JRC Alphatron Marine AlphaTurn, AlphaWind AlphaLine Series, AlphaWind AlphaLine MFM, AlphaWind AlphaLine MFL Installation And Operation Manual

Page 1

AlphaTurn

Rate of Turn Indicator (MED)

Installation and Operation Manual

www.jrc.am

Page 2

Contents

I Preface..........................................................................................................4

I.1 Revision History........................................................................................................................................................4

I.2 Glossary.................................................................................................................................................................... 4

I.2.1 Definitions.........................................................................................................................................................4

I.2.2 Abbreviations....................................................................................................................................................5

I.3 Norms and Standards...............................................................................................................................................6

II Safety Information......................................................................................7

II.1 Pictorial Indication....................................................................................................................................................7

II.2 Cautions................................................................................................................................................................... 7

II.3 Notices......................................................................................................................................................................7

II.4 Warranty...................................................................................................................................................................8

II.5 Storage.....................................................................................................................................................................8

III Introduction................................................................................................9

1 Installation Instructions...........................................................................10

1.1 Mechanical Installation...........................................................................................................................................10

1.1.1 Supplied Parts...............................................................................................................................................10

1.1.2 Dimensions....................................................................................................................................................10

1.1.3 Mounting Instrument......................................................................................................................................10

1.1.4 Fitting Instrument Mounting Frame...............................................................................................................11

1.1.5 Fitting Instrument Water Seal.......................................................................................................................11

1.1.6 Instrument Electric Connections................................................................................................................... 12

1.1.7 Cable............................................................................................................................................................. 12

1.1.8 Cable Preparation.........................................................................................................................................13

1.1.8.1 Cable Preparation Sending Sides........................................................................................................13

1.1.8.2 Cable Preparation Receiving Sides.....................................................................................................14

1.1.9 Grounding Instrument....................................................................................................................................14

1.1.10 Instrument Power Supply............................................................................................................................14

1.1.11 Serial Interfaces..........................................................................................................................................15

1.1.12 Serial Connection........................................................................................................................................16

1.1.13 Relay........................................................................................................................................................... 17

1.1.14 Connecting Serial Ports.............................................................................................................................. 18

1.1.15 Connecting Dimmer.....................................................................................................................................19

1.2 Software Installation...............................................................................................................................................20

1.2.1 Selecting Active Software............................................................................................................................. 20

1.2.1.1 Software Applications...........................................................................................................................20

1.2.2 Software Updates..........................................................................................................................................21

1.2.3 Watchdog Protection.....................................................................................................................................21

2 Operation...................................................................................................22

2.1 Power..................................................................................................................................................................... 22

2.2 Main Screen...........................................................................................................................................................22

2.3 Menu Handling.......................................................................................................................................................24

2.3.1 Default Values AlphaLine Instrument........................................................................................................... 25

2.4 Indication Handling.................................................................................................................................................26

2 | Contents

Page 3

2.5 Settings...................................................................................................................................................................30

2.5.1 Generic Settings............................................................................................................................................30

2.5.1.1 Generic Settings Menu........................................................................................................................ 30

2.5.1.2 Touch Screen Calibration (TOUCH CAL)............................................................................................31

2.5.1.3 Cleaning Display ( CLEAN MODE )....................................................................................................32

2.5.1.4 Change Theme (THEME).................................................................................................................... 33

2.5.1.5 Change Date and Time (DATE/TIME).................................................................................................34

2.5.1.6 About the AlphaLine instrument (ABOUT)...........................................................................................35

2.5.1.7 ROT Settings (ROT SET)....................................................................................................................36

2.5.2 Advanced Settings........................................................................................................................................37

2.5.2.1 Advanced Settings Menu (ADV SET)..................................................................................................37

2.5.2.2 Central Dimming (CNTRL DIM)...........................................................................................................38

2.5.2.3 Ethernet Configuration (ETH CONFIG)...............................................................................................39

2.5.2.4 Serial Port Configuration (UART CONFIG)......................................................................................... 40

2.5.2.5 Serial Port Monitor (SERIAL MON)..................................................................................................... 41

2.5.2.6 Factory Reset (RESET)....................................................................................................................... 42

2.5.2.7 Log (LOG)............................................................................................................................................43

2.5.2.8 NMEA Talker (NMEA TALKER)...........................................................................................................44

2.5.2.9 NMEA Settings ( NMEA SET )............................................................................................................45

3 Maintenance.............................................................................................. 46

4 Appendix A................................................................................................47

4.1 Hardware Specifications.........................................................................................................................................48

4.1.1 Specifications MFM.......................................................................................................................................48

4.1.2 Available Accessories...................................................................................................................................48

4.2 Software Specifications..........................................................................................................................................49

4.2.1 Supported NMEA Sentences IEC 61162......................................................................................................49

4.2.2 Indication List................................................................................................................................................49

4.3 Mechanical Drawings.............................................................................................................................................50

4.3.1 Mechanical Drawing MFM............................................................................................................................ 50

4.4 Electric Diagrams...................................................................................................................................................51

4.4.1 Cable Diagram AlphaTurn............................................................................................................................ 52

4.4.2 Connection Diagram AlphaTurn....................................................................................................................53

4.5 Schematics.............................................................................................................................................................54

4.5.1 Schematics AlphaLine MF Display Unit........................................................................................................55

4.5.2 Schematics AlphaLine Instrument.................................................................................................................56

3 | Contents

Page 4

I Preface

The Alphatron Marine AlphaLine instrument range was designed for navigation and control of ships and is based on

generic hardware and software, allowing for many different applications.

• Thoroughly read this instruction manual before installation and operation of the equipment.

• We recommend to keep this manual nearby the equipment to ensure ready access to it.

I.1 Revision History

Revision No. Software Version Description Date

V1.0.6 R1_035 First issue 16 December 2016

V1.0.7 R1_050 Textual changes 27 September 2017

V1.0.8 R1_061 Textual changes 09 October 2017

I.2 Glossary

The glossary contains a list of definitions and a list of abbreviations.

I.2.1 Definitions

The meaning of standard definitions as used in this manual are explained in Table 1: Definitions on page 4.

Redundant A device that is equipped with multiple part of the same type, for example a double

power supply. This equipment will continue to function when one of the redundant part

fails.

Heading users Navigation equipment that uses heading/course information for functioning.

Hardware The physical parts of the AlphaLine instrument.

LEDs Light-emitting diodes. These are used for signaling statuses of hardware and software

signals to the user.

Central alarm system /

Bridge watch monitoring

NMEA protocol Protocol standard for transmitting and receiving of asynchronous serial data sentences.

Talker Device which transmits data. This is usually called transmitter or TX.

Listener Device which receives data. This is usually called receiver or RX.

ISO GND Isolated Ground. This is a ground connection to be used for reference signal. It is

Grounding point/stud Point on the chassis of the AlphaLine instrument which should be connected to the ship's

Printed Circuit Board A printed circuit board, or PCB, is used to mechanically support and electrically connect

(Galvanic) isolated Electrical separation of two circuits. There is no current flowing directly from one circuit

System that is connected to all vital systems on a ship and that is able to give a

centralized indication of the (alarm)status of all connected systems.

different from EARTH and should normally not be connected to EARTH.

mass.

electronic components using conductive pathways, or traces, etched from copper sheets,

laminated onto a non-conductive substrate.

to another. Electrical energy and/or information can still be exchanged between the

sections by other means, such as by induction or by optical means (like transformers or

opto couplers).

CAN bus Controller Area Network. This is a network based serial bus system used for exchanging

information. It is the advanced version of RS485/422 serial buses.

4 | Preface

Page 5

Reverse polarity protection This is a part of the power supply hardware that prevents any damage to the equipment

when the power supply is connected to the wrong polarity.

ROT signal Rate Of Turn (ROT) signal indicates the course change of a ship in degrees per minute.

This signal can be analog using voltage or current, or can be an NMEA data signal.

Heading/bearing repeaters Navigation type of instruments displaying the heading/course of a ship.

Baud rate This is the transmission speed of serial interfaces in characters per second.

Transmitting interval The frequency at which complete NMEA sentences are being transmitted in number of

times per second.

Factory setting Instrument setting for backlight color, language, number of connected apparatus, etc. as

configured as a new instrument by the factory.

Flash memory Non-volatile type of memory. This type of memory retains its contents even when the

instrument is turned off.

Firmware (Embedded) software inside the processors of the AlphaLine instrument.

Compass safe distance The minimum distances to equipment that will not cause an unacceptable deviation of

the ship's standard and steering compasses.

Table 1: Definitions

I.2.2 Abbreviations

Abbreviations as used in this manual are explained in Table 2: Abbreviations on page 5.

A Ampere

ARD AlphaLine Repeater Display

CAN Controller Area Network

DC Direct Current

DP Dynamic Position

ECDIS Electronic Chart Display Information System

GPS Global Positioning System

I/O Inputs and Outputs

I.S. Inter Switch

LED Light-Emitting Diode

mA Milliampere

mm Millimeter

NC Normally Closed

NMEA National Marine Electronics Association

NO Normally Open

OA Operational Alarm

TAP Type Approval Program

PCB Printed Circuit Board

RCU Remote Control Unit

5 | Preface

Page 6

ROT Rate Of Turn

VAC Volts Alternating Current

VDC Volts Direct Current

VDR Voyage Data Recorder

W Watt

Table 2: Abbreviations

I.3 Norms and Standards

The AlphaTurn complies with the applicable standards, norms and regulations:

• IEC 60945 (2002) including IEC 60945 Corrigendum 1 (2008)

• Standard DNV 2.4

• IEC 61162 series

• IEC 62288 (2014)

• ISO 20672 (2007)

6 | Preface

Page 7

II Safety Information

II.1 Pictorial Indication

• DANGER

• Indicates a hazardous situation which, if not avoided, will result in death or serious injury. This signal word is

limited to the most extreme situations.

• WARNING

• Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

• CAUTION

• Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

• NOTICE

• Indicates information considered important but not related to injury. It is typically used to prevent damage to

equipment or property.

II.2 Cautions

• CAUTION

• Do not disassemble or modify the equipment. Failure to observe this instruction may cause a fire, electric

shock, or equipment failure.

• CAUTION

• Do not insert or remove the power cord or operate switches with a wet hand. Otherwise, you may suffer an

electrical shock.

• CAUTION

• Operate the equipment only at the power supply voltage of 24 VDC. Failure to observe this instruction can

cause a fire, electric shock, or equipment failure.

• CAUTION

• Do not scratch, damage, modify, heat, pull, excessively bend, or heavily load the power supply cable. It may

cause a fire, or electric shock.

• CAUTION

• Immediately turn off the power and disconnect the power supply cable if the equipment is generating any

smoke or odor, or is overheated. Immediately inform your local service agent of the symptom to have it

repaired. Prolonged equipment operation under such a condition can cause a fire or electric shock.

• CAUTION

• Do not place a vessel containing liquid on the equipment. It may cause a fire, electrical shock, or a failure to

the equipment if knocked over.

• CAUTION

• When unplugging the instrument, be sure to remove the cord terminal correctly. If the cord is pulled, the cord

may get damaged resulting in a fire or an electrical shock.

II.3 Notices

• NOTICE

• Any modification to this equipment without prior written permission from ALPHATRON MARINE B.V. will void

the warranty.

• NOTICE

• Installation of this product shall only be done by a certified installation company approved by either

ALPHATRON MARINE B.V. or by an official ALPHATRON MARINE distributor. Acting otherwise will void the

warranty.

• NOTICE

7 | Safety Information

Page 8

• This product must be installed in accordance with the installation methods described in this manual. Acting

otherwise will void the warranty.

