Page 1

I & M Mark HPX and HPAX Series

3170 Wasson Road • Cincinnati, OH 45209

Phone 513.533.5600 • Fax 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve Control Valves must only be used, installed and repaired in accordance with these Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event

of leakage or other malfunction, call a qualified service person; continued operation may cause system failure or

a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling a valve, be sure to release all spring tension.

IntroductIon

Contained in this manual are installation instructions,

maintenance and parts information for the 2 through

6-inch Mark HPX2D, HPX5T, HPAX2, HPAX5, ASME

Class 900 and 1500 ratings. 2 inch ASME Class 2500

also included. Refer to the appropriate manuals for

instructions for the accompanying actuator, positioner

and additional accessories.

Only trained or experienced personnel should carry

out the operation and installation of all pressure

equipment. If you have any questions regarding the

equipment, contact your Jordan Valve representative.

A serial number identifies each Series H valve and

is stamped on the valve body. Please reference this

number when communicating with your Jordan Valve

representative.

Installation & Maintenance Instructions for the

Mark HPX and Mark HPAX Globe and Angle Style

Control Valves

2. Ensure the pipeline is free of welding slag,

chips and other debris by blowing out the

line before installation.

3. Position the valve on the line so the flow

direction indicator corresponds to the di rection of the flow of the pipeline.

4. Jordan Valve recommends the installation

of a standard three-valve maintenance by

pass. This will allow isolation of

the control valve without shutting down

the pipeline system.

5. Install approved gaskets between the

valve body and the pipeline flanges.

6. If the actuator has been shipped sepa-

rately, refer to the mounting procedure in

the applicable instruction manual.

InstallatIon

Exceeding the recommended pressure and temperature limits from Table 1, or those indicated on the

nameplates of your Jordan Valve Controls valve, can

result in personal injury and property damage. Jordan

Valve recommends the installation of a relief valve to

protect against overpressure situations.

Mark HPX900 and 1500 Series, HPX2D and HPX5T are

designed to meet specific conditions for fluid control,

temperature, pressure and pressure drop. The limiting

factor on these valves can be the body/trim material

combinations. Do not install these valves in any other

applications without first consulting with your Jordan

Valve representative.

1. Inspect the valves for shipping damage and

foreign debris while uncrating.

7. If the valve body arrives without packing

installed in the packing box, it will be

necessary to install the packing before

putting the valve into service. To

complete these procedures, follow the

instructions under “packing maintenance”

in this manual.

8. Note: It may be necessary to adjust the

packing to prevent leakage. Prior

to shipping the packing was tightened,

and may require some adjustment

for specific conditions.

