Page 1

INSTRUCTIONINSTRUCTION

MANUALMANUAL

MULTI INFORMATION DISPLAYMULTI INFORMATION DISPLAY

NWZ-4610NWZ-4610

Page 2

Page 3

i

General Information

Thank you for purchasing the Japan Radio Co., Ltd. NWZ-4610 Multi Information Display (MID). This

equipment receives NMEA data from various sensors for display.

٨ Before attempting to operate this equipment, read this instruction manual thoroughly to ensure

correct and safe operation in accordance with the warning instructions and operation procedures.

٨ You are strongly recommended to store this instruction manual carefully for future reference.

In the event that you have an operational problem or malfunction, this manual will provide useful

instructions.

7ZPNA4284

Page 4

ii

Before You Begin

Symbols Used In This Manual

In this manual, and on the equipment, we use several warning signs to call your attention to

important items that, if not handled correctly, could present danger to yourself or property.

These warning note classifications are as described below.

Please be fully aware of the importance of these items before using this manual.

Indicates warning items that, if ignored, may

result in serious personal injury or even death.

Indicates cautionary items that, if ignored, may

result in personal injury or physical damage.

Examples of Related Symbol Marks Used in this Manual and on the Unit

Each mark is intended to alert the user to the presence of

precautions including danger and warning items. The picture in each

mark (“Electric shock” in the example on the left.) alerts you to

operations that should be carefully performed.

Each

mark is intended to alert the user to the presence of prohibited

activity. The picture/word in/beside each mark (“Disassembling

Prohibited” in the example on the left.) alerts you to operations that are

prohibited.

Each

mark is intended to alert the user to the presence of

necessary instructions. The picture in each

mark (“Disconnect the

power plug” in the example on the left.) alerts you to operations that

must be performed.

WARNING LABEL

You can see the warning label on the top of the unit.

Do not attempt to remove the warning label from the unit or impair or modify it.

Page 5

iii

Usage Hints

Do not remove the cover of this unit. Otherwise, you may touch a

high-voltage part and suffer from an electric shock.

Turn off the power on/off switch, and turn off the power supply

breaker when you for maintenance check this unit for

maintenance. Otherwise, a fire, an electric shock, or a failure may

occur.

Do not disassemble or modify this unit. Otherwise, a fire, an

electric shock, or a failure may occur.

Do not place a vessel containing water, etc. or a metallic object on

this unit. When water spills or when water or the object enters the

unit, a fire, an electric shock, or a failure may occur.

Do not use this unit at a voltage other than the supply voltage

stated on the unit. Otherwise, a fire, an electric shock, or a failure

may occur.

Do not insert or remove the power cord or operate switches with a

wet hand. Otherwise, you may suffer from an electric shock.

Do not damage or modify the power cord. Placing a heavy object

onto, heating, stretching or bending the cord may cause a fire or

an electric shock.

Do not check or repair in this unit. Please call our field

representative or your nearest JRC office for inspection and repair

services. Otherwise It may cause a fire or an electric shock.

In the event that you spill or drop any liquids or metals etc., turn off

the unit, turn off the power supply breaker, and contact your sales

agent outlet or one of JRC branch offices, sales centers or liaison

offices. Otherwise continuing operation may cause a fire, an

electric shock or a malfunction.

In the event that smoking or burning odors are detected,

immediately terminate operation of the unit and contact your sales

agent outlet or one of JRC branch offices, sales centers or liaison

offices. Never attempt to check or repair the interior of the unit.

Otherwise continuing operation may cause a fire or an electric

shock.

AC

WARNING

Page 6

iv

Without qualified service personnel, do not attempt to install this

unit. Contact our service center or agent for any electrical work or

installation of this unit. Otherwise it may cause a malfunction.

Do not install this unit at the place exposed to direct sunlight for a

long time or hit by hot wind or where the temperature rises above

55℃. Otherwise it may cause a fire or a breakdown.

Do not place the unit on a wobbly stand or any unsteady

foundation. Otherwise it may cause the unit to fall, resulting in an

injury or a damage.

Do not put this unit in the cabinet, and do not cover with the

nonporous thing such as cardboard. Heat shuts oneself up, and it

may cause a fire or a breakdown.

When this unit is suddenly moved from a cool place to a warm

place, drew condensation water may form on the inside windows,

and the liquid crystal part can become visually difficult. In this

case, leave the unit for a while until becoming dry condition. Then

operate the unit.

When installing this set, be sure to connect the grounding wire or

the grounding plate to the grounding terminal of the unit.

Otherwise you may suffer from an electric shock.

Do not turn on the power switch of the unit while the ship is on the

shore. Otherwise, the transducer may malfunction.

Do not use an organic solvent such as thinner or benzine when

you clean the surface of the unit. For cleaning the surface, remove

the dust and wipe with clean dry cloth. Otherwise, the painting on

the surface may be damaged

CAUTION

Page 7

v

External View

Page 8

Contents

General Information ...................................................................................................................... i

Before You Begin .......................................................................................................................... ii

Usage Hints .................................................................................................................................. iii

External View ................................................................................................................................ v

Chapter 1 Introduction .......................................................................................................... 1-1

1.1. Function ............................................................................................................................... 1-1

1.2. Features ............................................................................................................................... 1-2

1.3. Components ......................................................................................................................... 1-3

1.3.1. Standard equipment ....................................................................................................... 1-3

1.3.2. Options........................................................................................................................... 1-3

1.4. Construction ........................................................................................................................ 1-4

1.5. System Configuration ......................................................................................................... 1-5

Chapter 2 Names and Functions of the Components ........................................................ 2-1

Chapter 3 Display Screen ..................................................................................................... 3-1

3.1. Display Screen ..................................................................................................................... 3-1

Chapter 4 Operation .............................................................................................................. 4-1

4.1. Menu ..................................................................................................................................... 4-2

4.2. Basic Operation ................................................................................................................... 4-8

4.2.1. Turning on the power ..................................................................................................... 4-8

4.2.2. Starting (Normal) ............................................................................................................ 4-8

4.2.3. Starting (Abnormal) ........................................................................................................ 4-9

4.2.4. Starting (Abnormal) ........................................................................................................ 4-9

4.2.5. Turning off the power ..................................................................................................... 4-9

4.2.6. Adjusting the back light (lighting) by using the key ...................................................... 4-10

4.2.7. Adjusting contrast ........................................................................................................ 4-10

4.2.8. Turning off the alarm buzzer ........................................................................................ 4-10

4.2.9. Switching display ......................................................................................................... 4-10

4.2.10. Alarm display ............................................................................................................... 4-10

4.2.11. Selecting items from the menus .................................................................................. 4-11

4.2.12. Entering a numeric value ............................................................................................. 4-12

4.3. User Mode Change ............................................................................................................ 4-13

4.4. User Setting Screen Display ............................................................................................ 4-13

4.5. Setting Display .................................................................................................................. 4-14

4.5.1. Adjusting contrast ........................................................................................................ 4-14

4.5.2. Adjusting back light ...................................................................................................... 4-15

4.5.3. Setting a click sound .................................................................................................... 4-15

4.5.4. Setting a display screen............................................................................................... 4-15

4.5.5. Selecting a back light color .......................................................................................... 4-21

4.5.6. Setting graph scale ...................................................................................................... 4-22

4.5.7. Registering user display .............................................................................................. 4-22

4.6. System Settings ................................................................................................................ 4-23

4.6.1. Selecting units ............................................................................................................. 4-23

4.6.2. Setting the time difference ........................................................................................... 4-24

4.6.3. Setting date display format .......................................................................................... 4-25

4.6.4. Displaying as loran c time difference ........................................................................... 4-25

4.6.5. Setting transducer position of depth sounder (exclusive to JFE-380/680) .................. 4-25

4.6.6. Setting water depth offset of depth sounder ................................................................ 4-26

4.7. Language Settings ............................................................................................................ 4-27

4.8. Alarm Settings ................................................................................................................... 4-27

4.8.1. Setting the alarm range ............................................................................................... 4-28

4.8.2. Setting a system alarm ................................................................................................ 4-28

4.8.3. Setting a vessel speed alarm ...................................................................................... 4-29

4.8.4. Setting a TRIP alarm ................................................................................................... 4-29

4.8.5. Setting the water temperature alarm ........................................................................... 4-30

4.8.6. Setting the water depth alarm ...................................................................................... 4-30

4.8.7. Setting the wind velocity alarm .................................................................................... 4-30

4.8.8. Setting the air temperature alarm ................................................................................ 4-31

4.8.9. Setting the atmosphere alarm ..................................................................................... 4-31

4.8.10. Setting the humidity alarm ........................................................................................... 4-31

4.8.11. Setting a buzzer sound and screen back light ............................................................. 4-32

4.9. Setting Installation ............................................................................................................ 4-33

Page 9

4.9.1.

Changing to a maintenance mode ............................................................................... 4-33

4.9.2. Setting a model ............................................................................................................ 4-34

4.9.3. Selecting a dimmer unit ............................................................................................... 4-34

4.9.4. Dimmer linked control and data sharing with RS-485 ................................................. 4-35

4.9.5. Setting a serial port ...................................................................................................... 4-38

4.9.6. Setting a contact port ................................................................................................... 4-42

4.9.7. Outputting alarm history ............................................................................................... 4-43

4.9.8. Checking installation .................................................................................................... 4-43

4.9.9. Checking the input port ................................................................................................ 4-44

4.9.10. Self-diagnosis .............................................................................................................. 4-44

4.9.11. Displaying an alarm ..................................................................................................... 4-45

4.9.12. Displaying the software version ................................................................................... 4-46

4.9.13. Performing master reset .............................................................................................. 4-46

4.9.14. Demonstration ............................................................................................................. 4-47

4.9.15. Outputting setting value ............................................................................................... 4-47

4.9.16. Setting the current to be displayed .............................................................................. 4-47

4.10. Setting daisy chain ........................................................................................................ 4-48

Chapter 5 Maintenance ......................................................................................................... 5-1

5.1. Daily Maintenance ............................................................................................................... 5-2

5.2. Alarm .................................................................................................................................... 5-3

5.3. Troubleshooting for Malfunctions or Abnormalities ....................................................... 5-4

5.4. Repair Unit ........................................................................................................................... 5-5

5.4.1. Repair unit...................................................................................................................... 5-5

5.4.2. Regular Replacement Parts ........................................................................................... 5-5

Chapter 6 Installation ............................................................................................................ 6-1

6.1. Affixing Display Unit Nameplate Labels ........................................................................... 6-2

6.1.1. Affixing product nameplate ............................................................................................ 6-2

6.1.2. Affixing model identification plate .................................................................................. 6-2

6.2. Display Unit Installation ...................................................................................................... 6-3

6.2.1. Selecting the position for installation ............................................................................. 6-3

6.2.2. Mounting the display unit using a rack .......................................................................... 6-4

6.2.3. Mounting using a flash mount ........................................................................................ 6-6

6.2.4. Removing the display unit by flash mounting ................................................................ 6-8

6.3. Cable Connection ................................................................................................................ 6-9

6.3.1. DC12/24V DATA connector ......................................................................................... 6-10

6.3.2. DATA1 connector ......................................................................................................... 6-13

6.3.3. SENSOR/DATA2 connector ......................................................................................... 6-17

6.4. Optional Peripheral Connection ...................................................................................... 6-21

6.4.1. Dimmer unit connection ............................................................................................... 6-21

Chapter 7 After-Sales Service .............................................................................................. 7-1

7.1. When Ordering a Repair ..................................................................................................... 7-1

7.2. Recommendation of Overhaul ........................................................................................... 7-1

Chapter 8 Disposal ................................................................................................................ 8-1

8.1. Disposal of the Equipment ................................................................................................. 8-1

Chapter 9 Specifications ....................................................................................................... 9-1

Appendix ..................................................................................................................... Appendix-1

Appendix 1 Outline and Setting Drawing ................................................................. Appendix-1

Appendix 2 Default value ........................................................................................... Appendix-3

Appendix 3 Setting value memo............................................................................. Appendix-7

Page 10

Page 11

1-1

Chapter 1 Introduction

1.1. Function

The Multi Information Display (MID) is the display unit that receives NMEA data items from various

sensors to display them.

The screen can be split to up to 4 areas for use. Only necessary information can be displayed by

selecting data to be displayed in the areas.

There are three modes in which six screens can be registered, and up to 18 screens can be registered.

Page 12

1-2

1.2. Features

NWZ-4610 Multi Information Display (MID) has the following features:

1) Display of various NMEA data items

2) Selection of display contents and screen layout

3) Distribution of power supply in daisy chain mode

4) Selection of display screen in each mode

5) Sharing of data and interlocking of dimmer between display units at RS-485 interface

Page 13

1-3

1.3. Components

The standard equipment and options are shown in the tables below.

