Page 1

Swing Type Gathering Device F Q R

A-1

/'f9

-1-:IV.t~C.

fJ

~iii

u

S159•S160•

PARTS LI

1.

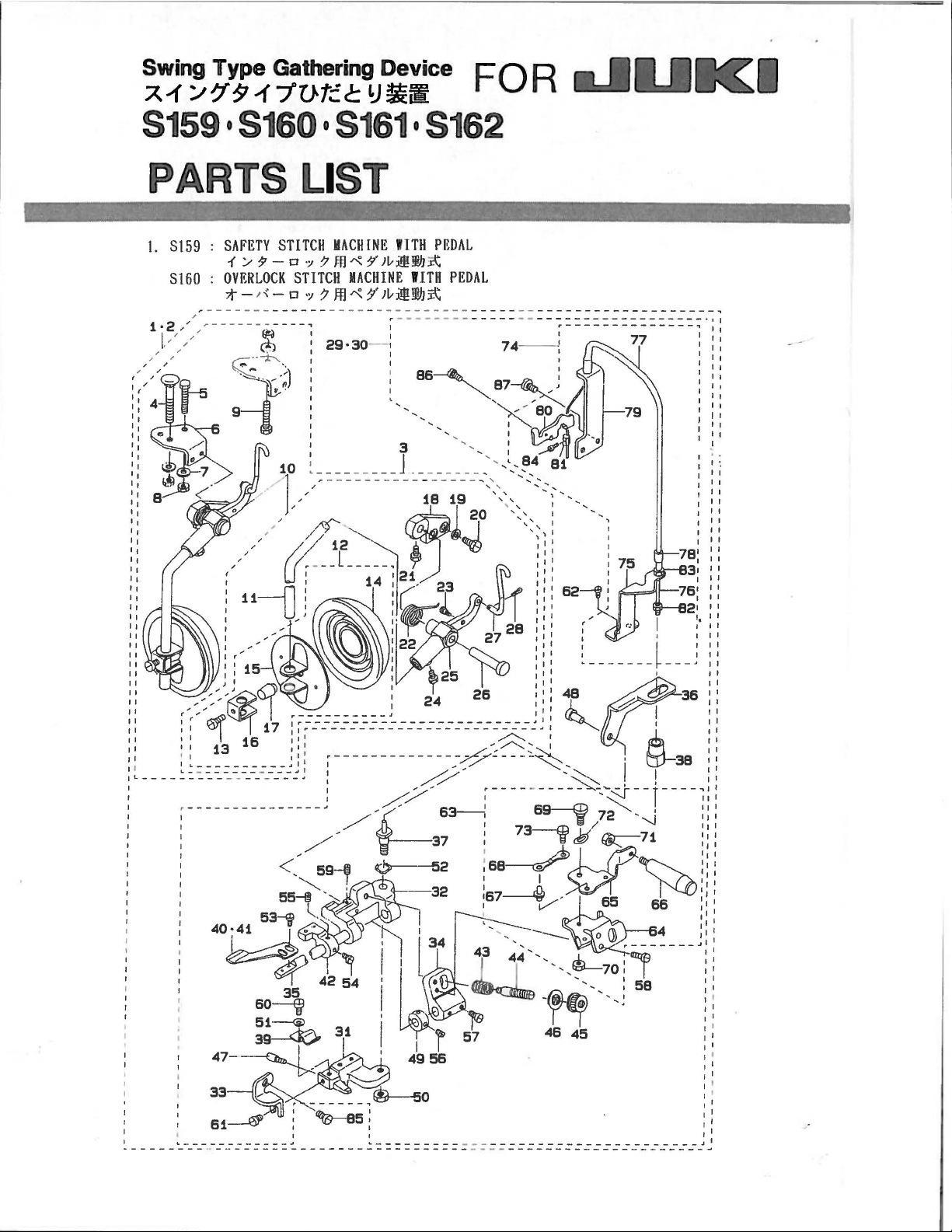

S159

S160

SAFETY

1

OVERLOCK

:;t-

:.--

7-

r

STITCH

a

STITCH

~-

Cl

·"/

..

, 7 ffl.r{ 7'

7 ffl

S161

ST

MACHINE

""-

7'

Jv:i!t!!IYJJ\:

MACHINE

Jv:i!t!ll!h:r\

I

- 1

I

29·30

•S162

WITH

PEDAL

liTH

PEDAL

33

~5:

I

---------~----------------------------

•------------•

~0

I

1 I

•---------

---

----

----------------------'

