Page 1

DU-1281-7

INSTRUCTION MANUAL

Page 2

CONTENTS

1. SPECIFICATIONS .......................................................................................................... 1

2. PREPARATION BEFORE OPERATION

2-1. Installing the knee lifter....................................................................................................................................... 2

2-2. Installing the waste oil receiver.......................................................................................................................... 2

2-3. Lubrication ........................................................................................................................................................... 3

2-4. Oiling state ........................................................................................................................................................... 3

2-5. Adjusting the amount of oil in the hook.................................................................................................................. 3

2-6. Adjusting the oil in the pump ............................................................................................................................. 4

2-7. Installing the synchronizer ................................................................................................................................. 4

2-8. Installing the belt cover and the bobbin winder ............................................................................................... 4

......................................................................... 2

3. HOW TO ADJUST AND HOW TO USE THE SEWING MACHINE ................................ 5

3-1. Attaching the needle ........................................................................................................................................... 5

3-2. Threading the machine head .............................................................................................................................. 5

3-3. Adjusting the stitch length and reverse-feed stitching .................................................................................... 6

3-4. Indication of the direction of rotation of the bobbin case ............................................................................... 6

3-5. Thread tension ..................................................................................................................................................... 6

3-6. Presser foot pressure.......................................................................................................................................... 7

3-7. How to install the intermediate presser............................................................................................................. 7

3-8. Hand lifter ............................................................................................................................................................. 7

3-9. Height of the feed dog ......................................................................................................................................... 8

3-10. Adjusting the inclination of the feed dog .......................................................................................................... 8

3-11. Adjusting the stitch length for forward stitching and reverse stitching ........................................................ 8

3-12. Adjusting the waling foot and presser foot ....................................................................................................... 9

3-13. Needle-to-hook relationship ............................................................................................................................. 10

3-14. Feed timing ........................................................................................................................................................ 10

3-15. Relation between the counter knife and the tip of the thread trimmer blade (left) ..................................... 11

3-16. Adjusting the mesh of the knife ....................................................................................................................... 11

3-17. Adjusting the thread trimming cam ................................................................................................................. 12

3-18. Adjusting the amount of mesh of the thread trimmer blades ....................................................................... 12

3-19. Adjusting the counter knife pressure .............................................................................................................. 13

3-20. Auxiliary thread tension .................................................................................................................................... 13

3-21. One-touch type manual reverse stitching ....................................................................................................... 13

4. TROUBLES IN SEWING AND CORRECTIVE MEASURES ........................................14

Page 3

1. SPECIFICATIONS

Application Pouches, bags, shoes

Sewing speed Max. 2,000 sti/min

Stitch length Max. 8 mm Thread #8 - #30

Lift of presser foot

Thread take-up lever Link-type thread take-up lever Motor to be used Servomotor

Needle bar stroke 38mm Oil be used Spindle oil

Needle to be used DP x 17 (DB x 1 can be used.)

Noise

Hand lifter : 6 mm

Knee lifter : 16 mm

- Equivalent continuous emission sound pressure level (LpA) at the workstation:

A-weighted value of 79.0 dB; (Includes KpA = 2.5 dB); according to ISO 10821- C.6.2 -ISO

11204 GR2 at 2,000 sti/min.

Needle system

Stitch adjusting method Dial

Lubrication method Automatic lubrication

DP x 17 #16 - #23 (Standard #22)

DB x 1 #20 - #23

● Applicable JUKI control box and motor

SC-921C

Destination

*

-AA

Classification

of control box

Control box ................................SC-921 (Machine head setting (memory switch No. 95) "du12")

Motor .........................................M-51N

Position sensor ..........................SY-2

(Synchronizer)

Motor pulley ...............................Outside diameter: 75 mm (Marker: 80) Part No.: MTSP00750A0

V belt .........................................Size M M-40 Part No.: MTJV0040000

– 1 –

Page 4

2. PREPARATION BEFORE OPERATION

2-1. Installing the knee lifter

1) Fully draw out knee lifter shafts

❷

Then, install it on the sewing machine.

❶

❶

2) Attach driving arm

3) Connect right and left driving arms

to respective shafts ❷.

❶

with link ❸.

❷

4) Install knee lifter lever

to driving arm ❶ on the

❹

left side.

