Page 1

NJJ−95B

Handy Search

Instruction Manual

Page 2

Preface

Thank you very much for purchasing this JRC NJJ-95B Handy Search

The NJJ-95B RC radar nondestructively locates, detects, and displays the depths

and positions of reinforcing steel bars in reinforced concrete structures.

●Before attempting to operate the NJJ-95B, please read through this instruction

manual carefully to learn all of its features and ensure correct and trouble-free

operation.

●Keep the instruction manual handy for reference. Refer to the manual for

information about the NJJ-95B or when experiencing trouble during operation.

DC01-NJJ-95B

First edition September 2006

i

Page 3

ii

Before Operation

Pictorial Indication

Various icons are included in this manual and are shown on these

equipment so that you can operate them safely and correctly and

prevent any danger to you and/or to other persons and any damage to

your property during operation. Such indications and their meanings

are as follows.

Please understand them before you read this manual.

WARNING

This indication is shown where any person is supposed to be in danger of

being killed or seriously injured if this indication is neglected and this

equipment is not operated correctly.

CAUTION

This indication is shown where any person is supposed to be injured or any

property damage is supposed to occur if this indication is neglected and this

equipment is not operated correctly.

Examples of Pictorial Indication

Electric

shock

The

mark indicates CAUTION (including DANGER

and WARNING).

Detailed content of the specific CAUTION (“Electric

Shock” in the example on the left.) is shown in the mark.

Disassembling

Prohibited

Prohibition

The mark indicates prohibition.

Detailed content of the prohibited action (“Disassembling

Prohibited” in the example on the left.) is shown in the

mark.

Disconnect the

power plug

Instruction

The z mark indicates instruction.

Detailed content of the instruction (“Disconnect the power

plug” in the example on the left.) is shown in the mark.

●JRC assumes no liability for any damage (such as damage

caused to reinforcing steel bars, electrical pipes, gas pipes,

etc.) arising from search results using this radar.

Page 4

iii

FCC NOTICES:

This device complies with part 15 of the FCC Rules:

Operation is subject to the following conditions:

1. This device many not cause harmful interference, and

2. This device must accept any interference received, Including interference that

may cause undesired operation

Warning:

Changes or modifications to this unit not expressly approved by the party

responsible for compliance could void the user’s authority to operate the

equipment.

Operation of this device is restricted to law enforcement, fire and rescue

officials,scientific research institutes, commercial mining companies, and

construction companies. Operation by any other party is a violation of 47

U.S.C. § 301 and could subject the operator to serious legal penalties.

Coordination Requirements.

(a) UWB imaging systems require coordination through the FCC before the

equipment may be used. The operator shall comply with any constraints on equipment

usage resulting from this coordination.

(b) The users of UWB imaging devices shall supply detailed operational areas to

the FCC Office of Engineering and Technology who shall coordinate this information with

the Federal Government through the National Telecommunications and Information

Administration. The information provided by the UWB operator shall include the name,

address and other pertinent contact information of the user, the desired geographical

area of operation, and the FCC ID number and other nomenclature of the UWB device.

This material shall be submitted to the following address:

Frequency Coordination Branch., OET

Federal Communications Commission

445 12th Street, SW

Washington, D.C. 20554

ATTN: UWB Coordination

(d) Users of authorized, coordinated UWB systems may transfer them to other qualified

users and to different locations upon coordination of change of ownership or location to the FCC

and coordination with existing authorized operations.

(e) The NTIA/FCC coordination report shall include any needed constraints that

apply to day-to-day operations. Such constraints could specify prohibited areas of

operations or areas located near authorized radio stations for which additional

coordination is required before operation of the UWB equipment. If additional local

coordination is required, a local coordination contact will be provided.

(f) The coordination of routine UWB operations shall not take longer than 15

Page 5

iv

business days from the receipt of the coordination request by NTIA. Special temporary

operations may be handled with an expedited turn-around time when circumstances

warrant. The operation of UWB systems in emergency situations involving the safety of

life or property may occur without coordination provided a notification procedure, similar

to that contained in CFR47 Section 2.405(a)-(e), is followed by the UWB equipment user.

NOTICE: Use of this device as a wall imaging syste m is prohibited by FCC regulatio ns.

Page 6

v

<Precautions for Use>

WARNING

Do not use any battery pack other than the BP-3007-A1 or any AC adapter

other than the PW-3009-W.

Doing so may cause fire, electric shock, or breakdown.

Do not short-circuit the terminals of the battery charger or battery pack.

Doing so may cause fire, explosion, or breakdown.

Do not insert metallic or flammable objects into the compact flash memory

card slot. Doing so may cause injury, fire, electric shock, or breakdown.

Do not disassemble, modify, heat, or place battery pack in fire.

Doing so may cause fire, explosion, or breakdown.

Do not use any charger other than the specified battery charger to charge the

battery pack.

Doing so may cause fire, electric shock, or breakdown.

Do not attempt to disassemble, modify, or attempt to repair the NJJ-95B by

yourself.

Doing so may cause fire, electric shock, or breakdown.

If the power cord is damaged (exposure of the core wire, open circuit failure,

or break in the sheath), contact our nearest branch office, sales outlet, or

service station for a replacement power cord. Use of a damaged power cord

may cause fire or electric shock.

Do not connect/disconnect the plug while your hands are wet.

Doing so could cause an electric shock.

Do not use (place) the NJJ-95B in a location where it is exposed to flammable

or corrosive gas.

Doing so could cause fire, personal injury, or breakdown.

Handy Search is a drip-proof construction but must not be placed in water.

Do not expose the NJJ-95B to water or moisture, and do not use it in rainy

weather. Doing so could cause an electric shock or breakdown.

Stop using the NJJ-95B immediately when a sign of malfunctioning is

detected, and follow only the detailed procedure in this instruction manual. If

it cannot be restored to normal operation, contact our nearest branch office,

sales outlet, or service station. Use of the NJJ-95B in an abnormal state could

cause fire or breakdown.

Should the NJJ-95B emit an abnormal sound, odor, or smoke, immediately

turn off the power switch, remove the battery pack, disconnect the power plug

from the socket outlet, and contact our nearest branch office, sales outlet, or

service station.

Use of the NJJ-95B in an abnormal state could cause fire, electric shock, or

breakdown.

Before disposing of the used lithium ion battery, insulate the charging

terminals by taping or the like. Otherwise, the battery could cause fire or

explosion if short-circuited.

Page 7

CAUTION

Making a judgement on the search results considering the depth sensing

capability of the NJJ-95B:

Since the depth sensing capability of the radar is subject to the conditions of

the object of investigation, judging the search results with no consideration of

the depth sensing capability may cause the cutting of rebar.

Put your hand through the hand strap and hold the NJJ-95B.

Dropping of the radar may cause an accident such as a device breakdown or

personal injury.

When disconnecting the power cord, hold the plug. Pulling the power cord by

itself may cause cord damage, fire, or electric shock.

Do not place the NJJ-95B on an unstable place such as a wobbly table or

sloping surface.

Doing so may cause a personal injury or breakdown when it drops or falls.

Do not use (place) the NJJ-95B in a humid or dusty location, or a location

where water, oil, or chemical may splash onto the radar. Doing so may cause

fire, electric shock, or breakdown.

Do not use (place) the NJJ-95B in a location where it is subject to vibration or

shock.

Doing so may cause a personal injury or breakdown.

When loading/unloading printing paper, be careful not to cut or jam your

fingers in the printer.

Point the antenna surface in the direction of the object (concrete) while you

are performing a probe.

If it is pointed into the air or otherwise unsuitable direction, it can cause

malfunction of other equipment or other such accidents.

Do not use the NJJ-95B in the vicinity of a radio or TV set.

Doing so may cause noise or poor reception such as disturbance of television

pictures. Doing so also adversely affects the depth sensing capability of the

radar, and may cause the cutting of reinforcing steel bars.

Do not use the NJJ-95B near a cell phone or transceiver that transmits

electromagnetic waves. Electromagnetic waves from the cell phone or

transceiver may adversely affect the depth sensing capability of the radar, and

may cause the cutting of reinforcing steel bars.

When the NJJ-95B is used for probing on a road, take safety precautions such

as providing guard fences to prevent traffic accidents.

vi

Page 8

<Appearance of the NJJ-95B>

vii

Page 9

Table of Contents

Preface i

BeforeOperation ii

<PrecautionsforUse> v

<AppearanceoftheNJJ‑95B> vii

GlossaryofTerms xi

1 DescriptionofEquipment 1

1.1Function 1

1.2Features 3

1.3Configuration 6

1.4OverallSystemDiagram 7

1.5Configuration 8

2 PartsNamesandFunctions 10

2.1HandySearchNJJ‑95B 10

2.2ExampleofScanTestScreen 14

2.2.1Scantestscreenexample(duringtesting) 14

2.2.2Scantestscreenexample(notduringtesting) 16

2.3ParameterSettingsScreen 19

2.3.1Displaycolor 19

2.3.2Inversionofthescreen 20

2.3.3Displaymode 21

2.3.4Gradationsystem 22

2.3.5Calibrationmethod 22

2.3.6Depthcalibration 23

2.3.7Date,time 23

2.3.8DataNo. 24

2.3.9Distancecompensation 24

2.3.10OutputDataFormat 25

2.3.11DisplayRange 25

2.3.12CharacterMode 25

2.3.13Returntostandard 26

2.4CFControlscreen 27

3 OperatingMethod 28

3.1ScanningTestPreparation 30

3.2ScanTest 36

3.2.1Power‑onProcedure 36

3.2.2ScanTest 36

3.2.3Sensitivity 38

3.2.4AntennaMark 38

viii

Page 10

3.2.5Realtimemanualdeductionprocessing 40

3.3 OperationwhilenotScanTesting42

3.3.1Modeswitching 42

3.3.2Sensitivityswitching 43

3.3.3Cursoroperation 43

3.4ImageProcessing 45

3.4.1Manualsurfacewaveprocessing 45

3.4.2PeakProcessing 47

3.4.3Reproductionoforiginalimage 49

3.4.4Fixedsurfacewaveprocessing 50

3.4.5Deductionprocessing 50

3.5HowtoDetermineDepthsandSampleScanTestData 52

3.6ExternalOutputMethods 54

3.6.1PrinterOutput 54

3.6.2Datasavingincompactflashmemory 56

3.7CFControlScreen 62

3.7.1Displayingthethumbnailimagesofsaveddata 62

3.7.2Readingsaveddata 62

3.7.3Deletingsaveddata 63

3.7.4MethodforinitializationofCompactFlash 65

3.8Power‑offProcedure 67

3.9Clearinguptheradarandaccessories 67

3.10AbouttheBatteryPackandCharger 68

3.10.1BatterypackBP‑3007series 69

3.10.2ChargingDeviceBC‑3008series 72

4 Options 74

4.1PrinterDPU‑3445series 75

4.1.1Printer'smainpartsnamesandfunctions 75

4.1.2PrinterSpecification 76

4.1.3Connectingthebatterypack/powersource 77

4.2ACAdapterPW‑0904‑W1series 81

4.2.1ACAdapterSpecification 81

4.2.2ConnectingtheACadapter 81

5 Theory 82

5.1PrincipleofOperation 82

5.2ApplicableConditions 83

6 MaintenanceInspection 85

6.1DailyInspection 85

ix

Page 11

6.2DailyMaintenance 85

6.3Troubleshooting 86

7 After‑salesService 88

8 Disposal 89

8.1DisposalofUsedBatteryPack 89

8.2DisposaloftheNJJ‑95B 89

9 Specification 90

9.1HandySearchNJJ‑95B 90

9.2BatterypackBP‑3007series 92

9.3ChargingDeviceBC‑3008series 92

10 WheretoContact 93

x

Page 12

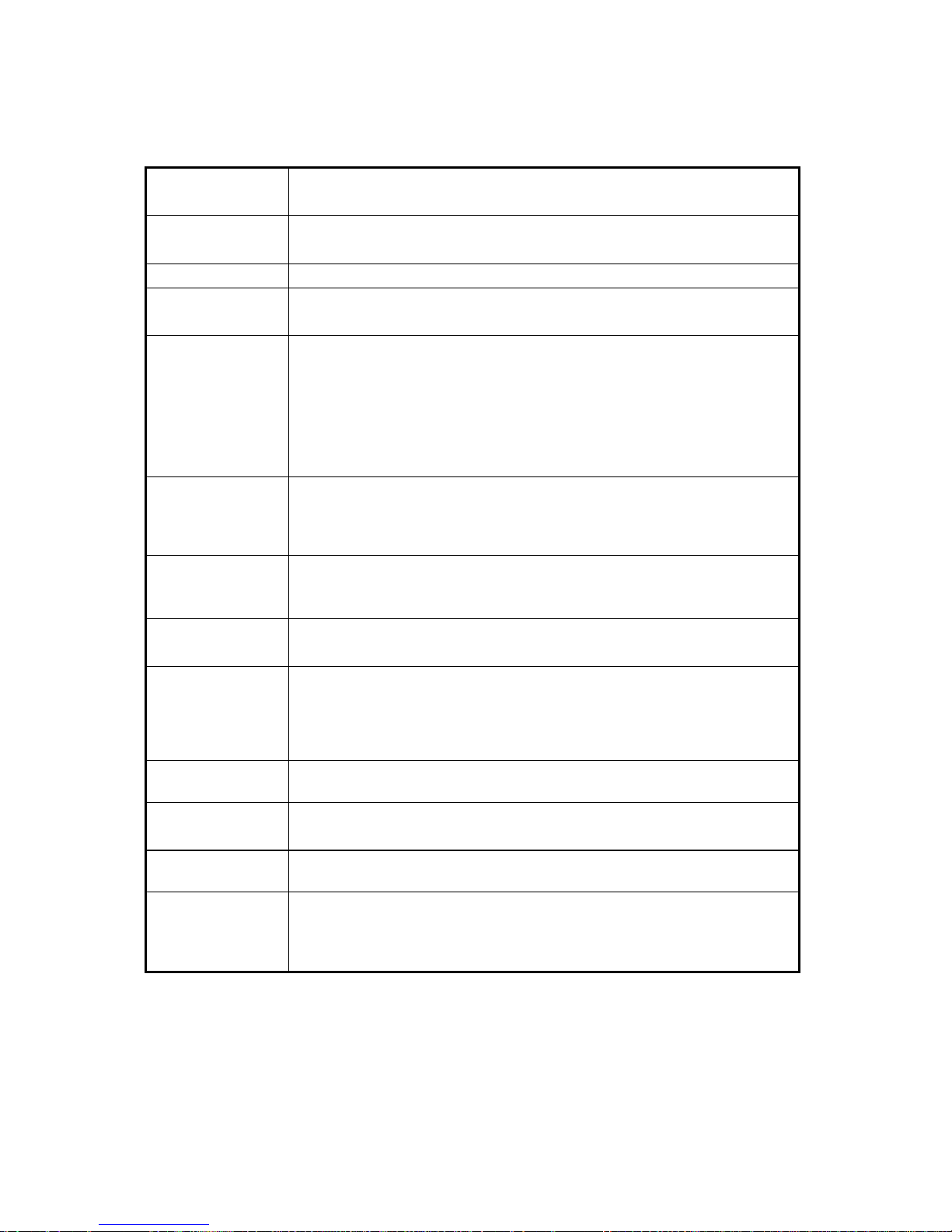

Glossary of Terms

A mode

Displays received waveform as it is. The conditions of concrete directly

underneath the Handy Search are displayed as reflected waveform in real

time.

B mode

Displays the vertical cross section of a scan point by gradating the

reflected waveform shown in A mode according to reflection intensity and

continuously displaying it.

BA mode Displays both B-mode and A-mode images at the same time.

Real time

Auto surface wave

processing

Image processing that uses internal fixed surface wave data to

automatically remove the wave reflected from the surface of the concrete

during scanning and only shows the reflected wave from rebar etc.

Real time

Manual

Deduction

processing

Image processing used in the case that the effect of the reflected waves

from the surface of the concrete can not be fully removed using the

internal fixed surface wave data of the real time auto surface wave

processing. Thus, reflected waves in the form of stripes remain in the

scanning results.

Image processing where an arbitrary line is designated while scanning.

The data of the designated line is subtracted from the scanning results

data, and the reflected wave from the concrete surface is automatically

removed. Thus, only the reflected waves from rebar etc. are shown.

Manual

Surface wave

processing

Image processing where an arbitrary line is designated from scanning

results. The surface portion of the data from the designated line is

subtracted from the scanning results data, and the reflected wave from

the concrete surface is automatically removed. Thus, only the reflected

waves from rebar etc. are shown.

Peak processing

Image processing that shows only the waveform of the first peak on the

+side of the scanning results.

This enables removal of multiple reflected signals and only displays the

upper rebar.

Fixed surface

wave processing

Image processing that uses internal fixed surface wave data to remove

the wave reflected from the surface of the concrete and only shows the

reflected wave from rebar etc.

Deduction

processing

Image processing where an arbitrary line from the scanning results is

designated and the designated line is subtracted from the scanning

results data. Stripe reflected waves throughout the entire depth, such as

reflected waves from the concrete surface and reflected waves from the

rear surface etc., are removed and only the reflected waves from rebar

etc. are shown.

Reproduction of

original image

This processing restores the image processing result to the original state

and displays unprocessed raw data.

Distance feed

system

Method that performs scanning in accordance with Handy Search's

traveling distance, using the distance detector mounted on the wheels of

the Handy Search.

Time feed system

Method that performs B-mode scanning at preset time intervals,

regardless of movement of the Handy Search.

Relative dielectric

constant

Object-specific coefficient. The radio wave propagation rate changes with

the value of the relative permittivity. Therefore, the wave propagation

velocity and scanning depth change change based on the relative

permittivity of the concrete. Calculation error of scanning depth can be

reduced by setting a depth calibration value.

xi

Page 13

1 Description of Equipment

This equipment is indispensable for repairing/rebuilding and maintaining reinforced

concrete structures using its accurate and speedy diagnostic technology.

The Handy Search concrete internal probe vehicle, NJJ-95B, (hereafter called this

radar) radiates electromagnetic waves through the surface of concrete and receives

reflected signals from objects found inside such as reinforcing steel bars, cavities, or

other objects that have different electrical characteristics from concrete. Object

position and depth are then displayed and recorded as image data.

CAUTION

Making a judgement on the search results considering the depth sensing

capability of the NJJ-95B:

Since the depth sensing capability of the radar is subject to the conditions of

the object of investigation, judging the search results with no consideration of

the depth sensing capability may cause the accidental cutting of rebar.

1.1 Function

This radar has the following functions:

• Sense depth :5 – 300 mm

*1

• Display mode: :B mode (vertical cross section)

BA mode (vertical cross section and reflected waveform

display)

• Image processing during sensing : Automatic real-time surface wave

processing

Real time manual deduction processing

• Sensing method :Distance feed system (sensing method based on the

distance the main body moves)

Time feed system (sensing at preset time intervals)

• Sense deptch :Max 15 m (case of using time feed – 150 seconds)

• Internal memory :Max 15 m (case of using time feed – 150 seconds)

Image processing: : Manual surface wave processing, fixed surface wave

processing, peak processing, deduction processing, and reproduction of original

image

• External output

*2

:Printer output (IrDA)

• Saving data :Compact flash memory card

‑1‑

Page 14

*1: For the case that the relative dielectric constant of concrete is a uniform 6.2

and the upper rebar has a diameter of 6 mm or more

*

2: The printer is optional.