---------------------~

Page 2

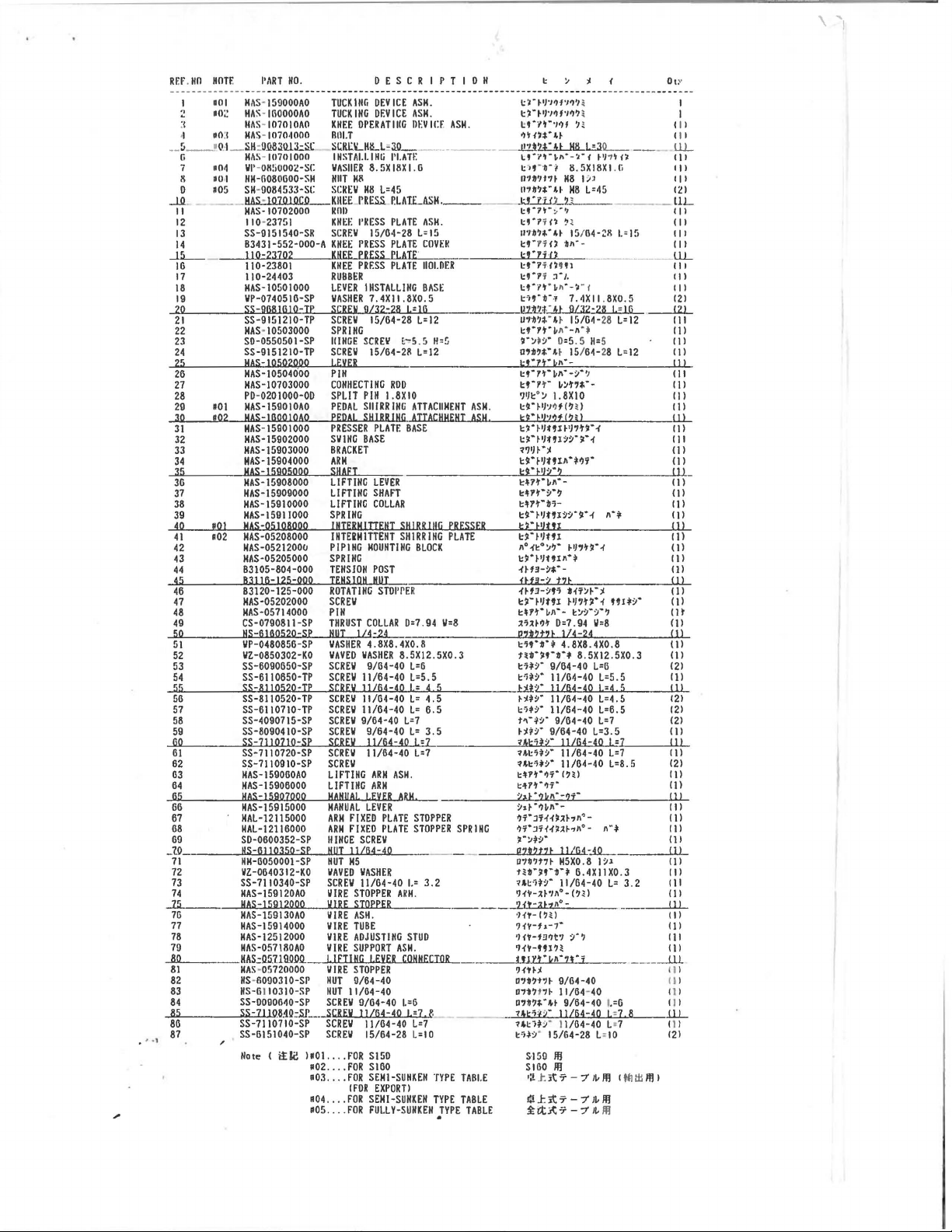

RF.F. HO

HOTf.

101

"o

::

:t

•I

10

--~--IQ:I_

.J.O....

II

12

13

14

..lL........ 110·23702

16

17

18

19

20

21

22

23

24

zr,

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55 SS·8l!0520·TP

56

57

58

59

60

61

62

63

64

Gr,

66

67

68

69

_1.0

71

72

73

74

75

76

77

78

79

80

81

82

83

84

ar;

~~---~SS~-~7~1

86

87

. ,

~ '

:1

G

7

10~

H

All

I

0 105 SH-

_

WOI

p02

pOl

102

,

l'ART HO.

HAS·I59000AO

HA

S- I

uOOOOAO

HAS·I07010AO

HAS·I07MOOO

:iH:.Uli8:iQ13.:..

HAS·I070IOOO INS

WI'-OH!i0002·SC

HH-6080600-SH

90114533-SC

HAS·I07010CO

HAS

- 10702000

110·23751

SS

-9151540-

B3431·552·000·A

110·23801

110·24403

HAS-10501000

WP-0740516-SP

SS-9681610-TP

SS-9151210-TP

HAS

· I0503000

S0

-0550501-SP

SS-9151210-TP

HAS-10502000 I EYER

HAS-10504000

HAS-10703000

P0

-0201000·00

HAS·159010AO

HAS·!OOO!OAO

MAS-15901000

HAS-15902000

HAS-15903000

MAS-15904000

HAS

-15905000

MAS-15908000

HAS-15909000

HAS-15910000

HAS-15011000

HAS-051

08000

HAS-05208000

HAS-0521200~

HAS-05205000

B3105-804·000

83116-125·000

B3120·125·000

HAS-05202000

HAS-05714000

CS-0790811-SP

HS-61

60520-SP

WP-0480856-SP

WZ-0850302-KO

SS-6090650-SP

SS-6110650-TP

SS-8110520-TP

SS-6110710-TP

SS-4090715-SP

SS-8090410-SP

SS-7110710-SP

SS·7l10720·SP

SS-7110910-SP

HAS·159060AO

HAS-15906000

HAS-15907000

MAS-15915000

HAL-12115000

MAL-12116000

S0-0600352-SP

NS·6l10350·SP

HK-6050001-SP

WZ-0640312-KO

SS-7110340KAS·159120AO

HAS-15912000

HAS·159130AO

HAS-15914000

KAS-12512000

HAS·057180AO

KAS.:ll.5.1l9.0.0.Q.

