Page 1

1

2

3

4

INSTALLATION INSTRUCTION

For JSK 37H Fifth Wheel Topplate

Replacement for Holland™ Models FW 8, FW 35, FW 2000 & FW 3500

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD CAUSE A HAZARDOUS CONDITION!

INSTALLING YOUR JSK37H TOPPLATE WILL RAISE

THE INSTALLED FIFTH WHEEL HEIGHT BY 3/4”.

CAUTION

WARNING

A. REMOVE OLD TOPPLATE:

1. Remove the excess grease from the topplate as required.

2. Remove the bracket pins and discard.

3. Using a suitable lifting device, lift the old topplate from the mounting

bracket and discard.

4. Inspect the bracket bushings. Remove and replace if distorted or damaged.

B. INSTALL MODEL JSK 37H TOPPLATE:

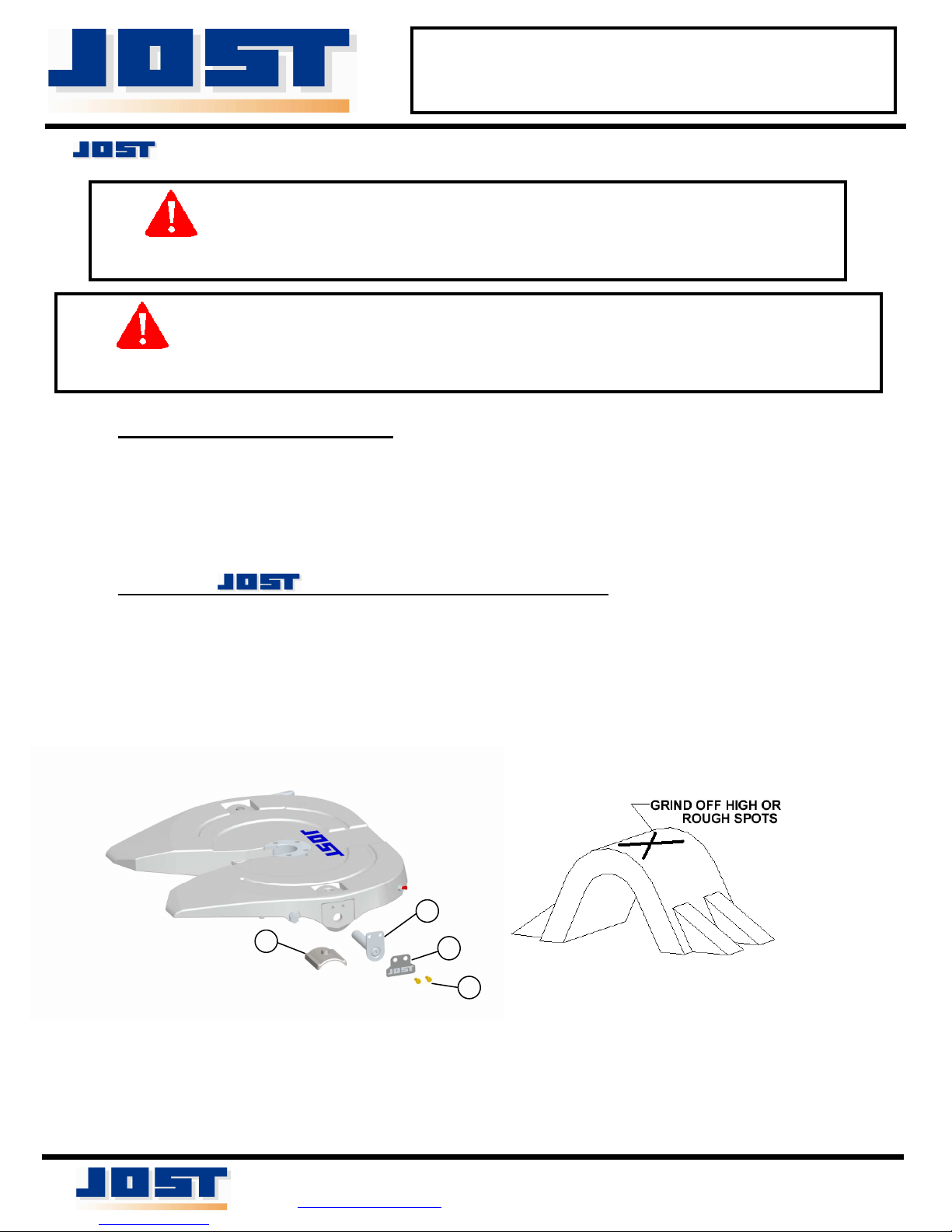

1. Remove the hex head cap screws (figure 1 item 1) and locking tabs (item 2).

2. Remove the bracket pins (item 3).

3. Inspect the top of the bracket cap and grind off any high or

rough spots (see figure 2).

