Page 1

I & M Mark ED & ET Series 8-Inch

3170 Wasson Road • Cincinnati, OH 45209

Phone 513.533.5600 • Fax 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Installation & Maintenance Instructions for the

Mark ED & ET Series 8-Inch Globe Style Control

Valve

Warning: Jordan Valve Control Valves must only be used, installed and repaired in accordance with these Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event

of leakage or other malfunction, call a qualified service person; continued operation may cause system failure or

a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling a valve, be sure to release all spring tension.

IntroductIon

Contained in this manual are installation instructions,

maintenance and parts information for the Mark ED and

ET Series 8-inch Globe Style Control Valves. Refer to the

appropriate manuals for instructions for the accompanying actuator, positioner and additional accessories.

Only trained or experienced personnel should carry out

the operation and installation of all pressure equipment.

If you have any questions regarding the equipment, contact your Jordan Valve Controls representative.

MaIntenance

Before beginning any maintenance, it is important

to isolate the control valve and release all pressure

contained in the valve body and the actuator.

Disconnect any operating lines providing air

pressure, control signals or electrical power to the

actuator.

Note: Caution must be used in the disassembly.

The seating surfaces and surface nish of the

cage; seat ring, stem, and plug are critical for

proper sealing. Nicks and scratches will affect

the ability to seal the valve in the future.

InstallatIon

The Mark ED and ET Series 8” valve should not be

installed in systems that exceed the ANSI specified temperature and pressure ratings.

Inspect the valves for shipping damage and foreign

debris when uncrating.

1. Ensure the pipe is free of welding slag, chips,

and other debris by cleaning out the lines

before installation.

2. Install approved gaskets between the valve

body and the pipeline flanges.

3. Jordan Valve recommends a standard three-

valve maintenance bypass be installed. This

allows isolation of the valve body without shut

ting down the pipeline system.

4. Install the valve so that the flow direction arrow

on the body coincides with the actual process

flow through the valve.

5. Although the valve can be installed in any po-

sition, the typical installation has the actuator

vertical above the valve body. Support

for the actuator will be necessary if there is

vibration in the line or if the valve body is

positioned 45 degrees or more below vertical.

Disassembly

1. Disconnect and remove the actuator from

the body.

2. Remove the nuts or cap screws from the

bonnet flange.

3. Thread one of the actuator stem locknuts

onto the stem and continue threading it

down to the bottom of the thread run out.

4. Remove the bonnet by lifting it straight up

with a hoist. Attach the hoist by either a

double cable hoisting sling under

the bonnet or by the lifting rings attached

to the packing flange stud bolts or

on the 5” yoke bosses to

two yoke stud bolts 180° apart.

5. Caution must be used when lifting the

bonnet to ensure that it clears the

body and stud bolts completely. Any

damage to the seating surface

will compromise future sealing ability

6. To prevent damage to the seating surface,

place the bonnet-valve plug assembly on

a wooden or cushioned surface.

Page 2

Mark ED anD ET SEriES 8-inch GlobE STylE conTrol ValVES

Replacing the Plug Stem or Load Ring

1. Unscrew the locknuts from the stem.

2. Loosen the packing flange nuts.

3. Lean the bonnet over.

4. Draw the plug and stem out of the bonnet.

5. If valve plug is damaged it will be necessary

to replace both the valve plug and stem. If the

stem is damaged, a new valve stem can

be inserted in the original valve plug.

Replacing the Stem

1. Remove the old groove pin

2. Remove the old stem, and replace with new

stem.

3. Tighten the new stem until the thread bottoms

out against the plug.

