Page 1

ILLUSTRATE

FOR

PAR

5 LIST

HEAVY

KARPEl

Model

Kl

G

8 I

DUTY

MACHI

2K

E

~

.

·,

421

NORTH

National

MIDLAND

Distributors

AVE .• SADDLE BROOK, N.J.

of

Juki

& Kin

g/

me

Industrial Sew

07662•

(20

1)

796·8800

(2

12) 929-4415

/ng

Machine"

Page 2

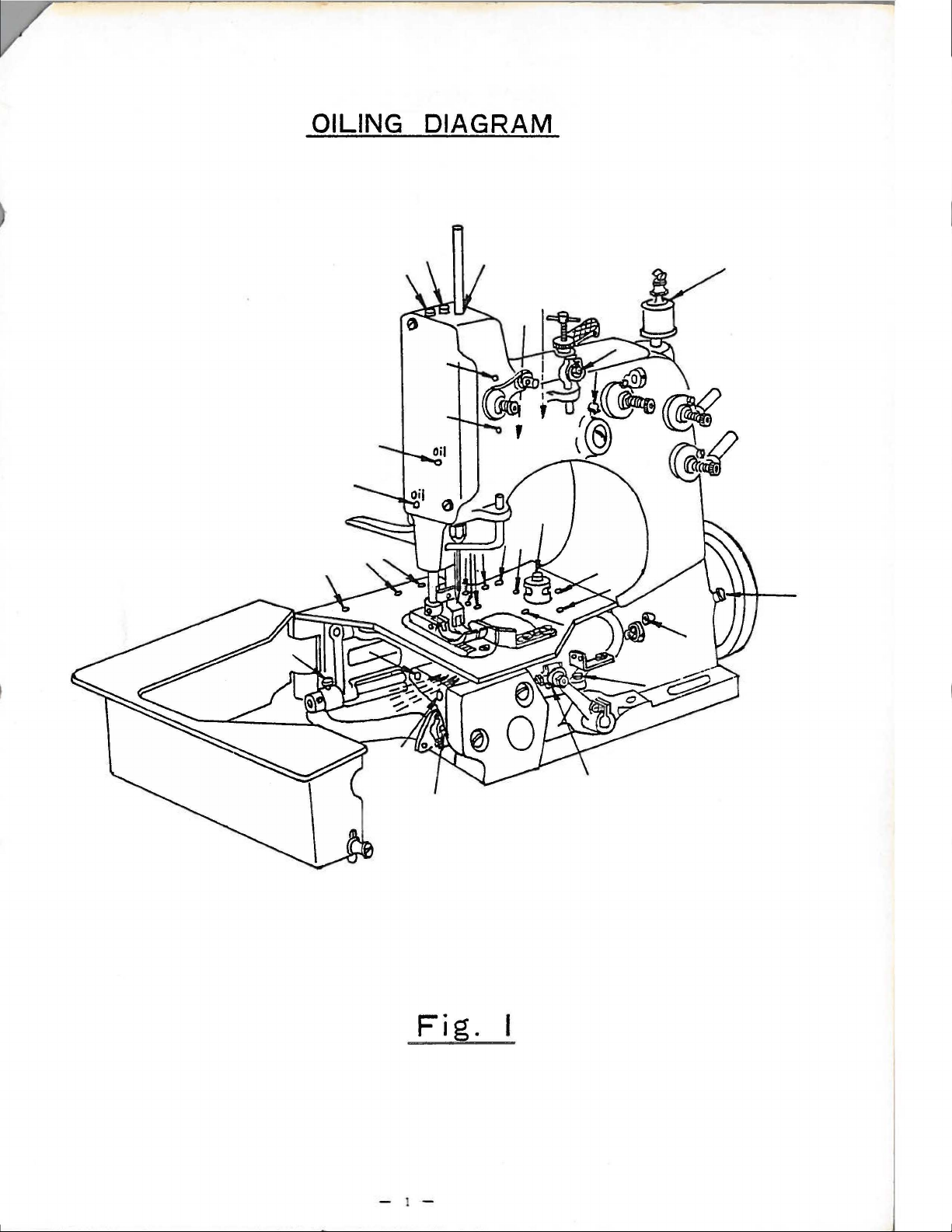

OILING DIAGRAM

Fig.

- I -

I

Page 3

THREADING

DIAGRAM

Fig.

-

2

2-

Page 4

THREADING AND ADJUSTMENT

FOR

INSTRUCTIONS

812K

Stitch

1.

2.

3.

One

needle

type

505-EFD-1

Clean

eccentrics

wicks

from

oiling

Put

plate.

needle

plate

Remove

machine.

machine

to

the

and

in a

(Figure

corry

oil

new

The

point

the

KINGLINE MODEL

heavy

on

the

reservoir

run

needle

in

3).

presser

Loosen

duty

(modified).

