Page 1

MODEL

LZ-582-3

HIGH

LOCKSTITCH

INDUSTRIAL

Instruction

SPEED,

SINGLE

ZIGZAG

SEWING

NEEDLE,

MACHINES

Book

TOKYO

JUKI

INDUSTRIAL

CO..LTD.

Page 2

CONTENTS

I.

GENERAL

*

SPECIFICATIONS

II.

INSTALLING

RUNNING

1.

2.

III.

HOW

1. Cautions on operation 5

2.

3.

4.

5.

6.

7.

8.

9. Adjusting the zigzag width of throw

10.

11. Adjusting

12. Adjusting the

DESCRIPTION

THE

How

to

install

Motor

Lubrication

How

Threads

How

Threading

How

How

The

pulley

TO

OPERATE

to

insert

to

wind

the

to pass the bobbin

to

maintain

knee

lifter

the

MACHINE

the

machine

and

belt 4

THE

the

needle

the

bobbin

&

PREPARATION

MACHINE

thread

machine

thread

thread

pressureofthe

stitch

tension

presser foot 12

length 13

1

3

FOR

3

3

5

5

8

8

8

10

10

11

11

12

IV.

ADJUSTING

THE

MACHINE

1. How to remove the sewing hook. 13

2.

Relation

between

the

needle

and

the

sewing

hook

3. When synthetic thread is used 16

13

15

Page 3

I

GENERAL

DESCRIPTION

JUKI

sewing

constructed to withstand high speed sewing

pletely

and

spent oil dripping

and

1) The movement of the zigzag width of throw of the needle bar has

a

certain

MODEL

machines.

automatic. A

as a result, all essential parts are completely encased to prevent any

soiling

Besides above, these machines have following good features:

the

periodofrest.

LZ-582

The

sewing

special

from

the front of arm during the running operation

sewing cloth.

and

LZ-583

hook,

research

I \

are

thread

was

UUK.

p,

high

speed

zigzag

take-up

and

the lubrication is com

given

etc. are

to the

leakage

industrial

specially

of oil

Page 4

Due to this rest period feature of the needle bar, there is no width

of throw while the needle is piercing the cloth. This prevents the crack

ing of the needle eye or curving of the needle, thereby producing

attractive

garments.

2) The sewing hook driven by bevel gear

As the sewing hook is driven by the transmission power of the bevel

gear, the

"play"

of the sewing hook is negligible

and

also as the bevel

gear is protected by a case, its durability factor is very high.

3)

Thread

pull-off

lever

This machine is equipped with a thread pull-off lever to make the

pulling

the

outofthe

thread

sewing hook

tightening,

thread

eithertoright

easier.

or left.

Thus,

there

is no flaw

of

4) Special steel used on all essential parts

The zigzag forked rod, which is one of the important parts of the

zigzag machine, is made of specially heat-treated steel to prevent undue

depreciation

alloy.

smooth even at high speed

practically

and

With

these features, the

negligible.

the needle

and

bar

frame is made of special aluminium

machine

therefore depreciation

is very light

and

and

the

vibration

running

are

is

5)

Automatic

The

matic, eliminating hand-oiling

lubrication

lubrication to the essential frictional parts is completely

during

the

running

of the machine.

this feature, the production efficiency is greatly boosted up,

6)

Forced

When

from

drain

machine

oil

drain

the

oil accumulatesatthe

the

needle

device, this

and

returns

device

bar

spent

to

and

oil is

the

the

siphoned

oil

reservoir.

- 2 —

jaw

presser

bar.

