JRC JMA-9132-SA, JMA-9123-9XA, JMA-9122-6XA, JMA-9122-6XAH, JMA-9110-6XAH Installation Manual

...Page 1

JMA-9133-SAJMA-9133-SA

JMA-9132-SAJMA-9132-SA

JMA-9123-7XA/9XAJMA-9123-7XA/9XA

JMA-9122-6XA/9XA/6XAHJMA-9122-6XA/9XA/6XAH

JMA-9110-6XA/6XAHJMA-9110-6XA/6XAH

JMA-7133-SAJMA-7133-SA

JMA-7132-SAJMA-7132-SA

JMA-7123-7XA/9XAJMA-7123-7XA/9XA

JMA-7122-6XA/9XA/6XAHJMA-7122-6XA/9XA/6XAH

JMA-7110-6XA/6XAHJMA-7110-6XA/6XAH

MARINE RADARMARINE RADAR

EQUIPMENTEQUIPMENT

INSTALLATIONINSTALLATION

MANUALMANUAL

Page 2

Page 3

Index

Cross Reference

JMA-9133-SA ...........................................................................................................i

JMA-9132-SA ..........................................................................................................ii

JMA-9123-7XA/9XA ...............................................................................................iii

JMA-9122-6XA/9XA ...............................................................................................iv

JMA-9122-6XAH .....................................................................................................v

JMA-9110-6XA/6XAH ............................................................................................vi

JMA-7133-SA ........................................................................................................vii

JMA-7132-SA .......................................................................................................viii

JMA-7123-7XA9XA ................................................................................................ix

JMA-7122-6XA/9XA ................................................................................................x

JMA-7122-6XAH ....................................................................................................xi

JMA-7110-6XA/6XAH ...........................................................................................xii

SECTION 1

EQUIPMENT COMPOSITION

1.1 GENERAL COMPOSITION ....................................................................1-1

1.1.1 JMA-9100 SERIES RADAR ....................................................................... 1-1

1.1.2 JMA-7100 SERIES RADAR ....................................................................... 1-2

1.2 LIST OF CIRCUITS ................................................................................1-4

1.2.1 JMA-9100 SERIES RADAR ....................................................................... 1-4

1.2.2 JMA-7100 SERIES RADAR ..................................................................... 1-11

SECTION 2

INSTALLATION OF SCANNER UNIT

2.1 EQUIPMENT CABLE .............................................................................2-1

2.1.1 CFQ-6912-** ...............................................................................................2-1

2.1.2 2695110056 ................................................................................................2-2

2.1.3 2695111153 ................................................................................................2-3

2.1.4 Cable end processing method .................................................................2-4

2.1.5 Connection to the display-unit side terminal block ............................... 2-7

2.2 INSTALLATION OF SCANNER UNIT ....................................................2-8

2.2.1 NKE-2103 type scanner ............................................................................ 2-8

2.2.2 NKE-2254 type scanner .......................................................................... 2-11

2.2.3 NKE-1125 type scanner .......................................................................... 2-13

2.2.4 NKE-1129 type scanner .......................................................................... 2-15

2.2.5 NKE-1130 type scanner .......................................................................... 2-17

2.2.6 NKE-1139 type scanner .......................................................................... 2-19

2.3 INSTALLATION OF TRANSMITTER RECEIVER UNIT ......................2-21

2.3.1 NTG-3225 type transmitter receiver ......................................................2-21

2.3.2 NTG-3230 type transmitter receiver ......................................................2-24

2.4 PRECAUTIONS ....................................................................................2-26

2.4.1 Installation of scanner unit .................................................................... 2-26

2.4.2 Routing coaxial cable and flexible waveguide ..................................... 2-29

2.4.3 Scanner installation position .................................................................2-31

Page 4

2.4.4 Confirmation during test run .................................................................2-35

2.4.5 Others .......................................................................................................2-35

SECTION 3

INSTALLATION OF DISPLAY UNIT

3.1 INSTALLATION OF DISPLAY UNIT ......................................................3-1

3.1.1 Exterior Drawing of NCD-4990 .................................................................3-2

3.1.2 Exterior drawing of NCD-4990T ............................................................... 3-3

3.1.3 Exterior drawing of NCD-4790 ................................................................. 3-6

3.1.4 Exterior drawing of NCD-4790T ............................................................... 3-7

3.2 INSTALLATION OF AC-DC CONVERTER NBA-5135 ........................3-10

3.2.1 NBA-5135 Packing List ........................................................................... 3-10

3.2.2 Exterior drawing of NBA-5135 ............................................................... 3-12

3.2.3 NCD-4990 .................................................................................................3-13

3.2.4 NCD-4990T ...............................................................................................3-17

3.2.5 NCD-4790 .................................................................................................3-18

3.2.6 NCD-4790T ...............................................................................................3-20

3.3 CONNECTIONS WITH SCANNER AND TRANSCEIVER ...................3-21

3.3.1 Connections with NKE-1125,NTG-3225,NKE-1130,NTG-3230 ............. 3-21

3.3.2 Connections with NKE-2103,NKE-2254 ................................................. 3-22

3.4 CONNECTION WITH GPS ...................................................................3-24

3.5 CONNECTIONS WITH VESSEL SPEED UNIT (2-AXIS LOG) ............3-26

3.6 CONNECTIONS WITH GYRO AND ELECTROMAGNETIC LOG ......3-27

3.7 CONNECTION WITH GYRO (IEC61162-1/2) .......................................3-29

3.8 CONNECTIONS WITH AIS ..................................................................3-31

3.9 CONNECTIONS WITH ECDIS .............................................................3-33

3.9.1 Transmission Port Setting (TX Port) ..................................................... 3-34

3.10 CONNECTION WITH ALARM MONITORING SYSTEM .....................3-36

3.11 EXAMPLE OF WIRING IN THE DEVICE .............................................3-38

3.12 DISPLAY UNIT LEDS FOR VARIOUS SIGNALS ................................3-39

3.12.1 Serial Signal ............................................................................................. 3-40

3.12.2 Power supply status ............................................................................... 3-41

3.12.3 Alarm Signal ........................................................................................... 3-42

3.12.4 Fan Alarm ................................................................................................. 3-43

SECTION 4

INITIAL SETTING

4.1 GYRO INTERFACE SETTING ...............................................................4-2

4.1.1 GYRO INPUT SETTING (STEP/SYNC setting) ......................................... 4-2

4.1.2 NMEA Input setting ...................................................................................4-5

4.2 TUNE ADJUSTMENT .............................................................................4-7

4.3 BEARING ADJUSTMENT ......................................................................4-8

4.4 RANGE ADJUSTMENT ..........................................................................4-9

4.5 NAVIGATOR SETTING ........................................................................4-10

4.6 TRUE BEARING SETTING ..................................................................4-11

4.7 ANTENNA HEIGHT SETTING .............................................................4-12

Page 5

4.8 CCRP SETTING ...................................................................................4-13

4.9 MAIN BANG SUPPRESSION SETTING ..............................................4-14

4.10 PERFORMANCE MONITOR SETTING ...............................................4-16

4.11 DATE/TIME DISPLAY SETTING ..........................................................4-18

4.12 INITIALIZATION OF SCANNER OPERATION TIME ...........................4-20

SECTION 5

OPTION UNIT

5.1 INSTALLATION OF INTERSWITCH UNIT ............................................5-1

5.1.1 Equipment cable end processing ............................................................5-1

5.1.2 Plug terminal block connection procedures .......................................... 5-2

5.1.3 Installation of interswitch unit ................................................................. 5-3

5.1.4 Setting ........................................................................................................ 5-7

