Page 1

MODEL

HIGH

SPEED,

INDUSTRIAL

EQUIPPED

MODEL

HIGH

SPEED,

LOCKSTITCH

EQUIPPED

MODEL

HIGH

SPEED,

INDUSTRIAL

EQUIPPED

MODEL

HIGH

SPEED,

INDUSTRIAL

EQUIPPED

DDL-552-2•553-2•555-2

SINGLE

NEEDLE,

SEWING

SINGLE

INDUSTRIAL

SINGLE

SEWING

SINGLE

SEWING

MACHINE

NEEDLE,

NEEDLE,

MACHINE

NEEDLE,

MACHINE

WITHANAUTOMATIC

DLN-415-2

WITHANAUTOMATIC

DLU-450-2

WITHANAUTOMATIC

DLD-432-2

WITHANAUTOMATIC

LOCKSTITCH

UNDERTRIMMER

NEEDLE

SEWING

UNDERTRIMMER

TOP

UNDERTRIMMER

DIFFERENTIAL

UNDERTRIMMER

MACHINE

AND

FEED.

BOTTOM

FEED

FEED

UKI

Instruction

"Qt

•JUKI

TSK

Book

TOKYO

JOKI

INDUSTRIAL

CO.,LTO

Page 2

CONTENTS

I.

GENERAL

1.

2. Main

II.

HOW

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

III.

HOW

1.

2.

3.

4.

5.

6. Adjusting

7. Adjusting

8. When low speed sewing is

9. Carefully

10. How

IV.

ADJUSTING

1. Adjusting

2. Adjusting

3.

4.

5. How to sharpen

6. Changing

7. Adjusting

8. Adjusting

9.

10. Adjusting

11. In

V.

DDL-552-2-3

DDL-553-2-3 DDL-553-2-4

DDL-555-2-3 DDL-555-2-4

VI.

DDL-555-2-2B

VII.

MALFUNCTIONS

DESCRIPTION

Outstanding

features

specifications

TO

INSTALL

Table

Installing

the

THE

motor

Limitoflow-speed

Lengthofbelt

Installing

Installing

Installing

Construction

Function

Howtohandle

Adjusting

TO

the

the

the

of

the

OPERATE

control

machine

pedal

and

operationofmotor

the

cord

the

clutch

THE

Cautiononoperation

Lubrication

Trial

Howtooperate

Threading

Howtoinstall

The

floating rangeofthe

and

runofthe

the

the

the

note

to

select

THE

the

the

adjusting

machine

the

machine 13

thread

needle

the

following

the

presser

MACHINE

timing of

positionofthe

the

fixed

the

the

moving knife 20

the

bobbin

the

slide shaft 22

Howtoinstall

caseofelectrical

and

the

installing angle of

DDL-552-2-4

DDL-555-2-4B

AND

MACHINE

rotationofthe

box

head

and

its

adjustment

control

box

and

machine

lever

cautions

switch

gap 10

MACHINE

the

oiling

amount

pedal

tension 13

stop

position

not

after

thread trimming 14

necessary 15

points

foot,

throat

the

plate, sewing

thread

trimming cam 16

hook

and

feed dog 15

moving knife 17

knife

correctly

second

thread

tension

disc 19

knife blade 20

thread presser 21

remove

the

knife

the

synchronizer

installing

base

malfunctions

CORRECTIVE

MEASURES

VIII. CIRCUIT DIAGRAM, TIME CHART 33

IX.

DIAGRAM

SHOWING

METHOD

OF

ASSEMBLING

TABLE

1

I

1

2

2

2

3

3

3

3

4

5

6

9

11

11

11

11

12

15

16

18

22

23

2^

25

27

28

35

Page 3

1.

Outstanding

1)

By a

sewing,

controlled,

2)

The

by

electric

features

Simple

operation

simple

operationofone

stopping

Stable

and

all

worriesofoperational

efficiency

thread

trimming

devicetoproduce

I.

GENERAL

pedal,

thread

trimming

tolerances

movementisinterlocked

constant,

with

stable

DESCRIPTION

this

machine

utmost

are

efficiency.

will

perform

ease. Also, as

eliminated.

with

the

rotationofthe

the

high

thread

speed

trimmer

machine

sewing,

is electrically

and

low

speed

controlled

3) All

All

foot,

needle

4)

This machine is

stepped on for high speed sewing until

pedalisstepped

5)

All

attachments

attachments

plate,

Dependable

on.

Compact

the

thread

canbeused

which

are

slide plate, etc. can be used on this

safety

device

equipped

construction

used

without

for

alterations

conventional

lockstitch

machine

with

a dependable safety device by which

the

thread trimming is completed after the thread trimming

machines,

without

any

trimming mechanisms are built-in inside the bed in rational

suchasfeed

alterations.

the

machine

ordersothat

dog,

cannot

presser

sewing area is amply wide and all attachments can be used freely.

2.

Main

specifications

Sewing speed DLD-432-2 Up to 4,200 s.p.m.(Cotton) Up to 4,000 s.p.m.(Synthetic Fiber)

Low-speed

the

machine

Threads

Sewing

Needles

hook

Motor

Electric

Safety

control

device

rotation

box

DLU-450-2 Up to

DLN-415-2 Up to

DDL-555-2 Up to

DDL-552-2 Up to

DDL-553-2Upto

of

Cotton

Synthetic

Cotton,

thread

thread

synthetic,

DB type automatic lubricating

DB

x 1

DA

Stop

positioner

needle

positioner)

AMCO

motor

Super

stop

Voltage

Voltage

IC

Built-in

control

power

control

inside

4,200

5,000

5,000

5,000

4,300

Maximum

Maximum

silk

x 1

clutch

motor

DC

46V,

AC 100, 115, 200,

system

the

motor

s.p.m.(Cotton) Up to

s.p.m.(Cotton)

s.p.m.(Cotton) Up to

s.p.m.(Cotton)

s.p.m.

150

s.p.m.

120

s.p.m.

hook

with bobbin thread guide groove attached

motor,

400W (Hitachi

DC 5V

240,

380,

lever

Up to

Up to

4,000

4,000

4,000

4,000

clutch

415V

s.p.m.(Synthetic Fiber)

s.p.m.(Synthetic

s.p.m.(Synthetic Fiber)

s.p.m.(Synthetic

motor

with

automatic

(All ±10%)

Fiber)

Fiber)

be

the

- 1 -

Page 4

II.

HOW

TO

INSTALL

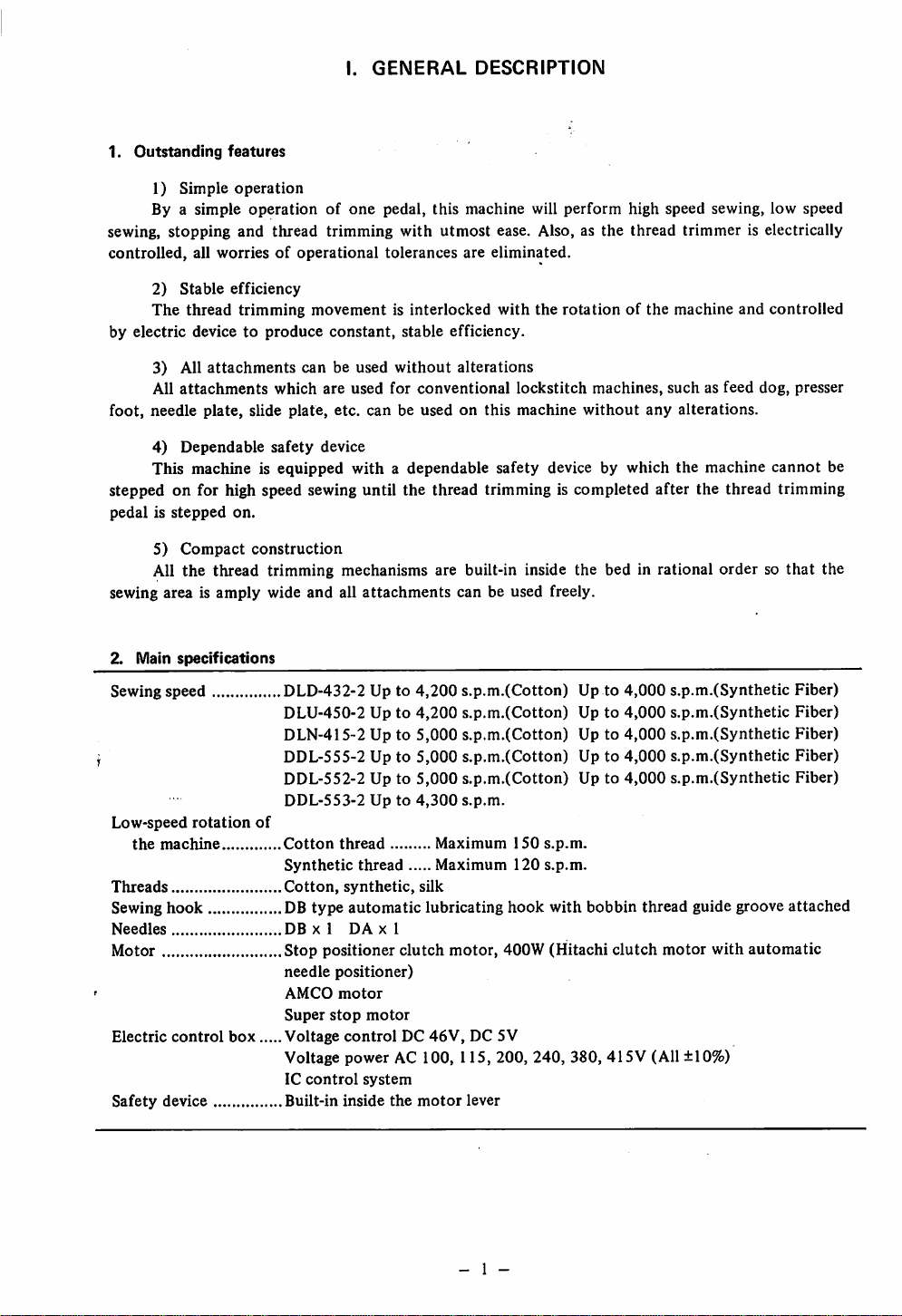

This

machine

machines.

lever,

trimming

machine

All operations are controlled by the pedal and by the

the

control

mechanism

If the adjustment of the pedal is inadequate or if the connections of the cords are wrong,the

will

not

After the

machine.

1.

Table

1)

The

installing

the dimensional diagram which is enclosed within this book.

2)

Fig.l

shows

*

The

installed

purpose of removing the rear cover of the motor easier.

2.

