Page 1

ENGLISH

LZ-2290A / IT-100D / SC-915

INSTruCTIoN MANuAL

Page 2

CoNTENTS

1. NAME oF EACH CoMPoNENT ..................................................................................................1

2. SPECIFICATIoNS .........................................................................................................................

2-1. Specications of the machine head ..................................................................................................2

2-2. Specications of the electrical box ...................................................................................................2

3. STITCH PATTErN TABLE ........................................................................................................... 3

4. INSTALLATIoN .............................................................................................................................

4-1. Installation of the sewing machine head .......................................................................................... 4

4-2. Removing the needle bar stopper ..................................................................................................... 5

4-3. Attaching the knee-lifter .....................................................................................................................5

4-4. Adjusting the height of the knee lifter ............................................................................................... 5

4-5. Installing the electrical box ................................................................................................................6

4-6. Connecting the power switch cord (Japan and general export area) ............................................6

4-7. Installing the operation panel (IT-100D) ............................................................................................6

4-8. Connecting the cords ......................................................................................................................... 7

(1) Preparation of wiring ........................................................................................................................................7

(2) Connecting the connectors ...............................................................................................................................

4-9. Attaching the connecting rod ..........................................................................................................11

4-10. Adjustment of the pedal .................................................................................................................11

4-11. Installing the thread stand ..............................................................................................................12

4-12. Installing the bird’s nest prevention (CB) type sewing machine ................................................ 12

4-13. Lubrication (LZ-2290A-SS • A-SU (-7) ) ..........................................................................................13

4-14. Test run ............................................................................................................................................14

(1) Turn ON the power ......................................................................................................................................... 14

(2) How to operate the pedal ............................................................................................................................... 14

5.

PrEPArATIoN BEForE SEWING ...........................................................................................

5-1. Inserting the needle ......................................................................................................................... 15

5-2. Removing the bobbin case ..............................................................................................................15

5-3. Winding the bobbin thread ............................................................................................................... 15

5-4. Placing the bobbin case and the bobbin ........................................................................................ 16

5-5. Threading the machine head ...........................................................................................................17

5-6. Adjusting the stitch length ...............................................................................................................17

5-7. Adjusting the condensation stitching .............................................................................................17

6. HoW To uSE THE oPErATIoN PANEL .................................................................................. 18

6-1. Names and functions of the respective sections ........................................................................... 18

6-2. Before setting the pattern ................................................................................................................20

(1) Limitation of the max. zigzag width ................................................................................................................20

(2) Setting the reference of stitch base line .........................................................................................................

6-3. Basic screen ..................................................................................................................................... 23

6-4. List of the display pictographs of each screen ..............................................................................24

6-5. Setting the sewing pattern ............................................................................................................... 35

(1) Selecting the zigzag pattern .......................................................................................................................... 35

6-6. Setting of the sewing shape ............................................................................................................. 37

(1) 2-step zigzag, 3-step zigzag and 4-step zigzag stitch .................................................................................... 37

(2) Scallop stitching .............................................................................................................................................

(3) Blind stitch sewing ..........................................................................................................................................

(4) Custom pattern stitching .................................................................................................................................

6-7. Reverse feed stitching ......................................................................................................................42

(1) Standard condensation ..................................................................................................................................43

(2) 2-point condensation ......................................................................................................................................

(3) Condensation custom .....................................................................................................................................

(4) Comparison table of the reverse stitch of each shape ...................................................................................

6-8. Selection of the kind of stitching ..................................................................................................... 48

(1) Overlapped stitching ....................................................................................................................................... 48

(2) Programmed stitching ....................................................................................................................................

6-9. Custom pattern .................................................................................................................................. 50

(1) Custom pattern setting ................................................................................................................................... 50

(2) New creation of the custom pattern ...............................................................................................................

(3) Custom pattern edit ........................................................................................................................................

(4) Registration, copy and deletion of the custom pattern ...................................................................................

6-10. Condensation Custom ....................................................................................................................54

(1) Condensation custom setting ......................................................................................................................... 54

(2) Condensation custom edit ..............................................................................................................................

6-11. Pattern stitching ..............................................................................................................................56

(1) Setting the pattern stitching ............................................................................................................................ 56

(2) Registering the pattern stitching .....................................................................................................................

(3) Copy and deletion of the pattern stitching ......................................................................................................

15

22

38

40

41

44

46

47

48

51

52

52

55

57

58

2

4

8

i

Page 3

6-12. Continuous stitching ......................................................................................................................59

(1) New creation of the continuous stitching ........................................................................................................ 60

(2) Continuous stitching edit ................................................................................................................................

(3) Copy and deletion of the continuous stitching ................................................................................................

60

62

6-13. Cycle stitching ................................................................................................................................. 63

(1) New creation of the cycle stitching ................................................................................................................. 63

(2) Cycle stitching edit .........................................................................................................................................

(3) Copy and deletion of the cycle stitching .........................................................................................................

(4) Teaching .........................................................................................................................................................

(5) Performing the constant-dimension stitching using the cycle stitching ..........................................................

63

65

66

67

6-14. Counter ............................................................................................................................................67

(1) Thread trimming counter ................................................................................................................................ 67

(2) Bobbin thread counter ....................................................................................................................................

67

6-15. Information ......................................................................................................................................68

(1) Sewing common data ..................................................................................................................................... 69

(2) Sewing management information ...................................................................................................................

(3) Communication mode ....................................................................................................................................

71

74

6-16. Setting for functions ..................................................................................................................... 78

(1) How to change over to the function setting mode .......................................................................................... 78

(2) Function setting list ........................................................................................................................................

(3) Detailed explanation of selection of functions ................................................................................................

81

85

6-17. External interface .......................................................................................................................... 91

(1) Media slot ....................................................................................................................................................... 91

(2) Ethernet port .................................................................................................................................................. 91

(3) RS-232C port .................................................................................................................................................91

(4) General input port (Production control switch connecting connector) ............................................................ 91

6-18. Setting the maximum sewing speed ........................................................................................... 92

6-19. Panel memory switch setting ....................................................................................................... 92

7. SEWING ...................................................................................................................................... 94

7-1. Adjusting the thread tension ............................................................................................................94

7-2. Adjusting the pressure of the presser foot .....................................................................................95

7-3. One-touch type reverse feed stitching mechanism .......................................................................95

7-4. Hand switch ....................................................................................................................................... 97

8. STANDARD ADJUSTMENT ....................................................................................................... 98

8-1. Adjusting the amount of oil in the hook (LZ-2290A-SS • A-SU (-7) )............................................. 98

8-2. Adjusting the amount of lubricating to face plate section (LZ-2290A-SS•A-SU(-7)) ................... 98

8-3. Adjusting the height of the presser bar .......................................................................................... 99

8-4. Adjusting the micro-lifting mechanism of the presser foot .......................................................... 99

8-5. Height and inclination of the feed dog ............................................................................................99

8-6. Hook adjusting mode ...................................................................................................................... 100

8-7. Attaching / removing the hook .......................................................................................................102

8-8. Adjusting height of the needle bar ................................................................................................ 103

8-9. Adjusting the needle-to-hook timing and the needle guard ........................................................103

8-10. Adjusting the stop position of the needle ...................................................................................104

8-11. Adjusting the thread trimmer .......................................................................................................104

8-12. Adjusting the needle thread feeding device (Thread trimmer type only) ................................ 105

8-13. Adjusting the bird's nest prevention (CB) type wiper ................................................................106

8-14. Replacing procedure of the bird’s nest prevention (CB) type presser knife ........................... 107

9. MAINTENANCE ........................................................................................................................ 108

(1) Replacing the power fuse ............................................................................................................................. 108

(2) Adjusting the contrast of the operation panel display ...................................................................................

(3) Draining (Bird’s nest prevention (CB) type only) ..........................................................................................

(4) Cleaning the dust bag (Bird’s nest prevention (CB) type only) .....................................................................

(5) Cleaning the cooling fan installed on the under cover ..................................................................................

(6) Cleaning the hook section ............................................................................................................................

(7) Cleaning the rear cover of the control box ...................................................................................................

(8) Cleaning the operation panel screen ...........................................................................................................

(9) Replacing procedure of the hook shaft oil wick ............................................................................................

(10) USB port ......................................................................................................................................................111

108

109

109

109

110

110

110

110

10. AT A TIME LIKE THIS ! ........................................................................................................... 112

11. Error DISPLAY

11–1. Error code list (Error display in panel) ....................................................................................... 114

.................................................................................................................... 113

12. TrouBLES AND CorrECTIVE MEASurES ...................................................................... 117

ii

Page 4

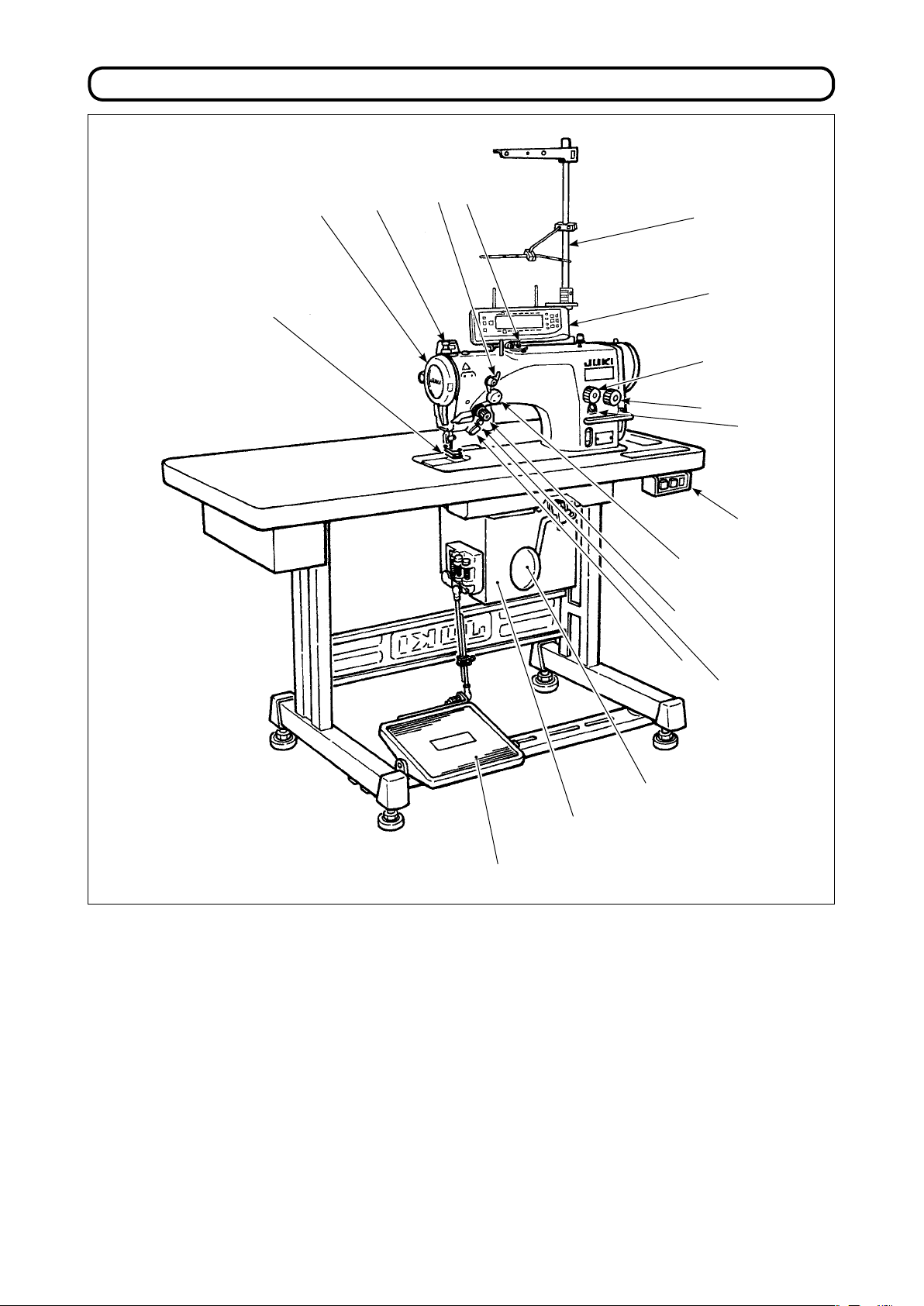

1. NAME oF EACH CoMPoNENT

!5

!4

4

3

2

!6

!3

!2

!1

!7

o

Needle thread draw-out device (LZ-2290A(U)-7)

1

Wiper switch (WB,CB type)

2

Thread take-up cover

3

Finger guard

4

Thread tension controller (Rotary tension)

5

Electrical box

6

Pedal

7

Knee lifter lever

8

Power switch

9

q

t

!0

i

y

u

Hand switch

!0

Stitch length dial

!1

Condensation dial

!2

Operation panel

!3

Bobbin winder

!4

Tension controller No. 1 (Pre-tension)

!5

Thread stand

!6

Oil supply opening

!7

Mirror inversion switch

!8

!8

– 1 –

Page 5

– 2 –

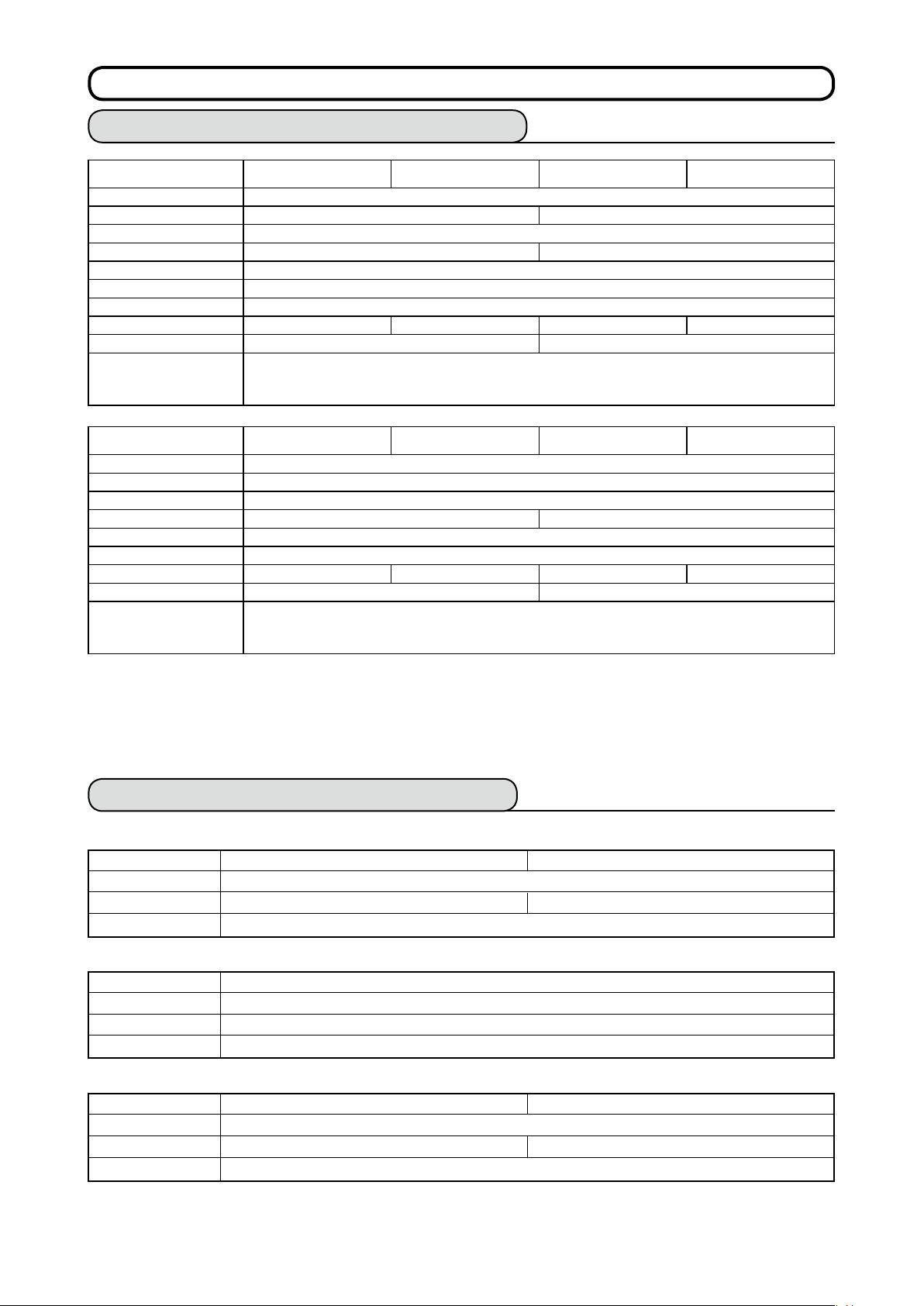

2. SPECIFICATIoNS

2-1. Specications of the machine head

Model LZ-2290A-SS LZ-2290A-SS-7 LZ-2290A-SU LZ-2290A-SU-7

Application Light-weight materials to medium-weight materials

Max. sewing speed 5,000 sti/min (*1) 4,500 sti/min (*1)

Max. zigzag width

Max. feed pitch

Stitch pattern 8 kinds 14 patterns (custom pattern : up to 500 stitches, 20 kinds can be stored.)

Needle SCHMETZ 438, ORGAN DPX5 : #65 to #90

Oil used JUKI New Defrix Oil No. 1

Thread trimmer Without With Without With

Feed method Standard feed Material slippage prevention

Noise - Equivalent continuous emission sound pressure level (L

Model

Application Light-weight materials to medium-weight materials

Max. sewing speed 4,000 sti/min (*1)

Max. zigzag width

Max. feed pitch

Stitch pattern 8 kinds 14 patterns (custom pattern : up to 500 stitches, 20 kinds can be stored.)

Needle SCHMETZ 438, ORGAN DPX5 : #65 to #90

Thread trimmer Without With Without With

Feed method Standard feed Material slippage prevention

Noise - Equivalent continuous emission sound pressure level (L

Minute-quantity

( )

lubricating type

(Dry-head type)

10 mm (*2)

5 mm (stepless ne adjustment) 2.5 mm (stepless ne adjustment)

) at the workstation :

pA

A-weighted value of 80.0 dB; (Includes K

11204 GR2 at 4,500 sti/min.

LZ-2290A-DS LZ-2290A-DS-7 LZ-2290A-DU LZ-2290A-DU-7

5 mm (stepless ne adjustment) 2.5 mm (stepless ne adjustment)

A-weighted value of 80.0 dB; (Includes K

11204 GR2 at 4,500 sti/min.

= 2.5 dB); according to ISO 10821- C.6.2 -ISO

pA

10 mm (*2)

) at the workstation :

pA

= 2.5 dB); according to ISO 10821- C.6.2 -ISO

pA

* 1. The max. sewing speed is limited by the amount of zigzag width per stitch.