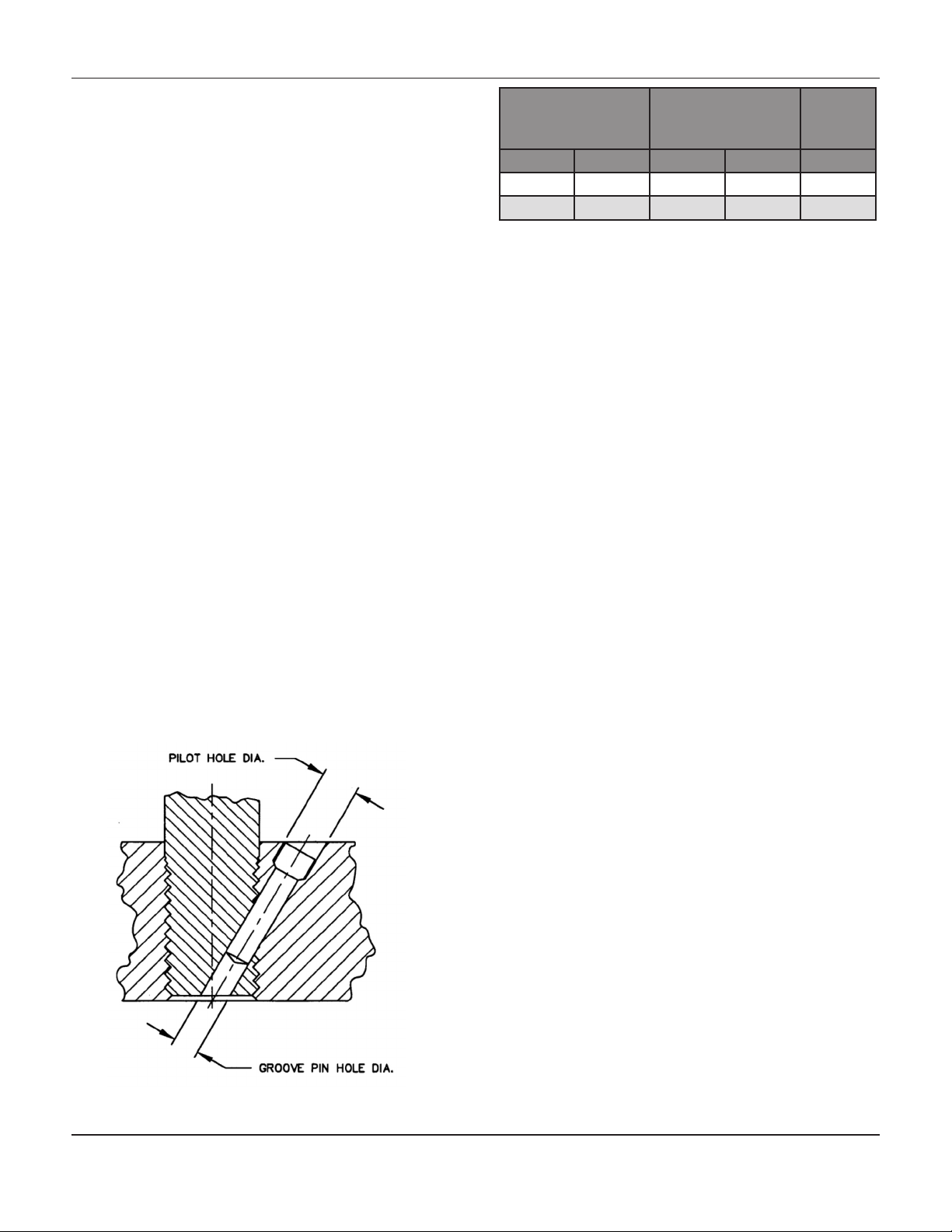

4. Drill through the stem using the hole in the valve

plug as guide. Remove any chips or burrs and

drive in a new groove pin to lock the assembly.

Refer to Table 1 for groove pin drill sizes.

Valve Stem

Connection (VSC)

Inches mm Lbf•Ft N•m Inches

3/4 19.1 237-339 175-250 3/16

1 25.4 420-481 310-355 1/4

Table 1: Stem Torque and Groove Pin Drill Sizes

Torque

Min/Max Values

Groove

Pin Drill

Size

Assembly

1. Ensure all gasket surfaces are clean.

2. Replace the valve plug piston ring or seal

ring with a new ring.

3. Assembly for design:

3.1. Mark "ED” Design Bodies:

For valve bodies using a carbon filled

TFE piston ring, at the split, slightly

spread the ring and install it over

the stem and into the piston ring

groove on the valve plug.

Graphite piston rings are supplied

as a complete ring and must be

broken into two sections. The piston

ring can be broken in half by scoring,

and then breaking over a hard

surface i.e.) edge of a table. Ensure

the broken ends are

re-matched when the

piston ring is installed in the piston

ring groove.

Figure 1: Groove Pin Pilot Holes

3.2. Mark "ET” Design Bodies:

Apply a lubricant to both back-up

ring and seal rings. Install the back up ring over the stem and

into the piston ring groove. Place

the seal ring over the top edge of the

valve plug, so that it slips into

the groove on one

side of the valve plug.

Cautiously stretch the seal ring to

work it over the top edge of

the valve plug. Avoid jerking sharply

on the seal, as the TFE in the seal

ring needs time to cold flow during

the stretching procedure. This

stretching procedure may make the

seal ring seem loose

in the groove, however it will contract

to its original size after installation of

the cage.

