Page 1

0

JRC FWA SYSTEM

INSTRUCTION MANUAL

Rev. 3.4

24/SEP./2008

Page 2

I

Introduction

Read this instruction manual carefully before use. Be sure you fully understand the

instructions in this manual before using the equipment.

After reading, save this instruction manual and refer to it as necessary. If you have any

questions about or there is something wrong with the equipment, refer to this manual.

Page 3

II

Before use

Warning Indications

This manual and the product use some icons to help you use the product properly and

prevent any damage to you and other people or property. The following icons classify the

potential damage if the indications are ignored or the product is used improperly. When

reading the manual, keep these in mind.

Examples of icons

A triangle is an alert to call your attention including a warning

or danger indication. The graphics within the triangle differs

depending on the caution. (The figure on the left shows a

caution for electrical shocks.)

icons indicate prohibition. A detailed prohibition description

is given in the vicinity of the icon. (The figure on the left

prohibits disassembly.)

icons require you to perform the item. A detailed

instruction is given in the vicinity of the icon. (The figure on the

left instruct to unplug the equipment.)

Warning labels

Do not remove, damage or alter the warning labels.

Warning

Caution

Wrong handling of this product may cause

serious personal injury or death.

Wrong handling of this product may cause

personal injury or damage to properties.

Dangerous

voltages

General

prohibitions

General

advice

Do not

disassemble

Unplug

Page 4

III

Precautions in Use

Warning

Don’t place containers having

water, chemicals or cosmetics, such as

vessels, flower pots and glasses, or small pieces of metals near or on top

of this product. Liquids spilled over or into or small metal pieces getti

ng

into the product may cause fire, electrical shocks or failures.

Turn off the power and stop using the unit immediately if something

abnormal such as fumes or smoke is detected, and contact our sales

department, branch or sales offce. Continuing to use

the product as is

may cause fire or electrical shock.

Page 5

IV

Cautions

This manual describes important points to operate and maintain the

equipment. Read the related sections when operating,

maintaining

and testing the unit.

Do not try to carry out a test or maintenance not

covered in this manual.

This equipment is a precision machine. A failure may occur if you do

not observe the following:

・ Do not jar or subject this equipment and the units to shocks.

・ During operation,

do not unplug the cable connected between the

WT and WT adapter. Before unplugging this cable,

first unplug the DC

jack from

the WT adapter and turn the power off.

・ Do not splash water on the WT adapter.

・ Do not use this equipment in a place with excessive dirt or dust.

Before touching a power-receiving terminal,

turn the input power off to

avoid electrical shocks.

Do not touch the rack of the WT duirng operation because it becom

es

hot.

When installing the Access Point (AP),

connect the ground wire to the

ground terminal. If the equipment is not grounded properly,

you may

get electrical shocks when the equipment becomes faulty or shorted.

When using a measuring instrument, conne

ct the ground terminal of

the measuring instrument to the ground terminal of this equipment.

If

the equipment is not grounded properly,

you may get electrical

shocks.

To avoid shock hazards,

do not open and touch the inside or

adjustment points except for maintenance or inspection.

If you modify

the equipment illegally,

you may be punished according to the Radio

Law.

Page 6

V

Cautions

Don’t use organic solvent for cleaning such as thinner and benzene because

this may damage the coating. Just wipe the surface with a clean dry cloth.

Befour plugging in or unplugging the coaxial cable between the AP-RFU and

AP-IFU, turn the power off.

The DC -48V power supply voltage for AP-IFU shall be SELV or TNV-1

depending on the network environment (0 or 1) acc. to IEC62102.

The Equipment for connection to AP-IFU Ethernet-interface(RJ-45)

shall be

appropriate to connect to TNV-1 circuits.

The Equipment for connection to WT adapter PC-interface (RJ-45) shall

be

appropriate to connect to TNV-1 circuits.

For the connection WT adapter to WT and a cable suitable for outdoor

use

shall be installed.

For the connection Terminal Equipment to AP-IFU and a cables suitable

for

outdoor use shall be installed.

For the connection AP-IFU to AP-RFU and a coaxial cable suitable for

outdoor

use shall be installed.

Page 7

VI

Avant usage

Indications Préventives

This manual and the product use some icons to help you use the product

properly and prevent any damage to you and other people or property. The

following icons classify the potential damage if the indications are ignored or the

product is used improperly. When reading the manual, keep these in mind.

Exemples d'icônes

Un triangle est une alerte pour attirer votre attention en cas de

danger ou de conseil de prudence. Le signe à l’interieur du

triangle diffère selon le risque. (L’exemple de gauche signale

un risque électrique.)

Les deux icônes de gauche indiquent une interdiction. Une

description plus détaillée est donnée près del'icône (la plus à

gauche interdit le démontage.)

Ce type d’icône exige que vous exécutiez l'action Une

description plus détaillée est donnée près de l'icône (la plus à

gauche exige de debrancher le matériel avant toute opération.)

Attention

N'enlevez jamais, n’endommagez jamais et ne changez jamais les signalisation de

danger.

(French)

Danger

Prudence

Une mauvaise utilisation de ce produit peut

causer de sérieux dommages corporels ou la

mort.

Une mauvaise utilisation de ce produit peut

causer des dommages corporels ou

endommager des biens.

Le manuel d’utilisation et le produit utilisent des icônes pour vous aider à utiliser correctement le

produit et prévenir tout dommages sur vous, sur des tiers ou sur

des biens. Les icônes qui suivent,

indiquent le niveau des dommages éventuels si les précautions indiquées sont ignorées ou si le

produit est mal utilisé. Quand vous lirez le manuel d’utilisation, faites attention à ces indications.

Danger

électrique

Débranchez

Ne pas

démonter

Inter

diction

générale

Conseil

général

Page 8

VII

Précautions d’utilisations

(French)

Ne placez pas de récipients contenant de l'eau, des produits chimiques ou des

produits de beauté, tels que vaisselle, pots de fleur et verres, ou de petits

morceaux de métal à coté ou sur ce produit. Les éclaboussures d

e liquides

sur ou à l’intérieur du produit, ainsi que les petits morceaux de métal pénétrant

le produit, peuvent provoquer le feu, des chocs électriques ou des pannes.

Coupez l’alimentation électrique et cessez immédiatement toute utilisation du

produit

si quelque chose d'anormal tel que vapeurs ou fumées sont détectées,

et contactez notre service commercial. Continuer à utiliser le produit dans ces

conditions, peut provoquer feu ou choc électrique.

Attention

Page 9

VIII

(French)

Attention

Ce manuel décrit les points importants pour l’utilisation et la maintenance du

Matériel. Lisez les chapitres correspondants pour l’ut

ilisation, la maintenance et

le test du Matériel. N'essayez pas d'effectuer un test ou une maintenance qui ne

soit pas décrit dans ce manuel.

Cet équipement est une machine de précision. Une panne peut se produire si

vous ne vous conformez pas pas à ce qui suit :

・

Ne cognez pas et ne soumettez pas ce matériel et ses éléments à des

chocs.

・

En cours d’utilisation, ne débranchez pas le câble reliant l’interface

utilisateur du terminal sans fil et l'adaptateur WT. Avant de déconnecter ce

câble, débranchez d’

abord la prise jack DC de l'adaptateur WT et mettez

hors-tension.

・N'éclaboussez pas l'adaptateur WT.

・

N'utilisez pas ce matériel dans un endroit excessivement sale ou

poussiéreux.

Avant de toucher à un terminal recevant l’alimentation, mettez hors-tensio

n

pour éviter des chocs électriques.

Ne touchez pas le rack du WT en cours d’utilisation parce qu'il devient chaud.

Lors de l’installation du Point d'accès, reliez le fil de terre à la masse du

terminal. Si le matériel n'est mis correctement à la masset

, vous pourriez

provoquez des chocs électriques et le matériel deviendrait défectueux ou en

court-circuit.

Lors de l’utilisation d’un instrument de mesure, reliez la masse de l'instrument

de mesure à la prise de terre du matériel. Si les matériels ne sont

pas

correctement mis à la masse, vous pouvez provoquer des chocs électriques.

Pour éviter les risques de détérioration, n'ouvrez pas et ne touchez pas

l'intérieur ou les points de réglage, excepté lors d'une maintenance ou d’une

inspection. Si vous appo

rtez des modification au matériel illégalement, vous

pouvez être poursuivi conformément aux lois en vigueur.

Page 10

IX

(French)

Attention

N'utilisez pas de solva

nt organique pour le nettoyage, tel que dissolvant et

benzène parce que cela peut endommager le revêtement. Essuyez juste la

surface avec un chiffon sec et propre.

Avant de brancher ou de débrancher le câble coaxial entre AP-RFU et AP-

IFU,

mettez hors-tension.

L’alimentation DC -48V pour AP-IFU peut être SELV ou TNV-

1 en fonction du

réseau (0 ou 1) conformément à la norme IEC62102.

Le matériel de connexion à AP-

IFU par une interface Ethernet (RJ 45) devra

être relié aux circuits TNV-1.

Le Matériel de

connexion à l’adaptateur WT par l’nterface PC (RJ 45) devra être

relié aux circuits TNV-1.

Pour la connexion de l’adaptateur WT à WT, un câble adapté à l’utilisation en

plein air sera utilisé.

Pour la connexion du Terminal à AP-IFU, un câble adapté à l’

utilisation en plein

air sera utilisé.

Pour la connexion de AP-IFU à AP-

RFU un câble coaxial adapté à l’utilisation

en plein air sera utilisé.

Page 11

X

Prima dell’utilizzo

Seguire attentamente le avvertenze

Questo manuale ed il prodotto usano delle icone per aiutarLa a utilizzare propriamente il

prodotto e prevengono eventuali danni a Lei o ad altre persone o beni materiale derivanti

dal cattivo utilizzo di questo prodotto. Le icone seguenti classificano il pericolo ed il danno

potenziale nel caso in cui le indicazioni fossero ignorate o nel caso in cui il prodotto fosse

usato impropriamente. Seguire attentamente le avvertenze.

Esempi di icone

Un triangolo è un allarme per chiamare la Sua attenzione. Esso

include un avvertimento o indicazione di pericolo. Le grafiche

all'interno del triangolo differiscono dal grado di cautela. (La

figura a sinistra mostra pericolo per shock elettrici.)

icone indicano proibizione. Una descrizione di proibizione

particolareggiata è data accanto all’ icona. (La figura sulla

sinistraproibisce lo smontaggio del prodotto.)

● icone La invitano a compiere il gesto indicato. Una

descrizione piu’ dettagliata è data accanto all’icona. (La figura

sulla sinistra richiede di scollegare il prodotto.)