5.1.5 Confirmation after installation ...............................................................5-11

5.1.6 Inter-board connection diagram ............................................................5-12

5.2 INSTALLATION OF POWER CONTROL UNIT ...................................5-14

5.2.1 Connection with NKE-2103 type and NKE-2254-6HS type scanners ..5-14

5.2.2 Connections to NKE-1125, NTG-3225, NKE-1130, and NTG-3230 ......5-16

5.2.3 Equipment cable end processing ..........................................................5-16

5.2.4 End processing of each cable core .......................................................5-16

5.2.5 Connection to display unit .....................................................................5-16

5.2.6 General system diagram of power control unit (JMA-7100) ..............5-18

5.2.7 General system diagram of power control unit (JMA-9100) ..............5-36

5.2.8 Inter-board connection diagram of power control unit ....................... 5-54

5.2.9 Exterior drawing of Power Control Unit ................................................5-60

5.3 INSTALLATION OF VDR .....................................................................5-62

5.3.1 Connections ............................................................................................ 5-62

5.3.2 VDR I/F kit ................................................................................................ 5-63

5.4 INSTALLATION OF SUB-OPERATION UNIT AND EXPANSION OF

TRACKBALL 5-64

5.4.1 Sub Operation Unit ................................................................................. 5-64

5.4.2 Expansion of trackball ............................................................................ 5-65

SECTION 6

Appendix

6.1 EXTERIOR DRAWING ...........................................................................6-1

6.1.1 NKE-1139 ...................................................................................................6-1

6.1.2 NTG-3230 .................................................................................................. 6-3

6.1.3 NKE-1130 .................................................................................................. 6-4

6.1.4 NKE-1129-7 ................................................................................................6-5

6.1.5 NKE-1129-9 ................................................................................................6-6

6.1.6 NTG-3225 ...................................................................................................6-7

6.1.7 NKE-1125-6 ................................................................................................6-8

6.1.8 NKE-1125-9 ................................................................................................6-9

6.1.9 NKE-2254-6HS .........................................................................................6-10

6.1.10 NKE-2103-6/NKE-2103-6HS ....................................................................6-11

6.1.11 NCD-4990 .................................................................................................6-12

6.1.12 NDC-1399-9 ..............................................................................................6-13

6.1.13 NCE-5163 .................................................................................................6-14

6.1.14 NWZ-170 ................................................................................................... 6-15

6.1.15 NCD-4790 .................................................................................................6-16

6.1.16 NDC-1399-7 ..............................................................................................6-17

6.1.17 NCE-5163 .................................................................................................6-18

Page 6

6.1.18 NWZ-173 ..................................................................................................6-19

6.2 GENERAL SYSTEM DIAGRAM ...........................................................6-20

6.2.1 General system diagram of JMA-7100 (Self-standing type) ................ 6-20

6.2.1.1 General system diagram of JMA-7132-SA (Self-standing)................... 6-21

6.2.1.2 General system diagram of JMA-7133-SA (Self-standing).................. 6-22

6.2.1.3 General system diagram of JMA-7122-6XA (Self-standing)................. 6-23

6.2.1.4 General system diagram of JMA-7122-9XA (Self-standing)................. 6-24

6.2.1.5 General system diagram of JMA-7122-6XAH (Self-standing) .............. 6-25

6.2.1.6 General system diagram of JMA-7123-7XA (Self-standing)................. 6-26

6.2.1.7 General system diagram of JMA-7123-9XA (Self-standing)................. 6-27

6.2.1.8 General system diagram of JMA-7110-6XA (Self-standing)................. 6-28

6.2.1.9 General system diagram of JMA-7110-6XAH (Self-standing) .............. 6-29

6.2.2 General system diagram of JMA-7100 (Desktop type) ........................ 6-30

6.2.2.1 General system diagram of JMA-7132-SA (Desktop) ..........................6-31

6.2.2.2 General system diagram of JMA-7133-SA (Desktop) ..........................6-32

6.2.2.3 General system diagram of JMA-7122-6XA (Desktop) ........................6-33

6.2.2.4 General system diagram of JMA-7122-9XA (Desktop) ........................6-34

6.2.2.5 General system diagram of JMA-7122-6XAH (Desktop)...................... 6-35

6.2.2.6 General system diagram of JMA-7123-7XA (Desktop) ........................6-36

6.2.2.7 General system diagram of JMA-7123-9XA (Desktop) ........................6-37

6.2.2.8 General system diagram of JMA-7110-6XA (Desktop) ........................6-38

6.2.2.9 General system diagram of JMA-7110-6XAH (Desktop)...................... 6-39

6.2.3 General system diagram of JMA-9100 (Self-standing type) ................ 6-40

6.2.3.1 General system diagram of JMA-9132-SA (Self-standing) ................... 6-41

6.2.3.2 General system diagram of JMA-9133-SA (Self-standing)................... 6-42

6.2.3.3 General system diagram of JMA-9122-6XA (Self-standing)................. 6-43

6.2.3.4 General system diagram of JMA-9122-9XA (Self-standing)................. 6-44

6.2.3.5 General system diagram of JMA-9122-6XAH (Self-standing) .............. 6-45

6.2.3.6 General system diagram of JMA-9123-7XA (Self-standing)................. 6-46

6.2.3.7 General system diagram of JMA-9123-9XA (Self-standing)................. 6-47

6.2.3.8 General system diagram of JMA-9110-6XA (Self-standing)................. 6-48

6.2.3.9 General system diagram of JMA-9110-6XAH (Self-standing) .............. 6-49

6.2.4 General system diagram of JMA-9100 (Desktop type) ........................ 6-50

6.2.4.1 General system diagram of JMA-9132-SA (Desktop) .........................6-51

6.2.4.2 General system diagram of JMA-9133-SA (Desktop) ..........................6-52

6.2.4.3 General system diagram of JMA-9122-6XA (Desktop) ........................6-53

6.2.4.4 General system diagram of JMA-9122-9XA (Desktop) ........................6-54

6.2.4.5 General system diagram of JMA-9122-6XAH (Desktop)...................... 6-55

6.2.4.6 General system diagram of JMA-9123-7XA (Desktop) ........................6-56

6.2.4.7 General system diagram of JMA-9123-9XA (Desktop) ........................6-57

6.2.4.8 General system diagram of JMA-9110-6XA (Desktop) ........................6-58

6.2.4.9 General system diagram of JMA-9110-6XAH (Desktop)...................... 6-59

6.3 INTER-BOARD CONNECTION DIAGRAM ..........................................6-60

6.3.1 Inter-board connection diagram of JMA-7100 ...................................... 6-60

6.3.1.1 Inter-board connection diagram of JMA-7132-SA ................................ 6-61

6.3.1.2 Inter-board connection diagram of JMA-7133-SA ................................ 6-62

6.3.1.3 Inter-board connection diagram of JMA-7122-6XA/9XA ...................... 6-63

6.3.1.4 Inter-board connection diagram of JMA-7122-6XAH............................ 6-64

6.3.1.5 Inter-board connection diagram of JMA-7122-6XAH(Desktop) ............ 6-65

6.3.1.6 Inter-board connection diagram of JMA-7123-7XA/9XA ......................6-66

6.3.1.7 Inter-board connection diagram of JMA-7110-6XA/6XAH....................6-67

6.3.1.8 Inter-board connection diagram of JMA-7110-6XA/6XAH(Desktop) .... 6-68

6.3.1.9 Inter-unit connection diagram of NCD-4790T....................................... 6-69

Page 7

6.3.2 Inter-board connection diagram of JMA-9100 ...................................... 6-70

6.3.2.1 Inter-board connection diagram of JMA-9132-SA ................................. 6-71

6.3.2.2 Inter-board connection diagram of JMA-9133-SA ................................ 6-72

6.3.2.3 Inter-board connection diagram of JMA-9122-6XA/9XA ...................... 6-73

6.3.2.4 Inter-board connection diagram of JMA-9122-6XAH............................ 6-74

6.3.2.5 Inter-board connection diagram of JMA-9122-6XAH (Desktop) ........... 6-75

6.3.2.6 Inter-board connection diagram of JMA-9123-7XA/9XA ...................... 6-76

6.3.2.7 Inter-board connection diagram of JMA-9110-6XA/6XAH....................6-77

6.3.2.8 Inter-board connection diagram of JMA-9110-6XA/6XAH (Desktop) ... 6-78

6.3.2.9 Inter-unit connection diagram of NCD-4990T......................................6-79

6.4 SCANNER UNIT INTERCONNECTION ...............................................6-80

6.4.1 NKE-2103 ................................................................................................ 6-81

6.4.2 NKE-2254 ................................................................................................ 6-82

6.4.3 NKE-1125 (AC110V) ................................................................................ 6-83

6.4.4 NKE-1125 (AC220V) ................................................................................ 6-84

6.4.5 NKE-1129 (AC110V) ................................................................................ 6-85

6.4.6 NKE-1129 (AC220V) ................................................................................ 6-86

6.4.7 NTG-3225 .................................................................................................6-87

6.4.8 NKE-1130 (AC110V) ................................................................................ 6-88

6.4.9 NKE-1130 (AC220V) ................................................................................ 6-89

6.4.10 NKE-1139 (AC110V) ................................................................................ 6-90

6.4.11 NKE-1139 (AC220V) ................................................................................ 6-91

6.4.12 NTG-3230 .................................................................................................6-92

Page 8

Page 9

Cross Reference

Cross Reference

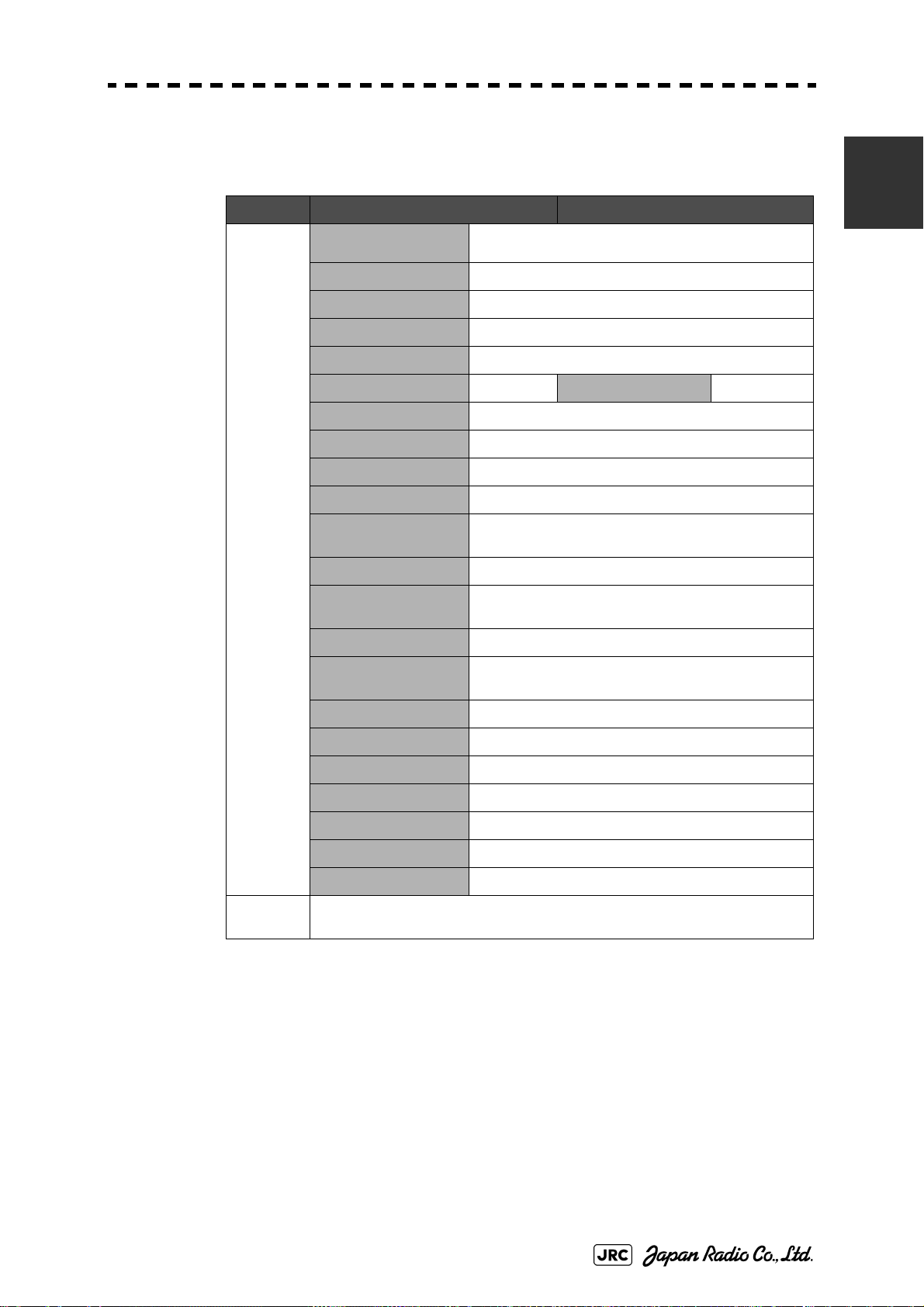

JMA-9133-SA

Tab le 1- 1: JMA-9100 SERIES RADAR LIST OF COMPOSITION (Self-Standing TYPE)

Tab le 1- 2: JMA-9100 SERIES RADAR LIST OF COMPOSITION (Desktop TYPE)

Scanner Unit: NKE-1139

Table1-5: JMA-9133-SA SCANNER and TRANSMITTER RECEIVER UNIT

2.1.2 2695110056

2.2.6 NKE-1139 type scanner

2.4 PRECAUTIONS

Transmiter Receiver Unit: NTG-3230

2.3.2 NTG-3230 type transmitter receiver

Display Unit (self standing): NCD-4990

Table1-11: NCD-4990/NCD-4990T DISPLAY UNIT

3.1 INSTALLATION OF DISPLAY UNIT

3.3.1 Connections with NKE-1125,NTG-3225,NKE-1130,NTG-3230

OPTION Interswitch Unit: NQE-3141-2/4A/8A

5.1 INSTALLATION OF INTERSWITCH UNIT

Power Control Unit: NQE-3167

5.2.2 Connections to NKE-1125, NTG-3225, NKE-1130, and NTG-

3230

5.2.5 Connection to display unit

VDR I/F Kit: CQD-1891

5.3 INSTALLATION OF VDR

i

Page 10

JMA-9132-SA

Tab le 1- 1: JMA-9100 SERIES RADAR LIST OF COMPOSITION (Self-Standing TYPE)

Tab le 1- 2: JMA-9100 SERIES RADAR LIST OF COMPOSITION (Desktop TYPE)

Scanner Unit: NKE-1130

Table1-6: JMA-9132-SA SCANNER UNIT

2.1.2 2695110056

2.2.5 NKE-1130 type scanner

2.4 PRECAUTIONS

Display Unit (self standing): NCD-4990

Table1-11: NCD-4990/NCD-4990T DISPLAY UNIT

3.1 INSTALLATION OF DISPLAY UNIT

3.3.1 Connections with NKE-1125,NTG-3225,NKE-1130,NTG-3230

OPTION Interswitch Unit: NQE-3141-2/4A/8A

5.1 INSTALLATION OF INTERSWITCH UNIT

Power Control Unit: NQE-3167

5.2.2 Connections to NKE-1125, NTG-3225, NKE-1130, and NTG-

3230

5.2.5 Connection to display unit

VDR I/F Kit: CQD-1891

5.3 INSTALLATION OF VDR

Page 11

Cross Reference

JMA-9123-7XA/9XA

Tab le 1- 1: JMA-9100 SERIES RADAR LIST OF COMPOSITION (Self-Standing TYPE)

Tab le 1- 2: JMA-9100 SERIES RADAR LIST OF COMPOSITION (Desktop TYPE)

