Page 1

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

1 of 28

09.10/03/Sie

as from S/N (control board): 1003061

JT

Page 2

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

2 of 28

09.10/03/Sie

1 ELECTRICAL SAFETY

THE JT CONTROL SYSTEM CARRIES DANGEROUS CURRENT

WHEN IT HAS BEEN CONNECTED TO THE MAINS.

THE JT CONTROL SYSTEM MUST WHEN IN OPERATION BE

EARTHED VIA A GROUND CONDUCTOR WHICH IS

CONNECTED TO THE FRAME TERMINAL PE.

INTERFERENCE VOLTAGE MAY BE PRESENT ALSO IN A

SWITCHED OFF JT CONTROL SYSTEM.

CHECK BY MEASURING WITH A VOLTMETER AT THE MAINS

TERMINALS AND THE RELAY OUTPUT TERMINALS THAT THE

JT CONTROL SYSTEM IS DEENERGIZED BEFORE

COMMENCING WORK.

THE ELECTRICAL INSTALLATION WORK

MUST ONLY BE CARRIED OUT BY AN

AUTHORIZED QUALIFIED CRAFTSMAN.

Warning symbols

For your own safety, please pay particular attention to the

instructions marked with the following symbols:

!

Danger! High voltage

General warning

Page 3

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

3 of 28

09.10/03/Sie

2 NOTES ON EMC LEGISLATION

The CE mark applied refers to [German] legislation of

09.11.92 governing electromagnetic compatibility (EMC).

Installation of the JT control system must be carried out by

staff trained in EMC.

The JT control system complies with the following

standards or equivalent documents.

1. EN 50081-1

2. EN 50082-2

The JT control system may be used in

− the home, commercial and trade sectors and small

business

− industry

providing that the following measures are observed:

(as shown in the Appendix "Connection Diagram")

• The delivered manufacturer`s mains filter must be used.

• All control cables are screened and connected to the

control equipment at one end.

• The connecting cable between the JT control system

and the vibrator is screened and connected at both

ends.

• The corresponding measures concerning the cabling in

chapter 7.3 must be observed.

Page 4

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

4 of 28

09.10/03/Sie

3 CONTENTS

1 ELECTRICAL SAFETY ............................................................................ 2

2 NOTES ON EMC LEGISLATION ............................................................. 3

3 CONTENTS .............................................................................................. 4

4 PREFACE ................................................................................................. 5

5 PURPOSE................................................................................................. 6

6 OPERATING PRINCIPLE ........................................................................ 6

7 INSTALLATION........................................................................................ 7

7.1 CONSTRUCTION .................................................................................. 7

7.2 NOTES ON INSTALLATION.................................................................. 7

7.3 WIRING.................................................................................................. 8

7.4 CONNECTIONS..................................................................................... 9

7.5 SPECIAL CHARACTERISTICS............................................................. 9

7.5.1 Regulator release................................................................................ 9

7.5.2 Output-side switching.......................................................................... 9

7.5.3 Actual value failure protection........................................................... 10

7.5.4 Switching on the setpoint signal........................................................ 10

7.5.5 Applications for coarse/fine feed setpoint ......................................... 10

7.5.6 Manual/automatic applications.......................................................... 10

7.5.7 Multiple drive applications................................................................. 10

8 COMMISSIONING .................................................................................. 11

8.1 CHECKS BEFORE SWITCHING ON THE MAINS VOLTAGE ........... 11

8.2 SWITCHING ON THE MAINS VOLTAGE ........................................... 11

8.3 SETPOINT INTEGRATOR .................................................................. 12

8.4 ACTUAL VALUE OUTPUT .................................................................. 12

8.5 OUTPUT RELAY.................................................................................. 13

9 SETTINGS / RECONFUGURATION...................................................... 14

AND

9.1 POSITION OF ADJ. ELEMENTS

9.2 EXPLANATION OF ADJUSTMENT ELEMENTS ................................ 14

9.3 MATCHING THE SETPOINT SOURCE .............................................. 15

9.4 FIXING THE CONTROL MODE .......................................................... 16

9.5 CHOOSING THE OUTPUT FREQUENCY.......................................... 16

9.6 MATCHING THE MAINS VOLTAGE ................................................... 17

9.7 CONTROL SYSTEM CALIBRATION................................................... 17

9.8 PI-REGULATOR .................................................................................. 17

9.9 STROKE SENSOR CONNECTION..................................................... 18

10 MAINTENANCE.................................................................................... 18

11 FAULT FINDING................................................................................... 18

12 ADDITIONAL EQUIPMENT ................................................................. 20

13 APPENDIX............................................................................................ 21

COMPONENTS....................... 14

13.1 TECHNICAL DATA ............................................................................ 21

13.2 TYPE KEY.......................................................................................... 23

13.3 SCOPE OF SUPPLY ......................................................................... 24

13.4 FUSES ............................................................................................... 24

13.5 DIMENSIONS .................................................................................... 25

13.6 CONNECTION DIAGRAM................................................................. 27

Page 5

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

5 of 28

09.10/03/Sie

4 PREFACE

The information contained in this manual refers exclusively to JT

control systems.

It is essential that you read this manual before installation and

commissioning.

The limits specified in the technical data must be observed when using

the control system.

The guarantee for manufacturers' drives and equipment does not

cover defects caused by misuse or incorrect use of these control

systems.

The manual is divided into individual sections in accordance with the

table of contents.

Section 1 "Electrical safety" and Section 2 " Notes on EMC legislation"

must be read before working with the JT control system.

It is essential that the user familiarises himself with this manual before

using the drive/equipment or before carrying out adjustment work

specific to the operations.

