Page 1

CHAPTER

Operation section

@

Page 2

CONTENTS

@. Operation section

1. NAME OF EACH SECTION OF THE OPERATION PANEL .......... @- 1

(1) Body.....................................................................................................................@- 1

(2) Buttons to be used in common.........................................................................@- 2

2. BASIC OPERATION OF THE SEWING MACHINE....................... @- 2

3. LCD DISPLAY SECTION AT THE TIME

OF INDEPENDENT SEWING........................................................ @- 8

(1) Data input screen ...............................................................................................@- 8

(2) Sewing screen ..................................................................................................@- 10

4. PERFORMING PATTERN No. SELECTION ............................... @- 12

5. NAMING THE PATTERN ............................................................. @- 13

6. SEWING METHOD AND SEWING SHAPE LIST ....................... @- 14

7. PERFORMING DATA SETTING OF SEWING BUTTON

WITH BLINDSTITCH (SHANK AND MARBLE BUTTONS) ....... @- 15

8. PERFORMONG DATA SETTING OF SEWING BUTTON

WITH BLINDSTITCH (FLAT BUTTON)....................................... @- 16

9. PERFORMING DATA SETTING

OF SEWING BUTTON DIRECTLY TO CLOTH............................ @- 17

10. PERFORMING DATA SETTING

OF SEWING FLAT BUTT ON WITH BLINDSTITCH .................... @- 18

11. PERFORMING SETTING OF COUNTER/STAY BUTTONS........ @- 19

12. PERFORMING NECK WRAPPING SEWING DATA ................... @- 20

13. PERFORMING SEWING METHOD SELECTION ....................... @- 21

14. PERFORMING SEWING SHAPE SELECTION .......................... @- 22

15. PERFORMING SETTING NUMBER

OF REVOLUTIONS OF SEWING MACHINE .............................. @- 23

16. PERFORMING SETTING STAY THREAD ................................... @- 24

17. PERFORMING INPUT

OF BUTTON SEWING THREAD TENSION................................. @- 25

(1) In case of simplified input ...............................................................................@- 25

(2) In case of detailed input...................................................................................@- 26

(3) Sewing data that can be changed...................................................................@- 27

18. PERFORMING INPUT

OF NECK WRAPPING THREAD TENSION ................................ @- 29

(1) In case of simplified input ...............................................................................@- 29

(2) In case of detailed input...................................................................................@- 30

(3) Sewing data that can be changed...................................................................@- 31

19. PERFORMING DETAILED INPUT OF NECK WRAPPING......... @ - 33

Page 3

20. CHANGING SEWING DATA ........................................................ @- 36

(1) Initial sewing data at the time of your purchase............................................@- 36

(2) Changing procedure of sewing data............................................................... @- 37

(3) Sewing data list ................................................................................................@- 38

21. PERFORMING NEW REGISTRATION OF THE PATTERN......... @- 42

22. COPYING SEWING PATTERN.................................................... @- 43

23. PERFORMING CHUCK ADJUSTMENT ..................................... @- 45

24. PERFORMING BUTTON CENTERING ....................................... @- 46

25. PERFORMING INPUT AND CHECK

OF DATA WITH STEP MOTION .................................................. @- 47

(1) Performing the step motion.............................................................................@- 47

(2) Data list..............................................................................................................@- 50

26. PERFORMING COMPENSATION

OF UNEVENNESS OF BUTTON................................................. @- 52

27. CHANGING SEWING MODE ...................................................... @- 53

28. LCD DISPLAY SECTION AT THE TIME

OF CYCLE STITCHING............................................................... @- 54

(1) Data input screen .............................................................................................@- 54

(2) Sewing screen ..................................................................................................@- 56

29. PERFORMING CYCLE STITCHING ........................................... @- 58

(1) Selection of the cycle data ..............................................................................@- 58

(2) Editing procedure of the cycle data................................................................@- 59

30. PERFORMING CHANGE OF DISPLAY

OF SEWING PRODUCT.............................................................. @- 61

31. USING COUNTER ....................................................................... @- 62

(1) Setting procedure of the counter....................................................................@- 62

(2) Count-up releasing procedure ........................................................................ @- 64

32. CHANGING MEMORY SWITCH DATA ....................................... @- 64

(1) Changing procedure of memory switch data................................................. @- 64

(2) Memory switch data list ................................................................................... @- 66

33. PERFORMING CHANGE OF NEEDLE....................................... @- 71

34. PERFORMING CHANGE OF CHUCK ........................................ @- 72

35. CUSTOMIZING DATA INPUT SCREEN ...................................... @- 74

(1) Registering procedure ..................................................................................... @- 74

(2) Register state at the time of your purchase ................................................... @- 75

36. CUSTOMIZING SEWING SCREEN............................................. @- 76

(1) Registering procedure ..................................................................................... @- 76

(2) Register state at the time of your purchase ................................................... @- 77

37. PERFORMING KEY LOCK ......................................................... @- 78

38. DISPLAYING VERSION INFORMATION..................................... @- 80

Page 4

39. USING CHECK PROGRAM ........................................................ @- 81

(1) Displaying the check program screen ............................................................ @- 81

(2) Performing sensor check ................................................................................. @- 82

(3) Performing LCD check ..................................................................................... @- 84

(4) Performing touch panel compensation .......................................................... @- 85

40. ERROR CODE LIST .................................................................... @- 87

41. USING COMMUNICATION FUNCTION ...................................... @- 93

(1) Handling possible data .................................................................................... @- 93

(2) Performing communication by using the smart media ................................. @- 94

(3) Performing communication by using RS-232C ............................................. @- 96

(4) Take-in of the data ............................................................................................ @- 97

42. INFORMATION FUNCTION ......................................................... @- 99

(1) Observing the maintenance and inspection information ........................... @- 100

(2) Inputting the inspection time ........................................................................ @- 102

(3) Releasing procedure of the warning ............................................................ @- 103

(4) Observing the production control information............................................ @- 104

(5) Performing setting of the production control information ......................... @- 106

(6) Observing the working measurement information ..................................... @- 109

43. COMMUNICATION SCREEN

OF MAINTENANCE PERSONNEL LEVEL............................... @- 112

(1) Data which are possible to be handledIn case of the maintenance .......... @- 112

(2) Displaying maintenance personnel level ..................................................... @- 113

44. INFORMATION SCREEN

OF THE MAINTENANCE PERSONNEL LEVEL ....................... @- 114

(1) Display of error record ................................................................................... @- 114

(2) Display of the cumulative working information ........................................... @- 115

Page 5

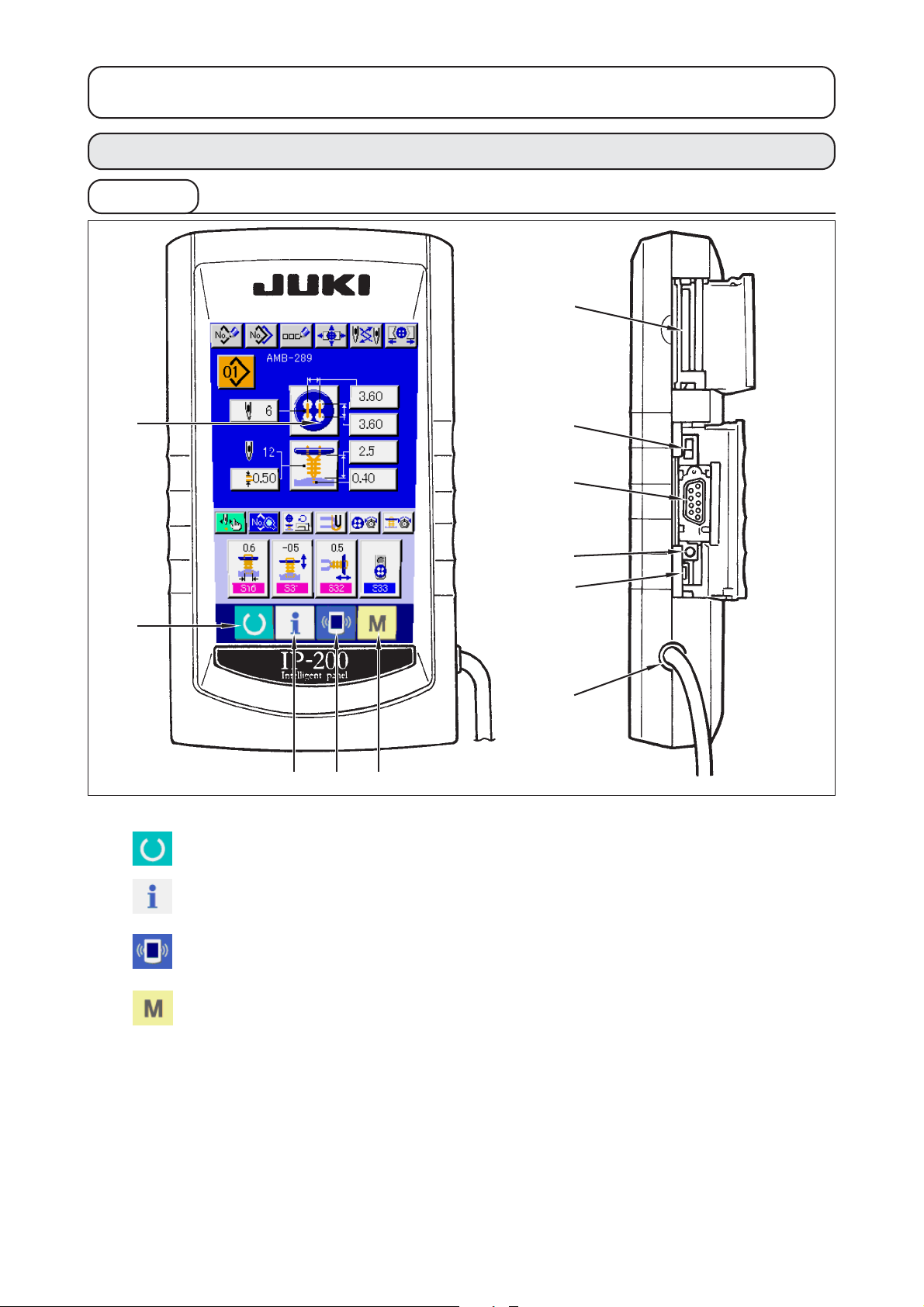

@. Operation section

1. NAME OF EACH SECTION OF THE OPERATION PANEL

(1) Body

6

1

2

3 4 5

1 Touch panel・LCD display section

2 READY key → Changeover of the data input screen and

7

8

9

!0

!1

the sewing screen can be performed.

3 INFORMATION key → Changeover of the data input screen and

the information screen can be performed.

4 COMMUNICATION key → Changeover of the data input screen and

the communication screen can be performed.

5 MODE key → Changeover of the data input screen and

the mode changeover screen which

performs various detail settings can be

performed.

6 Smart media card slot (Close the cover for use.)

7 Slide switch (Not used・OFF)

8 Connector for RS-232C communication

9 Variable resistor for color LCD → Screen contrast can be adjusted. Adjust it

screen contrast adjustment as you desire.

!0 Connector for external input

!1 Cable

@– 1

Page 6

(2) Buttons to be used in common

The buttons which perform common operations in each screen of IP-200 are as follows :

CANCEL button → This button closes the pop-up screen.

In case of the data change screen, the data being

changed can be cancelled.

ENTER button → This button determines the changed data.

UP SCROLL button → This button scrolls the button or the display in the

upward direction.

DOWN SCROLL button → This button scrolls the button or the display in the

downward direction.

RESET button → This button performs the release of error.

NUMERAL INPUT button → This button displays ten keys and input of numerals

can be performed.

SEWING DATA DISPLAY button → This button displays the sewing data list corresponding

to the pattern No. being selected.

→ Refer to

CHARACTER INPUT button → This button displays the character input screen.

→ Refer to

"20. CHANGING SEWING DATA".

"5. NAMING THE PATTERN".

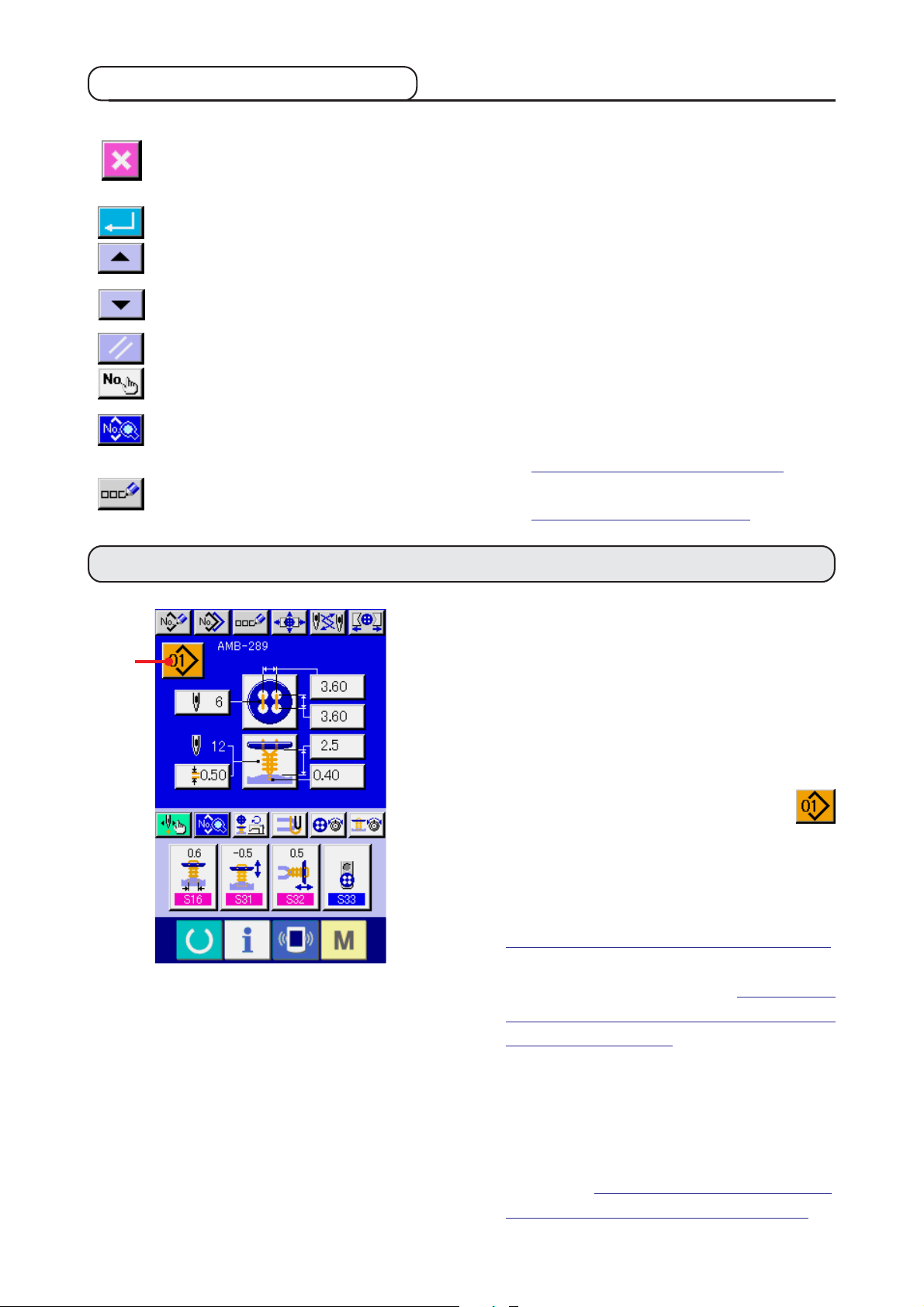

2. BASIC OPERATION OF THE SEWING MACHINE

1) Turn ON the power switch.

First, turn ON the power switch. DATA INPUT

1

screen is displayed after displaying WELCOME

screen.

2) Select the pattern No. you desire to sew.

When the power is turned ON, the data input

screen is displayed. Pattern No. button

1 which is selected at present is displayed in

the upper section of the screen. Press the

button to select the pattern No. For selecting

procedure of the pattern No., refer to

"4.

PERFORMING PATTERN No. SELECTION

When you purchase the sewing machine,

Pattern Nos. 1 to 10 described in

sewing data at the time of your purchase

have been registered". Select the pattern No.

you desire to sew from among these numbers.

(The No. to which the pattern has not been

registered is not displayed.)

".

"20. (1) Initial

* For the detailed explanation of this

screen, see

"3. LCD DISPLAY SECTION AT

THE TIME OF INDEPENDENT SEWING".

@– 2

Page 7

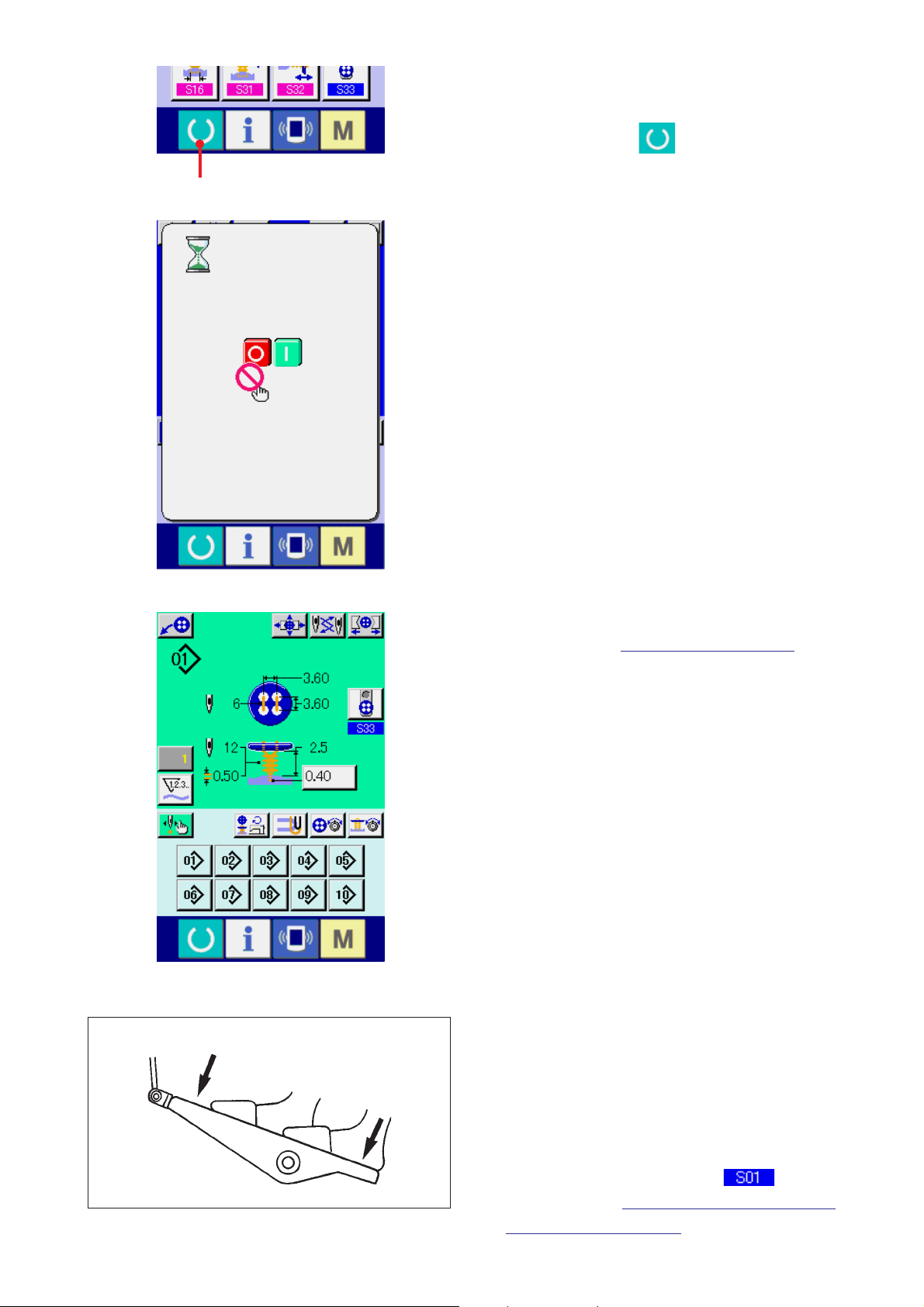

3) Set the sewing machine to sewing possible

state.

