Page 1

BK-7

INSTRUCTION MANUAL

Page 2

CONTENTS

Component parts list ......................................................................................................1

1. Installing the main body of automatic bobbin changer ...........................................2

1-1. Attaching the plate cover ...............................................................................................2

1-2. Installing the main body of automatic bobbin changer .............................................. 4

2. Wiring procedure ........................................................................................................5

(1) Wiring to the main body of BK-7 ...............................................................................5

(2) Wiring to the PS-700 ..................................................................................................5

3. Adjusting the installation ...........................................................................................8

3-1. Adjusting the installation of the automatic bobbin changer ......................................8

4. Explanation of operation of the control box of automatic bobbin changer ........15

5. Parts list for the BK-7 ...............................................................................................21

i

Page 3

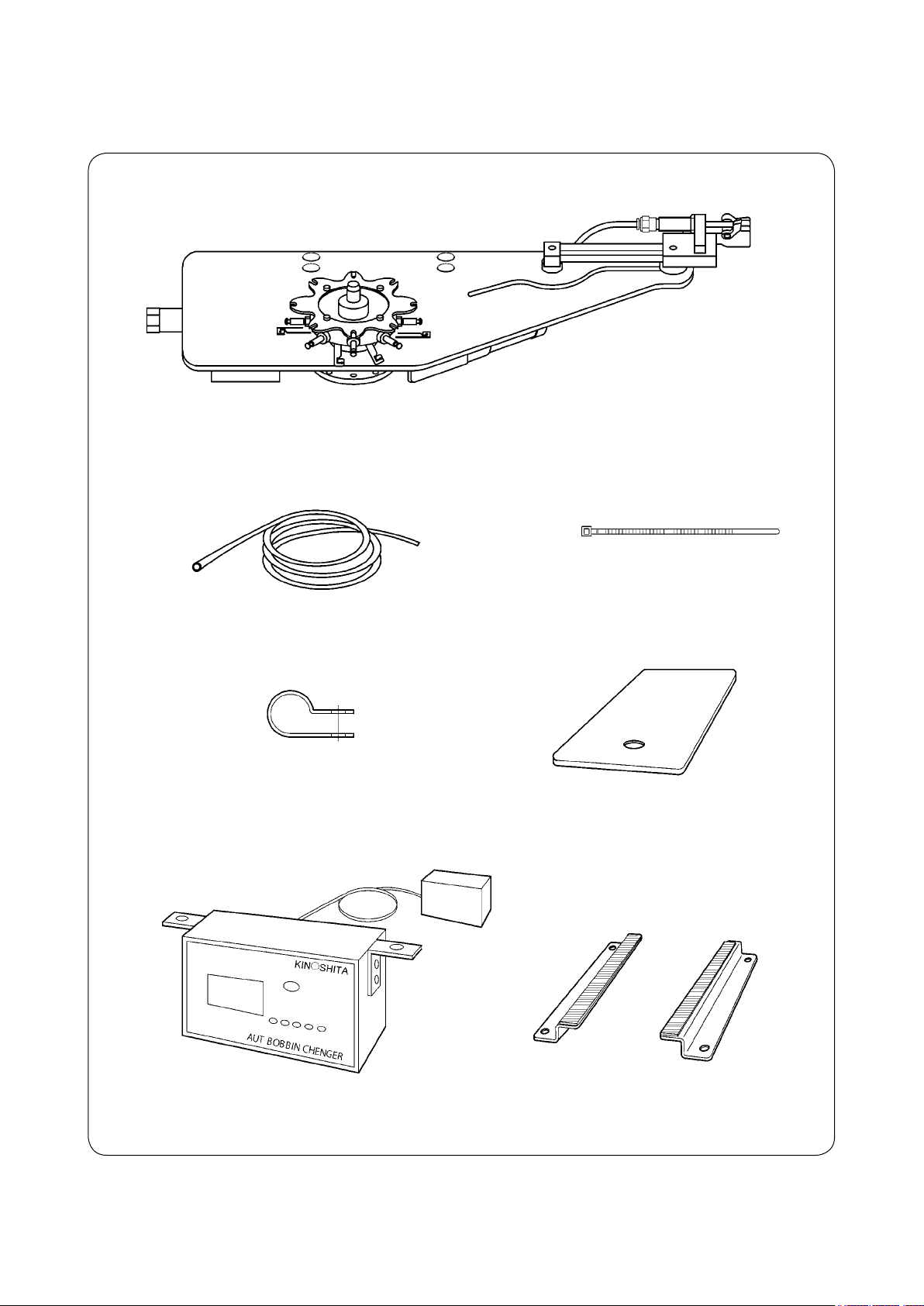

Component parts list

Check the below-stated parts.

Automatic bobbin changer asm., complete set

Setscrew, screw M6 × 20 L, 4 pieces

Cable clip band T-18R, 7 piecesAir hose ø8 × 800 mm

Cable clip SL-9N, 3 pieces

Control box, complete set

Setscrew, screw M5 × 20L, nut M5,

2 pieces each

Opening / closing door set, plate cover

Support plate

Setscrew, screw M4 × 16L, nut M4,

4 pieces each

– 1 –

Page 4

1. Installing the main body of automatic bobbin changer

WARNING :

1. Installation procedure of the automatic bobbin changer must be carried out by a trained technical

expert.

2. Request your distributor or a specialized electrician to carry out electric wiring.

3. Do not connect the power plug of the sewing machine before completing the installation

procedure.

If the start button is pressed during the work by mistake, the sewing machine will actuate, posing a

great risk.

4. Be sure to connect the ground wire.

If the ground wire connection is not proper, electric shock can be caused.

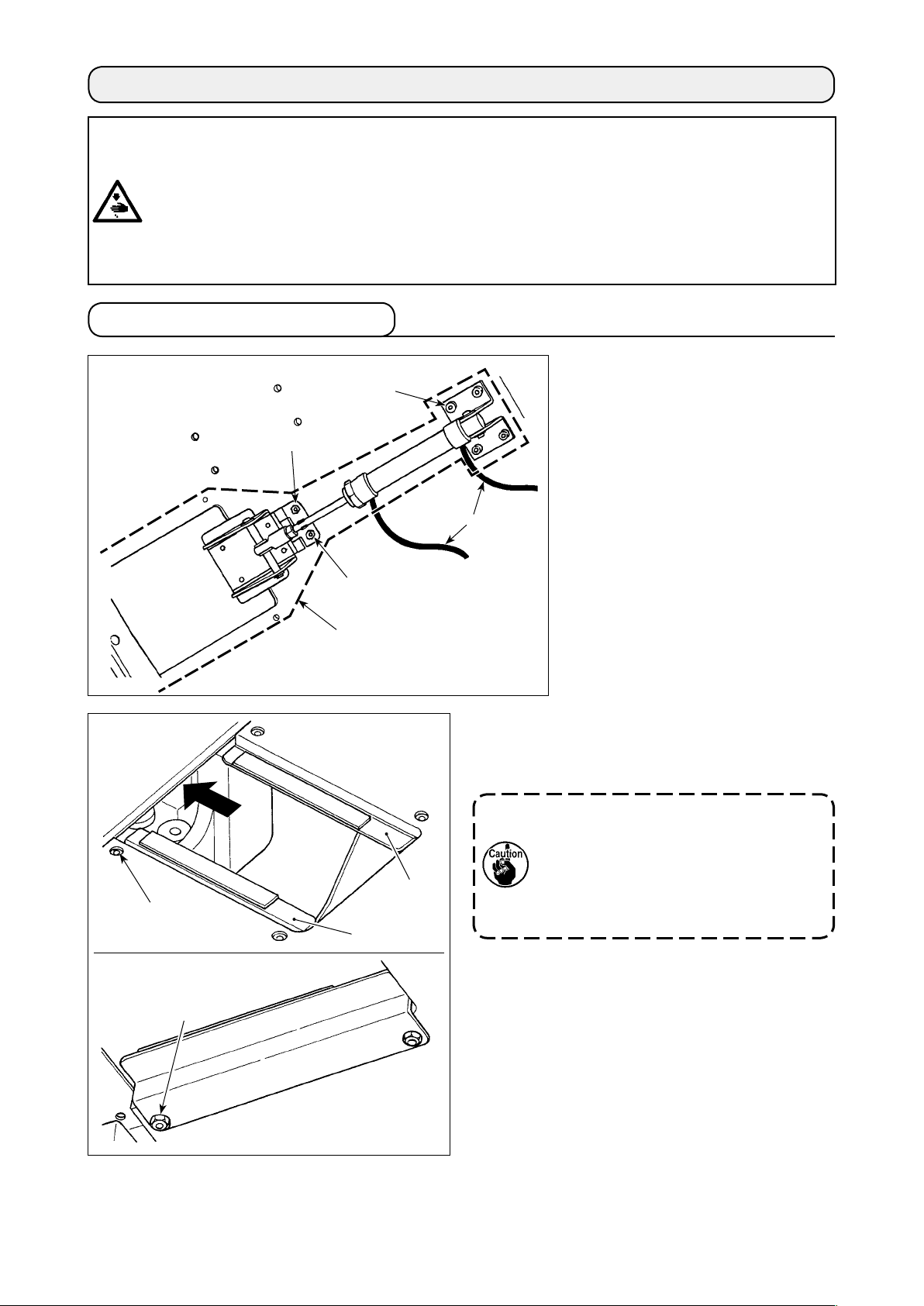

1-1. Attaching the plate cover

1) Pull out two air hoses ❾ from the

❶

❸

❾

manual valve.

Remove screws ❶ (four pieces)

and ❷ (two pieces) and nuts ❸

(two pieces). Detach the opening /

closing table cover asm.

Throat plate

❻

❼

❷

Opening /

closing table

Cover asm.

❺

❹

2) Attach support plates ❹ and ❺ with a table. Se-

cure them with screws ❻ (four pieces) and nuts

(four pieces).

❼

Support plates ❹ and ❺ are provided

with a magnet sheet on their top

surfaces. Attach the support plates with

their magnet-attached sides up and with

their sides with shorter base metal faced

toward the throat plate.

