Page 1

MODEL

HIGH

SPEED.

INDUSTRIAL

EQUIPPED

MODEL

HIGH

SPEED,

LOCKSTITCH

EQUIPPED

MODEL

HIGH

SPEED,

INDUSTRIAL

EQUIPPED

MODEL

HIGH

SPEED,

INDUSTRIAL

EQUIPPED

DDL-552-2-553-2-555-2

SINGLE

NEEDLE,

SEWING

SINGLE

INDUSTRIAL

SINGLE

SEWING

SINGLE

SEWING

MACHINE

NEEDLE,

SEWING

NEEDLE,

MACHINE

NEEDLE,

MACHINE

TOP

DIFFERENTIAL

WITHANAUTOMATIC

DLN-415-2

WITHANAUTOMATIC

DLU-450-2

WITHANAUTOMATIC

DLD-432-2

WITHANAUTOMATIC

LOCKSTITCH

UNDERTRIMMER

NEEDLE

FEED.

MACHINE

UNDERTRIMMER

AND

BOTTOM

UNDERTRIMMER

UNDERTRIMMER

FEED

FEED

Instruction

lIUKI

i

Book

TOKYO

JOKI

INDUSTRIAL

CO.,LTD.

Page 2

CONTENTS

I. GENERAL DESCRIPTION 1

1.

Outstanding

2.

Main

II. HOW TO

1.

2.

3.

4.

5.

INSTALL

Table

Installing

Limit

Lengthofbelt

Installing

6. Installing

7. Installing

Construction

8.

9.

Functionofthe

10.

Howtohandle

11.

Adjusting

III.

HOW

TO

OPERATE

1.

Cautiononoperation

2.

Lubrication

3.

Trial

runofthe

4. How to

5.

Threading

6.

Adjusting

7. Adjusting

8. When low

9.

Carefully

Howtoselect

10.

IV.

ADJUSTING

1.

Adjusting

2.

Adjusting

3.

Howtoinstall

4.

The

floating

5. Flow

6.

7.

8.

9.

10.

11.

V.

DDL-552-2-3

DDL-553-2-3

DDL-555-2-3 DDL-555-2-4

VI.

DDL-555-2-2B

to

Changing

Adjusting

Adjusting

Howtoinstall

Adjusting

In

caseofelectrical

features

specifications

THE

the

motor

of low-speed

the

control

the

machine

the

pedal

and

cord

the

the

clutch

THE

and

machine

operate

the

the

the

the

machine

thread

needle

speed

note

the

the

THE

MACHINE

the

timingofthe

the

positionofthe

the

rangeofthe

sharpen

the

the

the

the

moving

bobbin

slide

and

the

installing

DDL-552-2-4

DDL-553-2-4

DDL-555-2-4B

MACHINE 2

rotationofthe

machine

box

head

and

its

adjustment

operationofmotor

control

box

and

lever

cautions

switch

gap 10

MACHINE

adjusting

the

oiling

amount

pedal

tension

stop

sewing is

following

presser

fixed

knife

position

not

foot,

knife

second

blade

after

thread

trimming

necessary 15

points

throat

plate,

sewing

hook

and

feed

dog

thread

moving

correctly

thread

trimming

knife

tension

cam

disc

knife

thread

presser

shaft

remove

the

angleofthe

malfunctions

knife

installing

synchronizer

base

20

20

21

22

22

23

24

25

27

VII. MALFUNCTIONS AND CORRECTIVE MEASURES , 28

VIII.

IX.

CIRCUIT

DIAGRAM

DIAGRAM,

SHOWING

TIME

METHOD

CHART

OF

ASSEMBLING

TABLE

33

35

1

1

2

2

3

3

3

3

4

5

6

9

11

11

11

11

12

13

13

14

15

15

16

16

17

18

19

Page 3

1.

Outstanding

1)

Simple

By a

simple

sewing,

controlled,

by

foot,

2)

The

electric

3)

All

needle

4)

This

stopping

all

Stable

thread

devicetoproduce

All

attachments

plate,

Dependable

machineisequipped

steppedonfor

pedalisstepped

5)

Compact

All

the

sewing

areaisamply

features

operation

operation

and

worriesofoperational

efficiency

trimming

attachments

slide

safety

high

speed

on.

construction

thread

trimming

wide

of

thread

trimming

movementisinterlocked

constant,

canbeused

which

are

plate,

etc.

device

sewing

mechanisms

and

all

I.

GENERAL

one

pedal,

this

with

utmost

used

tolerances

stable

without

for

are

efficiency.

alterations

conventional

can be used on

withadependable

until

the

thread

are

attachments

canbeused

DESCRIPTION

machine

will

ease.

eliminated.

with

the

lockstitch

this

machine

safety

perform

Also,asthe

rotationofthe

without

device by

trimmingiscompleted

built-in

inside

freely.

the

high

speed

thread

machines,

suchasfeed

any

which

after

bedinrational

sewing,

trimmeriselectrically

machine

and

dog,

low

speed

controlled

presser

alterations.

the

machine

the

cannot

thread

trimming

ordersothat

be

the

2. Main

Sewing

Low-speed

Threads

Sewing

Needles

Motor

Electric

Safety

the

speed

machine

hook

device

specifications

rotation

control

box

DLD-432-2

DLU-450-2

DLN-415-2

DDL-555-2

DDL-552-2

DDL-553-2

of

Cotton

Synthetic

Cotton,

DB

DB

Stop

needle

AMCO

Super

Voltage

Voltage

IC

Built-in

type

x 1

positioner

positioner)

motor

stop

control

Up to

Up to

Up to

Up to

Upto5,000

Upto4,300

thread

thread

synthetic,

automatic

DA

x 1

motor

control

power

system

inside

the

4,200

4,200

5,000

5,000

silk

clutch

DC

AC

motor

s.p.m.(Cotton)

s.p.m.(Cotton)

s.p.m.(Cotton)

s.p.m.(Cotton)

s.p.m.(Cotton)

s.p.m.

Maximum

Maximum

lubricating

motor,

46V,

DC 5V

100,115,

lever

150

120

hook

400W

200,

s.p.m.

s.p.m.

with

(Hitachi

240,

Up to

4,000

Upto4,000

Upto4,000

Upto4,000

Upto4,000

bobbin

clutch

380,

415V

s.p.m.(Synthetic

s.p.m.(Synthetic

s.p.m.(Synthetic

s.p.m.(Synthetic

s.p.m.(Synthetic

thread

guide

motor

with

(All

±10%)

groove

automatic

Fiber)

Fiber)

Fiber)

Fiber)

Fiber)

attached

- 1 -

Page 4

This

machineisequipped

machines.

lever,

trimming

machine

machine.

1.

the

control

mechanism

If

the

will

After

Table

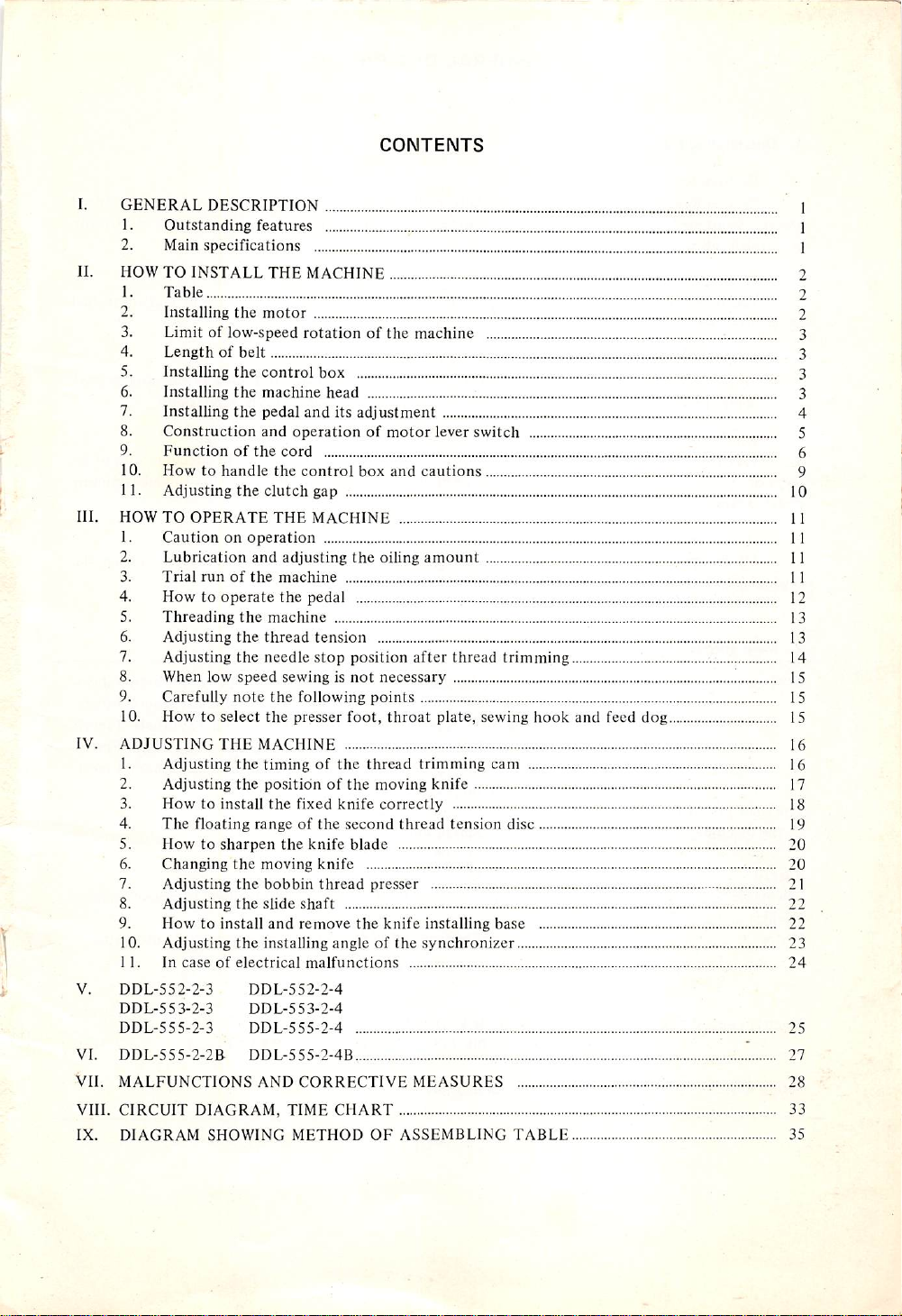

1)

The

the

2) Fig. 1

All

operations

box,

with

and

adjustmentofthe

not

function

the

machineisproperly

installing positionsofthe

dimensional

shows

the

diagram

rear

* The installed positionofthe

purposeofremoving

2.

Installing

1)

2)

Stop

Install

the

motor

motor

(automatic

the

motorasshowninthe

3) The installationofthe

4)

The

motor

rotates

counter-clockwise)

*

Before

installing

direction.

the

II.

HOW

TO

with

different

are

controlled

harmonious

the

needle

pedalisinadequateorif

properly.

by

cooperation

positioner

installed, give it a trial

table

whichisenclosed

viewofthe

set-up.

control

the

rear

coverofthe

positioner stopping

dimensional

motor

is same as any conventional lockstitching machine. (See Fig.2)

toward

machine

the

operator.

head,besure

INSTALL

kindsofdevices

the

pedal

with

clutch

legs,

motor

within

boxisrather

motor

clutch

(As viewed

to rotatethe

THE

MACHINE

than

andbythe

the

motor,

the

and

this

signals given

needle

the

threadisneatly

connectionsofthe

run

and

control

box

book.

far away from the

easier.

motor)

diagram.

is used on this machine.

from

motor

conventional

positioning

verify

the

etc.

are clearly

motor

the

pulley side, the

and

verify

out

from

synchronizer,

trimmed.

cords

are

correct

runningofthe

illustrated

but

this is for the

its

correct

lockstitching

the

motor

thread

wrong,

the

by

rotation

rotationjal

is

I I

Fig.