-2-

Page 3

Mark ED anD ET SEriES 8-inch GlobE STylE conTrol ValVES

Assembly Continued,

4. Replace the seat ring gasket, and install the seat

ring. If using a composition seat (TFE),

assemble it by placing the TFE disc onto

the disc retainer and then sliding this assembly

over the disc seat.

5. Place the cage onto the seat ring. Any rotational

orientation of the cage with respect to the valve

body is acceptable.

6. To ensure a good seal, clean all sealing surfaces

and examine surfaces for nicks and scratches.

Place the bonnet gasket in position.

7. Slide the valve plug assembly in the cage, and

then position the load ring on top of the cage.

8. Place the bonnet on the body ensuring that the

pipe plug (or lubricator) is on the downstream

side of the body.

9. Using good bolting practices, bolt the bonnet

to the body. Lubricate the studs and nuts us

ing good quality lubrication.

Tighten the bolts alternately.

Correct tightening of the bonnet bolts

accomplishes two objectives.

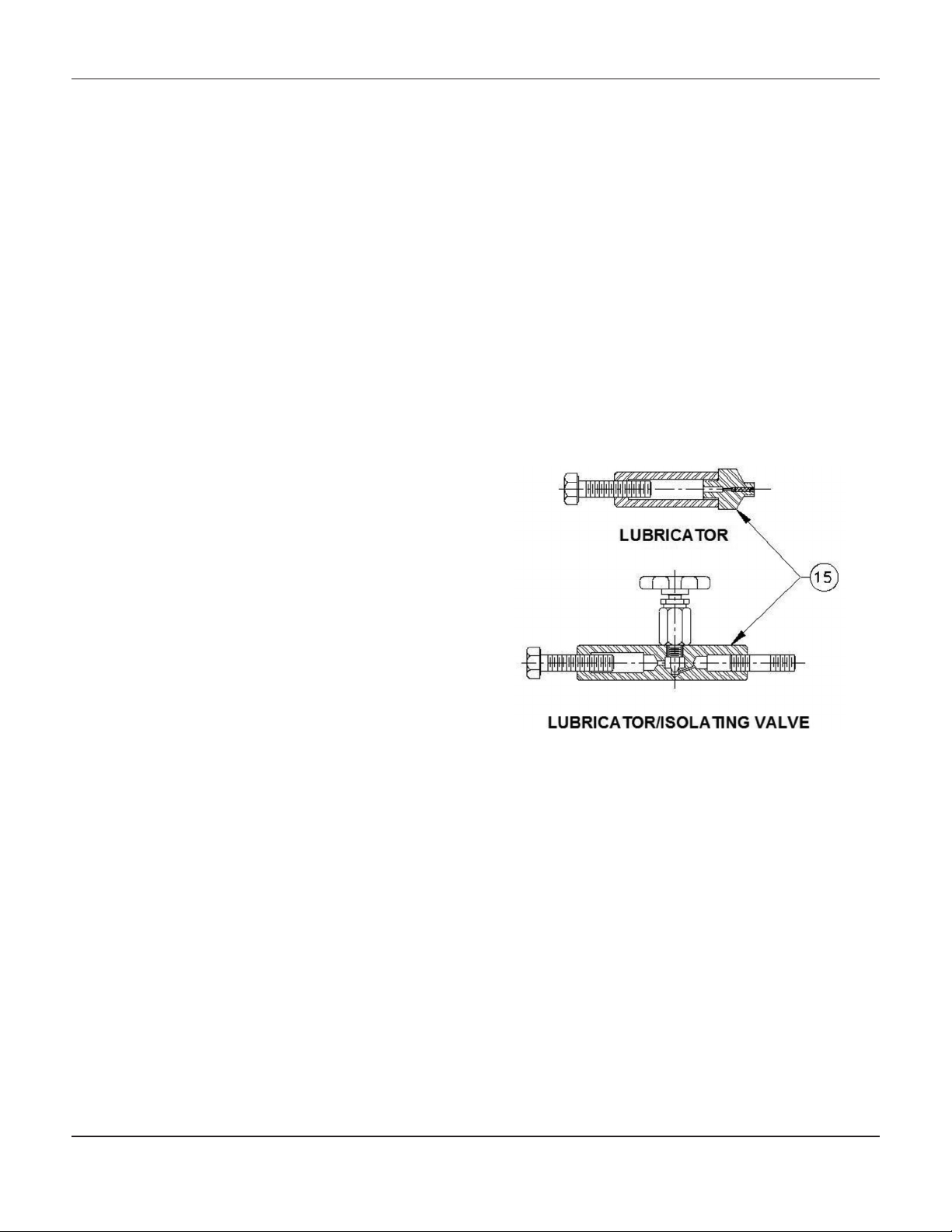

Packing Lubrication

The use of semi-metallic packing requires the use of a

lubricator or lubricator/isolating valve (Figure 2). The

lubricator or lubricator/isolating valve is mounted in

place of pipe plug (Figure 2, Key 15). For standard

service up to 450ºF, use Dow Corning lubricant or

equivalent. Do not lubricate packing used in oxygen

service.

Lubricator -To add lubricant to the packing box, turn

the cap screw in a clockwise direction.

Lubricator/Isolating Valve - Open the isolating valve,

turn the cap screw in a clockwise direction, and then

close the isolating valve.

9.1. To compress the bonnet gasket to form

a seal with the body joint.

9.2. Bolt loads are transmitted to the cage

through the load ring, which creates a

sealing load for the seat ring gasket.

10. Mount the actuator to the bonnet and make up

the stem connection. Refer to “Making Up the

Stem Connection” for proper procedure.

Figure 2: Lubricator and Lubricator/

Isolating Valve

-3-

Page 4

Mark ED anD ET SEriES 8-inch GlobE STylE conTrol ValVES

Replacing TFE V-Ring Packing

1. After the stem and valve plug have been

detached from the bonnet, the following parts

can be removed:

1.1. Packing nuts

1.2. Packing flange

1.3. Wiper ring

1.4. Packing follower

2. The old packing can be removed by one of two

methods:

2.1. Remove the packing by pushing it out

