JS-Technik LSLV-M100 User Manual

JS-Technik GmbH - Lether Gerwerbestrasse 10 - 26197 Großenkneten www.js-technik.de

Safety Information

Indicates an imminently hazardous situation which, if not avoided, will result in severe injury or

death.

Indicates a potentially hazardous situation which, if not avoided, could result in injury or

death.

Indicates a potentially hazardous situation that, if not avoided, could result in minor injury or

property damage.

• Do not open the cover of the equipment while it is on or operating. Likewise, do not

operate the inverter while the cover is open. Exposure of high voltage terminals or

charging area to the external environment may result in an electric shock. Do not

remove any covers or touch the internal circuit boards (PCBs) or electrical contacts on

the product when the power is on or during operation. Doing so may result in serious

injury, death, or serious property damage.

• Do not open the cover of the equipment even when the power supply to the inverter

has been turned off unless it is necessary for maintenance or regular inspection.

Opening the cover may result in an electric shock even when the power supply is off.

• The equipment may hold charge long after the power supply has been turned off. Use

a multi-meter to make sure that there is no voltage before working on the inverter,

motor or motor cable.

Read and follow all safety instructions in this manual precisely to avoid unsafe operating

conditions, property damage, personal injury, or death.

Safety symbols in this manual

Safety information

• This equipment must be grounded for safe and proper operation.

• Do not supply power to a faulty inverter. If you find that the inverter is faulty, disconnect

the power supply and have the inverter professionally repaired.

• The inverter becomes hot during operation. Avoid touching the inverter until it has

cooled to avoid burns.

• Do not allow foreign objects, such as screws, metal chips, debris, water, or oil to get

inside the inverter. Allowing foreign objects inside the inverter may cause the inverter to

malfunction or result in a fire.

• Do not operate the inverter with wet hands. Doing so may result in electric shock.

• Check the protection degree of circuits and equipments used in the inverter degree of circuit

protection and the degree of equipment protection.

The following connection terminals and components are electrical protection class 0 devices.

The circuit is protected by the essential insulation and electric shock may occur if the

insulation is done improperly. The same protection measures for electric cables must be

taken when the using or installing the following compornents, or when you connect a cable to

the following terminals or components.

- Multi-function terminals: P1–P3, P4 (Advanced I/O), P5 (Advanced I/O), CM

- Analog terminal inputs and outputs: VR, V1, I2 (Advanced I/O), AO, CM

- Other terminal block connectors: Q1(Standard I/O), EG (Standard I/O), 24, A1, B1, C1, A2

(Advanced I/O), C2 (Advanced I/O)

- Cooling fan

• This inverter is a protection class 1 product.

• Do not modify the interior workings of the inverter. Doing so will void the warranty.

• The inverter is designed for 3-phase motor operation. Do not use the inverter to operate a

single phase motor.

• Do not place heavy objects on top of electric cables. Doing so may damage the cable and

result in an electric shock.

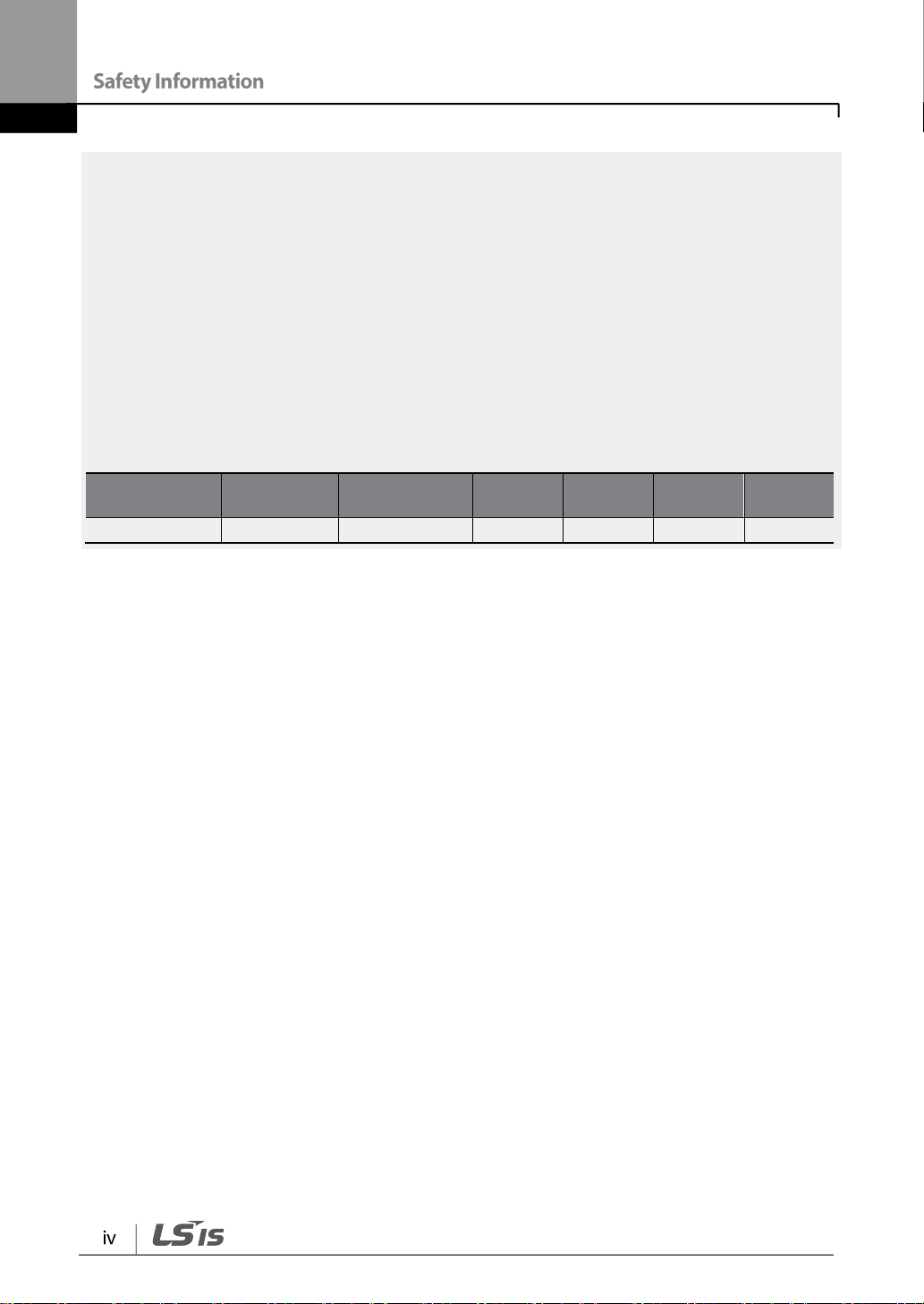

Note

Maximum allowed prospective short-circuit current at the input power connection is defined in

IEC 60439-1 as 100 kA. Depending on the selected MCCB, the LSLV-M100 Series is suitable

for use in circuits capable of delivering a maximum of 100 kA RMS symmetrical amperes at the

drive's maximum rated voltage. The following table shows the recommended MCCB for RMS

symmetrical amperes.

Remarque

Le courant maximum de court-circuit présumé autorisé au connecteur d’alimentation électrique

est défini dans la norme IEC 60439-1 comme égal à 100 kA. Selon le MCCB sélectionné, la

série LSLV-M100 peut être utilisée sur des circuits pouvant fournir un courant RMS symétrique

de 100 kA maximum en ampères à la tension nominale maximale du variateur. Le tableau

suivant indique le MCCB recommandé selon le courant RMS symétrique en ampères.

Working

Voltage

UTE100(E/N)

UTS150(N/H/L)

ABS33c

ABS53c

ABS63c

ABS103c

240V(50/60Hz)

50/65 kA

65/100/150 kA

30 kA

35 kA

35 kA

85 kA

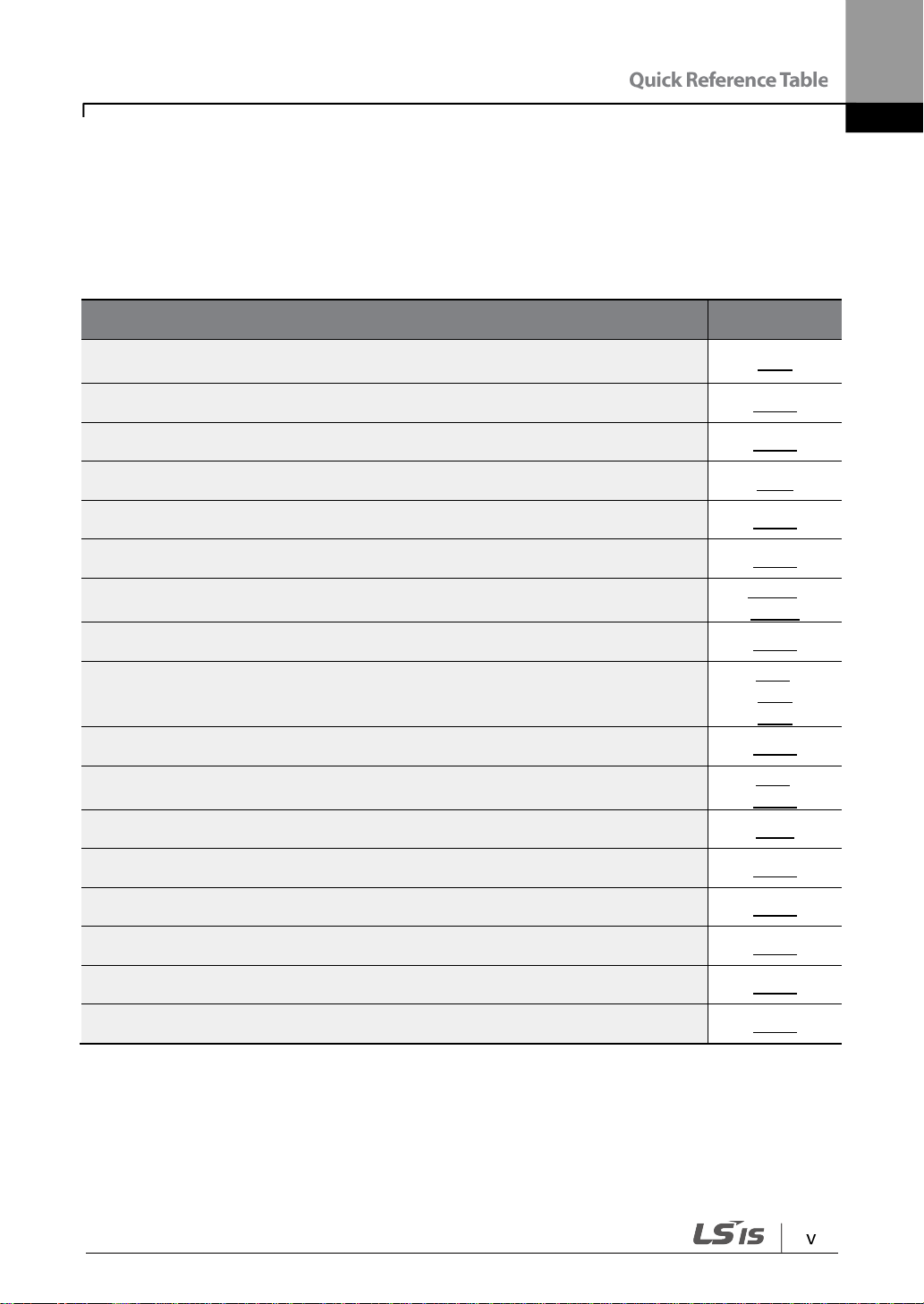

Quick Reference Table

Situation

Reference

I want to configure the inverter to start operating as soon as the power source

is applied.

p.85

I want to configure the motor’s parameters.

p.196

Something seems to be wrong with the inverter or the motor.

p.224

What are the recommended wiring lengths?

p.23

The motor is too noisy.

p.131

I want to apply PID control on my system.

p.122

What are the factory default settings for multi-function terminals?

p. 205,

p. 210

I want to review recent fault trip and warning histories.

p.158

I want to change the inverter’s operation frequency using a potentiometer.

p.69,

p.70

p.72

I want to install a frequency meter using an analog terminal.

p.144

I want to monitor the supply current to motor.

p.58,

p.153

I want to operate the inverter using a multi-step speed configuration.

p. 79

The motor runs too hot.

p.161

The inverter is too hot.

p.163

The cooling fan does not work.

p.152

I want to change the items that are monitored on the keypad.

p.239

I want to operate the inverter using a multi-step speed configuration.

p.153

The following table contains situations frequently encountered by users while working with

inverters. Refer to the typical and practical situations in the table to quickly and easily locate

answers to your questions.

