Juki LK-1850 Instruction Manual

HIGH-SPEED

BAR

TACKING

1-NEEDLE

INDUSTRIAL

CYLINDER

LK-1850

INSTRUCTION

•JUKI

BED

SEWING

MACHINE

MANUAL

LOCKSTITCH

BE185030B0A

Congratulations on

sewing machine.

To get the most

machine

use the

and

operate

unit

correctly, so please read this Instruc

tion Manual carefully before using it.

you will enjoy using it for a long time. It is also

necessary to keep this Instruction Manual taking

care

nottolose

your

purchase

of

outofmany functionsofthe

it in safe^, it is

necessary

We

it.

a JUKI

hope

to

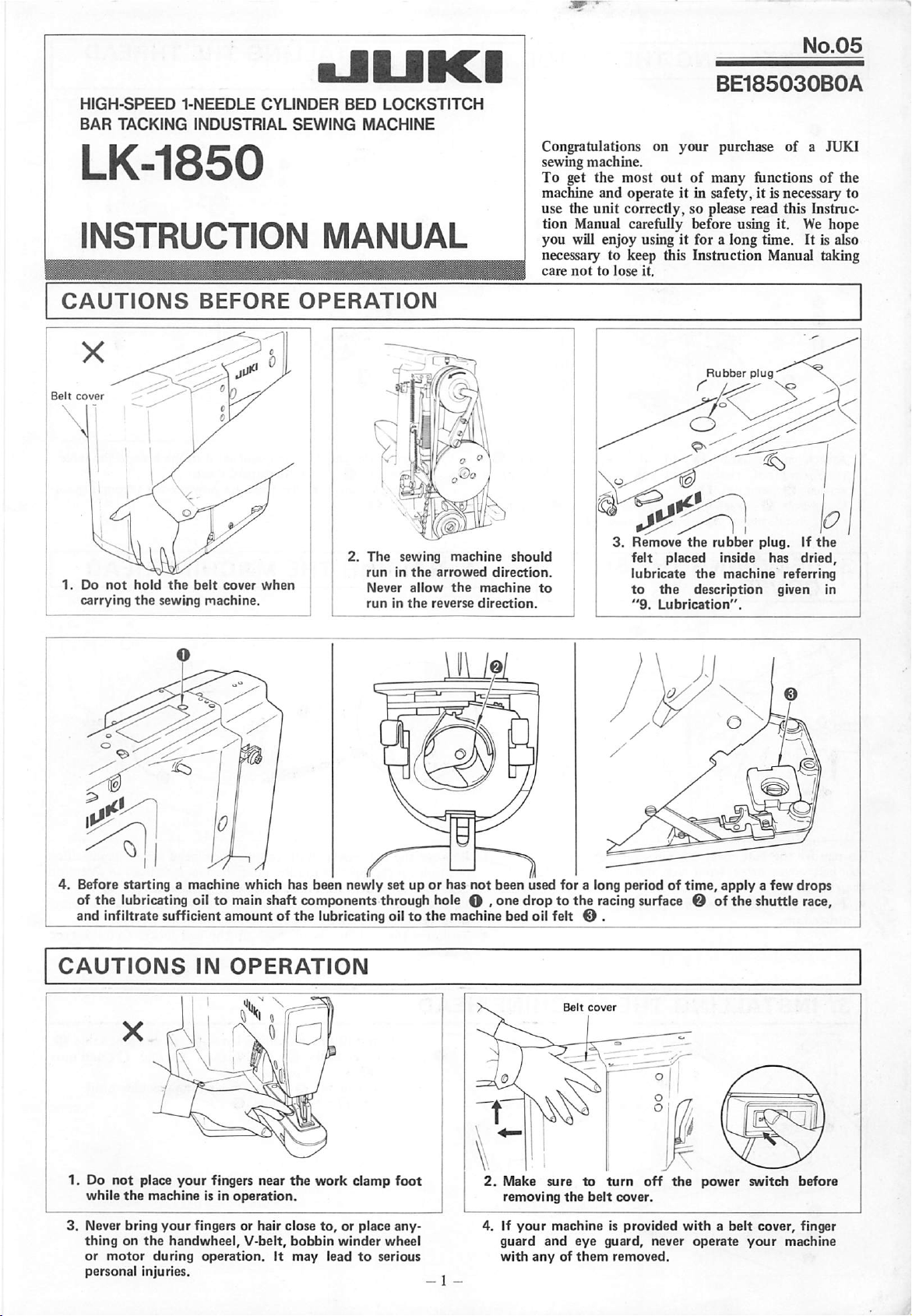

CAUTIONS

BEFORE

OPERATION

2.

