Page 1

ENGLISH

APW-895

INSTRUCTION MANUAL

* "CompactFlash(TM)" is the registered trademark of SanDisk Corporation, U.S.A.

Page 2

CONTENTS

i

!

. CAUTIONS BEFORE OPERATION

@

. CONFIGURATION OF THE MACHINE

#

. SPECIFICATIONS

1. MECHANICAL SPECIFICATIONS ......................................................................................................... 3

2. ELECTRICAL SPECIFICATIONS ........................................................................................................... 3

$

. INSTALLATION

1. REMOVING PACKING MATERIALS ...................................................................................................... 4

2. SECURING THE MACHINE.................................................................................................................... 4

3. CONNECTING THE FOOT PEDAL ........................................................................................................ 5

4. CONNECTING THE AIR COUPLER ..................................................................................................... 5

5. CONNECTING THE POWER PLUG ...................................................................................................... 6

6. ASSEMBLING THE THREAD STAND AND ATTACHING IT TO THE MACHINE ................................. 6

7. INSTALLING SP-46 (CLAMP BAR STACKER) (OPTIONAL) ............................................................... 7

8. INSTALLING SP-47 (ROLLER STACKER) (OPTIONAL) ...................................................................... 8

9. REMOVING THE HEAD FIXING PLATE ................................................................................................ 9

10. INSTALLING THE SUB-TABLE ........................................................................................................... 9

11. INSTALLING OPERATION PANEL IP-310 ........................................................................................... 9

12. LUBRICATING THE OIL TANK .......................................................................................................... 10

13. INSTALLING SA-120 (INTERLINING SUPPLYING DEVICE) (OPTIONAL) ...................................... 11

14. ADJUSTMENT OF SA-120 (INTERLINING SUPPLYING DEVICE) (OPTIONAL) ............................. 12

..........................................................................................................3

..............................................................................................................4

...............................................................................1

..........................................................................2

%

. PREPARATION OF THE SEWING MACHINE

1. HOW TO OPERATE THE SEWING MACHINE HEAD ......................................................................... 13

(1) How to attach the needles .............................................................................................................. 13

(2) Thread used .................................................................................................................................... 13

(3) How to pass the needle thread ....................................................................................................... 14

2. HOW TO REMOVE THE SEWING TABLE

(1) When replacing the bobbin thread .................................................................................................. 15

(2) Cautions to be taken when the sewing tables are removed ........................................................... 16

3. HOW TO WIND THE BOBBINS

4. HOW TO THREAD THE BOBBIN CASE ............................................................................................. 18

5. HOW TO INSTALL THE BOBBIN CASE.............................................................................................. 18

6. HOW TO ADJUST THE THREAD TENSION ....................................................................................... 19

7. SETTING THE MATERIAL TO BE SEWN ............................................................................................ 20

(1) Setting a garment body .................................................................................................................. 20

^

. HOW TO USE THE OPERATION PANEL

1. BASIC OPERATION OF THE OPERATION PANEL (IP-310) ............................................................. 21

(1) Conguration of IP-310

(2) Buttons used in common ................................................................................................................ 22

(3) Basic operation ............................................................................................................................... 22

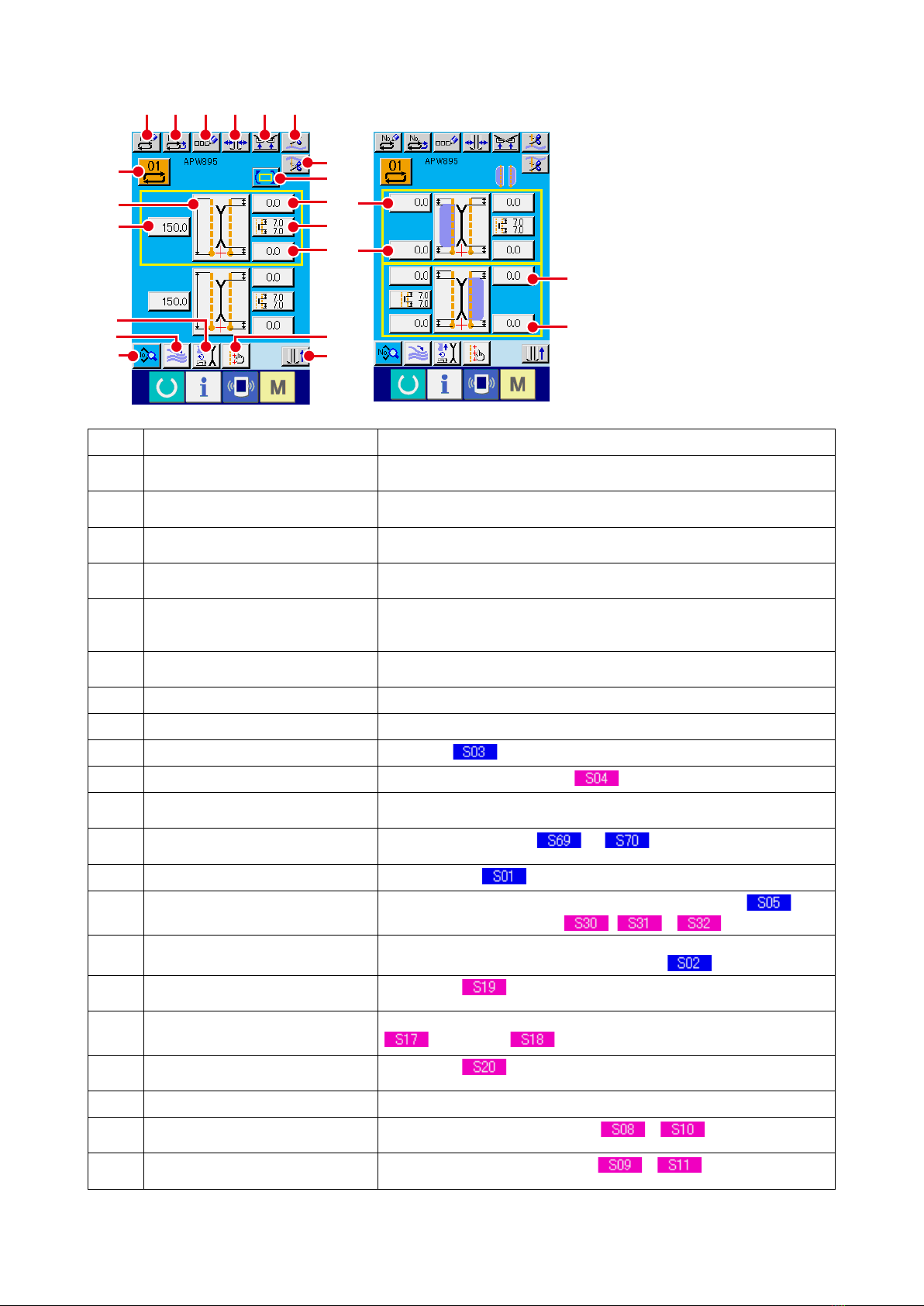

2. EXPLANATION OF THE BASIC SCREEN

(1) Input screen (Independent sewing mode)....................................................................................... 24

(2) Sewing screen (Independent sewing mode) .................................................................................. 25

(3) Input screen (Alternate sewing mode) ............................................................................................ 26

(4) Sewing screen (Alternate sewing mode) ........................................................................................ 27

(5) Input screen (Cycle sewing mode).................................................................................................. 28

........................................................................................................... 17

.................................................................................................................. 21

........................................................................................... 15

........................................................................................... 24

.............................................................13

....................................................................21

Page 3

(6) Sewing screen (Cycle sewing mode) ............................................................................................. 29

ii

3. USING THE COUNTER

(1) Setting procedure of the counter..................................................................................................... 30

(2) Releasing procedure of count-up .................................................................................................... 33

(3) Counter value changing procedure during sewing ......................................................................... 33

4. USING THE BOBBIN THREAD AMOUNT ADJUSTMENT COUNTER

(1) Setting procedure of the bobbin thread remaining amount adjustment counter ............................. 34

(2) Releasing procedure of the bobbin thread remaining amount detection count-up ......................... 36

5. CHANGING THE SEWING MODE

6. USING THE SEWING PATTERN .......................................................................................................... 38

(1) Performing the selection of pattern

(2) Performing the new creation of pattern ........................................................................................... 39

(3) Copying the pattern......................................................................................................................... 40

(4) Erasing the pattern.......................................................................................................................... 42

(5) Naming the pattern ......................................................................................................................... 43

(6) Editing procedure of the cycle sewing data .................................................................................... 44

7. CHANGING THE SEWING DATA

(1) Changing procedure of the sewing data ......................................................................................... 46

(2) Sewing data list ............................................................................................................................... 47

8. CHANGING THE MEMORY SWITCH DATA

(1) Changing procedure of the memory switch data ............................................................................ 55

(2) Memory switch data list................................................................................................................... 56

9. PERFORMING OPTIONAL SETTING .................................................................................................. 63

(1) Changing procedure of the optional setting .................................................................................... 63

(2) Optional setting list.......................................................................................................................... 64

10. CHANGING THE DEVICE SETTING .................................................................................................. 65

(1) Changing procedure of the device setting ...................................................................................... 65

(2) Device setting list ............................................................................................................................ 65

11. CUSTOMIZING THE PEDAL OPERATION ........................................................................................ 66

(1) Method to select and use the customized data............................................................................... 66

(2) Customizing the pedal operation data ............................................................................................ 67

12. CUSTOMIZING THE DATA INPUT SCREEN ..................................................................................... 69

(1) Customizing procedure ................................................................................................................... 69

13. PERFORMING THE CUSTOMIZING SETTING OF THE SEWING SCREEN ................................... 71

(1) Customizing procedure ................................................................................................................... 71

14. USING THE INFORMATION ............................................................................................................... 73

(1) Observing the maintenance inspection information ........................................................................ 74

(2) Releasing procedure of the warning ............................................................................................... 75

(3) Observing the production control information ................................................................................. 76

(4) Performing setting of the production control information ................................................................ 78

(5) Observing the operation measurement information ........................................................................ 80

15. USING THE COMMUNICATION FUNCTION ..................................................................................... 82

(1) Handling possible data ................................................................................................................... 82

(2) Folder structure of media ................................................................................................................ 82

(3) Performing communication by using the media .............................................................................. 83

(4) Take-in of the data .......................................................................................................................... 84

(5) Take-in of plural data together ........................................................................................................ 85

16. PERFORMING FORMATTING OF THE MEDIA ................................................................................. 87

........................................................................................................................ 30

............................................... 34

....................................................................................................... 37

................................................................................................. 38

......................................................................................................... 46

........................................................................................ 55

Page 4

&

iii

. MAINTENANCE

1. INSPECTION ........................................................................................................................................ 88

(1) Maintenance and inspection of the pneumatic device .................................................................... 88

(2) Maintenance and inspection related to the sewing machine .......................................................... 88

(3) With regard to the waste oil of the hook oil ..................................................................................... 89

(4) With regard to the cleaning of the hook shaft base ........................................................................ 89

2. MARKING LIGHT.................................................................................................................................. 90

(1) Marking light for sewing reference setting ...................................................................................... 90

(2) Adjusting the marking light irradiation position ................................................................................ 90

3. REPLENISHING GREASE TO THE DESIGNATED PLACE

(1) Place to keep grease

(2) Grease-up procedure ...................................................................................................................... 92

4. CONSUMABLE REPLACEMENT COMPONENTS.............................................................................. 94

5. TILTING THE MACHINE

6. REPLACING PROCEDURE BETWEEN DOUBLE-WELT AND SINGLE-WELT ................................. 97

(1) Replacing procedure between double-welt and single-welt

(2) Fine adjustment of the position of garment body clamp ................................................................. 97

(3) Replacing the binder ....................................................................................................................... 98

7. ADJUSTING THE CORNER KNIFE

8. ADJUSTING THE POSITION OF THE SENSOR FOR DETECTING FLAPS .................................... 100

9. CAUSES AND CORRECTIVE MEASURES AGAINST TROUBLES

WITH THE BOBBIN THREAD REMAINING AMOUNT DETECTING DEVICE ................................. 101

10. HOW TO ADJUST THE FOOT PEDAL ............................................................................................ 102

11. ERROR CODE LIST ......................................................................................................................... 104

12. INPUT NUMBER TABLE .................................................................................................................. 113

...........................................................................................................88

................................................................ 91

...................................................................................................................... 91

....................................................................................................................... 95

............................................................ 97

..................................................................................................... 99

Page 5

!

. CAUTIONS BEFORE OPERATION

Following items have to be checked every working day before the operation of the

machine and before the start of work hours.

1. Ascertainthatthesewingmachineislledwiththepredeterminedamountofoil.

2. Neveroperatethemachineunlessthelubricatingpartinthehookhasbeenlledupwithoil.

3. Ascertain that the pressure gauge indicates the designated air pressure of 0.5 MPa.

*

(This is necessary particularly when the compressor is stopped for a lunch break or the like.)

If the compressed air pressure is equal to or less than the designated value, troubles such

as interference between the parts can occur. It is therefore necessary to carefully check the

compressed air pressure.

4. Check whether the needle thread/bobbin thread need to be replenished.

5. To perform sewing immediately after turning ON the power switch, perform trial stitching

rst,thenproceedwithsewingofactualproductsafterthetestsewing.

6. Inordertopreventtheopticalbersensorofthebobbinthreadremainingamountdetecting

device from showing a detecting failure, be sure to clean thread waste around the hook

using an air gun once or more times a day.

7. Inordertoprotecttheapsensorfromshowingadetectingfailure,besuretocleanduston

thereectingtapeofthefoldingplateusinganairgunonceormoretimesaday.

− 1 −

Page 6

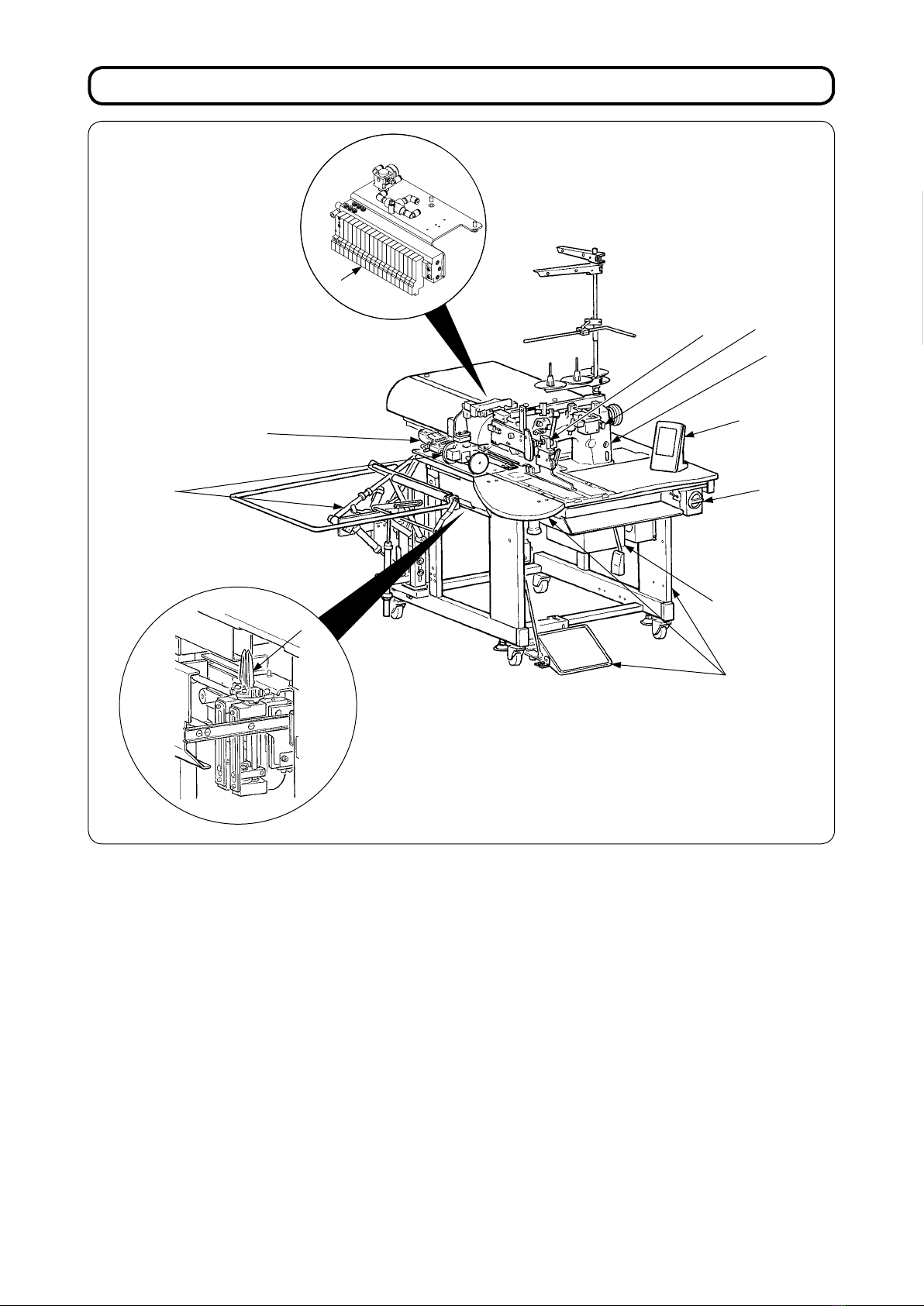

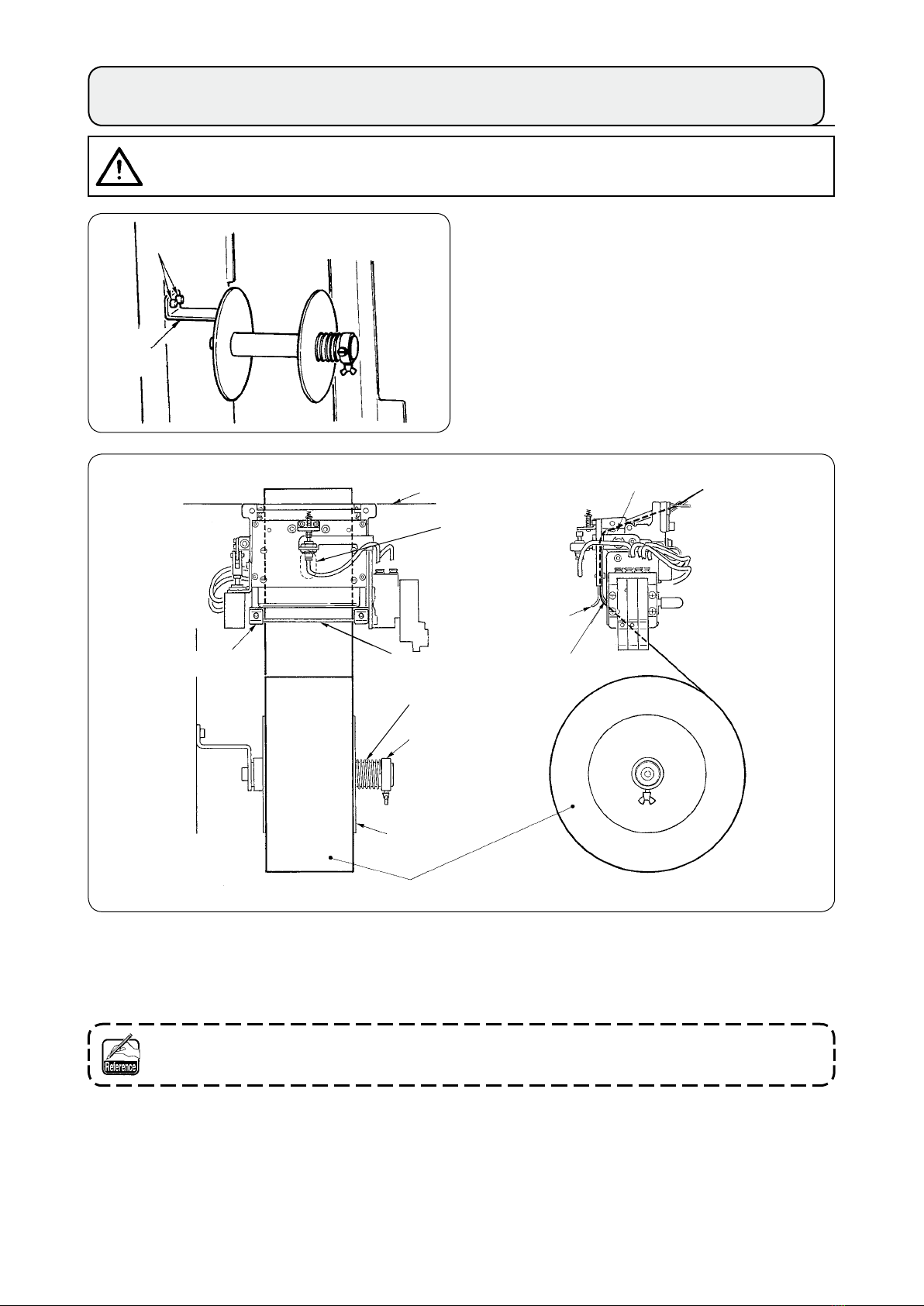

@

. CONFIGURATION OF THE MACHINE

E

ENGLISH

F

B

C

D

K

G

I

J

H

A

The APW-895 consists mainly of the following units.

