ENGLISH

AB-1351

INSTRUCTION MANUAL

* "CompactFlash(TM)" is the registered trademark of SanDisk Corporation, U.S.A.

CONTENTS

!

. Machine (about the sewing machine) ...............................1

Precautions for use .................................................................................................. 1

1. Conguration ........................................................................................................ 2

2. Specications ....................................................................................................... 3

2-1. Mechanical specications .............................................................................................. 3

2-2. Electrical specications ................................................................................................. 4

2-3. Sewing shape of belt-loops ........................................................................................... 4

2-4. Garment body presser/work clamp foot specications .............................................. 6

(1) Garment body presser .................................................................................................................. 6

(2) Work clamp foot of the sewing machine ....................................................................................... 7

3. Installation ............................................................................................................ 8

3-1. Removing the packing materials ................................................................................... 8

3-2. Fixing the machine ......................................................................................................... 9

3-3. Connecting the air coupler ............................................................................................ 9

3-4. Connecting the power plug .......................................................................................... 10

3-5. Assembling the thread stand and installing on the machine ................................... 12

3-6. Installing the machine head support bar .................................................................... 12

3-7. Installing the operation panel IP-420 .......................................................................... 12

3-8. Installing the auxiliary table ......................................................................................... 13

3-9. Installing the manual pedal (optional) ........................................................................ 13

3-10. Installing the belt loop feeding unit (optional) ......................................................... 14

3-11. Installing the additional marking light (optional) ..................................................... 15

4. Preparation of the sewing machine .................................................................. 16

4-1. Lubrication .................................................................................................................... 16

4-2. Attaching the needle ..................................................................................................... 16

4-3. Threading the machine head ....................................................................................... 17

4-4. Installing and removing the bobbin case ................................................................... 17

4-5. Installing the bobbin ..................................................................................................... 18

4-6. Adjusting the thread tension ....................................................................................... 18

4-7. Adjusting the thread take-up spring ........................................................................... 19

4-8. Example of the thread tension ..................................................................................... 19

5. Operating the sewing machine ......................................................................... 20

5-1. Emergency stop switch ................................................................................................ 20

(1) Method for operating the emergency stop switch ....................................................................... 20

(2) Precautions with the emergency stop switch ..............................................................................20

5-2. Winding a bobbin .......................................................................................................... 21

(1) To wind a bobbin while the sewing machine is performing sewing .............................................21

(2) To wind a bobbin independently ................................................................................................. 21

5-3. Thread clamp device .................................................................................................... 22

5-4. Placing a belt loop ........................................................................................................ 23

5-5. Adjusting the belt loop tension ................................................................................... 24

5-6. Setting the belt loop thickness .................................................................................... 24

i

5-7. Method for changing the belt loop width .................................................................... 25

5-8. Method for adjusting the workpiece stopper ............................................................. 26

5-9. Start switch .................................................................................................................... 26

@

. OPERATION (OPERATION PANEL) .................................

1. Introduction ........................................................................................................ 27

2. Method for using the operation panel .............................................................. 31

2-1. Name of each section of IP-420 ................................................................................... 31

2-2. Buttons to be used in common ................................................................................... 32

2-3. Basic operation of IP-420 ............................................................................................. 33

2-4. Liquid crystal display section when the belt loop individual sewing is selected ... 34

(1) Belt loop individual sewing data entry screen .............................................................................34

(2) Belt loop individual sewing screen ..............................................................................................36

2-5. How to change over the sewing shape ....................................................................... 38

2-6. How to change the belt loop length ............................................................................ 39

(1) How to change the belt loop dimensions .................................................................................... 39

(2) Changing the belt loop length (entire length) and precautions to be taken ................................41

(3) Changing the belt loop length by the selection of the frame of the work clamp foot .................. 41

2-7. How to lower the garment body presser and the work clamp foot .......................... 42

2-8. Using counter ................................................................................................................ 43

(1) Setting procedure of the counter ................................................................................................43

(2) Count-up releasing procedure ....................................................................................................46

(3) How to change the counter value during sewing ........................................................................ 46

2-9. How to register a new belt loop pattern number ....................................................... 47

2-10. How to name a belt loop pattern number ................................................................. 49

2-11. How to select a belt loop pattern number ................................................................. 50

(1) Selection on the data entry screen .............................................................................................50

(2) Selection by the direct button .....................................................................................................51

2-12. How to copy a belt loop pattern number .................................................................. 52

2-13. Belt loop teaching function ........................................................................................ 53

2-14. How to carry out the step operation ......................................................................... 55

(1) Setback step operation ............................................................................................................... 56

(2) Sewing position step operation ...................................................................................................56

2-15. Function of canceling grasping of a belt loop for the next sewing ....................... 58

2-16. How to carry out the bartacking setting ................................................................... 59

2-17. Liquid crystal display at the time of setting the bartacking ................................... 60

(1) LK unit data entry screen ............................................................................................................60

(2) LK unit sewing screen ................................................................................................................. 62

2-18. How to select the sewing shape (bartacking setting) ............................................. 64

2-19. List of sewing shapes ................................................................................................. 65

2-20. How to change the item data (bartacking setting) ................................................... 66

2-21. How to check the sewing shape ................................................................................ 67

2-22.

How to change the thread tension command from needle entry point to needle entry point

(1)

How to add/change the thread tension command from needle entry point to needle entry point

(2) How to delete the thread tension command from needle entry point to needle entry point ........ 69

2-23. How to register a new user-pattern ........................................................................... 71

2-24. How to change the sewing mode .............................................................................. 72

27

.... 68

... 68

ii

2-25. LCD section when the cycle sewing is selected ...................................................... 73

(1) Cycle sewing data entry screen ..................................................................................................73

(2) Sewing screen of the cycle sewing .............................................................................................75

2-26. How to carry out cycle sewing .................................................................................. 77

(1) Selection of the cycle-sewing data .............................................................................................77

(2) Method to create the cycle-sewing data .....................................................................................78

(3) Method to insert the cycle-sewing data ......................................................................................79

(4) Method for deleting the cycle sewing data .................................................................................. 80

(5) Method for deleting a step of the cycle sewing data ...................................................................80

2-27. How to edit the sewing data ....................................................................................... 81

(1) Method for changing the sewing data .........................................................................................81

(2) Sewing data list ........................................................................................................................... 82

2-28. How to change the memory switch data .................................................................. 93

(1) Method for changing the memory switch data ............................................................................ 93

(2) Memory switch data list ..............................................................................................................94

2-29. How to set the device ................................................................................................. 98

(1) Device setting changing procedure ............................................................................................98

(2) Listing of the device settings ....................................................................................................... 99

2-30. How to adjust the origin of work clamp foot .......................................................... 101

2-31. Using communication function ............................................................................... 102

(1) Handling possible data .............................................................................................................102

(2) Performing communication by using the media ........................................................................102

(3) Performing communication by using USB ................................................................................102

(4) Take-in of the data ....................................................................................................................103

(5) Taking in plural data together .................................................................................................... 104

2-32. Performing formatting of the media ........................................................................ 106

2-33. Trial stitching function ............................................................................................. 107

2-34. How to use information ............................................................................................ 109

(1) How to visually check maintenance/inspection information ......................................................109

(2) How to reset the warning ...........................................................................................................111

(3) How to set the time ....................................................................................................................111

2-35. How to re-start sewing from the position where the machine has stopped by the

detection of thread breakage ....................................................................................... 112

3. ERROR CODE LIST .......................................................................................... 113

4. Massage list ...................................................................................................... 126

#

. Maintenance ....................................................................130

1. Maintenance ...................................................................................................... 130

1-1. Discharging drainage water ....................................................................................... 130

1-2. Adjusting the height of the needle bar ...................................................................... 130

1-3. Adjusting the needle-to-shuttle relation ................................................................... 131

1-4. Adjusting the lift of the work clamp foot .................................................................. 132

1-5. The moving knife and counter knife ......................................................................... 132

1-6. Needle thread clamp device ....................................................................................... 133

1-7. Adjustment of the wiper ............................................................................................. 133

1-8. Thread breakage detector plate ................................................................................ 134

1-9. Draining waste oil ....................................................................................................... 134

iii

1-10. Amount of oil supplied to the hook ......................................................................... 134

1-11. Replacing the work clamp foot of the sewing machine ........................................ 135

1-12. Replacing the feed plate of the sewing machine ................................................... 135

1-13. Replacing the fork ..................................................................................................... 136

1-14. Replacing the fuse .................................................................................................... 136

1-15. Changing the voltage of 100/200V ........................................................................... 137

1-16. Replenishing the designated places with grease .................................................. 138

(1) Addition of grease to the machine head ...................................................................................138

(2) Addition of grease to devices .................................................................................................... 140

1-17. Troubles and corrective measures (sewing conditions) ....................................... 142

2. Option ................................................................................................................ 144

2-1. Optional parts .............................................................................................................. 144

2-2. Gauges ......................................................................................................................... 144

2-3. Miscellaneous ............................................................................................................. 144

2-4. Silicon oil pipes ........................................................................................................... 144

iv

!

. Machine (about the sewing machine)

Precautions for use

Following items have to be checked every working day before the operation of the machine and before the start

of work hours.

1. Ascertain that the oil pan is lled with the predetermined amount of oil.

2. Never operate the machine unless the oil pan has been lled up with oil.

3. Ascertain that the pressure gauge indicates the designated air pressure of 0.5 MPa.

* (This is necessary particularly when the compressor is stopped for a lunch break or the

like.)

If the compressed air pressure is equal to or less than the designated value, troubles such

as interference between the parts can occur. It is therefore necessary to carefully check the

compressed air pressure.

4. Check whether the needle thread/bobbin thread need to be replenished.

5. To perform sewing immediately after turning ON the power switch, perform trial stitching

rst, then proceed with sewing of actual products after the test sewing.

In the case drainage water accumulates in the regulator section, expel it from there before

6.

starting work.

