Page 1

I & M Mark H-900, H-1500 and

H-2500 Series

3170 Wasson Road • Cincinnati, OH 45209

Phone 513.533.5600 • Fax 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve Control Valves must only be used, installed and repaired in accordance with these Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event

of leakage or other malfunction, call a qualified service person; continued operation may cause system failure or

a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling a valve, be sure to release all spring tension.

IntroductIon

Contained in this manual are installation instructions,

maintenance and parts information for the Mark H-900,

H-1500 and H-2500 Series Valve Bodies. Refer to the

appropriate manuals for instructions for the accompanying actuator, positioner and additional accessories.

Only trained or experienced personnel should carry

out the operation and installation of all pressure equipment. If you have any questions regarding the equipment, contact your Jordan Valve representative. A

serial number identifies each Mark H Series valve and

is stamped on the valve body. Please reference this

number when communicating with your Jordan Valve

representative.

Installation & Maintenance Instructions for the

Mark H-900, H-1500 and H-2500 Series Globe

Style Control Valves

3. For continuous service applications, Jordan

Valve recommends a standard three-valve

maintenance bypass be installed. This

allows isolation of the valve body without

shutting down the pipeline system.

4. The valve should be positioned on the

line so the flow direction indicator

corresponds to the direction of flow in the

pipeline.

Note: The effectiveness of the pressure-energized

seal will be compromised if return ow exists

where the downstream pressure exceeds upstream pressure. The result could be leakage or

damage to the seal.

InstallatIon

These valves should not be installed in systems that

exceed the ANSI specified temperature and pressure

ratings. Inspect the valves for shipping, damage and

foreign debris when uncrating.

Be sure to use proper hoists with chains or slings

when uncrating and handling these valves. Refer to

Table 1 in the data sheet for valve body weights.

1. Ensure the pipe is free from welding slag,

chips and other debris by blowing out the line

prior to installation.

2. Install approved gaskets between the valve

body and the pipeline flanges. For butt weld

ends on the Mark ET Series trim configuration,

remove gaskets and seal rings prior to welding

the body into the pipeline.

5. The valve body should be positioned with

the actuator vertically above it. It

is possible to position the valve with an

orientation below vertical with support

supplied for the actuator. Support for the

actuator is required if there is excessive

vibration in the line, or if the valve body is

positioned more than 45 degrees off

vertical.