• NOTICE

• This product contains no operator serviceable parts. Service and repair shall only be carried out by personnel

trained and certified by ALPHATRON MARINE B.V.

• NOTICE

• Do not allow the instrument to fall or immerse into water. The equipment can be damaged.

• NOTICE

• If the instruments are not stored as described, it will void the warranty.

• NOTICE

• When cleaning the surface, do not use any organic solvent such as thinner or benzine. Otherwise, the paint

and markings on the surface may get damaged. For cleaning the surface, remove the dust and debris and

wipe with a clean dry cloth.

II.4 Warranty

Non-compliance with the installation, operation and maintenance requirements may void the warranty. Read Safety

Information on page 7.

Contact the Alphatron Marine dealer regarding the terms of the warranty.

II.5 Storage

The AlphaLine range of instruments are sensitive to humidity, temperature fluctuations and aggressive substances. Store

them appropriately.

• NOTICE

• If the instruments are not stored as described, it will void the warranty.

8 | Safety Information

Page 9

III Introduction

Each type in this navigation and control instrument product range consists of a display unit and, if applicable, one or

more external remote I/O modules.

The following display size is available for your AlphaLine instrument:

AlphaLine MFM 6.5 inch display LCD orientation vertical

The AlphaTurn is an MED Type Approved system for showing the rate of turn (ROT) on a standard ship's compass.

9 | Introduction

Page 10

1 Installation Instructions

Installation follows a generic method and is applicable to the complete range of AlphaLine instruments. This chapter

describes the installation into a console.

1.1 Mechanical Installation

• NOTICE

• This product must be installed in accordance with the installation methods described in this manual. Acting

otherwise will void the warranty.

The Location Class/Category of the AlphaLine instrument is: EXPOSED (may be used outside), but only if installed with

the optional sealing kit and according the installation instructions as mentioned in Mounting Instrument on page 10.

1.1.1 Supplied Parts

The AlphaTurn is supplied complete with the following parts.

• Display unit.

• Mounting frame with 2 sets of screws for fixing to either steel or wood.

• 3 x Phoenix connectors for power supply and signals.

• USB stick with manual.

• Mounting template.

• Grounding lug.

1.1.2 Dimensions

Carefully check the applicable drawing(s) of the instrument. See Mechanical Drawings on page 50.

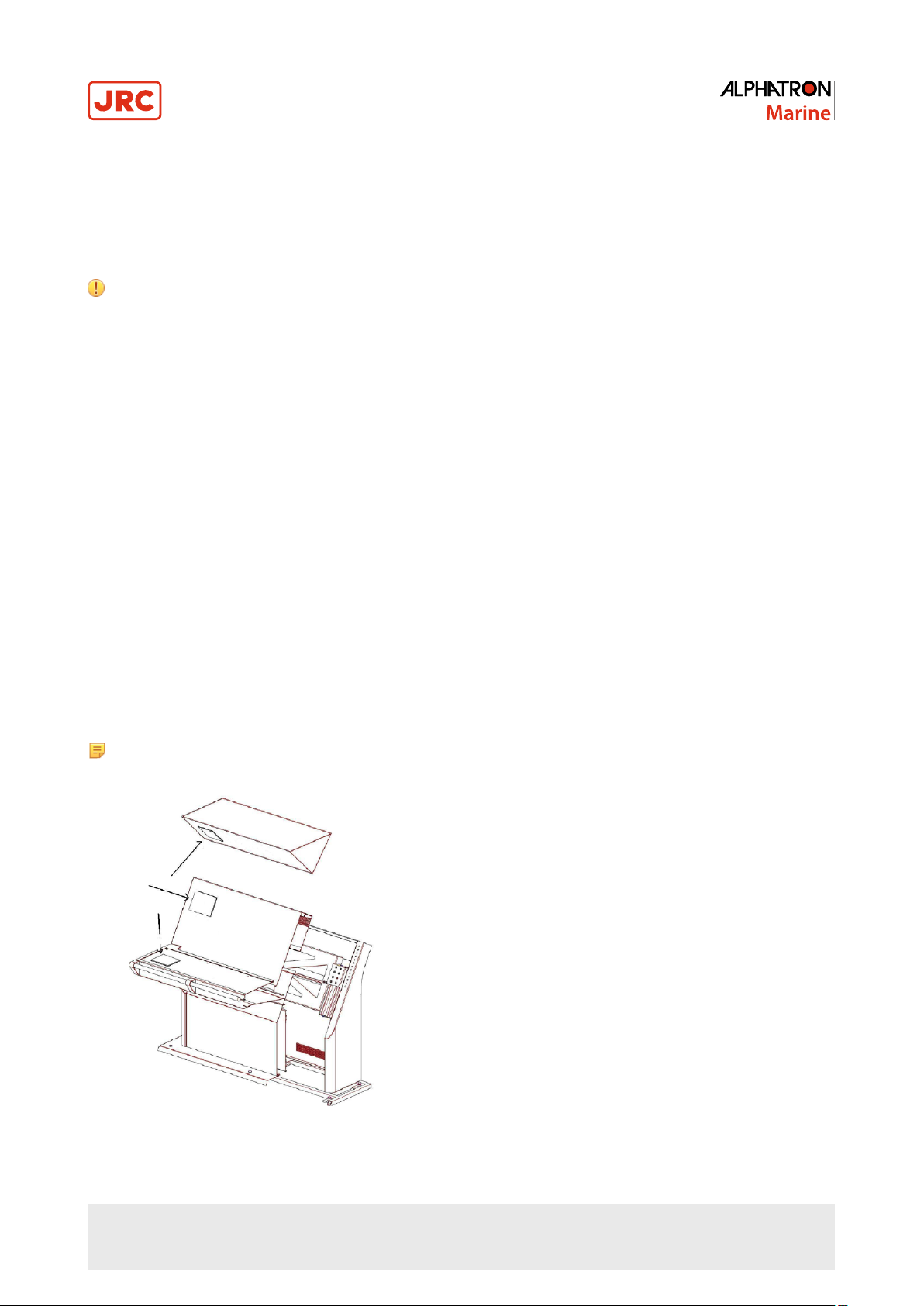

1.1.3 Mounting Instrument

The display unit can only be flush mounted. Carefully consider the location and angle of the display unit for maximum

visibility. Make sure that there is enough space to connect cables. The display unit can be installed horizontally, vertically

or under an angle, see Figure 1: Flush mounting on page 10.

Note For outdoor fitting, use appropriate sealing arrangement.

Figure 1: Flush mounting

10 | Installation Instructions

Page 11

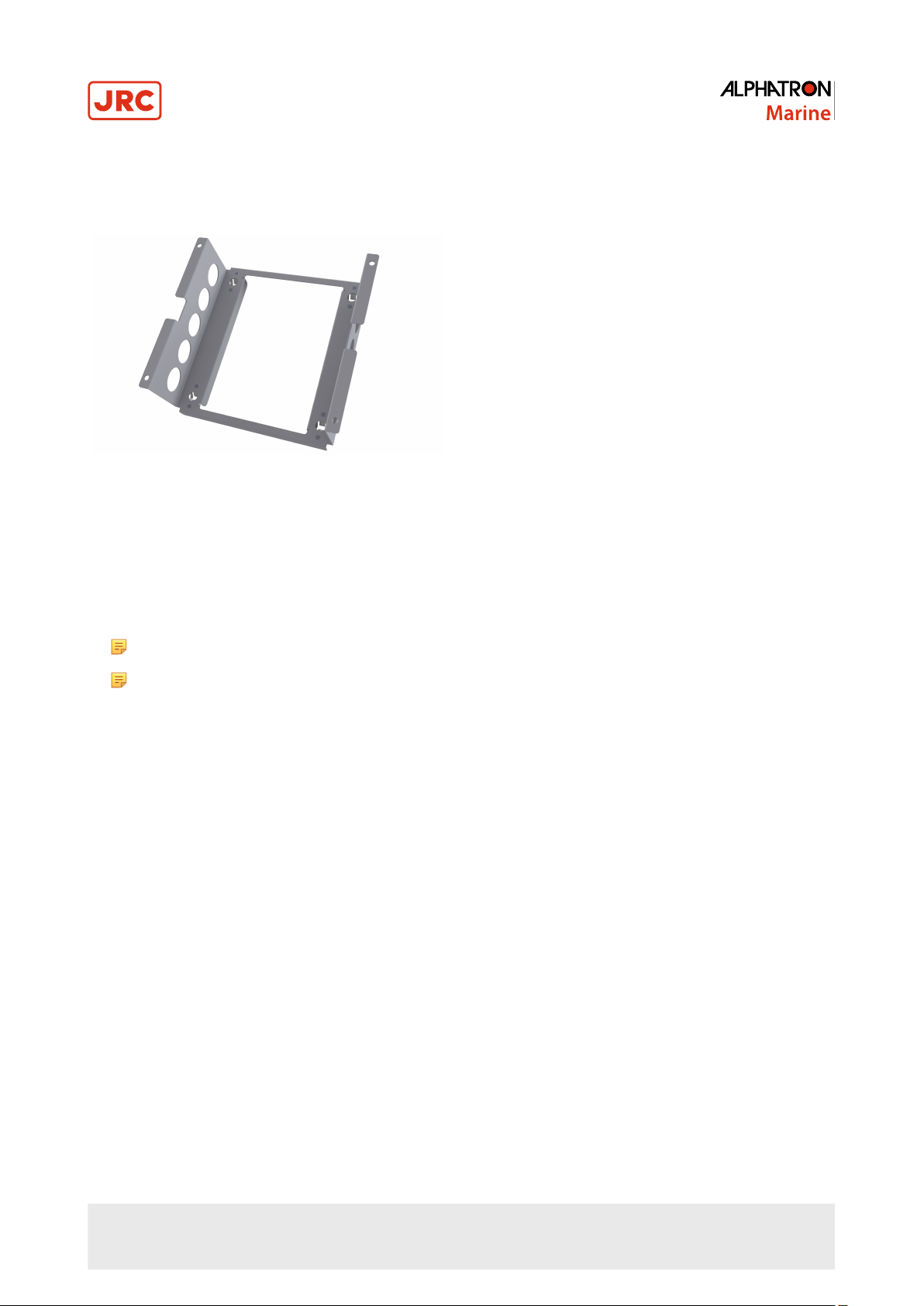

1.1.4 Fitting Instrument Mounting Frame

Prior to fitting the display unit, install the mounting frame.

Figure 2: Mounting Frame MFM

1. Make a square hole in the (overhead) console. Use the provided template. For dimensions, see Mechanical Drawing

MFM on page 50.

2. Push the mounting frame into the hole and attach it with four screws.

3. Push the display unit into the mounting frame.

Note The instrument is locked into position by a spring system.

Note Use the Overhead Mounting Kit for securing the display unit to an overhead console, to prevent the unit

from falling out.

