Page 1

R

Dry-head Type, High-speed, Computer-controlled, Single Thread,

Chainstich Button Sewing Machine

(with Automatic Thread Trimmer and Knot-tying Mechanism)

MB-1800

MB-1800A

ENGINEER’S MANUAL

29345105

No.00

Page 2

PREFACE

This Engineer’s Manual is written for the technical personnel who are responsible for the service and maintenance

of the machine.

The Instruction Manual for these machines intended for the maintenance personnel and operators at an apparel

factory contains operating instructions in detail. And this manual describes “Standard Adjustment”, “Adjustment

Procedures”, “Results of Improper Adjutment”, and other important information which are not covered by the

Instruction Manual. It is advisable to use the revevant Instruction Manual and Parts List together with this

Engineer’s Manual when carrying out the maintenance of these machines.

Page 3

CONTENTS

1. SPECIFICATIONS...................................................................................................................................1

2. NAME OF EACH COMPONENT.............................................................................................................2

(1) Name of the main unit ................................................................................................................................................. 2

3. OPERATION OF THE SEWING MACHINE ............................................................................................3

(1) Names of the operation panel switches .................................................................................................................... 3

(2) Pattern table ................................................................................................................................................................. 4

(3) How to operate and use the memory switch (User level) ........................................................................................ 5

4. STANDARD ADJUSTMENT ...................................................................................................................6

(1) Height of the needle bar.............................................................................................................................................. 6

(2) Positioning the needle and the looper....................................................................................................................... 6

(3) Timing the travel of the yoke slide............................................................................................................................. 8

(4) Timing of the tension disc No. 2 ................................................................................................................................ 8

(5) Lift and pressure of the button clamp ..................................................................................................................... 10

5. ADJUSTMENT OF THE THREAD TRIMMING MECHANISM ..............................................................10

(1) The mechanism and the name of each component of the thread trimmer .......................................................... 10

(2) Adjusting the position of the moving knife............................................................................................................. 12

(3) Adjusting the height of the thread separating claw of the moving knife ............................................................. 12

6. PROCEDURES IN DISASSEMBLING AND ASSEMBLING ................................................................14

(1) Name of each component ......................................................................................................................................... 14

(2) Disassembling the circuit board .............................................................................................................................. 16

(3) Disassembling the machine arm and bed ............................................................................................................... 18

(4) Disassembling the looper shaft ............................................................................................................................... 20

(5) Disassembling the driving shaft .............................................................................................................................. 22

7. ADJUSTMENT OF THE SENSORS......................................................................................................26

(1) Adjusting the starting sensor................................................................................................................................... 26

(2) Adjusting the presser lifter sensor .......................................................................................................................... 26

(3) Adjusting the feed origin sensor ............................................................................................................................. 28

(4) Adjusting the presser lifter stopper......................................................................................................................... 28

8. HOW TO OPERATE AND USE THE MEMORY SWITCH (SERVICE LEVEL) ....................................30

(1) Memory switch function table .................................................................................................................................. 31

9. HOW TO OPERATE AND USE THE INPUT CHECK MODE FUNCTION ........................................... 33

(1) INPUT CHECK CORRESPONDENCE TABLE .......................................................................................................... 34

10. HOW TO OPERATE AND USE THE ALL CLEAR FUNCTION ........................................................... 35

11. PARTS TO BE GREASESD..................................................................................................................36

12. ERROR LIST .........................................................................................................................................37

13. CHANGE-OVER OF THE POWER SOURCE VOLTAGE .................................................................... 38

14. CAUSE OF TROUBLES AND THE CORRECTIVE MEASURES.........................................................39

(1) Thread trimming troubles and the corrective measures ....................................................................................... 39

(2) Cause of troubles and the corrective measures for MB-1800 ............................................................................... 40

15. CIRCUIT BOARD DIAGRAM ................................................................................................................41

(1) MAIN circuit board..................................................................................................................................................... 41

(2) PWR circuit board ..................................................................................................................................................... 42

(3) PANEL circuit board.................................................................................................................................................. 42

16. BLOCK DIAGRAM 1/2 ..........................................................................................................................43

17. CONNECTION DIAGRAM AND CIRCUIT DIAGRAM ..........................................................................45

(1) Power connection diagram....................................................................................................................................... 45

(2) Sensor connection diagram ..................................................................................................................................... 46

(3) Motor circuit diagram ................................................................................................................................................ 47

(4) Encoder circuit diagram ........................................................................................................................................... 48

(5) Solenoid circuit diagram........................................................................................................................................... 48

18. DRAWING OF THE TABLE ..................................................................................................................49

Page 4

−1−

1. SPECIFICATIONS

1) Sewing area : X (lateral) direction 10 mm

Y (longitudinal) direction 6.5 mm (0.2 mm pitch)

2) Max. sewing speed : 1,800 rpm

3) Feed motion of button clamp : Intermittent feed (2-shaft drive by stepping motor)

4) Needle bar stroke : 48.6 mm

5) Needle : TQx7, TQx1 (TQx7 #16 at the time of delivery)

6) Button size : 10 to 28 mm

7) Lift of button clamp : Standard 10 mm Max. 14 mm

8) Memory of pattern data : EEP-ROM (32K byte)

9) Enlargement/reduction system : Increase/decrease of stitch length system

10) Limitation of sewing speed : Sewing speed can be optionally limited to 400 to 1,800 rpm with the

up/down key. (Adjustable in 100 rpm unit)

11) Pattern selection function : 1 to 99 patterns can be specified by selecting the pattern Nos.

12) Memory back-up : In case of a power interruption, the pattern being used will be

automatically stored in memory.

13) Sewing machine motor : 100W servo motor (direct-drive)

14) Dimensions of machine head : W : 240 mm L : 550 mm H : 360 mm

15) Mass : 25 kg

16) Power consumption : 150 W

17) Operating temperature range : 5 to 35˚C

18) Operating humidity range : 35 to 85% (no dew condensation)

19) Line voltage : Rated voltage ±10% 50/60 Hz

20) Noise : Workplace - related noise at sewing speed

n= 1,800 min-1 : LPA ≦ 80 dB(A)

Noise measurement according to DIN 45635-48-B-1.

* Reduce the max. sewing speed in accordance with the sewing conditions.

