Page 1

I.L^.

MODEL

HIGH

SINGLE

BUTTON-SEWING

MB-372

SPEED

THREAD

CHAINSTITCH

MACHINE

Instruction

Book

TOKYO

JUKI

INDUSTRIAL

CO..LTD.

Page 2

CONTENTS

1.

GENERAL

2.

SPECIFICATIONS

3.

NAMES

4.

CAUTIONS

5.

LUBRICATION

MOTOR

6.

NEEDLES

7.

8.

INSERTING

9.

THREADING

10.

THE

11.

FUNCTIONS

12.

THE

13.

ADJUSTING

14.

TO

PRODUCE

15.

POSITION

16.

TIMING

TENSION

17.

CHANGING

18.

STITCH

19.

HEIGHT

20.

ADJUSTING

21.

ADJUSTING

22. ADJUSTING

23.

CHANGING

ADJUSTING ITS HEIGHT

24.

CAUSES

25.

ATTACHMENTS

MACHINE

( i ) How to install the snap fastener attachment 22

(ii)

(iii)

{iv)

DESCRIPTION

OF

PARTS

PULLEY

THREAD

THREAD

THE

BEFORE

THE

THE

TENSION

OF

NIPPER

THE

OPTIMAL

OF

THE

NIPPER

DISC

THE

OPERATION

AND

BELT

NEEDLE

MACHINE

THE

THREAD

PULL-OFF

LEVER

NEEDLE BAR 10

STITCHING

NEEDLE

RELEASING

NO.

2 14

POSITION

GUARD

OF

PLUNGER

THE

CONDITION

BUTTON

OF

TRAY

SELECTING

OF

BUTTON

THE

THE

FOR

THE

OF

MALFUNCTIONS

TO

CLAMP

BUTTON CLAMP PRESSURE

BUTTON CLAMP STOP LEVER 18

2-HOLES AND 4-HOLES 18

BUTTON

MB-372

HOLDING

AND

BUTTON

CLAMP

REPAIRING

ATTACHING

AND

How to install the wrapped-around button clamp attachment 23

How to insall

How to

install

the

the

shank

button clamp attachment 25

metal

shank

button clamp attachment

•••

-15

•••

Page

1

2

3

4

4

5

6

6

7

8

8

9

12

14

15

17

17

19

21

21

27

Page 3

1.

GENERAL

DESCRIPTION

JUKI

machine.

as well as snap fasteners, shank

Model

It

MB-372

is widely used to

is a single thread, chain stitch, button sewing

attach

flat two hole or four hole

buttons

and

metal shank buttons.

is an ideal machine to attach these buttons on all knit

shirts, work uniforms, ladies' suits

This machine is equipped with 8 stitches, 16 stitches

and

these

stitches are interchangeable without changing the stop motion

and

men's suits.

goods,

and

buttons

This

men's

32 stitches

Page 4

cams. A speed slowing device, an exclusive

incorporated into this machine

and

consequently loosening of screws or

JUKI

attachment, is

malalignment of stitches which sometimes characterize a machine with

a stop motion mechanism is completely eliminated and assures a safe

and

stable stitching condition.

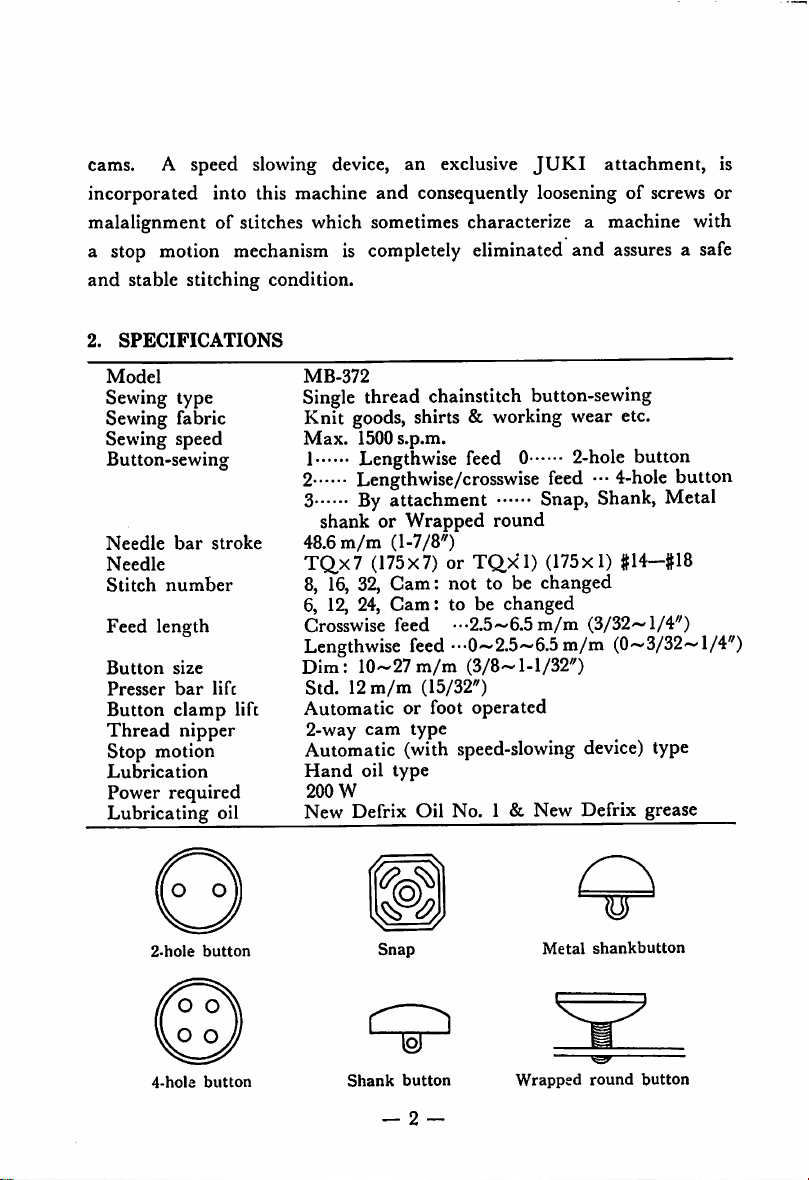

2.

SPECIFICATIONS

Model

Sewing type

Sewing fabric

Sewing speed

Button-sewiniar

Needle

Needle

Stitch

Feed

Button

Presser

Button

Thread

bar

number

length

size

bar

clamp

nipper

Stop motion

Lubrication

Power

required

Lubricating

2.hole

button

stroke

life

lift

oil

MB-372

Single

thread chainstitch button-sewing

Knit goods, shirts & working wear etc.

Max.

1500s.p.m.

1 Lengthwise feed 0 2-hole button

2 Lengthwise/crosswise feed

•••

4-hole

button

3 By attachment Snap, Shank, Metal

shank or

48.6

m/m

TQx7

8,

16,

6, 12, 24,

Crosswise feed •••2.5~6.5

Lengthwise

Dim:

Std.12m/m

Automatic or foot operated

2-way

Wrapped

(1-7/8")

(175x7) or

32,

Gam:

Cam:

feed

10-27

m/m

cam

type

round

TQxl)

(175x1) #14-#18

not to be changed

to be

changed

m/m

(3/32~l/4")

••-0^2.5^6.5m/m (0~3/32~l/4")

(3/8-1-1/32")

(15/32")

Automatic (with speed-slowing device) type

Hand

oil

type

200

W

New

Defrix

Oil

No.

