Page 1

AB-1360

INSTRUCTION MANUAL

* "CompactFlash(TM)" is the registered trademark of SanDisk Corporation, U.S.A.

Page 2

CONTENTS

I. MACHINE (ABOUT THE SEWING MACHINE) ......................1

Precautions for use .................................................................................................. 1

1. Conguration ........................................................................................................ 2

2. Specications ....................................................................................................... 3

2-1. Mechanical specications .............................................................................................. 3

2-2. Electrical specications ................................................................................................. 4

2-3. Shoelace specications ................................................................................................. 4

3. Installation ............................................................................................................ 5

3-1. Removing the packing materials ................................................................................... 5

3-2. Fixing the machine .......................................................................................................... 6

3-3. Connecting the air coupler ............................................................................................. 6

3-4. Connecting the power plug ............................................................................................ 7

3-5. Assembling the thread stand and installing on the machine ..................................... 7

3-6. Installing the machine head support bar ...................................................................... 7

3-7. Installing the operation panel IP-420 ............................................................................. 8

3-8. Installing the 3-pedal unit ............................................................................................... 8

3-9. Installing the additional marking light (optional) ......................................................... 9

4. Preparation of the sewing machine .................................................................. 10

4-1. Lubrication ..................................................................................................................... 10

4-2. Attaching the needle ..................................................................................................... 10

4-3. Threading the machine head ....................................................................................... 11

4-4. Installing and removing the bobbin case ................................................................... 11

4-5. Installing the bobbin ..................................................................................................... 12

4-6. Adjusting the thread tension........................................................................................ 12

4-7. Adjusting the thread take-up spring............................................................................ 13

4-8. Example of the thread tension ..................................................................................... 13

4-9. Installing the ejected loop receiver ............................................................................. 13

5. Operating the sewing machine ......................................................................... 14

5-1. Emergency stop switch ................................................................................................ 14

(1) Method for operating the emergency stop switch ....................................................................... 14

(2) Precautions with the emergency stop switch .............................................................................. 14

5-2. Winding a bobbin .......................................................................................................... 15

(1) To wind a bobbin while the sewing machine is performing sewing ............................................. 15

(2) To wind a bobbin independently .................................................................................................15

5-3. Thread clamp device ..................................................................................................... 16

5-4. Placing a shoelace loop ............................................................................................... 17

5-5. Adjusting the shoelace loop tension........................................................................... 17

5-6. Method for changing the loop width ........................................................................... 18

5-7. Start switch .................................................................................................................... 19

5-8. Adjusting the heat cutter temperature ........................................................................ 20

i

Page 3

II. OPERATION (OPERATION PANEL) ...................................21

1. Introduction ........................................................................................................ 21

2. Method for using the operation panel .............................................................. 25

2-1. Name of each section of IP-420 ................................................................................... 25

2-2. Buttons to be used in common ................................................................................... 26

2-3. Basic operation of IP-420 ............................................................................................. 27

2-4. LCD section when the shoelace loop individual sewing is selected ....................... 28

(1) Shoelace loop individual sewing data entry screen .................................................................... 28

(2) Shoelace loop individual sewing screen ..................................................................................... 30

2-5. How to change the shoelace loop length ................................................................... 32

(1) How to change the shoelace loop dimensions ...........................................................................32

(2) Changing the shoelace loop length (entire length) and precautions to be taken ........................ 33

2-6. How to lower the garment body presser and the work clamp foot .......................... 34

2-7. Using counter ................................................................................................................ 35

(1) Setting procedure of the counter ................................................................................................35

(2) Count-up releasing procedure ....................................................................................................38

(3) How to change the counter value during sewing ........................................................................ 38

2-8. How to register a new shoelace loop pattern number ............................................... 39

2-9. How to name a shoelace loop pattern number .......................................................... 41

2-10. How to select a shoelace loop pattern number ......................................................... 42

(1) Selection on the data entry screen .............................................................................................42

(2) Selection by the direct button .....................................................................................................43

2-11. How to copy a shoelace loop pattern number ........................................................... 44

2-12. How to carry out the step operation............................................................................ 45

(1) Setback step operation ............................................................................................................... 46

(2) Sewing position step operation ................................................................................................... 46

2-13. Function of canceling of a loop clamping for the next sewing ................................ 48

2-14. How to carry out the bartacking setting ..................................................................... 49

2-15. LCD section at the time of setting the bartacking ..................................................... 50

(1) LK unit data entry screen ............................................................................................................ 50

(2) LK unit sewing screen .................................................................................................................52

2-16. How to select the sewing shape (bartacking setting) ............................................... 54

2-17. List of sewing shapes ................................................................................................... 55

2-18. How to change the item data (bartacking setting) ..................................................... 56

2-19. How to check the sewing shape .................................................................................. 57

2-20. How to change the thread tension command from needle entry point to needle en-

try point .......................................................................................................................... 58

(1)

How to add/change the thread tension command from needle entry point to needle entry point ....... 58

(2) How to delete the thread tension command from needle entry point to needle entry point ........ 59

2-21. How to register a new user-pattern ............................................................................. 61

2-22. How to change the sewing mode ................................................................................ 62

2-23. LCD section when the cycle sewing is selected ........................................................ 63

(1) Cycle sewing data entry screen .................................................................................................. 63

(2) Sewing screen of the cycle sewing ............................................................................................. 65

2-24. How to carry out cycle sewing .................................................................................... 67

(1) Selection of the cycle-sewing data .............................................................................................67

ii

Page 4

(2) Method to create the cycle-sewing data .....................................................................................68

(3) Method to insert the cycle-sewing data ......................................................................................69

(4) Method for deleting the cycle sewing data ..................................................................................70

(5) Method for deleting a step of the cycle sewing data ................................................................... 70

2-25. How to edit the sewing data ......................................................................................... 71

(1) Method for changing the sewing data ......................................................................................... 71

(2) Sewing data list ...........................................................................................................................72

2-26. How to change the memory switch data .................................................................... 75

(1) Method for changing the memory switch data ............................................................................ 75

(2) Memory switch data list ..............................................................................................................76

2-27. How to set the device ................................................................................................... 79

(1) Device setting changing procedure ............................................................................................79

(2) Listing of the device settings .......................................................................................................80

2-28. How to adjust the origin of work clamp foot .............................................................. 81

2-29. Using communication function ................................................................................... 82

(1) Handling possible data ...............................................................................................................82

(2) Performing communication by using the media .......................................................................... 82

(3) Performing communication by using USB ..................................................................................82

(4) Take-in of the data ......................................................................................................................83

(5) Taking in plural data together ......................................................................................................84

2-30. Performing formatting of the media ............................................................................ 86

2-31. Trial stitching function.................................................................................................. 87

2-32. How to use information ................................................................................................ 89

(1) How to visually check maintenance/inspection information ........................................................ 89

(2) How to reset the warning ............................................................................................................ 91

(3) How to set the time ..................................................................................................................... 91

2-33. How to re-start sewing from the position where the machine has stopped by the

detection of thread breakage ....................................................................................... 92

3. Error code list ..................................................................................................... 93

4. Massage list ...................................................................................................... 104

III. MAINTENANCE ................................................................108

1. Maintenance ...................................................................................................... 108

1-1. Discharging drainage water ....................................................................................... 108

1-2. Adjusting the height of the needle bar ...................................................................... 108

1-3. Adjusting the needle-to-shuttle relation ................................................................... 109

1-4. Adjusting the lift of the work clamp foot................................................................... 110

1-5. The moving knife and counter knife .......................................................................... 110

1-6. Needle thread clamp device ........................................................................................111

1-7. Adjustment of the wiper ..............................................................................................111

1-8. Thread breakage detector plate ................................................................................ 112

1-9. Draining waste oil ....................................................................................................... 112

1-10. Amount of oil supplied to the hook ........................................................................... 112

1-11. Replacing the work clamp foot of the sewing machine .......................................... 113

1-12. Cleaning inside the hook cover ................................................................................. 113

1-13. Replacing the fork ....................................................................................................... 114

1-14. Replacing the fuse ...................................................................................................... 114

iii

Page 5

1-15. Replenishing the designated places with grease .................................................... 115

(1) Addition of grease to the machine head ................................................................................... 11 5

(2) Addition of grease to devices .................................................................................................... 11 7

1-16. Troubles and corrective measures (sewing conditions) ......................................... 120

2. Option ................................................................................................................ 122

2-1. Optional parts .............................................................................................................. 122

2-2. Miscellaneous .............................................................................................................. 122

2-3. Silicon oil pipes ........................................................................................................... 122

iv

Page 6

I. MACHINE (ABOUT THE SEWING MACHINE)

Precautions for use

Following items have to be checked every working day before the operation of the machine and before the start

of work hours.

1. Ascertain that the oil pan is lled with the predetermined amount of oil.

2. Never operate the machine unless the oil pan has been lled up with oil.

3. Ascertain that the pressure gauge indicates the designated air pressure of 0.5 MPa.

* (This is necessary particularly when the compressor is stopped for a lunch break or the

like.)

If the compressed air pressure is equal to or less than the designated value, troubles such

as interference between the parts can occur. It is therefore necessary to carefully check

the compressed air pressure.

4. Check whether the needle thread/bobbin thread need to be replenished.

5. To perform sewing immediately after turning ON the power switch, perform trial stitching

rst, then proceed with sewing of actual products after the test sewing.

6. In the case drainage water accumulates in the regulator section, expel it from there before

starting work.

7. Be sure to turn ON the power to the sewing machine after returning the loop clamp (loop

feeder unit) inside the unit cover.

* Be aware that the loop clamp interferes with the unit when the ready key is pressed while

the loop clamp rests on the sewing machine side after the power to the machine is turned

ON

– 1 –

Page 7

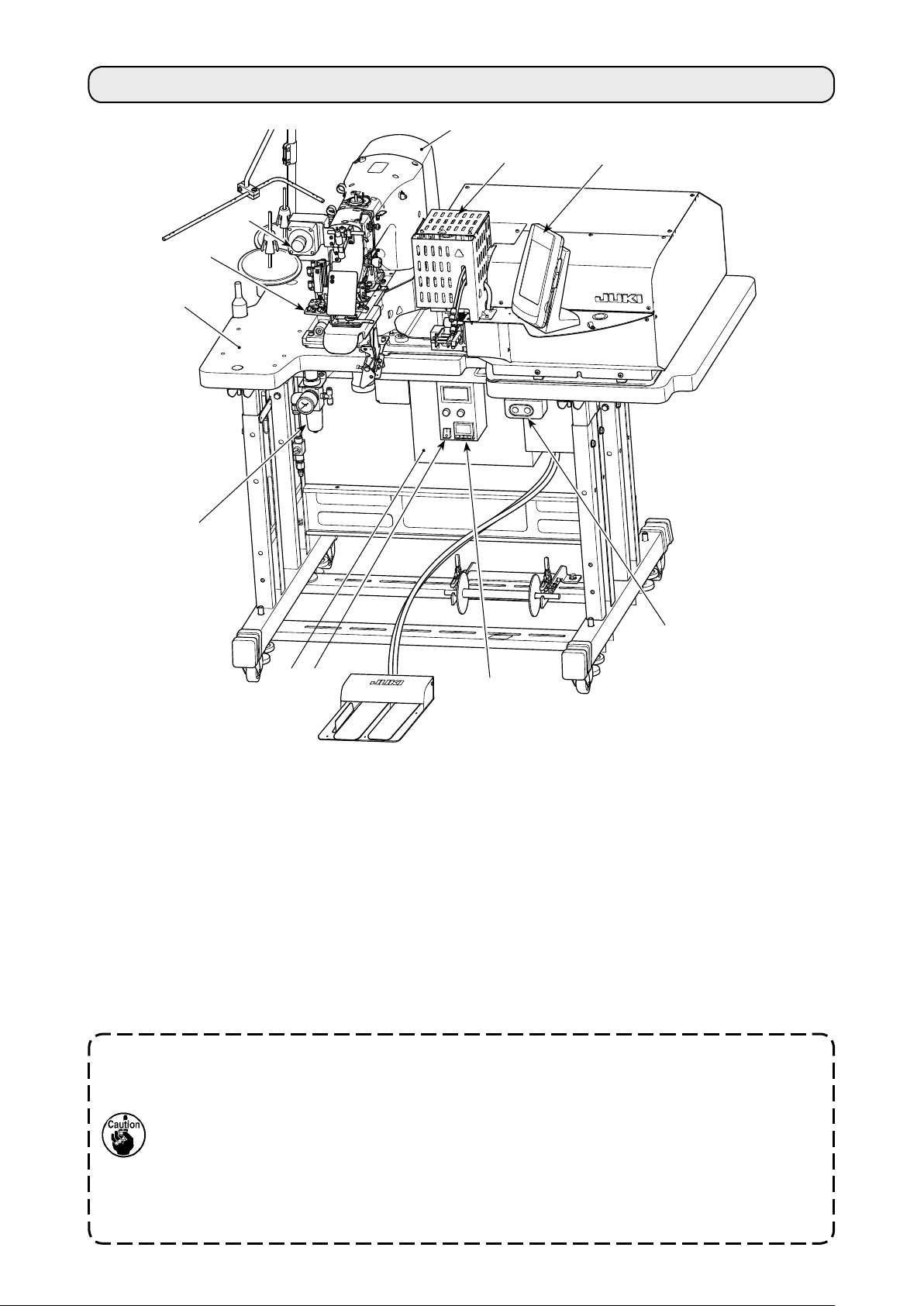

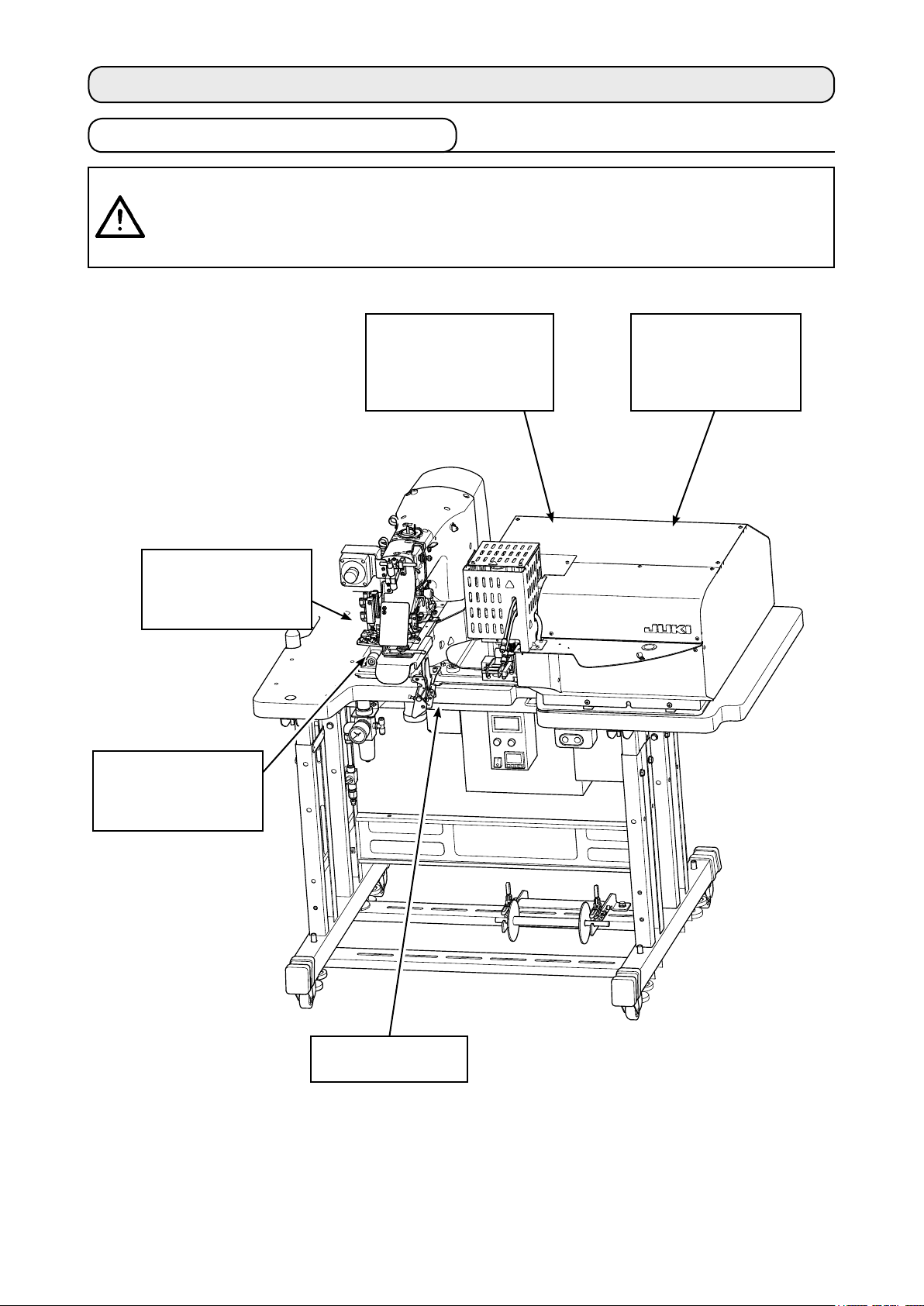

1. Conguration

E

A

D

C

H

B

G

J

F

K

This machine consists of the following eleven sections

I

.