2

Press READY key

2 , and POWER OFF

PROHIBITION screen is displayed. Make

preparations for sewing while this screen is

displayed.

When the sewing is in a possible state, the

back-light of LCD display changes to green

color.

A

B

* For the detailed explanation of the sewing

screen, refer to

"3. (2) Sewing screen".

4) Settimg of the sewing products

Setting procedures of materials and buttons are

different in sewing method.

Set them while operating the device by

depressing front part A or back part B of the

foot pedal.

* For the setting procedure of

method, refer to

"13. PERFORMING SEWING

Sewing

METHOD SELECTION".

@– 3

Page 8

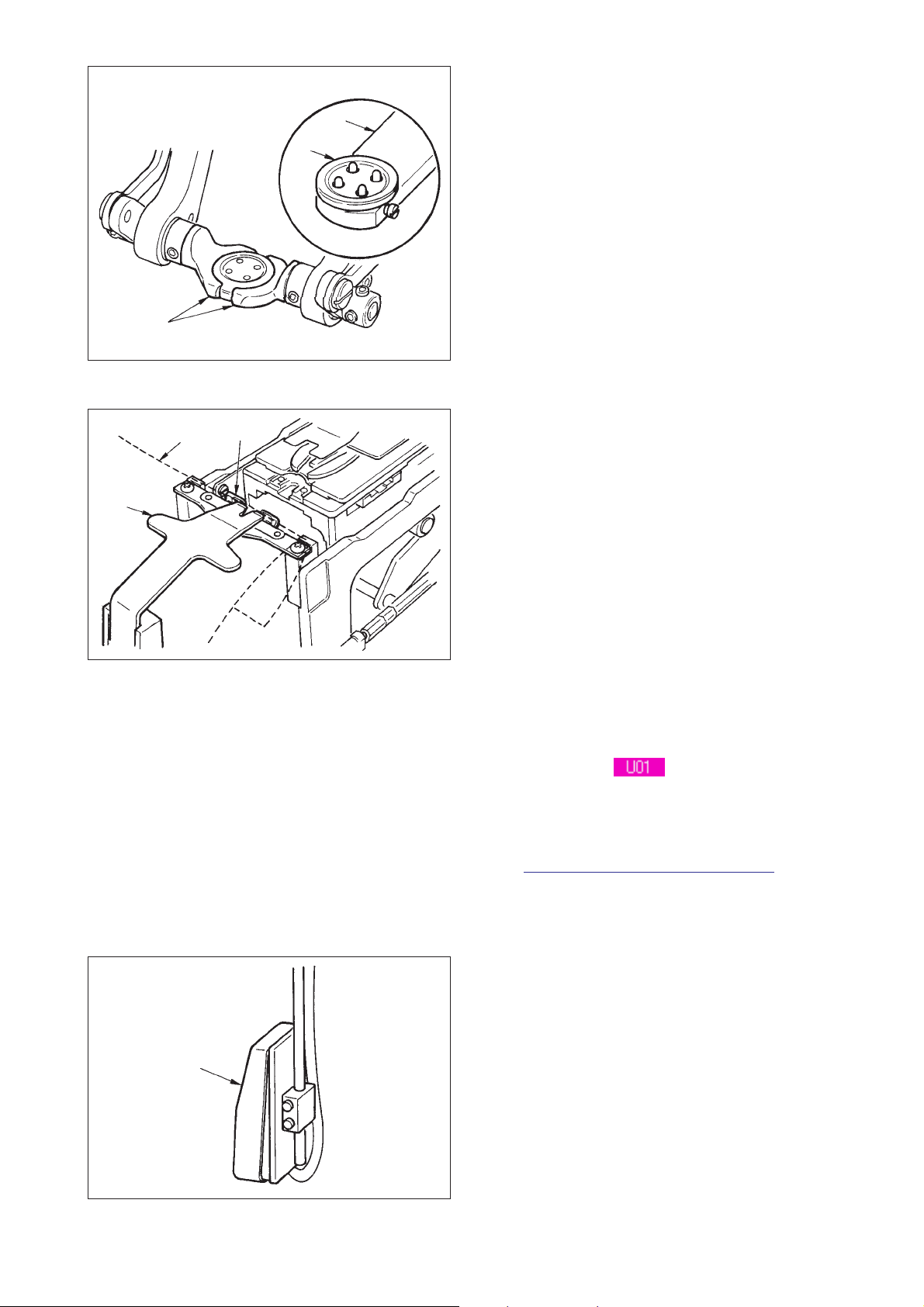

3

1

2

<In case of sewing flat/wrapped-around button

with blindstitch or sewing flat button with

blindstitch>

Set button 1 to button loader 2 and depress the

back part of the pedal to insert the button into button

chucks 3.

(When the button loader is not used, insert the

button by hand since the chuck is opened by

depressing the back part of the pedal.)

↓

5

4

6

Set cloth 4 to tongue 5 and make it come in contact

with tongue stopper 6. (Release of the tongue is

performed by depressing the back part of the pedal.)

↓

When the front part of the pedal is depressed, the

button chuck comes down to the sewing position

where the sewing is possible.

* By setting the pedal motion mode of memory

switch data

, the button chuck

automatically comes down to the sewing

position.

→ For the details of the memory switch data, refer

"32. (2) Memory switch data list".

to

7

↓

Sewing starts when start switch 7 is turned ON.

@– 4

Page 9

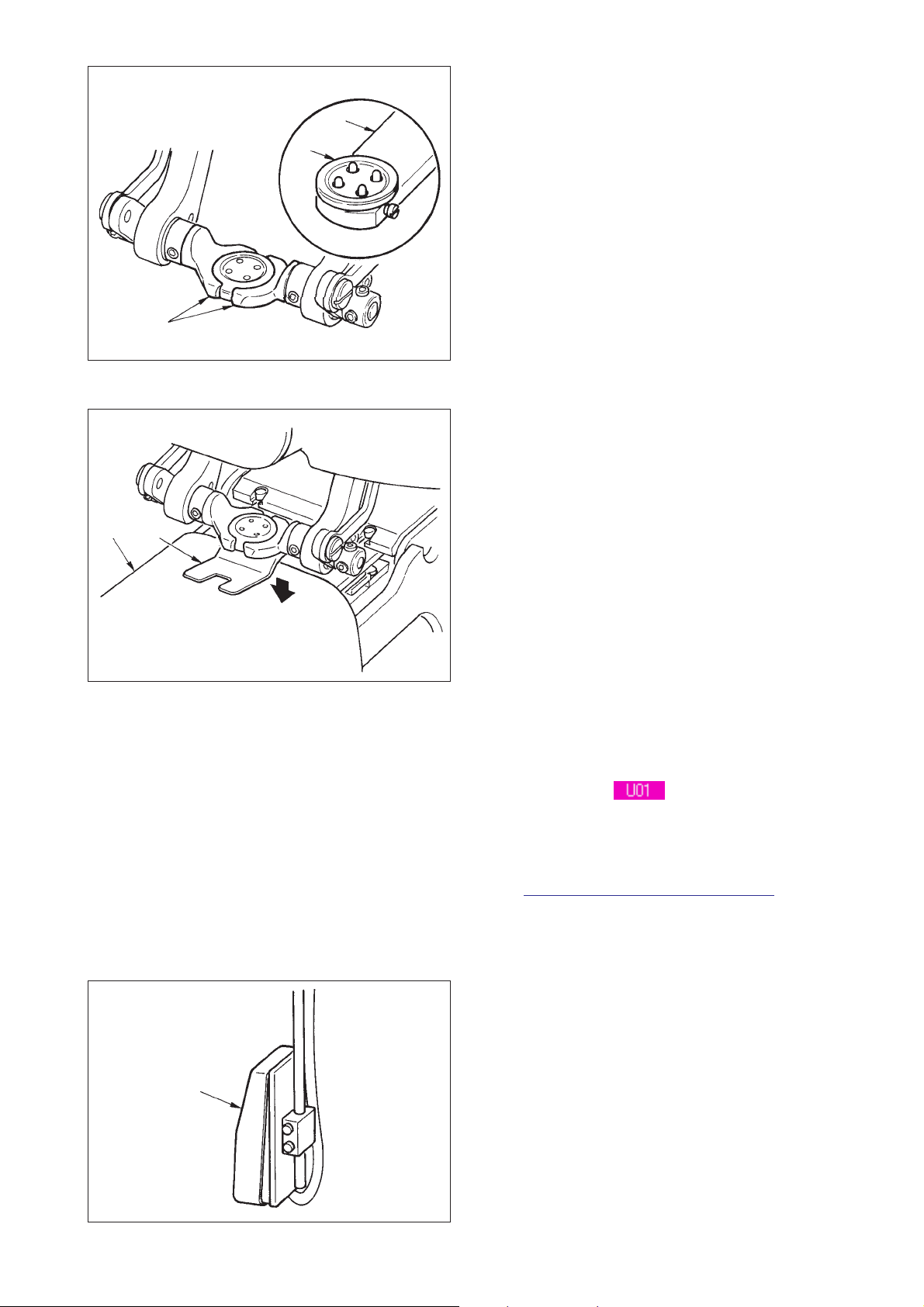

4

5

3

1

2

<In case of sewing flat button directly to cloth>

Set button 1 to button loader 2 and depress the

back part of the pedal to insert the button into button

chucks 3.

(When the button loader is not used, insert the

button by hand since the chuck is opened by

depressing the back part of the pedal.)

↓

Set cloth 4 under the needle, make the tongue

come in contact with the tongue stopper, and make

cloth presser 5 come down by depressing the front

part of the pedal to fix the cloth.

(By depressing the pedal reversely, the cloth presser

is released.)

↓

When depressing the front part of the pedal again,

the button chuck comes down to the sewing position

where the sewing is possible.

* By setting the pedal motion mode of memory

switch data

, the button chuck

automatically comes down to the sewing

position.

→ For the details of the memory switch data, refer

"32. (2) Memory switch data list".

to

↓

Sewing starts when start switch 6 is turned ON.

6

@– 5

Page 10

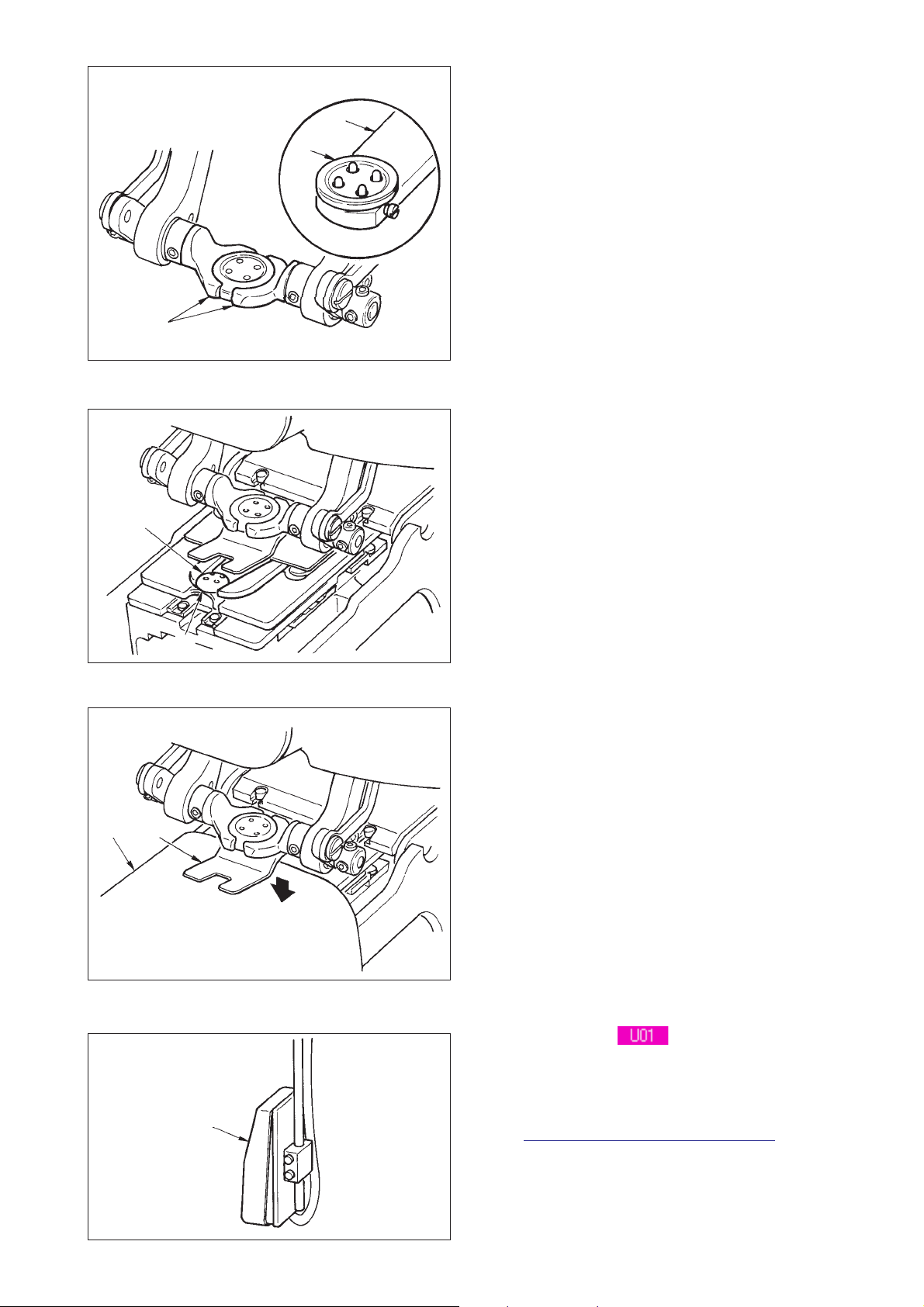

4

3

1

2

<In case of counter/stay button>

Set upper button 1 to button loader 2 and depress

the back part of the pedal to insert the button into

button chucks 3.

(When the button loader is not used, insert the

button by hand since the chuck is opened by

depressing the back part of the pedal.)

↓

Insert lower button 4 into button setting section 5

of the feed plate.

6

7

5

8

↓

Set cloth 6 under the needle, make the tongue

come in contact with the tongue stopper, and make

cloth presser 7 come down by depressing the front

part of the pedal to fix the cloth.

(By depressing the pedal reversely, the cloth

presser is released.)

↓

When the front part of the pedal is depressed, the

button chuck comes down to the sewing position

where the sewing is possible.

*By setting the pedal motion mode of memory

switch data

, the button chuck

automatically comes down to the sewing

position.

→ For the details of the memory switch data, refer

"32. (2) Memory switch data list".

to

↓

Sewing starts when start switch 8 is turned ON.

@– 6

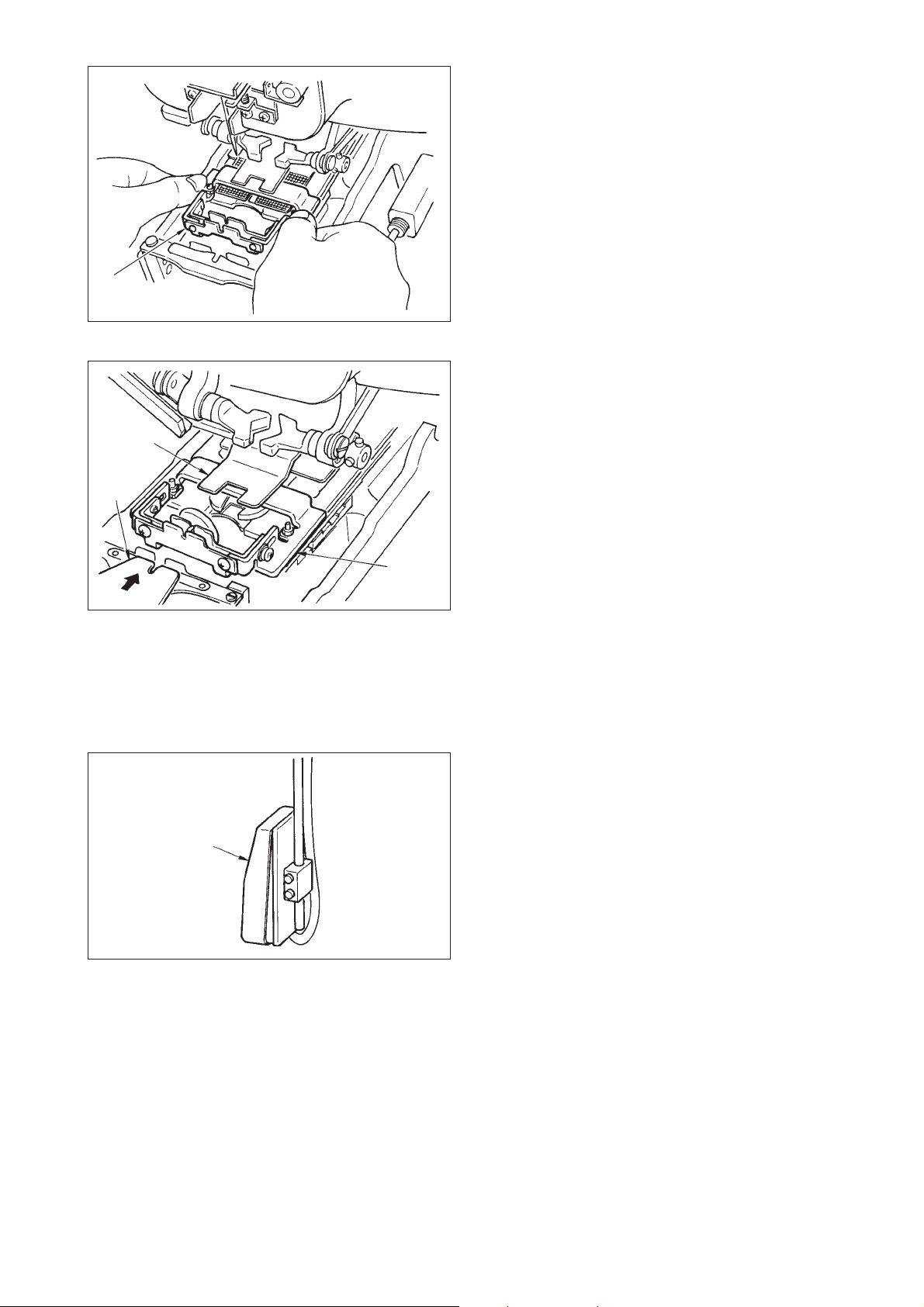

Page 11

1

3

<In case of neck wrapping sewing>

Install neck wrapping sewing unit 1 to the inserting

hole of the feed plate.

↓

Set tongue 2 by hand, and make cloth presser 3

come down to fix neck wrapping sewing unit 1.

(Tongue and neck wrapping sewing unit are

released by depressing the pedal reversely.)

2

4

1

↓

Set the sewing product to neck wrapping sewing

unit 1.

↓

Transport the sewing product up to the sewing start

position by depressing the front part of the pedal.

(When depressing the front part of the pedal again,

the sewing product returns to the set position.

↓

The sewing starts when start switch 4 is turned

ON.