Installing

the

is equipped with different kinds of

box,

with

and the

function

machine

positions

the

position

motor

harmonious

needle

properly.

is properly installed,

of the

rear viewofthe

of the control box is

cooperation

positioner clutch motor, the thread is neatly

table

legs,

set-up.

give

THE

MACHINE

devices

with

the

it a trial run and

than conventional lockstitching

signals

given

needle

positioning

verify

the correctrunning of the

motorandcontrolboxetc. are

rather

far

away

from

the

motor

out from the motor

synchronizer,

trimmed.

clearly

but thisisfor the

thread

illustrated by

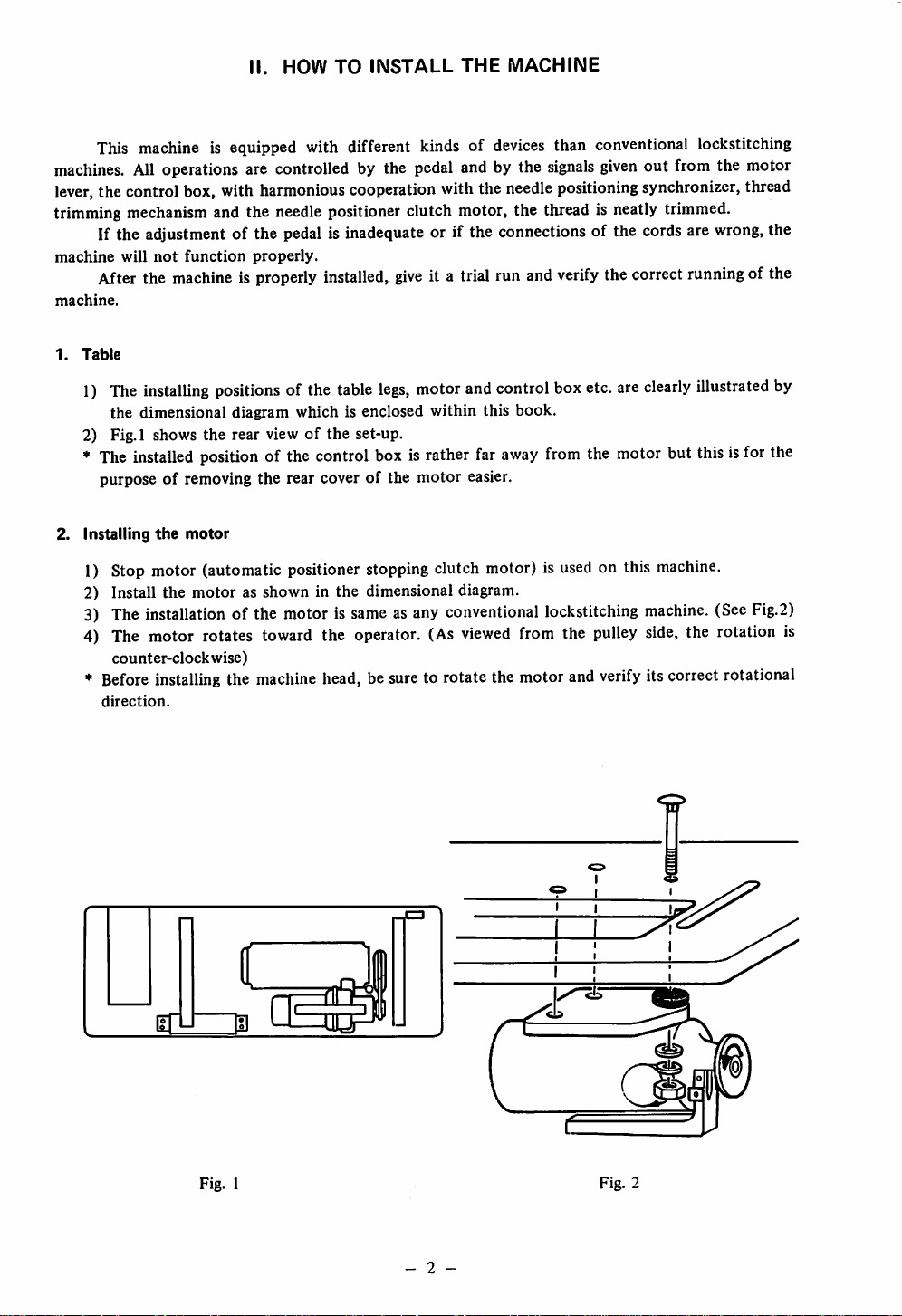

1) Stop motor (automatic positioner stoppingclutch motor) is

2) Install the

3)

The

4)

The

counter-clockwise)

*

Before

direction.

motor

installation

of the

motor rotates

installing

the

as shown in the dimensional diagram.

motorissame

toward

machine

the operator.

head,besure

asany

conventional

(As

viewed

to rotate the motorand

from

a

used

on this

lockstitching

the

pulley

verify

I I

I !

machine.

machine.

side,

(See

Fig.2)

the rotation is

itscorrect rotational

Fig. 1

- 2 -

Fig. 2

Page 5

50

cycle

3.

Limitoflow-speed

For

trimming

1)

With

determined,

the

sizeofthe

machine:

Outer

the

dia.ofmotor

pulley

High speed

Low

speed

the

For

cotton

For

synthetic

Hitachi,

low-speed

motor

rotation

Hitachi

NATIONAL

rotationofthe

thread,

the

limitoflow-speed

thread

thread

NATIONAL

revolution

pulley

with

the

125.5mm

s.p.m.

5060

s.p.m.

230

machine

motor,

number

high

116.5mm

4630

210

Under

Under

when

is also

and

150

120

low

105mm

4250

rotation

s.p.m.

s.p.m.

the

set.

speed

193

shouldbeas

high-speed

Following

rotational

95.5mm

3820

175

follows:

rotation

table

shows

revolution

the

relation

numberofrevolutionofthe

90.5mm

3610

160

81.0mm

3390

155

number

between

76.0mm

is

High speed

_9}

"o

>,

u

'

Low

o .

vo

4.

speed

Lengthofthe

The

lengthofthe

Lengthofbelt

*Note:

Putonthe

wheel.

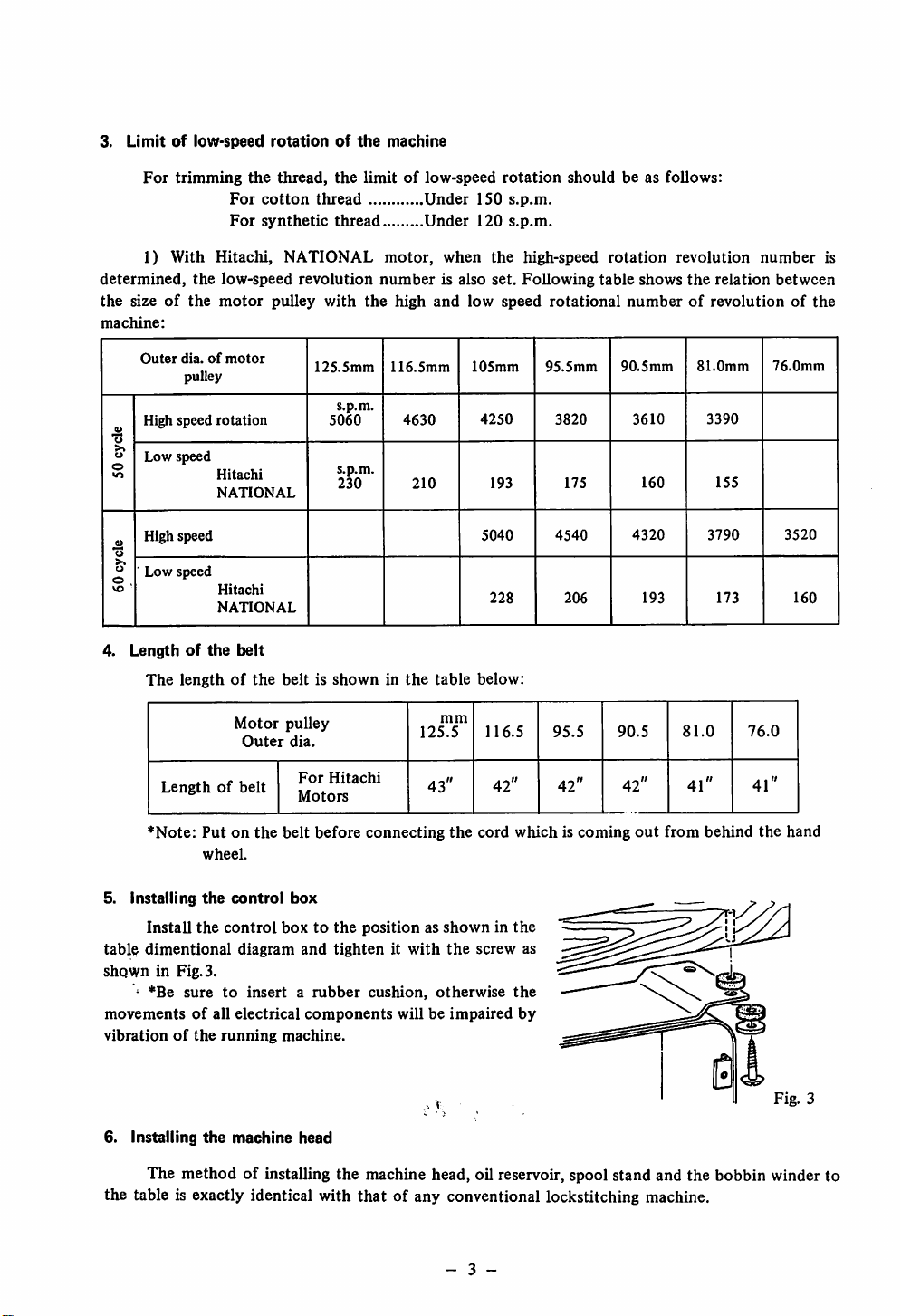

5. Installing

table

dimentional

shown

'

Install

in Fig. 3.

*Be

sure

the

the

movementsofall

vibrationofthe

Hitachi

NATIONAL

belt

beltisshowninthe

Motor

Outer

belt

control

control

boxtothe

diagram

to

insertarubber

electrical

running

machine.

pulley

dia.

For

Hitachi

Motors

before

box

and

components

table

mm

125.5

43"

connecting

the

positionasshowninthe

tightenitwith

cushion,

will be

the

otherwise

impaired

5040

228

below:

116.5

42"

cord

whichiscoming

screw

as

the

by

4540

95.5

42"

206

4320

193 173

90.5

42"

out

from

81.0

41"

3790

behind

76.0

41"

the

3520

160

hand

.

"1-

6.

Installing

The

the

table is exactly identical with

the

method

machine

of installing

head

the

machine head, oil reservoir, spool stand and

that

of any conventional lockstitching machine.

- 3 -

the

bobbin winder to

Fig. 3

Page 6

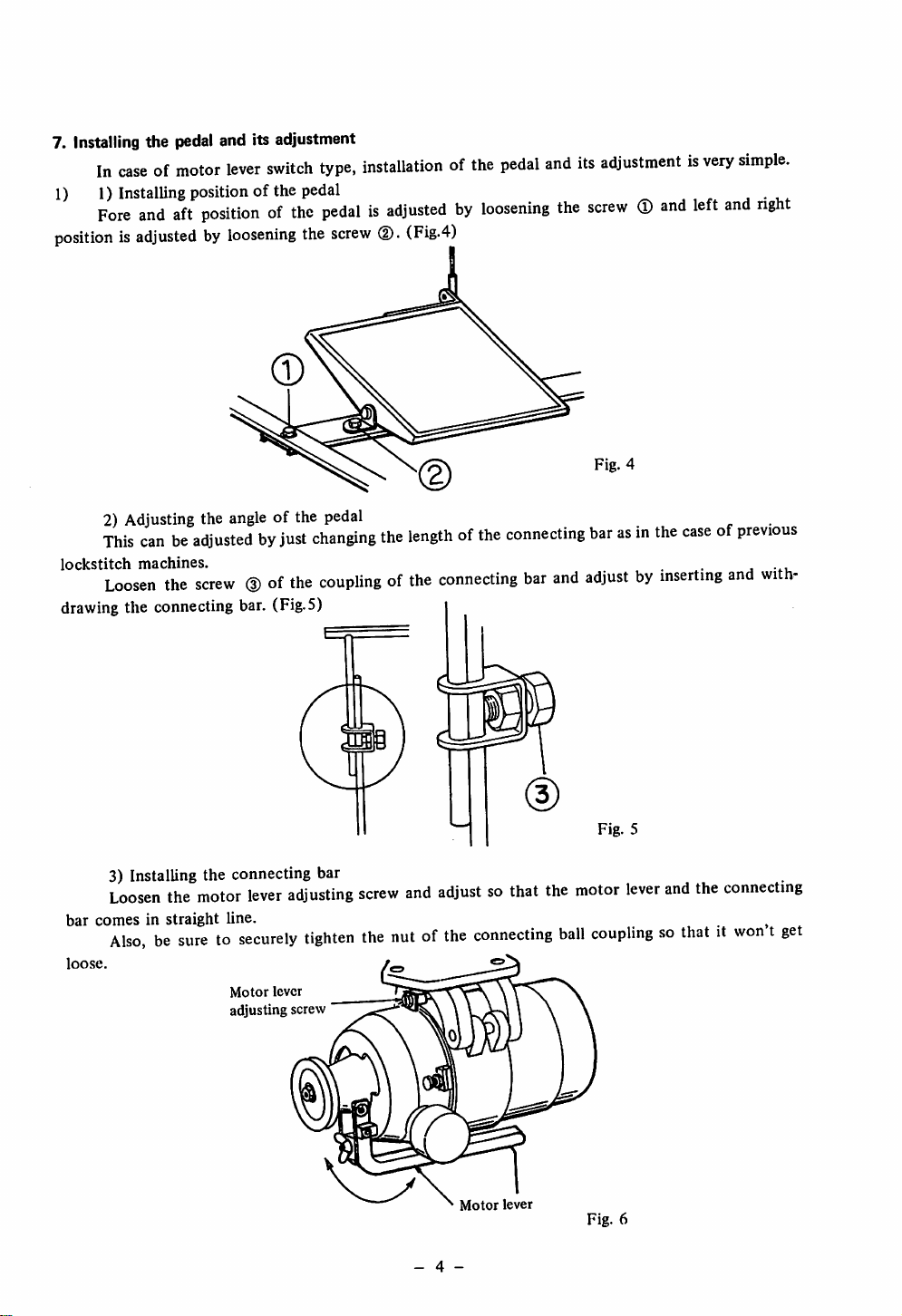

7. Installing the pedal and its adjustment

In

caseofmotor

1) 1)