The machine is able to automatically sew desired shoelace loop only by operating the start switch after

having placed a material (garment body) at the predetermined position on the machine.

When you press emergency stop switch H, the power to the devices are turned OFF to stop them.

A Mechanical section of the main body structure (table stand, table, covers, start switch, etc.)

B Loop feeder unit (loop feeding device, loop drawing device, heat cutter)

C Loop tension releasing unit

D Pneumatic control equipment section (pneumatic equipment, pneumatic piping, etc.)

E Sewing machine section

Control device

F

G Operation panel H Emergency stop switch

I Heat cutter controller

Power switch

J

K Heat cutter controller power switch

Heat the heat cutter to enable its operation, it is necessary to turn ON the heat cutter controller power switch K.

The power switch of the heat cutter is independent from the sewing machine power switch. It

is therefore necessary to turn OFF not only the heat cutter controller power switch but also

sewing machine power switch J when the sewing machine is not used.

In addition, it should be remembered that the heat cutter requires a certain period of time until

it becomes sufciently hot for use after turning ON the power switch. To ensure that the heat

cutter is operable whenever necessary, be sure to turn ON heat cutter controller power switch

K in prior and check that the heat cutter temperature is sufciently high. (For the adjustment

of temperature, refer to "I.5-8. Adjusting the heat cutter temperature" p.20.)

– 2 –

Page 8

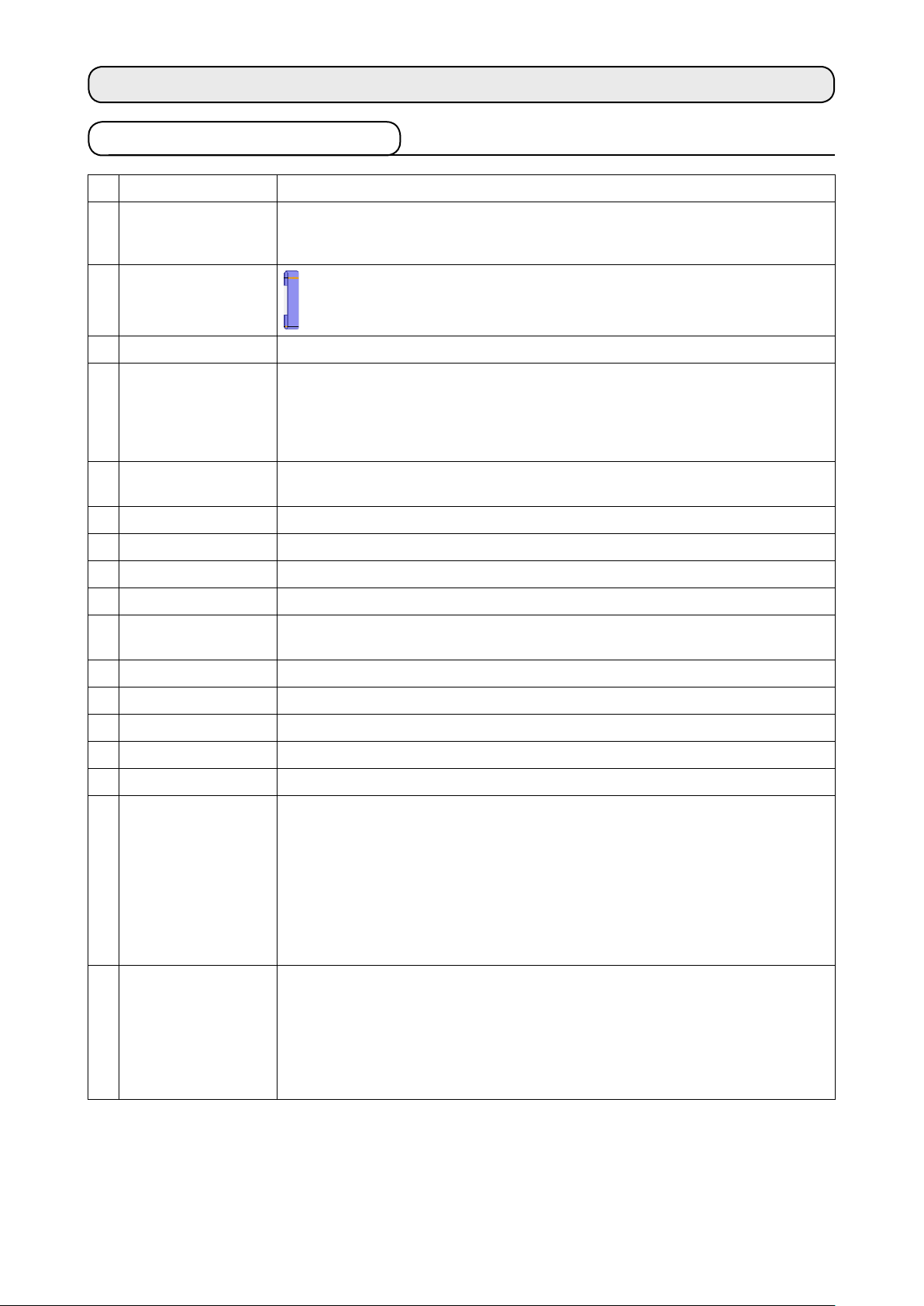

2. Specications

2-1. Mechanical specications

1 Sewing machine in use LK-1962/AB H (exclusive intermediate machine head AB-1360 based on LK-1900A SS)

Max. 2,500 sti/min (adjustable range: 400 to 2,500 sti/min)

2 Sewing speed

3 Loop shape

4 Shoelace loop width 6 to 12 mm

The stitching pitch has to be set at 3.2 mm or less. (Stitching pitch is input in increments

of 100 sti/min.)

5 Standard sewing

pattern

Lift of the work clamp

6

foot of sewing machine

7 Needle bar stroke 45.7 mm (for 1903A)

8 Needle ORGAN needle DP×17 #18 (Standard)

9 Hook in use Semi-rotary standard hook (x1.0)

10 Thread Filament #40

11 Safety feature

12 Lubrication oil JUKI New Defrix Oil No.2

13 Air pressure used 0.5 MPa

14 Air consumption 10 dm³ (ANR)/min or less

15 Dimensions W: 1,200 mm L: 850 mm H: 1,210 mm

16 Weight 205.5 kg

17 Noise Declaration

* Linear bartacking (exclusive pattern for AB-1360)

Pattern number selection method (from among 16-stitch) is adopted. The widthwise

pattern size is input on the operation panel. The lengthwise pattern size is restricted

to the 0 mm, and the widthwise one is restricted to the range from 7.6 to 15 mm. (The

lengthwise pattern size is input in increments of 0.1 mm.)

The distance from the top surface of the throat plate to the undersurface of the work

clamp foot is 20 mm.

The machine automatically stops in the case a loop clamping fault or thread breakage is

detected.

- Equivalent continuous emission sound pressure level (LpA) at the workstation :

A-weighted value of 82.0 dB; (Includes KpA = 2.5 dB); according to ISO 10821 - C.6.3

-ISO 112112 04 GR2 at 2,500 sti/min for the sewing cycle, 5.5s ON. (Pattern: No.4, 21

Stitches, Max Speed)

- Sound power level (LWA) ;

A-weighted value of 85.0 dB; (Includes KWA = 2.5 dB); according to ISO 10821 - C.6.3

-ISO 3744 GR2 at 2,500 sti/min for the sewing cycle, 5.5s ON. (Pattern: No.4, 21

Stitches, Max Speed)

18 Laser marking Class 2 laser product

Maximum output: 1.0 mW

Wave length: 650 nm

Safety standard

JIS C 6802:2005

IEC60825-1+A2:2007

– 3 –

Page 9

2-2. Electrical specications

1 Number of patterns that

can be stored in memory

2 Number of cycles that

can be stored in memory

3 Input power source Single-phase 220 – 240 VAC, 50/60Hz

4 Power consumption

99 patterns can be set.

Number of programs: 20

For each program, as many as 30 loops can be set.

Supply voltage uctuation: Rated voltage ± 10 % or less

Single-phase, 220 V type: 420 VA (instantaneous maximum power consumption: 655 VA)

* Average power when the machine sews 2,100 loops in eight hours.

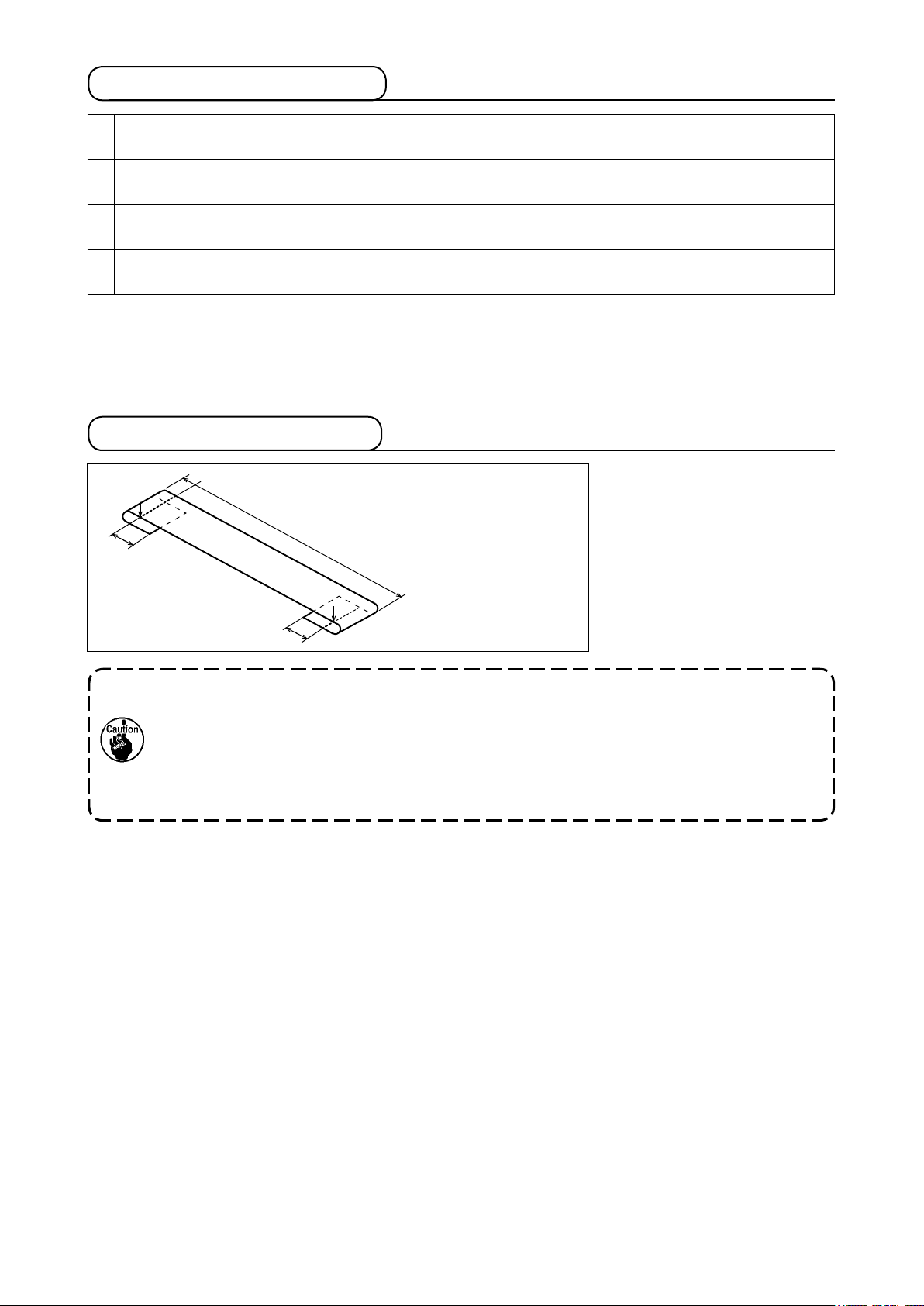

2-3. Shoelace specications

E

F

B

A = 4 mm *(0 to 15)

B = 12 to 17

E = 3 mm (0 to 5)

F = 4 mm (0 to 5)

A

The dimensions of the shoelace loop sewing shape displayed on the operation panel are

only for reference. The dimensions vary according to the shoelace loop material. Be sure to

adjust the settings of shoelace loop dimensions so that your desired nished dimensions

are achieved.

* Numerical values shown in parentheses are set values. They are not the nished dimen-

sions.

– 4 –

Page 10

3. Installation

3-1. Removing the packing materials

CAUTION

:

1. If you lift the machine, do not hold any of the devices or the mechanical section of the

sewing machine but hold the table.

2. When you move the machine, the machine head xation bolt must be attached to the

machine. Be sure to carefully keep the machine head xation bolt.

Remove the upper section

cover. Remove the string

and packing material

which are used to x the

loop drawing unit.

Remove the string and

packing material which

are used to x the loop

tension releasing unit.

Remove the upper

section cover. Remove

the string and packing

material which are

used to x the XY unit.

Remove the adhesive

tape which is used to

x the garment body

presser.

Remove the machine

head xation bolt.

– 5 –

Page 11

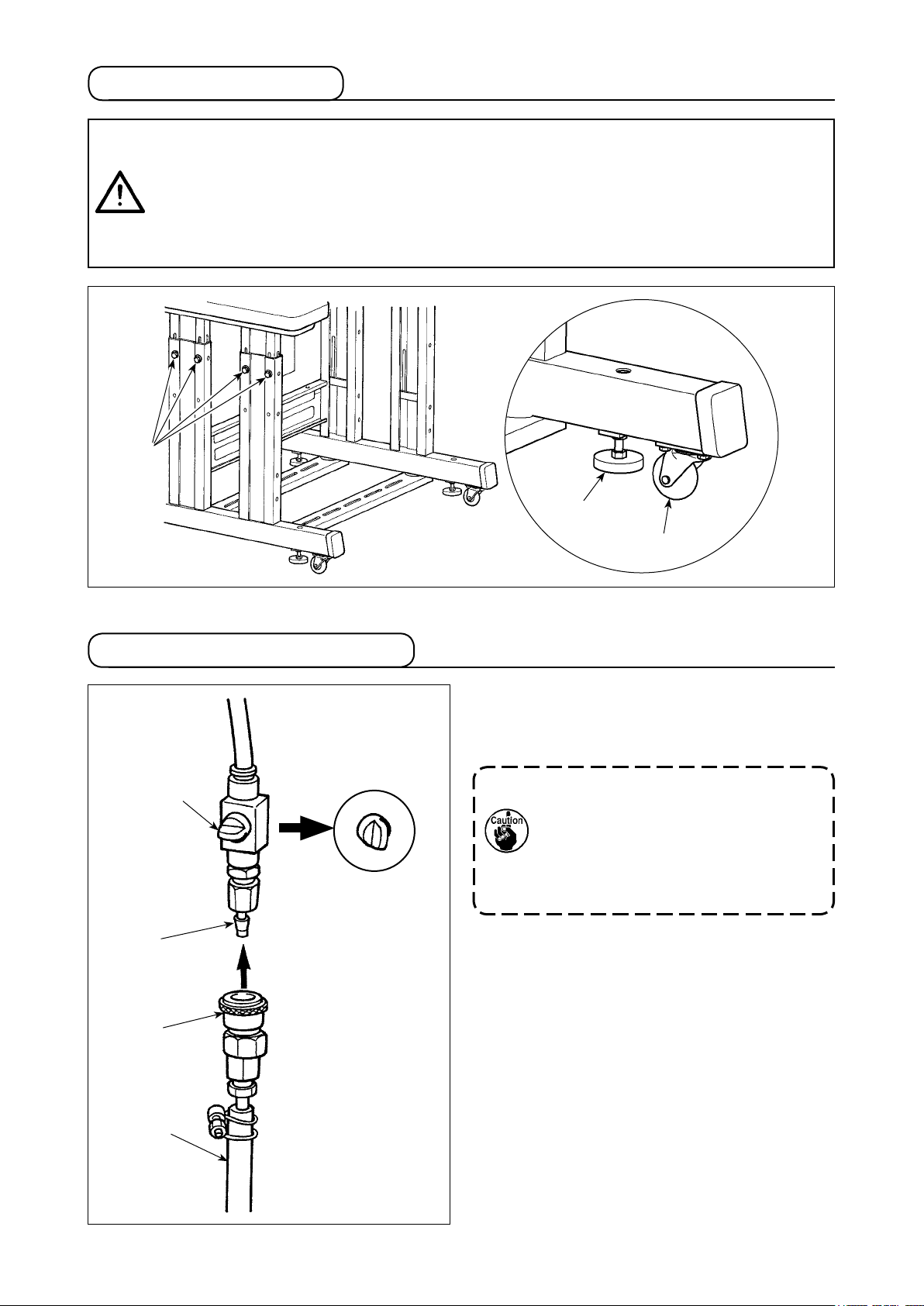

3-2. Fixing the machine

CAUTION

1. In order to protect against accidents causing personal injury or death, move the

machine to a level and stable place and secure it by lowering adjuster bolts ❷ (at four

locations) placed at the side of casters ❶.