Frame and structural components (Framesewing table, covers, foot switch, etc.)

A

Clamp foot unit and feed mechanism

B

Corner knife unit

C

Binder unit (Binder components and its driving components)

D

Pneumatic control unit (Pneumatic control devices and pipings)

E

Stacker unit (Optional)

F

Sewing machine head

G

Electric control unit (Control panel)

H

Operation panel

I

Power switch

J

Temporary stop switch

K

With this machine consisting of the aforementioned 11 units, you can do desired welting work simply

by setting materials (garment body, interlining piece, welting patch, etc.) in place and operating the

switches on the operation panel.

In addition, when temporary stop switch K is pressed during operation of the device, the device stops.

− 2 −

Page 7

#

. SPECIFICATIONS

1. MECHANICAL SPECIFICATIONS

1 Sewing machine LH-895 model of 2-needle, lockstitch machine with a center knife

Sewing speed 3,000 rpm (max.)

2

3 Stitch length Lockstitch: 2.0 to 3.4 mm (standard: 2.5 mm)

Condensation stitch: 0.5 to 1.5 mm (standard: 1.9 mm)

Back tack stitch: 0.5 to 3.0 mm (standard: 2.0 mm)

Condensation/Back tack stitch selectable

Types of welt Parallel double welt,

4

parallel single welt

5 Pocket lip length

(Welt lenght)

Welting width

6

(Needle gauge)

7 Needles ORGAN DP X 17 #14 to #18 (standard #16)

Possible to set in increments of 1 mm within the range of 18 mm (min.) to 220 mm (max.)

Note that the pocket length is 35 mm at the minimum when using the corner knife (50

mm in case of 14 mm gauge or more and 21 mm by adding a solenoid valve)

For the longer type (optional), the maximum sewing length will be 250 mm.

(Possible up to 300 mm without entering corner knife)

8, 10, 12, 14, 16, 18and 20 mm

(Optional: 22, 24, 26, 28, 30 and 32 mm)

Each with ap or without ap

8 Thread Spun thread #60 (Recommended)

9 Hook Full rotary, vertical-axis, self-lubrication hook

10 Thread take-up lever Slide thread take-up lever

Needle bar stroke 33.3mm

11

Cloth feed mechanism Driven by stepping motor

12

13 Control By a micro-computer

Safety mechanism

14

15 Lubricating oil JUKI New Defrix Oil No. 1

16 Operating air pressure 0.5MPa

Air consumption Approx. 40N R/min.

17

18 Dimensions of machine 1,095 mm (width) × 1,500 mm (length) × 1,165 mm (height)

19 Weight 238.5kg

Noise Workplace-related noise at sewing speed

20

Machine operation is automatically stopped if the cloth feed mechanism error detector,

the needle thread breakage detector or any of the various safety devices is actuated.

(1,580 mm - when including the stacker) (1,800 mm - when including the thread stand)

n = 2,800 min–1 : Lpa

Noise measurement according to DIN 45635-48-B-1.

84 dB(A)

≦

2. ELECTRICAL SPECIFICATIONS

The number of independent sewing patterns that can

1

be stored in memory

The number of alternate sewing patterns that can be

2

stored in memory

3

The number of cycles that can be stored in memory 20 (1 to 20)

4 Input power: Single phase/3-phase 200 to 240V 50/60 Hz (Optional 380V)

5 Power consumption 350VA

99 (1 to 99)

20 (1 to 20)

Voltage uctuation: Within + 10% of the rated voltage

− 3 −

Page 8

$

. INSTALLATION

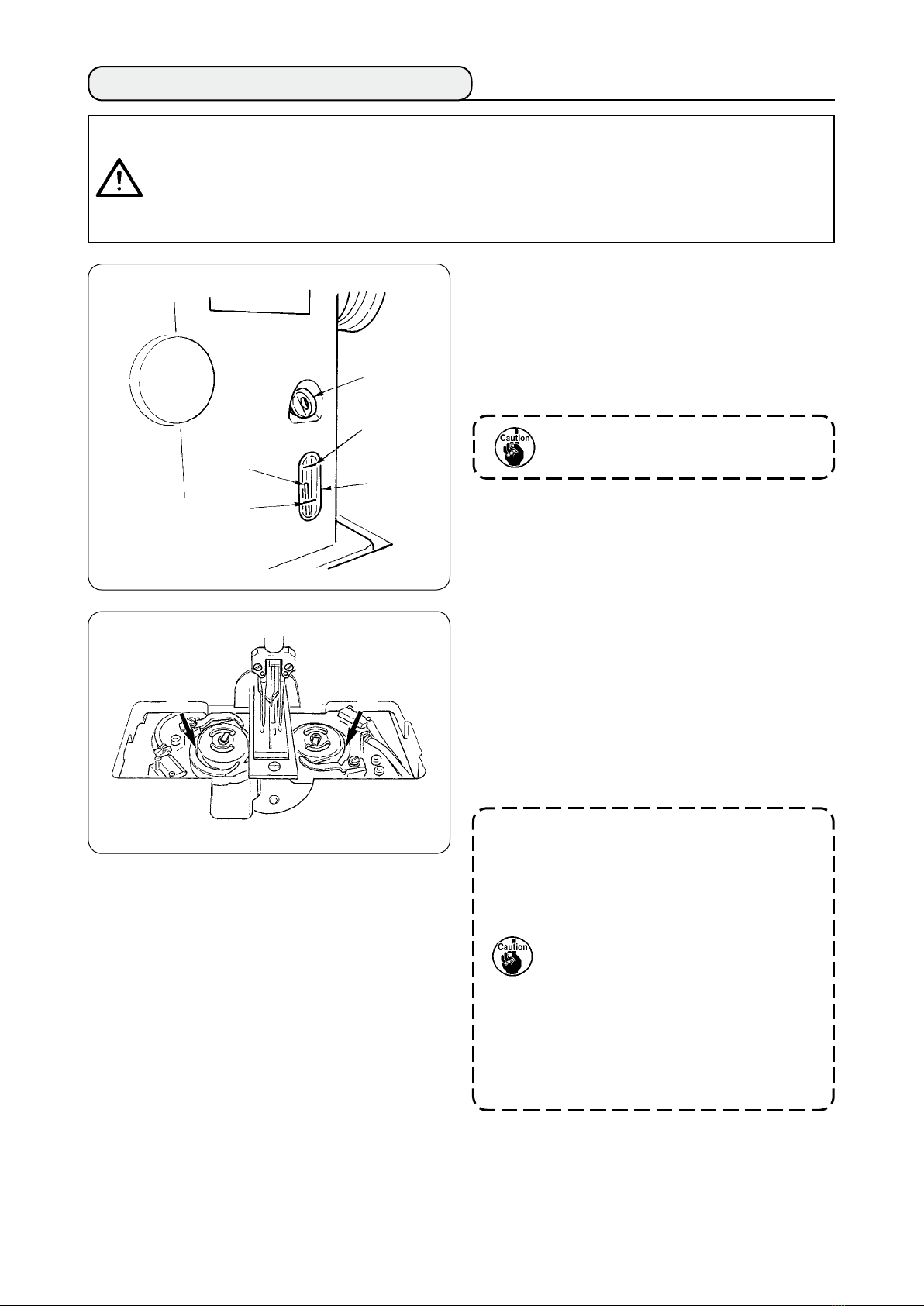

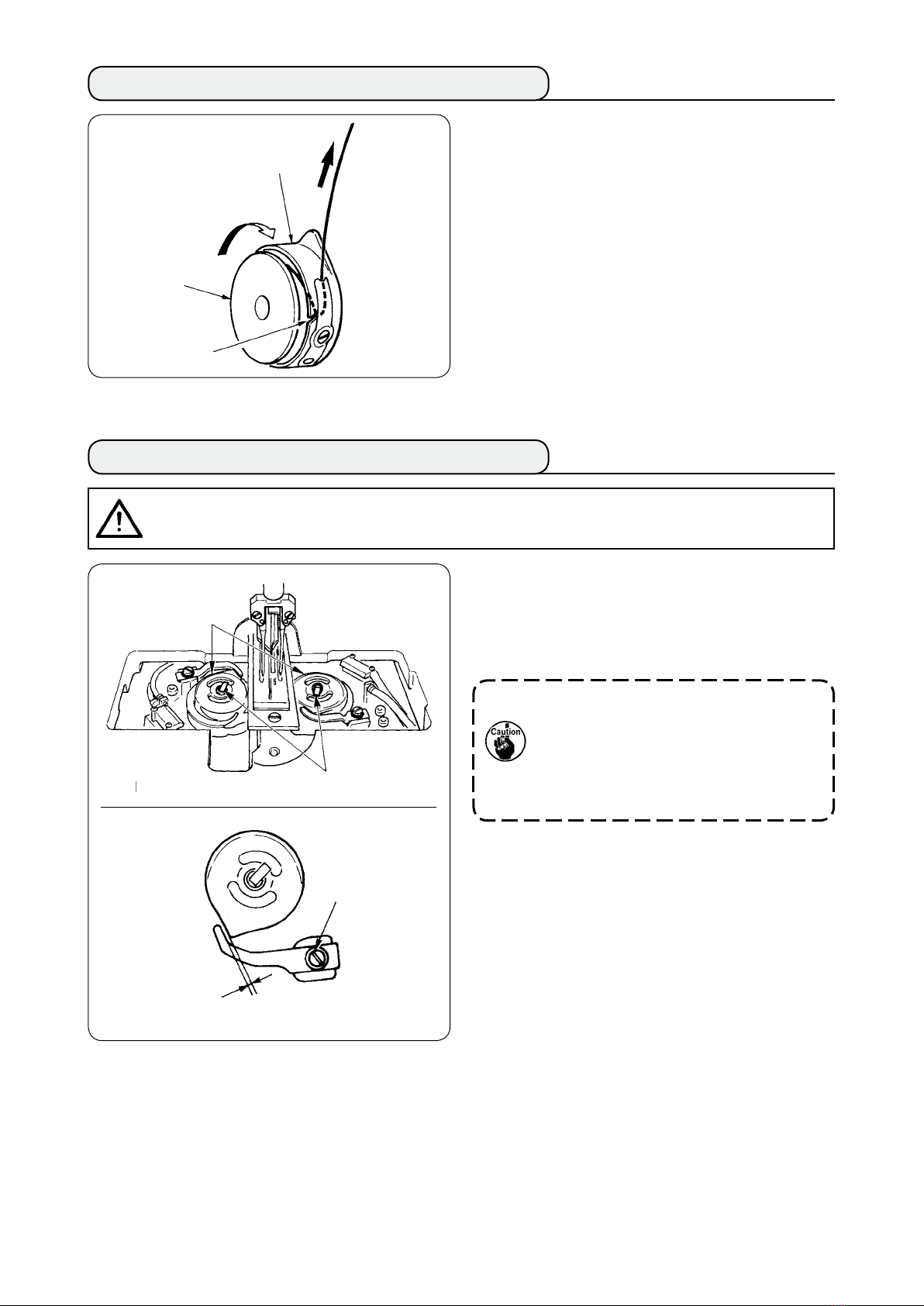

1. REMOVING PACKING MATERIALS

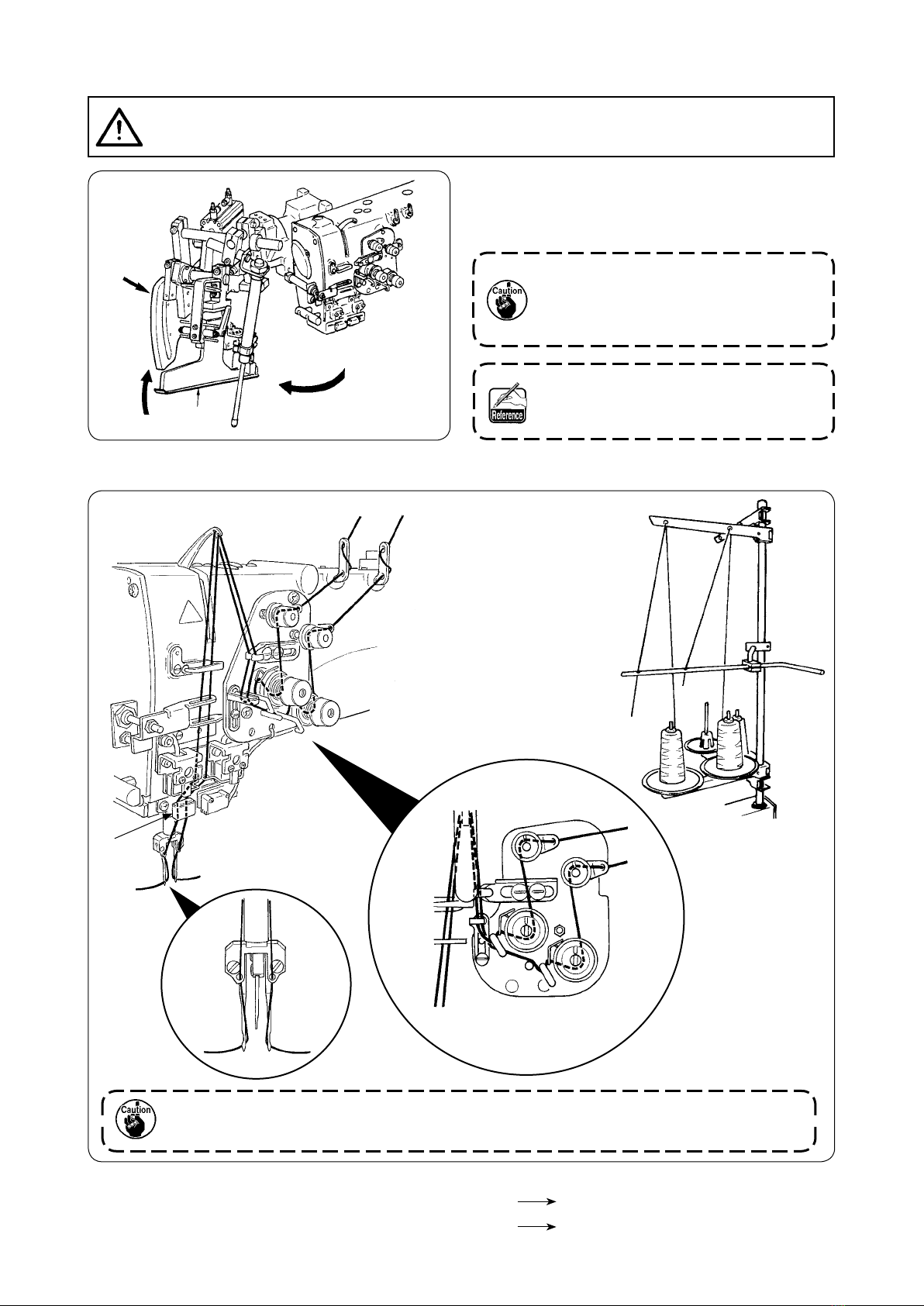

Remove the upper cover and remove

the string and packing materials that

havexedtheclampfoot.

Remove the string and packing

materialsthathavexedtheclamp

bar stacker.

Removethestringthathasxedthe

binder unit.

Draw out the corner knife unit and

removethestringthathasxedthe

unit.

2. SECURING THE MACHINE

CAUTION

Topreventafatalaccident,lowerandxadjustbolts

moving the machine to the level and stabilized place.

:

Cut and remove the clip band that

hasxedtheneedlebar.