1

- 2 -

Fig.

Page 5

3.

Limitoflow-speed

For

trimming

rotationofthe

the

thread,

For

cotton

For

synthetic

the

limitoflow-speed

thread

thread

machine

Under

Under

150

120

rotation

s.p.m.

s.p.m.

should

be as follows:

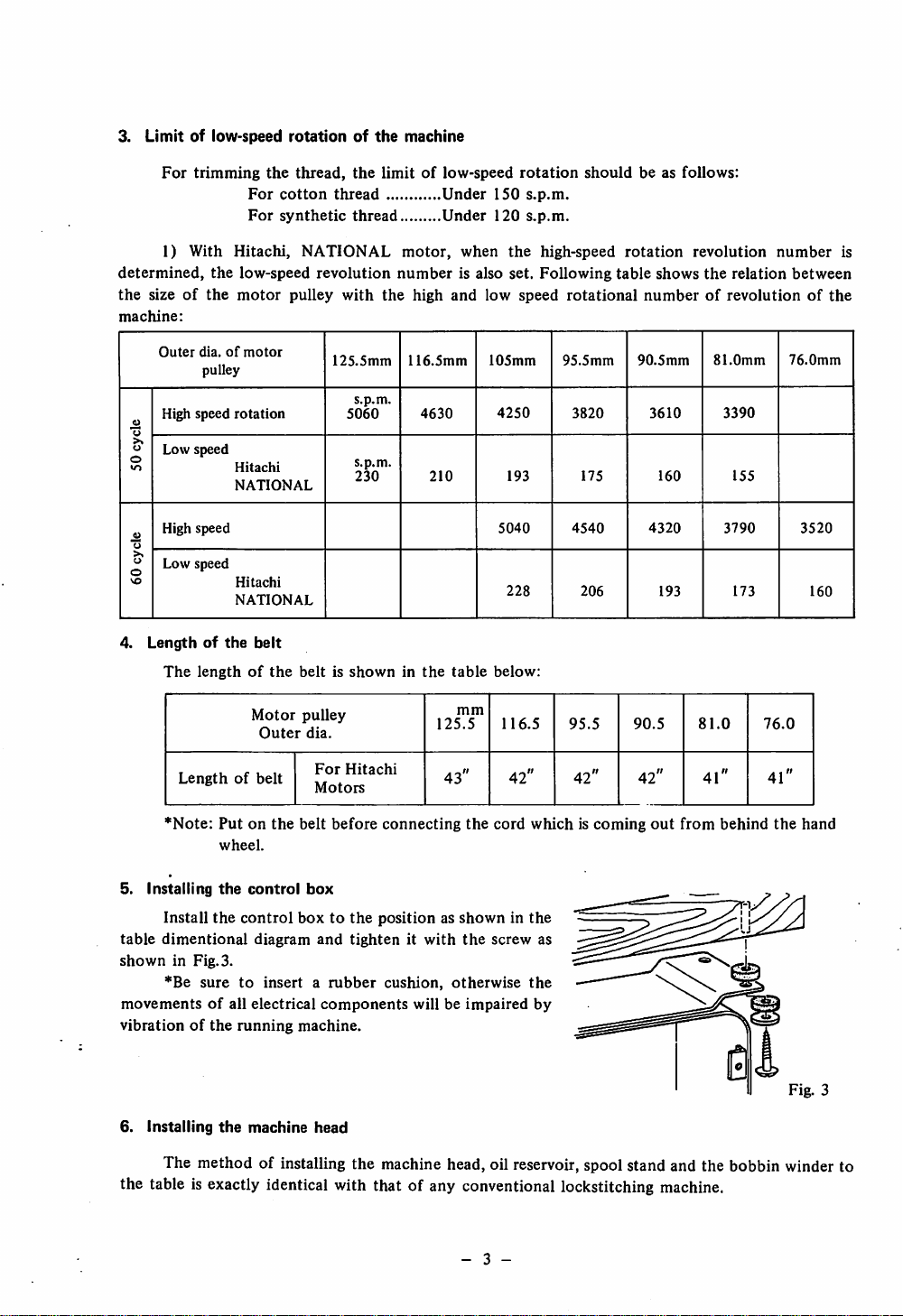

1) With

determined,

the

sizeofthe

machine:

Outer

High

.H

o

Low

o

lO

High

•3

u

Low speed

0

ve

4.

Lengthofthe

The

Lengthofbelt

Hitachi,

the

low-speed

motor

dia.ofmotor

pulley

speed

rotation

speed

Hitachi

NATIONAL

speed

Hitachi

NATIONAL

belt

lengthofthe

Motor

Outer

NATIONAL

revolution

pulley

with

125.5mm

5060

s.p.m.

s.p.m.

230

motor,

number

the

116.5mm

beltisshowninthe

pulley

dia.

For

Hitachi

Motors

high

4630

210

and

table

125.5

43"

when

the

high-speed

is also

set.

Following

low

speed

105mm

4250

193

5040

228

below:

mm

116.5

42" 42" 42"

rotational

95.5mm

3820

175

4540

206

95.5

rotation

table

shows

revolution

the

relation

number

numberofrevolutionofthe

90.5mm

3610

160

4320

193

90.5

81.0mm

81.0

41"

3390

155

3790

173

76.0

41"

is

between

76.0mm

3520

160

*Note:

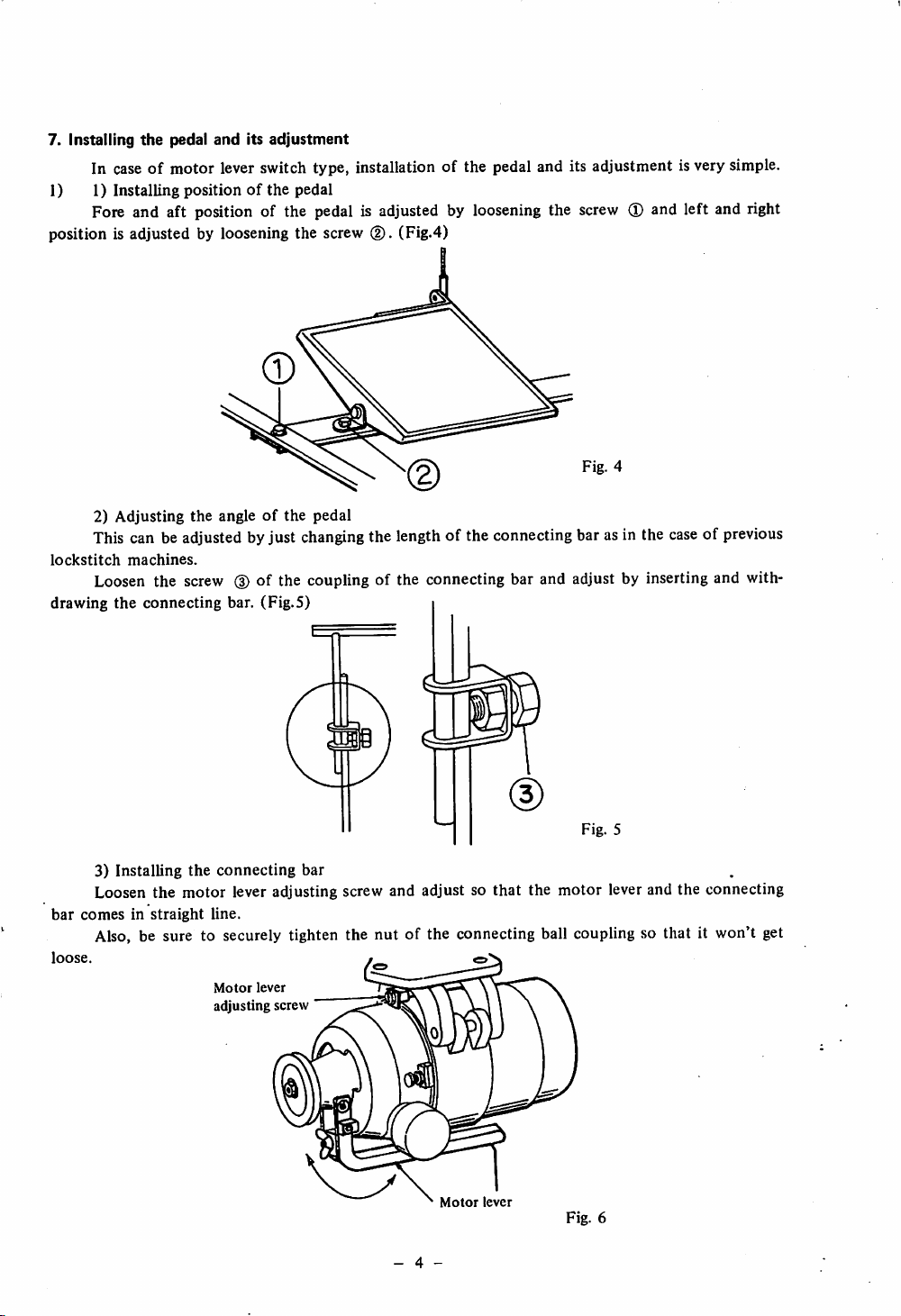

5.

Installing

Install

table

dimentional

shown

*Be

movementsofall

vibrationofthe

6.

Installing

Putonthe

wheel.

the

the

control

belt

control

boxtothe

diagram

in Fig. 3.

suretoinsertarubber

electrical

running

the

machine.

machine

before

box

and

tightenitwith

components

head

connecting

the

cord

whichiscoming

positionasshowninthe

the

screw

cushion,

will be

otherwise

impaired

the

by

out

from

behind

as

The method of installing the machine head, oil reservoir, spool stand and the bobbin winder to

the table is exactly identical with that of any conventional lockstitching machine.