Page 5

−2−

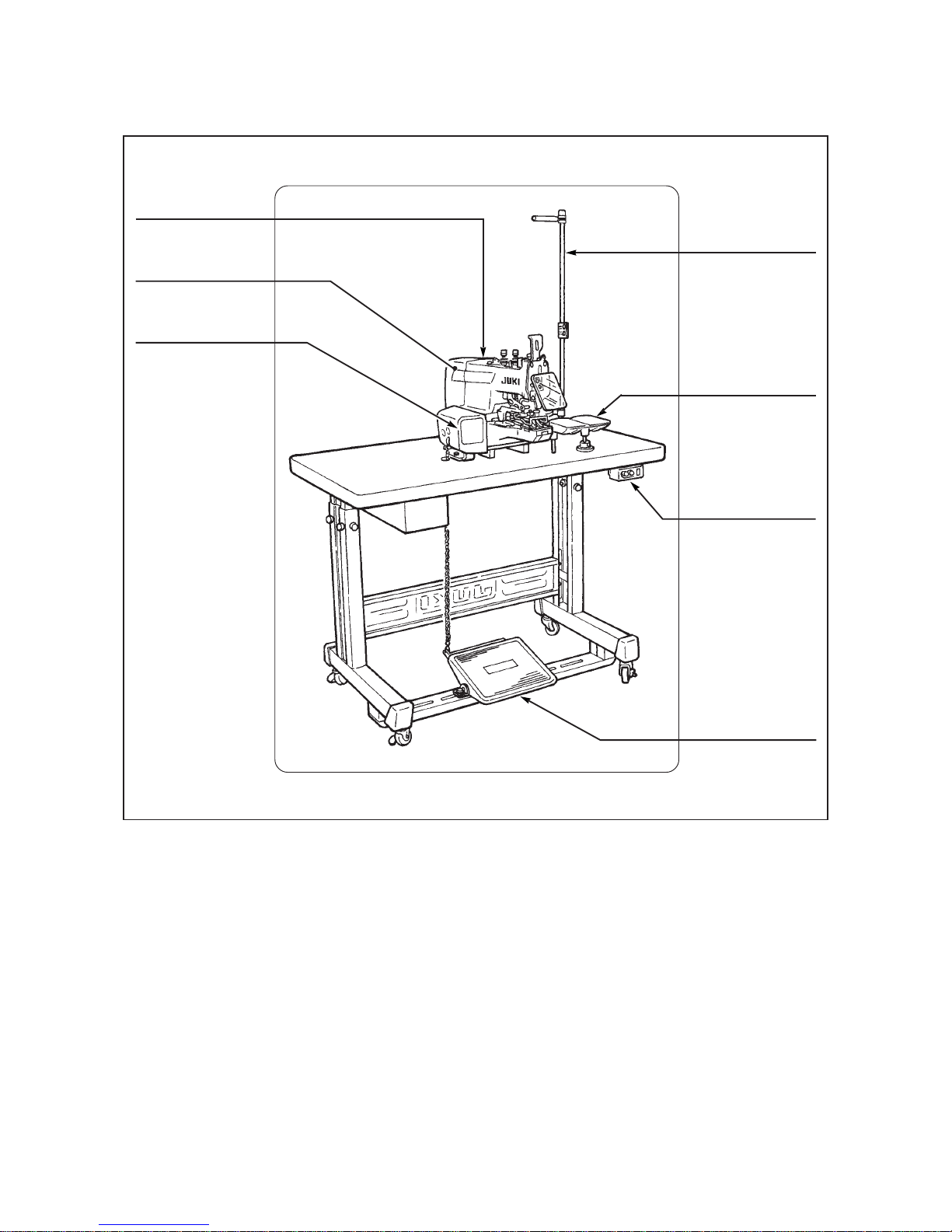

2. NAME OF EACH COMPONENT

(1) Name of the main unit

• Machine head

• Electrical

components

• Operation panel

• Thread stand

• Button tray

• Power switch

• Starting pedal

Page 6

−3−

3. OPERATION OF THE SEWING MACHINE

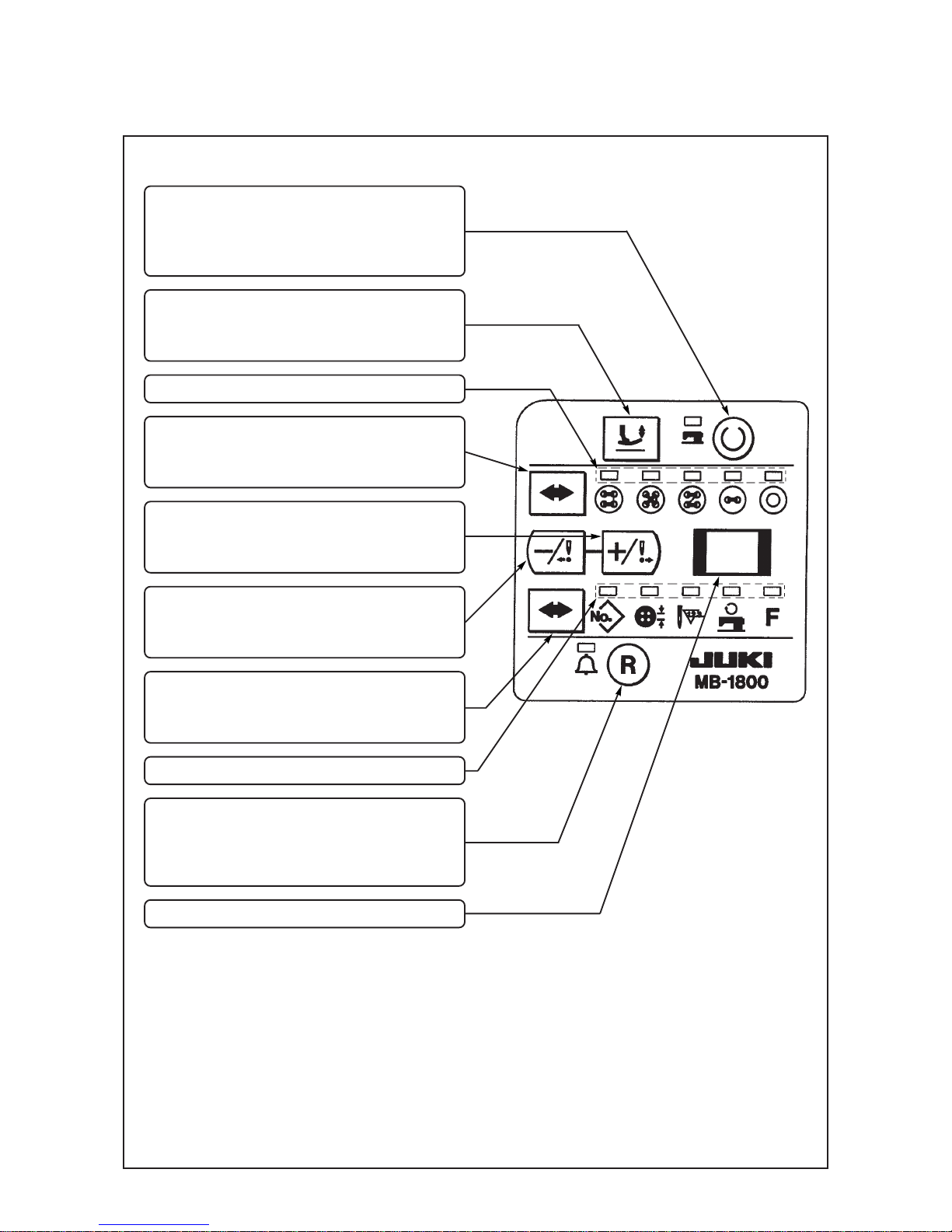

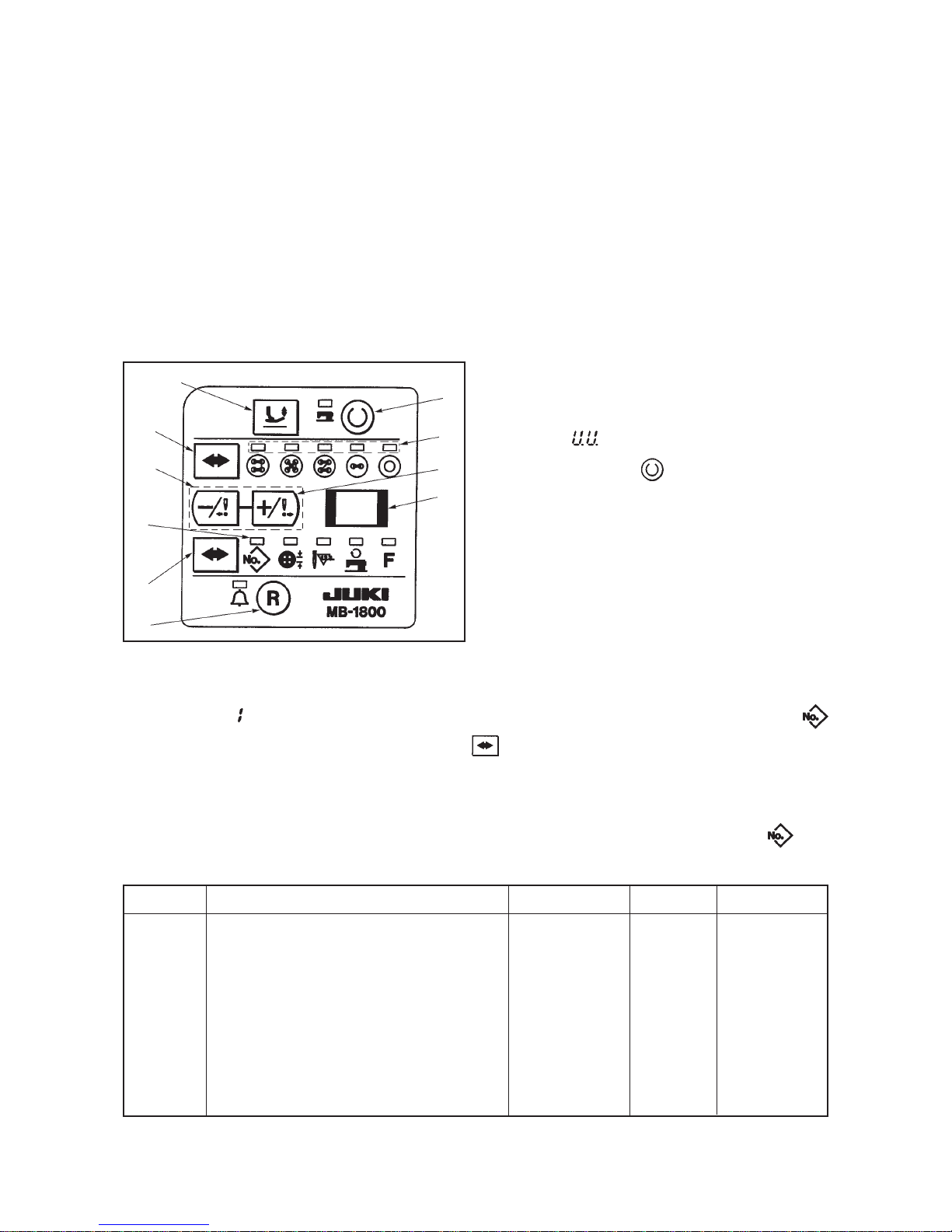

(1) Names of the operation panel switches

1 Set ready switch

This switch is used when making the sewing

machine from setting status to sewing

possible status.

2 Button clamp lifting switch

This switch performs up/down of the button

clamp.

3 Stitch shape selection LED

4 Stitch shape selection switch

This switch is used when changing the stitch

shape.

5 +/ Forward switch

This switch increases the set value or performs

traveling forward when confirming the feed.

6 −/ Backward switch

This switch decreases the set value or performs

traveling backward when confirming the feed.

7 Item selection switch

This switch is used when selecting the item

desired to be changed.

8 Item selection LED

9 Reset switch

This switch returns the various set values

to the original status or performs release

when an error occurs.

!0 Display section A

Page 7

−4−

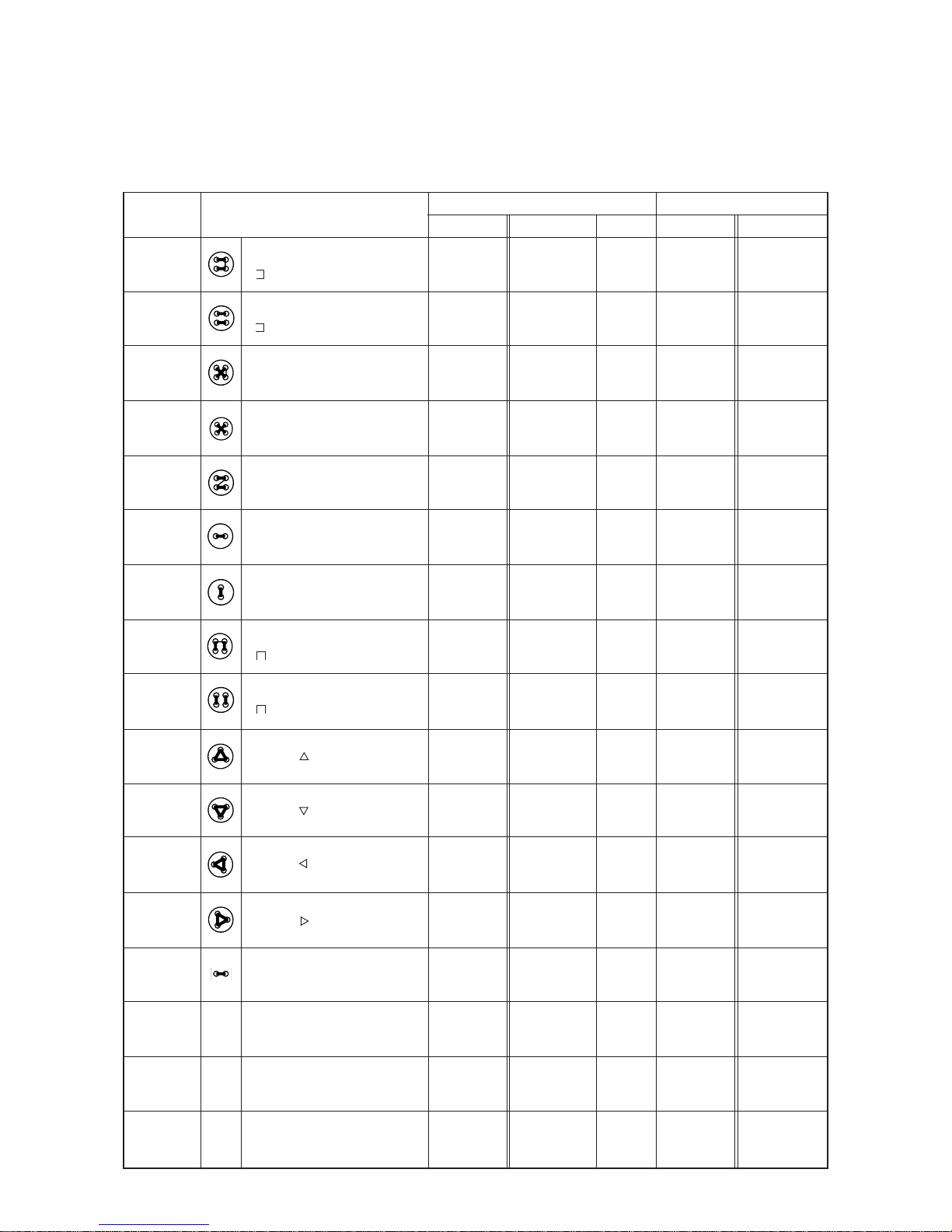

(2) Pattern table

Three same sewing sizes and numbers of stitches for each stitch shape have been stored in pattern Nos. 1 to

51 at the time of delivery.

By selecting sewing size and number of stitches from the table below, the stitch shape can be changed to the

three different kinds of patterns of the same stitch shape and be stored in memory.

Pattern No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

4-holed

( , crossover stitch : with)

4-holed

( , crossover stitch : without)

4-holed

( X, crossover stitch : with)

4-holed

( X, crossover stitch : without)

4-holed

( Z, crossover stitch : with)

2-holed (crosswise)

2-holed (lengthwise)

4-holed

( , crossover stitch : with)

4-holed

( , crossover stitch : without)

3-holed ( )

3-holed ( )

3-holed ( )

3-holed ( )

2-holed

(crosswise) label attaching

Wrapped-around

(crosswize size : 4 mm)

Wrapped-around

(crosswise size : 5 mm)

Wrapped-around

(crosswise size : 6 mm)

Initial value

2.6

2.6

2.6

2.6

2.6

2.6

2.6

2.6

2.6

2.6

2.6

2.6

2.6

10.0

2.6

2.6

2.6

Range

2.0 to 6.5

2.0 to 6.5

2.0 to 6.5

2.0 to 6.5

2.0 to 6.5

2.0 to 6.5

2.0 to 6.5

2.0 to 6.5

2.0 to 6.5

2.6, 2.8, 3.0

2.6, 2.8, 3.0

2.6, 2.8, 3.0

2.6, 2.8, 3.0

6.0, 8.0, 10.0

0.0 to 6.5

0.0 to 6.5

0.0 to 6.5

Unit

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

2.0

0.2

0.2

0.2

Initial value

15

16

15

16

15

8

8

15

16

17

17

17

17

5

16

16

16

Range

15, 19, 23, 27

16, 20, 24, 28

15, 19, 23, 27

16, 20, 24, 28

15, 19, 23, 27

8, 10, 12, 14

8, 10, 12, 14

15, 19, 23, 27

16, 20, 24, 28

17, 23

17, 23

17, 23

17, 23

5, 7

6, 10, 16

6, 10, 16

6, 10, 16

Stich size (mm) Number of stitches

Stich shape

Page 8

−5−

(3) How to operate and use the memory switch (User level)

1) The speed up to 3rd stitch can be set so that the sewing speed at the start of sewing is controlled and the

stitch is stabilized.