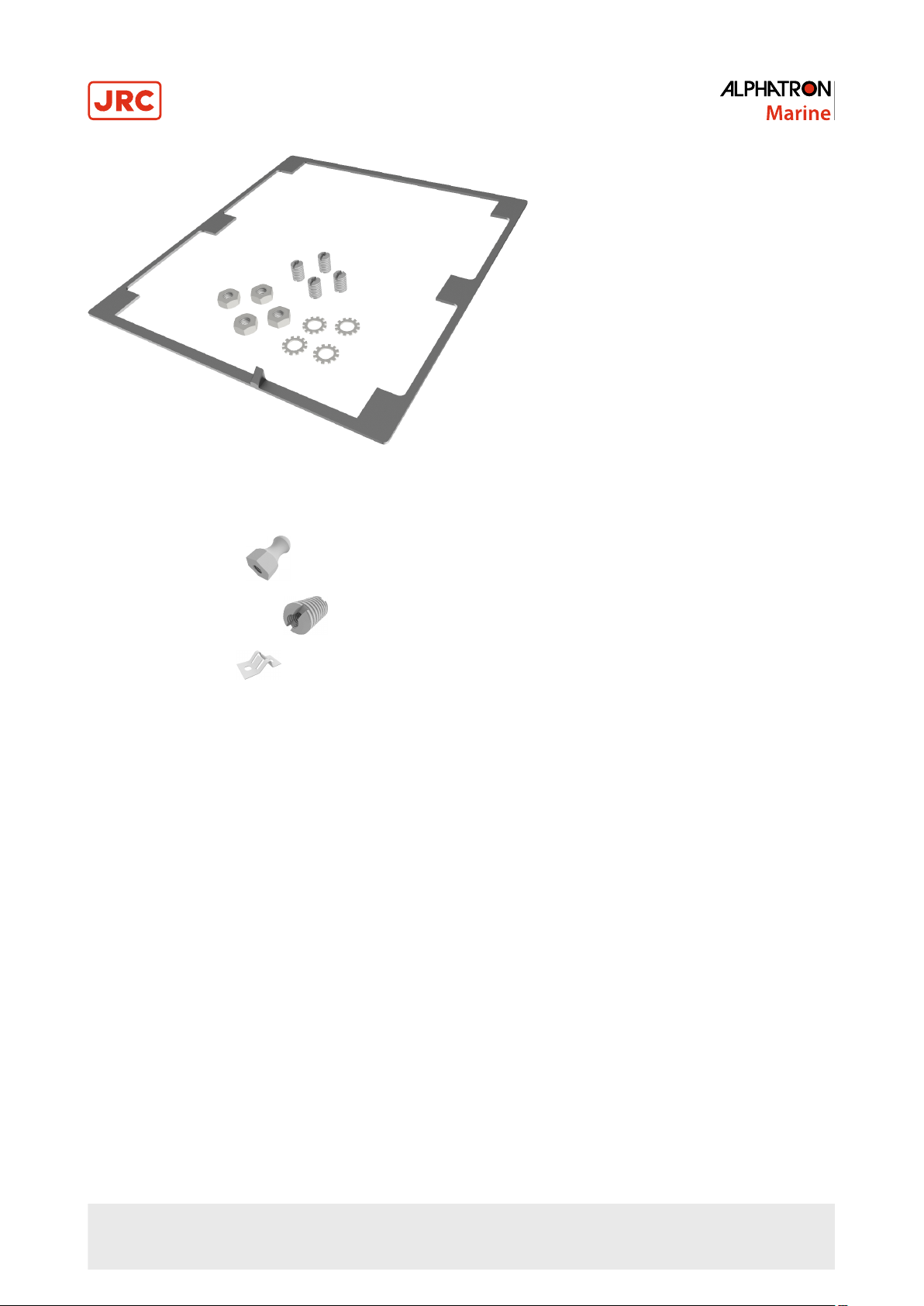

1.1.5 Fitting Instrument Water Seal

The instrument can be positioned outside, using a water seal. To apply the water seal, use the IP56 Kit and follow the

mounting instructions below.

The IP56 Kit for MFM consists of the following items:

• 1 gasket MFS

• 4 adapters M3-M6

• 4 lock washers M6

• 4 hex nuts M6

11 | Installation Instructions

Page 12

Figure 3: IP56 Kit for MFM

Mounting instructions:

1.

Remove the 4 snaps ( ) from the instrument.

2.

Add the 4 adapters M3-M6 ( ) to the instrument.

3.

Remove the 4 clips ( ) from the bracket.

4. Apply the gasket to the instrument.

INFO: Pay special attention to the small protruding cam, so that it fits exactly in the gap in the front panel.

5. Place the instrument in the bracket.

6. Mount the 4 lock washers and hex nuts.

1.1.6 Instrument Electric Connections

All AlphaLine instrument versions share the same electronics with identical connections.

For pin-outs, see Table 4: Serial Connector P12 (8 pins) on page 17 and Table 5: Serial Connector P19 (12 pins) on

page 17.

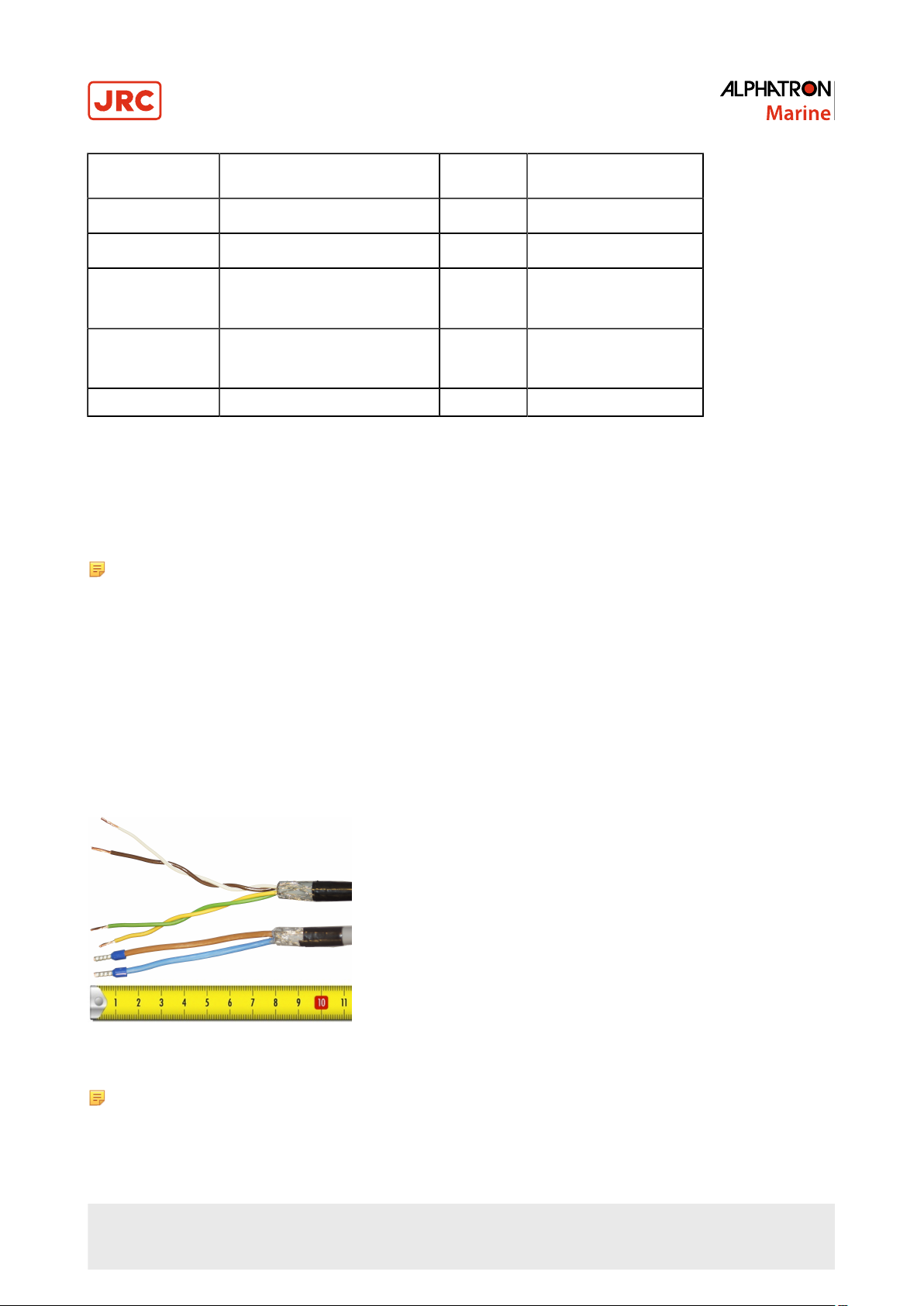

1.1.7 Cable

Use the following connection cables:

12 | Installation Instructions

Page 13

Name Specification Shield

(Y/N)

Power 2 x 1.5 mm

USB USB Y

2

Y IEC 60092-352

Norm

Serial

3 x 2 x 0.5 mm2 (inside cabinets)

3 x 2 x 0.75 mm2 (ship's cabling)

2 x 2 x 0.5 mm2 (inside cabinets)

Serial

2 x 2 x 0.75 mm2 (ship's cabling)

Ethernet Ethernet CAT 5e S/FTP Y

Table 3: Connection Cables

Y

Y IEC 61162-1

IEC 61162-2

1.1.8 Cable Preparation

Cable preparation and cable connections as described in this manual are essential for the correct functioning of the

instrument.

Note There are two type of cable sides (connections): sending cable sides and receiving cable sides. Normally,

the cable shield will be grounded only at the sending side of the cable. For a power cable, this is the power

supply side. For a data cable, this is the Tx side of the cable. For combined Tx/Rx cables, either side can be

grounded, but beware of grounding only one side.

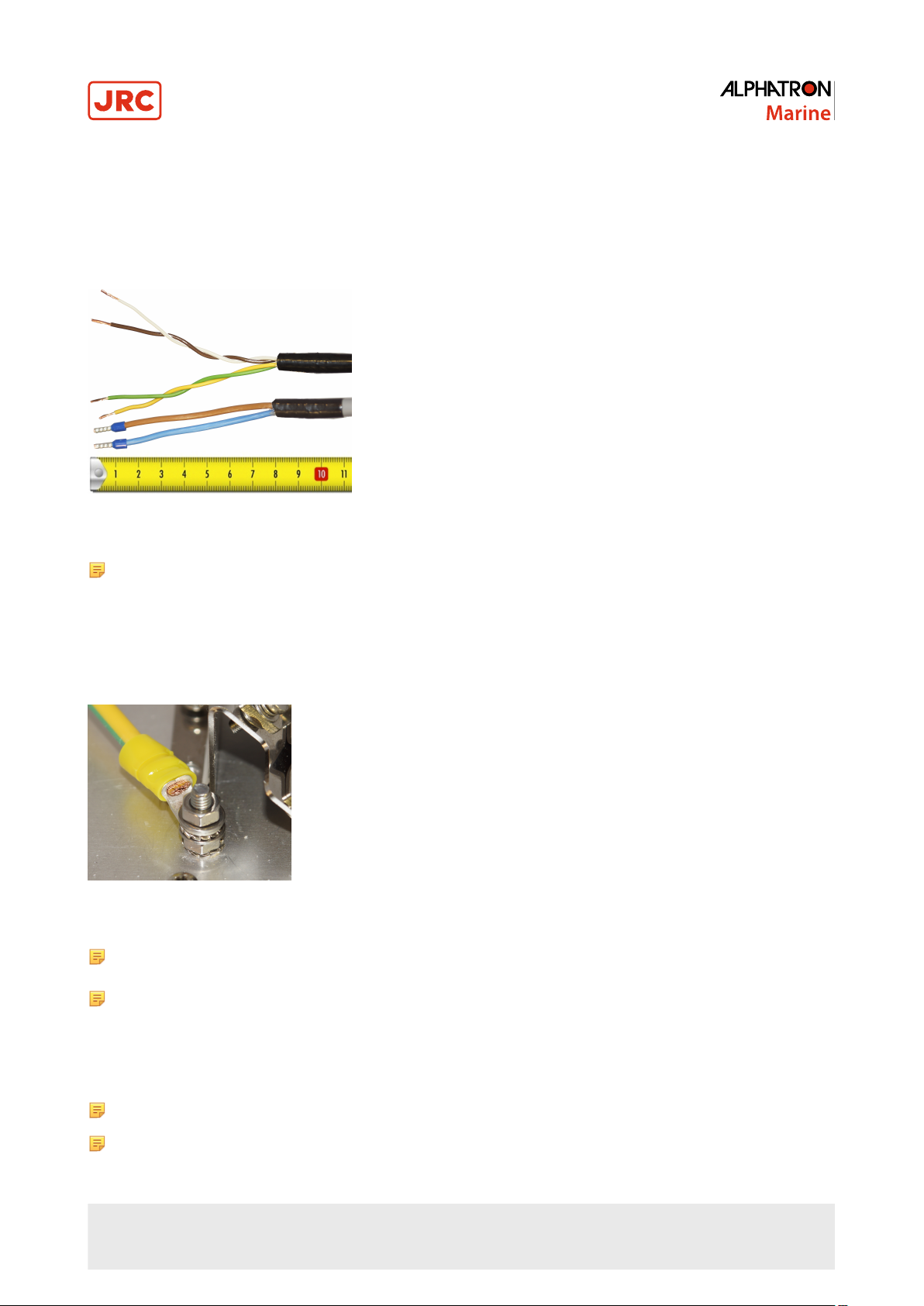

1.1.8.1 Cable Preparation Sending Sides

1. Remove approx. 80 mm of the plastic cable sheath, including the grounding shield.

2. Cut away approx. half of the length of the now visible cable shield and fold the remaining shield back over the cable

sheath.