1.3.1. Standard equipment

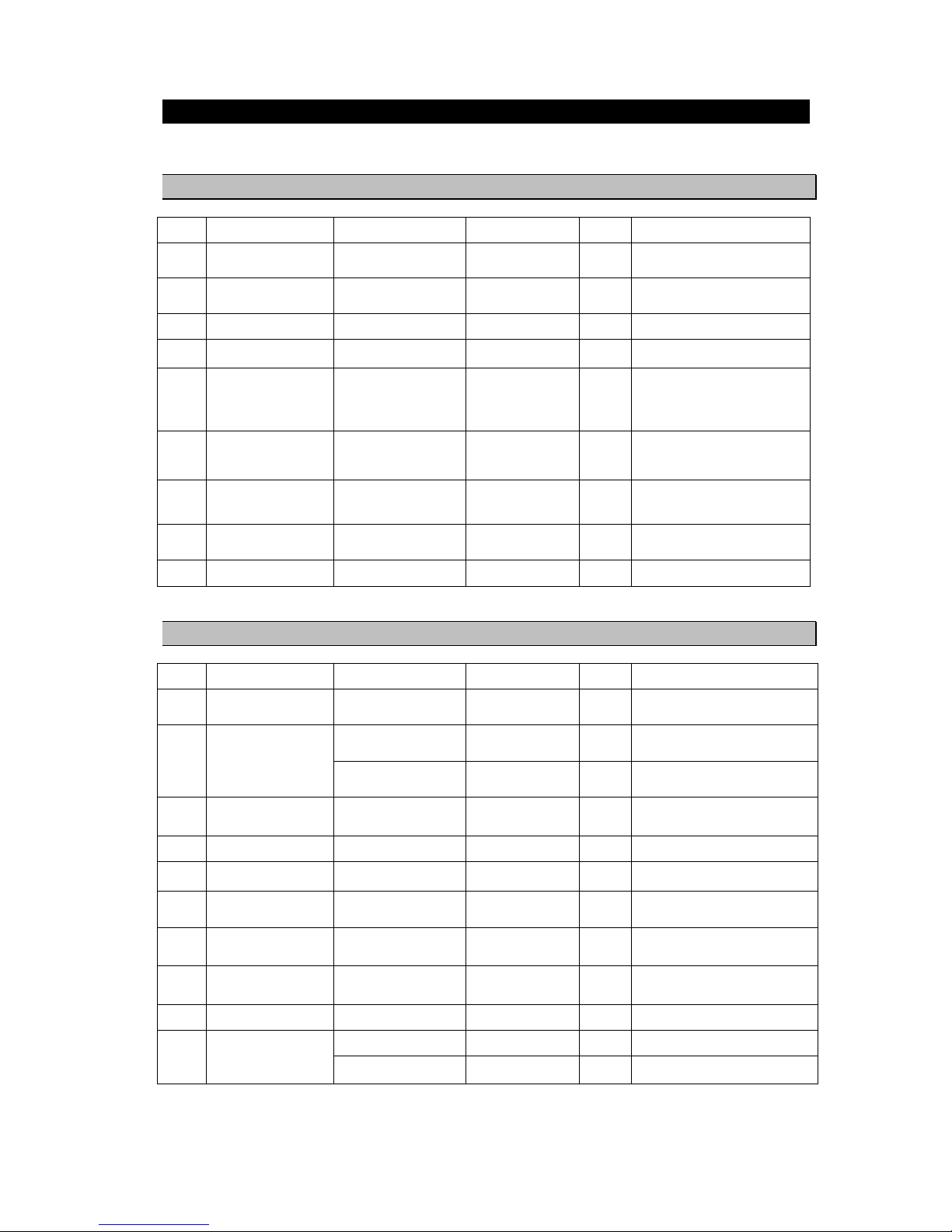

No. Description Model No. CODE QTY Remarks

1.1

DISPLAY NWZ-4610 NWZ-4610 1 Main Body

1.2

DATA POWER CABLE CFQ-5766A CFQ5766A 1

14 cores 2 m/ With Fuse holder

data, power, contact

1.3

FUSE MF60NR 250V 1 5ZFGD00205 2 Display unit 1A fuse

1.4

FRONT PANEL MTV305018A MTV305018A 1

1.5

BASE KITS MPBX47065 MPBX47065 1

Base

Knob Bolt

Gear Washer

Knob Washer

1.6

MODEL

IDENTIFICATION

PLATE

MPNN47524A MPNN47524A 1 For Rear

1.7

PRODUCT

NAMEPLATE

MPNN47529A MPNN47529A 1 For Front

1.8

Flush Mounting

Drawing

- - 1 For Flush Mount

2

QUICK REFERENCE 7ZPNA4352 7ZPNA4352 1 English/Japanese

1.3.2. Options

No. Description Model No. CODE QTY Remarks

1

AC POWER

RECTIFIER

NBD-577C NBD-577C 1 AC100/220V input

24V output

2

DATA POWER CABLE CFQ-5766D CFQ5766D 1 14 cores 10 m/ With Fuse holder

data, power, contact

CFQ-5766F CFQ5766F 1 14 cores 20 m/ With Fuse holder

data, power, contact

3

DATA CABLE CFQ-5767 CFQ5767 1 4 cores/3 m data

6-pin connector data line only

4

DATA CABLE CFQ-5768 CFQ5768 1 6 cores-14 cores/3 m daisy chain

5

DATA CABLE CFQ-5769 CFQ5769 1 For RS-485 4 cores/3 m

6

T-SHAPED

CONNECTOR

AA-040404-MMM-TL 5JCDX00071 1 For CFQ-5769 RS-485

7

JUNCTION BOX CQD-10 CQD-10A 1 12 terminals

8

DIMMER UNIT NCM-227 NCM-227 1 External dimmer unit

9

L-TYPE ADAPTER CFQ-9184 CFQ9184 1

10

INSTRUCTION

MANUAL

7ZPNA4284 7ZPNA4284 1 English

7ZPNA4283 7ZPNA4283 1 Japanese

Page 14

1-4

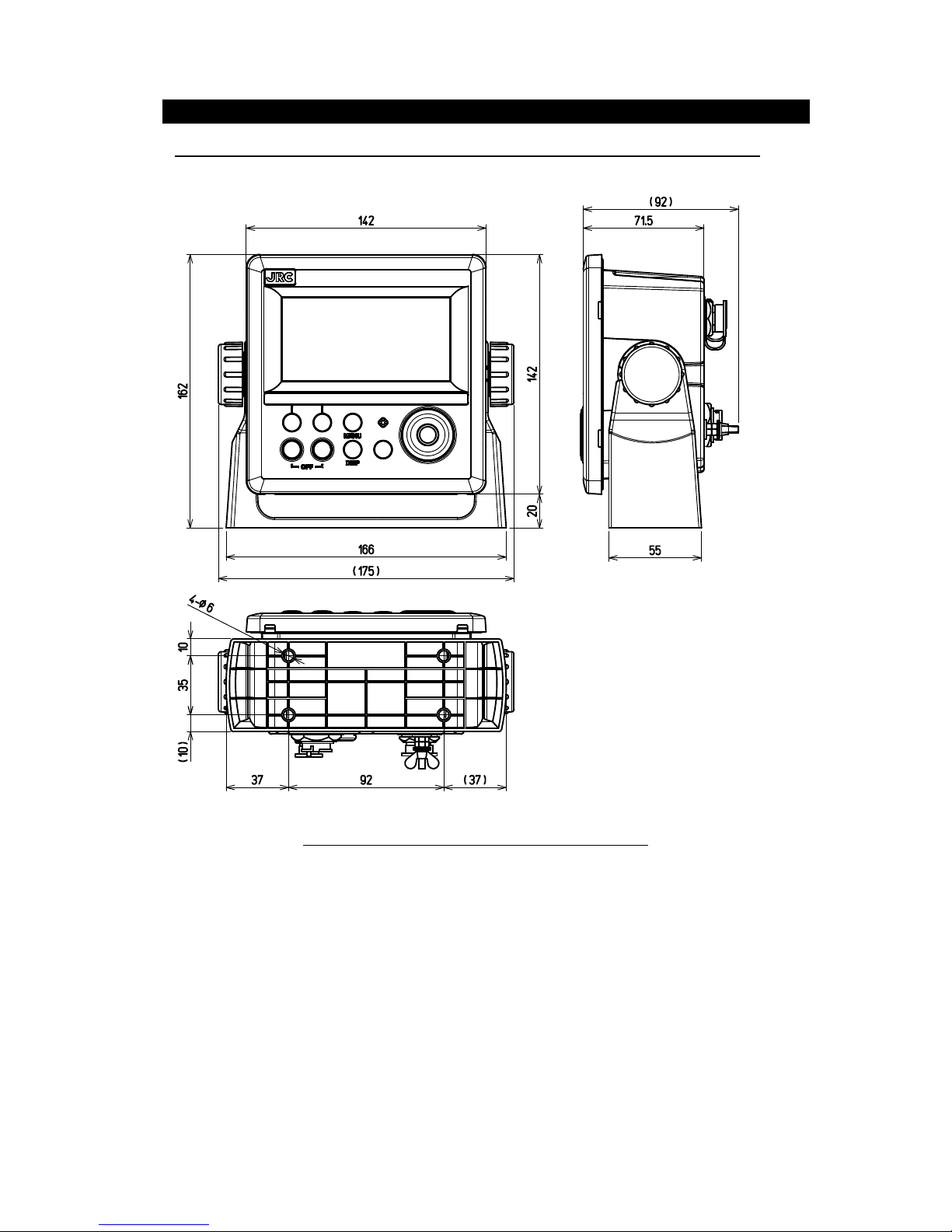

1.4. Construction

Display NWZ-4610

Figure 1.2 NWZ-4610 OUT LINE (Disk Form type)

Unit: mm

Mass: Approximately 0.8kg

Page 15

1-5

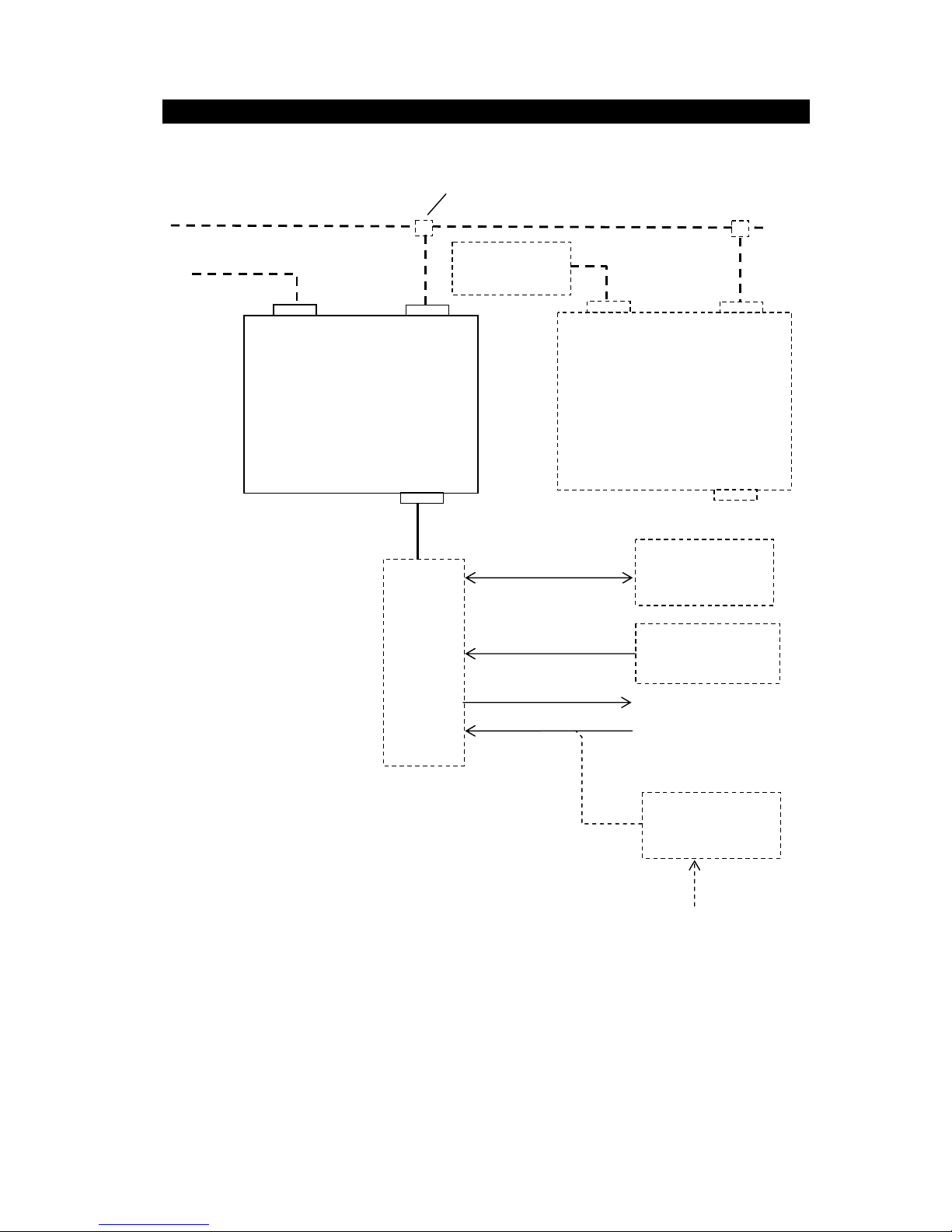

1.5. System Configuration

Junction

box

CQD-10

AC Power

Rectifier

NBD-577C

SENSOR/DATA2 DATA1

MID

NWZ-4610

DC12/24V DATA

Dimmer unit

NCM-227

External device

Sensors

SENSOR/DATA2 DATA1

MID

NWZ-4610

DC12/24V DATA

DC12/24V

100/220V AC

Log pulse

CFQ-5766A

2 m

Daisy chain

CFQ-5768 3m

RS-485

CFQ-5769 3m

RS-485

CFQ-5769 3m

RS-485

CFQ-5769

3m

T-shaped connector

AA-040404-MMM-TL

* 250V-TTYCS-1

3 ports

*250V-TTYCS-1

Max 15 m

*250V-TTYCS-1

*0.6/1kV-DPYC-1.5

*: Arranged by dockyard.