- 3 -

the

hand

Fig. 3

Page 6

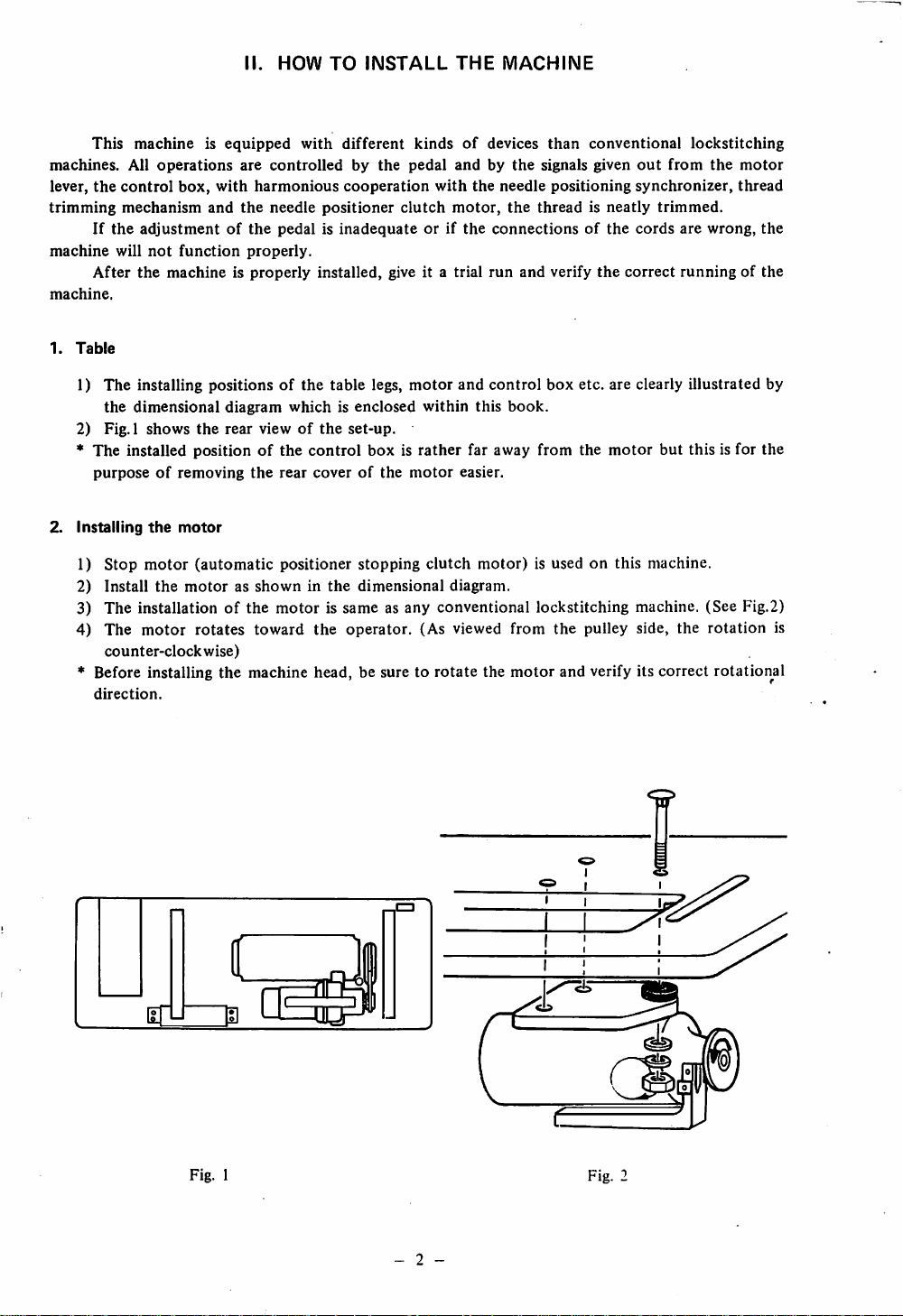

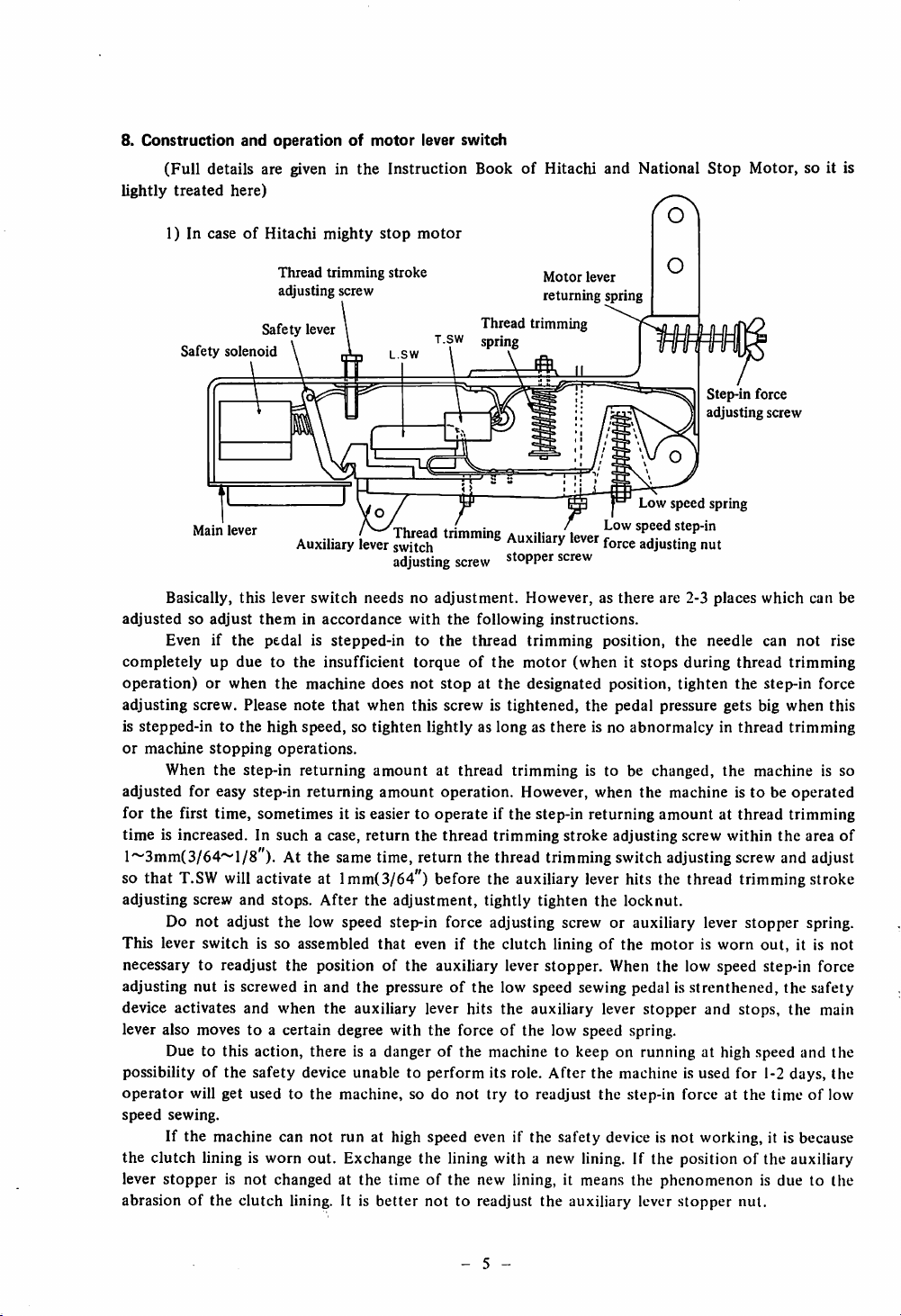

7. Installing

the

pedal

and

Its

adjustment

In case of motor lever switch type, installation of the pedal and its adjustment is very simple.

1) 1)

Installing

positionofthe

pedal

Fore and aft position of the pedal is adjusted by loosening the screw (I) and left and right

position is adjusted by loosening the screw

2) Adjusting the angleofthe pedal

(2).

(Fig.4)

Fig. 4

This can be adjusted by just changingthe length of the connecting bar as in the caseof previous

lockstitch

drawing the connecting bar. (Fig.5)

machines.

Loosen the screw

(3)

of the coupling of the connecting bar and adjust by inserting and with

ss

Fig. 5

3) Installing

Loosen the motor lever adjusting screw and adjust so that the motor lever and the connecting

bar

comesinstraight

Also, be sure to securely tighten the nut of the connecting ball coupling so that it won't get

loose.

the

connecting

line.

Motor

adjusting screw

lever

bar

- 4 -

Motor

lever

Fig. 6

Page 7

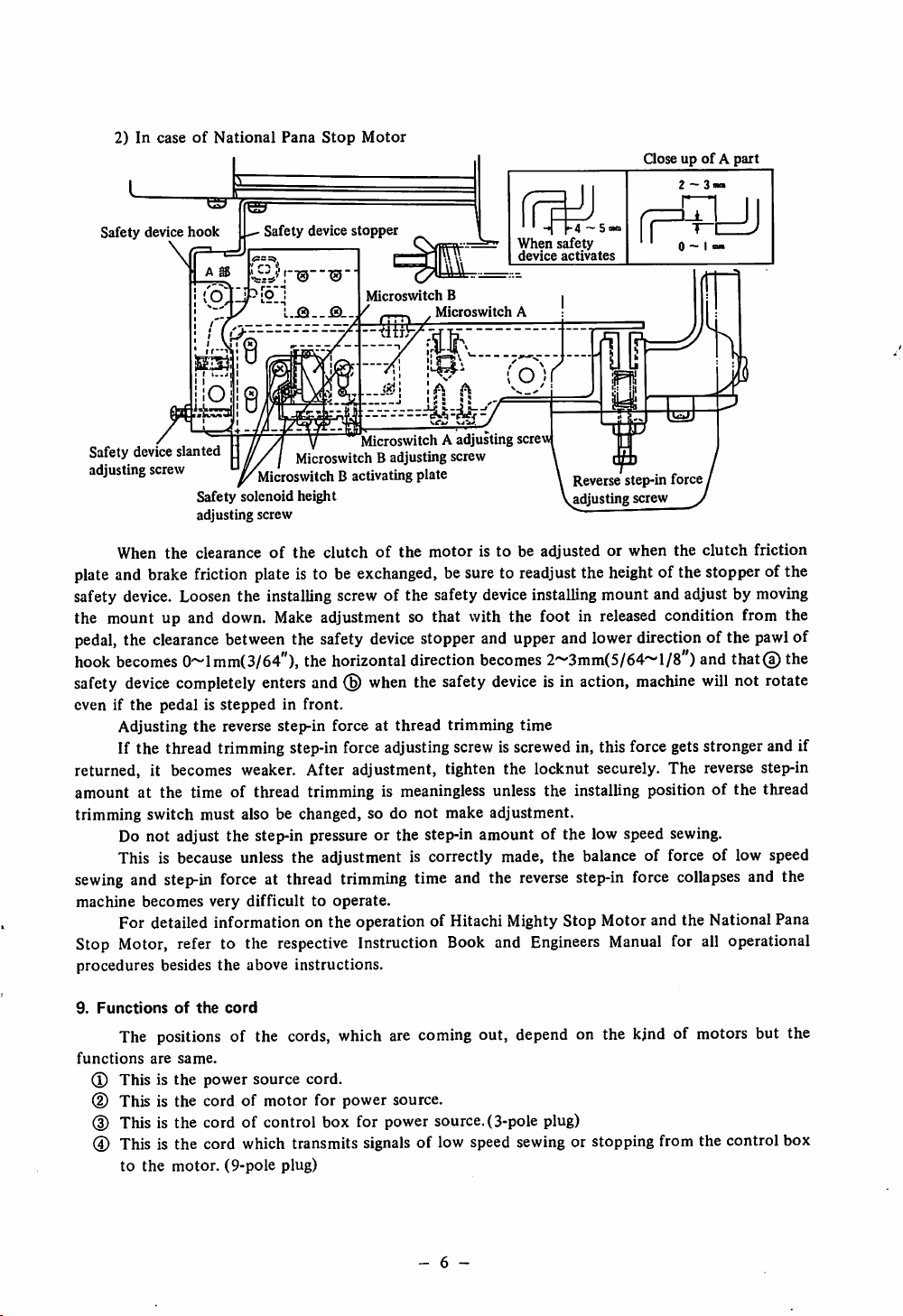

8.

Construction

(Full

lightly

treated

and

operationofmotor

details are given in

here)

the

Instruction

lever switch

BookofHitachi

and

National

Stop

Motor,

so it is

1) In caseofHitachi

Safety

Safety

solenoid

Main

lever

Basically,

adjustedsoadjust

Even if

completely

operation)orwhen

adjusting screw. Please

is

stepped-intothe

or

machine

When

adjusted

for

the

first time, sometimes it is easier to operate if the step-in returning amount at thread trimming

time

is increased. In

this

theminaccordance

the

pedal is stepped-in to

up

duetothe

high

stopping

the

step-in

for easy step-in

l~3mm(3/64~l/8"). At the sametime,return the thread

T.SW

will

so that

adjusting

screw

activate at lmm(3/64") before the auxiliary

and

mighty

Thread

trimming

adjusting screw

lever

Auxiliary

lever

switch

insufficient

the

machine

note

that

speed,sotighten

operations.

returning

returning

such

a case,

stops.

