Page 1

I & M Mark EW Series

3170 Wasson Road • Cincinnati, OH 45209

Phone 513.533.5600 • Fax 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve Control Valves must only be used, installed and repaired in accordance with these Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event

of leakage or other malfunction, call a qualified service person; continued operation may cause system failure or

a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling a valve, be sure to release all spring tension.

IntroductIon

Contained in this manual are installation instructions,

maintenance procedures and parts information for the

Mark EW Series Valve Body designs EWD, EWS and

EWT. Refer to the appropriate manuals for instructions

for the accompanying actuator and additional accessories.

Trained or experienced personnel should carry out

operation and installation of all pressure equipment.

If you have any questions regarding the equipment,

contact your Jordan Valve representative.

InstallatIon

Exceeding the recommended pressure and temperature limits indicated on the nameplates of your Jordan

valve control valve, can result in personal injury and

property damage. Jordan Valve recommends the

installation of a relief valve to protect against overpressure situations.

The Mark EW Series valve bodies are designed to

meet specific conditions for fluid control, temperature,

pressure and pressure drop. The limiting factor on

these valves can be the body/trim material combinations. Do not install these valves in any other applications without first consulting with your Jordan Valve

representative.

During installation, Jordan Valve recommends the use

of a sling to protect the painted surfaces of the valve.

Position the sling to avoid damage to tubing and accessories.

1. Inspect the valves for shipping damage and

foreign debris while uncrating.

Installation & Maintenance Instructions for the

Mark EW Series Globe Style Control Valve

2. Ensure the pipeline is free of welding slag,

chips and other debris by blowing out the line

before installation.

3. Position the valve so the arrow on the valve

body is in the same direction as the pipeline

flow.

4. Specific orientation of the control valve as sembly is flexible, unless limited by the

seismic criteria. Normal positioning

is with the actuator vertical above the valve

body. Should a different position be required,

be aware that the result may be uneven valve

plug and cage wear, and inefficient opera tion of the control valve system. Also,

be aware that the actuator may need addi tional support. Consult Jordan Valve for further

information on orientation.

5. Always employ proper piping and welding

practices when installing the valve in the line.

If welding is required, internal elastomeric

parts may remain in place. If the valve

has buttwelding ends and composition

trim, remove the composition trim prior

to welding into the line.

6. For flanged bodies, install an appropriate gas

ket between the pipeline and valve body flang

es.

7. With leak-off bonnet construction, remove the

pipe plugs (Figure 1, Keys 14 and 23)

to connect the leak-off piping. To avoid an

interruption of service during inspection or

maintenance, install a three-valve bypass

around the control valve assembly.

8. Most Jordan valves are shipped with

the actuator already installed according to

customer specifications. If your actuator has

been shipped separately, refer to the appropri ate mounting instructions in the actuator

manual.

Page 2

Mark EW SEriES GlobE StylE Control ValVES

MaIntenance

Internal valve components are subject to normal deterioration and must be inspected and replaced as required.

The necessity of inspections and replacement of parts

will depend on the severity of service conditions. Inspections and maintenance must be carried out on a regularly scheduled basis.

To ensure the safety of personnel and to protect against

property damage, the following steps should be carried

out before beginning disassembly.

1. To prevent the valve from opening suddenly,

disconnect any operating lines to the actuator.

This would include air pressure, electrical power

or control signal lines.

2. Isolate the valve by using the bypass valve or by

shutting down the process completely. Relieve

the pressure and drain the process fluid

from both sides of the valve.

3. Relieve the pressure contained in the actuator

by venting the actuator loading pressure

and relieving any power actuator spring

compression.

4. Lock-out procedures should be strictly adhered

to while the equipment is being serviced.