‑2‑

Page 15

1.2 Features

This device has the following features:

(1) The material of the object to be scanned can be either metallic or non-metallic

Reflected electromagnetic waves are generated at an interface when the

electrical property of an object is different from that of concrete. Thus, this radar

can probe polyvinyl-chloride pipes and cavities (dependent on the position and

size) as well as the reinforcing steel bars. Note that polyvinyl-chloride pipes and

cavities echo weakly in compared with the reinforcing steel bars.

If a polyvinyl-chloride pipe or cavity is near or below the reinforcing steel bars,

the reflected signals from the polyvinyl-chloride pipe or cavity may not be

obtained due to the strong reflected signals from the reinforcing steel bars. Thus,

care should be taken when you make a judgment on the search results.

(2) Detects rebars that cross the scanning direction

Rebar that cross the scanning direction transmit a large magnetic wave

reflection. On the other hand, rebar that is parallel to the scanning direction

transmit a smaller magnetic wave reflection. Even if scanning is performed

above rebar that is parallel to the scanning direction, this device can still detect

any rebar that is crosswise to the scanning direction.

(3) Obtaining continuous scanning results

The scanning results are obtained as a representation of the vertical cross

section of the inside of concrete. Thus, a comprehensive view of the internal

concrete conditions can be obtained.

(4) Obtaining scanning results at the site

Handy Search does not need to be secured to the surface of concrete.

Scanning is carried out while Handy Search is moved and results concerning

the internal conditions of the concrete can be provided immediately.

(5) Saving and reading scan data

Using a compact flash memory, scan data can be saved and reopened

(maximum of roughly 50 sets of data can be saved in text format for a depth of

15 m using a 512 MB compact flash). The data can also be loaded from the

compact flash memory card into a PC by using a card reader or the like.

(6) Printing without cable connection

The unit is equipped with IrDA, therefore, printing can be performed without

using a cable using a DPU-3345 series printer.

‑3‑

Page 16

However, the IrDA optical receptors for this unit and the printer must be set

facing each other at a distance of 50 ~ 500 mm (without any obstacles between

them).

(7) Performing real time automatic surface wave processing

Internal fixed surface wave data is used to automatically remove the wave

reflected from the surface of the concrete during scanning enabling the showing

of the reflected wave from rebar.

Furthermore, surface wave processing can be switched to processing that

uses scan data surface waves during scanning (real time manual deduction)

enabling highly accurate surface processing.

(8) Displaying the data of an arbitrary point after scanning (scroll function)

This radar can store 15m woth of data at a time and display the data of

arbitrary points continuously.

(9) Changing sensitivity and performing image processing for scan data

This radar can display scan results after changing sensitivity or performing

image processing (manual surface wave processing, peak processing,

reproduction of original image, fixed surface wave processing, or deduction

processing). Thus, performing a scan test again with a new sensitivity setting is

not necessary.

(10) A mark can be displayed in the scan results using the cursor mark function.

A maximum of 7 cursor marks can be placed in the scan results to display the

scan position and depth of the mark.

(11) Providing the screen inversion function

(11) Screen inversion function is available

In case of scanning from right to left on a wall surface, the display on the

screen is upright (normal). In the case of scanning left to right, the display will

be inverted.

Therefore, the user can achieve the correct display by performing the scan

either right to left or left to right.

(12) Recording of date and settings

The main unit records the date and settings (data number, sensitivity, etc.)

using a backup function. When data is output, the date and settings are

recorded.

‑4‑

Page 17

(13) Compact and light weight

This radar weighs only about 1.1 kg, so it is easy to operate.

(14) Operating with the battery pack and commercial power supply

This radar can operate with the battery pack for about 1.5 hours (at normal

temperature). It can also operate with the commercial power supply when an AC

adapter (optional) is used.

‑5‑

Page 18

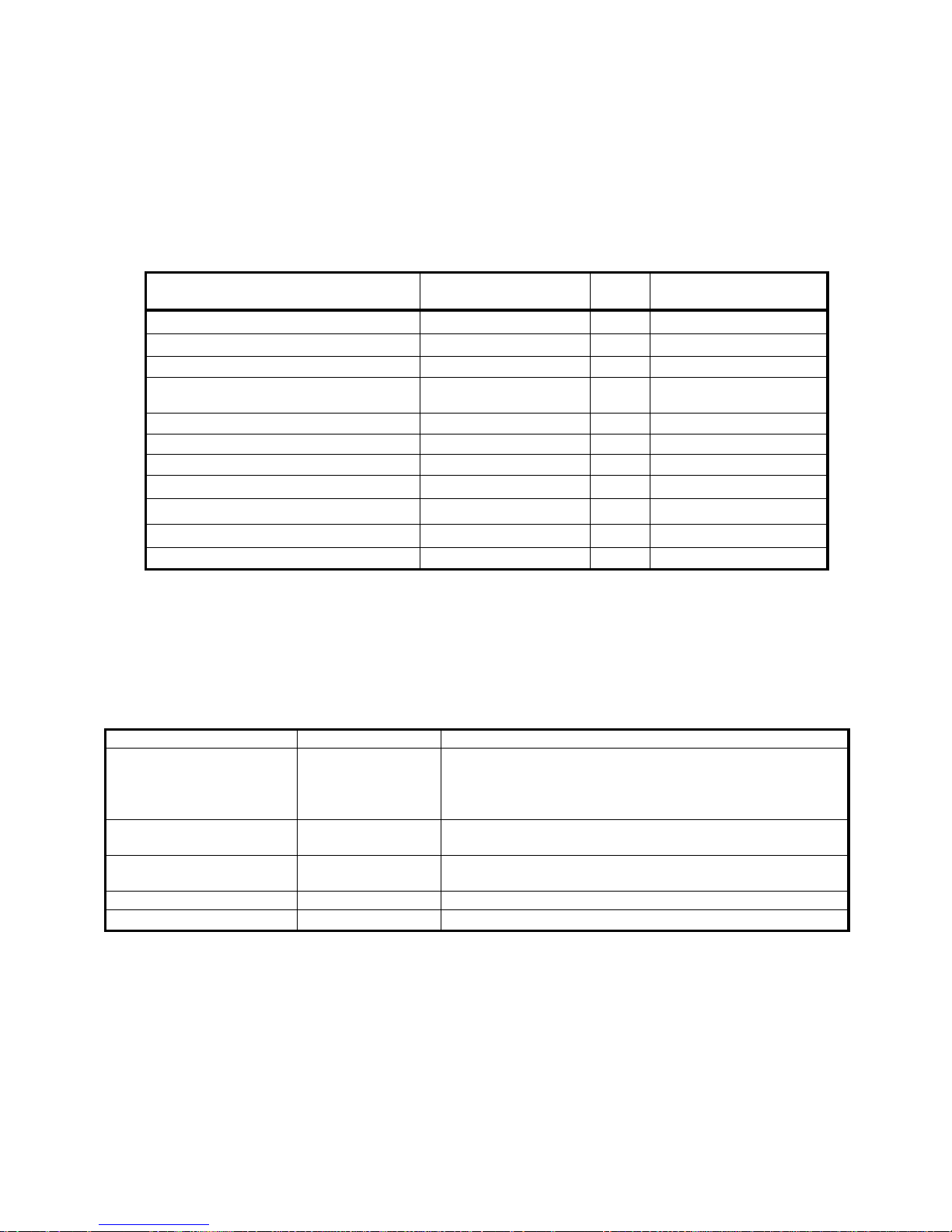

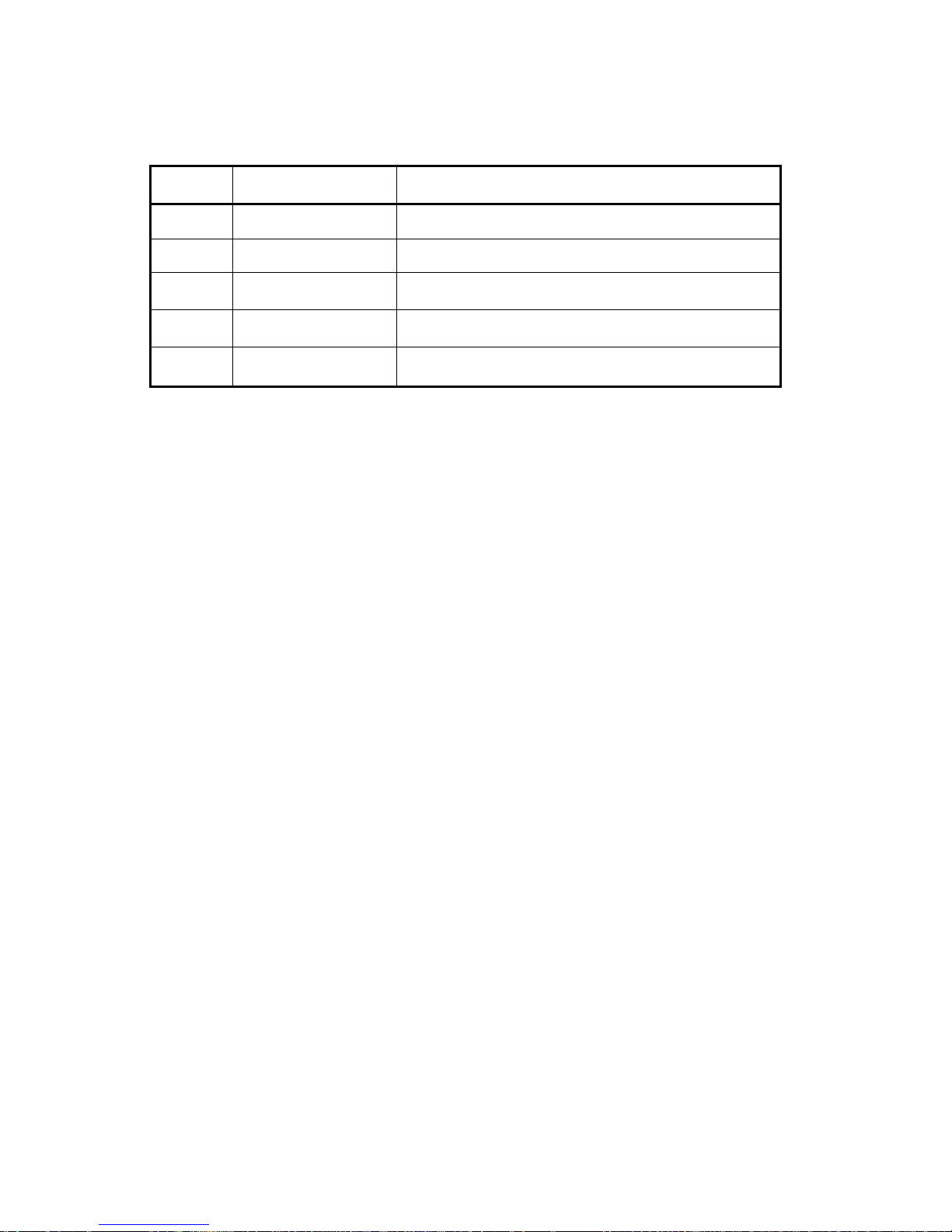

1.3 Configuration

Standard components

Table 1-1 shows the standard configuration of the Handy Search NJJ-95B

Table 1-1 Standard Components

Name Model Number

Quan

tity

Remarks

Handy Search NJJ-95B 1

Battery pack BP-3007 series 1

Battery charger BC-3008 series 1

AC cable CB-A01-J1-E series 1

For the battery

charger

Hand strap H‑7ZYMD0018 1

Compact flash memory card CF115‑512M 1 Memory size: 512MB

Storage box H‑7ZYMD0017 1

Instruction manual

DC00‑NJJ‑95B 1

Quick instruction sheet

DC10‑NJJ‑95B 1

License agreement for software DC20‑NJJ‑95B 1

Users Guide CD-R H‑7ZYMD0016 1

Options

Table 1-2 shows optional products that are provided in addition to the

standard components.

Table 1-2 Options

Name Model Number Remarks

Printer set CMZ-203

Set configuration: Printer (DPU-3445 series)

Paper holder (RH-48-00 series)

Battery pack (BP-3007 series)

Recording paper (TP451C)

AC adapter set CBD-2485

Set configuration: AC adapter (PW-0904-W1 series)

AC cable (CB-A01-J1-E) series

Battery charger set CBK-154

Set configuration: Adapter (BC-3008 series)

AC cable (CB-A01-J1-E series)

Battery pack BP-3007 series Shared between handy search and printer

Printing paper

TP451C

Set of 10 rolls

‑6‑

Page 19

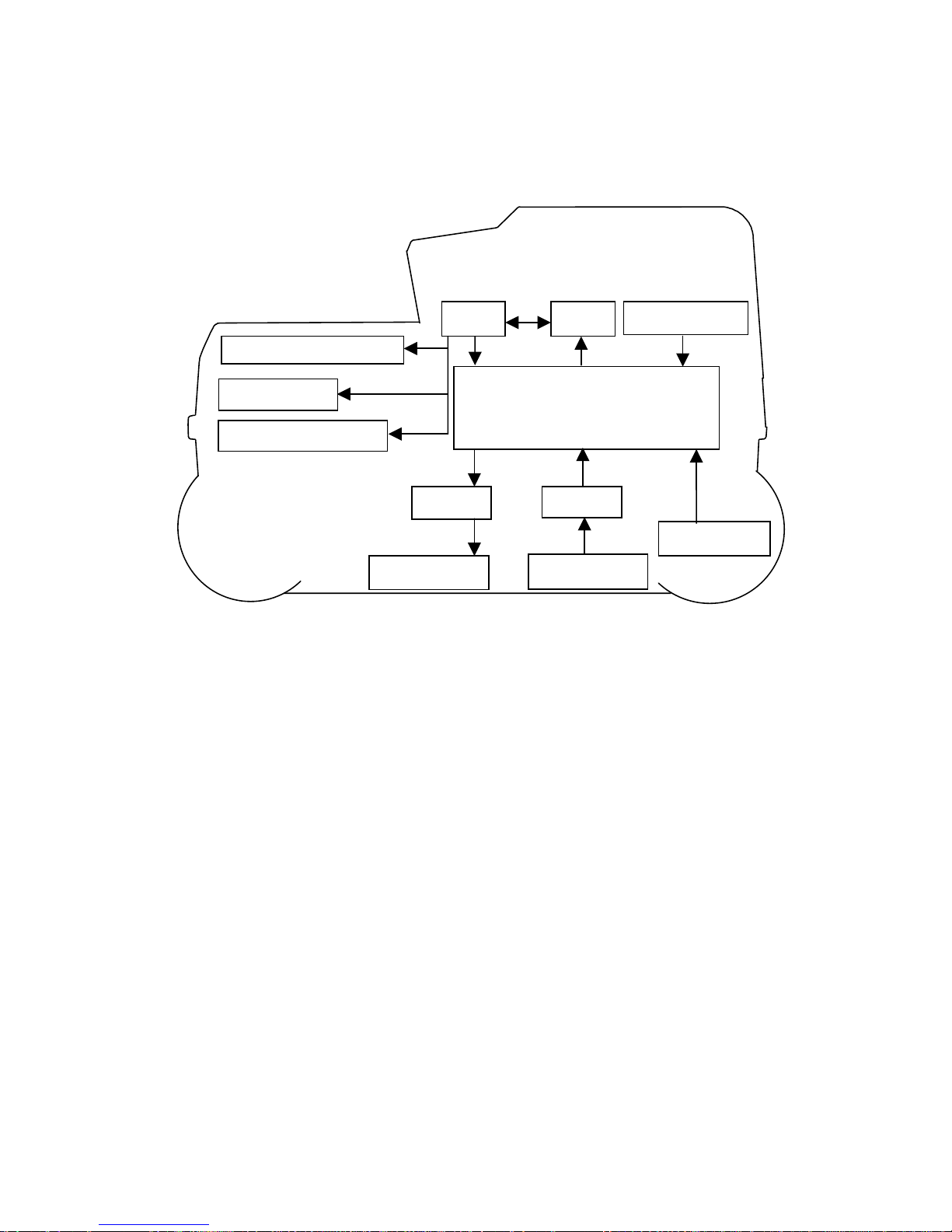

1.4 Overall System Diagram

Table 1-1 shows the total configuration of the Handy Search NJJ-95B

Trans

Rec. antenna

ReceiveTrans

Compact Flas

h

IrDA Trans

Control section

Op key

Distance Detector

Memo

CPU

LCD

Figure 1-1 Overall System Diagram

‑7‑

Page 20

1.5 Configuration

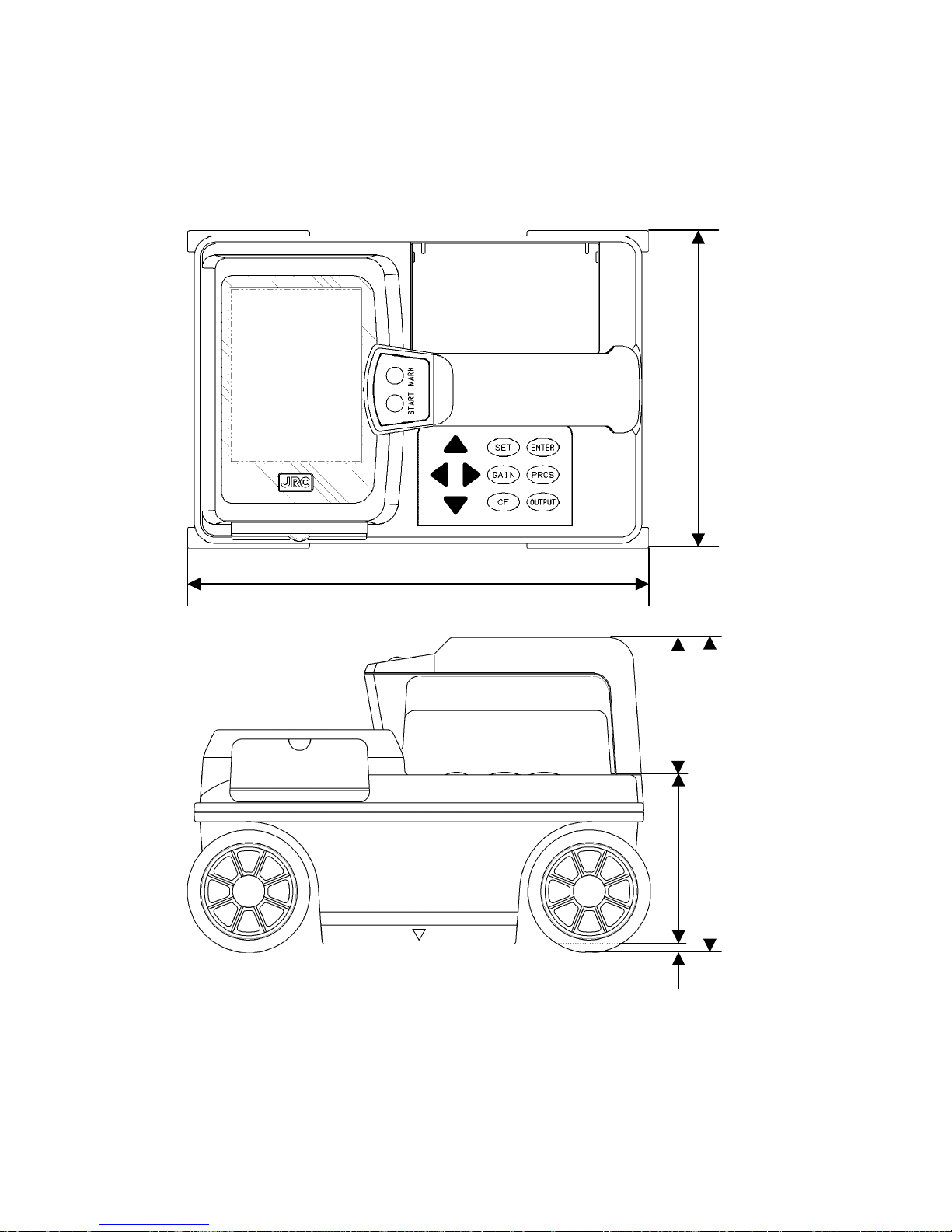

Figure 1-2 shows the external views of this radar.