KAS

-05720000

NS

-6090310-SP

NS-6

110310-

SS-0000640-SP

!!-J!0

.8.40:.sJ' .....

SS-7110710-SP

SS-6151040-SP

Note I

itli!

TUCKING

TUCK I HG

KHF.E

Rlli.T

~t;IU:~HILL=:!ll_

WASIIER

HilT

SCKEW

KIIELPRESS.

KOil

KNEE !'kESS

SK

SCRF.W

KHEE

KNEE

KHEE

RUBBER

LEVER

WASHER 7.4XI1.8X0

SCREW

SCREW

SPRING

IIIHGE

SCREW

PIH

CONHECTI

SPLIT

PEDAL

PEDAl

PRESSER

SWING

BRACKET

ARM

SHAFT

LIFTING

LIFTING

LIFTING

SPRING

!HTERHIUEHT

INTERMITTENT

PIPING

SPRING

TENSION

TENSION

ROTATING

SCREW

PIH

THRUST

HUT

WASHER

WAVED

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

LIFTING

LIFTING

HAHUAI

MANUAL

ARM

ARM

HINGE

NUT

HUT

WAVED

SP

SCREW

WIRE

WIRE

WIRE

WIRE

WIRE

WIRE

llfiiH!i

WIRE

HUT

SP

HUT

SCREW

~CKEW

SCREW

SCREW

1101

....

102

....

103

....

104

....

105

....

DESCRIPTION

DEVICE

OF.V

ICE

OPERATIIIG

TAI.I.IHli

I'I.ATI:

8.5XI8XI.6

H8

H8

L=45

P.LJ\tLASH. ____

PLATE

15/6-1·28

PRESS

PLATE

PRESLlliTE

PRESS

PLATE

INSTALLING

0/32·28 I =16

15/64·28 L=l2

SCRE~

15/64·28

NG

ROO

PIN

1.8XIO

SIIIRRING

SHIRRING

PLATF.

BASE

LEVER

SHAFT

COLLAR

SHIRR I UG

SHIRRING

HOUHTIHG

POST

HilT

STOI'PER

COLLAR

1/4.:.2.4.__

4.8X8 .

4X0

WASHER

8.5Xt2.

9/64·40

11/64·40

11/64-40

11/64·40

11/64·40

9/64·40

9/64·40

11/64-10 I

11/64·40

ARH

ASH

ARH

IEYER

A~

LEVER

FIXED

PLATE

FIXED

PLATE

SCREW

!1164·40

H5

WASHER

11/64·40

STOPPER

ARH

STOPPER

ASH

.

TUBE

ADJUSTING

SUPPORT

ASH

I.EYER

STOPPER

9/64-40

11/64-40

9/64·40 1.=6

11/64-40

11/64·40

15/64·28

FOR

St5D

fOR

SIGO

fOR

SEHI·SUHKEH

!FOR

EXPORT!

fOR

SEHI·SUNXEN

FOR

FULLY-SUNKEN

ASH

.

ASH

.

Of.V

II:

f.

ASH.

___ . _____

ASH.

L=15

COH:K

IIOI.OF.R

BASE

.5

E:-

5. 5

H=~

L=12

ATTACIIHEHT

ATTACHMENT

BASE

PRESSER

PLATE

BLOCK

0=7.

94

W=8

.8

5X0

.3

L=6

L=5.5

1.=

4 5

L=

4.5

L=

6.5

L=7

L=

3. 5

=7

L=7

.

STOPPER

STOPPER

1.=

3.2

.

STUD

.

CONNECTOR

L=7

e

L=7

L=IO

TYPE

TYPE

}YPE

ASH

ASH

SPRING

___

TABI.E

TABLE

TABLE

t~"f1)'11f'J1'1

t)"

f1)'J1f'J1~

t9"1t"·J~f

1t

J!1!tl.:ll

u·H-~n·-~-~

t-,•t·i

ll '

l~'lt?t

n'~~:l--~f

.J;£.lif,L~L__

t9"1t">"'l

t9

ll'l"b~:l-"~f

t~"

t!"li()

tt"7HH'I

t9"

t,·-w~n·-~

t'~~·t·.,

1!2:1J.:tf:.:M....JlLJ.2·28

u't~~.-~

t•·n·~n··n

~-~·~·

o'b't.".l.t

WWW-

t,·n·~~~·-,·•

t,·

2'Jt0:J 1.8XIO

.