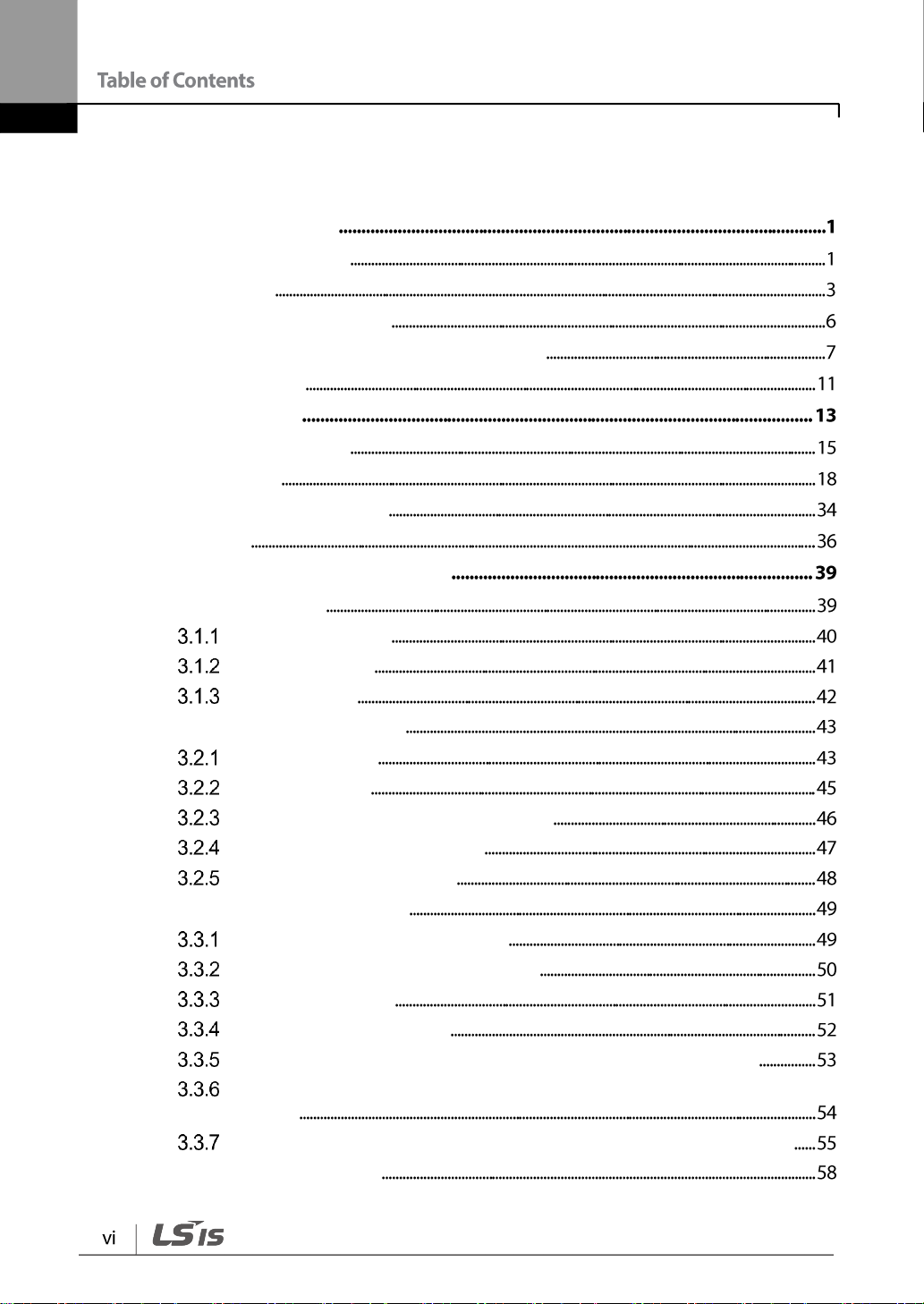

Table of Contents

1 Preparing the Installation

1.1 Product Identification

1.2 Part Names

1.3 Installation Considerations

1.4 Selecting and Preparing a Site for Installation

1.5 Cable Selection

2 Installing the Inverter

2.1 Mounting the Inverter

2.2 Cable Wiring

2.3 Post-Installation Checklist

2.4 Test Run

3 Learning to Perform Basic Operations

3.1 About the Keypad

About the Display

Operation Keys

Control Menu

3.2 Learning to Use the Keypad

Group Selection

Code Selection

Navigating Directly to Different Codes

Switching to a Different Code

Setting Parameter Values

3.3 Actual Application Examples

Acceleration Time Configuration

Frequency Reference Configuration

Frequency Setting

Initializing All Parameters

Frequency Setting (Keypad) and Operation (via Terminal Input)

Frequency Setting (External Potentiometer) and Operation (Terminal

Input)

Frequency Setting (Built-in Potentiometer) and Operation (Keypad)

3.4 Monitoring the Operation

Output Current Monitoring

Fault Trip Monitoring

4 Control Block Diagram

4.1 Setting Frequency

4.2 Setting Run Command

4.3 Controlling Acc/Dec and V/F Voltage

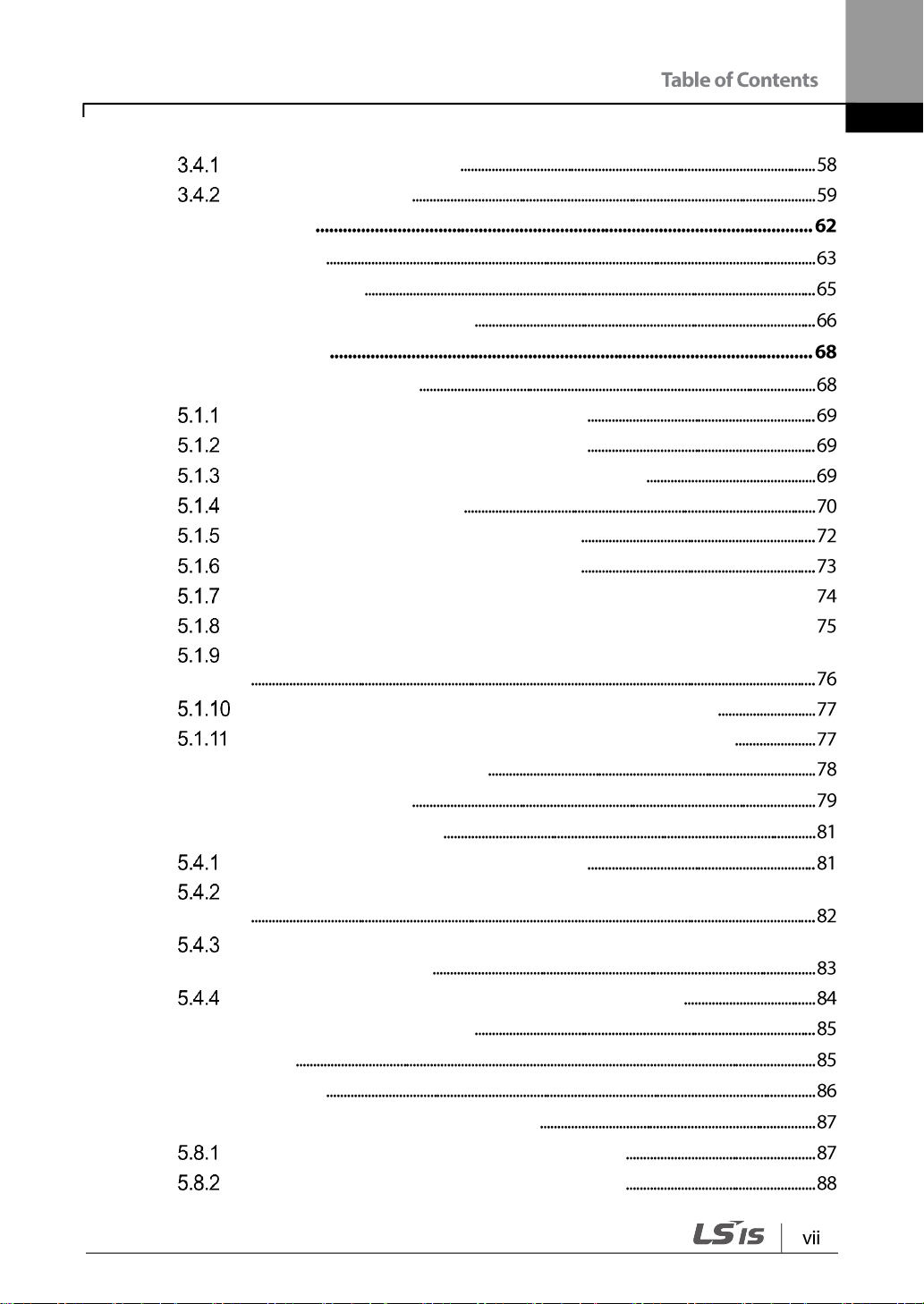

5 Learning Basic Features

5.1 Setting Frequency Reference

Keypad as the Source (KeyPad-1 setting)

Keypad as the Source (KeyPad-2 setting)

Built-in Volume input (V0) 0 – 5 [V] as the Source

V1 Terminal as the Source

Input Current (Terminal I2) as the Source

Input Voltage (Terminal I2) as the Source

Frequency Reference Setting via Built-in Volume (V0) and I2 Terminal

Frequency Reference Setting via Built-in Volume (V0) and I2 Terminal

Frequency Reference Setting via Built-in Volume (V0) and V1 Terminal

Frequency Reference Setting via RS-485 Communication

Frequency Reference Setting via Digital Volume (Up-Down)

5.2 Holding Analog Command Frequency

5.3 Setting Multi-step Frequency

5.4 Command Source Configuration

The Keypad as a Command Input Device

Terminal Block as a Command Input Device (Fwd/Rev Run Commands)

Terminal Block as a Command Input Device (Run and Rotation

Direction Commands)

