Page 1

•JUKI

Automatic

(Simpiified

Lockstitch

Operation

APW-193N

ENGINEER'S

Weiting

Type)

MANUAL

Machine

Page 2

PREFACE

This

Engineer's

This

manual

for the maintenance personnel and operators at a ganneni factory.

Itis

advisabletouse

sewing machinesofthese models.

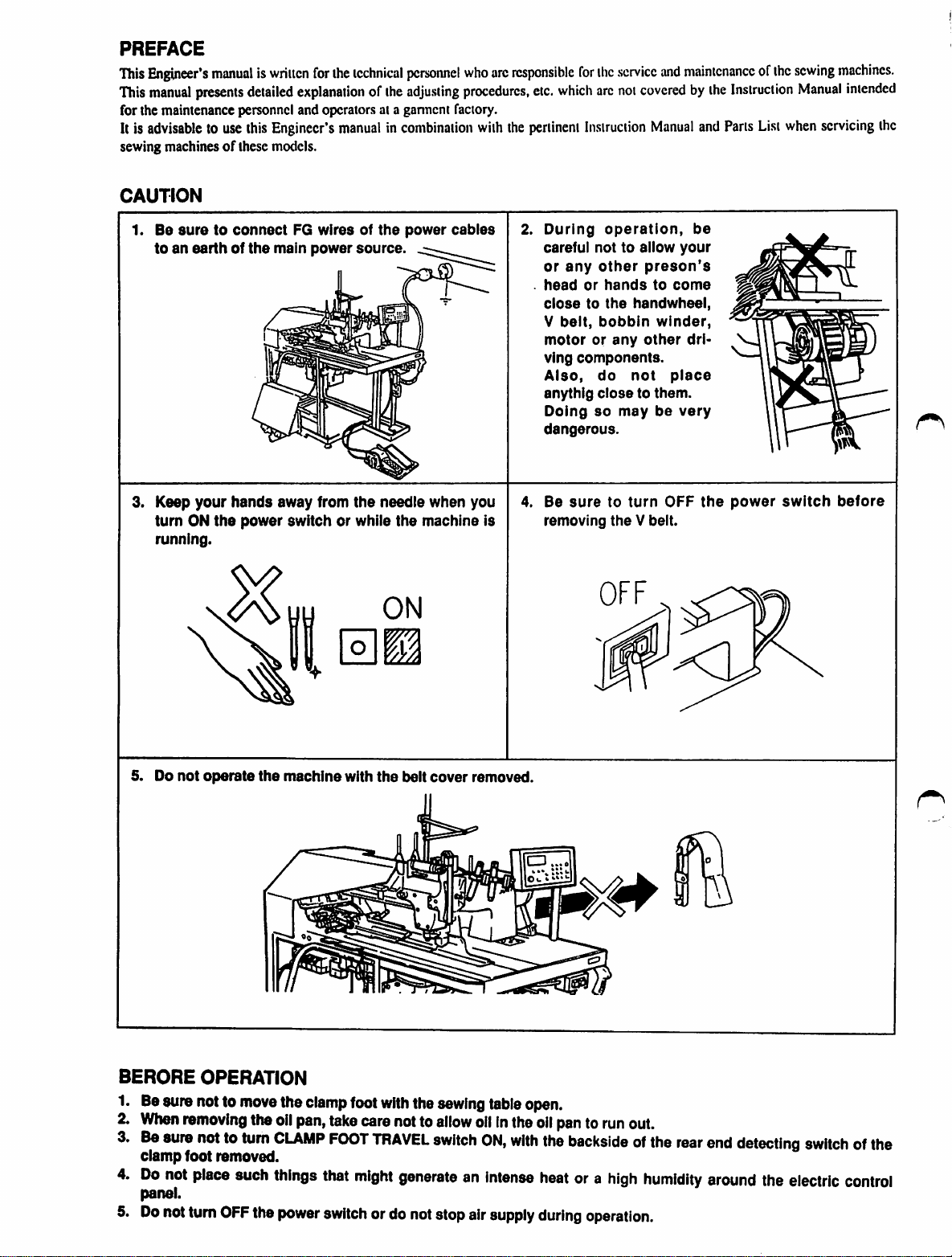

CAUTION

1.

Be

toanearthofthe

manualiswriitcn

presents

suretoconnect

detailed

this

for

ihe

explanationofthe

Engineer's

main

manualincombination

FG

wiresofthe

power

technical

source.

personnel

adjusting

power

cables

who

procedures,

with

are

responsible

the

pertinent

2.

for

the

service

etc.

which

arc

not

coveredbythe

Instruction

During

careful not to allow

or

head

closetothe

V

motororany

ving

Also,

anythig

Doing

dangerous.

operation,

any

other

or

hands

belt,

bobbin

components.

do

closetothem.

so

handwheel,

not

may

and

maintenanceofthe

Manual

and

be

your

preson's

to

come

winder,

other

dri-

place

be

very

Instruction

Parts

List

sewing

Manual

when

machines.

intended

servicing

the

3. Keep

turnONthe

running.

5. Do

not

your

operate

hands

power

away from

switch or while

the

machine

the

with

needle

the

ON

m

the

belt

when you

machine Is

cover

removed.

4. Be

removing

suretoturn

theVbeit.

OFF

the

power

switch

before

BERORE

1. Besure notto

When

Be

clamp

Do

panel.

Do

OPERATION

removing

sure

nottoturn

foot removed.

not

place

notturn

OFF

move

the

such

the

the

clamp

oil

pan,

take

CLAMP

things

power

FOOT

that

switch

foot

with

the

carenotto

TRAVEL

might

switch

generateanIntense

ordo notstopair

sewing

allow

table

oilInthe

ON,

with

supply

open.

oil

pantorun

the

backsideofthe

heat

during

ora

out.

high

operation.

rear

humidity

end

detecting

around

the

electric

switchofthe

control

Page 3

CONTENTS

1.

SPECIFICATIONS

(1) Mechanical Specifications 1

(2) Electrical Specifications I

2.

CONFIGURATIONOFTHE

3.

INSTALLATION

MACHINE

(1) Levelling the machine 3

(2) Installingthe accessorycomponents 3

(3) Installing the stacker and adjusting it 4

(4) Attaching the optional devices and adjusting them 9

4.

CONNECTIONOFELECTRIC

POWER

SOURCE

AND

AIR

SUPPLY

SOURCE

(1) Connection of electric power source 12

(2) Connection of the air supply source 12

5.

OPERATION

PANEL

SWITCHES

AND

INDICATOR

LAMPS

(1) Operation panel switches 13

(2) Manual

mode

and automatic

mode

(3) Example ofsetting data on cycle sewing 35

(4) Example of setting data for slant flap sewing 37

6.

HOWTOSET

OPERATE

THE

THE

MATERIALTOBE

SWITCHES

DURING

SEWNONTHE

SEWING

MACHINE

AND

(1) How to perform welting and sewing welts with flaps 38

(2) How to sew a welt pocket with the binder raised 39

7.

EXPLANATION

OF

VARIABLE

RESISTORS

AND

DIP

SWITCHES

(1) Explanation of function 42

(2) Setting for special-purpose functions using DIP switches 44

8.

CROSS

(I)

9.

MARK

LAMPS

Crass (+) mark lampsfor settingsewing 49

AIR

CONTROL

SWITCHES

(1) Foot valve switch 50

(2) Pointsrequiringspecial attentionwhen operatingthe air cylinder independently

(Manual

10.

PEDAL

11.

POINTSTOBE

12.

TEMPORARY

(1)

Temporary

(2)

Automatical

operationof thesolenoidvalve) 50

SWITCH

AND

KNEE

NOTED

STOP

BEFORE

.stopbymanual

temporary

.stop

SWITCH

OPERATION

operation

OPERATION

(3) List of alarm codes 55

(4) Listof check codes 60

1

2

3

12

13

16

38

42

49

50

51

53

54

54

54

Page 4

13.

ADJUSTMENTS

(1)

Binder

(2)

Adju.siing

(3)

Clamp

(4) Adju.sting the comer knife

14.

MAINTENANCE

(1)

Pneumatic

(2)

Sewing

(3)

Maintenance

(4)

Precautions

15.

SEWING

(1)

Removing

(2)

Lubrication

(3)

Needles

(4)

Threading

(5)

Thread

(6)

Adjasting

(7)

Relationofthe

(8)

Adju.siing

(9)

Adjasting

(10) Po.sition of the thread tension relea.serod

(11)

Adjasting

(12)

Po.sitionofthe

(13)

Timingofthe

(14)

Howtochange

16. ELECTRICAL CONTROLCOMPONENTS 93

(1)

Electrical

(2)

Indicationofthe

(3)

Relation

(4)

Explanationofthe

(5)

Howtoadjast

17. TROUBLESANDCORRECTIVE

18. FLOW CHART OF STANDARD OPERATION 104

19. ATTACHED MATERIALS 105

(1)

Control

(2)

Power

(3)

Pneumatic

clamp

foot,

welting

AND

.sy.stems

machine

and

for

the

MACHINE

the

oil

and

the

machine

tension

the

po.sitionofthe

hooktothe

the

needle

the

center

the

bobbin

.synchronizer

thread

control

between

the

box

connection

circuit

diagram

circuit

foot

traveling

patch

folding

INSPECTION

head

inspectionofthe

compre.s.sed

HEAD

pan

the

timing

belt

head

and

needle

needle

thread

knife,

knife

thread

knife

tension

over

the

flap

components

operation

LEDs

photoelectric

diagram

.servo

ofthe

and

input/output

driver

diagram

mechani.sm

plate

and

electrical

air

.supplying

windingabobbin

bar

frame

center

knife

di.scto.start

pre.sserofthe

cellofthe

MEASURES

needle

"floating"

thread

ofthe

flap

flap

pre.s.ser

.sy.stem.s

(the

air

and

bobbin

folding

plate

breakage

CPU

.sensor

mechanism

supply

.source)

thread

detecting

circuit

board

devices

knife

circuit

66

68

79

79

79

79

80

81

81

82

83

83

86

86

87

88

89

91

92

92

92

93

95

95

96

97

98

105

106

107

Page 5

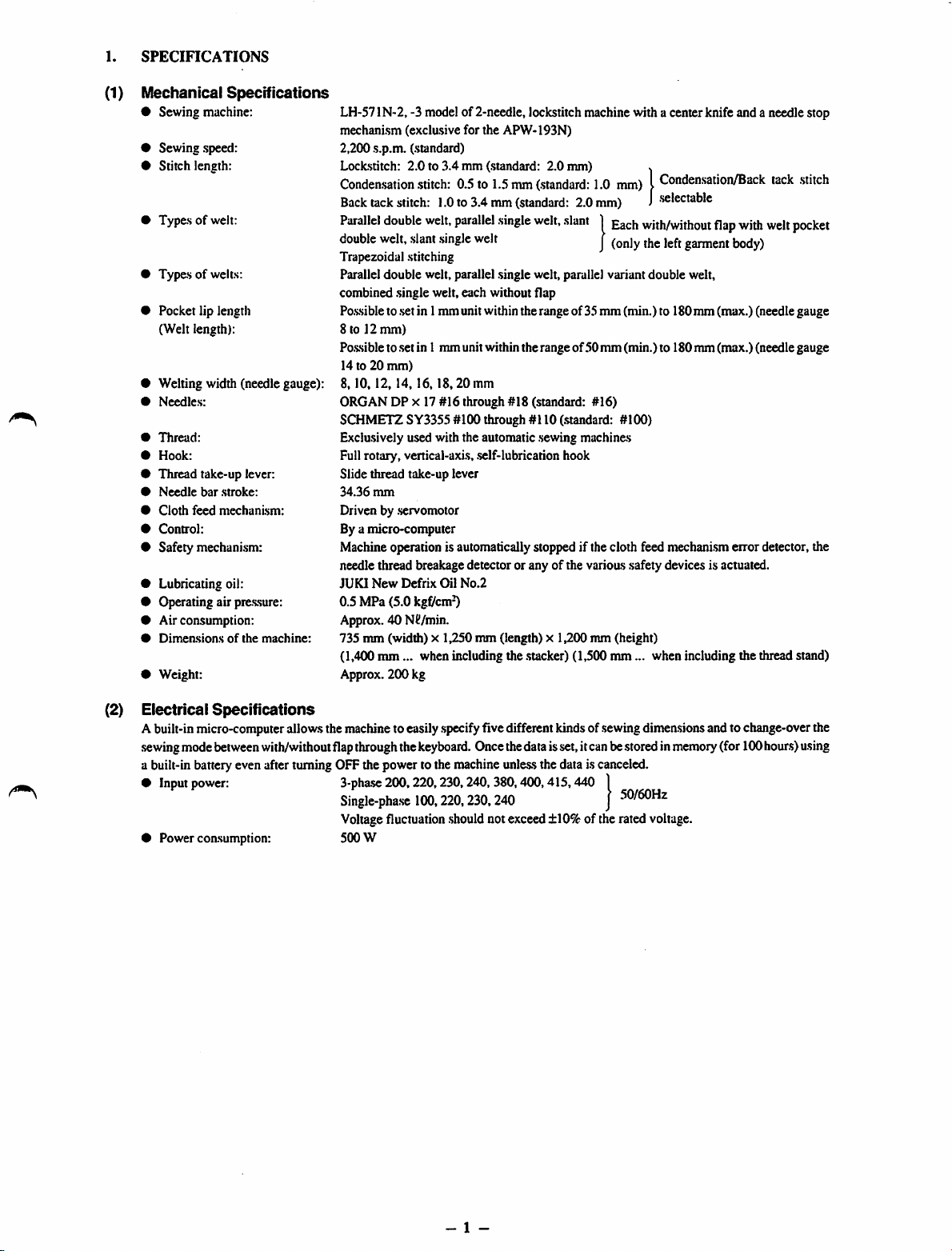

1.

SPECIFICATIONS

(1) Mechanical

• Sewing muchine:

• Sewing speed:

• Stitch length:

• Types of welt:

•

Typesofwelts:

• Pocket lip length

(Welt length):

• Welting width (needle gauge):

•

Needles:

•

Thread:

•

Hook:

• Thread take-up lever:

•

Needle

•

Cloth

•

Control:

• Safety mechanism:

• Lubricating oil:

• Operating air pressure:

• Air consumption:

•

Dimeasionsofthe

• Weight:

Specifications

bar

stroke:

feed

mechanism:

machine:

LH-571N-2, -3 modelof 2-needle, lockstitch machine with a center knife and a needle stop

mechanism (exclusive for the APW-193N)

2,200 s.p.m. (standard)

Lockstitch:

Conden-sation

Back

Parallel

double

Trapezoidal stitching

Parallel double welt, parallel .single welt, parallel variant double welt,

combined .singlewelt, each without flap

Po.s.sible

8 to 12

Po.s.sible

14 to 20

8.10.12,

ORGAN DP X 17 #16 through #18 (standard: #16)

SCHMETZ SY3355 #100 through #110 (.standard: #100)

Exclusively used with the automatic .sewing machines

Fullrotary, vertical-axis, .self-lubrication hook

Slide thread take-up lever

34.36

Driven by .servomotor

Bya micro-computer

Machineoperation is automaticallystopped if the cloth feed mechanismerror detector, the

needle thread breakage detector or any of the varioas safety devices is actuated.

JUKI

0.5MPa(5.0

Approx. 40 Nd/min.

735 mm (width) x 1,250 mm (length) x 1,200 mm (height)

(1,400

Approx. 200 kg

2.0to3.4

tack

stitch:

double

welt,

slant

to.setin 1mm unit withintherange of 35

mm)

to.setin 1 mm unitwithin the range of50 mm (min.) to 180mm (max.) (needle gauge

mm)

14,16,18,20

mm

New

Defrix

mm...

mm (standard: 2.0 mm) x

.stitch:

0.5to1.5mm(.standard:

1.0to3.4mm(standard:

welt,

parallel

single

single

welt

mm

Oil

No.2

kgf/cm-0

when including the .stacker)(1,500

welt,

slant1gach

2.0

1.0

mm)ICondensation/Back

mm)J.selectable

with/without

j

mm(min.)to

mm...

when including the thread stand)

flap

with

garment

180mm (max.) (needlegauge

body)

tack

welt

.stitch

pocket

(2) Electrical

Abuilt-inmicro-computerallowsthe machineto easily

sewingmode

a built-in battery even after turning OFF the power to the machine

•

Input

• Power coasumption: 500 W

Specifications

between

power:

with/withoutflapthroughthe

3-phase

200,220,230,240,

Single-phase

Voltagefluctuation

100,220,230,240

.specify

keyboard.

.should

fivedifferentkindsof

Oncethedataisset,itcanbestoredin

unle.ss

the data is canceled.

380,400,415,440

notexceed±10%of the rated voltage.

.sewing

dimensionsand tochange-overthe

|

J

50/60Hz

memory

(for100hours)using

- 1 -

Page 6

2.

CONnCURATION

The APW-I93N consists mainly of the following units;

O

Frame

and

(Frame,sewing table,covers, foot switch etc.)

®

Clamp

® Comer knife unit

0

Binder

0

Pneumatic

0 Stacker unit

0

Sewing

0 Electriccontrolunit(Control box)

O Oil

pan

0

Operation

0 Powerswitch

structural

foot

unit

unit

(Binder

control

machine

panel

OF

THE

components

and

feed

components

unit

head

MACHINE

mechanism

(Pneumatic

andits

control

driving

devices

components)

and

piping.s)

Fig. 1

With

this

machine,

place andoperating the switches on the operation panel.

youcando

desired

welting

work

simplybysetting

- 2 -

materials

(garment

body,

interlining

piece,

welting

patch

etc.)

in

Page 7

3.