Packing Maintenance

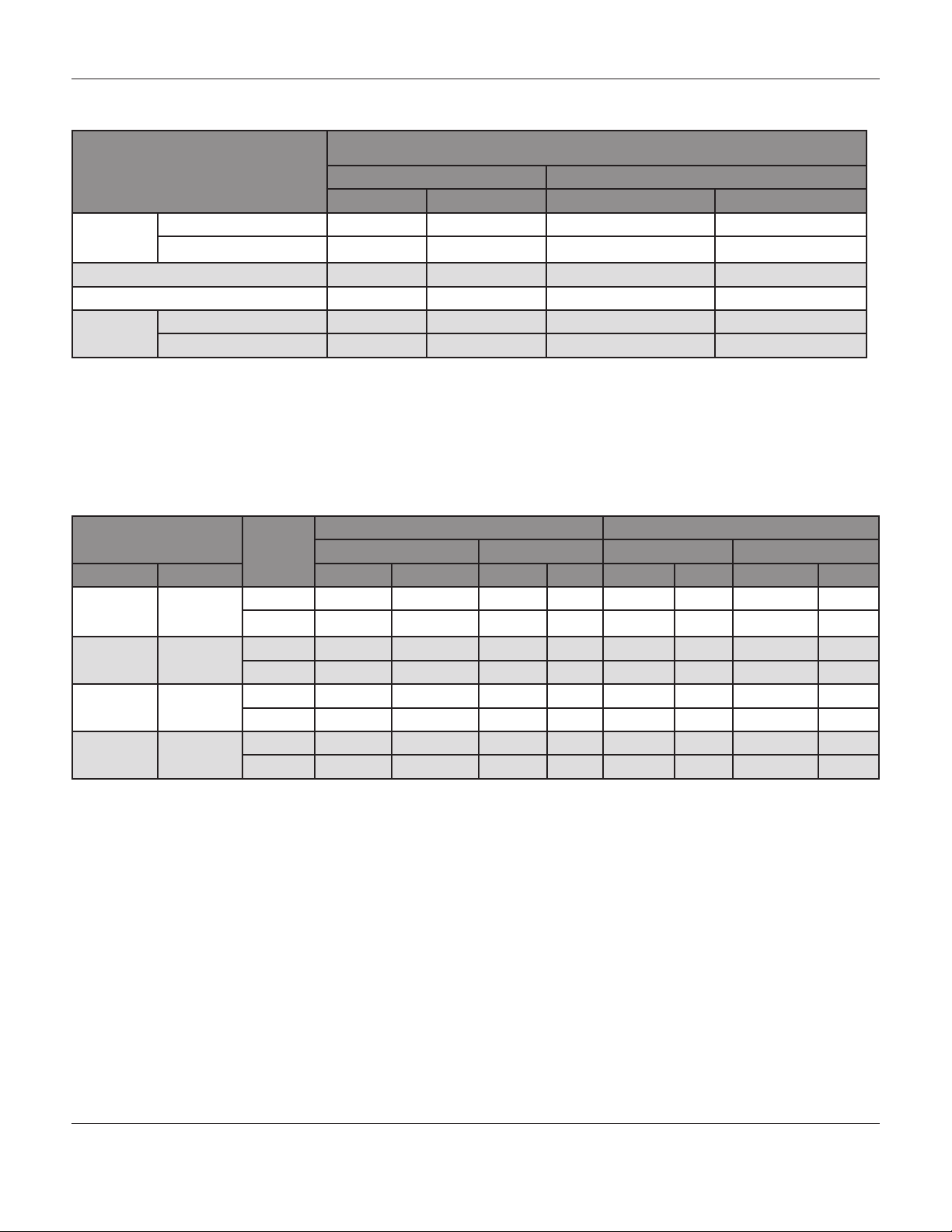

This section provides instruction for maintenance of TFE

V-Ring packing. If your Jordan Valve Mark EWD, EWS

or EWT Control Valve uses graphite laminate or filament packing, refer to the appropriate manuals. Refer to

Figure 2 for appropriate key numbers unless otherwise

indicated.

For packing that is spring-loaded single TFE V-ring

packing, a sealing force is maintained by the spring

(Figure 1, Key 5). If leakage around the packing follower

(Figure 1, Key 3) is detected, tighten the packing flange

nuts (Figure 1, Key 16). If this does not stop the leakage,

refer to the Replacing Packing section of this manual.

With packing that is other than spring-loaded, unwanted

leaking can be limited by tightening the packing flange

nuts to create a stem seal.

If leakage occurs from the inside diameter of the packing, and tightening the flange nuts does not stop the

leaking, the valve stem may be worn or nicked. If the

leakage originates from the outside diameter of the

packing, the leakage may be caused by nicks and

scratches around the packing box wall. While performing the following procedures, carefully inspect the valve

stem and packing box wall for imperfections.

Also, anytime that a gasket seal is removed or disturbed,

a new gasket should be installed during reassembly,

ensuring a proper seal.

The following instructions include packing maintenance,

trim replacement and lapping of metal seats.

Adding Packing Rings

If using packing with a lantern ring (Figure 1, Key 5),

packing rings may be installed above the lantern ring as

a temporary measure, which does not involve removing

the actuator from the valve body.

1. Remove the packing flange nuts (Figure 2, Key

16) and lift the packing flange and follower (Fig

ure 2, Keys 20 and 3) away from the valve body.

2. Old packing rings that have been installed on

top of the lantern ring may be removed,

but use caution to avoid any damage to the

valve stem or packing box wall. All metal parts

should be cleaned to remove any grit that would

prevent the packing from creating a seal.

3. If split-ring packing is being used, spread the

rings over the valve stem and slide them into the

packing box.

4. If solid-ring packing is used, take off the stem

connector and slip the rings over the end of the

valve stem.

-2-

Page 3

Mark EW SEriES GlobE StylE Control ValVES

Adding Packing Rings Continued,

5. After replacing the packing flange and packing

follower, tighten the packing flange nuts

(Figure 2, Key 16) just far enough to prevent

leakage under operating conditions.

6. If the valve-actuator stem connection was

disassembled during this process, refer

to the actuator manual for reassembly

instructions.

7. While returning the valve to service, monitor for

leakage around the packing follower. If required,

retighten the packing flange nuts.

Replacing Packing

Note: Prior to performing this procedure, isolate

the control valve from all line pressure and release

the pressure from both sides of the valve. Drain the

process media and release all pressure from the

actuator. Practice lockout procedures during the

operation.

1. Remove the operating lines from the actuator as

well as any leak-off piping from the bonnet.

2. Disconnect the stem connector and unscrew the

yoke locknut (Figure 2, Key 17) to remove the

actuator from the valve body.

3. Loosen the packing on the valve stem by

unscrewing the packing flange nuts (Figure 2,

Key 16). Remove all travel indicator parts and

stem locknuts from the valve stem threads.

Note: When lifting the bonnet (Figure 2, Key 18), it is

very important to ensure that the valve plug and stem

assembly remain in the valve and on the seat. If the

assembly were to drop out after being partially lifted,

damage to the seating surfaces would result. Parts

are also easier to handle in this way.

4. Remove the hex nuts (Figure 4, Key 39) holding

the bonnet and body together, and lift

the bonnet off of the valve stem.

5. When lifting the bonnet, if the valve plug and

stem assembly begin to lift as well, use a brass

or lead hammer

and lightly tap on the end of the stem to

release them.

6. Place the bonnet on a protective surface to pre-

vent damage to the surface of the bonnet

gasket.

7. Remove the bonnet gasket (Figures 3 and 4,

Key 33) and cover the valve body opening in or

der to prevent debris from entering the

body cavity and to protect the gasket surface.

8. Remove the following parts (Figure 2):

a. packing flange nuts (Key 16)

b. packing flange (Key 20)

c. upper wiper (Key 2)

d. packing follower (Key 3)

9. Use a rounded rod to push out the remaining

packing parts from the body side of the

bonnet. Be careful not to scratch the packing

box wall. Clean the packing box and metal

packing parts.

