Page 1

MODEL

HIGH

LOCK

INDUSTRIAL

SPEED

STITCH

DDL-552

-555

SINGLE

SEWING

NEEDLE,

MACHINE

-553

Instruction

Book

TOKYO

JUKI

INDUSTRIAL

CO.ITD

Page 2

We

thank

you

for purchasing JUKI Model DDL-552-553-555, high speed, single needle,

lockstitch

industrial

sewing machines.

DDL-SS2 is best suited for sewing general fabric; DDL-S53 is designed and constructed

for sewing heavy weight materials and DDL-555 is equipped with reverse feed mechanism

for a wide area of usage such as sewing men's shirts, blouses

hook,

The thread take-up, sewing

feed mechanism, etc. are all specially designed

and

other

general garments.

and

constructed for high speed sewing. Therefore, at high speed sewing, the running sound is

nominal

and

the

stitching

condition

is superb.

Before operating these machines, please read this INSTRUCTION BOOK carefully

and thoroughly digest the functions of these efficient machines and enjoy everlasting

pleasureofusing these machines.

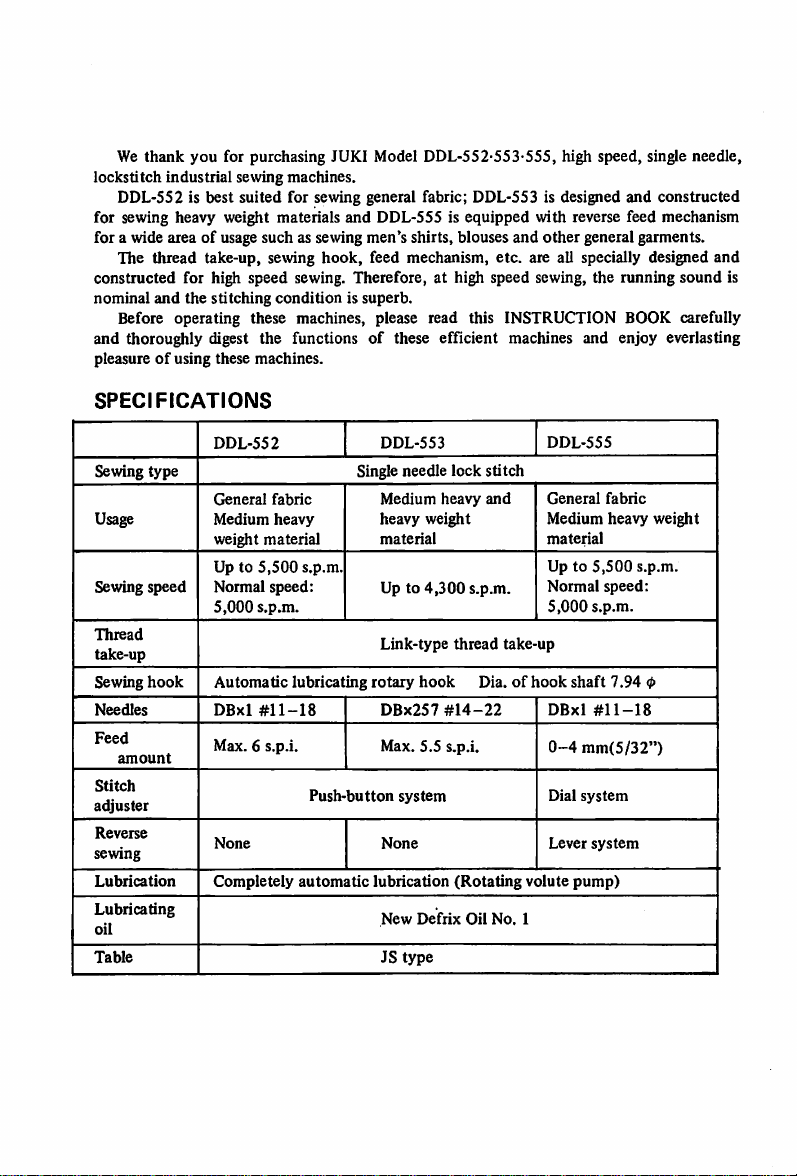

SPECIFICATIONS

Sewing

type

Usage

Sewing

speed

Thread

take-up

hook

Sewing

Needles

Feed

amount

Stitch

adjuster

Reverse

sewing

Lubrication

Lubricating

oil

Table

DDL-552

General

fabric

Medium

weight

Up to

heavy

material

5,500

Normal speed:

5,000

s.p.m.