INSTALLATION

(1) Levelling

(2) Instaliing

the

machine

the

accessory

Fig. 2

components

Yellow

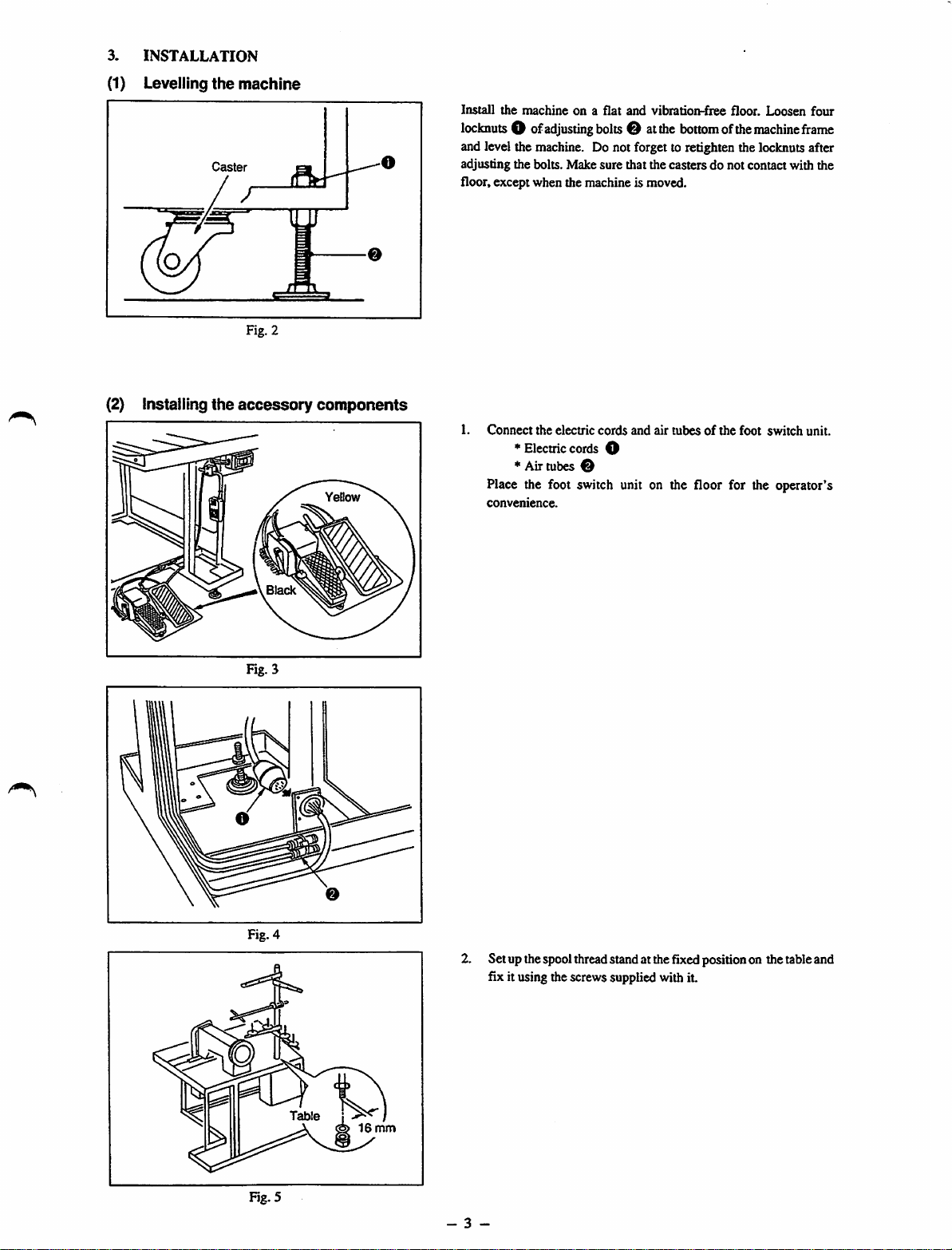

Install

the

locknuts

machineona

O of

adjusting

flat

bolts

and

vibration-fiee

O at

the

bottom

floor.

ofthe

Loosen

machine

four

frame

and level the machine. Do not forget to retighten the locknuts after

adjusting the bolts. Make sure that the casters do not contact with the

floor, except when the machine is moved.

1.

Connect

the

electric

cords

and

air

tubesofthe

foot

switch

unit.

^ Electriccords O

*

Air

tubes

Place the foot switch unit on the floor for the operator's

convenience.

Black

2. Set upthespoolthreadstandat thefixedpositionon the tableand

fix it using thescrewssupplied with it.

Table

Rg.5

1

16

mm

- 3 -

Page 8

(3)

Installing

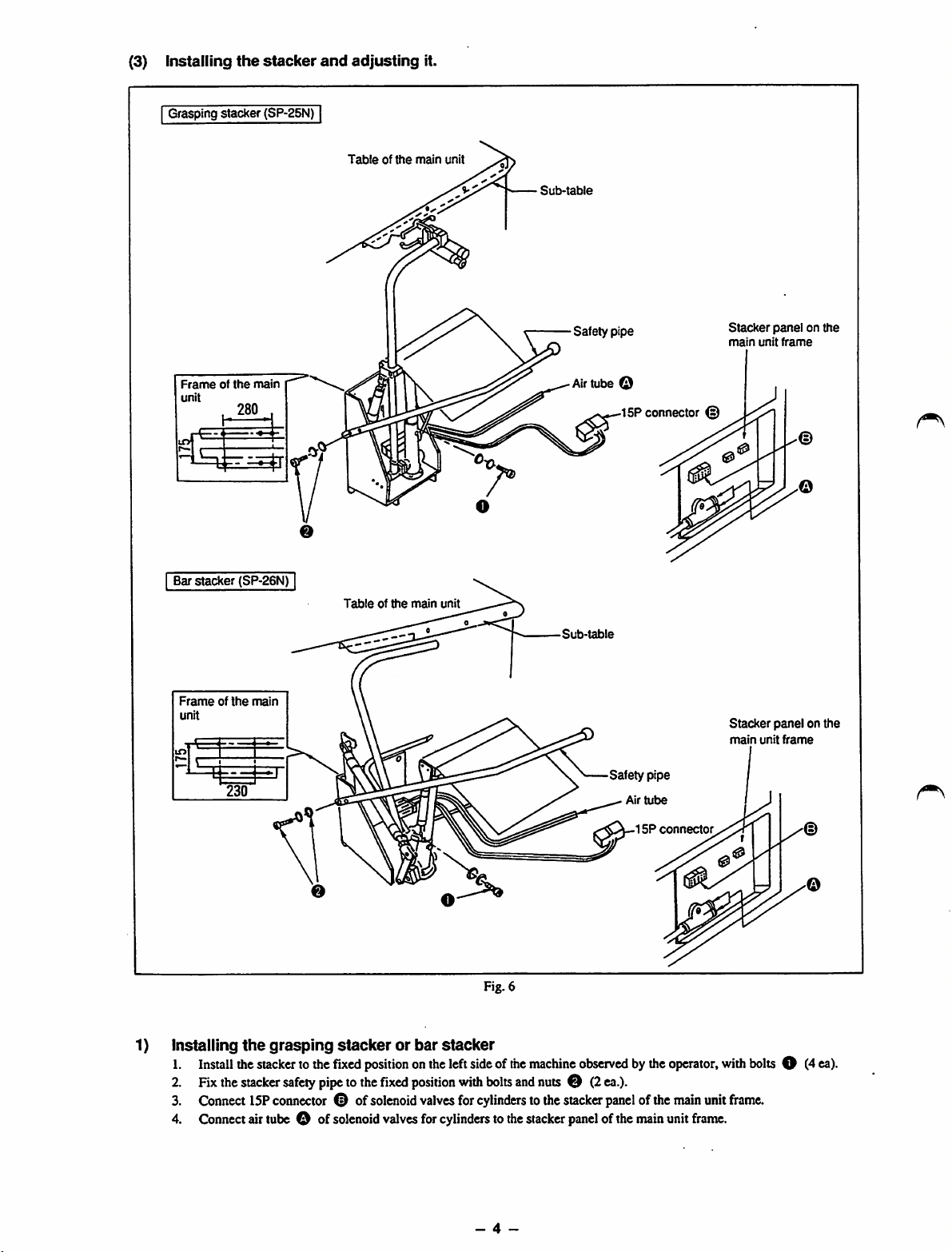

Grasping stacker (SP-25N)

the

stacker

and

adjusting

it.

Frameofthe

unit

Barstacker

main

280

(SP-26N)

Tableofthe

|

Tableofthe

main

main

unit

unit

Sub-table

Safety pipe

Air

tube O

15P connector (2)

Stacker

main

unit

panel

frame

on the

Frameofthe

unit

230

1) Installing

1.

Install

2. Fix

3.

4.

the

Connect

Connect

main

the

grasping

the

stacker

stacker

safety

15P

connector

airtube O of

stackerorbar

tothe

fixed

pipe

® of

solenoid

positiononthe

tothe

Hxed

solenoid

valves

stacker

position

valves

for

cylinders

left

sideofthe

with

for

Fig. 6

bolts

and

cylinders

tothe

•Sut)-table

machine

observedbythe

nutsO(2ea.).

tothe

stacker

stacker

panel

Safety pipe

Air

15P

panel

ofthe

ofthe

main

tube

connector

operator,

main

unit

unit

frame.

Stacker

main

with

frame.

panelonthe

unit

bolts

frame

O (4

ea).

- 4 -

Page 9

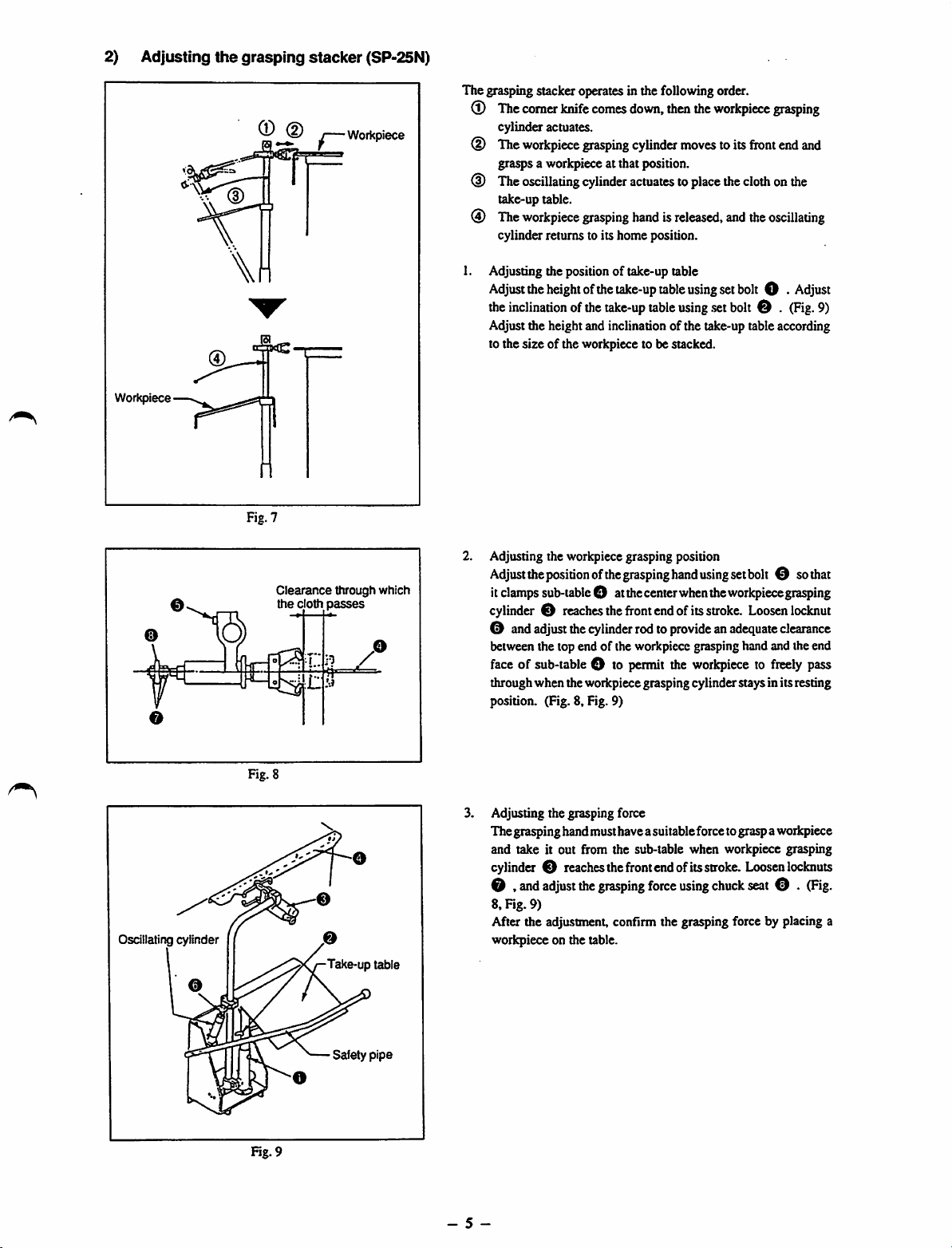

2) Adjusting

Workpiece

>-ii

the

r (D

grasping

Fig. 7

stacker

(SP-25N)

j—Workpiece

The grasping stacker operates in the following order.

®

The

comer

knife

comes

down,

then

the

workpiece

cylinder actuates.

(D The

(D

(i)

1.

workpiece

gra^s

The

oscillating

take-up table.

The

workpiece

cylinder returns to its home position.

Adjusting the position of take-up table

Adjust

the

the

inclination

Adjust the height and inclination of the take-up table according

to the

size

grasping

a workpiece at that position.

cylinder

grasping

height

ofthe

ofthe

of the workpiece to be stacked.

cylinder

actuatestoplace

handisreleased,

take-up

table

take-up

table

moves

using

using

.set

toits

front

the

clothonthe

and

the

setbolt O •

bolt

0 .

grasping

end

and

oscillating

Adjust

(Fig.

9)

Oscillating cylinder

Fig. 8

Clearance

the

cloth

through which

passes

o

Take-up table

2.

Adjusting the workpiece grasping position

Adjust

the

positionofthe

it

clamps

sub-table

cylinder0reaches

0 and

adjust

the

between the top end of the workpiece grasping hand and the end

face

of sub-table O to

throughwhen the workpiecegrasping cylinder staysin itsresting

position. (Fig. 8, Fig. 9)

3.

Adjusting the grasping force

Thegrasping handmusthavea suitableforce tograsp aworkpiece

and take it out from the sub-table when workpiece grasping

cylinder0reaches

0 ,

and

adjust

8, Fig. 9)

After the adjustment, confirm the grasping force by placing a

workpiece on the table.

O atthe

cylinder

the

grasping

grasping

the

front

the

hand

center

endofits

rodto

provideanadequate

permit

the

front

endofits

force

using

set

bolt

when

the

workpiece

stroke.

Loosen

workpiecetofreely

stroke.

Loosen

using

chuck

seat

0 so

grasping

locknut

clearance

pass

lockouts

0 .

(Hg.

that

Safety

pipe

Fig. 9

- 5 -

Page 10

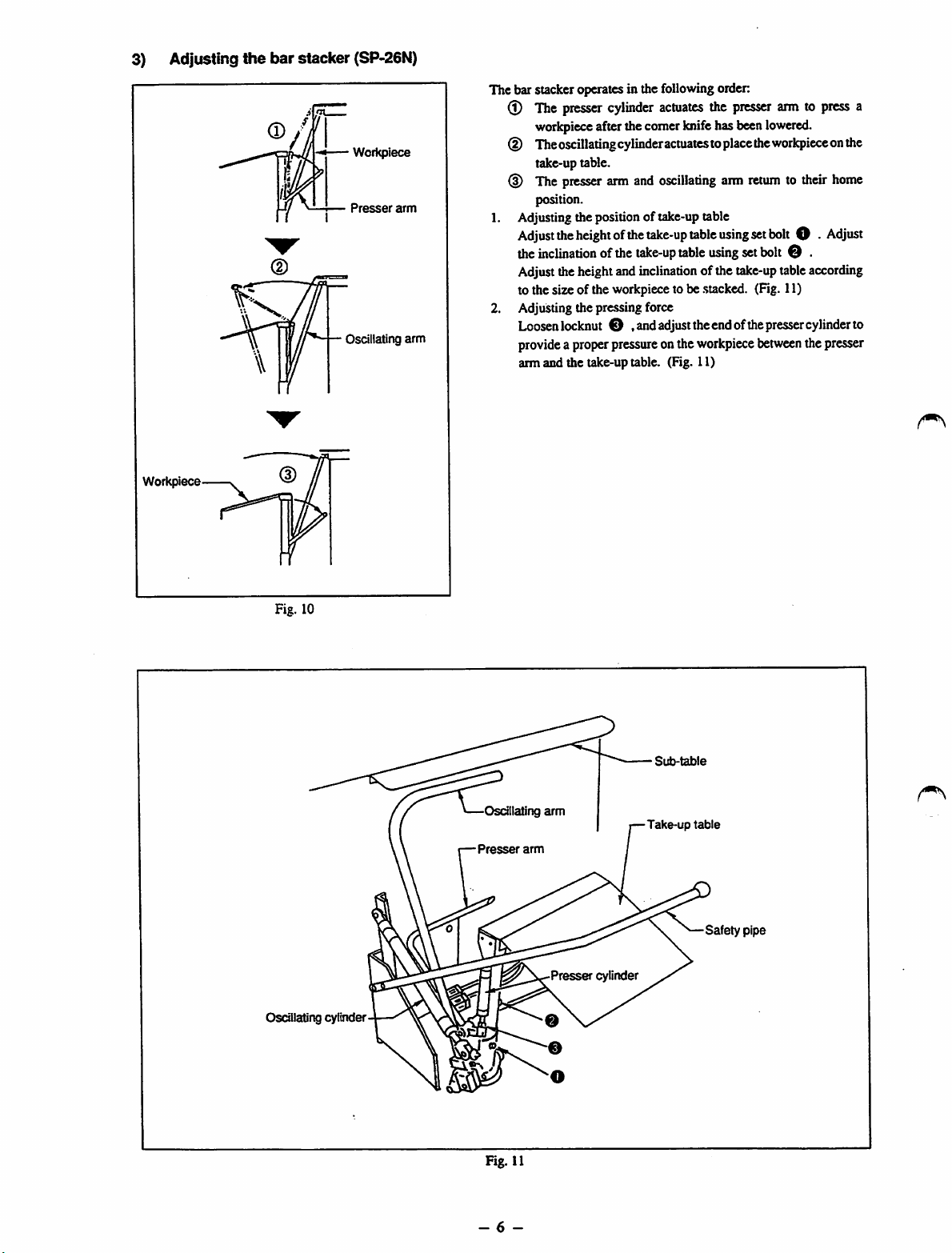

3) Adjusting

Workpiece

the

bar

stacker (SP-26N)

Presser

Oscillating

Workpiece

arm

arm

The bar stacker operates in the followingorder:

(l) The

(D Theoscillatingcylinder

(D The

1. Adjusting the position of take-up table

2. AdjuSdng the pressing force

presser

workpiece

take-up table.

position.