– 2 –

Page 5

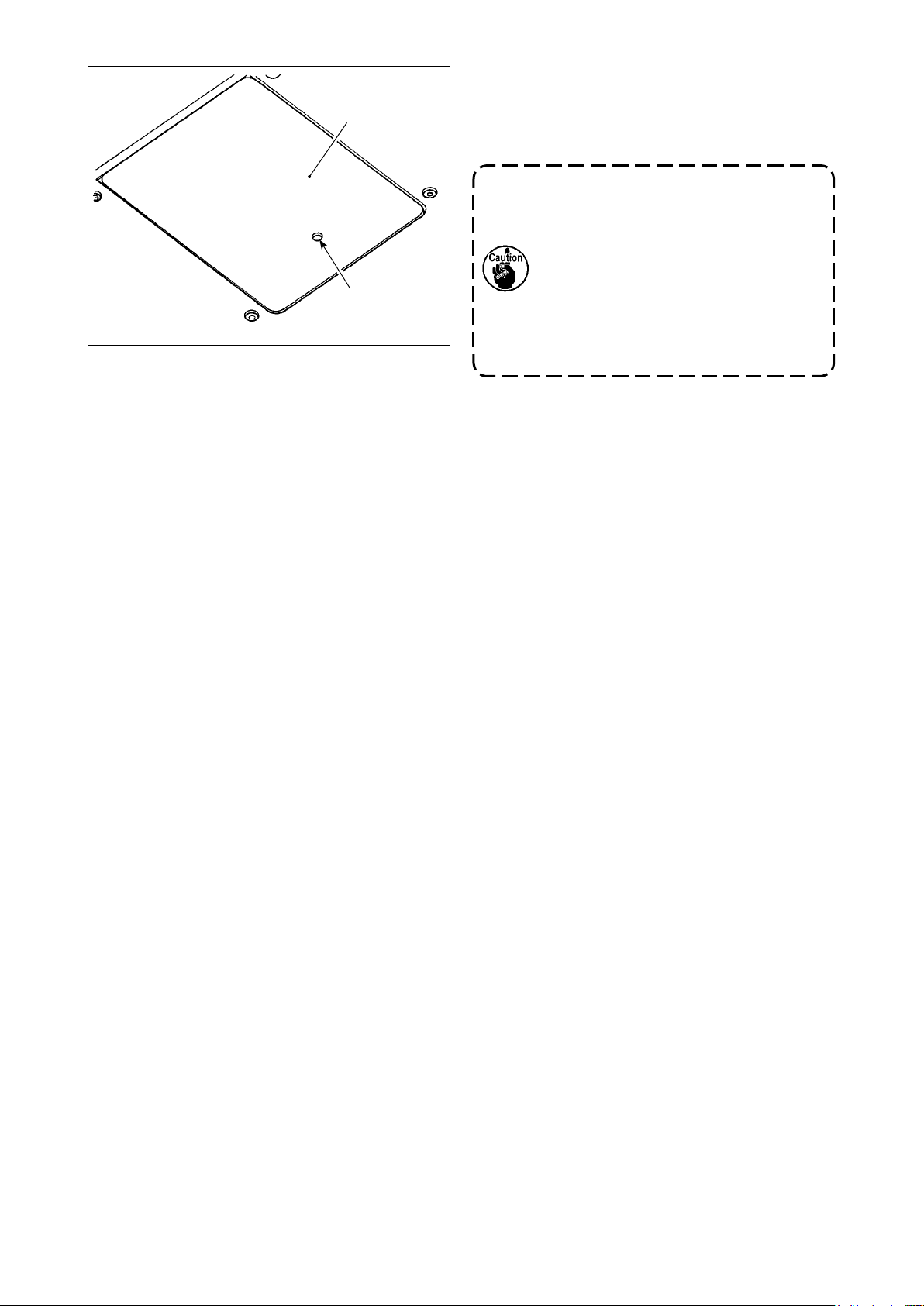

Throat plate

❽

A

3) Fit plate cover ❽ on the table.

Place it in such a way that hole portion A of the

opening / closing cover is brought to opposite side

of the throat plate.

1. Check to make sure that plate cover

does not project the table surface.

❽

If it projects the table surface, correct

by slightly bending part ❹ or ❺.

2. Afterttingplatecover❽ on the

table, carefully adjust the longitudinal

position of the cover so that it does

not come in contact with the throat

plate of sewing machine.

[How to open the plate cover]

Inserting a thin screw driver into hole portion A of

the opening / closing cover, open plate cover ❽.

– 3 –

Page 6

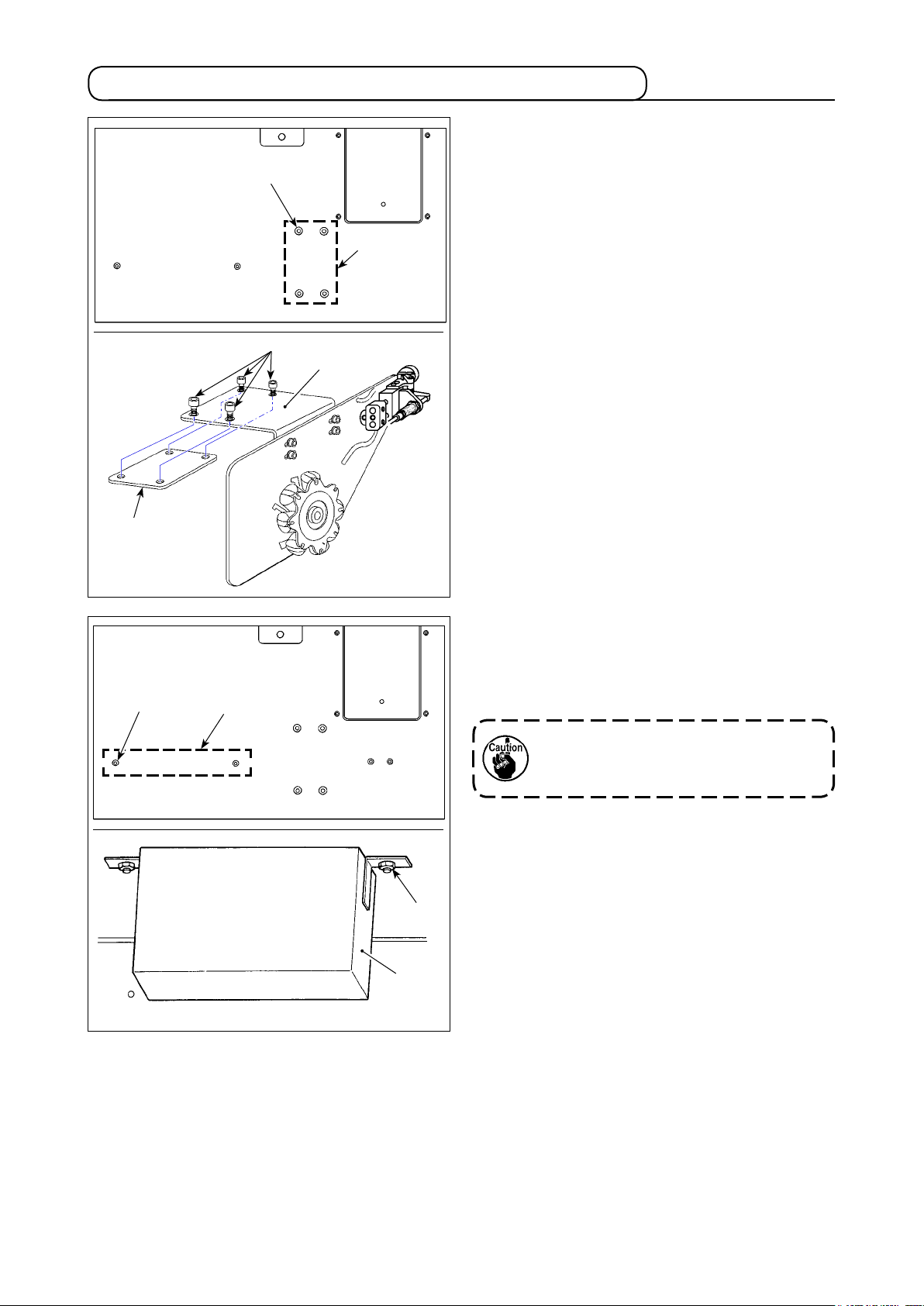

1-2. Installing the main body of automatic bobbin changer

1) Put screws ❶ (four pieces) into the top surface of

table. Fitting bobbin changer mounting plate ❷ on

❶

Location

of screws

which are to

be left in the

current state

❶

❷

❸

those screws, temporarily tighten the screws.

2) Adjust the nal position of the bobbin changer

following the steps of procedure for adjusting the

mounting position of bobbin changer. Then, tight-

en screws ❶ (four pieces) and screw plate ❸.

Location of screws

which are to be left in

the current state

❹

❺

❻

3) Put screws ❹ (two pieces) into the tapped holes

from the top surface of table. Hanging control box

of the bobbin changer on the screws, tighten

❺

nuts ❻ (two pieces).

Attach the control box in such a way that

its operation button faces to the operator

side.