Please contact the manufacturer directly if you have any questions

about the JT control system.

The manufacturer reserves the right to make product changes without

prior notice.

Page 6

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

6 of 28

09.10/03/Sie

5 PURPOSE

The JT Control Systems are intended for the operation of vibrating

systems with manufacturers` electromagnetic drives from an a.c.

mains.

With the JT Control System the stroke (vibration amplitude) of such

an installation can be adjusted from almost 0 to maximum.

In the control mode 'K' (= voltage regulation), fluctuations in the

supply voltage of ±10% have nearly no effect on the stroke.

In the control mode 'Y' (= stroke regulation), fluctuations of ±10%, as

well as a change in the mass conditions, e.g. through bunker

pressure, have no effect on the stroke.

6 OPERATING PRINCIPLE

With the potentiometer supplied or an external mA- or voltage signal

as the setpoint source, the stroke and therefore the feed rate of an

electromagnetic vibratory system can be continuously adjusted

within certain limits (minimum or maximum value resp.).

The setpoint signal is compared with the actual value signal. (The

actual value signal is, with the control mode 'K', the output voltage of

the control system to the drive and, with the control mode 'Y', the

signal of the stroke sensor on the vibratory system). The differential

signal (regulation deviation) is passed to a PI-action controller, which

generates the setting signal for the phase control system. The

setting signal determines the firing point of the thyristor-module.

The firing pulses are passed to the thyristor-module for galvanic

separation via a firing transformer. Firing takes place only within the

positive sinusoidal half-wave. The negative is suppressed by the

thyristor. The phase control within the positive sinusoidal half-wave

controls the electrical output of voltage and current, which is passed

to the vibratory system.

Page 7

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

7 of 28

09.10/03/Sie

7 INSTALLATION

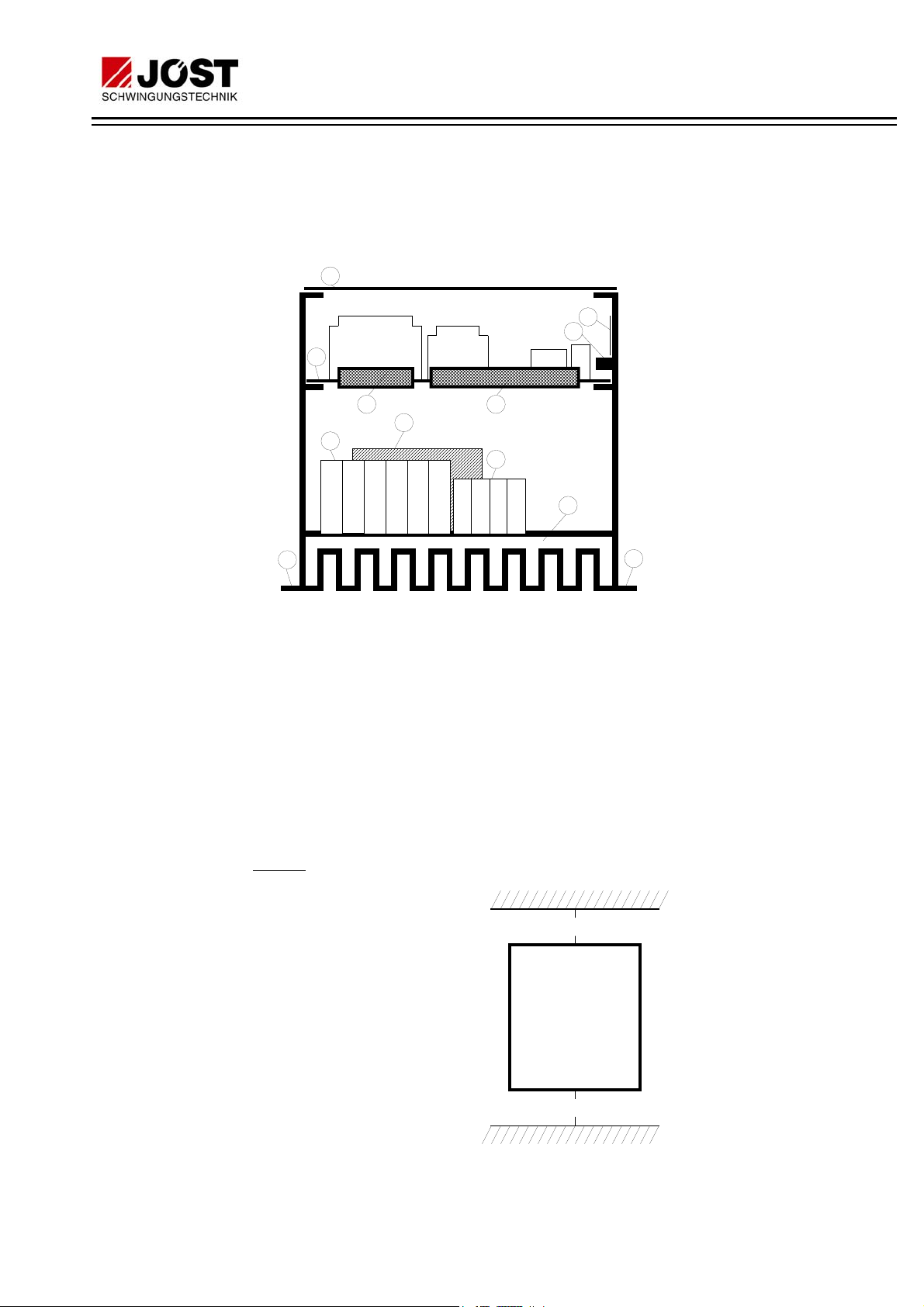

7.1 CONSTRUCTION

The major components of the JT control system are as follows:

1

5

10

2

3

6

7

12 34

9

1. Perspex cover

2. Control board

3. Connection plug X3 between control board and power

section

4. Control terminals X2

5. Rating plate

6. Thyristor-module with RC snubber network

7. Mains connection/drive/earth terminal X1

8. Heatsink

9. Fixing holes

10. Assembling bolt for screening

7.2 NOTES ON INSTALLATION

Cooling

:

4

4

17182627PE PE

8

9

The JT control system is

cooled by natural

convection. In order to

guarantee an adequate

air flow, the equipment

must be mounted upright

and the minimum

distances shown in the

adjacent illustration

observed. The cooling

air must be as clean as

possible and free of

aggressive substances.