3. Wrap insulating tape over half of the visible grounding shield.

4. Attach the remaining visible grounding shield to the metal saddle on the rear of the instrument. See Figure 4: Cable

Preparation Sending Cable Sides on page 13.

Figure 4: Cable Preparation Sending Cable Sides

Note Always check the drawing for the correct shielding of signals.

13 | Installation Instructions

Page 14

1.1.8.2 Cable Preparation Receiving Sides

1. Remove approx. 80 mm of the plastic cable sheath, including the grounding shield.

2. Wrap insulating tape over the cable end.

3. Attach the isolated cable end to the metal saddle on the rear of the instrument. See Figure 5: Cable Preparation

Receiving Cable Sides on page 14.

Figure 5: Cable Preparation Receiving Cable Sides

Note Always check the drawing for the correct shielding of signals.

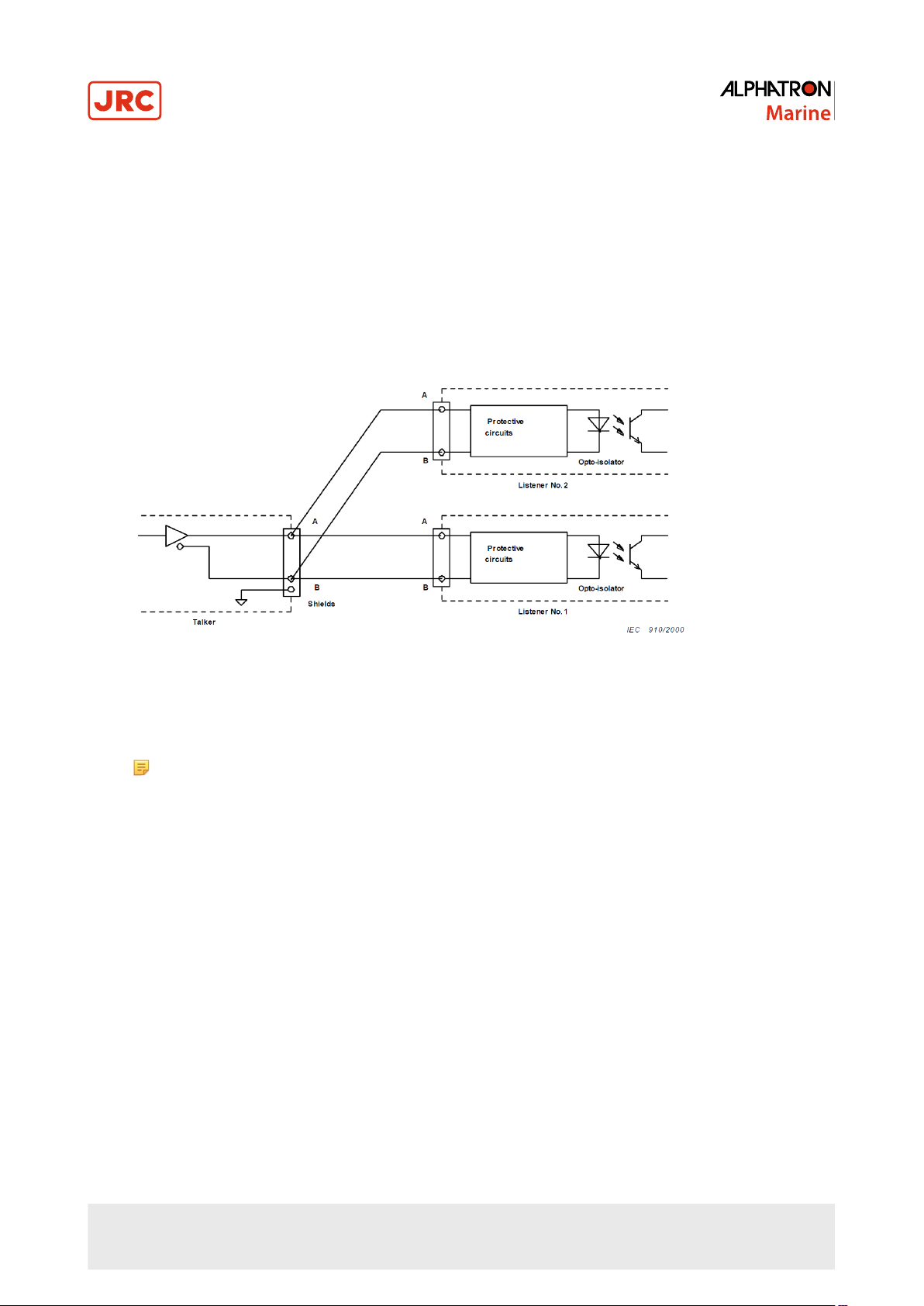

1.1.9 Grounding Instrument

To function properly, the AlphaLine instrument must be grounded to the ship’s mass.

For this purpose the instrument has a grounding bolt. Connect the grounding bolt to the ship’s mass with a low

impedance connection.

Figure 6: Grounding Bolt

Note The grounding strap must be as short as possible. If wire is used, use a minimum of 2.5 mm2 copper wire.

See Figure 6: Grounding Bolt on page 14.

Note Always check the drawing for the correct shielding of signals.

1.1.10 Instrument Power Supply

The AlphaLine instrument has one 24 VDC (nominal) power input. Power consumption is approx. 500 mA. Connect to a

power supply > 1 A.

Note The power supply input is protected against connecting to the wrong polarity.

Note In rush current approximately 4 A.

14 | Installation Instructions

Page 15

1.1.11 Serial Interfaces

This chapter provides extra information about the serial interfaces used in the Marine Electronics.

• IEC 61162-1

This standard is the most commonly used. In the standard, the sender (Tx side) and receiver (Rx side) are referred to

as talker and listener.

It has the following characteristics:

• Communication speed: baud rate of 4800, 8 databits, 1 stop bit, no parity.

• One talker (Tx side, commonly a sensor such as GPS) may be connected to one or more listeners (Rx side, e.g.

displays or computer systems such as ECDIS). The circuit looks as shown in Figure 7: IEC 61162-1 Circuits on

page 15.

Figure 7: IEC 61162-1 Circuits

There are some requirements to the wiring of the signal.

• Tx+ and Tx– are connected to Rx+ and Rx– respectively.

• On the transmitting side the shield of the cable is connected to earth , and is NOT connected on the listener side.

Note In case the NMEA signal is connected both ways, two cables should be used with proper shielding

as described above. (It is just above situation times two for the opposite direction).

Only one talker is connected to the bus, and multiple listeners may be connected to the same bus without the need

for a signal isolator/multiplier. However, it is not forbidden and good practice to use a multiplier since it eliminates

possible faults caused by short circuiting of the signal by a faulty listener. Alphatron is able to supply such a multiplier

if needed (NMEA Distribution Interface Mk.2).

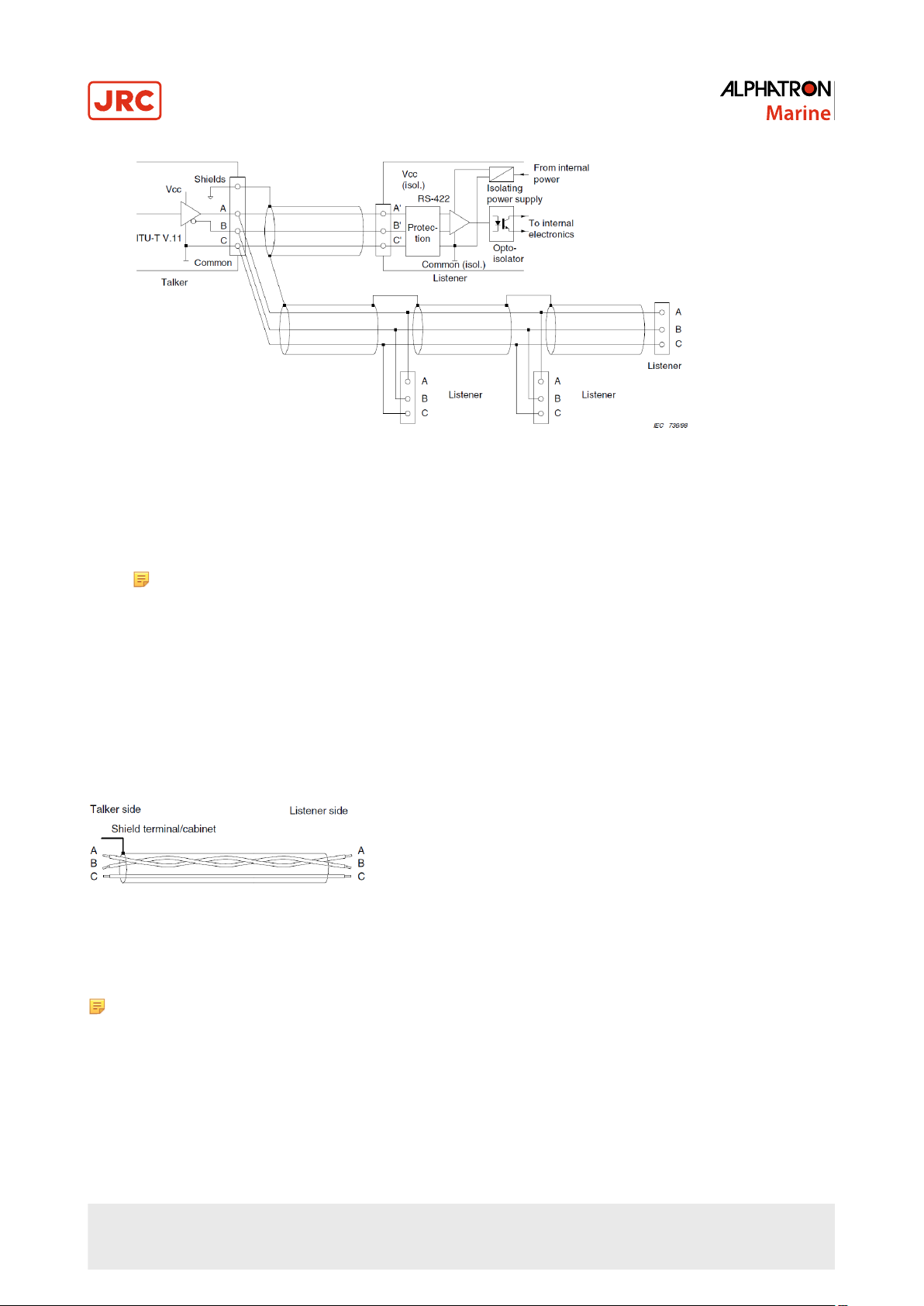

• IEC-61162-2

This standard is applied to provide better characteristics when the data transmission speed is higher.