2. When adjusting the leg height of the sewing machine, the leg xing bolts ❸ need to be

loosened to move the leg up or down. When the xing bolts have been loosened, there

is a danger for the legs to suddenly drop down. Therefore, be careful when loosening

the bolts.

❸

:

❷

❶

3-3. Connecting the air coupler

❹

❸

❶

Connect air coupler ❶ supplied with the unit as an

accessory to air hose ❷. Then, connect the air

coupler to coupler ❸ on the main body side.

1. After having connected coupler ❶

with air cock ❹ closed, carefully

open air cock ❹ to supply air.

2. Check to be sure that the pressure

gauge of the regulator indicates 0.5

MPa.

❷

– 6 –

Page 12

3-4. Connecting the power plug

CAUTION

In order to protect against accidents caused by a ground fault or dielectric voltage, be

sure to have the adequate power plug mounted by a person who has electrical expertise. It

is also important to connect the power plug to the grounded receptacle.

:

The method to connect the product to the power source differs by the product specications. Be sure to

connect the product to the power source according to the power specications.

① For the single-phase, 220 - 240 V type product

Connect the sky-blue/brown wire of the power cord to the supply terminal (220 - 240 VAC) and the

yellow/green one to the earth terminal respectively.

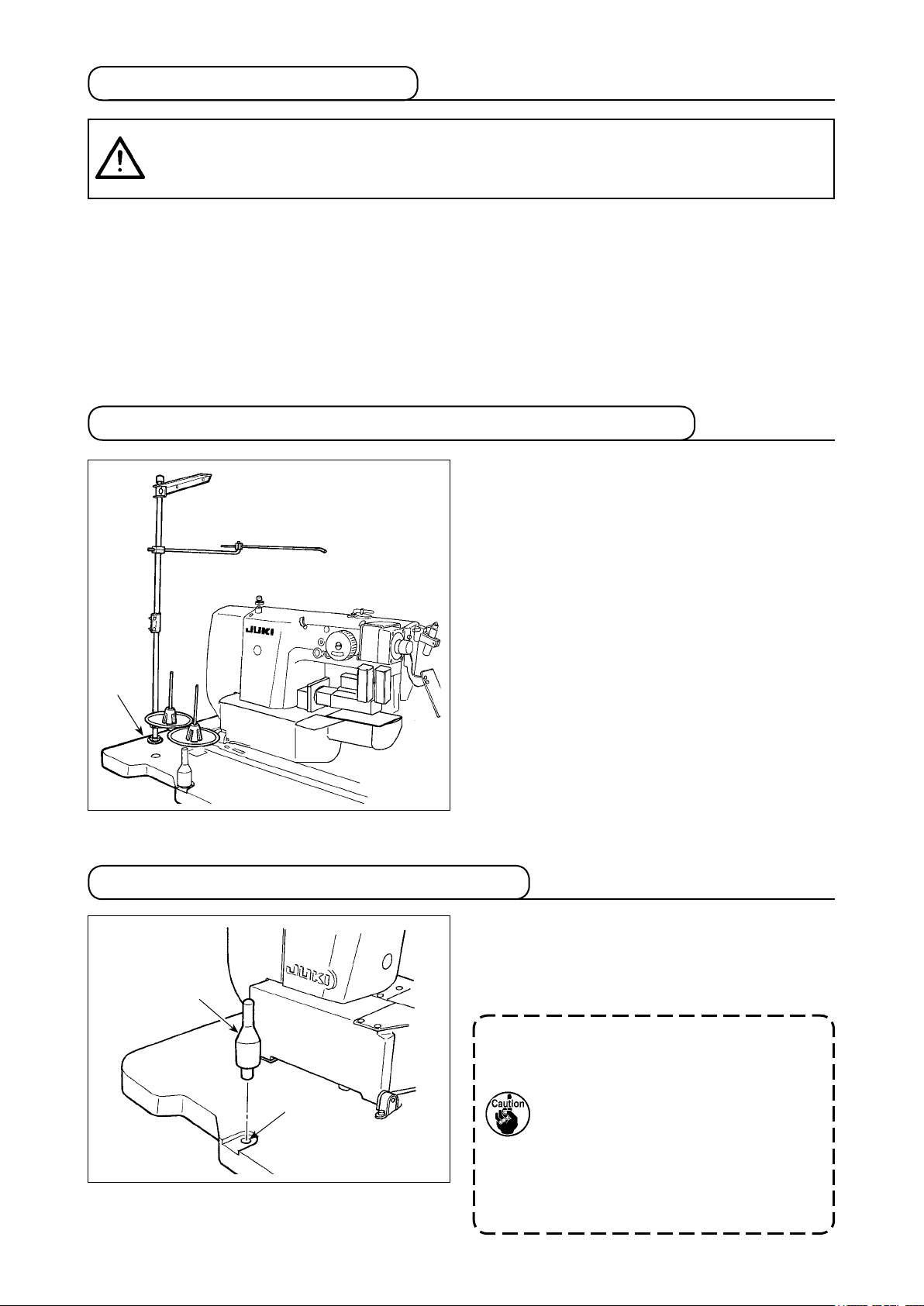

3-5. Assembling the thread stand and installing on the machine

Insert the thread stand in the hole in table ❶ and

x by fastening a washer and a nut placed on the

top and underside of table.

❶

3-6. Installing the machine head support bar

Securely mount machine head support bar includ-

ed in the accessories supplied with the unit.

Drive machine head support bar ❶ in hole ❷ in

❶

❷

the machine table.

When tilting the sewing machine, tilt

the sewing machine slowly so that no

excessive force will be applied to the

head support bar.

And when returning the sewing ma-

chine back to its original position,

be careful not to have your hand get

caught between the base and the sew-

ing machine bed.

– 7 –

Page 13

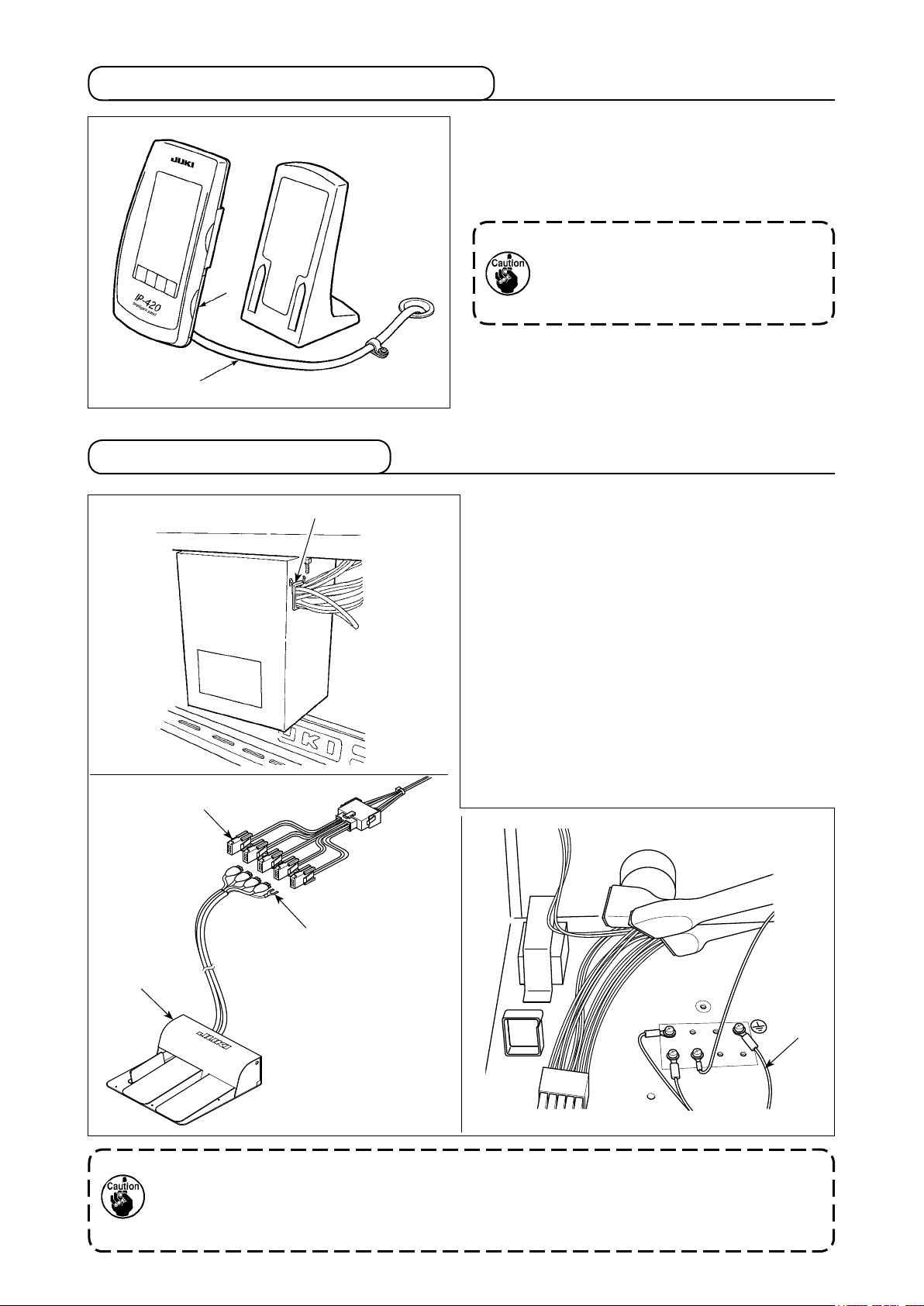

3-7. Installing the operation panel IP-420

❷

❶

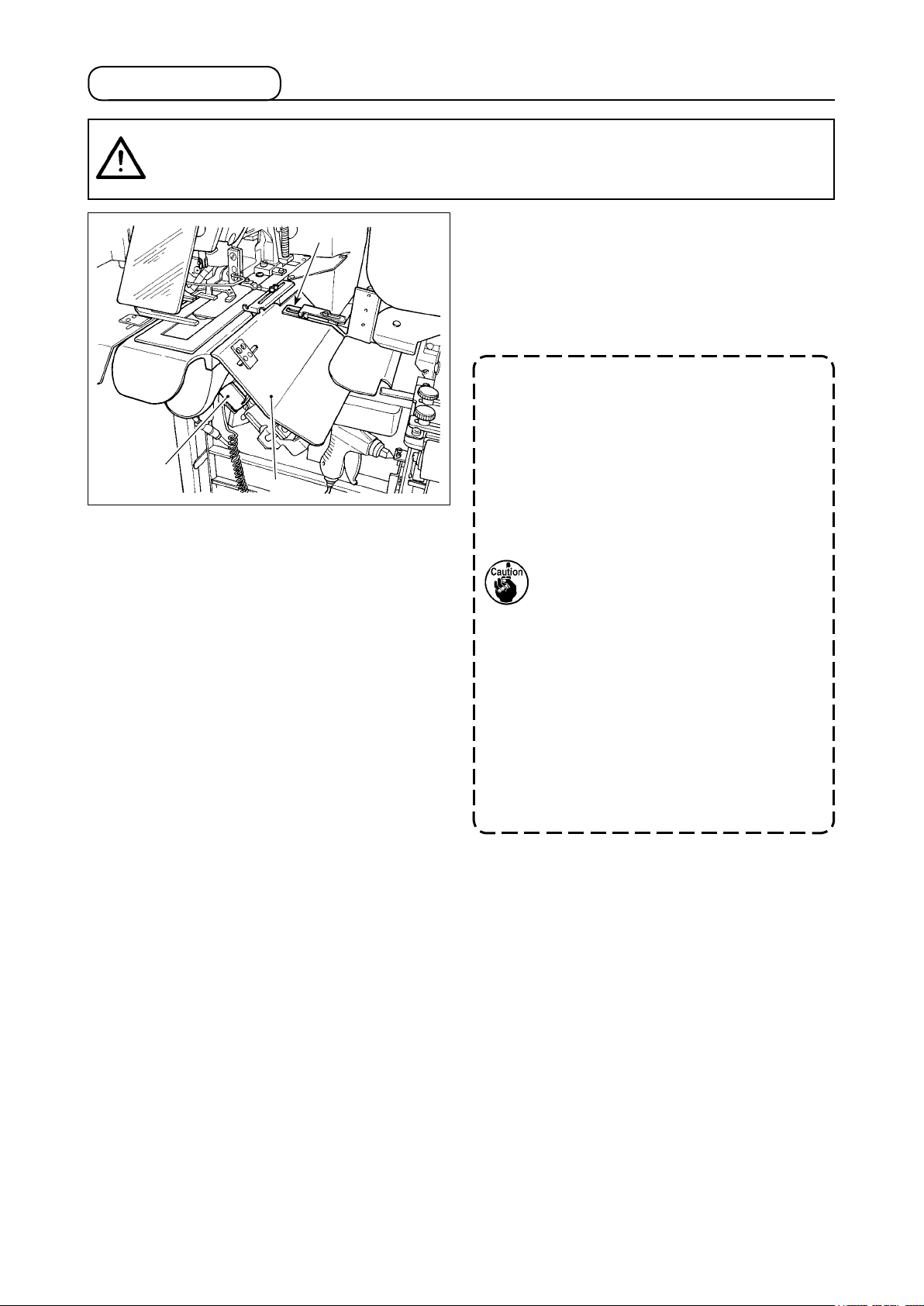

3-8. Installing the 3-pedal unit

Open the cover on right side face ❷ section of

the IP-420 and connect the connector of cable ❶

which is secured with adhesive tape on the upper

right face of the table to the IP-420.

To protect the operation panel IP-420

from malfunctioning due to static elec-

tricity, mount the operation panel on the

operation panel base.

❸

❹

❶

1) Remove cord retaining plate (17845009) ❶ which

is attached to the wiring draw-out opening of the

control box.

2) Pass the cable of 3-pedal unit (GPK470010AB)

❷ into the inside of the control box through wiring

draw-out opening.

3) Connect the connectors CN1 and CN2 of 3-pedal

unit ❷ to the connectors CN2 and CN5 of junction

cable (40033875) ❸ in the written order.

4) Fix earth cable❹ of the 3-pedal unit to the inner

bottom of the control box.

5) Attach cord retaining plate ❶ to the wiring draw-

out opening of the control box.

❷

If the cable of 3-pedal unit ❹ is wrongly connected to junction cable ❸, the pedal will fail to

operate though the machine will not fail. It is necessary to connect the cables as indicated.

In addition, do not connect two remaining connectors other than connectors CN1 and CN2

of 3-pedal unit ❷.

– 8 –

❹

Page 14

3-9. Installing the additional marking light (optional)

Insert exclusive junction cable ❶ into connector

CN85 ❷ of the junction board located behind the

❷

❶

main body.

(There are three CN85 connectors including the

one used as standard. You may insert the junction

cable any of the three connectors.)

– 9 –

Page 15

4. Preparation of the sewing machine

4-1. Lubrication

CAUTION

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt

start of the sewing machine.

:

Check that the place between lower line B and up-

per line A is lled with oil. Fill there with oil using

the oiler supplied with the machine as accessories

when oil is short.

* The oil tank which is lled with oil is only for lu-

bricating to the hook portion.

It is possible to reduce the oil amount when the

sewing speed used is low and the oil amount in

A

B

the hook portion is excessive. (Refer to

Amount of oil supplied to the hook" p.112

1. Do not lubricate to the places other

than the oil tank and the hook of Cau-

tion 2 below. Trouble of components

will be caused.

2. When using the sewing machine for

the rst time or after an extended

period of disuse, use the machine

after lubricating a small amount of oil

to the hook portion. (Refer to "III.1-3.

Adjusting the needle-to-shuttle rela-

tion" p.109.)

"III.1-10.

.)