Page 2

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

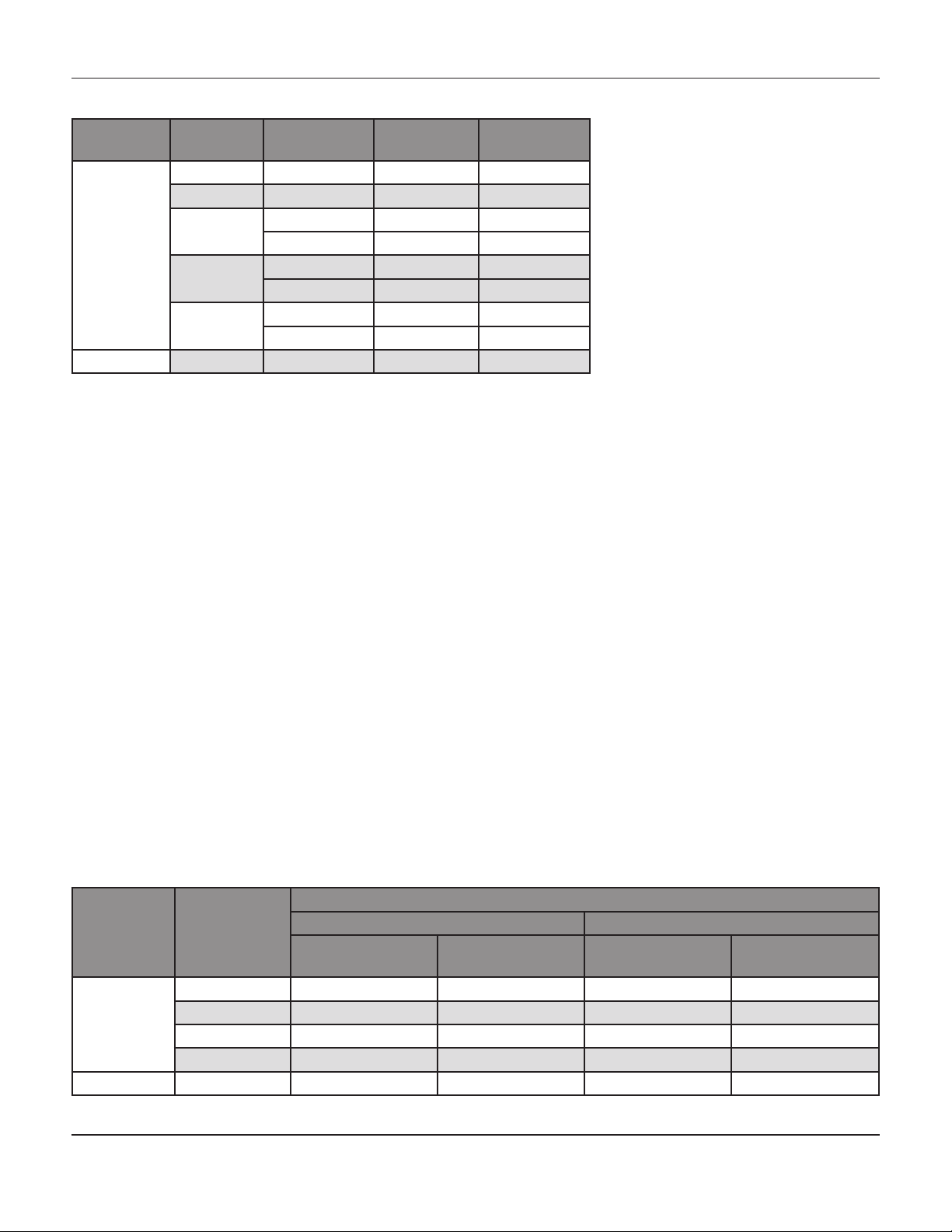

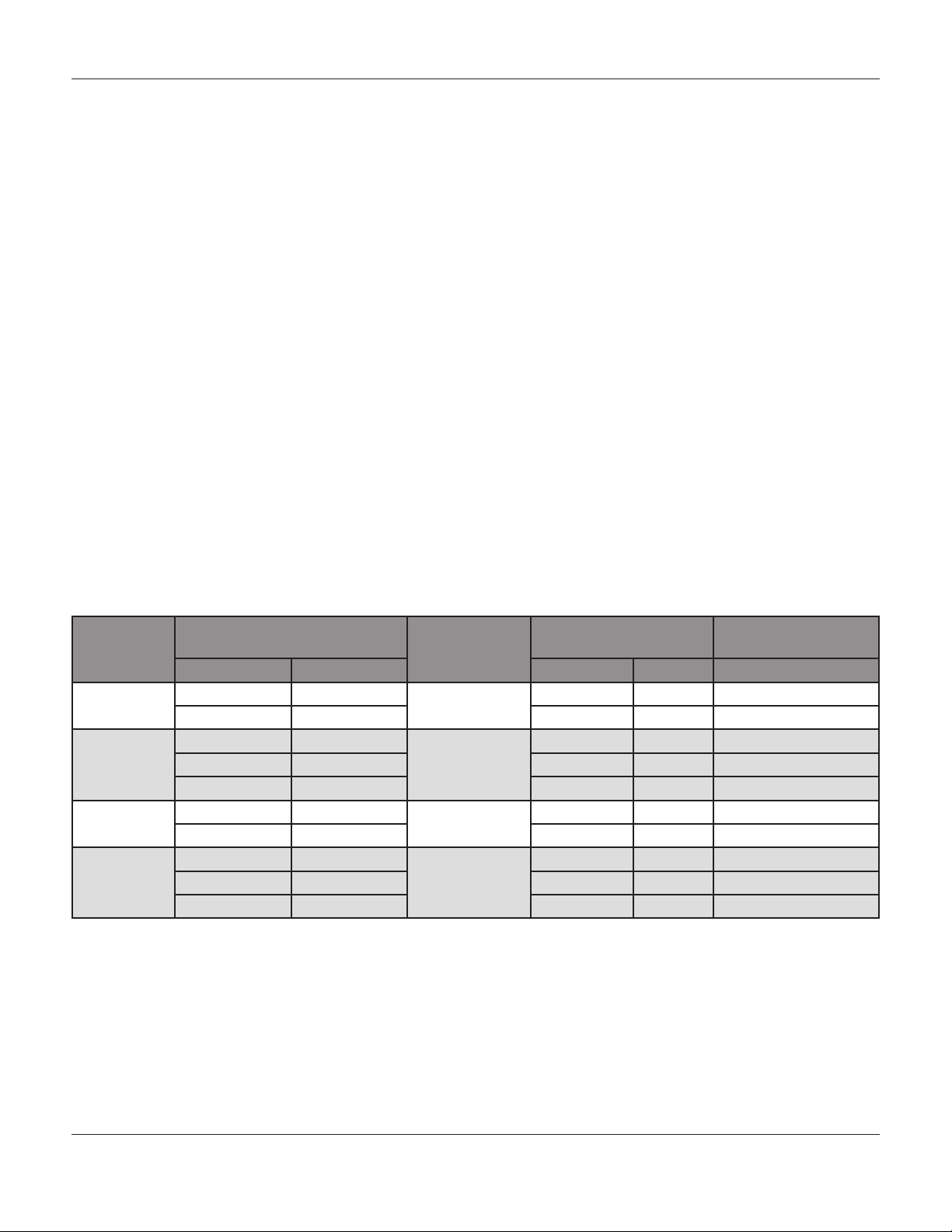

Table 1: Approximate Shipping Weights: Valve and Bonnet Assembly

Valve Type Valve Size

(Inches)

2 900 & 1500 158 72

2 2500 229 104

3 900 276 125

Globe Valve

4 900 507 230

6 900 1127 511

Angle Valve 2 900 & 1500 153 69

Class Pounds

Flanged

1500 284 129

1500 548 249

1500 1228 557

Kilograms

Flanged

MaIntenance

Internal valve components are subject to normal

deterioration and must be inspect and replaced as

required. The necessity of inspections and replacement

of parts will depend on the severity of service conditions.

Inspections and maintenance must be carried out on a

regularly scheduled basis.

To ensure the safety of personnel and to protect against

property damage, the following steps should be carried

out before beginning disassembly.

1. To prevent the valve from opening suddenly,

disconnect any operating lines to the actuator.

This would include air pressure, electrical power

or control signal lines.

2. Isolate the valve by using the bypass valve or

by shutting down the process completely

Relieve the pressure and drain the process fluid

from both sides of the valve.

3. Relive the pressure contained in the actuator

by venting the actuator loading pressure and

relieving any power actuator spring compre ssion.

4. Lock-out procedures should be strictly ad hered to while the equipment is being ser viced.

5. The Mark HPX Series use spiral-wound gas

kets that are compressed to provide

their seal. Spiral-wound gaskets are

designed for single service, and if they are

disturbed they must be replaced upon reas sembly. Used spiral-wound will not seal prop erly within the assembly.

Table 2: Torque for Body-To-Bonnet Bolting (using Nickel Never Seez Lubricant)