10. Inspect the valve stem threads and packing

box surfaces for any edges which might

cut the packing. Any defects could create leak

ing in the packing box and damage to

the new packing. If any surface nicks or

burrs cannot be improved by light sanding

replace the damaged parts.

11. Remove the covering which protects the body

covering and install a new bonnet

gasket (Figures 3 and 4, Key 33). Ensure that

the gasket seating surfaces are clean

and smooth.

Note: When the tightening procedures in Step 13 are

completed properly, the spiral wound gasket (Figures

3 and 4, Key 35) will be compressed enough to load

and seal the seat ring gasket (Figures 3 and 4, Key

36) and compress the edge of the bonnet gasket

(Figures 3 and 4, Key 33) and seal the body-to-bonnet

joint.

The lubricated stud bolt nuts (Figure 4, Key 39) can be

identified by the black film that coats the nut threads.

The bolting procedures in Step 13 will ensure that the

bolting threads are clean, and will evenly tighten the nuts

onto the studs in a crisscross pattern. Be sure to follow

the crisscross pattern since the tightening of one spiral

wound gasket may loosen an adjacent nut. Continue

repeating the pattern until each nut is tight, creating the

body-to-bonnet seal. Repeat this torquing procedure

once the operating temperature has been reached.

-3-

Page 4

Mark EW SEriES GlobE StylE Control ValVES

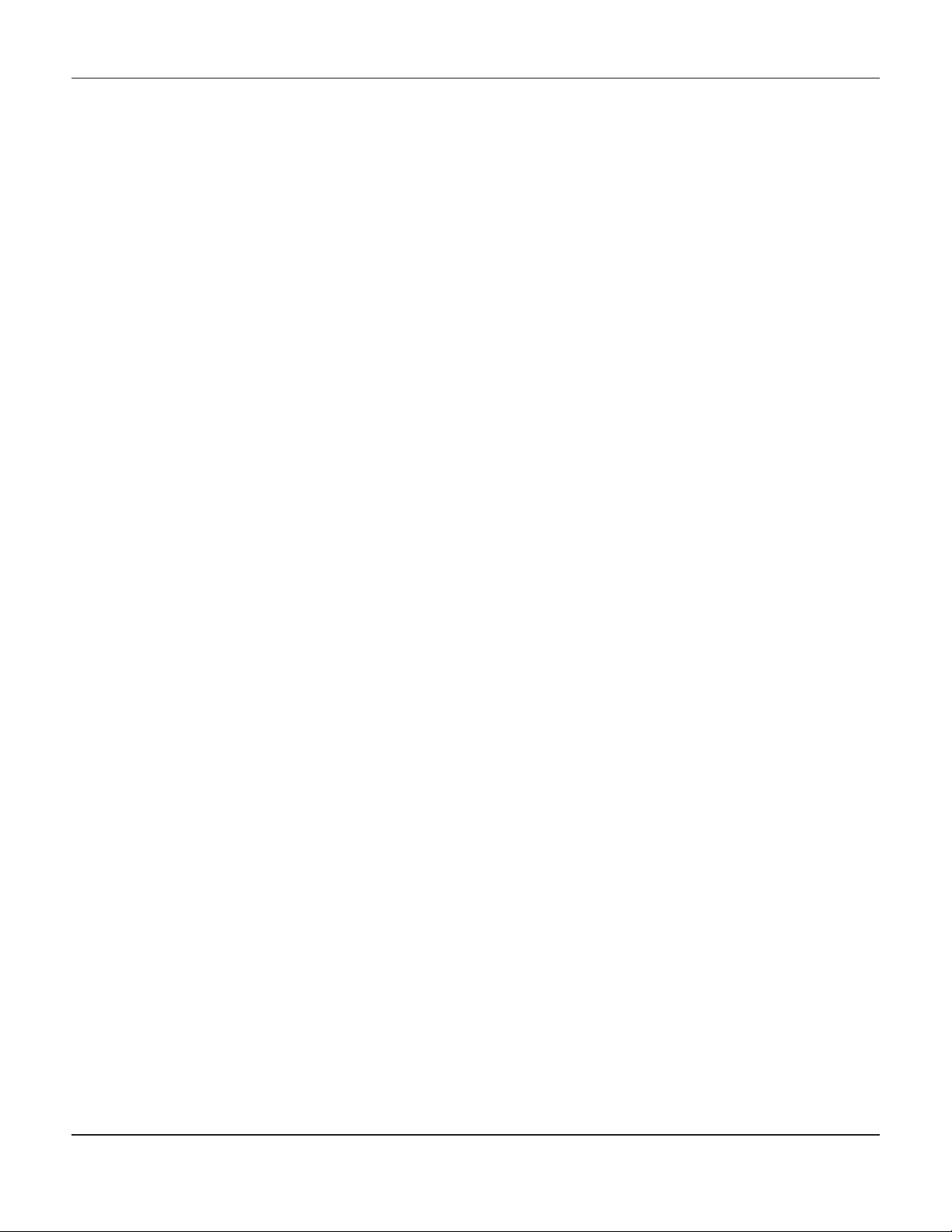

Table 1: Body-to-Bonnet Bolt Torque Guidelines

Bolt Torques

Body Size, Inches

Nonlubricated Bolting Stud Bolt Nuts Factory Lubricated

Ft•Lb N•m Ft•Lb N•m

8 x 6 Class 300 or 600 400 545 300 407

Class 900 970 1315 --- ---

12 x 6 400 545 300 407

10 x 8 550 745 --- ---

12 x 8 Class 300 or 600 540 732 --- ---

Class 900 2000 2712 --- ---

Table 2: Packing Flange Nut Torque Guidelines

Valve Stem Dia. ANSI

Class

Inches mm Lb•in N•m Lb•in N•m Lb•in N•m Lb•in N•m

1/2 12.7 300 28 3 42 5 59 7 88 10

600 39 4 58 7 81 9 122 14

3/4 19.1 300 64 7 95 11 133 15 199 23

600 87 10 131 15 182 21 274 31

1 25.4 300 108 12 162 18 226 26 339 38

600 149 17 223 25 310 35 466 53

1-1/4 31.8 300 152 17 228 26 318 36 477 54

600 209 24 314 36 437 49 655 74

PTFE Type Packing GRAPHITE Type Packing

Min. Torque Max. Torque Min. Torque Max. Torque

-4-

Page 5

Mark EW SEriES GlobE StylE Control ValVES

Packing Follower

Packing Ring

Lantern Ring

Packing Box Ring

R

R

**Garlock

*Grafoil

Upper Wiper

Packing Follower

Packing Ring

Lantern Ring

Packing Box Ring

Packing Ring

PTFE/Composition

R

*Grafoil

V - Ring

Upper Wiper

Packing Follower

Upper Wiper

Packing Follower

Female Adaptor

Female Adaptor

V - Ring

Male Adaptor

Lantern Ring

washer

Spring

Male Adaptor

Packing Box Ring

Lower Wiper

Packing Box Ring

Figure 1: TFE V-Ring Packing Arrangements

All Yoke Sizes

Single Packing

PTFE V-Ring

-5-

Packing Ring

Upper Wiper

Packing Follower

Lantern Ring

Packing Follower

V - Ring

Male Adaptor

Female Adaptor

Packing Ring

Packing Box Ring

Lantern Ring

Packing Box Ring

All Yoke Sizes

Double Packing

PTFE V-Ring

Lower Wiper

Notes:

* Grafoil

is a Registered Trademark for Packings, Seals, Gaskets and other Products of Garlock Garlock Inc.

R

** Garlock

Page 6

Mark EW SEriES GlobE StylE Control ValVES

Replacing Packing Continued,

12. Place the bonnet over the stem and onto the

stud bolts (Figure 4, Key 38) and lubricate with

an appropriate lubricant. If factory lubricated

stud bolt nuts will be used, additional lubrication

is unnecessary. Follow standard bolting

procedures and install the stud bolt nuts (Figure

4, Key 39), ensuring that the body-to-bonnet

joint will withstand test pressures and

application service conditions. Refer to

Table 1 for bolt torque guidelines, unless

