Page 1

I & M Mark D and DA Series

3170 Wasson Road • Cincinnati, OH 45209

Phone 513.533.5600 • Fax 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve Control Valves must only be used, installed and repaired in accordance with these Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event

of leakage or other malfunction, call a qualified service person; continued operation may cause system failure or

a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling a valve, be sure to release all spring tension.

IntroductIon

Contained in this manual are installation instructions,

maintenance procedures and parts information for the

1-inch and 2-inch Mark D and DA Series Globe and

Angle Style Control Valves. Refer to the appropriate

manuals for instructions for the accompanying actuator and additional accessories.

Trained or experienced personnel should carry out

operation and installation of all pressure equipment.

If you have any questions regarding the equipment,

contact your Jordan Valve representative.

Installation & Maintenance Instructions for the

Mark D & DA Globe and Angle Style Control Valves

3. Unless limited by existing seismic condi tions, the control valve assembly may be

installed in any position. The normal

method is with the actuator vertical above

the valve.

4. Install the valve so the process flow co-

incides with direction shown by the arrow

on the valve body.

5. Use accepted piping and welding

practices when installing the valve in the

line. For flanged valve bodies, use

suitable gaskets between the body

flanges and pipeline flanges.

Note

InstallatIon

Post-welding heat treatment may be required

Warning

Jordan Valve recommends the use of protective

clothing, gloves and eyewear when performing any

installation or maintenance.

Installation of the valve assembly under conditions

which exceed the limits outlined in this manual

or on the nameplate may result in personal injury.

Overpressure may cause sudden release of process pressure or bursting of assembly parts.

The valve conguration and construction materials

of each assembly are specied during ordering to

meet specic pressure, temperature, pressure drop

and controlled uid conditions. Do not operate any

part of the assembly outside of those conditions

without rst contacting Jordan Valve.

1. Before installing the valve, inspect the valve

body cavity for foreign material.

2. Remove all foreign materials such as scale or

welding slag from all pipelines.

on some valve body materials. Avoid damage

to internal elastomeric, plastic and metal parts

by removing all trim. For more information,

contact your Jordan Valve representative.

6. For screwed end connections, apply pipe

compound to pipeline threads.

7. Install a conventional 3-valve bypass

around the body to allow for continuous

operation during maintenance

and inspection.

8. If your actuator and valve body were

shipped separately, refer to the

proper Product Manual for actuator

mounting procedures.

Warning

Packing leakage could result in personal injury.

Valve packing is tightened prior to shipping

but may require readjustment to meet specic

service conditions.

Page 2

Mark D anD Da SerieS Globe anD anGle Style Control ValVeS

MaIntenance

Warning

Personal injury may result from sudden re

lease of any process pressure. Jordan Valve

recommends the use of protective clothing,

gloves and eye wear when performing

any installation or maintenance.

Isolate the valve from the system and relieve

pressure prior to performing maintenance.

Disconnect any operating lines providing air

pressure, control signals or electrical power

to the actuator.

Install bypass valves or completely shut

down the process to isolate the valve

from process pressure. Relieve all pressure

and drain process media from both sides of

valve.

Vent all pressure from the actuator and re

lieve pre-compression from actuator spring.

Depending on the severity of service, valve body

parts experience wear and tear and must be inspected and maintained according to conditions.

This manual includes instructions for lubrication and

maintenance of packing, trim maintenance and lapping of seating surfaces. All maintenance procedures

can be conducted while the valve remains in the line.

Note

If a gasket seal is disturbed while

removing or adjusting gasketed parts,

Jordan Valve recommends installing a new

gasket while reassembling. A proper seal

is required to ensure optimum operation.

Use lock out procedures to ensure the pro

cess remains shut down during maintenance.

Check the packing box for pressurized pro

cess uids even after the valve has been

removed from the pipeline, particularly when

removing packing hardware or packing rings,

or removing packing box pipe plug.

