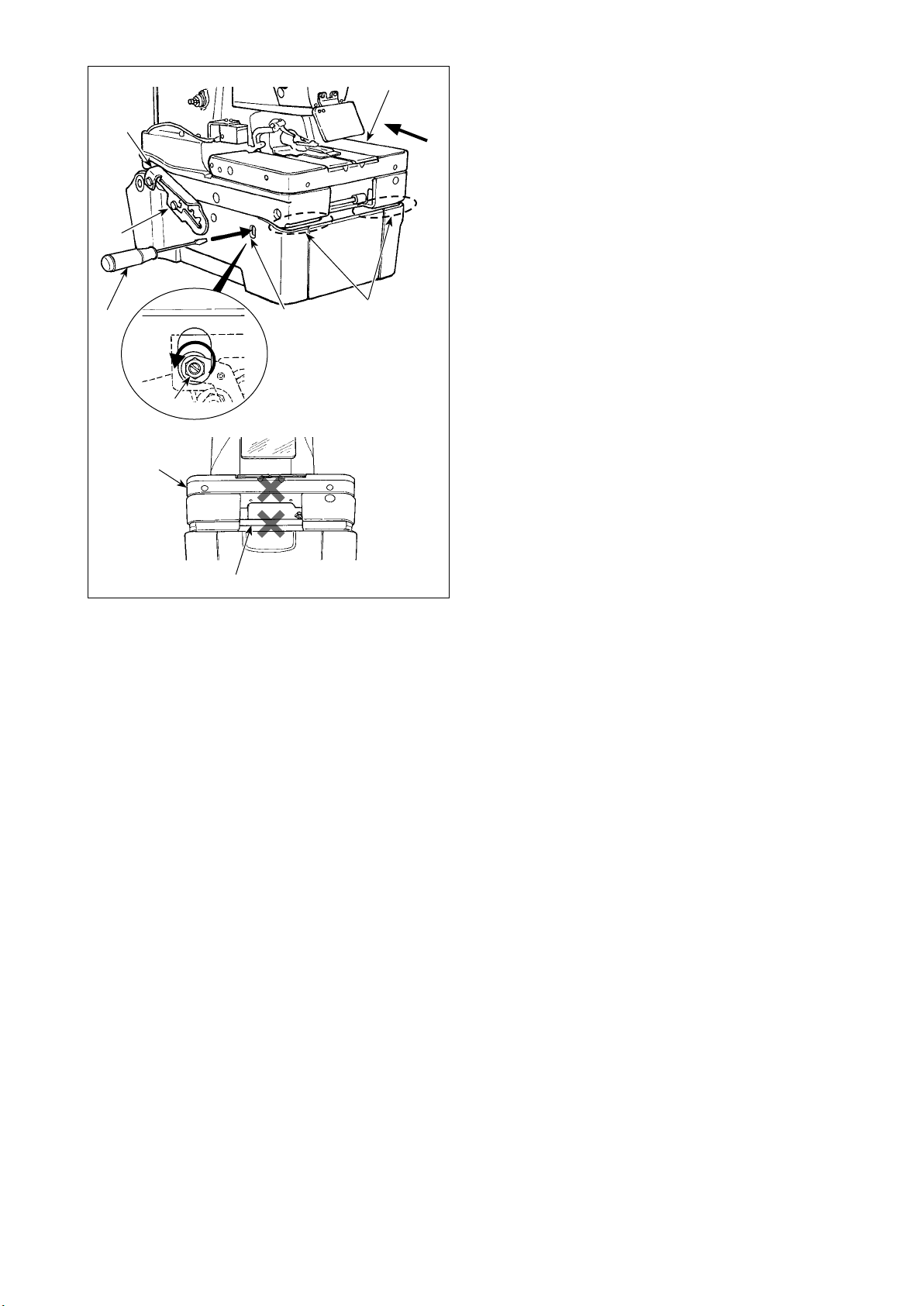

1) Remove accessory boxes ❶ and ❷ in the direction

of the arrow.

2) Remove upper foam polystyrene ❸ in the direction

of the arrow.

3) Remove the right and left intermediate foam poly-

styrene ❹ and ❺ in the direction of the arrow.

❶

4) Take out the sewing machine from the package, by four workers, holding the portions illustrated in the gure.

Place it on the oor.

Place a cardboard sheet or packing material between

the oor and the sewing machine in order to avoid

damaging the oor and to prevent the cords from

being pinched between the INT cover and the oor.

Cord

INT cover

– 8 –

Page 12

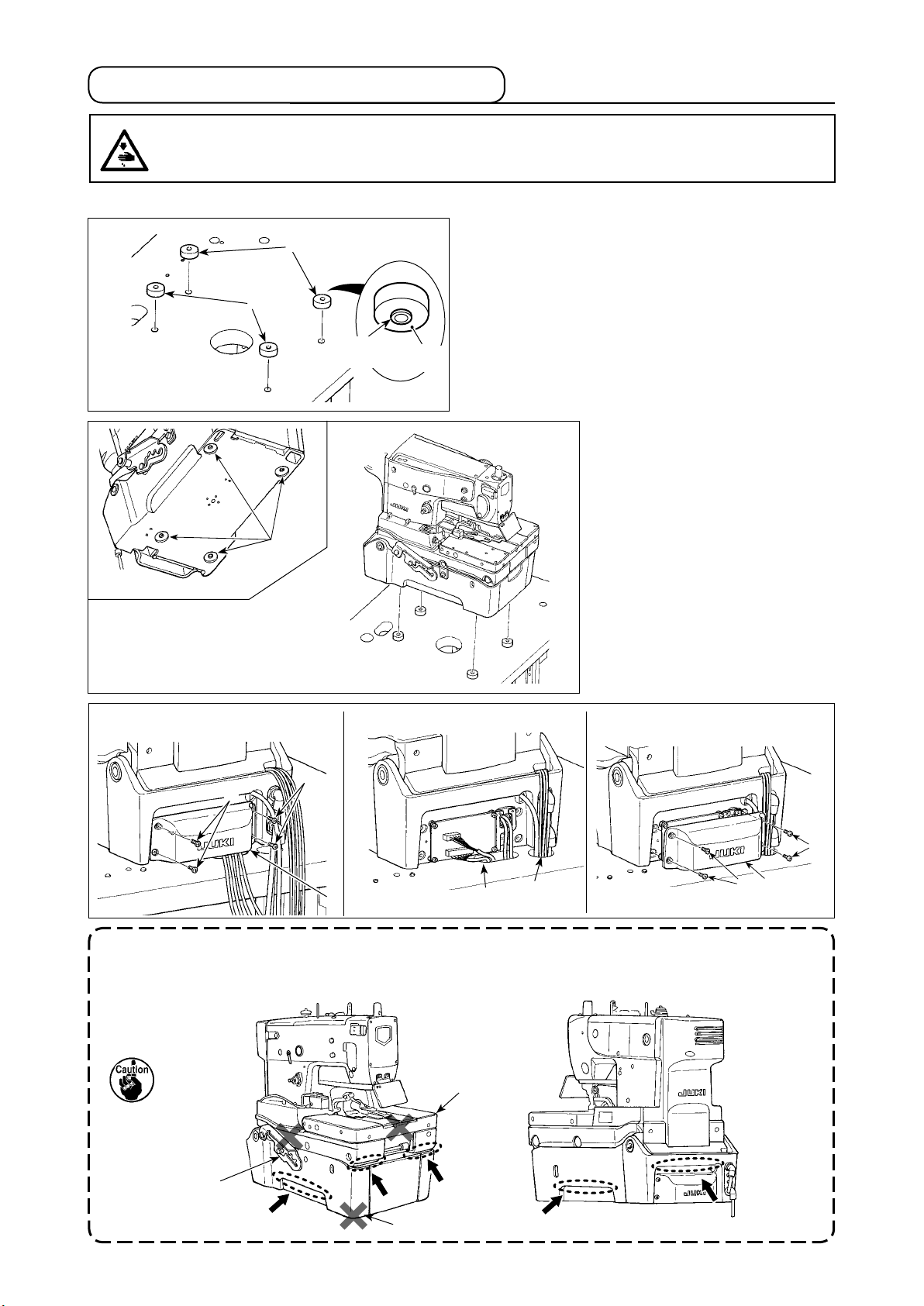

3-5. Installing the sewing machine

WARNING :

The sewing machine has to be carried by four or more workers.

Carry out the installation work on a level place.

(1) In the case of the table-xed type machine head

1) Remove the paper liners from four bolt rubbers B

❶

❶

❶. Place and adhere the liners over the holes in

the table. (Place the bolt rubber B with its convex

side faced downward.)

1)

2)

3)

❾

Under-

side

Paper

liner

2) Place the sewing machine on

the top surface of the table in

such a way that the concave

sections A of the bottom cover

t on bolt rubbers B ❶.

A

3) Remove four setscrews ❾.

Remove INT cover .

4)

Put air tubes and cords coming

from the sewing machine head

into the hole in the table.

5) Install INT cover with four

setscrews ❾.

4) 5)

❾

❾

Air tube

1. Lift the sewing machine head with four or more people by holding the sections marked with

dotted circle as shown in the gure.

2. Do not hold the underside of hinge stopper, bottom cover, and feed base.

Hinge stopper

Bottom cover

Cord

Feed base

❾

– 9 –

Page 13

6), 7)

❽

❻

❺

❼

❹

6) Remove machine head xing bolts ❽. Raise the

sewing machine to the 1st step of the hinge stop-

per.

When raising the sewing machine, refer to "3-6.

Raising and returning the sewing machine" p.

16.

WARNING :

Do not raise the sewing machine above

the 1st step of the hinge stopper.

If it is raised above the 1st step, the sewing machine can fall, resulting in personal

injury or sewing machine breakage.

8) to 10)

❻

❼

❺

❹

❸

❹

❺

❺

❹

❸

❷

7) Open front cover ❷. Insert a bolt ❸, a washer ❹

and a bolt rubber ❺ from the right front side of the

sewing machine, and temporarily x them with a

bolt rubber ❺ a washer ❹, a packing ❼ and two

nuts ❻.

8) Be sure to raise the sewing machine to the fourth

step of the hinge stopper.

Fix the sewing machine with remaining three bolts

❸, six washers ❹, six bolt rubbers ❺, three packings ❼ and six nuts ❻.

9) Remove bolt ❸ and two nuts ❻ which have been

used for temporarily xing.

WARNING :

If your body comes in contact with the

corner section of connector cover ❾ of

the lateral-direction motor during work,

unexpected injury can be caused. Be sure

to keep away from the corner section of

the connector cover.

❸

❼

❹

❺

❺

❹

❻

❸

❼

❹

❺

❺

❹

❻

❻

❸

❻

10) Attach bolt ❸ and two nuts ❻ removed in the

above step of procedure in the reverse direction

and x them.

Fix bolt ❸ and nuts ❻ in such a state that

bolt rubber ❺ is slightly squeezed.

1. Keep machine head xing bolt ❽ since

it is necessary when moving the sewing

machine. Whenever you move the sew-

ing machine, be sure to install the head

xing bolt in place.

2. Bolt ❸ is an M8 hexagon socket head

bolt (length: 85 mm). Nut ❻ is an M8 one.