Plan view drawing

149

216

Side view drawing

147

79

64 4

Fig. 1-2. Handy Search NJJ-95B external dimensions diagram

‑8‑

Page 21

Rearview

[Units in trigonometry: mm]

‑9‑

Page 22

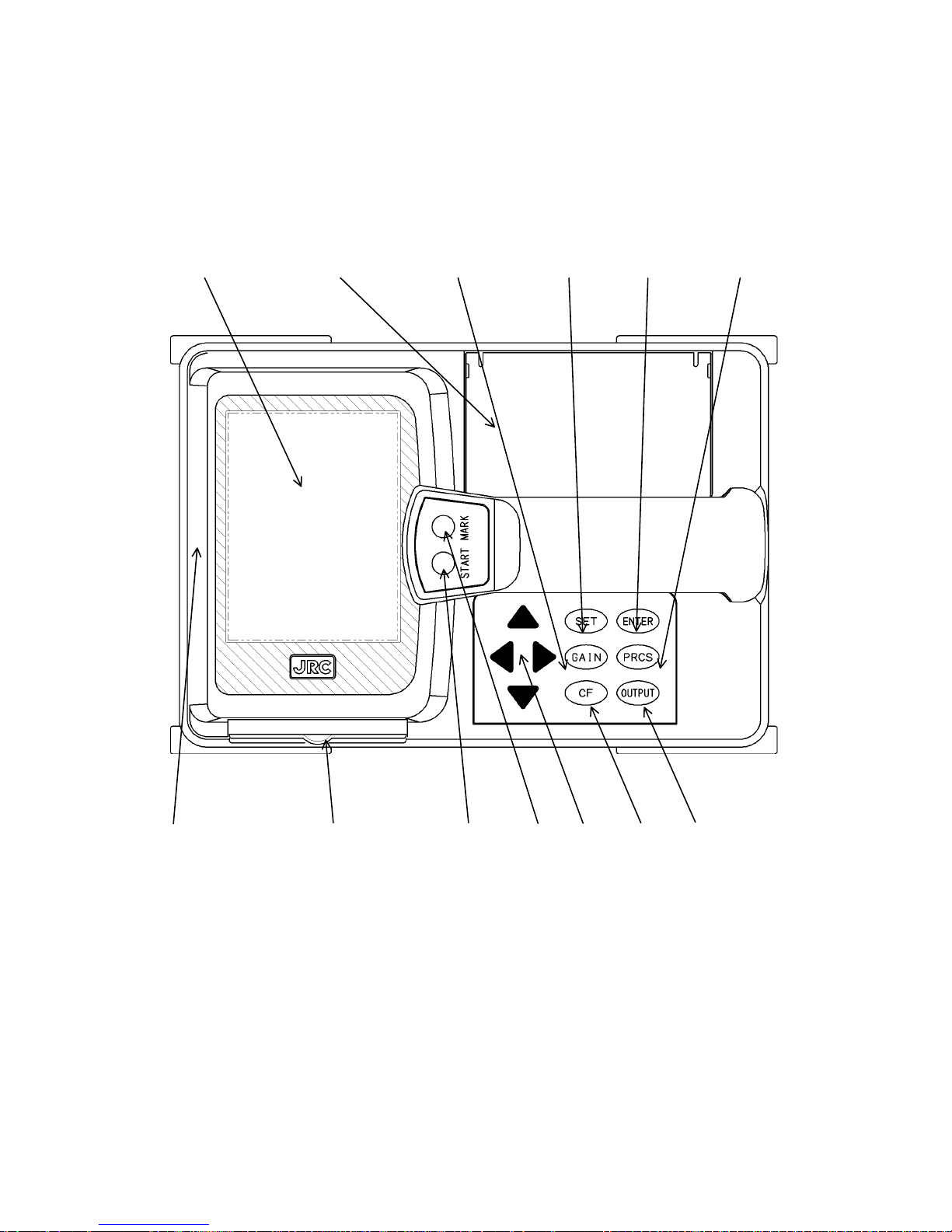

2 Parts Names and Functions

2.1 Handy Search NJJ-95B

This section shows the operation panel of this unit and explains the functions for each group.

1 2 3 4 5 6

7 8 9 10 11 12 13

Figure 2-1 Top View

‑10‑

Page 23

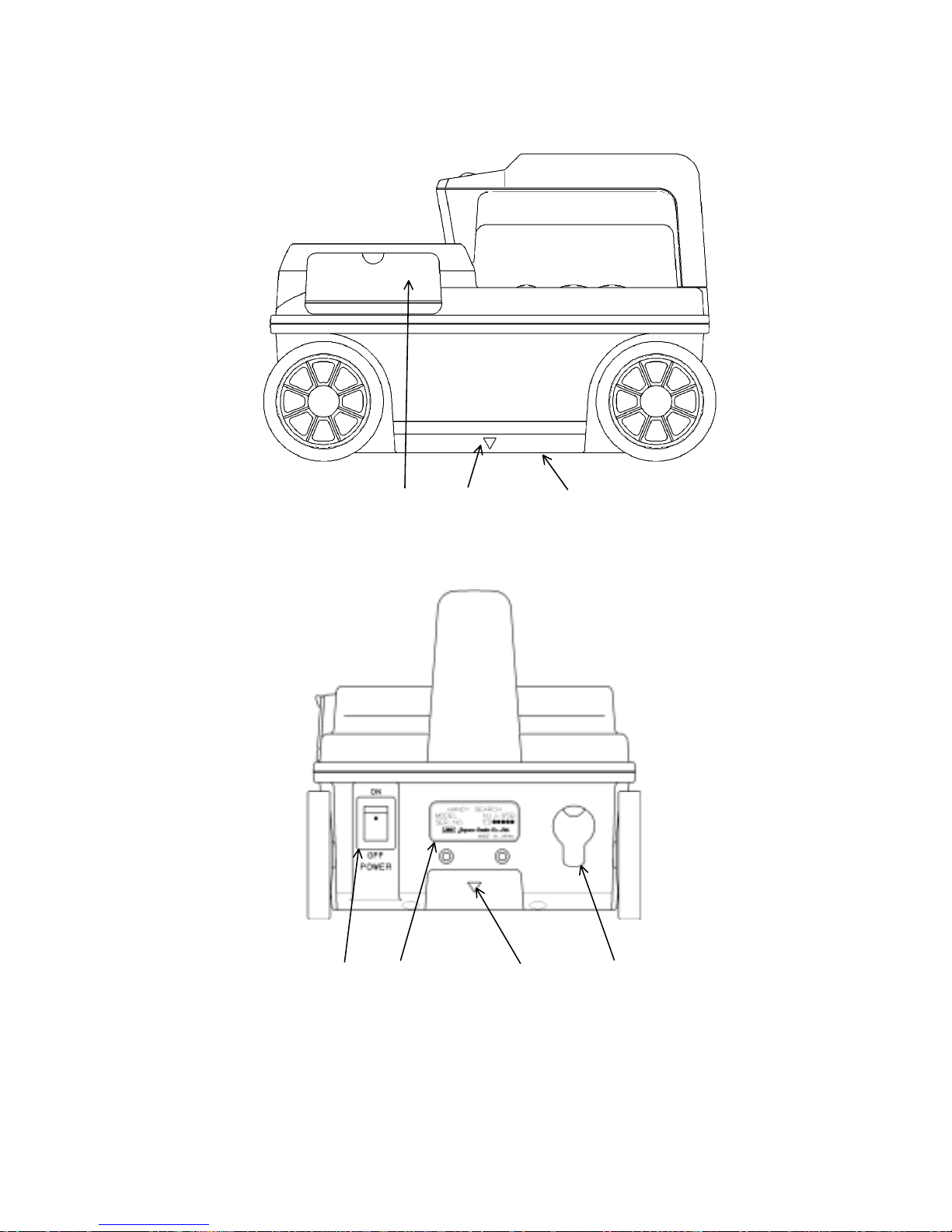

Table 2-1 Main Functions of Parts on the Handy Search

Number in

Square

Label Function

1 (None) Liquid crystal display

2 (None) Battery holder

3 GAIN Sets the sensitivity

4 SET Sets each of the parameters.

5 ENTER

Decision key for start of image processing and various types of

selection.

6 PRCS Switch to image processing mode.

7 (None) IrDA optical receptor for communicating with the printer

8 (None) Compact flash memory card slot

9 START Starts/stops scan tests.

10 MARK Displays a mark on the scan test screen.

11

Used for movement of cursor and screen and making changes to the

various parameters.

12 CF Switch to the CF control screen.

13 OUTPUT Key for outputting data.

‑11‑

Page 24

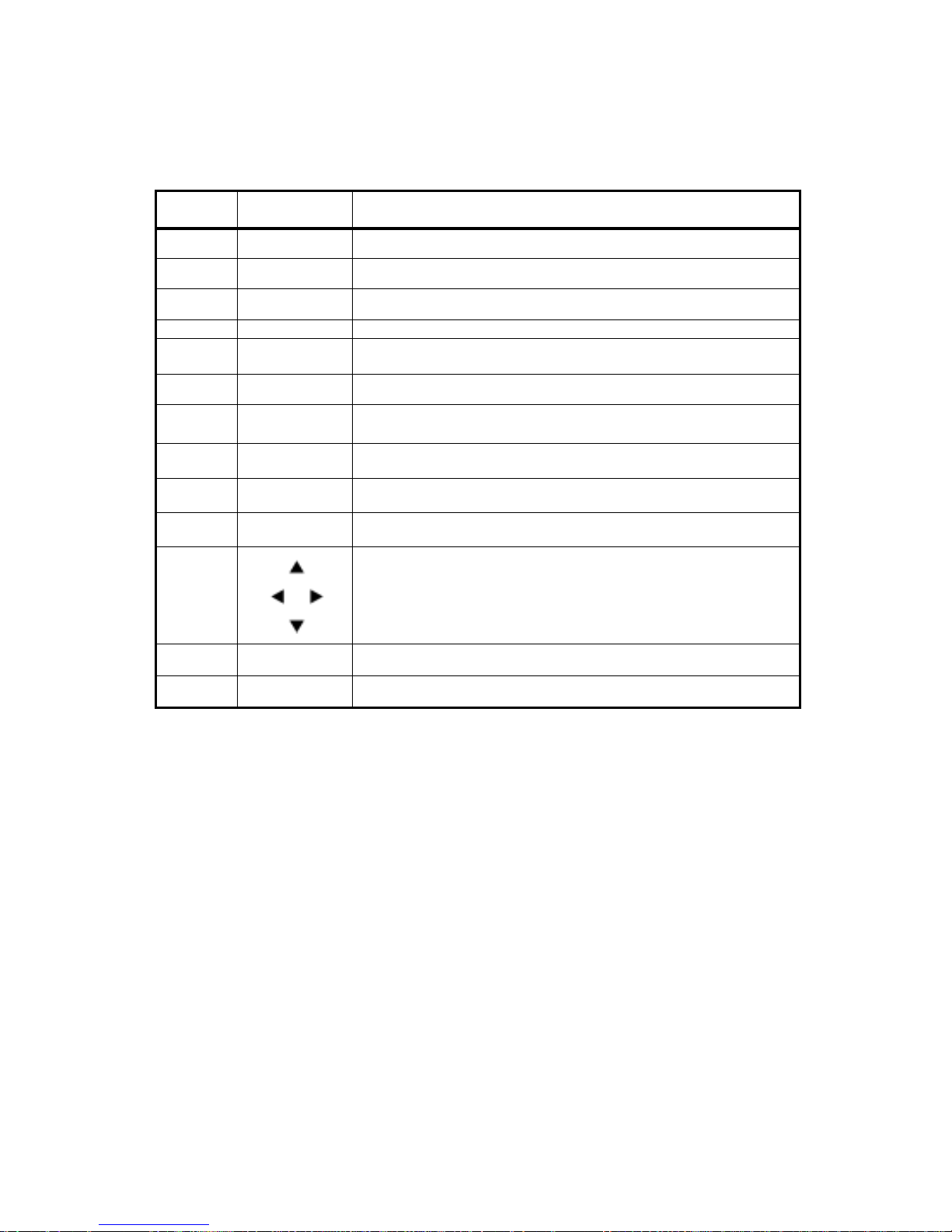

8 14 15

Figure 2-2 Side View

16 17 14 18

Figure 2-3 Rear View

‑12‑

Page 25

Table 2-2 Functions of Parts on the Side and Rear Panel

Number in

Square

Label Function

14

▼

Mark indicating the scan test position.

15 (None) Antenna face to radiate and receive electromagnetic waves

16 POWER ON OFF Turns power on and off.

17 (None) Equipment nameplate

18 (None) Connector for AC adapter

‑13‑

Page 26

2.2 Example of the Scan Test Screen

Describe the configuration for each of the scan test screens.

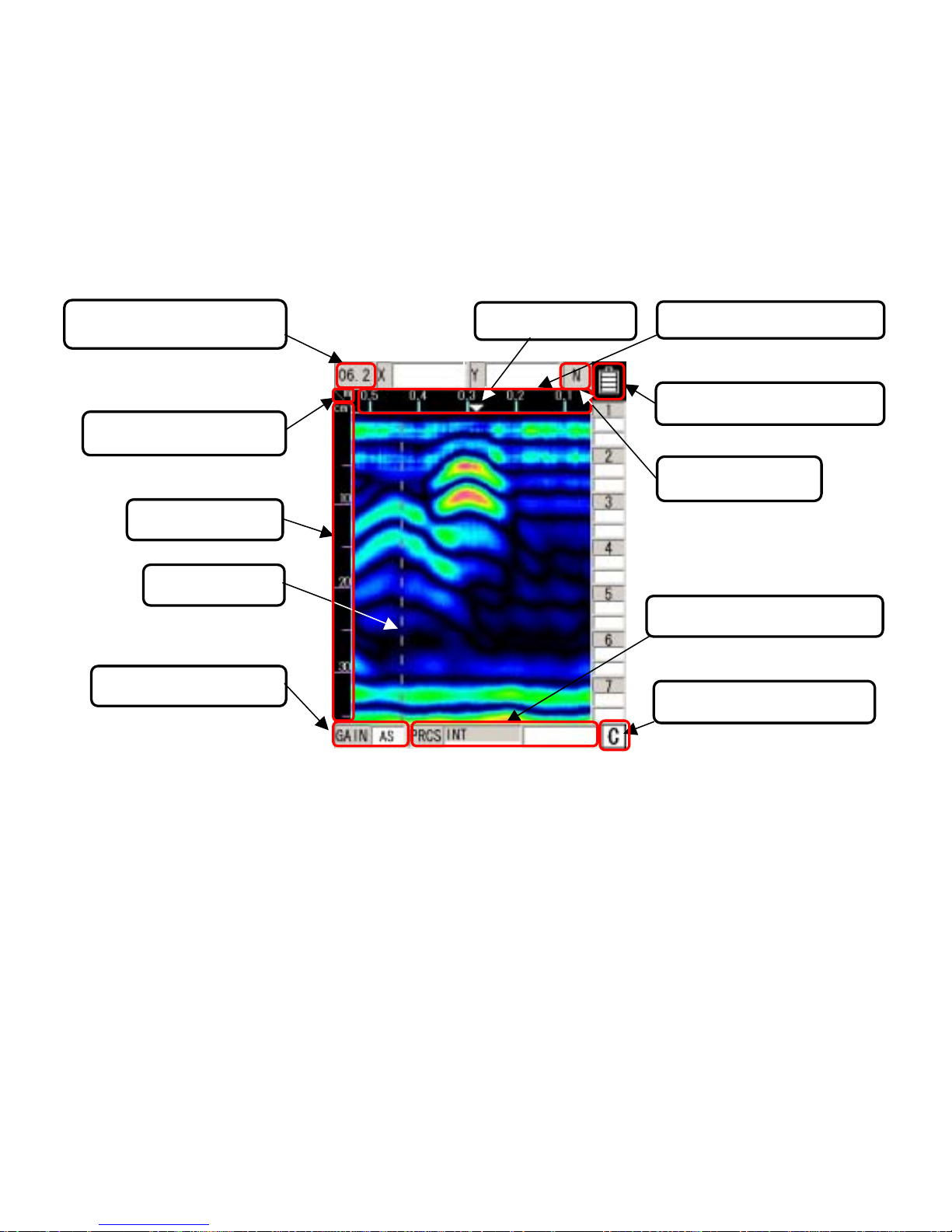

2.2.1 Scan test screen example (during testing)

An example of a scan test screen (during scanning) is shown in Fig. 2-4.

(2)Calibration method

(6)Antenna Mark

(7)Distance moved gauge

(1)Depth calibration value

(3)Depth gauge

(4)Fixed cursor

(8)Battery capacity display

(10)Image processing display

(11)External output display

(9)Display range

(5)Sensitivity display

Fig. 2-4 Scanning test screen example (during scanning)

(1) Depth calibration value

Displays the depth calibration value set at the parameter settings screen.

The method for setting the depth calibration value can be found in 2.3.6 Depth

Calibration.

(2) Calibration method

Displays the calibration method set using the parameter settings screen.

Distance feed system displays “m” and time feed system displays “s”.

The method for setting the calibration method can be found in section 2.3.5 of this manual

under “Calibration Method”.

‑14‑

Page 27

(3) Depth gauge

Displays a scanning depth gauge.

The scanning depth gauge changes based on the depth calibration value.

(4) Fixed cursor

The fixed cursor is the cursor that is used to designate surface waves used for real time

manual deduction processing.

See section 3.2.5 “Real Time Manual Deduction processing” for the method used for real

time manual deduction processing.

(5) Sensitivity display

Shows the scanning sensitivity setting.

See section 3.2.3 “Sensitivity for the method used to switch sensitivity”.

(6) Antenna mark

Antenna mark that shows a mark for the scan distance.

See section 3.2.4 “Antenna Mark” for how to use the antenna mark.

(7) Distance moved gauge

Gauge for the distance moved while performing a scanning test.

(8) Battery capacity display

Shows the general amount of capacity remaining in the battery pack that is being used.

(9) Display range

Shows the display range set using the parameter settings screen.

See section 2.3.11 “Display Range” for the method used to set the display range.

(10) Image processing display

Displays the image processed items for processing performed on the sense test results.

See section 3.4 “Image Processing” for how to process images.

(11) External output display

Shows the external output data destination set using the parameter settings screen.