Segnali di avvertimento

Si prega di non rimouvere, alterare o danneggiare tali etichette

(Italian)

Pericolo

Avvertenza

Una cattiva utilizzazione di questo prodotto puo’

provocare seri danni a persone mettendo i

suddetti in pericolo di vita

Una cattiva utilizzazione di questo prodotto puo’

provocare seri danni a persone o cose

Tensioni

pericolo

se

Proibizioni

Generali

Consiglio

Generale

Non smonti

Unplug

Page 12

XI

Precauzioni d’uso

(Italian)

Spenga immediatamente il prodotto se qualche anomalia come fumo o

vapori sono emanati dal prodotto. e contatti immediatamente il nostro ufficio

di vendite. Continuare ad usare il prodotto

in tali condizioni può causare

inizi di incendio o shock elettrici.

Non metta contenitori d’acqua, prodotti chimici o cosmetici, come vasi,

pentole ed occhiali o piccoli pezzi di metalli vicino o in cima a questo

prodotto. Liquidi versati sopra o al

l’interno del prodotto, piccoli elementi

metallici inseriti all’interno del prodotto possono provocare shock elettreici o

malfunzionamenti.

Pericoli

Page 13

XII

(Italian)

Avvertenze

Questo manuale descrive importanti precauzioni punti per l’utilizzo e la

manutenzione del prodotto. Legga le sezioni relative durante l’uso, in veglia o

durante la prova dell'unità.

Non tenti di eseguire prove o operazioni non

descritte in questo manuale.

Q

uesta attrezzatura è una macchina di precisione. Possono verificarsi

malfunzionamenti se non osserva le seguenti precauzioni:

・Non sottoponga questa attrezzatura a colpi o cadute

・Durante l’uso, non faccia scolleghi il cavo connesso t

ra l’unità senza fili e

l'adattatore di WT.

Prima di scollegare il dispositivo, rimuova il connettore dall'adattatore di WT

e in seguito spenga il dispositivo.

・Non metta a contatto l’adattatore WT con acqua.

・Non usi questa attrezzatura in un luoghi po

lverosi o poco puliti. Prima di

toccare un –

terminale di potenza ricevente, spenga il dispositivo per evitare

evitare shock elettrici.

Non tocchi l'intelaiatura del dispositivo WT poiche esso puo’ produrre calore.

Quando installa il punto di accesso, c

onnetta il filo di massa al terminale di

terra. Se l'attrezzatura non è collegata a terra propriamente, Lei puo’ ricevere

shock elettrici quando l'attrezzatura diviene difettosa o in corto circuito.

Quando usa un strumento di misura, connetta il termina

le di massa dello

strumento di misura al terminale di massa di questa attrezzatura. Se

l'attrezzatura non è collegata a terra propriamente, Lei puo’ ricevere shock

elettrici.

Per evitare pericoli di shock, non apra e non tocchi l'interno del dispositiv

o o I

punti di rettifica eccetto durante manutenzione o ispezione.

Se Lei modifica

illegalmente l'attrezzatura, Lei può essere punito secondo la Legge Radio

Page 14

XIII

(Italian)

Cautele

Non usi solventi organici come diluente e benzene

per pulire il dispositivo

perché questo può danneggiarne il rivestimento. Asciugi la superficie con una

stoffa asciutta e pulita.

Prima di collegare o scollegare il cavo coassiale tra l'AP-RFU ed AP-

IFU,

spenga il dispositivo.

La DC -48V tensione di alimentazione elettrica per AP-IFU sara’ SELV o TNV-

1

a seconda della rete elettrica utilizzata (0 o 1) con riferimento a IEC62102.

L'Attrezzatura per il collegamento ad AP-IFU Ethernet-interface(RJ-45)

sarà adatto per connettere ai circuiti di TNV-1.

L'Attrezzatura per il collegamento all'adattatore di WT PC-interface(RJ-

45) deve

essere compatibile con una connessione ai circuiti di TNV-1

Per il collegamento tra adattatore WTe WT dovrà essere utilizzato un cavo

appropriato per uso esterno.

Per il collegamento dell’attrezzatura completa al AP-

IFU dovrà essere utilizzato

un cavo adatto ad uso esterno

Per il collegamento tra AP-IFU e AP-

RFU dovrà essere utilizzato un cavo

coassiale appropriato per uso esterno.

Page 15

XIV

Bitte beachten vor der Inbetriebnahme

Warnhinweise und Kennzeichnungen

In dDiesem Handbuch und bei der Verwendung des Produktes werden

Kennzeichen benutzt, die Ihnen helfen sollen das Produkt richtig einzusetzen

und gleichzeitig verhindern sollen, dass Personenschäden entstehen. Bitte

lesen Sie die folgenden Hinweise sorgfältig und beachten die Angaben beim

Lesen des Handbuchs.

Beispiele für Kennzeichen und ihre Bedeutung

Ein Dreieck dient als Alarmzeichen und Warnung, um ihre

Aufmerksamkeit auf Gefahren zu lenken. Das Symbol im

Dreieck unterscheidet die Art der Gefahren (Die Figur auf

der Linke zeigt eine Warnung vor elektrischer

Hochspannung)

Kreisförmige Kennzeichen weisen auf ein Verbot hin.

Eine Verbotsbeschreibung wird in der Unterschrift des

Kennzeichens gegeben. (Die Figur links zum Beispiel

verbietet eine Demontage)

● Gefüllte kreisförmige Kennzeichen weisen Sie auf eine

beabsichtigtes Handlung hin. Sie werden aufgefordert die

Handlung durchzuführen. Eine ausführliche

Anweisungsbeschreibung wird in der Nähe des

Kennzeichens gegeben. (In der Figur links werden Sie

aufgefordert den Stecker aus der Steckdose zu entfernen)

Warnkennzeichnungen

Bitte entfernen, verändern oder beschädigen Sie die Kennzeichnung nicht.

(German)

Warnung

Caution

Falsche

Handhabung dieses Produktes kann

zu ernsthaften Personenschäden und sogar zum

Tod führen.

Falsche

Handhabung dieses Produktes kann

zu ernsthaften Personenschäden oder Schäden

an anderen Gegenständen führen.

Gefährliche

Hochspannung

Stecken Sie

Nehmen Sie

nicht

auseinander

Allgemein

Verbote

Allgemeiner

Rat

Page 16

XV

Vorkehrungen beim Gebrauch

(German)

Schalten Sie das Gerät unbedingt aus, wenn Sie ungewöhnliche Rauch

-

oder Dampfentwicklung beobachten, und kontaktieren Sie unseren zentralen

Vertrieb,

eine Filiale oder ein Vertriebsbüro in Ihrer Nähe. In diesem Fall darf

das Gerät nicht weiterverwendet werden. Eine weitere Benutzung kann zu

Bränden und elektrischen Kurzschlüssen führen.

Bitte stellen Sie keine Wasserbehälter, Chemikalien oder Kosmetik

a, wie

zum Beispiel Gefäße, Blumenvasen, Gläser oder kleine Metallstücke auf

oder in die Nähe des Produktes. Flüssigkeiten oder kleine Metallteile, die in

das Garät gelangen, könnten Brände, Kurzschlüsse oder Fehlfunktionen

hervorrufen.

Warnung

Page 17

XVI

(German)

Vorsicht

Dieses Handbuch enthält wichtige Informationen zur Bedienung und Wartung

des Gerätes. Lesen Sie bitte die entsprechenden Abschnitte bevor Sie das

Gerä

t in Betrieb bedienen, warten oder in anderer Weise testen. Bitte führen Sie

keine Tests durch, die im Manual nicht beschrieben sind.

Dieses Gerät ist ein hochgenaues Instrument.

・

Fehler können auftreten sollte das Gerät: Stössen oder starken

Erschütterungen ausgesetz wird.

・

Während des Betriebes muss die Kabelverbindung zwischen dem

Bedienelement des Funkterminal und dem WT-Adapter nicht gelöst werden.

・Um das Kabel zu entfernen, lösen Sie zuerst die DC-Versorgung

Stecker

des WT-Adapters und schalten das Gerät ab.

・Der WT-Adapter darf mit Wasser nicht in Berührung kommen.

・Vermeiden Sie den Betrieb des Gerätes in Umgebungen mit hoher Staub-

und Schmutzbelastung.

Berühren Sie den Rahmen des WT’s während des Betriebes auf keinen Fall, da

dieser Teil sehr heiss wird.

Wenn Sie den Access Point installieren, verbinden Sie zuerst den Erdungsdraht

mit dem Erdungsanschluss des Gerätes. Ungenügende Erdung des Gerätes,

kann im Falle von Fehlfunktionen oder Kurzschlüssen zu Stromschlägen führen.

Wenn Sie ein weiteres

Meßgerät einsetzen, verbinden Sie bitte den

Erdungsanschluss des Messgerätes sorgfältig mit dem Erdungsanschluss des

Gerätes. Ungenügende Erdung des Gerätes, kann zu Stromschlägen führen.

Bitte öffnen oder berühren Sie das Innenleben sowie die Einstellun

gsmittel des

Gerätes nicht, ausser im Falle von Wartungsarbeiten oder Inspektionen.

Wenn Sie unerlaubt Änderungen am Gerät vornehmen, zieht dies Massnahmen

in Anwendung des „RADIO Gesetzes“ nach sich.

Page 18

XVII

(German)

Cautions

Benutzen Sie kein organische Lösungsmittel, wie Verdünner und Benzole zur

Reinigung, we

il dies der Oberfläche des Gerätes beschädigen könnte.

Reinigen Sie die Oberfläche nur mit einem sauberen trockenen Stofftuch.

Bitte schalten Sie das Gerät aus, bevor Sie das Koaxialkabel zwischen AP-

RFU

und AP-IFU anschliessen oder entfernen.

Nach IEC62102 sollte die 48V DC–Spannngsversorgung für den AP-

IFU SELV

oder TNV-1 in Abhängigkeit von der Netzwerkumgebung ( 0 oder 1) sein.

Die Ausrüstung für Verbindung zu AP-IFU Ethernet-interface(RJ-45)

, wird

geeignet sein, sich in Verbindung mit TNV-1-Schaltungen zu setzen.

Die die Verbindung des WT-

Adapters zum WT sollte ein Kabel verwendet

werden, dass für den Aussenbereich geeignet ist.

Für die Verbindung vom WT-

Adapter zum WT sollte ein Kabel für

Aussenanwendungen gewählt werden.

Für die Verbindung vom Terminal des Gerätes zum AP-

IFU sollte ein Kabel für

Aussenanwendungen gewählt werden.