– 10 –

Page 14

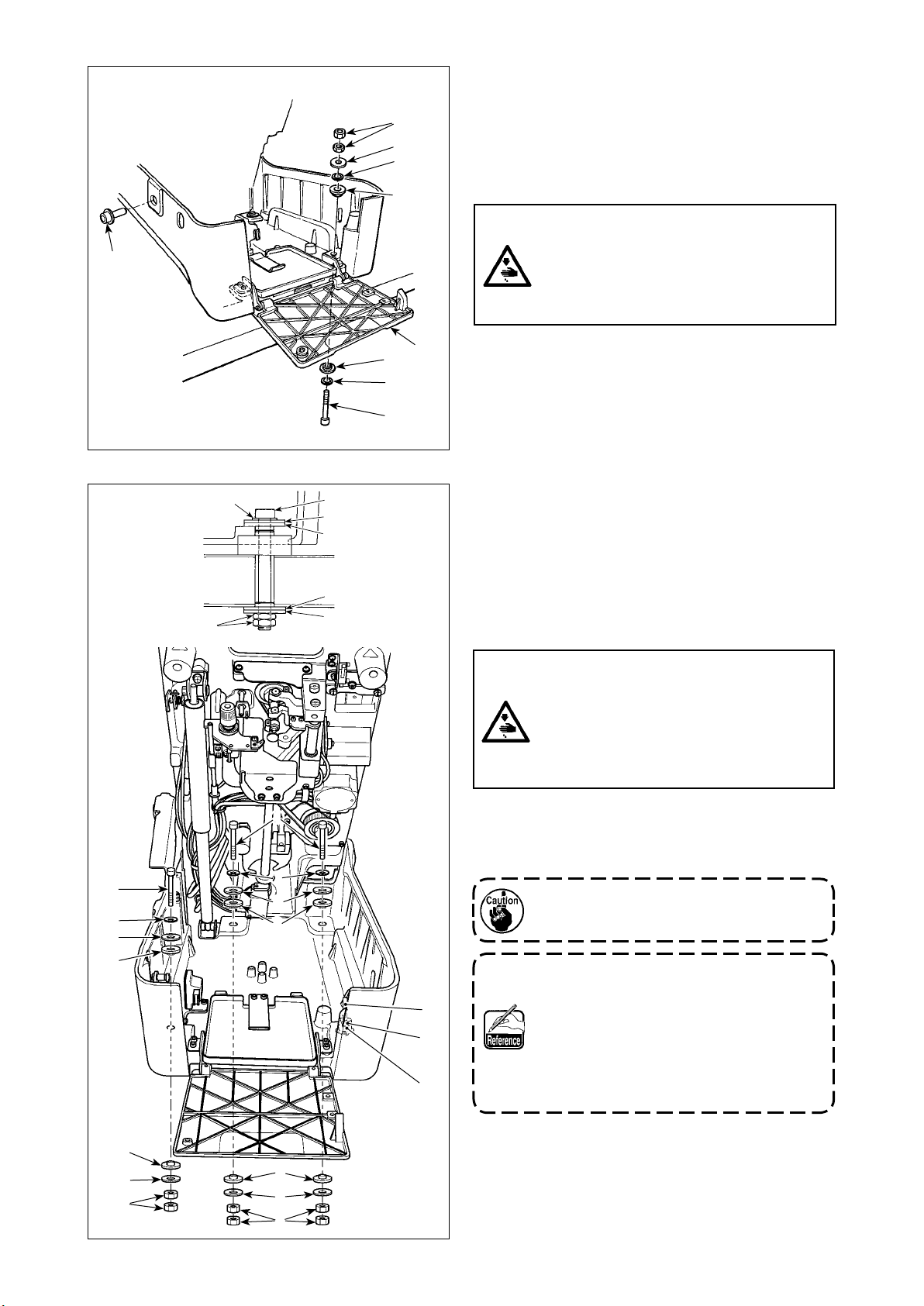

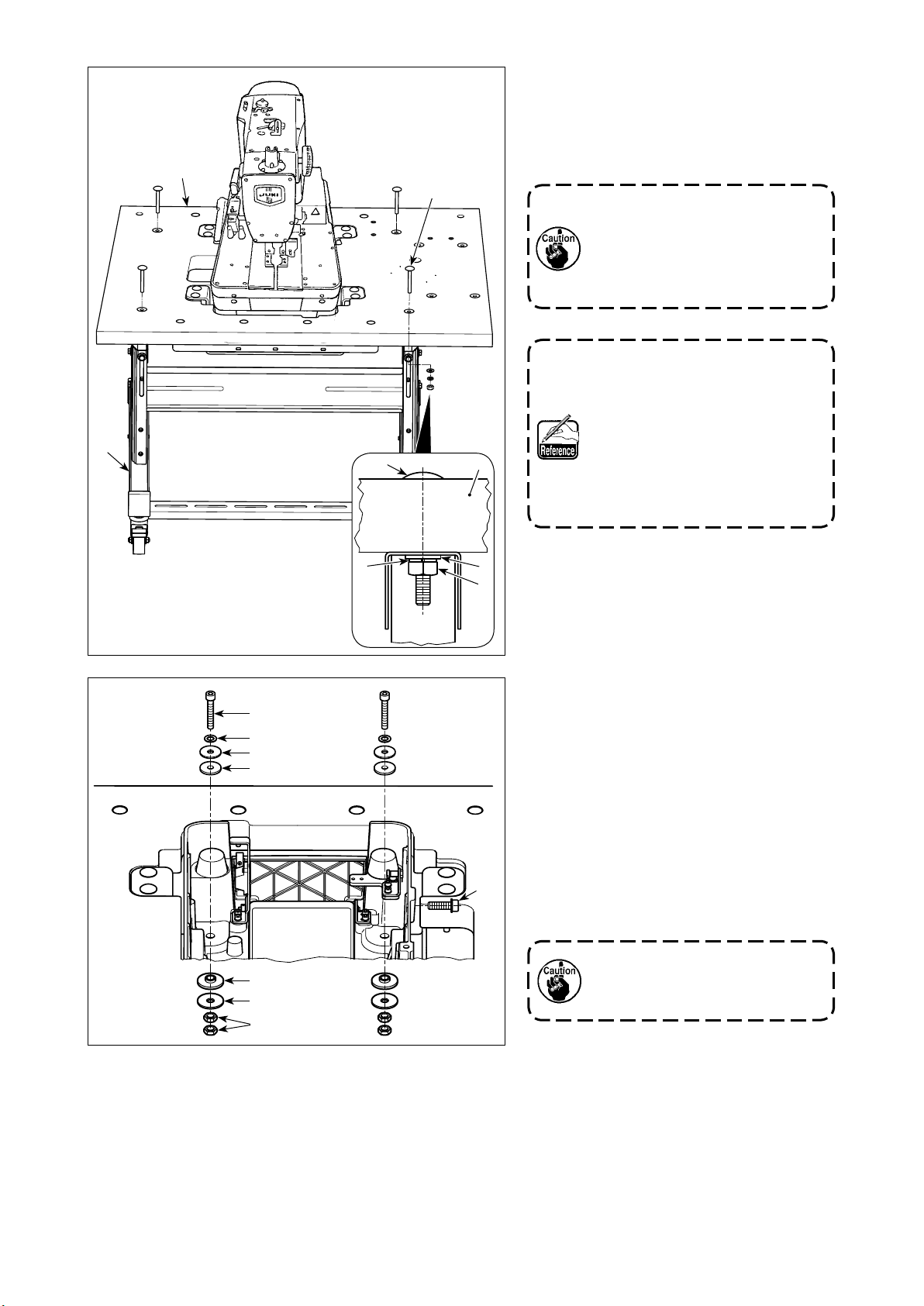

(2) In the case of the semi-sunken type machine head

❸

❸

❶

❹

❺

❻

❸

❷

❷

❶

① Installing the table reinforcing plate

1) Fix two table reinforcing plates ❷ on the table ❶ with eight bolts ❸ , eight plain washers ❹ , eight spring

washers ❺ and 16 nuts ❻.

The bolt ❸ is M6 carriage bolt length of which is 60 mm. The dimensions of the plain washer ❹ are

"φ12.5 xφ6.4 x t1.6". Spring washer ❺ is for M6 and nut ❻ is M6 (class 1).

Bolts ❸, plain washers ❹, spring washers ❺ and nuts ❻ are supplied with the kit for semi-sunken

type machine head (part number: 40157881).

❶

Under-

side

❷

Paper

liner

❶

⇦

A

② Assembling the bottom cover stay (front)

1) Remove paper liners ❸ from two bottom rubbers

B ❶ and afx them on bottom cover stay ❷.

* Afx two right-side bottom rubbers B ❶ with shifted

to the left side (in the direction of the arrow) with

respect to slot A in bottom cover stay ❷.

Under-

side

③ Assembling the bottom cover stay (rear)

1) Remove paper liners ❸ from two bottom rubbers

B ❶ and afx them on bottom cover stay ❷.

* Afx two right-side bottom rubbers B ❶ with shifted

to the right side (in the direction of the arrow) with

respect to slot A in bottom cover stay ❷.

❷

Paper

liner

❶❶

⇦

A

1. Insert bottom rubbers B ❶ into the respective holes in bottom cover stay ❷ while holding them

so that their projecting side is faced downward.

2. Carefully check the location of mounting holes in left-side bottom rubbers B ❶.

Bolt rubber B ❶ is the head accessories. In addition, bottom cover stay ❷ are supplied with the kit

for semi-sunken type machine head (part number: 40157881).

– 11 –

Page 15

A

B

❷

❷

❸

❶

❸

❶

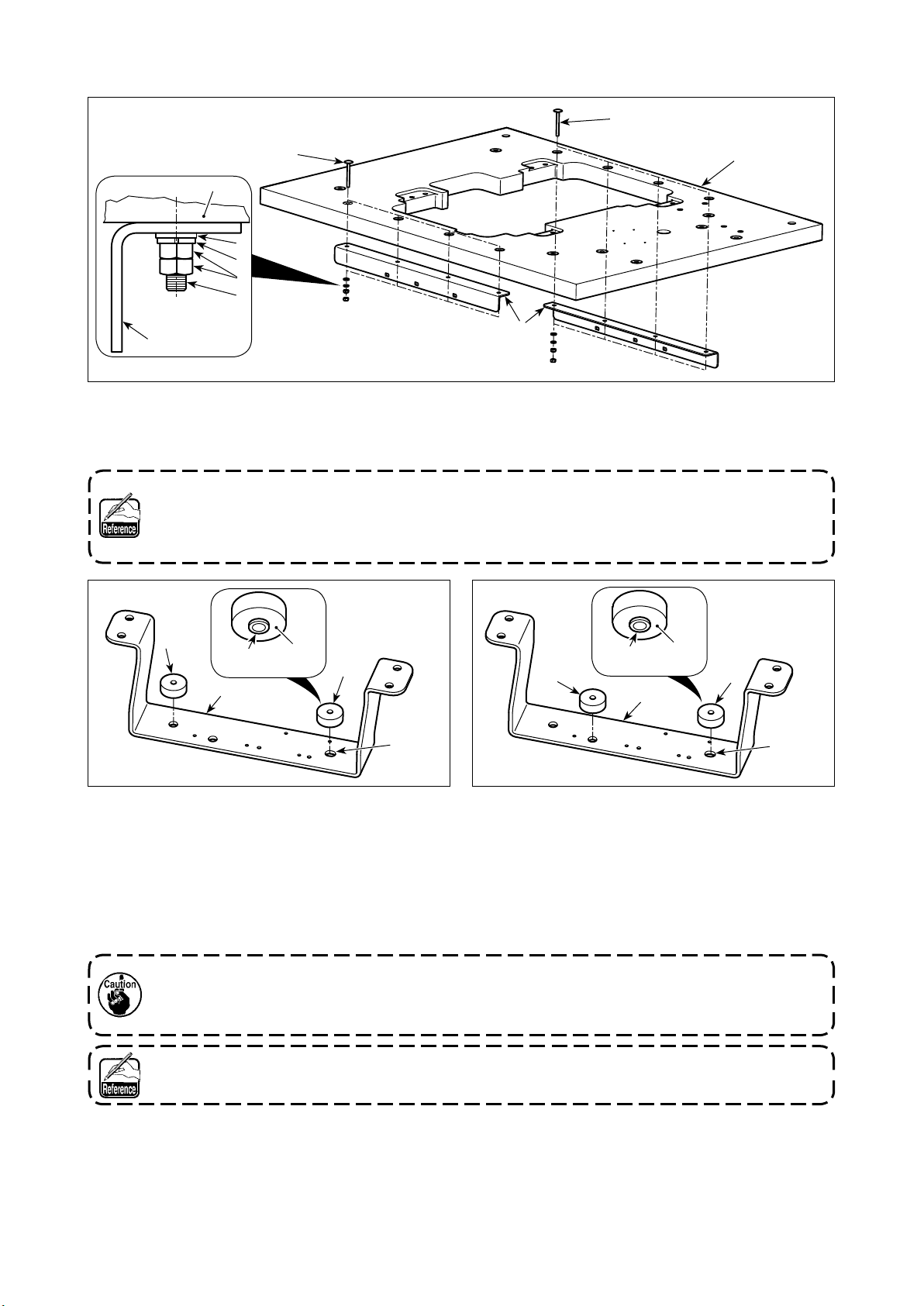

④ INSTALLATION

1) Place table ❶, bottom cover stay (front)

❷ and bottom cover stay (rear) ❸ on the

oor.