After

stop

motor

stroke

Thread trimming

tsw

L.SW

/^Thread

lever

switch

adjusting

needsnoadjustment.

with

torqueofthe

does

not

when

this screw is

amount

amount

return

the

the

adjustment,

spring

trimming

screw

the

following

the

thread

stopatthe

lightlyaslongasthere

at

thread

operation.

thread

tightly

Motor

lever

returning

Auxiliary

Auxiliary

stopper

However,asthere

instructions.

trimming

motor

designated

tightened,

trimmingistobechanged,

However, when

trimming

trimming

tighten

spring

lever

r

lever

force

screw

position,

(whenitstops

position,

the

pedal pressure gets big

is no

abnormalcyinthread

stroke

adjusting

switchadjusting

lever

hits the thread trimming stroke

the

locknut.

adjusting

the

Step-in force

adjusting screw

speed

spring

nut

are 2-3

places

the needle can

during

thread

tighten

machine istobe

screw

the

the

within

screw

which

not

trimming

step-in

when

trimming

machine

operated

the

and adjust

can be

rise

force

this

is so

area

Do not adjust the low speed step-in force adjusting screw or auxiliary lever stopper spring.

This lever

switch

is so assembled

that

even if the

clutch

liningofthe

motorisworn

out,

it is

not

necessary to readjust the position of the auxiliary lever stopper. When the low speed step-in force

adjusting

device activates and when the auxiliary lever hits the auxiliary lever

lever also moves to a certain degree

nut

is screwed in

and

the

pressureofthe low speed sewing pedal is

with

the

forceofthe low speed spring.

stopper

strenthened,

the

and stops, the main

safety

Due to this action, there is a danger of the machine to keep on running at high speed and the

possibilityofthe

operator

speed

will get used to

sewing.

safety

device unable to

the

machine,

perform

so do

not

its role.

try

to readjust

After

the machine is used for 1-2 days,

the

step-in force at

the

timeoflow

the

If the machine can not run at high speed even if the safety device is not working, it is because

the

clutch

lining is

worn

out.

Exchange

the

lining

with

a new lining. If the positionofthe auxiliary

lever stopper is not changed at the time of the new lining, it means the phenomenon is due to the

abrasion of the clutch lining. It is

better

not

to readjust the auxiliary lever

stopper

nut.

of

- 5 -

Page 8

2)IncaseofNational

Pana

Stop

Motor

GoseupofApart

Safety

device

hook

\

Safety device slanted

adjusting

When

screw

Safety

adjusting

the

clearanceofthe

Safety

device

stopper

Microswitch

Microswitch B adjusting screw

Microswitch B activating

solenoid

height

screw

MicroswitchAadjusting

clutchofthe

When

device

B

Microswitch

plate

motoristobeadjustedorwhen

A

screw

5

safety

activates

Reverse step-in force,

adjusting screw y

the

clutch

friction

plate and brake friction plate is to be exchanged, be sure to readjust the heightof the stopper of the

safety device. Loosen the installing screw of the safety deviceinstalling mount and adjust by moving

the mount up and down. Make adjustment so that with the foot in released condition from the

pedal,

the

hook

safety

even if

clearance

becomes

device

the

pedalisstepped

Adjusting

between the safety

0~lmm(3/64"),the

device

horizontal

stopper and upper and lowerdirectionof the

direction

completely enters and ® when the safety

in front.

the

reverse step-in force at thread trimming time

becomes

device

pawl

2~3mm(5/64~l/8")andthat@ the

is in action,

machine

will not rotate

of

If the thread trimming step-in force adjusting screw is screwed in, this force gets stronger and if

returned, it becomes weaker. After adjustment, tighten the locknut securely. The reverse step-in

amount at the time of thread trimming is meaningless unless the installing position of the thread

trimming switch must also be changed, so do

not

make adjustment.

Do not adjust the step-in pressure or the step-in amount of the low speed sewing.

This is because unless the adjustment is correctly made, the balance of force of low speed

sewing and step-in force at thread trimming time and the reverse step-in force collapses and the

machine

becomes

very difficult to

operate.

For detailed information on the operation of Hitachi Mighty Stop Motor and the National Pana

Stop Motor, refer to the respective Instruction Book and Engineers

procedures

besides

the

above

instructions.

Manual

for all operational

9.

Functions

of

the

cord

The positions of the cords, which are coming out, depend on the kjnd of motors but the

functions

(3)

d)

(3) This is

are

same.

Thisisthe

power

This is the cord of

the

cord of control box for power source. (3-pole plug)

source

motor

cord.

for power source.

® This is the cord which transmits signals of low speed sewing or stopping from the control box

to

the

motor.

(9-pole

plug)

- 6 -

Page 9

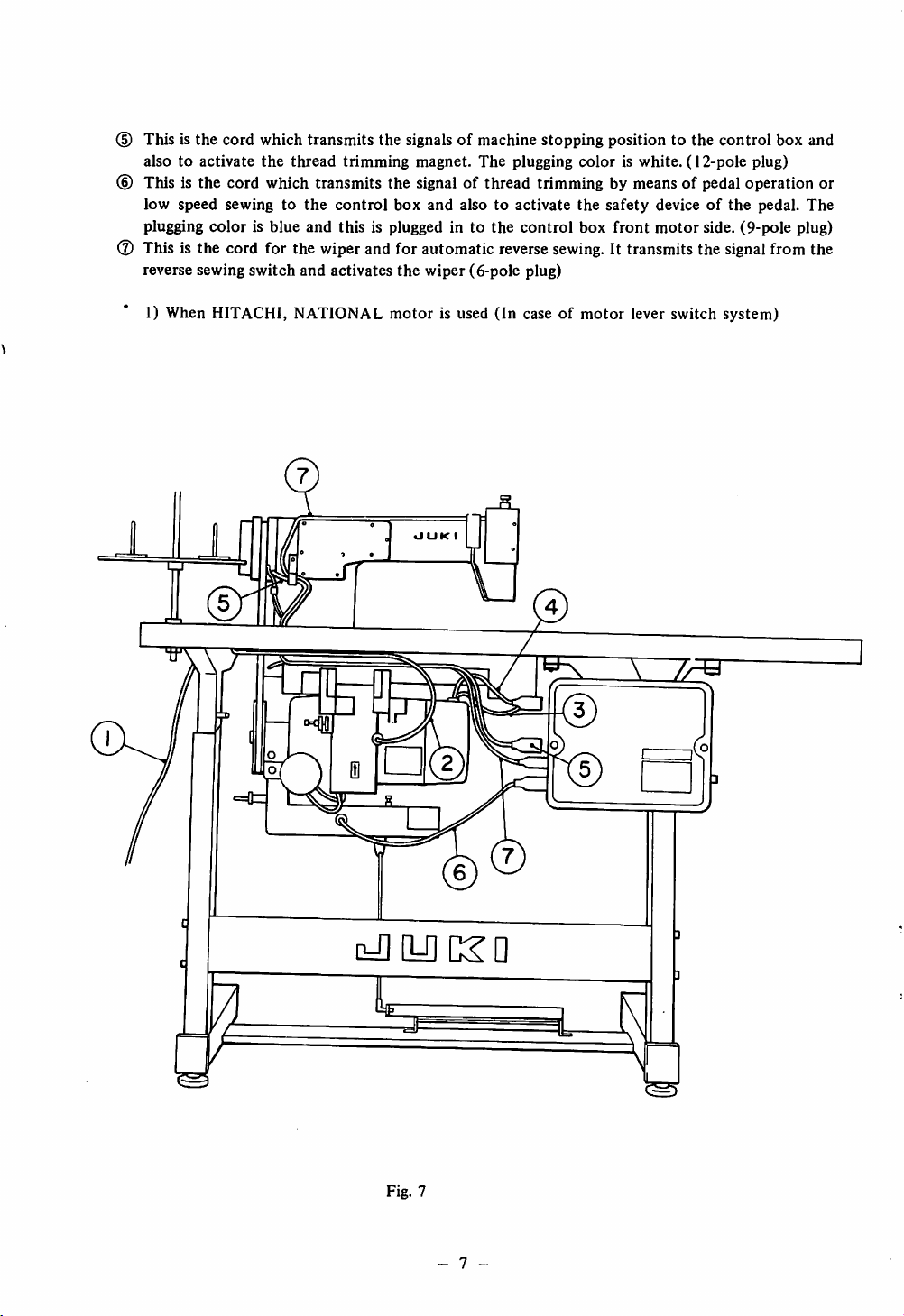

(D This is the cord which transmits the signalsofmachine stopping position to the control box and

alsotoactivate

the

thread

trimming

magnet.

The

plugging

coloriswhite.

(I2-pole

plug)

(D This is the cord which transmits the signal of thread trimming by means of pedal operation or

low

speed

sewingtothe

plugging

color

is blue and this is plugged in to

(?) This is the cord for the wiper and for automatic reverse

reverse sewing

switch

and

control

activates

box

the

and

alsotoactivate

wiper

(6-pole plug)

the

control

sewing.

the

safety

deviceofthe

box

front

motor

side. (9-pole plug)

It transmits the signalfrom the

pedal.

The

1) When HITACHI, NATIONAL

motor

•JUKI

is used

(In

caseofmotor

lever switch system)

[-flCLOKD

Fig.

7

- 7

Page 10

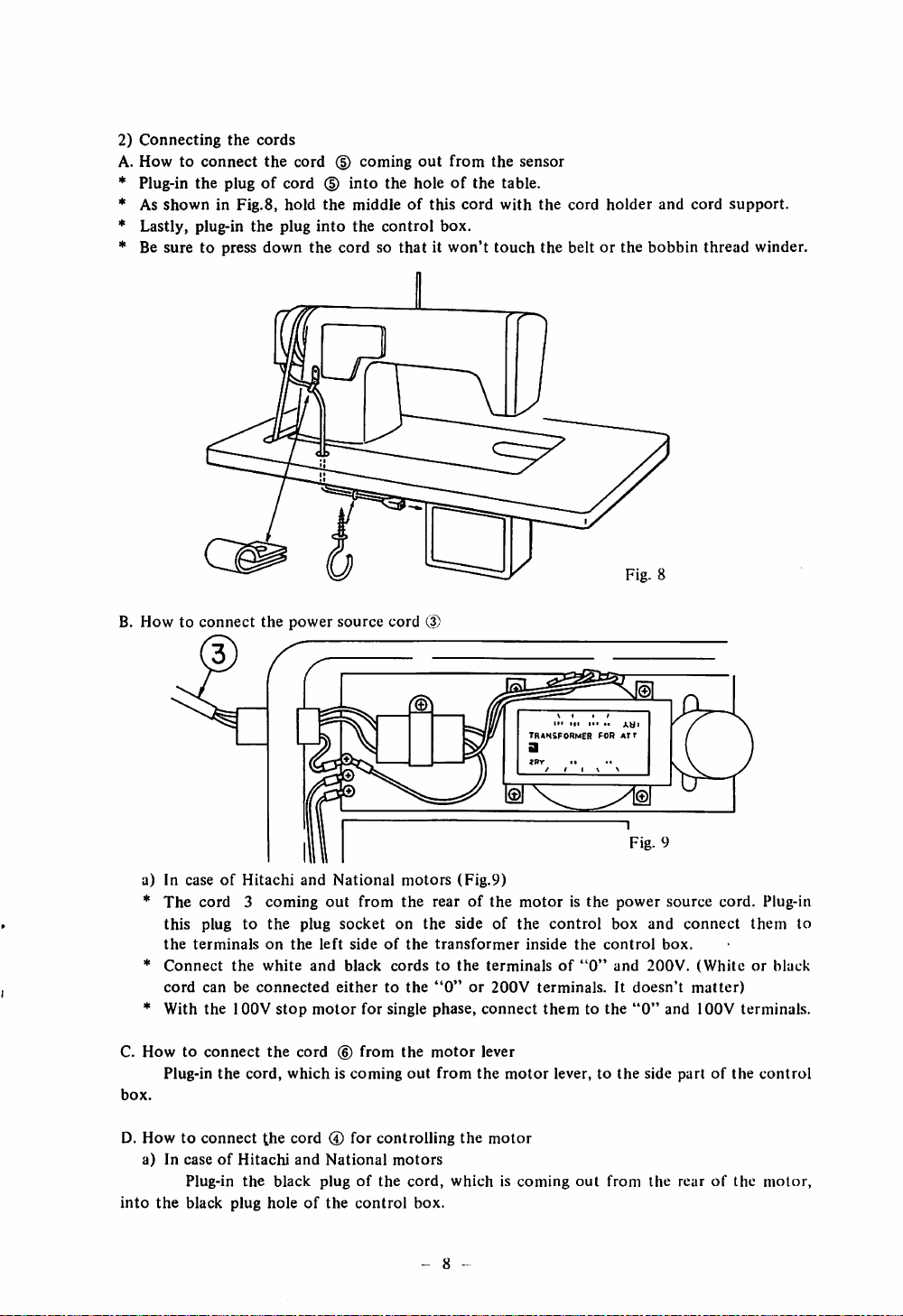

2)

Connecting

A.