❹

❸

❷

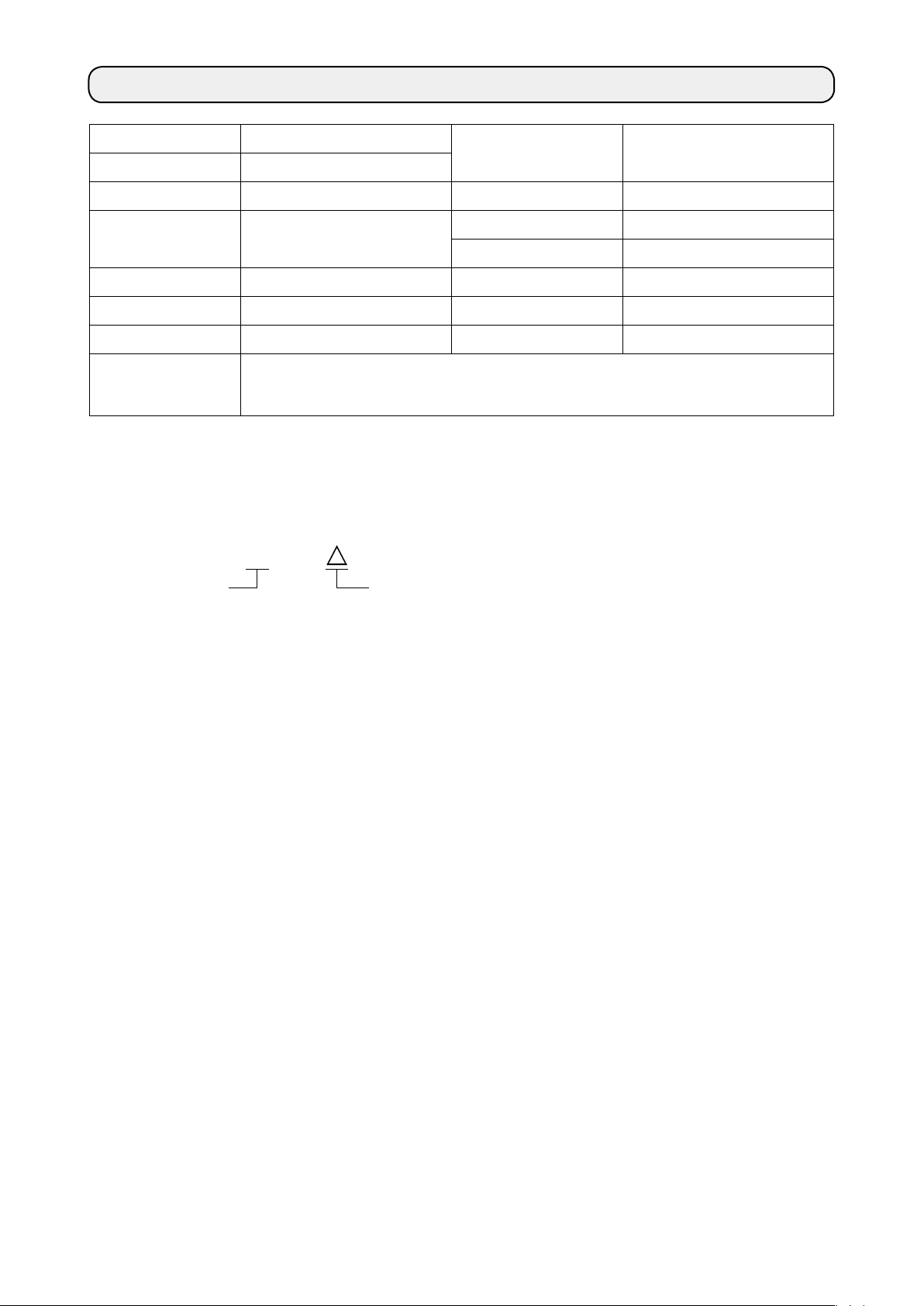

2-2. Installing the waste oil receiver

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

toward you.

together

❶

❻

❶ A

⇩

A

❸

❼

1) Fold mounting section

of waste oil receiver

A

bracket ❶ at a right angle.

2) Remove one lateral bracing strut setscrew

Insert folded mounting section A of waste oil re-

ceiver bracket ❶ into the section between strut

and lateral bracing strut ❹.

❸

3) Tighten lateral bracing strut

and waste oil

❹

receiver bracket ❶ with lateral bracing strut set-

screw ❷ together.