– 1 –

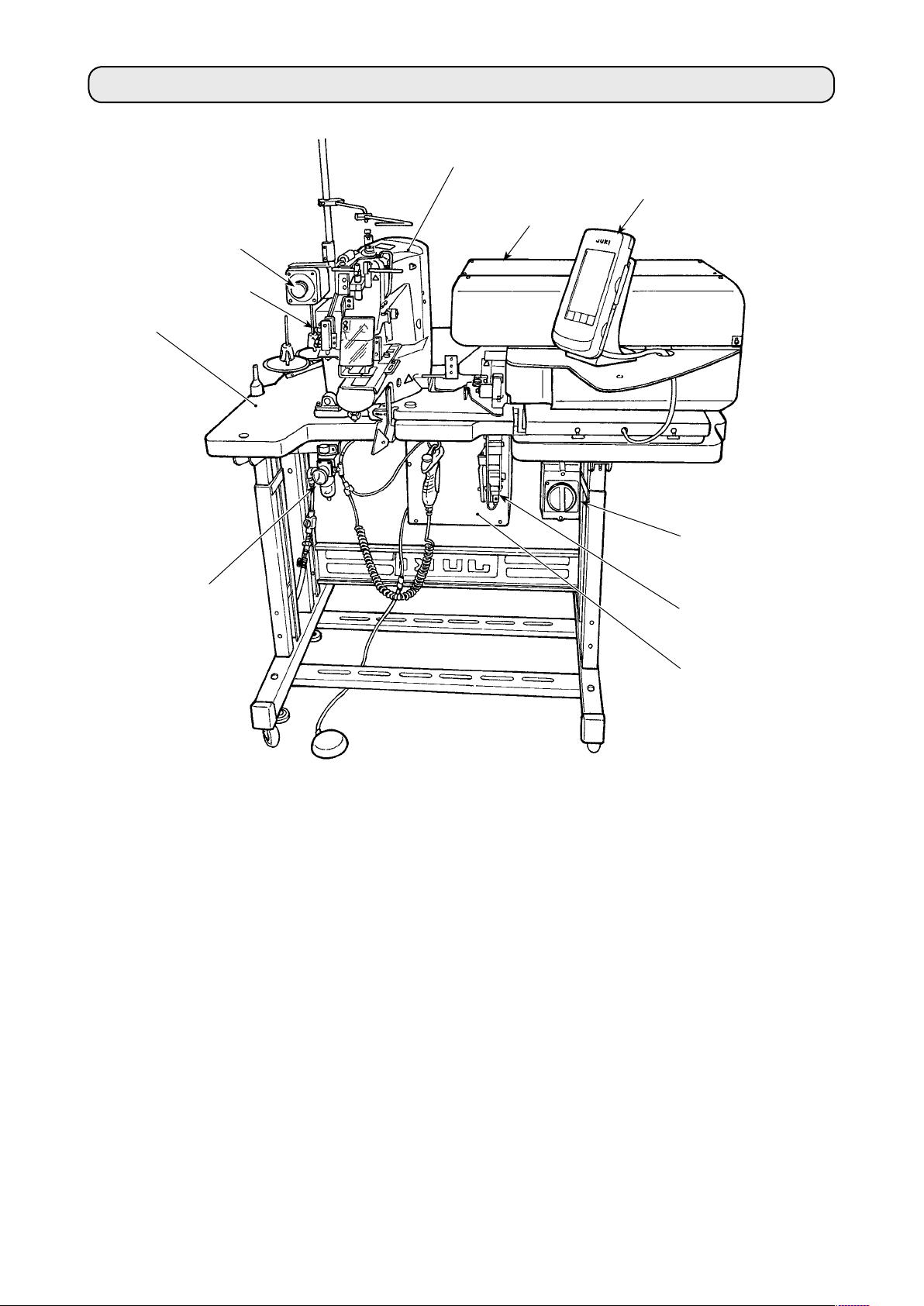

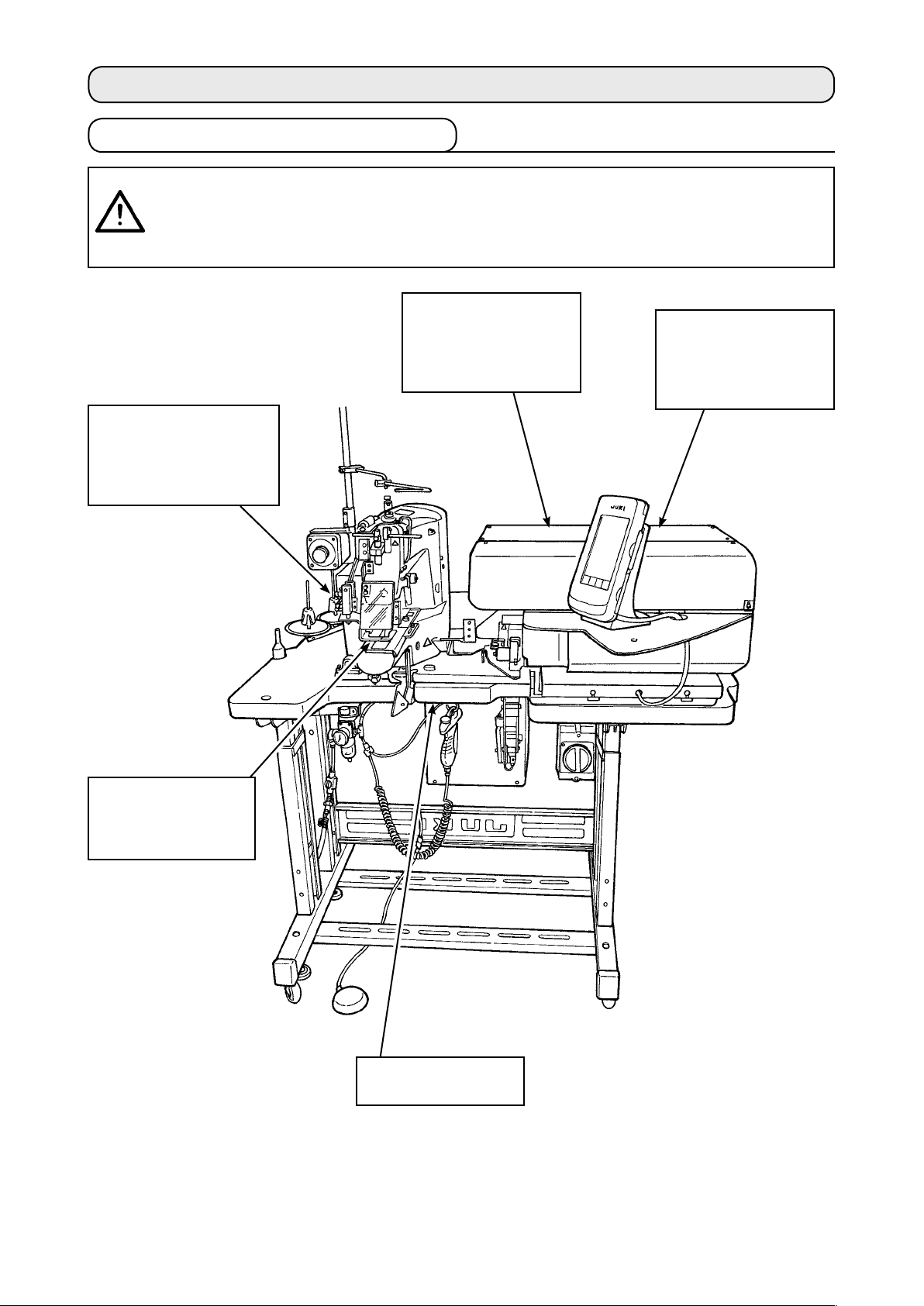

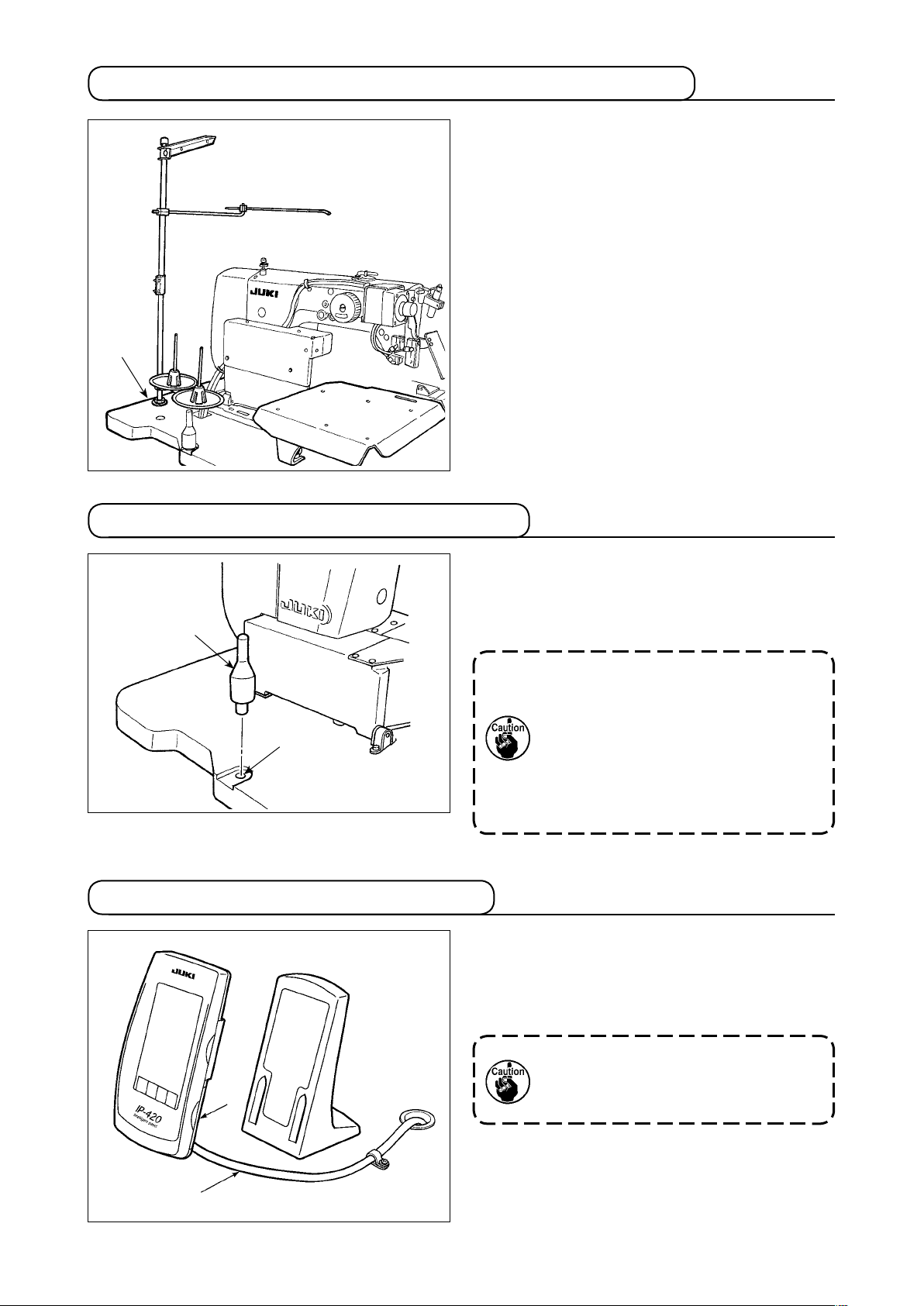

1. Conguration

H

C

A

E

G

B

D

This machine consists of the following nine sections:

Mechan

A

Belt loop feeder un

B

Belt loop tens

C

Pneumat

D

Sew

E

Control dev

F

Operat

G

Emergency stop sw

H

Belt-loop feed

I

Power sw

J

ical section of the main body structure (table stand, table, covers, start switch, etc.)

it (belt loop draw-out device, belt loop drawing device, etc)

ion releasing unit

ic control equipment section (pneumatic equipment, pneumatic piping, etc.)

ing machine section

ice

ion panel

itch

ing unit (optional)

itch

J

I

F

The machine is able to automatically sew desired belt-loops only by operating the start switch after

having placed a material (garment body) at the predetermined position on the machine.

When you press emergency stop switch

, the power to the dev

H

– 2 –

ices are turned OFF to stop them.

2. Specications

2-1. Mechanical specications

1

Sewing machine in use

2 Sewing speed Max. number of revolutions 2,500 sti/min (adjustable range: 400 to 2,500 sti/min)

3 Belt-loop shape

4 Belt-loop width 8 to 20 mm

5 Standard sewing

pattern

6 Lift of the work clamp

foot of sewing machine

7 Needle bar stroke 45.7 mm (for 1903A)

8 Needle ORGAN needle DP x 17 #14 (Standard)

9 Hook in use Semi-rotary standard hook (x1.0)

10 Thread Spun #50 (recommended) Filament #50

11 Safety feature The machine automatically stops in the case a belt-loop clamping fault or thread

12 Lubrication oil JUKI New Defrix Oil No.2

13 Air pressure used 0.5 MPa

14 Air consumption 10 dm³ (ANR)/min or less

15 Dimensions W: 1,200 mm L: 850 mm H: 1,210 mm

16 Weight 205.5 Kg

17 Noise

18 Laser marking Class 2 laser product

LK-1961/AB H (exclusive intermediate machine head AB-1351 based on LK-1900A SS)

The stitching pitch has to be set at 3.2 mm or less. (Stitching pitch is input in increments

of 100 sti/min.)

* Linear bartacking (exclusive pattern for AB-1351)

Pattern No. selection method (from among 12-stitch, 15-stitch, 21-stitch, 28-stitch,

36-stitch and 41-stitch) is adopted. The widthwise pattern size is input on the operation

panel. The lengthwise pattern size is restricted to the 0 mm, and the widthwise one is

restricted to the range from 6 mm to 23 mm.

increments of 0.1 mm.)

* Zigzag bartacking (exclusive pattern for AB-1351)

Pattern No. selection method (from among 28-stitch, 36-stitch, 42-stitch, 56-stitch and

64-stitch) is adopted. The widthwise and lengthwise pattern sizes are input on the

operation panel. The lengthwise pattern size is restricted to the range from 1 mm to 3.2

mm, and the widthwise one is restricted to the range from 6 to 23 mm. (The lengthwise/

widthwise pattern size is input in increments of 0.1 mm.)

The distance from the top surface of the throat plate to the undersurface of the work

clamp foot is 20 mm.

breakage is detected.

(The lengthwise pattern size is input in

Declaration

- Equivalent continuous emission sound pressure level (LpA) at the workstation :

A-weighted value of 82.0 dB; (Includes KpA = 2.5 dB); according to ISO 10821- C.6.3

-ISO 11204 GR2 at 2,500 sti/min for the sewing cycle, 5.5s ON. (Pattern: No.4, 21

Stitches, Max Speed)

- Sound power level (LWA) ;

A-weighted value of 85.0 dB; (Includes KWA = 2.5 dB); according to ISO 10821- C.6.3

-ISO 3744 GR2 at 2,500 sti/min for the sewing cycle, 5.5s ON. (Pattern: No.4, 21

Stitches, Max Speed)

Maximum output: 1.0mW

Wave length: 650nm

Safety standard

JIS C 6802:2005

IEC60825-1+A2:2007

– 3 –

2-2. Electrical specications

1 Number of patterns that

can be stored in memory

2 Number of cycles that can

be stored

3 Input power source S

4 Power consumpt

in memory

ion 3-phase, 200 V type: 250 VA (instantaneous maximum power consumption: 450 VA)

99 patterns can be set.

Number of programs: 20

For each program, as many as 30 belt-loops can be set.

ingle-phase 200 – 240 VAC, 50/60Hz

3-phase, 200 - 240 VAC, 50/60 Hz (switchable to single-phase 100 - 120 V)

Supply voltage uctuation: Rated voltage ± 10 % or less

Adaptable to 380/400/415 VAC with the addition of an optional transformer.

*

Single-phase, 220 V type: 280 VA (instantaneous maximum power consumption: 670 VA)

* Average power when the machine sews 4000 belt-loops in eight hours under No. 4

sewing mode.