See section 2.3.10 “External Output” for how to set up external output.

‑15‑

Page 28

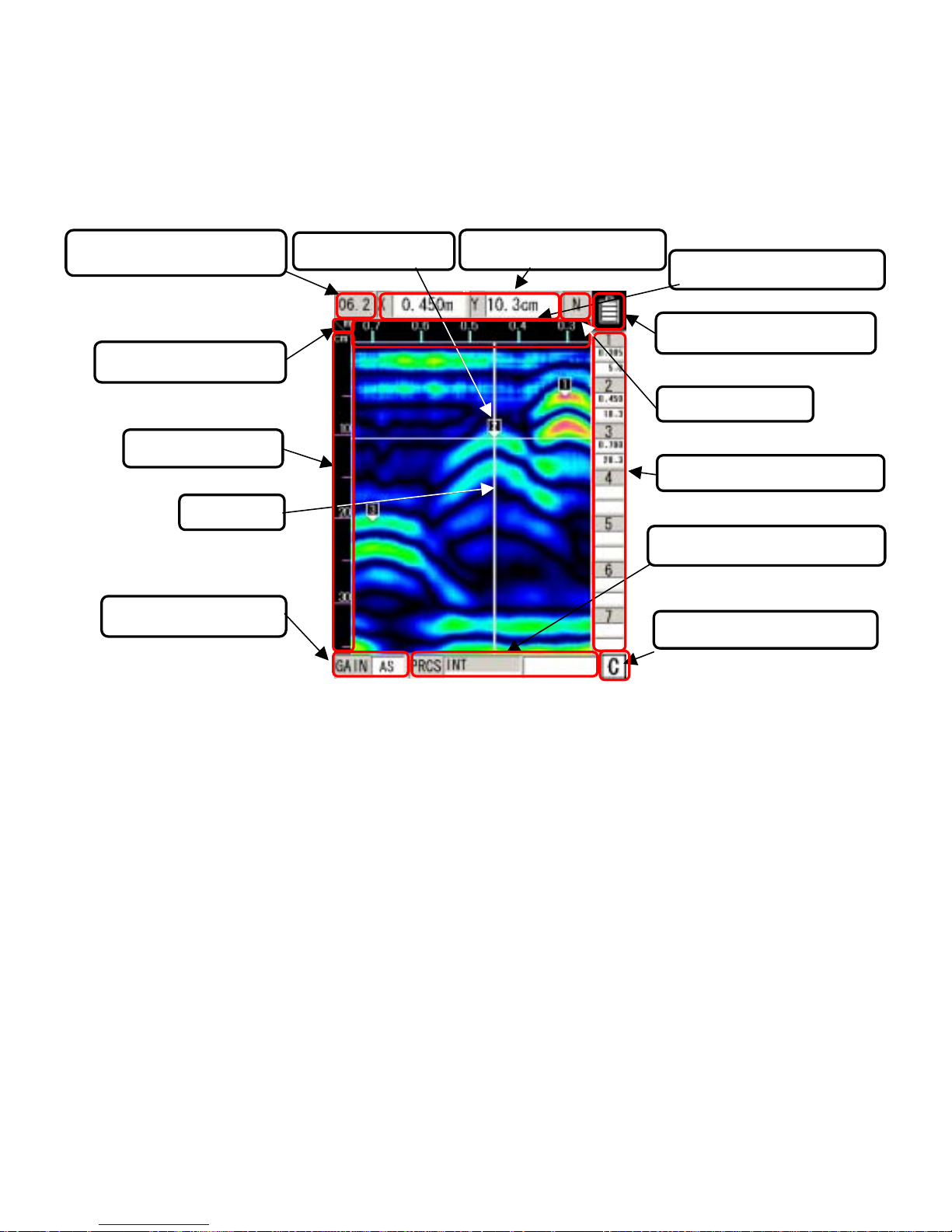

2.2.2 Scan test screen example (not during testing)

An example of a scan test screen (not during scanning) is shown in Fig. 2-5

Fig. 2-5 Sensing test screen example (not during sensing)

(6)Antenna Mark

(11)Cursor mark coordinates

(10)Dis

play

ran

g

e

(13)External out

p

ut displa

y

(12)Image processing display

(9)Battery capacity display

(5) Sensitivity display

(4)

Curso

r

(3) De

p

th gau

g

e

(1)Depth calibration value

(8) Distance moved gauge

(7)Cursor Coordinates

(2)Calibration method

(1) Depth calibration value

Displays the depth calibration value set at the parameter settings screen.

The method for setting the depth calibration value can be found in section 2.3.6 “Depth

Calibration”.

(2) Calibration method

Displays the calibration method set using the parameter settings screen.

Distance feed system displays “m” and time feed system displays “s”.

The method for setting the calibration method can be found in section 2.3.5 “Calibration

Method”.

(3) Depth gauge

Displays a scanning depth gauge.

The scanning depth gauge changes based on the depth calibration value.

‑16‑

Page 29

(4) Cursor

Indicates a cursor mark on the scanning test screen and is a “criss-cross” cursor that is

used to designate A mode waveform display points in B mode and for scrolling the

sensing test screen.

(5) Sensitivity display

Shows the scanning sensitivity setting.

See section 3.3.2 “Switching Sensitivity” for the method used to switch sensitivity.

(6) Cursor mark

A mark that shows an arbitrary point on the scanning test screen.

See section 3.3.3 “Cursor Operation” for how to display, erase the cursor mark.

(7) Cursor Coordinates

Shows the coordinates of the cross point of the cursor in item (4).

The distance moved is shown in “X” and depth in “Y”.

(8) Distance gauge

Distance gauge in the direction the scanning was performed.

Displays the distance the main unit has moved.

(9) Battery capacity display

Shows the general amount of capacity remaining in the battery pack that is being used.

(10) Display range

Shows the display range set using the parameter settings screen.

See section 2.3.11 “Display Range” for the method used to set the display range.

(11) Cursor mark coordinates

Displays the coordinates of the cursor mark in item (6).

Below each of the mark numbers, the movement distance (X) is shown in the first row

and the depth (Y) is shown in the second row.

(12) Image processing display

Displays the image processed items for processing performed on the test results.

See section 3.4 “Image Processing” for how to process images.

‑17‑

Page 30

(13) Output data display

Shows the output data destination set using the parameter settings screen.

See section 2.3.10 “External Output” for how to set up external output.

‑18‑

Page 31

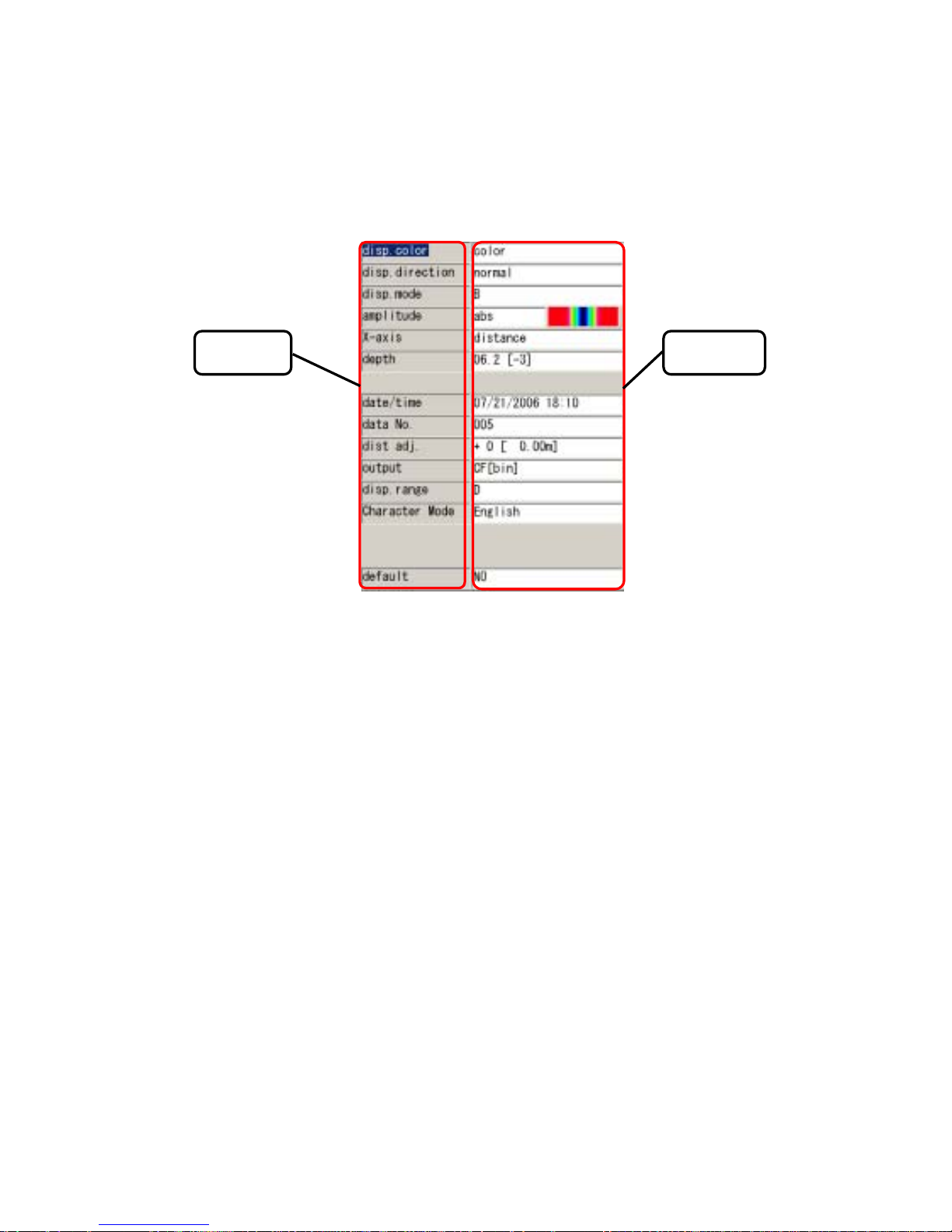

2.3 Parameter Settings Screen

While scanning is stopped, pressing of the 4 SET key enables switching the screen to the

parameter settings screen (see Fig. 2-6) and each of the settings can be changed. To return to the

scanning test screen, press the 4 SET key again.

Selections Settings

[Left column] [Right column]

Display color Color

Screen inversion Normal

Display Mode B

Level adjustment method Absolute value

Measurement method Distance feed

Depth calibration 06.2 [-3]

Date 2006/07/21 18:09

Data No. 005

Distance correction +0 [0.00 m]

External output CF [binary]

Display range Depth

Character mode Japanese

Return to standard No

Figure 2-6 Parameter Setting Screen

2.3.1 Display color

"Color" or "Monochrome" can be selected for the display color for the liquid crystal display of the

‑19‑

Page 32

main unit.

In order to change the display color, select “display color” from the settings using the ▲▼ cursor

keys (inverting display) and switch to item selection using the

cursor keys.

Select “color” or “monochrome” using the ▲▼ cursor keys or use the

cursor keys to switch

to item selection.

2.3.2 Inversion of the screen

This unit supports screen display inversion while it moves (scans) to the right and to the left,

thereby displaying the scanning test screen upside down. (See Figure 2-7.)

In order to invert the screen, select “Invert Screen” from the set up items using the ▲▼ cursor

keys (invert display) and switch to item selection using the

cursor keys.

Select “normal” or “inverted” using the ▲▼ cursor keys or use the

cursor keys to switch to

item selection.

Remarks

The direction of image data output by the printer (optional) is changed depending on the setting

of the screen inversion function.

For the printer to always output image data in the same direction, retain the same setting

"Normal or Reverse" for "Inversion of the screen."

• While the screen display is inverted, the cursor keys

▲▼ move in the opposite direction.

(They function in the same direction as when "Normal" is selected for "Inversion of the

screen.")

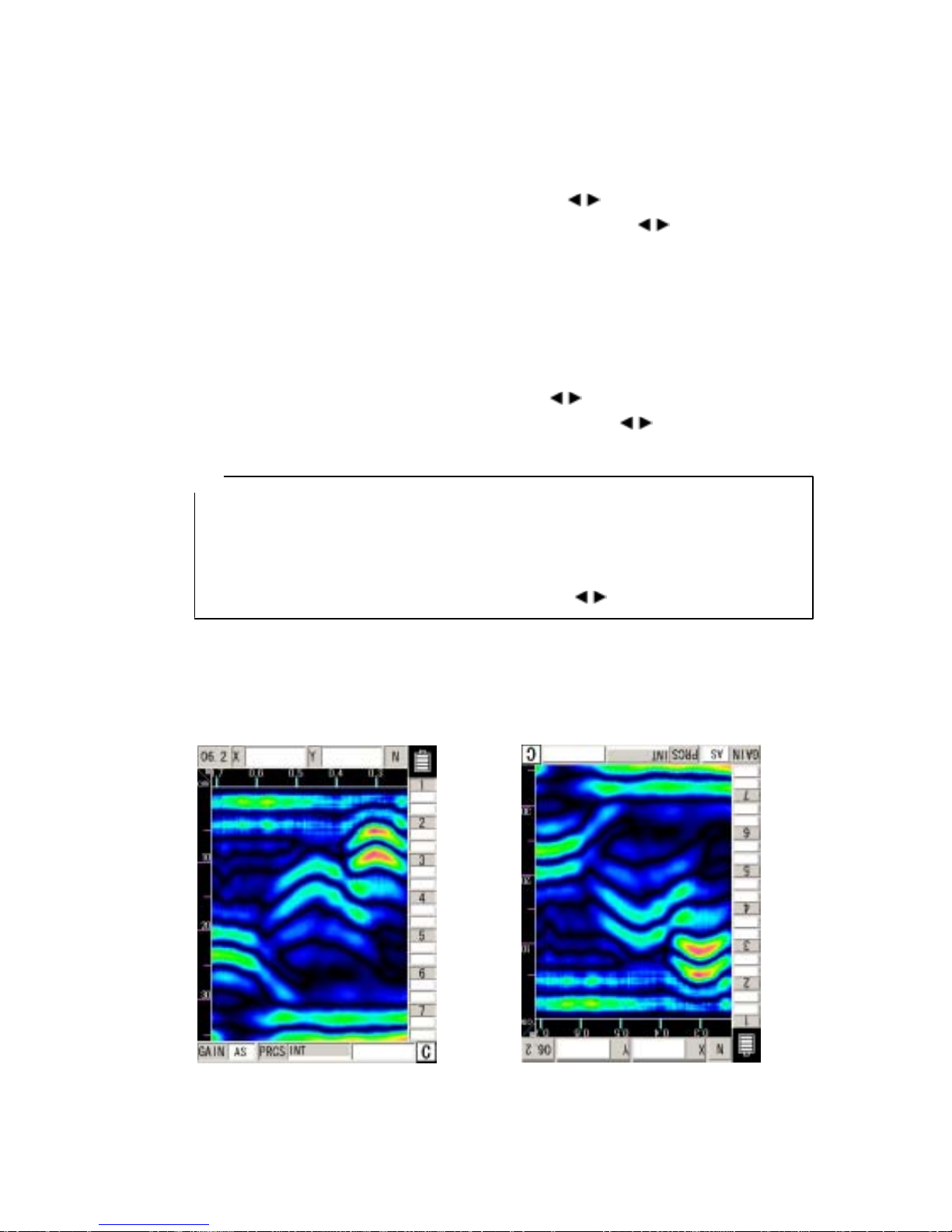

Screen display direction [Normal] Screen display direction [Reverse]

‑20‑

Page 33

Figure 2-7 Screen Inversion Function

2.3.3 Display mode

This unit can scan/display data in both "B” mode (vertical cross section) and "BA” mode (vertical

cross section and reflected waveform display).

In order to change the display mode, select “display mode” from the settings using the ▲▼ cursor

keys (inverting display) and switch to item selection using the

cursor key.

Select “B” or “BA” using the ▲▼ cursor keys or use the

cursor keys to switch to item

selection.

Remarks

• When the display mode is switched between "B" and "BA" after scanning, data scanned in "B

mode" is displayed in "BA mode," and data scanned in "BA mode” is displayed in "B mode." See

section 3.3.1 “Mode switching."

‑21‑

Page 34

2.3.4 Gradation system

"Absolute value" or "Offset" can be selected for the gradation system.

When "Color" is selected for "Display color," the absolute value gradation changes between Black

→ Indigo → Green → Yellow → Red as the A-mode amplitude increases as shown in Figure 2-8.

The offset gradation changes between Black → Indigo → Green → Yel l ow → Red from the left in A

mode as shown in Figure 2-9.

When "Monochrome" is selected for "Display color," the gradation changes between

White → Gray → Black in this order.

In order to change the gradation method, select “Gradation Method” from the set up items using

the ▲▼ cursor keys (invert display) and switch to item selection using the

cursor keys.

Select “absolute value” or “offset” using the ▲▼ cursor keys or use the

cursor keys to

switch to item selection.

Figure 2-8 Absolute Value Gradation Figure 2-9 Offset Gradation

2.3.5 Calibration method

"Distance feed" or "Time feed" can be selected as the scanning method of this unit.

When "Distance feed" is selected, the scanning method measures/displays data in units of 5 mm

in "B/BA mode" conforming to the wheels' moving distance. When "Time feed" is selected, the

scanning method measures/displays data at 50 ms intervals in "B/BA mode," regardless of the

wheels' moving distance.

In order to change the scanning method, select “Scanning Method” from the set up items using

the ▲▼ cursor keys (invert display) and switch to item selection using the

cursor keys.

Select “distance feed” or “time feed” using the ▲▼ cursor keys or use the

cursor keys to

switch to item selection

.

‑22‑

Page 35

2.3.6 Depth calibration

The depth calibration is the scan depth obtained from the wave propagation speed and reflected

time with the depth gauge corrected using the relative dielectric constant of concrete. The value

must be changed based on the condition (such as moisture content) of the concrete being scanned.

A large difference between the relative permittivity of the concrete being scanned and the depth

calibration value will cause a large depth error.

In order to reduce the depth error, detect an object where the depth can be confirmed (as with

rebar) and peform a correction of the depth guage by setting the depth calibration value so that the

depth displayed in the scanning results basically matches the actual depth.

If it is not possible to scan an object (such as the case with rebar) where the depth can be

confirmed, and the depth calibration value is unclear, it is recommended to set the depth calibration

to “08.0 (+0)”.

In order to change the depth calibration value, select “Depth Calibration” from the set up items

using the ▲▼ cursor keys (invert display) and switch to item selection using the

cursor keys.

Set the “depth calibration value” using the ▲▼ cursor keys and use the

cursor keys to

switch to item selection.

Remarks

●The intervals on the depth gauge are not equivalent. Confirm the depth using the cursor

display value.

2.3.7 Date, time

This radar contains a rechargeable button-type lithium battery with which dates and times can be

recorded.

In order to correct time and/or date, select “Date and Time” from the set up items using the ▲▼

cursor keys (invert display) and switch to item selection using the cursor keys.

Select the position of the date or time that you would like to correct using the

cursor keys

and change the values using the ▲▼ keys.

Switch to item selection using the

keys.

‑23‑

Page 36

2.3.8 Data No.

Data is recorded and numbered when externally output. The data number (Data No.) is

incremented each time data is recorded.