1 &

New

Defrix

grease

W

Metal

Snap

sbankbutton

4-hola

button

Shank

button

Wrapped

round

button

Page 5

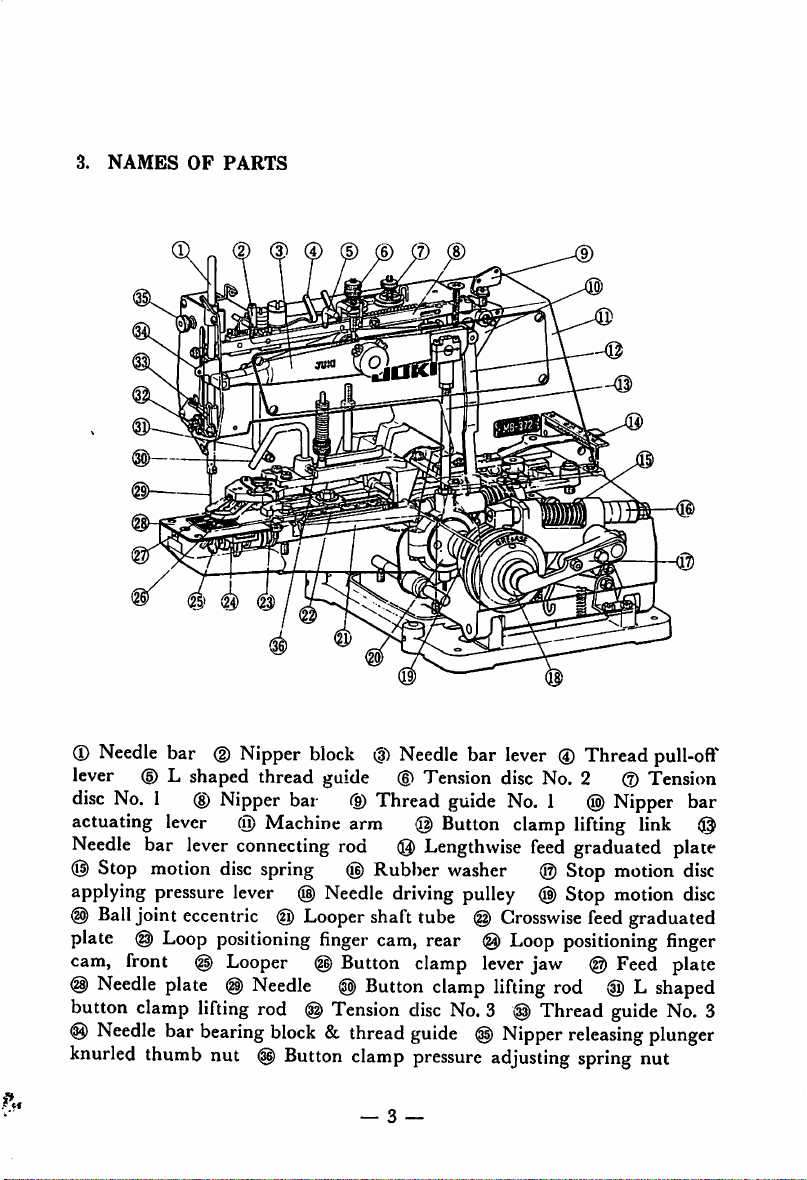

3.

NAMES

m

OF

PARTS

®

Needle

lever

disc

actuating lever @ Machine arm @ Button clamp lifting link

Needle

(!|)

Stop

applying pressure lever @

@>

Ball

plate @ Loop

cam, front @ Looper @ Button clamp lever jaw @ Feed plate

@

Needle

button

@

Needle

knurled

bar

(§)

Nipper

(D

L shaped thread guide ® Tension disc No. 2 0 Tension

No.

1

(D

Nipper

bar lever connecting rod

motion

joint eccentric @ Loopershaft tube

disc

positioning

plate

clamp

bar

thumb

@)

lifting

bearing

nut

block

bar 0 Thread

spring

(g)

Needle

finger

Needle

rod @

block

(g)

& thread

Button

@)

Tension

clamp

(|i)

Needle

(Q)

Rubber washer ® Stop motion

driving pulley @ Stop motion disc

cam,

Button

— 3 —

bar

guide

Lengthwise

(§)

rear @

clamp

disc

No.

guide

@

pressure

lever

® Thread

No.

1 @

feed

graduated plate

Crosswise

Loop

lifting

feed

positioning

rod

3 @ Thread

Nipper

adjusting

releasing

spring

pull-oft^

Nipper

bar

disc

graduated

finger

(0)Lshaped

guide

No.

plunger

nut

3

Page 6

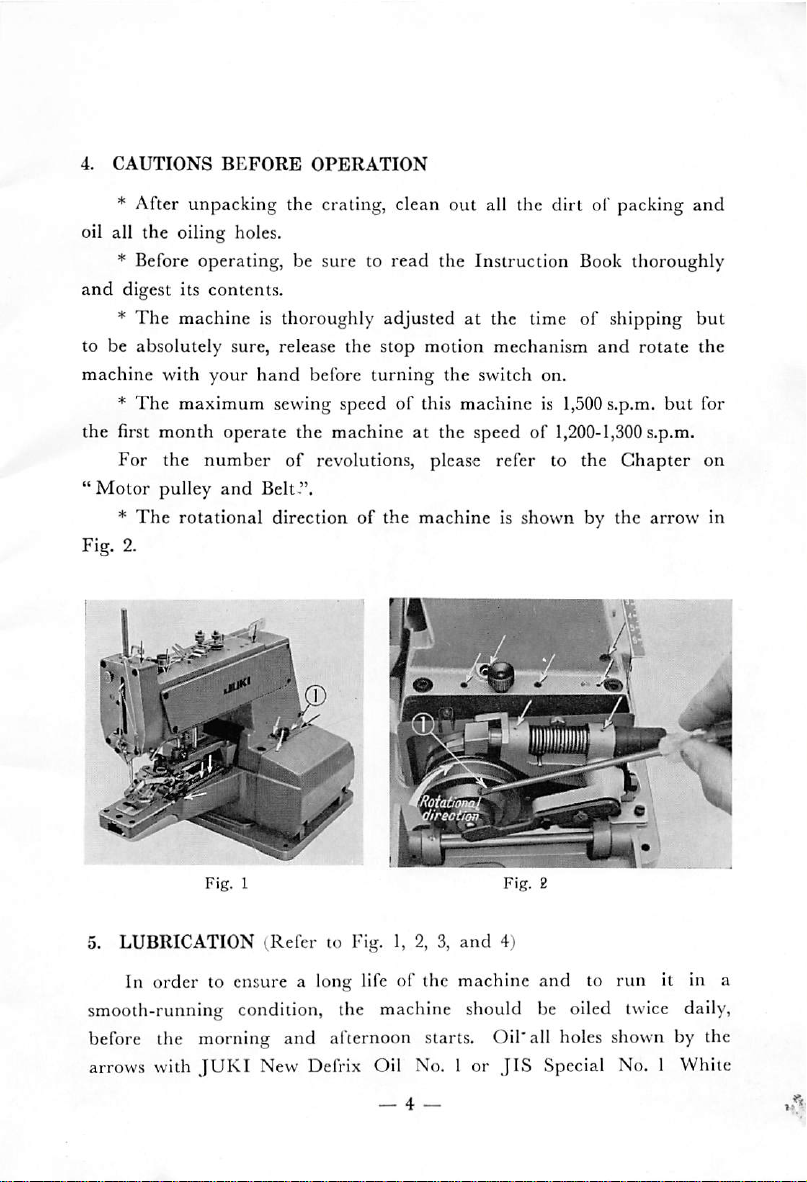

4.