using a rod inserted through bottom of

the bonnet.

2.2. Use a packing hook to remove the

packing. Note: To avoid damaging the

packing box walls use caution.

3. Clean the packing box bore, and all metal

parts. Complete all required maintenance.

4. Slide the valve plug into the cage already in

the valve body, install the load ring on the

cage, and use a new bonnet gasket. Mount

the bonnet to the valve body.

5. Complete the installation of the packing as il lustrated in Figure 3.

Note: Extra caution should be taken not to damage

the packing during the installation process.

6. Replace the packing flange (Key 27); tighten

the packing flange nuts (Key 29) until shoulder

of packing follower (Key 30) is approximately

5/8” from the top of the bonnet. If leakage is

detected around the packing follower, tighten

the packing flange nuts until leakage stops.

7. For graphite packing, tighten the packing

flange nuts to the maximum torque value in

Table 3. Then back off the nuts and retighten

them to the minimum torque value in Table 3.

8. For other Packing Types, in small equal incre ments tighten the flange nuts until one of the

nuts reach the minimum torque shown in Table

3. Then tighten the other nut until the packing

flange is level.

9. Mount the actuator and set the stem connector

to the required travel. Refer to “Making Up the

Stem Connection” procedure.

Lapping Metal Seats

In any valve body, a certain amount of leakage should

be expected with metal-to-metal seating. However, if

the leakage becomes excessive, lapping can enhance

the condition of the seating surfaces of the valve plug

and seat ring.

Deep nicks in the seating surfaces should be removed

by machining rather than lapping. There are many lapping compounds available commercially. Be sure to

use one of high quality.

Apply lapping compound to bottom of plug. In order

to position the cage and seat ring properly and to help

align the valve plug with the seat ring, bolt the bonnet to the body with gaskets (the old gaskets can be

used) in place during the lapping procedure. A simple

handle can be made from a piece of metal secured to

the valve stem with nuts.

Rotate the handle in opposite directions to lap the seating surfaces. Once lapping is complete, disconnect

bonnet, clean the seating surfaces, reassemble, and

then test for shutoff. If leakage is still excessive, repeat

lapping procedure.