2) Align bottom cover stay mounting hole A

in table ❶ with mounting holes B for the

respective bottom cover stays.

At this time, the distance between

the respective bottom cover stays

must be 309 mm, and the distance

between bottom cover stay (rear) ❸

and table ❶ must is 81 mm.

❺

309mm

81mm

3) Put the machine head on the bottom cover

stays.

At this time, put the machine head in such

a way that bottom rubber B ❹ ts in de-

pressed portions C in bottom cover ❺.

C

❺

❹

– 12 –

Page 16

1. Lift the sewing machine head with four or more people by holding the sections marked with

dotted circle as shown in the gure.

2. Do not hold hinge stopper ❻, bottom ❺ of bottom cover D and depressed portion E on the

side face.

❺

❻

❺

E

D

E

3. When putting the machine head on the bottom cover stays, carefully prevent handle ❼ and INT

cover ❽ from coming in contact with table ❶. In addition, do not place the wiring and piping

between INT cover ❽ and table ❶.

Wiring, piping

❶

❶

❼

❽

❾

❾❶

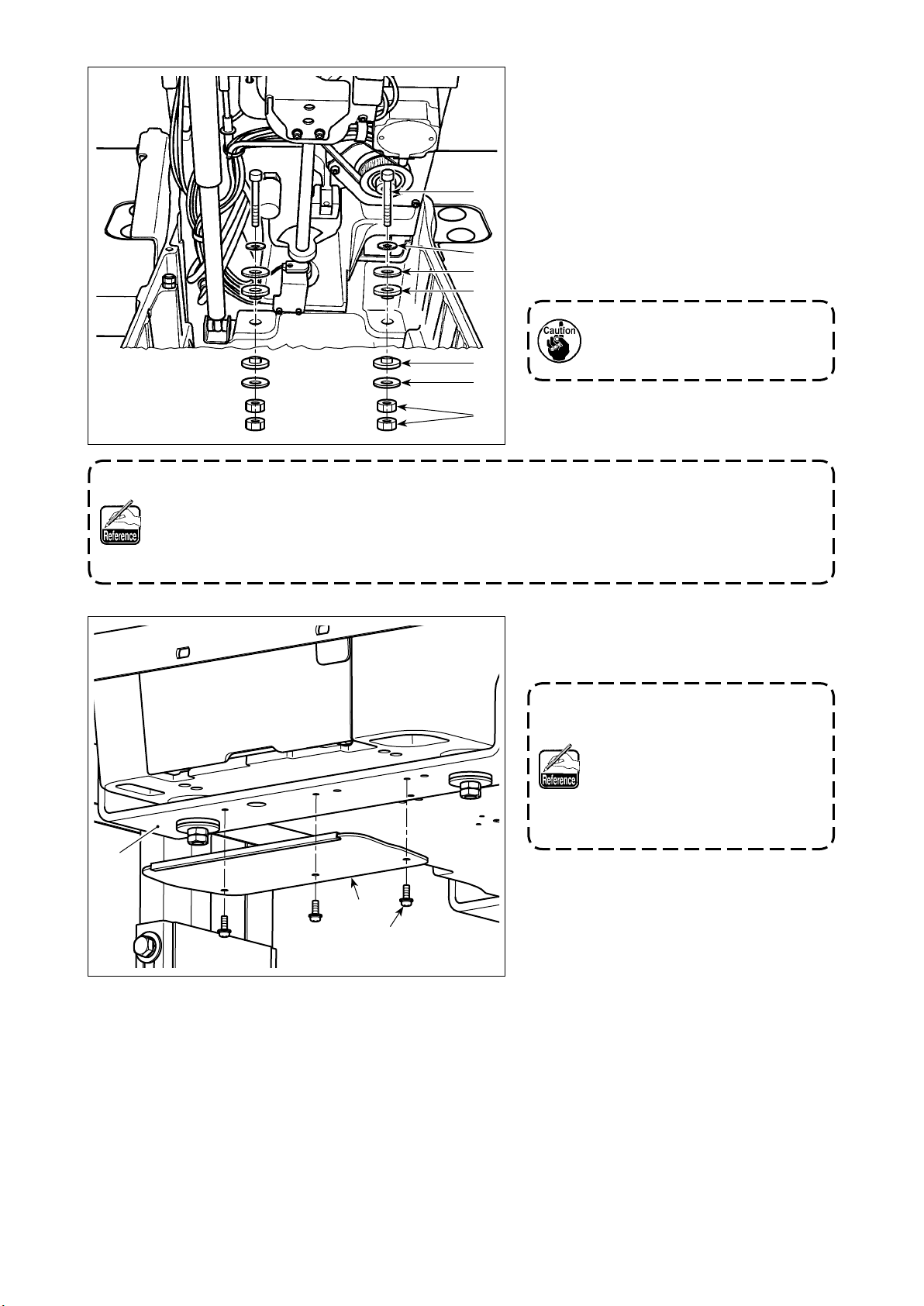

4) Lifting table ❶, join table ❶, bottom cover

stay (front) ❷ and bottom cover stay (rear)

❸ with eight bolts ❾, eight plain washers

, eight spring washers and 16 nuts

.

The bolt ❾ is M8 carriage bolt length

of which is 70 mm. The dimensions

of the plain washer are "φ30

xφ8.5 x t2". Spring washer is for

M8 and nut is M8 (class 1).

Bolts ❾, plain washers , spring

washers and nuts are sup-

plied with the kit for semi-sunken

type machine head (part number:

40157881).

– 13 –

Page 17

❶

❶

5) Holding table ❶ at its four corners with

four or more workers, place it on assembled table stand and x with four bolts

, four plain washers , four spring

washers and four nuts .

1. Lift the table ❶ has to be carried

by four or more workers.

2. Lift the table ❶ while keeping it

in a horizontal position without

tilting.

Bolt is carriage bolt with 18 5/16

threads and is 70 mm long. Plain

washer is of "φ18 xφ8.5 x t1.6".

Spring washer is of "φ15 x φ9 x

t2". Nut has 18 5/16 threads.

Bolt , plain washer , spring

washer , nut is the head acces-

sories.

6) Remove machine head xing bolts .

Raise the sewing machine to the 3rd step

of the hinge stopper.

When raising the sewing machine, refer to

"3-6. Raising and returning the sewing

machine" p. 16.

7) Secure the machine head by xing two

bolts , two packings , four plain wash-

ers , four bolt rubbers and four nuts

at two locations on this side of the sewing

machine.

Fix bolt and nuts in such a

state that bolt rubber is slightly

squeezed.

– 14 –

Page 18

8) Raise the sewing machine to the 4th step

of the hinge stopper.

When raising the sewing machine, refer to

"3-6. Raising and returning the sewing

machine" p. 16.

9) Secure the machine head by xing two

bolts , two packings , four plain wash-

ers , four bolt rubbers and four nuts

1. Keep machine head xing bolt since it is necessary when moving the sewing machine. When-

ever you move the sewing machine, be sure to install the head xing bolt in place.

2. The bolt is M8 hexagon socket head screws of which is 50 mm. The dimensions of the plain

washer are "φ30 xφ8.5 x t2" and nut is M8 (class 3).

Bolt , packing plain washer , bolt rubber , nut is the head accessories.

at two locations on far side of the sewing

machine.

Fix bolt and nuts in such a

state that bolt rubber is slightly

squeezed.

❷

10) Secure tray on bottom cover stay (front)

❷ with three setscrews .

Setscrew is an M4 round head

screw with washer and has a length

of 12 mm.

Tray and setscrews are sup-

plied with the kit for semi-sunken

type machine head (part number:

40157881).

– 15 –

Page 19

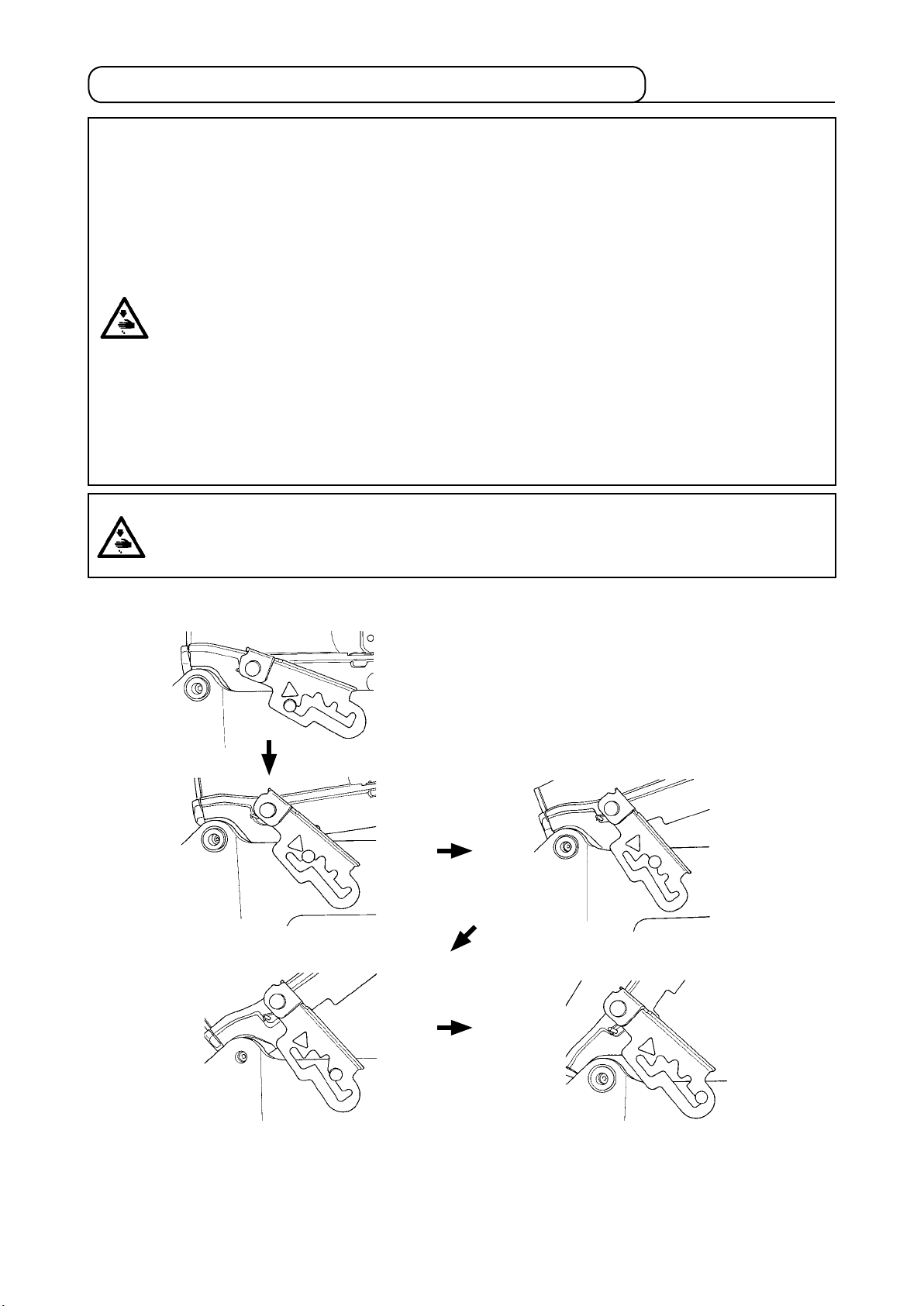

3-6. Raising and returning the sewing machine

DANGER :

1. Do not lift the sewing machine for any purpose other than for installation, repair or adjustment

in order to prevent accidents resulting in personal injuries due to pinching. In addition, the

sewing machine has to be lifted for repair or adjustment only by a maintenance technician

who is familiar with the machine.