In order to change the data No., select “Data No.” from the set up items using the ▲▼ cursor

keys (invert display) and switch to item selection using the

cursor keys.

Select the position that you would like to correct using the

cursor keys and change the

values using the ▲▼ keys.

Switch to item selection using the

keys.

Remarks

When data is to be recorded again, it can be easily managed by changing the value of Data No.

2.3.9 Distance compensation

This unit determines distance using the number of rotations the wheels make. Thus, wear of the

wheels causes an error in calculating the scanning distance. If the scanning distance has an error,

compensate the distance error.

In order to change the distance error correction value, select “Distance Correction” from the set up

items using the ▲▼ cursor keys (invert display) and switch to item selection using the

cursor

keys.

Set the “distance error correction value” using the ▲▼ cursor keys and use the

cursor keys

to switch to item selection.

(Example of distance error compensation)

a) Perform a 1m (actual value) scan test and stop the scanning.

b) Press the 4 SET key and switch to the parameter settings screen

c) Select the settings item “Distance Correction” using the ▲▼ cursor keys (invert display) and

switch to item selection using the

cursor keys.

d) d) Using the ▲▼cursor keys, set the correction value so that the distance of the last line

(displayed by [ ] to the right of the correction value) is as close as possible to 1 m.

e) Use the

cursor keys to switch to item selection and press the 4 SET key to return to the

scan test screen.

Remarks

●The distance of the last scan test line is displayed to the right of the compensation value.

When the compensation value is changed, the distance is also changed in accordance with

the new compensation value.

With this value as a rough standard, set a new compensation value.

‑24‑

Page 37

2.3.10 Output Data Format

Set the external output destination of scan test data. The table below shows the relationship

between external output destinations and output data formats.

The currently set external output destination is indicated with the character displayed at the lower

right of the scan test screen.

External Output

Destination

Output Data Format

Scan Test

Screen

Destination

on

Measurem

ent Screen

Printer (I) Print to the printer

CF [text] Saved in text format in compact flash memory

CF [binary] Saved in binary format in compact flash memory

In order to change external output, select “External Output” from the set up items using the ▲▼

cursor keys (invert display) and switch to item selection using the

cursor keys.

Set the “external output” using the ▲▼ cursor keys and use the

cursor keys to switch to

item selection.

See Section 3.6 External Output Methods for the operation method.

2.3.11 Display Range

The display range is an item for setting the display limits of the scanning depth. There

are three settings: “deep”, “standard”, and “shallow”.

Set the range of display based on depth of the object to be scanned using the following.

Depth of the object to be scanned is 30 cm or less: “deep”

The depth of the object to be scanned is 20cm or less: “standard” (same as

NJJ-95A)

Depth of the object to be scanned is 10cm or less: “shallow”

In order to change the display range, select “display range” from the settings using the ▲▼ cursor

keys (inverting display) and switch to item selection using the

cursor key.

Set the “display range” using the ▲▼ cursor keys and use the

cursor keys to switch to item

selection.

2.3.12 Character Mode

Switches displayed characters between Japanese and English.

In order to change the character mode, select “Character Mode” from the settings using the ▲▼

cursor keys (inverting display) and switch to item selection using the

cursor key.

Set the type of characters using the ▲▼ cursor keys and use the

cursor keys to switch to

item selection.

‑25‑

Page 38

2.3.13 Return to standard

This function changes all the parameters other than "Data, time" back to the standard settings.

In order to revert to standard settings, select “Return to Standard” from the set up items using the

▲▼ cursor keys (invert display) and switch to item selection using the

cursor keys.

Select “Yes” using the ▲▼ cursor keys and use the

cursor keys to switch to item selection.

‑26‑

Page 39

2.4 CF Control screen

While scanning is in off status and the 12 CF key is pressed, the screen switches to the CF control

screen and compact flash memory control can be performed. Return to the scan test screen by

pressing on the 12 CF key once more or “Cancel”.

See 3.6.2 ~ 3.7.4 for how to control the compact flash memory.

The CF control screen is shown in Fig. 2-10.

(3)Controlitems

(2)Thumbnails

(1)Fileselection

Figure 2-10 CF Control Screen

(1) File Selection

The filenames for data saved on the compact flash memory are displayed.

Select the file (inverted display) using the ▲▼ cursor keys.

(2) Thumbnail image display

Displays the file selected in (1) as a thumbnail.

(3) Control items

Control items for the compact flash memory.

Select (inverted display) an item using the

cursor keys and choose it with the 5 ENTER key.

‑27‑

Page 40

3 Operating Method

The numbers in squares in this chapter correspond to the numbers in Tables 2-1 and 2-2 on pages 8-11.

Furthermore, keys are displayed on this unit using bold Gothic characters.

WARNING

Do not use any battery pack other than the BP-3007-A1 or any AC adapter

other than the PW-3009-W.。

Doing so could cause fire, electric shock, or breakdown.

Do not short-circuit the terminals of the battery charger or battery pack.

Doing so could cause fire, explosion, or breakdown.

Do not insert anything metallic or flammable into the compact flash memory

card slot. Doing so could cause a personal injury, fire, electric shock, or

breakdown.

Do not use any charger other than the dedicated battery charger to charge

the battery pack.

Doing so could cause fire, electric shock, or breakdown.

Handy Search has a waterproof construction but must not be placed in water.

Do not expose the NJJ-95B to water or moisture, and do not use it in rainy weather. Doing so

could cause an electric shock or breakdown.

CAUTION

Making a judgment on the scan results considering the depth scanning capability of the

NJJ-95B.

Since the depth scanning capability of the radar is subject to the conditions of the object of

investigation, judging the scan results with no consideration of the depth scanning capability

may cause the cutting of rebar.

Put your hand through the hand strap and hold the NJJ-95B.

Dropping of the radar may cause an accident such as a device breakdown or personal injury.

Do not use any battery pack other than the BP-3007-A1 or any AC adapter other than the

PW-3009-W.

Doing so may cause fire, electric shock, or breakdown.

‑28‑

Page 41

CAUTION

Point the antenna surface in the direction of the probed object (concrete) while you are

performing a probe.。

If it is pointed into the air or otherwise unsuitable direction, it can cause malfunction of other

equipment or other such accidents.

Do not use the NJJ-95B in the vicinity of a radio or TV set.

Doing so may cause noise or poor reception such as disturbance of television pictures. Doing

so also adversely affects the depth sensing capability of the radar, and may cause the cutting

of reinforcing steel bars.

Do not use the NJJ-95B near a cell phone or transceiver that transmits electromagnetic

waves. Electromagnetic waves from the cell phone or transceiver adversely affect the depth

sensing capability of the radar, and may cause the cutting of reinforcing steel bars.

When the NJJ-95B is used for scanning on the road, take safety precautions such as

providing guard fences to prevent traffic accidents.

”

‑29‑

Page 42

3.1 Scanning Preparation

(1) Mounting the hand strap

A hand strap for drop prevention is provided as standard with this radar. Mount the hand strap on

the handle of the radar as shown in Figure 3-1, put your hand through the hand strap to grip the

handle, and start sense testing.

Figure 3-1 Hand Strap

(2) Connecting the power source (battery pack)

This radar can be operated with the battery pack or 100 VAC power when an optional AC adapter

is used.

Notes

●Use this radar in a place where the ambient temperature is 0 to 50 °C and the humidity is

45 to 80%.

●Do not move the radar in cold condition to a place where it is subject to sharp temperature

rise. Doing so generates condensation inside the radar that could cause a breakdown.

●Confirm that the power switch 16 is set to "OFF" before mounting/dismounting the

battery pack or the AC adapter.

‑30‑

Page 43

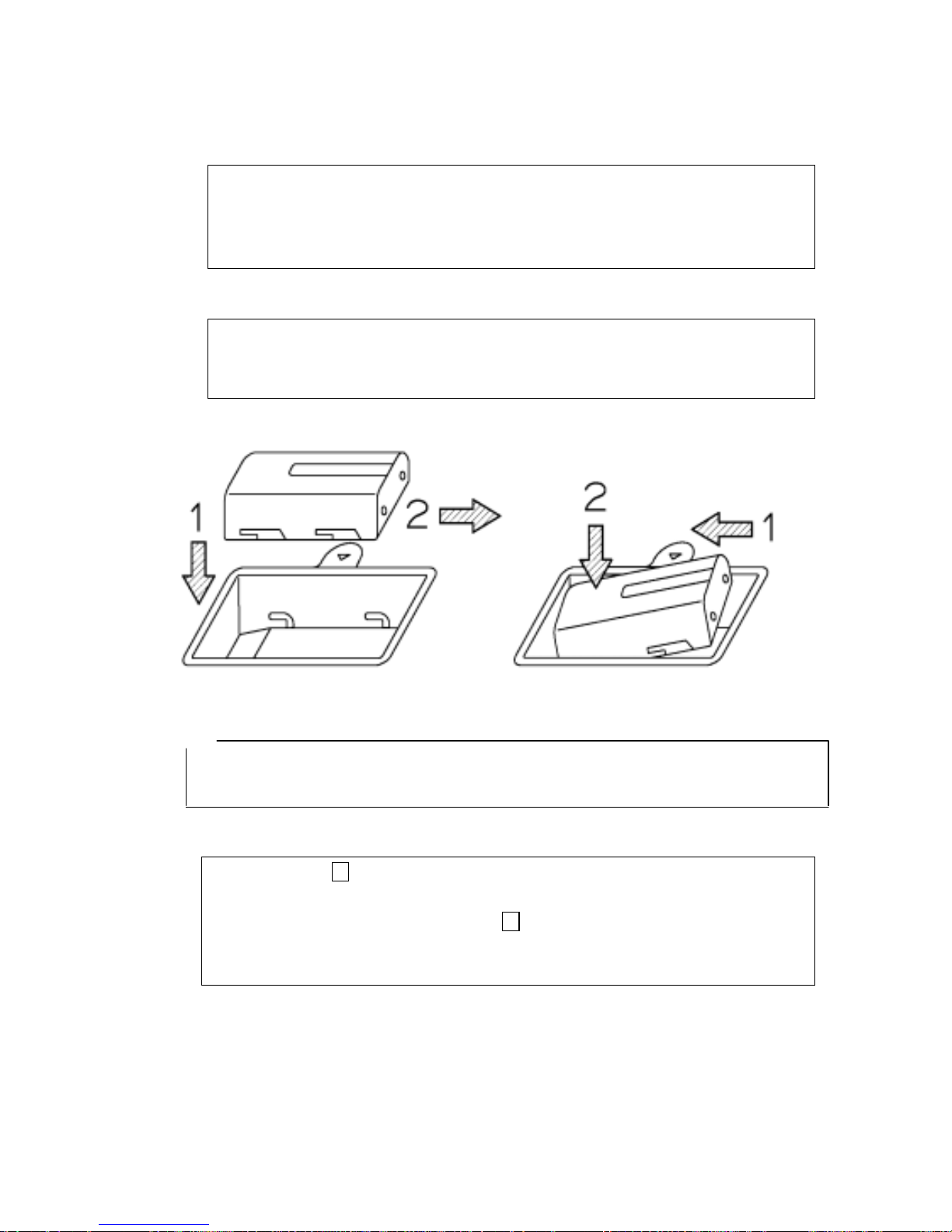

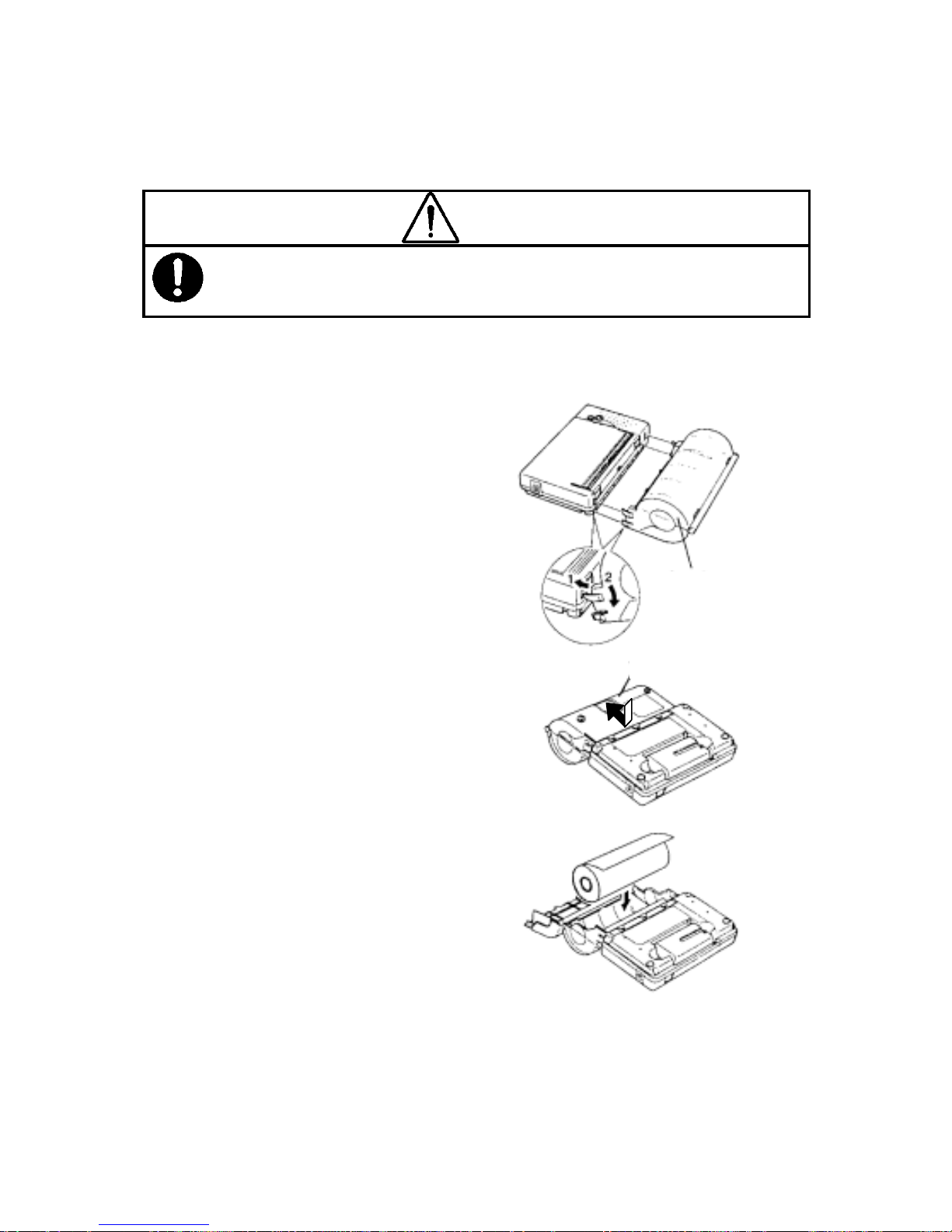

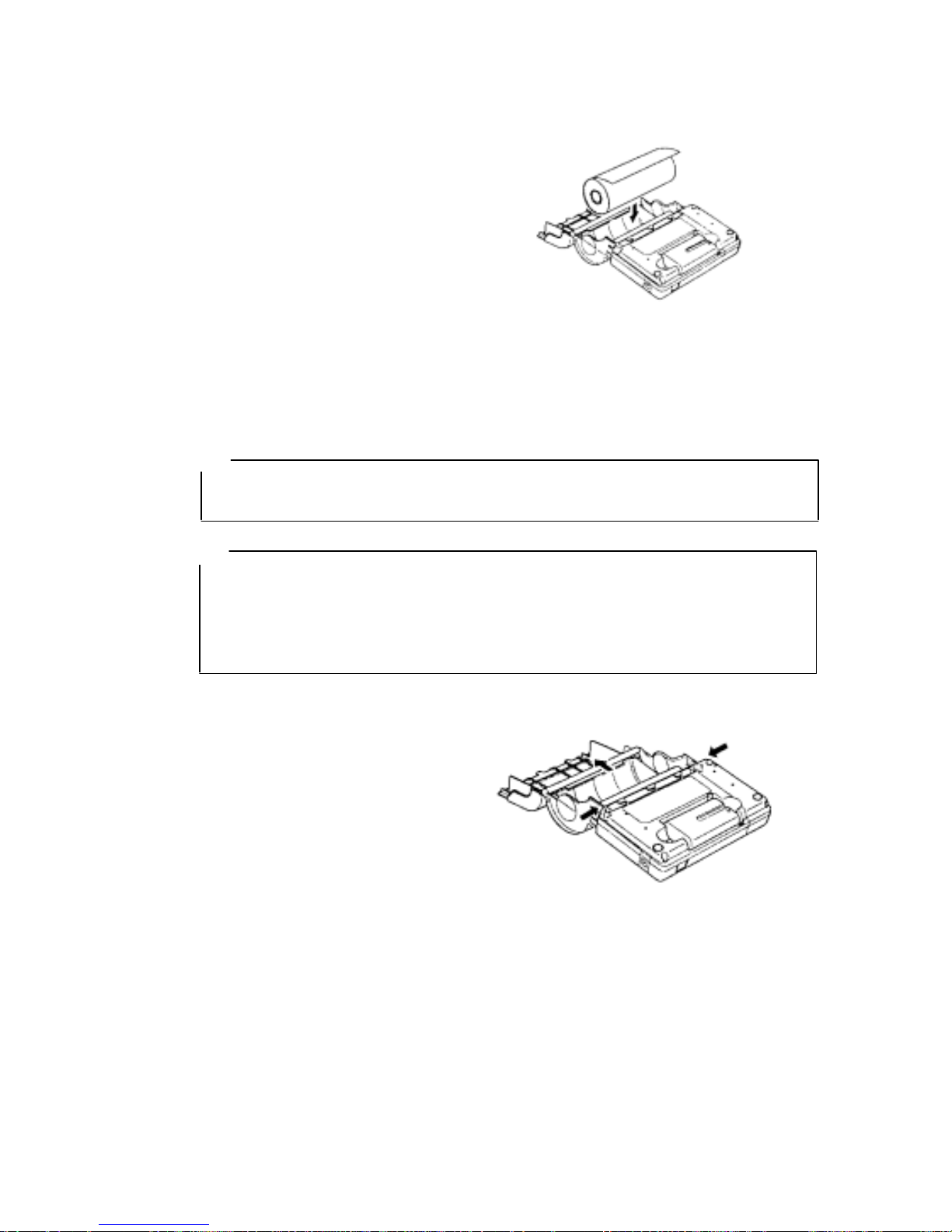

a) Mounting the battery pack (See Figure 3-2.)

1. Confirm that the 16 power switch is set to "OFF."

2. Open the battery cover 2 at the top of this unit, confirm the direction of the battery pack and

put it into the battery holder.

3. Push the battery pack forward to connect with the terminals, and close the battery cover 2.

b) Dismounting the battery pack (See Figure 3-3.)

1. Confirm that the 16 power switch is set to "OFF."

2. Open the battery cover 2 at the top of this radar, and slide the battery pack backward.

3. Push down the rear of the battery pack to raise its front, so it can be easily dismounted.

Figure 3-2 Mounting the battery pack Figure 3-3 Removing the battery pack

Remarks

• When opening the battery cover, hold onto the handle with your left hand, push up on battery

cover lock with your middle finger, open the battery cover slightly and lift the battery cover with

your right hand to easily remove the battery cover.