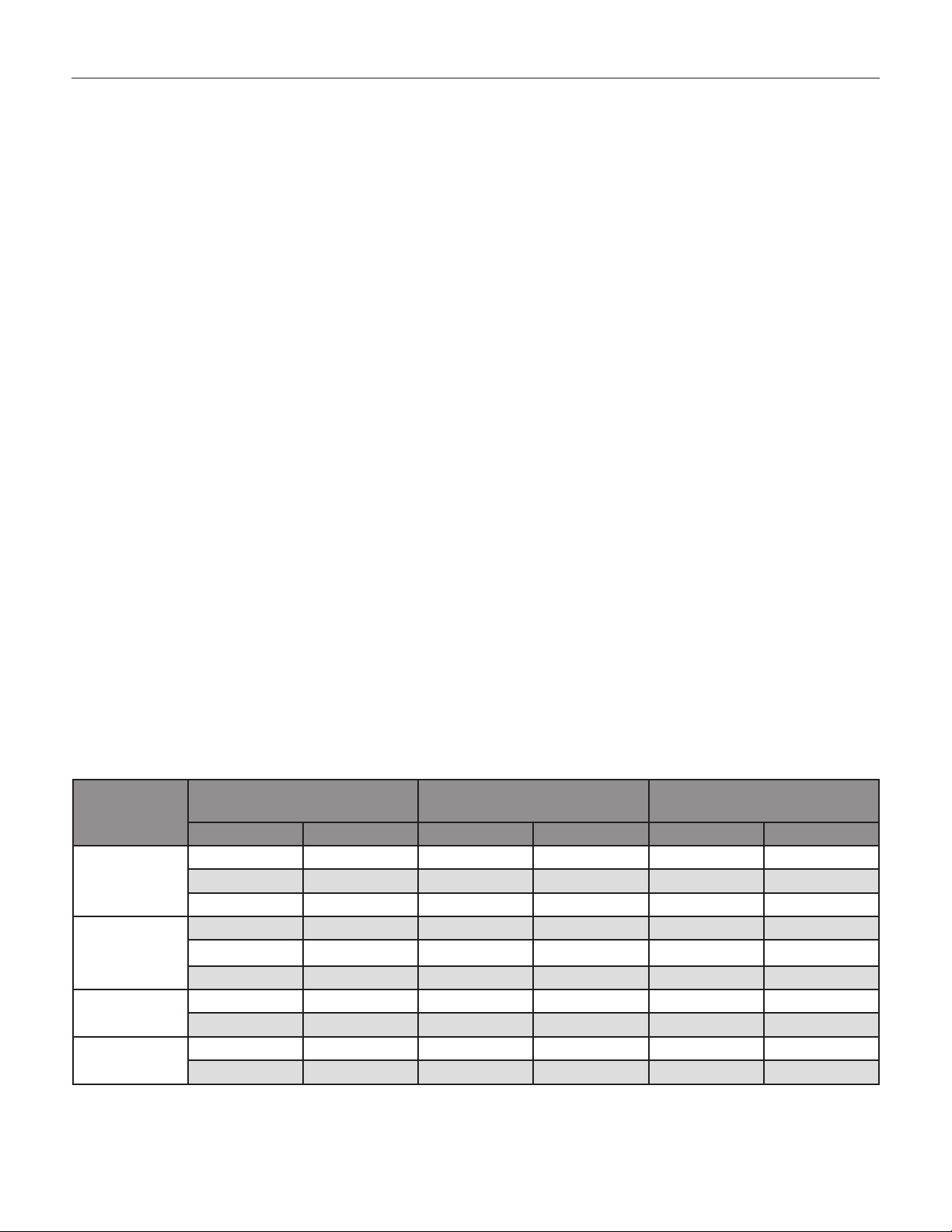

Table 1: Bolting Torque for Packing Box Nuts (Key 2)