2. If you nd the sewing machine is too heavy to lift, the gas spring may have malfunctioned

due to outgassing.

Never lift the sewing machine in such a state since the machine can drop to pinch hands,

ngers and arms resulting in serious injury.

* Carefully read the description given in "10-14. (6) Standard of replacing time of the gas spring"

p.94 and "10-14. (7) Replacing the gas spring" p.95.

3. Be sure to carry out the work while strictly observing the following in order to protect against

serious injury to hands, ngers and/or arms due to pinching in the relevant parts of the sewing

machine.

• Be sure to hold the sewing machine by the ribs located on the front side of the bed.

•

Be sure to securely x the sewing machine in the raised position by locking the hinge stopper.

4. Do hole hold any part other than the ribs located on the front side of the bed.

5. If you raise the sewing machine with the feed base remained this side, the feed base can move

to pinch hands and ngers resulting in an unexpected injury.

WARNING :

When raising/returning the sewing machine from/to its home position, check to be sure that the

sewing machine is locked by the support shaft in the stop position of each step of the hinge stopper.

The sewing machine can be raised/returned to/from four different heights.

1st step 2nd step

3rd step

4th step

– 16 –

Page 20

❹

❼

❻

❷

❺

❽

❸

❶

❷

1) To raise the sewing machine, rstly push feed

base ❷ away from you (in the direction of the

arrow), then insert at-blade screwdriver ❹ into

bottom-cover opening tool slot ❸, turn it counter-

clockwise to release the sewing machine up/down

lock ❺.

2) Turn at-blade screwdriver ❹ to keep the lock

in the released state, and slightly lift the sewing

machine by holding it by rib ❶ located on the front

side of the bed.

3) Carefully remove at-blade screwdriver ❹. Hold

ribs ❶ located on the front side of the bed with

your both hands to slowly lift the sewing machine

to the 1st step of hinge stopper ❻.

At this time, do not hold feed base ❷ and feed

guide shaft ❽.

4) Check to be sure that hinge stopper ❻ is locked

by support shaft ❼. Then, take hands off the ribs.

5) To raise the sewing machine to the 1st to 3rd steps

of the hinge stopper, hold ribs ❶ located on the

front side of the bed with your both hands to slowly

lift it to the required step of the hinge stopper.

– 17 –

Page 21

[To lift the sewing machine from the 3rd to 4th step of the hinge stopper]

6) Hold rib ❶ located on the front side of the bed with your right hand to draw hinge stopper ❻ in direction of

arrow A until the lock is released. Then, slowly lift the sewing machine.

7) Hold ribs ❶ located on the front side of the bed with your both hands to slowly lift the sewing machine to

the 4th step of hinge stopper ❻.

❶

❶

❻

A

❷

❽

❶

8) To return the sewing machine to its home position, rstly check to be sure that there is no tool such as a

screwdriver inside the bottom cover.

9) Hold rib ❶ located on the front side of the bed with your right hand to slightly lift the sewing machine. Then,

hold handle ❻ of the hinge stopper with your left hand and pull it toward you (in direction A) until the lock

is released, then slowly lower the sewing machine.

10) Take your left hand off the stopper section. While supporting ribs ❶ located on the front side of the bed

with your both hands, lower the sewing machine further.

DANGER :

1. Do not lower the sewing machine while keeping pulling the hinge stopper in direction A, in

order to prevent pining of ngers, hands and arms under the sewing machine leading to a

serious injury. (Be sure to take your hands off the hinge stopper.)

2. Do not hold feed base ❷ and feed guide shaft ❽.

11) At its each step, the hinge stopper is locked to secure the sewing machine at the corresponding height.

Following the procedure described in 9), hold rib ❶ on the front side of the bed with your right hand to

slightly lift the sewing machine. Then, hold the handle of the hinge stopper with your left hand to release

the lock and slowly lower the sewing machine.

12) The sewing machine is stopped again at the nal step of its lowering for the sake of safety. Following the

procedure described in 9), hold rib ❶ on the front side of the bed with your right hand to slightly lift the

sewing machine. Then, hold the handle of the hinge stopper with your left hand to release the lock and

slowly lower the sewing machine.

DANGER :

Take care to prevent pinching of hands and ngers between the sewing machine and the bottom

cover. It should be strictly prohibited to lower the sewing machine by two or more workers while

holding it by any section other than the ribs located on the front side of the bed since it can cause

a pinching accident resulting in a serious injury to hands, ngers and/or arms.

– 18 –

Page 22

3-7. Installing the poly oiler

❺

❷

❶

❸

❹

❼

❺

❺

1) Place the sewing machine in its home position.

2) nstall oil drain cock ❶, oil seal ❷ and washer ❸

on bottom cover ❺ with four setscrews ❹.

3) Raise the sewing machine.

4) Drive spring pin ❼ of bottom cover ❺ into bottom

cover ❺ until it is almost ush with bottom cover

❺.

Take care not to crack bottom cover ❺ when

driving in spring pin ❼.

❼

❼

❻

❻

❼

❶

❽

3-8. Installing the operation panel

❺

❷

❶

❸

❹

5)

Make a knot in the oil wick ❻ (ø2.5 mm). Insert oil

wick ❻ (ø2.5 mm) into spring pin ❼ of bottom cover

❺ until its end comes from oil drain cock ❶.

At this time, insert oil wick ❻ (ø2.5 mm) supplied

as accessories into the slit in spring pin ❼.

6) Install poly oiler ❽ on oil drain cock ❶.

Refer to "3-6. Raising and returning the

sewing machine" p. 16 when you raise or

return the sewing machine.

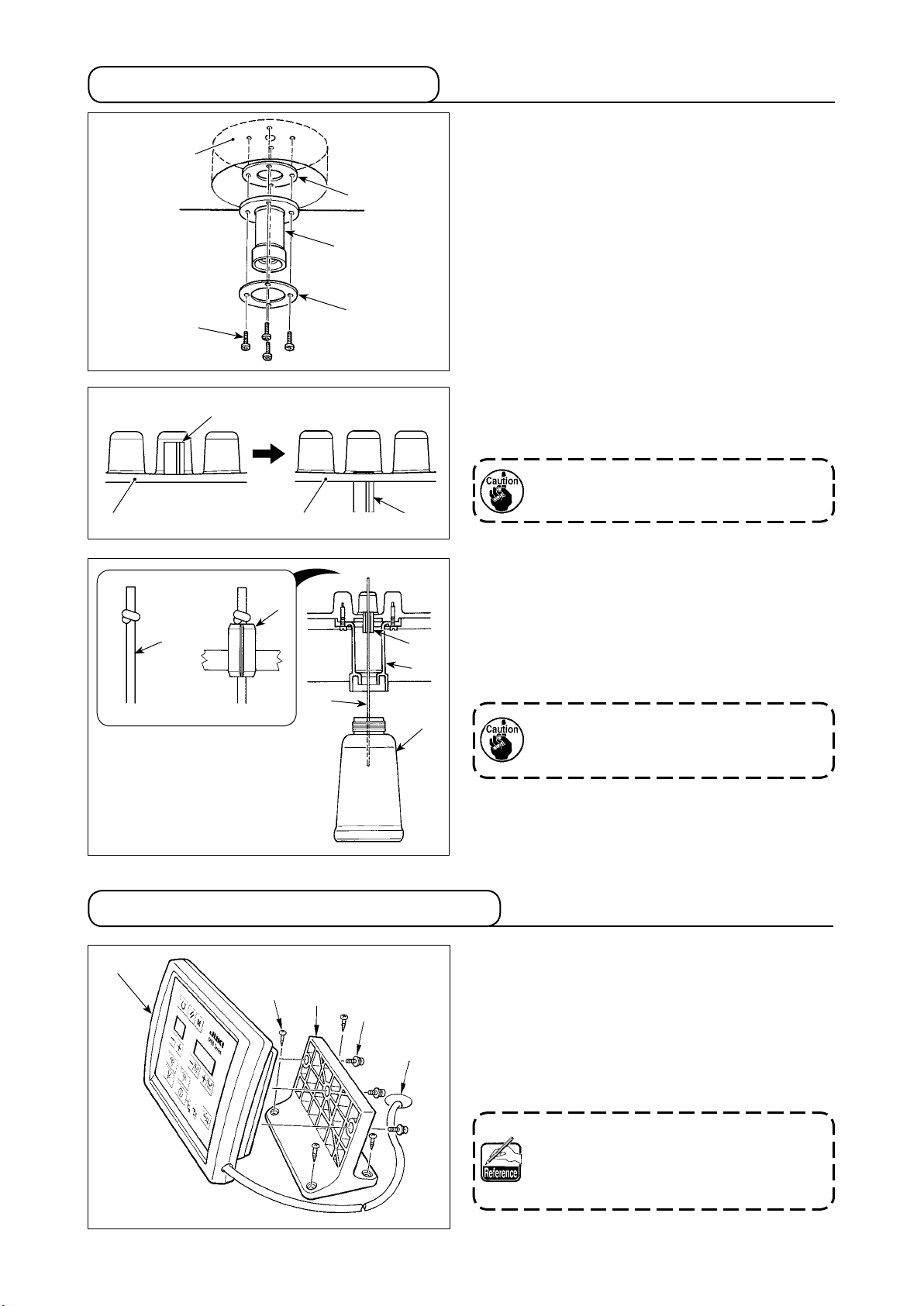

1) Fix operation panel installing plate ❶ on the table

at a desired location near its right end with four

wood screws ❷.

2) Put the cable of operation panel ❺ through hole

❹ in the table.

3) Fix operation panel ❺ on operating panel mounting

plate ❶ with three setscrews ❸.

Wood screw ❷ has the nominal diameter

of 3.8 mm and a length of 20 mm. Setscrew

❸ is an M4 round head screw with washer

and has a length of 16 mm.