The

runinthe

Never

runinthe

sewing

allow

machine

arrowed

the

reverse

should

direction.

machine

direction.

Rubber

plug'

3.

Remove

felt

to

lubricate

to

"9.

the

placed

the

the

description

Lubrication".

rubber

plug. If

inside has

machine

dried,

referring

given

the

in

4. Before starting a machine which has been newly set up or has

of

the

lubricating oil to mainshaft components through hole Q , one drop to the racing surface O of

and infiltrate sufficient amount of

CAUTIONS

IN

OPERATION

X A

1. Do

not

place

your

while

the

machine

fingers near

is in

operation.

9 a

the

the

lubricating oiltothe machine bed oil felt O .

work

clamp

foot

m

not

been used for a long period of time, apply a few drops

the

Belt

cover

2.

Make

sure

to

turn

off

the

removing

the

belt

cover.

power

shuttle race,

switch

before

3.

Never

bring

your

thingonthe

or

motor

personal

injuries.

handwheel,

during

fingers or

operation.

hair

V-belt,

close

It

to,orplace

bobbin

may

leadtoserious

winder

any

wheel

4. If

your

guard

with

machineisprovided

and

anyofthem

eye

guard,

removed.

never

withabelt

operate

cover,

your

finger

machine

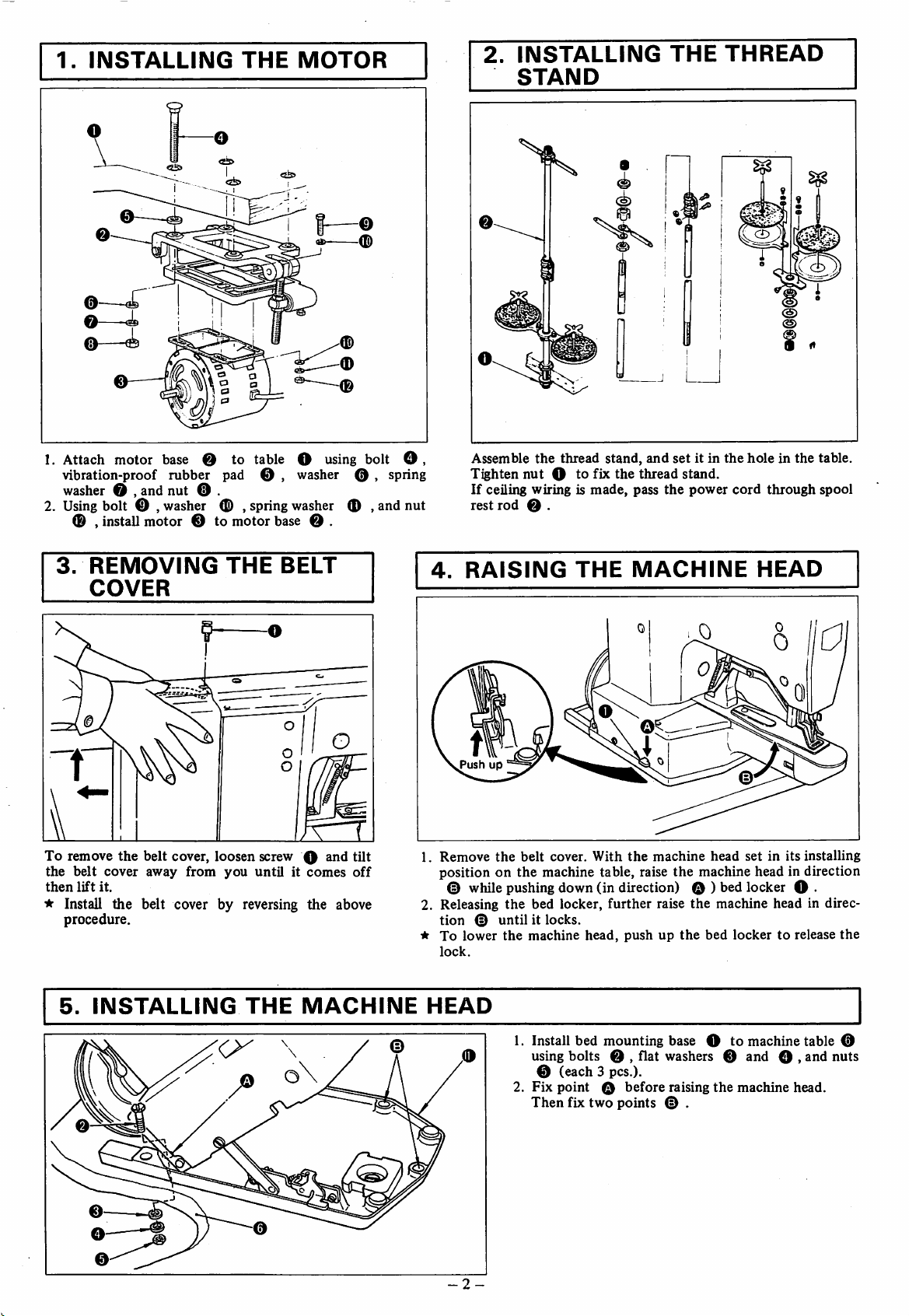

1.

NSTALLING

THE

MOTOR

INSTALLING

THE

THREAD

2.

STAND

I

a

1. Attach motor base e to table O using bolt

vibration-proof rubber pad 0 , washer

0,

washer 0 , and nut 0 .

2. Using bolt 0 , washer

® , install motor 0 to motor base

3.

REMOVING

(£)

, spring washer 0 , and nut

0.

THE

BELT

COVER

To remove

the

then

★

Install the belt cover by reversing the above

procedure.

belt

lift

the

belt cover, loosen screw 0 and tilt

cover

away

from

you

it.

untilitcomes

off

O,

spring

4.

1.

Remove

position on

Assemble

Tighten

If

ceiling

rest

RAISING

the

nut

wiringismade,

rod

9.

the

belt

the

thread

stand,

0 to fix

THE

cover.

machine table, raise

With

and

the

thread

pass

MACHINE

the

machine

set

it in

the

head

holeinthe

cord

setinits

stand.

the

power

the

machine head in direction

© while pushing down (in direction) 0 ) bed locker 0 .

2. Releasing

tion

*

To

lock.

©

lower

the

bed locker, further raise

untilitlocks.

the

machine

head,

pushupthe

the

machine head in direc

bed

lockertorelease

through

HEAD

table.

spool

installing

the

5.

INSTALLING

THE

MACHINE

HEAD

1. Install bed mounting base 0 to machine table 0

using bolts 0 , flat washers 0 and O , and nuts

0

(each

2. Fix

point

Then

-2-

fix

3 pcs.).

0

two

before

points

raising

© .

the

machine

head.