RS-485 Communication as a Command Input Device

5.5 Forward or Reverse Run Prevention

5.6 Power-on Run

5.7 Reset and Restart

5.8 Setting Acceleration and Deceleration Times

Acc/Dec Time Based on Maximum Frequency

Acc/Dec Time Based on Operation Frequency

Multi-step Acc/Dec Time Configuration

5.9 Acc/Dec Pattern Configuration

5.10 Stopping the Acc/Dec Operation

5.11 V/F(Voltage/Frequency) Control

Linear V/F Pattern Operation

Square Reduction V/F pattern Operation

User V/F Pattern Operation

Output Voltage Setting

5.12 Torque Boost

Manual Torque Boost

Auto Torque Boost

5.13 Stop Mode Setting

Deceleration Stop

Stop After DC Braking

Free Run Stop

5.14 Frequency Limit

Frequency Limit Using Maximum Frequency and Start Frequency

Frequency Limit Using Upper and Lower Limit Frequency Values

Frequency Jump

6 Learning Advanced Features

6.1 DC Braking

Stop After DC Braking

Start After DC Braking

DC Braking During Stop

6.2 Jog operation

Jog Operation 1-Forward Jog by Multi-function Terminal

Jog Operation 2-Fwd/Rev Jog by Multi-function Terminal

6.3 Up-down Operation

6.4 3-Wire Operation

6.5 Dwell Operation

6.6 Slip Compensation Operation

6.7 Simple Sensorless Control

6.8 PID Control

PID Basic Control

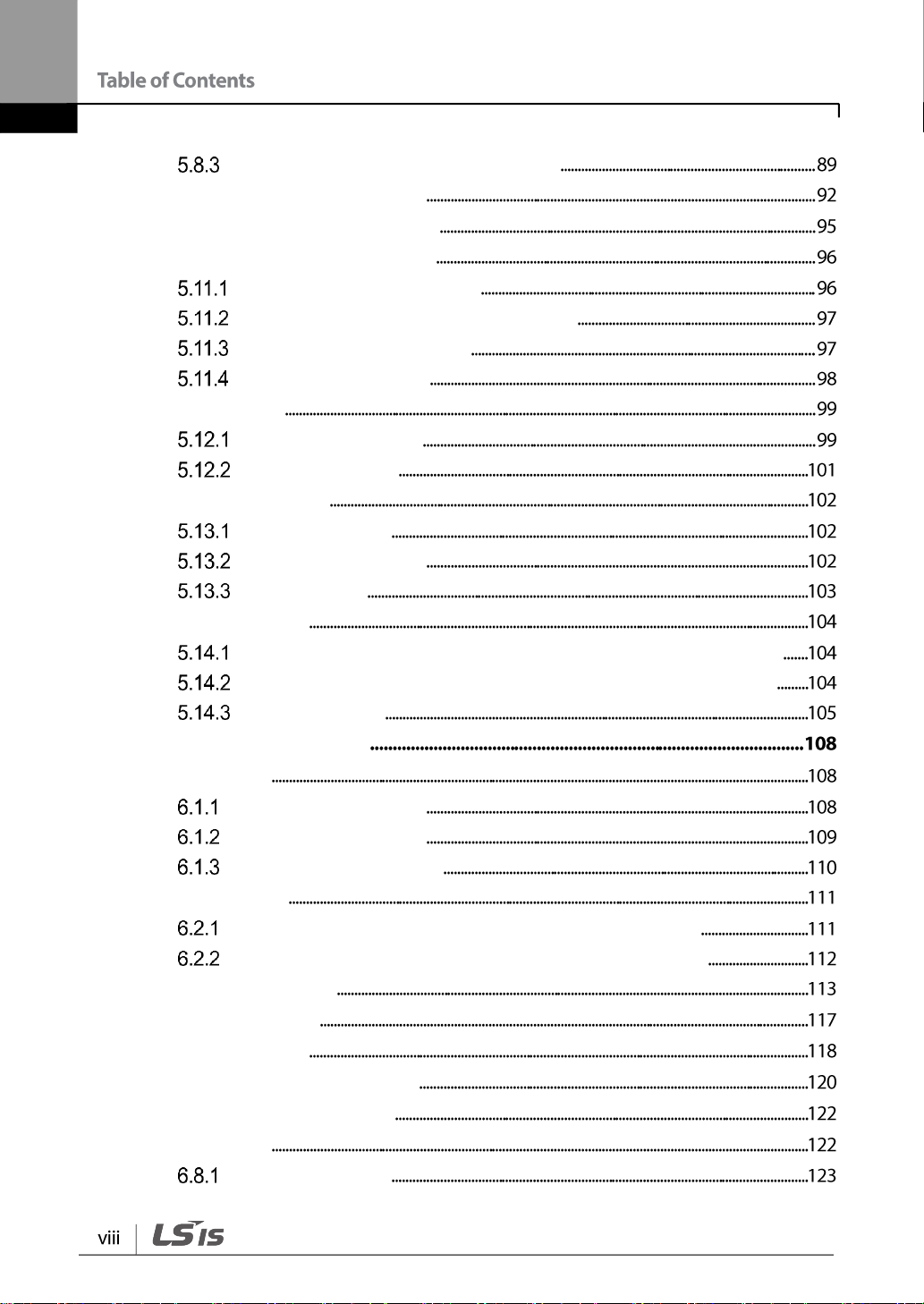

6.9 Energy Saving Operation

6.10 Speed Search Operation

6.11 Auto Restart Settings

6.12 Operational Noise Settings (carrier frequency settings)

6.13 2nd Motor Operation

6.14 Frequency Setting and 2nd Operation Mode Setting

6.15 Input Voltage Setting

6.16 Parameter Initialization

6.17 Parameter Lock

6.18 Voltage Trip Prevention During Deceleration

6.19 Brake Control

6.20 Analog Output

6.21 Digital Output

Multi-function Relay Output Terminal Settings

6.22 Draw Operation

6.23 Operation Mode Setting When Cooling Fan is Abnormal

6.24 Operation State Monitor

6.25 I/O Terminal Block State Monitor

6.26 Fault State Monitor

7 Learning Protection Features

7.1 Motor Protection

Electronic Thermal Motor Overheating Prevention (ETH)

Overload Early Warning and Trip

Stall Prevention

7.2 Inverter and Sequence Protection

Output Open-phase Protection

External Trip Signal

Inverter Overload Protection

Speed Command Loss

Dynamic Braking (DB) Resistor Configuration

Initial charging circuit trip(ROT)

8 RS-485 Communication Features

8.1 Communication Standards

8.2 Communication System Configuration

Communication Line Connection

Setting Communication Parameters

Setting Operation Command and Frequency

Command Loss Protective Operation

Parameter Group for Data Transmission

8.3 Communication Protocol

LS INV 485 Protocol

Modbus-RTU Protocol

8.4 Compatible Common Area Parameter

9 Table of Functions

9.1 Operation Group

9.2 Drive Group (PAR → dr)

9.3 Basic Function group (PAR→bA)

9.4 Expanded Function group (PAR→Ad)

9.5 Control Function group (PAR→Cn)

9.6 Input Terminal Block Function group (PAR→In)

9.7 Output Terminal Block Function group (PAR→OU)

9.8 Communication Function group (PAR→CM)

9.9 Application Function group (PAR→AP)

9.10 Protection Function group (PAR→Pr)

9.11 2nd Motor Function group (PAR→M2)

9.12 Config Mode group (PAR→CF)

10 Troubleshooting

10.1 Trips

Fault Trips

10.2 Troubleshooting Fault Trips

10.3 Troubleshooting Other Faults

11 Maintenance

11.1 Regular Inspection Lists

Daily Inspections

Annual Inspections

Bi-annual Inspections

11.2 Storage and Disposal

Storage

Disposal

12 Technical Specification

12.1 Input and Output Specification

12.2 Product Specification Details

12.3 External Dimensions (IP 20 Type)

12.4 Peripheral Devices

12.5 Fuse and Reactor Specifications

12.6 Terminal Screw Specification

12.7 Braking Resistor Specification

12.8 Continuous Rated Current Derating

12.9 Remote Keypad Option

Product Warranty

Index

기

본조작법

기

능알

람

표

제

어

블

록도

기

본

기

능

응

용

기

능

모

니터기능

보

호

기

능

통

신

기

능

1 Preparing the Installation

Note

Check the product name, open the packaging, and then confirm that the product is free from

defects. Contact your supplier if you have any issues or questions about your product.

This chapter provides details on product identification, part names, correct installation and

cable specifications. To install the inverter correctly and safely, carefully read and follow the

instructions.

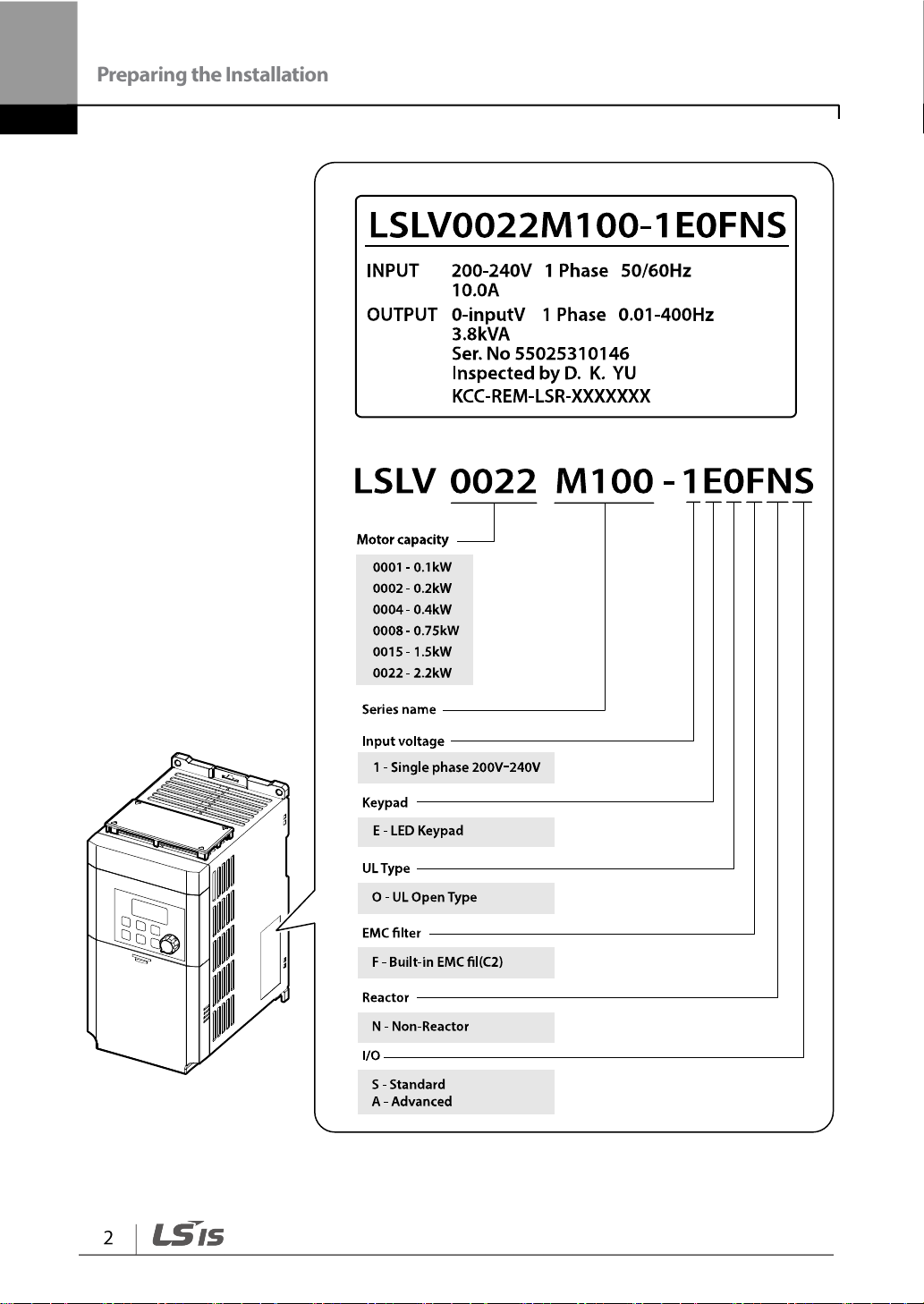

1.1 Product Identification

The M100 Inverter is manufactured in a range of product groups based on drive capacity

and power source specifications. Product name and specifications are detailed on the rating

plate. The illustration on the next page shows the location of the rating plate. Check the

rating plate before installing the product and make sure that the product meets your

requirements. For more detailed product specifications, refer to 12.1 Input and Output

Specification on page 242.

