Page 1

ASN-690

INSTRUCTION MANUAL

Page 2

CONTENTS

1. CONFIGURATION OF THE MACHINE ...................................................... 1

2. SPECIFICATIONS

3. INSTALLATION

3-1. Removing packing materials ............................................................................................................3

3-2. Securing the machine ........................................................................................................................ 3

3-3. Installing the dust collector ..............................................................................................................4

3-4. Installing the stacker .........................................................................................................................5

3-5. Installing the stacker cloth guide .....................................................................................................6

3-6. Installing the cloth plate and the cloth guide unit ..........................................................................7

3-7. Installing the thread stand ................................................................................................................8

3-8. Installing the regulator ......................................................................................................................8

3-9. Connecting the air coupler ................................................................................................................9

3-10. Connecting the starting pedal for the machine .............................................................................9

3-11. Joining the sub-table (only for the long table type) ....................................................................10

3-12. Connecting the power plug ........................................................................................................... 12

3-13. Installing the cloth receiving board (KM-5) (optional) ................................................................ 13

3-14. Installing the 3-pedal unit (PK-79) (optional) ............................................................................... 14

....................................................................................... 2

........................................................................................... 3

4. PREPARATION ......................................................................................... 15

4-1. Caution before operation ................................................................................................................15

4-2. Lubrication ........................................................................................................................................15

4-3. Threading the machine .................................................................................................................... 16

4-4. Adjusting the pressure of the presser foot and removing the presser foot ............................... 17

4-5. Adjusting the stitch length ..............................................................................................................17

4-6. Differential feed mechanism ...........................................................................................................18

5. OPERATION ............................................................................................. 19

5-1. Sewing procedure ............................................................................................................................ 19

5-2. Explanation of the operation panel ................................................................................................22

5-3. Description of the pedals and the switches on the machine head .............................................23

5-4. List of functions to be set ...............................................................................................................24

5-5. Details of selected functions ..........................................................................................................25

5-6. Other settings ................................................................................................................................... 28

5-7. Initialization of the setting data ......................................................................................................28

6. ADJUSTMENT .......................................................................................... 29

6-1. Stacker support board adjustment .................................................................................................29

6-2. Adjusting the position of the thread trimmer presser ..................................................................30

6-3. Adjusting the air blow ......................................................................................................................30

6-4. Adjusting the edge guide ................................................................................................................31

6-5. Adjusting the cloth guide ................................................................................................................32

6-6. Regulator adjustment ......................................................................................................................32

6-7. Adjusting the cloth chip suction force ........................................................................................... 33

6-8. Adjusting the sensors ......................................................................................................................34

i

Page 3

7. MAINTENANCE ........................................................................................ 36

7-1. Adjusting the knife ...........................................................................................................................36

7-2. Cleaning the machine head .............................................................................................................36

7-3. Checking the cartridge lter and replacing it ................................................................................ 37

7-4. Changing the machine oil ...............................................................................................................37

7-5. Changing needles ............................................................................................................................38

7-6. Drainage of lter regulator .............................................................................................................. 38

7-7. Cautions for the compressed air supply (source of supply air) facility .....................................39

7-8. Dust collector box ............................................................................................................................ 40

7-9. Cleaning the sensor ......................................................................................................................... 40

7-10. Consumable parts to be replaced ................................................................................................41

7-11. Replacing the fuse .........................................................................................................................42

7-12. Adjusting the belt tension .............................................................................................................43

7-13. Destination of connection for input/output connectors ............................................................. 44

7-14. Error codes ..................................................................................................................................... 45

7-15. Error code list ................................................................................................................................. 46

ii

Page 4

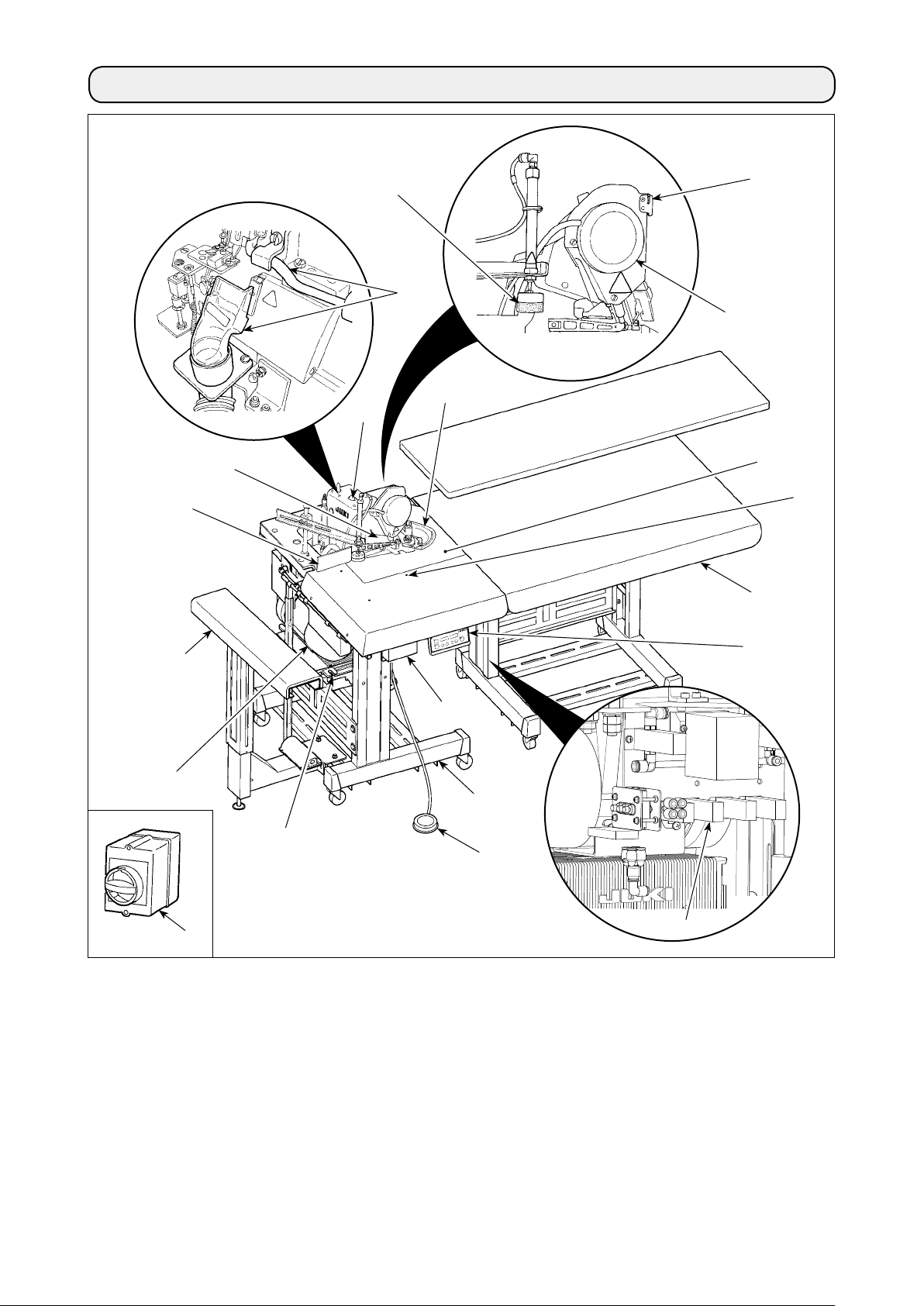

1. CONFIGURATION OF THE MACHINE

J

K

P

R

L

I

F

E

D

Q

C

B

H

G

T

Main body structural mechanism section

A

(table stand, machine support and sewing table

covers)

Stacker unit

B

Sub-table

C

Cloth plate

D

Sewing machine head

E

Cloth guide

F

Control box

G

Sewing machine motor

H

Start switch for the stacker

I

Stacker cloth guide

J

N

A

O

M

Side cutter

K

Dust collector

L

Pneumatic controller

M

Power switch

N

Starting pedal for the sewing machine

O

Thread trimmer presser

P

Cloth feeding air blow

Q

Pause switch

R

Operation panel CP-18

S

Power switch (EU type)

T

(also used as the emergency stop switch)

S

– 1 –

Page 5

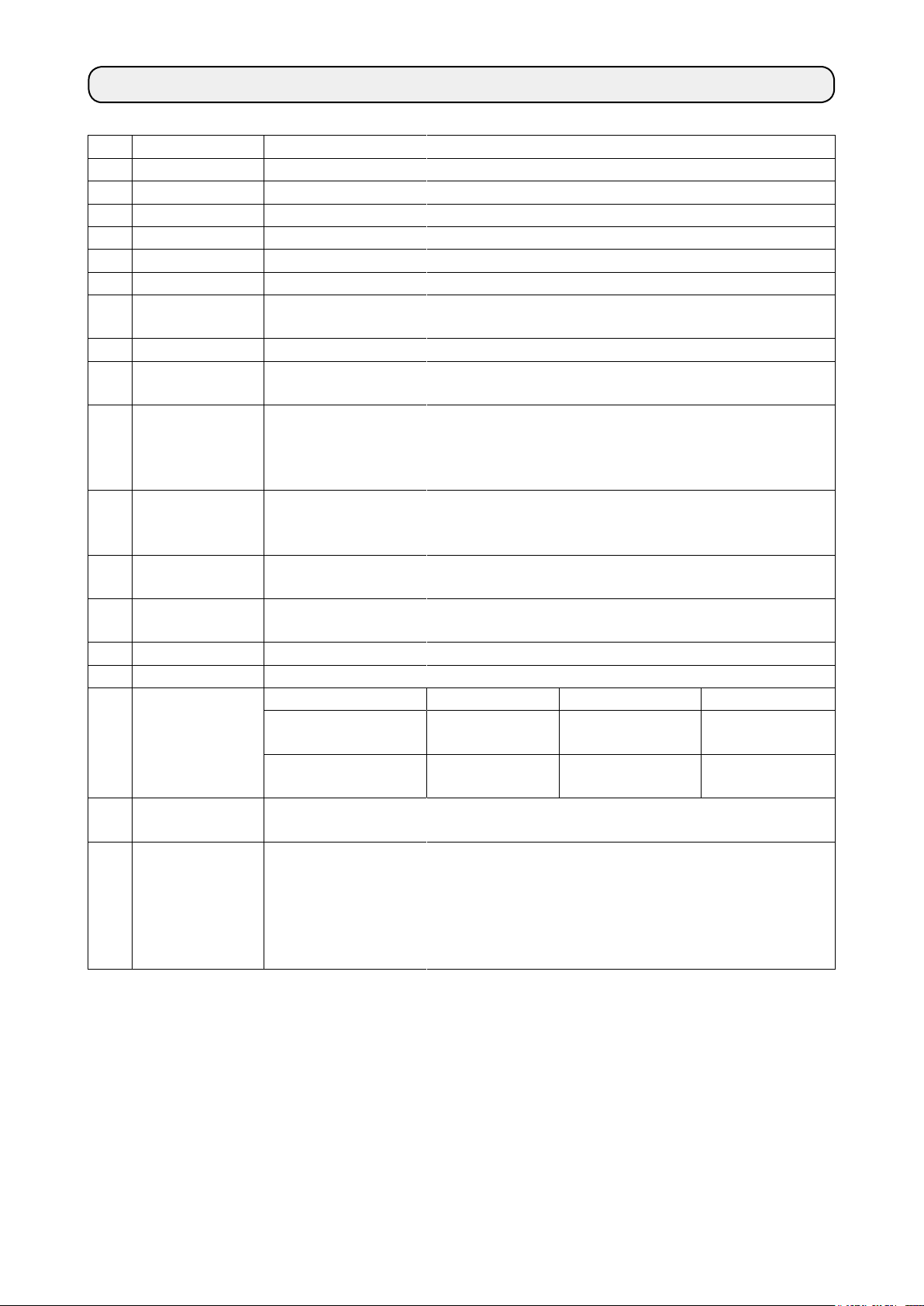

2. SPECIFICATIONS

1 Machine head MO-6904S 1-needle overlock machine

1

2 Sewing speed Max. 8,000 sti/min

3 Stitch system JIS E13 (USA standard : 504)

4 Stitch length 0.8 to 4 mm

5 Overedging width 4.0 mm (E), 4.8 mm (F), 5.6 mm (G)

6 Needle ORGAN DC×27 #9 to #14 (Standard : #11)

7 Thread Spun thread #60 (recommended)

8 Chain-off thread

Pneumatic side cutter

cutter

9 Presser foot lift Max. 7 mm (for the machine provided with AK-139)

10 Differential feed

Gathering 1 : 2 (max. 1 : 4), stretching 1 : 0.7 (max. 1 : 0.6)

ratio

11 Sewing specica-

A Cutting curve

tions

B Material size

C Number of plies of material

12 Number of piec-

70 (slacks)

es that can be

stacked

13 Power consump-

420VA or less (operating rate 50 %)

tion

14 Pneumatic pres-

0.5MPa

sure

15 Air consumption 250dm3/min(ANR)

16 Lubricating oil JUKI MACHINE OIL 18

17 Dimensions Type Width Length Height

Short table type 790 mm 575 mm

Long table type 1500 mm

18 Mass of the ma-

chine

Short table type : 110 kg

Long table type : 160 kg

19 Noise - Equivalent continuous emission sound pressure level (LpA) at the workstation :

A-weighted value of 90.5 dB; (Includes KpA = 2.5 dB); according to ISO 10821- C.6.3

-ISO 11204 GR2 at 8,000 sti/min.