External device

Sensors

CFQ-5767

3m

Page 16

1-6

Page 17

2-1

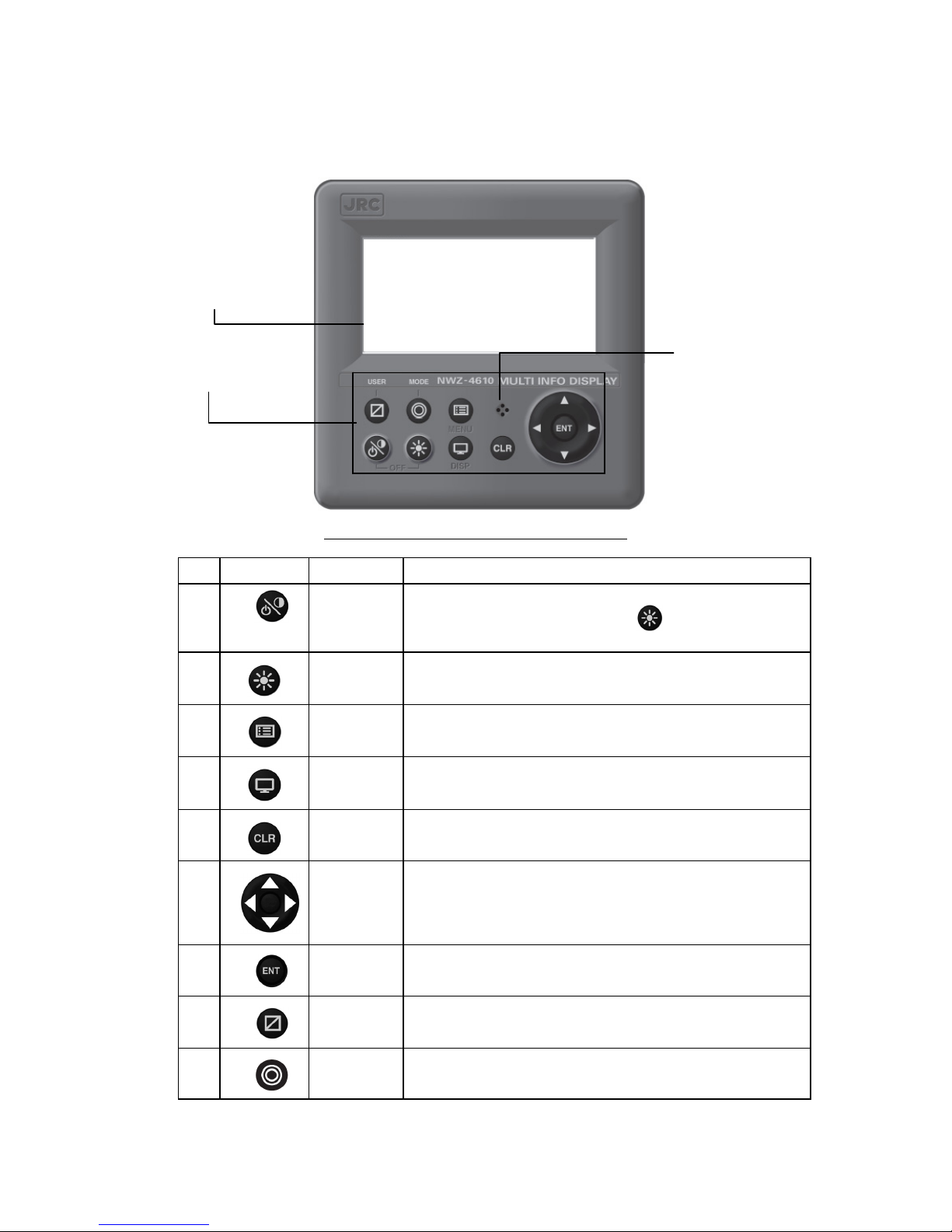

Chapter 2 Names and Functions of

the Components

Display

Buzzer

Operation panel

Figure 2.1 Operation panel of main display unit

No. Keys Name Functions

1 Power/

Contrast key

Turns on the power. This key also adjusts the screen contrast.

The power is turned off when the

key and this key are

pressed at the same time.

2

Dimmer key

Adjusts the brightness.

3

Menu key

Displays the main menu.

4 Display key Changes the display screen.

5 Clear key Cancels operation and stops the alarm.

6

Cursor key

Moves the cursor.

7 Enter key Sets the entries.

8 USER key Changes the screen to the user registration screen.

9 MODE key Change the user mode.

Page 18

2-2

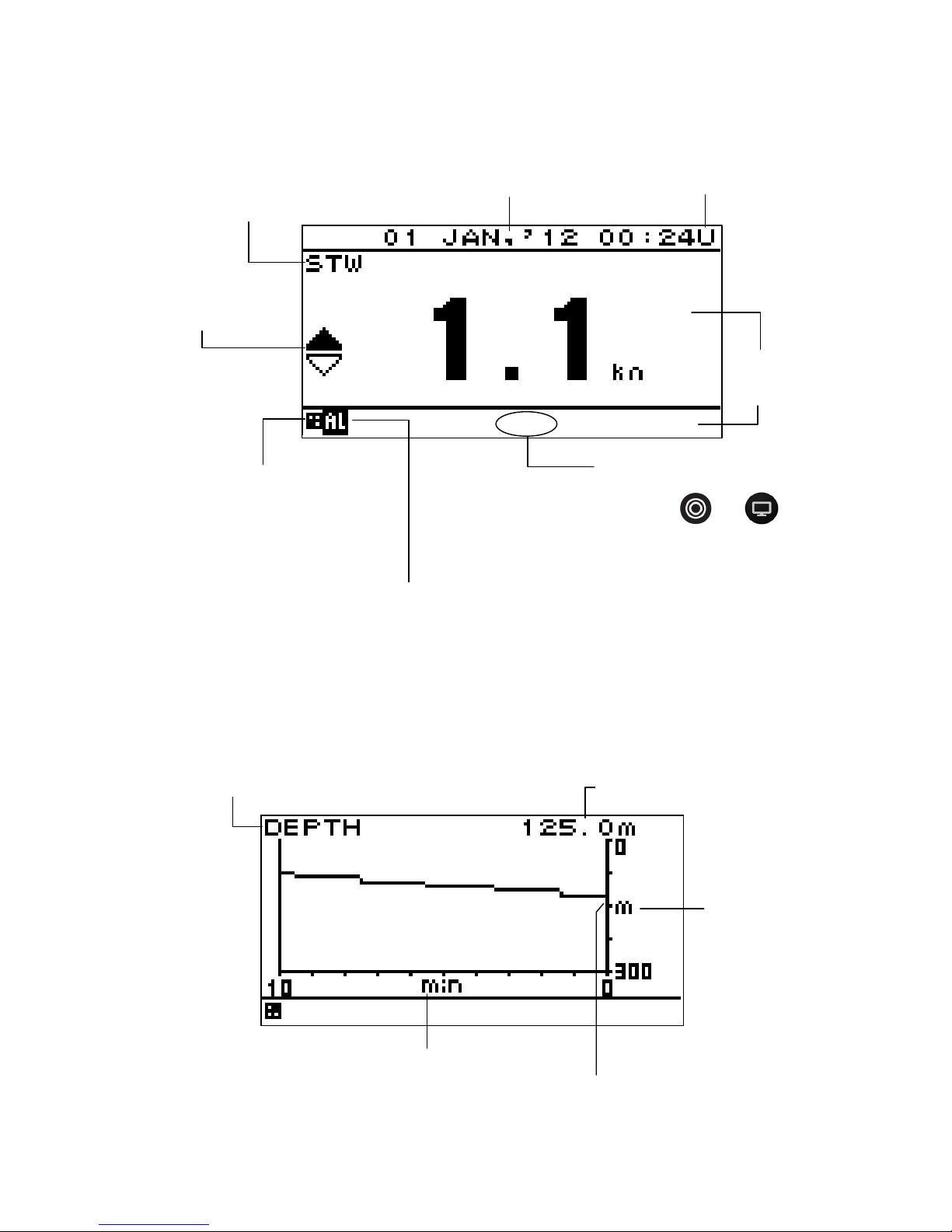

Reading the Display

Numeric display screen

Graphic screen

Graph screen

Screen title

Screen number

The display mode and the screen number

are displayed. When

or is

pressed, M1 to M3: Mode and D1 to D6:

Screen number are displayed for 3

seconds.

[S]: Simulation mode

During simulation mode, [S] blinks.

[M]: Equipment mode

During equipment mode, [M] is turned on.

During simulation mode, [M] is turned off.

Alarm icon

This displayed while an alarm occurs. For the

alarm contents, check the alarm information.

Display area

Freeze indicator

During operation, the black part moves.

If the black part does not move, the

screen freezes.

Ship speed and

direction

U: UTC

L: Local time

Date and time

If date and time data is not received, "-" is displayed.

Graph title

Current measured value

Horizontal axis: Elapsed time [minute]

More left data is older.

Vertical axis

measured

value

Current

measured

value

Status bar

Page 19

2-3

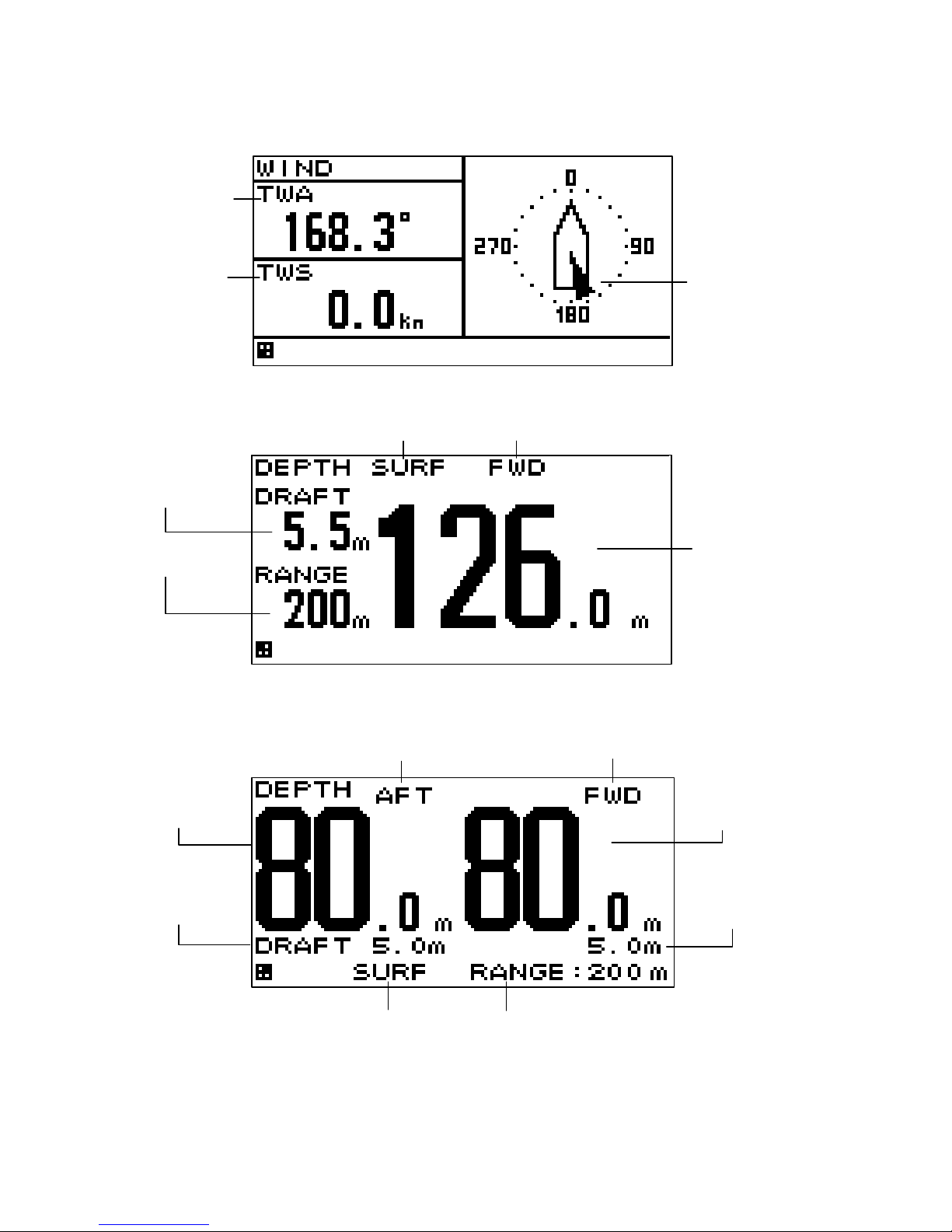

Wind direction/wind velocity screen

The left and right keys can be used to switch between true and relative.

Special screen for JFE-380/680

1) Single Transducer

Display mode Position of Transducer

Offset

Depth

Range

2) Dual Transducer

Position of Transducer1 Position of Transducer2

Depth of Depth of

Transducer1 Transducer2

Offset of Offset of

Transducer1 Transducer2

Display mode Range

True win d

direction

True win d

velocity

Wind direction

Arrow from

windward

Page 20

2-4

COG screen

When the COG is invalid, "---.-" is displayed.