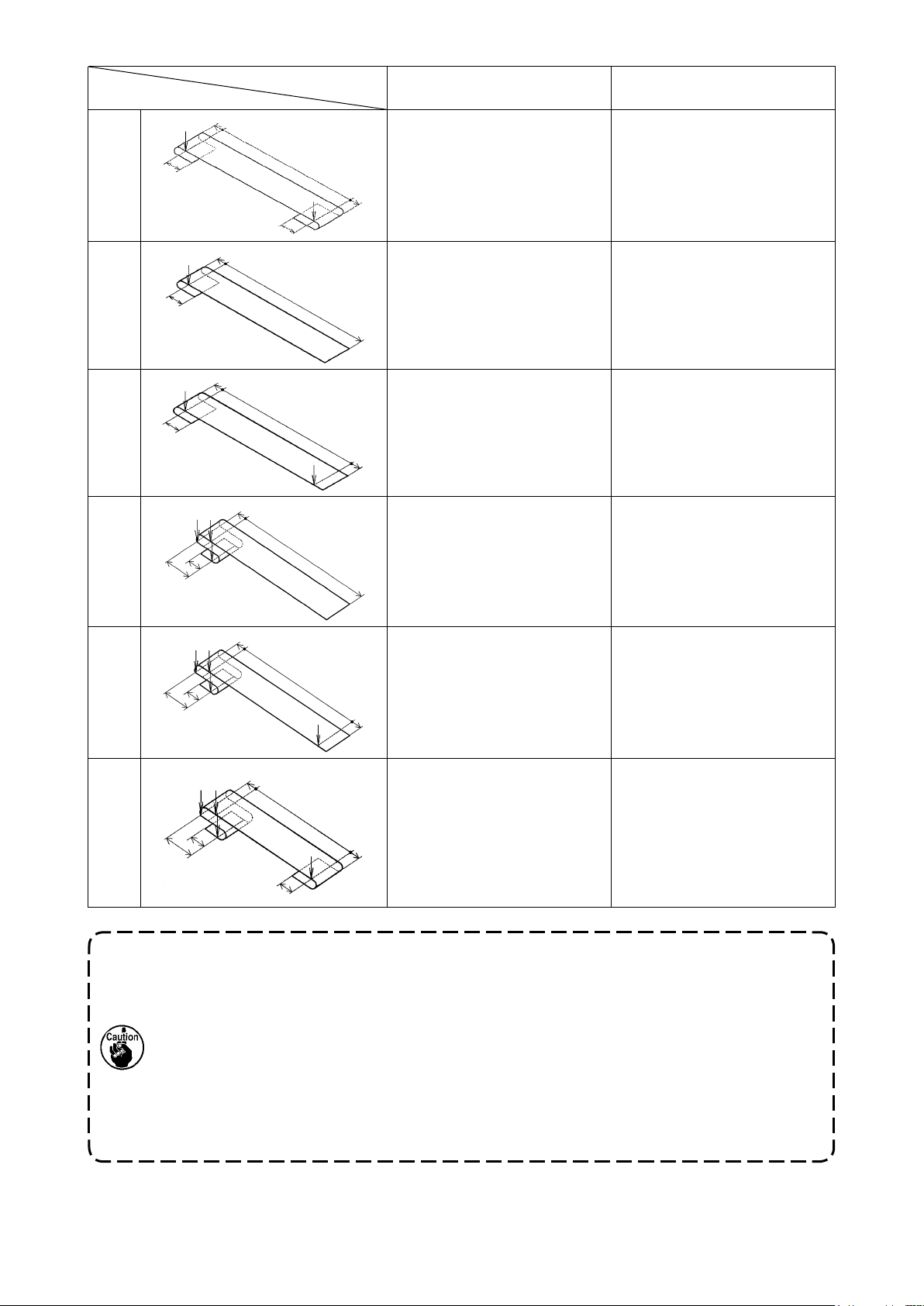

2-3. Sewing shape of belt-loops

B

No.1

A

Work clamp foot for linear

bartacking

A = 4 mm * (-10 to 19)

B = 59 to 99 mm

Work clamp foot for zigzag

bartacking

A = 6 mm * (-9 to 21)

B = 59 to 99 mm

No.2

No.3

No.4

No.5

B

A

D

A

C

D

A

C

D

A

C

C

B

B

B

F

A = 4 mm * (-10 to 19)

B = 15 to 30 mm

C = 45 to 99 mm

A = 4 mm * (-10 to 19)

B = 45 to 109 mm

C = 5 to 11 mm

D = (2) mm

A = 4 mm * (-10 to 19)

B = 30 to 50 mm

C = 5 to 11 mm

D = 5 to 30 mm

E

E = 6 mm * (-14 to 16)

A = 4 mm * (-10 to 19)

B = 30 to 61 mm

C = 5 to 11 mm

D = 2 to 8 mm

E

E = 2.5 mm * (-2.5 to 7.5)

F = 10 mm * (0 to 20)

A = 6 mm * (-9 to 21)

B = 15 to 30 mm

C = 45 to 99 mm

A = 6 mm * (-9 to 21)

B = 45 to 109 mm

C = 5 to 11 mm

D = (2) mm

A = 6 mm * (-9 to 21)

B = 30 to 50 mm

C = 5 to 11 mm

D = 5 to 30 mm

E = 12 mm * (-12 to 22)

A = 6 mm * (-9 to 21)

B = 30 to 61 mm

C = 5 to 11 mm

D = 2 to 8 mm

E = 4 mm * (-1 to 9)

F = 10 mm * (0 to 20)

No.6

A = 4 mm * (-16 to 19)

B

A

C

B = 45 to 99 mm

C = 15 to 30 mm

D = 2.5 mm * (-2.5 to 7.5)

D

A = 6 mm * (-9 to 21)

B = 45 to 99 mm

C = 15 to 30 mm

D = 4 mm * (-1 to 9)

– 4 –

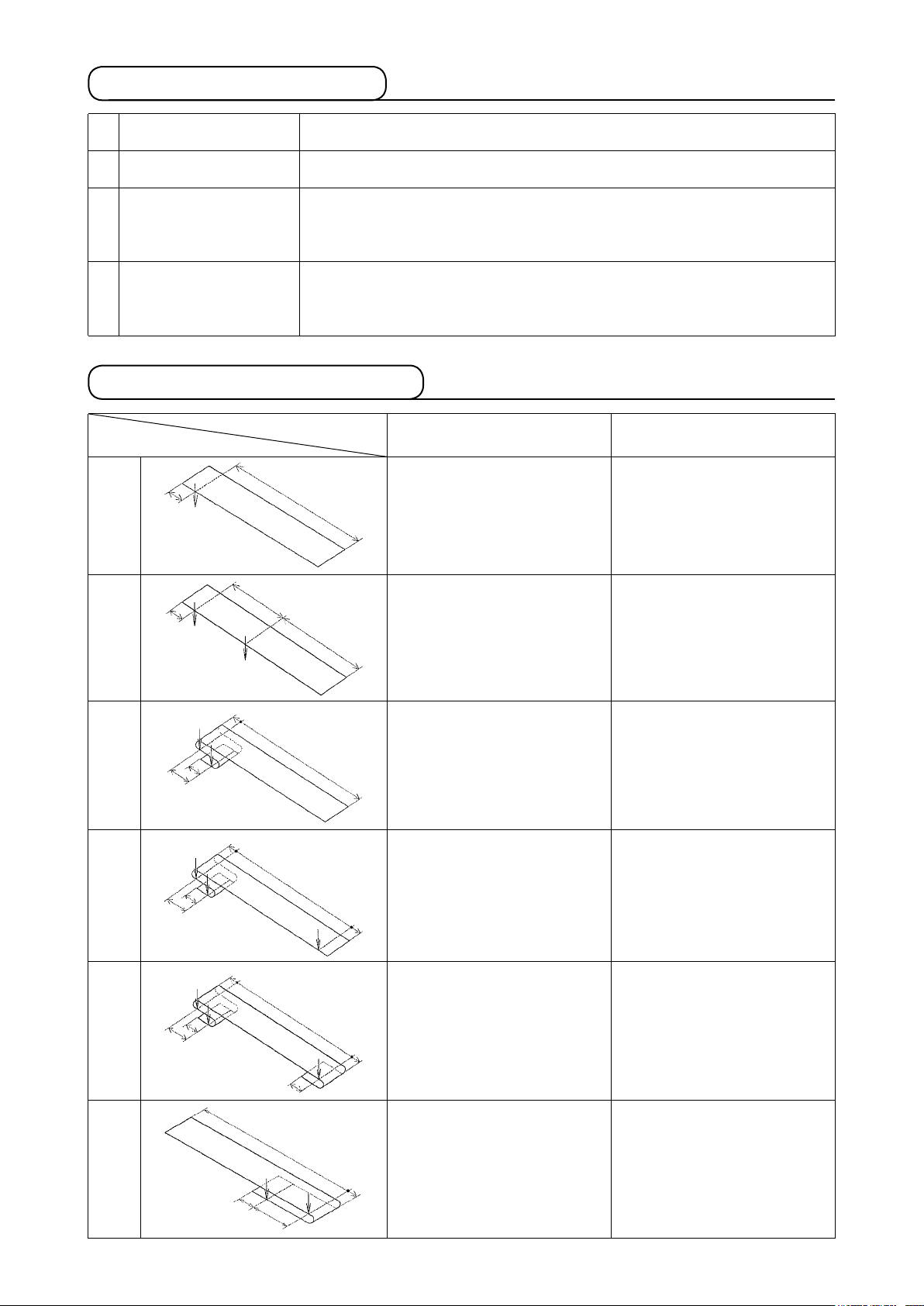

No.7

Work clamp foot for linear

bartacking

D

B

A

F

A = 10 mm * (0 to 1

B = 30 to 63 mm

D = 4 mm * (0 to 10)

E = 4 mm * (0 to 10)

E

F = 10 mm * (0 to 20)

Loosening amount = 0 to 20 mm

5)

Work clamp foot for zigzag

bartacking

A = 10 mm * (0 to 1

B = 30 to 63 mm

D = 3 mm * (0 to 10)

E = 3 mm * (0 to 10)

F = 10 mm * (0 to 20)

Loosening amount = 0 to 20 mm

5)

No.8

No.9

No.10

No.11

D

A

D

A

D

A

C

D

A

C

B

B

B

B

A = 10 mm * (0 to 1

B = 49 to 109 mm

D = 4 mm * (0 to 10)

A = 10 mm * (0 to 1

B = 30 to 60 mm

D = 4 mm * (0 to 10)

E = 6 mm * (-14 to 16)

E

Loosening amount = 5

A = 4 mm * (-10 to 19)

B = 45

to 109 mm

C = 5 to 11 mm

D = 4 mm * (0 to 4)

A = 4 mm * (-10 to 19)

B = 30 to

C = 5 to 11 mm

D = 4 mm * (0 to 4)

E

E = 6 mm * (-14 to 16)

Loosening amount = 5 to 30 mm

5

0 mm

5)

5)

to 30 mm

A = 10 mm * (0 to 1

B = 45 to 109 mm

D = 3 mm * (0 to 10)

A = 10 mm * (0 to 15)

B = 30 to 60 mm

D = 3 mm * (0 to 10)

E = 12 mm * (-12 to 22)

Loosening amount = 5 to 30 mm

A = 6 mm * (-9 to 21)

B = 45 to 109 mm

C = 5 to 11 mm

D = 3 mm * (0 to 4)

A = 6 mm * (-9 to 21)

B = 30 to 50 mm

C = 5 to 11 mm

D = 3 mm * (0 to 4)

E = 12 mm * (-12 to 22)

Loosening amount = 5 to 30 mm

5)

No.12

D

B

A

C

F

A = 4 mm * (-10 to 19)

B = 30 to

C = 5 to 11 mm

D = 4 mm * (0 to 4)

E

E = 2.5 mm * (-2.5 to 7.5)

F = 10 mm * (0 to 20)

Loosening amount = 4 to 16 mm

6 mm

5

A = 6 mm * (-9 to 21)

B = 30 to 56 mm

C = 5 to 11 mm

D = 3 mm * (0 to 4)

E = 4 mm * (-1 to 9)

F = 10 mm * (0 to 20)

Loosening amount = 4 to 16 mm

1. The range of belt-loop feeding length (the entire length of a belt-loop shown on the

operation panel) is from 58 mm to 130 mm. If the belt-loop feeding length exceeding the

aforementioned range is set, an error will occur.

2. In the case "distance B + distance D" exceeds 66 mm for pattern No. 4 or No. 5, "dis-

tance B + loosening amount/2" exceeds 66 mm for pattern Nos. 7 and 12, or "distance B

+ loosening amount" exceeds 66 mm for pattern Nos. 9 and 11, an error will occur.

3. The dimensions of the belt loop sewing shape displayed on the operation panel are

only for reference. The dimensions vary according to the belt-loop material. Be sure to

adjust the settings of belt loop dimensions so that your desired nished dimensions

are achieved.

* Numerical values shown in parentheses are set values. They are not the nished dimen-

sions.

