Page 1

BE5554S0B0A

w

MODEL

High

Speed,

Industrial

Automatic

DDL-555-4

Single

Sewing

Thread

Needle.

Machine

Trimmer

Instruction

nJ

U

Kl

Lockstitch

Equipped

with

Book

TOKYO

JUKI

INDUSTRIAL

CO..LTO

Page 2

INSTRUCTION

BOOK

JUKI DDL-SSS-4 model is designed to sew white shirt, blouse and similar articles using general

shirtings

Especially,

and others are designed for high-speed operations, so

a high speed

Carefully read through this Instruction Book

conditionatall

and

many

other

the

componentsofthis

without

times.

materials.

vibrationornoise.

model

suchasthread

that

and

operate

take-up, sewing

hook,

feed mechanism

the machine is satisfactorily operated at

your

machine in the

optimum

sewing

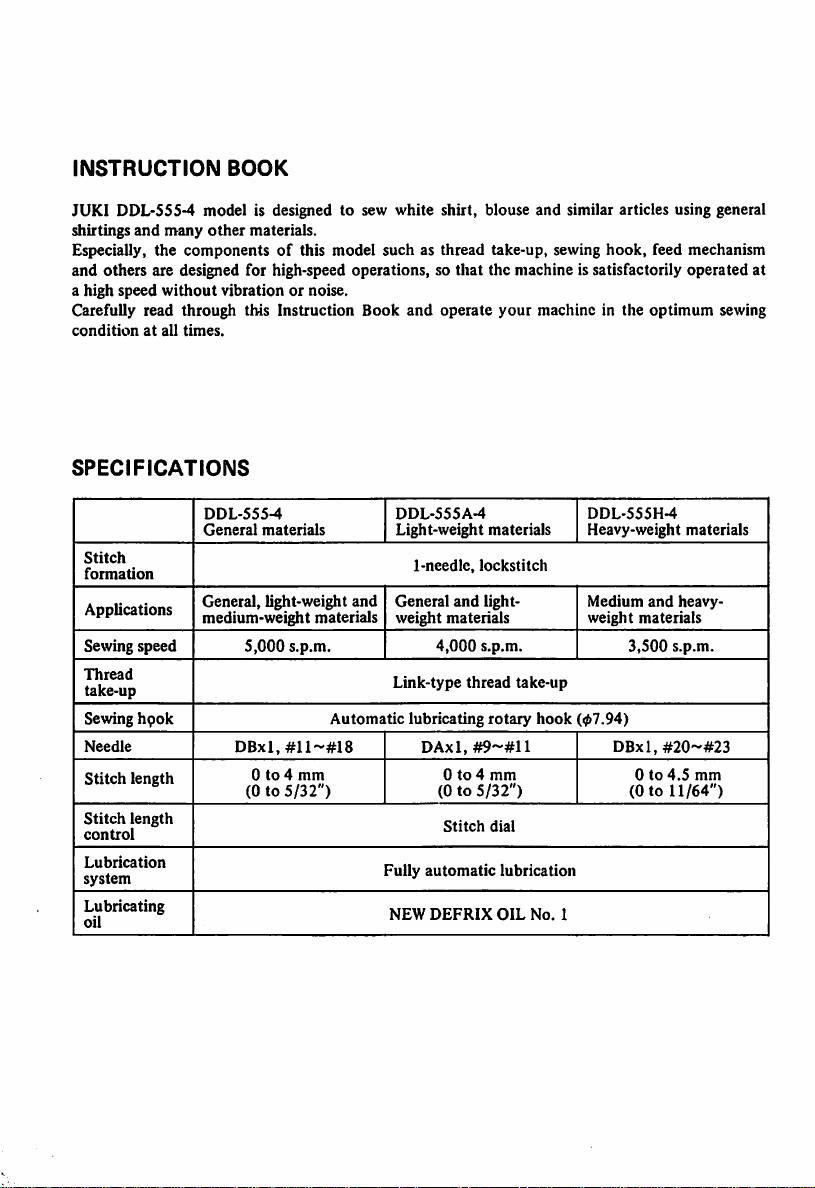

SPECIFICATIONS

Stitch

formation

Applications

Sewing

speed

Thread

take-up

Sewing

hpok

Needle

Stitch

length

Stitch

length

control

Lubrication

system

Lubricating

oil

DDL-555-4

General

materials

General, light-weight

medium-weight materials

S,000

s.p.m.

and

Automatic

DBxI,#ll~#I8

0to4

mm

(0to5/32")

DDL-555A-4

Light-weight materials

1-needle,

General

and

lockstitch

light

weight materials

4,000

s.p.m.

Link-type

thread

lubricating

rotary

DAxl,#9~#Il

0to4

mm

(0 to

5/32")

Stitch

dial

Fully

NEW

automatic

DEFRIX

lubrication

OIL

take-up

hook

No.

DDL-555H-4

Heavy-weight materials

Medium

and

heavy

weight materials

3,500

s.p.m.

(07.94)

DBxl,

#20'-#23

0to4.5

(0 to

11/64")

1

mm

Page 3

CONTENTS

I.

INSTALLATION

1. Attaching the thread

2. Installing the oil reservoir 1

3. Motor pulley and belt 2

4. Installing and adjusting the pedal 3

5. Installing the synchronizer 4

6. Connecting the cords 5

7. Confirming the operating voltage 6

8. Mounting the belt cover and bobbin winder on the table 7

stand

to the table I

I

II. HOW TO

1.

2.

3.

OPERATE

General

instruction

Lubrication

Checking

THE

MACHINE

and

amountofoil 9

the pedalaction 10

4. Howto operate the pedal 11

5. Adjusting the pedal pressureandstroke 12

6. Automatic count-back stitching 13

7.

Passing

the needlethread 14

8.

Bobbin

9.

Adjusting

thread

the threadtension 16

15

10. Attaching the needle 17

11. Presser

foot

18

12. Stitch lengthadjustment 19

Reverse

13.

HI. ADJUSTMENT 20

1.

stitchingby

Feed

mechanism 20

using

the

reverse

feedcontrol

lever

19

2. Replacingthe sewinghook 22

3. Sewinghook position related to the needle 23

4. Heightof the presserbar 24

5. Thread take-upaction 25

6. Returningpressureof the

7.

Adjusting

8.

Sharpening

IV. HOWTO ADJUST THE WIPER 28

1.

Adjusting

2.

Adjust

V. HOW TO USE AND ADJUST

1. Formingthe

the

needle

the counterknife 27

the positionof the wiper 28

the

position

switch-back

reverse

stop

of the

feedcontrol lever 25

position

after

thread

trimming

wiper

magnet

THE

SWITCH-BACK BUTTON 29

stitches 29

26

28

2. Adjustingthe position of the switch-backlever 29

3. Adjustingthe reversestitch length 30

8

8

VI.

AUTOMATIC

1. How to operate AK-2 30

PRESSER

FOOT

LIFTER

(AK-2)

2. Adjusting the presser lifter stroke 30

VII.

TROUBLES

VIII.

DIAGRAM

IX. DIMENSIONAL DIAGRAM OF THE TABLE (TOP SURFACE) 36

AND

CORRECTIVE

SHOWING

MEASURE 31

METHODOFASSEMBLING

TABLE

30

35

Page 4

I.

INSTALLATION

1.

Attaching

the

thread

standtothe

table

Assemble the thread stand and set it up on the machine table by using the installation holes in the

tableasillustrated.

Do not tighten the clamping nut too much. When power source issupplied by the overhead wires,

pass the power supply cord through the spool rest rod.

2. Installing

oi

Operator

the

Rubber

side

oil reservoir

cushion

reservoir

j-vf-r

Hinge

side

Install

the

oil

reservoirinsuchamanner

is supported by the 4 corners of an opening in

the

table.

1. Nail in the 2 felt pads of 4 mm (5/32")

thicktothe2corners

near

the

2. Nail in the 2 felt pads of 6 mm (15/64")

thick

to the remaining 2

side).

3. Place

4.

5.

- 1 -

Insert

your

Put

ions.

the

oil reservoir on the

the

rubber

finger.

the

round

felt

cushions

pads

into4corners

to 4

operator.

corners

felt

pads.

rubber

that

(hinged

by

cush

it

Page 5

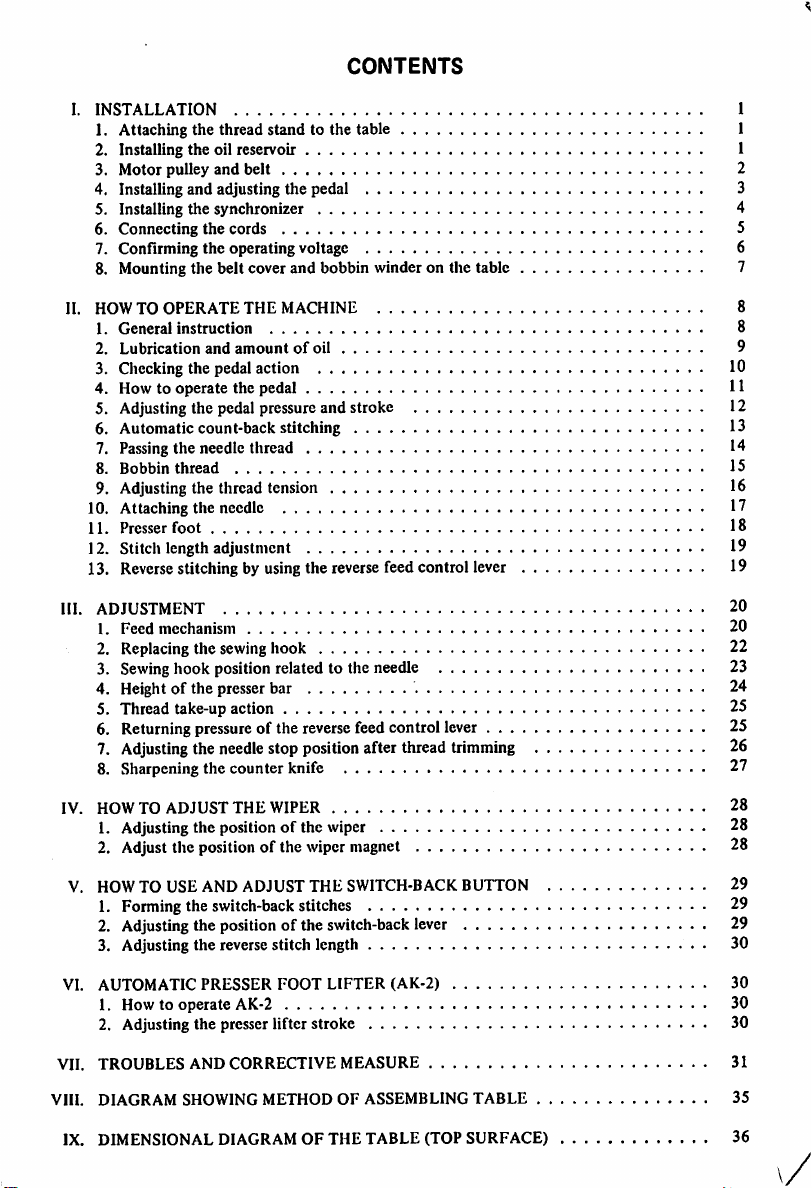

3.

