Page 1

1-Needle, Unison-feed, Lockstitch Machine

-*'+**1~'8-~

~J

~

~

/

LU-1508N

1-Needle, Unison-feed1 Lockstitch Machine

(For Extra-heavy-weignt Materials)

-*'+**1~'8-~

~J

~

~

/(mJJtt*l>

LU-1508NH

PARTS LIST

HOW

1.

2.

3.

4.

J~-

1.

2.

3.

4. 1 7

TO

MAKE

As

to

"#01"

and

Codes on

Parentheses mean

Dotted lines on

•J

llC

llc

the

"Qty" column

· Each numeral indicates

· "0.1" and "2.5" indicate

'Y

lJ

A

:J...

""'-VO)#o1.

.lil

61

0)

llc

!f.

li

m

61

0)

< >

:J..

t-

"'

- v

USE OF THIS

"#02"

refer to

that

the

the

Figures indicate assembly parts.

~

_:::·frj

#02

.

([~Jllc

~

1;1:

• m

:m

0)-

- - - -

the

"Note" given

the

number

the

length (in meters)

corresponding

ffl

':

~

G 'L

~O)mli.

J<

t.,

• 0.1.

.111 ~ .nh.x

~

1;1: • *it

L-

of

,..__-:;

2.5

-c

p

m

PARTS

at

the

bottom

parts

required.

of

the

respective parts.

part

is a

subpart

FO)"iti!c"O)~PJJ ~ :::

~

0)

llc

fill

li

.o

-f

:m

&-.'!

"~

"'('

,.,_,

.o

.:

that

. ~ ~ (

"'('

~.>

.o

t

~

,

q;

.:

'*

LIST

of

the

constructs

ll1

fiL

;;i.

t

~

.Q":

L-

* -t •

respective pages.

an

assembly part.

~oo·r~ ~'

-

1-

Jv

)

~

'*

L-

* -t •

.

~

t.,

* T •

29359007

No.1337-00

Page 2

Page 3

LIUKI

9

JUKI (EUROPE) GMBH

KIELER STRASSE 303A

D-22525 HAMBURG/GERMANY

JUKI CORPORATION

8-2-1 KOKURYO-CHO, CHOFU-SHI

TOKYO

182-8655, JAPAN

HERSTELLERERKLARUNG

im Sinne

Hiermit

Klasse

Bestimmungsort-Code .........

zum Einbau in eine Naheinheit oder Nahanlage bestimmt ist und daB ihre lnbetriebnahme so lange untersagt ist,

bis

soli, den Bestimmungen

Angewendete harmonisierte Norman, insbesondere :

EN 292-1

Andere Norman und/oder technische Spezifikationen :

ISO/DIS 10821 .

Die Anforderungen

Die Anforderungen

der EG-Maschinenrichtlinie 98/37/EG, Anhang

erklaren wir, daB die Nahmaschine (Nahmaschinenoberteil)

.........................

festgestellt wurde, daB die Naheinheit oder Nahanlage, in die dieses Nahmaschinenoberteil eingebaut warden

I EN 292-2, EN 60204-31

1.

....................... .

..

JE

....

....

.. .

der

EG-Maschinenrichtlinie entspricht.

der

EG-Niederspannungsrichtlinie 73/23/EWG sind erfullt.

der

EG-EMV-Richtlinie 89/336/EWG sind erfullt.

DE

II

B

MANUFACTURER'S DECLARATION

In

accordance with the EC Machinery Directive 98/37/EC, Annex

We hereby

Style ..........................

Destination Code ............... .IE

has been determined to be incorporated into a sewing unit

until the sewing unit

conformity with the provisions of the EC Machinery Directive.

Applied harmonized standards : in particular :

EN 292-1

Applied standards and/or technical specifications :

ISO/DIS 10821.

The requirements of the EC Low

The requirements of the EC EMC Directive 89/336/EEC are met.

JUKI CORPORATION

declare that the sewing machine (sewing head) described as

.1

.•.

•.•.........•..........

.............

or

sewing system into which this sewing machine is to be incorporated has been declared in

I EN 292-2, EN60204-31.

Voltage Directive 73/23/EEC are met.

.

or

sewing system and that it must not be put into service

EN

II

B

General

Quality Assurance & Control Dept

Manager

Rev. 02

29180403

Page 4

DECLARATION

En

conlormlltl

Nous

RBh!rence

Codo

est

desllntle 6 6tre lncorporoe dans una unlltl

serv1ce

aux

dlsposlllons

Normos

EN

292·1, EN

DU

FABRICANT COMMUNAUTE

ovoc

los

dlroctlvos dolo Communouttl Europtlenne

dtlclorons

par

In

prtlsonto

quo

In machine 6 coudre

............... 1

do

dosllnnllon

est

interdllejusqu'6

hormonlsaes oppllqu6es, notomment

de

292·2,

.. . .•.

In

dlrecllve

EN

.1.~

.....

ce

quoin conlormil6

CE

60204·31

.

sur

las

machines oil

EUROPEENNE

ou

una

de

cella

Aulres normos el/ou sp6clficollons techniques ISO/DIS

Las

normes liguranl

Las

normes ligurnnl

dans

dans

las

Directives

las

Directives

CEE

CEE

de basso

EMC

89/336/CEE sonl

dtlcrile

lnstannllon

uniiB

ou

BIB

constaiBe

10821

tens1on

98137/CE,

comma

de

couture

de

cane

73123/CEE

respectBes

Annexa

su11

at

que

1nstallal1on

sent

respeciOes

.

so

de

II

B

mise

couture

FR

DICHIARAZIONE DEL FABBRICANTE

Secondo

le

direllive

CE

per macchlnori 98/37/CE, Allegate

Con

Ia

presenle

d1chlariamo

Modello •................

Codice

di destinazione ...... JE

en

il

predeslinala

ad

il

cucltura oppure l"unlt6 automatlca dl cucitura, sulla quale

corrisponde

Norma

EN

Alire norma

.

I

requ

I requisili delle O

suo

collaudo operative

aile

applocate

292

·1,

EN

e/o

isili delle Direlli

per

direllive

dopo

292·2,

specd1che

ir

.!

..................

il

montagg1o

CE

armonlzzaione,

EN

60204·31

ve

EC

elii

ve

EC

che

In

strulluro della mocchina per

.

...

.

in

una uni

non

ta

verro

ellelluato fino a quando

per macchinan.

In

tecniche : ISO/DIS

Basso

Vollaggio 73/23/EEC

EMC

89/336

di

cuc1tura

particolare :

10821

EEC

sono

oppure

,

sono

rispe11a1

II

B.

cucire

:

in

una

unita

automatlca

sia

stallo costatato

Ia

testa dove essere montata,

rlspellali.

1.

che

dl

cucitura

l"unlt6

IT

dl

DECLARACION

De

conlormldad

Por

Ia

Estilo .....................

C6dlgo

estd destineda a

comprobarse antes

cliche

cabezal

Normas

EN

292·1,

Otras

Cumple

Cumple

PRODUCENTERKUERING

I henhold til

Vi

erklmrer

Type .......

Kode

er

bestemt til

enheden

Anvendle

EN

292·1,

Anvendte

ISO/DIS

Kravene

Kravene i

DE

FABRICANTE;

con

Ia

Directiva

CE

presente declaramos

de

destinaci6n ....... JE ...... .

d&OBinstalarse,

armonizadas utllizadas, especialmente :

EN

292·2,

normas

y/o

los

requlsijos

los

requisites

EU-maskinregulativ

harmed,

...

................ .l

lor beslemmelsessted ....... JE

at

blive indbygget i

eller systemet er erklmret i overensstemmelse

harmoniserede

EN

292·2,

standarder

10821.

i EU·Iavstromsregulativ

EU

EMC

que

ha

.l

.....................

ser

montada

su

EN

en

montaje

cumple

60204·31

de

especlllcalones

de

Ia

Directive

de

Ia

Directive

98137/EF,

at

symaskine-overdel

..............

en

standarder,

EN

60204·31

og/eller

teknlske

73123/E0F

regulativ

89/336/E0F imodekommes.

tBcnlcas

.....

sabre

mBqu1nas

side

determinado

.

una unldad

que

Ia

unidad de

con

las

: ISO/DIS

CE

sobre

CE

sabre

lillmg

.......

.

......

.

syenhed"OIIer

ismr :

spec

tfrkatloner :

im11dekommes.

98/37/CE,

que

de

costura o tnstalcl6n

cos

lura o inslalaci6n de

dispos

ici

ones

10821.

baja

tens6n

EMC,

89/336/CEE

II

B

sysystem

mad

Anexo

el

tipo

de

de

Ia

Directiva

73/23/CEE.

og

at

EU

maskindirektivet.

.

den

II

Ia

maquina

ikke mil

B.

de

coser

de

costura, debiendo

costura

en

sabre

maquinas CE.

tages i brug

ES

DECLARACAO

De acordo

Os

abaixo

Modele ...•......•....... . !..

C6digo destine ....

o!

Ia

destinado a ser incorporado

que

prolblda

que

ossa

com

as

Normas

EN

292·1,

Outras normas

Os

requisites

Os requisllos

OA

FABRIKANTENVERKLARING

Conform

vedlgheld,

Wij

verklaren hiermee dat

. .......................

Code

l11r

van

bestemd

totdat bewesen

worden

Toegepaste,

EN

292·1,

Andre

norman

Tevens

Tevens

DE

CONFORMIDADE

com

a Di

rectiva

assinados

declaram

...............

........

JE ....

a

coloca~aO

parte

determrna~6es

harmonizadas

de

bestemming

is

conform

is

voldaan

is

voldaan

em

superior

de

da

EN

van

voor

EN

aplicadas,

292·2,

EN

a/ou

especlfi~coes

da

Directive

da

Directive

bepallngen

de

machines.

...

!... ...................... .

....

bouwing

Is

dat

de

is

met

de

geharmoniseerde

292·2,

EN

en/of

technische specificatles :

aan

de

ann

de

van

60204·31

Maquinaria

CE

da

da

que a maquina

.. .

.......

.

numa

servi~o

maqulna

directive

60204·31

unidade

antes

de

a unidade

da

costura

CE

relative a maquinas.

especlalmente :

to!cnicas:

de

Balxa

Vollagem

881336/EEC

de

..

JE

in

eenheid of

maatregelen

alsen

alsen

daCE

de

CE·machinerichllijn

naalmachine

.....

een

norman,

omschreven

.

naai·eenheid of naaisysteem

de

naai·instailatie waarin

van

namelijk:

van

de

Laagspanning

van

de

Eleldromagnetische Verdraagzaamheid (89/336/EEG)

CE

98137/CE, anexo

de

costura

de

costura

sera

incorporada

ISO/DIS

da

CE

EMC

estejam

98137/EG,

de

E.

G.·richtlijnen

ISO/DIS

descrita

ou

numa

da

costura

10821

.

73123/EEC

de

Annex

als

10821

.

(73123/EEG).

II

B

como

instala~ao

ou

a

ser

daclarada

eslejam

acordo

en

dat

daze

naaikop moat lngebouwd

op

machines.

de costura E

instala~o

da

em

contormldode

de

acordo.

.

liB,

met

betrekking

het

opstarte verboden

cos

lura

NL

tot

PT

em

de

is

4HJ\DEH TOY ICATAEEYAETH

IIi

1.1.1/IOJva

.,.,

p • 1.1.11xavo.v

611A0oi

R"OU

Toi

nA!j

rr;piJT<tL

6TL

8'1AOJ9EL

ono<o

npo8LaTpa<l>iJt

I•

EN292-1,

AAAa

Avran:ot<

EK

Avran:OI<

EK

TILVERKARENSDEKLARATION

I enlighet

VI

forklarar ha

Typ

Bet

ackning kod

mAste

!OrrAn

OvarensstAmmer

TiiiAmpad

EN

292·1,

Tilla

mpad

Kravet pA

Kravet pA

JJ.t

rout 6 pout

1.1.1

7t!fJL.TOci

not

Pllt

8rv

Ba

tt/lapJJ.oT!i

nporun:a

nrp£

n:tpL

mad

......................

vara

inmonterad I

den sOmnadsautomat eller del sOmnadssystem vari symaskinen skall byggas r

standard

EN

standard

EU

EC

98/37/EK.

8La

TO

U

tbEt'CIL.

aav:

...........

...............

.1

nci

TI<O

nplinEL

6YL

rou

t<aL

t<aLIII

Direktiv

den

hAr

J. ···············

....

JE .......

en

sOmnadsau!omat

EU

RAdets

.........................

IuJJ./louALou

aoiJJ.'I/IOJva

or•t

Yci

OYLt

89/336/

symaskinen

1.1.1

va

!Vf10JJJ.aYOJ9EL

Ba

rr;pliJTa

EVUOJJJ.aYOJ9rL

EN292-2, EN60204·31

p£

vtra•

xa1.1.11Aiit

pL

VITaL

JJ.IIXaVIiJ v

EU

RAdets

rmed

au

..