Firmly tighten lateral bracing strut set-

screw ❷.

❷

.

❹

❷

❺

❶

4) Place waste oil receiver

bracket ❶. Insert tube ❼ coming from oil pan

into waste oil receiver ❺.

* Adjust the length of tube

tance between oil pan ❻ and waste oil receiver

.

❺

– 2 –

on waste oil receiver

❺

according to the dis-

❼

❻

Page 5

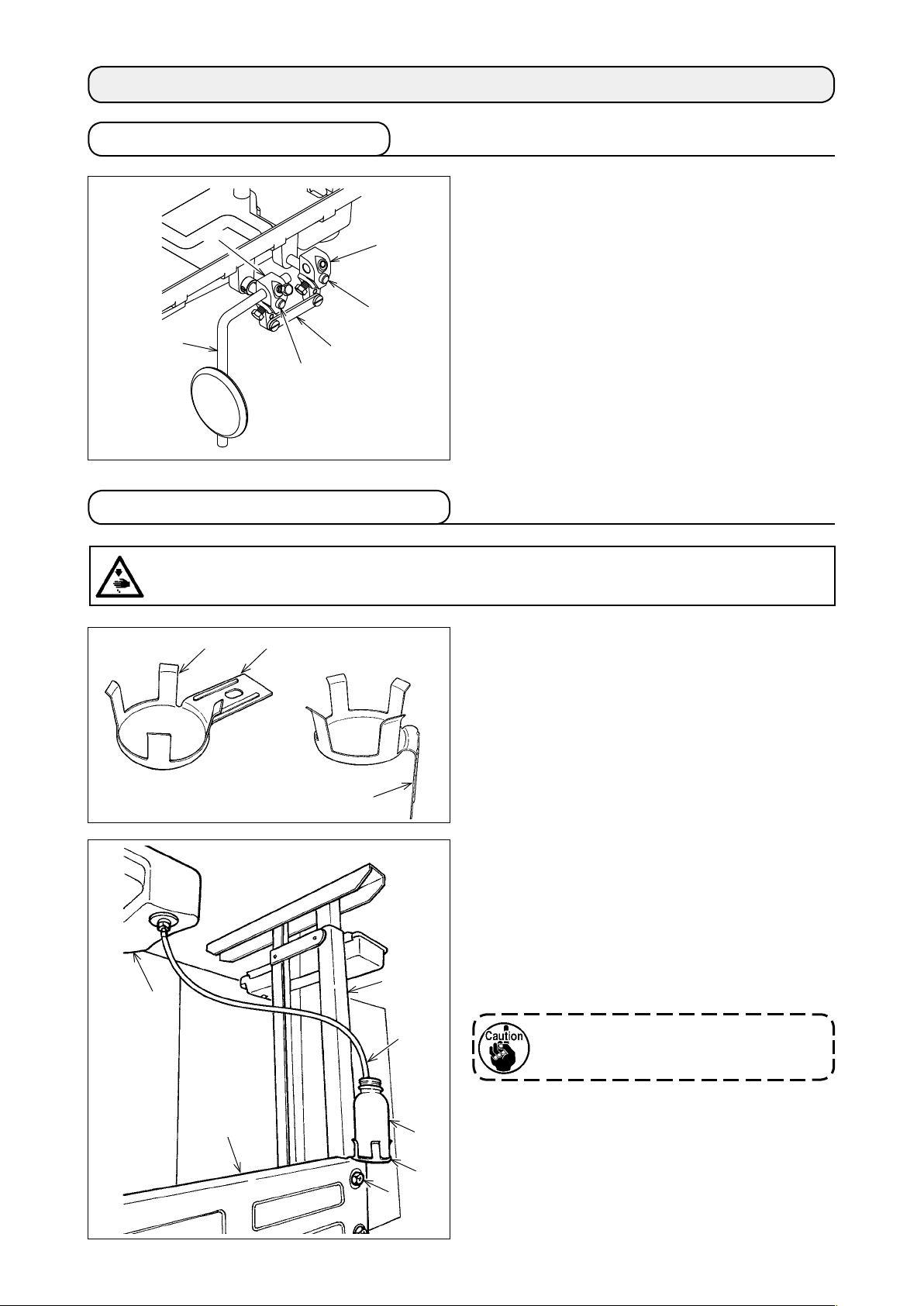

2-3. Lubrication

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

❷

❶

2-4. Oiling state

❶

1) Fill the oil tank with oil up to line H

❶

.