Should the cooling air

contain dust, the cooled

areas must be cleaned regularly.

a

JT-

Control

System

60 mm

JT 14 to JT26:

a = 60 mm

JT45 to JT70:

a = 80 mm

Page 8

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

8 of 28

09.10/03/Sie

Mounting:

Fixing dimensions, also for the mains filter, are to be found in the

appendix.

The JT Control system is fixed on the assembly board with four

screws inserted through slots.

Fit four fixing screws, hook on the control unit and tighten the four

screws.

The control system should be placed in a shock- and vibration-free

position.

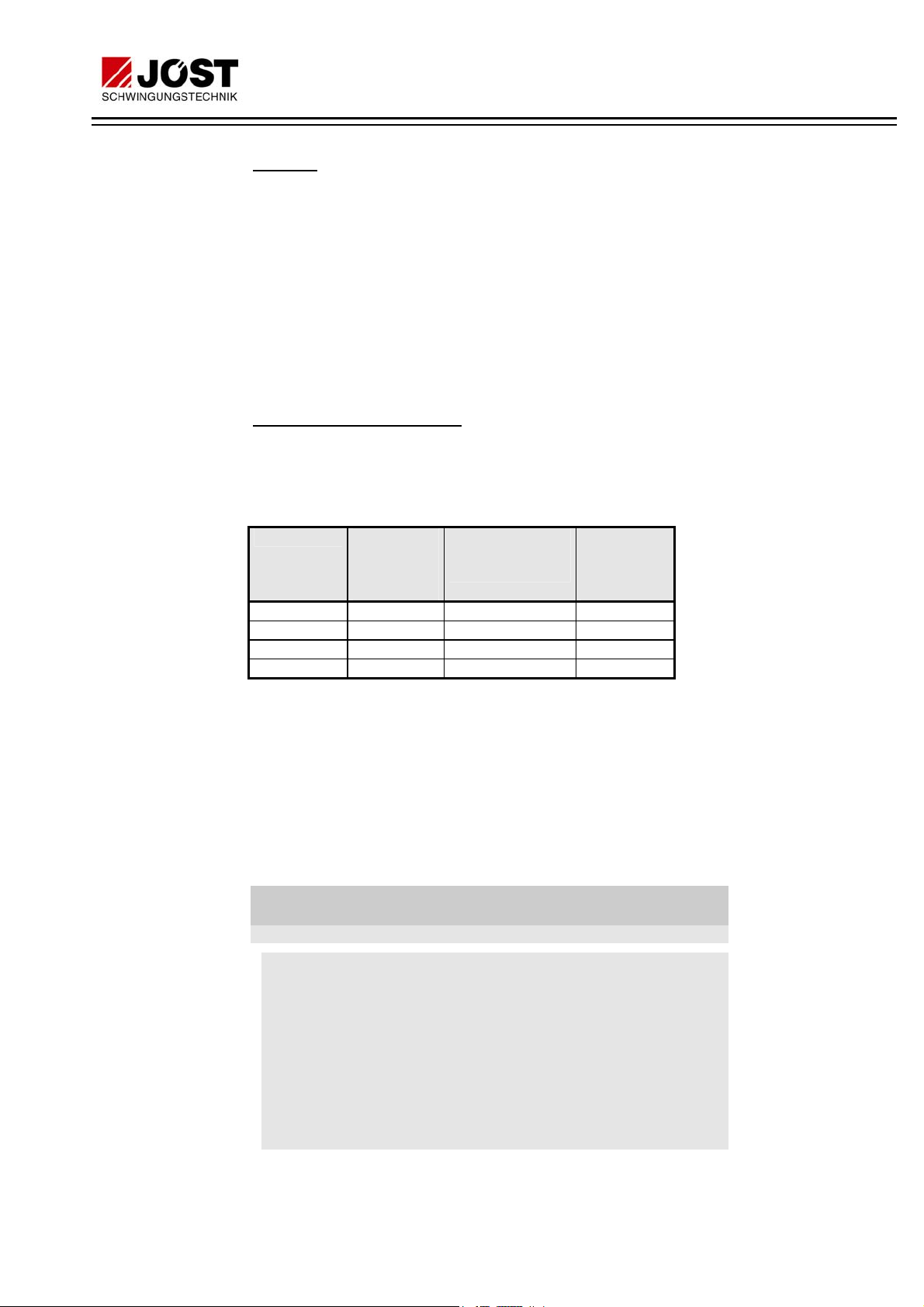

7.3 WIRING

Mains and drive cable sizes:

Values are based on a cable length of 50 m between the control

system and drive. The cable diameters must be increased

appropriately for longer distances.

Allocation table: Control system / back-up fuse / cable / mains filter

JT-type 2-pole

back-up

fuse

[A, retarded]

Mains and drive

cable crosssection

1)

1) 2)

[mm²]

matching

mains filter

3)

Type

JT 14/... max.16 2.5 2x16

JT 26/... max. 35 6.0 2x35

JT 45/... max. 50 10.0 2x50

JT 70/... max. 80 25.0 2x80

1)

adapted to IN of the drive.