기

본조작법

기

능알

람

표

제

어

블

록도

기

본

기

능

응

용

기

능

모

니터기능

보

호

기

능

통

신

기

능

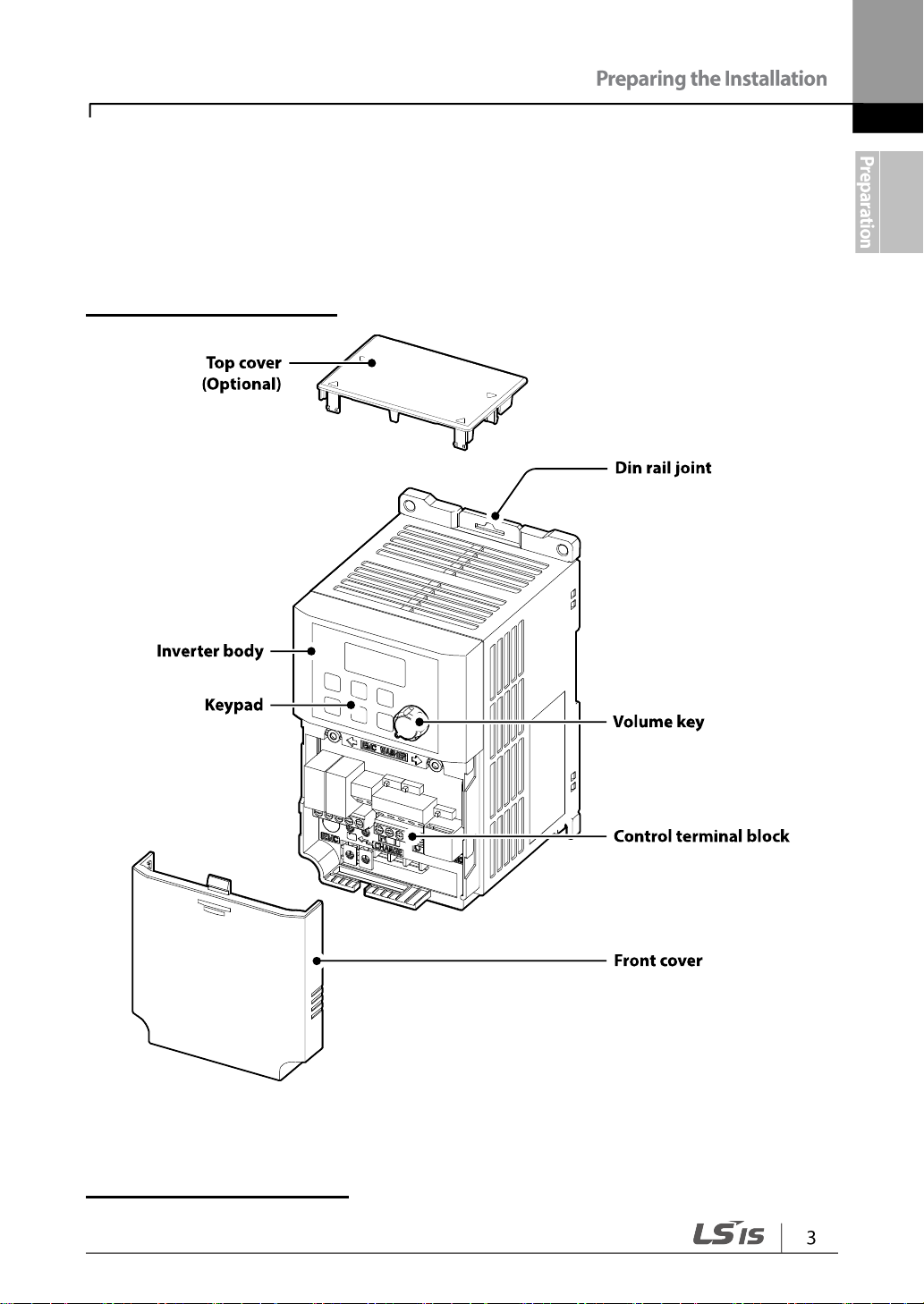

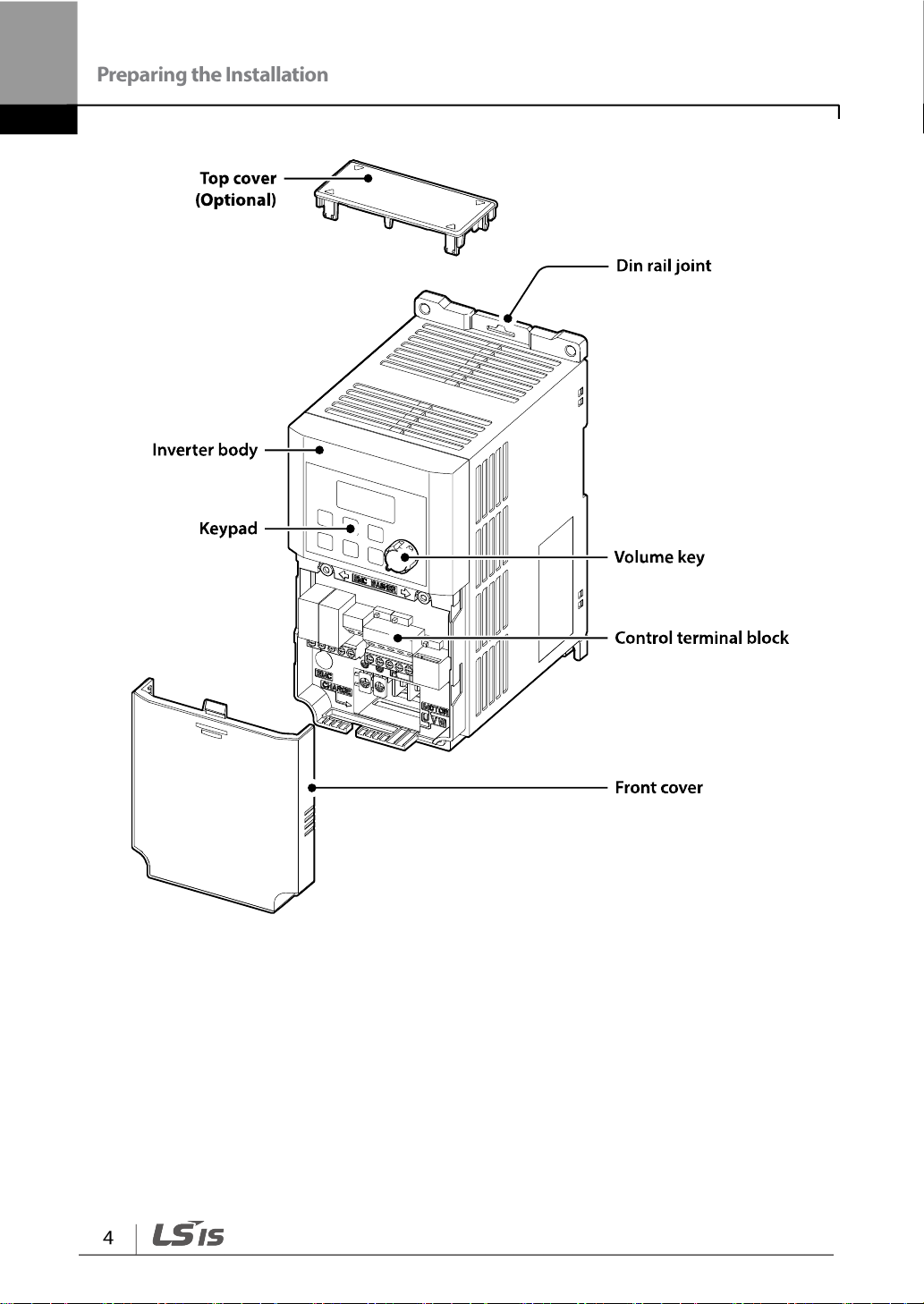

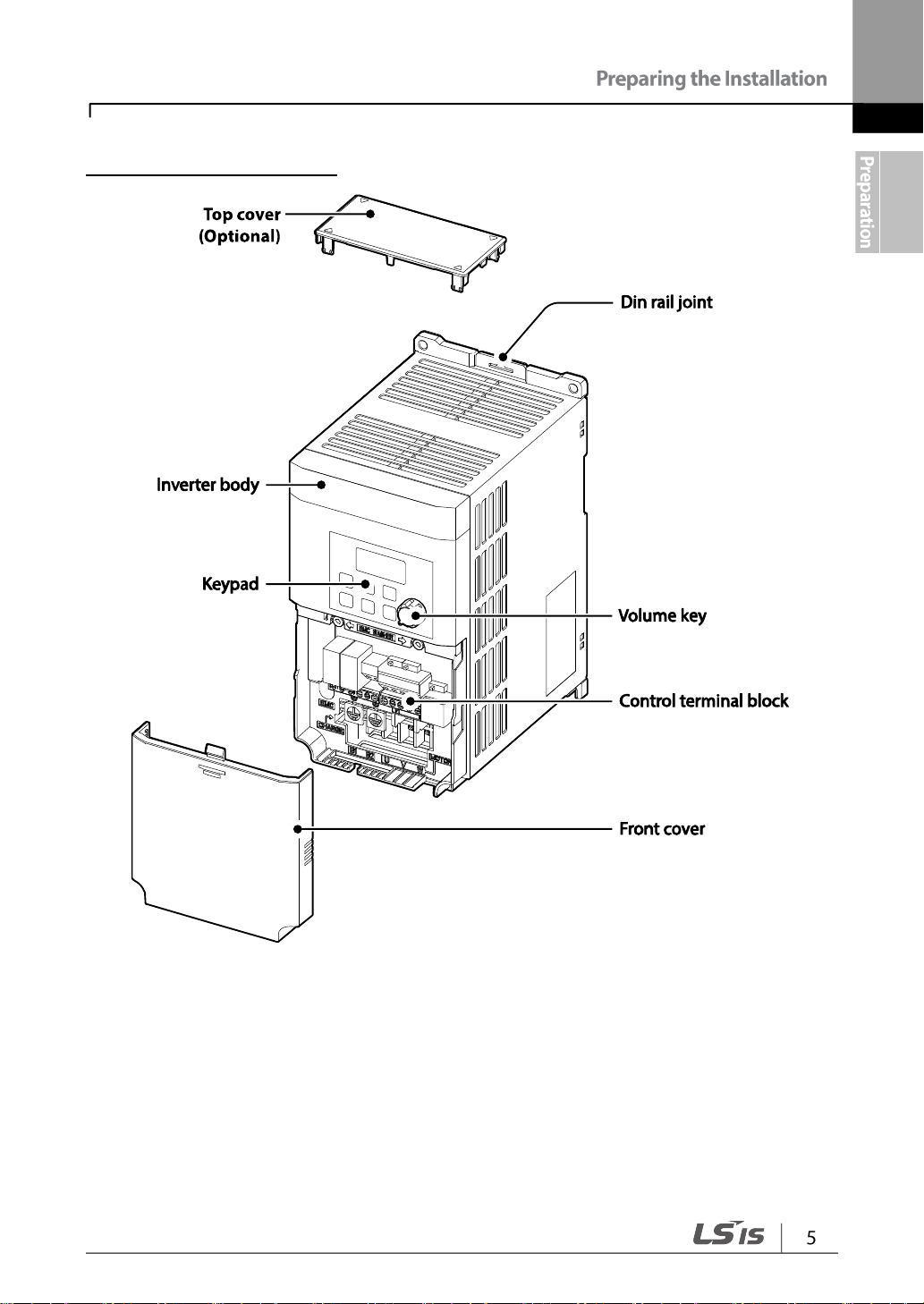

1.2 Part Names

The illustration below displays part names. Details may vary between product groups.