2) Carry out periodical inspection while the sewing

machine is in use to check the oil quantity. If the

oil surface level is below line L ❷, add oil until

the oil surface reaches line H ❶.

(Use "spindle oil".)

Run the sewing machine to check how oil splashes

on oil sight glass ❶.

2-5. Adjusting the amount of oil in the hook

❶

Decrease

Increase

– 3 –

Turn screw ❶ to adjust the oil quantity.

Turning screw ❶ in the "+" direction increases the oil

quantity, or in the "−" direction decreases it.

After adjusting the oil quantity with the

screw, run the sewing machine idle for 30

seconds or more. Then, check the oil be-

ing splashed from the hook.

Page 6

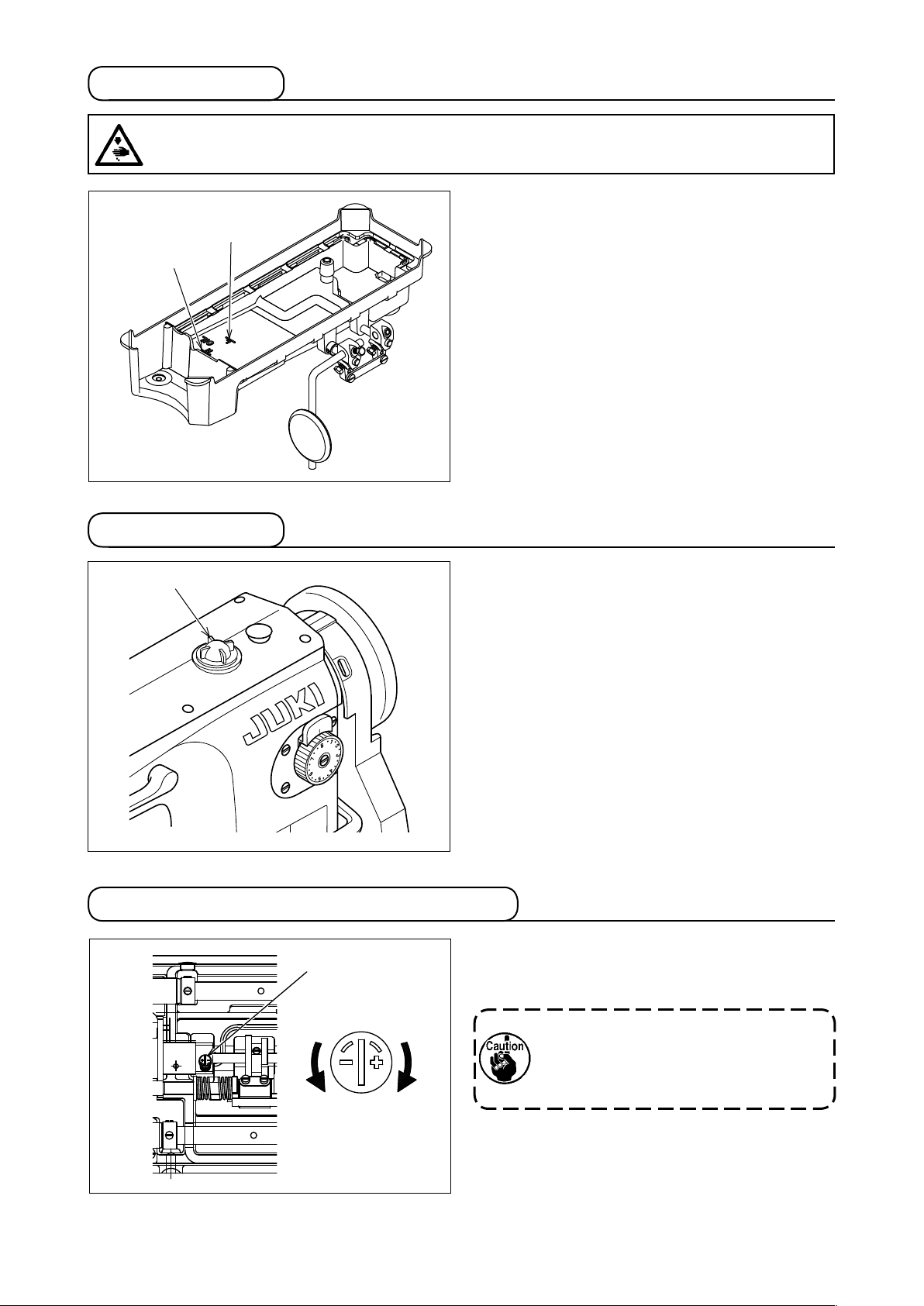

2-6. Adjusting the oil in the pump

❶

❷

2-7. Installing the synchronizer

❷

❶

1) In the standard state, bypass hole ❷ is fully

closed with adjusting plate ❶.