Page 2

Mark H-900, H-1500 and H-2500 Control ValVes

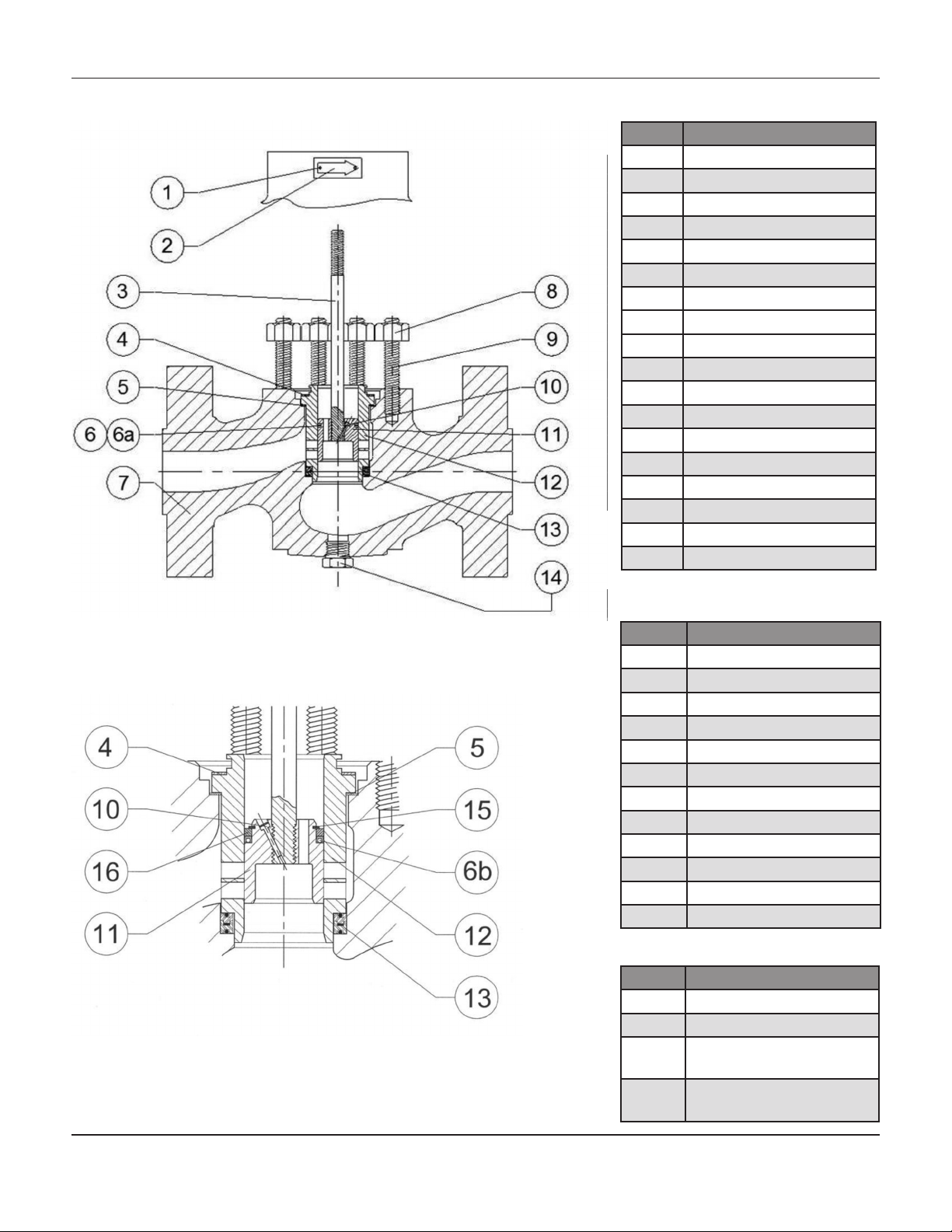

Parts reference

Body Parts (Figures 1 & 2)

Key Description

1 Drive Screws

2 Flow Arrow

3 Valve Stem

4 Bonnet Gasket

5 Cage Gasket

6 Inner Piston Ring

6a Outer Piston Ring

6b Seal Ring

7 Body

8 Hex Nuts

9 Stud Bolts

10 Groove Pin

11 Valve Plug

12 Cage

13 O-Ring Retainer

14 Pipe Plug (Optional)

15 Retaining Ring

16 Backup Ring

Figure 1: Mark H-900, H-1500 and H-2500 Valve Body Showing

Mark ED Trim

Figure 2: Mark H-900, H-1500 and H-2500 Valve Body Showing

Mark ET Trim

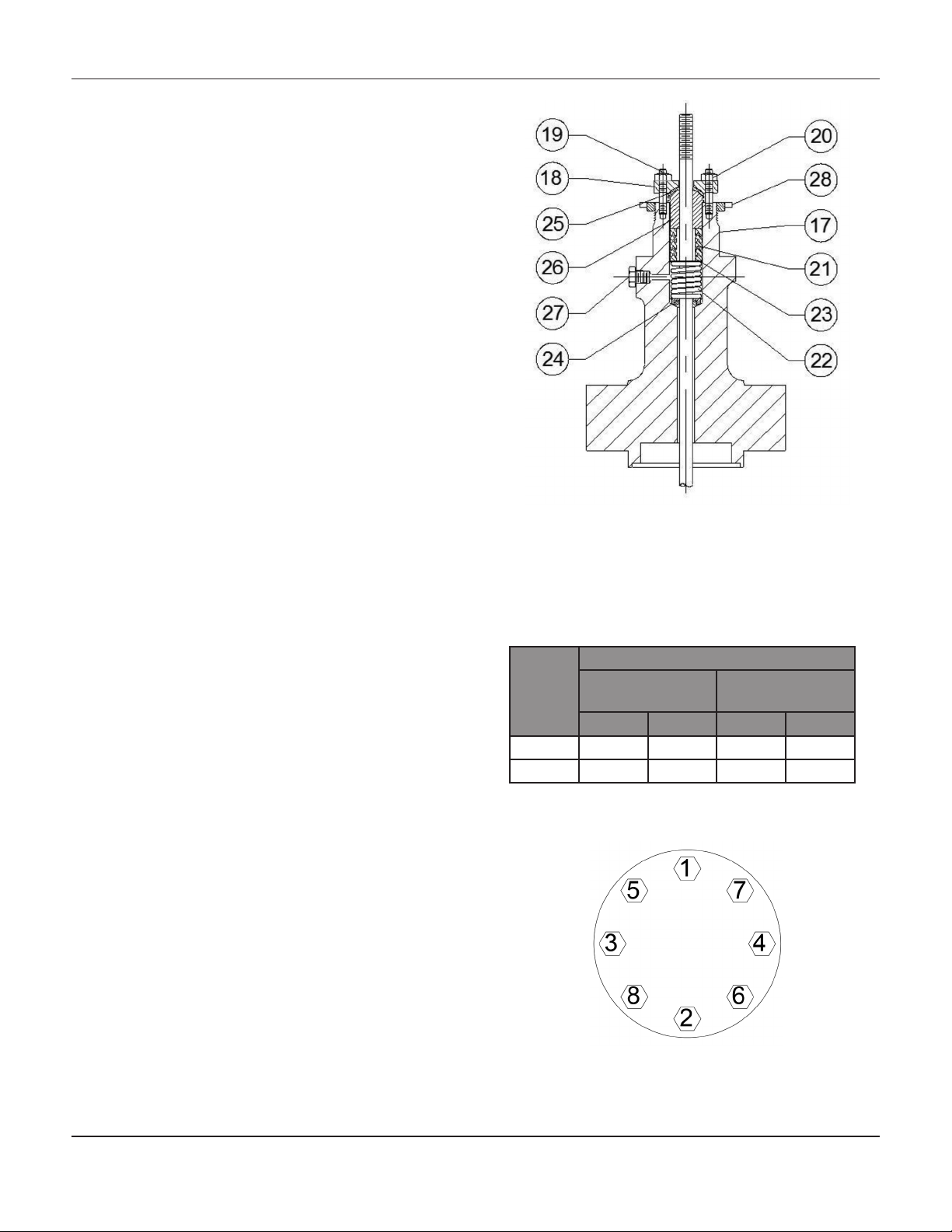

Bonnet Parts (Figure 3)