0.1~0.2 kW (Single Phase)

0.4~0.75 kW (Single Phase)

기

본조작법

기

능알

람

표

제

어

블

록도

기

본

기

능

응

용

기

능

모

니터기능

보

호

기

능

통

신

기

능

1.5~2.2 kW (Single Phase)

1.3 Installation Considerations

Items

Description

Ambient Temperature

1)

14–122F (-10–50℃)

Ambient Humidity

95% relative humidity (no condensation)

Storage Temperature

- 4–149F (-20–65℃)

Environmental Factors

An environment free from corrosive or flammable gases, oil residue or

dust

Altitude/Vibration

Lower than 3,280 ft (1,000 m) above sea level/less than 1G (9.8

m/sec2)

Air Pressure

70~106 kPa

Inverters are composed of various precision, electronic devices, and therefore the

installation environment can significantly impact the lifespan and reliability of the product.

The table below details the ideal operation and installation conditions for the inverter.

1) The ambient temperature is the temperature measured at a point 2” (5 cm) from the surface of the

inverter.

기

본조작법

기

능알

람

표

제

어

블

록도

기

본

기

능

응

용

기

능

모

니터기능

보

호

기

능

통

신

기

능

Do not allow the ambient temperature to exceed the allowable range while operating the

inverter.

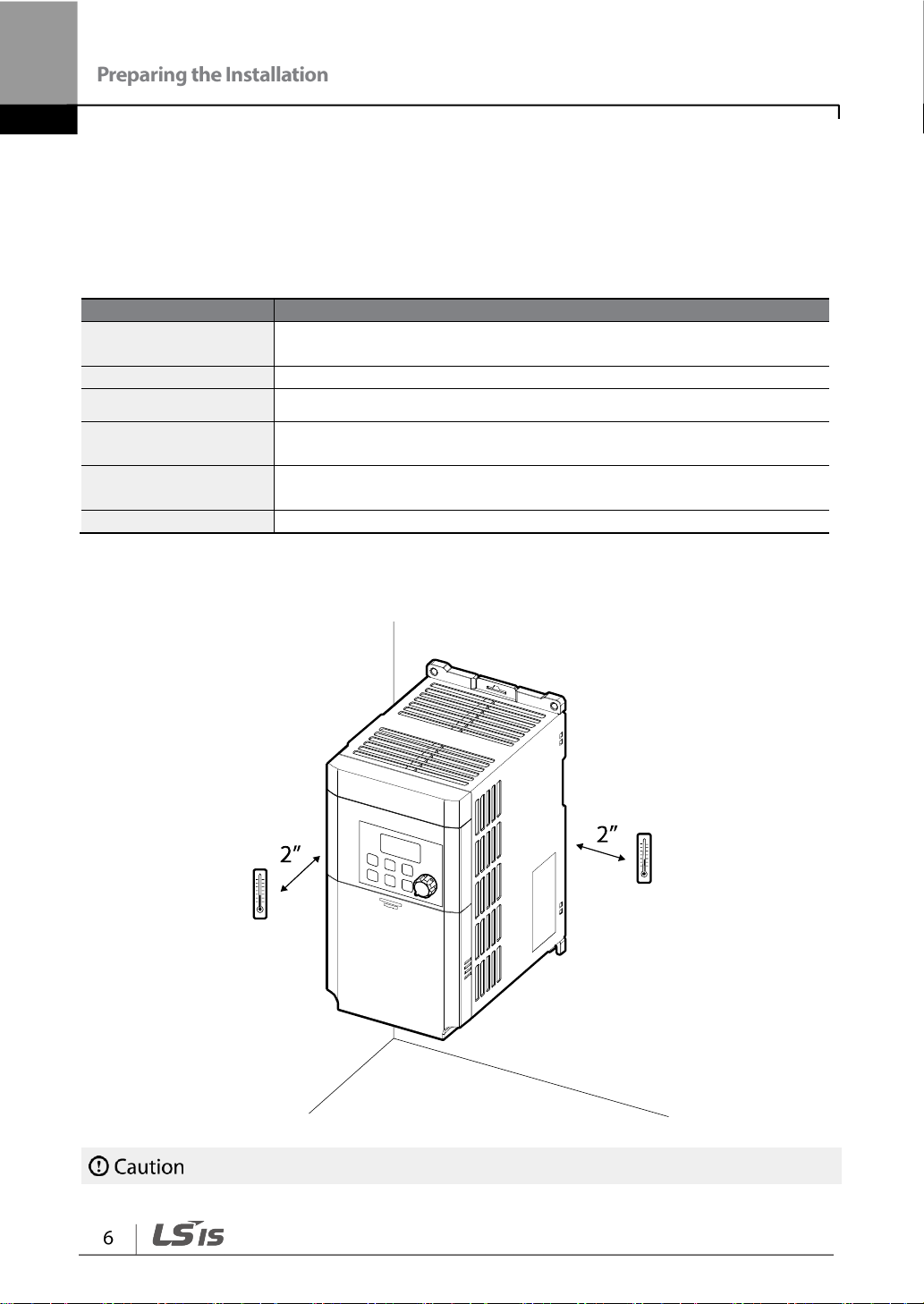

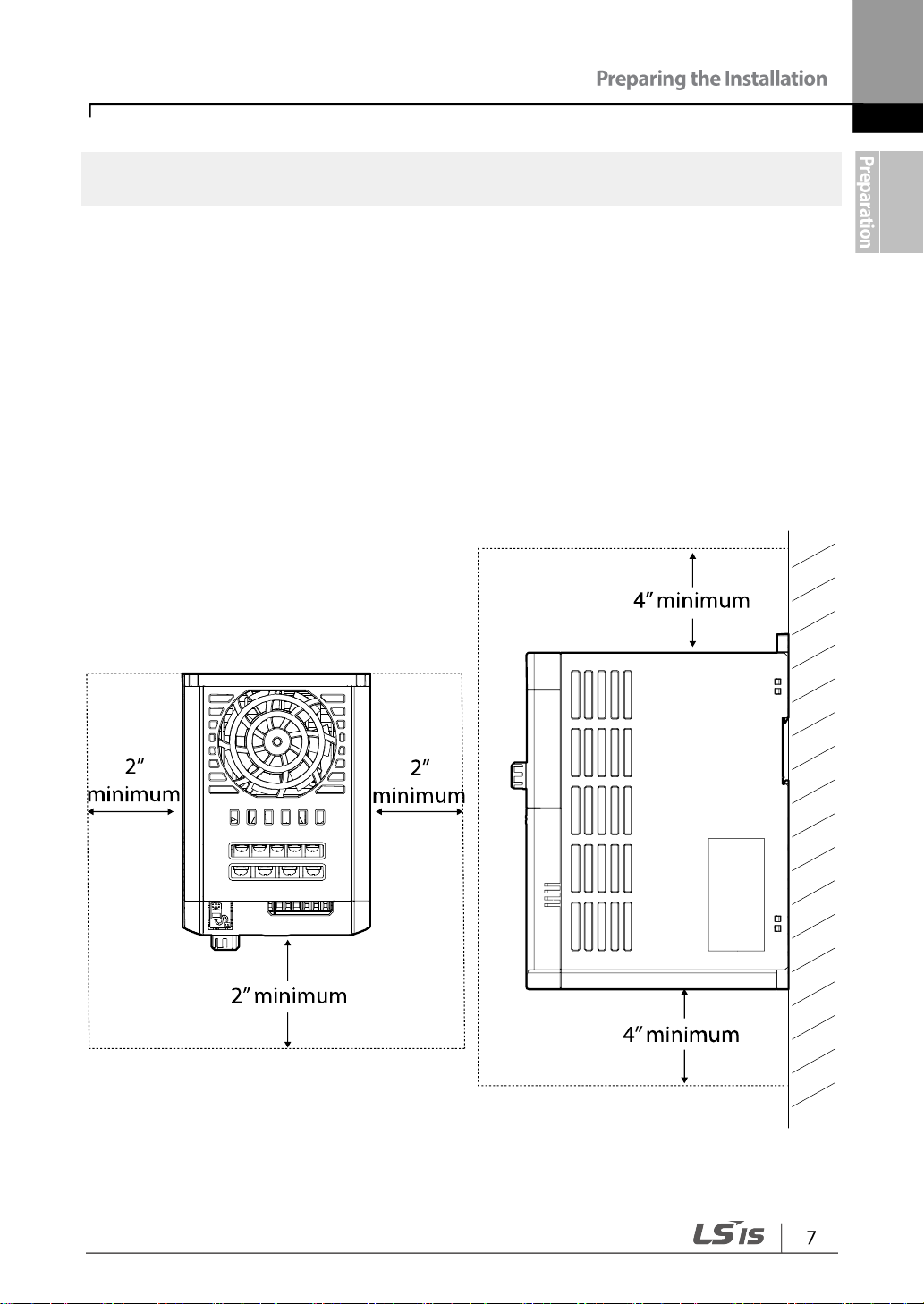

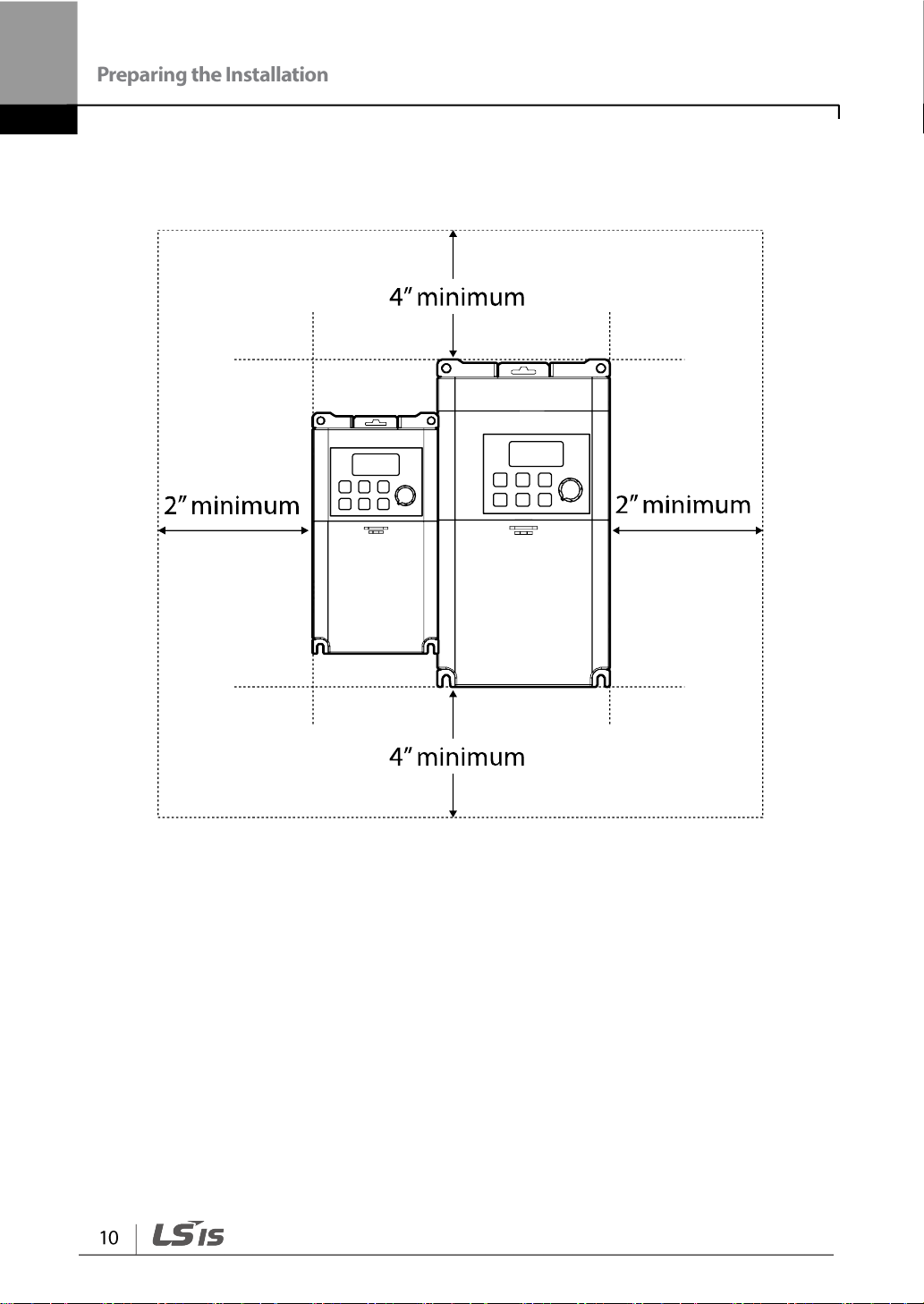

1.4 Selecting and Preparing a Site for Installation

When selecting an installation location consider the following points:

• The inverter must be installed on a wall that can support the inverter’s weight.