2) The wider bypass hole ❷ is opened, the less the

oil quantity becomes.

❸

❹

❺

1) Screw whirl-stop ❺ into the tapped hole in the

arm in the gure and x it with nut ❻.

2) Mount synchronizer ❶ on handwheel ❷.

3) Move whirl-stop ❺ to adjust the position at which

the needle stops.

Determine the stop position by adjusting the in-

❻

* Needle-up stop position

Align white marker dot ❸ on the handwheel with

black marker dot ❹ on the machine arm.

* Needle-down stop position

Align black marker dot ❸ on the handwheel with

black marker dot ❹ on the machine arm.

stalling angle of the synchronizer ❶.

2-8. Installing the belt cover and the bobbin winder

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

1) Bore wood-screw guide holes A, B, C and D in

45

❷

❸

❶

❺

❹

❻

D

38

38

3

3

45

26

26

53

53

(mm)

(mm)

C

A

169.5

169.5

B

the table.

2) Fit belt cover struts ❶ and ❷ in tapped holes in

the machine arm.

3) Adjust the position of bobbin winder ❸ and x it

in guide holes A and B with wood screws.

4) Temporarily x belt cover C ❹ in guide holes C

and D.

5) Mount belt cover A ❺ and belt cover B ❻ to

struts ❶ and ❷.

6) Adjust the position of belt cover C ❹ and fix it

with the wood screw.

– 4 –

Page 7

3. HOW TO ADJUST AND HOW TO USE THE SEWING MACHINE

3-1. Attaching the needle

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

The standard needle is DPx17. DBx1 needle is also

applicable.

1) Turn the handwheel to move the needle bar up to

❷

A

❶

its highest position.

2) Loosen needle clamping screw

, and hold nee-

❷

dle ❶ so that long groove A in needle ❶ faces

exactly to the left.

3) Insert the needle into the needle

bar until it will

❶

go no further. Securely tighten the needle clamp-

ing screw ❷.

3-2. Threading the machine head

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

❶

❷

❸

❹

❽

❼

❾

❺

❻

Bring the thread take-up

lever to its highest position.

Thread the machine head

according to the numbers in

the gure in the numerical

order.

– 5 –

Page 8

3-3. Adjusting the stitch length and reverse-feed stitching

❶

To change the stitch length, press push-lever ❶ and

turn stitch dial ❷.

[Reverse feed stitching]

Push reverse feed lever ❸ down. The machine per-

forms reverse feed stitching as long as the lever is

held depressed.

❷

Release the lever, and the machine will immediately

resume the forward stitching mode.

❸

3-4. Indication of the direction of rotation of the bobbin case

Fit a bobbin ❶ in bobbin case ❷ to allow bobbin ❶

Rotation

direction of

the bobbin

A

❶

to turn in the direction of the arrow when drawing

bobbin thread A.

❷

3-5. Thread tension

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

1) Adjusting the needle thread tension

toward A to increase the nee-

❶

toward A to in-

❷

B

❶

A

B

❷

Turn tension nut

dle thread tension, or toward B to decrease it.

2) Adjusting the bobbin thread tension

Turn thread tension screw

crease the bobbin thread tension, or toward B to

decrease it.

A

– 6 –

Page 9

3-6. Presser foot pressure

❶

❷

1) Adjust the pressure of the presser foot according

2) The pressure of the presser foot

3-7. How to install the intermediate presser

Tighten screw ❷ while shifting intermediate presser

❶

to the sewing product.

and that of

❶

the walking foot ❷ can be adjusted separately.

* Use the machine with the minimum pressure

which is necessary.

upward.

3-8. Hand lifter

❷

❶

Turning presser bar lifting lever ❶ in the direction of

arrow A lifts the presser foot.

❶

A

– 7 –

Page 10

3-9. Height of the feed dog

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

❷

1mm

1mm

from the surface of throat plate ❷.