........

mad

enllgt :

292·2,

EN

60204·31

ochleller

tekni

LAgspAnnlngs

EMC

D.rektiv

Direktiv

891336/EEC

Tou

napci

nap6

VYOt,

........... JE .......... .

at

va

II

for

/.I.OVci8a

rtB•L

JJ.OVci8a

aurJI

1.1.1

TEXVLI<l~

an:a•rli

o11t

73/23/

anaLrlj

EOK.

Maskiner,

nedan

·· ..

...

. .

Direktrv fiir

Maskiner.

sk specifrkation

73123/EEC

Ar uppfyllda.

IuJJ.flouAL

p r

111.1.a

6

..

..

" '

AELYOUPTLa

!)

YO

11

pat<YOI.I.IIXavlj

Y'lt

ra

n:p6runa:

npo8LaTn:atllr~:ISO/DIS10821.

o••t

EOK.

O<Lt

98137/EC,

bask

riven

oiler

sOmnadssystem,

ISO/DIS

I

B.

YL

II

!j

f1VUYIIJJ.a

UVUY'IJJ.a

EK.

Y'lt

Y'lt

TiliAgg

som

10821

ou

Tilt

panTOJJ.IIXaV!j

pa<Mt

EL8Lt<.,T<pa:

Of111TL

Of111TL

II

B

:

och

fAr

.

ar upplyllda.

EK

patlllit

rav

8rv

f1YO

YIIPEL

YLt

at

at

into tagas I bruk

t<aL

Tilt

Yilt

EL

VALMISTAJAN

Direktiivin

98137/EU

Malli

....................

MAArAnpAAkoodi

on

tarkoitettuompeluyksikOn

saa

ottaa

kAyiiOOn

89/

392/ETY

vaatimustenmukaisuusvakuutus.

Koneenosen

EN

292·1,

EN

Muut

standard~

EY

PrenjAnnitadirektiivin

EY

EMC

Direktiivin

SV

PRODUSENTERKUERING

i

samsvar

med

Vi

erklmrer

herved

Klasse

......................

Bestemmelsessteds·kode ........

mA

bygges

Inn i en

oiler somsystemet

n,

Mask

indirektiv.

Anvendte

harmoniserte

EN

292·1, EN

Anvendle

normer

Kravene

H11lge

Kravene

ilolge EU·EMC·Direktiv 89/336/EEC er opplylt.

ANTAMA

VAKUUTUS

, Lille II

B,

mukaisesti ilmollamme

.. !

..........

........... .

........... JE ........

•..

rakenteelllseksl

ennenkuin

siihen

EN

60204·31

on

ompeluyksikOstA

lilttyvien

sovellettu seuraavia

ja

suunnlltelussa

292·2,

tal spesifikaatlot:

73/23/ETY

891336/ETY

mAAniyksiA

EU·Maskindrrektiv

at

symaskinen

...

!

......

....

.......

JE

Sllmenhet

ellet

den

skat

normer

60204·31

et

bygges

: 1 smrdeleshet :

292·2,

som

EN

og/eller teknlske

EU·Lavspemingsdlrektlv

KONEENOSAKSI

osaksi

kansalllsten

ISO/DIS

10821.

mAAr4yksiA

on

noudatattu.

98137/EC,

trllegg

....... .

.....

..

.

s11msystem,

inn

I,

er

spes

ilikastoner : ISO/DIS

73123/EEC

TARKOITETUSTA

lAten,

ettA

tal

hitetiAvAksi

tal

ompelujArjestelmAsUi

sUdOsten

yhden

mukaisia standardeja :

on

noudatettu.

II

B

og

at

den

lkke

erklmrt I

ma

samsvar

10821.

er opplylt.

LAITTEESTA

ompelukone

ompelujArjestelmAAn.

on

annettu dlrektiivin

mukatnen

lgangsettes

mad

f11r

s11menheten

bestemmelsene i EU"s

SitA

NR

Fl

ei

EY·

Page 5

How to Install the belt cover for

U-2210 SERlE

LU-2210~1J-AJf.I~JIJ

. .

•

~:::;y~f~J=Il9"~im::

-~~(J)~?t:,

....

:

·.

'':

. M (J)t;l(.;~ffiL

!~r~J1fXI)1'.tlt~.:co

0755205 SK3482500SC X 2

1

belt cover

. .

·.

· .. · . . ' . . . . . .

Y'("'\JlJ

C wood screw

1'1J

1--:hJ~

• Before putting

/

~-

has

to

be

enclosed

QXi

'i

ii

the

machine into service, the belt cover

attached

in

this bag as illustrated the figure.

to

the machine head using screws

No.OO

29182706

•

~:::;y~ffl"9"c~ta,

E(J1Jic.Jt::ll:*-@

*t;lt_;~tq)~llt)"'\JlJ

*Ti$1J.J~it"t1J'6,

1--:t.J)~-~~

if~G

-r

<

t.:~L

)

0

•

I \

' '

• Incline the machine head after loosening the wood

screws and moving the belt cover

the direction shown by the arrow.

/\

I \

10mm

I \

to

the

extreme in

Page 6

Page 7

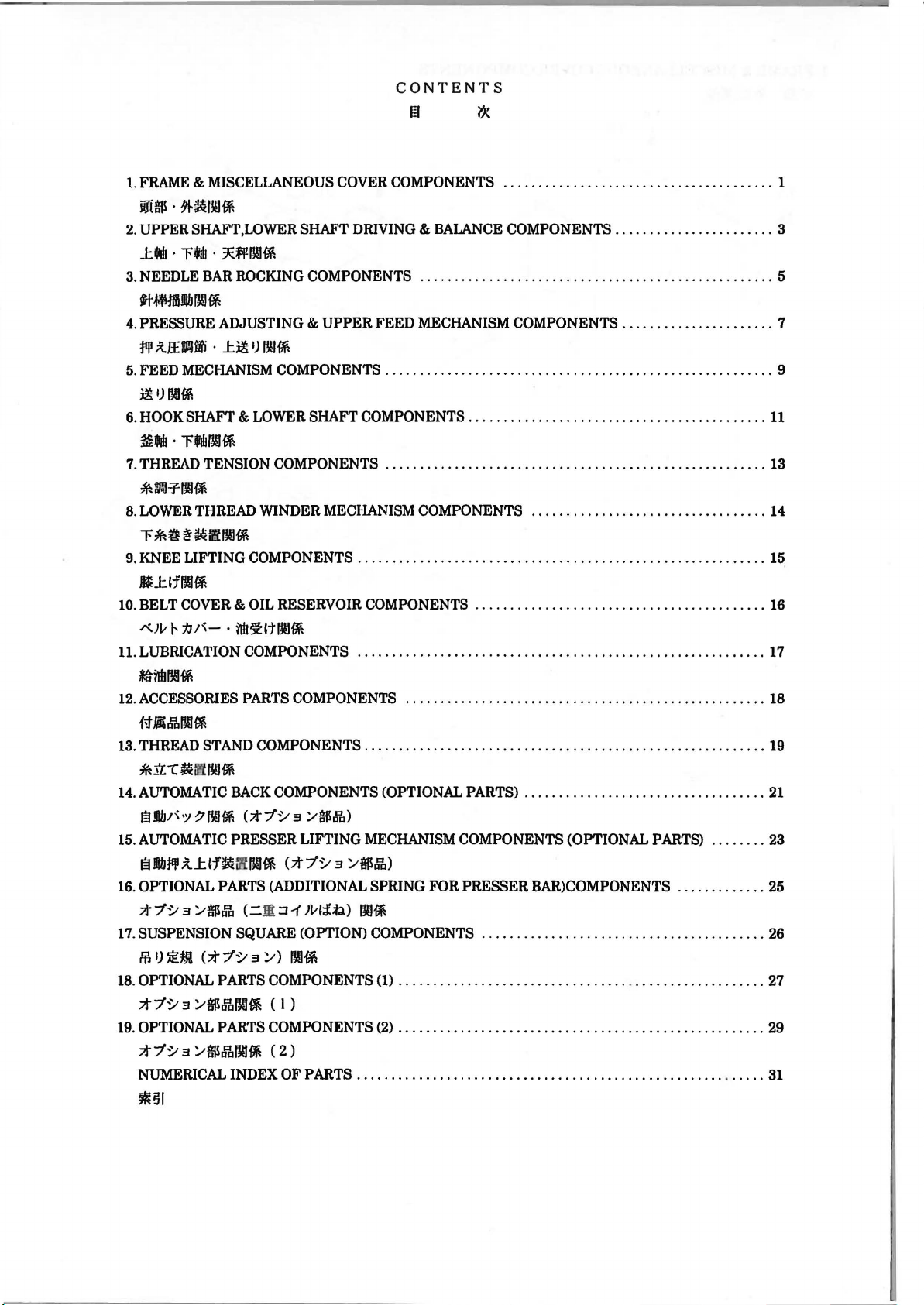

CONTENTS

~

1.

FRAME & MISCELLANEOUS COVER COMPONENTS

iiJim1·~~00{j

2.

UPPER

J:flll·rflll·~fi!lOO{j

3. NEEDLE BAR ROCKING COMPONENTS . ....

ft~lll!JbOOfj

4.

PRESSURE ADJUSTING &

ttJl

5. FEED MECHANISM COMPONENTS .

~·Joo~

6. HOOK SHAFT & LOWER SHAFT COMPONENTS

SHAFT,LOWER SHAFT DRIVING & BALANCE COMPONENTS

itJIPJ!Jfli

·

J:~

I)

UPPER

mJ{j

FEED MECHANISM COMPONENTS

....

......

~

..............

...

..................

...

...........................

.................

.

........................

.............

.......

....

...

..............

........

. . . . .

..

.......

............

!iiflll·rfiiiOO{j

7.

THREAD TENSION COMPONENTS

:fMJ~-=fOO{j

8. LOWER THREAD WINDER MECHANISM COMPONENTS ...

r*(fli!~I!OO{j

9.

KNEE LIFTING COMPONENTS . .

JJlJ:IffMJ{j

10. BELT COVER & OIL RESERVOIR COMPONENTS

~JI.t

"jJJ{,-

11. LUBRICATION COMPONENTS .

~7dJOO{j

12. ACCESSORIES PARTS COMPONENTS

NMI~OO~

13. THREAD STAND COMPONENTS

*n:-c~f100fJi\

14. AUTOMATIC BACK COMPONENTS (OPTIONAL PARTS) . . .

IUb''

15. AUTOMATIC PRESSER LIFTING MECHANISM COMPONENTS (OPTIONAL PARTS)

Ellb!lllitJ:If~

16. OPTIONAL PARTS (ADDITIONAL SPRING FOR PRESSER BAR)COMPONENTS

7t7""Y3;:.tJm~<=

17. SUSPENSION SQUARE (OPTION) COMPONENTS

M

•J

~m

18. OPTIONAL PARTS COMPONENTS

7t7""Y

19. OPTIONAL PARTS COMPONENTS

7t7""Y

NUMERICAL INDEX

.