Motor

You

The

pulley

must

use the M-typc V-belt.

under

mentioned table indicate tlie maximum sewing speeds related to tlie

and

belt

the length of belts. The elTective diameterofthe

(13/64")

Ou

meter

motor

from

the

outer

diameter.

5,060

4,630

4,250

4,000

3,820

3,610

3,390

3,160

2,950

2,740

Sewing

50Hz

s.p.m.

ler

125

115

105

100

95

90

85

80

75

70

dia

of

pulley

mm

Motor

pulley

Part

No.

MTS-P01200AO

MTS-POl

MTS-POIOOOAO

MTS-P00950AO

MTS-P00900A0

MTS-P00850A0

MTS-P00800A0

MTS-P00750A0

MTS-P00700A0

MTS-P00650A0

100

AO

motor

motor

pulley is obtained by deducting 5 mm

speed

5,040

4,780

4,540

4,320

4,000

3,790

3,520

3,260

60Hz

s.p.m.

Belt

length

44"

43"

42"

MTJ-VM004400

MTJ-VM004300

MTJ-VM004200

pulley and

Belt

Part

No.

(Note)

The

center

ableinthe

If

the

(Howtoinstall

holeonthe

market

beltistoo

the

can

long,

pulley)

motor

pulleyistapered,

notbeused

the

connecting

and

the

normal

pulleys

commercially

for

these

machines.

rod

may

not

work

smoothly.

Remove

into

with

the

the

pulley

cover 0

motor

shaft

keyofthe

and

by aligning the key way

shaft.

Tighten

(D and fix it in position by set screw (3).

To remove the

motor

pulley, take

pulley cover and reverse the above mentioned

procedure

- 2 -

for installation.

put

the

pulley

out

avail

pulley

nut

the

Page 6

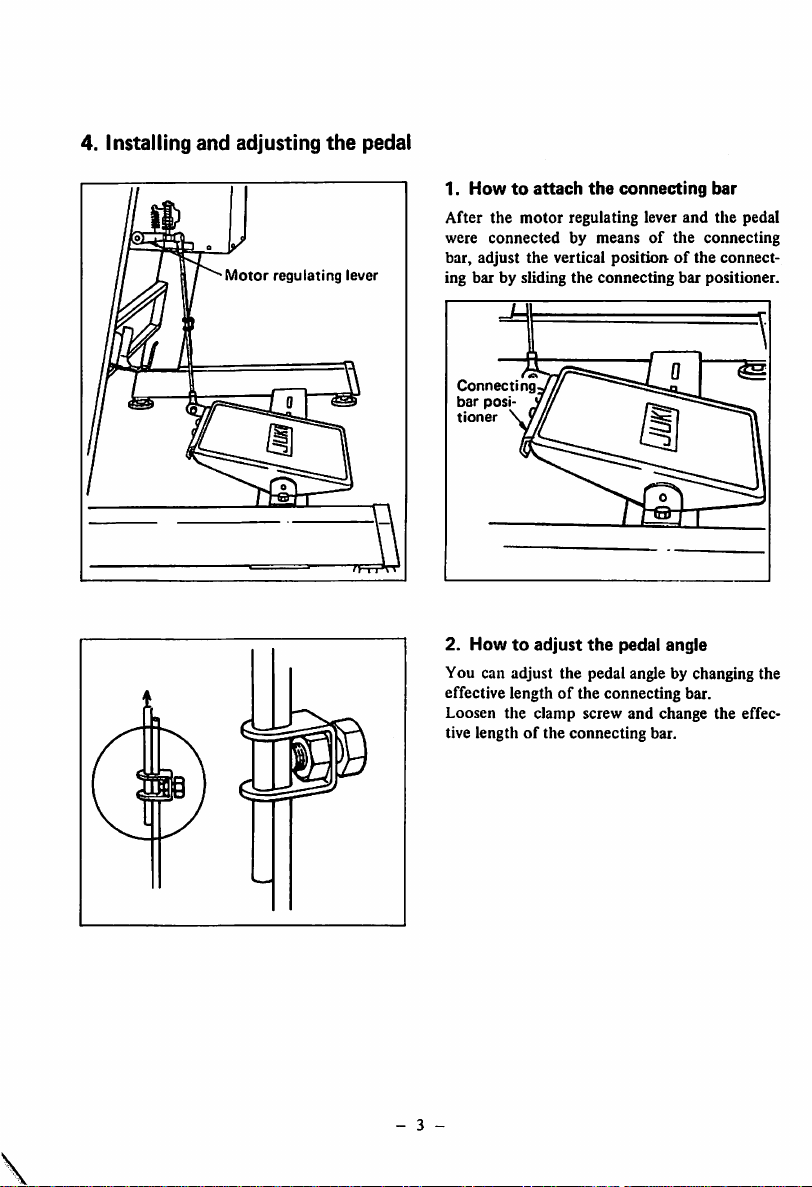

4. Installing

and

adjusting

Motor

regulating

the

lever

pedal

1.

Howtoattach

After

the

were

bar,

ing bar by sliding

Connecting

bar

tioner

2.

You can adjust

motor

connected

adjust

the

posi

Howtoadjust

the

connecting

regulating lever

by meansofthe

vertical

positionofthe

the

connecting

the

pedal angle

the

pedal angle by changing

and

bar

effective lengthofthe connecting bar.

Loosen

the

clamp

screw

and

tive length

of

the

connecting

change

bar.

bar

the

pedal

connecting

connect

positioner.

the

the

effec

- 3 -

Page 7

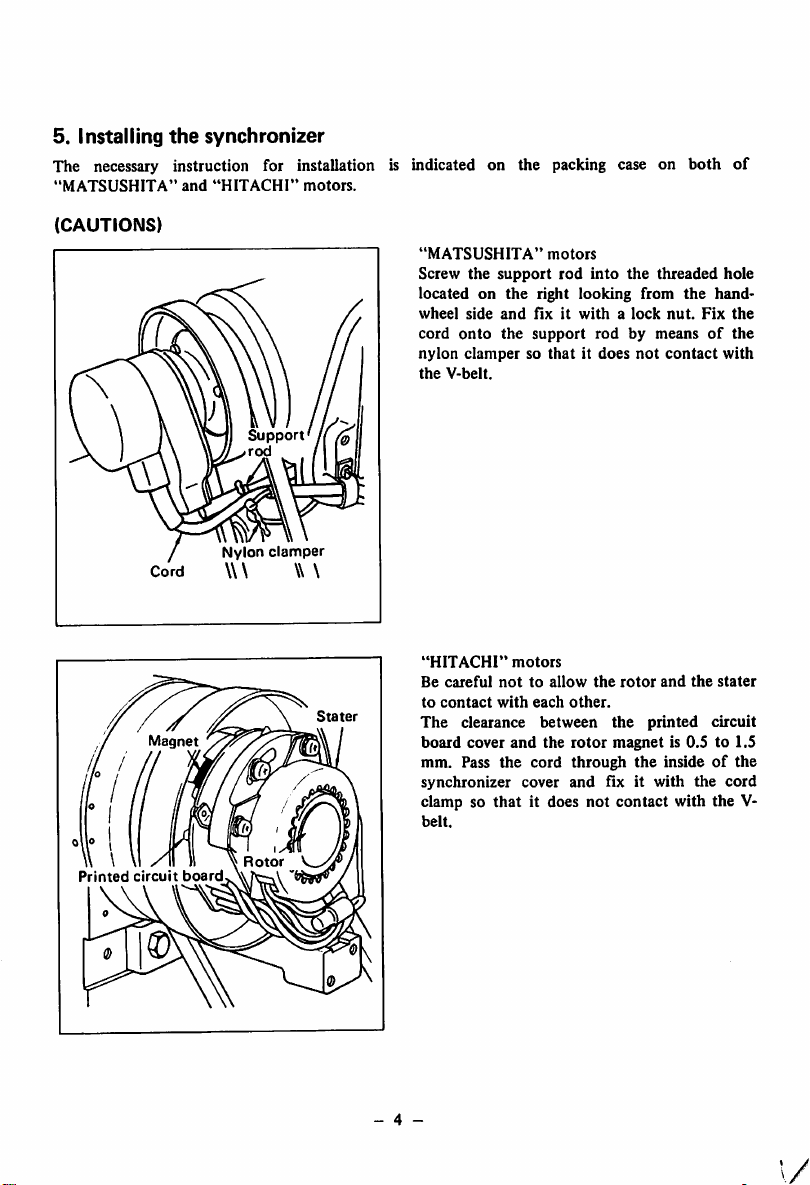

5.

Installing

the

synchronizer

The necessary instruction for installation is indicated on the packing case on both of

"MATSUSHITA"

and

"HITACHI"

motors.

(CAUTIONS)

Cord

Nylon

\\\

Support

rod

clamper

\\ \

"MATSUSHITA"

Screw

the

located on

wheel

side

cord

onto

nylon

clampersothat

the

V-belt.

motors

support

rod

the

right looking from

and

fixitwithalock

the

support

into

the

threaded

the

nut.