Howtoconnect

* Plug-in

* As

showninFig.8,

the

the

plugofcord

* Lastly, plug-in

* Be suretopress

cords

the

cord(Dcoming

hold

the

plug

down

(§)

into

the

the

middleofthis

into

the

control

the

cordsothatitwon't

out

from

holeofthe

cord

box.

the

table.

with

touch

sensor

the

the

cord

holder

beltorthe

bobbin

Fig. 8

and

cord

thread

support.

winder.

B. How to

connect

a) In caseofHitachi

*

The

cord 3

this plug

the

terminals

*

Connect

cord

canbeconnected

*

With

the

C.

Howtoconnect

Plug-in

the

box.

D.

Howtoconnect

a) In

caseofHitachi

Plug-in

into

the

black

plug

to

the

lOOV

cord,

the

the

power

and

coming

the

on

white

the

stop

the

out

plug

left

and

motor

cord

whichiscoming

the

cord0for

and

National

black

plugofthe

holeofthe

source

cord (J)

National

socket

black

eithertothe

(6)

motors

from

the

on

sideofthe

cordstothe

for

single

from

the

controlling

motors

control

(Fig.9)

rearofthe

the

sideofthe

transformer

"0"or200V

phase,

motor

out

from

the

cord,

whichiscoming

box.

TRAKSFORMER

a

*»r

/ / 1 V \

motoristhe

control

inside

terminalsof"0"

terminals.Itdoesn't

connect

lever

the

motor

motor

themtothe

lever, to

»•

the

out

m

xai

f^OR

ATr

Fig.

power

box and

control

and

"0"

the

side partofthe

from

9

source

box.

200V.

and

the

rearofthe

connect

matter)

cord.

Plug-in

them

(Whiteorblack

lOOV

terminals.

control

motor,

to

- 8

Page 11

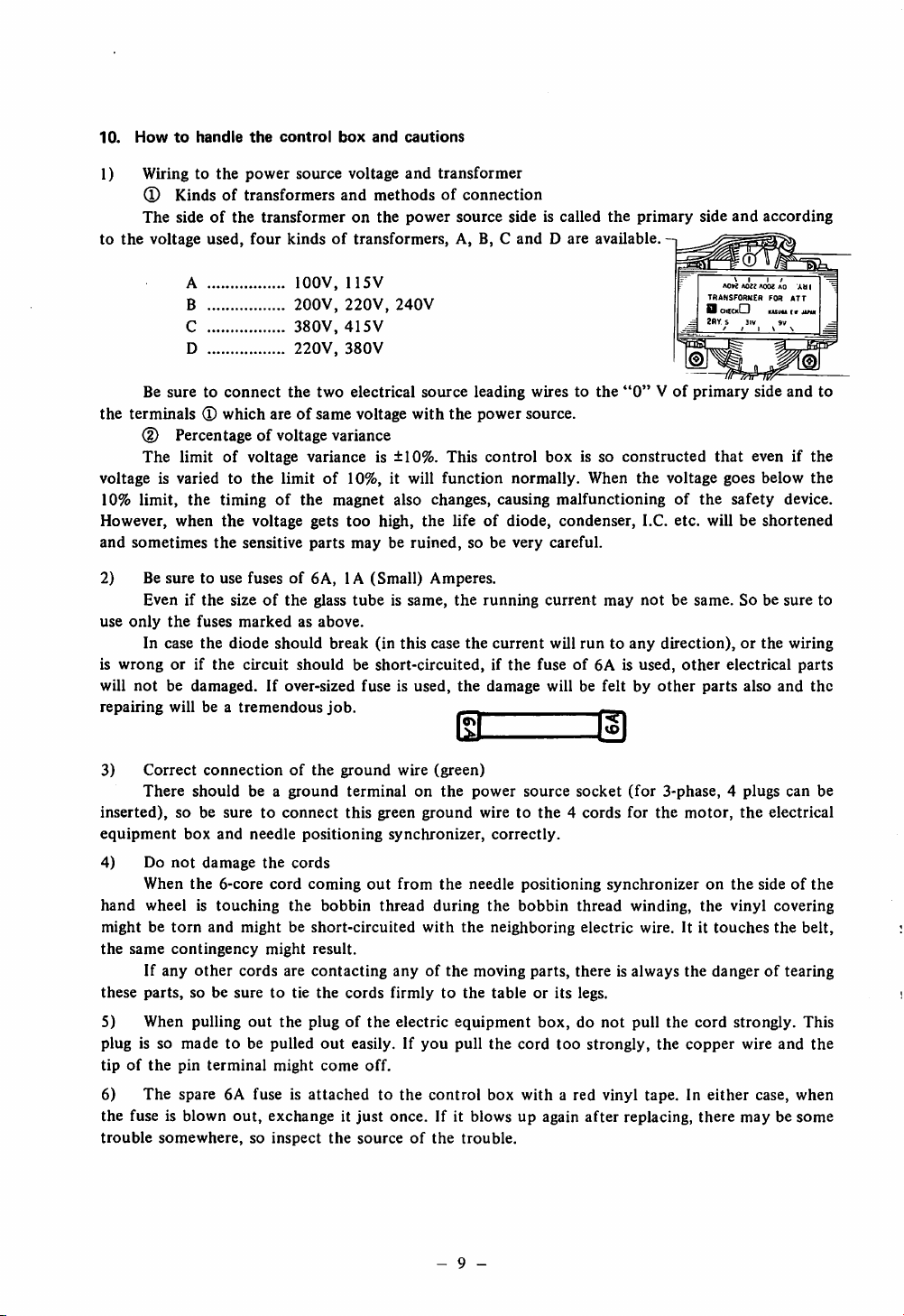

10.

Howtohandle

the

control

box

and

cautions

1) Wiring to

the

power

(D Kindsoftransformers

The

sideofthe

to

the

voltage

A lOOV,

B

C

D

Be

suretoconnect

the

terminals®which

used,

transformer

four

kindsoftransformers,

the

areofsame

(D Percentage of voltage variance

The

limitofvoltage

voltage is varied to

10%

limit,

the

However, when

and

sometimes

2) Be

use

is

will

repairing

sure

Evenifthe

only

the

In

case

wrongorif

notbedamaged.

will

the

limitof10%, it will

timingofthe

the

voltage gets

the

sensitive

to use fusesof6A,1A(Small)

sizeofthe

fuses

markedasabove.

the

diode

should

the

circuit

If over-sized

be a

tremendous

source voltage

and

and

transformer

methodsofconnection

on

the

power

source

A, B, C

115V

200V,

220V,

240V

380V,

415V

220V,

380V

two

electrical

voltage

varianceis±10%.

source

with

the

This

leading

power

control

function

magnet

parts

also changes, causing

too

high,

the

mayberuined,

life of diode, condenser, I.C. etc. will be

so be

Amperes.

glass

tubeissame,

break

(in

this

case

the

the

running

current

shouldbeshort-circuited,ifthe

fuseisused,

job.

the

damage

Ht

sideiscalled

andDare

wires to

the

available.

the

source.

box

is so

normally.

When

malfunctioningofthe

very

careful.

current

will

may

runtoany

fuseof6A is

will be

feltbyother

primary

"0"Vof

constructed

the

notbesame.Sobe

side

A0>? A022 AOOZAO Ati I

TRANSFORMER

D

oicckIZI

2RY.S 3IV 9V

primary

that

voltage goes

direction),orthe

used,

other

parts

and

according

VI

I /

FOR

kuiiu

side

evenifthe

below

safety

shortened

electrical

also

ATT

!• Jin

and

device.

sure

wiring

parts

and

to

the

to

the

Correct

3)

There

inserted),

equipment

4) Do

so be

not

When

hand

wheelistouching

mightbetorn

the

same

contingency

If

any

these

parts,

5)

When

plug is so

tipofthe

6)

the

trouble

madetobe pulled

pin

The

spare 6A fuse is

fuse is blown

somewhere,

connectionofthe

should

be a

suretoconnect

box

and

needle

damage

the

and

other

so be

pulling

terminal

the

6-core

cord

mightbeshort-circuited

might

cords

suretotie

out

the

might

out,

exchange it

so

inspect

ground

positioning

cords

coming

the

bobbin

result.

are

contacting

the

plugofthe

out

come

attached

ground

wire

terminalonthe

this

green

synchronizer,

out

from

thread

anyofthe

cords

firmlytothe

electric

easily. If

off.

to the

just

once. If it blows up again

the

sourceofthe

(green)

ground

the

during

with

you

control

- 9 -

power

source

socket

wiretothe4cords

correctly.

needle

the

the

neighboring

moving

tableorits

equipment

pull

the

positioning

bobbin

parts,

box,donot

cord

synchronizeronthe

thread

electric

there

is always

legs.

too

strongly,

box with a red vinyl tape. In

after

trouble.