Stem Diameter

Valve Rating

3600 or to

Class 1500

6000 or Class

2500

9000 psi 12.7 0.5 6 54 8 264

10,000 psi 12.7 0.5 6 54 8 72

mm in N•m Lbf•in N•m Lbf•in

9.5 0.375 4 36 5 48

12.7 0.5 7 66 11 96

19.1 0.75 16 144 24 216

9.5 0.375 5 42 7 60

12.7 0.5 9 78 12 108

19.1 0.75 20 180 30 264

19.1 0.75 20 180 30 264

19.1 0.75 20 180 30 264

Minimum Recommended

Torque

Maximum Recommended

Torque

-2-

Page 3

Mark D anD Da SerieS Globe anD anGle Style Control ValVeS

Packing Lubrication

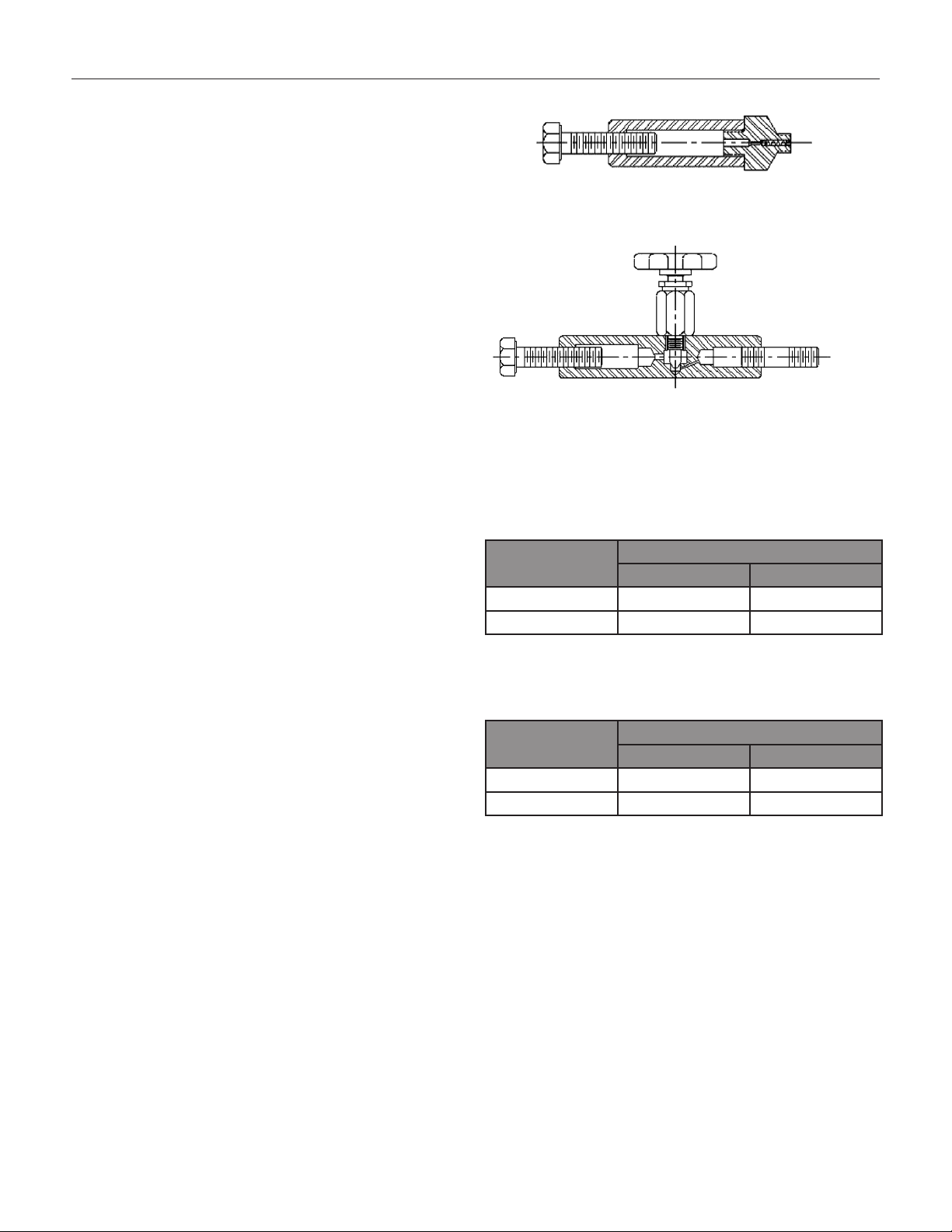

An optional lubricator or lubricator/isolating valve

(Figure 1) may have been installed in place of the pipe

plug within the tapped bonnet. This is used for PTFE/

composition or other packing that require lubrication.

Use a silicon-base lubricant. Packing used in oxygen

service does not require lubrication.

Lubricator - turn the cap screw clockwise to force the

lubricant into the packing box.

Lubricator/isolating valve - open the isolating valve

before turning the cap screw to add lubricant, and

close the isolating valve after lubrication is completed.