Fix

rodbymeansofthe

it does

not

contact

hole

hand-

the

with

Printed

Magnet

circuit

board

Rotor

Stater

- 4 -

"HITACHI"

Be

careful

to

contact

The

clearance

board

cover

mm. Pass

synchronizer

clamp so

belt.

that

motors

nottoallow

with

each

between

and

the

the

cord

cover

it does

the

other.

rotor

through

and

not

rotor

the

magnet

fix it

contact

and

printed

is 0.Sto1.5

the

insideofthe

with

with the V-

the

the

stater

circuit

cord

1/

Page 8

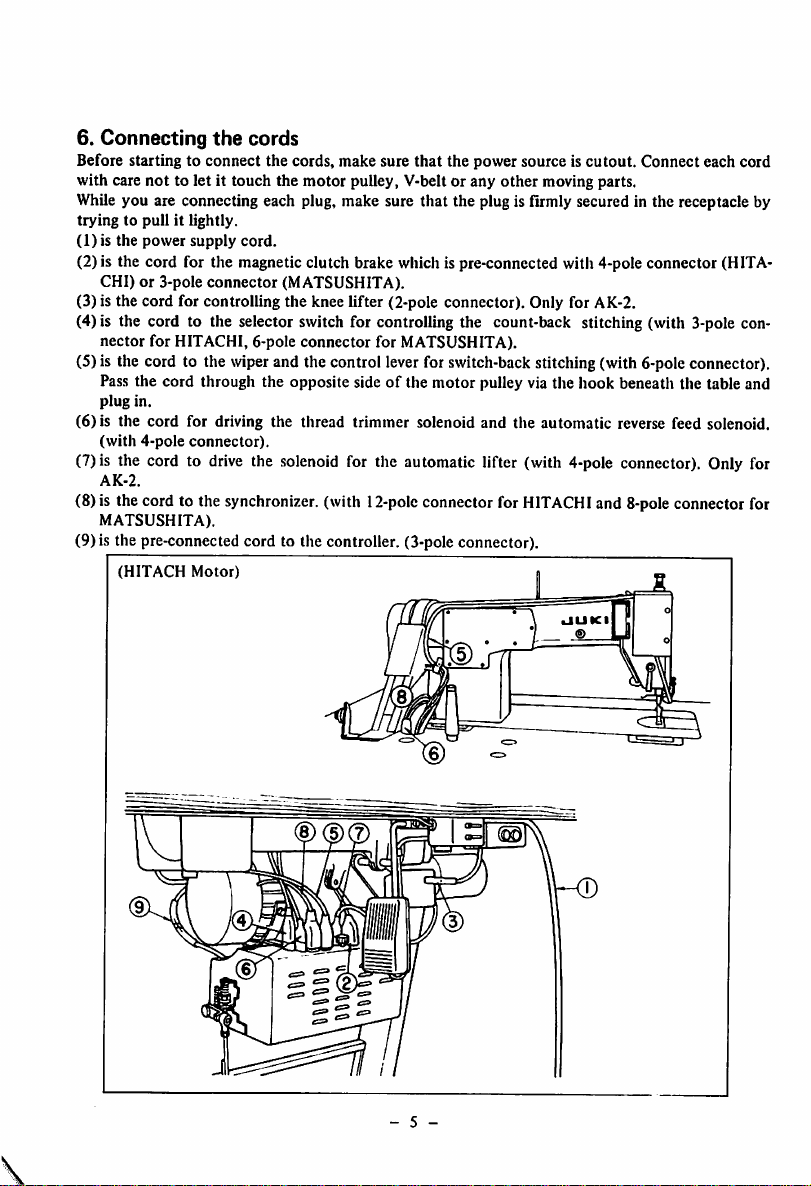

6.

Connecting

Before starting to connect the cords, make sure

the

cords

that

the power source is

cutout.

Connect each cord

with care not to let it touch the motor pulley, V-belt or any other moving parts.

While you are connecting each plug, make sure that the plug is firmly secured in the receptacle by

tryingtopull

(1) is the

power

it lightly.

supply

cord.

(2) is the cord for the magnetic clutch brake which is pre-connccted with 4-pole connector (HITA

CHI)or3-pole

(3) is the cord for controlling the knee lifter (2-pole connector). Only for AK-2.

connector

(MATSUSHITA).

(4) is the cord to the selector switch for controlling the count-back stitching (with 3-pole con

nector for HITACHI, 6-pole connector for MATSUSHITA).

(5) is the cord to the wiperand the control lever for switch-backstitching (with 6-poleconnector).

Pass the cord through the opposite sideofthe motor pulley via the hook beneath the table and

plug

in.

(6) is the cord for driving the thread trimmer solenoid and the automatic reverse feed solenoid,

(with

4-pole

(7)is the cord to

AK-2.

(8)is the cord to the synchronizer, (with

MATSUSHITA).

connector).

drive

the

solenoid

for the automatic lifter (with 4-pole connector). Only for

12-poIc

connector for

HITACHI

and 8-poleconnectorfor

(9) is the pre-connected cord to the controller. (3-pole connector).

(HITACH

Motor)

- 5 -

Page 9

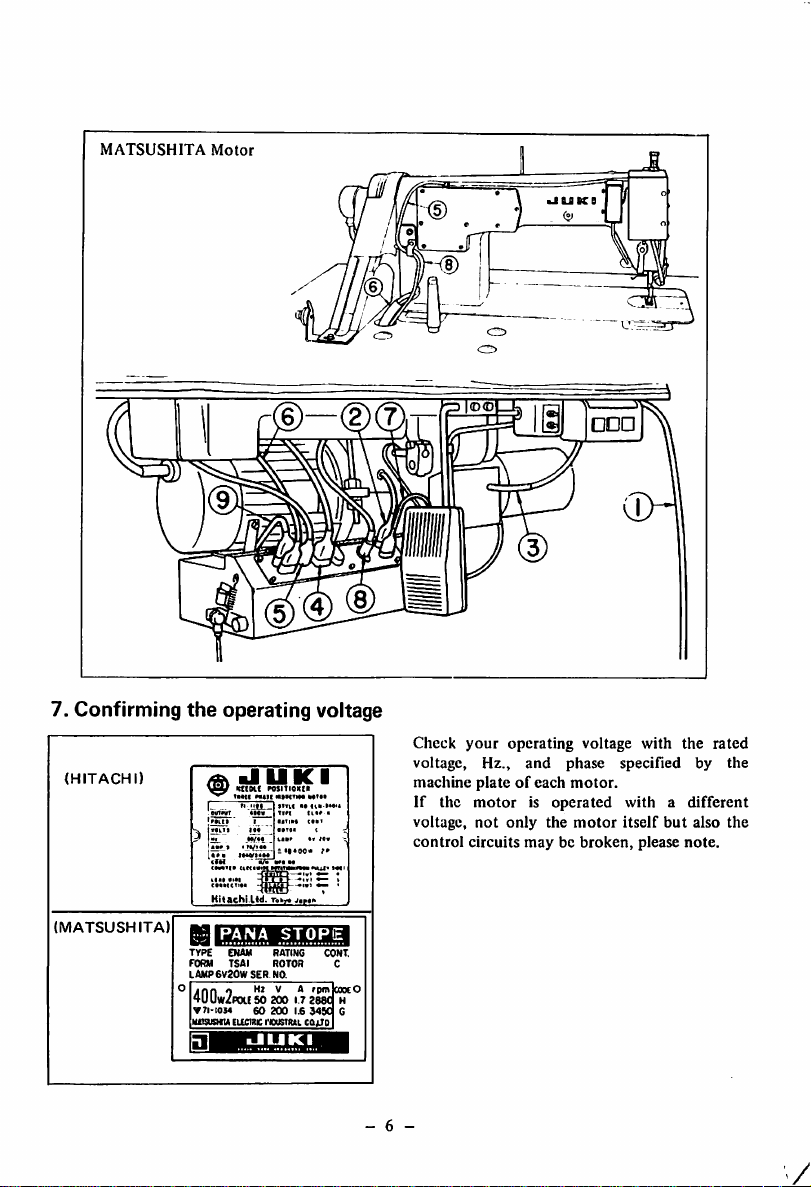

MATSUSHITA

Motor

>JUKB

I®®

7. Confirming

(HITACHI)

(MATSUSHITA)

the

operating voltage

HlOchi.Ud.

Totx

j.Mi

PANA

TYPE ENAM RATING CONT.

FORM TSAI ROTOR C

LAWP6V20WSER

jnn

4UUw/P0US0 200 17 2e8C H

•

n-i034

imsusTO

STORE

NO.

0 V A

60

200

Eiicwic

rcusTittL

•JUKI

rptnlcoocO

Ij6

34S0

cajjo

G

- 6 -

Clieck

voltage,

machine

If the

voltage,

control

your

operating voltage with the

Hz.,

and

plateofeach

phase

motor.

motorisoperated

not

only

the

circuits

motor

maybebroken,

specified

by

withadifferent

itself

but

also

please

note.

rated

the

the

V

Page 10

8. Mounting

Mount

the

procedure

belt

detailed

the

cover

below

belt

and

cover

:

bobbin

and

bobin

winderonthe

winderonthe

machine

table

table

accordingtothe

drawing

and

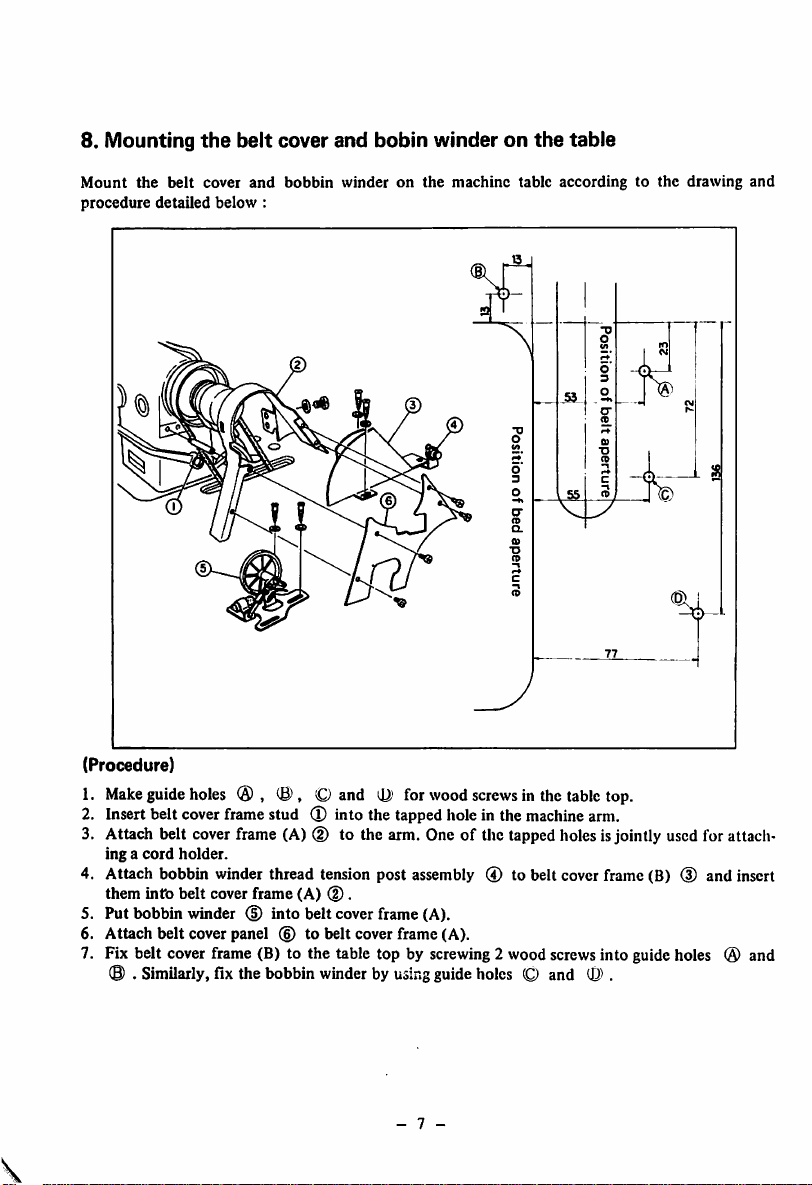

(Procedure)

1.