Scanner Unit: NKE-1129

Table1-7: JMA-9123-7XA/JMA-9123-9XA SCANNER and TRANSMITTER-RECEIVER

UNIT

2.1.2 2695110056

2.2.4 NKE-1129 type scanner

2.4 PRECAUTIONS

Transmiter Receiver Unit: NTG-3225

2.3.1 NTG-3225 type transmitter receiver

Display Unit (self standing): NCD-4990

Table1-11: NCD-4990/NCD-4990T DISPLAY UNIT

3.1 INSTALLATION OF DISPLAY UNIT

3.3.1 Connections with NKE-1125,NTG-3225,NKE-1130,NTG-3230

OPTION Interswitch Unit: NQE-3141-2/4A/8A

5.1 INSTALLATION OF INTERSWITCH UNIT

Power Control Unit: NQE-3167

5.2.2 Connections to NKE-1125, NTG-3225, NKE-1130, and NTG-

3230

5.2.5 Connection to display unit

VDR I/F Kit: CQD-1891

5.3 INSTALLATION OF VDR

iii

Page 12

JMA-9122-6XA/9XA

Tab le 1- 1: JMA-9100 SERIES RADAR LIST OF COMPOSITION (Self-Standing TYPE)

Tab le 1- 2: JMA-9100 SERIES RADAR LIST OF COMPOSITION (Desktop TYPE)

Scanner Unit: NKE-1125

Table1-8: JMA-9122-6XA/JMA-9122-9XA SCANNER UNIT

2.1.2 2695110056

2.2.3 NKE-1125 type scanner

2.4 PRECAUTIONS

Display Unit (self standing): NCD-4990

Table1-11: NCD-4990/NCD-4990T DISPLAY UNIT

3.1 INSTALLATION OF DISPLAY UNIT

3.3.1 Connections with NKE-1125,NTG-3225,NKE-1130,NTG-3230

OPTION Interswitch Unit: NQE-3141-2/4A/8A

5.1 INSTALLATION OF INTERSWITCH UNIT

Power Control Unit: NQE-3167

5.2.2 Connections to NKE-1125, NTG-3225, NKE-1130, and NTG-

3230

5.2.5 Connection to display unit

VDR I/F Kit: CQD-1891

5.3 INSTALLATION OF VDR

iv

Page 13

Cross Reference

JMA-9122-6XAH

Tab le 1- 1: JMA-9100 SERIES RADAR LIST OF COMPOSITION (Self-Standing TYPE)

Tab le 1- 2: JMA-9100 SERIES RADAR LIST OF COMPOSITION (Desktop TYPE)

Scanner Unit: NKE-2254-6HS

Table1-9: JMA-9122-6XAH SCANNER UNIT

2.1.1 CFQ-6912-**

2.2.2 NKE-2254 type scanner

2.4 PRECAUTIONS

Display Unit (self standing): NCD-4990

Table1-11: NCD-4990/NCD-4990T DISPLAY UNIT

3.1 INSTALLATION OF DISPLAY UNIT

3.2 INSTALLATION OF AC-DC CONVERTER NBA-5135

3.3.2 Connections with NKE-2103,NKE-2254

OPTION Interswitch Unit: NQE-3141-2/4A/8A

5.1 INSTALLATION OF INTERSWITCH UNIT

Power Control Unit: NQE-3167

5.2.1 Connection with NKE-2103 type and NKE-2254-6HS type

scanners

5.2.5 Connection to display unit

VDR I/F Kit: CQD-1891

5.3 INSTALLATION OF VDR

v

Page 14

JMA-9110-6XA/6XAH

Tab le 1- 1: JMA-9100 SERIES RADAR LIST OF COMPOSITION (Self-Standing TYPE)

Tab le 1- 2: JMA-9100 SERIES RADAR LIST OF COMPOSITION (Desktop TYPE)

Scanner Unit: NKE-2103

Table1-10: JMA-9110-6XA/JMA-9110-6XAH SCANNER UNIT

2.1.1 CFQ-6912-**

2.2.1 NKE-2103 type scanner

2.4 PRECAUTIONS

Display Unit (self standing): NCD-4990

Table1-11: NCD-4990/NCD-4990T DISPLAY UNIT

3.1 INSTALLATION OF DISPLAY UNIT

3.2 INSTALLATION OF AC-DC CONVERTER NBA-5135

5.2.1 Connection with NKE-2103 type and NKE-2254-6HS type scanners

OPTION Interswitch Unit: NQE-3141-2/4A/8A

5.1 INSTALLATION OF INTERSWITCH UNIT

Power Control Unit: NQE-3167

5.2.1 Connection with NKE-2103 type and NKE-2254-6HS type

scanners

5.2.5 Connection to display unit

VDR I/F Kit: CQD-1891

5.3 INSTALLATION OF VDR

vi

Page 15

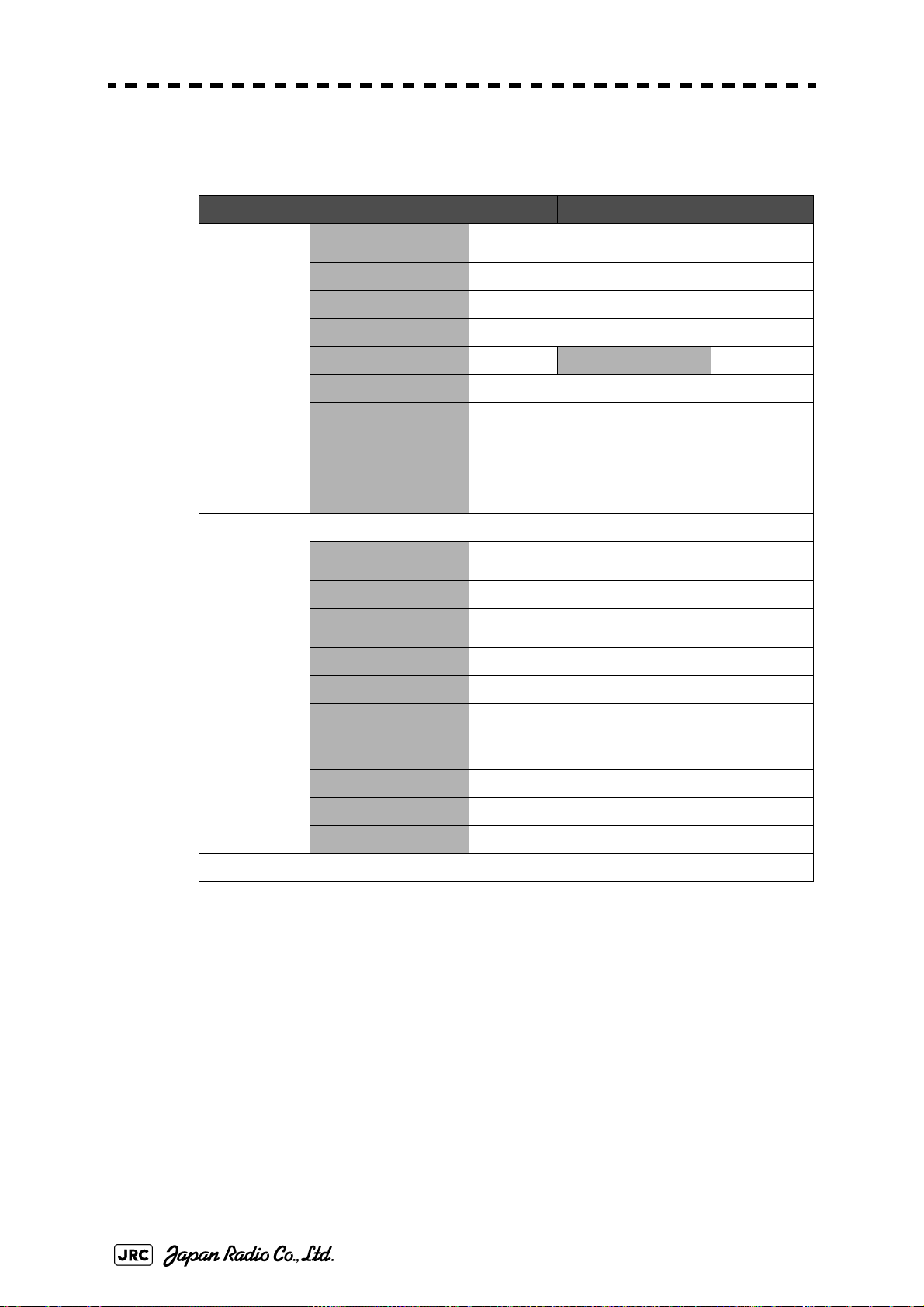

Cross Reference

JMA-7133-SA

Tab le 1- 3: JMA-7100 SERIES RADAR LIST OF COMPOSITION (Self-Standing TYPE)

Tab le 1- 4: JMA-7100 SERIES RADAR LIST OF COMPOSITION (Desktop TYPE)

Scanner Unit: NKE-1139

Table1-12: JMA-7133-SASCANNER and TRANSMITTER RECEIVER UNIT

2.1.2 2695110056

2.2.6 NKE-1139 type scanner

2.4 PRECAUTIONS

Transmiter Receiver Unit: NTG-3230

2.3.2 NTG-3230 type transmitter receiver

Display Unit (self standing): NCD-4790

Table1-18: NCD-4790/NCD-4790T DISPLAY UNIT

3.1 INSTALLATION OF DISPLAY UNIT

3.3.1 Connections with NKE-1125,NTG-3225,NKE-1130,NTG-3230

OPTION Interswitch Unit: NQE-3141-2/4A/8A

5.1 INSTALLATION OF INTERSWITCH UNIT

Power Control Unit: NQE-3167

5.2.2 Connections to NKE-1125, NTG-3225, NKE-1130, and NTG-

3230

5.2.5 Connection to display unit

VDR I/F Kit: CQD-1891

5.3 INSTALLATION OF VDR

vii

Page 16

JMA-7132-SA

Tab le 1- 3: JMA-7100 SERIES RADAR LIST OF COMPOSITION (Self-Standing TYPE)

Tab le 1- 4: JMA-7100 SERIES RADAR LIST OF COMPOSITION (Desktop TYPE)

Scanner Unit: NKE-1139

Table1-13: JMA-7132-SA SCANNER UNIT

2.1.2 2695110056

2.2.5 NKE-1130 type scanner

2.4 PRECAUTIONS

Display Unit (self standing): NCD-4790

Table1-18: NCD-4790/NCD-4790T DISPLAY UNIT

3.1 INSTALLATION OF DISPLAY UNIT

3.3.1 Connections with NKE-1125,NTG-3225,NKE-1130,NTG-3230

OPTION Interswitch Unit: NQE-3141-2/4A/8A

5.1 INSTALLATION OF INTERSWITCH UNIT

Power Control Unit: NQE-3167

5.2.2 Connections to NKE-1125, NTG-3225, NKE-1130, and NTG-

3230

5.2.5 Connection to display unit

VDR I/F Kit: CQD-1891

5.3 INSTALLATION OF VDR

viii

Page 17

Cross Reference

JMA-7123-7XA9XA

Tab le 1- 3: JMA-7100 SERIES RADAR LIST OF COMPOSITION (Self-Standing TYPE)

Tab le 1- 4: JMA-7100 SERIES RADAR LIST OF COMPOSITION (Desktop TYPE)

Scanner Unit: NKE-1139

Table1-14: JMA-7123-7XA/JMA-7123-9XASCANNER and TRANSMITTER RECEIVER

UNIT

2.1.2 2695110056

2.2.4 NKE-1129 type scanner

2.4 PRECAUTIONS

Transmiter Receiver Unit: NTG-3225

2.3.1 NTG-3225 type transmitter receiver

Display Unit (self standing): NCD-4790

Table1-18: NCD-4790/NCD-4790T DISPLAY UNIT

3.1 INSTALLATION OF DISPLAY UNIT

3.3.1 Connections with NKE-1125,NTG-3225,NKE-1130,NTG-3230

OPTION Interswitch Unit: NQE-3141-2/4A/8A

5.1 INSTALLATION OF INTERSWITCH UNIT

Power Control Unit: NQE-3167

5.2.2 Connections to NKE-1125, NTG-3225, NKE-1130, and NTG-

3230

5.2.5 Connection to display unit

VDR I/F Kit: CQD-1891

5.3 INSTALLATION OF VDR

ix

Page 18

JMA-7122-6XA/9XA

Tab le 1- 3: JMA-7100 SERIES RADAR LIST OF COMPOSITION (Self-Standing TYPE)