(4 places) located at the side of caster 1 after

2

2

1

− 4 −

Page 9

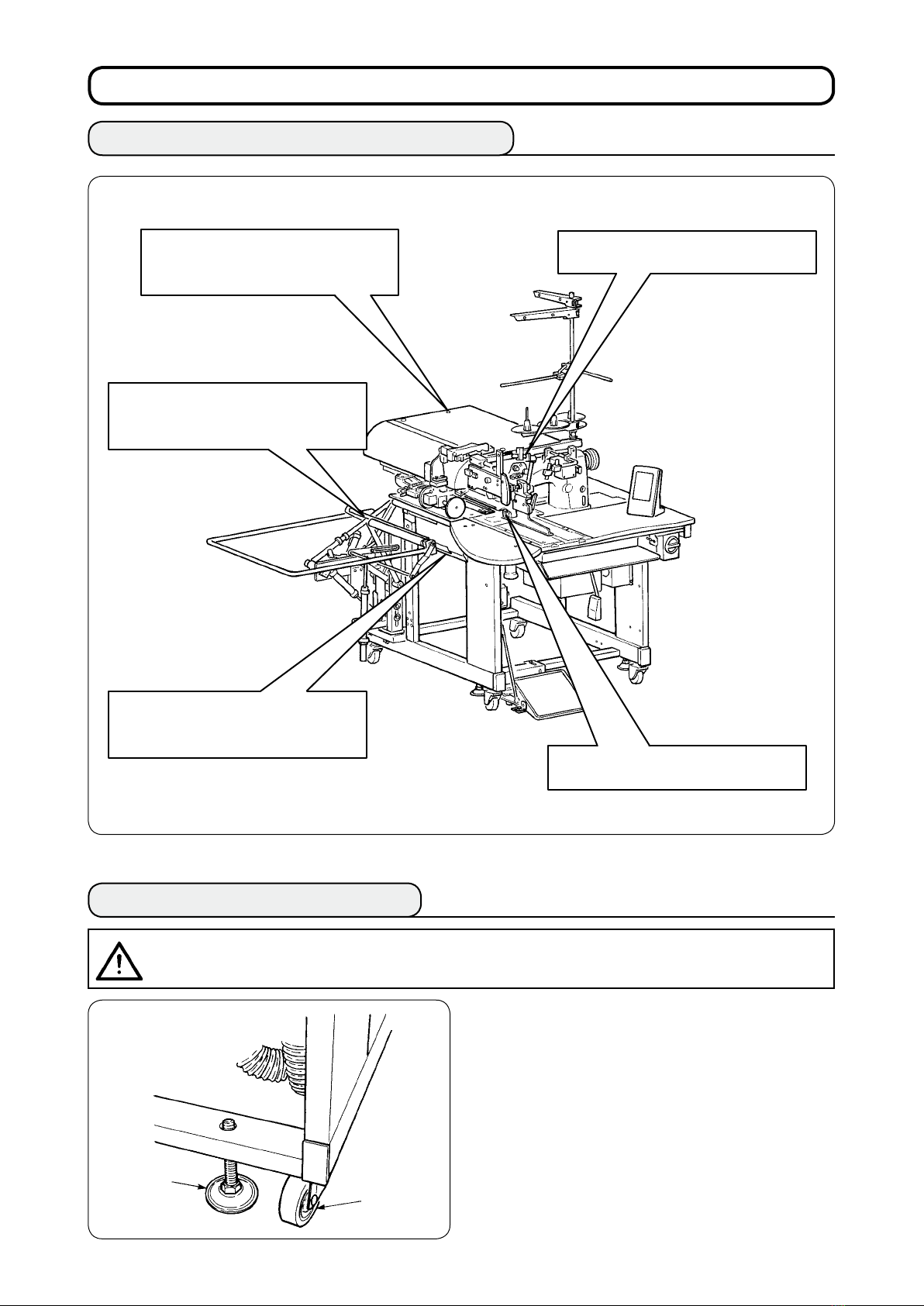

3. CONNECTING THE FOOT PEDAL

1

2

Install the pedal base to the machine frame

1

with screws 2.

Connect pedal bases A an d B wi th two

2

screws 1.

A

3

C

1

B

Posi tion of the pedal can be optionally

adjusted within the range of the slot.

Connect the connecting rods with xing screw

3

.

3

When connecting, do not connect the rods

with connecting rod C on the sensor side

pulled downward,

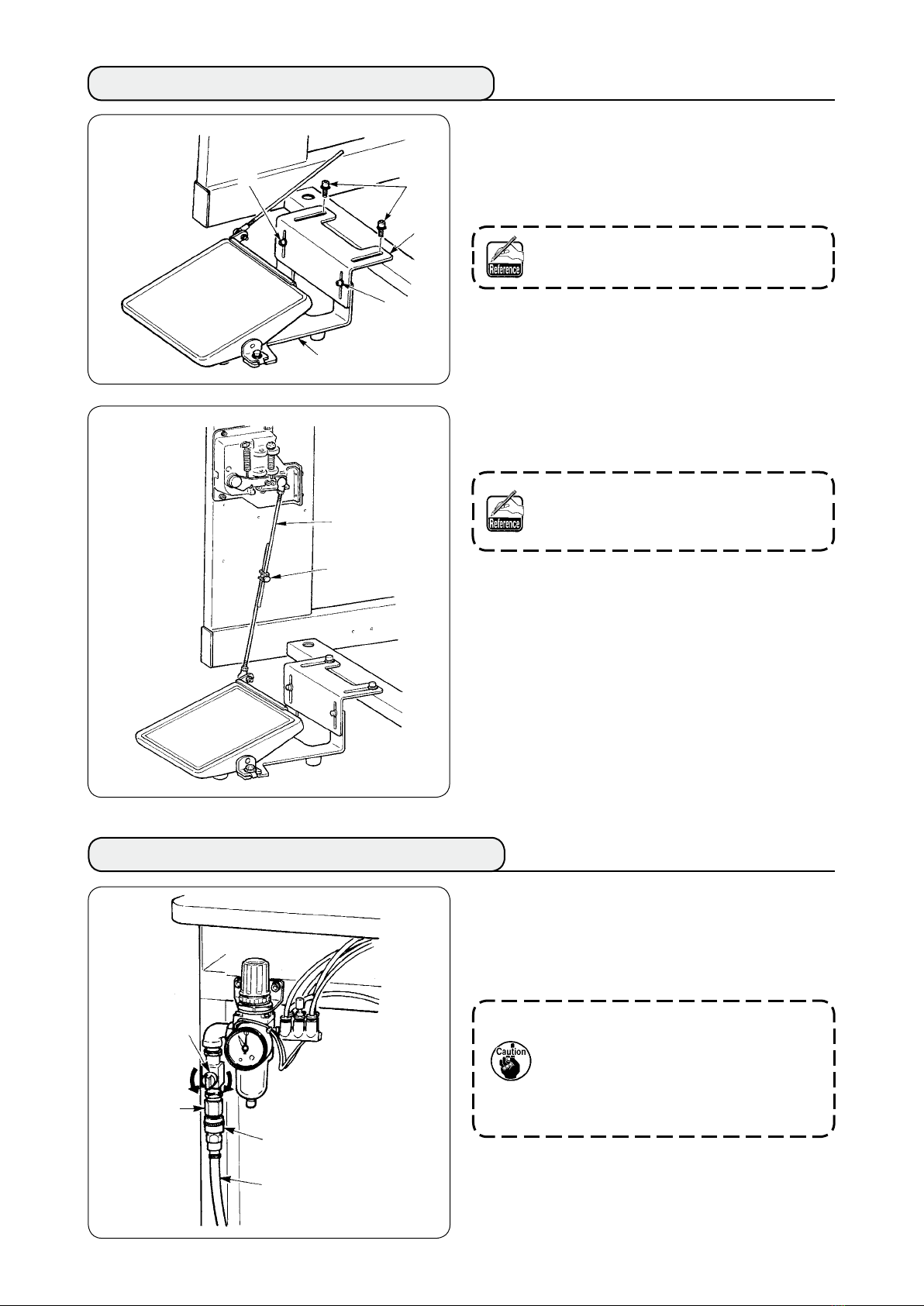

4. CONNECTING THE AIR COUPLER

Connect one end of air coupler A supplied with

the machine as an accessory to air hose 2. Then

connect the other end to coupler 3 on the main

unit side.

1

3

A

2

− 5 −

• Connect coupler A to the main

unit with air cock 1 closed, then

carefully open air cock 1 to allow the

compressed air to be supplied.

• Make sure that the pressure gauge of

the regulator reads 0.5 MPa.

Page 10

5. CONNECTING THE POWER PLUG

CAUTION

To prevent possible accidents caused by leakage or dielectric strength, an appropriate power plug

shall be installed by a person who has an expert knowledge of electricity. Be sure to connect the

power plug to the receptacle that is well grounded.

:

Connection of the power plug to the power depends on the specications of the product. Adjust the

power plug to the power specications to connect.

In case of the product of single-phase, 200 to 240V specications :

1

Connect the sky-blue and brown wires of the power cord to the power terminal (AC200 to 240V)

and the yellow/green wire to the ground (earth) terminal respectively.

In case of the product of 3-phase, 200 to 240V specications :

2

Connect the red, white and black wires of the power cord to the power terminal (AC200 to 240V)

and the yellow/green wire to the ground (earth) terminal respectively.

In case of the product with the optional high voltage transformer (with SA-128) :

3

It is possible to connect to 380/400/415V by setting of the input tap of transformer (standard

setting at the time of delivery : 380V). Connect the sky-blue and brown wires of the power cord

to the power terminal (AC380/400/415V) and the yellow/green wire to the ground (earth) terminal

respectively.

*

This product performs operation by the single-phase connection for 3-phasse 380/400/415V.

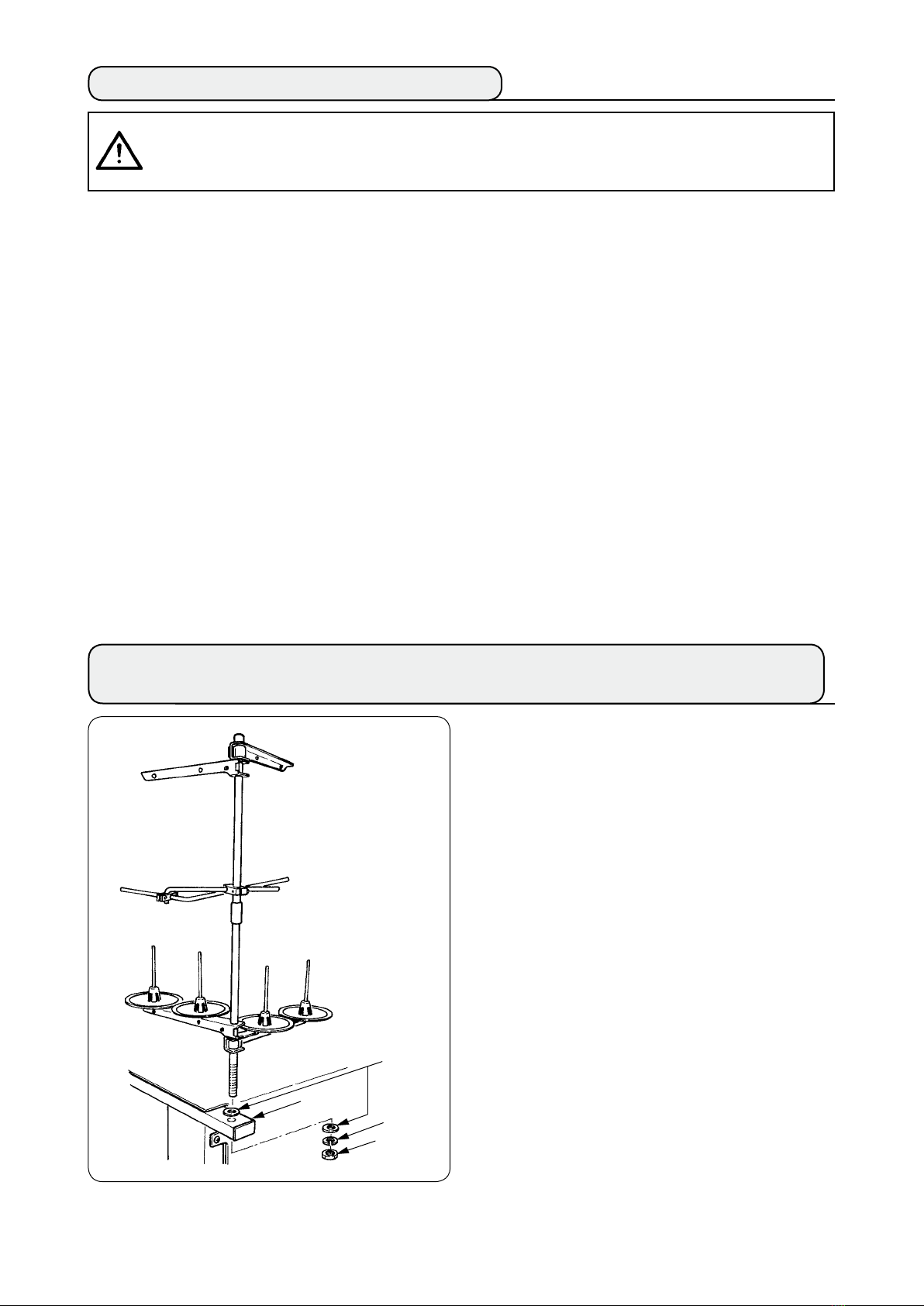

6. ASSEMBLING THE THREAD STAND AND ATTACHING IT TO THE MACHINE

Putting nut and washer between main unit frame

and x the thread stand as illustrated in the left-

1

hand gure.

Washer

1

Spring

washer

Nut

− 6 −

Page 11

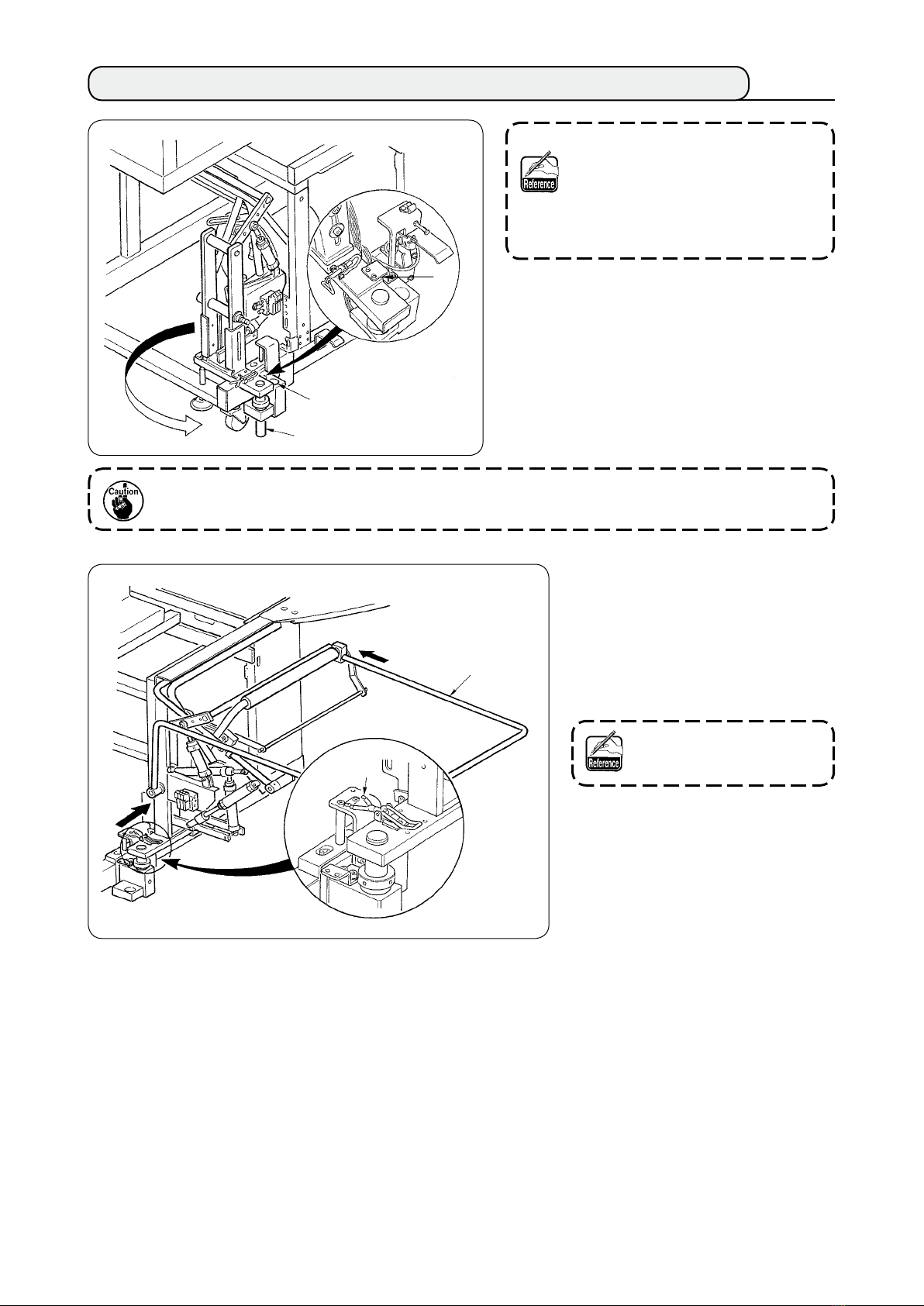

7. INSTALLING SP-46 (CLAMP BAR STACKER) (OPTIONAL)

Clamp bar stacker is delivered in the

statethatitisxedintheframeatthe

time of delivery with the clamp bar

stacker mounted. It is necessary to

change the installing position to the

normal using position.

1

Remove stacker xing plate 1.

1

Turn the whole stacker in the direction of

2

the arrow and take it out from inside of

the frame.

Change stacker turning shaft A section

3

B

A

At this time, take care to prevent the stacker cord, the air piping, etc. from being caught.

D

3

to stacker base hole B.

Lock the whole sta c ke r with

4

hinge

Enter safety bar 3 from C and

5

D

.

2

directions and fix it at the

position where is almost parallel

to the oor.

C

2

Atthistime,conrmthatair

is being supplied.