----SETTING

thoroughly.

main

the

oil

for

five

needle,

should

its

highest

feet,

the

shaft.

to

and

minutes

class

screw

flat

bed

Fill

Run

the

bearings.

that

1970.

center

position

cloth

(::::

812K

machine

oiling

they

at

2.000

in

plates

93A)

HEAVY DUTY KARPET KING

for

overseoming

UP MACHINE

system

the

machine

contact

size

the

should

and

on

See

R.P .M..

100

front

be

the

and

that

the

(SOE)

end

1}

feed

right

oil

slowly

the

oil

holes

Oiling

and

of

;!"

inches

dog

side

all

for a minute

wicks

check

the

for

of

rugs

bearings,

ore

in

the

diagram

location

throat

above

convenient

the

feed

and

particularly

to

saturated

strops.

(Figure

of

p l

ate

the

top

access

bar

carpets.

allow

by

Repeat

1)

needle

needle

of

and

the

the

is

available.

slot.

the

to

push

the

flow

the

in

throat

the

the

oil

throat

The

rear

4.

1

1-z

needle

Pla

ce

the

The

looper

(Figure

Fig.

II

guard

left

gouge

4). This

3

(::

81225K)

hand

is

adjustment

looper

set

when

for

enough

in

the

the

is

accomplished

Feed

to

looper

looper

the

holder

is

Dog

rear

at

its

by

rocker

Fig.

to

and

farthest

ovoid

set

the

and

its

looper

poini

raising

4

contacting

gouge

of

travel

or

lowering

the

to

to

needle.

~-4

the left

the

inch.

boll

Left

- 3 -

hand looper

Page 5

joint

(#

15442K)

in

the

slot.

Raising

the

ball

joint

decreases

the

looper

gauge

and

5.

6.

7.

8.

lowering

Set

the

left

it. This

rocker.

Set

point

Set

connecting

(:!;

is

Set

~~"

position

the

adjustment

the

rear

of

the

distance

269

&

obtained,

the

right

to

looper

it

acts

hand

needle

travel.

rod

:;

the

(Figure

drive

18)

then

hand

left

the

reverse.

looper

is

readily

guard

between

(#

81241)

on

the

tighten

looper

of

the

5).

The

lever

so

centers

straps

pitman

the

gauge

center

looper

(:;;

81238)

Looper

that

made

so

that

rod

nuts

gauge

it is

(#

at

and

so

of

on

gauge

up

by

it

barely

6038K

4-

%

and

that

the

the

is

available

to

the

loosening

contacts

& #

".

turning

reassemble

the

point

needle

of

the

right

cross

back

the

6039K)

This is

the

the

of

when

hand

for

of

the

two

screws

the

needle

of

the

done

rod

until

connecting

the

right

the

looper

looper

setting

needle

at

right

by

loosening

the

hand

is

the

without

(#

95)

its

hand

desired

rod

looper

is

at

its

controlled

looper.

in

the

most

forward

looper

the

measurement

in

the

extreme

deflecting

looper

drive

two

nuts

machine.

passes

left

by

moving

9.

shaft.

the

gauge,

tightening

make

cross

This

cross

looper

casting.

respect

drive

When

without

adjustment

To

lever

sure

shaft.

may

shaft

drive

to

leve

right

deflecting

increase

clockwise

move

the

that

be

done

and

Re-check

the

r is

shifted.

hand

for

the

lever

screws

there

by

at

the

lever

the

needle

looper

it. It

setting

the

and

on

is

tight

each

the

looper

to

decrease

the

the

no

end

pushing

same

up

setting

time

moves

must

right

gauge,

opposite.

looper

play

forward

time

setting

against

of

the

the

to

also

cross the

hand

drive

the

move

the

When

in

the

on

the

looper

loop

right,

looper

looper

lever,

the

the

with

er

it

left

is

must

hand

made

pass

looper

by

I

I

L

Right

Fig.

the

needle

as

loosening

hand

close

the

5

as

as

looper

close

possible.

two

screw

as

possible

The

(:;:;:

318)

at

the

front

of

the

machine

(¢

81

255).

it

downward

be

turned

position

Moving

slightly

while

the

brings

retightening

the

by

and

block

looper

loosening

the

moving the

upward

closer

the

holding

screws.

- 4 -

brings

to

the

looper

the

left

screws

shaft

looper

hand

and

bearing

closer

looper.

holding

or

sliding

to

the

The

loopers

the loopers

needle

block

and

moving

themselves

in

the

can

desired

Page 6

10.

With

right

hand

looper

at

its

extreme

left

position.

set

the

right

hand

looper

thread

11.

12.

13.

take-up

looper

Put

the

front

This

guard

plate

the

screw.

the

presser

freely.