2) Effective/ineffective of the knot-tying functon can be selected.

3) Operating/non operating of the wiper can be selected.

In case the wiper is installed and set to the non-operating setting, when the pattern without crossover

thread is selected, the wiper works only when the crossover thread is trimmed, and it does not work after

thread trimming at the time of completion of sewing.

In case of the pattern with crossover thread as well, the wiper does not work after thread trimming at the

time of completion of sewing with this setting.

In case of the setting of operating the wiper, the wiper always works at the time of thread trimming.

1 Starting of the memory switches

In the state that +/− switches 2 are simultaneously

pressed, turn ON the power, and the memory switches

are in the state of setting.

At this time, “ ” is displayed in display section A 3.

Press set ready switch 5 and all 5 stitch shape

selection LEDs 9 flash on and off. This state means

that the memory switches are being inputted.

2 Setting procedure of the memory switches

There are the memory switches 1 to 8.

Switch N0. “ ” is displayed in the display section A 3 and item selection LED !0 of the pattern No.

lights up. In this state, press item selection switch 4, and the memory switch No. and the description

are alternately displayed in display section A 3.

In the state that the memory switch No. is displayed, press the + switch 8 and the memory switch No.

increases by one.

When the description of the memory switch is displayed, item selection LED !0 of the pattern No. goes

off.

When setting is completed, turn OFF the power. Return ON the power to return to the normal setting state.

Remarks

400 to 1,800 rpm

400 to 1,800 rpm

400 to 1,800 rpm

400 to 1,800 rpm

400 to 1,800 rpm

400 to 1,800 rpm

Switch No.

1

2

3

4

5

6

7

8

Description

Speed of 1st stitch of soft start

Speed of 2nd stitch of soft start

Speed of 3rd stitch of soft start

Speed of 1st stitch after trimming crossover thread

Speed of 2nd stitch after trimming crossover thread

Speed of 3rd stitch after trimming crossover thread

Knot-tying function 0 : Ineffective 1 : Effective

Wiper operation 0 : Non operating 1 : Operating

Initial setting

18* 100 [rpm]

18* 100 [rpm]

18* 100 [rpm]

18* 100 [rpm]

18* 100 [rpm]

18* 100 [rpm]

1 (Operating)

0 (Non operating)

Setting range

4 to 18

4 to 18

4 to 18

4 to 18

4 to 18

4 to 18

0.1

0.1

1

2

3

4

5

6

7

8

9

!0

Page 9

−6 −

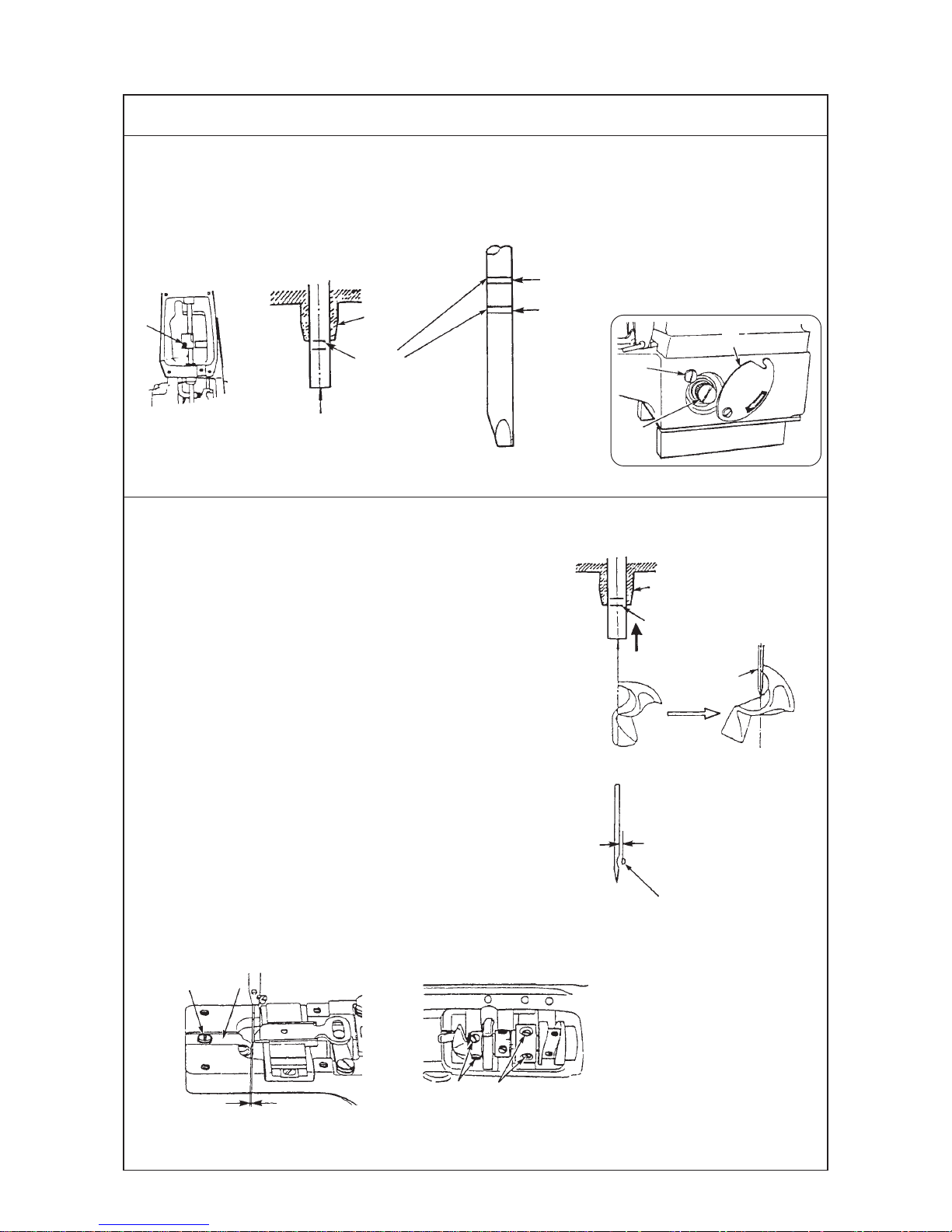

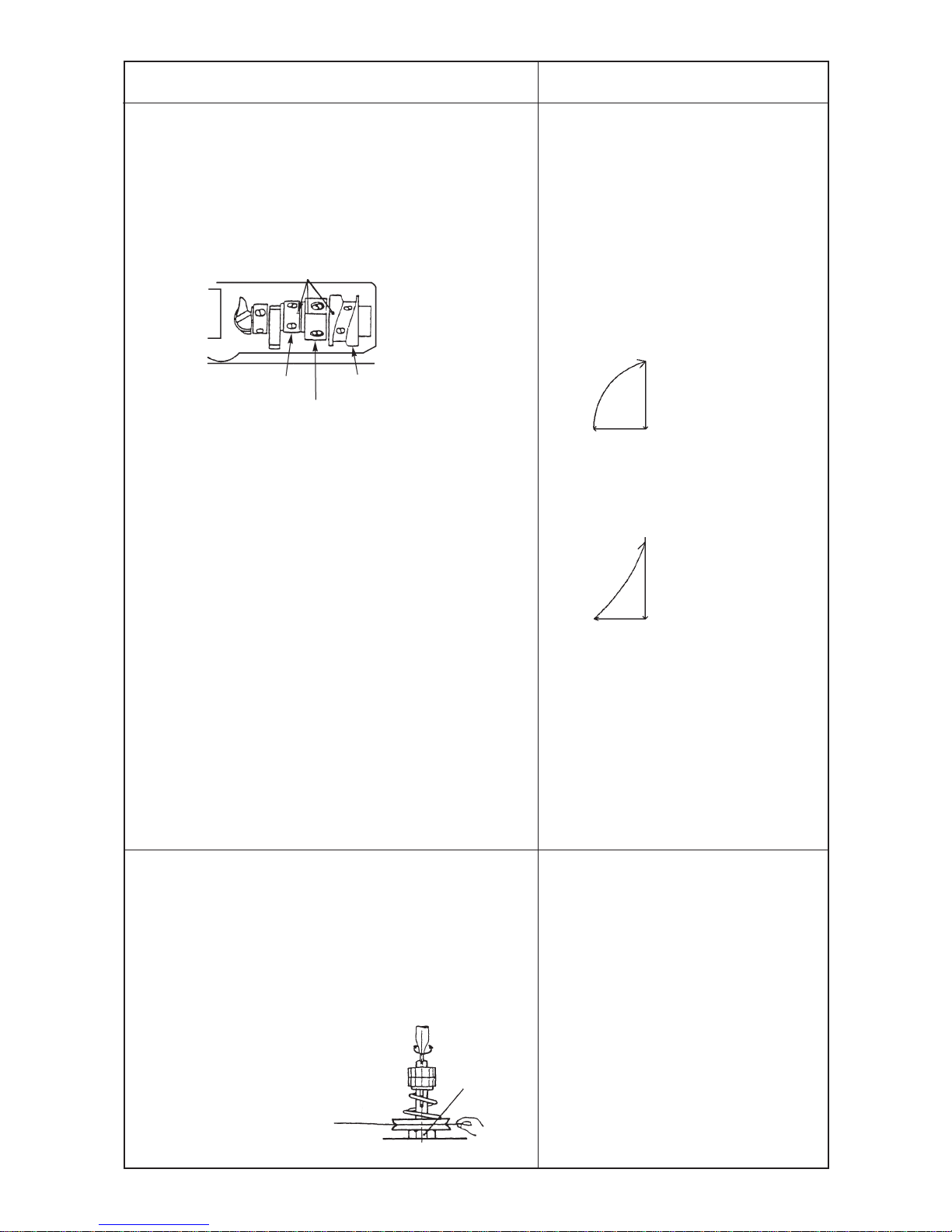

(1) Height of the needle bar

The upper engraved line of the two engraved lines for TQx1 and TQx7 should be aligned with the bottom of

the lower bushing when the needle bar is at its lowest position.

4. STANDARD ADJUSTMENT

(2) Positioning the needle and the looper

1) Looper timing

When the needle bar is ascending from its lowest

position and the lower engraved line on the needle

bar is aligned with the bottom of the lower bushing,

the looper’s blade point should coincide with the

center of the needle.

(When the needle bar is ascending.)

2) Clearance between the needle and looper

The clearance is 0.05 to 0.1 mm when the looper’s

blade point coincides with the center of the needle.

3) Clearance between the needle guide and needle

The clearance between the needle guide and

needle is 0.05 to 0.1 mm when the needle bar is at

its lowest position.

Height of the needle bar

For TQx1

For TQx1

Engraved line

(upper engraved line)

Lower

bushing

Looper timing

Lower bushing

Engraved line

Looper’s blade

point coincides

with center of

needle.

Clearance between needle and looper

0.05 to 0.1 mm

Looper’s blade point

Clearance between needle guide and looper

Needle guide

0.05 to 0.1 mm

Screw

1

2

3

4

1

2

3

4

Standard Adjustment

Page 10

−7 −

™ If the needle bar is too high, skipped

stitches will be produced.

If the needle bar is too low, the needle

will come in contact with the looper.