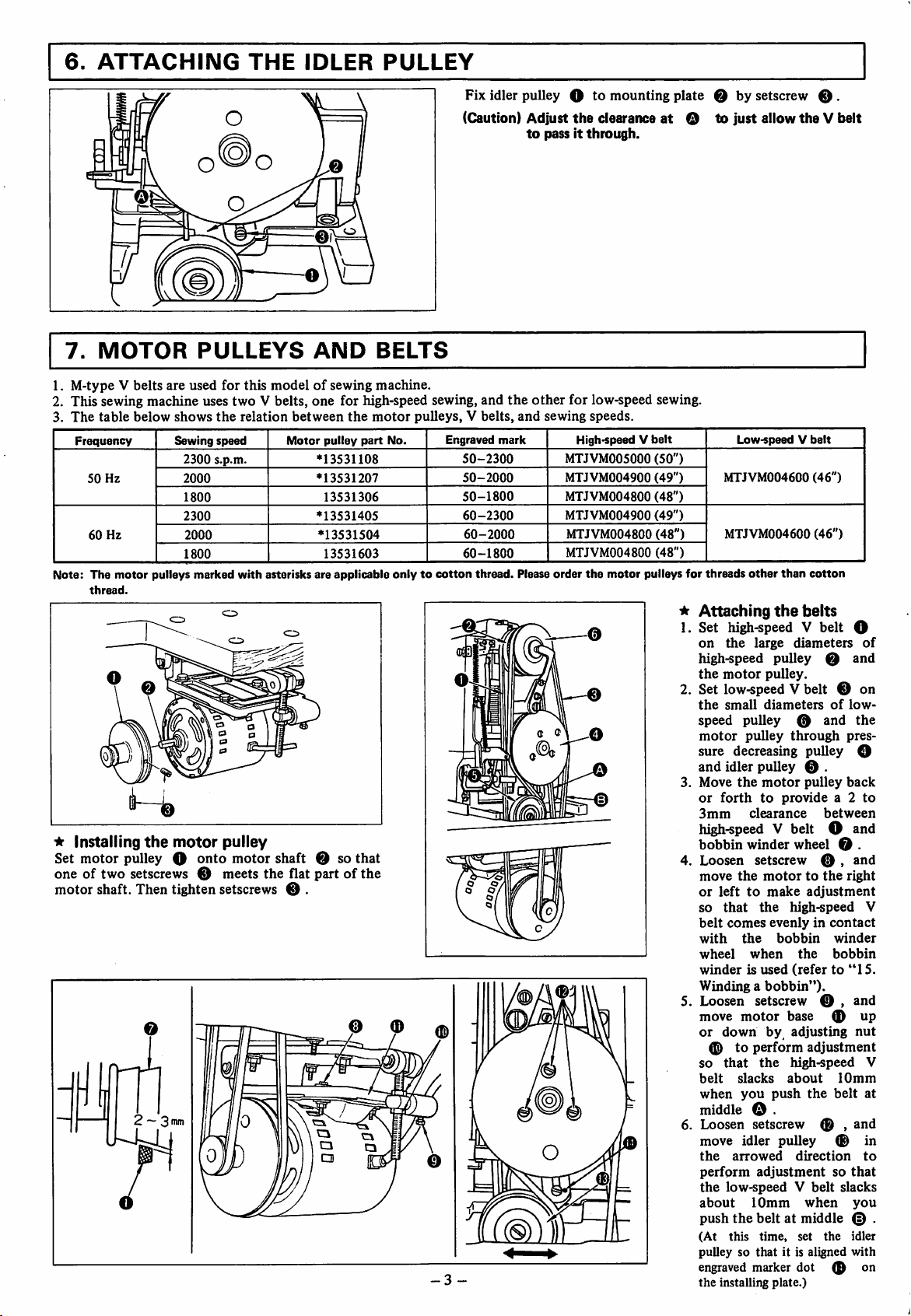

6.

ATTACHING

THE

IDLER

PULLEY

Fix idler pulley Otomounting

(Caution) Adjust

to

pass It

7.

MOTOR

1. M-type V

2. This sewing machine uses two V belts, one for high-speed sewing, and

3.

The

Frequency

Note: The

ir Installing

Set

motor

one of two setscrews e meets the flat part of

motor

belts

table

below

50

Hz

60

Hz

motor

thread.

the

pulley O

shaft. Then tighten setscrews O .

PULLEYS

are

used

for

this

shows

the

relation

Sewing

speed

2300

s.p.m.

2000

1800

2300

2000

1800

pulleys marked with asterisks are applicable

motor

onto

pulley

motor

AND

BELTS

modelofsewing machine.

between

Motor

shaft O so

the

pulley

*13531108

*13531207

13531306

*13531405

*13531504

13531603

motor

part

that

the

pulleys,Vbelts,

No.

onlytocotton

Engraved

-3

50-2300

50-2000

50-1800

60-2300

60-2000

60-1800

thread.

-

the

mark

other

and

Please

sewing

order

plate O by setscrew

the

clearanceatO

through.

for low-speed sewing.

speeds.

High-speed V

MTJVM005000

MTJVM004900

MTJVM004800

MTJVM004900

MTJVM004800

MTJVM004800

the

motor

belt

(50")

(49")

(48")

(49")

(48")

(48")

pulleys

2.