Lubricator

Packing Maintenance

Contact your Jordan Valve representative for specific

packing orientation, composition and arrangements.

1. For spring-loaded single PTFE V-ring pack

ing, the spring (Key 16) maintains a sealing

force on the packing. Stop leakage around

the packing follower (Key 11) by tightening

the packing nuts. If the shoulder of the

packing box is touching the top of the bonnet

and leakage cannot be controlled, please

see “Packing Replacement.”

2. If there is packing leakage with other than

spring-loaded packing, try tightening the

packing flange nuts (Key 2) to the minimum

torque value shown in Table 1. Do not exceed

the maximum torque value shown in Table

1. Exceeding the maximum torque value may

cause excessive friction to result.

3. If the packing (Key 13) is relatively new and

tightening the packing flange nuts does not

stop the leakage; a worn or nicked valve stem

or damaged packing box bore might prevent a

proper seal. Follow the steps for Packing

Replacement and inspect the valve stem and

packing box wall during the procedure

Lubricator/Isolating Valve

Figure 1: Optional Lubricator and Lubricator/

Isolating Valve

Table 2: Torque for Bonnet to Body Joint

Valve Size (in.)

1 780 1060

2 1500 2030

Table 3: Torque for Seat Ring (Key 8)

Valve Size (in.)

1 300 407

2 515 698

Recommended Torque

Lbf•ft N•m

Recommended Torque

Lbf•ft N•m

-3-

Page 4

Mark D anD Da SerieS Globe anD anGle Style Control ValVeS

Packing Replacement

Warning

Prior to performing any maintenance

procedures, review the warning notes at the

beginning of the Maintenance section.

1. Isolate the control valve from the line pressure,

release pressure from both sides of the valve

body, and drain the process media from both

sides of the valve.

2. Disconnect any operating lines providing air

pressure, control signals or electrical power

to the actuator. Use lockout procedures to en sure the above measures stay in effect while

you work on the equipment.

3. Disconnect the stem connector, and then re move the actuator from the valve body by un screwing the actuator yoke locknut (Key 4).

4. Loosen the packing flange nuts (Key 2) so the

packing is not tight on the valve stem. Remove

travel indicator parts and stem locknuts from

the valve stem threads.

5. Unscrew the bonnet (Key 6) from the valve

body (Key 7). Carefully lift off the bonnet and

plug/stem assembly (Key 19) as a unit.

11. Inspect the valve stem threads and pack

ing box bore for any sharp edges that might

cut the packing. Scratches or burrs could

cause packing box leakage or damage to new

packing.

12. Install a new bonnet gasket (Key 17), making

sure the gasket seating surfaces are clean

and smooth. Carefully install the plug/stem

assembly into the valve body. Then slide the

bonnet over the stem and thread it tightly into

the valve body, see torque values in Table 3.

13. Use the sequence shown in Figure 2 to install

new packing and associated parts.

14. Slip a smooth-edged pipe over the valve stem,

and gently tap each soft packing part into the

packing box.

15. Slide the packing follower, upper wiper, and

packing flange (Keys 11, 10, and 3) into

position.

16. Lubricate and install the packing flange studs

(Key 1), and nuts.

17. For spring-loaded PTFE V-ring packing, tighten

the packing flange nuts (Key 2) until the

shoulder of the packing follower (Key 11) is

approximately 5/8” above the top of the bonnet.

6. Remove the plug/stem assembly from the bon net. If you plan to re-use the valve plug, pro tect the plug seating surface and the stem

threads to prevent damage.

7. Remove the bonnet gasket (Key 17).

8. Cover the opening in the valve body to protect

the gasket surface and prevent foreign material

from entering into the valve body.

9. Remove the packing flange nuts, packing

flange, upper wiper, and follower (Keys 2, 3,

10, and 11). Carefully push out all the

remaining packing box parts from the bonnet

using a rounded rod or other tool that will not

scratch the packing box wall or bottom guide

bushing.

10. Clean the packing box bore and the metal

packing box parts.

18. For other packing arrangements, tighten the

packing flange nuts (Key 2) alternately

in small equal increments. Continue until one

of the nuts reaches the minimum torque shown

in Table 1. Then tighten the remaining pack

ing flange nut until the packing flange is level

and at a 90-degree angle to the valve stem.