up

of the

during

arm,

it invites oil leakage

However,

the

with

running

auto

With

this forced

of

the

Page 5

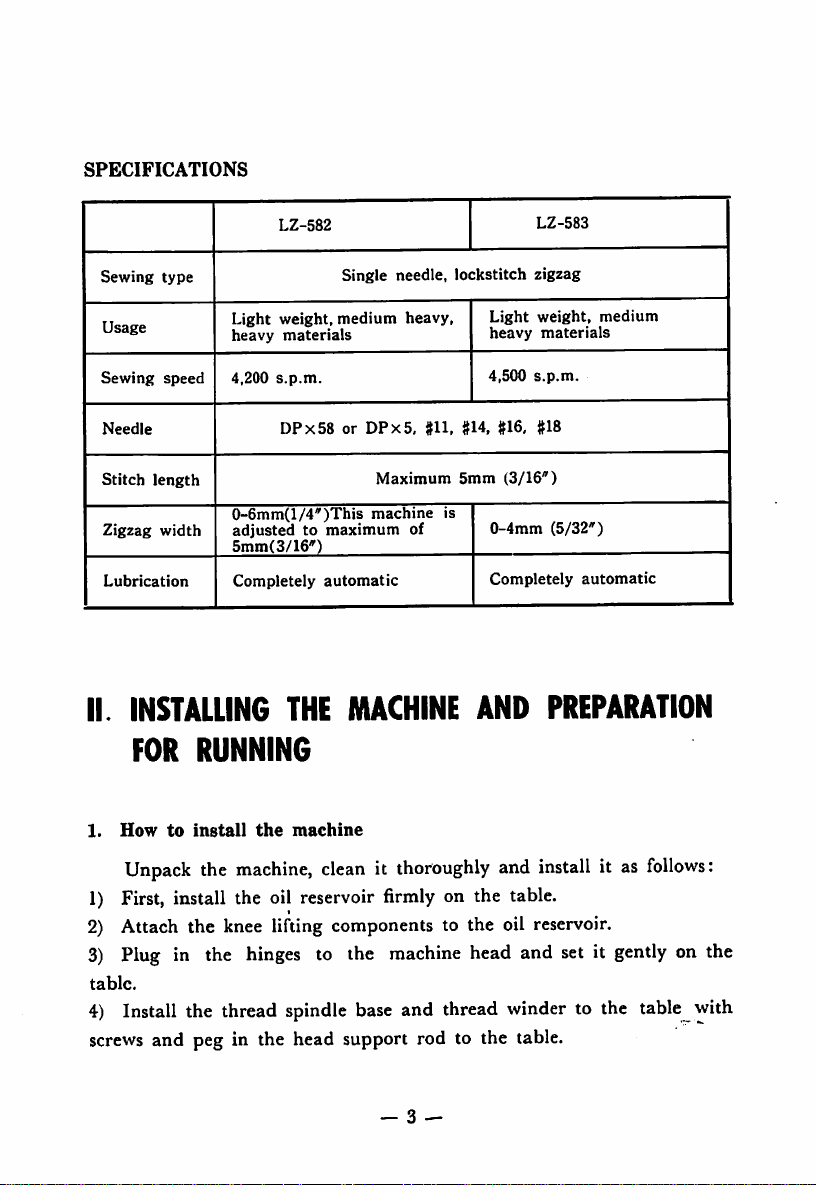

SPECIFICATIONS

Sewing

Sewing

Stitch

II.

type

Usage

speed

Needle

length

Zigzag

width

Lubrication

INSTALLING

FOR

LZ-582

Light

weight,

heavy

materials

4,200

s.p.m.

DPx58orDPx5.

0-6mm(l/4'')This

adjustedtomaximum

5mm(3/16")

Completely

THE

RUNNING

Single needle,

medium

automatic

heavy,

Maximum

machine

MACHINE

of

#11,

is

lockstitch

Light

heavy

4,500

1114,

#16. #18

5mm

(3/16")

0-4mm

Completely

AND

LZ-583

zigzag

weight,

s.p.m.

materials

(5/32")

automatic

medium

PREPARATION

1.

How

to

install

Unpack

the

the

machine

machine,

cleanitthoroughly

and

install

it as

follows:

1) First, install the oil reservoir firmly on the table.

2) Attach the knee lifting components to the oil reservoir.

3)

Plug in the

table.

hinges

to the

machine

head and set it

gently

on the

4) Install the thread spindle base and thread winder to the table with

screws

and peg in the head support rod to the table.

— 3 —

Page 6

2.