Up to 4 mm : 5,000 sti/min (LZ-2290A-SU : 4,500 sti/min, LZ-2290A-DS

•

A-DU (-7) : 4,000 sti/min),

up to 5 mm : 4,000 sti/min, up to 6 mm : 3,500 sti/min, up to 8 mm : 3,000 sti/min

• Properly set the number of revolution in accordance with the product to be sewn and process.

* 2. Max. zigzag width is limited to 8 mm at the time of standard delivery.

2-2. Specications of the electrical box

For general export

■

Supply voltage Single phase 200V / 220V / 240V 3-phase 200V / 220V / 240V

Frequency 50 Hz / 60 Hz

Rated currency 4.6A / 4.3A / 4.0A 3.0A / 2.7A / 2.3A

Operating environment

For CE

■

Supply voltage Single phase 220V / 230V / 240V

Frequency 50 Hz/60 Hz

Rated currency 4.3A / 4.2A / 4.0A

Operating environment

For JUS

■

Supply voltage Single phase 100V / 110V / 120V 3-phase 200V / 220V / 240V

Frequency 50 Hz / 60 Hz

Rated currency 8.0A / 7.5A / 7.0A 3.0A / 2.7A / 2.3A

Operating environment

Temperature : 0 to 40˚C Humidity : 90% or less

Temperature : 0 to 40˚C Humidity : 90% or less

Temperature : 0 to 40˚C Humidity : 90% or less

Page 6

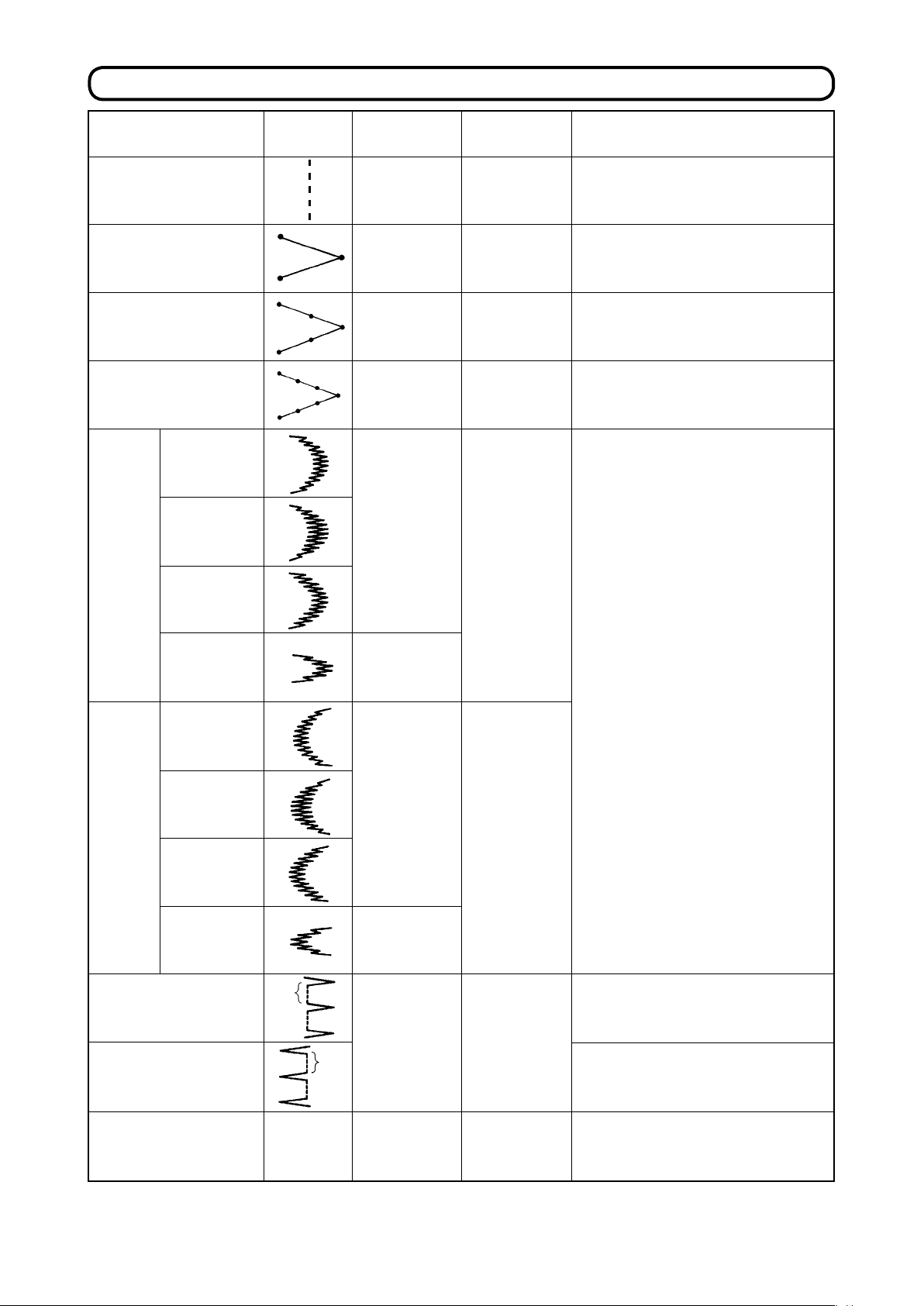

3. STITCH PATTErN TABLE

-

Name of pattern

Straight stitch

2-step zigzag stitch

3-step zigzag stitch

4-step zigzag stitch

Stitch pat

tern

Number of stitches

for pattern

1

2

4

6

Max.zigzag width

—

10

10

10

Remarks

Scallop

(right)

Scallop

(left)

Standard

scallop

Crescent

scallop

Equal-width

scallop

Equal-width

scallop

Standard

scallop

Crescent

scallop

Equal-width

scallop

24

12

24

10

10

Equal-width

scallop

Blind stitch (right)

Blind stitch (left)

Custom pattern

12

a

2+a

a

500

10

10—

– 3 –

Page 7

– 4 –

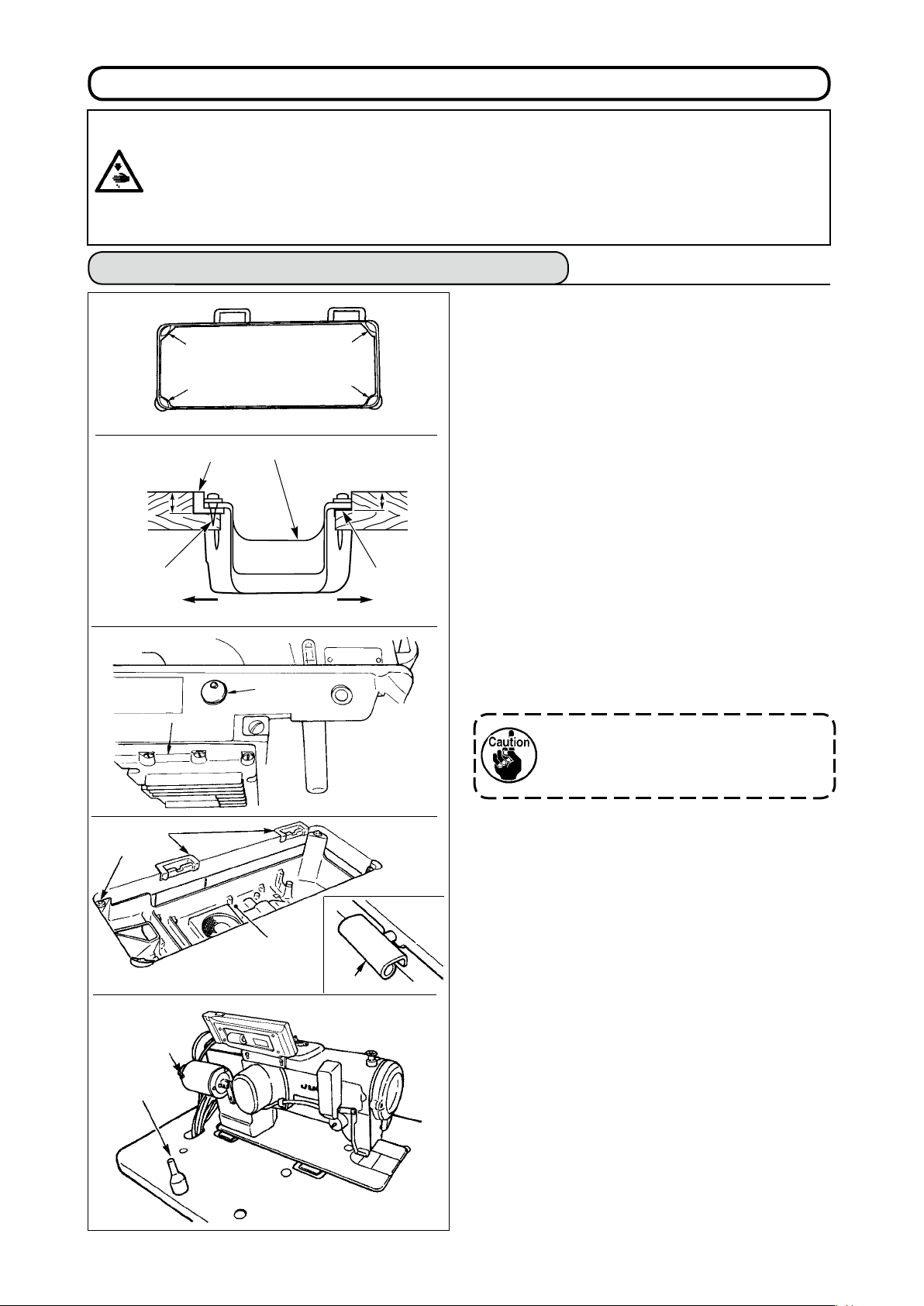

4. INSTALLATIoN

WArNING :

• Perform the installation of the sewing machine by the technical personnel who have been trained.

• To prevent personal injury, ask our dealer or the electrician for electric wiring.

• Be sure to perform the work with two persons or more when transporting the sewing machine and use a

lorry when moving it.

• To prevent personal injury caused by abrupt start of the sewing machine, do not connect the power plug

until the set-up of the sewing machine is completed.

• Be sure to earth the ground wire to prevent personal injury caused by leak.

• Be sure to attach safety protection cover, nger guard, etc.

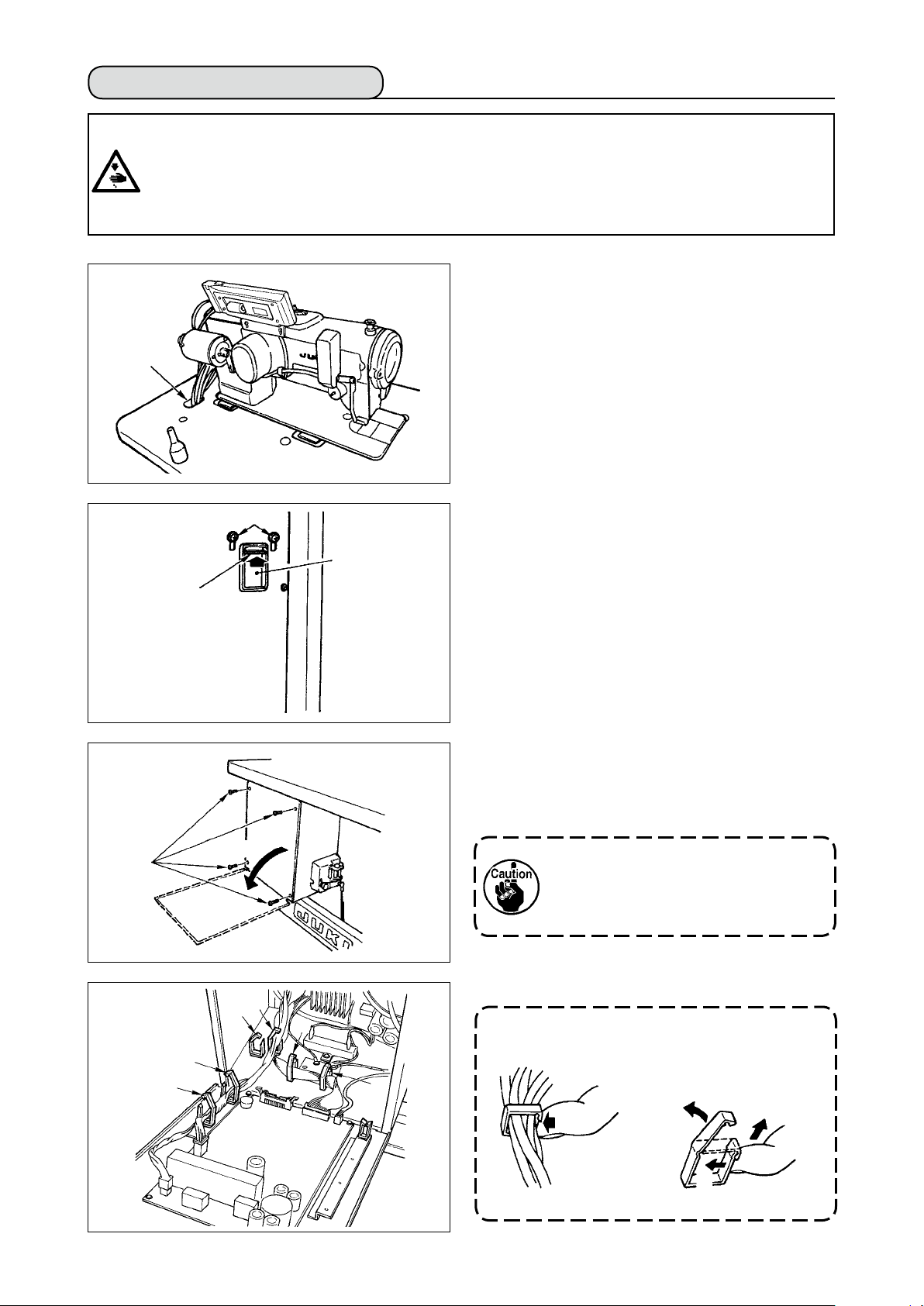

4-1. Installation of the sewing machine head

Installing the under cover

■

1) The under cover should rest on the four corners

3

3

of the machine table groove.

23.5 mm

3

2

8

7

1

1

A

5

4

B

1

19.5 mm

3

2) Fix two rubber seats

side) using nails

on side

1

as illustrated above. Fix two

2

(operator’s

A

cushion seats 3 on side B (hinged side) using a

rubber-based adhesive. Then place under cover

on the xed seats.

4

3) Remove air vent cap

bed. (Be sure to attach cap

attached to the machine

5

when transporting

5

the machine head in the state that the machine

head is removed from the machine table.)

If the sewing machine is operated without removing air vent cap 5, oil leakage

from gear box portion 7 may occur.

4) Fit hinge

into the opening in the machine bed,

1

and t the machine head to table rubber hinge 8

before placing the machine head on cushions 3

on the four corners.

6

9

4

1

5) Attach head support rod

to the machine table.

6

(However, this step is not necessary for the ma

chine with AK

device.)