– 4 –

Page 7

2. Wiring procedure

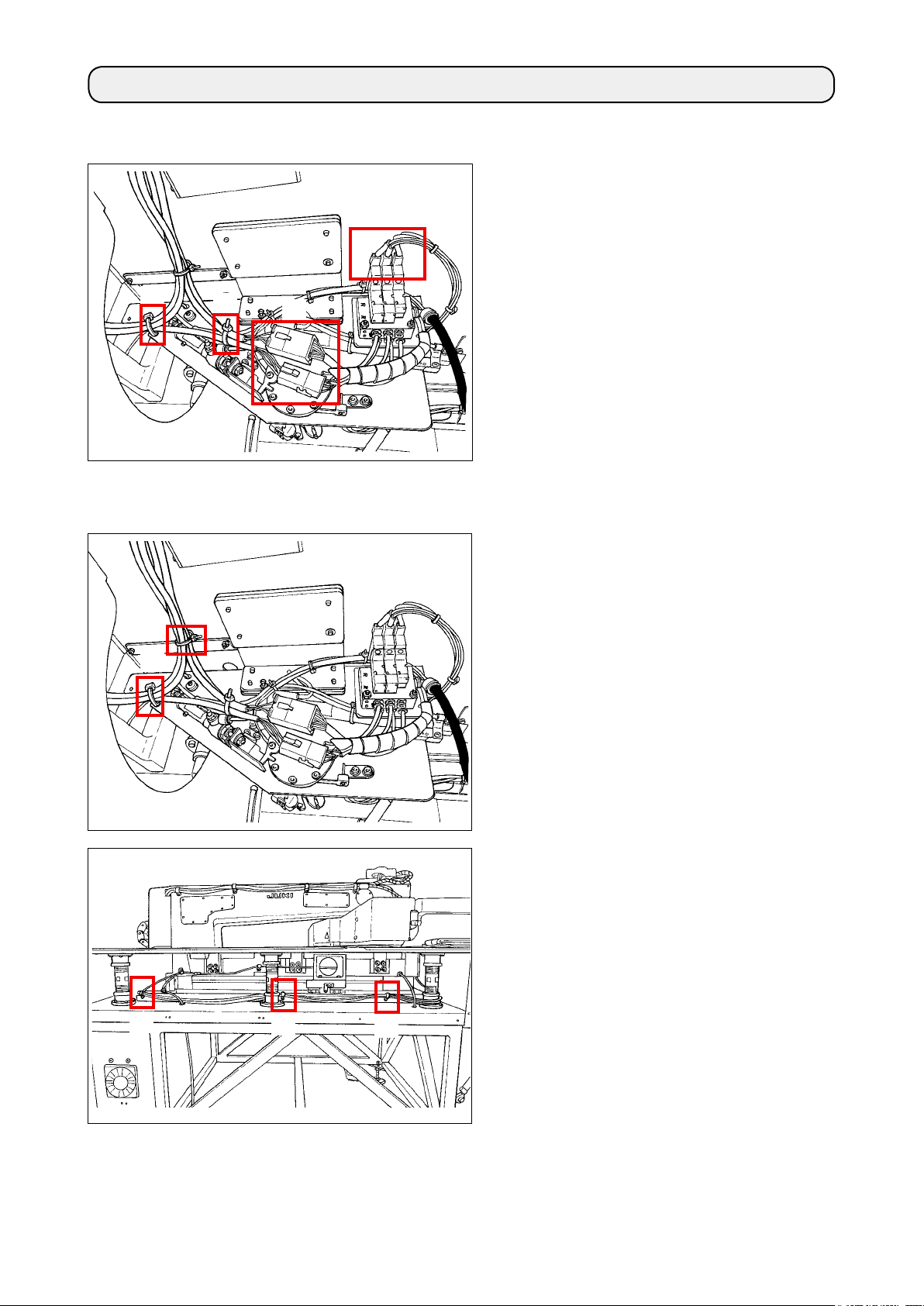

(1) Wiring to the main body of BK-7

②

(2) Wiring to the PS-700

②

①

③

Connect the two wirings coming from the main

①

body of BK-7 and two wirings coming from the

controller while matching their connector num-

bers.

Secure the wirings at two locations with cable

②

clip bands as illustrated in the gure. At this

time, take care not to x the cores.

Connect the cords to the connectors in the

③

order or white one, red one and blue one from

the left as illustrated in the gure.

①

Secure the wirings at two locations as illustrat-

①

ed in the gure. At this time, take care not to

x the cores.

Detach the side cover.

②

Remove cable clamps which secure the Y-ori-

③

gin sensor wirings at three locations. They are

to be changed with the cable clamps supplied

with the unit in the below-stated Step ⑤.

③

③

③

– 5 –

Page 8

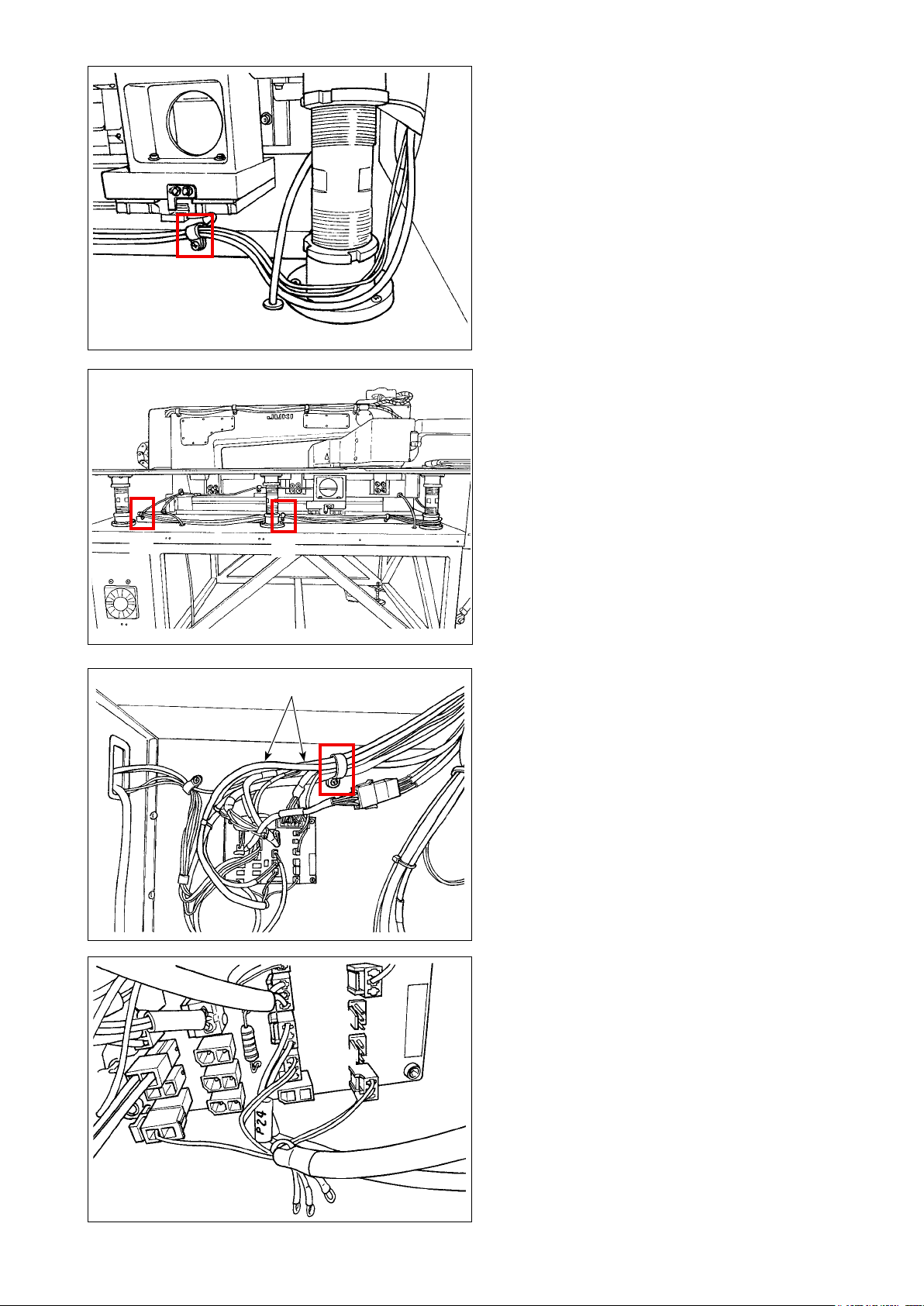

⑤

④

For wiring of cables, pass the two cables

④

coming from the controller along the outside of

strut (this is the wiring route).

Secure the Y origin sensor wirings together

⑤

with the aforementioned two cables and air

tube using the cable clamp supplied with the

unit.

At this time, take care not to bend the wirings

located at the root of Y origin sensor.

Secure the aforementioned three cables, air

⑥

tube and Y origin sensor wirings with cable

clamps supplied with the unit at two locations

as illustrated in the gure.

⑥

⑥

⑦

⑧

Open the storage door on the rear side of the

⑦

main body of PS-700. Draw the cables, wirings

and air tube through the hole into the sewing

machine table.

Pass two wirings through the cable clamps

⑧

which have already been attached to secure

them.

Connect the wirings to the connectors at four

⑨

locations on the PCB.

CZ1324

CZ1316

CZ1320

CZ1327

– 6 –

Page 9

⑩

⑫

After the completion of connection of wirings

⑩

to the PCB, secure the wirings with cable clip

bands.

Close the storage door. Attach the side cover.

⑪

Also detach the air tube which has been con-

⑫

nected to the manual valve.

⑭

Connect the air tube that is wired from BK-7, to the Y union as illustrated in the gure.

⑬

After you have connected the air tube, cut off the original cable tie. Secure the piping with a new cable tie.

⑭

– 7 –

⑬

Page 10

3. Adjusting the installation

3-1. Adjusting the installation of the automatic bobbin changer

WARNING :

1. Adjustment procedure has to be carried out by a trained technical expert.

2. Be sure to turn OFF the power to the sewing machine and to the automatic bobbin changer, and

unplug them. Turn OFF the air supply to decrease the air pressure to "0 (zero)".

It is quite dangerous to actuate the sewing machine and / or the bobbin changer during the

adjustment work.

How to check the installation position of the automatic bobbin changer

■

1. The illustration shown below rep-

resents the state that the opera-

tor grasps the bobbin arm ⑬ and

presses bobbin case ① against

sewing machine hook ⑫ with the

air supply turned ON.

Turn ON the

air supply.

Chuck cylinder

⑪

Clearance

Hook of the

⑫

sewing

machine

Claw opening/

④

closing lever

Bobbin case

①

3. Dimension of clearance provided when chuck claw ③

grasps bobbin case ① and presses it against sewing

machine hook ⑫.

2. Put bobbin ② in the bobbin case. Push claw

opening / closing lever ④ until the bobbin case is

pressed against the sewing machine hook ⑫. In

this state, measure the clearance.

0.3 to 0.5mm

Bobbin arm

Arm head

⑩

⑬

Chuck claw

③

Bobbin

②

Clearance

Press against

the hook

Clearance: 0.3 to 0.5 mm

(in the state the bobbin case is pressed

against the hook)

– 8 –

Page 11

How to adjust the installation position

■

With respect to the X direction, loosen main body anchor bolts ⑨ (four pieces) of the automatic bobbin

・

changer mounting bracket ⑤. Move bobbin changer mounting bracket ⑤ to the right and left to adjust the

installation position of the bobbin changer.

With respect to the Y direction, loosen base tightening bolts ⑥ (four pieces) of bobbin changer base plate

・

. Move base plate ⑦ back and forth to adjust the installation position of the bobbin changer.

⑦

With respect to the Z direction, loosen base tightening bolts ⑥ (four pieces) of bobbin changer base plate

・

. Move base plate ⑦ up and down to adjust the installation position of the bobbin changer.

⑦

If the aforementioned clearance is too small, bobbin case ① and sewing machine hook ⑫

can be broken when arm head ⑩ moves toward the hook side. On the other hand, if the

aforementioned clearance is too large, chuck claw ③ can fail to grasp the bobbin case, causing

a chuck error.