Adjust

the

the

inclinadon

cylinder

afterthecomerknifehasbeen

presser

arm and

heightofthe

ofthe

actuates

actuates

oscillating

take-up

take-up

table

table

the

toplacethe

using

using

Adjusttheheightandinclination of the

to the size of the workpieceto be

.stacked.

presser

arm

take-up

Loosenlockout O .andadjusttheendofthe

provide

a properpressure onthe

arm and the take-up table. (Fig. 11)

workpiece

arm to

lowered.

workpiece

returntotheir

set

bolt

O •

set

bolt

O .

tableaccording

(Fig. 11)

presser

between

press

onthe

home

Adjust

cylinderto

thepresser

a

Fig. 10

Oscillating cylinder

Osdilating

Presser

arm

arm

Presser

0

cylinder

•

Sub-table

-Take-up

table

Safety

pipe

Fig. 11

- 6 -

Page 11

4) Attaching

1. Attach the roller stacker on the left-hand side face of the main unit frame, and fix it with three screws taking care to set the

roller in parallel to the main unit table.

Roller

Main

stacker

the

unit

attaching

roller

frame

stacker

position

PJ304040505

(SP-36N)

^6

tube

2.

Pa.ss

theairtube O for

connector©for

© in

Fig.

3.

Connect

illustrated in the figure below.

air

shown

tube

roller

above

O .

Fig. 12

roller

oscillating

oscillating

inthe

written

15P

connector©and2Pconnector©respectively

Stackerpanel on the

main

unit

cylinder

frame

solenoid

order.

and

valve,

outputcablefordrivingroller,theupperdetection

the

motor

power

cable

* Whenattachingtherollerstackerto themachine, puta plug toone

side of the hole for quick-coupling

ofthe2P

connectorOthrough

tothe

stacker

panel

ofthe

joint

sen.sor

holes

main

cableofthe

® , ®

unit

frame

and

as

Fig. 13

- 7 -

Page 12

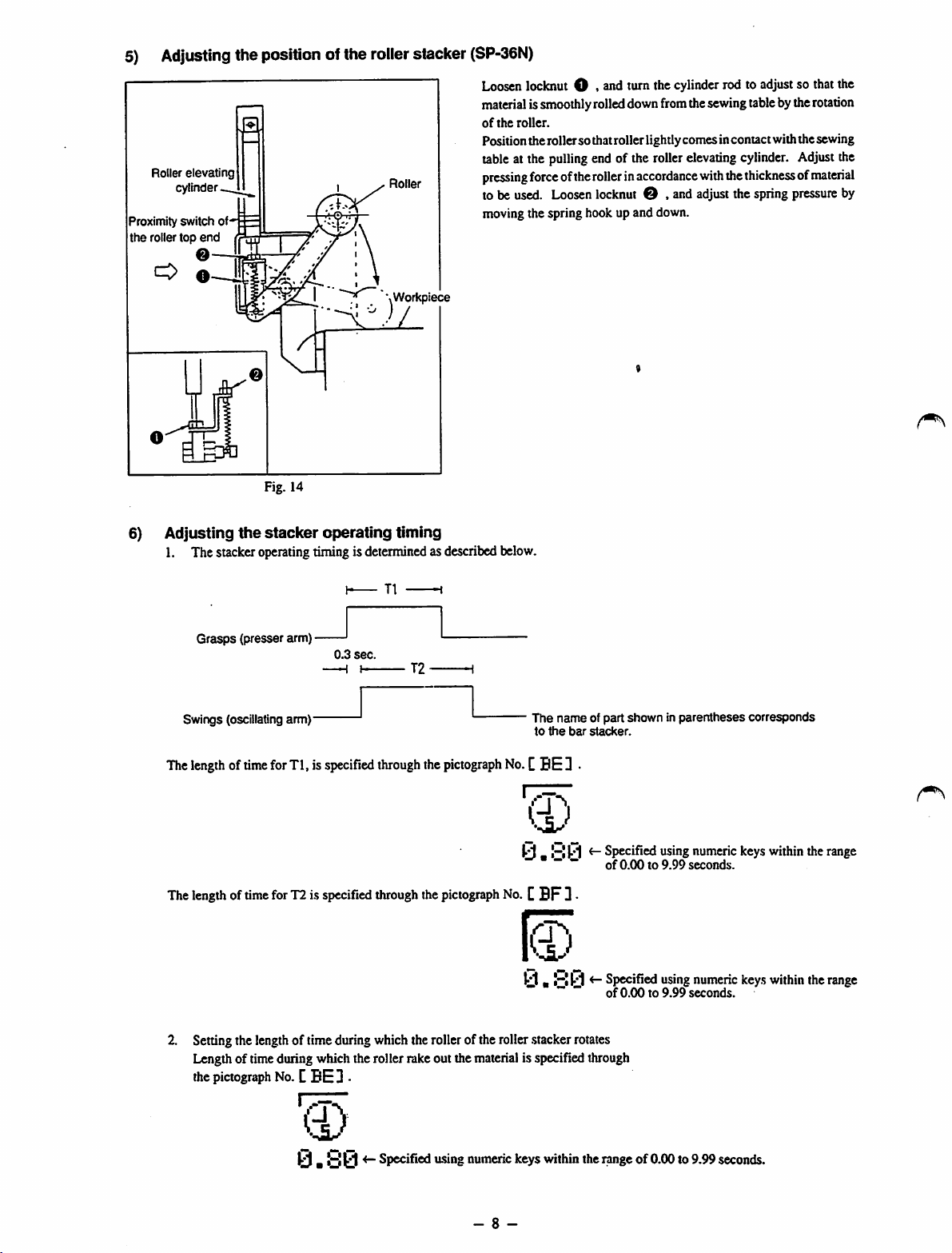

5) Adjusting the position of the rollerstacker

Roller

elevating

cylinder

Proximity switch of*'

the roller top

O

end

©-

0-

Fig. 14

Roller

\Workpiece

(SP-36N)

Loosenlockout O . end turn the cylinderrod to adjustso thatthe

material

issmoothlyrolleddownfromthesewingtablebythe

of

the

roller.

Positiontherollersothatroller lightlycomesincontact withthe sewing

tableat the

pressing

to be

moving the spring hook up and down.

force

used.

pulling

end of the rollerelevating cylinder. Adjustthe

ofthe

rollerinaccordance

Loosen

locknut

© , andadjustthe spring

with

the

thicknessofmaterial

rotation

pressure

by

6)

Adjusting

1. The stackeroperatingtiming is determinedas described below.

Swings (oscillating

The

The

the

Grasps

(presser arm) •

lengthoftime

lengthoftime

stacker

arm)'

for

Tl, is

for

T2is

operating

0.3

sec.

-H

I T2

specified

specified

timing

T1

through

through

the

pictograph

the

pictograph

The name of part shown in parenthesescorresponds

to

the

bar

stacker.

No.

CBE D

y.y0

No.CBF

ti.yy

*" ~ ~ of 0.00 to 9.99 seconds.

~ *"

3

<-

Specified

of

0.00to9.99

<-

specified

using

using

numeric

seconds.

numeric

keys

keys

within

within

the

the

range

range

2. Setting the lengthof time during which the rollerof the roller.stackerrotates

Lengthof timeduring which the roller rake out the materialis specifiedthrough

the

pictograph

No.CBE3 •

Ci)

ir- Specified u.sing numeric keys within the rangeof0.00 to 9.99 seconds.

- 8 -

Page 13

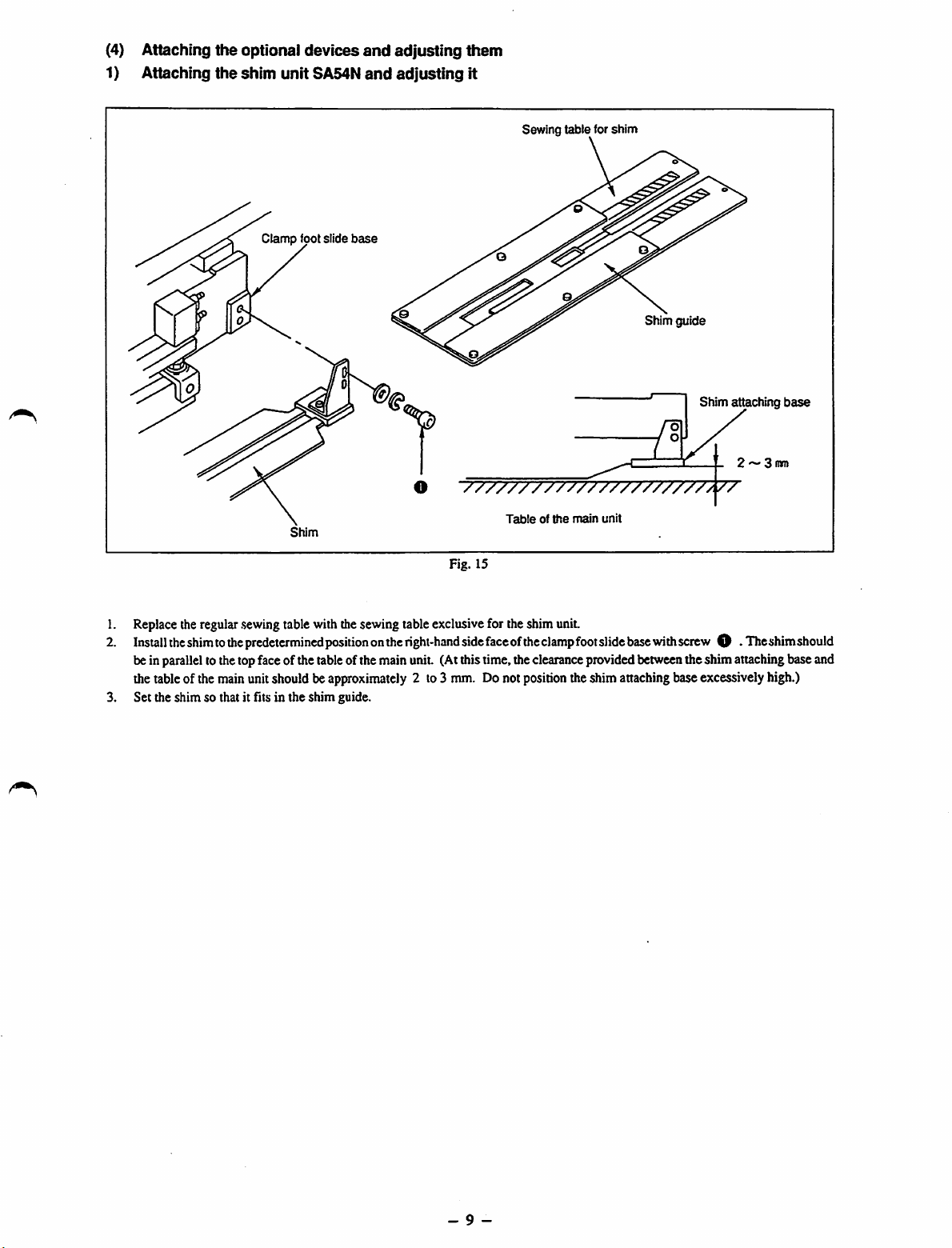

(4) Attaching

1) Attaching

the

the

optional

shim

unitSA54N

Clamp

devices

foot slide

base

and

and

adjusting

adjusting

them

It

Sewing

table

for

shim

Shim guide

Shim attaching

2 ~ 3

O

"7777777777777777777777/77

side

Tableofthe

faceofthe

position

Shim

Fig. 15

1. Replacetheregular

2.

Install

the

shimtothe

beinparallelto thetopface of thetableof the main unit. (Atthistime,theclearanceprovidedbetweentheshim attachingbase and

thetableof themainunitshould be

3. Set the shim so that it fits in the shim guide.

.sewing

table withthesewing tableexclusivefor theshim unit.

predetermined

positiononthe

approximately

right-hand

2 to3 mm. Donot

main

unit

clamp

foot

slide

base

with

screw

O •

theshimattaching baseexcessively high.)

The

base

mm

shim

should

- 9 -

Page 14

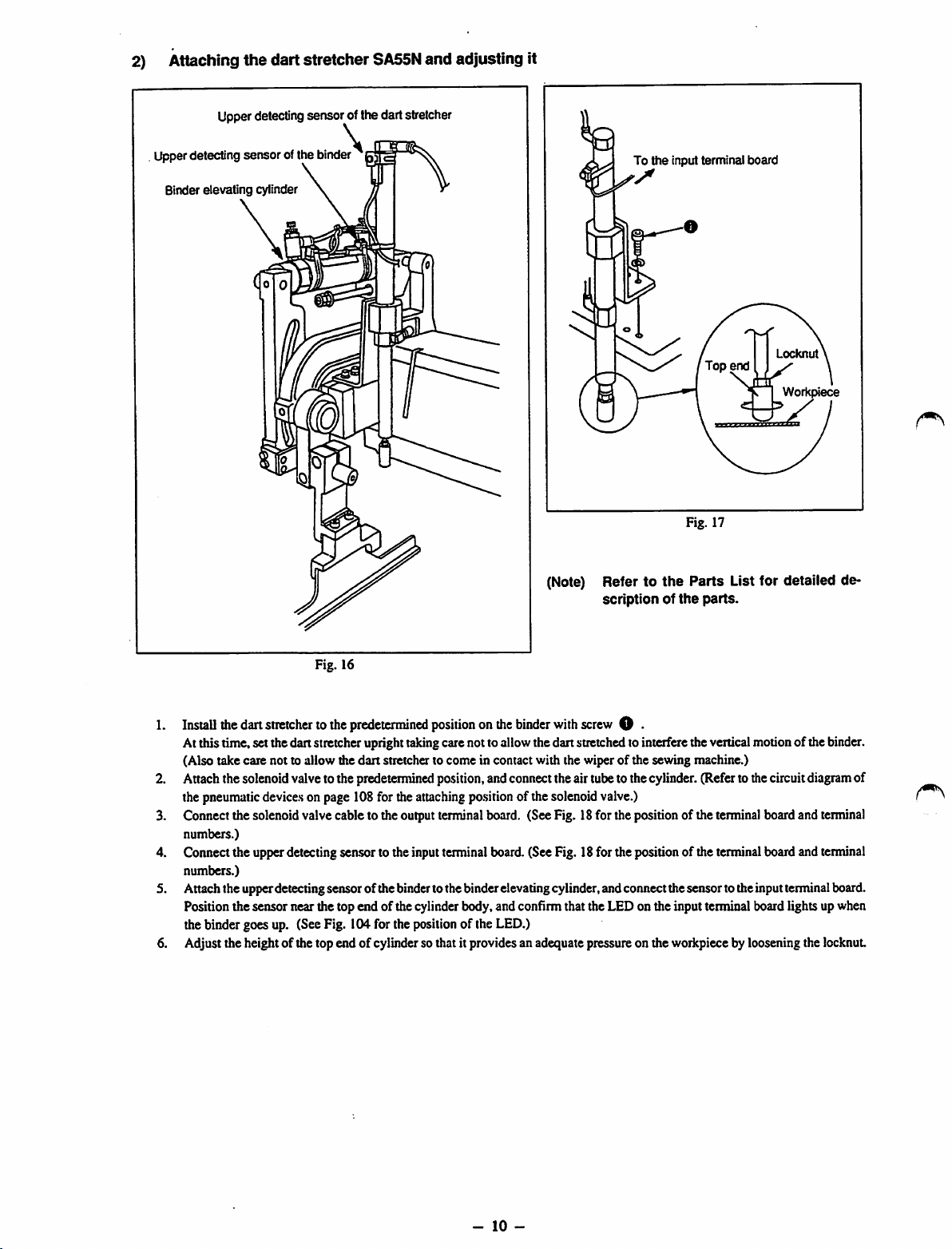

2) Attaching the dart stretcher

Upperdetectingsensor ofthe dart stretcher

SA55N

and adjusting it

Upperdetecting sensor ofthe binder '

Binder

elevating

cylinder

\

To

(Note) Refer to

scriptionofthe

the

input terminal

Fig. 17

the

Parts

board

Locknut

Workpiece

List for detailed de

parts.

Fig. 16

Install

the

dart

stretchertothe

Atthis time, setthedan stretcheruprighttakingcarenotto allowthedan stretchedto interferetheverticalmotionof the binder.

(Also take care not to allow the

Attachthe solenoidvalveto the predetermined position,andconnecttheairtubeto the cylinder.(Referto thecircuitdiagramof

thepneumatic

Connect the solenoidvalve cable to the outputterminalboard. (SeeFig. 18for the positionof theterminalboardand terminal

3.

numbers.)

4.

Cormectthe upperdetectingsensor to the inputterminal board.(SeeFig. 18for the positionof the terminalboard and terminal

numbers.)

Attachthe upperdetectingsensor ofthe bindertothe binderelevatingcylinder,andconnectthesensor totheinputterminalboard.

Position the sensor near the top end of the cylinderbody,and confirm that the LED on the input terminal board lights upwhen

the binder goes up. (SeeFig. 104for the positionof the LED.)