COG

Page 21

3-1

Chapter 3 Display Screen

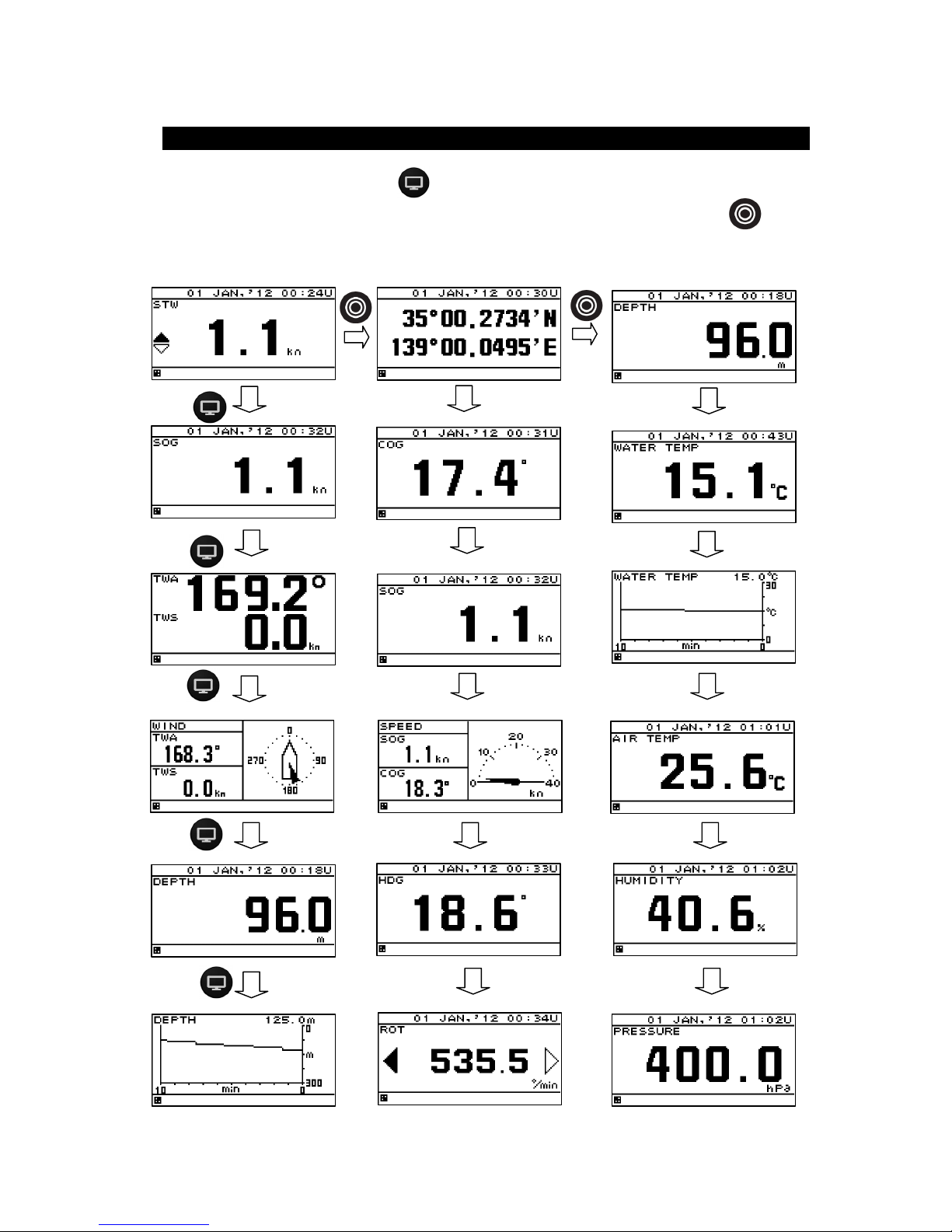

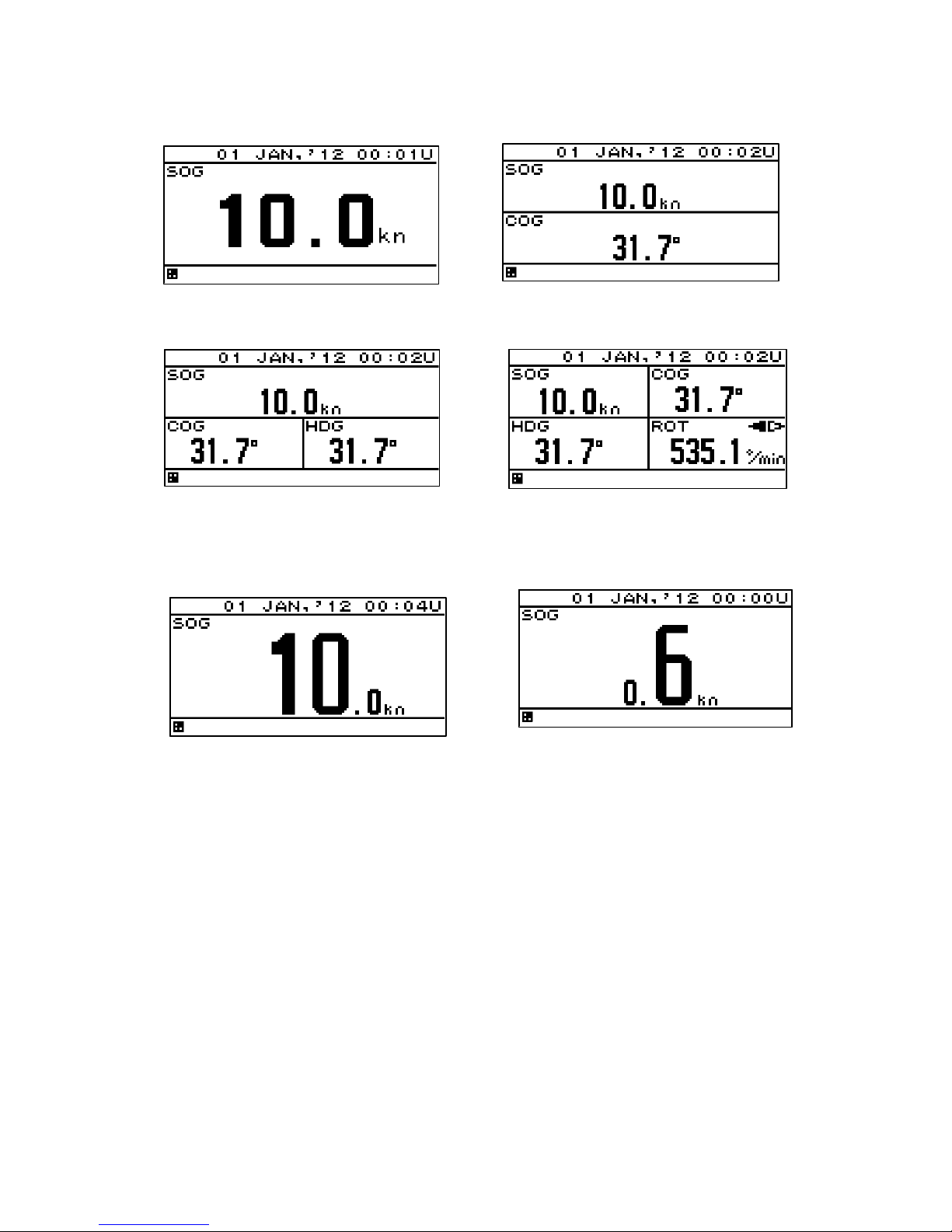

3.1. Display Screen

The screen is switched each time the

key is pressed. Up to six screens can be displayed. The

screen after the power is turned on becomes the screen when it is turned off. When the

key is

pressed, the mode is switched. The following screens are factory-set.

Mode 1 Mode 2 Mode 3

Page 22

3-2

Split screen display

The screen can be split into 1 to 4 areas to display multiple information items.

1-split screen 2-split screen

3-split screen 4-split screen

Enlarged part display

Integer part or decimal can be highlighted.

Enlarged integer part screen Enlarged decimal part screen

Page 23

4-1

Chapter 4 Operation

Do not place a vessel containing water, etc. or a metallic object on this unit.

When water spills or when water or the object enters the unit, a fire, an electric

shock, or a failure may occur.

Do not use this unit at a voltage other than the supply voltage stated on the unit.

Otherwise, a fire, an electric shock, or a failure may occur.

Do not insert or remove the power cord or operate switches with a wet hand.

Otherwise, you may suffer from an electric shock.

Do not damage or modify the power cord. Placing a heavy object onto, heating,

stretching or bending the cord may cause a fire or an electric shock.

When this unit is suddenly moved from a cool place to a warm place, drew

condensation water may form on the inside windows, and the liquid crystal part

can become visually difficult. In this case, leave the unit for a while until

becoming dry condition. Then operate the unit.