Motor

pulley

and

belt

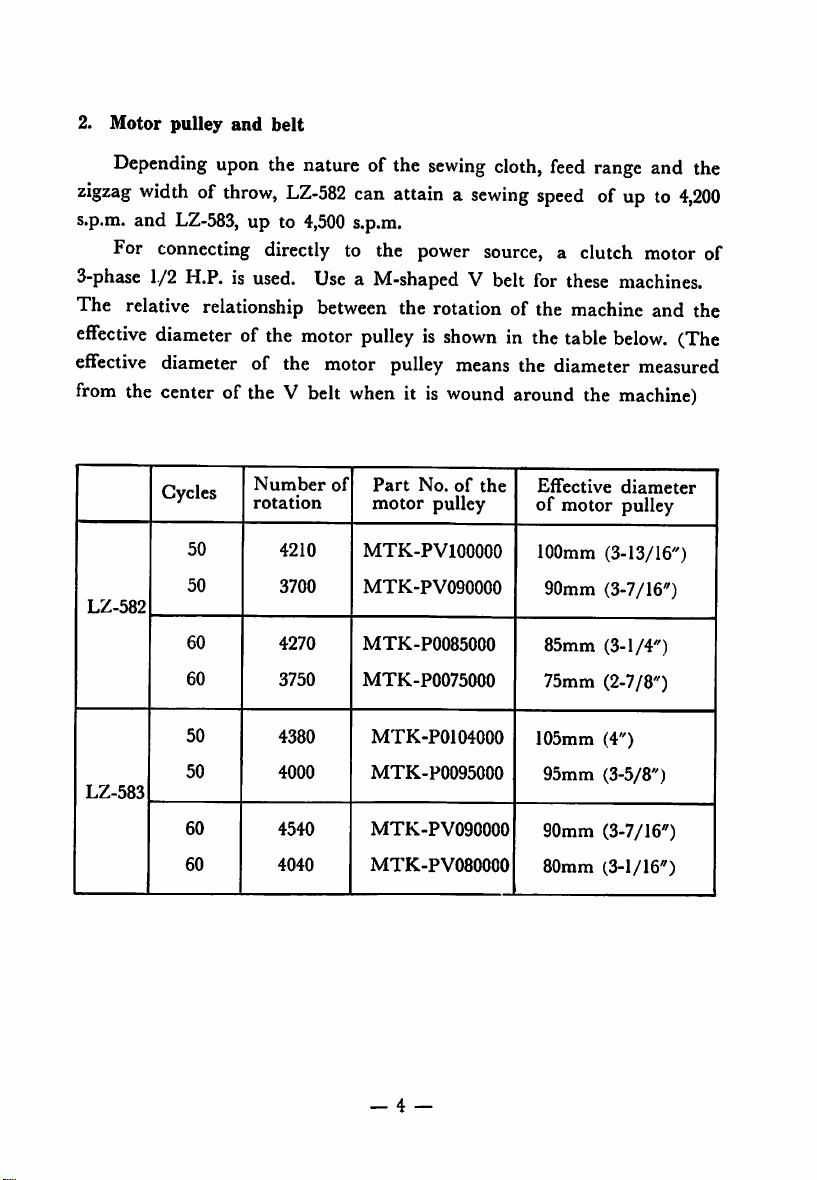

Depending

zigzag

s.p.m. and

widthofthrow,

upon

LZ-583,

the nature of the

LZ-582

up to

4,500

can

s.p.m.

sewing

cloth,

attainasewing

feed

speed

range

and the

ofupto4,200

For connecting directly to the power source, a clutch motor of

3-phase

1./2

H.P. is used. Use a M-shaped V belt for these machines.

The relative relationship between the rotation of the machine and the

effective

effective

from

LZ-582

LZ-583

diameter

of the

motor

pulleyisshowninthe

table

below.

diameter of the motor pulley means the diameter measured

the center of the V belt

Cycles

50

50

60

60

50

50

Number

rotation

4210

3700

4270

3750

4380

4000

when

it is

of

Part

motor

MTK-PVIOOOOO

MTK-PV090000

MTK-P0085000

MTK-P0075000

MTK-P0104000

MTK-P0095000

wound

No.ofthe

pulley

around the

Effective

machine)

diameter

of motor pulley

100mm (3-13/16")

90mm (3-7/16")

85mm

75mm (2-7/8")

105mm

95mm

(3-1/4")

(4")

(3-5/8")

(The

60

60

4540

4040

MTK-PV090000

MTK-PV080000

— 4 —

90mm

80mm

(3-7/16")

(3-1/16")

Page 7

Ill

HOW

TO

OPERATE

THE

MACHINE

1. Cautions on

*

Do

not

*

The

machine

side,itis

direction).

* Run the

month

nature of the work and the capability of the operator.

*

Rust

preventing

so after the machine is unpacked, be sure to clean this oil well and

before

machine a trial spin.