(for

3-phase,4plugs

for

the

motor,

winding,

wire. It it

the

pull

the

the

copper

replacing,

the

electrical

sideofthe

the

vinyl

covering

touches

the

dangeroftearing

cord

strongly.

wire

and

either

case, when

there

maybesome

can

be

belt,

This

the

Page 12

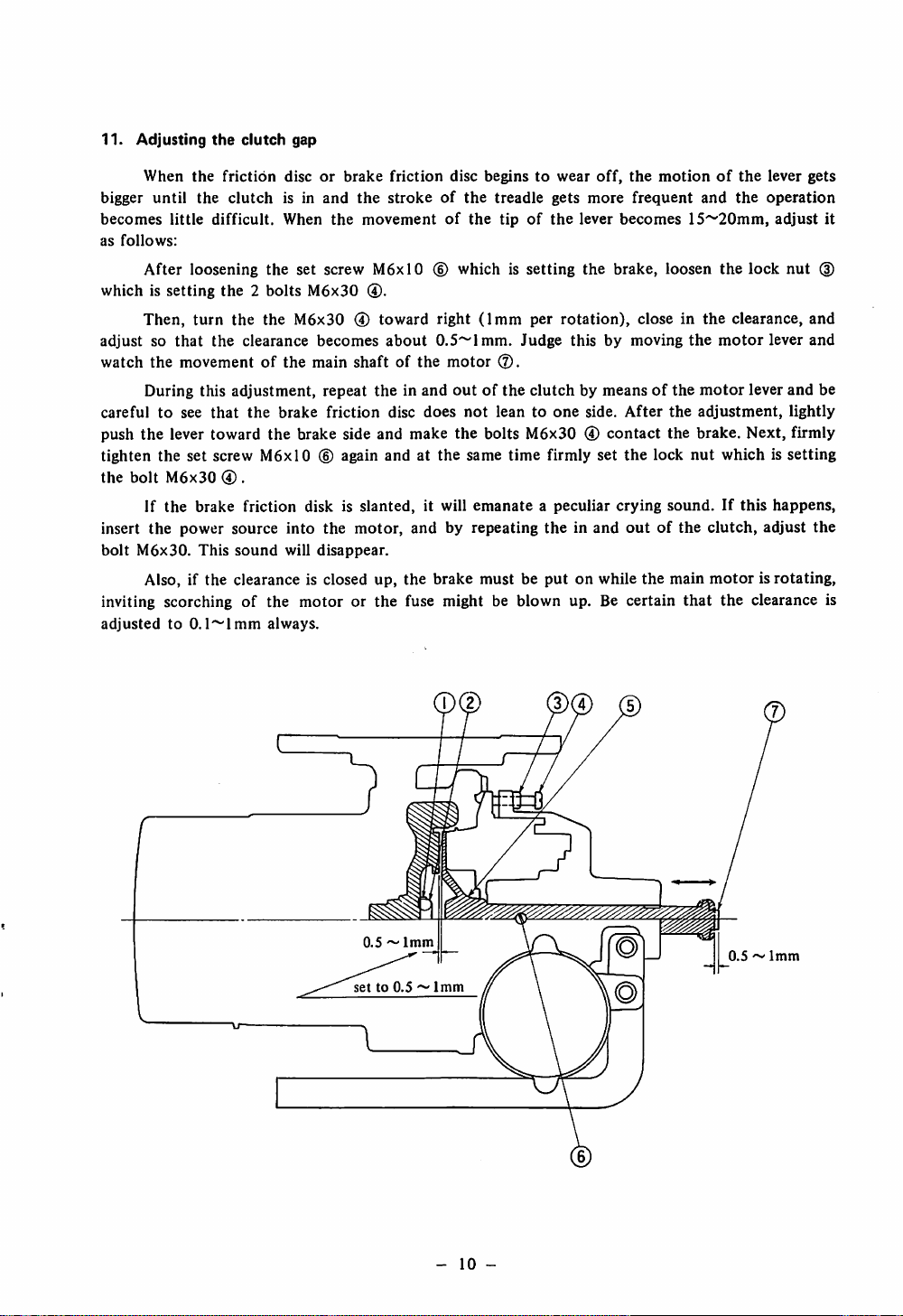

11.

Adjusting

When

bigger

until

becomes

as

follows:

After

which is

Then,

adjustsothat

watch

the

During this

carefultosee

push

the

tighten

the

bolt

If

insert

the

bolt

M6x30.

the

the

the

little

difficult.

loosening

setting

turn

the

movement

that

lever toward

the

set

screw

M6x30

the

brake

power

This

clutch

friction

clutch

discorbrake

is in

When

the

the2bolts

the

the

clearance

of

the

adjustment,

the

brake

the

M6xl0

0 .

friction

source

into

sound

will

Also, if the clearance is closed up,

inviting scorching of the

adjustedto0.l~lmm

always.

gap

friction

and

the

strokeofthe

the

movementofthe

set screw

M6x30

M6xl0

0.

M6x300toward

becomes

main

repeat

friction

about

shaftofthe

theinand

disc

disc

beginstowear

(D which is

right

(1mm

0.5~lmm.

motor

outofthe

does

not

treadle

gets

tipofthe

setting

per

rotation),

Judge

clutchbymeansofthe

leantoone

brake side and make the bolts M6x30 0

® again

disk is

the

disappear.

motor

and

slanted,

motor,

at the same

it will

and

by

the

brake must be

time

firmly

emanateapeculiar

repeating

theinand

put

or the fuse might be blown up. Be certain

off,

the

motionofthe

more

frequent

lever

becomes

the

brake,

loosen

close in

thisbymoving

side.

After

the

contact

set

the brake. Next, firmly

the

lock

crying

sound.Ifthis

outofthe

on while

the

and

the

15~20mm,

the

the

clearance,

the

motor

motor

adjustment,

nut

whichissetting

clutch,

main

motorisrotating,

that

the

lever

gets

operation

adjust

lock

nut

and

lever

and

lever

and

lightly

happens,

adjust

the

clearance is

it

(3)

be

0.5~1mm

setto0.5~1mm

-

10

-

0.5^1mm

Page 13

I.

HOW

TO

OPERATE

1.

Cautionsonoperation

Turn

the

switchononce

direction

* Unpack

* Before

* Do

*

*

of

the

machine.

the

machine

operating

BOOKonDDL-552,

not

run

the

The

machine

counter-clockwise).

For

the

first

should

month,

s.p.m. for DLN-415-3

increase

* When

*

When

* When

the

the

the

the

speed

power

power

machine

* If the needle does

turn

the

switch

this

machine

Do

dependingonthe

switchisturned

switchisturned

head

not

off.

and

machine,

553

without

rotate

not

drop

and

has to be

stop

THE

and

after

settingitup,

and

555orDLN-4I5,

toward

run

the

the

speedto4,500

3,800

at the

* When transporting the machine, do

* Sometimes when the

pedal to the rear

cannotbedone.Insuch

down

and

normal

power

immediately

a case,

trimming

canberesumed.

switch is

after

just

MACHINE

after

turningitoff,

steponthe

clean it well.

please

read

and

digest

DLU-450,

filling up

the

machineinthe

s.p.m.

on,donot

on,donot

tilted

top

not

the

oil reservoir,

operator.

(As

reverse

s.p.m.

viewed

for DDL-552-3

for DDL-553-3, DLU-450-3

natureofwork

put

touch

for

oilingorcleaning,besuretoturn

your

the

and

hands

position even when the pedal is

touch

the cover on

turned

on and the thread is

these actions, the needle will

steponthe

pedal

toward

every

paragraphofthe

DLD-432

from

direction.

the

capabilityofthe

around

hand

wheel.

the

rear partofthe hand wheel.

front

pedal

and

observe

thoroughly.

the

pulley

and

DDL-555-3

and

DLD-432-3.

and

under

steppedontoward

trimmed

not

once

come

and

butifyou

the

the

INSTRUCTION

side,

the

operator.

the

needle parts.

the

switch

steponthe

down

and

needle

rotational

direction

and

4,300

After

that,

off.

the

rear,

trimming

will

come

is

2.

Lubrication

Before

machine oil to

separate

3.

Trial

and

running

the

instruction

runofthe

adjusting

the

"HIGH"

volume.

machine

the

oiling

amount

machine, fill up the oil reservoir

mark. Please refer to

the

chapteron"Lubrication

with

the

designated

and

JUKI

drainage"onthe

* At first, verify the correct movement of the machine without passing the thread.

1) When the power switch is turned on, the needle always stops at the raised position. In case

the needle does not

measures"

and

2)

Step

If the machine does not function even after these re-adjustments, refer to the

functions

to

ascertain

3)

and

After

that

stop

make

at the raised position, refer to the

proper

adjustment.

chapter

on "Malfunctions and corrective

on the pedal lightly toward front and verify the correct low speed sewing operation.

chapter

corrective

the pedal is

the

measures".

steppedonfront

machine

stops

with

(away

from

the

needleatlower

the

operator)

position.

and

the

foot

is released, be sure

industrial

on "Mal

- 11 -

Page 14

4) Step on the pedal toward rear and verify the thread trimming operation.

5) Re-adjusting the low-speed switch and verifying the correct working of the safety

device.

Step on the pedal toward rear (the thread trimming switch will start) and if you hear the sound

of the magnet working from under the bed, immediately step on the pedal toward front.

If these movements are repeated over and over again, invariably there willbea position where

the pedal will not move toward front any more. At this position, the machine will be stopping but

if the machine should

machineatthis

6) Insert the needle and start sewing.

Note:

*"Front"

*"Rear"

4.

Howtooperate

As

shown

move

position.

means

means

the

pedal

in Fig. 10,

for

low-speed

away

toward

the

pedalofthis

from

the

sewing,

the

operator

operator

machine

re-adjust the

functions

low-speed

in 4 stages as follows:

sewing

switch to stop the

(D The machine is stopping by just resting your foot lightly on the pedal.

(D

When

(D

®

the pedal is stepped on lightly to front, it

When

the pedalis stepped on further

When

the pedal is stepped on

fully

strongly

toward rear, the

becomes

to front, it

machine

low-speed

becomes

will

sewing.

high

speed

sewing.

perform thread

trimming.

* Normal thread trimming can be performed even if the pedal is stepped on abruptly to the rear

either

from

high

speedorlow

speed

sewing.

* After the machine has started the trimming, the trimming can be done even if the pedal is returned

to

the

needle

neutral

goesupand

position.Itis

stops.

not

necessarytokeeponsteppingonthe

pedaltothe

rear

until

the

High

" ~

speed

Low

speed

^Stopped

Thread trimming

-

12

position

HIGH

SPEED

LOW

SPEED

STOPPED

POSITION

THREAD

TRIMMING

Fig.

10

-

Page 15

♦

When

the

machine is

* If the lowered needle is to be raised up again,

and

stops

after

(Caution)

the

stopped,

trimming

the

needle always comes

action.

down

and stops.

step

on the pedal toward rear fully. Needle goes up

After completing the trimming (stepping the pedal to rear), if you try to step on the pedal to

front suddenly, sometimes the pedal will not move. This is because the safety device inside the pedal

is acting to prevent any undue damage to the machine. In such a case, return the pedal to the rear

once and then step on the pedal toward front once more and the machine will start its normal

running.

5.

Threading

*The

ing the machine, step on the pedal toward rear once and do

needle

*Pass

6.

Adjusting

Adjusting

machine. Please follow

and

555,

attachedtothis

the

needle always

willgoup

the

needle thread in

the

DLN-415,

machine

stops

at the raised position. But if it is at

and

stops

there.

the

thread

tension

the

thread

the

DLU-450orDLD-432.

machine,

(Fig.28)

tensionofthis

procedures as

the

adjustmentislittle

orderof(T)

outlined

However, please

the

lowered position when

the

trimming action once. Then

~ ® as shown in Fig.27.

machineisexactly

in the INSTRUCTION BOOK on DDL-552, 553

different

than

note

other

like a

that

conventional

duetothe

lockstitch

thread

machines.

thread

the

lockstitching

trimmer

^ First tension disc

WeakIStrong

(Adjusts

the

thread

remaining at

the

needle

trimming >

(4)

Strong

w

Second

(adjusts

tention)

Fig.

Weak

11

-

13

-

Fig. 12

length

of)

eye

after

tension

disc

the

thread

Page 16

1)

Thread

When fine

take-up

cotton

spring

thread or synthetic threads (tetoron, nylon etc.) are used, the tension of the

take-up spring may become too strong or the range of movement of the spring may become too wide,

causing skip-stitching

thread.

Be

extremely

2)

Adjusting

*When

the tension of the first thread tension is made stronger, the thread remaining at the tip of

just

careful.

the

first

before

thread

the

tension

machine

disc

stops

and

sometimes

the

machine

does

not

trim

the

the needle eye becomes shorter after trimming and when it is made weaker, the remaining thread

becomes

longer.

*For fine tlireads (synthetic fiber), weaken the tension and for thick thread, make it stronger.

3)

Adjusting

* Normally, the adjustmentofthis disc is same as any

* However, please

the

thread

might

4)

Adjusting

The

adjustment

the

second

note

breakatthe

the

bobbin

of the

thread

tension

other

lockstitching machines.

that

when synthetic thread is used, if the tension is adjusted

startofsewing.

thread

tension.

bobbin

thread

tension is practically

sameasany

conventional

too

weak,

lockstitch

ing machine. However, if the tension is too weak, the bobbin might spin idly at the trimming instant,

causing the needle thread to

"float"

up at the

start

of sewing, and for synthetic threads, thread

breakage or slipping out of the needle thread at the start of sewing might occur. Be very careful.