– 5 –

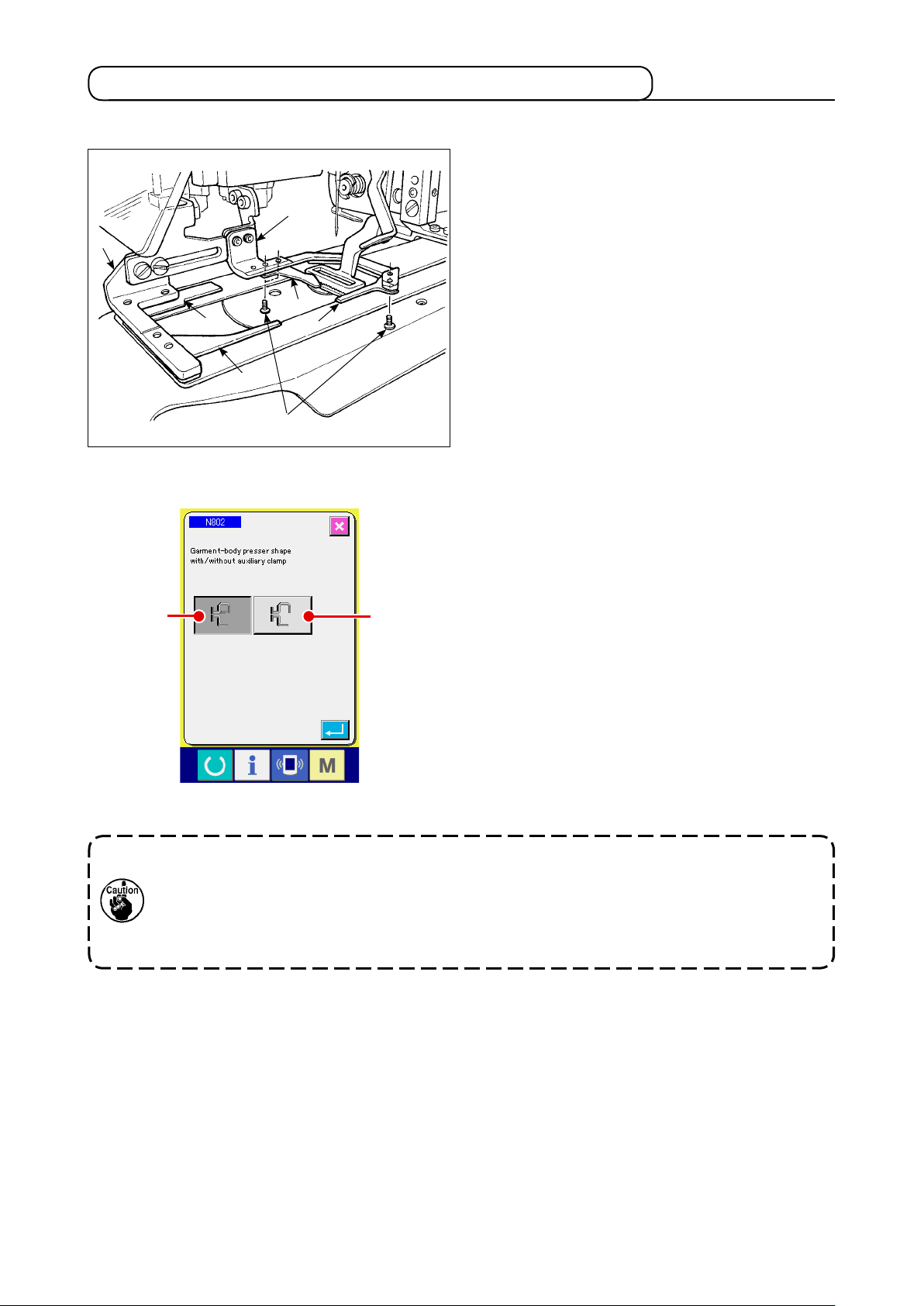

2-4. Garment body presser/work clamp foot specications

(1) Garment body presser

Garment body presser 1 and 2 for securing the

garment body is provided as standard with auxil-

ary clamps 3, 4, 5 and 6.

1

i

2

A

5

6

7

3

4

B

e aware that the auxiliary clamps 3 may be

B

r

equired to be removed according to the sewing

shape of the belt-loop.

In

the case of two kinds of sewing shapes; No. 2

and No. 6, auxiliary clamp

Loosen two screws 7

has to be removed.

3

and remove the auxiliary

clamps 3 from the garment body presser 1.

If you have changed the garment body presser,

set the machine setting N802 according to the

garment body presser actually being used.

itional clamp is provided

Add

A

itional clamp is not provided

Add

B

Refer to

→

"@-2-29. How to set the device"

, p.98

.

1. For belt loop shapes Nos. 5 and 7, auxiliary clamps 4 and 6 are damaged since they

are rubbed by the fork pin which rolls the belt loop. If the auxiliary clamps are heavily damaged, they can deform or break. It is necessary to periodically change auxiliary

clamps with new ones.

2. Install the auxiliary clamps at right angles to garment body pressers 1 and 2. Be sure

to check that the auxiliary clamps do not interfere with other parts.

– 6 –

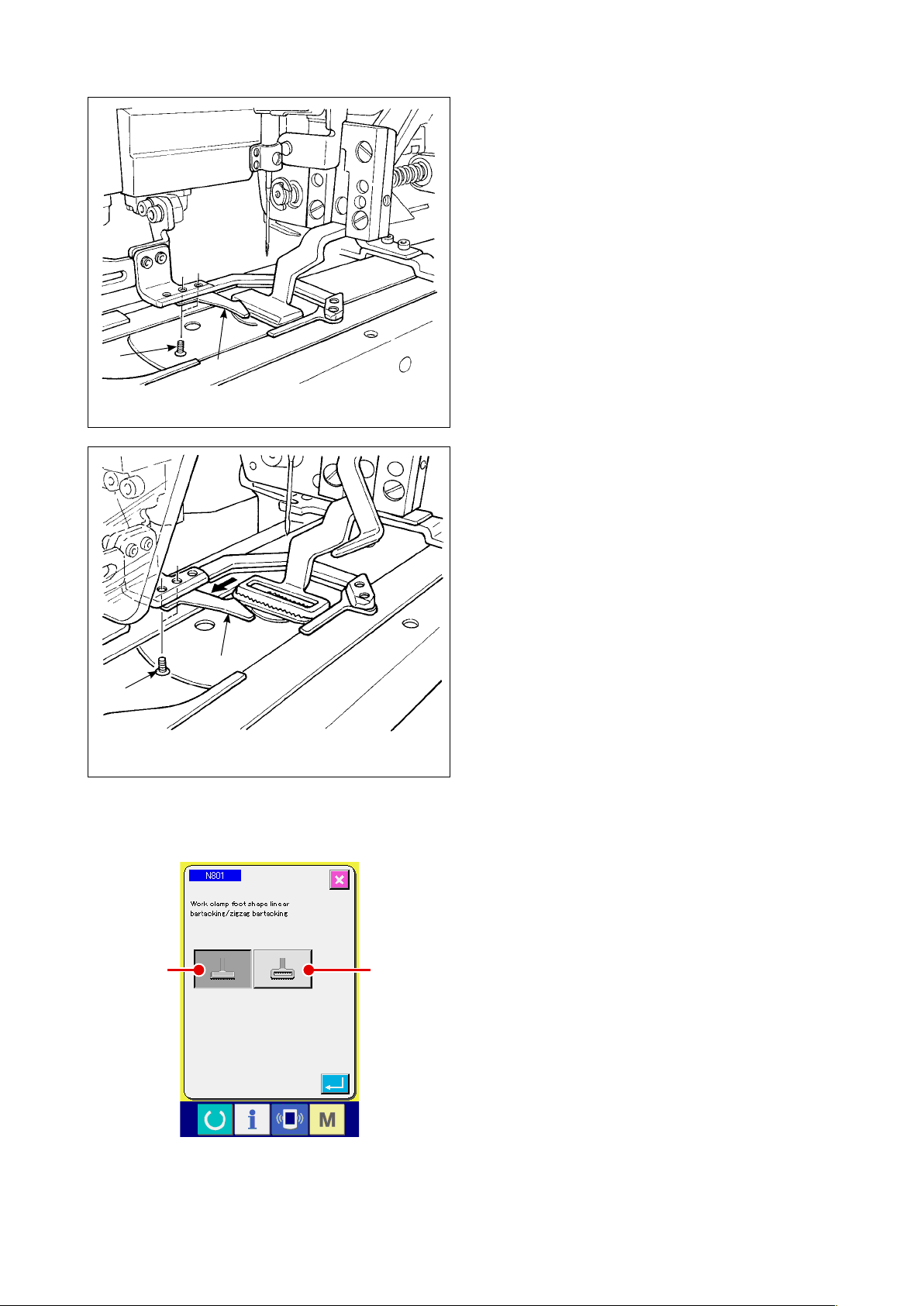

(2) Work clamp foot of the sewing machine

The work clamp foot of the sewing machine for linear bartacking is mounted as standard.

It is used when liner bartacking is used for sewing

various kinds of belt loops.

7

7

3

Work clamp foot of the sewing

machine for linear bartacking

3

Work clamp foot of the sewing

machine for zigzag bartacking

Be aware that, to carry out zigzag bartacking, the

currently installed work clamp foot and the feed

plate have to be replaced with those for zigzag

bartacking, and zigzag bartacking has to be set on

the operation panel.

In addition, when the work clamp foot for zigzag

bartacking is installed, auxiliary clamp

e re-positioned accordingly by loosening two

b

has to

3

screws 7 as shown in the gure at the left. (Refer to

clamp foot specications", p.6.

"!-2-4 (1) Garment body presser/work

)

A

B

If you have changed the work clamp foot of the

sewing machine, set the machine setting N801

according to the work clamp foot actually being

used.

ing frame for linear bartacking

Feed

A

initial value)

(

ing frame for zigzag bartacking

Feed

B

"@-2-29. How to set the device"

– 7 –

Refer to

→

, p.98

.

3. Installation

3-1. Removing the packing materials

CAUTION

:

1. If you lift the machine, do not hold any of the devices or the mechanical section of the

sewing machine but hold the table.

2. When you move the machine, the machine head xation bolt must be attached to the

machine. Be sure to carefully keep the machine head xation bolt.

Remove the cover.

Remove the string and

packing material which are

used to x the belt loop

tension releasing unit.

Remove the cover.

Remove the string and

packing material which

are used to x the belt

loop drawing unit.

Remove the upper

section cover. Remove

the string and packing

material which are used

to x the XY unit.

Remove the adhesive

tape which is used to

x the garment body

presser.

Remove the machine

head xation bolt.

– 8 –

3-2. Fixing the machine

3

CAUTION

1. In order to protect against accidents causing personal injury or death, move the

machine to a level and stable place and secure it by lowering adjuster bolts 2 (at four

locations) placed at the side of casters 1.

2. When adjusting the leg height of the sewing machine, the leg xing bolts 3 need to be

loosened to move the leg up or down. When the xing bolts have been loosened, there

is a danger for the legs to suddenly drop down. Therefore, be careful when loosening

the bolts.

:

1

2

3-3. Connecting the air coupler

4

3

1

Connect air coupler 1

an accessory to air hose 2.

coupler to coupler 3 on the ma

1. After having connected coupler 1

with air cock 4 closed, carefully

open air cock 4 to supply air.

2. Check to be sure that the pressure

gauge of the regulator indicates 0.5

MPa.

supplied with the unit as

Then, connect the air

in body side.

2

– 9 –

3-4. Connecting the power plug

CAUTION

In order to protect against accidents caused by a ground fault or dielectric voltage, be

sure to have the adequate power plug mounted by a person who has electrical expertise. It

is also important to connect the power plug to the grounded receptacle.

:

The method to connect the product to the power source differs by the product specications. Be sure to

connect the product to the power source according to the power specications.

For the single-phase, 200 - 240 V type product

1

Connect the sky-blue/brown wire of the power cord to the supply terminal (200 - 240 VAC) and the

yellow/green one to the earth terminal respectively.

For the 3-phase, 200 - 240 V type product

2

Connect the red/wh

ite/black wire of the power cord to the supply terminal (200 - 240 VAC) and the

yellow/green one to the earth terminal respectively.

For the product prov

3

ided with an high-voltage optional transformer

Connect the black wires (three) of the power cord to the supply terminal (380 - 415 VAC) and the

yellow/green wire to the earth terminal respectively. The product can be connected to 380/400/415

V power terminals according to the setting of the input tap of the transformer. (Standard setting at

the time of shipment: 380 V)

In the case the single-phase, 200 - 240 V type product is modied to the 3-phase, 380/400/415 V

4

type one

Opt

ional parts are required.

• High-voltage optional transformer Parts No.: 40005422

• Power cord Parts No.: 40070548

In the case of the 3-phase, 380/400/415 V power supply, this product is operated under the

single-phase connection state.