WARNING

CAUTION

Page 24

4-2

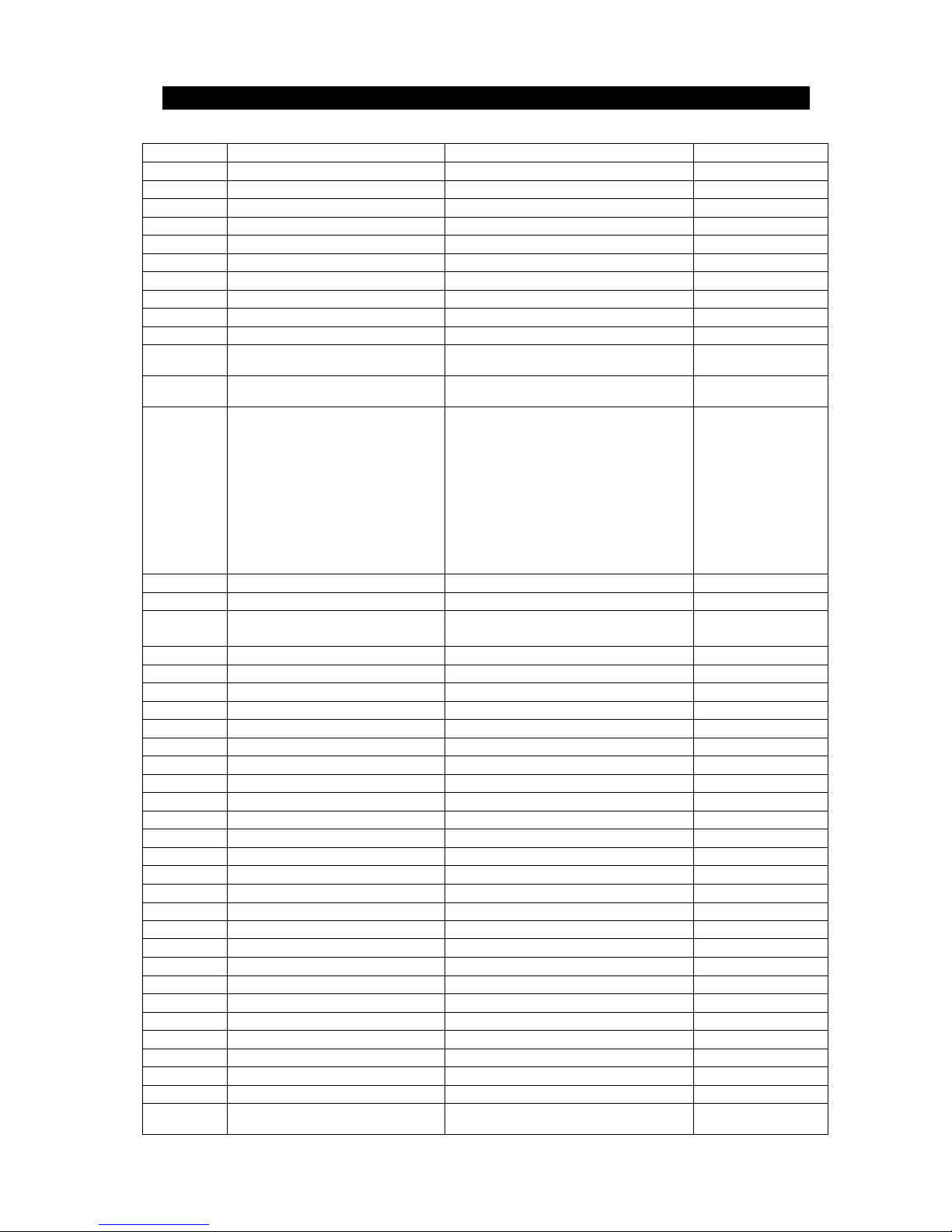

4.1. Menu

Normal menu

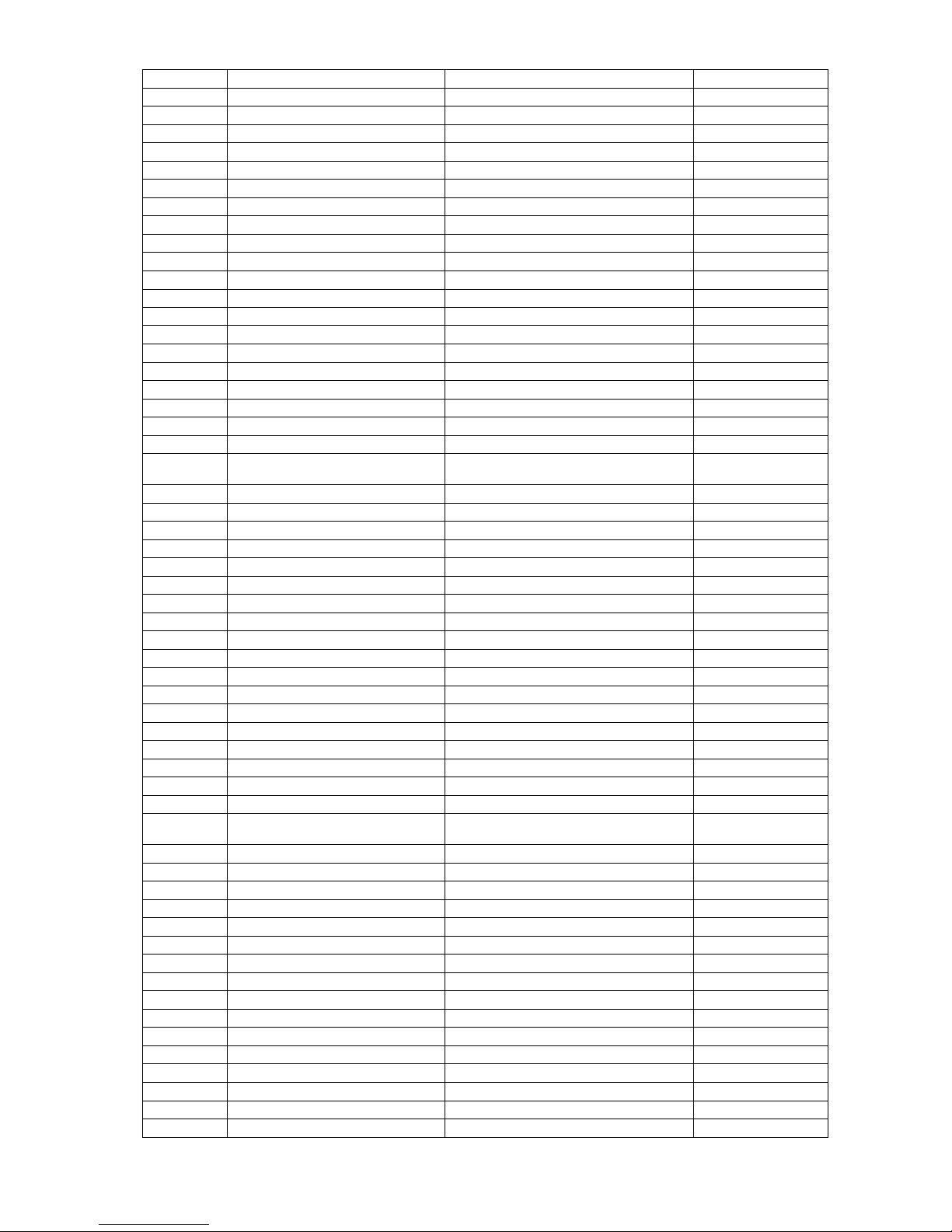

Main menu Sub menu Range remarks

DISPLAY LCD 4.5

CONTRAST 1-13 4.5.1

DIMMER MAXIMUM 4-13 4.5.2

DIMMER TYPICAL 3-12 4.5.2

DIMMER MINMUM 2-11 4.5.2

CLICK SOUND ON/OFF 4.5.3

MODE1 4.5.4.1

DISPLAY1 4.5.4.2

SEGMENTATION1 4.5.4.3

DISPLAY 4.5.4.4

OWN SHIP

LAT/LON/HDG/ROT/COG/

SOG/PITCH/ROLL/HEAVING/

4.5.4.4

WEATHER

WATER TEMP/TWA/TWS/AWS/

AIRTEMP/PRESSURE/HUMIDITY

4.5.4.4

DOPPLER

TRIP/ODO/DEPTH/STW/

BOW STW/

STERN STW/SOG(LOG)/

BOW SOG(LOG)/

STERN SOG(LOG)/

CORRENT L1 SPD/

CORRENT L1 DIR/

CORRENT L2 SPD/

CORRENT L2 DIR/

CORRENT L3 SPD/

CORRENT L3 DIR/

4.5.4.4

ENGINE RUDDER/ENGINE/SHAFT 4.5.4.4

OFF 4.5.4.4

DISPLAY MODE

NORMAL/SPECIAL1/SPECIAL2/AUTO

RANGE

4.5.4.4

AUTO SCREEN ON/OFF 4.5.4.4

SOUND SOUND1/SOUND2/OFF 4.5.4.4

TIME 1-10sec 4.5.4.4

SEGMENTATION2 4.5.4.3

DISPLAY1/2 Same as DISPLAY1/1 4.5.4.4

DISPLAY2/2 Same as DISPLAY1/1 4.5.4.4

AUTO SCREEN ON/OFF 4.5.4.4

SOUND SOUND1/SOUND2/OFF 4.5.4.4

TIME 1-10sec 4.5.4.4

SEGMENTATION3 4.5.4.3

DISPLAY1/3 Same as DISPLAY1/1 4.5.4.4

DISPLAY2/3 Same as DISPLAY1/1 4.5.4.4

DISPLAY3/3 Same as DISPLAY1/1 4.5.4.4

AUTO SCREEN ON/OFF 4.5.4.4

SOUND SOUND1/SOUND2/OFF 4.5.4.4

TIME 1-10sec 4.5.4.4

SEGMENTATION4 4.5.4.3

DISPLAY1/4 Same as DISPLAY1/1 4.5.4.4

DISPLAY2/4 Same as DISPLAY1/1 4.5.4.4

DISPLAY3/4 Same as DISPLAY1/1 4.5.4.4

DISPLAY4/4 Same as DISPLAY1/1 4.5.4.4

AUTO SCREEN ON/OFF 4.5.4.4

SOUND SOUND1/SOUND2/OFF 4.5.4.4

TIME 1-10sec 4.5.4.4

SPECIAL 4.5.4.3

DISPLAY

SINGLE DEPTH/DUAL DEPTH/

WIND

4.5.4.4

Page 25

4-3

Main menu Sub menu Range remarks

AUTO SCREEN ON/OFF 4.5.4.4

SOUND SOUND1/SOUND2/OFF 4.5.4.4

TIME 1-10sec 4.5.4.4

GRAPHIC 4.5.4.3

DISPLAY

WIND/ DEPTH/WATER TEMP/

SPEED1/SPEED2/RUDDER

4.5.4.4

AUTO SCREEN ON/OFF 4.5.4.4

SOUND SOUND1/SOUND2/OFF 4.5.4.4

TIME 1-10sec 4.5.4.4

OFF 4.5.4.3

DISPLAY2 Same as DISPLAY1 4.5.4.2

DISPLAY3 Same as DISPLAY1 4.5.4.2

DISPLAY4 Same as DISPLAY1 4.5.4.2

DISPLAY5 Same as DISPLAY1 4.5.4.2

DISPLAY6 Same as DISPLAY1 4.5.4.2

MODE2 Same as MODE1 4.5.4.1

MODE3 Same as MODE1 4.5.4.1

BACK LIGHT WHITE/ORANGE 4.5.5

GRAPH SCALE 4.5.6

DEPTH 4.5.6

TIME 5min/10min/20min/30min 4.5.6

MAX 1-3048m 4.5.6

MIN 0-3047m 4.5.6

WATER TEMP 4.5.6

TIME 5min/10min/20min/30min 4.5.6

MAX

-36-+37C

4.5.6

MIN

-37-+36C

4.5.6

USER DISPLAY

DISPLAY1/DISPLAY2/DISPLAY3/

DISPLAY4/DISPLAY5/DISPLAY6/OFF

4.5.7

SYSTEM UNIT 4.6.1

DIST/SPD NM,kn/km,km/h/mi,mi/h/m,m/s 4.6.1

TEMP

C/F

/

4.6.1

DEPTH m/ft/fm 4.6.1

WIND kn/km/h/mi/h/m/s 4.6.1

TIME DIFF -13:30 - +13:30 4.6.2

DATE DISP 4.6.3

TIME DISP

DD MMM,’YY HH:MM /

MMM DD,’YY HH:MM /

YY-MMM-DD HH:MM

4.6.3

LORAN C 4.6.4

LORAN C ON/OFF 4.6.4

GRI 4.6.4

TD1 0-99 4.6.4

TD2 0-99 4.6.4

TD1 CORR -9.9 - +9.9 4.6.4

TD2 CORR -9.9 - +9.9 4.6.4

DEPTH 4.6.5/4.6.6

TRANS FWD/MID/AFT 4.6.5

OFFSET -99.9 - +99.9 4.6.6

LANG. LANG.

English/Japan/France/Germany/Italy/

Norway/Spain/Vietnam/Indonesia

4.7

Other than English /

Japanese, it is due to add

one by one.