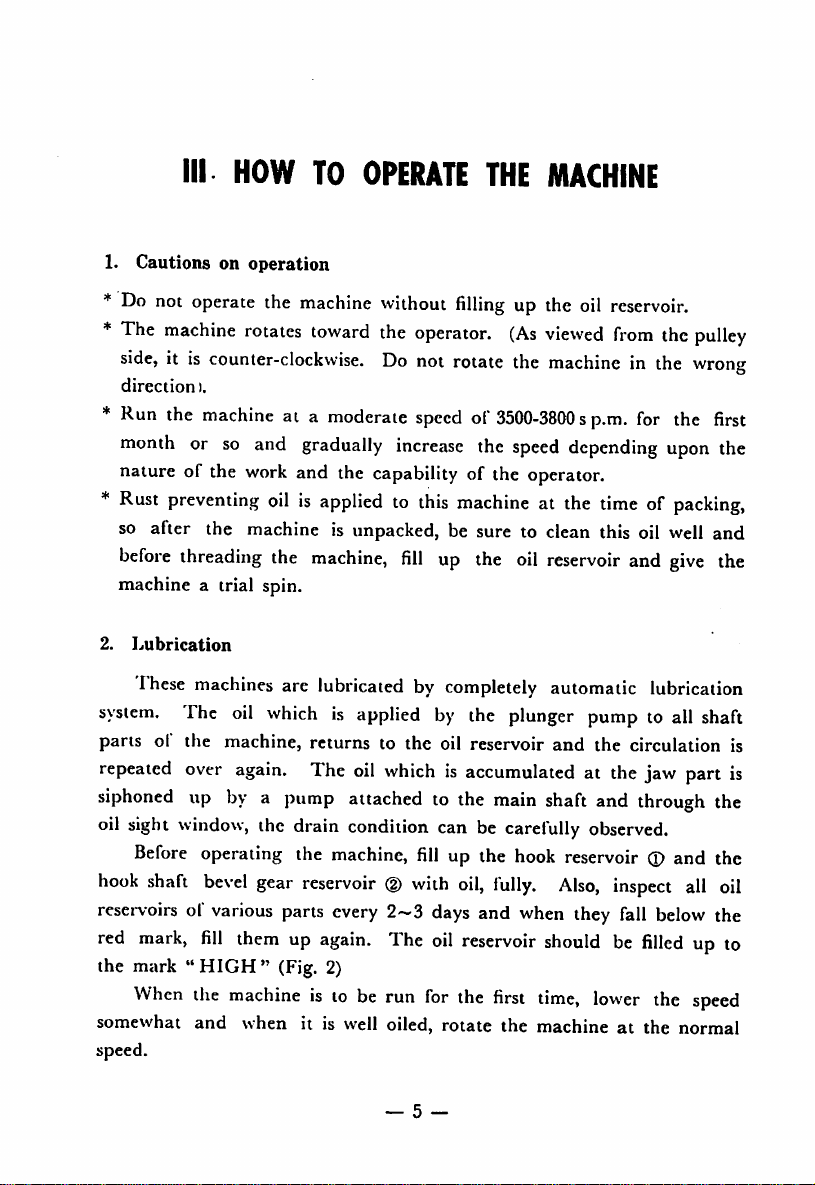

2.

system.

parts

repeated

threading

Lubrication

Ihese

oi the machine, returns to the oil reservoir

over

siphoned

oil sight

hook

resei-voirsofvarious

red

the mark

window,

Before

shaft

mark,

"HIGH"

When

somewhat and when it is well oiled, rotate the machine at the normal

speed.

operation

operate

the

rotates

machine

toward

without

the

counter-clockwise.Donot

machine

or

so

machines

The

up

operating the

bevel

fill

the

at a

moderate

and

gradually

oilisappliedtothis

the

machine,

are lubricated by

oil

which

again.

byapump

the drain condition can be carefully

gear

is applied by the plunger pump to all shaft

The

oil

whichisaccumulated

attachedtothe

machine,

reservoir

parts

(2)

every

themupagain.

(Fig. 2)

machineisto

be run

filling

up the

operator.

speedof3500-3800sp.m.

increase

fill

up

completely

fill

up the

with

2-3

days

The

oil

for

(As

rotate

the

the

speed

machine

the

main

oil,

fully.

and

reservoir

the

first

viewed

machineinthe

at the

oil

reservoir

automatic lubrication

and

shaft

hook

when

shouldbefilled

time,

oil

reservoir.

from

the

for

the

depending

upon

timeofpacking,

and

give

the circulation is

at the jaw part is

and

through

observed.

reservoir

Also,

they

inspect

fall

lower

(p and the

below

the

pulley

wrong

first

the

the

the

all

oil

the

up to

speed

— 5

Page 8

- •

'v.;