71b~ltfMJ{j

,_,

7

OOfJi\

(71'

7""Y

3

;:.tgJS~)

flt

OOfJi\

(7t7"Y 3

m

~~~~~>oo~

<7t7"Y 3

3

;:.tJm~OO~

3

;:.tgfl~n&l~

;:.t)

( I )

(

OO{j

2)

OF

PARTS

........

.......

................

......

;:.tJm~)

(1)

(2)

...........................................

....

. . . .

....................................

..

....

.....

.......................................

...

......

.

.....

..........

....

...................

.....................................................

.

...............

........................

.....

.......

....

....

...............

................................

......

.

.............

..

......................

....

......................

..

................

..

................

.........

.

................

.............

.............

.

............

.

...............

..

........

..........

...

.....

..

....

. . 11

.

..

...

...

.....

..

....

........

.....

...

.......

1

3

5

7

9

13

14

15

16

17

18

19

21

23

25

26

27

29

31

*51

Page 8

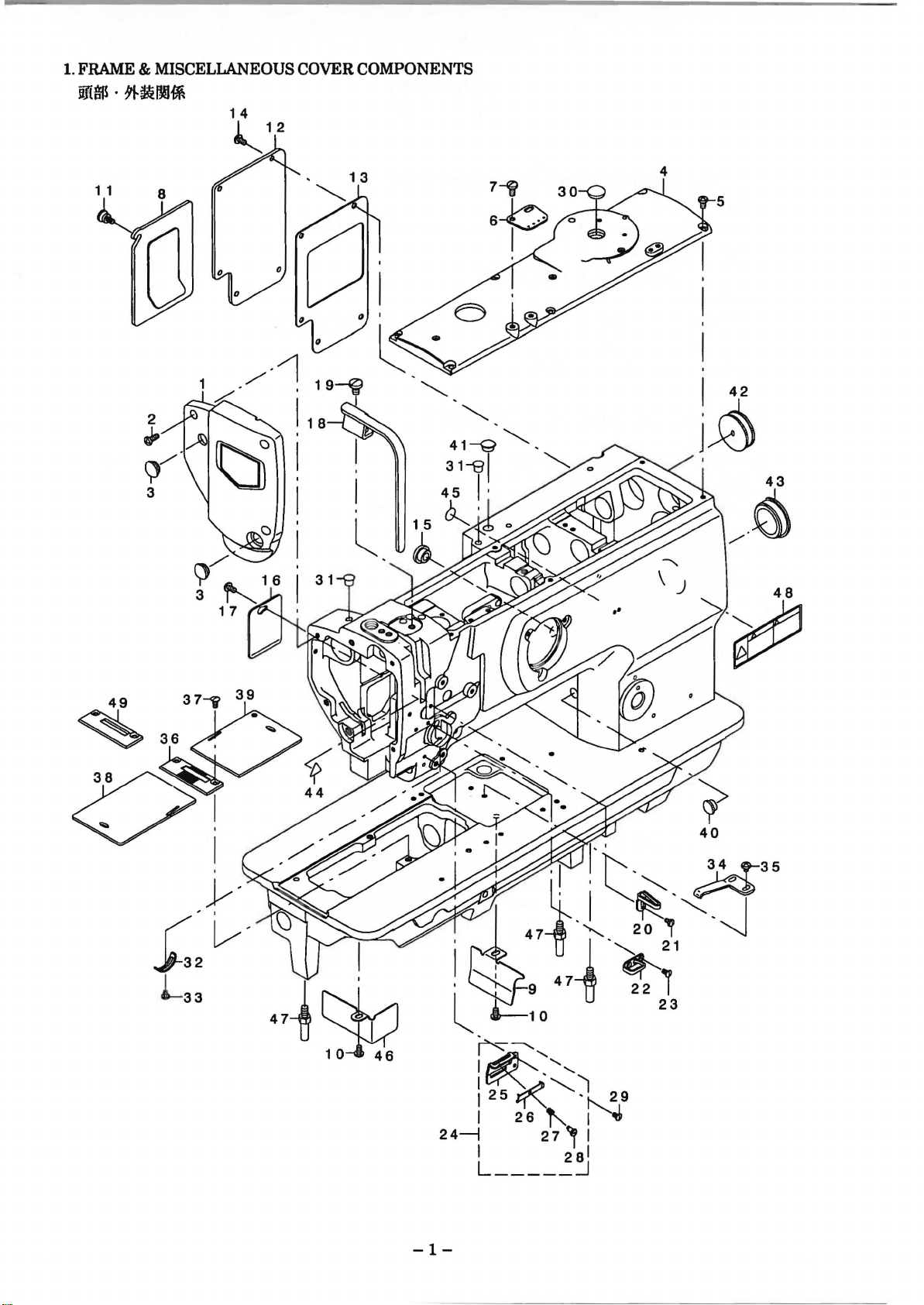

1.

FRAME & MISCELLAN

BJl!m

.

51-~00~

'

EOUS COVER CO

1 4

~12

MPONENTS

5

I

I

I

'

1

42

j~

I

~

3

~

1 7

/~

16

-1-

Page 9

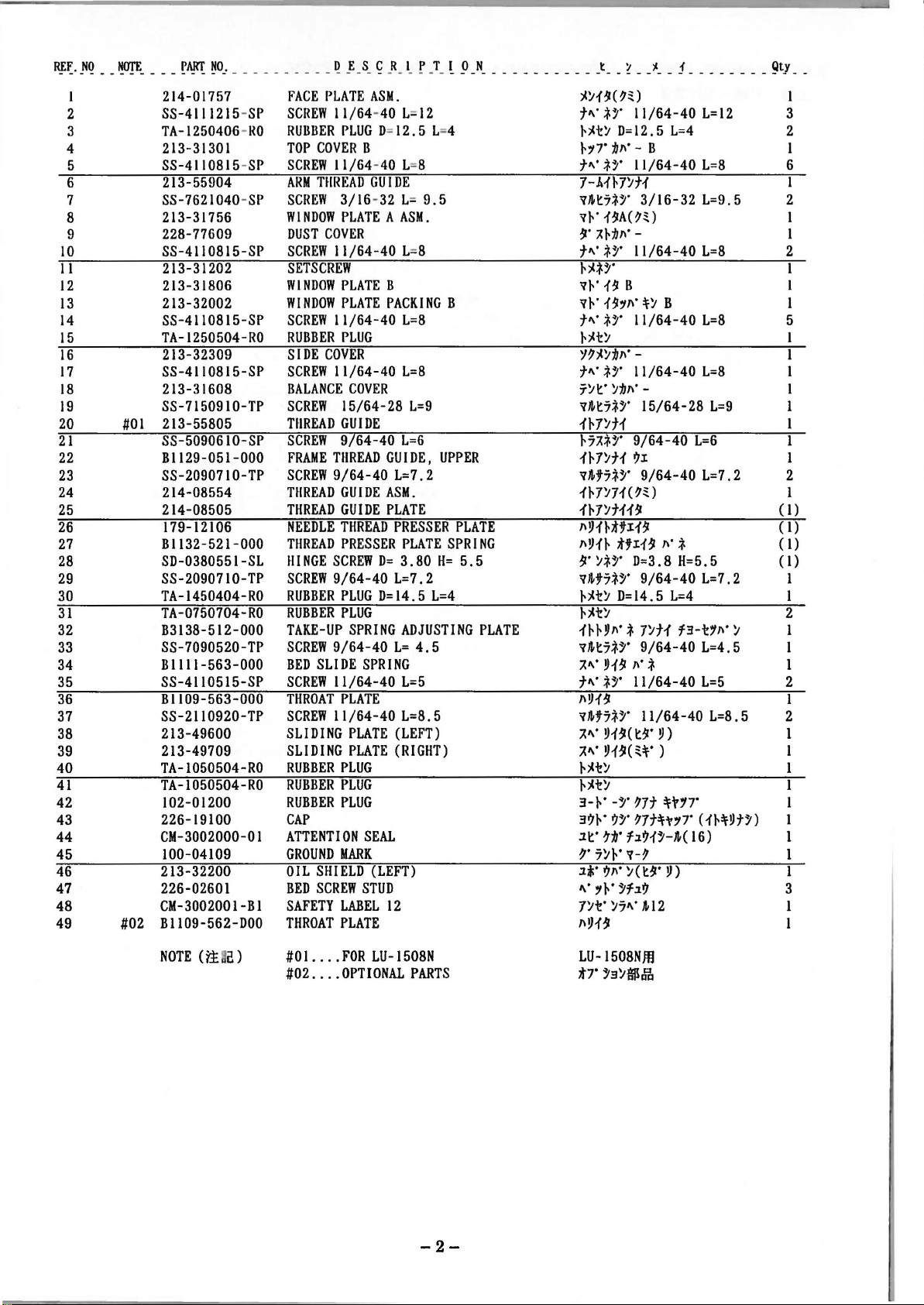

R!=~._NQ _ -~-

___

~AJfr

~0_.

_________

-

~

_E

_S_ g _R_

I_ f_T_ ~ ,!)_N

____________

t __ !

__

'/.

__

j_

_______

9tJ __

10

II

I2

13

14

15

16

I7

I8

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

2

3

4

5

6

7

8

9

FACE

PLATE

I

214-01757

SS-4111215-SP

TA-1250406-RO

213-31301

SS-4110815-SP

213-55904

SS-7621040-SP

213-31756

228-77609

SS-4110815-SP

213-31202

2I3-3I806

213-32002

SS-4110815-SP

TA-1250504-RO

213-32309

SS-4II08I5-SP

213-31608

SS-7150910-TP

213-55805

#01

SS-5090610-SP

Bll29-051-000

SS-2090710-TP

214-08554

214-08505

179-12106

B Il32-521-000

SD-0380551-SL

SS-2090710-TP

TA-1450404-RO

TA-0750704-RO

B3138-512-000

SS-7090520-TP

Bllll-563-000

SS-4110515-SP

Bll09-563-000

SS-2110920-TP

213-49600

213-49709

TA-1050504-RO

TA-1050504-RO

102-01200

226-I9100

CM-3002000-01

100-04109

213-32200

226-02601

CM-3002001-81

B1109-562-DOO

#02

SCREW

RUBBER

TOP

COVER

SCREW

ARM

THREAD

SCREW

WINDOW

DUST

SCREW

SETSCREW

WINDOW

WINDOW

SCREW

RUBBER

SIDE

SCREW

BALANCE

SCREW

TliREAD

SCREW

FRAME

SCREW

THREAD

THREAD

NEEDLE

THREAD

HINGE

SCREW

RUBBER

RUBBER

TAKE-UP

SCREW

BED

SLIDE

SCREW

THROAT

SCREW

SLIDING

SLIDING

RUBBER

RUBBER

RUBBER

CAP

ATTENTION

GROUND

OIL

SHIELD

BED

SCREW

SAFETY

THROAT

ASM.

II/64-40 L;l2

PLUG

D=l2.5 L=4

8

11/64-

40

L=8

GUIDE

3/16-

32

L= 9. 5

PLATE A ASM.

COVER

11/64-40 L=8

PLATE

8

PLATE

PACKING

11/64-40

L=8

PLUG

COVER

11/64-40

L;8

COVER

15/64-28

GUIDE

9/64-40

THREAD

9/64-40

GUIDE

GUIDE

THREAD

PRESSER

SCREW

9/64-40

PLUG

L=6

GUIDE,

L=7.2

ASM.

PLATE

PRESSER

PLATE

D=

3.

L=7.2

D=l4

PLUG

SPRING

9/64-40

ADJUSTING

L=

SPRING

11/64-40

L=5

PLATE

11/64-40

PLATE

PLATE

L=8

(LEFT)

(RIGHT)

PLUG

PLUG

PLUG

SEAL

MARK

(LEFT)

STUD

LABEL

12

PLATE

L=9

80

.5

4.5

.5

B

UPPER

PLATE

SPRING

H=

5. 5

L=4

PLATE

)!~{~(?~)

tl\·~~·

~~~t~

~17

t"'~}'

7-MH~t1

v~t7~}'

'i'~'{~A(~~)

~·~~'br.'-

t"'

