Page 1

I & M Mark CFR Series

3170 Wasson Road • Cincinnati, OH 45209

Phone 513.533.5600 • Fax 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Warning: Jordan Valve Control Valves must only be used, installed and repaired in accordance with these Installation & Maintenance Instructions. Observe all applicable public and company codes and regulations. In the event

of leakage or other malfunction, call a qualified service person; continued operation may cause system failure or

a general hazard. Before servicing any valve, disconnect, shut off, or bypass all pressurized fluid. Before disassembling a valve, be sure to release all spring tension.

IntroductIon

These Installation Instructions provide installation and

Start Up procedures for the Mark CFR Regulator.

InstallatIon

It is recommended that only qualified or authorized

personnel install and maintain the Mark CFR regulator.

Prior to installing, make sure there is no damage to

the regulator, as well as foreign debris in all tubing or

piping connections to the installation.

Ensure proper safety procedures are adhered to

during installation and maintenance.

Warning:

Do not install any pressure equipment where

service conditions exceed the manufacturer’s

specications. Over pressuring of regulator may

result in leakage, equipment damage or injury.

Excessive pressure can cause the pressure

containing parts to burst, or accumulated gas to

explode. The Mark CFR Filter Regulator should not

be used with hazardous gas unless vented to a safe

area.

The Mark CFR regulators internal relief valve does

not provide overpressure protection. The internal

relief valve is designed for minor seat leakage only.

Additional overpressure protection may be required

should the inlet pressure exceed the maximum

pressure rating of the downstream equipment, or

maximum allowable outlet.

Periodically inspect the regulator for damage, and

after an overpressure condition. Remove from service

and replace or maintain the regulator as required.

1. Install the regulator so that the direction of flow

is from the IN to the OUT, as marked on the

regulators housing.

Installation & Maintenance Instructions for the

Mark CFR Series Supply Regulators

2. For best drainage, install the regulator so that

the drain valve (12) is at the lowest possible

point.

3. Prevent plugging of the spring case vent and

keep the spring case from collecting moisture,

corrosive chemicals or other materials

by orienting the vent to the lowest possible point

on the spring case. For panel mounted vented

installations, the 1/4" NPT spring case vent may

be remotely vented by installing tubing

or piping.

4. To change the filter/drain orientation, rotate the

filter cap with regards to the regulator body.

Change the spring case/vent orientation

by rotating the spring case in relation to

the regulator body.

Warning

Never adjust the control spring to produce pressure beyond its highest outlet pressure range. Over

pressuring the spring can cause bursting of pressure containing parts, or explosion of accumulated

gas. If the range of the control spring does not reach

the desired outlet pressure install a spring with the

proper range according to the maintenance section.

5. Suitable means of venting the regulator inlet

and outlet pressures for regulator

shutdown may be achieved by installing

upstream block and vent valves

and downstream block and vent

valves if required.

6. Apply pipe compound or suitable Teflon tape to

the male pipe threads prior to making connec

tions, take care not to get excess pipe

compound inside piping or regulator.

7. Install 1/4" NPT supply tubing or pipe fitting to

the inlet of the regulator body marked

“IN”. Proceed to install 1/4” tubing or pipe fitting

to the other side of the regulator body marked

“OUT”.

8. The additional 1/4" NPT outlet may be used for

an optional Jordan Valve pressure gauge. If a

gauge is not being utilized, a 1/4" NPT

plug must be used.

Page 2

Mark CFr SerieS PreSSure reduCing SuPPly regulatorS

InstallatIon contInued,

9. Should the Mark CFR regulator be installed

in an existing installation, it may be nec-

essary to install spacers on the mounting bolts

to adapt to the installation. If mounting

bolts are too long place a spacer on

the mounting bolt and ensure at

least two full threads of engagement.

startup and adjustment

1. Once installation is complete and downstream

equipment is properly adjusted, slowly open the

supply and downstream shutoff

valves (if installed) while using pressure gauges

to monitor supply and outlet pressure.