Automatic

DBxl

lubricating

#11-18

Max. 6 s.p.i.

None

Completely

s.p.m.

Push-button

automatic

DDL-553

Single needle

Medium

heavy

weight

material

Up to

4,300

Link-type

rotary

hook

DBx257

Max. 5.5 s.p.i.

system

None

lubrication

New

Defrix

JS

type

lock

heavy

s.p.m.

thread

#14-22

(Rotating

Oil

DDL-555

stitch

and

General

Medium heavy weight

material

Up to

Normal

5,000

take-up

Dia.ofhook

DBxl

0-4

Dial

Lever

volute

No.

1

fabric

5,500

speed:

s.p.m.

shaft

7.94

#11-18

mm(5/32")

system

system

pump)

s.p.m.

<l>

Page 3

TABLE

OF

CONTENTS

(DDL-552-553-555)

Installingtheoil reservoir 2

MotorpuUey and the belt 2

Cautions on operating the machine 3

Lubrication 3

1.

Adjusting

2. TheoUadjusting pin 4

3.

Adjusting

Threading the machine 5

Preparation

Inserting & removing the bobbin case 6

Windingthe bobbin thread 6

How to insert the bobbin 6

The thread tension 7

Adjusting the needle thread tension 7

Thread take-up spring 7

Adjusting the bobbin thread tension 7

Presserfoot and feed dog 8

Adjusting the pressureofthe presser foot 8

The

presser

Height of the feed dog 8

The stitch length 9

Adjusting

Adjusting

Reverse

Inserting

the

Installing

Relation

between

Adjusting

Adjusting

Adjusting

theoil

supply

to the

face

part 4

theoil

supply

to thehook

of

the bobbin thread 6

foot

hand

lifter

the stitch

the stitch length

sewing

length

(DDL-555)

(DDL-552-553)

(DDL-555)

components

needle

and

removing

the

height

the

amount

the

pressing

the

sewing

thehookandtlie

of the

presser

ofthe

thread

pressure

of the

hook

needle

bar

take-up.

feed

lever

(DDL-555)

Page

4

8

9

9

9

12

(Note)

Due to improvements on the machine, some parts of the operationalprocedures

of this INSTRUCTION BOOK might be changed without notice.