– 19 –

Page 23

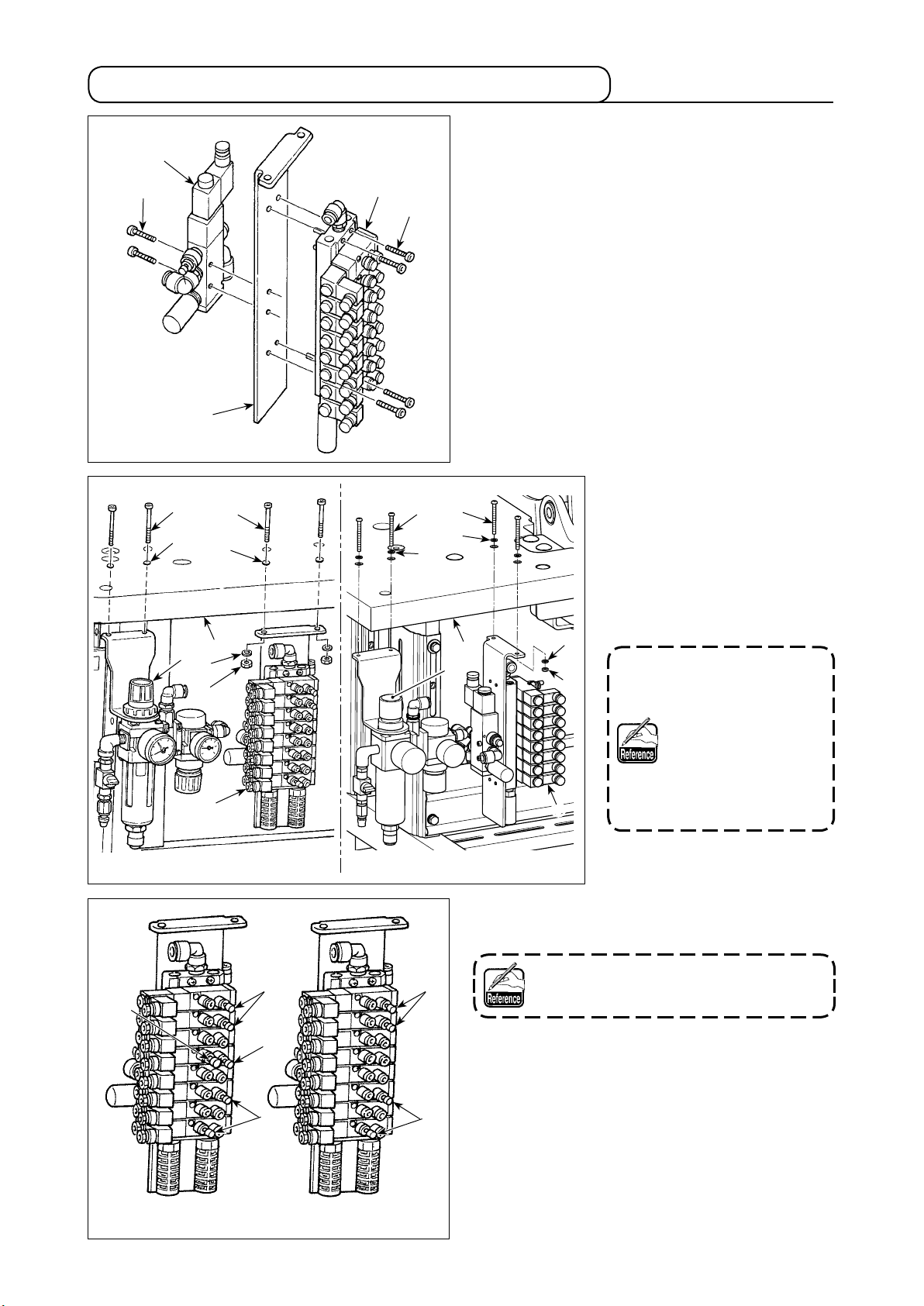

3-9. Installing the regulator and the manifold

1) Install manifold asm. on manifold mounting plate

❾ with four setscrews .

2) Install solenoid valve on manifold mounting

plate ❾ with two setscrews .

❸

❹

❾

❼

❻

❸

❹

❻

❼

3) Install regulator asm. ❶ on

table ❷ with two setscrews

❸ and two washers ❹.

4) Install manifold ❺ on table ❷

with two setscrews ❻, four

washers ❼ and two nuts ❽.

❷

❶

❼

❽

❺

Table-xed type Semi-sunken type

❷

❶

5) Attach plugs and to manifold asm. at the

locations shown in the gure at left.

Plug is for ø4 hole and plug is for ø6

❺

hole.

❼

❽

Setscrews ❸ and ❻

are pan head screws

M5 of length 50 (mm).

Setscrews and are

hexagon socket head

screws M4 of length

30. Nuts ❽ are hexagon

nuts M5.

00 type 01 type

– 20 –

Page 24

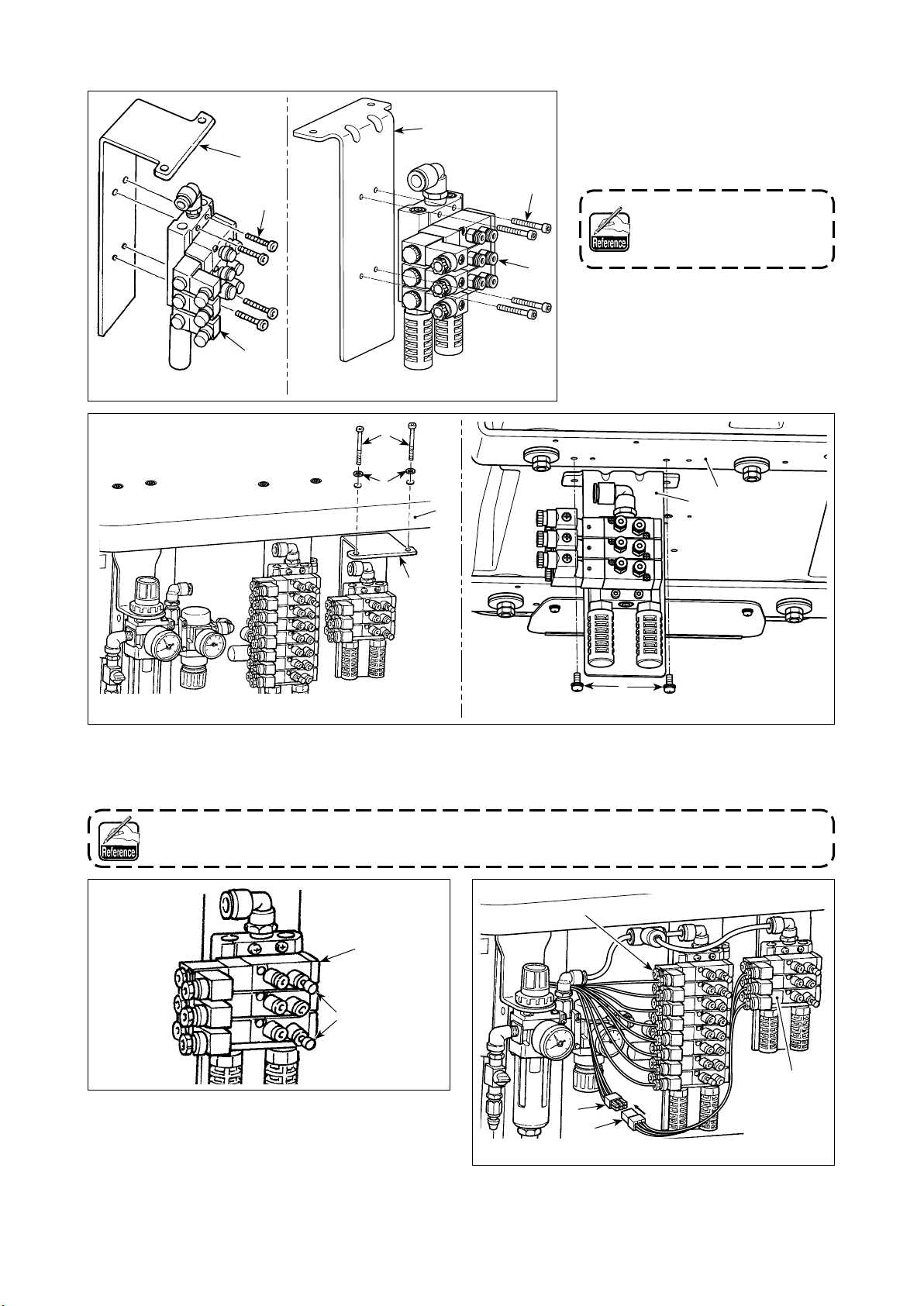

[For the needle thread clamp unit]

❷

❸

❶

❷

1) Install manifold asm. ❶ for the

needle thread clamp on manifold

mounting plate ❷ with four setscrews ❸.

❸

Setscrew ❸ is M4 hexa-

gon socket head screws of

which is 30 mm.

❶

Table-xed type

Table-xed type

Semi-sunken type

❺

❽

❹

❷

❷

❼

Semi-sunken type

❻

2) For the table-xed type machine head, install manifold mounting plate ❷ which has been assembled in 1)

on table ❹ with two setscrews ❺ and two washers ❽. For the semi-sunken type machine head, install it

on bottom cover stay (rear) ❻ with two setscrews ❼.

Setscrew ❺ is M5 50-mm long pan head screw. Setscrew ❼ is M5 12 mm long pan head screw with

washer.

❶

❾

3) Attach plug ❾ to manifold asm. ❶ for the needle

thread clamp at the locations shown in the gure

at left.

For one of plugs ❾, remove No. 39 of the manifold

asm. and attach the plug instead. (Pipe is connect-

ed to No.39.)

– 21 –

❶

A

B

4) Connect connector A of standard manifold and

connector B of manifold asm. ❶ for the needle

thread clamp.

Page 25

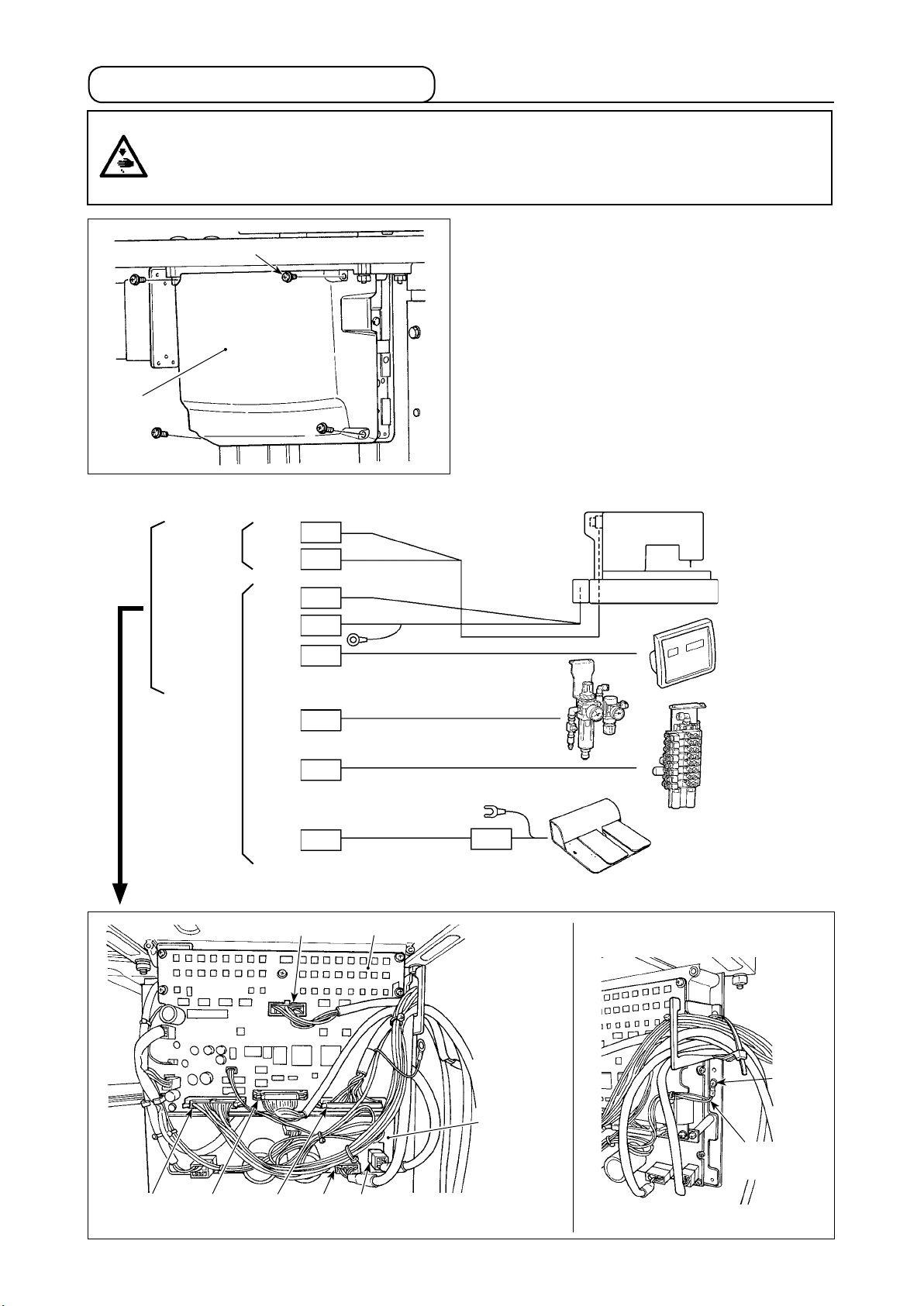

3-10. Connecting the cords

DANGER :

To prevent personal injuries caused by electric shock hazards or abrupt start of the sewing

machine, carry out the work after turning OFF the power switch and a lapse of 5 minutes or more.

