R

Computer-controlled, Direct-drive,

High-speed, 1-needle, Lockstitch,

Zigzag Stitching Machine (Quick-reverse type)

LZ-2290A-SR

/ IP-100D / SC-916

INSTRUCTION MANUAL

NOTE : Read safety instructions carefully and understand them before using.

Retain this Instruction Manual for future reference.

E-No.01

40016921

IMPORTANT SAFETY INSTRUCTIONS

Putting sewing systems into operation is prohibited until it has been ascertained that the sewing systems in

which these sewing machines will be built into, have conformed with the safety regulations in your country.

Technical service for those sewing systems is also prohibited.

1. Observe the basic safety measures, including, but not limited to the following ones, whenever you use the

machine.

2. Read all the instructions, including, but not limited to this Instruction Manual before you use the machine.

In addition, keep this Instruction Manual so that you may read it at anytime when necessary.

3. Use the machine after it has been ascertained that it conforms with safety rules/standards valid in your

country.

4. All safety devices must be in position when the machine is ready for work or in operation.

The operation without the specified safety devices is not allowed.

5. This machine shall be operated by appropriately-trained operators.

6. For your personal protection, we recommend that you wear safety glasses.

7. For the following, turn off the power switch or disconnect the power plug of the machine from the

receptacle.

7-1 For threading needle(s), looper, spreader etc. and replacing bobbin.

7-2 For replacing part(s) of needle, presser foot, throat plate, looper, spreader, feed dog, needle guard, folder,

cloth guide etc.

7-3 For repair work.

7-4 When leaving the working place or when the working place is unattended.

7-5 When using clutch motors without applying brake, it has to be waited until the motor stopped totally.

8. If you should allow oil, grease, etc. used with the machine and devices to come in contact with your eyes or

skin or swallow any of such liquid by mistake, immediately wash the contacted areas and consult a medical

doctor.

9. Tampering with the live parts and devices, regardless of whether the machine is powered, is prohibited.

10. Repair, remodeling and adjustment works must only be done by appropriately trained technicians or

specially skilled personnel. Only spare parts designated by JUKI can be used for repairs.

11. General maintenance and inspection works have to be done by appropriately trained personnel.

12. Repair and maintenance works of electrical components shall be conducted by qualified electric

technicians or under the audit and guidance of specially skilled personnel.

Whenever you find a failure of any of electrical components, immediately stop the machine.

13. Before making repair and maintenance works on the machine equipped with pneumatic parts such as an air

cylinder, the air compressor has to be detached from the machine and the compressed air supply has to be

cut off. Existing residual air pressure after disconnecting the air compressor from the machine has to be

expelled. Exceptions to this are only adjustments and performance checks done by appropriately trained

technicians or specially skilled personnel.

14. Periodically clean the machine throughout the period of use.

15. Grounding the machine is always necessary for the normal operation of the machine. The machine has to

be operated in an environment that is free from strong noise sources such as high-frequency welder.

16. An appropriate power plug has to be attached to the machine by electric technicians. Power plug has to be

connected to a grounded receptacle.

17. The machine is only allowed to be used for the purpose intended. Other used are not allowed.

18. Remodel or modify the machine in accordance with the safety rules/standards while taking all the effective

safety measures. JUKI assumes no responsibility for damage caused by remodeling or modification of the

machine.

19. Warning hints are marked with the two shown symbols.

Danger of injury to operator or service staff

Items requiring special attention

i

FOR SAFE OPERATION

1. To avoid electrical shock hazards, neither open the cover of the electrical box nor

touch the components mounted inside the electrical box.

1. To avoid personal injury, never operate the machine with any of the finger guard or

safety devices removed.

2. To prevent possible personal injuries caused by being caught in the machine, keep

your fingers, head and clothes away from the handwheel while the machine is in

operation. In addition, place nothing around it.

3. To avoid personal injury, never put your hand under the needle when you turn “ON”

the power switch or operate the machine.

4. To avoid personal injury, never put your fingers into the thread take-up cover while the

machine is in operation.

5. The hook rotates at a high speed while the machine is in operation. To prevent possible

injury to hands, be sure to keep your hands away from the vicinity of the hook during

operation. In addition, be sure to turn OFF the power to the machine when replacing

the bobbin.

6. To avoid possible personal injuries, be careful not to allow your fingers in the machine

when tilting/raising the machine head.

7. To avoid possible accidents because of abrupt start of the machine, turn OFF the

power to the machine when tilting the machine head or performing replacement of

parts, adjustment of the machine, etc.

8. The motor does not produce noise while the machine is at rest. To avoid possible

accidents due to abrupt start of the machine, be sure to turn OFF the power to the

machine.

9. To avoid electrical shock hazards, never operate the sewing machine with the ground

wire for the power supply removed.

10. To prevent possible accidents because of electric shock or damaged electrical

component(s), turn OFF the power switch in prior to the connection/disconnection of

the power plug.

11. To prevent fires, periodically draw out the power plug from the plug socket and clean

the root of the pins and the space between pins.

12. Do not turn OFF the power switch while the machine is in operation.

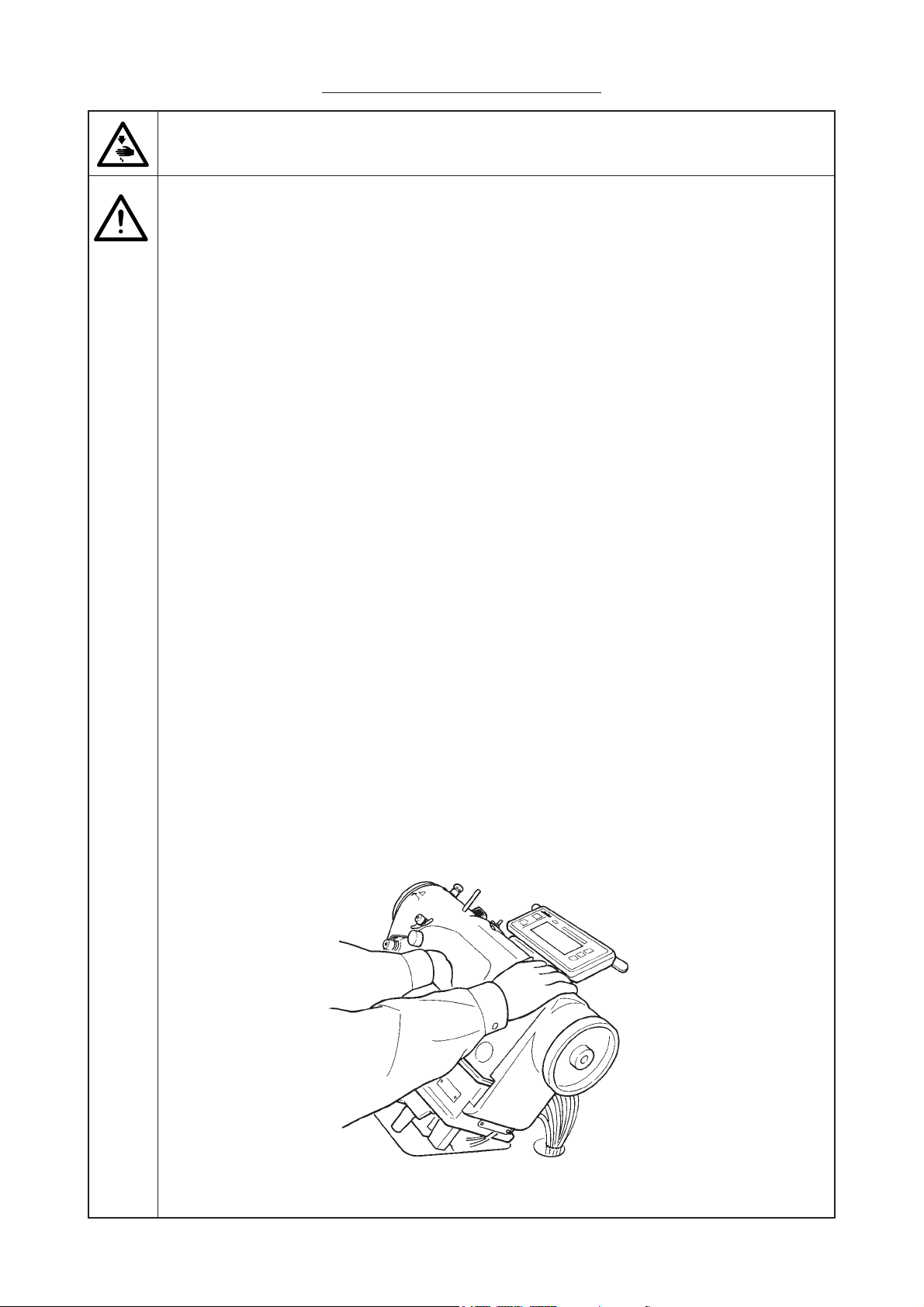

13. Hold the upper side of the machine head with both hands and perform the work quietly

so as not to allow your fingers or the like to be caught in the machine when tilting the

machine head or returning it to the home position.

14. Be careful that any load is not applied to the operation panel section.

ii

CAUTION BEFORE OPERATION

WARNING :

To avoid malfunction and damage of the machine, confirm the following.

• Remove the air-vent cap (red color) attached to the sewing machine bed.

• Be sure to fill the oil tank with oil before use.

• Remove the needle bar stopper.

• Clean the sewing machine thoroughly before using it for the first time.

• Remove all dust collected on the sewing machine during the transportation.

• Confirm that the voltage and phase are correct.

• Confirm that the power plug is properly connected.

• Never use the sewing machine in the state where the voltage type is different from the designated

one.

• The direction of rotation of the sewing machine is counterclockwise as observed from the

handwheel side. Be careful not to rotate it in reverse direction.

• Do not tilt the machine head toward this side since oil leakage or parts breakage occurs.

•A safety switch is installed so that the sewing machine cannot be operated with the machine

head tilted.

When operating the sewing machine, turn ON the power switch after properly setting the head on

the table.

• Before starting a test run, remove the bobbin case and the needle thread from the machine.

• For the first month after set-up, use the machine at a reduced sewing speed of 3,000 rpm or less.

• Operate the handwheel after the sewing machine has totally stopped.

iii

CONTENTS

1. NAME OF EACH COMPONENT ............. 1

2. SPECIFICATIONS ................................... 2

2-1. Specifications of the machine head .......... 2

2-2. Specifications of the electrical box ........... 2

3. STITCH PATTERN TABLE ..................... 3

3-1.

Initial value of the stitch pattern and the table ....

4. INSTALLATION ....................................... 6

4-1.

Installation of the sewing machine head ........

4-2. Removing the needle bar stopper ............. 7

4-3. Attaching the knee-lifter ............................. 7

4-4. Adjusting the height of the knee lifter ....... 7

4-5. Installing the electrical box ........................ 8

4-6. Connecting the power switch cord ............ 8

4-7.

Installing the

operation

panel (IP-100(D)) ....

4-8. Connecting the cords ................................. 9

(1) Preparation of wiring .................................... 9

(2) Connecting the connectors ........................ 10

4-9. Attaching the connecting rod................... 14

4-10. Adjustment of the pedal ......................... 15

4-11. Installing the thread stand ...................... 15

Installing the bird’s nest prevention (CB)

4-12.

type sewing machine ..................................

4-13. Lubrication

..................................................

15

17

4-14. Test run .................................................... 18

(1) Turn ON the power .................................... 18

(2) How to operate the pedal ........................... 18

5. PREPARATION BEFORE SEWING ..... 19

5-1. Inserting the needle .................................. 19

5-2. Removing the bobbin case ....................... 19

5-3. Winding the bobbin thread ....................... 19

Placing the bobbin case and the bobbin ....

5-4.

5-5. Threading the machine head .................... 21

5-6. Adjusting the stitch length ....................... 21

Adjusting the condensation stitching ........

5-7.

6.

HOW TO USE THE OPERATION PANEL ...

6-1.

Names and functions of the respective sections ....

6-2. Before setting the pattern ......................... 2

(1) Limitation of the max. zigzag width ............ 24

(2) Setting the reference of stitch base line ..... 26

(3) Setting the feed amount ............................. 27

6-3. Basic screen .............................................. 28

List of the display pictographs of each screen...

6-4.

6-5. Setting the sewing pattern ....................... 52

(1) Selecting the zigzag pattern ....................... 52

6-6. Setting of the sewing shape ..................... 54

(1) Standard zigzag, 2-step zigzag and

3-step zigzag stitch .................................... 54

(2) Scallop stitching ......................................... 56

(3) Blind stitch sewing ..................................... 59

(4) Custom pattern stitching ............................ 60

(5) T stitch, left ................................................. 61

(6) T stitch, right .............................................. 62

(7) Pattern 1 .................................................... 64

(8) Pattern 2 (fagoting) .................................... 65

(9) Pattern 3 .................................................... 67

(10) Pattern 4 .................................................. 69

6-7. Setting of the number of rotations........... 71

20

21

22

22

29

6-8. Reverse feed stitching .............................. 71

(1) Standard condensation .............................. 72

(2) 2-point condensation .................................. 74

(3) Condensation custom ................................ 75

(4) Comparision table of the reverse

stitch of each shape .................................. 76

4

6

8

6-9. Selection of the kind of stitching ............. 77

(1) Overlapped stitching .................................. 77

(2) Programmed stitching ................................ 77

6-10. Custom pattern ........................................ 79

(1) Custom pattern setting ............................... 79

(2) New creation of the custom pattern ........... 80

(3) Custom pattern edit .................................... 81

(4) Registration, copy and deletion

of the custom pattern ................................. 81

6-11. Condensation Custom ............................ 83

(1) Condensation custom setting ..................... 83

(2) Condensation custom edit ......................... 84

6-12. Pattern stitching ...................................... 85

(1) Setting the pattern stitching ....................... 85

(2) Registering the pattern stitching ................ 86

(3)

Copy and deletion of the pattern stitching ....

87

6-13. Continuous stitching .............................. 88

(1) New creation of the continuous stitching ... 89

(2) Continuous stitching edit ............................ 89

(3)

Copy and deletion of the continuous stitching ...

91

6-14. Cycle stitching ......................................... 92

(1) New creation of the cycle stitching ............. 92

(2) Cycle stitching edit ..................................... 92

(3) Copy and deletion of the cycle stitching ..... 94

(4) Teaching .................................................... 95

(5) Performing the programmed stitching

using the cycle stitching ............................ 96

6-15. Counter ..................................................... 96

(1) Thread trimming counter ............................ 96

(2) Bobbin thread counter ................................ 96

6-16. Information ............................................... 97

(1) Sewing common data ................................ 98

•

Limiting procedure of max.zigzag width limitation ..

4

• Max.zigzag width limitation value ....................98

• Reference of stitch base line .......................... 98

• Reverse feed limitation value ......................... 98

• Normal feed limitation value ............................98

• Mirror function setting ...................................... 99

Position of the stitch base line of condensation custom ..

•

• Counter function ..............................................99

• Key lock ........................................................... 99

• Selection of max. zigzag width limitation

display when the power is turned ON ............

(2) Sewing management information ............ 100

(3) Communication mode .............................. 103

98

99

99

6-17. Setting for functions ............................. 107

(1) How to change over to the function

setting mode ............................................ 107

(2) Function setting list .................................. 110

(3)

Detailed explanation of selection of functions....

114

6-18. External interface .................................. 119

(1) Smart media slot ...................................... 119

(2) RS-232C port ........................................... 119

(3)

General input port (Production control

switch

connecting connector) ................... 119

iv

7. SEWING............................................... 120

7-1. Adjusting the thread tension .................. 120

7-2.

Adjusting the pressure of the presser foot ..

7-3. One-touch type reverse feed

stitching mechanism .............................. 121

7-4. Pattern 2 (fagoting) sewing .................... 122

7-5. Hand switch ............................................. 123

121

8. STANDARD ADJUSTMENT ............... 124

8-1.

Adjusting the amount of oil in the hook ...

Adjusting the amount of lubricating to face

8-2.

plate section .................................................

8-3.

Adjusting the height of the presser bar ....

Adjusting the micro-lifting mechanism

8-4.

of the presser foot .....................................

8-5.

Height and inclination of the feed dog ......

8-6. Hook adjusting mode .............................. 126

8-7. Attaching / removing the hook ............... 127

8-8. Adjusting height of the needle bar ........ 128

8-9. Adjusting the needle-to-hook

timing and the needle guard .................. 128

8-10.

Adjusting the stop position of the needle ..

8-11. Adjusting the thread trimmer ............... 129

8-12. Adjusting the needle thread

feeding device ....................................... 130

8-13. Adjusting the bird’s nest

prevention (CB) type wiper .................. 131

8-14.

Replacing procedure of the bird’s nest

prevention (CB) type presser knife .......