The

height

rear

teeth

the

adjustment

Screw

tongue

eyelet

gauge

feed

needle

in

front

THIS FACTOR IS VITAL.

the

(:

(;:=

81266KB)

is

not

dog,

guard

is

Place

bars

of

project

edge

81203KA-1)

readily

of

the

the

with

the

feed

(Figure

guide

cloth

1/

changed

plates

close

adjusted

needle

presser

the

dog

32"

3).

on

is

against

in a

when

to

the

slot

feet

pressure

is

correct

above

to

the

vertical

with

needle

by

and

on

the

cloth

the

position

nut

(::::

throat

without

loosening

moving

the

released

when

throat

plate

presser

9937)

plate

the

the

machine

as

at

its

plate.

and

foot

being

is

loosened.

back

deflecting

screw

guard

and

much

as

hightest

A

stop

abjust

stitch

careful

on

the

it.

(::::

90)

into

position

check

tongue.

the

convenient.

point

screw

it

so

that

machine

in

top

vertical

of

travel

is

that

the

left

and

of

the

and

The

the

provided

the

edge

hand

set

throat

retightening

movement

bars

must

tips

to

guide

the

of

move

of

the

maintain

14.

1

5.

Draw

Threading

Adjust

This

by

regulator

18A)

feed

(Figure 6).

feed

80651)

stitch

l

After

is

need

it

the

adjustment

loosening

on

rocker

driving

and

engthens

the

set, res

le

barely

the

the

shortens

guard

thread

diagram

stitch

stud

side

(:::

Raising

arm

lowering

the

stitch.

stitch

et

the

contac

length

is

the

nut

of

80233)

the

length

rear

so

ts

into

(Figure

made

stitch

(::::

the

the

(::::

it

that

the

HA

the

to

machine

2)

is

available.

give

the

Shorten

Lengthen

and

desired

'

start

operating

number

on a piece

of

stitches

per

of

inch.

stud

rug

nut

materia

l.

needle

forward

when

position

in

its

of

most

trave

l.

- 5

Fig.

6

Page 7

16.

17.

Regulate

to

feed

Adjust

left

hand

the

properly

the

pressure

left

looper

. A

hand

thread

an

the

comparatively

looper

just

thread

tightens

presser

feet

heavy

take-up

as

the

so

that

pressure

(

~

81266K)

left

the

hand

springs

is

usually

outward

looper

exert a pressure

required.

or

clockwise

thread

comes

until

off

sufficient

the

the

right

18.

19.

20.

21.

hand

THE

cane

The

high

thread.

beaded

Make

obtained,

NEEDLE

looper.

CONE

as

needle

enough

I o

thread

drawn

RIGHT

AT

the

left

and

The

appearance

sewing

check

THREAD

pull

less

tension,

from

HAND

{CAUTION -NO

THIS

to

left

test

the

LOOPER

TIME).

hand

right

hand

give

positive

hand

of

on a single

the

following

CONTROL

needle

or

raise

cone

looper

looper

the

thread

on

THREAD

All

looper

lower

needle

the

LEFT

the

left

moves

thread

and

consistent

thread

thread

thickness

thread

into

the

frame

upstroke

CONTROL

HAND

hand

to

the

tension

of

controls.

stitch,

eyelet.

of

LOOPER

looper

end

tension

control

should

at

the

rug

or

the

needle.

THREAD

thread

of

its

should

to

be

purl

or

material.

move

Most

of

travel

the

just

edge.

If

purl

the

SHOULD

should

to

the

be

set

as

needle

high

satisfactory

down,

needle

BE

be

right.

low

and

enough

increase

thread

DRAWN

drawn

as

possible

right

to

samples

should

from

hand

give

are

needle

FROM

the

yet

looper

a

not

be

22.

To

pull

the

right

clockwise,

{:::;:

9937)

LEFT

HAND

The

clockwise

should

to

the

right.

hand

is

left

until

be

mare

being

loosened.

drawn

right

looper

LOOPER

hand

the

careful

looper

left

from

hand

THREAD

hand

thread

that

thread

the

looper

cone

tension

the

left

CONTROL

control

looper

as

thread

or

hand

thread

the

into

move

looper

eyelet

just

left

the

right

(take-up)

tightens

hand

stitch,

hand

gauge

looper

or

looper

is

should

as

the

moves

move

not

thread

changed

be

adjusted

left

hand

to

purl

the

down,

tcke-up

when

looper

end

reduce

nut

outward

thread

of

its

{eyelet

or

trave

)