accepted bolting procedures demand

otherwise.

13. Refer to Figures 1 and 2 and install new packing

and metal packing box parts. Using a smooth-

edged pipe placed over the pipe stem,

gently tap each soft packing part into the

packing box. Ensure that air is not trapped

between adjacent soft parts.

14. Slide the packing follower, upper wiper and

packing flange (Figure 2, Keys 3, 2 and 20) into

position. Lubricate the packing flange

studs (Figure 2, Key 21) as well as the packing

flange nuts (Figure 2, Key 16), and replace the

packing flange nuts.

15. If using spring-loaded TFE V-Ring packing,

tighten the packing flange nuts using accepted

bolting procedures.

16. Install the actuator onto the valve body assem-

bly and refer to the actuator instruction

manual for directions on reconnecting

the actuator and valve stem.

Trim Removal

Unless otherwise indicated, key numbers in this section

reference Figure 3 for Design EWD and Restricted Trim,

Figure 4 for Mark EWS and Figure 5 for Mark EWT constructions, as well as Class 900 12 x 6-inch construction.

1. Remove the actuator and bonnet, referring to

Steps 1 through 8 in the Replacing Packing

section.

The graphite piston ring(s) (Key 29) in a Mark EWD body

is brittle and in two pieces. Handle with care to avoid

dropping or rough handling of the piston ring(s).

The surface finish of the valve stem (Key 30) is critical for creating a good packing seal. Also,

the inside surface of the cage (Key 26) is important for

smooth valve plug operation and for creating a seal with

the piston ring (Key 29) or seal ring (Key 50). Seating

surfaces of the valve plug (Key 25) and the seat ring

(Key 32) on a metal-seat construction are important for a

tight shutoff. Protect these parts and their surfaces, and

include them in any inspections.

2. If packing parts require replacement, remove

them at this time according to instructions in the

Packing Replacement section of this manual.

Remove the cage adaptor (Key 27)

for any restricted trim body through 8 x 4-inches.

Wrap these parts for protection.

3. Remove the valve plug and stem assembly from

the valve body, setting it on a clean surface. If

the valve plug is being reused, protect the valve

plug seating surface from scratches.

4. Remove the cage (Key 26) and associated gas

kets (Keys 33, 34 and 35). If the cage becomes

stuck in the valve body, tap the exposed

portion of the cage around the circumference,

using a rubber mallet.

5. Remove the following parts:

a. Seat ring (Key 32)

b. Disc seat (Key 44)

c. Seat ring gasket (Key 36)

d. Seat ring adaptor (Key 28)

e. Adaptor gasket (Key 37)

6. The Mark EWS and EWT TFE-seat construction

use a disc (Key 45) placed between the

disc seat and disc retainer (Key 43).

7. Inspect all parts for wear or damage that would

interfere with operation of the control

valve. If replacement or repair of trim parts is

necessary, refer to Lapping Metal Seats or Valve

Plug Maintenance procedures in this manual.

Note: When lifting the valve plug stem (Key 30) and

the attached valve plug (Key 25) from the valve body,

ensure that the cage (Key 26) remains in the body

(Key 24). If the cage were to drop out of the body after

being lifted partially out, cage damage will result.

Use caution to avoid damage to the gasket sealing

surfaces.

-6-

Page 7

Mark EW SEriES GlobE StylE Control ValVES

Lapping Metal Seats

With metal-seat constructions, lapping of the seating

surfaces can improve shutoff. Use a commercial lapping product or a mixture of 600-grit carborundum and

solidified vegetable oil and lap the seating surfaces of

the valve plug and seat ring (Figures 3, 4 and 5, Keys 25

and 32). Deep nicks should be machined out rather than

ground out.