− 7 −

Page 12

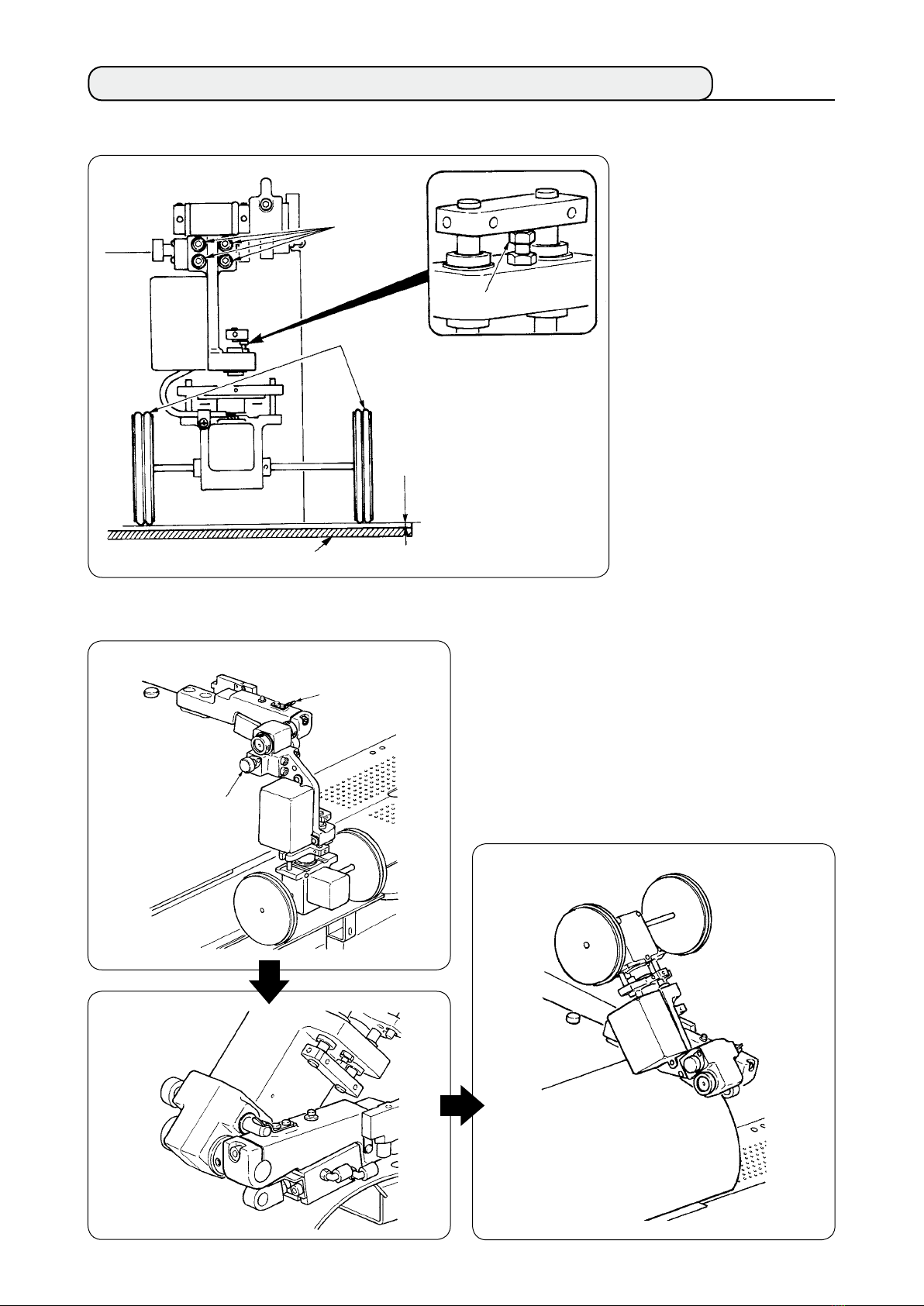

8. INSTALLING SP-47 (ROLLER STACKER) (OPTIONAL)

(1) Adjusting the position

Conrming parallelism

1

Make sure that stacker table

and rubber roller 3 are

2

5

3

0.5mm

4

installed parallel with each

other.

If not, loosen four setscrews

to adjust.

2

Conrming the clearance

2

Make sure that the clearance

between stacker table

and rubber roller 3 is

4

approximately 0.5 mm.

If it is not approximately 0.5

mm, loosen nut 5 to adjust.

(2) Maintenance

(Working state)

1

4

2

When the roller stacker is not used or adjusting

the corner knife, the roller stacker can be turned

upward with the procedure below.

Draw release lever 1 and couple the roller

stacker with xed spring 2 (refer to Fig. 1). Then

the roller stacker is put in the waiting state.

(Waiting state)

Fig. 1

− 8 −

Page 13

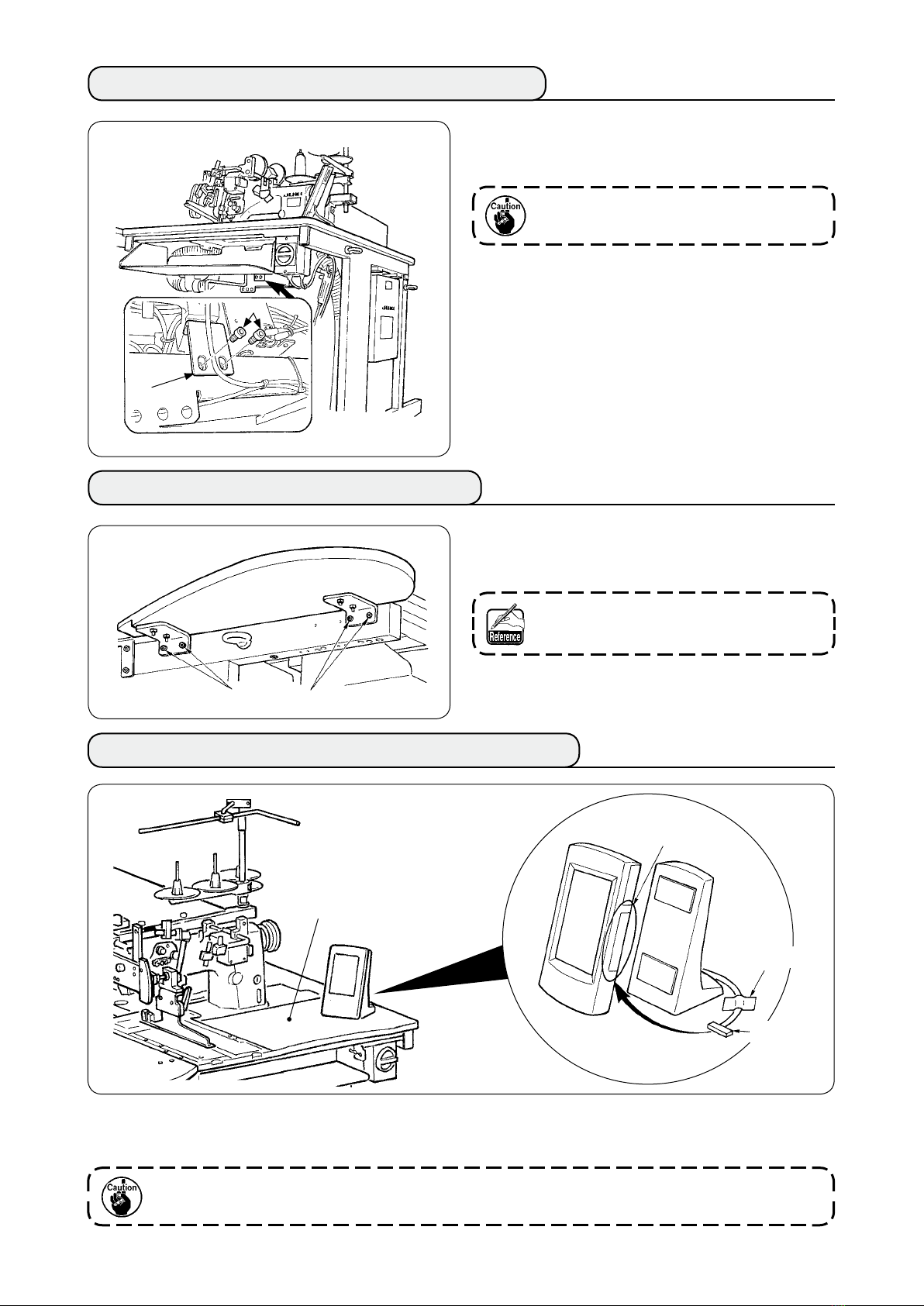

9. REMOVING THE HEAD FIXING PLATE

Remove xing screws 2 of head xing plate 1.

2

1

10. INSTALLING THE SUB-TABLE

Install the sub-table with four screws 1 as shown

in the gure.

Be sure to x the machine and the frame

when performing re-transportation.

At this time, x the sub-table so as to be

ushwiththemaintable.

1

1

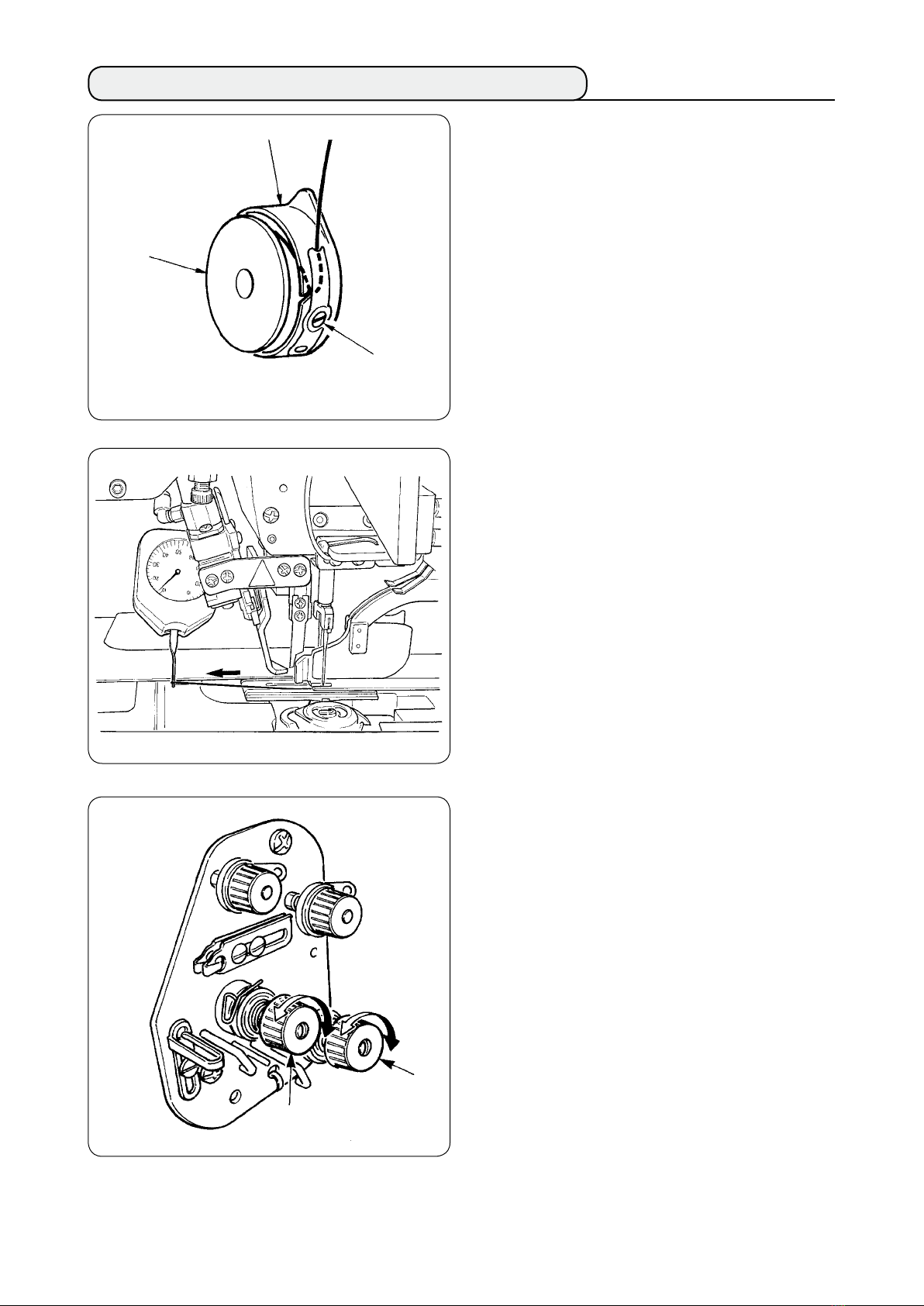

11. INSTALLING OPERATION PANEL IP-310

B

C

Tape

Connector

As shown in the figure above, open the lid on the right-hand section C of IP-310 and connect the

connector which is xed with tape to the right-hand top surface B of the table.

To prevent malfunction due to static electricity, install operation panel IP-310 on the panel base to

use and do not change the position of the panel base.

− 9 −

Page 14

12. LUBRICATING THE OIL TANK

CAUTION

1. To prevent accidents caused by abrupt start of the sewing machine, do not connect the power

plug until lubrication has been completed.

2. Topreventinammationorrash,immediatelywashthepartwhenoilhasstucktoyoureyesor

body.

3. If oil has been swallowed, diarrhea or vomiting may occur. Put oil to the place where children

cannot reach.

:

Fill the oil tank with the oil for hook lubrication

before operating the sewing machine.

Remove oil cap 1 and ll the oil tank

1

with JUKI MACHINE OIL No. 1 (Part No. :

1

MDFRX1600C0) using the oiler supplied with

the machine as accessories.

Upper

engraved

marker line

3

To prevent entering of dust, be sure to

attach the cap for use.

2

Fill the oil tank with the oil until the top end of

Lower

engraved

marker line

2

oil amount indicating rod 3 comes between

the upper engraved marker line and the lower

engraved marker line of oil amount indicating

window

2

.

When oil amount is excessively large, oil

leaks from the air hole or adequate lubrication

cannot be performed. So, be careful.

When operating the sewing machine and

A

A

3

the top of oil amount indicating rod 3 has

lowered up to oil amount indicating window 2,

start lubricating.

− 10 −

• Atthetimeofinitiallling,lltheoil

tank with oil of 200cc as the standard

andconrmthattheoilamount

indicating rod is working.

• When operating a newly installed

machine or a machine which has not

been used for a relatively long period

of time, make the machine run at 2,000

rpm or less for the purpose of breakin. In addition, use the machine after

applying oil to races A of the right/left

hooks.

• For the oil for hook, purchase JUKI

MACHINE OIL No. 1 (Part No. :

MDFRX1600C0).

• Besuretolltheoiltankwithclean

oil.

Page 15

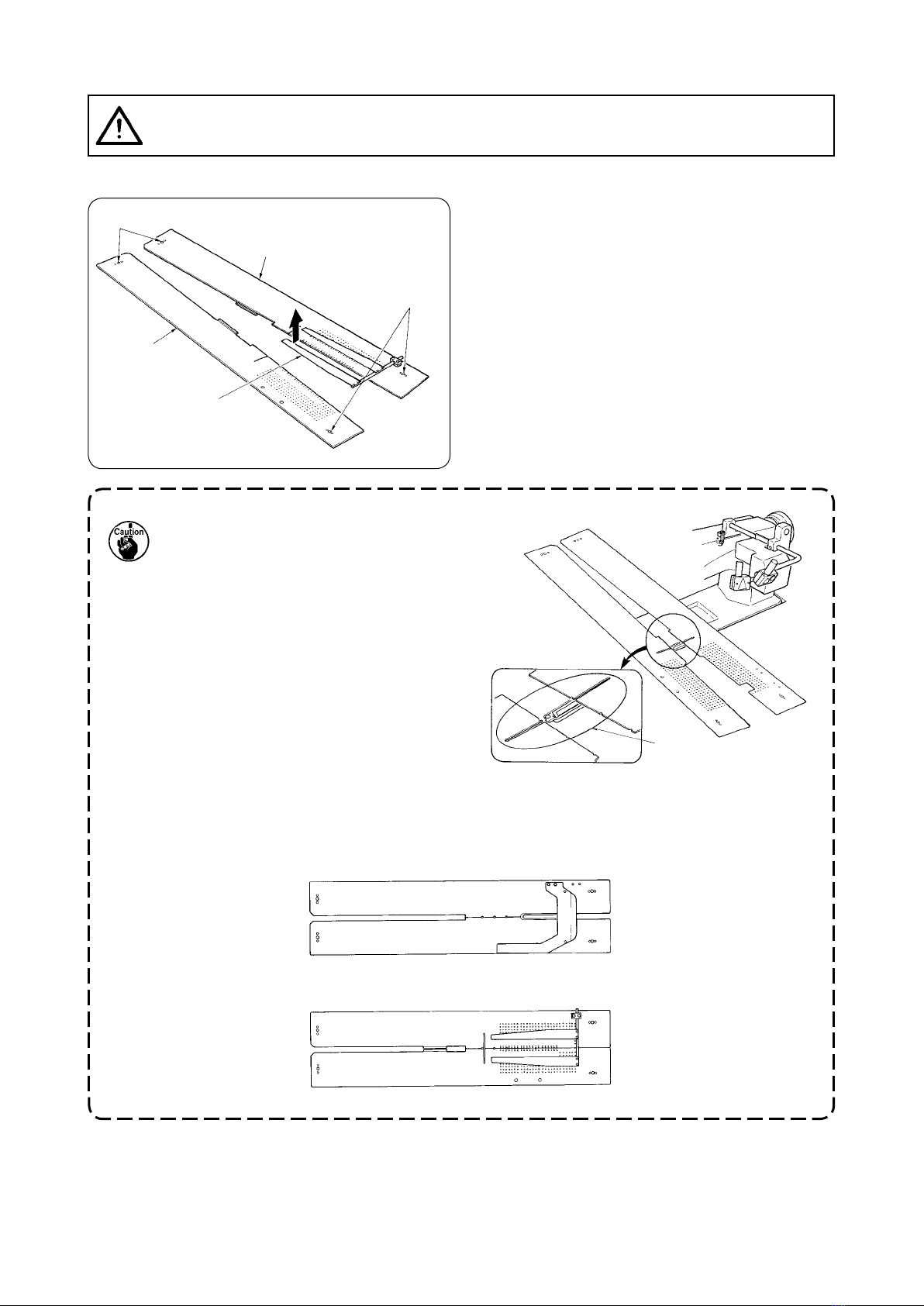

13. INSTALLING SA-120 (INTERLINING SUPPLYING DEVICE) (OPTIONAL)

CAUTION

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

2

1

:

Fix interlining installing plate 1 to the

1

machine frame with two screws 2.

Sewing table

Notch

Roller

Guide A

Guide plate

Interlining

Set interlining as shown in the gure above.

2

Guide B

Spring

Set collar

Side plate

Guide B

The roll core that can be used is 40 to 70 mm wide and 200 mm in roller diameter (max.).

Pass the interlining between guide B and guide A and roller, and route it up above the table.

3

Feed the interlining up to the roller section using the notch of the guide plate.

Adjust the lateral position of two guides, two guide pins and side plate (on the right) to allow the

4

interlining to be fed straight up above the sewing table.

Position the set collar on the left-hand side to allow the side plate to lightly hold the interlining by

5

spring. Then x the set collar there.