~9-~1J'J~t(?~l

Wt

t~·~•JttlPJ7H'f

t~"f'Jf'l~,-~-f

~?1Jt"~

t9"

t9"

tn~·~~~--

tH~"""?

tH~"H·

t9"f'JHI"~"9"f

t)"

t~"f')Hl

n•o(t.:J?" t•

~)'t'Jttln"*

.fH3-~t.·-

1tf3·:i'

f~fll-~f;

t)"t'Jt9l

tHt"~A--t~~-,.

~Hf~~

P?t2tn

t'f

tU")t·~·*

tH:i'"

tHV

ill?"

f~f~·

t'i*""

t~·~:;.·

t~?:i'"

•&tjW

~4tH~~ol.tH:i'"

tH~·~7·

tHt"~f"

:ht'

:;..~-~~~~--

~T"Jf.ff)~~·n•-

~'i"J'iH)~f•n•-

)"~1ll"

PUU1f

D"lt~t?f

t>t")t"~"*

~&tH:i'"

?f1'-~f'ln•-tnl

?it-~f1n•-

H'·I2

?f'f·f1·7"

?1,·f3~t7

?1'f-"l2<

tuWWW'i

HU-"

D"11?t7~

D"11?

D'/~2:1-

_

~&tH:)"

UtH~-

tH

Sl50

Sl60

•!!.l:

(!J:il:

~tt:.<:'i'-?'/1.

, Il l

O:t."

~f

...

llll.J.=.J.

l!.5XI8XI.I;

H8

HB

"1i

0 "

15/64-~

YT

0

tn·

1i

J"/.