Follow valve assembly procedures until the cage (as well

as cage retainer and bonnet spacer if used) is in place,

and the bonnet is bolted to the body. Create a simple

handle from a piece of strap iron and lock to the valve

body with nuts. Rotate the handle in each direction to

lap the seats. After rotating directions, remove the bonnet and clean the seat surfaces. Completely reassemble

the valve according to directions in the Trim Maintenance section. Test the valve for shutoff and repeat the

procedure if leaking is still excessive.

Valve Plug Maintenance

Key numbers in this section refer to the following Figures

in the manual:

• Figure 3 for Mark EWD Valve Plugs

• Figure 4 for Mark EWS Valve Plugs

• Figure 5 for Mark EWT Valve Plugs

Note: If the piston ring (Key 29) or seal ring (Key

50) are being replaced, protect the surfaces of the

ring groove in the valve plug, or any surfaces of the

replacement ring. Scratches in these surfaces may

prevent proper seal of the replacement ring.

Remove the valve plug (Key 25) according to instructions in the Disassembly section, and proceed as fol-

lows:

Mark EWD – Carbon Filled TFE Piston Ring

a. The piston ring has a split in one place, and if

damage is visible, the ring can be spread

slightly and removed from the groove in the

valve plug.

b. When installing a carbon-filled TFE piston ring,

spread the ring slightly apart at the split. Install it

over the stem and into the valve plug groove.

Ensure the open side faces along the stem,

depending on the flow direction and as shown

in View A, Figure 3.

Mark EWD – Graphite Piston Ring

a. The Mark EWD graphite piston ring is in two

pieces and can be easily removed.

b. The new graphite piston ring is supplied as a

complete ring and must be broken into

two equal portions. Do this by placing the ring

horizontally in a vise and applying pres

sure until the ring snaps. Alternately, place

the ring on the edge of s smooth hard surface

and strike squarely with a hammer.

c. When installing the ring in the valve plug groove,

be sure to match the broken ends of the ring.

Mark EWT Seal Ring – Without Spring Loading

a. This is a closed ring which must be pried or cut

from the groove and therefore cannot be reused.

After the seal ring is removed, the elastomeric

back-up ring can be slightly spread and

removed.

b. When installing a seal ring without spring load

ing, apply lubricant to the back-up ring and the

seal ring (Keys 48 and 51). Install the back-up

ring over the stem (Key 30) and fit into

the groove.

c. Place the seal ring over the top of the valve plug

(Key 25) so it enters the groove on one side of

the valve plug. Gently nudge the seal

ring over the top of the valve plug. Allow time

for the TFE material to cold-flow during

the procedure, so avoid jerking on the ring.

The ring may soom loose when first in the

groove, but will contract shortly after placement

in the cage.

Mark EWT – Spring Loaded Seal Ring

a. When used with valve plugs having a port

diameter of 5-3/8 inches (136.5mm) or less,

the spring loaded seal ring may be removed

without damage by first extracting the retaining

ring (Key 47) with a screwdriver. Slowly slide

the metal back-up ring (Key 51) and seal ring

(Key 48) off of the valve plug (Key 25).

b. When used with valve plugs having a port diam

eter of 7-inches (178 mm) or greater, the spring

loaded seal ring must be pried or cut from its

groove and cannot be reinstalled.

c. The spring loaded seal ring must be placed so

that the open side faces the top or bottom of

the valve plug, according to the flow direction

(Figure 3, View A).

-7-

Page 8

Mark EW SEriES GlobE StylE Control ValVES

Mark EWT – Spring Loaded Seal Ring Continued,

d. To install the seal ring on a valve plug with

5-3/8-inches (136.5 mm) port diameter

or less, first slide the seal ring (Key 48) onto the

valve plug, followed by the metal back-up ring

(Key 51). Then install the retaining ring (Key 47),

inserting one end into the groove, turning the

plug to press the entire ring into the groove.

Use caution so as to avoid scratching the ring

or plug surfaces.

e. For installation of the seal ring onto a valve plug

with a port diameter of 7-inches (178 mm) or

greater, apply lubricant and gently stretch the

seal ring over the top edge of the valve plug.

Allow time for the TFE material to cold-flow during the

procedure, so avoid jerking on the ring. The seal ring

may seem loose when first in the groove, but will contract shortly after placement in the cage.

Note: Do not reuse an old stem or connection stud

with a new valve plug. If this were to be attempted,

a new groove pin hole would need to be drilled into

the stem, which weakens the stem and may cause it

to fail in service. However, a used valve plug may be

reused with a new stem.

f. When replacing the Mark EWD, EWS and EWT

valve stem (Key 30), drive out the groove pin

(Key 31) and unscrew the stem from the

valve plug.

g. Tightly turn in the new valve stem and refer to

Table 5 for the correct drill size. Use the

hole in the valve plug as a guide

and drill through the stem. Remove any

chips or burrs and drive in the new groove pin,

locking the assembly.

4. Install the cage assembly (Key 26). The cage

can be oriented in any rotation with respect to

the valve body.

5. Slide the valve plug (Key 25) and stem assem-

bly into the cage, ensuring that the piston ring or

seal ring (Key 29 or 48) is placed evenly

in the entrance chamber at the top of the cage

(Key 26) or cage retainer (Key 53). This

will avoid damage to the ring.

6. Place the gaskets (Keys 35, 34 or 37 if used,

and 33) and shim (Key 53) on top of the

cage or cage retainer. If there is a cage

adaptor (Key 27) or a bonnet spacer (Key 54)

place an additional flat sheet gasket on

the retainer or spacer.

Note: If reusing the packing, and if it has not been removed from the bonnet, use caution when installing

the bonnet to avoid damage to the packing from the

valve stem threads.