~)!~~·

v~·

V~'{~1TI'=\'~

t"'

~~~t~

'}~j.~j}r.'-

t"·~~·

:;~t·

v~t7*~·

{~]Yt{

~7~*~·

{~]Yt{

v~'7*~·

{~Til{(?~)

1H~t11~

r.HM,.t1~

r.9{~

~·~*~·

V~17*~'

~;It~

~'J.tY

{~~9!'1'*

v~t7*~·

~1\'

t"'*~'

l\9{~

v~t7*~·

~1\'

~1\'

~'J.tY

~'J.tY

3-~·

31)~'1)~'~7t=\'t17'

~t't'b'f~l){,-~(16)

~·

~i'l)T'I'

l\'1~'~f~')

7~t'Y7"'~12

!'19{~

11/64-40

D=l2.5

'

j}r.'- 8

11/64-40

3/16-32

~~·

11/64-40

1~

B

~~·

11/64-40

11/64-40

~'bTl'-

15/64-28

9/64-40

').I

9/64-40

t'J.I{~

D=3.8

9/64-40

D=

14. 5 L=4

7~t1

9/64-40

9{~

l\'

*

11/64-40

11/64-40

91~(t~·

91~(

7~~·

9)

~=\''

)

-~·~rt

v-~

~(t~·

L=l2

L=4

L=8

L=9.5

L=8

B

L=8

L=8

L=9

L-6

L=7.2

l\'

~

H=5.5

L=7.2

f3-t,T'I'~

L=4

.5 I

L=5

L=8.5

=\'t,7·

({~=\'~t')

9)

I

3

2

I

6

I

2

I

I

2

I

I

I

5

I

I

I

I

I

I

I

I

2

I

(1)

(1)

(1)

(1)

I

I

2

I

1

2

I

2

1

I

1

I

I

I

1

1

I

3

I

I

NOTE

(i£

c)

#01 ... .

#02

....

FOR

LU-1508N

OPTIONAL

PARTS

-2-

LU-1508NJI)

Jt7'

}3~lm8l!

Page 10

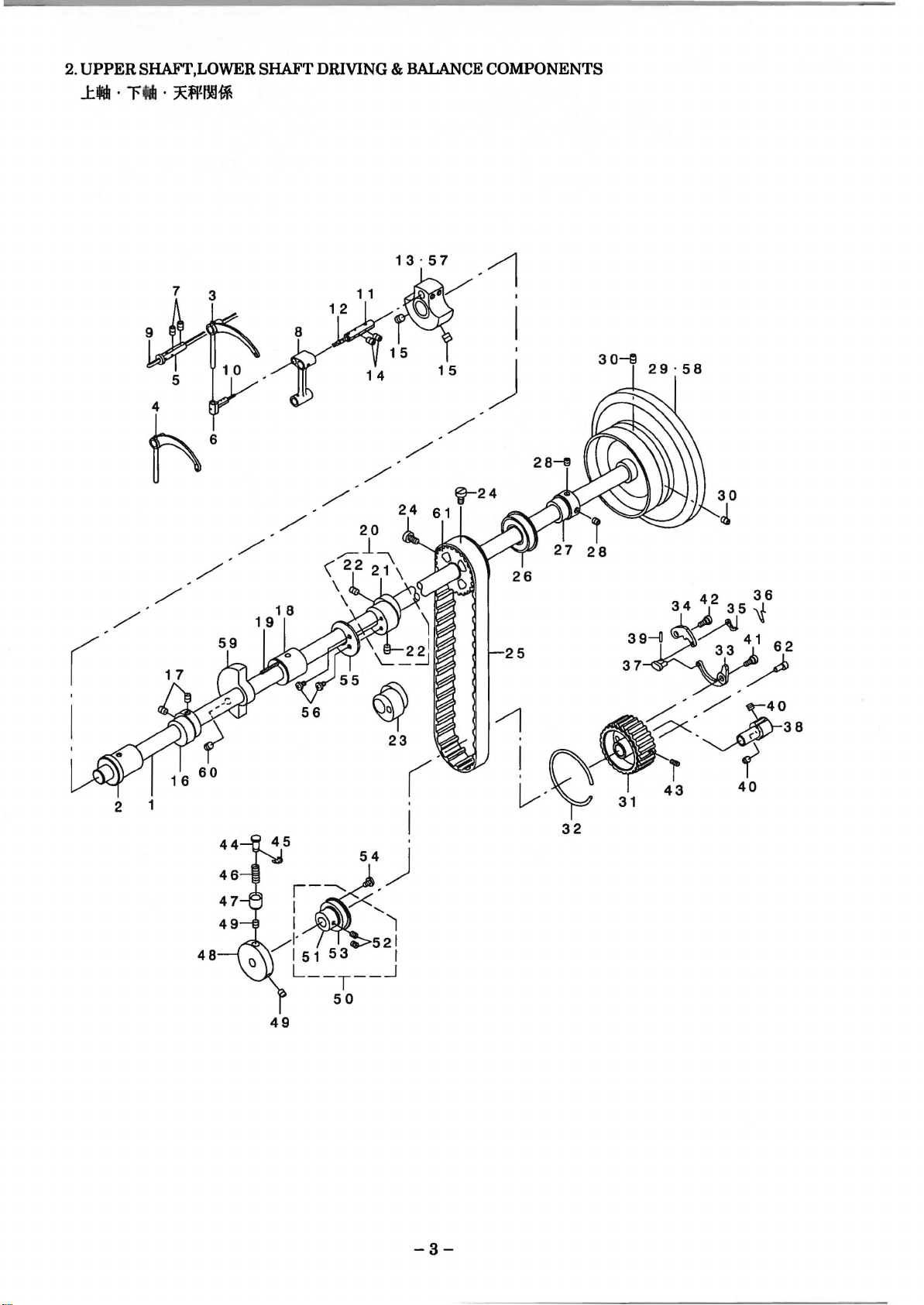

2.

UPPER

J:fdl·rfi·~WOO~

SHAFT,LOWER

SHAFT

DRIVING & BALANCE COMPONENTS

30~

30

~

(

23

16

60

2

45

54)

48

I

r~·

I I

/1·

I

L

49

51

__

53

50

X,

T

521

__

I

_j

-3-

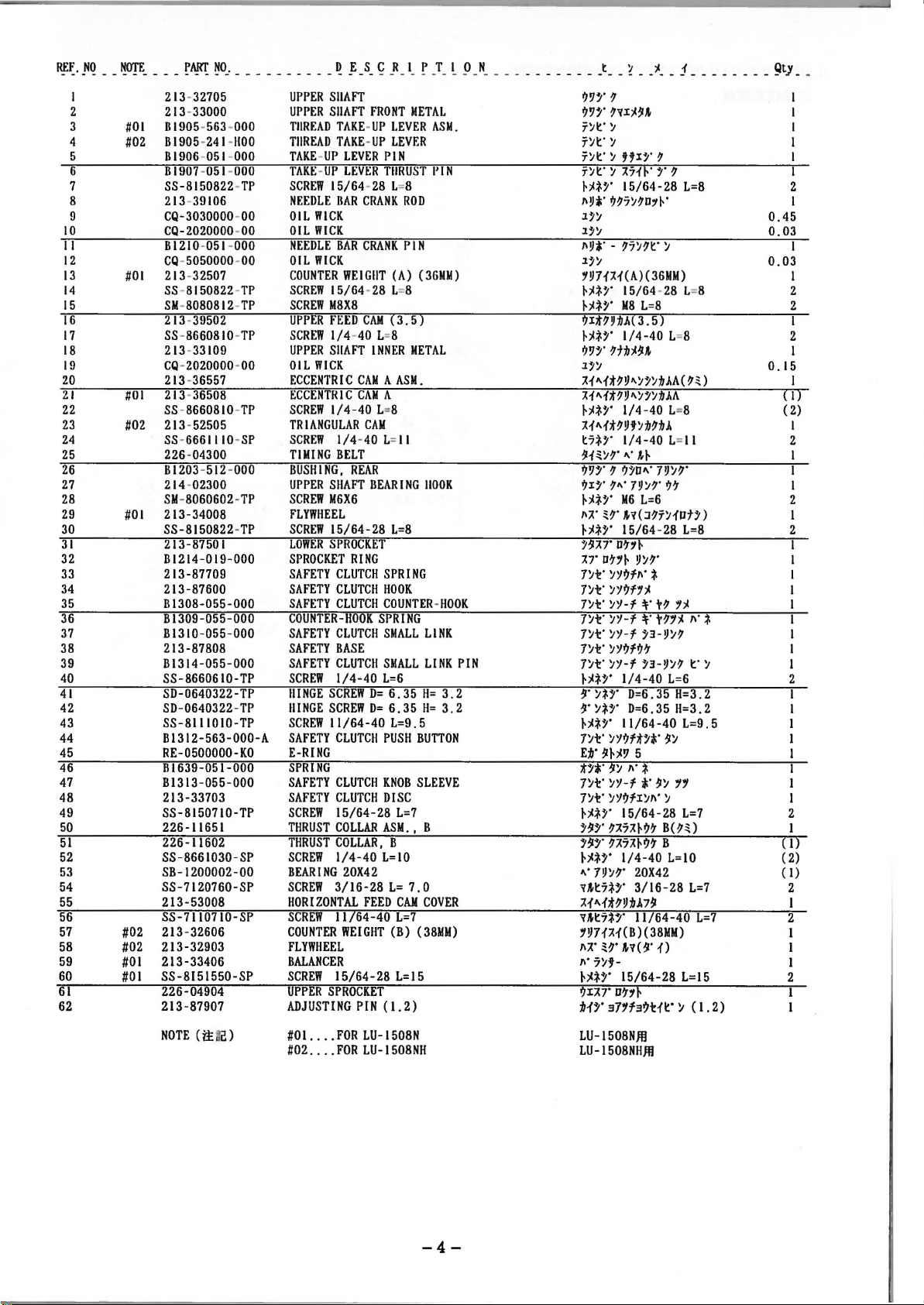

Page 11

R!=~--NQ _ -~-

I

2

3

4

#01

#02

5

6

7

8

9

10

II

12

13

#01

14

15

16

17

18

19

20

21

#01

22

23

#02

24

25

26

27

28

29

#01

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

#02

#02

#01

#01

61

62

___

~~

~0_.

_________

213-32705

213-33000

81905-563-000

81905-241-HOO

81906-051-000

81907-051-000

SS-8150822-TP

213-39106

CQ-3030000-00

CQ-2020000-00

Bl210-051-000

CQ-5050000-00

213-32507

SS-8150822-TP

SM-8080812-TP

213-39502

SS-8660810-TP

213-33109

CQ-2020000-00

213-36557

213-36508

SS-8660810-TP

213-52505

SS-6661110-SP

226-04300

Bl203-512-000

214-02300

SM-8060602-TP

213-34008

SS-8150822-TP

213-87501

BI214-019-000

213-87709

213-87600

BI308-055-000

Bl309-055-000

Bl310-055-000

213-87808

Bl314-055-000

SS-8660610-TP

SD-0640322-TP

SD-0640322-TP

SS-8111010-TP

Bl312-563-000-A

RE-0500000-KO

81639-051-000

Bl313-055-000

213-33703

SS-8150710-TP

226-11651

226-11602

SS-8661030-SP

SB-1200002-00

SS-7120760-SP

213-53008

SS-7110710-SP

213-32606

213-32903

213-33406

SS-8151550-SP

226-04904

213-87907

-~

~-S-

~

UPPER

SHAFT

UPPER

SHAFT

TIIREAD

THREAD

TAKE-UP

TAKE-UP

SCREW

NEEDLE

OIL

WICK

OIL

WICK

NEEDLE

OIL

WICK

COUNTER

SCREW

SCREW

UPPER

SCREW

UPPER

TAKE-UP

TAKE-UP

LEVER

LEVER

15/64-

BAR

CRANK

BAR

CRANK

WEIGHT

15/64-

MBXB

FEED

CAM

1/4-

40

SHAFT

FRONT

PIN

TIIRUST

28

28

L=8

INNER

01 L WICK

ECCENTRIC

ECCENTRIC

SCREW

TRIANGULAR

SCREW

TIMING

BUSHING,

UPPER

SCREW

CAM A ASM.

CAM

A

1/4-40 L=8

CAM

1/4-

40 L=ll

BELT

REAR

SHAFT

BEARING

M6X6

FLYWHEEL

SCREW

15/64-28

LOWER

SPROCKET

SPROCKET

SAFETY

SAFETY

SAFETY

COUNTER-HOOK

SAFETY

SAFETY

SAFETY

SCREW

HINGE

HINGE

SCREW

SAFETY

RING

CLUTCH

CLUTCH

CLUTCH

CLUTCH

BASE

CLUTCH

1/4-40

SCREW

D=

SCREW

D=

11/64-40

CLUTCH

SPRING

HOOK

COUNTER-HOOK

SPRING

SMALL

SMALL

L=6

PUSH

E-RING

SPRING

SAFETY

SAFETY

SCREW

THRUST

THRUST

SCREW

BEARING

SCREW

HORIZONTAL

SCREW

COUNTER

CLUTCH

CLUTCH

KNOB

DISC

15/64-28

COLLAR

ASM.

COLLAR,

1/4-40

L=IO

20X4

2

3/16-28

FEED

11/64-40

WEIGHT

FLYWHEEL

BALANCER

SCREW

UPPER

ADJUSTING

15/64-28

SPROCKET

PIN

(1.2)

_R_I_ ~ _T_ ~ ,9

METAL

LEVER

ASM.

LEVER

I'

IN

L=8

ROD

PIN

(A)

(36MM)

L=8

( 3. 5)

METAL

IIOOK

L=8

LINK

L I

NK

PIN

6.35 H-3.2

6.35

H=

3.2

L=9.5

BUTTON

SLEEVE

L=7

, B

8

L=

7. 0

CAM

COVER

L-7

(B)

(38MM)

L=l5

_N

____

________

f)'}')'

f)'}')''JVI~~~

r~t·

;:~t·~

;:~t·

r~t· ~ ~7-W

~~*}''

119*'

l}'~

l}'~

119i'

lj~

'9701'(A)(36MM) I

~~*j'

~~W

f)Ilt'J9:bA(3.5)

~~*j'

f)'}j''Jt:b~~~.

lj~

A1'~1'lt'J9~~}'~:bAA('J~)

~1'~1'lt'J9~~}'~:bAA

~~*j'

~1'~1'lt'J9f~:b'J:bJ.

t7*'J"

~1'~~"·~·

f)'}j'

f)Ij'

~~w

/I~'~'J'!.V(J'J1~1'Dt'J)

~~*j'

'J~A7'DIJ'f

u·

7Yt''J'Jf)fll'* I

lYt''J'JfJf'~

7'Jt''J'J-f

7'Jt'~'J-f

7'Jt' 'J'J-f H-9'J'J

7'Jt'

7'Jt''J'J-f

~~*'J'

~''J*'J'

~''J*'J'

~~*}''

7'Jt''J'/fJft'Ji.'~~

E:IJ'

lt'l*'

7~t·

l'Jt''J'Jf)fi'J/1'~

~~*j'

j~j''JA7A~fJIJ

:t~Y

~~*''

~'79'1'1'

v!.t7*''

~1'~1'lt'J9:bA7~

V!.t7*'/' 11/64-40

Y971'A1'(8

IIA'~'J'

11'7~f-

~~*j'

fJIA7'DIJ'~

:b1''1'37,f39t1't''J

t __ ~ _ _

'1-

_ _ j

________

'J

~

~

jfi}'"

'J

,.

15/64-28

fJ'J7~'Jo,~·

-

'J7~'Jt'

15/64-

118

"

L=8

~

28

L=8 2

L=8

1/4-40 L=B

1/4-40 L=B

1/4-40 L=

,.~

'J

f)jp~· 79~'J'

'J~'

79~'1'

11s

15/64-28

o~J'~

9~'1·

ll

fJIJ

L=s

L=B

··t'J

'~

~·t"'~

/1'~

'J'JfJffJIJ

j3-9'J'J

1/4-40

D=6.35

D=6.35

t''J

L=6

H=3.2

H=3.2

11/64-40 L=9.5 I

~~~'J

5 I

?J'J

/1' *

'J'J-f

,.