Make

guide

holes

® ® , O and for

2. Insert belt cover frame stud

(T)

into the tapped hole in the machinearm.

wood

screws

in the

table

top.

3. Attach belt coverframe (A) (D to the arm. One of the tappedholesisjointly usedfor attach

ing a

cord

holder.

4. Attach bobbin winder thread tension post assembly ® to belt cover frame (B) (D and insert

them

intb

belt cover frame (A)

5. Put bobbin winder (D into belt cover frame (A).

6.

Attach

belt

cover

panel

(D.

(6)tobelt

cover

frame

(A).

7. Fix belt cover frame (B) to the table top by screwing2wood screwsinto guide holes ® and

(8)

. Similarly, fix the bobbin winderby

using

guideholes (Q and .

- 7 -

Page 11

II.

1.

HOW

General

TO

OPERATE

instruction

THE

MACHINE

After the machine has been set up, bring down the needle by rotating the handwheel with

hand,

switchonthe

watching

from

the

the

open

machineontrial

and

rotationofthe handwheel.

sideofthe

handwheel.

check

The

that

the

handwheel

motor

must

rotatesinthe

rotate

correct

counterclockwise watching

direction

your

by

If you fail to judge it, you can repeat to switch on and off the machine until the direction is found,

o

Cleanupthe

installed

machine.

o Before starting to operate the machine, read through the separate INSTRUCTION BOOK,

o Do

not

drive

the

o Do

not

replace

machine

the

before

motor

pulley with a larger

the

oil

reservoir

one

is filled

with

within first 1

the

month.

lubricating

oil.

You may operate the machine at a higher speed depending on the necessityofsewing works

and operator's ability after the first 1 montli has passed,

o Keep away

o Do

tion or cleaning or removing

not

from

fail to

the

switch

needle

off

dropping

the

machine

the

V-belt.

place

before

when

you switch

you

tilt

the

the

machine

machine

head

on.

backwards

for

lubrica

(If you mistakenly tread on the pedal, the motor puUeywill be stopped immediately by means

of

the built-in safety device in the case of

you

move

the

o Whan

of

the

handwheel.

machinetoother

"HITACHI"

places, do

motor

not

hold it with

assembly.)

the

cover located on

the

rear

o Even if you tread on the pedal backwards (heel-down) immediately after the machine is switch

ed on or

the

thread

is trimmed,

the

needle

would

not

come

downorthe

thread

trimmer

would

not work. Such thread trimming motion is performed only after the pedal has been trod once

forwards

(toc-down).

- 8

Page 12

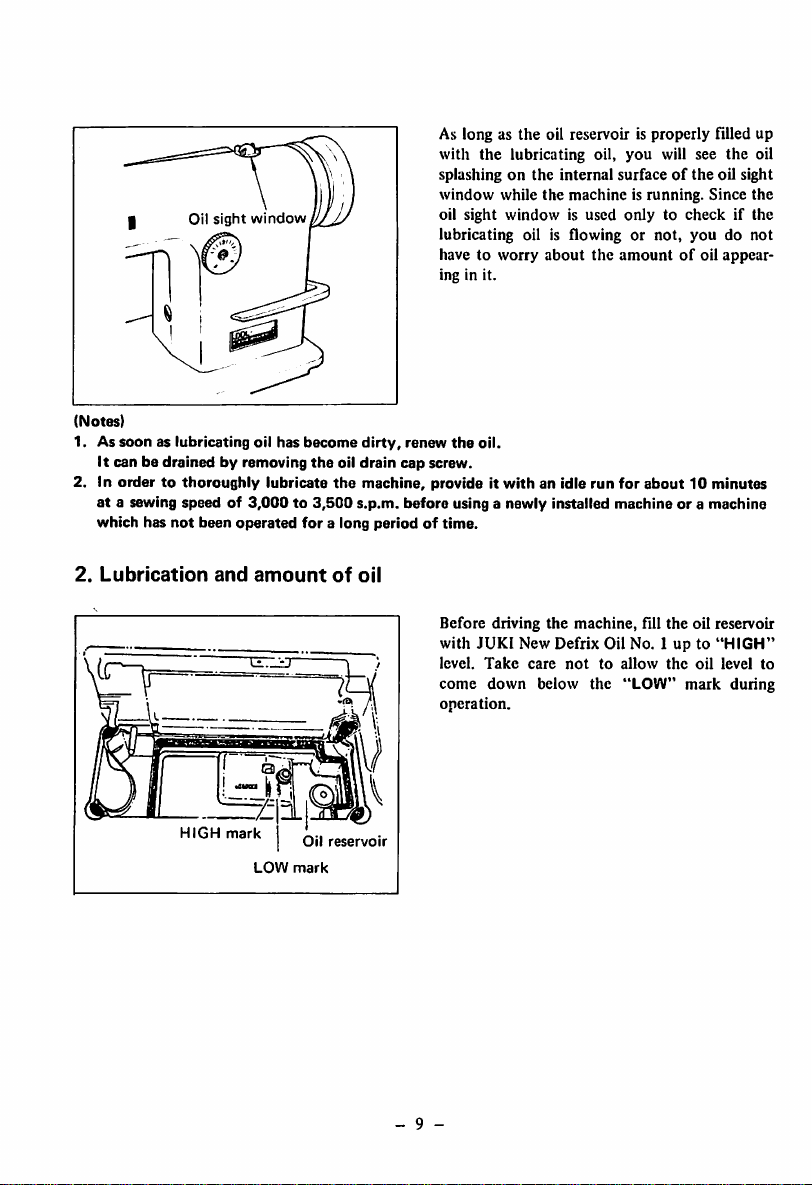

Oil

(Notes)

1. As

soonaslubricating

It

canbedrainedbyremoving

2. In

ordertothoroughly

at

a sewing

which

2.

Lubrication

speedof3,000to3,500

has

not

been

sight

and

window

oil

lubricate

operated

amount

has

become

the

oil

the

for

a long

of

dirty,

renew

drain

cap

machine,

s.p.m.

before

periodoftime.

oil

As long as the oil reservoir is properly filled up

with the lubricating oil, you will see the oil

splashingonthe

window

oil sight

lubricating oil is flowing or

have to

worry

ing in it.

the

oil.

screw.

provideitwithanidle

using a newly installed

while

window

internal

the

about

surfaceofthe

machine

is used

is running. Since

onlytocheckifthe

the

amountofoil

run

for

machineora

oU sight

not,

youdonot

appear

about10minutes

machine

the

HIGH

mark

LOW

Oil

mark

reservoir

Before driving

with

JUKI

level.

Take

the

machine,

fill

the

New Defrix Oil No. 1 up to

care

nottoallow

the

come down below the "LOW" mark during

operation.

- 9 -

oil reservoir

"HIGH"

oil

level

to

Page 13

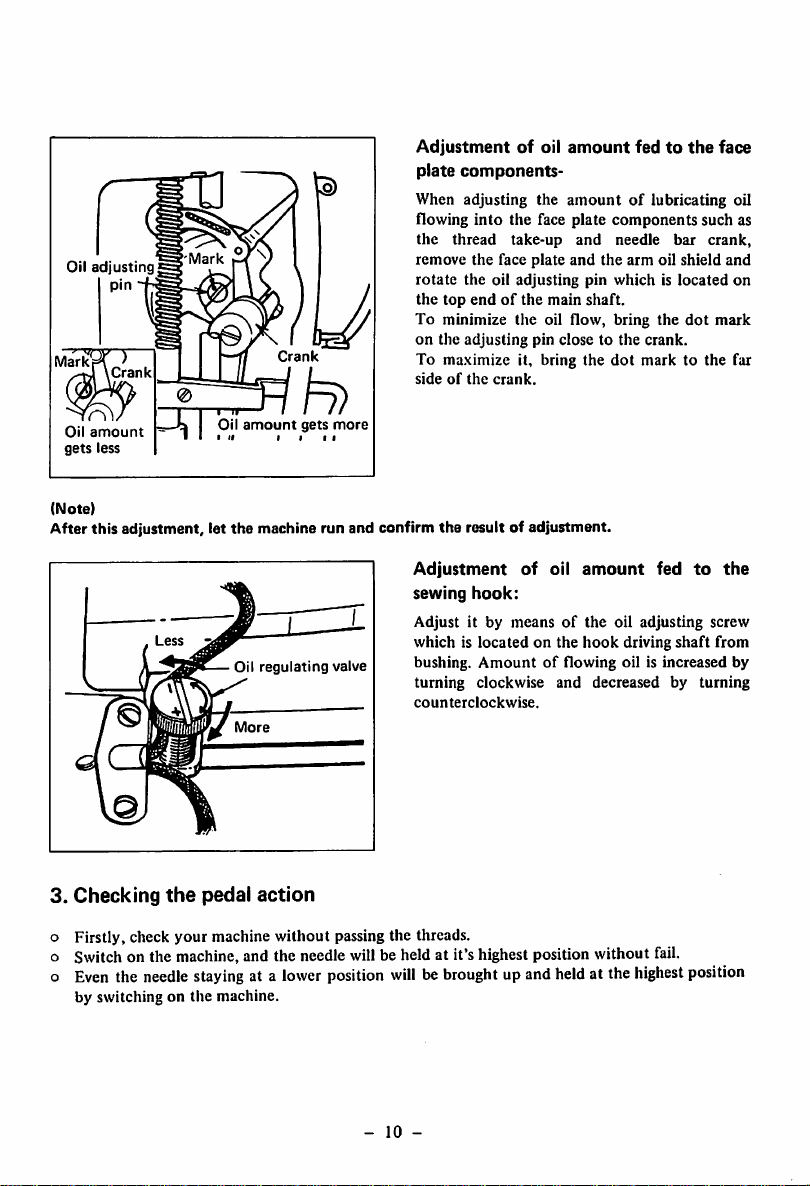

Mark

Oil

adjusting

pin

Crank

Mark

Crank

Adjustmentofoil

plate

components-

When adjusting the

flowing

into

the

thread

remove

the

rotate

the

face

the oil adjusting pin which is

top

endofthe

amount

fedtothe

amountoflubricating oil

the face plate components such as

take-up

plate

main

and

and

the

shaft.

needle

arm

oil

To minimize the oil flow, bring the

on the

adjusting

To ma.\imize it, bring the

sideofthe

crank.

pin close to

the

crank.

dot

mark to the far

bar

shield

located

dot

face

crank,

and

on

mark

r\

Oil

amount

gets

less

(Note)

After this adjustment, let

3.