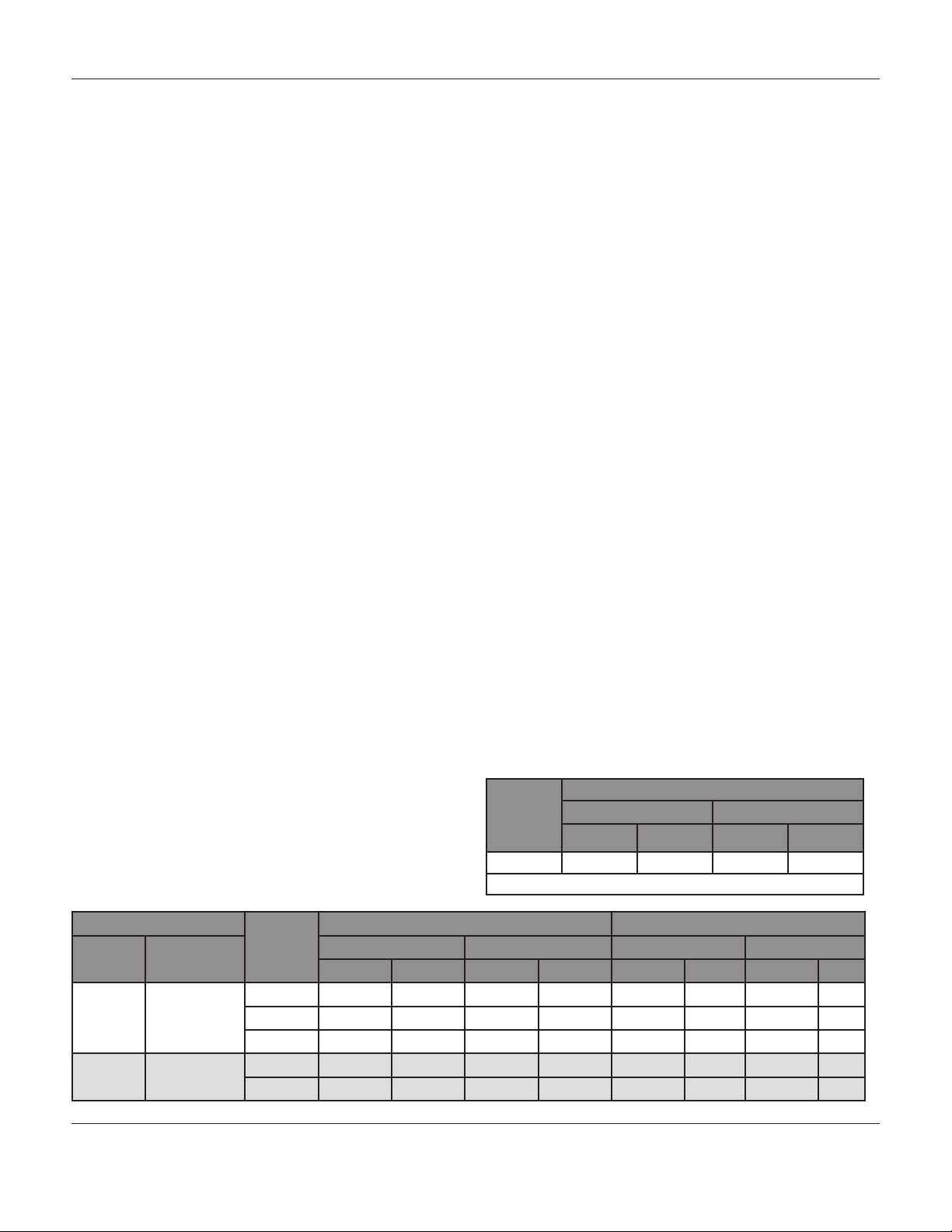

Table 2: Body to Bonnet Torque

Valve Size

Bolt Torques

SA 193-B7, B8M

N•m Lbf•Ft N•m Lbf•Ft

a

SA-193-B8M

b

8 746 550 529 390

Table 3: Torque Values for Packing Flange Nuts

Valve Stem Diameter

Inches Mm Min. Torque Max. Torque Min. Torque Max. Torque

ANSI

Rating

Lbf•in N•m Lbf•in N•m Lbf•in N•m Lbf•in N•m

PTFE Type Packing Graphite Type Packing

a- Strain Hardened; b- Annealed

3/4 19.1 150 47 5 70 8 99 11 149 17

300 64 7 95 11 133 15 199 23

600 87 10 131 15 182 21 274 31

1 25.4 300 108 12 162 18 226 26 339 38

600 149 17 223 25 310 35 466 53

-4-

Page 5

Mark ED anD ET SEriES 8-inch GlobE STylE conTrol ValVES

Single Packing

All Yoke sizes

Notes:

a.) Grafoil is a registered trademark of Union Carbide

b.) Quickset is a registered trademark of Garlock Inc.

Making Up the Stem Connection

Direct-Acting Actuators

1. Move the valve plug to the closed position.

2. Thread the actuator stem locknuts to the bottom

of the plug stem threads. Position the

travel indicator disc, cupped edge downward,

over the stem. Apply enough spring force to the

actuator stem to ensure the actuator is in the

“full up” position.