Für die Verbindung AP-IFU zu AP-

RFU sollte ein Koaxialkabel für den

Aussenbereich installiert werden.

Page 19

XVIII

CONTENTS

Introduction......................................................................................................................................I

Before use......................................................................................................................................II

Precautions in Use........................................................................................................................III

Avant usage..................................................................................................................................VI

Précautions d’utilisations.............................................................................................................VII

Prima dell’utilizzo...........................................................................................................................X

Precauzioni d’uso.........................................................................................................................XI

Bitte beachten vor der Inbetriebnahme......................................................................................XIV

Vorkehrungen beim Gebrauch....................................................................................................XV

CONTENTS..............................................................................................................................XVIII

1. OVERVIEW.......................................................................................................................... 1-1

1.1. FCC Notice............................................................................................................... 1-1

1.2. CERTIFICATION NOTE FROM INDUSTRY CANADA............................................ 1-2

1.3. System Configuration............................................................................................... 1-2

1.4. Deployment Schemes..............................................................................................1-3

1.5. Components............................................................................................................. 1-4

2. Specifications.......................................................................................................................2-7

2.1. General..................................................................................................................... 2-7

2.2. External Views of the Units ...................................................................................... 2-9

2.2.1. AP-RFU (Omni Antenna)...................................................................................... 2-9

2.2.1.1. AP-RFU (Omni Antenna) Nameplate.......................................................... 2-10

2.2.1.2. AP-RFU (Omni Antenna) Mounting Bracket................................................2-11

2.2.2. AP-RFU (Sectoral-Horn Antenna) ...................................................................... 2-12

2.2.2.1. AP-RFU (Sectoral-Horn Antenna) Nameplate............................................ 2-13

2.2.2.2. AP-RFU (Sectoral-Horn Antenna) Mounting Bracket.................................. 2-14

2.2.3. AP-IFU................................................................................................................ 2-15

2.2.3.1. AP-IFU Nameplate......................................................................................2-16

2.2.4. WT ...................................................................................................................... 2-17

2.2.4.1. WT Nameplate............................................................................................. 2-18

2.2.4.2. WT Mounting Bracket.................................................................................. 2-19

2.2.5. WT (External Antenna) ....................................................................................... 2-20

2.2.5.1. WT (External Antenna) Nameplate............................................................. 2-21

2.2.6. WT Adapter......................................................................................................... 2-22

2.2.6.1. WT Adapter Nameplate............................................................................... 2-22

2.2.7. WT AC Adapter................................................................................................... 2-23

Page 20

XIX

2.2.8. Antenna direction adjustment tool...................................................................... 2-24

3. AP...................................................................................................................................... 3-25

3.1. AP-RFU..................................................................................................................3-25

3.1.1. Overview.............................................................................................................3-25

3.1.2. Antenna section.................................................................................................. 3-25

3.1.3. RF section........................................................................................................... 3-25

3.1.4. IF section............................................................................................................ 3-25

3.1.5. Operations and Indications................................................................................. 3-26

3.1.5.1. Indications ................................................................................................... 3-26

3.1.5.2. Switches...................................................................................................... 3-26

3.1.6. Terminals.............................................................................................................3-27

3.1.6.1. Omni Antenna.............................................................................................. 3-27

3.1.6.2. Sectoral-Horn Antenna................................................................................ 3-27

3.2. AP-IFU.................................................................................................................... 3-28

3.2.1. Overview.............................................................................................................3-28

3.2.2. IF section............................................................................................................ 3-28

3.2.3. Operations and Indications................................................................................. 3-30

3.2.3.1. Indications ................................................................................................... 3-30

3.2.3.2. Switches...................................................................................................... 3-32

3.2.3.3. Terminals..................................................................................................... 3-33

4. WT .....................................................................................................................................4-36

4.1. WT.......................................................................................................................... 4-36

4.1.1. Overview.............................................................................................................4-36

4.1.2. Antenna section.................................................................................................. 4-36

4.1.3. RF section........................................................................................................... 4-36

4.1.4. IF section............................................................................................................ 4-36

4.1.5. Digital section .....................................................................................................4-37

4.1.6. Interface section .................................................................................................4-37

4.1.7. Power supply......................................................................................................4-37

4.1.8. Operations and Indications................................................................................. 4-39

4.1.8.1. Indications ................................................................................................... 4-39

4.1.8.2. Switches...................................................................................................... 4-41

4.1.8.3. Terminals..................................................................................................... 4-42

4.1.8.3.1. WT............................................................................................................4-42

4.1.8.3.2. WT Adapter ..............................................................................................4-43

5. CONSTRUCTING A POINT-TO-MULTIPOINT SYSTEM (AP) ......................................... 5-45

Page 21

XX

5.1. Overview................................................................................................................. 5-45

5.2. Installing the AP-RFU and AP-IFU......................................................................... 5-46

5.2.1. Installing the AP-RFU (Omni Antenna)............................................................... 5-46

5.2.2. Installing the AP-RFU (Sectoral-Horn Antenna)................................................. 5-48

5.2.3. Setting AP-RFU(Sectoral-Horn Antenna)for Vertical or Horizontal Polarization 5-51

5.2.4. installing the AP-IFU........................................................................................... 5-52

5.2.4.1. Installing the AP-IFU.................................................................................... 5-52

5.2.4.2. Example of Installing the AP-IFU................................................................ 5-53

5.2.4.3. Opening and Closing the AP-IFU Cover.....................................................5-54

5.3. Adjusting the Direction of the AP-RFU................................................................... 5-55

5.3.1. Adjusting the Direction of the AP-RFU (Omni Antenna)..................................... 5-55

5.3.2. Adjusting the Direction of the AP-RFU (Sectoral-Horn Antenna)....................... 5-55

5.3.3. Direction adjustment of the antenna...................................................................5-56

5.4. Connecting a Cable between AP-RFU and AP-IFU...............................................5-57

5.4.1. AP-RFU (Omni Antenna).................................................................................... 5-57

5.4.2. AP-RFU (Sectoral-Horn Antenna) ...................................................................... 5-58

5.5. Connecting Cables from the AP-IFU to external.................................................... 5-59

5.5.1. Connecting the Power cable connector..............................................................5-61

5.6. The confirmation of AP-IFU....................................................................................5-63

5.7. Waterproofing Connectors ..................................................................................... 5-64

5.7.1. Self Bonding tape ...............................................................................................5-64

5.8. Connecting the AP Local Management Tool.......................................................... 5-66

5.9. Configure the AP parameters.................................................................................5-67

5.9.1. AP Local management tool ................................................................................5-67

5.9.1.1. Configure the AP network parameters........................................................ 5-67

5.9.1.2. Reset the AP................................................................................................ 5-68

5.9.1.3. Measure the cable loss............................................................................... 5-69

5.9.2. Register the AP ID number to OpS....................................................................5-71

5.10. Check sheet of AP Installation ...............................................................................5-72

6. CONSTRUCTING A POINT-TO-MULTIPOINT SYSTEM (WT) ........................................ 6-73

6.1. Overview................................................................................................................. 6-73

6.2. OpS ........................................................................................................................6-74

6.2.1. Register the WT ID number to AP......................................................................6-74

6.3. Connecting the WT Local Management Tool......................................................... 6-76

6.4. WT Local management tool ................................................................................... 6-76

6.4.1. Configure the WT................................................................................................ 6-76

Page 22

XXI

6.5. Installing the WT..................................................................................................... 6-77

6.5.1. Installing the WT................................................................................................. 6-77

6.5.2. Example of Installing the WT.............................................................................. 6-79

6.5.3. Setting the WT for Vertical or Horizontal Polarization........................................ 6-80

6.6. Installing the WT (External Antenna)...................................................................... 6-81

6.6.1. Installing the WT (ExternalΦ30cm Antenna)......................................................6-81

6.6.2. Installing the WT (ExternalΦ60cm Antenna)......................................................6-85

6.7. Adjusting the Direction of the WT...........................................................................6-89

6.7.1. Connecting the WT Local Management Tool ..................................................... 6-90

6.7.2. Roughly Adjusting the Direction.........................................................................6-91

6.7.3. Finely Adjusting the Direction............................................................................. 6-92

6.7.4. The receive level and the distance..................................................................... 6-93

6.8. Installing the WT Adapter....................................................................................... 6-97

6.9. Connecting Cables to the WT................................................................................ 6-98

6.10. Waterproofing WT small window.......................................................................... 6-100

6.11. When you use the cable with the LAP sheath for outdoor................................... 6-104

6.12. Waterproofing Without Using a Cold-Shrinkable Tube........................................ 6-106

6.13. Testing .................................................................................................................. 6-108

6.13.1. Perform a continuity test............................................................................ 6-108

6.13.2. Measure the packet loss rate....................................................................6-109

6.14. Check sheet of WT Construction ..........................................................................6-110

7. CONSTRUCTING A POINT-TO-POINT SYSTEM ...........................................................7-111

7.1. Overview(WT Construction flow)...........................................................................7-111

7.2. Connecting the WT Local Management Tool........................................................7-112

7.3. Configure the WT(master).....................................................................................7-113

7.4. Configure the WT(slave).......................................................................................7-115

7.5. Installing the WT....................................................................................................7-116

7.5.1. Installing the WT(master/slave).........................................................................7-116

7.5.2. Example of Installing the WT.............................................................................7-118

7.5.3. Setting the WT for Vertical or Horizontal Polarization.......................................7-119

7.6. Installing the WT (External Antenna).................................................................... 7-120

7.6.1. Installing the WT (ExternalΦ30cm Antenna)....................................................7-120

7.6.2. Installing the WT (ExternalΦ60cm Antenna)....................................................7-124

7.7. Adjusting the Direction of the WT.........................................................................7-128

7.7.1. Adjusting the Direction of the WT..................................................................... 7-128

7.7.1.1. Connecting the WT Local Management Tool ............................................ 7-129

Page 23

XXII

7.7.1.2. Roughly Adjusting the Direction................................................................ 7-132

7.7.1.3. Finely Adjusting the Direction.................................................................... 7-133

7.7.2. The receive level and the distance................................................................... 7-134

7.8. Installing the WT Adapter(master/slave)..............................................................7-136

7.9. Connecting Cables to the WT(master/slave).......................................................7-137

7.10. Waterproofing WT small window.......................................................................... 7-139

7.11. When you use the cable with the LAP sheath for outdoor................................... 7-142

7.12. Waterproofing Without Using a Cold-Shrinkable Tube........................................ 7-143

7.13. Testing .................................................................................................................. 7-146

7.13.1. Ping test.....................................................................................................7-146

7.13.2. Measure the packet loss rate (with WT Local mnagement tool)............... 7-147

7.13.3. Measure the packet loss rate (with OpS).................................................. 7-148

7.14. Check sheet of Point to Point Construction......................................................... 7-149

8. Standard Tools to be Used.............................................................................................. 8-150

9. INITIAL VALUES.............................................................................................................. 9-151

9.1. Point to Multipoint system ....................................................................................9-151

9.1.1. Initial values for AP parameters (Point to Multipoint System)..........................9-151

9.1.2. Initial values for WT(1 - 239) parameters (Point to Multipoint system)............ 9-153

9.1.3. Initial values for VID(2 - 4094) table parameters (Point to Multipoint system). 9-153

9.1.4. Initial values for AP-IFU swiches...................................................................... 9-154

9.1.5. Initial values for WT(Master) parameters (Point to point System) ................... 9-155

9.1.6. Initial values for WT (Slave) parameters (Point to point System) .................... 9-156

10. System example Point to Multipoint system...................................................... 10-157

11. System example Point to Point...........................................................................11-161

Page 24

1-1

1. OVERVIEW

JRC FWA SYSTEM is a broadband wireless point-to-multipoint communication system

operating at 24-26 GHz that provides high-speed IP access. The 80Mbps/40Mbps wireless

transmission rate is available on one frequency channel having the RF bandwidth of 26MHz.

