CHAPTER

Mechanical section

!

CONTENTS

!

. Mechanical section

1. SPECIFICATIONS ..........................................................................................!- 1

(1)Specications ...............................................................................................................!- 1

(2) Shapes of buttons ........................................................................................................!- 2

1) Specications for 4-holed and 2-holed buttons ............................................................................!- 2

2) Specications for shank button and marble button ......................................................................!- 2

3) Specications for stay button .......................................................................................................!- 3

4) Counter button specications .......................................................................................................!- 3

(3)Conguration ................................................................................................................!- 4

2. INSTALLATION ..............................................................................................!- 5

(1) Set-up of the table ........................................................................................................!- 5

(2) Connecting the power source cord ............................................................................!- 6

1) Voltage specications ...................................................................................................................!- 6

2) Connecting single phase 200V, 220V, 230V and 240V ................................................................!- 6

3) Connecting three phase 200V, 220V and 240V ...........................................................................!- 6

(3) Changing the voltage of 100 / 200V ............................................................................!- 7

(4) Installing the sewing machine main unit ....................................................................!- 8

(5) Tilting the sewing machine head ................................................................................!- 8

(6)Removingthexedplatefortransport ......................................................................!- 9

(7) Installing the operation panel ......................................................................................!- 9

(8) Installing the air regulator .........................................................................................!- 10

(9) Connecting the cords .................................................................................................!- 11

(10) Managing the cord ....................................................................................................!- 12

(11)Installingtheeyeprotectioncoverandthengerguard ......................................!- 12

(12) Installing the thread stand .......................................................................................!- 13

(13) Attaching the button tray .........................................................................................!- 13

3. PREPARATION BEFORE OPERATION ......................................................!- 14

(1) Inserting the needle ....................................................................................................!- 14

(2) Threading the needle-thread .....................................................................................!- 14

(3) Adjusting the stay (counter) button stopper ............................................................!- 15

(4) Replacing the button chuck ......................................................................................!- 16

(5) Set of the button neck wrapping ...............................................................................!- 17

(6)Setofthesewingatbuttonwithblindstitch ..........................................................!- 17

4. ADJUSTMENT OF THE SEWING MACHINE ..............................................!- 18

(1) Adjusting the needle and the looper .........................................................................!- 18

1) Adjusting the needle bar height ..................................................................................................!- 18

2) Adjusting the clearance between the needle and the looper ......................................................!- 18

(2) Adjusting the position of the york slide ...................................................................!- 19

(3) Adjusting the needle and the needle guide ..............................................................!- 20

1) Adjusting the position of the needle and the throat plate ............................................................!- 20

2) Adjusting the clearance between the needle and the needle guide ..........................................!- 20

(4) Adjusting the thread trimmer mechanism ................................................................!- 21

1) Adjusting the position of the moving knife ..................................................................................!- 21

2) Adjusting the moving knife thread separation nail ......................................................................!- 21

(5) Adjusting the wiper mechanism ................................................................................!- 22

(6) Adjusting the chuck open mechanism .....................................................................!- 22

5. MAINTENANCE ...........................................................................................!- 23

(1) Replacing the attachments ........................................................................................!- 23

1) Replacing the button set pin (optional) .......................................................................................!- 23

2) Replacing the carrier pin ............................................................................................................!- 23

3) Replacing the tongue stopper ....................................................................................................!- 24

(2) Replacing the fuse ......................................................................................................!- 25

(3) Greasing parts ............................................................................................................!- 26

6. AIR CIRCUIT DIAGRAM ..............................................................................!- 28

7. DRAWING OF THE TABLE .........................................................................!- 29

(1) Table.............................................................................................................................!- 29

(2) Auxiliary table .............................................................................................................!- 30

!

. Mechanical section

1. SPECIFICATIONS

(1)Specications

Model AMB-289

Name of model

Application Various buttons sewing (Buttons which can be sewn with the sewing machine)

Feature

Computer-controlled, high-speed, single-thread, chainstitch, button-neck-wrapping

machine

The machine comes standard with plural sewing patterns by computer-controlled feed,

needle throwing, thread tension and thread trimmer. It can perform efficiently highquality button sewing and a multipurpose button sewing machine that can be used as the

general machine.

Sewing speed

Button size

Needle

Thread take-up lever Needle bar thread take-up lever : Stroke 60 mm

Needle throwing method Stepping motor drive

Feed method Stepping motor drive

Presser lifting method Stepping motor drive

Cloth presser method Air drive

Thread trimmer method Air drive

Thread tension adjustment Active tension (VCM) method

Dimensions Width : 600 x Height : 400 x Length : 600 (mm)

Weight of head 65kg

Number of data that can be

stored in memory

Number of times of cycle

sewing

Basic shape setting range

Max. 1,800 rpm (buttons with neck wraps), 1,200 rpm (button sewing)

Normal speed 1,500 rpm (buttons with neck wraps), 1,000 rpm (button sewing)

Sewing buttons without button neck : 8 mm to 38 mm

Sewing buttons with neck wraps : Max. 32 mm

Counter button : 8 mm to 25 mm

Counter button neck wrapping : Total of material and front button is up to 32 mm.

SM332EXTLG-NY (Standard) #12 to #18

Max. 99 patterns

Number of registered patterns : 20 patterns (1 cycle 30 patterns)

Interval between buttonholes : 1.5 to 6.0 mm (in increments of 0.1 mm)

Height of neck wraps : 0, 1.5 to 10.0 mm (in increments of 0.1 mm)

Number of crossover threads : 2 to 64 threads (in increments of 2 threads)

Pattern selection Pattern No. designation method (scroll 1 to 99 patterns)

Memory backup Pattern data, sewing data, cycle sewing data

Sewing count

Power requirements Single phase 200V, 220V, 230V and 240V, Three phase 200V, 220V and 240V 400VA

Noise

Number of times of sewing count method (0 to 9999) up/down

Sewing counter is possible.

Workplace-related noise at sewing speed

n = 1,800 min–1 : Lpa ≦ 83 dB(A)

Noise measurement according to DIN 45635-48-A-1.

!