When the feed dog height needs to be adjusted ac-

cording to the sewing specications or after the feed

Feed dog ❶ is factory-adjusted to jut out 1.0 mm

❶

dog is replaced, do as follows :

1) Loosen screw

2) Move feed bar

❹

❸

3-10. Adjusting the inclination of the feed dog

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

The feed dog has been factory-adjusted so that it is

levelled (horizontal state).

Adjust the inclination of the feed dog according to

the sewing conditions.

1) Loosen feed rock shaft crank setscrew

2) Turn the eccentric shaft in direction

3) After the adjustment, rmly tighten feed rock shaft

❷

Marker dot

A

B

❶

.

❸

up and down to adjust the

❹

height of the feed dog. Then, rmly tighten the

clamping screw.

.

❶

(to lower

A

the front section) or direction B (to raise the front

section) while pressing the slot in eccentric shaft

with a screwdriver.

❷

crank setscrew ❶.

Position of marker dot on

eccentric shaft

Standard

Directly above

Directly below

Feed dog

Standard

3-11. Adjusting the stitch length for forward stitching and reverse stitching

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

(four).

❶

with a screwdriver

with a screwdriver

❶

A

B

❷

1) Loosen mounting base setscrews

2) Turning stitch adjusting pin

❷

in direction A increases the stitch length for for-

ward stitching.

3) Turning stitch adjusting pin

❷

in direction B decreases the stitch length for re-

verse stitching.

4) After the adjustment, rmly tighten mounting base

setscrews ❶ (four).

– 8 –

Page 11

3-12. Adjusting the waling foot and presser foot

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

(1) Amount of the alternating vertical movement of the walking foot and presser foot

❶

❷

4) In the case the vertical movement amount of the walking foot and that of the presser foot are adjusted

equally, the lift amount can be adjusted from 2.0 mm to 5.0 mm with the alternating vertical movement dial.

1) Amount of the alternating vertical movement of

the walking foot and presser foot is to be adjusted

with alternating vertical movement dial ❶ on the

top cover.

2) Align the number on the alternating vertical move-

ment dial with marker dot ❷ on the top cover.

3) The number on the alternating vertical movement

dial indicates the lift amount of the walking foot

and presser foot when the vertical movement

amount of the walking foot and that of the presser

foot are adjusted equally.

(2) To change the balance of the alternating vertical movement between the walking foot

and presser foot

The vertical movement amount of the walking foot

❷

❶

and that of the presser foot are equal as standard. It

is possible to slightly reduce the vertical movement

amount of the presser foot according to the sewing

product.

* For example, in the case it is desired to increase

the vertical movement amount of the waling foot

and decrease that of the presser foot

1) Remove rubber plug

of the top cover.

❶

2) Turn the handwheel until the presser foot slightly

goes up from the throat plate and stop there.

3) Loosen walking bar adjusting lever clamping screw

❷

.

4) Since the presser foot comes down to the surface of the throat plate by the spring force, re-tighten walk-

ing bar adjusting lever clamping screw ❷ at that position.

(3)Adjusting the feed pitch of the walking foot

Top feed amount has been adjusted to 1:1 with re-

spect to the bottom feed amount. However, it is pos-

A

❶

B

sible to change the top feed amount with respect to

the bottom feed amount according to sewing condi-

tions.

● Loosen nut ❶. Adjust the position of the block up

and down.

* Upper position → Feed pitch, small

* Lower position → Feed pitch, large

A

B

– 9 –

Page 12

3-13. Needle-to-hook relationship

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

❷

Upper

marker line

A

C

❶

B

D

❸

Lower

marker line

❺

❶

❹

❺

0.02 to 0.07mm

❹

❻

1) Positioning the needle bar.

Tighten needle bar connection screw ❸ in needle bar connection ❷ so that the marker line of the needle

bar aligns with the bottom end of needle bar lower bushing ❶ at the lowest position of the needle bar.

(Fourth line A from the bottom for a DB x 1, second line C from the bottom for DP x 17)

After the height of the needle bar has been properly adjusted, check that the needle bar does not

come in contact with the walking foot.

2) Position the needle and the hook.

Adjust so that the specied marker line (third line B from the bottom for a DB x 1 needle, or line D at the

bottom for a DP x 17 needle) on the ascending needle bar aligns with the bottom end of lower bushing

. Further adjust to make hook point ❹ nearly meet the center of needle ❺, and adjust the clearance

❶

between needle ❺ and hook point ❹ to 0.02 to 0.07 mm. Then tighten hook screw ❻.