7. Mount the bonnet onto the valve body and

complete assembly procedures according to

Steps 13 through 17 of the Replacing Packing

section. If new packing is not being installed,

omit Steps 14 and 15. Be sure to review

the “Note” prior to step 13.

Parts Ordering

Each Jordan Valve body-bonnet assembly has a serial number which can be found on the valve body. The

same number will appear on the nameplate when the

body assembly is shipped from the Jordan Valve manufacturing facility as part of a control valve assembly.

Refer to this serial number when contacting your Jordan

Valve representative.

Trim Replacement

Key numbers in this section are referenced in Figures as

follows:

• Figure 3 for Mark EWD

• Figure 3 for Restricted Trim Detail

• Figure 5 for Class 900 8 x 6-inch and Mark

EWT constructions

1. With a restricted-trim seat ring construction,

install the adaptor gasket (Key 37) and seat ring

adaptor (Key 28).

2. Install the seat ring gasket (Key 36), seat ring or

liner (Key 32) or disc seat (Key 44).

3. With TFE-seat construction, install the disc and

disc retainer (Keys 43 and 45).

When ordering replacement parts, refer to the part number for each part required, according to the following

parts list.

-8-

Page 9

Mark EW SEriES GlobE StylE Control ValVES

Table 3: Groove Pin Replacement and Valve Stem to Plug Torque

Valve Stem Connection (VSC)