CAUTIONS

BEFORE

OPERATION

* After unpacking the crating, clean out all the dirt of packing

oil all the oiling holes.

* Before operating, be sure to

and

digest its

*

The

to be absolutely sure, release

machine with your

*

The

contents.

machine is thoroughly adjusted at the time of shipping but

hand

before

maximum

sewing speedofthis

the first month operate the machine at the speed of

For

the

"Motor

*

number

pulley

The

It

and

rotational direction of

of

revolutions, please refer to the

Belt".

the

read

the Instruction Book thoroughly

stop

motion

turning

the

machine is shown by the

mechanism

the switch on.

machine

is 1,500s.p.m.

1,200-1,300

and

Chapter

rotate

but

s.p.m.

arrow

and

the

for

on

in

oia

'ireotiM

5. LUBRICATION

In order to ensure a long life of the machine

(Refer

to Fig. 1, 2, 3,

and

4)

and

to run it in a

smooth-running condition, the machine should be oiled twice daily,

before the morning

arrows with

JUKI

and

afternoon starts. Oil*all holes shown by the

New Defrix Oil No. I or

— 4 —

JIS

Special No. 1 White

Page 7

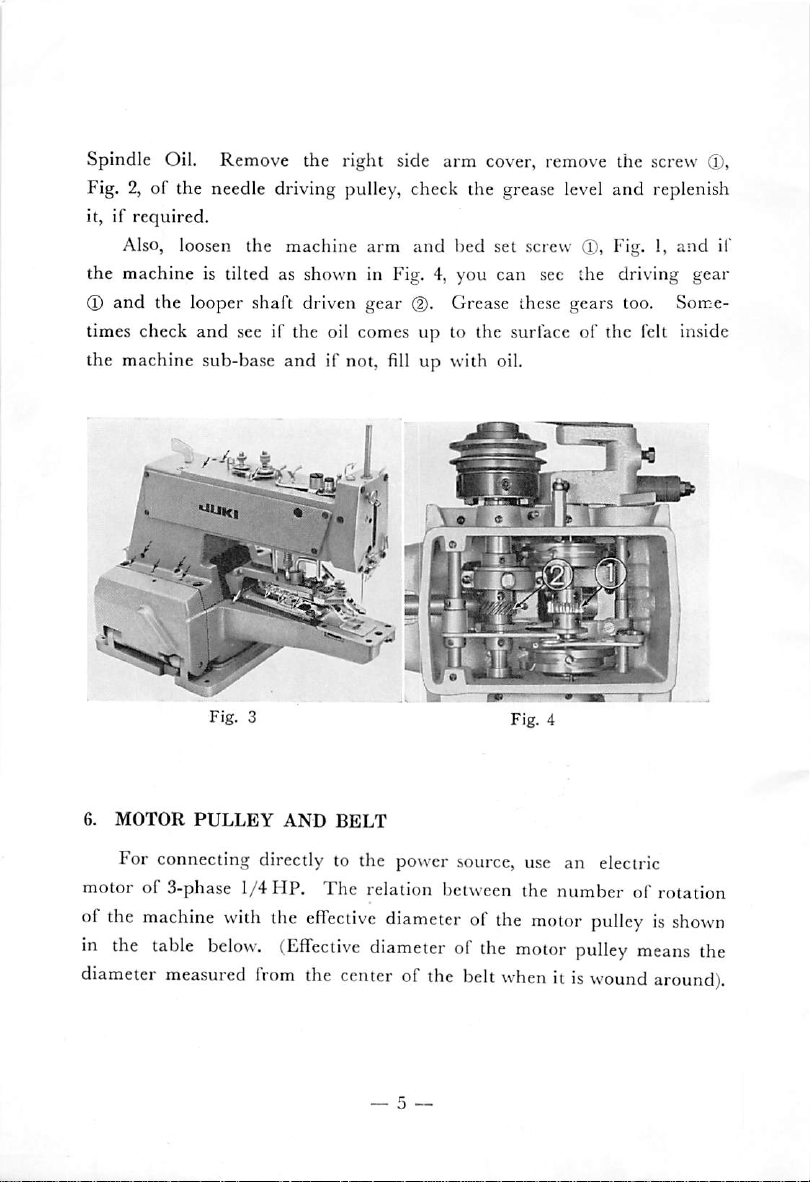

Spindle Oil. Remove the right side arm cover, remove the screw d),

Fig. 2, of the needle driving pulley, check the grease level and replenish

it, if required.

Also, loosen the machine

the

machine is tilted as shown in Fig. 4, you can sec the driving

(T)

and

the looper shaft driven

and

times check

the machine sub-base and if not, fill up with oil.

see if the oil comes up to the surface of the felt inside

arm

gear

and

bed set screw ®, Fig. 1,

(2).

Grease these gears too. Some

and

gear

=

il"

6.

MOTOR

For connecting directly to the power source, use an electric

motor of 3-phase 1/4

of the

in the

diameter

PULLEY

machine

table

measured

with

below.

AND

HP.

the

(Effective

from

BELT

The

relation between the

effective

diameterofthe

the

centerofthe

diameter

— 5 —

of the

belt

numberofrotation

motor

motor

whenitis

pulleyisshown

pulley

wound

means

around).

the

Page 8

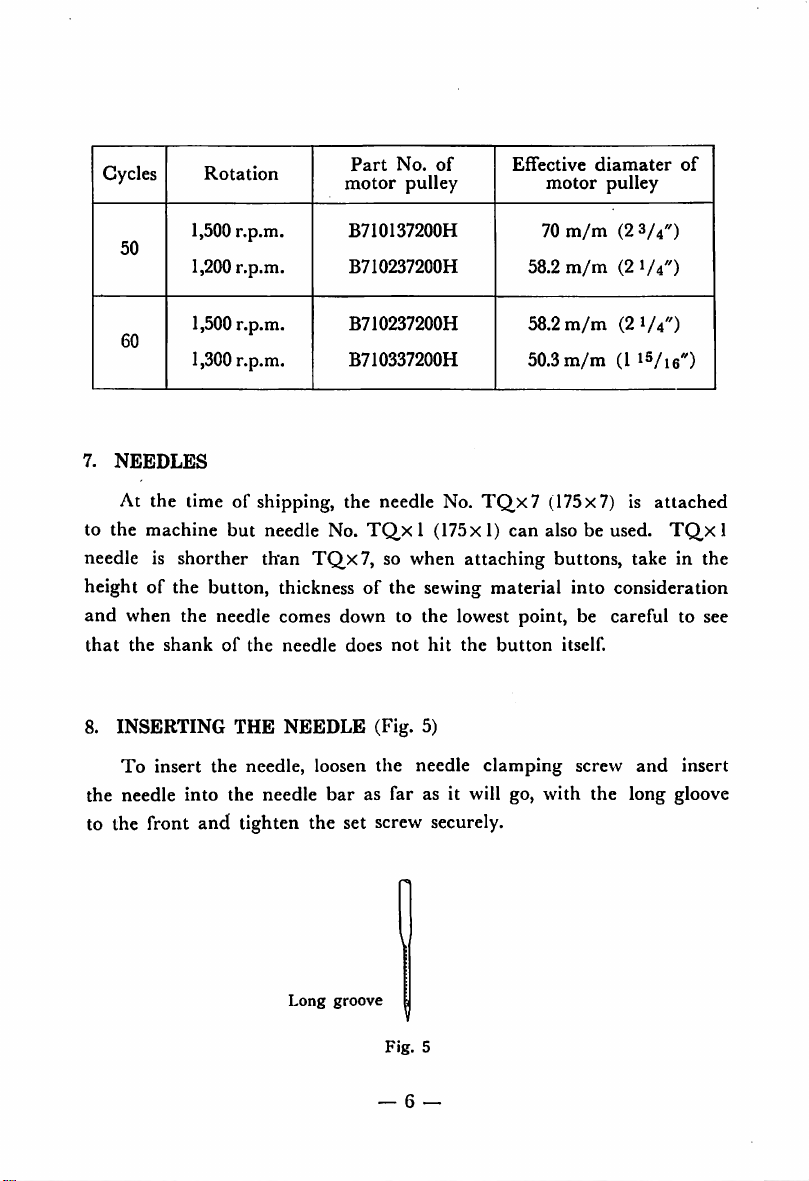

Cycles

Rotation

Part

motor

No.

pulley

of

Effective

motor

diamater

pulley

of

1,500

50

r.p.m.