Tab le 1- 4: JMA-7100 SERIES RADAR LIST OF COMPOSITION (Desktop TYPE)

Scanner Unit: NKE-1125

Table1-15: JMA-7122-6XA/JMA-7122-9XA SCANNER UNIT

2.1.2 2695110056

2.2.3 NKE-1125 type scanner

2.4 PRECAUTIONS

Display Unit (self standing): NCD-4790

Table1-18: NCD-4790/NCD-4790T DISPLAY UNIT

3.1 INSTALLATION OF DISPLAY UNIT

3.3.1 Connections with NKE-1125,NTG-3225,NKE-1130,NTG-3230

OPTION Interswitch Unit: NQE-3141-2/4A/8A

5.1 INSTALLATION OF INTERSWITCH UNIT

Power Control Unit: NQE-3167

5.2.2 Connections to NKE-1125, NTG-3225, NKE-1130, and NTG-

3230

5.2.5 Connection to display unit

VDR I/F Kit: CQD-1891

5.3 INSTALLATION OF VDR

x

Page 19

Cross Reference

JMA-7122-6XAH

Tab le 1- 3: JMA-7100 SERIES RADAR LIST OF COMPOSITION (Self-Standing TYPE)

Tab le 1- 4: JMA-7100 SERIES RADAR LIST OF COMPOSITION (Desktop TYPE)

Scanner Unit: NKE-2254-6HS

Table1-16: JMA-7122-6XAH SCANNER UNIT

2.1.1 CFQ-6912-**

2.2.2 NKE-2254 type scanner

2.4 PRECAUTIONS

Display Unit (self standing): NCD-4790

Table1-18: NCD-4790/NCD-4790T DISPLAY UNIT

3.1 INSTALLATION OF DISPLAY UNIT

3.2 INSTALLATION OF AC-DC CONVERTER NBA-5135

3.3.2 Connections with NKE-2103,NKE-2254

OPTION Interswitch Unit: NQE-3141-2/4A/8A

5.1 INSTALLATION OF INTERSWITCH UNIT

Power Control Unit: NQE-3167

5.2.1 Connection with NKE-2103 type and NKE-2254-6HS type

scanners

5.2.5 Connection to display unit

VDR I/F Kit: CQD-1891

5.3 INSTALLATION OF VDR

xi

Page 20

JMA-7110-6XA/6XAH

Tab le 1- 3: JMA-7100 SERIES RADAR LIST OF COMPOSITION (Self-Standing TYPE)

Tab le 1- 4: JMA-7100 SERIES RADAR LIST OF COMPOSITION (Desktop TYPE)

Scanner Unit: NKE-2103

Table1-17: JMA-7110-6XA/JMA-7110-6XAH SCANNER UNIT

2.1.1 CFQ-6912-**

2.2.1 NKE-2103 type scanner

2.4 PRECAUTIONS

Display Unit (self standing): NCD-4790

Table1-18: NCD-4790/NCD-4790T DISPLAY UNIT

3.1 INSTALLATION OF DISPLAY UNIT

3.2 INSTALLATION OF AC-DC CONVERTER NBA-5135

3.3.2 Connections with NKE-2103,NKE-2254

OPTION Interswitch Unit: NQE-3141-2/4A/8A

5.1 INSTALLATION OF INTERSWITCH UNIT

Power Control Unit: NQE-3167

5.2.1 Connection with NKE-2103 type and NKE-2254-6HS type

scanners

5.2.5 Connection to display unit

VDR I/F Kit: CQD-1891

5.3 INSTALLATION OF VDR

xii

Page 21

Modified November 20, 2008 11:28

1 EQUIPMENT COMPOSITION

2 INSTALLATION OF SCANNER UNIT

3 INSTALLATION OF DISPAY UNIT

4 INITIAL SETTING

5 OPTION UNIT

1

2

3

4

6 APPENDIX

5

6

Page 22

Page 23

SECTION 1

EQUIPMENT COMPOSITION

EQUIPMENT COMPOSITION

1.1 GENERAL COMPOSITION ....................................................................1-1

1.1.1 JMA-9100 SERIES RADAR ....................................................................... 1-1

1.1.2 JMA-7100 SERIES RADAR ....................................................................... 1-2

1.2 LIST OF CIRCUITS ................................................................................1-4

1.2.1 JMA-9100 SERIES RADAR ....................................................................... 1-4

1.2.2 JMA-7100 SERIES RADAR ..................................................................... 1-11

Page 24

Page 25

JMA-9100/7100 Installation Manual > 1.EQUIPMENT COMPOSITION > 1.1 GENERAL COMPOSITION

1.1 GENERAL COMPOSITION

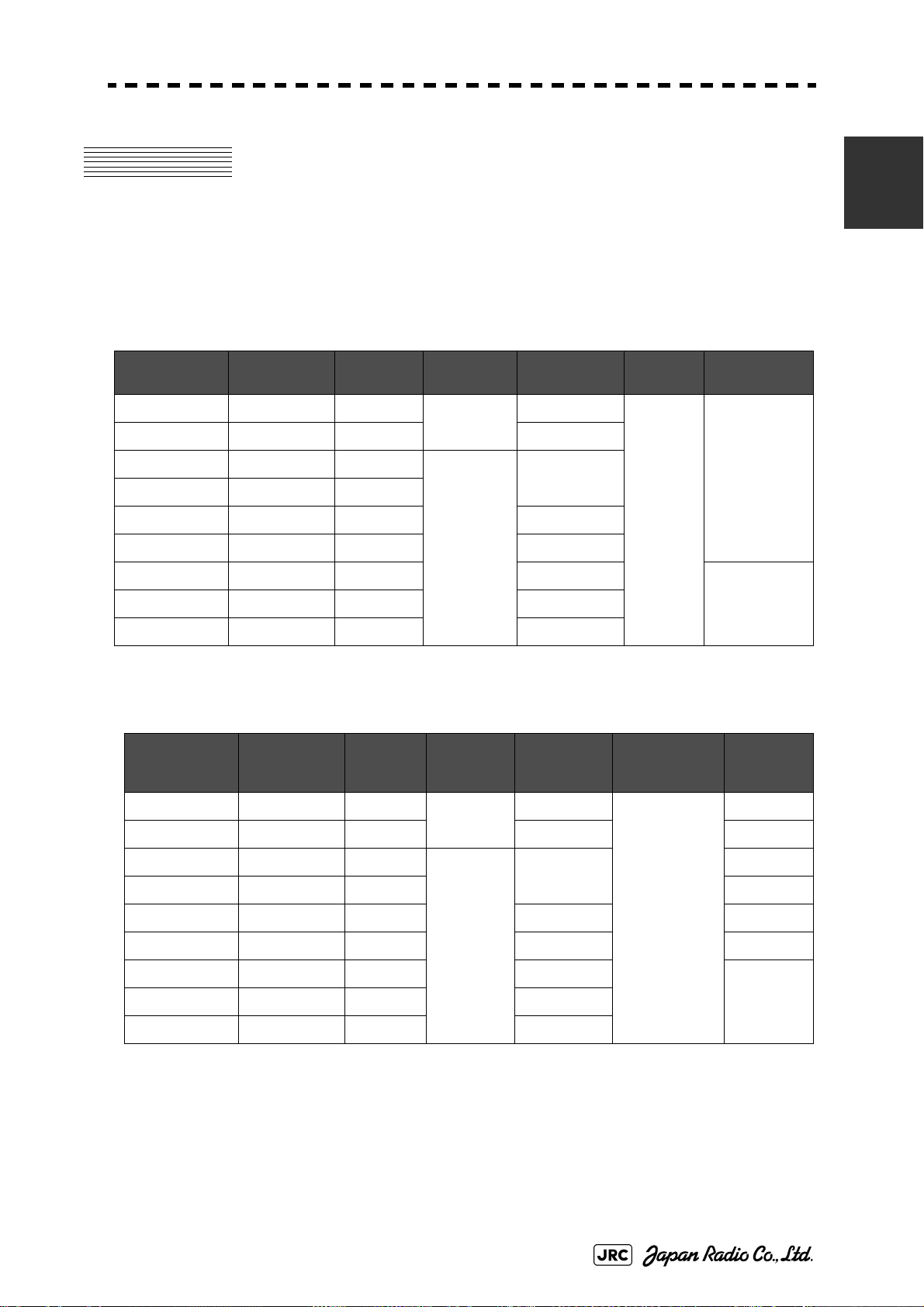

1.1.1 JMA-9100 SERIES RADAR

Table1-1: JMA-9100 SERIES RADAR LIST OF COMPOSITION (Self-Standing TYPE)

1

MODEL SCANNER UNIT RADIATOR

JMA-9133-SA NKE-1139 NJU-84 NTG-3230 NCD-4990

JMA-9132-SA NKE-1130

JMA-9123-7XA NKE-1129-7 NAX-16B-7 NJU-85 NTG-3225

JMA-9123-9XA NKE-1129-9 NAX-16B-9

JMA-9122-6XA NKE-1125-6 NAX-16B-6

JMA-9122-9XA NKE-1125-9 NAX-16B-9

JMA-9122-6XAH NKE-2254-6HS NAX-16B-6

JMA-9110-6XA NKE-2103-6 NAX-16B-6

JMA-9110-6XAH NKE-2103-6HS NAX-16B-6

PERFORMANCE

MONITOR

TRANSMITTERR

ECEIVER UNIT

―

―

―

― NBA-5135

―

―

DISPLAY

UNIT

Tabl e 1-2: JMA-9100 SERIES RADAR LIST OF COMPOSITION (Desktop TYPE)

MODEL SCANNER UNIT RADIATOR

JMA-9133-SA NKE-1139 NJU-84 NTG-3230 Display unit:

JMA-9132-SA NKE-1130

JMA-9123-7XA NKE-1129-7 NAX-16B-7 NJU-85 NTG-3225

JMA-9123-9XA NKE-1129-9 NAX-16B-9

JMA-9122-6XA NKE-1125-6 NAX-16B-6

JMA-9122-9XA NKE-1125-9 NAX-16B-9

JMA-9122-6XAH NKE-2254-6HS NAX-16B-6

JMA-9110-6XA NKE-2103-6 NAX-16B-6

JMA-9110-6XAH NKE-2103-6HS NAX-16B-6

PERFORMANC

EMONITOR

TRANSMITTER

RECEIVER UNIT

――

――

――

―

―

―

DISPLAY UNIT AC-DC

NWZ-170

Radar Process

Unit:

NDC-1399-9

Operation Unit:

NCE-5163

AC-DC

CONVERTER

―

(Built in a

display unit)

CONVERTER

―

―

―

NBA-5135

*1Input voltage is selectable. '1' or '2' suffix is attached to model name of scanner

unit. '1' means AC100-115V(50/60Hz) and '2' means AC220-240V(50/60Hz) for

type of scanner unit NKE-1139, NKE-1130, NKE-1129-7,NKE-1129-9, NKE1125-6 and NKE-1125-9. Others are DC input.

*2HEATER OPTION is available at suffix 'D' exclude type NKE-2103.