6.

iD

to

just

allow

the

V belt

Low-speedVbelt

MTJVM004600

MTJVM004600

for

threads

Attaching

other

than

the

(46")

(46")

cotton

belts

Set high-speed V belt O

on

the

large

diameters

high-speed pulley ^

the

motor

pulley.

Set low-speed V belt 0 on

the

small

diameters

of

speed pulley 0 and

motor

pulley

through

sure decreasing pulley O

and

idler pulley 0 .

Move

the

motor

pulley

or

forth

to

provide

3mm

high-speed

bobbin

clearance

V belt O and

winder wheel 0 .

Loosen setscrew

move

the

motortothe

or

lefttomake

so

that

the

belt

comes

evenlyincontact

with

the

wheel

winderisused

Winding a

Loosen

move

when

bobbin").

setscrew

motor

bobbin

base 0

a 2

between

0,

adjustment

high-speed

winder

the

bobbin

(referto"15.

0 ,

or down by, adjusting

0

to

so

belt

when

that

perform

the

slacks

you

high-speed

about

push

adjustment

the

belt

middle o

Loosen

setscrew

0 ,

move idler pulley 0 in

the

arrowed

perform

the

low-speedVbelt

about

push

the

(At

this

pulley so

engraved

the

installing

direction

adjustmentsothat

10mm

belt

that

when

at middle 0 .

time,

set

it is aligned

the

marker dot 0 on

plate.)