1,200r.p.m.

1,500r.p.m.

7.

60

NEEDLES

1,300

r.p.m.

At the time of shipping, the needle No.

to the machine

needle is shorther

but

needle No.

than

B710137200H

B710237200H

B710237200H

B710337200H

TQx7,

70

m/m(23/4")

58.2

m/m(21/4")

58.2

m/m

(21/4")

50.3

m/m(115/is")

TQx7

TQx

1 (175x1) can also be used.

(175x7) is attached

TQx

so when attaching buttons, take in the

height of the button, thickness of the sewing material into consideration

and

when the needle comes down to the lowest point, be careful to see

that

the

shank

of

the

needle

8.

INSERTING

To

insert the needle, loosen

THE

NEEDLE

the needle into the needle

does

not

hit

the

button

itself.

(Fig. 5)

the

needle

bar

as far as it will go, with the long gloove

clamping

screw

and

insert

to the front and tighten the set screw securely.

1

Long

groove

V

Fig.

5

— 6 —

Page 9

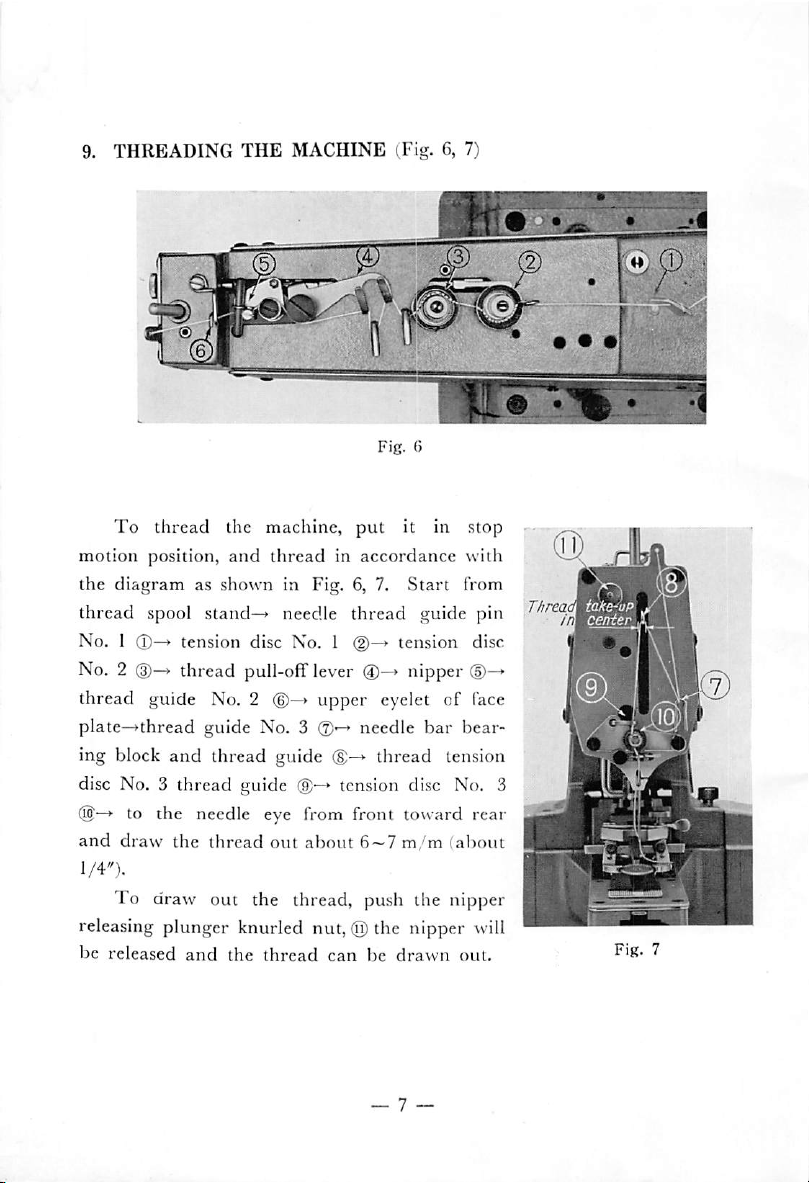

To

thread

motion

the

thread

No. I

No. 2

position,

diagram

spool

♦

(g)—»

thread guide No. 2

plate—»thread guide No. 3

ing block

disc No. 3

» to

the

and

draw

1/4").

the machine,

and

threadinaccordance

as shown in Fig. 6, 7.

stand—»

tension disc No. I

needle

put

thread

d)—»

it in stop

Start

guide pin

tension disc

thread puIl-ofTlever »nipper

(6)—♦

upper eyelet of (ace

(2)—*

and

thread

thread

needle eye from front

the

thread

guide

out

guide

(9)-^

about

needle

(§)—*

tension disc No. 3

6-^7

bar

thread

toward

m/m

with

from

(§)—•

bear

tension

rear

(about

To draw out the thread, push the nipper

releasing plunger knurled nut, @ the nipper will

be

released

and

the

thread

can

be

drawn

out.