It has the following characteristics:

• Communication speed: baud rate of 38400, 8 databits, 1 stop bit, no parity.

• One talker (Tx side, commonly a sensor such as GPS) may be connected to one or more listeners (Rx side, e.g.

displays or computer systems such as ECDIS). The circuit looks as shown in Figure 8: IEC 61162-2 Circuits on

page 16.

15 | Installation Instructions

Page 16

Figure 8: IEC 61162-2 Circuits

The main difference with the IEC 61162-1 standard is that a COMMON signal is added here for a good reference to

isolated ground.

• Tx+ and Tx– are connected to Rx+ and Rx– respectively.

• The shield of the cable is connected to the earth on the transmitting side, and is NOT connected on the listener.

Note In case the NMEA signal is connected both ways, two cables should be used with proper shielding

as described above. (It is just above situation times two for the opposite direction).

Only one talker is connected to the bus, and multiple listeners may be connected to the same bus without the need

for a signal isolator/multiplier. However, it is not forbidden and good practice to use a multiplier since it eliminates the

possible faults caused by short circuiting of the signal by a faulty listener. Alphatron is able to supply such a multiplier

if needed (NMEA Distribution Module Mk.2)

The cable should be of a shielded type, and the shield connected to the earth on the talker side and NOT to earth on the

listener side.

The IEC 61162 specifies a number of different cables which can be used. Of these cables, Alphatron recommends to use

single shielded cable, as shown in Figure 9: Single Shielded Cable on page 16.

Figure 9: Single Shielded Cable

So, for a two way connection two times 3 wire cable is used with shield connected on the talker side.

Note For Modbus we recommend to use the IEC 61162-2 connections on equipment. IEC 61162-1 ports are

also usable and tested to work with Modbus on speeds up to 38400 baud, however the IEC 61162-2 ports are a

little better suited because of the C wire for signal ground reference.

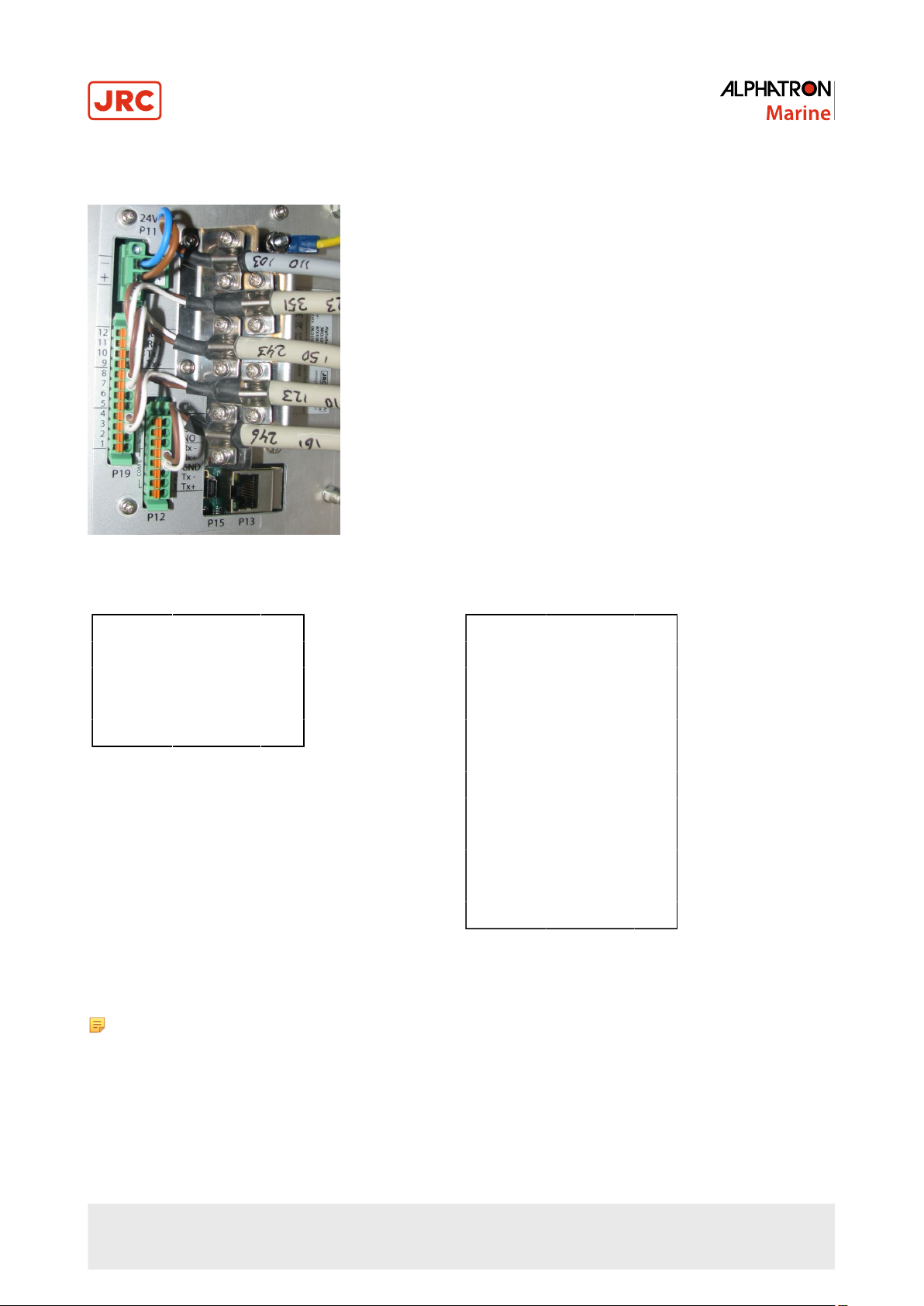

1.1.12 Serial Connection

The AlphaLine instrument has four IEC 61162 serial ports with Transmit (Tx) and Receive (Rx) connections. Three ports

are of type IEC 61162-1, one port is of type IEC 61162-2.

The instrument has two serial connectors, connector P12 with 8 connections and connector P19 with 12 connections.

16 | Installation Instructions

Page 17

For pin connections, see Figure 10: Serial pin connections on page 17, Table 4: Serial Connector P12 (8 pins) on

page 17 and Table 5: Serial Connector P19 (12 pins) on page 17.

Figure 10: Serial pin connections

1 COM0 IEC 61162-2 Tx+

2 COM0 IEC 61162-2 Tx–

3 COM0 IEC 61162-2 GND

4 COM0 IEC 61162-2 Rx+

5 COM0 IEC 61162-2 Rx–

Table 4: Serial Connector P12 (8 pins)

Note The instrument should always be connected according to the cable diagram. See Electric Diagrams on

page 51. Ensure connection to the correct COM port.

1.1.13 Relay

1 COM1 IEC 61162-1 Tx+

2 COM1 IEC 61162-1 Tx–

3 COM1 IEC 61162-1 Rx+

4 COM1 IEC 61162-1 Rx–

5 COM2 IEC 61162-1 Tx+

6 COM2 IEC 61162-1 Tx–

7 COM2 IEC 61162-1 Rx+

8 COM2 IEC 61162-1 Rx–

9 COM3 IEC 61162-1 Tx+

10 COM3 IEC 61162-1 Tx–

11 COM3 IEC 61162-1 Rx+

12 COM3 IEC 61162-1 Rx–

Table 5: Serial Connector P19 (12 pins)

One relay output is available for legacy alarm monitoring systems without serial ALR connection. This AlphaLine

instrument relay output is located on the 8-pin connector on the following pins. Use the NC (Normally Closed), or NO

(Normally Open) connection depending on the application.

For pin lay out, see Table 6: Relay Connector P12 (8 pins) on page 18.

17 | Installation Instructions

Page 18

6 Relay Normally Open

7 Relay Common

8 Relay Normally Closed

Table 6: Relay Connector P12 (8 pins)

1.1.14 Connecting Serial Ports

Serial data from sensors such as GPS, Speedlog and others is commonly known as NMEA. In the regulations is referred

to the IEC standard for the correct protocol description. These are IEC 61162-1 and IEC 61162-2. The manual will use

both these standards as there is a difference between them.

For detailed information on both standards, please read the IEC-61162-1 and IEC 61161-2 documents.

Serial Port IEC Standard

COM 0 61162-2

COM 1 61162-1

COM 2 61162-1

COM 3 61162-1

Table 7: Serial Ports

To make connections: Connect the data signal to the COM port as shown in the Electric Diagrams on page 51.

18 | Installation Instructions

Page 19

1.1.15 Connecting Dimmer

AlphaLine instruments can accept IEC 61162-1 dimmer messages with the $--DDC format.

Connect the signal to the designated dimmer connector as shown on the connection diagram, see Electric Diagrams on

page 51.

Figure 11: Dimmer Message

19 | Installation Instructions

Page 20

1.2 Software Installation

The software version for this AlphaLine instrument is 1.X.

1.2.1 Selecting Active Software

The AlphaLine instrument is stocked in the warehouse with all software pre-installed. The commissioning engineer will

select the function the AlphaLine instrument requires.

When a AlphaLine instrument is started up for the first time, or after a RESET, a selection menu appears where the

required application can be selected. See Figure 12: First Start up Screen (Empty) on page 20.

Figure 12: First Start up Screen (Empty)

1. Search for the required application by touching the < or > buttons.

2. Touch the Start application button once the required application appears in the window.

The AlphaLine instrument will restart and install the selected application. This will take a couple of minutes to

complete. Please be patient.

Note DO NOT switch off or disconnect the AlphaLine instrument while installing – this will corrupt the

software and make the AlphaLine instrument inoperable.

Note When the installation has been completed, the main screen of the application will appear.

1.2.1.1 Software Applications

The selection menu shows the whole range of AlphaLine instruments applicable to this screen format and orientation,

with the name of the software application displayed in the window. This name is different from the commercial name of

the instrument. Below, you will find the correct software application name for the AlphaTurn.

Software Application Name Commercial Name Instrument

ROT_MED_6,5_PT_SEA AlphaTurn

Table 8: MFM Software Applications

20 | Installation Instructions

Page 21

1.2.2 Software Updates

Alphatron Marine is constantly improving and updating its products by developing new functionalities and improving

usability and performance.

Visit our support website www.jrc.am/support for the newest manuals and to check that your product is still running the

latest software. Due to the nature of our products and solutions, software and relevant instructions will be available to

authorized distributors and dealers only.

Software update files and procedures are made available by Alphatron and can be acquired from the Alphatron Service

Desk at www.jrc.am/support.

Note DO NOT shut down the device during an update procedure, because this can cause irreversible damage

to the files on the internal storage device.

1.2.3 Watchdog Protection

AlphaLine display unit is guarded by a watchdog application. When the software freezes for an unknown reason,

then after a pre-programmed period, the display unit will restart itself and ensures that the display unit is functional

continuously.