− 11 −

Page 16

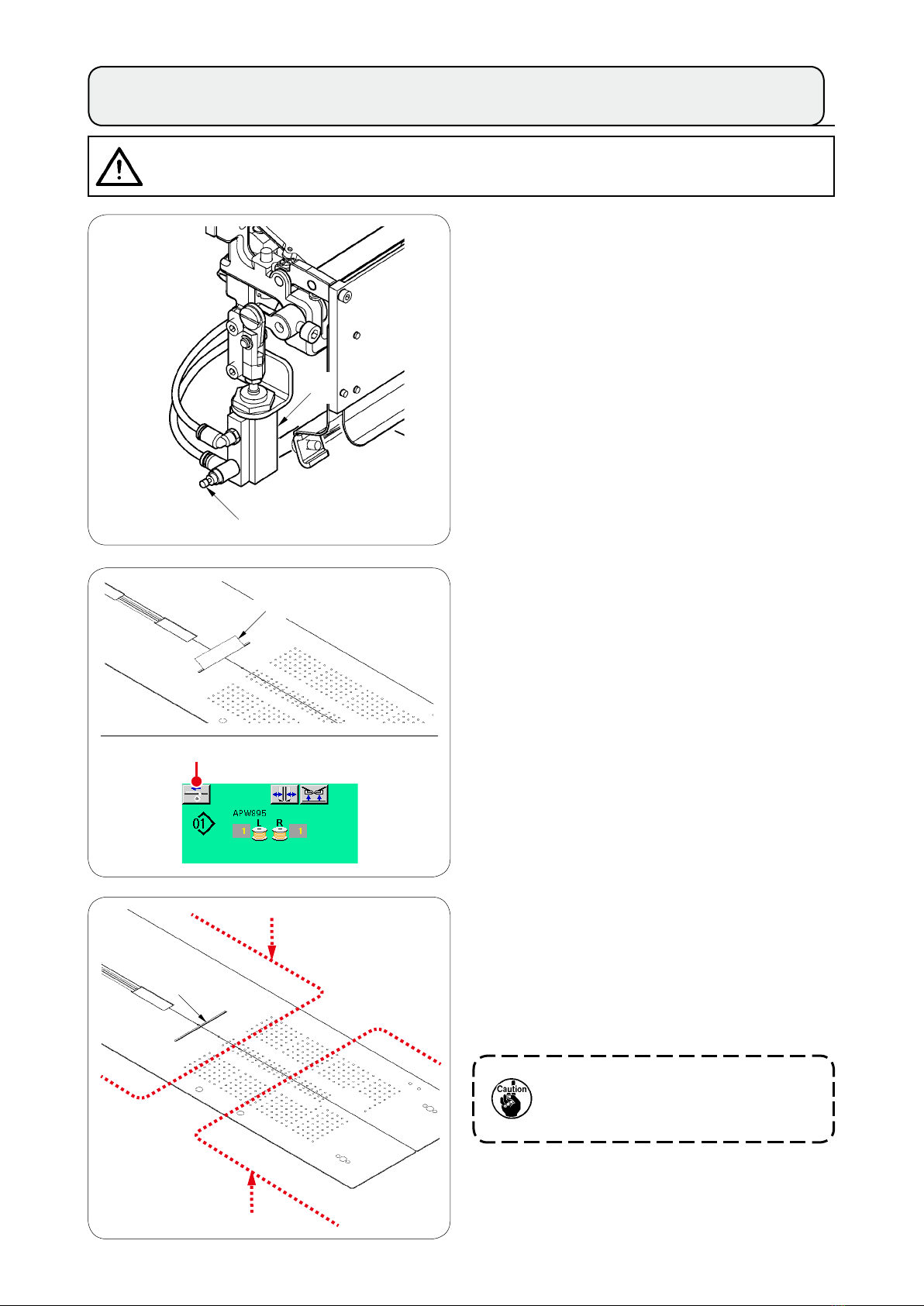

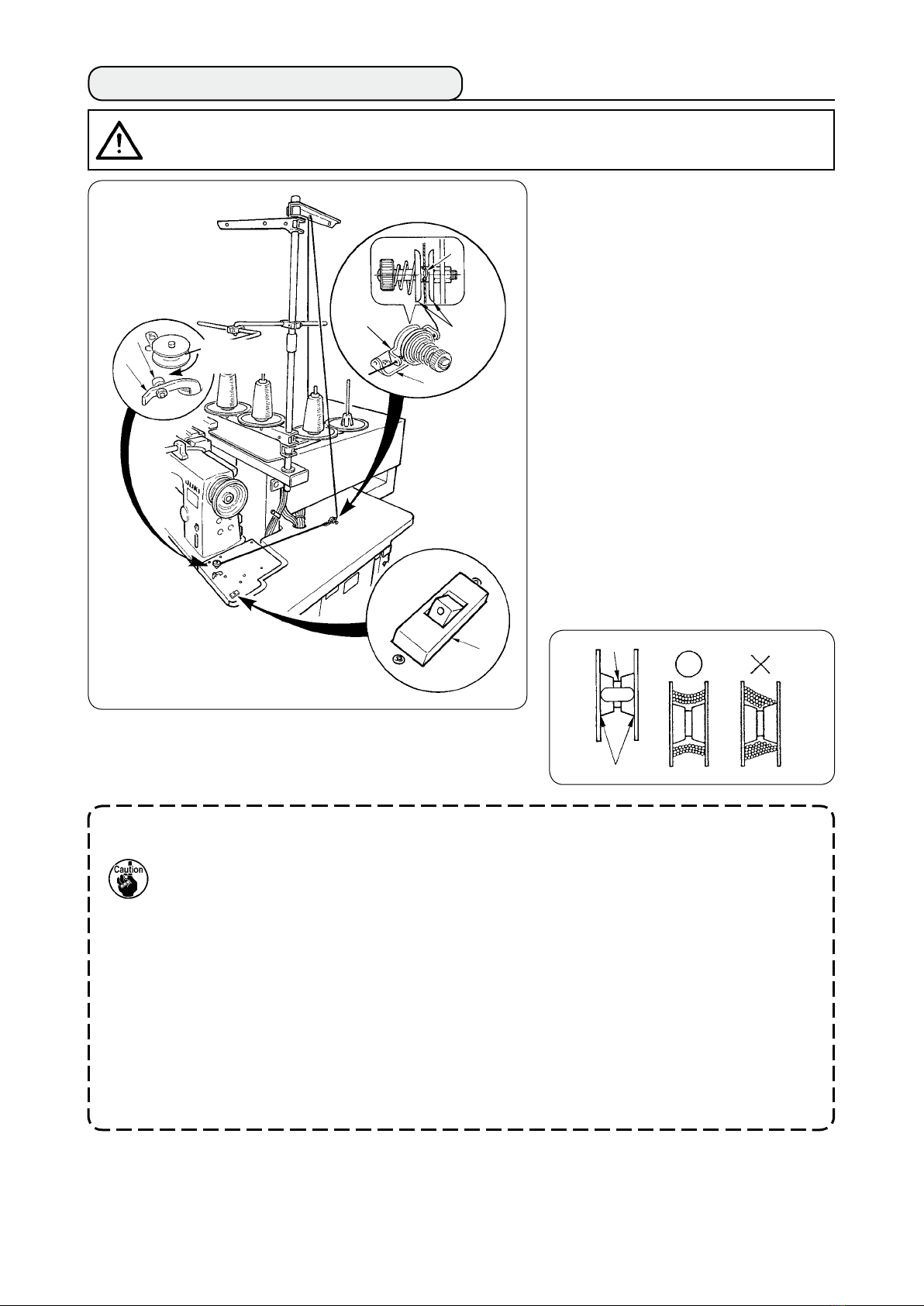

14. ADJUSTMENT OF SA-120 (INTERLINING SUPPLYING DEVICE) (OPTIONAL)

CAUTION

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

:

Adjustment of the interlining feeding amount

1

is performed with memory switch (U03).

However, perform further ne adjustment

with the speed controller 2 of the interlining

feeding cylinder

1

.

(When tightening the speed controller 2, the

amount is decreased and when loosening it,

1

2

3

the amount is increased.)

When a new interlining 3 is mounted, press

2

interlining supply button 4, perform feeding

of the trial sewing several times and use the

device after conrming the feeding amount

and the parallel feeding of the interlining.

6

4

5

(Caution when operating)

When using the interlining supplying device

with rear reference 5, the interlining at the

sewing start remains long since it is away

from interlining outlet 6. So, use the device

with front reference 7.

For handling the sewing tables, refer to

"%-2-(2) Cautions to be taken when the

sewing tables are removed".

7

− 12 −

Page 17

%

. PREPARATION OF THE SEWING MACHINE

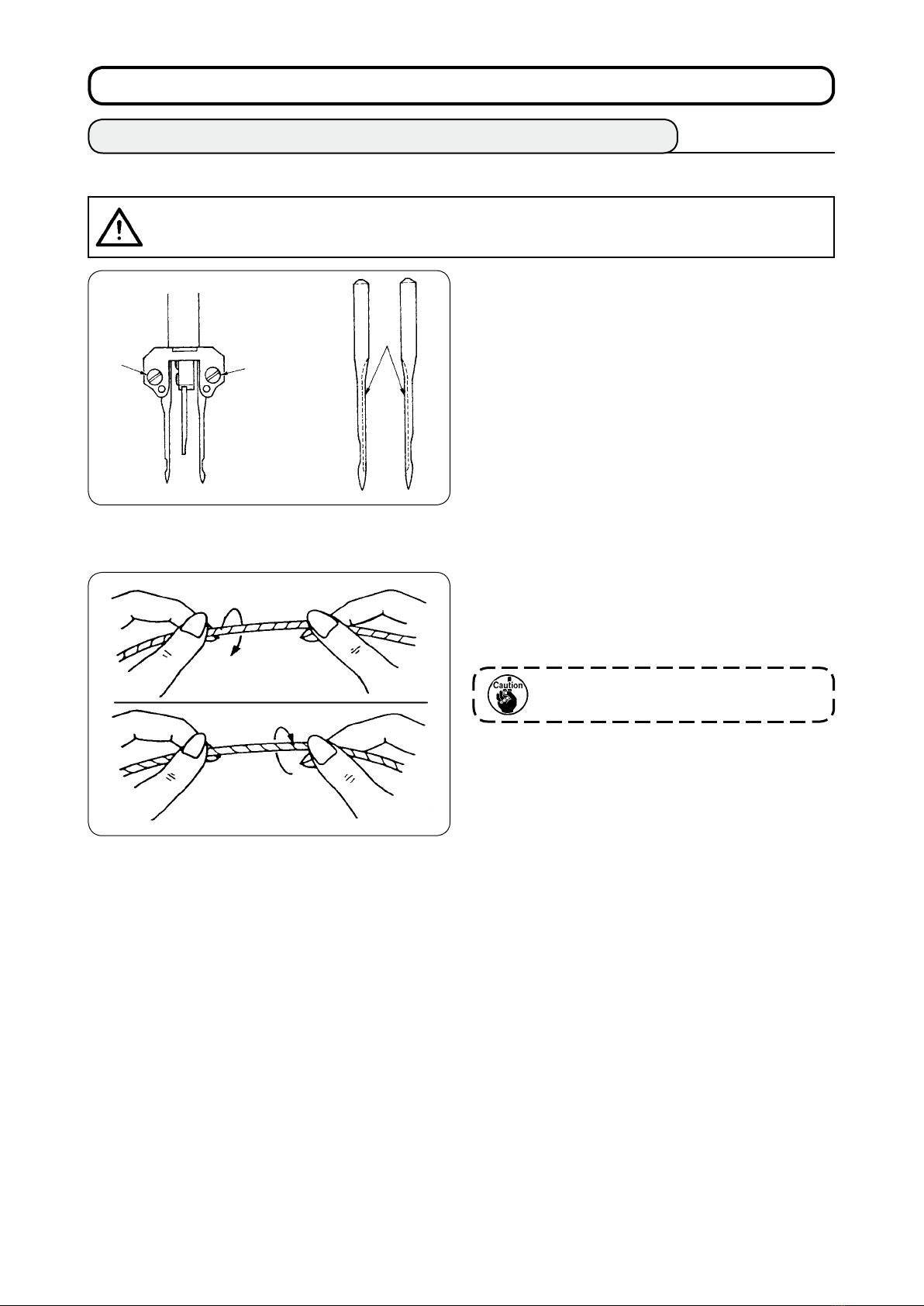

1. HOW TO OPERATE THE SEWING MACHINE HEAD

(1) How to attach the needles

CAUTION

Turn OFF the power before starting the work so as to prevents accidents caused by abrupt start of the

sewing machine.

2

(2) Thread used

:

Needles used are DP X 17 #14 to #18 (standard

#16). Use the specied needle.

1

2

Insert left- and right-hand sides needles as far as

they will go pointing their long grooves 1 at each

other and tighten needle clamp screws 2.

• Use the left hand twist thread for the needle

thread.

• Either twist thread will do for the bobbin thread.

Right hand twist thread

Left hand twist thread

Use a new thread which is uniformly

twisted.

− 13 −

Page 18

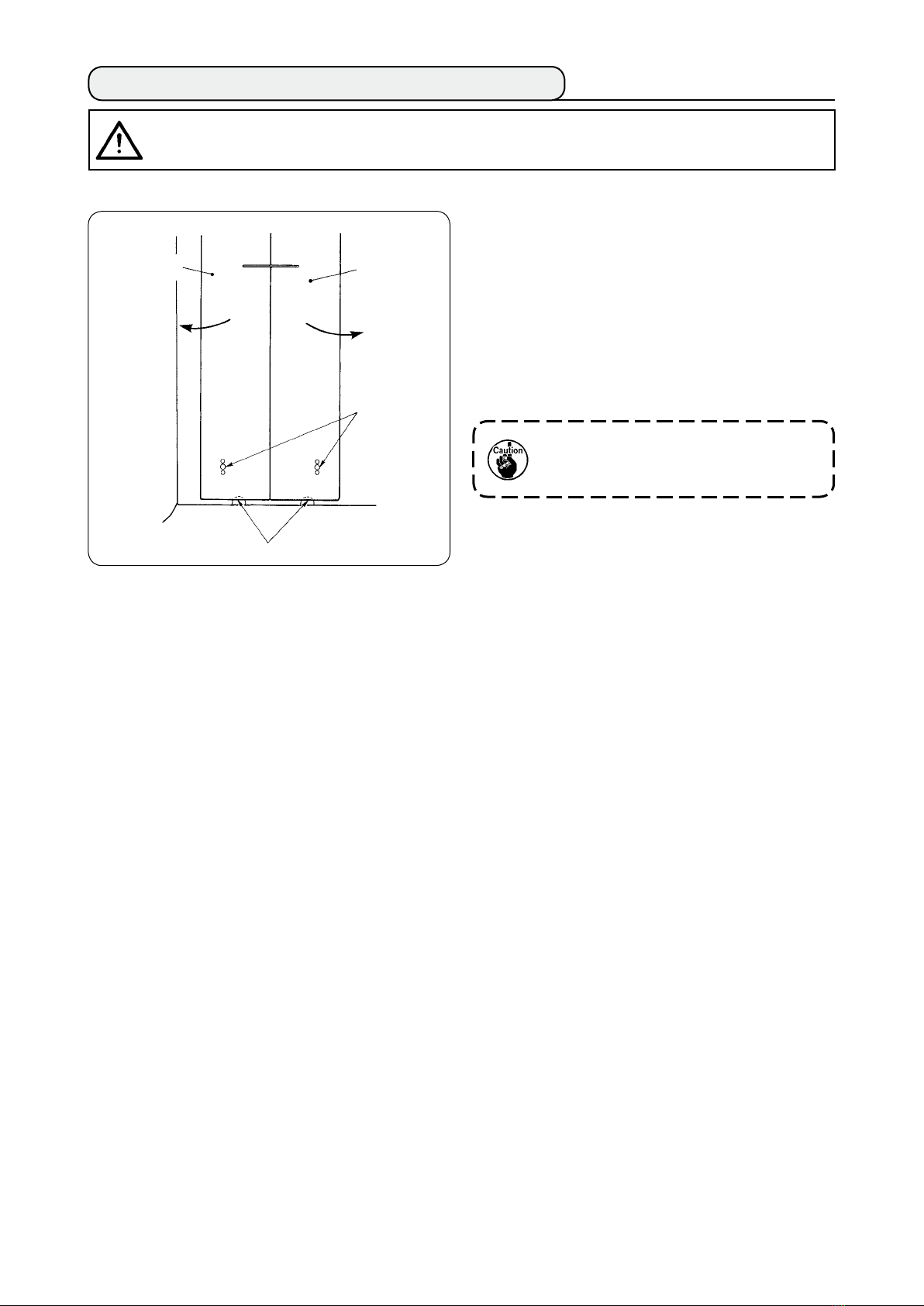

(3) How to pass the needle thread

CAUTION

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

:

Lift binder 1 in the direction A, Hold section

1

B by hand and turn the whole binder in the

direction C.

B

A

1

Then pass needle thread in the order as shown in the gure below.

2

C

B

A

Be sure to press section B since welting

width may become improper when the

binder is pressed and turned in the

direction C.

Binder is locked with the ball plunger.

Rather strongly turn the binder in the

direction C to release the lock.

C

A

B

A

A

B

A B

A

Periodically replace thread guide felt C. Sewing trouble due to rough motion of thread during

sewing can be prevented.

B

B

Pass the needle thread in the illustrated order.

Left-hand side needle thread toward the sewing machine

Right-hand side needle thread toward the sewing machine

− 14 −

A

B

Page 19

2. HOW TO REMOVE THE SEWING TABLE

CAUTION

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

:

(1) When replacing the bobbin thread

2

A

1

Pin

Move the clamp foot to the rear end of its

1

stroke.

Insert your ngers into notches A in the bottom

2

of right- and left-hand sewing tables 1 and 2,

and push up the sewing tables.

Move the tables in the direction of the arrow

3

keeping the above state, and you can see the

bobbin case.

At this time, move the sewing tables so as

not to allow the sewing tables to come in

contact with the needles.

After replacing the bobbin thread, return the

4

sewing tables in place by following the above-

mentioned steps of procedure in the reverse

order. Now, rmly set the sewing tables on the

throat plates and the pins.