To prevent accidents caused by unaccustomed work or electric shock, request the electric expert

or engineer of our dealers when adjusting the electrical components.

❷

❶

1) Loosen four setscrews ❷ of control box cover ❶.

Remove control box cover ❶.

2) Connect the cords to the respective connectors

on MAIN PWB, SDC PWB. (Fig. 1)

3) Fix the shielded ground wire of the INT PCB signal

cord at location A of the control box with a screw.

(Fig. 2)

SDC PWB

MAIN PWB

CN15

CN17

CN30

CN45

CN34

CN35

CN44

CN43 9P

CN30 White

9P

4P

16P

50P

26P

3P

30P

White

White

White

Brown

Gray

White

Blue

Red

MAIN PWB

Sewing

machine head

Operation

panel

Air

switch

Solenoid

valve

10P

Foot pedal switch

(Option)

CN44

Blue

CN34

Gray

CN45

Brown

CN17

White

CN15

White

(Fig. 1)

– 22 –

A

SDC PWB

Shielded

ground wire

(Fig. 2)

Page 26

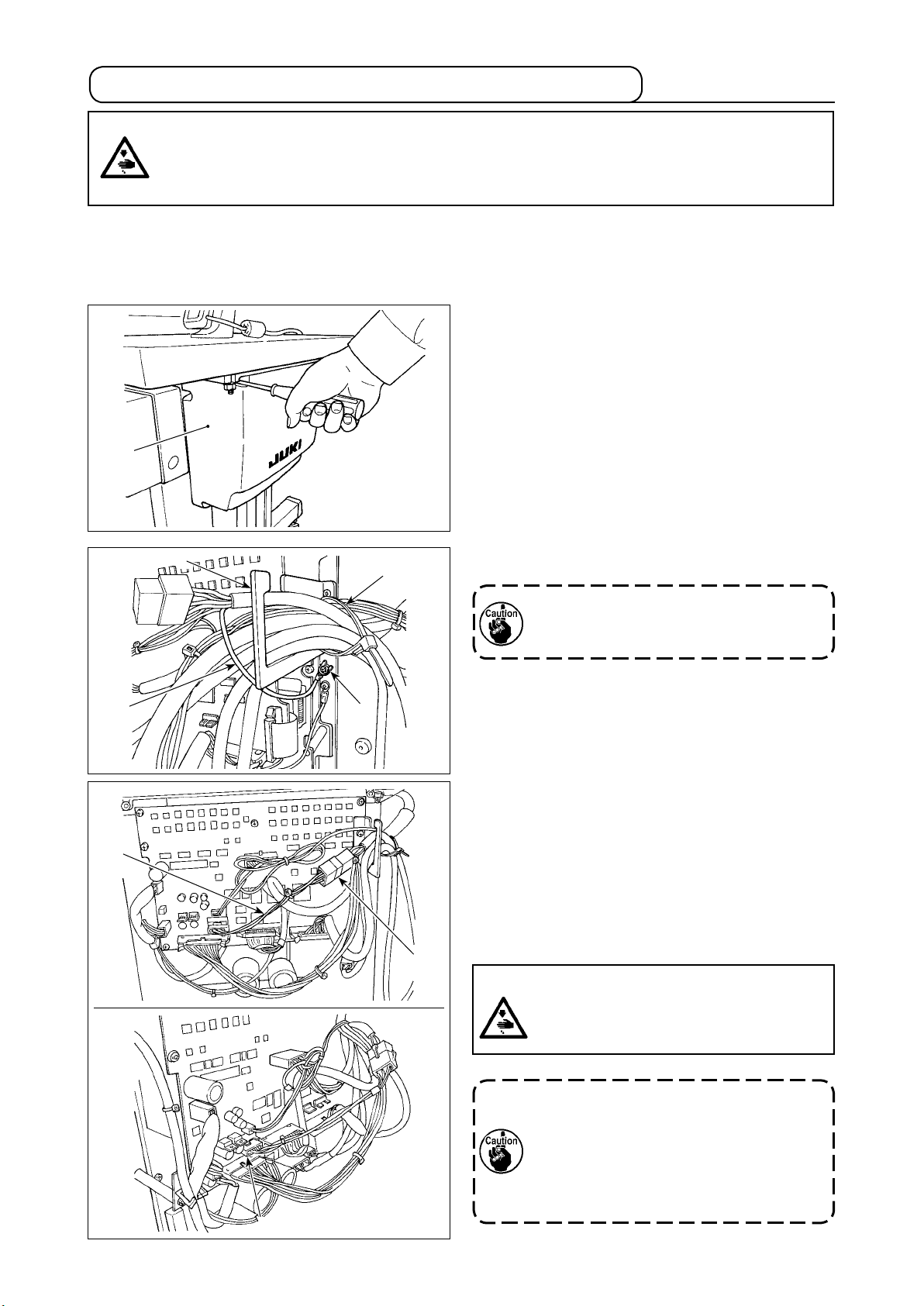

3-11. Handling the cords

DANGER :

To prevent personal injuries caused by electric shock hazards or abrupt start of the sewing

machine, carry out the work after turning OFF the power switch and a lapse of 5 minutes or more.

To prevent accidents caused by unaccustomed work or electric shock, request the electric expert

or engineer of our dealers when adjusting the electrical components.

❶

❷

1) Bring the cords under the table into the control box.

2) Put the cord brought into the control box through

cord exit plate ❶ and x cable clip band ❷.

❸

3) Install control box lid ❸ with four setscrews ❹.

❹

– 23 –

Page 27

3-12. Installing the foot pedal switch (optional)

DANGER :

To prevent personal injuries caused by electric shock hazards or abrupt start of the sewing

machine, carry out the work after turning OFF the power switch and a lapse of 5 minutes or more.

To prevent accidents caused by unaccustomed work or electric shock, request the electric expert

or engineer of our dealers when adjusting the electrical components.

The hand switch is provided on the standard type machine.

To use the optional foot pedal switch (part number: 40033831), connect it in the procedure described below.

When installing the foot pedal switch, the foot pedal switch junction cable asm. (part number: 40114433) is

also required. Refer to "11-6. Others" p. 98.

1) Loosen the four setscrews in the control box to

remove cover ❶.

❶

❹

❷

❸

2) Fix earthing wire ❷ of the foot pedal switch at

❺

A

location A of the control box.

Pass the earthing wire through cord exit

plate ❸. If not, it can be caught under the

cover when closing it.

3) Connect foot pedal switch junction cable ❹ to the

foot pedal switch cable (B) and connect the oppo-

site side of the junction cable to CN43 connector

on the PWB (C).

4) Fix the cable.

Loosen cable clip band ❺. Fix the foot pedal switch

cables (excluding earthing wire ❷) by means of

cable clip band ❺ together with other related ca-

B

bles.

DANGER :

It is very important to carefully connect the

cables to the correct connectors on the

PWB. Wrong connection poses a great risk.

Even in the case the optional foot pedal

switch is installed on the sewing machine,

the hand switch is still enabled. Carefully

operate the switches since the sewing

machine is activated by operating either

switch.

C

– 24 –

Page 28

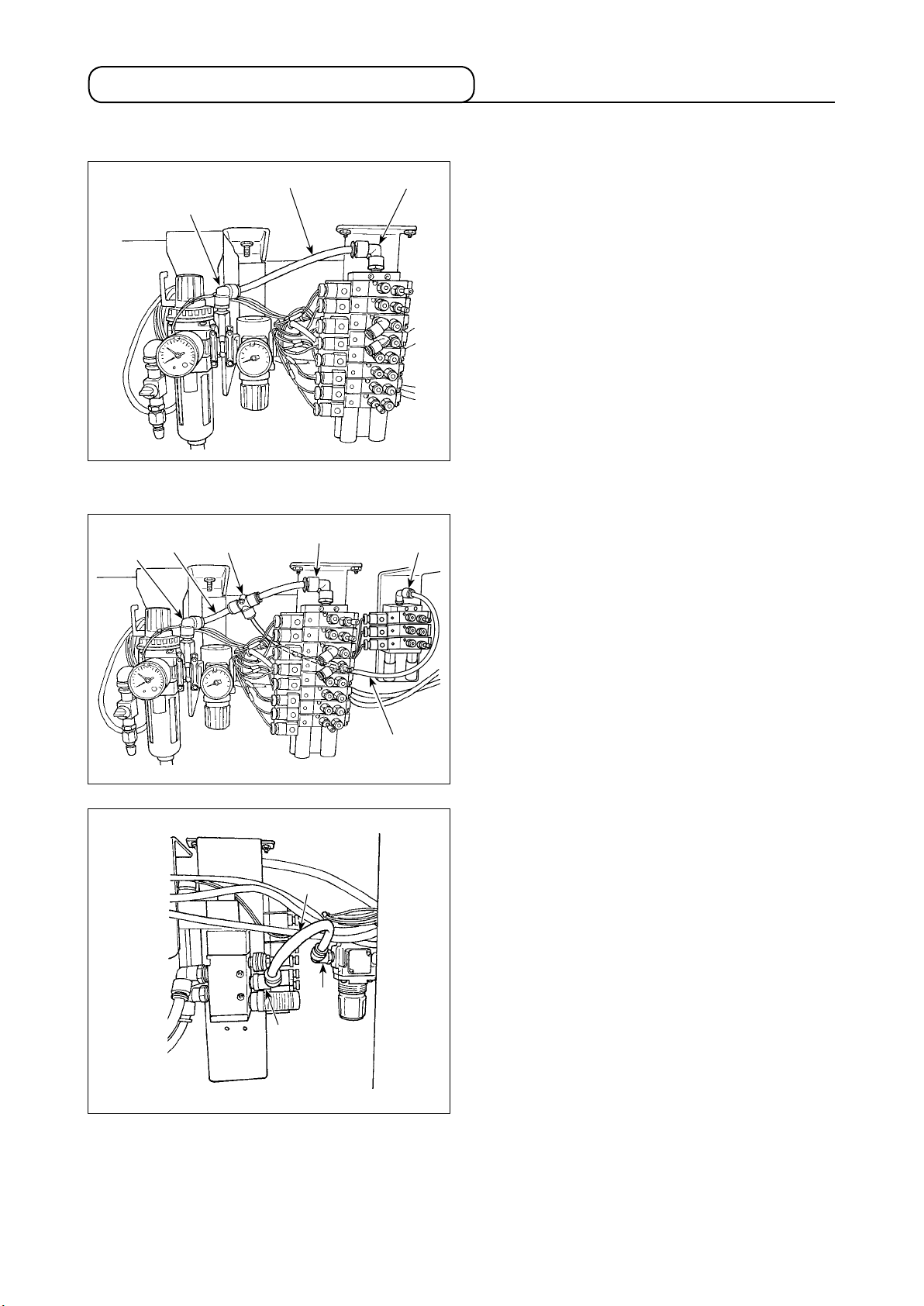

3-13. Connecting the air supply

(1) Connecting the regulator and the manifold

❸

❶

[For the needle thread clamp]

❶

❸

❹

❷

❷

❻

1) Connect joint ❶ of the regulator and joint ❷ of the

manifold by means of the air tube ø10 ❸.

1)-1. Connect air tube ø10 ❸ and joint ❷ of the manifold by means of T-joint ❹ which has a short air

tube.

1)-2. Connect T-joint ❹ and joint ❻ of the manifold

for the needle thread clamp by means of air tube

ø10 ❼.