2)

The local regulations governing earthing and cables must be

observed.

3)

To be used within the scope of the EC directive 89/336/EEC

concerning EMC.

As the connecting cable between electromagnetic drive and

stationary terminal box we recommend the use of a flexible cable of

the type H07RN-F resp. NSSHöU-J. For the use of screened cables

we recommend the type ÖLFLEX 540 CP.

Additional measures within the scope of the EMC

directive 89/336/EEC:

(also refer to connection diagram in the appendix)

Mains supply: For this case, the delivered mains filter must be

switched into the mains supply line of the JT

control system. The filter must be directly mounted

on the left hand side next to the JT control system.

Sufficient ground contact must be observed. The

connection between the filter (wiring side named

„LOAD“) and the JT control system must be as

short as possible. For the filter types upto 2x35 the

filter-own output wires must be used. As from the

filter type 2x50 the connection must be made by

single wires of max. 20 cm length.

Page 9

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

9 of 28

09.10/03/Sie

For the mains supply all filters are fitted with

clamps on the „LINE“ side. The connection of the

ground conductor is built as threaded bolt as from

filter type 2x50.

Drive connection:A screened cable between JT control system

and drive must be used. The screen connection

must be as short as possible and connected to

ground on both ends.

Control cable:

The control cable must be screened

multicore flexible cable with a conductor cross-section of 0.5 or 0.75

mm² for the control system connection.

N:B.: Earth the cable screen - as short as possible - at the JT control

system end. Use the assembling bolt (see 7.1 „Construction“,

Pos.10).

The control cables must be positioned at least 0.5 m from the drive

cable, to prevent interference.

7.4 CONNECTIONS

Please refer to the connection diagram in the appendix or the

connection sheet enclosed with the control system for the assignment

of terminals for the mains, drive and control system cables.

N.B.: If the setpoint potentiometer is used, please ensure that the

correct connection sequence is observed.

7.5 SPECIAL CHARACTERISTICS

7.5.1 Regulator release

The control system is fitted with an input for the regulator release

(control system terminals X2.14/15).

The regulator is blocked when the terminals are open. The drive will

be idle.

The regulator is released when the terminals are shorted. The drive

will vibrate.

. We recommend a screened,

When the drive is switched off by the regulator release,

connection terminals X1.3/4 will not be disconnected

from the mains.

If the operating process requires the drive to be switched on and off

frequently, the "regulator release" must be used instead of switching at

the mains. The control system therefore remains connected to the

mains current.

7.5.2 Output-side switching

It is only permissible to switch the output if the control system is

switched off (at the mains end or via the regulator release). Switches

or contactors with appropriate maximum loads must be used for this.

Page 10

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

10 of 28

09.10/03/Sie

When switching between the control system and the drive, the "V"

protective unit

remain on the drive when the control system is switched off.

7.5.3 Actual value failure protection

The control system is provided with a built-in actual value failure

protection facility. If the actual value fails, e.g. through cable fracture

on the stroke sensor, the drive is operated with a constant voltage

which is reduced as vis-a-vis the maximum output voltage. The

stroke can then no longer be influenced via the setpoint. Only after

the fault has been corrected is normal operation possible again.

7.5.4 Switching on the setpoint signal

If switching is to be carried out in the setpoint cables, relays with gold

contacts or hermetically sealed relays must be used, because of the

low switching voltage (U ≤ 10V=, I ≤ 20 mA). Please note that, with

mA signals, the load resistor is located on the control board.

(see section on "Additional Equipment")

must be used. It must

7.5.5 Applications for coarse/fine feed setpoint

A setpoint pre-setting is possible for coarse and fine feed in metering

and weighing applications. If the setpoint is preset by potentiometers,

a second potentiometer is required (to be ordered separately). The

setpoint for coarse feed will then be preset from the first potentiometer,

and for the fine feed from the second. An example of wiring can be

found in the appendix "Connection diagram". Terminals 26/27 only

function as post terminals for the slider, i.e. they are not used for the

control system.

An external setpoint signal (mA or V) can also be used for the

aforementioned applications. A signal of 2 Volts would then be the fine

feed value, and 8 volts the coarse feed value for example.

7.5.6 Manual/automatic applications

Manual/automatic applications means that the actual setpoint (=

automatic) comes from an external source (regulator / PLC as mA or

V). A setpoint from a manual potentiometer can be provided by

switching instead of the automatic setpoint of the control system (->

manual). An example of wiring can be found in the appendix

"Connection diagram".

The selector switch S2 (setpoint source) must then be set to the

automatic setpoint signal.

7.5.7 Multiple drive applications

Should more than one drive be connected to a control system, it is

necessary to connect the single drives through separating diodes (

section on "Additional equipment")

. Please consult the manufacturer.

see

Page 11

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

11 of 28

09.10/03/Sie

8 COMMISSIONING

8.1 CHECKS BEFORE SWITCHING ON THE MAINS VOLTAGE

The JT control system is pre-set ex works to the vibrating plant

supplied, and can thus be used without any further adjustments.

Exception: A tag on the control system makes reference to further

adjustment.

The adjustment trimmers P1-P4 and the selector

!

Should settings be required other than those supplied, please read the

section "Settings/Reconfiguration".

Check the following points before switching on the mains voltage:

switches SW 1 and SW2 on the JT control board may

not be altered.

1. The control system must be connected to the appropriate

vibrating plant

2. The information on the rating plate on the control system must

match the details of the drive. It is especially important that the

output frequency of the control system matches the vibration

frequency of the drive.