– 1

!– 2

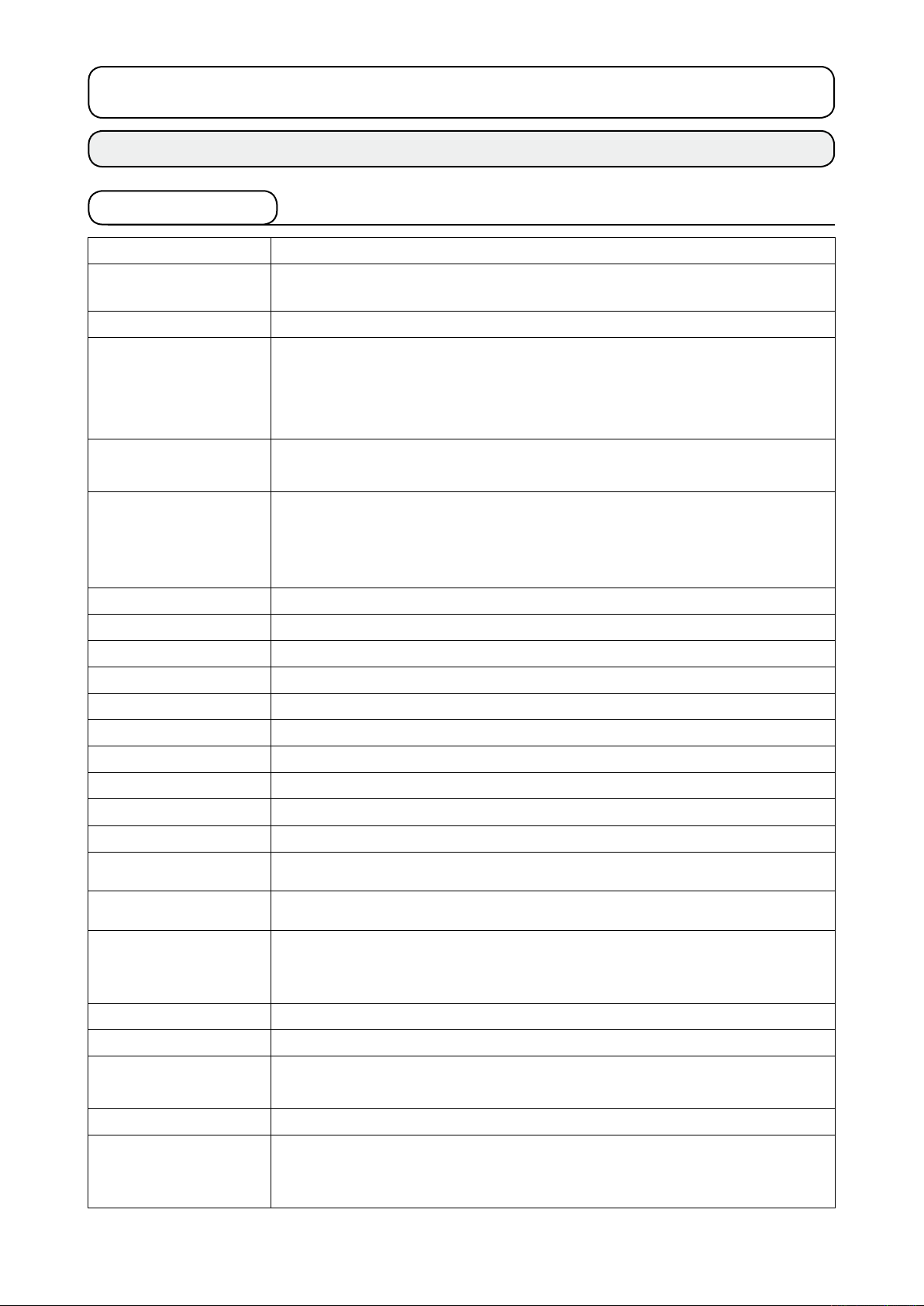

(2) Shapes of buttons

1)Specicationsfor4-holedand2-holedbuttons

B

A

C

B

2

E

1

E

G

G

G

3

E

G

3

E

D

A : Buttonhole diameter

D

F

H

Needle used : ø 1.5 mm or more when using #12 to #16

Needle used : ø 2 mm or more when using #16 to #18

F

H

B : Distance between buttonholes 1.5 to 6.0 mm (in increments of 0.1 mm)

C : Location of buttonholes All holes must be located equidistant from the center of each button.

Min. outside diameter : ø 8 mm

D : Outside diameter

Max. outside diameter : ø 32 mm

Line height : within ± 0.25 mm

E1 : Button with a round edge

R (roundness) of button edge must be a 3 mm radius or less.

E2 : Button with a V-shaped edge Within 120˚ angle

E3 : Button with an angular edge The thickness must be 5 mm or less.

F : Bulge 5 mm or less

G : Area around buttonholes Must be smooth

H : Thickness of button 8 mm or less

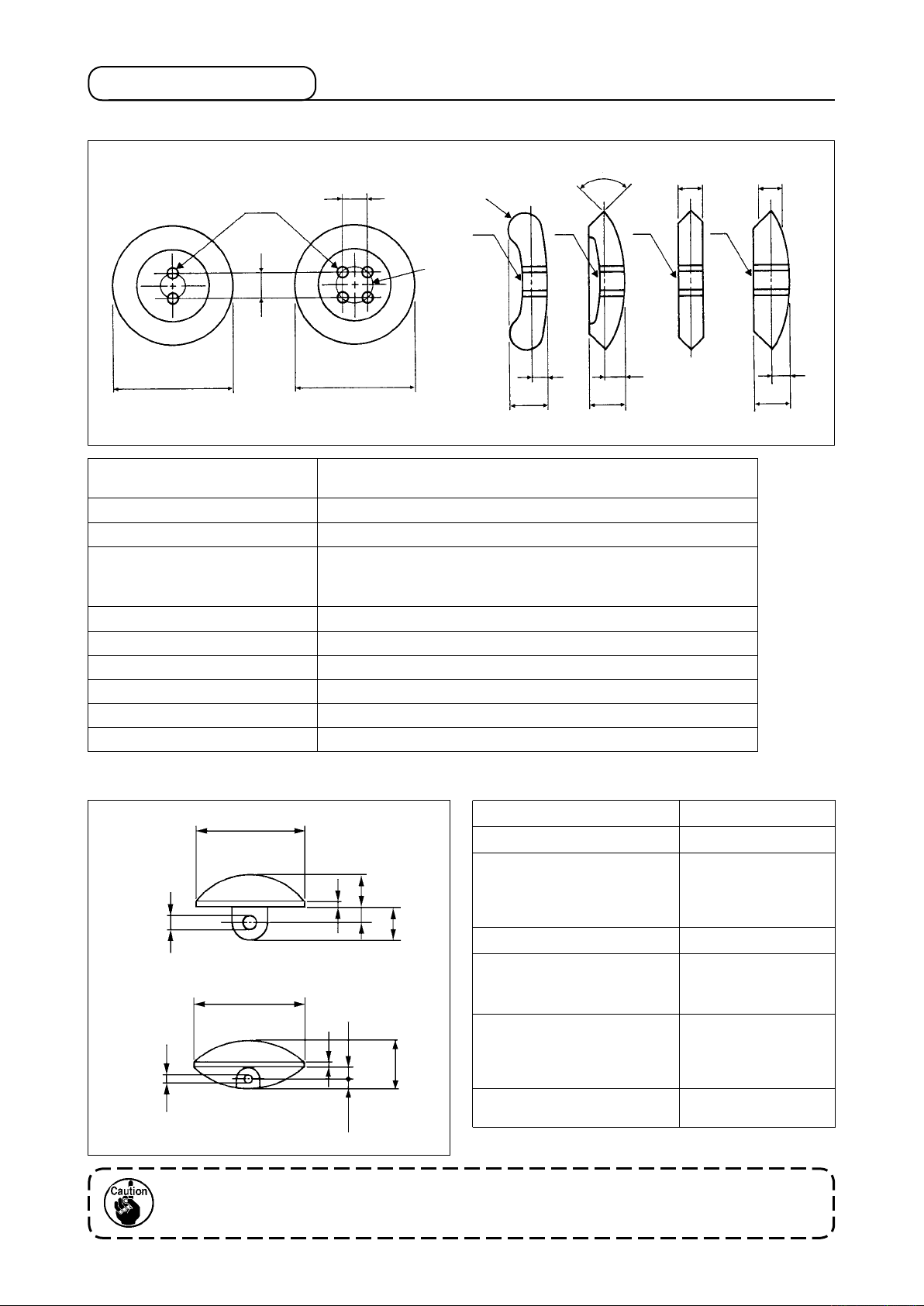

2)Specicationsforshankbuttonandmarblebutton

F

H

F

A : Buttonhole diameter ø 1.5 mm or more

B : Thickness of button 6.8 mm or less

C : Distance from the bottom

E

B

A

C

D

of the button head to the

center of the buttonhole

Shank button :

1 mm to 6 mm

Marble button :

1.5 mm or more

D : Length of shank 8 mm or less

E : H e i g ht of th e st r a i gh t

F

section on the side face of

3.5 mm or less

button

C

A

E

B

F : Outside diameter

Min. outside diameter:

ø 8 mm

Max. outside diameter:

ø 32 mm

G

the hole to the button edge

G : Distance from the center of

2 mm or less

When the button loader is used, there are cases where the buttons cannot be used due to the

shape. So, be careful.