124

124

125

125

125

129

132

9. MAINTENANCE

9-1. Replacing the power fuse ....................... 133

Adjusting the contrast of the operation

9-2.

panel display .............................................

9-3. Draining

(Bird’s nest prevention (CB) type only) .......

9-4. Cleaning the dust bag

(Bird’s nest prevention (CB) type only) .......

9-5. Cleaning the cooling fan ......................... 135

9-6. Cleaning the hook section ...................... 135

9-7.

Cleaning the rear cover of the control box ...

9-8. Cleaning the operation panel screen .... 135

9-9. Replacing procedure of the hook

shaft oil wick ........................................... 136

...................................

133

134

134

134

135

9-10. Applying the exclusive grease ......... 136

10. AT A TIME LIKE THIS !..................... 137

11. ERROR DISPLAY.............................. 138

11-1.

Error code list (Error display in panel)

139

...

12. TROUBLES AND CORRECTIVE

MEASURES ....................................... 143

v

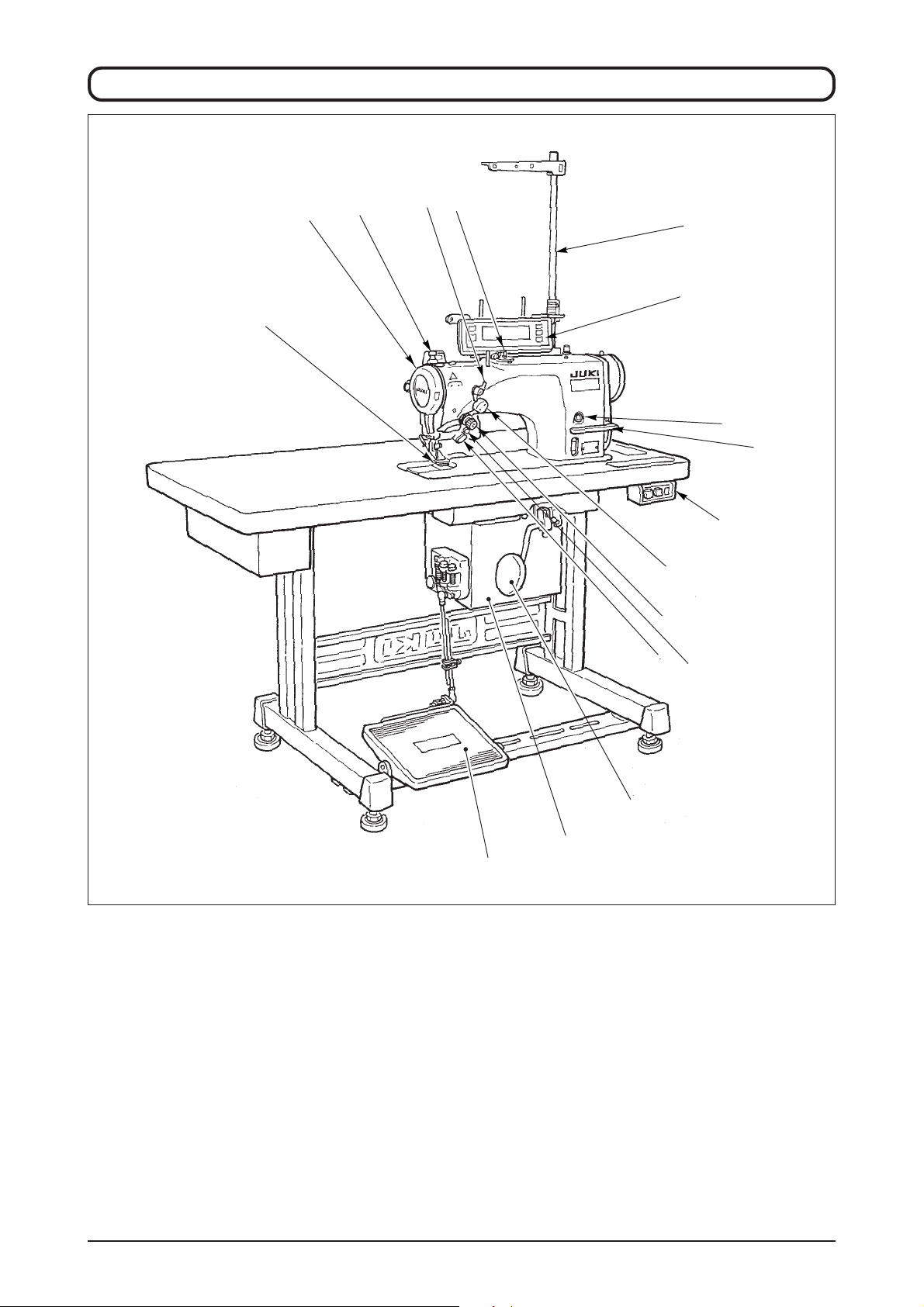

1. NAME OF EACH COMPONENT

!3

!2

4

3

2

!4

!1

!5

!7

9

1

5

!0

!6

8

6

7

1 Needle thread draw-out device 8 Knee lifter lever !5 Oil supply opening

2 Wiper switch 9 Power switch !6 Mirror inversion switch

3 Thread take-up cover !0 Hand switch !7 Reverse feed control lever

4 Finger guard !1 Control panel

5 Thread tension controller (Rotary tension) !2 Bobbin winder

6 Electrical box !3 Tension controller No.1

7 Pedal

(Pre-tension)

!4 Thread stand

1

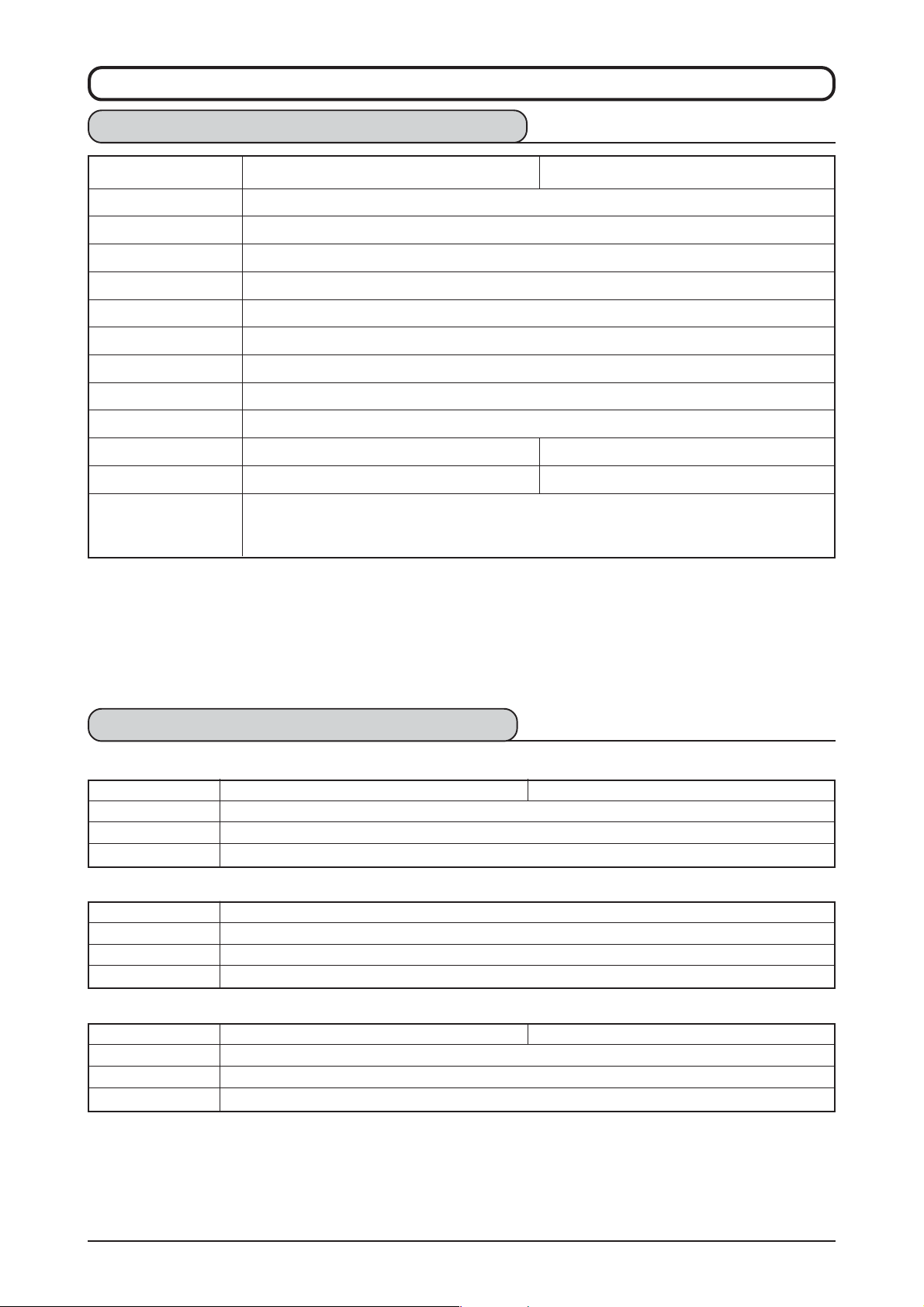

2. SPECIFICATIONS

2-1. Specifications of the machine head

Model LZ-2290A-SR-7-WB LZ-2290A-SR-7-CB

Application Light-weight materials to medium-weight materials

Max. sewing speed 5,000 rpm (*1)

Max. zigzag width 10 mm (*2)

Max. feed pitch 5 mm (normal/reverse feed)

Stitch pattern 14 kinds 20 patterns

Needle SCHMETZ 438 #75 (Needle at the time of delivery)

Oil used JUKI New Defrix Oil No. 1

Thread trimmer With

Feed method Standard feed (Computer controlled system)

Wiper method Front sweeping method Side sweeping method

Thread clamp method ――― Air clamp method

Noise Workplace-related noise at sewing speed

Minute-quantity

( )

lubricating type

n=4,500 min-1 : LPA ≦ 81 dB(A)

Noise measurement according to DIN 45635-48-A-2

* 1. The max. sewing speed is set to 4,000 rpm at the time of delivery (depending on the delivery area).

• The speed is limited by setting of the zigzag width of the sewing pattern and feed amount since the

speed is controlled by the amount of zigzag width per stitch and feed amount.

• Properly set the number of revolution in accordance with the product to be sewn and process.

* 2. Max. zigzag width is limited to 8 mm at the time of standard delivery.

2-2. Specifications of the electrical box

■ For general export

Supply voltage Single phase 200V / 220V / 240V 3-phase 200V / 220V / 240V

Frequency 50 Hz / 60 Hz

Electric power 600VA

Operating environment

■ For CE

Supply voltage Single phase 220V / 230V / 240V

Frequency 50 Hz/60 Hz

Electric power 600VA

Operating environment

■ For JUS

Supply voltage Single phase 100V / 110V / 120V 3-phase 200V / 220V / 240V

Frequency 50 Hz / 60 Hz

Electric power 600VA

Operating environment

Temperature : 0 to 40˚C Humidity : 90% or less

Temperature : 0 to 40˚C Humidity : 90% or less

Temperature : 0 to 40˚C Humidity : 90% or less

2

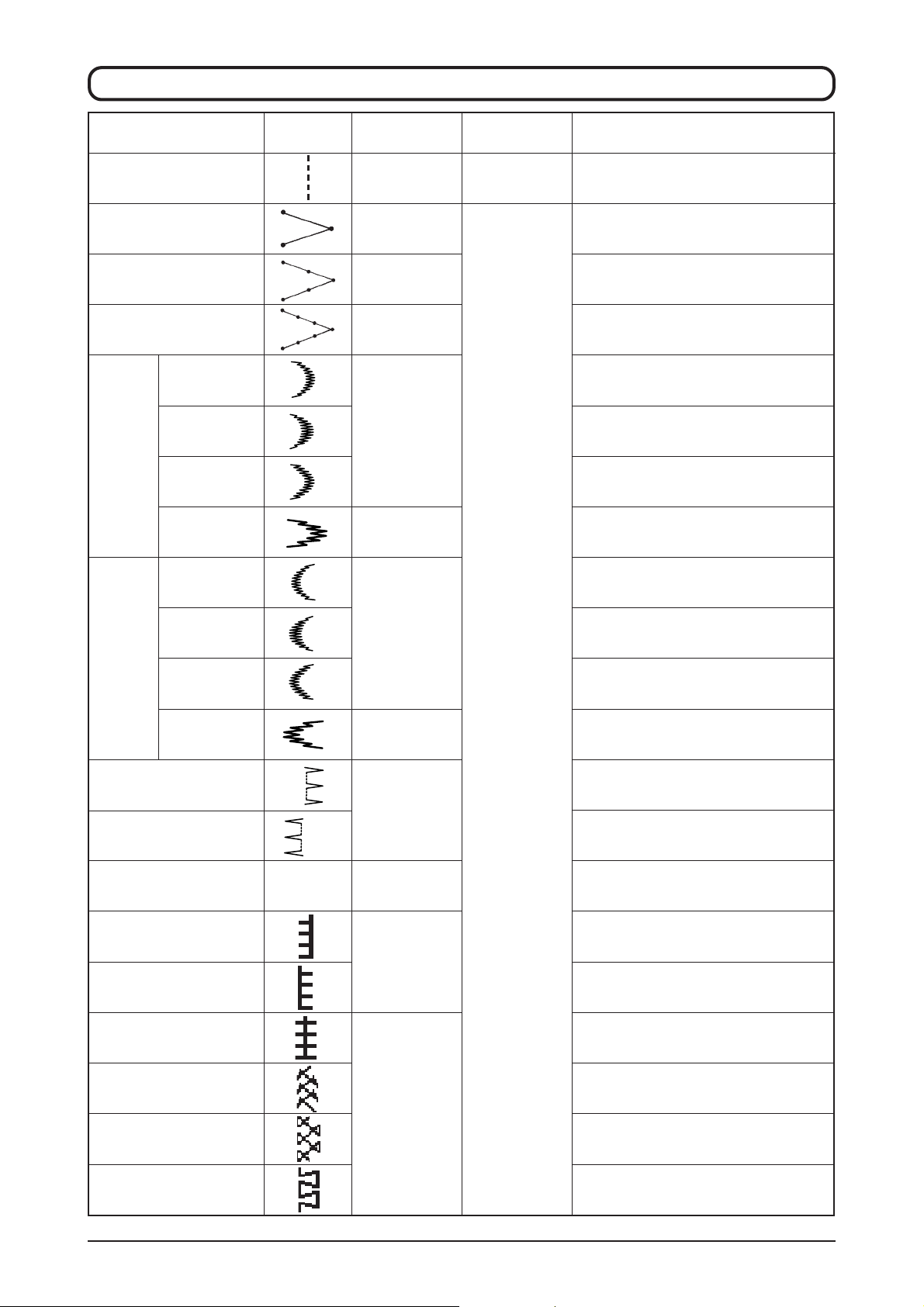

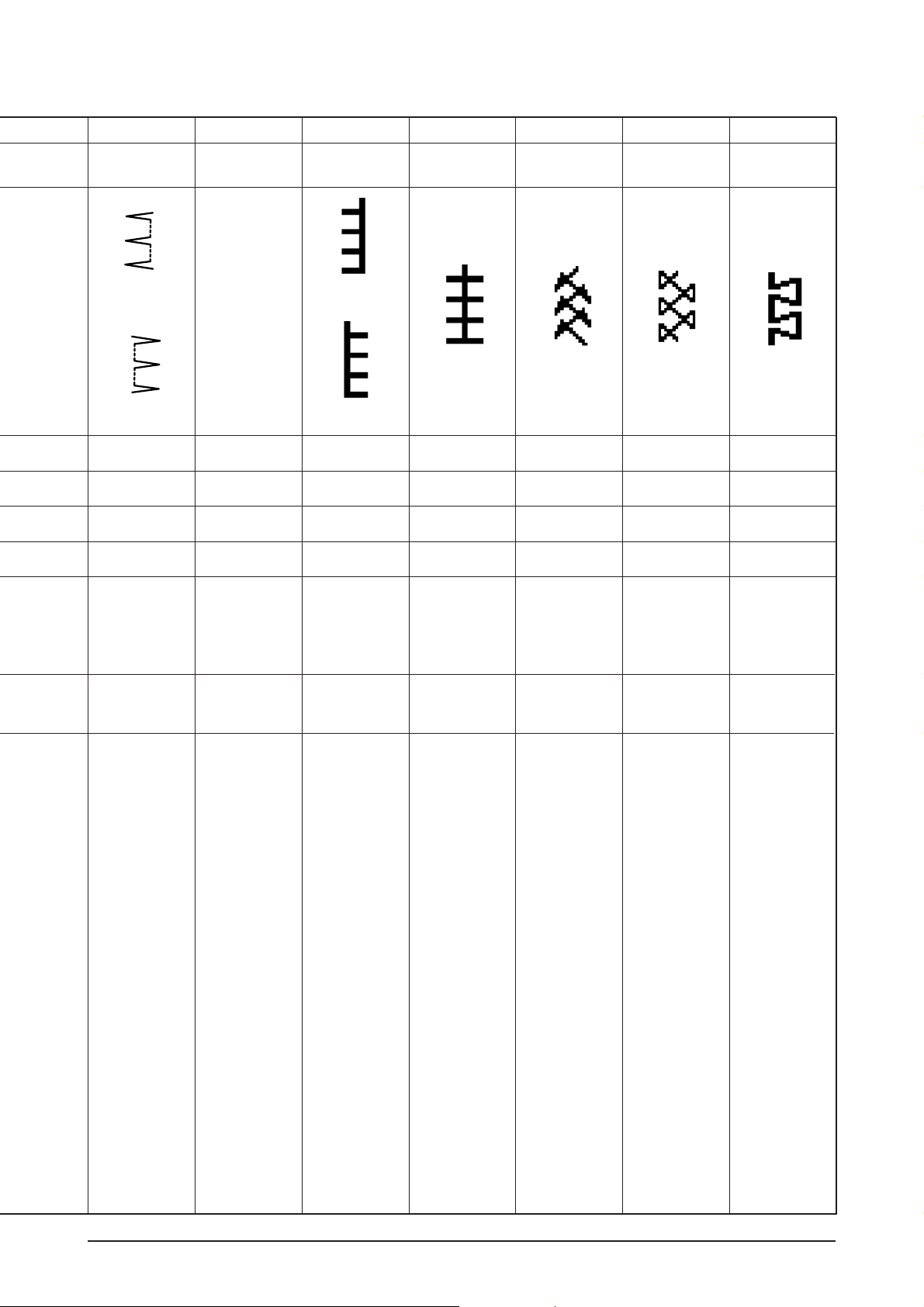

3. STITCH PATTERN TABLE

Name of pattern

Straight stitch

Standard zigzag stitch

2-step zigzag stitch

3-step zigzag stitch

Standard

scallop

Crescent

Scallop

(right)

scallop

Equal-width

scallop

Equal-width

scallop

Stitch

pattern

Number of stitches

for pattern

1

2

4

6

24

12

Max.zigzag

width

――

Remarks

Standard

scallop

Crescent

Scallop

(left)