* As a rule, this machine is used with a bobbin case in which a magnet is built-in to prevent

idle spinning of the bobbin. (Part number is D 1837555 BAO and sold separately)

7. Adjusting

the

standard

control box) to right and left so that, after the thread is trimmed and

red

mark

standard

will

stop

the

needle

stop

position after thread trimming (Fig.13)

After the thread is trimmed, this machine can change

needle

on

the

If the adjusting

stopping

below

* If the thread should slip

stop

arm

and

knobisrotated

position,

the

white

rotate

mark

toward the

position (in caseofA) and if

the

standard

stopping

out

position

even if the length of needle thread is adjusted

the

on

needle

the

it's

(in

position

hand

wheel

"FAST"

rotated

caseofB).

the

needle

stop

position.Toadjust to

adjusting

are

matched

knob®(on

the

needle has stopped,

with

each

direction, the needle will

toward

the

"SLOW"

direction,

the

other.

stop

after

sideofthe

above the

the

the

is trimmed, rotate the adjusting knob toward the "SLOW" direction, (toward [B] direction).

* If the needle should hit the wiper, rotate the knob toward the

[A]

direction).

(Caution)

"FAST"

direction, (toward

If the adjusting knob is rotated too much toward the "SLOW" direction (toward B direction),

sometimes

the

machine

does

not

stop.Insuch

a case

rotate

the

knob

toward

the

"FAST"

direction.

iBl [A]

o

"SLOW"

Adju-sting

T7T777T7T77-

knob

Standard

stop

position

"777V7/////

Throat

needle

•

plate

^?^"FAST"

Adjusting

y

knob

Fig.

13

the

needle

thread

-

14

-

Page 17

8. When low speed sewing is not necessary (Fig.14)

* Be sure to cut off the power and make adjustment. When low speed sewing is not necessary

at

the

startofsewing;

(2)

Cut

off

the

power

source.

(2)

Open

the

coverofthe

control

box.

(D Pull out the inserted ® of the figure from the pin @ and insert it into the pin lij.

Thus, the low speed

function.

sewing

function can be eliminated without affecting the thread trimming

r

Fig.

14

9.

Carefully

the

remaining

might

break.Insuch

* Be

result.)

*

When

note

the

certain

thread

skip-stitching

a case,

following

that

the

at

re-adjust

the

points

needle

needle

occurs,

the

thread

comes

eye

after

the

bobbin

timingofthe

out

trimming

thread

needle

smoothly

will

may

with

from

become

break

the

sewing

but

the

short

thread

the

hook.

and

needle

spindle.

thread

thread

(Otherwise,

slipping

does

out

not

10. Howtoselect

1)

Presser

2)

Throat

3)

Needle

4)

Sewing

5)

Feed

but

if an

extremely

the

moving

dog

knife

1)

2)

the

foot

plate

hook

moves

Presser

Throat

presser

thick

foot

plate

feed

fully.

foot,

throat

Select

smallaandbparts

Select

small

Finer

needle

Automatic

If a

feed

dog

dogisused,

plate, sewing

needle

eye

andApart.

for

less

thread

lubricating

whichiscommonly

the

hook

backsideofthe

hook

and

(Fig.

15)

slippage

withagroove

usedisadopted,

feed

dog

dog

teeth

mightbescratched

thereisno

Na

Fig.

15

-

15

-

problem,

when

Page 18

IV.

ADJUSTING

THE

MACHINE

This machine consists of lockstitching part and the thread trimming part. The lockstitching

function is same as all other previous models, so this text will cover the thread trimming part only.

1. Adjusting

the

timingofthe

1) Howtojudge

In

order

to change

the

timingofthe

indicated

Tilt

before

the

lineonthe

the

upper

thread

hand

machine,

dead

cam roller (Fig.17) will

that

condition,

hand

wheel

matchedsothat

(Fig.

18 (D)

will

are

rotate

cometoa

the

indicated

matched

indicating line (Fig. 18

synthetic

thread.

thread

trimming

the

correct

the

timingofthe

lengthofthe

thread

trimming cam. This can be

wheel,

accordingtothe

turn

the

hand

wheel

point

and if

the

sewing

enter

the

cam

grooveofthe

the

hand

wheelinthe

point

where

it will

lineofthe

togetherasshown

®)ismatched

a

arm

in Fig.

with

(Z

cam

trimming

cam

remaining at the needle eye

done

easily by matching the arm with

kindofthread

with

your

hand

until

hook

presser (Fig. 16 (D) is pushed deeply to right, the

cam (Fig. 17)

reverse

(Fig.18 (D)

the

Thread

cam

direction

not

rotate

any

more.Atthis

and

the

18,itbecomesacotton

indicating

line (Fig. 18 (D), it

trimming

used-cotton

the

and

than

the

indicated

after

thread

will be

interlocked

conventional

pointifcam

lineofthe

thread

becomes

Rotational

trimming,

or

synthetic

take-up

timing.

comes

way,

hand

Butifthe

a timing

direction

adjust

the

thread.

Just

there. In

and

the

timing

wheel

for

is

2)

Howtomatch

First,

No.2,

and

cotton

thread,

the

green

Then,bypushing

roller,

and

normal

not

finally

hook

rotate

tighten

loosen

match

color

without

any

Fig. 16

match

(D),

shaft

more,

the

DLD-432-2

the

the2set

the

indicating

red

(Fig.

the

rotating

rotational

push

cam

set

timingofthe

screwsofthe

lineofthe

color

(i)

18)

sewing

the

hook

direction

the

screws

with

hook

cam

(Fig.

thread

trimming

the

presser

shaft,

with

against

17)inthe

Cam

arm

red

rotate

your

-

Cam

arm

color

the

16

roller

roller

shaft

set

screw

trimming

cam

(Fig.

with

the

(2)

and

(Fig.

16 (3))toright,

the

cam

only

finger tips. At

thread

orderofNo.2

trimming

-

cam

17)inorder

indicating

for

synthetic

toward

and

Rotate

direction

Fig.

lineofthe

interlock

the

the

position

cam

No.l.

17

from

thread,

reverse

thrust

caminthis

with

hand

set

screw

hand

red

the

cam

direction

where

collar

Thrust

Set

screw

No.l

and

wheel.

color®with

and

the

(Fig.

the

than

cam

17)

(For

cam

the

does

and

collar

No.2

Page 19

2. Adjusting

showninFig.

1)The

the

position of

correct

19,

position

when

the

moving knife

of the

the tip of the

moving

moving

knife

knife

whenithas

has

retreated

moved

to its

maximum

to 2~2.5mm(l/6 ~3/32 )

range

from

is, as

the

center of the needle. When the retreated range is less than this position, it cannot scoop up the

needle or bobbin thread at the trimming instant, whileif it's too much, the feed dog and the

knife

might

knife

correctly.

hit each other. Therefore, it is

Green

(3

Fig. 18

very

important to

2 ~

match

2.5mm

the position of the

Needle Moving knife

moving

moving

Fig. 19

2)

Howtomatch

the

positionofthe

moving

knife

This is adjusted by changing the right or left position of the moving knife shaft (Fig.20 (D)

when

the

changes, so

a. First,

b. Move

moving

th

the

knife

c. Loosen

d.

Match

(In

caseofcotton

Rotate

e.

front

and

f. Move

g.

With

this

cam

cannot

h.

Temporarily

i.

Tighten

j. At

this

machine

match

loosen

the

shaft

both

the

the

the

the

point,

stops.

By

this

the

positionofthe

the

magnet set screw

magnet

becomes

indicating

set

whenitcomestofront,

camtoright

condition,

link

(Fig.20

adjusting

set

screw

rotate

tighten

lock

verify

nut

greater

screwsoftrimming

lineofthe

thread,

No.2

and

as

you

anymore.

the

set

nut.

(Fig.20

the

(Fig.20

andifit's

match0with®of

(Fig.20

left

pull

screw

®)

following:

adjustment,

thread

(Fig.20®and

0)

downwards

(D). If

loosened,

cam ®

hand

wheel

®)

(indicated

push

the

and

interlock

the

camtoright,

No.2 ®ofthe

the

interlockingofthe

trimming

this

and

with

sewing

cam

toward

pull

out

and

adjust

nutisscrewedindeep,

the

range

gets

the

thrust

the

indicating

Fig.18

and

for

point)ofthe

hook

pressertoright.

the

cam

and

moveittoward

cam.

cam

and

the

shaft

direction,

the magnet link pin

the

less.

collar

synthetic

trimming

the

cam

screwed-in

®.

lineofthe

roller.

teh

amountofthe knife

the

arm.

thread,

cam so

arrow

the

cam

(Fig.20

retreating

match0with

thatitcomes

direction

0 Is the indicating line of the pulley matched?

@ Is

the

k.

1.

m.

@ Is

Tighten

Push

Attach

roller inserted

the

retreated

the

two

the

thrust

the

magnet

collar

smoothly

into

the

rangeofthe moving knife

set

screwsofthe

against

link

pininits

the

cam

cam

and

original

cam groove?

securely.

tighten

position.

2~2.5mm?

the

two

set

screws,

also.

roller

(3)).

range

until

also

of

(3))

to

the

-

17

-

Page 20

The

simple

step

partofthe

parallel,

(Note)

1) No

the

the

matter

retreating

2) Verify if

methodtojudge

bed and

positioniscorrect.

how

rangeofthe

the

moving knife disposes

slight

the

the

the

correct

positionofthe

forked baseofthe

right or

moving

left

knife.

the

position

thread

s

0

0

0

knife

adjustment

properly

3

moving

knife

are paralled to

may

be, it has a big bearing on

as shown in Fig.21.

Fig.

wouldbeto

each

other.Ifthey

20

verifyifthe

are

Fig. 21

3.

Howtoinstall

The

correct

the

fixed

knife

correctly

methodofinstalling

the

fixed

knifeisshowninFig.22.

The

standard

distance

the center of the needle to the tip of the fixed knife is 4.2mm(5/32"). The tip of the fixed knife

shouldbe0.6mm

When

the

cutting

the

cutting

be

changed,besure

installation

above

the

angleofthe

partofthe

power

becomes

(Fig.22A).

the

fixed

to verify

installing

installing

knife

most

powerful.

the

sharpnessofthe

surface.

fixed

and

the

(Fig.23).

knife's

moving

When

-

18

tipischanged,

knifeisprecisely

the

fixed

knifeistobeadjustedorwhen

blade

andatthe

the

cutting

matched,

same

time,

power

then

adjust

changes.

and

the

only

angle

from

When

then

it is

to

of

Page 21

Moving knife

Lower

of

throat

part

plate

Needle

The

In

U

that

(Note):

Graded

part

of

bed

Fixed

Shorter Longer

Length of remaining thread

after trimming

Fig.

22

fixed knife

can

be installed by moving it to

knife

0.6mm

the

case, the length of the remaining thread of needle thread and the bobbin thread not

DLN-415-2

Set

the

rightofthe

feed

adjusting

Fixed

Fig.

standard

knife

23

installation

only gets longer by the distance the fixed knife has moved, but because the timing of the

trimming also is delayed which makes the length of the thread at the tip of

much

longer

(Fig.25)

In the caseofsynthetic thread, move the fixed knife to right to delay the timing of the thread

the

trimming. However, to make

of

the

thread

trimmer.

(Chapt.

adjustment complete, it is also necessary to adjust the timing

IV-1).

dial to

the

needle eye

"0'

position.

4.