Torque

Valve

Rating

Class 900

and 1500

Class 2500 2 540 390 7i30 530

Valve Size,

Inches

2 290 180 390 240

3 540 390 730 530

4 720 540 970 730

6 1250 950 1700 1300

B7, B16, BD and

660 Studs

Lbf•ft N•m

B8 and B8M

Studs

-2-

B7, B16, BD and

660 Studs

B8 and B8M

Studs

Page 3

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

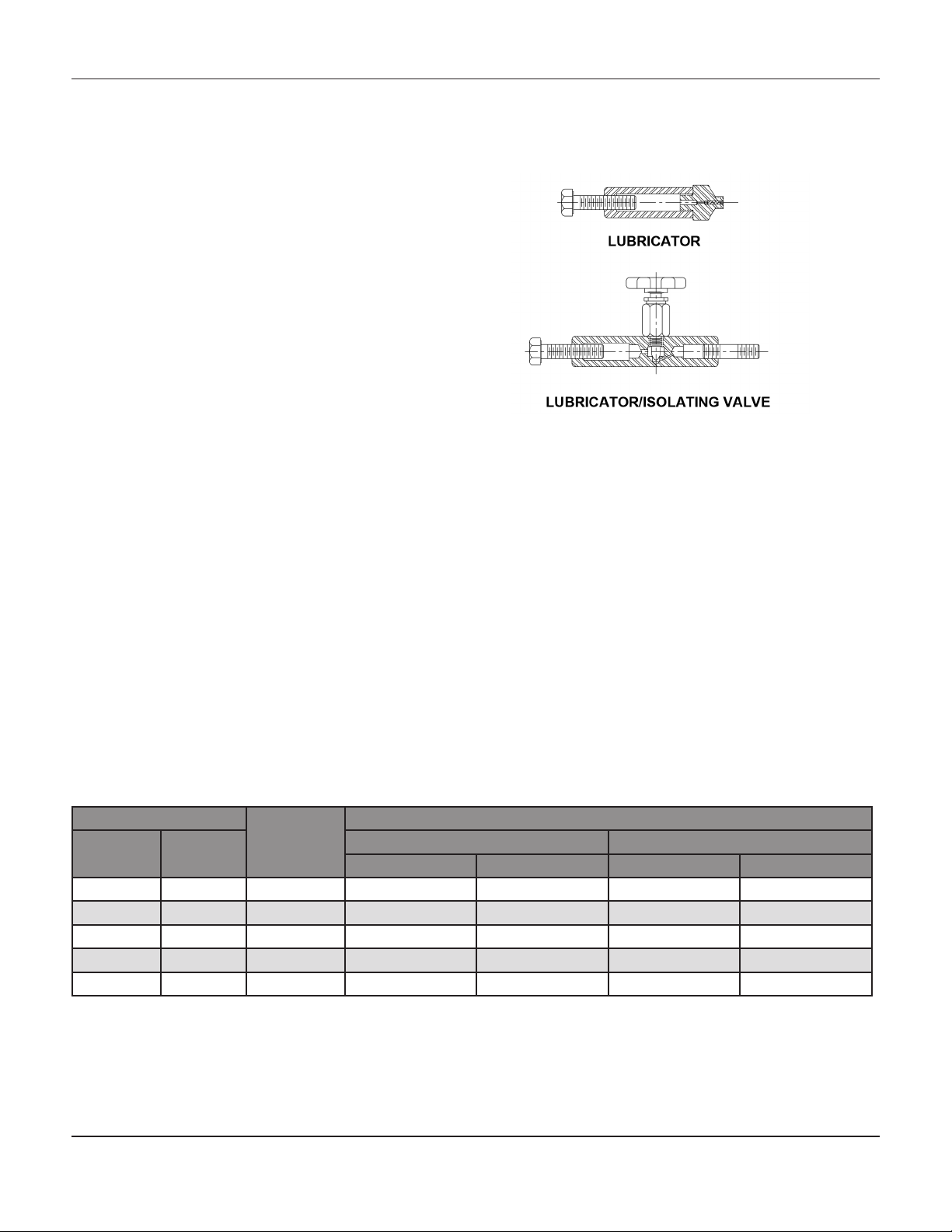

Packing Lubrication

These instructions are for the lubricator or lubricator

isolating valve (Figure 1). If the lubricator or lubricator isolating valve have been installed, they will be in

place of the pipe plug (Key 16, Figures 3 and 5) and are

designed for packing that requires lubrication, including

PTFE/composition. Jordan Valve recommends a siliconbased lubricant. Lubricant is not recommended for

oxygen services or for processes that operate in excess

of 500F. To add lubricant to the packing box, turn the

capscrew in a clockwise direction.

For Lubricator/Isolating Valve

1. Open the isolating valve.

2. Turn the capscrew in a clockwise direction.

3. Close the isolating valve.

Packing Leakage

Spring-Loaded PTFE V-ring packing

To eliminate leakage, tighten the packing flange nuts

(key 2, Figures 3 and 5). If leakage cannot be controlled

in this manner, the packing will need to be replaced.

Other Packing

If packing other than Spring-Loaded PTFE V-ring has

been used, attempt to eliminate the leaking and create

a stem seal by tightening the packing flange nuts to the

minimum recommended torque given in Table 4. If leakage continues, the packing will need to be replaced.

Figure 1: Lubricator and

Lubricator/Isolating Valve

New Packing

If tightening the appropriate flange nuts does not solve

the leakage problem and the packing is relatively new,

leakage could indicate damage to the packing box wall

or to the stem. Inspect the valve plug stem for a good

surface finish as well as the packing box wall for nicks

and scratches that could compromise the seal.

Hint:

If leakage originates from the outside diameter of

the packing, check the packing box wall for nicks or

scratches. If leakages originates from the inside diameter of packing, check the stem for nicks or scratches.

Table 3: Recommended Torque for Packing Flange Nuts (non live-loaded)