Blind stitch (right)

Blind stitch (left)

Custom pattern

T stitch (left)

T stitch (right)

scallop

Equal-width

scallop

Equal-width

scallop

a

――

24

10

12

{

A

2 +

{

a

500

3

Pattern 1

Pattern 2 (fagoting)

Pattern 3

Pattern 4

6

3

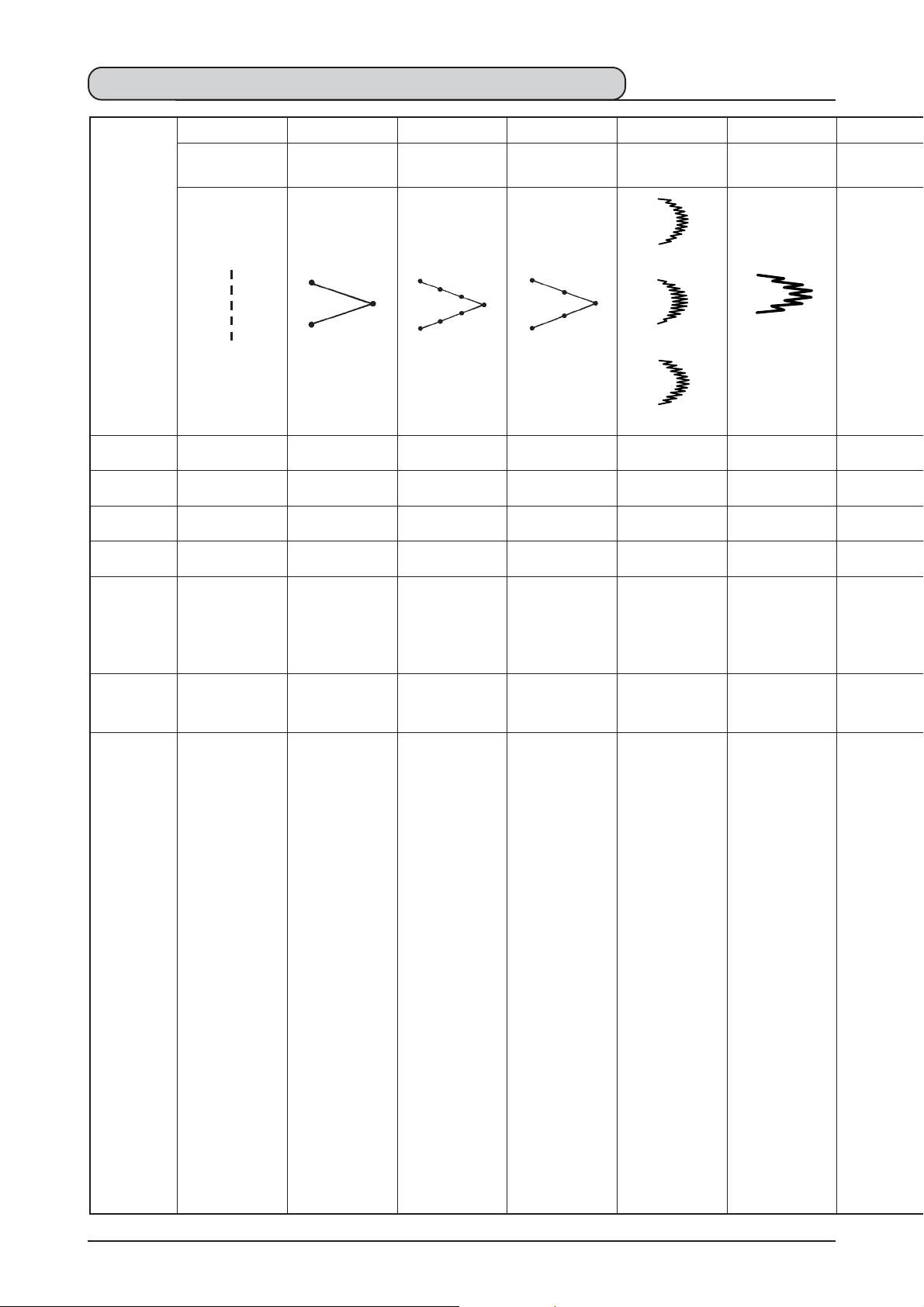

3-1. Initial value of the stitch pattern and the table

123456

Straight stitch

Standard zigzag

stitch

3-step zigzag

stitch

2-step zigzag

stitch

Scallop 24

stitches

Standard scallop

Scallop 12

stitches

Zigzag width

Normal feed

amount

Reverse feed

amount

Number of

stitches

Related

input

Related

mechanical

adjustment

――

2.0

0.0

――

31, 54, 55

P

4.0

1.5

0.0

――

32, 54, 55

P

8.0

1.0

0.0

――

32, 54, 55

P

6.0

1.0

0.0

――

32, 54, 55

P

Crescent scallop

Equal-width scallop

8.0

0.5

0.0

――

P 32, 33, 56,

57, 58, 98,

99

P123 P123

Equal-width scallop

8.0

0.8

0.0

――

P 32, 33, 56,

57, 58, 98,

99

Remarks

4

7

Blind stitch

a

{

8

Custom pattern

9

T stitch

10

Pattern 1

11

Pattern 2

(Fagoting)

12

Pattern 3

13

Pattern 4

(Left)

a

{

(Right)

3.0

1.5

0.0

4

P 34, 59

―――

――

――

――

――

P 45, 60, 79,

80, 81, 82,

83, 98, 99

(Left)

(Right)

3.0

2.5

0.0

――

P35, 36, 37

38, 61, 62,

63

6.0

2.5

0.0

――

P 37, 38, 64,

65

6.0

1.6

– 2.0

――

P 39, 40, 65,

66, 67

P122

70

6.0

2.0

– 2.0

――

6.0

2.1

2.4

――

P 41, 42, 67,68P 43, 44, 69,

There are

cases where

the stitch

shapes are

not stabilized

in case of

some patterns

which

frequently

repeat

normal and

reverse feed

stitching.

Use the

machine at

the sewing

speed of

approximately

2,000 rpm.

5

4. INSTALLATION

WARNING :

• Perform the installation of the sewing machine by the technical personnel who have been trained.

• To prevent personal injury, ask our dealer or the electrician for electric wiring.

• Be sure to perform the work with two persons or more when transporting the sewing machine and use a

lorry when moving it.

• To prevent personal injury caused by abrupt start of the sewing machine, do not connect the power plug

until the set-up of the sewing machine is completed.

• Be sure to earth the ground wire to prevent personal injury caused by leak.

• Be sure to attach safety protection cover, figer guard, etc.