Base tightening bolt

+X

⑥

Base plate

⑦

Sewing

⑫

-Y

machine hook

+Y

Main body

⑨

mounting bolt

Mounting bracket

⑤

Screw plate

⑧

-X

Screw plate

⑮

Bobbin case

①

Bobbin

②

Chuck claw

③

Claw opening / closing lever

④

Mounting bracket

⑤

Base tightening bolt

⑥

Base plate

⑦

+Z

-Z

Screw plate

⑧

Main body mounting bolt

⑨

Arm head

⑩

Chuck cylinder

⑪

Sewing machine hook

⑫

Bobbin arm

⑬

Bobbin cassette

⑭

Screw plate

⑮

Bobbin cassette

⑭

Arm head

⑩

– 9 –

Page 12

Detailed procedure of installation and adjustment

★ ⑧⑨⑩⑪の上下のランプは〈自動モード〉の場合でも、ボビンチェンジャー各部の

動作に従って自動的に順次点灯します。

○○○○○○

⑦ ⑧ ⑨ ⑩ ⑪

4、オートボビンチェンジャーコントロールBOX操作説明

○

■

1) Install the automatic bobbin changer to the sewing machine with M6 cap bolt No. 79 and mounting plate

No. 77.

2) Install the control box to the predened location.

3) Connect and wire the cables and connect the air hose referring to

4) Turn ON the power and air supply. Check to make sure that the lamps mounted on the control box light up

as described below.

Lamps to be checked whether they light up

Power lamp; ❸ Automatic mode lamp; ❹ Bobbin replacement lamp; ❺ Bobbin presence lamp

❸ ❹ ❺

⑫ ③ ④ ⑤

"2. Wiring procedure" p.5

.

㻼㻻㼃㻱㻾

○

Manual mode lamp

⑬ 手動モード時ランプ

㻻㻺

❷

②

㻌㻭㼁㼀㻻㻌㻌 㻌㻌㻮㻻㻮㻮㻵㻺

㻌㻹㻻㻰㻱㻌㻌 㻌㻌㻯㻴㻭㻺㻳㻱

○○○

㻮㻻㻮㻮㻵㻺

㻯㻭㻿㻿㻱㼀㼀㻱㻌

㻌㻯㻴㻭㻺㻳㻱

㼀㻾㻻㼁㻮㻸㻱

○

⑥

⑧⑨⑩⑪各キーの

○ ① ② ③ ④ ⑤

MANUAL ○ ○ ○ ○ ○

㻻㻲㻲

㻌㻭㼁㼀㻻㻌㻮㻻㻮㻮㻵㻺㻌㻯㻴㻭㻺㻳㻱㻾

❶

①

Power switch

❶

Cassette replacement key

❷

Automatic mode lamp

❸

Bobbin replacement lamp

❹

Bobbin presence lamp

❺

Fault lamp

❻

Manual mode key

❼

Chuck opening / closing key

❽

Cassette feed key

❾

Arm head key

Power lamp

Manual mode lamp

❼ ❽ ❾

❽❾

⑧⑨⑩⑪

Backward travel lamp

各キーの後退ランプ

❻

❽❾

Forward travel lamp

前進ランプ

5) Pull out white tube, A side, A located at the center of 3-way solenoid valve. Then, insert plug cap B sup-

plied with the unit.

A

B

– 10 –

Page 13

6) Change over the operation method of the control box to the manual operation.

When manual mode key ❼ is pressed, manual mode lamp (orange) lights up, automatic mode lamp

・

(green) goes out and the operation mode is changed over to the manual mode.

❸

When arm head key is pressed once, the chuck unit can be moved back and forth (sewing machine

・

side ⇔ bobbin changer side).

Manual mode lamp

Manual mode key

Back and forth direction

❼

→

→

Bobbin changer side

Bobbin cassette

⑭

Forward

travel lamp

Backward

travel lamp

Sewing machine side

Each of ❽, ❾, keys

Each of ❽, ❾, keys

Sewing machine

⑫

hook

Check to make sure that the

chuck unit is returned to the

bobbin cassette side.

If the chuck unit is not

returned to the bobbin

cassette side, danger will

be incurred!

Bobbin cassette

⑭

DANGER :

Sincetheplugcapisttedoverthesolenoidvalve,theairisnotsuppliedtothecylinderonthehead

returning side. If arm head key is pressed again, in this state, the chuck head will abruptly return

to the cassette side, inviting great danger.

Be sure not to press arm head key unlessyouhaveconrmedthatyouhavereturnedthechuck

unit to bobbin cassette ⑭ side by hand. If the chuck unit is not returned to the bobbin cassette side,

theriskofpinchingyourngersinthechuckunitwillbeinvited.

– 11 –

Page 14

7) Chucking the bobbin case, check the installation clearance between the bobbin case and sewing machine

hook ⑫. Then, x the automatic bobbin changer.

Once the chuck can be moved by hand, put the bobbin case in the bobbin changer cassette. Press

・

chuck opening / closing key ❽ to let the chuck grasp the bobbin case.

Moving the chuck head in the aforementioned state, check the operation of putting the bobbin case in

・

and out of the sewing machine hook.

Loosen base tightening bolts ⑥ of the bobbin changer. Finely adjust the position of the automatic bob-

・

bin changer to the optimum one with respect to X, Y and Z directions to allow the bobbin case to be

put in and out of the sewing machine hook. Once the automatic bobbin changer is correctly positioned,

tighten the base tightening bolts to secure it.

Adjusting the clamp clearance between bobbin case

Press push button ❽ to place the chuck

opening / closing key in the ON state.

Then, grasp bobbin arm ⑬ and press

bobbin case ① against the hook. In this

state, measure the clearance between

bobbin case and chuck.

Turn ON the

air supply.

Bobbin arm

⑬

0.3 to 0.5 mm

Bobbin case

①

Sewing machine

⑫

hook

For adjustment of the

lateral position of the

automatic bobbin changer

Base tightening bolt

⑥

-Y

+Y

+Z

-Z

Cautions regarding the setting position of the bobbin changer in the longitudinal direction (Y

direction)

If the clearance provided between the bobbin case that is placed in the sewing machine

・

hook and the chuck is too small when the chuck rests on the sewing machine side,

breakage of the bobbin and hook and mis-chucking can be caused. On the other hand, if the

aforementioned clearance is too large, malfunctions such that the chuck fails to grasp the

bobbin case arm can occur.

Finely adjust the setting position of the bobbin changer in longitudinal direction so that a

・

clearance of 0.3 to 0.5 mm is provided between the bin case and the chuck when the chuck

grasps the bobbin case arm.

Chuck opening / closing key ON

❽

Free

-X

+X

Main body

⑨

mounting bolt

For adjustment of

the longitudinal and

vertical positions

Claw opening / closing lever

④

Clearance:

0.3 to 0.5 mm

Pressing

dimension

– 12 –

Page 15

8) Return the chuck unit to the cassette side by hand. Press arm head key .

③②①

⑤

④

TROUBLE

Turn ON the air supply to the chuck unit so that it cannot be moved by hand. Detach the plug cap tted

・

to the solenoid valve. Then, reconnect the originally-connected white tube to the solenoid valve.

<Completion of preparation for piping>

・

The installation of the automatic bobbin changer to the sewing machine is completed with the afore-

mentioned steps of procedure. Operating the automatic bobbin changer manually, check whether

it performs operations normally referring to

automatic bobbin changer" p.15

.

"4. Explanation of operation of the control box of

<Check the operation buttons>

Cassette feed key

❾

Automatic forward / backward

carrying of bobbin

Arm head key

Bobbin presence lamp ON

❺

POWER

ON

OFF

❶

AUTO BOBBIN CHANGER

Chuck opening /

❽

closing key

❹

❸

BOBBIN BOBBIN

AUTO

CHANGE

MODE

❷

❼

❽ ❾

❺

③②①

TROUBLE

④

❻

⑤

❽❾

Forward travel lamp

❽❾

Backward travel lamp

Power switch

❶

Cassette replacement key

❷

Automatic mode lamp

❸

Bobbin replacement lamp

❹

Bobbin presence lamp

❺

Fault lamp

❻

Manual mode key

❼

Chuck opening / closing key

❽

Cassette feed key

❾

Arm head key

Power lamp

Manual mode lamp

– 13 –

Page 16

DBK

DBKDBK

DBK700

700700

700AAAA----1111

加藤

加藤加 藤

加 藤藤藤藤藤

2017

20172017

2017・・・・04

0404

04・・・・07

0707

07

1111

55

5555

55 ワリダシオクリツ メ

ワリダシオクリツメワリダシオクリツメ

ワリダシオクリツメ

51

51 51

51 カセットワリダシボス

カセットワリダ シボスカセットワリダ シボス

カセットワリダ シボス

47

4747

47 キンセツセンサークミ

キンセツセンサークミキンセツセンサークミ

キンセツセンサークミ

59

59 59

59 ナット

ナットナ ット

ナットMMMM5555

52

5252

52 アナツキボルト

アナツキボルトアナツキボルト

アナツキボルトMMMM5555××××5555

50

5050

50

バ ネザガネ

バネザガネバネザガネ

バネザガネMMMM4444

46

4646

46 センサトリツケカナグ

センサトリツケカナグセンサトリツケカナグ

センサトリツケカナグ

56

5656

56 ワリダシフレトメステー

ワリダシフレトメステーワリダシフレトメステー

ワリダシフレトメステー

2222

54

5454

54 シリンダートリツケカナグ

シリンダートリツケカナグシリンダートリツケカナグ

シリンダートリツケカナグリンダートリツケカナグ

リンダートリツケカナグリンダートリツケカナグ

リンダートリツケカナグンダートリツケカナグ

ンダートリツケカナグンダートリツケカナグ

ンダートリツケカナグダートリツケカナグ

ダートリツケカナグダートリツケカナグ

ダートリツケカナグートリツケカナグ

ートリツケカナグートリツケカナグ

ートリツケカナグトリツケカナグ

トリツケカナグトリツケカナグ

トリツケカナグリツケカナグ

リツケカナグリツケカナグ

リツケカナグツケカナグ

ツケカナグツケカナグ

ツケカナグケカナグ

ケカナグケカナグ

ケカナグカナグ

カナグカナグ

カ ナ グナ グ

ナグナグ

ナ グググググ

1111

53

53 53

53 シリンダークミ

シリンダークミシリンダーク ミ

シリンダークミφφφφ16

1616

16××××30

3030

30

57

5757

57 ワリダシツメフレトメ

ワリダシツメフ レトメワリダシツメフ レトメ

ワリダシツメフ レトメ

60

60 60

60 バネザガネ

バネザガネバネザガネ

バネザガネMMMM5555

58

5858

58 シリンダーナット

シリンダーナットシリンダ ーナット

シリンダーナット

1111

1111

49

4949

49 アナツキボルト

アナツキボルトアナツキボルト

アナツキボルトMMMM4444××××6666

1111

2222

43

4343

43

バンドヒキバネ

バンドヒキバネバンドヒキバネ

バンドヒキバネ

41

41 41

41 ナット

ナットナ ット

ナットMMMM4444

40

40 40

40 アナツキボルト

アナツキボルトアナツキボルト

アナツキボルトMMMM4444××××16

1616

16

2222

1111

1111

1111

1111

45

4545

45

バ ネザガネ

バネザガネバネザガネ

バネザガネMMMM4444

3333

2222

44

4444

44 アナツキボルト

アナツキボルトアナツキボルト

アナツキボルトMMMM4444××××6666

3333

1111

NO

NONO

NO

....