3)Specicationsforstaybutton

Buttonhole

diameter

Right

side

Outside

Buttonhole pitch

diameter

Thickness of button

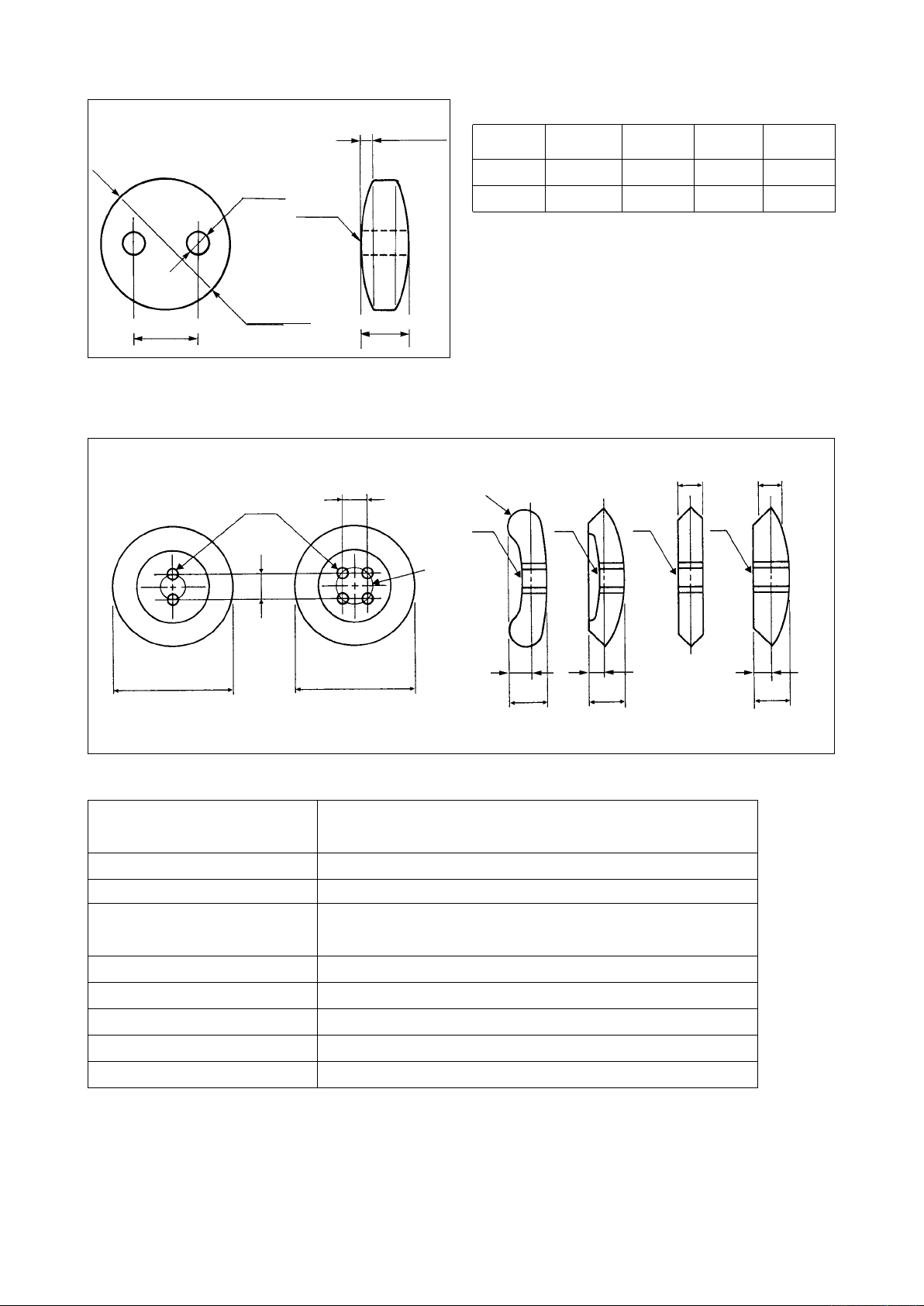

4)Counterbuttonspecications

1 mm or *

less

1

Commendable dimension

Outside

diameter

Buttonhole

diameter

Buttonhole

pitch

Type A 8.5mm 2.5mm 3.1mm 2.0mm

Type B 10.2mm 3.2mm 4.0mm 2.0mm

*1 For the stay buttons, use those, the amount

of convex on the right side of which is 1 mm

or less.

Thickness

of button

2

B

1

E

E

A

G

G

G

G

C

B

D

D

F

H

F

H

Commendable dimension

A : Buttonhole diameter

B : Distance between buttonholes 1.5 to 6.0 mm

C : Location of buttonholes All holes must be located equidistant from the center of each button.

Needle used : ø 1.5 mm or more when using #12 to #16

Needle used : ø 2 mm or more when using #16 to #18

2

E

F

H

D : Outside diameter

Min. outside diameter : ø 8 mm

Max. outside diameter : ø 25 mm

E1 : Button with a round edge R (roundness) of button edge must be a 2 mm radius or less.

E2 : Button with an angular edge The thickness must be 5 mm or less.

F : Height of button edge 2 mm or less

G : Area around buttonholes Must be smooth

H : Thickness of button 5 mm or less

!

– 3

!– 4

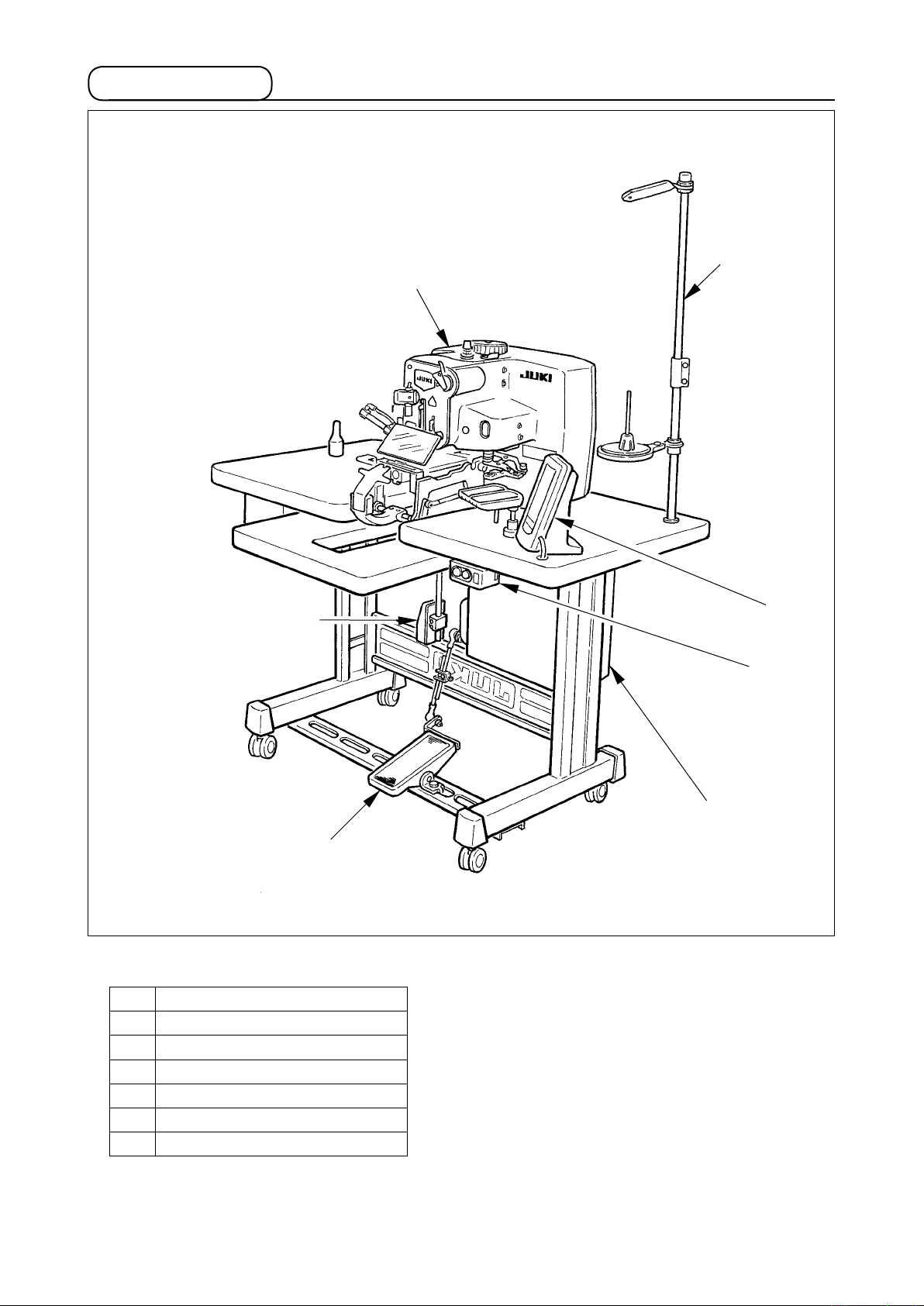

(3)Conguration

7

2

6

5

AMB-289 consists of the following components.

Power ON/OFF switch

1

Machine head (AMB-289)

2

Operation panel (IP-310D)

3

Control box (MC-640)

4

Foot pedal

5

Start switch

6

Thread stand device

7

3

1

4

2. INSTALLATION

WARNING :

To prevent possible accidents caused by the fall of the sewing machine, perform the work by two

persons or more when the machine is moved.