3. Move the actuator stem to the full downward po-

sition by applying full loading pressure

to the diaphragm case. Measure the distance

between the lower end of the actuator stem and

the travel indicator disc on the stem locknuts.

4. Slowly decrease the load on the actuator, allow

ing the stem to rise up approximately by 1/8”.

Using the two-piece stem connector and

cap screws, secure the actuator stem and valve

plug stem together.

5. Place the travel indicator disc against the bot-

tom of the stem connector. Secure the disc in

place with the upper locknut. Adjust the

travel indicator scale so it reads “closed.”

Double Packing

All Yoke sizes

6. Relieve the diaphragm loading pressure

and check for sufficient travel. i.e.) Move

ment of valve plug to the fully “Open”

position. Tighten the lower stem locknut

against the upper locknut. The connection

is now complete.

To increase desired length of travel:

a. Loosen both stem locknuts away

from the stem connector by ap-

proximately 1/4” and then tighten

them together.

b. This adjustment will allow a wrench

to be used on the locknuts to

screw the valve plug stem to the

desired position.

c. Caution: ensure that the valve plug

is not seated while being rotated.

Do not exceed the 1/8” adjustment

made in Step 4.

d. Retighten the stem connector and

locknuts after adjustment.

e. Reposition the travel indicator

scale to reflect the change.

Figure 3: Packing Arrangements

-5-

Page 6

Mark ED anD ET SEriES 8-inch GlobE STylE conTrol ValVES

Making Up the Stem Connection Cont.,

Reverse-Acting Actuators

1. Close the valve plug ensuring the valve plug is on

the seat.

2. Supply enough spring force to the actuator stem to

ensure the actuator is in full “Down” position. Increase the loading pressure to the diaphragm case

to allow the actuator stem to rise sufficiently so the

locknuts can be screwed onto the valve plug stem.

Thread the locknuts down on the valve plug stem

as far as possible. Set the travel indicator on the

locknuts, “cupped” edge downward.

3. Slowly release the pressure in the diaphragm case,

allowing the actuator to return to the full down position. Measure the distance between the lower end

of the actuator stem and the travel indicator disc.

4. Increase the load on the actuator, causing the stem

to rise up by approximately 1/8”. Using the twopiece stem connector and cap screws, secure the

actuator stem and valve plug stem together.

5. Move the travel indicator disc against the bottom of

the stem connector.

6. Secure the disc with the upper locknut. Change the

travel indicator scale so that it reads closed.

7. Open the valve plug by increasing the diaphragm

loading pressure. Secure the lower stem locknut

against the upper locknut. The connection is now

complete.

8. To increase travel see “To increase desired length of

travel” instructions.

Parts orderIng

A serial number identifies every Mark E Series valve

body-bonnet assembly, which can be found on the front

of the valve. Please refer to this number when contacting your Jordan Valve representative.

-6-

Page 7

Mark ED anD ET SEriES 8-inch GlobE STylE conTrol ValVES

Mark e serIes 8-Inch globe ValVes

Parts Reference

Key Part Name

1 Valve Plug Stem

2 Body

3 Bonnet Gasket

4 Load Ring

5 Groove Pin

6 Valve Plug

7 Seat Ring

8 Flow Arrow

9 Hex Nut

10 Stud Bolt or Cap Screw

11 Piston Ring (Design ED

Only)

13 Cage

Key Part Name

14 Seat Ring Gasket

15 Pipe Plug

16 Drive Screw

17 Disc Retainer (Soft Seat Only)

18 Disc Seat (Soft Seat Only)

19 Seal Ring (Design ET Only)

20 Disc (Soft Seat Only)

21 Packing Ring

22 Bonnet

23 Pipe Plug

24 Packing Spring / Lantern Ring

25 Special Washer

Key Part Name

26 Upper Wiper

27 Packing Flange

28 Stud

29 Nut

30 Packing Follower

31 Locknut (3-9/16” Yoke

Boss Only)