Key Description

17 Bonnet

18 Packing Flange

19 Stud Bolts

20 Hex Nuts

21 Packing Set

22 Packing Spring

23 Packing Spring

24 Packing Box Ring

25 Felt Wiper

26 Packing Follower

27 Pipe Plug

28 Locknut

Bonnet Parts Not Shown

Key Part Name

29 Individual Packing Rings

30 Individual Packing Rings

31 Pipe Nipple for Lubricator

Isolating Valve

32 Lubricator / Isolating

Valve or Lubricator

-2-

Page 3

series H-900, H-1500 and H-2500 Control ValVes

MaIntenance

Internal valve components are subject to normal deterioration and must be inspected and replaced as required.

The necessity of inspections and replacement of parts

will depend on the severity of service conditions. Inspections and maintenance must be carried out on a regular

basis.

Before beginning any maintenance, it is important to isolate the control valve and release all pressure contained

in the valve body and the actuator.

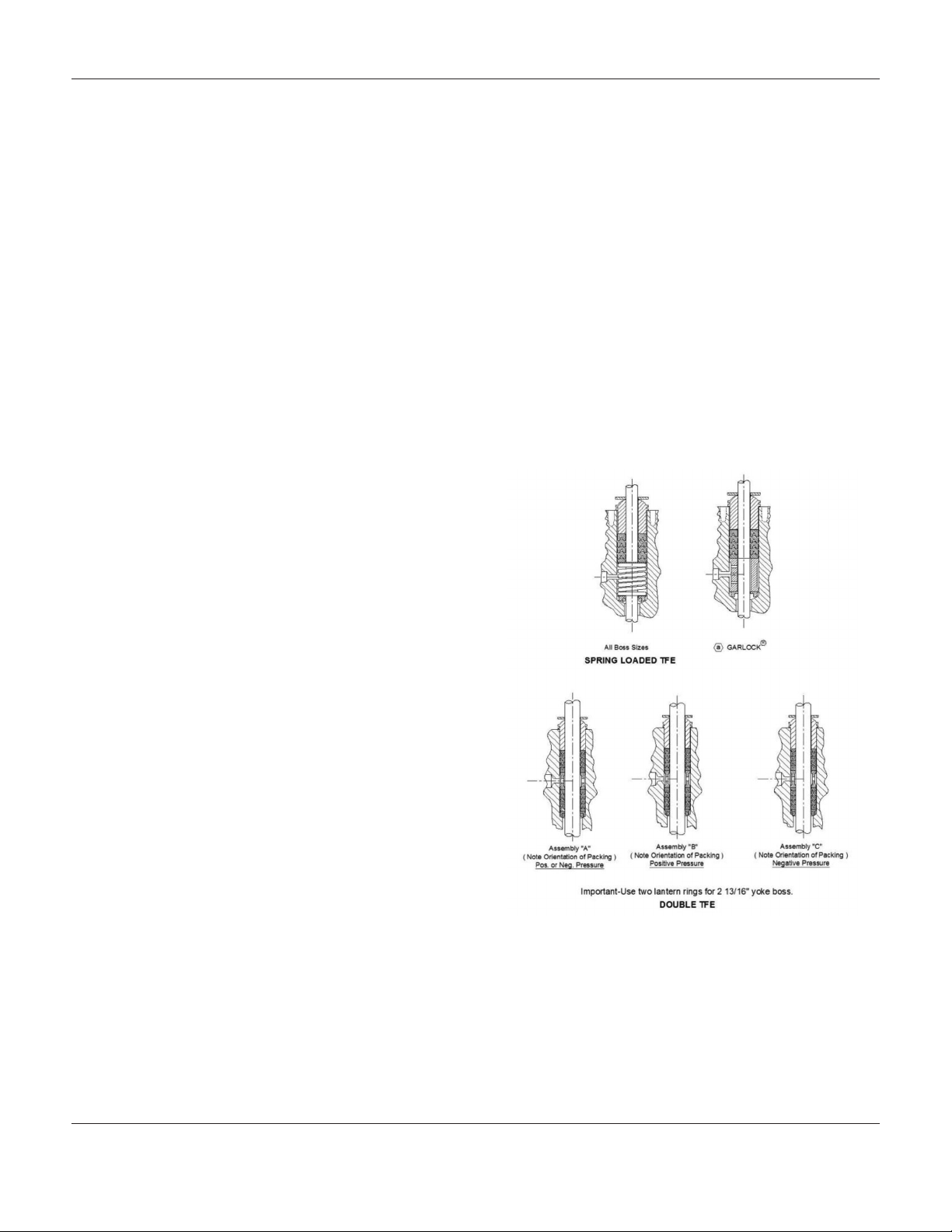

Packing Replacement

These instructions refer to the replacement of single or

double TFE V-Ring, Garlock and Grafoil packing. Key

numbers refer to Figures 1, 2 and 3.

