Operation

Manual'

.

for

Model

61OO

Daisywheel

printer

.i:r

r!

{-

lAll

efforts

have been

made to ensure the accuracy

ol the contents of this

manual.

.'

t-ver,

should any

errors be detected,

JUKI wouid

greatly

appreciate

being in_

NOTICE:

All rights

reserved. Reproduction

of any

part

of this

manual in any form whatsoever

without

Juki express

written

p€rmission

is forbidden.

The contents

of this

manual are $rbiect to change

without notic€.

l.of

them.

can

assume no responsibility

tor any errors

in

this

notdthstanding. JUKI

Iuo

their consequencrs.

o copyright

1983 by TOKYO JUKI

Tokyo, Japan

INDUSTRIAL

CO., LTD.

FCC

COMPLIANCE

STATEMENT

FOR AMERICAN

USERS

This

equipment

generates

and uses radio

lrequency enetgy

and ifnot

installed and used

prop€.Iy,

that is, in stdct accordance

with

the manufacturcr's

instructions, may

cause

interference

to radio and television

reception.

[t

has

been

type tested and found

to

comply with

the limits for a

Class B computing

device in accordance

with the specifica-

tions in Subpart J

of Pa 15 of FCC

rules, which

are designed to

provide

reasonable

protection

against such interference

in a residential

installation. However,

there is no

guarantee

that interference will not

occur in a

pa

icular

installation.

U

this

equipment

does cause intederence

to radio or tQlevision

reception,

which can

be d€termined

by

tuming the equipment

off and on, the use!

is encouraged

to try to

correct the inter-

ference

by one or more of

the following

mea$$es:

Reorient

the receiving antenna.

Relocate the

computer with respect

to the receiver.

MoVe the computer

away from

the receiver.

Plug

the computer into

a diflerent outlet

so that

computer and receiver

are on

different branch chcuits-

If necessary,

the user should consult the

dealer or an experienced

radio/television

techni-

cian for additional

suggestions. The us€r may

find the followinS

boollet

pr€par€d

by the

Federal

Communications Commission helpful:

"How

to Identify

and Resolve RadiqTV

Interfercnce Problems".

This booklet is

available from the

U.S.

coveminent

hintins

Office, Washington, D.C.

20402, Stock No.

00+00G00345-4.

d

Settin$, Canridge

Ribbon . . . . . . . . ...............

6

Attaching a Oai3y

Whelto the Printer....... ........

7

Setting

Paper

bn

ttig 9fin'ier

.3'.

. . 1 ......8,

6.'l Lo.ding eEDet

gn theDtinter . . . . . . . .......

8

6,2

Fine

odiu.lhfit 6Fthc

printing po.ition

. . . : .c . . . . . . . . . . . . . . , . , . gl

6.3 corr€cting tho

poiition

of

papor

. . . . . . .., .

.

9-r

INTRODIJCTION

1.

General Oescription

2.

Spocific.tioni

Print

speed

Print wheel

Print wheel

life

Number

of characte$

per

line

This

is a daisy wheel

printer

controlled by a micro

processor

unit. The

printer,

which is

a rqsult of

the state-of-the-art engineering

combined with

superior fianufacturing

tech-

niques,

piovides

superior

perfomance

and many advsntages

such as the easy

drop-in

type daisy

wheel replacement, use of IBM

cartridge ribbons, moderate

price,

low

power

consumption

and long service life. ln

addition, the

printer

head

driven by.a linear motor

permits

simpler mechanism

and

highe!

accuracy ofptinting

position

at the

same time.

Max:

paper

width

Carriage motidn

Carriage retum

time

Paper

ieed

Min. feed

Ribbon

-

Interface

Temperature

Relative

Humidity

Dimension

Weight

Max.

f8

cps

l7

cps

(Shannon

text, l0

ch/inch)

lO0

characteIs/wheel

(Triumph-Adler

compatible)

l0 million

characters/wheel

.