3. The nominal mains voltage must lie within the voltage range

specified on the rating plate (entry under "V" on the rating plate).

4. The fuse holder with super-quick acting fuse supplied must be

inserted in the mains cable to the terminal X1.1.

5. The fuse must have the ampere value matching the control

system (see type designation on the rating plate and

allocation table in the Section 'Fuses' in the appendix).

6. The control system must be earthed via the PE terminal.

7. The measures to observe EMC legislation must be implemented

(see section 2).

8. The mains cable must be connected to the appropriate terminals

9. The drive cable must be connected to the appropriate terminals

10. The appropriate setpoint source must be connected (see type

designation on the rating plate and explanation of the type key in

the appendix).

11. Set the setpoint source to minimum (0/4 mA, 0V, or setpoint

potentiometer to 0).

12. Terminals 14/15 must be bridged if no external regulator

release is connected.

Only applicable if an external regulator release is connected: A

break contact must be connected to terminals 14/15 and the

bridge used must be removed

Only for control units of Type JT../..E..K.. : (voltage reguation)

13.The control terminals X2.17/18 must be bridged.

Only for control units of Type JT../..E..Y.. : (stroke regulation)

13.The control terminals X2.17/18 must not

14.The stroke sensor supplied with the equipment must be

mounted on the vibratory machine and correctly connected to

the control system.

8.2 SWITCHING ON THE MAINS VOLTAGE

The points listed under 8.1 must be checked before the mains voltage

is switched on.

be bridged.

Page 12

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

12 of 28

09.10/03/Sie

The mains voltage can now be switched on.

A dangerously high voltage will now be present in the JT

control system.

The green light emitting diode LED1 „Voltage on“ must now light.

The red light emitting diode LED2 „Regulator release“ must be off.

N.B.: If LED2 is on, the regulator release must be obtained by

closing the contact at terminals X2.14/15

The make contact of output relay at terminals X2.12/13 is closed.

The vibrating plant must now work at minimum vibration amplitude.

The setpoint signal can now be slowly set to maximum. The vibration

plant must operate at the maximum setpoint with the vibration

amplitude, as specified in the technical documentation for the

equipment.

When the setpoint signal is increased, consideration

!

If there is no fault in operation, the operating setpoint may be adjusted

and the material to be conveyed supplied.

Should further adjustment of the control system be required due to

customer's circumstances, please read the section "Settings /

Reconfiguration".

must be given to the operating noise level of the vibrating

plant. If contact noises can be heard, the vibrating plant

must be stopped immediately. The plant can be switched

on again after the cause of the problem has been

rectified.

8.3 SETPOINT INTEGRATOR

In applications where the vibratory machine is to reach the preset

stroke slowly, there is the possibility of delaying the setpoint signal

by means of a soft start stage.

The acceleration period can be infinitely preset between 0 and 15

seconds with the trimming potentiometer P5 on the control board.

Trimming potentiometer P5 at the left-hand stop corresponds to

approx. 0 seconds. Trimming potentiometer P5 turned clockwise up

to the right-hand stop corresponds to 15 seconds.

N.B.: P5 can be actuated with a narrow screwdriver through

the opening in the perspex cover. Please consult the

position diagram to find the location of P5 (see 9.1).

8.4 ACTUAL VALUE OUTPUT

The control system is equipped with an actual value output 0 - 10 V=

as standard. It can be used for connecting display/monitoring

units.This output has not been calibrated in the works. Calibrating is

done with the trimming potentiometer P6 on the control board. If the

actual value output is used, the output must be calibrated at

maximum setpoint value. To do this, connect a voltmeter

(measurement range 20 V=, Ri > 10 KΩ) to the control terminals

X2.11 (+) and X2.7 (0V). Set 10 V= on the voltmeter with P6 by

turning anticlockwise. After that the corresponding

display/monitoring unit can be connected.

NOTE: P6 can be actuated with a narrow screwdriver

through the opening in the perspex cover. Please consult

the position diagram for the location of P6 (see 9.1).

Page 13

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

13 of 28

09.10/03/Sie

When applying the stroke control unit 'J', refer to the

corresponding manual, to set the actual value output.

8.5 OUTPUT RELAY

A voltageless make contact of the output relay is available at the

control terminals X2.12/13.

Contact closed: Mains voltage on and regulator release provided,

i.e. control sytem in operation.

Contact open: Mains voltage off and/or regulator release not

provided.

Contact rating: see 'Technical data'

Page 14

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

14 of 28

09.10/03/Sie

9 SETTINGS / RECONFUGURATION

9.1 POSITION OF ADJ. ELEMENTS and COMPONENTS

X6

GND

P1 P2 P3 P4 P5

LED1

P6

Mains transformer

SW1

1234

SW2

12345

Si1

400V

500V

GE

230V

R42

50mAT

X3

LED1: Light emitting diode (green) for „Voltage on“

LED2: Light emitting diode (red) for „Regulator release“

X4

Diagnosisplug

-

+

C4

LED2

Relay

X2

X2

9.2 EXPLANATION OF ADJUSTMENT ELEMENTS

IMPORTANT NOTE:

!

Unauthorised resetting of the adjustment elements can

cause malfunctions in the control system.

It is essential to read the following before changing the

settings.

Trimming potentiometer:

There are six trimming potentiometers on the control board.

Function of the trimming potentiometers:

P1: Limitation of the maximum output voltage *)

P2: Adjustment of the minimum output voltage

P3: Matching the actual value signal

P4: Setting the rated stroke

P5: Adjustment of the soft start time

P6: Calibration of the actual value output

*) P1 has been sealed in the works and must not

Selector switch (DIP switch):

be adjusted!