Stem Diameter Valve Body

Inches mm Lbf•ft N•m

1/2 12.7 900 9 13 12 18

1/2 12.7 1500 11 16 15 22

1/2 12.7 2500 13 18 18 24

3/4 19.1 900 20 30 27 41

3/4 19.1 2500 30 45 41 61

Rating

Min Max Min Max

-3-

Torque

Page 4

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

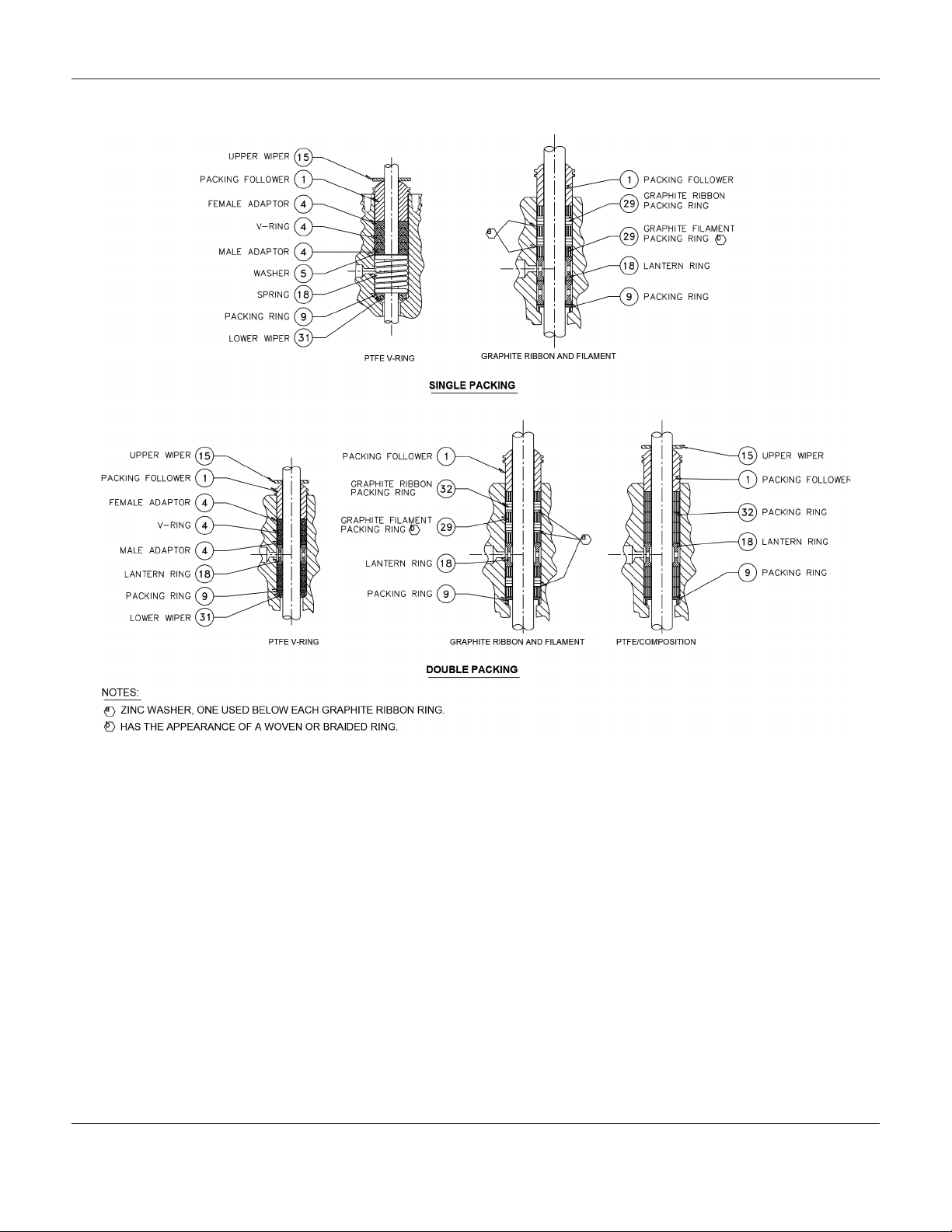

Figure 2: Mark HPX and HPAX Series Packing Arrangements

Replacing Packing

Prior to beginning any maintenance, it is important to

isolate the valve from the line pressure, and to release

all pressure from the valve body. Disconnect all operating lines to the actuator, including air pressure, electrical power or control signal lines. The process pressure

should be released both upstream and downstream of

the valve. Drain the process fluid from both sides of the

valve.

Employ lock-out procedures to ensure the safety of personnel and equipment during valve service.

Note: Extreme caution must be used during disassembly. Nicks and scratches will affect the ability to

seal the valve in the future.

1. Remove the cap screws in the stem connector

and separate the two halves.

2. Exhaust any actuator pressure and disconnect

the actuator supply line and any leakoff piping.

3. Remove the actuator from the bonnet (key 6)

by removing the yoke lock nut (key 15) and

then remove the actuator from the bonnet.

-4-

Page 5

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

4. Back off the packing flange nuts (key 2) until

the packing is free of constriction against the

valve plug stem (key 20). Remove any

additional equipment from the valve plug

stem threads, including the travel indicator disk

and stem locknuts.

5. When removing the bonnet ensure the valve

plug and stem assembly (keys 20 and 22)

remain off the seat ring (key 23). This will

prevent damage to the seating surfaces as a

consequence of the assembly falling from

the bonnet after being partially raised.

6. Apply caution to avoid damage to the gasket

seating surface.

7. Caution must be used when handling the Mark

HPXd and HPAX2 piston rings. These rings are

brittle and in two pieces.

8. Remove the bonnet in the following steps. Do

not remove a jammed bonnet with equipment

that can store energy. Sudden release

of the bonnet can result in unexpected and

potentially dangerous movement. If the

cage becomes jammed it is important to provide

support for the cage. This will prevent the cage

from falling unexpectedly.

9. Loosen the bonnet hex nuts (key 8) which attach

the bonnet to the valve, by approximately 1/8 of

an inch (3mm).

10. Pry between the bonnet (key 6) and valve body

(key 21) to loosen the body to bonnet gasket

joint. Continue prying around the bonnet until the

bonnet loosens. If no fluid is released from the

joint, unscrew the bonnet nuts (key 28)

completely.

11. Carefully remove the bonnet and valve plug

assembly (key 6, 20, 22) as a unit. Ensure that

the valve plug and stem assembly (keys'

20 and 22) remains on the seat ring (key 23)

and avoid nicking or scratching the gasket seal-

ing surface.

12. To remove the bonnet from the valve stem

remove the bonnet hex nuts (key 8). Carefully

lift the bonnet off the valve stem. In the event

that the valve plug and stem assembly become

detached they can be tapped back down with a

lead or brass hammer. Place the bonnet on a

suitable surface such as wood or cardboard to

protect it from damage.

13. Remove parts in this order:

13.1. Valve Plug Assembly (key 20, 22)

13.2. Bonnet Gasket (key 19)

13.3. Cage (key 12)

13.4. Seat Ring (key 23)

13.5. Seat Ring Gasket (key 24)

14. Clean all gasket surfaces with a wire brush, fol-

lowing the direction of the serrations.

15. Cover the valve body openings to protect the

gasket surfaces.

16. Unscrew the packing flange nuts (key 2)

17. Remove the following from the bonnet:

17.1. Packing flange (key 3)

17.2. Upper wiper (key 13)

17.3. Packing follower (key 14)

18. Push the remaining packing parts from the valve

side of the bonnet. This can be done with a

rounded rod or any other tool that will not cause

damage or scratch the packing wall.

19. Clean the packing box and the following metal

components: spring or lantern ring,

packing box ring, packing follower and,

if required, the v-ring packing washer. Finish all

required maintenance.

20. Examine the valve stem threads for sharp edges

that may damage the new packing. Emery cloth

or a whetstone can be used to smooth out any

sharp edges or burrs.

21. Remove the protective covering from the valve

body. Using a new seat ring gasket (key 24) and

bonnet gasket (key 19), install the seat ring (key

23) and cage (key 12).

22. Install the stem and plug assembly (key, 20, 22).

Slip the bonnet (key 6) over the stem and line it

up with the studs.

23. Replace the packing hex nuts (key 2)

23.1. For pre-lubricated hex nuts (identified

by the black film coating on the nut

threads) tighten the hex nuts finger tight.

23.2. For all other nuts, Jordan Valve recom-

mends that you lubricate the stud

threads with Never Seez Pure Nickel

special lubricant or equivalent. Tighten

the hex nuts finger tight.

24. To centre the trim, the valve will need to be

stroked several times. Using proper bolt

ing procedures tighten the nuts to no more than

1/4 of the torque values specified in Table 4.

-5-

Page 6

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

25. Increase the torque on each nut by an additional

1/4 of the torque value using the standard

crisscross pattern. Repeat this pattern

until the torque values in Table 4 have

been reached. Apply the final torque value

again and if any bolts turn, all of the bolts

will require retightening.

26. Using the appropriate arrangement from Table

2, install new packing and metal packing box

parts. It may be necessary to pre-lubricate

packing parts with silicone-based grease.

27. Using a smooth-edged pipe, cautiously tamp

each soft packing part into the packing

box. To prevent trapping air between the rings,

add one ring at a time without forcing them

below entrance chamber of the packing

box. With each additional ring the stack should

only be pushed down the thickness of one ring.

28. Install:

28.1. Packing Follower (key 14)

28.2. Wiper (key 13)

28.3. Packing Flange (key 3)

29. Lubricate both the packing flange studs (key 1)

and the faces of the packing flange nuts (key 2).

Finger tighten the packing flange nuts.

30. For packing type:

30.1. Spring-loaded PTFE V-Ring (Figure 2):

tighten the packing flange nuts

until there are no leaks.