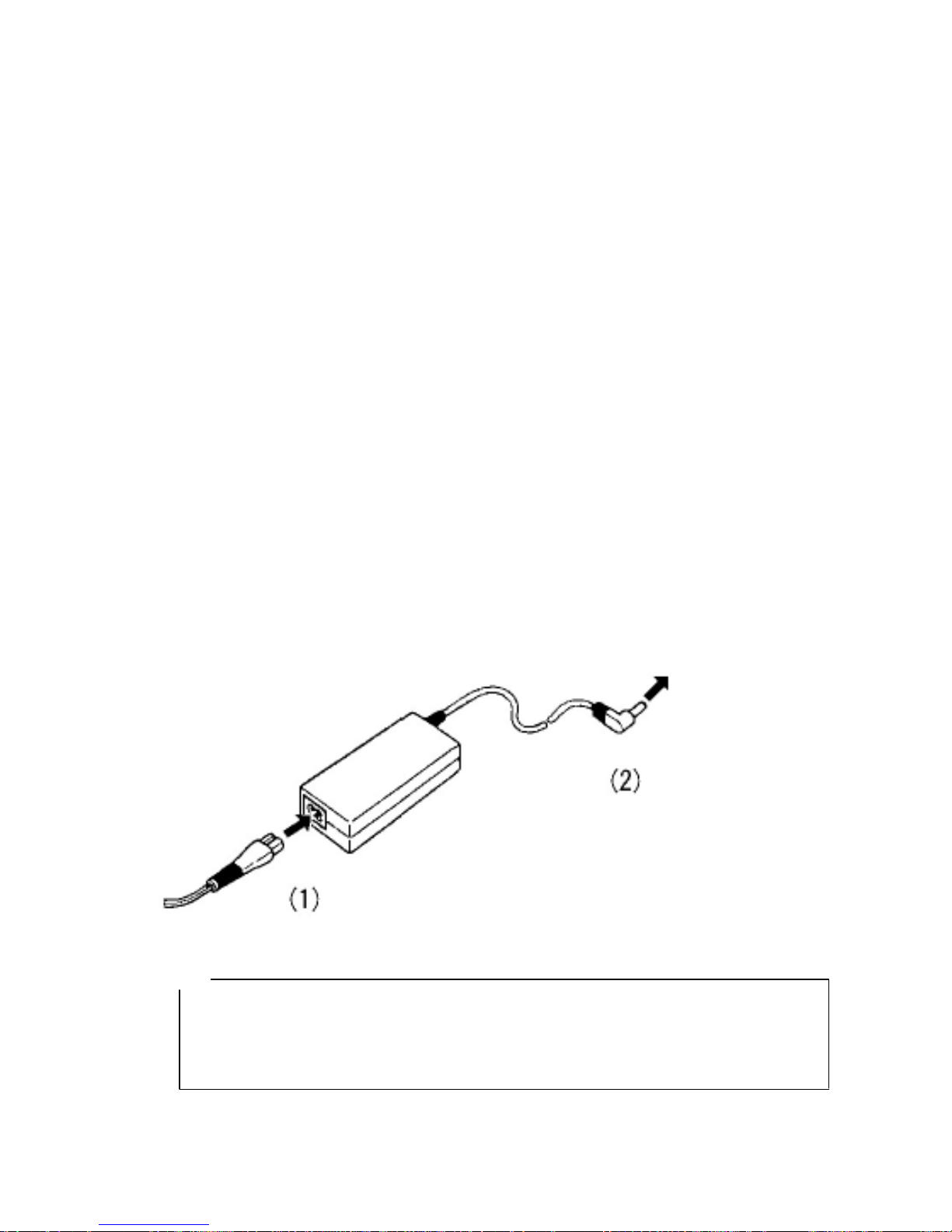

c) Mounting the AC adapter

1. Confirm that the 16 power switch is set to "OFF."

2. Connect the AC cable to the AC power connector on the AC adapter.

3. Open the AC adapter input connector cover 18 at the rear, and connect the DC jack of the AC

adapter.

4. Connect the AC adapter cable to the socket outlet.

‑31‑

Page 44

d) Dismounting the AC adapter

1. Confirm that the power switch 16 is set to "OFF," and disconnect the AC adapter cable from

the socket outlet.

2. Pull out the AC adapter DC jack from this unit and close the connector cover for the 18 AC

adapter input.

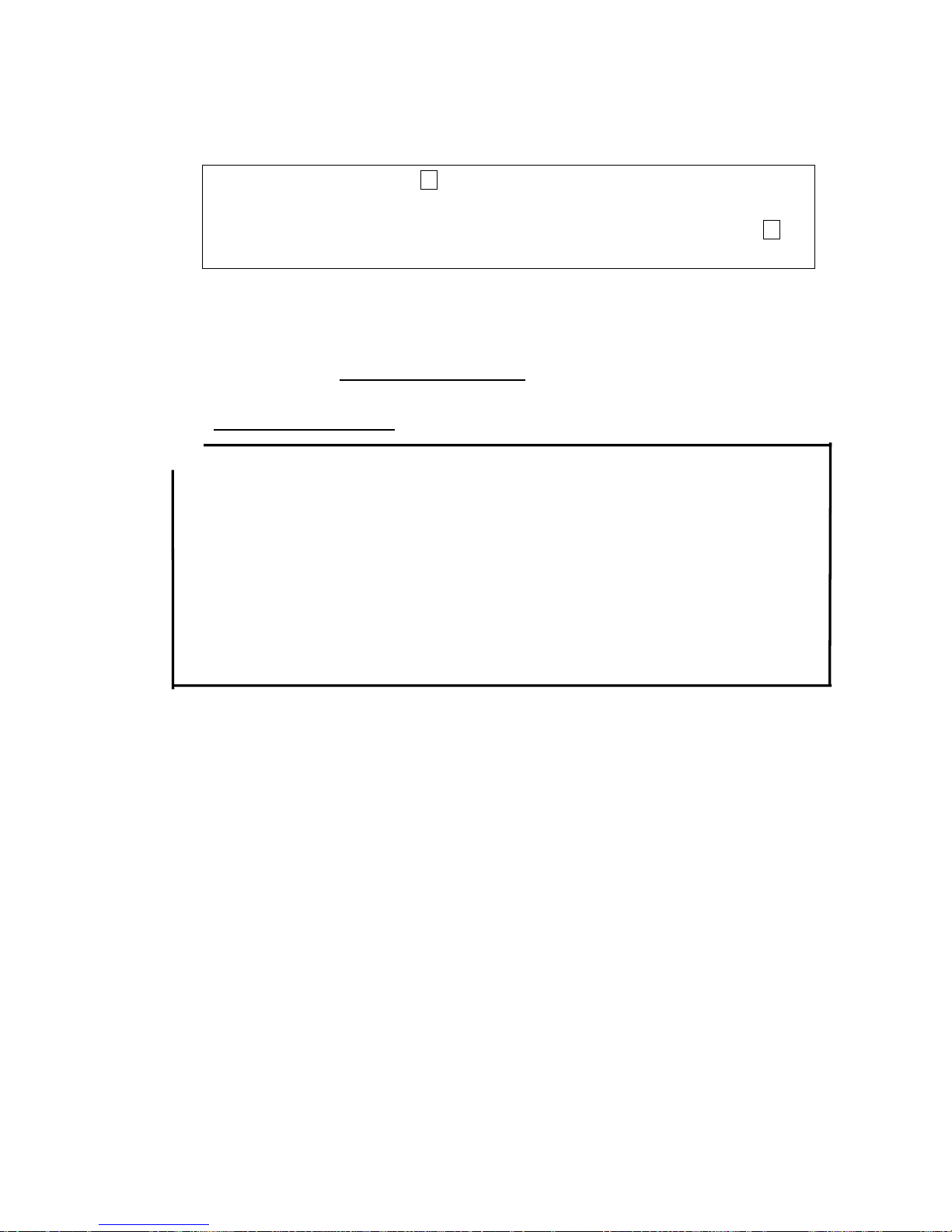

3)Mounting/dismounting a compact flash memory card

This radar can save scan test data by using a compact flash memory card.

To save scan test data, mount the compact flash memory card according the procedure

in Figure 3-4 while the radar power switch is off

.

To dismount the compact flash memory card, perform the procedure in Figure 3-5 while

the radar power switch is off

.

Notes

● Mount/remove the compact flash memory card while the power switch of this unit

is off.

● Make sure of the insertion direction before mounting the compact flash memory card.

● Operation of this unit has been confirmed with compact flash CF115-512M

manufactured by IO Data. The unit may not operate with a compact flash memory

card of another company, so an IO Data compact flash memory card should be

used.

● Be sure to initialize the compact flash memory using this unit. If this is performed

using other equipment (NJJ-95B, PC etc.) the compact flash may not be recognized.

● Please do not use a compact flash memory that was used with a NJJ-95A. As the

data format used by NJJ-95A and NJJ-95B are different, this may cause an error.

‑32‑

Page 45

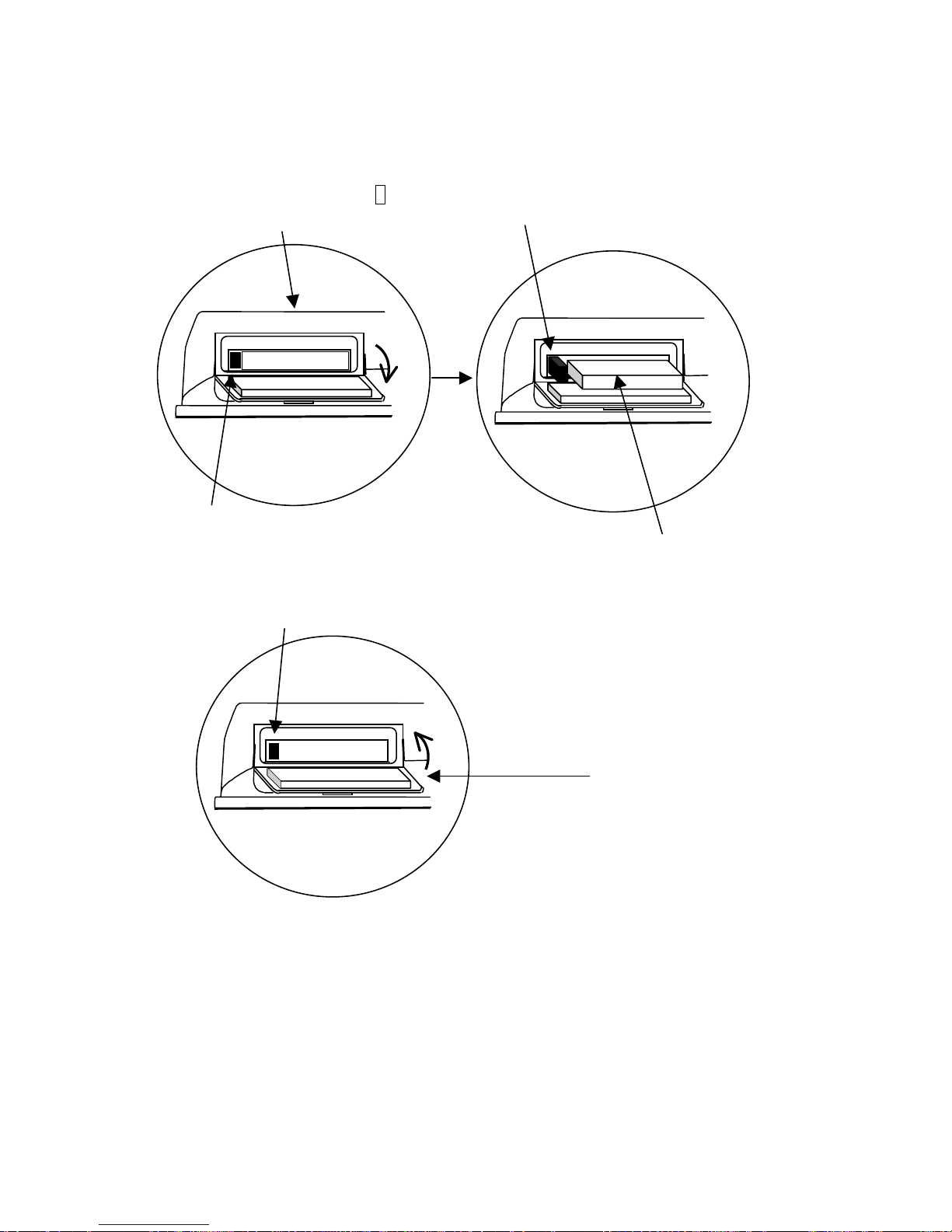

(1) Open the lid over the 8

compact flash insert opening

(2) If the eject switch is extended, push in the switch.

Figure 3-4 Mounting the Compact Flash Memory Card

Compact Flash

Memory Card

Compactflash

(3) Insert the compact flash

memory card

(4)

Close the lid after insertion

‑33‑

Page 46

(4) Pull out the compact flash

(3) Press the eject again to enable pulling th

e

compact flash ou

t

Compactflash

(1) Open the lid of the 8

compact flash insert openin

g

(2) Push the eject so that the ejec

t

button is pushed in

(5) Push the eject button so that the

eject button is pushed in

(6) Close the lid as was to start with

Figure 3-5 Dismounting the Compact Flash Memory Card

‑34‑

Page 47

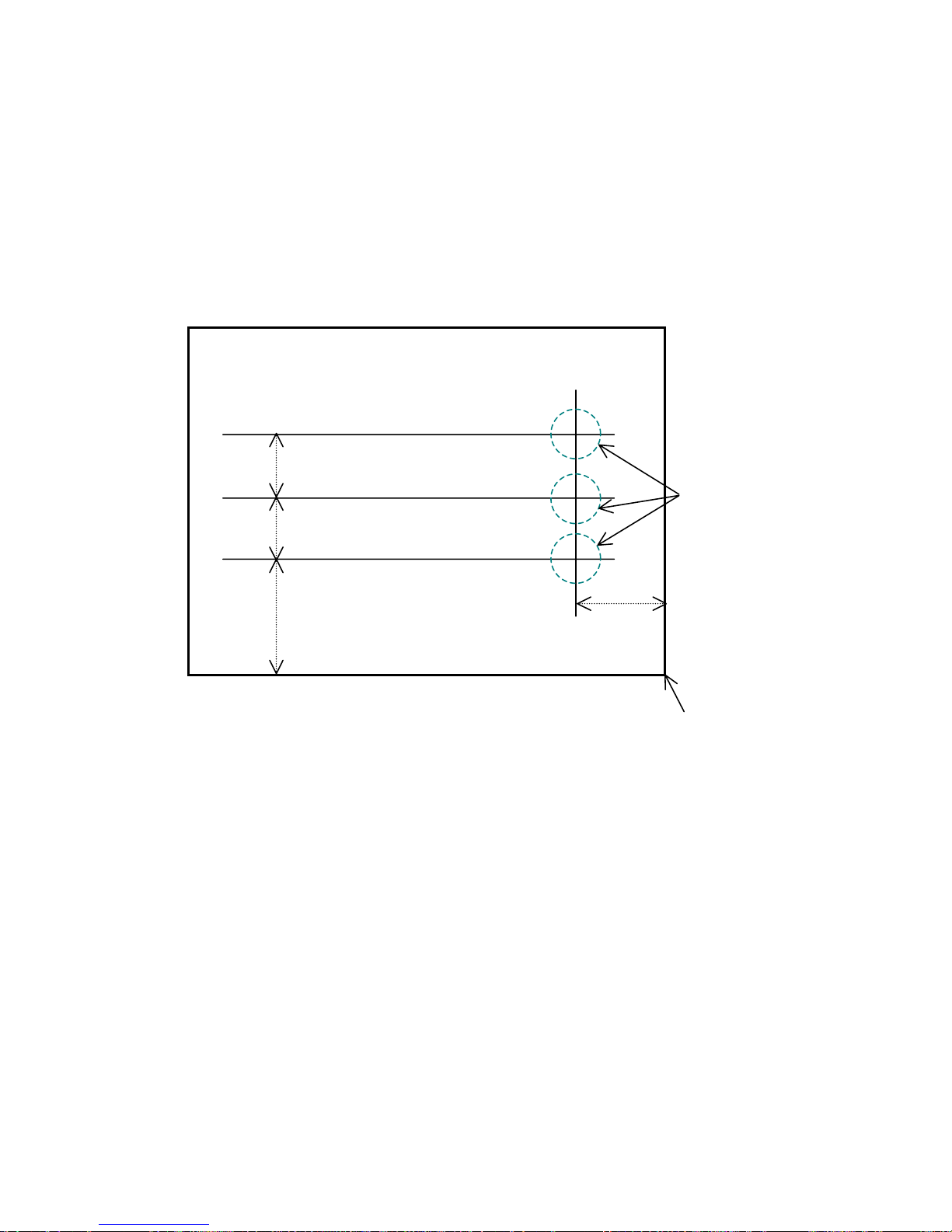

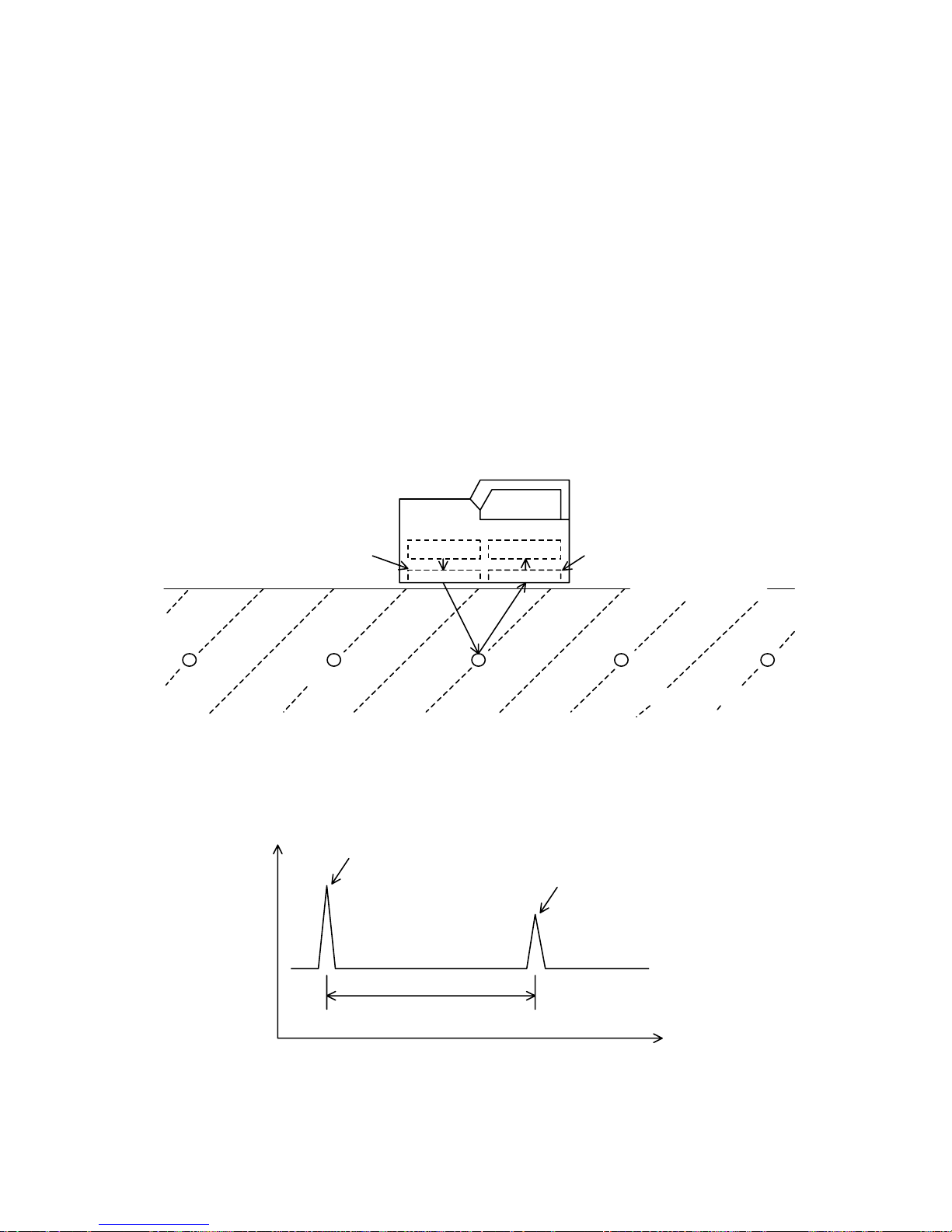

(4) Target Preparation for Scanning

Using chalk (or similar) make markings on the concrete surface to indicate where to start

testing (starting line) and where to scan (scan test line).