1. Release all loading pressure in the actuator and

remove control lines.

2. Remove the cap screws from the stem

connecter and detach the halves of the stem

connecter.

Figure 3: H-900, H-1500 and H-2500

Bonnet Parts

3. Unscrew the yoke locknut (Figure 3, Key 28) and

separate the actuator from the bonnet

(Figure 3, Key 17).

4. Remove the hex nuts (Figure 1, Key 8) and lift

the bonnet (Figure 3, Key 17) and valve plug

and stem assembly from the valve body

(Figure 1, Key 7). Set those components on a

clean surface and protect the gasket sealing

serrations in the bottom of the bonnet. These

serrations are essential for a tight seal between

the body and bonnet during reassembly.

5. Remove the bonnet gasket (Figure 1 and 2,

Key 4).

6. Loosen the packing flange nuts (Figure 3, Key

20) so the packing becomes loose around the

stem.

7. Remove the hex nuts from the valve plug stem

(Figure 1, Key 3) and pull the valve plug and

stem assembly out of the bonnet. Place

this assembly on a protective surface.

8. Remove the hex nuts (Figure 3, Key 20), the

packing flange (Figure 3, Key 18), the packing

follower (Figure 3, Key 26) and the felt

wiper (Figure 3, Key 25).

Table 1: Recommended Bonnet Bolt Torque

Body

Size

(in)

3 404 548 404 548

4 540 732 540 732

Class H-900 &

Ft-lb N-m Ft-lb N-m

Figure 4: Typical Bolting Pattern

Bonnet Bolt Torque

Class H-2500

H-1500

-3-

Page 4

Mark H-900, H-1500 and H-2500 series Globe style Control ValVes

Packing Replacement cont'd

9. Use a packing hook to remove the packing

parts, or push them toward the top of the bon net using a small rod. Be careful not to scratch

the wall of the packing box.

10. Clean the metal packing parts and the pack ing box, and check the valve stem and pack ing box surfaces for nicks or scratches.

Remove any light scratches with sanding. If

damage exists that cannot be sanded out, the

valve plug stem and bonnet must be replaced.

11. Install a new bonnet gasket (Figures 2 and 3,

Key 4) onto the cage (Figures 2 and 3, Key

12).

Note: The valve plug assembly of the ED and ET t

inside the cage with tight tolerances. When installing the valve plug assembly be sure not to damage

the piston rings or the seal ring (Figures 2 and 3,

Keys 6, 6a, 6b).

When the bonnet is being mounted, the threads of

the valve plug stem will slide through the packing

box. If the packing has been installed, carefully attach the bonnet to avoid cutting the packing on the

stem threads.

14. Refer to Figure 3 and arrange the packing

parts as outlined. Slide the new packing care

fully over the valve plug stem, and ensure that

the packing parts are not damaged by the

threads of the valve plug stem.

15. Reinstall the packing flange and hex nuts

(Keys 18 and 20). Tighten the hex nuts until

the shoulder of the packing follower (Key 26) is

snug against the packing box.

16. Mount the actuator onto the valve body assem bly and reconnect the actuator and valve stem

referring to procedures in the appropriate ac tuator manual.

12. Insert the valve plug assembly in the cage,

mounting the bonnet onto the body. Ensure

that the leak-off piping (or pipe plug, Figure 3,

Key 27) is facing downstream.

13. Apply lubricant to the body stud bolts (Figures

1 and 2, Key 9) and the hex nuts (Figures 1

and 2, Key 8). Thread the nuts onto the body

stud bolts using good bolting practices. Refer

to Table 1 for proper bolt torques and tighten

the nuts in a criss-cross pattern (See Figure 4).

When the control valve assembly reaches

operating temperature, repeat the procedure.

Proper tightening of the bonnet nuts ensures

a positive sealing of the cage seals and the

spring seal.

Note: Repeating the bolting pattern may be necessary since tightening one nut may loosen an adjacent nut. The body-to-bonnet seal will be complete

when none of the nuts will turn at the recommended

torque.

Figure 5: Packing Arrangements

See Table 1 for Recommended Torque Values

GARLOCK is a registered trademark for packings, seals,

gaskets and other products of Garlock.

-4-

Page 5

Mark H-900, H-1500 and H-2500 series Globe style Control ValVes

Trim Maintenance

Refer to this section for instructions regarding disassembly, replacement of valve plug parts, grinding metal

seats and assembly of the valve body as required when

replacing trim.

During trim maintenance, always replace the gaskets

(Keys 4 and 5). With Mark ET trim, also replace the seal

ring (Key 6b).

Disassembly

1. Complete steps 1 through 6 in the section titled

“Packing Replacement”.

2. Lift out the cage (Key 12) and cage gaskets

(Key 5). If the cage is stuck, insert a

blunt tool into the groove around

the top of the cage and pry it free.

3. Complete the required maintenance following

instructions in the sections “Replacing

Valve Plug Parts”, “Lapping Metal Seats”, or “As

sembly” as appropriate.