110

charactem

(10 pitch)

'

132

charactem

(12 pitch)

165

characters

(15 pitch)

82 to 220

characteN

(Proportional

spacing

Bldirectional,

increrlrentai motion:

I

/120

inch

Max. 1,000 ms

Bidirectional,

Friction

feed

1/48 inch

Cartridge Type: tBM Typewriter

ribbon

Single strike ribbon

Multi

strike ribbon

PaBllel

(Centronics

compatible)

(Option:

RS232C

serial)

4l"F - 95"F

(5'C

to

35'C)

(Operatins)

30% to 85%

(Operating,

Non-condensation)

AC 100 v,

120 v, 220 v, 240 v,

50 & 60 Hz

Max.sow'

20.5" W x

5.9"

Hx

14.2' D

(520

mm x l5l mm

x 360 mmI

27.5

lbs.

approx.

.

(12.5

kgs. approx.)

t-

INSTALLATION

OF THE PRINTER

1. Unpacking

Before

unpacking the

printer,

carefully

check the exterior

of the carton containing

rne

printer.

If any damaged

incurred during

transportation has

been found,

immedBr€ry

contact

the shop

you

bought the machine

1.1 Unpacking

procedurc

Unpack

the

printer

in accordance

with the iollowing

st€ps:

Step l: Open the carton.

Step 2: Pull out straight the

pdnter

together

v/ith its shock-absorbing

materials.

Step 3 : Place

the

printer

along

ivith the shock-absorbing

materials

on a table

ot

other

plain

spot.

Step 4: Remove

the shock-absorbing matedals

from

the

printer.

Step 5 :

Take the vinyl

cover off the

printer.

1.2 Rgpacking

the

printer

Repack the

printer

in reverce order from

unpacking

procedure.

Repack

the

printer

when storing

it o! sending

it for repair.

Caution

It is

advisable to keep

the

packing

materials for

possible

reshipment of

the

printer.

2. Checking ths Plinter Pan3

The

printer

is fumished

with the standard

accessories

shown below. If

any missed or

damaged

parts

have

been found out,

contact the source

ofyour

purchase.

fi,

o"o"

3. Single{trike

Ribbon

fu

o. e"*.

/-)

s.

oo",,tion

_#

code

\/

Manu.l

vtv

No. Name

Qlv

l.

2.

3.

5.

Daisy wheel

printer

Daisy wh€el

Single-strike

ribbon

Power cord

Operation Manual

I

I

1

I

I

2

3.

3.1

Initalling

the

Printer

Installing

locstion

lnstall

the

printer

with

attention

paid

to the

following.

(l)

Mount

the

printer

on a level

and tough

table

ofstand.

At this

time,

place

the

printer

so

that its rubber

feet

all

rest

on the

table

or stand

evenly.

(2)

Do

not install

the

printer

at

a

place

exposed

to

direct

sunlight,

or hot

or con-

taminated

air_

(3)

Do

not connect

the

printer

to a receptacle

used

also

for a large

motor,

cooler

or

other equipment

which

produce

electrical

noise.

(4)

Always

keep

the ambient

temperature

at 40

degee F

(5

degree

C) through

95 degree

F

(35

degree

C) while

operating

the

pri;ter.

Be careful

not

to subject

the

printer

to

shocks

or

a sudden

temperature

change.

Romoving

the

paper

table

protection

shegt

The

paper

table

and

platen

are wrapped

with

from

shocks

or

vibration

during

transportation.

this

sheet.

Remember

(o

set this

protection

sheet

on me

when

reshipping

the

printer.

3.2

If.it

is

difficult

to remove

the sheet,

open

or

take

olf

the soundprcofing

cover

to

take

the

sheet

out in

the following

way:

Step I :

Open

the

soundprooling

cover

towards

you

till

upright

position.