Adjust the height of the top end of cylinderso that it provides an adequate pressureon the workpiecebylooseningthe locknut

6.

device.s

predetermined

dan

positiononthe

stretcher to come in contact with the wiper of the sewing machine.)

onpage 108for theattaching

binder

po.sition

of thesolenoidvalve.)

with

screw

O •

-

10

-

Page 15

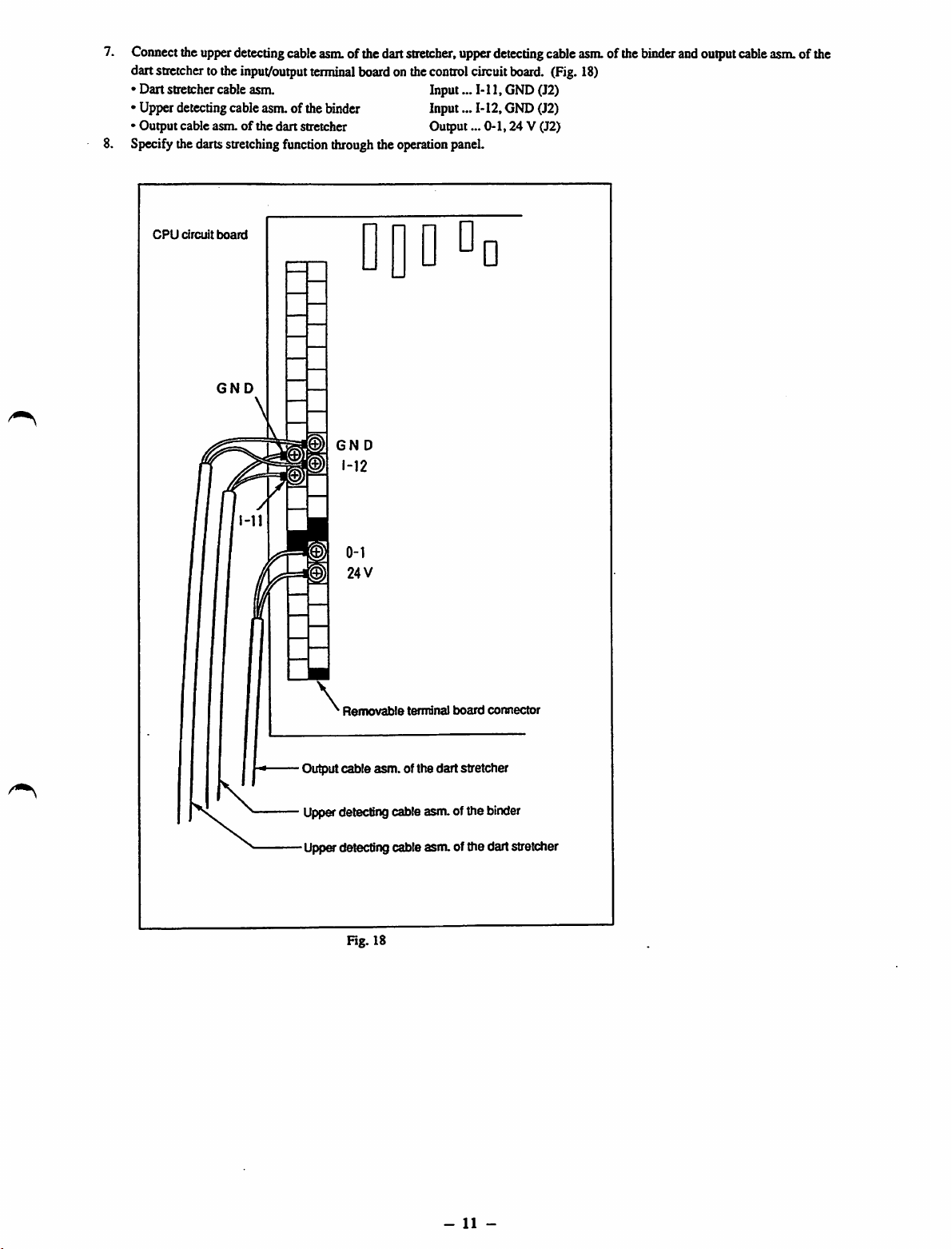

7.

Connect

dartstretcher to the

• Dart stretchercableasm. Input...

• Upper detectingcable asm.of the binder Input...

• Output cable asm. of the dart stretcher Output...

Specifythedartsstretchingfunctionthroughthe operation panel.

CPU

the

circuit

upper

board

detecting

input/output

cable

asm.

terminal

ofthedart

boardonthe

stretcher,

DQDDd

GND

GN

D

control

upper

circuit

Ml,

M2,

detecting

board.

GND(J2)

GND(J2)

0-1,24

cable

V (J2)

asm.

(Fig.18)

ofthe

binder

and

output

cable

asm.ofthe

Removable

Output

cable

\

Upperdetectingcable asm.of the binder

Upp&detecting cable asm. of the dart stretcher

Fig. 18

terminal

asm.

of the dart stretcher

board

connector

-

11

-

Page 16

4.

CONNECTIONOFELECTRIC

POWER

(1)Connection of electric power source

Connect

the

power

supply

cordofthe

sure that the sewingmachine rotatesin thecorrectdirection.

[Rotating direction]

Turn

the

handwheel

directionofthe

from

the

handwhecl's

wires

(R.S.T.).

[Precaution in the electric connection]

1. Connect the ground wire to the earth without exception.

2. Quality of power

• Voltagefluctuation

• Rapid change of power voltagemaystop the machine.

• Surge

(2)

Connectionofthe

toletthe

handwheel.

Whenthewire

side)tostop

currentorelectromagnetic

air

supply

Air

operation

needle

down

the

mu.st

notexceed± 10%of the ratedvoltage.

paneltothe

toits

connectioniscorrect,

needle

inits

inductioninpower

source

cock

SOURCE

AND

power

lowest

dead

point

and

the

highest

dead

position.Ifnot,

may

Airpressure adjusting knob

AIR

SUPPLY

source

outlet

turn

handwheel

leadthe

SOURCE

(R.S.T.E.).

the

power

willrotateinthe

alternate

machinetomalfunction.

supply

When

switch

counterclockwise

the

connectionoftwo

connecting

"ON"as

you

the

lead

watch

direction

wires

wires,

make

the

rotating

(viewed

outofthree

Airsupply

Air

pressure

gauge

/

Airniter regulator

\ ^

Fig. 19

1. Securely connect the air supply

2.

Open

theaircockand

knob.

[Precautions for the air supply source]

Referto the article[(4) Precautionsforthecompressedairsupplying(theairsupplysource)devices]ofInspectionandmaintenance.

(Page 80)

adjust

theair

ho.se

(1/4")to the air cock locatedon the rear face of the machine.

pressure

sothattheair

pressure

gauge

indicates

S.O

kgf/cnF

(0.S

MPa)

bytheair

pre.ssure

adjusting

-

12

-

Page 17

5.

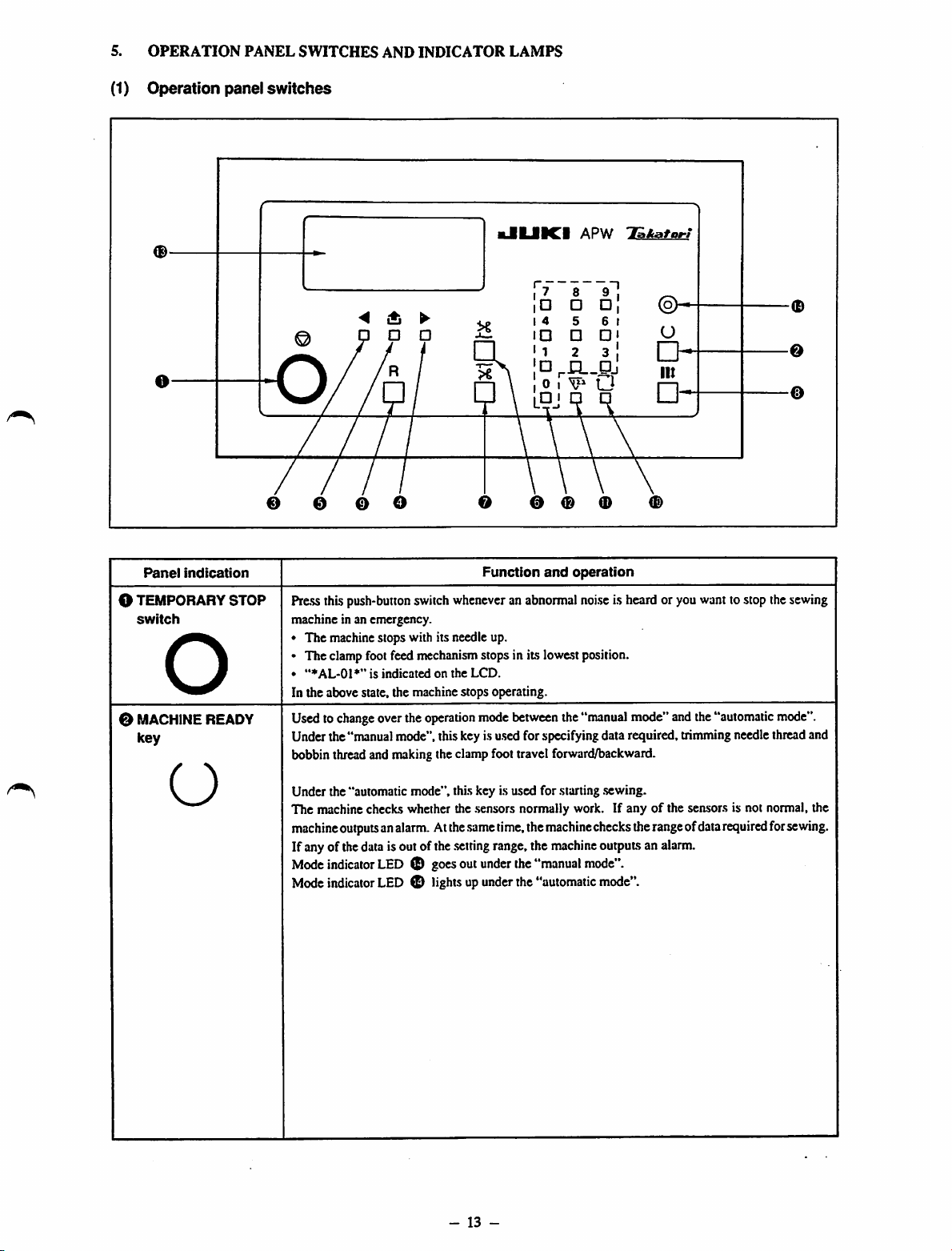

(1)

OPERATION

Operation

PANEL

panel

SWITCHES

switches

AND

INDICATOR

LAMPS

Panel

indication

O TEMPORARY

switch

STOP

o

0 MACHINEREADY

key

kJIIJIICI

APW

rL.Pj

T&kafort

T1

0 e o o 0 0 0

Function

Press this push-button switchwheneveran abnormalnoiseis heard or you wanttostop thesewing

machine in an emergency.

• The machinestops with its needle up.

• The clampfootfeed mechanism stops in its lowestposition.

•

"♦AL-01*"

In the above state, the machine stops operating.

Usedto

Under the"manualmode", this key is

bobbin thread and

change

is

indicatedonthe

overthe

operation

nnaking

LCD.

mode

u.sed

theclamp foot travel forward/backward.

and

operation

between

the"manualmode" andthe"automatic

for specifyingdata required, trimmingneedlethreadand

-0

0

©

mode".

O

Under the "automatic mode", this key is used for starting .sewing.

The machine checks whether the .sensors normally work. If anyofthe sensors is not normal, the

machine

outputsanalarm.Atthe

If anyof thedata isoutofthe

Mode

Mode

indicator

indicator

LED0goes

LED0lightsupunder

.same

.setting

out

-

13

time,

range,the

under

-

the

the

"manual

the

"automatic

machine

machine

checks

outputsan

mode".

mode".

the

range

alarm.

ofdata

required

for

sewing.

Page 18

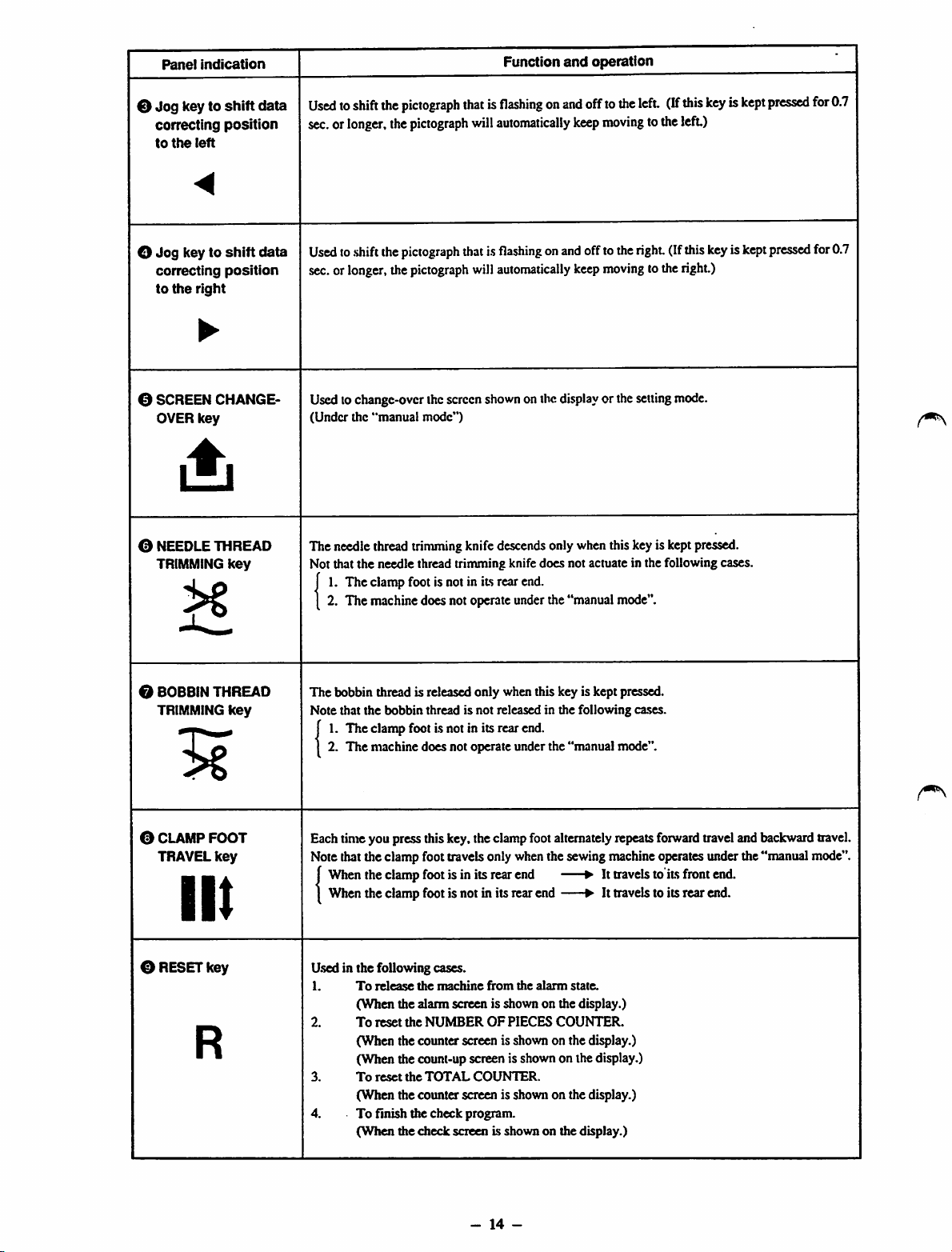

Panel

indication

Function

and

operation

0

Jog

key to

shift

data

correcting

to

the

position

left

<

O

Jog

key to

shift

data

correcting

to

the

position

right

•

0 SCREEN CHANGE

OVER

key

0 NEEDLE THREAD

TRIMMING

key

Usedtoshift

sec.orlonger,

Used

sec.or

Usedtochange-over thescreen

(Under

The needle thread trimmingknife descendsonly whenthiskeyis keptpressed.

Not that the needle thread trinruningknife does not actuate in the following cases,

f1.The

[ 2. The

the

toshiftthe

longer,

the

"manual

clamp

machine

pictograph

the

pictograph

pictograph

the

pictograph

mode")

footisnotinits

does

not

thatisflashingonand

will

automatically

thatisflashingonand

will

automatically

shown

onthe

display

rear

end.

operate

under

the

"manual

offto

the

left.

keep

moving

totheleft)

offtotheright(If

keep

moving

tothe

or the

setting

mode".

(If

mode.

this

keyiskept

this

right.)

keyiskept

pressed

pressed

for

0.7

for0.7

0 BOBBINTHREAD

TRIMMING

0 CLAMP

TRAVEL

key

FOOT

key

III

0 RESETkey

R

The

bobbin thread is released only when this key is kept pressed.

Note that the bobbin thread is not released in the following cases.

J1.The

1 2.

Eachtimeyou pressthiskey.the clampfootalternately repeats

Notethatthe clamp foot travelsonly whenthe sewingmachine operatesunder the"manual mode".

j

1

Used in the following cases.

1.

2.

3.

4. To finish the check program.

clamp

footisnotinits

The

machine

When

the

When

the

To

(When

To

(When the counter screen is shown on the display.)

(When the count-up screen is shown on the display.)

To

(When the counter screen is shown on the display.)

(When

does

clamp

footisin

clamp

footisnotinits

release

the

machine

the alarm screen is shown on the display.)

reset

the

NUMBEROFPIECES

reset

the

TOTAL

the

check

rear

end.

not

operate

under

the

"manual

its

rear

end

rear

end

from

the

alarm

state.

COUNTER.

COUNTER.

screen is shownon the display.)

mode".

forward

•Ittravelstoits

• It

travelstoits

traveland backwardtravel.

front

end.

rear

end.