30.2. Graphite: initially tighten the packing

flange nuts to the maximum torque

value in Table 3. Release the

packing flange nuts and retighten

them to the maximum torque value given

in Table 3.

30.3. Other packing types: tighten the pack

ing flange nuts in small increments alter-

nately. Repeat the process until

one of the nuts reaches the maximum

torque value from Table 5. Now

continue tightening the flange nuts

until the packing flange is level and at

right angles (90 degrees) to the

valve stem.

Table 4: Valve Stem Connection Torque and Drill Size for Groove Pin Hole

Valve Size,

Inches

2 1/2 12.7 HPX2D, HPAX2,

3

4 3/4 19.1 HPX2D,

6

Trim Removal

1. Remove the actuator and the bonnet. Refer to

steps 1-4 in replacing packing.

2. Remove the valve plug and stem assembly (key

20, 22). If the assembly is to be reused protect

the valve stem and plug seating surface

from nicks and scratches by taping them.

Valve Stem Diameter

Valve Design

Inches mm Lbf•ft N•m

3/4 19.1 175-250 237-339 1/8

1/2 12.7 HPX2D,

3/4 19.1 175-250 237-339 3/16

1 25.4 310-355 420-481 1/4

1 25.4 310-355 420-481 1/4

3/4 19.1

1 25.4 310-355 420-481 1/4

1-1/4 31.8 610-670 827-908 1/4

HPX5T, HPAX5

HPX5T

HPX5T

HPX2D,

HPX5T

3. Remove:

3.1. Cage (key 12)

3.2. Bonnet Gasket (key 19)

3.3. Seat Ring (key 23)

3.4. Seat Ring Gasket (key 24)

4. Follow the steps in the valve plug maintenance

procedure to complete the remaining steps for

rim removal.

Valve Stem

Connection

60-85 81-115 1/8

60-85 81-115 1/8

175-250 237-339 3/16

175-250 237-339 3/16

Drill Size for Groove

Pin Inches

-6-

Page 7

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

Valve Plug Maintenance

1. Remove the valve plug and stem assembly (key

20, 22) using the trim removal procedures.

2. Follow the instructions for your specific equip

ment:

2.1. For the Mark HPX2D and HPAX2 valves,

remove both halves of the piston rings

(key 11) from the grooves in the

valve plug.

2.2. For the Mark HPX5T and HPAX5 valves,

pry the retaining ring (key 27) off the

valve plug with a screwdriver. Gently

slide the backup ring (key 28) and seal

ring (key 29) of the valve plug.

3. For replacement of the valve plug stem drive

out the groove pin from the valve plug

and unscrew the stem.

4. Note: When replacing a valve plug always re

place the corresponding valve plug stem. The

stem and pin should be ordered as an

assembly.

5. Screw the stem (key 20) into the valve plug (key

22), tightening the stem to the recommended

torque given in Table 2. Determine the correct

drill size (Table 2) and drill through the

stem using the groove pinhole as a guide.

6. To lock the assembly, drive in the groove pin

(key 10).

7. If required, lap the seating surfaces prior to

installing the piston rings or seat ring. Use the

trim replacement instructions for the piston

ring and seat ring installation and reassembly of

the valve.

3. The Mark HP Series designs have spiral

gaskets, which are compressed to provide

their seal. Spiral-wound gaskets are designed for

single service. If they are ever disturbed they will

need to be replaced on reassembly. The

previously used gasket may be used to lap the

seat but the gasket must be replaced with a new

gasket.

4. Using the instructions under trim replacement,

install “old” seat ring gasket, seat ring, cage and

the “old” bonnet gasket.

5. Install the valve plug and stem assembly without

piston rings or seal ring into the cage.

6. Slip the bonnet over the valve stem. Fasten the

bonnet by securing four of the hex nuts.

7. It will be necessary to attach a handle to the

valve stem. This could be a piece of strap metal

attached by stem locknuts.

8. Turn the handle alternately in both directions

thereby lapping the seat, taking care not

to gull the seat and plug.

9. When complete, disassemble stopping to mark

the positions of the cage with a soft-tipped

marker.

10. Clean the seating surfaces, replace the gaskets

and reassemble. Test for leakage and repeat the

lapping procedure if required.

11. The position of the seat ring and cage must re-

main constant to preserve the effects of lapping.

Ensure that when parts are removed for

maintenance and cleaning, they are returned to

their original position.

Trim Replacement

Seat Lapping

With metal-to-metal seating in any valve, a small amount

of leaking can be expected. If the leakage becomes

excessive it is possible to limit the valve leakage by seat

lapping.

1. Eliminate any deep nicks through machining

rather than grinding.

2. Apply a good quality lapping compound mixture

of 280 to 600-grit to the bottom of the valve plug.

Complete all necessary maintenance on the trim including cleaning all gasket surfaces. Inspect sealing surfaces. Nicks and scratches will prevent the gasket from

sealing properly.

1. Replace:

1.1. Seat Ring Gasket (key 24)

1.2. Seat Ring (key 23)

1.3. Cage (key 12)

1.4. Piston Rings (key 11)

1.5. Seal Rings (key 29)

-7-

Page 8

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

2. For Mark HPX2D and HPAX2:

2.1. New piston rings will be delivered in one

piece. The piston ring can be broken in

half by scoring and breaking over a hard

surface such as a table edge. The other

recommended method is to break the

ring with the use of a smooth or

taped jawed vise. Install

the new ring in the vise and apply

pressure until the ring becomes an oval.

Continue applying pressure until the ring

on both sides. If just one side snaps

do not try to rip off the other side.

Apply pressure until the second

side breaks.

2.2. Remove the protective covering from the

valve plug and stem assembly.

2.3. Insert the piston rings into the piston ring

grooves matching the broken ends.

3. For Mark HPX5T and HPAX5:

3.1. Install for flow-down applications (see

Figure 4, view A), install the ring with the

open side facing the seat ring end of the

valve plug.

3.2. Install the back-up ring (key 28) on the

valve plug (key 22) and secure with the

retaining ring (key 27).

4. Install the valve plug (key 22) in the cage (key 12)

and place the bonnet gasket (key 19) on

the cage.

5. After lubricating the bonnet stud threads (key 7)

and the faces of the bonnet hex nuts (key 8),

tighten the hex nuts finger tight.

6. Tighten the bolts in a three-step process:

6.1. Begin by tightening the bolts to 1/4

of the specified normal torque (Table

2) using the standard crisscross

bolting pattern.

6.2. Using the same method tighten the

bolts to an additional 1/4 of

the specified normal torque value

(Table 2)

6.3. Continue tightening bolts to the

nominal torque value from Table 2.

7. Test the nuts by applying the final torque

value. If the nuts still rotate, tighten all the

nuts again.

8. Install the packing and the packing box

components following the instructions from

“Replacing Packing”.

