I & M Mark HPX and HPAX Series

3170 Wasson Road • Cincinnati, OH 45209

Phone 513.533.5600 • Fax 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve Control Valves must only be used, installed and repaired in accordance with these Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event

of leakage or other malfunction, call a qualified service person; continued operation may cause system failure or

a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling a valve, be sure to release all spring tension.

IntroductIon

Contained in this manual are installation instructions,

maintenance and parts information for the 2 through

6-inch Mark HPX2D, HPX5T, HPAX2, HPAX5, ASME

Class 900 and 1500 ratings. 2 inch ASME Class 2500

also included. Refer to the appropriate manuals for

instructions for the accompanying actuator, positioner

and additional accessories.

Only trained or experienced personnel should carry

out the operation and installation of all pressure

equipment. If you have any questions regarding the

equipment, contact your Jordan Valve representative.

A serial number identifies each Series H valve and

is stamped on the valve body. Please reference this

number when communicating with your Jordan Valve

representative.

Installation & Maintenance Instructions for the

Mark HPX and Mark HPAX Globe and Angle Style

Control Valves

2. Ensure the pipeline is free of welding slag,

chips and other debris by blowing out the

line before installation.

3. Position the valve on the line so the flow

direction indicator corresponds to the di rection of the flow of the pipeline.

4. Jordan Valve recommends the installation

of a standard three-valve maintenance by

pass. This will allow isolation of

the control valve without shutting down

the pipeline system.

5. Install approved gaskets between the

valve body and the pipeline flanges.

6. If the actuator has been shipped sepa-

rately, refer to the mounting procedure in

the applicable instruction manual.

InstallatIon

Exceeding the recommended pressure and temperature limits from Table 1, or those indicated on the

nameplates of your Jordan Valve Controls valve, can

result in personal injury and property damage. Jordan

Valve recommends the installation of a relief valve to

protect against overpressure situations.

Mark HPX900 and 1500 Series, HPX2D and HPX5T are

designed to meet specific conditions for fluid control,

temperature, pressure and pressure drop. The limiting

factor on these valves can be the body/trim material

combinations. Do not install these valves in any other

applications without first consulting with your Jordan

Valve representative.

1. Inspect the valves for shipping damage and

foreign debris while uncrating.

7. If the valve body arrives without packing

installed in the packing box, it will be

necessary to install the packing before

putting the valve into service. To

complete these procedures, follow the

instructions under “packing maintenance”

in this manual.

8. Note: It may be necessary to adjust the

packing to prevent leakage. Prior

to shipping the packing was tightened,

and may require some adjustment

for specific conditions.