positionisadjustedbyloosening

Installing

Fore

and

lever

position

aft

positionofthe

switch

ofthe

type,

pedal

pedalisadjustedbyloosening

the

screw

installationofthe

(Fig.4)

pedal

and

the

its

adjustmentisvery

screw

(T)

and

Fig. 4

left

simple.

a •

and

right

U4-

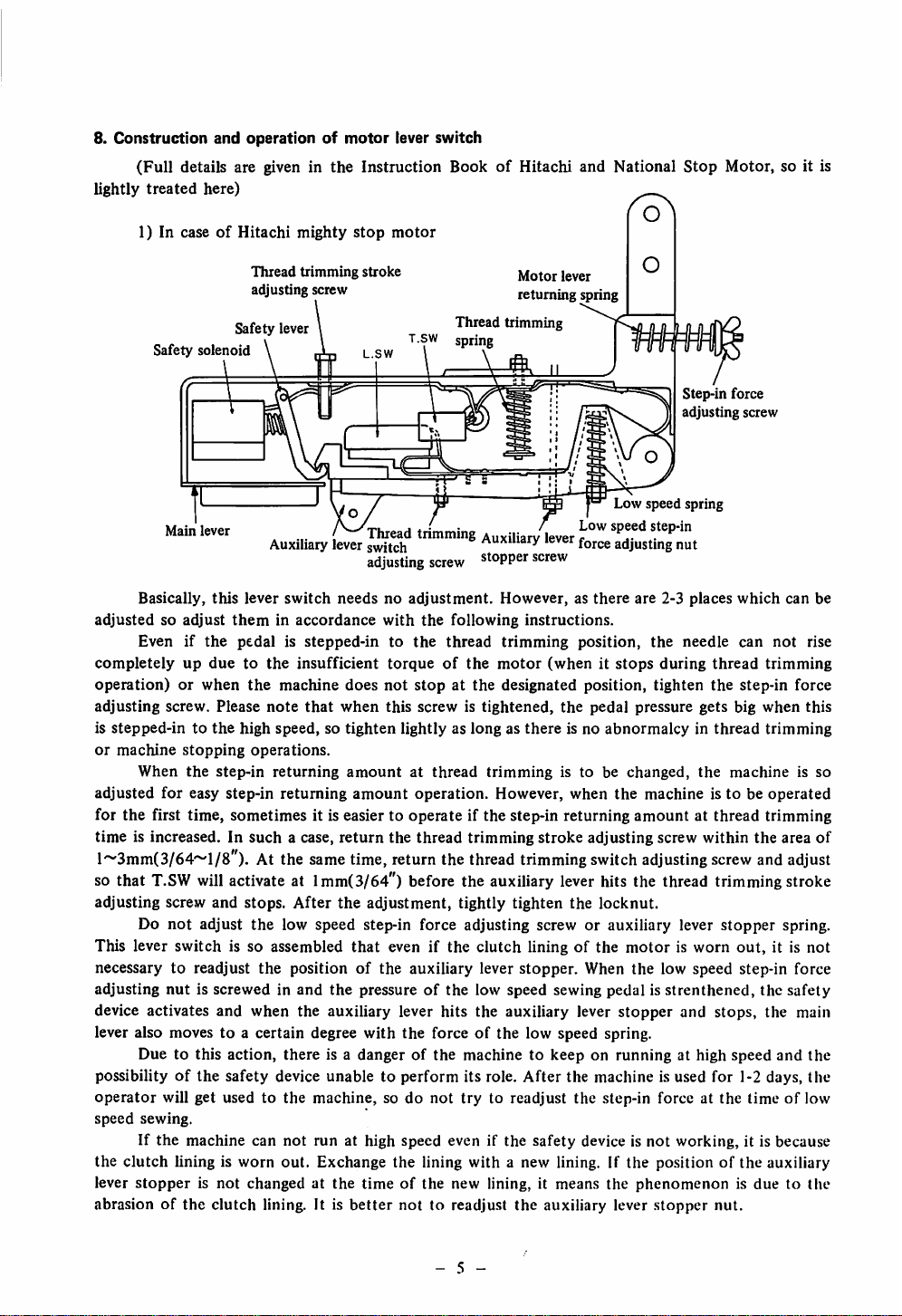

2) Adjusting the

This

canbeadjustedbyjust

lockstitch machines. j

Loosen

drawing

3) Installing the connecting bar

Loosen

bar comes in straight line. ^

the

the connecting bar. (Fig.5)

the

Also,besuretosecurely

loose.

angle

screw(Dof

motor

lever

Motor

lever

adjusting screw

of the pedal

changing

the

couplingofthe

adjusting

tighten

the

screw

the

nutofthe

lengthofthe

connecting

and

adjustsothat

connecting

connecting

bar

barasin

and

adjustbyinserting

the

motor

ball

couplingsothatitwontget

Fig.

5

lever

the

caseofprevious

and

and

the

connecting

with

Motor

lever

- 4 -

Fig.

6

Page 7

8.

Construction

(Full

lightly

treated

and

operationofmotor

details are given in

here)

the

Instruction

lever switch

BookofHitachi and National

Stop

Motor, so it is

1)IncaseofHitachi

Safety

Safety solenoid

Main

lever

Basically,

adjustedsoadjust

Even if

completelyupduetothe

operation)orwhen

adjusting

is

stepped-intothe

or

machine

When

adjusted

for

the

first time, sometimes it is easier to operate if the step-in returning

time

is increased. In

this

theminaccordance

the

screw. Please

stopping

the

step-in

for

easy

step-in

pedalisstepped-intothe

high speed, so

l~3mm(3/64~l/8"). At the sametime, return the thread

so that

adjusting screw and stops.

This lever

necessarytoreadjust

adjusting

device activates and when the auxiliary lever hits the auxiliary lever

T.SW

Do

will

activate at lmm(3/64") before the auxiliary leverhits the thread trimmingstroke

not

adjust

switch

is so assembled

nut

is screwed in and

mighty

Thread

adjusting screw

lever

Auxiliary

lever

switch

insufficient

the

machine

note

operations.

returning

returning

such

a case,

After

the

low speed step-in force adjusting screw or auxiliary lever

the

positionofthe

stop

motor

trimming

/^

lever

stroke

L.SW

Thread

switch

adjusting

needsnoadjustment.

with

torqueofthe

does

not

that

when

this screw is

tighten

amount

amount

return

the

the

adjustment,

that

even if

the

pressureofthe

Motor

returning

Thread

T.sw spring

trimming

screw

the

following

thread

stop

at the designated position,

lightly as

at

thread

operation.

thread

trimming

Auxiliarv'lever

Auxiliary

stopper

However,asthere

instructions.

trimming

motor

tightened,

longasthere

trimming

However,

trimming

trimming

tightly

the

auxiliary lever

tighten

clutch

liningofthe

stopper.

low speed sewing pedal is

lever

spring

lever

force

screw

position,

(whenitstops

the

pedal

is no

abnormalcyinthread

is to be

when

stroke

adjusting

switchadjusting

the

locknut.

When

adjusting

the

stopper

changed,

motorisworn

the

lever also moves to a certain degree with the force of the low speed spring.

Due to this

possibilityofthe

operator

speed

the

lever

will get used to the machine, so do

sewing.

If

the

clutch

stopperisnot

abrasionofthe

action,

safety

machine can

lining is worn

changed at

clutch

there

is a dangerofthe machine to

device

unabletoperform

not

run at high speed even if the

out.

Exchange the lining with a new lining. If the position of

the

timeofthe

lining. It is

better

not to readjust the auxiliary lever

its role.

not

try

to readjust the step-in force at

new lining, it means the

keeponrunning

After

the machine is used for 1-2 days,

safety

device is

Step-in force

adjusting screw

speed

spring

nut

are

2-3

places

which

can

the

needle

during

tighten

pressure

machineistobeoperated

amount

screw

low speed step-in force

strenthened,

and stops, the main

at high

not

working, it is because

phenomenonisdue

stopper

can

not

thread

trimming

the

step-in force

gets

big

when

trimming

the

machine

at thread trimming

within

the

area

screw

andadjust

stopper

the

spring.

out,

it is

the

speed

and

timeoflow

the

auxiliary

safety

to the

nut.