- Sound power level (LWA) ;

A-weighted value of 94.0 dB; (Includes KWA = 2.5 dB); according to ISO 10821- C.6.3

-ISO 3744 GR2 at 8,000 sti/min.

*

... In-curve R200 or more

... Out-curve R300 or more

... 400 mm or less (width), 650 mm or more (length)

… Limited to one

(1800 mm

2

(875 mm

*

)

790 mm 880 mm

2

*

)

880 mm

1

*

"sti/min" is an abbreviation for "stitches per minute."

2

*

Machine dimensions including the stacker

– 2 –

Page 6

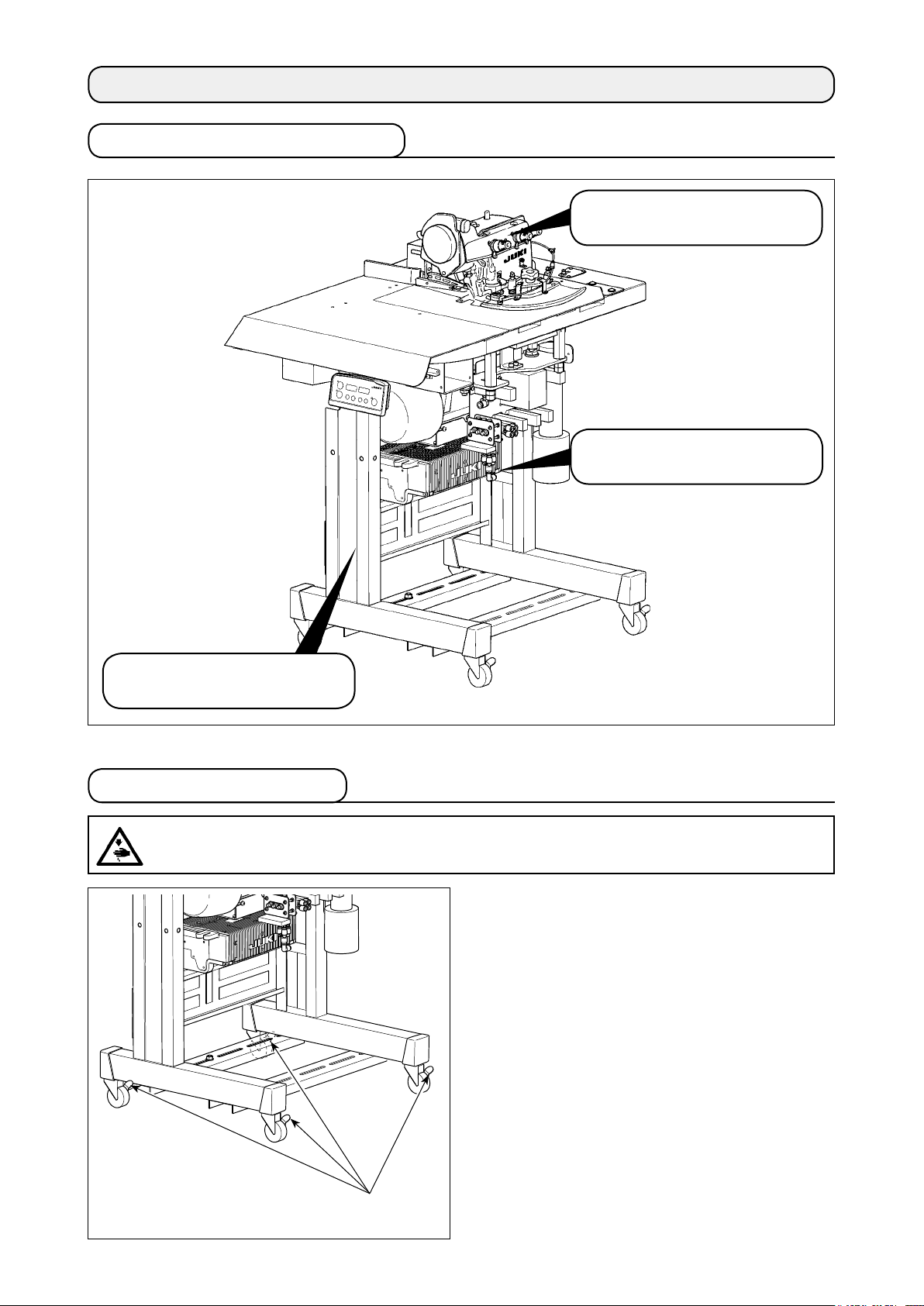

3. INSTALLATION

3-1. Removing packing materials

Remove the string which secures

the power cable.

Remove the tape which secures

the cloth plate.

Remove the string which secures

the hose.

3-2. Securing the machine

CAUTION

To avoid possible personal injuries, be sure to move the machine to a level and stable place and lock

casters ❶.

:

❶

– 3 –

Page 7

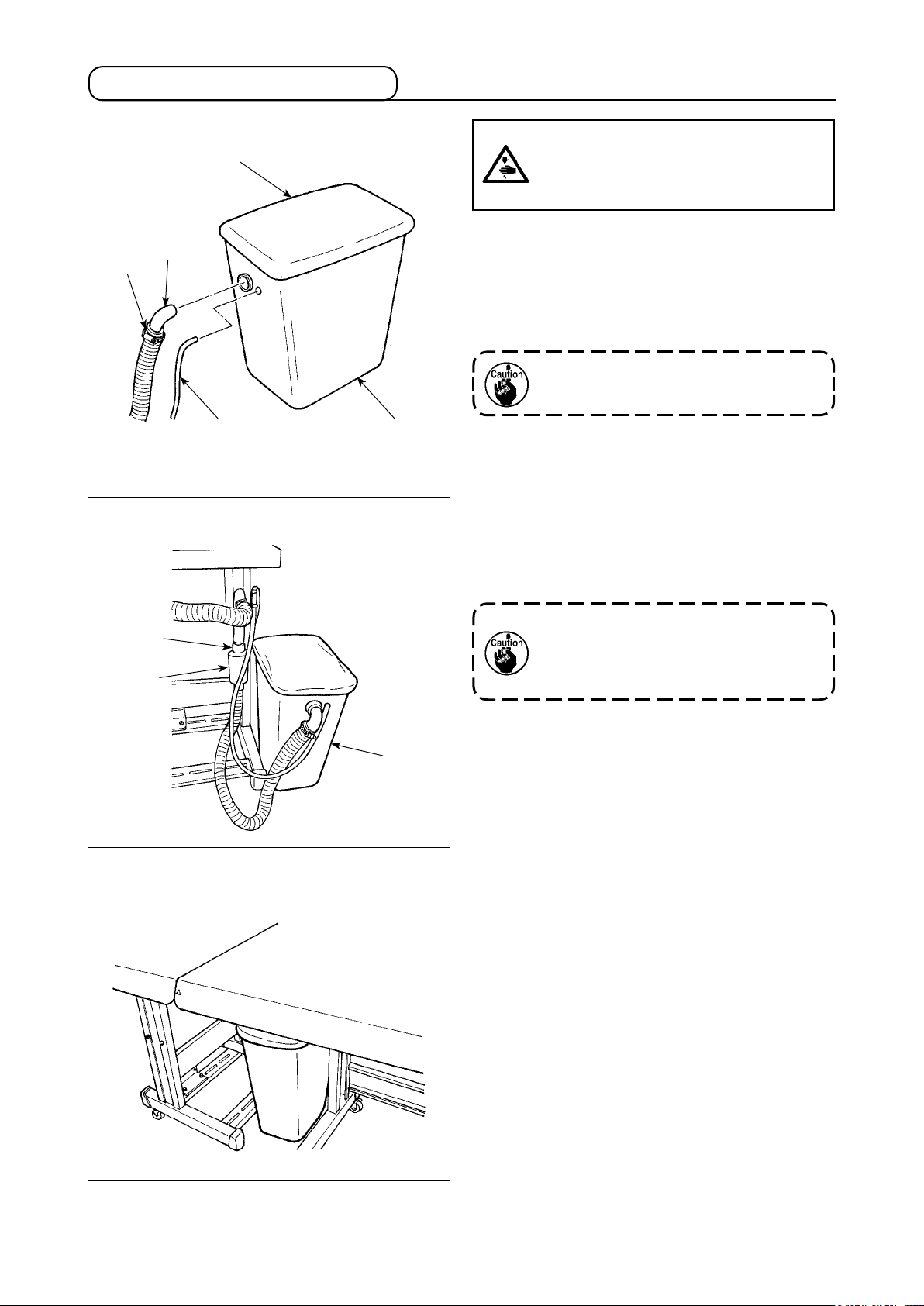

3-3. Installing the dust collector

❹

❷

❺

CAUTION :

If the dust collector is not securely installed, blown-out dust or lint can get in

eyes, resulting in personal injury.

1) Plug the lings blowing hose ❷ and the chain-

off thread blowing hose ❸ into the dust collec-

tion box ❶.

2) Install lter ❹ so that it completely covers the

top of the box.

When dumping dust from the dust collec-

tion box, also clean up lter ❹.

Short table type

❺

❻

❸

❶

Install the dust collection box ❶ to the rear of the

main unit, as shown in the gure.

(Conguration position differs depending upon speci-

cation.)

Conrm that the hose mounting bracket ❺

is completely tightened (the same for other

mounting hardware). Note that the noise

mufer ❻ is optional.

❶

Long table type

– 4 –

Page 8

3-4. Installing the stacker

CAUTION

Be sure to carry out installation of the stacker by two or more workers in order to protect against

accidents caused by the stacker unit when it accidentally falls.

:

1) Install the stacker unit on the base with screws

and washers ❷ (at two locations each).

❶

2) Adjust adjusting bolt ❸ to make the support rod

of the stacker parallel to the installing plane.

❷

❶

❹

❺

❸

❻

3) Connect air tube ❹ to joint ❺ and air tube ❻ to

joint ❼ in numerical order.

❼

– 5 –

Page 9

3-5. Installing the stacker cloth guide

❷

❸

❶

Installing stacker cloth guide ❶ on the guide base

with hand screw ❷ and washer ❸.

❹

Adjust the orientation of the cloth guide according to

the clamping position at the stacker unit ❹.