@– 7

Page 12

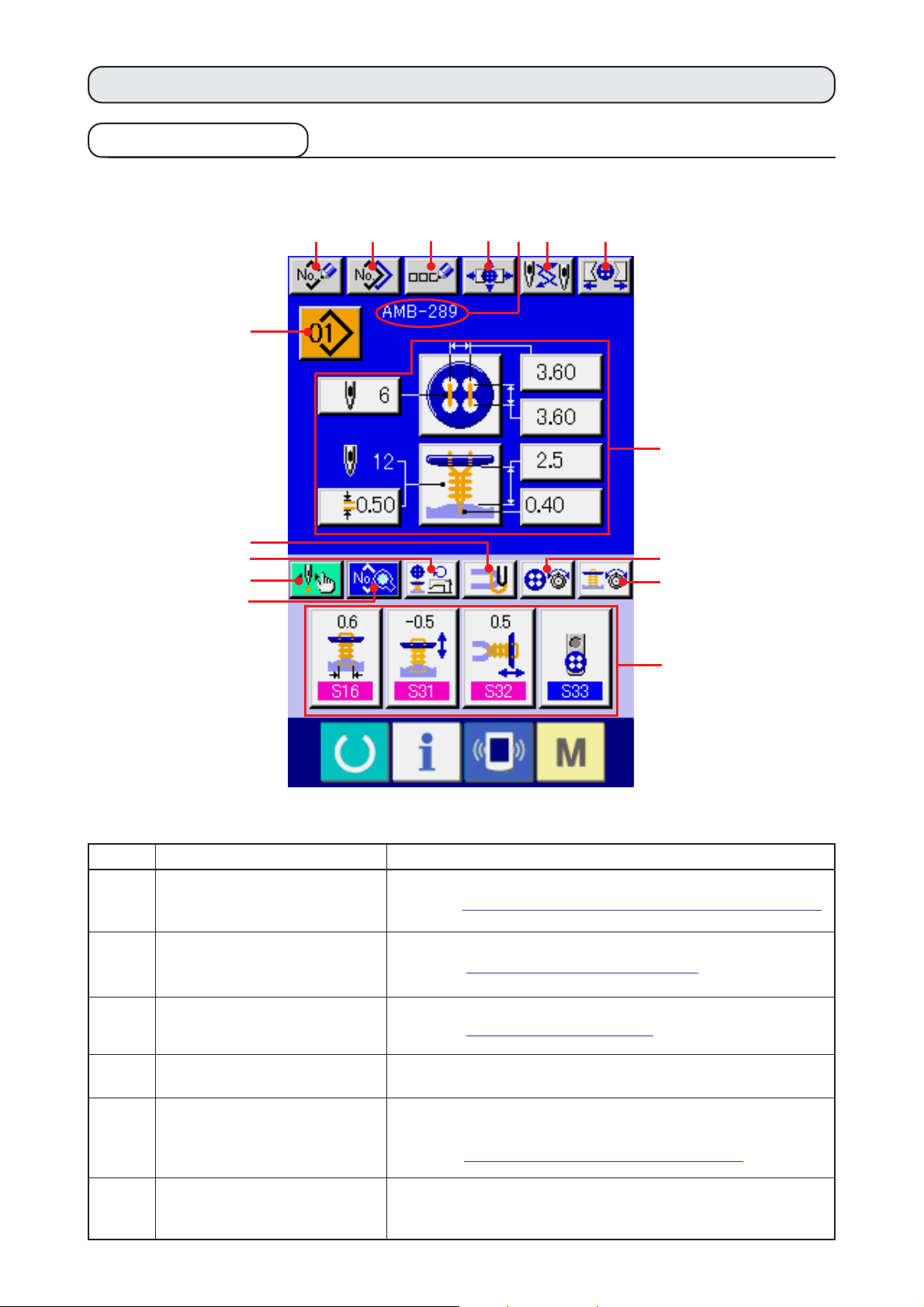

3. LCD DISPLAY SECTION AT THE TIME OF INDEPENDENT SEWING

(1) Data input screen

G

K

J

P

I

AB C EFD

O

H

L

M

N

Symbol Display Description

A

B

C

D

E

F

PATTERN NEW REGISTER button

PATTERN COPY button

PATTERN NAME SETTING button

PATTERN NAME display

NEEDLE CHANGE button

CHUCK CLOSE/OPEN button

Pattern No. new register screen is displayed.

→Refer to

Sewing pattern copy screen is displayed.

→Refer to "22. COPYING SEWING PATTERN".

Sewing pattern name input screen is displayed.

→Refer to "5. NAMING THE PATTERN".

Name which has been inputted to the sewing pattern being selected is displayed.

This button performs origin retrieval, makes needle come down, and

displays the needle change screen.

→

Refer to "33. PERFORMING CHANGE OF NEEDLE".

This button performs close/open of the chuck.

Chuck is opened as long as the button is pressed.

"21. PERFORMING NEW REGISTER OF SEWING PATTERN"

@– 8

.

Page 13

Symbol Display Description

G

PATTERN SELECTION button

Pattern No. being selected at present is displayed on this button and

when the button is pressed, the pattern No. change screen is displayed.

→

Refer to "4. PERFORMING PATTERN NO. SELECTION".

H

I

CONTENTS OF PATTERN display

SEWING DATA CHANGE button

Contents of the pattern which is registered to the pattern No. being selected at

present are displayed. The respective display sections consist of buttons and can

be changed. The contents of display differ in accordance with the sewing method.

* Sewing flat/wrapped-around button with blindstitch

→

Refer to "7. PERFORMING DATA SETTING OF SEWING

BUTTON WITH BLINDSTITCH (SHANK/MARBLE BUTTON)"

and "8. PERFORMING DATA SETTING OF SEWING BUTTON

WITH BLINDSTITCH (FLAT BUTTON)".

* Sewing flat button directly to cloth

→

Refer to "9. PERFORMING DATA SETTING OF SEWING FLAT

BUTTON DIRECTLY TO CLOTH".

* Sewing flat button with blindstitch

→

Refer to "10. PERFORMING DATA SETTING OF SEWING FLAT

BUTTON WITH BLINDSTITCH".

* Counter/stay button

→

Refer to

* Neck wrapping sewing

→

Refer to

Sewing data list screen is displayed.

→

Refer to "20. CHANGING SEWING DATA".

"11. PERFORMING SETTING OF COUNTER/STAY BUTTONS"

"12. PERFORMING DATA SETTING OF NECK WRAPPING SEWING DATA"

.

.

J

K

L

M

N

O

NUMBER OF REVOLUTIONS

SETTING button

STAY THREAD SETTING button

BUTTON SEWING THREAD

TENSION SETTING button

NECK WRAPPING THREAD

TENSION SETTING button

CUSTOMIZE button

CHUCK ADJUSTMENT button

Number of revolutions setting screen is displayed. Change of number of revolutions

of sewing machine for button sewing and that for neck wrapping can be performed.

→

Refer to "15. PERFORMING SETTING NUMBER OF REVOLUTIONS

OF SEWING MACHINE",

Stay thread setting screen is displayed.This screen is displayed only in

case of sewing flat/wrapped-around button with blindstitch or flat button

with blindstitch, and setting of stay thread is possible.

→

Refer to "16. PERFORMING SETTING STAY THREAD".

Button sewing thread tension setting screen is displayed.

→

Refer to

Neck wrapping thread tension setting screen is displayed. This screen is displayed only

in case of sewing flat/wrapped-around button with blindstitch or neck wrapping sewing.

→

Refer to

Sewing data which are more frequently used can be laid out to four buttons.

When this button is pressed, the laid-out sewing data change screen is displayed.

→

Refer to

Chuck adjustment screen is displayed.

→

Refer to "23. PERFORMING CHUCK ADJUSTMENT".

"17. PERFORMING INPUT OF BUTTON SEWING THREAD TENSION"

"18. PERFORMING INPUT OF NECK WRAP THREAD TENSION"

"35. CUSTOMIZING DATA INPUT SCREEN"

.

.

.

P

STEP SEWING button

When this button is pressed, the step sewing screen which performs

input and check of needle entry point is displayed.

→

Refer to "25. PERFORMING INPUT AND CHECK OF DATA WITH

STEP MOTION".

@– 9

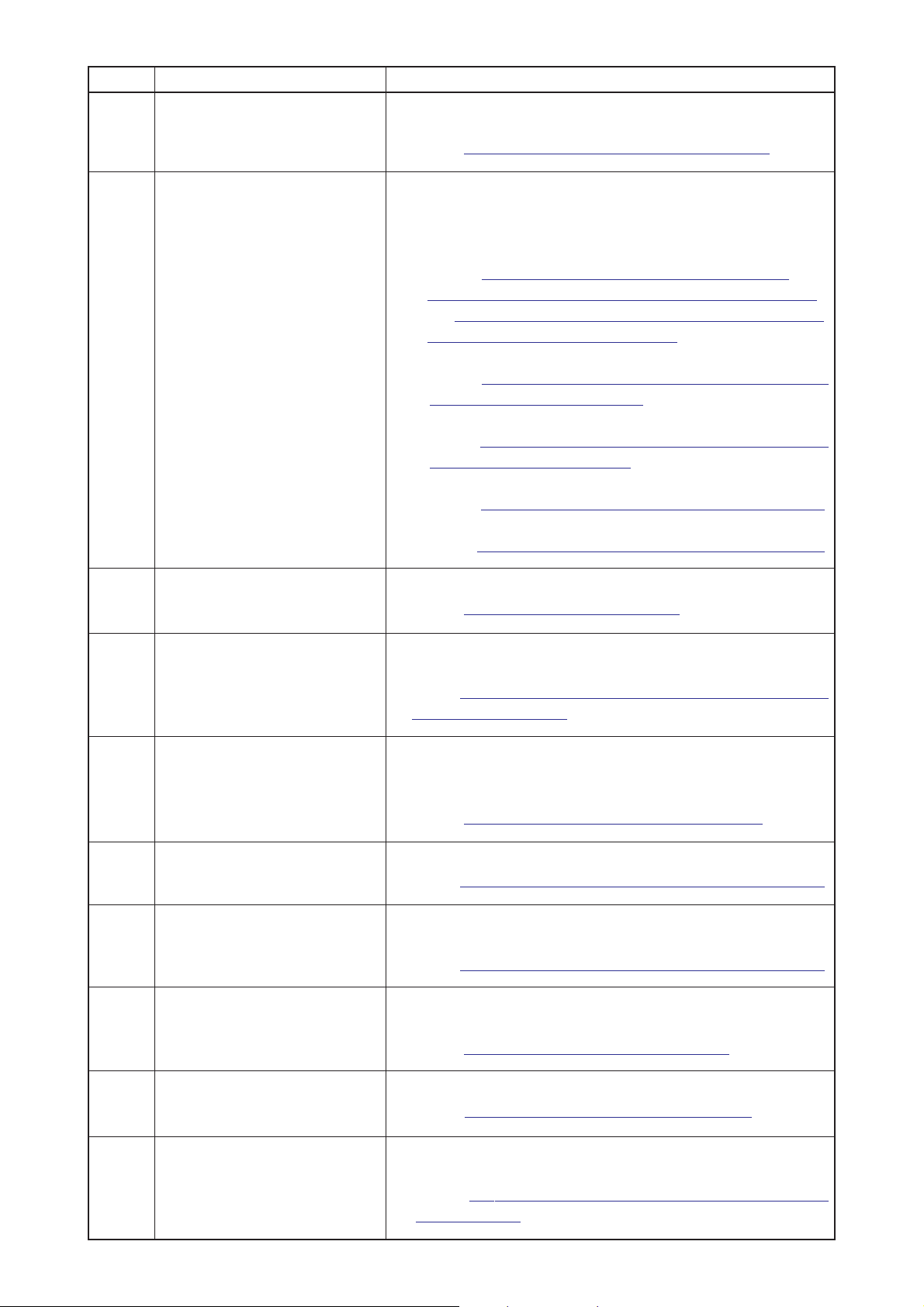

Page 14

(2) Sewing screen

G

H

J

K

M

L

DEFA

BC

R

I

N

O

P

Q

Symbol Display Description

A

B

C

D

E

CHUCK ADJUSTMENT button

BUTTON CENTERING button

PATTERN NAME display

LOADER MOTION button

NEEDLE CHANGE button

Chuck adjustment screen is displayed.

→Refer to "23. PERFORMING CHUCK ADJUSTMENT".

This is not displayed in the initial state.

→Refer to "24. PERFORMING BUTTON CENTERING".

Pattern name which is set in the pattern data during sewing is displayed.

When this button is pressed, loader works and sets button to the chuck.

This button makes needle come down, and the needle change screen is displayed.

→Refer to "33. PERFORMING CHANGE OF NEEDLE".

@– 10

Page 15

Symbol Display Description

F

CHUCK CLOSE/OPEN button

This button performs close/open of the chuck.

Chuck is opened as long as the button is pressed.

G

H

I

J

K

L

M

PATTERN NO. display

PATTERN CONTENTS display

BLINDSTITCH AMOUNT SETTING

button

COUNTER VALUE CHANGE

button

COUNTER CHANGE OVER button

STEP SEWING button

NUMBER OF REVOLUTIONS

SETTING button

Pattern No. during sewing is displayed.

Contents of pattern registered to pattern No. during sewing are displayed.

Contents of display depend on the sewing method. Blindstitch amount

only can be set in the sewing screen.

Setting of blindstitch amount is possible.

* This is displayed only in case of sewing flat/wrapped-around button

with blindstitch or flat button with blindstitch.

Existing counter value is displayed on this button. When the button is

pressed, the counter value change screen is displayed.

→Refer to

Display of sewing counter/No. of pcs. counter can be changed over.

→Refer to ""31. USING COUNTER".

When this button is pressed, the step sewing screen which performs

input and check of needle entry point is displayed.

→Refer to

Number of revolutions setting screen is displayed. Change of number of revolutions

of the sewing machine for button sewing and that for neck wrapping can be performed.

→

Refer to "15. PERFORMING SETTING NUMBER OF

REVOLUTIONS OF SEWING MACHINE".

"31. USING COUNTER".

"25. PERFORMING INPUT AND CHECK OF DATA WITH STEP MOTION"

.

N

O

P

Q

R

STAY THREAD SETTING button

BUTTON SEWING THREAD

TENSION SETTING button

NECK WRAPPING THREAD

TENSION SETTING button

DIRECT button

BUTTON LOADER SELECTION

button

Stay thread setting screen is displayed. This screen is displayed only in

case of sewing flat/wrapped-around button with blindstitch or flat button

with blindstitch, and setting of stay thread is possible.

→Refer to "16. PERFORMING SETTING STAY THREAD".

Button sewing thread tension setting screen is displayed.

→Refer to

Neck wrap thread tension setting screen is displayed. This screen is

displayed only in case of sewing flat/wrapped-around button with

blindstitch or neck wrapping sewing.

→Refer to

Pattern No. is changed over to pattern No. which is registered to the button.

→Refer to "36. CUSTOMIZING SEWING SCREEN".

Button loader being selected at present is displayed on the button.

When the button is pressed, the state of button loader can be changed.

"17. PERFORMING INPUT OF BUTTON SEWING THREAD TENSION"

"18. PERFORMING INPUT OF NECK WRAP THREAD TENSION"

.

.