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

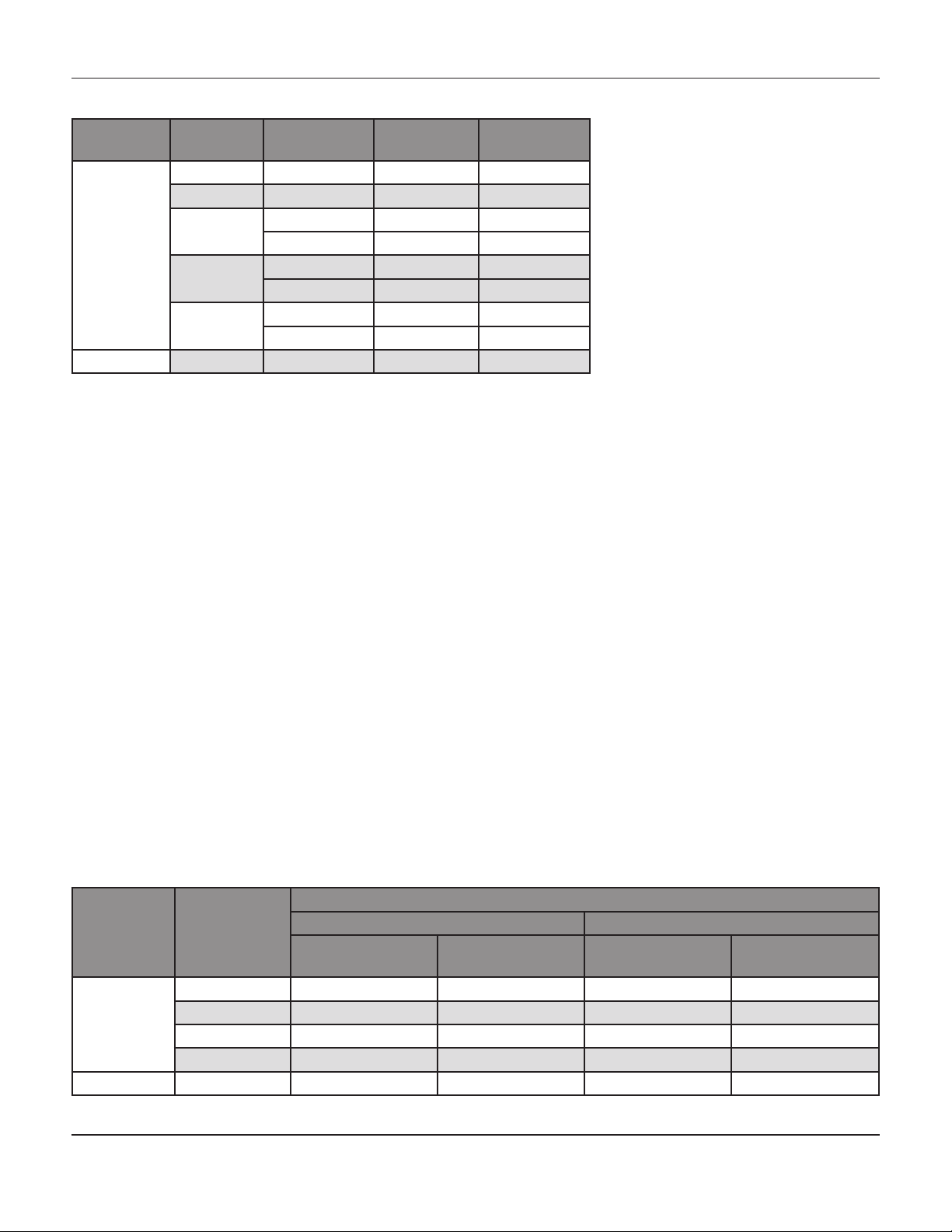

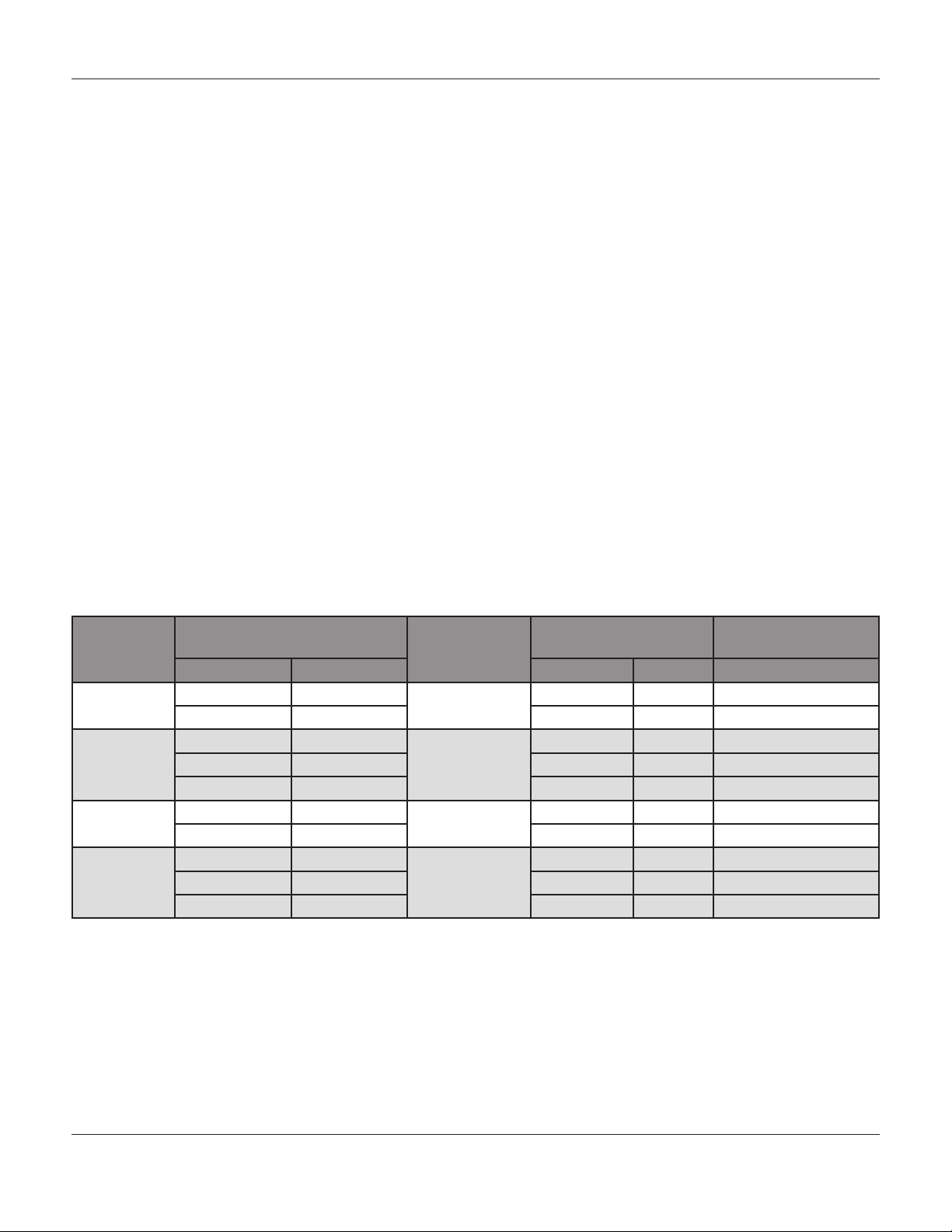

Table 1: Approximate Shipping Weights: Valve and Bonnet Assembly

Valve Type Valve Size

(Inches)

2 900 & 1500 158 72

2 2500 229 104

3 900 276 125

Globe Valve

4 900 507 230

6 900 1127 511

Angle Valve 2 900 & 1500 153 69

Class Pounds

Flanged

1500 284 129

1500 548 249

1500 1228 557

Kilograms

Flanged

MaIntenance

Internal valve components are subject to normal

deterioration and must be inspect and replaced as

required. The necessity of inspections and replacement

of parts will depend on the severity of service conditions.

Inspections and maintenance must be carried out on a

regularly scheduled basis.

To ensure the safety of personnel and to protect against

property damage, the following steps should be carried

out before beginning disassembly.

1. To prevent the valve from opening suddenly,

disconnect any operating lines to the actuator.

This would include air pressure, electrical power

or control signal lines.

2. Isolate the valve by using the bypass valve or

by shutting down the process completely

Relieve the pressure and drain the process fluid

from both sides of the valve.

3. Relive the pressure contained in the actuator

by venting the actuator loading pressure and

relieving any power actuator spring compre ssion.

4. Lock-out procedures should be strictly ad hered to while the equipment is being ser viced.

5. The Mark HPX Series use spiral-wound gas

kets that are compressed to provide

their seal. Spiral-wound gaskets are

designed for single service, and if they are

disturbed they must be replaced upon reas sembly. Used spiral-wound will not seal prop erly within the assembly.

Table 2: Torque for Body-To-Bonnet Bolting (using Nickel Never Seez Lubricant)