~~

"

15/64-28

'JA7A~fJIJ

1/4-40

L=7

B('J~)

B

L=IO

20X42

3/16-28

L=7

L-7

)(

38MM)

!.V(~'1')

15/64-28

L=l5

(1.2)

9tJ

0.45

0.03

0.03

0.15

(I)

(

2

(I)

(2)

(I)

2

I

2

1

I

I

2

I

I

_ _

I

I

I

I

I

I

2

I

I

2

I

2

I

I

2)

I

2

I

I

I

2

I

2

I

I

I

I

I

I

I

I

2

I

I

I

I

I

I

I

NOTE

(it

I

a)

#01

#02

....

....

FOR

LU-1508N

FOR

LU-1508NH

-4-

LU-1508N11J

LU

-1508NH11J

Page 12

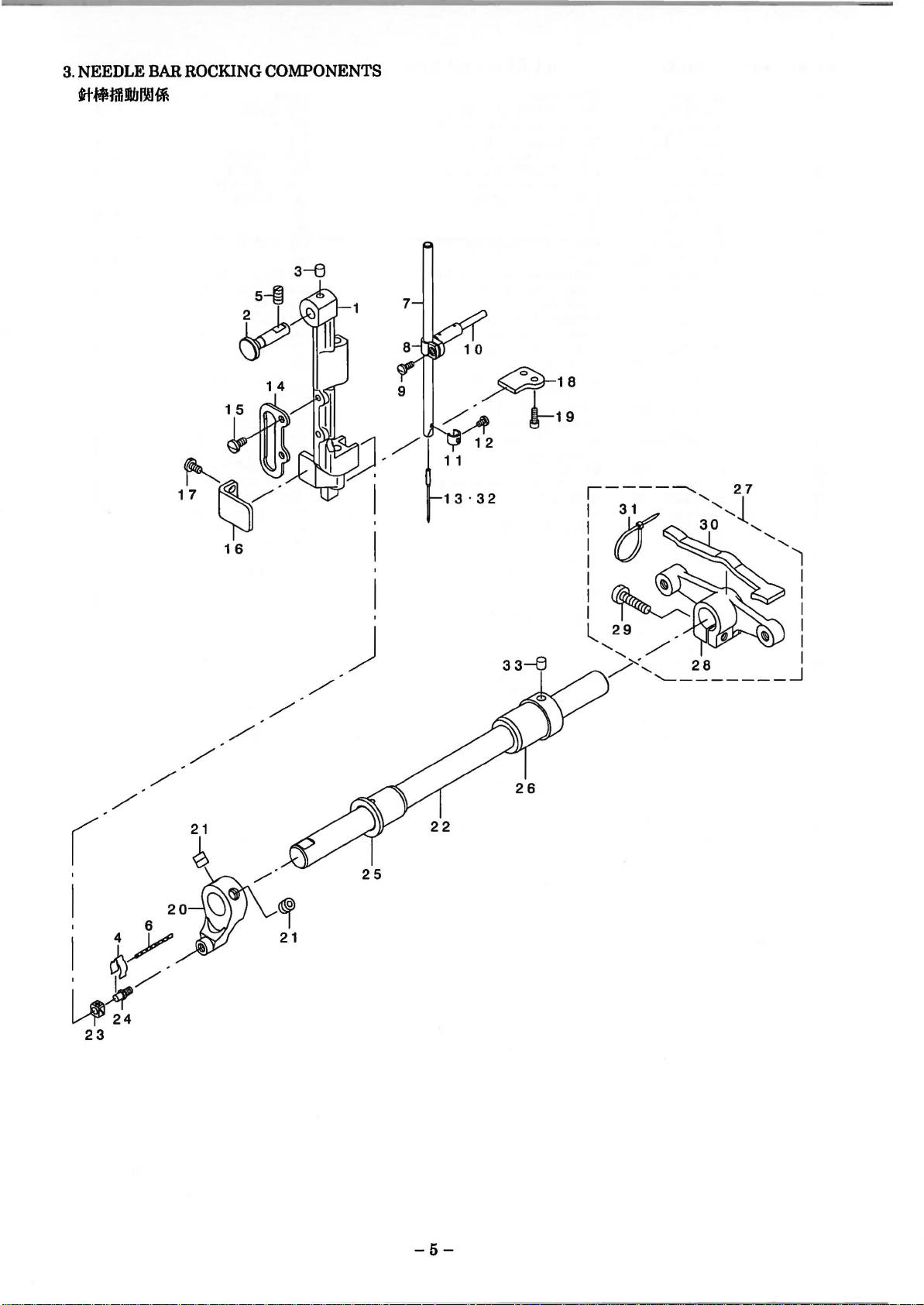

3. NEEDLE BAR ROCKING COMPONENTS

lttft.IIJIIJOO~

1

p--18

()I

I

2)-/~

I !

1 s 1

)

I

I

I

/A

11

12

~13.

32

3--19

25

~

21

-5-

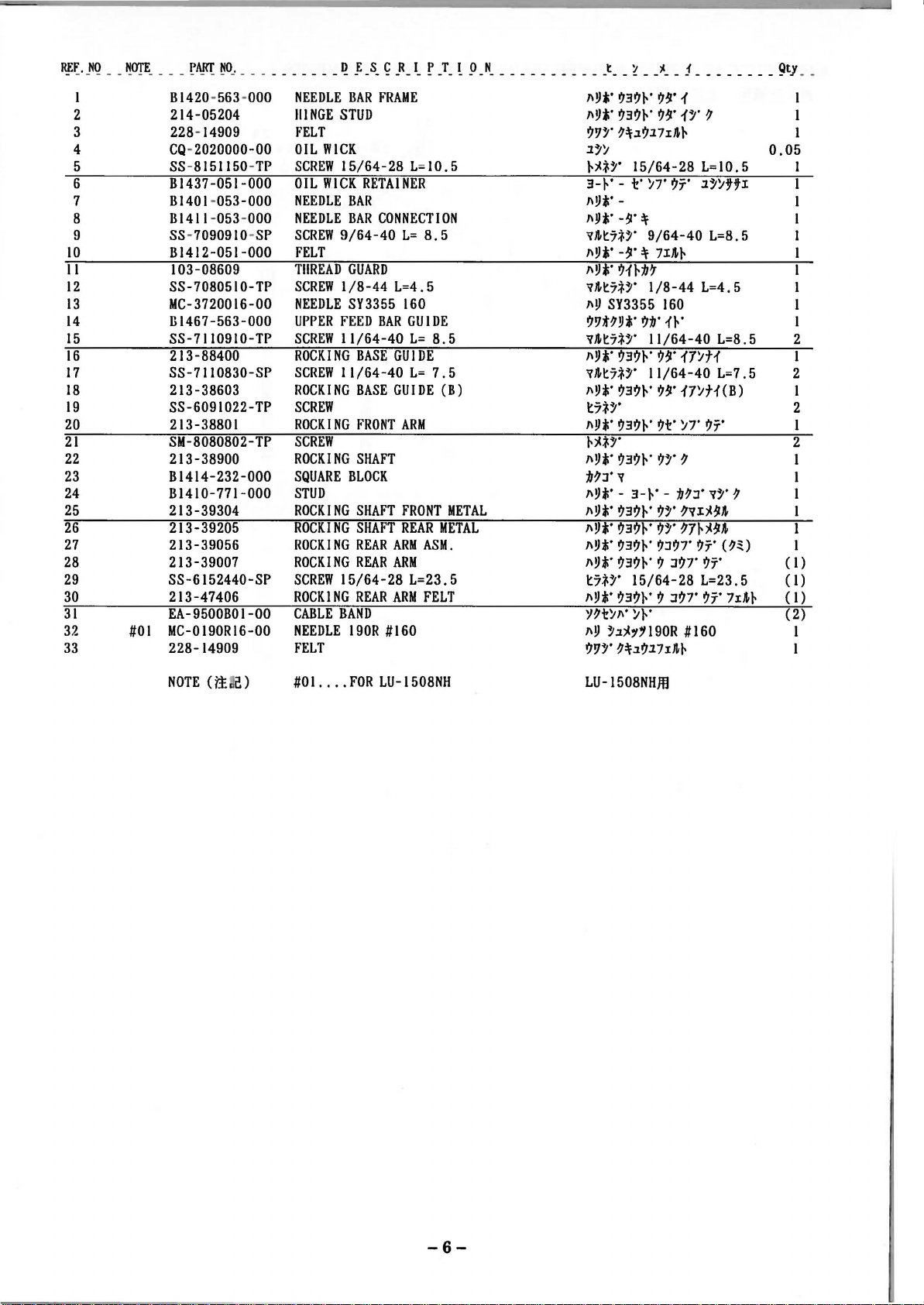

Page 13

~~·

_NQ

__

~O'!'E

-

___

rA¥!:

~

_.

______

____

I!

J.:

_s_

~

_R_I_ ~ _T

_

~

9

_N

____________

t

__

! __

"J.

_ _ 1 ________

9tJ

__

I Bl420-

2

3

4

5

6

7

8

9

10

214-05204

228-14909

CQ

SS-8151150-TP

Bl437-051-000

Bl401

B

SS-7090910-SP

Bl412-051-000

563-000

-2020000-00

-053-000

1411-053-000

II 103-08609

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3?.

33

SS-7080510MC-3720016-00

lll467-563-000

SS-7110910-TP

213-88400

SS-711

213-38603

SS-6091022-TP

213-38801

SM-8080802-TP

213-38900

81414-232-000

Bl410-771-000

213-39304

213-39205

213-39056

213-39007

SS-6152440-SP

213-47406

EA-9500BO

#01

MC-0190RI6-00

228-14909

0830-SP

TP

1-00

NEEDLE

Ill

NGE

BAR

STUD

FELT

OIL

WICK

SCREW

OIL

NEEDLE

NEEDLE

SCREW

15/64-28 L=

WICK

BAR

BAR

9/64-40

FELT

TIIREAD

SCREW

NEEDLE

UPPER

SCREW

ROCKING

SCREW

ROCKING

GUARD

1/8-44 L=4.5

S¥3355

FEED

11/64-40

BASE

I 1/64-40

BASE

SCREW

ROCKING

FRONT

SCREW

ROCKING

SQUARE

SHAFT

BLOCK

STUD

ROCKING

ROCKING

ROCKING

ROCKING

SCREW

ROCKING

CABLE

NEEDLE

SHAFT

SHAFT

REAR

REAR

15/64-28 L=23.5

REAR

BAND

190R

FELT

FRAME

l0.5

RETAINER

CONNECTION

L=

8.5

160

BAR

GUIDE

L=

8.5

GUIDE

L=

7.5

GUIDE

(B)

ARM

FRONT

REAR

METAL

ARM

ASM.

ARM

ARM

FELT

#160

METAL

"~··

\)3\)~'1)1).'

"~*'\)3\)~'1)1).'{~'~

\)'"'

?~.J.\).l7d~

.l~Y

~~*~·

15/64-28 L=l0.5

3-~·-

t'Y7'\)'j'

1\

~*·

- I

"9*'

-1).'

v~t7*''

1\~i'-1).'~

"~*'i){~j]~

'i~t7*~·

1\9

S¥3355

\)'lt?~t·

v~t7*~·

l\9i'~3~~·~1J'{7Yt-f

v~t7*~·

l\~i'l)3l)~'l)IJ'{7Yt-f(B)

t7*~·

l\9i'~3i)~·~t·Y7'~7'

~~*''

"9*'

~3l)V

1/~J'V

"~*·- 3-~·-

l\9i'l)3~~·~~·?vi~IJ~

"9*'~3\)~·~~·~y~~IJ~

l\9i'l)3\)~'~J\)7'\)'j'

1\9

*'

~31)

t7*''

15/64-28 L=23.5

l\9i'i)3~~·~

Y?tYI\'

YV

1\9

'.J.~1,190R

\)f)''~~.J.~.l7d~

{

.l~Y,,I

~

9/64-40 L=8.5

7I~~

1/8-

44

L=4.5 I

160

i)j]

'

-~~

.

11/64-40

11/64-40

')~·

~.