1) Adjusting the looper timing

™ Loosen the two screws 3 in the looper and cam sleeve

and adjust in the rotating direction of the looper and

cam sleeve so that the looper’s blade point aligns with

the center of the needle when the lower engraved line

of the needle bar is aligned with the bottom of the lower

bushing. Then tighten the screws 3.

2) Clearance between the needle and looper

Loosen two screws 4 in the looper support ring and adjust

in the longitudinal position of the looper when the looper’s

blade point is aligned with the center of the needle. Then

tighten the screws 4.

3) Clearance between the needle guide and needle

Loosen the screw 2 in the needle guide 1 and adjust in

the longitudinal position of the needle guide 1 so that the

clearance between the needle guide 1 and needle should

become 0.05 to 0.1 mm when the needle bar is at its lowest

position. Then tighten the screw 2.

™ If the clearance between the needle

and looper is too excessive, it is likely

to produce skipped stitches. If the

clearance is too small, in accordance

with the material used, the needle will

come in contact with the looper

resulting in needle breakage and

looper’s blade point breakage.

™ For thick materials and overlapped

sections, adjust the clearance between

the needle guide and needle so that

the needle guide touches the needle

by 0.1 to 0.2 mm.

1) Slightly loosen knob 1 and turn cover 2 in the direction

of the arrow and you will find hand pulley 3.

2) Turn the hand pulley by hand, loosen setscrew 4 in the

needle bar thread-take up lever and adjust so that the

upper engraved line of the two engraved lines on the

needle bar aligns with the bottom of the lower bushing

when the needle bar is at its lowest position.

Adjustment Procedures Results of Improper Adjustment

Page 11

−8 −

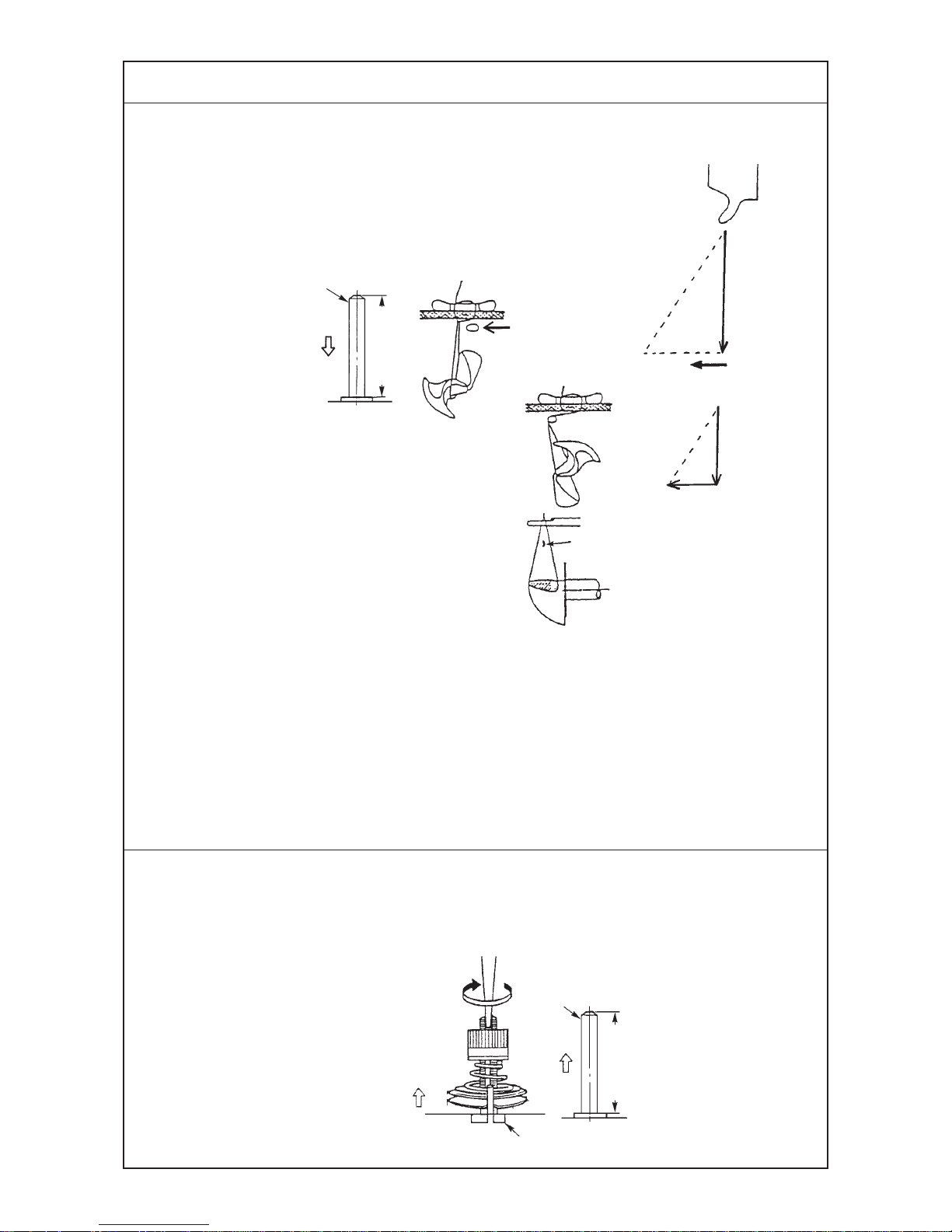

(3) Timing the travel of the yoke slide

1) Crosswise travel timing of the yoke slide

The height of the descending needle bar is 53 to 58

mm when the yoke slide advances and begins to

travel from the right to the left (TQx7).

(In case of TQx1, 43 to 48 mm)

2) Lengthwise travel timing of the yoke slide

The yoke slide should go back immediately after

the blade point of the looper has passed the thread

triangle. And, it is good for the looper to go back

like a slant line of the movement of the triangle.

3) Lengthwise positioning of the yoke slide

Position the yoke slide so that the blade point of

the looper passes through the center of the thread

triangle.

(Use a 4-hole button, 9 or 10 stitches for positioning.)

(4) Timing of the tension disc No. 2

The tension disc No. 2 should float when the height of ascending needle bar becomes 54 to 57 mm.

(In case of TQx1, 44 to 47 mm)

Needle bar

53 to 58 mm

Advances and begins to

travel from right to left.

It is good for

the looper to

go back like

a slant line.

Yoke slide

(Begins to travel from right to left.)

Blade point of looper

54 to 57 mm

Begins to float

Screw driver

Needle bar

Standard Adjustment

Page 12

−9 −

™ For adjusting the timing of the travel of the yoke slide,

align the engraved marks of the loop positioning finger

cam and the triangle loop positionig finger cam with the

engraved mark of the cam and looper sleeve after

completing the adjustment of looper so that the engraved

marks are on a straight line. Then temporarily tighten the

screw.

1) Adjust the crosswise travel timing of the yoke slide in the

rotational direction of the triangle loop positioning finger

cam.

When the timing is higher than 58 mm (48 mm), adjust

the timing in the rotational direction of the cam.

And when it is lower than 53 mm (43 mm), adjust in the

reverse rotational direction.

The center of the cam is aligned with the center of the

yoke slide support in the longitudinal position of the cam.

2) Adjust the lengthwise travel timing of the yoke slide in the

rotational direction of the loop positioning finger cam.

For the triangle movement of the yoke slide, it is good for

the yoke slide to go back in a slant line. When the yoke

slide goes back like a swollen line, adjust the cam in the

reverse rotational direction, and when it goes back like a

hollow line inside, adjust the cam in the rotational direction.

3) Adjust the longitudinal position of the yoke slide by moving

the loop positioning finger cam in the lengthwise direction.

™ If the triangle loop positioning finger

cam begins to travel too late, thread

breakage, thread remaining, baloon

stitch, and insufficient tightness of

stitches will result. On the contrary, if

it begins to move too early, the needle

will come in contact with the yoke slide.

™ If the loop positioning finger cam

begins to go back too early, the retreat

of the yoke slide will become like a

swollen line and the looper will hook

the thread twice.

™ On the other hand, if it begins to retreat

too late, its retreat will become like a

hollow line and the needle will come in

contact with the yoke slide.

™ If the longitudinal position of the yoke

slide is improper, the looper will hook

the thread twice or the needle will come

in contact with the yoke slide.

™ Loosen the adjusting nut of the tension post No. 2 and

insert a screwdriver into the tension post No. 2 to adjust

the timing.

The timing of the start of floating is when the thread

tension is lost after passing the thread through the thread

tension No. 2, holding it with fingers and turning the

handwheel by ha

™ If the thread tension is released too

early, thread remaining and/or poor

tightness of stitches will result.

On the other hand, if the timing of

thread tension release is too late,

thread will break.

Looper

Engraved points

Triangle loop

positioning

finger cam

Cam and looper sleeve

Loop positioning finger cam

Yoko slide retreats

like a swollen line.

Yoko slide retreats

like a hollow line.

Screw driver

Timing of start of floating

is when thread tenshon is

lost at the time of needle

bar ascending.

Nut

Adjustment Procedures Results of Improper Adjustment

Page 13

−10 −

(5) Lift and pressure of the button clamp

1) Lift of the button clamp

A Standard : 12 mm

Max. : 9 mm

2) Pressure of the button clamp

Adjust the position of the pressure adjusting nut to

4 to 5 mm.