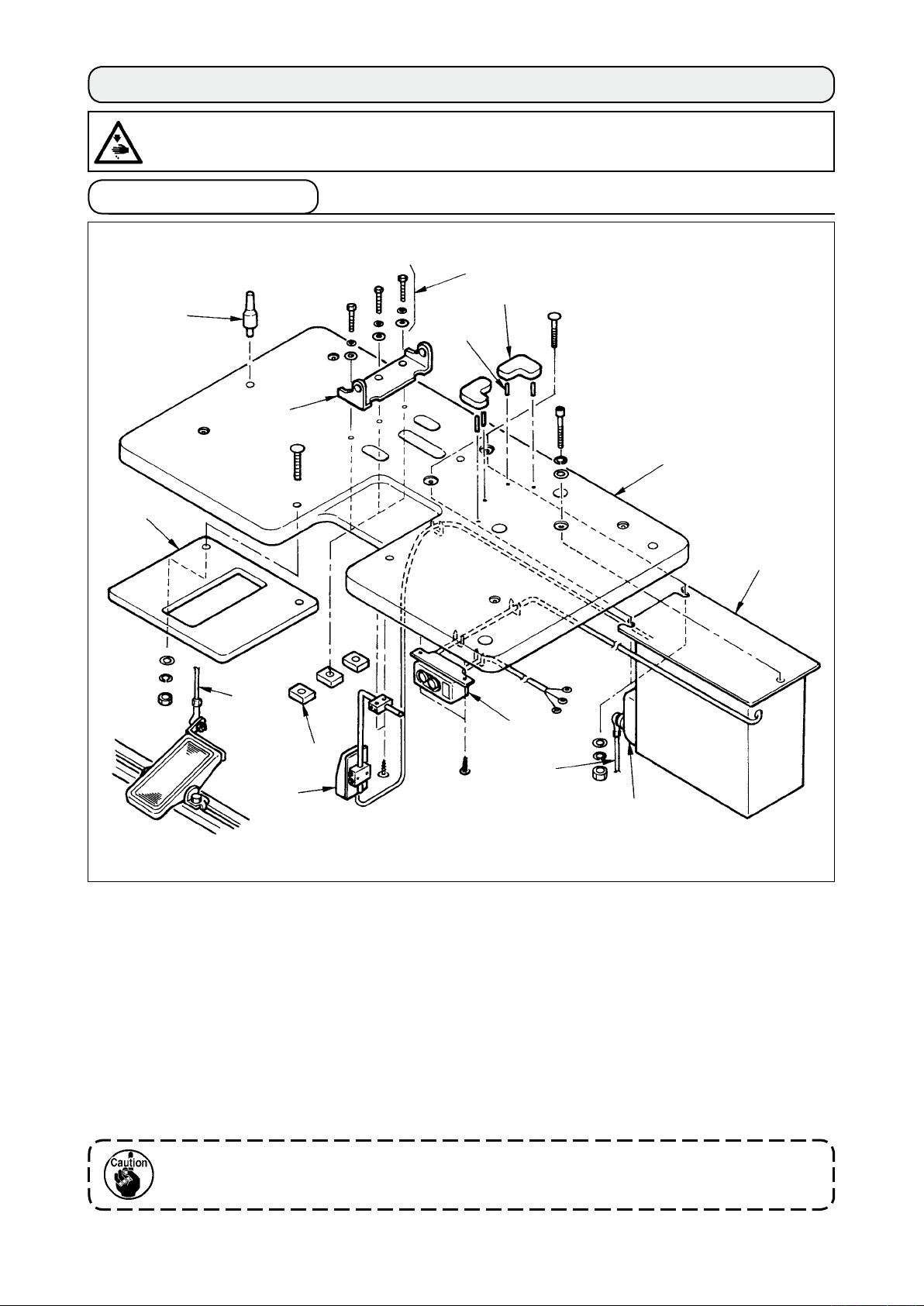

(1) Set-up of the table

8

!3

!1

7

6

5

1

2

9

3

!2

9

4

!0

1) Fix control box 2, power switch 3, auxiliary table !3 and start switch 4 to table 1.

Note) Install auxiliary table

!3

before installing start switch 4.

2) Fix the cables of power switch 3 and start switch 4 with staples.

3) Pass arm stay xing screws !1 (3 pcs.) through arm stay 5, instal on the table, and x them with

nuts !2.

4) Drive pins 6 to the table, and insert rubber cushions 7.

5) Fix head support bar 8 on table 1.

6) Connect the pedal (left-hand side) and control box pedal sensor !0 with connecting rod 9

supplied as accessories.

Adjust the positions of the pedals so that connecting rods 9 and control box 2 do not come in

contact with each other.

!

– 5

!– 6

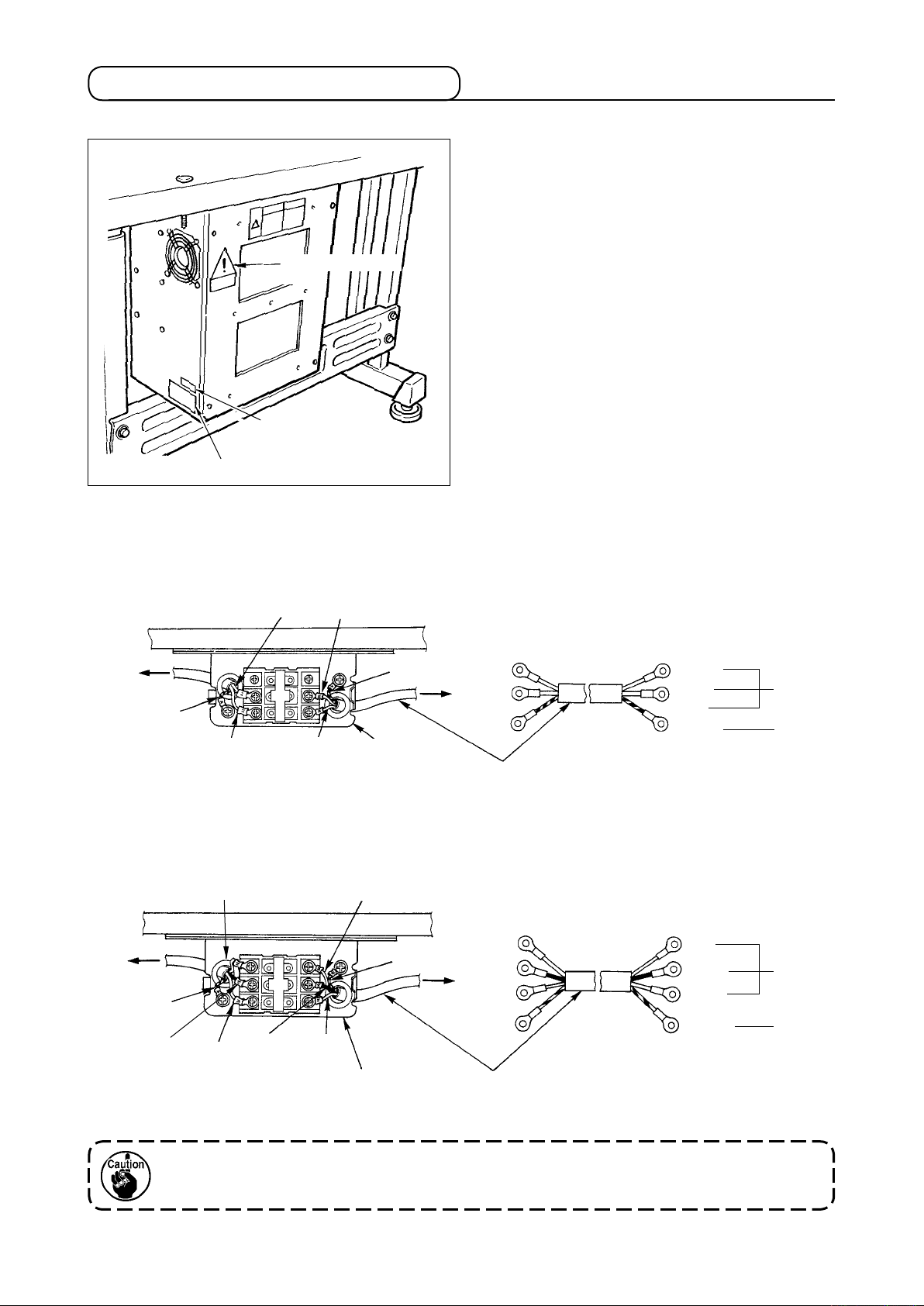

(2) Connecting the power source cord

1)Voltagespecications

Power source specications are indicated on the

voltage indication seal. (3-phase type only)

F o r o t h e r t y p e mac hi ne s , p o w e r sou r c e

specications are indicated on the voltage caution

seal and the rating label.

Voltage caution

seal

Voltage indication seal

(3-phase type

Rating label

only)

2) Connecting single phase 200V, 220V, 230V and 240V

Connect so as to supply the power to the white wire and the black wire as shown in the illustration.

Co n n ec t th e co r d in ac c or d a nc e wi t h t h e

specications.

Light blue

Table

Control box

Green/Yellow

Brown

Light blue

Brown

Green/Yellow

Plug

Power switch

3) Connecting three phase 200V, 220V and 240V

Table

Control box

Green/Yellow

Black

White

Red

Black

White

Green/Yellow

Plug

Red

Power source cord

Brown

Light

blue

Green/

Yellow

Red

White

Black

Green/

Yellow

AC200 V

AC220 V

AC230 V

AC240 V

GND

AC200 V

AC220 V

AC240 V

GND

Power switch

1. Never use under the wrong voltage and phase.

2. When changing the voltage, refer to the item of "Changing the voltage of 100 / 200V".

Power source cord

(3) Changing the voltage of 100 / 200V

WARNING :

To prevent personal injuries caused by electric shock hazards or abrupt start of the sewing

machine, carry out the work after turning OFF the power switch and a lapse of 5 minutes or more.

To prevent accidents caused by unaccustomed work or electric shock, request the electric expert

or engineer of our dealers when adjusting the electrical components.

It is adaptable to the voltage of single phase 100V to 120V/3-phase 200V to 240V by changing the

voltage changeover connector mounted on FLT p.c.b.

(Caution) When the changing procedure is wrong, the control box will be broken. So, be very

careful.

Changing procedure of the changeover connector

1. Turn OFF the power source with the power

switch after conrming that the sewing machine

has stopped.