Torque

Valve

Rating

Class 900

and 1500

Class 2500 2 540 390 7i30 530

Valve Size,

Inches

2 290 180 390 240

3 540 390 730 530

4 720 540 970 730

6 1250 950 1700 1300

B7, B16, BD and

660 Studs

Lbf•ft N•m

B8 and B8M

Studs

-2-

B7, B16, BD and

660 Studs

B8 and B8M

Studs

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

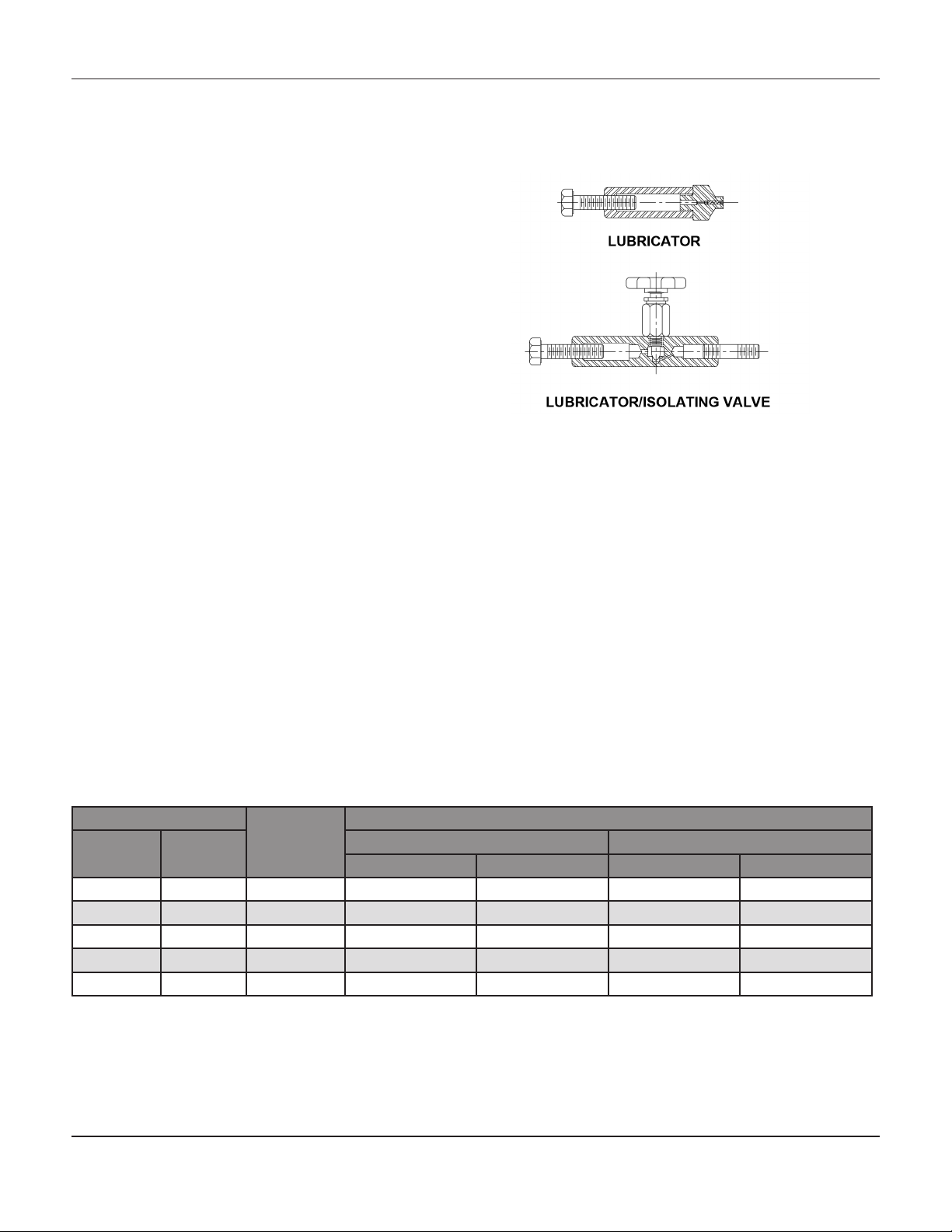

Packing Lubrication

These instructions are for the lubricator or lubricator

isolating valve (Figure 1). If the lubricator or lubricator isolating valve have been installed, they will be in

place of the pipe plug (Key 16, Figures 3 and 5) and are

designed for packing that requires lubrication, including

PTFE/composition. Jordan Valve recommends a siliconbased lubricant. Lubricant is not recommended for

oxygen services or for processes that operate in excess

of 500F. To add lubricant to the packing box, turn the

capscrew in a clockwise direction.

For Lubricator/Isolating Valve

1. Open the isolating valve.

2. Turn the capscrew in a clockwise direction.

3. Close the isolating valve.

Packing Leakage

Spring-Loaded PTFE V-ring packing

To eliminate leakage, tighten the packing flange nuts

(key 2, Figures 3 and 5). If leakage cannot be controlled

in this manner, the packing will need to be replaced.

Other Packing

If packing other than Spring-Loaded PTFE V-ring has

been used, attempt to eliminate the leaking and create

a stem seal by tightening the packing flange nuts to the

minimum recommended torque given in Table 4. If leakage continues, the packing will need to be replaced.