@– 11

Page 16

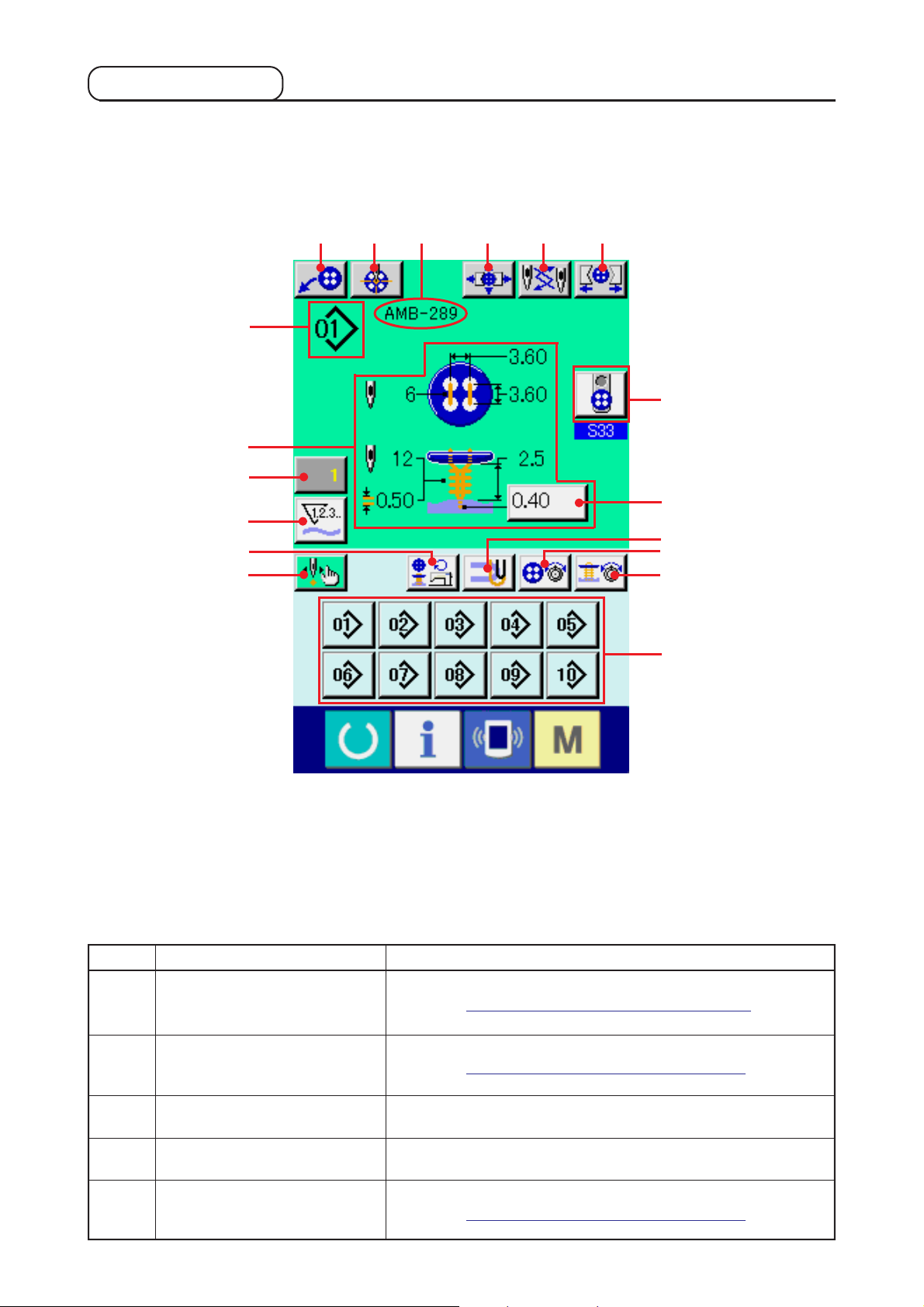

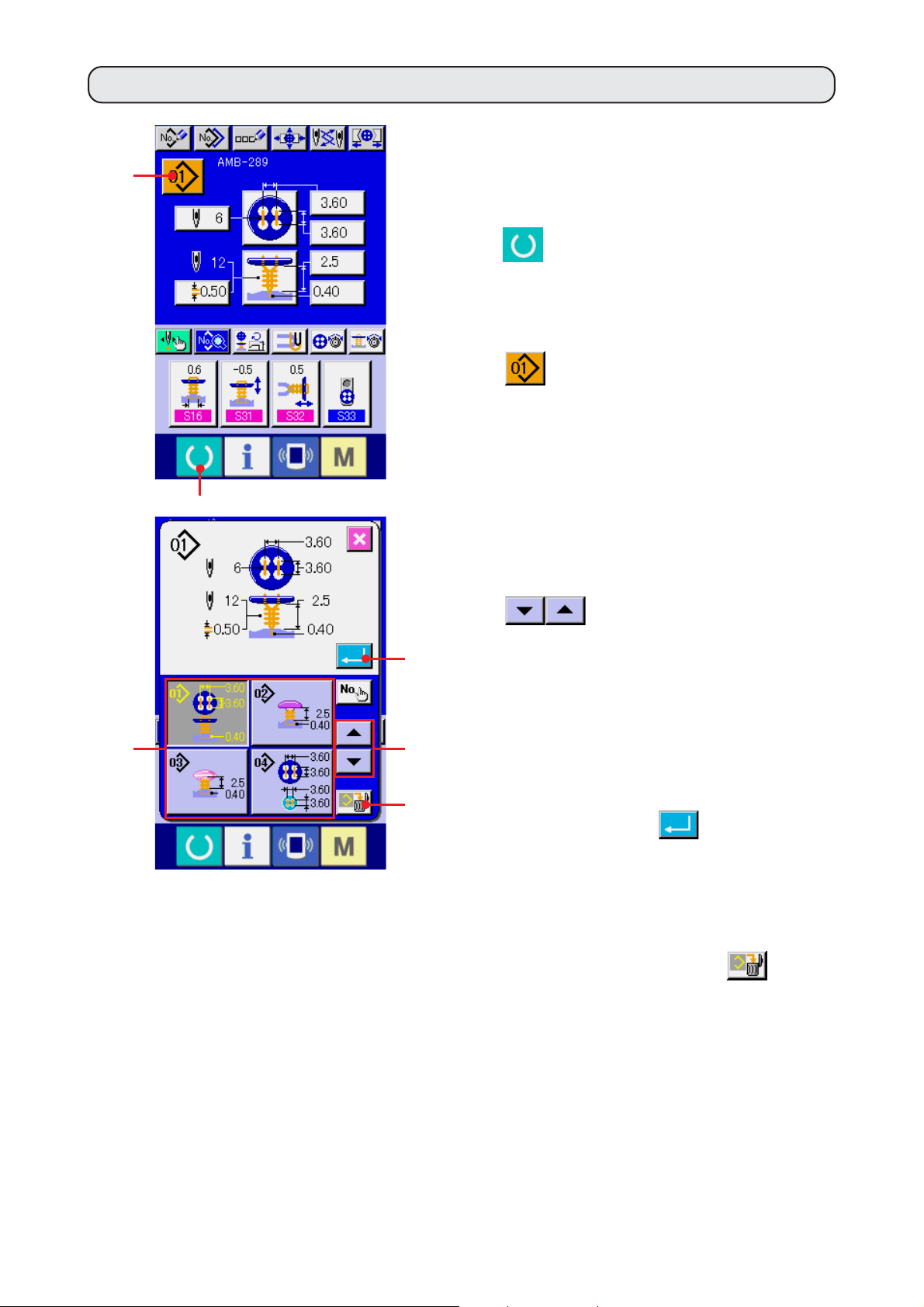

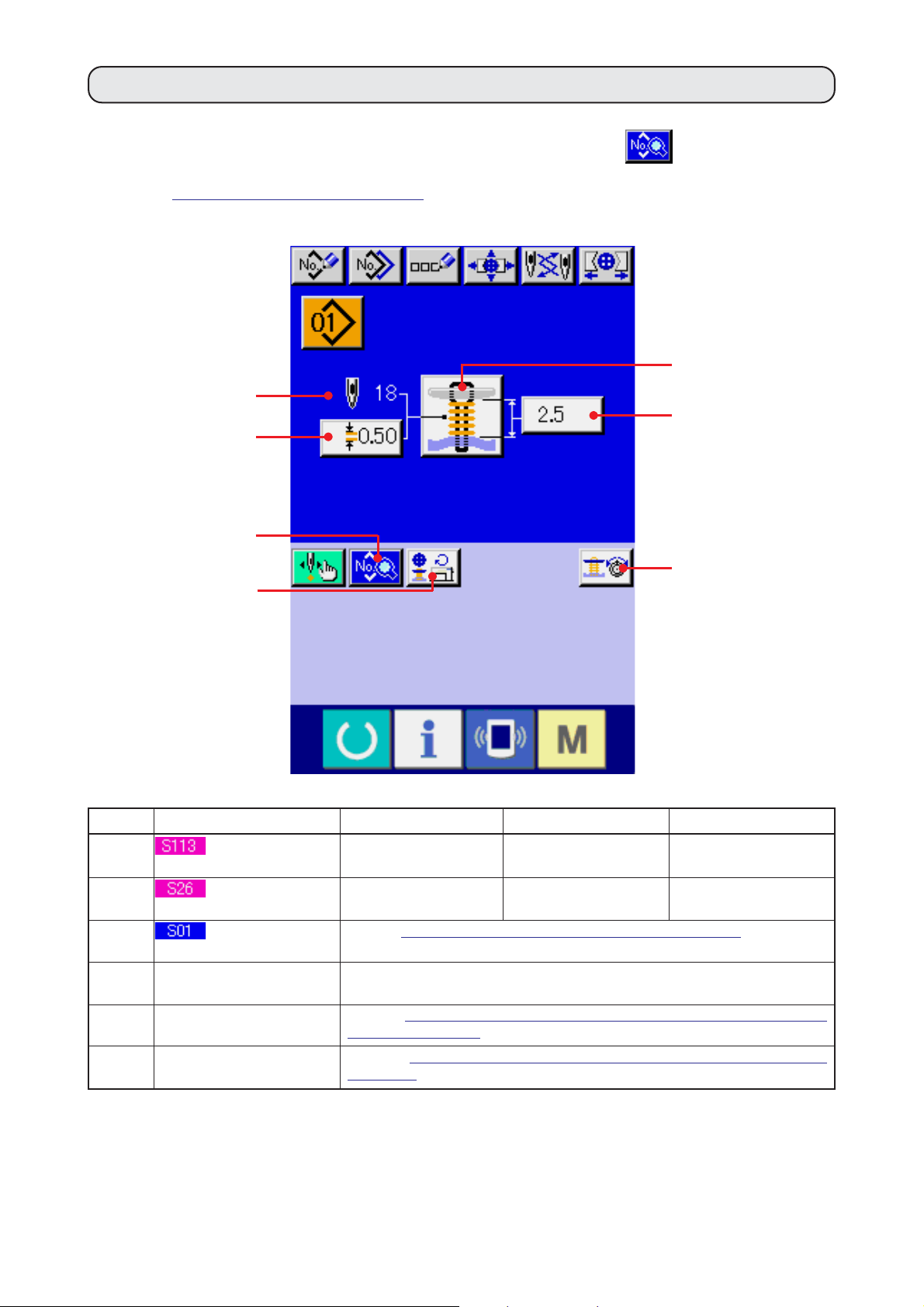

4. PERFORMING PATTERN No. SELECTION

1) Display the data input screen.

Only in case of the data input screen (blue), the

2

1

contents of setting can be changed. In case of

the sewing screen (green), press READY key

1 and display the data input screen.

2) Call the pattern No. selection screen.

Press PATTERN NO. SELECTION button

2 and the pattern No. selection screen

is displayed. Pattern No. which is selected at

present and the contents are displayed in the

upper part of the screen and the list of the

pattern No. buttons which have been registered

is displayed in the lower part.

4

5

3

6

3) Select the pattern No.

When UP or DOWN SCROLL button

3 is pressed, the pattern No.

buttons 4 which have been registered are

changed over in order. The contents of the

sewing data inputted in the pattern No. are

displayed in the button. Here, press the pattern

No. button 4 you desire to select.

4) Determine the pattern No.

Press ENTER button

5, and the pattern

No. selection screen is closed. Then the

selection has been finished.

* When you desire to delete the registered

pattern, press DELETE button

6.

However, the pattern which has been registered

to the cycle stitching cannot be deleted.

@– 12

Page 17

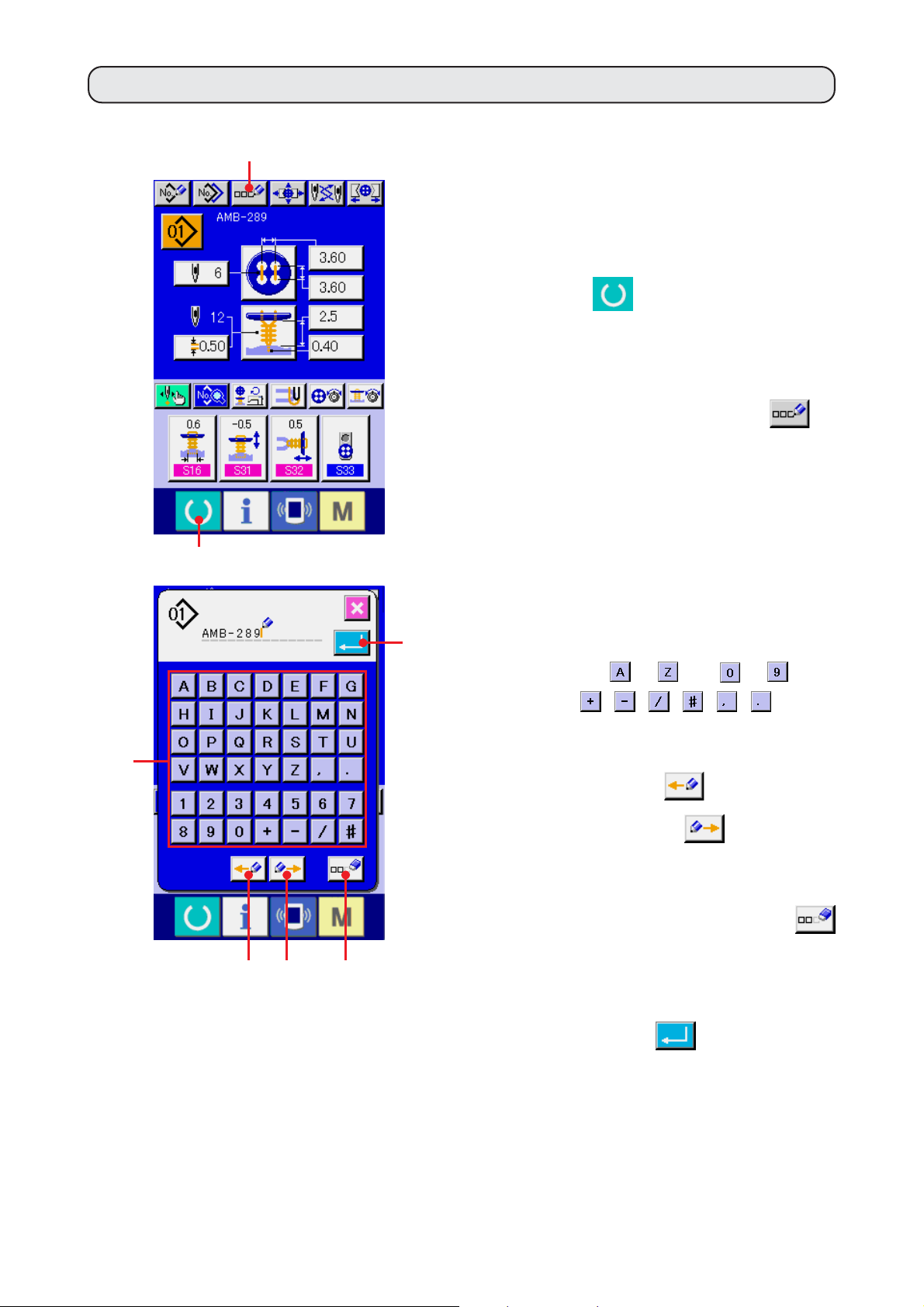

5. NAMING THE PATTERN

As many as 14 characters can be inputted to the patterns respectively.

2

1) Display the data input screen.

Only in case of the data input screen (blue),

input of the pattern name can be performed. In

case of the sewing screen (green), press

3

1

7

READY key

1 and display the data input

screen (blue).

2) Call the character input screen.

Press CHARACTER INPUT button

and the character input screen is displayed.

3) Input the character.

Press the character button 3 you desire to input,

and input of the character can be performed.

Characters (

symbols (

to and to ) and

, , , , , ) can be

inputted. As many as 14 characters can be

inputted. The cursor can travel with CURSOR

LEFT TRAVEL button

4 and CURSOR

2

4 5 6

RIGHT TRAVEL button

desire to delete the inputted character, adjust

the cursor to the position of the character you

desire to delete and press DELETE button

6.

4) Finish inputting the character.

Press ENTER button 7 and inputting the

character is finished. After the finish, the

inputted character is displayed in the upper part

of the data input screen (blue).

@– 13

5. When you

Page 18

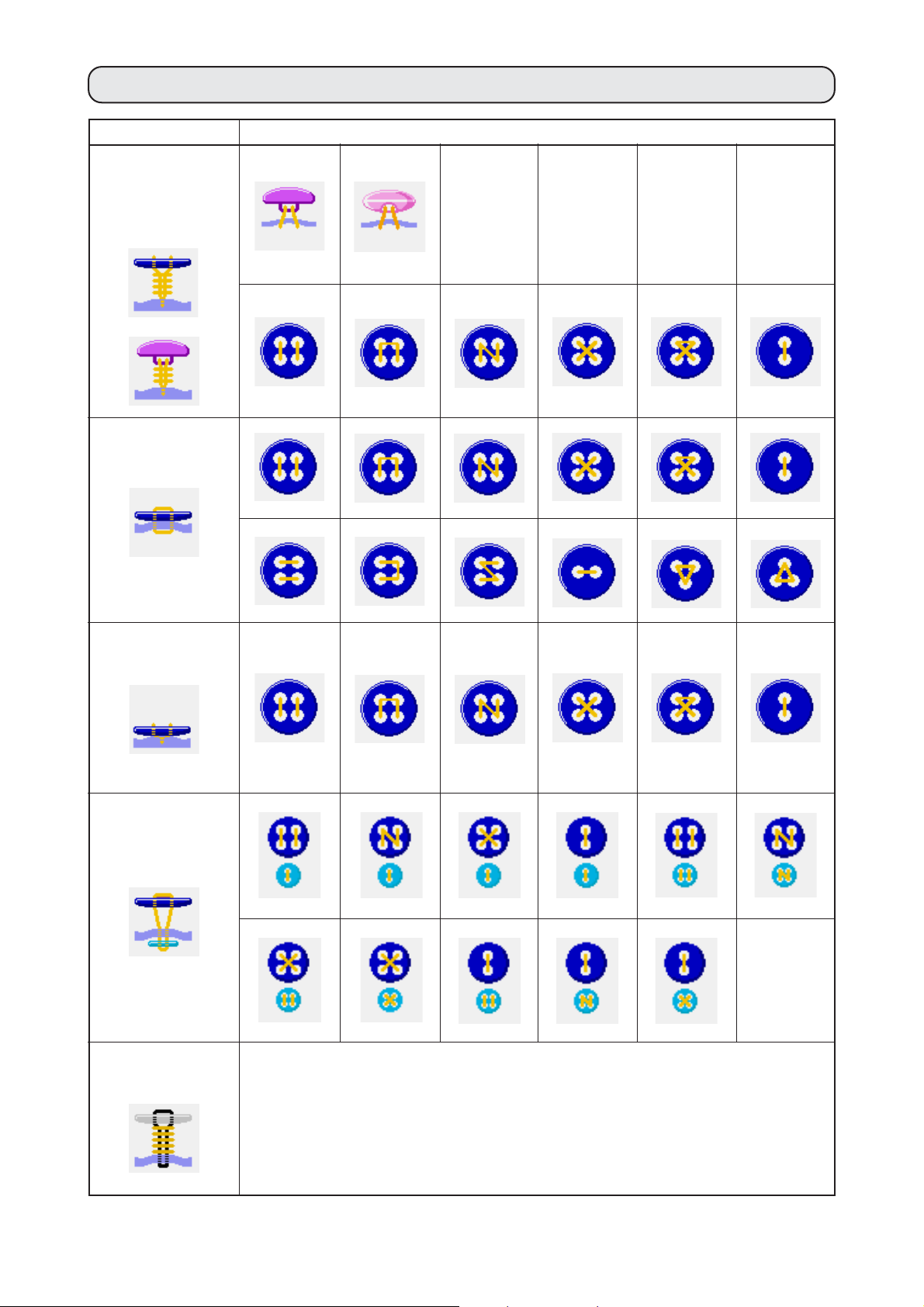

6. SEWING METHOD AND SEWING SHAPE LIST

Sewing method Sewing shape

Sewing flat/

wrapped-around

button with

blindstitch

Sewing flat button

directly to cloth

Sewing flat button

with blindstitch

Sewing counter/

stay button

Sewing button with

neck wraps

–––

@– 14

Page 19

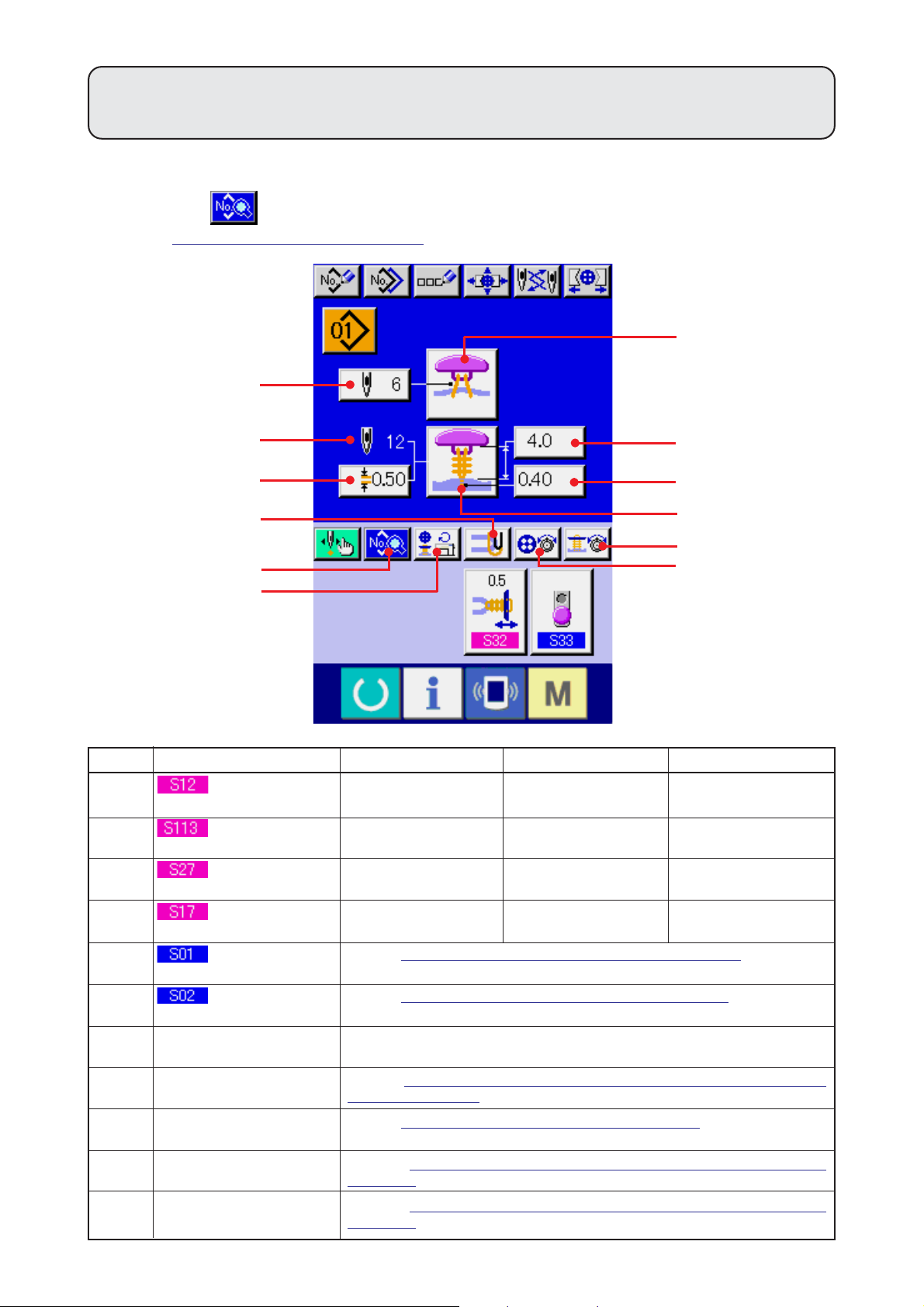

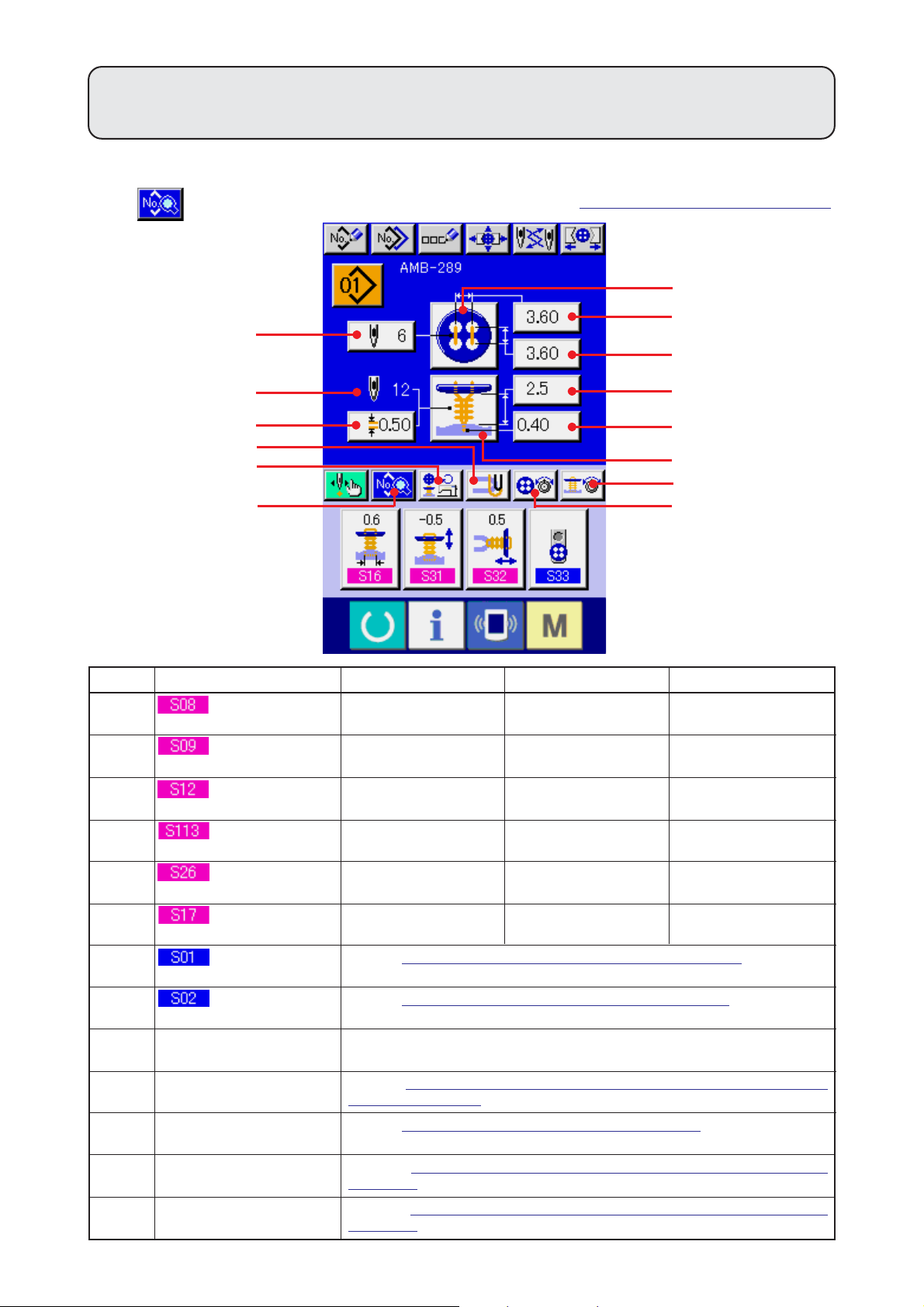

7.