l

- 6 -

Page 8

94

\'~

-

~~~

80648

376

@m

880687

376

~

\~

Rrfoi

l~

IV

I

Ol

A

II

J

ii,.,

~

l

80631

80437A

880688

22574

/ 1\

,/ I \

I

881201A

i

80438

~

81239

0

I -

~

80440

Plate

No.

1

Page 9

89

94

Set

screw

Set

screw

guard.

for

for

Plate

Hinge

Presser

pin.

bar

No.

lifter

1

guide

plate

and

Looper

thread

pes.

2

pes

.

4

376

420

22574

80437A

80438

80440

80631

80648

80649

880687

880688

881201

Screw

Lifter

Screw

Cloth

Spring

Locking

presser

Lifter

Lifte r

Face

Top

cover.

Cloth

for

lever

for

plate

for

bolt

bar

lever.

lever

plate.

plate.

Face

stud.

Cloth

swinging

Locking

knob.

lifter

spring.

plate.

plate.

bolt.

guide

extension

plate

.

hinge

pin

pes.

2

pe.

pes.

3

.

pc.

pe.

1

pe.

pes.

2

pe

.

pc.

1

pc

.

pe.

pc.

881201A

81239

Cloth

Cloth

plate

plate

swinging

swinging

extension.

extension

locking

bolt

pc.

pc

.

.

1

••

l3

-

Page 10

@

80630C

80630

80694C

806948

81222

806948

88062

l H

@

806300

29782H

HA66K

80681

#...._

!4E

®

0

/

~

80685

80621A

~

2539

I

HA95

HA81

Plate

so

~

80674

No.2

Page 11

HA

66K

Key

far

Pulley

hub.

Plate

Na.

2

pc.

74E

80

HA

81

HA

95

22539

29782H

80621A

B80621H

80630

80630C

806300

80652

80674

Screw

Screw

Spat

Set

screw

Plung

Main

Wheel

Wheel

Ne-edle

Needle

Needle

Needle

Wheel

far

for

screw

screw

shaft

hub.

rim.

lever

lever

lever

lever

hub

Main

shaft

Wheel.

for

Main

far

Main

for

Main

assembly.

connecting

connecting

connecting

connection

lock

washer.

collar.

shaft

shaft

shaft

bushing

bushing

bearing

rod

tube.

rod

tube

tube

rod

bearing

housing.

housing.

sponge

nut

(left

nut

(right

(lower).

hale.

thread).

thread).

2

pes.

4

pes.

pc.

pc.

pc.

pc.

pc.

pc.

pc.

pc.

pc.

pc.

pc.

80681

80685

806948

80694C

81222

Main

Main

Main

Main

Main

shaft

shaft

shaft

shaft

shaft.

collar.

bushing

bushing,

bushing,

and

left

right.

housing.

and

middle.

pc.

pc.

1

pes.

2

pc.

pc.

- 10 -

_ j

Page 12

225608

I

@HAl

HA

1038

80667

~~

/

/

03~

'-_"-.

I - .

\.

~

\.

,_

~

~

225608

81256A

80667

~

/

AS137

\

~

~

~

225608

<?

~

.

.,~

~

81256

28C

95

~

80665KD

J

•

28C

80676AC-2

80676AC-4

376A

~

~

i

376A

81266KA

-

~

!

-·

35871A

AS137KA

Plate

No.3

Page 13

Plate

No.

3

HS

HA

HS

AS

AS

AS

28C

528

88

95

1 03B

106

107

108

110-2

110-3

110-4

137

137A

137KA

376A

Set

screw

Frame

Set

screw

Set

screw.

Frame

Tension

Tension

Tension

Tension

T

ensian

Tension

Frame

Frame

Base

Looper

far

rolling

far

thread

past.

spring

reg1,1lating

spring

spring

spring

thread

thread

thread

thread

Frame

thread

Rolling

eyelet.

ferrule.

far

far

far

eyelet

eyelet

eyelet

guide

thread

guide

thread

nut.

right

hand

left

hand

needle

support.

assembly.

assembly

set

screw.

eyelet.

axle

guide.

looper

looper

thread.

(twa

assembly.

thread.

thread.

thread

hale).

4

pes.

pc.

pc.

3

pes.

pc.

3

pes.

3

pes.

3

pes.

pc.

pc.

pc.

4

pes.

pc.

pc.

2

pes.

HA1348

HA1349

22560B

22743

35871A

80250

80250A

80250B

80665KD

80667

80668

80676A

80676AC-2

80676AC-3

80676AC-4

Frame

Frame

Set

screw

Screw

Base

Frame

Frame

Frame

Needle

Tension

Needle

Tension

Thread

Thread

Thread

tension

tension

far

thread

needle

needle

needle

thread

disc

thread

disc.

tension

tension

tension

far

Frame

guide.

stop

past

past

Frame

rolling

thread

thread

thread

guide,

pin.

take-up

assembly

assembly

assembly

ferrule,

ferrule,

thread

rolling

rolling

rolling

(lower).

rolling thr

front.

rear.

guide.

thread

for

Right

for

Left

for

Needle

guide

thread

thread

thread

hand

ead

hand

axle.

guide

guide

guide.

guide

looper

looper

thread.

assembly.

support.

roller.

thread.

thread.

3

pes.

3

pes.

3

pes.

pc.

pc.

pc.

pc.

pc.

pc.

3

pes.

pc.

6

pes.

pc.

pc.

pc

.

81256

81256A

81266KA

Frame

Frame

Base

thread

thread

thread

eyelet.

eyelet

guide

assmbly.

assembly.

-

12

-

2

pes.

2

pes.

pc.

Page 14

80673B

80644

80617

90

~

80246

29774KD