9. Using the actuator instructions mount the

actuator.

10. If leakage occurs in the packing when the

valve is put back into service, it may be nec essary to retighten the packing flange nuts.

Parts orderIng

Every Jordan Valve Mark HPX and HPAX valve is

identified by a serial number, located on the valve

body. Please quote this number when communicating with Jordan Valve regarding your valve.

Note: If pre-lubricated hex nuts are used, lubrication will

not be necessary. Jordan Valve recommends Never-Seez

Pure Nickel special lubricant or equivalent for lubricating.

-8-

Page 9

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

Mark HPX Series Valves

Figure 3- 2" Mark HPAX2 Valve

HPX5 Valve Trim

Figure 4- Mark HPX5 Trim

-9-

Page 10

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

Figure 5- 2" Mark HPX2 Valve

Parts Reference

Key Description Key Description Key Description

1 Packing Flange Stud 11 Piston Ring 21 Body

2 Packing Flange Nut 12 Cage 22 Valve Plug

3 Packing Flange 13 Upper Wiper Felt 23 Seat Ring

4 Packing Set (TFE or Graphoil) 14 Packing Follower 24 Seat Ring Gasket

5 Packing Washer 15 Yoke Lock Nut 25 Drive Screw

6 Bonnet 16 Pipe Plug 26 Flow Arrow

7 Bonnet Stud 17 Spring/Lantern Ring 27 Retaining Ring

8 Bonnet Hex Nut 18 Lubricant 28 Back Up Ring

9 Lower Wiper 19 Bonnet Gasket 29 Seal Ring

10 Groove Pin 29 Valve Stem

-10-

Page 11

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

Mark HPX and HPAX Series Valves

Parts List

Key Description Stem

Size

1 Packing Flange

Stud

2 Packing Flange

Nut

1/2" 1E9444X0212 19* Bonnet Gasket N/A See Tables

3/4" 1E9449X0162

1/2" 1E944335252 20* Valve Stem N/A See Tables

3/4" 1E944635252

3 Packing Flange 1/2" 1E944223072 21*

3/4" 1E944823072

Part Numbers Key Description Stem

Size

C

Valve Body N/A Contact Jordan

Part Numbers

Valve

TFE Packing Set 1/2" 1R290201012

3/4" 1R290401212

4*

Graphol

Packing Set

1/2" 1V3802X0022

3/4" 1V2396X0022

22 Valve Plug N/A See Following

Tables

5 Packing Washer 1/2" 1F125136042 23* Seat Ring N/A See Tables

3/4" 1F125036042

A

6

Bonnet N/A Contact Jordan

24* Seat Ring Gasket N/A See Tables

Valve

7 Bonnet Stud N/A Contact Jordan

25

D

Drive Screw N/A ---

Valve

8 Bonnet Hex Nut N/A Contact Jordan

26

D

Flow Arrow N/A ---

Valve

9* Lower Wiper 1/2" 1J872206332

Ret. Ring 1-7/8” Port o

10A4330X012

3/4" 1J872306332

10* Groove Pin 1/2" --- Ret. Ring 1-7/8” Port o 10A4219X012

D

2

N/A

3/4" --- Ret. Ring 3-5/8” Port o 16A5484X012

11* Piston Ring N/A See Tables Ret. Ring 4-5/8” Port o 10A4225X012

12* Cage N/A See Tables Ret. Ring 5-3/8” Port o 10A5410X012

13* Upper Wiper

Felt

14 Packing

Follower

1/2" 1J872706332 28*

3/4" 1J872806332 3/4"

1/2" 1E944335072 29*

3/4" 1E944735072 3/4"

D

D

Back Up Ring 1/2" See tables

Seat Ring 1/2" See Tables

15* Yoke Lock Nut 1/2" 1E807423062 A-If required as a replacement, specify valve size, stem diam-

3/4" 1E832723062

16 Pipe Plug 1/2" 1A767535072

3/4" 1A767535072

17 Spring /Lantern

Ring

B

18

Lubricant N/A ---

1/2" 1F125537012

3/4" 1F125637012

eter, serial number and desired material

B-Never Seez Nickel Special

C-If required as a replacement, specify valve size, stem,

diameter, serial number and desired material

D-Not Shown

*-Recommended Spare Parts

-11-

Page 12

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

Key 11: Graphite Piston Ring for Mark HPX2D Series (2 to 4-inch) and Mark HPAX2 Series (2-inch only)

Valve Size

Inches Quantity

2 2 1-7/8 47.6 1U2216X0012 1U2216X0022

3 2 2-7/8 73.0 1U2300X0012 1U2300X0022

2 2-7/8 73.0 1U2300X0012 1U2300X0022

4

6

Key 29: Seal Ring for Mark HPX5T Series (2 to 6-inch) and Mark HPAX5 Series(2-inch only)

Valve Size

Inches

2 1-7/8 47.6 10A4216X012

3 2-7/8 73.0 10A4215X012

4

2 3-5/8 92.1 16A5482X012 16A5482X022

4 4-3/8 111.1 1U2392X0012 1U2392X0022

3 5-3/8 136.5 11A9727X022 11A9727X032

Port Diameter Key 11 Seal Ring

Inches mm Valve Body Rating

2-7/8 73.0 10A4215X012

3-5/8 92.1 16A5485X012

Port Diameter Class 1500

Inches mm -425oF to 800oF

(253oC to 426oC)

Class 1500

801oF to 1000oF

(427oC to 537oC)

4-3/8 111.1 10A4223X012

6

5-3/8 136.5 10A5411X022

-12-

Page 13

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

Key 20: Valve Stem for Class 1500

Valve Stem

Valve

Size,

NPS

1 2-13/16

2 2-13/16

2 5 1 25.4

Yoke

Boss

Inches

And

3-9/16

And

3-9/16

Connection

in. mm in. mm 316 SST

1/2 12.7

3/4 19.1

1/2 12.7

3/4 19.1

Valve Stem

Travel

Description

0.75 19.1 M-Form or M-Flute w/0.25”

(6.4mm) port

0.75 19.1 M-Flute w/0.375” or 0.5”

(9.5 or 12.7mm) port

0.75,

1.125

0.75,

1.125

0.75,

1.125

0.75,

1.125,

0.75,

1.125,

0.75,

1.125

0.75 19

1.125 29

19.1, 29M-Form w/0.5”, 0.75” or 1”

(12.7, 19.1, 254.mm) port

19.1, 29M-Form w/0.75” or 1”

(19.1, 25.4mm) port

19.1,

29

19.1,

29,

1.5

1.5

1.5 38

38

19.1,

29,

38

19.1, 29HPAXS w/0.75”(19.1mm)

HPAXS with 0.75”