❶

Material feeding direction

– 6 –

Page 10

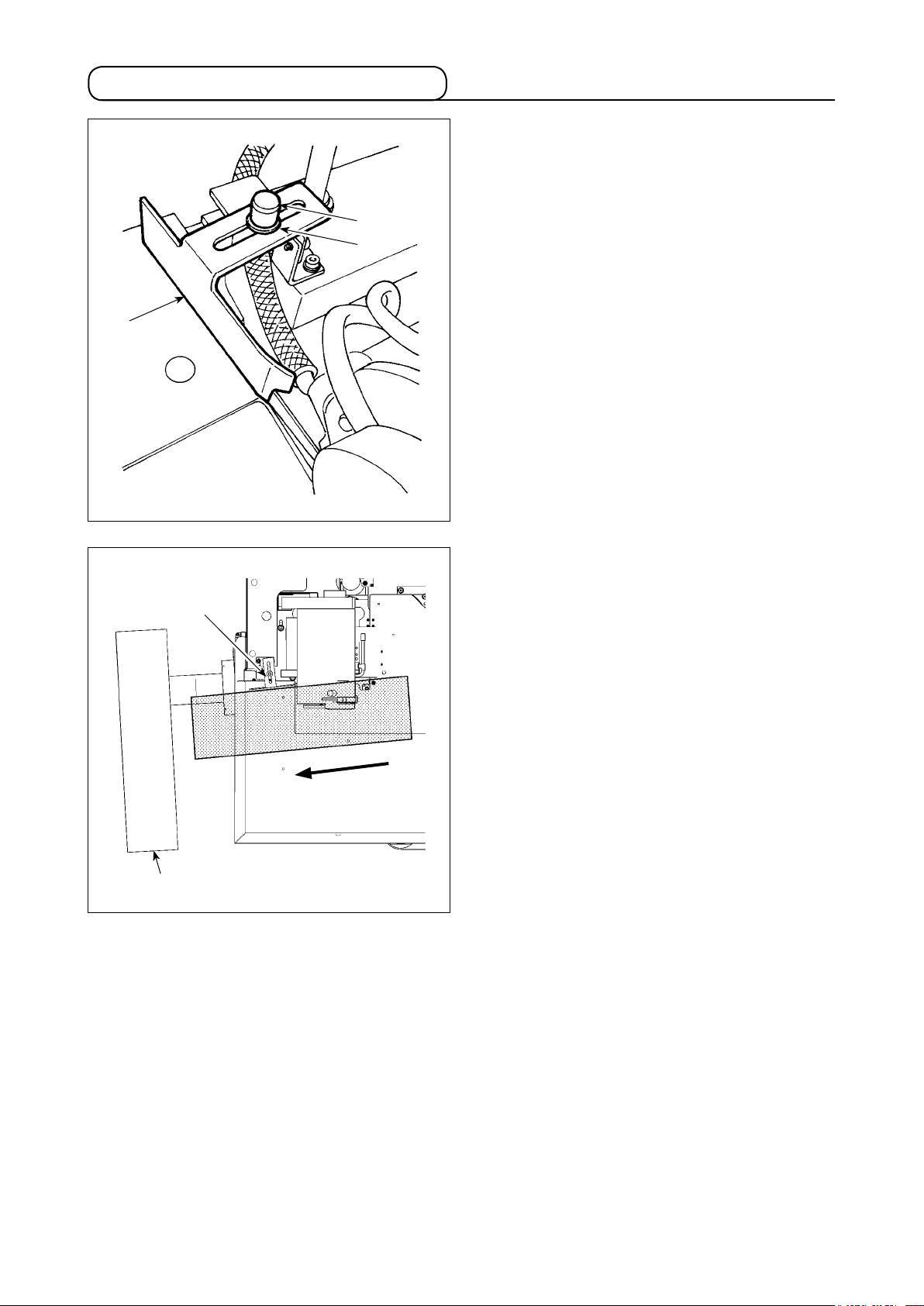

3-6. Installing the cloth plate and the cloth guide unit

1) Place the cloth plate on the sewing machine

Cloth plate

❶

table.

2) Put the slots (at two locations) in the cloth guide

unit as illustrated in the gure over two studs ❶

(at two locations) of the cloth plate over. Fix the

studs ❶ with washer ❸ and thumb screws ❷.

3) Connect air tube ❹ to joint ❺.

Installing position

❸

Cloth guide unit

❷

❺

❸

❹

❷

– 7 –

Page 11

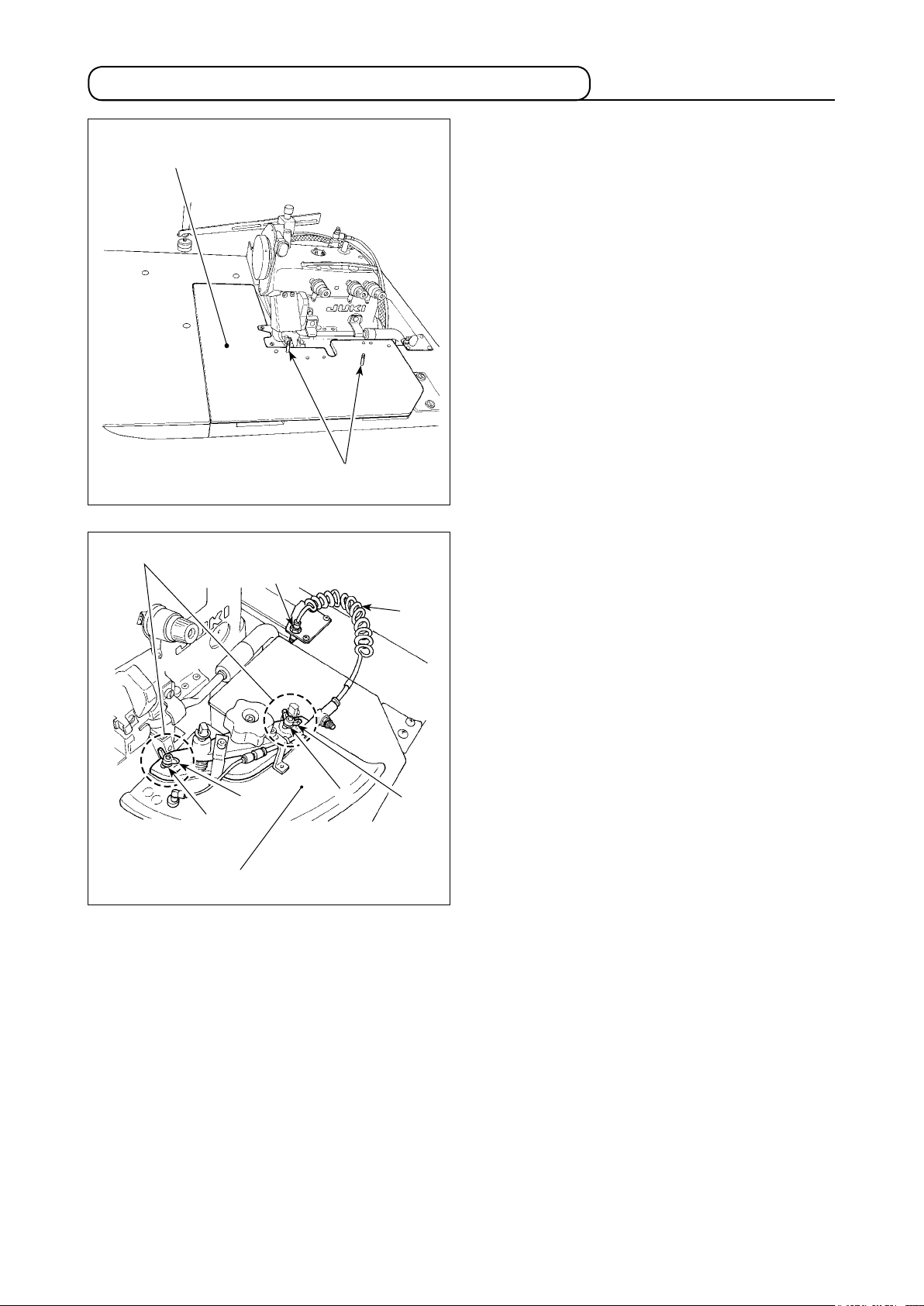

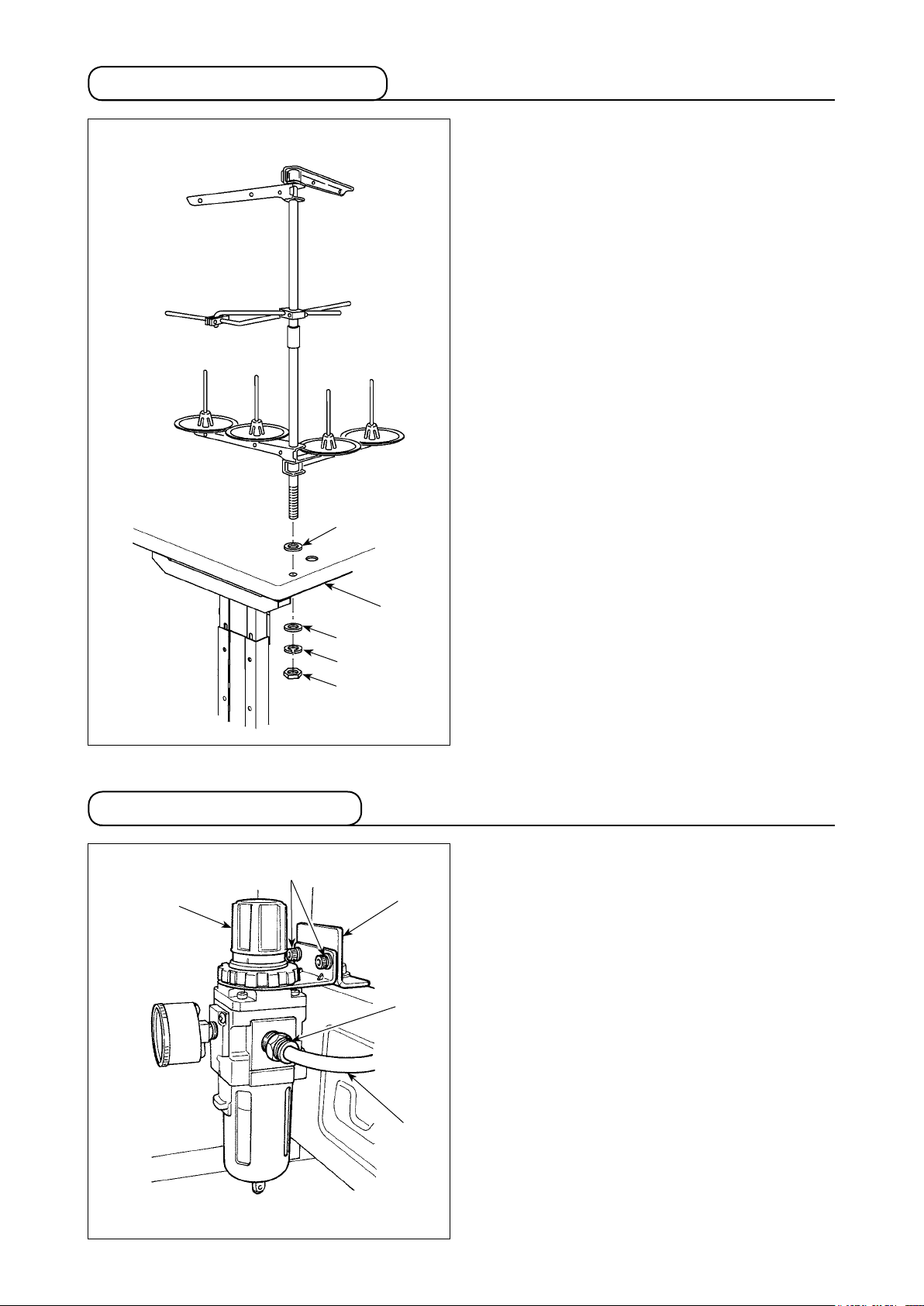

3-7. Installing the thread stand

Washer

Insert the thread stand into the hole in table ❶ with

a washer placed between them and x with the nut

and washers from under the table as illustrated in

the gure at left.

3-8. Installing the regulator

❸

❶

❶

Washer

Spring washer

Nut

❷

❺

Fix regulator ❶ on mounting plate ❷ with screws ❸

(at two locations).

Connect ø8 air tube ❹ to joint ❺.