~

BP108

80656

80643

29066L

80650

~0246

;tO

88

~80644

80636A

~

2~29

tQ

)

HA56

~

ll

0673

A

01225~

~")

~J

it

88

Plate

No.

4

Page 15

Plate

No.

4

HA

54A

HA

56

HA

58C

HA

580

HA

58F

81

88

90

91

95

HS

1000

BP

108

HA

212K

21111

22526

22565C

22729

29066L

29774KO

51134V

Needle

Needle

Needle

Needle

Needle

Spat

Set

screw.

Screw

guide

Screw

Set

screw

Stop

Clamp

Thread

Needle

Screw

Screw

Screw

Needle

Needle

Needle

bar

clamp

bar

bar

bar

screw

for

tongue.

for

screw

screw

guide

bar

for

far

for

lever

bar

lever

link.

nut.

connection

connection

connection

for

Needle

Needle

Needle

for

Needle

for

Tension

for

for

connection

Needle

Needle

Needle

connecting

connection

link

plate

lever

lever.

Needle

Needle

plate.

lever

lever

pin

assembly.

tension

tension

spring.

lever.

needle

link

upper

disc.

bar

connection

bar

connection.

post

collar.

link

lower

ball

stud

rod

upper

assembly.

ferrule

ferrule

guard

pin.

pin.

fork.

(front).

(rear).

and

and

bearing

Cloth

plate

Needle

assembly.

edge

lever

ball.

pc.

pc.

pc.

pc.

pc.

pc.

6

pes.

3

pes.

pc.

pc.

pc.

2

pes.

pc.

pc.

2

pes.

pc.

pc.

pc.

pc.

2

pes.

80046

80246

80615

80617

80636A

80643

80644

80650

80656

80659

80669

80673A

806738

80676

81203KA

81203KA-1

81203KA-2

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Tension

Cloth

Cloth

Cloth

bar

lever

lever.

bar.

lever

lever

lever

lever

lever

bar

bar

bar

bar

disc.

plate

plate

plate

connection

shaft

bushing.

ball

stud

shaft.

shaft

hole

connection

ball.

connection.

connection

bushing

bushing

edge

edge

edge

(lower).

(upper).

guide.

guide

guide

tension

fork.

plug

bearing,

tension

tongue.

assembly.

post.

screw.

post

upper.

ferrule

(front).

pc.

2

pes.

pc.

pc.

pc.

pc.

2

pes.

pc.

pc.

pc.

pc.

pc.

pes

2

pes.

pc.

pc.

pc.

81224K

81225

Needle

Needle

plate.

plate

front

needle

guard.

- 14 -

pc.

pc.

Page 16

06

80632

~,.,~

tlj)

98

22870

~

0/

'()

98 98 98

\0

806668

(482C}

"'

~~

.?~

9.5~

\

I

I

,.

(482q

~

a$£

B06668C

80663

!

~

1

~

I

64Y

~

3.57338

8

0667

~

0

80267

/ (

(9

1/

l.J

80660

80662A

,

~

I

'

I

1

1

8066

!

31220KA

l

I

-- :s --

Plate

No.

5

Page 17

Plate

Na.

5

64Y

HA

65E

95

98

258

11639H

22513

22870

357338

80220C

80267

80632

80660

Presser

Hinge

Set

Screw

Nut

Hand I iHer

Set

lifter

Lock

Presser

Hand

Presser

Presser

screw

screw

far

for

screw

lever

nut

lifter.

spring

lifter

far

foot

bar

bar

regulator

far

for

Presser

Presser

lever

stud

for

Presser

screw

Presser

shank

lifter.

(left).

Right

bar

.

pin.

presser

bar

collar.

screw

foot

spring

(right).

screw.

lifter.

pin.

tongue.

regulator

faat.

screw.

pc.

pc.

2

pes.

8

pes

.

pc.

pc.

pc.

pc.

pc

.

pc.

pc

.

pc

.

pc.

80661

80662

80662A

80663

80664

806668

806668C

80667

812200

81220KA

81297KA

Presser

Presser

Presser

Presser

Presser

Presser

Presser

Presser

Presser

Presser

Presser

bar

bar

bar

spring

spring

bar

bar

spring

foot

faat

faat

(right).

bushing

bushing

(upper).

(lower).

collar.

collar

pin.

assembly

assembly

tongue.

(upper).

(lower).

with

(left).

(right).

screw.

pc

.

2

pes.

2

pes.

2

pes.

2

pes.

4

pes.

4

pes.

pe

.

pe.

pe.

pe.

- 16 -

Page 18

r;)

T26

93A

1t

80666BC

~

(482C)

~

97X

HA18A

@

:..------

---------

29099K

81006

81

<IIJij

©Jj

----------

-

81205A

81225K

(Jlij

~

~

HA43X

~

96

93A

Plate

No.

6

Page 19

Plate

Na.

6

HA

HA

HA

HA

T

HA

AS

HS

SA

10

1 1

18

18A

20

20A

23

26

43X

69H

70A

70A

81

89

Feed

Feed

Feed

Nut

far

Nut

far

Washer

Washer

Feed

Stop

Feed

Washer

Feed

Feed

Screw

Set

screw

rocker

bar

bar

Feed

Stitch

far

far

bar

screw

lift

cam.

far

cam

cam

far

shaft.

prong.

shaft.

cam

regulating

Feed

Stitch

shoe.

far

Stitch

Feed

ailing

ailing

Feed dri

far

Feed

ailing

cam

ailing

regulating

regulating

dog

screw.

felt

holder.

felt.

ving

rocker

felt

holder.

stud.

felt

stud.

eccentric.

and

holder.