32 Packing Set

33 Pipe Plug

34 Packing Box Ring

35 Bolt

36 Nut (5” Yoke Boss Only)

Standard Bonnet

3-9/16” Yoke Boss, 3/4” Stem

Figure 4: Bonnet Assemblies, Mark E Series 8” Globe Valves

-7-

Extension Bonnet

5” Yoke Boss, 1” Stem

Page 8

Mark ED anD ET SEriES 8-inch GlobE STylE conTrol ValVES

Mark ED Construction

Metal Seat Ring

Figure 5: Body Assemblies, Mark E Series 8” Globe Valves

Mark ET Construction

Soft Seat Ring

Mark e serIes 8-Inch globe ValVes

Parts Reference

Key Description Part Number

1 Valve Plug Stem, 316 SST See Following Table

2 Valve Body See Following Table

3

Bonnet Gasket

4

Load Ring

5 Groove Pin,

316 SST

6 Valve Plug See Following Table

7 Seat Ring 416 SST 20A3260X012

8 Flow Arrow, SST 1V106038982

9 Hex Nut, Steel (16 req’d), Steel Bodies Only 1A445224072

10 Stud Bolt, Steel (16 req’d) 1D945231012

Metal Seat -425oF to 800oF (-254oC to 427oC), material 10A3265X012

Over 800oF (427oC), Laminated Graphite 10A3265X022

Composition Seat, Nitrile 10A3265X032

-150oF to 600oF (-101oC to 316oC), 17-4PH SST 20A3267X012

-425oF to 1100oF (-254oC to 593oC), Inconel 718 20A3267X022

-400oF to 500oF (-240oC to 260oC), Corrosive Service, K Monel 20A3268X012

3/4” VSC (19.1 mm) 1V326035072

1” VSC (25.4 mm) 1V334035072

Alloy 6 20A3260X152

-8-

Page 9

Mark ED anD ET SEriES 8-inch GlobE STylE conTrol ValVES

Parts Reference

Key Description Part Number

11 Piston Ring, Graphite,

Design ED Only

13

Cage

14 Seat Ring,

Gasket,

Metal Seat

15 Pipe Plug Steel (LCC & WCB Bodies) 1A771528992

16 Drive Screw (2 req’d), CD PL Steel 1A368228982

17 Disc Retainer, 316 SST, Composition Seats Only 10A4466X012

18 Disc Seat, 316, Composition Seats Only 20A4467X012

19 Seal Ring, TFE, Spring Loaded, -100oF to 450oF (-73oC to 232oC), Design ET Only 10A3261X012

20 Disc, TFE, -70oF to 400oF (-57oC to 204oC), Composition Seats Only 20A4468X012

21

Packing

Ring

22 Bonnet See Following Table

23 Pipe Plug (Tapped Extension

Bonnets Only)

24 Spring, 316 SST

(TFE V-Ring Packing Only)

Lantern Ring, 316 SST

(Laminated Graphite Packing, 2 req’d, Other Packing,

1 req’d)

25 Special Washer, 316 SST

(TFE V-Ring Packing Only)

Equal Percentage

Linear 17-PH SST 20A3247X012

Quick Opening 17-PH SST 20A3249X012

Metal Seat -425oF to 800oF (-254oC to 427oC), material 10A3266X012

Composition Seat, Nitrile 10A3266X032

316 SST (316 SST Bodies) 1A771535072

Graphite (2

req’d)

TFE (8 req’d) 3/4” Stem (19.1 mm) 1E319101042

Laminated

Graphite (4

req’d)

Non-Oxidizing Service 10A3262X012

Oxidizing Service 10A3262X022

17-PH SST 20A3245X012

316 SST Ni Coated 20A5467X012

316 SST CR PL 20A4348X012

316 SST Ni Coated 20A5468X012

316 SST CR PL 20A4349X012

316 SST Ni Coated 20A5469X012

316 SST CR PL 20A4350X012

-425oF to 800oF (-254oC to 427oC), material 10A3266X022

3/4” Stem (19.1 mm) 1D749001052

1” Stem (25.4 mm) 1D751801052

1” Stem (25.4 mm) 1D7518X0012

3/4” Stem (19.1 mm) 1V239601652

1” Stem (25.4 mm) 1U676801652

Steel (Steel Bonnets) 1A767524662

316 SST (316 SST Bonnets) 1A767535072

3/4” Stem (19.1 mm) 1F125637012

1” Stem (25.4 mm) 1D582937012

3/4” Stem (19.1 mm) 0N028435072

1” Stem (25.4 mm) 0U099735072

3/4” Stem (19.1 mm) 1F125036042

1” Stem (25.4 mm) 1H982236042

-9-

Page 10

Mark ED anD ET SEriES 8-inch GlobE STylE conTrol ValVES

Parts Reference

Key Description Part Number

Upper Wiper, Felt

26

(Not req’d for Laminated Graphite Packing)