- 1 -

Page 4

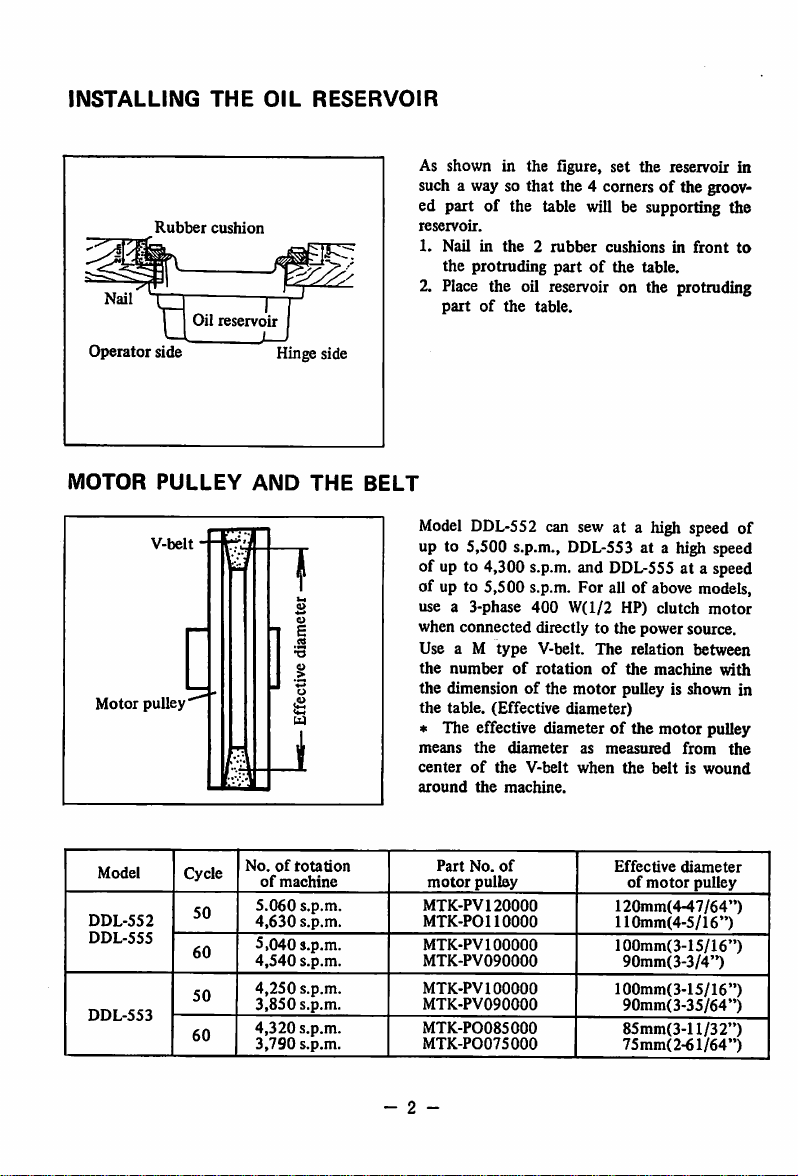

INSTALLING

Rubber

Operator

side

Oil

THE

cushion

reservoir

OIL

Hinge side

RESERVOIR

As shown in the flgure, set the reservoir in

such a way so that the 4 comersofthe grooV'

ed part of the table will be supporting the

reservoir.

1.

Nailinthe2rubber

the protruding

cushionsinfront

partofthe table.

to

2. Place the oil reservoir on the protruding

partofthe

table.

MOTOR

Motor

Model

DDL-552

DDL-555

DDL-553

PULLEY

V-belt

pulley

Cycle

50

60

50

60

AND

THE

No.ofrotation

of

machine

5.060

s.p.m.

4,630

s.p.m.

5,040 s.p.m.

4,540

s.p.m.

4,250

s.p.m.

3,850

s.p.m.

4,320

s.p.m.

3,790

s.p.m.

BELT

Model DDL-552 can sew at a high speed of

up to 5,500 s.p.m., DDL-553 at a high speed

of up to 4,300

s.p.m.

and

DDL-555

of up to 5,500 s.p.m. For all of above models,

use a 3-phase

400

W(l/2

HP)

when connected directly to the power source.

Use a M

the

the dimension of the

the

type

V-belt.

numberofrotationofthe

The

motor

pulley is shown in

table. (Effective diameter)

* The effective diameter of the motor pulley

means

the

centerofthe

around

the

Part

No.

motor

pulley

MTK-PVl

MTK-POllOOOO

MTK-PVl

MTK-PV090000

MTK-PVl

MTK-PV090000

MTK-P0085000

MTK-P0075000

20000

00000

00000

diameter

machine.

of

V-belt

as

measured

when

the

Effective

of

120mm(4-47/64")

110mm(4-5/16")

100mm(3-15/16")

90mm(3-3/4")

100mm(3-15/16")

90mm(3-35/64")

85mm(3-ll/32")

75mm(2-61/64")

at a speed

clutch

relation

machine

from

beltiswound

diameter

motor

motor

between

with

the

pulley

- 2 -

Page 5

CAUTIONS

1

Do

not run the

with

fresh

oil.

ON

OPERATING

machine,

under

THE

any

circumstances,

MACHINE

before

theoil

reservoirisfilled

2. Always rotate the machine toward the operator. Do not run the machine in the re

verse

direction.

3.