1111

2222

1111

1111

39

3939

39

ブレーキ バンド

ブレーキバンドブレーキバンド

ブレーキバンド

36

3636

36

バ ネザガネ

バネザガネバネザガネ

バネザガネMMMM4444

1111

1111

1111

5555

37

3737

37 シリンダクミ

シリンダクミシリンダクミ

シリンダクミφφφφ16

1616

16××××150

150150

150

3333

42

4242

42

バ ネザガネ

バネザガネバネザガネ

バネザガネMMMM4444

1111

1111

48

4848

48 キンセツシメビス

キンセツシメビスキンセツシメビス

キンセツシメビス

86

8686

86 アナトメネジ

アナトメネジアナトメネジ

アナトメネジMMMM8888××××12

1212

12

98

98 98

98 ストレートツギテ

ストレートツギテストレートツギテ

ストレートツギテ

32

32 32

32 シテンネジピン

シテンネジピンシテンネジピン

シテンネジピン

31

31 31

31 シリンダナット

シリンダナットシリンダナット

シリンダナット

1111

35

3535

35 アナツキボルト

アナツキボルトアナツキボルト

アナツキボルトMMMM4444××××6666

1111

1111

89

89 89

89 ナット

ナットナ ット

ナットMMMM6666

34

343 4

34 シリンダトリツケカナグ

シリンダトリツケカナグシリンダ トリツケカナグ

シリンダトリツケカナグ

93

9393

93 アナツキボルト

アナツキボルトアナツキボルト

アナツキボルトMMMM4444××××6666

91

9191

91 マルザガネ

マルザガネマルザガネ

マルザガネMMMM6666

92

9292

92 エアーブラケット

エアーブラケットエアーブラ ケット

エアーブラケット

95

9595

95 アナツキボルト

アナツキボルトアナツキボルト

アナツキボルトMMMM4444××××25

2525

25

94

94 94

94 バネザガネ

バネザガネバネザガネ

バネザガネMMMM4444

87

8787

87 アナトメネジ

アナトメネジアナトメネジ

アナトメネジMMMM8888××××12

1212

12

1111

90

9090

90 ナット

ナットナ ット

ナットMMMM6666

85

8585

85 コウキュウオシバネ

コウキュウオシバネコウキュウオシバネ

コウキュウオシバネ

1111

ヒンメイ

ヒンメイヒンメイ

ヒンメインメイ

ンメインメイ

ン メ イメ イ

メイメイ

メ イイイイイ

14

1414

14

ボビンカンゴウビス

ボビンカンゴウビスボビンカンゴウビス

ボビンカンゴウビス

84

84 84

84 コウキュウ

コウキュウコウキュウ

コウキュウφφφφ4444

1111

1111

38

3838

38

ブレーキ バンドホジカナグ

ブレーキバンドホジカナグブレーキバンドホジカナグ

ブレーキバンドホジカナグ

4444

1111

1111

1111

8888

1111

8888

8888

2222

1111

1111

1111

1111

2222

1111

2222

2222

1111

2222

2222

1111

2222

4444

33

3333

33 アナクボミ

アナクボミアナクボミ

アナクボミMMMM3333××××3333

1111

2222

6666

2222

1111

1111

4444

1111

1111

1111

96

96 96

96 サイレンサ

サイレンササイレンサ

サイレンサ

2222

スウ

スウスウ

ス ウウウウウ

2222

4444

1111

2222

NO

NONO

NO

....