PERFORMING DATA SETTING OF SEWING BUTTON WITH BLINDSTITCH

(SHANK AND MARBLE BUTTONS)

Items that can be set in the data input screen of sewing flat/wrapped-around button with blindstitch (shank

and marble buttons) are those below. In case of performing more detailed setting, press SEWING DATA

DISPLAY button

→Refer to

"20. CHANGING SEWING DATA".

H and set it from the sewing data screen.

A

G

B

J

H

I

F

C

D

E

L

K

Symbol Item Input range Edit unit Initial value

A

B

C

D

E

F

G

I

J

K

L

Number of stitches

of button sewing

Neck wrapping pitch

Button sewing height

Blindstitch amount

Sewing method

selection

Sewing shape

selection

Number of stitches of neck

wrapping display

Number of revolutions of

sewing machine setting

Stay thread setting

Button sewing thread

tension setting

Neck wrapping thread

tension setting

2 to 32

0.05 to 2.00

0 to 15.0

–1.00 to 5.00

Refer to

Refer to "14. PERFORMING SEWING SHAPE SELECTION".

Number of stitches of neck wrapping actually sewn is displayed.

Refer to "15. PERFORMING SETTING NUMBER OF REVOLUTIONS OF

SEWING MACHINE"

Refer to "16. PERFORMING SETTING STAY THREAD".

Refer to "17. PERFORMING INPUT OF BUTTON SEWING THREAD

TENSION".

Refer to "18. PERFORMING INPUT OF NECK WRAPPING THREAD

TENSION".

"13. PERFORMING SEWING METHOD SELECTION".

.

2 stitches

0.05mm

0.1mm

0.05mm

6

0.50

4.0

0.40

@– 15

Page 20

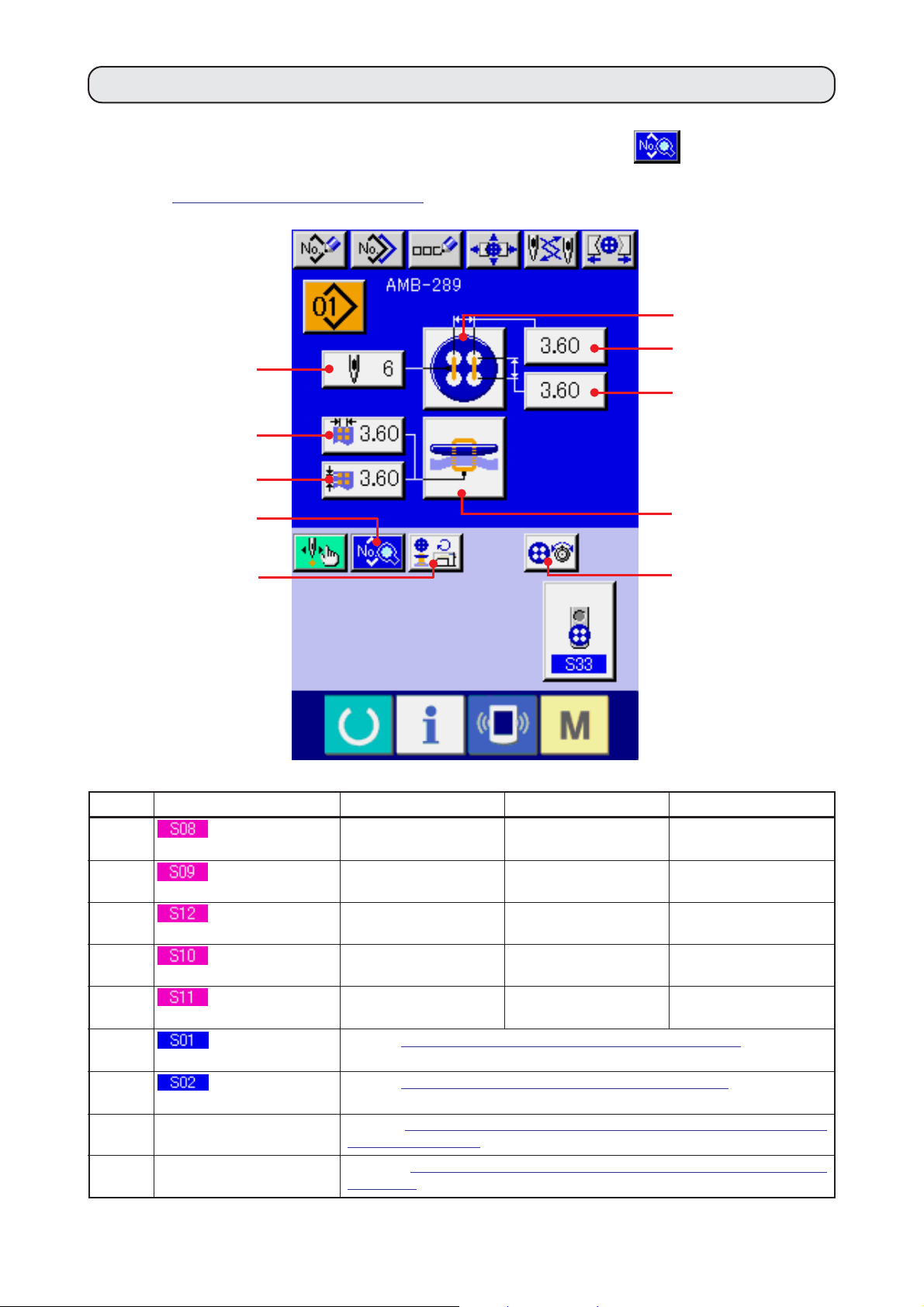

8.

PERFORMONG DATA SETTING OF SEWING BUTTON WITH BLINDSTITCH

(FLAT BUTTON)

Items that can be set in the data input screen of sewing flat/wrapped-around button with blindstitch (flat

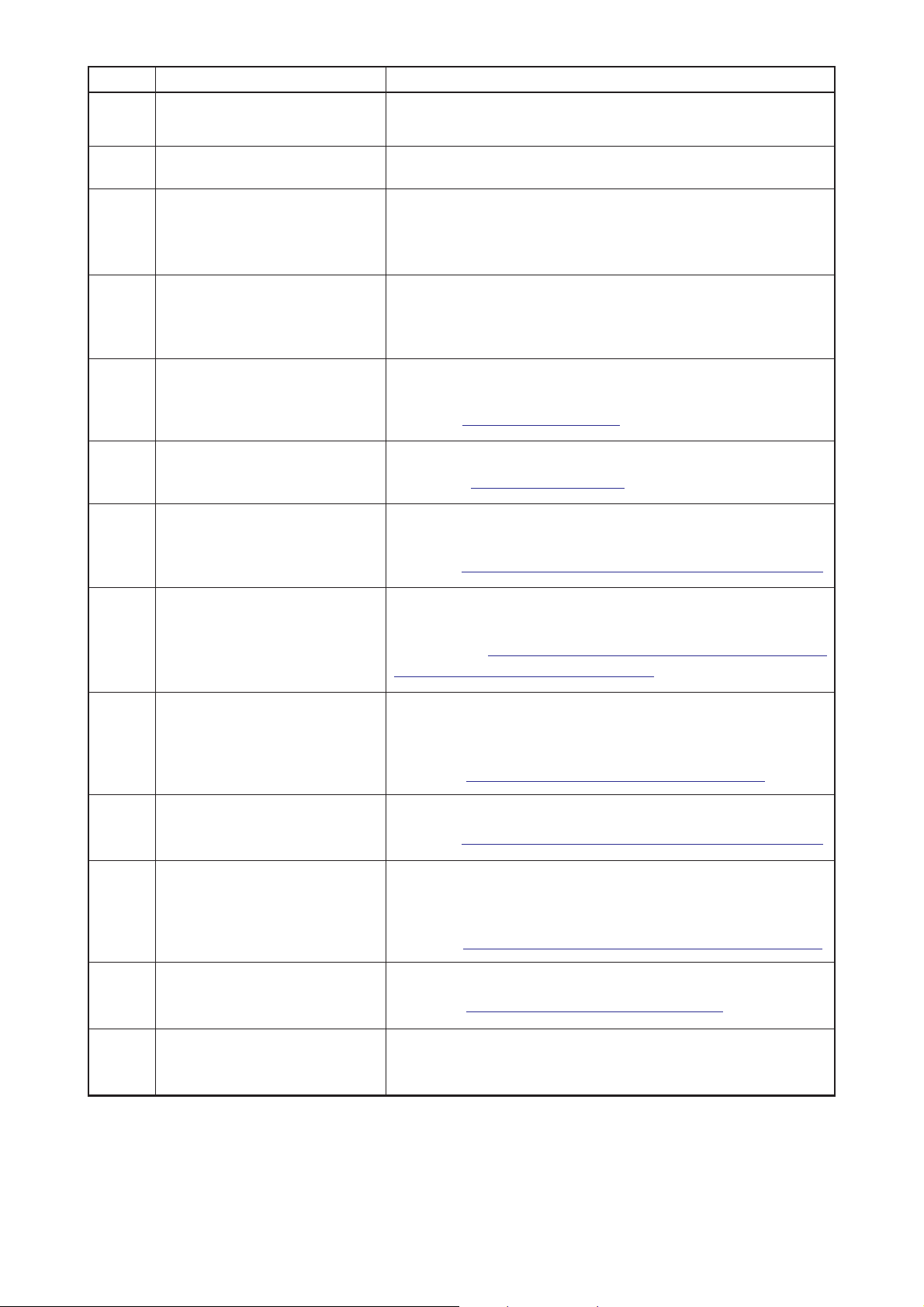

button) are those below. In case of performing more detailed setting, press SEWING DATA DISPLAY

button

N and set it from the sewing data screen. →Refer to "20. CHANGING SEWING DATA".

H

B

C

A

I

D

K

J

N

Symbol Item Input range Edit unit Initial value

A

B

C

D

Buttonhole interval

(longitudinal)

Buttonhole interval

(lateral)

Number of stitches

of button sewing

Neck wrapping pitch

0.10 to 6.00

0.10 to 6.00

2 to 32

0.05 to 2.00

0.05mm

0.05mm

2 stitches

0.05mm

E

F

G

M

L

3.60

3.60

6

0.50

E

F

G

H

I

J

K

L

M

Button sewing height

Blindstitch amount

Sewing method

selection

Sewing shape

selection

Number of stitches of neck

wrapping display

Number of revolutions of

sewing machine setting

Stay thread setting

Button sewing thread

tension setting

Neck wrapping thread

tension setting

0.5 to 15.0

–1.00 to 5.00

Refer to "13. PERFORMING SEWING METHOD SELECTION".

Refer to "14. PERFORMING SEWING SHAPE SELECTION".

Number of stitches of neck wrapping actually sewn is displayed.

Refer to "15. PERFORMING SETTING NUMBER OF REVOLUTIONS OF

SEWING MACHINE"

Refer to

Refer to "17. PERFORMING INPUT OF BUTTON SEWING THREAD

TENSION".

Refer to

TENSION".

"16. PERFORMING SETTING STAY THREAD".

"18. PERFORMING INPUT OF NECK WRAPPING THREAD

.

0.1mm

0.05mm

2.5

0.40

@– 16

Page 21

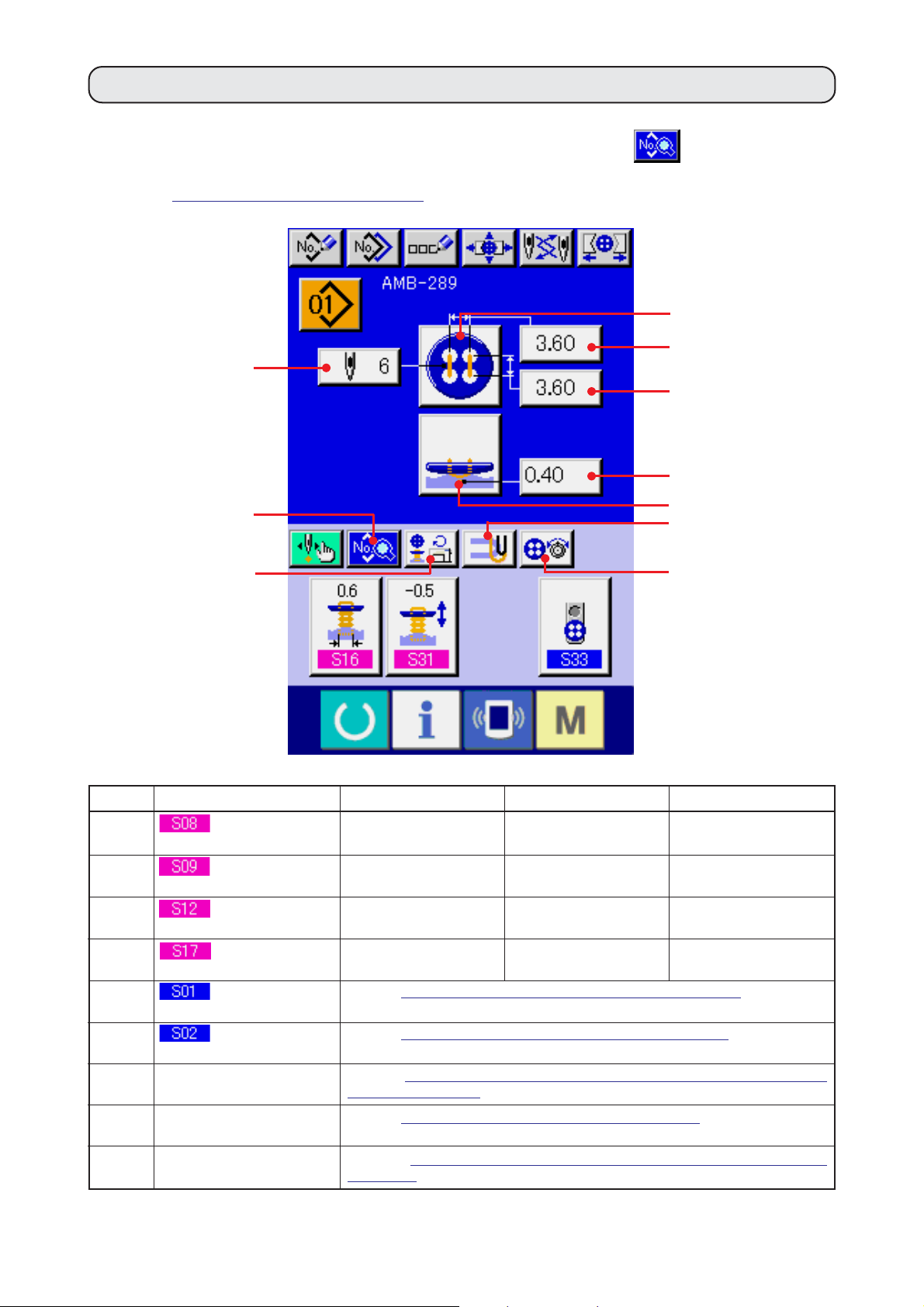

9.

PERFORMING DATA SETTING OF SEWING BUTTON DIRECTLY TO CLOTH

Items that can be set in the data input screen of sewing flat button directly to cloth are those below. In case

of performing more detailed setting, press SEWING DATA DISPLAY button

H and set it from the

sewing data screen.

→Refer to

"20. CHANGING SEWING DATA".

G

B

C

A

E

D

H

I

Symbol Item Input range Edit unit Initial value

A

B

C

D

E

F

G

I

J

Buttonhole interval

(longitudinal)

Buttonhole interval

(lateral)

Number of stitches

of button sewing

Interval of bottom

needle entry (longitudinal)

Interval of bottom

feed needle entry (lateral)

Sewing method

selection

Sewing shape

selection

Number of revolutions of

sewing machine setting

Button sewing thread tension

setting

feed

0.10 to 6.00

0.10 to 6.00

2 to 32

0.10 to 6.00

0.10 to 6.00

Refer to

Refer to "14. PERFORMING SEWING SHAPE SELECTION".

Refer to "15. PERFORMING SETTING NUMBER OF REVOLUTIONS OF

SEWING MACHINE"

Refer to

TENSION".

"13. PERFORMING SEWING METHOD SELECTION".

.

"17. PERFORMING INPUT OF BUTTON SEWING THREAD

0.05mm

0.05mm

2 stitches

0.05mm

0.05mm

F

J

3.60

3.60

6

3.60

3.60

@– 17

Page 22

10.

PERFORMING DATA SETTING OF SEWING FLAT BUTTON WITH BLINDSTITCH

Items that can be set in the data input screen of sewing flat button with blindstitch are those below. In case

of performing more detailed setting, press SEWING DATA DISPLAY button

G and set it from the

sewing data screen.

→Refer to

"20. CHANGING SEWING DATA".

F

B

C

A

D

G

H

Symbol Item Input range Edit unit Initial value

A

B

C

D

Buttonhole interval

(longitudinal)

Buttonhole interval

(lateral)

Number of stitches

of button sewing

Blindstitch amount

0.10 to 6.00

0.10 to 6.00

2 to 32

–1.00 to 5.00

0.05mm

0.05mm

2 stitches

0.05mm

E

I

J

3.60

3.60

6

0.40

E

F

H

I

J

Sewing method

selection

Sewing shape

selection

Number of revolutions of

sewing machine setting

Stay thread setting

Button sewing thread

tension setting

Refer to "13. PERFORMING SEWING METHOD SELECTION".

Refer to "14. PERFORMING SEWING SHAPE SELECTION".