Although

to

DDL-553at3,800

at an

operator.

normal

appropriate

the

machines

speed

and

s.p.m.

speed

can

attainamaximum

for

DDL-552

and

for

DDL-555at4,500

depending

operate

on the

speed,

for

the

at a

normal

s.p.m.

natureofwork

first

month

speedof4,500

After

that,

and

run

the

capabilityofthe

drop

the

the

speed

s.p.m.,

machines

LUBRICATION

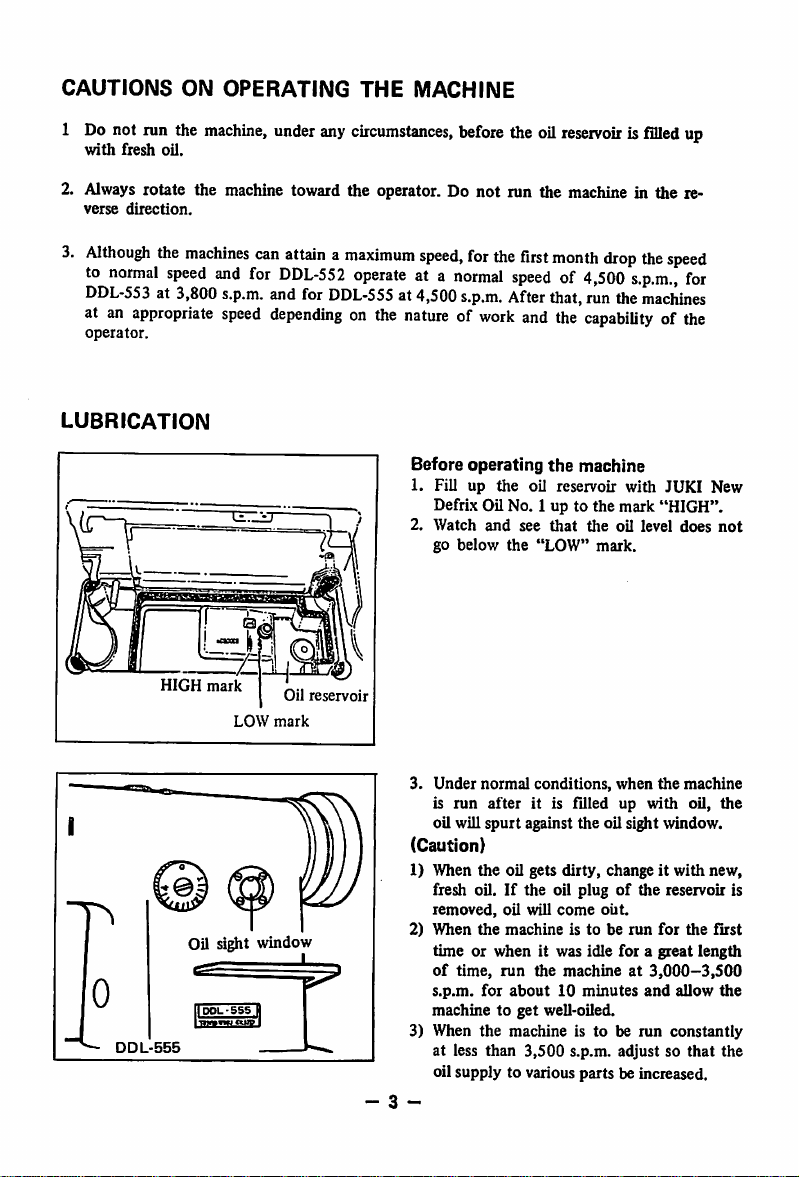

Before

operating

1. Fill up the oil reservoir with JUKI New

Defrix Oil No. 1 up to the mark "HIGH".

2.

Watch

and

go

below

the

see

"LOW"

the

that

machine

the

oil level

mark.

does

up

for

not

HIGH

mark

LOW

Oil sight window

IDOL-SSS

•mtrm ntTffI

Oil

reservoir

mark

3.

Under

normal

is

run

oil will

(Caution)

1) When the oil gets dirty, change it with new,

fresh oil.

removed,

2)

When

time or when it was idle for a great length

of

time,

H

- 3 -

s.p.m.

machinetoget

3) When

at less than

oil supply to various parts be increased.

conditions,

after

it is filled up with oil,

spurt

against

If

the oil plugofthe reservoir is

oil will

the

for

the

come

machineistoberun

run

the

about10minutes

well-oiled.

machineistoberun

3,500

when

the

machine

the

oil sight window.

out.

for

the

first

machineat3,000-3,500

and

allow

s.p.m. adjust so

constantly

that

the

the

the

Page 6

Oil

Oil

gets

Z

adjusting

pin

amount

less

II•••''

n I I II

Needle

"Oil

adjusting

\

^

Oil

Counterweight

Crank

amount

If

crank

pin

shaft

adjusting

1^

gets

11

pin

Oil

bar

Grooveofeccentric

Arm

more

screw

1. Adjusting the oil supply to the face

part

When adjusting the oil supply to the thread

take-up and needle bar crank components,

remove

the

face

plate

and

the

oil preventing

plate and adjust by turning the oil adjusting

pin at the tip of the main

1. When

2. When

the

comes

near

less.

the

sideofthe

red

the

red

crank,

(Caution)

The

oil

amount

after

the

adjustment,sowhen

thisinmiiid.