1111

2222

4444

1111

1111

1111

1111

2222

26

2626

26 セットカラー

セットカラーセットカラー

セットカラー

27

2727

27 カムスラストカラー

カムスラストカラーカムスラストカラー

カムスラストカラーAAAA

28

2828

28 カムスラストカラー

カムスラストカラーカムスラストカラー

カムスラストカラーBBBB

1111

1111

29

2929

29 アナクボミ

アナクボミアナクボミ

アナクボミMMMM4444××××5555

97

97 97

97 ウメセン

ウメセンウメセン

ウメセンMMMM5555

1111

1111

30

3030

30 アナツキボルト

アナツキボルトアナツキボルト

アナツキボルトMMMM4444××××12

1212

12

1111

1111

7

7 7

7 スライダーピン

スライダーピンスライダーピン

スライダーピン7

7 7

7 スライダーピン

スライダーピンスライダーピン

スライダーピン

16

1616

16 アナツキボルト

アナツキボルトアナツキボルト

アナツキボルトMMMM6666××××10

1010

10

1111

2222

2222

1111

1111

1111

1111

2222

2222

1111

73

7373

73

ボビンマ ワリトイタ

ボビンマワリトイタボビンマワリトイタ

ボビンマワリトイタ

19

1919

19 キュウユフェルト

キュウユフェルトキュウユフェ ルト

キュウユフェルト

75

75 75

75 ミシントリツケイタ

ミシントリツケイタミシントリツケイタ

ミシントリツケイタ

74

74 74

74 マルアタマビス

マルアタマビスマルアタマビス

マルアタマビスMMMM3333××××5555

78

7878

78 トリツケ

トリツケトリツケ

トリツケMMMM6666ネジイタ

ネジイタネジイタ

ネジイタ

77

7777

77 トリツケ

トリツケトリツケ

トリツケMMMM6666ネジイタ

ネジイタネジイタ

ネジイタ

76

7676

76 ---

--- ---

---

2222

80

8080

80 アナツキボルト

アナツキボルトアナツキボルト

アナツキボルトMMMM6666××××20

2020

20

81

81 81

81 バネザガネ

バネザガネバネザガネ

バネザガネMMMM6666

82

8282

82 カセット

カセットカセット

カセットφφφφ10

1010

10ピン

ピンピン

ピン

79

79 79

79 アナツキボルト

アナツキボルトアナツキボルト

アナツキボルトMMMM6666××××20

2020

20

1111

69

6969

69 ナット

ナットナ ット

ナットMMMM4444

71

7171

71

ボビンカセット

ボビンカセットボビンカセット

ボビンカセット

65

6565

65 アナツキボルト

アナツキボルトアナツキボルト

アナツキボルトMMMM4444××××6666

62

6262

62

バ ネザガネ

バネザガネバネザガネ

バネザガネMMMM4444

68

68 68

68 ボビンカセットクミ

ボビンカセットクミボビンカセットクミ

ボビンカセットクミ

スウ

スウスウ

ス ウウウウウ

67

6767

67 シタイトホジイタ

シタイトホジイタシタイトホジイタ

シタイトホジイタ

66

66 66

66 バネザガネ

バネザガネバネザガネ

バネザガネMMMM4444

70

7070

70

ボビンピン

ボビンピンボビンピン

ボビンピンMMMM4444

63

6363

63 アナツキボルト

アナツキボルトアナツキボルト

アナツキボルトMMMM4444××××8888

61

6161

61 アナツキボルト

アナツキボルトアナツキボルト

アナツキボルトMMMM4444××××8888

64

6464

64

バ ネザガネ

バネザガネバネザガネ

バネザガネMMMM4444

72

7272

72 ボビンマワリトメスペーサ

ボビンマワリトメスペーサボビンマワリトメスペーサ

ボビンマワリトメスペーサビンマワリトメスペーサ

ビンマワリトメスペーサビンマワリトメスペーサ

ビンマワリトメスペーサンマワリトメスペーサ

ンマワリトメスペーサンマワリトメスペーサ

ンマワリトメスペーサマワリトメスペーサ

マワリトメスペーサマワリト メスペーサ

マワリトメスペーサワ リトメスペーサ

ワリトメスペーサワ リトメスペーサ

ワリトメスペーサリトメスペー サ

リトメスペーサリトメスペーサ

リトメスペーサトメスペーサ

トメスペーサトメスペーサ

トメスペーサメスペーサ

メスペーサメスペーサ

メスペーサスペーサ

スペーサスペーサ

スペーサペーサ

ペーサペーサ

ペーサーサ

ーサーサ

ー サササササ

1111

2222

88

8888

88 マルザガネ

マルザガネマルザガネ

マルザガネMMMM6666

18

1818

18 アナクボミ

アナクボミアナクボミ

アナクボミMMMM4444××××5555

2222

2222

83

838 3

83 マワリトメピン

マワリトメピンマワリトメピン

マワリトメピンφφφφ4444××××30

3030

30

11

1111

11 カイヘイレバー

カイヘイレバーカイヘイレバー

カイヘイレバー

12

1212

12 カイヘイシリンダー

カイヘイシリンダーカイヘイシリンダー

カイヘイシリンダー

13

1313

13 シリンダーナット

シリンダーナットシリンダ ーナット

シリンダーナット

9

9 9

9 カイヘイツメ

カイヘイツメカイヘイツメ

カイヘイツメ9

9 9

9 カイヘイツメ

カイヘイツメカイヘイツメ

カイヘイツメ

8

8 8

8 チャックヘッウド

チャックヘッウドチャックヘッウド

チャックヘッウド8

8 8

8 チャックヘッウド

チャックヘッウドチャックヘッウド

チャックヘッウド

21

212 1

21 ワンタッチツ ギテ

ワンタッチツギテワンタ ッチツギテ

ワンタッチツギテ

20

2020

20 アナクボミ

アナクボミアナクボミ

アナクボミMMMM4444××××5555

17

1717

17 アナクボミ

アナクボミアナクボミ

アナクボミMMMM4444××××5555

99

99 99

99 エルボツギテ

エルボツギテエルボツギテ

エルボツギテ

1111

1111

15

15 15

15 スプリングピン

スプリングピンスプリングピン

スプリングピンAW

AWAW

AW12

1212

12

22

2222

22 エアーチューブ

エアーチューブエア ーチューブ

エアーチューブφφφφ4444

23

2323

23 アナクボミ

アナクボミアナクボミ

アナクボミMMMM4444××××5555

24

2424

24 アナクボミ

アナクボミアナクボミ

アナクボミMMMM4444××××5555

ミシン

ミシンミシン

ミシン取付

取付取付

取付けけけけ及及及及びびびび名称図

名称図名称図

名称図シン

シンシン

シン取付

取付取付

取付けけけけ及及及及びびびび名称図

名称図名称図

名称図ンンンン取付

取付取付

取付けけけけ及及及及びびびび名称図

名称図名称図

名称図取付

取付取付

取付けけけけ及及及及びびびび名称図

名称図名称図

名称図付付付付けけけけ及及及及びびびび名称図

名称図名称図

名称図けけけけ及及及及びびびび名称図

名称図名称図

名称図及及及及びびびび名称図

名称図名称図

名称図びびびび名称図

名称図名称図

名称図名称図

名称図名称図

名称図称図

称図称図

称 図図図図図

25

252 5

25 カムスライドピ ン

カムスライドピンカムスライドピン

カムスライドピン

10

1010

10 カイヘイバネ

カイヘイバネカイヘイバネ

カイヘイバネ

107

107 107

107 操作

操作操作

操作ボックス

ボックスボックス

ボックス

100

100100

100

デンジエアバル ブクミ

デンジエアバルブクミデンジエアバルブクミ

デンジエアバルブクミ3333レン

レンレン

レン

102

102102

102 シリンダセンサクミ

シリンダセンサクミシリンダセンサクミ

シリンダセンサクミ

105

105 105

105 エアーチューブ

エアーチューブエアーチューブ

エアーチューブ

101

101 101

101 バルブハーネス

バルブハーネスバルブハーネス

バルブハーネス

104

104 104

104 スパイラルチューブ

スパイラルチュー ブスパイ ラルチューブ

スパイラルチュー ブ

103

103 103

103 シリンダセンサ

シリンダセンサシリンダセンサ

シリンダセンサ

2

2 2

2 セ ンターピン

センターピンセンターピン

センターピン2

2 2

2 セ ンターピン

センターピンセンターピン

センターピン

1

1 1

1 ベ ースプレート

ベースプレートベースプレート

ベースプレート1

1 1

1 ベ ースプレート

ベースプレートベースプレート

ベースプレート

6

6 6

6 チャックスライダー

チャックスライ ダーチャックスライダー

チャックスライ ダー6

6 6

6 チャックスライダー

チャックスライ ダーチャックスライダー

チャックスライ ダー

1111

4444

5

5 5

5 セ ンターブロック

センターブロックセンターブロック

センターブロック5

5 5

5 セ ンターブロック

センターブロックセンターブロック

センターブロック

4

4 4

4 セ ットカラー

セットカラーセットカラー

セットカラー4

4 4

4 セ ットカラー

セットカラーセットカラー

セットカラー

3

3 3

3 セ ットカラー

セットカラーセットカラー

セットカラー3

3 3

3 セ ットカラー

セットカラーセットカラー

セットカラー

ヒンメイ

ヒンメイヒンメイ

ヒンメインメイ

ンメインメイ

ン メ イメ イ

メイメイ

メ イイイイイ

4444

106

106 106

106 一山

一山一山

一山ナックル

ナックルナックル

ナックル

木下精密工業株式会社

木下精密工業株式会社木下精密工業株式会社

木下精密工業株式会社下精密工業株式会社

下精密工業株式会社下精密工業株式会社

下精密工業株式会社精密工業株式会社

精密工業株式会社精密工業株式会社

精密工業株式会社密工業株式会社

密工業株式会社密工業株式会社

密工業株式会社工業株式会社

工業株式会社工業株式会社

工業株式会社業株式会社

業株式会社業株式会社

業株式会社株式会社

株式会社株式会社

株式会社式会社

式会社式会社

式会社会社

会社会社

会 社社社社社

ボビンチェンジャ

ボビンチェンジャ

ボビンチェンジャ

ボビンチェンジャ----ビンチェンジャ

ビンチェンジャビンチェンジャ

ビンチェンジャ----ンチェンジャ

ンチェンジャンチェンジャ

ンチェンジャ----チェンジャ

チェンジャチェンジャ

チェンジャ----ェ ン ジ ャ

ェンジャェンジャ

ェンジャ----ン ジ ャ

ンジャンジャ

ンジャ----ジ ャ

ジャジャ

ジャ----ャャャャ--------

1/3

1/31/3

1/3

A3

A3A3

A3

81

後退緑ランプ退緑ラン プ緑ランプランプ

81

8181

80

80

8080

79

79

7979

8888

14

14 9999 27

1414

10

10

1010

11

11 15

15

1111

1515

50

50

49

49

5050

4949

16

16

1616

6

6

6 6

47

47

46

46

4747

4646

100 233

100

18

18

1818

5

5

5 5

100 233

5

5

5 5

27

25

2

2

2 2

22

22

222 2

53

53

5353

61

61

62

62

6161

6262

48

48

4848

25

2727

2525

3

3

23

23

106

3 3

54

54

5454

56

56

5656

106

2323

106106

65

65

66

66

6565

6666

77

77

7777

75

75

7575

31

31

3131

57

5757

19

19

1919

DRIVE SIDE →

32

32

33

33

3232

3333

26

2626

22

222222 12

21

2222

2121

2

2 7

7

2 2

7 7

79

79

797 9

77

77

777 7

35

35

3535

34

34

3434

24

24

2424

55

55

52

52 51

5555

51

5252

5151

4090

99991 1

11

1221

1111

1212

6

6

6 6

25

25

2525

75

75

757 5

1

1

BASE PLATE

1 1

36

36

3636

92

37

37 93

3737

45

45

4545

40

40

4040

39

3957

3939

9226

9292

41

41

42

42

4141

4242

44

44

4444

44

44

38

38

1

4444

1

3838

1 1

BOBBIN

CATCHER

80

80

808 0

← OPERATION SIDE

CASSETTE UNIT

94

94

93

9494

9393

107

107

107107

⑪

POWER ランプ

ON

OFF

① 電源スイッチ源スイッチスイッチ

6666

73

73

7373

74

74

747 4

72

72

7272

82

82

8282

85

85

8585

84

84

8484

83

83

8383

70

7071

71

7070

7171

101

101

101101

98

98

9898

ボビン交換ランプ

自動モードランプ動 モードランプモード ランプ

③

④

BOBBINAUTO

CHANGE

MODE

CASSETTE CHANGE ②→

手動モードランプ

手動モードキーMANUAL動モードキーMANUALモードキーMANUAL ⑦→→

⑫→→

AUTO BOBBIN CHANGER

チ ャ ッ ク 開 閉 キ ー ⑧⑧

カセット送りキー ⑨

アームヘッドキー ⑩

105

105

105105

95

95

9595

ボビン有りランプ

⑤

BOBBIN

① ②

②

①

4444

③

③

75

75

757 5

80

80

8080

31

31

3131

32

32

3232

34

34

3434

47

47

4747

37

37

3737

異常ランプ常ランプランプ

TROUBLE ⑥

④

④

26

26

27

27

2626

2727

25

25

2525

32

32

3232

34

34

3434

51

51

5151

52

52

5252

68

68

6868

67

67

676 7

4090

77

77

7777

81

81

8181

33

33

3333

100

100

100100

99

99

9999

⑥

前進ランプ進ランプラ ンプ

⑤

⑤

No. Name of part

1 BASE PLATE 1 61 SCREW M4×8 2

2 CENTER PIN 1 62 SPRING_WASHER M4 2

3 SET_COLLAR 1 63 SCREW M4×8 2

4 SET_COLLAR 1 64 SPRING_WASHER M4 2

5 CENTER BLOCK 1 65 SCREW M4×6 2

6 CHUCK SLIDER 1 66 SPRING_WASHER M4 2

7 SLIDER PIN 2 67 LOWER THREAD HOLDER 1

8 CHUCK HEAD 1 68 BOBNIN CASSET ASSY 1

9 OPEN FOOT 1 69 NUT M4 8

10 OPEN SPRING 1 70 BOBBIN PIN M4 8

11 OPEN LEVER 1 71 BOBNIN CASSET 1

12 AIR CYLINDER 1 72 BOBBIN STOPPER WASHER 1

13 AIR CYLINDER NUT 1 73 BOBBIN STOPPER PLATE 1

14 BOBBIN LINK SCREW 1 74 SCREW M3×5 4

15 SPRING PIN AW12 1 75 BRAKET 1

16 SCREW M4×10 2 76 --- 1

17 SCREW M4×5 1 77 PLATE 1

18 SCREW M4×5 3 78 PLATE 1

19 OIL FELT 1 79 SCREW M6×20 4

20 SCREW M4×5 1 80 SCREW M6×20 4

21 ONE TOUCH JOINT 1 81 SPRING_WASHER M6 4

22 AIR TUBEφ4 1 82 SPRING_WASHER M6 1

23 SCREW M4×5 1 83 PIN φ4×30 1

24 SCREW M4×5 2 84 BALL φ4 2

25 CAM SLIDE PIN 1 85 SPRING 1

26 SET_COLLAR 1 86 SCREW M8×12 1

27 CAM THRUST_COLLAR A 1 87 SCREW M8×12 1

28 CAM THRUST_COLLAR B 1 88 WASHER M6 2

29 SCREW M4×5 1 89 NUT M6 4

30 SCREW M4×12 2 90 NUT M6 4

31 AIR CYLINDER NUT 1 91 WASHER M6 4

32 SCREW PIN 2 92 AIR BRAKET 1

33 SCREW M3×3 2 93 SCREW M4×6 2

34 AIR CYLINDER BRAKET 1 94 SPRING_WASHER M4 2

35 SCREW M4×6 2 95 SCREW M4×25 2

36 SPRING_WASHER M4 2 96 SILENCER 2

37 AIR CYLINDER ASSYφ16×150 1 97 JOINT 2

38 BRAKE BAND HOLDER BRAKET 1 98 STRAIGHT UNION 6

39 BRAKE BAND 1 99 ELBOW UNION 1

40 SCREW M4×16 1 100 3-PORT SOLENOID VALVE 1

41 NUT M4 1 101 POWER CABLE 3

42 SPRING_WASHER M4 1 102 CYLINDER SENSOR ASSY 3

43 SPRING 1 103 CYLINDER SENSOR 1

44 SCREW M4×6 2 104 SPIRAL TUBE 1

45 SPRING_WASHER M4 2 105 AIR TUBE 5

46 SENSOR BRAKET 1 106 KNUCKLE 1

47 SENSOR ASSY 1 107 OPERATION BOX 1

48 SCREW 1

49 SCREW M4×6 2

50 SPRING_WASHER M4 2

51 CASSET FEED BOSS 1

52 SCREW M5×5 8

53 AIR CYLINDER ASSYφ16×30 1

54 AIR CYLINDER BRAKET 1

55 FEED_PLATE 1

56 FEED_ SHAKE STOP STAY 1

57 FEED_PLATE SHAKE STOP 1

58 AIR CYLINDER NUT 1

59 NUT M5 2

60 SPRING_WASHER M5 2

Quan-

No. Name of part

tity

Quan-

tity

– 14 –

Page 17

4. Explanation of operation of the control box of automatic bobbin

★ ⑧⑨⑩⑪の上下のランプは〈自動モード〉の場合でも、ボビンチェンジャー各部の

動作に従って自動的に順次点灯します。

○○○○○○

⑦ ⑧ ⑨ ⑩ ⑪

4、オートボビンチェンジャーコントロールBOX操作説明

○

changer

Upper and lower lamps of ❽, ❾ and automatically light up in sequence according to the operations

★

carried out by the relevant sections of automatic bobbin changer (even under the automatic mode).