stud

Feed

.

bar.

pc.

pc.

pc.

pc.

pc.

pc.

pc.

pc.

pes.

2

pc.

pc.

pc.

pc.

pc.

4

pes.

93

93A

96

97X

98

29099K

80233

802348

80292

80651

80654

806668

80666BC

80696

Set

screw

Screw

needle

Spat

Screw

Screw

Feed

Feed

Feed

Feed

Feed

Stitch

Feed

Feed

Stitch

far

far

Feed

guard.

screw

far

Supporting

far

Feed

driving

rocker.

bar.

rocker

driving

regulating

rocker

rocker

regulating

Feed

far

Feed

eccentric

shaft

eccentric

shaft

shaft

dog.

bar

bar

bushing.

stud

collar.

collar

stud.

prong,

lifter

cam.

feed

shaft

collar.

assembly.

connection.

bushing.

with

Feed

dog

screw.

pc.

bar

shoe

and

Feed

bar

pes.

4

pc.

.

p~.

pes.

4

pc.

pc.

pc.

pes.

2

pc.

pc.

pes.

2

pes.

2

pc.

Feed

Feed

driving

dog.

bar

81006

B1205A

Bl225K

Feed

rear

eccentric.

needl

e g

uard.

-

IS

-

pc.

pc.

pc.

Page 20

29198K

98

18

®

~OA

80236

~

80645

~~

-....--~-~

01255

6038K

Plate

No.

7

Page 21

18

Nut

for

Looper

drive

Plate

connecting

No

rod

. 7

and

Boll

joint.

3

pes.

HS

136

269

318

6038K

6039K

22517

22729

29198K

29442N

36K

73X

81

95

96

98

Looper

Set

screw

Spot

Set

screw

Spot

Screw

Clomp

Nut

for

Clomp

Looper

Looper

Screw

Screw

Right

Looper

connecting

for

screw

for

screw

for

Looper

screw

Looper

screw

rocker

rocker

for

Looper

for

Looper

hand

drive

Looper.

for

Looper

Looper

for

Looper

for

drive

for

connecting

connecting

looper

eccentric

rod

driving

rocker

Looper

connecting

Right

drive

lever

rocker

boll

joint

driving

eccentric.

drive

hand

assembly.

lever

(right

drive

looper

rod

rod

lever.

boll

stud

assembly.

washer.

ecc<entric.

shaft

hand).

lever

sha

rod

(left thr

rocker

boll

joint

boll

joint

fork

.

rocker.

ft

rocker.

ead)

shaft

(left).

(right).

.

bearing.

2

2

2

2

2

pc.

pes.

pc

.

pc.

pc.

pes.

pes.

pc.

pes.

pc

.

pc

pes

pc

.

pc

.

pc

.

.

.

80236

80636A

80638A

80642

80645

80691

81207K

81213A

81238

81240

81240A

81241

81251A

81255

81257

Looper

Looper

Looper

Looper

Looper

Looper

Right

Looper

Looper

Looper

Looper

Looper

Right

Right

Right

drive

lever

drive

drive

drive

drive

hand

rocker

drive

drive

drive

rocker

hand

hand

hand

eccentric

boll

lever

eccentric.

e.:centric

eccentric

looper.

(right

lever

lever

lever

connecting

looper

looper

looper

stud

shaft

hand).

.

shaft.

shaft

rocker

reeker

rocker

connecting

fork.

rocker

connection

connection

bushing.

rod.

shaft.

shaft

shaft

bearing.

.

boll

boll

bearing.

bearing

stud.

stud

nut.

attaching

screw

washer.

pc.

pc

.

pc

.

pc.

pc.

pc.

pc.

pc.

pc

.

pc.

2

pes

.

pc

.

pc.

pc.

2

pes.

81266K

Left

hand

looper

thread

toke-up.

-

20

pc.

Page 22

12987\~@

88

i

~

,,

.

~

~

e.9

88

•15465F

29442N

~------------------·

81

~

"

80236

95

81237

80691

~

8120

8K

80636A

22729

e-

~1266KB

~

®

80645

~

--

-- -

---15442K

~

9937

~1135<

15442L

(@)

@

81213

@

9937

20

15444F

Plate

No.

8

Page 23

Plate

No.

8

20

73X

81

88

95

9937

11354

12987A

15442K

15442L

15444F

15465F

22729

Washer

Set

screw

Spot

Set

screw

Set

screw

Nut

for

Looper

Check

Looper

Looper

Washer

Looper

Screw

far

screw

Looper

rocker

nut

rocker

rocker

for

rocker

for

Looper

far

Looper.

for

for

Looper

for

Looper

double

for

Looper

double

double

Looper

cone.

Looper

rocker

Looper

rocker

rocker

lever

double

driving

rocker

driving

double

ball

joint

rocker

ball

joint

b-:~11

joint

double

ball

stud

eccentric.

cone.

eccentric

ball

stud.

cone

connection

connection

ball

fork.

ball

joint

stud.

joint

and

stud

joint

right

Looper

.

assembly.

.

left

stud

stud

.

rocker.

.

pc.

pes.

2

pc.

pes.

2

pes.

3

2

pes.

pes.

2

2

pes.

pc.

pc.

pc

.

pc.

pc.

29442N

80236

80636A

80642

80645

80691

81208K

81213

81237

81260

81261

81266KB

Looper

Looper

Looper

Looper

Looper

Looper

Left

hand

Looper

Looper

Left

hand

Left

hand

Right

driving

drive

lever

drive

drive

drive

rocker

driving

hand

eccentric

ball

eccentric.

eccentric