(19.1mm) port

M-Form, M-Flute

HPX, HPAX, HPX5T,

HPAX5, HPXS, HPAXS

M-Form HPX, HPAX,

HPX5T, HPAX5 1P6696X0012 1P669735162

port

HPAXS w/1” (25.4mm) port 16A4704X322 16A4704X512

M-Form w/1” (25.4mm)

port

M-Form w/1.25” (31.8mm)

port

HPAXS w/1.25” (31.8mm)

port

M-Form w/1” (25.4mm)

port

M-Form w/1.25” (31.8mm)

port

M-Form w/1.5” (38.1mm)

port

HPAXS w/1.25” (31.8mm)

port

HPX, HPAXS w/1.875”

(47.6mm) port

HPX, HPAXS w/1.875”

(47.6mm) port

M-Form w/1.5” (38.1mm)

port

HPX, HPAXS w/1.875”

(47.6mm) port

Material

316SST

Standard

Bonnet

1N821035162 10A8840X512

1N821035162 10A8840X512

10A8840XB42 1P669435162

1K5878X0012 1L384135162

16A4704X322 16A4704X532

1N821035162 23B0035X062

16A4704X042 16A4704X492

10A3282X012 11A3429X152

10A3282X012 11A3429X152

13A9206X312 13A9206X372

11A3429X232 1L199035162

11A3429X232 1L199035162

11A3429X232 1L199035162

13A9206X332 13A9206X392

1K778335162 11A3429X922

11A3429X232 1L199035162

1L2687X0012 11A3429X452

1L2687X0012 11A3429X452

Extension

Bonnet

-13-

Page 14

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

Key 20: Valve Stem for Class 1500 Continued,

Valve

Size,

NPS

2 5, Type

3

4

Yoke

Boss

Inches

2-13/16

And

3-9/16

5, Type

2-13/16

And

3-9/16

Valve Stem

Connection

in. mm in. mm 316 SST

1 25.4

667

1/2 12.7 1.5, 2 38,

3/4 19.1 1.5, 2 38,

5 1 25.4

667 1 25.4 1.5, 2 38,

3/4 19.1 1.5, 2 38,

Valve Stem

Travel

0.75,

1.125,

1.5

1.5 38

2 50.8

19,

29,

38

50.8

50.8

50.8

50.8

Description

M-Form HPX, HPAXS

w/1.5”, 1.875” (38.1,

47.6mm) port

HPAXS w/1.25” (38.1mm)

port

HPX2D w/2.875” (73mm)

port

HPX5T w/2.875” (73mm)

port

HPX2D w/2.875” (73mm)

port

HPX5T w/2.875” (73mm)

port

HPXS w/2,875” (73mm)

port

HPX2D 1K778335162

HPX5T 1L2687X0012

HPXS 1N325635162

HPX2D 1L2687X0012

HPX5T 1K928935162

HPXS 1N6682X0032

HPX2D 1L144635162

HPX5T 1K744736162

HPXS 1L2687X0012

HPX2D w/3.625” (92.1mm)

port

HPX2D w/2.875” (73mm)

port

HPX5T w/3.625” (92.1mm)

port

HPX5T w/2.875” (73mm)