19. Mount the actuator on the bonnet (Key 6) and

connect the actuator and valve plug stem ac cording to the procedure in the appropriate

actuator instruction manual.

20. Check for leakage around the packing follower

when you put the control valve assembly into

service. Retighten the packing flange nuts as

required.

-4-

Page 5

SerieS D Globe anD SerieS Da anGle Style Control ValVeS

Trim Maintenance

Disassembly

1. Remove the actuator and the bonnet as de scribed in steps 1 through 3 of the “Replacing

Packing” procedure.

Warning

The seating surfaces and surface nish of

the seat ring (Key 8), stem (packing seal) and

plug (Key 19) are critical for tight shutoff.

Protect these parts from damage if you plan

to re-use them in the valve.

2. Remove the plug/stem assembly (Key 19) and

the packing parts from the bonnet.

3. If you re-use the valve plug, protect the valve

plug seating surface and the stem threads to

prevent damage.

4. Remove the packing parts as described in the

“Packing Maintenance” procedure.

5. Use a socket wrench to remove the seat ring

(Key 8).

6. Remove the seat ring (Key 8) and seat ring

gasket (Key 9) from the valve body.

7. Inspect parts for damage or wear that would

prevent proper operation of the valve body.

Clean the gasket surfaces.

8. Replace trim parts as necessary or use the

“Lapping Metal Seats” procedure.

Lapping Metal Seats

In any valve body with metal-to-metal seating, a certain

amount of leakage should be expected. However, if

the leakage becomes excessive, lapping can enhance

the condition of the seating surfaces of the plug and

seat ring. Deep nicks in the seating surfaces should be

removed by machining rather than lapping.

There are many lapping compounds available commercially. Be sure to use one of high quality.

Apply the lapping compound to the bottom of the valve

plug. Partially assemble the valve so the seat ring and

valve plug are in place and the bonnet (with bushing

installed) is screwed hand-tight into the body.

Make a simple handle from a piece of metal attached to

the plug stem with nuts. Rotate the handle in opposite

directions with light downward pressure to lap the seat.

Once lapping is complete, remove the bonnet and plug/

stem assembly as a unit, and clean the seating surfaces,

reassemble, and then test for shutoff. If leakage is still

excessive, repeat the lapping process.

Assembly

1. Thoroughly clean the valve body gasket sur-

faces, seat ring and bonnet threads.

2. Apply Never-Seez Nickel lubricant or equivalent

to the threads of the seat ring (Key 8), bonnet

(Key 6), and their mating threads in the body.

3. Put the seat ring gasket (Key 9) into the body.

Screw the seat ring into the body. Use

a socket wrench to tighten the seat ring to the

torque values shown in Table 3.

4. Clean the bonnet gasket-seating surface, and

install a new bonnet gasket (Key 17).

5. If you had not removed the plug/stem assembly

and packing from the bonnet, then install the

bonnet (Key 6) and plug/stem assembly (Key

19) as a unit, into the valve body. To prevent

galling ensure the seating surface of the

plug does not contact the seating surface of the

seat ring. Thread the bonnet tightly into

the valve body; see torque values in Table 2.

6. If you chose to remove the plug/stem assembly

and packing from the bonnet, then remove any

protective covering from the plug/stem

assembly (Key 19) and carefully install it

into the valve body.

7. Slide the bonnet (Key 6) over the stem and

thread it tightly into the valve body.

-5-

Page 6

Mark D anD Da SerieS Globe anD anGle Style Control ValVeS

Assembly Continued,

8. Use the sequence shown in Figure 2 to install

new packing and associated parts.

9. Place a smooth-edged pipe over the valve

stem, and gently tap each soft packing part into

the packing box bore.

10. Slide the packing follower, upper wiper, and

packing flange (Keys 11, 10, and 3) into

position. Lubricate and install the packing

flange studs (Key 1), and packing flange nuts

(Key 2).

11. For spring-loaded PTFE V-ring packing, tighten

the packing flange nuts (Key 2) until the shoul der of the packing follower (Key 11) is approxi mately 5/8” from the top of the bonnet.

For other packing arrangements, tighten the

packing flange nuts (Key 2) alternately in

small equal increments. Continue until one of

the nuts reaches the minimum torque value

shown in Table 1. Then tighten the remaining

packing flange nut until the packing flange is

level and at a 90° angle to the valve stem.