Checking

the

amount

the

Oil

More

pedal

gets

I I

machine run and confirm

regulating

action

II

more

valve

the

result of adjustment.

Adjustment

sewing

Adjust it by

whichislocatedonthe

bushing.

of

oil

amount

hook:

meansofthe

Amountofflowing oil is increased by

oil adjusting screw

hook

turning clockwise and decreased by turning

counterclockwise.

Firstly, check your machine without passing the threads.

Switch on the machine, and the needle will be held at it's highest position without fail.

Even

the

needle

staying

at a

lower

by switching on the machine.

position

willbebrought

upand

held

at the

driving

highest

fed

to

shaft

position

the

from

-

10

-

Page 14

4.

Howtooperate

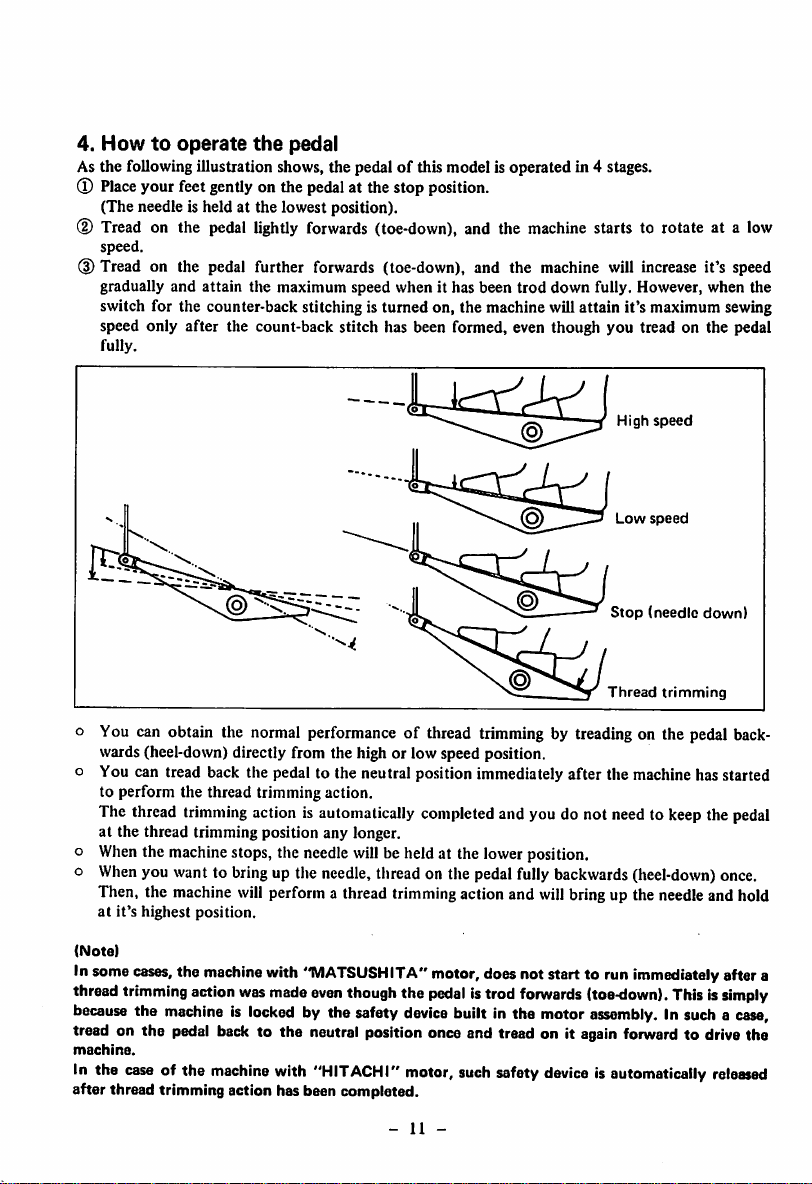

As the following illustration shows, the pedalofthis model is operated in 4 stages.

®

Place

your feetgentlyon the pedalat the stop position.

(The needle is held at the lowest position).

(D Tread on the pedal

speed.

(D Tread on the pedal further forwards (toe-down), and the machine will increase it's speed

gradually and attain the maximum speed when it has been

switch for the counter-back stitching is turned on, the machine will attain it's maximum sewing

speed only

fully.

after

the

pedal

lightly

forwards

the count-back stitch has been formed, even though you tread on the pedal

(toe-down), and the

machine

trod

starts to rotate at a low

down fully. However, when the

High

speed

Low

speed

Stop

(needle

Thread

trimming

down)

o You can obtain the normal performance of thread

wards (heel-down) directly from the high or low speed position,

o You can tread back the pedal to the neutral position immediately after the machine has started

to perform the thread trimming action.

The thread

at the thread trimming position any longer,

o

When

o

When

trimming

the machine stops, the needle willbe held at the lower position,

you want to bringup the

action is automatically completed and you do not needto keepthe

needle,

threadon the pedalfully

trimming

by treading on the pedal back

pedal

backwards

(heel-down)

once.

Then, the machine will perform a thread trimmingactionand willbringup the needleand hold

at

it's

highest position.

(Note)

Insome

cases,

the

machine

thread

trimming

because

tread on the pedal back to the neutral position once and tread on it again forward to drive the

machine.

In the

case

after thread trimming action has been completed.

action

the

machineislocked

of the

was

machine

with

"MATSUSHITA"

made

even

by the safety

with

"HITACHI"

thoughthe

device

motor,suchsafety

-

motor,does not start to run immediately after a

pedal

istrod

built in the motor

forwards

(toe-down).

assembly,

Thisis

in sucha

deviceisautomatically

11

-

simply

case,

released

Page 15

5. Adjusting

the

pedal pressure and stroke

(MATSUSHITA)

Adjustment

Adjustment

nutofthe

backward

pressure

spring.

C?

I Pedalpressure

^spring

grooves

(HITACHI)

Adjustmentofthe

Adjust the forward pressure by changing

positionofthe

"HITACHI"

The

pressure is

the

left

and

is increased to

"MATSUSHITA"

The

pressure is reduced by moving the spring

to the right

and

Adjustmentofthe

"HITACHI"

spring.

motor:

reduced

motor:

is increased to

motor;

forward

pressure

by moving tiie spring to

the

right.

the

left.

backward pressure

the

The backward pressure can be adjusted by

means of the adjustment nut of the backward

pressure spring. The pressure is increased by

tightening the spring and reduced by loosening.

(MATSUSHITA)

Motor

regulating

Connecting

(u

lever

(HITACHI)

rod

Adjustmentofthe

pedal

stroke

The pedal stroke can be adjusted by changing

the

with the

"HITACHI"

The

with

creased by the right

"MATSUSHITA"

The

with the right hand

increased by

-

12

-

connectionofthe

motor

regulating lever.

motor:

stroke is reduced by connecting

the

left

hand

stroke is reduced by connecting the rod

the

sideofthe

hand

motor:

left

hand

upper

side.

.side

of the lever and is

side.

connecting rod

the

lever

rod

and

in

Page 16

6. Automatic count-back stitching

You

can

form

the

count-back

without

operationofthe feed

Count-back

at

Count-back

at

BACK

TAG SW.

START

0FF|^^l6iA

END(»*')

)

OFF^^-SiT

•JUKI

(Note)

When the selector switch for the automatic count-back stitching is not used (with a

motor): Disconnect the swjtch from the motor control box.

When

it is

used,

insertaconnector

( 4 ,

Fig.

paragraph

5)on the motorcontrolbox.

stitches

control

the

the

Selector

formingacount-

back

startofa

Selector

formingacount-

back

endofa

stitch

start.

stitch

end.

switch

stitchatthe

seam

switch

stitchatthe

seam

J

whichiswiredasillustrated

at the start and/or the end of a

lever or switch-back lever.

(T)

You can preset the machine to form the

count-back

endofthe

lector

switches.

(D If the numberofcount-back stitch is

enough for your sewing purpose, turn

the selector switch and produce the neces

sary length of reverse stitches manually by

making usofthe

or

the

switch-back

(3) When the selector switch for

turned

on,

automatically

ately by treading on the pedal backwards

before or after forming the count-back

stitchatthe

tiiough you tread on the pedal for thread

for

line.

for

line.

trimming while the count-back

being formed, the thread trimming action

will not be performed prior to the forma

tionofthe

said

® When the selector switch for

turned on, the thread trimming action will

be

performed

been

formedatthe

you tread on the pedal for thread trimming

while the machine is forming a count-back

stitch at the endofa

will trim off the thread after completing the

said

count-back

below

(Option.

PartNo.

seam

line

stitches at

seam

you

trim

startofa

count-back

after

the

line by

reverse feed

lever.

can

let

off

the

the

count-back

endofa

.seam

stitch.

intothe

position

D6010555DA0)

start

meansofthe

the

thread

seam

stitch.

line, the machine

automatically

and/or

the

not

off

control

lever

"Start"

machine

immedi

line.

Even

stitch

"End"

stitch

has

seam

line.

HITACHI

of 3-p

plug

se

is

to

is

is

If

A

O

o

o

13

Page 17

7. Passing

o ir the machine stops leaving the needle at a lower position, tread on the pedal backwards for

performing an idle thread trimming before passing the needle thread.

Then,

o Pass the needle thread in the

the

needle

the

needle will go up

thread

and

order

stayatthe

highest

from ® to ® as shown in the illustration.

position,

I

-

14

-

Page 18

8.

Bobbin

thread

Bobbin

Adjustment

—Thread

case

screw

Tension

screw

Thread

post

bracket

hole

Thread

passing

Hook

tension

hole

Inserting

1. Bring up

2.

3.

4.

Winding

1.

2. Push

3. Adjust the winding adjustment screw so

and

removing

the

needle to its highest

by

manually

Tilt

rest

table.

Liftupthe

the

bobbin

Bobbin will

latchislifted.

To

insert

into

the

on

tiic

rotating

machine

the

bobbin

case.

not

the

hook

the

head

rubber

pads

case

fall

bobbin

shaftsothat

down

bobbin case rests in tlic

close

the

latch.

the

bobbin:

Thread

the

bobbin

winderinthe

illustrated

times

bobbin

the

about

and

wind

round

the

the

bobbin.

bobbin

down

winder pulley

threadiswound

80 per

centofits capacity.

the

touch

round

the

bobbin

handwheel.

back

and

allowitto

attachedtothe

latch

and

as long as the

case, fully

the

noseofthe

hook

groove

thread

end

trip latch to let

the

belt.

the

bobbin

case:

position

take

out

insert

and

order

several

the

that

for

4. When the bobbin is wound unevenly,

correct it by moving the thread tension post

bracket.