A four-way (SW1) and a 5-way (SW2) selector switch (DIP switches)

is arranged on the control board.

The individual switches are sliding switches. These are numbered 14 and 1-5 from left to right respectively.

Page 15

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

15 of 28

09.10/03/Sie

Operation of the sliding switches is permissible only

!

when the power (mains) is turned off. The perspex cover

of the control system must be removed for adjustment.

SW 1 *)

ON

1234

Function of the selector switches in the ON

position (slide switch pushed upwards):

Control mode 'K' (voltage regulation)

Control mode 'Y' (stroke regulation)

*) SW 1 has been sealed in the works and must not

Function of the selector

switches in the ON position

(slide switch pushed upwards):

Output frequency 25/30 Hz

ON

SW 2

123 45

1

Actual value attentuation

Setpoint with „life zero“ (4 mA)

Setpoint as voltage signal or via

setpoint potentiometer

Setpoint as mA-signal

be adjusted !

9.3 MATCHING THE SETPOINT SOURCE

The control system is matched to the various setpoint sources with

selector switch SW2 (1-3).

Operation of the sliding switches is permissible only

!

To gain access to the slide switches, the cap of SW 2 must be

raised on the right-hand side with a small screwdriver. On

completion of the work, close the cap again and screw the perspex

cover on tight.

N.B.: Changing the setting of SW2 (1-3) does not

when the power (mains) is turned off. The perspex cover

of the control system must be removed for adjustment.

resetting the trimmers P1-P6.

necessitate

Page 16

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

Setting switches SW 2 (1-3):

SW 2

ON

12345

SW 2

ON

12345

SW 2

ON

12345

E000

(installation set)

Setpoint value 0-10V at terminal X2.7/8

and/or setpoint potentiometer at X2.5/7

Setpoint 0-20 mA at terminal X2.7/8

Setpoint 4-20 mA at terminal X2.7/8

JT-UK

16 of 28

09.10/03/Sie

9.4 FIXING THE CONTROL MODE

The control mode is determined with selector switch SW 1.

Operation of the sliding switches is permissible only when

!

switches, the cap of SW 1 must be raised on the right-hand side with

a small screwdriver. On completion of the work, close the cap again

and screw the perspex cover on tight.

ON

ON

N.B.: The switches of SW 1 must always be switched in pairs.

the power (mains) is turned off. The perspex cover of the

control system must be removed for adjustment.

To gain access to the slide

SW 1

1234

SW 1

1234

Changing the control mode requires a readjustment

the trimmers P1-P6. This may only be carried out by the

manufacturer's service department.

Control mode 'K' (voltage regulation)

Control mode 'Y' (stroke regulation)

of

9.5 CHOOSING THE OUTPUT FREQUENCY

The output frequency of the control system is determined with SW 2

(5).

Operation of the sliding switches is permissible only

!

To gain access to the slide switch, the cap of SW 2 must be raised

on the right-hand side with a small screwdriver. On completion of the

work, close the cap again and screw the perspex cover on tight.

when the power (mains) is turned off. The perspex cover

of the control system must be removed for adjustment.

Page 17

9.6 MATCHING THE MAINS VOLTAGE

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

SW 2

ON

12345

SW 2

ON

12345

N.B.: Changing the output frequency requires a readjustment

of the trimmers P1-P6. This may only be carried out by

the manufacturer's service department.

There is a selector plug on the control board for selecting the mains

voltage.

E000

(installation set)

Output frequency 50 or 60 Hz resp.

Output frequency 25 or 30 Hz resp.

JT-UK

17 of 28

09.10/03/Sie

Selector plug carries mains voltage.

Control system

the selector plug is re-plugged. Check for isolation from

N.B.: Changing the mains voltage requires a readjustment

9.7 CONTROL SYSTEM CALIBRATION

The control system should be calibrated by the manufacturer's

service department.

Slight stroke over- or undershooting in the upper max. vibration

range can be readjusted with the trimming potentiometer P4.

the supply! The perspex cover of the control system

must be removed.

the trimmers P1-P6. This may only be carried out by the

manufacturer's service department.

Mains voltage

between

200 - 250 V

380 - 440 V

460 - 525 V

must be isolated from the mains before

Selector plug

position

GE

- 230

GE

- 400

GE

- 500

Pull selector plug with

insulated pointed pliers

and plug into new

position.

of

9.8 PI-REGULATOR

Due to the capacitor C4 (see 9.1) the control characteristic is affected. Increasing

the capacitor value will result in a higher dampening of the regulation. The

standard value is 2.2µF / 16V for voltage regulation. For stroke regulation in

conjunction with sensor JSEN1 C4 will be increased to 4.4µF (2x 2.2µF in

parallel). This is marked on the rating plate with the addition „-005“.

C4 is an electrolyte-capacitor. Pay particular attention to the exact polarity when

soldering in.

Page 18

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

18 of 28

09.10/03/Sie

9.9 STROKE SENSOR CONNECTION

For stroke regulation the sensor JSEN1 must be connected to the control system

as an actual value source. The sensor output signal, between 0 mA and max.

20mA, is proportional to the stroke. Within the JT control system this mA-signal is

converted into a voltage signal by using resistor R42 [390

When combining the JT control system with the sensor type G5/Y resp. G6/Y

(almost in existing installations), the resistor R42 must be removed using a side

cutting pliers.

10 MAINTENANCE

The JT control system is largely maintenance-free.

However, under very dusty conditions, regular cleaning is essential.

The operating current of the drive should be measured during each

maintenance inspection with a TRMS ammeter. In addition, the

maximum vibration amplitude of the vibrating plant must be checked

(see the documentation on the drive for the nominal values)

Ω] (see 9.1).