❹

– 8 –

Page 12

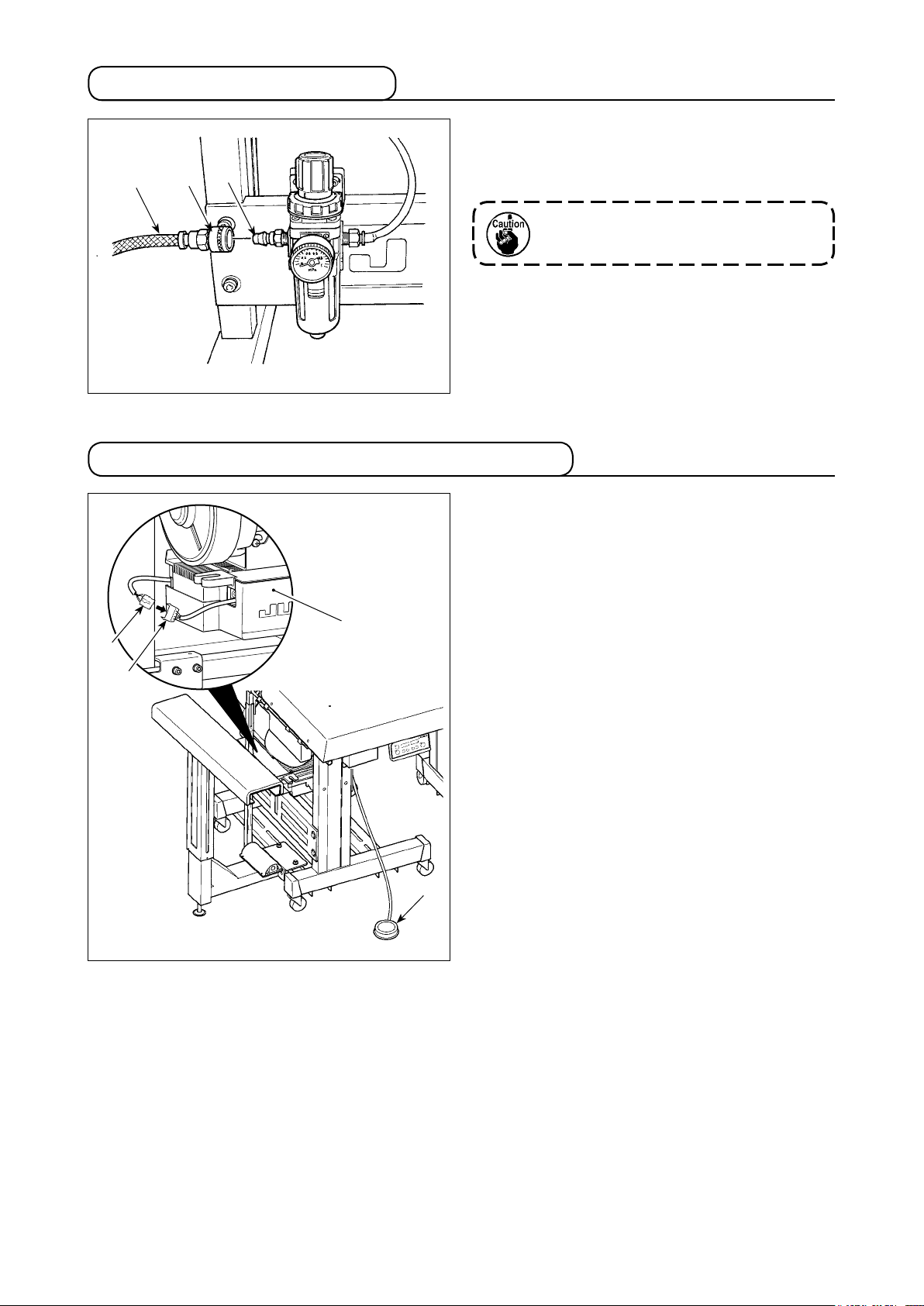

3-9. Connecting the air coupler

Connect the air coupler ❶ supplied with the unit as

an accessory rstly to air hose ❷, secondly to cou-

❷

❶

❸

pler ❸ on the main body side.

Make sure that the pressure gauge of the

regulator reads 0.5 MPa.

3-10. Connecting the starting pedal for the machine

Connector ❷ of starting pedal ❶ to junction connec-

tor ❹ coming from control box ❸.

❷

❸

❹

❶

– 9 –

Page 13

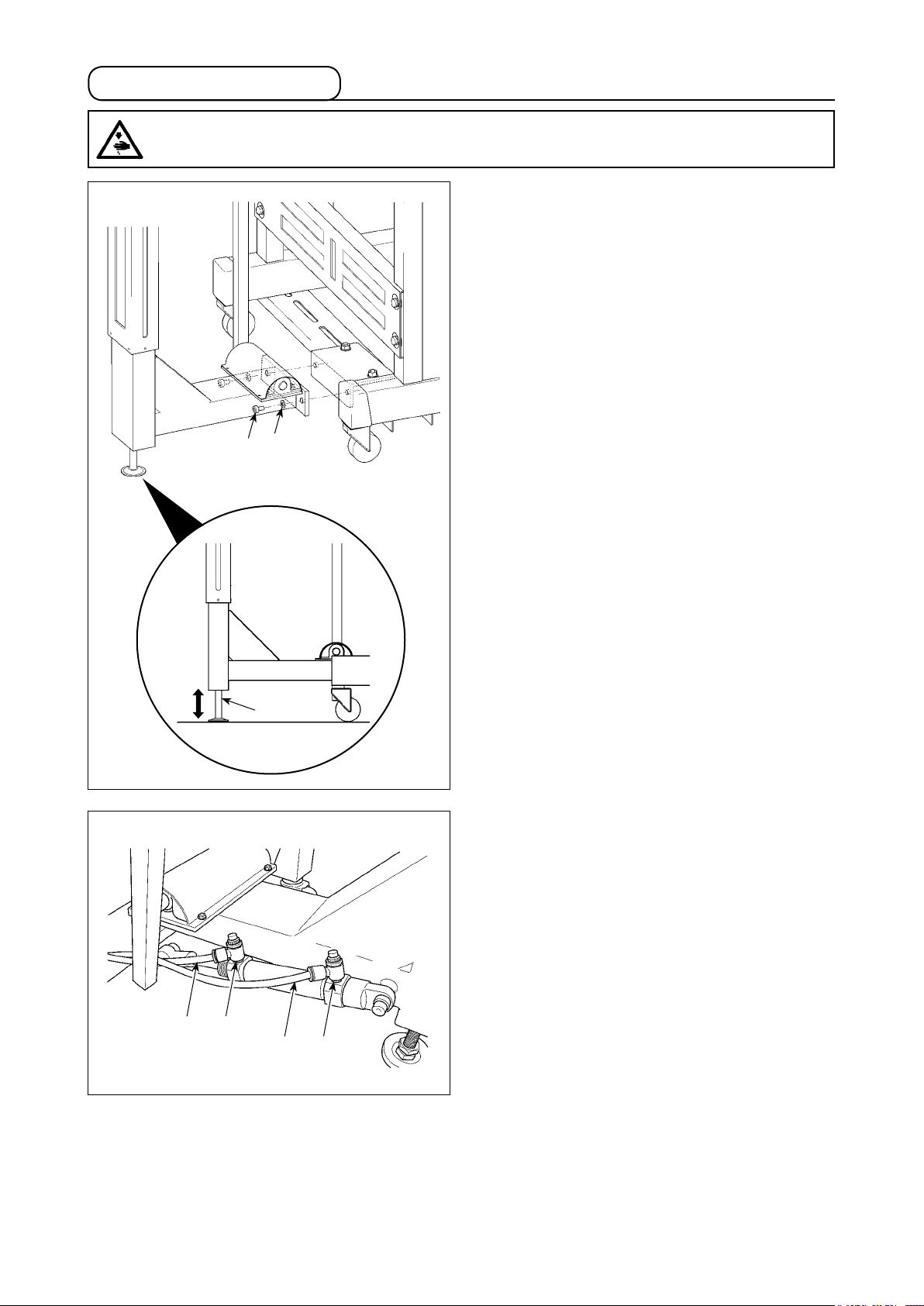

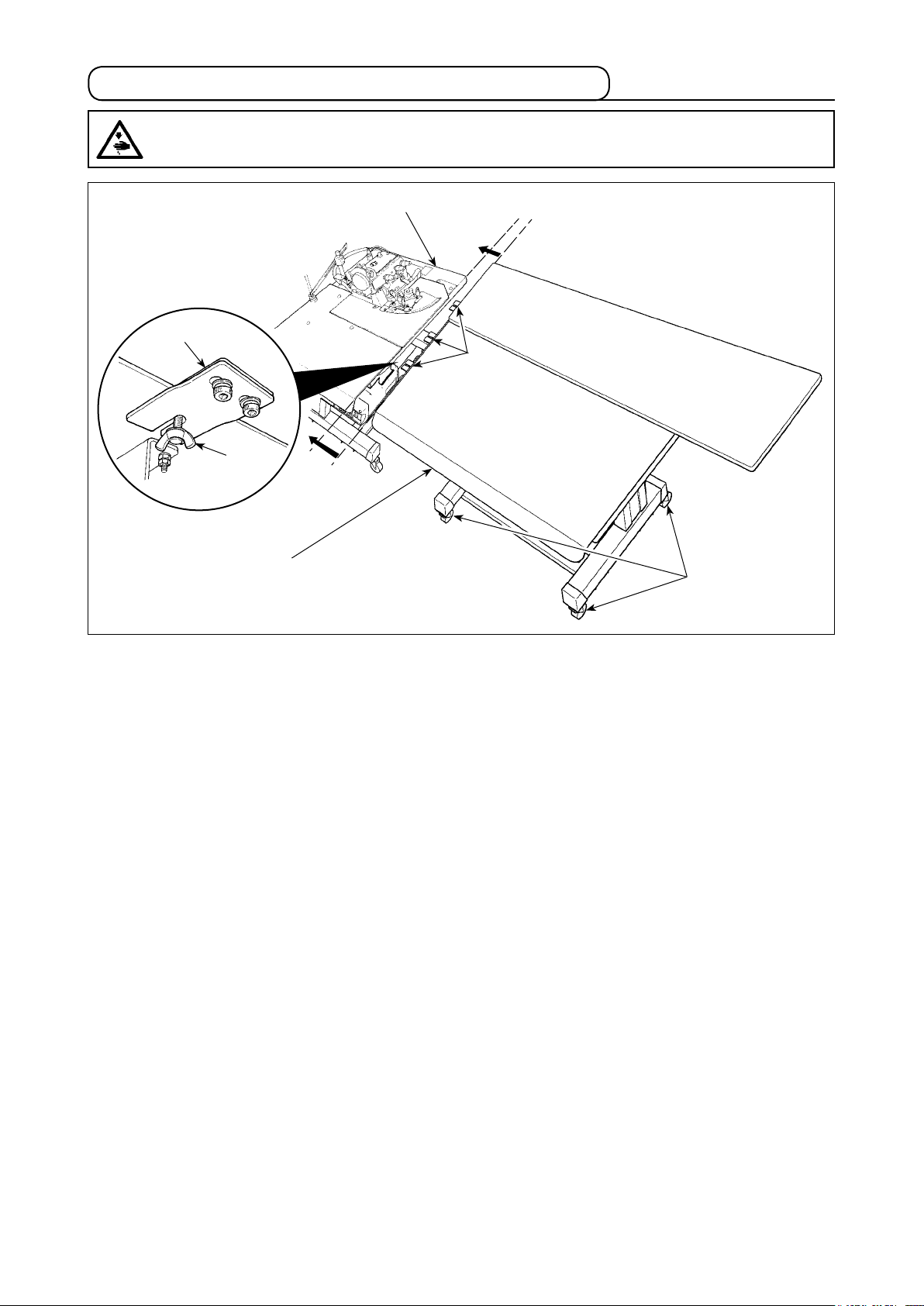

3-11. Joining the sub-table (only for the long table type)

CAUTION

Connect the sub-table to the main-body table taking care not to allow your ngers caught between

them.

:

Main-body table

❹

❶

❷

Sub-table

❸

Butting the sub-table and the main-body table with no clearance provided between them, x clips ❶ (at three

locations) with thumbscrews ❷. Lock casters ❸ (at four locations) to secure the sub-table.