be

rise

this

is so

of

not

the

the

- 5

Page 8

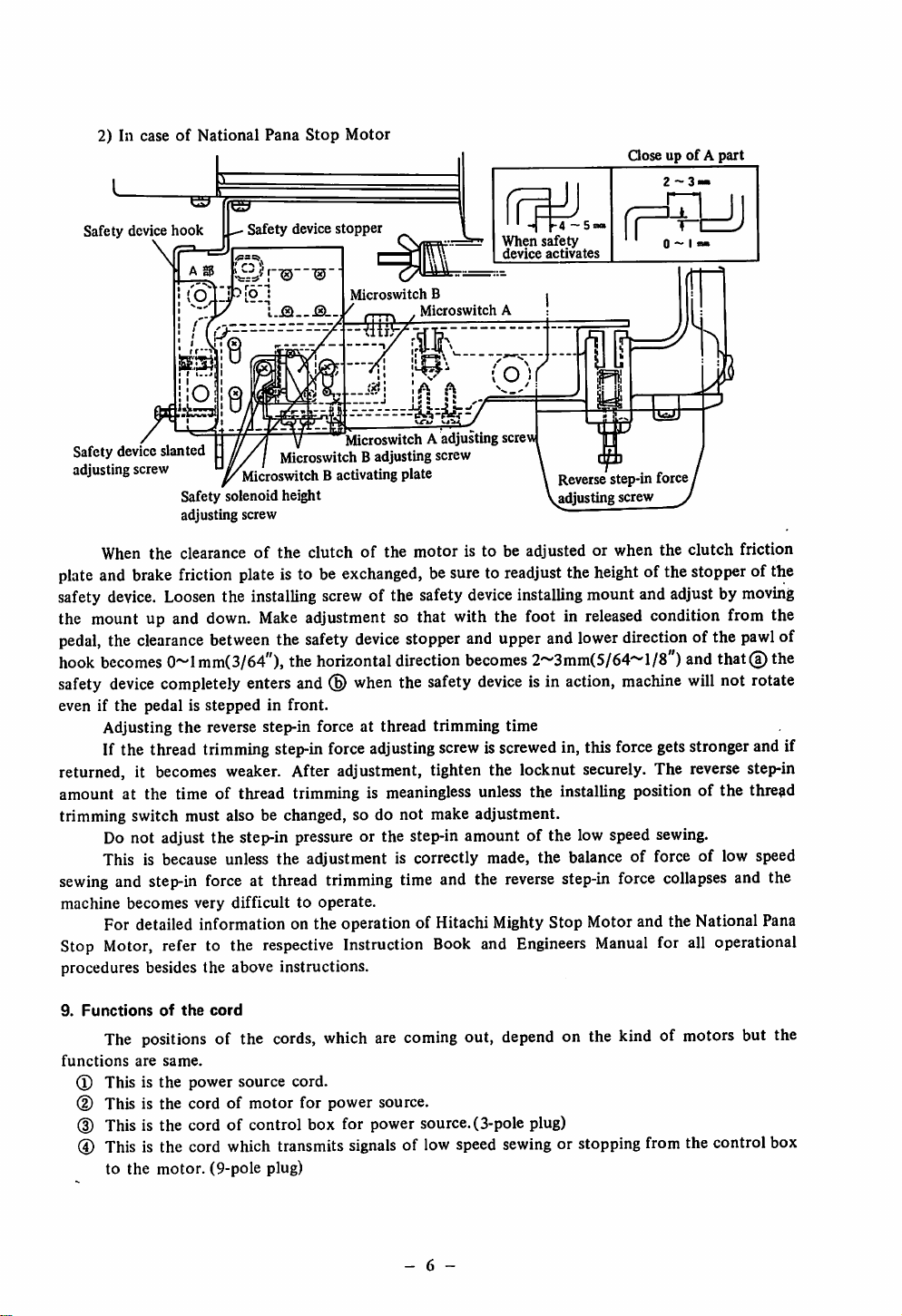

2) In caseofNational

Pana

Stop

Motor

QoseupofApart

2-3.

Safety device

hook

\

Safety device slanted

adjusting

screw

Safety solenoid height

adjusting screw

Safety

device

stopper

Microswitch

Microswitch B adjusting screw

Microswitch B activating plate

Microswitch A adjusting screw

B

Microswitch

When

device

A

>-4 — 5 not

ifety

Si

ictivates

s

Reversestep-in force

adjusting screw

0 - 1 «

m

When the clearanceofthe clutch of the motor is to be adjusted or when the clutch friction

plateand brakefriction plateis to be

safety

device.

the mount up and

pedal,

the

hook

becomes

safety

device

even if the pedal is

Adjusting

Loosen

clearance

the installing

down.

Make

between

0~lmm(3/64"), the

completely enters and

stepped

the

reverse step-in force at thread trimming time

the safety

in front.

exchanged,

screw

of the safety

besureto readjust the

device

installing mount and adjustby

adjustment so that with the foot in

device

stopper and upper and

horizontal

(B)

when

direction

the safety

becomes

device

2~3mm(5/64~l/8")

is in action,

height

released

lower

direction of the

machine

of the stopper of the

moving

condition from the

pawl

and

that@ the

will

not rotate

If the thread trimming step-inforce adjustingscrew isscrewedin, this force gets stronger and if

returned, it

becomes

weaker.

After adjustment, tighten the locknut securely. The

reverse

step-in

amount at the time of thread trimming is meaningless unless the installing position of the thread

trimming switch must also be changed, so do

not

make adjustment.

Do not adjust the step-in pressure or the step-in amount of the low speed sewing.

This is because unless the adjustment is correctly made, the balance of force of low speed

sewing

machine

and

step-in

becomes

force

at thread trimming time and the

very

difficulttooperate.

reverse

step-in force

collapses

and the

For detailed information on the operation of Hitachi MightyStop Motor and the National Pana

Stop

Motor,

procedures besides the above instructions.

refer to the

respective

Instruction

Book

and

Engineers

Manual

for all operational

of

9.

Functions

The positions of the

functions

(l)

Thisisthe

(D This is the

are

of

same.

the

cord

power

source

cordofmotor

cords,

cord.

for

which are

power

source.

coming

out, depend on the kind of motors but the

(D This is the cord of control box for power source.(3-pole plug)

@ This is the cord which transmits

to the motor. (9-pole plug)

signals

of low speed

- 6 -

sewing

or stopping from the control box

Page 9

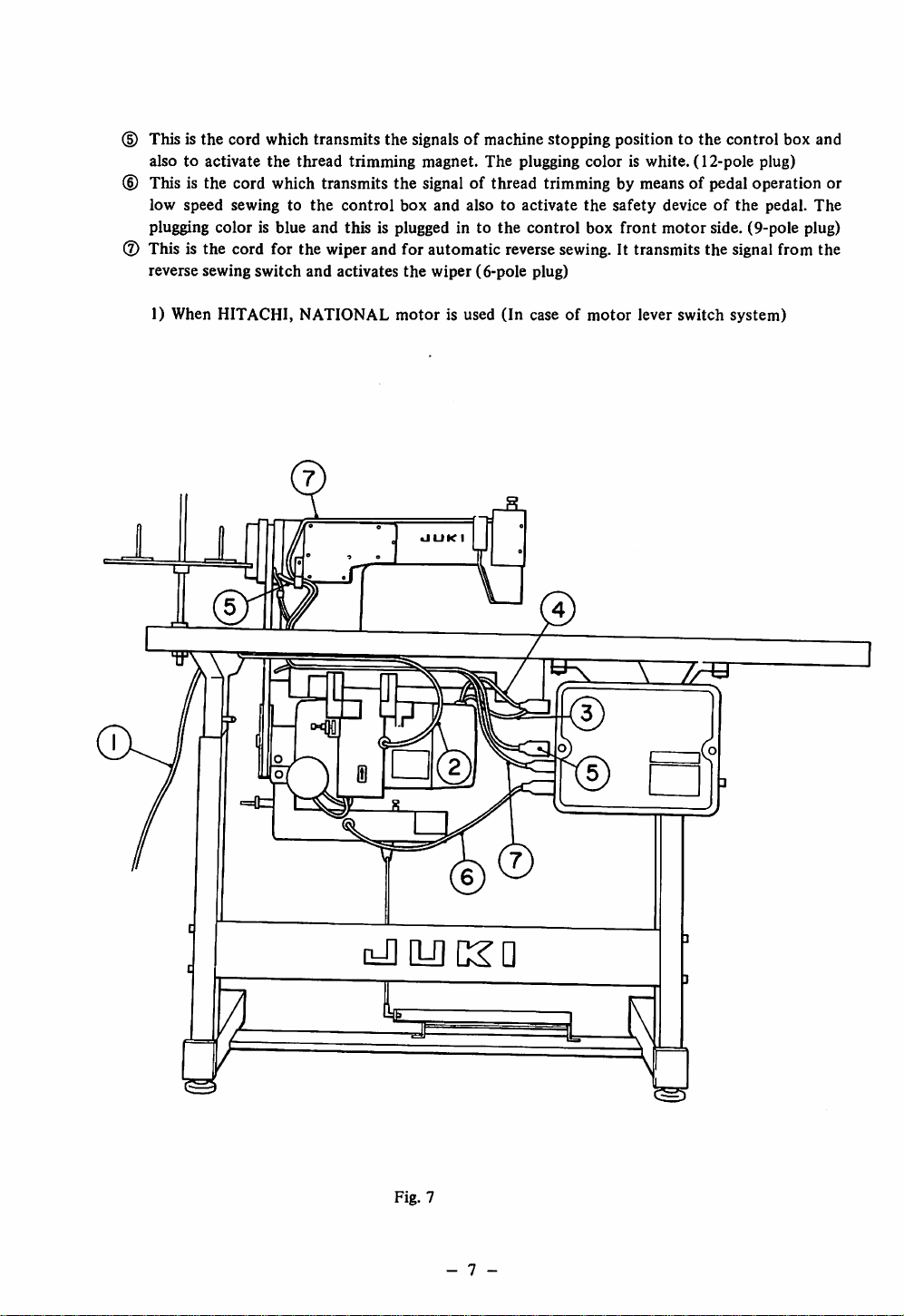

® This is the cord which transmits the signals of machine stopping position to the control box and

alsotoactivate

the

thread

trimming

magnet.

The

plugging

coloriswhite.

(12-pole

plug)

(D This is the cord which transmits the signal of thread trimming by means of pedal operation or

low

speed

sewingtothe

plugging

(2)

This is the cord for the wiper and for automatic reverse

reverse sewing

color

is blue

switch

and

and

control

this

is plugged in to

activates

box

the

and

alsotoactivate

wiper

(6-pole

the

control

sewing.

plug)

the

safety

deviceofthe

box

front

motor

side. (9-pole plug)

It transmits the signalfrom the

pedal.

The

1) When HITACHI, NATIONAL

JJ

motor

UUK

is used

I

(In

caseofmotor

lever switch system)

i-i][U]c:^a

Fig. 7

- 7

Page 10

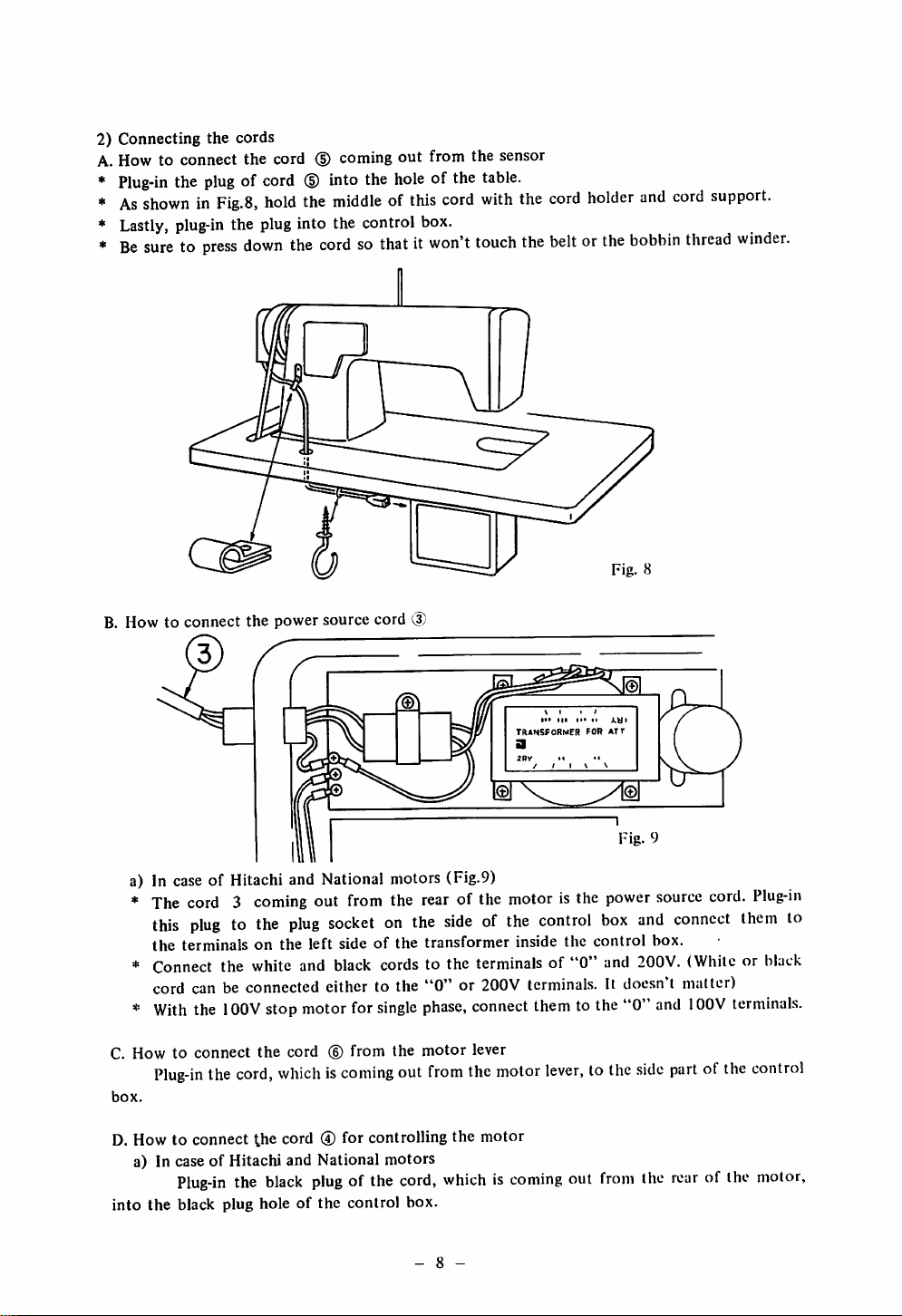

2) Connecting the cords

A. How to connect the cord (D coming

Plug-in

As

Lastly,

Be

the

plug

of cord

showninFig.8,

plug-in

suretopress

the plug into the control box.

down

(§)

into the

hold

the

middleofthis

the

cordsothatitwon't

out

from the sensor

hole

of the

cord

table.

with

touch

the

cord

the

beltorthe

holder

and

cord

bobbin

support.

thread

winder.