2. Draw out the power cord from the power plug

socket after conrming that the power switch is

turned OFF. Then wait for ve minutes or more.

3. Remove the front cover.

4. Remove four screws xing the rear cover of the

control box and slowly open the rear cover.

A. In case of using with 3-phase 200V to 240V

1

A

• Changing the changeover connector

Connect to 200V the 100/200V changeover

connector of FLT p.c.b. 1 located on the side

of the Box Side of the control box.

• Connect the crimp style terminal of AC input

cord to the power plug as shown in the gure.

B

C

WHITE

BLACK

RED

GREEN/

YELLOW

WHITE

BLACK

RED

GREEN/

YELLOW

WHITE

BLACK

RED

GREEN/

YELLOW

WHITE

BLACK

RED

GREEN/

YELLOW

WHITE

BLACK

RED

GREEN/

YELLOW

WHITE

BLACK

RED

GREEN/

YELLOW

(Plug side)

(Plug side)

(Plug side)

B.

In case of using with single phase 100V to 120V

• Changing the changeover connector

Connect to 100V the 100/200V changeover

connector of FLT p.c.b. 1 located on the side

of the Box Side of the control box.

• Connect the crimp style terminal of AC input

cord to the power plug as shown in the gure.

(Caution) Securely perform the insulation

treatment to the red terminal which is

not used with insulation tape or the like.

(Whentheinsulationisinsufcient,

there is a danger of electric shock or

leakage current.)

C.

In case of using with single phase 200V to 240V

• Changing the changeover connector

Connect to 200V the 100/200V changeover

connector of FLT p.c.b. 1 located on the side

of the Box Side of the control box.

• Connect the crimp style terminal of AC input

cord to the power plug as shown in the gure.

(Caution) Securely perform the insulation

treatment to the red terminal which is

not used with insulation tape or the like.

(Whentheinsulationisinsufcient,

there is a danger of electric shock or

leakage current.)

5. Check that the change has been performed

without fail before closing the rear cover.

6. Be careful that the cord is not pinched between

the rear cover and the control box main unit.

Close the rear cover while pressing the lower

side of rear cover, and tighten four screws.

!

– 7

!– 8

(4) Installing the sewing machine main unit

WARNING :

To prevent possible accidents caused by the fall of the sewing machine, perform the work by two

persons or more when the machine is moved.

Adjust the sewing machine head to the hole of

arm stay, and insert shaft 1. Fix shaft 1 with

screws 2 in the state that the end faces of shaft

are protruded on the both sides.

1

Be careful that wiring and air pipe

coming out from the bottom face

of the se w i n g m a c h ine are n o t

2

1

crushed.

(5) Tilting the sewing machine head

WARNING :

Whentilting/raisingthe sewing machine head, perform the work so asnottoallowyour ngers to

be caught in the machine. In addition, to avoid possible accidents caused by abrupt start of the

machine, turn OFF the power to the machine before starting the work.

1

When tilting the sewing machine head, tilt quietly

the sewing machine until head support bar 1

comes in contact with it.

1. Make sure that sewing machine

head support bar 1 is placed

on the table before tilting the

sewing machine.

2. To protect fall-down, be sure to

tilt the sewing machine in a level

place.

3. Keep the table in the state that

anything is not put on the top

surface of table

(6)Removingthexedplatefortransport

2

1

[Reference]

3

2

Remove xed screw 1 and remove xed plate for

transport 2.

Fixed screw 1 and fixed plate for

transport 2 are necessary when

transporting with the machine head

sing l e unit. So, kee p them wit h

care.

In case of the complete transport

¡

In case of the complete transport, x the sewing

machine to th e table with screw 1, two flat

washers 2 and nut 3 supplied as accessories

in order to safely transport the sewing machine.

1

(7) Installing the operation panel

3

1

Fix operation panel attaching plate 1 on the

table with woodscrew 2 and pass the cable

through hole 3 in the table.

2

!

– 9

!– 10

(8) Installing the air regulator

!1

3

2

1

4

!0

5

6

7

8

9

1) Install lter installing plate 1 on the right side of the stand side support with screw 3.

2) Fix air regulator 2 on lter installing plate 1 with screw 4.

3) Fix elbow union 5 on the right section of air regulator 2.

4) Insert air hose 6 into elbow union 5.

5) Insert reducing union T 7 into the top end of the air hose, and insert stop plug 8 into the hole of

ø6.

Use the branch section (ø6) of reducing union T 7 when using the air gun.

Air gun set (G57602540A0) is available as optional.

6) Insert air tube 9 coming from the main unit of machine head into reducing union T 7.

7) Insert pressure sensor relay cord !0 into connector !1 of air regulator 2.

8) Winding pressure sensor relay cord !0 around air tube 9, insert it into the control box (CN41).

9) Supply air, and adjust the air pressure to 0.5 Mpa.

(9) Connecting the cords

Perform the connection of the cords as shown in the gure below.

CN14

CN16

Sewing machine head

MAIN

circuit

board

CN33

CN34

SDC circuit board

CN16

CN16

CN14

SDC circuit board

CN14

1

CN38

CN39

CN40

CN41

Cord

clamp A

CN43

CN44

CN33

CN38

Start

switch

CN39

CN40

CN43

CN44

CN34

CN41

Operation panel

Filter regulator

1) Pass 5 c ords ( CN39, 4 0, 41, 4 3 and 4 4 )

connecting to the right side among the cords

connecting to MAIN circuit board through cord

clamp A as shown in the gure, and connect

them to the respective connectors. Connect

CN38 to the conne c t o r wi t h o u t pa s s i n g

through cord clamp A.

2) Directly connect two cords connecting to the

left side of MAIN circuit board to CN33 and

CN34.

3) Connect the cords connecting to SDC circuit

board directly to CN14 and CN16.

4) Fix the earth wire with the setscrew 1.

!

– 11

!– 12

(10) Managing the cord

1) Slowly tilting the sewing machine, check that the cords are not forcibly pulled.

2) Fix the cords with cord setting plate 1 as shown in the gure.

When you tilt the sewing machine, make sure that the sewing machine head

support bar 2 is placed on the table.

2

1

(11)Installingtheeyeprotectioncoverandthengerguard

WARNING :

Be sure to attach this cover to protect the eyes from the disperse of needle breakage.

Be sure to install eye protection cover 1 and

nger guard 2, and use the sewing machine.

1

2

(12) Installing the thread stand

2

1

(13) Attaching the button tray

1) Assemble the thread stand, and set it in the

hole in the top right corner of the machine

table.

2) Tighten locknut 1 to x the thread stand.

3) When ceiling wiring is possible, pass the

power cable through spool rest rod 2.

1) Fix base 1 on the table with wood screw 2.

2) Insert button tray 4 in the hole of base 1

and fix it with setscrew 3 after adjusting

the position to that where the button can be

taken with ease.

4

3

1

2

I t i s p o ss i bl e t o c h an g e t h e

lo a d er set po s i ti o n a s we l l . It

i s r e c o m me n d ed to pe r f o rm

positioning them together.

(Memory switch U04)

!

– 13

!– 14

3. PREPARATION BEFORE OPERATION

(1) Inserting the needle

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

Hold needle with its recessed part facing toward

side

"A"

machine, insert the needle into the needle hole

of needle bar until it will go no further, and tighten

setscrew 1 with a at-blade screwdriver.

Use a SM332EXTLG-NY(#11 to #18).

2

2

3

3

1

1

A

as observed from the front of the sewing

When attaching the needle, turn

OFF the power to the motor.

Attach stop plug 2 supplied as

accessories (insert magnet 3

supplied as accessories into

the top end) to the needle. It is

recommendedtoconrmthatthe

needle is vertical.

(2) Threading the needle-thread

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

Pass the needle thread in the order 1 to !3 as shown in the gures.

2

3

4

9

!0

7

1

5

!1

8

!3

!2

6

(3) Adjusting the stay (counter) button stopper

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

Loosen screws 3 and adjust so that the clearance

between stopper 1 and pin 2 is 0.5 to 1 mm with

the button used set. Then x the stopper.

2

6

4

5

0.5 to 1mm

3

1

1. The size applicable to the stay

bu t t o n is ø8 to ø 2 5 , a n d th e

thickness is 2 mm or less.

2. Feed plate is made so as to make

it easy to set the stay button of ø8

to ø10. Replace the feed plate with

the feed plate for counter button

when using the button which is not

clamped with stay button clamps

and 6, or using the button, the

5

needle entry position of which is

notttothewindowofgauge

4

.

[Reference]

6

5

Counter button B set

(40021447)

6

4

7

5

7

To change the feed plate to the feed plate

for counter button, there are two kinds of

methods ; changing as a set and replacing the

components.

In case of replacing as a set

¡

1) Purchase the set (40020807) of feed plate

for counter button. Loosen two screws 8

and replace the feed plate.