7.4XII .8X0.5

f

15/64·28

0

=5.5 H=

15/6~·

n ·

~~~'*"-

1

/'J?f(,U

~1Jtf!n"*~7"

t'I:O

t•lt!I

J?t)".f

t?t

Hr~~-~

t1J7~)·

0=7.

94

1/4-24

"b"1 4.8X8.4X0.8

8.5XI2.

9/64·40

11/64·40

1

1/64·40

11/64·40 L=4.5

11/64·40

9/64·40

9/64·40

11/64-40 I

11/64-40

11/64·40

m1

?W·?i"

11/64-:!2_

H5XO

G.

11/64-40

.U

:i'"2

9/64·40

t"l

t 11/64-

"

.l.t

9/64-40 I.=G

11/64·40 L=7 8 II l

11

/64·40

:i'

" 15/64·28 L=

If!

If!

it'i'-?'l~lfl

'i'

-?'J~Ifl

Q__ ___

t11?

t0

I :o

L=45

____

R

l =

-

_______

-~

I =

L=12

"*

5

2 8

L=

,

n"*

f

"I*""

-~

W=8

5X0

L=6

L=5

.5

L=4

L=6.5

L=7

L=3

. 5

=7

L=7

L=8.

n"f

. 8 I

:i'

> I I 1

4XIIX0

L=

40

L•7

IO

t

111

l5

16

_l2L

l2

.3 (I l

'i

5

.3

3.2

___

___ilL

___

___

f{J!±l

lfl>

Oo·

Ill

Ill

Ill

Ill

Ill

Jll

II

Il

II

I I l

II)

121

Il l

UL

til

111

til

121

llL

I II

Ill

I II

Ill

UL

I II

Ill

II 1

121

Ill

Ill

Ill

Ill

Ill

II

I I I

II

Ill

Ill

Ill

II

II l

(

!!

Ill

Ill

II l

Ill

!

Ill

Ill

Ill

II l

II

II

I I I

11

(II

Cl

Ill

!21

Ill

II

121

121

(21

(I

II

Ill

121

Ill

())

Ill

Ill

I I I

Ill

(JJ

01

Ill

Ill

\

....

I

I

I

l

I

ll

l

ll

I

l

t

l

l

1

l

l

l

I

Page 3

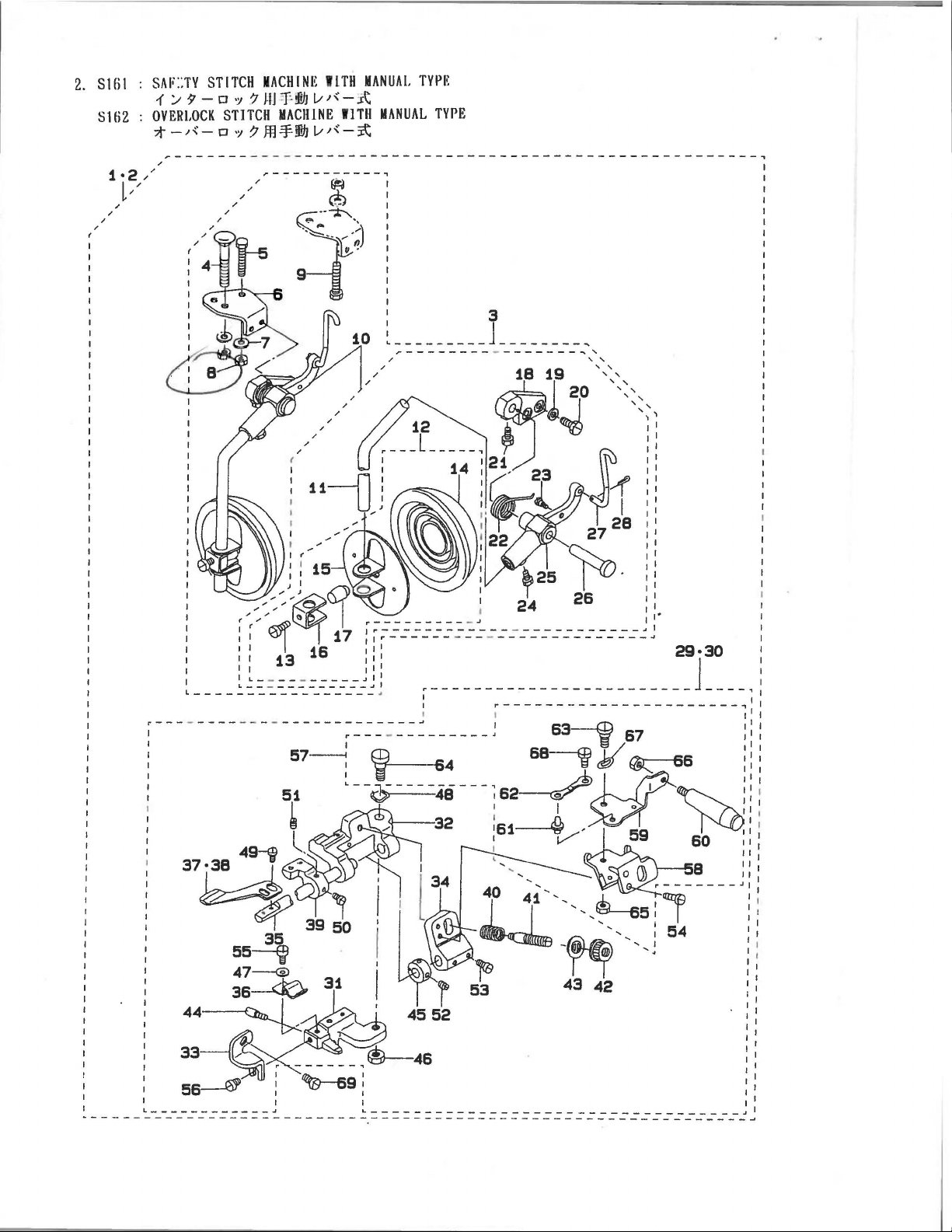

2.

St61

St62

SAI'::TV

1

OVERLOCK

71'

STITCH

/~-o

_,{-

o

IIACHINg

·:~

'JW

STITCH

•y

7

'f:.

!liJJLn{-.i:\';

MACHiNE

ffl"F!WJ

Ln{-:t\';

liTH

WITH

MANUAL

MANUAL

TVPF.

TYPE

1•2

~-------

/

//

---

- -

------------------------------------------

l//

/

/

/

/

(

3

_________

~----------------~'

/ ' '

/ ' '

/ ' '

/ ' '

/

/

/

/

/

/

/

l

________

~

' '

' '

' '

''

'

5'

49~

37~b·

55~

47---®

36~

44~

33~

56~

--------------------------.===============~=~=:::::::::::::::~~

------------•

l.

~

35

31

'

------,~46

~9:

~

I

Page 4

PART

REF.

HO

HOTE

n01

n02

4

uo:1

_S_!!.O.L_SH~UOl!J.O.lJ~SC_SCKEV

6

7

64

66

67

68

60

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

65

IO

II

12

13

14

1'1

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

JB

39

40

41

42

43

44

4'1

46

47

48

n04

n04

0

105

~~

HO.

HAS·IOIOOOAO

HAS·I02000AO

HAS·I07010AO

HAS-10704000

HAS-10701000

VI'-0850002-SC

HH-0080600-SH

SH-0084533-SC

HAS·I07010CO

HAS-10702000

110·23751

SS-9151540-SR

83431·552·000-A

110·23.702

110-23801

110·24403

HAS-10501000

VP-0740516-SP

SS-9681610-TP

SS-9151210-TP

HAS-10503000

S0-0550501-SP

SS-9151210-TP

HAS-10502000 I EYER

HAS-10504000

HAS

· 1

0703000

PD-0201000·00

HAS

· 1

61010AO

HAS-162010AO

MAS-15901000

HAS•15902000

MAS-15903

HAS-15904000

HAS-15905000

HAS-15911000

MAS-05108000

HAS-05208000

MAS-05212000

HAS-05205000

B3105·804·000

B3116·125·000

B3120·125·000

HAS-05202000

CS·0790811·SP

HS-6160520-SP

VP-0480856-SP

WZ-0850302-KO

SS-6090650-SP

SS-6110650-TP

SS-8110520-TP

SS-8110520-TP

SS-6110710-TP

SS-4090715-SP

SS-7110710-SP

SS-7110720-SP

MAS-159060AO

HAS-15906000

HAS-15007000

HAS·1'i915000.

HAL-12115000

HAL-12116000

SD-0600352-SP

SD-0790801-SP

HS·G110350·SP

HH-6050001-SP

WZ-0640312-KO

SS-7110340-SP

ss:7!10840·SP

~ute

I

i£6.!

000

IAOI

n02

nOJ

A04 ... .

nt15 ... .

DESCRIPTION

TUCKING

DEVICE

TUCKING

DEVICE

KHEE

OPERATING

BOLT

H8 I =30

IHSTAI.I.IHG

WASIIER

H.5X18XI.O

HUT

H8

SCREV

H8

EE

JUG

FIXED

FIXED

N

fiE

11/64·