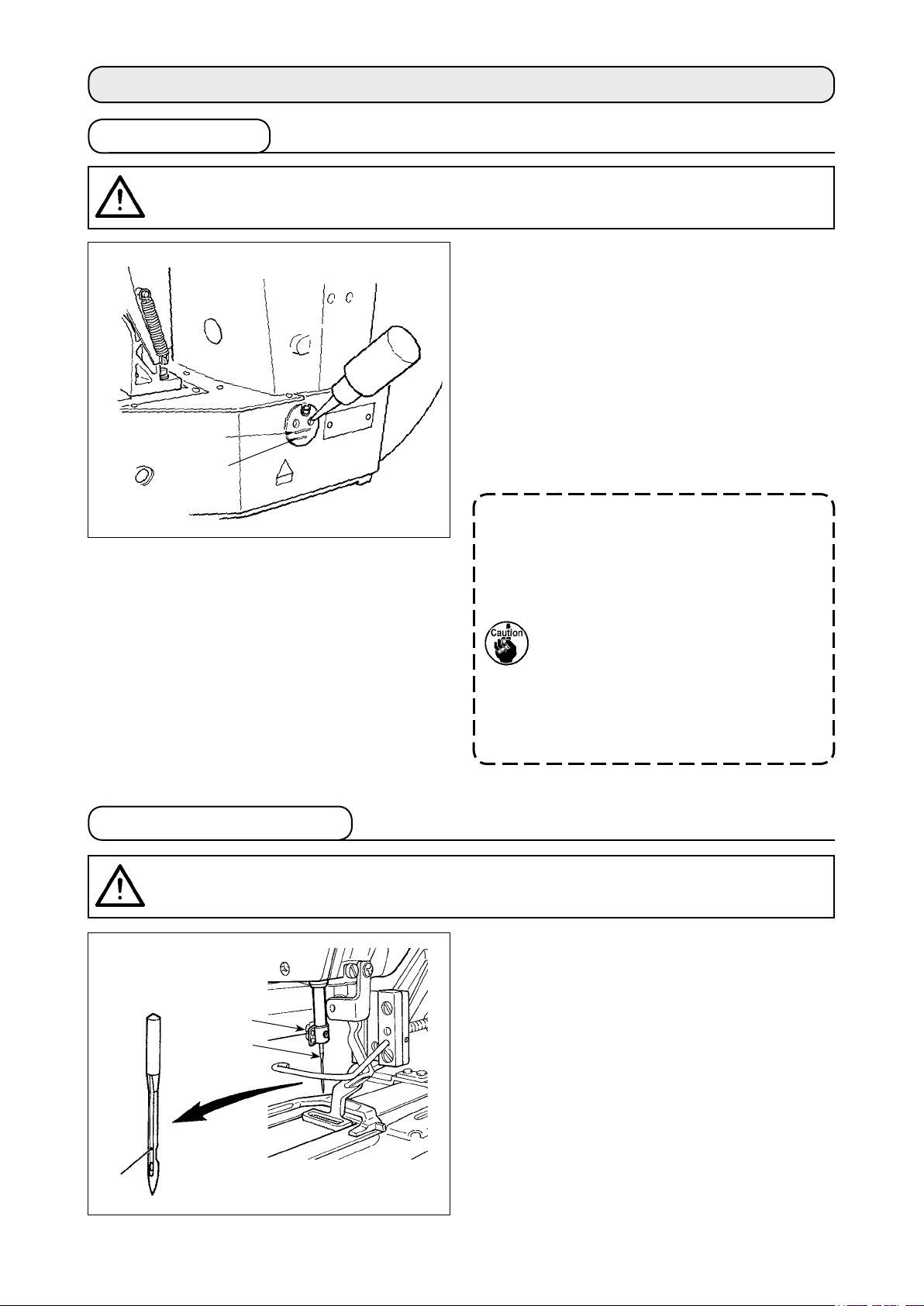

4-2. Attaching the needle

CAUTION

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt

start of the sewing machine.

❸

:

❶

❷

Loosen setscrew ❶ and hold needle ❷ with the

long groove facing ❸ toward you. Then fully insert

it into the hole in the needle bar, and tighten set-

screw ❶.

– 10 –

Page 16

4-3. Threading the machine head

CAUTION

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt

start of the sewing machine.

:

❶

❷

Draw the thread after having threaded the needle so that approximately 4 cm thread trails from the nee-

dle eyelet.

1. When you use silicon oil, pass the thread through silicon-thread thread guide ❶. (Sili-

con-thread thread guide is an optional part.)

2. Wind thread on needle clamp thread guide ❷ to form an S-shape as shown in the gure

given above in order to ensure stable sewing and thread trimming.

4-4. Installing and removing the bobbin case

CAUTION

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt

start of the sewing machine.

:

1) Open hook cover ❶.

❸

2) Raise latch ❸ of bobbin case ❷, and remove

the bobbin case.

3) When installing the bobbin case, fully insert it into

the hook shaft, and close the latch.

❷

❶

If it is not fully inserted, bobbin case ❷

may slip off during sewing.

– 11 –

Page 17

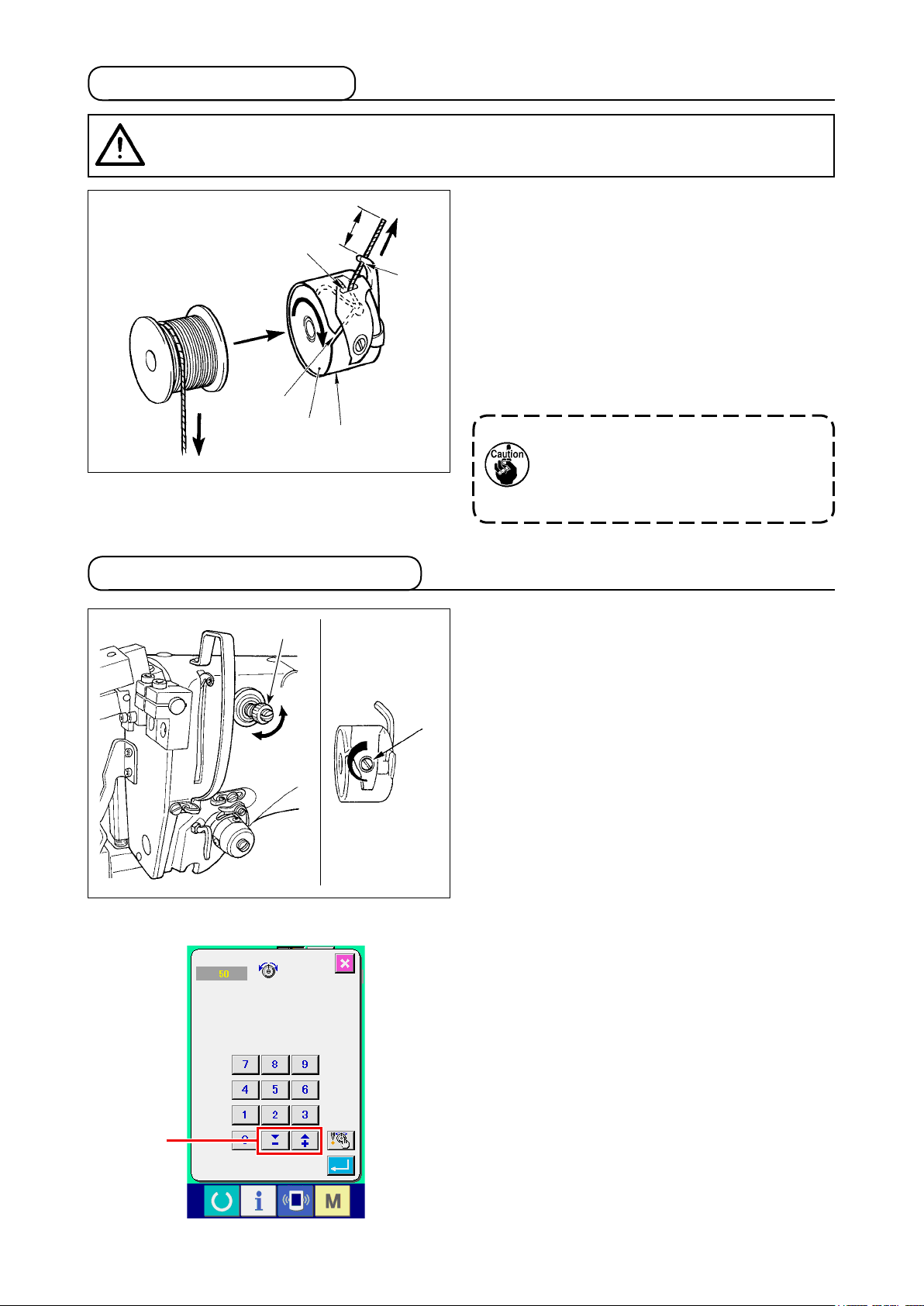

4-5. Installing the bobbin

CAUTION

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt

start of the sewing machine.

:

2.5 cm

❹

❸

❶

❷

4-6. Adjusting the thread tension

❺

1) Set the bobbin ❶ into bobbin case ❷ in the

direction shown in the gure.

2) Pass the thread through thread slit ❸ of bobbin

case ❷, and pull the thread as it is. By so doing,

the thread will pass under the tension spring and

be pulled out from thread hole ❹.

3) Pass the thread through thread hole ❺ of the

horn section, and pull out the thread by 2.5 cm

from the thread hole.

If the bobbin is installed in the bobbin

case orienting the reverse direction, the

bobbin thread pulling out will result in

an inconsistent state.

❶

Long

Short

Adjusting the needle thread tension

❷

If thread tension controller No. 1 ❶ is turned

clockwise, the length of remaining thread on the

needle after thread trimming will be shorter. If it is

turned counterclockwise, the length will be longer.

Shorten the length to an extent that the thread is

not slipped off.

(The standard length of thread remaining on the

needle is approximately 4 cm.)

The needle thread tension is adjustable on the

operation panel. The bobbin thread tension is ad-

justable by means of ❷.

The needle thread tension to be applied to the

bartacking sections can be set by means of thread

tension setting button A on the operation panel.

A

– 12 –

Page 18

4-7. Adjusting the thread take-up spring

The standard stroke of thread take-up spring ❶ is

10 to 11 mm, and the pressure at the start is 0.5

to 0.6 N.

❶

1) Adjusting the stroke

Loosen setscrew ❷, and turn thread tension asm.

❹

❸.

Turning it clockwise will increase the moving

amount and the thread drawing amount will in-

❸

❷

crease.

2) Adjusting the pressure

To change the pressure of the thread take-up

spring, insert a thin screwdriver into the slot of

thread tension post ❹ while screw ❷ is tightened,

and turn it. Turning it clockwise will increase the

pressure of the thread take-up spring. Turning it

counterclockwise will decrease the pressure.

4-8. Example of the thread tension

When using the sewing machine for the rst time, adjust the thread tension referring to the table below.

Thread Material

Nylon bonded thread #40 Sports shoes material 60 to 65 10 mm [13 mm] 0.5 N

Needle thread

tension setting

Thread take-up spring

moving amount

[Thread drawing amount]

Strength

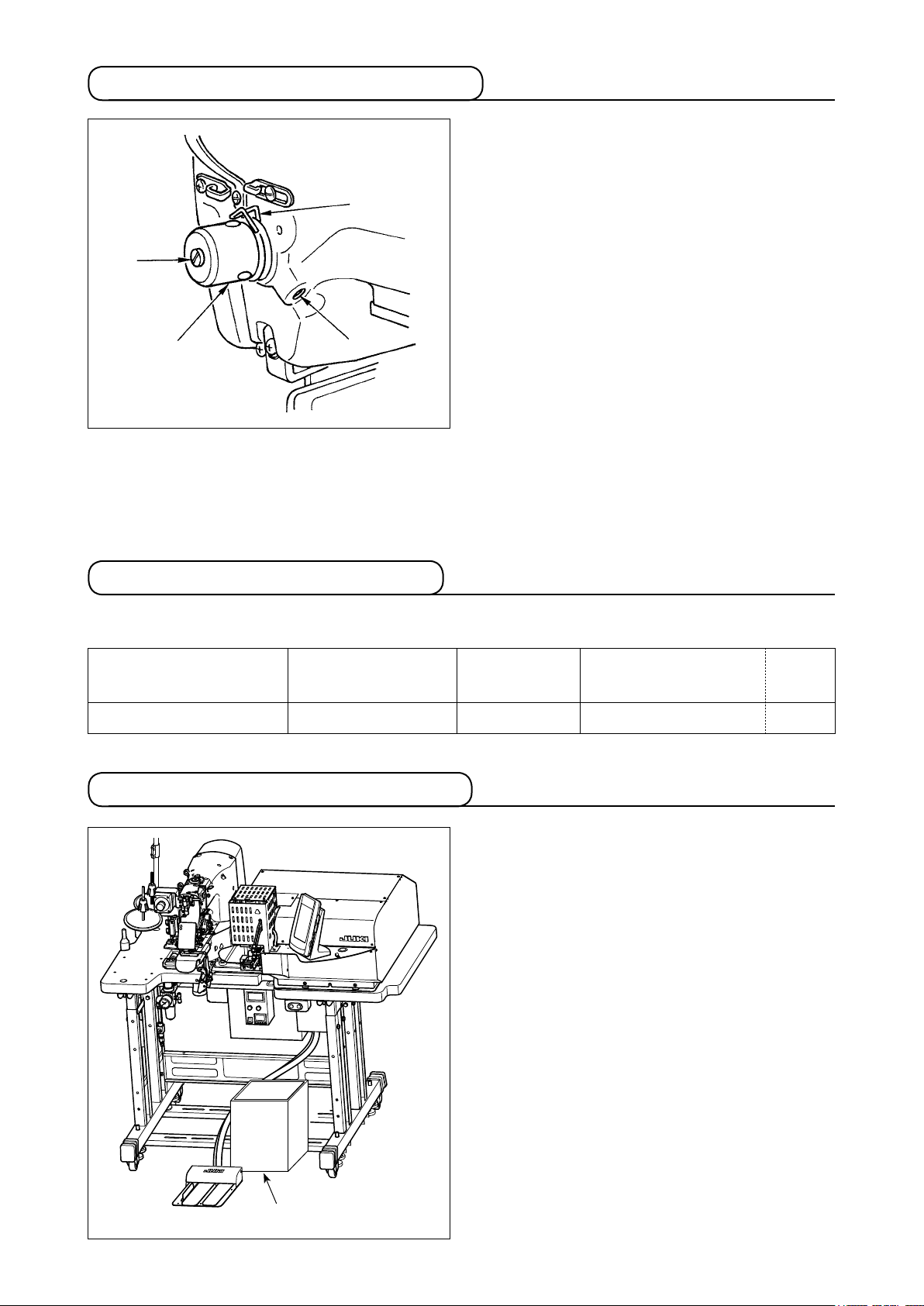

4-9. Installing the ejected loop receiver

The loop feeder unit ejects the rst loop before start-

ing sewing in order the ensure the predetermined

cutting length. Install a large collection box for col-

lecting ejected loops.

Loop collection box

– 13 –

Page 19

5. Operating the sewing machine

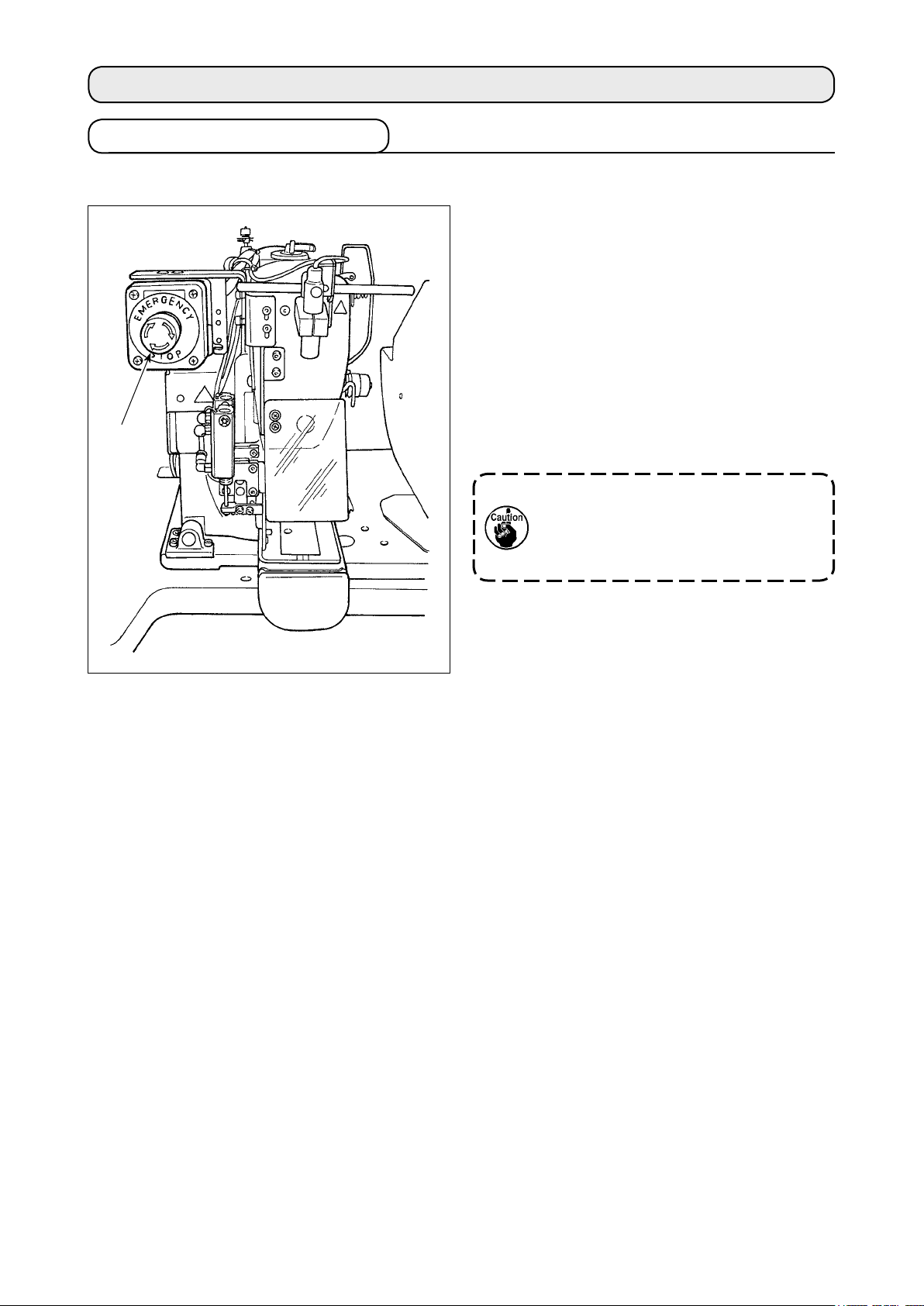

5-1. Emergency stop switch

(1) Method for operating the emergency stop switch

Emergency stop switch ❶ is mounted on the up-

per left section of the sewing machine head.