The wireless transmission rate depends upon the selected modulation system

(16QAM/QPSK), which is controlled for each subscriber terminal to be adapted with the

radio propagation path environment such as the distance from the access point and rainfall

conditions. The maximum throughput (average data transmission rate of an Ethernet

frame) received and transmitted by an access point is 46Mbps.

The data transmissions in radio channel are encrypted by different keys for each subscriber

terminal to ensure sufficient security. The system can deal with the subscribers fairly in

assigning the bandwidth, regardless of the distances of subscriber terminals from the base

station.

1.1. FCC Notice

FCCID: CKENTG335-EL0, CKENTG335-EL2, CKENTG337-EL0, CKENTG337-EL2

CKENTG337-XL0, CKENT337-XL2

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference.

(2) This device must accept any interference received, including interference that may

cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Page 25

1-2

Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Caution . Changes or modifications to this equipment could void the user’s authority to

operate the equipment.

1.2. CERTIFICATION NOTE FROM INDUSTRY CANADA

ICID: 768B-NTG335L0, 768B-NTG337L0, 768B-NTG335L2, 768B-NTG337L2

While this equipment meets the technical requirements for its operation in its rated paired

block arrangement, this block arrangement is different than the 40 + 40 MHz block

arrangement prescribed in documents RSS-191 and SRSP-324.25. The operation of this

equipment IS NOT permitted if the out-of-band and spurious emission limits are not met at

the edge of any contiguous licensed spectrum. It should be noted that all current relevant

spectrum policies, licensing procedures and technical requirements are still applicable. For

additional information, please contact the local Industry Canada office.

Access Point

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

Wireless Terminal

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

1.3. System Configuration

One Access Point (AP) has the capacity of linking with up to 239 subscriber terminals to

configure a point-to-multipoint (P-MP) communications system. An omni-directional

antenna (with horizontal directivity of 360°) mainly for a residential area of detached houses

and a Sectoral-Horn-type antenna (90° × 10° directivity) mainly for multi-tenant building are

available.

Wireless Terminal (WT), including the antenna and all the electric circuits, is designed

compactly (19cm x 19cm x 7cm) and can easily be installed at any outside places of

residential houses. WT is connected to a PC through one LAN cable and supplied with

power through a tiny power supply adapter.

Page 26

1-3

Second layer isolation of subscriber traffic is provided by 802.1Q VLAN-tag. Broadband

Access Server (BAS) terminates access layer functions and relay user traffic to IP backbone

network.

The Operation System (OpS) allowing the installation and registration of subscriber

terminals and the supervision of its operational status is optionally available.

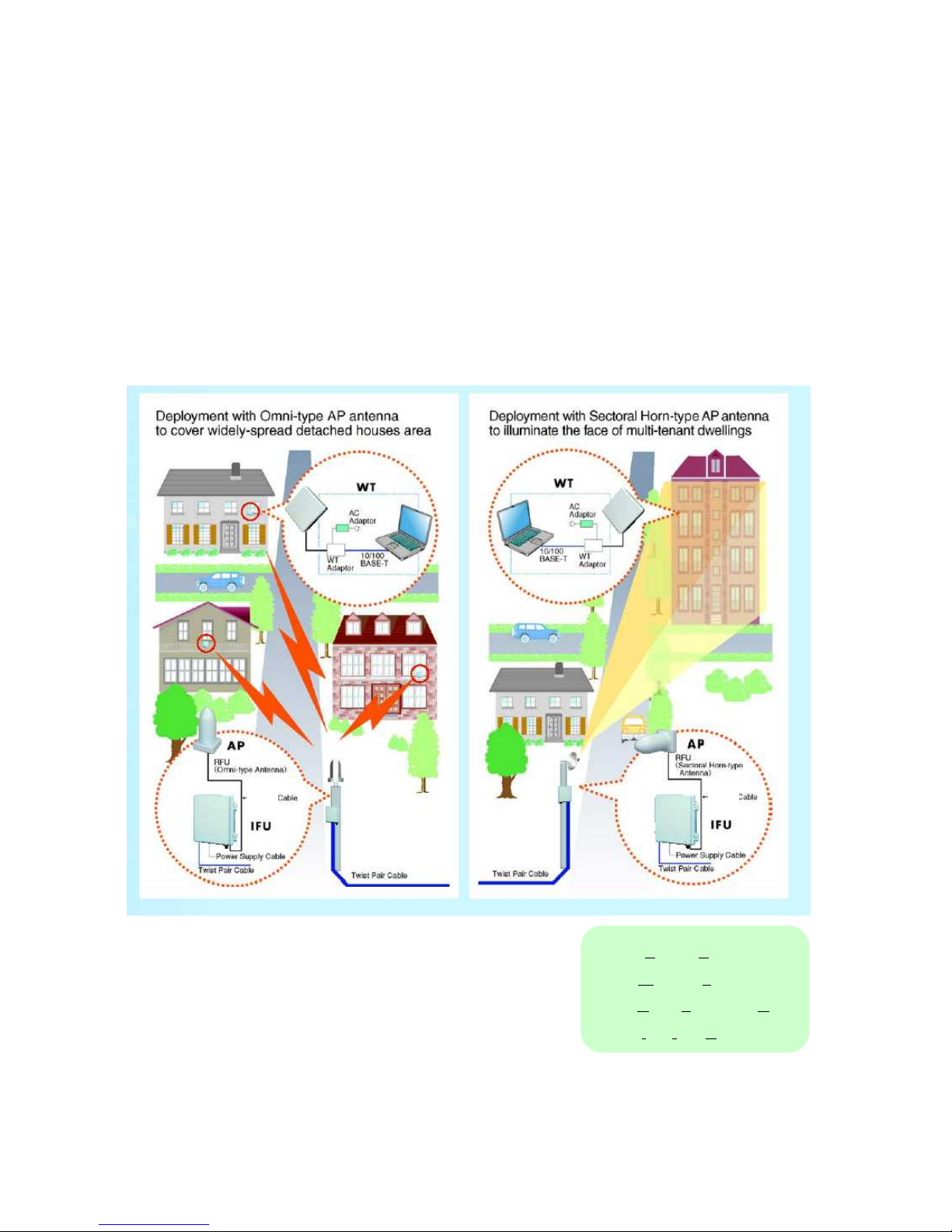

1.4. Deployment Schemes

Figure 1-1 is deployment schemes of JRC FWA systems.