A difference in height between the top face of the main-body table and that of the sub-table may be observed

on some installation site.

If such a difference is observed, adjust so that the tables are same in height with spacers ❹ for adjusting the

height of the clips. (Three spacers are supplied.)

If the sub-table is lower than the main-body table :

・

Add the supplied spacer(s) appropriately.

If the sub-table is higher than the main-body table :

・

Remove spacer ❹ and change with a thinner one.

– 10 –

Page 14

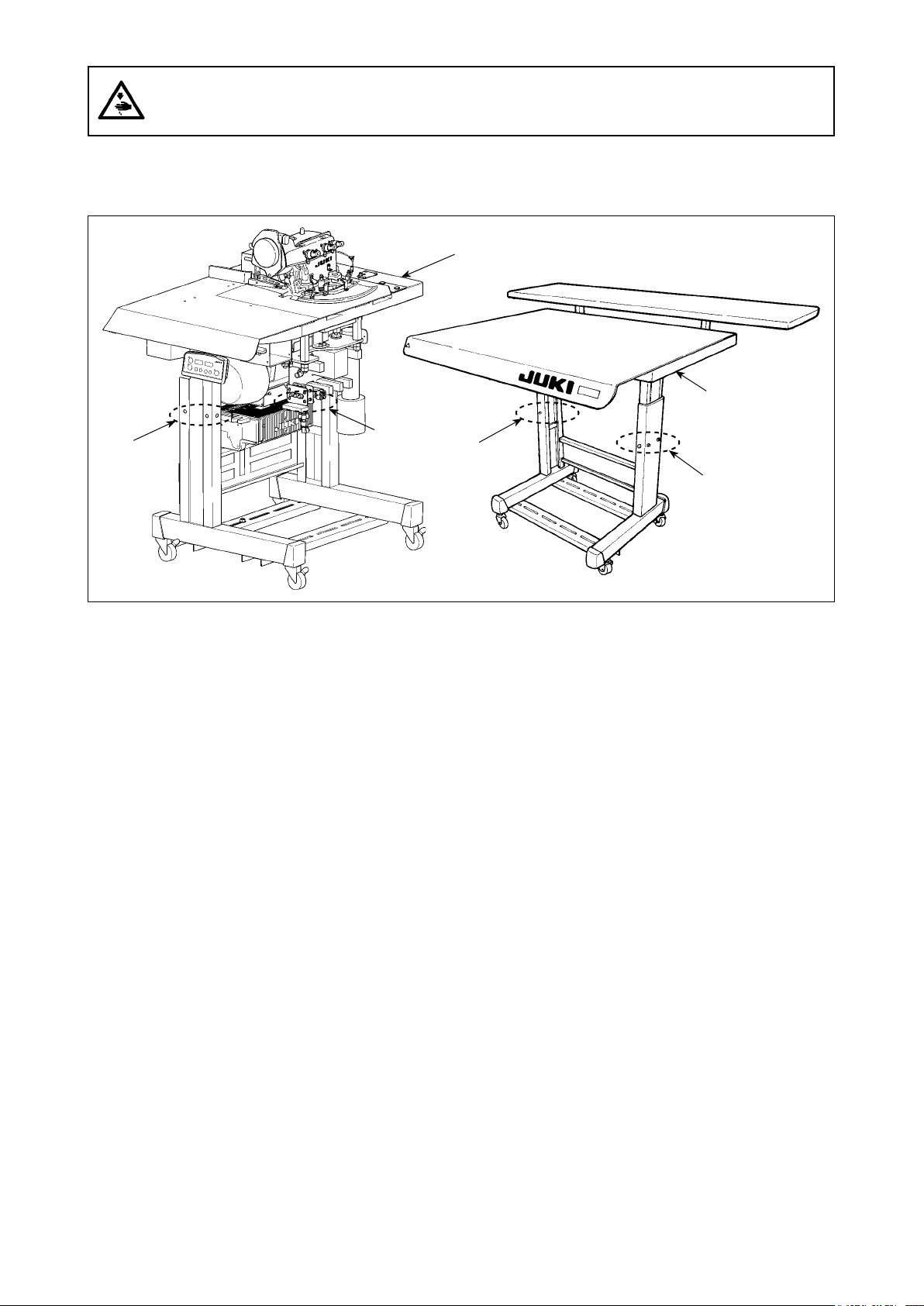

CAUTION :

To protect against possible personal injury or death, be sure to connect the tables while supporting

the machine by four or more workers.

If the difference in height between the sub-table and the main-body table cannot be eliminated with spacer ❹,

adjust the height of the main-body table (or the height of the sub-table).

Main-body table

Sub-table

❺

❺

❻

❻

To adjust the height of the main-body table, loosen screws ❺ that secure the casters (at six locations) to

adjust the height of the main-body table to that of the sub-table and tighten the screws ❺.

To adjust the height of the sub-table, loosen screws ❻ that secure the casters (at six locations) to adjust the

height of the sub-table to that of the main-body table and tighten the screws ❻.

– 11 –

Page 15

3-12. Connecting the power plug

CAUTION

To prevent possible accidents caused by leakage or dielectric strength, an appropriate power plug

shall be installed by a person who has an expert knowledge of electricity. Be sure to connect the

power plug to the receptacle that is well grounded.

:

Connection of the power plug to the power depends on the specications of the product. Adjust the power

plug to the power specications to connect.

In case of the product of single-phase, 200 to 240V specications (CE specications) :

①

Connect the sky-blue and brown wires of the power cord to the power terminal (AC200 to 240V) and the

yellow/green wire to the ground (earth) terminal respectively.

In case of the product of single-phase, 200 to 240V specications (other than CE specications) :

②

Connect the black and white wires of the power cord to the power terminal (AC 200 to 240V), and the

yellow/green wire to the ground (earth) terminal respectively.

In case of the product of 3-phase, 200 to 240V specications :

③

Connect the red, white and black wires of the power cord to the power terminal (AC200 to 240V) and the

yellow/green wire to the ground (earth) terminal respectively.

– 12 –

Page 16

3-13. Installing the cloth receiving board (KM-5) (optional)

❶

❷

❹

❸

❺

1) Fix support rods ❷ on cloth holding table ❶ with wood screws ❸ and washers ❹ (at four locations

each).

2) Fix the cloth holding table mounted with the support rods on the sub-table with screws ❺.

The cloth holding table can be adjusted to four different heights using the xing holes in the support

rod.

❺

– 13 –

Page 17

3-14. Installing the 3-pedal unit (PK-79) (optional)

Connect the connector of the pedal to the junction

connector coming from the control box.

The gure shows differential feed switch ❶, pause

switch ❷ and high-/low-speed changeover switch ❸

from left to right.

❶ ❷ ❸

Differential feed

❶

switch

Pause switch As long as this switch is held depressed, the pause function works. The machine returns

❷

High-/low-speed

❸

changeover switch

As long as this switch is held depressed, the differential feed function works.

to the normal operation (running) by releasing the switch.

Changeover from the high-speed to low-speed can be done only by a depress on this

switch.

The machine returns to the normal operation (running) by releasing the switch.

– 14 –

Page 18

4. PREPARATION

4-1. Caution before operation

CAUTION :

To avoid possible malfunctions and damage of the machine, check the following items.

• Before you put the machine into operation for the rst time, be sure to thoroughly clean it.

• Check to be sure that the voltage has been correctly set.

• Make sure that the power plug is connected properly.

• Never use the machine under a voltage that is different from the specication.

4-2. Lubrication

CAUTION :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

• Lubrication to chain-off thread trimming device

Lubricant inlet

Pipe holder

Knife plate (asm.)

❶

Cloth plate side cover

Remove screw ❶ from the top end of the oil

hose at the rear section of the machine. The

upper limit of the oil quantity is at the top of the

pipe holder.

Oil consumption differs depending on the condi-

tion of use. The oil quantity should be checked

on a daily basis.

As a guide, lubricate the chain-off thread trim-

mer at the following intervals :

❶

❷

❷

· Once a day for the continuous use

· Normally once every three to four days

The chain-off thread trimmer has not been

factory-oiled at the time of delivery.

JUKI MACHINE OIL 18 should be used for

lubrication.

1) Remove oil cap ❶.

2) Pour JUKI MACHINE OIL 18 into the oil reser-

voir.

3) Supply oil until the pointer bar almost reaches

the upper red marker line when oil gauge ❷ is

observed from the side.

If the oil amount pointer bar exceeds the

red marker line, the oil quantity becomes

excessive resulting in oil leakage. Be sure

to stop adding the oil before the red mark-

er line is reached.

– 15 –

Page 19

4-3. Threading the machine

How to remove the cloth plate

★

Remove the cloth plate by holding the cloth plate

guide base.

Do not touch the curve sensor (optional)

mounted on the cloth plate.

To thread the machine head, remove the cloth plate

in advance.

When using an untwisted thread such as

wooly nylon thread or weak thread, do

not wind it round the intermediate thread

guide.

How to thread the needle thread silicon oil

★

tank

When the needle cooler is used. Pass the thread

under the center pawl.

When the needle cooler is not used. Pass the thread

above the center pawl.

– 16 –

Page 20

4-4. Adjusting the pressure of the presser foot and removing the presser foot

1) Adjust the pressure of the presser foot by loos-

❶

❹

❸

❷

ening rst nut ❹ and turning presser foot adjust

screw ❶.

When the adjust screw is turned clockwise, the

pressure will increase. When it is turned coun-

terclockwise, the pressure will decrease.

After the adjustment, be sure to turn nut ❹ with-

out fail.

2) To open presser foot ❷ sidewayd, raise the nee-

dle to the highest position of its stroke and lower

presser bar lifting lever ❸.

4-5. Adjusting the stitch length

CAUTION :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

❶

1) Slowly turn the handwheel as you keep depress-

2) With the above condition maintained, align the

3) Reset the pushbutton ❶ after setting the dial.

❷

To carry out adjustment, remove the cloth

plate in advance.

ing pushbutton ❶, and you will nd a point at

which the pushbutton goes in farther.

desired scale mark on the handwheel with mark

on the belt cover.

❷

– 17 –

Page 21

4-6. Differential feed mechanism

CAUTION :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

To carry out adjustment, remove the cloth

plate in advance.

❷

❶

❸

1) Loosen differential feed lock nut ❷. Move lever

up for stretching stitch or down for gathering

❶

stitch.

2) When you want to move the lever ❶ only slight-

ly, use differential feed minute-adjust screw ❸.

3) When the differential feed adjusting lever is

set to graduation S, the machine will perform

stretching with a differential feed ratio of 1 : 0.8.

When the lever is set to graduation 0, the differ-

ential feed ratio between the main feed dog and

the differential feed dog will be 1 : 1.

4) The maximum differential feed ratio for gather-

ing is 1 : 2. The graduations beyond 0 are used

as standard.

5) After the adjustment, securely tighten locknut ❷.

– 18 –

Page 22

5. OPERATION

5-1. Sewing procedure

CAUTION :

• Never start the machine with the eye protector cover raised in order to prevent injury accidents

caused by the needle and the knife.

• The machine becomes hot when it is running continuously or after it has run, never touch the

sewing machine.

❷

❶

1) Press ON button ❶ of the power switch to turn

ON the power.

When the buzzer is kept beeping imme-

diately after turning ON the power, press

OFF button ❷ on the sewing machine to

turn OFF the power since connection of

the cord or power voltage may be wrong.

Indication given after turning the power on

2) After the power to the machine is turned on, the

indication shown below appears on the opera-

tion panel.

The setting item "SEM" ashes on and off.

Fig. A

❸

The machine will not start as long as the

lamp ashes on and off. If this indication

does not appear on the operation panel, turn

off the power to the machine. If the machine

head is not selected correctly, the indication

will not appear on the operation panel.

Refer to the Engineer's Manual for details.

CAUTION :

Never remove the cloth guide while the

machine is ready for sewing in order to

prevent accidents caused by abrupt start

of the machine.