B. How to connect the power source cord

a) In case of Hitachi and National motors (Fig.9)

*

The

cord3coming

this

plugtothe

the terminals on the left side of the transformer inside the control box.

*

Connect

cord can be connected either to the

*

With

C. How to

Plug-in

box.

D. How to connect

a) In case of Hitachi and

into

the

the

white

the

lOOV

connect

Plug-in

black plug hole of the control box.

the

the

cord,

the

the

out

from

plug

socketonthe

and

black

stop

motor

for

cord (6) from the

whichiscoming

cord ® for controlling the

National

black

plug

of the

the

cords

single

out

motors

cord,

(3)

rear

of the

motor

sideofthe

to the

terminals

"0"

or 200V terminals. It

phase,

connect

motor

lever

from

the

motor

motor

whichiscoming

\ 1 1 '

transformer

a

2Ry

/ / 1 \ \

control

of "0"

them

lever,tothe

M

isthe

out

AWi

for

att

•!

Fig.

power

box

and

cloesn

to the"0"

from

9

source

and

200V.

and

side

the

connect

t matter)

partofthe

rear

cord.

Plug-in

them

to

(Whiteorblack

lOOV

terminals.

control

of the

motor,

- 8

Page 11

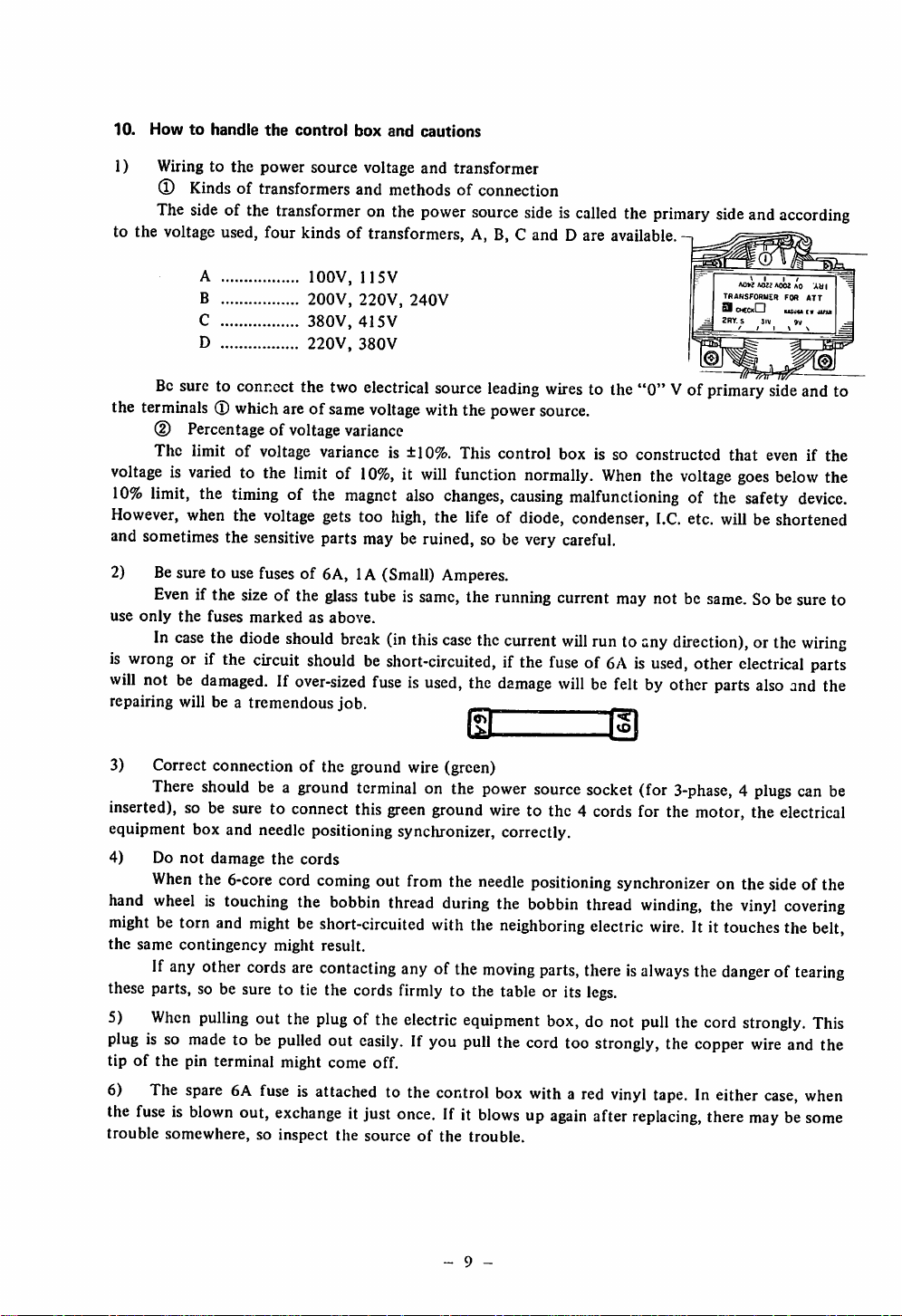

10.

Howtohandle

1) Wiring to the power source voltage and transformer

® Kinds of transformers and methods of connection

The

side

to the voltage used, four kinds of transformers, A, B, C and D are available.

of the

the

control

transformer

box

on the

and

cautions

power

source

sideiscalled

the

primary

side

and

according

A lOOV, 115V

B

C

D

Be

sure to connect the two electrical source

the terminals® whichareof same

(D Percentage of voltage variance

The limit of voltage variance is ±10%. This control box is so constructed that even if the

voltageisvaried

10%

limit,

However,

and sometimes the sensitive parts may be ruined, so be very careful.

2) Besure to use fuses of 6A, 1A (Small) Amperes.

use

is

wrong

will

repairing will be a tremendous job. -

3) Correct connection of the ground wire (green)

Even

only

In

not be

when

the

case

or if the

There

inserted),

equipment box and needle positioningsynchronizer, correctly.

4) Do

hand

so be

not

When

wheelistouching

mightbetorn

the

same

contingency

If

any

these

parts, so be sure to tie the

5)

When

plug

is so

tipofthe

6)

the

trouble

pin

The

spare6Afuseisattached

fuseisblown

somewhere,

to the limit of

the

timing

the

if the sizeof the

fuses

markedasabove.

the

diode

damaged.Ifover-sized

should

suretoconnect

damage

the 6-core cord coming out from the

and

mightbeshort-circuited

other

cords

pulling

made

to be

terminal

out,

200V,

220V,

380V,

415V

220V,

380V

voltage

10%,itwill

of the

voltage

should

circuit

magnet

gets too

glass

tube is

break

shouldbeshort-circuited,

fuseisused,

be a

ground

terminal

this

the

cords

the

bobbin

might result.

are

contacting

cords

out

the

plug

of the

pulled

out

easily.

might

come

off.

exchange

so inspect

it just

the

sourceofthe

240V

leading

with the power

function

also

changes,

high,

the life of diode, condenser,

same,

the runningcurrent may not be

(in

this

case

the

normally.

causing

current

if the

the

damage

dL

on the

green

thread

anyofthe

firmly

electric

If you

to the

once.

power

sourcesocket(for

ground

with

during

the

wire

to the 4

needle

positioningsynchronizer on the sideof the

the

bobbin

neighboring

moving

to the table or its

equipment

pull

the

cord

control

box

If it

blowsupagain

trouble.

withared

wires

to the

"0"

source.

When

the

malfunctioning

will

runtoany

fuseof6Aisused,

willbefelt

by other

dl

cords

for the motor,the

thread

winding,

electric

parts,

thereisalways

legs.

box,

do not

too

after

pull

strongly,

vinyl

replacing,

wire.

tape.Ineither

Vof

voltage

I.C.

direction),

3-phase,4plugs

the

the

AOK AOJJ

TRANSFOHUER FOR ATT

9

OCCkCI

2RY. S Siv 9v

primary

goes

of the

etc.

will

same.

other

electrical

parts

the

It it

touches

the

dangeroftearing

cord

copper

there

AOOJ

AO AMI

usuuc»iini

sideand to

below

safety

device.

be shortened

Sobesureto

orthe

wiring

parts

also

and the

can be

electrical

vinyl

covering

the

belt,

strongly.