ThreadX

int

u

IJ

Page 10

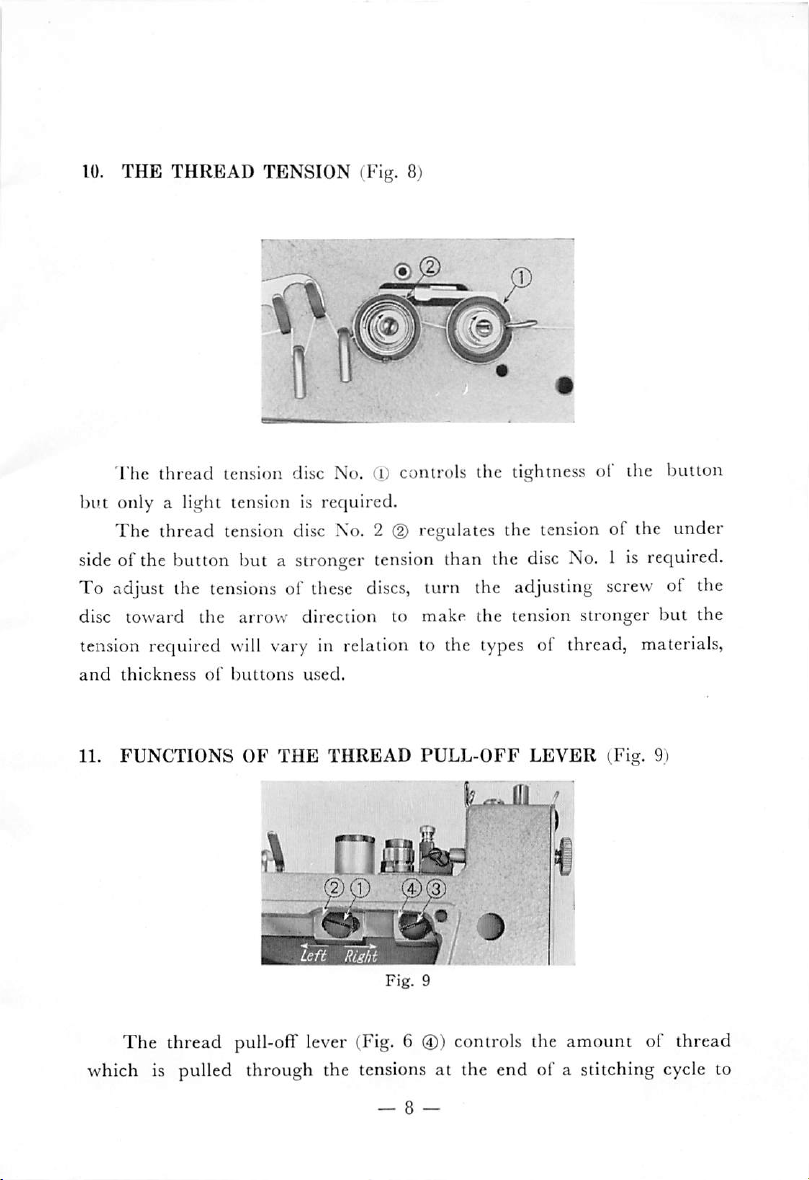

10.

THE

THREAD

TENSION

(Fig. 8)

The thread tension disc No.

Ci)

controls the tightness of the button

but only a light tension is required.

The

thread tension disc No. 2(Dregulates the tension of the under

sideofthe button but a stronger

To adjust the

disc toward the arrow direction to make the tension stronger

tensionsofthese

tension

discs,

than the

disc

No.

turn the adjusting screw of the

1 is required.

but

the

tension required will vary in relation to the types of thread, materials,

and

thickness

11.

FUNCTIONS

The

of

buttons

OF

THE

used.

THREAD

@0)

PULL-OFF

LEVER

(Fig. 9)

thread pull-off lever (Fig. 6 ®) controls the amount of thread

which is pulled through the tensions at the end of a stitching cycle to

Page 11

provide sufficient thread for the first stitch of the following cycle.

should be adjusted according to the size

fiat

button,

This

rear

side front cover

shank

adjustmentismade

block

(D

button,

by inserting a screw driver through the hole of the left

and

etc.

by loosening screw ®

move the block to

right, the sagging of the thread is increased

the sagging decreases.

When,atthe

end

of a sewing cycle,ifthe tail of the

through the button hole (Fig. 10 arrow A), move it to left

appears toward the arrow B (Fig.

tail

of

the

thread

will

not

come

10),

out.

and

kinds of buttons such as

of

the

right

and

left.

If

it's moved to

and

if it's moved to left,

thread

but

move it toward right so

nipper

appears

if the tail

that

It

bar

the

12. THE THREAD

o

NIPPER

oo.

(Fig. 11)

•i®]

0.8-1.2%

nipper

B

Fig.

The

function of the thread

o'

o

o.

10

drawing out when, at the conclusion of a sewing cycle, the button clamp

ing device goes up and cuts the thread.

hold

the

thread

until

it's

cut.

However, during the sewing operation, adjust the nipper so

will not hold the thread. As shown in Fig.

loosening the nipper bar block set screw(DFig. 9, so that during the

running, the clearance between the nipper block and the nipper becomes

— 9 ~

.

'a:6

J

is to prevent the

The

nipper will pinch

11,

make this adjustment by

thread

from

and

that

it

Page 12

0.8~1.2m/m (about

and

lefttoattain

this

3/64")

clearance.

and by

moving

the nipper bar

block

to right

13. ADJUSTING

There are two timing lines at the top of the needle

liming lines at the bottom, a total of 4 timing lines

adjusting the height of the

lines when using short needles (TQ,Xl); for using long needles (TQ,x7)

use the lower

Step on the pedal

THE

NEEDLE

Fig.

12

pairoftiming

fully

BAR

(Fig. 12, 13)

Fig.

13

bar

and

two

(Fig.

12).

For

needle

lines.

bar,

use

the upper pair of timing

to release the stop motion trip lever and in

that position rotate the motor pulley toward the operating direction

with your right hand

lowest

A),

position,

depending

upon

(Fig.2)and when the needle bar has reached the

the upper line of the each pair of liming

the

lengthofneedle

used,

shouldbeeven

lines

(Fig.

with the

14

Page 13

lower edge of the needle bar bushing

If it's not

guide cjamp

tion and

the needle bar lower bushing.

make

even,

loosen

screw®(Fig.

the upper

the needle bar bearing block and thread

13)

when the

timing

At this point, bear in mind the

(i)

When the needle

screw (Fig. 13 ®) goes into the slot of the needle bar lower bushing.

(ii) Lightly tighten the needle

screw,

and

slot (Fig. 7)

(iii)

and

after installing the face plate,

thread

Timing

As per Chapter

guide comes to the center of the machine

and

the needle

bar

has risen, be sure that the needle clamping

bar

then tighten the set screw.

and

the looper

13,

the upper liming line of the pair of timing lines

(T).

line

even

following

Fig.

14

bearing block

needle

bar is at its

with the

lower

important points:

and

adjustsothat

lowest

posi

timing line of

thread guide clamp

the

bearing block

arm

front cover

became even with the lower edge of the needle bar lower bushing at the

lowest point of the needle bar, so rotate the pulley toward the operating

direction and adjust so that the lower timing line comes even with the

needle bar lower bushing. At this position, (Fig.14B) match the point

of the looper (Fig. 15 @) with the center of the needle

and

the

point

at

clearance between the needle

tighten the looper set screw (Fig. 15

(D)

securely.

0.05—0.1

and

m/m

make the

and

then

Page 14

Fig.

16

14. TO

is by a

timing of the

cam (front). The latter should be applied when disassembling the

machine and

adjusting the

There

simple

PRODUCE

arc two methods to produce an ideal slilching condition: one

OPTIMAL

STITCHING

CONDITION

{Vig. 15, 16)

adjustment of the looper and the other is to match the

looper

for

looper,

positioning

finger

with the

any other purposes, do not

refer

to the chapter on "Timing

loop

positioning

move

the machine. For

the

needle

finger

and

Page 15

the

looper"

(i)

Adjusting the

(Chapter 13 (iii)).

loop

positioning finger lever (Fig.

15,

16)

Release the stop motion and rotate the machine toward the operat

ing direction twice. (To release the stop motion, the machine must be

rotated

cam

more

than

twice).

At the lowest position of the needle bar, loosen the screw

and

looper sleeve(Dby locking from under the bed, slide the cam

(g)

of the

and looper sleeve toward the front and create a clearance with the loop

positioning finger cam (rear). To prevent the machine from moving

during the adjustment, lightly tighten one side of the cam and looper

sleeve screw

rotate

position of the loop positioning finger (Fig. 16 ®), make a clearance of

0.5~1.0m/m between the needle and the loop positioning finger edge as

showninFig.

(ii) Timing the loop positioning finger cam {front) (Fig. 15)

In

carved line of the loop positioning finger cam (rear) (I) with the cam

and

looper sleeve

(g).