Make sure the start line and the scan test line are orthogonal.

(As necessary, in order to perform a retest, use and endpoint of the wall as a standard

for the start line and scan test line)

A scan test applicable set up example is shown in Fig. 3-6.

1m

(Wall Surface)

Object to be sens

e

tested

(

Concrete etc.

)

These should be

orthogonal

2m 1m

Start line

1m

Scan test line 3

Scan test line 2

Scan test line 1

Fig. 3-6 Scan test applicable setup example

Origin

(End of wall, power outlet etc.)

‑35‑

Page 48

3.2 Scan Test

3.2.1 Power-on Procedure

The 1 liquid crystal display lights up roughly 5 seconds after the power is turned on by turning on

the 16 power switch, and next the initialization screen is displayed. After the initialization screen

completes, the scan test screen is displayed.

After confirming that the scan test screen is displayed on the liquid crystal display, start the scan

test.

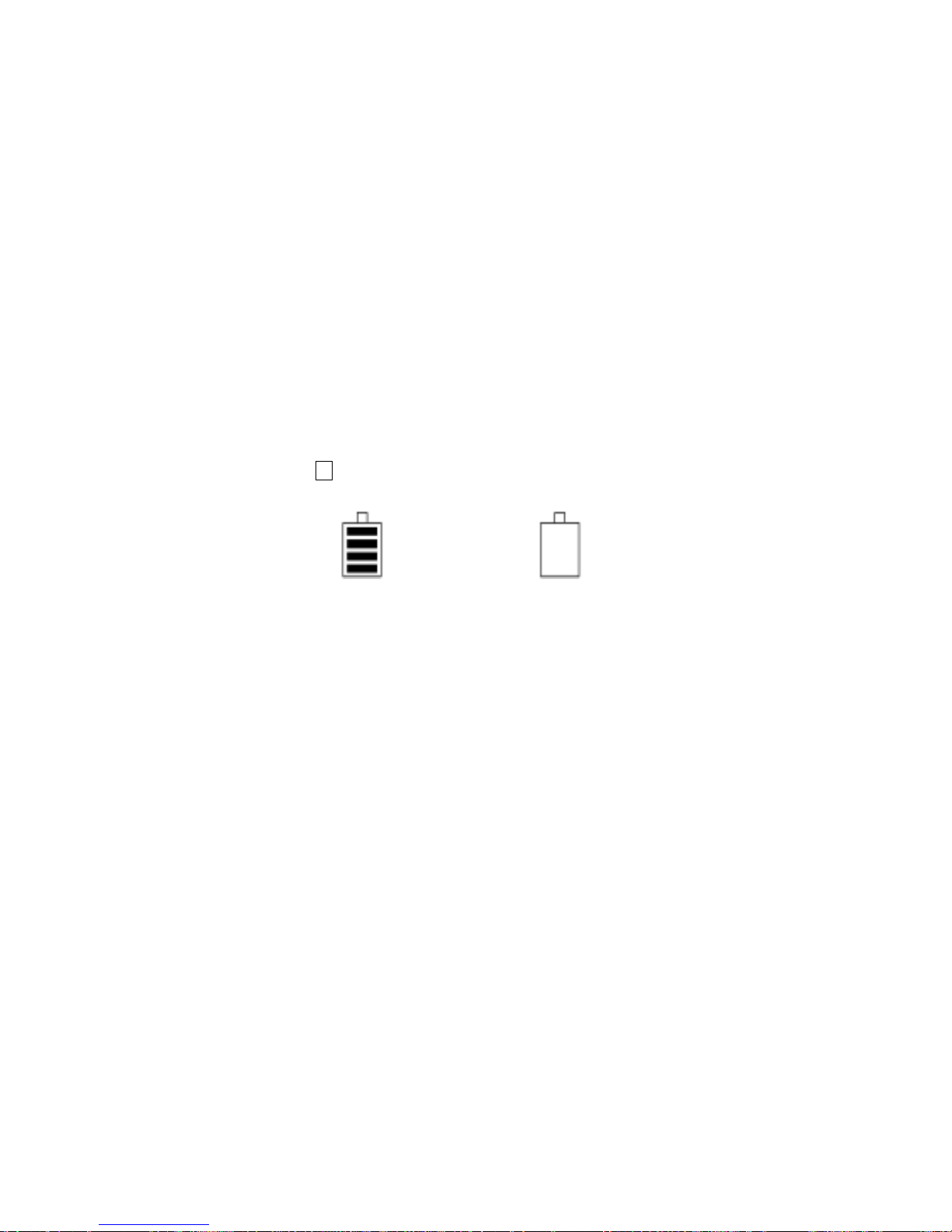

The battery availability indicator is displayed with an approximate value at the upper right of the

LCD screen 1. (See Figure 3-7.)

About 75~100% , About 50~75%, About 25~50%, About 0~25%, About 0%

Figure 3-7 Battery Capacity Indicator

Notes

• This unit gives priority to the AC adapter for power input. Therefore it operates with the AC

adapter when both the battery pack and AC adapter are connected. If the AC adapter is

connected while operating using the battery, the power turns off and then back on.

3.2.2 Scan Test

The scan test method is shown below.

a) Place the 14 V on the side of the unit over the start line and the forward/backward 14 V

over the scan test line.

b) Press 9 START. After about one second, a short single buzzer sound is generated, the

fixed cursor is displayed at a position of about 10cm of the movement distance scale on the

B mode screen, and then scan test preparation is complete.

c) Move the unit on top of the scan test line at a speed of less than 40 cm/s by rotating the

wheels. If speed exceeds 40 cm/s, a buzzer sounds and the data for that timeframe is

invalid. Please perform the scan test again.

d) Press 9 START again to finish. A double buzzer sound is generated and the scan test is

stopped.

However, if the scan distance reaches 15 m, the buzzer sounds twice and the scan test

automatically finishes.

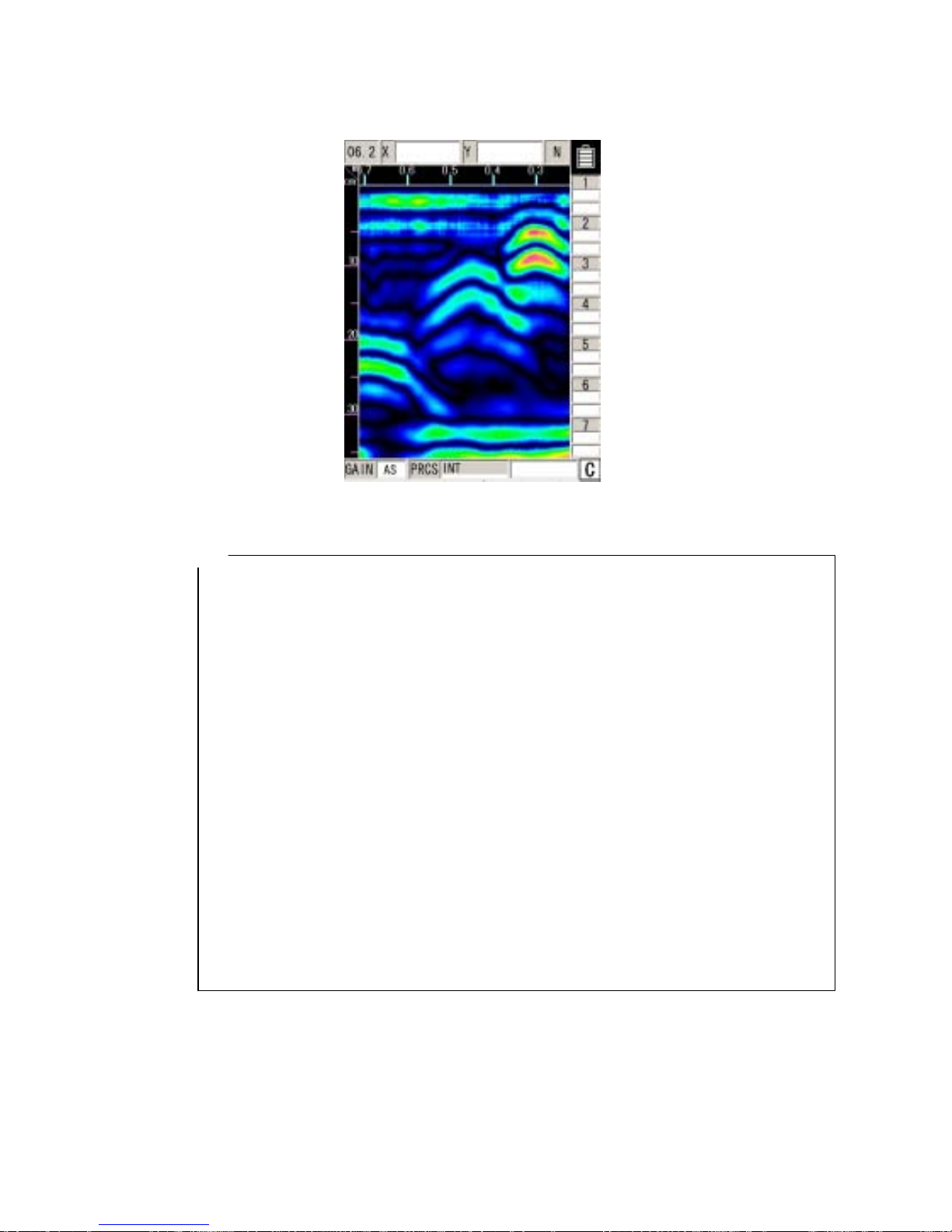

Figure 3-8 shows an example of scan test.

‑36‑

Page 49

Figure 3-8 B Mode Sense Test

Remarks

• For the settings such as B/BA mode, Distance feed/Time feed, Absolute value gradation/Offset

gradation, Depth calibration value, and Sensitivity, see section 2.3 “Parameter Setting Screen."

• Automatic real-time surface wave processing may not eliminate all waves reflected by the

concrete surface depending on the conditions. If the peak processing of image processing is

performed in this state, waves reflected by reinforcing steel bars may become invisible.

The waves reflected by reinforcing steel bars can be displayed by the method explained in

section 3.2.5 “Manual real-time deduction processing" or section 3.4 “Image

processing."

• If the unit is moved too fast, a buzzer will sound. Data at the time is not displayed.

• Even if this unit moves in the direction opposite to the traveling direction, data will be displayed

on the assumption that the antenna moves in the traveling direction.

• The latest scan test data in B mode includes data about the antenna's center mark "

▼" at the

lower part of the case.

• The position of the fixed cursor on the B-mode display indicates the rear end of this radar, and it

can be used to identify the position of the reinforcing steel being scan tested. (See Figure 3-9

for the fixed cursor.)

‑37‑

Page 50

3.2.3 Sensitivity

When the power is turned on, sensitivity is set to “A shallow”. “A shallow” is a sensitivity setting that

is applicable to the detection of rebar with a depth of less than 10 cm in general concrete.

"A" of "A shallow" indicates the overall sensitivity; "shallow" indicates depth sensitivity.

There are five levels for overall sensitivity: "-2, -1, A, +1, +2." In general, use the unit in the "A"

setting. Use the +side to increase sensitivity and use the –side to reduce sensitivity.

There are two levels for depth sensitivity: "shallow and deep." Select "shallow" when the object to

be probed is at a depth less than 10 cm. Select "deep" when the object to be probed is at a depth of

10 cm or more.

To change the sensitivity, press 3 GAIN .The sensitivity is changed as follows:

A, shallow → +1, shallow → +2, shallow → -2, deep → -1, deep → A, deep → +1, deep →

→ +2, deep → -2, shallow → -1, shallow → A, shallow → +1, shallow →

Remarks

• To change sensitivity for scanning results, press 3 GAIN after scanning.

If sensitivity is changed after scanning, the unit uses the new sensitivity for the next

scanning.

For the changing of sensitivity after scanning, see "Section 3.3.2 Sensitivity Switching."

3.2.4 Antenna Mark

If core-boring or reinforced rebar locations are known beforehand (shown on a

construction diagram) the NJJ-95B can mark the locations by placing an “Antenna Mark”

at the applicable places during scanning.

The method of use for this antenna mark is shown below.

a) Place the 14 V on the side of the unit over the start line and the forward/backward 14 V

over the sense test line.

b) Press 9 STA RT. After about one second, a short single buzzer sound is generated, the

fixed cursor is displayed at a position of about 10cm of the movement distance scale on the

B mode screen, and then scan test preparation is complete.

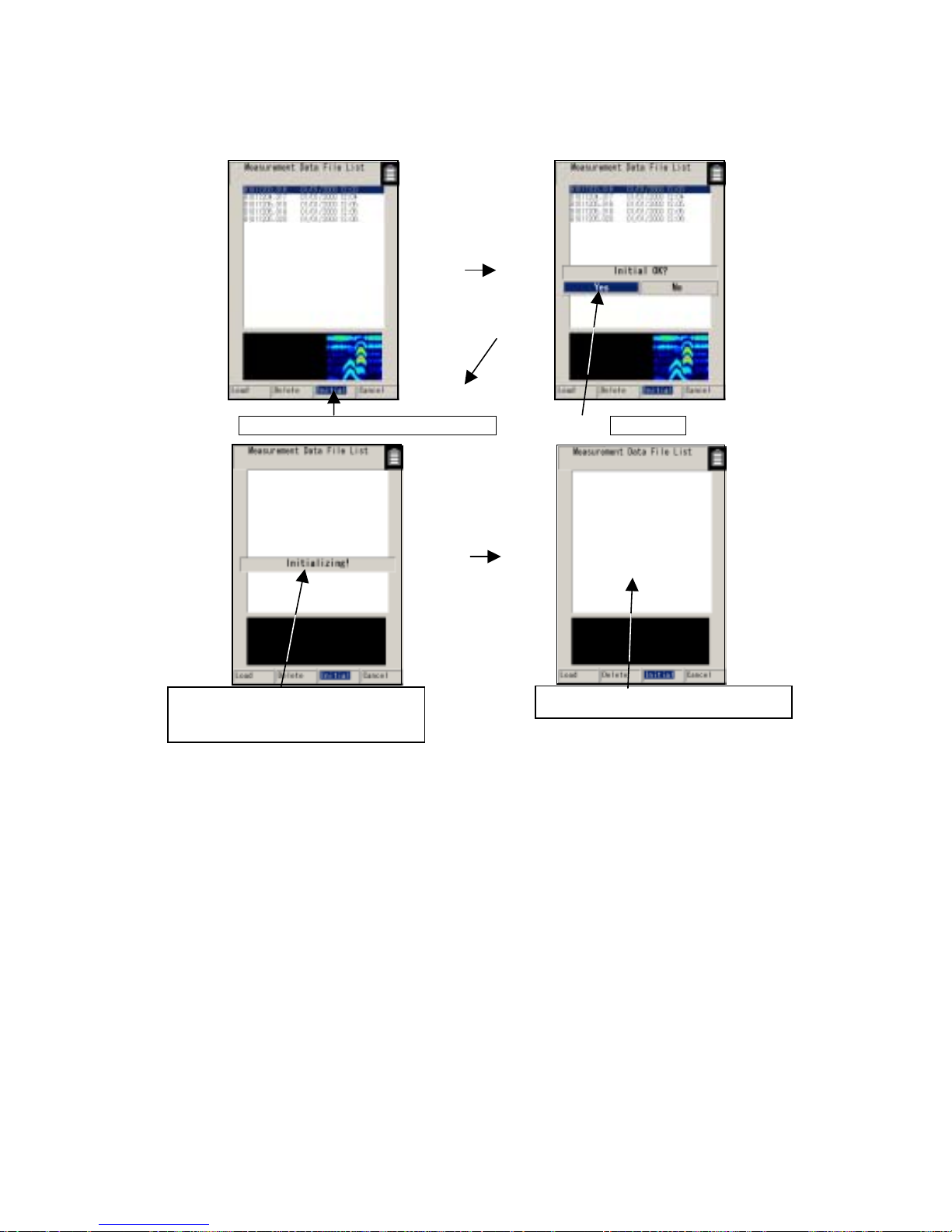

c) Move the unit on top of the scan test line at a speed of less than 40 cm/s by rotating the

wheels. If speed exceeds 40 cm/s, a buzzer sounds and the data for that timeframe is

invalid. Please perform the scan test again.

d) Push 10 MARK when the 14 V on the side of this unit overlaps the rebar position or

core-boring as based on design blueprints. (A ▼ is shown on the movement distance

gauge)

e) Press 9 START again to finish. A double buzzer sound is generated and the scan test is

‑38‑

Page 51

stopped.

However, if the scan distance reaches 15m, the buzzer sounds twice and the scan test

automatically finishes.

‑39‑

Page 52

3.2.5 Real time manual deduction processing

Waves reflected by objects to be probed (e.g., reinforcing steel) at a position near the concrete

surface are difficult to identify because they are combined with waves reflected by the concrete

surface (called surface waves). This radar contains the standard surface wave data (fixed surface

wave data) with which it eliminates the influence of the concrete surface waves in real time, thereby

making it easy to identify the waves reflected by the objects to be probed.

However, with the condition of the concrete surface and moisture content in the concrete and for

special concrete, the effect of the reflected wave from the surface of the concrete may not be fully

removed even if auto surface wave processing for standard surface waves is performed and there

may be lateral stripe reflected waves near the surface.

In this type of situation switch to real time surface wave processing based on surface waves in the

scanning data to remove lateral stripe reflected waves.

Perform manual deduction processing as explained below.

a) Place the 14 V on the side of the unit over the start line and the forward/backward 14 V

over the scan test line.

b) Press 9 STA RT. After about one second, a short single buzzer sound is generated, the

fixed cursor is displayed at a position of about 10cm of the movement distance scale on the

B mode screen, and then scan test preparation is complete.

c) Move the unit on top of the scan test line at a speed of less than 40 cm/s by rotating the

wheels. If speed exceeds 40 cm/s, a buzzer sounds and the data for that timeframe is

invalid. Please perform the scan test again.

d) When results for objects that are not being probed overlap with the fixed cursor position,

push 5 Enter. (See Figure 3-9.)