*

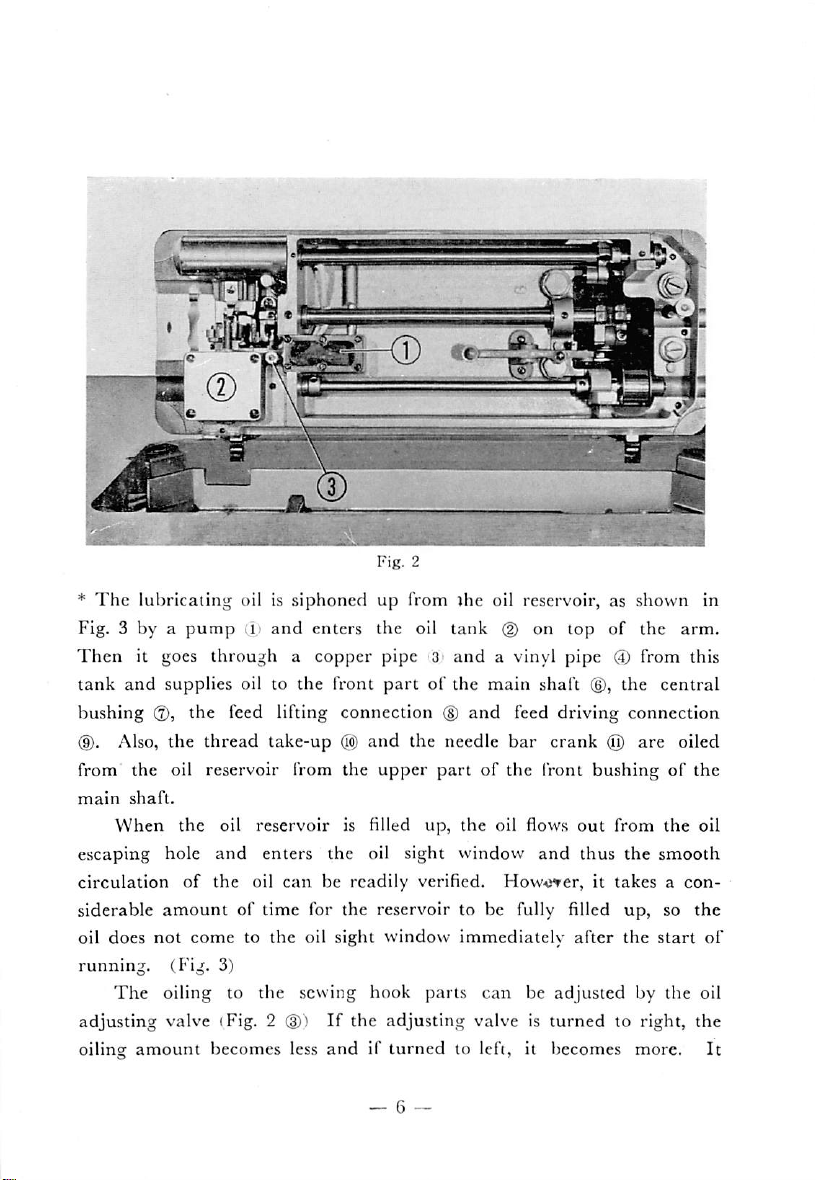

The

lubricating oil is siphoned up from ihe oil reservoir, as shown in

Fig. 3 by a

Then

tank

and

bushing

pump

(i)

and

enters

it goes through a copper pipe 3

supplies oil to the front

(2),

the feed lifting connection ®

d). Also, the thread take-up @

from the oil reservoir from the

main

shaft.

When

escaping hole

circulation

siderable

oil does

running.

The

adjusting valve (Fig. 2 ®)

oiling

the

oil reservoir is filled up, the oil flows

and

of

amount

not

cometothe

enters

the

oil

of time for the reservoir to be fully filled up, so

the oil sight window

can

be

oil sight

(Fig. 3)

oiling to the sewing hook

If

amount

becomes less

andifturned

. - '•.V*

the

oil

tank

@ on

and

a vinyl pipe

partofthe

main

and

and

the needle bar crank @ are oiled

upper

part

of the front bushing of the

top

shaft ®,

feed driving connection

out

and

thus

readily

the adjusting valve is

verified. How^j^er, it

window

immediately

parts

can

be

turned

after

adjusted

to lefi, it becomes more.

of

the

arm.

(J)

from this

the

central

from

the

the

smooth

takesacon

the

start

by the oil

to right, the

oil

the

of

It

_ 6 —

Page 9

11

10

6

Fig.

3

takes a certain time interval before the oiling amount to the sewing hook

becomes steady. This is because the oil is carried through the oil wicks

and

does not change immediately after adjusting, so have this in mind

when adjusting the oiling amount.

(.Note)

1) For lubrication, use

Esso Spinesso

Oil

No. 34.

JUKI

industrial oil (New Defrix No. 1) or

2) Do not run the machine before filling up the oil reservoir or

various

cially in summer.

other

oil

reservoirs.

3)

If

oil of low viscosity is used, it might invite oil leakage, espe

On

the other hand, if oil of too high viscosity is

used, the circulation of the oil becomes bad and might invite scorching

of parts.

4)

The

of shipping

amount

but

of oil for the sewing hook is adjusted at the time

this

amount

may

vary

according to the

temperature

the locality. Be sure to verify the correct amount by removing the

needle plate

and

by attaching a piece of paper, judge the

amount

of oil

of

— 7 —

Page 10

splashing the paper.

5)

When

lint

hardsorcloth

stick to the screenofthe

pump

screen. Constantly inspect the screen

dust

get

into

the

oil reservoir, it will

and

lower the working efficiency of the

and

clean it thoroughly when it's

clogged up.

6) When running the machine idly, be sure to fix the position of

the presser foot by means of the push button.

If

the machine is

run

idly with the presser foot raised up too high, it will result in malfunc

tioningofthe

3.

How

For

to

insert

LZ-582

machine.

the

and

LZ-583

needle

machines, use needle type

DPx58orDPx5

(135x5). There are many types of needles so please select the correct

type depending upon the thickness of the thread and the nature of the

sewing

material.

To insert the needle, rotate the hand wheel

and

raise up the needle

bar to the highest position ahd then loosen the needle clamping screw.

Hold the needle so that the long groove of the needle is facing the

operator and

goes in

insert

the

needle

and

clamp in the needle clamp screw tight.

deep into the

needle

hole as far as it

4.

Threads

The

needle

or left twist. But do

thick

thread.

5.