9

-

Page 8

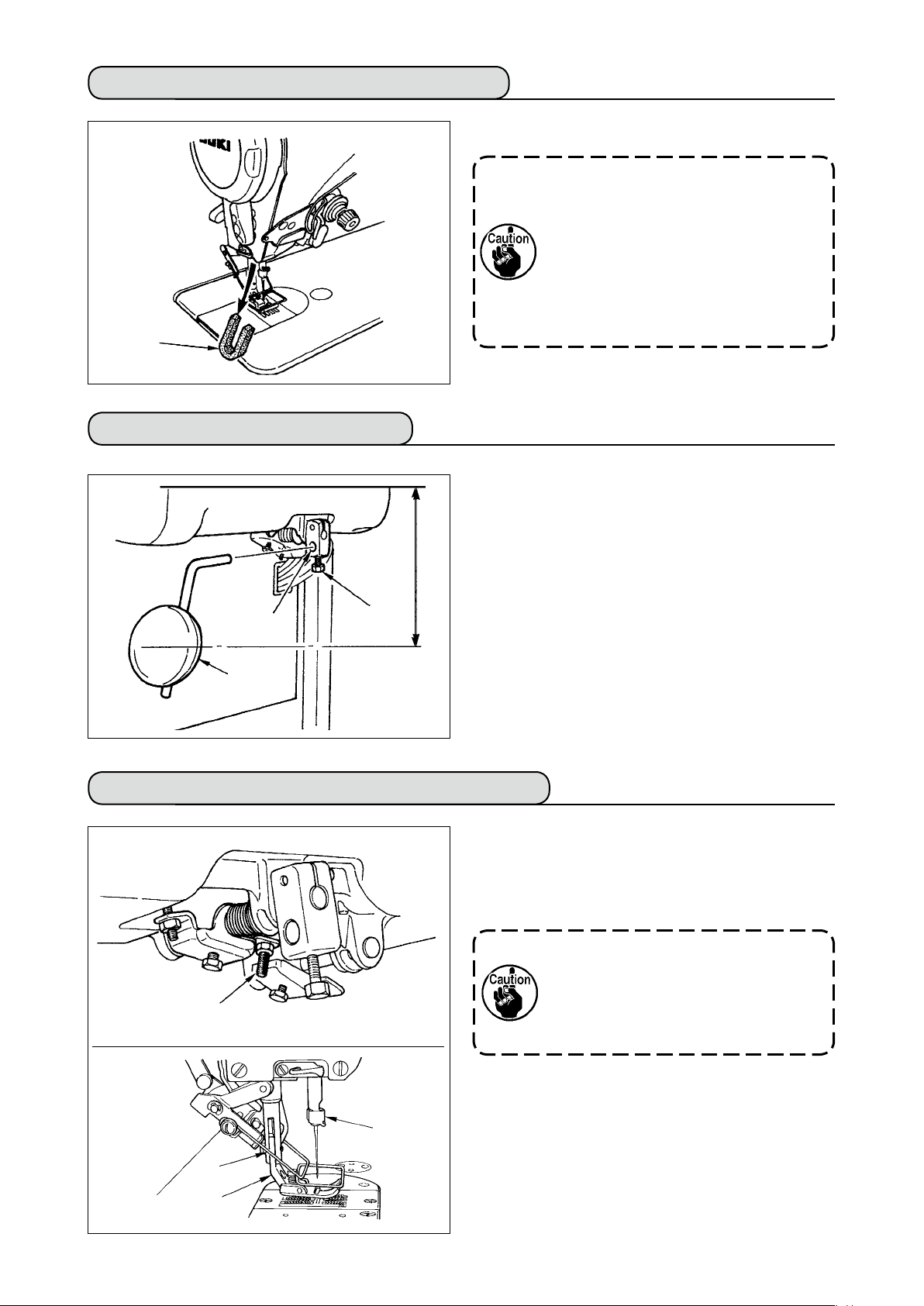

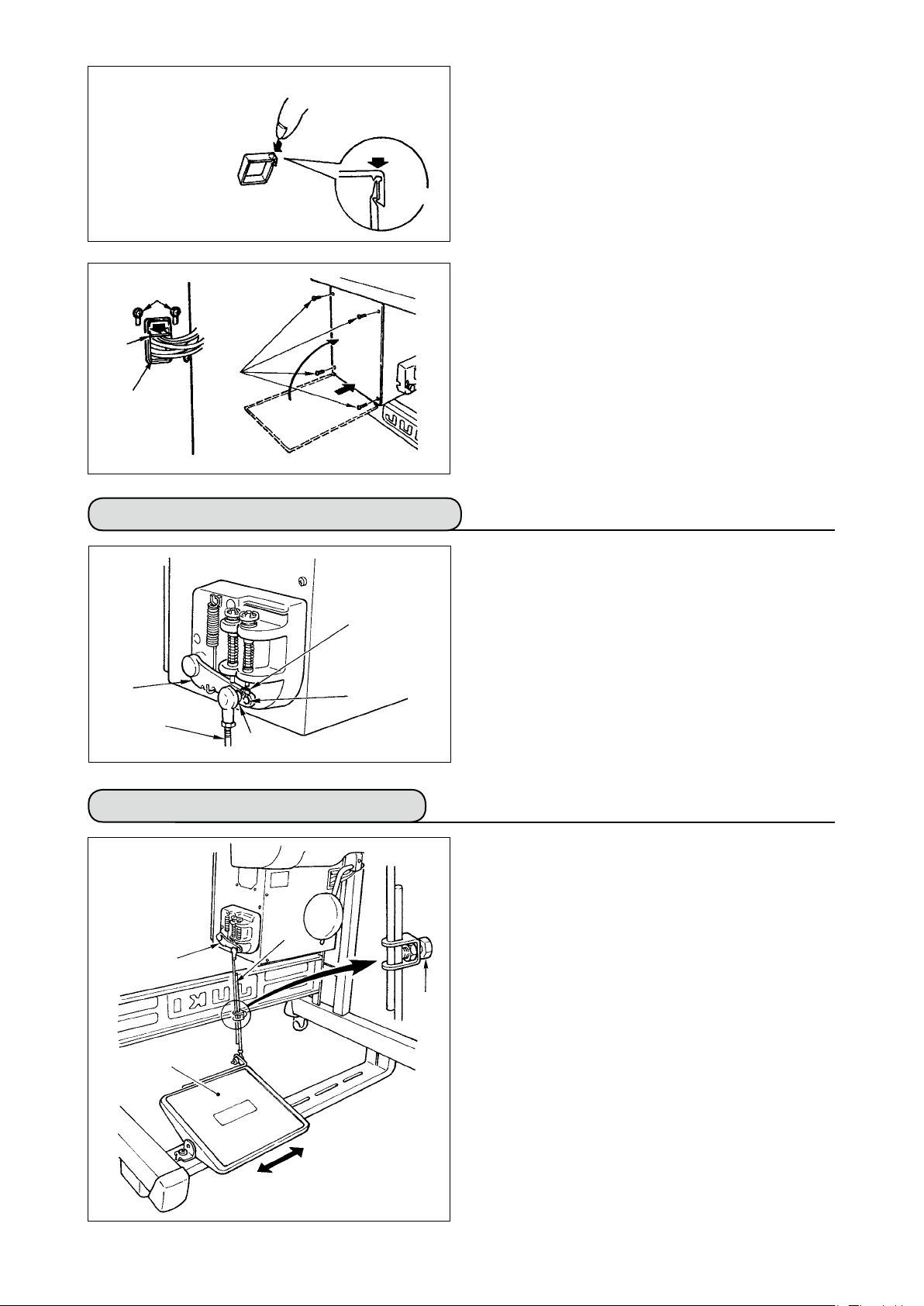

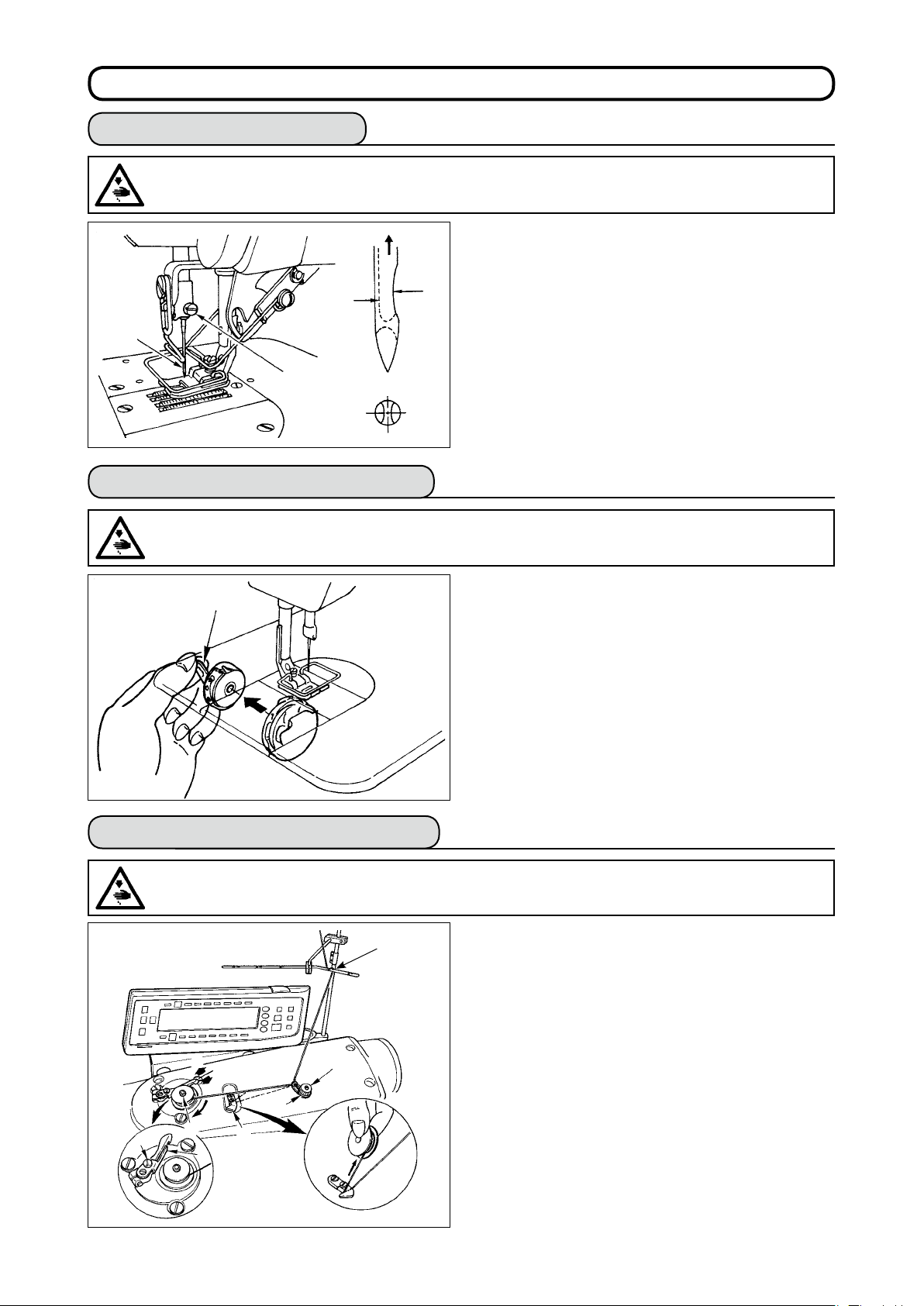

4-2. Removing the needle bar stopper

1

4-3. Attaching the knee-lifter

220 mm

Remove needle bar stopper

Keep the needle bar stopper which has

been removed, and install this needle

bar stopper when transporting the sewing machine. The needle bar stopper

may be cut when it is strongly drawn

out. Slightly move the needle bar to

the right or left and slowly draw out the

needle bar stopper.

Insert knee lifter pad

into attaching hole

1

for transportation.

1

2

and

tighten it with bolt 3.

* Adjust the position of knee lifter pad 1 to a con-

venient place. For the reference dimension, the

position is 220 mm from the bottom face of table.

2

1

3

4-4. Adjusting the height of the knee lifter

1) The standard height of the presser foot lifted us-

ing the knee lifter is 10 mm.

2) You can adjust the presser foot lift using knee

lifter adjust screw 1.

1

Do not operate the sewing machine in

the state that presser foot 3 is lifted by

10 mm or more since needle bar 2 and

presser foot 3, or wiper 4 and presser

foot 3 come in contact with each other.

4

2

3

– 5 –

Page 9

– 6 –

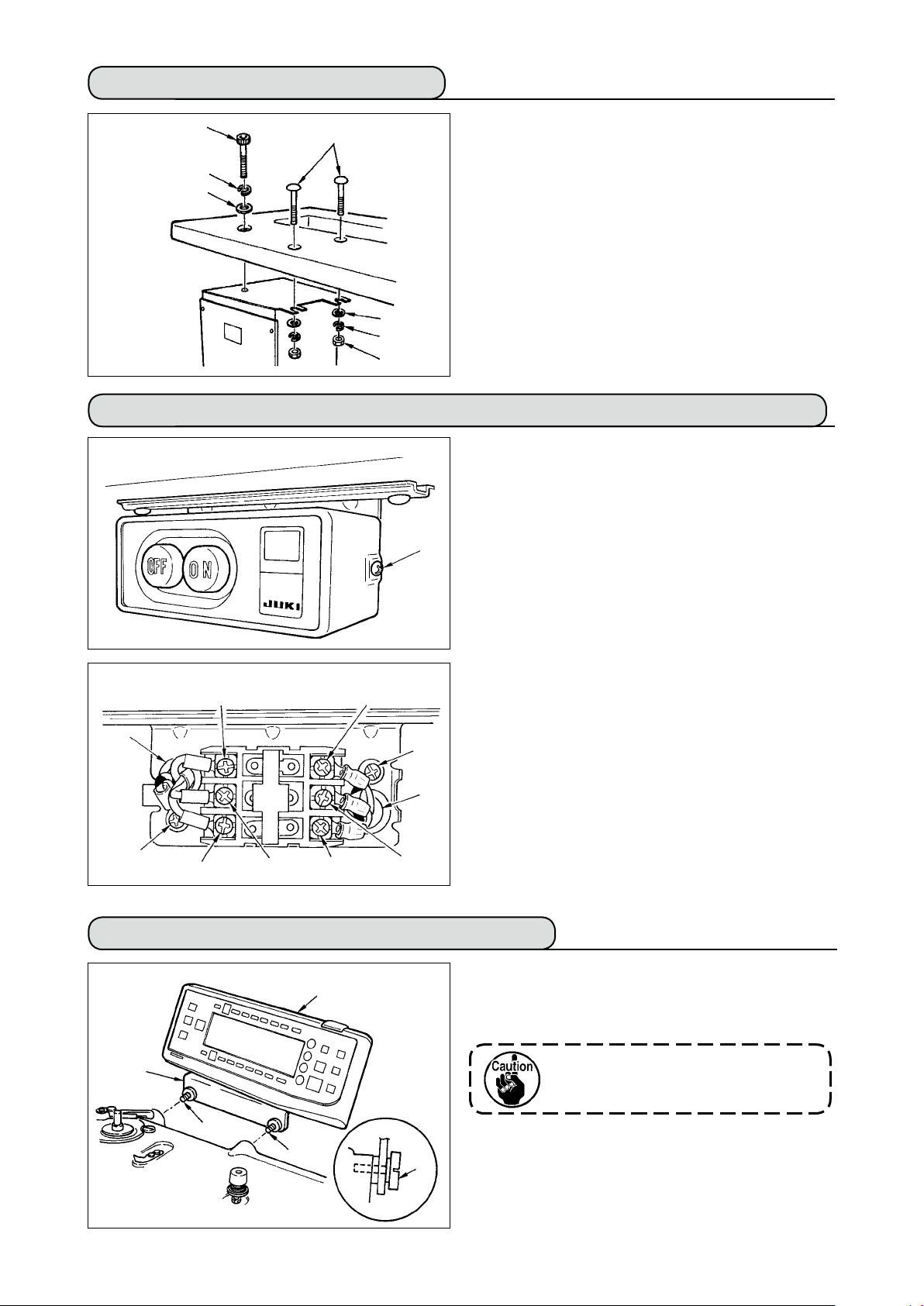

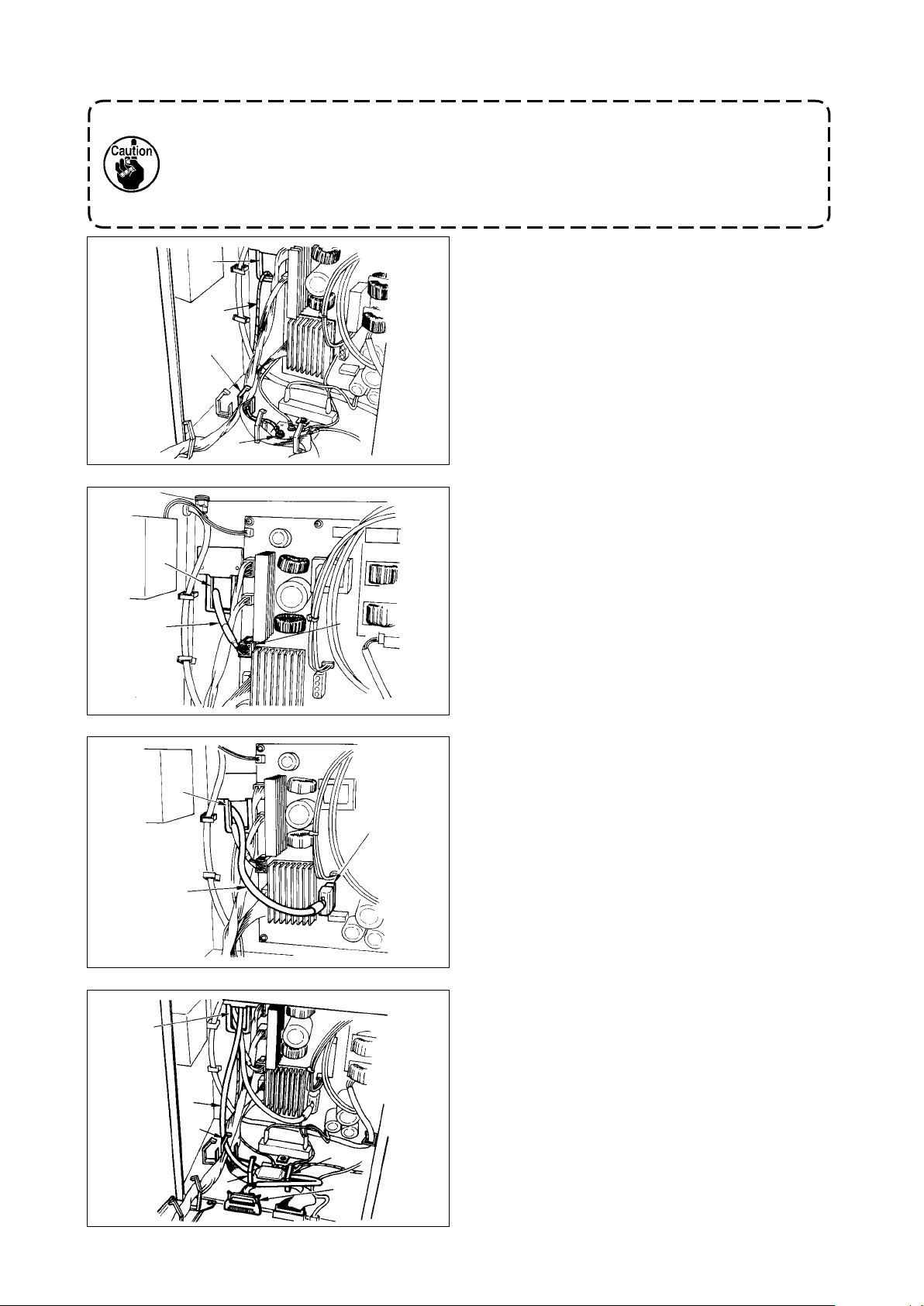

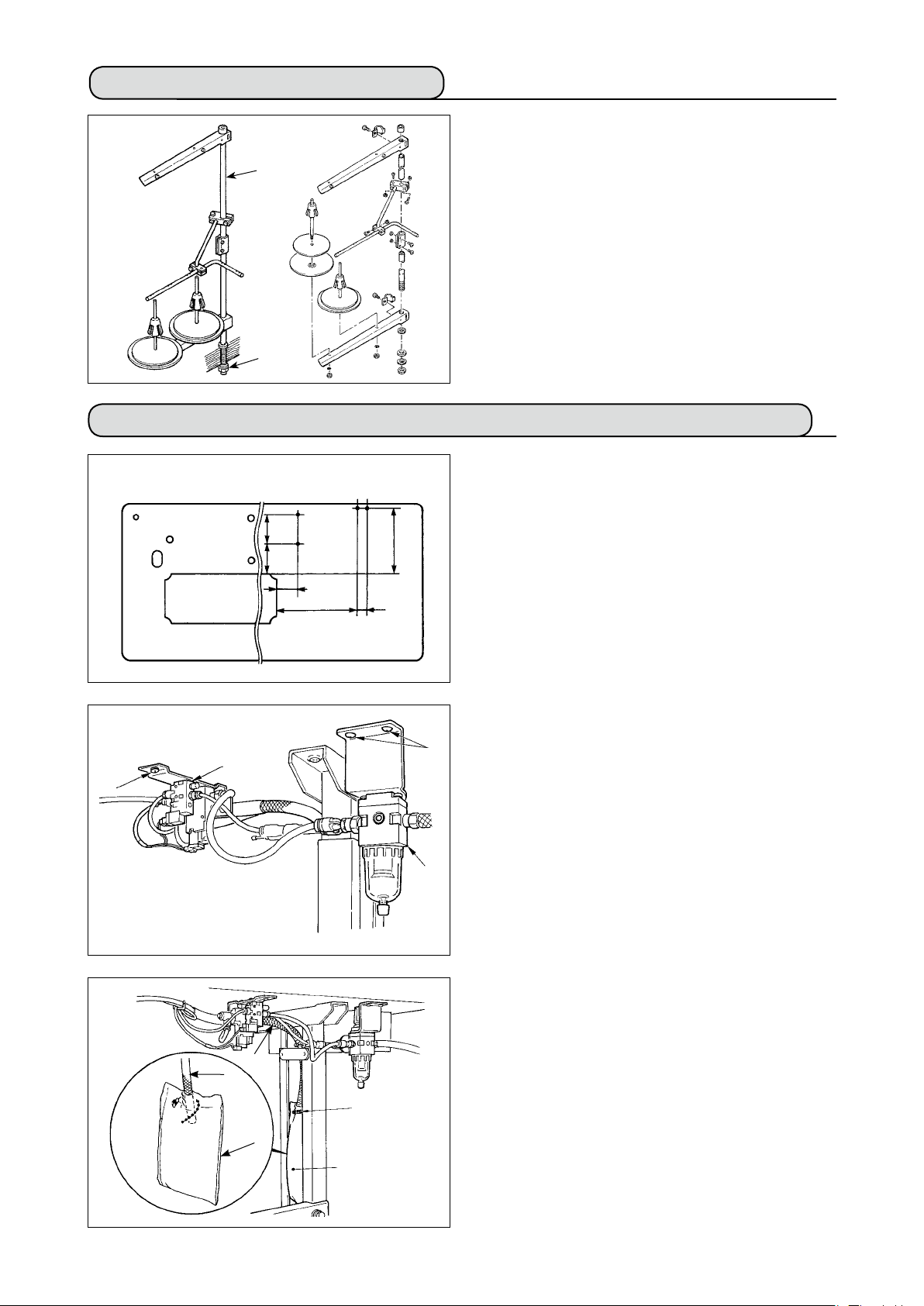

4-5. Installing the electrical box

5

1

6

7

Install the electrical box on the under side of the

table using round-head bolts

spring washers 3 and nuts

chine at the location illustrated, and using bolt having

hexagonal indentation on the head

and plain washer 7 supplied with the machine at

6

the location illustrated.