4 to 5 mm

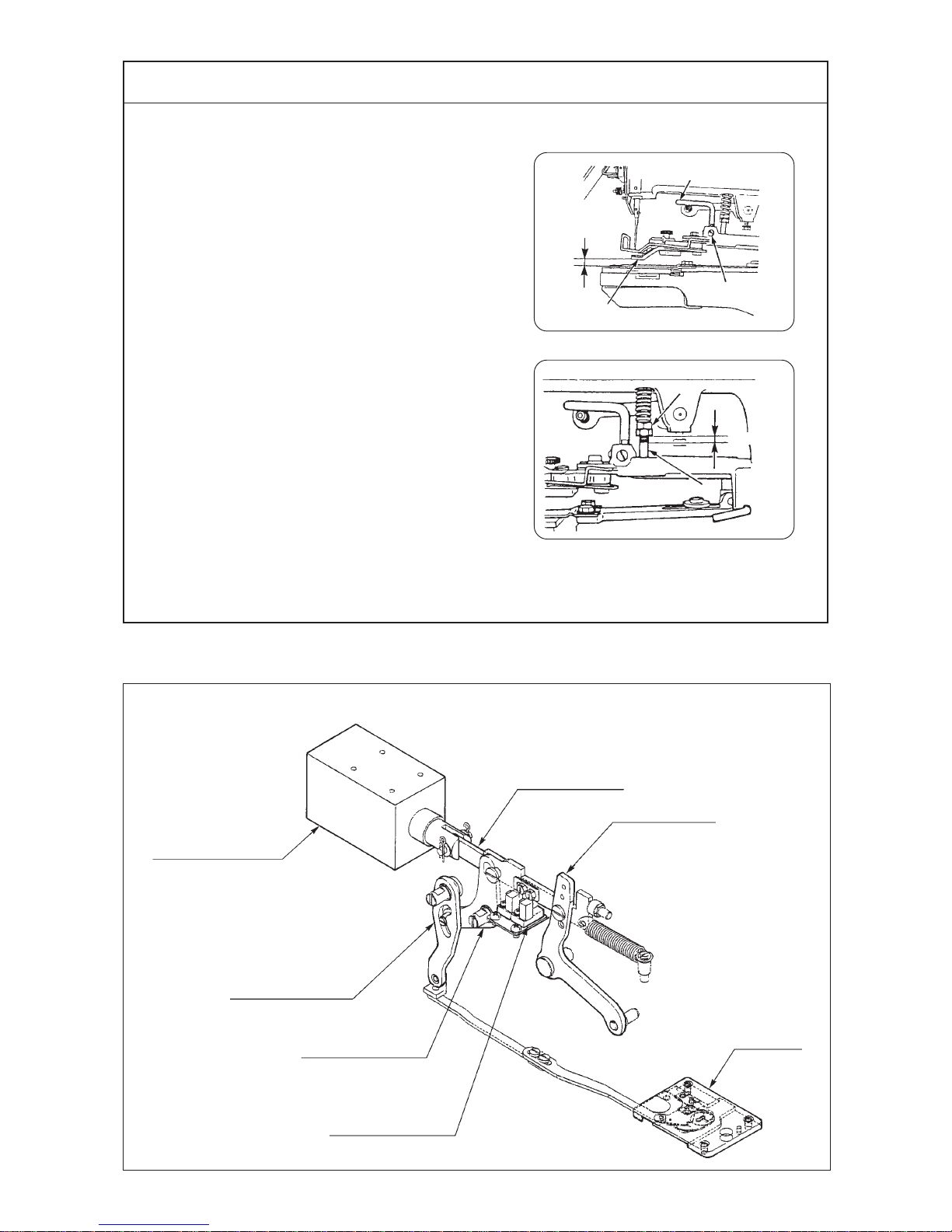

5. ADJUSTMENT OF THE THREAD TRIMMING MECHANISM

(1) The mechanism and the name of each component of the thread trimmer

Throat plate

Presser lifter solenoid

Thread trimming arm

Thread trimming lever

Presser lifter sensor

Presser lifter link

Presser lifter lever

1

2

3

A

1

2

Standard Adjustment

Page 14

−11 −

1) The knife moves in accordance with the lifting of the button

clamp. Therefore, the length of the remaining thread on

the wrong side of a fabric depends upon the height of the

button clamp at which the thread is trimmed.

For the adjustment, insert something of 10 mm thick into

section A and make a state that button clamp jaw levers

1 are lifted .

Loosen screw 2 and tighten screw 2 to fix the button

clamp in the state that lifting hook 3 is pressed to the

lower side.

2)

Make adjustment by turning the pressure adjusting nut 1.

™ Increasing the lifting amount of the

button clamp will increase the length

of the remaining thread. Especially in

case of MB-372, thread tightness

becomes strong at the end of sewing

resulting in thread breakage and thread

slip-off.

™ If the lifting amount of the button clamp

is too low, the length of the remaining

thread will become short resulting in

thread slip-off.

™ If the pressure of the button clamp is

too low, the thread end at the start of

sewing will come out on the wrong side

of the fabric unevenly by 10 to 20 mm.

Adjustment Procedures Results of Improper Adjustment

Page 15

−12 −

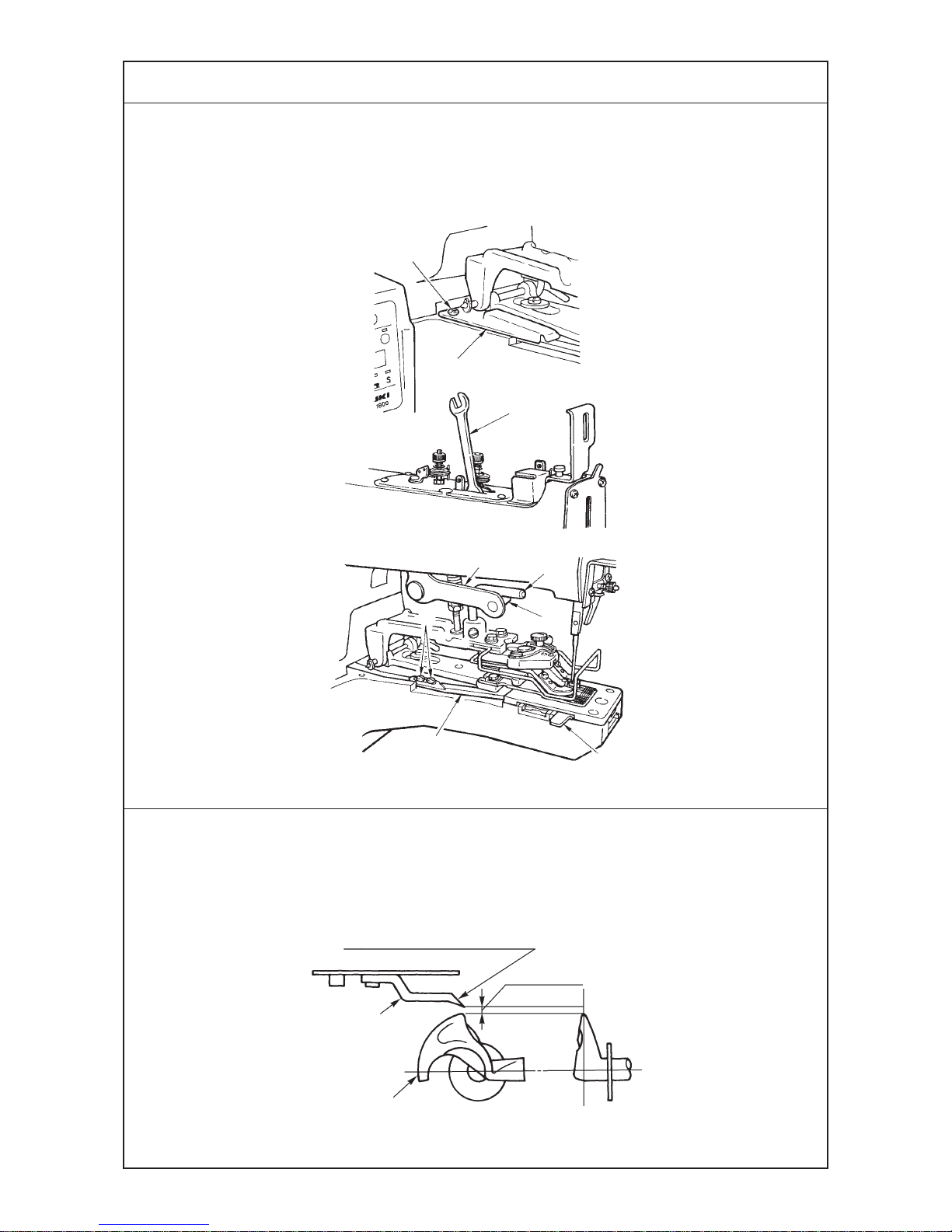

(2) Adjusting the position of the moving knife

Adjust the position so that the distance between the thread trimming connecting plat (front) and the edge of

the slot in the throat plate should be 12 to 13 mm when the button clamp is at its highest position.

(3) Adjusting the height of the thread separating claw of the moving knife

Make adjustment so that the clearance between the thread separating claw 1 and the looper 2 should

become 0.5 to 0.7 mm.

0.5 to 0.7 mm

Top end of thread separation nail

1

2

3

4

5

6

7

8

9

1

2

Standard Adjustment

Page 16

−13 −

1) Remove cover 1 with setscrew 2.

2) In order to place thread trimming connecting plate A 9 to

the most advanced position, lift the presser lifter lever to

such an extent that roller 4 and hook 5 of presser lifter

lever 3 come in contact with each other and insert spanner

6 as shown in the figure on the left.

3) Insert gauge 7 into the end face of the throat plate groove,

loosen screws 8, make the top end of thread trimming

connecting plate A 9 come in contact with gauge 7, and

tighten screws 8.

™ If the thread separating claw is too high,

the claw may fail to separate the thread

on the needle from that on a fabric. As

a result, thread may not be trimmed,

or the both threads are trimmed

together, causing thread slippage from

the needle in the subsequent stitching

start.

™ If this dimension is excessively large,

the thread trimming timing is delayed

and the remaining thread on the wrong

side of cloth is lengthened.

If the dimension is excessively small,

the thread trimming timing

becomes too

early, thread trimming

failure such as

poor tightness of stitche (easily frayed)

at the last stitch, simultaneous thread

trimming of two threads due to the

failure of thread separation, no thread

trimming, etc. is apt to occur.

™ Make adjustment by bending the thread separating claw

1.

Adjustment Procedures Results of Improper Adjustment

Page 17

−14 −

6. PROCEDURES IN DISASSEMBLING AND ASSEMBLING

(1) Name of each component

Feed needle bearing

Needle bar upper bushing

Needle bar clamp

Needle bar lower bushing

Yoke slide

Triangle loop positioning finger cam

Loop

positioning

finger cam

Needle bearing

Thrust bearing

Rocking rod fulcrum shaft

Screw gear

Crank rod hinge screw

Crank rod

Procedures in disassembling and assembling

Page 18

−15 −

Cautions in disassembling Cautions in assembling

Page 19

−16 −

(2) Disassembling the circuit board

1) Cover components

2) Circuit board components

Control box cover

Side cover

POWER circuit boardMAIN circuit board

POWER circuit board

Setscrew 1

MAIN circuit board

Setscrew 3

Circuit board installing plate

Collar

Setscrew 3

Setscrew 2

Procedures in disassembling and assembling

Page 20

−17 −

Disassembling and assembling of the circuit board

Disassembling

1) Remove the control box cover and the side cover.

Remove all connectors connected to the circuit board.

2) Loosen setscrews 1 by 2 to 3 mm.

3) Remove setscrews 2, hold the circuit board installing plate

by hand and draw it out in the direction of the arrow and

you can remove the circuit board in the state that it is

connected to the circuit board installing plate.

4) Remove 8 setscrews 3, and MAIN circuit board and

POWER circuit board can be removed.

Assembling

1) Assemble in the order of MAIN circuit

board, collar, circuit board installing

plate, collar and POWER circuit board.

Cautions in disassembling Cautions in assembling

Page 21

−18 −

(3) Disassembling the machine arm and bed

1) Bed components

2) Arm components

• Rubber base • Crank rod

Stud

Base cover

Rubber base

• Starting spring • Throat plate

Starting lever spring

Setscrew

Bed connecting bolt

Procedures in disassembling and assembling

Page 22

−19 −

Disassembling and assembling the machine arm and bed

Disassembling

(Note) When disassembling the machine arm and bed,

remove the whole set of the circuit board.

For removing procedure of the circit board, see

the item “Disassembling the circuit board” P.16.

1) Tilt the machine head, remove the rubber base, stud and

setscrews, and remove the cover and packing.

2) Remove the screws in the crank rod.

3) Again, directly attach four studs to the machine bed and

place the rubber base.

4) Raise the machine head, loosen four setscrews in the

throat plate and remove the throat plate.

(Note) At this time, if the screws in the thread trimming

connecting plate are removed, it is necessary

to again adjust the position of the moving knife

when assembling.

5) Remove the starting lever spring.

6) Remove the arm/bed connecting bolts and remove the

machine arm while rocking and lifting it. Finally, remove

the knock pins.

Assembling

1) Hold the machine arm and place it on

the surface of the machine bed so that

the thread trimming connecting plate

and the crank

rod are placed in the

predeterminded

positions on the

machine bed.

2) After entering the knock pins and

determining the position, enter the

connecting bolts to fix the machine

arm.

3) Hook the starting lever spring.

4) Install the throat plate.

5) Tilt the sewing machine, remopve the

rubber base and studs, enter the base

cover and packing and again

assemble it. At this time, move the

sensor slit attached to the stepping

motor to the position as shown in the

figure below.

6) Raise the sewing machine and

assemble the circuit board. Refer to

the item of “Circuit board” P.16.

Fig.

Cautions in disassembling Cautions in assembling

Page 23

−20 −

(4) Disassembling the looper shaft

1) Disassembling

2) Screw gear components

3) Adjustment

Screw gear

Looper support screw

Oil seal

Loop positioning finger cam setscrew

Needle bearing

Thrust collar

Looper installing shaft

Triangle loop positioning finger cam

Looper shaft

Thrust collar

Thrust bearing

Needle bearing

Thrust bearing

Loop positioning finger cam

Thrust collar

0.01 to 0.5 mm

43.5 mm

0.01 to 0.5 mm

A

B

Procedures in disassembling and assembling

Page 24

−21 −

Disassembling and assembling the looper shaft

Disassembling

1) Disassemble the machine arm and bed. Refer to the item

“Disassembling the machine arm and bed” P.18.