How

to

Set

the

wind

bobbin

thread

the

thread

or the bobbin thread could be either right twist

not

use inferior gradeofthread

bobbin

thread

winder

on

the

table

with

with flaws or too

screws

as

shown

Fig. 4. When the trip latch @ is knocked down, the bobbin winder ©

— 8 —

in

Page 11

Fig.

4

should correctly contact the belt. To wind the bobbin thread, insert

the

bobbin

0 deep into the

pulley

shaft as far as it

goes.

Then,

pass

the thread through the thread eye(Dand pass it between the thread

tension

disc

(§).

(The pressure of the thread tension disc is adjusted

according to the kind of thread and the woundcondition). Forsynthetic

thread like nylon etc., make it weak, somewhat.

Wind the tip of this thread around the bobbin from under, knock

down the trip latch ®

Run

the

machine

to make the

When the thread is not wound evenly to the bobbin, loosen the

screw

®,

bobbin

move

the thread

and

and

thread

contact the bobbin winder

wind

the

to be

tension

bobbin

woundtoabout

disc

thread

80%.

base(Dto right and leftto change

but

(D

to the belt.

use

the

screw

(§)

the slant of the winding thread and find the right winding position.

When

the winding is completed, the

trip

latch

will come off

and

the

rotation of the boobin winder will automatically stop. The winding of

the bobbin thread should be done during the running ot the machine.

(Note)

Lubricate the shaft part of the

— 9 —

bobbin

winder,

occasionally.

Page 12

6. Threading

the

machine (Fig. 5)

Pass the needle thread in the order of

(D--(§)

as shown in Fig, 5.

After the threading is completed, pull out the tip of the passed thread

about

10cm

(about

(Note) When using thick cotton thread

threads,

tuck

them

4").

in

between

the

1150

small

or over or nylon or tetoron

tension

discs

attached

to

the

thread guide bar and pass it through the 3-eyelet thread guide.

I

O

O

Fig.

7. Howtopass

Pass the bobbin

the

5

bobbin

thread

thread

(Fig. 6)

into the bobbin case, then pass it

Fig.

6

under

the

thread tension disc spring and as shown in Fig. 6, pass it through the

thread

eye in the front

and

into

the

sewing hook.

—10—

Page 13

8.

How

to

maintain

thread

tension

As shown in Fig. 7

and

8, the thread tension should be so maintained

that the intersecting of the needle thread and the bobbin thread should

come to

sobecareful.

the

Please note

a)

When

b)

When

c)

When

d)

When

e)

When

f)

When

center of

the

the

the

sewing cloth.

that

in the following cases, thread breakage may result,

thread

bobbin

passing is

thread

wrong

is all goneorbroken

the sewing hook is installed wrong

the sewing hook is bruised

the

the

needle

thread

thread

path

tension is too strong

is bruised

Fig.

9. Adjusting

To

change

7

the

zigzag width of throw (Fig. 9)

the

widthofthrowofthe needle, loosen the knob

Fig.

8

(T)

the name plate in the center of the arm and by matching the lever

to the designated graduation, set the knob.

— 11 —

of

(g)

Page 14

10.

The

knee

lifter

(Fig.

10)

Fig.

10

When you

first, raise

buttonQof

foot will come to a stop at

bring

down the presser foot,

will

come

11.

Adjusting

want

up

the

the face plate

down.

the

pressureofthe

the presscr foot to stay in the raised

presser foot by

the

knee lifter,

andifthe knee lifter is lowered,

about

6mm

(1/4") above the face plate. To

just

activate the knee lifter

presser

foot (Fig. 10)

To increase the pressure of the cloth pressing power,

If

it is

foot adjusting screw to your right.

become weaker.

kind

of sewing cloth

The

feeding power of the cloth varies according to the

but

it is

about

—12—

3kg~8kg.

turnedtoyour

up

then

push

and

turn

(6.6 lbs~17.61bs)

condition,

the

push

the

presser

presser foot

the presser

left, it will

Page 15

12. Adjusting the stitch

To change the stitch length, do as follows:

Push the push button

the hand wheel

carved

tell my

hand

part

When

the tip of the button has

feeling

wheel.

2;

of the

it) match the graduation

The

scaleonthe

leng^th

(Fig.

11)

(X)

attached to the upper

face

coverand rotate

slowly toward you until the button falls into the

ratchet

pawl.

fallen

into the

figure

hand

wheelisshowninmm.

carved

part,

with the mark on the

When this adjustment is completed, do not touch this button ever

during

the

running

of the machine.

(you

can

Fig.

11

IV ADJUSTING

1. How to remove

the

sewing hook (Fig. 12)

THE

MACHINE

The removing of the sewing hook is exactly like any other industrial

sewing machines.

The

only

difference is

— 13 -

that

the

hook is so-called front

Page 16

type which means it is facing the operator.