Tighten the screw for increasing the thread

length

to be

wound

and

loosen

for

reduce.

5. As soon as the

bobbin

in filled, the bobbin

winder will automatically stop.

(Note)

In order not to wound

withasynthetic

screw so

thr

inserting

1.

thread

Take

that

the

tension

the

bobbin

the

bobbininyour

thread,

thread

post

the

is lightly

socket,

into

bobbin

adjust

the

bobbin

handsothat

too

the

drawn

tight

tension

from

case:

the thread is directed clockwise and place it

into

the

bobbin

the

slotinthe

case.

fingers

bobbin

and pull up

case.

2. Take the thread in your

toward

3. Pull the thread, and it will pass through the

thread tension spring.

""Make

sure that the bobbin spins in the

bobbin

the

caseinthe

arrow

when

direction

the

threadisdrawn.

indicated

with

it

as

-

15

Page 19

9. Adjusting

Decreased

the

thread

Decreased

V\S—Increased

tension

Thread

Increased

Thread

No.

No.

tension

1

tension

2

Needle

thread

tension:

Needle thread tension is adjusted by the thread

tension

nuts

No. 1

and

No, 2

thread

tension

increased by a clockwise turn and reduced by a

counter-clockwise

o

Thread

tension

turn,

No.

1.

The length of needle thread remaining in the

needle

after

when

the

thread

tension

nut

No. 1 is

ened, and vice versa. Tighten the tension

thread trimming becomes

whenathin

used

used.

o

Thread

thread

like

and

loosenitwhenathick

tension

No.

2

synthetic

short

tight

nut

thread

thread

Adjust the thread tension nut No. 2 so that

the

needle

and

bobbin

threads

are

inter-

looped in the middle of the material. Do not

excessively reduce the thread tension when

sewing with a synthetic thread, or the

thread may be broken at the start of sewing.

is

is

is

thread

take-up

spring

Moving

range

Thread

tension

bar

(Note)

Thread

Thread

set

Tension

set

screw

screw

take-up

tension

bracket

bar

Thread

tension

socket

spring

When using a thin cotton or synthetic thread,

excessive

tensionorstroke.

Otherwise, stitch may be skipped at the end of

Thread

take-up

spring

Adjust the thread take-up spring for the follow

ing

standard:

Thread

Cotton

Cotton

Synthetic

Thread

No.

#40orless

#50ormore

Stroke

7to10

mm

(9/32"

to 25/64")

6to9

mm

(15/64" to 23/64")

6to9

mm

(15/64"

to 23/64")

o To change the stroke of the thread take-up

spring, loosen the screw of the thread

tension post socket and turn the thread

tension post in either direction,

o To change the tension of the thread

spring, loosen the screw of the thread

tension post socket, remove the thread

tension post and adjust the tension after

loosening

the

set

screw.

Tension is increased by turning the thread

tension post in the clockwise direction, and

vice

versa.

take

care not to provide

the

take-up spring with an

sewing and the threads will not be trimmed.

-

16

-

Tension

20 to 35g

15 to 30g

7 to 20g

tate-up

Page 20

Howto adjust the thread length remaining in the needle after thread trimming:

o In order to prevent the needle thread from slipping

. face of the materialat the start of

sewing,

a proper length of needlethreadmust beleft in the

needle eye after thread trimming.

o The thread length is adjusted by the thread tension No. 1.

o It is possible to provide the thread trimmer with different timing of action to trim a synthetic

thread from that of cotton thread. Consult withour distributorsor agentsin your areafor this

modification.

0

1

o

off

and produce neat stitch on the bottom

Increased

Adjusting

10.

Attaching

Use

a proper size of

screw

the

material as listed below;

Needle

#9

11

14

X 1

xl

16

18

21

22.23

8-9

11

14

DB

DA

Reduced

needle

DB,\1

or DAxl needle according to the

Thread

Cotlon

#80

80-60

60-50

30-20

30-

8

80

60

50

Synthetic

#80

80-60

60-50

50-30

30-20

8

80

60

50

Bobbin

Bobbin

tightening or loosening

bobbin

thread

tension:

thread

tension can be adjusted by

the

case.

Turn

tension screwofthe

the

screw

clockwise

increasing and counterclockwise for reducing

the

bobbin

thread

tension.

Fine

Light-weight

General

cloth

thickness and

Georgette, nylon,

broadcloth

Broadcloth, light-weight knits

Cotton

typeofthread

Material

gabardine,

tetron

drill

Medium-weight Coatings

Heavy-weight

Extra-heavy

Extra-heavy

Fine

Light-weight

General

cloth

Denim

Cantton,

Cantton,

canvas

canvas

Georgette, nylon,

broadcloth

Broadcloth,

Cotton

fine

gabardine, drill

tetron

knits

for

and

-

17

-

Page 21

11.

Needle

Presser

foot

Screw

Adjusting!

screw

Groove

Let the needle bar go up to its highest position

by the handwheel. Loosen the needle clamp

hold

screw,

right, insert the needle

a needle facing its recess to the

into

the needle clamp as

far as it will go and tighten the needle clamp

screw.

Adjusting

the

presser

foot

pressure:

Pressure applied by the presser foot to the

works is increased by rotating the presser spring

regulator in the clockwise direction and vice

versa. It is

when

Tighten the lock

advisabletoset

general

cloth

is sewn.

nut

after adjusting the presser

it to

about

5 Kg

spring regulator.

Hand

lifter

Presser

lifter:

Turn the hand lifting lever located in the rear of

the

machine

the

presser foot will go up for

(13/64")

Push

down

come

from

down

head

hand

to press

eithertoleft

the

throat

lifter,

plate

and

the pre.sser

the

work. By the knee

lifter, the presser foot will go up for

10 mm

(25/64")

-

18

-

from

the

throat

or right,

about

surface.

foot

plate surface.

and

5 mm

will

about

Page 22

12.

Stitch

13.

length

Stitch

adjustment

length

Reverse stitching by using

N

Feed

control

I

Stitch length is adjusted by the stitch dial

located

above

the

reverse

feed

control

lever.

Set a desired

the pointer pin fi.xcd to the machine arm.

*The ma.ximumstitch length is 4 mm (5/32").

stitch

length

(mm)ofthe

dial to

E

the

reverse feed

Push

as a

Release

lever

immediately

forward

/

down

desired

your

direction.

control

the

reverse

reverse

hand

go up to feed

lever

feed

control

stitchiscompleted.

from

the

lever,

the

material in

lever as

and

long

it will

the

OOL-SBS-4

19

-

Page 23

III.

ADJUSTMENT

1.

Feed

mechanism

Thrust

Set

screw

collar

\Feed

eccentric

n

drive

\ II

cam

w

Adjusting

the

feed

timing:

(excepting DDL-555H-4):

To

obtain

the

standard

feed timing, align

the

engraved line on the feed drive eccentric cam

with

the

dot

markonthe

adjustment,

and

stitches

puckering

will

haveanideal

Loosen 2 setscrewsonthe

thrust

stitch

will be eliminated

thread

feed drive

collar.Bythis

tension.

eccentric

cam properly position the cam and firmly

tighten 2 setscrews.

mm

If

it is preferable to

nism

with

an earlier

timing in

ping

eccentric

arrow.

ordertoprevent

during

stitching,

caminthe

Feed

Feed

Needle

dog

provide

timing

move

direction

Needle

dog

mm(

Throat

the feed

than

the

the

work

the feed drive

shownbythe

Throat

mecha

standard

from

plate

plate

slip

If

it is necessary to delay the timingoffeed

mechanism in

sioninstitches,

caminthe

do

not

becomeacauseofneedle

-

20

-

order

move

direction

moveittoo

Feed

to improve

the

feed

shownbythe

much,

otherwiseitmay

breakage.

Needle

dog

the

drive

Throat

thread

eccentric

arrow.

ten

But,

plate

Page 24

Front

Screw

(Note)

The

heightofthe

up

driver

Standard

DotL_^

Set

feed

Front

screw

dog

mustbecorrected

down

Adjusting

the

feed

dog

Inclination

(excepting DDL-555H-4):

The

feed dog

adjustedtohorizontal

tion). It can be changed, if necessary, according

to

the

varied sewing

o

Descent

Puckering is

is easily

o

Ascent

Cloth

fabric

o The standard inclinationofthe feed dog is

that

the

is aligned

Loosen

insertascrew

the

feed

direction. The front top of the feed dog will

be raised to

shaftisturned

by an

every

time

after

of

each

machine has been

position

(front-up)

comming

(front-down)

slipping

texture

arrow,

changing

conditions,

position:

prevented

out.

and

and

position:

breakage

chain-off

arc prevented,

engraved

with

2 setscrewsofthe feed bar

dot

on the feed bar

the axesof2 setscrews.

driver

bar

the

and

blade

shaft

and

turn

highest position when the

90"inthe

vice versa.

its

inclination.

into

direction

(standard

thread

of

knitted

the

slot

90"ineither

shown

posi

shaft

shaft,

in

•

Feed

H

driving

ri"

fork

,^CIamp

screw^

Adjusting

the

feed

dog

height:

The standard heightofthe feed dog is to Jut

out

its

teeth

0.8 mm

(1/32")

plate surface when sewing general materials. It

is advisable to change the feed dog height to

about 0.6 mm (1/64") for sewinglight-weight

materials

weight

If

the

occurred.

Loosen

crank, set

securely

-

21

-

and

about

materials.

1.0 mm

the

feed dog

throat

teeth

plate surface, puckering seam may be

the

setscrewofthe

the

feed bar for a

tighten

the

setscrew.

Feed

dog

Juts

(3/64")

out

proper

0.8mm

j/^c

feed

above the

too

much

rocker

position

Throat

throat

for heavy

above

shaft

and

plate

Page 25

2. Replacing

qpt

bet

Feed

base

lT0

the

sewing

«rrpw

Bobbincase positioning

screw f ,

hook

,.

Hook

When

the

sewing

hook

new

one

duetosome

following

1.

2.

3.

Set

screw

4. Loosen 2 sewing

5.

6.

7. Pull

procedure;

Manually

needle

reaches

Remove

Loosen

holder

the

positioning

positioning

Manually

feed

bar

Rotate

hold

reaches its highest position.

the

it in

out

the

turn

the

finger.

rotate

sewing

the

"'When installing

above

procedure.

has to be replaced with

reasons,

the

handwheel

its

highest

position.

bobbin

case

setscrew

and

of

finger

hook

screws.

the

handwheel

hookbyyour

position

sewing

the

hook

sewing

as illustrated.

to the left.

removeitin

until

the

needle.

the

bobbin

and

remove

until

finger

hook,

reverse

the

the

case

the

the

and

the

22

Page 26

3.