The

floating

1)

How

rangeofthe

to verify

second

the

floating range

thread

tension

disc

At the position where the take-up has come just before the upper dead point, lower the presser

foot and when the hook thread presser (Fig. 16 (D) is pushed hard to right, verify that the floating

rangeofthe

Bring

center

Moving knife

second

2) Adjusting

(DTo increase the floating

thread

tension

the

floating range of the second thread tension disc (Fig.26)

discis0.5~lmm.

range,

loosen nut

(B)

and tighten nut

(2)To decrease the floating range, loosen nut ® and tighten nut

After

the

adjustmentiscompleted,

to

Mxed

knife

1(0

0

Sewing

hook^—

tighten

When

is

Standard

both

fixed

moved

\

Moving

Bobbin

to right

presser

<3)

knife

knife

thread

and

(g)

nuts.

(jg).

®

(D

@ ® ©

1

Fig.

24

Fig. 25

-

19

Fig.

26

-

Page 22

5.

Howtosharpen

The shape of the blade tip of the fixed knife greatly affects the cutting power of

most cases,

just

the

sharpen

knife

blade

the

blade of the fixed knife and the cutting becomes sharper.

the

knife. In

1) It is very important that the blade surface of the moving knife should contact the blade of

fixed

knife.

® Just sharpen the

X in

Fig.27)

® The cutting power becomes weak when the B surface tip is

change

the

"A"

angleofx

surface (Fig.27) and cutting becomes better. (Note the angle shown by

when

sagging

sharpening.

and blunted. So, do not

® When cutting power is not so good even though the blade tips are sharpened, it is because the

blade surface of the moving

same

time.

Correct

* To

improve

markofFig.29.

When

the

the

contacting

the D

knife

and

inclination

angleofthe

of the

sideofFig.28

the

fixed knife is

moving

does

not cut

fixed

and

knife.

fixed

well,

not

contacting to right

knife,

change

shorten

the

the

angle

angle

and

and

of the

when

leftatthe

arrow

theC

side

does not cut well, make the angle larger.

Fixed

Shave

off

sharpen

Blade

B

corners

well

surface

and

Sharpen this surface

A

surface

tip

Fixed

Moving knife

knife

knife

C & D parts of moving knife and fixed knife

should

contact

each

otheratthe

Fig.

6. Changing

To

change

1)

Loosen

pin

the

moving

the

the

(Fig.32

knife

moving

knife

(D).

27

knife,doas

forked

base

follows:

pin

set

screw

(Fig.32

®)

and

pull

Fig.

out

28

the

knife

2) Remove the moving knife hinge screw (Fig.30 (D), move the knife forked base (Fig.30 (D)

and

the

the

3) Move

screw

moving

moving

the

(Fig.3IB).

knife

knife

knife

from

forked

For

(Fig.30

the

knife

basetothe

this

purpose,

Fig. 29

(D)tothe

forked

position

use

position

base.

showninFig.31B

the

special

shown

in Fis.31 A

spannerinthe

and

remove

accessories

and

remove

the

box.

m

Fixed

knife

same

forked

the

knife

time

base

pin

hinged

Fig.

of

30

-

20

-

Page 23

For installing back,

reverse

the

above

procedure. After the knife

hinged

screw

move the moving knife with your hand and see if it movessmoothly without any rattling. Match the

knife forked base to the position shown in Fig.31C and firmly insert the knife forked base pin into

the forked base. (If the knife moving shaft is moved to right or left, the pin will go in deep into

the base). When the shaft is moved to right, be sure to see that the knife moves to right, also.

N (

Knife

Moving

forked

base

knife

Fig.

7.

Adjusting

the

If

the

bobbin

trimming time,

thread

slippage at

On

the

of

the

bobbin

tipofthe

1)

The

When

needle

the

should be pulled

bobbin

thread

31A

bobbin

the

thread

thread

presser

bobbin

the

startofsewing.

contrary,ifit is

thread

correct

presser and

presser at

eye

after

the

positionofthe

thread

trimming

out

easily. At this position, the clearance between

the

Knife hinged

Moving

presser

will

not

not

the

trimming

lever is pressed

upper

Knife

forked

screw

knife

(Fig.32

rotate

inserted

trimming

bobbin

carved

base

Fig.

31B

(D)ispenetrating

and

the

bobbin

deep

enough,

time, shortening

and

invites

thread

thread

presser

hard

partofthe

bobbin

too

thread will be trimmed

the

needle

the

slipping

against

the

shouldbe1.5~2mmasshown

deep

thread

out.

stopper

Knife

forked

base

Moving

knife

Fig.

toward

the

bobbin

too

thread

will slip

remaining

side,

the

the

tip (Bobbin presser)ofthe

is tightened,

31C

case at

short,

causing

out

from

the

amountatthe

bobbin

thread

in Fig.47.

the

tip

£

DLD-4322

Fig.

Fig. 32

2)

Howtoadjust

Loosen

the

ond down. At this instant, adjust

the position of the thread trimming stopper arm (Fig.26

After

adjusting, tighten

shaft is

not

contacting the

contacting, refer to

shaft

collar.

the

bobbin

screws

(Fig.32

bottom

the

chapteron"Adjusting

thread

presser

0),

and

adjust

by moving

the

fore and

the

set screwofthe

aft

position of the bobbin thread presser and adjusting

stopper.

of the cam groove when the

the slide

21

the

bobbin

@).

thread

As shown in figure.

Be sure to verify

stopper

shaft"

and re-adjust

-

33

presser in

that

the

and

tipofthe

is deeply inserted. If

the

positionofthe

1.5

outorup

roller

it's

slide

Page 24

8.

Adjusting

The

the

moving

slide

range

shaft

of the slide shaft (Fig.34

(D)

is 5.4mm(7/32").This is adjusted by

moving

the slide collar (Fig.34 (D) toward the shaft direction. Also, the position of the cam roller shaft arm

(Fig.34 (D) should be 13.5mm(33/64") as shown in Fig.34.

*

The

adjusting

procedure

is as follows:

(D Determine the position of the thread trimming arm stopper depending upon the position of

the

hook

thread

presser.

(D Adjust the position of the slide collar so that the moving range of the slide shaft comes to

5.5mm(7/32").

(D Adjust the position of the thread trimmer magnet (DC solenoid).

When

the

thread

adjust

thread

there

the

position of

trimming

should

trimming

the

magnet

be no clearance

arm

has

movedtothe

thread trimming magnet so

plunger

hits

between

the

the

20mm

rubber

two

endsofthe

ring

position

that

and

stops

were it is

the

snap ring which is

and

also

rubber

ring.

almost

when

touching

attachedtothe

the

magnet

the

stopper,

is pulling,

13.5mm

Fig.

9. How to install and remove

To

remove

the

knife

34

the

knife installing base

installing base

(Fig.35

®),

do as follows in

Fig. 35

order:

(DTake out the sewing hook.

© Loosen the knife forked base(Fig.35 (D),and pull out the knife forked basepin (Fig.35 (D).

(DAfter removingthe hook thread presser link hinged screw(Fig.35 (D),and if the hook presser

hinged screw (Fig.35@)knife installing base set screw (Fig.35

base

will

come

off.Toinstall

back,

reverse

this

order.

d))

is pulled

out,

the knife installing

-

22

-

Page 25

10.

Adjusting

This synchronizer has adopted

is impossible to verify the position of the synchronizer by the tester by pullingout the 12P

the position of the synchronizer

semi-leading

(Fig.36)

element, non-contacting type

called

hole IC, so it

plug.

Therefore, the position of the synchronizer should be adjusted in the following order:

®

Remove

the

belt.

(DRemove the coverCDof the synchronizer and loosen the screw (3).

(DTurn

the

power source switch to

"ON".

@ Match the black indicating line of the pulley with the red indicating line of the machine head,

d) If the synchronizer is moved gently by the hand without moving the pulley, the auxiliary

motor will either rotate or stop. So, at the position where the auxiliary motor has started to stop,

tighten

the

screw

© Replace

(g).

the

cover of the synchronizer to the original position.

(Note) When the above adjustments are made, do not loosen the screw

this part is either loosened or released, sometimes the synchronizer does not function. So,

use

extreme

caution.

0

Fig.

36

(B)

(+ screw), absolutely. If

(S)

-

23

-

Page 26

11. In caseofelectrical

discrepancies: (Refer

No.

Mairunctions

1

Docs

not

2

speed

Main

over-heated

motor

runatlow

is

1.

Defective

2. Motor

stopatupper

malfunctions,

measures

Causes

L.SW

switch.

cord

is pulled

stop

be

sure

to

malfunctions and corrective

for

complete

out

(does

not

position).

3. Inadequate plug-in of bi-directional-

triode thyristor printed board.

4. Wireofauxiliary

connected.

motor

is dis

5. Inadequate returningofMB clutch

part.

6. Low speed function changing pin is

connectedtothe

(Inside

the

1. No

clearanceatclutch

low speed (ofO side.

control

box).

part.

2. One phase of 3 phases is disconnected

(single phase running).

to

investigate

the

following

details)

Corrective

* Exchange the L.SW switch.

* Plug-in correctly.

* Plug-in correctly.

*

Connector

is

disconnected.

*

Repair

the

inside

clutch

* Replug-in the pin to the

*

Adjust

the

*

Inspect

the plug-in

power

source

(Verify the fuseofthe power source of

the

plant)

measures

the

motor

part

with

"on"

clearanceofclutch

conditionofthe

cord.

(end

cover)

oil stone.

side.

part.

3

4

5

6

Auxiliary

over-heated

Enters

into

speed

running

the

power

"ON".

Machine

stop

(keeps

running

at low

speed)

Docs

not

low

speed.

trimming

performed

stopsatany

position.

motor

source

does

rotate

Thread

not

and

low

on

is

1.

Inadequate

returningofthe

2. Inadequate lead relay

of

3. One phase

3 phases is disconnected.

1. Inadequate position of L.SW switch.

with

2.

Defective

3. 12P

L.SW

switch.

connectorofheadispulled

4. Inadequate adjustmentofthe adjust

ing

knobofstopping position.

5. Pedal cord is pulled

upper stopping position).

1.

not

Defective

2.

Too

3.6Afuseisblown

L.SW

much

clearanceofmagnet

switch.

out.

4. Pressureofreturning springofmotor

leveristoo

5.

12P

1.1Afuseisblown

at

weak.

connectorofheadispulled

out.

(contact

out

(make it to

MB part.

point)

out

brake.

out.

* Repair the clutch

part

with oil stone.

* Exchange the lead relay.

*

Connector

is

disconnected.

* Adjust

* Exchange

inside

the

motor

the

positionofL.SW switch.

the

L.SW switch.

* Re-plug-in the connector.

*

Rotate

the

knob

toward

direction.

the

* Re-plug-in the connector.

* Exchange the L.SW switch.

* Re-adjust the clearance.

* Exchange the 6A fuse.

* Tighten the adjusting screw.

* Re-plug-in correctly.

* Exchange

thelAfuse.

(end

"FAST"

cover)

-

24

-

Page 27

V. HIGH SPEED, SINGLE NEEDLE, LOCKSTITCH, AUTOMATIC

UNDERTRIMMER

EQUIPPED

WITHAWIPER

DDL-552-2-3

DDL-553-2-3

DDL-555-2-3

1.

Adjusting

the

positionofthe

Model

wiper

The position of the wiper is adjusted accordingto the thickness of the

adjust

it as

follows:

DDL-552-2-4

DDL-553-2-4

DDL-555-2-4

sewing

cloth. Normally,

1) Rotate the hand wheel toward the regular direction and as shown in Fig.37, bring the white

point ® of the hand wheel so that it

will

match with the red point(Dof the frame.

Q)

!r~@

2mm

Fig. 37

2)

Then,asshown

of the

wiper

so that it

that

the

space

(approx. 5/128").

between

in Fig.38, insert

will