Page 1

Machine time

is substantially

reduced !!

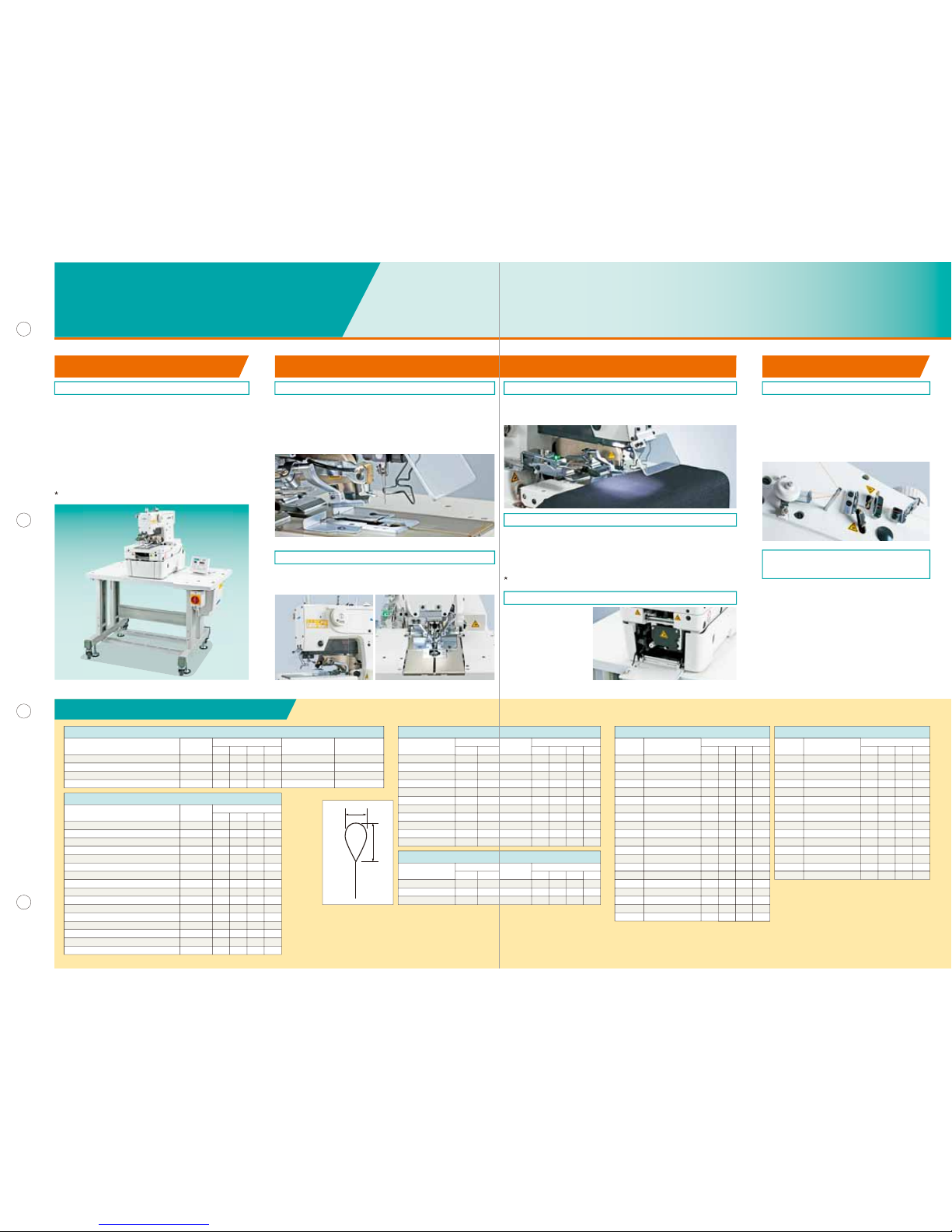

MEB-3810J-01A-A1

MEB-3810 Series

Computer-controlled, Eyelet Buttonholing Machine 〈for jeans and cotton pants

〉

MEB

-

38 10

The machine achieves a maximum sewing speed as high as 2,500 sti/min

and is provided with a cloth cutting knife which operates at an increased speed,

thereby promising increased productivity.