[Precaution to be taken when changing the power of the high-voltage optional transformer]

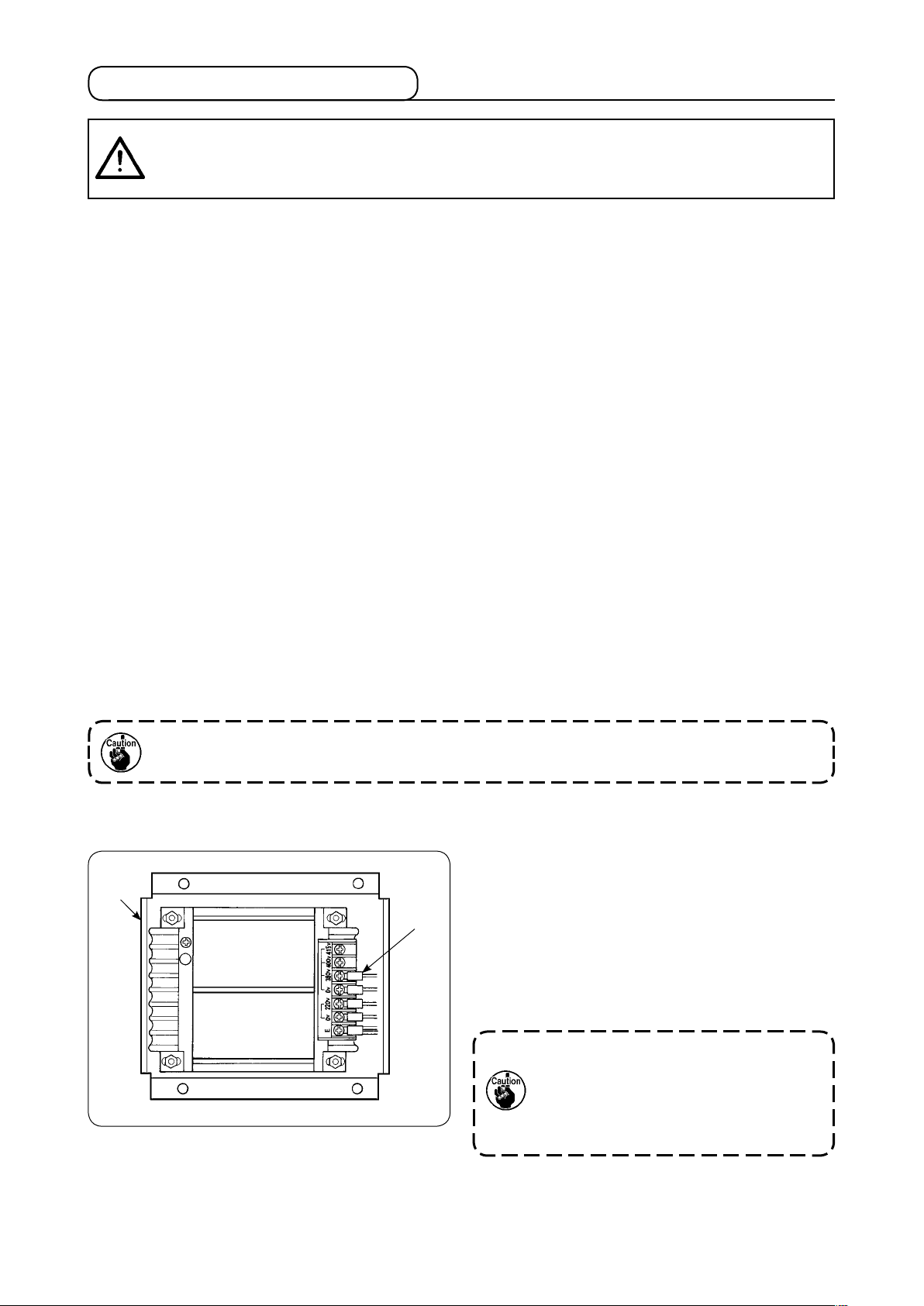

To use high-voltage optional transformer 1

the input voltage of 400 V or 415 V, you need to

1

2

replace input power cord

tional transformer 1

power input cord 2

(brown) which is connected to

of high-voltage op-

2

correspondingly. Change

the 380 V power terminal with the one for 400 V or

415 V connection.

In order to protect against accidents,

the aforementioned work should be

carried out after having left the sewing

machine for 5 minutes or more with

the power switch turned OFF and the

cord removed.

with

High-voltage optional transformer 1 i

the side face of the control box.

– 10 –

s placed on

CAUTION

:

To protect against accidents such as an electric shock, be sure to turn the power off and

remove the power cord from the receptacle before the following work.

[How to install the high-voltage optional transformer (part number: 40090561)]

1) Loosen four screws on the front side of emeritch 1. Open the sw

1

gency stop sw

Remove the power cord (brown, sky blue,

yellow/green wires) from the secondary side

(on the side 2

is printed).

2) Connect the power cord to the optional trans-

former. Connect the power cord (40005423:

Three-w

ire cord) supplied with the unit to the

optional transformer.

Brown wire → 380/400/415 V (accord

2

3

the power specications)

Blue wire → 0 V (next to the 380 V)

ellow/green wire →

Y

E (on the ring terminal side)

Connect the cord on the control box side (the

(Inner part of the emergency stop switch)

cord which has been removed in Step 1).

Brown wire → 220 V

Sky blue wire → (next to the E)

Yellow/green wire → E

itch box.

ing to

2−1 2−2 2−3

(Wiring of the optional transformer)

Su

cord

On the control box

side

C

E 0V 220V 0V 380V 400V 415V

ommon (ground)

E

econdary

S

side

(indicated

as 2)

pplied po w e r

3) Install optional transformer on the side face

of control box 2. Refer to "HIGH VOLTAGE

TRANSFORMER SETUP INSTRUCTION

(40005426)" for connect

ing procedure.

4) Connect the power cord supplied with the unit

to emergency stop switch 1.

Brown wire → 2-1

Sky blue wire → 2-2

Yellow/green wire → E

(Brown and sky blue wires respectively have a

fork terminal.)

5) Re-tighten the four screws of emergency switch

Take care not to leave a gap in the switch.

.

1

6) Change the cord on the plug side of the

power switch. (40070548: 4-wire cord)

Open the power switch. Remove connection

cords on the side of L1, L2 and L3.

Black 1, 2 and 3 wires (on the forked terminal

side) → L1, L2 and L3

in the power switch

Yellow/green wire → Ground (in the power switch)

* Discard the cord mounted your machine at

the time of delivery.

– 11 –

3-5. Assembling the thread stand and installing on the machine

Insert the thread stand in the hole in table 1 and

x by fastening a washer and a nut placed on the

top and unders

1

ide of table.

3-6. Installing the machine head support bar

1

2

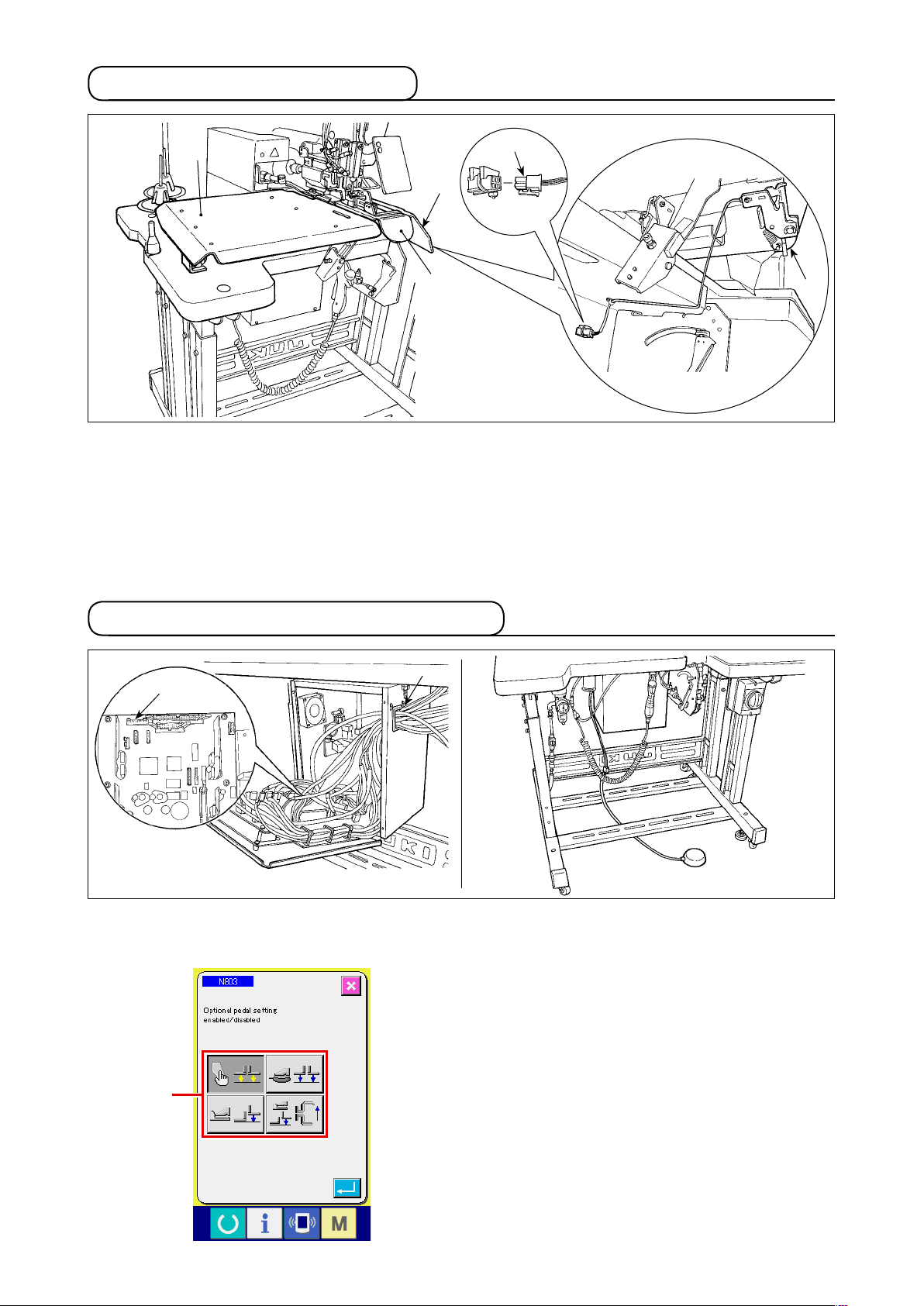

3-7. Installing the operation panel IP-420

Securely mount machine head support bar included in the accessories supplied with the unit.

i

Drive machine head support bar

n hole 2 in

1

the machine table.

When tilting the sewing machine, tilt

the sewing machine slowly so that no

excessive force will be applied to the

head support bar.

And when returning the sewing machine back to its original position,

be careful not to have your hand get

caught between the base and the sewing machine bed.

Open the cover on right side face 2 section of

the IP-420 and connect the connector of cable 1

ich is secured with adhesive tape on the upper

wh

right face of the table to the IP-420.

1

2

To protect the operation panel IP-420

fro m ma lfuncti onin g du e to sta tic

electricity, mount the operation panel

on the operation panel base.

– 12 –

3-8. Installing the auxiliary table

1

2

3

4

2

Loosen the buttery nut on the top surface of the table. Install the auxiliary table for attaching straps left

ight 2 in place.

and r

1

Install it at such a location where a clearance of 3 mm is provided between the throat plate 3 and each

iliary table.

aux

Remove the start switch connector provided as standard at the time of delivery. Then, insert start switch

connector 4 wh

ich has been mounted on auxiliary table right 2.

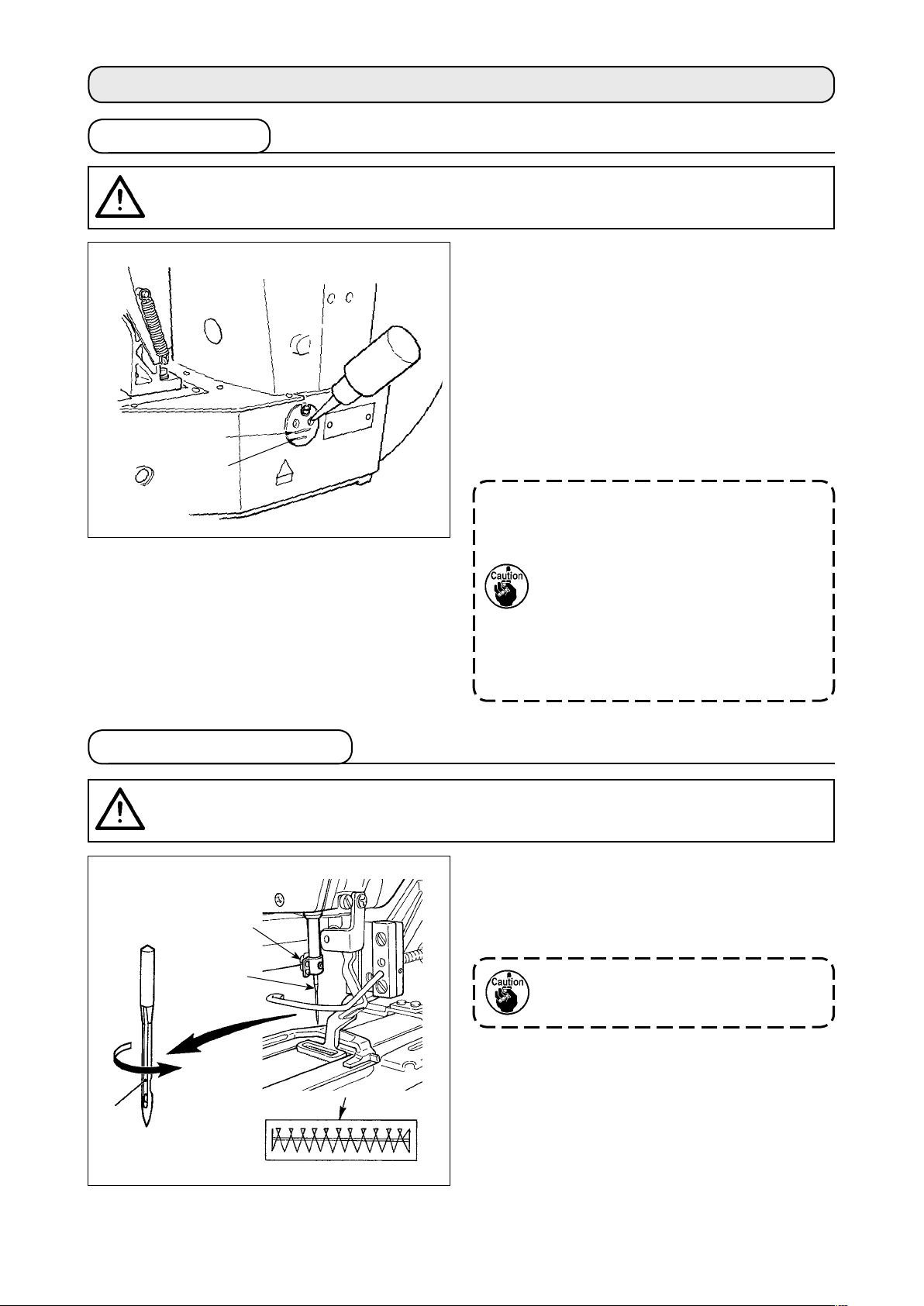

3-9. Installing the manual pedal (optional)