Watchdog application is fed by a task with the lowest priority in a multitask environment. See Figure 13: Watchdog

Application on page 21. If one task freezes, the scheduler performs a context switch to other tasks with the same or

higher priority. This way, the task with a lowest level will not be scheduled and the watchdog will not be fed. And finally,

the watchdog will reset the processor.

21 | Installation Instructions

Figure 13: Watchdog Application

Page 22

2 Operation

2.1 Power

The unit must be connected to the power at all times.

Use the power button in the front panel of the instrument to switch the power ON and OFF.

Note In the OFF position, the power button is still dimly lit for easy identification in the dark. This only applies

when the instrument is connected to the power supply.

Note In a blackout situation, the instrument will always return to the last power state. This means that if the

instrument was switched ON before a blackout, it will be ON after a blackout. The same applies to the OFF

status. When the instrument is switched ON, the power button is lit in accordance with the DIM setting of the

LCD backlight, so the power buttons dims together with the LCD panel.

2.2 Main Screen

When the AlphaLine Instrument is switched ON, it will boot into the AlphaLine Instrument application. The application will

show the instrument specific data applicable to the particular instrument.

During the initialization time, while the instrument is starting up, the screen displays Figure 14: Splash Screen Rate of

Turn Indicator on page 22 . Depending on the display, the lower half of the screen shows the size of the instrument.

Figure 14: Splash Screen Rate of Turn Indicator

After the initialization time has been completed, the main screen appears. The main screen displays four standard

buttons. See Figure 15: Main Screen AlphaTurn on page 23 and Table 9: Main Screen Buttons on page 23.

22 | Operation

Page 23

Figure 15: Main Screen AlphaTurn

Functionality of the buttons is as described in table below.

Shows the instrument is functioning normally. If there's a malfunction a colored alert

symbol will show here.

Opens the MENU, where settings can be adjusted. This button also shows the

functionality of the instrument by rotating. If it stops rotating, the software of the

instrument is either very busy or it has crashed.

Touching this button will set the LCD DIM level brighter.

Touching this button will set the LCD DIM level one step less bright.

Table 9: Main Screen Buttons

23 | Operation

Page 24

2.3 Menu Handling

Menu handling is standardized for all different menu screens and for all different instruments. See Figure 16: Menu

Example on page 24 for an example of the MENU and Table 10: Explanation of On-screen Buttons and Icons on

page 24 for an explanation of the on-screen buttons and icons.

Figure 16: Menu Example

Go to main screen. Touch again to go to MENU.

Go back to the previous screen without saving settings.

Undo the last value change.

Accept and save current settings and applied settings will be saved.

Undo all settings and exit MENU

Scroll between standard settings using the + or – button

Standard settings are divided into several screens. Navigate through these screens

using the < or > button.

Table 10: Explanation of On-screen Buttons and Icons

24 | Operation

Page 25

2.3.1 Default Values AlphaLine Instrument

When the AlphaTurn is reset, it will return to the start-up screen, where a new instrument can be selected. The newly

selected instrument will contain the default values.

The default values for the AlphaTurn are shown in the table below.

Menu -> Theme

Illumination DAY

Menu -> Date_Time [1/2]

Year Compulsory Input

Month Compulsory Input

Day Compulsory Input

Menu -> Date_Time [2/2]

Hour Compulsory Input

Minutes Compulsory Input

Time Zone Compulsory Input

Menu -> ROT_Set

Menu -> ADV_SET -> CNTRL_DIM

Menu -> ADV_SET -> Eth_Config

Menu -> ADV_SET -> UART Config [1/2]

ROT Damping DISABLED

Damping Time (s) 1

INPUT ON

IP Address 192.168.31.31

Subnet Mask 255.255.255.0

Gateway 192.168.31.1

UART UART 0

Parity NONE

Stop Bits 1

Menu -> ADV_SET -> UART Config [2/2]

25 | Operation

Data Bits 8

Baud Rate 4800

Page 26

Protocol NMEA

Menu -> ADV_SET -> NMEA_TALKER

TALKER **

USED / UNUSED USED

Menu -> ADV_SET -> ROT_Set

MODBUS DISABLED

Menu ->ADV_SET ->NMEA_SET

SENTENCE NONE

INTERVAL [ms] 1000

PORT OFF

Table 11: Default Values for AlphaTurn

2.4 Indication Handling

If a malfunction occurs, a visual notification (=Important Indication) will be displayed.

For indication handling while operating the MAIN screen, see Figure 17: Indication Handling in Main Screen (example)

on page 27.

26 | Operation

Page 27

Figure 17: Indication Handling in Main Screen (example)

For indication handling while operating the MENU, see Figure 18: Indication Handling in Menu (example) on page 28.

27 | Operation

Page 28

Figure 18: Indication Handling in Menu (example)

28 | Operation

Page 29

Icon

Number

Table 12: Indication Management Icons

Icon Name Icon Description

0 Normal Condition Stationary circle with gray tick mark

1 Important Indication Yellow message icon and indication text. Touching

this icon toggles the visibility of the indication text.

Icon Graphic

(on display unit)

29 | Operation

Page 30

2.5 Settings

All instruments have generic and advanced settings.

All users are authorized to use the generic settings. Only the commissioning engineer has access to the advanced

settings, which are only needed during commissioning or troubleshooting.

2.5.1 Generic Settings

Every user of the AlphaLine instrument can access the generic settings.

2.5.1.1 Generic Settings Menu

Touch the MENU button in the main screen to enter the MENU with generic settings, see Figure 19: Generic Settings

Menu on page 30.

Figure 19: Generic Settings Menu

Select the button to configure a specific setting, or touch the ← button to return to the main screen.

30 | Operation

Page 31

2.5.1.2 Touch Screen Calibration (TOUCH CAL)

The touch screen can be calibrated by following the instructions that appear on the screen.

Figure 20: Touch Screen Calibration

Menu

1. In the MENU, touch the TOUCH CAL button.

The TOUCH SCREEN CALIBRATION MENU appears, see Figure 20: Touch Screen Calibration Menu on page

31.

2. Calibrate the screen by touching the CONFIRM CALIBRATE THE TOUCH SCREEN button.

The calibration screen appears with text requesting to touch the four numbered reference points that appear on the

screen, see Figure 21: Calibration Reference Points on page 31.

3. Touch the four reference points in sequence 1 to 4, as they light up.

The application will determine whether the sequence is carried out correctly.

4. If the text VALID CALIBRATION appears, then the calibration is performed accurately. Test calibration for accuracy

by dragging a finger across the screen, see Figure 22: Calibration Lines on page 31.

The line that appears on the screen should follow the finger.

5. Touch the ACCEPT button if calibration appears to be correct, or touch the AGAIN button to repeat the calibration

process.

6. If the text INVALID CALIBRATION...PLEASE RETRY appears, touch the AGAIN button to repeat the calibration

process.

Figure 21: Calibration Reference

Points

Figure 22: Calibration Lines

31 | Operation

Page 32

2.5.1.3 Cleaning Display ( CLEAN MODE )

The purpose of CLEAN MODE is to clean the surface of the display unit without accidentally activating a function. When

the CLEAN MODE is started, the touch screen will be deactivated for 60 seconds. Within this period the instrument

will remain functional, but it is not operable. Except when an alarm is activated, then the touch screen will be activated

immediately and the instrument will be operable again.

Figure 23: Clean Screen Menu Figure 24: Clean mode Countdown (Example)

To start CLEAN MODE, perform the following actions:

1. Touch the CLEAN MODE button in the MENU.

The CLEAN SCREEN screen appears, see Figure 23: Clean Screen Menu on page 32.

2. Touch the CONFIRM CLEANING THE SCREEN button to start the CLEAN MODE.

The AlphaLine instrument switches to the CLEAN MODE COUNTDOWN page and starts the countdown sequence,

see for example Figure 24: Clean mode Countdown (Example) on page 32.

Note For safety reason, if an alert is active and needs attention of the operator, CLEAN MODE can not be

started.

The touch screen is now deactivated and surface can be cleaned. After 60 seconds, or at an active alert, the instrument

will become operable again.

32 | Operation

Page 33

2.5.1.4 Change Theme (THEME)

2.5.1.4.1 Change Illumination

Contrast brightness can be easily adjusted to Day, Dusk and Night settings.

Figure 25: Theme

1. In the MENU, touch the THEME button.

The THEME MENU appears, see Figure 25: Theme on page 33 .

2. Touch the + or – buttons to select the desired ILLUMINATION value.

INFO: Three different ILLUMINATION values can be selected, in accordance with ambient light; DAY, DUSK and

NIGHT.

3. Touch the √ button to confirm the chosen setting.

The MENU appears again.

33 | Operation

Page 34

2.5.1.5 Change Date and Time (DATE/TIME)

The date and time can be adjusted.

Figure 26: Date/Time Screen 1 Figure 27: Date/Time Screen 2

1. In the SETTINGS screen, touch the DATE/TIME button.

The DATE/TIME screen appears, see Figure 26: Date/Time Screen 1 on page 34.

2. Touch the + and – buttons to set the correct DATE values.

3. Touch the > button to select the TIME screen, see Figure 27: Date/Time Screen 2 on page 34.

4. Touch the + and – buttons to set the correct TIME values.

5. Touch the √ button to confirm the chosen values and return to the SETTINGS screen.

6. To abort, touch the ← button to return to the SETTINGS screen.

34 | Operation

Page 35

2.5.1.6 About the AlphaLine instrument (ABOUT)

The ABOUT screen contains the name and version of the software and when it was built.

Figure 28: About the ROT Indicator

1. In the MENU, touch the ABOUT button.

The ABOUT MENU appears, see for example Figure 28: About the ROT Indicator on page 35 .

Note When asking for manufacturer's support, this information will be useful.

2. Touch the ← button to return to the SETTINGS screen.

35 | Operation

Page 36

2.5.1.7 ROT Settings (ROT SET)

The purpose of ROT Damping is to dampen the result on the screen when the ship is unstable.

Figure 29: ROT Damping Menu

To set up the ROT Damping settings, execute the following procedure:

1. In the MENU touch the ROT SET button.

The ROT DAMPING MENU appears, see Figure 29: ROT Damping Menu on page 36.

2. Set DAMPING to DISABLED or ENABLED by touching the + or – buttons.

3. Set the DAMPING TIME by touching the + or – buttons.

INFO: Set the DAMPING TIME to 1 - 10 seconds for sea application.

4. Touch the √ button to confirm the chosen setting.

The MENU appears again.

36 | Operation

Page 37

2.5.2 Advanced Settings

The advanced settings are password protected and are for use by commissioning engineers only.

2.5.2.1 Advanced Settings Menu (ADV SET)

A password is required to open the menu.

Figure 30: Password Screen

Figure 31: Advanced Settings Menu

1. In the MENU, touch the ADV SET button.

The PASSWORD screen appears, see Figure 30: Password Screen on page 37.

2. Key in the password and confirm with the √ button.

The ADVANCED SETTINGS MENU appears, see Figure 31: Advanced Settings Menu on page 37 .