11 FAULT FINDING

Please make a note of the following details before reporting a defect to

our service department:

− type of the control system (see rating plate)

− control system number (see rating plate)

− Serial number of the power stage (on the heatsink)

− Serial number of the control board (on the underside of the control

board)

− mains voltage (measured)

− drive data

− defects established

Page 19

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

19 of 28

09.10/03/Sie

This page has been deliberately left blank

Page 20

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

20 of 28

09.10/03/Sie

12 ADDITIONAL EQUIPMENT

The following additional equipment is available for the JT control system:

− Stroke control unit "J"

Limit value switch to monitor the stroke within MIN/MAX limit value

contacts.

− Fault signalling unit "H"

Current relay to monitor the drive current. If the minimum level is not

reached, e.g. due to a cable breakage, a fault signalling contact is closed.

− Motor potentiometer "P"

This unit is required for remote adjustment of the setpoint value via „+/-“

switches and for the setpoint potentiometer for larger cable distances.

− Setpoint voltage source "Q"

Provides a constant voltage of 10 V= for the setpoint potentiometers.

− Protective unit "V"

Required for protection of the drive, when switching between the control

system and the drive takes place.

− Separating diodes "F"

When more than one drive is connected to a control system, it may be

necessary to install this component to prevent mutual electrical

interference.

− Protective device "N"

Necessary to limit the current in drives protected for use in hazardous

(Ex.) locations. Must be connected between the control system and said

drive.

Page 21

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

21 of 28

09.10/03/Sie

13 APPENDIX

13.1 TECHNICAL DATA

POWER STAGE

Nominal mains voltage 230 V, 400 V, 500 V,

(2Ph/1Ph+N), switchable

Mains voltage ranges 200 - 250 V

380 - 440 V

460 - 525 V

Perm. voltage fluctuations + 5 %, (based on mains voltage

range max.)

- 10 %, (based on mains

voltage range min.)

Nominal mains frequency 50/60 Hz; ± 1 %

max. output current 14 / 26 / 45 / 70 A

Output frequency 50 or 25 Hz

60 or 30 Hz

Max. power dissipation Pv (W)

JT 14 26 45 70

Pv 21 39 68 105

CONTROL AND REGULATION SECTION

Supply voltage as mains voltage

Internal voltages ± 15V stabilized, short-circuit

Setpoint input 0/4 - 20 mA, int. load 250

Setpoint integrator adjustable (0 - 15 sec)

Actual value input adjustable sensitivity;

Regulator PI-characteristics

Setpoint linearisation activated at voltage regulation

Actual value output 0 - 10 V, RL

proof

+10V stabilized, short circuit

proof, for max. 4 setpoint

potentiometers (5 K

0 - 10 V; 0/1 - 5 V;

selectable by DIP-switch

failure protection;

with stroke regulation:

0 - 10 V AC/DC;

internal load when combined

with sensor JSEN1: 390

with voltage regulation:

0 - U

mode

mains

(V)

≥ 10 KΩ

Ω)

Ω;

Ω;

Page 22

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

22 of 28

09.10/03/Sie

Indicating light 2 x LED; one for ´voltage on´,

the other one for ´regulator

release´

Regulator release via external potentialfree break

contact;

closed-circuit principle

Operating indication relay make contact,

switching capacity:

1A/250VAC/30VDC.

Ext. contactors must be

provided with RC- or VDR

protective circuits resp. freerunning diodes

OTHER DATA

Tests EN 50081-1

Type of cooling air self-cooling

Max. installtion altitude 1000 m (if over 1000m: please

Perm. moisture stress DIN 40040 F

Degree of protection (DIN 40050) IP 00

Operating temperature 0°C to + 45°C

Storage and transport temp. - 10°C to + 85°C

Installation position vertical

Perm. constant vibration level

Weight 3.5 kg

Dimensions 190 x 160 mm (WxH) base

MAINS FILTER

Filter

Type

2x16 500 16 2,5 4,0 / cable 2,0

2x35 500 35 2,5 4,0 /cable 2,0

2x50 500 50 2,5 25 / terminal 3,5

2x80 500 80 5,1 25 / terminal 3,5

nominal

volt. [V]

nominal

current [A]

EN 50082-2

consult manufacturer)

≤ 0.5 G

surface

167 mm deep

leakage

current [mA]

Connection at

„LOAD“ [mm²]

Weight

[kg]

Page 23

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

23 of 28

09.10/03/Sie

13.2 TYPE KEY

The designation of the JT control system on the rating plate is made

up as follows:

JT 14 / 400 Exxx - 50 K 10 - yyy

special design

000 - 999

Additional connection

0 = no separating diodes

1 = separating diodes

Setpoint signal

1 = potentiometer

2 = 0 - 10 V

3 = 0 - 20 mA

4 = 4 - 20 mA

5 = special signal

6 = universal, 1 and 2 preset

Control mode

K = voltage regulation

Y = stroke regulation

Output frequency (Hz)

50, 60, 25, 30,

Exxx = installation set

(always E000)

Gxxx = casing

xxx = 000 to 999

e.g. G000 = standard execution

G001 = with coarse/fine feed

G002 = Manu/Auto setpoint

Nominal mains voltage (V)

e.g.: 400

max. output current (A)

14 / 26 / 45 / 70

Control system type

Page 24

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

24 of 28

09.10/03/Sie

13.3 SCOPE OF SUPPLY

The following are supplied with the JT control system:

1 setpoint value potentiometer with scale and rotary knob

1 connection diagram

1 fuse (super-quick acting)

1 fuse holder

Additional supply within the validity of the EMC-Directive:

1 Mains filter (JT-filter) /

Additionally required for control system type JT../..E000-..

regulation):

1 stroke sensor JSEN1 (

13.4 FUSES

Allocation table: Fuse holder / control system:

Control

system type

JT 14/... 16 14x51 Type1 DIN-rail

JT 26/... 32 14x51 Type1 DIN-rail

JT 45/... 63 22x57 Type2 DIN-rail

JT 70/... 80 R 1/

!