2

3

4

4-6. Connecting the power switch cord

1) Loosen screw 1 located on the side of the power

2) Connecting the input power cord of electrical box

When the input power cord of electrical box is 4P

¡

1

8

6

9

B

7

2

A

5

4

3

Put 4P cord from hole A of the power switch and

securely x green/yellow cord to

black cord to 3 and red cord to

When the input power cord of electrical box is 3P

¡

Put 3P cord from hole A of the power switch and

securely x green/yellow cord to 5, brown cord to

2

3) Connecting the power cable supplied as accessories

In case of 3-phase power cable

¡

Put power cable from hole B of the power switch, and

In case of single phase power cable

¡

Put power cable from hole B of the power switch,

4) Installing the power switch cover

Securely tighten screw 1 located on the side of

, plain washers

1

supplied with the ma

4

, spring washer

5

2

,

-

(Japan and general export area)

switch supplied as accessories and remove the

power switch cover.

, white cord to

5

with screws.

4

and sky blue cord to 3 with screws.

securely x green/yellow cord to 9, white cord to 6,

black cord to 7 and red cord to 8 with screws.

and securely x green/yellow cord to 9 and other

cords to 6 and 7 with screws. 8 is not used.

the power switch.

2

,

4-7. Installing the operation panel (IT-100D)

1

2

3

3

3

1) Install operation panel

using screws 3 which have been assembled to

panel installing bracket

on the machine head

1

.

2

Do not disassemble the operation

panel to prevent it from breakage.

Page 10

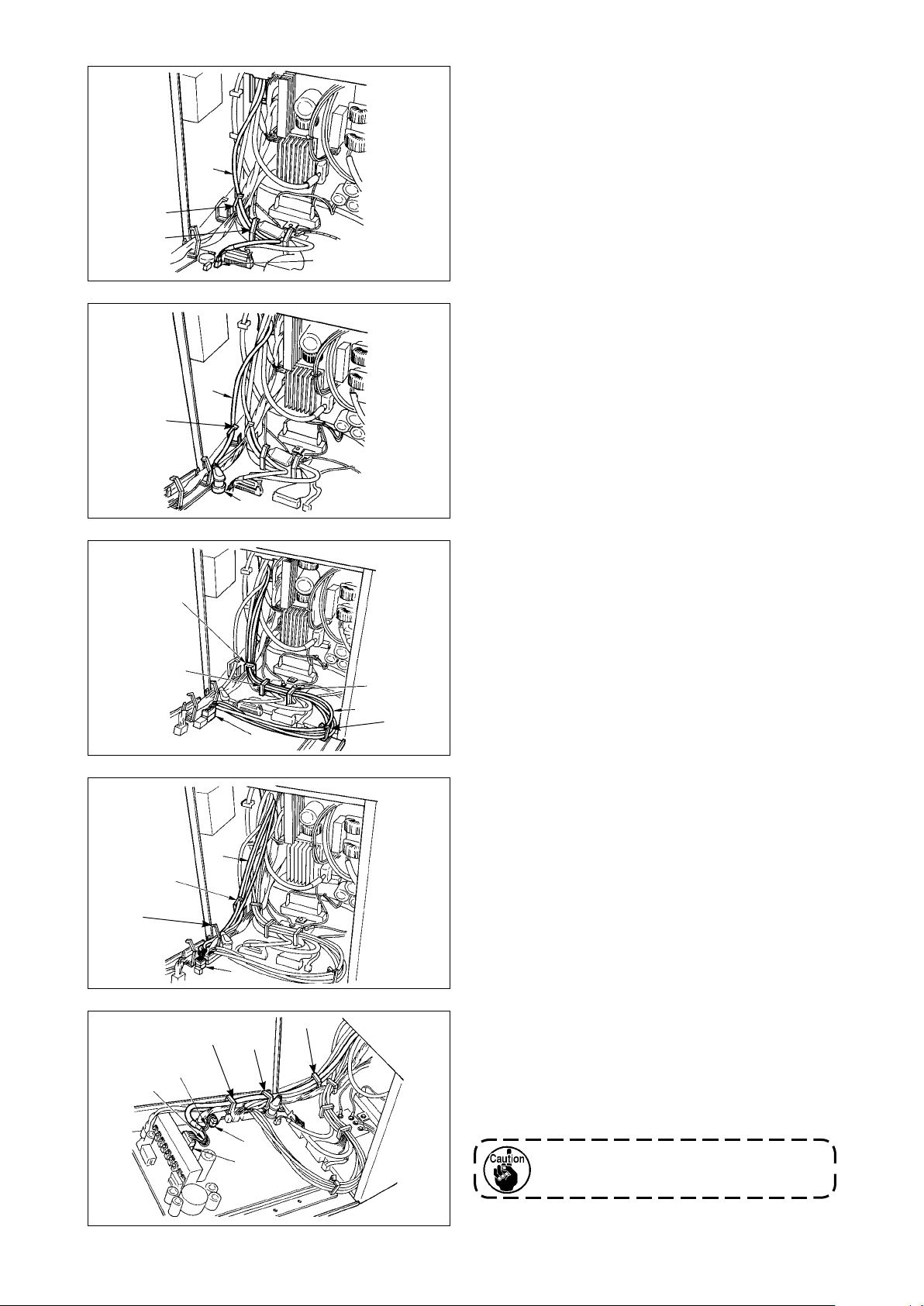

4-8. Connecting the cords

WArNING :

• To prevent personal injury caused by abrupt start of the sewing machine, carry out the work after turning

OFF the power switch and a lapse of 5 minutes or more.

• To prevent damage of device caused by maloperation and wrong specications, be sure to connect all the

corresponding connectors to the specied places.

• To prevent personal injury caused by maloperation, be sure to lock the connector with lock.

• As for the details of handling respective devices, read carefully the Instruction Manuals supplied with the

devices before handling the devices.

(1) Preparation of wiring

A

1) Pass the cords coming from the machine head to

the underside of the table through hole A in the

table.

D

2) Loosen screws D and lift cord presser plate C of

cord passing hole B located on the front cover to

B

C

the top and temporarily tighten the plate.

3) Remove four screws E xing the rear cover of

the electrical box. When opening the rear cover,

pressing it with your hands, slowly open it by ap

-

proximately 90˚ until it stops as illustrated.

E

Slowly

Be sure to lend your hand to the rear

cover in order not to let the rear cover

fall. In addition, do not apply force to the

rear cover opened.

4) Remove the locks of cord clamps a, b, c, d, e, and f.

b

a

e

f

c

d

How to remove the cord clamp

1

Lightly pressing

1

Pull down the clamp.

2

The clamp goes up.

3

3

2

1

* See P.11 for how to lock the cord clamp.

– 7 –

Page 11

– 8 –

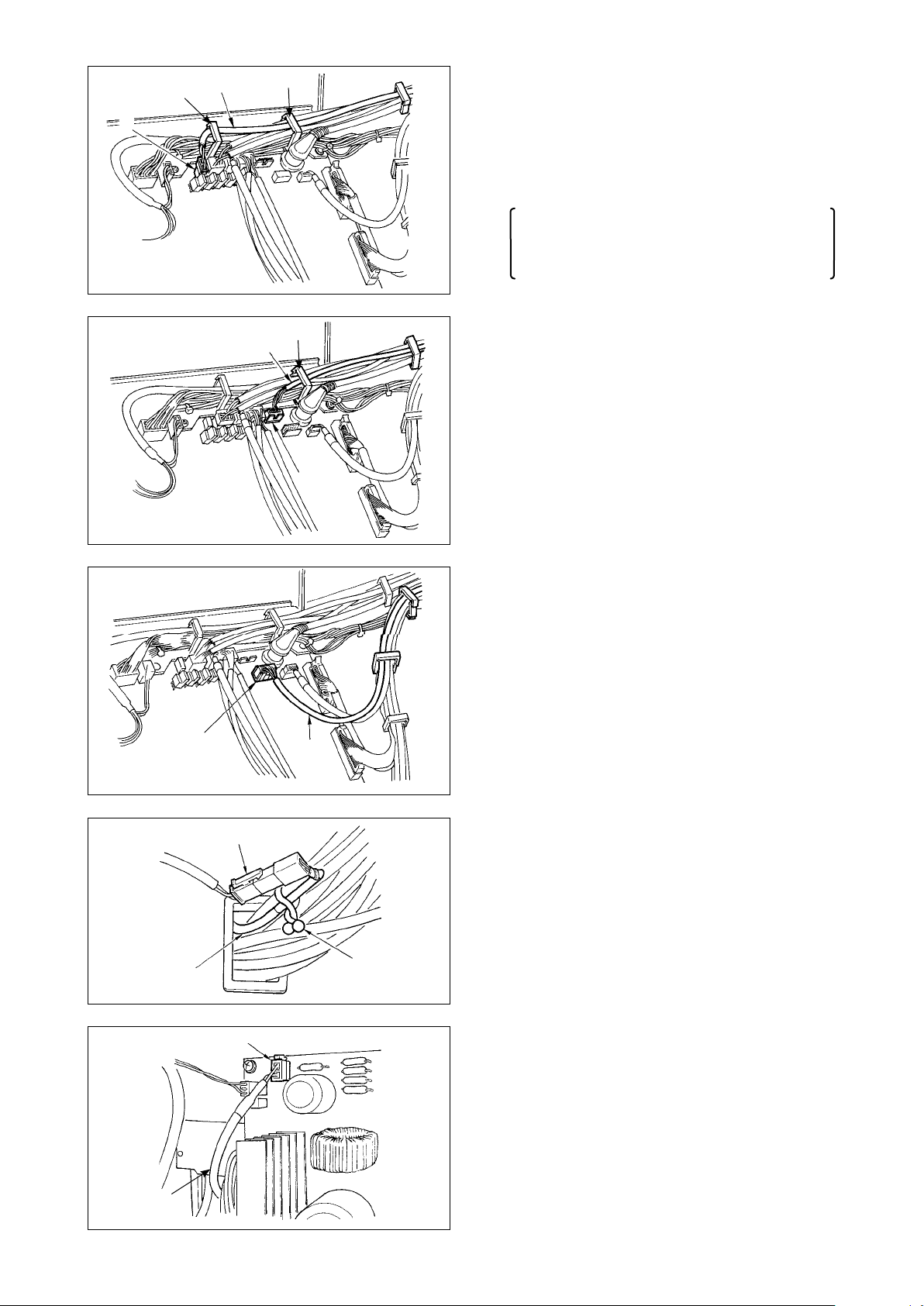

(2) Connecting the connectors

• Each connector has the inserting direction. Check the direction and securely insert it. (In

case of the type with lock, insert up to the lock.)

• If the connector is forcibly inserted, trouble or accident will be caused.

• Never pull out the connectors inserted at the time of delivery.

• The sewing machine fails to work if the connectors are not properly inserted. Not only the

problem such as the error warning or the like but also breakage of the sewing machine or

electrical box will occur.

B

1

b

2

B

Connect cords in the following order.

5) Insert yellow/green earth cord

coming from

1

the machine head inside the electrical box

through front cover through hole B, and pass it

through cord clamp “b” as illustrated and tighten

it with screw at the position 2 in the illustration.

6) Insert white square connector 9P black cord 3

coming from the machine head inside the electri

cal box through front cover through hole B, and

insert it into connector CN38 4 of the circuit

board attached to the front cover.

-

3

4

7) Insert white connector 4P black cord 5 coming

from the machine head inside the electrical box

B

through front cover through hole B, and insert it

into connector CN21 6 of the circuit board at-

6

5

tached to the front cover.

8) Insert white connector 26P cord 7 coming

B

from the operation panel inside the electrical

box through front cover through hole B, pass it

through cord clamps “b”, “c” and “d”, insert it into

u

b

connector CN34 8, and lock it.

d

c

i

Page 12

9) Insert black connector 4P white cord

coming

9

from the machine head inside the electrical box

through front cover through hole B, and insert it

into connector CN31

o

b

c

!0

!0

.

10) Insert gray round connector 7P cord

!1

com-

ing from the machine head inside the electrical

box through front cover through hole B, pass it

through cord clamp “a”, and insert it into connec-

!1

a

!2

tor CN30 !2.

11) Insert white connector 12P cord

coming from

!3

the machine head inside the electrical box through

b

front cover through hole B, pass it through cord

clamps “b”, “c”, “d” and “g”, and insert it into con

-

nector CN53 !4.

c

d

!3

g

!4

Close cord clamps “b”, “c” and “d”.

12) Insert white connector 6P three cords !5 com-

ing from the machine head inside the electrical

box through front cover through hole B, pass it

!5

a

e

!6

a

!7

!8

f

e

through cord clamps “a” and “e”, and insert it into

connector CN54 !6.

13) Insert white connector 10P cord !7 and blue

connector 2P cord

coming from the machine

!8

head inside the electrical box through front cover

through hole B, pass them through cord clamps

“a”, “e” and “f”, and insert the white 10P into con-

!9

@0

nector CN51

The blue 2P connector is attached only

for the machine with thread trimmer.

and the blue 2P into CN46

!9

@0

.

Close cord clamps “a”, “e” and “f”.

– 9 –

Page 13

– 10 –

@2

@1

f

e

a

When the Auto-lifter (AK121) is used :

14) Insert white connector 2P cord

coming from

@

1

the machine head inside the electrical box

through front cover through hole B, pass it

through cord clamps “a”, “e” and “f”, and insert it

into connector CN40

@2

.

Change the setting of function setting No.

23 from “0” to “1” after completing all set-up

procedure. For the details, see p.78 and p.81.

@6

@3

e

a

When the bird’s nest prevention device is used

(CB type)

15) Insert white small connector 6P cord

@3

com-

ing from the machine head inside the electrical

box through front cover through hole B, pass

it through cord clamps “a” and “e”, and insert it

into connector CN52 @4.

@4

When foot pedal for standing work (PK70 or 71) is

b

c

used :

16) Insert black connector 12P cord

inside the

@5

electrical box through front cover through hole

B coming from the foot pedal for standing work,

pass it through cord clamps “b” and “c”, and

insert it into connector CN32

@5

@6

.

@7

@7

@8

#0

@9

17) Connect white connector 2P of cord @7 sup-

plied as accessories to which red connector 2P

and white connector 2P are attached to white

connector 2P

of under cover of the machine

@8

head.

Fix omega lock

supplied as accessories with

@9

the neighboring cords and cord @7 as shown in

the gure.

18) Insert red connector 2P side of cord

as accessories to which red connector 2P and

white connector 2P are attached inside the elec

trical box through front cover through hole, and

insert it into red connector CN25 #0.

supplied

@7

-

Page 14

How to lock the cord clamp

When the insertion of the connector is completed,

lock the cord clamps.

4

Lightly press the corner of clamp.

4

(Cord clamp is locked with a click.)

2

C

1

B

A

4

3

Clamp

4-9. Attaching the connecting rod

3

Take care so that the cord is not caught between

q

the rear cover and the electrical box main body,

close the rear cover while pressing section A on

the lower side of the rear cover, and tighten four

screws 1.

Press down cord presser plate C of cord through

w

hole B of the front cover, press the cord, and

tighten screws 2.

1) Fix connecting rod

lever

with nut

2

2) Installing connecting rod

to installing hole

1

.

3

to installing hole A

1

of pedal

B

will lengthen the pedal depressing stroke, and the

pedal operation at a medium speed will be easier.

2

1

B

A

4-10. Adjustment of the pedal

2

1

3

4

Installing the connecting rod

■

1) Move pedal 3 to the right or left as illustrated by

the arrows so that motor control lever 1 and con-

necting rod 2 are straightened.

Adjusting the pedal angle

■

1) The pedal tilt can be freely adjusted by changing

the length of the connecting rod.

2) Loosen adjust screw 4, and adjust the length of

connecting rod 2.

– 11 –

Page 15

– 12 –

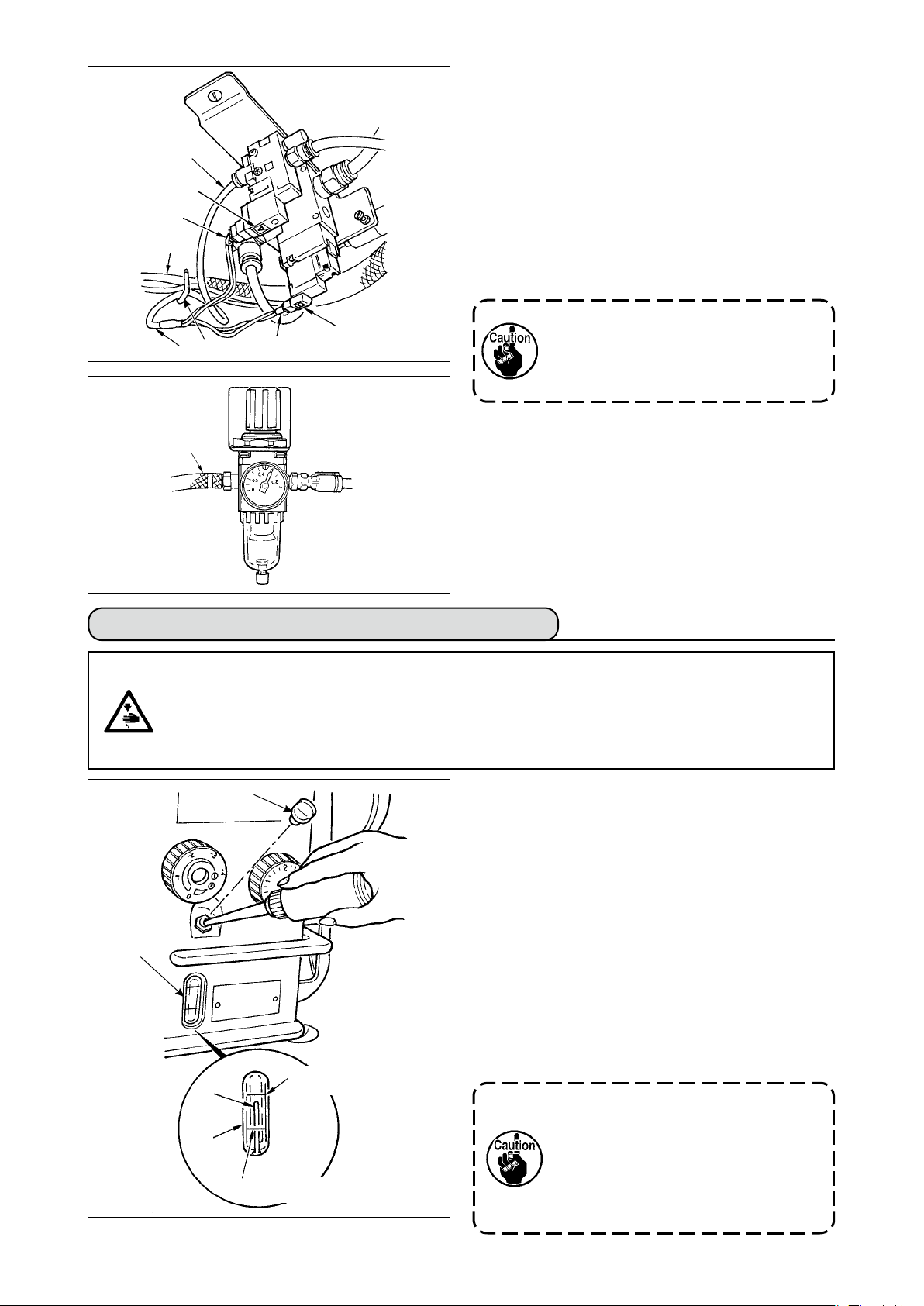

4-11. Installing the thread stand

1) Assemble the thread stand unit, and insert it in

the hole in the machine table.