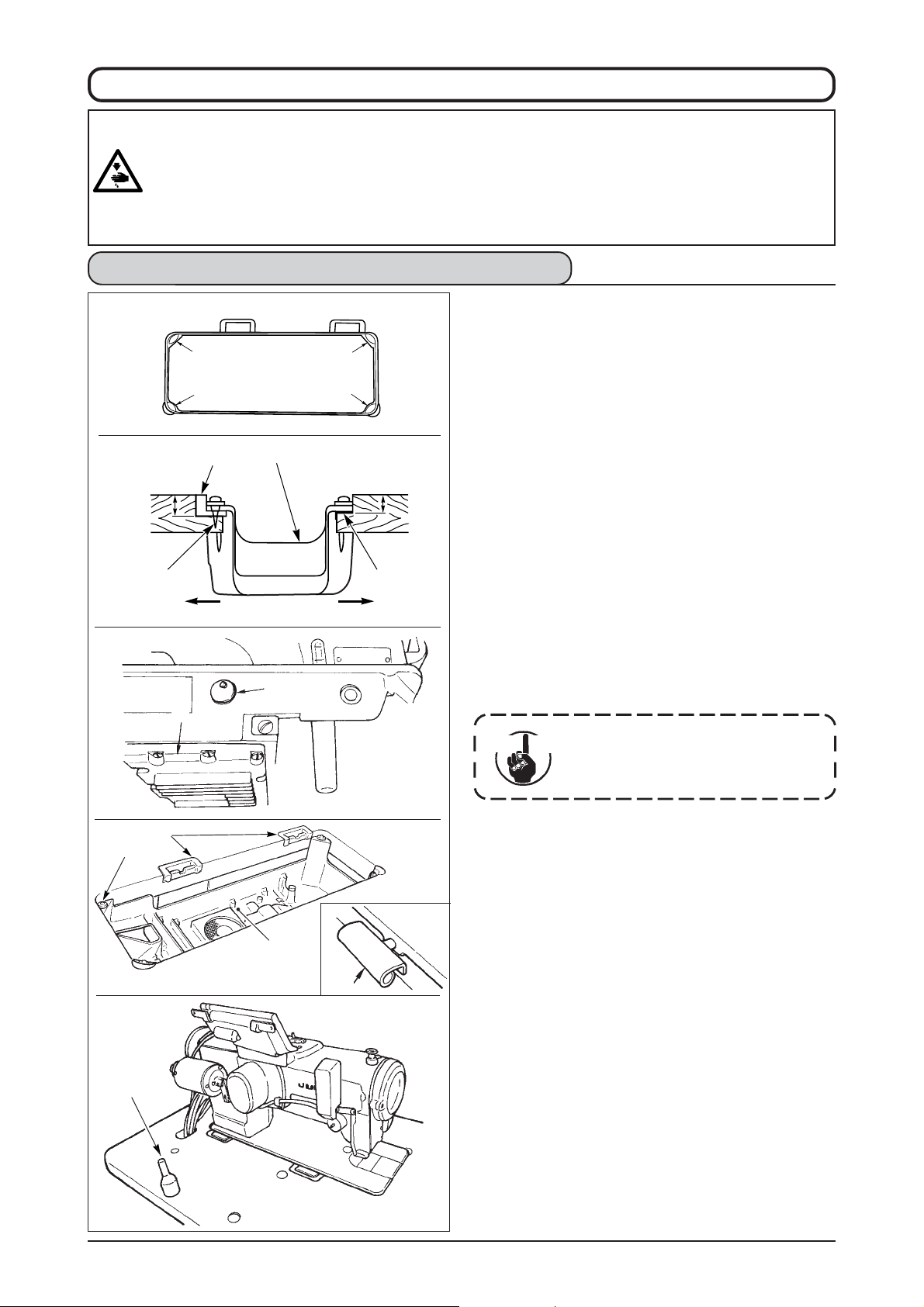

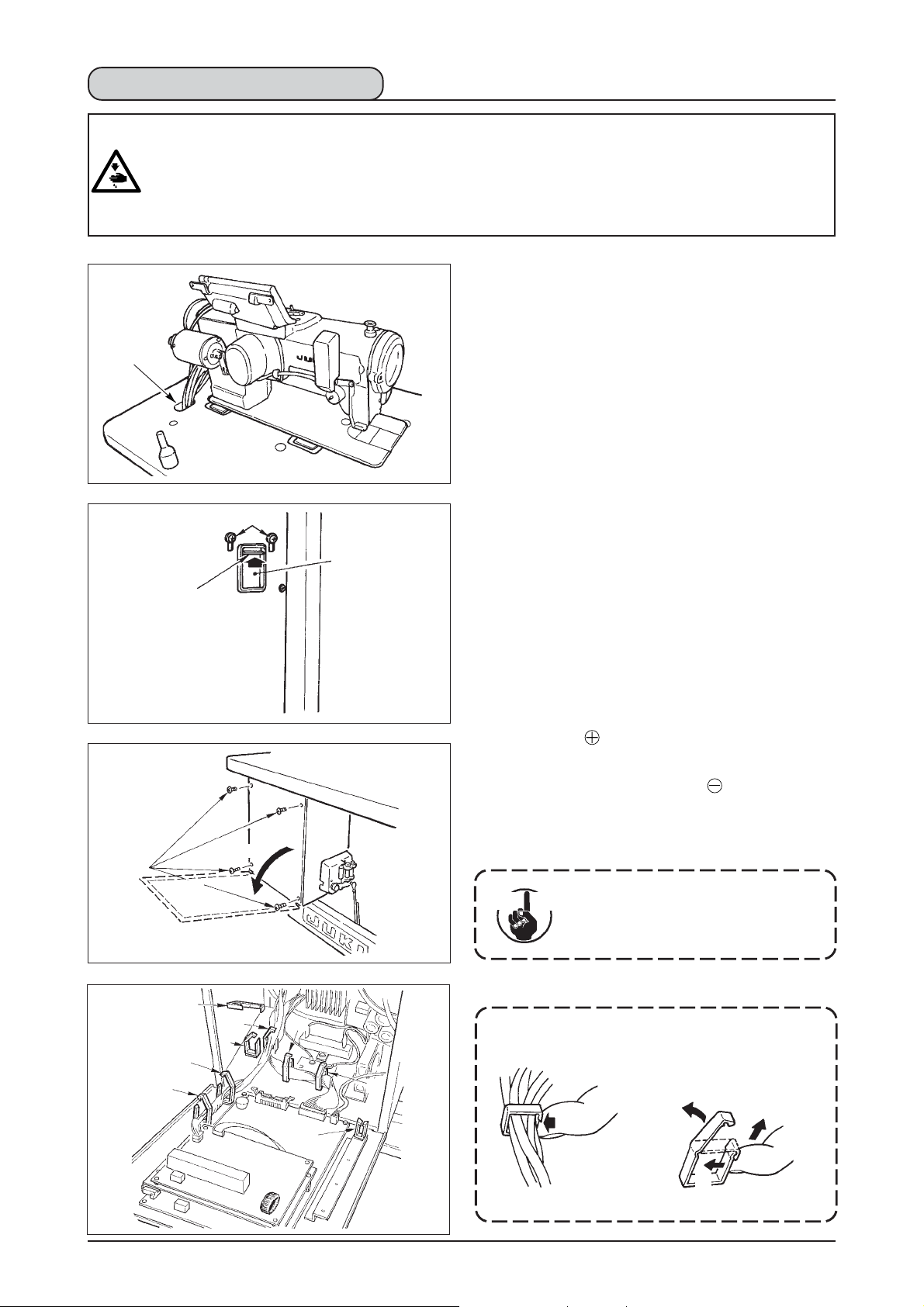

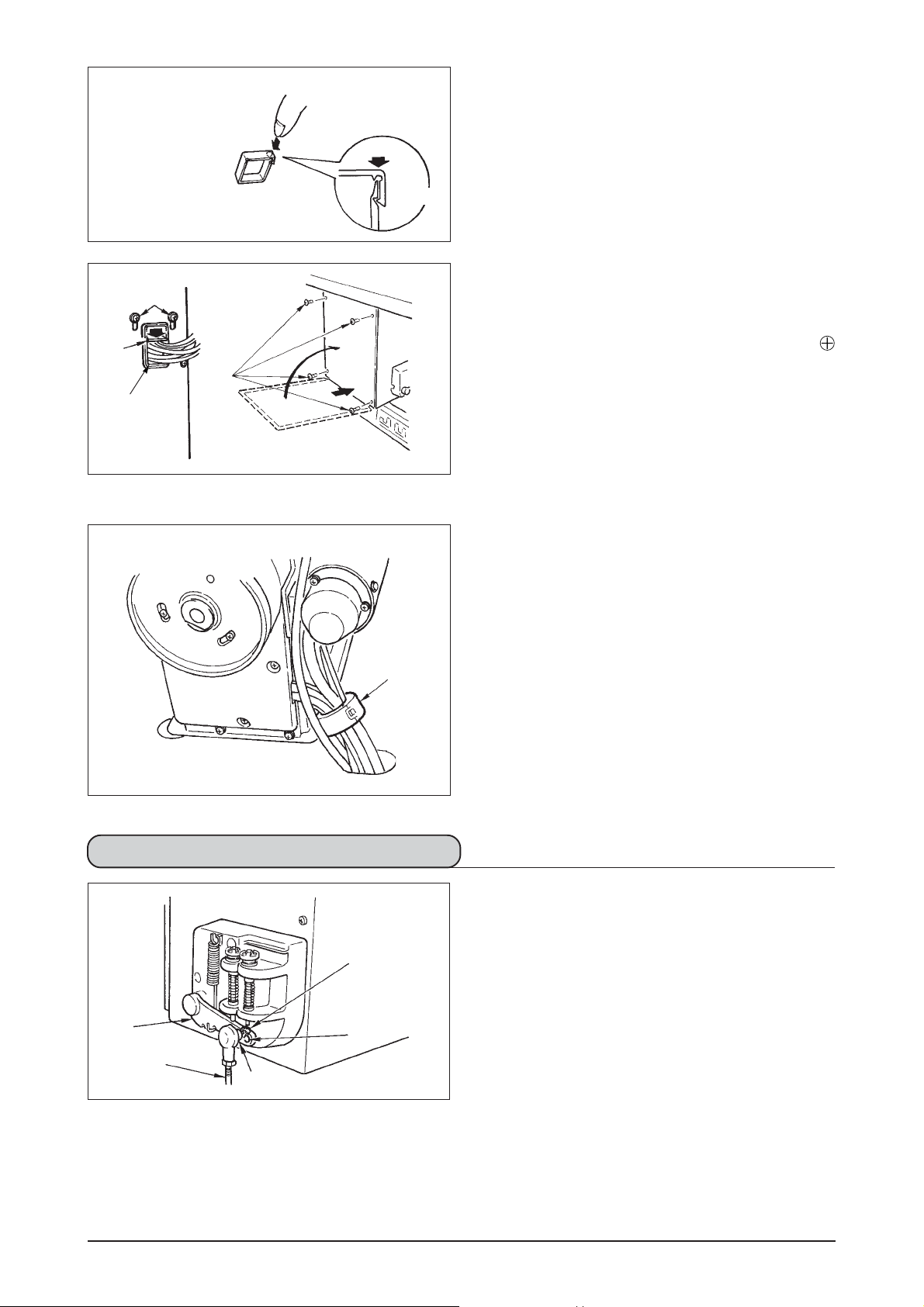

4-1. Installation of the sewing machine head

■ Installing the under cover

1) The under cover should rest on the four corners of

3

3

the machine table groove.

23.5 mm

3

8

7

1

1

A

5

4

1

19.5 mm

B

2) Fix two rubber seats 1 on side A (operator’s side)

using nails 2 as illustrated above. Fix two cushion

seats 3 on side B (hinged side) using a rubberbased adhesive. Then place under cover 4 on the

fixed seats.

32

3) Remove air vent cap 5 attached to the machine

bed. (Be sure to attach cap 5 when transporting

the machine head in the state that the machine head

is removed from the machine table.)

If the sewing machine is operated

Cau tion

without removing air vent cap 5, oil

leakage from gear box portion 7

may occur.

4) Fit hinge 1 into the opening in the machine bed,

and fit the machine head to table rubber hinge 8

before placing the machine head on cushions 3

on the four corners.

4

1

5) Attach head support rod 6 to the machine table.

6

6

4-2. Removing the needle bar stopper

Remove needle bar stopper 1 for transportation.

1

4-3. Attaching the knee-lifter

Insert knee-lifter into attaching hole 2 and tighten it

with bolt 3.

* Adjust the position of knee lifter pad 1 to a

mm

2

220

3

* In case of the machine with AK device, knee lifter

Keep the needle bar stopper which has

been removed, and install this needle

bar stopper when transporting the

Cau tion

convenient place. For the reference dimension, the

position is 220 mm from the bottom face of table.

pad 1 is optional. (Part No. 22934251)

sewing machine.The needle bar

stopper may be cut when it is strongly

drawn out. Slightly move the needle bar

to the right or left and slowly draw out

the needle bar stopper.

1

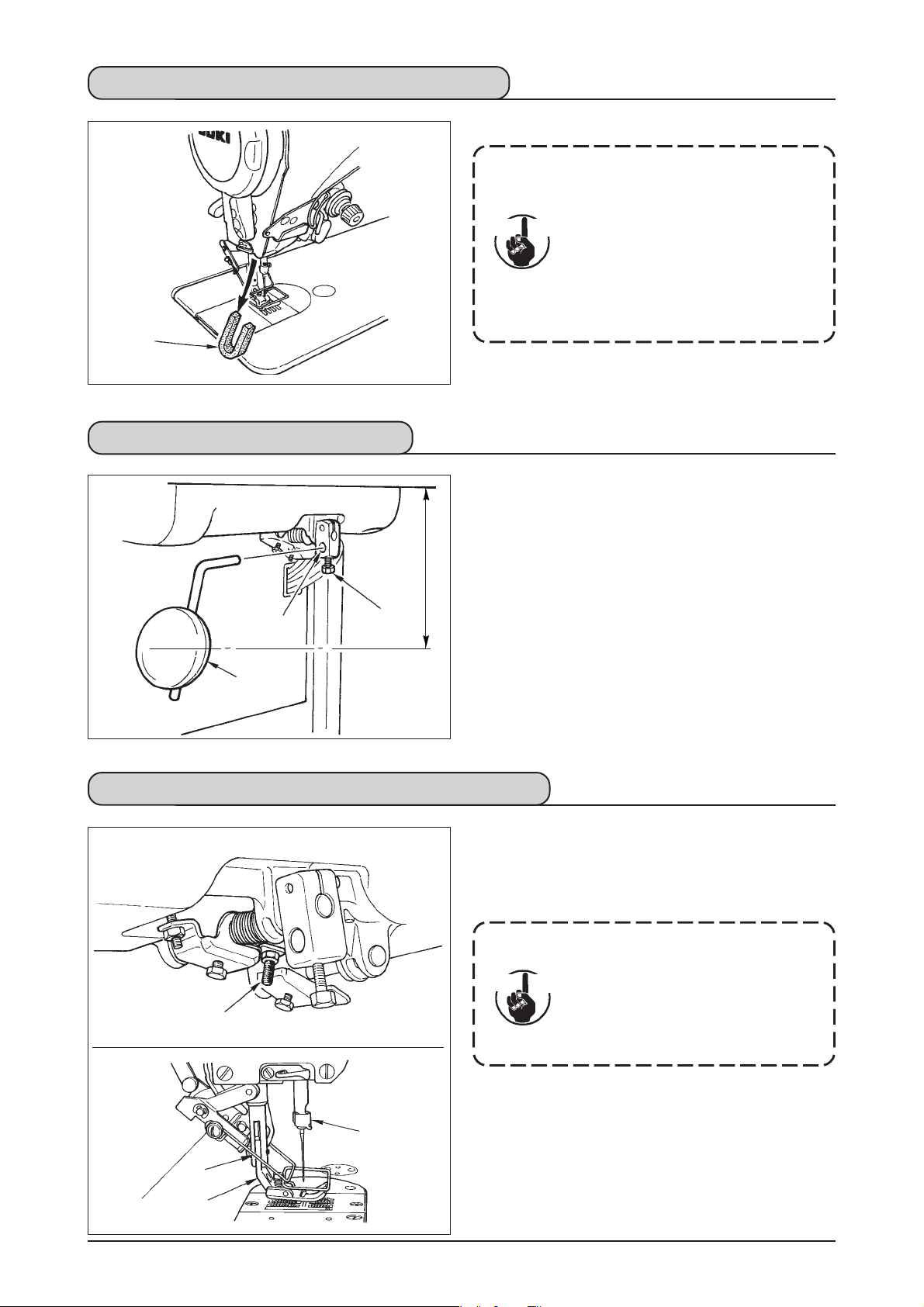

4-4. Adjusting the height of the knee lifter

1) The standard height of the presser foot lifted using

the knee lifter is 10 mm.

2) You can adjust the presser foot lift using knee lifter

adjust screw 1.

Cau tion

1

Do not operate the sewing machine

in the state that presser foot 3 is

lifted by 10 mm or more since needle

bar 2 and presser foot 3, or wiper

4 and presser foot 3 come in

contact with each other.

4

2

3

7

4-5. Installing the electrical box

5

1

7

6

Install the electrical box on the underside of the table

at the location illustrated using round-head bolt 1, plain

washer 2, spring washer 3 and nut 4 supplied with

the machine, and using bolt having hexagonal

indentation on the head 5, plain washer 6 and spring

washer 7 supplied with the machine.

2

3

4

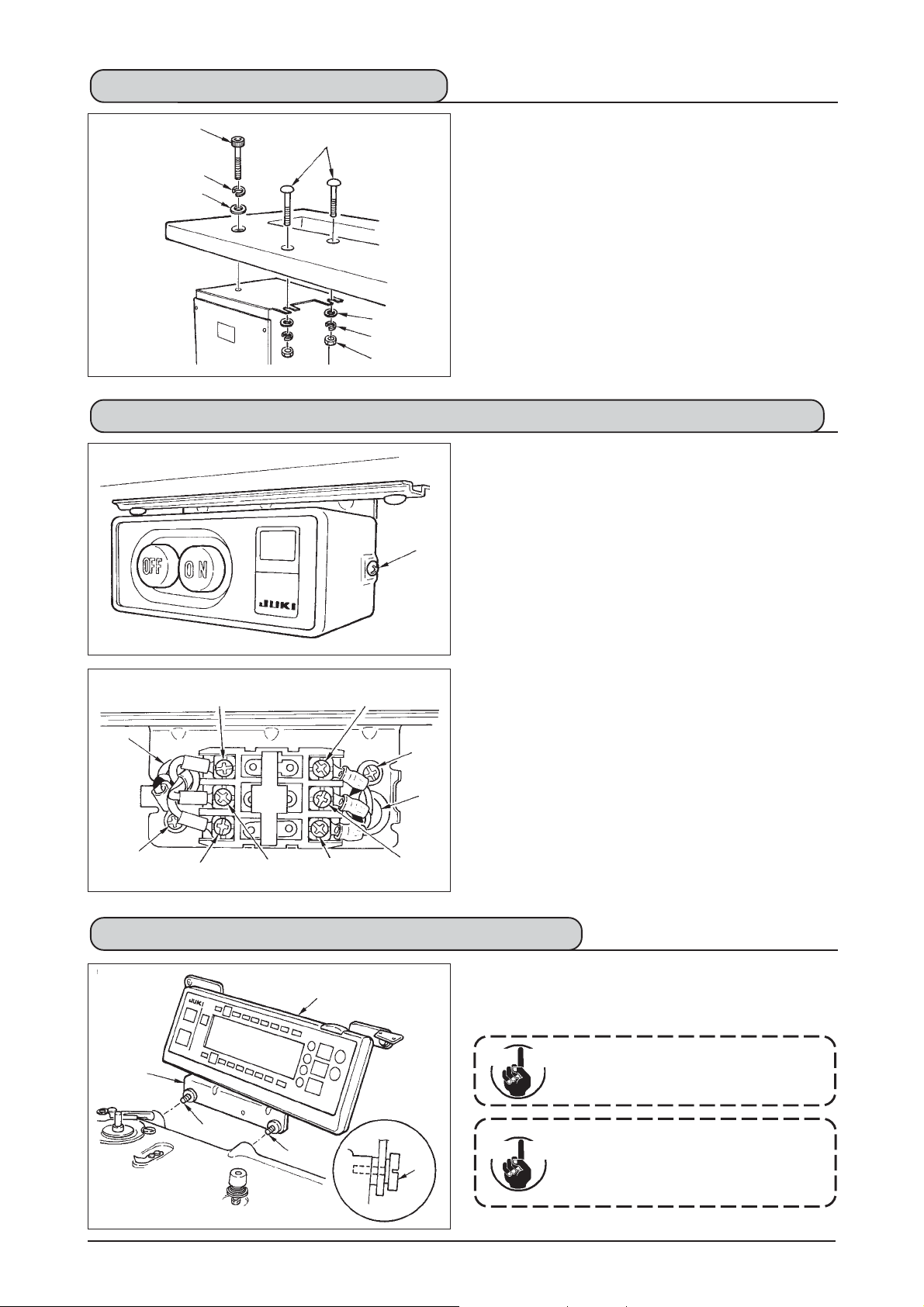

4-6.

Connecting the power switch cord (Japan and general export area)

1) Loosen screw 1 located on the side of the power

switch supplied as accessories and remove the

power switch cover.

2) Connecting the input power cord of electrical box

¡

When the input power cord of electrical box is 4P

1

Put 4P cord from hole A of the power switch and

securely fix green/yellow cord to 5, white cord to

2, black cord to 3 and red cord to 4 with screws.

¡

When the input power cord of electrical box is 3P

Put 3P cord from hole A of the power switch and

securely fix green/yellow cord to 5, brown cord to

2 and sky blue cord to 3 with screws.

3)

Connecting the power cable supplied as accessories

2

6

¡In case of 3-phase power cable

Put power cable from hole B of the power switch,

A

9

and securely fix green/yellow cord to 9, white cord

to 6, black cord to 7 and red cord to 8 with screws.

¡In case of single phase power cable

B

Put power cable from hole B of the power switch,

and securely fix green/yellow cord to 9 and other

cords to 6 and 7 with screws. 8 is not used.

5

4

3

8

7

4) Installing the power switch cover

Securely tighten screw 1 located on the side of

the power switch.

4-7. Installing the operation panel (IP-100 (D))

1) Install operation panel 1 on the machine head using

1

2

3

3

3

8

screws 3 which have been assembled to panel

installing bracket 2.

Cau tion

Cau tion

Do not disassemble the operation

panel to prevent it from breakage.

Clamp the cord coming from the

panel and that of the machine head

with the clip band supplied as

accessories.

4-8. Connecting the cords

WARNING :

• To prevent personal injury caused by abrupt start of the sewing machine, carry out the work after turning

OFF the power switch and a lapse of 5 minutes or more.

• To prevent damage of device caused by maloperation and wrong specifications, be sure to connect all the

corresponding connectors to the specified places.

• To prevent personal injury caused by maloperation, be sure to lock the connector with lock.

• As for the details of handling respective devices, read carefully the Instruction Manuals supplied with the

devices before handling the devices.