1- 1

Page 26

JMA-9100/7100 Installation Manual > 1.EQUIPMENT COMPOSITION > 1.1 GENERAL COMPOSITION

Ex)NKE-1139-1 D, NKE-1129-92 D, NKE-2254-6HSD,

AC 100-115V 50/60Hz 1φ

1:

AC 220-240V 50/60Hz 1φ

2:

HEATER OPTION

D:

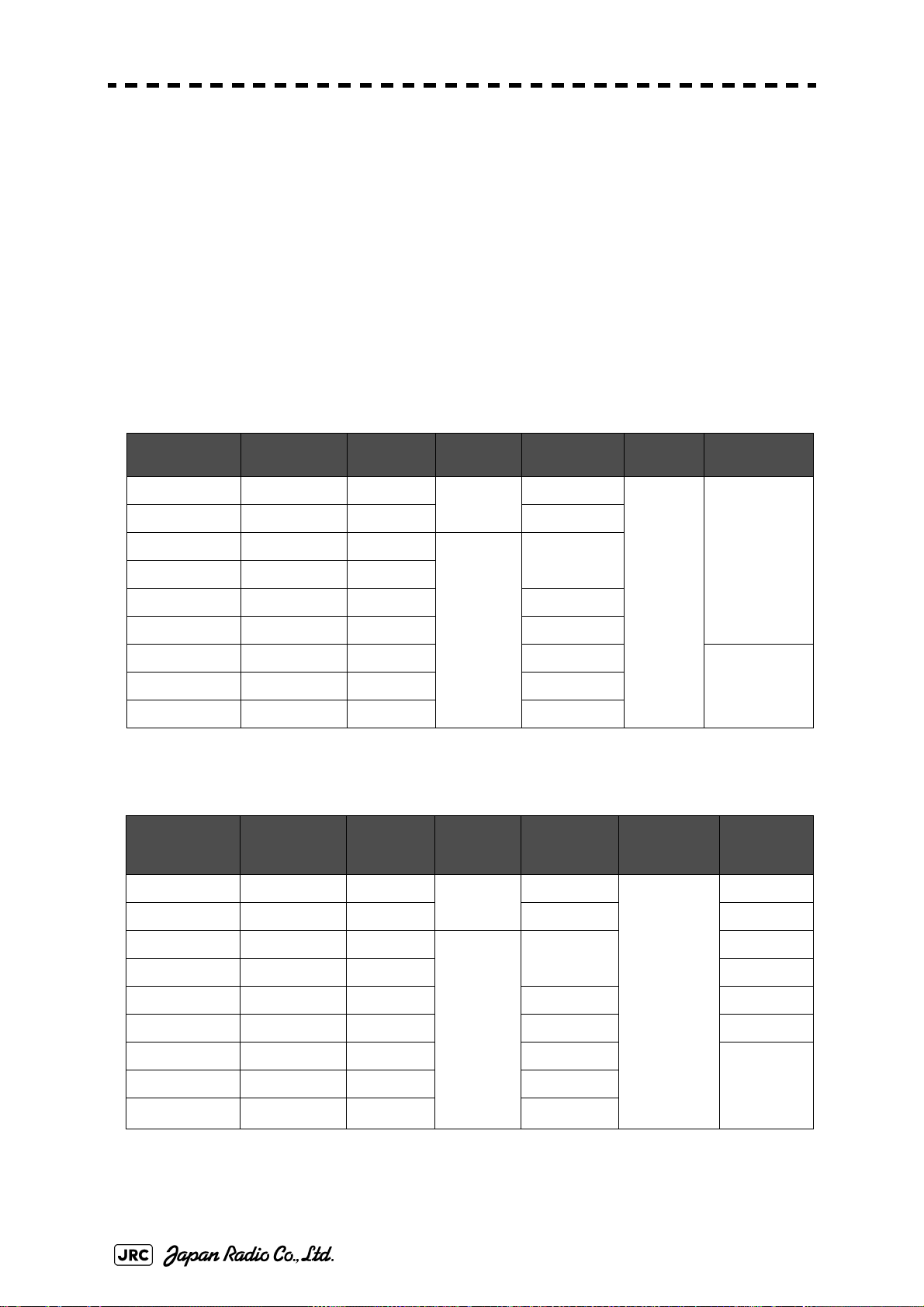

1.1.2 JMA-7100 SERIES RADAR

Table1 -3: JMA-7100 SERIES RADAR LIST OF COMPOSITION (Self-Standing TYPE)

MODEL SCANNER UNIT RADIATOR

JMA-7133-SA NKE-1139 NJU-84 NTG-3230 NCD-4790

JMA-7132-SA NKE-1130

JMA-7123-7XA NKE-1129-7 NAX-16B-7 NJU-85 NTG-3225

JMA-7123-9XA NKE-1129-9 NAX-16B-9

JMA-7122-6XA NKE-1125-6 NAX-16B-6

JMA-7122-9XA NKE-1125-9 NAX-16B-9

JMA-7122-6XAH NKE-2254-6HS NAX-16B-6

JMA-7110-6XA NKE-2103-6 NAX-16B-6

JMA-7110-6XAH NKE-2103-6HS NAX-16B-6

PERFORMAN

CEMONITOR

TRANSMITTER

RECEIVER UNIT

―

―

―

― NBA-5135

―

―

DISPLAY

UNIT

Table1- 4: JMA-7100 SERIES RADAR LIST OF COMPOSITION (Desktop TYPE)

MODEL SCANNER UNIT RADIATOR

JMA-7133-SA NKE-1139 NJU-84 NTG-3230 Display unit:

JMA-7132-SA NKE-1130

JMA-7123-7XA NKE-1129-7 NAX-16B-7 NJU-85 NTG-3225

JMA-7123-9XA NKE-1129-9 NAX-16B-9

JMA-7122-6XA NKE-1125-6 NAX-16B-6

JMA-7122-9XA NKE-1125-9 NAX-16B-9

JMA-7122-6XAH NKE-2254-6HS NAX-16B-6

JMA-7110-6XA NKE-2103-6 NAX-16B-6

JMA-7110-6XAH NKE-2103-6HS NAX-16B-6

PERFORMAN

CEMONITOR

TRANSMITTER

RECEIVER UNIT

――

――

――

―

―

―

DISPLAY UNIT AC-DC

NWZ-170

Radar Process

Unit:

NDC-1399-9

Operation

Unit:

NCE-5163

AC-DC

CONVERTER

―

(DISPLAY UNIT

に内蔵)

CONVERTER

―

―

―

NBA-5135

1- 2

Page 27

JMA-9100/7100 Installation Manual > 1.EQUIPMENT COMPOSITION > 1.1 GENERAL COMPOSITION

*1Input voltage is selectable. '1' or '2' suffix is attached to model name of scanner

unit. '1' means AC100-115V(50/60Hz) and '2' means AC220-240V(50/60Hz) for

type of scanner unit NKE-1139,NKE-1130,NKE-1129-7,NKE-1129-9,NKE-11256 and NKE-1125-9. Others are DC input.

*2HEATER OPTION is available at suffix 'D' exclude type NKE-2103.

Ex)NKE-1139-1 D, NKE-1129-92 D, NKE-2254-6HSD,、

AC 100-115V 50/60Hz 1φ

1:

AC 220-240V 50/60Hz 1φ

2:

HEATER OPTION

D:

1

1- 3

Page 28

JMA-9100/7100 Installation Manual > 1.EQUIPMENT COMPOSITION > 1.2 LIST OF CIRCUITS

1.2 LIST OF CIRCUITS

1.2.1 JMA-9100 SERIES RADAR

Table1 -5: JMA-9133-SA SCANNER and TRANSMITTER RECEIVER UNIT

NKE-1139-1 NKE-1139-2

SCANNER

UNIT

SCANNER UNIT

INTERCONNECTION

RADIATOR CTG-270

SAFETY SWITCH CSD-657

ENCODER CHT-71A1

CAX-14

TRANSMITTE

R

RECEIVER

UNIT

MOTOR MDBW10823

AC100V MOTOR DRIVER

BREAK CIRCUIT CFA-255

BREAK CONTROL CIRCUIT

BREAK UNIT NZR-17

HEATER CONTROL PART

PERFORMANCE MONITOR

NTG-3230

TRANSCEIVER UNIT

INTERCONNECTION

MODULATOR UNIT NMA-553-1

MODULATOR UNIT

INTERCONNECTION

MODULATOR CIRCUIT CPA-264

RECEIVER CIRCUIT NRG-229

RECEIVER UNIT

INTERCONNECTION

IF CIRCUIT CAE-499

7EPRD0035

AC220V MOTOR DRIVER

CCB-655

CHG-215

NJU-84

CMK-594

CMB-407

CMA-902

7EPRD0034

DISPLAY

UNIT

RF CIRCUIT CAF-595

T/R CONTROL CIRCUIT CMC-1205R

RELAY FILTER CIRCUIT CSC-656

POEWR SUPPLY CIRCUIT

NCD-4990/T

CBD-1682A

1- 4

Page 29

SCANNER

UNIT

JMA-9100/7100 Installation Manual > 1.EQUIPMENT COMPOSITION > 1.2 LIST OF CIRCUITS

Tab l e 1-6: JMA-9132-SA SCANNER UNIT

NKE-1130-1 NKE-1130-2

SCANNER UNIT

INTERCONNECTION

RADIATOR CTG-270

SAFETY SWITCH CSD-656

ENCODER CHT-71A

MOTOR MDBW10823

CAX-13

1

AC100V MOTOR DRIVER

BREAK CIRCUIT CFA-255

BREAK CONTROL CIRCUIT

BREAK UNIT NZR-17

MODULATOR UNIT NMA-551-1

MODULATOR UNIT

INTERCONNECTION

MODULATOR CIRCUIT CPA-264

RECEIVER CONTROL

UNTI

RECEIVER UNIT NRG-229

RECEIVER UNIT

INTERCONNECTION

IF CIRCUIT CAE-499

RF CIRCUIT CAF-595

T/R CONTROL CIRCUIT CMC-1205R

RELAY FILTER CIRCUIT CSC-656

POWER SUPPLY CIRCUIT

7EPRD0035

AC220V MOTOR DRIVER

CCB-655

CMB-406

NZT-1130

CMA-902

CBD-1682A

7EPRD0034

DISPLAY

UNIT

HEATER CONTROL PART

PERFORMANCE MONITOR

NCD-4990/T

1- 5

CHG-215

NJU-84

Page 30

JMA-9100/7100 Installation Manual > 1.EQUIPMENT COMPOSITION > 1.2 LIST OF CIRCUITS

Tab l e 1-7: JMA-9123-7XA/JMA-9123-9XA SCANNER and TRANSMITTER-RECEIVER UNIT

NKE-1129-1 NKE-1129-2

SCANNER

UNIT

SCANNER UNIT

INTERCONNECTION

SAFETY SWITCH CSD-655

ENCODER CHT-71A1

MOTOR MDBW10822

CAX-12

TRANSMITTER

RECEIVER

UNIT

AC100V MOTOR DRIVER

7EPRD0035

AC220V MOTOR DRIVER

BREAK CIRCUIT CFA-253

BREAK CONTROL CIRCUIT

CCB-655

BREAK UNIT NZR-15

HEATER CONTROL PART

PERFORMANCE MONITOR

CHG-216

NJU-85

NTG-3225

TRANSCEIVER UNIT

INTERCONNECTION

CMK-593

MODULATOR UNIT NMA-552-1

MODULATOR UNIT

INTERCONNECTION

CMB-405

MODULATOR CIRCUIT CPA-264

RECEIVER CIRCUIT CFR-229

RECEIVER UNIT

INTERCONNECTION

NRG-162A

IF CIRCUIT CMA-866A

RF CIRCUIT CMC-1205R

7EPRD0034

T/R CONTROL CIRCUIT CSC-656

RELAY FILTER CIRCUIT CBD-1682A

DISPLAY UNIT NCD-4990/T

1- 6

Page 31

SCANNER

UNIT

JMA-9100/7100 Installation Manual > 1.EQUIPMENT COMPOSITION > 1.2 LIST OF CIRCUITS

Table1- 8: JMA-9122-6XA/JMA-9122-9XA SCANNER UNIT

NKE-1125-61,NKE-1125-91 NKE-1125-62,NKE-1125-92

SCANNER UNIT

INTERCONNECTION

SAFETY SWITCH CSD-654

ENCODER CHT-71A

MOTOR MDBW10822

CAX-11

1

DISPLAY

UNIT

AC100V MOTOR DRIVER

BREAK CIRCUIT CFA-253

BREAK CONTROL CIRCUIT

BREAK UNIT NZR-16

MODULATOR UNIT NMA-550-1

MODULATOR UNIT

INTERCONNECTION

MODULATOR CPA-264

MAG FILTER CIRCUIT CFR-229

RECEIVER UNIT NRG-162A

RECEIVER CIRCUIT CMA-866A

T/R CONTROL CIRCUIT CMC-1205R

RELAY FILTER CIRCUIT CSC-656

POWER SUPPLY CIRCUIT

HEATER CONTROL PART

PERFORMANCE MONITOR

NCD4990/T

7EPRD0035

AC220V MOTOR DRIVER

CCB-655

CMB-404

CBD-1682A

CHG-216

NJU-85

7EPRD0034

1- 7

Page 32

JMA-9100/7100 Installation Manual > 1.EQUIPMENT COMPOSITION > 1.2 LIST OF CIRCUITS