The machine is a newly developed highly-durable

eyelet buttonholing machine for jeans/cotton pants.

Page 2

MEB

-

38 10

The machine achieves not only a maximum sewing speed as high as 2,500 sti/min,

but also reduced vibration and noise. The machine is a newly developed

highly-durable simple-design eyelet buttonholing machine for jeans/cotton pants.

Part name

Overedging width Needle size

Part No.

Application

J00 J01 C00 C01

Projection of the arm frame of the machine head has been reduced. In

addition, the cloth cutting knife is located closer to the operator side as

compared with the conventional model. Viewability, when placing the

material on the sewing machine, is improved, thereby contributing to

improved workability. In addition, the thread clamp mechanism of the

needle thread clamp (optional) has been improved for better viewability.

The surface onto which the material is placed is flattened (for the machine

with an overall thread trimmer). The material can, therefore, be placed on

the machine with ease to improve workability.

Increased productivity

Throat plate

Part name Part No.

Application

J00 J01 C00 C01

Work clamp (for eyelet buttonhole)

Part No.

Application

Max. cutting

length (mm)

J00 J01 C00

Pattern (mm)

X Y C01

Application

J00 J01 C00 C01

Cloth cutting knife (for eyelet buttonhole)

Part No.

Application

Max. cutting

length (mm)

J00 J01 C00

Pattern (mm)

X Y C01

Cloth cutting knife (for straight buttonhole)

Improved workability and operability

LIST OF THE REPLACEMENT GAUGES

◎ : Provided as standard No symbol : Optional △ : Accessory 㽎 : Installation is invalid

Part No.

Size

(mm)

Knife guard (for eyelet buttonhole)

Application

J00 J01 C00 C01

Part No.

Size

(mm)

Knife guard (for straight buttonhole)

X

Y

Shape

An LED light is provided as standard on the underside of the jaw of the

machine head. The area around the needle entry is thus brightened to improve

workability.

A retractable bottom cover is

adopted. Daily maintenance

(threading, adjustment of the

looper thread, cleaning, etc.)

can be carried out without

raising the machine head.

Photo: Provided with the needle thread clamp (optional)

A00 (for narrow stitch bite)

B00 (for wide stitch bite)

A01 (for narrow stitch bite)

B01 (for wide stitch bite)