2

2) Tighten locknut 1 to x the thread stand.

3) For ceiling wiring, pass the power cord through

spool rest rod 2.

1

4-12. Installing the bird’s nest prevention (CB) type sewing machine

(bottom surface of the machine table)

106107

75

291

1

2

34

(mm)

233

3

4

1) Punch dots on the positions of the setscrews of

solenoid valve (asm.) and regulator (asm.) on the

bottom surface of the machine table.

Besides, awling is performed on JUKI genuine

table.

2) Fix solenoid valve (asm.)

with wood screw

1

2

supplied with the sewing machine as accesso-

ries.

3) Fix regulator (total asm.)

with wood screw

3

4

supplied with the sewing machine as accesso-

ries.

4) Connect ø6 and ø8 hoses attached to regulator

(total asm.)

to the respective solenoid valves.

3

9

9

5

5

6

5) Insert dust bag 5 into the top end of hose

dust bag and x it with band

supplied with the

6

sewing machine as accessories.

9

for

Page 16

ø 8

ø 4

!1

7

!0

8

!1

!0

6) Adjust solenoid valve cord (asm.) 7 to the solenoid valve and the hot marker of the cord, and

connect it.

Connect 6P connector

to CM52 connector

!0!1

inside the electrical box.(Refer to “When the bird’

s nest prevention device is used, p. 10".)

7) Connect air hose ø4 coming from the machine

head to the solenoid valve section and air hose

ø8 to the dust bag suction port respectively.

8) Fix the solenoid valve and the air hose on the

table with staple

1. Fix the staple to such an extent that

the air hose is not crushed.

2. Determine the position of the staple

so that the cord and the air hose do

not hang from the table.

supplied as accessories.

8

9) Connect the air pipe

!2

to 0.6 MPa.

4-13. Lubrication (LZ-2290A-SS • A-SU (-7) )

WArNING :

1. Do not connect the power plug until the lubrication has been completed so as to prevent accidents due to abrupt start of the sewing machine,

2. To prevent the occurrence of an inammation or rash, immediately wash the related portions if

oil adheres to your eyes or other parts of your body.

3. If oil is mistakenly swallowed, diarrhea or vomitting may occur. Put oil in a place where children

cannot reach.

Fill the oil tank with oil for hook lubrication before

operating the sewing machine.

1) Remove oil hole cap 1 and ll the oil tank with

JUKI New Defrix Oil No. 1 using the oiler supplied

with the machine.

2) Fill the oil tank with oil up to the place where the

top of oil amount indicating rod 3 aligns with

the upper engraved line of oil amount indicating

window 2. If the oil is lled excessively, it will

leak from the air vent hole in the oil tank or proper

lubrication will be not performed. So, be careful.

3) When you operate the sewing machine, rell oil if

the top end of oil amount indicating rod 3 comes

down to the lower engraved marker line of oil

amount indicating window 2.

2

1

3

2

Upper engraved

marker line

Lower engraved

marker line

and set the air pressure

!2

• When you use a new sewing ma

chine or a sewing machine after an

extended period of disuse, run your

machine at 3,000 to 3,500 sti/min for

the purpose of break-in.

• For the oil for hook lubrication, pur

chase JUKI New Defrix Oil No. 1 (Part

No. : MDFRX1600C0).

-

-

– 13 –

Page 17

– 14 –

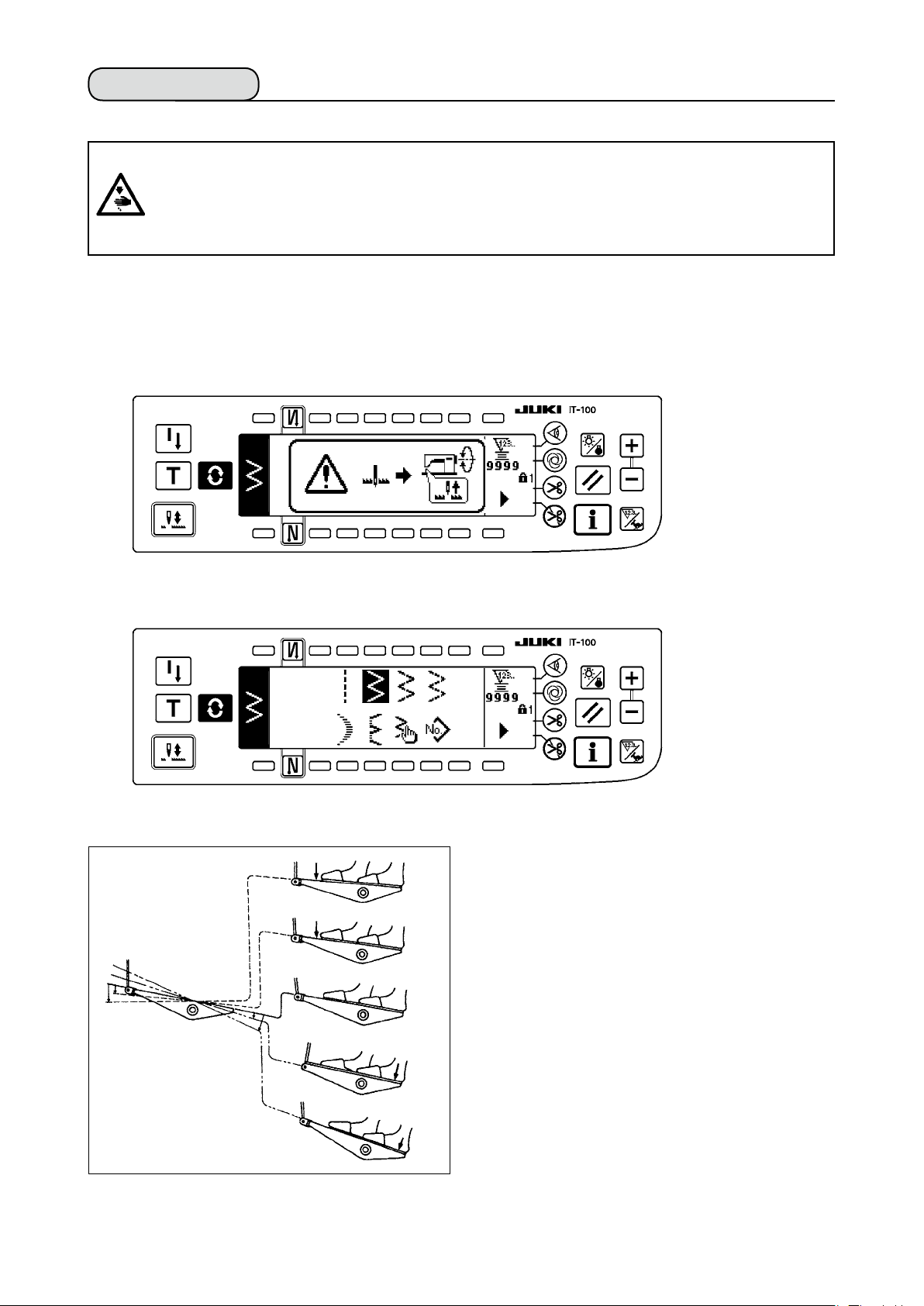

4-14. Test run

(1) Turn ON the power

WArNING :

• Check again the power voltage before connecting the power cord.

• Check that the power switch is turned OFF and connect the power cord to the power receptacle.

• Be sure to connect the earth wire.

• In case where the buzzer keeps beeping immediately after turning ON the power, there is a possi

bility of the wrong connection of cord or wrong power voltage. Turn OFF the power.

1) When the needle bar is in its UP position, zigzag origin detection is performed.

2) When the needle bar is in the position other than UP position :

Display as shown in the gure below appears. Turn the handwheel to bring the needle bar to needle UP

position and the display changes to the next screen. Then the needle moves left and right, and zigzag

origin detection is performed.

-

(2) How to operate the pedal

h

A

B

C

D

E

The pedal is operated in four stages.

1) Lightly depress the front part of the pedal for lowspeed operation

2) Further depress the front part of the pedal for

high-speed operation A. (Note that the sewing machine will enter the high-speed operation

mode after the completion of reverse feed stitching if the automatic reverse feed stitching function

is specied with the corresponding switch.)

3) Bring the pedal back to its neutral position, and

the sewing machine will stop running C.

(The needle stops in the highest / lowest posi-

tion.)

4) Strongly depress the back part of the pedal, and

the thread trimmer will be actuated E.

Lightly depress the back part of the pedal, and

the presser foot will go up D. Further depress the

back part of the pedal, and the thread trimmer will

be actuated.

B

.

Page 18

5.

PrEPArATIoN BEForE SEWING

5-1. Inserting the needle

WArNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

B

1

2

A

5-2. Removing the bobbin case

WArNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1) Turn the handwheel by hand to raise the needle

to its highest position.

2) Loosen the needle clamp screw 2 . Hold the nee-

dle 1 so that the long groove

on the needle is

B

facing exactly toward you.

3) Insert the needle deep into the hole of the needle

bar in the direction of the arrow until it will go no

further.

4) Securely tighten the screw 2 .

5) Conrm that the long groove B on the needle

faces toward you.

1

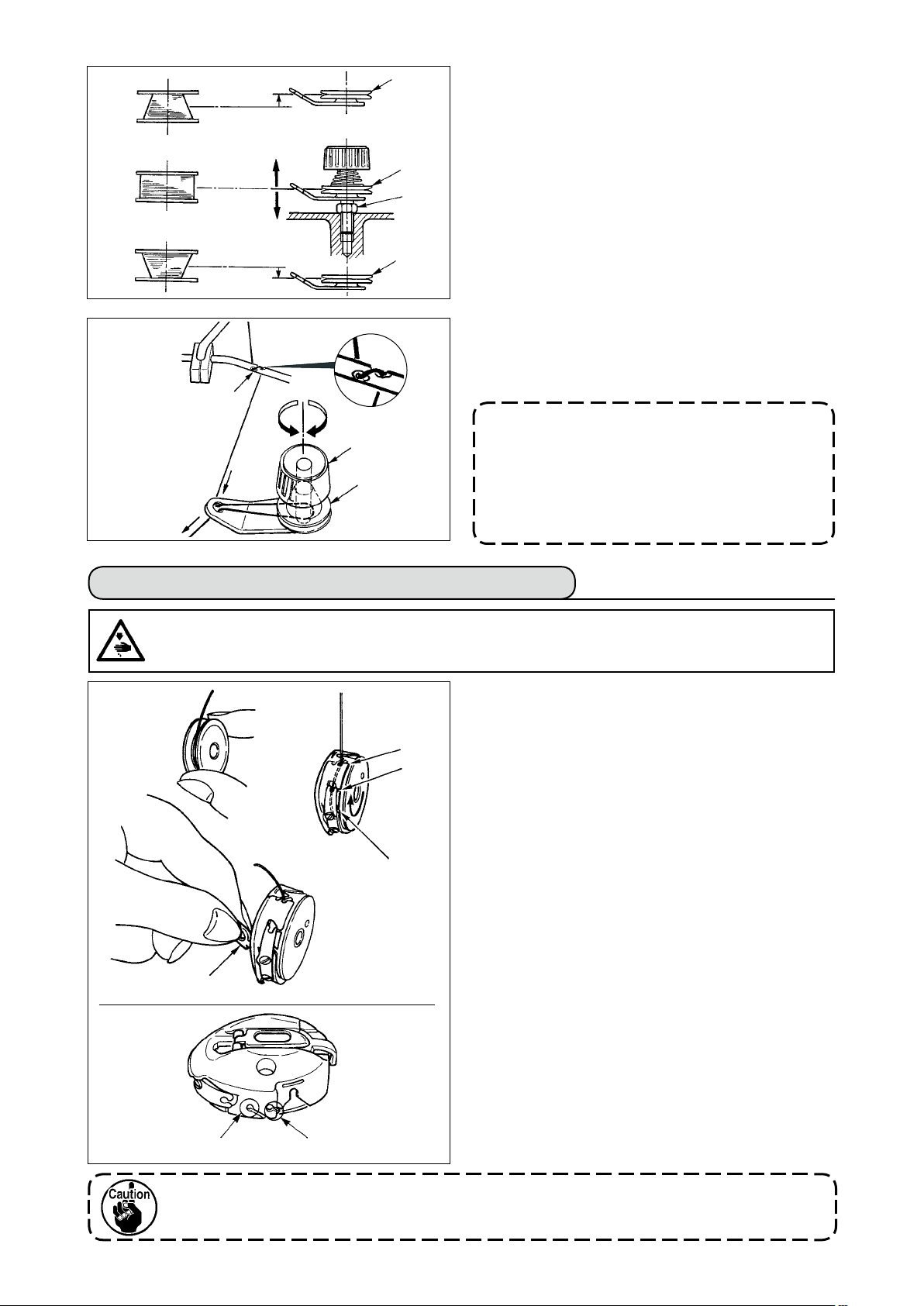

5-3. Winding the bobbin thread

WArNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1

7

5

B

A

C

6

2

8

3

1) Turn the handwheel by hand to raise the needle

to its highest position.

2) Raise bobbin case latch 1 and remove the bob-

bin case.

1) Insert the bobbin deep into the bobbin winder

spindle

2) Pass the bobbin thread pulled out from the spool

rested on the right side of the thread stand following

the order from 1 as shown in the gure on the left.

Then, wind the end of the bobbin thread on the bob

bin several times.

3)

Press the bobbin winder adjusting plate 6 in the

direction of A and start the sewing machine. The bob

bin rotates in the direction of C and the bobbin thread

is wound up. The bobbin winder spindle

matically stop as soon as the winding is nished.

4) Remove the bobbin and cut the bobbin thread with

the thread cut retainer

5)

To adjust the winding amount of the bobbin thread, loosen

setscrew 7 and move bobbin winder adjusting plate 6

to the direction of A or B. Then, tighten setscrew

To the direction A : The amount is decreased.

To the direction B : The amount is increased.

until it will go no further.

5

.

8

will auto-

5

7

.

-

-

– 15 –

Page 19

– 16 –

(Threading)

1

2

6) In case that the bobbin thread is not wound

evenly on the bobbin, loosen the nut 4 and turn

the bobbin thread tension to adjust the height of

the thread tension disk 2.

A

2

4

• It is the standard that the center of the bobbin is

as high as the center of the thread tension disk.

• Move the position of the thread tension disk 2 to

the direction A as shown in the gure on the left

B

2

when the winding amount of the bobbin thread on

the lower part of the bobbin is excessive and to

the direction B as shown in the gure on the left

when the winding amount of the bobbin thread on

the upper part of the bobbin is excessive.

After the adjustment, tighten the nut 4 .

7) Turn the thread tension nut 3 to adjust the tension of the bobbin thread winder.

Note 1. When winding bobbin thread, start winding

3

2. When winding bobbin thread in the state

2

in the state that the thread between bobbin

and thread tension disk 2 is tense.

that the sewing is not performed, remove

needle thread from the thread path of the

thread take-up and remove bobbin from the

hook.

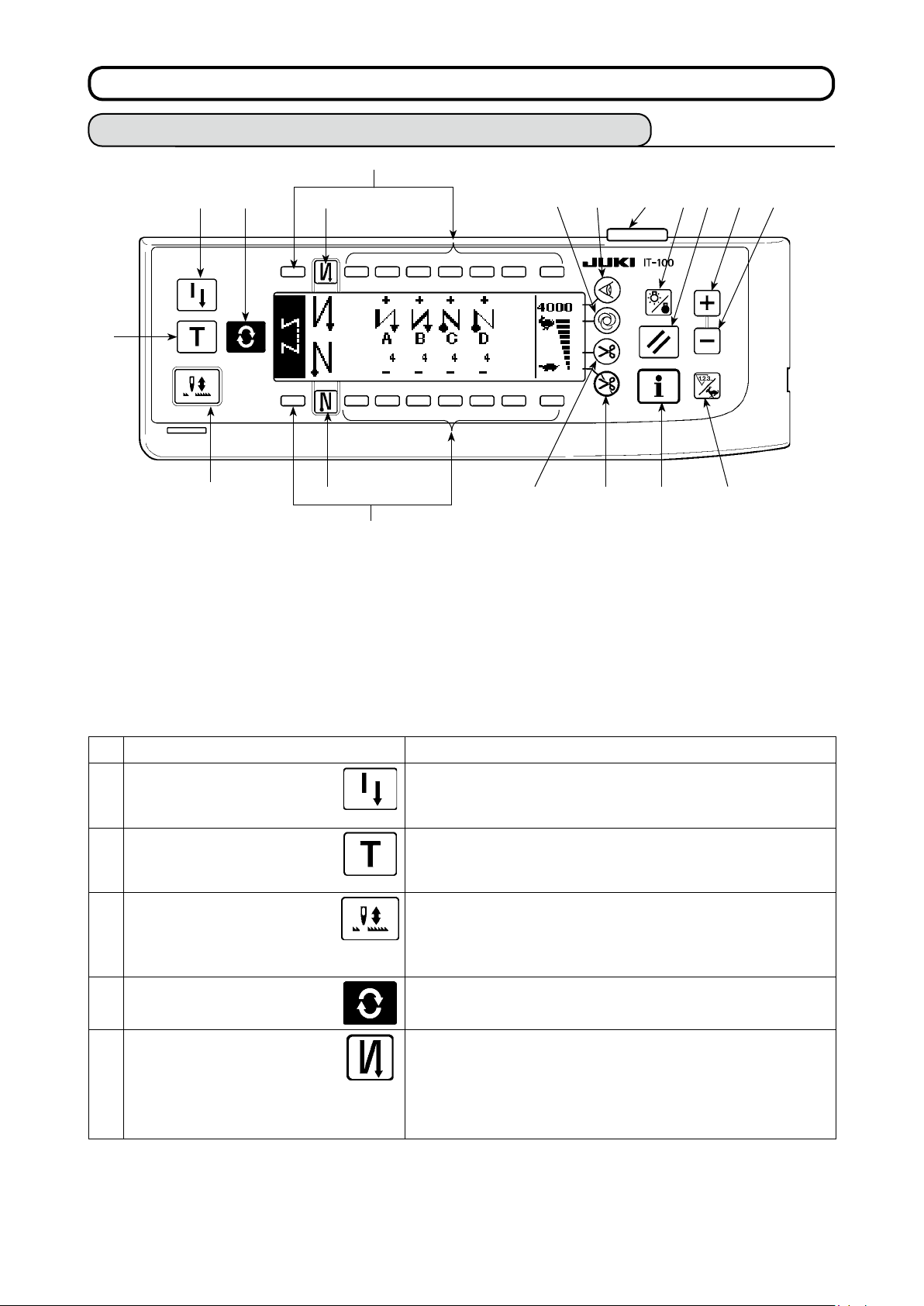

5-4. Placing the bobbin case and the bobbin

WArNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1) Turn the handwheel by hand to raise the needle

to its highest position.