3. Select the button to configure a specific setting, or touch the ← button to return to the MENU.

37 | Operation

Page 38

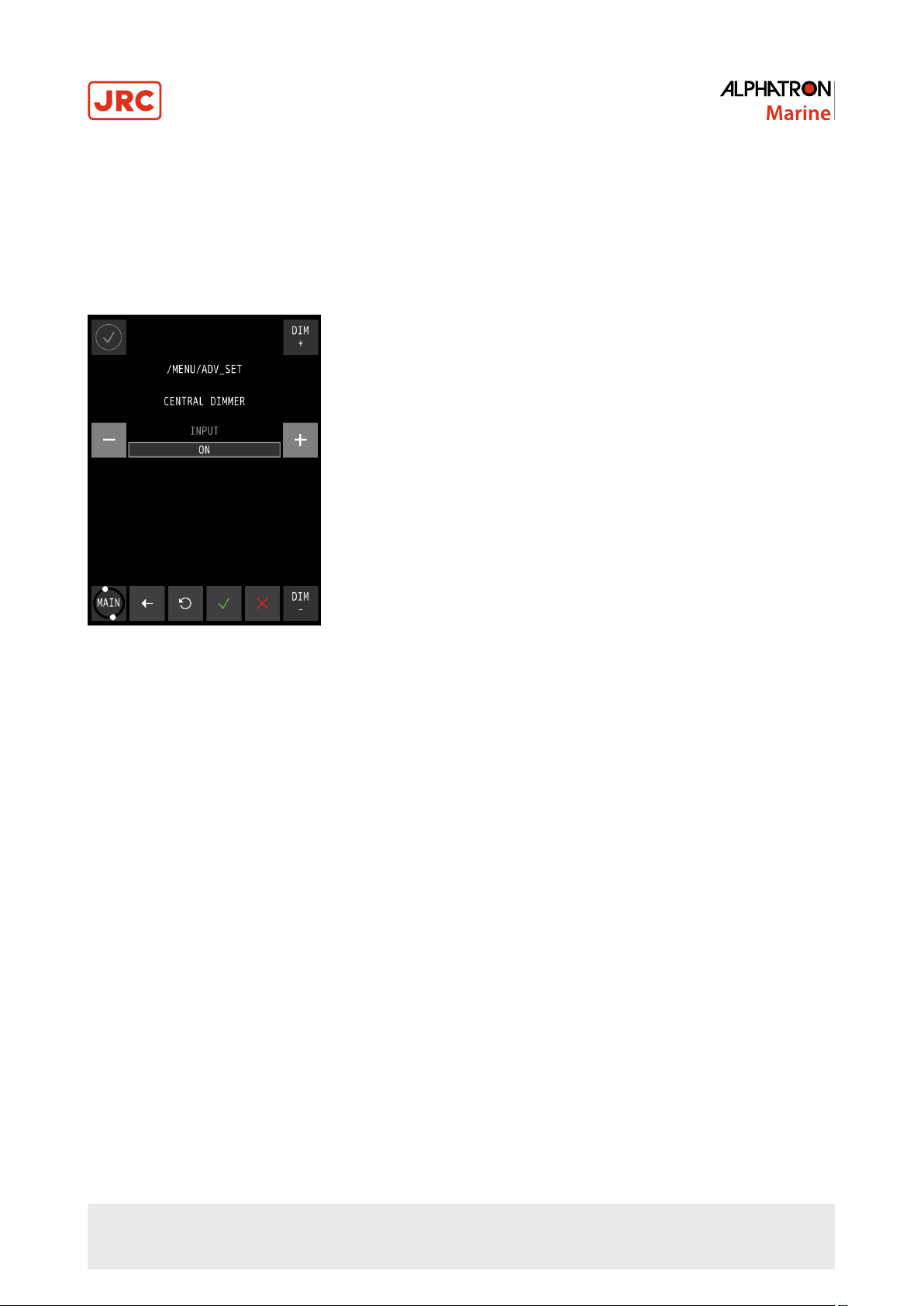

2.5.2.2 Central Dimming (CNTRL DIM)

The AlphaLine instrument supports central dimming as a listener (slave) from a standard (IEC 61162-1) dimming

sentence.

This dimming signal should be connected to serial port COM3, see Table 5: Serial Connector P19 (12 pins) on page 17.

Also see Figure 10: Serial pin connections on page 17.

If a central dimmer is connected, it can be enabled through the CENTRAL DIMMER menu, see Figure 32: CENTRAL

DIMMER menu on page 38.

Figure 32: CENTRAL DIMMER menu

1. In the MENU, touch the ADV SET button.

The PASSWORD screen appears.

2. Key in the password and confirm with the √ button.

The ADVANCED SETTINGS MENU appears.

3. Touch the CNTRL DIM button.

The CENTRAL DIMMER screen appears, see Figure 32: CENTRAL DIMMER menu on page 38.

4. Touch the + or – button next to INPUT to select ON or OFF.

5. Touch the √ button to confirm the chosen setting.

38 | Operation

Page 39

2.5.2.3 Ethernet Configuration (ETH CONFIG)

The AlphaLine instrument has one network interface to connect to a ship's network.

This can be useful when the instrument is connected to a remote interface or a PLC which uses Modbus/TCP. The

Ethernet interface can also be used for IEC 611612-450 signals.

Note This option has been included for future use.

Figure 33: Ethernet Menu Figure 34: Numeric Pad

1. In the MENU, touch the ADV SET button.

The PASSWORD screen appears.

2. Key in the password and confirm with the √ button.

The ADVANCED SETTINGS MENU appears.

3. Touch the ETH CONFIG button.

The ETHERNET screen appears, see Figure 33: Ethernet Menu on page 39.

4. Touch the bar below IP ADDRESS, SUBNET MASK, or GATEWAY to change these.

The numeric pad appears every time one of the bars is touched, see Figure 34: Numeric Pad on page 39.

5. Touch the numbers to insert new numbers and touch the X button to delete numbers.

6. Touch the √ button when numbers are correct.

7. Touch the √ button again to confirm the IP ADDRESS, SUBNET MASK and GATEWAY settings.

39 | Operation

Page 40

2.5.2.4 Serial Port Configuration (UART CONFIG)

The AlphaLine instrument is equipped with 4 serial ports (also called UART or COM).

The settings of the serial ports are divided over two screens as shown in Figure 35: UART Screen 1 on page 40 and

Figure 36: UART Screen 2 on page 40. Use the < or > button to toggle between the screens.

The default setting for NMEA (IEC 61162-1) data is 4800 baud, 8 databits, 1 stopbit. The default setting for Modbus over

serial port is 19200 baud, 8 databits, 1 stopbit and EVEN parity. See also Default Values AlphaLine Instrument on page

25.

Select and configure NMEA when a sensor is connected with the standard NMEA signals. Select ModbusMaster when

an interface (such as Analog Interface Mk.2 or AlphaTurn Interface Mk.2) is used.

Figure 35: UART Screen 1 Figure 36: UART Screen 2

1. In the MENU, touch the ADV SET button.

The PASSWORD screen appears.

2. Key in the password and confirm with the √ button.

The ADVANCED SETTINGS MENU appears.

3. Touch the UART CONFIG button.

The UART screen 1 appears, see Figure 35: UART Screen 1 on page 40.

4.

• Touch the + or – button to set UART from 0 to 3.

• Touch the + or – button to set PARITY to ODD, EVEN, FORCED 0, FORCED 1, NONE.

• Touch the + or – button to set STOP BITS to 1 or 2.

5. Touch the > button to toggle to screen 2, see Figure 36: UART Screen 2 on page 40 and follow the same principle

as for screen 1. Touch the < button to return to screen 1.

6. Touch the √ button when the settings are correct.

7. If settings are modified, restart the instrument to initialize the serial port again.

40 | Operation

Page 41

2.5.2.5 Serial Port Monitor (SERIAL MON)

It is possible to show serial data transmitted and received over the serial ports.

Usually, NMEA signals should be viewed as ASCII data and Modbus data should be viewed as HEX data. Received data

as well as sent data can be viewed (but not simultaneously). Select the appropriate button (Tx/Rx). For NMEA, Rx is

normally used.

Figure 37: Serial Port 1 Figure 38: Serial Port 3

1. In the MENU, touch the ADV SET button.

The PASSWORD screen appears.

2. Key in the password and confirm with the √ button.

The ADVANCED SETTINGS MENU appears.

3. Touch the SERIAL MON button.

The SERIAL PORT MONITOR 1 screen appears, see Figure 37: Serial Port 1 on page 41.

4. Touch the < or > buttons to select next port, see Figure 38: Serial Port 3 on page 41.

5. Touch the Rx/Tx buttons to show the Received/Transmitted data.

6. Touch the ASCII/HEX buttons to show the characters in ASCII code or in HEX values.

7. Touch the ← button to return to ADVANCED SETTINGS MENU.

Note All serial ports are configured the same way, the Serial Port screen has the following options:

• Baud rate: - Baud rate is a setting for Modbus devices, NMEA talkers, and other devices. It is also known

as symbol rate and modulation rate. The term roughly means the speed that data is transmitted. It is a

derived value based on the number of symbols transmitted per second. Valid values are: 1200, 2400,

4800, 9600, 19200, 38400, 57600 or 115200. The default value for NMEA is 4800. The default value for

Modbus communication is 19200.

• Data bits: - The numbers of data bits in each character can be 7 (for true ASCII), 8 (for any kind of data,

as this matches the size of a byte) 8 data bits are almost universally used in newer applications. 7 bits

is only used on special occasions. Valid values are: 7 or 8. The default value for NMEA and Modbus

communication is 8.

• Stop bits: - Stop bits sent at the end of every character allow the receiving signal hardware to detect the

end of a character and to resynchronize with the character stream. Electronic devices usually use one

stop bit. Valid values are: 1 or 2. The default value for NMEA and Modbus communication is 1.

41 | Operation

Page 42

• Parity: - Parity is a method of detecting errors in transmission. When parity is used with a serial port, an

extra data bit is sent with each data character, arranged so that the number of 1 bits in each character,

including the parity bit, is always ODD or always EVEN. If a byte is received with the wrong number of 1's,

then it must have been corrupted. However, an EVEN number of errors can pass the parity check. Valid

values are: N ( None ), O ( Odd ) or E ( Even ). The default value for NMEA is N (None). The default value

for Modbus communication is E (Even).

2.5.2.6 Factory Reset (RESET)

All menu settings can be reset to the factory default setting. For an overview of the default settings, see Default Values

AlphaLine Instrument on page 25.

Figure 39: Execute Factory Reset Figure 40: First Start-Up Screen

1. In the MENU, touch the ADV SET button.

The PASSWORD screen appears.

2. Key in the password and confirm with the √ button.

The ADVANCED SETTINGS MENU appears.

3. Touch the RESET button.

The EXECUTE FACTORY RESET screen appears, see Figure 39: Execute Factory Reset on page 42.

4. Touch the CONFIRM RESET ALL SETTINGS TO FACTORY DEFAULTS button for a full reset to factory default

values.

The AlphaLine instrument reverts to the first start-up screen, see Figure 40: First Start-Up Screen on page 42.

5. To return to the previous menu screen, touch the ← button.

42 | Operation

Page 43

2.5.2.7 Log (LOG)

The log screen shows information useful for fault finding.

Figure 41: Log Screen

1. In the MENU, touch the ADV SET button.

The PASSWORD screen appears.

2. Key in the password and confirm with the √ button.

The ADVANCED SETTINGS MENU appears.

3. Touch the LOG button.

The log screen appears, see Figure 41: Log Screen on page 43.

4. Touch the ˅ or ˄ buttons to scroll through the readings.

5. Take a picture of the log screen and contact the Alphatron Service Desk at www.jrc.am/support about errors.

Note Use for example a mobile phone to take a picture.

6. Touch the ← button return to the ADVANCED SETTINGS MENU.

INFO: Touching the MAIN button takes you back to the main screen.

43 | Operation

Page 44

2.5.2.8 NMEA Talker (NMEA TALKER)

With this menu, some additional NMEA sentence filters can be applied on the address field of an NMEA sentence. The

address field consists of a talker ID and a sentence formatter (for example ROT). This is depending on the configuration

of the software.