2) Remove the throat plate and remove the components

related to the yoke slide and the looper.

(Same components as those of MB-373)

3) Loosen the setscrews of the screw gear and tilt the

machine bed.

4) Loosen the setscrews of the thrust collars and draw out

the looper shaft in the direction of the arrow mark (f).

Assembling

1) Fully apply grease to the inside of the

bushing.

(It is not necessary when filling grease

with grease gun or the like from the

grease hole on the surface of the

machine bed after setting up.)

2) Enter two thrust collars and the screw

gear on the looper shaft.

3) Fit the thrust collars at the position

where the dimension from section A

to top end B of looper shaft is 43.5

mm.

4) The thrust collar in the front side is for

prevention of slip-off of the needle

bering. Press the looper shaft

backward (in the direction of the arrow

a) and fix it so that a clearance of 0.1

to 0.5 mm is provided between the

thrust collar and the bushing.

5) Raise the sewing machine and tighten

the screw gear. At this time, adjust the

thrust play of the looper shaft to 0.01

to 0.5 mm.

6) Assemble the components related to

the looper and the yoke slide.

(Same adjustment as that of MB-373)

Cautions in disassembling Cautions in assembling

Page 25

−22 −

(5) Disassembling the driving shaft

• Disassembling

1) For the removing procedure of the circuit board, base cover and crank rod, see P.18.

2) Bushing and stator setscrew

4) Motor cover 5) Driving shaft (asm.) 6) Encoder

7) Stator 8) Rotor 9)

Setscrew and bushing of screw gear

• Assembling

1) Screw gear 4) Rotor 5) Stator

8) Bushing

Motor cover

Ball bearing

Encoder

Driving shaft bushing, left

Ball bearing

Servo-motor

Stator setscrew

Bushing setscrew

Screw gear

Crank rod

Thrust bearing

Driving shaft bushing, right

Ball bearing

4 to 4.2 mm

7.6 to 7.8 mm

Stator setscrew

Stator

Thrust bearing

Screw gear

Hand pulley

Bushing, rightBushing, left

7.7 mm

Procedures in disassembling and assembling

Page 26

−23 −

Disassembling and assembling of the driving shaft

(Note) Do not disassemble the driving shaft except

when it has broken since since the motor is

built in.

Disassembling

** Prepare before disassembling a clean board which is

not affected by magnetism and a piece of clean cloth so

that the rotor is not directly touched by hand.

1) Remove the circuit board. See the item “Circuit board”

P.16.

Tilt the sewing machine, remove the base cover and

remove the setscrews in the crank rod.

2) Loosen setscrews in the bushing, setscrews in the stator

and loosen the hand pulley.

3) Assemble again the studs and the rubber base, and raise

the sewing machine.

4) Remove setscrews in the motor cover and draw out the

whole driving shaft.

5) Put the driving shaft which has been drawn out on a clean

board which is not affected by magnetism.

** Once again pay attention to the following matters before

disassembling the driving shaft which has been drawn

out.

1 Chech whether there is anything such as iron powder

or the like which is attracted by the magnet in the

neighbourhood.

2 Check whether there is any electronic apparatus

which is easily affected by the magnetism.

3 Prepare a piece of clean cloth to wrap the rotor.

4 Wash the hands to make them clean.

6) Loosen setscrews and draw out the encoder together with

the motor cover.

7) Draw out the stator from the driving shaft. Pressing the

driving shaft, slowly draw out the stator with force on the

board since the stator is pulled by the strong magnetism

from the rotor located inside the stator.

(Note) If the force is quickly applied, the stator and the

rotor come off suddenly at the position where

the magnetism is lost. As a result, the parts may

be dropped. So, be careful.

8) Hold the rotor so that it is wrapped in a piece of clean

cloth, loosen the setscrew, and draw it out from the driving

shaft.

Wrap the rotor which has been drawn out in a piece of

cloth.

(Note) The black section of the rotor is a strong

magnet.

If there is a screwdriver or a screw in the

neibourhood, it is attracted to the manet with

force. As a result, it may be broken by the shock.

So, be careful.

9) Loosen the setscrew in the screw gear, and remove

bushings, right and left, thrust bearing and hand pulley.

Assembling

1) Install the screw gear.

(Clearance : 4 to 4.2 mm)

2) Enter the thrust bearing and the

bushings, and install the hand pulley.

3) Install the rotor. Hold it so that the

screw section comes out and install it

so that there is no clearance in the

thrust direction.

4) In this state, enter the rotor in the

machine bed.

Do not take the cloth covering the rotor.

5) Next, enter the stator. Set the direction

of the cord as shown in the figure and

slowly enter the stator while pressing

the driving shaft. When the magnetism

of the rotor works, the stator enters

with force as if it is absorbed. On the

contrary, the driving shaft tries to jump

out. Accordingly, hold the driving shaft

by hand.

6) Install the motor cover.

Keep the setscrew in the encoder held

loosened.

7) Tilt the sewing machine.

8) First, determine the position of the

bushing on the right-hand side.

Fix it so that the dimension from the

end face of the machine bed is 7.7 mm.

9) Next, fix the bushing on the left-hand

side while making the driving shaft

come in contact with the bushing on

the right-hand side.

10) Fix the crank rod.

11) Remove the studs and the rubber base

and again assemble them together

with the base cover and the packing.

At this time, move the sensor slit attached

to to the stepping motor.

For the position of the sensor slit, refer

to the figure on P.19.

Cautions in disassembling Cautions in assembling

Page 27

−24 −

(5) Disassembling the driving shaft

• Assembling and adjusting procedure of the servo-motor

15) Stator setscrew 16) Cord outlet 17) Operation panel

18) Panel display 20) Fixing stator 21) Encoder

23) Encoder setscrew 24) Encoder “0” display

Stator setscrew

Cord outlet

Encoder

installing screw

Driving shaft setscrew

Procedures in disassembling and assembling

Page 28

−25 −

12) Raise the sewing machine and install

the circuit board. Refer to the item

“Circuit board”. P.16.

13) Connect all connectors with the side

cover removedand install the control

box cover.

14) Tilt the sewing machine. Turn the hand

pulley to bring the needle bar to its

lowest position.

15) Check that the stator setscrew is

loosened.

16) Enter the stator cord so that it comes

to the cord outlet. At this time, do not

fix the stator.

17) Pressing three buttons (arrow mark,

“-”, and arrow mark from the top)

located on the left end of the operation

panel, turn ON the power.

18) [no] is displayed in the display section

of the operation panel.

19) In this state, the stator is in the

excitation mode, and the rotor and the

stator are fixed.

At this time, “W” phase and “V” phase

of the rotor are excited.

Excitation duty is 20% and current

value is approximately 4 [A].

20) In this state, turn again the hand pulley

and adjust so that the needle bar is

brought to its lowest position. Fix the

stator in this state. The rotor and the

stator have come to the most proper

position since they are pulling each

other.

21) Raise the sewing machine. Enter the

hexagonal wrench key when the

encoder setscrew is at the position as

shown in the figure.

(Encoder should be temporarily

tightened in the center of the slot.)

22) Pressing the three buttons located on

the left side of the operation panel, turn

ON the power.

23) Loosen the driving shaft setscrews of

the encoder and fix them at the

position where the setscrew No. 1

comes almost just above.

(The position just above overlaps with

the encoder screw. Tighten the screw

at the slighly front side.) Hand tightening

24) Loosen the encoder setscrews, adjust

the position to “0” while observing the

operation panel. Then tighten the

setscrews.

(The value varies –9 to +9.)

20 to 40 kgf

25)Turn OFF the power and install the

side cover.

26) Tighten the stator setscrew.

Cautions in disassembling Cautions in assembling

Page 29

−26 −

(1) Adjusting the starting sensor

7. ADJUSTMENT OF THE SENSORS

(2) Adjusting the presser lifter sensor

Needle

Presser lifter sensor

plate setscrew

Presser lifter

lowering sensor LD1

Presser lifter

lifting sensor LD4

Moving knife

Setscrew

Presser lifter sensor

Thrust collar

Starting lever

Sensor slit

Starting sensor

Sensor slit

Starting sensor plate setscrew

Starting lever

Starting lever

bracket setscrew

Starting

sensor

Starting lever stopper

Starting lever

bracket

1

Standard Adjustment

Page 30

−27 −

(1) Adjusting the starting sensor

1) Loosen the starting sensor plate setscrews.

2) In the state that the starting lever comes in contact with

the starting lever stopper, adjust so that the sensor slit

does not pass the sensor and is as high as the sensor,

and fix the starting sensor plate setscrews. (20 to 30 kgf)

3) For the crosswise direction, loosen the starting lever

bracket setscrews and adjust so that the sensor slit of the

starting lever passes the center of the sensor.

4) When the aforementioned adjustment cannot complete

the adjustment, loosen the sensor slit setscrews and adjust

the position of the sensor slit.

(2) Adjusting the presser lifter sensor

1) Remove the top cover and the control box cover.

2) Tilt the sewing machine.

(When the machine is put in this state, the sewing machine

does not rotate if the starting pedal is depressed by mistake

when adjusting with the power switch ON.)

3) Turn ON the power switch and press the presser lifter

switch, and loosen presser lifter sensor plate setscrews

1 with the presser lifted.

4) When the sewing machine is in the starting possible

position (position where moving knife does not come in

contact with needle), adjust so that LD1 on the MAIN circuit

board goes out, then lights up, and fix the sensor with the

setscrews.

5) Check that LD4 on the MAIN circuit board goes out, then

lights up when the presser is lifted by 2 to 3 mm from the

throat plate with the knot-tying adjusting plate.

Adjustment Procedures Results of Improper Adjustment

Page 31

−28 −

(3) Adjusting the feed origin sensor

Sensor slits are in the same direction.

(4) Adjusting the presser lifter stopper

Sensor slit

Setscrew

Origin sensor

Origin sensor installing plate setscrew

Origin sensor

installing plate

setscrew

Origin

sensor,

left LD2

Origin

sensor,

right LD3

10 mm

Standard Adjustment

Page 32

−29 −

(3) Adjusting the feed origin sensor

1) Remove the hinge screw attached to the machine arm,

enter the sensors in the hole of the feed plate, and fix

them with the screw hole in the bed.

2) Tilt the sewing machine.

3) Turn ON the power switch. (Remove the control box cover.)

4) Loosen the origin sensor installing plate setscrews.

5) Fix the left-hand sensor as observed from the front of the

sewing machine at the position where LD2 on the MAIN

circuit board goes out, then lights up. (30 to 40 kgf)

6) Fix the right-hand sensor as observed from the front of

the sewing machine at the position where LD3 on the MAIN

circuit board goes out, then lights up. (30 to 40 kgf)

(4) Adjusting the presser lifter stopper

1) Loosen the nut and adjust so that the distance from the

end face of the machine arm to the end face of the presser

lifter stopper should be 10 mm.

Adjustment Procedures Results of Improper Adjustment

Page 33

−30 −

8. HOW TO OPERATE AND USE THE MEMORY SWITCH (SERVICE LEVEL)

The operation to adapt the various specifications, more stabilized stitching, etc. can be performed by selecting

or changing the various operations, various timings, time, etc. of the sewing machine.

1) Pressing – /Backward switch and + /Forward switch, turn ON the power, and the display section becomes

as shown below. Then the mode will be the display model of the user level. At this time, all of the stitch

shape selection LED and the item selection LED flash on and off.