wire

case,

This

and the

when

maybesome

the

9 -

Page 12

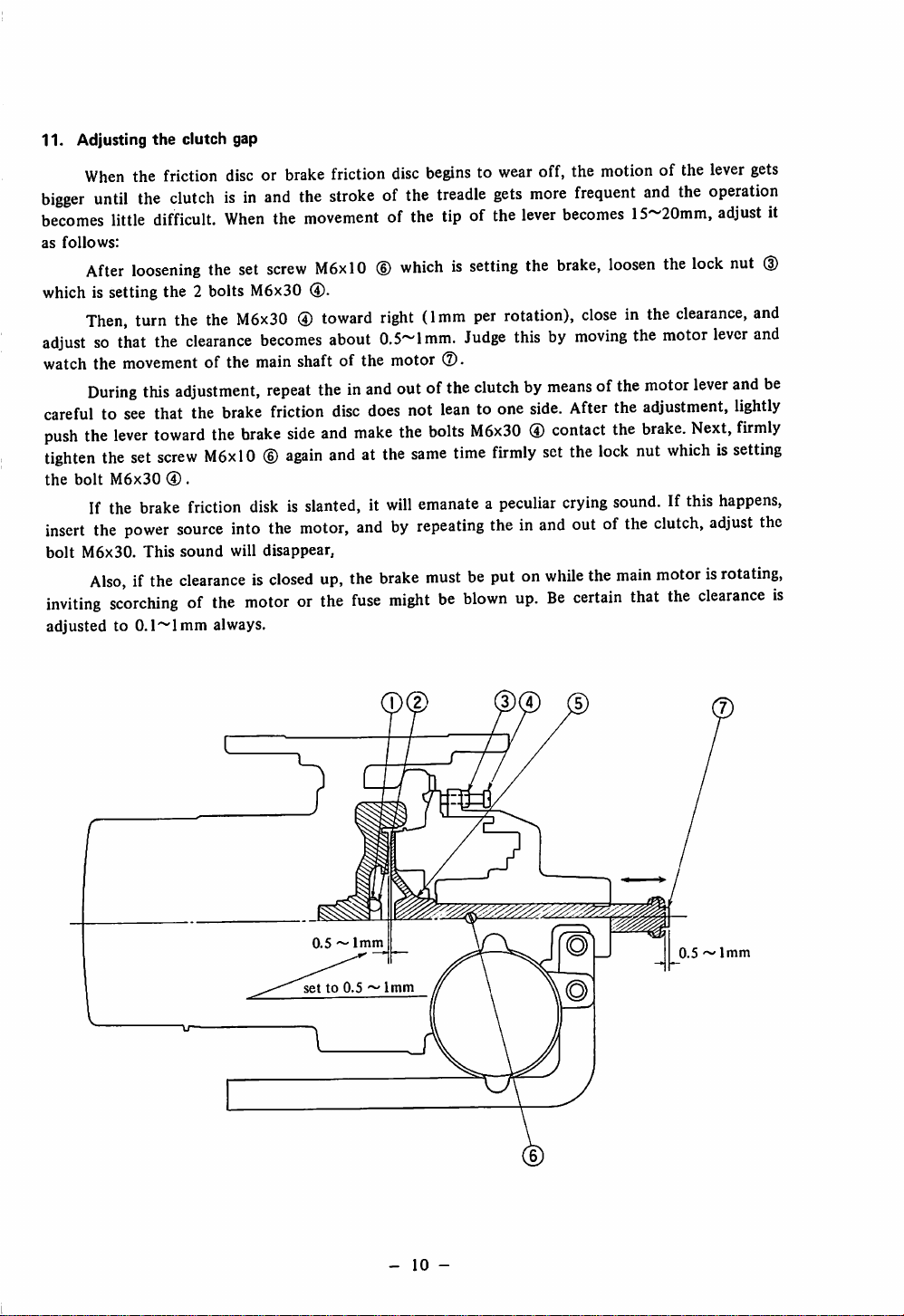

11. Adjusting

When

bigger

until

becomes

as

follows:

After

which is setting the 2 bolts M6x30 ®.

Then,

adjustsothat

watch the movement of the main shaft of the motor

During

carefultosee

push

the

tighten

the

bolt

If the

insert

the

bolt

M6x30.

Also,ifthe

inviting

adjustedto0.1~lmm

the

clutch gap

the

friction

the

clutchisin

little

difficult.

loosening

turn

lever

the

set

M6x30

power

this

brake

This

the

the

the

the

clearance

adjustment,

that

the

toward

screw

M6xl0®again

® .

friction

source

sound

clearanceisclosed

scorchingofthe

discorbrake

and

the

When

the

movement

set

screw

M6xl0®whichissetting

M6x30®toward

becomes

repeat

theinand

brake

friction

the

brake

side

and

diskisslanted,itwill

into

the

motor,

will

disappear,

up,

motororthe

always.

friction

disc

strokeofthe

of the tip of the

right

about

0.5~lmm.

outofthe

disc

does

not

make

the

andatthe

same

andbyrepeating

the

brake

fuse

mightbeblown

beginstowear

treadle

(1mm

per

Judge

(2).

off, the

gets

more

lever

becomes

the

brake,

rotation),

thisbymoving

clutchbymeansofthe

leantoone

bolts

M6x30®contact

time

emanateapeculiar

side.

firmly

set

crying

theinand

mustbeputonwhile

up.Becertain

motion

frequent

15~20mm,

loosen

closeinthe

the

After

the

the

the

lock

sound.

outofthe

the

main

that

of the

lever

and

the

operation

adjust

the

lock

nut

clearance,

motor

lever

motor

lever

adjustment,

brake.

Next,

nut

whichissetting

If this

happens,

clutch,

adjust

motorisrotating,

the

clearance

gets

(D

and

and

and

be

lightly

firmly

the

it

is

0.5~1mm

setto0.5~1mm

-

10

-

0.5^1mm

Page 13

III.

HOW

TO

OPERATE

1.

Cautionsonoperation

Turn

the switch on

direction

of

the

machine.

once

THE

and

MACHINE

after

turning it off,

steponthe

pedal and observe the

rotational

* Unpack the machine and after setting it up, clean it well.

* Before operating this machine, please read and digest every paragraph of the INSTRUCTION

BOOK

on DDL-552, 553 and 555 or DLN-4I5, DLU-450, DLD-432 thoroughly.

* Do not run the machine without filling up the oil reservoir.

* The machine should rotate toward the operator. (As

counter-clockwise).

Do

not

run

the

machineinthe

* For the first month, drop the speed to 4,500 s.p.m. for

s.p.m. for

DLN-415-3

and 3,800 s.p.m. for

DDL-553-3,

viewed

reverse

from the pulley side, the direction is

direction.

DDL-552-3

DLU-450-3

and

and

DLD-432-3.

DDL-555-3

and 4,300

After that,

increase the speed depending on the nature of work and the capability of the operator.

*

When

the power switch is turned on, do not put your hands around and under the needle parts.

* When the

power

switch is

turned

on, do

not

touch

the

hand wheel.

* When the machine head has to be tilted for oiling or cleaning, be sure to turn the switch off.

* If the needle does not stop at the top position evenwhenthe pedalisstepped on toward the rear,

turn

the

switch

off.

* When transporting the machine, do not touch the cover on the rear part of the hand wheel.

* Sometimes when the power switch is turned on and the thread is trimmed but if you step on the

pedal to the rear immediately after these actions, the needle will not come down and trimming

cannotbedone.

down

and

normal

In such a case,

trimming

canberesumed.

just

steponthe

pedal

toward

front

once

and

the

needle will

come

2. Lubrication and adjusting

the

oiling

amount

Before running the machine, fill up the oil reservoir with the designated JUKI industrial

machine oil to the "HIGH" mark.

separate

3.

Trial

instruction

runofthe

volume.

machine

Please

refer to the chapter on "Lubrication and drainage" on the

* At first, verify the correct movement of the machine without passing the thread.

1) When the power switch is turned on, the needle always stops at the raised position. In case

the needle does not stop at the raised position, refer to the chapter on "Malfunctions and corrective

mea.sures"

and

make

proper

adjustment.

2) Step on the pedal lightly toward front and verify the correct low speed sewing operation.

If the

machine

functions

to ascertain

and

3) After the pedal is stepped on front (away from the operator) and

that

does not function

corrective

the

machine

measures".

stops

with

even

after thesere-adjustments, referto the chapteron "Mal

the

foot is released, be sure

the

needle at

lower

position.

-

II

-

Page 14

4) Step on the pedal

5)

Re-adjusting

Step

on the

of the

magnet

If these

the

pedal

will

if the

machine

machineatthis

6) Insert

Note:

*"Front"

*"Rear"

the

pedal

working

movements

not

move

should

the

move

position.

needle

means

means

toward

low-speed

toward

from

rear

under

rear and

switch

(the

thread

the

bed,

verify

and

immediately

are repeatedoverand over

toward

and

front

for

low-speed

start

away

toward

any

sewing.

from

the

operator

more.Atthis

sewing,

the

operator

the tlircad

verifying

trimming

again,

re-adjust

trimming

the

correct

switch

will

step

on the

invariably there

position,

the

the

low-speed

operation.

working

start)

andifyou

pedal

machine

sewing

of the

safety

hear

tov/ard

will

bea position

front.

willbestopping

switch

device.

the

sound

where

but

to stop the

4. Howtooperate

As

showninFig.

CD

The

(D

When

(D

When

@

When

*

Normal

either from high speed or low speed sewing.

thread

* After the

to the

neutral

needle

goesupand

the

pedal

10, the

pedal

machineisstopping

the

pedalissteppedonlightly

the

pedalissteppedonfurther

the

pedalissteppedonfully

trimming

machine

can be

hasstarted the

position.Itis

stops.

of this

byjust

performed

trimming,

not

necessarytokeeponsteppingonthe

machine

resting

functions in 4

your foot

to front, it

lightly

becomes

stronglytofront,itbecomes

toward

High speed

Low

Stopped position

"

Thread

rear,

the

machine

even

if the pedalisstepped on abruptly to the rear

the

trimming

speed

trimming

canbedone

stagesasfollows:

on the

pedal.

low-speed

sewing.

high

will

perform

even

if the

pedal

speed

thread

pedal

to the

sewing.

trimming.

isreturned

rear

until

HIGH

LOW

STOPPED

POSITION

the

SPEED

SPEED

THREAD

TRIMMING

Fig.

10

-

12

-

Page 15

* When the machine is stopped, the needle always comes down and stops.

* If the lowered needle is to be raised up again, step on the pedal toward rear fully. Needle goes up

and

stops

after

the

trimming

(Caution)

After completing the trimming (stepping the pedal to rear), if you try to step on the pedal to

front suddenly, sometimes the pedal

is acting to prevent any undue damage to the machine. In such a case, return the pedal to the rear

once

and

then

step

on

running.

5.

Threading

*The needle always stops at the raised position. But if it is at the lowered position when thread

ing the machine, step on the pedal toward rear once and do the trimming action once. Then the

needle will goupand

*Pass the needle thread in the order of (D ~

the

machine

stops

the

pedal

there.

action.

toward

will

not

move.

front

Thisis becausethe safety deviceinsidethe pedal

once

more

and

the

©as

shown in Fig,27.

machine

will

start

its

normal

6. Adjusting

machine. Please follow the procedures as outlined in the INSTRUCTION BOOK on DDL-552, 553

and 555, DLN-4I5, DLU-450 or DLD-432. However, please note

attachedtothis

the

thread

tension (Fig.28)

Adjusting the thread tension of this machine is exactly like a conventional lockstitching

that

due to the thread trimmer

machine,

the

adjustmentislittle

different

than

other

lockstitch

machines.

First

tension

disc

WeakIStrong

(Adjusts

the

thread remaining at

the

trimming >

length

needle

eye

after

(D

(4)

Strong

w

Second

tension

Weak

(adjusts

tention)

the

disc

thread

of

i

Fig. 11

-

13

-

Fig. 12

Page 16

1)

Thread

When

take-up

causing

thread.

the

becomes

spring

skip-stitching

Be

2) Adjusting the first thread tension disc

*When

needle

*For fine threads (synthetic

3) Adjusting the second thread tension

*

Normally,

*

the thread might break at the start of sewing.

4) Adjusting the

The

ing

machine.

causing

the

breakageorslipping

*Asa rule, this

idle

spinning

7.

Adjusting

After

the

standard

control

red mark on the arm and the white mark on the hand wheel are matched with each other.

box)toright

If the

standard

will stop below the standard stopping position (in case of B).

* If the thread should slip out even if the length of needle thread isadjustedafter the thread

is trimmed, rotate the adjusting knob toward the

* If the needle should hit the wiper, rotate the knob toward the "FAST" direction, (toward

[A]

direction).

(Caution)

If the

sometimes the machine does not stop. In such a case rotate the knob toward the "FAST" direction.

take-up.^ring

fine cotton thread or synthetic

may

become

extremely

the tension of the firstthread tension is madestronger,the threadremaining at the tip of

eye

longer.