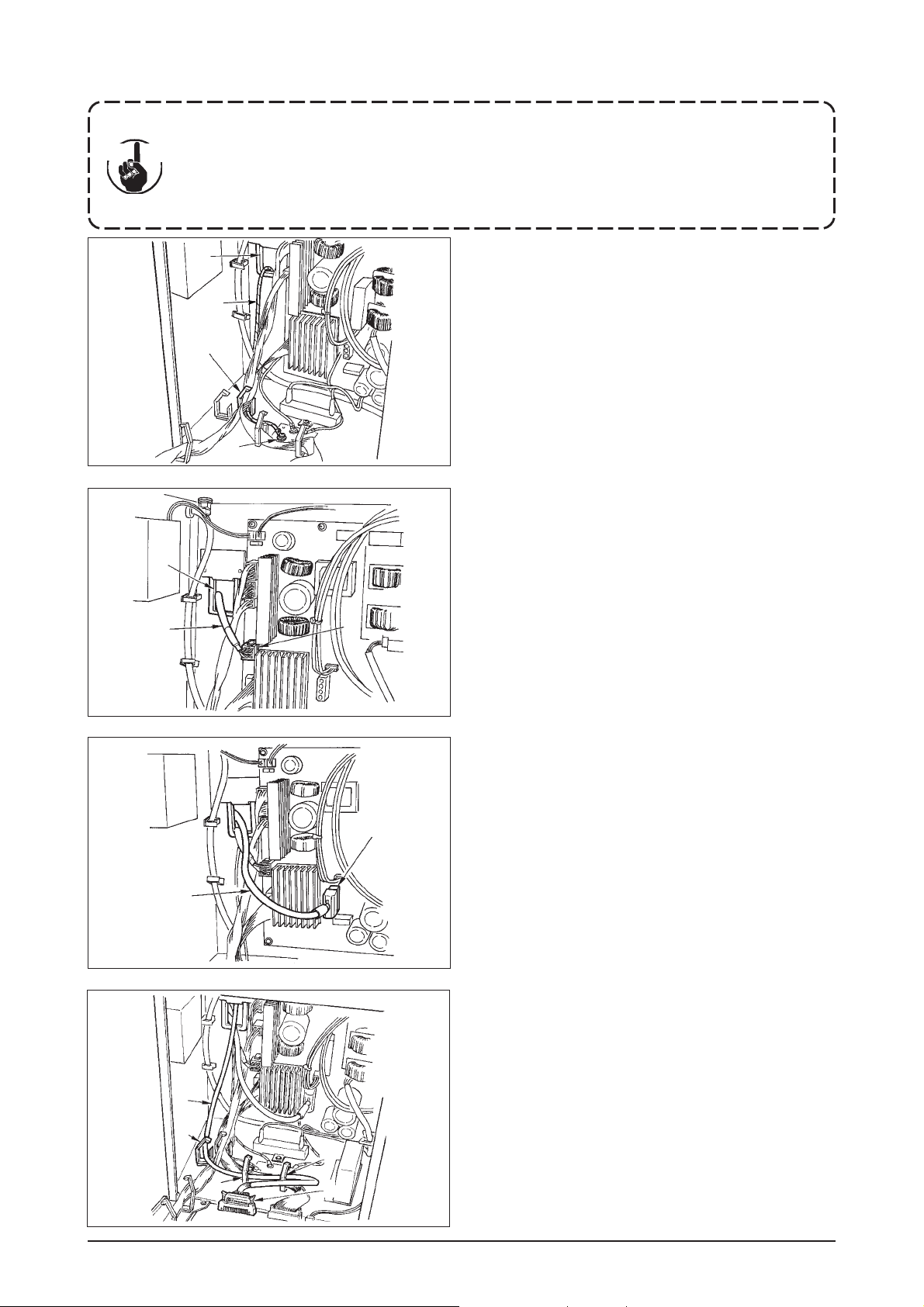

(1) Preparation of wiring

A

1) Pass the cords coming from the machine head to

the underside of the table through hole A in the table.

D

2) Loosen screws D and lift cord presser plate C of

cord passing hole B located on the front cover to

B

C

the top and temporarily tighten the plate.

3) Remove four screws fixing the rear cover of the

electrical box.

(Caution) Do not touch other screws.

When opening the rear cover, pressing it with your

hands, slowly open it by approximately 70˚ until it

E

Slowly

stops as illustrated.

Be sure to lend your hand to the rear

Cau tion

cover in order not to let the rear

cover fall. In addition, do not apply

force to the rear cover opened.

4)

j

b

a

e

f

c

d

g

Remove the locks of cord clamps a, b, c, d, e, f and j.

How to remove the cord clamp

1 Lightly pressing

2 Pull down the clamp.

3 The clamp goes up.

1

* See P.14 for how to lock the cord clamp.

3

1

2

9

(2) Connecting the connectors

• Each connector has the inserting direction. Check the direction and securely insert it.

(In case of the type with lock, insert up to the lock.)

Cau tion

• If the connector is forcibly inserted, trouble or accident will be caused.

• Never pull out the connectors inserted at the time of delivery.

• The sewing machine fails to work if the connectors are not properly inserted. Not only

the problem such as the error warning or the like but also breakage of the sewing machine

or electrical box will occur.

B

3

B

Connect cords in the following order.

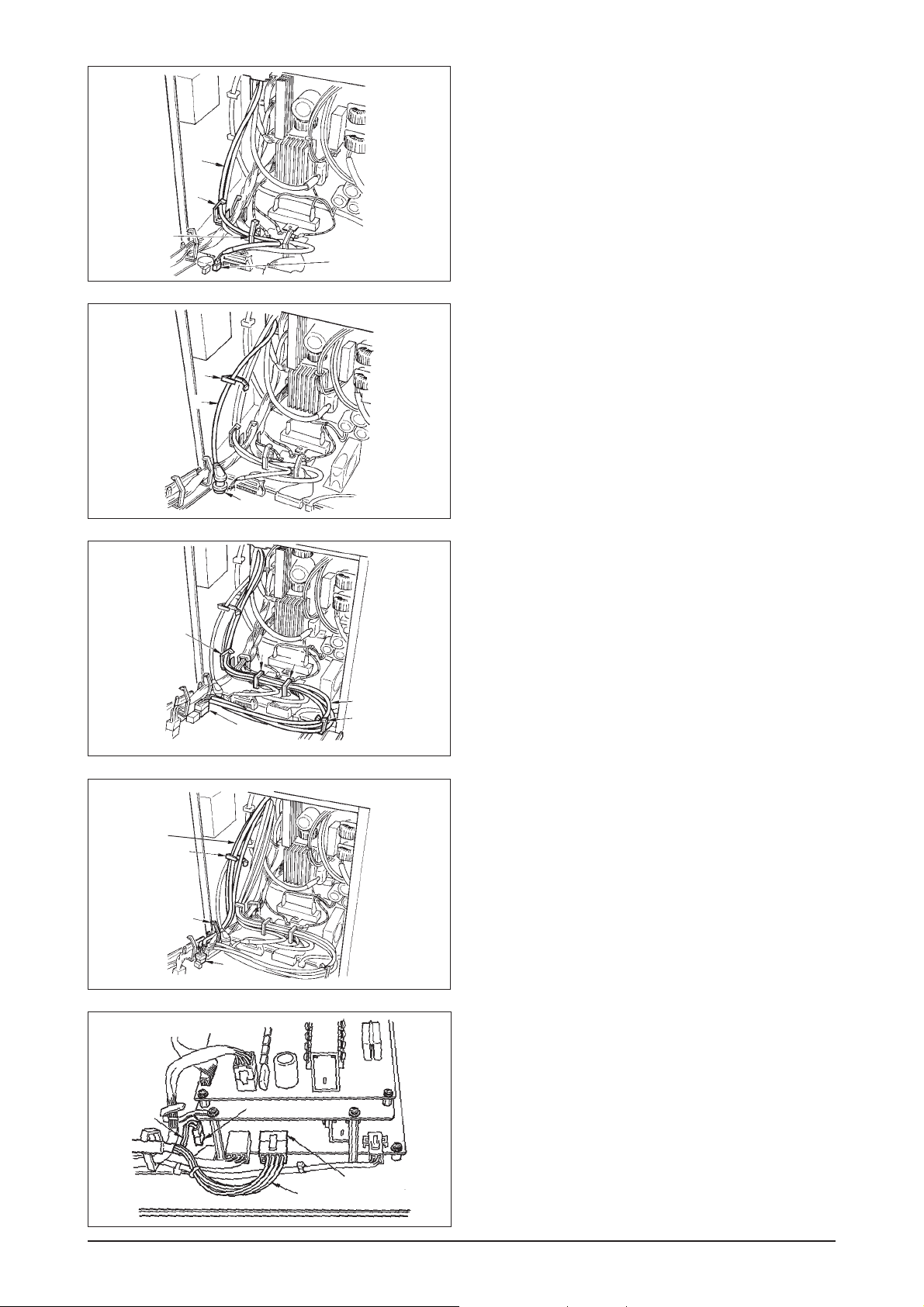

5) Insert yellow/green earth cord 1 coming from the

1

machine head inside the electrical box through front

cover through hole B, and pass it through cord clamp

b

“b” as illustrated and tighten it with screw at the

position 2 in the illustration.

2

6) Insert white square connector 9P black cord 3

coming from the machine head inside the electrical

box through front cover through hole B, and insert

it into connector CN38 4 of the circuit board

attached to the front cover.

4

7

5

a

7) Insert white connector 4P black cord 5 coming from

the machine head inside the electrical box through

front cover through hole B, and insert it into

connector CN21 6 of the circuit board attached to

6

the front cover.

8) Insert white connector 26P cord 7 coming from the

control panel inside the electrical box through front

cover through hole B, pass it through cord clamps

“a”, “c” and “d”, insert it into connector CN34 8,

and lock it.

d

c

8

10

9) Insert black connector 4P white cord 9 coming from

the machine head inside the electrical box through

front cover through hole B, and insert it into

connector CN31 !0 through cord clamps a and c.

9

a

c

!0

10) Insert gray round connector 7P cord !1 coming

from the machine head inside the electrical box

through front cover through hole B, pass it through

j

!1

!2

cord clamp “j”, and insert it into connector CN30

!2.

!5

11) Insert white connector 12P cord !3 coming from

the machine head inside the electrical box through

front cover through hole B, pass it through cord

a

c

d

!3

!4

g

clamps “a”, “c”, “d” and “g”, and insert it into

connector CN53 !4.

Close cord clamps “a”, “b”, “c” and “d”.

12) Insert white connector 6P cords !5 coming from

the machine head inside the electrical box through

front cover through hole B, pass it through cord

j

clamps “e” and “j”, and insert it into connector

CN54 !6.

e

!6

!7

!8

13)-1 Insert white connector 10P cord !9 and blue

connector 2P cord !7 coming from the machine

head inside the electrical box through front cover

through hole B, pass them through cord clamps

“e”, “f” and “j”, and insert the white 10P into

connector CN51 @0 and the blue 2P into CN46

!8.

@0

!9

11

!9

13)-2 Insert white connector 10P cord !9 coming from

the machine head to the rear of the connector

as shown in the figure.

@1

14) Insert black square connector 8P cord @1 coming

from the machine head inside the electrical box

through front cover through hole B, pass it through

cord clamps “e”, “f”, “h” and “j”, and insert the

h

@2

black square 10P into connector CN72 @2.

15) Insert black connector 4P cord @3 coming from

the machine head inside the electrical box through

front cover through hole B, pass it through cord

@3

@4

h

clamps “e”, “f”, “h” and “j”, and insert the black

4P into connector CN73 @4.

12

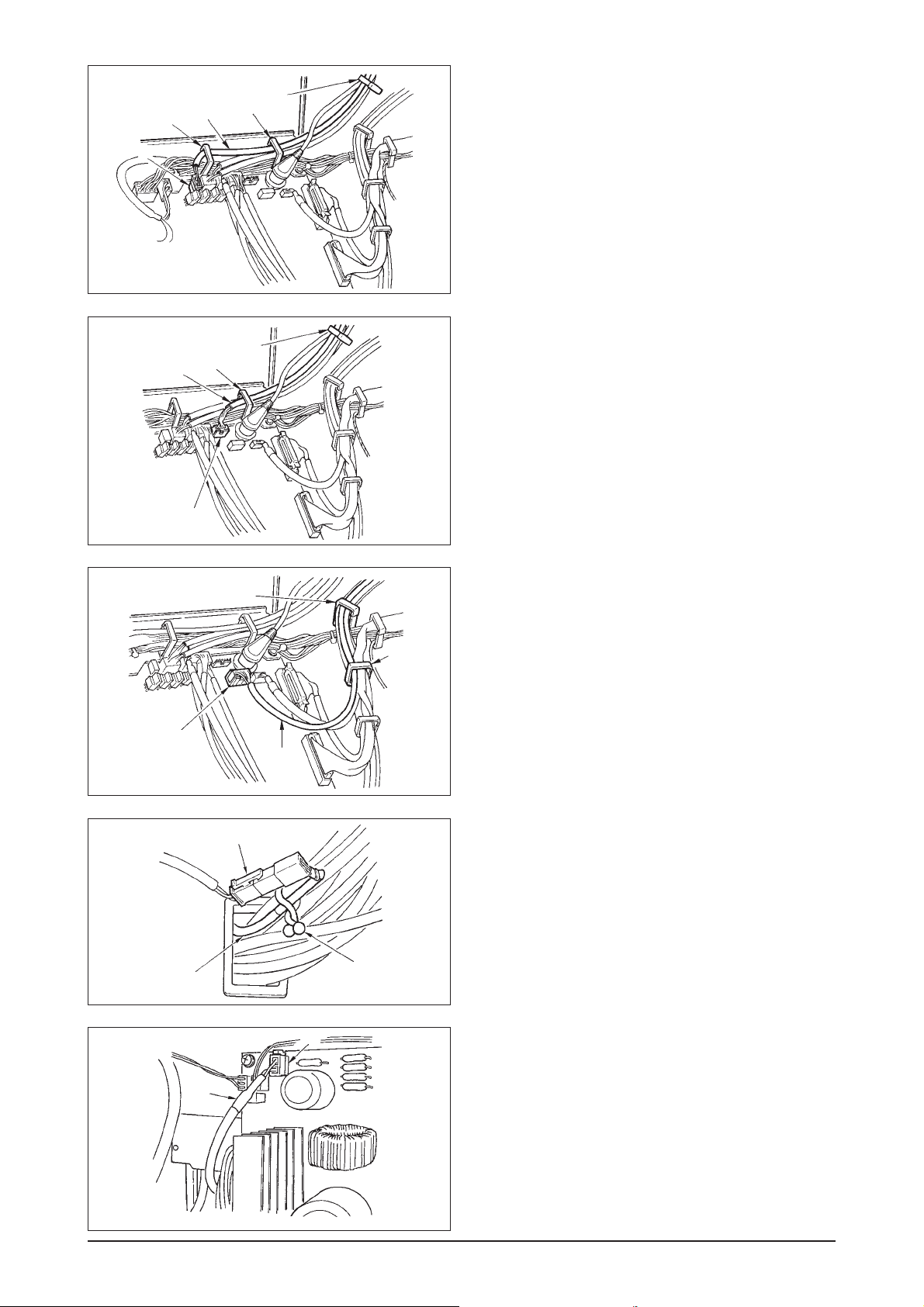

16) Close cord clamps “e”, “f” and “j”.

j

e

f

@6

When the Auto-lifter (AK121) is used :

j

@5

f

@7

@8

e

j

e

17) Insert white connector 2P cord @5 coming from

the machine head inside the electrical box through

front cover through hole B, pass it through cord

clamps “e”, “f” and “j”, and insert it into connector

CN40 @6.

Change the setting of function setting No. 23

from “0” to “1” after completing all set-up

procedure. For the details, see p.107 and p.110.

When the bird’s nest prevention device is used

(CB type)

18) Insert white small connector 6P cord @7 coming

from the machine head inside the electrical box

through front cover through hole B, pass it through

cord clamps “e” and “j”, and insert it into connector

CN52 @8.

#0

#1

#2

When foot pedal for standing work (PK70 or 71) is used :

a

c

@9

#3

19) Insert black connector 12P cord @9 inside the

electrical box through front cover through hole B

coming from the foot pedal for standing work, pass

it through cord clamps “a” and “c”, and insert it

into connector CN32 #0.

20) Connect white connector 2P of cord #1 supplied

as accessories to which red connector 2P and

white connector 2P are attached to white

connector 2P #28 of under cover of the machine

head.

Fix omega lock #3 supplied as accessories with

the neighboring cords and cord #1 as shown in

the figure.

#1

#4

21) Insert red connector 2P side of cord #1 supplied

as accessories to which red connector 2P and

white connector 2P are attached inside the

electrical box through front cover through hole, and

insert it into red connector CN25 #4.

13

How to lock the cord clamp

When the insertion of the connector is completed, lock

the cord clamps.

4

4Lightly press the corner of clamp.

(Cord clamp is locked with a click.)

2

C

1

B

[For CE territory]

4

3

Clamp

q Take care so that the cord is not caught between

the rear cover and the electrical box main body,

close the rear cover while pressing section A on

the lower side of the rear cover, and tighten four

screws 1.

A

w Press down cord presser plate C of cord through

hole B of the front cover, press the cord, and tighten

screws 2.

22) Install core clamp #5 supplied as accessories at

the position as shown in the figure.