The reflected wave that the fixed cursor is pointing to can be processed into a surface

wave by real time manual deduction. The resulting data of this processing is indicated in “A”

mode or “BA” mode.

A “↓” is shown at the position that the real time manual deduction processing was

performed on the movement distance guide. In the “Processing” area at the bottom right of

the screen, <<Manual>> is displayed.

e) Press 9 STA RT again to finish. A double buzzer sound is generated and the scan test is

stopped.

However, if the scan distance reaches 15m, the buzzer sounds twice and the scan test

automatically finishes.

‑40‑

Page 53

Remarks

• Real time manual deduction processing performs the same processing as deduction

processing for image processing during scanning.

See section 3.4.5 “Deduction Processing" regarding deduction processing.

• If image processing is performed for scan data by using real-time manual deduction

processing and the surface wave data for manual surface wave processing is rewritten,

data may not be reproduced during scanning.

See section 3.4 “Image Processing."

• If scanning is to be performed again after scanning is complete using real-time manual

deduction processing, automatic real-time surface wave processing using the fixed

surface wave data will be performed.

• The fixed cursor position shows the rear end of this unit and can be used to decipher the

position of the rebar during scanning.

Example of where results for object that is not being probed

overlaps with the fixed cursor position

(Press 5 ENTER)

Figure 3-9 Display after real-time manual deduction processing

‑41‑

Page 54

3.3 Operation while not Scanning

3.3.1 Mode switching

This radar can scan test/display data in both "B mode (vertical cross section)" and "BA mode

(vertical cross section and reflected waveform display)". When the display mode is switched

between "B" and "BA" after scanning, data scan tested in "B mode" is displayed in "BA mode," and

data scan tested in "BA mode" is displayed in "B mode." (See Figure 3-10.)

When the “Distance feed system” method is being used as the “Scan test method”, one screen

displays 49 cm of sense test (movement) distance in “B mode” (maximum recordable test distance

is 15 m). In “BA mode” one screen is the same as in A mode, which is 32.5 cm shown in B mode

(maximum recordable scan test distance is 15 m).

The A-mode (waveform display) portion in BA mode indicates the waveform at the vertical cursor

position in BA mode.

Perform the following procedure to switch between the "B mode" and "BA mode:"

a) Push 4 SET while scanning is stopped and switch to the parameter settings screen.

b) Select the settings item “Display Mode” using the ▲▼ cursor keys (invert display) and

transfer to item selection using the

cursor keys.

c) Select “B” or “BA” using the ▲▼ cursor keys or use the cursor keys to transfer to

set up items.

d) Push 4 SET to switch to the scan test screen.

Remarks

• If the display mode is switched from “B” mode to “BA” mode or vice versa when the scan

testing stops then the display mode last selected when the scan testing restarts will be in

operation when scan testing is resumed.

B mode BA mode

‑42‑

Page 55

Figure 3-10 B-mode/BA-mode Display

3.3.2 Sensitivity switching

As sensitivity can be switched for the scan test results in the same way as during scanning,

scanning does not have to be performed again after changing sensitivity.

Sensitivity is displayed, for example, as "A shallow." "A" indicates the overall sensitivity; "shallow"

indicates sensitivity to depths.

There are five levels for overall sensitivity: "-2, -1, A, +1, +2." In general, use the unit in the "A"

setting. Use the +side to increase sensitivity and use the –side to reduce sensitivity.

There are two levels for depth sensitivity: "shallow and deep." Select "shallow" when the object to

be probed is at a depth less than 10 cm. Select "deep" when the object to be probed is at a depth

of 10 cm or more.

To change the sensitivity, press 3 GAIN .The sensitivity is changed as follows:

A, shallow → +1, shallow → +2, shallow → -2, deep → -1, deep → A, deep → +1, deep →

→ +2, deep → -2, shallow → -1, shallow → A, shallow → +1, shallow →

Remarks

If sensitivity is changed when scanning is stopped and scanning is performed again, the new

sensitivity set while scanning was stopped will be used for scanning.

3.3.3 Cursor operation

Figure 3-11 shows sample display with cursor operation.

(1) Cursor Display

If the cursor keys

, ▼ are pushed after scanning is complete, a vertical cursor is displayed

on the 1 liquid crystal display screen.

The cursors on the screen move vertically when the ▲▼ keys are pressed, and horizontally

when the

keys are pressed. The distance and depth at the intersecting point are displayed

in the upper area of the screen.

If the scan test data does not fit into the scan test screen, the vertical cursor disappears when it

reaches the right or left end of the screen, and the scroll mode is enabled to continuously display

the data stored in the memory.

(2) Cursor Mark Display

With scanning stopped, if the vertical/horizontal cursor intersection point is moved to the

position of the rebar etc. and 10 MARK is pushed, a cursor mark (▼ symbol and number) is

displayed at the cursor intersection point. The coordinates of the cursor mark are distance moved

and depth and are shown on the right side of the 1 liquid crystal display. Up to seven cursor

marks can be displayed.

To delete a cursor mark, move the cursor onto the cursor mark and press 10 MARK.

‑43‑

Page 56

Remarks

• When switching from a scanning stopped state to scanning state, all of the cursor marks are

erased.

Cursor coordinates

Cursor mark coordinates

Cursor Mark

Cursor

Figure 3-11 Cursors and Cursor Marks

‑44‑

Page 57

3.4 Image Processing

Image processing is processing that is performed on data input through scanning and enables

easy deciphering of objects that are being probed for from the scanning results.

This radar contains the following five types of image processing:

a)

b)

c)

d)

e)

Manual surface wave processing

Peak processing

Reproduction of original image

Fixed surface wave processing

Deduction processing

3.4.1 Manual surface wave processing

Manual surface wave processing is used when the effect of reflection near the surface of the

concrete on the scanning results can not be completely removed. (See Figure 3-12.)

(1) Move the cursor to a location where there is not an object that is being

probed

A: Before processing B: After processing

Figure 3-12 Display before/after Manual Surface Wave Processing

‑45‑

Page 58

The operation is performed as described below.

a) a) Press the 6 PRCS key .

“Inverted display” is shown as the item for “Processing” at the bottom of the screen and

operation switches to image processing.

b) Set "Manual" using the cursor keys

▲▼.

c) Use the cursor keys

to move the cursor to a location where there is not a object to

be probed in the sense test results. (See Figure 3-12 A-(1))

d) Press 5 ENTER . Manual surface wave processing will be performed while the reflected

wave at the cursor position is used as the surface wave. At this time, the mark "↓" is

displayed at the previous cursor position.

(See Figure 3-12B.)

e) To end the image processing mode, press the 6 PRCS key again.

“Normal display” is shown as the item for “Processing” at the bottom of the screen and

image processing mode is exited.

Remarks

• When "Manual" is set with the cursor keys

▲▼ after manual surface wave processing

(including real-time manual deduction processing) and deduction processing, image data will

be displayed using manual surface wave processing that uses the surface wave at the cursor

position (indicated by “↓”) of the last-executed processing. (Manual surface wave processing

can be newly performed by moving the cursor and pressing 5 ENTER.))

→ See section 3.2.5 “Real Time Manual Deduction processing” regarding real time

manual deduction processing.

• If manual surface wave processing and deduction processing (including real time manual

surface wave processing) after scanning are not performed, the image does not change

when the cursor keys ▲▼ are used to set operation to “manual”.

(Manual surface wave processing can be performed by moving the cursor and pressing 5

ENTER.))

• To perform manual surface wave processing again, repeat steps c) and d).

• Manual surface wave processing and deduction processing are almost the same but have a

different depth processing range.

• Manual surface wave processing: area where the effect of surfaces waves is high

• Deduction processing: full scanning depth

→ See "Section 3.4.5 Deduction processing" regarding deduction processing.

‑46‑

Page 59

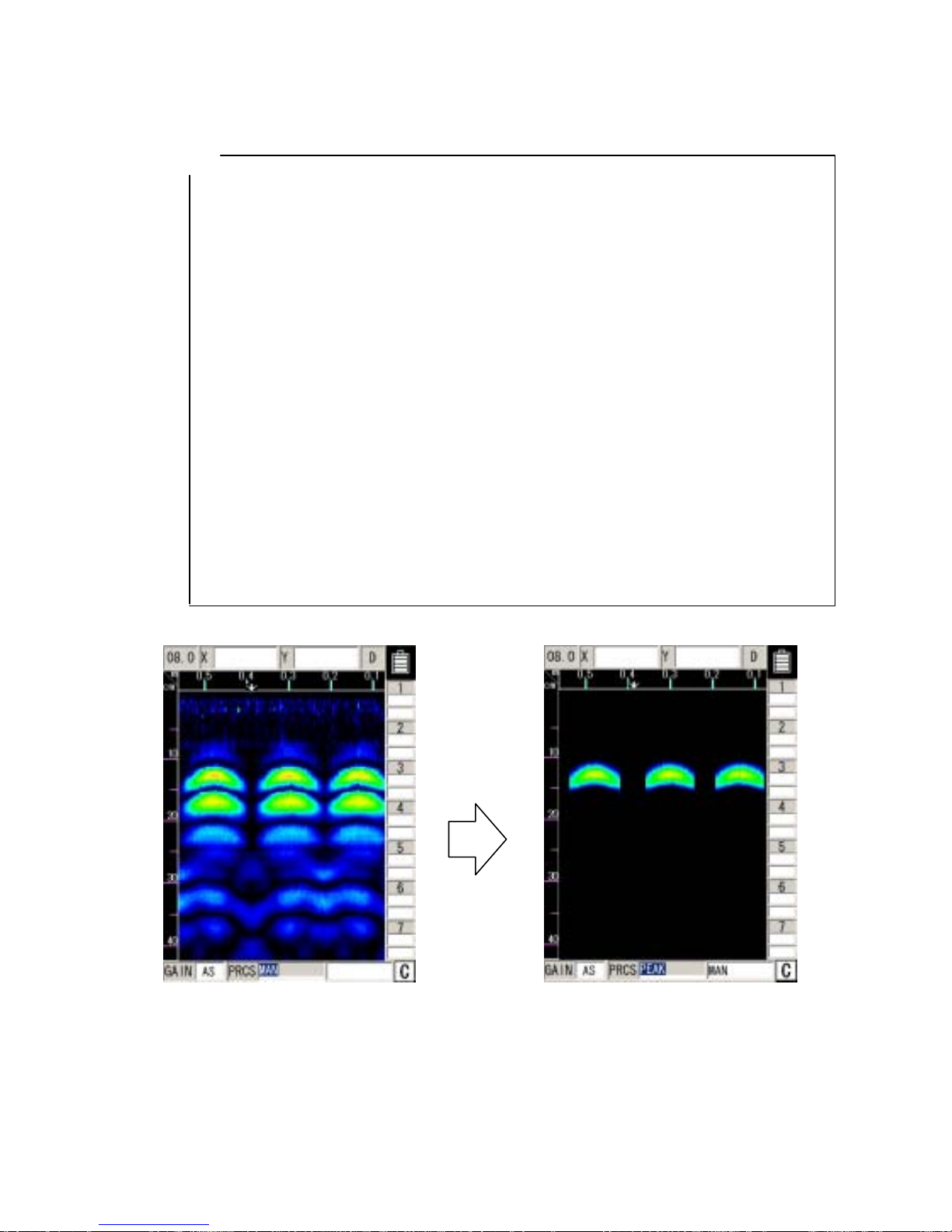

3.4.2 Peak Processing

Peak processing deletes multiple reflected waves of surface wave processing results and displays

only the reflected waves from objects being probed (rebar etc.). Use this when it is difficult to see the

depth of the objects being probed due to multiple reflected waves.

Note that peak processing cannot be used for probing objects (e.g., cavities) that have a lower

relative permittivity than concrete.

Peak processing can be performed for the results of fixed surface wave processing (including

real-time automatic surface wave processing), manual surface wave processing (including real-time

manual surface wave processing), and deduction processing.

Procedure for reduction processing:

a) a) Press the 6 PRCS key.

“Inverted display” is shown as the item for “Processing” at the bottom of the screen and

operation switches to image processing.

b) Set "Peak" using the cursor keys

▲▼.

c) c) Select “Peak manual," “Peak fixed," or “Peak deduction" using the cursor keys

.

Peak processing will be performed for the relevant process results.

d) To end the image processing mode, press the 6 PRCS key again.

“Normal display” is shown as the item for “Processing” at the bottom of the screen and

image processing mode is exited.

Figure 3-13 shows sample display when peak processing is performed for the result of manual

surface wave processing.

‑47‑

Page 60

Remarks

• The display items at the bottom of the screen and their meanings are as follows:

• Peak manual: Peak processing for the result of manual surface wave processing

• Peak fixed: Peak processing for the result of fixed surface wave processing

• Peak deduction: Peak processing for the result of deduction processing

• If “Peak manual" or “Peak deduction" is set without manual surface wave processing or

deduction processing being performed after scanning, the same data as when “Peak fixed" is

set will be displayed.

• If reflected waves shaped as horizontal stripes appear near the surface of concrete after

scanning (with automatic real-time surface wave processing performed), the setting of “Peak

fixed" may cause waves reflected by the reinforcing steel bars to be invisible due to the

remaining horizontal stripes.

In this case, use the following method (1) or (2) to solve the problem:

1. Perform manual surface wave processing for scanning results to eliminate

the reflected horizontal stripe waves from the data, and then perform “Peak

manual."

2. Perform deduction processing for scanning results to eliminate reflected

horizontal stripe waves from the data, and then perform “Peak deduction."

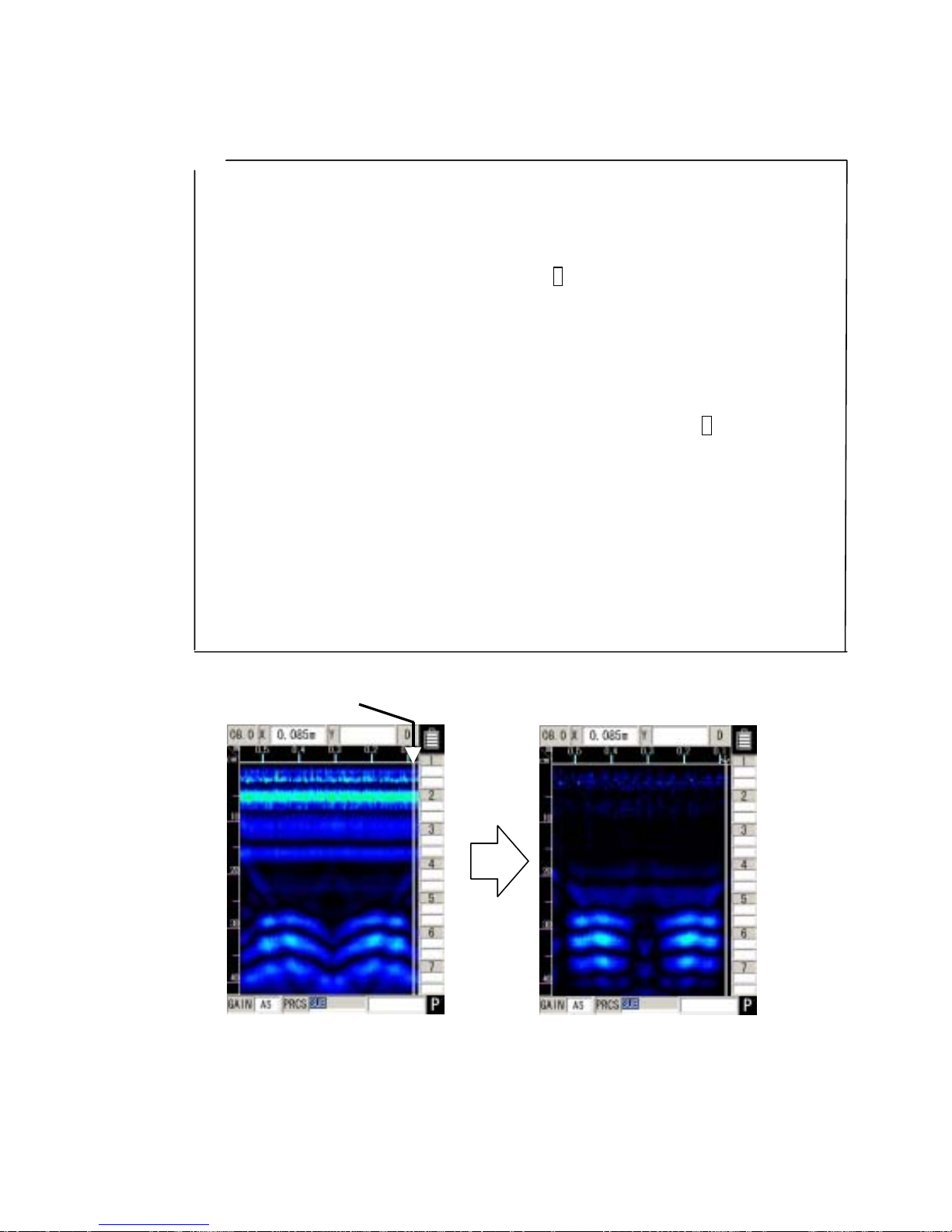

A: Before processing B: After processing

Figure 3-13 Peak processing

‑48‑

Page 61

3.4.3 Reproduction of original image

This processing restores the image processing result to the original state and displays

unprocessed raw data.

Procedure for reduction processing: (See Figure 3-14.)

a) a) Press the 6 PRCS key.

“Inverting display” mode will be indicated at the bottom right hand side of the screen as

the operation switches to image processing from the manual mode..

b) Set "Original image" using the cursor keys ▲▼. Reproduction of original image will be

performed.

c) To end the image processing mode, press the 6 PRCS key again.

“Normal display” is shown as the item for “Processing” at the bottom of the screen and

image processing mode is exited.

A: Before processing B: After processing

Figure 3-14 Reproduction of original image

‑49‑

Page 62

3.4.4 Fixed surface wave processing

This image processing displays surface processing results using internal fixed surface waves.

(Same as real time automatic surface wave processing results)

Procedure for reduction processing:

a) a) Press the 6 PRCS key.

“Inverting display” mode will be indicated at the bottom right hand side of the screen as

the operation switches to image processing from the manual mode.

b) Set "Fixed" using the cursor keys ▲▼. The result of surface wave processing performed

with the fixed surface wave will be displayed.

c) To end the image processing mode, press the 6 PRCS key again.

“Normal display” is shown as the item for “Processing” at the bottom of the screen and

image processing mode is exited.

3.4.5 Deduction processing

Deduction processing eliminates reflected horizontal stripe waves from the screen after

completion of scanning for extremely deep depths of 20 cm or more as shown in Figure 3-15A.

Procedure for reduction processing:

a) Press the 6 PRCS key.

“Inverting display” mode will be indicated at the bottom right hand side of the screen as

the operation switches to image processing from the manual mode.

b) Set "Deduction" using the cursor keys ▲▼.

c) Use the cursor keys

to move the cursor to a location where there is not a object to

be probed in the scan test results. (See Figure 3-15 A-(1))

d) Press 5 ENTER. Deduction processing will be performed with the reflected wave at the

cursor position.

At this time, the mark "È" is displayed at the previous cursor position. (See Figure 3-15

B.)

e) To end the image processing mode, press the 6 PRCS key again.