• The location must be free from vibration. Vibration can adversely affect the operation of

the inverter.

• The inverter can become very hot during operation. Install the inverter on a surface that

is fire-resistant or flame-retardant and with sufficient clearance around the inverter to

allow air to circulate. The illustrations below detail the required installation clearances.

• Ensure sufficient air circulation is provided around the inverter when it is installed. If the

inverter is to be installed inside a panel, enclosure, or cabinet rack, carefully consider the

position of the inverter’s cooling fan and the ventilation louver. The cooling fan must be

positioned to efficiently transfer the heat generated by the operation of the inverter.

기

본조작법

기

능알

람

표

제

어

블

록도

기

본

기

능

응

용

기

능

모

니터기능

보

호

기

능

통

신

기

능

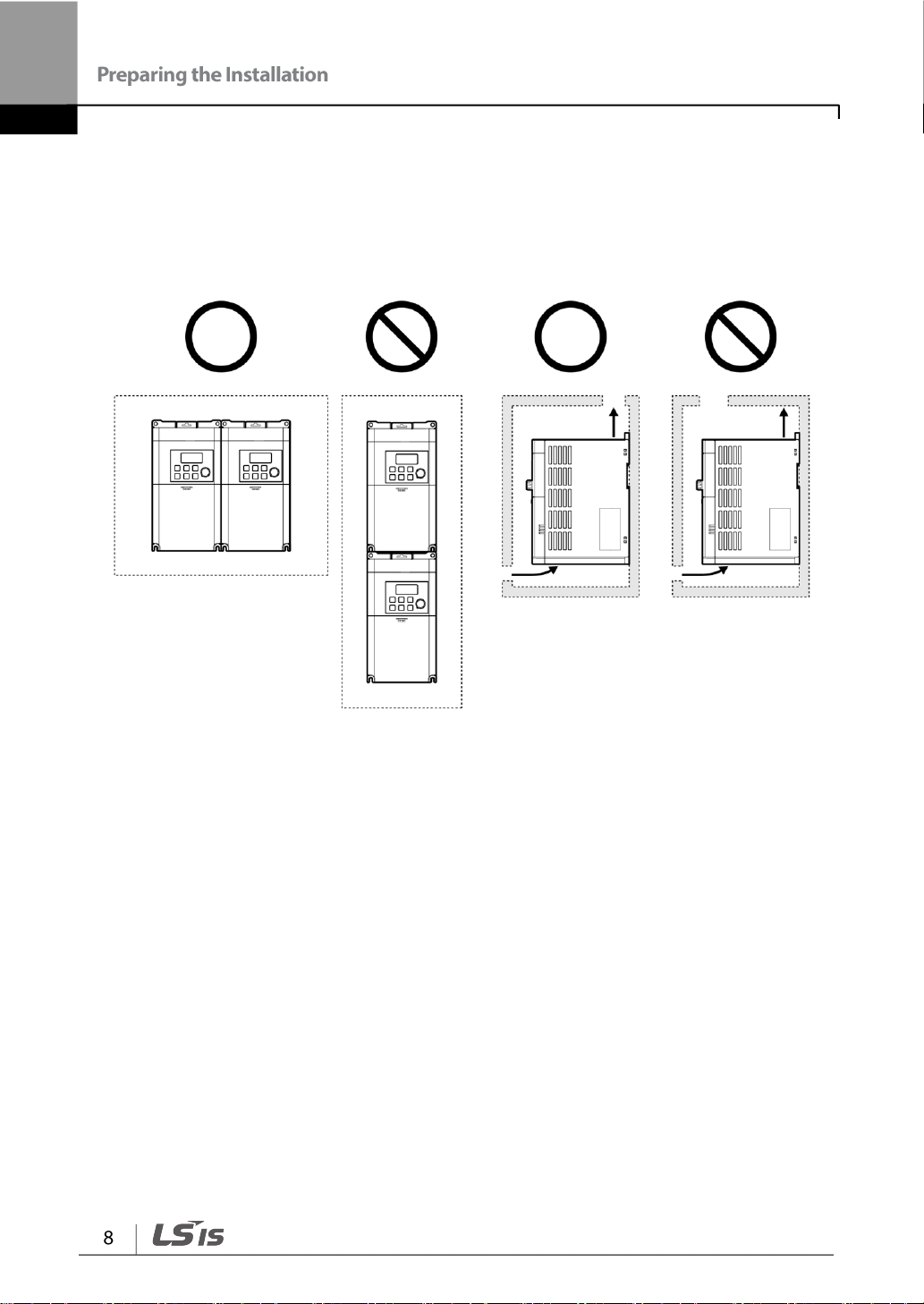

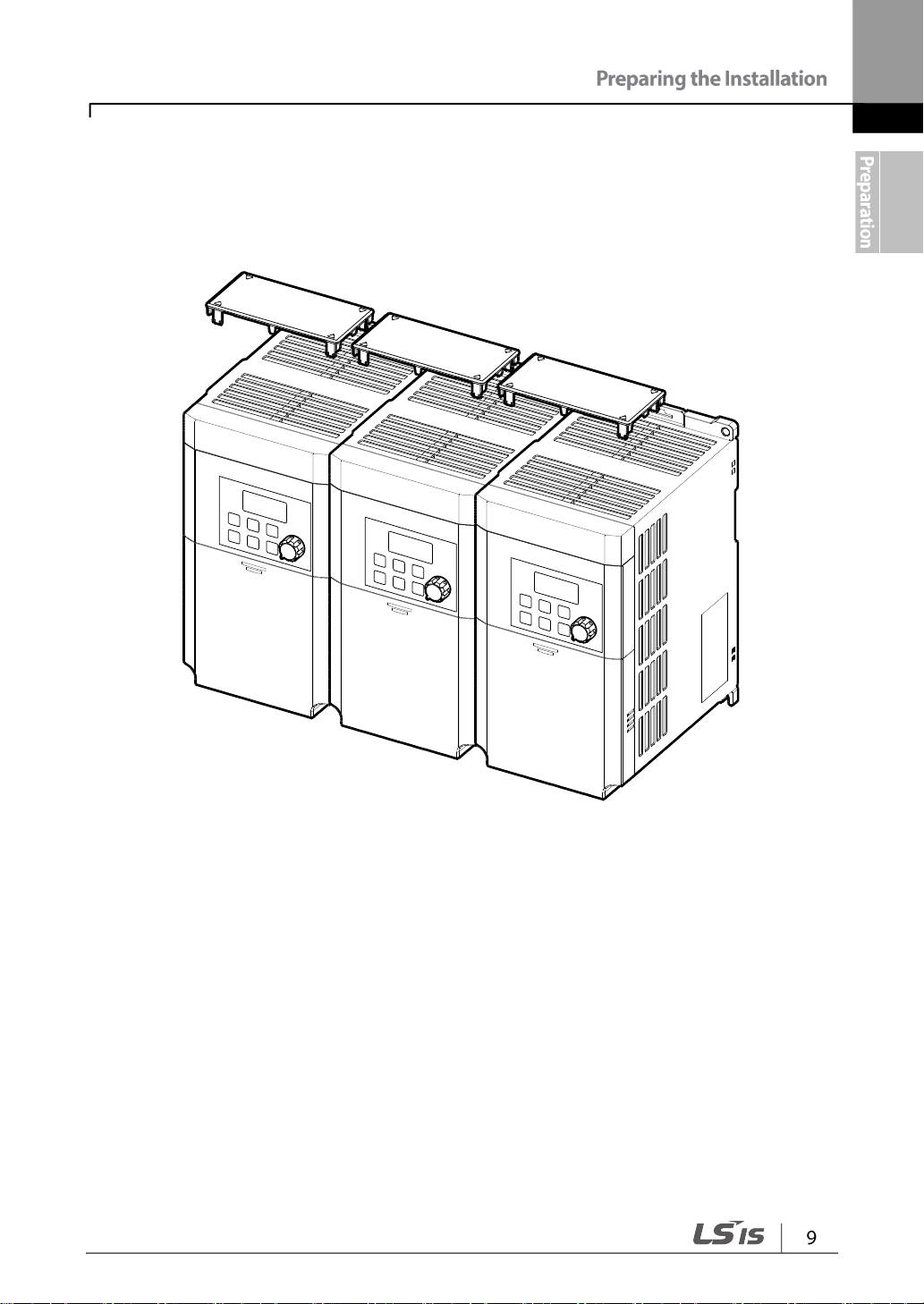

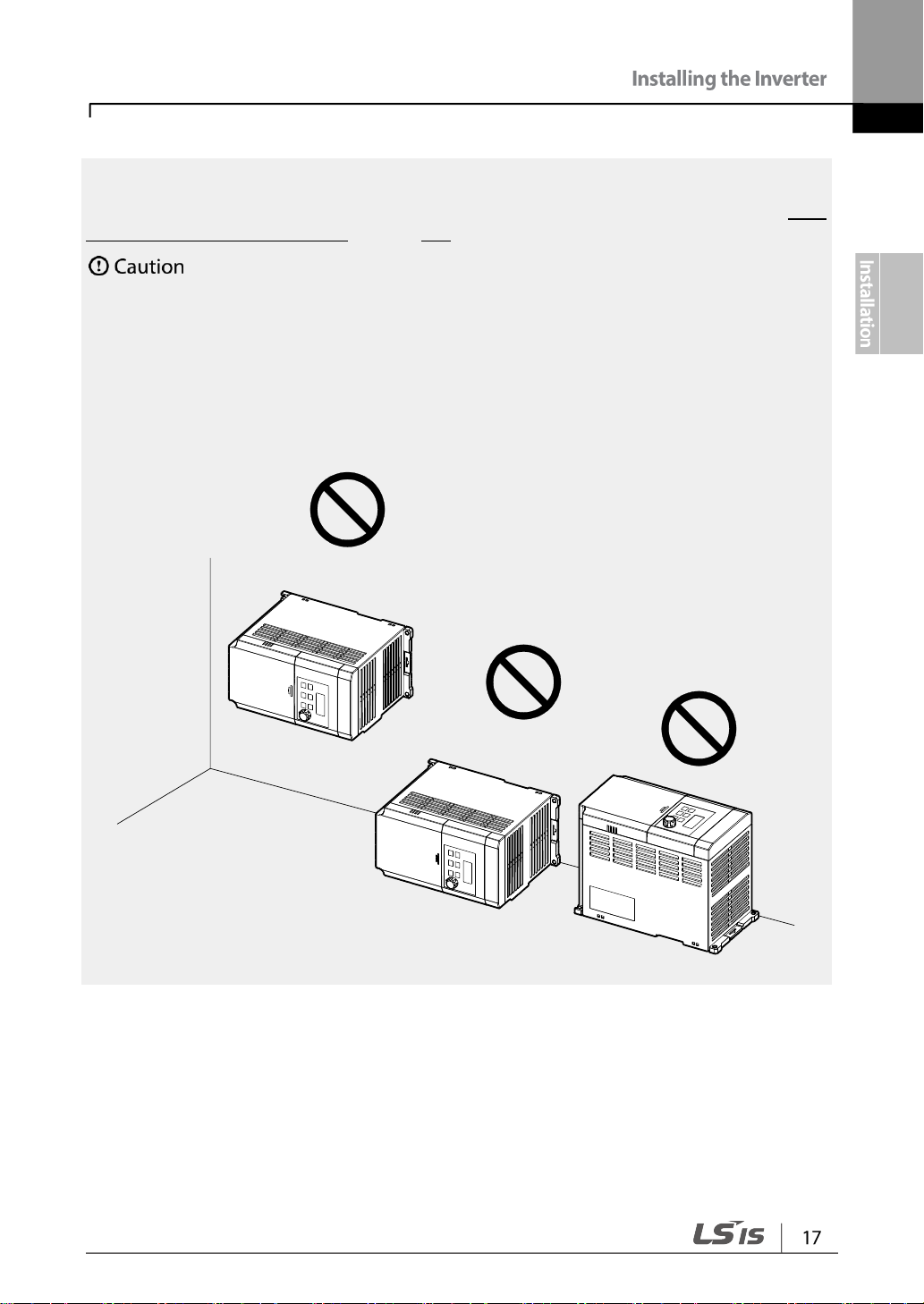

• If you are installing multiple inverters in one location, arrange them side by side and

remove their top covers (optional). The top covers MUST be removed for side-by -side

installations. Use a flat head screwdriver to remove the top covers.