H5

FOR S16

FOR

FOR

I

FOR

FOR

PRESS

PRF.SS

PRESS

PRESS

PRESS

ER

ET

1/4·24

FOR

WASUER

11/64·40 I

11/64·40

11/64·40

11/64·40

0/64·40

SCRlW

SCREW

VASHER

11/64·40

L=45

15/64·28

IHSTALLIHG

9/32·

15/64·28

SCREW

15/64·28

PIH

SHIRRING

SHIRRING

PLATE

HOUHTIHG

POST

HUT

STOPPER

COl

4.8X8.4X0.8

9/64·40

11/64·40 I

11/64·40

ARM

ARM

LEVER

Sl62

SEN I ·Sil!IKF.H

EXPORTI

SEH I

f lli.I.Y·S

KHEE

ROO

KNEe

SCREW

KHEE

KHEE

KH

RUBBER

LEVER

\lASHER 7.4XII.8X0.5

SCRE\1

SCREW

SPRING

IIIHGE

SCREW

PIH

COHHECTIHG

SPLIT

PEDAL

PEPAI

PRESS

S\IIHG BASE

BRACK

ARM

SHAfT

SPRING

IHTERHITTEHT

1HTERMITTEHT

PIPING

SPRING

TEHSIOH

TEHS10H

ROTATING

SCREV

THRUST

HUT

WASHER

VAVEO

SCREW

SCREV

SCREW

SCREW

SCREW

SCRE\1

SCREV

SCREW

LIFTING

LIFT

HAHUAL

MANUAl I EYER

ARM

ARM

HI

HIHGE

HUT

HUT

VAVED

SCREW 11! 64·40

SCREW

....

....

....

ASH.

ASH.

DEVICE

PLATE

PI

ATE

ASil.

PLATE

ASH

L=15

PLATE

COVER

PLATE

PLATE

HOLDER

BASE

28 I =16

L=l1.8

0=5.5

U=5

L=ll.8

ROO

1.8XIO

ATTACHMENT

ATTACHHEHT

BASE

SUIRRIHG

SUI

RR I HG

BLOCK

I.AR

P=7

94

8.5X12.5XO.J

L=6

=55

L=

4.5

L=

4. 5

L=

6.5

L=7

=7

L=7

ASH.

ARM.

PLAT

PLATE

_

E STOP

PER

STOPPER SPRING

0=7.94

H=8

1.=

3. 2 .,,L

1.=7.8

l

TYPE TABLf

·SUHKEH TVI

UHKEIJ TYI'I'

ASH.

.

PRESSER

PLATE

11=8

___

'E Tli

ASH.

ASH

____

BLE

T

A~!.F

~~-fll'l~t·J~n

~~-fii'1~1·J~'

~t·n··,~f

~H);t;"U

U?t'J;t;" U

~··n·~n'-)"1

t;t

U?.,l?f

P?*?;t" U

t!"Zil)

~t·n·

~t·Y'I~

P?

tt"lH)

WZW

tt'lHHtl

t

t"lf

tt'lt"~ll"-)'1

t'lt

P'tbWU

P'lt?

tt•n·~~~-·11'1

)'~~:;,·

P'lb?t."

tt'z!r"W·

tt'H"~n·-::-·?

tt•zt

?11t·~

t)'fii'JH(?

t)"t'l'l?f!V}

t)"f11~tH11?H"-1

t)"f'lttl~~·~·--1

~?•H·~

t~"f11tf1A"*~'·

tnW,

t9"f'lt9I??")"-I

t~·fllttl

t)"f'ltfl

11•

·tt•

tn•Jttiii"t

-lfl3·?;f;"·

-IH3·?

-IH3·Wi

t)"f'l~91

l'lam

P'l*?t'H

t'W:II"t

tu·~,·t•*

t'i~::-·

t'ljW

f,Jif~·

f~*~·

t'iH"

H"t?"

1&l:'W

''";*~·

t~n-~.;·

t·tH"~

:), f

hl..:!/.1£.:.._

H.JfH)H•A

~··Jffl)lhA'

,

..

>i; . II l

)·~f:)

p-mm

U?:t?t?

t<1J")'"1J"

''t·,;

Sl61

s1a2

~1

Jli.J:k

·~;t"r1:···-·

~

n

H8

I =

3.0

f

•r t 8.5XI8XI.O

::-

) ?

1?t''f

J ' £ 11l

"r t

;f;

'U

'f

·

1.8XIO

~?·

9/64·40

11/64·40 I

11/64·40 L=4.5

11/64·40

11/64·40 L=6.5

,·

·1~n·

"

f H5

,,.

v

!·.

J>Y·

'l'/tH

H8

I~

>

H8

L=45

H

·,

~

15/04·

28

bll"·

7.4KII.8X0.5

!1/.J.CZR..

15/04·28

0=5.5

11=5

15/64·

28

~~t'Jt.·-

t )

11•t

fii?H"

-1

t'H

tl'i'~f·~

fi,H.-1

P=7

94

11=8

1/4·24

4.8X8.4X0.8

8.5X12.5XO.J

L=6

=5

L=4.

9/64·40

L=7

11/64·40 I

11/64·40

!?ll

..

1r'

. _ _ _ _ .... _ ...

• I

·

n·;. Il l

0=7.94 11=8

11

/64·40 _

XO.

8 1

5-

·i

6.4XIIX0. 3

11/64·40

1.=

11/G4·

40

i.=i.8

IIJ

m

..

'J

IL

Jl

l I f

f " 'J'

I~

Jlj

'II IIJ

L=15

.L:.l.lL. ___

''It?"

'i

5 •

=j

__

L=7

J I

3.

;i

~

il\

_ill_

__w_

11!

.!Z

___ilL

Ill

Ill

Ill

II l

....llL

Ill

__

l.l)_

Il

Il l

Ill

I

I

I

Ill

II

II

Ill

Ill

Ill

12i

II

Ill

!ll

Ill

Ill

UL

!ll

Ill

121

Ill

II

Ill

1·1)

CJ

(11

Ill

Ill

Ill

(11

(!

Ill

Ill

1(1

Ill

(ll

I

1l

(!

II

Ill

())

Ill

II

Ill

Ill

Ill

12l

Ol

121

12l

12l

I

II

ll

II

I

I

I

L

I

l

l

l

l

l

l

il5ll

~

\>J(t\1),

order

or

c:-~~1<1:

for further

To

information.

please

cont

act

:

"'::.(1)1\-':J

*The