ALARM SYSTEM ON/OFF 4.8/4.8.1/4.8.2

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

SPEED

OVER/UNDER/IN RANG/OUT

RANG/OFF

4.8.3

OVER 4.8.3

OVER 0-99.9kn 4.8.3

SOUND ON/OFF 4.8.11

Page 26

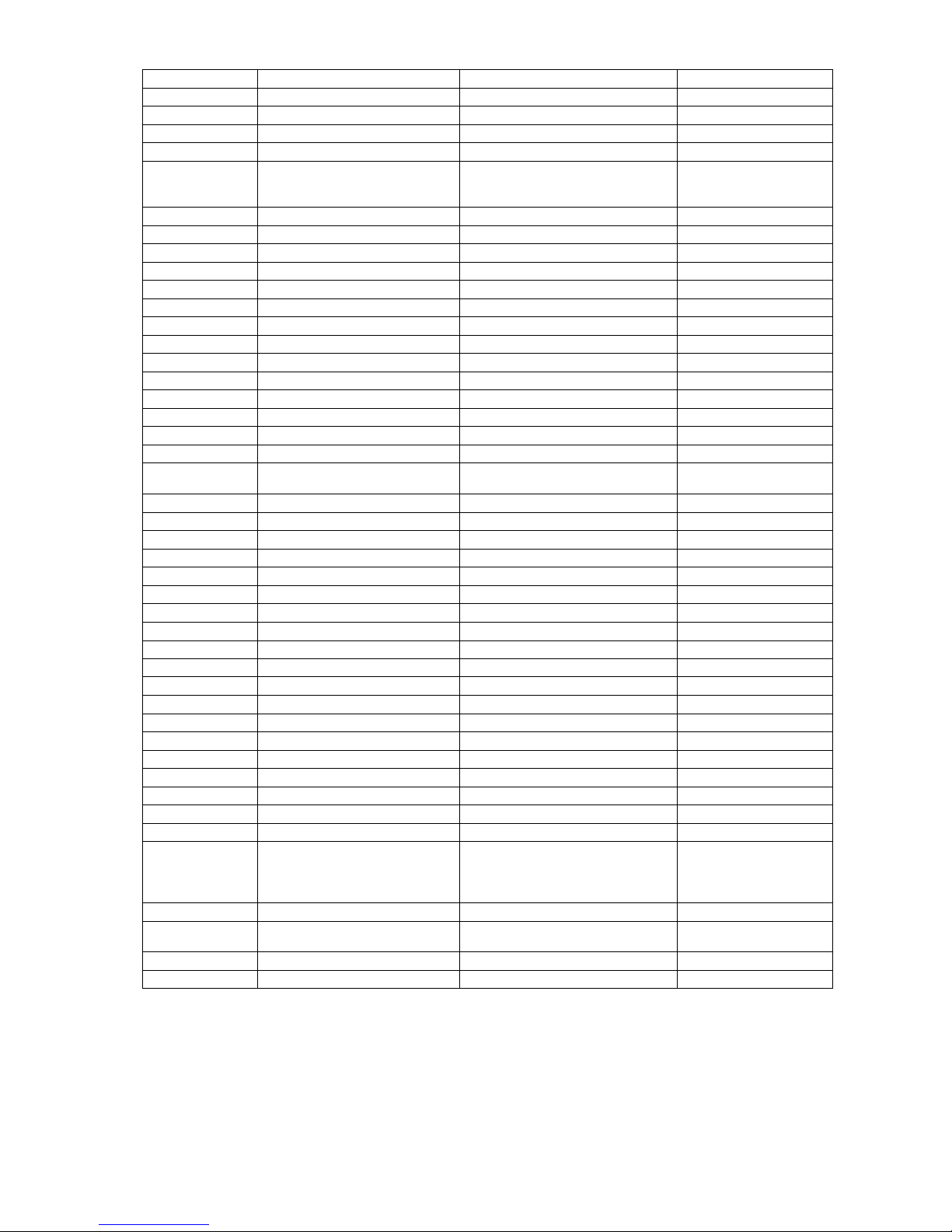

4-4

Main menu Sub menu Range remarks

LCD COLOR ON/OFF 4.8.11

UNDER 4.8.3

UNDER 0-99.9kn 4.8.3

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

IN RANGE 4.8.3

MAXIMAUM 0-99.9kn 4.8.3

MINIMUM 0-99.9kn 4.8.3

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

OUT RANGE 4.8.3

MAXIMAUM 0-99.9kn 4.8.3

MINIMUM 0-99.9kn 4.8.3

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

TRIP OVER/OFF 4.8.4

OVER 4.8.4

OVER 0-99.9kn 4.8.4

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

WATER TEMP

OVER/UNDER/IN RANG/OUT

RANG/OFF

4.8.5

OVER 4.8.5

OVER

-99.9 - +99.9C

4.8.5

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

UNDER 4.8.5

UNDER

-99.9 - +99.9C

4.8.5

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

IN RANGE 4.8.5

MAXIMAUM

-99.9 - +99.9C

4.8.5

MINIMUM

-99.9 - +99.9C

4.8.5

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

OUT RANGE 4.8.5

MAXIMAUM

-99.9 - +99.9C

4.8.5

MINIMUM

-99.9 - +99.9C

4.8.5

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

DEPTH

OVER/UNDER/IN RANG/OUT

RANG/OFF

4.8.6

OVER 4.8.6

OVER 0 – 999.9m 4.8.6

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

UNDER 4.8.6

UNDER 0 – 999.9m 4.8.6

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

IN RANGE 4.8.6

MAXIMAUM 0 – 999.9m 4.8.6

MINIMUM 0 – 999.9m 4.8.6

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

OUT RANGE 4.8.6

MAXIMAUM 0 – 999.9m 4.8.6

MINIMUM 0 – 999.9m 4.8.6

Page 27

4-5

Main menu Sub menu Range remarks

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

WIND OVER/OFF 4.8.7

OVER 4.8.7

OVER 99.9kn 4.8.7

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

AIR TEMP

OVER/UNDER/IN RANG/OUT

RANG/OFF

4.8.8

OVER 4.8.8

OVER

-99.9 - +99.9C

4.8.8

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

UNDER 4.8.8

UNDER 0 – 999.9m 4.8.8

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

IN RANGE 4.8.8

MAXIMAUM

-99.9 – +99.9C

4.8.8

MINIMUM

-99.9 – +99.9C

4.8.8

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

OUT RANGE 4.8.8

MAXIMAUM

-99.9 – +99.9C

4.8.8

MINIMUM

-99.9 – +99.9C

4.8.8

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

PRESSURE

OVER/UNDER/IN RANG/OUT

RANG/OFF

4.8.9

OVER 4.8.9

OVER 0 – 9999.9 hPa 4.8.9

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

UNDER 4.8.9

UNDER 0 – 9999.9 hPa 4.8.9

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

IN RANGE 4.8.9

MAXIMAUM 0 – 9999.9 hPa 4.8.9

MINIMUM 0 – 9999.9 hPa 4.8.9

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

OUT RANGE 4.8.9

MAXIMAUM 0 – 9999.9 hPa 4.8.9

MINIMUM 0 – 9999.9 hPa 4.8.9

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

HUMIDITY

OVER/UNDER/IN RANG/OUT

RANG/OFF

4.8.10

OVER 4.8.10

OVER 0 – 99.9 % 4.8.10

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

UNDER 4.8.10

UNDER 0 – 99.9 % 4.8.10

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

IN RANGE 4.8.10

Page 28

4-6

Main menu Sub menu Range remarks

MAXIMAUM 0 – 99.9 % 4.8.10

MINIMUM 0 – 99.9 % 4.8.10

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

OUT RANGE 4.8.10

MAXIMAUM 0 – 99.9 % 4.8.10

MINIMUM 0 – 99.9 % 4.8.10

SOUND ON/OFF 4.8.11

LCD COLOR ON/OFF 4.8.11

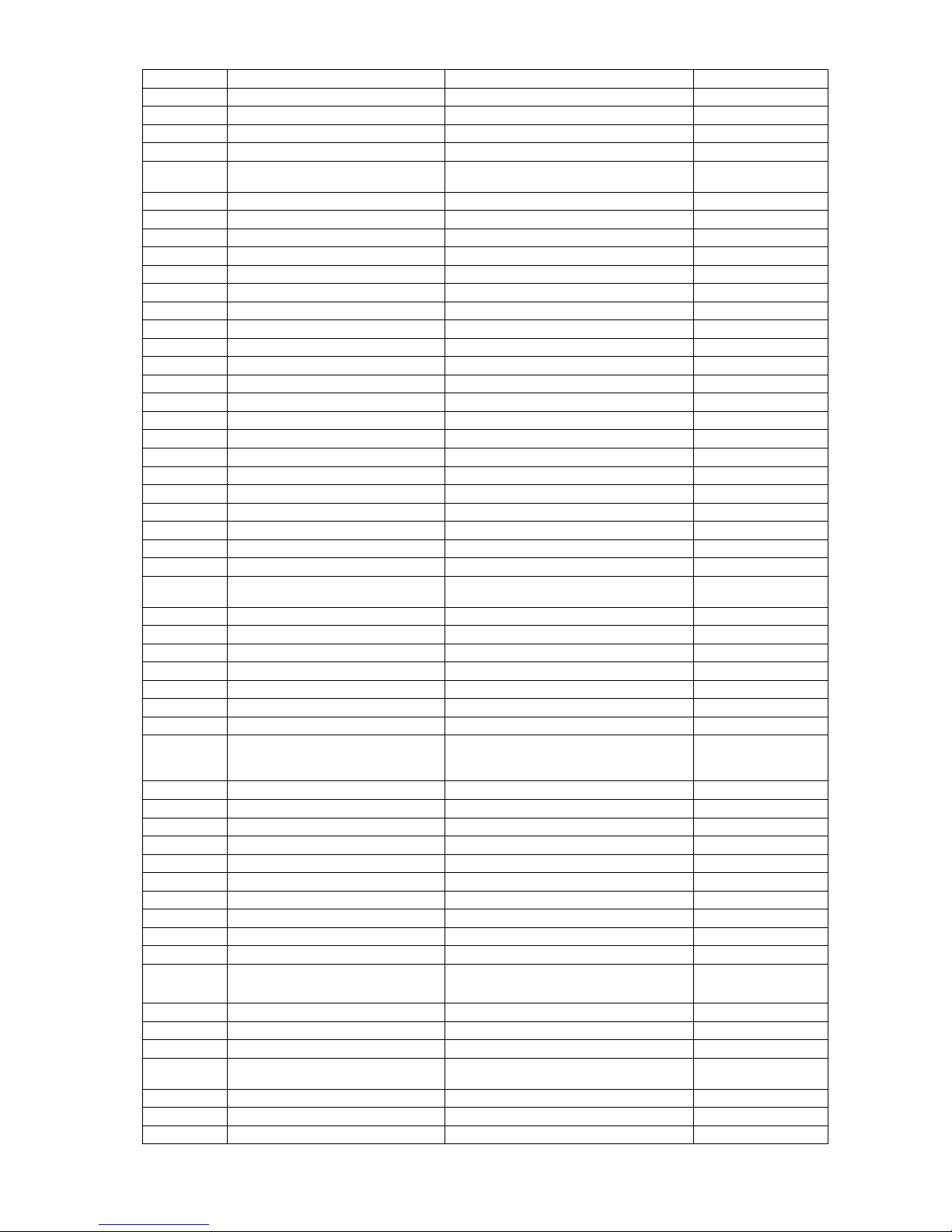

Maintenance menu

Main menu Sub menu Range Reference/remarks

DAISY CHAIN ON/OFF 4.10

INTERFACE DATA I/O 4.9.5

DATA IN/OUT1 4.9.5

NMEA 4.9.5

DATA IN/OUT SEND/RECEIVE 4.9.5

VERSION 1.5/2.1/2.3/4.0 4.9.5 SEND only

SENTENCE Sentence list 4.9.5 SEND only

BIT RATE 4800/9600/19200/38400 4.9.5

IEC 4.9.5

DATA IN/OUT SEND/RECEIVE 4.9.5

SENTENCE Sentence list 4.9.5 SEND only

BIT RATE 4800/9600/19200/38400 4.9.5

DATA IN/OUT2 4.9.5

NMEA 4.9.5

DATA IN/OUT SEND/RECEIVE 4.9.5

VERSION 1.5/2.1/2.3/4.0 4.9.5 SEND only

SENTENCE Sentence list 4.9.5 SEND only

BIT RATE 4800/9600/19200/38400 4.9.5

IEC 4.9.5

DATA IN/OUT SEND/RECEIVE 4.9.5

SENTENCE Sentence list 4.9.5 SEND only

BIT RATE 4800/9600/19200/38400 4.9.5

DATA IN/OUT3 4.9.5

NMEA 4.9.5

DATA IN/OUT SEND/RECEIVE 4.9.5

VERSION 1.5/2.1/2.3/4.0 4.9.5 SEND only

SENTENCE Sentence list 4.9.5 SEND only

BIT RATE 4800/9600/19200/38400 4.9.5

IEC 4.9.5

DATA IN/OUT SEND/RECEIVE 4.9.5

SENTENCE Sentence list 4.9.5 SEND only

BIT RATE 4800/9600/19200/38400 4.9.5

DATA IN/OUT4 4.9.5

NMEA 4.9.5

VERSION 1.5/2.1/2.3/4.0 4.9.5 SEND only

SENTENCE Sentence list 4.9.5 SEND only

BIT RATE 4800/9600/19200/38400 4.9.5

IEC 4.9.5

SENTENCE Sentence list 4.9.5 SEND only

BIT RATE 4800/9600/19200/38400 4.9.5

RS-485 4.9.4.4

NMEA 4.9.4.4

VERSION 1.5/2.1/2.3/4.0 4.9.4.4 SEND only

SENTENCE Sentence list 4.9.4.4 SEND only

BIT RATE 38400/57600/76800/115200 4.9.4.4

Page 29

4-7

Main menu Sub menu Range Reference/remarks

IEC 4.9.4.4

SENTENCE Sentence list 4.9.4.4 SEND only

BIT RATE 38400/57600/76800/115200 4.9.4.4

CONTACT INPUT DIMMER/ACK 4.9.6.1

CONTACT OUTPUT

200PULSE/NM/

400PULSE/NM/

OFF

4.9.6.2

DIAGNOSIS CONFIG OUT/ERROR LOG OUT 4.9.7/4.9.15

MAINTENANCE INPUT DATA 4.9.9

DIAGNOSIS 4.9.10

DISPLAY DIAG 4.9.10

MONITOR TEST 4.9.10

BUZZER TEST 4.9.10

ERROR LOG 4.9.11

ALARM 4.9.11

ERROR LOG 4.9.11

SOFT VERSION 4.9.12

DISPLAY VER 4.9.12

APP VER 4.9.12

SERIAL NUMBER 4.9.12

BARCODE 4.9.12

MASTER

RESET

GRAPH RESET 4.9.13

DISPLAY RESET 4.9.13

DEMO MODE DEMO TYPE 4.9.14

STATIC 4.9.14

COURSE 0-359.9° 4.9.14

STRAIGHT 4.9.14

SPEED 0-99.9kn 4.9.14

COURSE 0-359.9° 4.9.14

RIGHT 4.9.14

SPEED 0-99.9kn 4.9.14

COURSE 0-359.9° 4.9.14

LEFT 4.9.14

SPEED 0-99.9kn 4.9.14

COURSE 0-359.9° 4.9.14

DATE 4.9.14

TIME 4.9.14

LATITUDE 4.9.14

LONGITUDE 4.9.14

DEMO MODE START/END 4.9.14

SOFT UPDATE DISPLAY -

DESPLAY TYPE MID/LOG/GPS/OFF

4.9.2

Factory setting: OFF

"GPS" is due to add one

by one.

RS-485ID 1-10 4.9.4

DIMMER

GROUP

1-10 4.9.4.3

DIMMER KEY/EXT DIMMER 4.9.3

CURRENT LAYER/DATA No 4.9.16

Page 30

4-8

4.2. Basic Operation

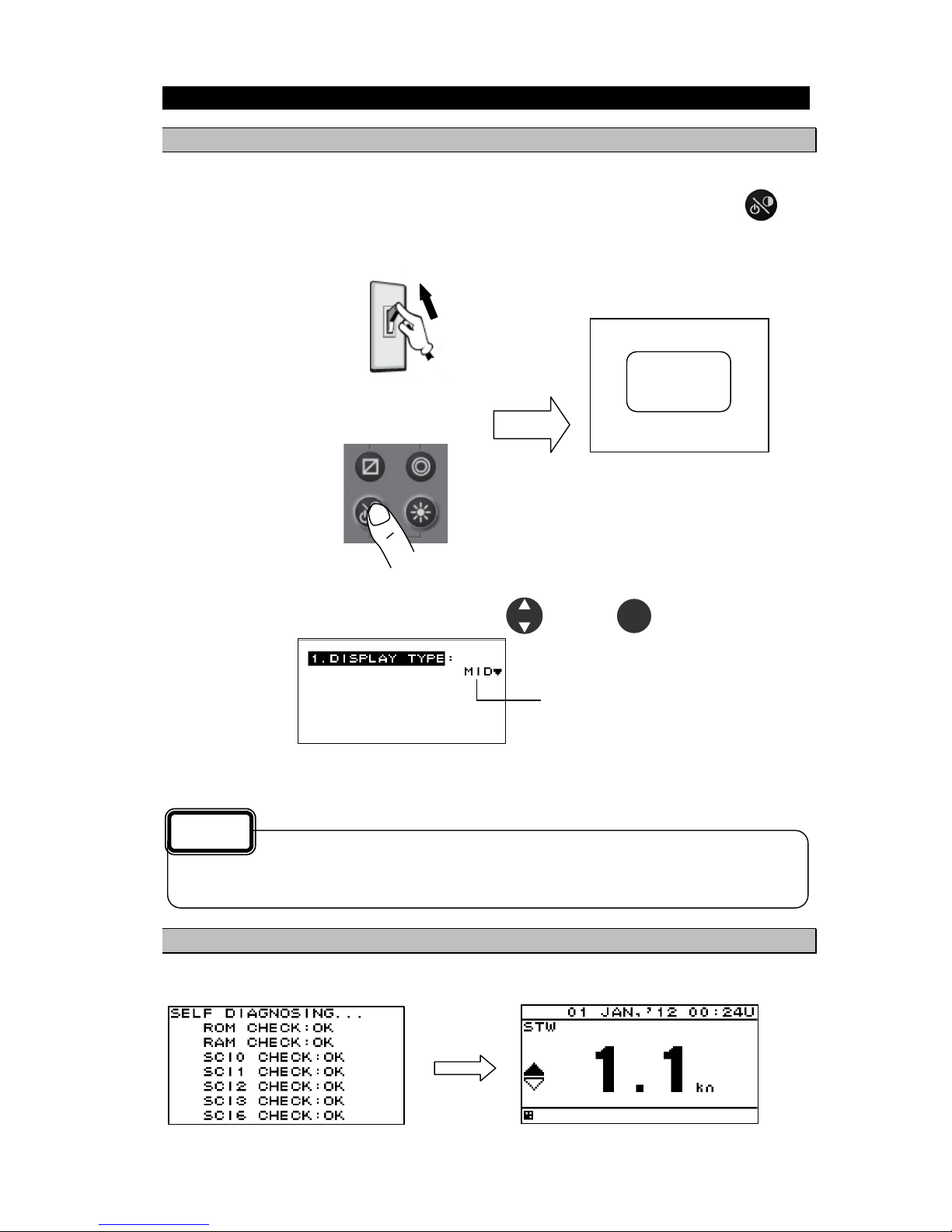

4.2.1. Turning on the power

When the main power is turned on, the power to the display unit is automatically turned on.

In the state in which the power is turned off by the display unit key operation, pressing the

key

turns on the power.

When the main power is OFF

Turning on the main power

When the main power is ON

Turning on the power

Pressing the power key

When the power is ON for first time.

The following screen is displayed. Select a Model with and press .

Model

When "LOG" is selected wrong

Refer to "Caution" in "4.9.2 setting a model".

4.2.2. Starting (Normal)

If all the self-check results are ‘OK’, the screen is automatically changed to the normal screen.

All OK

If the power cannot be turned on, check the main power of the power distribution board and the

cable connection to the display unit.

Caution

JRC

ENT

ON

Page 31

4-9

4.2.3. Starting (Abnormal)

If the self-diagnosis results are errors “NG,” the results are displayed as follows.

4.2.4. Starting (Abnormal)

When the program is corrupted, the following screen is displayed. Turn off the power and contact JRC

or one of our agents.

4.2.5. Turning off the power

If the

key and the key are pressed and held down simultaneously, the power will be

turned off and the screen display will turn off.

When any abnormality (NG) is found, contact JRC or one of our agents.

Caution

R0004

Recovery

mode.

The power may be turned on due to the release timing of your finger.

In this case, first release the and then release the .

Supplement

Page 32

4-10

4.2.6. Adjusting the back light (lighting) by using the key

The brightness of display and operation panel backlight can be set to one of four levels (bright, medium,

dark, off).

Whenever

is pressed, the level changes in the order of bright – medium – dark – off –dark –

medium – bright.

4.2.7. Adjusting contrast

Contrast can be adjusted over 13 levels.

Whenever

is pressed, the contrast is reduced (or increased) from the current setting and after

the contrast reaches the lowest (or highest) level, the contrast increases (reduces) gradually.

4.2.8. Turning off the alarm buzzer

Buzzer sound can be turned off by pressing

.

The buzzer sounds if an alarm occurs.

4.2.9. Switching display

The display screen is switched whenever

is pressed.

4.2.10. Alarm display

When an alarm occurs, the event is notified with a popup menu and alarm sound.

When

is pressed, the popup menu is cleared and the buzzer sound stops. However, display of

“

” remains on the status bar unless the alarm is cancelled.

Even after the popup menu is cleared and the buzzer sound is stopped, the invalid numerical number

keeps blinking until the alarm is cancelled.

To check the alarm again after clearing the popup menu, display the alarm history by referencing

“4.9.11 Displaying an alarm”

The brightness levels other than “off” can be set. See “4.5.2 Adjusting back light”.

An external dimmer unit can also be used for adjusting brightness. See “4.9.3 Selecting a

dimmer unit”.

Supplement

Page 33

4-11

4.2.11. Selecting items from the menus

This section shows the procedure for selecting items from the menus and determining the selection.

Procedure

1. Move the cursor to a required item by using

and press . The item is selected and a

submenu is opened to enable selection of details.

Menu

Submenu

2. Move the cursor to a required item by using

and press . The cursor moves to the

setting value selection.

3. Select a setting value with

and press or . The setting value is confirmed.

4. To return to the previous item, press

or .

The selected

item is displayed

in reverse video.

Setting value

selection

Power must not be off for 10 seconds after setting. When not doing so, the setting value may not

be saved.

Supplement

Page 34

4-12

4.2.12. Entering a numeric value

This section describes the procedure for entering a numeric value.

Procedure

1. Move the cursor to the field in which a value is to be entered by using

.

2. Set a numeric value to be entered by using

and press or .

3. Move the cursor to the right most field and press

or . The setting value is confirmed.

Select a field by using

Select a numeric value by using

If the numeric value that can be entered is restricted by an input range, enter the digits from the

highest order.

To prevent the value from exceeding the input range, the input of the low-order digits is restricted

by the value of the high-order digit.

Example) The input range is from 1 to 10:

If 1 is input in the high-order digit, only 0 can be set as the low order digit.