Emergency stop switch ❶ is turned ON by strong-

ly pressing in the red button. It is turned OFF by

turning it counterclockwise.

If you turn ON emergency stop switch ❶ while the

machine is in operation, the power is turned OFF

to cause the machine to stop operation.

At this time, the loop cutting operation as well as

❶

the loop feeding switch of the heat cutter also

stop.

If you turn OFF emergency stop switch

❶ with the power switch remained ON,

the power is re-turned ON. Take care of

abrupt re-turn ON of the power.

To turn OFF the power for any purpose other than

an emergency stop, operate the power switch.

(2) Precautions with the emergency stop switch

When emergency stop switch ❶ stays ON, the sewing machine cannot be powered up even if you turn

ON/OFF the power switch. The work clamp foot of the sewing machine may depress the loop clamp or

the loop loosening rod according to the operation timing of emergency stop switch ❶. If this phenome-

non occurs, turn OFF the power to the sewing machine and manually lift the work clamp foot of the sew-

ing machine to move it so as to avoid interference. Then, re-turn ON the power to the sewing machine.

– 14 –

Page 20

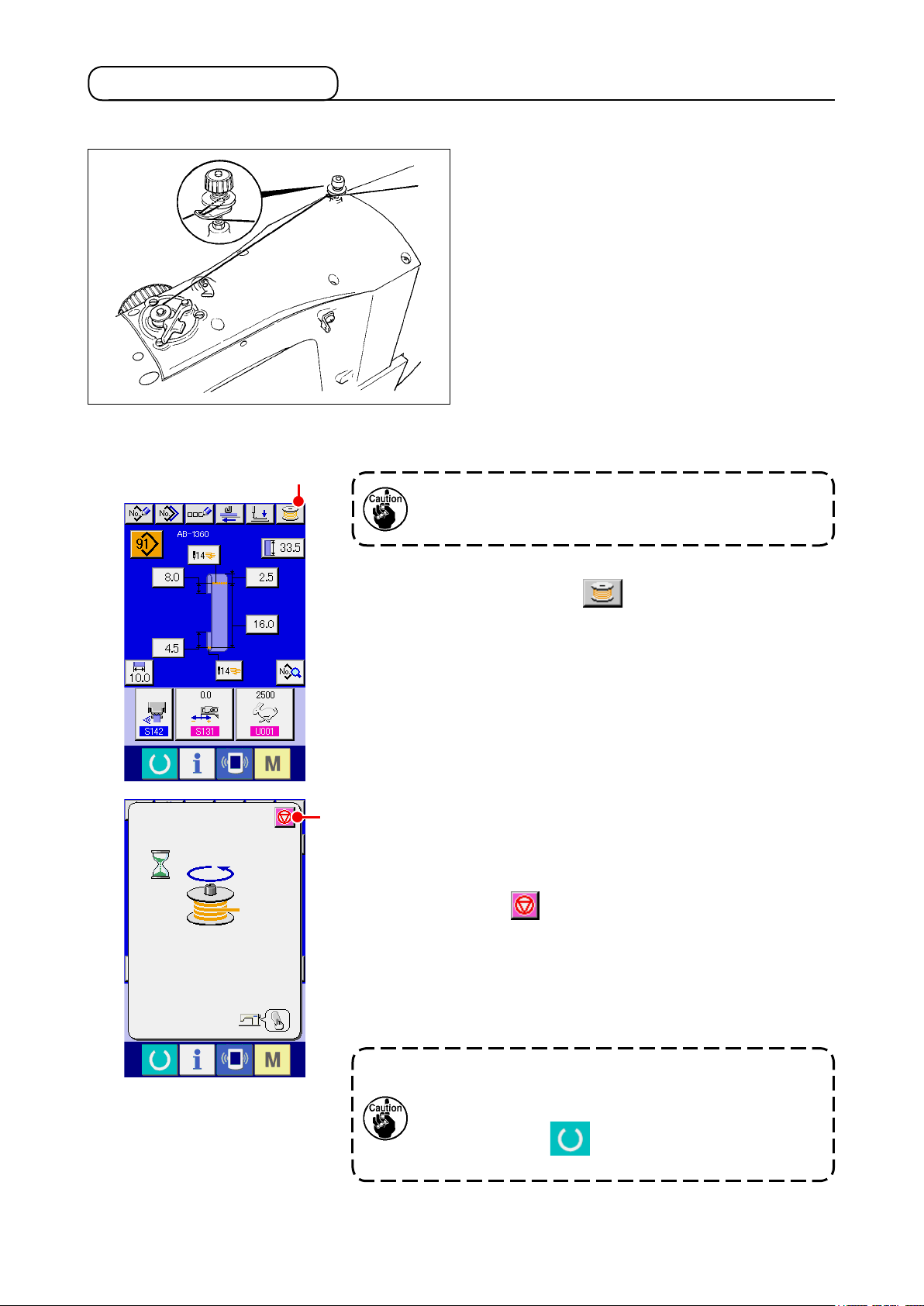

5-2. Winding a bobbin

(1) To wind a bobbin while the sewing machine is performing sewing

Thread the bobbin winder and wind the bobbin

thread onto the bobbin as illustrated in the gure.

(2) To wind a bobbin independently

A

In the case you only want to carry out bobbin winding

on the sewing machine, unthread the needle and remove

the bobbin from the hook.

① Displaying the bobbin thread winding screen

Press bobbin winding button A on the shoelace loop data

input screen (blue), and the bobbin winding screen appears on

the screen.

② Starting bobbin winding

B

Press the start switch, and the sewing machine rotates to start

bobbin winding.

③ Stopping the sewing machine

Press stop button B, and the sewing machine stops and

returns to the normal mode. If you press the start switch again

during bobbin winding, the sewing machine stops under the bob-

bin winding mode. If you press the start switch again in this state,

the sewing machine re-starts bobbin winding. Use this operating

procedure when you want to wind thread on two or more bobbins.

The bobbin winding will not start immediately after

turning the power ON. To activate the bobbin winding

function, set a pattern number or the like rst, then press

the set ready key to invoke the sewing screen. In

this state, the bobbin winding function is enabled.

– 15 –

Page 21

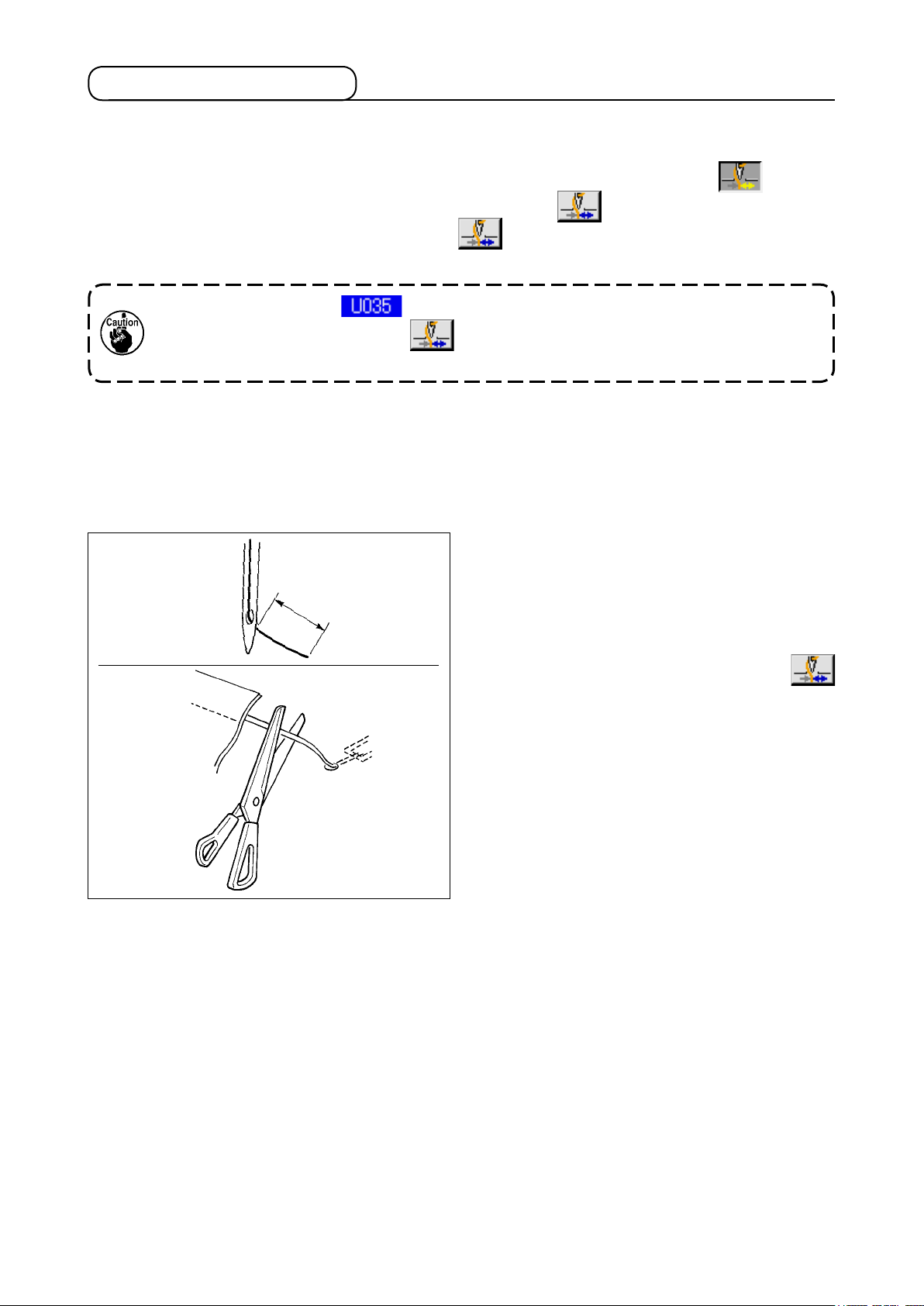

5-3. Thread clamp device

Trouble of sewing (slip-off of needle thread, stitch skipping, or stain of needle thread) at the time of high-

speed start can be prevented with the thread clamp device.

The thread clamp device will operate when the thread clamp button has been selected , but it will

not operate when the thread clamp button has not been selected .

Changeover of ON/OFF motion is performed with key. When the thread clamp device is in the

OFF state, the sewing machine is automatically set to the soft-start mode.

1. When memory switch is "1" (prohibited), the thread clamp does not work. Fur-

thermore, the thread clamp key will not be displayed.

2. Memory switch, refer to "II.2-26. How to change the memory switch data" p.75.

* Matters that demand special attention when using the needle thread clamp

(1) In case of with the needle thread clamp (motion), make shorter the length of needle thread remaining on

the needle at the sewing start for use. When the length of needle thread is lengthened, needle thread

on the wrong side of material is apt to protrude. In addition, when the length is excessively lengthened,

the end of needle thread held by the needle thread clamp may be rolled in the seams.

1)

1) In case of with the needle thread clamp, the

standard of the length of needle thread is 33 to

36 mm.

33 to 36 mm

2) When needle thread is long after replacing thread

or the like or sewing while holding needle thread

3)

by hand, turn OFF the THREAD CLAMP

key.

3) When the needle thread held with the thread

clamp is rolled in the seams, do not draw the

material forcibly and cut the connecting needle

thread with the scissors or the like. The seams

are not damaged since it is the needle thread at

the sewing start.

(2) It is possible to adjust needle thread shorter by making the needle thread clamp work while holding the

stabilized sewing at the start of sewing and the gathering (bird's nest) of needle thread on the wrong

side of material can be lessened. However, for the pattern which the stitch length for neatly rolling in

needle thread is short, needle thread may protrude from the wrong side of material.

In addition, thread waste could accumulate around the hook due to thread trimming when the thread

clamp device is used. Be sure to periodically clean inside the hook cover referring to "II.1-12. Cleaning

inside the hook cover" p.113.

– 16 –

Page 22

5-4. Placing a shoelace loop

❸

❹

❷

❶

Pass the loop through guide ❶, pull up lever ❷ at

the roller section and insert the loop under roller ❸.

When you route the shoelace loop

under the gear, insert it until it appears

from the loop cutting knife.

* When the heat cutter controller power is ON, a

shoelace loop is fed by means of the motor by

pressing loop feeding switch ❹ of the heat cutter

controller is pressed.

When the machine is used under a high

shoelace loop tension, the entire length

of the fed shoelace loop is shortened.

In such a case, malfunctions such that

the shoelace of the predetermined

length cannot be sewn or that the shoe-

lace loop cut edge is not

straight can occur. To prevent those malfunctions,

it is necessary to adjust

the shoelace loop tension

adequately.

5-5. Adjusting the shoelace loop tension

When you have changed the shoelace loop, you need to re-adjust

A

the shoelace loop tension without exceptions.

Press the shoelace loop tension button A on the sewing

screen.

The more the shoelace loop tension is adjusted in a negative direction, the less the shoelace loop tension becomes. (The shoelace loop tension can be set and stored in memory on a sewing-pattern by sewing-pattern basis.)

As a guide, adjust the shoelace loop tension so that the entire

length of the shoelace loop fed from the shoelace loop feeding

section and clamped at the loop clamping section is shorter than

the entire shoelace loop length displayed when selecting a sewing pattern by approximately 1 mm.

To change the shoelace loop length after the aforementioned

adjustment, nely adjust the feed length so that the entire loop

length as shown in the relevant sewing pattern is achieved, refer-

ring to in

p.72

.

If the sewing machine is operated under a high shoelace loop tension, the entire length

of the shoelace loop fed becomes shorter than required. In this case, problems such that

the shoelace loop cannot be sewing at the predetermined length or that the cut end of the

shoelace loop is not straight can occur. To prevent such problems, adjust the shoelace loop

tension adequately.

– 17 –

Page 23

5-6. Method for changing the loop width

❶

❷

A

1) To change the loop width, loosen setscrew ❷ of

left-side shoelace loop guide ❶ and adjust the

guide width so that it matches the shoelace loop

width. Lightly pressing guide ❶ against shoelace

loop, adjust guide ❶ to allow the shoelace loop

smoothly pass through the guide with no lateral

play.

The right-side shoelace loop guide is

used as an across-the-width reference.

So, it is not necessary to adjust it every

time the loop width is changed. How-

ever, adjust the guide position in the

similar matter as described above if the

lateral position of shoelace loop does

not align with the reference.

2) Enter a value of shoelace loop width into shoe-

lace loop width setting section A on the opera-

tion panel screen. At the same time, change the

dimensions of a seam for attaching a shoelace

loop. Refer to "II.2-5. How to change the shoe-

lace loop length" p.32 for the method for

changing the seam dimensions.

If the bartacking width of which is ex-

tremely wider than the shoelace loop

width setting specified through the

operation panel is sewn, the garment

body presser and the loop clamp can

interfere with each other (error No.

M596). If the alarm is given, change the

bartacking width setting to decrease the

bartacking width.

– 18 –

Page 24

5-7. Start switch

CAUTION

When you press the start switch, the garment body presser comes down. At the same

time, the loop clamp moves toward the sewing machine at a high speed. Take added care

to keep your hands away from the loop clamp during work.

:

Once you have completed preparation for sewing,

❷

you can bring the sewing machine into operation

by pressing start switch ❶.

When the loop clamp ❷ has clamped the shoe-

lace loop, operation of the start switch ❶ will be

accepted.