❾

❼

2) Connect joint ❽ of the cloth trimming regulator

and joint ❾ of the cloth trimming solenoid valve

by means of the air tube ø10 ❺.

❺

❽

– 25 –

Page 29

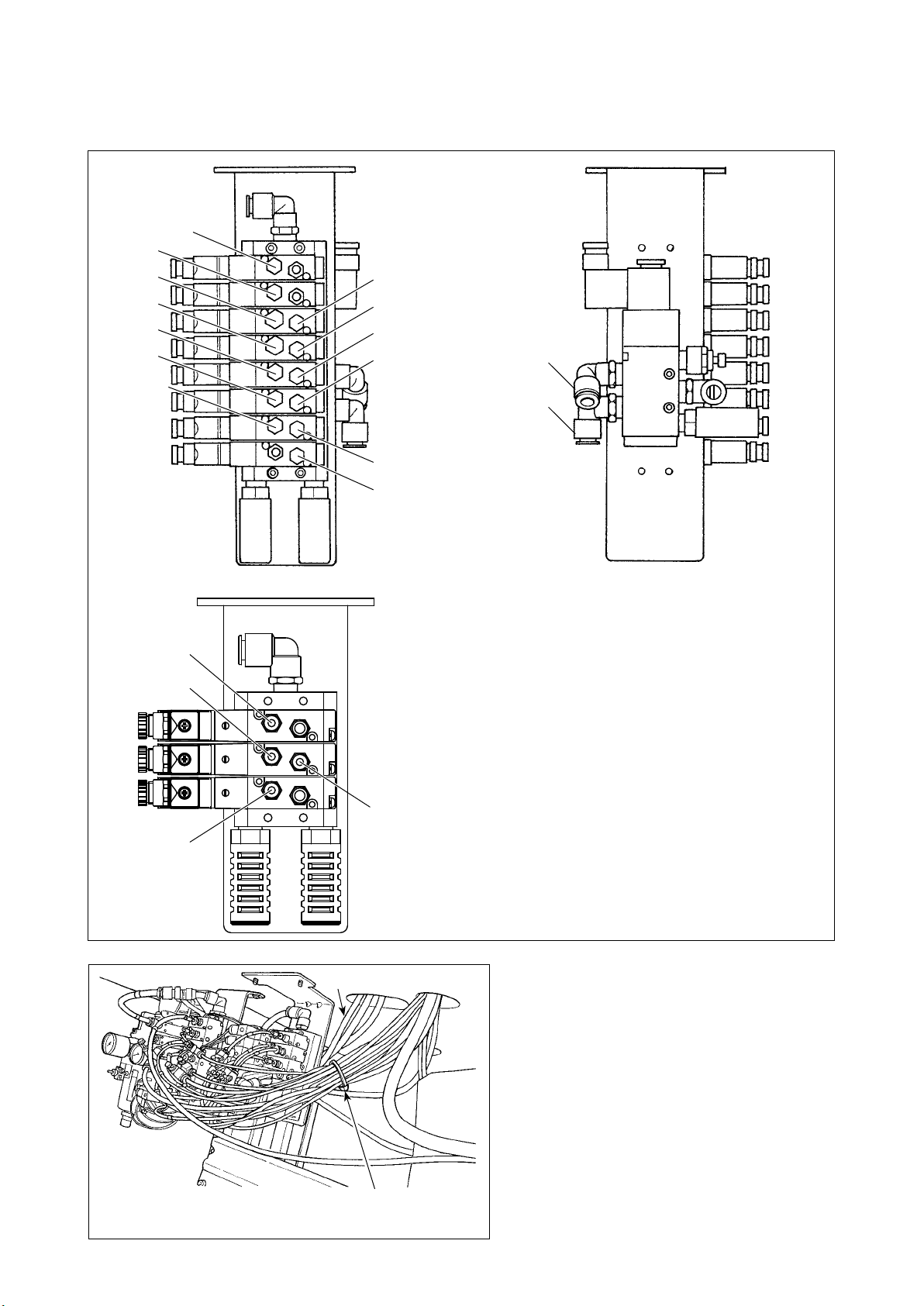

(2) Connecting the air tubes

Connect the respective air tubes coming from the sewing machine head to the respective solenoid valves

matching their numbers correspondingly.

No.1

No.2

No.3

No.5

No.7

No.9

No.10

No.4

No.6

No.8

No.39

(In the case of the

needle thread clamp)

No.11

No.12

[In the case of the needle thread clamp unit]

No.35

No.36

No.15

No.16

No.38

No.37

Cable

Cable clip band (L150) supplied

with the unit as an accessory

After the connection of the respective air tubes,

neatly bundle the cables etc. coming from the

sewing machine with the cable clip band sup-

plied with the unit as an accessory.

– 26 –

Page 30

3-14. Installing the air hose

❸

❷

❶

Open

Close

❺

❹

■ Connecting the air hose

Connect the air hose to the regulator using the

hose band and quick-coupling socket joint supplied

with the unit.

■ Adjusting the air pressure

Open air cock ❶.

[Main regulator]

Pull up and turn air pressure regulating knob ❸ of

main regulator ❷ to adjust the pneumatic pressure

to 0.5 MPa. Then, push down the knob to x it.

[Regulator for cloth trimming knife pressure]

Pull down air pressure regulating knob ❺ of reg-

ulator ❹ for the cloth trimming knife pressure and

turn it to adjust the air pressure to 0.35 MPa. Then,

push up the knob to x it.

(The air pressure of the cloth trimming knife can be

adjusted in the range of 0.2 to 0.4 MPa by means

of regulator ❹.)

Regulator ❹ for the cloth trimming knife has

been factory-adjusted to 0.35 MPa. Do not

increase the air pressure unless it is really

necessary. Increased air pressure can cause

a decrease in sharpness of the knife and/or

knife breakage.

After the completion of the respective air pressures

adjustment, close air cock ❶ to remove air. Then,

re-open the air cock to adjust the respective air

pressures.

* The air is removed by closing air cock ❶.

– 27 –

Page 31

3-15.

Cautions for the compressed air supply (source of supply air) facility

As large as 90 % of failures in pneumatic equipment (air cylinders, air solenoid valves) are caused by "con-

taminated air."

Compressed air contains lots of impurities such as moisture, dust, deteriorated oil and carbon particles. If

such "contaminated air" is used without taking any measures, it can a cause of troubles, inviting reduction in

productivity due to mechanical failures and reduced availability.

Be sure to install the standard air supply facility shown below whenever the machine provided with pneumat-

ic equipment is used.

Standard air supply facility to be prepared by the user

Air compressor

After cooler

Auto-drain

Air tank

Main line lter

Auto-drain

Air dryer

Mist separator

Filter regulator

Air solenoid valve

Quality of the air supply

When the supply air contains a considerable amount of moisture

Ambient environment

When our machine is installed at a place where the temperature greatly

changes in the morning and in the evening from that in the daytime or

freeze is like to occur

In the aforementioned cases, be sure to install an air dryer.

When the supply air contains a considerable amount of carbon and dust

(Most troubles in the air solenoid valves are caused by carbon.)

Be sure to install a mist separator.

Standard equipment supplied by JUKI

Air cylinder

Cautions for main piping

• Be sure to slope main piping by a falling gradient of 1 cm per 1 m in the direction of air ow.

• If the main piping is branched off, the outlet port of the compressed air should be provided at the

top part of the piping using a tee in order to prevent drain settling inside the piping from owing

out.

• Auto drains should be provided at all lower points or dead ends in order to prevent the drain from

settling in those parts.

– 28 –

Page 32

3-16. Installing the thread stand

1) Assemble the thread stand asm. and install it in the hole in the rear left part of the table.

2) Tighten locknut ❶ so that the thread stand is xed.

❶

– 29 –

Page 33

3-17. Installing the thread guides

❷

❶

❶

1) Remove two thread guide plates ❶ and setscrew

❷.

2) Reverse one of thread guide plates ❶. Install the

thread guides so that they turn by approximately

40° to allow the thread to pass smoothly.

40° 40°

❹

❸

❺

3) Install thread guide bar ❸.

At this time, install thread

guide bar ❸ so that hole

❹ in thread guide bar ❸

is oriented to hole ❺ in the

AT thread guide.

❹

– 30 –

Page 34

3-18. Installing the eye protection cover and the nger guard

DANGER :

The eye protection cover and the nger guard are used to protect eyes against ying broken needle.

Be sure to use the sewing machine with them installed without exceptions.

1) Assemble nger guard ❶ to safety plate bracket

❷

❶

❺

❻

❹

❸

❷ with two setscrews ❸.

Assemble nger guard ❶ equally with respect to

safety plate bracket ❷.

2) Assemble eye protection cover ❹ to safety plate

bracket ❷ with two setscrews ❺ and two washers

❻.

3) Install the assembled eye protection cover and

nger guard asm. ❼ on face plate ❾ with screws

❽.

Setscrew ❸ is an M4 hexagon socket head

cap screw and has a length of 8 mm. Set-

screw ❺ is an M4 round head screw and

has a length of 6 mm. Setscrew ❽ is an M4

round head screw and has a length of 6 mm.

❼

❾

❽

– 31 –

Page 35

3-19. Installing the cloth chip bag

❶

1) Connect cloth chip suction device ❶ and cloth chip

tube ❷. Fix them with hose band ❻.

❷

❶

❻

❸

2) Install suspension hook ❸ to an easy-to-access

location on the underside of the table.

3) Suspend cloth chip bag ❹ on suspension hook

❸.

❹

❹

❶

❷

❺

4) Open the zipper of cloth chip bag ❹ to put cloth

chip suction device ❶ in it.

5) Place cloth chip suction device ❶ in the top part

of cloth chip bag ❹ and close the zipper.

Adjust the length of cloth chip tube ❷ by cutting it

short at the point immediately below the table.

Be sure to empty the cloth chip bag before

If cloth chip tube ❷ is excessively long, cloth

chip tube ❷ can be clogged with cloth chips

since cloth chips can interrupt the air ow

from cloth chip suction device ❶.

cloth chips in the bag reach the top of cloth

chip suction device ❶.

– 32 –

Page 36

3-20. Installing/removing the presser unit

Carefully prevent contact between the cloth trimming knife and the work clamp plate when moving

the feed base by hand or installing/removing the work clamp unit.

❹

❺

❹

❸

❹

❷

❻

❹

❷

❶

■How to install

1) Install the presser unit so that presser lever ❸ ts

in the letter “U” of presser base ❷.

2) Adjust the hole of presser plate ❺ to cloth open

pin ❹.

3)

Turn clamp holding plate ❶ to hold presser plate ❺.

■How to remove

1) Turn clamp holding plate ❶ to remove from presser plate ❺.

2) Lifting presser plate ❺, remove it so as to draw it.

❶

❺

It is comparatively easy to install or remove the presser unit by moving feed base ❻ to the cloth

cutting position.

When moving feed base ❻ by hand, follow the aforementioned caution.

❻

– 33 –

Page 37

4. PREPARATION BEFORE OPERATION

4-1. Lubrication of the machine and how to lubricate

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start

of the sewing machine.

* Use JUKI MACHINE OIL No. 18 as the machine oil.

(1) Lubricating the arm oil tank

Lubricate arm tank ❶ to such an extent of approxi-

mately 80 %.

In addition, add oil in the case the oil level has de-

❶

creased below the red marker dot during the daily use

of the sewing machine.

(2) Lubricating the bed oil tank

[ In the case of the table-xed type machine head ]

A

❷

❷

[ In the case of the semi-sunken type machine head ]

A

❷

B

B

Lubricate bed oil tank ❷ up to the MAX. line A.

In addition, when the oil surface falls below the MIN line

B during daily use, add an adequate quantity of oil.

If oil is added so that the oil level exceeds

the MAX line A, the oil will spill out of the

oil hole when the machine head is tilted

until it will go no further. Be careful when

replenishing the oil tank with oil.