Sewing

hook

position relatedtothe

Clamp

screw

needle

Adjust the sewing hook position related to the

needle in

1. Bring up the needle to its lowest position by

2.

the

handwheel.

Loosen

tion.

the

following way :

the

screwofthe

needle

bar

connec

Blade

the

hook

Needle

point

sewing

(Needle

^

^

^

•

>

Needle

lower

Upper

indicating

Lower

line

Needle

bar

bushing

line

indicating

bar

3

4.

(Sewing

5.

Lower

indicating

(At

this

position,

the

blade

^ sewing hook with

of

line

match

pointofthe

the

center

the

needle)

Sewing

hook

of

6. Mold by

7.

8. By

9. Do

10.

bar

height)

Align

the

bar

lower

Tighten

Loosen

hook.

upper

with

the

bottom

bushing.

the

needle

hook

position)

2 .setscrews to release

hand

taking-up

Rotate

position.

the

handwheel

engraved line

the

bottom

end

bushing.

keeping

the needle bar in

mention-position,

of

the

sewing

hook

not

keep

away

the

more

tighten

liook

needle.

Securely

engraved lineofthe needle

the

of

endofthe

bar

connection

sewing

the

needle bar reaches

of

the

needle

the

hookinthe

until

the

needle

bar

screw.

sewing

the

align

the

pointed

with

the

needle

axes.

pointed

the

than

sewing

endofthe

O.OSmmfrom

hook

sewing

screws.

bar

thread

lower

lower

above

end

the

-

23

-

Page 27

4. Heightofthe

presser

Presser

screw

bar

bar

clamp

When correcting the height or angleofthe

presser bar after replacing the presser

some

other

reasons,

from the face plate

remove

and

the

loosen the screwofthe

rubber

foot

or

plug

presser bar guide bracket by inserting a screw

driver through the opening in the face plate.

Securely tighten the screw after adjusting the

^

presser bar height.

Howtouse

the

pressure

reducer:

It is possible to sliglitly reduce the pressure

applied by the presser foot when the pressure

reducer is used. This system is

when a floating presser

hastobe

continue

turned

to

stitch

Loosen the lock

foot

roundatan

inadifferent

nut

(g)

and

quite

useful

is used or a work

endofa

seam

direction.

properly tighten

the adjusting screw (g) , and the presser foot

will be raised up from the

so

that

the

turned

material

round

easily

the

throat

in

the

needle.

plate surface,

machine

can

to

be

-

24

-

Page 28

5.

Thread

take-up

action

6.

Returning

Thread

guide

(A)

pressureofthe

Increased

Reduced

reverse

It is recommendable to change

up

action

stitch

crease

according to

length, in

stitches.

the

thread

length

and

tightened

o When sewing heavy-weight materials, in

the

thread

the

typesofmaterial

ordertoobtain

takenbythe

take-up lever by lowering the thread guide

(A).

o When sewing light-weight materials,

the tliread length taken by the thread

take-up

lever by positioning

the

guide (A) in the middle or higher place.

This adjustment can be made after loosening

the

setscrewofthe

feed

control

In

ordertoallow

to

immediately

after

the

lever is forced

is necessary to

use

the

being released in

machine

thread

lever

the

reverse

return

back

reduce

at a low sewing

guide (A).

to its

any

by a

the

feed

stanby

sewing

strong

returning

speedorwith

control

conditions,

spring.Ifit

pressure to

fine stitch, slightly loosen the adjusting nut

take-

well-

thread

reduce

thread

lever

position

a

®.

-

25

-

Page 29

7. Adjusting

the

needle

stop

position

after

thread

trimming

You can adjust Hieposition at which the needle stops after a thread trimming has been completed.

The

standard needle

hand

wheel

with

the

stop

position is shown by the coincidenceofthe white

red

dodonthe

machine

arm.

This

adjustment

can be

dot

made

marked on the

by changing

the

installation angle of the sensing elementofthe synchronizer component. Refer to the separate

Instruction Book prepared for the

Stater

\

motor

assembly for the detailsofadjustment.

flange

"HITACHI"

Remove

the

component and adjust the installation angle

motor;

cover

from

the

synchronizer

of the printed circuit board within the adjust

able range of the oval holes on the stater flange.

White

Red

dot

Printed

circuit

board

cover

Magnetic

"MATSUSHITA"

Remove

the

cover

motor:

from

the

synchronizer

adjust the installation angle of the magnetic

plate.

-

26

-

and

Page 30

8.

Sharpening

Horn

Sharpen

Blade

1 /

this

this

the

corner

face-./

tip"""^^

N

counter

knife

y

^

As

soonasyou

trimmer has become dull, resharpen the

counter

knife

Put

the

resharpened

\

it's correct position shown by the following

illustration.

If you move the installing positionofthe

counter

knife to the right from the standard

noticed

immediately.

counter

that

knife

the

thread

back

to

position, the length of thread remaining on

the needle

and

vice

versa.

after

trimming becomes longer

Needle

Moving

center-

"*

knife

a

Counter

Shorter

I

The

of

knife

the

remaining

thread

becomes;

length

—

Counter

Longer*

I .omm

Stepped

of

the

Bottom

the

part

bed

knife

throat

face

plate

of

-

27

-

Page 31

IV.

HOW

TO

1.

Adjusting

ADJUST

the

positionofthe

THE

WIPER

wiper

You must adjust the position of the wiper according to the thickness of the material to be sewn in

the

following

way;

1)

Rotate

normal direction so

on

r

the

(D on

the

handwheel

handwheel

the

frame.

that

coincide

manually in

the white

with

the

dot

red

dot

2) Insert the wiper (D into the wiper driving

shaft

(2) so

that

the

vertical

clearance

between the wiper edge and the needle

point becomes 2 mm and also the parallel

clearance

straight inside faceofthe

between

the

needle

wiper becomes

center

and

1 mm. Fix the wiper at such a position by

tighteningthe lock nut (3) .

the

(D

the

2. Adjust

Wiper

the

positionofthe

switch

wiper magnet

Pull the plunger fully into the coil, loosen the

screw 0 which is clamping the wiper magnet

and

that

of2mm

Afteracorrect

the

the screw. When

off

28

—

adjust

the

positionofthe

wiper magnet so

the wiper tip is positioned with a clearance

from

the

center

wiper magnet at

position

the

wiper

switch.

lineofthe

has

that

position by tightening

youdonot

been

use

needle.

obtained,

the

wiper,

fix

turn

Page 32

V.HOW

1.

Forming

2.

Adjusting

I

TO

USE

AND

the

switch-back

the

positionofthe

ij

ADJUST

Swi

tch-back

button

f

THE

stitches

switch-back

DK Tighten the

SWITCH-BACK

Push

tiie

machine

form

the

As long as the

machine

As

soon

machine

When

you

reverse

feed

switch-back

will

perform

switch

back

buttoniskept

will

perform

as

the

will

reversedtothe

sew

control

BUTTON

button,

a reverse

stitches.

the reverse feed.

button

the

half

lever.

pressed,

is

released,

normal

stitches,

and

feed

feed.

use

lever

You

may

change

the

back buttonC1to a suitable height for your

positionofthe

operation.

Loosen

the

screw

(2) ,

move

the

up

and

down

and

obtainasuitable

screw

firmlyafter adjustment.

switch

switch

lever

height.

the

to

the

the

the

3.

Adjusting

the

reverse

stitch

length

-

An excessive lengthofreverse

formed by the

operate

be

advisable

reverse feed by decreasing the stitch length of

reverse feed in

length

with

To

lessen

this

new

the

the

operator

device.Insuchacase,itwould

to

shorten

comparison

normal

lengthofthe

stitch

until he gets used to

the

seam

line

with

feed, if it is permissible.

reverse

stitch,

the screw (I) and push up the stopper plate

d).

If you push it down to the normal and

reverse

feeds

are

identical.

29

-

is usually

with

the

stitch

loosen

the

Page 33

VI. AUTOMATIC PRESSER FOOT LIFTER, AK-2(Optional attachment)

The automatic presser foot lifter

AK-2

is an optional attachment which is capable of lifting the

presser foot and holding it at the heighest position for 10 to 15 secondsafter thread trimming has

been

made.

A special

1.

Howtooperate

motor

is used

AK-2

for

this

lifter

AK-2.

If you want to raise the presser foot during a

sewing

work,

presser

diately

foot

after

press the knee

will be

the

knee

switch.

Such

comming

switchisreleased.

down

raised

imme

If you want to bring down the presser foot

which

has

been

raisedasthe

resultofan

auto

matic run, tread on the pedal forwards (toe-

Knee

switch

2.

Adjusting

Coupler

the

presser lifter

stroke

down)orpush

1. Loosen the lock

2. Lower the presser foot

by

3.

Push

loosening

the

knee

and

release

nutofthe coupler.

the

lock

nut.

switchtodrive

the

knee

stopper

the

switch.

(A) fully

solenoid.

4. You can adjust the strokeofthe presser

foot by rotating the plunger on the far side

of

the

8.

Loosen

your

end/of

become

the

hand

the

about

solenoid;

a clockwise

counterlockwise

(The

maximum

presser

5. Raise

footisabout8mm

stopper

servoir by activating

6. Raise the

half

turn

7. Tighten

the

(B) so

connecting

the

coupler

presser

the

lifter

that

Presser

lifter

stopper

Presser

Stopper(A)

lifter

V

lever

Presser

tM\li

lock

nutofthe

and

adjust the heightofthe

knee

lifter

rod

Plunger

(B)

lifter

stopper

and

the

(B),

knee

push

stopper

lifter

1 mm (3/64"). After obtaining a proper position, retighten each lock nut.

the

stroke

turn

and

is decreased by a

turn.

stroke

performed

(A)

untilithits

the

stopper

after

lock

releasing

solenoid.

(A) by rotating it

the

nutsofthe

respectively.

lever

towards

the

playing gap between the

rod

locatedonthe

is increased by

by

(5/16")).

the

another

knee switch.

stopper

(A) and

the

solenoid

machine

oil re

with

head

the

top

-

30

-

Page 34

VII.

TROUBLES

AND

CORRECTIVE

MEASURE

Troubles

1.

Thread

breakage

2.

Stitch

skipping

Causes

1)

Thread

qualityispoor.

2)

Threadistoo

needle

3)

Threadisbrokenbythe

heatofthe

4)

Thread

5)

Thread

hook,

discs,

components

burrs.

thick

size.

needle.

tensionistoo

pathonthe

throat

plate,

thread

take-uporother

has

scratches

6) Stitches are skipping.