However,

adjustment

careful.

becomes

the adjustment of this

please

However,

needle

threadto"float"upat

of the

the

needle

the thread is

needle

adjusting

stopping

position

adjusting

too

strongorthe

just

before

the

shorter

note

bobbin

of the

if the

outof

machineisused

bobbin.

stop

stop

and

after

fiber),

that

when

thread

bobbin

tension

the

needle

(Part

number

position

trimmed,

position,

rotate the

leftso that,after the

knobisrotated

(in

caseofA)

knob is rotated too

threads

rangeofmovementofthe

machine

stops

trimming

weaken

discissame

synthetic

tension.

thread

tensionispractically

istoo

weak,

the

thread

at thestartof

with a bobbin

is D

after

thread

this

machine

needle

toward

and

much

the

ifit's

(tetoron,

and

and

when

the tension and for thick thread,

threadisused,

the

bobbin

startofsewing,

1837555

trimming

can

position

threadistrimmed

"FAST"

rotated

"SLOW"

toward

nylon

eic.)arc

sometimes

it is

as any other lockstitching

the

made

ifthe

sameasany

might

spin

and

sewing

caseinwhichamagnet

BAO

and

might

sold

used,

spring

may

machine

weaker,

tensionisadjusted

conventional

idly

at the

for

synthetic

occur.Bevery

separately)

(Fig.13)

change

the

needle

stop

position.

adjusting

direction,

toward

direction, (toward [B] direction).

the

"SLOW"

knob

(I)

and

the

needle

the

needle

the

"SLOW

direction (towardBdirection),

the

tension

become

does

not

the

remaining

make

it stronger.

machines.

trimming

threads,

is built-in to

To adjust to

(on the

has

stopped,

will

stop

direction,

too

trim

too

lockstitch

careful.

side

above

the

of the

wide,

thread

weak,

instant,

thread

prevent

of the

needle

the

the

the

IB)

[A]

^^"FAST"

"SLOW"

Adjusting

)iiiii)ii)i

knob

Standard

stop

position

i/mmn

Throat

needle

plate

Adjusting

knob

Fig.

13

-

14

-

Page 17

8. When low speed cewing is

not

necessary (Fig.14)

* Be sure to cut off the power and makeadjustment.

at

the

startofsewing;

(T)

Cut off the power source.

(D

open

the cover of the control box.

(3)

Pull

function.

Thus,

out the

the low

inserted

speed

® of the

sewing

figure

function can be eliminated without affecting the thread trimming

n

Fig.

from

the pin

14

When

fg)

and

low speed

insert

sewing

is not necessary

it into the pin (0.

9. Carefully

note

the following points

* Be certain that the needle thread comes out smoothly from the thread spindle.

(Otherwi.se,

the remaining thread at the needle eye after trimming will become short and thread slipping out

might

result.)

* When skip-stitching occurs, the bobbin thread may break but the needle thread docs not

break. In such a case, re-adjust the timing of the needle with the sewing hook.

10.

How

to selectthe

1) Presser foot Select small a and b parts (Fig.15)

2) Throat plate Select small needle eye and A part.

3) Needle Finer needle for less thread slippage

4) Sewing hook Automatic lubricating hook with a groove

presser

foot, throat plate,

sewing

hookandfeed dog

5) Feed dog If a feed dog which is commonly used is adopted, there is no problem,

but if an extremely thick feed dog is used, the backside of the dog teeth might be scratched when

the moving

knife

1)

2)

Presser

Throat

moves fully.

foot

plate

}

Na

Fig.

15

-

15

-

Page 18

IV.

ADJUSTING

THE

MACHINE

This machine consists of lockstitching part and the thread trimming part. The lockstitching

function is same as all

other

previous models, so this text will cover the thread trimming part only.

1. Adjusting

the

timingofthe

indicated

before

cam

roller

that

condition,

hand

the

1)

Howtojudge

In

order

lineonthe

Tilt

the

the

upper

(Fig.

wheel

will

matchedsothat

(Fig. 18 (D)

are

indicating line

synthetic

thread.

timingofthe

the

to change

thread

hand

machine,

dead

point

17) will

rotate

the

cometoa

the

indicated

matched

(Fig.l8

(D)

thread

trimming

correct

the

trimming

wheel,

turn

enter

hand

timingofthe

lengthofthe

cam.

accordingtothe

the

hand

andifthe

the

point

sewing

cam

grooveofthe

wheelinthe

where

wheel

lineofthe

togetherasshown

is matched with

cam

trimming

thread

This can be

with

hook

reverse

it will

not

arm

(Fig.18 (D)

in Fig. 18, it

the

indicating line

Thread

cam

cam

remaining at

done

the

easily by

kindofthread

your

hand

until

presser (Fig. 16 (D) is

cam

(Fig.

17)

direction

rotate

than

any

more.Atthis

and

the

becomesacotton

(Fig.l8

trimming

needle eye

used-cotton

the

and

the

after

matching

thread

pushed

will be

interlocked

conventional

trimming,

the

arm

or

synthetic

take-up

deeplytoright,

way,

pointifcam

indicated

lineofthe

thread

hand

timing. But if

(D), it becomes a timing for

Rotational

direction

Mil

with

comes

there.

and

timing is

adjust

the

thread.

just

the

In

the

wheel

the

2)

Howtomatch

First,

No.2,

and

cotton

thread,

the

green

Then,bypushing

roller,

and

normal

not

finally

hook

rotate

tighten

loosen

match

color

without

any

Fig. 16

match

(D),

shaft

more,

the

DLD-4322

the

timingofthe

the2set

the

screwsofthe

indicating

red color (i) with

(Fig.

18)

the

sewing

rotating

the

rotational

push

the

cam

set

screws

lineofthe

hook

hook

direction

cam

(Fig.

Cam

roller

Cam

roller

set

screw

trimming

cam

with

the

shaft

cam

(Fig.17) in

indicating

arm

thread

trimming

arm

the

red color (D and for

presser (Fig.16 (D)toright,

shaft,

rotate

the

cam

only

with

your

finger tips. At

against

17)inthe

the

thread

orderofNo.2

-

16

trimming

-

synthetic

toward

the

cam

and

Rotate

direction

Fig.

17

order

from

lineofthe

thread, red

interlock

the

reverse

position

thrust

No.l.

caminthis

with

hand

set

screw

hand

the

cam

direction

where

collar

wheel.

color

and

the

(Fig.

No.l

(I)

the

than

cam

17)

Set

Thrust

screw

and

(For

with

cam

the

does

and

collar

No.2

Page 19

2.

Adjusting

shown

centerofthe

needleorbobbin

knife

knife

1)

The

in Fig.l9,

might

correctly.

the

correct

hit

Green

positionofthe

positionofthe

when

the tip of the

needle.

When

threadatthe

each

other.

moving

the

retreated

trimming

Therefore,

knife

moving

moving

range

instant,

it is

knife

whenithas

moved to

its

maximum

knifehasretreated to 2~2.5mm(l/6"~3/32")

is less

than

this

whileifit's

very

important

position,itcannot

too

much,

to

match

2

~2.5mm

the

feed

the

positionofthe

dog

scoop

and

range is, as

from

the

up

the

the

moving

moving

Needle

Fig. 18

Moving

knife

Fig. 19

2) How to match the position of the moving knife

This is adjusted by changing the right or left position of the moving knife shaft (Fig.20

®)

when the machine stops. By this adjustment, the interlocking of the cam and the cam roller also

changes, so match the positionofthe thread trimming cam toward the shaft direction, also.

a. First, loosen the magnet set screw (Fig.20 (D and pull

b. Move the magnet link (Fig.20 (£)) downwards and adjust the .screwed-in

out

the magnet link pin (Fig.20 (D).

amount

of the knife

moving shaft adjusting nut (Fig.20 (D). If this nut is screwed in deep, the retreating range of

th the knife becomes greater and if it's loosened, the range gets less.

c. Loosen

both

set screws of trimming cam

(7)

and the thrust collar (6).

d. Match the indicating line of the hand wheel with the indicating line of the arm.

(2)

(In case of cotton thread, match (D with

of Fig.18 and for synthetic thread, match (D with

e. Rotate the set screw No.2 (Fig.20®)(indicated point) of the trimming cam so that it comes to

front and when it comes to front, push the sewing hook presser to right.

f. Move

the

cam to right and left

and

interlock

the

cam

and

the

cam roller.

g. With this condition, as you pull the cam to right, move it toward teh arrow direction until the

cam

cannot

h.

Temporarily

i.

Tighten

j. At this

(D

Is the indicating line of the pulley matched?

(2)Isthe

rotate

anymore.

the

point,

tighten

lock

nut.

verify

the

(Fig.20

the

set

screw

(D)

following:

No.2(Dof

the

roller inserted smoothly into the cam groove?

cam.

(DIs the retreated range of the moving knife 2~2.5mm?

k. Tighten the two set screwsofthe cam securely.

1.

Push the thrust collar against the cam and tighten the two set screws,

m. Attach the magnet link pin in its original position.

(3))

-

17

-

Page 20

The simple

step

partofthe

parallel,

(Note)

1) No

the

the

matter

retreating

2) Verify if

methodtojudge

bed and

positioniscorrect.

how slight

rangeofthe

the

moving knife disposes

the

the

the

correct

forked baseofthe

position of

the

moving knife would be to verify if

knife are paralled to

each

other.Ifthey

the

are

right or left position adjustment may be, it has a big bearing on

moving

knife.

the

thread

properly as shown in Fig.21.

s

0

3. HowtoInstall

The

correct

®(2)(3)®(4

the

fixed

knife

correctly

methodofinstalling

wism

the

0

fixed

knifeisshowninFig.22.

Fig.

Fig. 21

The

20

standard

distance

from

the center of the needle to the tip of the fixed knife is 4.2mm(5/32"). The tip of the fixed knife

shouldbe0.6mm

When

the

cutting

the

cutting

be

changed,

installation

above

the

the

angleofthe

partofthe

power

be sure to verify

(Fig.22A).

fixed

becomes

installing

installing

knife

most

powerful.

the

sharpnessofthe

surface.

fixed

and

the

(Fig.23).

knife's

moving

When

tipischanged,

knife

is precisely

the

fixed

knifeistobeadjustedorwhen

blade

andatthe

the

same

cutting

matched,

time,

power

then

adjust

changes. When

and

only

then

it is

the

angle

to

of

18

-

Page 21

Movingknife

Lower

of

throat

part

plate

Needle

a

Shorter Longer

Length of remaining thread

after trimming

Fig.

22

i.5bb

Graded

of

bed

(Note):

part

0.6mm

DLN-415-2

Set

the

feed adjusting dial to

Fixed

Fig.

knife

23

The fixed knife can be installed by moving it to the right of the standard installation position.

In that case, the length of the remaining thread of needle thread and the bobbin thread not

only gets longer by the distance the fixed knife has

moved,

but

because

the timing of the

trimming also is delayed which makes the length of the thread at the tip of the needle eye

much

longer

(Fig.25)

In the case of synthetic thread, move the fixed knife to right to delay the timing of the thread

trimming. However, to make the adjustment complete, it is alsonecessaryto adjust the timing

of

the

thread

trimmer.

(Chapt.

IV-1).

"0".

4.

The

floating

1)

At

rangeofthe

Howtoverify

the

position

the

where

second

floating

the

take-up

thread

range

has

tension

come

disc

just

before

the

upper

dead

foot and when the hook thread presser (Fig. 16 (D) is pushed hard to right, verify

rangeofthe

Bring

center

Moving knife

2)

Adjusting

second

thread

the

tension

floating

disc is

rangeofthe

0.5~lmm.

second

(DTo increase the floating range, loosen nut

©To

decrease the floating range, loosen nut

After

the

adjustmentiscompleted,

to

Fixed

knife

l(M

Sewing

tighten

Wlien

is

Standard

thread

(B)

and tighten nut

(g)

and tighten nut

both

®

and

fixed

movedtoright

knife

Moving knife

Bobbin

thread

presser

tension

(B>

disc

nuts.

(Fig.26)

©.

©.

point,

®

lower

that

(D

® d) ©

the

presser

the floating

Fig.

24

Fig.

-

25

19

-

Fig.

26

Page 22

5. Howtosharpen

The

shape

most

cases,

just

1)

It is

fixed

©

Just

sharpen

X in

Fig.27)

®

The

cutting

change the angleofx when sharpening.