Figure 1: Lubricator and

Lubricator/Isolating Valve

New Packing

If tightening the appropriate flange nuts does not solve

the leakage problem and the packing is relatively new,

leakage could indicate damage to the packing box wall

or to the stem. Inspect the valve plug stem for a good

surface finish as well as the packing box wall for nicks

and scratches that could compromise the seal.

Hint:

If leakage originates from the outside diameter of

the packing, check the packing box wall for nicks or

scratches. If leakages originates from the inside diameter of packing, check the stem for nicks or scratches.

Table 3: Recommended Torque for Packing Flange Nuts (non live-loaded)

Stem Diameter Valve Body

Inches mm Lbf•ft N•m

1/2 12.7 900 9 13 12 18

1/2 12.7 1500 11 16 15 22

1/2 12.7 2500 13 18 18 24

3/4 19.1 900 20 30 27 41

3/4 19.1 2500 30 45 41 61

Rating

Min Max Min Max

-3-

Torque

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

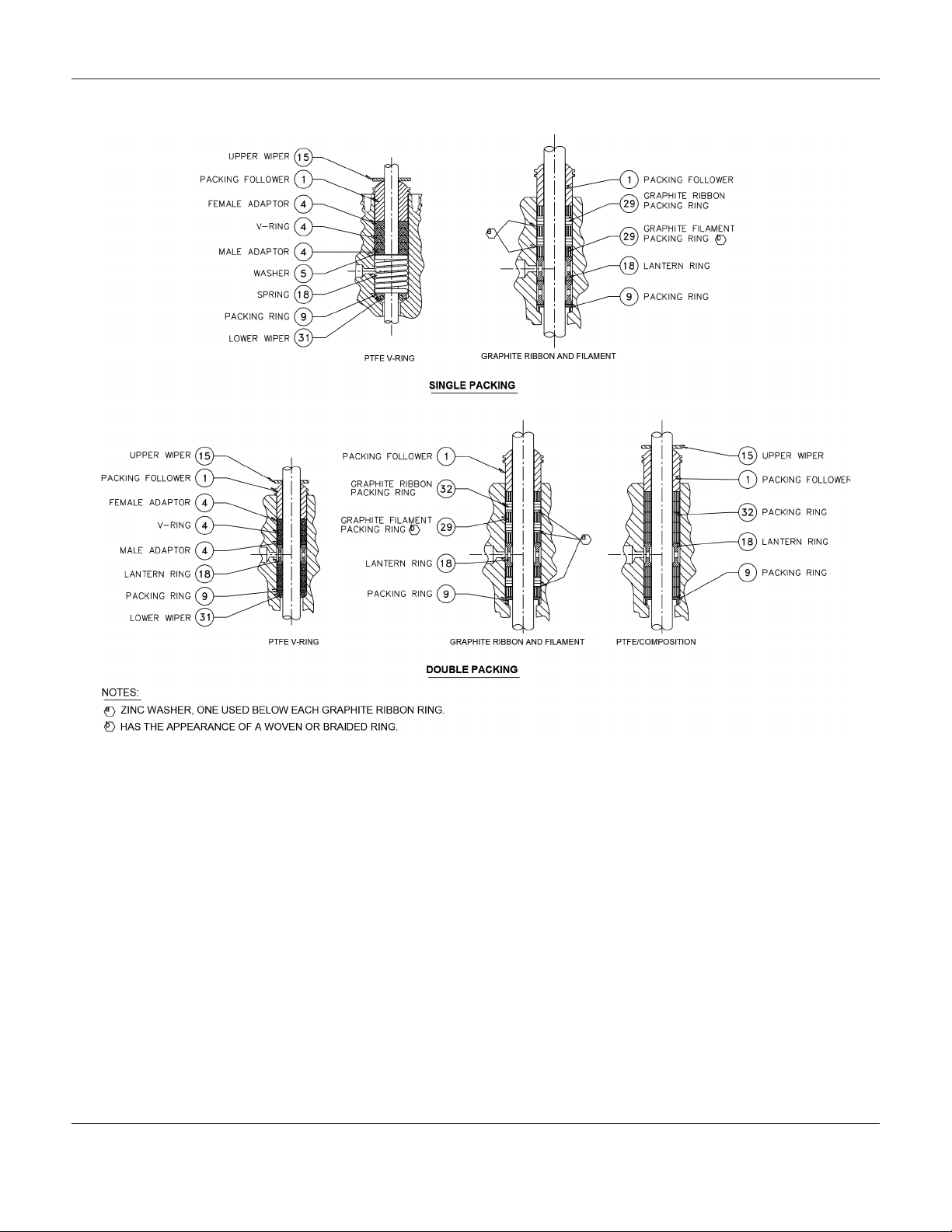

Figure 2: Mark HPX and HPAX Series Packing Arrangements

Replacing Packing

Prior to beginning any maintenance, it is important to

isolate the valve from the line pressure, and to release

all pressure from the valve body. Disconnect all operating lines to the actuator, including air pressure, electrical power or control signal lines. The process pressure

should be released both upstream and downstream of

the valve. Drain the process fluid from both sides of the

valve.

Employ lock-out procedures to ensure the safety of personnel and equipment during valve service.

Note: Extreme caution must be used during disassembly. Nicks and scratches will affect the ability to

seal the valve in the future.

1. Remove the cap screws in the stem connector

and separate the two halves.

2. Exhaust any actuator pressure and disconnect

the actuator supply line and any leakoff piping.

3. Remove the actuator from the bonnet (key 6)

by removing the yoke lock nut (key 15) and

then remove the actuator from the bonnet.

-4-

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

4. Back off the packing flange nuts (key 2) until

the packing is free of constriction against the

valve plug stem (key 20). Remove any

additional equipment from the valve plug

stem threads, including the travel indicator disk

and stem locknuts.

5. When removing the bonnet ensure the valve