Raise the sewing machine to the 2nd step of the hinge.

Add oil in bed oil tank ❷ until the oil surface reaches

the underside of MAX line A.

In addition, when the oil surface falls below the MIN line

B during daily use, add an adequate quantity of oil.

Be aware that oil will spill out from the oil

hole when tilting the machine head if the

added oil surface exceeds the underside

of MAX line A.

– 34 –

Page 38

(3) Lubricating the looper and spreader components

1) Remove the presser plates, right and left.

2) Apply two to three drops of oil to looper link ❶,

spreader link ❷, spreader, right ❸, spreader, left

❹

❺

❸

❹ and spreader actuating cam ❺.

❶

❷

Be sure to lubricate the components once

a day. If the frequency of lubrication is

small, especially, worn-out of ❸, ❹ and

❺ is caused and stitch skipping or needle

breakage will occur.

(4) Lubricating the looper bracket oil tank

❻

Put oil in looper bracket oil tank ❻ until its MAX

line is reached.

In addition, when the oil surface falls below the MIN

line during daily use, add an adequate quantity of

oil.

Put oil in the looper bracket oil tank using

the oiler (smaller one) supplied with the unit

while taking care not to spilling oil around

the tank.

Oil spilled around tank can y toward the

operator by the looper bracket operation

when the machine is running. Be sure to

wipe up the spilled oil to prevent the above.

– 35 –

Page 39

(5) Lubricating the needle bar and the gear section

Lubricate the components at the time of delivery or after an extended period of disuse.

❸

❹

❾

❽

❶

❶

❶

❶

❷

1) Loosen setscrews ❶ and remove face plate ❷.

2) Apply one or two drops of oil to needle bar bushing

❸, needle bar ❹ and felt ❽.

❶

❶

3) Loosen setscrew ❾. Remove rear cover .

❻

❾

❺

❼

❺

4) Loosen setscrew ❺ and remove the upper face

cover ❻.

❺

Remove the cover with care since the air

tube is connected with the cord.

5) Apply oil to gear lubricating felt ❼ in the sewing

machine arm.

6) After lubrication, install face plate ❷ and upper face

cover ❻.

Be careful not to allow the cords to be

caught in the machine.

– 36 –

Page 40

4-2. Attaching the needle

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

❶

Insert the needle

until it will go no

further.

Groove of the needle

The correct direction of the needle is that needle

thread guide ❶ faces the opposite side of groove of

the needle.

1. Use the most suitable size of needle in

accordance with the kind and thickness

of thread and kind of material to be used.

2. When changing the size of needle, be

sure to adjust the clearance between the

needle and the looper. (Refer to "10-5.

Clearance between the needle and the

looper" p. 84.)

– 37 –

Page 41

4-3. Threading the machine head

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

(1) Threading the upper thread (needle thread)

Ⓑ

Ⓐ

Ⓑ

Ⓐ

Ⓒ

Ⓒ

– 38 –

Page 42

(2) Threading the lower thread (looper thread)

For the model provided with the

needle thread clamp unit

Needle thread trimmer type

Gimp

Looper thread

Thread trimmer retaining plate

2. In the case of the overall thread trimmer type machine, pass the looper thread through the needle

In the case of the needle thread trimmer type machine, allow the thread trimmer retaining plate

If thread waste is clamped by the looper thread clamp or the thread trimmer retaining plate, remove

1. When passing the looper thread, turn looper bracket by 180 degrees of an angle in advance.

hole in the throat plate and allow the looper thread clamp to clamp it. Then, start sewing.

to clamp the looper thread and gimp. Then, start sewing.

it. If sewing is carried out when the thread waste remains clamped by either of them, the looper

thread cannot be clamped properly, resulting in stitch skipping at the beginning of sewing.

– 39 –

Page 43

(3) Threading the machine with gimp

In case of thin thread, insert gimp

in the gimp presser plate.

4-4. How to set the cloth on the sewing machine

❶

❶

❷

❷

❷

1) Enter the sewing material until it comes in contact with cloth patches ❶, right and left.

2) Loosen setscrews ❷, right and left and adjust the sewing position by moving the cloth patches to and fro.

– 40 –

Page 44

5. STRUCTURE OF THE OPERATION SWITCH

5-1. Structure of the operation panel

❺

❽

❼

❶

❷

❹❸

❻

❾

[Table of functions of the operation panel]

No. Name

Sewing LED

❶

READY key

❷

RESET key

❸

MODE key

❹

2-digit LED

❺

4-digit LED

❻

– key

❼

+ key

❽

❾ –/BACKWARD

key

Description

This LED goes out when the sewing machine is in data setting state

and lights up when the sewing machine is in sewing state. The status

of the LED is changed over by the Ready key.

This key is used to change over the status between the setting state

and the sewing state.

This key is used to release the error, reset the counter or release the

threading mode.

This key is used to activate the auxiliary function mode under which

the sewing mode, operation mode, pattern copy/deletion and memory

switch are set.

This LED displays pattern No. in the normal state and displays data

number when setting the data.

This LED displays cut length in the normal state and displays content

of data when setting the data. It also displays the count value on the

counter and error number etc.

This key is used to decrement the pattern No. in the normal state and

to decrement the data number when setting the data.

This key is used to increment the pattern No. in the normal state and to

increment the data number when setting the data.

This key is used to decrement the set value of data or the count value

on the counter when setting data. It is used to move the feed backward

by one stitch in the pause state.

– 41 –

Page 45

No. Name

+ / FORWARD

key

THREAD

TENSION

LED

THREAD

TENSION key

Description

This key is used to increment the set value of data or the count value on

the counter when setting the data. It is used to move the feed forward by

one stitch in the pause state.

This LED lights up when displaying/setting the needle thread tension.

This key is used to display/set the needle thread tension.

COUNTER

LED

COUNTER

key

THREADING

key

KNIFE ON/

OFF key

BEFORE-CUT

KNIFE LED

AFTER-CUT

KNIFE LED

DATA LED

DATA key

This LED lights up when displaying/setting the counter.

This key is used to display/set the set value of the counter.

This key is used to place the machine in the threading mode. (Note 1)

This key is used to change over the operation status of the cloth cutting

knife between enable/disable. The before-cut knife /after-cut knife LED

lights up/goes out. (Note 2)

This LED lights up when the cloth cutting knife operates as before-cut

knife.

This LED lights up when the cloth cutting knife operates as after-cut knife.

This LED lights up when displaying/setting the data. (Note 3)

This key is used to display/set the pattern data. (Note 3)

Note 1 : The key is disabled immediately after the power-on. It is enabled after the completion of feed-base

origin retrieval by pressing the ready key once.

Note 2 : In the case Data No. 3 of the pattern data (before-cut knife/after-cut knife) is set to "without knife",

the Before-cut knife/After-cut knife LEDs stays off.

Note 3 : These keys are enabled only in the setting state where the sewing LED goes out.

(Reference) The 2-digit LED and 4-digit LED display data as shown below.

Numeric values 0 1 2 3 4 5 6 7 8 9

Digital display

Characters A B C D E F G H I J K L M

Digital display

Characters N O P Q R S T U V W X Y Z

Digital display

– 42 –

Page 46

5-2. Temporary stop switch

Temporary stop switch

5-3. Hand switch

Start switch lamp

This switch stops the operation of the sewing machine.

[Presser switch (right) ❶]

This switch performs up/down of the presser.

❷

❶

5-4. Foot switch (optional)

❷

[Start switch (left) ❷]

This switch performs the start of sewing.

When the start switch is effective, the start

switch lamp ashes on and off.

Before starting the sewing machine, close

the front cover.

[Presser switch ❶]

This switch performs up/down of the presser.

[Start switch ❷]

This switch performs the start of sewing.

Before starting the sewing machine, close

the front cover.

❶

– 43 –

Page 47

6. HOW TO USE THE OPERATION PANEL

In the case the sewing machine stops with its needle-bar rested in any position other than the upper

end when the READY key is pressed, Error (E030) will occur to stop the sewing machine.

In this case, turn the hand pulley to move the needle bar to its upper stop position. Error (E030)

will disappear when the upper stop position is reached. In this state, press the READY key

again to light up sewing LED A .

Standard patterns of pattern numbers 90 to 99 have been factory-set at the time of shipment. Refer

In addition, the needle bar will automatically return to the upper stop position when you press the READY

key

bar rests at any position between the upper stop position and a point short of the lower dead point.

even in the case the needle bar is not brought to its upper stop position as long as the needle

6-1. Basic operation of the sewing machine

to "15. STANDARD PATTERN LIST" p. 107 for pattern shapes.

A

1) Press – key ❹ or + key ❺ to select the

target pattern number B you want to sew.

❶

2) Press Ready key ❶ to light up Sewing LED

A to enable sewing. At this time, the presser foot

B

comes down and the feed bar and needle retrieve

the respective origins.

❹

❺

The presser and the feed base operate.

Be careful that hands or ngers are not

being caught in them.

3) Place the sewing material under the presser foot.

Press the Presser foot switch to lower the presser

foot. Press the Start switch to start sewing.

Before starting the sewing machine, close

the front cover.

6-2. Setting the thread tension

The actual thread tension varies in accordance with the kind or thickness of thread used even when

the set value is the same. Adjust the thread tension value to the thread used. If the thread tension

set value is high, stitch skipping may be caused.

❶

C

D

❽

Thread tension to be applied to the respec-

tive sections of the sewing pattern can be

changed separately. Refer to "9-1. Operating

procedure of thread tension compensation

of each section" p. 73.

❼

❻

1) Press Thread tension key ❽ to light up

Thread tension LED D. The LED displays the set

value of the thread tension.

2) Set the value of the thread tension C by pressing

–/BACKWARD key ❻ or +/FORWARD key

❼.

3) The set value is stored in memory when you press

Ready key ❶ or press the Start switch to

start sewing.

4) When you press Thread tension key ❽ while

Thread tension LED D stays on, the screen returns

to the normal display.

If the pattern number is changed or the power

is turned off without taking the procedure 3),

the set value will not be stored in memory.

– 44 –

Page 48

6-3. Temporarily stopping the sewing machine

■ How to stop the sewing machine

1) Press temporary stop switch ❶.

2)

The sewing machine stops and “E050” is displayed.

■ How to re-start

1) While "E050" is shown on the screen, press RESET

key ❷ to release the error and to restore the

screen to the display before the occurrence of the

❶

❷

❼

❻

error.

2) Re-start the sewing machine using the start switch,

or press –/BACKWARD key ❻ or +/FOR-

WARD key

travels forward/backward stitch by stitch.

Further, press RESET key ❷ to return the

sewing machine to the sewing start position.

1. Operation of –/BACKWARD ❻

key, +/FORWARD

SET key

trimming.

2. When temporarily stopping the sewing

machine during sewing and returning

the sewing machine to the start position

with RESET key

thread, cut the thread with scissors or

the like and perform the work. The work

can be performed without applying a

forced load to needle or sewing product.

❼ and the feed mechanism

❼ key or RE-

❷ cannot perform thread

❷, draw out needle

Before starting the sewing machine, close

the front cover.

– 45 –

Page 49

6-4. Performing re-sewing

Sewing can be performed without cloth-opening operation of the presser foot.

❶

<Mode setting screen>

❶

<Sewing mode setting screen>

❸

Step of operation

described in 2)

❸

❻

❻

❼

❼

If the Sewing LED stays ON, press the

Ready key ❶ to turn it OFF.

1) Press Mode key ❸ to display the mode setting

screen. Press –/BACKWARD key ❻ or +/

FORWARD key ❼ to display "oPEn".

2) Press Ready key ❶ to display the sewing

mode setting screen.

3) Set the sewing mode to "0", "1" or "2" by pressing

–/BACKWARD key ❻ or +/FORWARD key

❼.

4) Press Ready key ❶ to nish setting. If you

press Mode key ❸, the data you have set will

be cancelled.