To

remove

raise

up

positioner

remove

the

lever®and

hook,

remove

the

needle

needle might break)

the

the

needle

installing

thread

by

the

is in

sewing

bar to

screw®and

pull-off

loosening

sewing

lowered

hook.

hook,

the

lever

set

the3set

(Be

position

tilt

the

uppermost

remove

screw

screws(Dwhich

careful

when

machine

position,

the

needle

remove

when

you

take

head

you

to the

remove

positioner.

the

thread

are

do

this

the

hook

other

the

needle

Next,

pull-off

clamping

because

out, the

side,

the

if

Fig.

12

Page 17

2.

Relation

between

the

needle

and

the

sewing

hook

The relationship between the needle and the sewing hook is as

shown in Fig. 13--lb.

At

first,

if the installed position of the zigzag forked rod triangle

cam

which throws

of

"needle

the

needle

barisnot

correct, the so-called malfunction

flow" occurs (when the needle is piercing the cloth, the

needle sways sidewaysj. Adjust the position of this cam as shown in

Fig. 14 so

that

it will function properly.

To determine the position of the needle throw, remove the cap (Fig.

5

(ij)!

near the arm thread guide bar,

loosen

the set screw of the bevel

gear of the main shaft, and as you watch the needle drop, adjust the

position by slowly sliding the position ol the gear

and

at the correct

position of the needle throw, tighten the set screw of the gear securely.

(Fig. 13, 14, 15, 16).

Start

motion

Throat

plate

Needle

of

Endofneedle

motion

I-g.

13

Needle hole of

Start

needle

Needle

motion

of

|

the

stitching

Fig.

Fig.

-

, 'il 1

throat

15

Needle

\]IEnd

.1

needle

motion

Throat

14

plate

16

—

of

Needle

Start

needle

motion

plate

stitching

Needle

of

Fig.

' End of

eedle

lotion

15

Page 18

Next,

to adjust the

position

of the

needle

drop,asshowninFig.

16,

the needle should be so adjusted that it will drop not too far to left ®

or too far to right

is the correct

correct position, loosen the eccentric shaft set screw ®

shaft(Dis rotated by a

left, so

adjust

To match the

see

that

no skip stitching should occur.

ing hook point

(Fig. 18)

The correct relation between the needle and the tip of the

hook

should

needle

needle

the

line

base.

center of the needle and the point of the sewing hook match each other.

bar

bar with the

needle

below

bar.

the

At this point, install the

Thus, when the needle has risen to

the center of the needle and the point of the

cide and the

the point of the hook becomes

(g)

but should throw uniformly to the center ©. This

position

with this eccentric shaft.

and

of the

sewing

the needle should be 0.0—0.1mm as a

screw

hook

needle

drop

driver, the

with the

The

position.

needle

needle

clearance between the sew

To adjust to this

and

will lean to right or

eye,

if the eccentric

it is

necessary

standard.

sewing

be such that with the width of throw at

to the lowest position, match the indicated line above the

lower

Next,

needle

bar

rotate

with

part of the

the

the

needle

hand

lower

sewing

bar vibrating

wheel

and

part of the

hook in such a way that the

1.75mm

above its

sewing

clearance

between

1.6—1.7mm.

the upper part of the

(Fig.

19)

"0",

bring the

base

match

needle

the

indicated

barvibrating

lowest

hook should coin

needle

eye

and set

point,

and

to

—16—

Page 19

I

-Mi

Fig.

17

3.

When

synthetic

threadisused

Fig.

(T)

Hook point

®

Needle

Fig.

16

18

When some synthetic thread is to be used for some purpose, attach

an Eslen case

between the 2 sheets of felt

(2)

on top of the thread guide plate

(D

and pass it through the thread hole ® of

(D,

pass the thread

the thread guide bar. When you do this, do not clamp the synthetic

thread on the thread tension disc (|) which is on the upper part of the

thread

guide

bar.

(Fig. 20)

—

17

—

Page 20

Fig.

For

5—lOgr,

19

synthetic

thread,

the needle thread

make

the

from-35-45

tension

gr, the stroke of the take-upspring

of

the

Fig.

bobbin

20

thread

from

from II—14mm and its tension about 20gr.

Also

the relative position of the sewing hook point with the needle

should be such

the

hook

from the

that

point

should coincide

lowest

when the

width

of throw is 0, the needle center

when

the

needle

bar

has risen 1.2—1.4mm

and

point, and also the needle bar and the sewing hook is

so set that the distance between the needle eye's upper point and the

pointofthe

♦

Winding

hook comes to

amount

of

the

1.7—2.1

bobbin

mm.

thread

The bobbin thread

should

be wound about

70%

during the

sewing.