2.

The

oil

adjusting

The oil adjusting pin has a carved groove

1.

as shown in the figure. When this groove

and

the

oil

holeofthe

together, the oil amount gets more.

When

the

red

markonthe

without

groove

the

2.

the oil hole, the oil

The

side

shaft

markofthe adjusting pin

crank,

the

oil

amount

mark

does

comes to

the

oil

not

amount

change

the

opposite

gets

Immediately

adjusting,

pin

main

shaft

is at the oppositesideof

amount

gets less.

oil adjuster shows

carved groove.

gets

more.

have

come

the

Oil regulating valve

3. Adjusting

components

The

supplyofoil to

can be adjusted by

the

hook

1. If this

the

2. If this

amount

- 4 -

oil

shaft.

valve

amount

valve

gets less.

the

oil supplytothe

the

hook

the

oil regulating valve on

is turned toward0

gets

more.

is turned

to0

hook

components

side(right),

side(left), the

Page 7

THREADING

Rotate

the

1.

Pass

2.

Pass

3.

Pull

hand

the

needle

the

thread

out about 10

THE

MACHINE

wheeltoright

thread

in the

to the

needle

cni(4")

and

order

eye

of the

place

shown

from

thread

the

left to

from

thread

by the

right.

the

take-uptothe

flgure.

needle

eye.

highest

position.

(U)

- 5 ~

Page 8

PREPARATION

OF

THE

BOBBIN

THREAD

Bobbin

Trip

case

Adjusting screw

latch

— ^

Thread

Hfii\

f(l!r

Hook

Tension

base

hole

Thread

passinghole

Inserting & removing

1.

Rotate

the

hand

wheel

the

with

bring the needle to its highest position.

2.

Tilt

the machine and support it by tlie head

support

on the table.

3. Lift up the knob of the bobbin case and

takeitout.

*Ifyou

4.

Winding

1.

2.

bobbin

To

into

of

the

of

the

Set

screws.

Pass

hold

will

insert

the

bobbin

hook

the

the

the

shaftoftlie

bobbin

the

knobinopen

not

fall

the

bobbin

case fully

and

then

bobbin

threadinthe

thread

windertothe

off.

case,

hooksothat

close

order

figure and wind it around the bobbin

several

times.

3. Knock down the trip latch and contact the

disc

pulley to the

4. Adjust the winding amount by the winding

belt

adjustingscrewso that about 80%is wound.

5.

When

the

the

threadiswound

thread

tension

disc

correcttoeven winding

6. When the winding is completed, the trip

latch

will be released

stop

automatically.

How

to

1.

Hold

the

case so

condition.

2. Pass the

of

the

3.

Then

the

thread

out

through

insert

the

bobbin

that

the

threadtothe

bobbin

pull the

tension spring and

the

and

bobbin

and

insertitto

thread

case.

thread

anditwill pass under

thread

hole.

bobbin

your

case

hand

and

condition,

insertitdeep

the

the

knob.

table

nose

groove

with

move

and

enters

the

showninthe

unevenly,

basetoleft

condition.