Table1 -9: JMA-9122-6XAH SCANNER UNIT

NKE-2254-6HS

SCANNER UNIT

SCANNER UNIT

INTERCONNECTION

SAFETY SWITCH CSD-653

ENCODER CHT-71A

MOTOR 7BDRD0045A

CAX-15

MOTOR CONTROL

POWER SUPPLY

BREAK CIRCUIT CFA-257

MODULATOR UNIT NMA-550-1

MODULATOR UNIT

INTERCONNECTION

MODULATOR

CIRCUIT

MAG FILTER CIRCUIT CFR-229

RECEIVER UNIT NRG-162A

RECEIVER CIRCUIT CMA-866A

T/RCONTROL CIRCUIT

POWER SUPPLY

CIRCUIT

HEATER CONTROL PART

PERFORMANCE

MONITOR

DISPLAY UNIT NCD-4990/T

AC-DC

NBA-5135

CONVERTER

CBD-1779

CMB-404

CPA-264

CMC-1205R

CBD-1682A

CHG-216

NJU-85

1- 8

Page 33

JMA-9100/7100 Installation Manual > 1.EQUIPMENT COMPOSITION > 1.2 LIST OF CIRCUITS

Table1 -10: JMA-9110-6XA/JMA-9110-6XAH SCANNER UNIT

NKE-2103-6,NKE-2103-6HS

SCANNER UNIT

SCANNER UNIT

INTERCONNECTION

ENCODER CHT-71A

MOTOR 7BDRD0048

BREAK CIRCUIT CFA-252

CAX-10

1

TRANSMITTER

RECEIVER UNIT

TRANSMITTER

RECEIVER UNIT

INTERCONNECTION

MODULATORCIRCUIT CME-363

POWER SUPPLY CIRCUIT

MOTOR CONTROL POWER

SUPPLY

RECEIVER UNIT NRG-610

RECEIVER UNIT

INTERCONNECTION

IF AMP CIRCUIT CAE-529-1

PERFORMANCE MONITOR

DISPLAY UNIT NCD-4990/T

AC-DC

CONVERTER

NBA-5135

NZT-2103

CMK-599

CBD-1783

CBD-1779

CMA-823

NJU-85

1- 9

Page 34

JMA-9100/7100 Installation Manual > 1.EQUIPMENT COMPOSITION > 1.2 LIST OF CIRCUITS

Table1-11: NCD-4990/NCD-4990T DISPLAY UNIT

NCD-4990 NCD-4990T

RADAR

NDC-1399-9 NDC-1399-9

PROCESS

UNIT

OPERATION

UNIT

RADAR PROCESS

CDC-1324

CIRCUIT

AIS PROCESS

CDC-1325

CIRCUIT

ARPA PROCESS

CDC-1186D

CIRCUIT

GYRO I/FCIRCUIT CMJ-462E

MOTHER BOARD CQC-1192

TERMINAL BOARD

CQD-2097

CIRCUIT

POWER SUPPLY CBD-1661

RADAR PROCESS

UNIT

INTERCONNECTION

CML-763

RADAR PROCESS

UNIT

INTERCONNECTION

NCE-5163 NCE-5163

OPERATION

CCK-973

CIRCUITA

OPERATION

CCK-974

CIRCUITB

OPERATION

CCK-976

CIRCUITD

OPERATION UNIT

INTERCONNECTION

CMD-996-R

OPERATION UNIT

INTERCONNECTION

CML-763T

CMD-996-RT

MONITOR UNIT

AC-DC

CONVERTER

RADAR PROCESS

NWZ-170

CIRCUIT

AIS PROCESS

CML-799

CIRCUIT

ARPA PROCESS

CCK-972

CIRCUIT

GYRO I/FCIRCUIT CML-764-R

MONITOR UNIT

INTERCONNECTION

NBA-5135 *(Only for NKE-2103-6/6HS,NKE-2254-6/6HS)

CML-764-RT

1- 10

Page 35

JMA-9100/7100 Installation Manual > 1.EQUIPMENT COMPOSITION > 1.2 LIST OF CIRCUITS

1.2.2 JMA-7100 SERIES RADAR

Table1-12: JMA-7133-SASCANNER and TRANSMITTER RECEIVER UNIT

NKE-1139-1 NKE-1139-2

SCANNER

UNIT

TRANSMITTER

RECEIVER

UNIT

SCANNER UNIT

INTERCONNECTION

RADIATOR CTG-270

SAFETY SWITCH CSD-657

ENCODER CHT-71A1

MOTOR MDBW10823

AC100V MOTOR DRIVER

BREAK CIRCUIT CFA-255

BREAK CONTROL CIRCUIT

BREAK UNIT NZR-17

HEATER CONTROL PART

PERFORMANCE MONITOR

NTG-3230

TRANSCEIVER UNIT

INTERCONNECTION

7EPRD0035

AC220V MOTOR DRIVER

CAX-14

CCB-655

CHG-215

NJU-84

CMK-594

1

7EPRD0034

MODULATOR UNIT NMA-553-1

MODULATOR UNIT

INTERCONNECTION

MODULATOR CIRCUIT CPA-264

RECEIVER CIRCUIT NRG-229

RECEIVER UNIT

INTERCONNECTION

IF CIRCUIT CAE-499

RF CIRCUIT CAF-595

T/R CONTROL CIRCUIT CMC-1205R

RELAY FILTER CIRCUIT CSC-656

POEWR SUPPLY CIRCUIT

DISPLAY UNIT NCD-4790/T

CMB-407

CMA-902

CBD-1682A

1- 11

Page 36

JMA-9100/7100 Installation Manual > 1.EQUIPMENT COMPOSITION > 1.2 LIST OF CIRCUITS

Table1 -13: JMA-7132-SA SCANNER UNIT

NKE-1130-1 NKE-1130-2

SCANNER

UNIT

SCANNER UNIT

INTERCONNECTION

RADIATOR CTG-270

SAFETY SWITCH CSD-656

ENCODER CHT-71A

MOTOR MDBW10823

CAX-13

AC100V MOTOR DRIVER

7EPRD0035

AC220V MOTOR DRIVER

BREAK CIRCUIT CFA-255

BREAK CONTROL CIRCUIT

CCB-655

BREAK UNIT NZR-17

MODULATOR UNIT NMA-551-1

MODULATOR UNIT

CMB-406

INTERCONNECTION

MODULATOR CIRCUIT CPA-264

RECEIVER CONTROL

NZT-1130

UNTI

RECEIVER UNIT NRG-229

RECEIVER UNIT

CMA-902

INTERCONNECTION

IF CIRCUIT CAE-499

RF CIRCUIT CAF-595

T/R CONTROL CIRCUIT CMC-1205R

RELAY FILTER CIRCUIT CSC-656

POWER SUPPLY CIRCUIT

CBD-1682A

7EPRD0034

DISPLAY

UNIT

HEATER CONTROL PART

PERFORMANCE MONITOR

NCD-4790/T

CHG-215

NJU-84

1- 12

Page 37

JMA-9100/7100 Installation Manual > 1.EQUIPMENT COMPOSITION > 1.2 LIST OF CIRCUITS

Tab l e 1-14: JMA-7123-7XA/JMA-7123-9XASCANNER and TRANSMITTER RECEIVER UNIT

NKE-1129-71,NKE-1129-91 NKE-1129-72,NKE-1129-92

SCANNER

UNIT

SCANNER UNIT

INTERCONNECTION

SAFETY SWITCH CSD-655

ENCODER CHT-71A1

MOTOR MDBW10822

CAX-12

1

TRANSMITTER

RECEIVER

UNIT

AC100V MOTOR DRIVER

BREAK CIRCUIT CFA-253

BREAK CONTROL CIRCUIT

BREAK UNIT NZR-15

HEATER CONTROL PART

PERFORMANCE MONITOR

NTG-3225

TRANSCEIVER UNIT

INTERCONNECTION

MODULATOR UNIT NMA-552-1

MODULATOR UNIT

INTERCONNECTION

MODULATOR CIRCUIT CPA-264

RECEIVER CIRCUIT CFR-229

RECEIVER UNIT

INTERCONNECTION

IF CIRCUIT CMA-866A

RF CIRCUIT CMC-1205R

7EPRD0035

AC220V MOTOR DRIVER

CCB-655

CHG-216

NJU-85

CMK-593

CMB-405

NRG-162A

7EPRD0034

T/R CONTROL CIRCUIT CSC-656

RELAY FILTER CIRCUIT CBD-1682A

DISPLAY UNIT NCD-4790/T

1- 13

Page 38

JMA-9100/7100 Installation Manual > 1.EQUIPMENT COMPOSITION > 1.2 LIST OF CIRCUITS

Table1- 15: JMA-7122-6XA/JMA-7122-9XA SCANNER UNIT

NKE-1125-61,NKE-1125-91 NKE-1125-62,NKE-1125-92

SCANNER

UNIT

SCANNER UNIT

INTERCONNECTION

SAFETY SWITCH CSD-654

ENCODER CHT-71A

MOTOR MDBW10822

CAX-11

DISPLAY

UNIT

AC100V MOTOR DRIVER

7EPRD0035

AC220VMOTOR DRIVER

BREAKCIRCUIT CFA-253

BREAK CONTROL CIRCUIT

CCB-655

BREAK UNIT NZR-16

MODULATOR UNIT NMA-550-1

MODULATOR UNIT

CMB-404

INTERCONNECTION

MODULATORCIRCUIT CPA-264

MAG FILTER CIRCUIT CFR-229

RECEIVER UNIT NRG-162A

RECEIVERCIRCUIT CMA-866A

T/R CONTROL CIRCUIT CMC-1205R

RELAY FILTER CIRCUIT CSC-656

POWER SUPPLY CIRCUIT

HEATER CONTROL PART

PERFORMANCE MONITOR

CBD-1682A

CHG-216

NJU-85

NCD-4790/T

7EPRD0034

1- 14

Page 39

JMA-9100/7100 Installation Manual > 1.EQUIPMENT COMPOSITION > 1.2 LIST OF CIRCUITS

Tabl e 1-16: JMA-7122-6XAH SCANNER UNIT

NKE-2254-6HS

SCANNER UNIT

SCANNER UNIT

INTERCONNECTION

SAFETY SWITCH CSD-653

ENCODER CHT-71A

MOTOR 7BDRD0045A

CAX-15

1

MOTOR CONTROL

POWERSUPPLY

BREAK CIRCUIT CFA-257

MODULATOR UNIT NMA-550-1

MODULATOR UNIT

NTERCONNECTION

MODULATORCIRCUIT CPA-264

MAG FILTER CIRCUIT CFR-229

RECEIVER UNIT NRG-162A

RECEIVERCIRCUIT CMA-866A

T/R CONTROL CIRCUIT CMC-1205R

POWER SUPPLY CIRCUIT

HEATER CONTROL PART

PERFORMANCE MONITOR

DISPLAY UNIT NCD-4790/T

CBD-1779

CMB-404

CBD-1682A

CHG-216

NJU-85

1- 15

Page 40

JMA-9100/7100 Installation Manual > 1.EQUIPMENT COMPOSITION > 1.2 LIST OF CIRCUITS