2) Take a bobbin by your right hand with the thread

drawn out about 5 cm from the thread end of the

bobbin and place it into the bobbin case as illustrated.

3)

Thread the bobbin case in the order of the numbers

and pull it out through the thread path as illustrated.

The bobbin rotates in the bobbin case in the direction

shown by arrow when bobbin thread is drawn.

4) Raise bobbin case latch 1 and hold it between

your two ngers as shown in the gure on the left.

5) Insert the bobbin case into the sewing hook shaft

as far as it will go by putting your hand from the

under cover of the inner hook. (Click sounds.)

6) Release the bobbin case latch to let it steadily

rest in the closing position.

How to use the bobbin case thread hole

■

1) Use hole A mainly for zigzag stitches other than

2-step zigzag stitch and scallop zigzag stitch.

2) Use hole B mainly for 2-step zigzag stitch and

scallop zigzag stitch.

1

3

2

1

B

A

There may be a case where several stitches at the start of sewing are difcult to be knotted

when thread trimmer is used with thin lament thread such as (#50, #60 or #80) using hole B.

At this time, use the other hole or perform the sewing starting from the right.

Page 20

5-5. Threading the machine head

WArNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

5

2

3

1

LZ-2290A-7

With thread

trimmer

LZ-2290A

Without thread

trimmer

With auxiliary

thread take-up

1) Turn the handwheel by hand to bring the needle to the most raised position.

2) Pass the thread in the order of the numbers as illustrated.

3) Pull out the thread about 10 cm from the needle after passing it through the needle.

Without auxiliary

thread take-up

4

6

5-6. Adjusting the stitch length

A

1

2

1) Turn the stitch length dial 1 in the direction of

the arrow so that the number corresponding to

the desired stitch length meets the marker dot A

engraved on the machine arm.

2)

Numbers on the stitch length dial are calibrated in mm.

3) To perform reverse feed stitching, press down the

feed lever 2 . The sewing machine performs reverse feed stitching as long as you keep the feed

lever held pressed. The feed lever will return to its

home position and the sewing machine will run in

the normal stitching direction when you release

the feed lever.

5-7. Adjusting the condensation stitching

Turn the thread

once.

Stitch length can be reduced at the start or end of

B

sewing. This feature is used for fastening stitch.

1) Turn condensation stitching adjusting dial

3

in

the direction of the arrow mark, and adjust the de

3

1

sired number to engraved dot

arm.

2)

The number of the graduation is shown in the unit of mm.

3)

Turn condensation stitching adjusting dial

on the machine

B

in the

3

direction of + to reduce the reverse feed stitch length.

Example : When stitch length dial 1 is used with the

graduation of +2, the maximum adjustment value

of condensation stitching adjusting dial

3

becomes -2. (It is possible to adjust within the range

of -2 to +2.)

Maximum feed amount is regulated to ±2 according to the gauge delivered (feed dog :

22581508). Adjustment can be performed up to the range of maximum +5 to -4 by replacing the

gauge (feed dog : 22540009).

4) Note that the graduations on the dial are mere reference. Adjust the condensation stitching while actu-

ally observing the nished seam.

– 17 –

-

Page 21

– 18 –

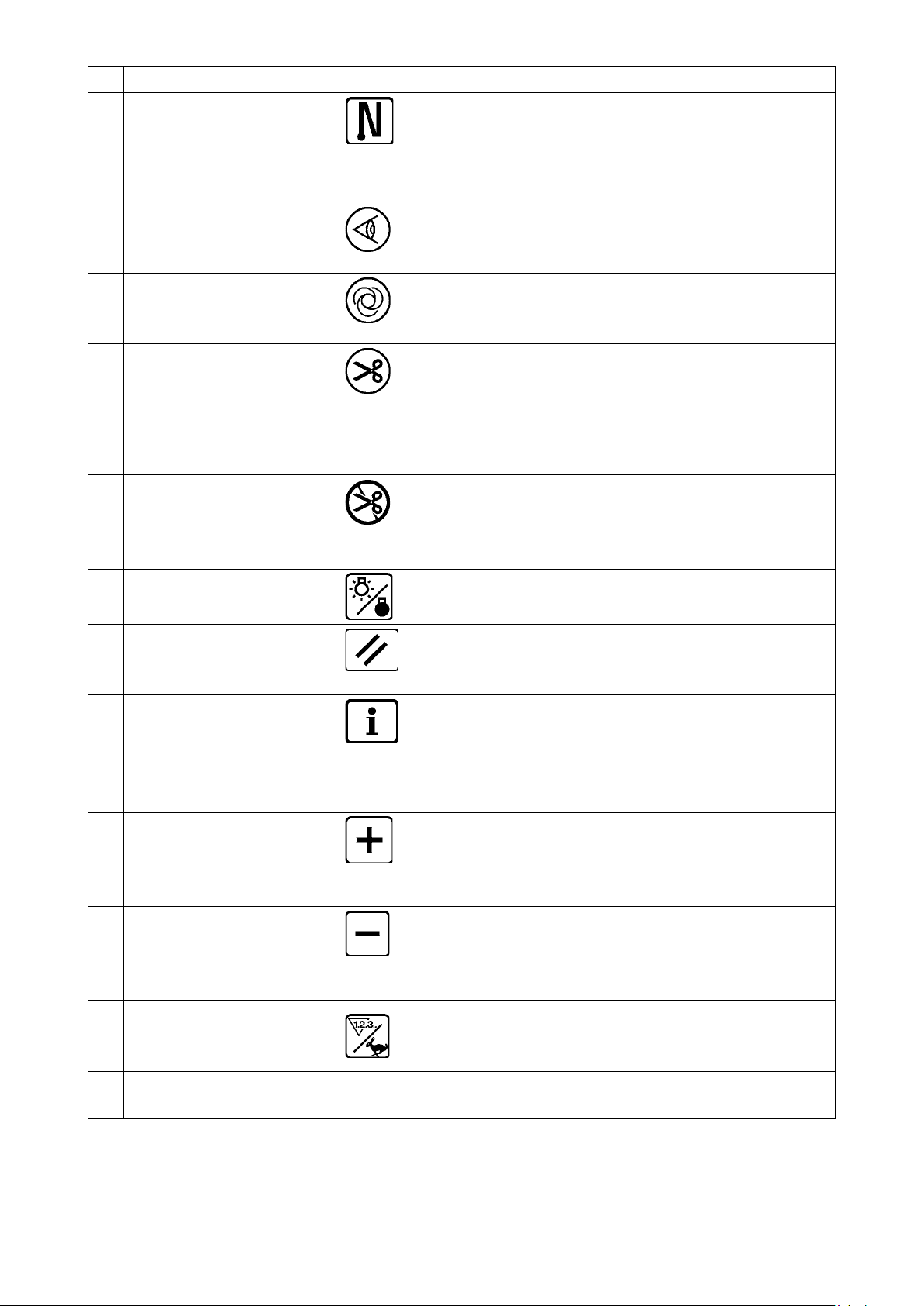

6. HoW To uSE THE oPErATIoN PANEL

6-1. Names and functions of the respective sections

!7

1 4 5

2

3

!7

Re-sewing switch

1

Teaching switch

2

Needle up/down compensating switch

3

Screen changeover switch

4

With/without reverse feed stitch at sewing start switch

5

With/without reverse feed stitch at sewing end switch

6

Material edge sensor switch

7

One-shot automatic sewing switch

8

With/without automatic thread trimmer switch

9

7

8

96

Thread trimming prohibiting switch

!0

Backlight switch

!1

Reset switch

!2

Information switch

!3

+ switch

!4

– switch

!5

Counter/speed changeover switch

!6

General-purpose switch

!7

Power display lamp

!8

!1 !2 !4 !5

!8

!6!3!0

Re-sewing switch

1

Teaching switch

2

Needle up/down compensating switch

3

Screen changeover switch

4

With/without reverse feed

stitch at sewing start switch

5

Switch Description

This switch is used to continue sewing from the step on the

way after replacing bobbin thread when bobbin thread has

run out during program stitching step.

This is the switch to set the setting of the number of stitches

with the value of number of stitches which has been actually sewn.

This is the switch to perform needle up/down compensating

stitching. (Needle up/down compensating stitching and one

stitch compensating stitching can be changed over with function

setting No. 22.)

This is the switch to change over the screen.

This is the switch to turn ON/OFF automatic reverse feed

stitch at sewing start.

* This switch cannot be used with the sewing machine

which is not provided with automatic reverse feed stitching device.

Page 22

Switch Description

With/without reverse feed

stitch at sewing end switch

6

Edge sensor switch

7

One-shot automatic sewing

switch

8

With/without automatic

thread trimmer switch

9

Thread trimming prohibiting

switch

!0

Backlight switch

!1

This is the switch to turn ON/OFF automatic reverse feed

stitch at sewing end.

* This switch cannot be used with the sewing machine

which is not provided with automatic reverse feed stitching device.

Selects use/disuse of the material edge sensor in the case

the material edge sensor (edge) is installed on the sewing

machine.

When this switch is pressed, the sewing machine automati-

cally operates until the material edge sensor detects the

material edge or until the set number of stitches is reached.

This switch is used to automatically trim the thread when

the material edge sensor detects the material edge or until

the set number of stitches is reached.

* This switch cannot be used with the sewing machine

which is not provided with the automatic thread trimming

device.

This switch prohibits all thread trimmings.

* This switch cannot be used with the sewing machine

which is not provided with the automatic thread trimming

device.

This switch is used to change over the operation of the

backlight of the LCD between ON and OFF.

Reset switch

!2

Information switch

!3

Plus switch

!4

Minus switch

!5

Counter/speed changeover

!6

switch

General-purpose switch

!7

This is the switch to make the value of bobbin thread coun-

ter or sewing counter the set value. This switch is enabled

after thread trimming.

This switch is used to change over the screen between the

information function screen (sewing common data mode,

function setting mode, communication mode, version dis-

play, etc.) and the normal sewing screen.

This switch is enabled after thread trimming.

This switch is used to increase the set value of the bobbin

thread counter or the number of pcs. counter at the time of

setting. It should be remembered that this switch is enabled

after thread trimming.

This switch is used to decrease the set value of the bobbin

thread counter or the number of pcs. counter at the time of

setting. It should be remembered that this switch is enabled

after thread trimming.

This switch is used to change over the display between the

counter display and the maximum sewing speed limitation

display.

This switch has different functions depending on the

screen.

– 19 –

Page 23

– 20 –

6-2. Before setting the pattern

WArNING :

Provide a clearance of 0.5 mm or more between the needle and the gauges when replacing the

gauges such as presser foot, throat plate, etc.

If the clearance is smaller than the specied value, it is in danger of

causing the needle to be broken or the like.

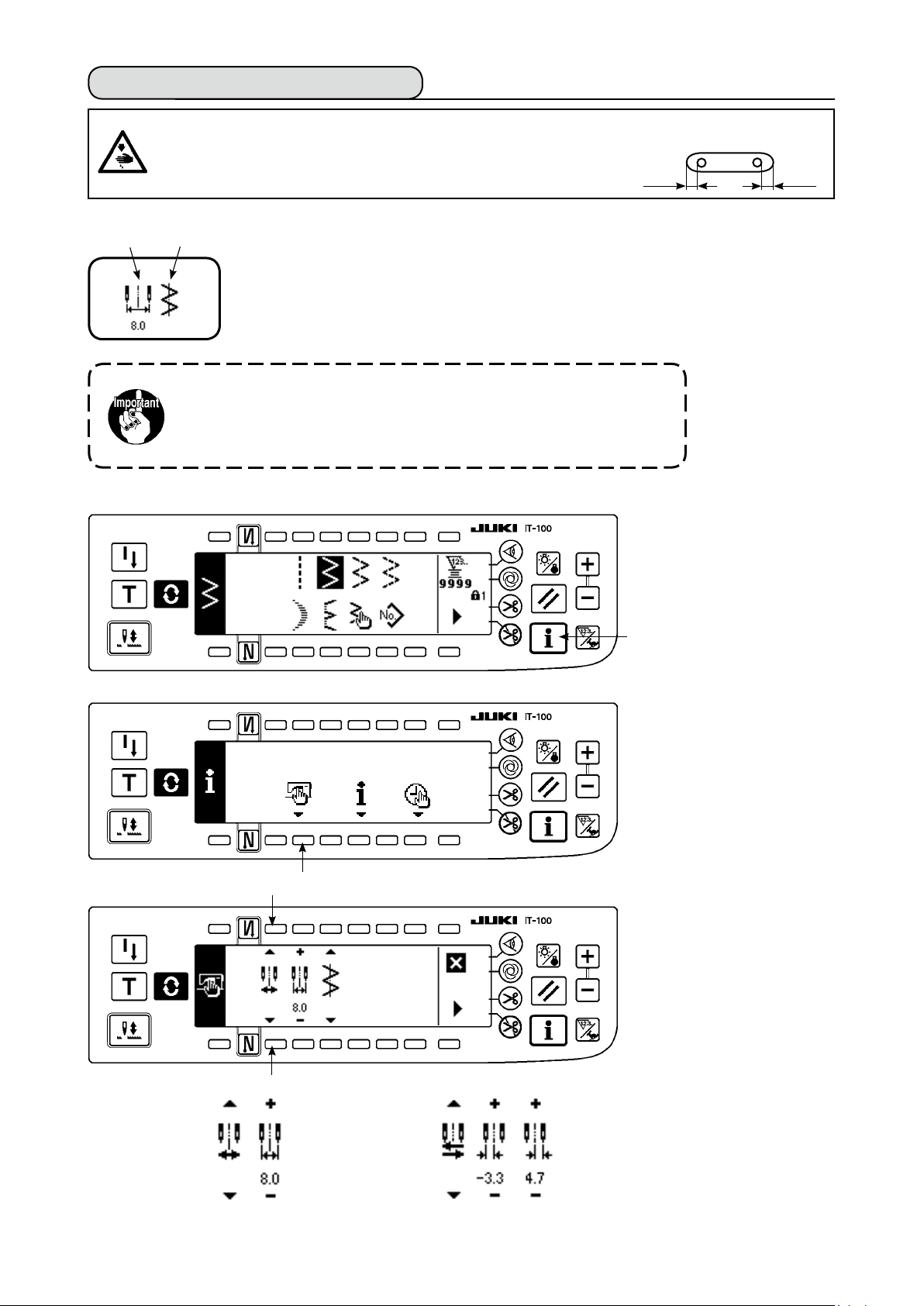

(1) Limitation of the max. zigzag width

q

Changeover of limiting procedure of max. zigzag width limitation value

■

w

• Max. zigzag width can be limited in accordance with the gauge.

• There are two kinds of limitations of max. zigzag width.

(1) Zigzag width symmetrical in the center

(2) Specifying left/right positions

Max. zigzag width limitation value and reference of stitch base line are displayed when

the power is turned ON.

Max. zigzag width limitation value (Screen changes in case of specifying left/right positions.)

1:

Reference of stitch base line

2:

Max. zigzag width limitation value and reference of stitch base line can be performed

with ON/OFF.

0.5

1) Press switch 1.

0.5

e

e

w

q

2) Press switch 2.

3) Figure on the left side is

the zigzag width symmet-

rical in the center mode.

Every time switch

pressed, specifying left/

right positions and zigzag

width symmetrical in the

center can be changed

over alternately.

3

is

⇔

(1) Zigzag width symmetrical in the center

(2) Specifying left/right positions

Page 24

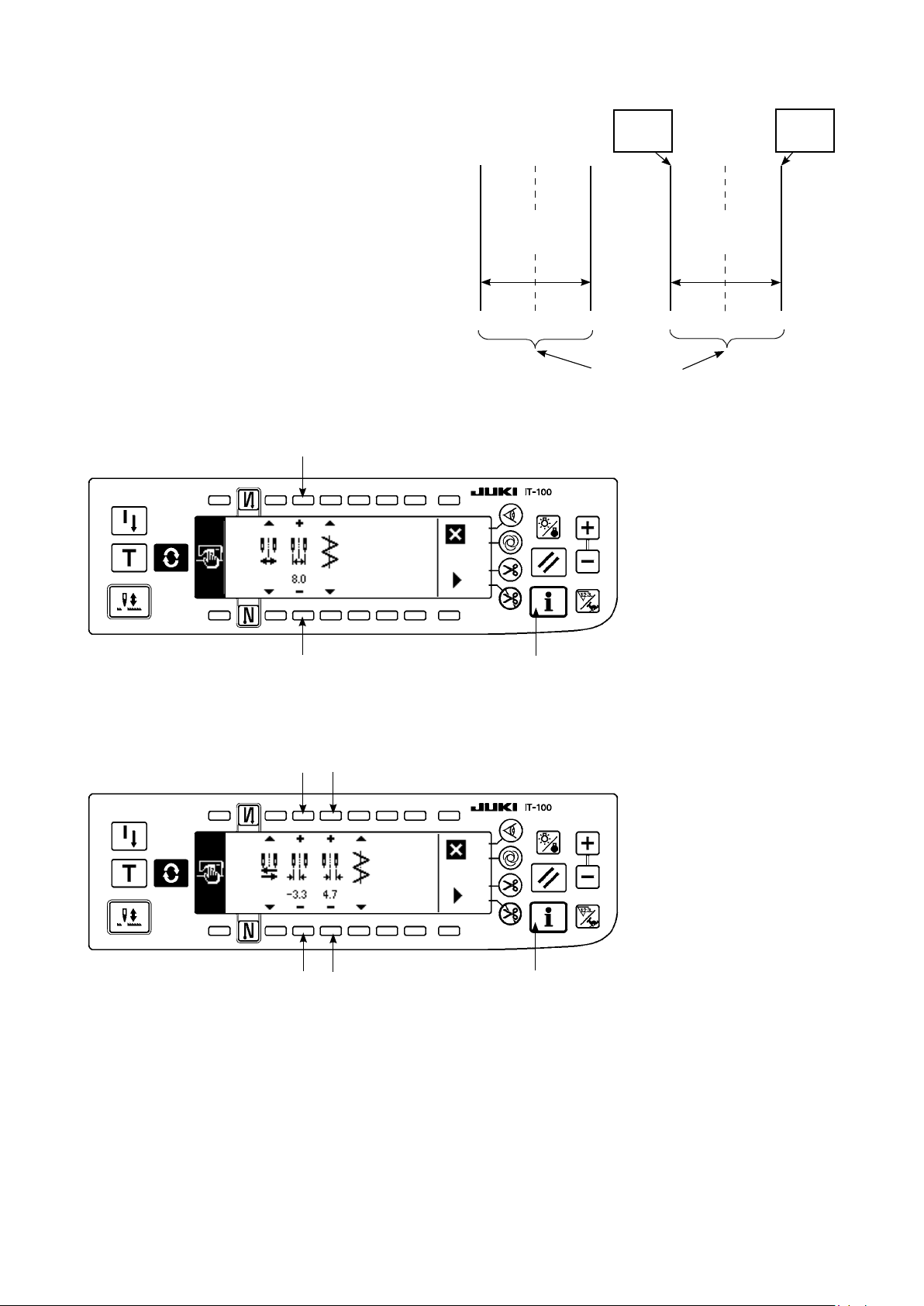

How to set max. zigzag width limitation value

■

Determine whether limitation of zigzag width symmet-

rical in the center or limitation of left/right positions

in the order of 1) to 3) of the previous page in accor-

dance with the gauge used.