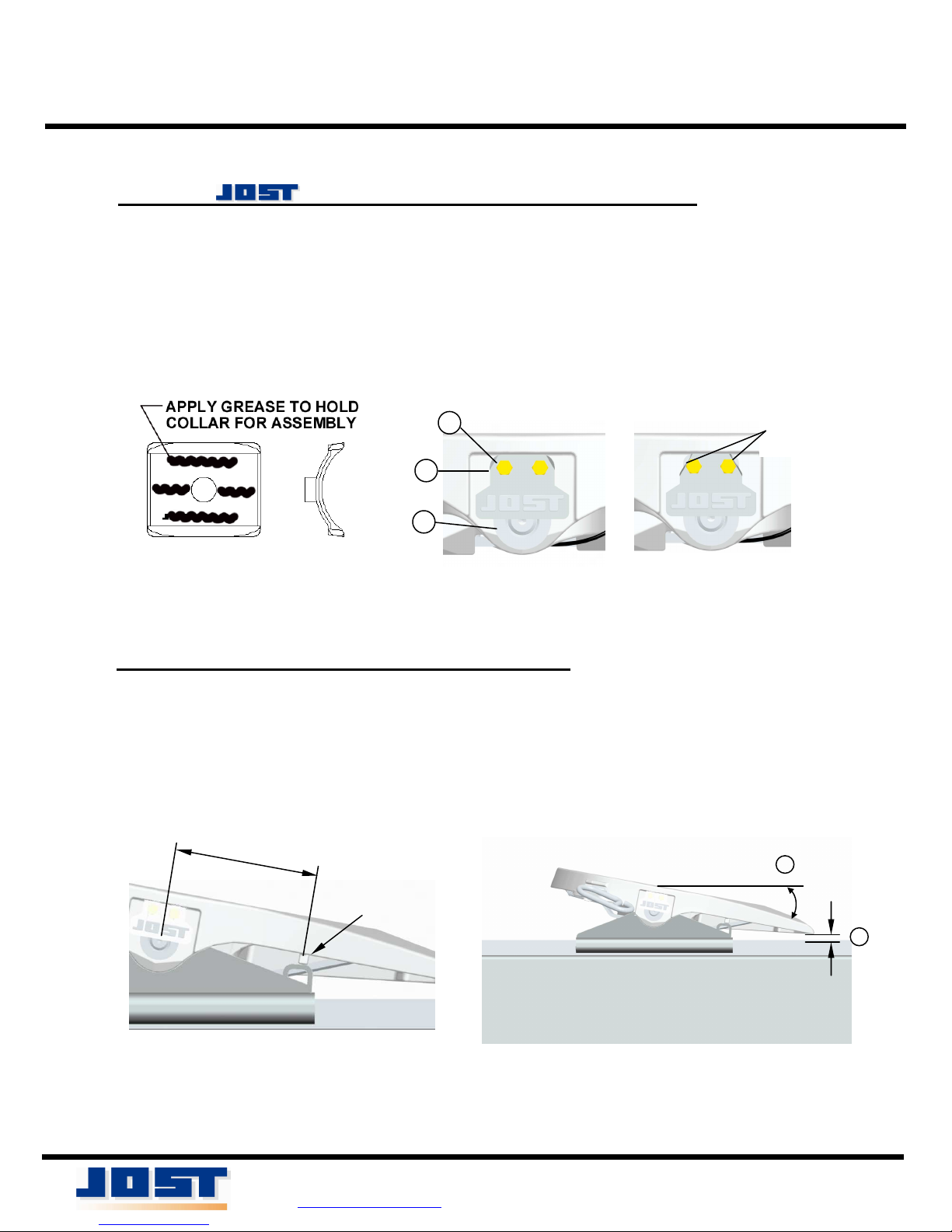

4. Apply grease to the top surface of the pivot bracket collars (item 4)

as shown in figure 3.

5. Install pivot collars (item 4) into the pivot pockets of the fifth wheel topplate.

FIGURE 1 FIGURE 2

The right to alter specifications is reserved.

1770 Hayes Street

Grand Haven, MI 49417

www.jostinternational.com

Ph. (616) 846-7700 (800) 253-5105

Fax (616) 846-0310

Page 1 of 3

LT SK37H-01 Rev.H

Page 2

FIGURE

6

CASTING LUG

GAP

C. INSTALL MODEL JSK 37H TOPPLATE (CONT.):

6. Using a suitable lifting device, lower the new Jost topplate onto the

mounting bracket.

7. Install the pivot pins (figure 4 item 3) aligning the flange with the

threaded holes in the topplate casting.

8. Align a locking tab (item 2) with each pivot pin and install the hex head

cap screws (item 1) thru the locking tabs, the pivot pin flange and into

the topplate casting ears.

9. Bend the locking tabs over each cap screw as shown in figure 4.

FIGURE 3 FIGURE 4

D. VERIFY MOUNTING BRACKET TILT STOPS:

stops. (see figure 5)

1. The topplate casting lugs must rest squarely on the mounting bracket tilt

2. The topplate tilt angle must be 20 degrees or less. (figure 6 item 1)

3. The tails of the topplate must not contact the frame rails or the slide bed.

(item 2)

4. Modify the mounting bracket tilt stops as needed.

8-3/4”

FIGURE 5

The right to alter specifications is reserved.

1770 Hayes Street

Grand Haven, MI 49417

www.jostinternational.com

1

2

3

Ph. (616) 846-7700 (800) 253-5105

Fax (616) 846-0310

BEND TABS

AFTER TIGHTENING

1

2

Page 2 of 3

LT SK37H-01 Rev.H

Page 3

E. INSPECTION AND LUBRICATION PRIOR TO USE:

1. Review the installation. Be certain that all steps were completed properly.

2. Check the fifth wheel locking mechanism using a lock tester. It must lock and

unlock as described in the Maintenance Procedures provided with your fifth

wheel. For additional copies of the Maintenance Procedures contact Jost.

CHECK THE LOCKING MECHANISM PRIOR TO USE. DO NOT

WARNING

3. Apply grease to the top of the fifth wheel (where it contacts the trailer plate).

USE ANY FIFTH WHEEL THAT FAILS TO OPERATE PROPERLY!

The right to alter specifications is reserved.

1770 Hayes Street

Grand Haven, MI 49417

www.jostinternational.com

Ph. (616) 846-7700 (800) 253-5105

Fax (616) 846-0310

Page 3 of 3

LT SK37H-01 Rev.H

Loading...

Loading...