Refer to "15. PERFORMING SETTING NUMBER OF REVOLUTIONS OF

SEWING MACHINE"

Refer to

Refer to "17. PERFORMING INPUT OF BUTTON SEWING THREAD

TENSION".

"16. PERFORMING SETTING STAY THREAD".

.

@– 18

Page 23

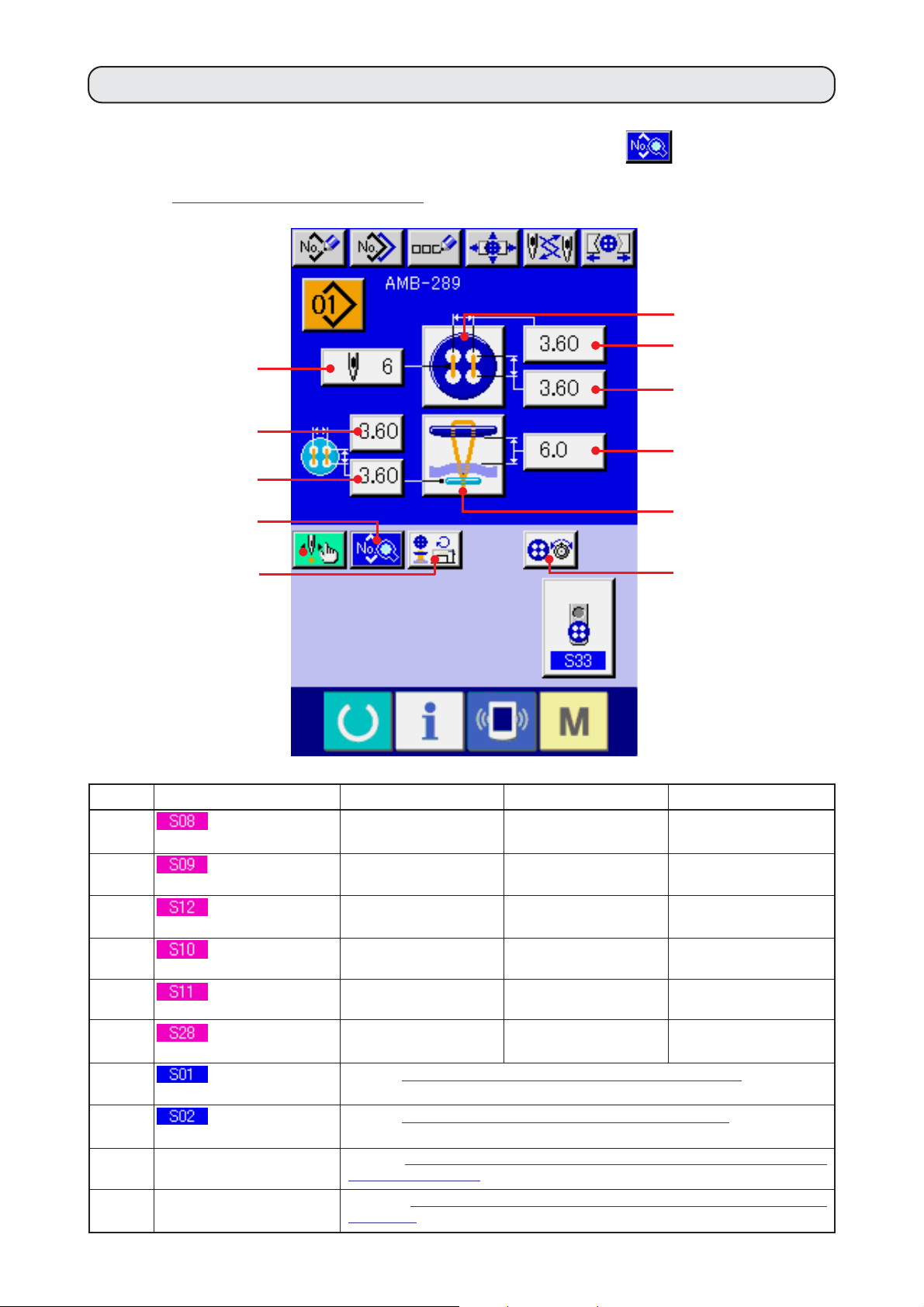

11. PERFORMING SETTING OF COUNTER/STAY BUTTONS

Items that can be set in the data input screen of counter and stay buttons are those below. In case of

performing more detailed setting, press SEWING DATA DISPLAY button

sewing data screen.

→Refer to

"20. CHANGING SEWING DATA".

C

E

D

I and set it from the

H

B

A

F

I

J

Symbol Item Input range Edit unit Initial value

A

B

C

D

E

F

G

H

J

K

Buttonhole interval

(longitudinal)

Buttonhole interval

(lateral)

Number of stitches

of button sewing

Interval of bottom

feed needle entry (longitudinal)

Interval of bottom

feed needle entry (lateral)

Button height

(counter button)

Sewing method

selection

Sewing shape

selection

Number of revolutions of

sewing machine setting

Button sewing thread

tension setting

0.10 to 6.00

0.10 to 6.00

2 to 32

0.10 to 6.00

0.10 to 6.00

0 to 20.0

Refer to "13. PERFORMING SEWING METHOD SELECTION".

Refer to "14. PERFORMING SEWING SHAPE SELECTION".

Refer to "15. PERFORMING SETTING NUMBER OF REVOLUTIONS OF

SEWING MACHINE"

Refer to

TENSION".

"17. PERFORMING INPUT OF BUTTON SEWING THREAD

.

0.05mm

0.05mm

2 stitches

0.05mm

0.05mm

0.1mm

G

K

3.60

3.60

6

3.60

3.60

6.0

@– 19

Page 24

12. PERFORMING NECK WRAPPING SEWING DATA

Items that can be set in the data input screen of neck wrapping sewing are those below. In case of

performing more detailed setting, press SEWING DATA DISPLAY button

sewing data screen.

→Refer to

"20. CHANGING SEWING DATA".

D

A

E

E and set it from the

C

B

G

F

Symbol Item Input range Edit unit Initial value

A

B

C

D

F

G

Neck wrapping pitch

Button sewing height

Sewing method

selection

Number of stitches of neck

wrapping display

Number of revolutions of

sewing machine setting

Neck wrapping thread

tension setting

0.05 to 2.00

0.5 to 15.0

Refer to "13. PERFORMING SEWING METHOD SELECTION".

Number of stitches of neck wrapping actually sewn is displayed.

Refer to "15. PERFORMING SETTING NUMBER OF REVOLUTIONS OF

SEWING MACHINE"

Refer to

TENSION".

"18. PERFORMING INPUT OF NECK WRAPPING THREAD

.

0.05mm

0.1mm

0.50

2.5

@– 20

Page 25

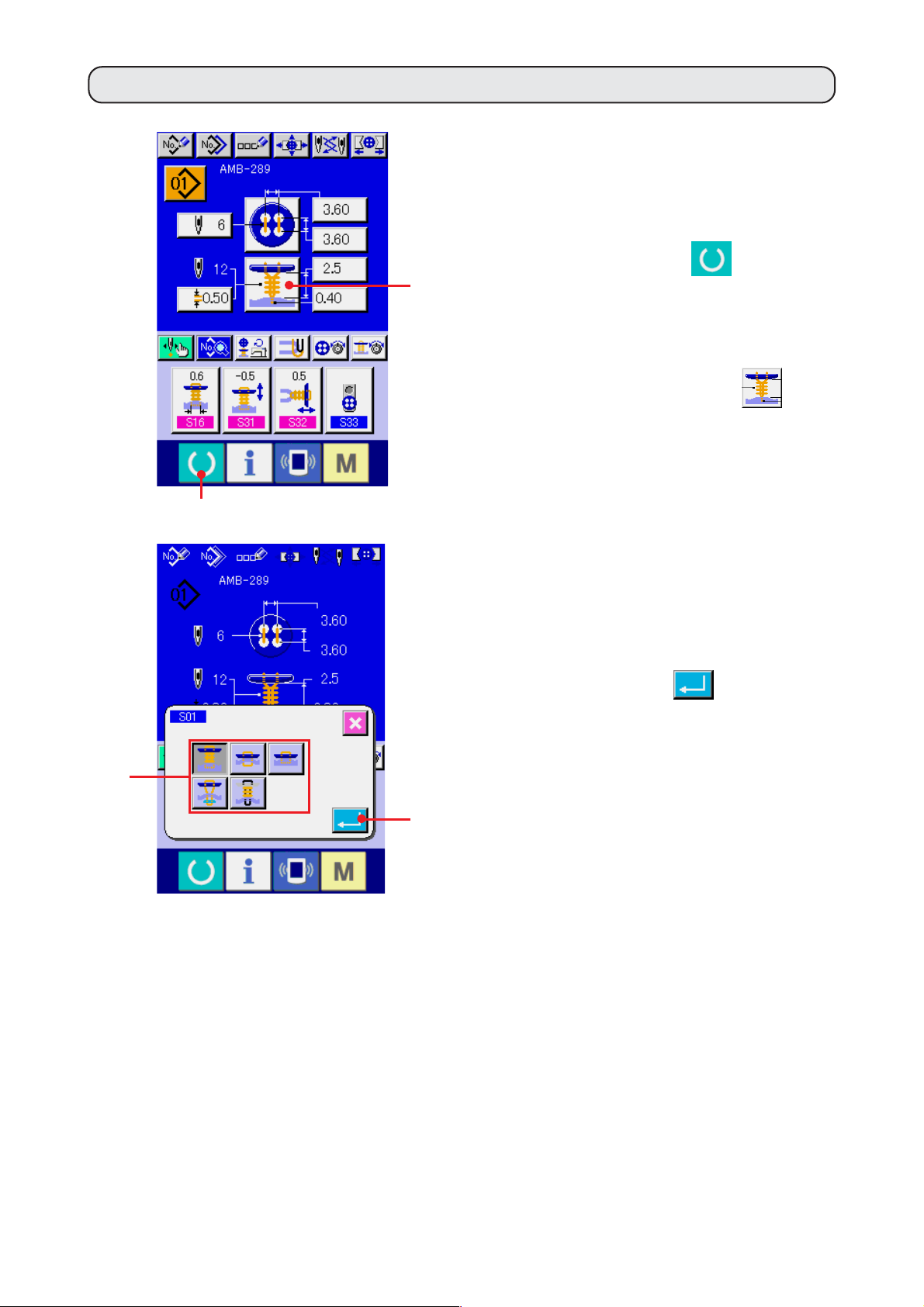

13. PERFORMING SEWING METHOD SELECTION

1) Display the data input screen.

Only in case of data input screen (blue),

selection of the sewing shape can be

performed. In case of the sewing screen

1

2

(green), press READY key

1 and display

the data input screen (blue).

2) Call the sewing method selection screen.

Press SEWING METHOD button

2 and

the sewing shape selection screen is displayed.

3) Select the sewing method.

Select SEWING METHOD button 3you desire

to sew.

4) Finish the sewing method selection.

Press ENTER button

4 to finish the

3

sewing method selection and the selected

sewing shape is displayed in the data input

screen (blue).

4

@– 21

Page 26

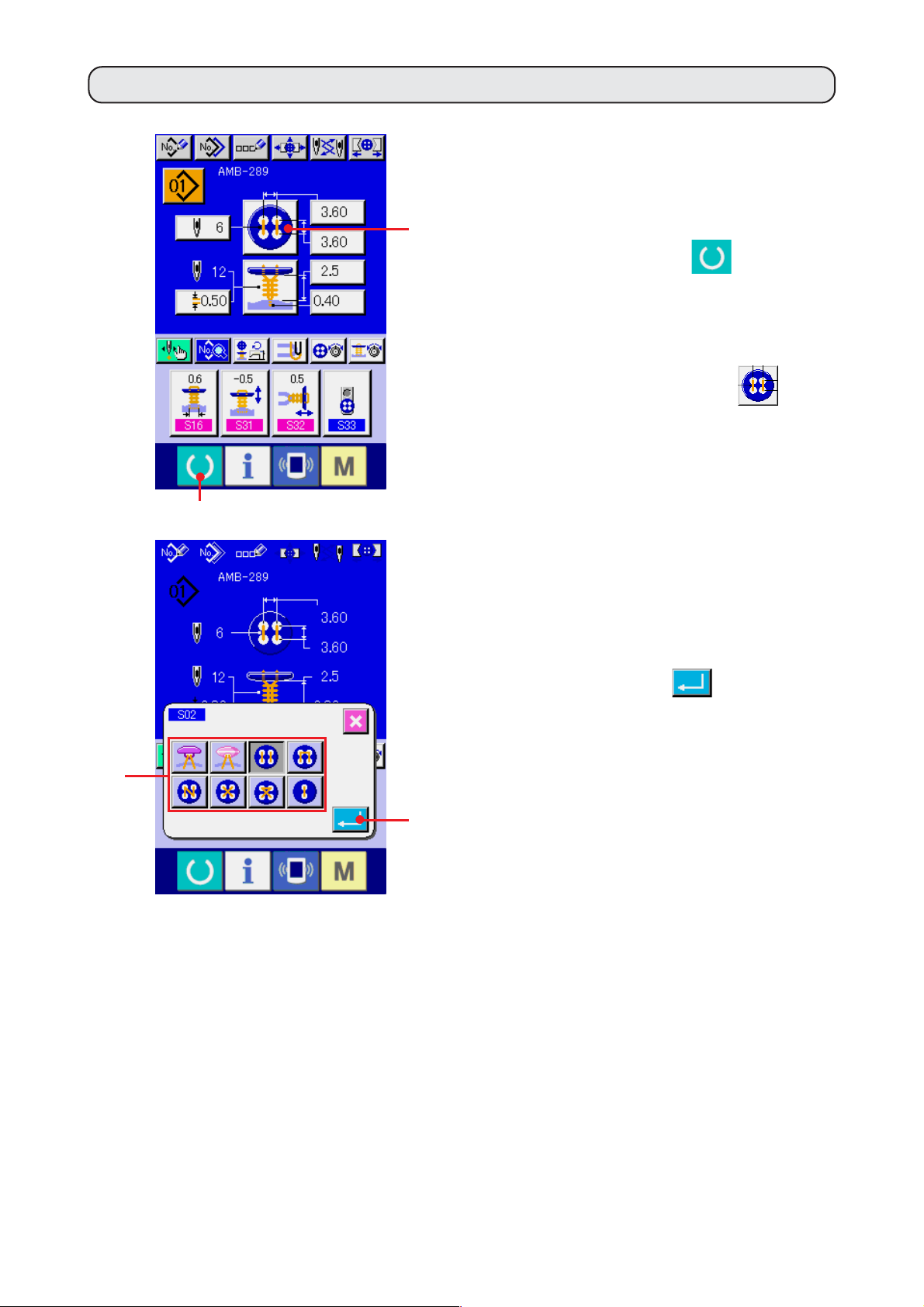

14. PERFORMING SEWING SHAPE SELECTION

1) Display the data input screen.

Only in case of the data input screen (blue),

the selection of sewing shape can be

2

performed. In case of the sewing screen

1

(green), press READY key

1 and display

the data input screen (blue).

2) Call the sewing shape selection screen.

Press SEWING SHAPE button

2 and

the sewing shape selection screen is displayed.

3) Select the sewing shape.

Select SEWING SHAPE button 3 you desire

to sew.

4) Finish the sewing shape selection.

Press ENTER button

4 to finish the

3

shape selection and the selected sewing shape

is displayed in the data input screen (blue).

4

@– 22

Page 27

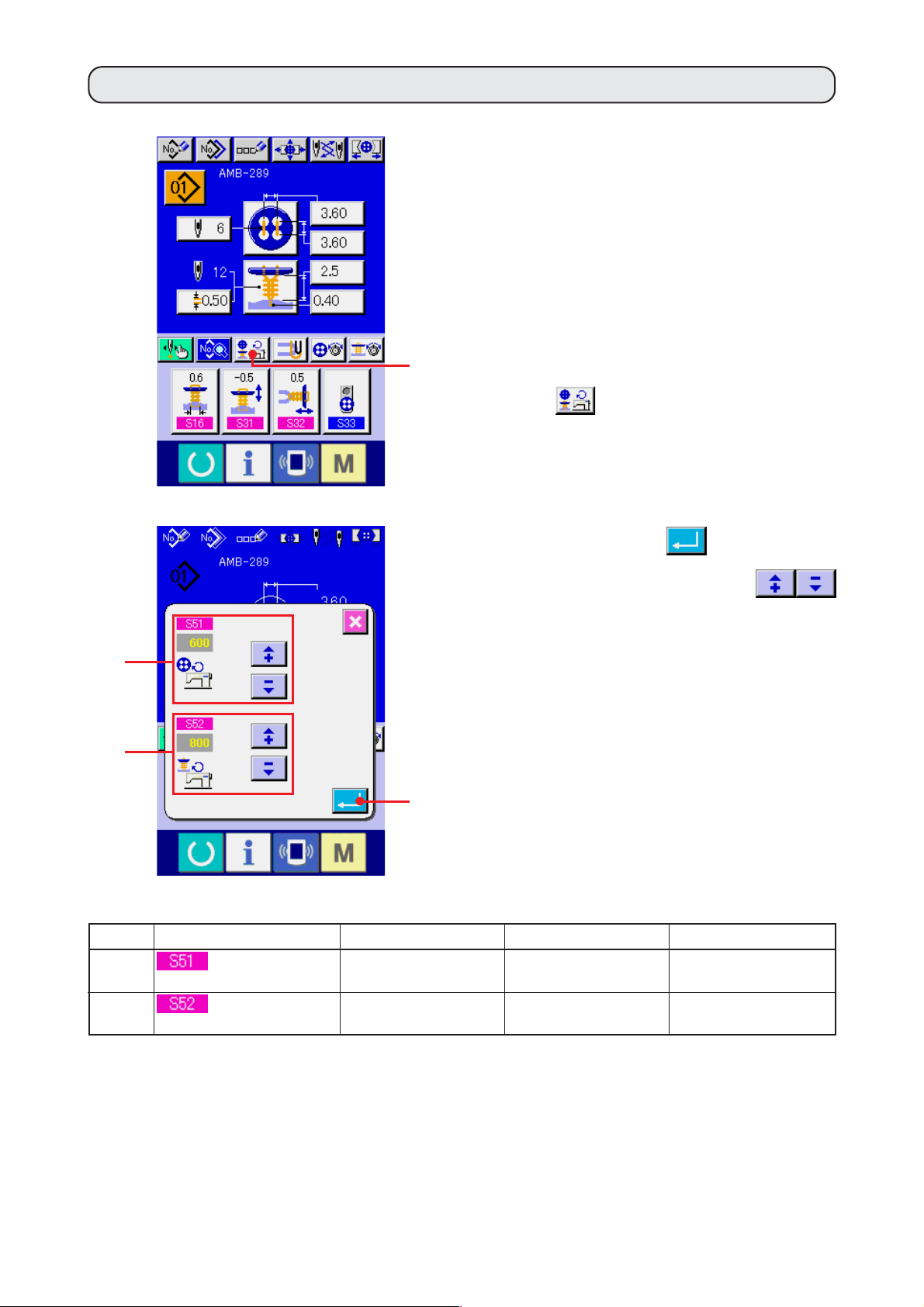

15.

PERFORMING SETTING NUMBER OF REVOLUTIONS OF SEWING MACHINE

1) Display the data input screen.

Setting of number of revolutions of sewing

machine can be performed in the data input

screen and the sewing screen.

2) Display the number of revolutions setting

screen.

1

Press NUMBER OF REVOLUTIONS SETTING

2

3

4

button

1 and the number of revolutions

setting screen is displayed. Setting of number

of revolutions for button sewing and that for

neck wrapping can be performed.

Press ENTER button

4 after inputting

with the arrow mark (up/down)

buttons 2 and 3, and determine the data.

Symbol Item Input range Edit unit Initial value

2

3

Number of

revolutions for button sewing

Number of

revolutions for neck wrapping

200 to 1200

200 to 1800

100rpm

100rpm

600

800

@– 23

Page 28

16. PERFORMING SETTING STAY THREAD

When sewing flat/wrapped-around button with blindstitch or sewing flat button with blindstitch is selected,

STAY THREAD SETTING button is displayed in the data input screen and the sewing screen.