Power must not be off for 10 seconds after setting. When not doing so, the setting value may not

be saved.

Supplement

Page 35

4-13

4.3. User Mode Change

The user mode can be changed.

Up to three user modes are available, and six screens can be registered in one mode.

For details about how to register the screens in each mode, refer to “4.5.4 Setting a display screen”.

Procedure

1. Press the

key.

Each time the key is pressed, mode 1 changes to mode 2 and to mode 3.

4.4. User Setting Screen Display

From among the screens registered in the display screen, the user-set screen can be displayed.

The user-set screen can also be displayed quickly from other screen by registering the most often-used

screen.

The user-set screen cannot be registered in each use mode.

For details about how to set user screen, refer to “4.5.7 Registering user display”.

Procedure

1. Press the

key.

To return to the original screen, press the

key.

Page 36

4-14

4.5. Setting Display

When “Display” is selected on the main menu, a display menu is displayed.

On the display menu, LCD (contrast and back light), click sound, screen selection, and back light color

can be set.

Each submenu is outlined below.

1) LCD: Adjusts the contrast and sets the back light level.

2) CLICK SOUND: Turns on/off the click sound.

3) MODE 1: You can select MODE 1 screen.

4) MODE 2: You can select MODE 2 screen.

5) MODE 3: You can select MODE 3 screen.

6) BACK LIGHT: You can select the brightness color (white/orange).

7) GRAPH SCALE: You can set the depth and temperature graph scale.

8) USER DISPLAY : You can select the user-set screen.

4.5.1. Adjusting contrast

Adjust the LCD contrast.

The darkest contrast is 1 and the lightest contrast is 13.

The default setting is 7.

Procedure

1. Display a main menu by pressing

.

2. Select “DISPLAY”, “LCD”, and “CONTRAST” in this order by using

.

3. Enter a contrast value by using

and press .

Continued

Page 37

4-15

4.5.2. Adjusting back light

Brightness can be changed by using

. Four levels of brightness are available, bright, medium,

dark, and off.

This section shows how to set a level value of each brightness.

Procedure

1. Display a main menu by pressing

.

2. Select “DISPLAY”, “LCD”, and “DIMMER MAXIMUM/TYPICAL/MINIMUM” in this order by using

.

3. Select a brightness value by using

and press .

4.5.3. Setting a click sound

Turn on/off a key-operation click sound.

ON: Enables a click sound. When the key is pressed, a click sound is emitted.

OFF: Disables a click sound.

Procedure

1. Display a main menu by pressing

.

2. Select “DISPLAY” and “CLICK SOUND” in that order by using

.

3. Select “ON” or “OFF” by using

and press .

4.5.4. Setting a display screen

Up to six display screens can be registered in this display unit.

The display screen can be switched either manually by using

or automatically (auto screen

function).

The auto screen function enables the setting of a switching interval. Switching can also be notified by

emitting a buzzer sound.

Only the integer section or the decimal section of a indication character can be expanded and displayed.

(Display mode)

The setting of the auto screen function and the display mode are performed by "STEP3."

The screen structures of each display screen include customized screens that can be set freely, special

screens that do not allow any setting, and graphic screens. The contents to be displayed on the

display screen can be selected.

The screen selection procedure is as follows.

STEP1 Select the display screen from user mode.

STEP2 Select a screen structure.

STEP3 Select the display contents.

Enter the highest value in “MAXIMUM” and the lowest value in “MINIMUM”.

Supplement

Page 38

4-16

4.5.4.1. Selecting User Mode

MID can set up to three user modes.

Up to six screens can be registered in each mode, and up to 18 screens can be registered.

Press the

key to change the set user mode.

User mode 1 User mode 2 User mode 3

Select the user mode before selecting the display screen.

Procedure

1. Display a main menu by pressing

(normal mode).

2. Press the

key to select “DISPLAY,” and press the key.

3. Press the

key to select “MODE1,” “MODE2,” or “MODE3,” and press the key.

User mode

The user mode refers to scenes such as going to a waypoint, arriving at a waypoint, calling at a

port, ....

The user can select more convenient screens by registering six screens that suit each scene

(user mode).

Supplement

or automatic

Page 39

4-17

4.5.4.2. STEP1 Selecting a display screen

Up to six display screens can be registered in this display unit.

Procedure

1. Display a main menu by pressing

(normal mode).

2. Press the

key to select “DISPLAY,” “MODE1,” “MODE2,” or “MODE3” in order, and press

the

key to select the user mode.

3. Press the

key to select display screen from “DISPLAY1” to “6.DISPLAY6,” and press the

key.

Select a display from DISPLAY1

to DISPLAY6

or automatic

Page 40

4-18

4.5.4.3. STEP2 Selecting a screen structure

The screen structures of each display screen include customized screens that can be set freely, special

screens that do not allow any setting, and graphic screens.

Select a screen structure.

When display structure selection is set to “OFF”, the display screen cannot be registered.

Customized screen

One screen can be segmented into screens 1 to 4. Up to four contents can be displayed

concurrently.

Special screen and graphic screen

Users cannot change the screen structure. Special contents for the model are displayed on the

screen.

The following screen structures can be selected.

1) SEGMENTATION1: Full screen

2) SEGMENTATION2: The screen is segmented into two sections.

3) SEGMENTATION3: The screen is segmented into three sections.

4) SEGMENTATION4: The screen is segmented into four sections.

5) SPECIAL: Special screen for MID.

6) GRAPICH: Graphic screen

Select a screen

structure

Screen structure

Procedure

1. Select a display screen by referencing “STEP1”.

2. Select a screen structure from “SEGMENTATION1”, “SEGMENTATION2”, “SEGMENTATION3”,

“SEGMENTATION4”, “SPECIAL” and “GRAPHIC” by using

and press .

Select

SEGMENTATION1,

SEGMENTATION2,

SEGMENTATION3,

SEGMENTATION4,

SPECIAL,

GRAPHIC. or

OFF

or automatic

DISPLAY1

DISPLAY2

DISPLAY3

DISPLAY4

SPECIAL

GRAPHIC

Customized

screen

Page 41

4-19

4.5.4.4. SETP3 Selecting display contents

Select as many display contents as the number of screens that are created by segmentation. For

instance, for a 2-segmentation screen, select the display content for one half of the screen and then

select the display content for the other half of the screen (see the diagram below).

The display content of a customized screen is divided according to the category. Initially, select a

category and a display item. "Table4-1 shows the categories and display contents".

A special screen and a graphic screen are not classified according to the category.

Only the integer part or a decimal part of some item that is selected on a 1-segmentation customized

screen can be expanded (Display mode).

If display content selection is set to “OFF”, no information is displayed in the area.

Set the auto screen function and display mode (only segmentation 1 screen) in STEP3. The following

functions can be set.

1-1) AUTO SCREEN: ON – Enables the auto screen function.

OFF – Disables the auto screen function.

1-2) SOUND : SOUND1 – The buzzer of "Pippi" sound is sounded at the time of a screen

change.

SOUND2 – The buzzer of "Pip" sound is sounded at the time of a screen

change.

OFF – Does not emit a buzzer sound even if the screen is switched.

1-3) TIME: Sets a screen switching time. A time of up to 10 seconds can be set.

2-1) DISPLAY MODE: normal It displays in the character of the same size.

special 1 Only integer part is expanded and displayed.

special 2 Only a decimal part is expanded and displayed.

auto range Integer part or a decimal part is expanded and it displays the

optimal.

Example) Procedure for selecting display contents for a 2-segmentation screen

Screen structure

Selecting display contents for 2-segmentation screen

Procedure

1. Select a screen structure by referencing “STEP1” and “STEP2”.

Customized screen

2. Select a screen section to be displayed by using

and press .

Select the screen section from the following:

segmentation1 screen: “DISPLAY’

segmentation2 screen: “DISPLAY 1/2” “DISPLAY 2/2”

segmentation3 screen: “DISPLAY 1/3” “DISPLAY 2/3” “DISPLAY 3/3”

segmentation4 screen: “DISPLAY 1/4” “DISPLAY 2/4” “DISPLAY 3/4” “DISPLAY 4/4”

: Select display

contents of the

1/2 screen

Select display

contents of the

2/2 screen.

: Select a

category of the

1/2 screen

: Select a

category of the

2/2 screen.

Page 42

4-20

3. Select a category by using

and press .

4. Select display contents by using

and press .

5. Go to procedure 6 when setting an auto screen.

Fixed screen and graphic screen

2. Select “DISPLAY” by using

and press .

3. Select display contents by using

and press .

4. Go to procedure 6 when setting an auto screen.

Table 4 -1 Display category and display contents

Category Display contents

OWN SHIP LAT/LON, SOG, COG, HDG(Heading), ROT, PITCH, ROLL, HEAVING

WEATHER Temperature, true wind direction, true wind velocity, relative wind direction,

relative wind velocity, air temperature, atmosphere, humidity

DOPPLER Forward/backward speed through water, bow speed through water, stem

speed through water, forward/backward speed over ground, bow speed

over ground, stem speed over ground, layer L1 current direction, layer L1

current speed, layer L2 current direction, layer L2 current speed, layer L3

current direction, layer L3 current speed, TRIP, ODO (Odometer), water

depth

ENGINE Rudder angle, engine speed, shaft speed

Special screen Single mode water depth, dual mode water depth, wind direction/wind

velocity

Graphic screen Speed1,Speed2, rudder angle, wind direction, water depth graph, water

temperature graph

Setting an auto screen

On an auto screen, set a screen switching time and whether a buzzer sound is emitted at screen

switching.

6. Select “ON” or “OFF” under “AUTO SCREEN” by using

and press .

7. Select “SOUND1”,"SOUND2" or “OFF” under “SOUND” by using

and press .

Select a display

content

Select a category

Page 43

4-21

8. Select “TIME” by using .

9. Enter a switching time by using

and press .

Starting an auto screen

1. Switching the USER MODE to use an auto screen function

2. Press and hole for 1 second or more.

Stopping an auto screen

1. Press any keys except and .

Setting a display mode

The display mode can be set only with segmentaion1 screen.

The contents of a display with an effective auto range are SOG, STW, ROT, depth, current, trip, and

total distance (ODO).

Even if it sets up an auto range by the other contents of a display, it becomes the normal display.

An auto range changes a display in the following range.

Auto range

The contents of a

display

Integer part expanded

display

Usual display Decimal part

expanded display

SOG/STW 10kn or more 1.0 - 9.9kn 0.9kn or less

ROT

More than 600°/ min 1.0-599.9° / min 0.9°/ min or less

Depth 10 m or more 9.9m or less -

Tot a l d is tan ce /

Trip

10NM or more

1.00 - 9.99NM

0.99NM or less

Current 10kn or more 1.0 - 9.9kn 0.9kn or less

1. The contents of a display are set up with the above-mentioned operating procedure.

2. Select the “ DISPLAY MODE” by using and press .

3. Select the “NORMAL”, SPECIAL1“”, “SPECIAL2” or “AUTO RANGE” by using and

press .

Example) SOG display

Integer part expanded display Normal display Decimal part expanded display

4.5.5. Selecting a back light color

Select white or orange as the back light color of the screen that is normally used.

Procedure

1. Display a main menu by pressing

.

2. Select “1. DISPLAY” and “BACK LIGHT” in this order by using

.

3. Select “WHITE” or “ORANGE” by using

and press .

Page 44

4-22

4.5.6. Setting graph scale

The vertical axis and horizontal axis scale of the water temperature and water depth graphs can be set.

For detail screen, refer to page 2-2.

Horizontal axis setting

TIME: The maximum display time of the horizontal axis is set.

The time that can be set is 5 minutes, 10 minutes, 20 minutes, and 30 minutes.

Vertical axis setting

MAX: The maximum value of the display value is set.

MIN: The minimum value of the display value is set.

Procedure

1. Press the

key to display the main menu.

Water depth

2. Press the

key to select “DISPLAY,” “GRAPH SCALE,” and “DEPTH” in order.

3. Press the

key to enter “TIME,” “MAX,” or “MIN,” and press the key.

Water temperature

2. Press the

key to select “DISPLAY,” “GRAPH SCALE”, and “WATER TEMP” in order.

3. Press the

key to enter “TIME,” “MAX,” or “MIN,” and press the key.

4.5.7. Registering user display

From among the screens registered in the display screen, the user display assigned to the

key

can be registered.

Procedure

1. Press the

key to display the main menu.

2. Press the

key to select “1.DISPLAY” and “USER DISPLAY” in order.

3. Press the

key to select the screens to be registered from “DISPLAY1” to “DISPLAY6,” and

press the

key.

Page 45

4-23

4.6. System Settings

Select “SYSTEM” on the main menu to display the system settings screen.

To change the system settings, place the unit in maintenance mode.

An overview of each submenu is as follows.

1) UNIT: Set the units of distance/ship speed, temperature, water depth, and wind velocity.

2) TIME DIFF: Set the time difference between UTC and local time.

3) DATA DISP: Select the date format.

4) LORAN C: Convert latitude and longitude to LORAN C time difference.

5) DEPTH: Set the position and offset of the transducer that displays the water depth.

4.6.1. Selecting units

You can set the units of distance/ship speed to NM, kn, km, km/h, mi, mi/h or m, m/s.

You can set the unit of temperature to °C or °F.

You can set the unit of water depth to m, ft or fm.

You can set the unit of wind velocity to kn, km/h, mi/h or m/s.

Procedure

1. Refer to “4.9.1 Changing to a maintenance mode” to display the maintenance menu.

2. Press the

key to select “SYSTEM” and “UNIT” in order.

3. Press the

key to select “DIST/SPD,” “TEMP,” “DEPTH” or “WIND.”

4. Press the

key to select the unit, and press the key.

Speed Distance

Water Temperature Wind

Depth

Page 46

4-24

4.6.2. Setting the time difference

You can set the time difference between UTC and local time.

For Japan, the time difference is +9 hours, so you would input +09:00.

When a time difference is set, “L” is displayed on the upper right of the screen.

Procedure

1. Refer to “4.9.1 Changing to a maintenance mode” to display the maintenance menu.

2. Press the

key to select “SYSTEM” and “TIME DIFF” in order.

3. Press the

key to enter the time difference, and press the key.