2.0〜3.2mm

2.0〜4.0mm

2.0〜3.2mm

2.0〜4.0mm

Nm90〜Nm110

Nm90〜Nm110

Nm90〜Nm110

Nm90〜Nm110

40115403

40115405

40115404

40115406

◎

㽎

㽎

㽎

㽎◎◎

㽎

㽎

㽎

㽎

◎

Work clamp (left) 22mm

Work clamp (right) 22mm

Work clamp (left) 32mm

Work clamp (right) 32mm

Edging work clamp (left) 22mm

Edging work clamp (right) 22mm

Edging work clamp (left) 32mm

Edging work clamp (right) 32mm

Edging work clamp (left) 34mm

Edging work clamp (right) 34mm

Edging work clamp (left) 38mm

Edging work clamp (right) 38mm

Compensating work clamp (left) 34mm

Compensating work clamp (right) 34mm

Compensating work clamp (left) 38mm

Compensating work clamp (right) 38mm

14059802

14059703

14059604

14059605

40039844

40039843

40035239

40035238

40115241

40115240

40115239

40115238

40115325

40115324

40115309

40115316

◎

◎

◎

◎

㽎

㽎

㽎㽎◎

◎

㽎

㽎

◎

◎

㽎

㽎

40115664

40115665

32063604

※1

32063703

※1

32063802

※1

32063901

※1

32064008

※1

32064107

※1

32064206

※1

32064305

※1

32066904

※1

28

38

24

32

38

24

32

38

24

32

38

◎

◎

㽎

㽎

㽎

㽎

◎

◎

㽎

㽎

㽎

㽎

㽎

㽎

2.8

2.8

2.9

2.9

2.1

2.1

2.1

3.2

3.2

3.2

2.7

4.3

4.3

4.4

4.4

3.2

3.2

3.2

5.4

5.4

5.4

5.1

14041404

※1

32065302

※1

32065401

※1

38

24

32

0

0

0

0

0

0

△

◎

△

◎

㽎

㽎

△

◎

△

◎

㽎

㽎

㽎

㽎

㽎

㽎

40115670

40115669

40115668

40115667

40115666

32067209

※2

32067308

※2

32067407

※2

32067506

※2

32067605

※2

32067704

※2

32067803

※2

32067902

※2

32068009

※2

32068108

※2

32068207

※2

32068306

※2

32068405

※2

32068504

※2

32068603

※2

38

26

22

20

16

38

36

34

32

30

28

26

24

22

20

18

16

14

12

10

14042501

※2

32064404

※2

32064503

※2

14042600

※2

32064602

※2

32064701

※2

14042808

※2

32064800

※2

14042907

※2

32064909

※2

32065005

※2

14043109

※2

32065104

※2

32065203

※2

14043301

※2

38

36

34

32

30

28

26

24

22

20

18

16

14

12

10

MEB-3810J-01A-A1/MC-621ES/JTE01

Improved viewability around the needle entry JUKI's unique active tension

Two different thread trimmers are

prepared, i.e., the overall thread trimmer

and the needle thread trimmer

The machine is provided as standard with an LED light

Achievement of lower vibration and lower noise

Retractable bottom cover

Ease of placement of the material on the machine is increased

For the needle thread tension control, JUKI's unique

active tension mechanism is adopted to electronically

control the needle thread tension during the stitching

cycle. As a result, improved seam quality is achieved. In

addition, the sewing capabilities have been improved

to prevent stitch skipping, as well as to produce

well-tensed seams.

Two different thread trimmers are prepared. One of them

can be selected according to the customer's needs.

The overall thread trimmer has been newly designed

putting importance on productivity. It promises thread

trimming without fail and trims the thread in a short time.

The operator is no longer required to carry out fine

adjustments of the thread trimmer when changing the

sewing length.

A sewing machine with a needle thread trimmer has

been newly added to the MEB Series in response to

customer needs.

Quality improvement

The MEB-3810 reduces the machine time by approximately 22%*

due to its maximum sewing speed of 2,500 sti/min and its

speed-up cloth cutting knife, thereby demonstrating increased

productivity.

Then newly adopted direct-driven main shaft by means of a

compact AC servomotor not only achieves enhanced

responsiveness, but also achieves both reduced noise and

reduced vibration. In addition, the machine has adopted an

air-driven cloth cutting knife which promises excellent

responsiveness and operates faster than the conventional knife.

Machine time is substantially reduced

Adoption of a direct-driven main shaft and a revamping of the curve sections

of the thread take-up cam and looper cam contribute to remarkably reduced

vibration and noise. Vibration has been reduced by 7.7dB* and noise has

been reduce d by 1 .5dB* as compared with the conventional model to

produce this operator-friendly machine.

Condition: Measured at the maximum sewing speed

(MEB-3810: 2,500 sti/min; conventional MEB-3200: 2,200 sti/min)

The cloth cutting knife for the conventional MEB-3200 can be installed on the MEB-3810 by using a spacer (optional). The part number of the spacer is 40115728.※1

The knife guard for the conventional MEB-3200 can be installed on the MEB-3810 by using a spacer (optional). The part number of the spacer is 40115639.※2

Condition: Number of stitches: 21 for the straight section (one side),

11 for the eyelet section; knife length: 22 mm

Page 3

SEWING MACHINERY BUSINESS UNIT

JULY, 2012 Printed in Japan(C)

2-11-1, TSURUMAKI, TAMA-SHI,

TOKYO

206-8551, JAPAN

PHONE : (81) 42-357-2254

FAX :

(

81

)

42-357-2274

http://www.juki.com

✽

Specifications and appearance are subject to change without prior notice for improvement.