1) Display the stay thread setting screen.

Press STAY THREAD SETTING button

1 and the stay thread setting screen is

displayed.

1

Setting of number of stitches 2 of the stay

thread and amount 3 of the stay thread can

be performed.

Press ENTER button

2

3

4

Symbol Item Input range Edit unit Initial value

2

of stay thread

Number of stitches

Without

:

stay thread

and determine the data.

– – –

4 after inputting,

:

1 stitche

3

thread

Amount of stay

:

1 stitche

:

2 stitches

:

3 stitches

0 to 5.0

@– 24

0.1mm

1.5

Page 29

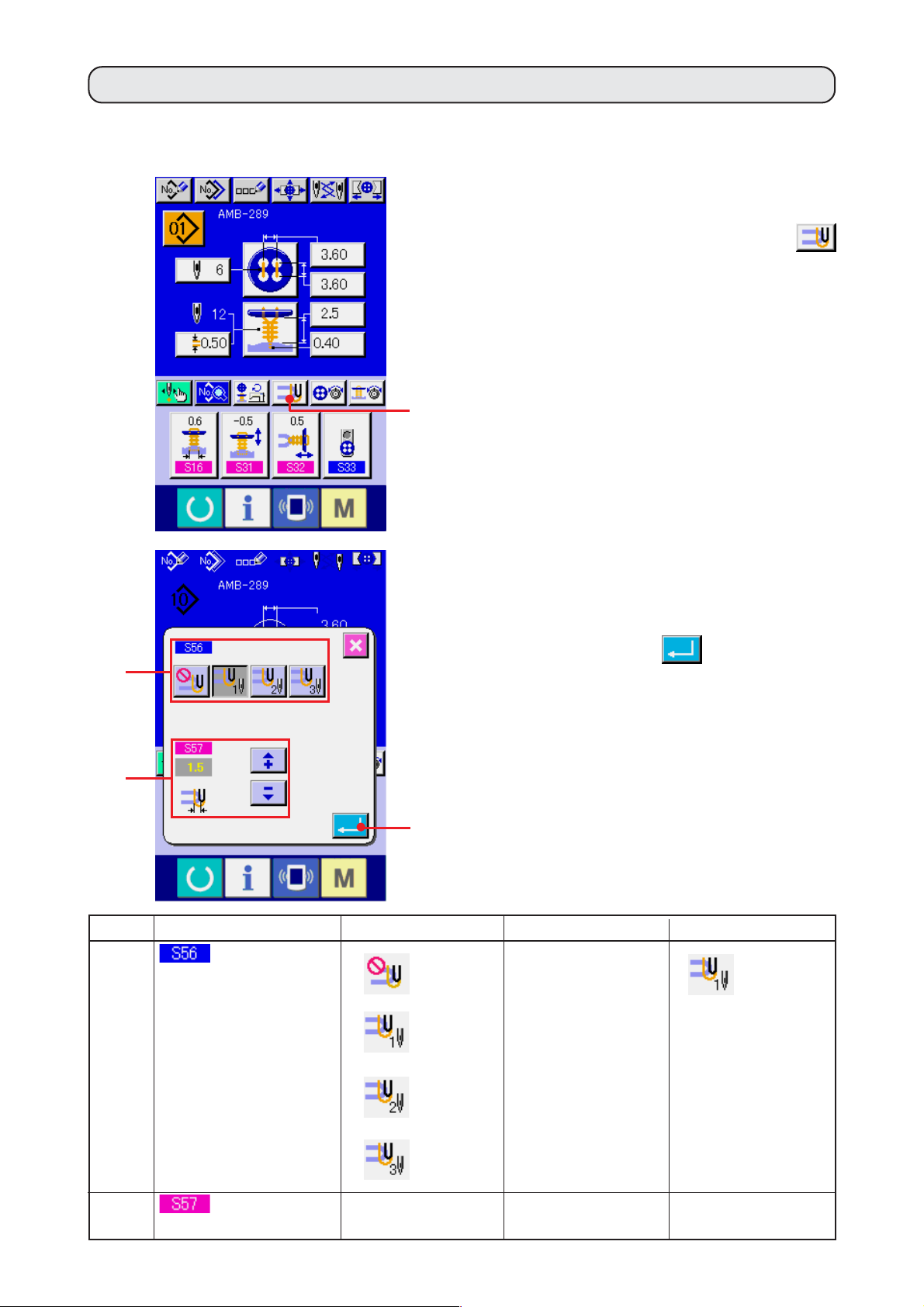

17. PERFORMING INPUT OF BUTTON SEWING THREAD TENSION

When selecting sewing flat/wrapped-around button with blindstitch, sewing flat button directly to cloth,

sewing flat button with blindstitch, or sewing counter/stay button in the data input screen and the sewing

screen, BUTTON SEWING THREAD TENSION SETTING button is displayed.

(1) In case of simplified input

1) Display the button sewing thread tension

simplified setting screen.

Press BUTTON SEWING THREAD TENSION

2

1

5

SIMPLIFIED SETTING button

1 and the

button sewing thread tension simplified setting

screen is displayed, and setting of the thread

remaining length before sewing and the thread

tension of the normal stitches for button sewing

can be performed.

Initial set value is the value when

polyester spun thread #50 thread is

used.

The edit of data can be performed with ARROW

MARK (UP/DOWN)

buttons (2 and

4) and SCROLL BAR 3 respectively. The data

can be determined at the time of editing.

When CANCEL button

5 is pressed,

3

4

the screen is closed and the data input screen

is displayed.

@– 25

Page 30

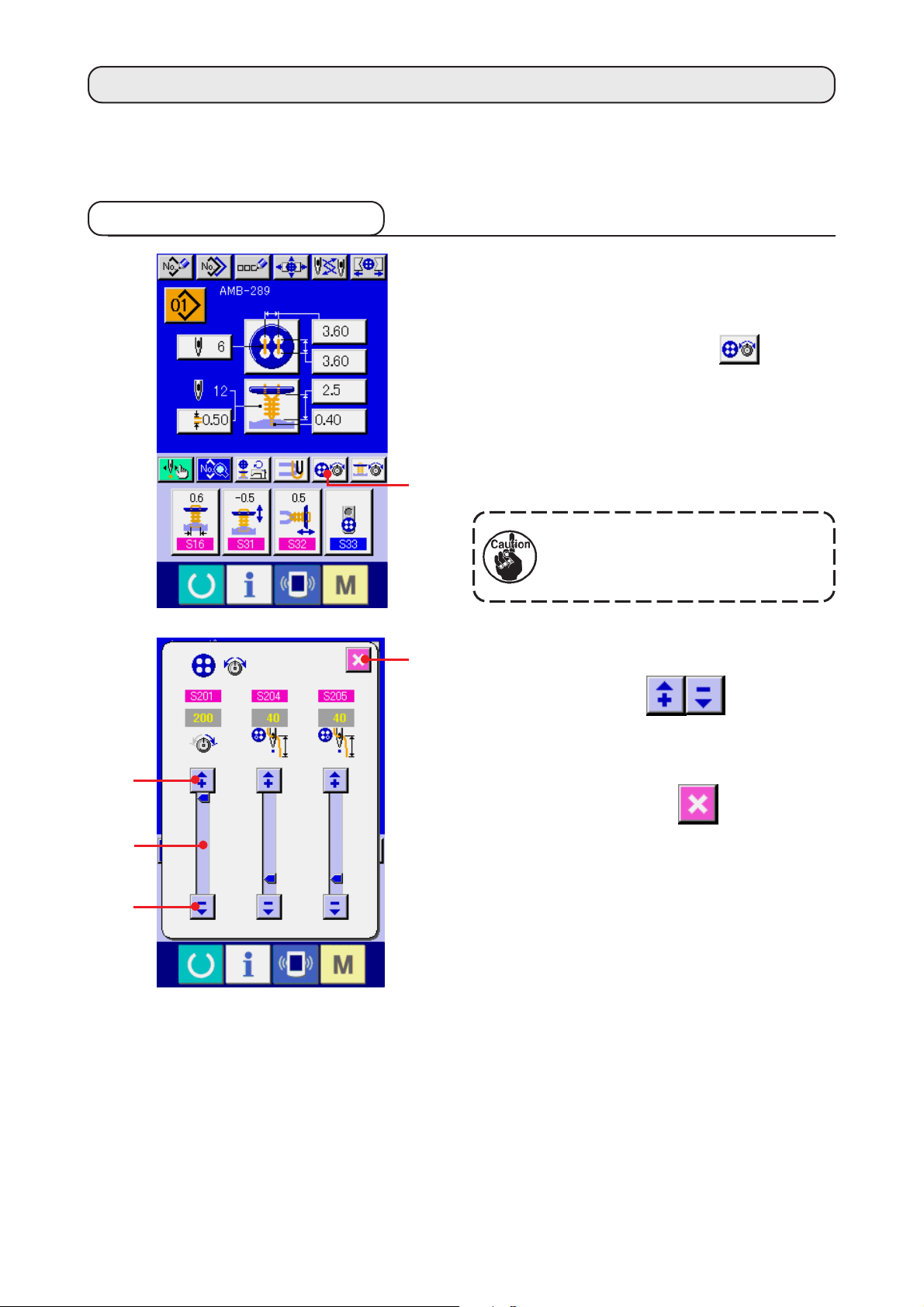

(2) In case of detailed input

Display the data input screen and the sewing screen after the button sewing thread tension setting button

has been set to the detailed input state in the customizing screen.

→ Refer to

"35. CUSTOMIZING DTA INPUT SCREEN" and "36. CUSTOMIZING SEWING SCREEN".

1) Display the button sewing thread tension

detailed setting screen.

Press BUTON SEWING THREAD TENSION

3

2

1

6

DETAILED SETTING button

1 and the

button sewing thread tension detailed setting

screen is displayed, and setting of the thread

remaining length before sewing and the thread

tension of the normal stitches for button sewing

can be performed.

Initial set value is the value when

polyester spun thread #50 thread is

used.

Turn the thread tension screen at each stitch

of the last stitch, 1st stitch and 2nd stitch in

order with TURN PAGE button

2 and

setting of the thread tension can be performed.

The edit of data can be performed with ARROW

MARK (UP/DOWN)

buttons (3 and

4

5

@– 26

5) and SCROLL BAR 4 respectively. The data

can be determined at the time of editing.

When CANCEL button

6 is pressed, the

screen is closed and the data input screen is

displayed.

Page 31

(3) Sewing data that can be changed

1) Normal stitches for button sewing

No. Item Setting range Edit unit Initial value Remarks

Thread tension of lower side of needle for button

sewing (normal stitches)

Changeover angle of thread tension for button

sewing (normal stitches)

Thread tension of upper side of needle for button

sewing (normal stitches)

Thread remaining length before sewing left side

for button sewing

Thread remaining length before sewing right side

for button sewing

0 to 200

180 to 355

0 to 200

1 to 100

1 to 100

1

1˚

1

1

1

110

280

1

45

45

30˚0˚

360˚

2) The last stitch for button sewing (It can be set only at the time of detailed setting.)

No. Item Setting range Edit unit Initial value Remarks

Thread tension of lower side of needle for button

sewing (the last stitch)

Changeover angle of thread tension for button

sewing (the last stitch)

Thread tension of upper side of needle for button

sewing (the last stitch)

0 to 200

180 to 360

0 to 200

1

1˚

1

200

280

70

30˚0˚

360˚

@– 27

Page 32

3) 1st stitch for button sewing (It can be set only at the time of detailed setting.)

No. Item Setting range Edit unit Initial value Remarks

Thread tension of the start of 1st stitch for button sewing

0 to 200

1

200

Thread tension of lower side of needle for button

sewing (1st stitch)

Changeover angle of thread tension for button

sewing (1st stitch)

Thread tension of upper side of needle for button

sewing (1st stitch)

30˚0˚

0 to 200

180 to 355

0 to 200

1

1˚

1

200

280

200

360˚

4) 2nd stitch for button sewing (It can be set only at the time of detailed setting.)

No. Item Setting range Edit unit Initial value Remarks

Thread tension of lower side of needle for button

sewing (2nd stitch)

Changeover angle of thread tension for button

sewing (2nd stitch)

Thread tension of upper side of needle for button

sewing (2nd stitch)

30˚0˚

0 to 200

180 to 360

0 to 200

1

1˚

1

200

280

200

360˚

@– 28

Page 33

18. PERFORMING INPUT OF NECK WRAPPING THREAD TENSION

When sewing flat/wrapped-around button with blindstitch or neck wrapping sewing is selected in the data

input screen and the sewing screen, the neck wrapping thread tension setting button is displayed.

(1) In case of simplified input

1) Display the neck wrapping thread tension

simplified setting screen.

Press NECK WRAPPING THREAD TENSION

2

1

5

SIMPLIFIED SETTING button

1 and the

neck wrapping thread tension simplified setting

screen is displayed. Then setting of thread

remaining length before sewing and the thread

tension of the normal stitches for neck wrapping

can be performed.

Initial set value is the value when

polyester spun thread #50 thread is

used.

The edit of data can be performed with ARROW

MARK (UP/DOWN)

buttons (2 and

4) and SCROLL BAR 3 respectively. The data

can be determined at the time of editing.

3

4

When CANCEL button

5 is pressed,

the screen is closed and the data input screen

is displayed.

@– 29

Page 34

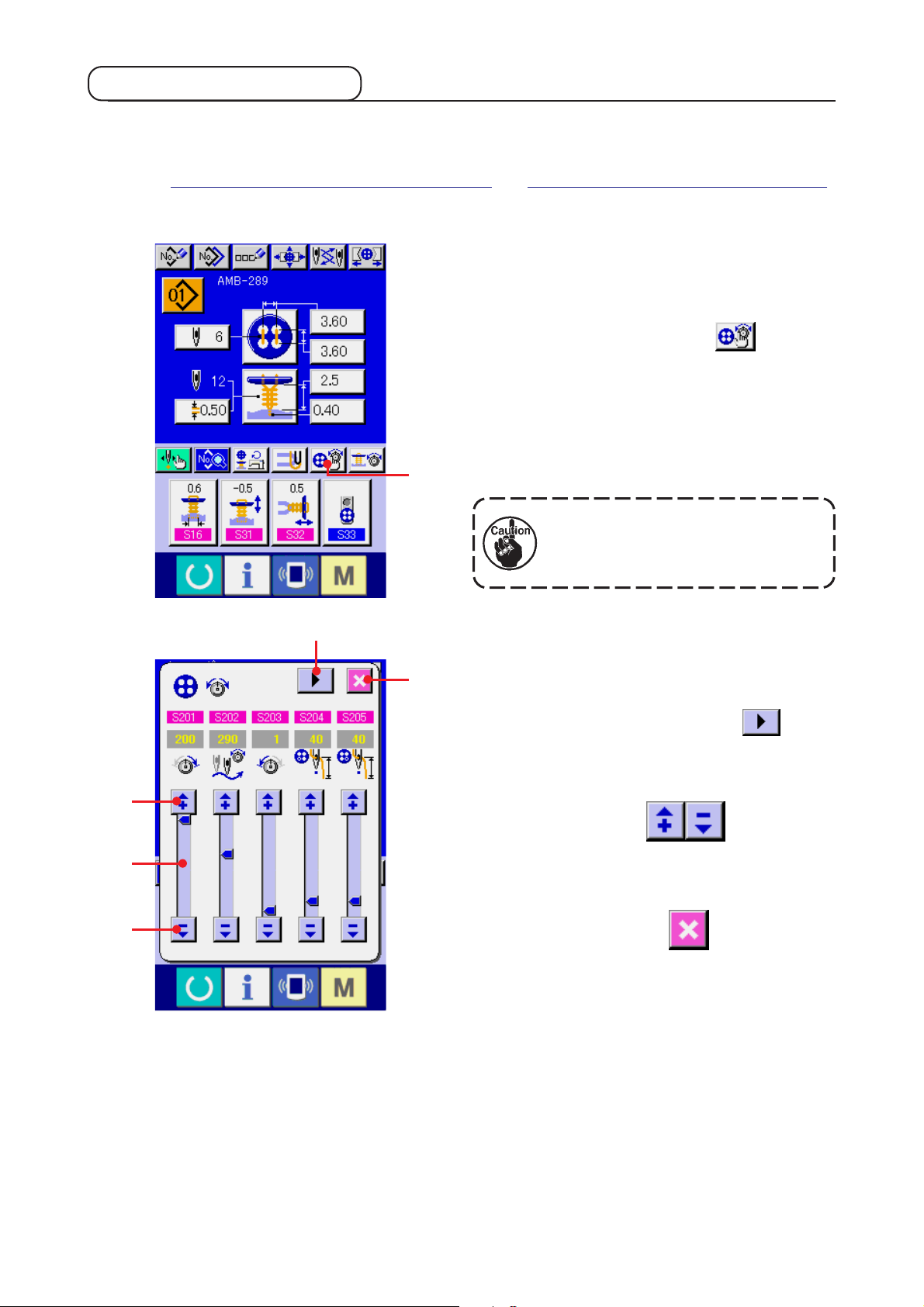

(2) In case of detailed input

Display the data input screen and the sewing screen after the neck wrapping thread tension setting

button has been set to the detailed input state in the customizing screen.

→ Refer to

SCREEN".

"35. CUSTOMIZING DATA INPUT SCREEN" and "36. CUSTOMIZING SEWING

1) Display the neck wrapping thread tension

detailed setting screen.

Press NECK WRAPPING THREAD TENSION

3

2

1

6

DETAILED SETTING button

1 and the

neck wrapping thread tension detailed setting

screen is displayed. Then setting of thread

remaining length before sewing and the thread

tension of the normal stitches for neck wrapping

can be performed.

Initial set value is the value when

polyester spun thread #50 thread is

used.

Turn the thread tension screen at each stitch

of the last stitch, 1st stitch and 2nd stitch in

order with TURN PAGE button

2 and

setting of the thread tension can be performed.

The edit of data can be performed with ARROW

MARK (UP/DOWN)

buttons (3 and

4

5

@– 30

5) and SCROLL BAR 4 respectively. The data

can be determined at the time of editing.

When CANCEL button

6 is pressed, the

screen is closed and the data input screen is

displayed.

Page 35

(3) Sewing data that can be changed

1) Normal stitches for neck wrapping sewing

No. Item Setting range Edit unit Initial value Remarks

Thread tension of lower side of needle for neck

wrapping (normal stitches)

Changeover angle of thread tension for neck

wrapping (normal stitches)

Thread tension of upper side of needle for neck

wrapping (normal stitches)

Thread remaining length before neck wrapping

sewing

0 to 200

180 to 355

0 to 200

1 to 100

1

1˚

1

1

130

290

1

55

30˚0˚

360˚

2) The last stitch for neck wrapping sewing (It can be set only at the time of detailed setting.)

No. Item Setting range Edit unit Initial value Remarks

Thread tension of lower side of needle for neck

wrapping (the last stitch)

Changeover angle of thread tension for neck

wrapping (the last stitch)

Thread tension of upper side of needle for neck

wrapping (the last stitch)

0 to 200

180 to 355

0 to 200

1

1˚

1

200

345

200

360˚

<1 stitch before the last stitch for neck wrapping>

30˚0˚

@– 31

360˚

Page 36

3) 1st stitch for neck wrapping sewing (It can be set only at the time of detailed setting.)

No. Item Setting range Edit unit Initial value Remarks

Thread tension of the start of 1st stitch for neck

wrapping

Thread tension of lower side of needle for neck

wrapping (1st stitch)

Changeover angle of thread tension for neck

wrapping (1st stitch)

Thread tension of upper side of needle for neck

wrapping (1st stitch)

0 to 200

0 to 200

180 to 355

0 to 200

1

1

1˚

1

200

200

290

200

30˚0˚

360˚

4) 2nd stitch for neck wrapping sewing (It can be set only at the time of detailed setting.)