the

pulley will

the

bobbin

will be in

ri^t-twist

thread passing hole

can

be pulled

- 6 -

Page 9

THE

THREAD

TENSION

Weaker

'-'Thread

Ehread

Movingrange

(Tl^ad

take-up

springy

tension

bar

set

Stronger

tension

nut

bracket

screw , / /

Adjusting

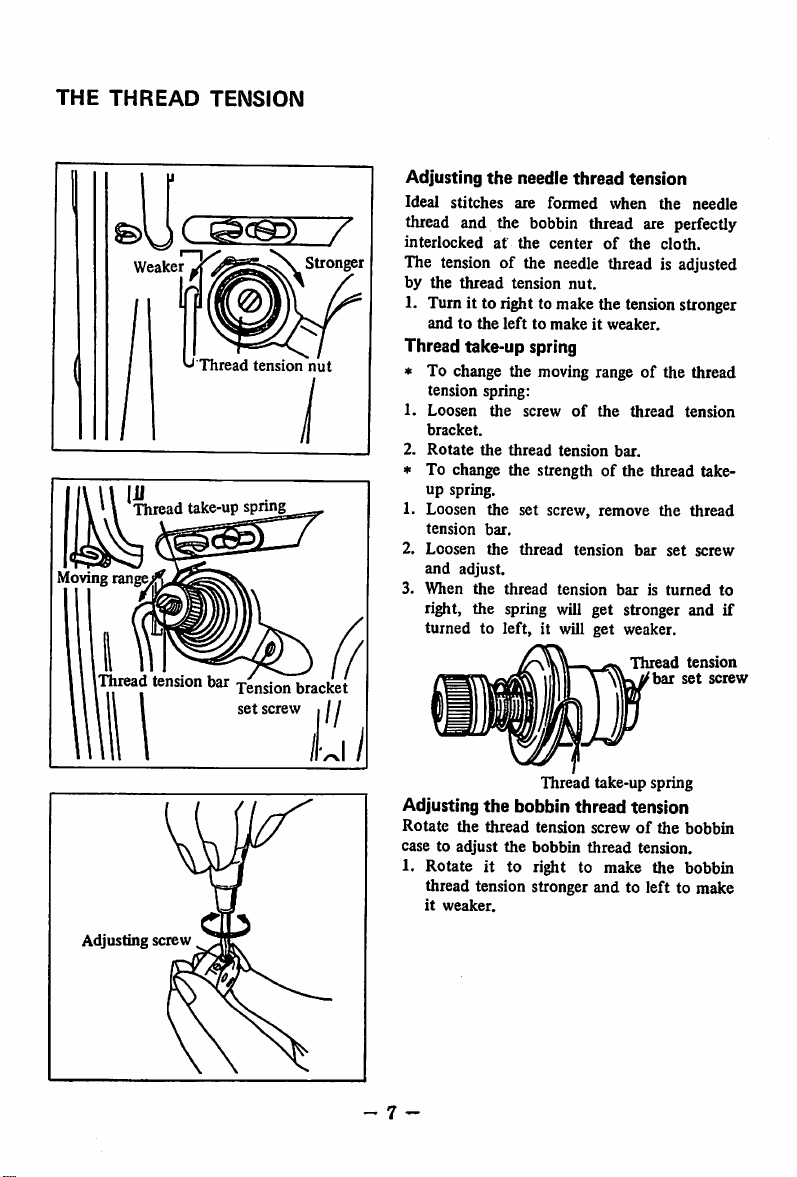

Ideal

stitches

the

needle

are

thread

formed

tension

when

the

needle

thread and the bobbin thread are perfectly

interlockedatthe

centerofthe

cloth.

The tension of the needle thread is adjusted

by

the

thread

tension

nut.

1. Turn it to right to make the tensionstronger

andtothe

lefttomakeitweaker.

Thread take-up spring

* To change the moving range of the thread

tension spring:

1.

Loosen

bracket.

2.

Rotate

» To change the strengthofthe thread take-

up spring.

1. Loosen the set screw, remove the thread

tension

2.

Loosen

and

3.

When

right, the spring will get stronger and if

turnedtoleft,

the

bar.

the

adjust.

the

the

screwofthe

thread

thread

thread

tension

tension

it will

tension

get

thread

tension

bar.

bar

set

baristurned

weaker.

Thread

tension

bar

set

screw

screw

to

Adjusting screw

Thread

take-up spring

Adjusting

Rotate

casetoadjust

1. Rotate it to right to make the bobbin

_ 7 -

the

bobbin

the

thread

the

thread tension stronger and to left to make

it

weaker.

thread

tension

tension screwofthe

bobbin

thread

tension.

bobbin

Page 10

PRESSER

FOOT

AND

FEED

DOG

Pressure

screw

0

Hand

hfter

adjusting

Nut

—

Hill

JUKI

N!|^

Adjusting

1.