-

14

-

Page 19

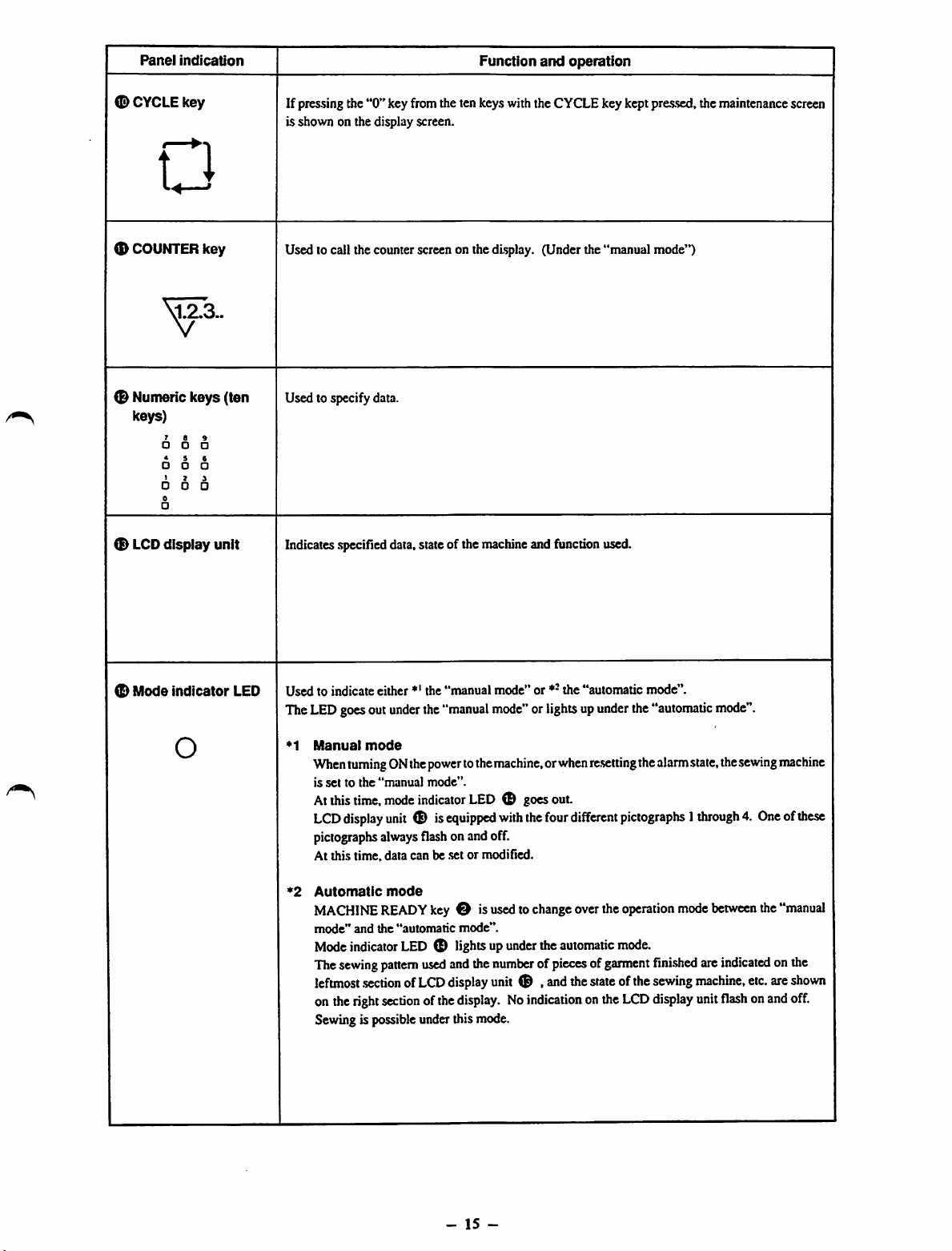

Panel

indication

Function

and

operation

<D

CYCLE

key

n

<D

COUNTER

0 Nunteric keys (ten

keys)

®

LCD

key

5573..

• •

* i

• o

I 7

• •

0

•

display unit

If pressing the

is shown on the display screen.

Used to call the counter screen on the display. (Under the "manual mode")

Used to specify data.

Indicates

"0"

.specified

key from the ten keys with the CYCLE key kept pressed, the maintenance screen

data,state of the machineand function used.

(D

Mode

indicator

O

LED

Used

to indicate either *' the

The

LED

goesout

•^1

Manual

When

is

settothe

Atthis

LCD

pictographs

At this time, data can be set or modified.

*2

Automatic

MACHINE

mode"

Mode

The

sewing

leftmost

onthe

Sewingis possibleunder this mode.

under

mode

turningONthe

"manual

time,

mode

display

unit

always

mode

READY

and

the

"automatic

indicator

pattern

.sectionofLCD

right

section

"manual

the

"manual

power

tothe

mode".

indicator

® is

equipped

flash

onandoff.

key

O is

mode".

LED (D lightsup

used

andthe

display

ofthe

display.Noindication

mode"

or *-

the

"automatic

mode"

orlightsup

machine,orwhen

LED

O goesout.

with

the

usedtochange

under

theautomatic

four

le-setting

different

overthe

numberofpiecesofgarment

unit

® ,

and

the

state

onthe

mode".

under

the

"automatic

the

alarm

mode".

state,the

sewing

pictographs1through4.Oneofthese

operation

mode.

ofthe

LCD

mode

fini.shed

sewing

display

between

are

indicated

machine,

unit

flash

the

etc.

onand

machine

"manual

onthe

are

shown

off.

-

15

-

Page 20

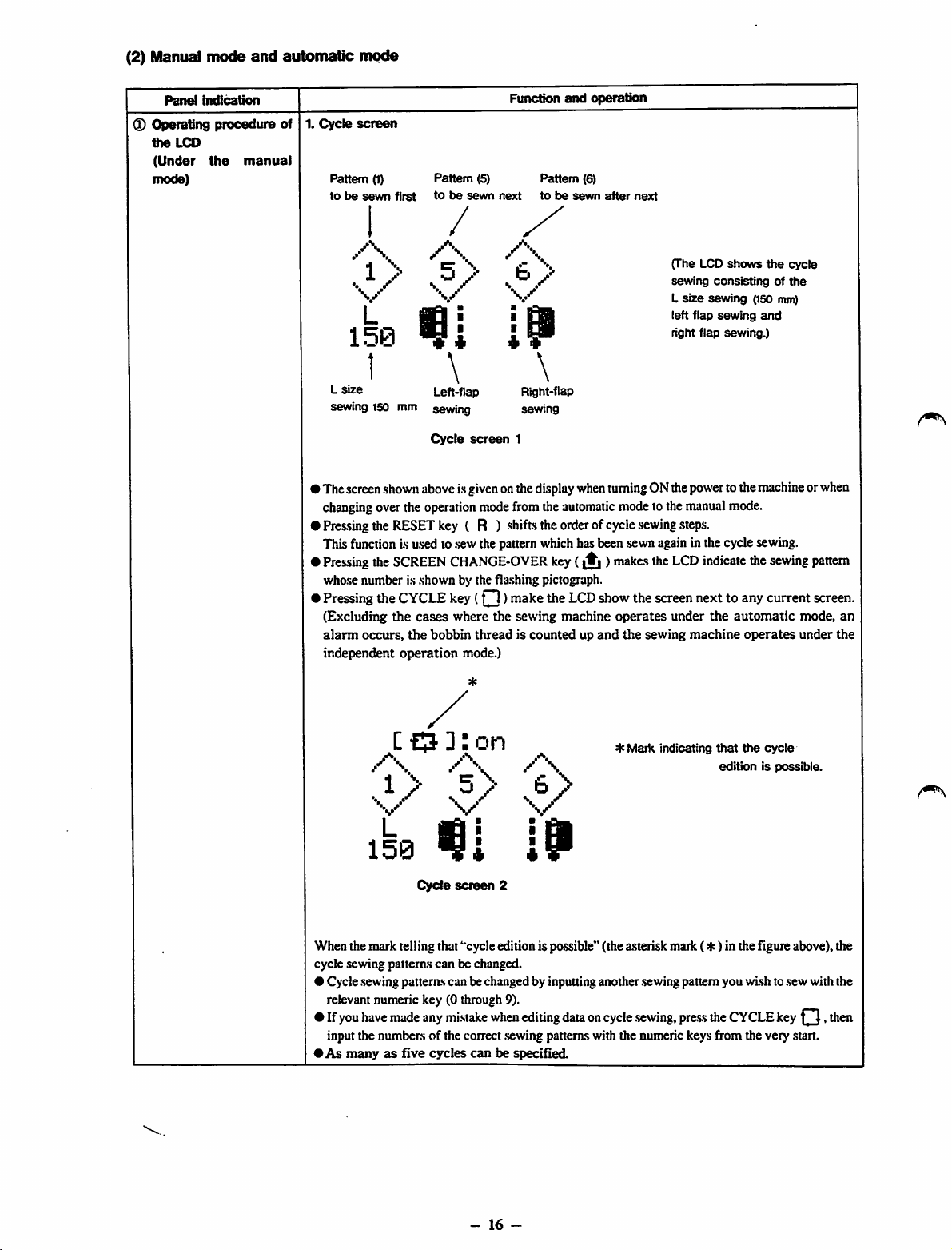

(2) Manual

mode

and

automatic

mode

Panel

Operating

the

LCD

(Under

mode)

indication

procedure

the

manual

Funcdon

1.

Cycle

of

screen

Pattern

(1)

tobesewn

Pattern (5) Pattern (6)

first

tobesewn

next

and

tobesewn

operation

after

next

/

/\

'

.

V

L

m

I

I

150

I

L

size

sewing

150

mm

• ThescreenshownaboveisgivenonthedisplaywhenturningONthepowertothemachineorwhen

changing

•

Pressing

Thisfunctionis used to

•

Pressing

whose number is shown by the fla.shing pictograph.

•

Pressing

(Excluding

alarm

independent

overthe

theRESETkey ( R ) shiftstheorderofcycle

the

SCREEN

the

the

occurs,

Left-flap

sewing

Cycle

operation

CYCLE

cases

the

bobbin

operation

\

screen

.sew

CHANGE-OVER

key

where

mode.)

Right-flap

sewing

1

mode

fromthe

thepatternwhichhasbeen sewnagainin thecyclesewing.

(O )

make

the

threadiscountedupand

sewing

automatic

key

(|^)makes

the

LCD

machine

modetothe

show

operates

the

sewing

the

the

sewing

(The LCD

sewing

L

size

left

right flap

manual

.steps.

LCD

screen

under

shows

consistingofthe

sewing

flap

sewing

sewing.)

mode.

indicate

nexttoany

the

automatic

machine

operates

the

(ISO

and

the

sewing

current

mm)

cycle

mode,

under

pattern

screen.

an

the

CO

/"•s

*•!\ 'ir\

..1/

]:

on

b

s/

\ ^

*

Mark

indicating

that

the

cycle

editionispossible.

L

150

Cycle

screen

When the mark telling that "cycle edition is po.ssible"(the asterisk mark (4c) in the Hgure above), the

cycle .sewing patterns can be changed.

• Cycle .sewingpatternscan bechanged by inputting another .sewingpattern you wish to.sewwith the

relevant numeric key (0 through 9).

• If you have made any mi.stakewhen editing data on cycle .sewing,pre-ssthe CYCLEkey . then

input the numbers of the correct .sewingpatterns with the numeric keys from the very

•As

manyasfive

cycles

canbespecified

19

2

.start.

-

16

-

Page 21

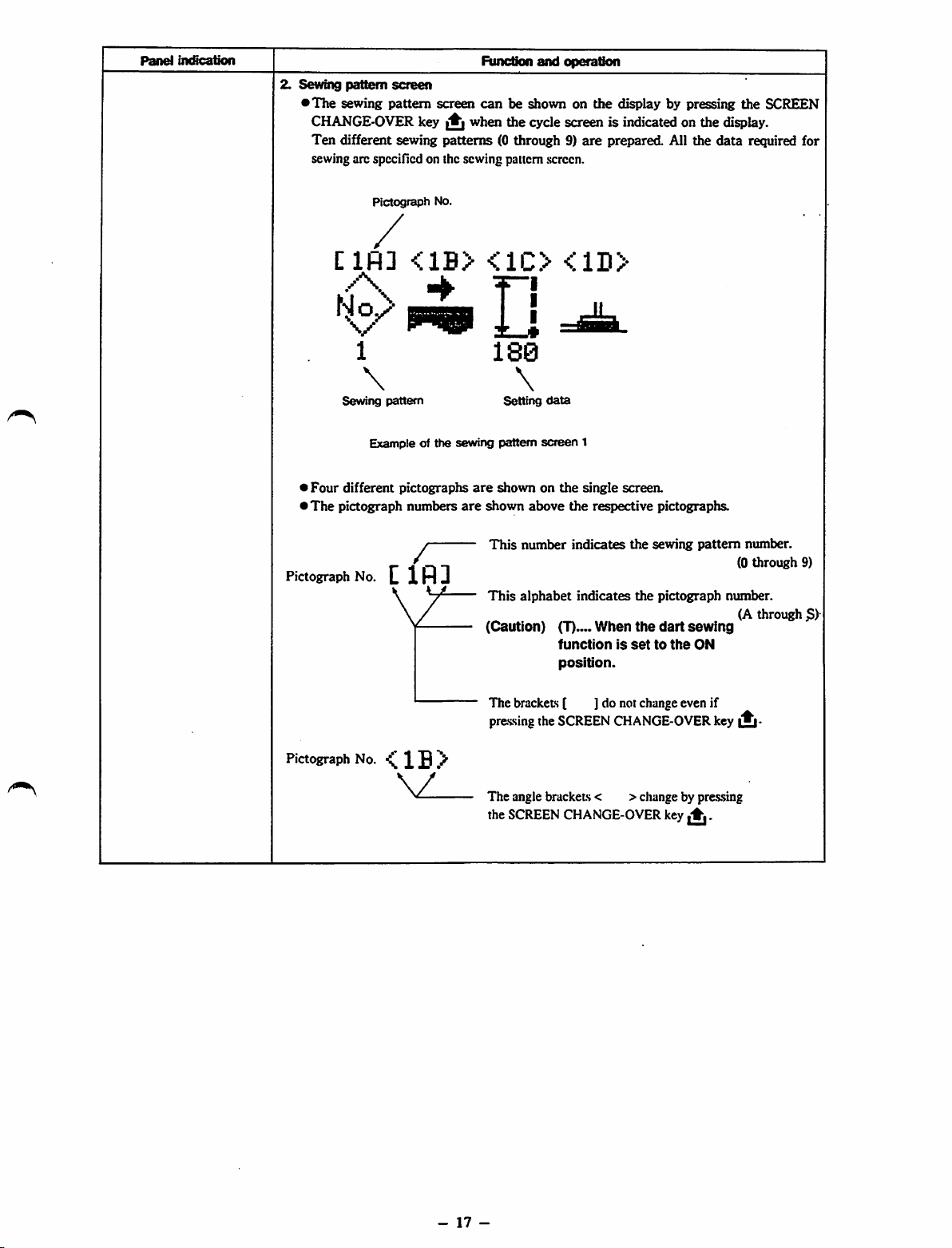

Panel

indication

Function

2.

Sewing

pattern

screen

•

The

sewing pattern screen

CHANGE-OVER

Ten

different sewing

sewing arc spccillcd on the sewing pattern screen.

key^when

patterns

can

be shown on the display by pressing the SCREEN

the

(0 through 9}

and

operation

cycle

screenisindicatedonthe

are

prepared

All the

display.

data

required for

Clfl]

Sewing

>

Four

different

*The

pictograph

Pictograph

Pictograph

1

\

pattern

Exampleofthe

pictographs

numbers

No.

Clfll

No.

<1B>

/"

sewing

are

are

<1C>

u

180

\

Setting

pattern

shownonthe

shown

above

This

number

This

alphabet

(Caution)

<1D>

data

screen

(T)

function

position.

1

single

the

respective

indicates

indicates

When

screen.

the

the

the

is

settothe

pictographs.

sewing

pattern

pictograph

dart

sewing

ON

number.

(0

through

number.

(A

through

9)

S)

Pictograph

No.^1B>

The brackets [ ] do not change even if

pressing the SCREEN CHANGE-OVER key

The angle brackets < >change by pressing

the

SCREEN

CHANGE-OVER

key

^.

-

17

-

Page 22

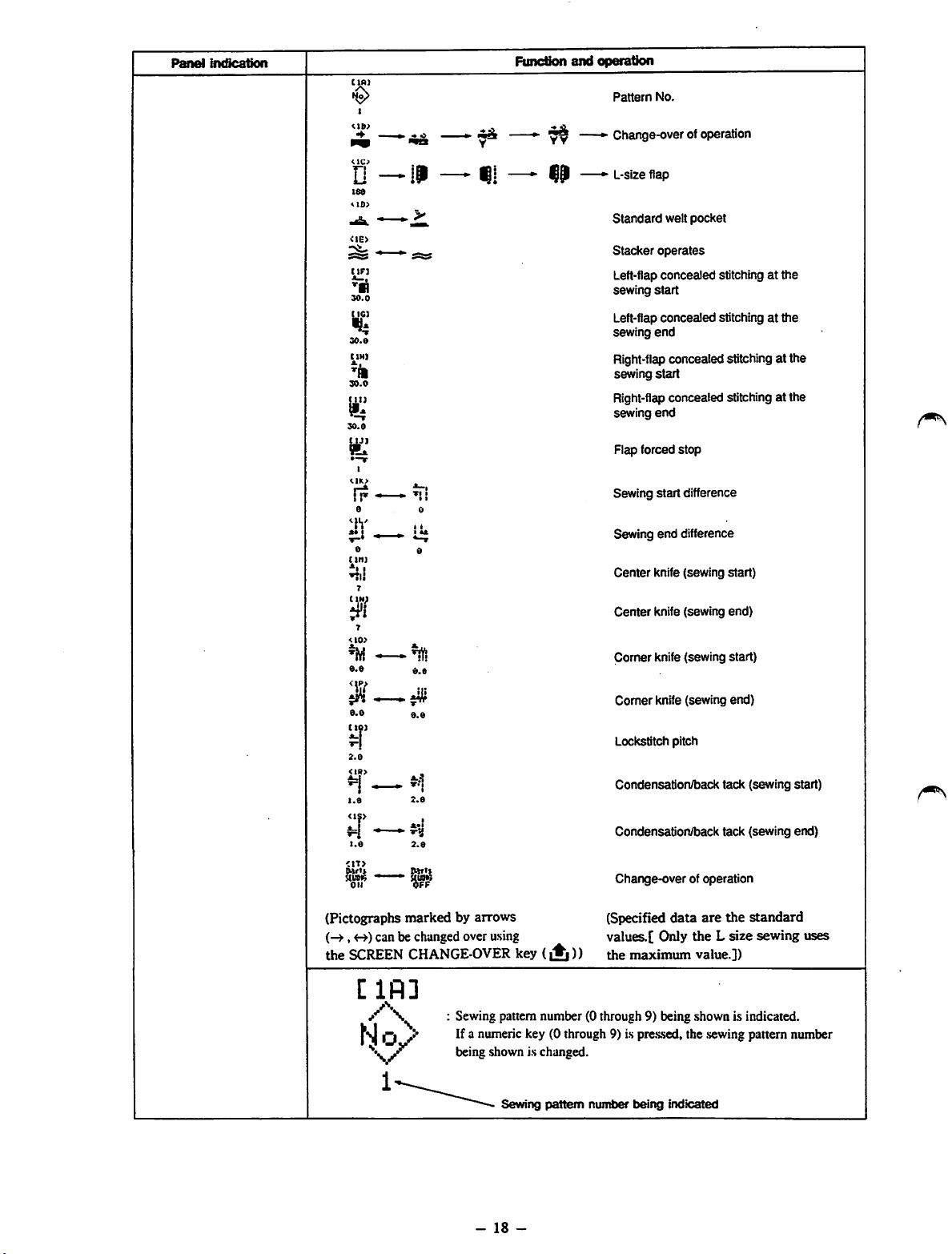

Panel

Imfication

Function

b

iMJ

and

operation

Pattern

No.