of

and

low-

the

pres

back

to

and

right

V

and

up

nut

V

10mm

at

and

to

slacks

you

idler

with

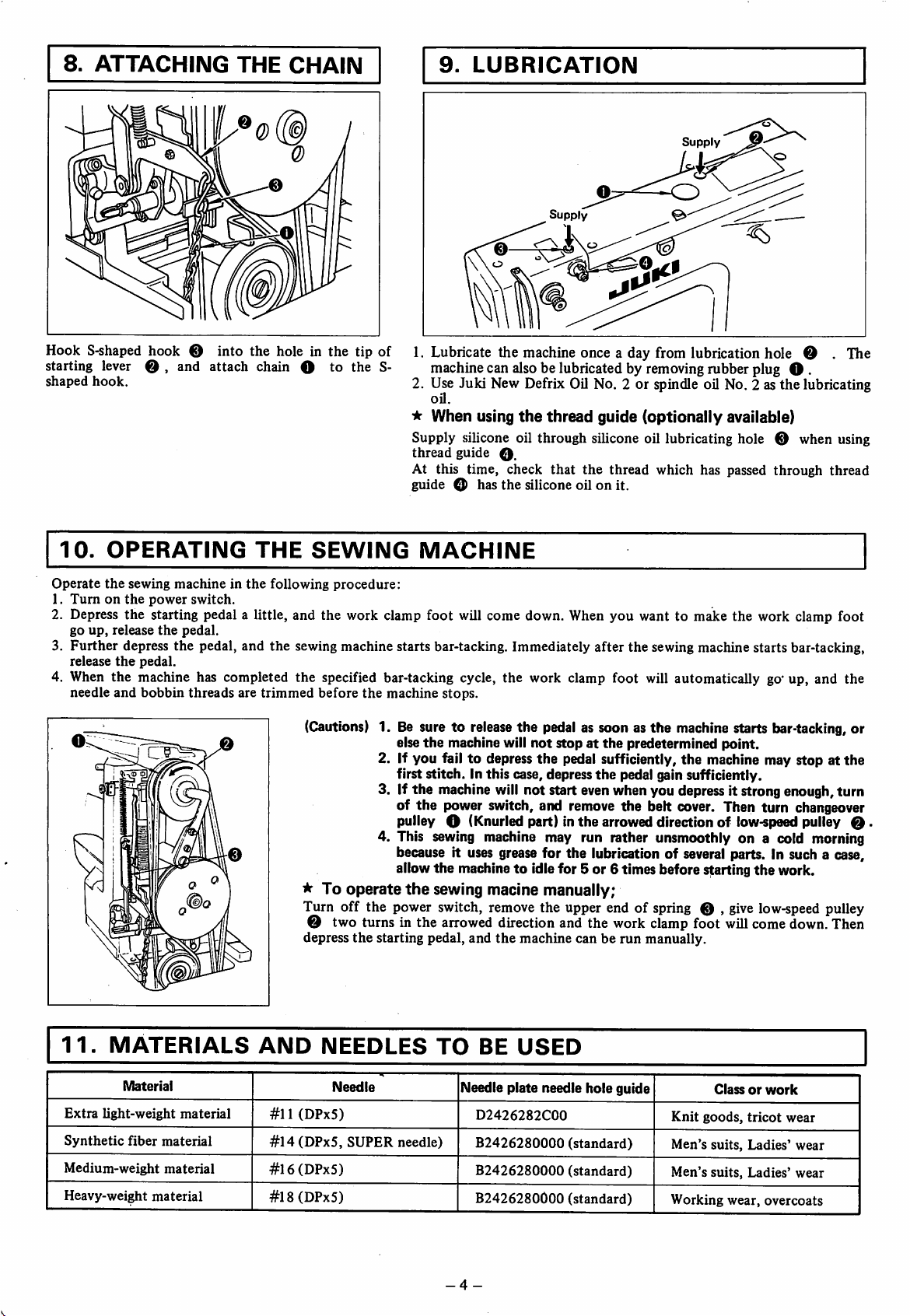

8.

ATTACHING

THE

CHAIN

9.

LUBRICATION

Supply

Supply

Hook S-shaped hook 0 into the hole in the tip of

starting lever O , and

shaped

10.

Operate

1.

Turnonthe

hook.

OPERATING

the

sewing

power

attach

machineinthe

switch.

chain O to

THE

SEWING

following

the

procedure:

1. Lubricate the machine once a day from lubrication hole O . The

S-

machine can also be lubricated by removingrubber plug O .

2. Use Juki New Defrix Oil No. 2 or spindle oil No. 2 asthe lubricating

oil.

* When using

Supply silicone oil through silicone oil lubricating hole 0 when using

thread guide

At this time, check

guide 0 has

the

thread

0,

that

the

silicone oilonit.

guide (optionally available)

the

thread which has passed through thread

MACHINE

2. Depress the starting pedal a little, and the work clamp foot will come down. When you want to make the work clamp foot

go

up,

release

the

pedal.

3. Further depress the pedal, and

release

the

pedal.

4. When the machine has completed the specified bar-tacking cycle, the work clamp foot will automatically

needle

and

bobbin

threads

are

the

sewing machine starts bar-tacking. Immediately after the sewing machine starts bar-tacking,

trimmed

before

the

(Cautions) 1. Be sure to

machine

else

the

stops.

release

machine will