In case of replacing the components

¡

1) P u rch a s e th e c o unt e r bu t ton B se t

(40021447), loosen two screws 8, and

remove the feed plate from the machine

head.

2) Replace the components 4, 5, 6, and

with counter button B set (40021447).

7

4

8

8

3

1

!

1. Maximum size to be applied is

ø25.

2. When installing the feed plate,

insert it until it goes no further

andxit.

– 15

!– 16

(4) Replacing the button chuck

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1

3

2

<Button chuck correspondence table>

When replacing chuck 1, loosen screws 2 and

replace it with exclusive screwdriver 3 supplied

as accessories.

Part No. Description

40020932

40020931 Button chuck (medium) (standard) ø 14 to 25 mm Installed on machine head

40020930 Button chuck (large) ø 25 to 38 mm Accessory

Button chuck (small) ø 8 to 16 mm

Outside diameter of button

that can be used

Remarks

Accessory

(5) Set of the button neck wrapping

1

Groove B

Groove

A

Groove A

2

Groove

B

3

Height of

button neck

wrapping

5

Whe n perfo rming the but ton nec k wrapp ing

process of stay (counter) button, use the button

neck wrapping attachment (accessories) 1.

Loosen screws 2 and move holder plate 3 to

and fro to perform the adjustment of the height of

button neck wrapping attachment.

Conrmthatbuttonneckwrapping

positioning grooves A and B are

straight front and rear.

[Setting procedure of the button neck wrapping

attachment]

Insert convex 4 of the attachment to concave 5

of the feed plate at the time of the button neck

wrapping process pattern.

4

(6)Setofthesewingatbuttonwithblindstitch

When performing the sewing flat button with

2

1

blindstitch, insert underplate spacer A 1 supplied

as accessories (Part No. : 40020764) to the pin

position. In addition, fix it with screws 2 when

using it always.

Select and use a proper underplate spacer from

among the underplate spacers below according to

the thickness of cloth.

Discription

UNDER_PLATE_

SPACER A

UNDER_PLATE_

SPACER B

UNDER_PLATE_

SPACER C

Thickness

t=1.6 40020764 Accessory

t=2.0 40020769 Optional

t=2.6 40020770 Optional

Part No. Remarks

!

– 17

!– 18

4. ADJUSTMENT OF THE SEWING MACHINE

(1) Adjusting the needle and the looper

1) Adjusting the needle bar height

Use the timing gauge supplied as accessories.

Loosen screw

1

case of SM332EXTLG-NY (standard needle) or

plane

in case of SM332SUPLG-NY aligns with

B

the height of the throat plate when the needle bar

comes down to the lowest position.

and adjust so that plane

1

A

in

Perf o r m the a d j ustme n t a t t h e

needle rocking origin (marker line).

Marker

line

To align

A

29.6mm

34.6mm

B

[Needle list]

JUKI Part No. Needle Part No.

MSM3AAN1100 NEEDLE SM332EXTLG-NY #11

MSM3AAN1200 NEEDLE SM332EXTLG-NY #12

MSM3AAN1400 NEEDLE SM332EXTLG-NY #14

MSM3AAN1600 NEEDLE SM332EXTLG-NY #16

MSM3AAN1800 NEEDLE SM332EXTLG-NY #18

MSM3ABN1100 NEEDLE SM332SUPLG-NY #11

MSM3ABN1200 NEEDLE SM332SUPLG-NY #12

MSM3ABN1400 NEEDLE SM332SUPLG-NY #14

MSM3ABN1600 NEEDLE SM332SUPLG-NY #16

MSM3ABN1800 NEEDLE SM332SUPLG-NY #18

2) Adjusting the clearance between the needle and the looper

Use the timing gauge supplied as accessories.

Loosen two screws 1, move looper 2 and adjust

by loosening screw 4 so that the clearance

D

between the needle and the blade tip of looper

is 0.05 to 0.1 mm when plane C in case of

SM332EXTLG-NY (standard needle) or plane D in

case of SM332SUPLG-NY aligns with the height

C

37.6mm

of the needle bar.

In addition, adjust so that the left position of

needle 3 aligns with the top end of looper 2 as

32.6mm

observed from the front.

1

4

0.05 to 0.1mm

2

3

2

To align

(2) Adjusting the position of the york slide

1

1

0 to 0.2mm

2

0.2 to 0.4mm

Fig. 1

Approx. 6mm

1) The position of york slide

has been factory-

1

assembled so that the clearance between

york slide 1 and the needle is longitudinally

0.2 to 0.4 and laterally 0 to 0.2 mm when the

needle bar comes to the lowest position.

(Refer to Fig. 1.)

2) Adjust the lateral position of york slide

1

by

loosening setscrews 2 and moving york slide

laterally.

1

3) Adjust the longitudinal position of york slide

by loosening setscrew 3 and moving york

1

slide cam 4 longitudinally. The motion timing

of york slide cam 4 at this time is adjusted

by making the engraved marker line on york

slide cam 4 directly below and tightening the

cam with setscrew 3 when the needle bar is

at the lowest position.

4) Timing of the york slide motion is performed

in the order that the york slide moves from

the left to the right and starts retracting

immediately after the blade tip of looper has

passed the triangle of the thread.

(Posi tion w here t he need le bar goes u p

approximately 6 mm from the lowest position)

5) Loosen setscrews 7 in york slide triangle

cam 6 and turn the cam in the direction of

rotation to perform this adjustment.

5

6

Blade tip of looper

Locus of york slide

3

4

Marks made by the electron pen have

been put on york slide cam 4 and

york slide triangle cam 5 at the time

of delivery from factory. Make them

as the standard of timing adjustment.

6) For the locus of york slide motion, loosen

setscrew 4 in york slide cam 5 and turn

the cam in the direction of rotation to adjust

so that the locus becomes a triangle while

keeping the clearance (0 to 0.2 mm) between

the n e e dle and the y o r k slide when t h e

needle goes up.

!

– 19

!– 20

(3) Adjusting the needle and the needle guide

1) Adjusting the position of the needle and the throat plate

Loosen screws 1 and adjust the throat plate so

that the needle enters the center of the needle

1

Center

2) Adjusting the clearance between the needle and the needle guide

hole.

0 to 0.1mm

Loosen screw 1 and adjust so that the clearance

between needle guide 2 and the needle is 0 to 0.1

mm at the lowest position of the needle bar.

1

2

(4) Adjusting the thread trimmer mechanism

1) Adjusting the position of the moving knife

First adjustment

0

1

2

1

3

13 to 14 mm

2

3

Second adjustment

5

4

7

3 to 5 mm

[Waiting position]

1. L o o s e n s c r ew s 1 a nd c l o s e t h e

clearance with stopper 2 so that the

dimension between the edge of fixed

knif e link 3 a nd the gro o ve end o f

throat plate is 13 to 14 mm. Then fix

screws 1.

[Thread trimming position]

1. Adjust the clearance between the blade point

of moving knife 7 and the right end of the slot

of throat plate is 3 to 5 mm in the state that

air only is ON (solenoid valve No. 14), loosen

screws 5, actuate the cylinder, and x screws

5

2. After the adjustment, check that moving knife

link 4 smoothly moves.

2) Adjusting the moving knife thread separation nail

Top end of thread separation nail

B e n d t hr ea d se p a r a t i o n n a i l 1 u si ng a

screwdriver or the like and adjust so that a

0.5 to 0.7mm

1

clearance of 0.5 to 0.7 mm should be provided

between thread separation nail 1 and looper 2.

in the state that the clearance is closed.

When the work is

completed, do not

forget to perform the

release of lock 6 of

the solenoid valve.

6

2

!

– 21

!– 22

(5) Adjusting the wiper mechanism

8

9

!0

4

7

5

3

6

1

1) Turn OFF the air, and draw wiper 1 until it

goes no further.

2) Adjust wiper cylinder installing bases A 3

and B 4 with the respective setscrews

and 6 so that the vertical clearance

5

between needle tip 2 and the top surface

of wiper 1 is 3 to 5 mm and the lateral

dimension between needle tip 2 and the

thread holding section of wiper 1 is 6 to

8 mm at the sewing machine stop position

(needle bar upper dead point).

3) Fix spring A 7 so that wiper 1 and spring A

equally come in contact with each other

7

on the plane within the range of the stroke

of cylinder 8.

4) Adjust th e hol ding force of thread w ith

spring B 9.

5) To adjust the holding force, loosen screw

and adjust so that thread slips off with

!0

the force of approximately 20 to 25g when

polyester spun thread #50 is held.

2

3 to 5mm

1

6 to 8mm

(6) Adjusting the chuck open mechanism

3

1

When the mode is changed over to the manual

button control mode, raise hook A 1 to decrease

the open amount. Adjust the open amount by

loosening screws 2 and sliding hook B 3 to the

right and left.