Step

2: Pull

up

and

lemove

the

soundproofing

cover.

a sheet

to

protect

the

pape!

table

Before

using

the

printer,

take

off

paper

table

as it

was originally

s€t

Knob

Pap€r

table

prot€ction

Soundproofing

cover

3.3

R€moving

the

fixars

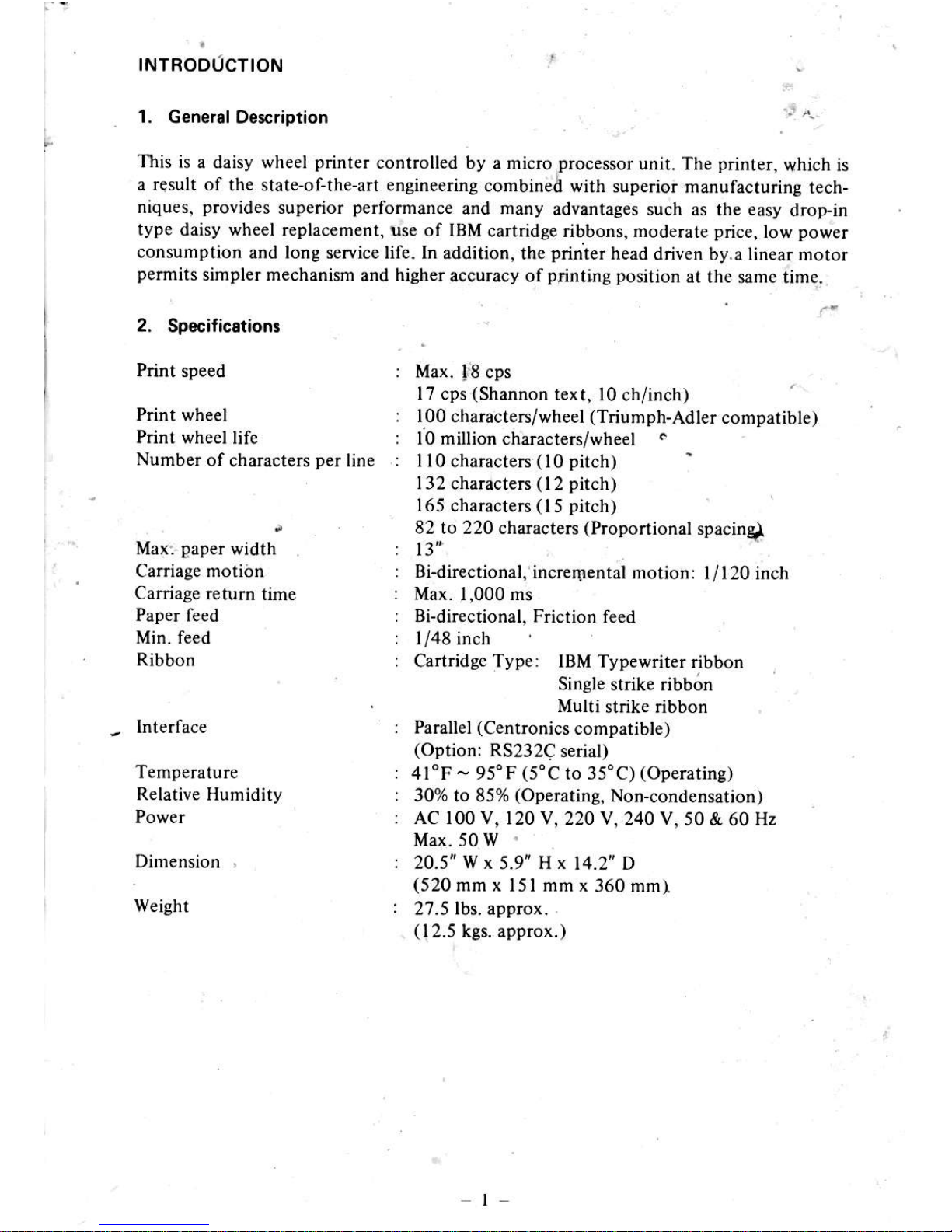

The

carriage

is fixed with

two buffers which

protect

the carriage from shocks

or

vibration

during

transportation.