Replacing Valve Plug Parts

These instructions are for the TFE V-ring packing. Grafoil and Garlock packing is also available and is supplied with complete replacement instructions.

Note: Do not use an old stem with a new valve

plug. Using an old stem would require drilling a new

groove pin hole, and doing so would weaken the

stem.

1. To replace the valve plug stem (Key 3), begin

by driving out the groove pin (Key 10)

and removing the stem.

2. Insert the new stem, threading it completely

into the valve plug (Key 11). Ensure that

all threads are engaged.

3. Refer to Table 2 and drill the proper sized

groove pin hole through the stem. Insert the

groove pin which fastens the assembly togeth er.

4. To replace the valve plug rings follow the in

structions appropriate for your trim configura tion:

4.1. Mark ED Trim: remove both piston

rings (Keys 6 and 6a) and replace them

if they show damage or uneven wear.

Install the rings while avoiding exces sive bending. Slip the ring with

a straight cut over the valve plug and

insert the ring into the groove. The ring

with the stepped cut slips over the

valve plug. Rotate the rings in

the groove until the two cuts are in op posite sides of the groove.

4.2. Mark ET Trim: Raise the end of the

retaining ring (Key 15) using a screw

driver. Rotate the plug and lift the ring

out and up. Avoid scratching any plug

or ring surfaces. Remove the metal

backup ring (Key 16) and TFE seal ring

(Key 6b). Refer to Figure 6 and install

the seal ring for

proper flow direction. Install the metal

backup ring. Insert one end of the

retaining ring (Key 15) into the groove

of the valve plug. While turning the

plug, press the ring into the groove,

being careful not to scratch the valve

plug and retaining ring.

5. Continue with procedures for “Lapping Metal

Seats” or “Assembly” as required.

Table 2: Drill Size for Groove Pins

Port Size Valve Stem

Connection

in mm in mm in mm

1-5/16 33.3 1/2 12.7 3/32 2.4

1-7/8 47.6 1/2 12.7 1/8 3.2

3/4 19.1 1/8 3.2

1/2 12.7 1/8 3.2

2-5/16 58.7

2-7/8 73.0

3-7/16 87.3 3/4 19.1 3/16 4.8

3/4 19.1 3/16 4.8

1 25.4 3/16 4.8

1/2 12.7 1/8 3.2

3/4 19.1 3/16 4.8

1 25.4 1/4 6.4

1 25.4 1/4 6.4

Drill Size

-5-

Page 6

Mark H-900, H-1500 and H-2500 series Globe style Control ValVes

Lapping Metal Seats

While some leakage is expected with any metal-tometal seating in a valve body, excessive leakage can

be improved by lapping or grinding the valve plug and

seat ring. Deep nicks should be machined out. A good

quality commercial-grade lapping compound should be

used.

Apply lapping compound to the valve plug seating

surface. During lapping, the bonnet must be bolted to

the body and the gaskets (old gaskets may be used) in

place in order to keep the valve plug in line with the seat

ring. A simple grinding tool can be made using a piece

of strap iron fastened to the valve plug stem with nuts.

Rotate the handle in opposite directions to lap the seating surfaces.

After grinding, remove the bonnet and clean the seating

surfaces. Test for proper shutoff and repeat the process

if necessary.

Assembly

Caution must be used when working around the sealing

surfaces. Any nicks or scratches will compromise the

sealing ability. Prior to installing the seals, the sealing

surface should be wiped with a clean cloth.

1. Install the o-ring retainer (Key 13) into the valve

body.

2. Install the cage gasket (Key 5).

3. Install the cage (Key 12) into the valve body.

4. Proceed with steps 11 through 16 of the section

titled “Packing Replacement”.

Parts orderIng

Valves manufactured by Jordan Valve have individual

serial numbers, found on the valve nameplate. Please

refer to that number when ordering parts or contacting

your Jordan Valve Sales Representative. Individual part

numbers are listed in the following section. Please include these numbers when ordering replacement parts.