~

J\)7' l)'j'

J~7'\)7'7x~~

L=8.5

L=7.5

~

1/?J'v~·~

(?~)

#160

I

0.05

I

I

I

I

I

I

I

I

2

I

2

I

2

I

2

I

I

I

I

I

I

(I)

(I)

(I)

(2)

1

I

NOTE

(

tl:

a

i!)

#01

.... FOR

LU-1508NH

LU-

1508NHJfl

-6-

Page 14

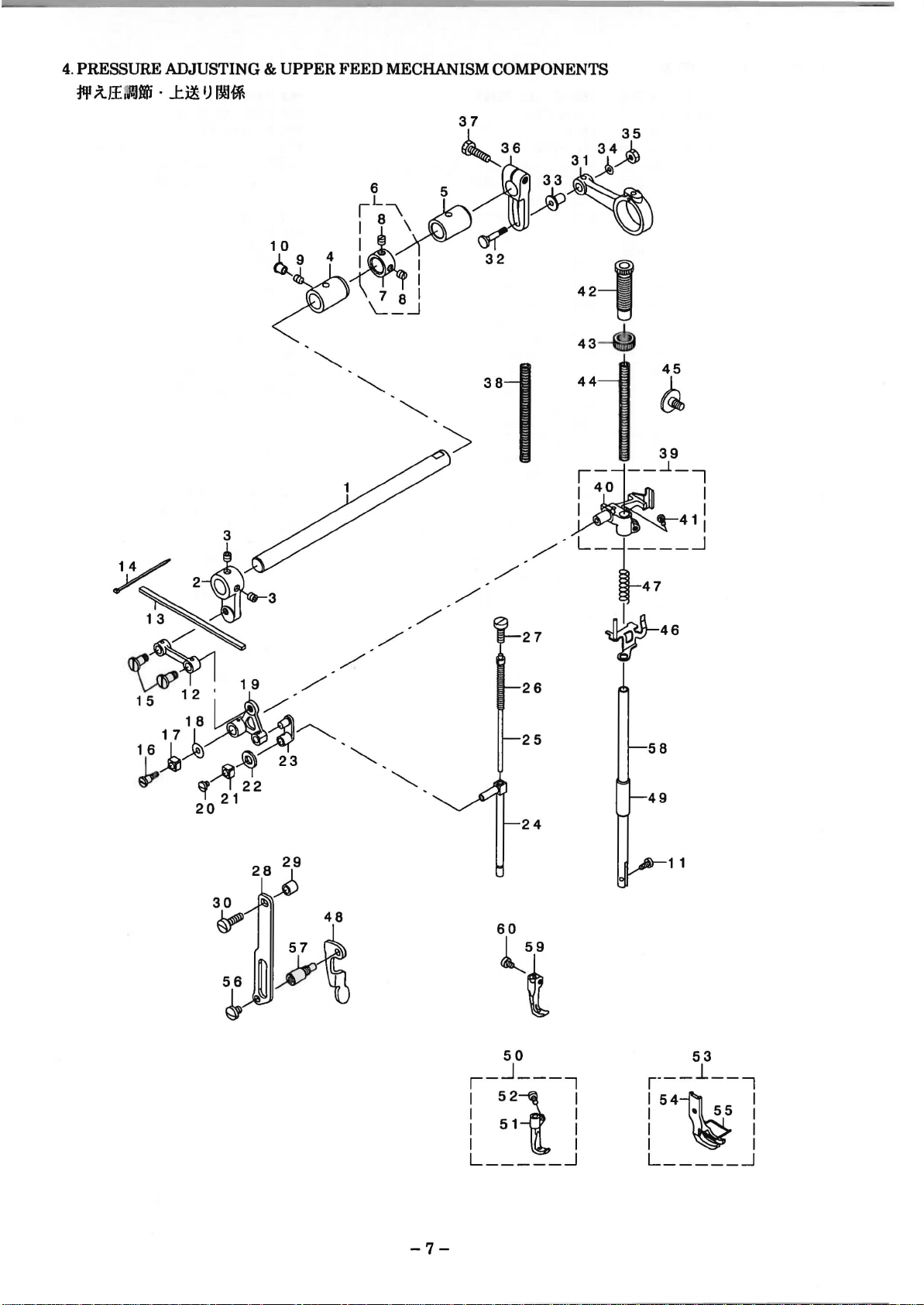

4.

PRESSURE ADJUSTING &

¥1'

;ltlf,p.JfOi

.

J:~

1)

00~

UPPER

FEED MECHANISM COMPONENTS

37

10

(-._"

•

"36

31

3:1

~33~

:\\h~fi

iJv-

m~

\._ _ _j

I

a2

38

~

-1

42

43

45

44

~

50

r_j

I

I

I I

I I

L

-7-

___

521

51

_____

-,

_j

53

r---1----,

I

I

154~

I "

I I

I I

L

_____

55

_j

I

I

Page 15

RJ:~._Nq _ -~-

I

2

3

4

5

6

7

8

9

10

II

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

#03

39

40

41

42

43

44

45

46

47

48

49

50

#01

51

52

53

54

55

56

57

58

59

60

#02

#02

___

rA¥J.:

~0

~

213-40401

213-40500

SS-8660612-TP

213-41904

213-78302

229-04155

229-04106

SS-8660610-TP

SS-8150710-SP

TA-0750704-RO

SS-6090910-TP

213-39908

213-47109

EA-9500800-00

83016-141-1100

SD-0640701-SP

81414-555-000

WP-0501046-SC

213-40807

SS-7110510-SP

81414-555-000

105-09701

81465-053-000

81466-563-000

81467-053-0AO

81468-053-000

SS-6151780-SP

214-06509

135-14310

SS-6151920-SP

213-40104

D1456-055-BOO

D1455-055-BOO

WP-0482086-SD

NS-6110530-SP

213-40203

SM-9062250-SC

BI510-141-HOO

213-41052

213-41003

SS-711

0910-TP

213-40906

110-71701

BI502-246-000

SD-0800481-SP

2t3-4l151

81462-053-000

214-06103

BI510-155-000

81470-241-HAO

B1470-241-HOO

81471-241-HOO

81525-241-HAO

B1525-241-HOO

103-37905

SS-7150740-SP

214-06608

B1501-241-HOO

213-50004

BI471-241-HOO

______

__

_

-

~

J:_S_ ~ _R

UPPER

FEED

FEED

1/4-

40

METAL

SIIAFT

SHAFT

SHAFT

1/4 15/64-

PLUG

9/64-

FEED

SIIAFT

FRONT

METAL

THRUST

THRUST

40

LINK

UPPER

SCREW

FRONT

FEED

MAIN

MAIN

SCREW

SCREW

RUBBER

SCREW

UPPER

FELT

CLIP CVHINGE

Ill

SLIDE

WASIIER

TRIANGULAR

SCREW

SLIDE

NGE

70S

SCREW,

SCREW

BLOCK

5 X

13

LEVER

II /64-

BLOCK

FELT

WALKING

WALKING

WALKING

WALKING

SCREW

UPPER

BAR

BAR

BAR

BAR

15/64FEED

GUIDE

ROLLER

SCREW

15/64-28 L=l9.0

OPPER

FEED

HINGE

CONNECT!

WASHER

NUT

11/64-40

UPPER

SCREW

PRESSER

PRESSER

PRESSER

SCREW

PRESSER

ROD

SCREW

NG

STUD

4. 8XII.

FEED

REAR

146

L=22

SPRING

BAR

BAR

11/64-40

ADJUSTING

NUT

PRESSER

HINGE

THREAD

THREAD

PRESSER

PRESSER

WALKING

WALKING

SPRING

SCREW

RELEASE

RELEASE

LIFTER

BAR

FOOT

FOOT

SCREW

PRESSER

PRESSER

FINGER

SCREW

GUIDE

PRESSER

UPPER

FOOT

FOOT

GUARD

15/64-28

PLATE

BAR

FEED

FOOT

SPACER

SCREW

_l_ r _T_!

p_N

__

. _ _

..

ARM

L=6

COLLAR

ASM.

COLLAR

L=6

28

L=7

40

L=9

8

D-6.

35 11=7 §· 'I:W

X I

40

L=5

DRIVING

LINK

ASM.

SPRING

28 L=l7.0

PLATE

5X2

ARM

HOLDER

ASM.

HOLDER

L=

8.5

SCREW

D= 8 H=

HOLDING

4.9

PLATE

SPRING

LEVER

LOWER

BUSHING

ASM.

ASM.

L=7

_____

t

__ ~ _ _

t.

_ _ j

________

tj'

9

')9lt?W 'I

')9lt?9t'

~j.~,.

')9lt?W

~-f

o)W

o)!W

~j.~,.

~j.~,.

~j.t'J

t7~,.

')9lt'19

')9lt?99'1?7.d~

~1'/'JTI'

L-{~01~·

Tl9

t7f''b'~.5X14XI

t'l'b'I7J

V-'t?~,.

Tl9i'

o).IP-7

')9lt?9

'17'

o)'j'

1/4-40

L=6

?V.Ij.~-'

..

-ft'IW'Jj.~-'

'I~?~~§~(

?~?~~')~

9'1'1

••

')~'

&~·

'I~)

1/4-40

L=6

15/64-28

9/64-40

'/~'

~·

D=G.

~

11/64-40

~

?~'o)P1~7.I-'~

3-~·

L=7

L=9

60

'1~,.

8 2

35

11=7

7'.17-{JP

L=

7'/HJP

-9'1?

5 I

(I)

(

o).Ilt?9i'o)

')9lt?9T1'~

')9lt?9*' -

t?~,.

o).Ilt?9'b'-{~'-{~

-{~~9W

t?~,.

§:tf'I~D'~

')9lt?9

o)9Jt'l9

'''*'Jtf.ITI'

15/64-28

3JD

15/64-28

01~·

~·

'IW

P1~'

~'1~1,'?

?~

~

L=17

L=19

t?f''b' ~ 4.8XII.5X2 I

P1'b'lt1~

&9t?9Jo)7'

D''b?*'

Jtf:tf3-t1TI'~

ltf:t$'1)~

ltf.I$'1)~·~

v-'t?~,.

Jtf:tf3o)t1~,.

ltf:t

ltf:t

~·'I~,.

-{~J.-'j.o)~-{§(~1J'§)

-{~J.-'j.

tt:rn·~TI·-

ltf.Ii'-

')9t?9n

')9t?9n

~,.

ttzn

ttxn

J.t''b'-~'

V-'t?~,.

'b'

-'~

'

:13o)t'

:13o)t'

D=8

')~-{~

'~j.~-'

'I~

-{~.

-{~~

11/64-40

&7'

146

L=22

~(?~)

11/64-40

~,.

t'~

Tl'

~

H=4.9

Tl'

~

?~

15/64-28

..

•

-t

L=8.5

L-7

(I)

(I)

{I)

(I)

(I)

(I)

tf.Ii'-

')9t'l9n

~,.

__

I

I

2

I

I

I

2)

I

I

I

I

I

2

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

1

I

I

I

I

I

NOTE

(iU:D

#OI

#02

....

....

FOR

LU-1508N

FOR

LU-1508NH

-8-

LU

-1508N}fi

LU-

1508NH}fi

Page 16

5.FEEDMEC

~

1)

00~

~

23

(}).

27

HANISM COMPONENTS

•

l~-

68

85

86

.La

~

55

95

<b

58

~

~

22

21

57

§-59

1 1

-9-

92

Page 17

~._Nq

I

2

3

4

5

6

7

8

9

10

II

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

til

62

63

64

65

66

67

68

69

70

11

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

_-~-

___

#01

#02

#01

#02

#01

#02

#02 I 00 • 83202

#02

#02

#01

#02

#OJ

#01

#02

#02

#02

#02

#02

#02

#02

#02

#02

#02

#02

#02

#02

#02

#02

#02

#02

#02

#02

#03

#03

#03

#03

#03

#03

~A_!{!:

~0_.