❸ ❹ ❺

⑫ ③ ④ ⑤

㻼㻻㼃㻱㻾

○

Manual mode lamp

⑬ 手動モード時ランプ

㻻㻺

❷

②

㻌㻭㼁㼀㻻㻌㻌 㻌㻌㻮㻻㻮㻮㻵㻺

㻌㻹㻻㻰㻱㻌㻌 㻌㻌㻯㻴㻭㻺㻳㻱

○○○

㻮㻻㻮㻮㻵㻺

㻯㻭㻿㻿㻱㼀㼀㻱㻌

㻌㻯㻴㻭㻺㻳㻱

㼀㻾㻻㼁㻮㻸㻱

○

⑥

○ ① ② ③ ④ ⑤

MANUAL ○ ○ ○ ○ ○

㻻㻲㻲

㻌㻭㼁㼀㻻㻌㻮㻻㻮㻮㻵㻺㻌㻯㻴㻭㻺㻳㻱㻾

❶

①

Power switch

❶

When power switch ❶ is placed in <ON>, the power lamp lights up. (If the power lamp does not

・

light up, check the voltage of the 24 VDC connection point.)

Check the voltage of the connection destination.

When power switch ❶ is placed in <ON>, automatic mode lamp ❸ and cassette feed key ❾, arm

・

head key and chuck opening / closing key ❽ light up respectively. (Automatic mode)

Caution: If the backward travel lamps (green) of keys ❽, ❾and fail to light up, it is assumed

When the bobbin case is loaded in the cassette at the bobbin changing position, bobbin presence lamp

・

lights up. When no bobbin case is present at the bobbin changing position, the lamp goes out.

❺

that some fault has occurred. Request the serviceperson for inspection.

❼ ❽ ❾

❽❾

⑧⑨⑩⑪

Backward travel lamp

各キーの後退ランプ

❻

⑧⑨⑩⑪各キーの

❽❾

Forward travel lamp

前進ランプ

Cassette replacement key

❷

When the manual mode is selected:

・

When this switch is pressed under the manual mode, the automatic bobbin changer does not operate.

In the case the cassette is manually rotated by four or eight turns, the fault lamp lights up in order to

prevent improper operation. In this state, the bobbin changer will no longer operate.

This switch is used for resetting the fault lamp which ickers (when the preset nal counter value is

reached).

When the automatic mode is selected:

・

Normal operation When replacement of all of the bobbin cases (four or eight pieces) loaded in

①

When this switch is pressed after the replacement of cassette, the automatic

the automatic bobbin changer is completed, fault lamp ❻ ickers and the bobbin changer stops.

bobbin changer takes out a bobbin case from the newly installed cassette and

feeds it to the sewing machine.

– 15 –

Page 18

Forced replacement of the bobbin cassette

②

This function is provided to allow the cassette to be changed in the case of changing the

thread color, etc. before it is emptied. (Regardless of the number of bobbins already used,

the cassette replacement operation is carried out forcibly.)

When this switch is pressed while the sewing machine is at rest and the automatic bobbin

changer rests at its origin (in this state, the green lamp of the respective cylinders light up

and the bobbin presence (in the sewing machine) lamp and bobbin lamp on the bobbin

changer side go out), fault lamp ❻ ickers, bobbin cases are taken out from the sewing

machine to the bobbin changer side, and the chuck section retracts toward the sewing

machine side. (At this time, fault lamp ❻ keeps ickering. Replace the bobbin cassette

with a new one. When this switch is pressed again, the automatic bobbin changer takes

out a bobbin from the newly installed cassette and feeds it the sewing machine.

Automatic mode button

❸

When the automatic mode button ❸ lights up, the automatic bobbin changer is placed in the mode

・

under which it automatically replaces the bobbin (automatic mode).

Bobbin replacement lamp

❹

This lamp only lights up at the moment when the thread trimming signal and the count-completed sig-

・

nal are received from the sewing machine (bobbin thread remaining amount detector, counter circuit).

When the thread absence signal and the count complete signal are received, the automatic bobbin

・

changer automatically changes the bobbin.

Bobbin presence lamp

❺

This lamp lights up when the bobbin case is put in the cassette at its bobbin changing position.

・

Fault lamp

❻

Fault lamp ❻ ickers or lights up in the following cases.

・

<When the fault lamp lights up>

1. In the case the chuck fails to grasp the bobbin case (mis-grasping of the bobbin case on the

sewing machine side and on the automatic bobbin changer side)

2. In the case the automatic bobbin changer stops operation halfway and fails to complete operation

within the specied time since the cylinder advancing end sensor fails to detect or has broken.

3. In the case the cylinder sensor has failed.

<The fault lamp ickers>

1. In the case all of the bobbins (four or eight pieces) loaded in the cassette have been used.

When the manual mode is selected

If the cassette is manually rotated by one turn (four or eight bobbin cases) under the manual

mode, the fault lamp will light up and the cassette cannot be rotated further in order to prevent

improper operation. To re-start the automatic bobbin changer, press cassette replacement

key ❷. (Cassette replacement key ❷, under the manual mode, is only used for resetting the

ickering fault lamp. If this key is pressed, the bobbin changer will not move.)

Under the automatic mode (automatic mode is selected)

When the fault lamp ickers, the automatic bobbin changer returns all of the bobbin cases to the

cassette and the arm head enters the standby state on the sewing machine side. When cassette

replacement key ❷ is pressed after the replacement of the cassette, the bobbin changer takes

out a bobbin case from the newly-installed cassette and feeds it to the sewing machine.

* In the case the bobbin cassette is not fully loaded with bobbin cases (i.e., the number of bobbin

cases loaded in the bobbin cassette is smaller than the maximum loadable number of bobbin

cases), the bobbin changer operates while skipping the empty portions. However, when the cassette rotates four or eight turns to feed four or eight pieces of cassettes to the sewing machine,

the fault lamp ickers and the bobbin changer stops. Then, the cassette changer will be placed

in the standby state under which the bobbin changer waits for replacement of the cassette.

– 16 –

Page 19

Keys used for manual operation

Manual mode key

❼

When manual mode key ❼ is pressed, the manual mode lamp lights up.

・

The automatic bobbin changer can be operated manually with below-stated keys ❽, ❾and .

・

When manual mode key ❼ is pressed again while all of the lower lamps (green) of the ❽, ❾and

・

light up, automatic mode lamp ❸ lights up to return the operation mode to the < Automatic mode >.

Chuck opening / closing key

❽

When chuck opening / closing key ❽ is pressed once, the chuck grasps the bobbin case arm (i.e.,

・

chuck closes) and forward travel lamp (red) lights up. When the chuck opening / closing key is pressed

again, the chuck releases the bobbin case arm (i.e., chuck opens) and backward travel lamp (green)

lights up.

* After the completion of operation, light up the backward travel lamp (green).

Cassette feed key

❾

The cassette feed key is enabled when the arm head is distantly positioned from the cassette.

・

(The forward travel lamp (yellow) of the arm head key lights up.)

When cassette feed key ❾ is pressed once, the cassette is fed once and the forward travel lamp (yellow)

・

lights up.

When the key is pressed again, the cylinder returns to its home position and the backward travel lamp

(green) lights up.

Arm head rotating key

The arm head rotating key is enabled when the arm head is distantly positioned from the cassette.

・

When arm head key is pressed once, the arm head travels forward from the bobbin changer side to

・

the sewing machine side and the forward travel lamp (red) lights up.

When the key is pressed again, the arm head travels backward to the bobbin changer side and back-

ward travel lamp (green) lights up.

* After the completion of the operation, return the arm head to the bobbin changer side. (The backward

travel lamp (green) lights up.)

Arm head forward / backward travel key

When arm head forward / backward travel key is pressed once, the arm head travels forward to the

・

sewing machine side and the cassette side and the forward travel lamp (red) lights up.

When the key is pressed again, the arm head leaves the sewing machine side and the cassette side

and backward travel lamp (green) lights up.

* After the completion of the operation, move the arm head away from the sewing machine side and the

cassette side. (The backward travel lamp (green) lights up.)

– 17 –

Page 20

Automatic operation (normal operation)

■

[Precautions]

1. Be sure to turn OFF the power switch of the sewing machine in any of the following cases.

If not, the sewing machine will run when you press the start button by mistake during the

work, inviting great danger.

* When the bobbin case in the sewing machine hook is replaced

* When the sewing machine is disused or the operator leaves the sewing machine side

2. Be sure to turn OFF the power switch of the automatic bobbin changer when attaching / de-

taching the cassette. If the bobbin changer is operated by mistake, great danger will be invited.

The automatic bobbin changer carries out the following operations when receiving the "bobbin re-

・

placement command" from the sewing machine.

Conditions to be satised to allow the automatic bobbin changer to accept the "bobbin replacement

・

command" are as stated below.

If one of the conditions is not satised, the automatic bobbin changer will not start the bobbin re-

placement operation even if the sewing machine outputs the "bobbin replacement command".

① Automatic mode…The select switch is placed in the "automatic" side.

② Origin position…The green lamps of all the cylinders light up.

"Bobbin presence" lamp goes out… No bobbin is present at the position of the bobbin presence /

③

absence check sensor of the automatic bobbin changer.

In the case all of the four or eight bobbins loaded in the cassette of the bobbin changer are used up

・

(replaced), the bobbin changer stops in the state all of the four or eight empty bobbin are loaded in

the cassette, the arm bed retracts to the sewing machine side, and the fault lamp ickers.