Figure 1-1 Deployment Schemes of JRC FWA Systems

AP: Access Point

WT: Wireless Terminal

RFU: R

adio Frequency Unit

IFU: Interface Unit

IFU

IFU

Page 27

1-4

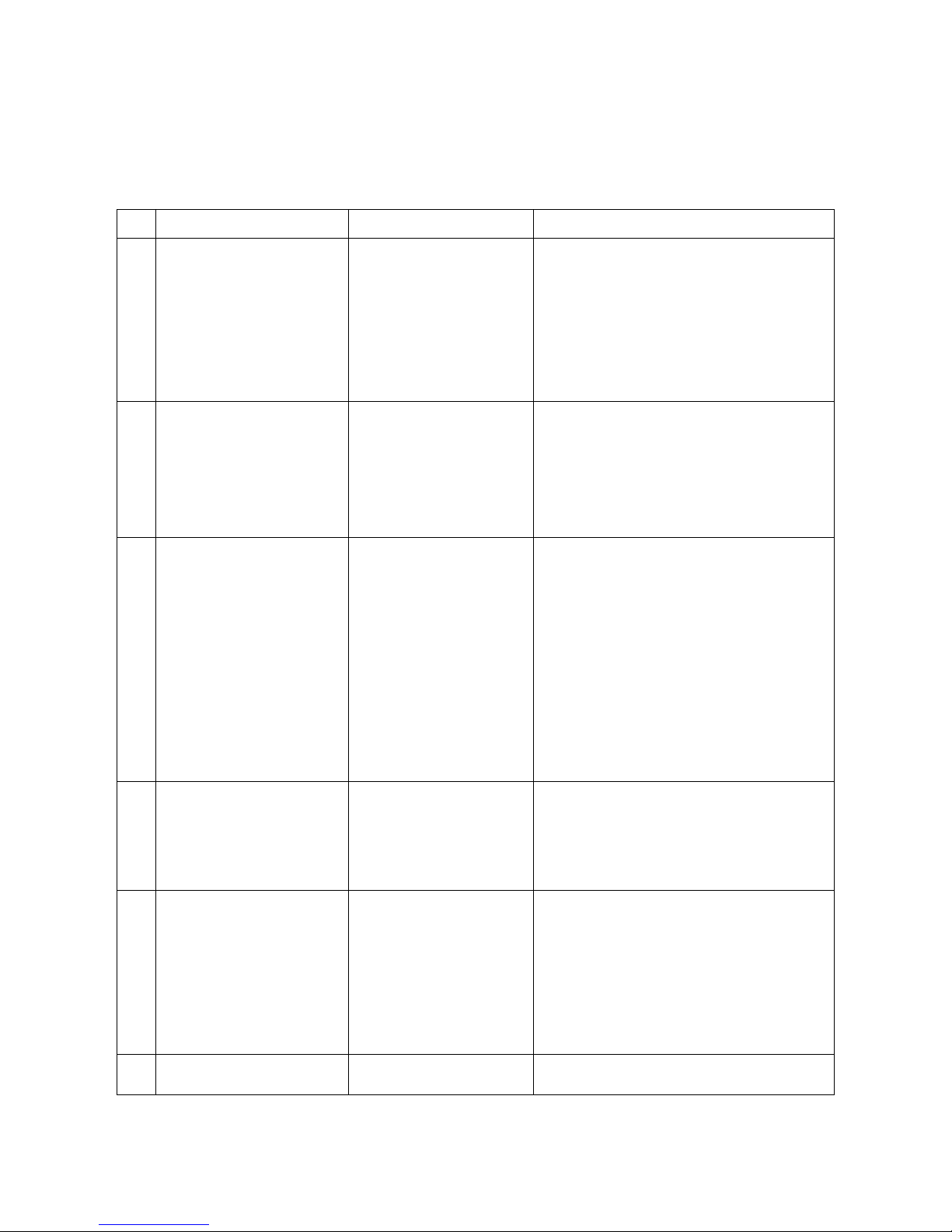

1.5. Components

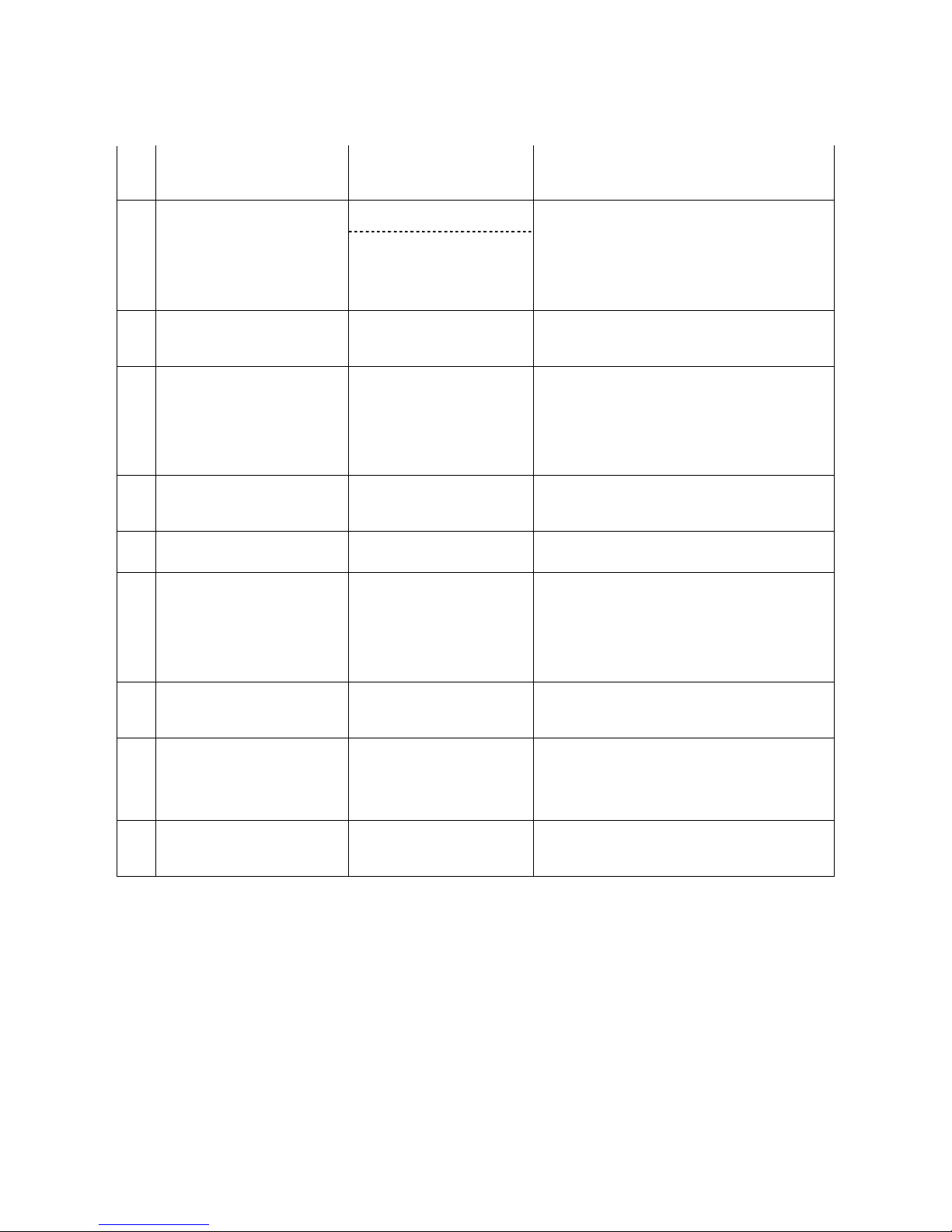

Table 1-1 Components

No.

Name Model Description

1 AP-RFU(Sectoral-Horn) NTG-335<1><2><4> The AP-RFU (Sectoral-Horn) is a radio unit

that accommodates both the antenna and

transceiver in the same housing. Connecting

an AP-IFU to the AP-RFU constitutes an AP

and allows connecting multiple WTs over radio

links.

2 AP-RFU(Omni) NTG-339<1><2><4> The AP-RFU (Omni) is a radio unit that

accommodates both the antenna and

transceiver in the same housing. Connecting an

AP-IFU to the AP-RFU constitutes an AP and

allows connecting multiple WTs over radio links.

3 AP-IFU NTJ-111<4> The AP-IFU converts Ethernet frames into radio

signals and vice versa. Connecting an AP-RFU

to the AP-IFU constitutes an AP. It supports the

100BASE-TX electrical network interface to

allow connecting a unit such as a router.

Assigning an IP address for maintenance and

monitoring allows transmission and reception of

maintenance signals via SNMP through a

network interface.

3.1

DC-48V connector (AP) NRW-203-PF8-ULCSATUV The DC -48V connector (AP) is for an external

power cable. The connector is connected to the

terminal for the AP-IFU power supply

connector.

4 WT NTG-337<1><3><4> The WT is a radio unit that accommodates all

the antenna, radio transceiver, signal processor

and interface section in the same housing. It

supports 10BASE-T and 100BASE-TX user

interfaces to connect a personal computer and

hub.

4.1

WT adapter NQD-2049<4> The WT adapter sends both Ethernet signals

Page 28

1-5

from the PC and 24 VDC from the AC

adapter to the WT through an Ethernet cable.

It also sends signals from the WT to the PC.

NBG-317<3> 4.2

AC adapter

(100V to 240V AC)

NBG-399R

The AC adapter supplies 24 VDC to the WT.

NBG-399R is latest.

4.3

AC adapter cable H-7ZCCM0132

or

H-7ZCCM0135

It use for NGB-399R.

H-7ZCCM0132:Atype (USA)

H-7ZCCM0135:Ctype (Europe)

MPBX39464A 4.4

WT mounting bracket

MPBX44142

The WT mounting bracket is used to mount

the WT on a pole or similar object.

MPBX44142 is latest.

4.4

CS Sleave

(WT aperture)

MPPK31288 The cold-shrinkable tube is mounted on the

small window of the WT to make the WT

waterproof and dustproof.

5 Antenna direction

adjustment tool

NKK-163 There are antenna direction adjustment tools

for the AP and WT.

6 JRC Local management tool

CD-ROM

H-7YZCM5074B AP Local management tool 、 WT Local

management tool、AP Local management

tool instruction manual and WT Local

management tool instruction manual are

included in this CD-ROM.

6.1 AP Local management tool H-7YZCM5053A Connecting a computer with this software

installed to the AP-IFU allows you to execute

the maintenance and management functions

for the AP. Use the AP local management

cable to connect between the PC and

AP-IFU.

6.2 WT Local management tool H-7YZCM5052A Connecting a computer with this software

installed to the WT allows you to execute the

maintenance and management functions for

the WT. Use an Ethernet cable to connect

between the PC and WT.

6.3 AP Local management tool

instruction manual

H-7YZCM5061 instruction manual of AP Local management

tool

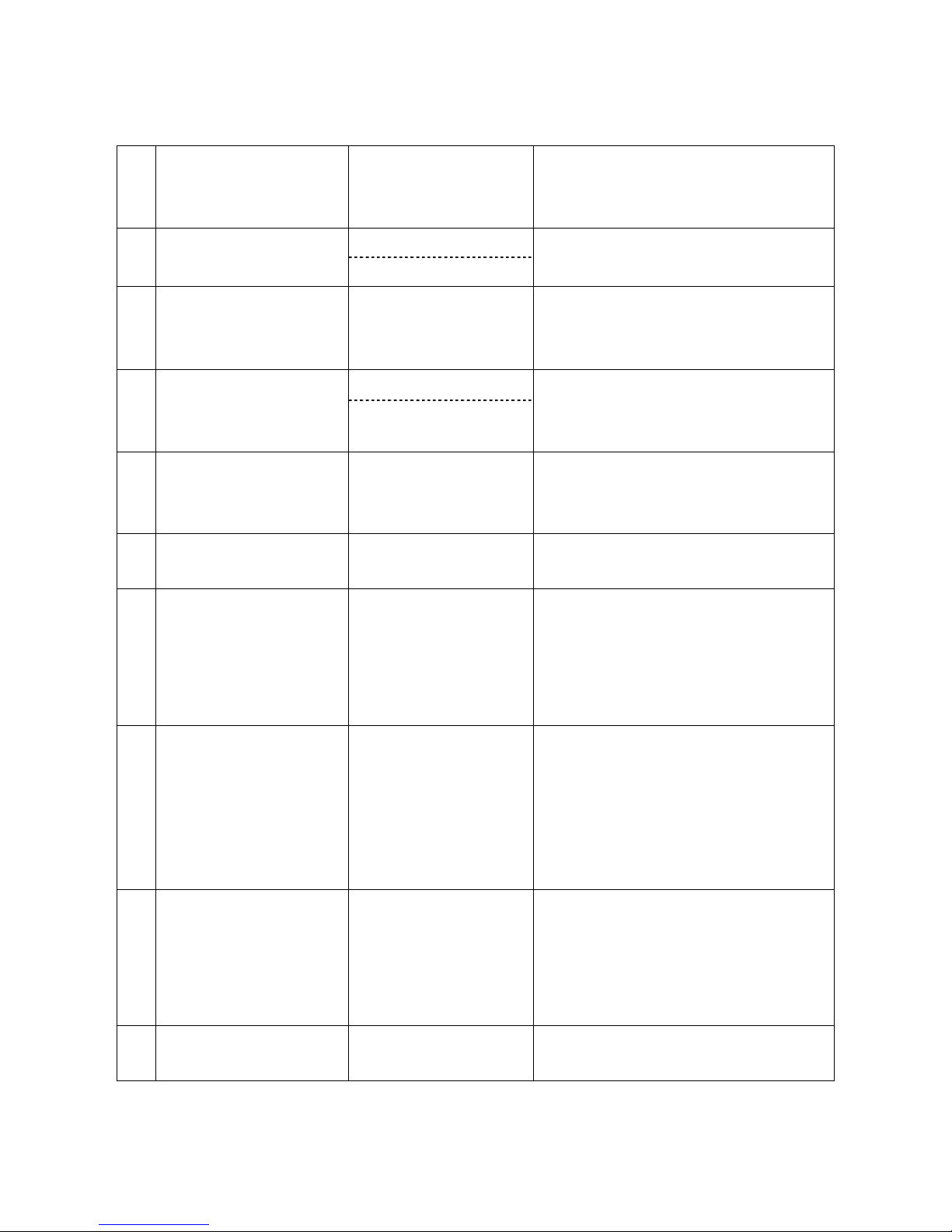

Page 29

1-6

6.4 WT Local management tool

instruction manual

H-7YZCM5060 instruction manual of WT Local management

tool

H-7ZCCM5040A 7 AP local management cable

H-7ZCCM0121A

Use this cable to connect a PC with the AP

local management tool installed to the

AP-IFU.