2

1

Open the cover of the control box. Insert connector CN88 of the manual pedal into connector 1 CN51

in the control box via the junction cable (40073659). Pass the cable through 2

Change the setting to “with optional pedal” on the

machine setting N803 A.

Refer to

→

"@-2-29. How to set the device"

in the control box.

, p.98

.

A

– 13 –

3-10. Installing the belt loop feeding unit (optional)

1

Mount the belt loop feeding unit on the table and

x it by tightening screws 1

the table.

exclusive junction cable 2

ing unit side.

3

2

Connect

board located behind the main body.

Connect junction cable

feed

In the case the belt loop feeding unit

is to be installed on the machine, the

belt loop guide parts installed as standard at the time of delivery have to be

removed.

on the underside of

to the junction

to connector 3 on the

2

4

5

6

Pull out plug 5

nect air tube 6

from air coupling 4. Then, con-

on the belt loop feeding unit side

to air coupling 4.

Change the setting to “with belt loop feeding auxiliary unit” on the machine setting N806 A.

A

– 14 –

Refer to

→

"@-2-29. How to set the device"

, p.98

.

3-11. Installing the additional marking light (optional)

Insert exclusive junction cable 1 into connector

of the junction board located behind the

2

1

CN85 2

main body.

(There are three CN85 connectors including the

one used as standard. You may insert the junction

cable any of the three connectors.)

– 15 –

4. Preparation of the sewing machine

4-1. Lubrication

CAUTION

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt

start of the sewing machine.

:

Check that the place between lower line B and upper line A is lled with oil. Fill there with oil using

oiler supplied with the machine as accessories

the

when oil is short.

* The oil tank which is lled with oil is only for lubri-

ating to the hook portion.

c

It is possible to reduce the oil amount when the

number of rotation used is low and the oil amount

A

B

in the hook portion is excessive. (Refer to

Amount of oil supplied to the hook", p.134

1. Do not lubricate to the places other

than the oil tank and the hook of

Caution 2 below. Trouble of components will be caused.

2. When using the sewing machine for

the rst time or after an extended

period of disuse, use the machine

after lubricating a small amount of

oil to the hook portion. (Refer to

"#-1-3. Adjusting the needle-tohook relation”, p.131.)

"#-1-10.

.)

4-2. Attaching the needle

CAUTION

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt

start of the sewing machine.

B

3

:

1

2

A

Loosen setscrew 1 and hold needle 2

long groove facing 3

toward you. Then fully insert

with the

it into the hole in the needle bar, and tighten setscrew 1.

If the seam shown in A is produced,

adjust the needle orientation slightly in

direction B.

– 16 –

4-3. Threading the machine head

CAUTION

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt

start of the sewing machine.

:

1

2

For synthetic thread

Draw the thread after having threaded the needle so that approximately 4 cm thread trails from the needle eyelet.

When you use silicon oil, pass the thread through silicon-thread thread guide 1.

thread thread guide is an optional part.)

(Silicon-

4-4. Installing and removing the bobbin case

CAUTION

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt

start of the sewing machine.

:

1) Open hook cover 1.

3

2) Raise latch 3 of bobb

in case 2, and remove

the bobbin case.

3) When installing the bobbin case, fully insert it

into the hook shaft, and close the latch.

2

1

If it is not fully inserted, bobbin case

may slip off during sewing.

2

– 17 –

4-5. Installing the bobbin

CAUTION

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt

start of the sewing machine.

:

2.5 cm

4

3

1

2

4-6. Adjusting the thread tension

5

1) Set the bobbin 1 into bobbin case 2 in the

direction shown in the gure.

Pass the thread through thread slit 3 of bob-

2)

in case 2, and pull the thread as

b

it is. By so

doing, the thread will pass under the tension

spring and be pulled out from thread hole

3)

Pass the thread through thread hole 5 of the

horn sect

ion, and pull out the thread by 2.5

4

cm from the thread hole.

If the bobbin is installed in the bobbin

case orienting the reverse direction,

the bobbin thread pulling out will result in an inconsistent state.

.

1

Long

Short

Adjusting the needle thread tension

2

If thread tension controller No. 1 1 is

turned

clockwise, the length of remaining thread on the

needle after thread trimming will be shorter. If it is

turned counterclockwise, the length will be longer.

Shorten the length to an extent that the thread is

not slipped off.

(The standard length of thread remaining on the

needle is approximately 4 cm.)

The needle thread tension is adjustable on the op

erat

ion panel. The bobbin thread tension is adjust-

able by means of 2.

The needle thread tension to be applied to the

bartacking sections can be set by means of thread

tension setting button

on the operat

A

ion panel.

-

A

– 18 –

4-7. Adjusting the thread take-up spring

1

4

3

2

The standard stroke of thread take-up spring 1 is

8 to 10 mm, and the pressure at the start is 0.1 to

0.3N.

1)

Adjusting the stroke

Loosen setscrew

, and turn thread tens

2

ion

asm. 3.

urning it clockwise will increase the moving

T

amount and the thread drawing amount will

increase.

2) Adjusting the pressure

To change the pressure of the thread take-

up spring, insert a thin screwdriver into the

slot of thread tension post

while screw 2

4

is tightened, and turn it. Turning it clockwise

will increase the pressure of the thread takeup spring. Turning it counterclockwise will

decrease the pressure.

4-8. Example of the thread tension

When using the sewing machine for the rst time, adjust the thread tension referring to the table below.

Thread Material

Polyester spun thread #50 Wool 50 to 55 10mm [13mm] 0.2N

Polyester lament thread #50 Wool 30 to 35 10mm [13mm] 0.1N

Needle thread

tens

ion setting

Thread take-up spring moving

amount [Thread drawing amount]

Strength

– 19 –

5. Operating the sewing machine

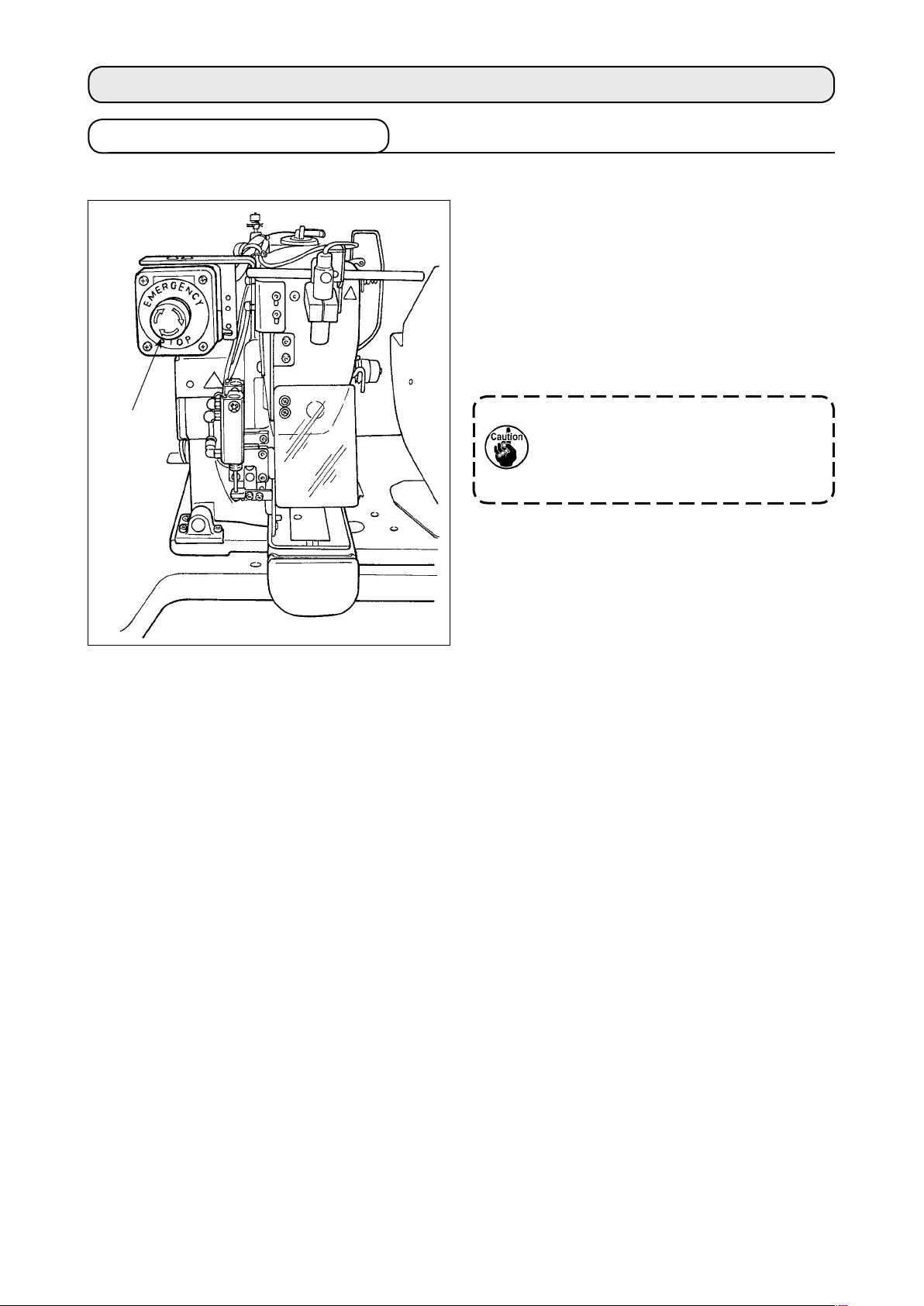

5-1. Emergency stop switch

(1) Method for operating the emergency stop switch

Emergency stop switch 1 is mounted on the upper left section of the sewing machine head.

Emergency stop switch

ly pressing in the red button. It is turned OFF by

turning it counterclockwise.

If you turn ON emergency stop switch

machine is in operation, the power is turned OFF

to cause the machine to stop operation.

i

s turned ON by strong-

1

while the

1

1

To turn OFF the power for any purpose other than

an emergency stop, operate the power sw

If yo u t urn OFF em ergency st o p

switch 1 with the power switch remained ON, the power is re-turned

ON. Take care of abrupt re-turn ON of

the power.

itch.

(2) Precautions with the emergency stop switch

When emergency stop switch 1

ON/OFF the power switch. The work clamp foot of the sewing machine may depress the loop clamp or

the belt loop loosening rod according to the operation timing of emergency stop switch

nomenon

the sewing machine to move it so as to avoid interference. Then, re-turn ON the power to the sewing

machine.

occurs, turn OFF the power to the sewing machine and manually lift the work clamp foot of

stays ON, the sewing machine cannot be powered up even if you turn

.