1. Operate the sewing machine taking

care not to allow your hands move

above safety cover ❸ since the

hands can interfere with the loop

❶

❸

2. If you do not keep the start switch

3. You may also press the start switch

clamp.

held pressed for a sufciently long

time, sewing will be interrupted. Be

sure to keep the start switch fully

held pressed.

while the loop clamp clamps the

shoelace loop and travels to the

standby position after the comple-

tion of sewing. In that case, the loop

clamp will not stop at the standby

position but will move directly to

the sewing position to start the next

sewing. Be sure to exercise added

care during this procedure.

– 19 –

Page 25

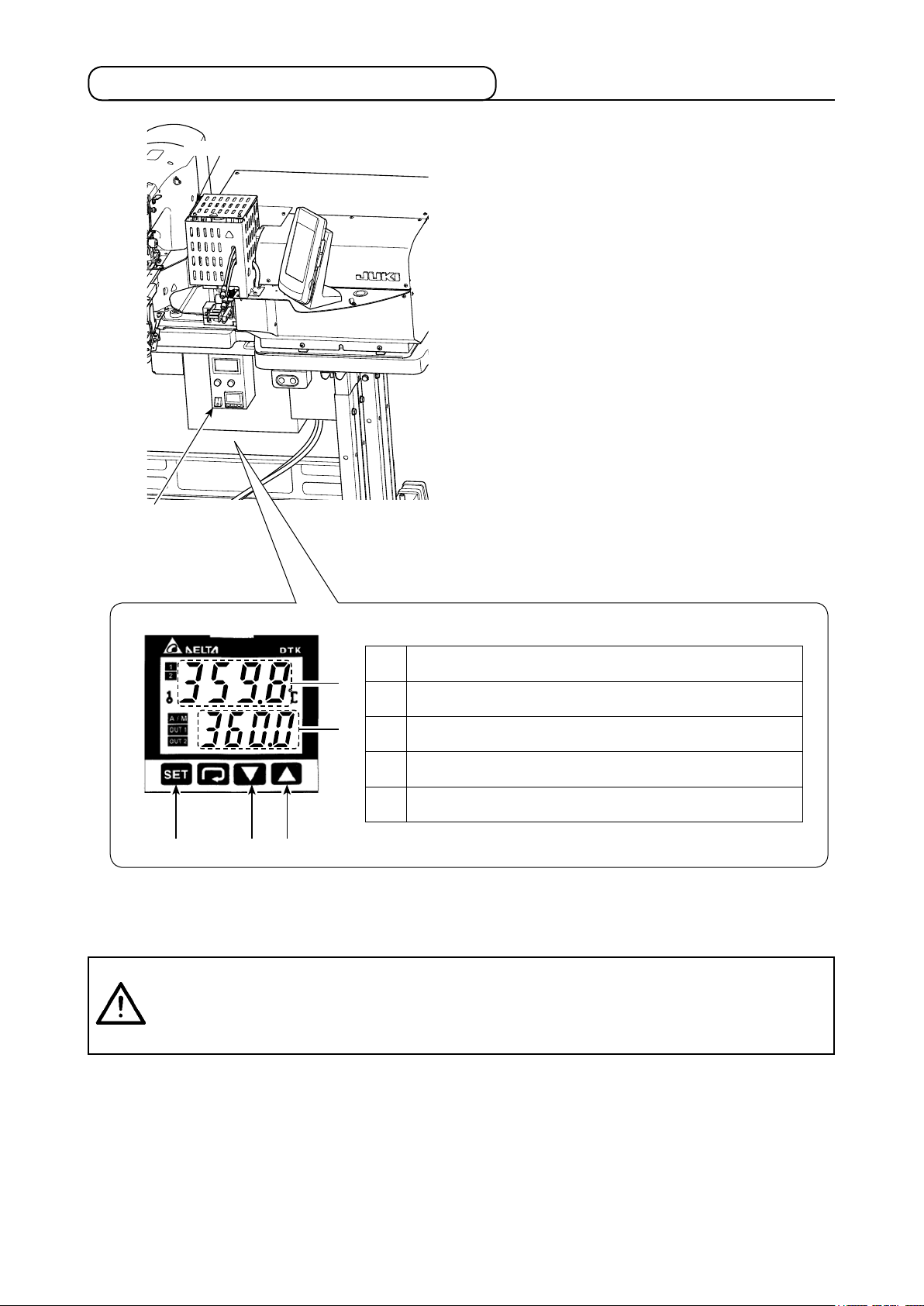

5-8. Adjusting the heat cutter temperature

Heat cutter

Heat cutter controller

It is necessary to adjust the heat cutter tempera-

ture so that it can cut the shoelace loop to be

sewn. (Standard temperature: 360 °C)

Gradually raise the heat cutter temperature while

carrying out trial stitching the shoelace loop to be

sewing until the heat cutter is hot enough to cut

the shoelace loop and weld the cut end without

fail. If the temperature is raised excessively high,

the loop cut end will melt and cut thread waste will

be likely to be produced. In such a case, lower the

heat cutter temperature.

Preset temperature increases.

❶

❹

❸

❷❺ ❶

Preset temperature decreases.

❷

Preset temperature is displayed.

❸

Actual temperature of the cutter section is displayed.

❹

Preset temperature is conrmed.

❺

Adjustment of temperature is carried out on the heat cutter controller panel.

Set the temperature with buttons ❶ and ❷ and conrm the setting with button ❺.

CAUTION

When the temperature indication is displayed on the heat cutter controller panel, the

heater built in the heat cutter is in the heated state.

The temperature of the heat cutter is very high. Be sure to keep your body from the heat

cutter so as to prevent a burn.

:

– 20 –

Page 26

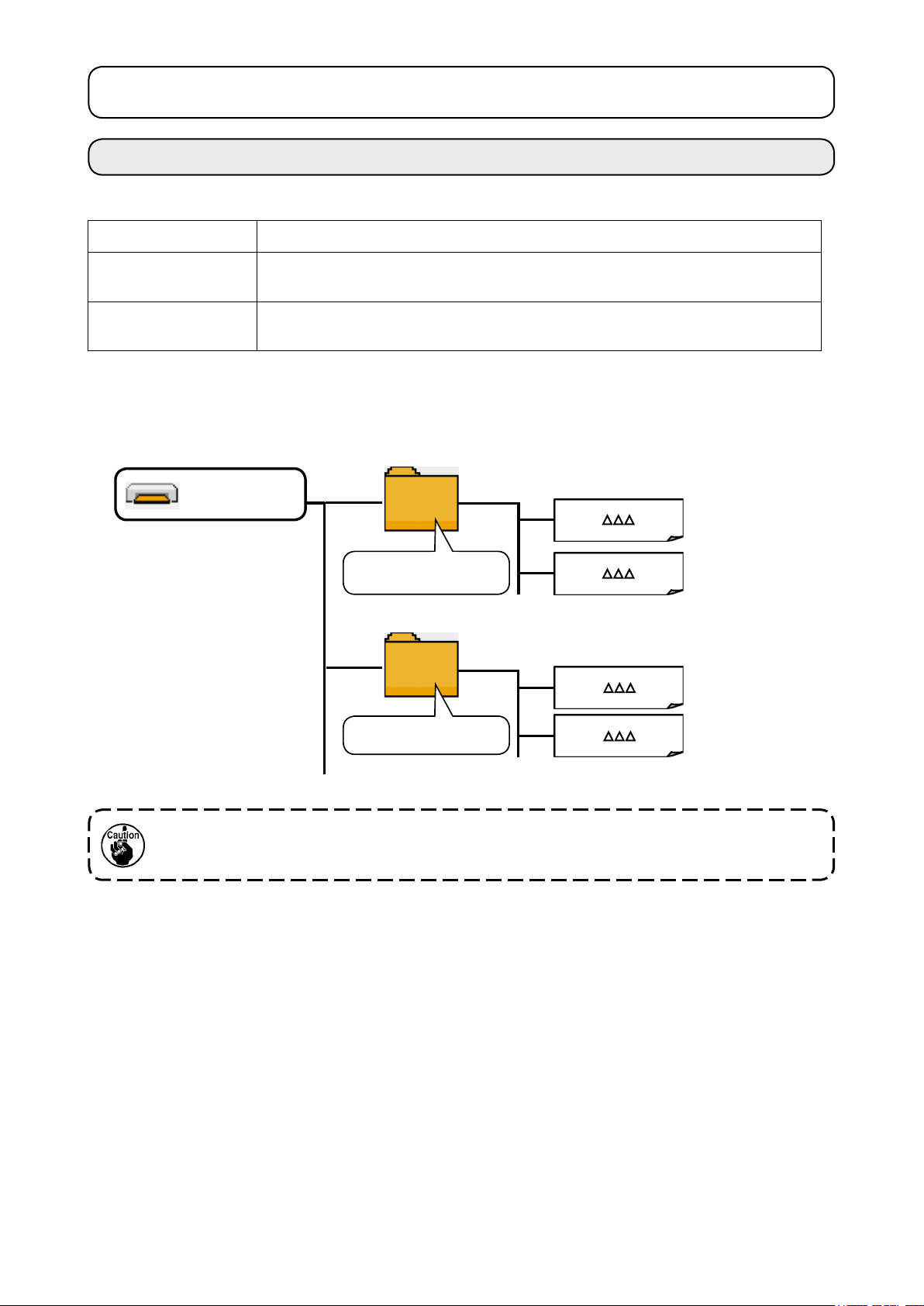

II. OPERATION (OPERATION PANEL)

1. Introduction

1) Type of sewing data handled by the IP-420

Pattern name Description

Vector format data File that extension is “.VDT”

Read from media. Max. 999 patterns can be used.

Sewing data File that extension is “.EPD”

Read from media. Max. 999 patterns can be used.

2) Folder structure of the media

Store each le in the directories below of the media.

Media drive

VD ATA

Store vector format

data.

AB-1351

Store sewing data.

VD00 .VDT

VD00 .VDT

AB00 .EPD

AB00 .EPD

Vector format data:

Store in /VDATA.

Sewing data:

Store in /AB-1351.

1. Data that are not stored in the directories above cannot be read. So, be careful.

2. Be aware that the AB-1360 is not able to read the data of the AB-1351 (for belt-loop attaching).

– 21 –

Page 27

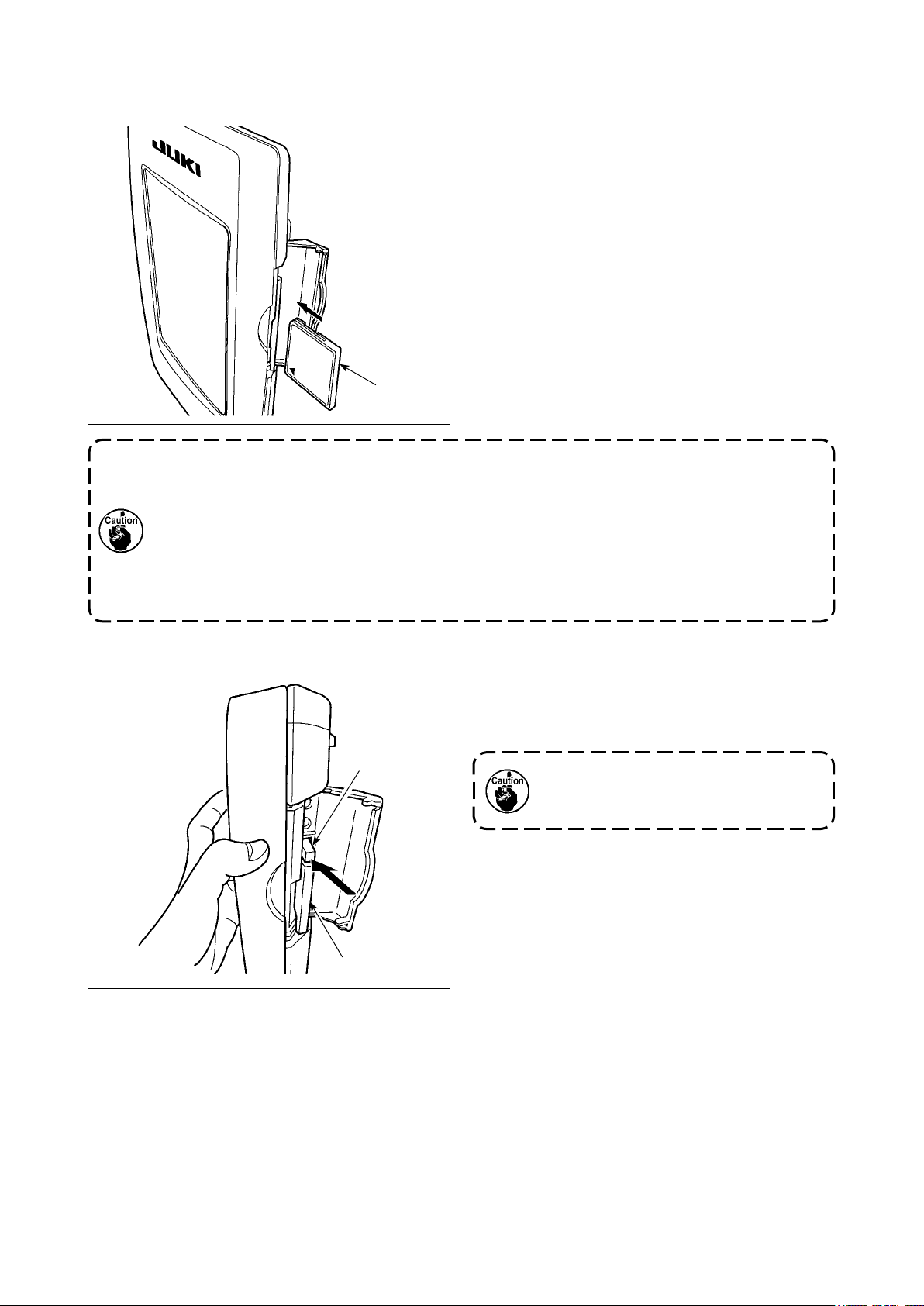

3) CompactFlash (TM)

Inserting the CompactFlash (TM)

■

1) Turn the label side of the CompactFlash (TM)

to this side (place the notch of the edge to the

rear.) and insert the media that has a small

hole to the rear.

2) After completion of setting of the media, close

the cover. By closing the cover, it is possible

to access. If the media and the cover come in

contact with each other and the cover is not

closed, check the following matters.

• Check that the media is securely pressed

until it goes no further.

Media

• Check that the inserting direction of the media

is proper.

1. When the inserting direction of the media is wrong, panel or media may be damaged.

2. Do not insert any item other than the CompactFlash (TM).

3. The media slot in the IP-420 accommodates to the CompactFlash (TM) of 2GB or less.

4. The media slot in the IP-420 supports the FAT16 which is the format of the CompactFlash (TM). FAT32 is not supported.

5. Be sure to use the CompactFlash (TM) which is formatted with IP-420. For the formatting procedure of the CompactFlash (TM), see "II-2-30. Performing formatting of the

media" p.86.

Removing the CompactFlash (TM)

■

❷

❶

1) Hold the panel by hand, open the cover, and

press the media removing lever ❶. The media

is eject.

❷

When the lever ❶ is strongly pressed,

the media ❷ may be broken by protruding and falling.

2) When the media ❷ is drawn out as it is, removing is completed.