#5

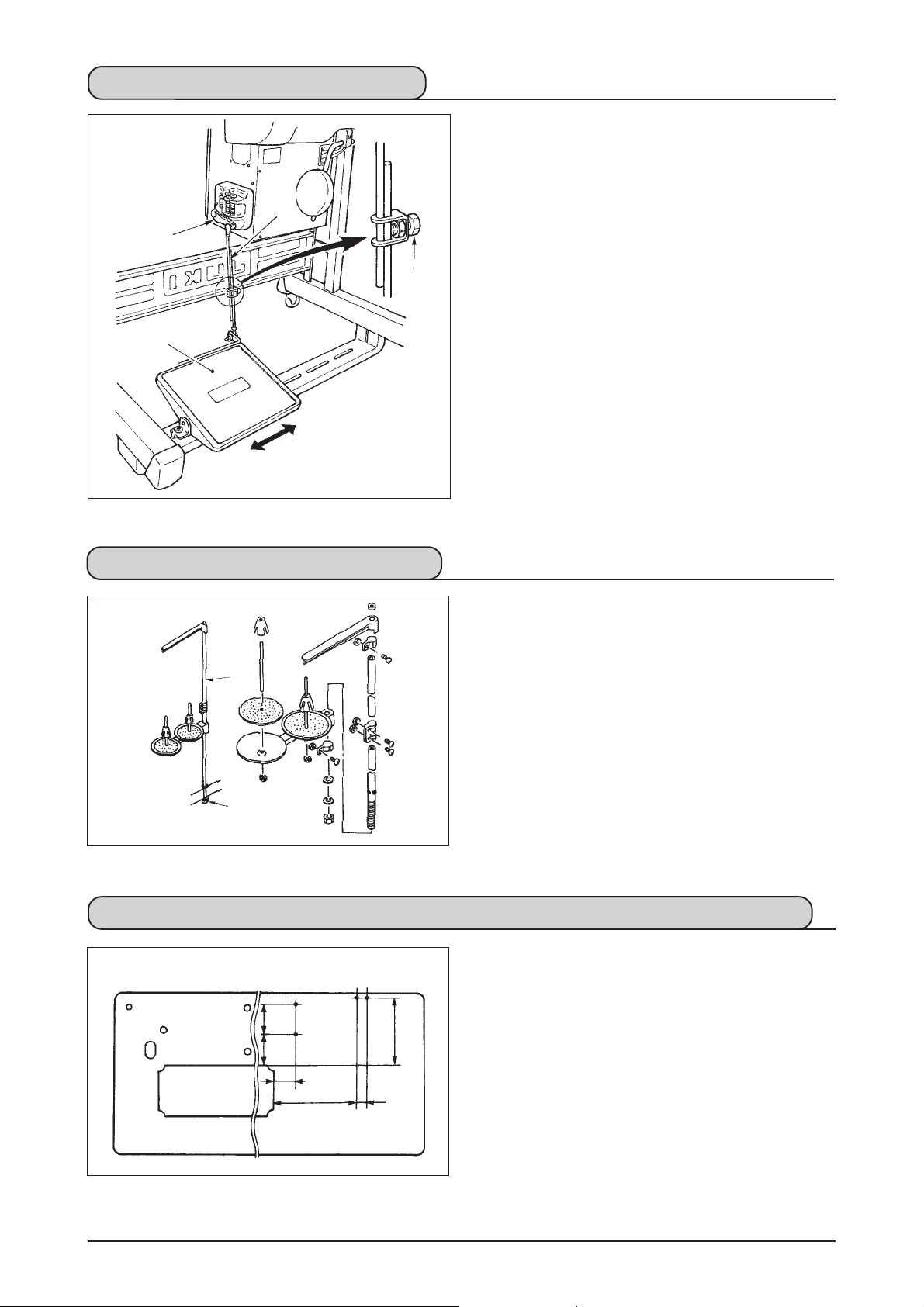

4-9. Attaching the connecting rod

3

2

1

B

A

1) Fix connecting rod 1 to installing hole B of pedal

lever 2 with nut 3.

2) Installing connecting rod 1 to installing hole A will

lengthen the pedal depressing stroke, and the pedal

operation at a medium speed will be easier.

14

4-10. Adjustment of the pedal

2

1

3

4

■ Installing the connecting rod

1) Move pedal 3 to the right or left as illustrated by

the arrows so that motor control lever 1 and

connecting rod 2 are straightened.

■ Adjusting the pedal angle

1) The pedal tilt can be freely adjusted by changing

the length of the connecting rod.

2) Loosen adjust screw 4, and adjust the length of

connecting rod 2.

4-11. Installing the thread stand

1) Assemble the thread stand unit, and insert it in the

hole in the machine table.

2) Tighten locknut 1 to fix the thread stand.

2

1

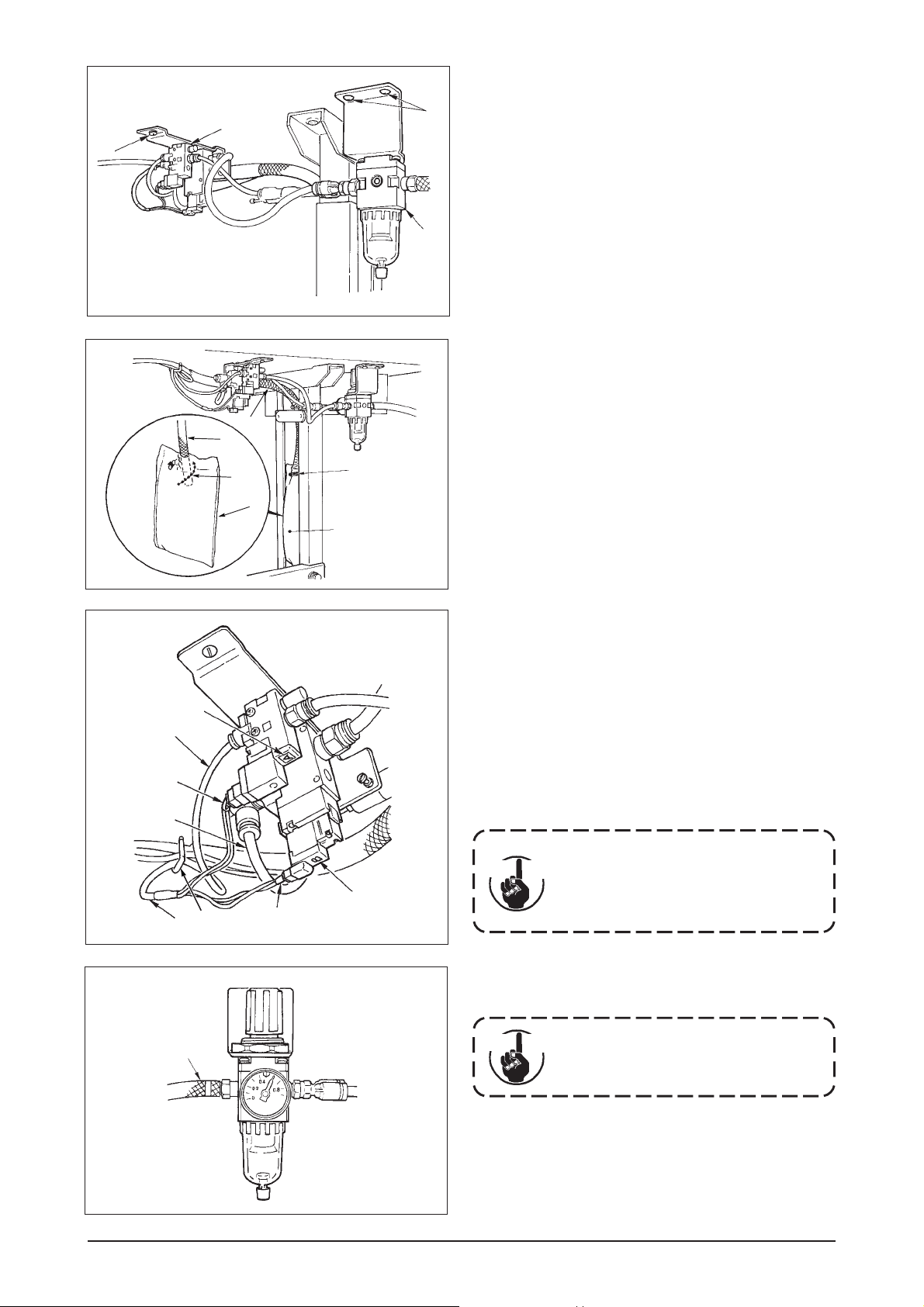

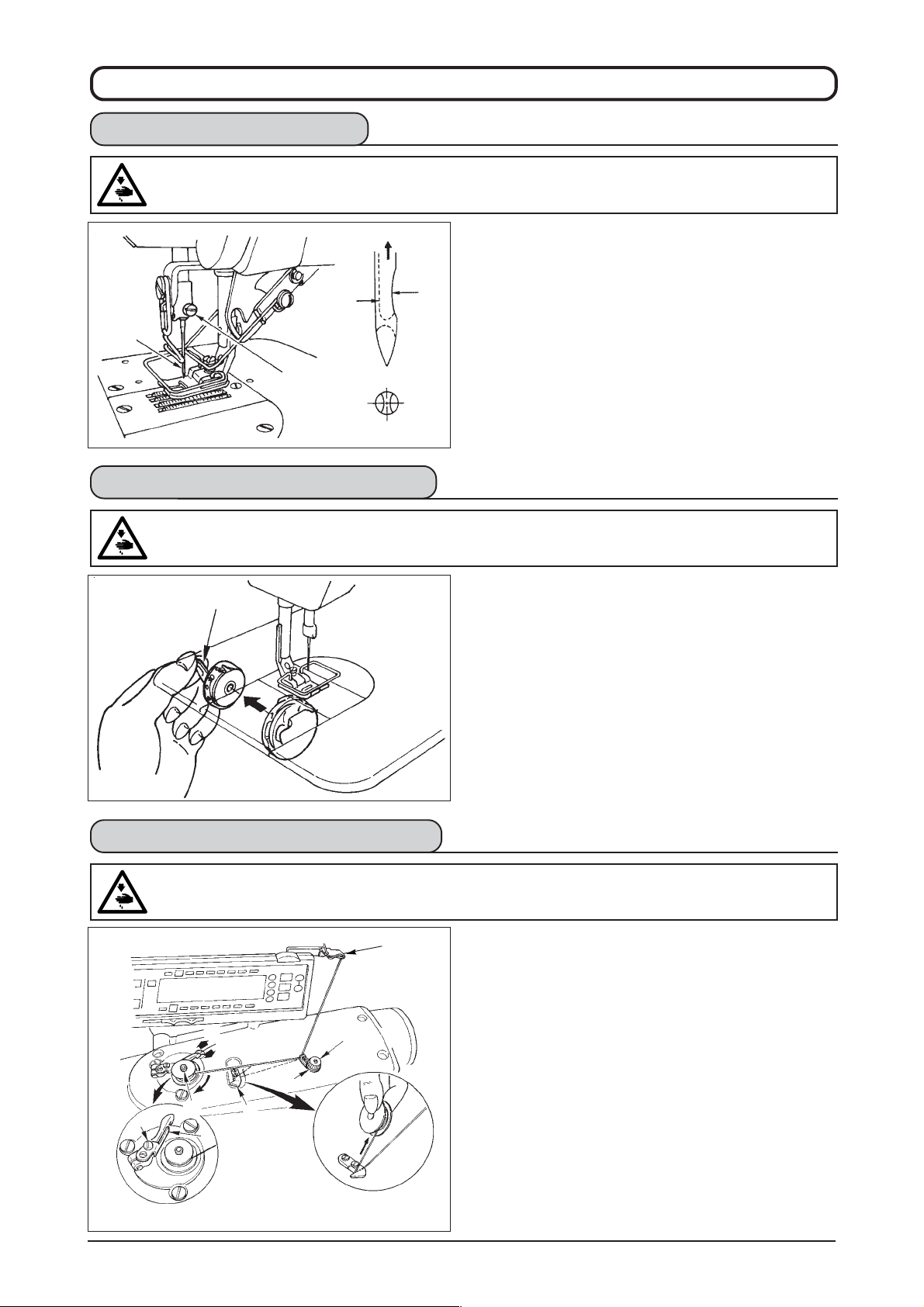

4-12. Installing the bird’s nest prevention (CB) type sewing machine

(bottom surface of the machine table)

(mm)

106107

233

3) For ceiling wiring, pass the power cord through spool

rest rod 2.

1) Punch dots on the positions of the setscrews of

solenoid valve (asm.) and regulator (asm.) on the

bottom surface of the machine table.

Besides, awling is performed on JUKI genuine table.

75

291

34

15

2

9

1

9

3

4

2) Fix solenoid valve (asm.) 1 with wood screws 2

supplied with the sewing machine as accessories.

3) Fix regulator (total asm.) 3 with wood screw 4

supplied with the sewing machine as accessories.

4) Connect 6 and 8 hoses attached to regulator (total

asm.) 3 to the respective solenoid valves.

5) Insert dust bag 5 into the top end of hose 4 for

dust bag and fix it with band 6 supplied with the

sewing machine as accessories.

φ4

φ8

!1

7

!0

8

6

5

!1

5

6

!0

6) Adjust solenoid valve cord (asm.) 7 to the solenoid

valve and the hot marker of the cord, and connect it.

Connect 6P connector !0!1 to CM52 connector

inside the electrical box.(Refer to “When the bird’s

nest prevention device is used, p. 13”.)

7) Connect air hose ø4 coming from the machine head

to the solenoid valve section and air hose ø8 to the

dust bag suction port respectively.

8) Fix the solenoid valve and the air hose on the table

with staple 8 supplied as accessories.

1. Fix the staple to such an extent that

Cau tion

the air hose is not crushed.

2. Determine the position of the staple

so that the cord and the air hose

do not hang from the table.

16

!2

9) Connect the air pipe !2 and set the air pressure to

0.6 MPa.

Cau tion

• When air pressure is used under

the specified value, clamp trouble

will be caused.