•::(J)J\-':J~:AH<I.I993~101'11Jlli(J)J!Iiliilf±lll'l:'liUII·

*This

~:A

t--l<llll.lii~Jll(J)I:~~l!itJ:<

descriplion covered

parts list

is

edoted

and

on

thos

parts list

pronted

on

;:ll!"r·l>lflf.J•if!iOll:T.

os

subject to change for improvement of the commodoty wi!hout notice

EOI!~t.,/:'I;(J)Z:'r.

accordance

woth

the product specificatoons as of October t993

Page 5

Swing-type gathering device

FOR

a.IUK

5159.

51

61 . 516.2

51

60

INSTRUCTION MANUAL

Preface

Congratulations on your

applicable to

Please

M0-3900E Series arc the auachmcnts for guthcring.

read this Instruction Manual carefully before using it. We hope you will enjoy using it

1. Name

Swing-type gathering device I(

St59

: Swing-type

S161: Swing-type gatheri

St60

: Swing-type gathering device for ovcrlock machines (pedal-operated)

Sl62:

Swing-type gathering device for ovcrlock machines (lcvcr-opemlcd)

2.

Applicable models

M0-3904EM0-3914E-BD6

M0-3912E-DF6

M0-3916E-DD4

M0-3916E-DF6

M0-3916E-RH6

OE6

purch11Sc

g<Jthcrin

ofu

JUKI

g11thcring

Jr the

M0-39<XlE

g device for safety stitch machines (pedal-operated)

ng

device for safety stitch machines (lever-operated)

device. S159, S 160, S

Series

of

ovcrlock/s:Jicty stitch machine

M0-3904E-OF6

M0-3914E-BE6

M0-3916EM0-3916E-FF6

M0-3943E-FBD6

DE4

161

and S 162 models

of

gathering devices which arc

for.

a long time.

3.

Specifications

Application

Sewing speed

Differential

feed ratio

Lift

of

the

presser foot

4. Parts

For continuous

knits and broadcloth.

7,000 s.p.m.

Up to

Overlock machines

(Adjust appropriately in accordance with the type

Overlock machine: 6 mm Safety-stitch machine: 6 mm

(5 mm only for RH6)

to

be

gather ing and partial shirring on light-weight materials including kniued fabric, light-weight

I

:3

Safety stitch machines I :3

of

material

to

be used.)

replaced when the gathering device

safety stitch machine

To operate an ovcrlock/safety slitch machine

be

components need to

changed accordingly . Choose the llpproprimc parts from among those listed in the table below .

(1) Safety stitch machines (M0-3916E or 3943E) S159 or

~zc

e

Presser joint

Main feed dog

Differential feed dog 12172904

Throat plate

•

Gathering foot

0))4

12154654 12154654 12154753 12154852

12170700 12170700 12170809 12170908 12170908 11884806

R4508JODDOB R4508JOEDOB R4608JOFDOA

- - -

in

combination with the

DE4 DF6 FF6

12172904 12173407 12173407

St59, St60,

R4612JOFDOA R461750HDOA R4612JODE02

* Usc the gathcnng foot only when the RH6 gauge set1s used.

is

used with the oyerlock/

S161

or

St62

gathering device, the gauge

S161

RH6

12154951

12173407

• MAS0510800A

FBD6

11975950

11885902

-

Page 6

(2) Overlock machines (M0-3904E, -3912E or -3914E) 5160 or 5162

~c

e

joint

Presser

Main feed

Differential feed

Titroat

5.

Adjusting the gathering foot

dog

dog

plate

OE6

11878857 11974250

11883402

12171807 12171807

R4300JOEEOR R4300JOFEOA

OF6

11883402

806

11879350

11883402 11883402 11886603

12171807

R4305JODEOA

RE6

11879350

12171807 12171906

R4305JOEEOA R4308JOFEOO

DF6(3912) ,

11974052

,

Good

Not good

Gathering foot

\

' Throat plate I

The gathering foot comes

parallel contact with the throat

plate.

Adjust the gathering foot by

pressing down section

Adjust the gathering foot by

pressing

up

section

C.

in

C.

(1

)Adjust the gathering foot so that it comes