12. Mount the actuator on the bonnet (Key 6),

connect the actuator and plug/stem according

to the procedure in the appropriate actuator

instruction manual.

13. Check for leakage around the packing follower

(Key 11) when you put the control valve

assembly into service. Retighten the packing

flange nuts as required.

Parts Ordering

Each body-bonnet assembly is assigned a serial number, which can be found on the nameplate. Refer to

this serial number when contacting your Jordan Valve

representative.

When ordering replacement parts, specify the serial

number, key number, and part description, from the following Parts Lists.

Upper Wiper

Packing Follower

Female Adaptor

V-Ring

Male Adaptor

Washer

Spring

PTFE V-Ring **Garlock

Upper Wiper

Packing Follower

Female Adaptor

V-Ring

Male Adaptor

Lantern Ring

Packing Follower

Packing Ring

Lantern Ring

R

*Grafoil

R

Single Packing

All Yoke Sizes

Upper Wiper

Packing Follower

Female Adaptor

V-Ring

Male Adaptor

Lantern Ring

PTFE V-Ring

Packing Follower

Packing Ring

Lantern Ring

Packing Ring

Packing Box Ring

*Grafoil

R

PTFE/Composition

Upper Wiper

Packing Follower

Packing Ring

Lantern Ring

Packing Ring

Packing Box Ring

Double Packing

All Yoke Sizes

Notes:

* Grafoil

** GarlockR is a Registered Trademark for Packings, Seals, Gaskets and other Products of Garlock Garlock Inc.

Figure 2: Packing Arrangements

-6-

Page 7

Mark D anD Da SerieS Globe anD anGle Style Control ValVeS

Mark D Series Control Valve Assembly

1

2

3

4

5

6

7

10

11

12

13

14

15

16

8

9

Figure 3: Mark D Series Globe Valve

-7-

17

18

19

Page 8

Mark D anD Da SerieS Globe anD anGle Style Control ValVeS

Mark DA Series Angle Valve Assembly

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

17

9

Figure 3a: Mark DA Series Angle Valve

-8-

18

19

Page 9

Mark D anD Da SerieS Globe anD anGle Style Control ValVeS

Parts List

Key Quantity Part Name Material Part Number

1 2

2 2

3 1

4 1

5

6 1

7 1

8 1 Seat Ring – see following table Key 8

9 1

10 1

11 1

12 1

13 1

14 3

15 1

16 1

17 1

18 1

19 1 Plug and Stem – see following table Key 19

*M-Flat trim available upon request, contact a Jordan Valve representative for more information.

1

(optional)

Packing Flange Stud Bolt – 2-1/8” Boss Stainless Steel 1E94413103

Packing Flange Stud Bolt – 2-13/16” Boss 1E94443103

Packing Flange Stud Nuts – 2-1/8” Boss Stainless Steel 1E94403103

Packing Flange Stud Bolt – 2-13/16” Boss 1E94453103

Packing Flange – 2-1/8” Boss Steel, CD Plated 1E94372410

Packing Flange – 2-13/16” Boss 1E94422307

Yoke Locknut – 2-1/8” Steel 1E79302306

Yoke Locknut – 2-13/16” 1E80742306

Pipe Plug Stainless Steel 1A76752466

Lubricator or Lubricator / Isolator --- AJ5428000A

Bonnet – 2-1/8” Boss, 1” Body Stainless Steel /

Bonnet – 2-13/16” Boss, 2” Body 2F1342000A

Body – Consult your CVS Controls Representative for valve body, style, size and material