− 15 −

Page 20

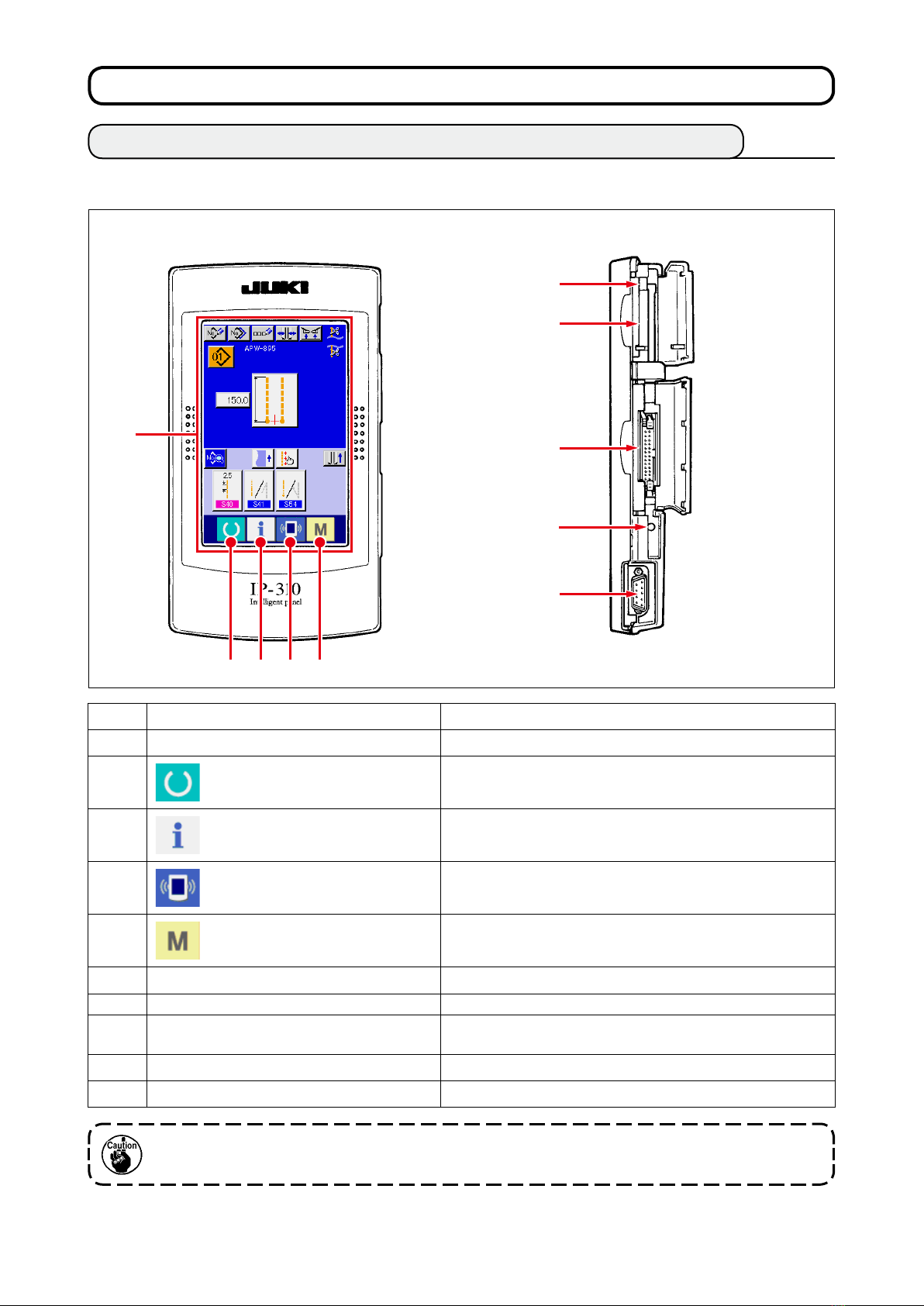

(2) Cautions to be taken when the sewing tables are removed

CAUTION

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

:

When you remove the sewing tables, be sure to accurately set them by following the points below.

Securely t the pins, rear (left) (right) over the

Pins, rear

1

1

pin holes.

Securely t pin holes, front (left) (right) over

2

the pins.

Plate spring

2

Pin holes, front

1. In case of the machine provided

with SA-120 (automatic interlining

supplying device), return the sewing

tables to their home positions while

lifting the sewing tables so that the

plate spring section is not bent.

Outlet of interlining

supply

2. In case of removing the sewing tables with the types below, take care not to bend pocket bag

clamping device and interlining clamping device.

Pocket bag clamping device (standard)

1

Pocket bag clamping device (for interlining supply)

2

− 16 −

Page 21

3. HOW TO WIND THE BOBBINS

CAUTION

To prevent damage, avoid contact with bobbins while the machine is in operation.

:

Put bobbin into the thread winder

1

shaft until it will go no further.

Pass thread through thread guide

2

plate 8, open thread tension disk

and put the thread into the slit of

7

thread tension rod

Pass thread in the order as

3

shown in the gure, and wind the

thread onto bobbin by four or ve

1

2

Direction of

rotation

8

4

7

3

turns. (The direction of the arrow

corresponds to the direction of

rotation of the bobbin.)

Press bobbin thread guide 1 and

4

the bobbin rotates.

The thread winder will automatically

5

stop as soon as it has wound up

the bobbin to a predetermined

amount.

4

.

9

1. If you want to wind a bobbin, start winding it from recess 5asillustratedinthegureabove.If

you start to wind a bobbin from portion 6, the detection of run-out of bobbin thread will fail to

be performed normally.

2. To ensure the appropriate remaining amount of bobbin thread, it is important to wind the bobbin

uniformly. Be sure to check that the bobbin is uniformly wound particularly at the start of

bobbin winding.

If the bobbin fails to be uniformly wound with thread, properly adjust the lateral position of

tension post socket 3.

3. It is most suitable to wind the bobbin with thread to approximately 80% of the outer diameter of

the bobbin. The winding amount can be adjusted with winding amount adjustment screw 2.

4. Do not press lever 1 except when winding bobbin thread. Motor continues to run and trouble

will be caused.

5. When abnormalities such as overload of the thread winding motor, etc. are delected, thermal

switch 9 is shut off. When thermal switch is shut off, turn ON thermal switch 9 again after

turning OFF it to return.

5

6

− 17 −

Page 22

4. HOW TO THREAD THE BOBBIN CASE

Hold in hand a bobbin in the way that it spins

1

clockwise and put it into the bobbin case.

Bobbin case

Pass the thread through slot 1 in the bobbin

2

case.

Pull the thread to pass it under the tension

3

spring.

Bobbin

1

5. HOW TO INSTALL THE BOBBIN CASE

CAUTION

Turn OFF the power before starting the work so as to prevent accident caused by abrupt start of the

sewing machine.

:

Raise hook levers 1 and take out the bobbin

1

cases together with the bobbins.

2

1

3

When tting, t the bobbin cases into the

2

hook driving shaft and tilt levers

When bobbin cases, left and right, 2 are

replaced, make sure that the clearance

between the opener which is extremely

receded and the bobbin case is 0.2 to 0.3

mm. If the clearance is not 0.2 to 0.3 mm,

loosen setscrew 3 and adjust it.

1

.

0.2 to 0.3mm

− 18 −

Page 23

6. HOW TO ADJUST THE THREAD TENSION

Adjusting bobbin thread tension

Bobbin case

Bobbin

Bobbin thread

tension adjustment

screw

1

Turn bobbin thread tension adjustment screw

clockwise to increase the bobbin thread

tension or turn the screw counterclockwise to

decrease it.

As shown in the left-hand gure, standard

bobbin thread tension is 0.25 to 0.35N when

measuring with the tension gauge.

2

1

Adjusting needle thread tension

2

First, adjust the right- and left-hands bobbin

thread tension.

Then in accordance with the bobbin thread

tension obtained, adjust the right- and

left-hand sides needle threads tension

appropriately by turning thread tension

adjustments nuts 1 and 2 respectively.

Turning the nuts clockwise will increase

the thread tension or turning them

counterclockwise to decrease it.

− 19 −

Page 24

7. SETTING THE MATERIAL TO BE SEWN

(1) Setting a garment body

Garment body

clamp (left)

Garment body

Garment body

clamp rubber

Garment body

clamp (right)

Use a garment body that is

larger than the garment body

clamp rubber piece adhered

under the right and left garment

body clamps.

If a garment body of which size

is smaller than the garment

body clamp rubber piece, the

rubber piece can come off or the

machine can malfunction.

If it is necessary to use a small

material, mount a shim type

gauge (optional) on the machine.

− 20 −

Page 25

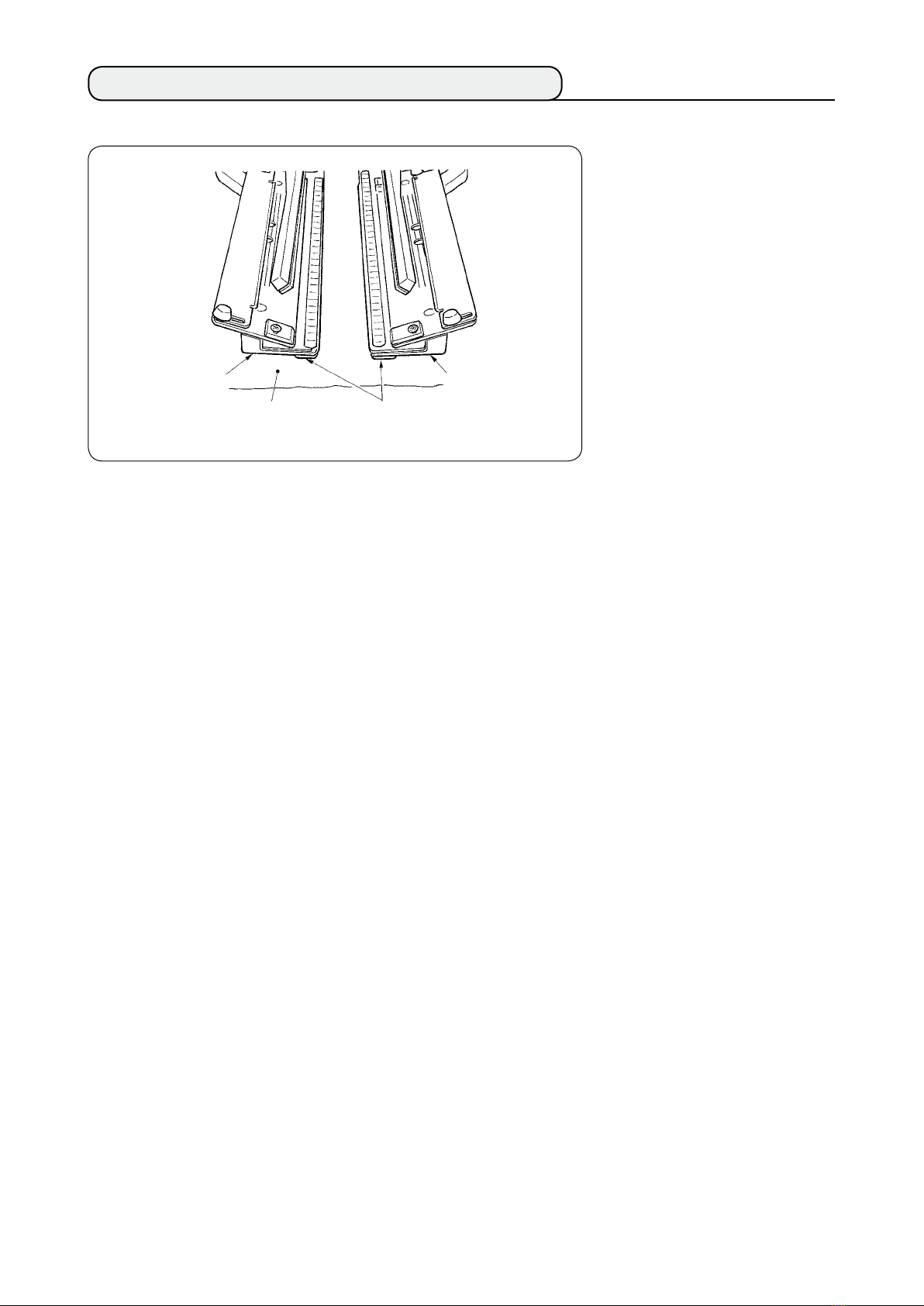

^

. HOW TO USE THE OPERATION PANEL

1. BASIC OPERATION OF THE OPERATION PANEL (IP-310)

(1)CongurationofIP-310

[ Front ] [ Right side ]

!0

6

1

Symbol

1

2

3

4

2 3 4 5

Name

TOUCH PANEL, LCD display section

READY key

INFORMATION key

COMMUNICATION key

9

8

7

Description

Change-over of the data input screen and the sewing screen is

performed.

Change-over of the data input screen and the information screen is

performed.

Change-over of the data input screen and the communication

screen is performed.

5

6

7

8

9

!0

Media slot Close the cover for use.

CONNECTOR for RS-232C communication

VARIABLE RESISTOR for adjusting contrast of

colored LCD screen

CONNECTOR for external input

MEDIA take-out lever

MODE CHANGEOVER key

Change-over of the data input screen and the mode change-over

screen which performs various details setting.

Contrast of the screen can be adjusted. Adjust it as you like.

When READY key is pressed rst after turningON the power, origin retrieval of the clampfoot is

performed. At this time, the clamp foot moves. So, be careful.

− 21 −

Page 26

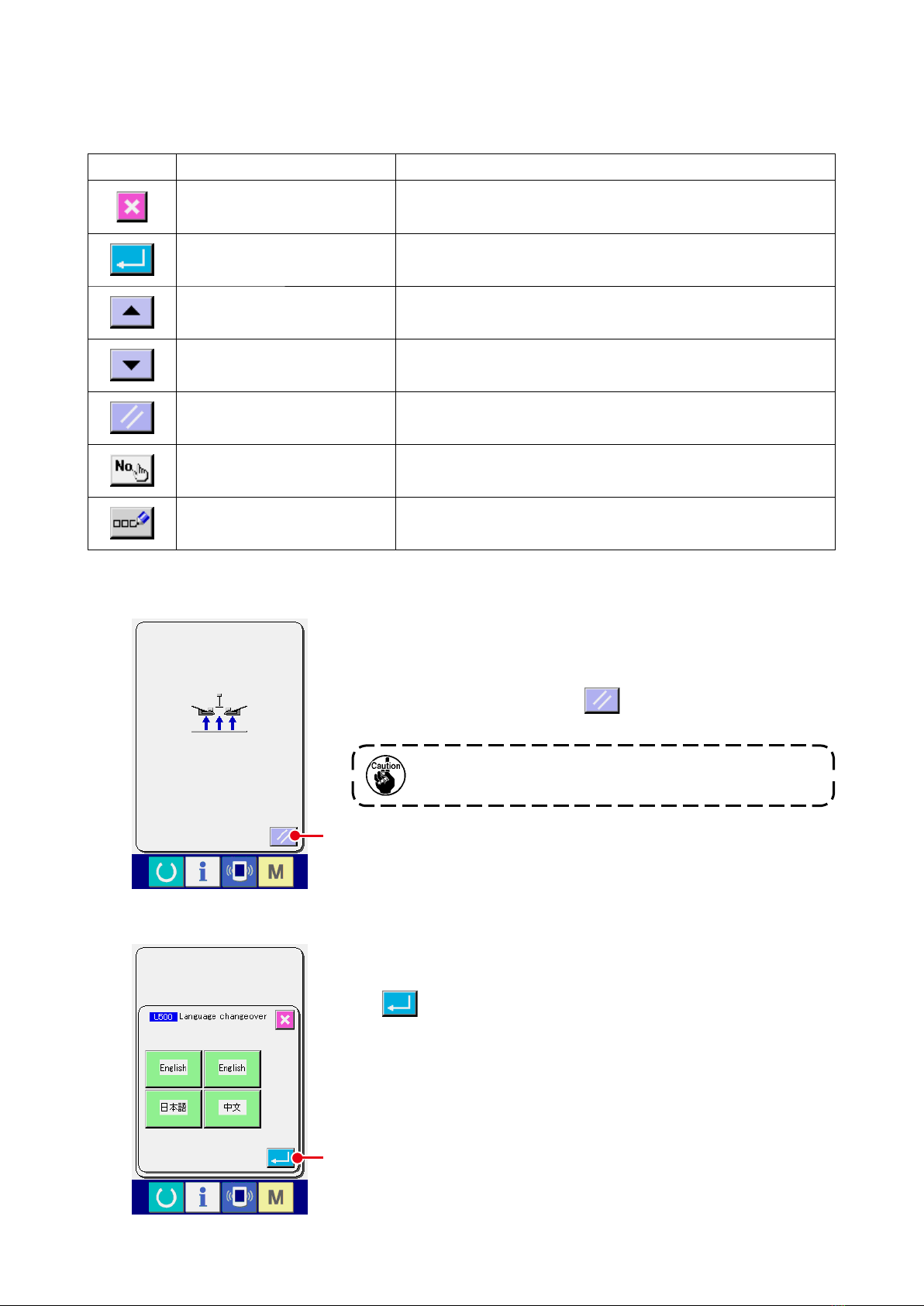

(2) Buttons used in common

Buttons that perform common operation in the respective screens of IP-310 are as described below.

Pictograph Name

CANCEL button

ENTER button Data changed are determined.

UP SCROLL button This button scrolls button or display upward.

DOWN SCROLL button This button scrolls button or display downward.

RESET button This button releases error and the like.

NUMBER INPUT button Ten keys are displayed and input of number can be performed.

CHARACTER INPUT button Character input screen is displayed.

(3) Basic operation

Description

Pop-up screen is closed. In case of the data change screen, the data during

changing can be cancelled.

Turn ON the power switch.

1

First, turn ON the power switch.

Reset pop-up screen is displayed after displaying WELCOME

screen. Press RESET button

When RESET button is pressed, the binder goes up. So, be

careful.

A

A

.

Next, language selection pop-up screen is displayed. After

selecting the language you desire to display, press ENTER button

B. Then the independent sewing input screen (screen A) of

the gure below is displayed.

(This screen is displayed only once at the time of your purchase.)