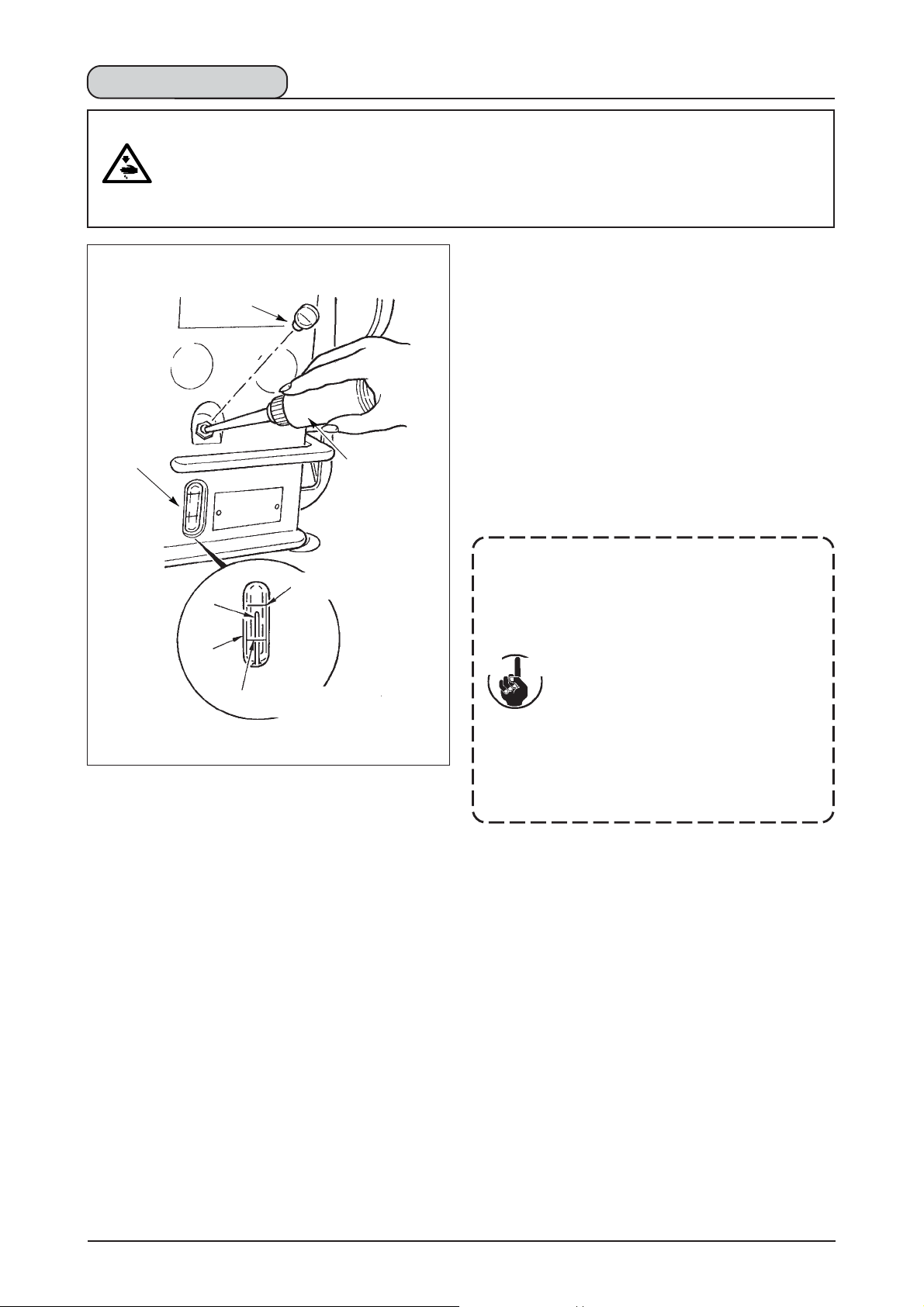

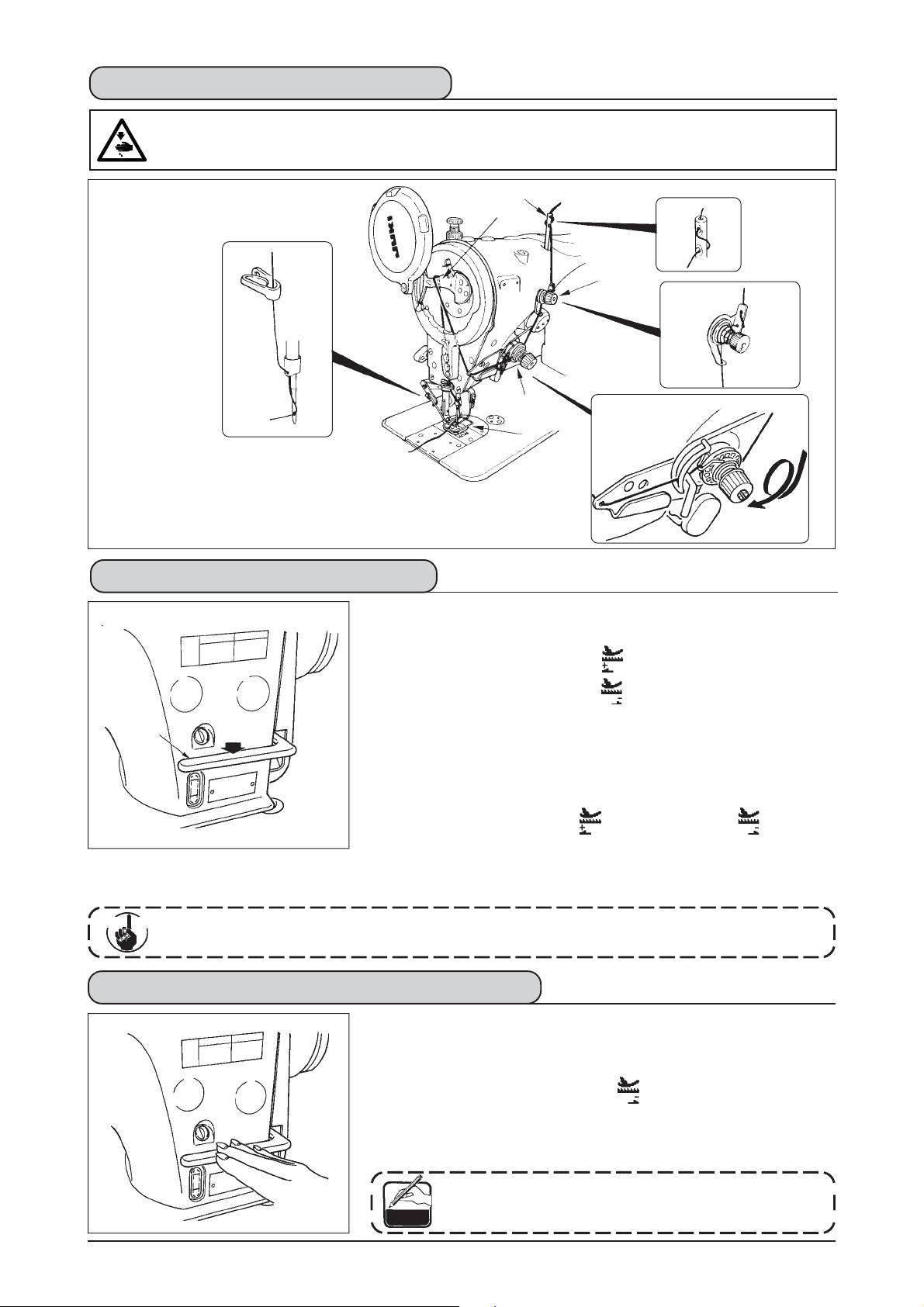

4-13. Lubrication

WARNING :

1. Do not connect the power plug until the lubrication has been completed so as to prevent accidents

due to abrupt start of the sewing machine,

2. To prevent the occurrence of an inflammation or rash, immediately wash the related portions if oil

adheres to your eyes or other parts of your body.

3. If oil is mistakenly swallowed, diarrhea or vomitting may occur. Put oil in a place where children

cannot reach.

1

2

4

Fill the oil tank with oil for hook lubrication before

operating the sewing machine.

1) Remove oil hole cap 1 and fill the oil tank with JUKI

New Defrix Oil No. 1 using the oiler supplied with

the machine.

2) The amount of oil should reach up to the engraved

marker line of oil tank 2.

If the oil is filled excessively, it will leak from the air

vent hole in the oil tank or proper lubrication will be

not performed. So, be careful.

3) When you operate the sewing machine, refill oil if

the top end of oil amount indicating rod 3 comes

down to the lower engraved marker line of oil

amount indicating window 4.

3

2

Upper engraved

marker line

Lower engraved

marker line

Cau tion

• When you use a new sewing

machine or a sewing machine after

an extended period of disuse, run

your machine at 3,000 to 3,500 rpm

for the purpose of break-in.

• For the oil for hook lubrication,

purchase JUKI New Defrix Oil No.

1 (Part No. : MDFRX1600C0).

• For oiling, perform with oiler

(B19210120A0) supplied as

accessories. Be careful that dust

such as thread waste or the like is

not oiled when oiling.

17

4-14. Test run

(1) Turn ON the power

WARNING :

• Check again the power voltage before connecting the power cord.

• Check that the power switch is turned OFF and connect the power cord to the power receptacle.

• Be sure to connect the earth wire.

• In case where the buzzer keeps beeping immediately after turning ON the power, there is a possibility

of the wrong connection of cord or wrong power voltage. Turn OFF the power.

1) When the needle bar is in its UP position, zigzag origin detection is performed.

2) When the needle bar is in the position other than UP position :

Display as shown in the figure below appears. Turn the handwheel to bring the needle bar to needle UP

position and the display changes to the next screen. Then the needle moves left and right, and zigzag

origin detection is performed.

(2) How to operate the pedal

h

A

B

C

D

E

The pedal is operated in four stages.

1) Lightly depress the front part of the pedal for low-

speed operation B .

2) Further depress the front part of the pedal for high-

speed operation A. (Note that the sewing machine

will enter the high-speed operation mode after the

completion of reverse feed stitching if the automatic

reverse feed stitching function is specified with the

corresponding switch.)

3) Bring the pedal back to its neutral position, and the

sewing machine will stop running C.

(The needle stops in the highest / lowest position.)

4) Strongly depress the back part of the pedal, and

the thread trimmer will be actuated E.

Lightly depress the back part of the pedal, and the

presser foot will go up D. Further depress the back

part of the pedal, and the thread trimmer will be

actuated.

Cau tion

18

One stitch only becomes soft start (approximately 200 rpm) by pedal operation immediately

after turning ON the power.

5.PREPARATION BEFORE SEWING

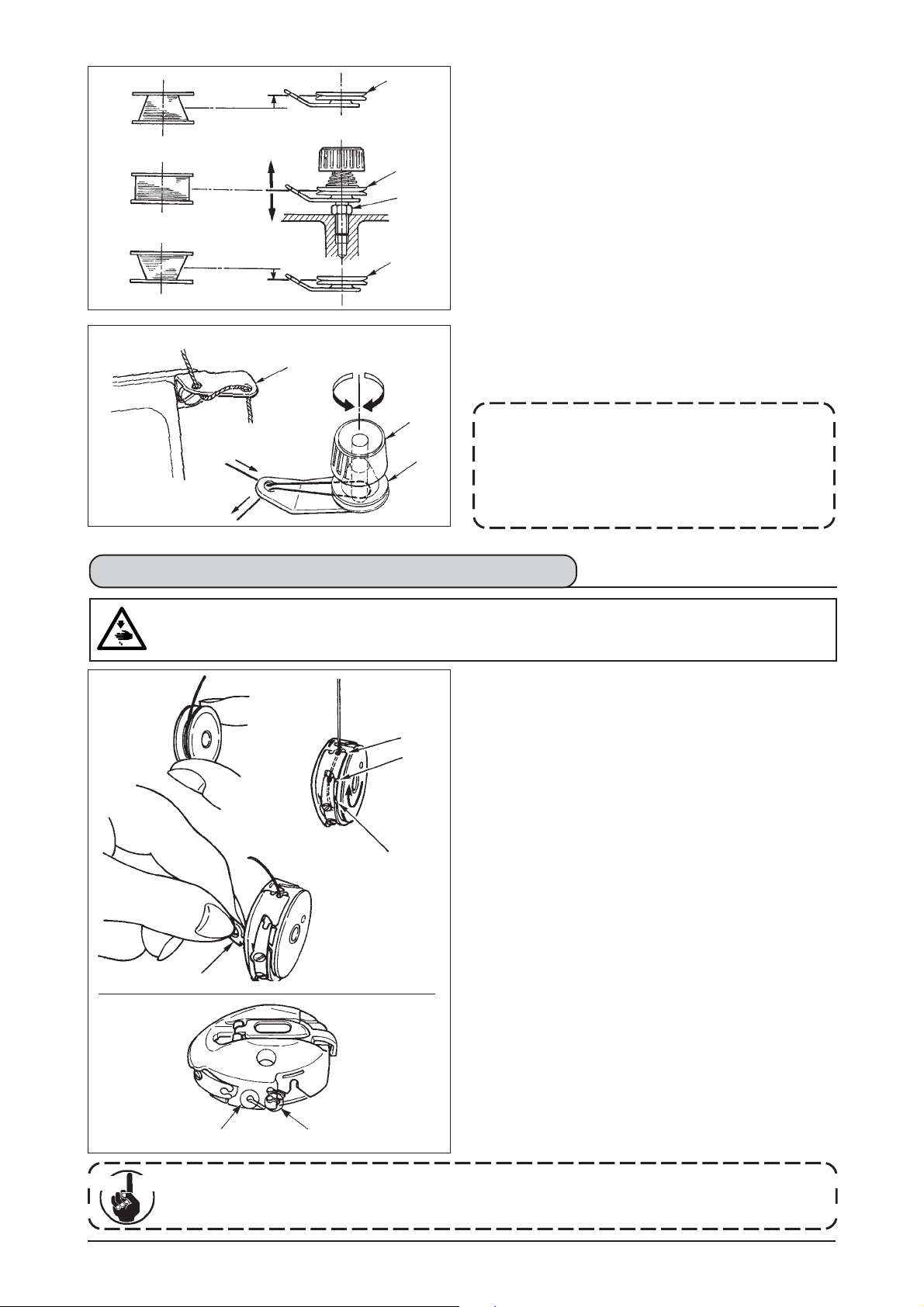

5-1. Inserting the needle

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1) Turn the handwheel by hand to raise the needle to

its highest position.

2) Loosen the needle clamp screw 2 . Hold the needle

B

1

2

5-2. Removing the bobbin case

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

A

1so that the long groove B on the needle is facing

exactly toward you.

3) Insert the needle deep into the hole of the needle

bar in the direction of the arrow until it will go no

further.

4) Securely tighten the screw 2 .

5) Confirm that the long groove B on the needle faces

toward you.

1

5-3. Winding the bobbin thread

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1

7

5

6

B

A

C

2

8

3

1) Turn the handwheel by hand to raise the needle to

its highest position.

2) Raise bobbin case latch 1 and remove the bobbin

case.

1) Insert the bobbin deep into the bobbin winder spindle

5 until it will go no further.

2) Pass the bobbin thread pulled out from the spool rested

on the right side of the thread stand following the order

from 1 as shown in the figure on the left. Then, wind

the end of the bobbin thread on the bobbin several times.

3) Press the bobbin winder adjusting plate 6 in the

direction of A and start the sewing machine. The

bobbin rotates in the direction of C and the bobbin

thread is wound up. The bobbin winder spindle 5 will

automatically stop as soon as the winding is finished.

4) Remove the bobbin and cut the bobbin thread with

the thread cut retainer 8 .

5) To adjust the winding amount of the bobbin thread,

loosen setscrew 7 and move bobbin winder adjusting

plate 6 to the direction of A or B. Then, tighten

setscrew 7.

To the direction A : The amount is decreased.

To the direction B : The amount is increased.

19

(Threading)

2

6) In case that the bobbin thread is not wound evenly

on the bobbin, loosen the nut 4 and turn the bobbin

thread tension to adjust the height of the thread

tension disk 2.

A

2

4

• It is the standard that the center of the bobbin is

as high as the center of the thread tension disk.

• Move the position of the thread tension disk 2 to

the direction A as shown in the figure on the left

B

2

when the winding amount of the bobbin thread on

the lower part of the bobbin is excessive and to

the direction B as shown in the figure on the left

when the winding amount of the bobbin thread on

the upper part of the bobbin is excessive.

After the adjustment, tighten the nut 4 .

1

7) Turn the thread tension nut 3 to adjust the tension

of the bobbin thread winder.

3

2

Note 1. When winding bobbin thread, start winding

in the state that the thread between bobbin

and thread tension disk 2 is tense.

2. When winding bobbin thread in the state that

the sewing is not performed, remove needle

thread from the thread path of the thread

take-up and remove bobbin from the hook.

5-4. Placing the bobbin case and the bobbin

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1) Turn the handwheel by hand to raise the needle to

its highest position.

2) Take a bobbin by your right hand with the thread

drawn out about 5 cm from the thread end of the

bobbin and place it into the bobbin case as

illustrated.

3) Thread the bobbin case in the order of the numbers

and pull it out through the thread path as illustrated.

The bobbin rotates in the bobbin case in the direction

shown by arrow when bobbin thread is drawn.

4) Raise bobbin case latch 1 and hold it between your

two fingers as shown in the figure on the left.

5) Insert the bobbin case into the sewing hook shaft as

far as it will go by putting your hand from the under

cover of the inner hook. (Click sounds.)

6) Release the bobbin case latch to let it steadily rest

in the closing position.

■How to use the bobbin case thread hole

1) Use hole A mainly for zigzag stitches other than

standard zigzag stitch and scallop zigzag stitch.

2) Use hole B mainly for standard zigzag stitch and

scallop zigzag stitch.

1

3

2

A

1

B

A

Cau tion

20

There may be a case where several stitches at the start of sewing are difficult to be knotted when

thread trimmer is used with thin filament thread such as (#50, #60 or #80) using hole B. At this time,

use the other hole or perform the sewing starting from the right.

5-5. Threading the machine head

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1

4

3

5

1) Turn the handwheel by hand to bring the needle to the most raised position.

2) Pass the thread in the order of the numbers as illustrated.

3)

Pull out the thread about 10 cm from the needle after passing it through the needle.

2

Turn the thread

once.

5-6. Adjusting the stitch length

1)

Adjustment of the stitch length is performed with the operation panel.

For the setting procedure of the respective sewing patterns, refer to “6-5.

Setting the sewing pattern”.

Normal feed : Press +/– keys of

Reverse feed : Press +/– keys of

2) Numerical value of the operation panel is indicated in mm.

3) When performing the reverse feed stitching, press down reverse feed

control lever 1. The sewing machine performs reverse feed stitching as

long as you keep the lever held pressed. The reverse feed control lever

will return to its home position and the sewing machine will run in the

normal stitching direction when you release the reverse feed control lever.

Example) In case of normal feed :

the sewing range becomes normal feed +4 to –3. The maximum

reverse feed becomes –3 when reverse feed control lever 1 is pressed.

Besides, it is possible to adjust the stitch length of normal/reverse feed up to

5 mm at the maximum by inputting.

Cau tion

1

There may be the cases where the feed amount of the operation panel and the actual sewing pitch are different

from each other in case of the use in the state other than the standard delivery or material used. Compensate

the pitch in accordance with the sewing product.

5-7. Adjusting the condensation stitching

Condensation stitching means that feed pitch amount is reduced and tie

stitching is performed by operating the reverse feed control lever at the

start or end of sewing.

1) Adjustment of the stitch length is performed with the operation panel.

Reverse feed : Press +/– keys of to input. Tie stitching can

performed by inputting the reverse feed amount to “0”.

2) Note that the tie stitching value is mere reference. Adjust the condensation

stitching while actually observing the finished seam.

3) Numerical value of the operation panel is indicated in mm.

It is possible for the gauge delivered (feed dog part No. : 40018430) to adjust up

to 5 mm of normal/reverse feed at the maximum. There is a possibility that

Reference

material is apt to fall in case of the process where the feed amount is small. Use

the gauges such as feed dog and the like in accordance with the process.

to input.

to input.