-6-

Page 7

Mark H-900, H-1500 and H-2500 series Globe style Control ValVes

Mark H-900, H-1500 and H-2500 serIes desIgn ValVe BodIes

Key Description Part Number

1 Drive Screws, SST (2 req’d) 1A368228982

2 Flow Arrow, SST 1V106038982

3 Valve Stem See Following Tables

4 Bonnet Gasket* Class H-900 and Class H-1500 3” Body Size 10A4154X012

4” Body Size 10A5457X012

Class H-2500 3” Body Size 10A4107X012

4” Body Size 10A4154X012

5 Cage

Gasket

6 Piston Ring or Seal Ring See Following Tables

7 Body See Following Tables

8 Hex Nuts See Following Tables

9 Stud Bolts See Following Tables

10 Groove Pin See Following Tables

11 Valve Plug See Following Tables

12 Cage See Following Tables

13 O-Ring Retainer See Following Tables

14 Pipe Plug (Optional) Steel for LCC and WCB Bodies 1A771528992

15 Retaining Ring See Following Tables

16 Backup Ring See Following Tables

17 Bonnet See Following Tables

18 Packing Flange 2-13/16” Boss, 1/2” Stem Steel (Standard) 1E944223072

Class H-900 and Class H-1500 3” Body Size 10A4155X012

4” Body Size 10A5458X012

Class H-2500 3” Body Size 10A4108X012

4” Body Size 10A4155X012

316SST for CF8M Bodies 1A771535072

316 SST 1F380335072

3-9/16” Boss, 3/4” Stem Steel (Standard) 1E944823072

316 SST 1F380435072

19 Stud Bolts (2 Req’d) 2-13/16” Boss, 1/2” Stem Steel (Standard) 1E944431032

316 SST 1E944435222

3-9/16” Boss, 3/4” Stem Steel (Standard) 1E944931032

316 SST 1E944935222

20 Hex Nuts (2 Req’d) 2-13/16” Boss, 1/2” Stem Steel (Standard) 1E944524112

316 SST 1E944535252

3-9/16” Boss, 3/4” Stem Steel (Standard) 1E944624112

316 SST 1E944635252

-7-

Page 8

Mark H-900, H-1500 and H-2500 series Globe style Control ValVes

Key Description Part Number

21 Packing Set See Following Tables

22 Lantern Ring or Spring See Following Tables

23 Special Washer See Following Tables

24 Packing Box Ring See Following Tables

25 Felt Wiper See Following Tables

26 Packing Follower See Following Tables

27 Pipe Plug Steel, for LCC and LCB Bodies 1A767524662

316SST for CF8M Bodies 1A767535072

28 Locknut, Steel 2-13/16” Boss, 1/2” Stem 1E807423062

3-9/16” Boss, 3/4” Stem 1E832723062

29 Packing Ring See Following Tables

30 Packing Ring See Following Tables

31 Pipe Nipple for Lubri-

cator Isolating Valve

32 Lubricator / Isolating Valve AJ5428000A2

Lubricator 0V0873000A2

* Recommended Spare Part

For LCC Bonnets 1D239726232

For all other Bonnets 1B292738332

Key 3: Valve Stem*

ANSI Body

Rating

Class H-900

and Class

H-1500

Class H-2500

B: Availabe in both port sizes (Full and Restricted)

Body Size (In) Stem Size Port Size Part Number

in mm in mm

1/2 12.7 B B 1K587435162

3

4 3/4 19.1 B B 1U444635162

3

4

3/4 19.1 1-7/8 47.6 1U444635162

1/2 12.7 B B 1K587235162

3/4 19.1 2-5/16 58.7 1K588035162

3/4 19.1 1-7/8 47.6 1U444635162

2-7/8 73.0 1K588035162

2-7/8 73.0 1K588035162

-8-

Page 9

Mark H-900, H-1500 and H-2500 series Globe style Control ValVes

Key 6: Piston Ring (Mark ED) or Seal Ring (Mark ET)*

Port Size Mark ED Piston Ring Mark ET Seal Ring

ANSI Body

Rating

Body

Size

(In)

in mm

Alloy #25 and

17-4 PH SST

450oF to 800oF

(232oC to 427oC)

Spring-Loaded FEP

-425oF to -100oF

(-253oC to -73oC)

Spring-Loaded TFE

-10 0oF to 450oF

(-73oC to 232oC)

Class H-900

and Class

H-1500

Class H-2500

Key 7: Body LCC Steel

ANSI Body

Rating

Class H-900

and Class

H-1500

Class H-2500

3 1-7/8 47.6 10A4214X012 10A4216X022 10A4216X012

4 2-5/16 58.7 10A4204X012 10A4206X022 10A4206X012

3 1-5/16 33.3 10A4205X012 10A4207X022 10A4207X012

4 1-7/8 47.6 10A4214X012 10A4216X022 10A4216X012

Connections

900 lb RF 30A5287X032 30A5304X032

1500 lb RF 30A5289X032 30A5306X032

Butt

Weld

2500 lb RF 30A4065X032 30A4110X032

Butt

Weld

2-7/8 73.0 10A4213X012 10A4215X022 10A4215X012

3-7/16 80.6 10A5348X012 10A5351X012 10A5351X022

2-5/16 58.7 10A4204X012 10A4206X022 10A4206X012

2-7/8 73.0 10A4213X012 10A4215X022 10A4215X012

End

RTJ 30A5291X032 30A5308X032

RTJ 30A5293X032 30A5310X032

80 30A5295X032 30A5312X032

160 30A5297X032 30A5314X032

RTJ 30A4067X032 30A4112X032

80 30A4069X032 30A4114X032

XXS 30A4071X032 30A4116X032

Body Size, Inches

Without Drain Plug Tapping

3 4

WCB Steel

ANSI Body

Rating

Class H-900

and Class

H-1500

Class H-2500

* Recommended Spare Part

Connections

900 lb RF 30A5287X012 30A5304X012

1500 lb RF 30A5289X012 30A5306X012

Butt

Weld

2500 lb RF 30A4065X012 30A4110X012

Butt

Weld

End

RTJ 30A5291X012 30A5308X012

RTJ 30A5293X012 30A5310X012

80 30A5295X012 30A5312X012

160 30A5297X012 30A5314X012

RTJ 30A4067X012 30A4112X012

80 30A4069X012 30A4114X012

XXS 30A4071X012 30A4116X012

Body Size, Inches

Without Drain Plug Tapping

3 4

-9-

Page 10

Mark H-900, H-1500 and H-2500 series Globe style Control ValVes

Key 7: Body Cont, CF8M

ANSI Body

Rating

Class H-900

and Class

H-1500

Class H-2500

Key 8: Hex Nuts

Key 9: Stud Bolts

Temperature Capabilities Class H-900 and Class H-1500 Body

Valve

Body

Material

(oF) (oC)