Keep

these cariage

fixers for

possible

reshipment in the future.

Step l: Hold the

printer

cover as shown below and lift it.

Step 2:

When the

cover

lock on

your

side has b€en disengaged,

draw

off

the cover

towards

you.

Step 3: Remove the right carriage fixer.

Step 4: Move the carriage to the riglt and remove the left

carriage

fixer. AC

corC

and ribbon can be taken out.

The

daisy motor is fixed not to slip out

during transportation.

Step Ir

Cht the

motor

band and rcmove it ftom

the carriage.

Step 2: Remove the lever fixer from

lhe carriaBe.

The

platen

is fixed with two materials

which

protect

the

platen

from

shocks or

vibration

dudng tmnsportation-

Step l: Remove the

platen

fixer from both

side of the

platen-

-4-

Caution lt is recommended

that

the original

packing

re5hipment

or

other lransponing

purposes.

material

be retained for

Right

carriag€ fixlr

r::r '------1"1

L-Elflr

L-18,

-5-

4.

s.ning !

c.rttidge

Ribbon

Eithei

a single

stdke

ribbon

or

multi strike

dbbon

can be

ured

When a cartridge

ribbon

has been

sei on

the

printer,

the

printer

will automatically

s€t

itself

for '

feed amount

suited

to that

ribbon.

step l:

Pu[

the ribbon

load

lever toward

you.

Step 2:

Pass the

lead

tape

of the ribbon

thrcugh

the thl€e

guides'

Step 3:

Push do*n

the

cartridge

until

it is

held by the

clip spring'

3.

Clip lp.ing

Turn L€lr

PICA

Turn

Right

ELITE

L Ribbon lo.d

l.wr

Step

4:

Tum the

cartridg;

knob

countertlockwise

dlection

until

the inked

pafi of the

ribbon

teaches

the

Printing

Part'

Step

5:

Retum

the

ribbon

load

levcr to

its original

position'

5.

Ribbon

lod l€v.t

Supplement:

Repllcing

a cartridge

ribbotr

whcn the

ribbon

is seen

to be

drnost

running

out

throwh

the

cT t'idge

slit'

replace

the

ribbon

in

the

following

prccedut€'

Step

l:

Pull

thc dbbon

load

lever

toward

you

Step

2:

Pull

up the

cadridge

off the

printer'

2.

Guide

(three

in total)

-------t'<-->-

(---)

GE=

EP

4. Knob

Carrridg.

tlit

f-t e:

-O

A<\'

gu

Ceutio4

(l)

Do not forcibly

pull

up

the cartridge without

puUing

the ribbon

load

lever

toward

you.

.

R ibbon lord tever

When

the end zone

of

ribbon

leaches to the

print position,

piinted

characteN could not

be lecognized clearly

Periodicaly

clean the ribbon

path

and lemove

paper

dust and ink

flake from

interior.

5. Atlrching

r D.iry Wh.el to tho Printot

The

dlopin design of the

daisy wheel

permits

easy

setting

and leplacement

of the daisy

wheel.

Stcp I i

Draw

the daisy

setting

lever

toward

you.

Step 2: Dlop the daisy wheel into

the daisy cale of

the

printer.

CNtion The

type surface of th€ daisy wheel should face

to the

platen.

Step 3: Push the

daisy s€tting

lever

to the front.

Supplement: Removing

the

daisy wheel.

Step l: Pull

the daisy setting

lever

toward

you.

St€p 2: Held

and

pull

up the

daisy wheel.

(2)

(3)

Rem.inins ribbon

RA

\Y/J

)

Oriry iatting

4,

"o>

'€.