B

− 22 −

Page 27

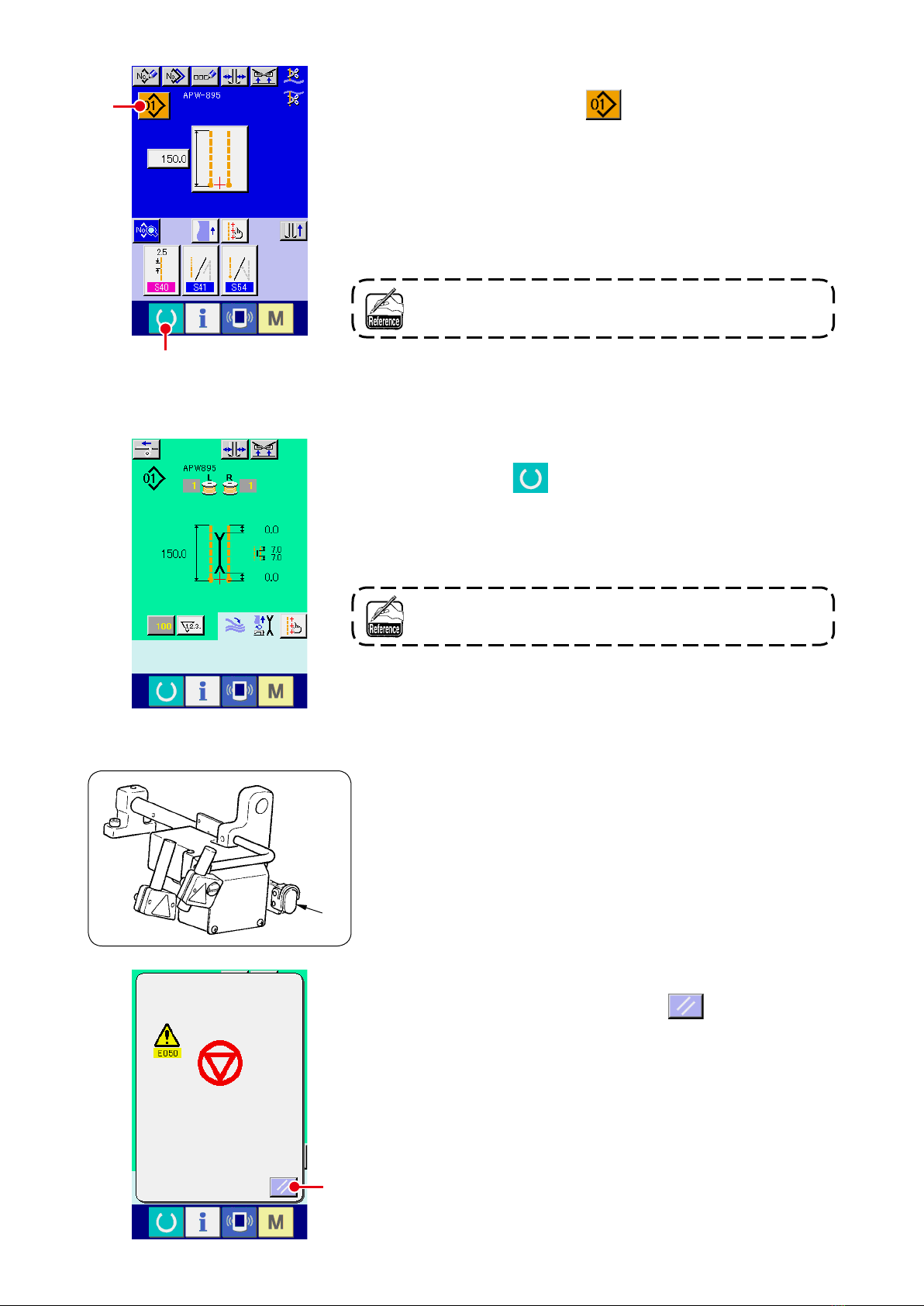

Select pattern No. you desire to sew.

2

C

D

The independent sewing

input screen (screen A)

When PATTERN NO. button C is pressed, the pattern No.

can be selected. For the selecting procedure of pattern No., see

“VI-6. (1) Performing the selection of pattern”

.

At the time of your purchase, pattern Nos. 1 to 10 have been

registered. Change the sewing data in accordance with the

sewing types for use. (The number to which the pattern has not

been registered is not displayed.)

Start sewing

3

For the detailed explanation of input screen, see “^-2. EX

PLANATION OF THE BASIC SCREEN”.

When READY key

is pressed in the independent sewing

D

input screen (screen A), the green sewing screen (screen B)

is displayed and the sewing operation is started by the pedal

operation.

Sewing screen (screen B)

For the details of the sewing screen, see “^-2. EX

PLANATION OF THE BASIC SCREEN”.

To stop the device during operation

4

When temporary stop switch E is pressed during sewing, the

device can be stopped.

E

At this time, the error screen is displayed to inform that stop

switch is pressed. When RESET button

error is released and the screen returns to the input screen.

is pressed, the

F

F

− 23 −

Page 28

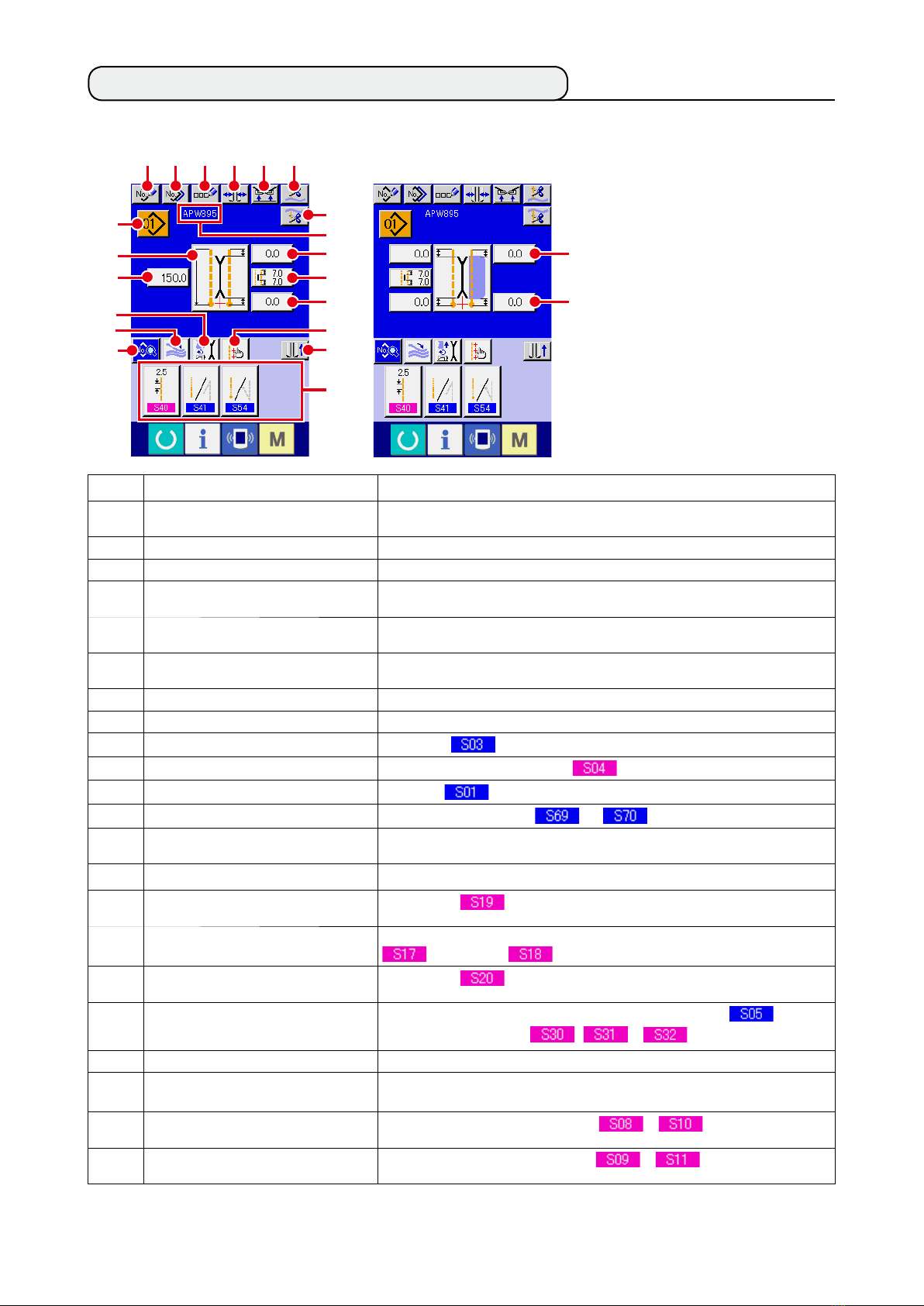

2. EXPLANATION OF THE BASIC SCREEN

(1) Input screen (Independent sewing mode)

A B C D E F

H

I

J

K

L

M

G

N

O

P

Q

R

S

U

V

T

Symbol Name of button Description

NEW CREATION button Independent sewing pattern new creation screen is displayed and new register of the pattern

A

COPY button

B

CHARACTER INPUT button Character input screen is displayed and the name can be inputted to the pattern data.

C

TYPE OF WELT CHANGE-OVER button Type of welt change-over screen is displayed, and change-over of type of welt and

D

CLAMP UP PROHIBITION AT SEWING END

E

button

NEEDLE THREAD TRIMMING button When this button is pressed, needle thread trimming knife comes down and the needle

F

BOBBIN THREAD TRIMMING button Bobbin thread trimming knife opens while this button is pressed.

G

PATTERN NO. LIST button Pattern No. list screen is displayed and the pattern data can be selected.

H

SEWING MODE CHANGE-OVER button Sewing mode is selected.

I

L SIZE LENGTH SETTING button In case of L size sewing, sewing length is set.

J

MOTION MODE SETTING button With/without of motion of sewing machine motor, center knife and corner knife.

K

STACKER MOTION/STOP CHANGE-OVER button

L

SEWING DATA DISPLAY button Sewing pattern edit screen is displayed. Detailed sewing data that are not displayed in the

M

PATTERN NAME display Names that are inputted in pattern Nos. are displayed.

N

CORNER KNIFE MOTION POSITION AT

O

SEWING START SETTING button

CENTER KNIFE SETTING button Center knife data edit screen is displayed, and center knife cutting position of sewing start

P

CORNER KNIFE MOTION POSITION AT

Q

SEWING END SETTING button

MARKING LIGHT SETTING button

R

CLAMP FOOT MOVE button Clamp foot is moved to the front or to the back.

S

SEWING DATA SHORTCUT button Shortcut buttons (max. 4 items) of the sewing data that are set in customizing in the sewing

T

FLAP DROP DATA AT SEWING START

U

SETTING button

FLAP DROP DATA AT SEWING END

V

SETTING button

It is possible to customize display/non-display of the respective buttons.

*

For the details, refer to

“^-12. CUSTOMIZING THE DATA INPUT SCREEN”

data can be performed.

Independent sewing copy source pattern list screen is displayed and the pattern can be copied.

adjustment of parallelism of the binder can be performed.

When this button is pressed, the clamp is returned in the lowered state at sewing end.

It is convenient to use this button at the time of adjusting the marking light or trial sewing.

thread trimming operating screen is displayed.

This button selects motion/stop and of stacker.

input screen can be selected and edited.

Cutting position of corner knife at sewing start is set.

and sewing end is set.

Cutting position of corner knife at sewing end is set.

Marking light setting screen is displayed. Selection of sewing reference and setting

of marking irradiation position, , or is performed.

screen are displayed.

Flap concealed stitching data at sewing start or is set.

Flap concealed stitching data at sewing end or is set.

.

− 24 −

Page 29

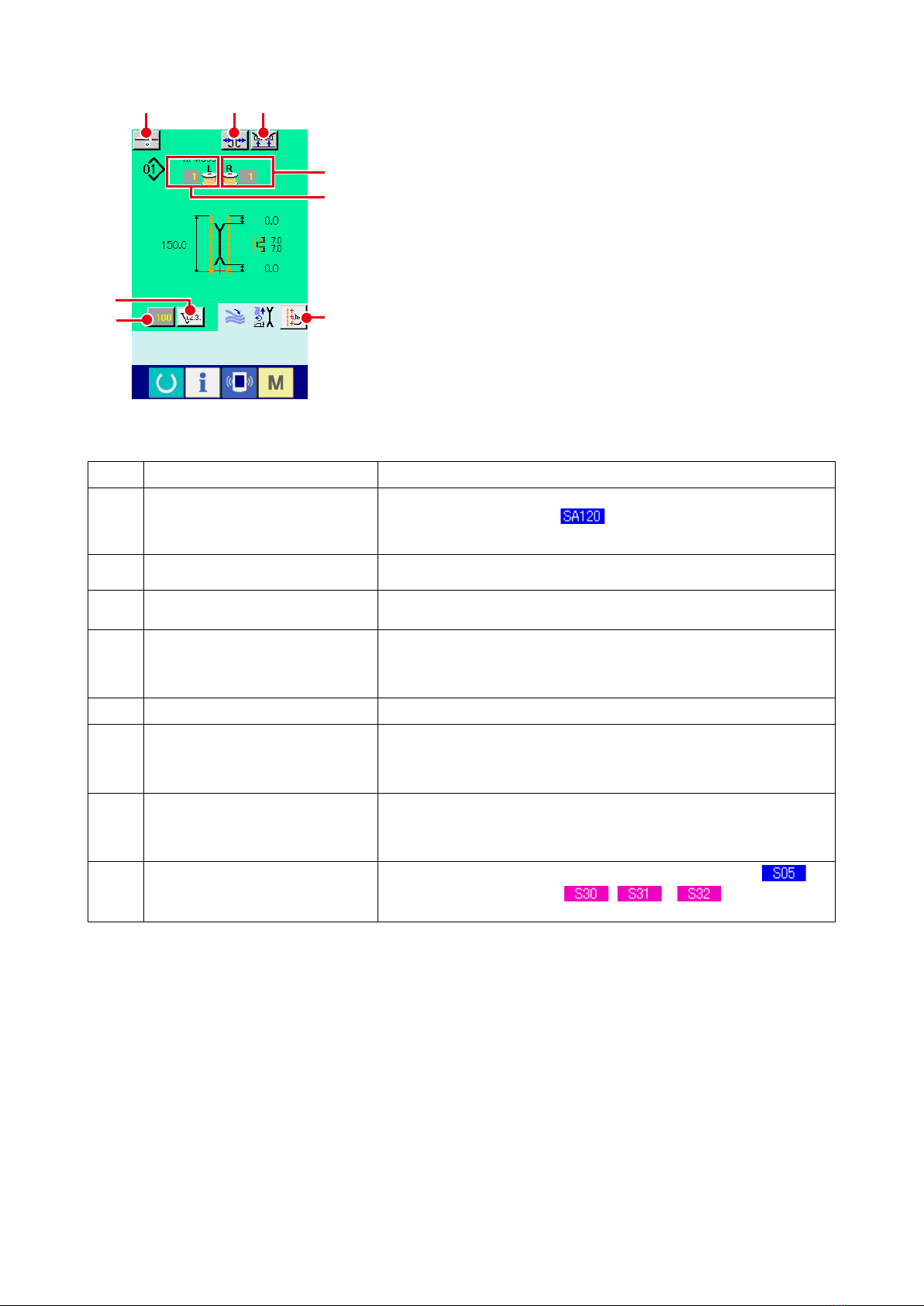

(2) Sewing screen (Independent sewing mode)

A B

C

F

G

D

E

Symbol Name of button Description

INTERLINING SUPPLY button When this button is pressed, interlining is supplied.

A

H

This is displayed when “With” of , automatic interlining supplying device is set

*

with the optional setting.

B

TYPE OF WELT CHANGE-OVER button

CLAMP UP PROHIBITION AT SEWING END

C

button

COUNTER CHANGE-OVER button

D

E

COUNTER VALUE CHANGE button This button changes the counter value which is displayed at present.

BOBBI N THREAD (RI GHT) REM AINING

F

AMOUNT VALUE

BOB BIN THREAD (LEFT) REMAINI NG

G

AMOUNT VALUE

MARKING LIGHT SETTING button

H

It is possible to customize display/non-display of the respective buttons.

*

For the details, refer to

“^-12. CUSTOMIZING THE DATA INPUT SCREEN”

Type of welt change-over screen is displayed and change-over of type of welt and

adjustment of parallelism of the binder can be performed.

When this button is held pressed, the clamp is returned in the lowered state at sewing end.

It is convenient to use this button at the time of adjustment of marking light or trial sewing.

When this button is pressed, the display of sewing counter and number of pcs. counter is

changed over.

This button is displayed only when both sewing counter and number of pcs. counter are

*

ON.

This button detects reecting light from bobbin and informs that bobbin thread remaining

amount is running out. When one stitching completes, the counter value is subtracted, and

the count-up screen is displayed when “0” is reached.

This button is displayed only when the reecting light from bobbin is detected.

*

This button detects reecting light from bobbin and informs that bobbin thread remaining

amount is running out. When one stitching completes, the counter value is subtracted and

the count-up screen is displayed when “0” is reached.

This button is displayed only when the reecting light from bobbin is detected.

*

Marking light setting screen is displayed, and selection of sewing reference and

setting of marking irradiation position , or can be performed.

It is possible to customize display/non-display of the respective buttons.

.

− 25 −

Page 30

(3) Input screen (Alternate sewing mode)

A B C D E F

H

I

J

G

O

P

Q

R

T

U

V

M

L

K

Symbol Name of button Description

NEW CREATION button Alternate sewing data new creation screen is displayed and new register of data can be

A

COPY button Alternate sewing data copy source No. list is displayed and alternate sewing data can be

B

CHARACTER INPUT button Character input screen is displayed and name input can be performed n the alternate sewing

C

TYPE OF WELT CHANGE-OVER button Type of welt change-over screen is displayed ,and change-over of type of welt and

D

CLAMP UP PROHIBITION AT SEWING END

E

button

NEEDLE THREAD TRIMMING button Needle thread trimming knife comes down and needle thread trimming in motion screen is

F

BOBBIN THREAD TRIMMING button Bobbin thread trimming knife opens while this button is pressed.

G

ALTERNATE SEWING DATA NO. LIST button Alternate sewing data No. list screen is displayed and alternate sewing data can be selected.

H

SEWING MODE CHANGE-OVER button

I

L SIZE LENGTH SETTING button

J

SEWING DATA DISPLAY button Sewing pattern edit screen is displayed. This button selects detailed sewing data that are not

K

STACKER MOTION/STOP CHANGE-OVER

L

button

MOTION MODE SETTING button

M

MARKING LIGHT SETTING button

N

NEXT SEWING DATA CHANGE-OVER button Sewing pattern to be sewn next which is enclosed with yellow frame is changed over.

O

CORNER KNIFE MOT ION POSITION AT

P

SEWING START SETTING button

CENTER KNIFE SETTING button Center knife data edit screen is displayed and center knife cutting position of sewing start

Q

CORNER KNIFE MOT ION POSITION AT

R

SEWING END SETTING button

CLAMP FOOT MOVE button Clamp foot is moved to the front or to the back.

S

T、V

U、W

It is possible to customize display/non-display of the respective buttons.

*

For the details, refer to

FLAP CONCEALED STITCHING DATA AT

SEWING START SETTING button

FLAP CONCEALED STITCHING DATA AT

SEWING END SETTING button

“^-12. CUSTOMIZING THE DATA INPUT SCREEN”

N

S

performed.

copied.

data.

adjustment of parallelism of the binder can be performed.

When this button is held pressed, clamp is returned in the lowered state at the time of

sewing end.

It is convenient to use this button at the time of adjusting marking light or trial sewing.

displayed.

Sewing mode is selected.

In case of L size sewing, sewing length is set.

displayed in the input screen and can edit the data.

This button selects motion/stop and of stacker.

With/without motion of sewing machine motor, center knife and corner knife.