18«

<I0>

tin

30.0

Kg

30.0

CIH]

'/I

30.0

30.0

tyj

•-T

r?

a

^h'

a

titi]

ni!

Y

^ Change-over of operation

» L-size flap

Standard

Stacker

Left-flap

sewing

Left-flap

sewing

Right-flap

sewing

welt

pocket

operates

concealed

stitching at

start

concealed

stitchingatthe

end

concealedstitchingat the

start

the

Right-flap concealed stitching at the

sewing

end

Flap forced

Sewing

Sewing

I

Center

stop

start

difference

end

difference

knife (sewing

start)

7

<10>

a.a

II

0.0

ctoi

2.0

<IR>

1.0

<1S>

<1T>

Oi'i*

UUO«

oil

(Pictographs

(-^,

the

can be changedover asing

SCREEN

[IR]

/\

0.0

0.0

2.0

*•!

2.0

Il»Tll

markedbyarrows

CHANGE-OVER

Sewing pattern number (0 through 9) being shown is indicated.

If a numeric key (0 through 9) is

being shown is changed.

key

(A

Center

knife (sewing

Corner knife (sewing start)

Comer

knife (sewing end)

Lockstitch pitch

Condensation/back tack (sewing start)

Condensation/back tack (sewing end)

Change-overof operation

(Specified

data

are

values.[ Only the L

))

the

maximum

pre.s.sed,

value.])

the .sewingpattern number

end)

the

size

standard

sewing

uses

Sewing

pattern

-

18

-

number

being

indicated

Page 23

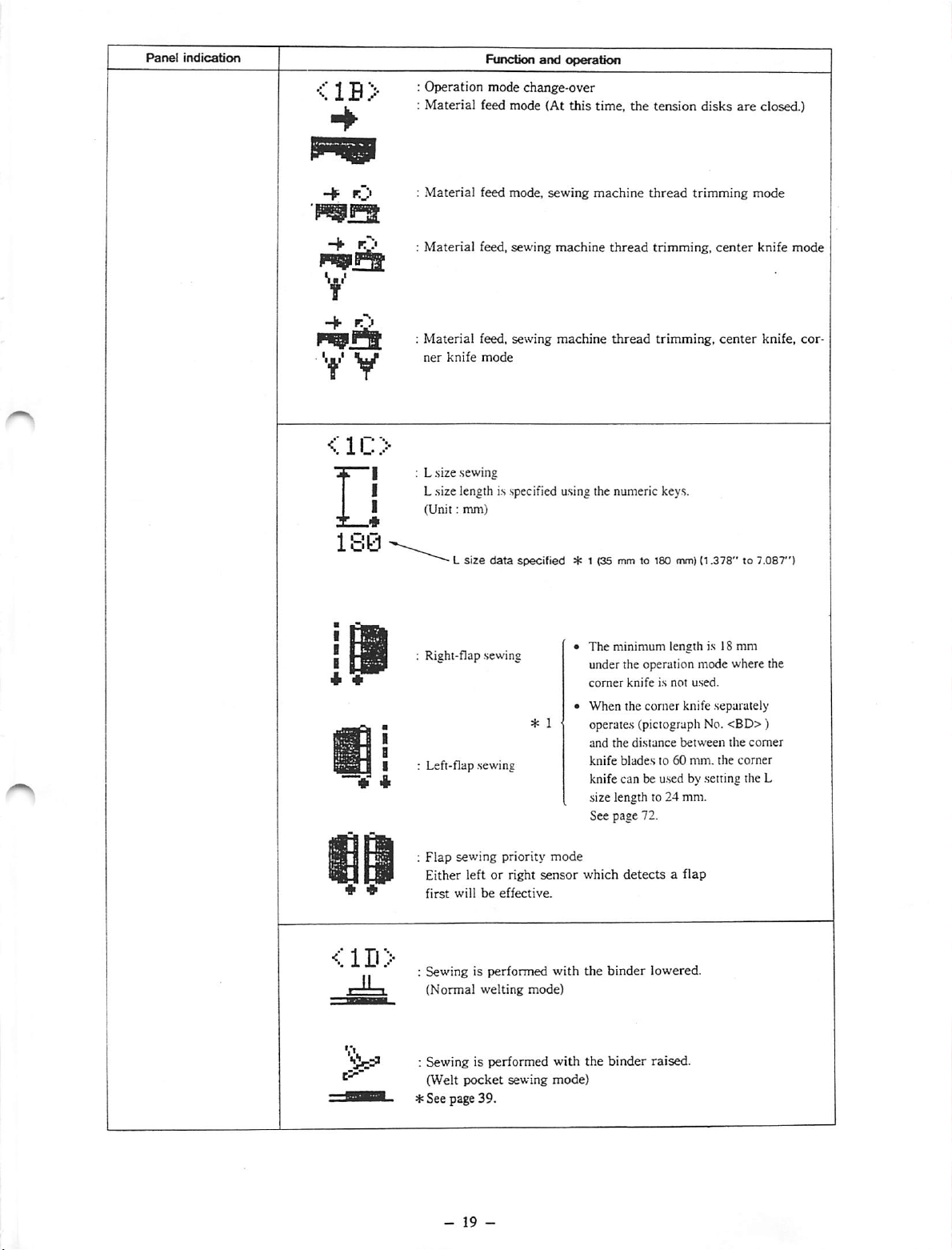

Panel

indication

Function

and

operation

<1B>

L :

y V

<1C>

X—*

180-

:

Operation

Material

;

Material

:

Material

Material

ner

L size sewing

L size length is specified using the numeric keys.

I

(Unit:

knife

L

mm)

size

feed mode,

feed,

feed, sewing

mode

mode

change-over

feed mode (At

sewing

sewing

data

specified

this

time,

the

machine

machine

machine

thread

thread

* 1 (35 mm to 100 mm)

tension

thread

trimming,

trimming,

disks

are

closed.)

trimming

(1.378"to7.087")

center

center

mode

knife

knife,

mode

cor

<1D>

Right-flap .sewing

Left-flap .sewing

Flap

sewing priority

Either left or right

first

willbeeffective.

: Sewing is performed

(Normal

welting

: Sewing is performed

(Welt

pocket

sewing

*See

page 39.

mode

sensor

mode)

The minimum length is 18 mm

under the operation mode where the

comer

knifeisnot

When the corner knife separately

used.

operates (piciograph No.

and

the

distance

knife

bladesto60

knife can be u.sed by .setting the L

size length to 24 mm.

See page 72.

which

detectsaflap

with

the

binder

with

the

binder

mode)

between

mm.

lowered.

raised.

<BD>)

the

the

comer

corner

Page 24

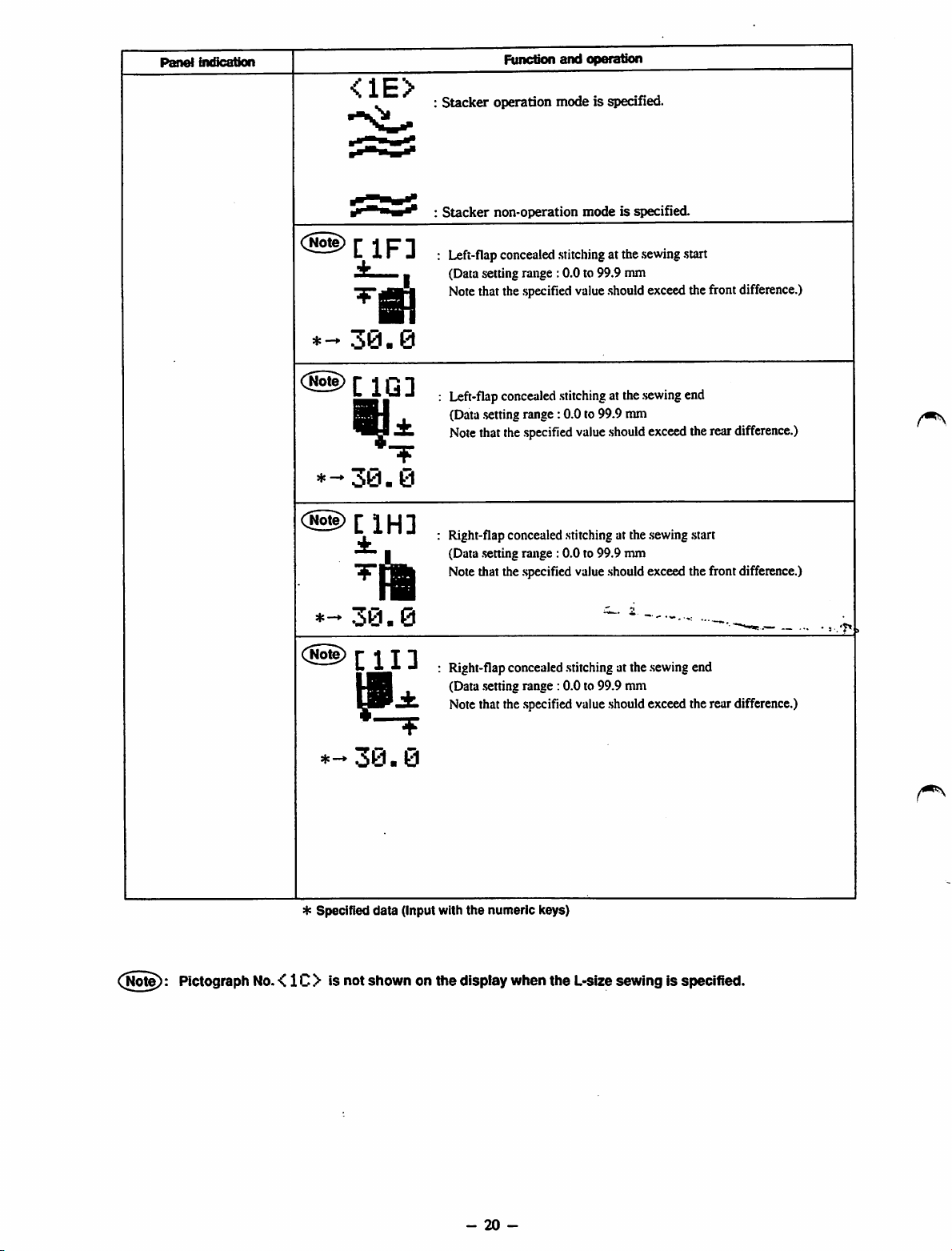

Panel

incQcation

Function

and

operation

<1E>

30

• 0

±

*-30.0

(@)[iH]

n

*-*

30-

:

Stacker

:

Stacker

I

operation mode is specified.

non-operation

Left-flapconcealedstitchingat the

(Data setting range :0.0 to 99.9 mm

Notethat thespecified value

Left-flap

(Data

Note

Right-flap concealed stitching at the sewing .start

(Data .settingrange : 0.0 to 99.9 mm

Note that the .specifiedvalue should exceed the front difference.)

concealed

.setting

range: 0.0 to 99.9 mm

thatthe

.specified

mode

stitching

value

is specified.

.sewing

.start

.should

exceedthefrontdifference.)

atthe

sewing

end

should

exceed

therear

0

difference.)

(jiote):

Plctograph

No.

<1C> is

C@)

♦

-30.0

4: Specified

not

[11]

data

shown

Right-flap concealed stitching at the .sewingend

(Data .settingrange :0.0 to 99.9 mm

Note that the .specifiedvalue .shouldexceed the rear difference.)

(Input with

onthe

the

numeric

display

when

keys)

the

L-size

sewingisspecified.

-

20

-

Page 25

Panel

indication

C

IJ]

Flap

forced

Function

stop

and

operation

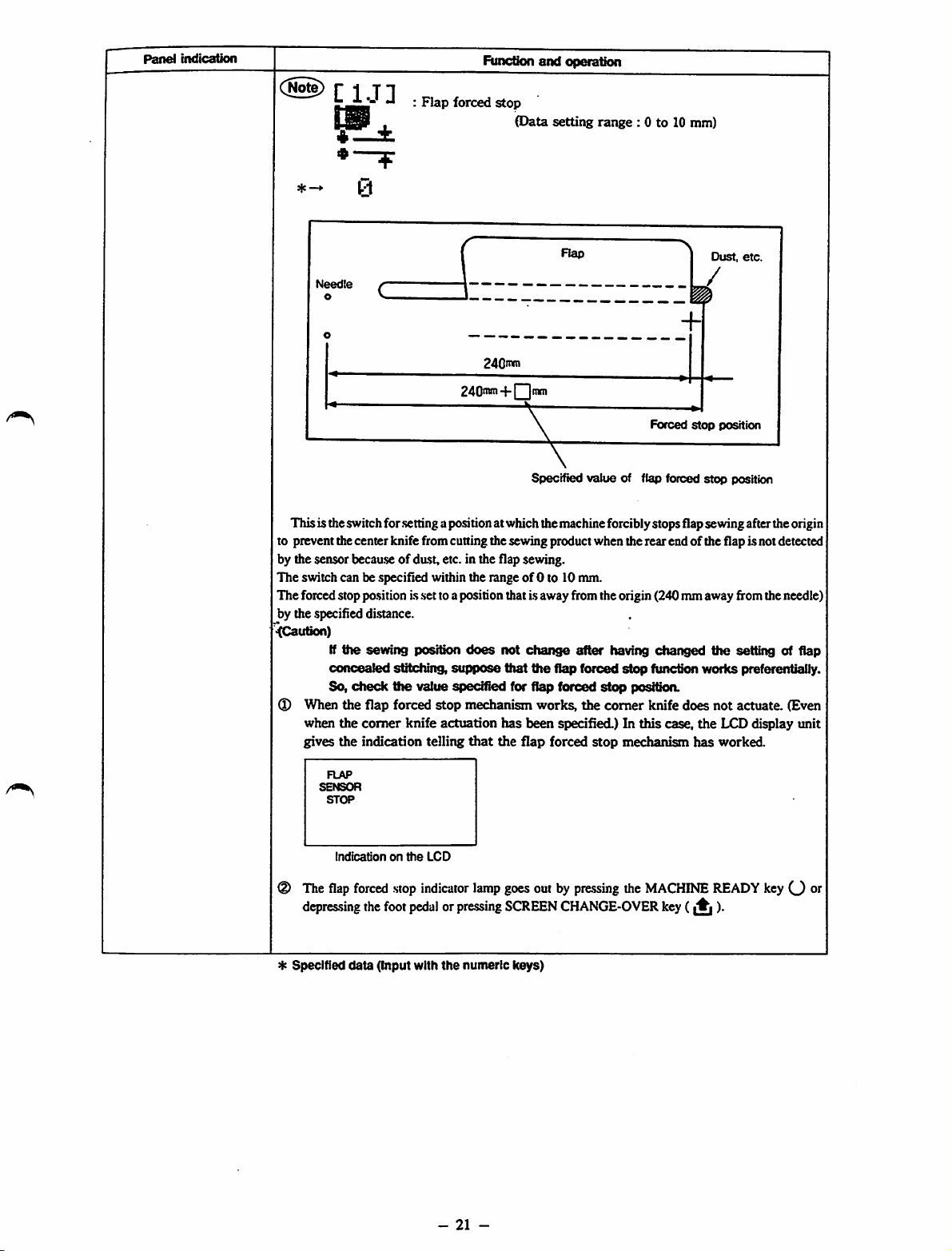

(Data setting range : 0 to 10 nun)

Rap

Needte

o

240"*"

240'w-i-|

Thisis theswitchfor

to prevent thecenter knife fromcuning thesewing product when therear end of the flap is notdetected

by the sensor

The

switch can be specified within the rangeof0 to 10 mm.

The forced stoppo.sition is .settoa position that isaway from the origin (240 mmaway fromtheneedle)

by the specified distance.

<(Caution)

I

When

when

gives

becau.se

If

the

concealed

So,

check

the

the

the

.setting

apositionat whichthemachineforciblystopsflapsevnngafterthe origin

of dast, etc. in the flap sewing.

sewing

flap

comer

indication telling

position

sfttctdng,

the

value specified for flap forced

forced

knife

does

stippose

stop

mechanism

actuation

that

not

has

the

ttiat

Itnm

Specified

change

the

works,

been

flap

value

after

flap

forced

stop

the

comer

specified.) In

forced

stop

of flap forced

having

stop

posftkm.

mechanism

>

Dust,

etc.

/

Forced

stop

position

stop

position

changed

function worlcs preferentially.

knife

this

case,

the

does

not

the

LCD display unit

has

worked.

setting of flap

actuate.

(Even

The

depres.sing

*

Specified

Indicationonthe

flap

forced

the

data

(Input with

LCD

stop

indicator

foot

pedalorpressing

the

-

lamp

numeric

21

-

goesout by

SCREEN

keys)

pressing

CHANGE-OVER

the

MACHINE

key

(A

READY

)•

keyO

oi"

Page 26

Panel

indication

Function

and

operation

<1K>

I

IT

I 1

0

^1!

6

<1L>

i

±«

B

qp—*

0

I

l±

0

C

IM]

±i

I

^ll

7

Sewingstart

hand

(Data setting range: 0 to 20 mm)

(When this data is set to zero (0), the left-hand .seamand right-hand seam

are made in parallel with each other.)

Sewing startdifference (The left-hand

hand

(Data .setting

(When this data is .setto zero (0), the left-hand

are made in parallel with each other.)

Sewing end difference (The left-hand side seam is .shorterthan the right-

hand

(Data .settingrange: 0 to 20 nun)

(When this data is .setto zero (0), the left-hand seam and right-hand seam

are made in parallel with each other.)

Sewing end difference (The right-hand side .seamis shorter than the left-

hand

(Data .setting range : 0 to 20 mm)

(When this data is .setto zero (0), the left-hand seam and right-hand seam

are made in parallel with each other.)