H-7ZCCM0121A is latest.

8 PMP-OpS

(CD-ROM)

H-7YZCM5076C The PMP-OpS is included in this CD-ROM.

8.1

PMP-OpS H-7YZCM5056A The PMP-OpS (Point-to-Multipoint Operation

System) is an SNMP manager dedicated to a

JRC FWA system with a point-to-multipoint

configuration.

8.2

PMP-OpS

INSTRUCTION MANUAL

H-7YZCM5062 The PMP-OpS INSTRUCTION MANUAL

9 PP-OpS (CD-ROM) H-7YZCM5077B The PP-OpS is included in this CD-ROM.

9.1

PP-OpS H-7YZCM5055A The PP-OpS (Point-to-Point Operation

System) is an SNMP manager dedicated to a

JRC FWA system with a point-to-point

configuration.

9.2

PP-OpS

INSTRUCTION MANUAL

H-7YZCM5063 The PP-OpS INSTRUCTION MANUAL

10

JRC FWA SYSTEM

INSTRUCTION MANUAL

(CD-ROM)

H-7YZCM0102C INSTRUCTION MANUAL is included in this

CD-ROM.

10.1

JRC FWA SYSTEM

INSTRUCTION MANUAL

H-7YZCM0101B INSTRUCTION MANUAL.

Subject to change without notice.

<1> Frequency Type

L0 : 24.050〜24.549GHz

L1 : 24.549〜24.997GHz

L2 : 24.997〜25.445GHz

H1 : 25.557〜26.005GHz

H2 : 26.005〜26.453GHz

X0 : 24.050〜24.549GHz (External Antenna)

X2 : 24.997〜25.445GHz (External Antenna)

<2> Antenna Type

H : Horizontal Polarization

V : Vertical Polarization

<3> AC Power Cable Piug Type

E : Europe

U : USA

<4> RoHS

Blank : non RoHS

R : RoHS

Page 30

2-7

2. Specifications

2.1. General

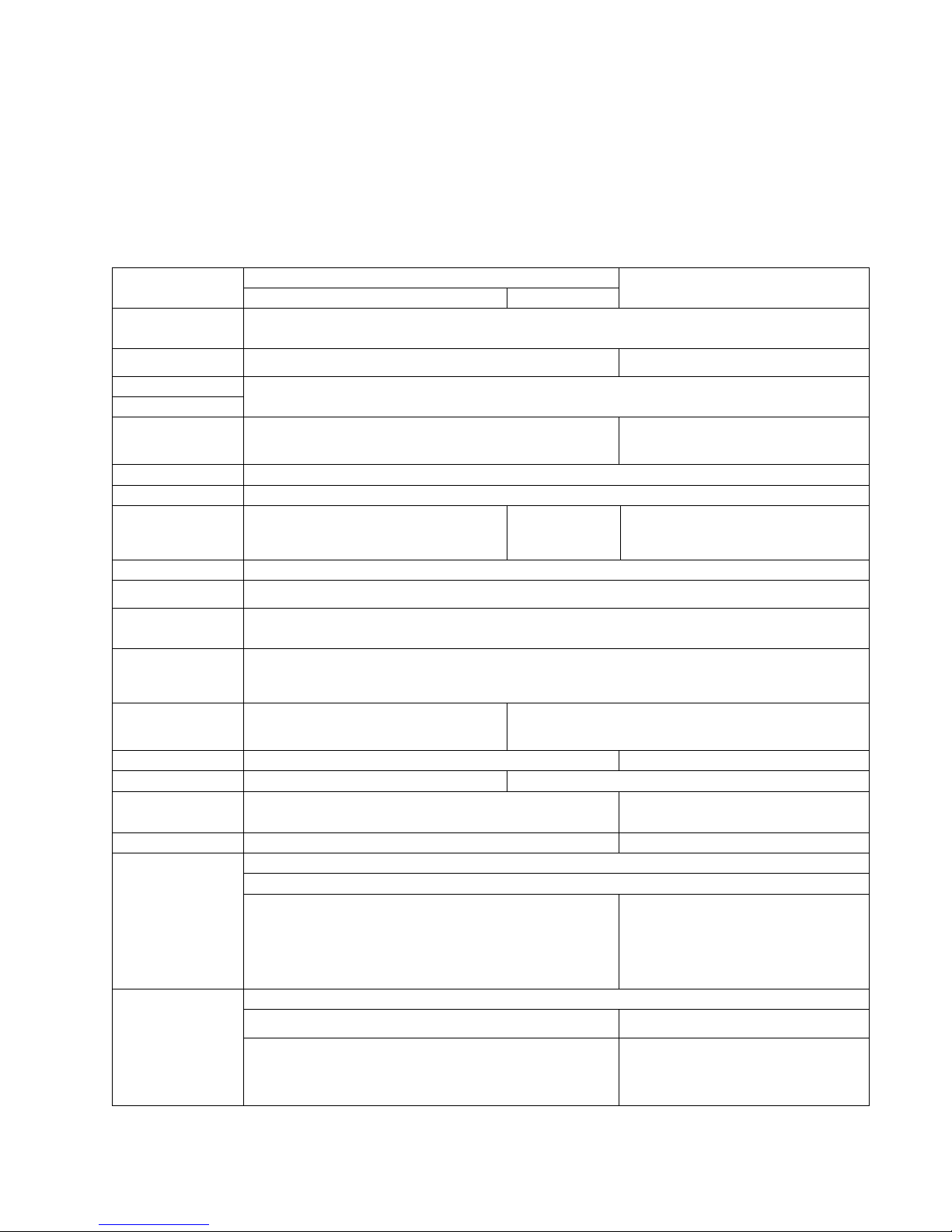

Table 2-1 JRC FWA SYSTEM Specifications

Point to Multipoint System

Item

AP WT

Point to Point System

Frequency Band EL0 EL1 EL2 EH1 EH2

[GHz]

24.050-24.549 24.549-24.997 24.997-25.445 25.557-26.005 26.005-26.453

Duplex/multiple

access

TDD/TDMA TDD

Modulation system QPSK/16QAM

Symbol rate 20M symbol/s

Radio Transmission

rate

QPSK:40Mbps 16QAM:80Mbps QPSK:40Mbps 16QAM:80Mbps

(Data throughput) (Max.23Mbps) (Max.46Mbps) (Max.16Mbps) (Max.32Mbps)

Occupied bandwidth 26MHz (QPSK/16QAM)

Channel spacing 28MHz

Transmit output power

QPSK:+14dBm

QPSK (ATPC):

-6 to +14dBm

QPSK: -6 to +14dBm

16QAM (ATPC):

-8.5 to +11.5dBm

16QAM: -8.5 to +11.5dBm

Frequency Stability ±10ppm

Transmitter spurious

emission

-30dB/MHz or less

RF spectrum mask QPSK:ETSI Type A

16QAM:ETSI Type B

Minimum receiving

level (BER=10

-6

)

After an error

correction

QPSK: -79dBm or less 16QAM: -69dBm or less

Antenna type and gain

Omni: 6.5dBi High-gain flat antenna: 31dBi

(typ)

90°X10°Sectoral Horn:15.5dBi

External Antenna

: 35.7dBi(30cm) / 41.1dBi(60cm) / 44.6dBi(90cm)

/ 46.9dBi(120cm)

Max number of WTs 239 WTs per AP Interface 100BASE-TX 10BASE-T/100BASE-TX

MAC processing

VLAN (IEEE802.1Q)

User data are distributed by using

VLAN-TAG to each WT

-

MAC address filtering

enable disable

SNMP (agent) Remote operation is possible by OpS (option).

SNMP V2, Private MIB, VLAN TAG (IEEE802.1q)

AP setup/control

WT setup/control

Test

Alarm log

WT Operating Status List

Remote downloading

Bandwidth Table

Parameter setup/Control (Master)

Alarm Log (Master)

Traffic information (Master)

Network configuration (Master)

Local management Local management is possible by Local management tool (option).

AP: Serial interface(Exclusive cable use)

WT: Ether interface

Master/Slave: Ether interface

Setup (AP,WT)

Control (AP,WT)

Radio link monitor (WT)

Log (AP,WT)

Tool Setup (AP,WT)

Setup

Control

Radio link monitor

Log

Tool Setup (AP,WT)

Page 31

2-8

Power -48 V DC 100 to 240 V AC

35W (MAX) 35VA (MAX)

Physical RFU:Dimensions W190XH190XD362(mm) RF Unit (Internal Antenna):Dimensions W190XH190XD61(mm)

Weight 3kg Weight about 2kg

RF Unit (External Antenna):Dimensions W220 XH220XD53(mm)

Weight about 3kg

IFU:Dimensions W275XH325XD165(mm) WT Adapter:Dimensions W45XH95XD40(mm)

Weight 8kg Weight about 100g

AC Adapter:Dimensions W60XH38XD120(mm) (NBG-317)

W52XH30XD108(mm) (NBG-399R)

Weight about 330g

Temperature

-33degree Celsius - +50degree Celsius cold

start at minimum –10degree Celsius ambient

RF Unit: -33degree Celsius - +50degree Celsius cold start at

minimum –10degree Celsius ambient

WT Adapter: -20degree Celsius - +50degree Celsius

AC Adapter: 0degree Celsius - +40degree Celsius

Humidity 20% - 80% non-condensing

Page 32

2-9

2.2. External Views of the Units

2.2.1. AP-RFU (Omni Antenna)

(in mm)

Figure 2-1 External View of the AP-RFU (Omni Antenna)

(b)

(a)

Omni Antenna

(c)

Page 33

2-10

2.2.1.1. AP-RFU (Omni Antenna) Nameplate

Nameplate(a)

Nameplate(b)

Nameplate(c)

Figure 2-2 Nameplate

<1>

L0 : 24.050〜24.549GHz

L1 : 24.549〜24.997GHz

L2 : 24.997〜25.445GHz

H1 : 25.557〜26.005GHz

H2 : 26.005〜26.453GHz

<4>

Blank : non RoHS

R : RoHS

<2>

H : Horizontal Polarization

V : Vertical Polarization

<3>

EL0 : 24.050〜24.549GHz

EL1 : 24.549〜24.997GHz

EL2 : 24.997〜25.445GHz

EH1 : 25.557〜26.005GHz

EH2 : 26.005〜26.453GHz

SER.NO :

MADE IN JAPAN.