Table1 -17: JMA-7110-6XA/JMA-7110-6XAH SCANNER UNIT

NKE-2103-6,NKE-2103-6HS

SCANNER UNIT

SCANNER UNIT

INTERCONNECTION

ENCODER CHT-71A

MOTOR 7BDRD0048

BREAK CIRCUIT CFA-252

CAX-10

TRANSMITTER

RECEIVER UNIT

TRANSMITTER

RECEIVER UNIT

INTERCONNECTION

MODULATORCIRCUIT CME-363

POWER SUPPLY

CIRCUIT

MOTOR CONTROL

POWER SUPPLY

RECEIVER UNIT NRG-610

RECEIVER UNIT

INTERCONNECTION

IF AMP CIRCUIT CAE-529-1

PERFORMANCE

MONITOR

DISPLAY UNIT NCD-4790/T

AC-DC

NBA-5135

CONVERTER

NZT-2103

CMK-599

CBD-1783

CBD-1779

CMA-823

NJU-85

1- 16

Page 41

JMA-9100/7100 Installation Manual > 1.EQUIPMENT COMPOSITION > 1.2 LIST OF CIRCUITS

Table1 -18: NCD-4790/NCD-4790T DISPLAY UNIT

NCD-4790 NCD-4790T

RADAR PROCESS

UNIT

NDC-1399-7 NDC-1399-7

RADAR PROCESS

CIRCUIT

CDC-1324

1

OPERATION

UNIT

AIS PROCESS

CIRCUIT

ARPA PROCESS

CIRCUIT

GYRO I/FCIRCUIT CMJ-462E

MOTHER BOARD CQC-1192

TERMINAL

BOARD CIRCUIT

POWER SUPPLY CBD-1661

RADAR PROCESS

UNIT

INTERCONNECTION

NCE-5163 NCE-5163

OPERATION

CIRCUITA

OPERATION

CIRCUITB

OPERATION

CIRCUITD

OPERATION UNIT

INTERCONNECTION

CDC-1325

CDC-1186D

CQD-2097

CML-763

CCK-973

CCK-974

CCK-976

CMD-996-R

RADAR PROCESS

UNIT

INTERCONNECTION

OPERATION UNIT

INTERCONNECTION

CML-763T

CMD-996-RT

MONITOR UNIT NWZ-173 NWZ-173

AC-DC

CONVERTER

NBA-5135 *(Only for NKE-2103-6/6HS,NKE-2254-6/6HS)

1- 17

Page 42

JMA-9100/7100 Installation Manual > 1.EQUIPMENT COMPOSITION > 1.2 LIST OF CIRCUITS

1- 18

Page 43

SECTION 2

INSTALLATION OF SCANNER UNIT

INSTALLATION OF SCANNER UNIT

2.1 EQUIPMENT CABLE .............................................................................2-1

2.1.1 CFQ-6912-** ...............................................................................................2-1

2.1.2 2695110056 ................................................................................................2-2

2.1.3 2695111153 ................................................................................................2-3

2.1.4 Cable end processing method .................................................................2-4

2.1.5 Connection to the display-unit side terminal block ............................... 2-7

2.2 INSTALLATION OF SCANNER UNIT ....................................................2-8

2.2.1 NKE-2103 type scanner ............................................................................ 2-8

2.2.2 NKE-2254 type scanner .......................................................................... 2-11

2.2.3 NKE-1125 type scanner .......................................................................... 2-13

2.2.4 NKE-1129 type scanner .......................................................................... 2-15

2.2.5 NKE-1130 type scanner .......................................................................... 2-17

2.2.6 NKE-1139 type scanner .......................................................................... 2-19

2.3 INSTALLATION OF TRANSMITTER RECEIVER UNIT ......................2-21

2.3.1 NTG-3225 type transmitter receiver ......................................................2-21

2.3.2 NTG-3230 type transmitter receiver ......................................................2-24

2.4 PRECAUTIONS ....................................................................................2-26

Page 44

2.4.1 Installation of scanner unit .................................................................... 2-26

2.4.2 Routing coaxial cable and flexible waveguide ..................................... 2-29

2.4.3 Scanner installation position .................................................................2-31

2.4.4 Confirmation during test run .................................................................2-35

2.4.5 Others .......................................................................................................2-35

Page 45

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.1 EQUIPMENT CABLE

2.1 EQUIPMENT CABLE

2.1.1 CFQ-6912-**

This is a 19-core shielded composite cable.

The cable length is indicated in the asterisks ** area in the model name, and the

available cable lengths are 5, 10, 20, 30, 40, 50, and 65 meters.

This cable is used to connect an NKE-2103 type scanner or an NKE-2254 type

scanner to the display unit.

2

Fig 2-1: Cross-sectional drawing of CFQ-6912

Table2-1: CFQ-6912 wire

Core(NO) AWG No. of Wire /φ Color Remarks

1 AWG24 7/0.2T Black1 Coaxial

2 AWG24 7/0.2T Black2 Shield

3 AWG24 7/0.2T Green

4 AWG24 7/0.2T Yellow

5 AWG24 7/0.2T White

6 AWG22 17/0.16T Black

7 AWG22 17/0.16T Orange

8 AWG16 50/0.18T Blue

9 AWG16 50/0.18T Gray

10 AWG16 50/0.18T Purple

11 AWG16 50/0.18T Brown

12 AWG16 50/0.18T White

13 AWG16 50/0.18T Orange

14 AWG16 50/0.18T Red

15 AWG16 50/0.18T Green

16 AWG16 50/0.18T Yellow

17 AWG16 50/0.18T Black

18 AWG16 50/0.18T Sky

19 AWG16 50/0.18T Pink

maximum diameter 14.5mm

2- 1

Page 46

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.1 EQUIPMENT CABLE

2.1.2 2695110056

This is a 14-core shielded composite cable.

This cable is used to connect an NKE-1125 type scanner or an NKE-1130 type

scanner, and an NTG-3225 type transmitter-receiver or a NTG-3230 type

transmitter-receiver to the display unit.

Fig 2-2: Cross-sectional drawing of 2695110056

Table2-2: 2695110056 wire

Core (No.) Cross

1 0.5 19 / 0.18 Black 1 Coaxial Cable

2 0.5 19 / 0.18 Black 2 Coaxial Cable

3 0.5 19 / 0.18 Black 3 Coaxial Cable

4 0.5 19 / 0.18 Black 4 Coaxial Cable

5 5.5 35 / 0.45 Yellow

6 5.5 35 / 0.45 Green

7 5.5 35 / 0.45 Brown

8 0.3 12 / 0.18 White Twisted pair cable with

9 0.3 12 / 0.18 Orange

10 2 37 / 0.26 Red

11 2 37 / 0.26 Blue

12 1.25 50 / 0.18 Black

13 1.25 50 / 0.18 Purple

14 0.5 1 / 0.18 Gray Shield wire

No. of wire / φ Color

Section

(m2)

Remarks

Shield sheath white

maximum diameter 23.0mm

2- 2

Page 47

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.1 EQUIPMENT CABLE

2.1.3 2695111153

This is an 18-core shielded composite cable.

This cable is used to connect an interswitch to the display unit.

2

Fig 2-3: Cross-sectional drawing of 2695111153

Table2-3: 2695111153 wire

Wire NO. Cross

A1 0.5 19 / 0.18 Black 1 Coaxial

A2 0.5 19 / 0.18 Black 2 Coaxial

B1 0.5 19 / 0.18 Blue Shield

B2 0.5 19 / 0.18 Yellow Shield

B3 0.5 19 / 0.18 Green Shield

B4 0.5 19 / 0.18 Red Shield

B5 0.5 19 / 0.18 Purple Shield

B6 0.5 19 / 0.18 Clear Shield

C1 0.3 12 / 0.18 Blue 2 Cores Shield

C2 0.3 12 / 0.18 Yellow 2 Cores Shield

D1 0.5 19 / 0.18 Brown

D2 0.5 19 / 0.18 Black

D3 0.5 19 / 0.18 Orange

D4 0.5 19 / 0.18 Gray

D5 0.5 19 / 0.18 Pink

D6 0.5 19 / 0.18 SkyBlue

No. of wire / φ Color

Section

(m2)

0.3 White

0.3 White

maximum diameter 18.0mm

Remarks

2- 3

Page 48

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.1 EQUIPMENT CABLE

2.1.4 Cable end processing method

Allow for sufficient cable length so that maintenance, inspection, and repair work

can be easily executed. Ensure a place to store the cable.

1) CFQ-6912

Cut off the metal shell connector.

Fig 2-4: CFQ-6912 Cutting position

Remove about one meter of the outer skin, and then process the double braided

shield according to the procedures shown below.

abt. 80 mm

taping

abt.

1000 mm

Terminal

CFQ-6912

Width for

clamping cable

abt.

30 mm

Fig 2-5: CFQ-6912 Processing of braided shield

Outer Shield

Outer Shield

2- 4

Page 49

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.1 EQUIPMENT CABLE

Process each cable end according to the procedures shown below.

Coaxial Cable

Shield Cable

Fig 2-6: CFQ-6912 End processing of each wire

Shield Cable

(twisted pair)

Vinyl Cable

Twist each pair of the following colored wires and clamp them to the crimp-type

terminal. (V2-M4 recommended)

• RED.T/GRN.T →+terminal

• WHT.T/ORN.T →+terminal

• PUR.T/BRN.T →-terminal

• BLU.T/GRY.T → -terminal

2

Overlay those wires as shown in the drawingat the

right, and fix them onto the CBD-1684A (TB522) or

TB401 terminal block.

Twist each pair of the following colored wires and

connect them to the TB4101 of the terminal board

circuit CQD-2097.

• YEL.T/PNK.T →TB4101(+48V)

• BLK.T/SKY.T → TB4101(+48VG)

Fig 2-7: Fixing onto the

terminal block

2- 5

Page 50

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.1 EQUIPMENT CABLE

2) 2695110056、2695111153

Remove about one meter of the outer skin, and then process the double braided

shield according to the procedures shown below.

Coaxial Cable

Shield Cable

abt. 80 mm

taping

abt.

1000 mm

2695110056

2695111153

Width for

clamping cable.

30 mm

abt.

Inner Shield

Outer Shield

Fig 2-8: 2695110056 Processing of braided shield

Shield Cable

(twisted pair)

Vinyl Cable

terminal

Fig 2-9: 2695110056 End processing of each wire

2- 6

Page 51

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.1 EQUIPMENT CABLE

2.1.5 Connection to the display-unit side terminal block

The terminal block of the display unit's terminal board circuit is a plug terminal

block which does not require a crimp-type terminal. Connection procedures are

described below.

1) Use a tool, such as a flathead screwdriver, to press the control so as to open

the cable inlet.

2) Check the length of the uninsulated portion of the electric wire and its

alignment, and then insert the electric wire until the end comes in contact

with the rear of the inlet.

3) Remove the tool from the control and securely tighten the cable. Properly

connect the cable in reference to the inter-board connection diagram.

2

4) After the cable has been connected, gently tug at the cable to ensure that it is

securely fastened.

Press down the lever to

open the cable inlet.

2.5mm

Insert the cable until it comes

contact with the rear of the inl

Gently tug at the cable to ensu

tha t it is securely fastened.