Loosen the loop positioning finger

the

loop positioning finger

16.

order

to time the loop positioning finger

(D

carved line

cam

(rear) screw

cam

and

at

the

fartherest

cam

(front), match the

and

also with the carved line of the

(S),

advanced

loop positioning finger cam (front) © all on a straight line and then

tighten screws(D@. At this position, contact the

and looper

tighten

the

sleeve

(§)

set screw.

with the loop positioning

rear

end

finger

cam (rear) ®, then

of the

cam

(iii)

Verification

cams

offront and rear

Make sure that the height of the

at the

machine)

the needle

this height is

position

where

it

is within 55-^58mm

bar

upper bushing to the upper point of the needle bar.

less

than this, it might invite needle breakage.

positions

loop

beginstomove

(2-5/64"--2-1/4")

—13—

of the

loop

positioning

from

right to left

from

positioning

finger

finger

(Fig.16(D)

(facing

the

the upper point of

If

Page 16

15.

POSITION

OF

THE

NEEDLE

GUARD

(Fig. 16)

Adjustment should be made so

that

when the needle

barisat

the

lowest position, the clearance between the needle and the needle guard

@ comes to 0.05~0.1 mm by looseming the screw

guard

(g) to

rightorleft.

16.

TIMING

THE

NIPPER

RELEASING

DISC NO. 2 (Fig. 17)

Screw

Fig.

17

(Note:

The

This

is a very delicate technical adjustment, so be extremely

careful)

standard

motion is, as shown in Fig. 17, to

driving pulley toward the arrow direction as you pull the thread

the tension disc No. 2 will float up

and

quickly.

At this instant, the

height

to the top edge of the needle bar is

When

defective signs, as shown below, occur too frequently, try the

following

17, loosen

Insert

adjustments:

a screw

nut(Dand

driver

rotate the tension post toward the arrow direction.

from the needle

54'>'57

into

the

tension

(u)

and moving the needle

PLUNGER

Driver

OF

rotate

TENSION

the needle

the thread will be slipped

bar

upper

bushing surface

m/m (2-7/64'-2-3/16").

post

No. 2, as

shown

and

out

in Fig.

—

14

—

Page 17

When

this nut is tightened, the distance

bushing surface and the top edge of the needle bar becomes

standard distance and if this

direction of the arrow, this distance will become greater than standard.

tension

between

post is rotated in the

the

needle

bar upper

less

than

opposite

Defective

(i)

When

of

fabric

(ii)

When

instant

(iii) Too frequent thread breakage

17.

CHANGING

Normally, the button tray is attached to the right side of the

machine.

of

operation,

into the

18. STITCH SELECTING

But if

hole

signs

thread

tighteningofback

bad

the

th'-eadatstop

breaks

enroute

THE

this

loosen

the

which

I

Rotate

motion^t^pposite

Rotate

arrow

POSITION

OF

BUTTON

positionisinconvenient

button

is on the

{Vig.

left

tray

18)

side

leg

of the

set

Adjustment

tension

direction

tension

direction.

TRAY

depending

screw

front

post

no.2in

post

no. 2

upon

and

insert

part of the

toward

the

the

thenature

the

tray

table.

To

select

the

numberofstitches,

the

selectionbymeansofthe

latch

adjusting

screw©and

Fig.

stop

the

18

first

open

motion

cam

tightening

the

left

side

knob®,stitch

screw

©.

cover

do

selecting

Page 18

The

illustration which shows the selectionofstitches with the speed

slowing device in a released condition is shown in the figure, hut the

selection

( i ) S-s/i7c^ selecting (Fig. 19, 20)

cam knob

position

shown by ® Fig.

and

(ii)

car

The

Figure

This

8-stitch selecting

(D

.shown

becomes

16-slitch

be

made

without

20 shows the 8-stitch selecting.

toward the operator (Fig.

releasing the speed slowing device.

canbearranged

by pulling the stop motion

19)

and if this is moved to the

by the direction of the arrow, and set at the position

20,

an

8-stitch

selecting

Fig.

the stop motion cam

selection.

19

(T)

will stop half revolution

Fig.

20

With

the

8-slilch selected position, move the stop

(2).

The

stop motion

rotate

stitch

(iii) 32-stitch selecting (Fig. 20)

stitch selecting lever (D

one complete revolution at one sewing cycle

selecting.

With

the

16-stitch selected position, loosen screw

cam

with

the stitch selecting lever roll

0,

at the position shown in Fig. 19, will

your

hand

and

(J)

has gone up as shown in the Fig. 20, it

and

tighten

motion

cam

becomes a 16-

(a),

push down

screw

0.

knob

the

When

will push up the lever and with this action it will hold up the stop

motion

rotations)

tripping

and

lever ®. Thus, the cam will revolve once more (2

becomesa32-stitch

selecting.

Page 19

4'^5'ym

® ©

Fig.

21

If

the 32 stitch selecting cannot be obtained even, after all above

manipulations,

(D

toward

loosen

the

clamping

screw

rotate the adjusting

the arrow direction and re-tighten the clamp

screw

screw

(3).

19. HEIGHT OF

The

standard

clamp

foot

motion position is 12

the set

screw

BUTTON

distance

(D

and the upper

m/m

(g)

of the button clamp lifting rod and

CLAMP (Fig. 21)

between

the

surface

bottom

of the

(15/32"). To adjust to this distance, loosen

surface

feed

of

plate @ at the stop

move

it up or

the

20. ADJUSTING THE BUTTON CLAMP PRESSURE (Fig.

To adjust the button clamp pressure, rotate the button clamp pres

sure adjusting spring

surface of the button clamp pressure adjusting spring

screwed top

comestoabout

part

4~5m/m

nut

(Dsothat

the clearance between the

nut®and

of the button clamp pressure adjusting screw stud ®

(5/32*'-^3/16").

—

17

—

button

down.

21)

bottom

the

Page 20

21.

ADJUSTING

THE

BUTTON

CLAMP

Fig.

22

STOP

LEVER

(Fig. 22)

With the machine at stop motion

stop

lever

set

screw

(T)

and as the button

closebythe

showninFig.22and

or taken out, tighten the clamp screw

22.

ADJUSTING

First,

inches).

holes at the corners of the 4-hole square, match one side as the length

wise scale

(i)

Lengthwise scale (Fig. 23)

By

actionofbutton

measure

In the

pushing

and

case

the

down

after

FOR

2-HOLES

the distance

of 4 button

otherasthe

the

handle

clamp

makingiteasy

position,

clamp

lever

(2),

for

(1).

AND

4-HOLES

between

holes,

crosswise scale.

and indicator

the button

as all standard button

loosen

foot

set

the

the

buttontobe

spring

the button clamp

will

either open or

button

correctly

inserted

holes

(in mm or

holes

have

(Fig.23(D),

the indicator at the arrow position (0 position) for 2 holes and for 4

holes set it to the previously measured scale.

—

18

—

as

set

Page 21

Fig.

23

(ii)

Crosswise

After the lengthwise scale is set, next, set the crosswise scale. Loosen

the

crosswise

indicatortothe

releasing

the

needle

needle falls

center of the hole, loosen the nut

indicator,

fall in

the

the

stop

driving

tighten

center

scale (Fig.

feed

previously

motion

right

in

the

of

24)

indicator pin nut

measured

pulley

the

nut

the

hole.

plunger

(2)

from

toward

centerofeach

andbyrotating

(Fig.24(D),

position,

the

the operating

hole.