3) To adjust the hook, remove the throat plate rst. Loosen hook setscrew ❻ with a screwdriver and adjust

the hook position from the throat plate side.

3-14. Feed timing

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

1) Standard installing position of feed eccentric cam

and that of walking bar lifting eccentric cam ❷

Screw No. 1

Marker

❷

Main shaft

dot

bevel gear

Screw No. 2

Main shaft

Screw No. 1

❶

Marker dot

❶

are as shown in the gure.

2) To adjust the feed timing, open the top cover and

change the installing position of the feed eccentric cam of the walking foot.

3) Timing is advanced by adjusting feed eccentric

cam ❶ in the direction of the arrow.

Timing is retarded by adjusting it in the opposite

direction of the arrow.

If the timing is too late, needle breakage

can result. Adjust the timing appropriately

according to the stitch length.

– 10 –

Page 13

3-15. Relation between the counter knife and the tip

of the thread trimmer blade (left)

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

Blade section

Counter

knife

0.3mm

0.3mm

Thread trimmer

blade (left)

❷

❶

1) The standard position of the thread trimmer and

that of the counter knife are as shown in the g-

ure.

2) If the dimension in the figure is larger than 0.3

mm, a three-thread trimming error can occur

causing slip-off of the needle thread after thread

trimming. So, be careful.

On the other hand, if the dimension is excessively

small, a thread trimming error can be caused. So,

be careful.

* Adjusting the counter knife

Adjust the counter knife by moving counter knife

blade ❶ or knife mounting base ❷ in the direc-

tion A or B.

B

A

3-16. Adjusting the mesh of the knife

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

❸

9mm 5mm

9mm 5mm

❶

❷

Position of the thread trimmer (left) ❶ and counter

knife

❷

The standard positioning of the thread trimmer (left)

and counter knife ❷ is as illustrated in the gure.

❶

The thread trimmer (left) ❶ should be 9 mm and the

counter knife ❷ should be 5 mm away from the cen-

ter of the needle ❸.

– 11 –

Page 14

3-17. Adjusting the thread trimming cam

1.5~2.0mm

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

❸

❺

❶❷

tained when green marker dot ❶ on the handwheel

aligns with marker dot ❷ on the machine arm in the

case the thread trimmer is located at its initial posi-

tion and thread trimming cam ❸ comes in contact

with cam roller ❹.

Loosen thread trimming cam setscrew ❺ and carry

out adjustment.

If the setscrew is not securely tightened,

the thread trimming cam can rotate caus-

ing a faulty thread trimming. So, be care-

ful.

Standard position of the thread trimming cam is ob-

❹

3-18. Adjusting the amount of mesh of the thread trimmer blades

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

When knife ❶ reaches its travel end, the standard

depth of mesh between knife ❶ and counter knife ❷

is 1.5 to 2.0 mm.

❹

1.5 to 2.0 mm

❷

❸

❶

1) Turn the handwheel by hand and move the knife

upward.

❶

2) Loosen driving arm clamping screw

adjust the knife mounting base ❹.

3) Securely tighten driving arm clamping screw

. Manually

❸

❸

.

– 12 –

Page 15

3-19. Adjusting the counter knife pressure

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

❶

B

1) Loosen locknut ❶ of knife pressure regulating

screw ❷. Turning screw ❷ in direction A lowers

the blade tip to increase the knife pressure.

After the adjustment, tighten the nut.

2) As the thread thickness increases, the knife pres-

sure should be increased. However, it is neces-

sary to minimize the knife pressure as long as the

thread is trimmed by turning the screw in direction

.

B

A

❷

3-20. Auxiliary thread tension

Adjust the auxiliary thread tension with auxiliary

thread tension nut ❶.

1) Direction A to increase the tension →

The remaining length of the needle thread after

thread trimming is shortened

2) Direction B to decrease the tension →

The remaining length of the needle thread after

thread trimming is lengthened.

A

B

❶

3-21. One-touch type manual reverse stitching

❶

1) The sewing machine immediately is brought into

the reverse feed mode and starts reverse stitch-

ing only by pressing switch ❶.

2) Reverse stitching can be carried out as long as

the switch is held pressed.

3) The sewing machine is brought into the normal

feed mode by releasing the switch.