When the "cassette replacement" switch is pressed after the replacement of the cassette with empty

bobbins with the cassette loaded with the threaded bobbins, the bobbin changer feeds a new bobbin

to the sewing machine and the stops (The ickering fault lamp also goes out.)

– 18 –

Page 21

Connection

■

1) Connecting the power supply (control box)

The supply voltage is 24 VDC (white → 24 V; black → 0 V).

Never apply the AC voltage to the control box. Application of the AC voltage to the control box will

break it.

2) Connecting the automatic bobbin changer to the sewing machine

Bobbin changer side Sewing machine side

Wiring

color

White INPUT GND 0V

Black Sewing machine is running

Red Bobbin replacement command Output (output for down counter, etc.)

Yellow OUTPUT GND 0V

Brown Prohibition of operation

Green Bobbin replacement completed Input (used for clearing the counter)

Blue

Wiring number & name of sig-

nal

Automatic bobbin changer is

faulty

Output (output for operation, needle cooler, etc.)

Input (protection of thread trimmer, precedence stop at upper position, etc.)

Input (used for the case the fault indication, etc. is necessary)

Explanation of signals

From the sewing machine: "Sewing machine is in operation"

①

This is the signal for prohibiting the automatic bobbin changer from

operating while the sewing machine is in operation.

From the sewing machine: "Bobbin replacement command"

②

Output this signal at the timing of bobbin replacement such that the

counter completes counting. While the "sewing machine is in operation"

signal is being output, the automatic bobbin changer will not accept this

signal.

To the sewing machine: "Prohibition of operation"

③

This signal is output from the automatic bobbin changer to the sewing

machine in order to prevent malfunction while the automatic bobbin

changer is automatically replacing the bobbin, or when the manual

mode is selected.

To the sewing machine: "Bobbin replacement completed"

④

This signal is output for approximately 0.5 s upon the completion of

automatic bobbin replacement. It can be used to clear the counter, etc.

To the sewing machine: "Automatic bobbin changer is faulty"

⑤

This signal is output when the automatic bobbin changer is faulty (the

fault lamp lights up).

It is not output when the fault lamp ickers (during the replacement of

cassette).

– 19 –

Page 22

Signals related to the checking sensors

Case AMP 172163-1

Pin AMP 170363-1

CN pin number Name of signal Wiring color

1 +5V Arm forward / backward travel; advancing end Yellow

2 +5V Arm forward / backward travel; reversing end Blue

3 GND Arm forward / backward travel; common (-) Brown and grey

4 +5V Index; advancing end White / black 1

5 +5V Index; reversing end Green / black 1

6 GND Index; common (-) Red / black 1 Yellow / black 1

7 +5V Arm rotating; advancing end Brown / black 1

8 +5V Arm rotating; reversing end Grey / black 1

9 GND Arm rotating; common (-) Blue / black 1 White / black 2

10 +24V Bobbin presence / absence sensor (+) Black and white

11 GND Bobbin presence / absence sensor (-) Green

12 +5V Bobbin presence / absence sensor signal Red

13 +5V Reserved; advancing end Red / black 2

14 +5V Reserved; reversing end Yellow / black 2

15 GND Reserved; common (-) Green / black 2 Brown / black 2

Signals related to the valves

Case AMP 172171-1

Pin AMP 170365-1

CN pin number Name of signal Wiring color

1 GND Clamp SOL valve (-) White

2 +24V Clamp SOL valve (+) Black

3 GND Index SOL valve (-) Green

4 +24V Index SOL valve (+) Red

5 GND Arm rotating SOL valve (-) Brown

6 +24V Arm rotating SOL valve (+) Yellow

7 GND Arm forward / backward travel SOL valve (-) Grey

8 +24V Arm forward / backward travel SOL valve (+) Blue

9 *GND Reserved SOL valve (-) Red / black 1

10 *+24V Reserved SOL valve (+) White / black 1

11

12

13

14

15

Signals transmitted / received between the sewing machine and the automatic bobbin changer

Case AMP 172170-1

Pin AMP 170365-1

CN pin number Name of signal Wiring color

1 input From the sewing machine: Sewing machine is in operation Black

2 GND GND for input White

3 input From the sewing machine: Bobbin replacement command Red

4 output To the sewing machine: Automatic start Green

5 GND GND for output Yellow

6 output To the sewing machine: Operation prohibition command Brown

7 output To the sewing machine: Bobbin changer is faulty Blue

8 GND Reserved: GND Grey

9

10

11

12

– 20 –

Page 23

PS-700 PS-700

ーツリスト ーツリスト

ツリスト ツリスト

リスト リスト

スト スト

1111

1010

5. Parts list for the BK-7

79

79

7979

77

77

7777

51

51

86

86

5151

8686

52

52

5252

84

84

8484

78

78

7878

85

85

8585

87

87

8787

83

83

82

82

8383

8282

32

32

3232

3

AAAA

31

31

3131

33

33

3333

53

53

5353

61

61

6161

58

58

5858

59

59

5959

64

6464

62

62

6262

64

63

63

6363

60

6060

60

54

54

5454

66

6666

66

65

65

6565

25

25

2525

51

51

5151

55

55

5555

3 3

2

2

2 2

24

24

2424

26

26

2626

35

35

3535

81

81

8181

3

56

5656

57

57

5757

56

36

3636

36

52

52

5252

23

23

2323

80

8080

80

44

44

4444

34

34

3434

1

1

1 1

49

49

4949

43

43

4343

45

45

4545

67

67

6767

69

69

6969

68

68

6868

70

70

7070

71

71

17

17

1717

22

2222

22

7171

72

72

7272

73

73

7373

74

74

21

21

2121

6

6

6 6

7474

12

12

1212

13

13

1313

11

11

10

10

15

15

1515

9999

14

14

1414

8888

75

75

7575

5

5

5 5

19

19

1919

18

18

1818

7

7

7 7

20

20

2020

4

4

4 4

27

27

2727

AAAA

41

41

4141

42

42

4242

40

40

4040

38

38

3838

39

39

50

50

5050

3939

48

4848

48

93

93

9393

94

94

9494

46

46

4646

47

4747

47

28

28

2828

29

2929

29

30

3030

30

37

37

3737

16

16

1616

104

104

104104

47

47

4747

102

102

102102

103

103

103103

95

95

9595

96

96

9696

101

101

101101

98

98

9898

105

105

105105

100

100

100100

– 21 –

92

9292

92

99

99

9999

97

97

9797

22

22

2222

PS-700

PS-700

パーツリスト

パーツリスト 1111頁頁頁頁ーツリスト

ーツリスト 1111頁頁頁頁ツリスト

ツリスト 1111頁頁頁頁リ ス ト

リスト 1111頁頁頁頁ス ト

スト 1111頁頁頁頁ト

パーツリスト パーツリスト

ト 1111頁頁頁頁1111頁頁頁頁

ト ト

Page 24

No. Name of part Quantity Remarks No. Name of part Quantity Remarks

1

BASE PLATE

2

CENTER PIN

3

SET_COLLAR

4

SET_COLLAR

5

CENTER BLOCK

6

CHUCK SLIDER

7

SLIDER PIN

8

CHUCK HEAD

9

OPEN FOOT

10

OPEN SPRING

1 61

1 62

1 63

1 64

1 65

1 66

2 67

1 68

1 69

1 70

SCREW M4×8

SPRING_WASHER M4

SCREW M4×8

SPRING_WASHER M4

SCREW M4×6

SPRING_WASHER M4

LOWER THREAD HOLDER

BOBNIN CASSET ASSY

NUT M4

BOBBIN PIN M4

2

2

2

2

2

2

1

1

8

8

11

OPEN LEVER

12

AIR CYLINDER

13

AIR CYLINDER NUT

14

BOBBIN LINK SCREW

15

SPRING PIN AW12

16

SCREW M4×10

17

SCREW M4×5

18

SCREW M4×5

19

OIL FELT

20

SCREW M4×5

21

ONE TOUCH JOINT

22

AIR TUBE ø4

23

SCREW M4×5

24

SCREW M4×5

25

CAM SLIDE PIN

26

SET_COLLAR

27

CAM THRUST_COLLAR A

28

CAM THRUST_COLLAR B

29

SCREW M4×5

30

SCREW M4×12

31

AIR CYLINDER NUT

32

SCREW PIN

33

SCREW M3×3

34

AIR CYLINDER BRAKET

35

SCREW M4×6

36

SPRING_WASHER M4

37

AIR CYLINDER ASSY ø16×150

38

BRAKE BAND HOLDER BRAKET

39

BRAKE BAND

40

SCREW M4×16

1 71

1 72

1 73

1 74

1 75

2 76

1 77

3 78

1 79

1 80

1 81

1 82

1 83

2 84

1 85

1 86

1 87

1

1

2

1

2 92

2 93

1 94

2 95

2 96

1 97

1 98

1 99

1 100

BOBNIN CASSET

BOBBIN STOPPER WASHER

BOBBIN STOPPER PLATE

SCREW M3×5

BRAKET

--PLATE

PLATE

SCREW M6×20

SCREW M6×20

SPRING_WASHER M6

SPRING_WASHER M6

PIN ø4×30

BALL ø4

SPRING

SCREW M8×12

SCREW M8×12

AIR BRAKET

SCREW M4×6

SPRING_WASHER M4

SCREW M4×25

SILENCER

JOINT

STRAIGHT UNION

ELBOW UNION

3-PORT SOLENOID VALVE

1

1

1

4

1

1

1

1

4

4

4

1

1

2

1

1

1

1

2

2

2

2

2

6

1

1

41

NUT M4

42

SPRING_WASHER M4

43

SPRING

44

SCREW M4×6

45

SPRING_WASHER M4

46

SENSOR BRAKET

47

SENSOR ASSY

48

SCREW

49

SCREW M4×6

50

SPRING_WASHER M4

51

CASSET FEED BOSS

52

SCREW M5×5

53

AIR CYLINDER ASSY ø16×30

54

AIR CYLINDER BRAKET

55

FEED_PLATE

56

FEED_ SHAKE STOP STAY

57

FEED_PLATE SHAKE STOP

58

AIR CYLINDER NUT

59

NUT M5

60

SPRING_WASHER M5

1 101

1 102

1 103

2 104

2 105

1 106

1 107

1

2

2

1

8

1

1

1

1

1

1

2

2

– 22 –

POWER CABLE

CYLINDER SENSOR ASSY

CYLINDER SENSOR

SPIRAL TUBE

AIR TUBE

KNUCKLE

OPERATION BOX

* Part number of spare parts to be used

for purchase order

No.55 40190373

No.70 40190374

3

3

1

1

5

1

1

Loading...

Loading...