213·36052

213-36003

81604 ·051·000

SS-9151440-CP

IP-0621016-SD

SI-8050502

BI604·

RE-0500711-KP

CQ-2020000·00

213-64104

SS-/111410-SP

226-09408

213-78302

SS-8151150-TP

226·09309

SS-6121610-IP

229-04155

229-04106

SS·8660610·TP

102-05201

SD

NS ·6680320

213·37506

213·37704

SS-7110910-TP

213-31401

213·37803

SS·8150822·TP

213·38306

SS·7090610·SP

213 ·31902

SS·7090910·TP

213·37308

SD-0800402-TP

213·37605

213-38009

SS-6111610-SP

213-37209

213·38108

Sll-6061802 • TP

213·36805

213·36904

SS-6121860-SP

110·09909

R0-0922702·00

110-52101

229-12109

213·36656

213·36607

B1418-761-000

CQ-2020000-00

Sli213-36706

213-78906

SO

213-52103

213·52604

SS-8150822-TP

213·36300

213·36409

CS

CS-1201011-SH

SS-8660610·TP

RE-0900000-KO

213-88004

SS-6120930-TP

213·37001

213-37100

SS-7110710-SP

213-52901

WP-0612056-SD

WS-0610002-KP

SS-6153012-TP

213-52802

D2461·481-COO

B2507-372-000

RE-0400000-10

SS-6090910-SP

SS-7120710-SP

101-20004

137-89201

112-72614

WP-0502616-SD

111-00500

SS-7112420-SP

213-49303

BI611-055-000

SS-6110520-TP

101-22000

B3025-14l·ROO-X

SS-6121210-TP

WP·0650876·SD

NS-6150310-SP

228-14909

NOTE

-IP

012·000

-0900101-IP

· I

· I201010·

SP

8050612-TP

00080 I-SH

SH

(l£2)

_________

FEED

FEED

FEED

SCREW

IIASIIER

SCREW

·A

FEED

SNAP

OIL

FEED

SCREW

FEED

FEED

SCREW

FEED

SCREW

liA

IIAI

SCREW

NEEDLE

Ill

NUT

FEED

FEED

SCREW

SQUARE

FEED

SCREW

FELT

SCREW

ECCENtRIC

SCREW

FEED

Ill

SPRING

SPRING

SCREW

FEED

FEED

SCREW

fEED

FEED

SCREW

FEED

RUBBER

PIN

FEED

FEED

FEED

CONNECTING

OIL

SCREWII5X6

FEED

FEED

HINGE

fEED

REAR

FEED

SCREW

BACKWARD

BACKWARD f E£0

THRUST

THRUST

SCREW

E-RING

REvERSE

SCREW

BACiliARD

BACKWARD

SCREW

BACKWARD

WASHER

SPRING

SCREW

CHANGE

CONNECIING

CAll

ESCHEll

SCREW

SPRING

TENSION

FEED

WASHER

REVERSE

SCREW

FEED

SCREW

SCREW

CONNECTING

CUNNEC

SCREW

WASHER

NUT

FELT

#OI ••••

#02

#03

-~

BASE

BASE

BAR

SLIDE

15/64

6. 2XI3XI

iS

L• 5

BAR

SllAFT

RING

WICK

ROCKER

11/6'1-40

ROCK

ROCK

15/64 •

ROCKER

3/16-

IN

SIIAFT

N

SIIAFT

1/4·

BAR

NGE

SCREW

9/32 ADJUSTING

ADJUSTING

11/64·

BLOCK

ADJUST!

15/64-

SUPPORT

9/64-

9/64·

ADJUSTING

NGE

SCREW

ROOK

11/64·

ADJUST!

ADJUST!

116

L=

DIAL

DIAL

3/16-

REGULATOR

RING

REGULATOR

LINK

LINK

WICK

ROD

A

LINK

SCREW

IRIANGOLAR

CRANl

TRIANGULAR

15/64-28

FEED

COLLAR

COLLAR

1/4 ·

9

fEED

3/16-28

FEED

FEED

11/64-40

FEED

6. IX 18.

WASHER

15/64-28

BASE

ROLL

RING

4

9/64-40

3/16-28

SUSPENSION

SPRING

SPRING

FEED

11/64 -40 L=

DOG

(2.5X7

11/64-40 L=4.5

liNG

3/16-28

6. 5XI3X0.8

15/64-28

FOR

••••

FOR

••••

OPTIONAL

~-S-~ ~-'-~

ASII.

(A)

FORK

28 L•14

5

L• l4

SIIAFT

SIIAFT

IIETAL

28

L• IO. 5

SllAFT

CRANK

28 L•l6.5

TllRUST

COLLAR

Til

RUST

COLLAR

40

L=6

FRAIIE

ROD

be 9 liz I

28

BASE

BASE

COVER

40

L=

8.5

NG

BASE

SUPPORT

28

L=8

40

L=6

PIN

40

L=

8.5

ROD

D= 8

H=

4

40 L•l6

NG

A

NG

B

18

A

B

28

L=18

SCREW

PIN

.

FORKED

LINK

D=IO

H=8

en

CAll

L=8

LEVER

LEvER

ASII.

D=

12

I=

40

L=6

CON I RUt

L=9

LEVER

PRESSER

L=7

LINK

5X2

PIN

L=9

L=7

HOOl

LEVER

STOPPER

24

.2)

PIN

ARM

L=l2

LU-1508N

LU-1508NH

PARTS

SPRING

PIN

PIN

ROD

SHAFT

SHAfl

D=l2 1•

I 0

LEvER

B

PLATE

fOLCRUI

ASII

PIN

_T_ ~ ,9_N

AS II.

8

10

____________

t

__ ~ __

ll?,~·

t?,~·

t?H"

P11J?·

t7f"11"1- 6. 2XI3XI

Fm'

t?'~·

U1J

"

~~~?

.1)~

t?H"

Ylbf'~

~{"{li?Y,.?

~{"it?,.

~~·'·

~{"(t?~~:;·

bf'7'

~!W

?~7~~~~(?~)

~!,.

n7~~~~

~~·'·

"'*"

-

,.

~*'

P11J?t1~

ll?9fs~l:1~-!

t?Yf!l~t1~{7~

V't71-,. 11/64·

lf?9h?tH?:t'v

t?9f!l~t1~1ff:t

~~*'"

?d~tf:t

VJ,t71-,.

t!19h?O"~'H'

tJ,t7*'

ll?9f!l')t1P'~·

~-~*'

t?9f!l~l:1~{

b11'911'l'b?'

t7*'"

t?9f3~1:1A

t?9f3~1:1B

u111ntt:

t?H'1U

t?H" {U

t7*'"

t?9f3~t1W

09~?·

t!19

t!I?O

t?Yf3~1:1t

~{"{ll?99~?(?~)

~{"{ll!/'99!1?

7~~ 3-~·

:t7~

~~*'"

U"{li?9D'~·

U"-!ll?99!!?t·!!

~·

!11-,.

\'

'r!>lt!19w

~7~~!)~

~7~~.,~

~~1-,.

E1J"

~~JI?

\

'r?lf?HII

t71-'" 3/16-28

\ " 'r?ll?9lrll"

\"'r?ll?9ll'-f~

V-'t7W

7?n" t-E'

:JD

E1J"

~~~?

t7*)"

tJ,t71-'" 3/16-28

\'

f!7ti79G/I'

t·

!/:J"

t?Jw-

t7

,.11. *

/1"

1?lr11"

ubf'''

ll?911" (2.

t?9

~)I*'"

t7*)"

119t?9lr:l~,.

tit

?''""

t71o)"

t7f"1J" * 6.

D1t?t1~

~9,.

?\~~~,.,..~

LU-1508NJU

LU-1508NHJU

t?" ,!1!/lldl.

ll

__ f ________ 9tJ

{(A)?~

{

(

7~V~

·

.4~

15/64·

28 L•l4

{)"?

5

{'IT"

11/64-

40 L•l4

?MJ,

15/64-

28 L•I0.5

3/16-

28 L•IS

1/4-

40

L=6

3-~· .

p,~·

0=9 N=l

9/32-

28

40

15/64·

28

L=8

9/64·

40

L=6

~

" 9/64-

40

L=8.5

"

0=8

11=4

t,/1.

"'"

11/64·

40

L=16

'~

A

B

3/16-

28

L=l8

E'~

"

W *

-9!1?

t•

!I

115X0

.8

L=6

A

D=IO

H=8

-7'

!1

8

0•

12

1=10

D=l2

1=10

1/4-40

L=6

9

-

L=9

-8

11/64-40

~

4

9/64-40

L=9

L=7

·

II'

#J?'

t111"

9

,.

*

11·

u~

-

;1~1/1"

11/64-40

51JU7

.2)

11/64-40 L=4.5

?

3/16-28

L=12

5XI3X0

.8

15/64·28

. 5

L=8.5

*

?~

L=7

L=24

0.14

(0

(I)

(I)

(I)

(I)

(I)

(I)

(2)

(I)

(I)

.04)

(I)

(I)

(2)

__

I

I

I

I

2

I

2

I

I

I

2

I

2

2

I

2

4

2

2

2

I

2

I

2

I

I

I

I

2

I

I

I

I

I

I

I

I

I

I

I

I

I

2

I

I

3

I

I

I

2

I

I

I

2

I

I

-10-

Page 18

6. HOOK SHAFT & LOWER SHAFT COMPONENTS

~*'h·r*'hOO~

16~

17

18j

24---@

23

301

~

~

15~

13

2~/1

1 v

'

41-::~

I !

· ) A

40

~

21'

t--4

~-t~3

ti~

~5

8

Jr--19

l

22

r::

J-1o

?

40

'

20

26

3

9---§

/

/

/

-11-

Page 19

~~·-1«1

__ ~-___

~AJfi.:

I 213-35005

2

3

4

5

6

7

8

9

10

II

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

Bl820-563-000

81821-051-000

CQ-2020000-00

NS-61

BI822-563-000

Bl823-051-000

SS-7111810-SP

CQ-2020000-00

Bl824-563-000

WP-0371016-SD

SS-6090810-SP

#03

101-11102

213-78500

213-34701

101-09908

101-12407

SS-6153040-SP

WP-0850002-SP

SM-6082502-TP

B1843-563-000

NS-61

B1830-563-0AO

B9117-563-000

213-33604

B1802-563-000-A

CQ-2020000-00

SS-8151150-TP

B1803-515-0AO

B1830-563-BAO

#01

BI840-051-00A

#02

SS-8151150-TP

B1840-051-000

SS-8150510-TP

B1817-051-000

SS-8660670-SP

SS-8660530B1816-051-000

SS-8660810-TP

SS-8110422-TP

101-09700

#03

101-09809

#03

101-10906

#03

101-11003

#03

#03

101-11201

101-12506

#03

#03

101-12605

101-12704

#03

t_«>, _______

10420-SP

10420-SP

TP

___

~

~

_S_ ~ _R_I_ ~ _T_ ~ ,!)_N

IIOOK

SHAFT

BASE

BOBBIN

CRANK

OIL

NUT

BOBBIN

OPENING

SCREW

OIL

BOBBIN

WASHER

SCREW

THRUST

HOOK

HOOK

SADDLE

SADDLE

SCREW

WASHER

SCREW

OIL

NUT

VERTICAL-AXIS

CASE

OPENING

SCREW

STUD

WICK

11/64-40

CASE

OPENING

LEVER

11/64-40 L;

WICK

CASE

OPENING

3.7X8XI

9/64-40

WASHER

SHAFT

UPPER

SHAFT

LOWER

INSTALLING

INSTALLING

15/64-28

8.5X18X1.6

M8

L;25

ADJUSTING

11/64-40

CRANK

L=

1.3

SCREW

SEWING

BOBBIN

LOWER

SHAFT

HOOK

DRIVING

OIL

WICK

SCREW

15/64-28 L=10.5

BUSHING

HOOK

ASM. , FOR

VERT I CAL

SCREW

FEED

SCREW

HOOK

15/64-28 L=10.5

DRIVING

15/64-28

DRIVING

SCREW

SCREW

HOOK

DRIVING

SCREW

1/4-40

SCREW

THRUST

THRUST

WASHER,

WASHER,

BUSHING

THRUST

THRUST

THRUST

THRUST

THRUST

WASHER

WASHER,

WASHER

WASHER

WASHER

SHAFT

ASM.,

FEED

ECCENTRIC

SHAFT

1/4-40

1/4-40

SHAFT

L=8

11/64-40

THRUST

INTERMEDIATE

CAM

1.2

1.6

1.7

1.8

{RIGHT)

LEVER

LEVER

PIN

18

LEVER

7.5

METAL

METAL

BLOCK,

BLOCK,

L=30

HOOK

FRONT

EXTREME

L=

THICK

4.7

GEAR,

L=

6.1

L=

4.5

GEAR,

L=4

A

B

1.1

F

____________

LINK

CRAN

UPPER

LOWER

ASM.

METAL

T

SMALL

LARGE

t __ ~ __

:IJ'i''

f'b'fJ'

tbb'V

.l''./

D'b~t'~

tbb' v

tbb'V

v~t71''

.l''./

JI

__

f_

_______

~~·

{(~~·)

V7'J7{9'.1~

7'./t{

~7'./~t''.l

11/64-40

7'.1t{iJ7'

7'.1t{iJ7'

,.~

11/64-40

L=l8

0.

0.

9tJ

01

01

tbtJ' v 7'./t{

t7t'

b'

1 3.

7X8X1

t71''

9/64-40 L=7.5

bv''~iJ9~~~

tJv'·~iJ9~~~

h,.~,~~~~

bv''

~~·

bv''

~~·{~)I

t71'

' 15/64-28

t7t'

tJ'

u'tJnti'

tJv

.193-

D'tJ~t'~

bv

~~

,.

t'

'.1

,~,·~

'H'~VJ.)I~~

.l''./

~)11''

,~,. ~ ttJ)I~~

tJv

~~

''3iJIJ't~9tJ.A

~~1''

,.