(g)

again, move the

stop

Fig.

tighten

motion

If

the

pulley,

21

set the

the nut

disc

direction,

it does

make

crosswise

and rotating

verify

not

crosswise

(2),

and

fall in

the

needle

feed

by

if the

the

feed

23. CHANGING

ITS HEIGHT (Fig. 25,

With

the

attachment

the

pedal,

the

the engaging button clamp lifting link lever hinge

hole d) in its front

Thenifthe

installed

button

pedal,

holding

systemistobeemployed,

Model

is to

clamp

S-shaped

clamp

THE

BUTTON HOLDING CLAMP AND ADJUSTING

26)

MB-372

be

usedorwhen

holding

and

is

hung

will

tighten the screw.

Machine,

the

deviceisattached.

chain

hook,

on the

button

movebythe

please

order

—

19

—

when

clampingofbuttonsisdone

whichisconnectedtothe

clamp

actionofthe

the

pedal

the

For

screw

lifting

and

shank

this

link

pedal.

chain

button

purpose,

(T),

move

hole

When

separately.

clamp

by

loosen

it the

newly

d), the

pedal

Page 22

The

clamp holding range is measured by moving the button clamp

and

down

but

lifting lever stop up

when changing to automatic system

from pedal system, make absolutely certain that the button clamp lifting

lever stop

(J)

is pulled way up from the contacting surface of the machine

Fig.

25

When

convertingtoautomatic

open

this

space

wide

Fig.

26

—20—

system,

Page 23

24.

Nature

CAUSES

of

malfunctions

OF

MALFUNCTIONS

Reasons

AND

REPAIRING

Repairing

Thread

Thread

inadequate

First

stitching

comes

button

Thread

at

stop

breakage

tightening

thread

outontop

excessively

cutting

motion

bad

Loop

bad

Nipperisholding

thread

Needle

the

Inadequate

ing

Timingoftension

No.2bad

Tension

No.2bad

Needle

the

Button

bad

Inadequate

of

of

tension

Bad

disc

Needle

hole

Inadequate

of

button

Nipper

bad

Button

too

strong

positioning

does

centerofhole

not

motion

fall

loop position

of

tension

does

not

center

clamp

fall

of

hole

pressure

adjustment

lever

timingoftension

No.

2

hitting

the

rising

clamp

thread

clamp

range

holding

pressure

the

in

disc

disc

in

button

Quicken

timingofthe

Adjust

Adjust

lever

Adjust

of

Retard

tension

Adjust

disc

Adjust

ing

Adjust

pressure

Adjust

rear

Rotard

tension

thread

Reset

Make

jaw

from

Adjust

Adjust

pressure

the

lever

about

jaw

loop

No.

tension

the

the

lower

with

with

the

with

with

holder

right

the

disc

the

2

with

jaw

the

the

the

disc

needle

button

adjusting

right

and

positioner

bar

clamping

left

timing

2

button

clamping

bar

timing

adjust

fall

clamp

(15/32")

bar

clamp

nut

left

block

timing

of

clamp

block,

of

the

lever

block

loop

nipper

button

and

positioner

float

no.

tensionoftension

the

holder

button

nipper

float

and

12m/m

plate

nipper

button

21 —

Page 24

25.

ATTACHMENTS

TO

MB-372

BUTTON

ATTACHING

MACHINE

As shown In Fig. 27, by

button

clamp

components

in case of snap attaching, thread guide No. 3 ® (Fig.

kinds

of

buttons

can

be

changing

(T),

attached:

button

the various

clamp

work support plate or

attachments

29).

the following

such as

(Note: Please order corresponding attachments for different kinds

of

buttons)

(i)

Snap

fastener

(ii)

Wrapped-around

(iii)

Shank

(iv)

Metal

(i)

How to

First, remove the button clamp components

button clamp work support plate

fastener attachment. Then, after setting the cross-wise feed

length-wise feed at 4 m/m

supportplate®

button

shank

install

Fig.28in

button

snap

fastener

attachment

(g)

(5/32")

each, install the button clamp work

suchaway

(1)

Fig. 27, also the

and in their place, install the snap

and

the

for

the

needletofall

evenly

on the

four cornersof the square hole. Next, install the snap fastener clamp. Fig.

28(Dwhile it is holding the snap to the snap fastener clamp jaw lever

and

lower the needle

If

the needle does not fall correctly, loosen the hexagonal screws ©

and

the see

that

it falls into the

snap

hole correctly.

—22—

Page 25

and

correct it. Finally verify if the

support

plate (D

and

the

DH

shape

[Ih

shape of the button clamp work

at

the lower surface

of

the

snap

fastener clamp slide are in perfect unison or not. Next, exchange the

thread guide No. 3 ® to that of snap fastener as shown in Fig. 29.

The

thread guide No. 3 should be installed vertically.

Fig.

28

(ii)

How to install the wrapped-around button clamp (Fig. 30, 31, 32)

A.

Sewing

flow of

work

Fig.

29

In sewing in the wrapped-around button, there are 2 stages of work

flow:

around

the

so-called

" process.

"button attaching"

process

and the "wrapping

The button attaching process is a preliminary process before the

wrapping

around

process

and

the

distance

between

the

button

and

the

cloth is lengthened beforehand and the button is sewn on and finally

the warpped around process is done with the wrapped around attachment.

Page 26

B.

Installing

Fig.

the

rr

.

30

attachment

Fig.

31

a. Attaching the

button

attaching

attachment

(Fig. 30)

For the button attaching process, securely fix in the wrapped-around

button clamp snaking foot

wrapped around installing

to see that both button clamp jaw lever

(T)

to the button clamp jaw lever with the

screw(Dand guide pin screw

(2)

and

the clamp snaking foot

(§)•

Be

careful

(i) are placed equi-distant from the center of the button to the right

and

left

and

also

not

b.

Attaching

touch the

evenifthe

button

the

clamp

wrapped-around

needle

snaking foot

attachment

falls

(J).

into

the

button

hole,itwill

After the button attaching process is conpleted, remove the button

clamp component ® and button clamp work support plate(DFig.

and in the place of support plate

ment (Fig.31^).

This attachment should be adjusted by looseniug the

button necking attachment set screw Fig.

position

as the

central

pivot,

right and left should be all equi-distant.

the

(2),

install the wrapped-around attach

31

(g)

and with the needle fall

clearance

between

Also,

front

and rear and

the length of the wrap-

27,

Page 27

ping can be adjusted by the clearance between the button necking large

guide

(2),

Fig. 31

and

the small guide

(D,

Fig. 31.

C. Sewing process

a)

Howtoattach

buttons

When the button attaching attachment is installed, the sewing pro

cess can be done in the same manner as an ordinary flat button,

but

the distance from the button to the cloth is long, it is necessary to adjust

the thread adjusting lever beforehand to make the drawing

thread

longer.

outofthe

as

b) How to

Insert the button, which is already attached by the

wrap

the

button

button

attaching

process, into the position shown by the arrow (Fig. 31) by twisting it

somewhat as shown in Fig. 32.

The

graduation

should be so set

that

the

length-wise feed should be in the same position as in the case of 2-hole

buttons.

(iii) How to install

the

shank

button clamp attachment

A. Remove the button clamp component. Fig. 27 (i) and the button

clamp work support plate(Dand

(Fig. 33

fall in

(D).

Adjust the

the

middleofthe

button

needle groove

install the shank button clamp bracket

clamp bracket ® so

and

tighten

that

the needle will

the

screw d).

The shank button adapter ® is a part of a set with the button clamp

(§),

holder

shown in Fig. 34. Also, plug in the button clamp stud

(2)

of the

so install this adapter on the built-in button clamp position as

(g)

jaw

of the

arm

and

tighten the screw ©.

The button clamp block

(g)

should be fixed in such a position as to

into the hole

make it easier to handle depending on the size of the button or sewing

condition. Then, exchange the button holding clamp in accordance with

the method described in

Chapter

23.