2

When the mode is changed over to

the button loader motion mode, do

not forget to release hook A 1.

5. MAINTENANCE

(1) Replacing the attachments

1) Replacing the button set pin (optional)

1

2

B

4

When replacing button set pin 2, loosen knob 1

and replace it. However, when replacing the set

pin with those below, remove knob 1 and install it

in the screw hole on side B.

1

2

3

4

No. Part No. Description

1

2

3

4

17974056

17974254

17974452

40023428

Set pin for marble button

Set pin for shank button (ø 1.5 to ø 2.0)

Set pin for shank button (ø 2.0 or more)

Set pin for metallic button

3

0.3 to

0.7 mm

2) Replacing the carrier pin

When replacing carrier pin 4, loosen screws 3 and replace it.

At this time, adjusdt the height of the carrier pin to 0.3 to 0.7 mm from the top surface of the set pin.

<Carrier pin list>

Button carrier (for 4-holed button) Button carrier (for 2-holed button)

1 2 3 4 5

ø b

a

a

ø b

a

a

ø b

a

a

a

a

ø b

ø b

Stamp

A

B

C

Part No.

17856600

17856709

17856808

Dimensions

a 2.0

b 1.0 b 1.2 b 1.4 b 1.0 b 1.4

a 2.4

b 1.2 b 1.4 b 1.8 b 1.2 b 1.4

a 2.6

b 1.2 b 1.2 b 1.8 b 1.2 b 1.4

Stamp

D

E

F

F1

G

H

J

Part No.

17856907

17857004

17857103

17857202

17857301

Standard

spec

17857400

17857509

Dimensions

a 2.8

a 2.8

a 3.0

a 3.0

b

a 3.2

b

a

b 1.4 b 1.4 b 1.4

a 3.6

b

1.4

1.4

3.4

1.4

Stamp

K

K1

L

Part No.

17857608

17857707

17857806

!

– 23

Dimensions

a 4.0

a 4.0

a 5.0

Stamp

M

N

P

Q

R

S

T

Part No.

17858002

17858101

17858200

17858309

17858408

17858507

Standard

spec

17858606

Dimensions

a 2.0

a 2.4

a 2.6

a 2.8

b

a 3.0

b

a

a 3.4

b

Stamp

1.2

1.2

3.2

1.4

U

V

W

X

Y

Z

Part No.

17858705

17858804

17858903

17859000

17859109

17859208

Dimensions

a 4.0

a 4.2

a 4.4

a 4.6

b

a 4.8

b

a

1.4

1.4

5.0

!– 24

3) Replacing the tongue stopper

2

1

5

4

When using the standard 4-holed tongue (Part

No. 25006602) of the former AMB-189N, replace

the tongue stopper guide together.

1) Replacing the tongue

Remove screws 1 and replace tongue 2.

2) Replacing the tongue stopper guide

Remove screws 3 and replace tongue stopper

guide 4 with tongue stopper guide B (Part No.

: 40020763) 5 supplied as accessories.

3

3) Finally, perform the change of memory switch

level K12.

(2) Replacing the fuse

WARNING :

1. To avoid electrical shock hazards, turn OFF the power and open the control box cover after about

veminuteshavepassed.

2. Open the control box cover after turning OFF the power without fail. Then, replace with a new

fusewiththespeciedcapacity.

1

2

3

The machine uses the following three fuses :

For pulse motor power supply protection

1

5A (time-lag fuse)

Fo r sol enoid and pulse moto r pow er

2

supply protection

3.15A (time-lag fuse)

For control power supply protection

3

2A (fast-blow type fuse)

!

– 25

!– 26

(3) Greasing parts

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

Periodically perf orm grease-up every 6 mon ths as a s tanda rd, or per form grease-up when

(grease-up time) is displayed on the operation panel.

There are three kinds of the exclusive greases supplied as accessories.

Grease in grease tube (green, Part No. 13525506)

○

Greasing section

of rack and gear

Apply grease to rack, gear and cam section.

→

1) Remove the rear cover, and apply grease to

rack and gear section of Y top feed.

Greasing section of

rack on the front side

Greasing section of

rack on the rear side

2) Remove the rear cover and the side cover,

and apply grease to rack and gear section

of Y bottom feed.

• Move the bottom unit to the extreme front,

and apply grease to the front section of the

rack section.

• Move the bottom unit to the extreme rear,

and apply grease to the rear section of the

rack section.

3) Apply grease to the york slide cam and the

york slide triangle cam sections.

• Tilt the machine head

• Remove the looper cover.

• Turning the hand pulley, apply grease to the

lateral cam section.

For t he grea s ing sect ion of t h e

yoke slide cam, use grease in JUKI

grea s e A tu b e ( w hite, Pa r t No.

40006323).

Greasing

section of the

yoke slide

triangle cam

Grease in JUKI grease B tube (white, Part No. 40013640)

○

Remove the top cover and apply grease to the worm section.

→

Greasing

section of the

yoke slide cam

• Use the groove of top surface of worm,

Worm and worm

wheel section

turning with the atblade screwdriver, apply

grease to moving parts of the worm and

worm wheel.

Grease in JUKI grease A tube (white, Part No. 40006323)

○

Apply grease to other parts such as rotation fulcrum section, link moving section, etc.

→

(Caution) 1. When applying grease, apply new grease after carefully wiping old grease with a

piece of cloth or the like.

2. When the air gun or the like is blown to the greasing parts and the grease is

scattered, perform grease-up again.

!

– 27

!– 28

6. AIR CIRCUIT DIAGRAM

4

1

2

K

R

A

M

E

R

I

W

2

0

0

7

3

0

8

1

5

5

4

2

2

K

R

A

M

E

R

I

W

1

0

1

7

3

0

8

1

6

5

4

3

2

K

R

A

M

E

R

I

W

0

0

2

7

3

0

8

1

7

5

4

4

2

K

R

A

M

E

R

I

W

9

0

3

7

3

0

8

1

8

5

4

5

2

K

R

A

M

E

R

I

W

8

0

4

7

3

0

8

1

9

5

4

6

2

K

R

A

M

E

R

I

W

7

0

5

7

3

0

8

1

0

6

4

7

2

K

R

A

M

E

R

I

W

6

0

6

7

3

0

8

1

1

6

4

8

2

K

R

A

M

E

R

I

W

5

0

7

7

3

0

8

1

2

6

4

9

2

K

R

A

M

E

R

I

W

4

0

8

7

3

0

8

1

3

6

4

1

3

K

R

A

M

E

R

I

W

0

0

0

8

3

0

8

1

4

6

4

3

3

K

R

A

M

E

R

I

W

8

0

2

8

3

0

8

1

5

6

4

4

3

K

R

A

M

E

R

I

W

7

0

3

8

3

0

8

1

6

6

4

5

3

K

R

A

M

E

R

I

W

6

0

4

8

3

0

8

1

7

6

4

6

3

K

R

A

M

E

R

I

W

5

0

5

8

3

0

8

1

8

6

4

7

3

K

R

A

M

E

R

I

W

4

0

6

8

3

0

8

1

9

6

4

8

3

K

R

A

M

E

R

I

W

3

0

7

8

3

0

8

1

0

7

4

9

3

K

R

A

M

E

R

I

W

2

0

8

8

3

0

8

1

1

7

N

O

I

T

P

I

R

C

S

E

D

.

O

N

T

R

A

P

.

o

N

Y

T

'