3-IJ'

~~1''

'3-

*''

~)11'

'

~)11''

~·

{

*''

~~1''

~)11''

tJv'·~&9~~~

tJv'·~iJ9~~~

bv''~iJ9)1~~

tJv'·~iJ9~~~

bv''~iJ9)1~~

tJv'·~iJ9)1~~

tJv'·~iJ9)1~~

tJv'·~iJ9~~~

~7~~{~

{~~

iJI.

'~

1.3

L=30

1 8.

5X

18X

1.

6 I

~~

f3-t'*''

11/64-40

0.04

15/64-28 L=10.5 1

~~

15/64-28 L=10.5

t~9tJ.A

15/64-28

,..~·

1/4-40

1/4-40 L=4.5

,..~·

1/4-40

11/64-40

L=4.7

~v

L=6.1

~v

L=8

L=4

~7~~{~

~7~~{~

~7~~{~

~7~~{~

~7~~{~

~7~~{~

~7~~{~

~7~~{~

A

B

1.1

1.2

1.4

1.6

1.7

1.8

__

1

I

I

1

I

1

I

I

I

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

I

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

NOTE

(

tl:

ac)

#01 ... .

#02

#03

FOR

....

0PTIONAL

....

SELECTIVE

LU-1508NH

PARTS

PARTS

-12-

LU-1508NHJJ.I

t7'

,3'./HJS.fb

illmms~

Page 20

7.

THREAD TENSION COMPONENTS

IMIJ-TJMI~

24·25·26

'

~.

IO

II

I2

13

I4

I5

I6

I7

I8

I9

20

2I

22

23

24

25

26

_N~

I

2

3

4

5

6

7

8

9

_ _

~O'_!'E-

#OI

#OI

_ _ _

f~

_!l~.

_ _ _ _ _ _ _ _ _ _ p _

2I4-4I068

214-4I050

I03-20I09

B3I28-520-000

B3I37-05I-OAO

B3I25-0I2-000

226-I820I

B3I26-0I2-000

226-I7906

B3129-526-000

B3I20-I25-000

ll9-56802

101-24204

I07-4ll06

II0-45IOI

II0-72402

214-4IIOO

SS-40806IO-SP

SD-047028I-SP

NS-6ll03IO-SP

D3I62-555-BOO

PS-0600502-KP

SS-7II09IO-TP

2I3-48206

I03-2II07

230-06406

E_

THREAD

TENSION

SCREW

TENSION

TAKE-UP

THREAD

TENSION

THREAD

THREAD

TENSION

ROTATING

THREAD

THREAD

FIRST

THREAD

THREAD

TENSION

SCREW

HINGE

NUT

THREAD

SPRING

SCREW

TENSION

TENSION

TENSION

TENSION

POST

STUD

SPRING

SPRING

TENSION

RELEASE

TENSION

TENS I ON

SPRING

STOPPER

TENSION

TENSION

THREAD

TENSION

TENSION

RELEASE

I/8-44

SCREW

II/64-40

GUIDE

PIN

II/64-40

RELEASE

RELEASE

RELEASE

§ _ C _

~

COMPL.

TENSION

L=6.4

D=4.7

_I _ P_

!

_I_

ASM.

GUIDE

DISC

NUT

PIN,

A

DISK

DISK

PRESSER

(I.2)

KNOB,

BLUE

POST,

A

PLATE

SPRING

NUT

PLATE

H=2.8

L=

8.5

BAR

BAR

BAR

~

!l_

_ _ _ _ _ _ _ _ _ _

ASM.

_t

_ _ ~ _ _

'/.

__ j _ _ _ _ _ _ _ _

1'~f39:H?~)

1'H39SI(7,J" 9)

~~·?

1'H9/\'

1'H9/I'

~

1'~~91\'

~ 7~t1't'7

1'H3-~

{~:z~Jit'

1'~f3-H7

1'~f37H-7Jttz

1'H3-~

1'~f3-~t7

1'H37~,v~

~'1'11'H3-~j·-

~'1'1'HH37~t7

~·uf

~·1' I 1'~f39~

{~:z~J({~

t~·~~·

~·~*~·

p'~?t'~

{~:Z~J(Jt~$'f]

7.7'

v~t7*~·

{~:l~J(Jt~j·f]

{~:z~J(

t'~

~(A)

/\'~

~1'7~~·)1

1~f3?~1\·~

I/8-44

D=4.7

II/64-40

9~?'

t·

~

II/64-40

Jt~*·

?~

(1.2)

(7:t)

A

t1~

L=6.4

H=2.8

L=8.5

-

~~y

_ _

I

(1)

(I)

(I)

(I)

(I)

(2)

(4)

(2)

(2)

(2)

(2)

(I)

(

2)

(I)

(I)

(1)

(I)

(2)

(I)

(I)

I

2

I

I

NOTE

(tlla)

#OI

....

SELECTIVE

PARTS

-13-

Page 21

8. LOWER THREAD WINDER MECHANISM

r~@~~li'ltw~

COMPONENTS

10

II

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

BOBBIN

DEVICE

I

2

3

4

5

6

7

8

9

213-57967

225-37658

213-57959

225-38151

236-36202

213-56001

BI529-890-00C-A

106-18304

A3216-001-00A

B3205-210-000

81148-555-000

RC-0560711-KP

RE-0500000-KO

R0-0922702-00

SS-7091410-SP

Ss-6o9o52o-sr

145-12503

SS-6110810-TP

107-04807

SM-8050602-TP

I05-02300

SS-6090620-SP

213-55755

213-55706

D3162-555-BOO

NS-6110310-SP

03168-555-HOB

B3214-047-000

213-78708

110-72402

SU-604o8o0-SP

225-38706

BOBBIN

BOBIN

BOBBIN

BOBBIN

ADJUSTING

PRESSUR

VERTICAL

RUBBER

CUSHION

SPRING

RETAINING

E-RING

RUBBER

SCREW

SCREW

BOBBIN

SCREW

BOBBIN

SCREW

M5

THREAD

SCREW

LOWER

THREAD

FITTING

THREAD

NOT

II/64-40

TENSION

BOBBIN

THREAD

THREAD

SCREW

PACKING

ASM.

FITTING

SHAFT

CAll

LEVER

BASIS

COMPL.

SHAFT

PLATE

FOOT

SPRING

ROLLER

WASHER

RING

RING

RING

9/64-40

L=l3.5

9/64-40

L=

ADJUSTING

11/64-40

FRICTION

COTTER

9/64-40

GUIDE

WINDER

TENSION

TENSION

L=6

GUIDE

BASE

SPRING

TENSION

L=8

WHEEL

L=6

NO.I

POST

NUT

COMPL.

COMPL.

5.o

PLATE

ASII.

DISC

{~'l'\Y~f(~~)

-(~'l'\~91~~·-t(~1J"~)

-(~'l'\,.

~(,.1J"

{~vUJ.'"~(~1J"~)

-t~v'\vll·-

-t~v¥,·?~·-t

tfi/1"*

,.~~~·~

J"

.1.7(7"

••

t•

:,tf"

t?9

f3-tY

c~·nll7

E~·

~~JI7

09:,t~·

v~t7*'"

E7;'· 9/64-40

-(~'l'\f3~t1-(:9

t7W

-t~v'\vf'~·~v

~JI*'"

-t~¥m·u

t7*'" 9/64-40

'~-f~7:,tt{(~~)

'~-t~nt-tH'~~·-t

~·-t-tf

D'b?tY~

~·{I

-fH3-'

~·

UNH3~'*"

~·

-(

I

bn"

-(~'l'\~,~~·

~)

f39tY{~

D-7

71,~

71~)

E':_,11'*

5

9/64-40 L=l3.5

L=5

11/64-40

M5X0.8

L=8

L"6

L=6

-(~f3-'*"-

{~f3~'/l"

f7

-(~f3~'

11/64-40

*

~

t'~

-(II"'"':_,

7:,tt-(

(I)

(I)

(I)

(I)

(I)

(I)

(2)

(I)

(I)

(l)

(I)

(I)

(I)

(I)

(I)

(I)

3

I

2

I

2

I

(I)

(I)

(l)

(I)

(2)

(I)

(I)

2

1

I

-14-

Page 22

9.

KNEE LIFTING COMPONENTS

Jll.J:IfOO~

30

r

_____

l_

____

ffl

L

___________

~·

_NQ

__

~~

___

I

2

3

4

5

6 2I3-43702

7

8

9

10

II

12

13

14

15

16

17

18

19

20

2I

22

23

24

25

26

27

28

29

30

3I

32

33

34

35

36

213-43207

SII-6061202-TP

213-42555

213-42506

213-42605

213-43801

SII-6051602213-42704

RE-0800000-KO

2I3-43009

SII-6051602213-42803

SII-6051602Sll-8052502-TP

NI-605oooi -su

213-42902

SD-0700451-TP

213-43405

S0-0700451-TP

2I3-43355

SII-6062502-TP

228-63252

B3428-521-000

SS-709051

228-63203

229-32453

229-32404

229-34707

213-43157

SI-906I203-S£

213-43108

229-34509

229-34400

229-34202

229-3430I

f~

_

_NQ.

__________

TP

TP

TP

0-SP

KNEE

LinER

SCREW

116

KNEE

LinER

KNEE

LinER

KNEE

LinER

KNEE

LIF

KNEE

LinER

SCREW

115XO

KNEE

LInER

£-SHAPED

KN££

LIF I

SCREW

115XO

KNEE

LinER

SCREW

115XO

SCREW

115XO. 8 L=25

NUT

15X0.8

KNEE

LinER

HINGE

SCREW

KNEE

LinER

HINGE

SCREW

KNEE

LlF

SCREW

116

KNEE

LinER

PRESSER

SCREW

9/64-40

KNEE

LIF

BRACKET

BRACKET

SCREW

KNEE

PRESS

SCREW

16 L=I2

KNEE

PRESS

KNEE

PAD

KNEE

PAD

KNEE

PAD

KNEE

PAD

,!>

_

E_ § _C

_ ~ __

SUAFT

L=

I£R

SNAP

£R

IER

L=25

SPRING

IER

AS11.

PLATE

PLATE

PLATE

PLAI E SUPPORt

BASIS

12

SHAFT A ASII.

SHAFT

A

SHAFT

PIN

SHAFI A SPRING

SPRING

RACK

• 8

L=

16

SHAFT

B

RING

(81111)

L£Y£R

8

• 8

L=

16

LEVER

A

• 8

L=

16

LINK

D=7

H=4.5

CONNECTING

0=7

H=4.5

LEvER

ASI.

JOINT

AS11.

L=

4. 6

JOIN

I

PLATE

AS11.

LEVER

COVER

RUBBER

P_

!

PLATE

_I_

Q

_N

____________

t __ ~ _ _

tt'

7'1' ,.

11'11?7t$'

tf'

7'1'

tf'

7'1'

tt'

7'1'

EJ'

7'i'

tt'7'J'"'U'J

11'11?7t$'

tt'

7'1'

E11'

~~)19

EJ'

111'

11'11?7t$'

tt'7'J'W

11'11?7t$'

~"*''

n1b?t1F

tt'

7'1'

~·

:J*)'

tt'

7'1'

~·

:J*''

Ef'71J'

111'11?7t$'

tt'

7'1'

tt'

77)' ?

v

l.t?:W

Ef'77'1¥

tt'

7H7''

tt'

77~7''

tt·

11~1,.

tt'7TH(?~)

"*'*'

tt'TTW-

tt'

7'Jf~fl/l'

tt'77Hl'

tt'77H

Ef'7T'f§fh

"lo

_ _ j

________

?~'

~·

f

&~

116

L=l2

)'?A(?~)

)'?A

,.

?t'

:J

,.

1M' l

H

115XO. 8 L=

)'

?B

8 I

G"

-8

&~

115X0.8

-A

&~

115X0.8

15X0.8

9:J?

0=7

H=4.

lt:J'T1f~

0=7

H=4.

Tl(?,)

1.~

116

,~.

7(

?~)

tfi/1'

9/64 -40 L=4. 6

T

?~ 9''1~' ( ?~)

?H''J~·

?~m·~r

IF

16

Li

-

J.

16

L=l6

L=l6 I

I'~

5

5

L=25

*

'"*''

I 2

~~y

__

I

3

I

(I)

(I)

I

I

I

I

2

2

I

I

I

I

2

I

2

I

2

I

(I)

(I)

(I)

I

(I)

(2)

I

(I)

(I)

(I)

(I)

(I)

(I)

-15-

Page 23

10. BELT COVER & OIL RESERVOIR COMPONENTS

r\.Jv

".tJJ\-

·

iltl~ltOO~

i~-;.s,

I 3 I

I I

I I

I I

L

____

_j

~~._NQ

__

I

2

3

4

5

6

7

8

9

10

II

12

13

14

15

16

17

18

19

20