+4 and reverse feed :

–3,

amount of

be

21

6. HOW TO USE THE OPERATION PANEL

6-1. Names and functions of the respective sections

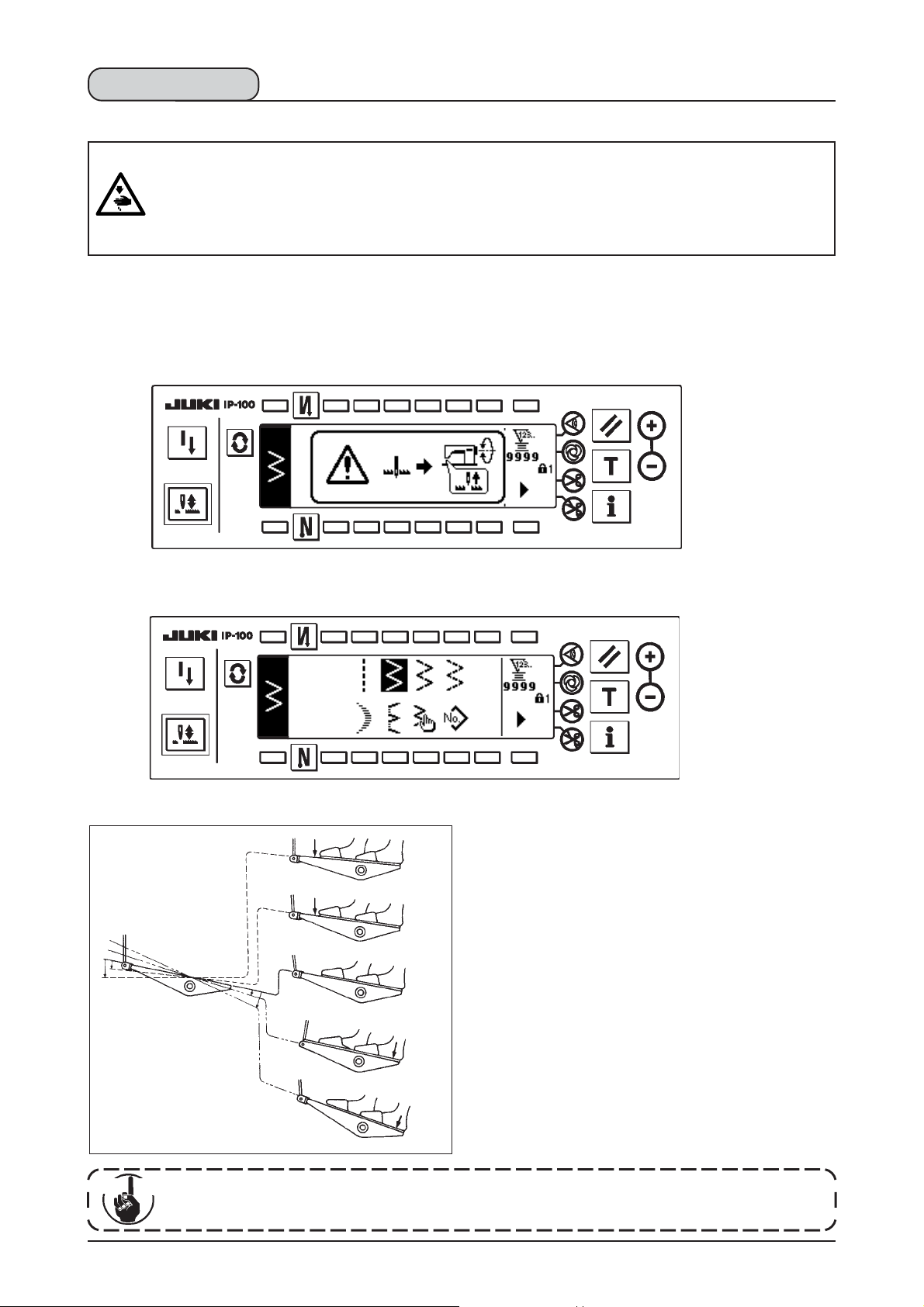

13 4

!8

!6

!7

2

1 Re-sewing switch

2 Needle up/down compensating switch

3 Screen changeover switch

4

With/without reverse feed stitch at sewing start switch

5

With/without reverse feed stitch at sewing end switch

6 Reset switch

7 Teaching switch

5

!0

!4

8 Information switch

9 Feed amount display switch

!0 One-shot stitching switch

!1

With/without automatic thread trimmer switch

!2Thread trimming prohibiting switch

!3Counter value setting switch

!4

Max.speed limitation variable resistor

!1 8

9

!2

!5

6 !3

7

!5Power display lamp

!6 Smart media cover

!7 Smart media slot

(Smart media inserting opening)

!8 Smart media

Optional :

( )

Part No.HX005750000

1 Re-sewing switch

2 Needle up/down

compensating switch

3 Screen changeover

switch

4 With/without reverse feed stitch

at sewing start switch

5 With/without reverse feed stitch

at sewing end switch

6 Reset switch

This switch is used to continue sewing from the step on the way

after replacing bobbin thread when bobbin thread has run out during

program stitching step.

This is the switch to perform needle up/down compensating stitching.

(Needle up/down compensating stitching and one stitch compensating

stitching can be changed over with function setting No. 22.)

This is the switch to change over the screen.

This is the switch to turn ON/OFF automatic reverse feed stitch at sewing start.

* This switch cannot be used with the sewing machine which is not provided with

automatic reverse feed stitching device.

For the details, see p. 71.

This is the switch to turn ON/OFF automatic reverse feed stitch at sewing end.

* This switch cannot be used with the sewing machine which is not provided with

automatic reverse feed stitching device.

For the details, see p. 71.

This is the switch to make the value of bobbin thread counter or

sewing counter the set value.

For the details, see p. 96.

22

7 Teaching switch

This is the switch to set the setting of the number of stitches with

the value of number of stitches which has been actually sewn.

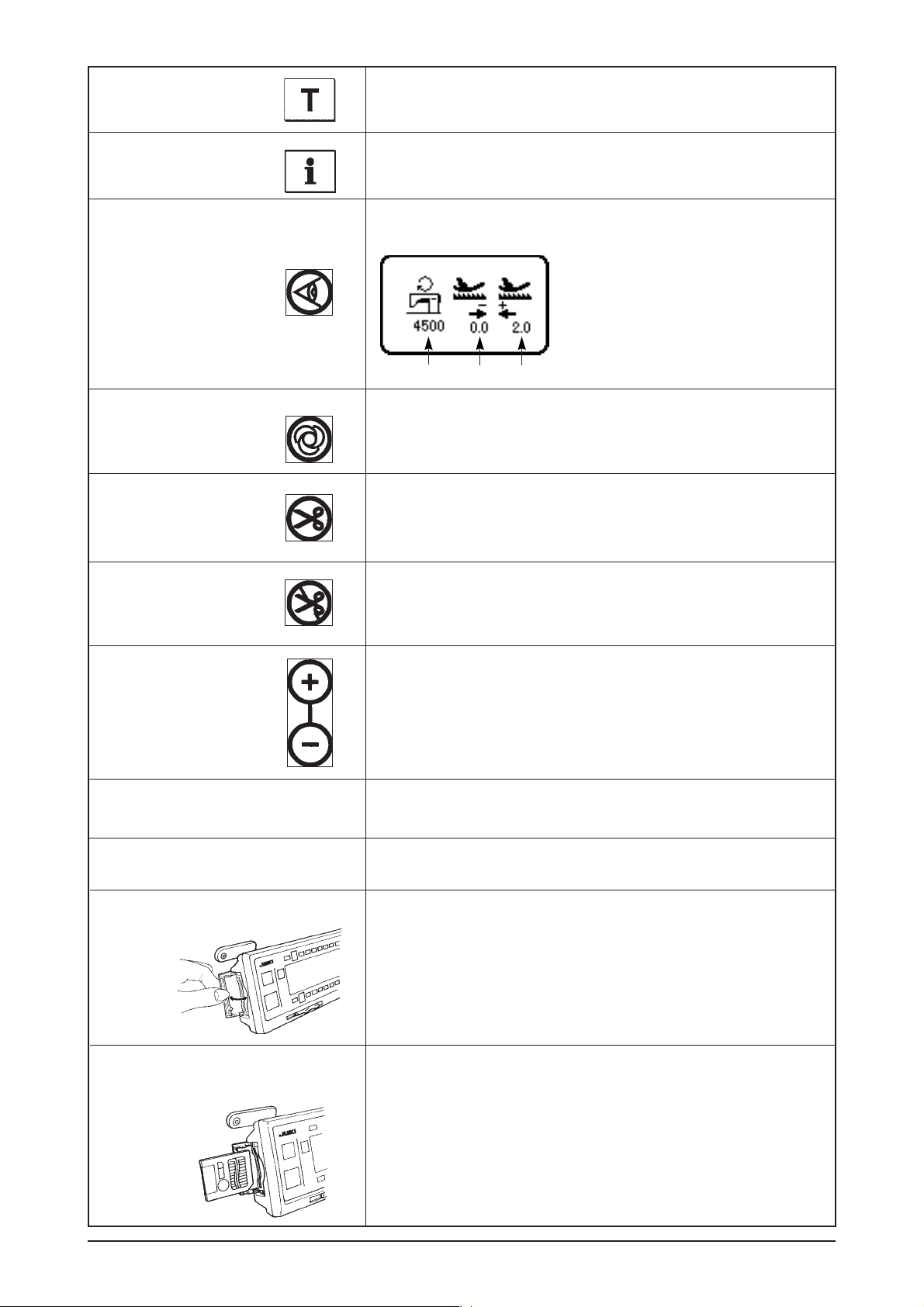

8 Information switch

9 Feed amount display switch

!0

One-shot stitching switch

!1 With/without automatic

thread trimmer switch

!2 Thread trimming

prohibiting switch

This is the switch to perform various function settings.

Number of rotations, normal feed amount and reverse feed amount

of the pattern which is selected at present are displayed.

1 : Number of rotations

2 : Reverse feed amount

3 : Normal feed amount

* The above amounts are not displayed

1 2 3

When this switch is set to effective at the time of program stitching,

the sewing machine automatically operates up to the specified

number of stitches.

When this switch is set to effective at the time of program stitching,

the sewing machine automatically performs thread trimming when

the specified number of stitches has been completed.

This switch prohibits all thread trimmings.

* This switch cannot be used with the sewing machine which is not

provided with the automatic thread trimming device.

at the time of cycle stitching.

!3 Counter value setting

switch

!4 Max. speed limitation variable

resistor

!5 Power display lamp

!6Smart media cover

!7 Smart media slot

(Smart media inserting opening)

This is the switch to set the value of bobbin thread counter or No. of

pcs. counter.

When moving the resistor in the left direction, max. speed is limited.

This lamp lights up when the power switch is turned ON.

This is the cover for smart media inserting opening.

To open the cover, place your finger on the notch located on the

side of the cover as shown in the figure and push the cover in the

direction of left slanting rear.

* The respective functions of the operation panel do not work with

the cover opened.

Do not close the cover unless smart media is completely inserted.

For the details, see p. 104.

To set smart media, insert smart media into smart media slot and

push it until it is almost hidden.

To remove smart media, push it further again and it protrudes to the

position where it can be held between your fingers. Now, draw it out.

* Be very careful of the inserting direction of smart media.

For the details, see p. 104.

23

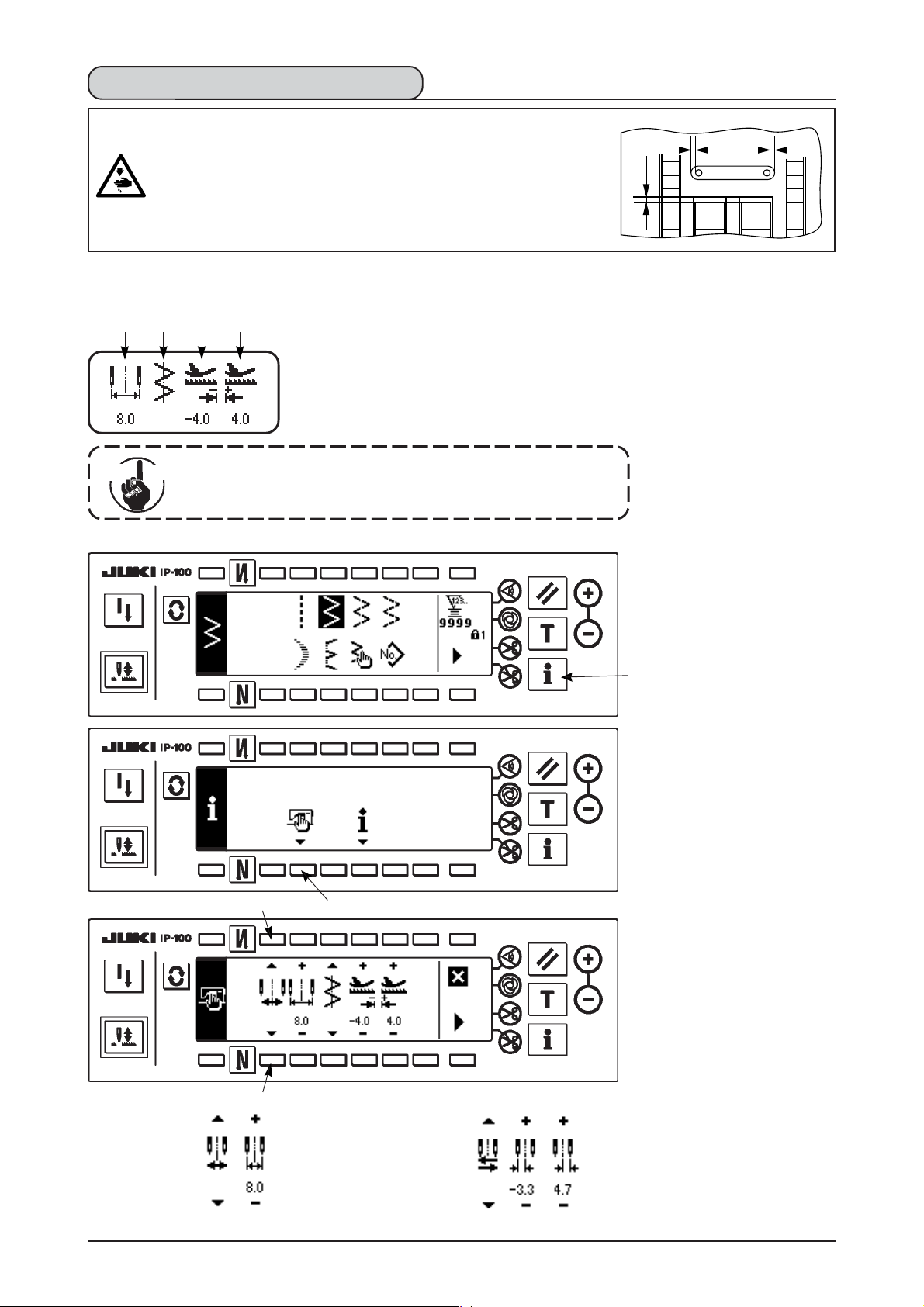

6-2. Before setting the pattern

WARNING :

• When using presser foot, throat plate and feed dog other than those delivered

as standard, needle may come in contact with throat plate and breaks, or feed

dog may come in contact with throat plate in case of some set values. Be sure

to perform the regulation of limitation values of 1, 3 and 4 in accordance

with the gauge used. The regulation at the time of delivery is as follows :

Max. zigzag width : 8 mm

Max. feed amount : 5 mm

• When replacing the gauge, provide a clearance of 0.6 mm or more between

needle, and presser foot and throat plate, and between throat plate and feed dog.

(1) Limitation of the max. zigzag width

Max. zigzag width limitation value, reference of stitch base line, normal feed amount limitation

value and reverse feed amount limitation value are displayed when the power is turned ON.

1 2 3 4

1 : Max. zigzag width limitation value (Screen changes in case of specifying left/right

positions.)

2 : Reference of stitch base line

3 : Max. reverse feed amount limitation value

4 : Max. normal feed amount limitation value

Display of max. zigzag width limitation value, reference of stitch base line, normal feed amount

limitation value and reverse feed amount limitation value can be performed with ON/OFF.

0.6

0.6

0.6

Impor tant

• Max. zigzag width can be limited in accordance with the gauge.

• There are two kinds of limitations of max. zigzag width.

(1) Zigzag width symmetrical in the center

(2) Specifying left/right positions

■Changeover of limiting procedure of max. zigzag width limitation value

1) Press switch 1.

1

2) Press switch 2.

3

2

3

(1) Zigzag width symmetrical in the center

24

3) Figure on the left side is the

zigzag width symmetrical in

the center mode.

Every time switch 3 is

pressed, specifying left/

right positions and zigzag

width symmetrical in the

center can be changed

over alternately.

⇔

(2) Specifying left/right positions

Loading...

Loading...