– 22 –

Page 28

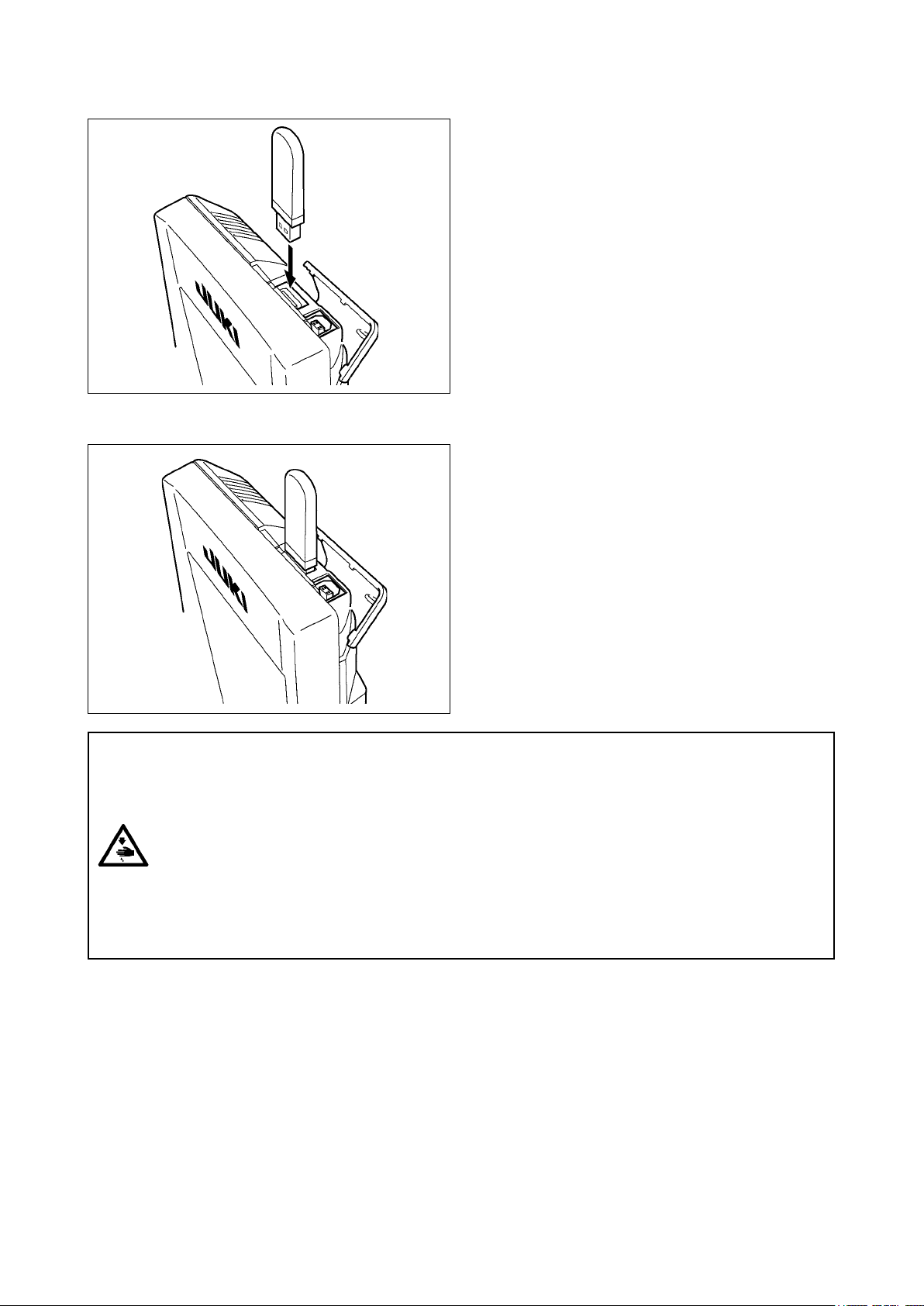

5) USB port

Inserting a device into the USB port

■

Disconnecting a device from the USB port

■

Slide the top cover and insert the USB device into

the USB port. Then, copy data to be used from the

USB device onto the main body.

After completion of copying the data, remove the

USB device.

Remove the USB device. Put the cover back in

place.

Cautions when using the media

• Do not wet or touch it with wet hands. Fire or electric shock will be caused.

• Do not bend, or apply strong force or shock to it.

• Never perform disassembling or remodeling of it.

• Do not put the metal to the contact part of it. Data may be disappeared.

• Avoid storing or using it in the places below.

Place of high temperature or humidity

Place of dew condensation

Place with much dust

Place where static electricity or electrical noise is likely to occur

– 23 –

Page 29

Precautions to be taken when handling USB devices

①

• Do not leave the USB device or USB cable connected to the USB port while the sewing machine is

in operation. The machine vibration can damage the port section resulting in loss of data stored on

the USB device or breakage of the USB device or sewing machine.

• Do not insert/remove a USB device during reading/writing a program or sewing data.

It may cause data breakage or malfunction.

• When the storage space of a USB device is partitioned, only one partition is accessible.

• Some type of the USB device may not be properly recognized by this sewing machine.

• JUKI does not compensate for loss of data stored on the USB device caused by using it with this

sewing machine.

• When the panel displays the communication screen or pattern data list, the USB drive is not recog-

nized even if you insert a medium into the slot.

• For USB devices and media such as CF(TM) cards, only one device/medium should be basically

connected/inserted to/into the sewing machine. When two or more devices/media are connected/

inserted, the machine will only recognize one of them. Refer to the USB specications.

• Insert the USB connector into the USB terminal on the IP panel until it will go no further.

• Do not turn the power OFF while the data on the USB ash drive is being accessed.

USB specications

②

• Conform to USB 1.1 standard

• Applicable devices *1 ������Storage devices such as USB memory, USB hub, FDD and card

reader

• Not-applicable devices ����� CD drive, DVD drive, MO drive, tape drive, etc.

• Format supported ��������FD (oppy disk) FAT 12

Others (USB memory, etc.), FAT 12, FAT 16, FAT 32

• Applicable medium size ����FD (oppy disk) 1.44MB, 720kB

Others (USB memory, etc.), 4.1MB ~ (2TB)

• Recognition of drives ������For external devices such as a USB device, the device which is

recognized rst is accessed. However, when a medium is connected

to the built-in media slot, the access to that medium will be given the

highest priority. (Example: If a medium is inserted into the media slot

even when the USB memory has already been connected to the USB

port, the medium will be accessed.)

• Restriction on connection ��� Max. 10 devices (When the number of storage devices connected to

the sewing machine has exceeded the maximum number, the 11th

storage device and beyond will not be recognized unless they are

once disconnected and re-connected. )

• Consumption current ������ The rated consumption current of the applicable USB devices is 500

mA at the maximum.

*1: JUKI does not guarantee operation of all applicable devices. Some device may not operate due to

a compatibility problem.

– 24 –

Page 30

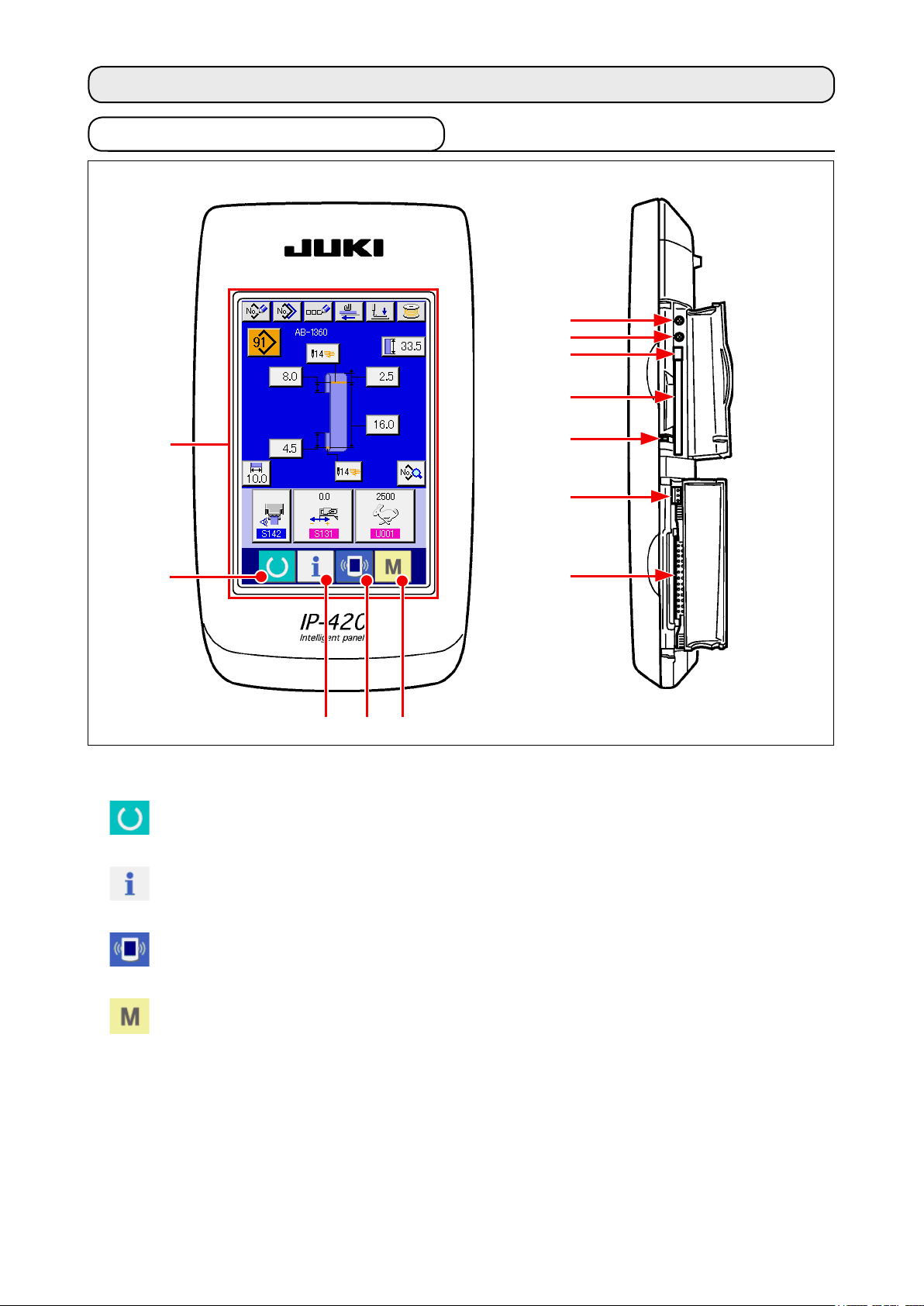

2. Method for using the operation panel

2-1. Name of each section of IP-420

①

②

(Front)

(Right side)

⑥

⑦

⑧

⑨

⑩

⑪

⑫

④ ⑤

③

Touch panel • LCD display section

①

SET READY key → Changeover of the data input screen and the sewing screen can be

②

performed.

INFORMATION key → Changeover of the data input screen and the information screen

③

can be performed.

COMMUNICATION key → Changeover of the data input screen and the communication

④

screen can be performed.

MODE key → Changeover of the data input screen and the mode changeover

⑤

screen which performs various detail settings can be performed.

Contrast control

⑥

Brightness control

⑦

CompactFlash (TM) eject button

⑧

CompactFlash (TM) slot

⑨

Cover detection switch

⑩

Connector for external switch

⑪

Connector for control-box connection

⑫

– 25 –

Page 31

2-2. Buttons to be used in common

The buttons which perform common operations in each screen of IP-420 are as follows:

CANCEL button → This button closes the pop-up screen.

In case of the data change screen, the data being

changed can be cancelled.

ENTER button → This button determines the changed data.

UP SCROLL button → This button scrolls the button or the display in the up-

ward direction.

DOWN SCROLL button → This button scrolls the button or the display in the

downward direction.

RESET button → This button performs the release of error.

NUMERAL INPUT button → This button displays ten keys and input of numerals

can be performed.

CHARACTER INPUT button → This button displays the character input screen.

→ Refer to

pattern number" p.41

PRESSER LOWERING button → Presser is lowered, and the presser lowering screen is

displayed. To lift presser, press presser lift button dis-

played in the presser lowering screen.

Bobbin winder button → Bobbin thread winding is performed.

→ Refer to

"II-2-9. How to name a shoelace loop

.

"I-5-2. Winding a bobbin" p.15

.

– 26 –

Page 32

2-3. Basic operation of IP-420

①

When the power is turned ON rst, the language selection

②

When SET READY key A is pressed, the back color of

Turn ON the power switch

screen is displayed. Set the language you use. (It is possible to

change with Memory switch ).

When ending the selection screen with CANCEL but-

ton or ENTER button without performing the

language selection, the language selection screen is

displayed whenever the power is turned ON.

Press SET READY key to move on to the sewing ready

state

LCD display is changed to green, and the sewing machine is set

to the sewing possible state.

A

– 27 –

Page 33

2-4. LCD section when the shoelace loop individual sewing is selected

(1) Shoelace loop individual sewing data entry screen

J

A

G

K

B

K

I

M

A

B C D E F

L

K

H

N

Symbol

A

B

C

D

E

F

Name of button Description

New pattern creating

button

Copy button Displays the copy source shoelace loop pattern number selection screen to allow

Character input button Displays the shoelace loop individual sewing character entry screen to allow entry

Feed button Insert a shoelace loop into the loop feeder unit and press this button to feed the

Presser lowering button The machine lowers the garment body presser and the work clamp foot and

Bobbin winding button Displays the bobbin winding screen to allow the machine to wind a bobbin.

Displays the new shoelace loop pattern number creation screen to allow registration

of new pattern data.

→ Refer to

copying of pattern data.

→ Refer to

of the name of pattern data.

→ Refer to

shoelace loop.

displays the presser lowering screen.

→ Refer to

foot" p.34

→ Refer to

"II-2-8. How to register a new shoelace loop pattern number" p.39

"II-2-11. How to copy a shoelace loop pattern number" p.44

"II-2-9. How to name a shoelace loop pattern number" p.41

"II-2-6. How to lower the garment body presser and the work clamp

.

"I-5-2. Winding a bobbin" p.15

.

.

.

.

– 28 –

Page 34

Symbol

Name of button Description

Pattern number list

G

button

Sewing data list button Displays the sewing data list screen. Detailed sewing data which is not displayed on

H

Shoelace loop width

I

button

Bartacking button Displays the LK individual data entry screen to shift to the bartacking setting mode.

J

Shoelace loop length

K

button

Shoelace loop length

L

input button

Sewing data

M

customization button

Displays the shoelace loop pattern number list screen to allow selection of pattern

data.

→ Refer to

the entry screen can be selected to edit sewing data.

Displays the shoelace loop width setting screen.

The number of buttons to be displayed on the screen differs with the sewing shape.

The number of stitches and the types of sewing shape (linear bartacking or zigzag

bartacking) will be displayed on the button.

→ Refer to

Displays the shoelace loop length setting screen. The buttons are displayed

according to the sewing shape and the settable shoelace loop length that can be

set. The number of buttons to be displayed on the screen differs with the sewing

shape.

Displays the shoelace loop length entry screen.

Displays the sewing data setting screen specied on the customization setting

screen of the data entry screen.

"II-2-10. How to select a shoelace loop pattern number" p.42

"II-2-14. How to carry out the bartacking setting" p.49

.

.

N

Symbol

A

B

Sewing data / adjustment

data customization

screen

Name of image Description

Name of shoelace loop

individual sewing data

Sewing shape display Sewing shape is displayed.

Displays the sewing data setting screen or the adjustment data setting screen

specied on the customization setting screen of the data entry screen.

Displays the name entered in the shoelace loop individual sewing data which is

currently selected.

– 29 –

Page 35

(2) Shoelace loop individual sewing screen

A

G

H

C

J

I

B C DA

E

D

E

B

F

Symbol

A

B

C

D

E

F

Name of button Description

Setback operation button Carries out the setback operation.

Next loop clamping

cancel button

Feed button When this button is pressed with a shoelace loop inserted into the loop feeder unit,

Presser lowering button The machine lowers the garment body presser and the work clamp foot and displays

Shoelace loop tension

button

Step operation button Displays the step operation selection screen and shifts to the step operation mode.

The machine carries out prohibition (cancel) or reset of loop clamping for the next

sewing.

→ Refer to

sewing" p.48

the feeder unit feeds the shoelace loop. It should be remembered, however, this

button cannot be pressed while the sewing machine is engaged in sewing or carries

out setback operation.

the presser lowering screen. It should be remembered, however, this button cannot

be pressed while the sewing machine is engaged in sewing or carries out setback

operation.

→ Refer to

foot" p.34

Displays the shoelace loop tension entry screen. At this time, the start switch action

will be prohibited.

It should be remembered, however, this button cannot be pressed while the sewing

machine performs the setback operation.

→ Refer to

"II-2-13. Function of canceling of a loop clamping for the next

.

"II-2-6. How to lower the garment body presser and the work clamp

.

"II-2-12. How to carry out the step operation" p.45

.

– 30 –

Page 36

Symbol

Name of button Description

Counter value change

G

button

Counter changeover

H

button

Direct-pattern next page

I

button

Direct pattern button Displays the shoelace loop pattern number specied on the direct pattern selection

J

Displays the current counter value on the button. When this button is pressed, the

counter value change screen is displayed.

→ Refer to

Bartacking counter display/shoelace loop counter display/bobbin thread counter

display can be changed over.

The button is displayed only in the case two or more of the aforementioned

counters are in the ON state.

: Bartacking counter

: Shoelace loop counter

: Bobbin thread counter

→ Refer to

Displays shoelace loop pattern numbers registered on the next page on J section.

screen.

"II-2-7. Using counter" p.35

"II-2-7. Using counter" p.35

.

.

Be aware that a press on this button activates the work

clamp foot and the garment body presser.

Symbol

A

B

C

D

E

Name of image Description

Shoelace loop pattern

number

Shoelace loop pattern

description

Shoelace loop width Displays the shoelace loop width which is currently set.

Name of shoelace loop

individual sewing data

Sewing speed Displays the sewing speed (set value) of the bartacking pattern which is being

Displays the shoelace loop pattern number which is currently selected.

Displays the description (sewing shape, dimensions) of the shoelace loop pattern

to be sewn.

Displays the name entered in the shoelace loop individual sewing data which is

currently selected.

sewing.

– 31 –

Page 37

2-5. How to change the shoelace loop length

(1) How to change the shoelace loop dimensions

Displaying the shoelace loop individual sewing data entry

①

screen

The shoelace loop dimensions can be changed on the shoelace

loop individual sewing data entry screen. On the sewing screen

of the shoelace loop individual sewing (green), press the set

A

B

ready key to display the shoelace loop individual sewing

data entry screen (blue).