3) When ❸ is pressed while it is ashing on and

off, the machine gets ready for sewing. Insert

the material along the cloth guide from the direc-

tion of the arrow as shown in Fig. A.

When the material is inserted on start sensor ❹

located this side of the throat plate, the machine

starts running to perform sewing.

❹

– 19 –

Page 23

❺

4) Once the material has come out of the sensor,

the machine stops after several stitches. The

stacker operates when the stacker selector

switch or stacker starting switch ❺ is depressed.

CAUTION :

• Do not place hands under the thread

trimmer presser in order to protect

against injury caused by trapping.

• Do not place your face near the stacker

while it is in operation since air is blown

out from the stacker blower outlet ❻.

• Do not place hands near receiving plate

of the stacker unit while the stacker

❼

is in operation.

❼

In the case of an out-curve

❻

When sewing an out-curve part of the ma-

terial, support the material by hand since

seams easily slip off the material edge.

– 20 –

Page 24

❽

5) When sewing is completed, make sure that the

sewing machine has stopped.

Then, press the OFF button ❽ of the power

switch to turn OFF the power.

– 21 –

Page 25

5-2. Explanation of the operation panel

Ⓐ

❷

switch : Used for returning the setting to the initial value.

❶

switch : Used for changing the contents of setting.

❷

When this switch is pressed, changeable positions ash on and off.

By pressing the switch, ashing position shifts in the left direction.

Starting the machine is prohibited while the switch lamp is ashing on and off (setting mode).

❸ ❹ ❺❶ ❻

Ⓑ

switch : Used for changing the contents of setting.

❸

By pressing the switch, ashing position shifts in the right direction.

switch : Used for changing the contents of the selected display (ashing section).

❹

When this switch is pressed, the set value is decreased.

❺

When this switch is pressed, the set value is increased.

switch : Used for determining the contents of setting.

❻

When this switch is pressed, ashing stops and the contents of setting are determined.

The machine enters the sewing mode under which it can start. When the material to be sewn is already

switch : Used for changing the contents of the selected display (ashing section).

placed on the machine under the Automatic mode, E333 will appear on the operation panel. In this case,

the machine is unable to enter the sewing mode. If the curve sensor is set effective, the same phenome-

non occurs when the material is already placed on the machine (E334). If E334 is displayed, check rstly

the neighboring area of the sensor whether the material has been placed on the machine. (The same

phenomenon occurs when dust settles on the sensor. Check the neighboring area of the sensor for

dust.) The operation level can be changed by keeping this switch held pressed for three seconds while

the switch light is ashing on and off.

If the power to the machine is turned off before having taken the aforementioned procedure, the data

changed will not be stored in memory.

Set item indication : Abbreviation of the name of the set item selected is displayed.

Ⓐ

Set contents indication : Content of the set item selected is displayed.

Ⓑ

– 22 –

Page 26

5-3. Description of the pedals and the switches on the machine head

Switch location Name and description of function

Sewing machine starting pedal

❶

The machine starts at the chain-off thread setting speed (at the high

speed if the manual start mode is selected) as long as this switch is

held depressed.

• When the automatic start mode is selected :

When the material is detected, the automatic starting is given priority.

The chain-off thread (starting pedal) is inoperative under the automatic

starting.

• When the manual start mode is selected :

❶

The material detection is inoperative.

The operation same with that taken when the material has come out of

the sensor under the automatic mode is taken by releasing the switch.

Stacker operation switch

❷

When the switch is pressed, the seam is changed to be last one regard-

❷

❸

less of the setting of the number of seams for activating the stacker.

The stacker works regardless of the use/disuse setting of the stacker.

❼ ❻ ❺

❹

Pause switch

❸

When the switch is pressed, E050 is displayed on the operation panel

to stop the machine. After the machine has stopped, the machine is

restored to the on state by pressing the panel switch.

Cloth plate open/close switch

❹

When this switch works, E302 is displayed on the operation panel to

stop the machine. To reset, turn the power off then on.

Low-/high-speed changeover switch (optional)

❺

Changeover from the high-speed to low-speed can be done only by a

depress on this switch.

As long as the switch is held depressed, the low-speed operation is

selected.

Temporary stop switch (optional)

❻

As long as this switch is held depressed, the temporary stop function

works.

The machine returns to the normal operation (running) by releasing the

switch.

Differential feed switch (optional)

❼

As long as this switch is held depressed, the differential feed function

works.

The speed to be employed while the function is working will be the one

for the curve sensor.

– 23 –

Page 27

5-4. List of functions to be set

Item

indication

1 S E M 1 - 1 The number of seams, current seam

2 C n T 0 No. of pcs. counter

3 S T K 0 Use/disuse of the stacker

4 S T d 1 0 Number of delay stitches for the thread trimming

5 S C d 0 Number of delay stitches for the stacker presser

6 S S T 5 5 Number of delay stitches for operating the stacker

7 S b d 5 0 0 Delay time of the stacker blow

8 S b L 7 0 0 Stacker blow time

9 S T F 2 0 Delay time of the thread trimmer presser 0

10 H S P 5 5 0 0 Speed of stitch for the high-speed mode

11 L S P 3 0 0 0 Speed of stitch for the low-speed mode

12 S S P 2 0 0 0 Speed of stitch for the curve sensor

13 d S P 2 0 0 0 Speed of stitch for producing chain-off thread

14 S T r 1 0 0 Start delay time

15 S T P 5 5 Number of delay stitches for stopping the machine

16 A U T 1 Setting of the start mode

17 C U b 1 Curve-mode setting

18 C U 1 1 Curve-mode seam setting

19 C S H 1 Curve differential feed mode setting

20 C S 1 1 Curve differential feed mode seam setting

21 C S S 0 Setting of the number of stitches for starting the

22 C S E 5 0 Setting of the number of stitches for ending the curve

23 d U S 2 0 Setting of the number of stitches for sucking chain-

24 C U r 2 Curl blow time

25 F L U 0 Presser-lifter lift waiting time

26 F L d 0 Presser-lifter lowering waiting time

Contents indication

(initial value)

Description Setting range

presser

and stopping the machine

curve mode

mode

off thread at the beginning of sewing

1 to 9

0 to 9999

0 to 1

0 to 99 stitches

0 to 999 stitches

0 to 999 stitches

0 to 9900 ms

0 to 9900 ms

to

200ms 2

200 to 8000

200 to 8000

200 to 8000

200 to 8000

0 to 9900 ms

0 to 999 stitches

0 to 1

0 to 1

0 to 1

0 to 1

0 to 1

0 to 999 stitches

0 to 999 stitches

0 to 999 stitches

0 to 60 seconds

0 to 9900 ms

0 to 9900 ms

sti/min

sti/min

sti/min

sti/min

Operation

level

*

*

*

*

1

1

1

2

2

1

2

1

1

1

1

2

2

1

2

1

1

1

1

1

1

2

2

2

2

* "sti/min" is an abbreviation for "stitches per minute."

Indication given when changing the operation level

★

L E v 1 Operation level 1 : Normal operation

(When turning the power on)

L E v 2 Operation level 2 : Detailed operation

The operation level can be changed by keeping the switch held depressed for

three seconds.

After the operation level has been changed, the indication which appears when turning on the power

to the machine is shown on the operation panel.

Listing of digitally displays

★

Numeral 0 1 2 3 4 5 6 7 8 9

Digital display

Character A B C D E F G H I J K L M

Digital display

Character N O P Q R S T U V W X Y Z

Digital display

– 24 –

Page 28

5-5. Details of selected functions

Setting of the number of seams (level 1)

①

The number of seams for activating the stacker is set.

The preset number of seams and the current seam are indicated.

Current seam (the ordinal position of the seam being sewn with respect to

the set number of stitches is indicated)

Set value (setting range 1 - 9)

Setting of the No. of pcs. counter (level 1)

②

The number of pieces of products to be sewn is set.

The No. of pcs. counter increments by one every time the stacker operates.

Setting range 0 to 9999

Setting of use/disuse of the stacker (level 1)

③

Whether the stacker is used or not is selected.

0 : Not used

1 : Used (The stacker is controlled when sewing the last seam.)

Setting of the number of delay stitches for the thread trimmer presser (level 2)

④

The number of stitches to be sewn before the thread trimmer presser works after the material has come

out of the sensor is set.

Setting range 0 to 99 stitches

Setting of the number of delay stitches for the stacker presser (level 2)

⑤

The number of stitches to be sewn before the stacker presser works after the thread trimmer presser has

worked is set.

Setting range 0 to 999 stitches

Setting of the number of delay stitches for operating the stacker and stopping the machine (level 1)

⑥

The number of stitches to be sewn before the sewing machine stops after the material has come out of

the sensor is set.

Setting range 0 to 999 stitches

Setting the delay time for the stacker blow (level 2)

⑦

The time to be elapsed before the stacker blow works after the stacker presser has worked is set.

Setting range 0 to 9900 ms

Setting the time for the stacker blow (level 1)

⑧

The length of time during which the stacker blow works after the delay time for the stacker blow has

elapsed.

Setting range 0 to 9900 ms

Setting the delay time for lifting the thread trimmer (level 2)

⑨

The time to elapsed before lifting the thread trimmer presser after the stacker blow has worked is set.

Setting range 0 to 200 ms

– 25 –

Page 29

Setting the speed of stitch for the high-speed mode (level 1)

⑩

The speed of stitch for the high-speed mode is set.

Setting range 200 to 8000 sti/min

Setting the speed of stitch for the low-speed mode (level 1)

⑪

The number of low-speed revolutions is set.

Setting range 200 to 8000 sti/min

Setting the speed of stitch for the curve sensor (level 1)

⑫

The speed of stitch for the section where the curve sensor is effective (from the number of stitches at

which the curve sensor starts to the one at which the sensor stops) is set.

Setting range 200 to 8000 sti/min

Setting the speed of stitch for producing chain-off thread (level 2)

⑬

The speed of stitch to be employed when operating the chain-off thread (starting) pedal.

*

*

*

Setting range 200 to 8000 sti/min

Setting of the start delay time (level 2)

⑭

The time to be elapsed before starting the machine after the material has been detected is set.

Setting range 0 to 9900 ms

Setting of the number of delay stitches for stopping the machine (level 1)

⑮

The number of stitches to be sewn before the machine stops after the normal-seam material (other than

the stack mode) has come out of the sensor is set.

Setting range 0 to 999 stitches

Setting of the start mode (level 2)

⑯

The start mode of the machine is set.

Either the automatic mode by the start sensor or the manual mode by the starting pedal is selected.

0 : Manual mode (The start sensor is inoperative.)

1 : Automatic mode

(The starting pedal is used as the chain-off thread switch.)

Curve mode setting (level 1)

⑰

Whether the curve sensor is used or not is selected.

0 : Not used

1 : Used

*

Curve mode seam setting (level 1)

⑱

Whether the curve sensor is used or not is selected for the specied seam.

0 : Not used

1 : Used

Curve differential feed mode setting (level 1)

⑲

Whether the differential feed mechanism is activated or not by means of the curve sensor is selected.

0 : Not used

1 : Used

* "sti/min" is an abbreviation for "stitches per minute."

– 26 –

Page 30

Curve differential feed mode seam setting (level 1)

⑳

Whether the differential feed mechanism is activated or not by means of the curve sensor is selected for

the specied seam.

0 : Not used

1 : Used

The number of stitches for starting the curve mode (level 1)

The number of stitches to be sewn before the curve mode or differential feed mode starts after the curve

sensor has detected a curved part of the material is set.

Setting range 0 to 999 stitches

The number of stitches for ending the curve mode (level 1)

The number of stitches to be sewn from the start to the end of the curve mode or differential feed mode

is set.

Setting range 0 to 999 stitches

The number of stitches for sucking chain-off thread at the beginning of sewing (level 2)

The number of stitches for sucking chain-off thread at the beginning of sewing is set.

Setting range 0 to 999 stitches

Curl blow output time (level 2)

The time to be elapsed before turning off the curl blow after the machine has stopped is set.

Setting range 0 to 60 seconds

Presser-foot lift waiting time (level 2)

The time to be elapsed before lifting the presser foot after the machine has stopped is set.