Drill Size,

in mm Ft•Lb N•m

3/4 19.1 3/16 175-250 238-340

1 25.4 1/4 310-355 420-481

1-1/4 31.8 1/4 610-670 830-910

In

Stem Torque

Minimum to Maximum

-9-

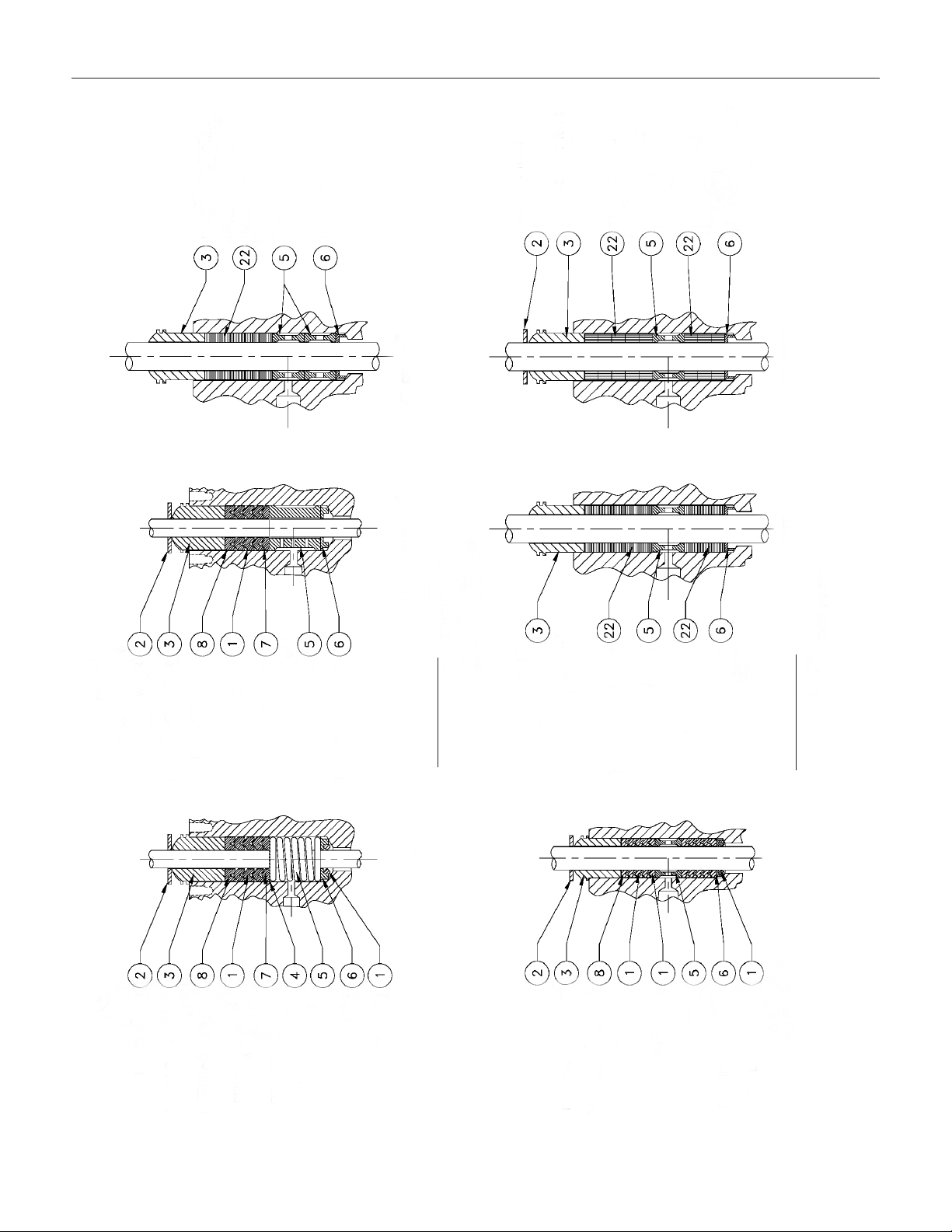

Figure 2. Typical Bonnets, shown with single

TFE V-Ring Packing Set

Page 10

Mark EW SEriES GlobE StylE Control ValVES

Parts Reference

Key Description

1 Single TFE V-Ring Packing Set

2 Upper Wiper

3 Packing Follower

4 Special Washer for TFE V-Ring Packing

5 Packing Box Spring / Lantern Ring

6 Packing Box Ring

7 Male Adaptor (Part of Gasket Set)

8 Female Adaptor (Part of Gasket Set)

10 Packing Ring

14 Cap Screw

15 Pipe Plug

16 Packing Flange Nuts

17 Yoke Locknut

18 Bonnet

19 Extension Bonnet Bushing

20 Packing Flange

21 Packing Flange Studs

22 Individual Packing Ring

23 Pipe Plug for Double Tapped Bonnet

24 Valve Body

Key Description

25 Valve Plug

26 Cage

27 Cage Adaptor

28 Seat Ring Adaptor

29 Piston Ring, Design EWD

30 Valve Plug Stem

31 Groove Pin

32 Seat Ring

33 to 37 Gasket Sets

38 Stud Bolt

39 Stud Bolt Nut

40 Pipe Plug

41 Flow Arrow

42 Drive Screw

43 Disc Retainer for TFE Seat

44 Disc Seat for TFE Seat

45 Disc, TFE

48 Seal Ring

51 Back-Up Ring

52 Hex Nut, Stud

-10-

Page 11

Mark EW SEriES GlobE StylE Control ValVES

Figure 3. Mark EWD Series through 12X6

-11-

See View A

Page 12

Mark EW SEriES GlobE StylE Control ValVES

Fig 4. 12x8 Class 900 Bonnet - 5” yoke boss bolting detail

Bonnet Assembly

See Fig. 2

A- See Gasket Sets

Fig 5. Typical 8x6 Valve Body

-12-

Page 13

Mark EW SEriES GlobE StylE Control ValVES

Parts List

Key No. Description Part Number

Single TFE V-Ring Packing Set

1

Includes Female Adaptor, Male

Adaptor, 3 Packing Rings and

Lower Wiper

2 Upper Wiper, Felt

3 Packing Follower, 316 SST

Special Washer, 316 SST

4

For TFE V-Ring Packing

Packing Box Spring, SST

For TFE V-Ring Packing

5

Lantern Ring, 316 SST

6 Packing Box Ring, 316 SST

3/4-inch (19.1 mm) Stem 1R290401012

1-inch (25.4 mm) Stem 1R290601012

1-1/4-inch (31.8 mm) Stem 1R290801012

Upper Wiper, Felt 1J872806332

1-inch (25.4 mm) Stem 1J872906332

1-1/4-inch (31.8 mm) Stem 1J873006332

3/4-inch (19.1 mm) Stem 1E944735072

1-inch (25.4 mm) Stem 1H982335072

1-1/4-inch (31.8 mm) Stem 1H998435072

3/4-inch (19.1 mm) Stem 1F125036042

1-inch (25.4 mm) Stem 1H982236042

1-1/4-inch (31.8 mm) Stem 1H995936042

3/4-inch (19.1 mm) Stem 1F125637012

1-inch (25.4 mm) Stem 1D582937012

1-1/4-inch (31.8 mm) Stem 1D387437012

3/4-inch (19.1 mm) Stem 0N028435072

1-inch (25.4 mm) Stem 0U099735072

1-1/4-inch (31.8 mm) Stem 0W087135072

3/4-inch (19.1 mm) Stem 1J873335072

1-inch (25.4 mm) Stem 1J873435012

1-1/4-inch (31.8 mm) Stem 1J873525012

7 Male Adaptor Included in Gasket Set

8 Female Adaptor Included in Gasket Set

3/4-inch (19.1 mm) Stem (2 req’d) 1D749101052

10 Packing Ring, Graphite

14 Cap Screw, Steel 5-inch Yoke Only, 8 req’d) 1A936224052

15 Pipe Plug, Steel 1/4-inch NPT 1A767524662

16 Packing Flange Nuts, 2 req’d

17 Yoke Locknut, Steel 2-13/16-inch Yoke 1E807423062

18 Bonnet See Following Tables

3/4-inch Stem Style 1 All Sizes 1R351824492

19 Extension

Bonnet

Bushing, Steel

1-inch Stem Style 1 8 x 6 and 12 x 6 1U567624492

1-1/4-inch Stem Style 1 8 x 6 and 12 x 6 1U527824492

1-inch (25.4 mm) Stem (3 req’d) 1D749601052

1-1/4-inch (31.8 mm) Stem (3 req’d) 1D751901052

3/4-inch (19.1 mm) Stem 1E944624112

1-inch (25.4 mm) Stem 1A343324112

1-1/4-inch (31.8 mm) Stem 1A368224112

3-9/16-inch Yoke 1E832723062

Style 2 8 x 6 and 12 x 6 1U763224492

-13-

Page 14

Mark EW SEriES GlobE StylE Control ValVES

Parts List Cont'd,

Key No. Description Part Number

3/4-inch (19.1 mm) Stem 1E944823072

20 Packing Flange, Steel

21 Packing Flange Studs, (2

req’d)