2) In this state, keep pressing – /Backward switch and + /Forward switch for 5 seconds. Then the display

section becomes as shown below, and the mode will be the display mode of the service level. At this time,

all of the stitch shape selection LED and the item selection LED flash on and off.

3) When the display mode of the service level appeared, press Set ready switch . Then the display section

becomes as shown below, and the memory switch No. 1 is displayed. The mode becomes the setting mode

of the service level.

At this time, all of the stitch shape selection LED flash on and off and only the pattern No. LED of the item

selection LED lights up.

4) Here, select the memory switch No. desired to be changed by pressing down – /Backward and + /Forward

switches. In this state, press Item selection switch and the display section becomes as shown below

(when the memory switch No. 1 is selected). Then set value corresponding to the memory switch No. is

displayed.

At this time, all of the stitch shape selection LED flash on and off, and the pattern No. LED of the item

selection LED goes out. In addition, when Item selection switch is pressed again, the state of step 3) will

appear.

5) In this state, set the value to the one desired to be changed by pressing down – /Backward and + /Forward

switches.

When the setting has been completed, turn OFF the power.

Display section

(Flashing display)

Display section

(Flashing display)

Display section

(Light-up display)

[Memory switch No. 1]

[Soft-start speed setting]

Display section

(Light-up display)

[Set value of memory switch No. 1]

Page 34

−31 −

(1) Memory switch function table

Unit

x100 [rpm]

x100 [rpm]

x100 [rpm]

x100 [rpm]

x100 [rpm]

x100 [rpm]

0 : Ineffective

1 : Effective

0 : Ineffective

1 : Effective

x10 [deg]

[sec]

x10 [msec]

x10 [msec]

Setting range

4 to 18

4 to 18

4 to 18

4 to 18

4 to 18

4 to 18

0/1

0/1

0 to 40

0 to 10

0 to 20

2 to 20

Setting level

User

User

User

User

User

User

User

User

Service

Service

Service

Service

Setting

initial value

18

18

18

18

18

18

1

0

18

5

5

5

Memory

switch No.

1

2

3

4

5

6

7

8

30

31

32

33

Soft start speed setting

(1st stitch at the sewing start)

Soft start speed setting

(2nd stitch at the sewing start)

Soft start speed setting

(3rd stitch at the sewing start)

Soft start speed setting

(1st stitch at the sewing start after

trimming crossover thread)

Soft start speed setting

(2nd stitch at the sewing start after

trimming crossover thread)

Soft start speed setting

(3rd stitch at the sewing start after

trimming crossover thread)

Knot-tying function selection

Wiper function selection

Knot-tying solenoid ON timing angle setting

(When memory switch No. 7, knot-tying

function is selected)

Knot-tying solenoid OFF timing time setting

(When memory switch No. 7, knot-tying

function is selected)

Wiper solenoid ON timing time setting

(When memory switch No. 8, wiper

function is selected)

Wiper solenoid ON hold time setting

(When memory switch No. 8, wiper

function is selected)

Speed of 1st stitch at the sewing start can be limited.

Speed of 2nd stitch at the sewing start can be limited.

Speed of 3rd stitch at the sewing start can be limited.

Speed of 1st stitch at the sewing start after trimming crossover thread can be

limited.

Speed of 2nd stitch at the sewing start after trimming crossover thread can

be limited.

Speed of 3rd stitch at the sewing start after trimming crossover thread can be

limited.

Drawing out thread at the sewing end is stopped and thread can be knotted.

When the without-crossover thread device is mounted, needle thread after thread

trimming can be wiped. In case the without-crossover thread device is mounted and

the pattern without crossover thread is selected at setting “0” : ineffective, needle thread

is automatically wiped only after trimming crossover thread (medium thread trimming).

Knot-tying solenoid ON timing angle (upper dead point of one stitch before

the last stitch is regarded as 0˚) can be changed.

Period of time of

Knot-tying solenoid OFF timing can be changed.

Period of time from thread trimming to wiper solenoid ON timing can be changed.

Period of holding time from wiper solenoid ON can be changed.

As the number is increased, the operating time of wiper becomes longer.

Setting item

Contents of setting

Page 35

−32 −

Unit

x10 [deg]

x10 [msec]

–

[msec]

–

x10 [msec]

Pulse

Pulse

x10 [msec]

–

[deg]

0 : Hole position

1 : Medium position

Setting range

0 to 40

0 to 20

0 to 10

30 to 90

0 to 10

10 to 40

-9 to 9

-9 to 9

5 to 20

0 to 10

-9 to 9

0/1

Setting level

Service

Service

Service

Service

Service

Service

Service

Service

Service

Service

Service

Service

Setting

initial value

20

0

6

45

6

24

0

0

10

6

0

1

Memory

switch No.

34

35

36

37

38

39

40

41

44

45

46

47

Thread trimming operation setting (1)

Thread trimming (presser lifting) solenoid ON timing

time setting

Presser lifting holding force setting

Thread trimming operation setting (2)

[Crossover thread trimming when without crossover thread

pattern is selected (medium thread trimming), or thread

trimming when memory switch No. 8, wiper function is selected.]

Thread trimming operation setting (3)

[Crossover thread trimming when without crossover thread

pattern is selected (medium thread trimming), or thread

trimming when memory switch No. 8, wiper function is selected.]

Thread trimming operation setting (4)

[Crossover thread trimming when without crossover thread

pattern is selected (medium thread trimming), or thread

trimming when memory switch No. 8, wiper function is selected.]

Thread trimming position setting (1)

Thread trimming position setting (2)

Thread trimming operation setting (1) [For BR]

Thread trimming operation setting (2) [For BR]

Feed pulse delivery timing setting

Thread trimming position function selection

Thread trimming (presser lifting) solenoid ON timing angle (upper

dead point of one stitch before the last stitch is regarded as 0˚)

can be changed. As the number is increased, the thread trimming

timing is delayed. As the number is decreased, thread trimmer

may interfere with needle. So, be careful.

Do not change.

Holding force when the presser goes up can be changed.

As the number is increased, the holding force is strengthened.

Thread trimming operation can be adjusted.

As the number is increased, operating force of thread trimming

is strengthened. However, the presser foot may rise. So, be

careful.

Do not change.

Do not change.

Thread trimming position can be adjusted. Thread trimming position is

determined by the set value of memory switch No. 40, thread trimming

position setting (1) or No. 41, thread trimming position setting (2).

Thread trimming position can be adjusted. Thread trimming position is

determined by the set value of memory switch No. 40, thread trimming

position setting (1) or No. 41, thread trimming position setting (2).

Thread trimming operation can be adjusted. As the number is

increased, operating force of thread trimming is strengthened.

Do not change.

Do not change.

Thread trimming position can be selected.

Setting item

Contents of setting

Page 36

−33 −

9. HOW TO OPERATE AND USE THE INPUT CHECK MODE FUNCTION

Troubles, defects, etc. of the printed circuit boards and elements can be checked by displaying the input state

of the various sensors and switches.

1) Pressing Set ready switch and Reset switch, turn ON the power. (“Function No. 1” is displayed.)

2) When Item selection switch is pressed down, the state of input assigned to “Function No. 1” is displayed.

3) In this state, when the feed mechanism, detecting plate, etc. are moved, the display changes in accordance

with the input state of the origin sensor. In this case, when the display is “1”, the origin sensor is in the input

state of OFF and when the display is “0”, the origin sensor is in the input state of ON.

4) When performing checking of other function No, press down Item selection switch again and the display

becomes the display state of step 1). In this state, select the function No. you desire to check by ptressing

down – /Backward and + /Forward switches and perform the operation of step 2).

Display section

(Flashing display)

Display section

(Light-up display)

[Example of display]

(Caution) Input of the origin sensor of feed stepping motor is assigned to “Function No. 1”. In this case,

left-hand side (10th digit) of the display section, as observed from the front of the sewing

machine, is the input state of the origin sensor of left-hand side stepping motor, and righthand side (1st digit) of the display section, as observed from the front of the sewing machine,

is the input state of the origin sensor of right-hand side stepping motor.

Page 37

−34 −

(1) INPUT CHECK CORRESPONDENCE TABLE

Function

No.

Left-hand side of display section

(10th digit)

Origin detection sensor (Left stepping motor)

: ON, : OFF [CN20-2]

Presser lifting detection sensor

: ON, : OFF [CN30-2]

Pedal start SW

: ON, : OFF [CN22-2]

STMG (Input signal for BR)

: ON, : OFF [CN24-2]

Pedal start SW

: ON, : OFF [CN28-2]

Not used.

[CN27-2]

Operation panel : Reset SW

: ON, : OFF [CN25-17]

Operation panel : − /Backward SW

: ON, : OFF [CN25-19]

Operation panel : Set ready SW

: ON, : OFF [CN25-22]

Not used.

[CN25-24]

SW1-1 (DIP SW)

: ON, : OFF

SW1-3 (DIP SW)

: ON, : OFF

SW1-5 (DIP SW)

: ON, : OFF

SW1-7 (DIP SW)

: ON, : OFF

Right-hand side of display section

(1st digit)

Origin detection sensor (Right stepping motor)

: ON, : OFF [CN21-2]

Presser lowering detection sensor

: ON, : OFF [CN30-5]

Not used.

[CN23-2]

WMG (Input signal for BR)

: ON, : OFF [CN24-4]

Pedal presser SW

: ON, : OFF [CN28-5]

Not used.

[CN27-5]

Operation panel : Stitch shape selection SW

: ON, : OFF [CN25-18]

Operation panel : + /Forward SW

: ON, : OFF [CN25-20]

Operation panel : Presser SW

: ON, : OFF [CN25-23]

Overheat monitoring sensor

: ON, : OFF [CN29-1]

SW1-2 (DIP SW)

: ON, : OFF

SW1-4 (DIP SW)

: ON, : OFF

SW1-6 (DIP SW)

: ON, : OFF

SW1-8 (DIP SW)

: ON, : OFF

Page 38

−35 −

10. HOW TO OPERATE AND USE THE ALL CLEAR FUNCTION

All of the data (size, number of stitches, etc.) of each pattern No. and the set value of the memory switch can be

cleared and returned to the set value at the time of delivery. However, when this operation is performed, all the

up-to-date data are deleted. So, be careful

1) Pressing Presser lifting switch and Reset switch, turn ON the power and the display section becomes as

shown below.

2) In this state, press Reset switch and the display section becomes as shown below. Then data deletion

operation starts.

3) When the data deletion operation has been completed, the display section becomes as shown below, and

the flashing is changed to light-up state. At this time, turn ON the power again after turning OFF the power,

and the set value is returned to the one at the time of delivery.

Display section

(Flashing display)

Display section

(Light-up display)

Display section

(Light-up display)

Page 39

−36 −

11. PARTS TO BE GREASESD

Apply or fill up grease to the following parts.

Crank rod hinge screw

Rocking rod fulcrum shaft

Needle bar upper bushing

Needle bar clamp

Needle bar lower bushing

Yoke slide

Triangle cam

Loop positioning

finger cam

Needle bearing

Thrust bearing

Screw gear

Crank rod

Feed needle bearing

Page 40

−37 −

12. ERROR LIST

Error No.

01

02

03

04

05

06

07

09

10

11

12

13

16

17

18

19

30

31

32

33

H

EE

Item

Trouble of sewing data

Trouble of 24V voltage

Dislocation of needle up-position

Dislocation of presser down detection

Trouble of presser solenoid

Trouble of servo encoder

Servo motor lock

System trouble

Trouble of stepping motor origin 1

Trouble of stepping motor origin 2

Overload of servo motor

Overload of servo motor

Trouble of nember of revolution

Trouble of servo voltage

Trouble of temperature

Overcurrent of servo motor

Trouble of external ROM

Trouble of external ROM

Trouble of external ROM

Trouble of external ROM

Temperature rise

Trouble of memory

Description

Pattern has not been inputted in the program of cycle stitching.