In

parallel contact with the top surface of the throat

plate over the length. ·

a.

Temporarily

lclism

b.

After

between

the

completi

tighten

the

screw

G,loosen

gathering

on

of sewing, tighten

foot

and

screw

the

throat plate.

screw

@),and

C)

adjust

and

screw

the

paral·

e.

(2)Adjustlng the vertical position and the lateral

position of the gathering foot

a.

Loosen

two

screws

Ci)

and

~rew

0

in

the

position of

3

mm

spaced

the

from

gathering

the

edge of the

foot,

the thrust collar,

in

the

lateral direction,

feed

dog

.

and

so

adjust

that

it

is

Page 7

Throat plate

Gathering fool

[When the

with the feed

Two

Main feed dog Differential feed dog

6.

Adjusting the lifting amount of the gathering foot(S159, 5160)

differential feed

pijch set to 2.2 mm]

or

three teeth (overlock machine)

~

3~~

Is

maximized

Gathering foot

rc1

=:::==::::=J

Throat plate

gathering foot

As

the

standard longitudinal position of

ering

foot

of

the

overlock machine or

safety stitch machine

ing

t~ction

The

size

of

forth

. Adjust

dance

with

(4)Adjusting the pressure of the gathering foot

a.

Swndurd

the

dance

ing

<1

.

Loosen

by

mm.

pressure of

gmhering

with

knob

screw

moving

(3)Adjusting

the

must

reach

.

gathers

the

longi

the

material

foot,

the material

0.)

0,

4D

up

or

longitudinal

the

2nd

or

3rd

the

1st or

when

the

differential

is

changed

the

is

1.5 kg. However, adjust it properly

and

down

by

tudinnl

position

to

be

used.

gathering

to

be

used.

adjust

the

. The standard lift of the gathering

position

the

gathering

tooth of the differential

2nd

tooth

of

the

feed

dog

moving

lifting amount

of

the

foot,

as measured at

(Adjust

the

gathering foot

gathering

the

pressure

of

the

of

foot,

the

feed

feed

dog

completes

foot

in

the

top

in

using

gathering

foot

the

gath-

dog

of

feed-

back

accor-

end

accor-

adjust-

foot

is

the

or

of

3

7.

Modifying the table (fully-sunken type)

When

using

(nvn)

the S 159

dimensions of the

table

or S

as

160

with

indicated

a fully-sunken

in

the figure

type

on

the

table,

lefL

modify

the

I

Page 8

8.

Installing the knee lifter

(1}Attach the knee lifter installing plate

A

Side view

of section A

in

place as illustrated below.

(2)Attach the knee lifter unit to the knee lifter lever

installing plate.

base

I)

Attach

knee

screw 0 and

2)

Put

shart

3)

Put

knee

feed

adjusting lever from

the

hole 0 in

rod will not

4)

Proper

I y position

knee

lifter with

screw

0.

lifter lever

washer

0 into

lifter connecting

the

come

knee

lever

off.

knee

ease.

base 0 to

0.

lifter lever

rod

this

and

secure

pad

t@

Then

the

frame

0.

and

tighten

(i) into

the

hole in

side

, insert

one

it with cotter pin 0

to allow

fix

the

the

operator

pad

at that position

support plate

screw

0.

the

differential

end

of

the

rod

so

to

operate

that

using

into

the

the

using

To

order

or

for further infonnation, please

Please

do

not

hesrtote

* The description

without notice.

to

con10ct

our di

Stributors

covered

In this Instruction manual Is subfect

contact

or

agents

in

your

area lor

further information

to

change

for

when

necessary

Improvement

.

of

the commodHy

Loading...

Loading...