– 13 –

Page 16

4. TROUBLES IN SEWING AND CORRECTIVE MEASURES

Trouble Cause Corrective measure

Thread breakage.

1.

(Thread is untwisted

or scraped.)

(Needle thread re-

mains on the wrong

side of the material

by 2 to 3 cm.)

2. Stitch skipping.

Thread path, needle tip, hook blade tip

①

or bobbin case positioning nger has

aws.

The needle thread tension is excessive.

②

The needle comes in contact with the

③

hook point.

Hook is not lubricated properly.

④

Needle thread tension is too low.

⑤

Thread take-up spring is too tight and

⑥

its stroke is too small.

The timing between the needle and

⑦

hook is too early or too late.

The clearance between the needle and

①

the hook point is too large.

The timing between the needle and

②

hook is too early or too late.

The pressure of the presser foot is too

③

low.

The clearance provided between the

④

top end of the needle eyelet and the

hook blade point is not correct.

The needle number selected is im-

⑤

proper.

When using synthetic thread and thin

⑥

thread.

○ Remove the scratches on the hook point

using a ne emery paper. Finish the bobbin

case positioning nger by bufng.

○ Adjust the needle thread tension properly.

○ Refer to "3-13. Needle-to-hook relation-

ship"p.10.

○ Increase the amount of oil supplied to the

hook according to "2-5. Adjusting the

amount of oil in the hook"p.3.

○ Adjust the needle thread tension.

○ Reduce the tension of the spring and in-

crease the stroke.

○ Refer to "3-13. Needle-to-hook relation-

ship"p.10.

○ Refer to "3-13. Needle-to-hook relation-

ship"p.10.

○ Refer to "3-13. Needle-to-hook relation-

ship"p.10.

○ Tighten the pressure regulator.

○ Refer to "3-13. Needle-to-hook relation-

ship"p.10.

○ Replace the needle with one which is one

count thicker.

○ Wind the needle thread on the needle.

3. Loose stitches.

4. Needle thread slips

out of the needle

eyelet simultaneously with thread trimming.

5. Needle thread cannot be trimmed.

(Bobbin thread can

be trimmed.)

6. Neither the needle thread nor the

bobbin thread are

trimmed.

7. Thread is not

trimmed sharply.

Bobbin thread does not pass through

①

the forked end of the tension spring on

the bobbin case.

Thread path has rough surface.

②

Bobbin does not spin smoothly.

③

Bobbin thread tension is too low.

④

Bobbin is wound too tightly.

⑤

The needle thread cannot be pulled up

⑥

when sewing heavy-weight materials

such as tent fabrics.

Auxiliary thread tension is too high.

①

Thread trimming timing is too early.

②

Returning force of the thread take-up

③

spring is too strong.

Last stitch skips. (Clearance between

①

the needle and the hook is too large)

Thread trimming timing is not correct.

①

Thread trimmer blade breakage

②

Knife pressure is inadequate.

③

Initial position of the thread trimmer is

④

faulty.

Thread trimmer fails to operate.

⑤

Thread trimming solenoid fails to oper-

⑥

ate.

Thread trimming timing is not correct.

①

Knife pressure is inadequate.

②

The blade is not sharp.

③

○ Properly thread the bobbin case.

Grind it using a ne emery paper or buff it up.

○

○ Replace the bobbin or the bobbin case.

○ Decrease the bobbin thread tension.

○ Increase the bobbin thread tension.

○ Retard the feed timing.

Refer to "3-14. Feed timing"p.10.

○ Decrease the auxiliary thread tension.

○ Refer to "3-17. Adjusting the thread trim-

ming cam"p.12.

○ Refer to "3-2. Threading the machine

head"p.5.

Replace the take-up thread guide.

○ Refer to "3-13. Needle-to-hook relation-

ship"p.10.

○ Refer to "3-17. Adjusting the thread trim-

ming cam"p.12.

○ Replace the thread trimmer blade with a

new one.

○ Increase the knife pressure.

○ Refer to "3-17. Adjusting the thread trim-

ming cam"p.12.

○ Manual check is necessary.

○ The motor solenoid operation needs to be

checked.

○ Refer to "3-17. Adjusting the thread trim-

ming cam"p.12.

○ Increase the knife pressure.

○ Replace the thread trimmer blade with a

new one.

– 14 –

Loading...

Loading...