Local time

+9 hour

Time difference

+9 hour

Page 47

4-25

4.6.3. Setting date display format

You can set the date display format to “DD MMM,'YY,” “MMM DD,'YY,” or “'YY-MMM-DD.”

YY: Year MMM: Month DD: Day

Procedure

1. Refer to “4.9.1 Changing to a maintenance mode” to display the maintenance menu.

2. Press the

key to select “SYSTEM,” “DATE DISP,” and “TIME DISP” in order.

3. Press the

key to select the date display format, and press the key.

4.6.4. Displaying as loran c time difference

The latitude and longitude can be displayed as RORAN C time difference.

Procedure

1. Refer to “4.9.1 Changing to a maintenance mode” to display the maintenance menu.

2. Press the

key to select “SYSTEM,” “LORAC C,” “LORAN C” in order.

3. Press the

key to select “ON.”

4. Set the GRI, TD1, TD2, TD1 CORR and TD2 CORR.

4.6.5. Setting transducer position of depth sounder (exclusive to JFE-380/680)

Select which transducer is used to display the measured water depth in the water depth value output

from depth sounder JFE-380/680.

This function is used to select the transducer position of the water depth value in the depth sounder

screen.

The transducer position that can be selected is Forward “FWD,” Medium “MID,” and Backward (AFT).

For detail screen, refer to page 2-3.

Procedure

1. Refer to “4.9.1 Changing to a maintenance mode” to display the maintenance menu.

2. Press the

key to select “SYSTEM,” “DEPTH,” and “TRANS” in order.

3. Press the

key to enter the transducer position, and press the key.

DD MMM YY format

MMM DD YY format

YY MMM DD format

Page 48

4-26

4.6.6. Setting water depth offset of depth sounder

You can set an offset in the received water depth value.

The offset that can be set is ±99.9 m.

When an offset is set, the received water value with the offset value added is displayed.

Procedure

1. Refer to “4.9.1 Changing to a maintenance mode” to display the maintenance menu.

2. Press the

key to select “SYSTEM,” “DEPTH,” and “OFFSET” in order.

3. Press the

key to enter an offset, and press the key.

Offset 10m

Page 49

4-27

4.7. Language Settings

You can set the display language to nine languages (English/Japanese (katakana)).

To change the language, place the unit in the maintenance mode.

A maximum of nine languages: Other than English / Japanese, it is due to add one by one.

Procedure

1. Refer to “4.9.1 Changing to a maintenance mode” to display the maintenance menu.

2. Press the

key to select “LANG” and “LANG” in order.

3. Press the

key to select the language, and press the key.

4.8. Alarm Settings

Selecting “ALARM” on the main menu displays the alarm setting screen.

When the set alarm occurs, the pop-up and the alarm icon “

” on the status bar alert the occurrence

of an alarm as well as the buzzer sounds. The screen lighting color can also be changed.

Pressing the

key stops pop-up, buzzer sound, and screen lighting, but the icon continues

appearing until the alarm has been resolved.

The unit must be placed in maintenance mode to change the alarm settings.

The following alarms can be configured.

1) SYSTEM: An alarm occurs when the system error occurs.

2) SPEED: An alarm occurs when the ship speed matches the set parameters.

3) TRIP: An alarm occurs when the distance matches the set parameters.

4) WATER TEMP: An alarm occurs when the water temperature matches the set parameters.

5) DEPTH: An alarm occurs when the water depth matches the set parameters.

6) WIND: An alarm occurs when the wind velocity matches the set parameters.

7) AIR TEMP: An alarm occurs when the air temperature matches the set parameters.

8) PRESSURE: An alarm occurs when the atmosphere matches the set parameters.

9) HUMIDITY: An alarm occurs when the humidity matches the set parameters.

When alarms are set to OFF, the alarm settings are cleared.

The alarm sound and screen brightness color when an alarm occurs can be set.

1) SOUND ON: The buzzer sounds when an alarm occurs.

OFF: The buzzer does not sound when an alarm occurs.

2) LCD COLOR ON: The screen brightness color changes when an alarm occurs.

OFF: The screen brightness color does not change when an alarm occurs.

If normal brightness color is set to white, it becomes orange, and vice versa.

Page 50

4-28

4.8.1. Setting the alarm range

An alarm occurs when the range is set and the value matches the set range.

You can select the range from OVER, UNDER, IN RANGE, and OUT RANGE depending on the alarm.

OVER: An alarm occurs when the value exceeds the set value.

UNDER: An alarm occurs when the value falls below the set value.

IN RANGE: An alarm occurs when the value is within the set range.

OUT RANGE: An alarm occurs when the value is outside the set range.

When setting the IN RANGE and OUT RANGE, set the upper limit and lower limit values.

When an alarm is set to OFF, alarm settings are cleared.

The alarm types and alarm range that can be set are as follows.

Alarm type Alarm range

OVER UNDER IN RANGE OUT RANGE OFF

SPEED

TRIP

– – –

WATER TEMP

DEPTH

WIND

– – –

AIR TEMP

PRESSURE

HUMIDITY

: Can be set.

Procedure

1. Refer to “4.9.1 Changing to a maintenance mode” to display the maintenance menu.

2. Press the

key to select “ALARM” and “ALARM TYPE” in order.

3. Set the alarm according to the alarm setting procedure.

4.8.2. Setting a system alarm

An alarm occurs when the system error occurs.

The following is an overview of the system error.

1) The data can not be received.

2) The data is invalid.

Procedure

1. Refer to “4.9.1 Changing to a maintenance mode” to display the maintenance menu.

2. Select “ALARM” and “SYSTEM” in this order by using

.

3. Select “ON” or “OFF” by using

and press .

4. Refer to “4.8.11 Setting a buzzer sound and screen back light” to set the alarm sound and screen

brightness.

Page 51

4-29

4.8.3. Setting a vessel speed alarm

When the vessel speed reaches the set range, the alarm is issued.

The range can be selected from OVER, UNDER, IN RANGE, and OUTRANGE.

OVER: An alarm is issued when the vessel speed reaches or exceeds the set speed.

UNDER: An alarm is issued when the vessel speed is equal to or slower than the set speed.

IN RANGE: An alarm is issued when the vessel speed is between the lower limit value and the upper

limit value.

OUT RANGE: An alarm is issued when the vessel speed is equal to or slower than the lower limit

value or equal to or higher than the upper limit value.

For IN RANGE and OUT RANGE, set the upper limit value and lower limit value.

Procedure

1. Refer to “4.9.1 Changing to a maintenance mode” to display the maintenance menu.

2. Select “ALARM” and “SPEED” in this order by using

.

3. Select “OVER, “UNDER”, “IN RANGE”, or “OUT RANGE” by using

.

4. Select "OVER", "UNDER", “MAXIMUM” or “MINIMUM” by using

.

5. Enter a vessel speed by using

and press .

6. Refer to “4.8.11 Setting a buzzer sound and screen back light” to set the alarm sound and screen

brightness.

4.8.4. Setting a TRIP alarm

An alarm is issued when the distance exceeds the set TRIP.

Procedure

1. Refer to “4.9.1 Changing to a maintenance mode” to display the maintenance menu.

2. Select “ALARM” and “TRIP” in this order by using

.

3. Select “OVER” by using

.

4. Select “OVER” by using

.

5. Enter a distance by using

and press .

6. Refer to “4.8.11 Setting a buzzer sound and screen back light” to set the alarm sound and screen

brightness.

Page 52

4-30

4.8.5. Setting the water temperature alarm

An alarm occurs when the water temperature exceeds the set value.

Procedure

1. Refer to “4.9.1 Changing to a maintenance mode” to display the maintenance menu.

2. Press the

key to select “ALARM” and “WATER TEMP” in order.

3. Press the

key to select “OVER,” “UNDER,” “IN RANGE,” or “OUT RANGE.”

4. Press the

key to select “OVER,” “UNDER,” “MAXIMUM,” or “MINIMUM.”

5. Press the

key to enter the water temperature, and press the key.

6. Refer to “4.8.11 Setting a buzzer sound and screen back light” to set the alarm sound and screen

brightness.

4.8.6. Setting the water depth alarm

An alarm occurs when the water depth exceeds the set value.

Procedure

1. Refer to “4.9.1 Changing to a maintenance mode” to display the maintenance menu.

2. Press the

key to select “ALARM” and “DEPTH” in order.

3. Press the

key to select “OVER,” “UNDER,” “IN RANGE,” or “OUT RANGE.”

4. Press the

key to select “OVER,” “UNDER,” “MAXIMUM,” or “MINIMUM.”

5. Press the

key to enter the water depth, and press the key.

6. Refer to “4.8.11 Setting a buzzer sound and screen back light” to set the alarm sound and screen

brightness.

4.8.7. Setting the wind velocity alarm

An alarm occurs when the wind velocity exceeds the set value.

Procedure

1. Refer to “4.9.1 Changing to a maintenance mode” to display the maintenance menu.

2. Press the

key to select “ALARM” and "WIND” in order.

3. Press the

key to select “OVER.”

4. Press the

key to select “OVER.”

5. Press the

key to enter the wind velocity, and press the key.

6. Refer to “4.8.11 Setting a buzzer sound and screen back light” to set the alarm sound and screen

brightness.

Page 53

4-31

4.8.8. Setting the air temperature alarm

An alarm occurs when the air temperature exceeds the set value.

Procedure

1. Refer to “4.9.1 Changing to a maintenance mode” to display the maintenance menu.

2. Press the

key to select “ALARM” and “AIR TEMP” in order.

3. Press the

key to select “OVER,” “UNDER,” “IN RANGE,” or “OUT RANGE.”

4. Press the

key to select “OVER,” “UNDER,” “MAXIMUM,” or “MINIMUM.”

5. Press the

key to enter the air temperature, and press the key.

6. Refer to “4.8.11 Setting a buzzer sound and screen back light” to set the alarm sound and screen

brightness.

4.8.9. Setting the atmosphere alarm

An alarm occurs when the atmosphere exceeds the set value.

Procedure

1. Refer to “4.9.1 Changing to a maintenance mode” to display the maintenance menu.

2. Press the

key to select “ALARM” and “PRESSURE” in order.

3. Press the

key to select “OVER,” “UNDER,” “IN RANGE,” or “OUT RANGE.”

4. Press the

key to select “OVER,” “UNDER,” “MAXIMUM,” or “MINIMUM.”

5. Press the

key to enter the atmosphere, and press the key.

6. Refer to “4.8.11 Setting a buzzer sound and screen back light” to set the alarm sound and screen

brightness.

4.8.10. Setting the humidity alarm

An alarm occurs when the humidity exceeds the set value.

Procedure

1. Refer to “4.9.1 Changing to a maintenance mode” to display the maintenance menu.

2. Press the

key to select “ALARM” and “HUMIDITY” in order.

3. Press the

key to select “OVER,” “UNDER,” “N RANGE,” or “OUT RANGE.”

4. Press the

key to select “OVER,” “UNDER,” “MAXIMUM,” or “MINIMUM.”

5. Press the

key to enter the humidity, and press the key.

6. Refer to “4.8.11 Setting a buzzer sound and screen back light” to set the alarm sound and screen

brightness.

Page 54

4-32

4.8.11. Setting a buzzer sound and screen back light

An alarm sound and the color of the screen back light at the occurrence of an alarm can be set.

When the back light color under the normal condition is set to white, the color is changed to orange and

when the back light color is set to orange, the color is changed to white.

1) SOUND ON: When an alarm occurs, the buzzer sound is emitted.

OFF: Even if an alarm occurs, the buzzer sound is not emitted.

2) LCD COLOR ON: When an alarm occurs, the back light color of the screen is changed.

OFF: Even if an alarm occurs, the back light color of the screen is not changed.

Procedure

1. Refer to “4.9.1 Changing to a maintenance mode” to display the maintenance menu.

2. Select “SOUND” by using

.

3. Select “ON” or “OFF” by using

and press .

4. Select “LCD COLOR” by using

.

5. Select “ON” or “OFF” by using

and press .

Select SOUND

Select LCD COLOR

Page 55

4-33

4.9. Setting Installation

After completing the installation that is described in Chapter 6, check the operation and set the details.

In the installation setting, implement the following operations according to the system specification of

the vessel.

1) Changing to a maintenance mode

2) Setting a model

3) Selecting a dimmer unit

4) Setting dimmer control linkage and data sharing

Setting RS-485ID

Setting a dimmer group

Setting data sharing

5) Setting the display screen

6) Setting daisy chain

4.9.1. Changing to a maintenance mode

Before starting installation, the mode must be changed to a maintenance mode to prevent an operation

error.

Change the mode to a maintenance mode by the initial operation.

Procedure

1. Display a main menu by pressing

(normal mode).

2. Press

and for 3 seconds.

3. The menu is changed to a maintenance menu (maintenance mode).

When the mode is changed to a maintenance mode, the [M] icon is displayed at the bottom of the

screen.

Normal mode

Maintenance mode

Figure 4.1 Transition of menu screens

Returning to a normal mode

When

and are pressed for 3 seconds or no operation is performed for 3 minutes, the

mode is reset to a normal mode.

When the power is turned on, the system starts in normal mode.

and 3 seconds

The [M] icon is

displayed.

Page 56

4-34

4.9.2. Setting a model

This display unit is set in the MID display unit.

When the model is set, the setting contents are initialized.

Procedure

1. Refer to “4.9.1 Changing to a maintenance mode” to display the maintenance menu.

2. Select “DISPLAY TYPE” by using

and press .

3. Select “MID” by using

and press .

4. When the following popup menu is displayed, press “YES”.

When “NO” is selected, the model setting is cancelled.

4.9.3. Selecting a dimmer unit

Specify whether an external dimmer unit (NCM-227) or a dimmer key is used for controlling the dimmer

unit of this display unit.

When an external dimmer unit is used, the contact input must be set to “DIMMER”. For the setting

method, see “4.9.6 Setting a contact port”.

When sharing a dimmer unit, set the same dimmer unit for the display units that share the dimmer unit.

Unless the same dimmer unit is set, linking cannot be performed.

To calibrate the external dimmer unit, refer to "7.1 Calibration of External dimmer unit "in service

manual.

Procedure

1. Refer to “4.9.1 Changing to a maintenance mode” to display the maintenance menu.

2. Select “DIMMER” by using

.

3. Select a dimmer unit by using

and press .

・When "LOG" is selected wrong, the following messages appears.