2.

"

3.

The

To stop the presser

1.

2. The presser foot will go up

(13/64")

3. To

4. With

the

pressureofthe

Turn

the

to

Turn

weaker.

Normal pressure

5 kg (11 lbs).

After

presser

Rotate

part

lifter

downtothe

go up

pressure adjusting screwtoright

make

the

pressure

this

screw to

adjustment,

foot

the

hand

eithertoright or left.

and

stops.

lower

the

presser

once

and

original position.

the

knee

about

10 mm

stronger.

left

to make

for

general fabric is

firmly tighten the

hand

lifter

footatthe

lifterinthe

foot,

activate

the

presser

lifter,

the

presser

(25/64")

presser

foot

the

pressure

about

nut.

lifted position:

rearofthe

about

foot

will

foot

the

face

5 mm

knee

come

will

Feed driving fork

~T7=

Clamp

screw*"

lU

Heightofthe

feed

dog

The height of the feed dog from the surface

the

throat

plate

is set

In sewing light weight materials, if this height is

too

high, shrink-stitching

To

adjust

Loosen

ing

forkofthe

the

the

1.

from0.7-0.8mm(l/32").

may

result.

heightofthe

clamping screwofthe

compound

feed dog:

feed.

2. Move the feed dog base up and down and

adjust

3. After adjusting, tightly tighten the clamping

screw.

Feed

- 8 -

dog

0.7~0.8om

Throat plate

feed

of

driv

Page 11

THE

STITCH

Feed

LENGTH

adjusting dial

Adjustingthe stitch length

(DDL-552-DDL-553)

The stitch lengthofDDL-552

adjusted by the push button ® at the center

of

the upper surface of the arm. Rotate the

hand wheel as you keep pressing down the ®

button.

When the button drops down deep into the

groove of the ratchet (you can feed it) push

down the button further and by rotating the

hand wheel, match the

wanted

(D with the indicator® of the

With this, the length of stitches can be obtained.

The figures on the

hand

numberofstitches per one inch. Release the

push

button

and

verify

to the original position.

The maximum stitch length for DDL-552 is

6 s.p.i. and for DDL-553is 5.5 s.p.i.

Reverse sewing can

(Caution)Donot

not

touch

machine is running.

(DOL-555)

The stitch length of this model can be adjusted

by rotating the feed adjusting dial on top of

the

feed

lever.

The figures on the graduation scale is shown in

millimeter

(mm).

1. Rotate the feed adjusting dial

rightorleft

and

2. Match the wanted figure with the pin

coming

out

from

the

* The maximum stitch length is 4mm(5/32").

number

wheel indicate

that

the

be done.

the

button

frame.

and

DDL-553 is

button

of stitches

frame.

the

returns

while

the

either

to

t

1.DDI--S5SJ

Feed

I

lever

Reverse sewing

(DDL-555)

1. For reverse sewing, push the feed lever

down.

2. As long as this lever is kept down, reverse

- 9 -

sewing can be

3.

Release

turn

to original position and normal straight

stitching can be resumed.

this

performed.

lever

and

the

feed

lever

will

re

Page 12

INSERTING

Set

screw

Needle

THE

NEEDLE

Groove

For

DDL-552

needles

needle.

and

There

and

for

are

DDL-555

DDL-553

many

models,

model,

size

use DBx2S7

numbersofneedles

use

DBxl

but size numbers depend on the thickness of

the using thread or the kinds of sewing cloth.

So, select a correct size and number for your

work.

1.

Rotate

the

hand

wheel

and

bring

the

bar

to the highestposition.

2. Loosen

the

needle clamp screw.

3. Hold the needle so

the

needle

comestoyour

that

the long groove of

left

needle

side.

4. Insert the needle deep into the needle hole.

5. Then securely tighten the needle clamping

screw.

INSTALLING AND REMOVING

r

Set

screw

Bobbin case

finger

positioning

screw

THE

SEWING HOOK

During the running of the machine, if thread

hards get into the hook or the position of the

hook changes for some reason or to exchange

the

hook

order:

1.

Rotate

bartothe

2.

Remove

withanew

the

hand

highest position.

the

one,

do as follows in

wheel and bring the needle

bobbin

case

and

the

needle.