TYPEW−AP

<3>

<3>

(Omni<2>)

<1><2><4>

FCCID:CKENTG335−

FCCID:CKENTG335−

768B-NTG339<1>

Page 34

2-11

2.2.1.2. AP-RFU (Omni Antenna) Mounting Bracket

(in mm)

Figure 2-3 Mounting Bracket

Page 35

2-12

2.2.2. AP-RFU (Sectoral-Horn Antenna)

(in mm)

Figure 2-4 External View of the AP-RFU (Sectoral-Horn Antenna)

(b)

(a)

Sectoral-Horn Antenna

(c)

Page 36

2-13

2.2.2.1. AP-RFU (Sectoral-Horn Antenna) Nameplate

Nameplate(a)

Nameplate(b)

Nameplate(c)

Figure 2-5 Nameplate

<1>

L0 : 24.050〜24.549GHz

L1 : 24.549〜24.997GHz

L2 : 24.997〜25.445GHz

H1 : 25.557〜26.005GHz

H2 : 26.005〜26.453GHz

<4>

Blank : non RoHS

R : RoHS

<2>

H : Horizontal Polarization

V : Vertical Polarization

<3>

EL0 : 24.050〜24.549GHz

EL1 : 24.549〜24.997GHz

EL2 : 24.997〜25.445GHz

EH1 : 25.557〜26.005GHz

EH2 : 26.005〜26.453GHz

SER.NO :

MADE IN JAPAN.

TYPEW−AP

<3><3>

(SectralHorn<2>)

<1><2><4>

FCCID:CKENTG335−

FCCID:CKENTG335−

768B-NTG335<1>

Page 37

2-14

2.2.2.2. AP-RFU (Sectoral-Horn Antenna) Mounting Bracket

(in mm)

Figure 2-6 Mounting Bracket

Page 38

2-15

2.2.3. AP-IFU

(in mm)

Figure 2-7 External View of the AP-IFU

(a)

DA TE :

SE R. N O. :

T YP E W− AP < EL 0 >

Page 39

2-16

2.2.3.1. AP-IFU Nameplate

Nameplate(a)

(in mm)

Figure 2-8 Nameplate

<1>

Blank : non RoHS

R : RoHS

DATE :

SER.NO.:

INPUT: DC−38.4V−−57.6V 0.8A

TYPEW−AP<EL0>

MADE IN JAPAN

<1>

Page 40

2-17

2.2.4. WT

(in mm)

Figure 2-9 External View of the WT

60

TO P

V

TO P

H

E T H E R

I

N P

U T

:

S ER .

N

O :

M A C :

.

:

:

: : :

MA

D E I

N

J A P

A N

D

C 2

4V

0 .

7

A

T Y

P

E

W −

WT

< E

L

0

>

FC

C

ID

: C

K E

NT

G

33 7

−

E L

0

(a)

(b)

(c)

61 190

190

(d)

Page 41

2-18

2.2.4.1. WT Nameplate

Nameplate(a)

Nameplate(b)

Nameplate(c)

Nameplate(d)

Figure 2-10 Nameplate

INPUT :

SER.NO :

MAC :

.

: : : : :

MADE IN JAPAN

DC24V 0.7A

TYPEW−WT

FCCID:CKENTG337−

<1>

EL0 : 24.050〜24.549GHz

EL1 : 24.549〜24.997GHz

EL2 : 24.997〜25.445GHz

EH1 : 25.557〜26.005GHz

EH2 : 26.005〜26.453GHz

<3>

U : USA Type AC Plug

E : European Type AC Plug

<2>

L0 : 24.050〜24.549GHz

L1 : 24.549〜24.997GHz

L2 : 24.997〜25.445GHz

H1 : 25.557〜26.005GHz

H2 : 26.005〜26.453GHz

<4>

Blank : non RoHS

R : RoHS

<2><3><4>

<2><3><4>

768B

-

NTG337<2>

Page 42

2-19

2.2.4.2. WT Mounting Bracket

74

45

or less

64

75

°

or less

(in mm)

Figure 2-11 External View of the Outdoor Mounting Brackets for the WT

(240)

150 or more

61

Pole for installation

(Applicable outer diameter : Φ31.8mm to Φ34mm)

Mounting Bracket

(It is possible to install

it only on the point

part in the pole.)

Page 43

2-20

2.2.5. WT (External Antenna)

Figure 2-12 External View of the WT (External Antenna)

TO

P V

T

O

P H

ETH ER

I NP

U

T

:

S

ER

.

N

O

:

M

AC :

.

:

:

:

: :

MAD

E

IN

J

A PAN

Page 44

2-21

2.2.5.1. WT (External Antenna) Nameplate

Nameplate(a)

Nameplate(b)

Nameplate(c)

Figure 2-13 Nameplate

INPUT :

SER.NO :

MAC :

.

: : : : :

MADE IN JAPAN

DC24V 0.7A

TYPEW−WT

FCCID:CKENTG337−

<1>

EL0 : 24.050〜24.549GHz

EL2 : 24.997〜25.445GHz

<3>

U : USA Type AC Plug

E : European Type AC Plug

<5>

XL0 : 24.050〜24.549GHz

XL2 : 24.997〜25.445GHz

<2>

X0 : 24.050〜24.549GHz

X2 : 24.997〜25.445GHz

<4>

Blank : non RoHS

R : RoHS

<2><3><4>

-<5>

Page 45

2-22

WT ADAPTER

MODEL NQD−2049

2.2.6. WT Adapter

(in mm)

Figure 2-14 External View of the WT Adapter

2.2.6.1. WT Adapter Nameplate

(in mm)

Figure 2-15 Nameplate

MODEL NQD−2049

WT ADAPTER

<1>

<1>

Blank : non RoHS

R : RoHS

Page 46

2-23

2.2.7. WT AC Adapter

(in mm)

Figure 2-16 External View of the WT AC Adapter

2000

52

30

108

1710

H-7ZCCM0132 (A Type)

H-7ZCCM0135 (C Type)

Page 47

2-24

2.2.8. Antenna direction adjustment tool

(in mm)

Shape of the scope is subject to change without notice.

Figure 2-17 Antenna direction adjustment tool

Page 48

3-25

3. AP

3.1. AP-RFU

3.1.1. Overview

The AP-RFU consists of three blocks: Antenna section, RF section and IF section.

3.1.2. Antenna section

The omni-directional antenna (with horizontal directivity of 360°) and the Sectoral-Horn-type antenna

( 90° × 10° directivity) look the same.

3.1.3. RF section

In the RF section, the transmission IF signals are up-converted into 24-26 GHz-band RF signals using

the local signal, which is generated by multiplying the 2.4 GHz synthesized oscillator. The next-stage

BPF eliminates unwanted sideband components. The up-converted 24-26 GHz-band RF signals are

amplified up to the desired level then fed to the antenna via the TDD-Switch and the Waveguide Filter.

The received 24-26 GHz-band RF signals by the antenna are fed in to the LNA via the Waveguide Filter

and the TDD-Switch. The output signals of the LNA are down-converted into IF signals using the local

signal, which is generated by multiplying the 2.4 GHz synthesized oscillator. The BPF is employed to

eliminate the image components (interference).

The TDD Switch selects the transmitting or receiving function. Detection of the transmiting burst at the

IF section turns the switch to the transmiting side.

3.1.4. IF section

In the receiving IF section, the output level to the AP-IFU is adjusted by the automatic gain control (AGC)

function, so that the input level of the AP-IFU does not saturate for the reception of the WT signal which

gives highest receiving level. The SAW filter eliminates the adjacent channel interference.

In the transmitting IF section, the detection of the transmiting burst signal controls the TDD-Switch in the

RF section to turn it to the transmiting side. The SAW filter provides the signal delay for the period of the

burst detection and the TDD-Switch turning time, as well as the elimination of the non-desired signal

component.

The IF section also has the compensation functionality for cable losses between the AP-RFU and

AP-IFU.

Page 49

3-26

The CPU in the IF section performs the AGC, the cable loss compensation, and the monitoring and

control functionalities.

Figure 3-1is a block diagram of the AP-RFU.

toIFU

AP-RFU

WG

BPF

RF

SW

LNA

SW

2.4GHz

Synth

26G:×5

×n

×2

DOWNCONV

TRSEL(RF)

PA×2UPCONV

FREQCNT

IF部

HY B

AS K

MO DEM

Te mp

CN T

D/ A

D/ A

AGC

×2

1282 .5

MHz

AT PC

AG C

21 3.75

MHz

MA X H OL D/

AV ER A GI NG

A/ D

TRCNT

Variable[20dB]

Te mp

CN T

RF U

|

IF U

Co nt

Te mp Se ns

VARATT

[30dB]

CA BL E

LO SS

DC+16V

LOGAMP

TMG

Gen

TH

CNT

Ob sta cl e

in for ma tio n

TRSEL(RF)

FREQCNT[DATLCLK/LE]

427.5

MHz

IFF req

1710 MHz

Horn

Antenna(V/H)

or

Omni

Antenna(V/H)

×3

BPF

SAW

BPF

BP F

LOGAMP

SAWBPF

AGC2

RXLVL

CNT

AUTOON/OFF

AGC2

RFU-IF

RFUPS

Sergeprotection

Coaxal

CABLE

HYB

COMP

Figure 3-1 AP-RFU Block Diagram

3.1.5. Operations and Indications

The AP-RFU does not have any operation or indication panels.

3.1.5.1. Indications

The AP-RFU does not have any LEDs or other status indicators.

3.1.5.2. Switches

The AP-RFU does not have any switches.