plug and stem assembly (keys 20 and 22)

remain off the seat ring (key 23). This will

prevent damage to the seating surfaces as a

consequence of the assembly falling from

the bonnet after being partially raised.

6. Apply caution to avoid damage to the gasket

seating surface.

7. Caution must be used when handling the Mark

HPXd and HPAX2 piston rings. These rings are

brittle and in two pieces.

8. Remove the bonnet in the following steps. Do

not remove a jammed bonnet with equipment

that can store energy. Sudden release

of the bonnet can result in unexpected and

potentially dangerous movement. If the

cage becomes jammed it is important to provide

support for the cage. This will prevent the cage

from falling unexpectedly.

9. Loosen the bonnet hex nuts (key 8) which attach

the bonnet to the valve, by approximately 1/8 of

an inch (3mm).

10. Pry between the bonnet (key 6) and valve body

(key 21) to loosen the body to bonnet gasket

joint. Continue prying around the bonnet until the

bonnet loosens. If no fluid is released from the

joint, unscrew the bonnet nuts (key 28)

completely.

11. Carefully remove the bonnet and valve plug

assembly (key 6, 20, 22) as a unit. Ensure that

the valve plug and stem assembly (keys'

20 and 22) remains on the seat ring (key 23)

and avoid nicking or scratching the gasket seal-

ing surface.

12. To remove the bonnet from the valve stem

remove the bonnet hex nuts (key 8). Carefully

lift the bonnet off the valve stem. In the event

that the valve plug and stem assembly become

detached they can be tapped back down with a

lead or brass hammer. Place the bonnet on a

suitable surface such as wood or cardboard to

protect it from damage.

13. Remove parts in this order:

13.1. Valve Plug Assembly (key 20, 22)

13.2. Bonnet Gasket (key 19)

13.3. Cage (key 12)

13.4. Seat Ring (key 23)

13.5. Seat Ring Gasket (key 24)

14. Clean all gasket surfaces with a wire brush, fol-

lowing the direction of the serrations.

15. Cover the valve body openings to protect the

gasket surfaces.

16. Unscrew the packing flange nuts (key 2)

17. Remove the following from the bonnet:

17.1. Packing flange (key 3)

17.2. Upper wiper (key 13)

17.3. Packing follower (key 14)

18. Push the remaining packing parts from the valve

side of the bonnet. This can be done with a

rounded rod or any other tool that will not cause

damage or scratch the packing wall.