✽

Read the instruction manual before putting the machine into service to ensure safety.

✽

This catalogue prints with environment-friendly soyink on recycle paper.

To order, please contact your nearest JUKI distributor.

Juki Corporation operates an environmental management system

to promote and conduct the following as the company engages in

the research, development, design, sales, distribution,and

maintenance of industrial sewing machines, household sewing

machines, industrial robots, etc., and in the provision of sales and

maintenance services for data entry systems:

(1) The development of products and engineering processes

that are safe to the environment

(2) Green procurement and green purchasing

(3)

Energy conservation (reduction in carbon-dioxide emissions)

(4) Resource saving (reduction of papers purchased, etc.)

(5) Reduction and recycling of waste

(6) Improvement of logistics efficiency (modal shift and

improvement of packaging, packing, etc.)

CodeApplication

J

C

Jeams

Cotton pants and working wear

CodeThread triming style

00

01

Needle thread trimming type

Overall thread trimming type

CodeOptions

ZZ

A1

Not provided

Needle thread clamp device

CodeTable stand

A

On the table

CodePower supply

E

K

N

200〜240V (for General Export)

200〜240V (for General Export)

200〜240V (for CE) (not provided with power switch)

3-phase

Single-phase

MEB3810 A

MC621 S

SPECIFICATIONS

WHEN YOU PLACE ORDERS OPTIONS

Please note when placing orders, that the model name should be written as follows:

Machine head

Control box

・2-pedal switch

[

Part No.40033831(Pedal switch, asm.

) ]

・Sub table asm.

(for sunken head setup)

[

Part No.40115994

]

The work clamp can be lifted/lowered

and the machine can be started using

the pedal switch.

※ To use the 2-pedal unit, pedal switch

cable asm. (Part No.40114433) is required.

*"sti/min" stands for "Stitches per Minute."

Stitch system

Sewing speed

Stitch length

Taper bar length

Work clamp height

Method for changing stitch shape

Buttonhole cutting method

Cloth cutting knife drive system

Needle (at the time of delivery)

Lubricating oil

Compressed air

Dimensions

Stitching shape patterns

Model name

1-needle, double chainstitch (with gimp)

400〜2,500sti/min

Air consumption

Power requirement and power consumption

Weight

49.5 l/min (11.6 cycle/min)

Single-/3-phase 200-240V, 250VA

Machine head: 110Kg ,Operation panel: 0.3Kg ,Control Box: 5Kg

10〜38mm (Needle thread trimming type)

10〜34mm (Overall thread trimming type)

3〜15mm

13mm

By selecting a program

By cut-before knife or cut-after or without buttonhole cutting

Pneumatic

D0×558 Nm90〜Nm120 (Nm110)

JUKI MACHINE OIL No.18 (equivalent to ISO VG18)

Main regulator : 0.5 MPa

Hammer pressure regulator : 0.35 MPa (standard), 0.4 MPa (Max)

Machine head : 382mm (W) × 656mm (D) × 584mm (H)

Completed-product : 1,050mm (W) × 700mm (D) × 1,248mm (H) (thread stand is not included)

The machine is provided as standard with 10 different stitching shape patterns of eyelet buttonhole.

As many as 89 different patterns can be stored in memory and selected.

Application Jeans

MEB-3810J

Cotton pants and working wear

MEB-3810C

Buttonhole

without a bartack

Buttonhole with

a round bartack

Buttonhole with

a straight bartack

Buttonhole

with a taper bar

Needle throwing width

Mechanical adjustment of the needle throwing width : 2.0〜4.0mm

Compensation of the needle throwing width (by the lower feed dog) : 1.5〜5.0mm

Loading...

Loading...