22 Individual Packing Ring

Pipe Plug

23

24 Valve Body See Following Tables

25 Valve Plug See Following Tables

26 Cage See Following Tables

27

28

29 Design EWD Piston Ring See Following Tables

30 Valve Plug Stem See Following Tables

31 Groove Pin

32 Seat Ring See Following Tables

33 to 37 Gasket Sets See Following Tables

38 Stud Bolt, Steel Contact Jordan Valve

39 Stud Bolt Nut, Steel Contact Jordan Valve

40 Pipe Plug for Drain-Tapped

for DoubleTapped

Bonnet

Cage Adaptor for RestrictedCapacity

6 x 4 x 2-1/2-inch Body

Seat Ring Adaptor for

Restricted-Capacity

6 x 4 x 2-1/2-inch Body

316 SST

Body

8 x 6-inch

through

12 x 8-inch

body

Design EWD

or EWT

1-inch (25.4 mm) Stem 0V002425052

1-1/4-inch (31.8 mm) Stem 0W085625052

3/4-inch (19.1 mm) Stem 1E944931032

1-inch (25.4 mm) Stem 0V002531032

1-1/4-inch (31.8 mm) Stem 0W086931032

3/4-inch (19.1 mm) Stem (8 req’d) 1E319101042

TFE

Graphite

Steel for WCB Steel Bonnet 1A369224092

316 SST for 316 SST Bonnet 1A369235072

WCB Steel for WCB Steel Body 1V705722012

410 SST HT for C5 or WC9 Steel Body 1V7057X0012

316 SST for 316 SST Body 1V705733092

WCB Steel for WCB Steel Body 1U239622012

410 SST HT for C5 or WC9 Steel Body 1U2396X0032

316 SST for 316 SST Body 1U239633092

3/4” (19.1 mm) stem diameter 1V326035072

1” (25.4 mm) or 1-1/4 (31.8 mm) stem diameter 1V334035072

3/4” (19.1 mm) stem diameter 1F723635072

1” (25.4 mm) or 1-1/4 (31.8 mm) stem diameter 1D269735072

Steel for WCB Steel Body 1A771528992

316 SST for C5 or WC9 Steel or 316 SST Body 1A771535072

1-inch (25.4 mm) Stem (8 req’d) 1D7518X0012

1-1/4-inch (31.8 mm) Stem (8 req’d) 1D7520X0012

3/4-inch (19.1 mm) Stem (2 req’d) 1D749001052

1-inch (25.4 mm) Stem (2 req’d) 1D751801052

1-1/4-inch (31.8 mm) Stem (2 req’d) 1D752001052

Sales Rep

Sales Rep

-14-

Page 15

Mark EW SEriES GlobE StylE Control ValVES

Parts List Cont'd,

Key No. Description Part Number

41 Flow Arrow, SST 1V106038983

42 Drive Screw, SST (2 req’d) 1A368228982

43 Disc Retainer for TFE-Seat (Design EWS or EWT) Contact Jordan Valve

Sales Rep

44 Disc Seat for TFE-Seat (Design EWS or EWT) Contact Jordan Valve

Sales Rep

45

48

51

Disc, TFE

(-70oF to

400oF)

Seal Ring,

Carbon Filled

TFE

EWT Only

Back-Up

Ring, EWT

only

8 x 6, 12 x 6 1V711906242

10 x 8

12 x 8

8 x 6, 12 x 6 10A2643X012

10 x 8

12 x 8

8 x 6, 12 x 6 1V660005292

Viton

0-400oF

8 x 6, 12 x 6 1V660005392

Ethylene-Propylene

(water or steam)

-40oF to 300oF

52 Hex Nut, Stud 12 x 8 Contact Jordan Valve

Sales Rep

53 Load Ring 8 x 6, 12 x 8 20A3267X012

Key 18 Bonnet, Steel

Body Size,

Inches

8 x 6

12 x 6

12 x 8 5 45A9272X012

Boss Size

Inches

3-9/16 3U509423022

5 2U509822012

Plain Bonnet, Tapped

-15-

Page 16

Mark EW SEriES GlobE StylE Control ValVES

Key 24 Valve Body, Steel

Body Size, Inches

End Connections

8 x 6 12 x 6 12 x 8

RF Flange 300 lb 2V720922012 32A0559X012 45A8259X012

RTJ Flange 2V721122012 32A0565X012 45A8261X012

RF Flange 600 lb 2V721022012 32A0562X012 45A8258X012

RTJ Flange 2V721222012 32A0566X012 458260X012

RF Flange 900 lb 31A8283X012 45A9274X012

RTJ Flange 31A9339X012 45A9275X012

Key 25 Valve Plug

Body

Size In

8 x 6

and

12 x 6

12 x 8 1-1/4 21A21A5283 21A5267X012 21A5358X022 21A5361X012

1. Alloy #6 on valve plug seat and guide

VSC In EWS EWD/EWT

316 SST 316 SST #6

1

316 SST 316 SST #6

3/4 11A5250X012 11A5256X012 1V658435072 21A5351X012

1 11A5251X012 11A5257X012 1V658535072 20A0103X012

1-1/4 11A5252X012 11A5258X012 1V658635072 20A4608X012

1

Key 26 Cage

Body

Material Equal Percentage Quick Opening Linear

Size In

8 x 6

and

12 x 6

17-4PH SST (Hard) 2U505933272 2U506333272 2U506133272

316 SST ENC 2U806748932 2U806948932 2U806848932

316 SST 2U693746102 2U693546102 2U693846102

12 x 8 17-4PH SST (Hard) 20A3245X012 20A2349X012 20A3247X012

316 SST ENC 20A3245X012 20A5469X012 20A5468X012

316 SST 20A4348X012 20A4350X012 20A4349X012

1. For Whisper Cage Contact A Jordan Valve Representative

-16-

Page 17

Mark EW SEriES GlobE StylE Control ValVES

Key 30 Valve Plug Stem (316 SST)

Body

Size In

8 x 6

and

12 x 6

12 x 8 1-1/4 11A3430X622

1. For Type 667 Only

Key 32 Seat Ring

Body Size

In

8 x 6 2V721546172 1V721646062

12 x 6 2V643946172 2V644046062

12 x 8 20A3260X012 20A3260X152

Stem Diameter In Plain Bonnet

Part Number

3/4 1L996435162

1 1N704735162

1K759135162

1-1/4 1K415435162

1K775335162

416 SST 316 SST with Alloy 6 Seat

MKEWIM/0414

1

1

Keys 33-37 Gasket Sets

Body Size

In

-425oF to 450oF 450oF to 800oF Over 800oF -70oF to 400oF

Metal Seat TFE Seat

8 x 6

and

1U5085X0092 1U5085X0062 5085X0072 1U5085X0082

12 x 6

12 x 8 10A3265X012 --- 10A3265X022 10A3265X032

Jordan Valve, a division of Richards Industries

3170 Wasson Road • Cincinnati, OH 45209

513.533.5600 • 800.543.7311 • 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Loading...

Loading...