availability

Seat Ring Gasket – 1” Body Mild Steel 1B19862001

Seat Ring Gasket – 2” Body 1B19882001

Felt Wiper – 3/8” Stem Felt 1J1826

Felt Wiper – 1/2” Stem

Packing Follower – 3/8” Stem Steel 1E94393507

Packing Follower – 1/2” Stem 1E94393507

Female Adapter Packing – 3/8” Stem TFE 1F12440101

Female Adapter Packing – 1/2” Stem 1F12430101

Packing – 3/8” Stem TFE 1C7526000A

Packing – 1/2” Stem 1C7527000A

Male Adapter Packing – 3/8” Packing TFE 1F12480101

Male Adapter Packing – 1/2” Packing 1F12470101

Washer – 3/8” Packing Stainless Steel 1F12523604

Washer – 1/2” Packing 1F12433604

Spring – 2-1/8” Boss, 3/8” Stem Stainless Steel 1F12543701

Spring – 2-13/16”, 1/2” Stem 1F12553701

Bonnet Gasket – 2-1/8” Boss, 1” Body Mild Steel 1B19822001

Bonnet Gasket – 2-13/16” Boss, 2” Body 1B19842001

Guide Bushing – 2-1/8” Boss Stainless Steel 1B16913501

Guide Bushing – 2-13/16” Boss 1B16923501

4140 L80

2F1383000A

-9-

Page 10

Mark D anD Da SerieS Globe anD anGle Style Control ValVeS

Key 8 Seat Ring

Body Size

(in)

1

2

Key 19 Valve Plug and Stem

Body

Size

(in)

Orifice Size

mm in

6.4 1/4

6.4 1/4 2 2N71480022 --- ---

1

6.4 1/4 3 2F32800022 2F13880042 1J68940022

9.5 3/8 3 2N73890022 2F31890032 1J68950022

12.7 1/2 3 2N73380022 2F13900032 1J68960022

19.1 3/4 3 2N73930022 2F13910032 1J68970022

6.4 1/4

9.5 3/8 3 27A87920062 2F14280022 1J81910022

2

12.7 1/2 3 2N73330022 2F14290022 1J81930022

19.1 3/4 3 2N62970022 2F14300022 1J81950022

25.4 1 3 2F32690082 2F14310022 1J81970052

31.8 1-1/4 3 --- 2L53310032 1V22340022

Orifice Size (in)

mm in

6.4 1/4 1B50973507 1B50970012 1J6886000A

9.5 3/8 1B50983507 1B50980012 1J6887000A

12.7 1/2 1B50993507 1B50990012 1J6888000A

19.1 3/4 1B51003507 1B51000012 1J6889000A

6.4 1/4 1B51063507 1B51060012 1J6899000A

9.5 3/8 1B51073507 1B51070012 1J8154000A

12.7 1/2 1B51083507 1B51080012 1J8156000A

19.1 3/4 1B51093507 1B51090012 1J8158000A

25.4 1 1B51103507 1B51100012 1J8160000A

31.8 1-1/4 1B58013507 1B58010012 1P7421000A

(in)

Stem

Size

(in)

3/8 2-1/8

1/2 2-13/16

Boss

Size

(in)

MKDandDAIM/0314/2K

316 SST 316 SST with Alloy 6

No.

of

Flutes

1 2N71470032 --- ---

3 2N71400022 2F14270022 1J81890022

Flute

316 SST

CVS Equal %

316 SST with Alloy

Tip

316 SST with

Tungsten Carbide

CVS Equal %

316 SST with

Carbide Tip

Table 4: Weights of Mark D Series Valve Body Assembly

Welded Flange* Short Body

Class

300RF

Class

900/1500RTJ

Class

600RF

ASME

900/1500RF

Jordan Valve, a division of Richards Industries

3170 Wasson Road • Cincinnati, OH 45209

513.533.5600 • 800.543.7311 • 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

ASME

300RF

ASME

900/1500RTJ

ASME

300RF

ASME Class

Class

6000

NPT

Class

3600

NPT

Welding

Body size Weight

1" Lbs 27.00 25.00 33.50 34.00 35.00 N/A N/A N/A

Kg 12.25 11.34 15.20 15.42 15.88

2" Lbs 52.50 50.50 50.50 54.00 58.00 62.00 67.00 72.00

Kg 23.81 22.90 22.90 24.49 26.31 28.12 30.39 32.66

* ANSI Standard Flanges only, welded Flanges

Body

size

* ANSI Standard Flanges only, welded Flanges

Weight

1" Lbs N/A N/A 45.00 45.00 N/A N/A N/A

Kg 20.41 20.41

2" Lbs 105.00 103.00 N/A N/A 98.50 99.00 142.00

Kg 47.63 46.72 44.68 44.91 64.41

Class

6000

Class

3600

Welding

Class

150RF

Welded Flange* Short body

Class

900/1500RF

ASME

600RF

2500

Loading...

Loading...