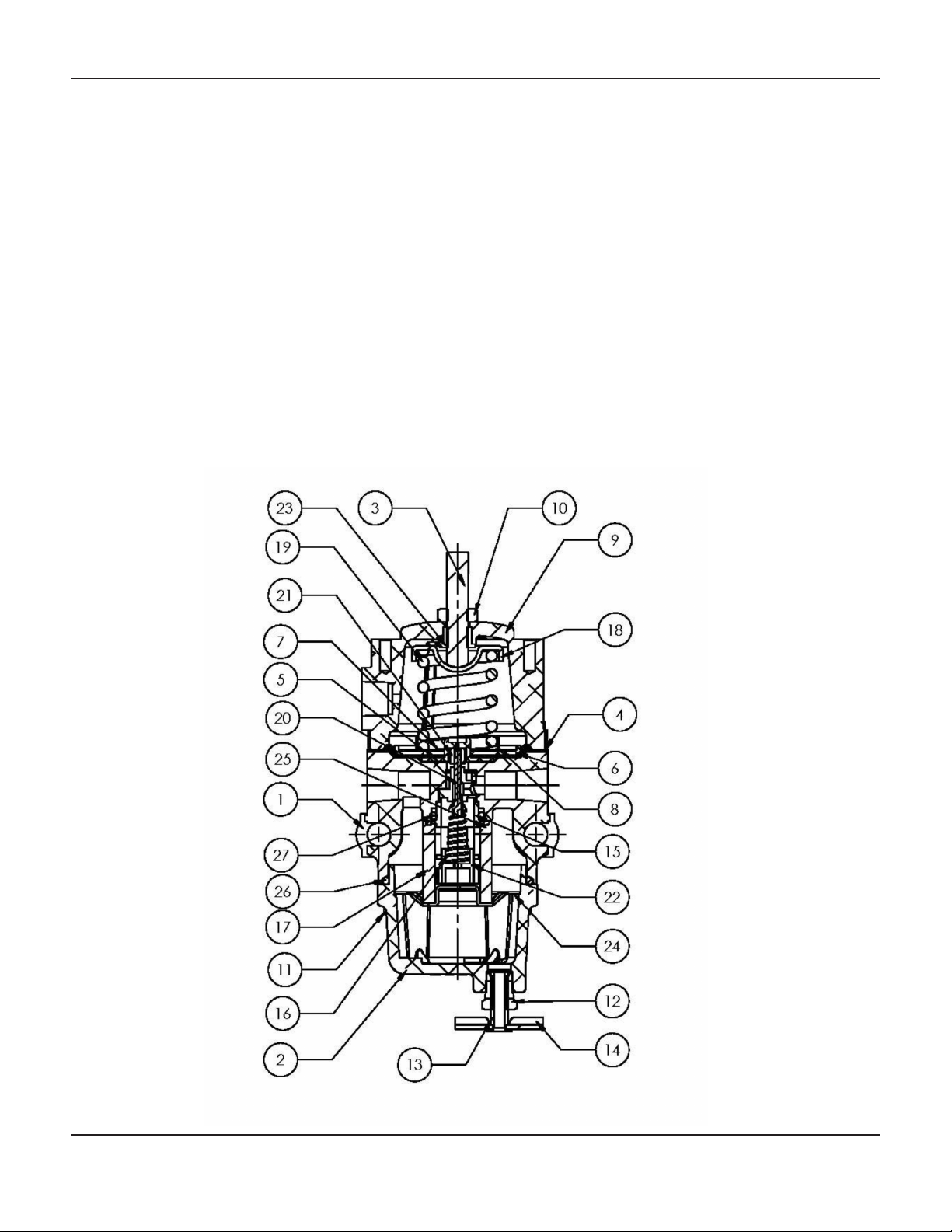

mark cFr assembly

2. Should outlet pressure adjustment be required,

install and monitor outlet pressure using

a gauge during the start-up procedure.

The Mark CFR regulator outlet pressure can

be raised or lowered by loosening the locknut

(10), and turning the adjustment screw (3),

clockwise to increase outlet pressure, or counter

clockwise to decrease outlet pressure.

3. Tighten the locknut (10) one the desired outlet

pressure has been properly set as required.

4. Periodically inspect the regulator for signs or

wear or damage, and repair or replace

as necessary.

For more information or questions, please contact a

Jordan Valve Representative.

-2-

Page 3

MKCFRIM/0214/2K

Mark CFr SerieS PreSSure reduCing SuPPly regulatorS

mark cFr parts lIstIng

Item Description Part Number Qty

1 Body, Aluminum T40643T0RG2 1

2 Dripwell, Aluminum T21040T0012 1

3 Adjusting Screw T14061T0012 1

4* Diaphragm

5 Push Post T14119T0012-2 1

6* Diaphragm Plate

7* Diaphragm Ret. Ring

8 Lower Spring Seat T14119T0012-5 1

Spring Case – 1/4" NPT Vent T14070T0042 1

9

Spring Case – Vent to atmosphere (drilled) T140707T0012 1

10 Lock Nut 1A946324122 1

11 Flange Screw 1B784028982 10

12 Drain Valve Body 1K418918992-1 1

13 Drain Valve Plug 1K418918992-2 1

14 Drain Valve Handle 1D5604000A2-3 1

15 Valve Cartridge Body T80434T0012 1

16 Valve Spring T14105T0012 1

17* Filter Element GE32761X012 1

18 Upper Spring Seat T14051T0012 1

Spring – 0 to 35 psig T14059T0012 1

19

Spring – 0 to 60 psig T14058T0012 1

Spring – 0 to 125 psig T14060T0012 1

20* Valve Plug T14053T0042 1

21* Soft Seat T14055T0012 1

22 Valve Retainer T14071T0012 1

23 Spring Case Insert T14070T0052 1

24 Filter Retainer T14052T0012 1

25 Filter Gasket T14081T0012 1

26 O-Ring T14380T0012 1

27 O-Ring T14380T0012 1

(1)

Items 4, 6 and 7 are included in Diaphragm Assembly

*Included in Mark CFR Repair Kit CFR-RK 1

(1)

(1)

(1)

T14119T0012-1 1

T14119T0012-3 1

T14119T0012-4 1

T14119T0022 Nitrile (no relief) 1

T14119T0012 Nitrile (with relief) 1

Jordan Valve, a division of Richards Industries

3170 Wasson Road • Cincinnati, OH 45209

513.533.5600 • 800.543.7311 • 513.871.0105 (f)

info@richardsind.com • www.jordanvalve.com

Loading...

Loading...