Center knife actuating po.sitionon the .sewingstart

(Data .setting

[The center knife .starts operating at the position that is away from the

shorter .seamby the .specifieddistance.]

side

side

side

side

difiference

one.)

one.)

range:

one.)

one.)

range:

(Theright-handside seam is shorter than the left-

.side

seam is shorter than the right-

0 to 20 mm)

seam

and right-hand seam

0 to

1.5

mm)

Z

•±-ii

T**

^ Specified

IN]

<10)

t'i

^iV!

0.0

-lY!

0.0

data

Centerknife actuating

(Data .setting

I

[The center knife .starts operating at the position that is away from the

shorter.seam by the specified distance.]

Recommendable data .setting

Coriierknife

(Data .settingrange : 0.0 to 10.0 mm)

l'

[The

.setting

(Refer to page 30)

The comer knifeactuates at the

.specified distance.]

Comerknife

(Data .settingrange : 0.0 to 10.0 mm)

[The

setting

(Refer to page 30)

Thecomer

specified distance.]

(Input wittt tlie numeric keys)

po.sition

range:

0 to 15 mm)

range:

actuating

valueiseffectiveonly

actuating

valueiseffectiveonly

knife

po.sition

position on the

actuates

at the

on the

7 to 15 mm

onthe

when

position

when

position

.sewing

end

.sewing

.start

thecomerknife

insidethe

sewing

start

thecomerknife

outside

the

actuates

.shorter

actuates

shorter

separately.

.seam

by the

separately.

seamby the

-

22

-

Page 27

Panel

indication

Function

and

operation

<1P>

ili

0.0

I I I

fi

±.4,

0.0

C

IQ]

±_i

"T"!

2.0

<1R>

1.0

2.0

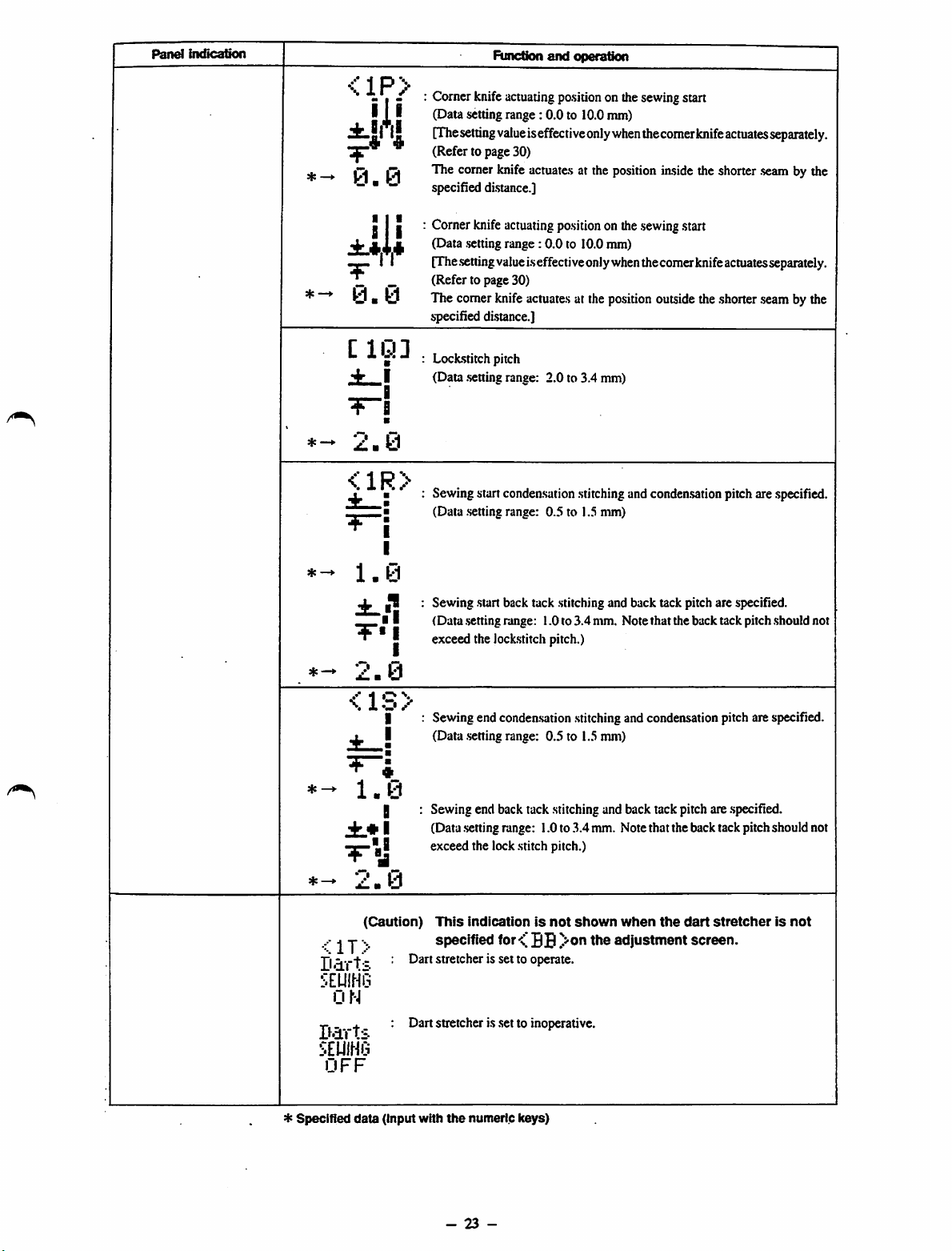

Comer knife actuatingpositionon thesewingstart

(Datasettingrange: 0.0 to 10.0nun)

[The

setting

value

iseffectiveonly

(Refer to page 30)

The comer knife

specified di.stance.]

Cornerknife

I

(Data .setting

[The

.setting

(Refer to page 30)

The comerknife

specified distance.]

Loclcstitchpitch

(Data

I

•

•

I

I

.setting

Sewingstart condeasation

(Data .settingrange: 0.5 to 1.5 mm)

Sewing start back tack .stitchingand back tack pitch are specified.

(Data .settingrange: 1.0to 3.4mm. Note that the back tack pitch should not

exceed the lockstitch pitch.)

actuate.s

actuating

range:

value

range: 2.0 to 3.4 mm)

po.sition

0.0 to 10.0 mm)

i.s

effectiveonlywhenthecomerknifeactuatesseparately.

actuate.s

when

thecomer

at the position iaside the shorter

onthe

.sewing

at the

position

.stitching

andcondensationpitch are specified.

start

outside

knife

actuates

theshorter

separately.

.seam

by the

.seam

bythe

*

Specified

Darts

smm

ON

Darts

smm

OFF

<1S>

1.0

jfc.* I

^•-1

2.0

(Caution)

j

data

I

H

(input

Sewing endcondeasation

(Data

.setting

range: 0.5 to 1.5mm)

Sewing end back tack stitching and back tack pitch are .specified.

(Data settingrange: 1.0to

exceed the lockstitch pitch.)

This

indicationisnot

specified

Dart stretcher is set to operate.

Dart stretcher is .setto inoperative.

with

the

for

numeric

keys)

BB

.stitching

.3.4

shown

and condensationpitch are specified.

mm. Notethat theback tackpitch should not

when

the

dart

stretcherisnot

adjustment

screen.

-

23

-

Page 28

Panel

indication

Function

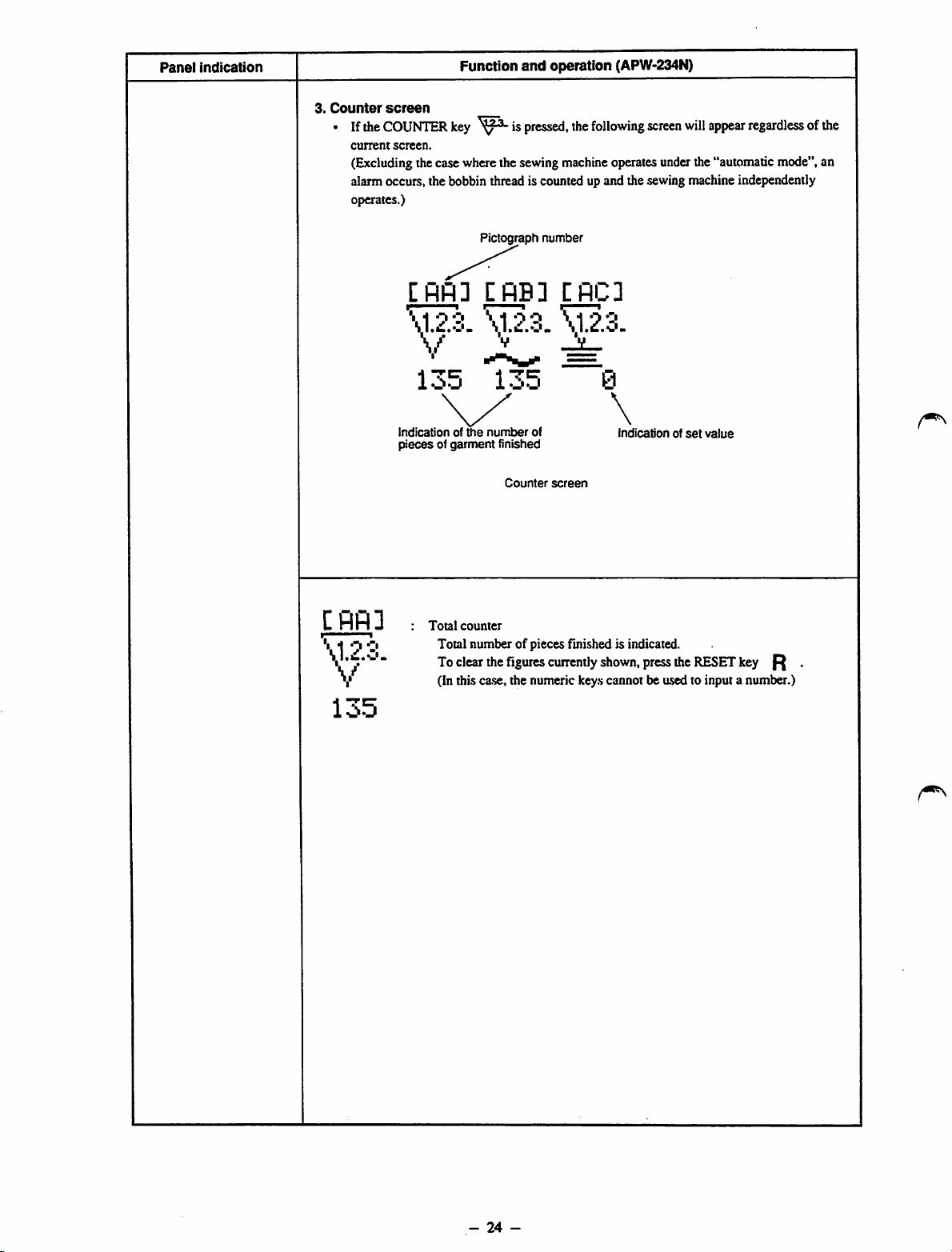

3.

Counter

• If the

screen

COUNTER

current

screen.

(Excludingthecasewherethesewing

alarm occurs, the bobbin thread is counted up and the sewing machine independently

operates.)

key is

and

operation (APW-234N)

pressed,

the

following

machine

operatesunderthe"automaticmode",an

screen

willappearregardless of the

C

flfl

\1.2.3.

V

[flfl]

\1.2.3.

V ^

135

Indicationofthe

piecesofgarment

3

Total

counter

Total number of pieces finished is indicated.

To

clear

(In this ca.se,the numeric keys cannot be used to input a number.)

Pictograph

CflB3

\1.2.3.

135

i-j

number

finished

Counter

the

figures

number

of

screen

currently

CflC3

\1.2.3.

0

\

shown,

indicationofset

press

the

value

RESET

key

^

135

-

24

-

Page 29

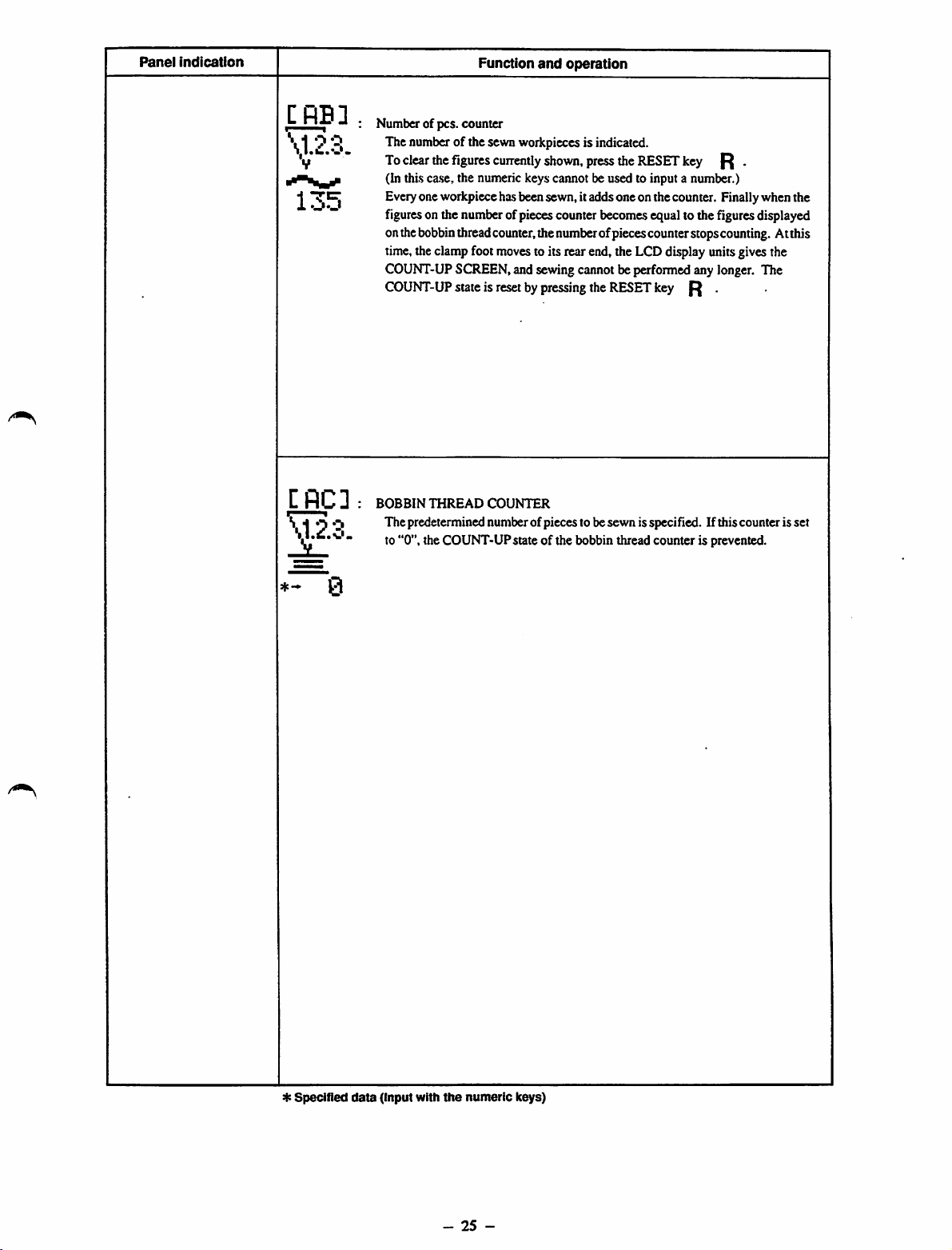

Panel

indication

Function

and

operation

[RB]

CflC]

\1.2.3.

Number of pcs. counter

The numberof the sewnworkpieces is indicated.

To

clear

the

figures

cuirently

(In thi.sca.se,the numeric keys cannot be used to input a number.)

Everyone workpiece hasbeensewn, itadds one onthe counter. Finallywhen the

figureson the numberofpiecescounter becomesequal to thefiguresdisplayed

onthebobbinthreadcounter,the numberofpiecescounterstopscounting. Atthis

time,theclampfoot movesto its rear end, the LCDdisplay unitsgivesthe

COUNT-UP

COUNT-UP

BOBBIN

Thepredetermined numberofpieces to besewn isspecified. If thiscounter is set

to "0", the COUNT-UP state of the bobbin thread counter is prevented.

SCREEN,and sewingcannot be performedany longer. The

stateisresetbypressing

THREAD

COUNTER

shown,

press

the

the

RESET

RESET

key

key

R .

R .

*-

0

*

Specified

data

(Input with

the

-

numeric

25

-

keys)

Page 30

Panel

Indication

4.