Marking light setting screen is displayed, and selection of sewing reference and

setting of marking irradiation position , or can be performed.

This is not displayed when ap priority sewing selection

*

Cutting position of corner knife at sewing start is set.

and sewing end .

Cutting position of corner knife at sewing end is set.

Flap concealed stitching data at sewing start or is set.

Flap concealed stitching data at sewing end or is set.

W

.

is ON.

− 26 −

Page 31

(4) Sewing screen (Alternate sewing mode)

A B C

F

G

H

D

E

Symbol Name of button Description

INTERLINING SUPPLYING button

A

TYPE OF WELT CHANGE-OVER button Type of welt change-over screen is displayed, and change-over of type of welt and

B

CLAMP UP PROHIBITION AT SEWING END

C

button

COUNTER CHANGE-OVER button When this button is pressed, display of sewing counter and number of pcs. counter is

D

COUNTER VALUE CHANGE button Counter value which is displayed at present is changed.

E

NEXT SEWING DATA CHANGE-OVER button Sewing pattern to be sewn next which is enclosed with yellow frame is changed over.

F

BOBBI N THREAD (RI GHT) REM AINING

G

AMOUNT VALUE

BOB BIN THREAD (LEFT) REMAINI NG

H

AMOU’NT VALUE

MARKING LIGHT SETTING button

I

I

When this button is pressed, interlining is supplied.

This is displayed when “With” of , automatic interlining supplying device is set

*

with the optional setting.

adjustment of parallelism of the binder can be performed.

When this button is held pressed, the clamp is returned in the lowered state at the time of

sewing end.

It is convenient to use this button at the time of adjustment of marking light and trial sewing.

changed over. This button is displayed only when both sewing counter and number of pcs.

counter are ON.

This is not displayed when ap priority sewing selection

*

This button detects reecting light from bobbin and informs that bobbin thread remaining

amount is running out. When one stitching completes, the counter value is subtracted, and

the count-up screen is displayed when “0” is reached.

This button is displayed only when the reecting light from bobbin is detected.

*

This button detects reecting light from bobbin and informs that bobbin thread remaining

amount is running out. When one stitching completes, the counter value is subtracted, and

the count-up screen is displayed when “0” is reached.

This button is displayed only when the reecting light from bobbin is detected.

*

Marking light setting screen is displayed, and selection of sewing reference and

setting of the position of marking irradiation , or .

is ON.

It is possible to customize display/non-display of the respective buttons.

*

For the details, refer to

“^-12. CUSTOMIZING THE DATA INPUT SCREEN”

− 27 −

.

Page 32

(5) Input screen (Cycle sewing mode)

A B C D E F

H

G

I

K

J

L

M

N

Symbol Name of button Description

NEW CREATION button Cycle sewing data No. new creation screen is displayed and new register of cycle sewing

A

COPY button Cycle sewing data copy source No. list screen is displayed and cycle sewing data can be

B

CHARACTER INPUT button Character input screen is displayed and name can be inputted to the cycle sewing data.

C

TYPE OF WELT CHANGE-OVER button Type of welt change-over screen is displayed and change-over of type of welt, and

D

CLAMP UP PROHIBITION AT SEWING END

E

button

NEEDLE THREAD TRIMMING button Needle thread trimming knife comes down and the needle thread trimming in motion screen

F

BOBBIN THREAD TRIMMING button While this button is held pressed, bobbin thread trimming knife opens.

G

CYCLE SEWING DATA NO. LIST button Cycle sewing data No. list screen is displayed and the cycle sewing data can be selected.

H

PATTERN DATA EDIT button Edit of pattern data which have been registered to cycle sewing data can be performed.

I

PATTERN DATA EDIT button (blank) When this blank button is pressed, the pattern list screen to register the pattern data to the

J

CYCLE RETURN button Pattern data to be sewn next which is displayed with white emphasis is moved forward by

K

CYCLE FEED button Pattern data to be sewn next which is displayed with white emphasis is moved backward by

L

PATTERN DATA DELETION button Pattern data which is displayed with white emphasis is deleted from register.

M

CLAMP FOOT MOVE button Clamp foot is moved to the front or to the back.

N

data can be performed.

copied.

adjustment of parallelism of the binder can be performed.

When this button is held pressed, the clamp is returned in the lowered state at the time of

sewing end.

It is convenient to use at the time of adjustment of marking light and trial sewing.

is displayed.

For the editing procedure, refer to

*

cycle sewing data is displayed, and it is possible to select and register the pattern data.

one. In case of rst pattern, it moves to the last pattern.

one. In case of the last pattern, it moves to the rst pattern.

“2-(1) Input screen (Independent sewing mode)”

.

It is possible to customize display/non-display of the respective buttons.

*

For the details, refer to

“^-12. CUSTOMIZING THE DATA INPUT SCREEN”

− 28 −

.

Page 33

(6) Sewing screen (Cycle sewing mode)

A B C

H

G

D

I

J

E

F

Symbol Name of button Description

INTERLINING SUPPLYING button When this button is pressed, interlining is supplied.

A

TYPE OF WELT CHANGE-OVER button Type of welt change-over screen is displayed, and change-over of type of welt and

B

CLAMP UP PROHIBITION AT SEWING END

C

button

CYCLE DATA display All pattern data that have been registered to the cycle sewing data are displayed.

D

COUNTER CHANGE-OVER button When this button is pressed, display of sewing counter and number of pcs. counter is

E

COUNTER VALUE CHANGE button Counter value which is displayed at present is changed.

F

BOBBI N THREAD (RI GHT) REM AINING

G

AMOUNT

BOB BIN THREAD (LEFT) REMAINI NG

H

AMOUNT

LEFT SCROLL button Pattern data to be sewn next is moved forward by one. In case of the rst pattern, it moves

I

RIGHT SCROLL button Pattern data to be sewn next is moved backward by one. In case of the last pattern, it moves

J

MARKING LIGHT SETTING button

K

K

This is displayed when “With” of , automatic interlining supplying device is set

*

with optional setting.

adjustment of parallelism of the binder can be performed.

When this button is held pressed, the clamp is returned in the lowered state at the time of

sewing end.

It is convenient to use this button at the time of adjustment of marking light and trial sewing.

changed over. This button is displayed only when both sewing counter and number of pcs.

counter are ON.

This button detects light from bobbin and informs that bobbing thread remaining amount is

running out. When one stitching completes, the counter value is subtracted, and the counter-

up screen is displayed when “0” is reached.

This button is displayed only when the reecting light from bobbin is detected.

*

This button detects reecting light from bobbin and informs that bobbin thread remaining

amount is running out. When one stitching completes, the counter value is subtracted, and

the counter-up screen is displayed when “0” is reached.

This button is displayed only when the reecting light from bobbin is detected.

*

to the last pattern.

to the rst pattern.

Marking light setting screen is displayed, and selection of sewing reference

and setting of the position of marking irradiation , and are

performed.

It is possible to customize display/non-display of the respective buttons.

*

For the details, refer to

“^-12. CUSTOMIZING THE DATA INPUT SCREEN”

− 29 −

.

Page 34

3. USING THE COUNTER

(1) Setting procedure of the counter

Display the counter setting screen.

1

Press MODE CHANGEOVER key from the input screen and

COUNTER SETTING button A is displayed on the screen.

A

B

Press this button and “COUNTER SETTING screen (screen A)” is

displayed.

Select the kind of counter.

2

There are three kinds of counters with this sewing machine,

sewing counter, number of pcs. counter and bobbin thread

remaining amount adjustment counter.

Press sewing counter button B in “counter setting screen

(screen A)”, and “sewing counter setting screen (screen B)” is

displayed. Then the kind of counter can be set.

Counter setting screen

(Screen A)

Sewing counter setting

screen (Screen B)

[ Sewing counter ]

UP counter

Every time one sewing is performed, the existing value is counter

up. When the existing value is equal to the set value, the count-

up screen is displayed.

DOWN counter

Every time one sewing is performed, the existing value is counted

down. When the existing value is reached to “0”, the count-up

screen is displayed.

Counter unused

Sewing counter is set to the prohibition.

− 30 −

Page 35

C

Counter setting screen

(Screen A)

Number of pcs. counter

(Screen C)

Press NUMBER OF PCS. COUNTER button C In “Counter

setting screen (screen A)”, and “number of pcs. setting screen

(screen C)” is displayed. Then the kind of counter can be set.

[ Number of pcs. counter ]

UP counter

Every time one of nished products is sewn, the existing value is

counted up.

In case of independent sewing : 1 time of sewing

*

In case of alternate sewing : 2 times of sewing

In case of cycle sewing : 1 time of cycle sewing

The number given in each case above is regarded as one of

nished products.

When the existing value is equal to the set value, the count-up

screen is displayed.

DOWQN counter

Every time one of nished products is sewn, the existing value

is counted down. When the existing value is reached to “0”, the

count-up screen is displayed.

Counter unused

Number of pcs. counter is set to the prohibition.

− 31 −

Page 36

Changing the target value of the counter

3

In case of the sewing counter, press button D, and in

D

case of the number of pcs. counter, press button E, and “

E

Numerical setting pop-up screen (screen D)” Is displayed. Then

the target value of counter can be set.

Here, input the target value of counter. When “0” is inputted to the

target value of counter, only the existing value is displayed during

sewing and the count-up screen is not displayed.

Numerical setting pop-up screen

(screen D)

Change the existing value of counter

4

F

In case of the sewing counter, press button F and in case

G

of the number of pcs. counter, press G, and “ Numerical

setting pop-up screen (screen E)” is displayed. Then the existing

value of counter can be set.

Here, input the existing value of counter.

Numerical setting pop-up screen

(screen E)

− 32 −

Page 37

(2) Releasing procedure of count-up

During the sewing work, the count-up condition is reached the

count-up screen is displayed and the buzzer sounds. Press CLEAR

button A to reset the counter, and the screen returns to the

sewing screen. And, counting starts again.

A

(3) Counter value changing procedure during sewing

A

Display the counter value change screen

1

When you desire to change the counter value during the sewing

work, press COUNTER VALUE CHANGE button A on the

sewing screen. Counter value change screen is displayed.

Change the counter value

2

Change the counter value with TEN keys to B or

button

C

D ).

(

▲▼

E

F

E

DC

Determine the counter value

3

Press ENTER button E and the data is determined. When

you desire to clear the counter value, press CLEAR button

− 33 −

F

.

Page 38

4. USING THE BOBBIN THREAD AMOUNT ADJUSTMENT COUNTER

(1) Setting procedure of the bobbin thread remaining amount adjustment counter

Display the counter setting screen

1

Press MODE CHANGEOVER key from the input screen,

COUNTER SETTING button A is displayed on the screen..

A

B

Press this button and “Counter setting screen (screen A)” is

displayed.

Set the bobbin thread remaining amount adjustment counter

2

to ON.

Press BOBBIN THREAD REMAINING AMOUNT

ADJUSTMENTCOUNTER MOTION SETTING button B,

and “Bobbin thread remaining amount adjustment counter setting

pop-up screen (screen B)” is displayed. Then the bobbin thread

remaining amount adjustment counter motion (ON/OFF) can be

set.

Counter setting screen

(Screen A)

Bobbin thread remaining amount

adjustment value setting screen

(Screen B)

[ Bobbin thread remaining amount detection ]

Bobbin thread remaining amount adjustment counter ON :

The counter detects the reecting light from bobbin and informs

that bobbin thread remaining amount is running out. Every time

one sewing is performed, the counter value is subtracted and the

count-up screen is displayed when the existing value is reached

to “0”.

Bobbin thread remaining amount adjustment counter OFF :

Bobbin th r e a d r e m a i n i n g a m o u n t d etection is set to the

prohibition.

− 34 −

Page 39

Counter setting screen

(Screen A)

Set the bobbin thread remaining amount adjustment value

3

Press BOBBIN THREAD REMAINING AMOUNT ADJUSTMENT

VALUE SETTING button C and the bobbin thread remaining

amount adjustment value setting screen (screen B) is displayed.

C

Here, input the bobbin thread remaining amount adjustment value

(0 to 9).

Set the number of times of sewing from detecting run-out of

bobbin thread by the sensor to performing the count-up display.

Bobbin thread remaining amount

adjustment value setting screen

(Screen B)

When you desire to lengthen the remaining length bobbin

thread :

When you desi re to short en the rema ining lengt h of

Decrease the number (toward “0”).

→

bobbin thread :

Increase the number (toward 9).

→

− 35 −

Page 40

Setting of the bobbin thread remaining amount adjustment counter

*

*

1) Set the bobbin thread remaining amount adjustment counter to the value shown in the table below.

2) Start the sewing to perform regular sewing. In case of test sewing, adjust the sewing length to that to be

sewn in the actual process.

3) As you continue sewing, the bobbin thread is gradually reduced and the run-out of bobbin thread is

displayed in the screen when the bobbin sensor detects the reecting light.

4) At this time, check the length of bobbin thread remaining on the bobbin and properly modify the value on

the counter.

5) Increasing the counter value by 1 will shorten the remaining length of bobbin thread by the amount that

is consumed for one time of sewing.

6) The remaining length of bobbin thread at the time when the indication of run-out of bobbin thread varies

by a certain extent. This variation depends on the type of thread, sewing length and the winding way of

thread.

The remaining length of bobbin thread is shown, as a guide, in the table below. Correct the counter value

in accordance with sewing conditions and the like so that the bobbin thread does not completely run out

during sewing.

[ The table shows the counter value when the sewing length is set to 150 mm ]

Thread count Counter value Bobbin thread remaining length for reference (m)

#40 1 0.4 to 2.6

#50 2 0.2 to 2.6

#60 2 0.4 to 2.8

#80 3 0.1 to 3.0

•

1.

2.

• The value of bobbin thread remaining amount counter is cleared by inputting the value of the

The bobbin thread remaining length has to be re-adjusted in the case described below.

When the sewing length for the sewing product has been changed.

When the thread count of bobbin thread has been changed.

bobbin thread remaining amount adjustment counter.

7) If the bobbin has run out of thread, the bobbin thread remaining amount detecting device is incapable of

performing “bobbin thread remaining amount detection”. So, it is very important to specify a value on the

bobbin thread remaining amount adjustment counter to allow the device to give the indication of “run-out

of bobbin thread” when the sufcient amount of bobbin thread remains.

(2) Releasing procedure of the bobbin thread remaining amount detection count-up

When the bobbin thread remaining amount counter value becomes

“0” at the sewing end, the count-up screen is displayed and the

buzzer sounds. Replace the bobbin thread of the bobbin where the

bobbin thread remains few.

When CL E A R button A is pressed, the bobbin thread

remaining amount counter value is reset and the screen returns to

the sewing screen.

A

− 36 −

Page 41

5. CHANGING THE SEWING MODE

Display the sewing mode selection screen

1

Press SEWING MODE CHANGEOVER key A and the

mode change-over screen is displayed.

B

A

Select the sewing mode

2

Press MODE SELECTION button B and the indication of button is changed.

When the independent

sew is selected

Determine the sewing mode.

3

When the alternate sewing

is selected

When the cycle sewing is

selected

Press MODE CHANGEOVER key A and the data input screen of the selected sewing mode is

displayed.

Independent sewing input

screen

Alternate sewing input

screen

− 37 −

Cycle sewing input screen

Page 42

6. USING THE SEWING PATTERN

(1) Performing the selection of pattern

Display the input screen

1

When the input screen of independent sewing mode, alternate sewing mode and cycle sewing mode is

displayed, the selection of pattern can be selected.

By customizing the sewing screen, the selection of pattern can be performed from the sewing screen as

well.

Call the pattern list screen

2

Press PATTERN LIST button , or A and the pattern list screen is displayed.

A AA

Select the pattern

3

Press pattern data you desire to select

C

B

Determine the pattern

4

B

B

.

C

B

When ENTER button C is pressed, the pattern is selected and the screen returns to the input

screen.

C

− 38 −

Page 43

(2) Performing the new creation of pattern

Display the input screen

1

When the input screen of independent sewing mode, alternate sewing mode and cycle sewing mode is

displayed, the new creation of pattern can be performed.

Call the sewing pattern new creation screen

2

Press NEW CREATION button , or A, and the pattern new creation screen is

displayed.

A A A

Input the pattern No.

3

Input pattern No. you desire to newly create with ten keys to B. It is possible to retrieve

pattern No. which has not been registered yet with

E

B

DC

Determine the pattern No.

4

B

button C and

▲▼

E

B

DC

D

.

E

DC

When ENTER button E is pressed, the pattern No. to newly create is determined and the screen

returns to the input screen.

− 39 −

Page 44

(3) Copying the pattern

The pattern which has been already registered can be copied to the sewing pattern which has not

registered yet. Copying of overwriting of pattern is prohibited. So, when you desire to overwrite, perform

it after erasing the pattern once.

For the erasing procedure, see

→

When performing copying the pattern No. which has been already registered, copy disapproved

error (E401) is displayed.

Display the input screen

1

When the input screen of independent sewing mode, alternate sewing mode and the cycle sewing mode

is displayed, it is possible to copy.

“^-6. (4) Erasing the pattern”

.

A

Call the pattern No. list screen of the copy source

2

Press PATTERN COPY button

displayed.

A A

, or A, and the copy source pattern list screen is

A

− 40 −

Page 45

Select the pattern of copy source

3

Select the pattern of copy source from PATTERN LIST button

B

.

Next, press COPY DESTINATION NO.. INPUT button C and the copy destination input screen

(screen B) is displayed.

C

B

Input the pattern No. of copy destination

4

B

Copy destination No. input screen (screen B)

C

B

C

Input the pattern No. of copy destination with ten keys to B. It is possible to retrieve the

pat6tern No. which has not been used yet with

buttons ( C and D ).

▲▼

B

Start copying

5

B

E E E

DC

Copy destination No. input screen (screen B)

DC

B

DC

When ENTER button E is pressed, copying starts. The pattern No. which has been copied is in

the selection state and returns to the copy source pattern list screen (screen A).

− 41 −

Page 46

(4) Erasing the pattern

Display the input screen

1

When the input screen of independent sewing mode, alternate sewing mode and cycle sewing mode is

displayed, it is possible to erase the pattern.

Call the pattern list screen

2

Press PATTERN LIST button , or A and the pattern No. list screen (screen A) is

displayed.

A

Select the pattern to be erased

3

A

A

Select the pattern to be erased from pattern list button B.

Next, press ERASE button C and the pattern erase conrmation screen is displayed.

B

Determine the pattern to be erased

4

B

C

Pattern No. list screen (screen A)

C

B

C

Press ENTER button in the pattern erase conrmation screen and the pattern is erased.

When CANCEL button is pressed, the screen returns to the original screen A without erasing the

pattern.

− 42 −

Page 47

(5) Naming the pattern

Display the input screen

1