(The presser foot automatically goes up when the machine has stopped after stacking.)

Setting range 0 to 9900 ms

Presser-foot lowering waiting time (level 2)

The period of time to be elapsed from the startup of sawing machine to the lowering of the presser foot.

Setting range 0 to 9900 ms

– 27 –

Page 31

5-6. Other settings

(1) Setting of the auto lifter function (optional)

ⒷⒶ

CAUTION :

When the auto-lifter function is used, do not

place your ngers under the presser foot.

When the optional auto-lifter device (AK) is attached,

the auto-lifter function is brought into action.

1) Turn ON the power switch while pressing switch

on the operation panel.

❶

2) LED display is turned to Ⓐ, Ⓑ (FL ON) with

❶

“beep”, and the function of auto-lifter becomes

effective.

3) Turn OFF the power switch, and turn ON the

power switch again to return to the normal

mode.

Air drive display (+24V)

4) Repeat the operation 1) to 3), and LED display

is turned to (FL OFF). Then, the function of auto-lifter does not work.

FL ON : Auto-lifter device becomes effective.

FL OFF : Auto-lifter function does not work.

1. To perform re-turning ON of the power, be sure to perform after the time of one second or more

has passed.

(If ON / OFF operation of the power is performed quickly, setting may be not changed over well.)

2. Auto-lifter is not actuated unless this function is properly selected.

5-7. Initialization of the setting data

Ⓐ

❸❷❶

All contents of function setting of the control box can

be returned to the standard set values.

1) Pressing all switches ❶, ❷ and ❸, turn ON

the power switch.

2) LED displays indication Ⓐ with the sound “peep”,

and initialization starts.

3) The buzzer sounds after approximately one

second (single sound three times, “peep”, “peep”,

and “peep”), and the setting data returns to the

standard setting value.

Do not turn OFF the power on the way of

initializing operation. Program of the main

unit may be broken.

4) Turn OFF the power switch, and turn ON the

power switch again to return to the normal

mode.

– 28 –

Page 32

6. ADJUSTMENT

6-1. Stacker support board adjustment

CAUTION :

To avoid possible accidents because of abrupt start of the machine or the device, turn OFF the power

to the machine, and expel air remaining in the machine by removing the pipe of the air supply before

carrying out assembling or adjustment works.

(1) Adjusting the stacker height

❶

❷

❸

❹

❺

1) Adjust the support board ❶ in accordance with

the type of material to be used.

2) When handle ❷ is loosened, the support board

can be moved up and down. When it is in the

correct position, tighten the handle tightly.

3) Loosen nut ❹. Loosen hexagon head bolt ❸

and adjust work clamp shaft ❺ in accordance

with the support board. After the adjustment, x

the nut by tightening the hexagon head bolt.

(2) Adjusting the orientation of the stacker

Material feeding direction

❷

Loosen nuts ❶ (at two locations) and adjust the ori-

entation of the stacker unit ❷.

If the stacked materials are not neatly

stacked, adjust the orientation of the

stacker unit so that stacker support board

is at right angles to the stacker cloth

❷

guide (material feeding direction).

❶

– 29 –

Page 33

6-2. Adjusting the position of the thread trimmer presser

Loosen screws ❷ (at two locations) which x cylin-

der mounting arm ❶ to adjust the arm to the right or

left. Adjust the thread trimmer presser to the position

at which it clamps the material to be sewn at the

center of its width.

When adjusting, x the thread trimmer

presser so that presser sponge ❸ is

aligned with the top face of the table with

the thread trimming cylinder brought to its

lower position. If the cylinder is inclined,

the thread trimmer presser may fail to

properly clamp the material or a cylinder

failure can occur.

❷

❶

❸

6-3. Adjusting the air blow

1) The amount of the following air blow should be

For the start sensor air blow

and curve sensor air blow

For the side cover air blow

adjusted by means of the speed controller ac-

cording to the type of material and pattern to be

sewn.

❶

❷

For material feeding

❹

❶ ❷ ❸

❸

❺

❻

Cloth feeding air blow

❶

Cloth feeding air blow

❷

Cloth feeding air blow

❸

Side cover air blow

❹

Start sensor air blow

❺

Curve sensor air blow (optional)

❻

2)

The air blowing amount is reduced by turning the

adjusting knob clockwise.

3)

The air blowing direction of the cloth feeding blow

can be changed by loosing the M4 nut mounted

underside of the table.

After changing the air blowing direction, be sure

to tighten the nut to x it. In addition, check to be

sure that the air hoses are fully tightened with a

clip band.

– 30 –

Page 34

6-4. Adjusting the edge guide

CAUTION :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

❹

❸

Material

❷

❶

❸

1) Edge guide ❶ works to adjust the overedging

width of the material. Adjust the overedging

width by adjusting edge guide ❶ to the right or

left using screws ❷.

2) Curl guide ❸ works to prevent the material edge

from curling. Adjust the curl guide with screw ❹

according to the cloth thickness.

Overedging width of the material

– 31 –

Page 35

6-5. Adjusting the cloth guide

CAUTION :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

Fig. A

❷

❸

❶

❹

1) By loosening two screws ❷, cloth guide posi-

tion can be adjusted in the direction shown by

arrow. After the adjustment of overedging width

of the material with edge guide ❹, adjust the

surface of edge guide ❹ and that of cloth guide

(Fig. A) are ush with each other.

❸

2) If the knob ❶ is turned to the right, cloth guide

is lowered, and if the knob is turned to the

❸

left, cloth guide is raised. Make adjustment ac-

cording to the cloth thickness.

❸

6-6. Regulator adjustment

CAUTION :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

❶

Tightening adjustment screw ❶ weakens the chain-

off thread suction power; loosening the screw

strengthens it.

– 32 –

Page 36

6-7. Adjusting the cloth chip suction force

CAUTION :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

❶

Tightening adjustment screw ❶ weakens the chain-

off thread suction power; loosening the screw

strengthens it.

The suction force for the cloth chip collec-

tor and the dust collector mounted on the

upper looper bracket is adjusted by means

of the same adjusting screw.

– 33 –

Page 37

6-8. Adjusting the sensors

Once the cloth guide has been adjusted to 5 mm position, check to be sure that the numeric value on the

main digital display shown on the amplier is 8000 or more when no material is placed under the sensor unit,

and that the numeric value on the main digital display is 6200 or less when the material is placed under the

sensor unit.

If the aforementioned requirements are not satised, the machine can malfunction. It is therefore

necessary to adjust the threshold of the amplier.

❶

Startup sensor amplier ❶ is located at the position

as illustrated in the gure.

Amplier ❷ for the curve sensor is located at the

rightmost position on the top face of the cloth plate.

❷

DPC indicator

Turns ON when Dynamic power control is

effective.

* This function is not used by this sewing machine.

L/D indicator

Setting status of L/D between "ON (L)

when the light enters" and "ON (D) when

the light is shielded" is displayed.

button

Set value for the light projecting

power is automatically set.

OUT Indicator

Turns ON when Output is ON.

Threshold

Green digital display

+/- UP/DOWN button

This button is used for nely adjusting the threshold

and changing the conguration parameter.

L/D button

△

This button is used for changing over the status

of L/D between "ON (L) when the light enters" and

"ON (D) when the light is shielded".

* The startup sensor has been set to the state "ON (D)

when the light is shielded". The curve sensor has been

set to the state "ON (L) when the light enters".

ST indicator

Turns ON when Smart tuning is in progress.

Amount of light

received

Red digital display

MODE button

□

This button is used for

changing over the mode

between the detection

mode and the setting

mode.

– 34 –

Page 38

(1) Setting thresholds for the start sensor and curve sensor

It is possible to detect two amounts of light received; i.e., the amount of light received when there is no material and that when there is a material. The intermediate value between those two amounts of light received

can be set as the threshold.

1)

Adjust the clearance provided between the cloth

Without-material state

guide and cloth plate to 5 mm before starting

adjustment.

Turn on the power to the machine.

Be sure to carry out adjustment under the

machine setting mode in order to prevent

accidents caused by abrupt start of the

machine.

Press once.

With-material state

Material

2) Open the sensor amplier cover.

3) Place no object to be detected at the sensor

irradiation position.

4) Press the button once.

is displayed with lighted.

5) Place a sheet of white paper (substitute for

the material) at the sensor irradiation positions

respectively on the cloth guide and on the cloth

plate. Then, press the button once.

is displayed with lighted.

6) The setting is completed when the screen is re-

stored to the one on which the specied thresh-

old and the current amount of light received are

displayed.

7) Close the sensor amplier cover.

8) Insert the material into the cloth guide unit.

Check to be sure that the amount of light re-

ceived do not exceed the threshold.

Press once.

Threshold Amount of light

received

– 35 –

Page 39

7. MAINTENANCE

7-1. Adjusting the knife

CAUTION :

• To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

• To protect against possible personal injury, never touch the blade of the knife with ngers and

hands.

• To prevent possible accidents caused by inexperienced persons and those resulting from

maladjustment, adjustment work should only be carried out by maintenance personnel who have

received safety training and are familiar with the sewing machine.

❹

❸

To adjust the extent of cutting uff at the overedged

edge of the material :

1) Loosen setscrew ❶. Tighten the setscrew with

lower knife ❷ pressed to the left.

2) Loosen setscrew ❸. Move upper knife as far as

needed and secure with the setscrew ❹.

3) Lower the upper knife to its lower end position.

Loosen setscrew ❶ to adjust so that the lower

knife comes in contact with the upper knife, then

tighten setscrew ❶.

❶

7-2. Cleaning the machine head

CAUTION :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

❷

1. Be sure to tighten screw ❶ before oper-

ating machine.

2. After the completion of adjustment,

make the knives cut a thread to check

for sharpness of the knives.

Clear lint from inside the looper cover and the needle

bar and components about once or twice a day. If

not, oil may leak the sewing material will be soiled.

– 36 –

Do not wipe the coated surface of the ma-

chine head with lacquer thinner. Doing so

will damage the coated surface.

Page 40

7-3. Checking the cartridge lter and replacing it

1. After a long period of usage, cartridge lter ❶

❷

❸

❹

may become clogged with dust.

If the machine is left in this state, the dirty oil

may fail to pass through cartridge lter ❶, and

the machine may wear out abnormally, or a sei-

zure may result.

Cartridge lter ❶ should normally be checked

※

once every six months, and cleaned or replaced

accordingly.

7-4. Changing the machine oil

❶

2. How to inspect the cartridge lter and replace it.

1) Remove rst oil discharging screw ❷.

2) Remove screws ❸, and lift top cover ❹ just

above until it comes off.

If top cover ❹ is shifted sideward, the oil

amount pointer bar and the cartridge lter

may be damaged.

3) Remove cartridge lter ❶ and check it. If the

lter is found to be abnormal, clean the relevant

components, or replace cartridge lter ❶.

4) Re-insert cartridge lter ❶ into its proper posi-

tion and return the cover. Do not forget to put

back the setscrews and tighten them up.

CAUTION :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

1) Use JUKI MACHINE OIL 18 in the machine

head.

❶

2) To change the oil, rst drain the oil out by un-

screwing screw ❶ on the tip of the oil drain hose

connected to the oil pan. At this time, remove

the cover from the oil inlet hole on top of the ma-

chine head.

3) Refer to

lubricate the machine.

"4-2. Lubrication" p.15

for how to

– 37 –

Page 41

7-5. Changing needles

CAUTION :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

❶

❷

The standard needle is DC×27 #11. You can also

use the DC×1 needle. In this case, however, the

clearance provided between the needle and the

looper may be required to be adjusted. If sewing

need to be carried out with a nely adjusted thread

tension, use the DC×27 needle.

1) Bring needle clamp ❶ to the highest position.

2) Loosen needle clamp screw ❷, and fully insert

the needle into the needle clamp hole with the

needle recess facing backwards as viewed from

the operator’s side.

3) Tighten the needle clamp screw ❷.

7-6. Drainage of lter regulator

CAUTION :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

1) Drainage of regulator ❶ must take place before

usage, and water must be eliminated.

(Loosen knob ❷, then drain the water.)

2) Be careful about moisture as it is harmful to air

control system.