Page 50

3-27

3.1.6. Terminals

3.1.6.1. Omni Antenna

(a) IF terminal connector

Contents Connect the AP-IFU with the coaxial cable.

Shape N-Type Jack for Coaxial

Applicable Connector N-Type Plug for Coaxial

Figure 3-2 Connecting Section of the AP-RFU (Omni Antenna)

3.1.6.2. Sectoral-Horn Antenna

(a) IF terminal connector

Contents Connect the AP-IFU with the coaxial cable.

Shape N-Type Jack for Coaxial

Applicable Connector N-Type Plug for Coaxial

Figure 3-3 Connecting Section of the AP-RFU (Sectoral-Horn Antenna)

TOP H

TOP V

(a)

IF terminal connector

TOP H

TOP V

(a)

IF terminal connector

Page 51

3-28

3.2. AP-IFU

3.2.1. Overview

AP-IFU consists of three blocks: IF section, digital section and interface section.

3.2.2. IF section

The transmission IF section performs quadrature modulation of 427.5MHz IF frequency according to the

transmission output from the digital modem installed in the WT-ASIC.

In the receiving IF section, the received burst signal level is adjusted by the automatic gain control (AGC)

function of the digital modem. The quadrature demodulator downconverts the received IF signal into the

baseband signal.

The digital section consists of a digital modem, TDD/TDMA framer, wireless MAC processor, and system

controller. These functionalities are equipped in the WT-ASIC.

The digital modem performs modulation and demodulation of transmitting and receiving burst signals.

The interface section has an interface between the AP and the upper unit (100BASE-TX).

The digital section consists of the wireless MAC processor, TDD/TDMA controller, modem and system

controller. The wireless MAC processor converts between the Ethernet frames that the interface section

handles and wireless MAC frames. It also schedules the dynamic slot assignment. The TDD/TDMA

controller performs scrambling, encryption, error correction and other processing. The system controller

performs operating parameter setting, state monitoring, control and testing for the modem, TDD/TDMA

processor, wireless MAC processor and network interface. It also sends and receives maintenance

signals via SNMP. It performs delay control, authentication and other procedures, operating parameter

setting, state monitoring, control and testing for the subordinate WTs over a DMF channel.

The transmission IF section in the IF section performs quadrature modulation for the transmission

baseband signals at 427.5MHz LOC frequency for upconversion to IF signals. It also controls the output

level to the desired level based on the control from the ASIC. The receive IF section equalizes the level of

the reception waves arriving in a wide level range using the automatic gain control (AGC) from the ASIC,

and then downconverts them into baseband signals.

Figure 3-4 is a block diagram of the AP-IFU.

Page 52

3-29

+5 V

Regulator

0/9 0

HYB

×2

0/0

BAL

UNB

LC B PF

213.7 5M Hz

LC L PF

+5 .0

LC B PF

+5 .0

LC L PF

digit al

ATT

[15dB]

UNB

BAL

-3 .3 V

+3 .3 MO D

+3 .3 DE M

+5 V

+16V

+1 6V

to RFU

Regulator

Regulator

0/0

0/9 0

AS K

MODEM

Interfacepart

PHYRST

(FROMAP-ASIC)

L2SWRST

(FROMAP-ASIC)

TRANS

LAYER2

SW

RJ-45

RJ-45

TRANS

PHY

TRANS TRANS

25 MH z

RS-232 C

driver/receiver

4pi n

MO JURA

MAC

TDD

AP-AS IC

Digitalpart

U-CPU

15 .6 25

MH z

Reset

IC

TMP

SENS

20 MH z

LVL CN TT /R

+16V(R FU)

+3.3V( forAP/MODEM-ASIC,IF )

+2.5V( forAP-ASIC)

+1.8V( forU-CPU,D-CPU,L2SW )

+1.5V( forMODEM-ASIC)

+5V(fo rANALOG⇒3.3V)

CABLELOSSATT(ATT)

AP-IFU

+2 .5 V

+3 .3 V

+1 .8 V

+3 .3 V

MOD

DEM

MODEM

ASIC

S- CPU

RT C

FR OM

64 M

se ri al

EE PR OM

32 ×8

SD RA M

8M ×1 6

D-CPU

FR OM

16 M

SD RAM

8M ×1 6

FR OM

16 M

SD RA M

8M ×1 6

27 .8 3M Hz

TX

RX

D-FIF O

D-FIF O

EDC

2. 5M Hz

SRST

[FROM AP-ASI C]

DRST

[FROM AP-ASI C]

URST

[FROM AP-ASI C]

MODEM- ASICR ST

(FROM S-CPU)

+1 .8 V

+5 V

Regulator

+3.3A SIC

ANALOG

+1 .5 V

TDDSELECT

IFU-MAC

(toPC)

DC-48 V

Pow

supply

conn.

Power

supply

connec tor

100 BA SE -

TX

Pow

supply

conn.

IFpart

SW

MOD I/ Q

(BA L)

DEM I/ Q

(UN BAL )

to RF U

Sergeprotection

Sergeprotection

Sergeprotection

IFU-PS

Coa xa l

CAB LE

Figure 3-4 AP-IFU Block Diagram

Page 53

3-30

3.2.3. Operations and Indications

3.2.3.1. Indications

Figure 3-5 AP-IFU Operation and Indication Panel

Table 3-1 AP-IFU Indications

LED State indication

a POWER Lit green: Power on

Extinguished: Power off

b ETHER 1 Lit green: ETHER link established

Flashing green: ETHER signal sent or received

Extinguished: ETHER link down (See Table 3-3, 4)

c ETHER 2 Lit green: ETHER link established

Flashing green: ETHER signal sent or received

Extinguished: ETHER link down (See Table 3-3, 5)

d IFU STATE Lit red: IFU alarm (See Table 3-3, 2)

Flashing green: Normal (CPU running)

Flashing orange: During initialization

e RFU ALARM Lit red: RFU alarm (Cause: RFU failure (See Table 3-3, 1) or

communication error between the IFU and RFU (See Table 3-3, 3))

Extinguished: RFU alarm cleared

f ETHER1 AUTO Lit green: AUTO (ETHER1 AUTO switch set to AUTO)

Extinguished: 100BASE full duplex

g ETHER2 AUTO Lit green: AUTO

Extinguished: 100BASE full duplex

h RST Unit reset switch

制御盤LED部拡大図

26G-2-AP-PWR

26G-2-AP-CNT

POWER

ETHER

1

ETHER

2

IFU

STATE

RFU

ALARM

AUTO

100

FULL

AUTO

100

FULL

ETHER1AUTO ETHER2AUTO

① ② ③ ④ ⑤ ⑥ ⑦

⑧

b

c d e f g a h

Page 54

3-31

Table 3-2 AP-IFU Controls

Switch Description

1 ETHER1 AUTO

Sets the ETHER1 interface (100BASE full duplex/AUTO).

After changing the switch setting, you have to reboot the unit (power off

and back on) to enable the new setting.

AUTO: AUTO

100FULL: 100BASE full duplex (factory setting)

2 ETHER2 AUTO

Sets the ETHER2 interface (100BASE full duplex/AUTO).

After changing the switch setting, you have to reboot the unit (power off

and back on) to enable the new setting.

AUTO: AUTO

100FULL: 100BASE full duplex (factory setting)

Table 3-3 Alarm Issuance and Clear Conditions

Item Initial state Issued when: Cleared when:

The RFU-CPU detects LOCALM

or TRSELALM three times each

for more than 10msec.

The RFU-CPU detects

no LOCALM or

TRSELALM three

times each for more

than 10msec.

LOCALM (local oscillator alarm)

occurs if the local oscillator lost

synchronization.

Synchronization is

recovered.

TRSELALM

(transmission/reception

switchover SW failure) occurs if

the transmission state continues

for more than 1sec.

Only by a reset.

1 RFU failure Cleared

IFU-CPU detects a RFU-IFU

communication error (monitoring

response).

IFU-CPU is cleared by

a single RFU-IFU

communication

(monitoring response).

Communication error among the

S-CPU, D-CPU and U-CPU.

No response to polling for 3sec

Cleared by a single

response.

2 IFU failure

Cleared

L2SW setting failure

If setting failed four times (once

for transmission and 3 times for

retransmission)

No recovery

3 Communication

error between

RFU and IFU

Cleared The S-CPU detects a

S-RFU-CPU communication

error.

No response to polling four

times (once for transmission

and 3 times for retransmission)

Cleared by a single

response.

4 ETHER 1 link

down

Issued PHY link down 3 times each for

100msec.

Recovered from PHY

link down 3 times each

for 100msec.

5 ETHER 2 link

down

Issued PHY link down 3 times each for

100msec.

Recovered from PHY

link down 3 times each

for 100msec.

Page 55

3-32

3.2.3.2. Switches

Figure 3-6 Switches on the AP-IFU

(a) Power switch

This is the switch to supply power to the AP-IFU and AP-RFU.

(b) ETHER1/ETHER2 switch

This is the switch to set AUTO or 100FULL.

(The shape of the switch may be changed.)

(c) RST switch

This is the switch to reset the unit.

(d) POWER LED

When on : Lit green

When off: Extinguished

① ② ③

④

a b c d

Factory setting: 100FULL

ETHER AUTO LED

AUTO: Lit green

100FULL: Extinguished

100

FULL

AUTO

ETHER1AUTO

ONOFF

・After changing the switch setting, you have to reboot the unit (power off and back on) to

enable the new setting.

Page 56

3-33

3.2.3.3. Terminals

Figure 3-7 Connecting Section of the AP-IFU (Open View)

Figure 3-8 Connecting Section of the AP-IFU (Bottom View)

Figure 3-9 (a),(b)Ethernet connector Figure 3-10 (c)MNT connector Figure 3-11 (f)Power cable connector

1 2

3

87654321

4321

1

2

3

4

TXD

RXD

NU

GND

1

2

3

GND

DC-48V

NU

1

2

3

4

5

6

7

8

TXD+

TXDRXD+

RXD-

GND

NU

NU

NU

e d f

g

SER.N O.

INPUT :

DATE :

MADE IN JA PAN

TYPEW− AP<EL0>

DC−48V 0.8A

a

b

c

Page 57

3-34

(a) ETHER1 connector

Connect the outside network Contents

The user signal distributed by internal SW-HUB,and output to ETHER1 and

ETHER2. ETHER1 is used usually.

Interface 100BASE-Tx

Connector shape RJ-45

Pin assign See Figure 3-9

(b) ETHER2 connector

Connect the outside network Contents

The user signal distributed by internal SW-HUB,and output to ETHER1 and

ETHER2. ETHER1 is used usually.

Interface 100BASE-Tx

Shape RJ-45