Q

1 7

8

1

9

1

0

0

4

R

O

T

A

L

U

G

E

R

R

E

T

L

I

F

1

2 5

9

1

9

1

0

0

4

Y

S

S

A

H

C

T

IW

S

R

E

V

K

C

U

H

C

1

3 6

9

1

9

1

0

0

4

Y

S

S

A

H

C

T

I

W

S

R

O

H

K

C

U

H

C

1

4 7

9

1

9

1

0

0

4

Y

S

S

A

T

C

I

W

S

P

U

D

E

E

F

1

5 8

9

1

9

1

0

0

4

Y

S

S

A

H

C

T

I

W

S

N

W

O

D

D

E

E

F

1

6 9

9

1

9

1

0

0

4

Y

S

S

A

H

C

T

I

W

S

N

E

P

O

E

U

G

N

O

T

1

7 2

0

0

1

2

0

0

4

Y

S

S

A

E

V

L

A

V

D

I

O

N

E

L

O

S

1

8

B

E

1

0

1

0

8

1

0

T

B

m

1

E

S

O

H

E

B

U

T

9

B

E

1

5

2

0

0

4

0

T

B

m

2

1

E

S

O

H

E

B

U

T

0

1

B

E

1

0

5

0

0

8

0

T

B

m

2

E

S

O

H

E

B

U

T

1

1

0

A

0

9

0

3

1

0

3

2

G

1

R

E

D

N

I

L

Y

C

R

I

A

2

1

0

A

4

0

5

0

0

6

0

A

P

1

R

E

D

N

I

L

Y

C

R

I

A

3

1

0

A

1

0

5

1

0

8

0

A

P

2

R

E

D

N

I

L

Y

C

R

I

A

4

1

0

A

0

1

0

2

0

0

1

A

P

2

R

E

D

N

I

L

Y

C

R

I

A

5

1

0

A

1

1

0

2

0

0

1

A

P

1

R

E

D

N

I

L

Y

C

R

I

A

6

1

0

A

2

0

5

7

0

0

1

A

P

1

R

E

D

N

I

L

Y

C

R

I

A

7

1

0

A

2

0

5

2

0

5

1

A

P

1

R

E

D

N

I

L

Y

C

R

I

A

8

1

0

B

6

0

0

2

0

6

1

A

P

1

R

E

D

N

I

L

Y

C

R

I

A

9

1

0

A

8

0

0

2

0

6

1

A

P

1

R

E

D

N

I

L

Y

C

R

I

A

0

2

0

A

6

0

5

1

0

0

2

A

P

1

R

E

D

N

I

L

Y

C

R

I

A

1

2

0

0

0

6

0

4

2

1

0

C

P

R

E

L

L

O

R

T

N

O

C

D

E

E

P

S

4

2

2

0

0

E

3

0

4

2

2

0

C

P

3

G

N

I

R

T

R

E

S

N

I

3

2

3

0

5

2

5

0

6

4

0

J

P

3

W

O

B

L

E

E

S

O

H

4

2

0

1

0

4

0

3

0

1

2

J

P

2

N

O

I

N

U

F

L

A

H

5

2

5

0

0

0

4

0

3

0

3

J

P

5

N

O

I

N

U

6

2

1

0

3

0

2

0

4

0

3

J

P

6

W

O

B

L

E

7

2

4

0

5

0

4

0

4

0

3

L

P

7

N

O

I

N

U

W

O

B

L

E

8

2

1

0

2

5

8

0

4

0

3

J

P

1

N

O

I

N

U

W

O

B

L

E

9

2

1

0

0

0

2

0

5

0

3

J

P

2

T

N

I

O

J

T

0

3

1

0

0

0

8

0

5

0

3

J

P

1

E

E

T

E

P

I

P

1

3

2

0

0

0

4

0

8

0

3

J

P

G

N

I

L

P

U

O

C

K

C

I

U

Q

1

2

3

2

0

5

0

4

0

1

0

3

J

P

4

W

O

B

L

E

E

S

O

H

3

3

0

0

0

4

1

0

0

5

X

P

6

G

U

L

P

4

3

0

0

0

1

0

0

0

5

9

X

P

1

G

U

L

P

4

1

K

R

A

M

E

R

I

W

6

0

0

5

3

0

8

1

5

3

4

2

K

R

A

M

E

R

IW

5

0

1

5

3

0

8

1

6

3

4

3

K

R

A

M

E

R

I

W

4

0

2

5

3

0

8

1

7

3

4

4

K

R

A

M

E

R

IW

3

0

3

5

3

0

8

1

8

3

4

5

K

R

A

M

E

R

I

W

2

0

4

5

3

0

8

1

9

3

4

6

K

R

A

M

E

R

I

W

1

0

5

5

3

0

8

1

0

4

4

7

K

R

A

M

E

R

I

W

0

0

6

5

3

0

8

1

1

4

4

8

K

R

A

M

E

R

I

W

9

0

7

5

3

0

8

1

2

4

4

9

K

R

A

M

E

R

I

W

8

0

8

5

3

0

8

1

3

4

4

0

1

K

R

A

M

E

R

I

W

7

0

9

5

3

0

8

1

4

4

4

1

1

K

R

A

M

E

R

I

W

4

0

0

6

3

0

8

1

5

4

4

2

1

K

R

A

M

E

R

I

W

3

0

1

6

3

0

8

1

6

4

4

3

1

K

R

A

M

E

R

I

W

2

0

2

6

3

0

8

1

7

4

4

4

1

K

R

A

M

E

R

I

W

1

0

3

6

3

0

8

1

8

4

4

5

1

K

R

A

M

E

R

I

W

0

0

4

6

3

0

8

1

9

4

4

6

1

K

R

A

M

E

R

I

W

9

0

5

6

3

0

8

1

0

5

4

7

1

K

R

A

M

E

R

I

W

8

0

6

6

3

0

8

1

1

5

4

8

1

K

R

A

M

E

R

I

W

7

0

7

6

3

0

8

1

2

5

4

9

1

K

R

A

M

E

R

I

W

6

0

8

6

3

0

8

1

3

5

4

0

2

K

R

A

M

E

R

IW

5

0

9

6

3

0

8

1

4

5

E

V

I

R

D

R

E

M

M

I

R

T

D

A

E

R

H

T

E

S

A

E

L

E

R

D

A

E

R

H

T

E

V

I

R

D

D

A

E

R

H

T

N

O

I

S

N

E

T

E

V

I

R

D

E

V

I

R

D

1

.

o

N

N

O

I

S

N

E

T

D

A

E

R

H

T

.

M

S

A

N

U

G

R

I

A

)

P

O

(

W

O

L

B

R

I

A

E

V

I

R

D

R

E

P

I

W

N

O

I

S

R

E

V

N

I

K

C

U

H

C

L

A

C

I

T

R

E

V

E

V

I

R

D

N

O

I

S

R

E

V

N

I

K

C

U

H

C

L

A

T

N

O

Z

I

R

O

H

E

V

I

R

D

E

V

I

R

D

N

E

P

O

/

E

S

O

L

C

K

C

U

H

C

H

T

O

L

C

H

C

T

I

T

S

D

N

I

L

B

E

V

I

R

D

R

E

S

S

E

R

P

E

V

I

R

D

R

E

S

S

E

R

P

H

T

O

L

C

N

O

T

T

U

B

T

A

L

F

/

E

S

O

L

C

E

U

G

N

O

T

E

V

I

R

D

N

E

P

O

E

V

I

R

D

L

A

C

I

T

R

E

V

E

U

G

N

O

T

2

2

2

2

2

2

4 2

2

3

1450

10

0

0

7

4

0

9

4

0

5

4

0

6

4

0

0

6

0

8

5

0

9

6

0

9

6

180

180

0

7

0

5

0

8

1

0

8

1

0

2

1

0

7

0

5

0

0

1

0

5

1

0

5

1

0

2

8

0

0

9

0

5

1

0

3

7

0

0

1

0

5

6

0

2

4

0

2

8

0

9

7

0

6

5

0

6

5

8

2

3

6

2

7

2

5

2

0

1

8

3

9

8

8

8

8

2

7

2

2

3

4

3

1

3

3

2

7

2

1

1

2

1

5

2

5

2

9

3

8

3

5

1

6

1

3

1

4

1

4

1

4

2

5

4

1

2

9

2

8

2

7

2

8

2

1

2

3

4

121

1

1

9

8

765

4

6

3

P

6

2

8

1

7

1

2

2

1

2

1

2

6

1

4

1

6

2

4

1

9

2

1

1

2

1

3

3

7

1

5

1

3

2

6

1

9

2

3

3

1

6

2

3

1

6

2

2

8

1

7

2

9

1

0

2

7

2

6

0

7

0

7

1

2

7

1

5

2

3

151

2

1

1

1

0

1

957

8

7

7

2

5

2

3

1

0

7

0

7

6

5

4

3

2

1

9

0

1

0

2

9

1

8

1

4

2

3

2

2

2

4

3

0

1

0

3

0

1

7

1

9

1

3

3

1

3

5

3

8

6

4

2

0

2

3

2

3

3

1

3

5

3

4

3

7

3

6

3

7

3

6

6

7

6

4

6

5

6

2

6

1

6

3

6

1

7

0

7

9

5

0

6

7

5

3

5

6

5

5

5

8

5

5

4

6

4

4

5

2

5

1

5

8

4

7

4

0

5

9

4

0

4

3

4

4

4

8

3

6

3

7

3

5

3

2

4

1

4

9

3

9

6

8

6

7. DRAWING OF THE TABLE

(1) Table

C1(Full periphery)

Part No. : 40020990

C1(Full periphery)

Top

surface

17 drilling

30 spot facing

4x4 drilling, depth 15

16 drilling

30 spot facing

Painting

4x2 drilling, depth 10

30 drilling

surface, depth 10

4x2 drilling on the bottom

Painting

3x10 drilling

16 drilling

!

2x10 drilling

– 29

6x2 drilling on the bottom surface, depth 10

Painting

JUKI logotype (by printing supplied by JUKI)

(2) Auxiliary table

Part No. : 17971805

15

40

20

All-round R2

All-round R2

2-11drilling

20

415

360

10

20

335

10

315

10

10

165

265

20

430

60

!– 30

Contents

ContentsContentsContents

Loading...

Loading...