If the amount of water is enormous, check

in addition the main unit of the compres-

sor for water.

❶

❷

– 38 –

Page 42

7-7. Cautions for the compressed air supply (source of supply air) facility

As large as 90 % of failures in pneumatic equipment (air cylinders, air solenoid valves) are caused by "con-

taminated air."

Compressed air contains lots of impurities such as moisture, dust, deteriorated oil and carbon particles. If

such "contaminated air" is used without taking any measures, it can a cause of troubles, inviting reduction in

productivity due to mechanical failures and reduced availability.

Be sure to install the standard air supply facility shown below whenever the machine provided with pneumat-

ic equipment is used.

Standard air supply facility to be prepared by the user

Air compressor

After cooler

Auto-drain

Air tank

Main line lter

Auto-drain

Air dryer

Mist separator

Filter regulator

Air solenoid valve

Quality of the air supply

When the supply air contains a considerable amount of moisture

Ambient environment

When our machine is installed at a place where the temperature greatly

changes in the morning and in the evening from that in the daytime or

freeze is like to occur

In the aforementioned cases, be sure to install an air dryer.

When the supply air contains a considerable amount of carbon and dust

(Most troubles in the air solenoid valves are caused by carbon.)

Be sure to install a mist separator.

Standard equipment supplied by JUKI

Air cylinder

Cautions for main piping

• Be sure to slope main piping by a falling gradient of 1 cm per 1 m in the direction of air ow.

• If the main piping is branched off, the outlet port of the compressed air should be provided at the

top part of the piping using a tee in order to prevent drain settling inside the piping from owing

out.

• Auto drains should be provided at all lower points or dead ends in order to prevent the drain from

settling in those parts.

– 39 –

Page 43

7-8. Dust collector box

CAUTION :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

1) Throw away waste cloth chips inside the dust collector box at least once a day. At this time, also clean

up the lter.

2) Fine cloth chip adhere to the suction port inside the box; blow them away with an air gun.

3) If a great deal of lint adheres to the intake, the suction power may be reduced.

7-9. Cleaning the sensor

CAUTION :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

When dust gathers around irradiating position for the

start sensor and curve sensor, the sensor may make

❷

erroneous detection resulting malfunction of the ma-

chine. To avoid this, be sure to remove dust from the

following four parts by blowing air with an air gun.

❶

❹

❸

• Irradiating point ❶ for the start sensor on the

top face of the cloth plate

• Irradiating point ❷ for the curve sensor on the

top face of the cloth plate

• Irradiating point ❹ for the start sensor on the

throat plate base A

(Remove the cloth plate to carry out the dust

removal procedure.)

• Irradiating point ❺ for the start sensor on the

rear face of the cloth plate

(Remove the cloth plate to carry out the dust

removal procedure.)

❸

❺

Rear face of the cloth plate

– 40 –

Page 44

7-10. Consumable parts to be replaced

CAUTION :

• Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

• To protect against possible personal injury, never touch the blade of the knife with ngers and

hands.

• To prevent possible accidents caused by inexperienced persons and those resulting from

maladjustment, adjustment work should only be carried out by maintenance personnel who have

received safety training and are familiar with the sewing machine.

The following parts are consumables. Be sure to periodically replace them with new ones.

Side cutter block

• Side cutter block

(Part number : MAT02503000)

If the block is not periodically replaced with a

new one, it can wear out to fail to trim chain-

off thread sharply, affecting the quality of thread

trimming at the end of sewing.

• Thread trimmer presser sponge

(Part number : 18072603)

If the sponge is not periodically replaced with a

new one, it can fail to clamp the material ade-

quately, affecting the quality of thread trimming

at the end of sewing.

Thread trimmer

presser sponge

– 41 –

Page 45

7-11. Replacing the fuse

DANGER :

To prevent personal injuries caused by electric shock hazards or abrupt start of the sewing machine,

remove the cover after turning OFF the power switch and a lapse of 5 minutes or more. To prevent

personal injuries, when a fuse has blown out, be sure to replace it with a new one with the same

capacity after turning OFF the power switch and removing the cause of the blown-out of the fuse.

1) Press the OFF button of the power switch to turn

OFF the power after conrming that the sewing

machine has stopped.

2) Draw out the power cord coming from the power

plug socket after conrming that the power

switch is turned OFF. Perform the work of step 3)

after conrming that the power has been cut and

it has passed for 5 minutes or more.

3) Loosen setscrew ❷ in cover ❶. Open cover ❶.

❷

Be sure to open/close cover ❶ while put-

ting a hand on it.

❶

4) Remove all the cables which are connected to

the control box.

5) Loosen setscrews ❹ of control box mounting

plate ❸. Detach the control box from the motor.

❹

❸

– 42 –

Page 46

[ Replacing fuse on PWR-T circuit board ]

(Caution) The illustration below shows the PWR-T PCB. The type of PCB differs by destination.

❺

❻

6) Holding the glass section of fuse ❺, remove the fuse.

(Caution) There is a risk of electrical shock when removing the fuse. Be sure to remove the fuse after LED

has totally gone out.

❻

5) Be sure to use a fuse with the designated capacity.

: 3.15 A/250 V Time-lag fuse

❺

(Power circuit protective fuse)

Part number: KF000000080

8) Install the control box to the motor.

9) Connect all the cables to the control box. (Refer to

connectors" p.44

.)

"7-13. Destination of connection for input/output

7-12. Adjusting the belt tension

15mm(9.8N)

Tension

adjust nuts

The belt tension should be adjusted by turning the

tension adjust nuts to change height of the motor,

so that the belt sinks down by about 15 mm (9.8N)

when it is depressed by band at the center of the belt

span.

If the belt tension is not adequate, the sewing ma-

chine may not rotate with consistency at the low- to

medium-speed operation.

The belt can increase in length as a result

of use. Be sure to periodically check and

adjust the belt tension appropriately.

– 43 –

Page 47

7-13. Destination of connection for input/output connectors

CAUTION :

• To prevent personal injury caused by abrupt start of the sewing machine, carry out the work after

turning OFF the power switch and a lapse of 5 minutes or more.

• To prevent damage of device caused by maloperation and wrong specications, be sure to

connect all the corresponding connectors to the specied places.

• To prevent personal injury caused by maloperation, be sure to lock the connector with lock.

• As for the details of handling respective devices, read carefully the Instruction Manuals supplied

with the devices before handling the devices.

Solenoid valves and sensors used with ASN-690 are connected to the connectors inside the control box as

described below: Connection state of the connectors can be checked by loosening front-cover xation screws

and opening the front cover.

❶

❷

❼

CN42 Curve sensor

❶

CN54 Startup sensor

❷

CN30 Motor signal connector

❸

CN48 Connector for the cloth plate open/close switch and halt switch

❹

CN38 Operation panel CP-18

❺

CN39 Connector for pedal junction cable

❻

CN56 Connector for solenoid valve

❼

CN36 Connector for solenoid valve

❽

CN37 Connector for solenoid valve

❾

CN201 Connector for starting pedal

CN206 Connector for 3-pedal unit (optional)

❽

❾❻❺❹❸

– 44 –

Page 48

7-14. Error codes

In case of the following, check again before you judge the case as trouble.

Phenomenon Cause Corrective measure

When tilting the sewing machine, the

buzzer beeps and the sewing machine cannot be operated.

Solenoids for thread trimming, reverse

feed, wiper, etc. fail to work. Hand

lamp does not light up.

When tilting the sewing machine

without turning OFF the power switch,

action given on the left side is taken

for safety sake.

When the fuse for solenoid power

protection has blown out

Tilt the sewing machine after turning

OFF the power.

Check the fuse for solenoid power

protection.

Presser foot does not go up even

when auto-lifter device is attached.

Sewing machine fails to run. Motor output cord (4P) is disconnect-

Auto-lifter function is OFF. Select “FL ON” by auto-lifter function

selection.

Cord of auto-lifter device is not connected to connector (CN37).

ed.

Connector (CN30) of motor signal

cord is disconnected.

Connect the cord properly.

Connect the cord properly.

Connect the cord properly.

In addition, there are the following error codes in this device. These error codes interlock (or limit function)

and inform the problem so that the problem is not enlarged when any problem is discovered. When you re-

quest our service, please conrm the error codes.

[Checking procedure of the error code]

Ⓑ

1) Turn ON the power switch with

switch ❸ held pressed.

2) The latest error number is displayed

on indicator Ⓑ with a blip.

3) Contents of previous errors can be

checked by pressing switch ❸ or

switch ❹.

❹❸

(When the conrmation of the contents

of previous error advanced to the last,

the warning sound peeps in single

tone two times.)

(Caution) When switch ❸ is pressed, the previous error code of the currently displayed one is

displayed. When switch ❹ is pressed, the next error code of the currently displayed one

is displayed.

– 45 –

Page 49

7-15. Error code list

No.

Description of error detected

E000

E003 Disconnection of synchro-

E004 Synchronizer lower position

E005 Synchronizer upper position

E007 Overload of motor • When the machine head is locked.

E050 The pause switch is

E070 Slip of belt • When the machine head is locked.

E071 Disconnection of motor

E302 Opening of the cloth plate

E333 The material is inserted on

E334 The material is inserted on

Execution of data initialization

(This is not the error.)

nizer connector

sensor failure

sensor failure

pressed

output connector

is detected.

the start sensor.

the curve sensor.

Cause of occurrence expected Items to be checked

• When the machine head is changed.

• When the initialization operation is executed.

• When position detection signal is not input

from the sewing machine head synchronizer.

• When the synchronizer has broken.

• Belt is loose.

• Machine head is not proper.

• Motor pulley is not proper.

• When sewing extra-heavy material beyond

the guarantee of the machine head.

• When the motor does not run.

• Motor or driver is broken.

• The connector of the switch has come off. • Check the connector of the pause switch

• Belt is loose.

• Disconnection of motor connector • Check the motor output connector for loose

• The cloth plate is not installed on the table. • Check whether the cloth plate is set on the

• Dust on the sensor

• Sensitivity of the sensor

• Check the synchronizer connector (CN33,

CN43) for loose connection and disconnection.

• Check whether the belt is loose.

• Check whether the synchronizer cord has

broken since the cord is caught in the machine head.

• Check the belt tension.

• Check the setting of the machine head.

• Check the setting of the motor pulley.

• Check whether the thread has been entangled in the motor pulley.

• Check the motor output connector (4P) for

loose connection and disconnection.

• Check whether there is any holdup when

turning the motor by hand.

for loose connection and disconnection.

• Check whether there is any holdup when

turning the motor by hand.

• Check the belt tension.

connection and disconnection.

table

• Dust around the sensor

• Adjustment of the sensitivity of the sensor.

• Setting of the L/D

E730 Encoder failure • When the motor signal is not properly

inputted.

E731 Motor hole sensor failure

E733 Inverse rotation of motor • This error occurs when the motor is run-

ning at 500 rpm or more in the opposite direction of that of rotation indication during

motor is running.

E811 Overvoltage • When voltage higher than guaranteed one

is inputted.

• 220V has been inputted to SC-510 of 110V

specications.

• 400V is applied to the box of 220V (230V).

E813 Low voltage • When voltage lower than guaranteed one

is inputted.

• 110V has been inputted to SC-510 of 220V

specications.

• 110V is applied to the box of 220V.

• Inner circuit is broken by the applied overvoltage.

E924 Motor driver failure • Motor driver has broken.

• Check the motor signal connector (CN30)

for loose connection and disconnection.

• Check whether the motor signal cord has

broken since the cord is caught in the machine head.

• Connection of the encoder of main shaft

motor is wrong.

• Connection for the electric power of main

shaft motor is wrong.

• Check whether the applied power voltage

is higher than the rated voltage + (plus)

10% or more.

• Check whether 110V/220V changeover

switch is improperly set.

In the aforementioned cases, POWER p.c.b

is broken.

• Check whether the voltage is lower than

the rated voltage – (minus) 10% or less.

• Check whether 110V/220V changeover

switch is improperly set.

• Check whether fuse or regenerative resistance is broken.

– 46 –

Loading...

Loading...