Limitation of zigzag

width symmetrical

in the center

0.0 0.0

L = -3.3

Setting

Limitation of

left/right

positions

R = +4.7

Setting

–4.0 +4.0

(A) In case of zigzag width symmetrical in the center

4

4

Max. zigzag

width limitation

value

8.0

1

Max. zigzag

width limitation

value

8.0

–3.3 +4.7

Zigzag

limitation area

1) Press +/– of switch 4

and set the limitation

value.

In case of the example, set

the value to 8.0.

2) Press switch 1 and the

screen returns to the

previous one.

(B) In case of specifying left/right positions

6

5

6

5

1

Change of left side position limitation

1) Press +/– of switch

5

to

set the left side limitation

value.

In case of the example, set

the value to -3.3.

Change of right side position limitation

2) Press +/– of switch

6

to

set the right side limita-

tion value.

In case of the example, set

the value to +4.7.

3) Press switch 1 and the

screen returns to the

previous one.

– 21 –

Page 25

– 22 –

(2) Setting the reference of stitch base line

• Reference position of stitch base line can be set to left, center and right.

Reference of center

stitch base line

How to set

■

Reference of left

stitch base line

0.0 0.0 0.0

Reference of right

stitch base line

1) Press switch 1.

2

3

3

1

1

2) Press switch

2

.

3) Figure on the left side

shows the reference of

center stitch base line.

Every time switch 3 is

pressed, reference of left

stitch base line, that of right

stitch base line and that of

center stitch base line are

changed over and set alter-

nately.

Reference of left

stitch base line

Reference of center

stitch base line

Reference of right

stitch base line

4) Press switch 1 and the

screen returns to the

previous one.

Page 26

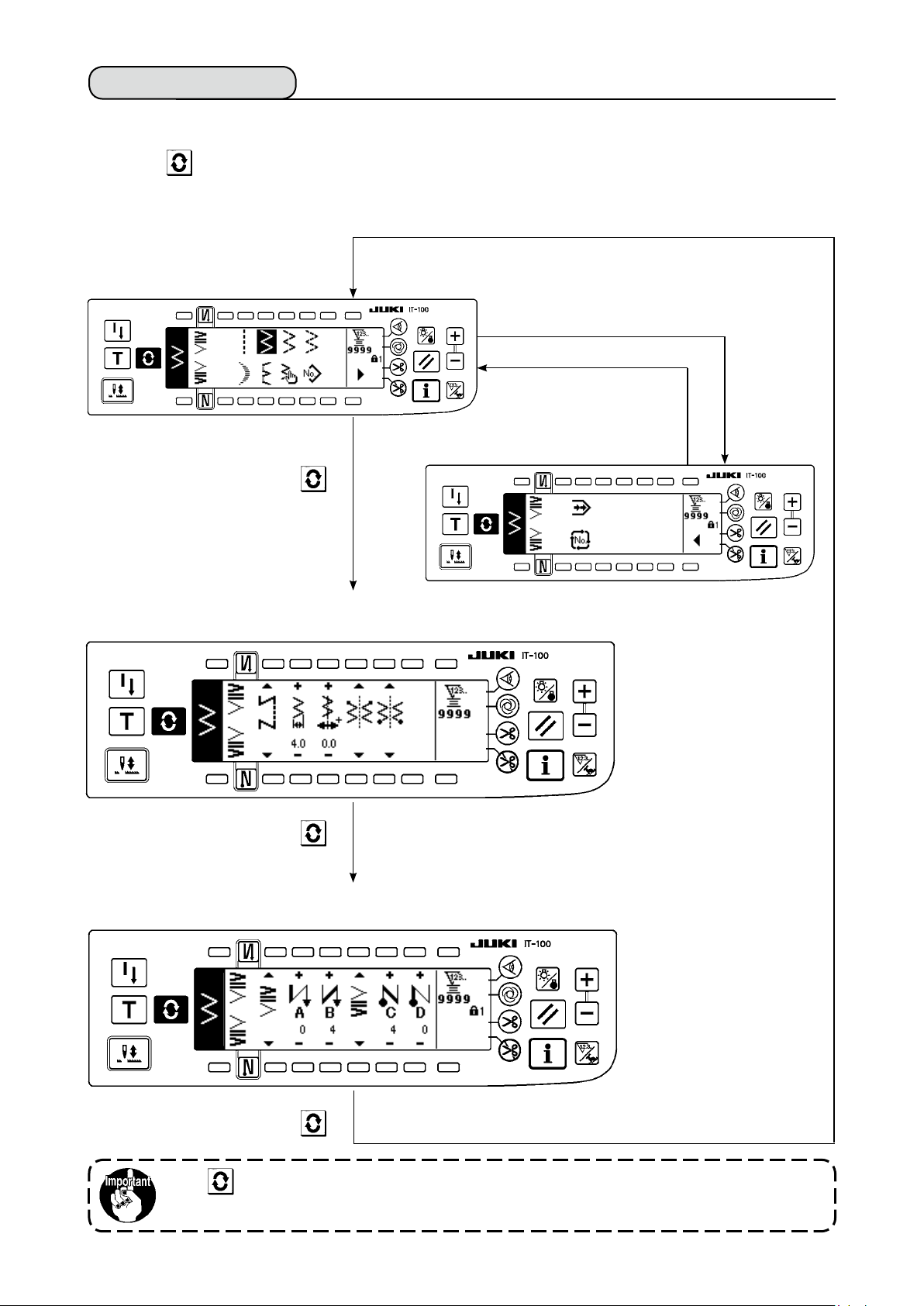

6-3. Basic screen

The screen after turning ON the power source becomes the screen at the time of turning OFF the power

source for the last time.

Every time

switch is pressed, the screen changes as follows :

Example) Free stitching of

on the set values.)

Sewing shape list rst screen

■

Selection of each shape is

performed.

* Free stitching means the

general sewing.

Sewing shape setting screen

■

Setting of zigzag width, position of stitch base line, etc. is performed.

2-step zigzag with reverse feed stitching (Contents of display change depending

Sewing shape list second screen

■

Press .

Press .

s

Press .

t

Press .

Reverse feed stitching setting screen

■

Setting of kind of condensation, number of stitches, etc. is performed.

Press .

When is pressed for approximately three seconds in a screen other than the sewing shape

list screen, the screen directly transits to the sewing shape list screen.

– 23 –

Page 27

– 24 –

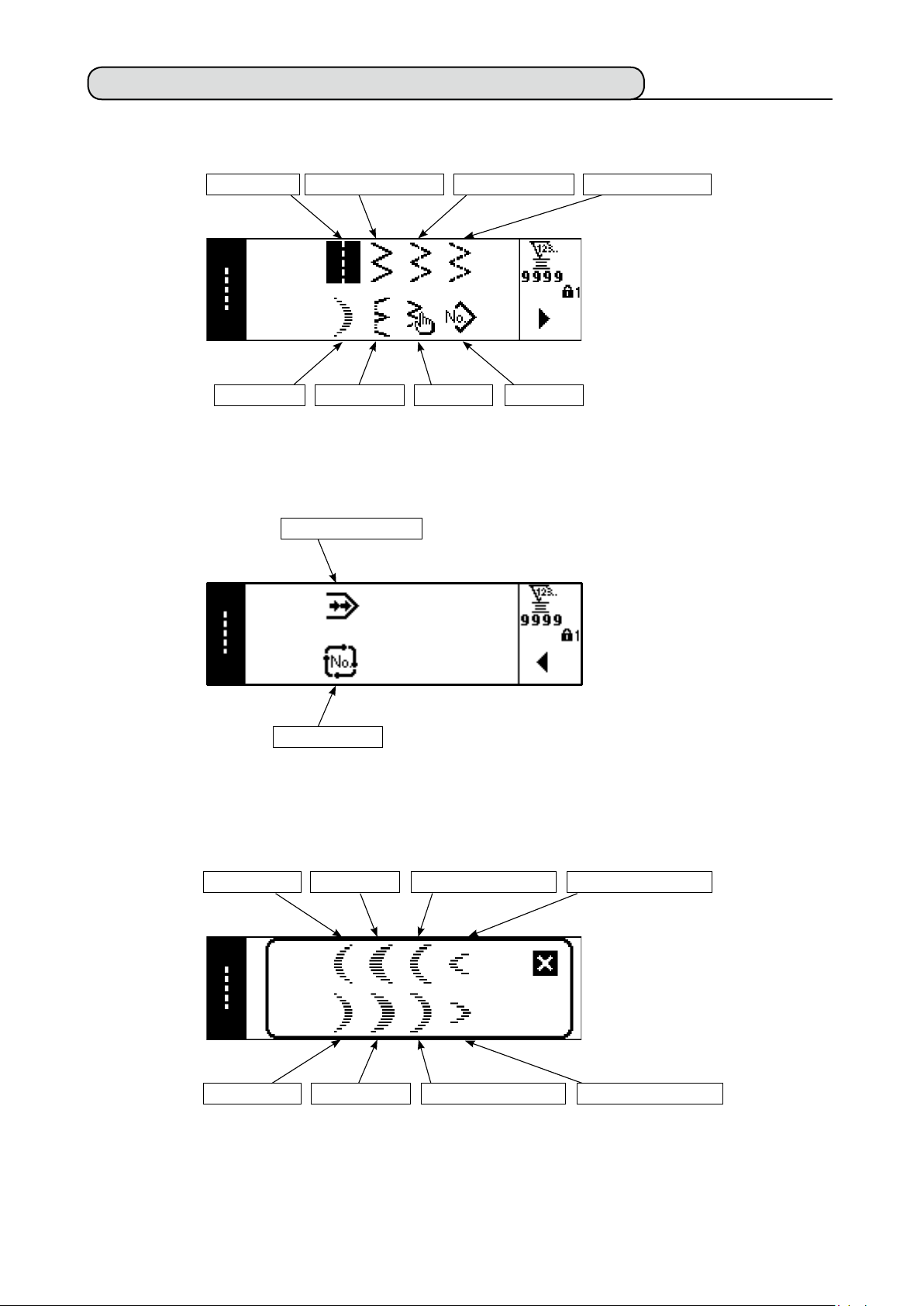

6-4. List of the display pictographs of each screen

Sewing shape list rst screen

■

Straight stitch

Scallop Custom Pattern

Sewing shape list second screen

■

2-step zigzag stitch

Continuous stitching

Blind stitch

3-step zigzag stitch

4-step zigzag stitch

Cycle stitching

Scallop selection pop-up screen

■

Right standard Right crescent

Left equal 12 stitchesLeft equal 24 stitchesLeft standard Left crescent

Right equal 12 stitchesRight equal 24 stitches

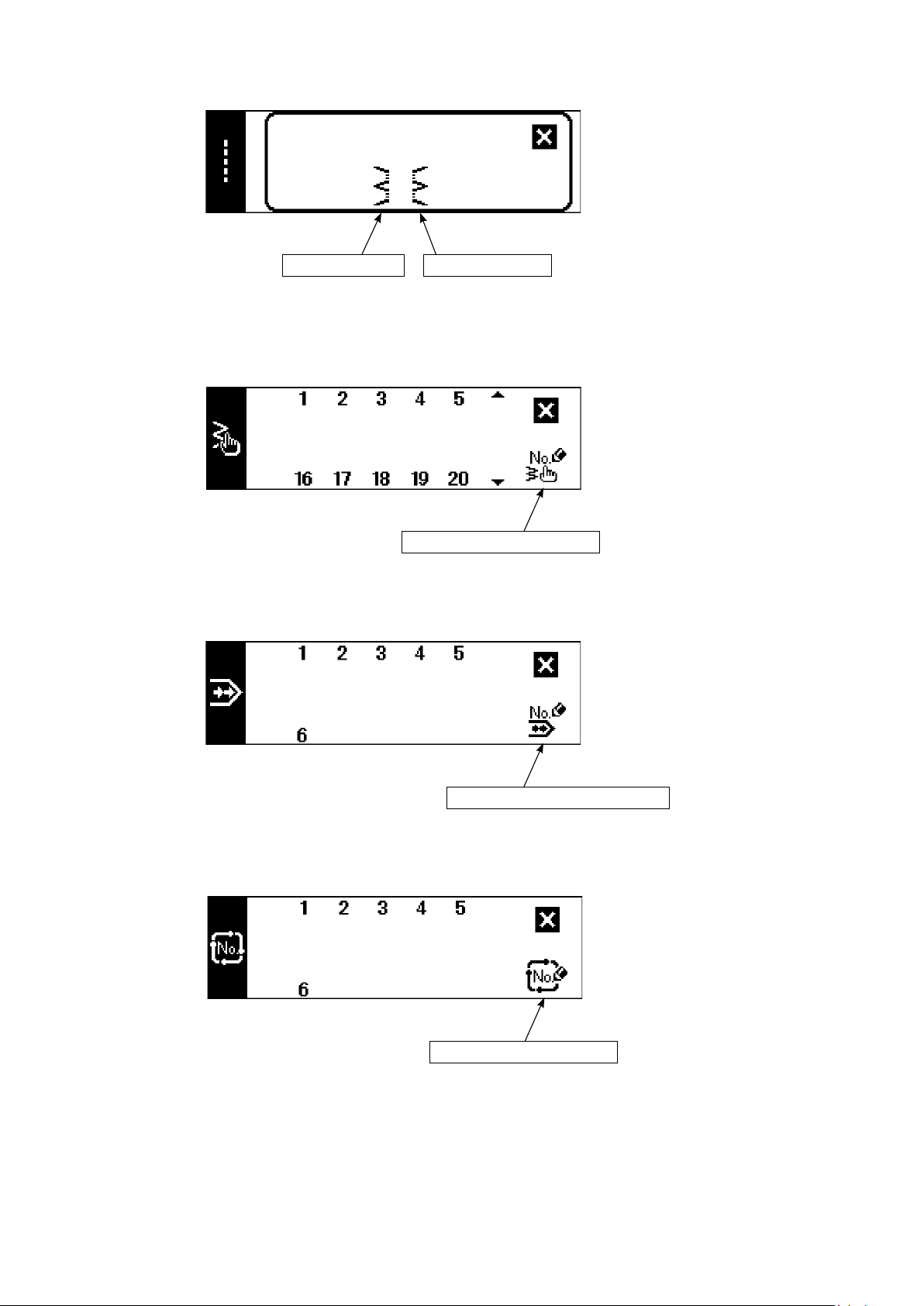

Page 28

Blind stitch selection pop-up screen

■

Left blind stitch Right blind stitch

Custom pattern selection pop-up screen

■

Custom pattern new creation

Continuous stitching selection pop-up screen

■

Cycle stitching selection pop-up screen

■

Continuous stitching new creation

Cycle stitching new creation

The key lock level has been set to "1" at the time of delivery, and pictographs of new creation are not displayed. When performing new creation in each mode, change the key lock level to "0". (Refer to the second

screen of sewing common data setting of (1) Sewing common data of 6-15. Information. )

In addition, the display of pattern No. at the time of delivery is "1" only.