eccentric

looper

looper

looper

looper

eccentric

stud

.

{left

hand).

lever

rocker

rocker

thread

assembly.

connecting

fork.

connection

connection

(left

hand).

cone

cone

take-up.

stud.

stud

bearing

ball

stud.

ba

ll

stud

bushing.

pc.

.

nut

.

pc.

pc.

pc.

pc.

pc.

pc

pc.

pc.

pc.

pc.

pc.

.

- 22 -

Page 24

21145

- -

211

04G

21104H@

21104KK

21104E

211048-9

_

__

,

21114A

Plate

No.

9

Page 25

Plate

Na.

9

211048-9

211048-20

21104E

21104G

21104H

211

04KC

21104KK

21104PD

21114A

21145

Thread

Thread

Thread

Thread

Thread

Thread

Thread

Thread

Thread

Thread

stud

stand

seat

stand

stand

stand

stand

stand

stand

stand

support

seat

support

cannectian.

seat

pin.

seat

pin

red

cannectian.

eyelet

seat.

base.

cane

wire.

(waad

red.

nut

.

).

red.

pc.

pc.

pes.

2

pes.

3

3

pes.

pc.

pes.

3

pes.

3

pc

.

pes.

3

-

24

-

Page 26

Part

No.

8A························6

HA

10

························6

11 ························6

18

·····················

HA1aA ························6

20

·····················

HA

20A

························6

HA

23

························6

T

26

························6

28C

························3

HS

36K

........................

HA

43X ........

HS

528

.............. ......

HA

54A

......................

HA

56 ........................

HA

sse ........................ 4

HA

sao ........................ 4

HA

SSF ........

64Y

........................

l:fA

65E ........................

HA

66K

........................

69H ......

AS

70A

........................

HS

70A

........................

73X

.....................

74E

........................ 2

80

......................

a1

...............

HA

a1

........................

aa

..................

a9

.....................

90

........................

91 ........

93

........................

93A

...

....

94 ........................

95

..........

HA

95

........................

96

.....................

Plate

................

..............

..................

4.6.7,8

3,4,a

................

.........

........

..

3.4.5,7.8

NUMERICAL

No.

6.7

6.a

....

7.a

1.6

6.7

.. 4

..

..

7

6

3

4

4

5

5

2

6

6

6

2

2

4

4

6

6

1

2

Part

HS

HA

HS

8P

AS

AS

AS

HA

HA1348 ....

HA1349 .......

LIST

No.

97X

.....................

98

...............

1000

.....................

1038

.....................

106

·····················3

.....................

107

.....................

108

.....................

108

1

10-2

1

10-3

110-4

136

.....................

137 .....................

137A ...

137KA

212K ...................

25a

...................

269

.....................

318

........

376

.................

376A

.....................

420

......

603aK

6039K

9937

11354 .................

11639H

12987A

15442K

15442L

15444F

15465F

211048-9 ...

211

21104E ...........

21104G

2 1

.. .

..................... 7

.............

.....................

.....................

.....

....

.........

.....................

048-20

.......

104H ....

OF

Plate

··················3

..

................

..................

................

.. ................

.............

....

.........

.................

.. ..

..........

............

.. ............

.................

...

.........

...

.. ........

....

......

........

........

..........

PARTS

No.

5.6.7

.. 3

..

.. 5

....

.. 1

......

....

...

. a

.. ..

..

.. 9

...

..

..

....

.. 9

......

. 9

6

4

3

J

3

4

3

3

7

7

7

J

3

3

7

a

5

a

a

a

a

a

9

9

Plate

Part

No.

21104KC

21104KK

21104PD

21111

21114A

21145

22513

22517

22526

22539

225608

22565C

3

3

4

1

22574

22729

22743

22a70

29066L

29099K

29198K .....................

29442N

29774KD ...........

297a2H

357338

35a71A

51134V

80046

a0220C

a0233

ao234B

ao236

a0246

80250

a0250A .......

ao250B ................. .. ..

80267

a0292

a

0437A ...............

ao43a

a0440

....

....

.............

.....................

.....................

.....................

.....................

....

.................

·····················S