®

When

blade

same time. Correct

♦

To improve the contacting of the

mark of Fig.29.

does

not

cut

Shave

and sharpen well

Sharpen this surface

A

surface

of the

sharpen

very

knife.

cutting

surface

When

well,

off

Blade

B

the

knife blade

blade

tipof the

the

blade

important

the

power

"A"

becomes

that

surface

powerisnotsogood

of the

moving

the

inclination angle of

the D side of Fig.28 does not cut well,shorten the angle and when the C side

make

the

angle

corners

tip

surface

of the

the

(Fig.27)

weak

knife

larger.

fixed

fixed

blade

surfaceofthe

when

even

and the

Fixed

knife

greatly

knifeand the cutting

affects

moving

and

cutting

the B

though

fixed

the

moving

knife

becomes

surface

the

blade

knife

is not

fixed knife.

and fixed knife,

Moving knife

the

cutting

becomes

knife

should

better.

(Note

tipissagging

tips

are

sharpened,itis

contactingtoright

change

power

and

the

sharper.

contact

the

angle

blunted.

angle

ofthe

knife.

the

blade

shown

So,donot

because

andleftat the

of the arrow

Fixed

In

of

by

the

knife

Fig.

27

Changing

the

moving knife

To change the moving knife, do as follows:

1)

Loosen

pin

2)

Remove

and

the moving knife from the knife forked base.

3)

Move

screw

the

(Fig.32

the

the

moving

the

(Fig.3IB).

knife

(D).

moving

knife

forked

knife

knife

forked

For

Fixed

base

hinge

(Fig.30

basetothe

this

purpose,

Fig. 29

knife

pin

(D)tothe

set

screw

position

use

screw

(Fig.32®)and

(Fig.30

®),

position

showninFig.31B

the

special

C&D

partsofmoving

should contact each other at the same time

Fig. 28

pull

out

the

knife

knife

and

forked

fixed

. . •

move

the

knife

forked

showninFig.31Aand

and

remove

spanner

in the

accessories

base

remove

the

knife

box.

(Fig.30

the

knife

base

/-n

(D)

pin

ol

hinged

Fig.

30

-

20

-

Page 23

move

knife

the

the

N (

Knife

forked

base

Moving knife

For

installing

the

moving

forked

forked

base). When

base.

Fig.

back,

reverse

knife

with

base to

the

position

(If

the

knife

the

shaftismovedtoright,besure

the

your

hand

showninFig.31C

moving

Knife hinged

Moving

/

31A

Knife

above

and

shaft

forked

screw

knife

procedure.

see

if it

is moved to right or

base

Fig.

moves

and

to see

31B

After

firmly insert

that

the

smoothly

the

knife

knife

hinged

without

the

knife

left,

the

movestoright,

Knife

Moving knife

screwistightened,

any

rattling.

forked

base

pin will go in

also.

forked

base

Fig.

31C

Match

pin

deep

the

into

into

7. Adjusting

the

bobbin

thread

presser

If the bobbin thread presser (Fig.32 (3)) is penetrating too deep toward the bobbin case at the

trimming time, the bobbin will not rotate and the bobbin thread will be trimmed too short, causing

thread

slippage at

the

startofsewing.

On the contrary, if it is not inserted deep enough, the needle thread will slip out from the tip

of the bobbin thread presser at the trimming time, shortening the thread remaining amount at the

tip of the needle eye after the trimming and invites thread slipping out.

1) The correct position of the bobbin thread presser

When the thread trimming lever is pressed hard against the stopper side, the bobbin thread

should be pulled out easily. At this position, the clearance between the tip (Bobbin presser) of the

bobbin thread presser and the upper carved part of the bobbin should be 1.5~2mm asshown in Fig.47.

1.5

~2mm

a

Fig.

DLD-432'2

32

V

Fig.

33

2) How to adjust the bobbin thread presser

Loosen

ond

down.Atthis

the

position

After

shaft is not contacting the bottom of the

contacting, refer to the chapter on "Adjusting the

shaft

collar.

the

screws

instant,

of the

adjusting,

(Fig.32 ®), and adjust by

adjust

the

fore

thread

trimming

tighten

the set

stopper

screw

and

arm

of the

cam

aft

moving

position

(Fig.26

the bobbinthread

ofthe

(D).Asshowninfigure.

stopper.Besuretoverify

-

groove

21

slide

-

when

the stopper is

shaft" and

bobbin

re-adjust

presser

in and out or up

thread

presser

that the tipofthe

deeply

the positionof the

and

inserted. If it's

adjusting

roller

slide

Page 24

8.

Adjusting

The

the

moving

slide

range

shaft

of the

slide

shaft

(Fig.34

®) is

5.4mm(7/32").

Thisisadjustedbymoving

the slide collar (Fig.34 (D) toward the shaft direction. Also, the position of the cam roller shaft arm

(Fig.34 (D) should be 13.5mm(33/64") as

*

The

adjusting

procedure

is as follows:

showninFig.34.

(D Determine the position of the thread trimming arm stopper depending upon the position of

the

hook

thread

presser.

(D Adjust the position of the slide collar so

that

the moving range of the slide shaft comes to

5.5mm(7/32").

(D Adjust the position of the thread trimmer magnet (DC solenoid).

When

the

thread trimming arm has moved to

the

position were it is almost touching

the

stopper,

adjust the position of the thread trimming magnet so that the snap ring which is attached to the

thread trimming magnet plunger hits the rubber ring and stops and also when the magnet is pulling,

there

shouldbeno

clearance

between

the

two

endsofthe

rubber

ring.

E

20mm

13.5mm

Fig.

34

9.

Howtoinstall

To remove

®Take

(D Loosen the knife forked base (Fig.35 (D), and pull

(D After removing

hinged screw

base

will

come

and

the

remove

knife

the

installing base (Fig.35

out the sewing hook.

the

hook

(Fig.35

®)

knife

off.Toinstall

installing base set screw

back,

knife

installing base

thread presser link hinged screw (Fig.35 (D), and if

reverse

this

®),

do as follows in

order.

out

(Fig.35

Fig.

order:

the

knife forked base pin

(D) is pulled

out,

35

the

the

hook

knife

(Fig.35

presser

installing

(D).

Page 25

10. Adjusting

This synchronizer has adopted semi-leading element, non-contacting type called hole IC, so it

is impossible to verify the position of the synchronizerby the tester by pulling out the 12P

Therefore, the position of the synchronizer should be adjusted in the following order:

®

(D

(DTurn

®

(D

the

position of

Remove

Remove the cover ® of the synchronizer and loosen the screw

Match

If the

the

belt.

the power source switch to

the

black

synchronizerismoved

the

synchronizer (Fig.36)

"ON".

indicating lineof the

gently

pulley

withthe redindicating lineof the

by the

hand

without

moving

®.

the

pulley,

machine

the

auxiliary

plug.

head.

motor will either rotate or stop. So, at the position where the auxiliary motor has started to stop,

tighten

the

(D

Replace

screw

®.

the

cover

of the synchronizer to the

original

position.

(Note)

When

the

above

adjustments

are

made,

do not

loosen

the

screw(©(+

screw),

absolutely.

this part is either loosened or released, sometimes the synchronizerdoes not function. So,

use

extreme

caution.

Fig.

36

0

0

If

-

23

-

Page 26

11. In caseofelectrical malfunctions, be sure

discrepancies: (Refer to malfunctions and corrective

measures for

complete

to

investigate

details)

the

following

No.

1

2

3

4

Malfunctions

Does

not

speed

Main

motor

over-heated

Auxiliary

over-heated

Enters

speed

running

the

power

"ON".

runatlow

motor

into

low

source

Causes

1.

Defective

2. Motor cord is pulled

stop at upper

3. Inadequate plug-in

triode

4. Wireofauxiliary

connected.

5. Inadequate returningofMB

part..

L.SW

thyristor

switch.

stop

printed

out

position).

of

bi-directional-

board.

motor

is dis

(does

not

clutch

6. Low speed function changing pin is

Corrective

* Exchange the L.SW switch.

* Plug-in

correctly.

* Plug-in correctly.

*

Connector

is

disconnected.

* Repair

the

* Replug-in the pin to the

inside

clutch

measures

the

motor

part

with oil stone.

"on"

(end

cover)

side.

connected to the low speed (ofO side.

(Inside

the

control

box).

the

is

1. No

clearanceatclutch

part.

2. One phaseof3 phases is disconnected

(single phase running).

* Adjust

* Inspect the plug-in conditionofthe

power

(Verify

the

is

1. Inadequate returningofthe MB part.

2. Inadequate lead relay (contact point)

of

3. One phase

3 phases is disconnected.

1. Inadequate positionofL.SW switch.

with

2.

Defective

3. 12P

L.SW

switch.

connectorofheadispulled

4. Inadequate adjustment of the adjust

ing

knobofstopping position.

5. Pedal cord is pulled

upper

stopping

position).

out

(make it to

out

* Repair the clutch part with oil stone.

* Exchange

*

Connector

is

disconnected.

* Adjust the positionofL.SWswitch.

* Exchange

* Re-plug-in

*

Rotate

direction.

* Re-plug-in

clearanceofclutch part.

source cord.

the

fuseofthe

plant)

the

lead relay.

inside

the

the

L.SW switch.

the

connector.

the

knob

toward

the

connector.

power

motor

the

source

(end

"FAST"

of

cover)

5

6

Machine

stop

running

does

(keeps

at low

speed)

Does

not

low speed.

trimming

performed

stopsatany

on

rotate

Thread

not

and

1.

not

Defective

2.

Too

3.6Afuseisblown

L.SW

much

clearanceofmagnet

switch.

out.

4. Pressure of returning springofmotor

leveristoo

5. 12P

at

1.lAfuseisblown

weak.

connectorofheadispulled

out.

brake.

out.

* Exchange

* Re-adjust the clearance.

* Exchange the 6A fuse.

* Tighten the adjusting screw.

* Re-plug-in correctly.

* Exchange

the

L.SW switch.

thelAfuse.

position.

-

24

-

Page 27

V. HIGH

SPEED,

UNDERTRIMMER

SINGLE

NEEDLE,

EQUIPPED

LOCKSTITCH,

WITH

A

WIPER

AUTOMATIC

1.

Adjusting

The

adjust

the

positionofthe

it as

follows:

1)

Rotate

positionofthe

wiper is adjusted

the

hand

wheel

point (Dofthe hand wheel so

z

wiper

toward

that

Model

it will

DDL-552-2-3

DDL-553-2-3

DDL-555-2-3

accordingtothe

the

regular

match

with

direction

the

DDL-552-2-4

DDL-553-2-4

DDL-555-2-4

thicknessofthe

andasshown

sewing

in Fig.37,

red point (Dofthe

frame.

cloth.

bring

2inin

Normally,

the

white

1mm

Fig. 37

Fig.

38

2) Then, as shown in Fig.38, insert the wiper ® into the driving shaft (D and bring the tip

of the

wiper

that

the

space

so that it

between

will

come

to 2mm(approx. 1/16") under the point of the

the

flat surfaceofthe

wiper

and

the

centerofthe

needle.

needle comes to

(approx. 5/128").

Make

sure

1mm

-

25

-

Page 28

2.

Adjusting

moving

1)

Pullinthe

the

wiper

the

positionofthe

plunger

magnetupand

comes to the position where it

this

adjustment,

securely

tighten

wiper

magnet

entirely

into

the

coil,

loosen

the

wiper

magnet

down

andasshowninFig.3,

will

be away from the needle center by 2mm (approx. 1/16"). After

the

wiper

magnet

set

screw.

adjustsothat

set

screw

the

edgeofthe

0

and

by

wiper

Fig.

2min

With

the

exceptionofabove, all

operating

-

instructions

26

-

and

adjustments

39

are same as DDL-555-2.

Page 29

VI. HIGH SPEED, SINGLE NEEDLE, LOCKSTITCH INDUSTRIAL

SEWING

AND

MACHINES

AUTOMATIC

WITH

REVERSE

AUTOMATIC

SEWING

THREAD

UNIT

TRIMMER

1.

Howtosew

(DIf the push

in reverse sewing

(D As long as this