– 25 –

Page 29

– 26 –

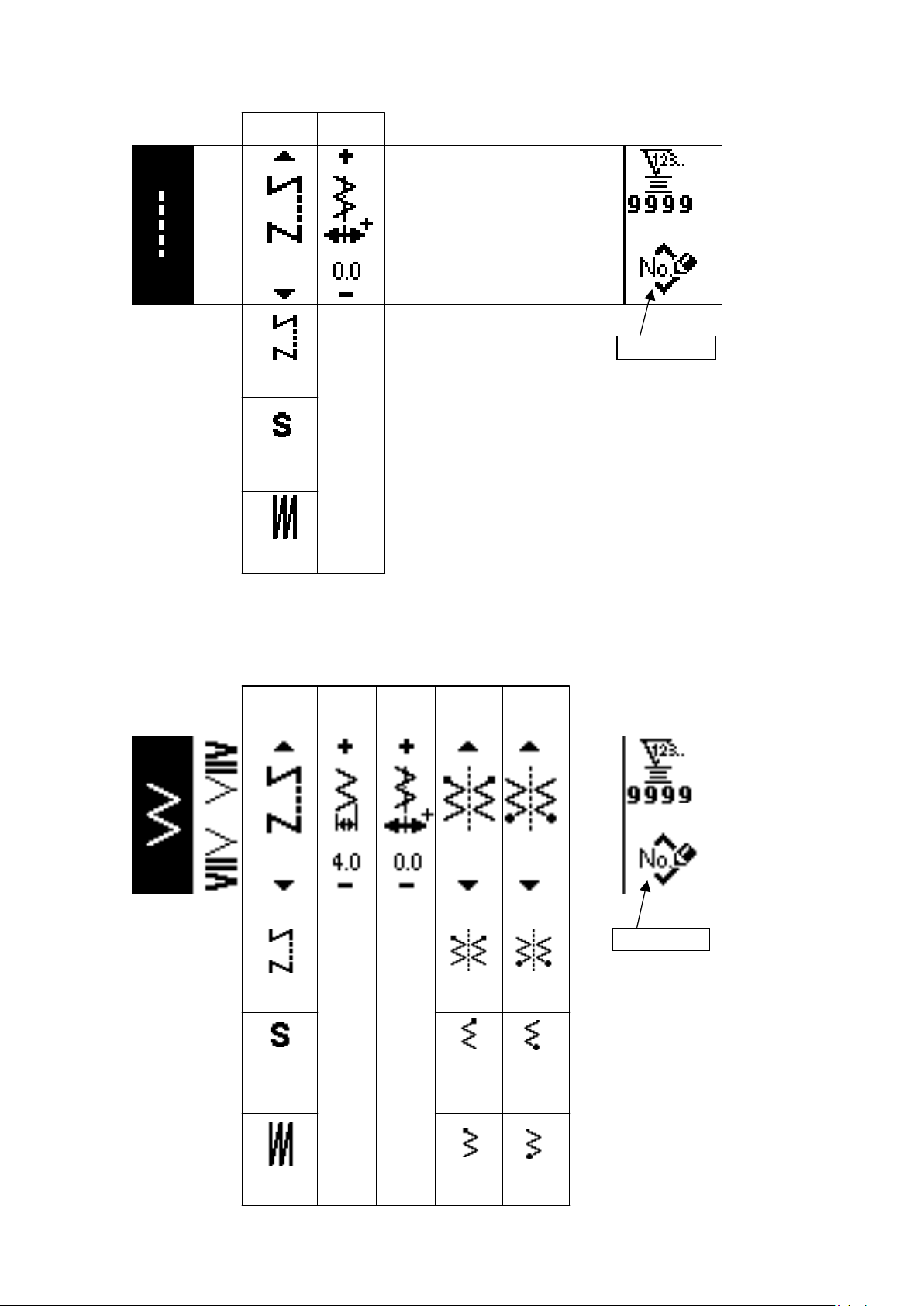

Straight stitch sewing shape setting screen

■

Kind of

sewing

Free

stitching

Programmed

stitching

Overlapped

stitching

Position of

stitch base line

Pattern register

– 5.0

to

5.0

Sewing shape setting screen of 2-step zigzag stitch/3-step zigzag stitch/4-step zigzag stitch

■

Kind of

sewing

Free

stitching

Programmed

stitching

Zigzag

width

0

to

10.0

Position of

stitch base

line

– 5.0

to

5.0

Position

at sewing

start

Optional

Right

Position

at sewing

end

Pattern register

Optional

Right

Overlapped

stitching

Left

Left

Page 30

Scallop sewing shape setting screen

■

Kind of

sewing

Free

stitching

Programmed

stitching

Zigzag

width

0

to

10.0

Position of

stitch base

line

– 5.0

to

5.0

Position

at sewing

start

Root • Crest

Root

Crest

Position

at sewing

end

Root • Crest

Optional

Stop

position

Pattern register

Optional

Root

Overlapped

stitching

Right

Left

* Stop position is displayed when the position at sewing end is optional.

– 27 –

Page 31

– 28 –

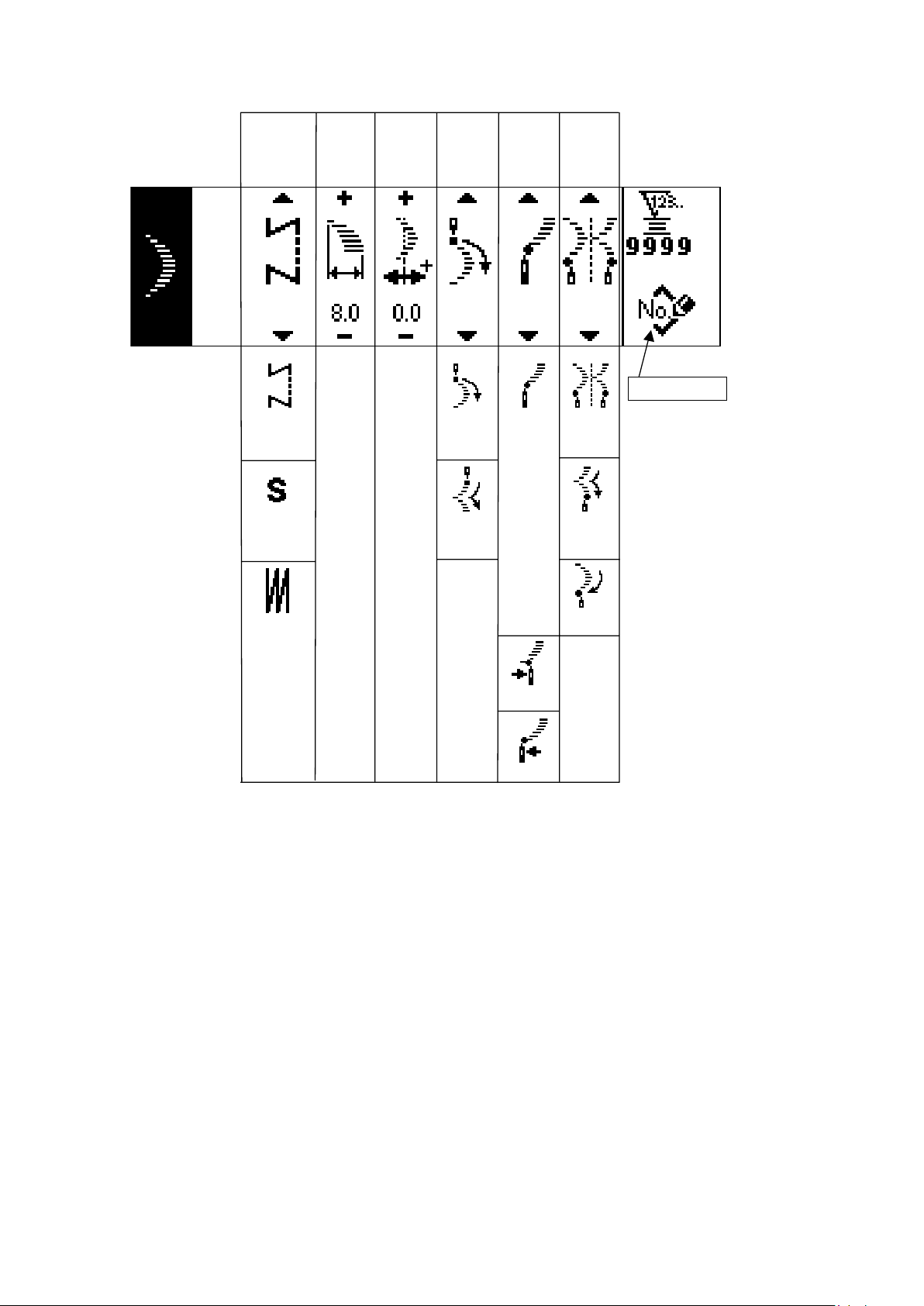

Blind stitch sewing shape setting screen

■

Kind of

sewing

Free

stitching

Programmed

stitching

Overlapped

stitching

Zigzag

width

0

to

10.0

Position of

stitch base

line

– 5.0

to

5.0

Number

of stitches

Pattern register

3

to

250

Custom pattern sewing shape setting screen

■

Kind of

sewing

Free

stitching

Programmed

stitching

Zigzag

width

0

to

10.0

Position of

stitch base line

– 5.0

to

5.0

Custom pattern

needle entry image

Edit screen

display

Pattern register

Copy, and

deletion screen

Pattern register

Overlapped

stitching

Copy

Deletion

Page 32

Custom pattern edit screen

Needle entry

point insertion

■

Step Zigzag

position

input

1

to

500

– 5.0

to

5.0

Feed

direction

Normal •

Reverse

Normal

Reverse

Custom pattern

needle entry image

Needle entry

point insertion

Last needle entry input

Determination

Needle entry

point delection

Pattern sewing shape setting screen

■

Sewing

shape

Selection of

sewing shape

Straight stitch

2-step zigzag stitch

3-step zigzag stitch

4-step zigzag stitch

Scallop

(8 kinds)

Blind stitch

(Right and Left)

Custom

(1 to 20)

Kind of

sewing

Free

stitching

Overlapped

stitching

Display of contents depends on shape.

Refer to each shape.

Copy and

deletion screen

Copy

Deletion

– 29 –

Page 33

– 30 –

Continuous stitching setting screen

■

Zigzag

width

0.0

to

10.0

Position of

stitch base

line

–5.0

to

5.0

Step

1

to

20

Pattern

No.

Number

of stitches

Edit screen

display

Copy and

deletion screen

Copy

Deletion

Continuous stitching edit screen

■

Step

1

to

20

Pattern

No.

1

to

99

Sewing

shape

Number

of stitches

0

Determination

to

500

* For the sewing shape, the shape which has been registered in the pattern is displayed.

* Number of stitches cannot be set to "0". (Determination switch prohibition)

Page 34

Cycle stitching setting screen

■

Step

Pattern

No.

Number of

stitches

Stop

state

Position

of

presser

foot

Edit screen

display

* Stop state is not displayed when the number of stitches is

(0 stitch).

* Position of presser foot is displayed except the case where the

number of stitches is (0 stitch) with the auto-lifter.

* Presser lifting time is displayed when the position of presser foot is

UP stop.

Copy and

deletion screen

Copy

Deletion

Cycle stitching edit screen

■

Step

1

to

20

No.

Pattern

No.

1

to

99

Continuous

stitching

No.

1

to

20

Number of

stitches

(0 stitch)

to

500

Stop

state

Needle

DOWN

stop

Thread

trimming

Needle

UP stop

Position

of presser

foot

Presser

foot UP

stop

Presser

foot

DOWN

stop

Presser

lifting

time

Determination

0.1

to

99.9

* Stop state is not displayed when the number of stitches is (0 stitch).

* Position of presser foot is displayed except the case where the number of stitches is (0 stitch)

with the auto-lifter.

* Presser lifting time is displayed when the position of presser foot is UP stop.

– 31 –

Page 35

– 32 –

Reverse stitching setting rst screen

■

Reverse

stitching

at sewing

start With/

without

Reverse

stitching

at sewing

start With/

without

Sewing start

Selection

of kind

Normal 0 to 19

Process

A

Process

B

0 to 19

Sewing end

Selection

of kind

Normal 0 to 19

Process

C

Process

D

0 to 19

Custom

2-point

Reverse stitching setting second screen (2-point condensation)

■

Width

adjustment

at sewing

start

0 to 19

Width

0 to 19

adjustment

at sewing

-

end

Custom

2-point

0 to 19

0 to 19

0.0

to

– 5.0

0.0

to

– 5.0

Page 36

Reverse stitching setting second screen (Condensation custom)

■

0.0

to

Width

adjustment

at sewing

end

0.0

to

10.0

Width

adjustment

at sewing

start

10.0

Sewing common data setting rst screen (When max. zigzag width limitation is set in the

■

center)

Limiting

procedure

of max.zigzag

width limitation

Center

Max.zigzag

width

limitation

value

0.0

to

10.0

Reference

of stitch

base line

Center

Left

Right

Left/Right

When the limiting procedure of max. zigzag width limitation is set to “Left/Right”, the display of max.

*

zigzag width limitation value is separately indicated left and right.

– 33 –

Page 37

Sewing common data setting rst screen (When limiting procedure of max. zigzag width

■

limitation is set to left/right)

Limiting

procedure

of max.zigzag

width limitation

Left/Right

Specifying left

position

0.0

to

10.0

Specify

ing right

position

0.0

to

10.0

-

Reference

of stitch

base line

Center

Left

Right

Center

* When the limiting procedure of max. zigzag width limitation is set to “Center”, the display of max.

zigzag width limitation value becomes that of symmetrical in the center.

Sewing common data setting second screen

■

Mirror

function

setting

1 pattern

Condensation cus

tom stitch

base line

Interlocking

Counter

function

ON

Level 1

Key

lock

Max.zigzag

width limitation

when turning

ON the power

Display

Continuous

Fixed

OFF

OFF

Level 2

– 34 –

Nondisplay

Page 38

6-5. Setting the sewing pattern

WArNING :

Be sure to check presser foot and gauge currently being used before sewing after changing the

zigzag pattern or zigzag width. In case where sewing is performed with the presser foot or gauge not

matching the zigzag width, it is in danger of accident such as needle breakage or the like.

(1) Selecting the zigzag pattern

When▲ is pressed, the second screen is displayed.

:

1

When ▲is pressed, the rst screen is displayed.

:

2

Straight stitch

2-step zigzag

Determined pattern

First screen

■

3-step zigzag

4-step zigzag

A

Second screen

■

1

Pattern sewing

Custom pattern

Blind stitch

Scallop

Continuous stitching

2

Cycle stitching

1) Select the zigzag pattern you desire to sew with the selection switch when the gure above is in the

screen. The determined pattern is displayed in section A.

2) For scallop and blind stitch, select the shape with the next screen.

– 35 –

Page 39

– 36 –

Determined pattern

Left standard scallop

Left crescent scallop

Left equal-width scallop of 24 stitches

Left equal-width scallop of 12 stitches

In case of the scallop

1) Press the scallop key

and the screen on the

left side appears.

Press the pattern switch you

desire to select.

Right equal-width scallop of 12

Right equal-width scallop of 24

Right crescent scallop

Right standard scallop

2) As an example, press

the crescent scallop

key and the screen on

the left side appears

to determine the pat-

tern.

Determined pattern

In case of the blind stitch

1) Press the blind stitch

key and the screen on

the left side appears.

Press the pattern

switch you desire to

select.

Right blind stitch

Left blind stitch

2) As an example, press

the left blind stitch key

and the screen on the

left side appears to

determine the pattern.

Page 40

6-6. Setting of the sewing shape

• Zigzag width can be set from “0” to 10 mm. (Set value is limited by the max.zigzag width limitation.)

• Stitch base line can be set as follows. When the center of zigzag is “0.0”, Right side : “+” Left side : “–”.

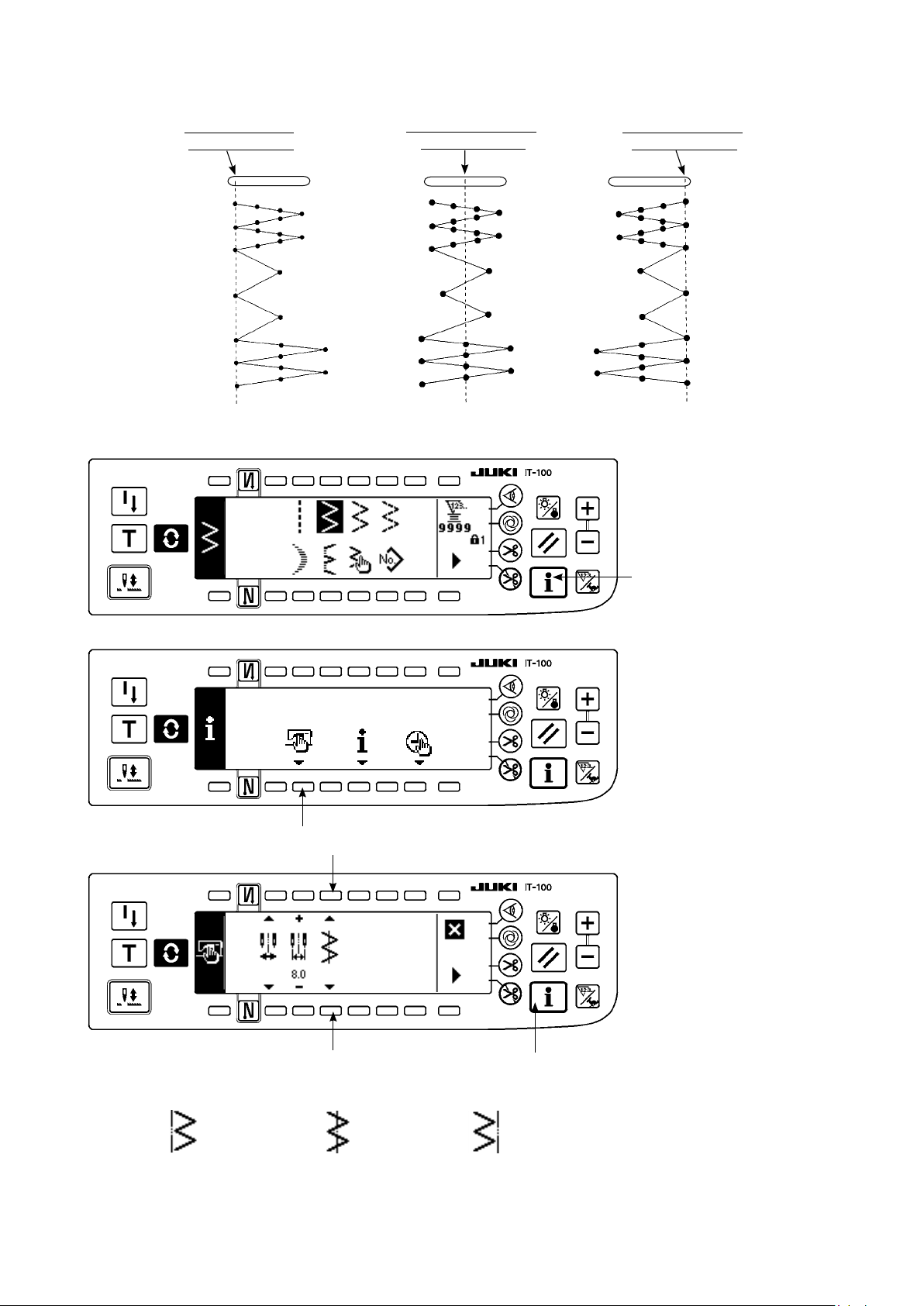

(1) 2-step zigzag, 3-step zigzag and 4-step zigzag stitch

Sewing shape list rst screen

■

2-step zigzag

1) Select 2-step (3-step or 4-step) zigzag stitch in the sewing shape list rst screen.

2) The selected shape reverses and is displayed on the left end of the screen.

3) Press to display the sewing shape setting screen.

Sewing shape setting screen

■

3-step zigzag

4-step zigzag

4455667

7

Setting of the zigzag

width

Change the zigzag width

with +/– of switch

Setting of the position

of stitch base line

Change the position of

stitch base line with +/– of

switch

5

.

4

.

Setting of the position of sewing start

Set the position of sewing start with

▲/▼

of switch

Sewing start Optional Sewing start Right Sewing start, left

Setting of the stop position

Set the stop position with

▲/▼

of switch

7

.

Stop position, optional Stop position, right Stop position, left

– 37 –

6

.

Page 41

– 38 –

(2) Scallop stitching

Sewing shape list rst screen

■

1

Scallop selection pop-up screen

■

h

1) Select scallop stitch-

in the sewing

ing

1

shape list rst screen.

Left standard

scallop

Right standard

scallop

Sewing shape list rst screen

■

Left crescent

scallop

Right crescent

scallop

Left equalwidth scallop of

24 stitches

Right equalwidth scallop of

24 stitches

h

Left equalwidth scallop of

12 stitches

2) Press the switch of

pattern to be selected

from the screen of the

left gure.

Right equalwidth scallop of

12 stitches

3) The selected shape

reverses and is indi-

cated on the left end

of the screen.

Sewing shape setting screen

■

q w e r t

q w e r t

4) Press to display

the sewing shape set-