port

Material

316SST

Standard

Bonnet

1K744735162 1L9086X00A2

13A9206X352 13A9206X412

1U217935162

1U4269X0012

10A9265X122

1P6696X0012

10A9265X202

1L400135162

1L400135162

10A6088X012

1K587935162

Extension

Bonnet

-14-

Page 15

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

Key 20: Valve Stem for Class 1500 Continued,

Valve

Size,

NPS

4

6

Valve Stem

Yoke

Boss

Inches

5 1 25.4

5, Type

667

2-13/16

And

3-9/16

5

Connection

in. mm in. mm 316 SST

1 25.4 1.5, 2 38,

3/4 19.1 2.5, 3 63.5,

1 25.4

1-1/4 31.8

1-1/4

X 2

31.8 X

50.8

Valve Stem

Travel

1.5 38

2 50.8

50.8

76.2

2.5 63.5

3 76.2

2.5 63.5

3 76.2

2.5 63.5 HPX2D w/5.375” (136.5mm) port Contact Jordan Valve

3 76.2 HPX2D w/5.375” (136.5mm) port Contact Jordan Valve

Material

Description

Standard Bonnet

HPX2D w/3.625” (92.1mm) port 1K7891X0012

HPX2D w/2.875” (73mm) port 1L877635162

HPX5T w/3.625” (92.1mm) port 10A3282X012

HPX5T w/2.875” (73mm) port 1N325635162

HPX2D w/3.625” (92.1mm) port 11A4329XN62

HPX2D w/2.875” (73mm) port 1N325635162

HPX5T w/3.625” (92.1mm) port 11A3429X232

HPX5T w/2.875” (73mm) port 1N6682X0032

HPX2D w/3.625” (92.1mm) port 11A3429X232

HPX2D w/2.875” (73mm) port 1K778335162

HPX5T w/3.625” (92.1mm) port 1P516435162

HPX5T w/2.875” (73mm) port 1L2687X0012

HPX2D w/5.375” (136.5mm) port 1J507135162

HPX5T w/5.375” (136.5mm) port 10A3282X012

HPX2D w/5.375” (136.5mm) port 10A3282X012

HPX2D w/4.375” (111.1mm) port 1K778335162

HPX5T w/5.375” (136.5mm) port 10A3282X012

HPX5T w/4.375” (111.1mm) port 1K778325162

HPX2D w/5.375” (136.5mm) port 11A4329X232

HPX2D w/4.375” (111.1mm) port 1L2687X0012

HPX5T w/5.375” (136.5mm) port 11A3429X232

HPX5T w/4.375” (111.1mm) port 1L2687X0012

HPX2D w/5.375” (136.5mm) port

HPX2D w/4.375” (111.1mm) port

HPX5T w/5.375” (136.5mm) port

HPX5T w/4.375” (111.1mm) port

HPX2D w/5.375” (136.5mm) port

HPX2D w/4.375” (111.1mm) port

HPX5T w/5.375” (136.5mm) port

HPX5T w/4.375” (111.1mm) port

HPX5T w/5.375” (136.5mm) port

HPX5T w/5.375” (136.5mm) port

1L2298X0012

10A6073X012

-15-

Page 16

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

Key 20: Valve Stem for Class 1500 Continued,

Valve Stem

Valve

Size,

NPS

4

Key 20: Valve Stem for Class 2500

Valve

Size,

NPS

2

Yoke

Boss

Inches

5, Type

667

Yoke

Boss

Inches

2-13/16

And

3-9/16

Connection

in. mm in. mm 316 SST

1 25.4 2.5, 3

1-1/4 31.8 2.5, 3

1-1/4

Connection

31.8 X

X 2

Valve Stem

in. mm in. mm 316 SST

1/2 12.7 0.75, 1,

3/4 19.1 0.75, 1,

50.8

Valve Stem

Travel

63.5,

76.2

63.5,

76.2

2.5, 3 63.5,

76.2

Valve Stem Travel

1.125, 1.5

1.125, 1.5

Material

Description

Standard Bonnet

HPX2D w/5.375” (136.5mm) port 11A3429X232

HPX2D w/4.375” (111.1mm)port 1L2687X0012

HPX5T w/5.375” (136.5mm)port 11A3429X232

HPX5T w/4.375” (111.1mm)port

HPX2D w/5.375” (136.5mm)port

HPX2D w/4.375” (111.1mm)port

HPX5T w/5.375” (136.5mm)port

HPX5T w/4.375” (111.1mm)port

HPX2D w/5.375” (136.5mm)port Contact Jordan Valve

HPX5T w/5.375” (136.5mm)port

Description

19.1, 25.4,

29, 38

19.1, 25.4,

29, 38

M-Form HPX2D, HPX5T, HPXS 1N821035162

M-Form HPX2D, HPX5T 1P6696X0012

10A6073X012

Standard Bonnet

Material

Key 12: Cages

Valve

Size

Inches

2

3

4

6

Description

Percentage

Percentage

Percentage

Percentage

Travel Material

Cage

Eq.

Linear 1-1/2 38 32B6025X012 32B6025X022 32B6026X012 32B6025X032

Eq.

Linear 2 51 42B8242X012 42B8242X022 42B8243X012 42B8242X032

Eq.

Linear 2 51 42B9322X012 42B9322X022 42B9323X012 42B9322X032

Eq.

Linear 3 76 43B0079X012 43B0079X022 43B0081X012 43B0079X032

in. mm 174-4 SST

w/1075 Heat

Treatment

1-1/8,

1-1/2

1-1/2, 238, 51 42B824X012 42B8240X022 42B8241X012 42B8240X032

1-1/2, 238, 51 42B9220X012 42B9320X022 42B9231X012 42B932X032

2-1/2, 364, 76 43B0078X012 43B0078X022 43B0080X012 43B0078X032

28, 38 32B6028X012 32B6028X022 32B6029X012 32B6028X032

SA-182-F22 Ion

Nitride

316 SST

Electrolized

NACE MR0175

17-4 SST

H1150 DBL

-16-

Page 17

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

Key 22: Valve Plug for 2 to 6-inch Jordan Valve Class 1500 Globe Valve

Valve

Size

Inches

2

Valve Stem

Valve

Design

HPX2D 1/2 12.7 1-7/8 47.6 32B6007X012 32B6007X022 32B6007X012 32B6006X012

HPX5T 1/2 12.7 1-7/8 47.6 32B6011X012 --- 32B6011X012 32B6010X012

HPX2D 1/2 12.7 2-7/8 73.0 32B8247X022 32B8247X032 32B8247X012 32B8246X012

Connection

in. mm in. mm

3/4 19.1 1-7/8 47.6 32B6008X012 32B6008X022 32B6008X012 32B6008X012

3/4 19.1 1-7/8 47.6 32B6013X012 --- 32B6013X012 32B6012X012

Port

Diameter

Trim 2, 3

and 4

316 SST

Trim 2, 3 and 4

316 SST

CoCr-A

Seat / Guide

Material

Trim 316 SST

CoCr-A

Seat/Guide

Trim 2, 3 and

4

416 SST

3

HPX5T 1/2 12.7 2-7/8 73.0 36A5429X012 --- 36A5429X012 36A5350X012

HPX2D

4

6

HPX5T 36A5437X132 36A5441X1022

HPX2D

HPX5T

3/4 19.1 2-7/8 73.0 32B8249X022 32B8249X032 32B8249X012 32B8248X012

3/4 19.1 2-7/8 73.0 36A5430X012 --- 36A5430X012 36A5351X012

32B9347X032 36A5441X0921

3/4 19.1 3-5/8 92.1

36A5441X0921

3/4 19.1 5-3/8 136.5 36A5441X092

1 25.4 5-3/8 136.5 36A5442X102 36A5442X1021

1-1/4 31.8 5-3/8 136.5 36A5443X082 36A5443X0821

2 50.8 5-3/8 136.5 36A943X072 38A6943X0721

3/4 19.1 5-3/8 136.5 36A5444X012

1 25.4 5-3/8 136.5 36A445X012 36A5445X012 36A5366X012

1-1/4 31.8 5-3/8 136.5 36A5446X012 36A5445X012 36A5367X012

36A5441X1022

36Z5442X1122

38A6943X0922

38A6943X0822

---

36A5441X052 36A5362X012

36A5441X052 36A5362X012

36A5442X042 36A5363X012

36A5443X042 36A5364X012

38A6943X042 39A6740X012

36A5444X022 36A5365X012

2 50.8 5-3/8 136.5 38A8300X012 38A8300X012 30B2224X012

1. For -20 to 650F (-29 to 353C) temperature range

2. For 500 to 105F (260 to 566C) temperature range

-17-

Page 18

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

Key 28: Back-Up Ring for all Mark HPX (2 to 6-inch) and HPAX (2-inch only) Valves

Valve Size,

Inches

2 1-7/8 47.6 10A4218X012 10A4218X022

3 2-7/8 73.0 10A4217X022 10A4217X012

4

6

Gasket Set (Includes Key 19 Bonnet Gasket and Key 24 Seat Ring Gasket

Valve Rating

Class

1500 2 (std) 12B7100X032 12B7100X042

Port Diameter Material

in. mm S31600 (316 SST) S41600 (416 SST)

2-7/8 73.0 10A4217X022 10A4217X012

3-5/8 92.1 16A5483S022 16A5483X012

4-3/8 111.1 10A4224X022 10A4224X012

5-3/8 136.5 10A5409X022 10A5409X012

Valve Size, Inches Material

N0660

(Inconel 600)/ Graphite

(Inconel 750)/ Graphite

3 (std) 12B7100X052 12B7100X062

MKHPXandHPAXIM/0214/2K

NO 7750

4 (std) 12B7100X082 ---

6 (std) 12B7100X112 ---

2500 2 (std) --- 12B7100X132

Key 23: Seat Ring

Valve Size,

Inches

Design Port Diameter Seat Ring Material

in. mm S31600 (316 SST) S41600 (416 SST)

2 HPX2D, HPX5T 1-7/8 47.6 22B6004X012 22B6005X012

3 HPX2D, HPX5T 2-7/8 73.0 22B6094X012 22B6095X012

HPX2D, HPX5T 3-5/8 92.1 22B9338X012 22B9339X012

4

HPX2D, HPX5T 2-7/8 73.0 22B9340X012 22B9341X012

HPX2D, HPX5T 5-3/8 136.5 23B0093X012 23B0094C012

6

HPX2D, HPX5T 4-3/8 111.1 23B0096X012 23B0096X012

Jordan Valve, a division of Richards Industries

3170 Wasson Road • Cincinnati, OH 45209

513.533.5600 • 800.543.7311 • 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Loading...

Loading...