7)

Bobbin

thread

low.

8)

The

needle

facetothe

1) Distance

hook

blade

is

not

2) Needle bar height is

3)

4)

5)

6)

7)

correct.

correct.

Needleisbent.

Needle

plateistoo

Needle

footistoo

Thread

needle.

Thread

tensionistoo

recess

correct

from

the .sewing

from

holeinthe

great.

slotinthe

great.

clings to

tension

does

the

the

No.

high.

8) Presser

9)

sufficient

works.

Bobbin

low.

foot

does

pressuretothe

thread

tensionistoo

not

for

high.

sewing

tension

not

direction.

needle

not

throat

presser

heated

1 is

give a

the

too

Corrective

o

o

o

Use

the

quality.

Correct

thread

Prevent

measures

threadofbetter

the

and

the

over-heating

thread).

o

Reduce

o

or

o Provide the sewing

o

o

o

o Align the engraved lineofthe

o

o Bring

n Bring

o

o

o

o

the

Remove

such

burrs

from

by using an

or replace

parts.

blade

from

timing.

Hn.sure the needle bar height.

Adjust

between

bobbin

Insert

rect

Correct

timingofthe .sewing

relatedtothe

needle

endofthe

bushing.

Replace

the

withaproper

the

needle

the

the

threads.

the

needleinthe

way.

the

bar

with

the

down

and

increa.sc

stroke

(it

weight

increase the .sewing

stroke.

Prevent

heating.

Reduce

turning

tension

Increase

pressure.

Increa.se

tension.

occurs

materials).

down

the

the

counter-clockwi.se

nut

the

the

combination

needle.

needle

from

(synthetic

thread

tension.

scratches

the

oilstoneorbuff.

defective

thread

or

path

hook

clearance

andacorrect

thread

tension

needle

and

cor

clearance

needle

needle.

the

bar

and

hook

bottom

lower

needle.

the

needle

sewing

in light

needle

bar

hook

bar

the

the

hook

needle

from

thread

ten.sion by

No.

1.

presser

bar

bobbin

thread

of

over

and

the

Page

17

16

23

17

17

23

23

16

18

17

- 31 -

Page 35

Troubles

Causes

Corrective

measures

Page

3.

Isolated

idling-

loops

("Baloonstitch")

4, Wobbling

or waving

stitches.

S.

Idle

stitching.

6.

Loose

stitch.

I) Sewing

2) Adjust

3)

4) Feed dog

5)

6)

7)

1)

2)

3)

4)

5) Needle bar

1) Inclinationofthe

2)

3) Positionofthe

4)

1)

2)

3)

4) Thread take-up lever excessive

5)

6) Feed dog

7)

8)

hook

the

sewing

Needleistoo

out

plate

Presser

Needle

too

Tensionofthe

up spring is

Bobbin

too

Needleistoo

Threadistoo

The

not

tion.

teeth

enough from the

surface.

footisnot

thread

low.

not

thread

high.

recessofthe

facetothe

thread

not

proper.

is

Presser

footisnot

not

proper.

Thread

tensions

proper.

Needle

thread

too

low.

Bobbin

thread

too

high.

Threadistoo

needle.

ly takes up

Feed

out

plate

Thread

pass

throat

thread

paths.

Tensionofthe

spring is

the

timingistoo

teeth

enough

from

surface.

does

through

plate, tension discs.

take-uporother

not

is defective.

hook.

thin.

does

not

throat

suitable.

tension

thread

enough.

tension

thin.

thick.

needle

correct

guide.

feed dog

suitable.

feed dog is

are

not

tension

tension

thick

for

thread.

early.

does

not

the

not

smoothly

the

sewing

thread

enough.

Jut

is

take-

is

does

direc

is

is

the

jut

throat

hook,

thread

take-up

0 Replace

o

o

o Increase the

the

Increase

stroke.

Useathicker

the

sewing

hook.

sewing

hook

needle.

heightofthe

feed dog.

o Use a feed dog which has a

wider

needle

slot

and

thread

thread

thread

partofthe

position).

3-(5).

tensions.

thread

thread

thread.

the

thread

arm.

the

a

guide.

height

larger

relief

bottom

o

Increase

tension.

o Increa.se the spring tension.

o

Reduce

tension.

o

Replace

o

Replace

o

Insert

correct

angle on its

face.

the

the

bobbin

the

the

the

needleinthe

direction.

needle

needle.

thread.

o Use a .smaller

o Raise the

feed dog

o

Refertothe

o Move the feed dog closer to

operator.

o

Reduce

o

Increase

tension.

o

Reduce

tension.

o Change the

the

o Move

guide

o Delay the feed timing.

o Slightly increase

the

o

Polish

front

(front-up

the

the

the

needle

upwards

(A)onthe

feed dog.

the

surfaceofthread

above

thread

needle

bobbin

combination

and

paths.

o Increase the spring tension.

22

17

21

16

16

16

17

17

17

21

the

16

16

17

of

17

25

20

of

21

16

-

32

-

Page 36

Troubles

Causes

9)

10)

Bobbin

stable

while it is being

out.

Bobbin

spin in

thread

fails to

the

tensionisnot

smoothly

bobbin

case.

pulled

Corrective

o

Replace

case.

o Replace it

bobbin.

measures

the

bobbinorbobbin

withanaluminium

Page

7. Puckering

8. Slipping

of

cloths.

o

Reduce

the

needle

1)

Needle

thread

paths

throat

plate,

thread

haveasmooth

proper.

does

not

case.

slotinthe

great.

too

high.

tensionistoo

on the sewing

tension

take up lever

too

early.

feed dog is o Correct the feed dog height.

thick.

spin in

the

throat

tension.

o

Polish

the

thread

surfaceofsuch

paths.

o Adjust the feed timing to

standardora

the

standard.

o Raise up the

feed dog

0

Replaceitwithathinner

needle.

o

Replaceitwithanaluminium

bobbin.

o Use a

a

Reduce

small

(front-up

throat

needle

the

thread take-up spring.

not

give a o Increase the pressure

presser

bar.

o Raise up the

feed dog (front-up position).

feed.

o Use a feed dog with the course

teeth.

o Use a feed dog with the up

right

o Use a feed dog

teeth.

of

a sharper pressure angle.

high.

2) Tliread

hook,

discs or

does

not

surface.

3) Feed timing is

4) Inclinationofthe feed dog

is

not

5) Positionofthe

too

high.

6)

Needleistoo

7) Bobbin

bobbin

8)

Needle

plateistoo

9) Tension of the thread take-up o

spring is

1) Presser foot does

sufficient pressure to the

cloths.

2) Inclinationofthe feed dog is

not

suitable.

3) Feed timing is too late. o Make the feed timing earlier.

4)

Failureinmaterial

thread

little

later

front

partofthe

position).

plate

which has

slot.

tensionofthe

of

front

partofthe

with

the

than

the

teeth

the

16

20

21

21

17

16

18

21

20

9. Irregular

stitches

(as sewing

speed

changes)

1) Sewing speed is too high.

2)

Needle

thread

tensionistoo

high.

3)

Bobbin

thread

throat

components

tensionistoo

plate,

tension

take-up lever

does

surface.

low.

4) Thread path on the sewing

hook,

discs,

thread

other

and

not

haveasmooth

o Reduce the sewing speed.

o

Reduce

tensioninrelation

bobbin

o

Increase

tensioninrelation

needle

o Polish such

thread.

using an

33

-

the

needle

thread

tension.

bobbin

thread

with

thread

with

paths

thread

the

oilstoneorbuff.

the

the

2

16

17

by

Page 37

Troubles

Causes

5)

Tensionofthe

spring is

6)

Thread

is

not

7)

Bobbin

spininthe

thread

not

enough.

take-up

guide (A) on the arm

properly

docs

positioned.

not

bobbin

smoothly

case.

Corrective

o

o Move the thread guide (A) up

o

measures

Reduce

the

stroke

increase

the

and

tensionofthe

take-up spring,

wards.

Replaceitwithanaluminium

bobbin.

Page

16

25

-

34

-

y

Page 38

VII.

JZ-D31

DIAGRAM

SHOWING

METHOD

OF

ASSEMBLING

TABLE

88101-552-000

SM-9082023-SE

WP-0871602-SE

WS-08614t0-KR

S0-1204215-SE

WP-1252210-SC

WS-1253010-KN

08207-012-000x2

88209-125-000

x4

x4

x4

x4l

x4

x4

x2

40

88204-012-000

SK-1211000-SC

D8203-555-B00

D7114-555-BAB

B8216-O12-0A0

88126-552

SM-9082023-SE

WP-0871602-SE

WS-0861410-KR

1

NM-6080721-SE

88212-125-000

B8213-125-AA0x2

D820I-555-C00

x2

x4

88102-552-000

88104-552-000

x2

x2

SK-3514000-SDx4

B8105-552-000

D8112-555-80E

SM-9061203-SE

WP-0671016-SE

WS-0621210-KR

88111-552-000

x3

x3

x3

88103-552-000

88112-552-000

WP-0871602-SE

WS-08614I0-KR

SM-9082023-SE

88110-652-000

NM-6120003-SE

88107-552-000

08113-555-800

x2

x2

x2

x2

D8II4-555-80E

SM-9082023-SE

WP-0871602-SE

WS-0861410-KR

MM-6080721-SE

35

x2

D8110-555-80E

08115-555-800

-

E

88108-552-000

I

^88109-552-000

Page 39

IX. DIMENSIONAL DIAGRAM

OF

THE

TABLE

(TOP

SURFACE)

-90-

rSoH

3-^6S(holetl

H—100

X^35£as

Ihoio)

sLTzfoi:'

is

1^%

POWER

SOURCE

SWITCH

installing

POSITION \

jiTTfTr

-40-'

-50

DRAWER

INSTALLING

miTION

STOPPER

INSTALLING

POSITION

LifU

106

•(525J-

LEG

INSTALLING

POSlTiON

t—80

"il.s

2

♦18

-Cf•

't

•«.

^

-76-

-tl5-

fzio

LEG

INSTALLING

POSITION

Ihol*il

Page 40

>.

-ip

I

TOKYO

TOKYO

Head Office & Plant: 2-1, 8-chome, Kokuryo-cho, Chofu-shi,

Business Office: 23-3, Kabuki-cho 1-chome,Shinjuku-ku, Tokyo

Cable:

JUKI

JUKI

TOKYO

INDUSTRIAL

Telex:

22967;

JUKI

232-2301

CO..

Tokyo,

'

LTD.

Japan

16Q,

Japan

hfedinTapan(T)

Loading...

Loading...