the pedalas soon as the machine starts bar-tacking, or

not

stopatthe

predetermined point.

go*

up, and the

2. If you fail to depress the pedal sufficiently, the machine may stop at the

first stitch. Inthis case, depress

3. If

the

machine will not start evenwhen you depress it strong enough, turn

the

pedal gain sufficiently.

of the power switch, and remove the belt cover. Then turn changeover

pulley0(Knurled

4. This

sewing

part)inthe

arrowed

directionoflow-spe^

pulley

machine may run rather unsmoothly on a cold morning

because it uses grease for the lubrication of several parts. In such a case,

allow

the

^ To

operate

machineto idle for 5 or 6 times before starting

the

sewing maclne manually;

the

work.

Turn off the power switch, remove the upper end of spring 0 , give low-speed pulley

0 two turns in the arrowed direction and the work clamp foot willcome down. Then

depress

the

starting pedal, and

the

machine can be run manually.

0

11.

MATERIALS

Material

Extra

light-weight

Synthetic

Medium-weight

Heavy-weight

fiber

material

material

material

material

AND

#11

#14

#16(DPx5)

#18(DPx5)

NEEDLES

Needle

(DPx5)

(DPx5, SUPER needle)

TO

BE

USED

Needle plate needle hole guide

D2426282C00

B2426280000

B2426280000

B242628O0OO(standard)

-4-

(standard)

(standard)

Knit

goods,

Men's

Men's

suits.

Working

Classorwork

tricot

suits.

Ladies'

Ladies'

wear,

overcoats

wear

wear

wear

Loading...

Loading...