• TALKER- This item is prepared for future expansion, it is now set to **, which means that the NMEA (IEC61162-1)

Talker ID is not checked. Any talker ID is always accepted with the selected sentence formatter.

• USED/UNUSED - This setting defines the acceptation of the sentence based on the combination of the selected

Talker ID and selected sentence formatter. If this is set to UNUSED all sentences formatted with the selected Talker

ID are ignored. For now, this makes it possible for example to reject some specific sentence formatter.

Figure 42: NMEA Talker Menu

1. In the MENU, touch the ADV SET button.

The PASSWORD screen appears.

2. Key in the password and confirm with the √ button.

The ADVANCED SETTINGS MENU appears.

3. Touch the NMEA TALKER button.

4. Select the correct sentence formatter by touching the < or > buttons.

INFO: The TALKER is fixed indicated as a "Wild card" by **.

5. Touch the + or – buttons to select USED or UNUSED.

6. Touch the √ button to confirm.

44 | Operation

Page 45

2.5.2.9 NMEA Settings ( NMEA SET )

The AlphaLine instrument is able to transmit NMEA sentence to the external listener.

In this software version, it only supports the sentence VBW and DDC.

Figure 43: NMEA OUTPUT

To set up the output settings, execute the following procedure:

1. In the MENU, touch the ADV SET button.

The PASSWORD screen appears.

2. Key in the password and confirm with the √ button.

The ADVANCED SETTINGS MENU appears.

3. Touch the NMEA SET button.

The NMEA OUTPUT MENU appears, see Figure 43: NMEA OUTPUT on page 45

4.

• Touch the + or - button to set SENTENCE to VBW, DDC or NONE.

• Touch the + or - button to set INTERVAL to 100, 250, 500, 1000, 2000 or BY CHANGE.

• Touch the + or - button to set PORT to OFF, UART0, UART1, UART2, UART3 or TCP.

5. Touch the √ button when the settings are correct.

Note Please refer to Supported NMEA Sentences IEC 61162 on page 49 for more details about the

supported sentences.

45 | Operation

Page 46

3 Maintenance

• NOTICE

• This product contains no operator serviceable parts. Service and repair shall only be carried out by personnel

trained and certified by ALPHATRON MARINE B.V.

• NOTICE

• When cleaning the surface, do not use any organic solvent such as thinner or benzine. Otherwise, the paint

and markings on the surface may get damaged. For cleaning the surface, remove the dust and debris and

wipe with a clean dry cloth.

46 | Maintenance

Page 47

4 Appendix A

Appendix A contains:

1. Hardware Specifications on page 48

2. Mechanical Drawings on page 50

3. Electric Diagrams on page 51

4. Schematics on page 54

47 | Appendix A

Page 48

4.1 Hardware Specifications

4.1.1 Specifications MFM

Box Contents upon Delivery

Rate of Turn Indicator MFM 3108.0096 grey / 3108.0098 black

Mounting bracket

Screws (4 pcs)

USB flash drive with manuals

Template for cut-outs

Physical Dimensions

Dimensions (WxHxD) 160x180x80 mm (6.30x7.09x3.15")

Panel cut-out (WxH) 138x172 mm (4.84x6.77")

Weight 1.23 kg (2.71 lbs)

Power Specifications

Power supply 24 VDC input +/- 20% (Single source)

Power consumption 12 W (24 VDC @ 500 mA in rush prox. 4 A)

Protection Reverse polarity protection

Start-up time 30 sec.

Operating Conditions

Operating temperature

Operating humidity Up to 95% (at 40°C)

Storage temperature -25°C to +70°C

Storage humidity Up to 95% (at 40°C)

IP rating IP56 front / IP22 back

Compass safe distance Std: 0.1m / Steering: 0.1m

Environmental according to DNV 2.4 table 2.1

Temperature Class D

Humidity Class B

Vibration Class A

EMC compatibility Class B

Enclosure Class C

-25°C to +55°C

1

Display Functionality

Font display text 7 mm (viewing distance = 2 m)

Font operation buttons 3.5 mm (viewing distance = 1 m)

Accuracy Resolution 0.1°/min

Acoustic noise level 0 db

Display Specifications

High quality TFT Touch screen 6.5"

Pixels 480 x 640 (aspect ratio 3:4)

Orientation Vertical

Light intensity Max. brightness 450 cd/m2

View angle (H/V) 140°/160°

Maximum colors 16.7 million

Input/Output Signals

COM 0 (IEC 61162-2) isolated Modbus RTU Rx/Tx

COM 1 (IEC 61162-1) isolated NMEA Rx/Tx

COM 2 (IEC 61162-1) isolated NMEA Rx/Tx

COM 3 (IEC 61162-1) isolated NMEA Rx/Tx

USB port (Mini) Used for software update/maintenance

Alarm output NOC contact (potential free)

Norms/Standards

IEC 60945 (2002) Incl. IEC 60945 Corrigendum 1 (2008)

Standard DNV 2.4 Det Norske Veritas

IEC 61162 series NMEA Definitions

IEC 62288 (2014) Testing methods

ISO 20672 (2007)

4.1.2 Available Accessories

Available Accessories

MFM IP56 Kit 3698.0018

Table 13: Available Accessories

1

Although the test conditions for bridge units provide for a maximum operation temperature of 55°C, continuous operation of all electronic components should, if

possible, take place at ambient temperature of 25°C. This is necessary for a long life and low service costs.

48 | Appendix A

Page 49

4.2 Software Specifications

4.2.1 Supported NMEA Sentences IEC 61162

Supported NMEA sentences (IEC 61162)

Primary IN $xxROT

Secondary IN $xxDDC

Secondary OUT $VDDDC

Table 14: Supported NMEA Sentences

4.2.2 Indication List

Indication list

Invalid checksum of NMEA ... sentence Checksum of incoming sentence is incorrect

Parsing of NMEA ... failed Contents of incoming sentence is incorrect

No Rate of Turn information received NMEA: Missing of correct ROT sentence (> 6 sec.)

Table 15: Indication List

49 | Appendix A

Page 50

4.3 Mechanical Drawings

4.3.1 Mechanical Drawing MFM

Figure 44: Mechanical Drawing MFM

50 | Appendix A

Page 51

4.4 Electric Diagrams

The cable diagrams and connection diagrams illustrate the connections to hardware, power and other equipment.

51 | Appendix A

Page 52

4.4.1 Cable Diagram AlphaTurn

Figure 45: Cable Diagram AlphaTurn

52 | Appendix A

Page 53

4.4.2 Connection Diagram AlphaTurn

Figure 46: Connection Diagram AlphaTurn

53 | Appendix A

Page 54

4.5 Schematics

This chapter contains the schematics of the AlphaLine instruments. The commissioning engineer uses the schematics to

be able to connect the signals according to the ship's requirements.

54 | Appendix A

Page 55

4.5.1 Schematics AlphaLine MF Display Unit

Figure 47: Schematics AlphaLine MF Display Unit

55 | Appendix A

Page 56

4.5.2 Schematics AlphaLine Instrument

1

1

2

2

3

3

4

4

5

5

6

6

H H

G G

F F

E E

D D

C C

B B

A A

Design:

Product:

Date :

Alphaline_ACB

21/01/2015

Sheet: Main.SchDoc of1 14Release

Alphatron Marine

152-01/1.5 -

DAT2

1

CD/DAT3

2

CMD

3

VDD

4

CLK

5

VSS

6

DAT0

7

DAT1

8

SWITCH A

A

SWITCH B

B

t

a

b

1

t

a

b

2

t

a

b

3

t

a

b

4

Mounting tabs

P14

Micro SD

QSPI

Memory

I2C

LCD

Touch

RS422

IO

SD

USB

Backlight

RESET

Power_feedback

ETH

Power_control

2. Controller

Vin+

Powerswitch

LED_Off_Anode

LED_Off_Cathode

Power_feedback

Power_control

Vin-

13. Power

ETH_RX_N

ETH_RX_P

ETH_TX_N

ETH_TX_P

ETH_LED_Link

ETH_LED_100M

3V3_ETH

RESET

ETH

10. Ethernet

QSPI

I2C

Memory

9. Memory

RS422

RS422_0_TX+

RS422_0_TX-

RS422_0_RX+

RS422_0_RX-

RS422_0_Shield

RS422_1_TX+

RS422_1_TXRS422_1_RX+

RS422_1_RX-

RS422_3_TX+

RS422_3_TXRS422_3_RX+

RS422_3_RX-

RS422_2_TX+

RS422_2_TXRS422_2_RX+

RS422_2_RX-

6. RS422

Touch

X-

Y+

5WSX-

Y-

X+

8. Touchscreen

IO

Joystick_push

Joystick_B

Joystick_A

Joystick_Y

Joystick_X

Potmeter_output

Motor-

Relay_NO

Relay_COM

Relay_NC

LED_On_Cathode

Buzzer_ext-

Joystick_5V

Potmeter_GND

Potmeter_3V3

Buzzer_ext+

Buzzer_int-

Buzzer_int+

5. IO

LCD

11. LCD

USB

4/5 wire touchscreen

USB_VBUS

USB_DUSB_D+

SD_DAT2

SD_DAT3

SD_DAT0

SD_DAT1

SD_CLK

SD_VDD

SD_CMD

SD_CD

SD

USB

USB_ID

7. USB_SD

TD+

1

TD-

2

RD+

3

TCT

4

RCT

5

RD-

6

Filter

8

9 10

11 12

Shield

Yellow

Green

P13

RJ45

1

2

P11

MSTBV 2,5/ 2-GF

1

2

3

4

5

6

7

8

P8

Micro Match

1

2

3

4

P6

Micro Match

1

2

3

4

5

P7

FPC 1mm

1

2

3

4

5

6

7

8

9

10

P2

FPC 1mm

P10

Solderpad

P9

1

2

3

4

5

6

7

8

9

10

P1

DF13

Backlight

EN

PWM

Cathode1

Anode1

Anode2

Cathode2

Backlight_Power

12. Backlight

Powerswitch B

Buzzer_ext +

Backlight

H3 H1

H2

H4

3V3

H2

3x IEC61162-1

Power 16-36V

Potmeter

Joystick

Motor

SD Card

Ethernet

On/Off

FID1FID2

R246 0E

R247 0E

1

2

3

4

5

Vbus

DD+

ID

GND

P15

Mini USB

1

2

3

4

5

6

7

8

P12

MCV 1,5/ 8-G-3,5-RN

1

2

3

4

5

6

7

8

9

10

11

12

P19

MCV 1,5/12-G-3,5-RN

1

2

3

4

5

6

P20

Micro Match

Relay

Rotary encoder

IEC61162-2

Buzzer_ext -

LED_On_Cathode

TP2

5016

TP3

5016

iNet Class: input isolatio n

LED_On_Anode

Connect shield to casing

12V

+

BUZ1

Internal buzzer

LVDS Connector

RGB Connector

Figure 48: Schematics AlphaLine Instrument

56 | Appendix A

Page 57

All over the world,

close to the customer

JRC/Alphatron Marine B.V.

Schaardijk 23 (harbor 115)

3063 NH Rotterdam

The Netherlands

T +31 10 453 4000 Document name: AlphaTurn

F +31 10 453 4010 Document nr. : 1000_06a

service@jrc.am Version : V1.0.8

www.jrc.am

The information in this document is subject to change without notice and

does not represent a commitment on the part of Alphatron Marine B.V.

©

All rights reserved Alphatron Marine B.V.

Centers of Excellence

Houston, Rotterdam, Singapore, Tokyo

Loading...

Loading...