Bringing up the shoelace loop length entry screen

②

When you press the button for the shoelace loop length you

want to change, the corresponding shoelace loop length entry

screen is displayed.

Change the shoelace loop length A as an example.

Press button A to display the shoelace loop length entry

screen.

Entering data

③

Enter a desired value with numeric keys and +/− button B.

Conrming your entry

④

Press enter button C, and the data you have entered is

C

conrmed.

* For the other shoelace loop lengths, you can change the data

following the steps of procedure described above.

The dimensions of the shoelace loop sewing shape

displayed on the operation panel are only for reference. The dimensions vary according to the shoelace

loop material. Be sure to adjust the settings of shoe-

lace loop dimensions so that your desired nished

dimensions are achieved.

– 32 –

Page 38

(2) Changing the shoelace loop length (entire length) and precautions to be taken

When you press button F, the shoelace loop length (entire

length) entry screen is displayed to allow you to change shoelace

F

loop length (entire length).

Enter the desired value with +/− button G . Then conrm your entry

with enter button H.

In the case the shoelace loop length (entire length) is

changed, the nal dimension (shoelace loop length F)

will change. So, be careful.

G

H

– 33 –

Page 39

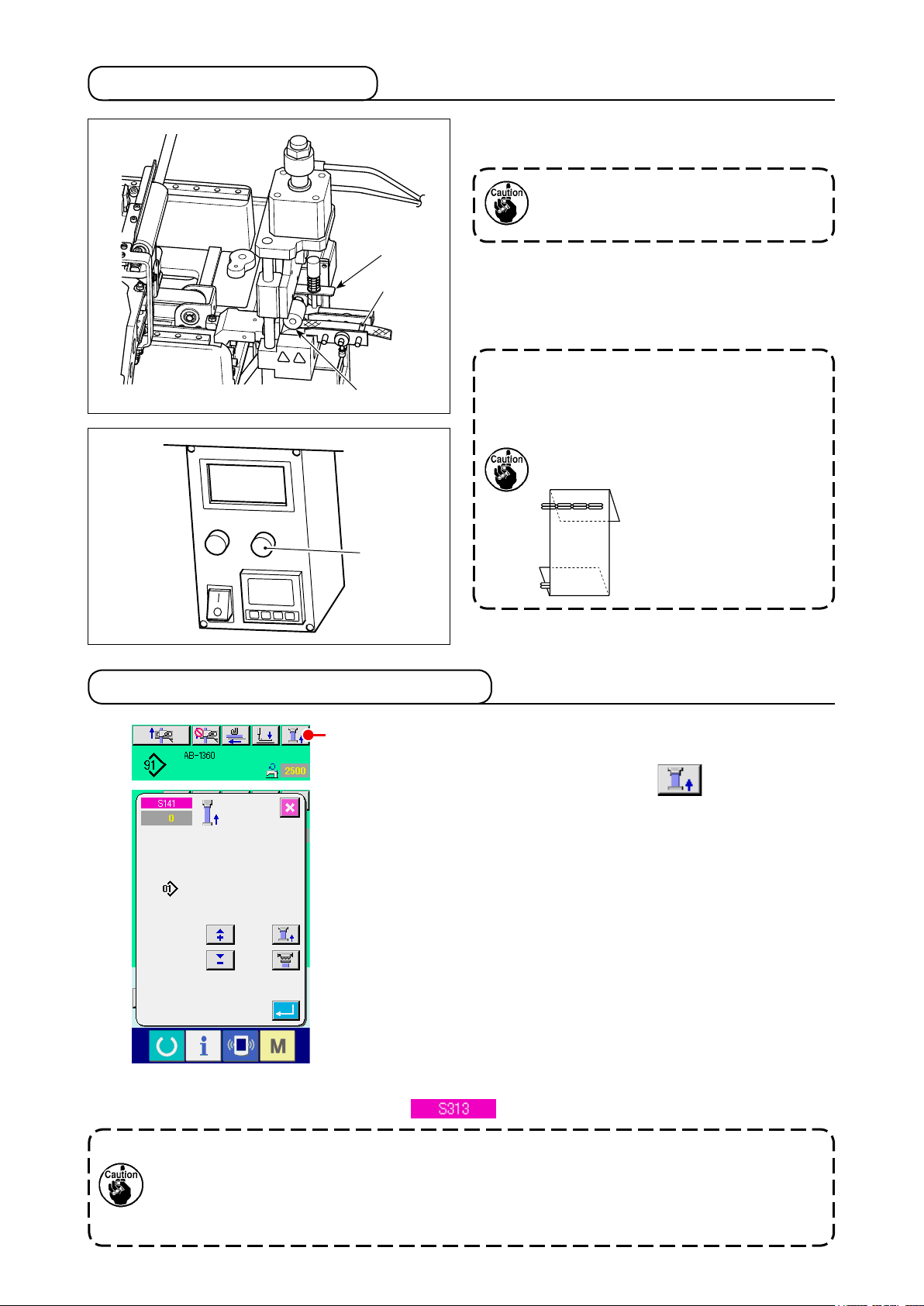

2-6. How to lower the garment body presser and the work clamp foot

A

When you press presser lowering button A on the shoelace loop individual sewing data entry screen (blue) on the sewing

screen of the shoelace loop individual sewing (green), the presser

lowering screen is displayed.

Even if you press the presser lowering button immediately after turning the power ON, the error buzzer will

sound and the presser lowering will not start.

Press set ready key to retrieve the origin to bring

up the sewing screen before pressing the presser lowering button.

When you press presser lowering button A, the sewing machine carries out the following operation and displays the presser

lowering screen.

The garment body presser comes down and moves backward.

B

The work clamp foot of the machine head comes down.

When you press presser lifting button B on the presser lowering screen, the sewing machine carries out the following opera-

tion and goes back to the entry screen (or sewing screen).

The garment body presser moves forward and goes up.

The work clamp foot of the machine head goes up.

When you press presser lowering button

or lifting button

machine head and the garment body presser operate

respectively. Take care not to allow your hands to be

caught by the garment body presser and the work

clamp foot.

, the work clamp foot of the

B

A

– 34 –

Page 40

2-7. Using counter

(1) Setting procedure of the counter

①

Display the counter setting screen

A

B

C

D

Press switch and the COUNTER SETTING button

is displayed on the screen. When this button is pressed, the

A

counter setting screen is displayed.

Selection of kinds of counters

②

This sewing machine has four different counters; i.e., the bart-

acking counter, shoelace loop counter, No. of pcs. counter and

bobbin thread counter.

E

When BARTACKING COUNTER TYPE SELECT button B,

SHOELACE LOOP COUNTER TYPE SELECT button C

or NO. OF PCS. COUNTER TYPE SELECT button D is

pressed, the corresponding counter type select screen is dis-

played. On this screen the counter type can be selected individ-

ually.

To set the bobbin thread counter, press page changeover button

F G

H

E to change over the page shown on the screen. Then,

press the bobbin thread counter type selection button F

to display the counter type selection screen.

– 35 –

Page 41

[Bartacking counter]

UP counter:

Every time the sewing machine sews a bartack, the counter

increases its current value by one. When the current value equals

to the preset value, the count-complete screen is displayed.

DOWN counter:

Every time the sewing machine sews a bartack, the counter

decreases its current value by one. When the existing value is

reached “0”, the count-up screen is displayed.

Counter disuse:

The bartacking counter does not count a nished shape even

when the machine has sewn the shape. The counter screen of the

sewing counter is not displayed.

[Shoelace loop counter]

UP counter:

Every time the sewing machine sews a shoelace loop, the counter

increases its current value by one. When the current value equals

to the preset value, the count-complete screen is displayed.

DOWN counter:

Every time the sewing machine nishes all the shoelace loops of a

garment under the cycle sewing .mode, the counter decreases its

current value by one. When the current value reaches 0 (zero), the

count-complete screen is displayed.

Counter disuse:

The shoelace loop counter does not count a nished shape even

when the machine has sewn the shape. The counter screen of the

sewing counter is not displayed.

[No. of pcs. counter]

UP counter:

Every time the sewing machine nishes all the shoelace loops of

a garment under the cycle sewing mode, the counter increases its

current value by one. When the current value equals to the preset

value, the count-complete screen is displayed.

DOWN counter:

Every time the sewing machine sews a shoelace loop, the counter

decreases its current value by one. When the existing value is

reached “0”, the count-up screen is displayed.

Counter disuse:

The shoelace loop counter does not count a nished shape even

when the machine has sewn the shape. The counter screen of the

No. of pcs. counter is not displayed.

[Bobbin thread counter]

UP counter:

The value shown on the counter increases by one for every 10

bartacking stitches. When the current value shown on the counter

reaches the set value, the count-complete screen is displayed.

DOWN counter:

The value shown on the counter decreases by one for every 10

bartacking stitches. When the current value shown on the counter

reaches zero (0), the count-complete screen is displayed.

Counter disuse:

The bobbin thread counter does not work even the machine

performs sewing. The count-complete screen for the bobbin thread

counter will not be displayed.

– 36 –

Page 42

Change of counter set value

③

I

J

K

Press button I for the bartacking counter, button

for the shoelace loop counter, button K for the No. of

J

pcs. counter or button G for the bobbin thread counter to

display the corresponding counter set value entry screen.

Here, enter the set value.

When “0” is entered in the set value, the display of count-up

screen is not performed.

L

M

N

Changing the current value on the counter

④

Press button L for the bartacking counter, button

for the shoelace loop counter, button N for the No. of

M

pcs. counter or button H for the bobbin thread counter to

display the corresponding counter current value entry screen.

Here, enter the existing value.

– 37 –

Page 43

(2) Count-up releasing procedure

When the count-up condition is reached during sewing work, the

count-up screen is displayed and the buzzer beeps. Press CLEAR

button A to reset the counter and the screen returns to the

sewing screen. Then the counter starts counting again.

A

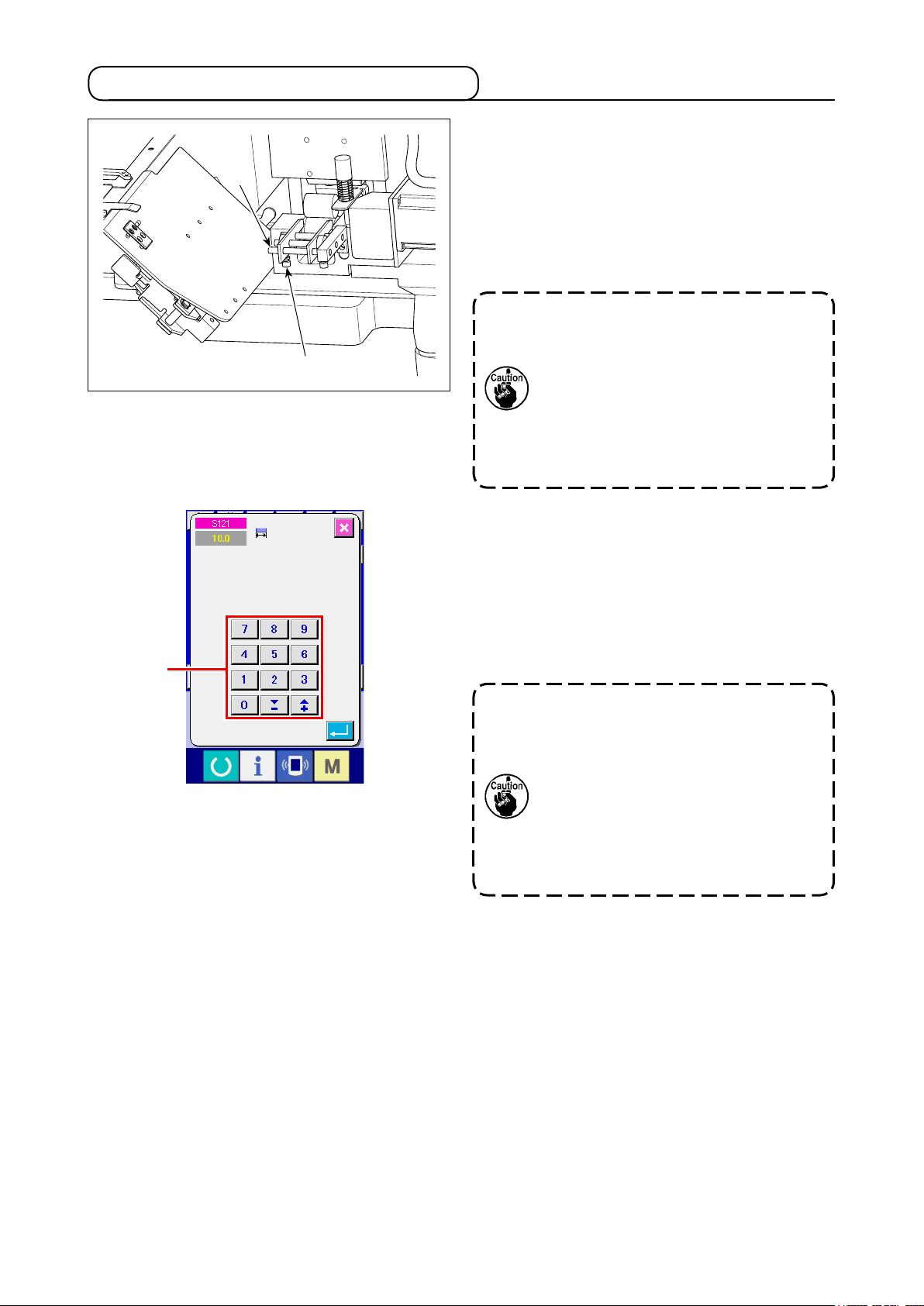

(3) How to change the counter value during sewing

Display the counter value change screen

①

When you desire to revise the counter value during sewing

work due to the mistake or the like, press COUNTER VALUE

A

B

CHANGE button A on the sewing screen. The counter

value change screen is displayed.

Change the counter value

②

Enter the value you desire with ten keys, or “+” or “-“ key B.

D

Determine the counter value

③

When ENTER button C is pressed, the data is deter-

mined.

When you desire to clear the counter value, press CLEAR but-

ton D.

C

– 38 –

Page 44

2-8. How to register a new shoelace loop pattern number

This section describes how to create a new shoelace loop pattern using the following shoelace loop pattern as an example.

Pattern number 15

Shoelace loop width 11 mm

Bartacking shape 22-stitch linear bartacking

Bartacking width 12 mm

A

Displaying the data entry screen

①

When you bring up the entry screen under the shoelace loop in-

dividual sewing mode or the shoelace loop cycle sewing mode,

new pattern creation is enabled. Press new creation button

A to display the new shoelace loop pattern number cre-

ation screen.

B

D

C

Entering a pattern number

②

Enter new pattern number 15 with numeric keys B. It is also

possible to search for an unregistered sewing pattern number

using +/− buttons (C, D).

E

When you press enter button E, the new pattern number

to create is conrmed and the shoelace loop width entry screen

is displayed.

– 39 –

Page 45

H

L

I

J

Entering a shoelace loop width

③

Enter 15 with numeric keys H or +/− buttons (I,

) to set the shoelace loop width to 11 mm. Press enter button

J

K to conrm your entry. Then, the standard pattern selec-

tion screen is displayed.

K

Selecting a standard pattern

④

Standard sewing pattern, 22-stitch bartacking with button L.

Press enter button M to conrm your entry. Then, the

bartacking information entry screen is displayed.

P

M

Entering a bartacking width

⑤

O

When you press X actual dimension value button N on

N

the bartacking information entry screen, and the rst bartacking

X actual dimension value setting screen is displayed.

Enter 12 with numeric key P or +/− buttons (Q, R)

to set the bartacking width to 12 mm. Press enter button

to conrm your entry. Then screen goes back to the bartack-

S

ing information entry screen.

Q

S

R

– 40 –

Page 46

Finishing the creation of a new pattern

⑥

When you press close button O on the bartacking informa-

tion entry screen, the screen goes back to the shoelace loop

data entry screen. Check to make sure that the parameters you

have set are included on the data entry screen.

If you press the cancel button on any of the screens

which appear on the steps of procedure beyond ③,

the screen returns to the shoelace loop data entry

screen. In this case, the values of the parameters you

have not set shown on the shoelace loop data entry

screen are their initial values.

2-9. How to name a shoelace loop pattern number

It is possible to enter as many as 14 characters for each shoelace loop pattern number.

A

Displaying the data entry screen

①

Only on the shoelace loop individual sewing data entry screen

(blue), the name of a shoelace loop pattern number can be

entered. On the sewing screen (green), press the set ready key

to display the data entry screen (blue).

Bringing up the character entry screen

②

When you press character input button A, and the char-

acter entry screen is displayed.

Entering characters

③

Characters can be entered by pressing character button B

F

corresponding to the desired character. As many as 14 alpha-

numeric characters ( to , to ) and symbols ( ,

, , and ). The cursor can be moved by means of cursor

B

C

D

E

leftward-travel button C or cursor rightward-travel button

D. If you want to delete the entered character, move the