WCB Steel -20 to 800 -29 to 427 1A440924072 10A5564X012 1A445224072 10A5565X012

LCC Steel -50 to 650 -45 to 343 1A440924072 10A5564X012 1A445224072 10A5565X012

-425 to -325 -254 to -198 1A4409X0012 10A5564X062 1A4452X0022 10A5565X062

-325 to -50 -198 to -46 1A440935252 10A5564X062 1A445235252 10A5565X042

CF8M

-50 to 450

-50 to 450

450 to 1000 232 to 538 1A440935252 1A365635222 1A445235252 10A5565X042

1000 to 1110 538 to 593 1A440935252 1A3656X0012 1A445235252 10A5565X032

Temperature Capabilities Class H-2500 Body

Valve

Body

Material

(oF) (oC)

WCB Steel -20 to 300 -29 to 149 1A440924072 1A365631012 1A445224072 1D945231012

LCC Steel -50 to 650 -45 to 343 1A440924072 10A5563X012 1A445224072 10A4221X012

-425 to -325 -254 to -198 1A4409X0012 1A3656X0022 1A4452X0022 1D9452X0032

-325 to -50 -198 to -46 1A440935252 1A365635222 1A445235252 1D945235222

CF8M

-50 to 450

-50 to 450

450 to 1000 232 to 538 1A440935252 1A365635222 1A445235252 1D945235222

1000 to 1050 538 to 566 1A440935252 1A3656X0012 1A445235252 1D9452X0022

1 Steel (B7) Bolting

2 Strain Hardened SST (B8M) Bolting

End

Connections

Body Size, Inches

Without Drain Plug Tapping

3 4

900 lb RF 30A5287X052 30A5304X052

RTJ 30A5291X052 30A5308X052

1500 lb RF 30A5289X052 30A5306X052

RTJ 30A5293X052 30A5310X052

Butt

Weld

80 30A5295X052 30A5312X052

160 30A5297X052 30A5314X052

2500 lb RF 30A4065X052 30A4110X052

RTJ 30A4067X052 30A4112X052

Butt

Weld

80 30A4069X052 30A4114X052

XXS 30A4071X052 30A4116X052

3” Body 4” Body

Key 8: Hex Nuts

(8 req’d)

Key 9: Stud

Bolts

Key 8: Hex Nuts

(8 req’d)

1

-46 to 232 1A440924072 1A365631012 1A445224072 10A5565X012

2

-46 to 232 1A440935252 1A365635222 1A445235252 10A5565X042

3” Body 4” Body

Key 8: Hex Nuts

(8 req’d)

Key 9: Stud

Bolts

Key 8: Hex Nuts

(8 req’d)

1

-46 to 232 1A440924072 1A365631012 1A445224072 1D945231012

2

-46 to 232 1A440935252 1A365635222 1A445235252 1D945235222

(8 req’d)

(8 req’d)

Key 9: Stud

Bolts

(8 req’d)

Key 9: Stud

Bolts

(8 req’d)

-10-

Page 11

Mark H-900, H-1500 and H-2500 series Globe style Control ValVes

Key 10: Groove Pin, 316 SST*

Port Size Valve Stem

Connection ED, ET

in mm in mm

1-5/16 33.3 1/2 12.7 1V322635072

1-7/8 47.6 1/2 12.7 1V322735072

3/4 19.1 2V322735072

1/2 12/7 1V322735072

2-5/16 58.7

2-7/8 73.0

Key 11: Valve Plug*

ANSI Body

Rating

Size (in)

Body

3/4 19.1 1V326035072

1 25.4 1V326035072

1/2 12.7 1V322735072

3/4 19.1 1V326035072

1 25.4 1V334035072

Port Size Valve stem Connection ED ET

in mm in mm 316 SST

Class H-900

and Class

H-1500

Class H-2500

Key 12: Cage

ANSI Body

Rating

Class H-900

and Class

H-1500

Class H-2500

1-7/8 47.6 1/2 12.7 20A4148X012 20A4150X012

3

4

3

4 1-7/8 47.6 3/4 19.1 20A9355X012 20A9357X012

Body

Size (in)