• Keep the distance between inverters at least 0.1’’.

• If you are installing multiple inverters, of different ratings, provide sufficient clearance to

meet the clearance specifications of the larger inverter.

기

본조작법

기

능알

람

표

제

어

블

록도

기

본

기

능

응

용

기

능

모

니터기능

보

호

기

능

통

신

기

능

1.5 Cable Selection

• Wherever possible use cables with the largest cross-sectional area for mains power wiring,

to ensure that voltage drop does not exceed 2%.

• Use copper cables rated for 600V, 75℃ for power terminal wiring.

• Use copper cables rated for 300V, 75℃ for control terminal wiring.

Load (kW)

Ground

Power I/O

mm2

AWG

mm2

AWG

R/S/T

U/V/W

R/S/T

U/V/W

Single Phase

200V

0.1

3.5

12 2 2

14

14

0.2

0.4

0.75

1.5

3.5

12

3.5

3.5

12

12

2.2

Terminal

Signal Cable

Without Crimp Terminal

Connectors

(Bare wire)

With Crimp Terminal Connectors

(Bootlace Ferrule)

mm2

AWG

mm2

AWG

P1~P5/CM/VR/V1/I2

/AO/Q1/EG/241)

0.75

18

0.5

20

A1/B1/C1/A2/C21)

1.0

17

1.5

15

When you install power and signal cables in the terminal blocks, only use cables that meet

the required specification for the safe and reliable operation of the product. Refer to the

following information to assist you with cable selection.

Ground Cable and Power Cable Specifications

Signal (Control) Cable Specifications

1) There are no P4, P5, I2, A2, and C2 terminals on the standard I/O, and there are no Q1 and EG

terminals on the Advanced I/O. For more details, refer to 2.2 Cable Wiring Step 4 Control Terminal

Wiring on page 24.

설치 준비

기본조작법

기능알람표

제어블록도

기본 기능

응용 기능

모니터기능

보호 기능

통신 기능

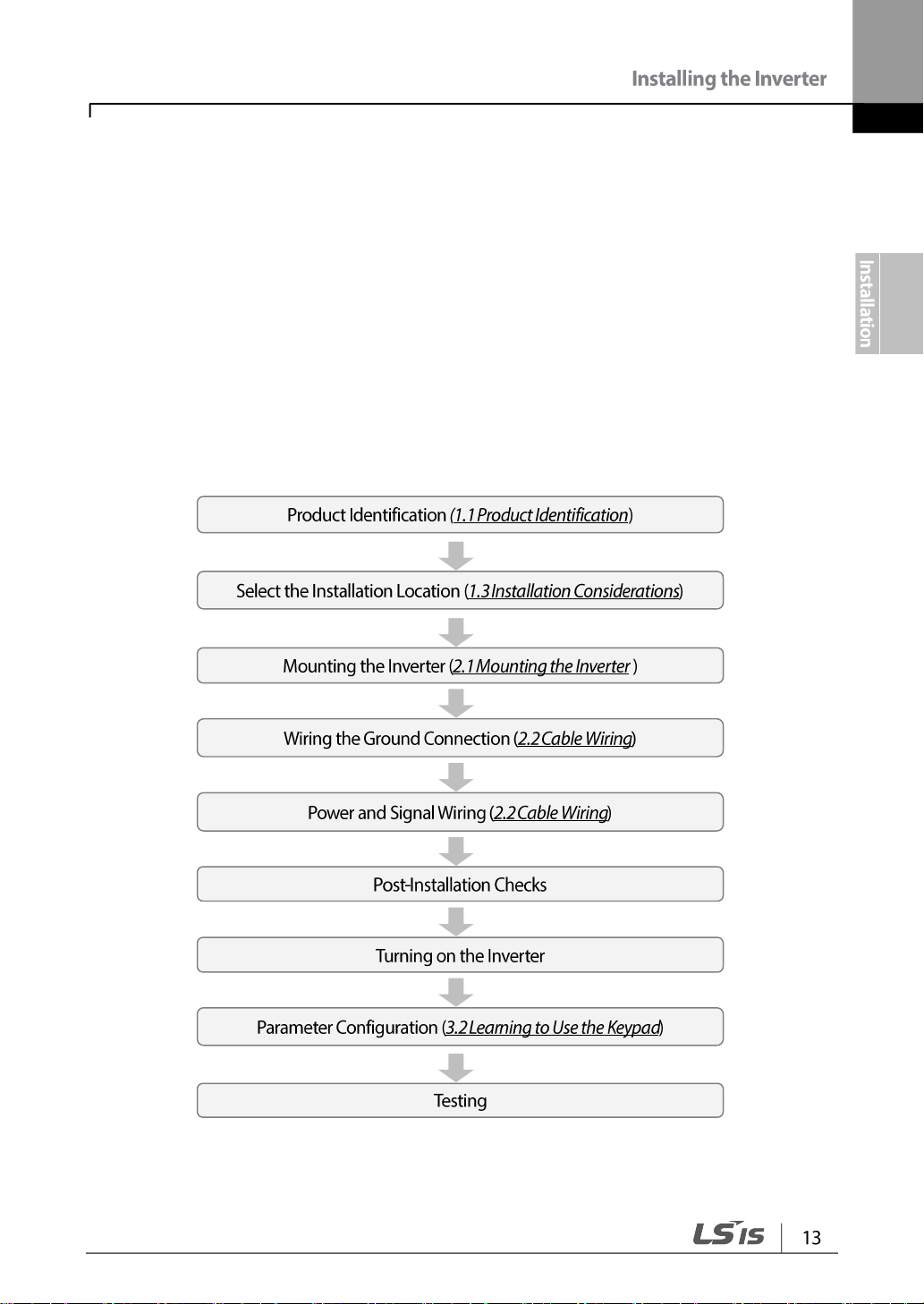

2 Installing the Inverter

This chapter describes the physical and electrical installation methods, including mounting

and wiring of the product. Refer to the flowchart and basic configuration diagram provided

below to understand the procedures and installation methods to be followed to install the

product correctly.

Installation Flowchart

The flowchart lists the sequence to be followed during installation. The steps cover

equipment installation and testing of the product. More information on each step is

referenced in the steps.

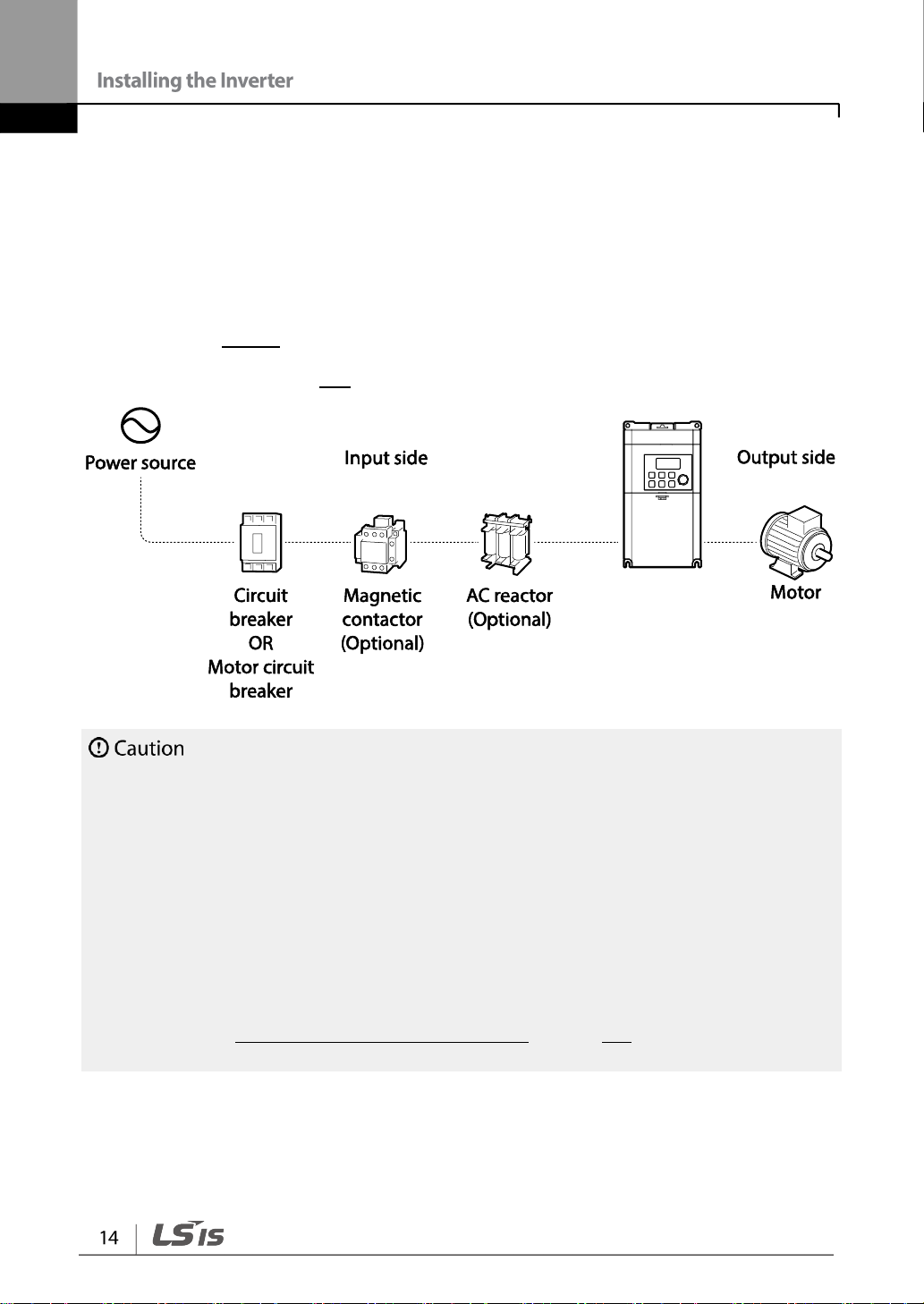

Basic Configuration Diagram

• Figures in this manual are shown with covers or circuit breakers removed to show a more

detailed view of the installation arrangements. Install covers and circuit breakers before

operating the inverter. Operate the product according to the instructions in this manual.

• Do not start or stop the inverter using a magnetic contactor, installed on the input power

supply.

• If the inverter is damaged and loses control, the machine may cause a dangerous situation.

Install an additional safety device such as an emergency brake to prevent these situations.

• High levels of current draw during power-on can affect the system. Ensure that correctly

rated circuit breakers are installed to operate safely during power-on situations.

• Reactors can be installed to improve the power factor. Note that reactors may be installed

within 30 ft (9.14 m) from the power source if the input power is 10 times over the inverter’s

power. Refer to 12.5 Fuse and Reactor Specifications on page 247 and carefully select a

reactor that meets the equipment.