--·····--············7

·····················-4

..

...................

.......

.. ...... ..

.....................

..................... 1

........... ..

.....................

.....................

.....................

.....................

...

...............

..

.. ...............

..

.. ..

...............

.....................

...................

..

..................

..........

...

..................

..

..................

..

..............

....... ...

..

..................

.. .....

.

.................... 5

.

.. ..

......... .......

.

.....

..............

......

.......

No.

....

..

4,7

......

...

...........

..

.......

....

.......

.. ..

.......

.a

7,a

. 4

..

..

. 4

. 6

7.a

. 3

.. I

. ,

. ,

9

9

9

4

9

9

2

3

4

3

s

4

6

7

2

5

3

4

.5

6

4

3

3

6

- iS -

Page 27

Port

No.

Plate

No.

Port

No.

Plate

No.

Port

No.

Plate

No.

80615

80617

80621A

889621 H ...........................

80630

80630C

806300

80631

80632

80636A

80638A

80642

80643

80644

80645

80648

80649

80650

...........................

...........................

...........................

...........................

...........................

...........................

...........................

···························5

.....................

...........................

........................

...........................

...........................

........................

...........................

...........................

...........................

4.7.8

7.8

7.8

4

4

2

2

2

2

2

1

7

4

4

1

1

4

80676AC-2

80676AC-3

8067

6AC-4

80681

80685

880687

880688

ao691

806948

80694C

ao696

a1

006

881201

8a1201A

a1203KA

81203KA-1

a1203KA-2 · ............... · ....

a1205A

.....................

.....................

...... · .... · ......

...........................

...........................

...........................

...........................

........................

...........................

...........................

...........................

...........................

...........................

...........................

........................

.....................

...........................

3

3

· .. 3

2

2

1

1

7.a

2

2

6

6

1

1

4

4

4

6

a1261

a1266K

81266KA

a1266K8

a1297KA

...........................

........................

.....................

.....................

.....................

a

7

3

a

5

80651

80652

80654

80656

80659

80660

80661

80662

80662A

80663

80664

80665KD

806668

806668C

80667

80668

80669

80673A

806738

80674

80676

80676A

...........................

...........................

...........................

...........................

...........................

...........................

...........................

...........................

...........................

...........................

...........................

........................

........................

.....................

........................

...........................

...........................

...........................

...........................

...........................

...........................

...........................

5.6

5,6

3,5

6

2

6

4

4

5

5

5

5

5

5

3

3

4

4

4

2

4

3

81207K

a120aK

81213

a1213A

812200

a1220KA

a1222

a1224K

81225 ...........................

81225K

a1237

8123a

a1239

81240

a1240A

81241

a1251A

a1255

81256

256A

a1

257

a1

1260

a

...........................

...........................

...........................

...........................

...........................

........................

...........................

...........................

...........................

...........................

...........................

...........................

...........................

...........................

...........................

...........................

...........................

...........................

...........................

...........................

...........................

7

a

s

7

5

5

2

4

4

6

a

7

1

7

7

7

7

7

3

3

7

a

-

26

-

Loading...

Loading...