—

25

—

Page 28

0.5-1.0

Fig.

34

B Adjusting the attachment

Make

sure

that

the needle grooveofthe

fits into the needle groove (D of the

If

it doesn't fit, then

screw

that

Rotate

it falls equi-distant, right

adjust

by loosening the

the pulley with

and

button

your

left, with the shankofthe shank

hand

adapter

clamp

and

(§)

Fig. 33 perfectly

work

support

button

clamp

drop the needle to see

plate

holder set

button

as the central pivot. When this is verified, tighten the button holder

set screw @. Also,

0.5-'1.0mm

surface

and

between

the

sewing cloth from pushing

left

make

the

end

sure

button

surface

out

that

thereisjust

clamp

of

the

the button.

—26—

work

adapter

sufficient

support

Then,

spaceofabout

plate

@ left

(8)

as to

prevent

tighten the screw

end

the

(§).

Page 29

Next,

loosen

shank button holding clamp © holds the exact center of the button.

To

adjust

®, loosen the thrust collar set screw ®, Fig. 35, and if the thrust collar

® Fig. 35 is rotated, the

an optimal pressure.

When you do

® Fig. 35 will not develop any rattling along the shaft direction.

G.

In order to attach the shank button

the

cross-wise

the

screw

® @ Fig.35 and makeadjustment so that the

the

holding

this,

feed as much as possible.

pressure

pressure

of the

of the spring will change, so set it at

be sure that the button clamp lever holding

shank

securely,

button

holding

try to minimize

clamp

To maintain a stable stitching condition, make doubly sure that the

needle is not contacting the needle

clamp work support plate, then start the button attaching task.

groove

of the adapter or the button

The holding pressure of the button holding clamp ® Fig. 35 should

be sufficiently strong enough so that the button does not move during

the stitching operation.

(iv)

How

to install the metal shank

A. To install the metal shank button clamp attachment, remove the

button clamp holder

Fig.

27

and, as

plate @ to the installing part of screw ©. At the same time, adjust the

(T)

and the button clamp

showninFig.

button

clamp

attachment

feed

plate(Das shownin

36,

attach the shank button clamp

(Fig.

36,

37)

feed

Fig.

35

—

27

Fig.

33

Page 30

Fig.

17

Fig.

37

38

@ so

shank button work support plate(Dand

that

the needle falls between the needle groove ©ofthe metal

then tighten the screw ©.

As the metal shank bvitton adapter ® is a part of the set of the

button clamp holder ©, attach it to the built-in clamp holder spot, as

showninFig.

B. To adjust this attachment,

to the footofthe

If

the metal shank

It

would be better at this time to raise up the right shoulder of the

button guard ®

shoulder.

Next, loosen the

that

the circular groove surface of the lower part of the adapter ®

37.

first,

insert the metal button to be attached

adapter

and

®.

button

guard

®, is too loose, tighten it, somewhat.

set the foot of the metal button solely by the left

button

clamp bracket set screw ©

and

adjust so

exactly meets the grooved surface of the work support plate ®.

After adjusting, drop the

right and left with the base of the metal button as the central pivot

when

this is verified,

be sure to

createadistance

tighten

needletosee

the

adapter

" a "

between

—

28

that

needle

falls

evenly

and

set

screw ®.

the

left

endofthe

—

And

here also,

work

sup-

to

Page 31

port plate

(§)

and the left end of the adapter ® just sufficient to prevent

the sewing cloth from pushing out the button, then tighten the set screw

Normally, this distance

C.

a) In

Cautions

ordertoattach

on sewing operation

"a"

is

l-'1.5m/m.

the metal shank buttons securely, try to make

the crosswise feed as little as possible.

b)

To

maintain

a stable stitching condition, be sure to verify

needle is not touching cither the adapter or the needle groove of

the work

support

plate

or the baseofthe metal

button.

that

the

Page 32

SUBCLASS

SINGLE

MACHINES

THREAD

INDUSTRIAL

OF

CHAIN

MODEL

STITCH

SEWING

MB-372

BUTTON

MACHINE

HIGH

SEWING

SPEED

SUBCLASS 1

Diameterofbutton

Distance

circumferenceofbuttons

Button

Button clamp lever

Button clamp lever jaw, left

Button clamp lever

Material

SUBCLASS

Diameterofbutton

Distance

FOR

between

clamp

lever

presser lower

2

FOR

between

SMALL

outer

jaw,

jaw

jaw

MEDIUM

outer

BUTTONS

10~20mm

(STANDARD

(3/8"~25/32")

Under

right

B-2555-372-000

holding spring right

B-2557-372-000

holding spring, left B-2558-372-000

plate

SIZE

12~20mm

diameter

B-2529-372-000

BUTTONS

(15/32"--'25/32")

of

buttons

Material presser lower plate for medium size buttons

(Note) All

SUBCLASS

Diameter

Distance

3

other

FOR

of

button

between

specifications

LARGE

outer

circumserence

SIZE

15—25mm

are

same as SUBCLASS 1

BUTTONS

(9/16"

of

5-7.5mm

Button clamp lever jaw, right

for large size

buttons

for large size buttons holding spring D-2555-372-C00

Button clamp lever jaw, left,

for large size buttons D-2557-372-C00

for large size

buttons

holding

spring

Material presser lower pleat D-2529-372-C00

4.8mm

4~6mm

—31/32")

buttons

MACHINE)

(5/32")

B-2556-372-000

(5/32"-1/4")

D-2529-372-B00

(3/16"-9/32")

D-2555-372-C00

D-2558-372-C00

SUBCL.\SS

Numberofstitches

(Note) All

4

6, 12, 24

other

specifications are same as

other

subclasses

Page 33

CONVERSION

TABLE

1

mm

1.5mm

2

mm

2.5mm

3

mm

3.5mm

4

mm

4.5mm

5

mm

5.5mm

6

mm

6.5mm

7

mm

7.5mm

8

mm

8.5mm

9

mm

9.5mm

10

mm

11

mm

12

mm--

13

mm-

14

mm--

15

mm--

16

mm--

17

mm-

18

mm-

19

mm--

20

mm-

Milli

Meter

5/128"

1/16"

1/16"

3/32"

1/8'

1/8"

5/32"

5/32"

3/16"

7/32"

1/4"

1/4"

1/4"

9/32"

5/16"

5/16"

3/8"

3/8"

3/8"

7/16"

15/32"

33/64"

35/64"

9/16"

5/8"

43/64"

11/16"

3/4"

25/32"

to

less

plus

plus

less

plus

plus

plus

less

less

plus

plus

plus

plus

less

less

plus

less

plus

less

plus

plus

plus

less

plus

plus

Inch

1/256"

1/64"

1/256'

1/128'

3/256"

5/256"

1/128'

1/256"

1/64"

i/256"

3/128"

3/256"

5/256"

3/128"

1/256"

1/64"

1/128'

1/256"

1/256"

3/640"

3/128"

3/640"

1/256"

1/64"

3/128"

InchtoMilli

1"

1/2"

1/4"

3/4'

1/8"

3/8"

5/8"

7/8"

1/16"

3/16"

5/16"

7/16"

9/16"

11/16"

13/16"

15/16"

1/32"

1/64"

1/128"

Meter

25.4

12.7

6.35

19.05

3.175

9.525

15.875mm

22.225mm

1.5785mm

4.7625mm

7.9375mm

11.1125mm

14.2875mm

17.4625mm

20.6375mm

23.8125mm

0.79375mm

0

396875mm

0.19844mm

'

m|n

mm

mm

mm

mm

mm

Loading...

Loading...