If this phe-

1

– 20 –

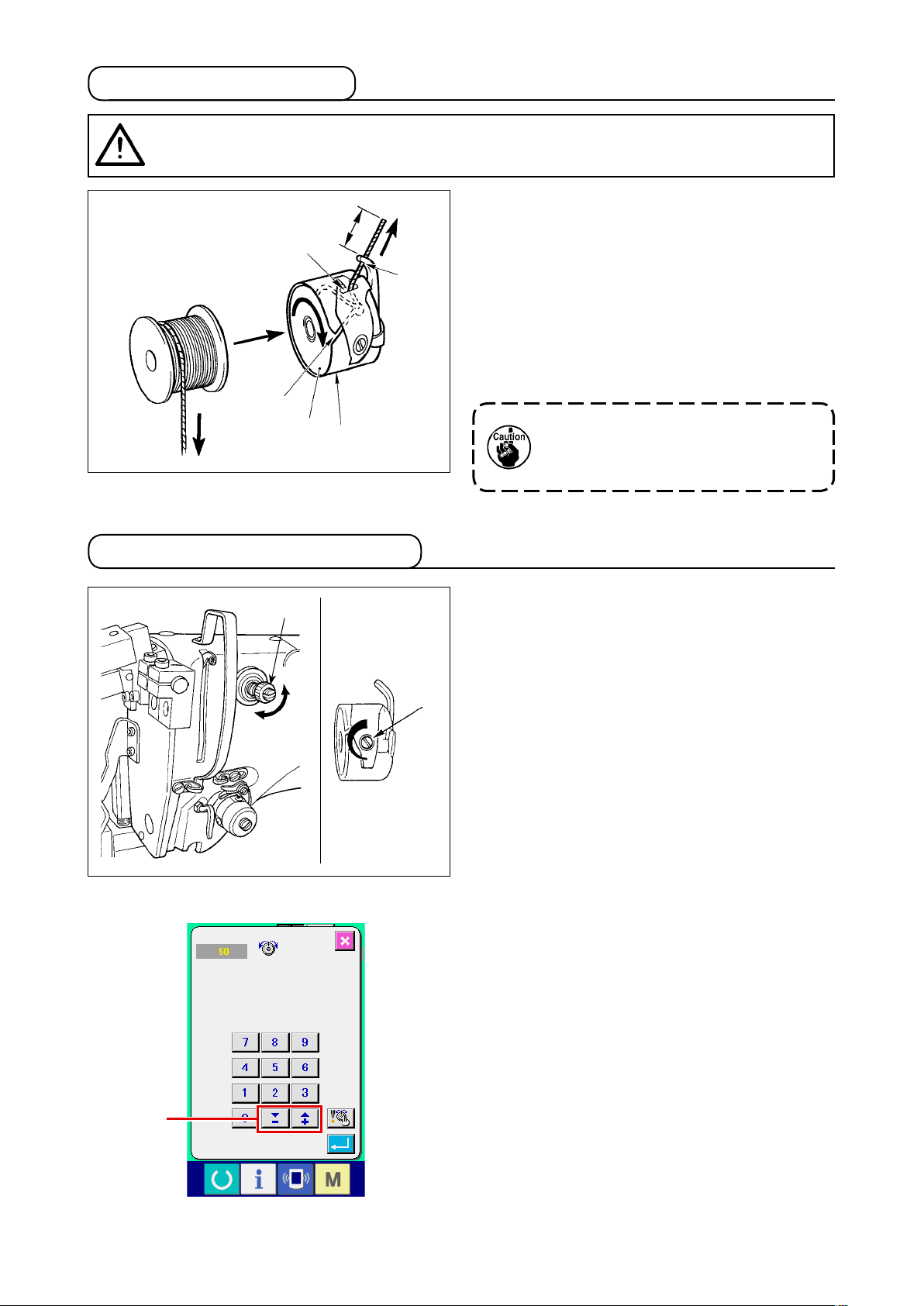

5-2. Winding a bobbin

(1) To wind a bobbin while the sewing machine is performing sewing

Thread the bobbin winder and wind the bobbin

thread onto the bobbin as illustrated in the gure.

(2) To wind a bobbin independently

A

In the case you only want to carry out bobbin winding

on the sewing machine, unthread the needle and remove the bobbin from the hook.

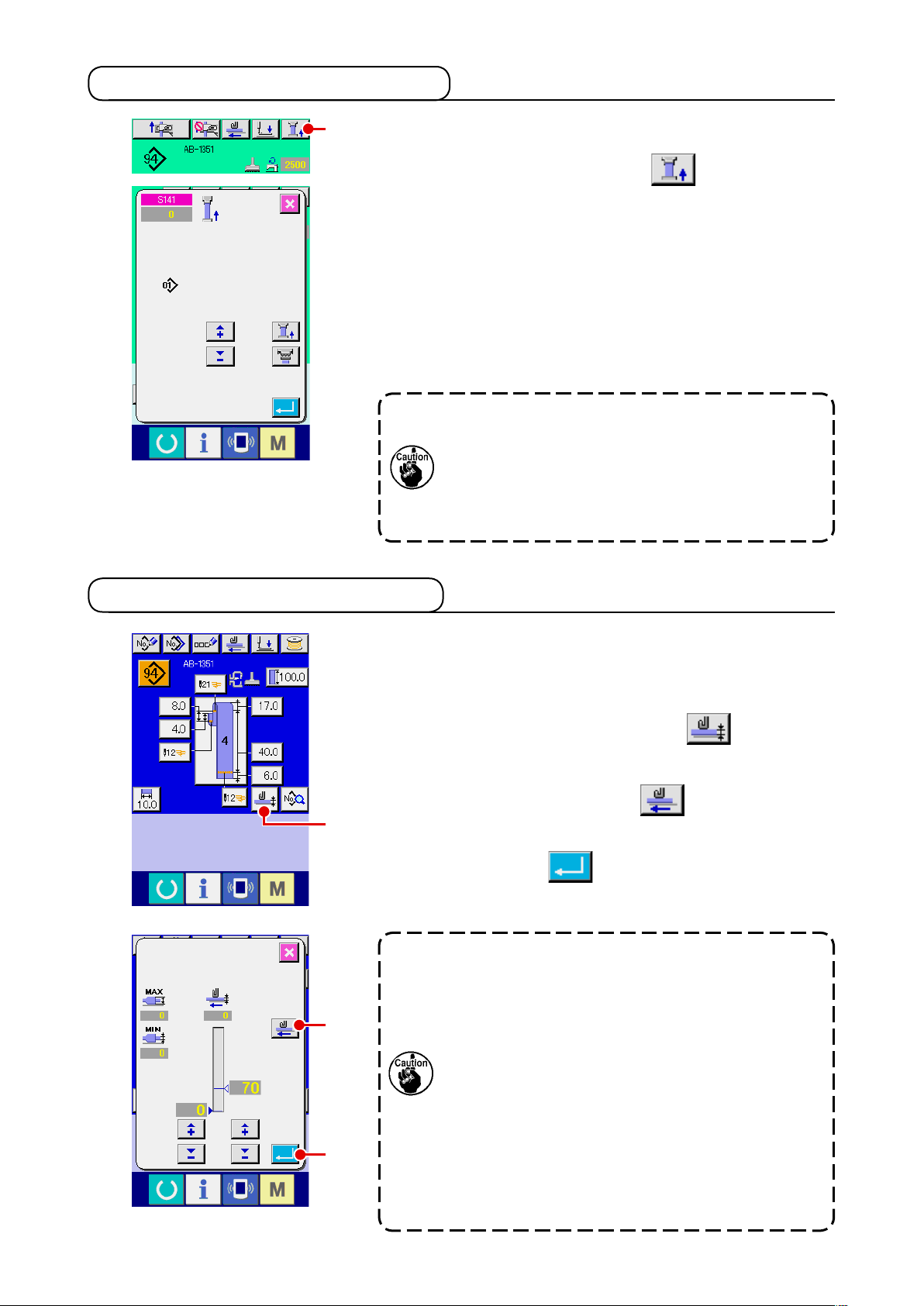

Displaying the bobbin thread winding screen

1

Press bobb

in winding button A on the belt loop data

input screen (blue), and the bobbin winding screen appears on

the screen.

S

tarting bobbin winding

2

B

Press the start switch, and the sewing machine rotates to start

bobbin winding.

topping the sewing machine

S

3

Press stop button

B, and the sew

ing machine stops and

returns to the normal mode. If you press the start switch again

during bobbin winding, the sewing machine stops under the

bobbin winding mode. If you press the start switch again in this

state, the sewing machine re-starts bobbin winding. Use this

operating procedure when you want to wind thread on two or

more bobbins.

The bobbin winding will not start immediately after

turning the power ON. To activate the bobbin winding

function, set a pattern number or the like first, then

press the set ready key to invoke the sewing

screen. In this state, the bobbin winding function is

enabled.

– 21 –

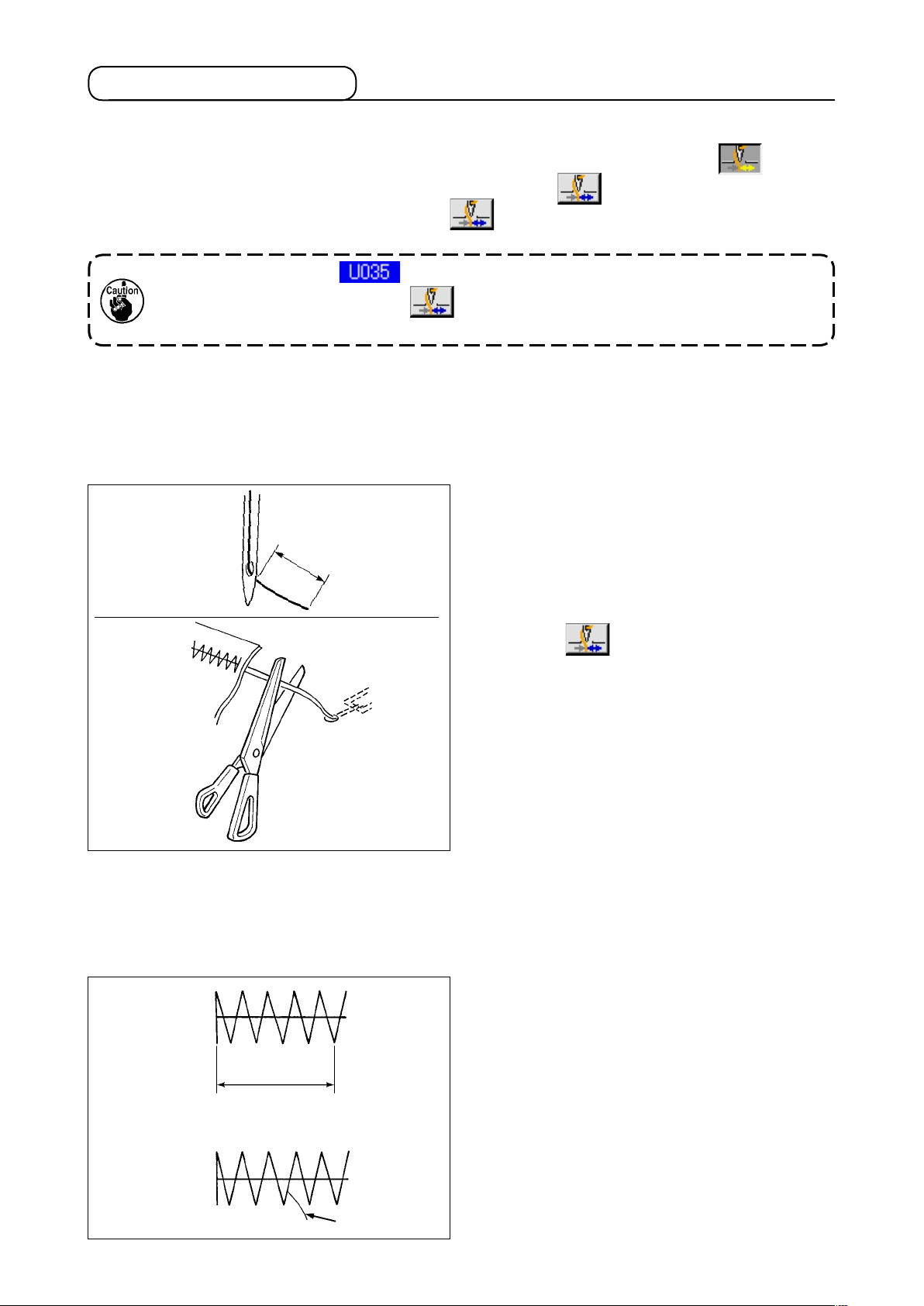

5-3. Thread clamp device

Trouble of sewing (slip-off of needle thread, stitch skipping, or stain of needle thread) at the time of highspeed start can be prevented with the thread clamp device.

The thread clamp device will operate when the thread clamp button has been selected

not operate when the thread clamp button has not been selected

.

, but it will

Changeover of ON/OFF motion is performed with

key. When the thread grasping device is in the

OFF state, the sewing machine is automatically set to the soft-start mode.

1. When memory switch is "1" (prohibited), the thread clamp does not work. Fur-

thermore, the thread clamp key

2. Memory switch, refer to "@-2-28. How to change the memory switch data”, p.93.

will not be displayed.

* Matters that demand special attention when using the needle thread clamp

(1) In case of with the needle thread clamp (motion), make shorter the length of needle thread remain-

ing on the needle at the sewing start for use. When the length of needle thread is lengthened,

needle thread on the wrong side of material is apt to protrude. In addition, when the length is

excessively lengthened, the end of needle thread held by the needle thread clamp may be rolled in

the seams.

In case of with the needle thread clamp, the

1)

33 to 36 mm

3)

1)

standard of the length of needle thread is 33

to 36 mm.