Page 21

LZ-582

LZ-582

B-I524-582-0A0

B-J109-582-000

B-l

613-582-000

LZ-582

Q

^8

Jt\

0

B-I524-582-CA0

8-1109-582-000

B-I6I3-582-000

LZ-582

1

0

1

0

B-I524-582-DA0

B-II09-582-D00

B-I6I3-582-D00

B-I524-582-EA0

B-tl09-582-E00

B-I6I3-582-E00

< >

O 1

^

kil—t

Y '

-u

= 1

Page 22

LZ-582

0

LZ-582

Fffcl

B-I524-582-FA0

B-M09-582-F00

B-I6I3-582-F00

LZ-583

B-l524-5a3-0A0

~2I

S

E

"nnrn

"Tnrm

B-IS24-982-MAd

B-II09-582-M00

B-16I3-582-M00

LZ-583

B-I524-583-BA0

'=z

_ •

f

i

8-1109-583-000

8-1613-583-000

S-l.109-583-000

8-1613-583-000

Page 23

LZ-583

B-I524-583-CA0

LZ-583

B-I524-583-EA0

©

B-1109-583-000

B-I6I3-583-000

LZ-583

B-I524-583-FA0

B-II09-383-F00

'B-I6I3-583-F00

B-II09-583-E00

B-I6I3-583-E00

LZ-583

:

i

B-I524-583-6A0

B-II09-583-G00

B-I6I3-583-G00

•«!

Page 24

LZ-583

LZ-583

B-l524-5e3-HA0

B-II09-583-H00

B-I6I3-583-H00

LZ-583

8-1524-583-J

80

.

,

•3D

6-11.4

to

B-I524-5S3-JA0

B-M09-583-D00

B-I6I3-583-D00

LZ-583

rM1

0

o

8-1524-583-KAO

8-1109-583-000

8-1613-583-000

8-1109-583-000

B-I6I3-583-000

Page 25

LZ-583

fpte=®'

(0)

LZ-583

0

B-I524-583-KB0

B-II09-583-D00

8-1613-583-000

LZ-582, 583

No

Model

Needle

1

LZ-S82

B-U09-S82-000

2

'

a

3

K-1109-582-lX)0

4

3-1109-582-E00

5 "

B-I109-S82-F(I0

a

6

B-U09-582-M0O

1

LZ-583

B-1109-583-000

a

2

a 9 m

3

a

4

B-1I09-583-E00

S

'

B-1109-S83-FA0

6

•

B-1109-583-GA0

7

B-1109-S83-H00

a

8

B-1109-583-D00

a

9

a 9 9

10

11

12

•

B-I109-583-E00

LISTOFEXCHANGING

Plate

Presser

a a

# M

9 9

9 9

B-1S24-582-0A0

B-1524-S82-CA0

B-1S24-582-DA0

B-1524-S82EA0

B-1524-582-FA0

B-1S24S82-MA0

B-1524-583'0A0

B

1524-583-BA0

B-1S24-583-CA0

B-1524-S83-EA0

B-1S24-S83-FA0

B-1524-583GA0

B-1S24-S83-HA0

B-1524-583-JA0

B-1524-S83-JB0

B-1524-S83-KA0

B-1S24-S33-KB0

B-1S24-S83-LA0

Foot

PARTS

Feed

dos

B-I613-S82-000

9 9

B-16I3-682-D00

B-16I3-582-EOO

B-1613-582-F00

B-1613-582-M00

B-16I3-S83-000

a a

a a

B-1613^583-E00

B-1613

583-FOO

B-1613-S83-G00

B-1613-583-H00

B-1613-S83-DOO

'

a a a

B-1613-S83-E00

B-I524-583-LA0

B-II09-583-E00

B-I6I3-583-E00

WidthofThrow

6 mm

(1/4')

'

5 mm

(3/16')

'

6

mm

5

mm

4mm

(5/32')

'

a

4

mm

9

3 mm

(1/8')

2mm

(1/16')

3

mm

3

mm

9

•

< M

M

Usase&Remarks

Standard

parts

For

garments

requiring stepped stitches

For

light

weight

materials

For

overseaming

For

spun

tex

materials

Standard

type

parts

Standard

parts

For medium heavy materials requiring

stepped

stitches

For light weight materials requiring

stepped

stitches

For heavy weight materials requiring

stepped

stitches

For

light

weight

materials

tricot

stitches

Light weight materials, overseaming

Light

weight

width

Extreme

Zigxag

Extreme

Zigxag

Light

Zigxag

Light

Overseaming

materials

2mm

light

weight materials

width

less

than

light

weight

width

weight

width

9 9 9

weight

materials

less

than

materials

less

than

materials

widthofthrow

run

xigzag

3 mm

3mm

3mm

3mm

Page 26

TMYI

Head

Office&Plank

Business

Cable

Office:

Address:

JUKI

jiim

2-1,

23|

JUKI

8-chome,

Kabuki-cho,

TOKYO

INDV8TIIAI

Kokuryo-cho,

Shinjuku-ku,

Telex;

22967

Chofu-shi,

Tokyo,

JUKITK

C0..1TD.

Tokyo,

Japan

Japan

Loading...

Loading...