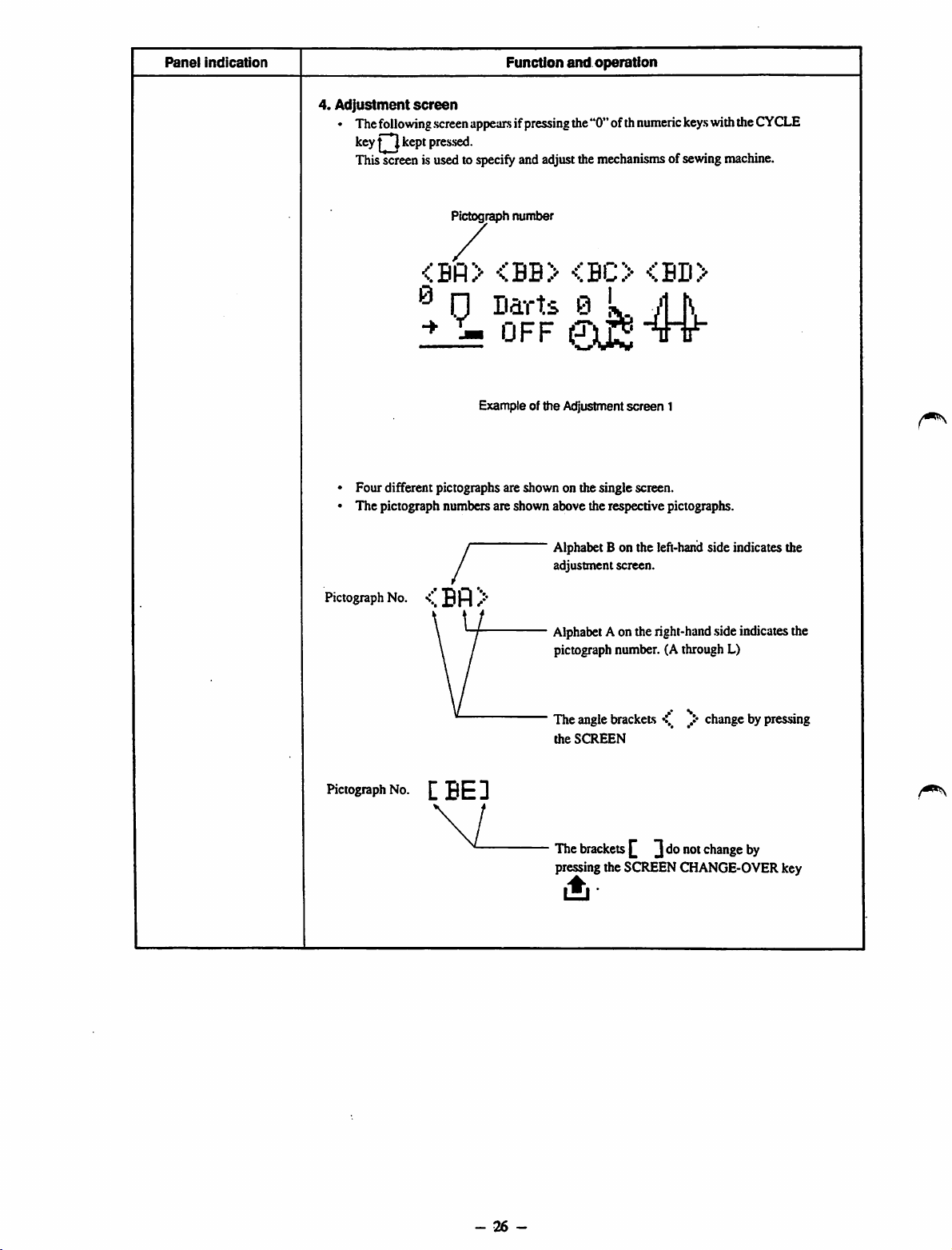

Adjustment

• The

following

key kept pressed.

Thisscreenis usedto

screen

screen

Function

appearsifpressing

specify

andadjustthe

and

operation

the"0"ofth

mechanisms

numeric

ofsewing

keys

withthe

machine.

CYCLE

Pictograph

. / .

®

1?

• Four different pictographs are shown on the single screen.

• The pictograph numbers are shown above the respective pictographs.

y

/

w

Pictograph

No. /•'

\

\ /

number

....

<.BU>

D?rU

UFF

Example of the Adjustment

0k M

Alphabet

adjustment

Alphabet

pictograph

Bonthe

Aonthe

<%BD>

tTt

screen

1

left-hand

screen.

right-hand

number.(Athrough

sideindicates the

side

indicates

L)

the

Pictograph

No.tBED

\ 1

•••

Theangle

the

The

pressing the SCREEN CHANGE-OVER key

brackets

SCREEN

brackets

y*

^ ]donot

changebypressing

change

by

•ii

-

26

-

Page 31

rvj

(T-

..W

g ®|4 r:

<0

w

g

time

ON

operation

operation

)

speed

mode

clamp foot return

The

» a

9 B- 3!

:£

Setting ofdart stretcher operation

S<B<8

f 8.1

rik°

Timing of needle thread trimming

_

il

<a

Corner knifesimultaneous operation -> Separate operation

"

c»

m ^

ai

oi

m

1

timer

Stacker

c/

z •

i

Z S

> o

2

timer

Stacker

E

for high

speed

Setting the sewing

(n

T3

speed

for low

speed

Setting the sewing

Sewingmachineindependentoperation mode

operation

independent

machine

Sewingmachineindependentoperation OFFtime

Sewing

^ Check program

Page 32

Panel

indication

Function

<

Bfl

0.

>

00

The positionof theclampfoot is changedoverafter thecompletionof

sewing. = Stops at the front end

(Data setting range: 0.00 to 9.99 sec.)

* Length of time during which the clampfootstops at thesewing end

position is

The position of theclampfoot is changedoverafter thecompletionof

sewing. = Returns to the middle position

set

and

operation

^ n

-*•

T

n

T

<BB>

narts.

OPTIOH

OFF

Darts

OF'TIOH

0 N

<

BC

>

The position of the clamp foot is changed over after the completion of

sewing. = Returns to the home position

: The position of the clamp foot is changed over after the completion of

sewing. = Stops at the rear end

Darts stretcher is not equipped.

Darts stretcher is equipped. (Optionally available)

Timer

of the thread trinuner (standard timing)

©A

Timer of the thread trimmer (intermediate timing: (Length of thread

remaining in the needle) Standard position + Approx. 10mm)

Timerof the thread nrimmer(latest timing: Thread trimmer actuates

when the clamp foot stops at the position of the comer knife.)

S

hp

* Specified

data

(Input with

the

-

numeric

28

-

keys)

Page 33

Panel

indication

<BD>

*-80

[BE]

*-0.80

CBF]

I®

*-^0.80

Function

: Corner knife simultaneous operation designated mode (standard)

(Caution)Inthis

with

(Refer to

: Comer knife separate operation designated mode under which thedistance

between the corner knife blades

f Data setting range for gauge size 8 to 12

1

Data

setting

^The

comer

knife

automatically opens, by separately operating the fixed side and moving

^side of the corner knife.

(Caution)Inthis

should

marked

(Refertopage72for

Stacker

timer

(Data setting range: 0.00 to 9.99 sec.)

For a grasping stacker: The period of time during which the stacker

grasps the workpiece is specified.

For a bar stacker: The period of time during which the stacker grasps

the workpiece is specified.

Fora roller stacker: The period of time during which theroller actuates

is specified.

(Specify 9.99 sec. when the cloth sensor is used.)

Stacker

timer

(Data setting range: 0.00 to 9.99 sec.)

For a grasping

.swingsis .specified.

Forabar

The period of timeduring which the stacker swings is specified.

Foraroller

stacker:

and

case,

the

sewing

page

range

for

canbeoperated

case,

lie fixed in

withanasterisk

(unit:

.stacker:

stacker:

operation

fix

the

corner

knife

unitinaccordance

length.

72 for

the

procedure.)

Ls

specified

mm:

35 to 180 mm

gauge

size14to20mm:50to

inthe

way

similar

the

corner

knife

unit

accordance

{*).

the

procedure.)

second)

The period of time during which the stacker

Not

used

with

tothe

(the

the

180

mm

case

moving

specified

where

side)

data

it ^

CBQ]

High

* —

2200

CBH]

L O W

*—

1500

* Specified

r,j

data

(Input with

Setting the sewing speed for high speed operation of the sewing

machine (locksdtching speed)

Recommended set value 2.200 s.p.m.

(Datasetting range 1,000to

Setting the sewing speedfor low speedoperation ofthe sewingmachine

(condensation stitching speed and back tack stitching speed)

Recommended set value l,5()0$.p.m.

(Data setting range 500 to 1,500 s.p.m.)

the

numeric keys)

2,2(X)

s.p.m.)

-

29

-

Page 34

Panel

Indication

Function

and

operation

<BI>

M-0

r.J

M-l

r.y

r'1-2

r..*

M-3

r.j

Sewingmachineindependentoperationmodeis

Tostartthesewing

independent

No operation

Continuous

Continuous low-speedoperationof sewing machine

Intennittenthigh-speedoperation of sewing machine

Intermittent low-speed operation of sewing machine

machine

operation

high-speed operationof sewingmachine

independent operation,

modeandset theDIPswitchappropriately.

set

specify

firstthe

M-4

[

0-1

*-2.

C

0-2

*^2.00

CBL]

Check

PGM.

Mode

BJ]

r.J

00

BK]

r. >

0

Theperiodof timeduringwhich thesewingmachineisinits"ON"state

inthesewing

operation mode.

(Data setting range:

The sewing machine independent operation mode starts up using the

DIP

(Ifthespecifiedvalue is 1.00sec. or smaller,thesewing machinedoes

not operate.)

The period of time during which the sewing machine is in its

state in the sewing machine, independent operation mode or in the

intermittentoperation mode.

(Datasettingrange: 1.00to 9.99 sec.)

The sewingmachineindependentoperationmode starts up using the

DIP

Gfthe specified value is 1.00sec. or smaller, the sewingmachinedoes

not operate.)

Checkprogrammodeis specified.

(Available modes are

The check programis started up by pressing the SCREEN

CHANGE-OVERkey .

switch.

switch.

machine

independentoperationmodeorintheintermittent

l.CX)

to 9.99 sec.)

0.1,2,3

and 4.)

"OFF'

Specified

(Input with

the

numeric keys.)

-

30

-

data

Page 35

Pane{

indication

0 LCD indication

the

automatic

mode

under

1}

The

following

screen

is given

Rmction

under

and

the

operation

automatic

mode.

Indicationofcycle

sewing

Indication

of

£3"

Patterntobe

Patterntobe

Patterntobe

• If the screen shown above is givenon the

is

operative.

sewn

sewn

sewn

after

first

next

next

-

-1

-

-5

•

'6

158

l»

Detailed

-T-|

operation

1

stacker

operationJSewing

^11

11i

ON

150

Numberofpcs.

LCD,

only the

counter

MACHINE

ofthe

sewingisindicated.

mode

•+

O

\ti.3-

8

♦

indication

READY

indication

/

key ( (_))

-

31

-

Page 36

Panel

indication

2)

Exampleofthe

Example

L

size=120

indication showing

1) •

ParallelLsize

mm

Tb

L B B

ta

i B a

±4

*

120

Function

sewing

g

s

a

and

detailed

operation

operationofsewing

Example

Lsize=

2) •

Right-slantLsize

120

mm

p.

!• •

l"

•

i

120

Example 3) * Left trapezoidal

L

size=120

mm

Ti

i

ii*

120

Example

4) •

Right

parallel

B®

sewing

.stitching

flap

sewing

Example

Example

5) •

6) •

Right-slant,

Left

trapezoidal

ii

right-flap

flap

sewing

sewing

(Welt

pocket

sewing)

-

32

-

Page 37

Panel

Indication

Function

and

operation

<DAlarm indication

When an alarm occurs, themachine immediately stops. The alarm number coiresponding to die

alarm occurred flasheson and off on the LQ> display unit to show that the machine stops in the

alarm

state.

1) Temporary stop

Alarm

number

Pictograph corresponding to

Pres.sing

2) Thread breakage detection

the

Alarm

RESET

numtier

key

R

releases

the

the

machine

temporary

from

stop

the

alarm

state.

/

Pressing

3) The thread takc-uplever isnotin its highestdead position.

the

Alarm

RESET

number

key

R

releases

the

machine

*flL-04*

(Caution) The AL-12is

1. Turn

highest dead point when

At

2. Turn

highest

Thenpress the

reset

the

handwheeltomake

this

ime,

the

the

handwheeltomake

dead

pointwhen

following

machine is automatically

RESET

the

procedure

the

the

clamp foot is in

the

the

clampfoot

key p .

thread

thread

from

the

alarm

described

take-up

takenip

is in

levergouptoits

its

front

released

its

from

levergouptoits

intermediate position.

state.

below.

endorrear end.

the

alarm.

-

33

-

Page 38

Panel

indication

<D

Bobbinthread count-

up

indication

Function

1)

When

the

figures

onthe

numberofpieces

the bobbin thread counter, the following screen appears.

Press

the

RESET

key

R ,

and

cleared

(number=0) andthecyclescreenwillbeshownontheLCDdisplayunit

the

and

counter

figures

operation

shownonthe

becomes

equal

tothe

figures

numberofpieces

displayed

counter

will

on

be

The message of

"COUNT-UP"

flashes on and off.

COUNT-UP

\1.2.3. \1.2.3.

*.,/

1234

Total counter Number of pcs. Bobbin thread counter

V

135

counter

\1.2.3.

~35

-

34

-

Page 39

(3) Example of setting

Let's

set

dataonthe

^

Pattern

No.

1

L .sizel.iO mm. trapezoidal.sewing(difference 5 mm)

Pattern

No.

.*5

Left-flap parallel

Pattern

No.

6

Right-flap parallel .sewingwith the .stackeractuated.

Step 1. Specifydata on cycle

Under

the

manual

keys in the writtenorder succe-ssively. This completes the setting of data on cycle

Step 2. Specify data on

•

After

step1,press

pattern .screen will appear on the LCD.

• Then,

pre.ss

2-1 Changing the

•

Pre.ss

the

CHANGE-OVERkey , and the flashing pictograph will be changed to another (the

another).

• Operate the

the de.scribedon the next page.

2-2 Change the sewing pattern of pattern No. 5

• Keep pre.ssingthe CURSOR shift key until the pictograph number [ 1A] flashes on and off. Then, pressthe 5ofnumeric

keys.

• Operate the CURSOR .shiftkey , SCREEN CHANGE-OVER key and numeric keys to .setdata tothevalues same

as those of panem 5 to the described on the next page.

2-3 Changing the

• Keep

pre.s.sing

keys.

• Operate the CURSOR

as tho.seof pattern 6 to the de.scribedon the next page.

•

Set

valuesofpattern

dataoncycle

following

.sewing

the 1 of the numerickeys,and the

.sewing

CURSOR

SCREEN

.sewing

example.

.sewing

with the .stackeractuated.

.sewing.

mode

(when

panern.

the

SCREEN

pattern

corre.sponding

shiftkey • tochangethe

CHANGE-OVER key and thenumeric keysto

pattern of pattern No. 6

theCURSOR .shiftkey until thepictograph number [5A] flasheson andoff. Then,pressthe 6ofnumeric

.shift

key M . SCREENCHANGE-OVER key andnumerickeys to

1

sewing

the

mode

indicator

CHANGE-OVER

to pattern No. 1

LED

goes

out),

pre.s.s

the

CYCLE

key{3.

.sewing

(1,5

key

|j|j

(when

the

cycle

.screenisshownonthe

.sewing

patternof pattern No. 1will be shownonthe LCD.

flashing

pictograph

(itemthatcan be

.set

datato the valuessameasthoseof pattern1to

modified).

.specified

*hen

press

1,5

and 6).

LCD).

Then

Thenpressthe

data will be changed to

.set

datato thevaluessame

and6numeric

the

sewing

SCREEN

Clft]

<1B> <1C>

/\

-» ^ i i 1 4.»|«

1

Set

valuesofpattern

<5B>

Set

valuesofpattern

Cc-A]

<eB> <oC> <dD> <6E> C6F]

C

150

<5C>

<1D>

<5B>

<1E>

<1K>

<1L>

5 5 0 0

Trapezoidal

5

<5E>C5F]

\ /

Changethe data on flapconcealed stitchinginaccordance withthe flapto be sewn.

6

30.0

sewing

C5G]

30.0.30.0

Cc-GD

30.0

30.0

Cir-n

CIN]

<10>

<lP>Cli!]

^1

I

'I'

0.0

0.0

with

the

difference

C5H]

[513

30.0

C6H3

E6I3

30.0

30.0

Change the data on flapconcealed stitchingin accordance withthe flap to be sewn.

set

to S mm

C5J]

<5K>

1 0 0 7 7

Cc-JD

<6K>

1 0 0 7 7

<1R>

±_i

2.0

1.0 1.0

<5L>

C5M]

<6L>Cc.M]

I

<1S>

. I

C5N3

<50> <5P>

0.0

0.0

C6N3

<60> <6P>Cfc93 <bR>

0.0

0.0

C5Q3

2.0

2.0

<5R>

<5:f.>

1.0 1.0

1.0

1.0

-

35

-

Page 40

Step

3. Confirming

Pre.s.s

the

.sewing.

Press

the

MACHINE

data

on cycle sewing

CYCLE

READY

key

key

Q .

Q ,

1

^

and

confirm

.1 > 5

150

and

the

machine

150

ii

that

the

following

on

\

\/

ll

\/

IQ'

• 1'

indicationisgivenonthe

-''.X

>•

.6 >

LCD.

J

will

operate

under

the

-f

I V

automatic

mode.

Now,

the

sewing

machine

can

start

jrI t

71 I

6

ii

±*

150

♦

JL^

i-i

11

-

36

-

Page 41

(4)

(l)

Ex^ple

Rightslant

of setting data on slant flap sewing

sewing

and left slant

sewing

Right

Right

slant

Startofsewing

slant

sewing Left

flap

sewing

Left

slant

slant

sewing

flap

sewing

Observea

which

A

pocket

A

pocket

In addition,

flap

To sew a right slant flap, ase the right flap sewing mode.

[Theflapforced stopfunction (inprevention ofcutting) will not

work unlessthe

reference.]

endofthe

with

with

sewing.

pocket

its

its

the

.sewing

from

the

front after

pocketIsup.

right

end

up...

left

end

up....

above

designation

end of the flap is aligned with the rear

sewingtocheck

Right

slant

Left

slant

applies

sewing

sewing

alsotothe

Rear

reference

Iftheleft

.slant

[ Ifyousetthe

Setthe DIP

.switch

[ How to set a

flap

.sewing

modeisspecified for the

DlP-1

SW-1

toitsON

to the ON

Flap

li^t

slant flap ]

.sewing

ofa right

po.sition,

po.sition

whenonlyrightor leftflapsare sewncontinuously.]

the

occurrence

ofthe

aforementioned

.slant

flap,

"AL-50"will

"AL-50"

occur.

canbe

prevented.

-

37

-

Page 42

6.

HOWTOSET

DURINC

(1)

How

to perform welting and sewing welts withflaps

For

the

standard

Before

starting

operation,

1)

Depress

The

2)

Set

Place

Now

3)

SetabodyOfgarment material.

the

interlining

an Interlining piece.

iui

interlining

the

interlining

Placeagarment

cro.ss-marklight on the far side.

4)

Depress

The

work

clamp

Remove

wrinkle.s,

5) Depress the pedal switch to the

The

work

clamp

6)

Set

a welting patch.

Placeawelting

7) Depress the pedal switch to the third

Thebinderwill comedown to clampthe weltingpatch and thenfold it.

8)

Flap

setting

Set

the

flaptobe

9) Depress the pedal switch to the 4th

The

flap

pre.sser

10) Depressthe pedal switch to the 5th

The

flap

presser

11)

Depress

The

rapid