N.B.: The fuse and fuse holder contained in the scope of supply

must be connected to the mains cable at terminal X1.1.

The super-quick acting fuse protects the thyristor in the

event of a short-circuit. Only the same type may be used

when the fuse is replaced.

Fuses for cable and drive protection are not our scope of

supply. Dimensioning acc. to nominal current of drive.

Fuse

[A FF]

With long periods of operation the temperature of the

fuse may exceed 100°C. Before replacing the fuse

allow it to cool for about 15 minutes.

Switch off the mains voltage before replacing the fuse.

(as far as not otherwise ordered)

resp. G5/Y or G6/Y

Fuse

[mm]

)

Fuse

holder

1/4

Type3 Screws

Attachment

Y.. (stroke

Page 25

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

25 of 28

09.10/03/Sie

13.5 DIMENSIONS

JT control system / Mains filter:

(Mains filter only within the scope of EC directive 89/336/EEC for

EMC)

160

150

50

38

LINE

Mains

filter

2x16

2x35

Depth: 121

Mounting:

by screws M5

5,5

LOAD

100

60

4,2

8,5

190

176

JT control sytem

JT14 to JT26

Depth: 167

Mounting: by screws M4

Clearance: above: 60 mm

Connection terminals

below: 80mm

106

160

Mains

filter

175190240

2x50

2x80

6,5

all dimensions in mm

LINE

Depth: 90

Mounting:

by screws M6

LOAD

4,2

8,5

190

176

JT control system

JT45 to JT70

Depth: 167

Mounting: by screws M4

Clearance: above:

Connection terminals

below:

80mm

80mm

106 160

Page 26

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

26 of 28

09.10/03/Sie

Fuse holder types 1 to 3:

26 34,8 67

106

Type1

Type2

140

118

Type3

O7

44

For JT14 / JT26 For JT70

Mounting:

DIN rail

Height incl.

swivell lever:

98mm

All dimensions in mm

For JT45

Mounting:

DIN rail

Height incl.

swivell lever:

112mm

Height incl.

screw cap:

95mm

5 K

Ω potentiometer with scale and rotary knob:

O 28mm

Scale : 64 x 64 mm

a

b

M10

O 6mm

Centre hole :

c

16

88

Rotaty knob :

Height :20 mm

44

∅ 11 mm

∅ 36 mm

Page 27

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

27 of 28

09.10/03/Sie

13.6 CONNECTION DIAGRAM

F

K

F1

4

*)

X1.

X1. X2.

43PE

*)

Vibrator

Mains

b

PE

12

Line

JT-FILTER

Load

sw br gn/ge

PE

JT../...E000

17 18 9 10

Terminals 17+18

PE

carry

dangerous

voltage

Output

Actual value output

0 - 10 V=

Ri > 10 k

V

X2.12PE

50mAT

0V

1

2

70V11 12 13

+24V

14 15 6+570V82627

a

Regulator release

Open: STOP

Close: START

Input

3

In operation

250VAC/30VDC

max. 1A

Setpoint

(See next page)

*)

Required measures according to EC-directive 89/336/EEC for EMC

N.B.:

1

Remove link 17-18 only if:

2

Stroke sensor connection only with JT../...E000-..Y.. : see next page

3

External contactors must be fitted with RC- or VDR protective circuits resp. free running diodes

Fuse F1 (super-quick-acting), fuse holder

4

and JT-FILTER will be partially delivered

Terminal X2.15 (24V) is only to be used for connecting the regulator release contact and the sensor JSEN1

a

Back-up fuse F: by customer; adapted to nominal current of drive

b

a) combined with separating diodes tpye "F"

b) stroke sensor JSEN1 resp. G5/Y or G6/Y is connected

Page 28

OPERATING MANUAL for

JT - CONTROL SYSTEMS

JT14/... JT26... JT45/... JT70/...

E000

(installation set)

JT-UK

28 of 28

09.10/03/Sie

Setpoint connection

Potentiometer

+0V

6578

X2

c

R1

b

5 k

a

External signal Manual-Auto mode

+0V

6578

X2

N.B.:

5

POTI R1:

6

POTI R2: order separately

Partially delivered with scale and knob.

Cable length max. 150m

Stroke sensor connection

JSEN1

see also: Connection diagram of JSEN1

17 18

X2

Link must

be removed

+24V 0V

15

250

+0V

6578

X2

0 - 10 V= 0/4 - 20 mA

(only with JT../...E000-..Y..)

10

9

PE

min. 3x 0.5 LiYCY

Setpoint coarse/fine

+0V

6578

X2

-+

0 - 10 V=

S1

AUTO-MANU

S1:

by customer

+-+-

5 k

R1

c

b

a

0/4 - 20 mA

X2

fine

coarse

+0V

6578

b

c

R1

b

c

R2

a

a

NC NC

26 27

by customer

Type:Type:

G5/Y , G6/Y

17 18 9 10

X2

Link must

be removed

0V

AC

braun

brown

JSEN1

gn

+

ge

O1

O2

-

Stroke sensor

br

gn

ws

br

grün

ws

weiß

gelb

ge

green

white

yellow

brun

vert

blanc

jaune

Loading...

Loading...