3 1-7/8 47.6 30A4137X012 30A4138X012 30A4131X012 30A4132X012

4 2-5/16 58.7 30A5335X012 30A5336X012 30A5329X012 30A5330X012

3 1-5/16 33.3 30A4091X012 30A4092X012 30A4086X012 30A4087X012

4 1-7/8 47.6 30A4137X012 30A4138X012 30A4131X012 30A4132X012

2-7/8 73.0 1/2 12.7 20A9531X012 20A9533X012

2-5/16 58.7 3/4 19.1 20A4094X012 20A4098X012

3-7/16 87.3 3/4 19.1 20A5338X012 20A5342X012

1-5/16 33.3 1/2 12.7 20A9363X012 20A9365X012

2-5/16 58.7 3/4 19.1 20A4093X012 20A4097X012

1-7/8 47.6 3/4 19.1 20A4094X012 20A4098X012

2-7/8 73.0 3/4 19.1 20A4140X012 20A4144X012

Port Size Equal Percentage Linear

in mm

2-7/8 73.0 30A4134X012 30A4135X012 30A4128X012 30A4129X012

3-7/16 87.3 30A5334X012 30A5333X012 30A5326X012 30A5327X012

2-5/16 58.7 30A4088X012 30A4089X012 30A4083X012 30A4084X012

2-7/8 73.0 30A4134X012 30A4135X012 30A4128X012 30A4129X012

3/4 19.1 20A9355X012 20A9357X012

3/4 19.1 20A4140X012 20A4144X012

17-4 PH SST

Hardened 316 SST

17-4 PH SST

Hardened 316 SST

-11-

Page 12

Mark H-900, H-1500 and H-2500 series Globe style Control ValVes

Key 13: O-Ring Retainer *

ANSI Body

Rating

Class H-900

and H-1500

Class H-2500 3 15A9173X012 15A0295X012 3H2500-SK-V 3H2500-SK-H

* Viton is a registered trademark of DuPont Dow Elastomers

Key 15: Retaining Ring

ANSI Body

Rating

Class H-900

and H-1500

Class H-2500 3 10A4210X012

Body

Size (in)

3 13A0295X012 13A0297X012 3H1500-SK-V 3H1500-SK-H

4 13A0296X012 13A0298X012 4H1500-SK-V 4H1500-SK-H

4 15A9174X012 15A0296X012 4H2500-SK-V 3H2500-SK-H

Body

Size (in)

3 20A4219X012

4 10A5350X012

4 10A4219X012

Upper Retainer

316 SS

Full Sized Trim

Lower Retainer

316 SS

Seal Kits

Viton* HSN

Key 16: Backup Ring

ANSI Body

Rating

Class H-900

and H-1500

Class H-2500 3 10A4208X012 10A4208X022

Key 17: Bonnet

ANSI Body

Rating

Class H-900

and Class

H-1500

Class H-2500 3

Body

Size (in)

3 20A4217X012 20A4217X022

4 10A5349X012 10A5349X022

4 10A4217X012 10A4217X022

Body

Size (in)

1/2 12.7 30A7504X012 30A7504X032 30A7504X052

3

4 3/4 19.1 30A5317X012 30A5317X032 30A5317X052

4 19.1 30A4119X012 30A4119X032 30A4119X052

3/4 19.1 30A5300X012 30A5300X032 30A5300X052

1/2 12.7 30A4075X012 30A4075X032 30A4075X052

3/4 19.1 30A4074X012 30A4074X032 30A4074X052

316 SST 316 SST

Stem Size

in mm

Full Sized Trim

with Alloy #6

WCB LCC CF8M

* Recommended Spare Part

-12-

Page 13

MKH-900,1500,2500/0214/2K

Mark H-900, H-1500 and H-2500 series Globe style Control ValVes

Key 21: Packing Set*

Boss Size Stem Size Spring-Loaded

in mm in mm

TFE V-Ring

2-13/16 71.4 1/2 12.7 1R290201012 1R290201012

3-9/16 90.5 3/4 19.1 1R290401012 1R290401012

Key 22: Lantern Ring or Spring

Spring-Loaded

Boss Size Stem Size

TFE V-Ring

in mm in mm No. Req’d Part Number No. Req’d Part Number

2-13/16 71.4 1/2 12.7 1 1F125537012 3 1J962335072

3-9/16 90.5 3/4 19.1 1 1F125637012 2 0N028435072

Keys 23, 24, 25, 26: Packing Parts

Includes Special Washer, Packing Box Ring, Felt Wiper, Packing Follower

Boss Size Stem Size

Key 23:

Special Washer

Key 24: Packing Box

Ring

316 SST

in mm in mm

(TFE V-Ring

Only)

17-4PH

SST

316 SST

Double

TFE V-Ring

(2 req’d)

Lantern Ring with Double

Key 25: Felt

TFE V-Ring (2 req’d)

Key 26: Fol-

Wiper

lower

316 SST

2-13/16 71.4 1/2 12.7 1F125136042 --- 1J873235072 1J872706332 1E944335072

3-9/16 90.5 3/4 19.1 1F125036042 1J873335072 1J872806332 1E944735072

Key 29 and 30: Packing Rings (Set only)

Boss Size Stem Size TFE Grafoil

in mm in mm No. Req’d Part Number No. Req’d Part Number

2-13/16 71.4 1/2 12.7 10 1E319001051 3 1V380201652

3-9/16 90.5 3/4 19.1 8 1E319101051 4 1V239601652

* Recommended Spare Part

Jordan Valve, a division of Richards Industries

3170 Wasson Road • Cincinnati, OH 45209

513.533.5600 • 800.543.7311 • 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Loading...

Loading...