3. Remove the bobbin case base positioning

finger set screw and take out the bobbin

case positioning finger.

4. Loosen the 3 screws

5.

Rotate

the

hand

of

the sewing hook.

wheel

and

raise up

feed base to its highest position.

Rotate

6.

and

the

7. Pull

*

To

the sewing

place it in

figure.

the

hooktoyour

install

the

hook

the

hook

with

position as shown in

left

and

takeitout.

back,

reverse

your

procedure.

the

hand

this

-10

Page 13

RELATION

BETWEEN

Clamp screw

THE

HOOK

AND

THE

NEEDLE

Match

the needle with the

follows:

1. Rotate the hand

bar to its lowest position.

2.

Loosen

the needlebar

(Note)

When

matching the timing of the needle and

wheel

sewing

andbringthe

clamping

set

hook as

needle

screw.

the sewing hook, be sure to set the feed,

adjusting dial to

"0".

(D

DETERMINE

OF

(D

DETERMINE

OF

Needle

Biade

pointy

the

sewing,

hook

THE

THE

THE

NEEDLE

THE

SEWING

(At

the

HEIGHT

BAR

^ Needle bar

lower

bushing

Upper

indicating

Lower

indicating

bar

•

indicating

line

match

pointofthe

hook

the

center

the

needle)

hook

line

with

Needle

POSITION

HOOK

Lower

this

position,

blade

sewing

Sewing

line

(Determine

the

height

of the

3. Match the upper carved line of the needle

bar with the lower edge of the needle bar

lower bushing.

4.

Tighten

(Determine

hook)

the needlebar

the position of the

clamping

5. Loosen the 3 clamping screwsof the hook

so that the hook can be rotated freely with

the

hand.

of

6. Place the

passing position.

7.

Rotate

carved

hook

with your hand to the thread

the

hand

wheel

and

lineofthe

needle

edge of the needle bar lower bushing.

8. In this condition, match the blade point of

the

hook

with

the

center

clearance

between

blade point td

tighten the hook

10.

-11-

9.

Make

and the

Securely

screw.

the

hook

needle

set

match

bar

with

lineofthe

the

O.OS

clamping

screw.

sewing

the

the

needle.

needle

mpi

bar)

lower

lower

and

set

Page 14

ADJUSTING THE HEIGHT OF THE PRESSER BAR

When

the height or the direction of the

presser bar is to be changed due to the

exchangeofpresser foot:

1. Remove the rubber plug of the face plate.

2. From this hole, adjust by loosening the

presser bar clamping screw.

3. After the adjustment, securely tighten the

set

Presser

bar

clamp

screw

screw.

ADJUSTING THE AMOUNT OF THREAD TAKE-UP

The

^

Thread

More

guide

Less

r~/

amount

be changed according to the length of stitches

or thicknessofthe

ideal

thread

1. When sewing heavy weight materiab, move

the thread guide to your left.

The thread take-up amount of the take-up

gets

2. When sewing light weight materials, move

the

The thread take-up amount gets less.

more.

thread

of

tension.

guide to

the

thread take-up should

sewing

clothtoproduce

your

riglit.

ADJUSTING

(DDL-555)

THE

PRESSING

PRESSURE

The reversing spring of the feed lever is

strengthened somewhat so

sewing, no matter what kindofstitches are to

be

original

When

machine istobe

the pressing pressure of the feed lever can be

lessenedbyloosening

the accompanying figure.

-

12

-

formed,

position.

the

OF

THE

the

lever

stitching

FEED

that

returns

pitch

is small or

run

by lowering

the adjusting nut

positively to

LEVER

at high speed

the

when

the

the

r.p.m.,

(T)

of

Page 15

I

lllllll

TOKYO

JUKI

IIKVO

Head

Office&Plant,

Business

Cable

Address:

JUKI

Office:

INDUSTRIAL

2-1,

23.

JUKI

8-chome,

Kabuki

TOKYO

cho,

Kokuryo

Sftiniuku

Telex:

G0..1T0.

cho.

Chofu

ku.

Tokyo.

232-2301

^BEB

shi.

Tokyo.

Japan

JUKISINJUK.U

PrintedinJapan

Japan

TOK

Loading...

Loading...