Trouble of power voltage, trouble of load on main shaft of machine head, trouble of

PWR circuit board

Trouble of load on main shaft of machine head, trouble of encoder,or loosenes of

encoder fixing screw

Foreign materials under presser, dislocation of presser down sensor, or defective

down sensor

Defective solenoid, dislocation of presser up sensor, or defective up sensor

Defective encoder or improper fixing of encoder

Trouble of load on main shaft of machine head, or defective servo motor

Defective control circuit board or defective program ROM

Trouble of origin sensor 1, dislocation of sensor, or trouble of load on stepping

motor 1 (left side of operator)

Trouble of origin sensor 2, dislocation of sensor, or trouble of load on stepping

motor 2 (right side of operator)

Trouble of load on main shaft of machine head (short time), or defective servo

motor

Trouble of load on main shaft of machine head (long time), or defective servo

motor

Defective control circuit board, defective encoder, or defective servo motor

Defective PWR circuit board

Cleaning of fan filter, excessive load on main shaft, or trouble of control circuit

board (high temperature of pre-driver)

Defective servo motor, or improper timing of encoder

ROM formatting error

Number of stitches (99) is over.

Moving amount of one stitch (lengthwise : 6.5 mm, crosswise : 10 mm) is over.

Outside of sewing possible area

Cleaning of fan filter, defective fan operation, or defective control circuit board

(temperature detection)

Defective control circuit board (EEPROM)

Error LED located on the left side of the reset switch flashes on and off or lights up when an error

occurs. When the LED lights up, the setting state will be made by pressing the reset switch and the

error will be released. Error No. will be displayed in the display section A.

(Note) Error Nos. 01, 03, 04, 31, 32, and 33 return to the state before the occurrence of the error by pressing

the reset switch.

Page 41

−38 −

13. CHANGE-OVER OF THE POWER SOURCE VOLTAGE

This sewing machine has been connected to the power source of 200V to 240V in the state of delivery from the

factory.

When using the machine with the power source of 100V to 120V, perform the work of change-over of voltage in

the order of the procedures below.

1) Remove the cover in the rear of the sewing machine and replace from 200V to 100V the connector of

connector No. CN32 (blue 2-pin) on the right side PWR circuit board as observed from the front side.

See the figure below.

2) Install the cover.

3) Connect the power plug to the receptacle.

4) Completion of the work.

(Caution)1. Perform the change-over after confirming the voltage of the place where the sewing machine

is set and the voltage in the sewing machine.

2. Do not connect the power plug to the receptacle.

CN32 connector section

Page 42

−39 −

14. CAUSE OF TROUBLES AND THE CORRECTIVE MEASURES

(1) Thread trimming troubles and the corrective measures

Troubles Causes Corrective measures

Correct the position of the moving knife

at the time of completion of the stop

motion.

Refer to the item “5. (2) Adjusting the

position of the moving knife”.

2. Both the thread on the

needle and that on the

wrong side of a fabric are

trimmed.

The trimming timing of the moving

knife is bad.

1. Thread is not trimmed.

The thread separating claw of the

moving knife fails to separate the

thread on a fabric from that on the

needle.

Adjust the position of the moving knife.

Refer to the item “5. (2) Adjusting the

position of the moving knife”.

The needle does not come down

into the correct point of a button

hole.

Make readjustment by the button

clamp holder.

The final stitch is skipped. Correct the position on the looper.

Refer to the item “4. (2) Positioning the

needle and the looper”.

The height of the thread separating

claw of the moving knife is not

correct.

Correct the height of the thread

separating claw of the moving knife.

Refer to the item “5. (3) Adjusting the

height of the thread separating claw

of the moving knife”.

Improper position of the moving

knife

3. The trimmed thread on the

wrong side of a fabric is too

long.

Improper height of the thread

separating claw of the moving

knife.

Correct the height of the thread

separating claw of the moving knife.

Refer to the item “5. (3) Adjusting the

height of the thread separating claw

of the moving knife”.

The lift of the button clamp is too

large.

Correct the position of the moving

knife.

Refer to the item “5. (2) Adjusting the

position of the moving knife”.

Readjust the lift to 10 mm.

Refer to the item “4. (5) Lift and

pressure of the button clamp”.

(Caution) Adjust the position of the moving knife within a range of 10 to 15 mm.

If the position of the moving knife is readjusted to less than 10 mm, the thread separating claw comes in

contact with the counter knife or the yoke slide insert, resulting in damaged thread separating claw of

the moving knife.

On the other hand, if it is readjusted to more than 15 mm, the thread separating claw may come in

contact with the positioning finger yoke slide while the machine is running, also causing breakage of

the thread separating claw.

Page 43

−40 −

Troubles Causes Corrective measures

(2) Cause of troubles and the corrective measures for MB-1800

1. The machine fails to sew at

the start of sewing.

Length of remaining thread is too

short.

Adjust the thread adjusting thread

guide.

Speed is fast. Use the soft-start function.

The needle is too thick for the

diameter of the hole in the button.

Replace the needle with a thinner one.

The thread tension post No. 2 fails

to release the thread at correct

timing.

Make the thread releasing timing

slightly earlier.

The needle does not enter the

center of the holes in the button.

Adjust the position of the button clamp

jaw lever holder.

2. Thread breakage

The needle does not enter the

center of the holes in the button.

Adjust athe position of the button

clamp jaw lever holder.

The thread tension post No. 2 fails

to release the thread at correct

timing.

Make the thread releasing timing

slightly earlier.

The thread tension post No. 2 does

not give sufficient tension.

Increase the tension of the thread

tension post No. 2.

3.

Buttons are not sewn tightly.

The last stitch skips. Adjust the looper.

The moving knife does not separate

the thread on the fabric with its

thread separating claw.

Adjust the position of the moving knife.

The needle does not enter the

center of the holes in the button.

Adjust the position of the button clamp

jaw lever holder.

4. Thread cannot be trimmed.

The moving knife does not separate

the thread on the fabric with its

thread separating claw.

Adjust the height of the thread

separating claw.

The moving knife does not separate

the thread on the fabric with its

thread separating claw.

Adjust the position of the moving knife.

The moving knife separation nail is

too high or too low.

Adjust the height of the thread

separating claw.

5. Needle thread is cut in two

places.

Page 44

−41 −

15. CIRCUIT BOARD DIAGRAM

(1) MAIN circuit board

Page 45

−42 −

(2) PWR circuit board

(3) PANEL circuit board

Page 46

−43 −

16. BLOCK DIAGRAM 1/2

PANEL pcb asm.

CN41

26P

3

Feed 1

stepping motor

!2

!3

Feed 2

stepping motor

!4

Servo-motor

!5

Servo-encoder

2

PWR pcbasm.

8

!7

!6

6P

CN17

15P

CN19

4P

7P

CN18

CN24

6P

CN26

6P

CN16

26P

CN25

Interface for BR

Serial interface

6P

CN11

2P

CN29

6P

CN33

2P

CN35

Control box power cord asm.

6P

CN26

Power switch

Power cord asm.

2P

CN32

7

Input change-over cord asm.

(Change-over 100V/200V)

5

Temperature

sensor cord asm.

1

MAIN pcb A asm.

!1

Presser sensor cord asm.

!0

Starting cord asm.

CN27

6P

CN28

9P

CN23

3P

CN22

3P

CN152PCN14

2P

CN12

2P

CN13

2P

CN203PCN21

3P

CN30

6P

6

Thread tension relay cord asm.

CN58

2P

2P

3P

3P3P 3P3P

CN51

CN52

CN53

CN54

CN55

9

Feed origin cord asm.

@8

Pedal switch asm.

@

9

Pedal cord asm.

3P

CN563PCN57

Presser lifter

solenoid asm.

Knot-tying

solenoid asm.

Wiper solenoid

asm.

Thread tension

solenoid asm.

Feed 1 origin

sensor

Feed 2 origin

sensor

Starting switch

Presser lifting

sensor

Presser

lowering sensor

Fan asm.

Presser switch

Start switch

!8

!9

@0

@1

@2

@3

@4@5

@

6

@7

#0

#1

Page 47

−44 −

Block diagram 2/2

Sensor connection diagram

Solenoid circuit diagram

Power connection diagram

Power connection diagram

Sensor connection diagram

Sensor connection diagram

Sensor connection diagram

Motor circuit diagram

Motor circuit diagram

Motor circuit diagram

Encoder circuit diagram

Power connection diagram

Power connection diagram

Solenoid circuit diagram

Solenoid circuit diagram

Solenoid circuit diagram

Solenoid circuit diagram

Sensor connection diagram

Sensor connection diagram

Sensor connection diagram

Sensor connection diagram

Sensor connection diagram

Power connection diagram

Sensor connection diagram

Sensor connection diagram

Sensor connection diagram

Sensor connection diagram

MAIN circuit board A asm.

PWR circuit board asm.

PANEL circuit board asm.

Temperature sensor cord asm.

Thread tension relay cord asm.

Input change-over cord asm.

Control box power cord asm.

Feed origin cord asm.

Starting cord asm.

Presser sensor cord asm.

Feed 1 stepping motor

Feed 2 stepping motor

Servo-motor

Servo-encoder

Power switch

Power cord asm.

Presser lifter solenoid asm.

Knot-tying solenoid asm.

Wiper solenoid asm.

Thread tension solenoid asm.

Feed 1 origin sensor

Feed 2 origin sensor

Starting switch

Presser lifting sensor

Presser lowering sensor

Fan asm.

Pedal switch asm.

Pedal cord asm.

Presser switch

Start switch

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

M8601630AA0

M86046300A0

M86026300A0

M85026300A0

M85196300A0

M85236000A0

M85046300A0

M85056300A0

M85066300A0

M85076300A0

M8901630000

M8901630000

M8903630000

M8904630000

HA004250000

M90245800A0

M85086300A0

M85096300B0

M85176300A0

M85186300A0

HD00057000A

HD00057000A

HD00057000A

HD000570000

HD000570000

M85405900A0

M85205900A0

M90115900A0A

HD001930000

HD001930000

No.

Part No. Name of part Circuit diagram

Page 48

−45 −

17. CONNECTION DIAGRAM AND CIRCUIT DIAGRAM

(1) Power connection diagram

PE

1 1

2 2

CN31

V

W

FG

U

Power cord asm.

Green

Red

White

Black

Power SW

L1T1L2T2L3

T3

Light blue

Brown

Green/Yellow

Control box power cord asm.

FG1

FG2

AC IN

AC IN

1 1

2 2

1 1

2 2

White

White

CN32 (100V)

100V

RTN

CN32 (200V)

NC

NC

PWR pcb asm.

MAIN pcb A asm.

1 1

2 2

3 3

FAN asm.

N.C

12345

6

N.C

N.C

N.C

N.C

N.C

CN34

+15V 1

+15V 1RET

+15V 2

+15V 2RET

+15V 3

+15V 3RET

1 1

2 2

3 3

4 4

5 5

6 6

1 1

2 2

3 3

4 4

5 5

6 6

+24V

+24V

+5V

PGND

PGND

GND

CN11CN33

+24V

+24V

+5V

PGND

PGND

GND

DC power cord asm.

Orange

Orange

Red

White

White

White

CN23

+24V

GND

N.C

Black

Red

Page 49

−46 −

(2) Sensor connection diagram

OPTIONAL

123456789

+5V

PRESSER

GND

+5V

START

GND

+5V

N.C

GND

CN28

BLUE

BROWN

BLACK

BLUE

BROWN

BLACK

123

456

+5V

FEED 1 ORIGIN

GND

123

CN20

BLUE

BROWN

BLACK

+5V

FEED 2 ORIGIN

GND

123

CN21

+5V

STARTING

GND

123

CN22

+5V

PRESSER LIFT

GND