Appropriate

flathead

screwdriver

Fig 2-10: Terminal block connection method

2- 7

Page 52

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.2 INSTALLATION OF SCANNER UNIT

2.2 INSTALLATION OF SCANNER UNIT

2.2.1 NKE-2103 type scanner

2- 8

Page 53

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.2 INSTALLATION OF SCANNER UNIT

2

2- 9

Page 54

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.2 INSTALLATION OF SCANNER UNIT

2- 10

Page 55

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.2 INSTALLATION OF SCANNER UNIT

2.2.2 NKE-2254 type scanner

2

2- 11

Page 56

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.2 INSTALLATION OF SCANNER UNIT

2- 12

Page 57

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.2 INSTALLATION OF SCANNER UNIT

2.2.3 NKE-1125 type scanner

2

2- 13

Page 58

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.2 INSTALLATION OF SCANNER UNIT

2- 14

Page 59

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.2 INSTALLATION OF SCANNER UNIT

2.2.4 NKE-1129 type scanner

2

2- 15

Page 60

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.2 INSTALLATION OF SCANNER UNIT

2- 16

Page 61

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.2 INSTALLATION OF SCANNER UNIT

2.2.5 NKE-1130 type scanner

2

2- 17

Page 62

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.2 INSTALLATION OF SCANNER UNIT

2- 18

Page 63

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.2 INSTALLATION OF SCANNER UNIT

2.2.6 NKE-1139 type scanner

2

2- 19

Page 64

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.2 INSTALLATION OF SCANNER UNIT

2- 20

Page 65

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.3 INSTALLATION OF TRANSMITTER RECEIVER

UNIT

2.3 INSTALLATION OF TRANSMITTER

RECEIVER UNIT

2.3.1 NTG-3225 type transmitter receiver

2

2- 21

Page 66

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.3 INSTALLATION OF TRANSMITTER RECEIVER

UNIT

2- 22

Page 67

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.3 INSTALLATION OF TRANSMITTER RECEIVER

UNIT

2

2- 23

Page 68

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.3 INSTALLATION OF TRANSMITTER RECEIVER

UNIT

2.3.2 NTG-3230 type transmitter receiver

2- 24

Page 69

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.3 INSTALLATION OF TRANSMITTER RECEIVER

UNIT

2

2- 25

Page 70

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.4 PRECAUTIONS

e

2.4 PRECAUTIONS

2.4.1 Installation of scanner unit

1) Precautions for transporting and storing the scanner

• An scanner is a heavy load. Be very careful about handling it.

• Do not allow the scanner fall on its side while it is stored or being installed.

• Do not apply rope to the scanner in the way that squeezes or deforms the radiating

section.

• When hoisting the scanner by a crane, do not hoist it by attaching a belt or a rope only

to the scanner's radiating section as shown in Fig 2-11.

• For the S-band, attach a rope to the hoisting eyebolts attached to the scanner's chassis,

and then hoist the scanner (Fig 2-12). If a belt or a rope is attached to the scanner's

support section located at the bottom of the radiating section, a load is imposed to the

joint between the radiating section and the chassis.

• For the X-band, wrap a cloth around the scanner's support section located at the bottom

of the radiating section, and then attach a belt or rope to it to hoist the scanner (Fig 2-

13).

Fig 2-12: S-band

Fig 2-11: Improper way to hoist

Attach a rope to th

hoisting eyebolts

Fig 2-13: X-band

2- 26

Page 71

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.4 PRECAUTIONS

2) Installation procedures

a.Maintain a flat level surface on which to install the scanner.

• Use sufficiently thick steel material and reinforcement material for the scanner's

installation surface (mount base) to reduce vibration and impact. Keep the mount base

flat and smooth.

• If there is a partial gap between the mount base and the scanner chassis's legs, work on

the installation surface so that it becomes flat and smooth, or make adjustments by

inserting metal shims. If a gap exists and the scanner is tightly clamped, the chassis will

distort and become damaged by vibration.

b.Avoid using vibration-proof rubber and resin

• Do not insert an elastic body, such as vibration-proof rubber or resin, between the mount

base and the scanner chassis' legs. If rubber or resin is inserted, the amplitude of

vibration increases, resulting in the possibility of damage to the scanner. Furthermore,

if installation bolts become loose due to deterioration of rubber or resin, the scanner

may be damaged or fall from its mount.

2

3) Installation and clamping method

a.Installation direction

• Installation should be done so that the cable gland is oriented toward the stern.

b.Bolts, nuts and tightening torque to be used

• Use stainless steel bolts for the scanner and uniformly tighten all of the bolts using

double nuts for each bolt so that the scanner will not become loose (Table 2-4).

• Although the length of the bolt will differ according to the thickness of the mount base,

use a bolt long enough so that more than 4 millimeters of thread protrudes beyond the

double nuts after the double nuts have been tightened.

Ta bl e 2- 4 : Length of scanner mounting bolts and tightening torque

Thickness of Mount

Base(mm)

S-band 19

X-band 12

Bolt Torque(N-m)

M12×65(mm) SUS304

M10×55(mm) SUS304

65

40

c.Use of washer and corrosion-resistant measures

• At the location where a bolt's head or nut comes in contact with the scanner chassis' legs

and the mount base, insert a plain washer which fits the bolt; and, at the location where

the nut comes in contact with the plain washer, insert a spring washer, and then securely

tighten the nuts (Fig 2-14).

• To prevent corrosion due to the contacts between different metals, such as the scanner

chassis' legs, installation surface, bolts, nuts, etc., cover the bolt's head and nuts with

sealant (Fig 2-14).

2- 27

Page 72

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.4 PRECAUTIONS

Fig 2-14: Use of washer and corrosion-resistant measures

d.Grounding and corrosion-resistant measures

• Ground the scanner chassis and the installation surface (hull) by using an earth line.

Apply sealant to the connection portion of the earth line to prevent corrosion and

damage by vibration (Fig 2-15).

Fig 2-15: Grounding and corrosion-resistant measures

2- 28

Page 73

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.4 PRECAUTIONS

2.4.2 Routing coaxial cable and flexible waveguide

In the case of the three-unit system consisting of the display unit, transmitterreceiver, and the scanner, use a Coaxial cable, shown in Fig 2-16, between the

transmitter-receiver and the scanner for the S-band, and use a Flexible waveguide,

shown in Fig 2-17, for the X-band.

1) Protecting coaxial cable and flexible waveguide

• Since cables and waveguides are hollow inside, when mounting them by using electric

wire bands, try not to fasten the bands too tightly around the cables and waveguides. If

they are fastened too tightly, the inside will become deformed or blocked, which may

cause the receiving sensitivity to decrease or the transmitter-receiver to be damaged.

Fig 2-16: Coaxial cable

Fig 2-17: Flexible waveguide

• Stabilize the coaxial cable and the flexible waveguide by supporting members that are at

maximum intervals of 1000 millimeters. Mount a supporting member for the horizontal

wiring portion on the compass deck at an angle of 300 to 400 millimeters, and put a

protective metal cover over the cable and waveguide.

2) Preventing the connecting portion from becoming detached due to vibration

2

• Keep the connecting portion between the coaxial cable and the flexible waveguide and

the scanner's chassis, and provide supporting members, as shown in Fig 2-18 and Fig 219, to prevent the connecting portion from becoming detached due to vibration.

• The distance from the connecting portion and the supporting member should be 400

millimeters for the S-band and 300 millimeters for X-band.

• If the distance from the connecting portion and the supporting member is longer than

the above distance, vibration may cause metal fatigue, resulting in the occurrence of

malfunction even if the connecting portion is not removed.

Co nn ect er MPD W00297

Be s traight from connecter to first su pport clamp

HF coaxial cable support clamp

Coaxial tube ground

Fig 2-18: Position of S-band supporting member

• For the cable end processing, refer to the procedure manual which comes with the cable.

Scanner terminal

Waveguide Clamp

Fig 2-19: Position of X-band supporting member

2- 29

Page 74

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.4 PRECAUTIONS

3) Permissible bending radius

• The permissible bending radius R of flexible waveguide is 200mm/400mm (E-bent/H-

bent). More sharp bending with less radius than this must be avoided.

• The permissible bending radius R of coaxial cable is 350mm. More sharp bending with

less radius than this must be avoided.

R=200mm(MIN)

(a) E-bent

E面曲げ半径

R=400mm(MIN)

(b) H-bent

H面曲げ半径

Fig 2-20: The permissible bending radius of flexible waveguide

Fig 2-21: The permissible bending radius of coaxial cable

2- 30

Page 75

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.4 PRECAUTIONS

2.4.3 Scanner installation position

1) Physical selection criteria

• Install the scanner at the center of the mast on the keel line.

• If the scanner cannot be installed at the above position for some reason, the amount of

deviation must be minimized. And, reinforce the mount base and the platform and take

precautions to protect the scanner from vibration and impact at the installation position.

To avoid the radiating section coming in contact with other installed objects while it is rotating,

ensure that there is at least 200 millimeters from the swing circle (turning radius) to other installed

objects (Fig 2-22). The swing circle of the JMA-7100/9100 radar's scanner is as shown in Table 2-

5.

min-height

必要最小高さ

2

Over 200m

Over 200mm

200m 以上

200mm 以上

min-offset

オフセット

最小

Fig 2-22: Installation of scanner

Tab le 2- 5: Swing circle

Scanner unit (length) Swing circle

NKE-2103-6/6HS (6ft)

NKE-1125-6 (6ft)

NKE-2254-6HS (6ft)

NKE-1129-7 (7ft) 2270mm

NKE-1125-9 (9ft)

NKE-1129-9 (9ft)

NKE-1130/1139 (12ft) 4000mm

reinforcing member

補強材

1910mm

2825mm

2- 31

Page 76

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.4 PRECAUTIONS

• Avoid having a rope or signal flag from winding around the radiating section thereby

preventing it from rotating.

• Avoid the effects of dust and heat caused by smoke from a chimney.

• When determining the appropriate scanner height and installation location, take into

consideration the reduction of vibration, the strength of the hull and the scanner mount

base, and maintenance properties.

• Provide for maintenance space: platform, safety link, hand rail, steps, etc. The lower

edge of a radar antenna should be a minimum of 500 mm above any safety rail.

• When installing the scanner, select a location where there are the fewest structural

objects in the surrounding area so that the capability to drive the motor will not be

depressed by the non-equability wind which is likely to rotate the scanner.

2) Electrical selection criteria

• The installation height of the scanner relates to the maximum detection distance

higher, the better. However, if it is too high, radio wave energy greatly attenuates above

the scanner's vertical beam width (the point -3dB from the peak of the main lobe). As a

result, it is difficult to detect a close-in target. Sea clutter also increases. Determine the

installation height by taking into consideration the weight, maximum length of the

cable, and maintenance after installation.

• If the installation height of the scanner is low, it is difficult to detect a long distance

target. The ship's mast, derrick, and chimney interfere with radiating beam causing the

range that cannot be viewed on the radar display to increase.

Generally, the lowest scanner installation position is supposed to be on the A-B line shown in

Fig 2-23.

1

. The

In the case of the JMA-7110/7122/7123/9110/9122/9123 type radar, 2 equals 20 .

In the case of the JMA-7132/7133/9132/9133 type radar, 2 equals 25 . Specifically, the scanner

position is normally elevated so that the chimney and the shrine-gate type mast do not interfere

with radiating beam.

The A-B line, or

surface of the sea in not more than 500 m or twice the ship length, depending which value is

smaller, for all load and trim conditions.

A

JMA-7110 / 7122 / 7123 / 9110 / 9122 / 9123 :θ=10°

JMA-7132 / 7133 / 9132 / 9133 :θ=12.5°

L line of sight from the radar antenna to the bow of the ship should hit the

B

L

θ

Fig 2-23: Lowest scanner installation height

• If it is considered that sufficient installation height cannot be provided when the scanner

is installed directly on the roof of the wheelhouse, use a mounting rack or radar mast

(Fig 2-24). Normally, when the scanner installation height is less than 2 meters from

the roof of the wheelhouse, provide a mounting rack assembled at an angle frame to

install the scanner. When the scanner installation height is 2 meters or higher from the

roof of the wheelhouse, provide a cylindrical radar mast to install the scanner. Consider

1.For more detail on THE MAXIMUM DETECTION DISTANCE, refer to the instruc-

tion manual chapter 6.

2- 32

Page 77

JMA-9100/7100 Installation Manual > 2.INSTALLATION OF SCANNER UNIT > 2.4 PRECAUTIONS

the convenience of the service staff who take care of installation, maintenance,

adjustment, and repair of the scanner by providing adequate footholds to the mounting

rack and the radar mast.

Installation

Height

Installation

Height

Fig 2-24: Mounting rack and mast for the scanner

• When installing the scanner, select a location where there are the fewest structural

objects in the surrounding area so that false echos which interfere with target detection

will not be generated by signal reflection from other scanners, deck structures, and