27 Packing Flange, Steel 3/4” Stem (19.1 mm) 1E944823072

28 Stud, Steel (2 req’d) 3/4” Stem (19.1 mm) 1E944931032

29 Nut, Steel (2 req’d) 3/4” Stem (19.1 mm) 1E944624112

30 Packing Follower, 316 SST 3/4” Stem (19.1 mm) 1E944735072

31 Locknut, Steel (3-9/16” Yoke Boss Only) 1E832723062

Packing Set, TFE V-Ring

32

(Includes male adaptor, female adaptor, lower

wiper and three packing rings)

33 Pipe Plug Steel (Steel Bonnets) 1A767524662

34 Packing Box Ring, 17-4PH SST 3/4” Stem (19.1 mm) 1J873335012

35 Cap Screw, Steel (8 req’d) (5” Yoke Boss only) 1A936224052

36 Nut, Steel (8 req’d) (5” Yoke Boss only) 1A343324122

3/4” Stem (19.1 mm) 1J872806332

1” Stem (25.4 mm) 1J872906332

1” Stem (25.4 mm) 0V002425052

1” Stem (25.4 mm) 0V002531032

1” Stem (25.4 mm) 1L692124112

1” Stem (25.4 mm) 1H982335072

3/4” Stem (19.1 mm) 1R290401012

1” Stem (25.4 mm) 1R290601012

316 SST (316 SST Bonnets) 1A767535072

1” Stem (25.4 mm) 1J873435012

Key 1: Valve Plug Stem

Valve

Stem Size

in mm in mm

3/4 19.1 3/4 19.1 Plain Bonnet, 19-3/8” Stem 1K588035162

1 25.4 1 25.4 Style 1 Extension Bonnet

Stem

Connec-

tion

Specications Part Number

Style 1 Extension Bonnet, 21” Stem 1U928235162

2” Travel, 24-3/16”

657 Actuator

667 Actuator, 2” – 3” Travel, 23-3/16” Stem 10A3282X012

Stem

3” Travel, 23-3/16”

Stem

1K7891X0012

10A3282X012

-10-

Page 11

Mark ED anD ET SEriES 8-inch GlobE STylE conTrol ValVES

Key 2: Valve Body

End Connection Steel (LCC) Steel (WCB) 316 SST

Without Drain Plug Tapping

RF Flg

RTJ Flg

Butt Weld Sch 40 30A3222LX012 30A3222WX012 30A3222X062

With Drain Plug Tapping

RF Flg

RTJ Flg

Butt Weld Sch 40 30A3230LX012 30A3230WX012 30A3230X062

MKEDandET8INCHIM/0214/2K

150 lb 30A3224LX012 30A3224WX012 30A3224X062

300 lb 30A3225LX012 30A3225WX012 30A3225X062

600 lb 30A3226LX012 30A3226WX012 30A3226X062

150 lb 30A3227LX012 30A3227WX012 30A3227X062

300 lb 30A3228LX012 30A3228WX012 30A3228X062

600 lb 30A3229LX012 30A3229WX012 30A3229X062

Sch 80 30A3223LX012 30A3223WX012 30A3223X062

150 lb 30A3232LX012 30A3232WX012 30A3232X062

300 lb 30A3233LX012 30A3233WX012 30A3233X062

600 lb 30A3234LX012 30A3234WX012 30A3234X062

150 lb 30A3235LX012 30A3235WX012 30A3235X062

300 lb 30A3236LX012 30A3236WX012 30A3236X062

600 lb 30A3237LX012 30A3237WX012 30A3237X062

Sch 80 30A3231LX012 30A3231WX012 30A3231X062

Key 2: Valve Body

Stem Size Valve Stem Connection Material

316 SST

in mm in mm 416 SST

Hardened

3/4 19.1 3/4 19.1 21A5356X012 21A5356X022 21A5362X012

1 25.4 1 25.4 21A5356X012 21A5357X022 21A5363X012

316 SST

Hard Faced Seat

& Guide

Key 22 Bonnet, Same material as body

3-9/16” Yoke Boss

Material Style

Plain 30A5471X012 ---

Steel

316 SST Style 1 Extension Tapped 30A3279X062 30A3280X062

Style 1 Extension Tapped 30A3279X012 30A3280X012

Untapped 30A3270X012 30A3274X012

Untapped 30A3270X062 30A3274X062

3/4” Stem

5” Yoke Boss

1” Stem

Jordan Valve, a division of Richards Industries

3170 Wasson Road • Cincinnati, OH 45209

513.533.5600 • 800.543.7311 • 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Loading...

Loading...