No. Item Setting range Edit unit Initial value Remarks

Thread tension of lower side of needle for neck

wrapping (2nd stitch)

Changeover angle of thread tension for neck

wrapping (2nd stitch)

Thread tension of upper side of needle for neck

wrapping (2nd stitch)

0 to 200

180 to 355

0 to 200

1

1˚

1

200

290

200

@– 32

360˚30˚0˚

Page 37

19. PERFORMING DETAILED INPUT OF NECK WRAPPING

When the neck wrapping pitch input button is changed to the neck wrapping detailed input button in the

cutomizing screen, detailed setting of the neck wrapping data can be performed.

→ Refer to

"35. CUSTOMIZING DATA INPUT SCREEN".

1) Display the data input screen.

Only in case of the data input screen (blue),

detailed input of the neck wrapping data can

be performed. In case of the sewing screen

2

4

3

5

!3

!1

1

6

8

!2

7

(green), press READY key

1 to display

the data input screen (blue).

2) Display the neck wrapping data detailed

input screen.

Press NECK WRAPPING DETAILED INPUT

button

2 and display the neck wrapping

data detailed input screen.

The data that can be set at the first page is the

sewing setting data of the last cycle and the

data pages of the previous cycles can be turned

in order with TURN PAGE button

3. In

addition, the page being set is displayed in

orange at 4.

5 is the number of stitches of neck wrapping

which is actually sewn, and the display is

updated every time each setting is changed.

!0

9

When DATA CHANGE buttons (6 to !3) are

pressed, the change pop-up is displayed.

@– 33

Page 38

The edit of data is performed with SELECTION

4

!4

!5

6

button or

button

buttons !4. Press ENTER

!5 to determine the data.

8

!3

!1

!0

Symbol Item Input range Edit unit Initial value

6

Number of times of neck wrapping

!2

7

9

Without

: neck

wrapping

: 1 time

: 2 times

: 2 times

– – –

7

8

wrapping

Neck wrapping height

Number of stitches at the top of neck

: 3 times

: 4 times

Perform editing in the data input screen or the sewing data

screen.

1 to 9

1 time

2

@– 34

Page 39

In case display of 4 is the first. , , ,

Symbol Item Input range Edit unit Initial value

9

!0

!1

!2

!3

Neck wrapping going height

(lower section of top)

Neck wrapping going pitch

(lower section of top)

Neck wrapping going pitch

(center of top)

Neck wrapping going height

(upper section of top)

Neck wrapping going pitch

(upper section of top)

0 to 2.0

0.05 to 2.0

0.05 to 2.0

0 to 2.0

0.05 to 2.0

0.1

0.05

0.05

0.1

0.05

0.10

0.10

0.50

0.0

0.10

In case display of 4 is the second. , ,

Symbol Item Input range Edit unit Initial value

9

!0

!1

!2

!3

Neck wrapping height

(lower section of 2nd)

Neck wrapping pitch

(lower section of 2nd)

Neck wrapping pitch

(center of 2nd)

Neck wrapping height

(upper section of 2nd)

Neck wrapping pitch

(upper section of 2nd)

0 to 2.0

0.05 to 2.0

0.05 to 2.0

0 to 2.0

0.05 to 2.0

0.1

0.05

0.05

0.1

0.05

0.2

0.10

1.0

0

0.10

In case display of 4 is the third. ,

Symbol Item Input range Edit unit Initial value

9

!0

!1

!2

!3

Neck wrapping height

(lower section of 3rd)

Neck wrapping pitch

(lower section of 3rd)

Neck wrapping pitch

(center of 3rd)

Neck wrapping height

(upper section of 3rd)

Neck wrapping pitch

(upper section of 3rd)

0 to 2.0

0.05 to 2.0

0.05 to 2.0

0 to 2.0

0.05 to 2.0

0.1

0.05

0.05

0.1

0.05

0.2

0.10

1.0

0

0.10

In case display of 4 is the fourth.

Symbol Item Input range Edit unit Initial value

9

!0

!1

!2

!3

Neck wrapping height

(lower section of 4th)

Neck wrapping pitch

(lower section of 4th)

Neck wrapping pitch

(center of 4th)

Neck wrapping height

(upper section of 4th)

Neck wrapping pitch

(upper section of 4th)

0 to 2.0

0.05 to 2.0

0.05 to 2.0

0 to 2.0

0.05 to 2.0

0.1

0.05

0.05

0.1

0.05

0.2

0.10

1.0

0

0.10

@– 35

Page 40

20. CHANGING SEWING DATA

(1) Initial sewing data at the time of your purchase

Patterns from 1 to 8 have been already registered at the time of your purchase and the data which are

different in sewing method and sewing shape are inputted in the sewing data as the initial value.

Pattern Data changed from Changed

No. Sewing method

Sewing flat/wrapped-

1

2

around button with

blindstitch

Sewing flat/wrappedaround button with

blindstitch

Sewing shape

Without

initial value value

Thread release compensation

Top position of neck wrapping

0.5 →0.0mm

0.5 →2.7mm

Button height (shank/marble)

Sewing flat/wrapped-

3

4

5

6

7

around button with

blindstitch

Sewing counter/stay button

Sewing counter/stay button

Sewing button with neck wraps

Sewing flat button with

blindstitch

– – –

Without

(longitudinal)

(longitudinal)

(lateral)

start of sewing of neck wrapping (longitudinal)

start of sewing of neck wrapping (longitudinal)

Without

Thread release compensation

Hole position of shank/marble button

N

eedle entry interval of bottom feed

1st stitch hole position of lower button

1st stitch hole position of lower button

Tie stitch position of 1st stitch at the

Tie stitch position of 2nd stitch at the

4.0 →2.5mm

0.5 →0.0mm

0.3 →2.5mm

3.6 →3.2mm

1.8 →1.6mm

1.8 →0.0mm

0.0 →0.5mm

1.0 →1.5mm

8

Sewing flat button directly

to cloth

Without

@– 36

Page 41

(2) Changing procedure of sewing data

1) Display the data input screen.

Only in case of the data input screen (blue),

change of the sewing data can be performed.

In case of the sewing screen (green), press

2

1

READY key

1 and display the data input

screen (blue).

2) Call the sewing data screen.

Press SEWING DATA button

2 and the

sewing data screen is displayed.

3) Select the sewing data to be changed.

Press UP/DOWN SCROLL button

3 and select SEWING DATA ITEM button 4

you desire to change. Data item which is not

used according to the shape is not displayed.

So, be careful.

4

3

5

4) Change the data.

For the sewing data, there are the data item to

change the numeral and data item to select the

pictograph. No. in pink color such as

put on the data item to change the numeral and

the set value can be changed with the + / –

button 5 which is displayed in the change

screen.

is

@– 37

Page 42

No. in blue color such as is put on the

data item to select the pictograph and the

pictograph which is displayed in the change

screen can be selected.

(3) Sewing data list

Sewing data are those that can be inputted to 99 patterns from pattern 1 to 99 and can be inputted

to each pattern.However, the sewing data that can be inputted differ according to the selected sewing

method or sewing shape.

No. Item

Sewing method

This item sets the sewing method.

: Sewing flat/wrapped around button with

blindstitch

: Sewing flat button

with blindstitch

: Counter/stay

button sewing

Stitch shape (sewing flat/wrapped-around button with blindstitch)

This item sets the stitch shape of sewing flat/wrappedaround button with blindstitch.

Stitch shape (sewing flat button directly to cloth)

This item sets the stitch shape of sewing flat button directly to cloth.

: Sewing flat button

directly to cloth

: Neck wrapping

Setting range

– – –

– – –

– – –

Edit unit

– – –

– – –

– – –

Initial display

Sewing flat/

wrapped-

around

button with

blindstitch

4-holed

button without

cross-over

stitches

(longitudinal)

4-holed

button without

cross-over

stitches

(longitudinal)

Remarks

Stitch shape (sewing flat button with blindstitch)

This item sets the stitch shape of sewing flat button with

blindstitch.

@– 38

– – –

– – –

4-holed

button without

cross-over

stitches

(longitudinal)

Page 43

No. Item

Stitch shape (counter/stay button sewing)

This item sets the stitch shape of counter/stay button

sewing.

* Selection of the shape of lower button is performed with

.

Setting range

– – –

Edit unit

– – –

Initial display

Front : 4holed button

without

cross-over

stitches

(longitudinal)

Rear : 4holed button

without

cross-over

stitches

(longitudinal)

Remarks

Upper buttonhole interval (longitudinal)

This item sets the needle entry interval of top feed.

Upper buttonhole interval (lateral)

This item sets the needle entry interval of top feed.

Needle entry interval of bottom feed (longitudinal)

This item sets the needle entry interval of bottom feed.

Needle entry interval of bottom feed (lateral)

This item sets the needle entry interval of bottom feed.

Number of stitches for button sewing

This item sets the number of stitches for button sewing.

Number of stitches at the start of button sewing (1 to 3 stitches)

This item sets the number of stitches at the start

of button sewing.

Compensation of lower left position of upper button

This item is set when cloth is pulled and the amount of blindstitch

on the left side is different from that on the right side.

0.10 to

6.00

0.10 to

6.00

0.10 to

6.00

0.10 to

6.00

2 to 32

1 to 3

–1.00 to

1.00

0.05mm

0.05mm

0.05mm

0.05mm

2 stitchs

1 stitch

0.05mm

3.60

3.60

3.20

3.20

6

1

0

Compensation of 3rd stitch at the start of sewing

This item compensates the position of 3rd stitch

at the start of sewing to prevent thread from

slipping off at the start of button sewing

Blindstitch width

This item has to be set within the range where needle

and tongue do not come in contact with each other.

Blindstitch amount

This item sets the blindstitch amount to cloth.

Buttonhole height of shank/marble button sewing

(Height from the feed plate)

This item is set to prevent the contact of needle

and buttonhole.

* 1 The maximum value of the range of data editing depends on the setting of K05.

0 to 0.5

0.0 to

K05

–1.00 to

5.00

0.0 to

10.0

@– 39

0.05mm

0.2mm

0.05mm

0.1mm

0

0.6

0.40

3.0

* 1

Page 44

No. Item

Thinning level of the stay button

This item decreases the number of cross-over stitches of

the lower side button at the time of stay button sewing.

: Without thinning : Thinning level 1

: Thinning level 2 : Thinning level 3

Setting range

– – –

Edit unit

– – –

Initial display

Without

thinning

Remarks

Lateral compensation of needle entry of lower button at the

time of sewing counter button (front : 4 holes, rear : 2 holes)

Perform compensation to such an extent that needle does not come

in contact with buttonhole within the range of lower buttonhole.

Number of stitches of tie stitch at the end of sewing flat button directly to cloth.

This item sets the number of stitches of tie stitch

at the end of sewing flat button directly to cloth.

Number of stitches of tie stitch at the end of counter sewing

This item sets the number of stitches of tie stitch

at the end of counter sewing.

Button sewing height

(only neck wrapping of sewing flat/

wrapped-around button with blindstitch)

This item sets the button holding height (finished

height) in the neck wrapping process.

Button height (shank/marble)

This item sets the button holding height (finished

height) in the neck wrapping process.

0 to 0.30

2 to 3

1 to 3

0.5 to

15.0

0 to 15.0

0.05mm

1 stitch

1 stitch

0.1mm

0.1mm

0.30

2

2

2.5

3.4

Button height (counter button)

This item sets the button holding height (finished

height) in the button sewing process.

Number of stitches at the start of sewing of neck

wrapping

This item sets the number of stitches at the start

of sewing of neck wrapping.

Number of stitches of tie stitch at the end of sewing

of neck wrapping

This item sets the number of stitches of tie stitch

at the end of sewing in the neck wrapping process.

Compensation of the button holding height at the time

of sewing flat/wrapped-around button with blindstitch

This item sets when compensating the button holding

height in the button sewing process and desiring to give

slackness between button and neck wrapping section.

Thread release compensation

This item is the compensation value of the button holding

height in the button sewing process. Sewing is performed

in the neck wrapping process by gradually returning the

compensation value to the former one.

This item is set when desiring to tightly wrap up to the root

of the button.

0 to 20.0

1 to 3

2 to 3

–5.0 to

5.0

–5.0 to

5.0

0.1mm

1 stitch

1 stitch

0.1mm

0.1mm

4.5

2

2

–0.5

0.5

@– 40

Page 45

No. Item

Button loader selection

<In case of shank/marble button>

: Loader OFF : Loader ON

<In case of normal button>

: Loader OFF : Loader ON

Setting range

– – –

Edit unit

– – –

Initial display

Loader used

(Front side)

Remarks

Number of times of wrapping

This item sets the number of times of thread

wrapping sewing in the neck wrapping process.

Number of stitches of thread air-blow

This item sets the number of stitches of thread

air-blow in the neck wrapping process.

Compensation of button height in the neck wrapping process

This item compensates the button holding height in the

neck wrapping process and adjusts the wrapped condition.

Button positioning motion With/without

: With : Without

This item sets whether the compensation motion of button positioning is

performed at the time of operation by operator before driving the sewing

machine. It is convenient to use this item when sewing buttons which are

uneven in shape.

* Compensation value which has been set here is applied to one button sewing

only and the compensation value returns to 0 after completion of sewing.

0 to 5

0 to 20

–5.0 to

5.0

– – –

1 time

1 stitch

0.1mm

– – –

0

6

0

Without

Needle height at the time of button positioning

This item sets the angle which automatically lowers

needle at the time of button positioning motion.

Set the angle which is easy to perform positioning

according to kinds of buttons, neck wrapping height, etc.

Thread drawing motor start position in the

button sewing process

This item sets the thread slack amount at the

start of sewing to stabilize thread remaining

amount at the start of sewing.

Number of stitches to start thread drawing

motor operation in the button sewing

process

This item sets number of stitches to hold the

thread slack amount set in No. S39.

Compensation of tension timing on cloth

side and rear side in the button sewing

process

This item changes the tension changeover

timing at the needle entry on cloth side and

rear side, and shifts the knotting position.

0 to 130

0 to 100

1 to 2

–90 to 90

1˚

1 pulse

1 stitch

1˚

80

30

1

0

@– 41

Page 46

21. PERFORMING NEW REGISTRATION OF THE PATTERN

2

3

1

6

1) Display the data input screen.

Only in case of the data input screen (blue),

new registration of the pattern can be

performed. In case of the sewing screen

(green), press READY key

1 and display

the data input screen.

2) Call the pattern new registration screen.

Press NEW REGISTRATION button 2

and the pattern new registration screen is

displayed.

3) Input the pattern No.

Input the pattern No. you desire to newly

register with the ten keys 3. When the pattern

No. which has been already registered is

inputted, the sewing shape which has been

registered is displayed in the upper part of the

screen. Select the pattern No. which is not

displayed and has not been registered. New

registration to the pattern No. which has been

already registered is prohibited. It is possible

to retrieve the pattern No. which has not been

4 5

registered with the –・+ button

・5).

4) Determine pattern No.

Press ENTER button

6 and the data

input screen of pattern No. which has been

newly registered is displayed.

(4

@– 42

Page 47

22. COPYING SEWING PATTERN

1

2

The sewing data of the pattern No. which has been

already registered can be copied to the pattern No.

which has not been registered.

Overwriting copy of the pattern is prohibited. When

you desire to overwrite, perform it after erasing the

pattern once.

→ Refer to

"4. PERFORMING PATTERN No. SELECTION"

1) Display the data input screen.

Only in case of the data input screen (blue),

copying is possible. In case of the sewing

screen (green), press READY key

1 and

display the data input screen (blue).

2) Call the pattern copy screen.

When pattern copy button

2 is pressed,

the pattern copy (copy source selection) screen

is displayed.

.

3

3) Select the pattern No. of copy source.

Select the pattern No. of copy source from the

list of pattern buttons 3.

Then press copy destination input button

4

4 and the copy destination input screen is

displayed.

@– 43

Page 48

4) Input the pattern No. of copy destination.

Input the pattern No. of copy destination with

ten keys 5. It is possible to retrieve the pattern

No. which is not used with –・+ buttons

(6・7).

5) Start copying.

Press ENTER button

8 and copying

starts.

8

Pattern No. which has been copied in the

selected state returns to the pattern copy (copy

source selection) screen after approximately

two seconds.

657

*1 Cycle data can be copied by the same method.

*2 When deletion is performed in case the remaining pattern No. which has been registered is

one, pattern deletion error (Error code 402) is displayed.

*3 When trying to perform copying to the pattern No. which has been already registered, copy

disapproval error (Error code 401) is displayed.

@– 44

Page 49

23. PERFORMING CHUCK ADJUSTMENT

1

1) Display the data input screen or the sewing

screen.

Only in case of the data input screen A or the

sewing screen B, the adjustment of chuck can

be performed.

A

2) Display the chuck adjustment screen.

Press CHUCK ADJUSTMENT button

1

and the chuck adjustment screen is displayed.

Origin retrieval is performed and the button

loader moves to the position of chuck.

1

B

2

3

4

5

6

7

@– 45

Height and position can be adjusted with

CHUCK HEIGHT ADJUSTMENT button 2 and

CHUCK LONGITUDINAL/LATERAL

POSITION ADJUSTMENT buttons 3.

Set the chuck to the state that is easy to be

adjusted with ORIGIN RETRIEVAL READJUST

button

4, CHUCK UP/DOWN button

5 and CHUCK OPEN/CLOSE button

6, and confirm the adjustment.

After the adjustment, press ENTER button

7 to determine the adjustment value.

Page 50

24. PERFORMING BUTTON CENTERING

Button centering button is not displayed in the initial state. Set the button centering button to the displayed

state in the customizing screen of the sewing screen.

2

1) Display the sewing screen.

Only in case of the sewing screen, centering of

the button can be performed.

In case of the data input screen (blue), the

sewing data screen, press READY key

1 and display the sewing screen (green).

2) Perform centering of the button.

3

1

4

5

Press BUTTON CENTERING button

2

and the button centering screen is displayed.

Adjust the needle position to the center of

needle with 4-direction ARROW MARK buttons

3. (It is possible to correctly adjust using the

gauge button.)

Then input the longitudinal/lateral data of the

buttonhole interval with

buttons (4

and 5).

After inputting, press ENTER button

6

to determine the data.

6

@– 46

Page 51

25.

PERFORMING INPUT AND CHECK OF DATA WITH STEP MOTION

(1) Performing the step motion

1) Display the data input screen or the sewing

screen.

Only in case of the data input screen A or the

sewing screen B, the step motion can be

performed.

A

1

2) Display the step motion selection screen.

Press STEP MOTION SELECTION button

1 and the step motion selection screen

is displayed.

B

1

It is possible to select SEWING MOTION STEP

3

2

MODE

operating the sewing machine and POINT

SETTING MODE

points in order.

When the respective buttons are pressed, the

input screen of the respective modes is

displayed.

When sewing preparations are not ready,

namely, tongue is not set, button is not set, and

so forth, SEWING MOTION STEP MODE

2 to perform setting while

3 to set needle entry

@– 47

button

sewing selection screen is displayed.

2 is not displayed when the step

Page 52

6

7

!1

8

9

5

3) Perform data setting.

[In case of POINT SETTING MODE]

Press STEP FORWARD/BACK buttons

(5 and 6), and input step moves.

Move to the step you desire to set and perform

setting with ARROW MARK buttons 7 .

Parameter that can be set differs according to

the sewing method and the stitch shape. For

the parameter, refer to

"25. (2) Data list".

In addition, move the needle up or down with

!0

NEEDLE UP/DOWN buttons (8

and 9) and adjust the relation of the position

between button and needle to the state that is

easy to check. It is convenient to set the data

by this adjustment.

After setting the data, press ENTER button

!0 to determine the data. When the data

is not determined, press CANCEL button

!1.

@– 48

Page 53

!5

!2

!6

!4

!8

!3

!7

[In case of SEWING MOTION STEP MODE]

Press NEEDLE FORWARD/BACK buttons

(!2 and !3) and the needle moves

stitch by stitch. In addition, it is possible to move

the needle stitch by stitch while actually sewing

with the start switch. Move the needle to the

needle entry point you desire to set and perform

the adjustment with ARROW MARK buttons !4.

Parameter that can be adjusted differs

according to the sewing method and the stitch

shape.

For the parameter, refer to

"25. (2) Data list".

* However, when

items are limited.

Press TURN PAGE button

!5 and the

screen is changed over to the other parameter

setting screen regarding the present needle

entry point.

In addition, when NUMBER OF

REVOLUTIONS SETTING button

!6 is