2)

When needle thread is long after replacing

thread or the like or sewing while holding nee

dle thread by hand, turn OFF the THREAD

CLAMP

3)

When the needle thread held with the thread

key.

clamp is rolled in the seams, do not draw the

material forcibly and cut the connecting needle

thread with the scissors or the like. The seams

are not damaged since it is the needle thread at

the sewing start.

-

(2) It is possible to adjust needle thread shorter by making the needle thread clamp work while holding

the stabilized sewing at the start of sewing and the gathering (bird's nest) of needle thread on the

wrong side of material can be lessened. However, for the pattern which the stitch length for neatly

rolling in needle thread is short, needle thread may protrude from the wrong side of material. Select

with/without thread clamp referring to the item below.

When the sewing length is short (less than ap-

(Right side)

proximately 10 mm), the end of needle thread may

protrude like beard even when adjusting needle

thread shorter.

10mm

(Wrong side)

N

eedle thread

– 22 –

5-4. Placing a belt loop

3

2

1

Press down multi-layered part detecting bracket

and lever 1 of the gear of the loop draw-out

3

ice to put the belt loop into the guide until it is

dev

placed under gear 2.

When you route the belt loop under

the gear, insert it until it appears from

the belt loop cutting knife.

*

In the case the sewing machine is ON, when

multi-layered part detecting bracket 3 i

s pushed

up, the gear is rotated by the motor to feed the

belt loop.

Route the belt loop

in the direction of the arrow.

Finally, route the belt loop in the guide roller sec-

ion on the table to allow it to trail downward.

t

Position the belt loop below the guide

roller so as to prevent it from being

hitched or being applied with an excessive resistance at the time of belt

loop feeding.

In the case the optional belt loop feeding unit is to

be mounted on the sewing machine, route the belt

loop as illustrated in the gure at left.

The belt loop feeding unit is provided

with a capability of detecting two different errors; one is the case the belt

loop has knots and the other is the

case the belt loop cannot be fed due

to an excessive resistance.

– 23 –

5-5. Adjusting the belt loop tension

A

When you have changed the belt loop, you need to re-adjust the

belt loop tension without exceptions.

Press the belt loop tension button A on the sewing

screen.

more the belt loop tension is adjusted in a negative direc-

The

ion, the less the belt loop tension becomes. (The belt loop ten-

t

s

ion can be set and stored in memory on a sewing-pattern by

sewing-pattern basis.)

As a guide, adjust the belt loop tension so that the entire length

of the belt loop fed from the belt loop feeding section and

clamped at the belt loop clamping section is shorter than the

entire belt loop length displayed when selecting a sewing pat

tern by approx

imately 1 mm.

If the sewing machine is operated under a high belt

loop tension, the entire length of the belt loop fed

becomes shorter than required. In this case, problems such that the belt loop cannot be sewing at

the predetermined length or that the cut end of the

belt loop is not straight can occur. To prevent such

problems, adjust the belt loop tension adequately.

-

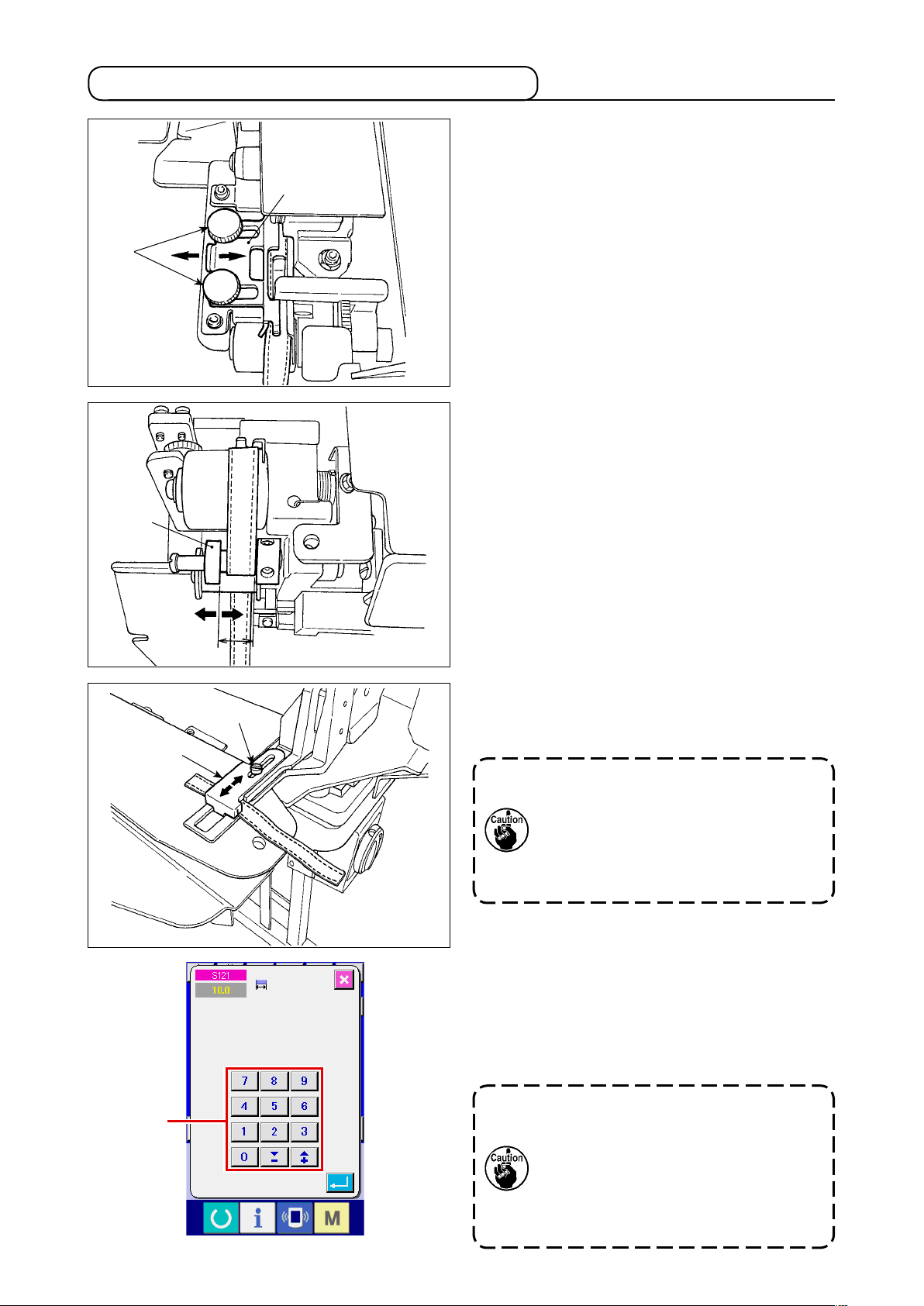

5-6. Setting the belt loop thickness

When you use a new belt loop, you need to set the belt loop

thickness without exceptions. If the belt loop has multi-layered

parts (splices), thickness of the multi-layered part has also to

be set.

Press belt loop

eration panel screen.

Route the belt loop to be used in the predetermined manner

and

A

B

C

fed as long as the feed key is held pressed. As long as you

keep the feed key held pressed, the belt loop is fed. Be sure to

press the enter button

normal-thickness part and multi-layered part of the belt loop un-

der the mult

1. If the belt loop thickness is smaller than the pre-

2. As a guide, the belt loop thickness is 1 to 1.8 mm.

thickness teaching button A on the op-

press belt loop feeding button

C after having passed both the

i-layered part detecting section.

determined value, the belt loop presence/absence

detector of the belt loop drawing device may

determine that the belt loop is absent even if the

belt loop is present. If the aforementioned error

occurs, operate the sewing machine with the belt

loop presence/absence detecting function disabled.

If the belt loop thickness exceeds the aforementioned range, the belt loop clamping section and

the work clamp foot of the sewing machine can

interfere with each other. To prevent this, be sure

to perform trial stitching in prior to conrm no

interference between them. Then, start sewing.

B. The belt loop is

– 24 –

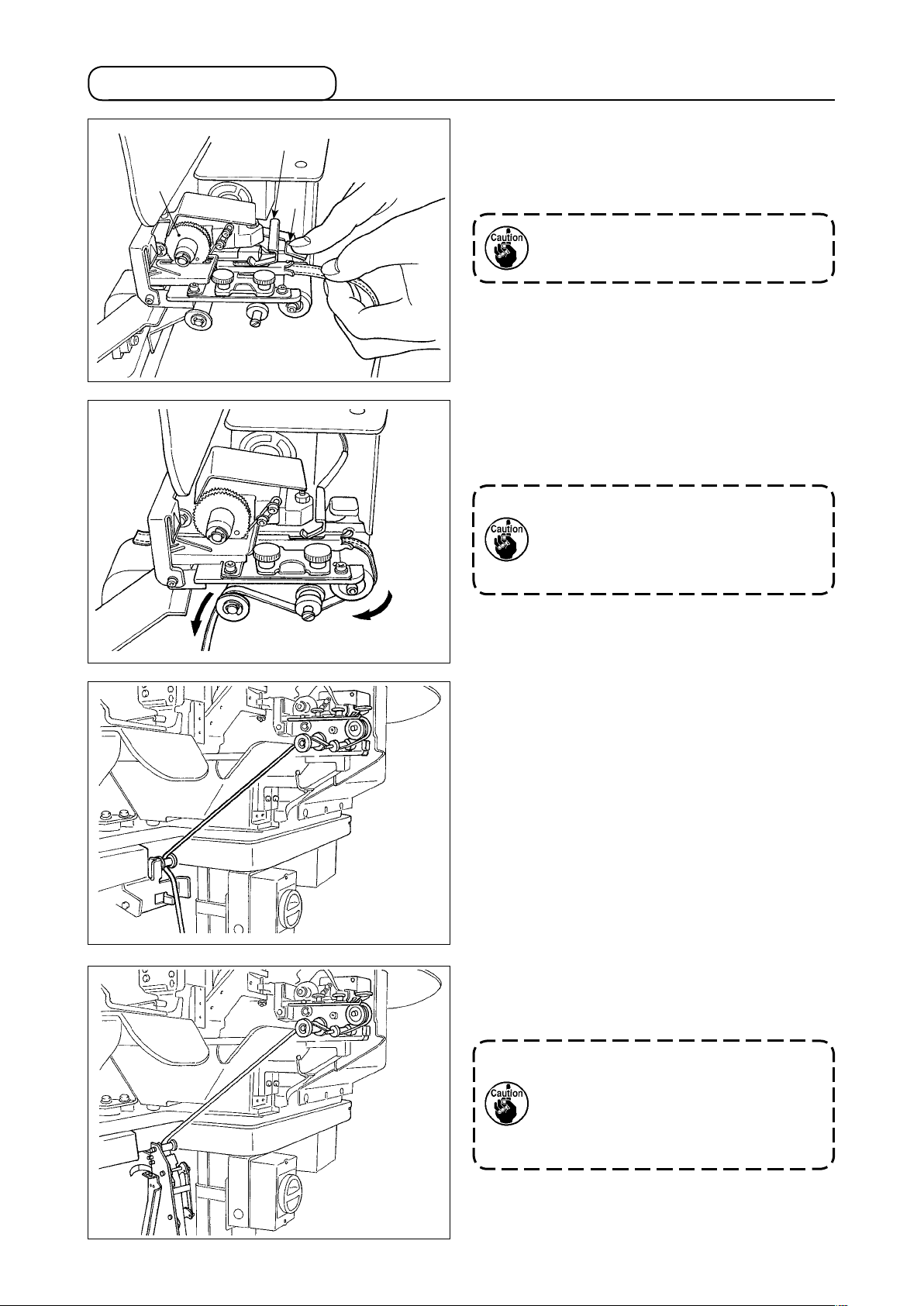

5-7. Method for changing the belt loop width

1) When you want to change the belt loop width,

1

Adjust so that the belt-loop passes through

2

Check that the top end of the belt loop gu

2) Adjust the position of guide 1 according to

1

loosen two screws 2 of belt loop gu

ide 1

to adjust the guide width to t the belt loop

idth.

w

the belt-loop guide smoothly with no exces

ive lateral space between the guide and the

s

belt loop, with guide

pressed lightly against

1

the belt loop.

ide

matches the belt loop width.

the belt loop width.

-

A

3

4

3) Loosen setscrew 4 of the belt loop clamp.

Adjust the position of loop clamp, upper 3

accord

ing to the belt loop width.

The width of the belt loop guide section and that of the belt loop clamping

section should be adjusted so that the

belt loop smoothly pass through and

that no widthwise play exists. If there

is an excessive widthwise play, the

belt loop attaching location can vary.

4) Enter a value of belt loop width into belt loop

width setting section

on the operat

A

ion

panel screen. At the same time, change the

dimensions of a seam for attaching a belt

loop. Refer to

belt loop length", p.39

ing the seam dimensions.

chang

If the bartacking width of which is extremely wider than the bartacking width

setting specified through the operation

panel is sewn, the garment-body presser

and the belt-loop clamp can interfere with

each other (error No. M596). If the alarm

is given, change the bartacking width setting to decrease the bartacking width.

"@-2-6. How to change the

for the method for

– 25 –

Loading...

Loading...