6. Seftino .

Pap6f

on tho

Printor

:

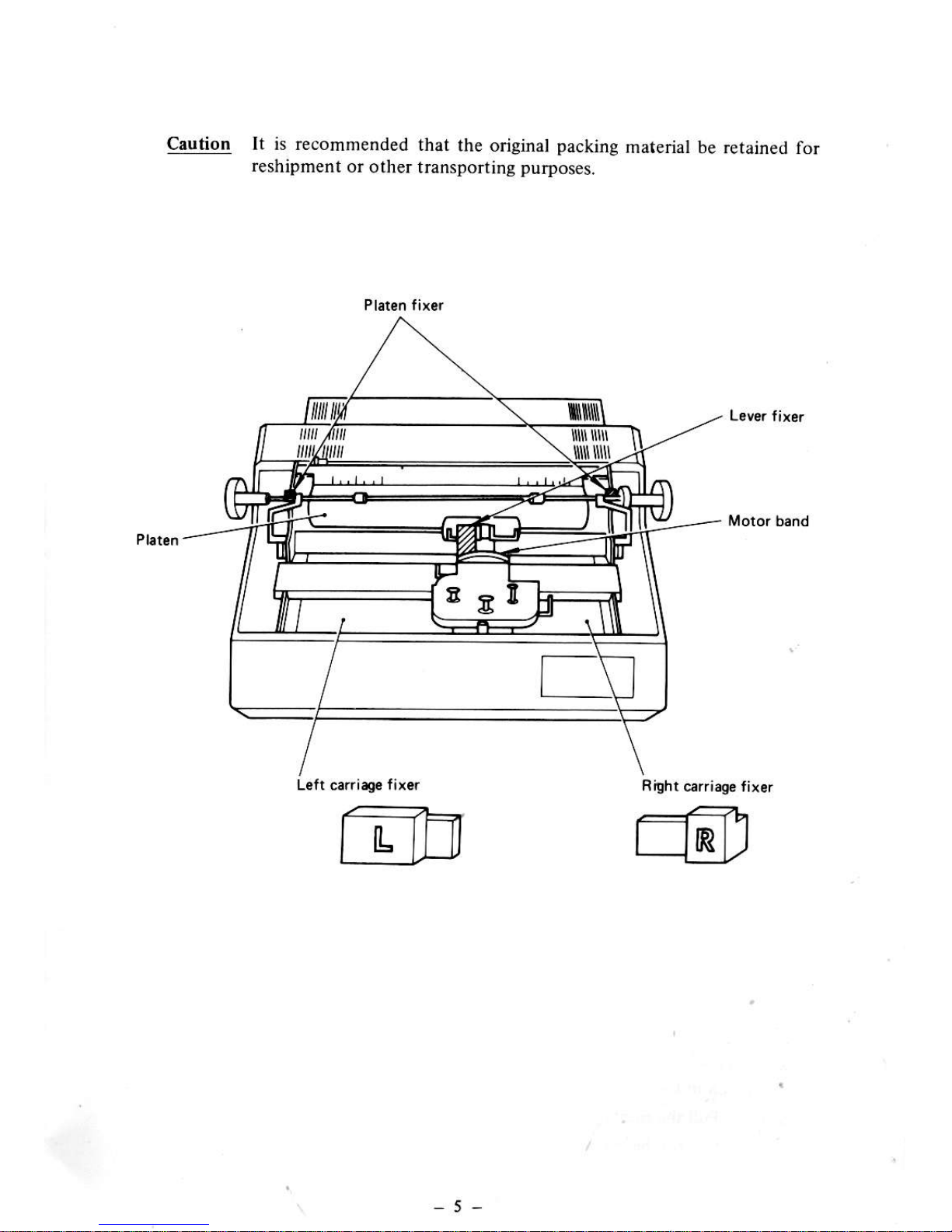

Paper of up to 13 inch width can be set on the

printer.