The reference diagram below shows a typical system configuration showing the inverter

and peripheral devices.

Prior to installing the inverter, ensure that the product is suitable for the application (power

rating, capacity, etc). Ensure that all of the required peripherals and optional devices

(resistor brakes, contactors, noise filters, etc.) are available. For more details on peripheral

devices, refer to 0 Unit: mm (inches)

Peripheral Devices on page 247.

설

치

준

비

기

본조작법

기

능알

람

표

제

어

블

록도

기

본

기

능

응

용

기

능

모

니터기능

보

호

기

능

통

신

기

능

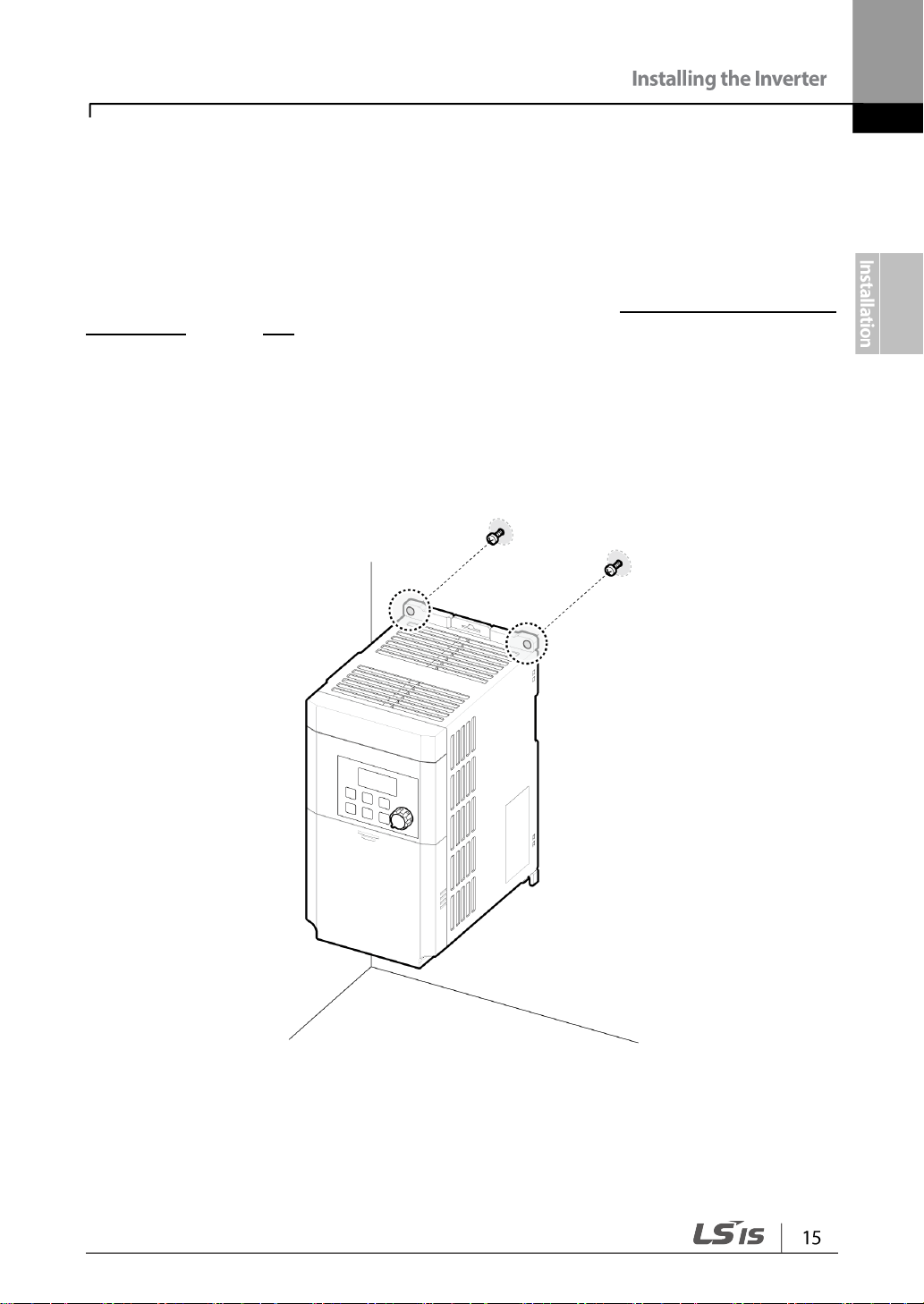

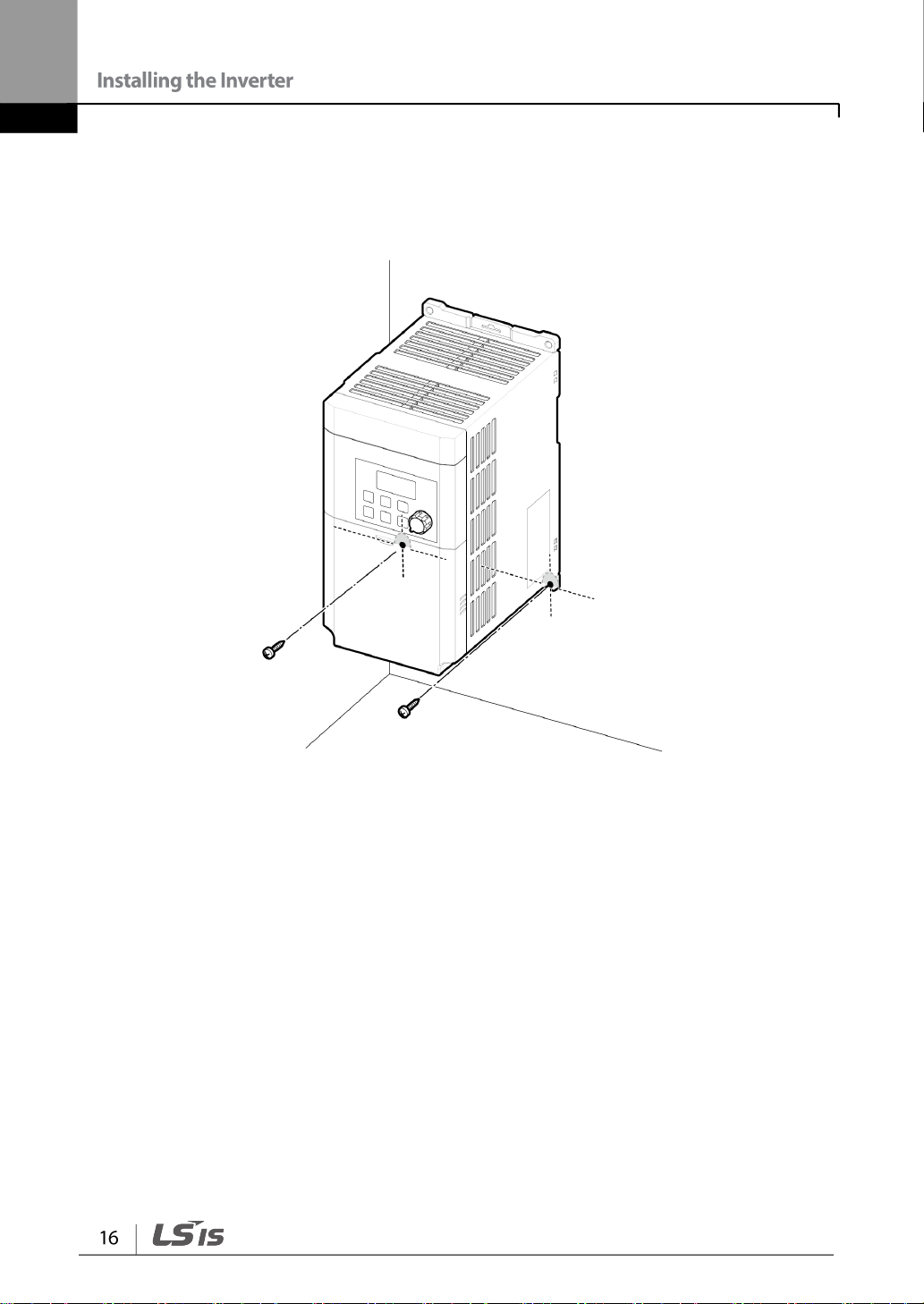

2.1 Mounting the Inverter

Mount the inverter on a wall or inside a panel following the procedures provided below.

Before installation, ensure that there is sufficient space to meet the clearance specifications,

and that there are no obstacles impeding the cooling fan’s air flow.

Select a wall or panel suitable to support the installation. Refer to 12.3 External Dimensions

(IP 20 Type) on page 245 and check the inverter’s mounting bracket dimensions.

1 Use a level to draw a horizontal line on the mounting surface, and then carefully mark

the fixing points

2 Drill the two upper mounting bolt holes, and then install the mounting bolts. Do not fully

tighten the bolts at this time. Fully tighten the mounting bolts after the inverter has been

mounted.

3 Mount the inverter on the wall or inside a panel using the two upper bolts, and then fully

tighten the mounting bolts. Ensure that the inverter is placed flat on the mounting

surface, and that the installation surface can securely support the weight of the inverter.

설

치

준

비

기

본조작법

기

능알

람

표

제

어

블

록도

기

본

기

능

응

용

기

능

모

니터기능

보

호

기

능

통

신

기

능

Note

The quantity and dimensions of the mounting brackets vary based on frame size. Refer to 12.3

External Dimensions (IP 20 Type) on page 245 for detailed information about your model.

• Do not transport the inverter by lifting with the inverter’s covers or plastic surfaces. The

inverter may tip over if covers break, causing injuries or damage to the product. Always

support the inverter using the metal frames when moving it.

• Use an appropriate transport method that is suitable for the weight.

• Do not install the inverter on the floor or mount it sideways against a wall. The inverter

MUST be installed vertically, on a wall or inside a panel, with its rear flat on the mounting

surface.

2.2 Cable Wiring

• Install the inverter before carrying out wiring connections.

• Ensure that no small metal debris, such as wire cut-offs, remain inside the inverter. Metal

debris in the inverter may cause inverter failure.

• Tighten terminal screws to their specified torque. Loose terminal block screws may allow the

cables to disconnect and cause short circuit or inverter failure. Refer to 12.6 Terminal Screw

Specification on page 248 for torque specifications.

• Do not place heavy objects on top of electric cables. Heavy objects may damage the cable

and result in electric shock.

• The inverter’s power is supplied by the supply grounding system. The TT, TN, IT, and corner-

grounded systems are not suitable for this inverter.

• The inverter may generate direct current to the inverter’s protective ground cable. Only type

B Residual Current Devices (RCD) or Residual Current Monitors (RCM) can be installed.

• Use cables with the largest cross-sectional area, appropriate for power terminal wiring, to

ensure that voltage drop does not exceed 2%.

• Use copper cables rated at 600V, 75℃ for power terminal wiring.

• Use copper cables rated at 300V, 75℃ for control terminal wiring.

• Connect the control terminals separately from the power terminal wiring or high potential

circuit (200 V relay sequence circuit).

• Ensure that there are no control terminal shorts or improper wiring. Control terminal shorts or

improper wiring may damage the inverter or cause malfunction.

• Use a shielded cable while making wiring connections at the control terminal. Unshielded

cables may cause the inverter to malfunction due to interference. Use an STP cable if ground

connections must be installed.

• If you need to re-wire the terminals due to wiring-related faults, ensure that the inverter

keypad display is turned off and the charge lamp under the front cover is off before working

on wiring connections. The inverter may hold a high voltage electric charge long after the

power supply has been turned off.

Remove the control terminal cover, and then install the ground connection as specified.

Complete the cable connections by connecting an appropriately rated cable to the terminals

on the power and control terminal blocks.

Loading...

Loading...