19. Clean the packing box and the following metal

components: spring or lantern ring,

packing box ring, packing follower and,

if required, the v-ring packing washer. Finish all

required maintenance.

20. Examine the valve stem threads for sharp edges

that may damage the new packing. Emery cloth

or a whetstone can be used to smooth out any

sharp edges or burrs.

21. Remove the protective covering from the valve

body. Using a new seat ring gasket (key 24) and

bonnet gasket (key 19), install the seat ring (key

23) and cage (key 12).

22. Install the stem and plug assembly (key, 20, 22).

Slip the bonnet (key 6) over the stem and line it

up with the studs.

23. Replace the packing hex nuts (key 2)

23.1. For pre-lubricated hex nuts (identified

by the black film coating on the nut

threads) tighten the hex nuts finger tight.

23.2. For all other nuts, Jordan Valve recom-

mends that you lubricate the stud

threads with Never Seez Pure Nickel

special lubricant or equivalent. Tighten

the hex nuts finger tight.

24. To centre the trim, the valve will need to be

stroked several times. Using proper bolt

ing procedures tighten the nuts to no more than

1/4 of the torque values specified in Table 4.

-5-

Mark HPX and HPaX SerieS Globe and anGle Style Control ValVeS

25. Increase the torque on each nut by an additional

1/4 of the torque value using the standard

crisscross pattern. Repeat this pattern

until the torque values in Table 4 have

been reached. Apply the final torque value

again and if any bolts turn, all of the bolts

will require retightening.

26. Using the appropriate arrangement from Table

2, install new packing and metal packing box

parts. It may be necessary to pre-lubricate

packing parts with silicone-based grease.

27. Using a smooth-edged pipe, cautiously tamp

each soft packing part into the packing

box. To prevent trapping air between the rings,

add one ring at a time without forcing them

below entrance chamber of the packing

box. With each additional ring the stack should

only be pushed down the thickness of one ring.

28. Install:

28.1. Packing Follower (key 14)

28.2. Wiper (key 13)

28.3. Packing Flange (key 3)

29. Lubricate both the packing flange studs (key 1)

and the faces of the packing flange nuts (key 2).

Finger tighten the packing flange nuts.

30. For packing type:

30.1. Spring-loaded PTFE V-Ring (Figure 2):

tighten the packing flange nuts

until there are no leaks.

30.2. Graphite: initially tighten the packing

flange nuts to the maximum torque

value in Table 3. Release the

packing flange nuts and retighten

them to the maximum torque value given

in Table 3.

30.3. Other packing types: tighten the pack

ing flange nuts in small increments alter-

nately. Repeat the process until

one of the nuts reaches the maximum

torque value from Table 5. Now

continue tightening the flange nuts

until the packing flange is level and at

right angles (90 degrees) to the

valve stem.

Table 4: Valve Stem Connection Torque and Drill Size for Groove Pin Hole

Valve Size,

Inches

2 1/2 12.7 HPX2D, HPAX2,

3

4 3/4 19.1 HPX2D,

6

Trim Removal

1. Remove the actuator and the bonnet. Refer to

steps 1-4 in replacing packing.

2. Remove the valve plug and stem assembly (key

20, 22). If the assembly is to be reused protect

the valve stem and plug seating surface

from nicks and scratches by taping them.

Valve Stem Diameter

Valve Design

Inches mm Lbf•ft N•m

3/4 19.1 175-250 237-339 1/8

1/2 12.7 HPX2D,

3/4 19.1 175-250 237-339 3/16

1 25.4 310-355 420-481 1/4

1 25.4 310-355 420-481 1/4

3/4 19.1

1 25.4 310-355 420-481 1/4

1-1/4 31.8 610-670 827-908 1/4

HPX5T, HPAX5

HPX5T

HPX5T

HPX2D,

HPX5T

3. Remove:

3.1. Cage (key 12)

3.2. Bonnet Gasket (key 19)

3.3. Seat Ring (key 23)

3.4. Seat Ring Gasket (key 24)

4. Follow the steps in the valve plug maintenance

procedure to complete the remaining steps for

rim removal.

Valve Stem

Connection

60-85 81-115 1/8

60-85 81-115 1/8

175-250 237-339 3/16

175-250 237-339 3/16

Drill Size for Groove

Pin Inches

-6-

Loading...

Loading...