6.1 Loading I

papgr

on

tho

ptinter

Step l:

Pull

the

paper

bail

lever

toward

you.

Step 2: Confirm rhat the release lever is sei away from

you.

Step 3 : Place

paper

between the

paper

table and the rear of the

platen.

Step 4: Tum the feed knob until the form reaches the

printing position.

Step 5:

Push the bail lever back.

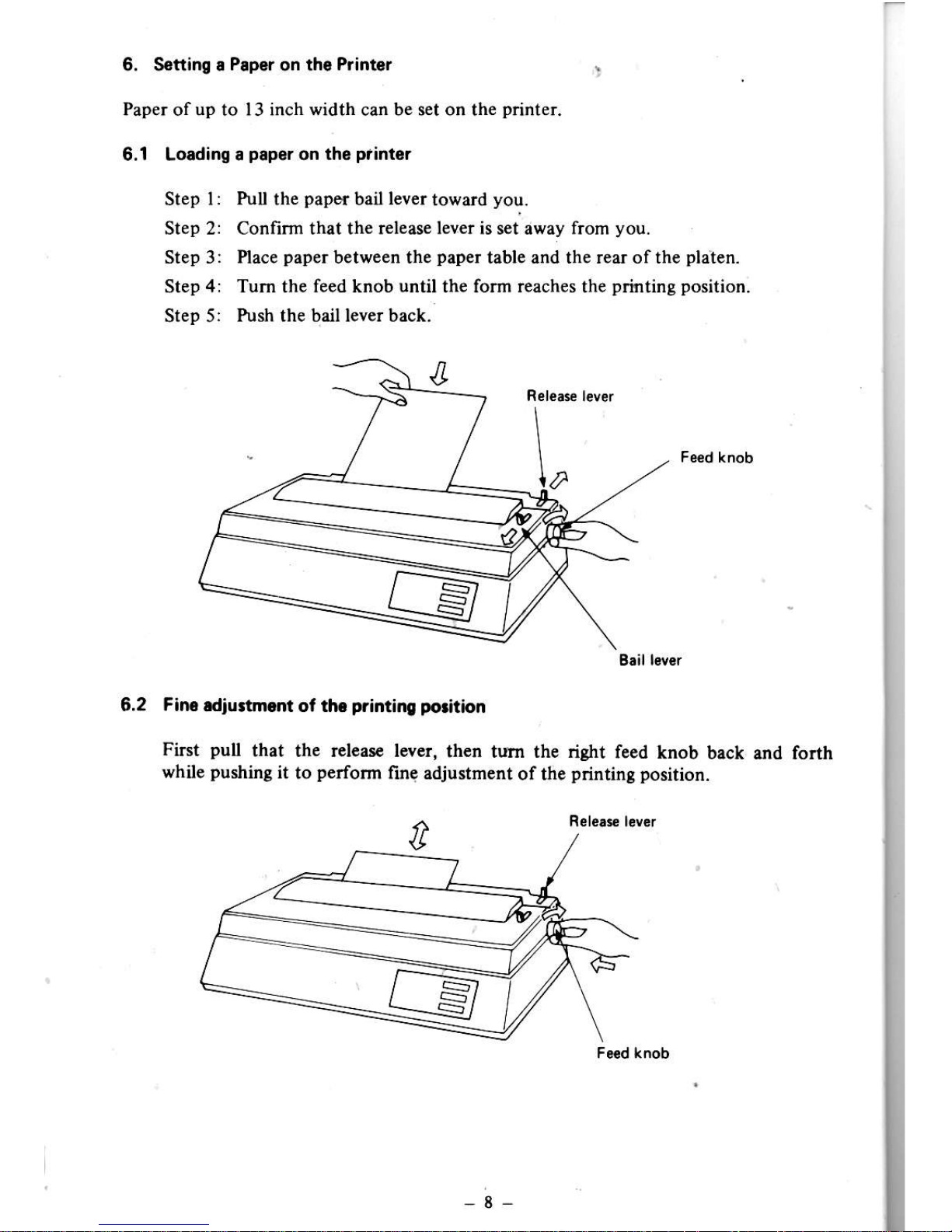

6.2 Fin diuttmnt

ot th.

primino polition

First

pul

that the rclcar€ lever,

then tum the riSht

feed knob

back rnd forth

while

pushing

it

to

perform

fin€ .djustment

of the

printinS positior.

Blil l.v.r

-8-

Corractin!

the

porition

of

a

plper

ii*tflrt

"t

the

printer

is crooked,

correct

it

in

ac@rdance

with

the

following

Step

1:

Pull

the release

lever

toward

you

Step

2: Open

the

soundproofing

cover

toward you.

..

Step

3: Align

the

side

edges

of

paper

as

shown

below

and

then

push

back

thc

rolease

lever-

Stqp

4:

Clote

the apoustic

cover

and

push

the

bail lever.

OPERATION

1. Switches and lndicators

The

power

switch

is

located

at the

panel

is located

at the right on

switches,

one

4-Step

selector slide

leit on the

back of the

printer

case, and the operation

the front.

The operation

panel

has thrce membrane

switch and three indicators.

1.1

Switchss

Power

SW:

Controls

the

primary

AC

power

supplied

to the

printer.

When

it is turned on the initial

state of the

pdnter

is:

(l)

LSI

(Line

Spacing Index)

fol.lows

to Dip SW.

(2)

CSI

(Column

Spacing Index) follo*s

to the switches on the operation

panel.

(3)

I-eft Margin is set at lst column.

(.4)

Right Maryin is set at the final column.

(5)

Horizontal Tab and Vertical Tab are not

set.

(6)

Top Margin is set at the top of

the

paper.

(?)

Bottom Margir is set at the end

of the

paper.

(&l

)

The

printer

is set

in

the on-line state, and READY lamp lights.

(8-2)

If

no

error

is

present,

CHECK lamp

goes

out.

(9)

Auto Backward Print Mode.

(10)

The

paper

length is set

at I I inches or 12.

(l

I ) Carriage is

positioned

at lst column.

(12)

The Print Wheel is

positioned

at the

home

position.

(

13) The Ribbon

is set at the

home

position.

(14)

The Power Indication kmp lights up.

/:N

.,'"a>.\

A",si'*

X.

.\y/

-10

(15)

Ready

lamp

lighrs up.

(16)

Remote

Mode.

Caution Before

tuming

on the

powet

switch, make

sure

that

papea

has

been

set on the

Drinter-

It is

important

to set

paper

correcdy

on the

printer

to obtain

the

best

pdnting

result.

Do not use

any other

AC

cord than

the }.core

cable turnished

with th€

printer.

Folm Fe€d

SW:

By

depressing

this switch, folm

feed

can be

performed

in the

pause

conditioir

and

paper

in fed

to as far as the

first line

or the

top maigin

of the

next

page.

Paure

SW:

Used to interrupt

the

operation

of the

printer

without erasing

the

data.

When

the

pause

switch

is

depressed, the

check

lamp will

light.

The

pause

is

leleased

by depressing

the rcs€t

switch.

Reset

SW:

Used

to release

the

pause,

check

ot eror

status.

The

check or errot

status is

released

by depressing

the rEsot

switch

after elimi

nating

the caus€.

Spacing

SW:

A 4-step

selector

slide switch

which

provides

s€lection

of

pS

(proportionaL

Spacing),

15

cpi,

12 cpiand

l0cpi.

S€t

this switch

at a

desired

spacing

before

powering

up

the

prilt€r.

C.hange

of the

spacing

pitch

retting

of this,witch

after

powering

up

the

printer

cal be made

by

the ESC

function

of

the host

computer.

-

ll

-

Loading...

Loading...